Grass trimmer

A technology for lawn mowers and cutting elements, applied in the field of lawn mowers, can solve the problems of high energy consumption, high power consumption, and short working time of battery packs, so as to improve safety performance, reduce energy consumption, reduce charging or replace batteries The effect of packet frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

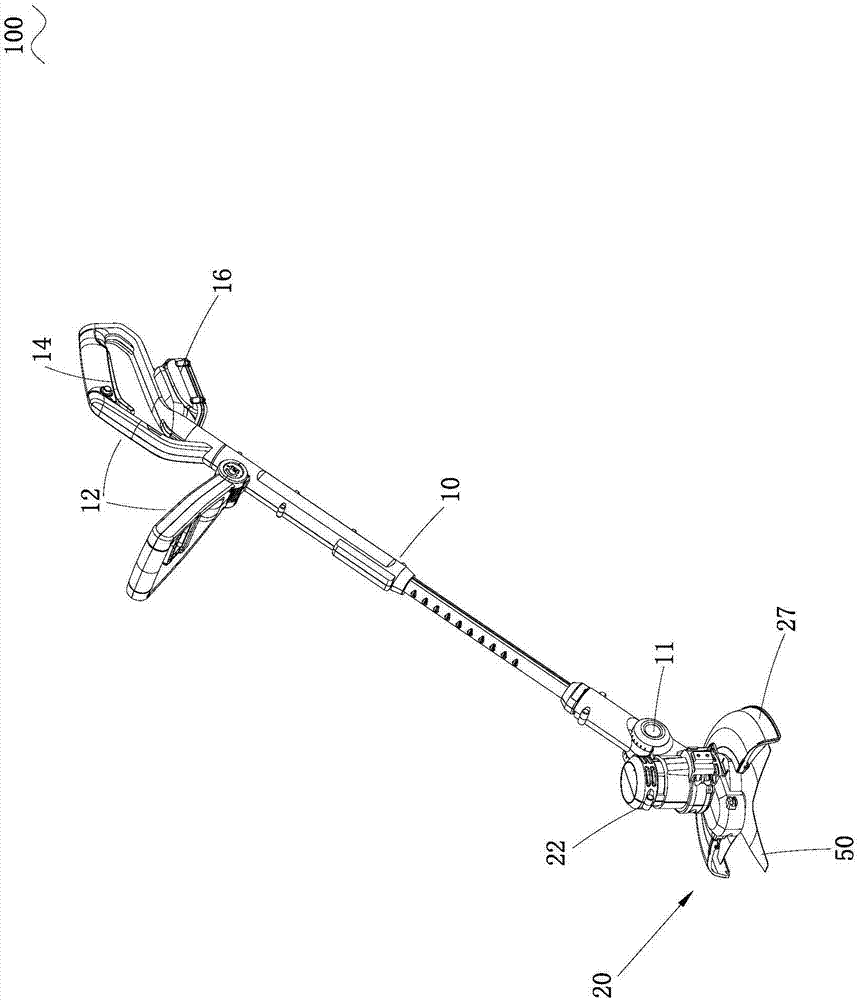

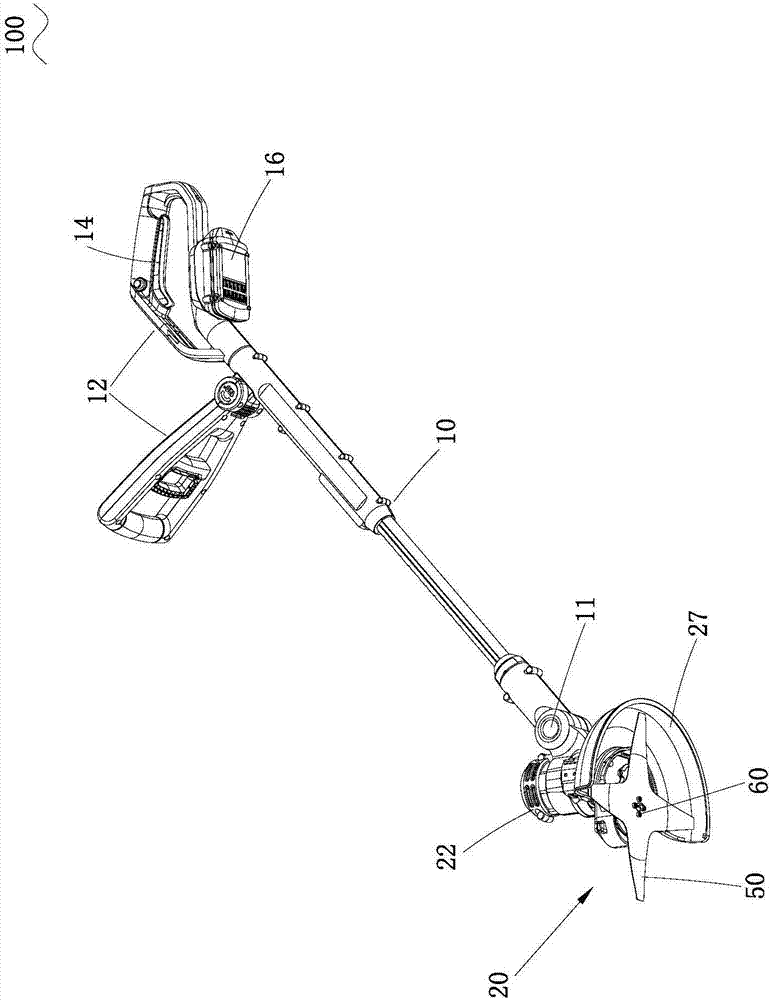

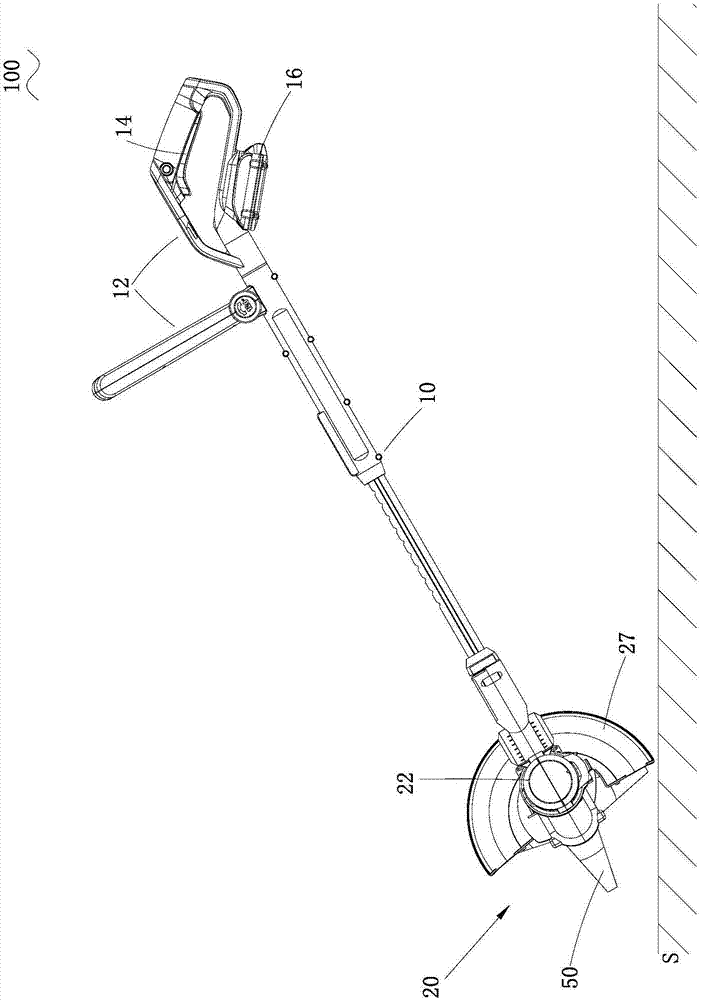

[0071] See figure 1 and figure 2 , The lawnmower 100 of this embodiment includes a longitudinally extending extension rod 10 , a working head 20 arranged at one end of the extension rod 10 , and a handle assembly 12 arranged at the other end of the extension rod 10 . The working head 20 includes a casing 22 , a motor 26 disposed in the casing 22 , and a cutting element 50 driven by the motor 26 to rotate around a first axis X.

[0072] A first shield 27 is also provided on the working head 20 , and the first shield 27 is fixedly arranged relative to the extension rod 10 . The first shield 27 has a predetermined arc angle and is used to shield the cutting element 50 within the coverage range of the arc angle. The first shield 27 is located in the direction of the handle assembly 12 of the working head 20 . Specifically, if figure 1 As shown, the first shield 27 includes an extension portion with a certain arc angle, and the extension portion extends toward the handle assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com