Patents

Literature

48results about How to "Advantages of production method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

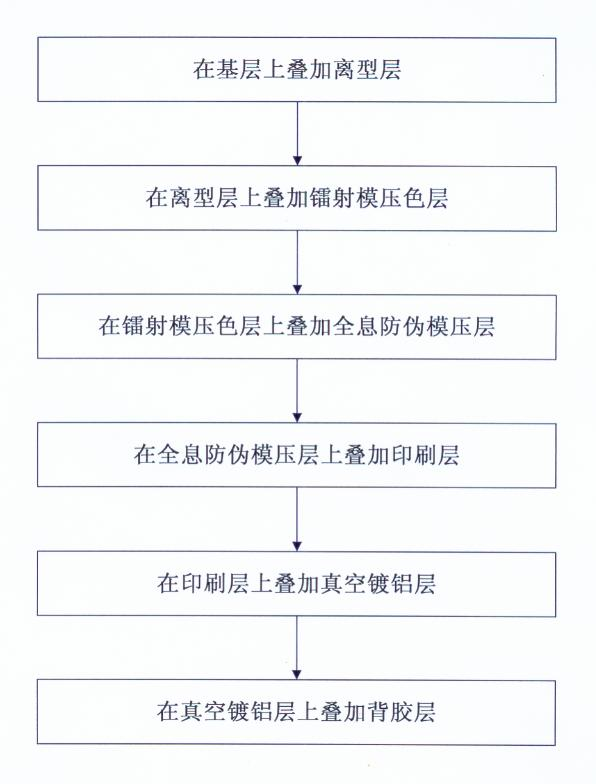

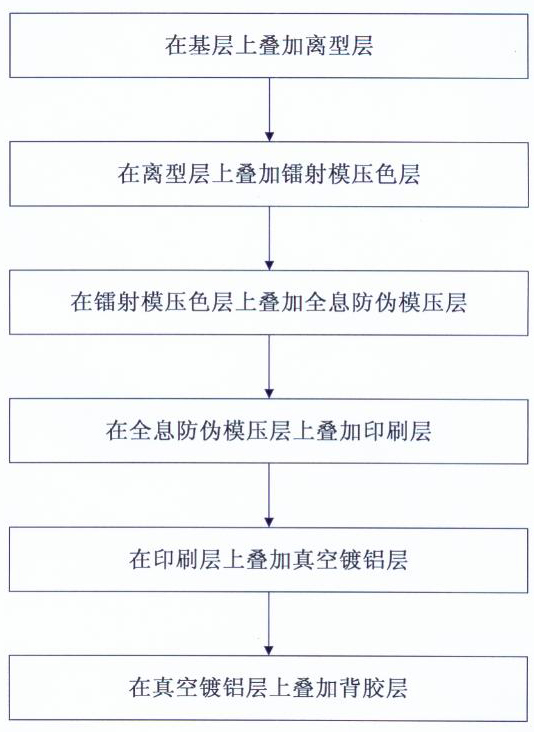

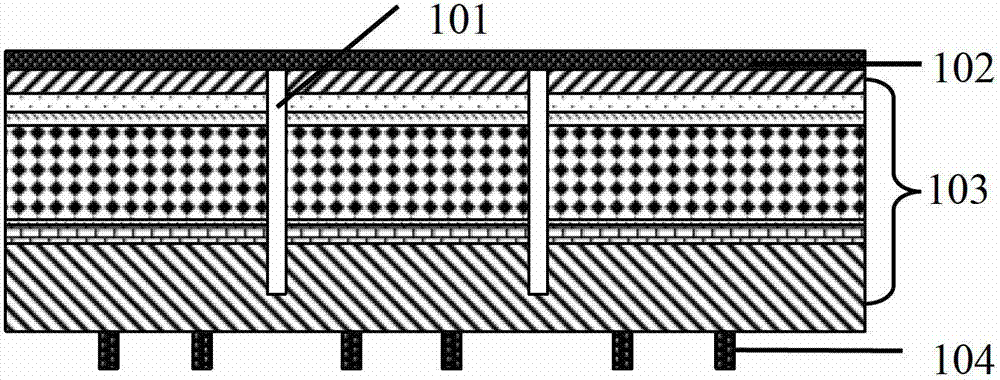

Method for manufacturing scratchable laser holography anti-fake foil

InactiveCN102092165AAdvantages of production methodHot stamping production efficiency is highSynthetic resin layered productsSpecial ornamental structuresInformation layerPolyester

The invention relates to a method for manufacturing scratchable laser holography anti-fake foil, taking a plastic polyester film as a substrate layer, comprising the following steps of: superposing a release layer on the substrate layer; superposing a laser molding color layer on the release layer, comprising evenly coating the dissolved resin on the surface of the release layer, and baking and drying via a five-section oven; superposing a holography anti-fake molding layer on the laser molding color layer, comprising forming visual laser patterns and information by a laser information layer via a roller coated with laser engraved laser plates; superposing a printing layer on the holography anti-fake molding layer; superposing a vacuum aluminized coating layer on the printing layer, comprising heating an evaporator to 1400-1500 DEG C, cooling the high-purity aluminum wires continuously sent to the evaporator into aluminum steam, evenly spraying aluminum molecules on the surface, and forming an aluminum film; and superposing a gum layer on the vacuum aluminized coating layer. The product manufactured by the method provided by the invention is high in printing production efficiency and is scratched once; the product has certain anti-fake effects and can replace a traditional method for scratching ink by a squeegee.

Owner:SHANGHAI SHENYONG STAMPING FOIL

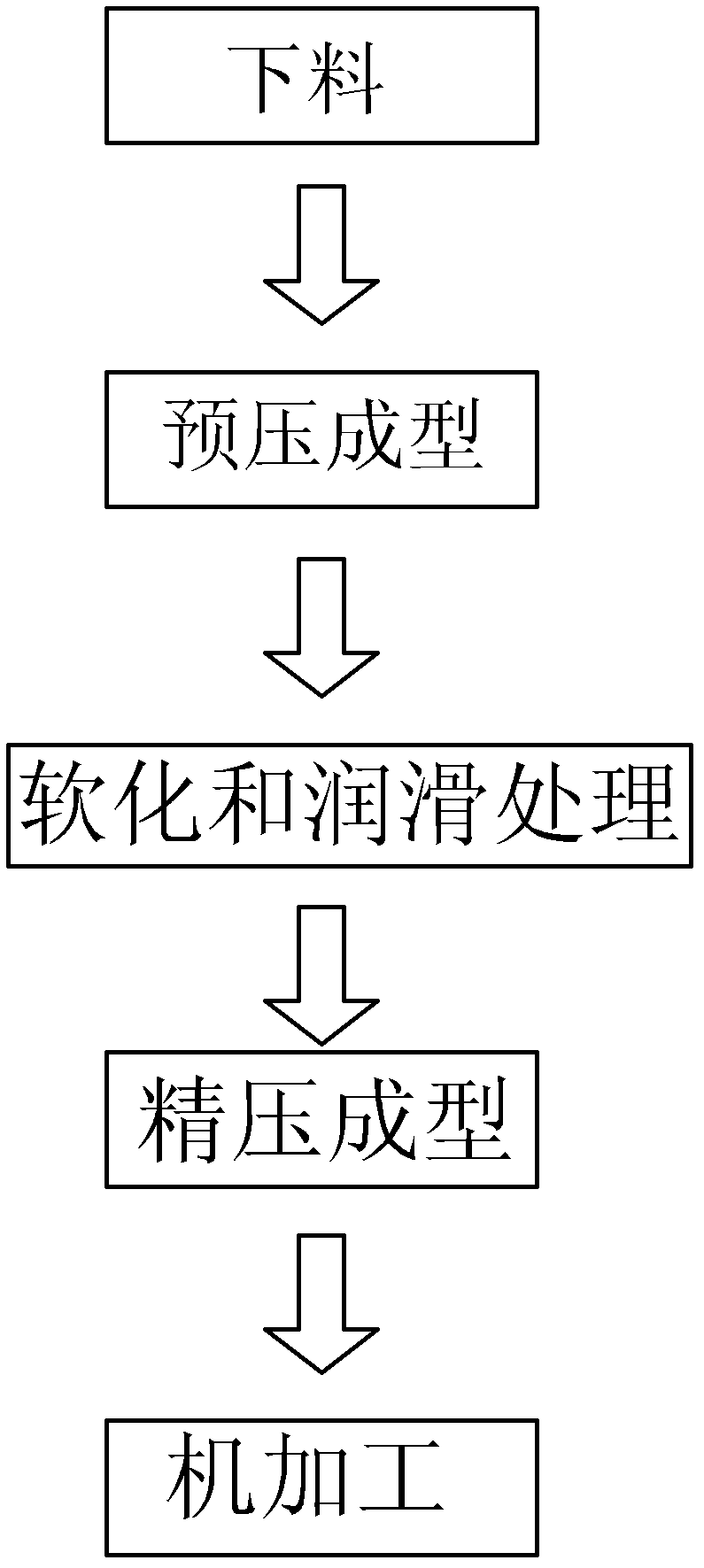

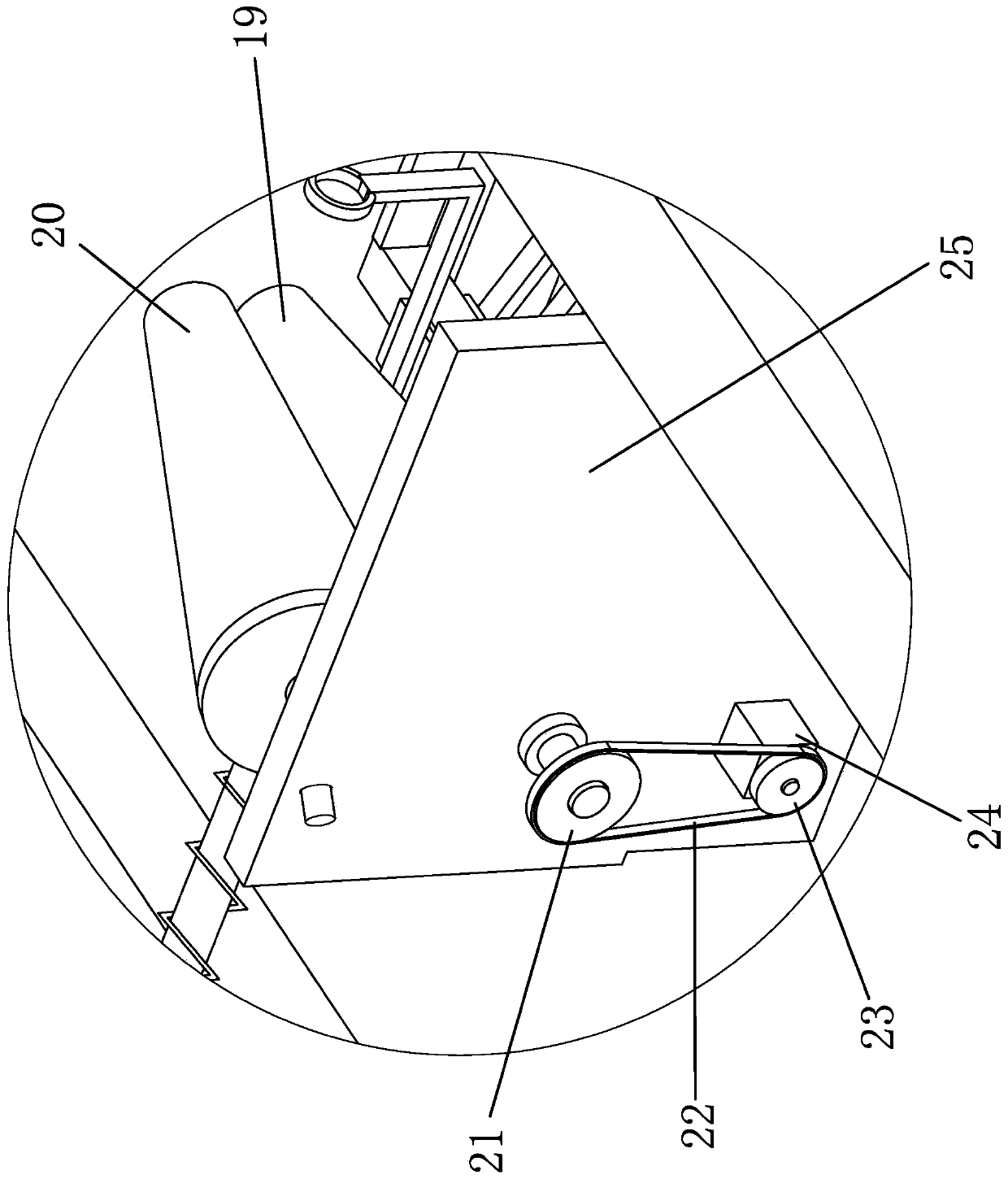

Method for manufacturing air condition compressor balance block

ActiveCN102248373ALow costIncreased production flexibilityMechanical engineering technologyWork in process

The invention provides a method for manufacturing an air condition compressor balance block, belonging to the technical field of mechanical engineering. By means of the method, the technical problems that the production efficiency is low, the reject rate is high and the like when high manganese steel is adopted to manufacture the air condition compressor balance block in a conventional method for manufacturing the air condition compressor balance block are solved. The method for manufacturing the air condition compressor balance block comprises the following steps of: A, blanking: cutting a section made from high manganese steel materials into blanks with a length corresponding to a required length; B, pre-pressing forming: putting the blanks in a mould and extruding into process products with shapes similar to the shapes of finished products; C, softening and lubricating treatments: carrying out the softening treatment and the phosphorization and saponification lubricating treatment on the process products; D, coining forming: putting the process products subjected to softening and the lubricating treatments in the mould to carry out extrusion forming to obtain semi-finished products; and E, machining: clamping the semi-finished products on a machine tool and machining to obtain the finished products. The method provided by the invention has the advantages of low production cost, high production efficiency and the like.

