Patents

Literature

124results about How to "No situation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

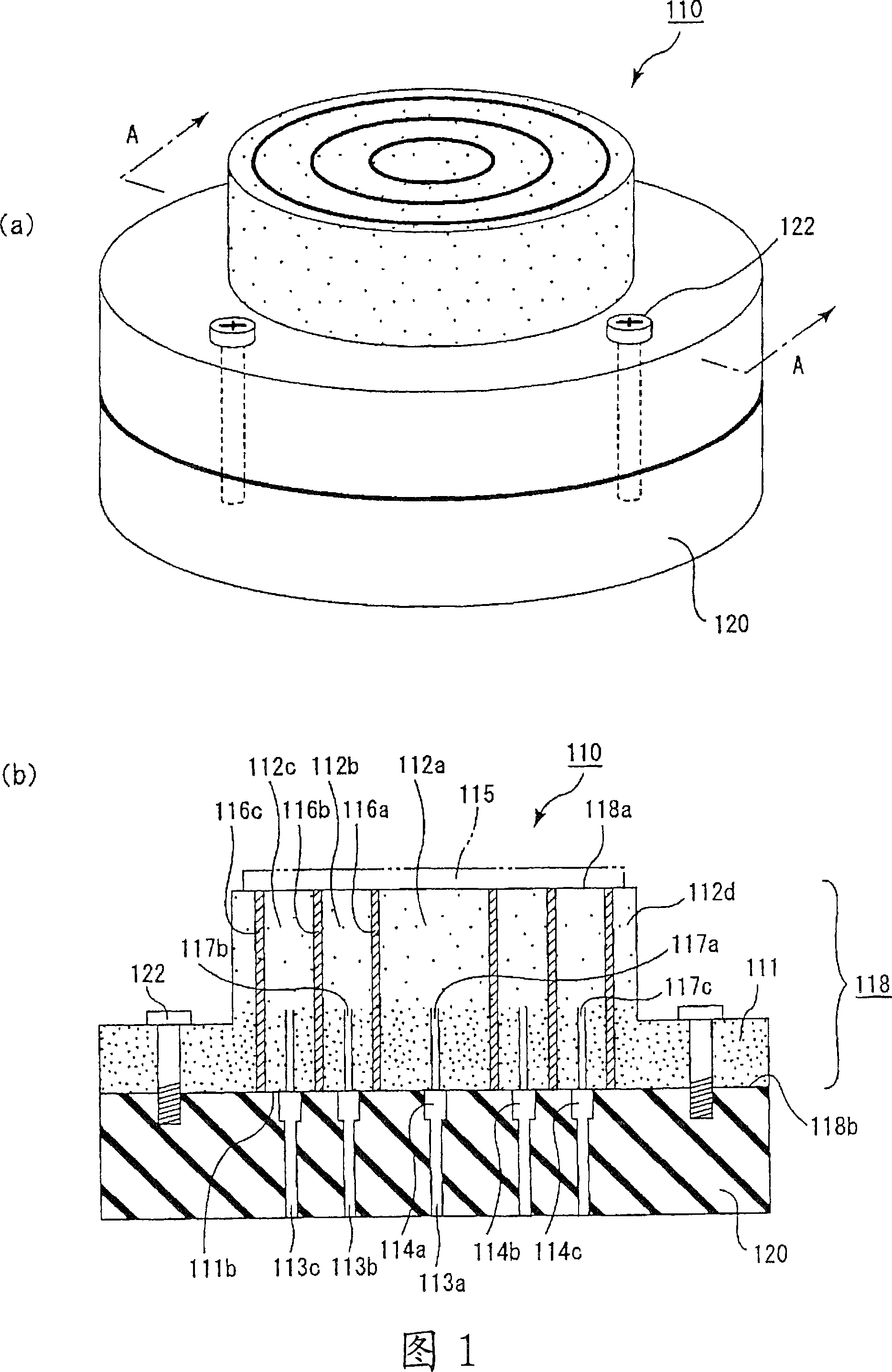

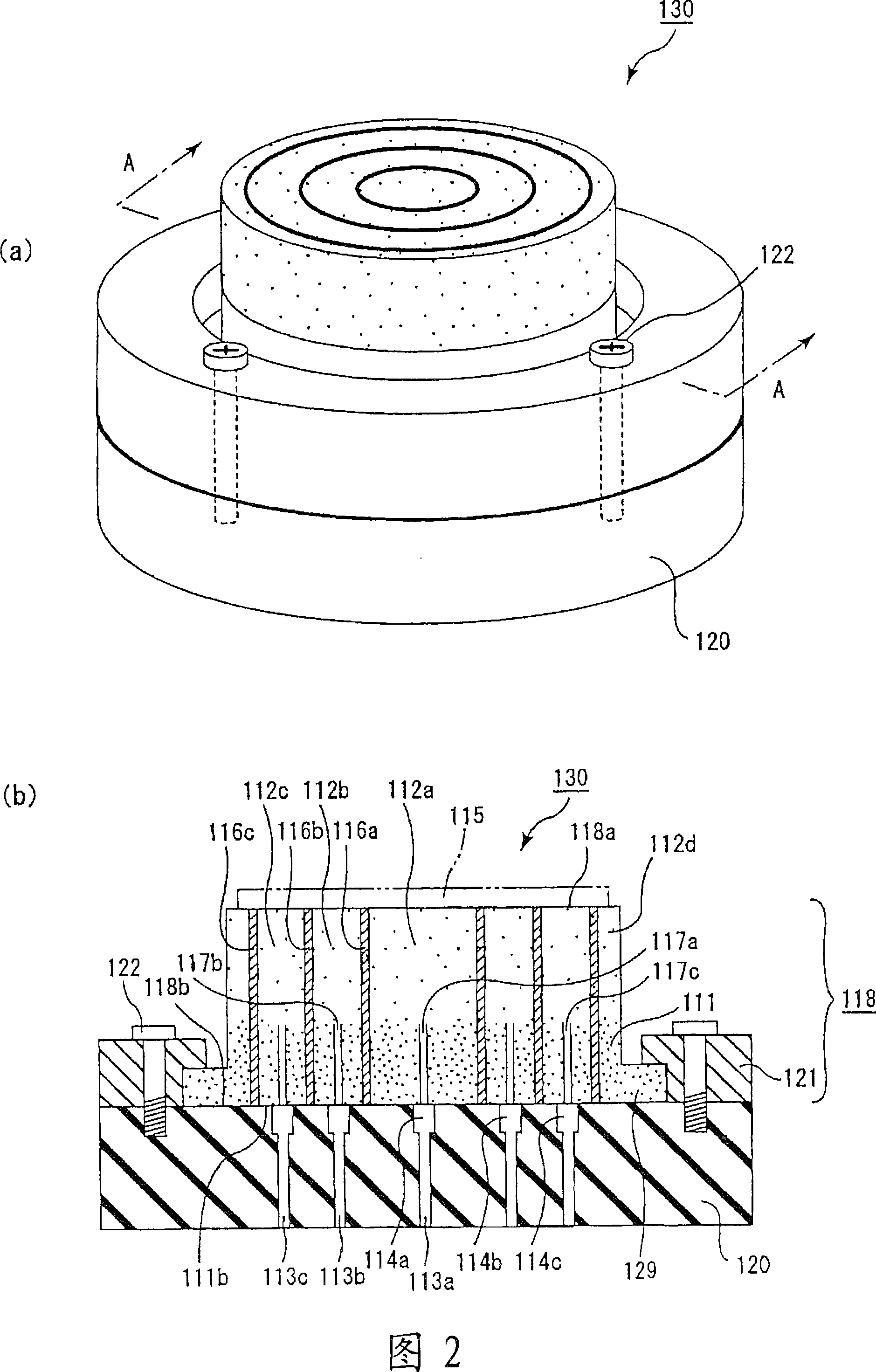

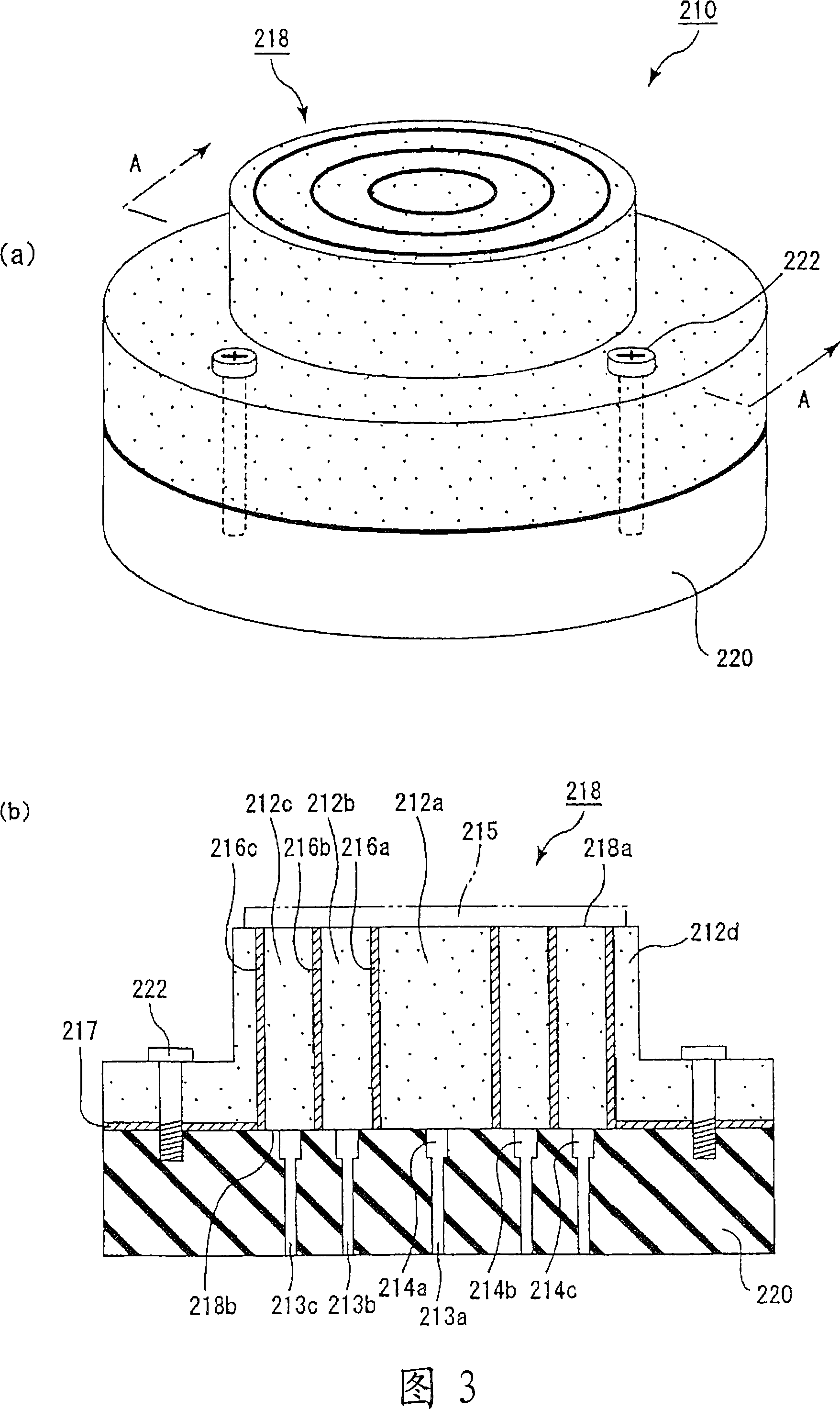

Vacuum chuck and suction board

ActiveCN1938122ADoes not produce uniformityNo situationSleeve/socket jointsSemiconductor/solid-state device manufacturingPorous ceramicsMaterials science

A vacuum chuck is provided for attaining uniform polishing of an object to be sucked. The vacuum chuck is provided by integrating a suction layer and a compact substance layer, which are formed of a porous ceramics, and positioning the suction layer on a side of sucking the object to be sucked. The vacuum chuck is provided with a suction board for sucking and holding the object to be sucked. The compact substance layer is formed by impregnating the porous ceramics with a metal.

Owner:IBIDEN CO LTD

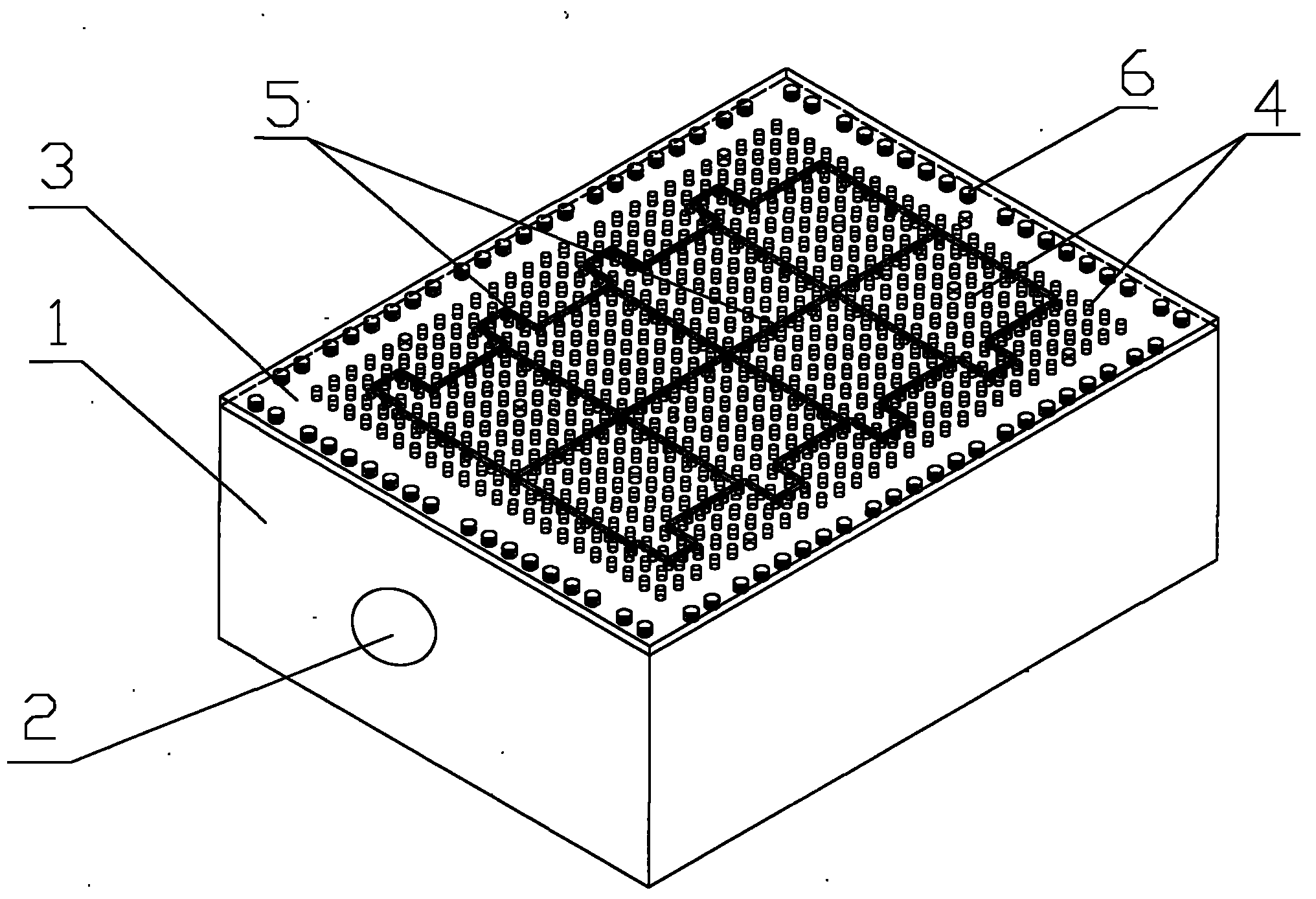

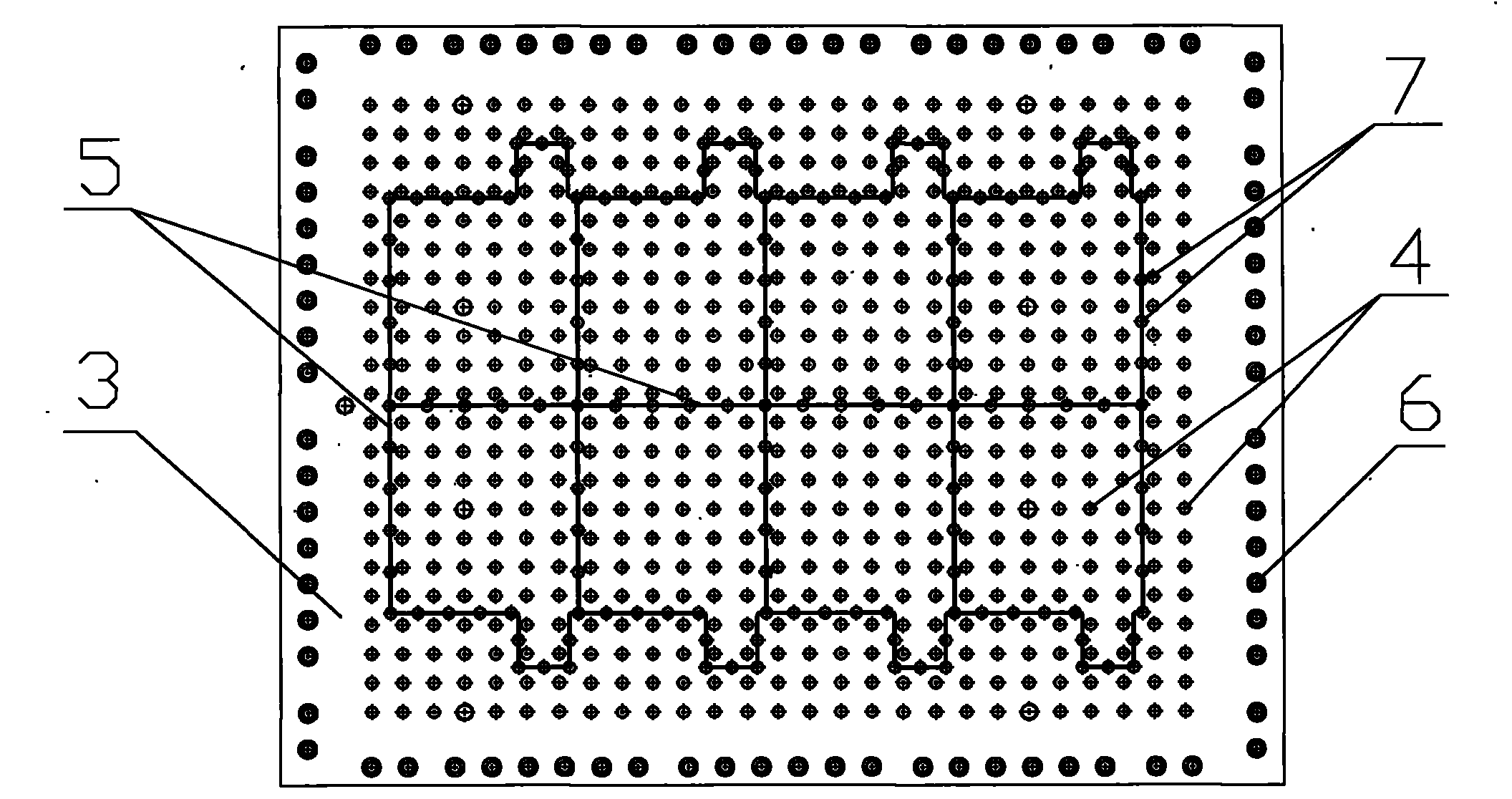

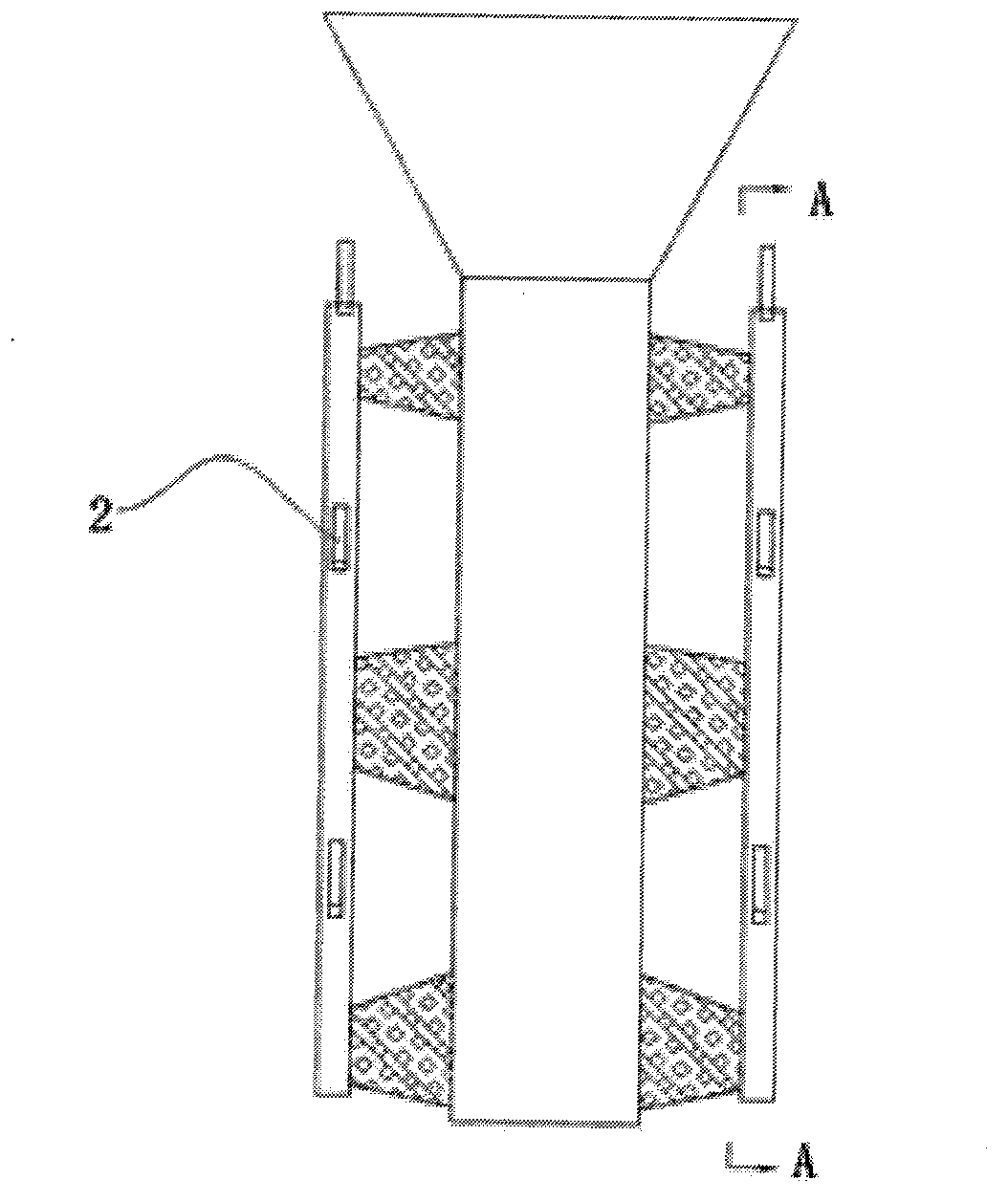

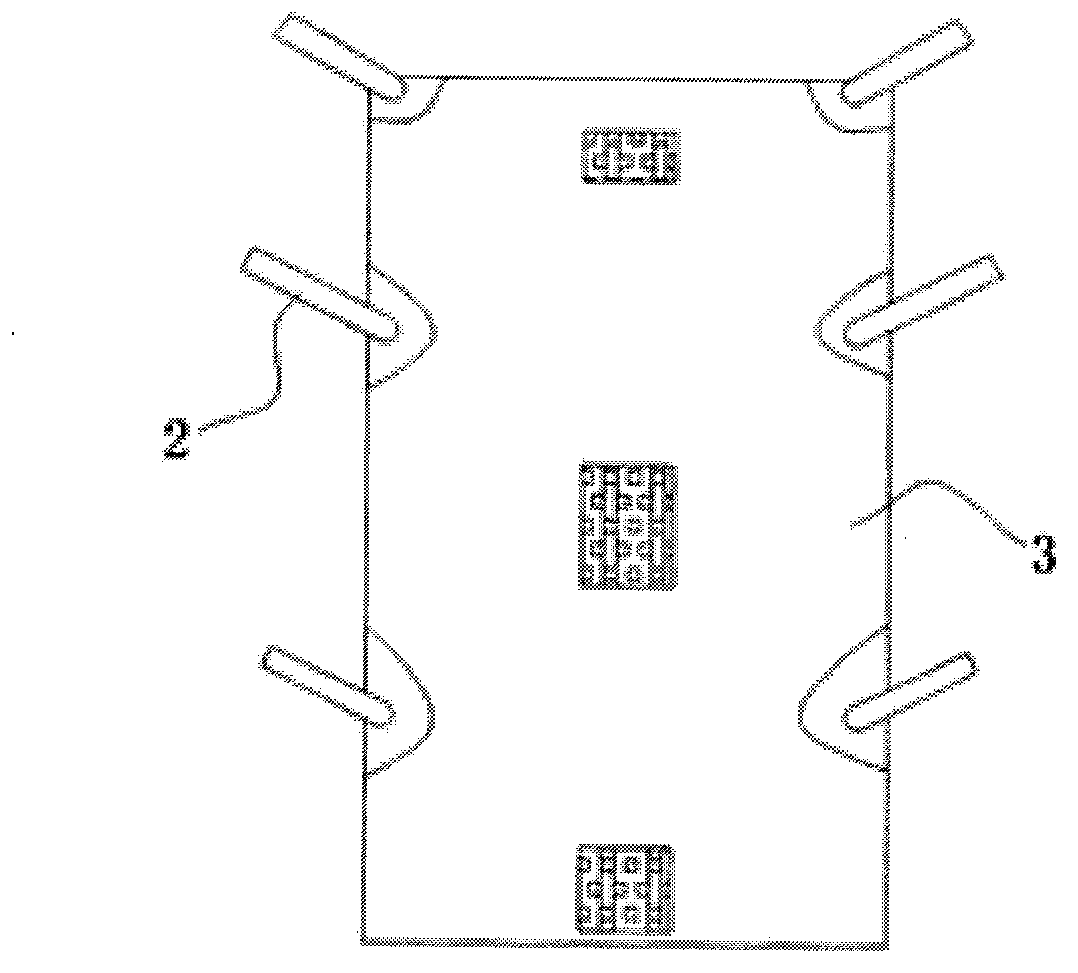

Vacuum adsorption device of battery pole piece

InactiveCN101774087ANo warpingNo situationLaser beam welding apparatusPlanar substrateElectrical battery

