Manufacturing method of tool for concrete finishing and thin film covering

A covering film and manufacturing method technology, applied in manufacturing tools, metal processing equipment, construction materials, etc., can solve the problems of concrete surface quality, affecting film covering, stacking concrete, etc., so as to improve the convenience of film covering and make Convenience and the effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

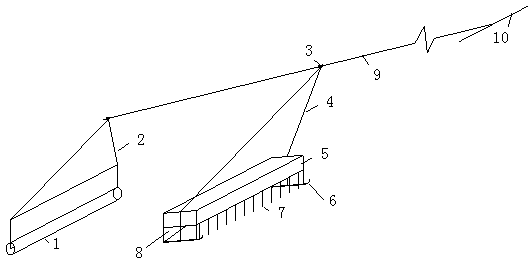

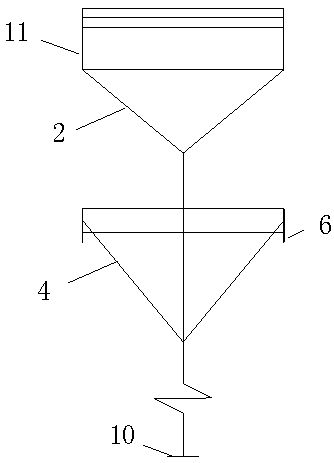

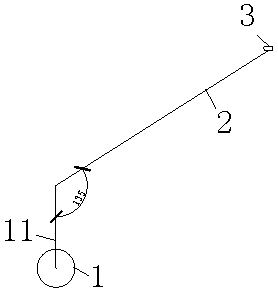

[0032] see now figure 1 and figure 2 , figure 1 It is the structural representation of the concrete surface closing and covering film tool of the embodiment of the present invention, figure 2 for figure 1 top view.

[0033] The preparation method of the tool for concrete surface closing and covering film of the present invention comprises the following steps:

[0034] a. Making film spreading frame:

[0035] The film spreading frame is made of φ20mm round steel, and the round steel is connected with each other in the form of butt welding. The plastic film reel 1 is nested on the fixed rod at the lower part of the tie rod, and a φ20mm round steel is welded at the position of 400mm above the fixed rod to pave the film. The stand is fixed for stability. The tie rod piercing pipe is made of DN25 iron pipe 3 with a length of 100 mm, which is welded with the first diagonal tie rod 2 .

[0036] b. Making a leveling frame

[0037] The roughening leveling frame is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com