Owner:浙江百达精工股份有限公司

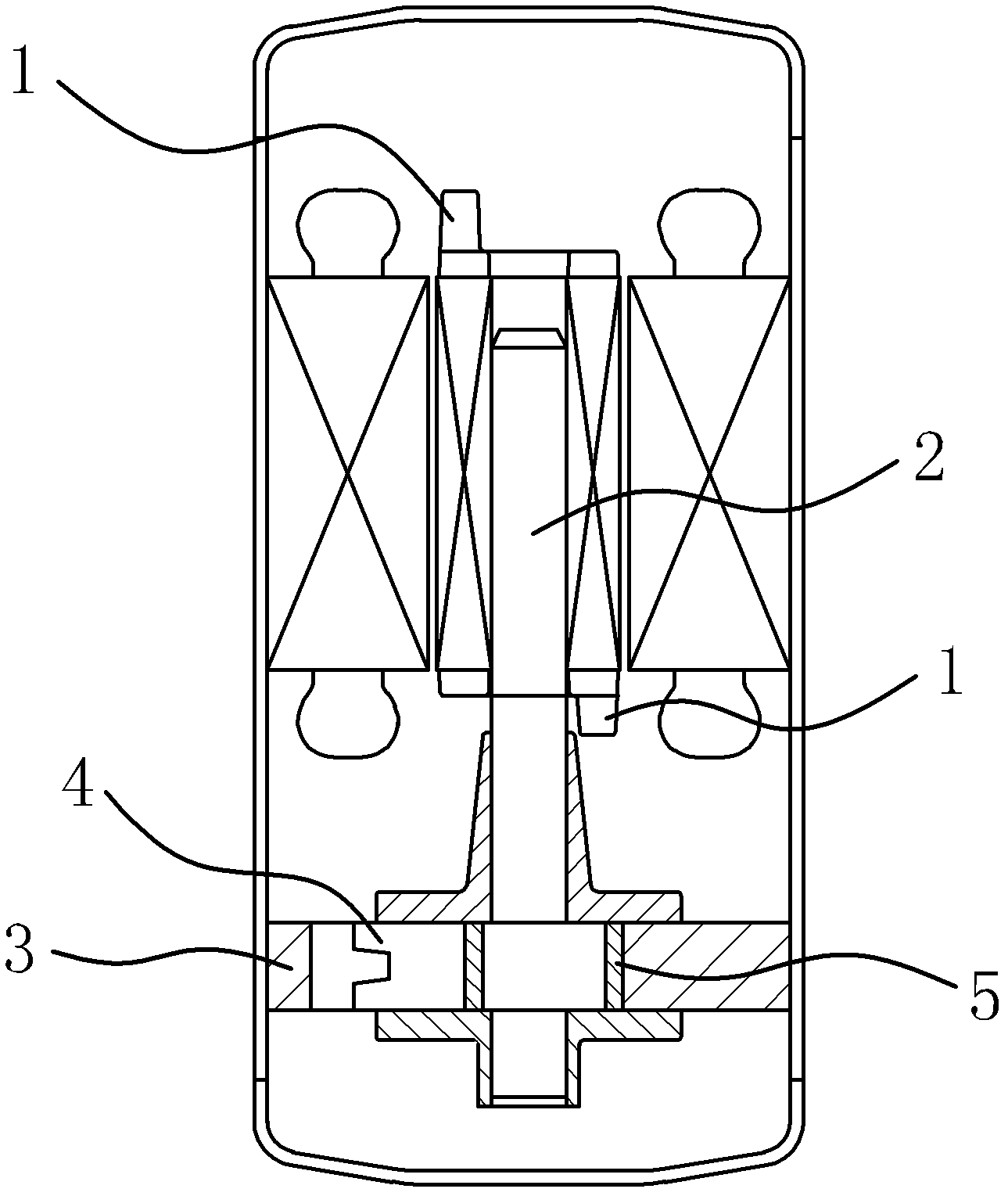

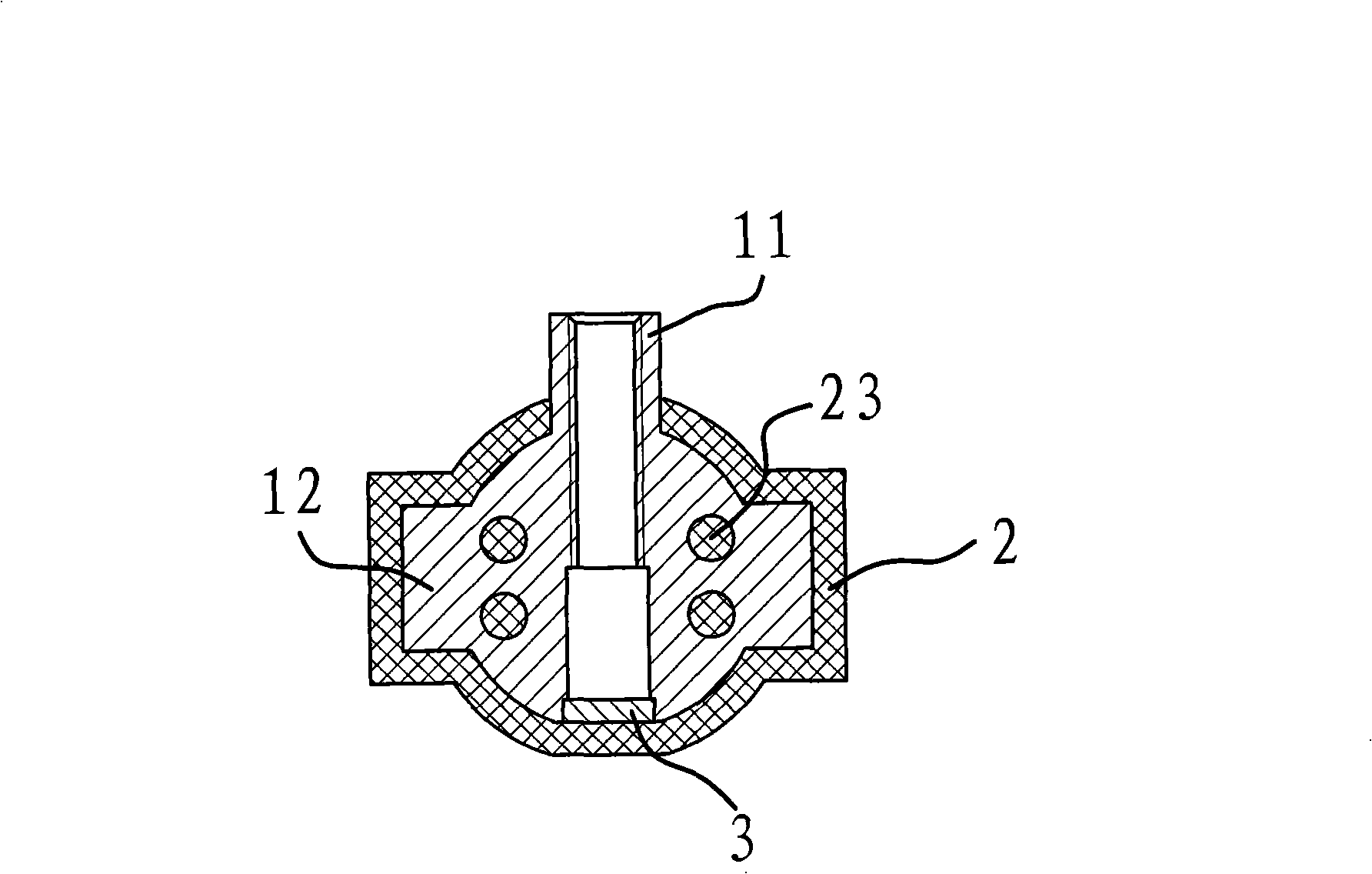

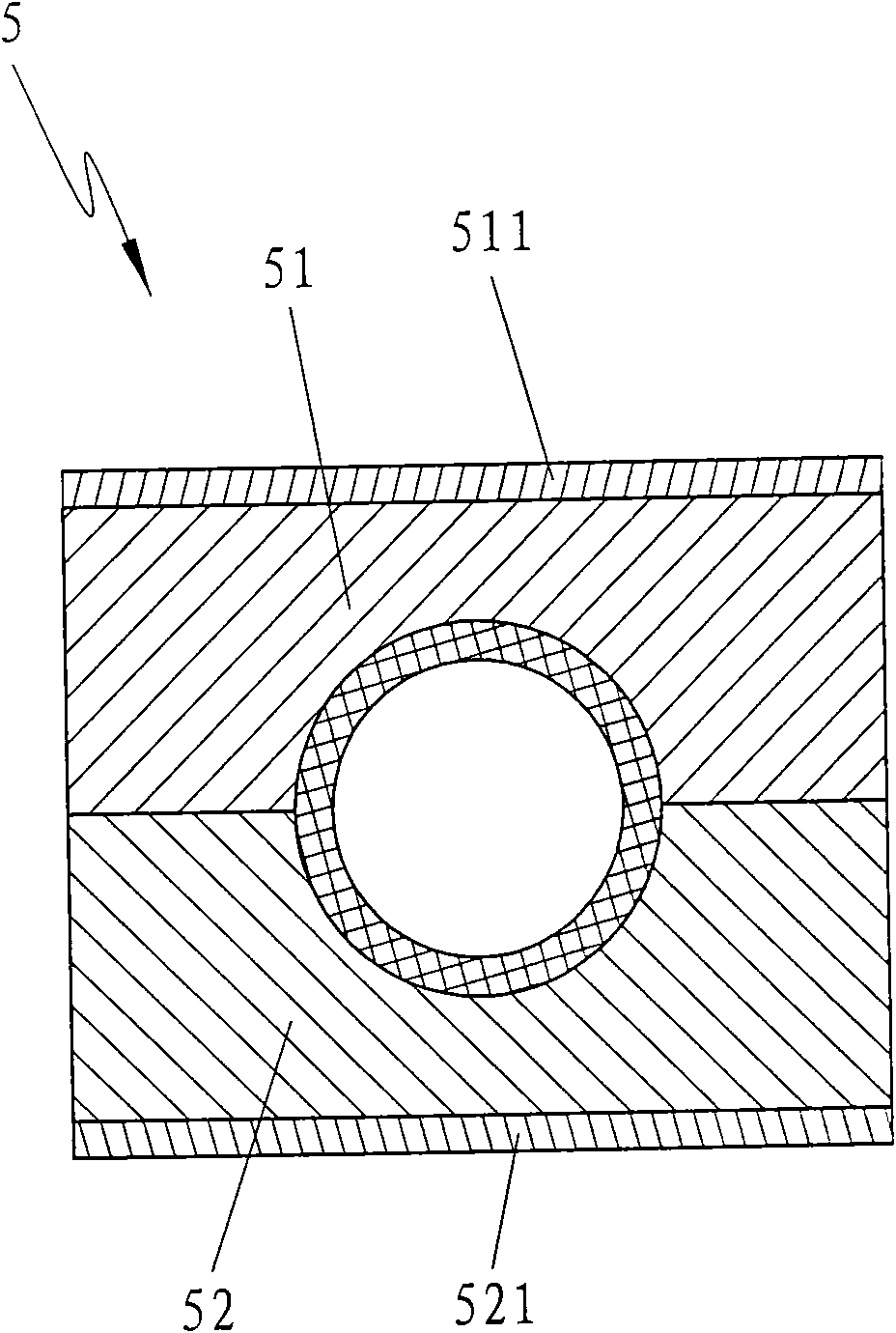

Production method of ball valve core

InactiveCN101362280AGuaranteed thicknessIncreasing the thicknessPlug valvesManufacturing technologyThick wall

The invention provides a method for producing the core of a ball valve, which belongs to the technical field of valve production, and solves the problems of thick wall of outer ball shell of the valve core, a large amount of material, and high production cost in the prior art. The production method of the core of the ball valve is realized through the following steps: firstly, the blank body of the outer ball shell is produced; secondly, a valve handle connecting seat is produced; thirdly, an inner straight pipe is installed; and fourthly, surface treatment is carried out. Through the production method, the material is greatly saved, and the cost for the core of the ball valve is reduced; the precision, the thickness and the integrity of the produced core of the ball valve can be guaranteed, and the intensity of the valve handle connecting seat and the valve handle connecting part is enhanced; the technological process is simplified, the reliability is good, and the rate of finished products is high; the appearance of the produced core of the ball valve is beautiful, and the core is comparatively perfect; galvanization is not needed, therefore, the environment protection property is good.

Owner:黄勇

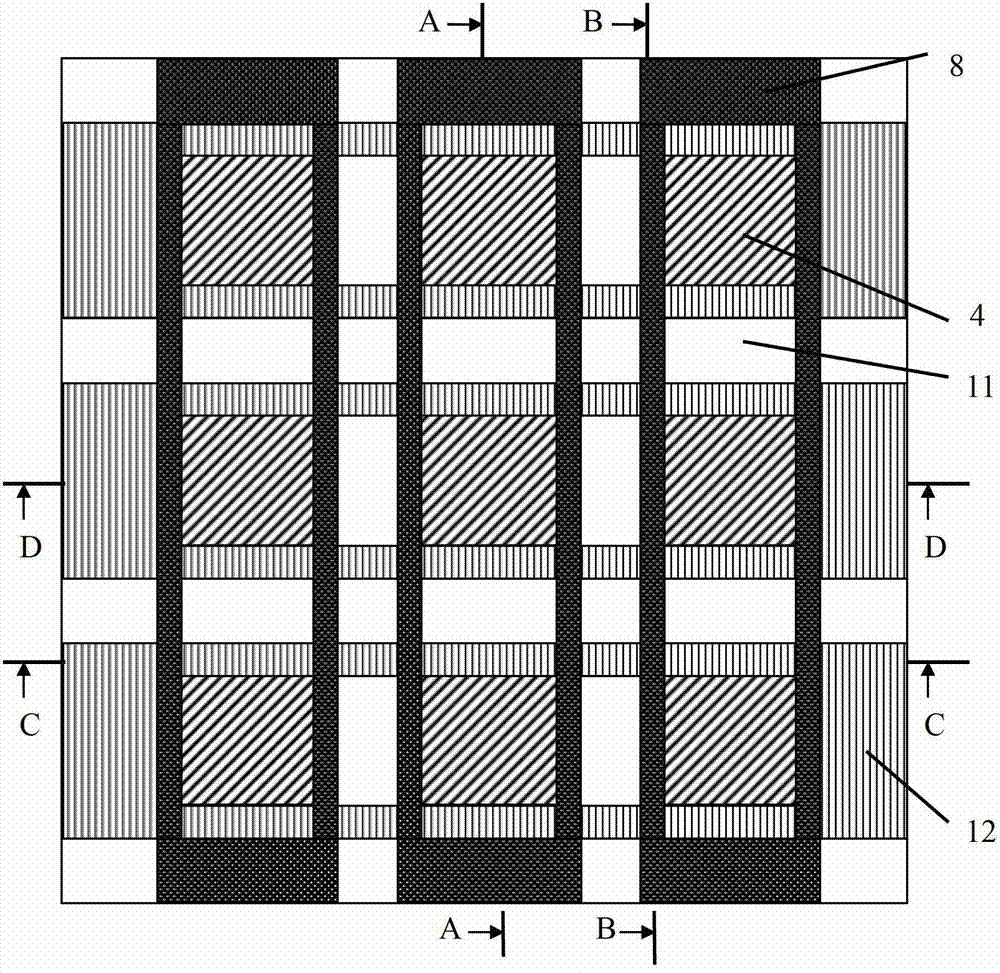

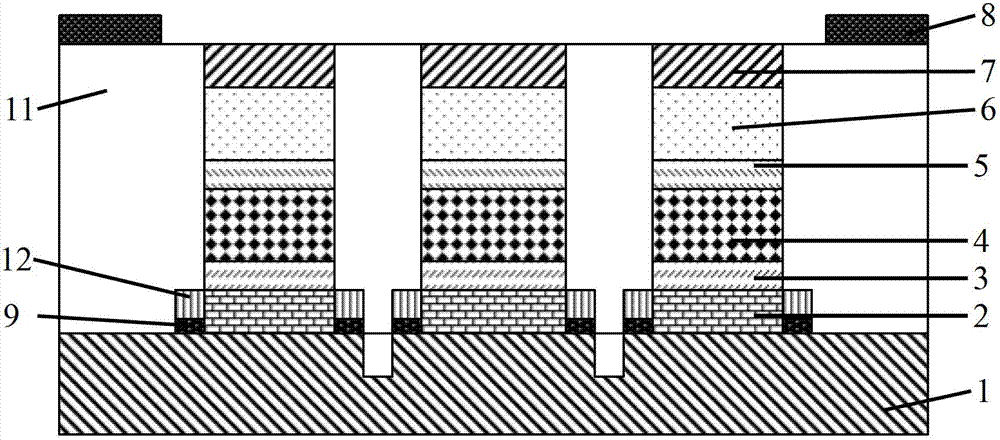

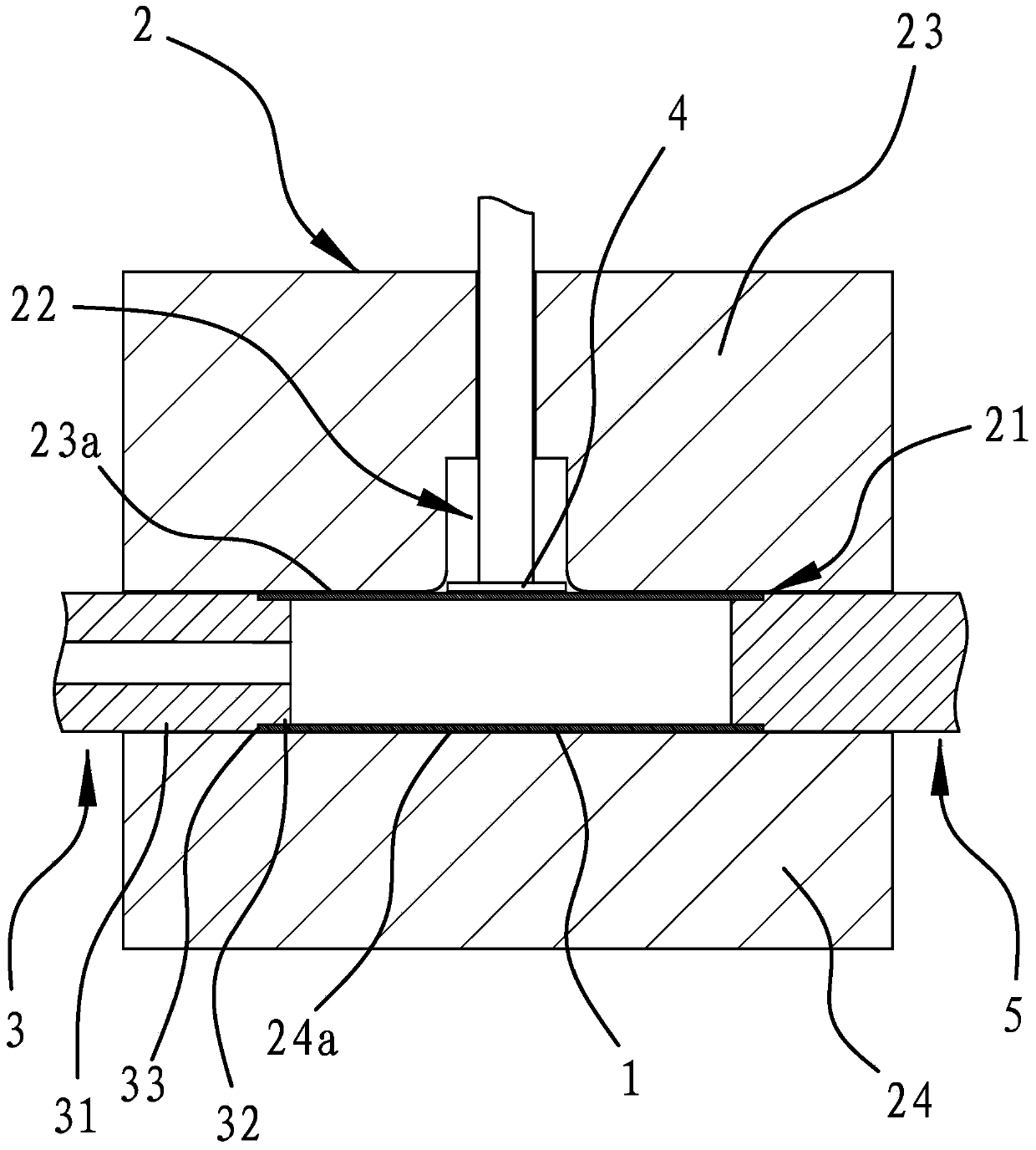

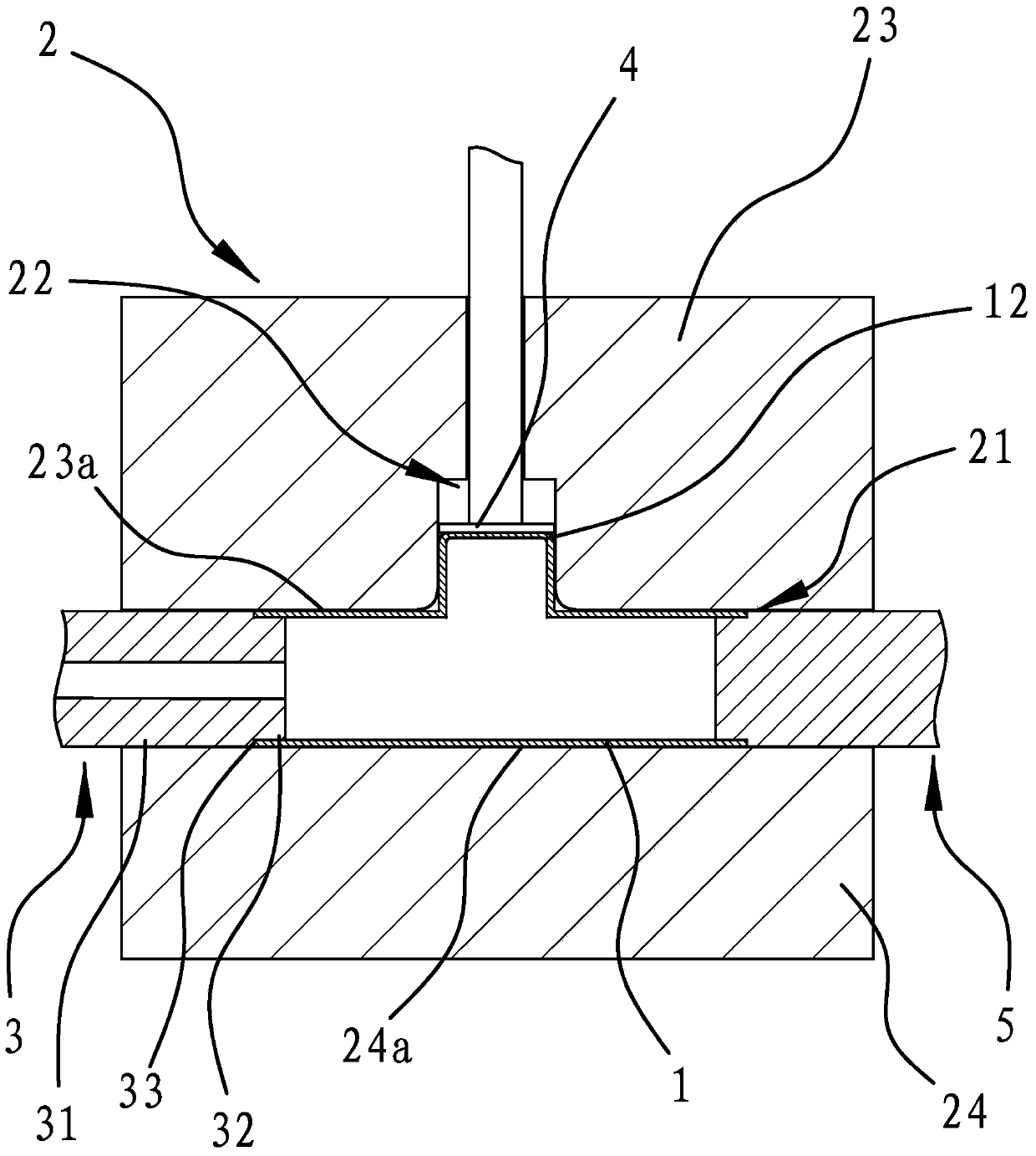

Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

ActiveCN102790144AAdvantages of production methodSimple structureSolid-state devicesSemiconductor devicesPlanar electrodeLed array

The invention discloses a method for manufacturing an AlGaInP-LED (Light Emitting Diode) integrated micro display component with a single-side electrode structure, wherein the steps comprises: etching multiple first grooves which are mutually intersected on a device body; growing a lower electrode metal layer on the bottom part of each groove to form the lower electrode metal layer; growing an insulating medium layer above a lower electrode; corroding an area of the lower electrode metal layer outside a lower electrode diagram downward till reaching a certain depth in an N-shaped substrate layer in order to form multiple second grooves; filling opaque diaphragms into the second grooves and the upper part of a protection medium of the lower electrode; manufacturing an upper electrode above a light emitting unit; and electroforming upper and lower electrode leads. With the adoption of the method for manufacturing the LED array micro display device with the planar electrode structure disclosed by the invention, the process difficulty resulting from the manufacturing of the electrodes on the front face and the back face respectively can be prevented; since the manufactured micro display device is provided with the double bar type upper and lower electrodes of which the different faces are perpendicular to each other, the more even current distribution can be obtained; and therefore, the micro display device available for even luminance is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Production method of flame-retardant automotive roof fabric

ActiveCN106183332AAdvantages of production methodImprove flame retardant performanceSynthetic resin layered productsLaminationManufacturing engineeringFast speed

The invention provides a production method of flame-retardant automotive roof fabric. By the production method, the technical problems that existing production methods have excessively complex steps, manual operation is needed, production speed is low and the like are solved. The production method of the flame-retardant automotive roof fabric includes a, raw material purchase, b, surface layer production, and c, compounding. The production method has the advantage of high production speed.

Owner:ZHEJIANG ADIENT WANFANG TEXTILE TECH CO LTD

Method for manufacturing lithium ion battery by using gel diaphragm

InactiveCN112103566AAdvantages of production methodImprove temperature consistencyFinal product manufactureSecondary cells charging/dischargingPole pieceLithium-ion battery

The invention provides a method for manufacturing a lithium ion battery by using a gel diaphragm. The method comprises the following steps of manufacturing a positive pole piece, manufacturing a negative pole piece, baking the pole pieces, laminating, preheating, carrying out primary hot pressing, carrying out primary cold pressing, manufacturing a battery cell, pre-charging, ageing, carrying outsecondary hot pressing, carrying out secondary cold pressing, forming and finishing the manufacturing of the battery cell. According to the manufacturing method of the lithium ion battery using the gel diaphragm, the gel diaphragm is adopted, firstly, preheating, hot pressing and cold pressing are conducted on the core package after lamination, and in the stage, the pressure of hot pressing and cold pressing is small, so that the gel diaphragm slightly adheres to a pole piece to achieve a fixed core package structure. Secondly, pressure is applied to the battery cell in a pre-charging stage; and finally, the procedures of hot pressing and cold pressing are added before the formation procedure, so that the tight bonding of the positive / negative pole piece and the gel diaphragm is realized.

Owner:TIANJIN ENERGIES

Method for manufacturing high-voltage power cable terminal by benzene hydrogenation process

InactiveCN102377127AAdvantages of production methodReasonable designApparatus for removing/armouring cablesCable terminationsAnti stressPower cable

The invention discloses a method for manufacturing a high-voltage power cable terminal by a benzene hydrogenation process. The method is characterized by comprising the following steps of: a, stripping and cutting a cable; b, stripping a copper shielding layer; c, making gas chromatographic marks; d, stripping a semiconductor; e, cutting an anti-stress cone of each phase of an insulating layer of a core; f, crimping a terminal; g, removing the insulting layer; h, arranging an insulating tube; i, fixing the insulating tube and a gas chromatographic tube; and j, performing enveloping processing. The method for manufacturing the high-voltage power cable terminal by the benzene hydrogenation process has the advantages of rational manufacturing steps, simple operations, safe and reliable process quality, high electrical properties and reduction in process cost.