The invention provides a vacuum adsorption device of a battery pole piece, which is suitable for laser cutting operation and has simple structure and strong practicality. The device comprises a sealed cavity which is provided with vents communicated with a vacuum generator; the key point is that the top surface of the cavity is a plane substrate provided with plural adsorption through holes; the substrate is provide with an indent clearance groove along the cutting line of the battery pole piece; the cavity and the vacuum generator form a vacuumizing device; under the vacuumizing action of the vacuum generator, the battery pole piece can be tightly adsorbed on the substrate without lifting and bending or collapsing; the substrate is provided with the indent clearance groove along the cutting line of the battery pole piece, thus avoiding the uneven substrate as the substrate is cut and scratched when laser light beams cut the substrate during laser cutting, ensuring the cutting quality of subsequent battery pole pieces, and prolonging the service life of the substrate. The device has simple and reasonable structure, favorable adsorption effect and better popularization and application values.

Owner:CHERY AUTOMOBILE CO LTD

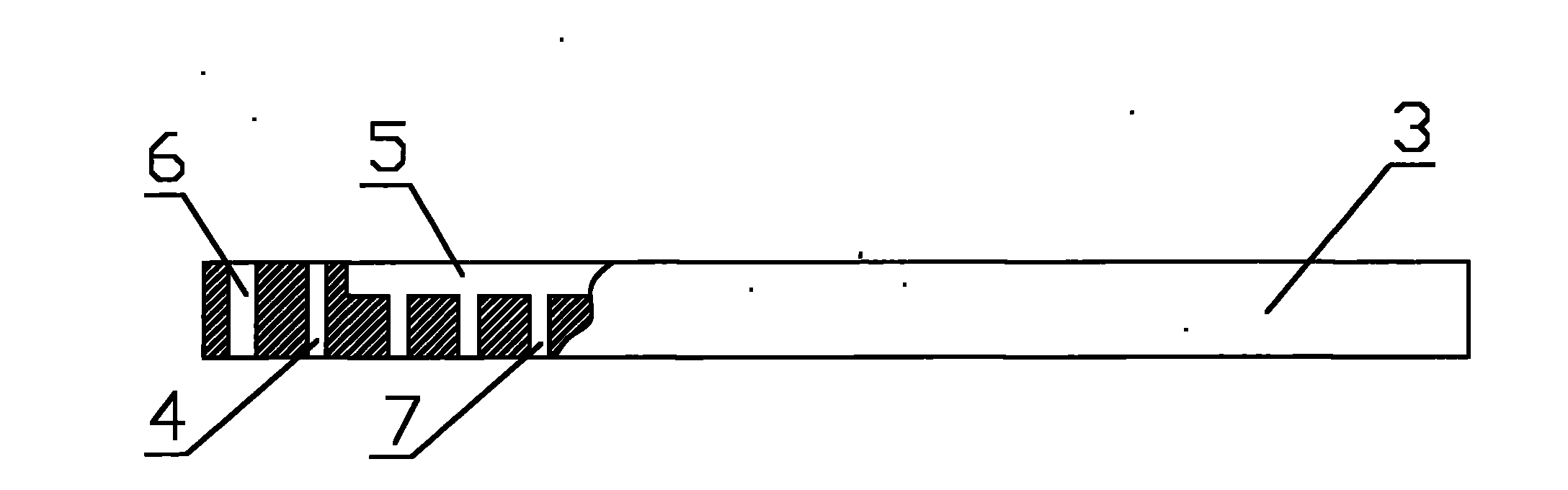

EVA heat treatment method of waste crystalline silicon solar cell module

ActiveCN103978010AEfficient separationEasy to sort and recycleWaste processingSolid waste disposalOrganosolvSilicon cell

The invention provides an EVA heat treatment technology of a waste crystalline silicon solar cell module, and can realize the effective separation of toughened glass, crystalline silicon cell pieces and a back plate of a waste crystalline silicon solar panel. The whole process has simple operation, no EVA residue in the heat treatment process, and the generated waste gas enters into an incinerator for incineration to avoid secondary pollution. The invention adopts the heat treatment process to effectively avoid environmental pollution caused by organic solvent volatilization in the process of EVA dissolution by an organic solvent, and also greatly shortens the processing cycle.

Owner:刘景洋

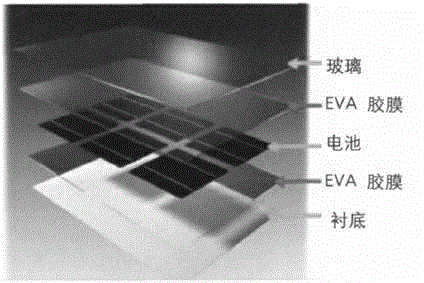

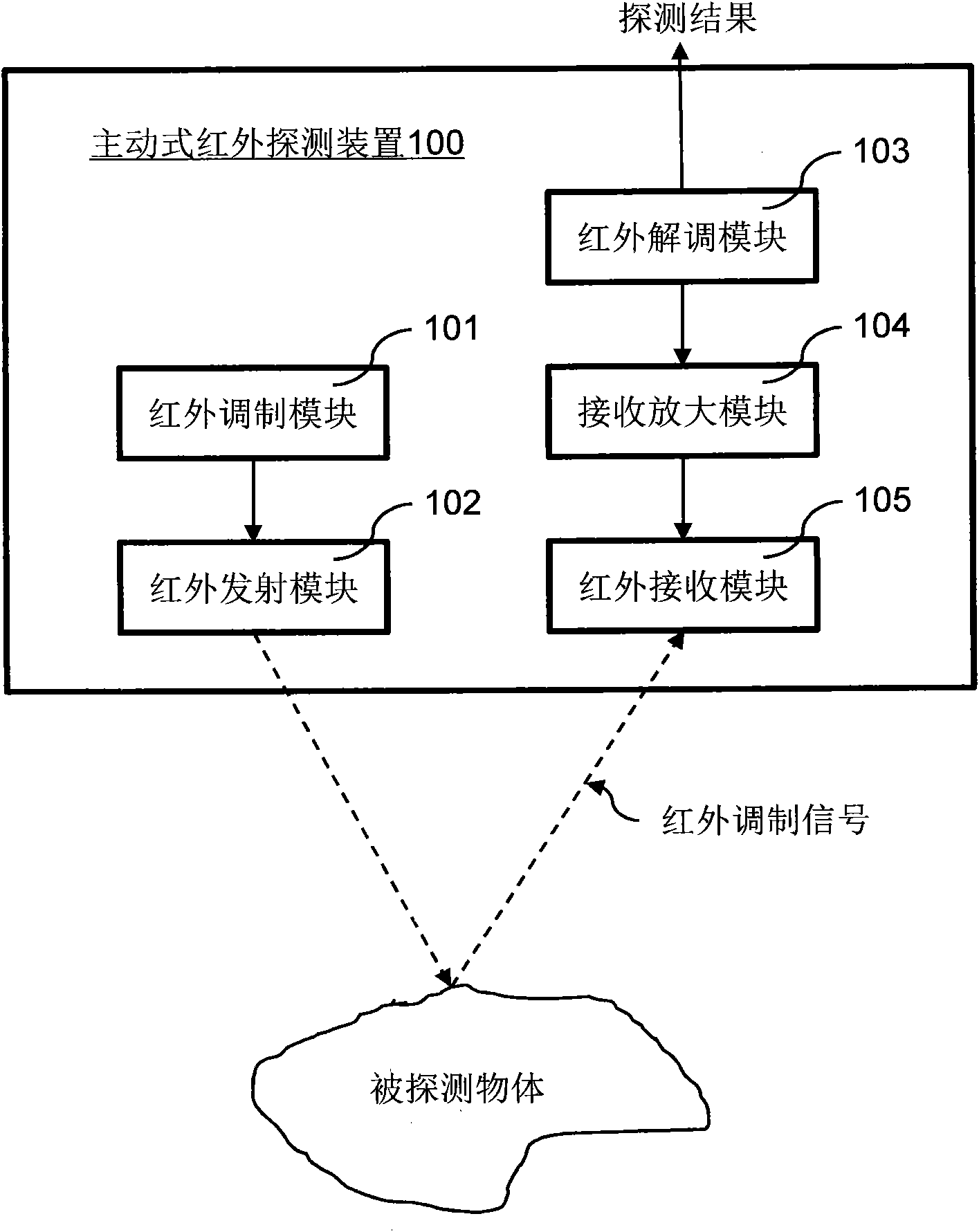

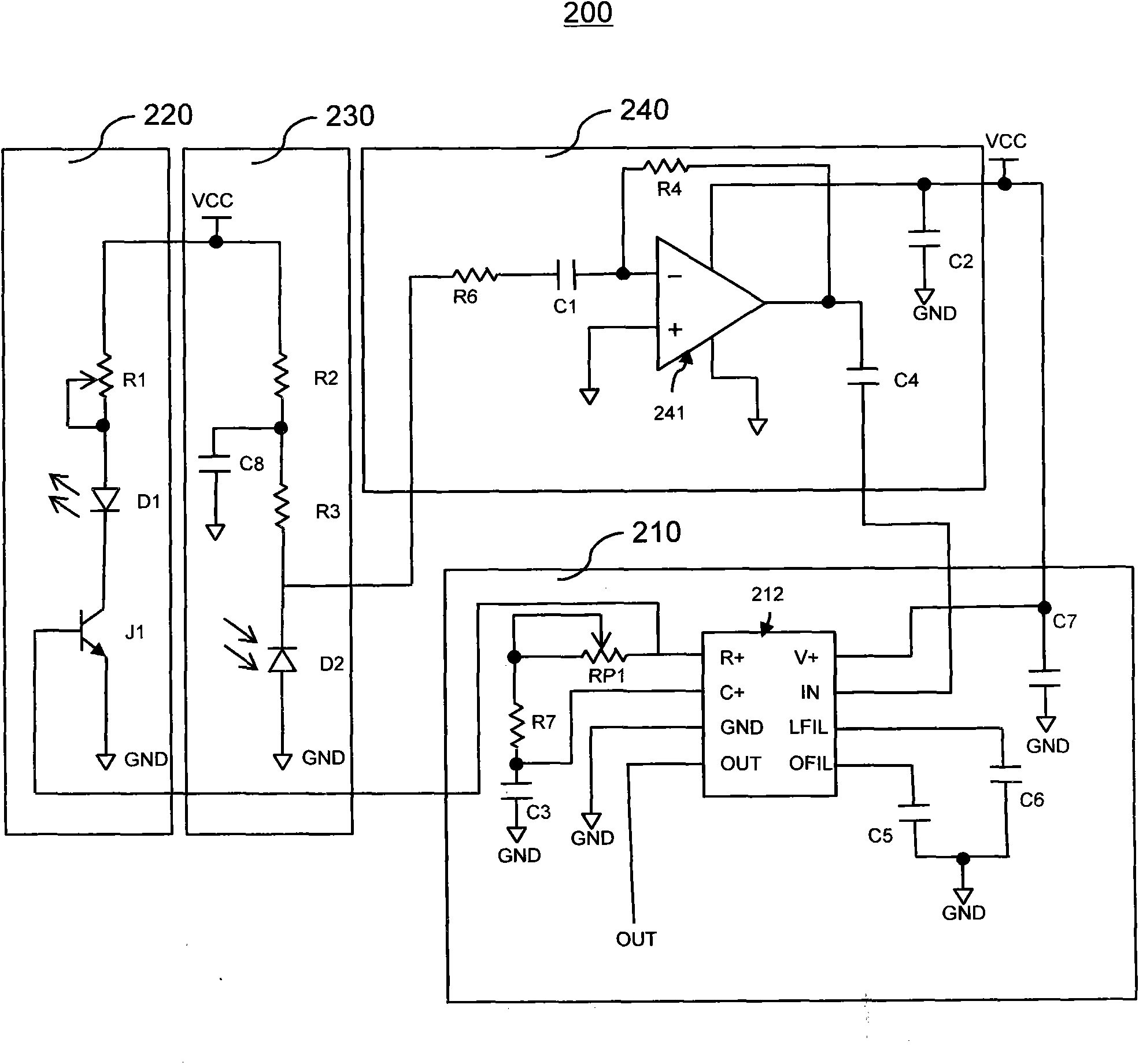

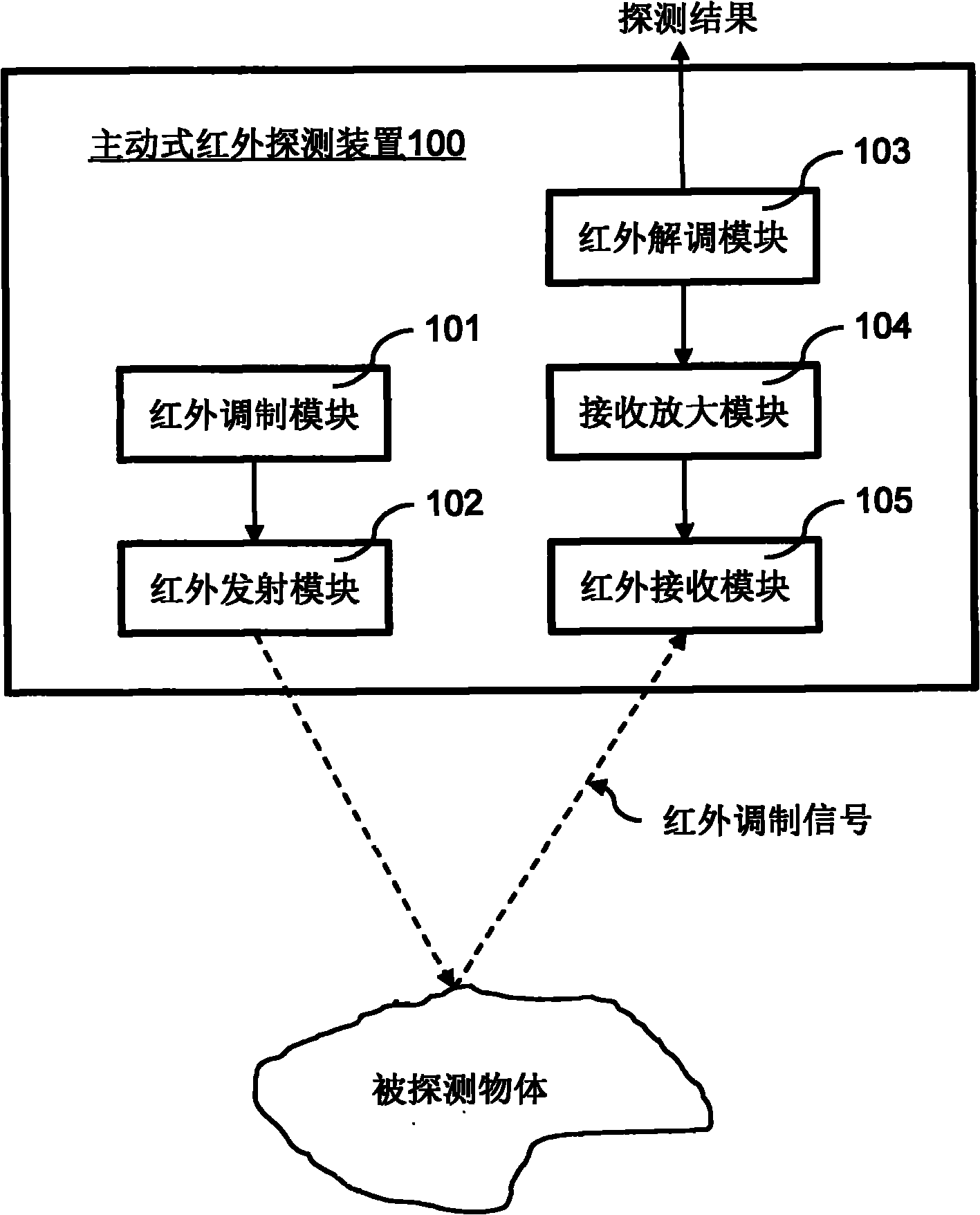

Active infrared detection device

ActiveCN101943762ANo received signalNo situationOptical detectionFrequency demodulationActive infrared

The invention discloses an active infrared detection device. The device comprises an infrared modulating module, an infrared transmission module, an infrared receiving module and an infrared demodulating module, wherein the infrared modulating module modulates an infrared modulating signal according to a preset frequency; the infrared transmission module transmits the infrared modulating signal to detect an object; the infrared receiving module receives the infrared modulating signal reflected by the detected object; and the infrared demodulating module demodulates the infrared modulating signal according to the preset frequency. The active infrared detection device transmits and receives the infrared ray with a 'special mark' by a method for modulating and demodulating the transmitted infrared ray with the same frequency signal, eliminates most infrared jamming caused by environmental factors, and acquires excellent antijamming capacity.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

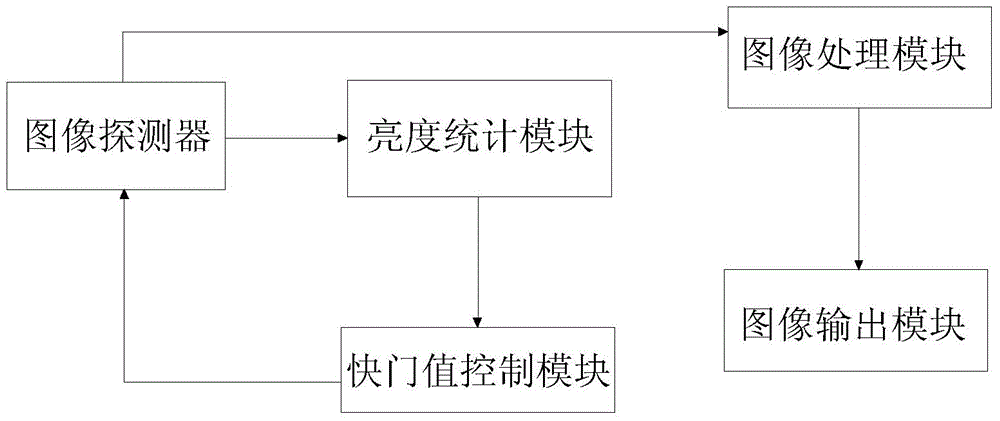

Exposure device and exposure method for electronic endoscope

InactiveCN104580923ASolve glareSolve flickeringTelevision system detailsColor television detailsImaging processingImage detection

The invention discloses an exposure device and an exposure method for an electronic endoscope. The exposure device comprises an image detection module, an image processing module and an image output module, wherein the image detection module comprises an image detector, a brightness statistics module and a shutter value control module. The exposure method comprises the following steps: transmitting a video signal of a detection region to the brightness statistics module by the image detector, obtaining a current brightness value Yc and a target brightness value Ya through the brightness statistics module, and transmitting the current brightness value Yc and the target brightness value Ya to the shutter value control module; calculating a target shutter value Sa and controlling a shutter to reach proper exposure quantity by the shutter value control module; sending the video signal of the detection region under the proper exposure quantity to the image processing module by the image detector; performing image processing on the received video signal by the image processing module, and transmitting the processed video signal to the image output module for outputting. According to the exposure device and the exposure method, a detection image is relatively clear, a situation of overexposure or over-darkness is avoided, the exposure speed is increased, and the problems of dazzling and flickering of the image are solved.

Owner:CHONGQING JINSHAN SCI & TECH GRP

Sycamore tree bark processing and drawing method

ActiveCN104441150AHigh economic valueAvoid crackingDecorative surface effectsWood treatment detailsComputer graphics (images)Solvent

The invention relates to a sycamore tree bark processing and drawing method. The sycamore tree bark processing and drawing method comprises the steps of selecting bark, steaming at high temperature, processing a solvent, fumigating, drawing and the like. The sycamore tree processing and drawing method is used for increasing the economic value of sycamore tree bark greatly; the bark processed by the processing method is difficult to crack in processing and using, and the rate of finished products and the quality of artware are improved.

