Patents

Literature

1910 results about "Metal cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

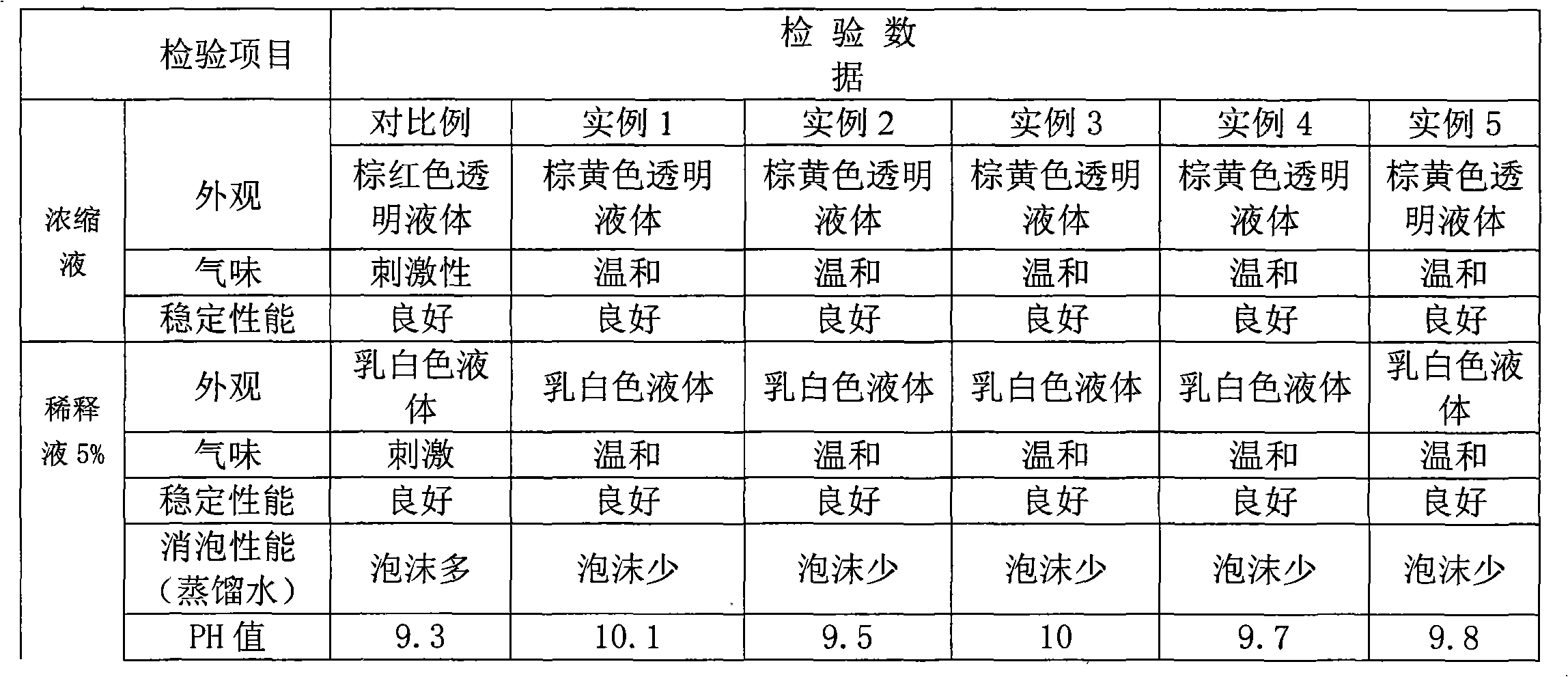

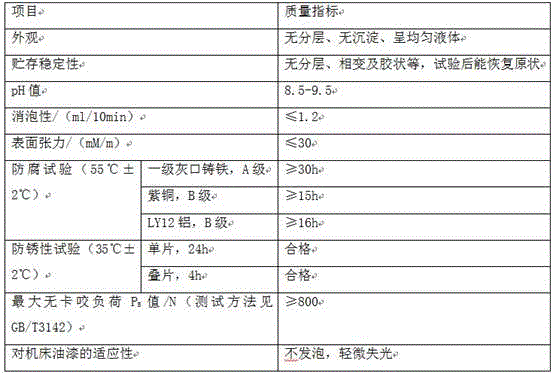

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