Owner:MCC5 GROUP CORP SHANGHAI

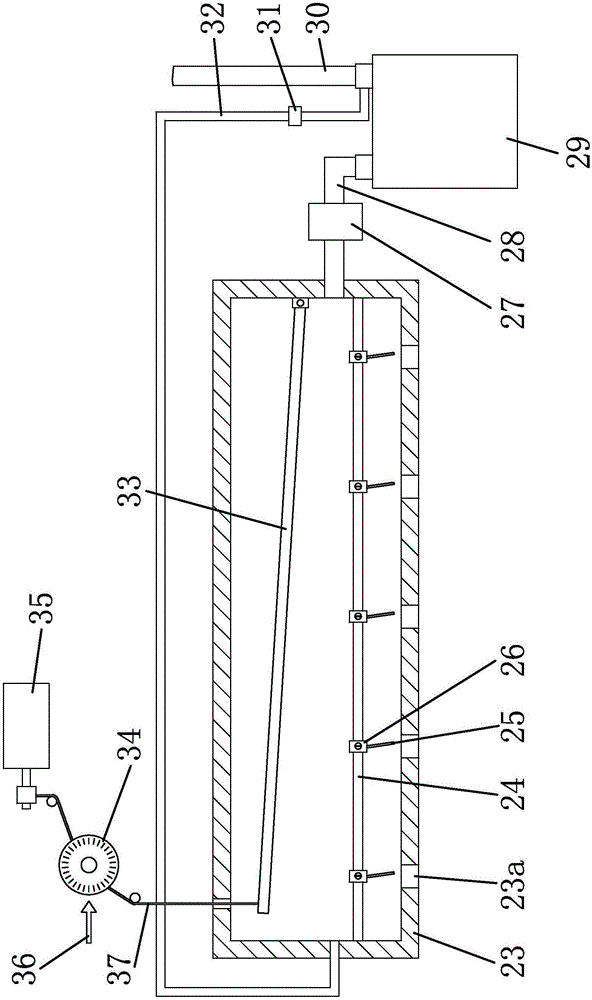

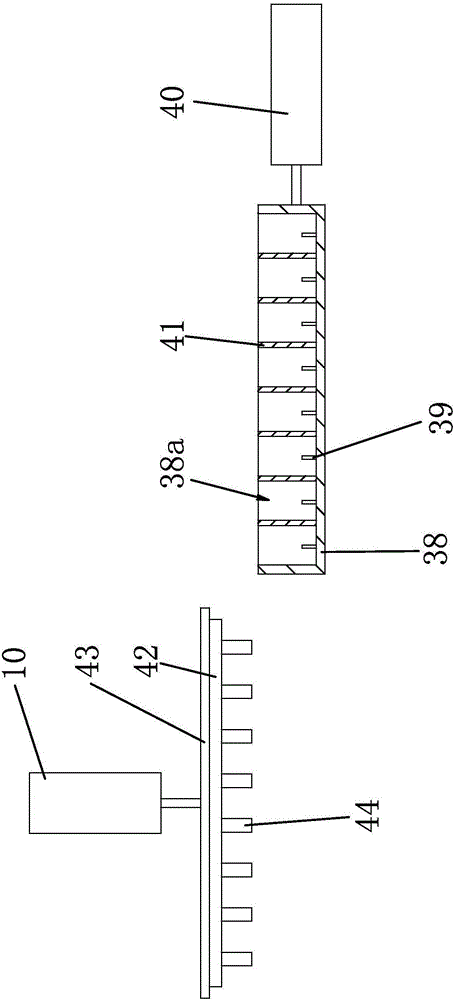

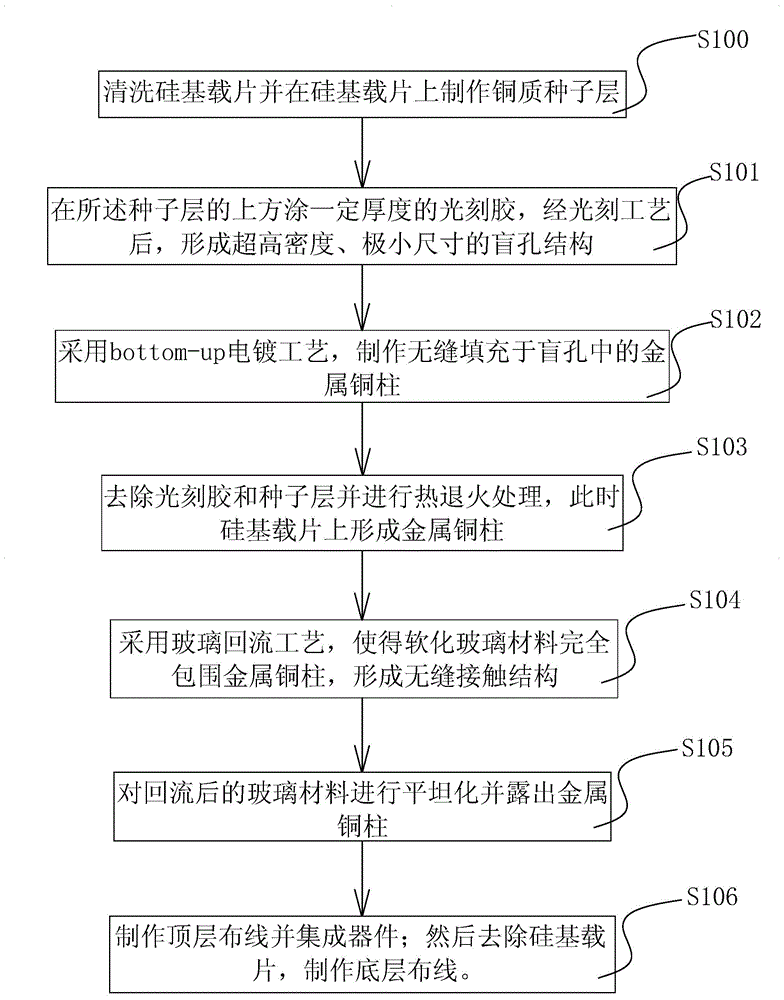

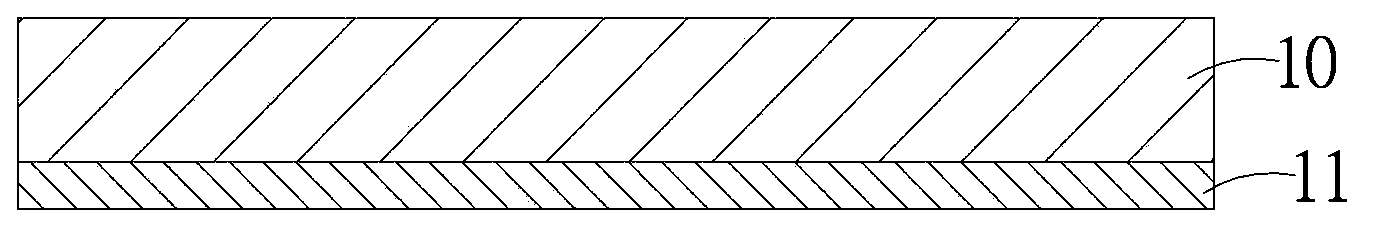

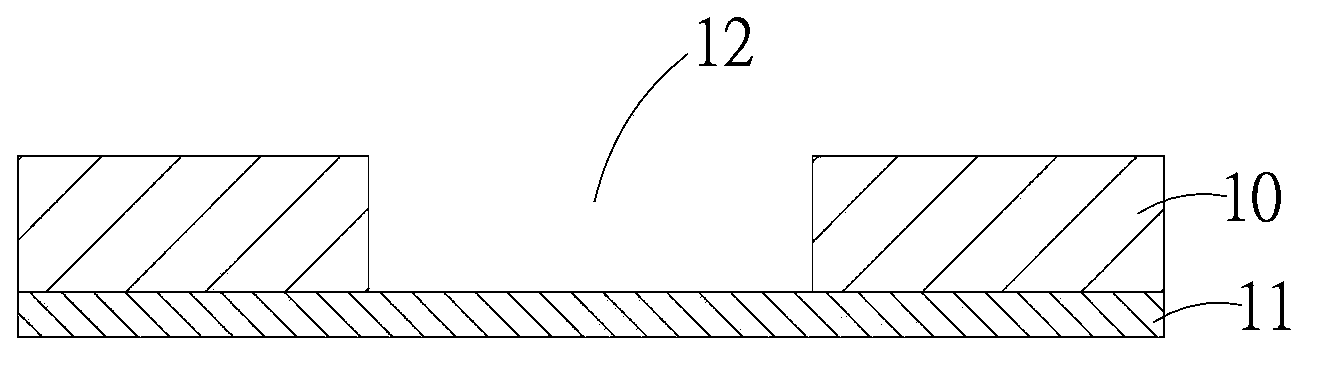

Manufacturing method of ultrathin glass adapter plate

ActiveCN104485288AAdvantages of production methodImprove reliabilitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingRefluxPhotoresist

The invention discloses a manufacturing method of an ultrathin glass adapter plate. The manufacturing method comprises the following steps: (1) washing silicon-based slide glass and manufacturing a copper seed layer on the silicon-based slide glass; (2) coating the seed layer with photoresist with certain thickness, and implementing a photolithography technique to form a blind hole structure with ultrahigh density and extremely small size; (3) manufacturing a metal copper cylinder filling the blind hole in a seamless way by adopting a bottom-up electroplating technology; (4) removing the photoresist and the seed layer, and carrying out thermal annealing to form the metal copper cylinder on the silicon-based slide glass; (5) implementing a glass reflux technology so that a softened glass material completely surrounds the metal copper cylinder to form a seamless contact structure; (6) carrying out flattening on the glass material subjected to reflux and exposing the metal copper cylinder; (7) carrying out top layer wiring and bottom layer wiring. The manufacturing method of the ultrathin glass adapter plate can be used for manufacturing the ultrathin glass adapter plate which is provided with a vertical interconnecting structure with ultrahigh density and extremely small size. The manufacturing method disclosed by the invention is simple in process steps and relatively low in manufacturing cost.

Owner:NAT CENT FOR ADVANCED PACKAGING

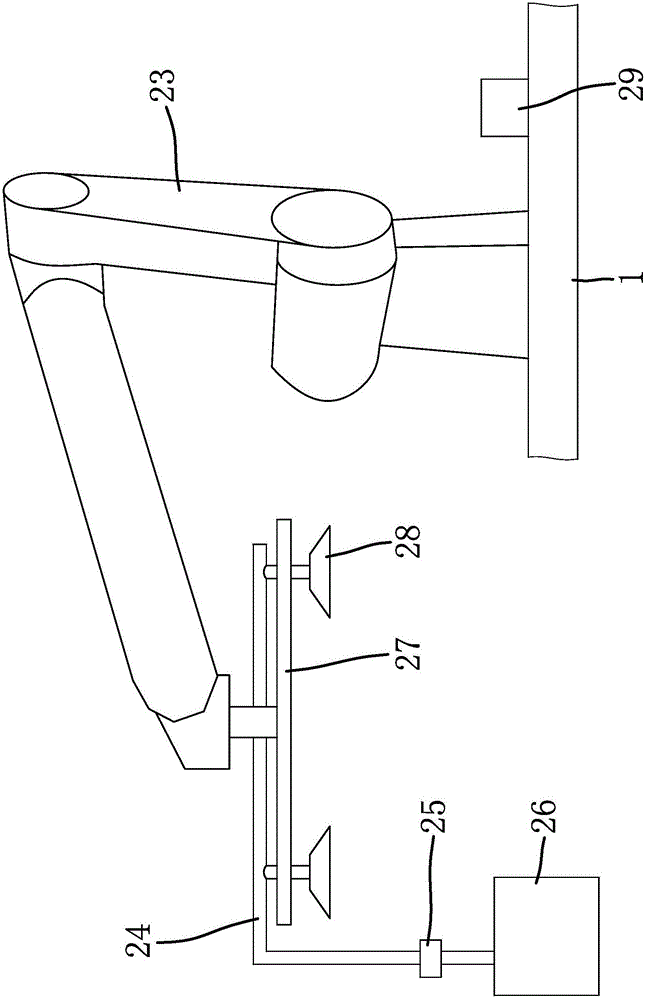

Method for manufacturing faucet shell

The invention provides a method for manufacturing a faucet shell, and belongs to the technical field of faucets. The method solves the problem that an existing method for manufacturing the faucet shell wastes time and labor. The method for manufacturing the faucet shell comprises the following steps of A, machining preparation, B, sealing, C, medium injection, D, extrusion and E, opening. The method for manufacturing the faucet shell has the advantages that the utilization rate of raw materials is high; the technological prejudice of technical staff in the field of faucet shell manufacturing is overcome; in the machining process, the method saves energy and is environmentally-friendly; and the application range is wide.

Owner:李仁波

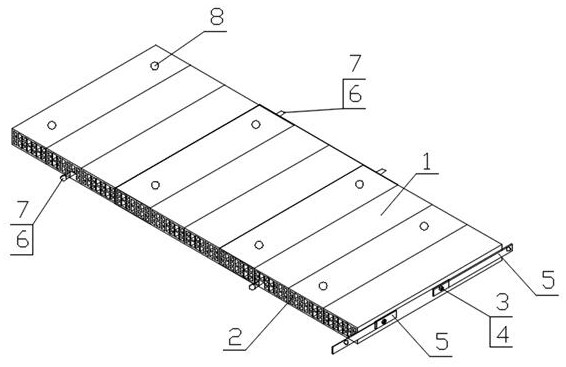

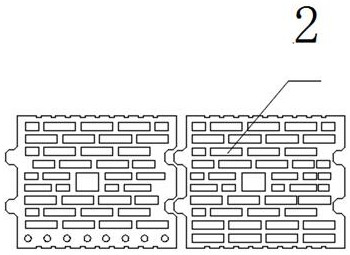

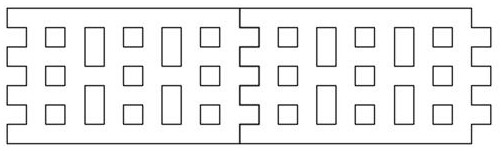

Manufacturing method of shale sintered composite plate for prefabricated building

InactiveCN111663710AImprove construction efficiencyShorten the construction periodWallsHeat proofingBrickThermal insulation

The invention discloses a manufacturing method of a shale sintered composite plate for a prefabricated building. A plurality of thermal insulation holes are formed in a hollow brick body. One or morepenetrating reinforcing steel bar holes for reinforcing steel bars to penetrate through are formed in the direction perpendicular to the direction of the thermal insulation holes. A viscose for connection is sprayed or painted quantitatively between ends of every two adjacent hollow brick bodies, and a reinforcing steel bar penetrates into each overall reinforcing steel bar hole; the viscose fulfills gaps between every two adjacent hollow brick bodies under extrusion; and the ends of the hollow brick bodies are provided with connecting blocks correspondingly, each connecting block is at leastprovided with two connecting holes, one connecting hole is connected with one end of the corresponding reinforcing steel bar, other holes serve as bolt connecting holes for fixing bolts, and the sintered composite plate is formed. Platy wall board structures of various areas are prefabricated in a factory and then transported to a construction site to be overall installed on site, so that construction efficiency is greatly improved, operators for on-site bricklaying construction are greatly reduced, a construction period is shortened, and construction cost is reduced.

Owner:重庆金彧新型环保建材有限公司

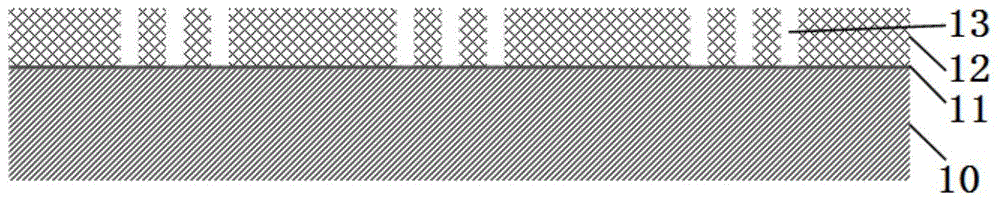

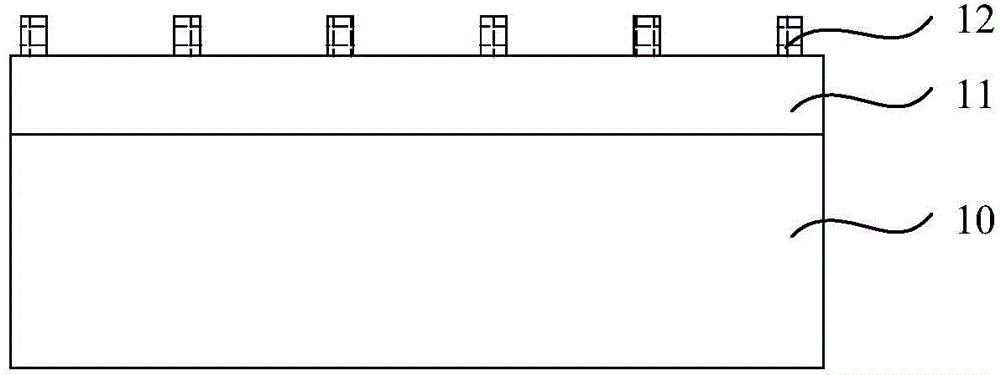

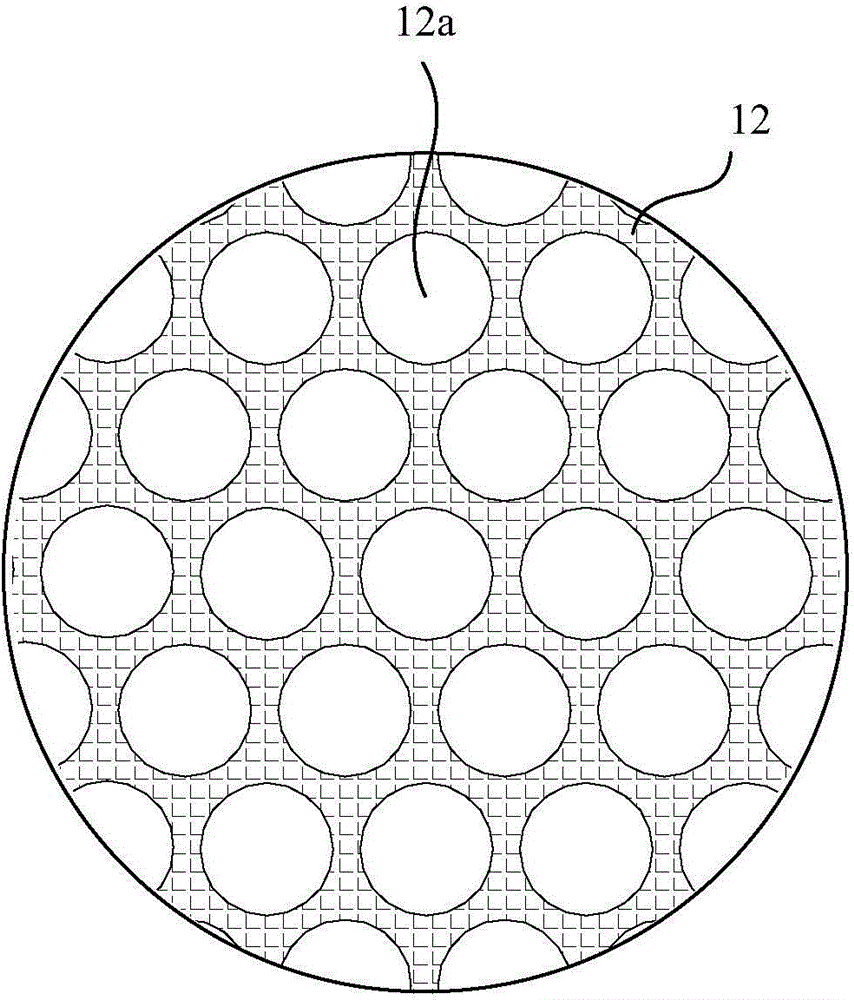

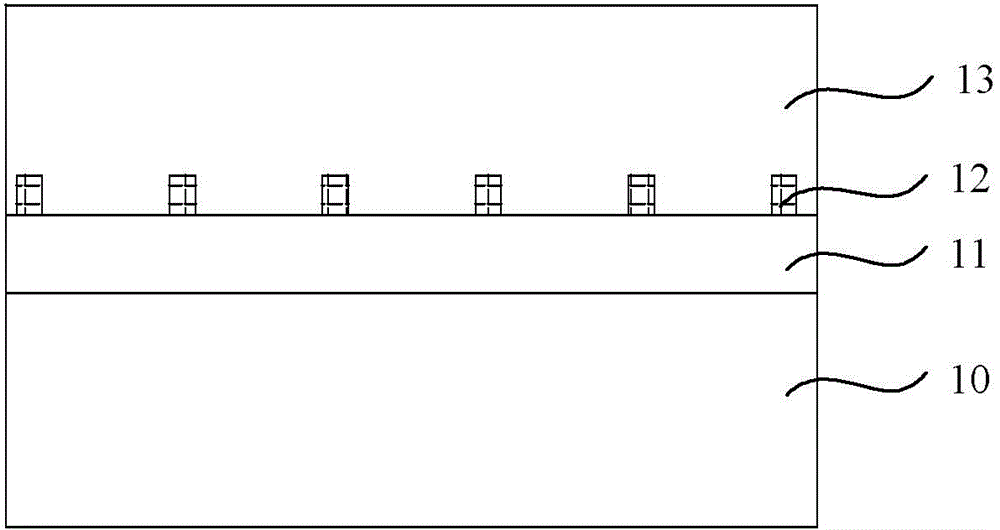

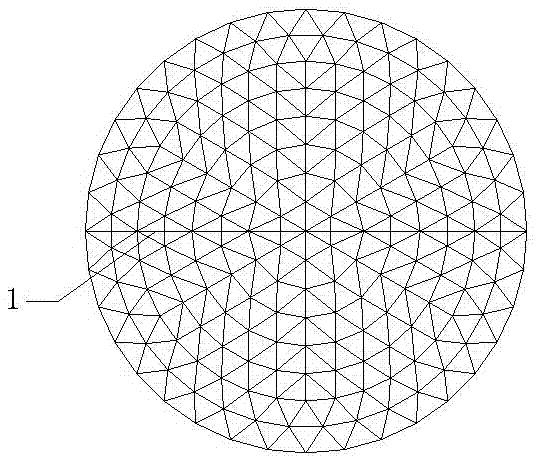

Substrate and epitaxial wafer for flip LED chips and making methods thereof

ActiveCN104835890AEliminate dislocation defectsAvoid reflectionsSemiconductor devicesQuantum efficiencyGallium nitride

The invention provides a substrate and an epitaxial wafer for flip LED chips and making methods thereof. The substrate comprises a gallium nitride substrate material and a dielectric layer with a graphical structure, and the dielectric layer is embedded into the gallium nitride substrate material. The substrate making method comprises the following steps: forming a lattice matching layer on a sapphire substrate; forming a dielectric layer with a graphical structure on the lattice matching layer, wherein the dielectric layer exposes part of the lattice matching layer; growing a gallium nitride substrate material on the lattice matching layer and the dielectric layer until the lattice matching layer and the dielectric layer are completely separated due to the stress of the gallium nitride substrate material; and removing at least part of the lattice matching layer. Both the gallium nitride substrate material and the dielectric layer embedded in the gallium nitride substrate material adopted by the substrate for flip LED chips provided by the invention have double functions of internal quantum efficiency increasing and external quantum efficiency increasing.