Owner:安徽宏润工艺品有限公司

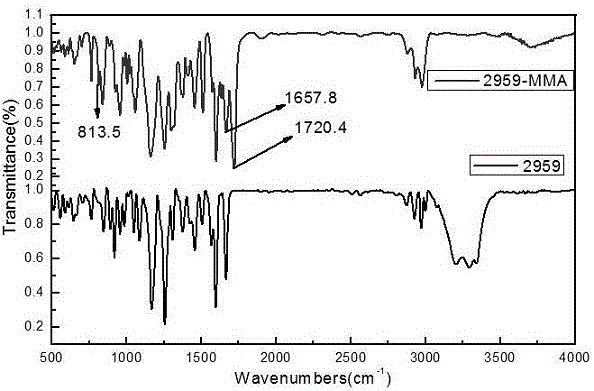

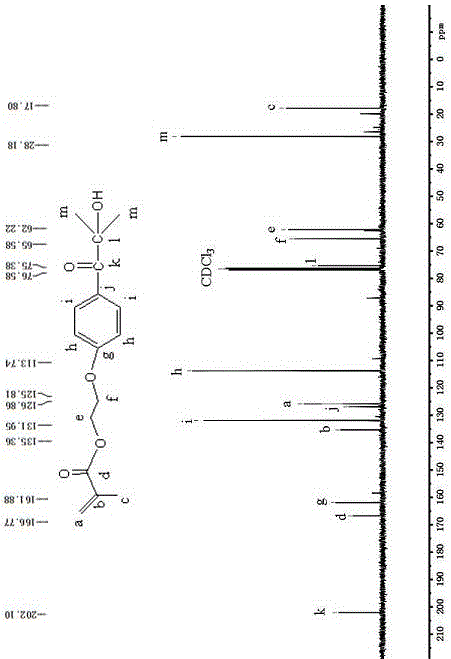

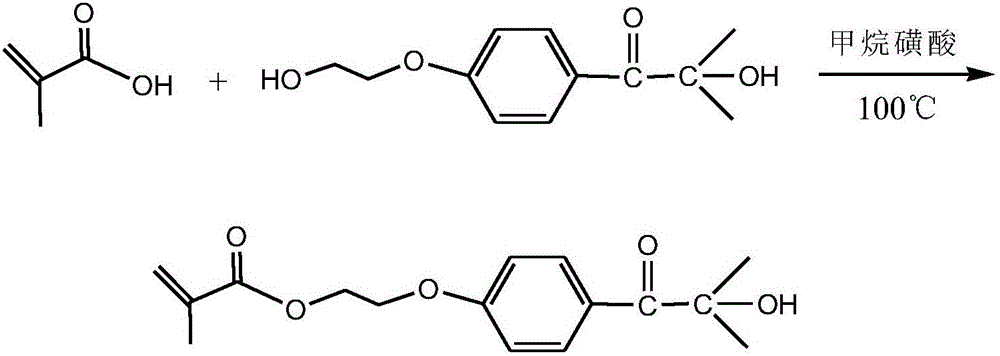

Method for preparing polymerizable photoinitiators

InactiveCN105859551AImprove migration abilityLow mobilityOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate EthersAdhesive

The invention discloses a method for preparing polymerizable photoinitiators. The polymerizable photoinitiators are prepared from methacrylic acid and 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone by the aid of direct esterification processes. The use quantity of polymerization inhibitors in a reaction system accounts for 0.01%-0.5% of the mass of the methacrylic acid, the use quantity of methane sulfonic acid which is a catalyst accounts for 0.1%-2% of the mass of the methacrylic acid, and a molar proportion of the methacrylic acid to the 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone is 1:1-1.2. Each polymerization inhibitor is methoxyphenol or hydroquinone or 2-tertiary butylhydroquinone, and a solvent is toluene or dimethylformamide or tetrahydrofuran. The method has the advantages that the polymerizable photoinitiators are excellent in compatibility with monomers and resin in photo-curing systems fragments obtained after the polymerizable photoinitiators are subjected to illumination pyrolysis are low in migration rate in cured films and are anti-yellowing, excellent initiation effects can be realized, and the method can be applied to the field of photo-cured coating, printing ink, adhesive and the like; the method for synthesizing the polymerizable photoinitiators is low in cost, processes for preparing the polymerizable photoinitiators are simple and convenient, and obvious application effects can be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

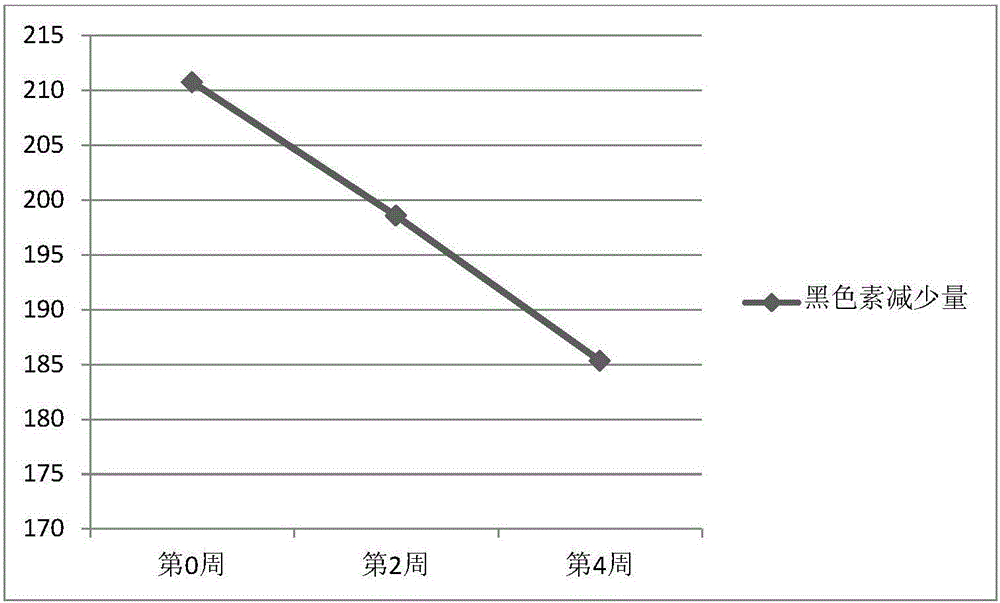

Skin whitening toning lotion containing lipidosome and preparation method thereof

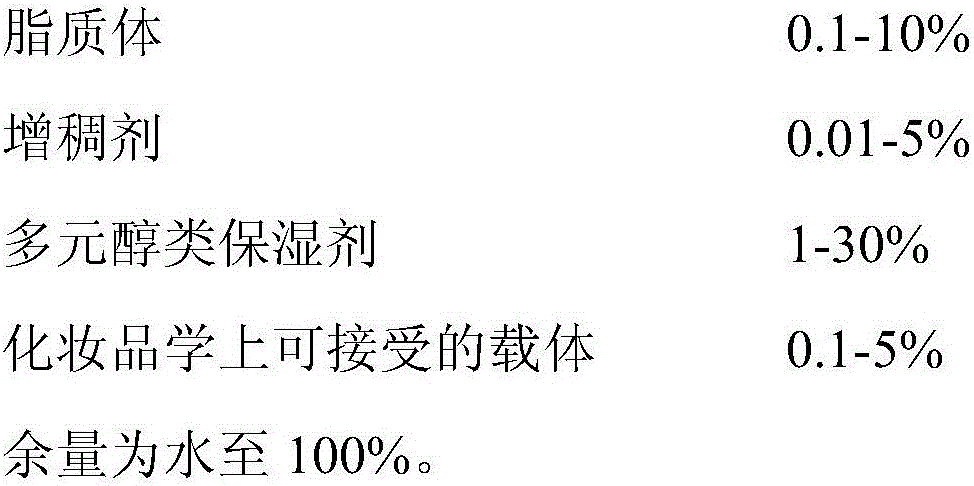

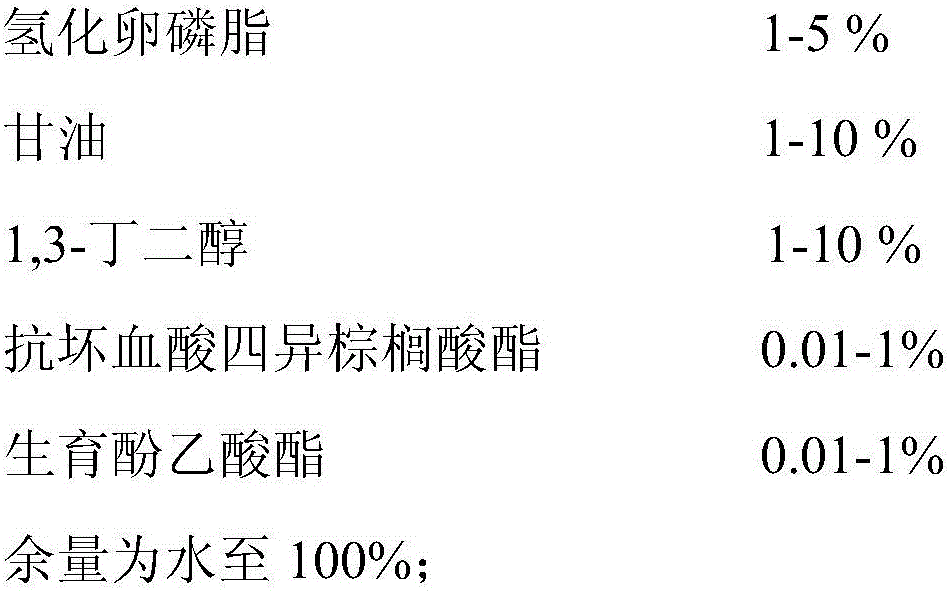

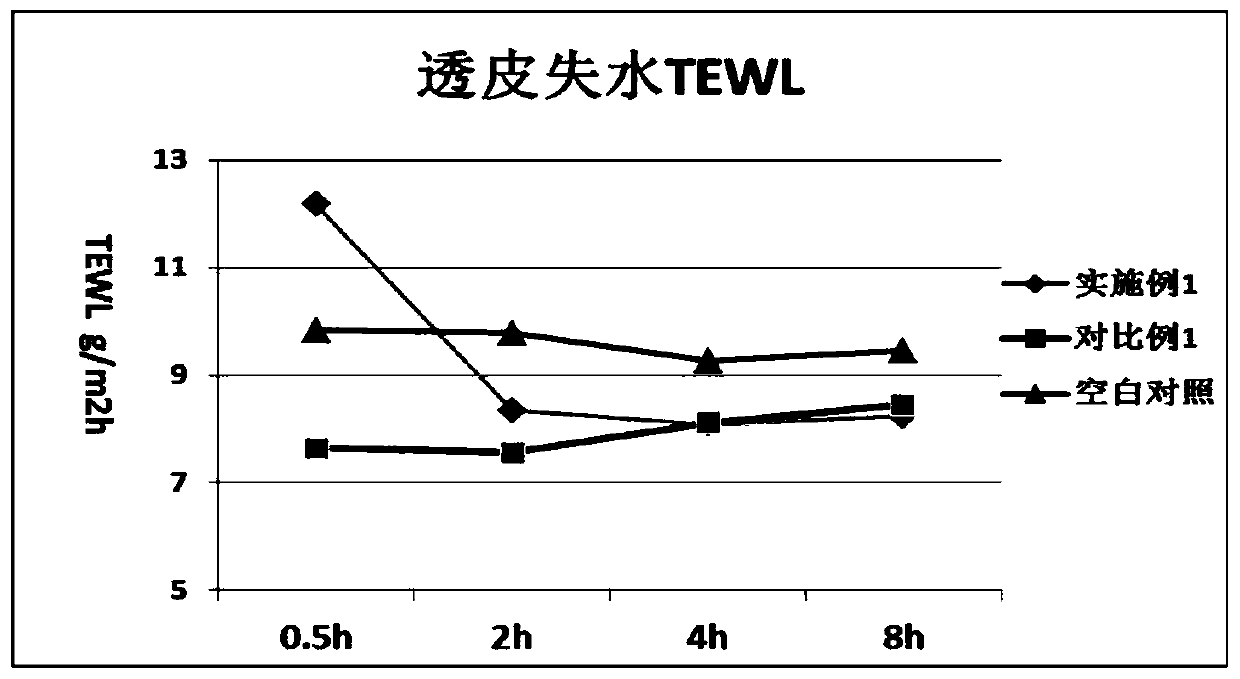

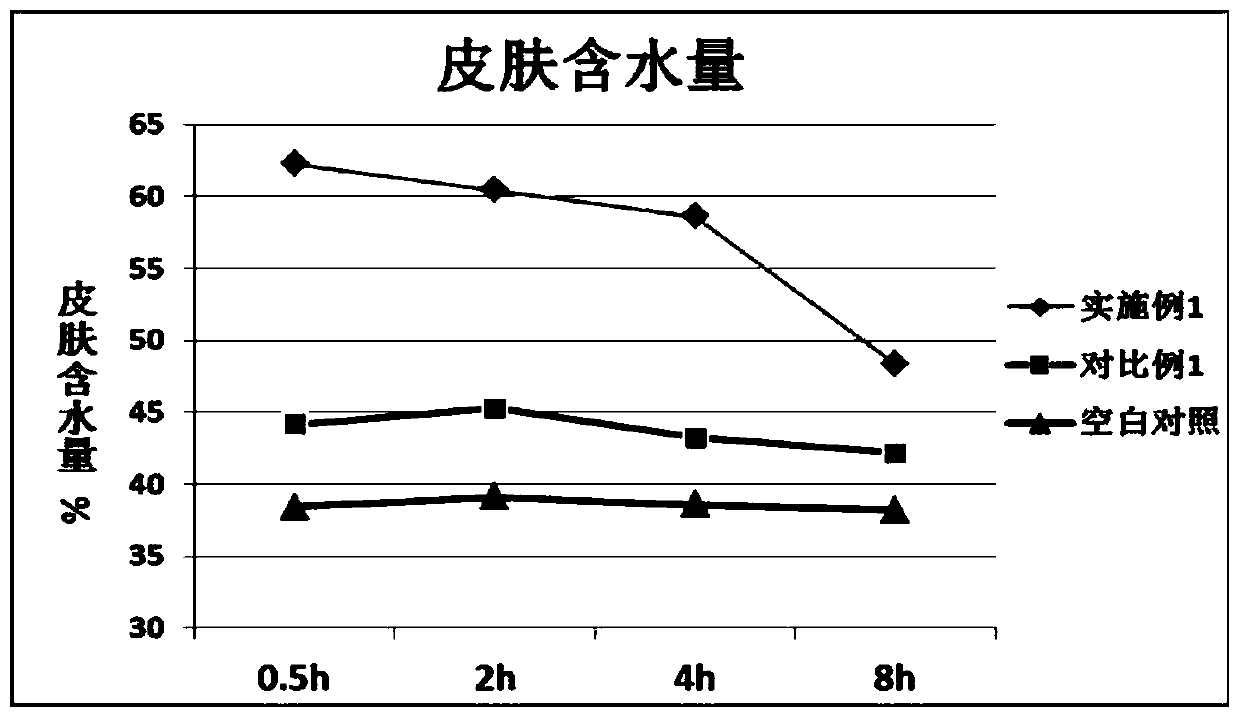

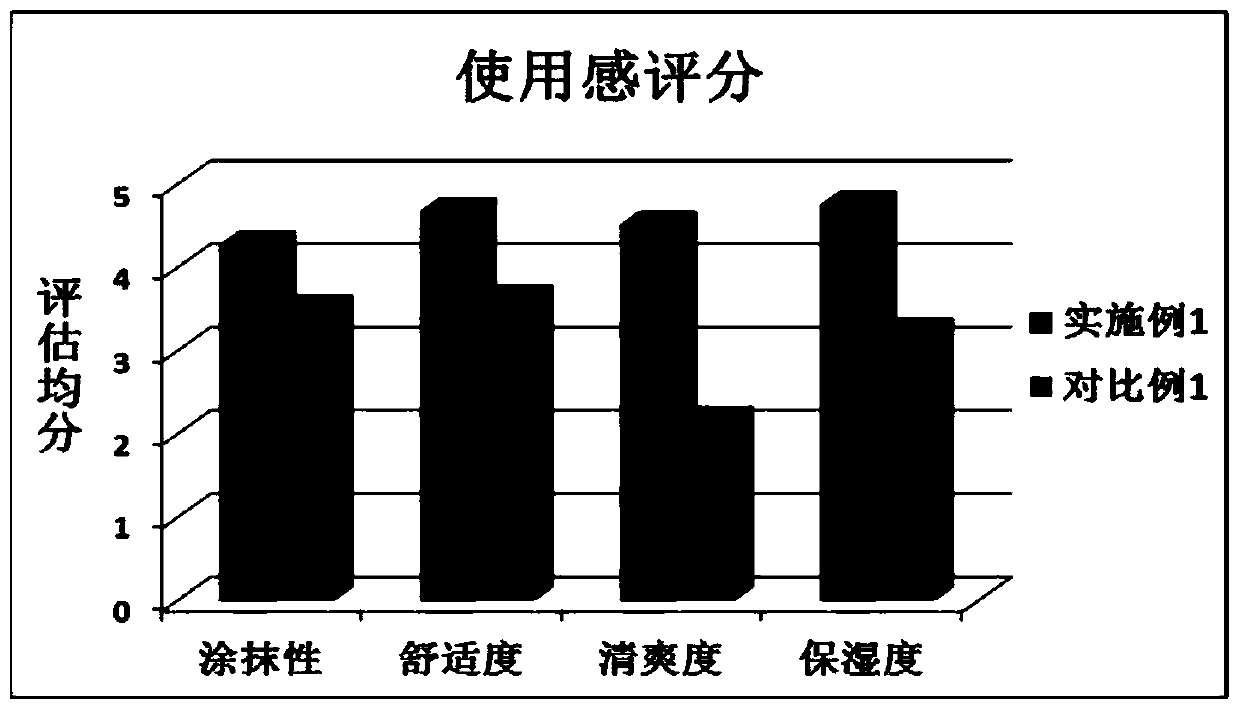

InactiveCN106214511AGood whitening effectNo discolorationCosmetic preparationsToilet preparationsMedicineAdditive ingredient

The invention relates to the field of cosmetics and particularly discloses skin whitening toning lotion containing lipidosome and a preparation method thereof. The skin whitening toning lotion is prepared from, by weight, 0.1-10% of lipidosome, 0.01-5% of thickener, 1-30% of polyalcohol humectant, 0.1-5% of cosmetically-accepted carrier and the balance water. The sum of the weight percentages is 100%. The lipidosome ingredient is added to the toning lotion, the formula is reasonable, the dry environment can be effectively resisted, the elastic and smooth skin can be restored, the skin is moisturized and tender, production of melanin is effectively restrained, the skin is brighter and whiter, the skin whitening toning lotion can deeply penetrate into the bottom layer of the skin, the dry environment is effectively resisted, the elastic and smooth skin is restored, and the skin is moisturized and tender.

Owner:上海乐宝日化股份有限公司

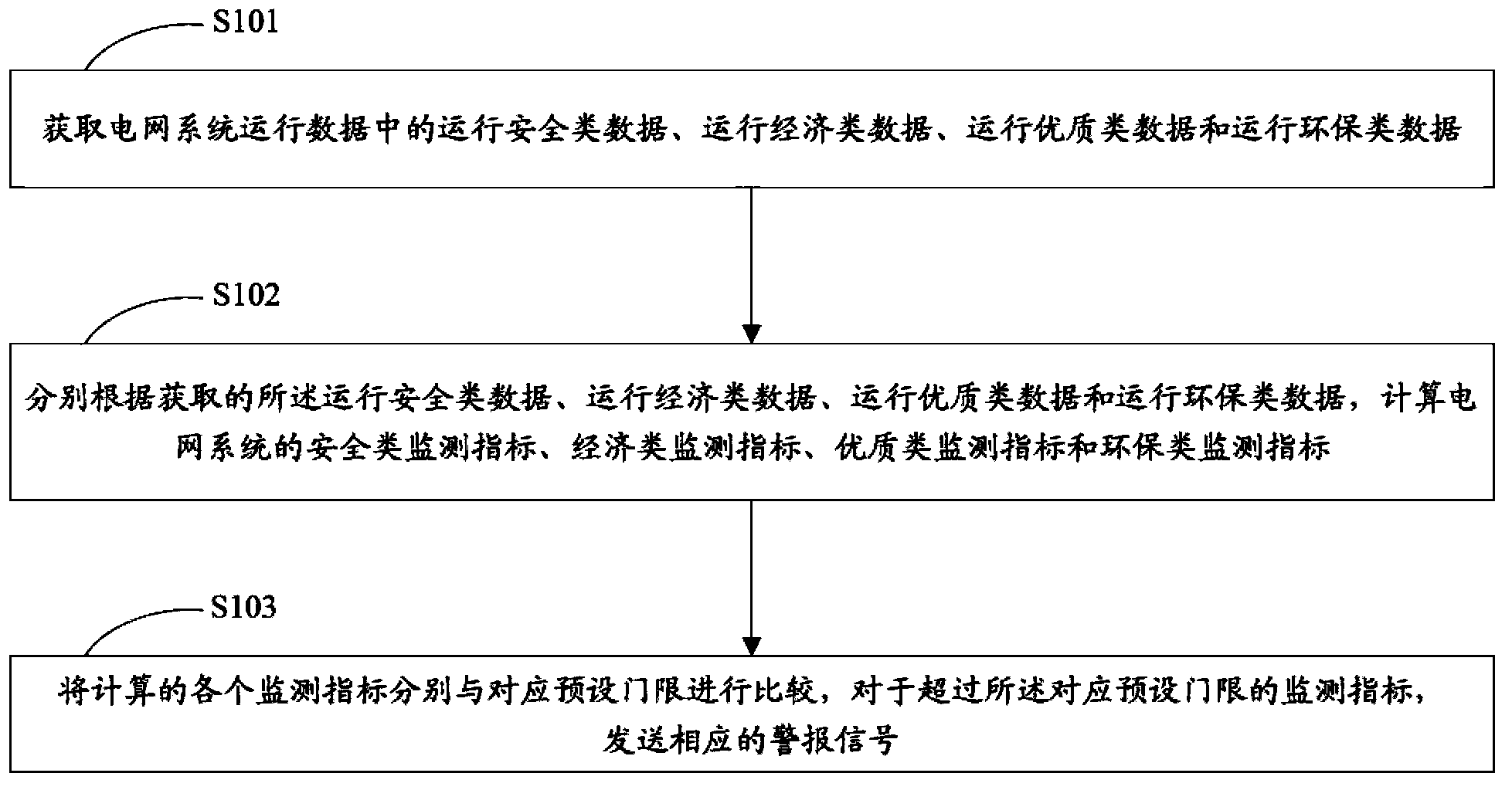

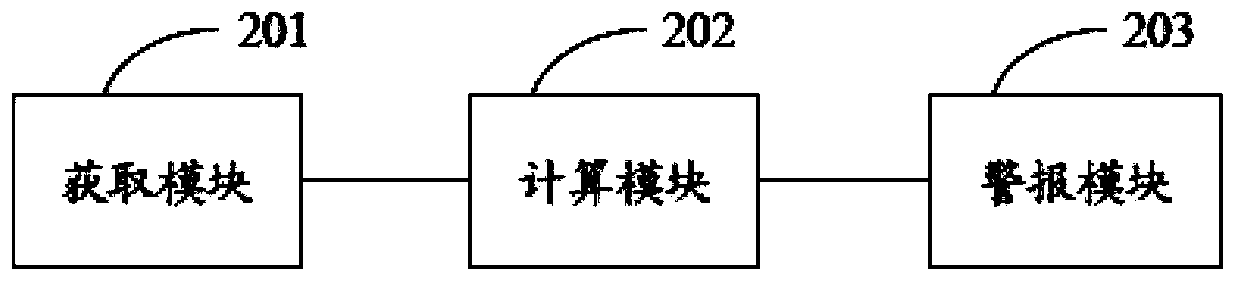

Alarm method and device for power grid system

The invention discloses an alarm method for a power grid system. The alarm method comprises the steps: obtaining operation security type data, operation economic type data, operation quality type data and operation environment-protection type data in operation data of the power grid system; calculating security type monitoring indexes, economic type monitoring indexes, quality type monitoring indexes and environment-protection type monitoring indexes of the power grid system; and comparing all the monitoring indexes with corresponding preset thresholds respectively, and for the monitoring indexes which exceed the corresponding thresholds, giving out corresponding alarm signals. In addition, the invention discloses an alarm device for the power grid system. The alarm signals can comprise a pre-warning signal and an alert signal. An index system for monitoring the power grid system by using an alarm mode is established, so the power grid system can be monitored completely and systematically in the aspects of security, economic performance, quality and environment protection. The alarm paths are clear, and false alarm and alarm failure cannot occur.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

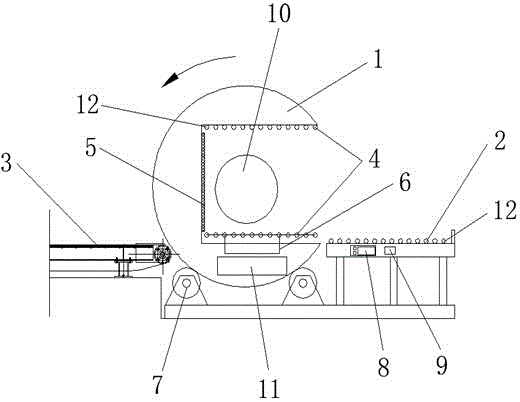

Device for turning transformer plate radiators during spraying paint

The invention discloses a device for turning transformer plate radiators during spraying paint. The device comprises a turning frame, a conveying belt and an operation waiting zone, wherein support pulleys are arranged at the bottom of the turning frame; transmitting belts, a cross beam, a pressing plate and a motor are arranged on the turning frame; the transmitting belts are arranged at the top and the bottom of the inside of the turning frame; servo motors are mounted inside the transmitting belts; the transmitting belts are in rolling shaft connection with the servo motors; the cross beam is arranged on the left side of the inside of the turning frame; the pressing plate is arranged at the bottom of one transmitting belt; a cylinder is mounted at the bottom of the pressing plate; a motor is mounted on the back of the turning frame; the conveying belt is arranged on the right side of the turning frame; a control panel, a control system and servo motors are arranged on the conveying belt; the servo motors are mounted inside the conveying belt; the servo motors are in rolling shaft connection with the conveying belt; the operation waiting zone is arranged on the left side of the turning frame. Through the device for turning transformer plate radiators during spraying paint, the operation efficiency can be improved; the device is capable of turning three groups of plate radiators at 180 degrees.