Owner:HANGZHOU SILAN AZURE

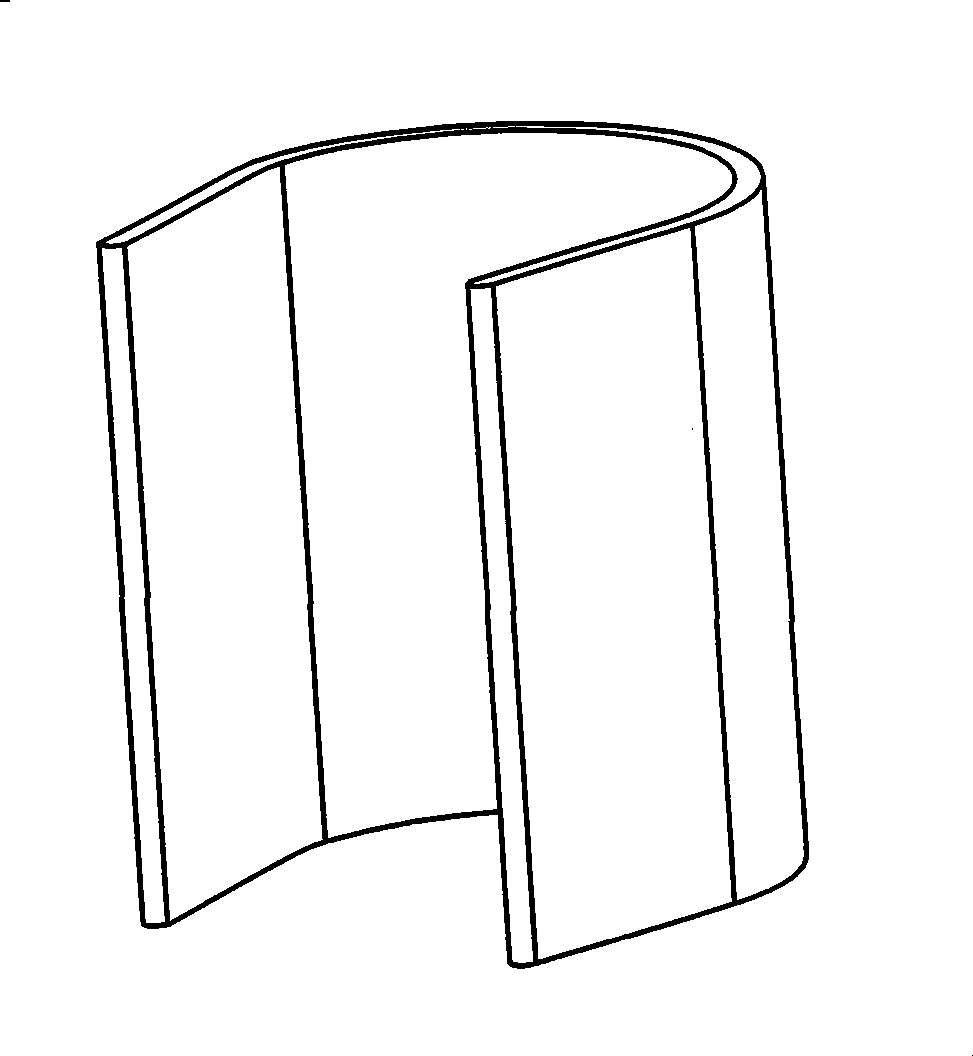

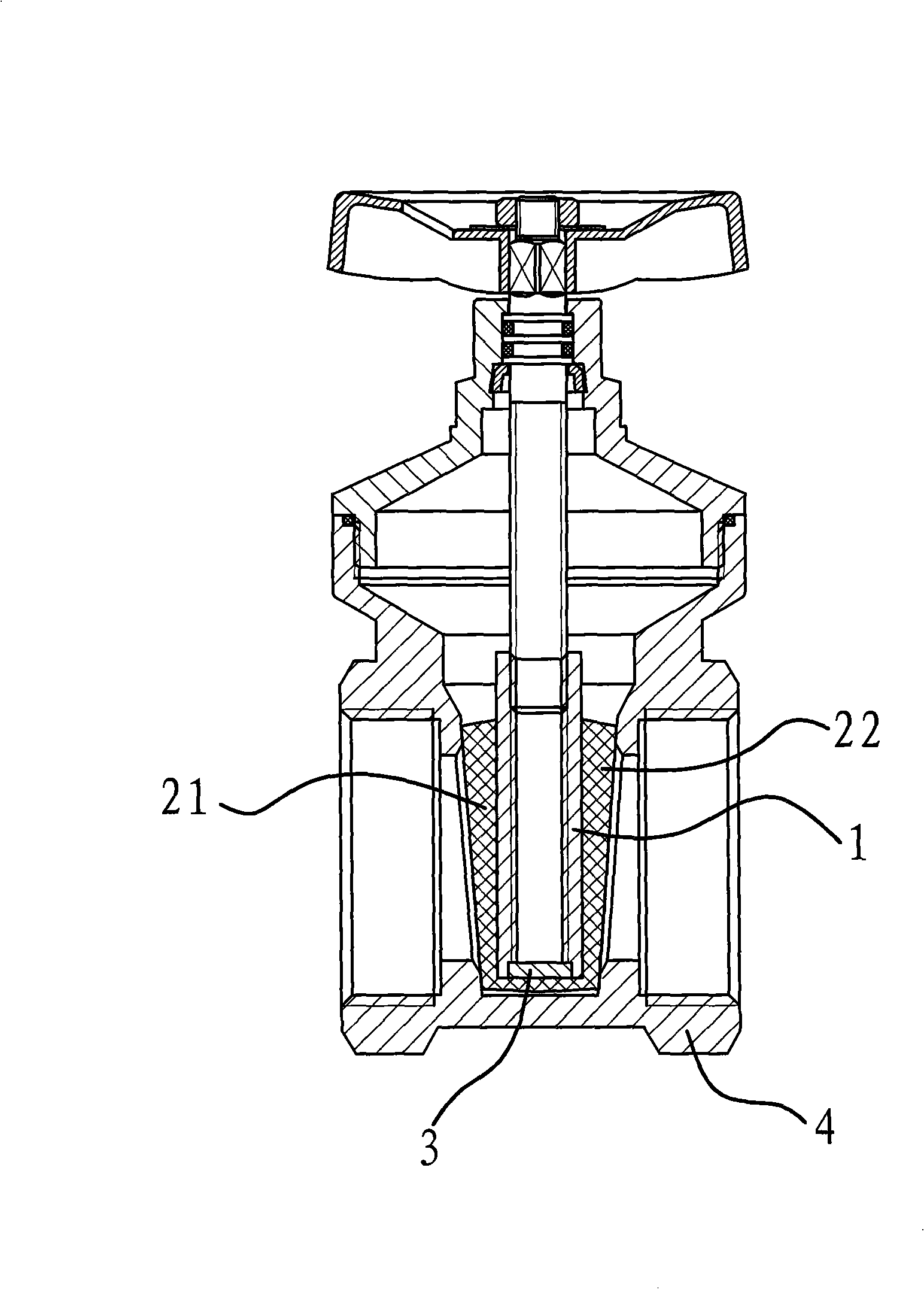

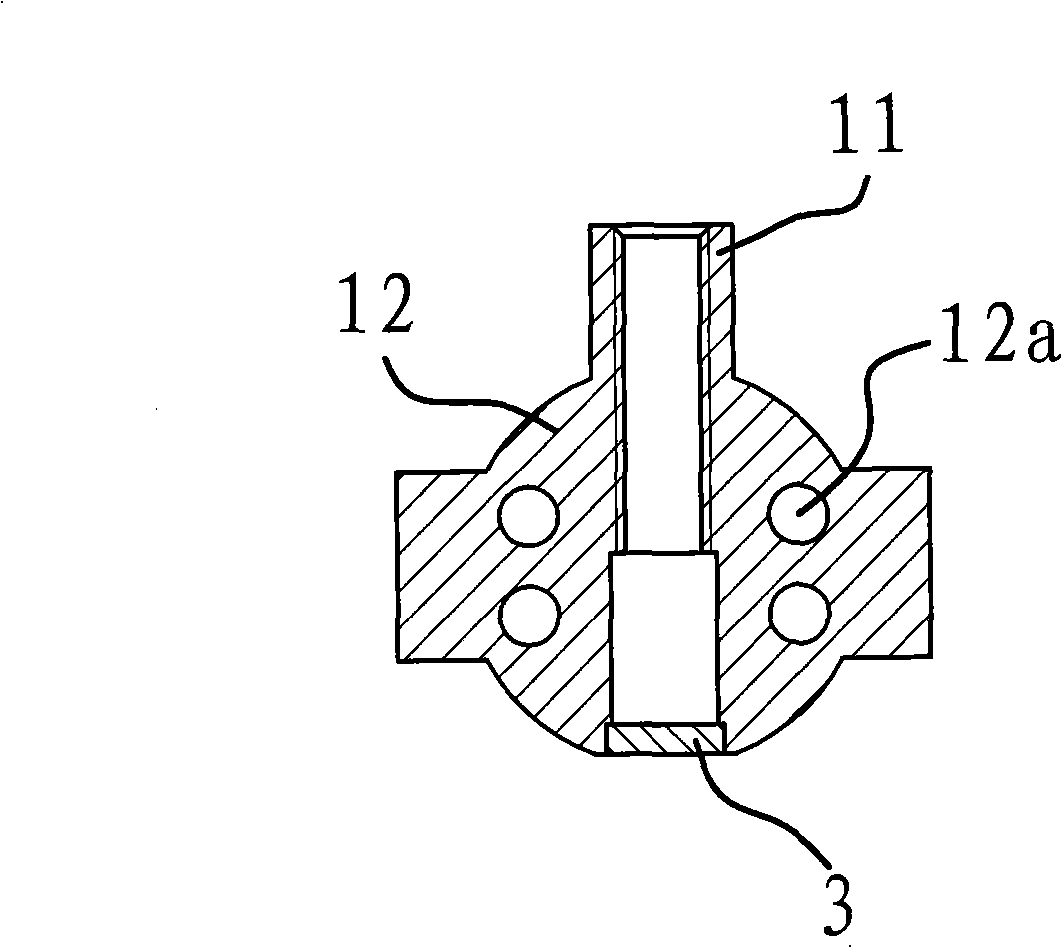

Valve plate of gate valve and method for manufacturing the same

InactiveCN101328980AStrong connectionGood binding rateOperating means/releasing devices for valvesSlide valveEngineeringCopper

The invention provides a valve plate for a gate valve and a manufacture method thereof, belonging to the valve technical field. The invention solves the problems that a sealing material of the valve plate of the prior gate valve is easily separated from the valve plate, and the method for manufacturing the valve plate of the gate vale has technical problems, such as complicated processing process and so on. The valve plate of the gate valve comprises a copper plate and a rubber inclusion coated and fixed outside the copper plate, wherein, the copper plate is provided with a plurality of through holes; the rubber inclusion is formed by a left part and a right part; a plurality of connectors passing through the through holes are arranged between the left part and the right part of the rubber inclusion; the connectors, the left part and the right part of the rubber inclusion are connected into a whole. The method for manufacturing the valve plate comprises the following steps of: a. opening the through holes; b. connecting a choke plug; c. forming, which is to place the copper plate in a mould, add solid rubber in the mould, heat the copper plate and the solid rubber in the mould to make the solid rubber melted into a liquid state, evenly coated on the outer surface of the copper plate and injected in the through holes of the copper plate, so that the valve plate is formed after cooling. The valve plate for the gate valve has the advantages of firm connection, simple structure, large withstood pressure of the gate valve, simple processing process, low manufacturing cost and so on.

Owner:浙江通满智能科技有限公司

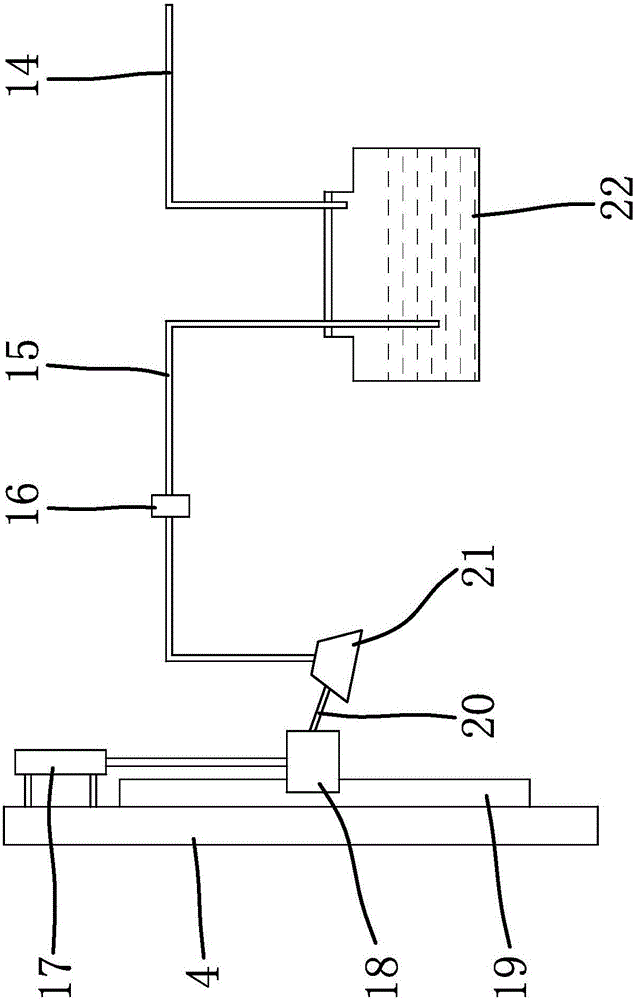

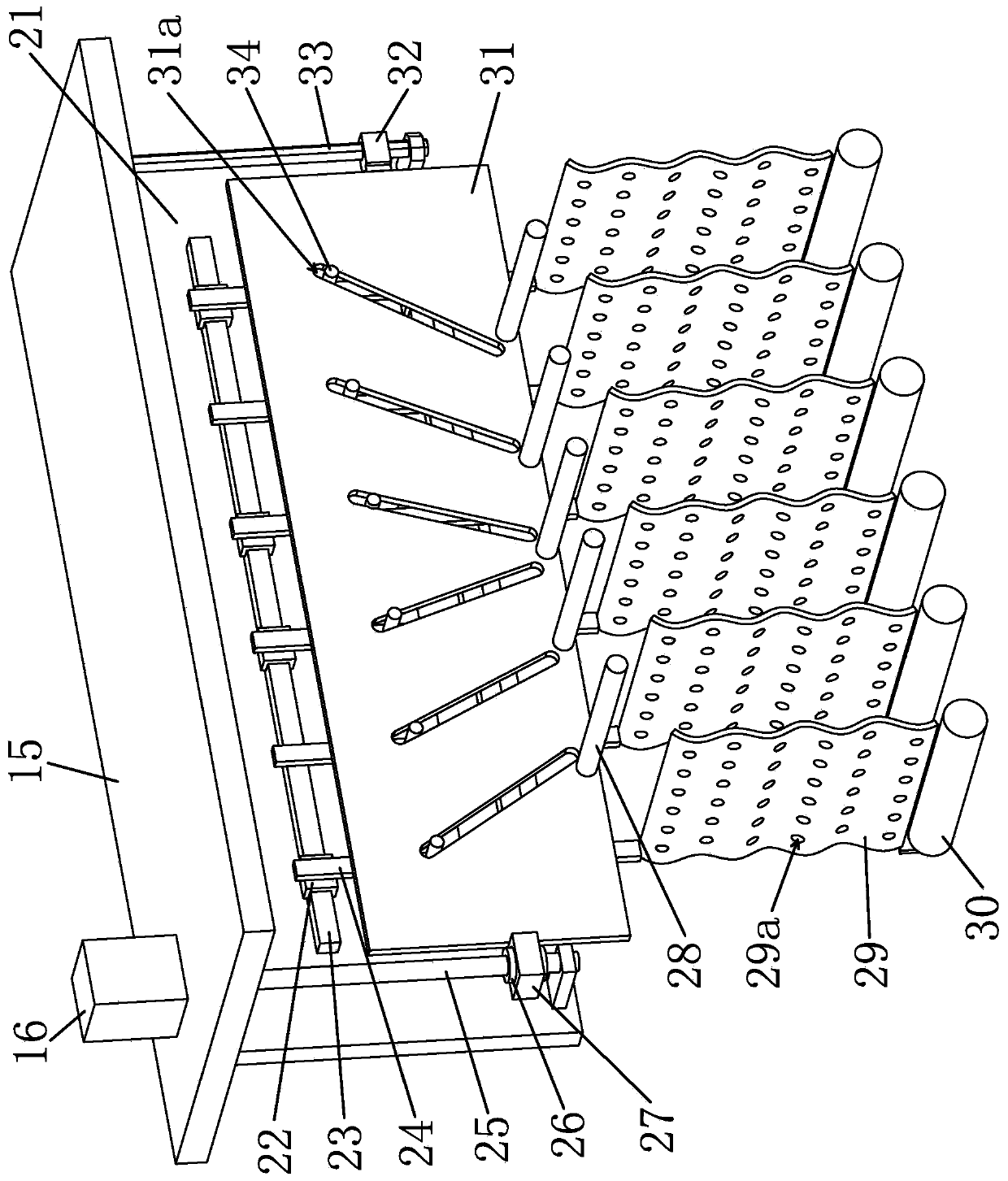

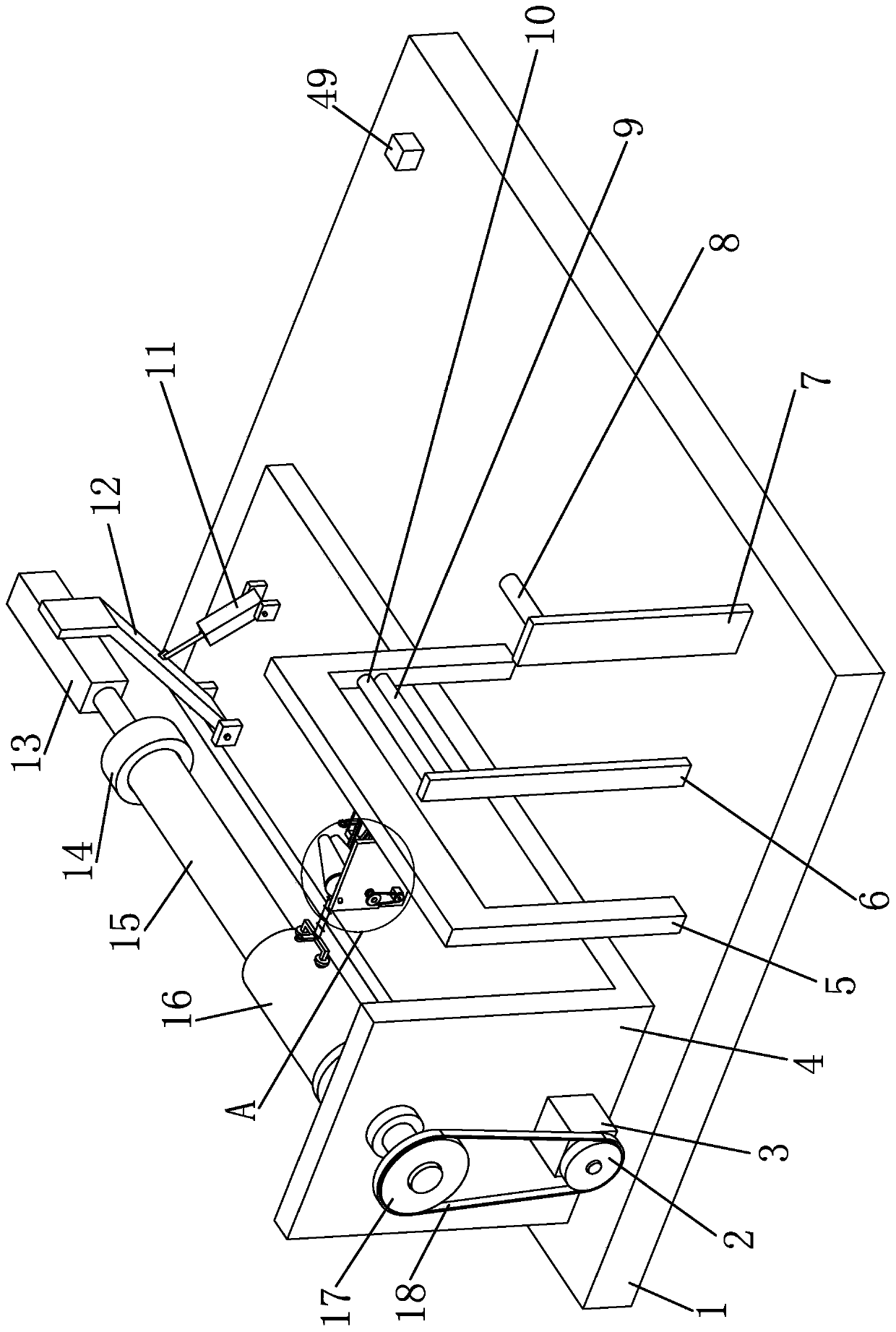

Manufacturing method of tool for concrete finishing and thin film covering

InactiveCN110449762AAdvantages of production methodSimple structureCeramic shaping apparatusBuilding material handlingBuilding constructionExtrusion

The invention discloses a manufacturing method of a tool for concrete finishing and thin film covering. The method is characterized by comprising the following steps of a, manufacturing a film pavingframe; b, manufacturing a roughening and leveling frame; and c, providing a pull rod, wherein one end of the pull rod is provided with a handle, and the other end continuously penetrates through top end steel pipes of the roughening and leveling frame and the film paving frame and is fixed with the top end steel pipes of the roughening and leveling frame and the film paving frame, and therefore the tool for concrete finishing and thin film covering is obtained. The manufacturing method of the tool for concrete finishing and thin film covering has the advantages of being simple in device structure and convenient in manufacturing; through optimizing the concrete surface leveling process and film covering process, finishing and covering can be combined into a whole through the two processes,so that concrete forming quality as well as construction progress are improved; and compared with an existing tool combining functions of concrete finishing and thin film covering, the method disclosed by the invention has the advantages that phenomena of extrusion and concrete bulking do not generate, the surface quality of concrete can be guaranteed, and subsequent film covering can be facilitated

Owner:MCC5 GROUP CORP SHANGHAI

Making method of digital jacquard functional sofa fabric

InactiveCN105904802AEasy to remove smokeAvoid wastingLiquid surface applicatorsLamination ancillary operationsCompound aEngineering

Owner:ZHEJIANG APOLLO LEATHER PROD CO LTD

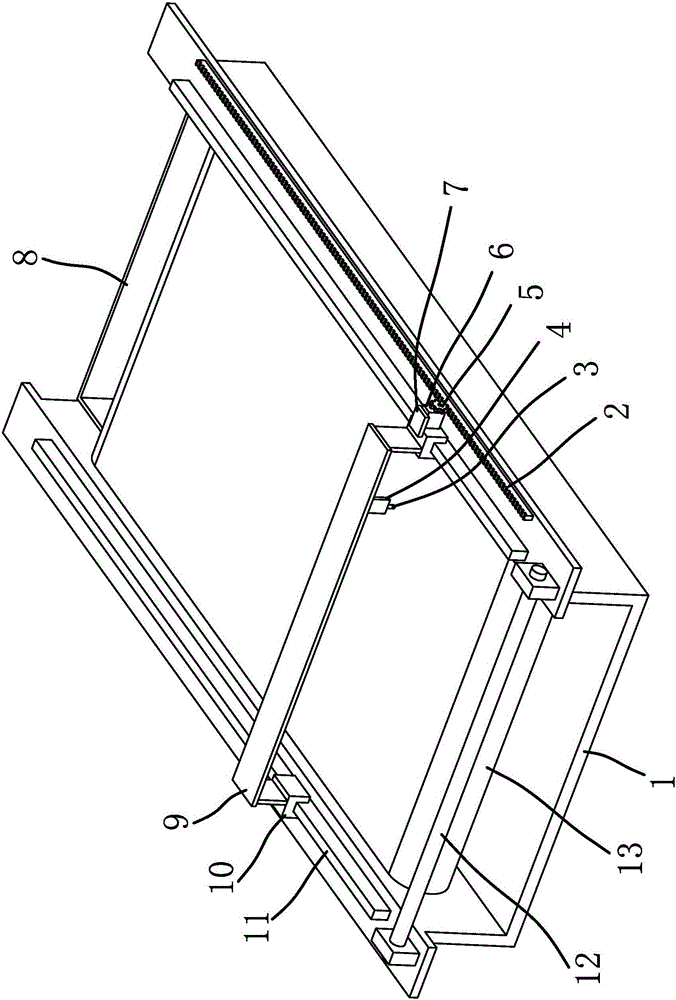

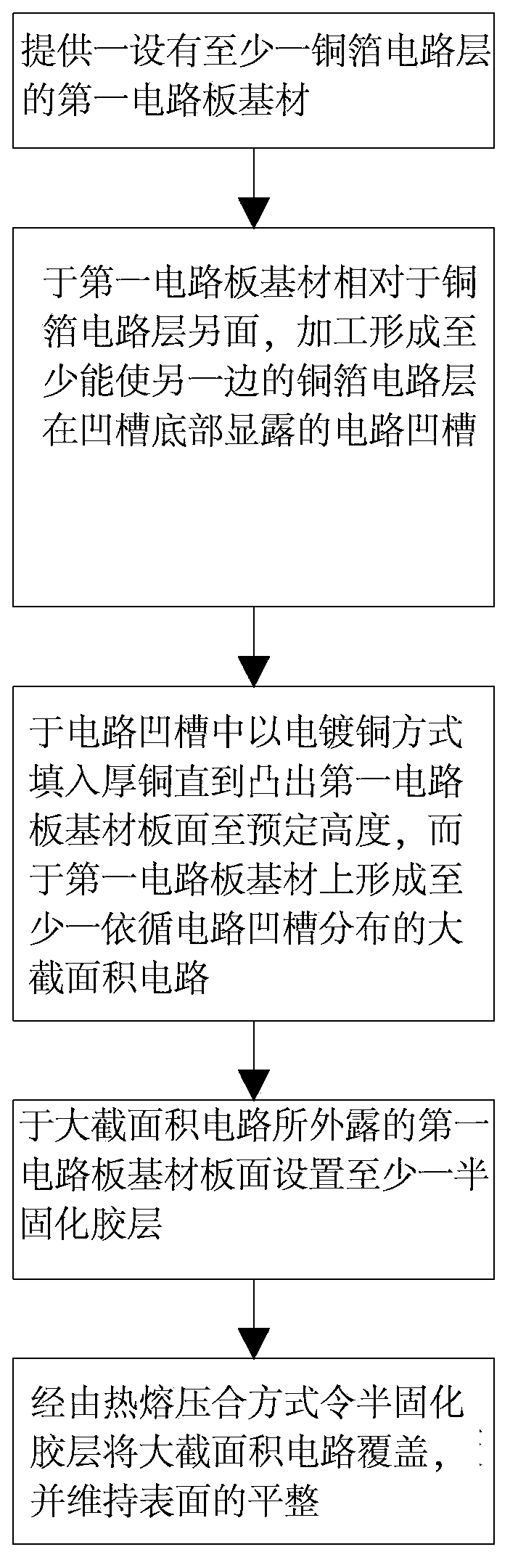

Circuit-board manufacturing method

InactiveCN103781284AReduce material costsAvoid wasting expensive metalsPrinted circuit assemblingCopper foilEngineering

The invention discloses a circuit-board manufacturing method and provides a circuit-board manufacturing method capable of manufacturing at least one large-cross-section circuit hidden in a board body on a circuit-board substrate. In the circuit-board manufacturing method, basically on a first circuit-board substrate provided with a copper-foil circuit layer, a circuit groove which is at least capable of making a copper-foil circuit layer at the other side exposed at the bottom part of the groove is formed through processing; then thick copper is filled into the circuit groove in an electrocoppering method until projecting out of the first circuit-board substrate for a preset height and thus the large-cross-section circuit which is distributed along the circuit groove is formed; and then the first circuit-board substrate exposed by the large-cross-section circuit is covered with at least one semi-cured adhesive layer and through a hot-melting laminating method, the semi-cured adhesive layer is made cover the large-cross-section circuit and flatness of the surface is maintained so that a circuit board, in which at least one thin circuit and least one large-cross-section circuit can be manufactured on the same first circuit-board substrate, can be obtained. Therefore, objectives of saving material cost, preventing waste of high-price metals and reducing pollution sources are achieved.

Owner:BOARDTEK ELECTRONICS CORP

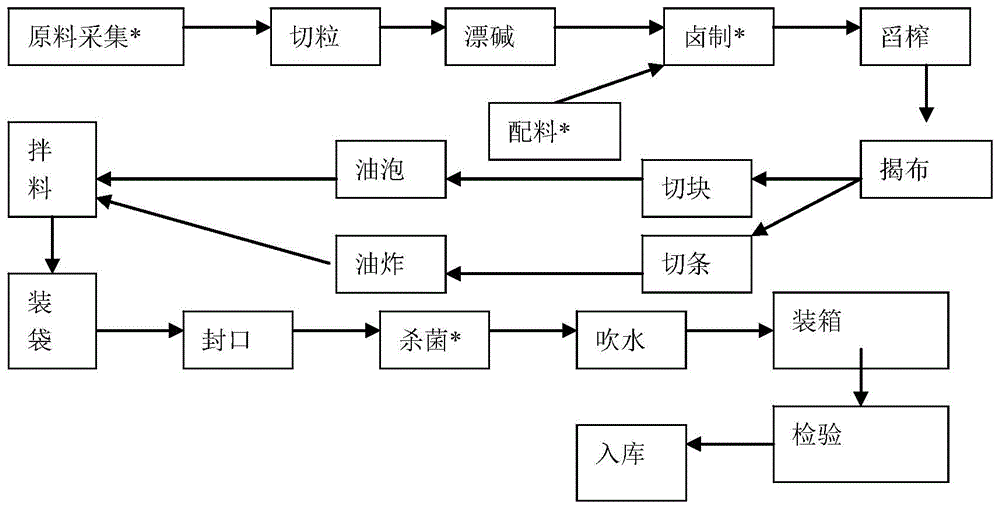

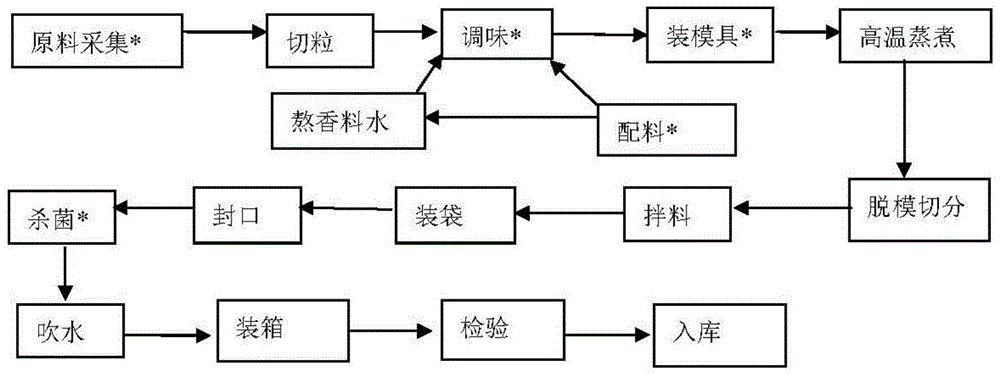

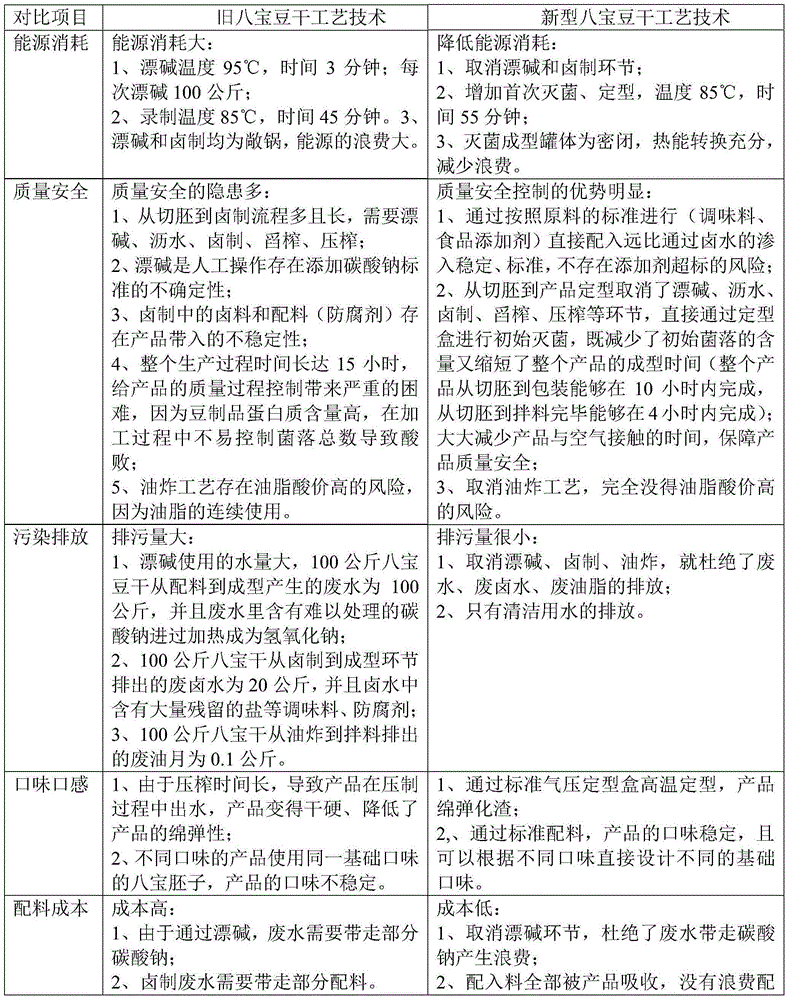

Producing method of eight-ingredient dried bean curd

ActiveCN105230801AAdvantages of production methodFull conversionCheese manufactureFood scienceBiotechnologyFlavor

The invention discloses a producing method of eight-ingredient dried bean curd, wherein the production method includes the following processes: raw material acquisition, grain-sized dicing, seasoning, mold loading, high-temperature steam cooking, demoulding segmentation, material mixing, bagging, mouth sealing, sterilization, water blowing, box packing, inspection, and warehousing. In the raw material acquisition process, dried bean curd is acquired as a raw material. The seasoning process includes the following steps: 1) decocting spice water; and 2) preparing ingredients, preparing a seasoner by using the spice water, adding the seasoner in the dried bean curd diced into grains in the grain-sized dicing process, and stirring evenly. In the mold loading process, the seasoned dried bean curd grains are metered, then poured in a mold box and laid flatly, the pressure intensity of 500 kPa-2000 kPa is applied in the mold box, a cover of the mold box covers, and the pressure intensity is kept by using the cover of the mold box. In the high-temperature steam cooking process, the mold box loaded with the dried bean curd grains is sent into a high-temperature sterilization kettle and is steam-cooked, the steam cooking temperature is 85-120 DEG C, and the steam cooking time is 15-55 minutes; and after the steam cooking is finished, the mold box is cooled in the high-temperature sterilization kettle, and is discharged out of the kettle after being cooled to 45-55 DEG C.

Owner:CHONGQING DUOWEIDUO FOOD CO LTD +1

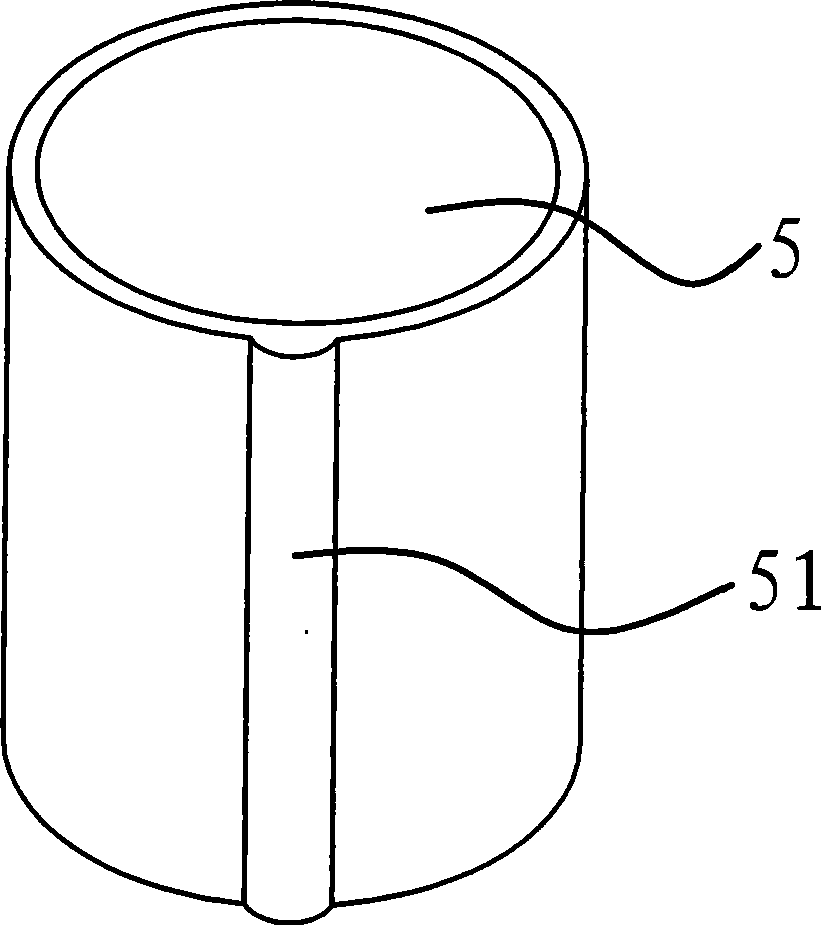

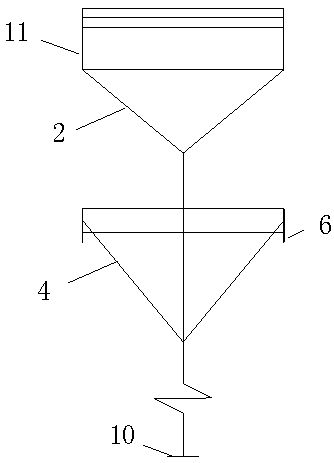

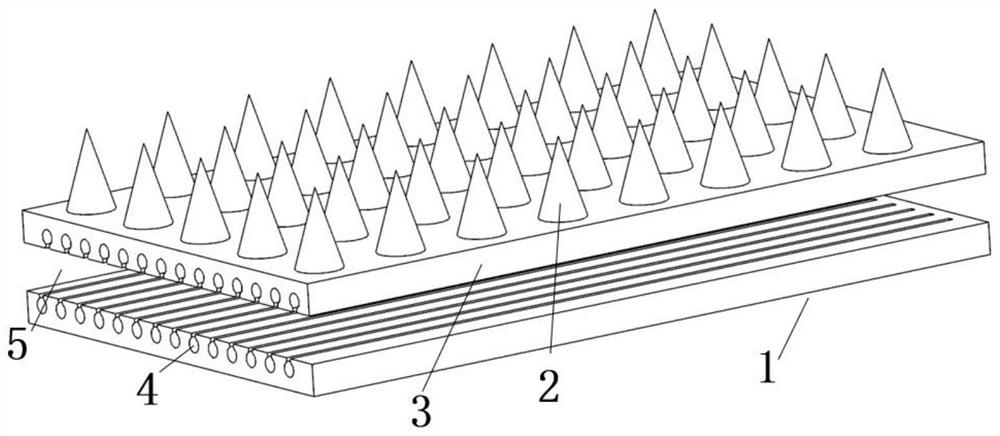

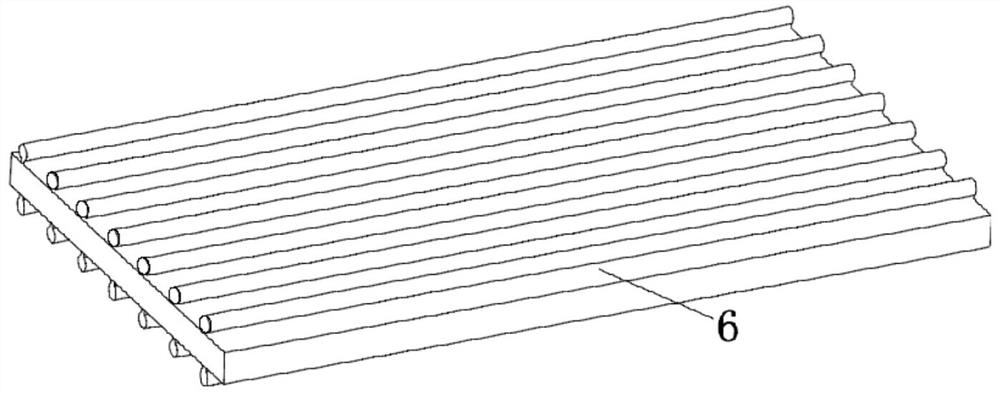

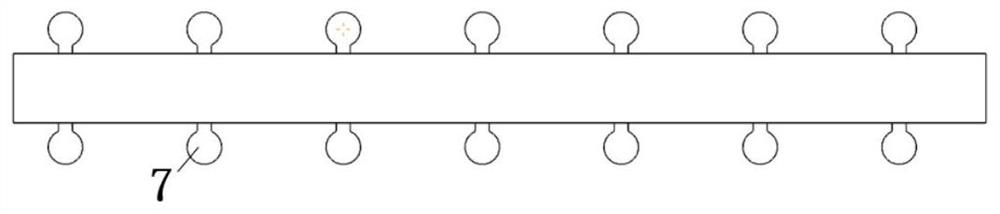

Ceramic vapor chamber structure provided with fins and based on tape casting method and manufacturing method of ceramic vapor chamber structure

PendingCN112985134AReduce shape constraintsReduce thermal resistanceIndirect heat exchangersLaminated elementsTape castingComposite material

The invention provides a ceramic vapor chamber structure provided with fins and based on a tape casting method. The ceramic vapor chamber structure comprises a vapor chamber, the fins and working medium fluid. The vapor chamber comprises an upper plate body and a lower plate body, a cavity is arranged between the upper plate body and the lower plate body, the multiple fins are uniformly distributed on the body outer side of the upper plate body, multiple channels are arranged on the bottom face of the upper plate body and the top face of the lower plate body, and the channels on the upper plate body and the lower plate body are arranged side by side. The working medium fluid is sealed in the cavity. The vapor chamber structure can solve the technical problems that an existing vapor chamber structure is poor in heat conduction capacity and poor in vapor chamber performance.