Owner:山东东升成套电气股份有限公司

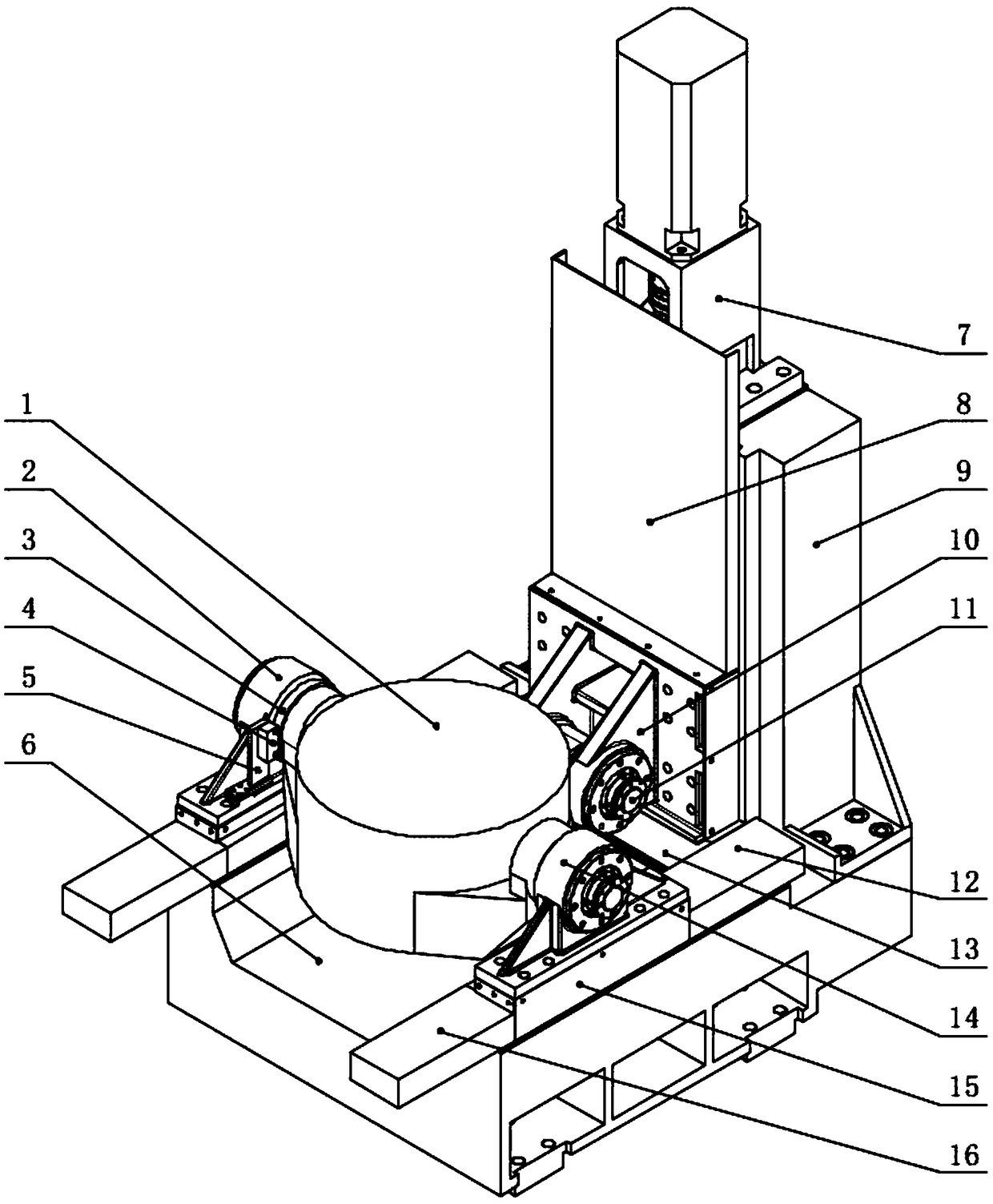

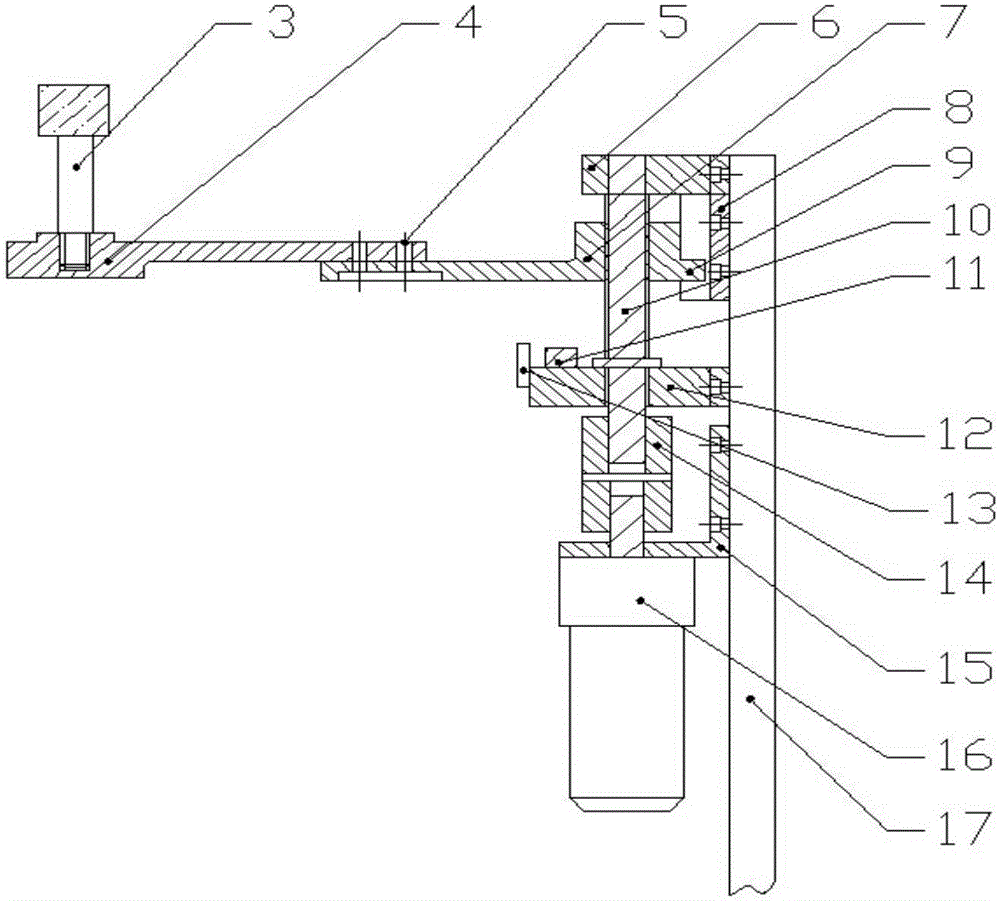

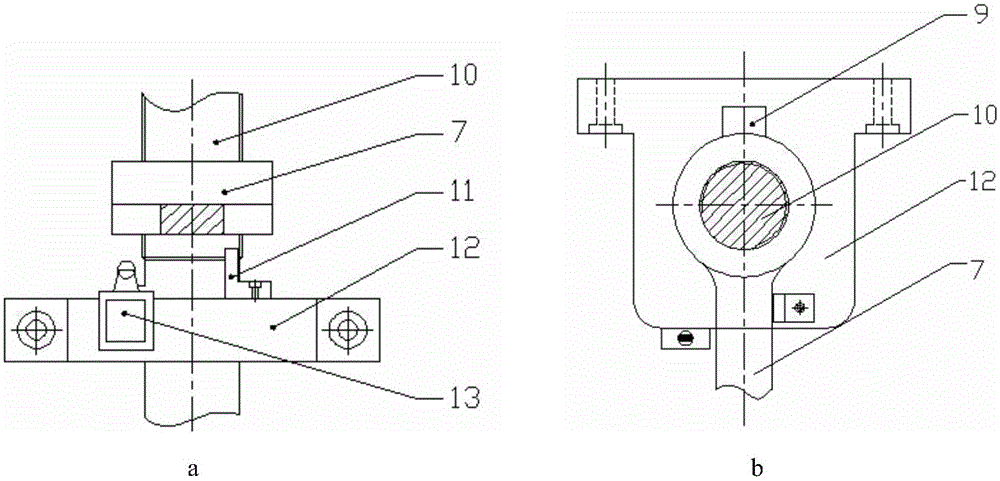

Cradle rotary table dragged by ball screw

ActiveCN108747436ANo wearNo thermal expansionLarge fixed membersMaintainance and safety accessoriesBall screwEngineering

The invention discloses a cradle rotary table dragged by a ball screw. The cradle rotary table dragged by the ball screw comprises a rotary table body, a base and a stand column perpendicular to the base, and further comprises a first swing mechanism, a second swing mechanism, a third swing mechanism and a dragging mechanism; the first swing mechanism and the second swing mechanism which are fixedto the base are arranged at the two ends of the rotary table body separately; the third swing mechanism is connected with a boss structure at the rear end of the rotary table body; and the dragging structure is arranged on the stand column and drives the third swing mechanism to move on the stand column. The cradle rotary table dragged by the ball screw does not generate the conditions of tooth surface abrasion, heating expansion and tooth surface adhesion, improves the transmission efficiency, enlarges the torque, reduces the cost, reduces the shaft end size and saves the space.

Owner:KEDE NUMERICAL CONTROL CO LTD

Sunscreen bar containing water-soluble component and preparation method thereof

PendingCN111000761ASolve the inability to add water-soluble components (water-soluble skin conditionersSolve sunscreenCosmetic preparationsMake-upSunscreen agentsPreservative

The invention discloses a sunscreen bar containing a water-soluble component, which belongs to the technical field of special cosmetics. The sunscreen bar containing water-soluble component is prepared from the components of, by weight, 5.00 to 40.00 part of sun-screening agent, 1.00 to 10.00 part of emulsifying agent, 1.00 to 30.00 part of water-soluble component, 10.00 to 92.00 parts of emollient and 1.00 to 20.00 part of powder. According to the invention, the water-soluble component is added into the sunscreen bar; the defect that water-soluble components (a water-soluble skin conditioner,a sun-screening agent, a film-forming agent, a humectant, a preservative and the like) cannot be added into a traditional pure oil sunscreen bar is overcome; the selection range of the raw materialsis widened; the formula cost and greasy feeling are reduced; moisturizing experience can be provided while moisturizing is achieved; and particularly, the sunscreen index can be increased by effectively reducing the 'window effect' by adding the water-soluble sun-screening agent which has a synergistic effect with an oil-soluble sun-screening agent.

Owner:苏州绿叶日用品有限公司

Casting method for pouring and molding thin-wall investment pattern steel casting

ActiveCN103506574ADoes not cause shrinkageWill not cause looseningFoundry mouldsFoundry coresWaxMetallurgy

The invention discloses a casting method for pouring and molding a thin-wall investment pattern steel casting, aiming to prevent the casting from cavity-shrinking, loosening or deforming. The method comprises the following steps: a. first preparing multiple wire-shaped metal materials with diameter of 0.5-1mm and length of 50-100mm and coating the outer surface of each wire-shaped metal material with a layer of wax with thickness of 0.1-0.2mm; b. inserting the wire-shaped metal materials from the last step into an assembled wax module, wherein the inserting thickness is 4-8mm; c. coating and smearing the wire-shaped metal materials with slurry and sands together with the wax module; d. after forming a module shell on the surface of the wax module, firstly destroying parts of module shell on the surface of the other end of the wire-shaped metal materials, drawing out the wire-shaped metal materials, and then performing dewaxing and roasting; e. finally pouring molten steel, wherein cavities which are formed in the module shell after the wire-shaped metal materials are drawn out can be used for drainage. By virtue of the method, the pass percent of the castings is enhanced.

Owner:JIASHAN SINHAI PRECISION CASTING

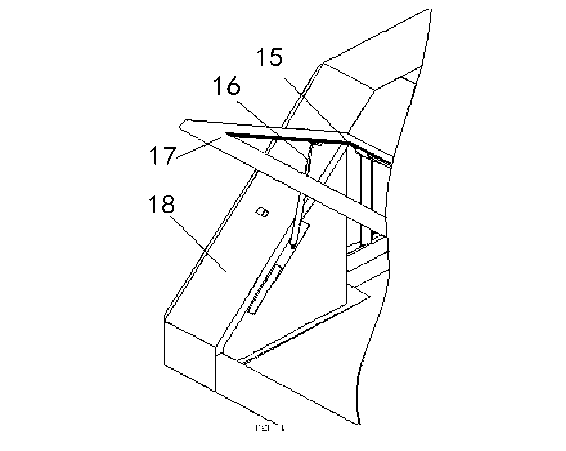

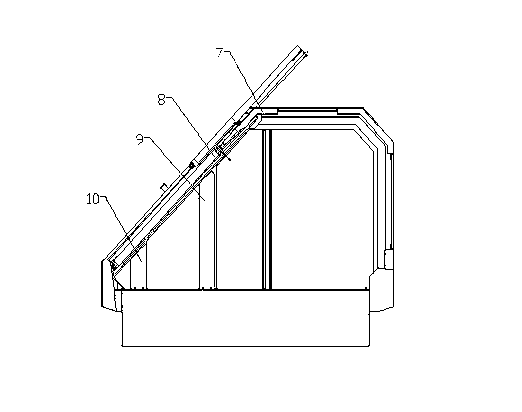

Automatic hoisting device for large-scale hood gate

ActiveCN102729095AAchieve openAchieve closureMaintainance and safety accessoriesSolenoid valveMachine tool

The invention discloses an automatic hoisting device for a large-scale hood gate, comprising left / right column assemblies, a hoisting cylinder assembly, a connecting assembly of the left / right columns, a guide rail assembly, a doorframe assembly, a safety brake assembly, a buffer assembly and light screen protection assemblies. The device is characterized in that the left / right column assemblies are arranged on a machine station, and are connected into an integral body by a front top plate and a front baffle plate of the connecting assembly, so the rigidity and the stability of the whole hood columns are enhanced. Hinge supports of the cylinder are arranged on a cylinder installing plate of the left / right columns, and a shaft-extension end of the cylinder is connected with a U-shaped bayonet of two sides of the doorframe. Front shoe plates and rear shoe plates of the guide rail installation assembly are fixed on the machine station. Before adjustment, space between the rear shoe plates ensures the left / right guide rails installing plates arranged on the rear shoe plates to be in parallel with the doorframe. A solenoid valve controls an air inlet direction of the cylinder and guarantees the cylinder telescoping to provide power for the doorframe and the doorframe slides along the guide rail direction, so automatic open and closure of the doorframe are realized.

Owner:SUZHOU VEGA TECH CO LTD

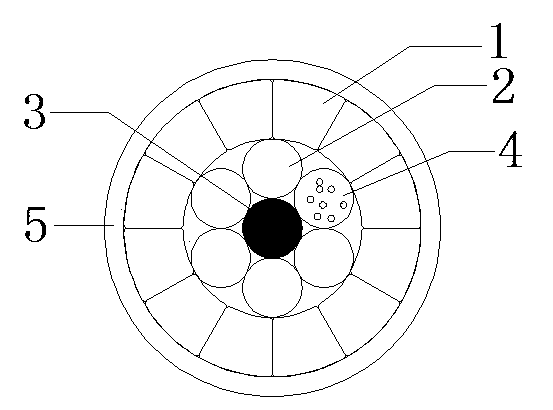

Reinforced optical fiber composite high-temperature-resistant overhead insulating cable

The invention discloses a reinforced optical fiber composite high-temperature-resistant overhead insulating cable which comprises a carbon fiber composite reinforced core. A plurality of round flexible aluminum wires and a stainless steel sleeve light unit are stranded on the outer side of the carbon fiber composite reinforced core in a concentric mode. A plurality of special-shaped flexible aluminum monofilaments which are distributed in a round shape are arranged on the outer sides of the round flexible aluminum wires and the outside of the stainless steel sleeve light unit, and a high-temperature-resistant insulating layer is arranged on the outer sides of the special-shaped flexible aluminum monofilaments. The reinforced optical fiber composite high-temperature-resistant overhead insulating cable is simple in structure, long in service life and suitable for reconstruction and construction of power grid overhead lines in urban and rural areas, can bear the tension strength of 2400Mpa, allows long-time operation temperature to be more than 180 DEG C, has communication and monitoring functions, can effectively solve the dropping problem of the cable, and guarantees safe operation of lines.

Owner:HENAN KOSEN CABLE

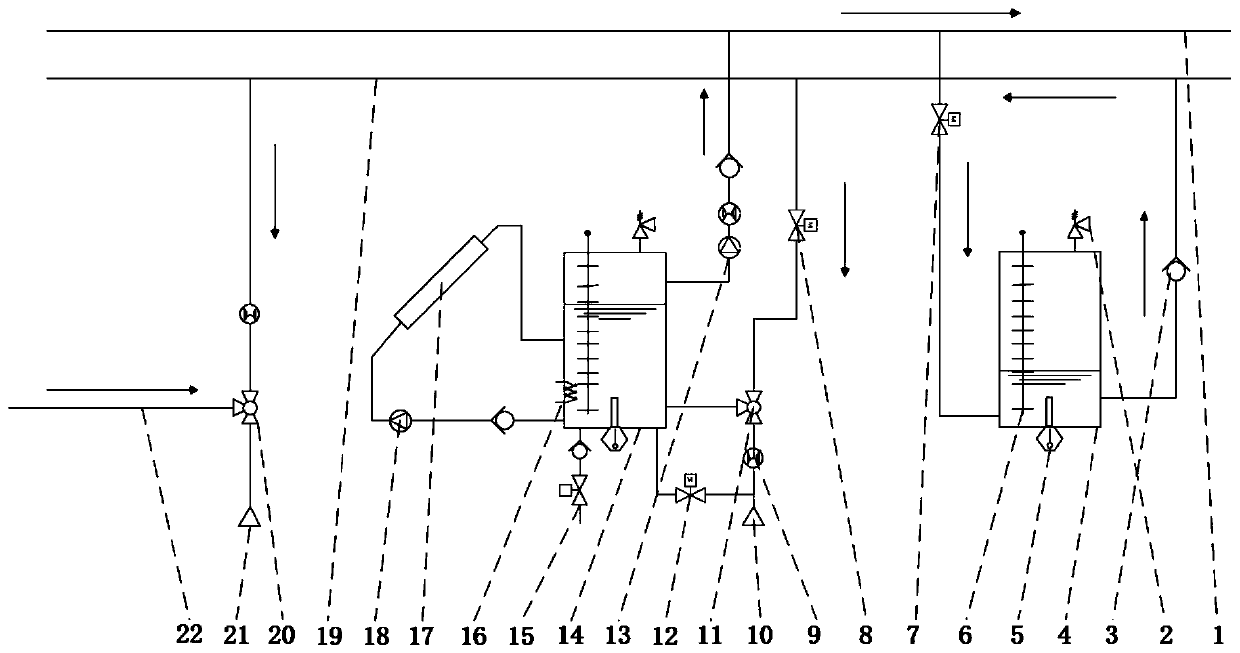

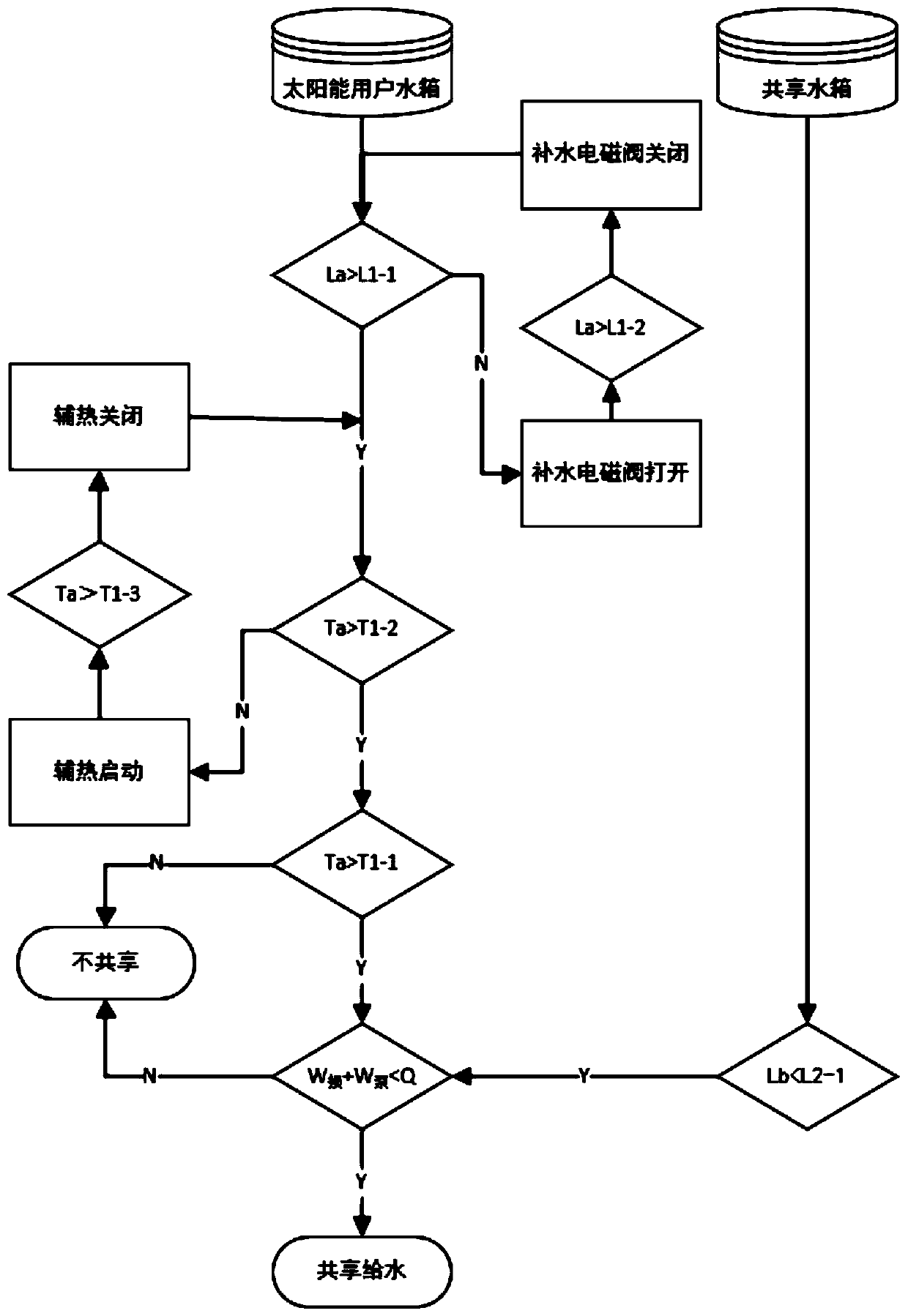

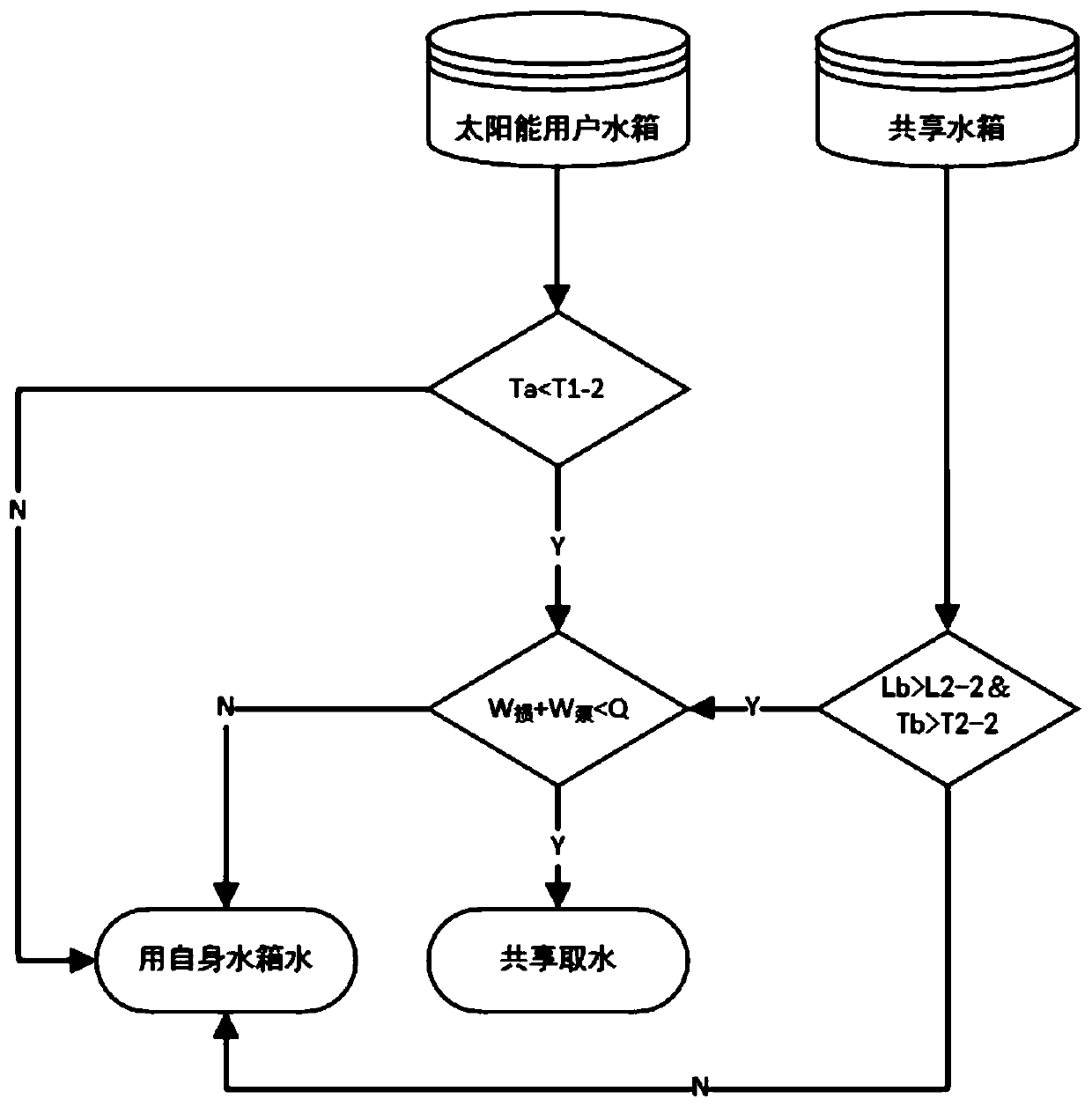

Regional distributed hot water sharing system and control method

ActiveCN110428302AIncrease profitMaximize outputSolar heating energySpace heating and ventilation detailsWater sharingThermal energy

The invention discloses a regional distributed hot water sharing system and a control method. The regional distributed hot water sharing system mainly comprises a solar heat collector, a solar user water tank, other energy user hot water pipes, a sharing water tank, a water supply main pipe, a water return main pipe, a remote water meter, a liquid level sensor, a temperature sensor, matched pumps,valves and pipelines, wherein the solar heat collector provides hot water for the solar user water tank; the solar user water tank is connected with a water supply and return main pipe; the remote water meter is used for metering hot water flow; the liquid level sensor is used for measuring the liquid level of the water tank; the temperature sensor is used for measuring the temperature of the water tank; and the pump, the valve and the pipeline are used for forming a heat energy sharing network. The regional distributed hot water sharing system is applied to a single multi-storey building ora low-storey building community. The users utilize solar water tank hot water, and two-way conveying of hot water between the users and the shared water tanks is achieved through the water supply header pipe and the water return header pipe, and the users in each area share one shared water tank and the same pair of header pipes, and the shared water tanks in the adjacent areas are connected, anda community hot water network is constructed, and the hot water supply and demand side imbalance problem is relieved in a sharing mode.

Owner:CENT SOUTH UNIV

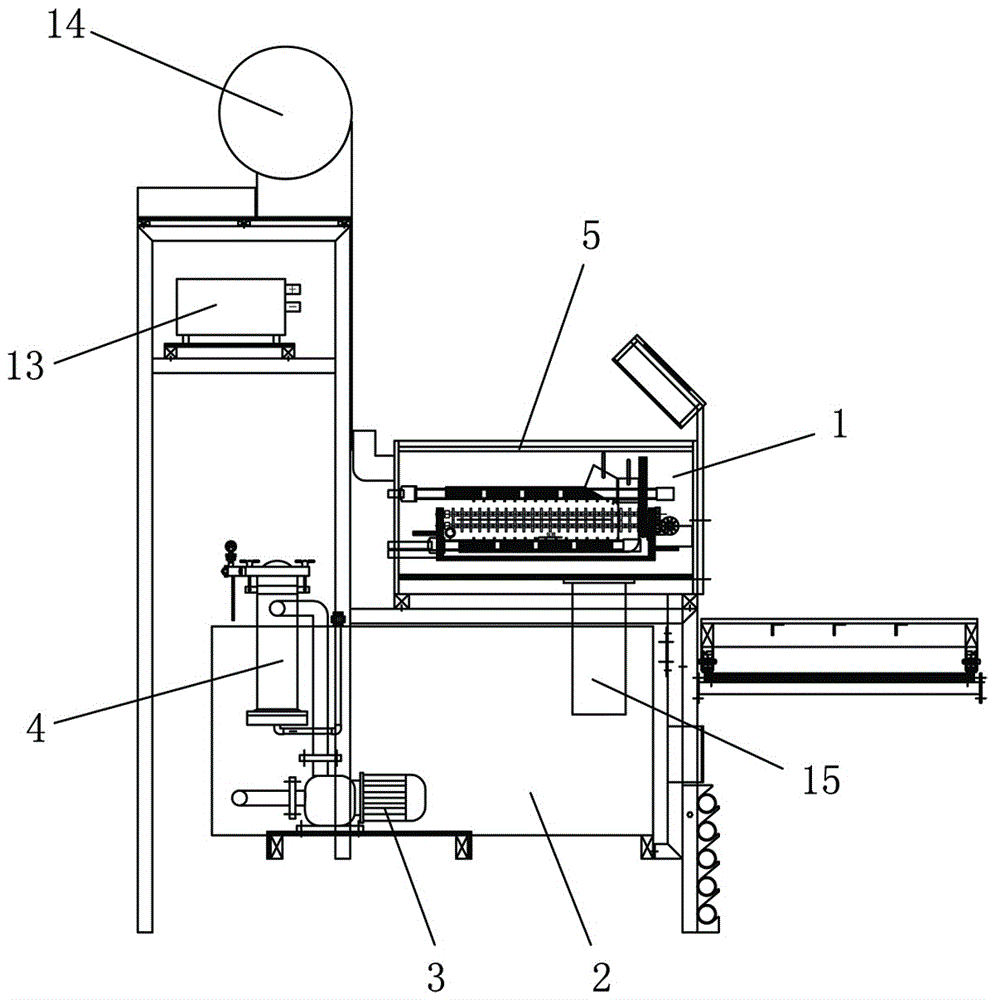

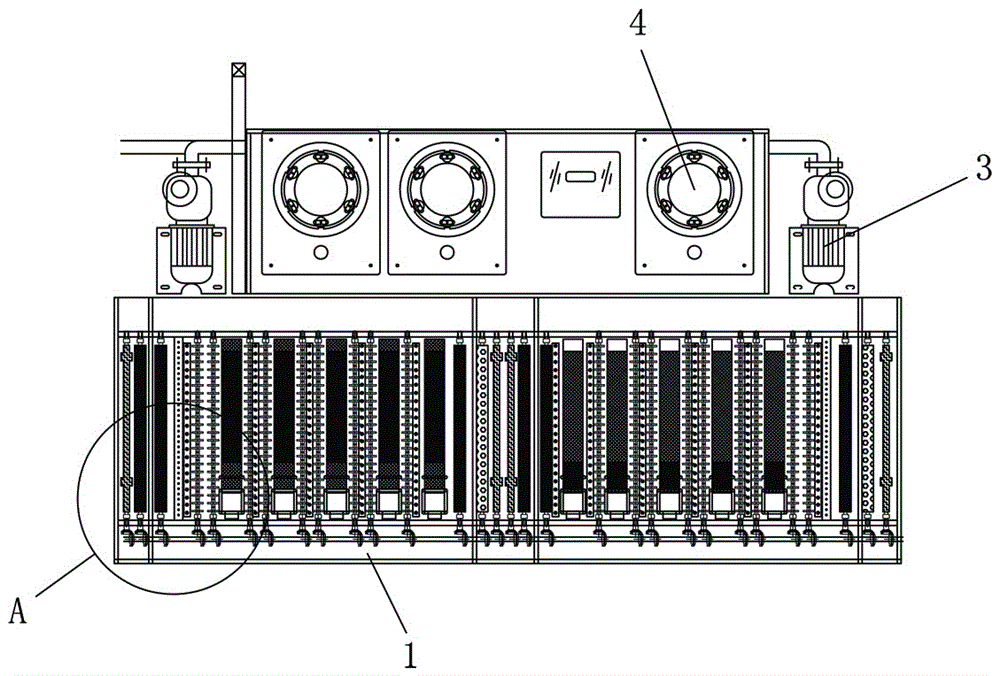

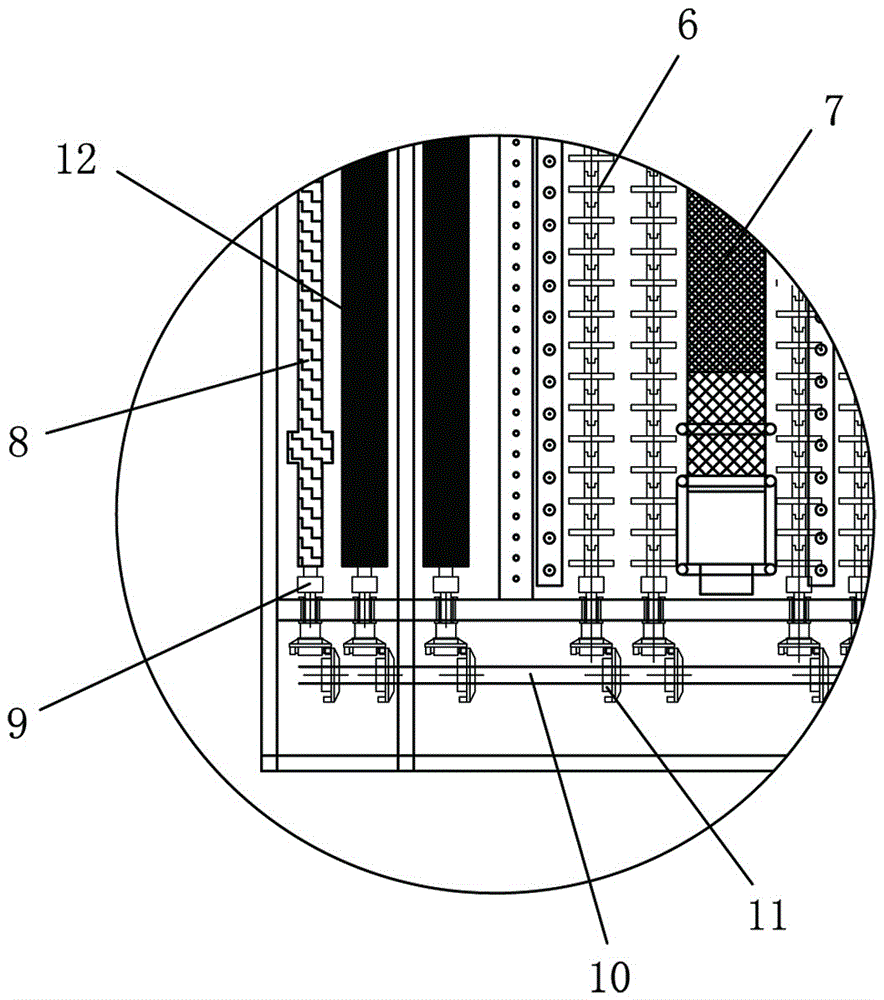

Horizontal electroplating production line for circuit boards

PendingCN107435163AImprove liquidityQuality improvementElectrolysis componentsProduction lineEngineering physics

The invention discloses a horizontal electroplating production line for circuit boards and relates to the technical field of electroplating for the circuit boards. The horizontal electroplating production line for the circuit boards comprises a cleaning device, an electroplating device and a dehumidifying device and further comprises a transfer device, wherein the cleaning device, the electroplating device and the dehumidifying device are horizontally distributed in the transverse direction; the transfer device can convey the circuit boards to the cleaning device, the electroplating device and the dehumidifying device and penetrates through the cleaning device, the electroplating device and the dehumidifying device; the circuit boards to be electroplated are horizontally placed on the transfer device; and liquid chemical in the electroplating device is in a perpendicular flowing state all the time. By means of the horizontal electroplating production line for the circuit boards, the mobility of the liquid chemical in interconnecting holes of the circuit boards can be improved, and thus electroplating meets the technical requirements for the high-quality and high-reliability interconnecting holes.