Owner:SOUTH CHINA UNIV OF TECH

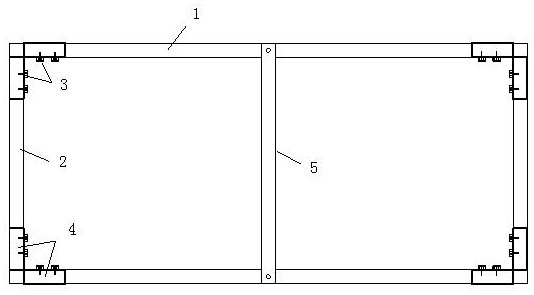

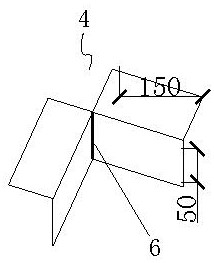

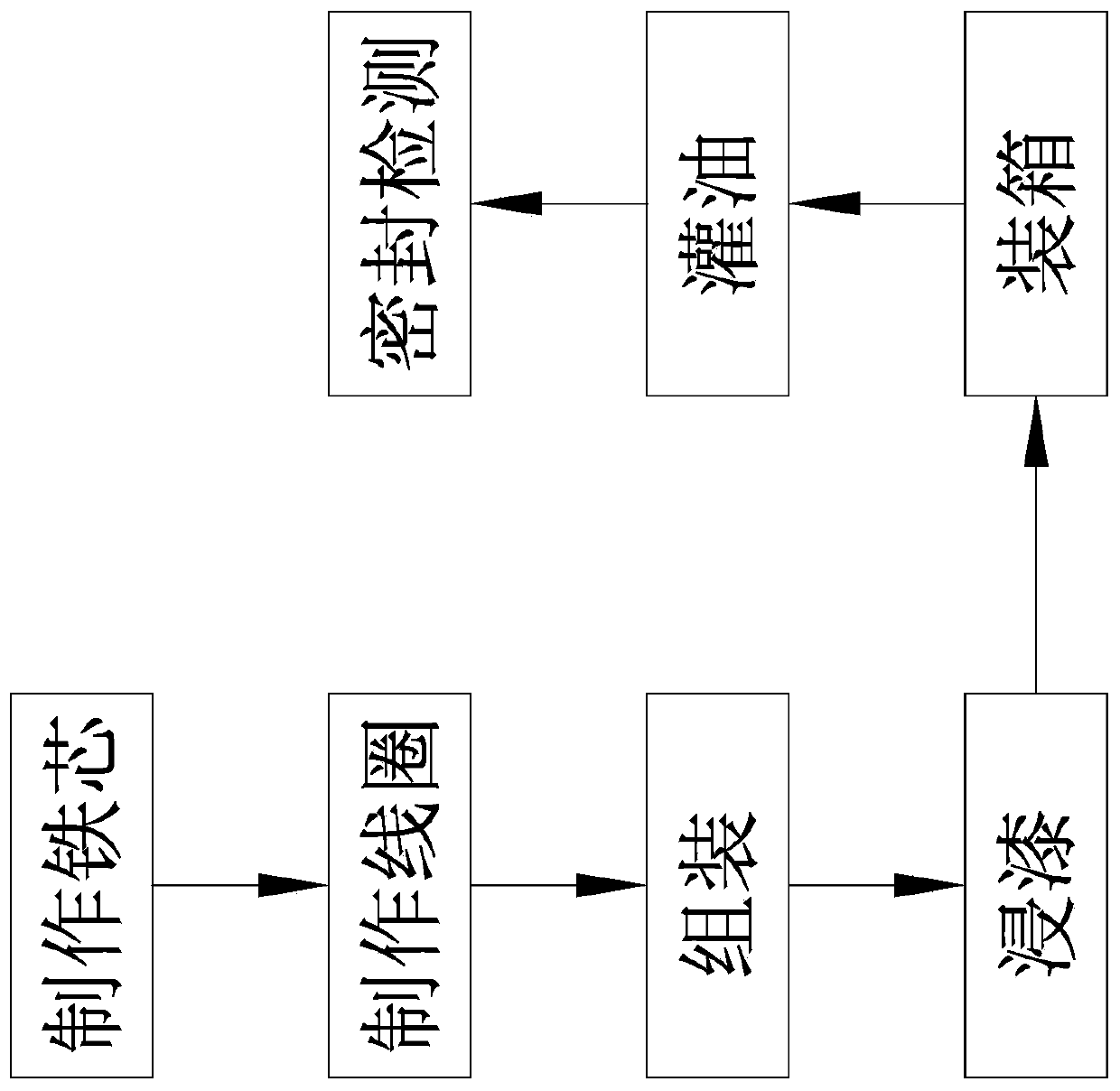

Method for manufacturing detachable toilet hanging mold support tool

InactiveCN111636678AAdvantages of production methodSimple structureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksPipeUltimate tensile strength

The invention provides a method for manufacturing a detachable toilet hanging mold support tool. The method is characterized by comprising the following steps of: a. Making a toilet hanging mold support tool main body; b. Making four limiting steel angles, wherein each limiting steel angle comprises two sections of steel angles, one side wide faces of the two sections of steel angles are vertically arranged, and the other side wide faces of the two sections of steel angles are horizontally arranged; c. Drilling a bolt hole at a matching position of the limiting steel angles and a corner of a rectangular frame; d. Providing a square steel pipe as a support rod of the rectangular frame, and the support rod is movably fixed at the centers of the two long sides of the rectangular frame by a bolt to achieve the effect of enhancing the strength of the long sides of the rectangular frame. According to the invention, the method for manufacturing a detachable toilet hanging mold support tool has the advantages of a simple tool structure and convenient production, being used by the handing mold in toilets with different, good forming of a concrete surface, convenient disassembly, being usedrepeatedly and reducing the engineering cost.

Owner:MCC5 GROUP CORP SHANGHAI

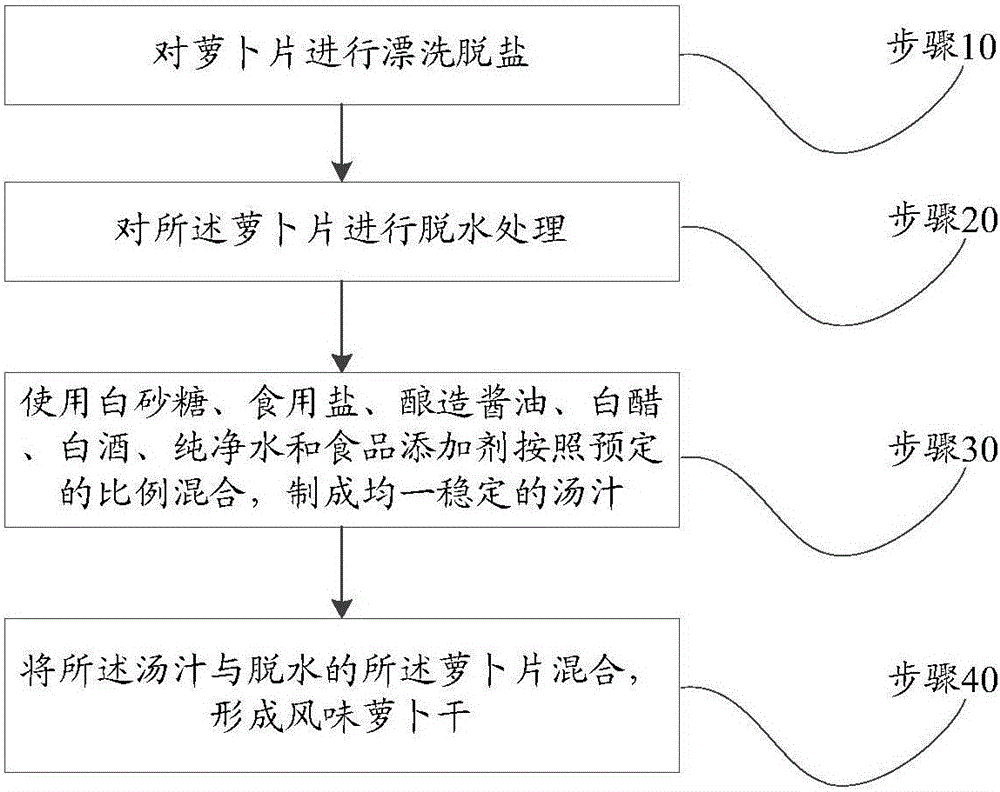

Making method of dried radishes

InactiveCN105995766AAdvantages of production methodImprove securityFruit and vegetables preservationFood ingredient for microbe protectionFood additiveFood flavor

The invention discloses a making method of dried radishes. The making method comprises the following steps of performing rinsing and desalting on radish slices; dehydrating the desalted radish slices; mixing white granulated sugar with edible salt, a fermented soy sauce, white vinegar, Baijiu, pure water and a food additive according to a predetermined proportion so as to make homogeneous stable cooking liquor; and mixing the cooking liquor with the dehydrated radish slices so as to obtain the flavored dried radishes. According to the making method of the dried radishes, the dehydrated radish slices are mixed with the cooking liquor, so that the flavored dried radishes are formed; after the dehydrated radish slices are mixed with the cooking liquor, because a part of water is lost, the cooking liquor is sufficiently absorbed; therefore, the radish slices not only have the taste of the radishes, but also have unique flavor; besides, salt, sugar and the like in the cooking liquor can effectively restrain and kill bacteria, so that the radish slices are delicious, the safety of products can be improved, and the quality guarantee period is prolonged.

Owner:海南罗牛山调味品有限公司

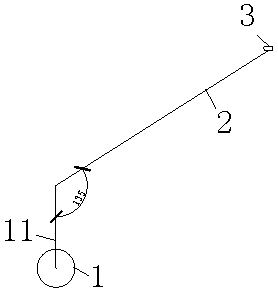

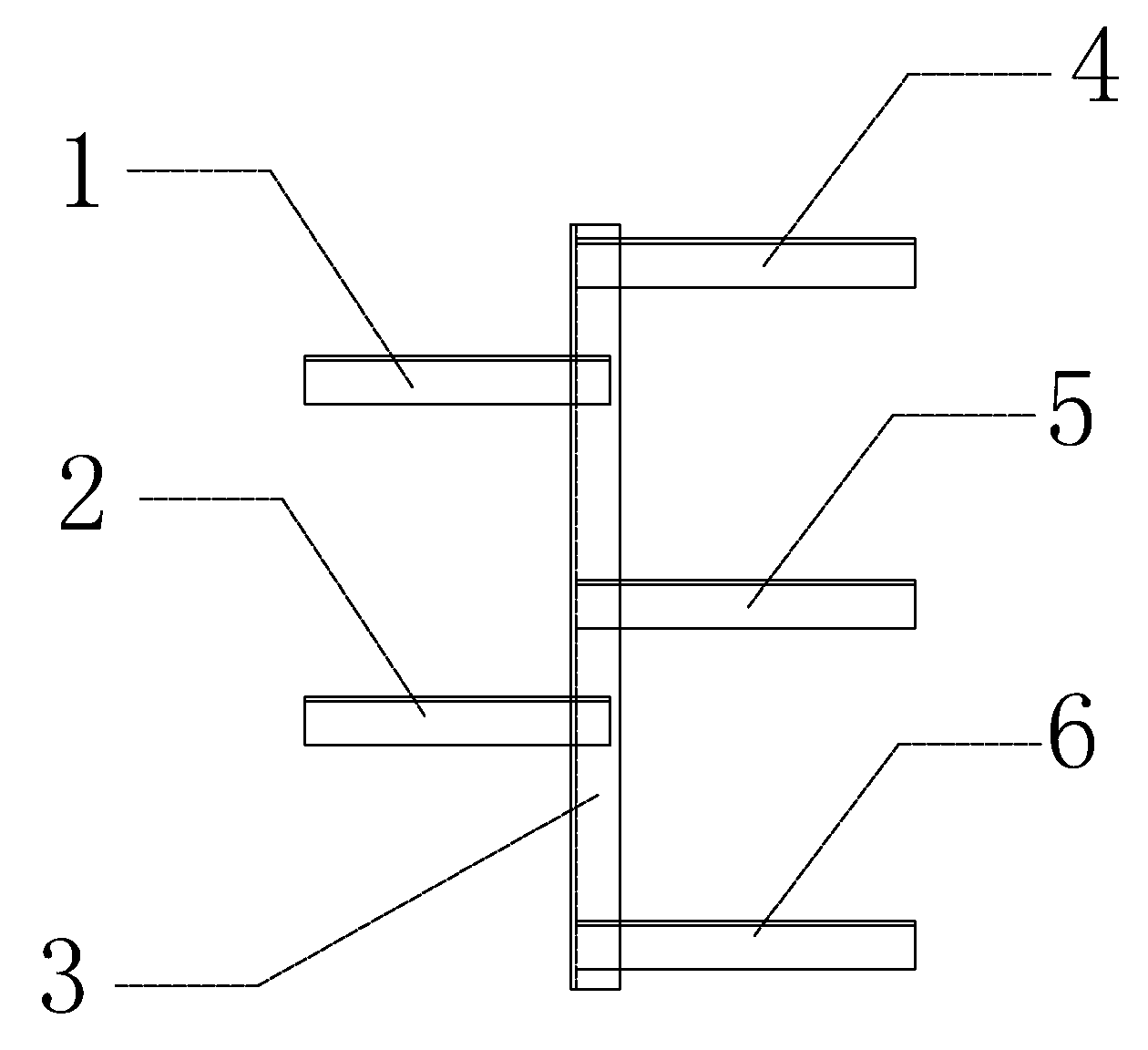

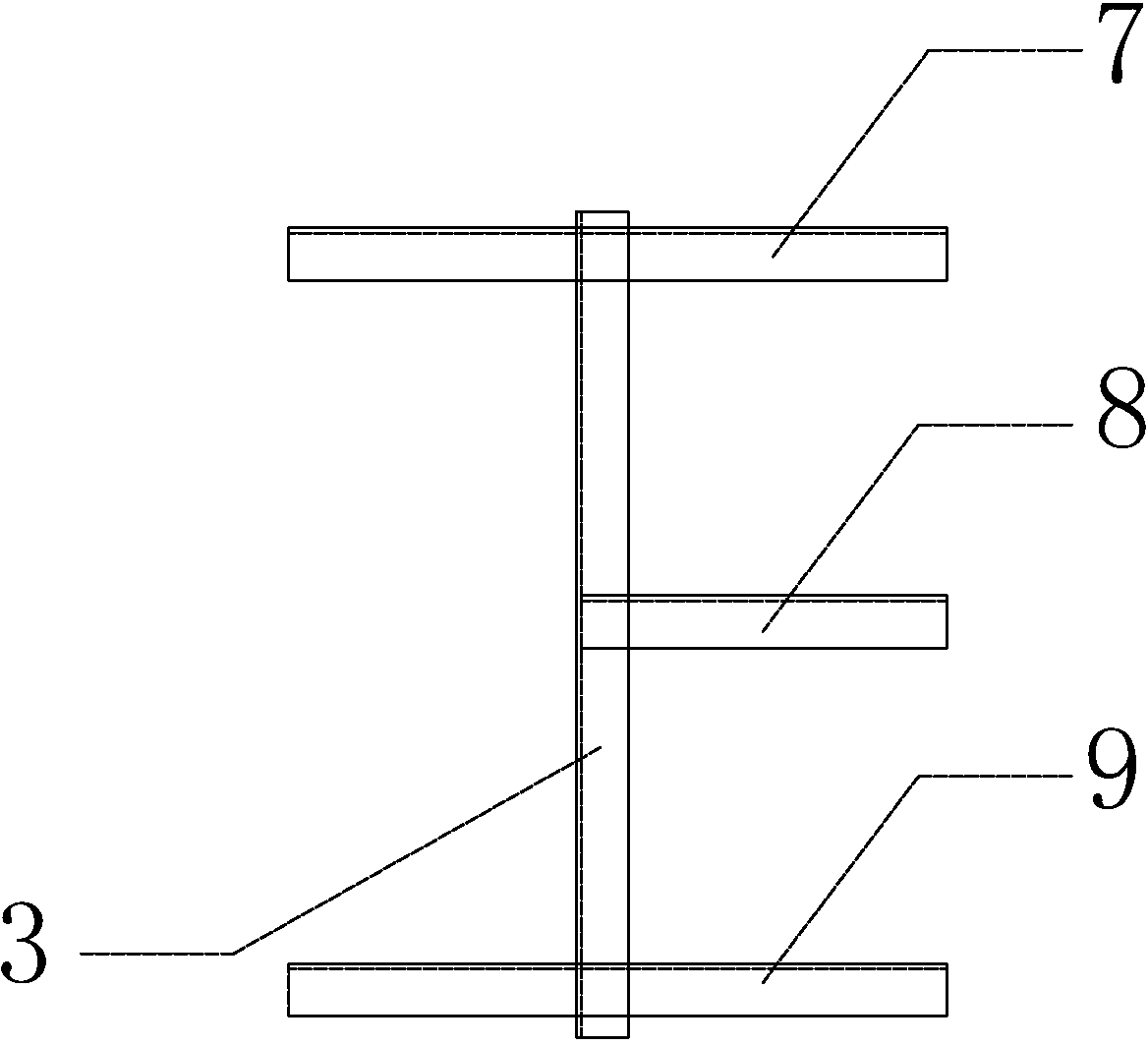

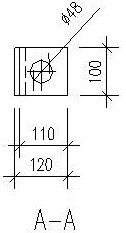

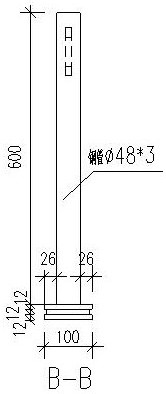

Trolley line support and manufacturing method thereof

ActiveCN103318763AAdvantages of production methodImprove stabilityLoad-engaging elementsStructural engineeringSteel columns

Owner:MCC5 GROUP CORP SHANGHAI

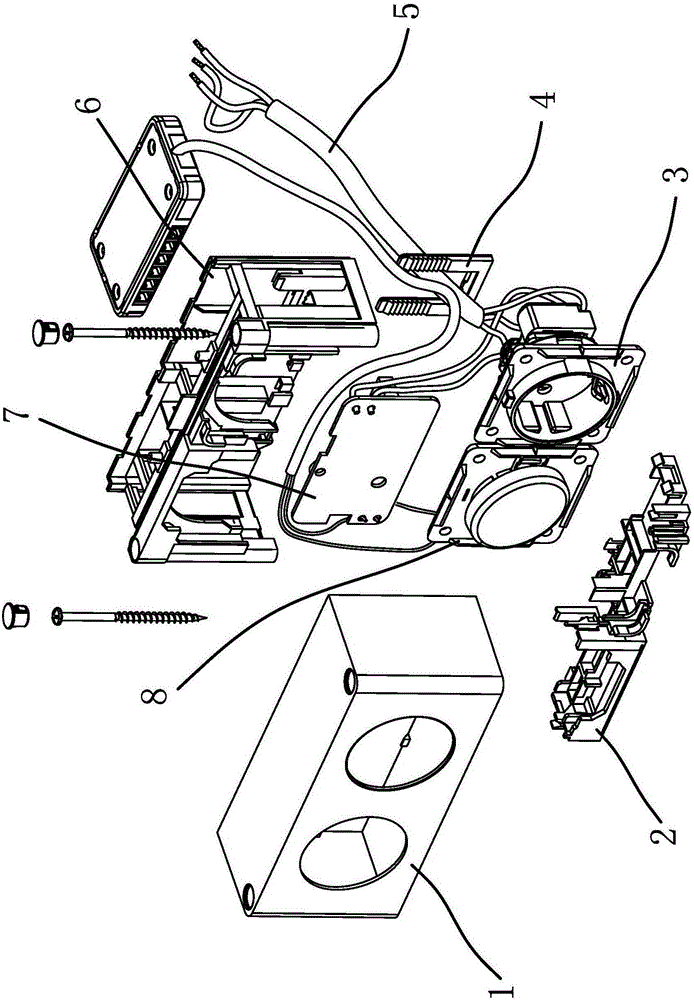

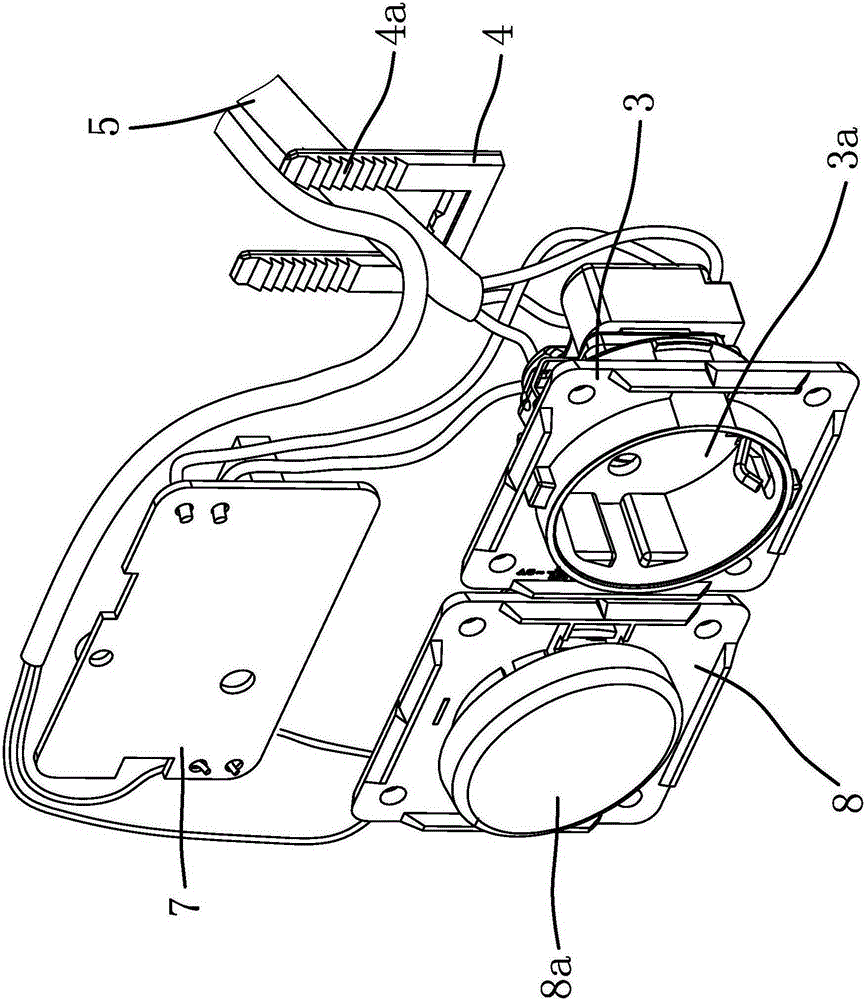

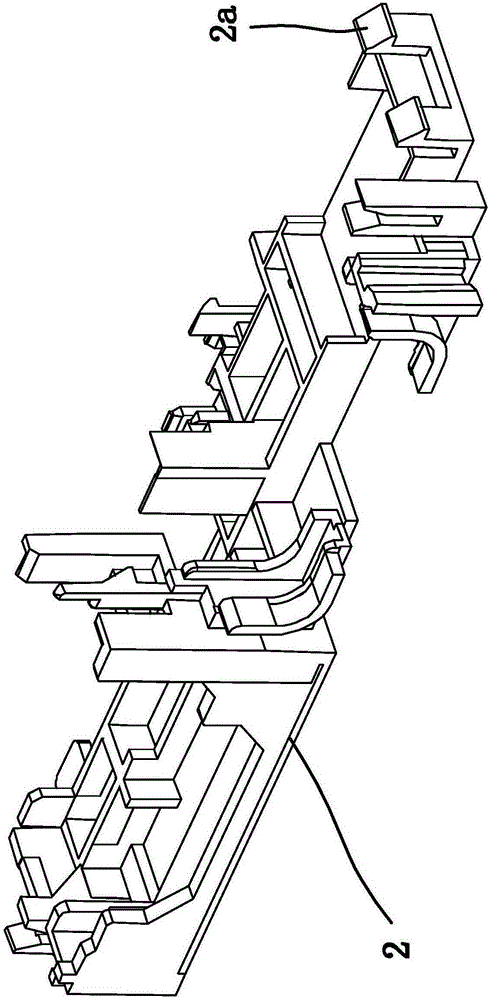

Buckling type LED drive power supply box and production method thereof

ActiveCN105202499AWell mixedImprove the mixing effectPoint-like light sourceElectric circuit arrangementsElastomerPolyethylene terephthalate