Owner:MLS

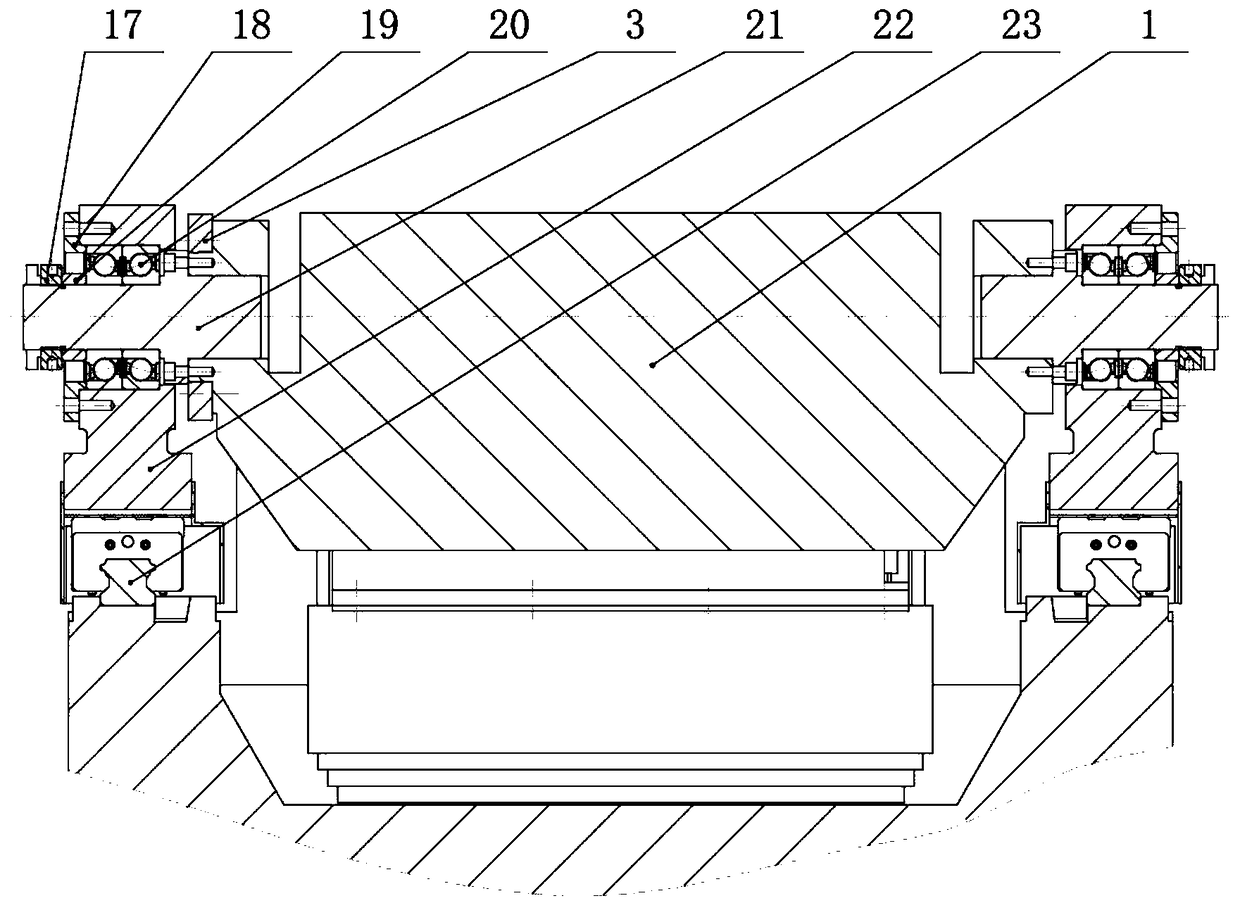

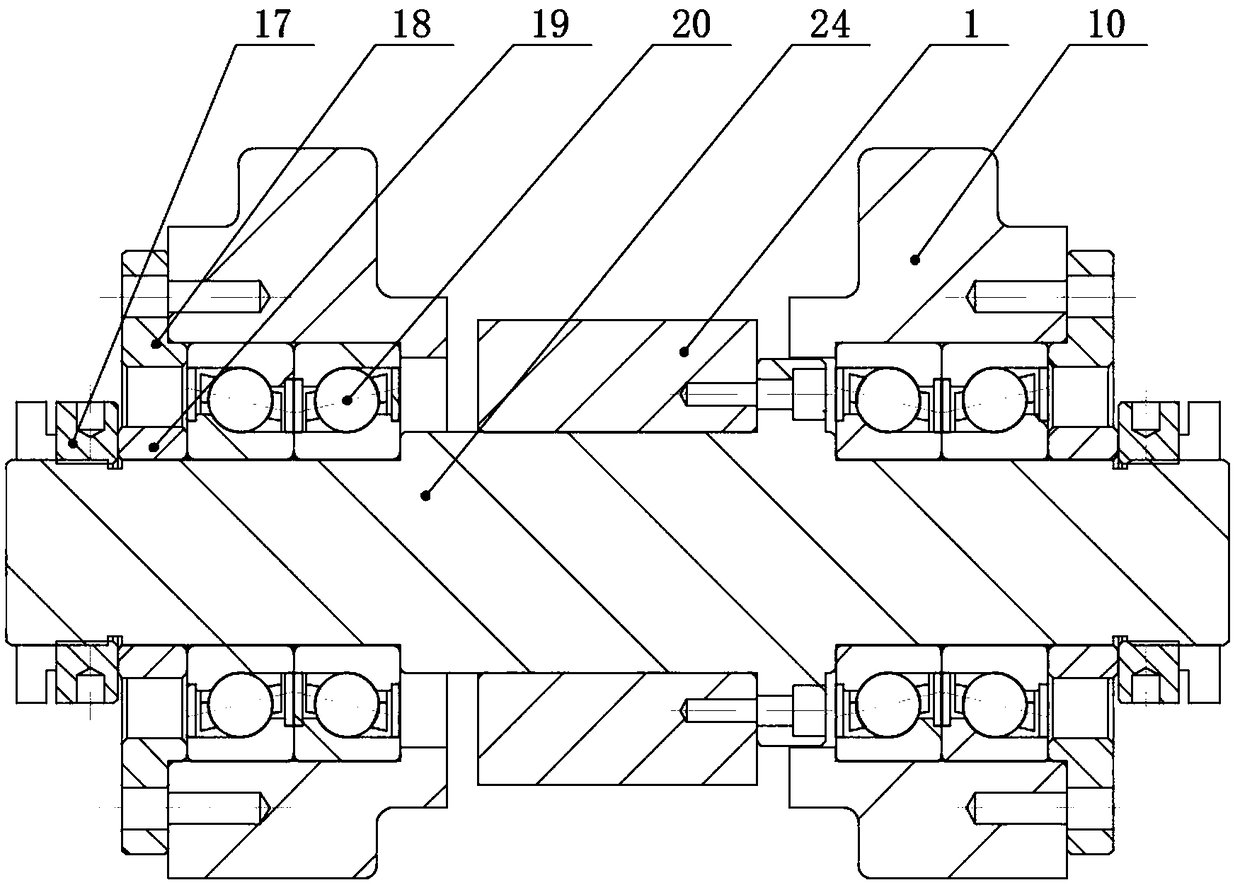

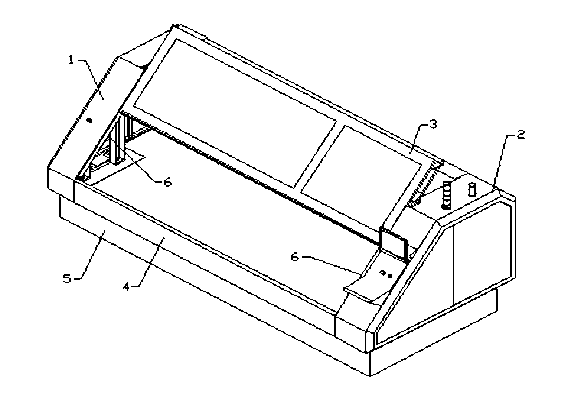

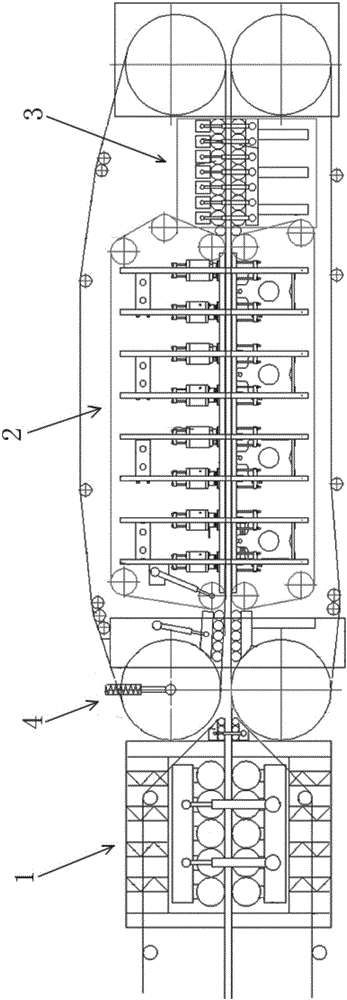

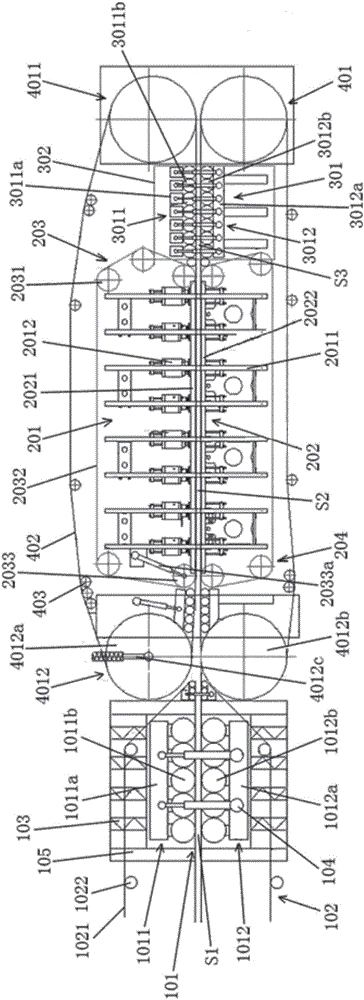

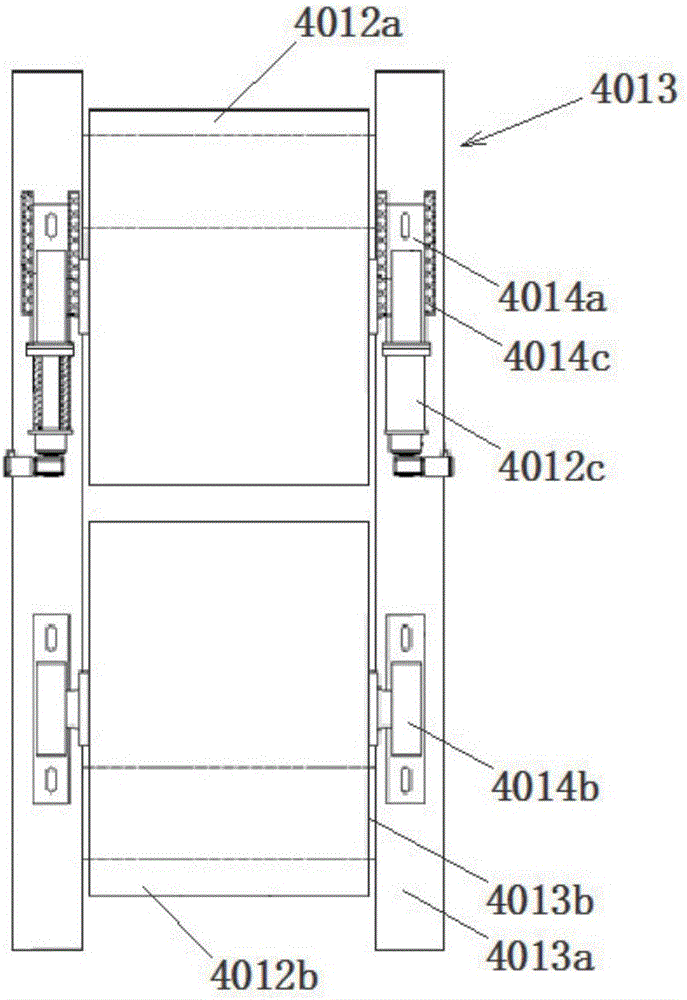

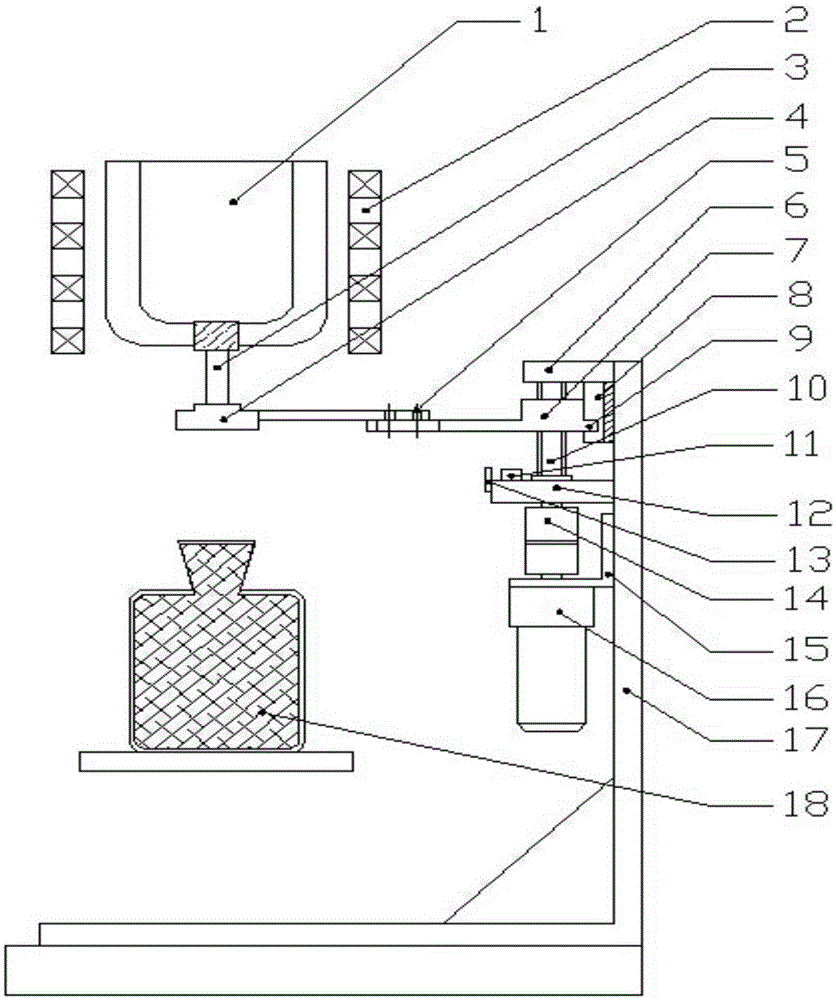

A continuous type press

PendingCN106607971ARealize continuous productionIncrease production capacityPlywood pressesVeneer pressesThermal isolationEngineering

The invention provides a continuous type press comprising a pre-heating and pressurizing unit, a heating and pressurizing unit, a cooling and pressurizing unit and a steel belt conveying unit used for connecting the heating and pressurizing unit and the cooling and pressurizing unit in series. The pre-heating and pressurizing unit comprises a first roller group mechanism used for providing pressure and a heating device used for providing non-contact heating, as well as a conveying device which is arranged between the first roller group mechanism, cooperates with the first roller group mechanism and is used for conveying mechanisms. The cooling and pressurizing unit comprises a second roller group mechanism used for providing pressure and a thermal isolation device used for maintaining the internal temperature of the cooling and pressurizing unit. The continuous type press has the advantages of low energy consumption, low cost, long service life, short production cycle, high plywood production efficiency and high forming quality.

Owner:CHINA FOMA GROUP

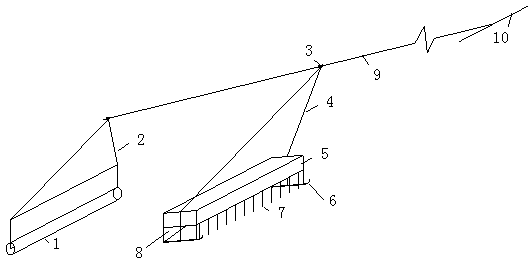

Manufacturing method of tool for concrete finishing and thin film covering

InactiveCN110449762AAdvantages of production methodSimple structureCeramic shaping apparatusBuilding material handlingBuilding constructionExtrusion

The invention discloses a manufacturing method of a tool for concrete finishing and thin film covering. The method is characterized by comprising the following steps of a, manufacturing a film pavingframe; b, manufacturing a roughening and leveling frame; and c, providing a pull rod, wherein one end of the pull rod is provided with a handle, and the other end continuously penetrates through top end steel pipes of the roughening and leveling frame and the film paving frame and is fixed with the top end steel pipes of the roughening and leveling frame and the film paving frame, and therefore the tool for concrete finishing and thin film covering is obtained. The manufacturing method of the tool for concrete finishing and thin film covering has the advantages of being simple in device structure and convenient in manufacturing; through optimizing the concrete surface leveling process and film covering process, finishing and covering can be combined into a whole through the two processes,so that concrete forming quality as well as construction progress are improved; and compared with an existing tool combining functions of concrete finishing and thin film covering, the method disclosed by the invention has the advantages that phenomena of extrusion and concrete bulking do not generate, the surface quality of concrete can be guaranteed, and subsequent film covering can be facilitated

Owner:MCC5 GROUP CORP SHANGHAI

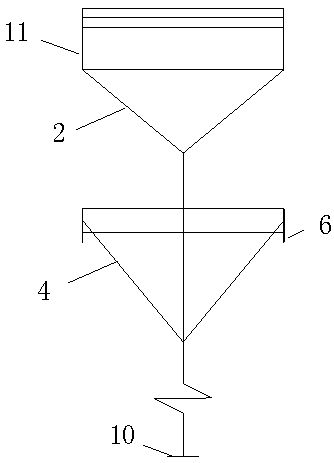

Bottom cork pulling type vacuum induction melting and casting control device

ActiveCN105081302AImprove interchangeabilityReduce the degree of reactionMelt-holding vesselsContact timeCrucible

The invention discloses a bottom cork pulling type vacuum induction melting and casting control device. A cork pulling mechanism is mounted on a support; a casting mould is located below a choke plug; and the choke plug in the cork pulling mechanism is mounted in a casting hole of a crucible and is matched with a screw rod by a cork pulling rod. According to the bottom cork pulling type vacuum induction melting and casting control device, bottom injection type casting is adopted, and no electrodes and no crucible oblique rotation mechanisms are needed, so that the structural complexity of apparatuses and the complexity of melting and casting working procedures are reduced. Meanwhile, the cork pulling rod is not in contact with a melt, so that the contact time of the melt and the crucible is shortened and the contact area of the melt and the crucible is reduced, and the reaction speed of metal and the melt is reduced; and the casting position of the metal melt is accurately positioned in the lower part, so that no splashing and casting missing conditions occur.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

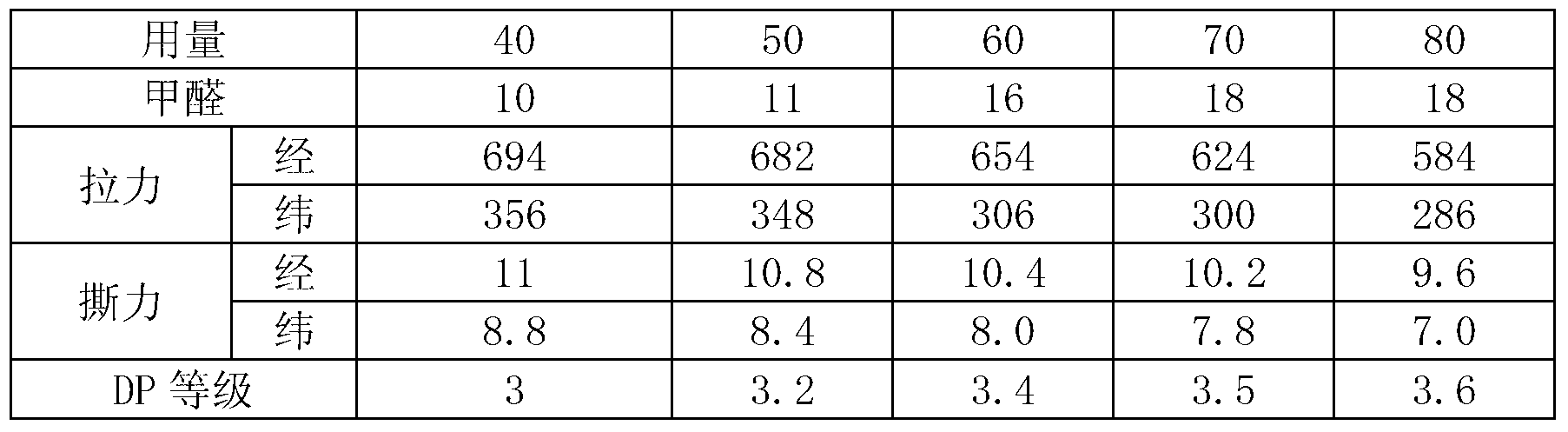

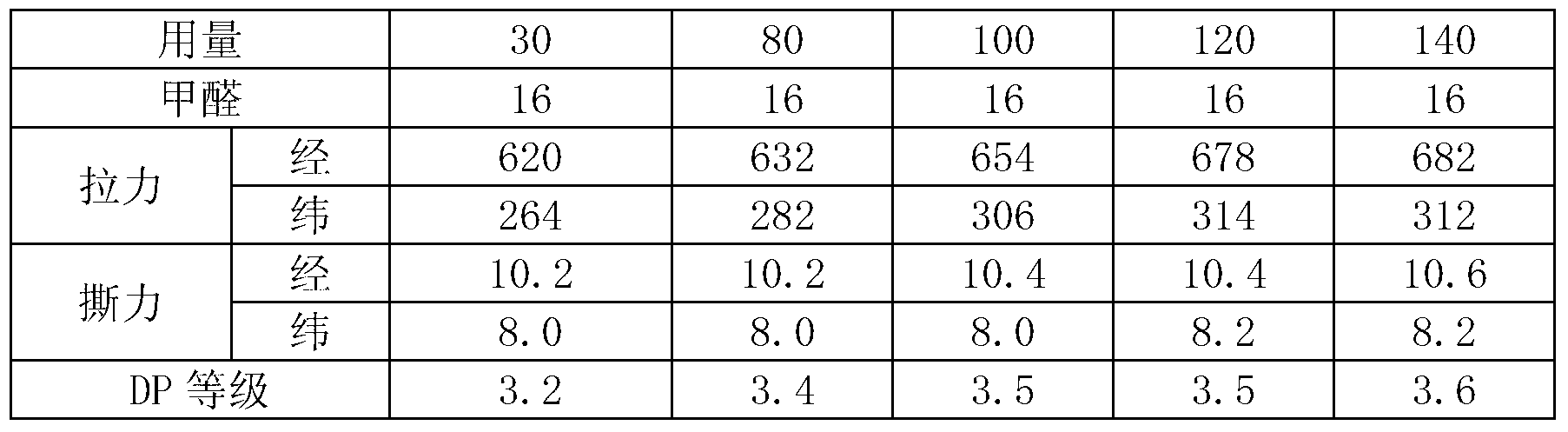

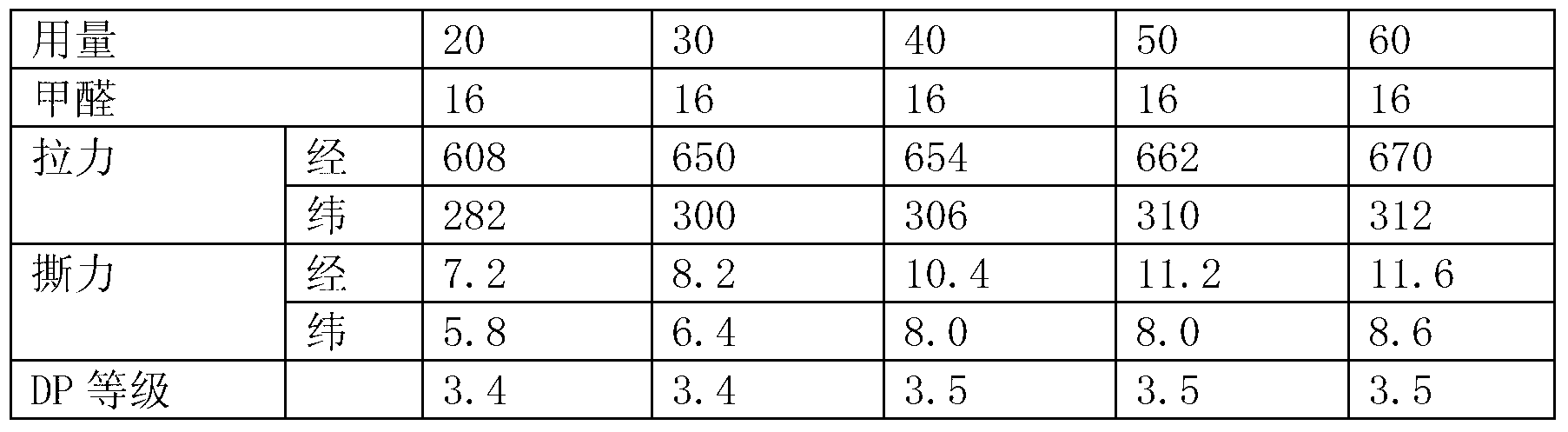

Non-strength-reducing easy-care finishing method for pure cotton fabrics

ActiveCN103215814AHigh strengthStrong without damageVegetal fibresPolymer sciencePolyether polyurethane

The invention discloses a non-strength-reducing easy-care finishing method for pure cotton fabrics, which is applied to an easy-care finishing process in the process of dyeing and finishing cotton fabrics. The method comprises the following steps of: A, preparing an easy-care finishing working solution, wherein the easy-care finishing working solution is prepared from the following components in parts by weight: 60 parts of etherified modified resins, 100 parts of modified polyether polyurethane, 30 parts of modified amino silicone, and 40 parts of PVC emulsion 20; B, padding: adjusting the pH value of the easy-care finishing working solution obtained in the step A to be 4-5, and dipping and rolling a fabric, so that the liquid carrying ratio of the fabric is 70%; and implementing a post-treatment process on the obtained product; C, drying: drying the fabric obtained in the step B for 2 min at a temperature of 95 DEG C; D, preshrinking treatment: carrying out conventional preshrinking treatment on the fabric obtained in the step C; and E, baking: baking the obtained product for 1 min at a temperature of 160 DEG C. The wear resistance and seam slippage of the obtained product are significantly improved, each index is superior to that of the existing process, and the product strength is almost not damaged.

Owner:HEBEI NINGFANG GRP

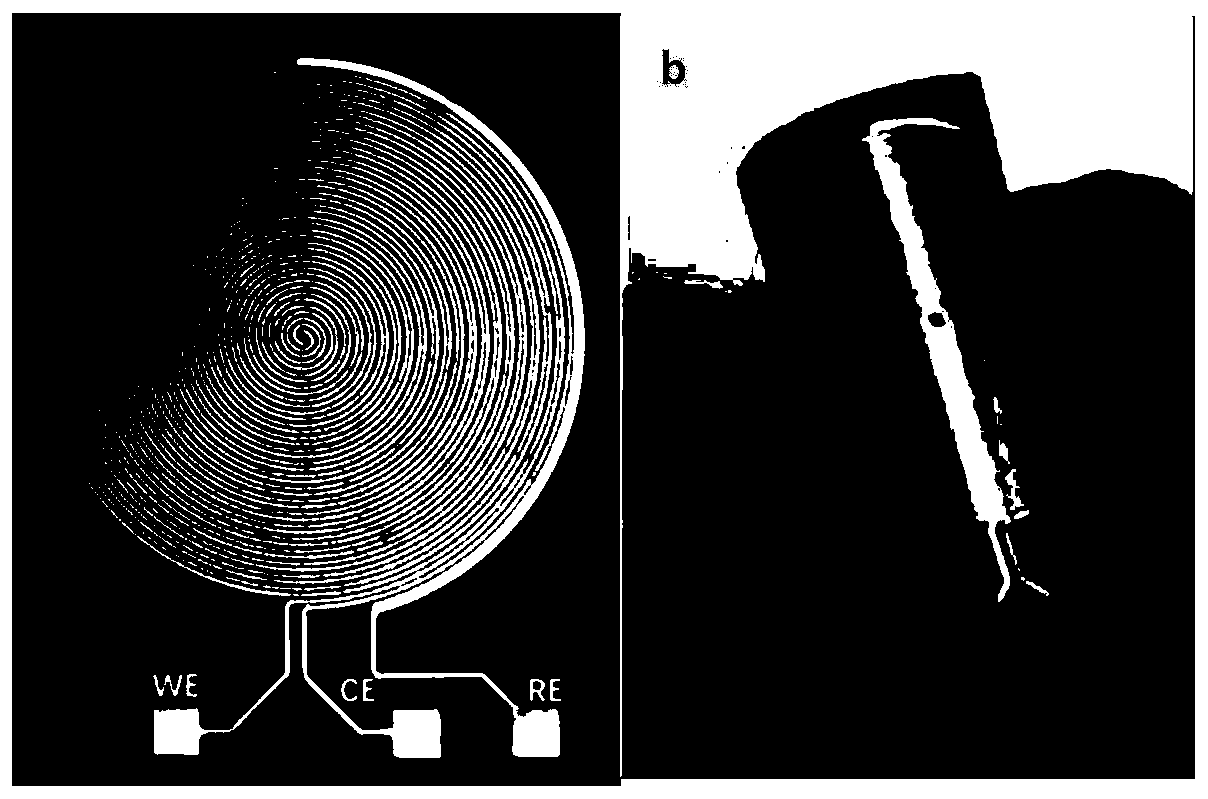

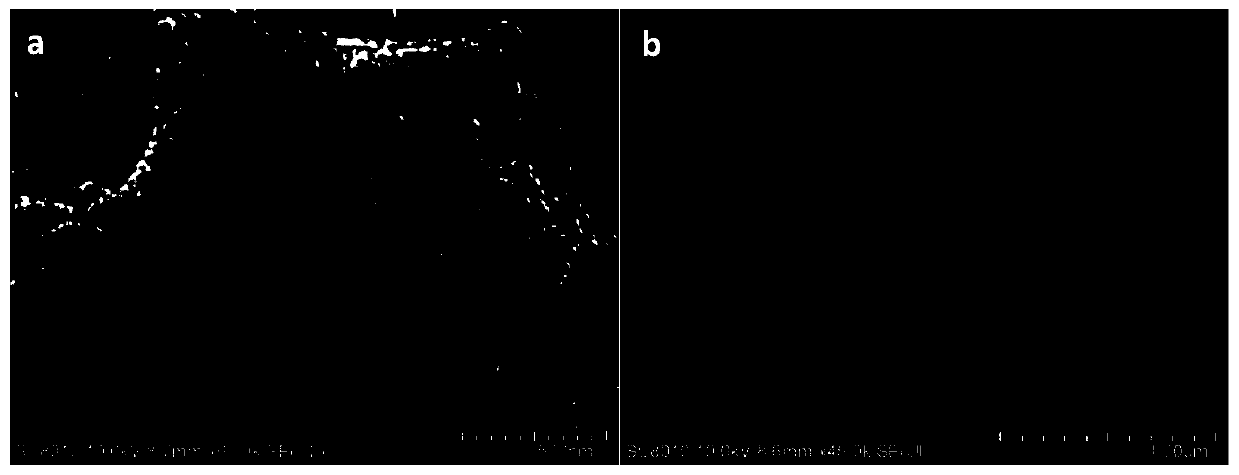

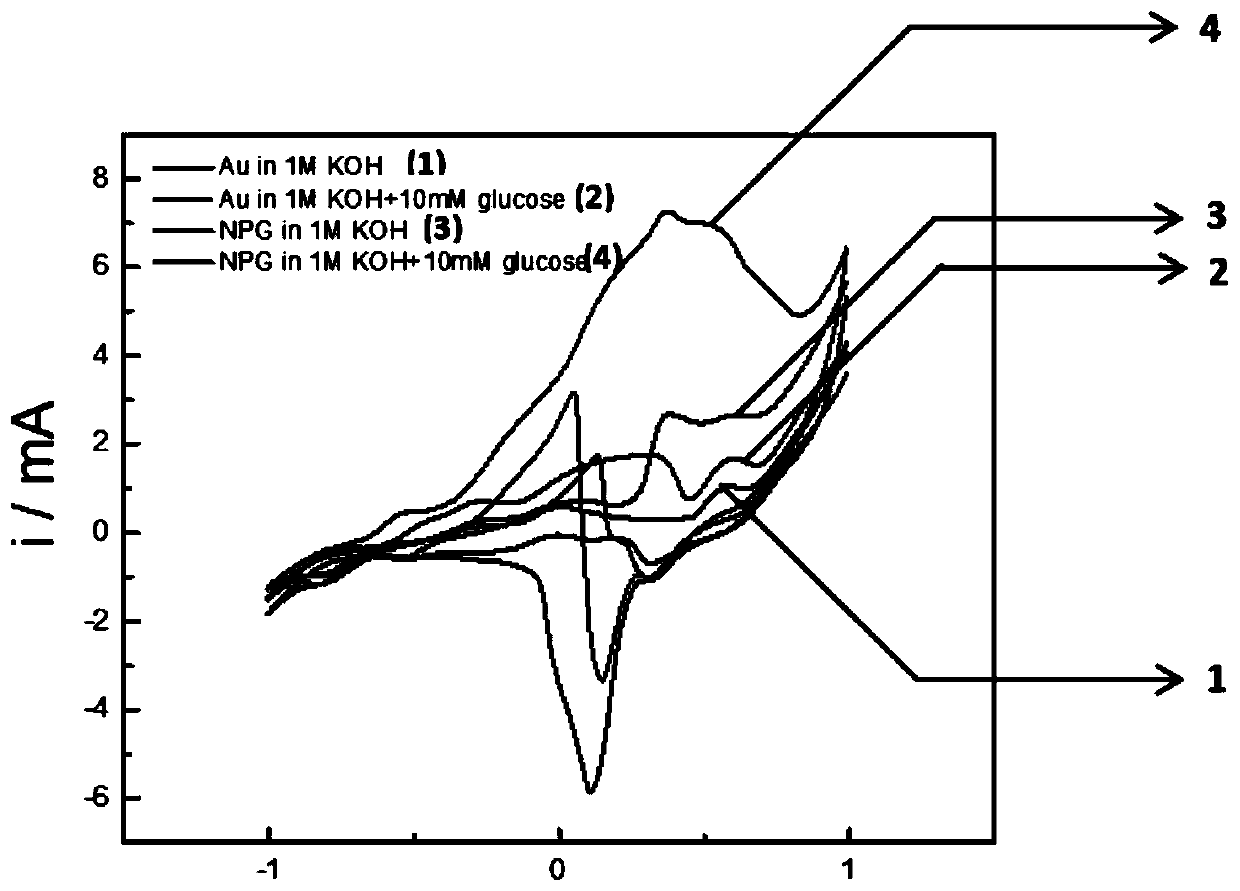

Nano porous gold enzyme-free flexible sensing electrode for detecting glucose through sweat, and preparation method and application thereof

InactiveCN110455894ASolving problems that cannot be applied to tiny sensorsSolving technical problems in modifying nanoporous goldMaterial electrochemical variablesMicrometerD-Glucose

The invention provides a nano porous gold enzyme-free flexible sensing electrode for detecting glucose through sweat, and a preparation method and application thereof. The invention provides a three-electrode coplanar integrated enzyme-free glucose sensing electrode, nano porous gold with high catalytic activity is combined with a fine interdigital electrode through electrodeposition, and a feasible method for electrodeposition of a nano material in a microelectrode area is provided. The nano porous gold modified flexible sensing electrode provided by the invention has higher sensitivity, extremely low detection limit, wider detection range and excellent stability and anti-interference performance, wherein the detection limit is 0.55 micrometers, in the detection ranges of 0.001-2.50mM and2.50-10.0mM, the electrode respectively has high sensitivity of 1297 mu A / mM.cm2 AND 854.7 mu A / mM.cm2.

Owner:HUIZHOU LEADAO ELECTRONICS MATERIAL

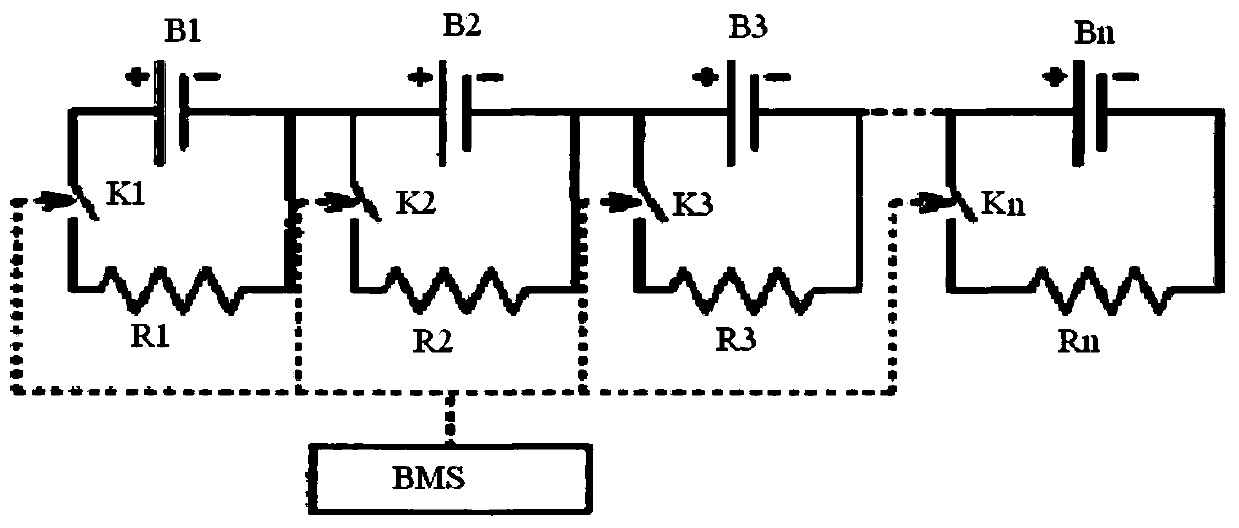

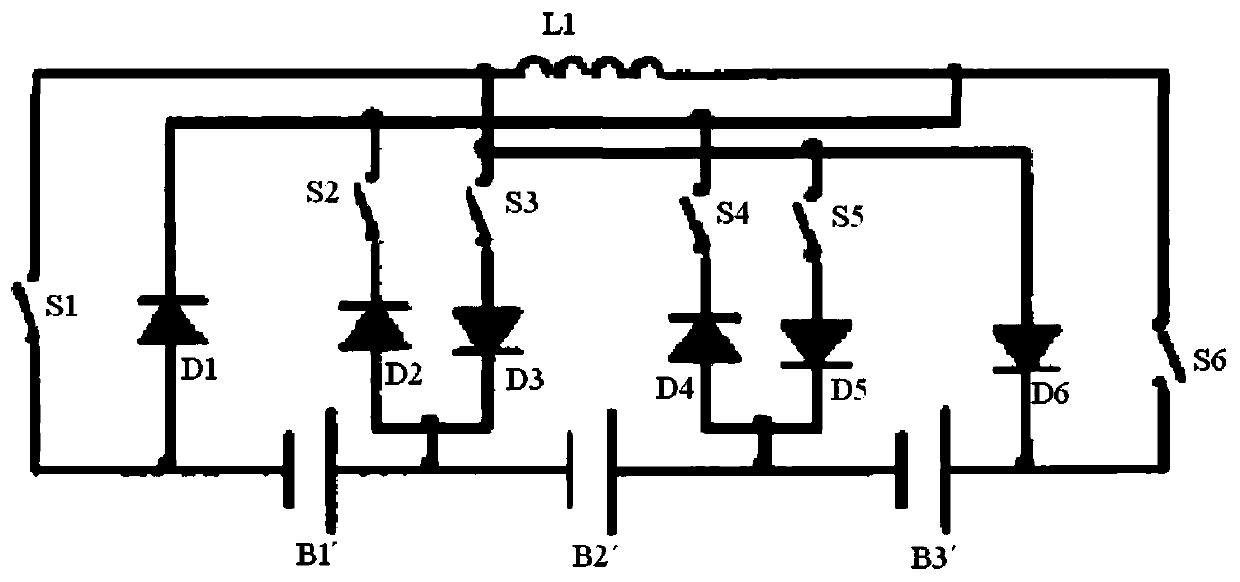

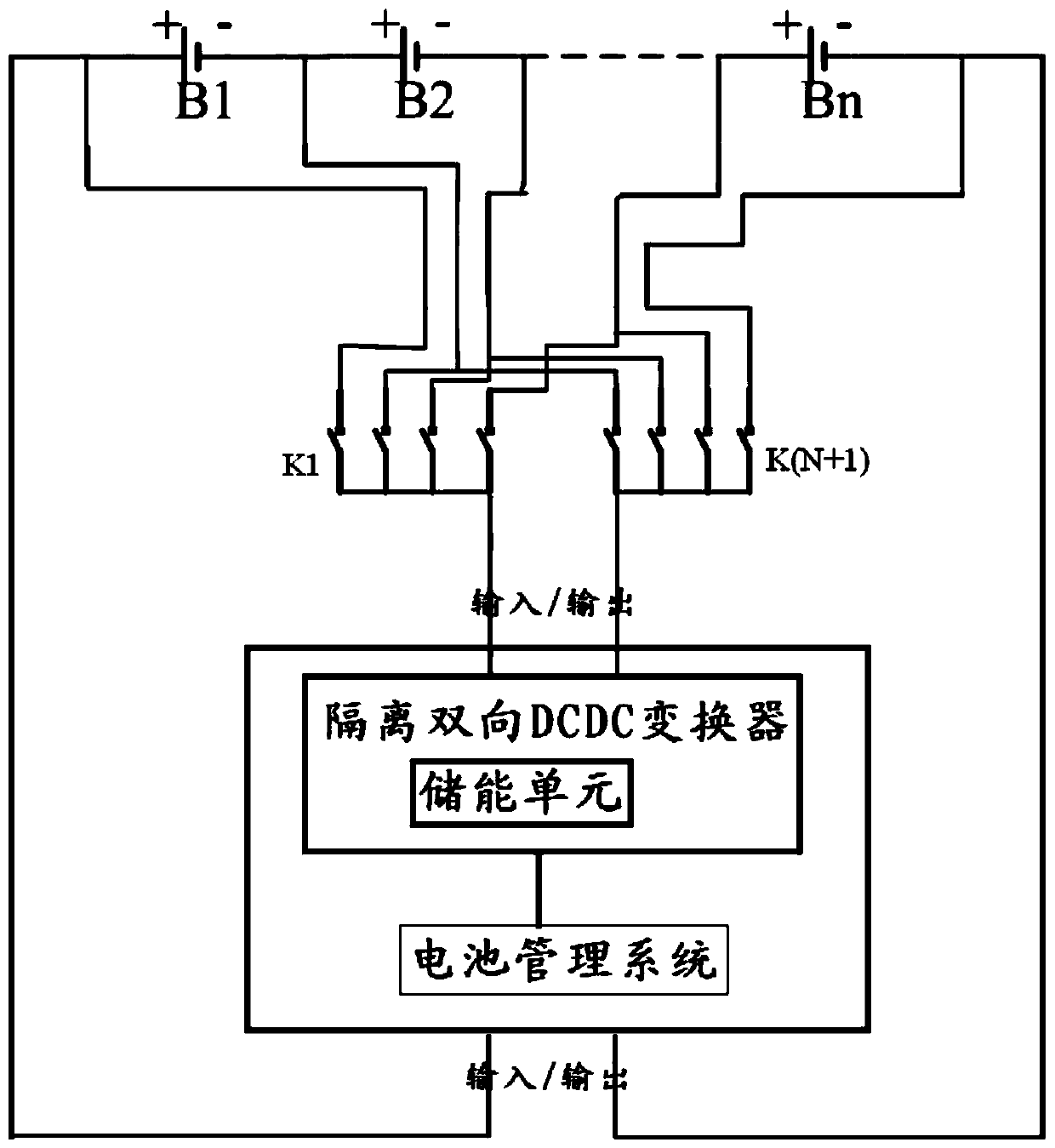

Battery voltage equalization device

InactiveCN109768589ASimple structureReduce points of failureBatteries circuit arrangementsElectric powerStopped workElectrical battery

A battery voltage equalization device is used for voltage equalization of batteries in a battery pack, and the respective batteries have an equal charge cutoff voltage U. The battery voltage equalization device comprises N+1 switches, an isolated bidirectional DCDC converter and a battery management system, wherein the isolated bidirectional DCDC converter has an energy storage unit, the input / output voltages of the isolated bidirectional DCDC converter are respectively N*U and U, and the battery management system is configured to monitor the voltage of each battery in real time, further determine whether the voltage of each battery is higher than "U-0.03V" when batteries with unbalanced voltages are detected, stops working if so, otherwise calculating the absolute value (FORMULA referred)of the difference between the voltage U' of each battery with unbalanced voltage and the average voltage (FORMULA referred) of N batteries, arranging all the batteries with unbalanced voltages into asequence S in the order of large to small, and charging or discharging the batteries to be equalized in the sequence S respectively by a battery management system according to the condition of under-voltage or over-voltage.

Owner:BEIJING KINGLONG NEW ENERGY TECH

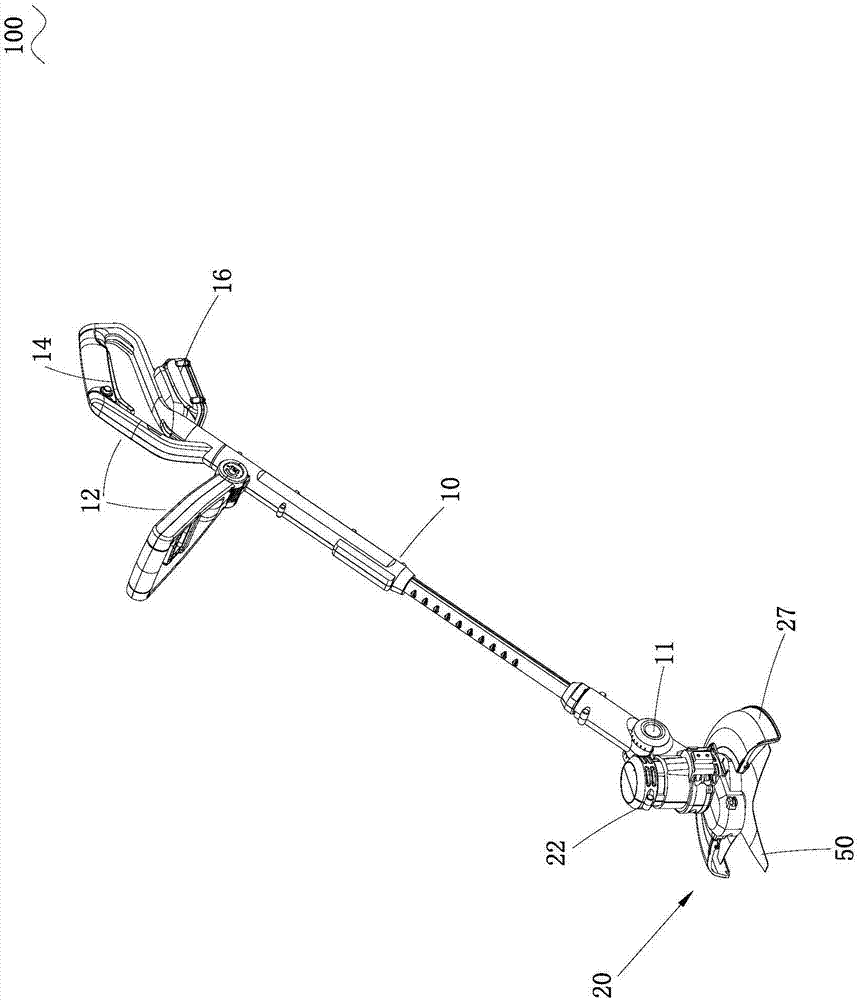

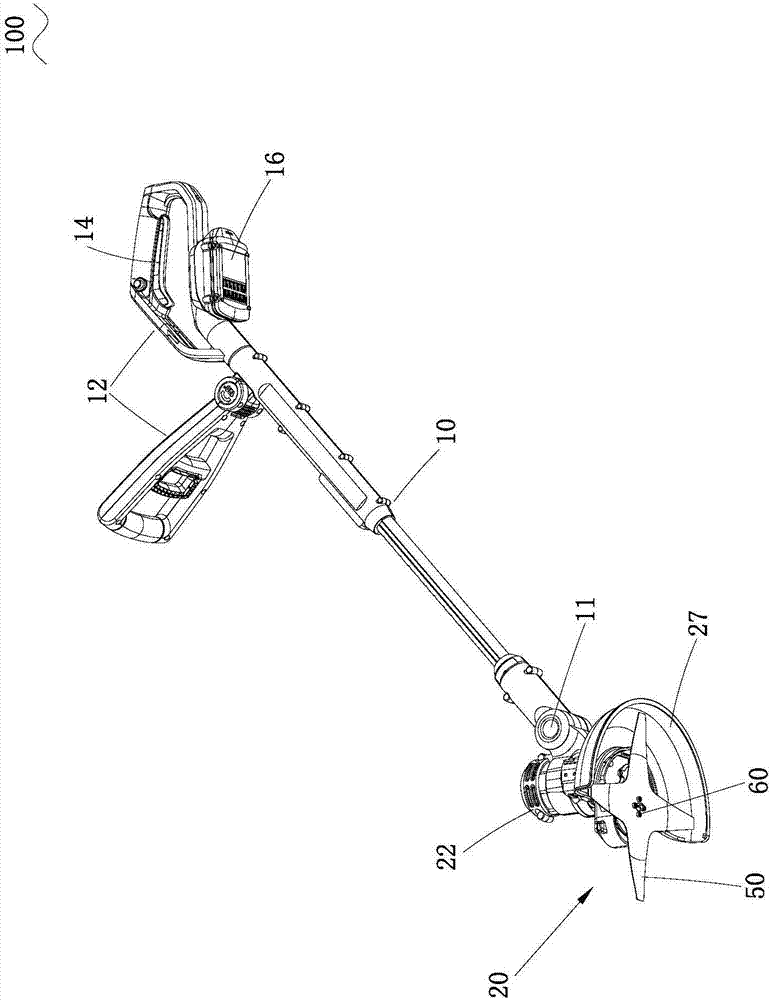

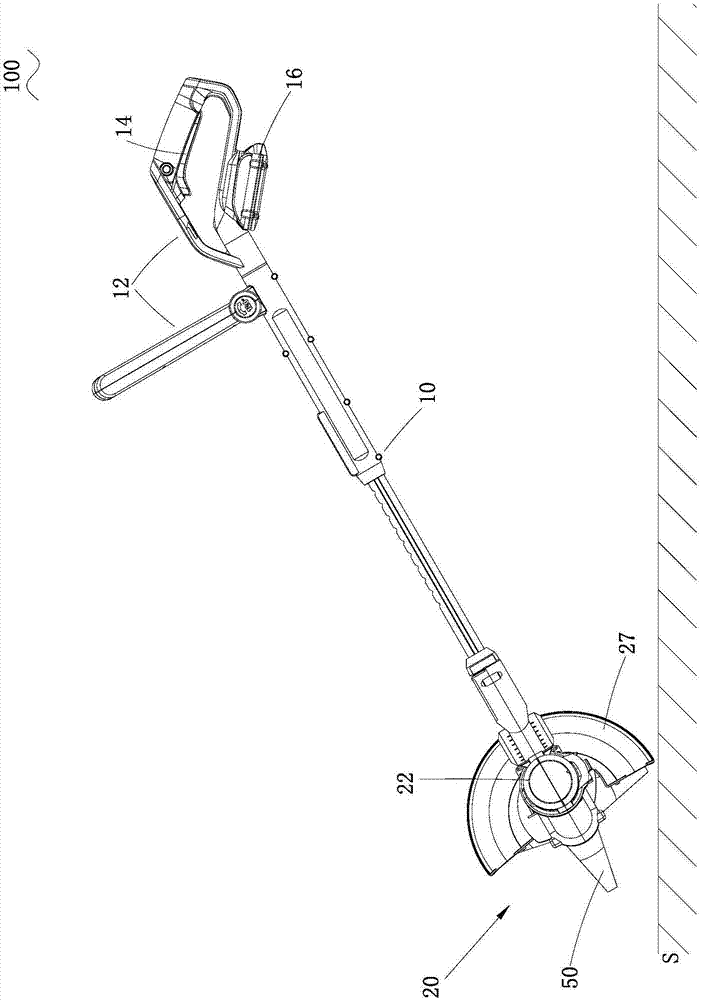

Grass trimmer

The invention discloses a grass trimmer which includes an extension rod, a handle assembly, a working head, a motor, and cutting elements. The motor drives the cutting elements to rotate, due to which the cutting elements begin to work. The cutting elements are provided with cutting edges which are made of metal. The optimal cutting edges are hard blades. As the hard blades with metal cutting edges replace regular mowing lines, the energy consumption of the grass trimmer is reduced. The grass trimmer does not have to change lines. At the same time, the kinetic energy produced by the rotation of the cutting elements and the speed of the cutting elements are within limits. The safety of the grass cutting with the metal cutting edges is also improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

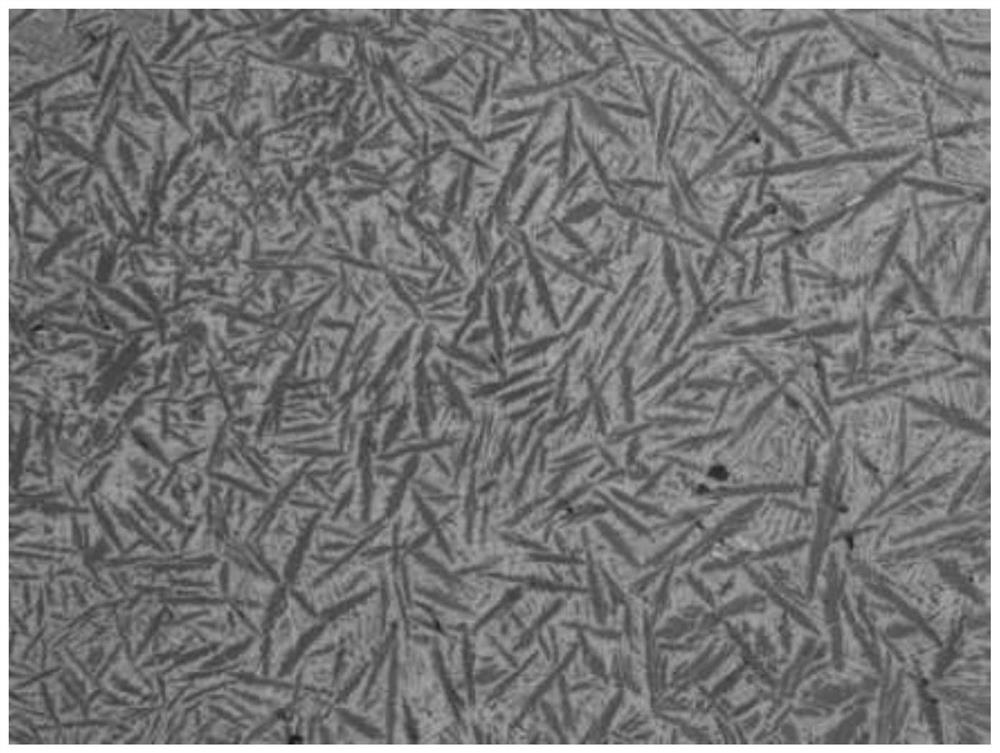

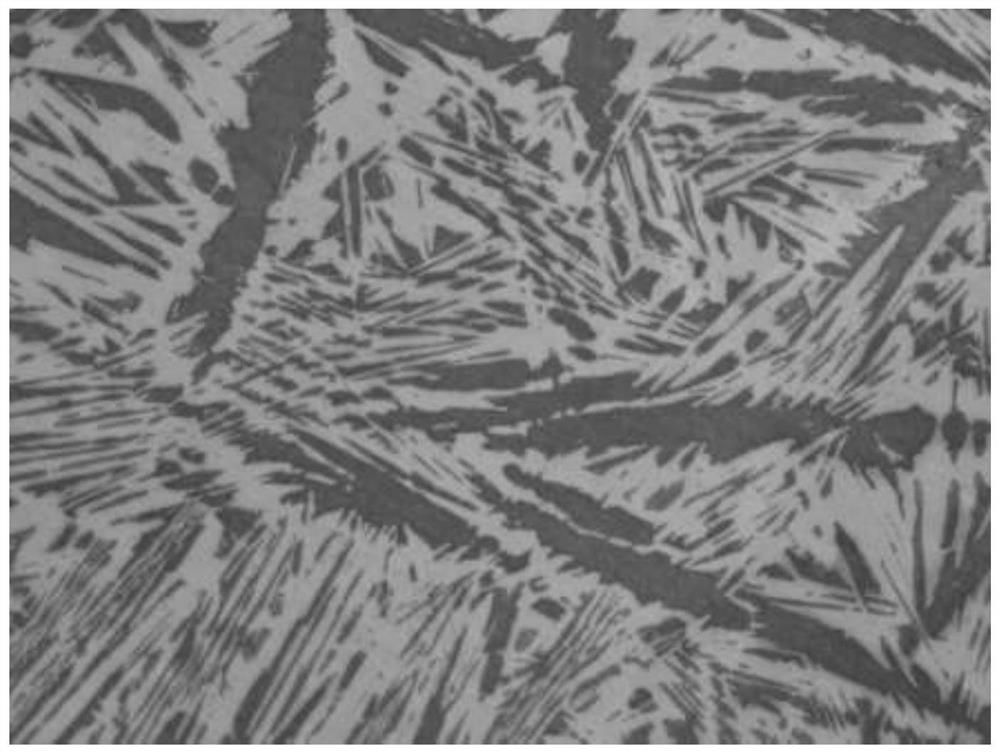

Control method for improving P-center segregation of weathering resistant steel

The embodiment of the invention provides a control method for improving P-center segregation of weathering resistant steel. The control method comprises the following process steps which are sequentially conducted: molten iron smelting of a blast furnace is conducted, molten iron desulfurization pretreatment is conducted, molten steel smelting of a converter is conducted, molten steel refining ofan LF furnace is conducted, continuous casting of a straight-arc-shaped slab casting machine is conducted, hot continuous rolling is conducted, and inspection, packaging and warehousing are conducted,wherein in the step of molten steel smelting of the converter, the molten iron entering the furnace requires that S is less than or equal to 0.015 wt%, the whole process of bottom blowing argon is adopted in the smelting process, the end point of the converter controls that C is 0.04-0.07 wt%, and P is less than or equal to 0.08 wt%. According to the provided control method, the problems of difficult control and high cost in the production of P-center segregation of the weathering resistant steel by an existing traditional continuous casting and rolling technology are solved.