The invention provides a buckling type LED drive power supply box and a production method thereof and solves the technical problems that the conventional power supply box does not have the characteristics of heat resistance and corrosion resistance and can be only used in simple environments and singly used, a production method of the power supply box is absent and the like. The buckling type LED drive power supply box comprises an outer box body and an inner box body, wherein an opening is formed in one end of the outer box body, the inner box body is clamped in the outer box body through the opening and comprises a large frame and a small frame, a plurality of clamping grooves are formed in one end, facing the small frame, of the large frame, a plurality of clamped parts corresponding to the clamping grooves are arranged at one end, facing the large frame, of the small frame, and the clamped parts are clamped in the clamping grooves. The large frame is prepared through injection molding of a composition material which comprises components in percentage by weight as follows: 50%-60% of polyethylene terephthalate, 15%-25% of polypropylene, 8%-12% of polyethylene-octene elastomer, 3%-7% of titanium dioxide and 4%-8% of silicon carbide, and the sum of the components is 100%. The production method of the buckling type LED drive power supply box is further provided. The buckling type LED drive power supply box and the production method have the advantages of high practicability and high production efficiency.

Owner:ZHEJIANG YUYANG ELECTRONICS IND CO LTD

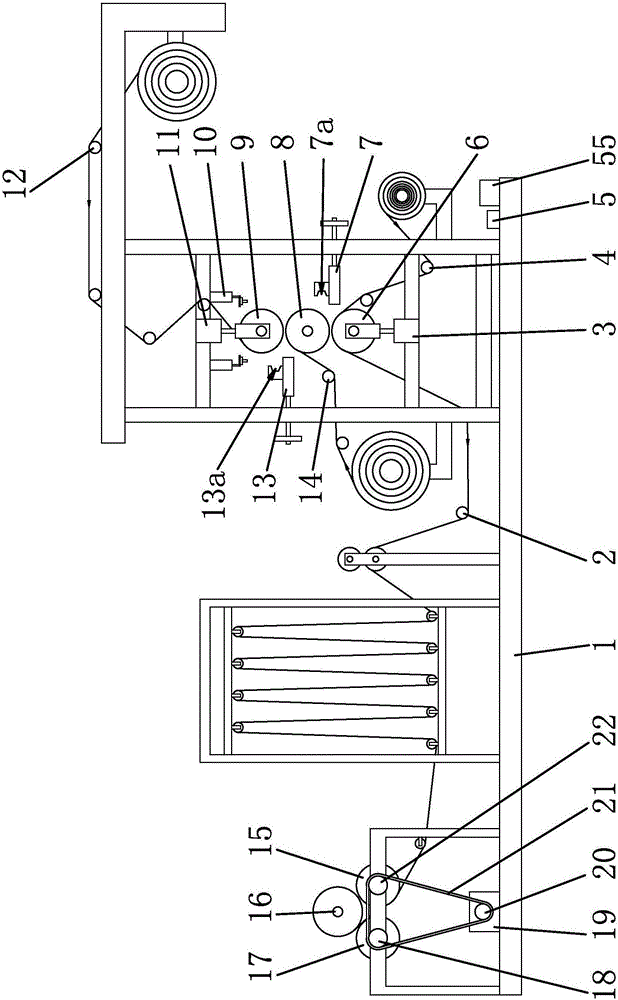

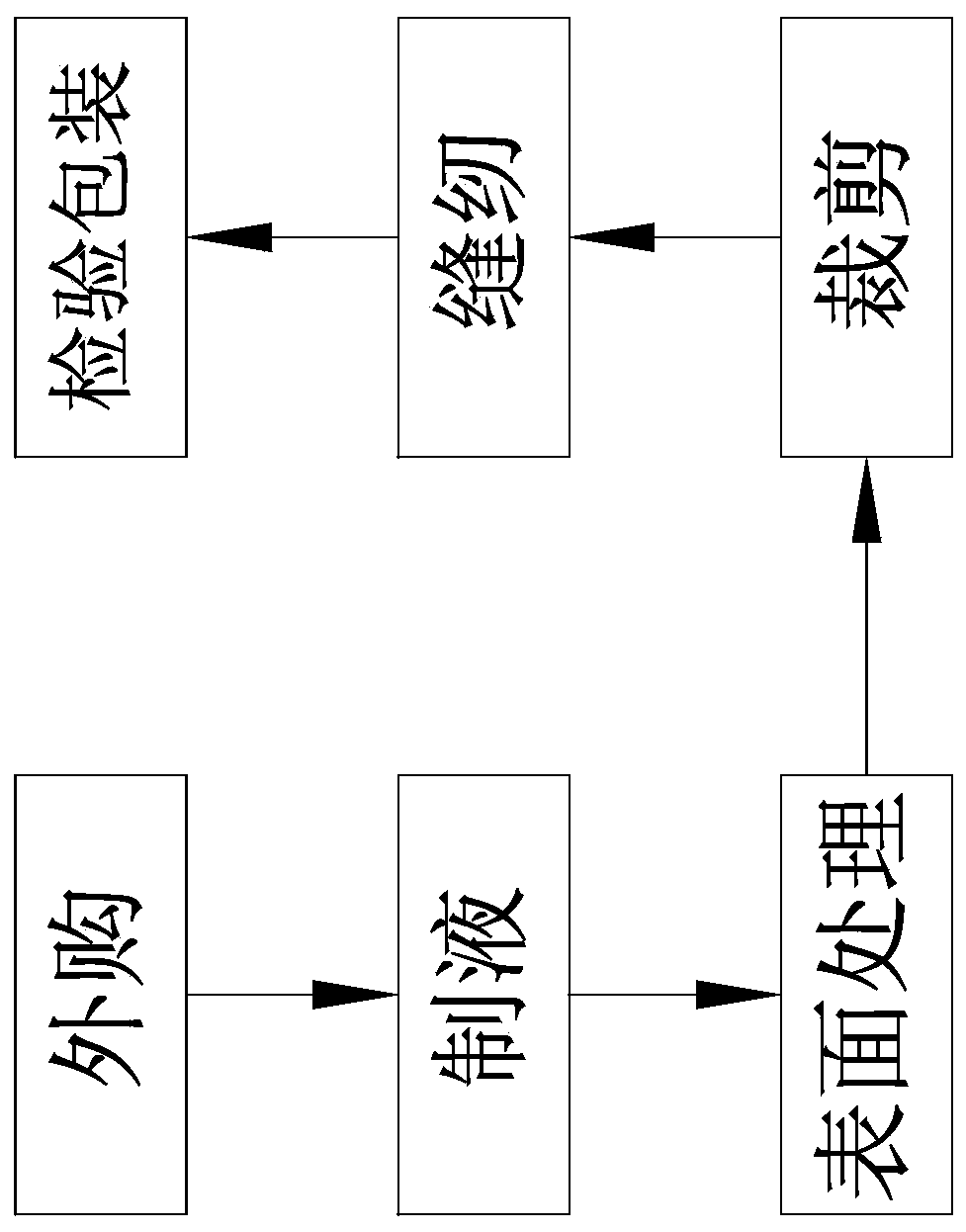

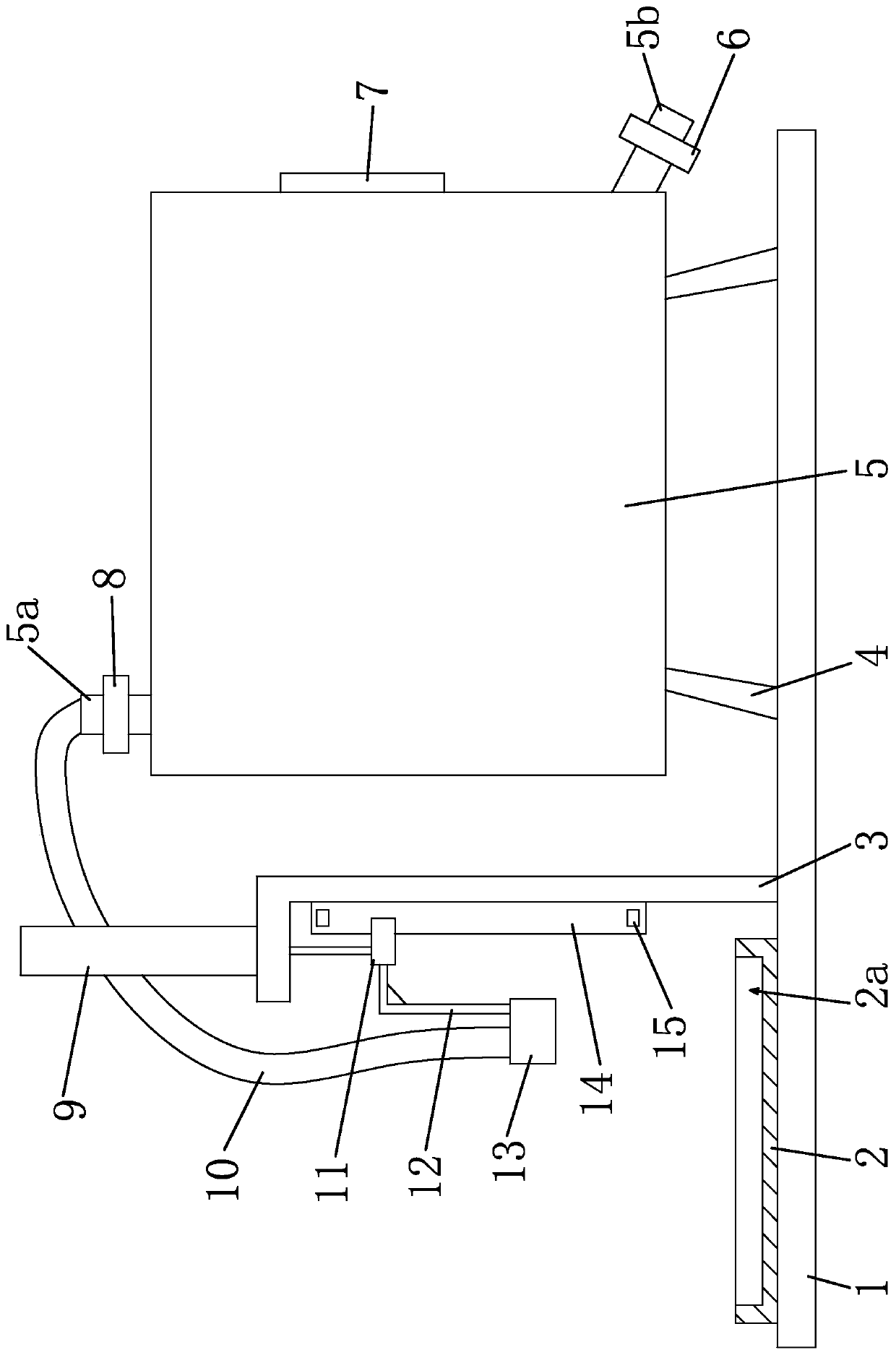

Method and device for manufacturing quick-drying cool nursing pad

PendingCN110067098AEasy to handleAdvantages of production methodTextile treatment containersLamination ancillary operationsSurface finishingBiomedical engineering

The invention provides a method and device for manufacturing a quick-drying cool nursing pad, which solves the technical problems that no corresponding production method is provided for existing nursing pads, so that the nursing pads cannot be manufactured in batches, and the manufacturing is cumbersome. The method for manufacturing the quick-drying cool nursing pad comprises the following steps:a, outsourcing; b, liquid preparation; c, surface treatment; d, cutting; e, sewing; f, inspection packaging. The method has the advantage of simplicity and convenience in manufacturing.

Owner:HAINING YIKANG TEXTILE

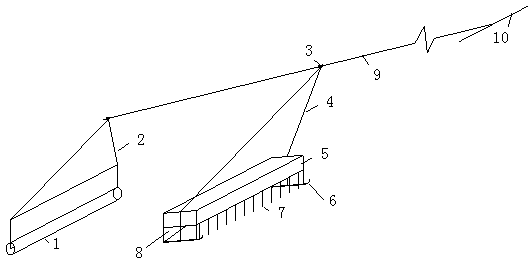

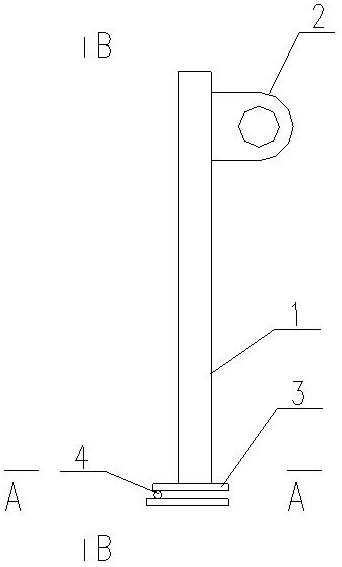

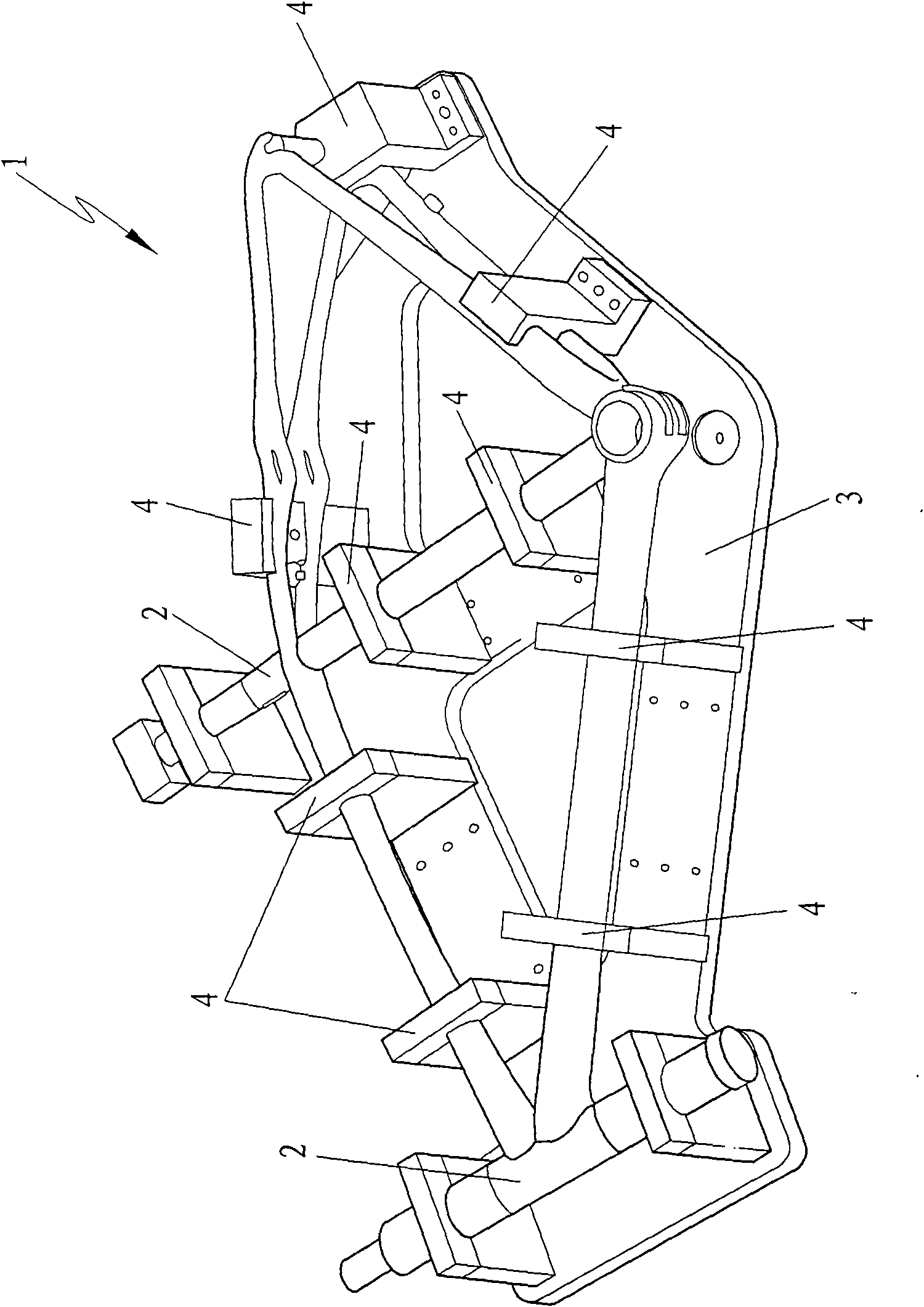

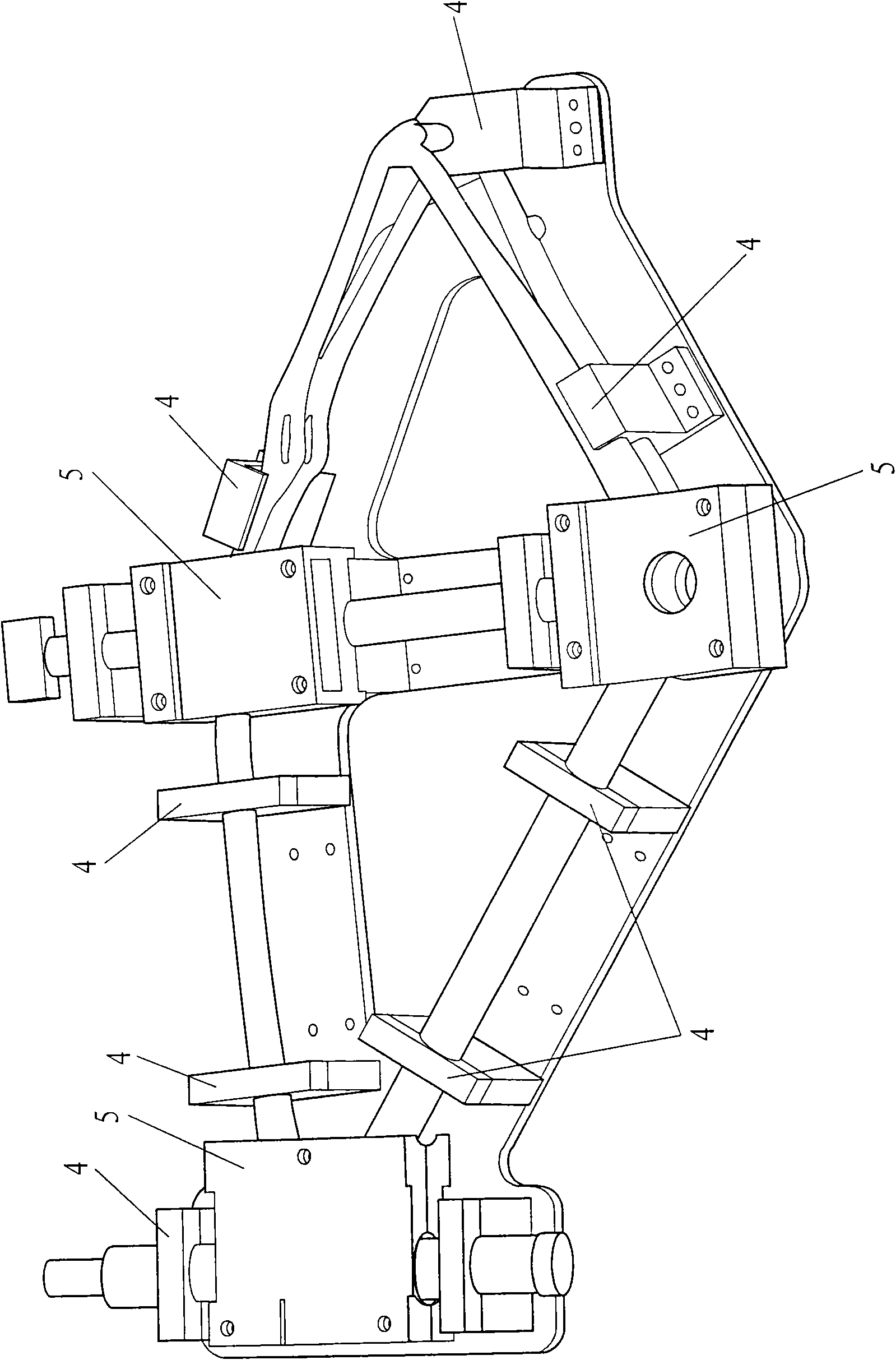

Manufacturing method of simple hoisting tool for factory building roof purline

PendingCN112357743AAdvantages of production methodSimple structureLoad-engaging elementsBolt connectionFlange

A manufacturing method of a simple hoisting tool for a factory building roof purline is characterized in that a factory building roof beam is successfully erected, and the manufacturing method comprises the following steps: a, determining the appearance and the size of the hoisting tool according to design, and manufacturing a hoisting tool vertical rod; b, manufacturing a hoisting lug, wherein the hoisting lug is a rectangular steel plate; and c, manufacturing a base, wherein during use, a groove between an upper panel and a lower panel can be clamped into an upper flange plate of the roof beam, one end of a lifting rope is bound with the purline, and the other end of the lifting rope is pulled by a constructor to convey the purline to the factory building roof purline through a fixed pulley for bolt connection or welding. The manufacturing method of the simple hoisting tool for the factory building roof purline has the advantages of being simple in device structure, convenient to manufacture, capable of being recycled and capable of saving cost.

Owner:MCC5 GROUP CORP SHANGHAI

Manufacturing method of oil-immersed transformer

InactiveCN110060861AHigh degree of intelligenceAdvantages of production methodEncapsulation/impregnationCoils manufactureTransformerFuel tank

The invention provides a manufacturing method of an oil-immersed transformer. The manufacturing method comprises the following steps of a, preparing an iron core: carrying out longitudinal shearing and transverse shearing treatment on a coiled material, and carrying out stacking treatment on an obtained silicon steel sheet to prepare the iron core; b, manufacturing a coil: winding a wire through awinding device to obtain a coil; c, assembling: enabling the iron core and the coil to be assembled into a whole to prepare a semi-finished product; d, paint dipping: enabling the semi-finished product to be subjected to paint dipping treatment through a paint dipping device; e, encasement: putting the semi-finished product into an oil tank and fixing; f, filling oil: carrying out vacuum oil injection treatment on the oil tank, wherein the vacuum degree in the vacuum oil injection tank is controlled to be 800-900 Pa during oil injection, and the oil temperature is controlled to be 50-60 DEG Cto obtain a finished product; g, sealing detection: putting the finished product into a drying oven to be detected, and controlling the temperature of the drying oven to be 65-75 DEG C and controlling the heat preservation time to be 4-6h, and observing whether oil leakage occurs or not. The preparation method disclosed by the invention has the advantages of rapid preparation and the like.

Owner:聊城鑫大变压器有限公司

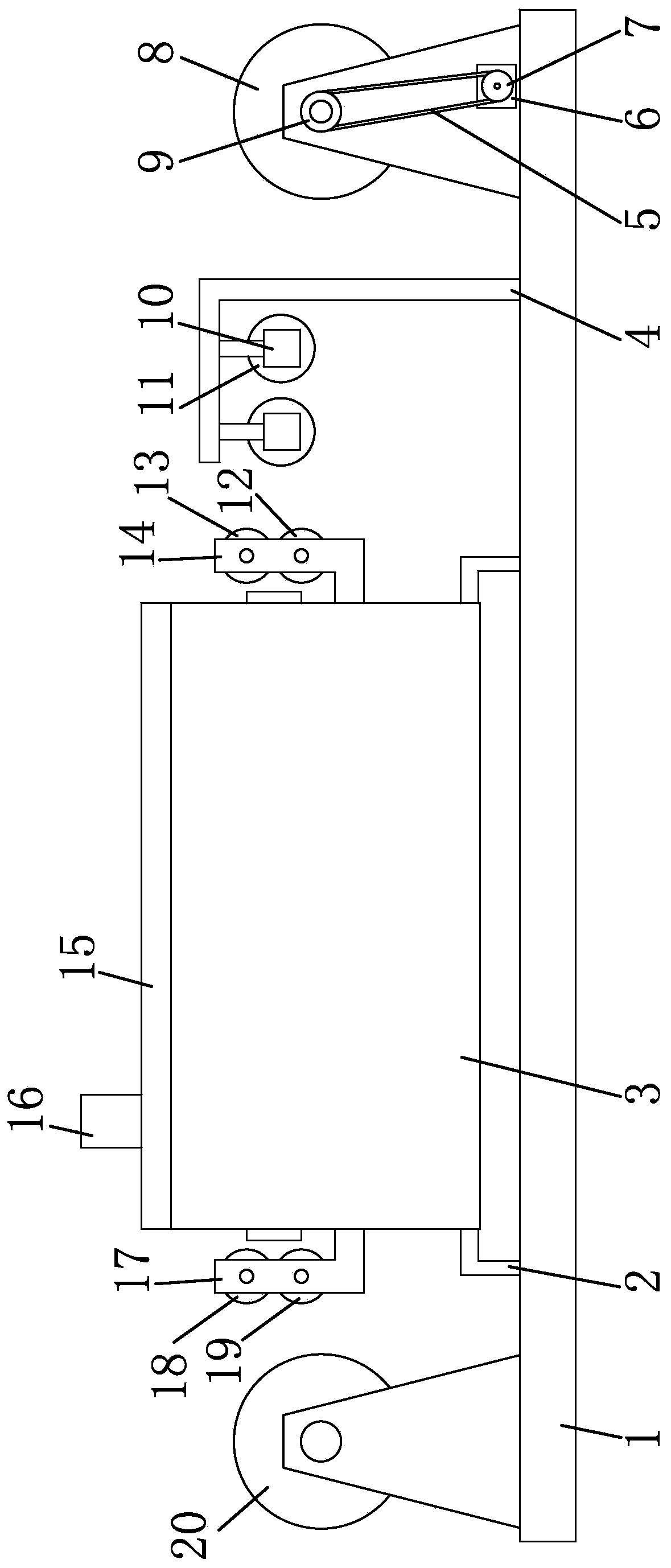

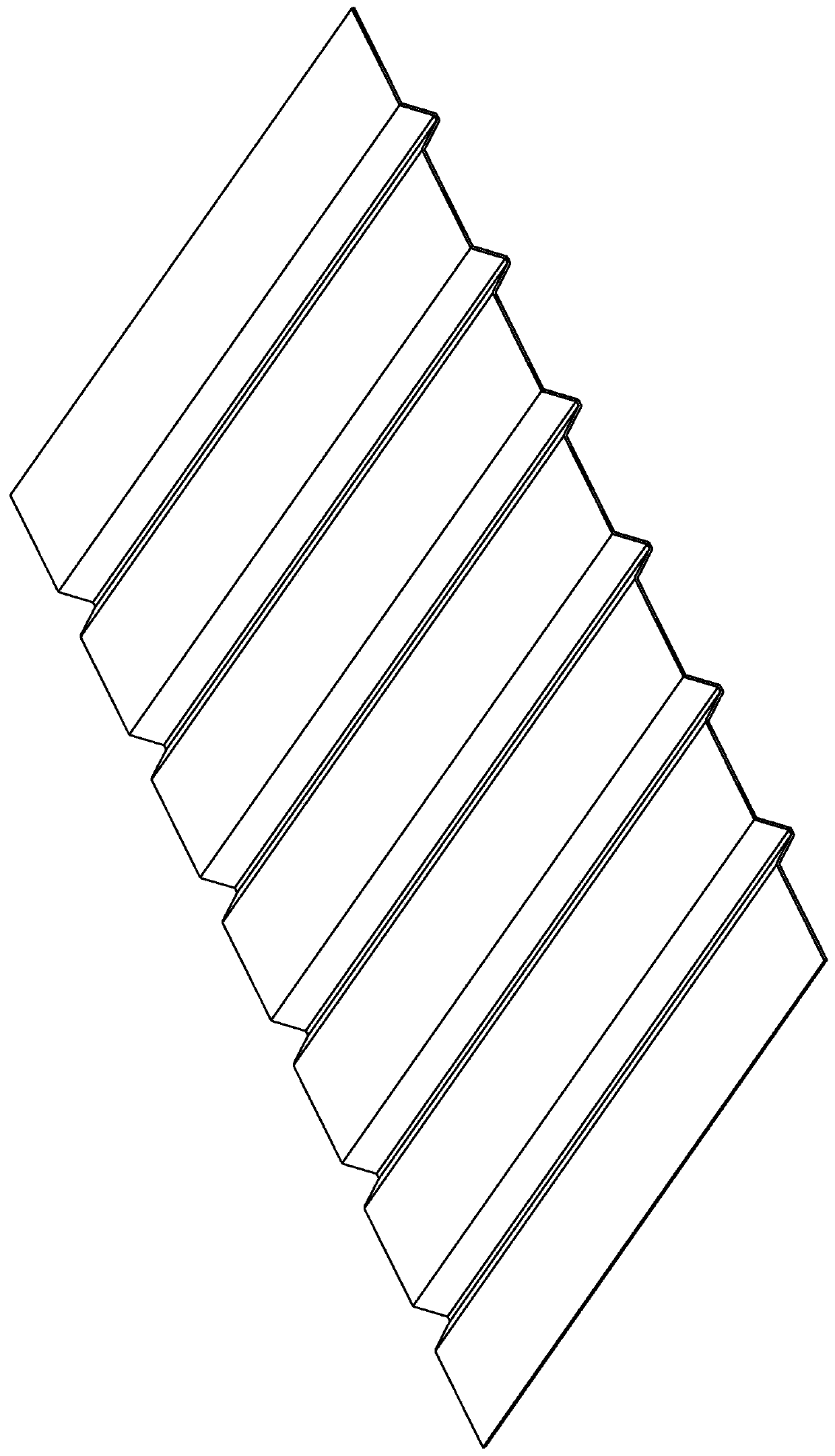

Manufacturing method of nano thermal insulation color steel plate

ActiveCN109701855AAdvantages of production methodRealize mass productionRotary stirring mixersPretreated surfacesThermal insulationUltraviolet

The invention provides a manufacturing method of a nano thermal insulation color steel plate. According to the manufacturing method of the nano thermal insulation color steel plate, the technical problems that no corresponding manufacturing method of an existing color steel plate exists, and manufacturing is tedious are solved; and the manufacturing method of the nano thermal insulation color steel plate comprises the following steps: a, leveling is conducted, and specifically, the steel plate is leveled through a steel plate straightening machine; b, forming is conducted, specifically, the steel plate in the step a is subjected to rolling forming through a steel plate rolling device, and a base body is manufactured; c, blending is conducted, and specifically, coating is prepared from thecomponents in parts by weight: 40-50 parts of saturated polyester resin, 4-7 parts of silicon oxide, 5-15 parts of micron-order hollow microbeads, 2.5-4.5 parts of toluenesulfonic acid, 0.6-1.8 partsof polyvinyl chloride, 5-15 parts of a pigment, 0.4-0.6 part of an ultraviolet absorbent, 0.5-1.5 parts of a curing agent, 1-3 parts of a defoaming agent and 20-30 parts of deionized water which are weighed to be put into a stirring device together to be evenly stirred; d, spraying is conducted, and specifically, the coating is sprayed on the upper surface of the base body through a spraying machine; and e, baking is conducted, and specifically, the base body in the step d is baked through an oven. The manufacturing method has the advantage that manufacturing is easy and convenient.

Owner:苏州林昊板业科技有限公司

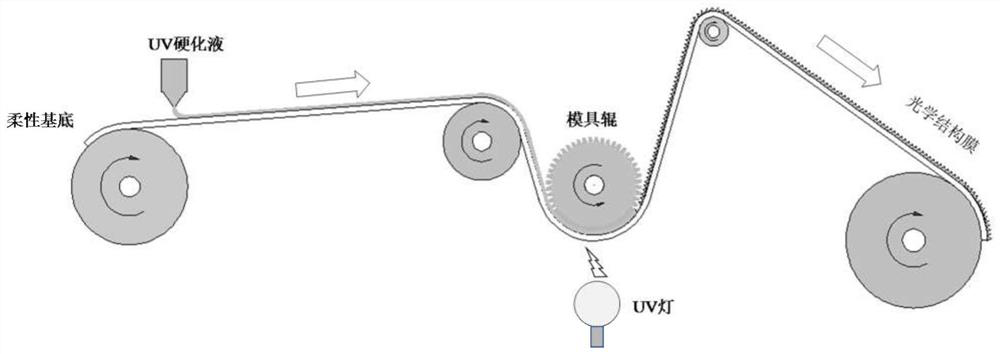

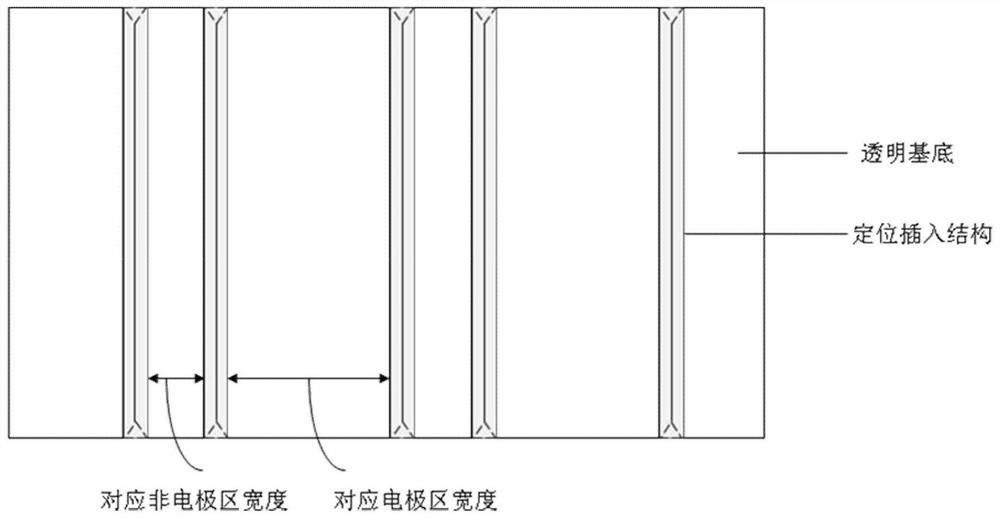

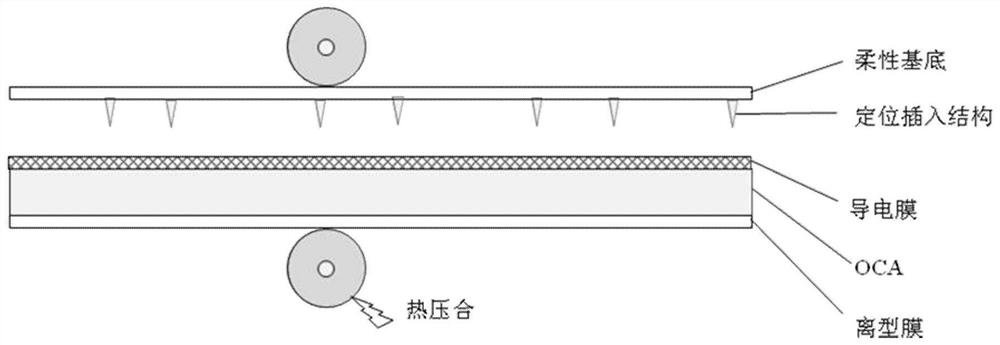

Optical structure film for carrying out electrode patterning on silver nanowire transparent conductive film and patterning method of optical structure film

ActiveCN111944414AEliminate Silver Migration ProblemsImprove etch marksPolyurea/polyurethane coatingsInput/output processes for data processingElectrically conductiveThermocompression bonding

The invention discloses an optical structure film for performing electrode patterning on a silver nanowire transparent conductive film and a patterning method of the optical structure film. An opticalstructure film with a positioning insertion structure and a silver nanowire transparent conductive film which is transferred to OCA optical cement in advance are subjected to thermocompression bonding, so that the high-hardness positioning insertion structure is embedded into the silver nanowire conductive film to realize electrode patterning of the conductive film so as to prepare a required conductive electrode pattern. According to the method, the problems of silver migration and etching marks of the silver nanowire transparent conductive film can be effectively solved, and the method is simple and high in reliability.

Owner:合肥微晶材料科技有限公司

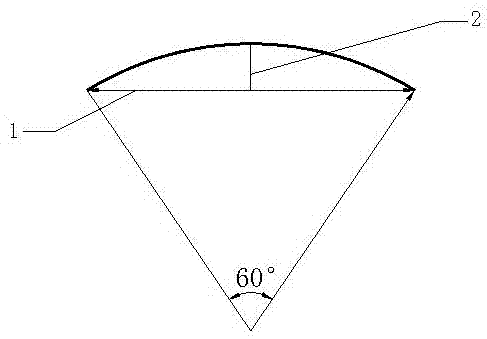

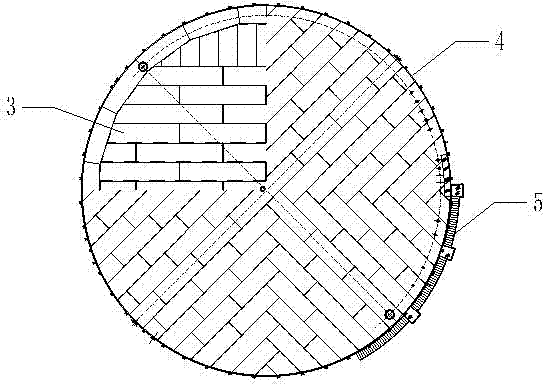

Manufacturing method of tank top steel skin plate of large-scale stainless steel tank

The invention discloses a manufacturing method of a tank top steel skin plate of a large-scale stainless steel tank. The manufacturing method is characterized by comprising the following steps: a, drawing an arrangement drawing of the tank top steel skin plate according to the design working drawing of the large-scale stainless steel tank; b, conducting blanking according to the arrangement drawing of the tank top steel skin plate, cutting steel plates and carrying out weld preparation, conducting machining or carrying out automatic and semi-automatic flame cutting machining, and carrying out manual flame cutting machining on the circular arc edge of the tank top steel skin plate; c, designing an arc sample plate of the tank top steel skin plate according to the 60-degree central angle of the spherical arched top of the construction drawing of the large-scale stainless steel tank; inspecting by the arc sample plate after the arc component of the tank top steel skin plate is machined and molded; and inspecting warpage of the tank top steel skin plate on a platform. The manufacturing method of the tank top steel skin plate of the large-scale stainless steel tank has the advantages of good formation degree of the tank top steel skin plate, capability of effectively ensuring the radian of the arched top plate and preventing the deformation and attractive appearance of the spherical spherical arched top.

Owner:MCC5 GROUP CORP SHANGHAI

Manufacture method for jointing and reinforcing pipe fitting made from composite materials

The invention discloses a manufacture method for jointing and reinforcing pipe fittings made from composite materials, which comprises the following steps: firstly, a part of preformed pipe fittings are jointed and then yarn is supplemented at jointing positions; then, jointed frame bodies are placed in a chassis to be positioned; positions which need to be supplemented and reinforced by the yarn are provided with heating moulds to heat partial points of the frame bodies so that the composite materials at yarn supplementing positions are melted, solidified and connected to be shaped. The manufacture method does not need to heat the integral supporting and shaping chassis but only pointedly partially heats and shapes the jointing positions of the frame bodies, thereby reducing the energy consumption; the manufacture method omits a back-and-forth carrying and moving process and a cooling process because the manufacture method does not need to heat the integral supporting and shaping chassis and can be operated when the chassis is arranged on a machine table, thereby having convenient operation; and the heating mould for partial heating can be fast heated. The invention has short working time in manufacture procedure, and can effectively enhance the productivity.

Owner:XIAMEN KEENTECH COMPOSITE TECH CO LTD

Method for producing eel fishing bait

InactiveCN107410237AAdvantages of production methodEasy to makeOther angling devicesAnimal scienceHusk

The invention relates to a method for producing an eel fishing bait. The method comprises the steps: 1. making 100g of wheat flour, 5g of fish meal, 5g of dried shrimp husks, 3 multivitamin B tablets, 2g of refined white sugar or honey and 2g of mutton fat ready; 2. dissolving the vitamin B tablets and the refined white sugar or honey with boiling water; 3. adding a spoon of refined white sugar or honey, four spoons of white wheat flour and half spoon of mutton fat to dissolve three vitamin B tablets (yellow); 4. mixing all the materials, and carrying out kneading until the softness and hardness are moderate; and 5. loading the mixture to a plastic bag, carrying out sealing, and taking out the mixture during fishing in the next day. The method has the characteristics that the production is simple, the materials are cheap, and the fragrance is unique. A mutton smell of the mutton fat and a fishy smell of the fish meal and the dried shrimp husks are especially greatly attractive to eels. The fishing bait is useful in July to November and has a better effect compared with earthworms.

Owner:周依宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com