Owner:LIUZHOU IRON & STEEL

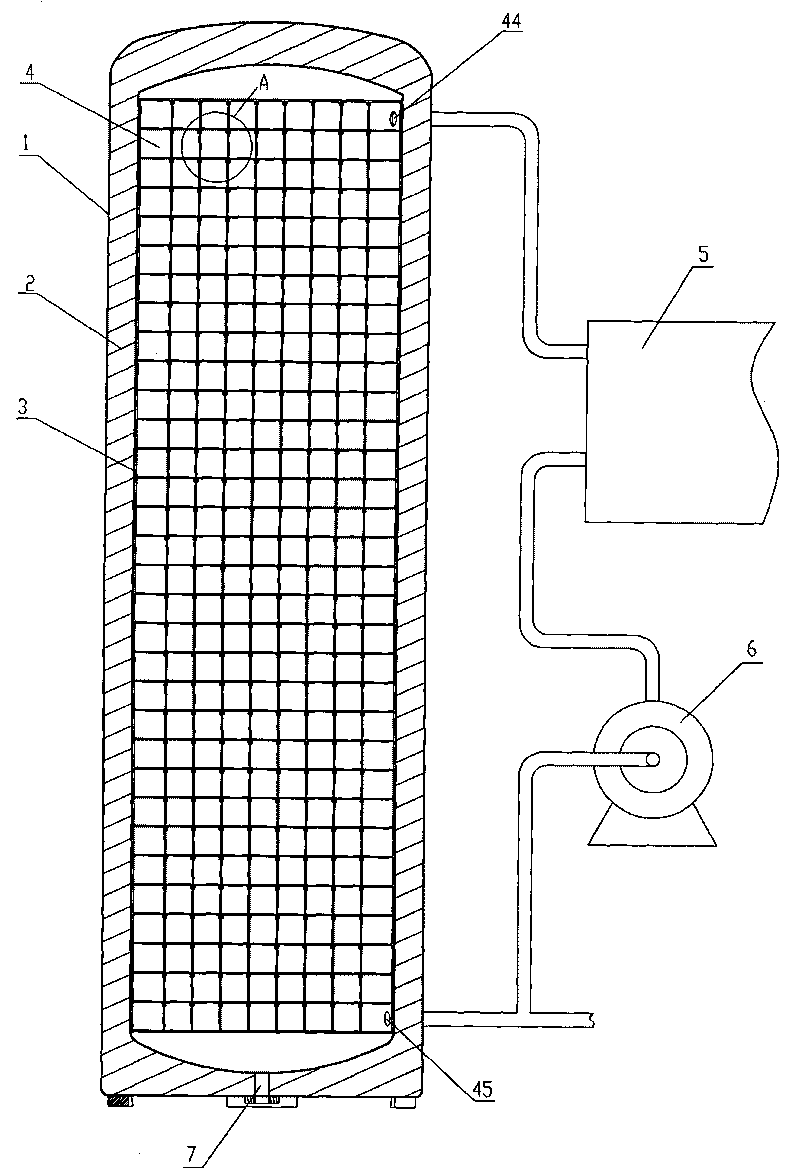

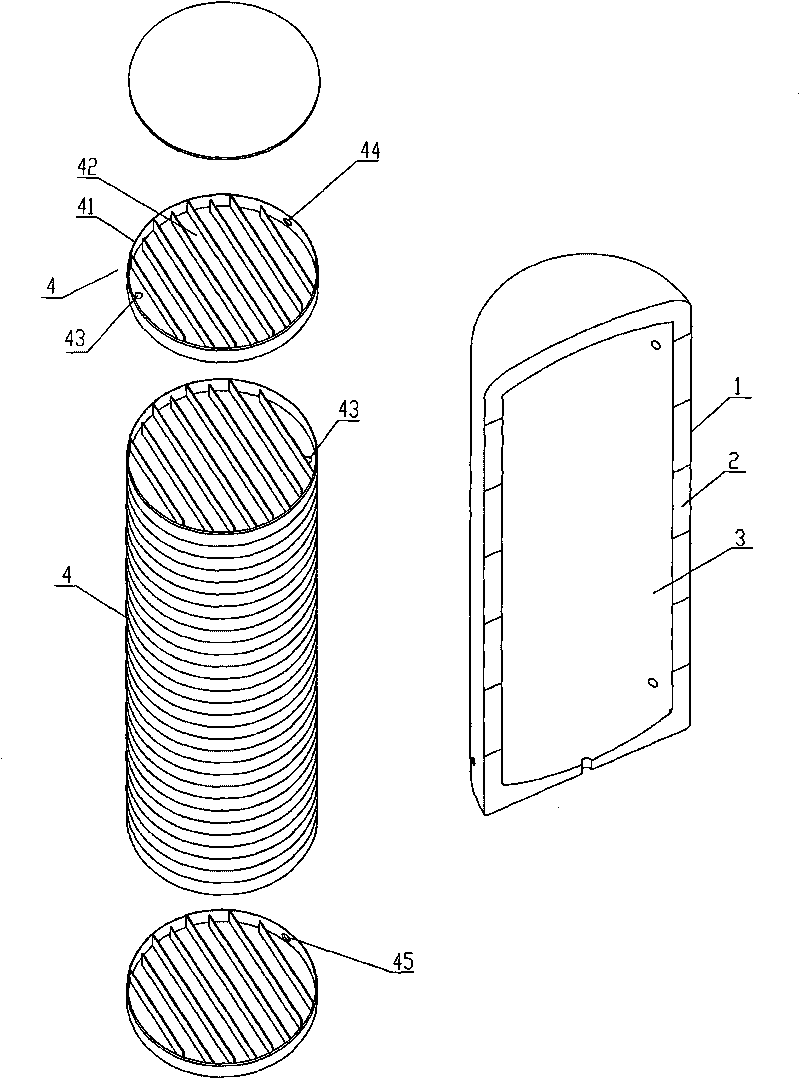

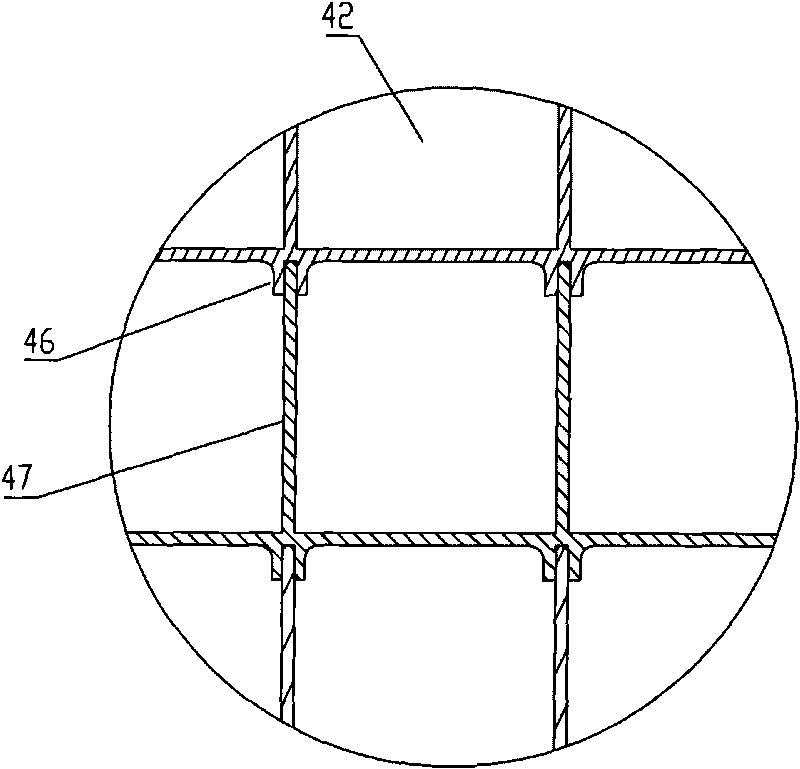

High-efficiency water tank for heat pump water heater

InactiveCN101699186AAvoid mixingReduce inefficient heating timeFluid heatersHeat recovery systemsHeating timeWater flow

The invention relates to a high-efficiency water tank for a heat pump water heater, which comprises a shell, an insulating layer and an inner chamber, wherein a plurality of layers of water flow units are arranged in the inner chamber from top to bottom in an overlapped way; the water flow unit comprises a surrounding edge and a elongated groove-shaped water flow channel inside the surrounding edge; the tail end of the water flow channel of each layer of water flow unit is provided with an open hole communicated with the head end of the lower layer of water flow unit; the head end of the water flow channel of the water flow unit at the top is provided with an upper opening connected with external equipment; and the tail end of the water flow channel of the water flow unit at the bottom is provided with a lower opening connected with the external equipment. The external equipment comprises a heat exchanger and a circulating water pump of the heat pump water heater. The invention has reasonable structure design, reduces the mixture of cold water and hot water in the water tank when the water flow circulates, improves the operating condition of a heat pump system, increases the energy efficiency of products, and shortens the heating time.

Owner:林志辉

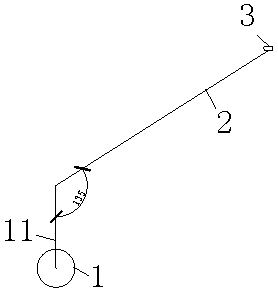

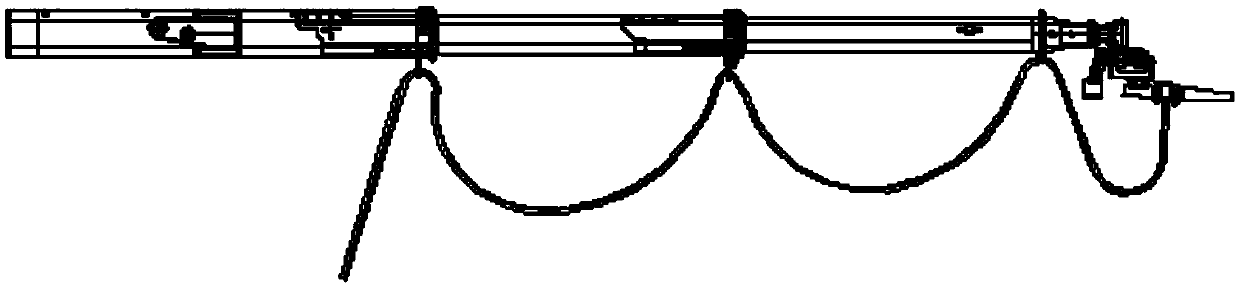

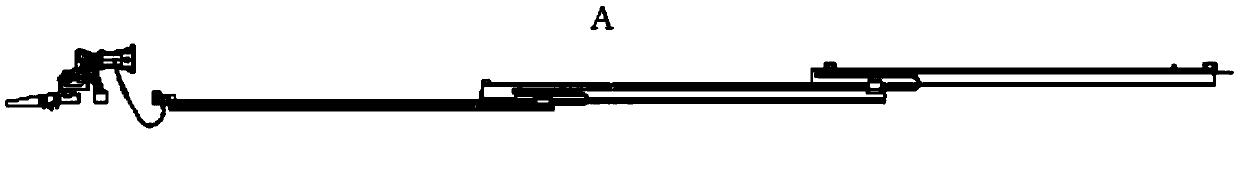

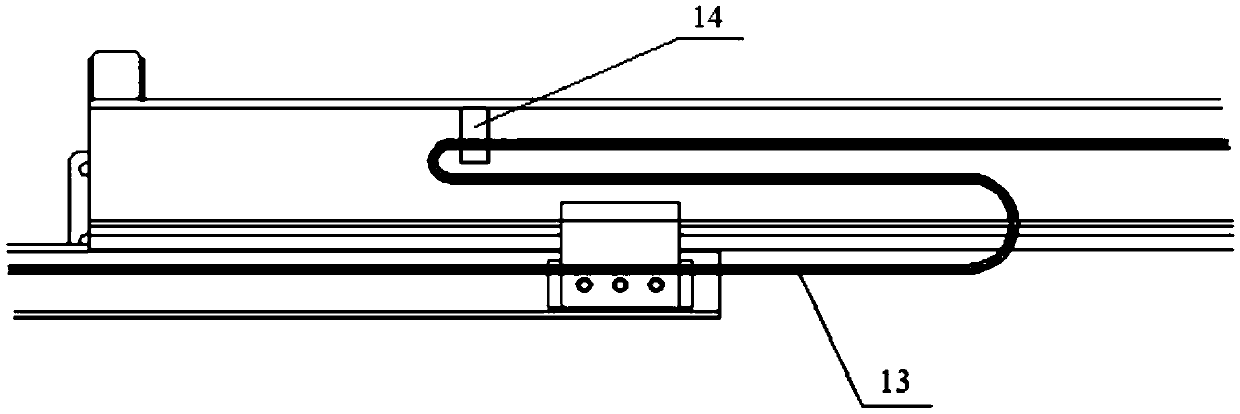

Pipeline protection device, cantilever crane system and concrete spraying vehicle

ActiveCN105514887ASo as not to damageNo situationPipe supportsUnderground chambersEngineeringCantilever

The invention provides a pipeline protection device. The device comprises a shield A, a shield B, a shield C, a bracket A, a bracket B, a bracket C and a bracket D, which are connected onto a cantilever crane; a pipeline is sequentially arranged in the shield C, the shield B and the shield A along the cantilever crane from the front end to the rear end; the rear end and front end of the shield C are fixedly connected onto a small arm respectively through the bracket D and the bracket C; the rear end of the shield B is movably connected onto the shield C; the front end of the shield B is fixedly connected onto a rear telescopic boom through the bracket B; the rear end of the shield A is movably connected onto the shield B; the front end of the shield A is fixedly connected onto a front telescopic boom through the bracket A; the shields can synchronously stretch and retract along with the telescopic booms. The device provided by the invention can be used for effectively protecting the pipeline and the service life of the pipeline is effectively prolonged. The invention further correspondingly provides a cantilever crane system and a concrete spraying vehicle.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

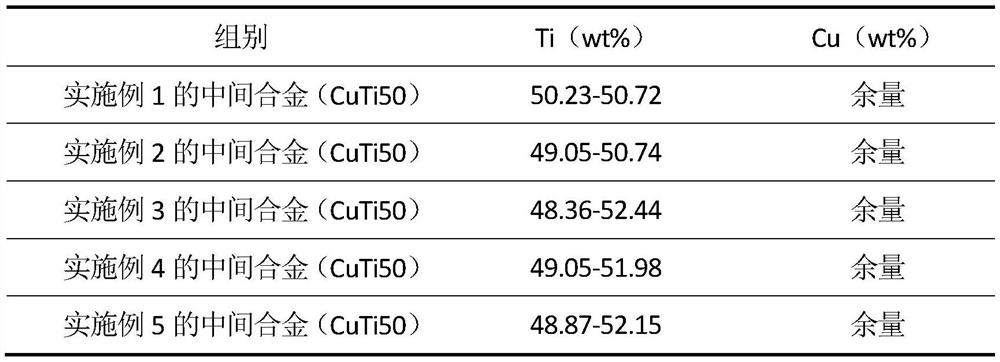

Method for preparing copper-titanium 50 intermediate alloy through magnetic suspension melting process

The invention discloses a method for preparing a copper-titanium 50 intermediate alloy through a magnetic suspension melting process. The method comprises the following steps that copper alloy elements are matched according to the weight percent content that Ti accounts for 31% to 55%, and the balance is Cu; the metal raw materials are contained in a cold crucible of a vacuum magnetic suspension furnace, powering on is carried out, vacuumizing is carried out, argon is introduced for shielding, power is improved gradiently, the temperature in the furnace is raised, and ingot metal fully melts and is in a half suspended state through joule heat released in the furnace; under the action of continuous long-range magnetic force, the melt is completely suspended, and electromagnetic stirring iscarried out; the formed alloy is continuously kept in a molten state for a period of time, and the alloy ingredients are homogenized; and finally pouring, cooling and outer circle turning are carriedout, and a CuTi50 intermediate alloy bar is obtained. The CuTi50 intermediate alloy prepared through the method has the advantages of being good in uniformity, free of inclusions and oxidation defects, low in gas content and the like, and the method can be used for copper-titanium alloy (the titanium content ranges from 1% to 5%) smelting.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

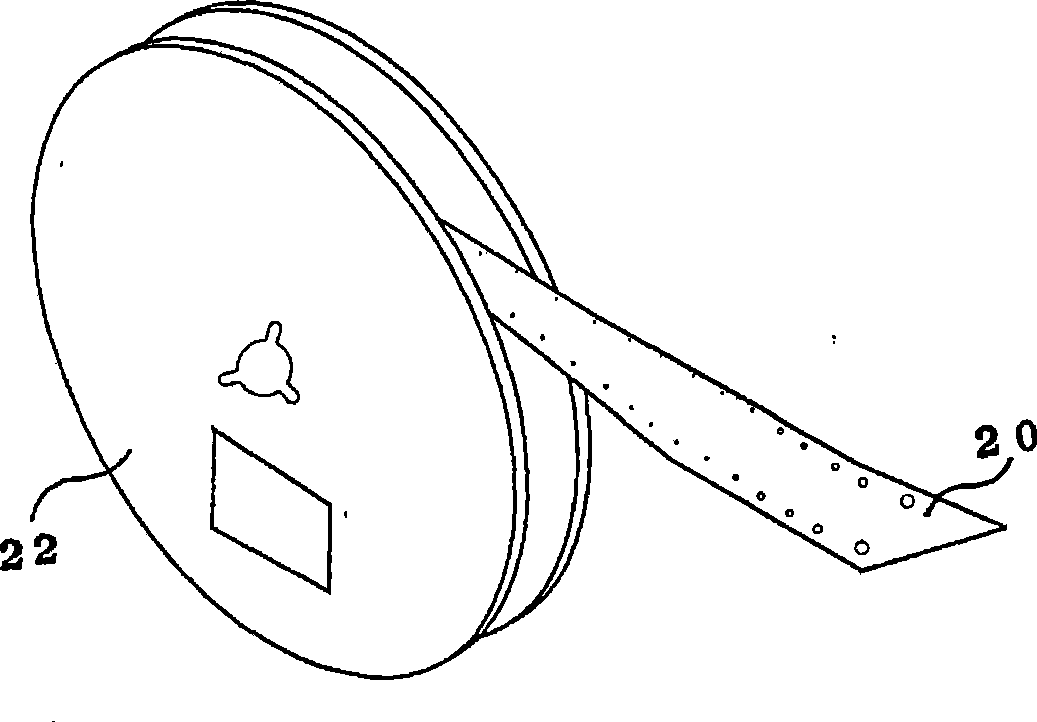

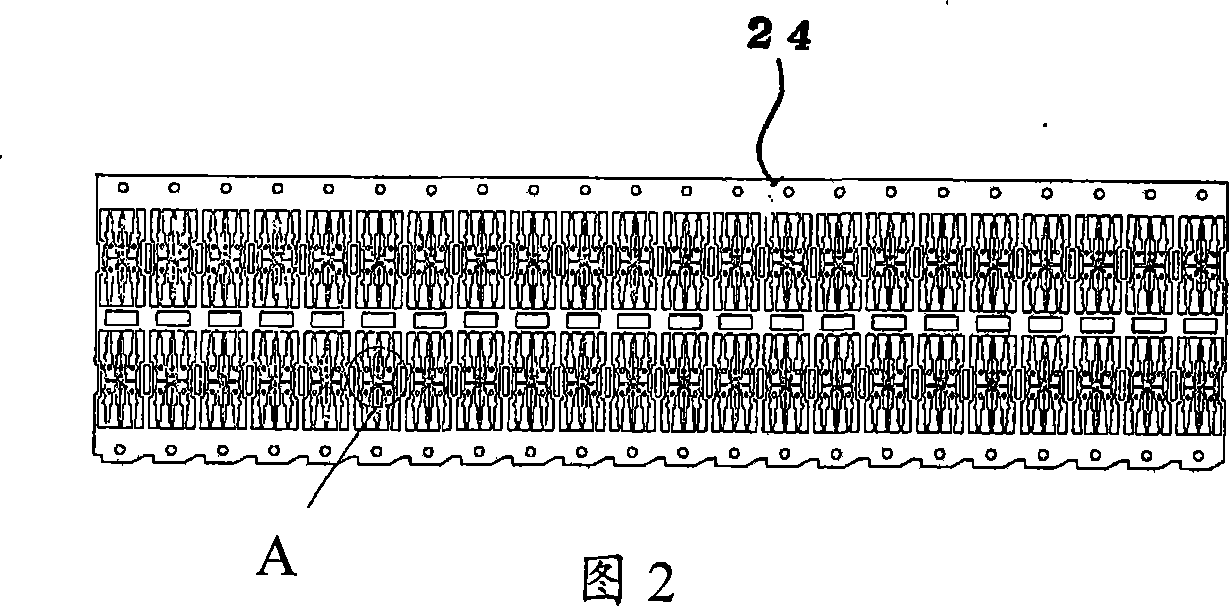

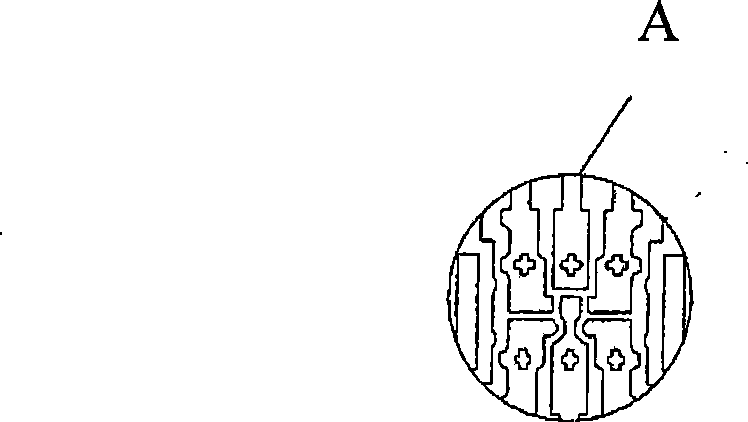

LED manufacturing method

ActiveCN101388424AWon't looseNo situationSolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsElectroplating

The invention is applied to the production method of an LED, and provides a production method of an LED on a tape type copper metal material sheet. The method comprises the following steps: forming a tape type copper metal material sheet, continuously punching circuits on the tape type copper metal material sheet to form a holder of circuit pattern for placing a diode crystal and electric terminals, plating multi-layer metal on the surface of the holder, continuously spraying metal and molding on the holder to form a protective body for an appointed pattern, providing a groove structure on the upper surface of the protective body, fixing the diode crystal on a holder which is located on the bottom of the groove structure of the protective body, and connecting the electrode terminals of the diode crystal and the terminal contacts of the holder through metal wires. The invention can improve the problem of LED production precision, makes production accurate and easy, and effectively reduces cost.

Owner:SHENZHEN SUNSCREEN CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com