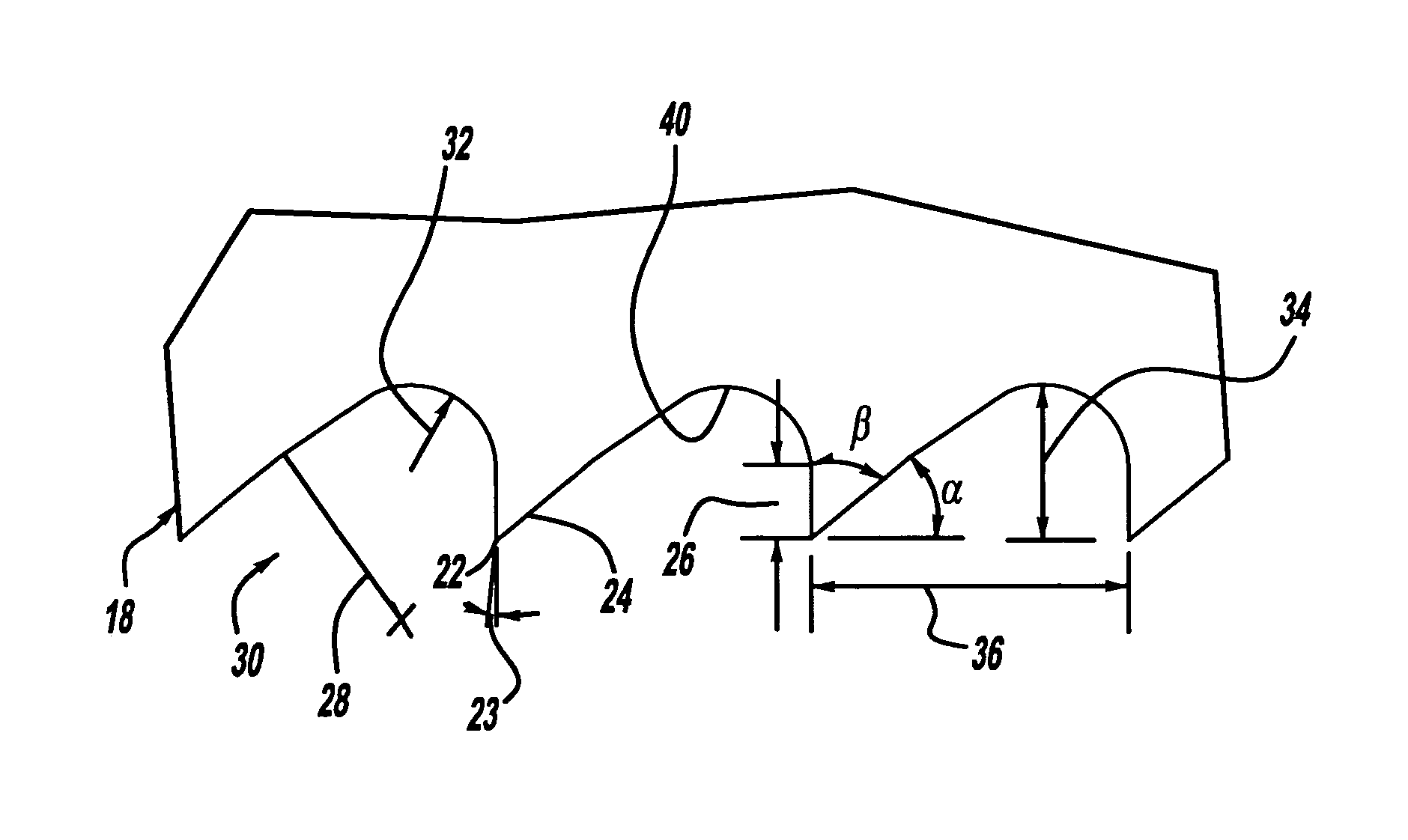

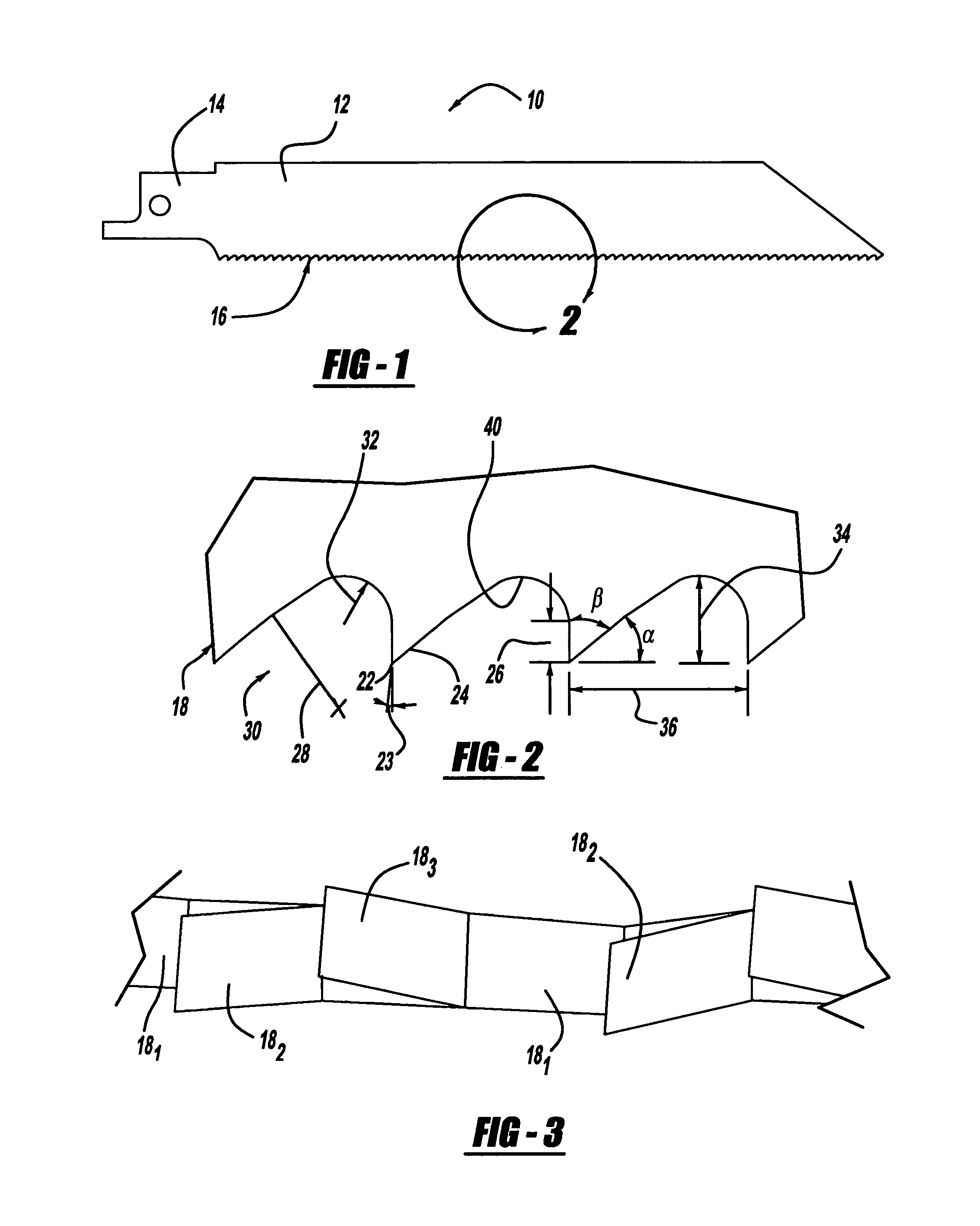

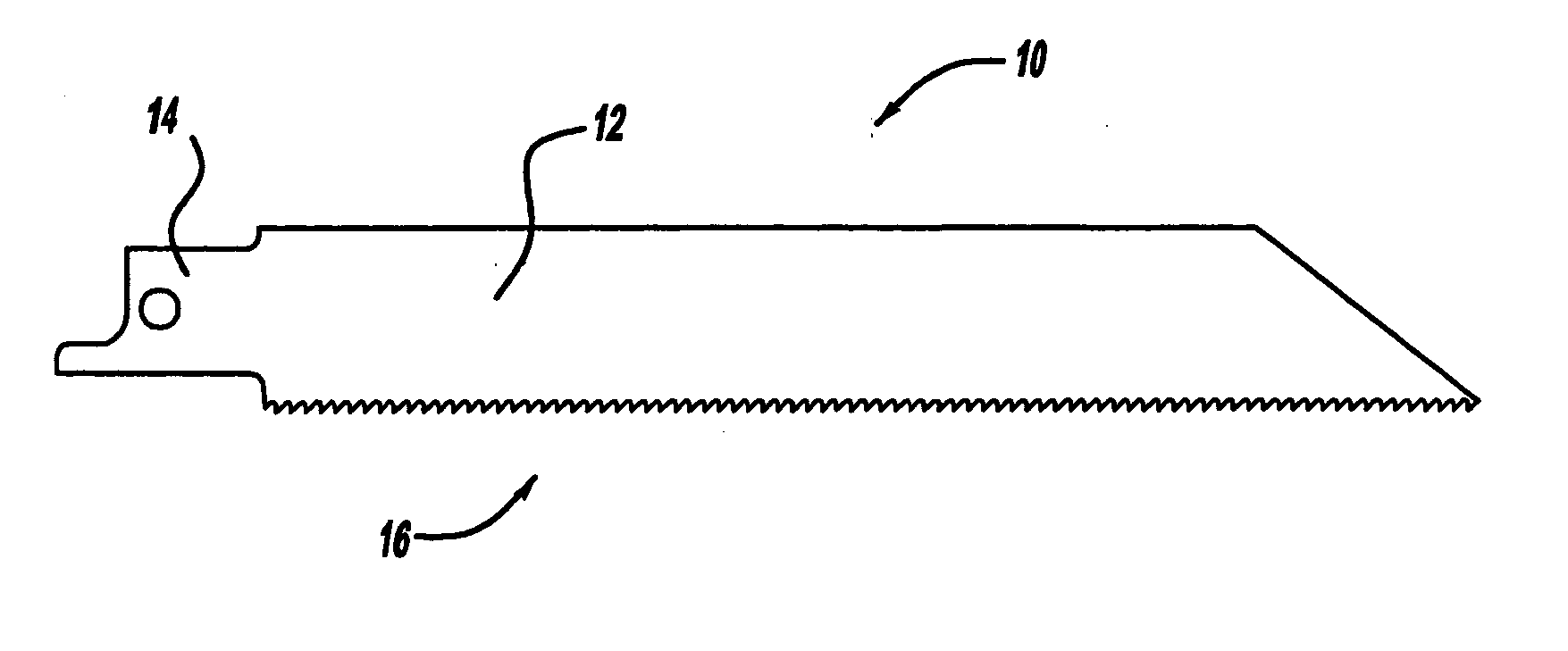

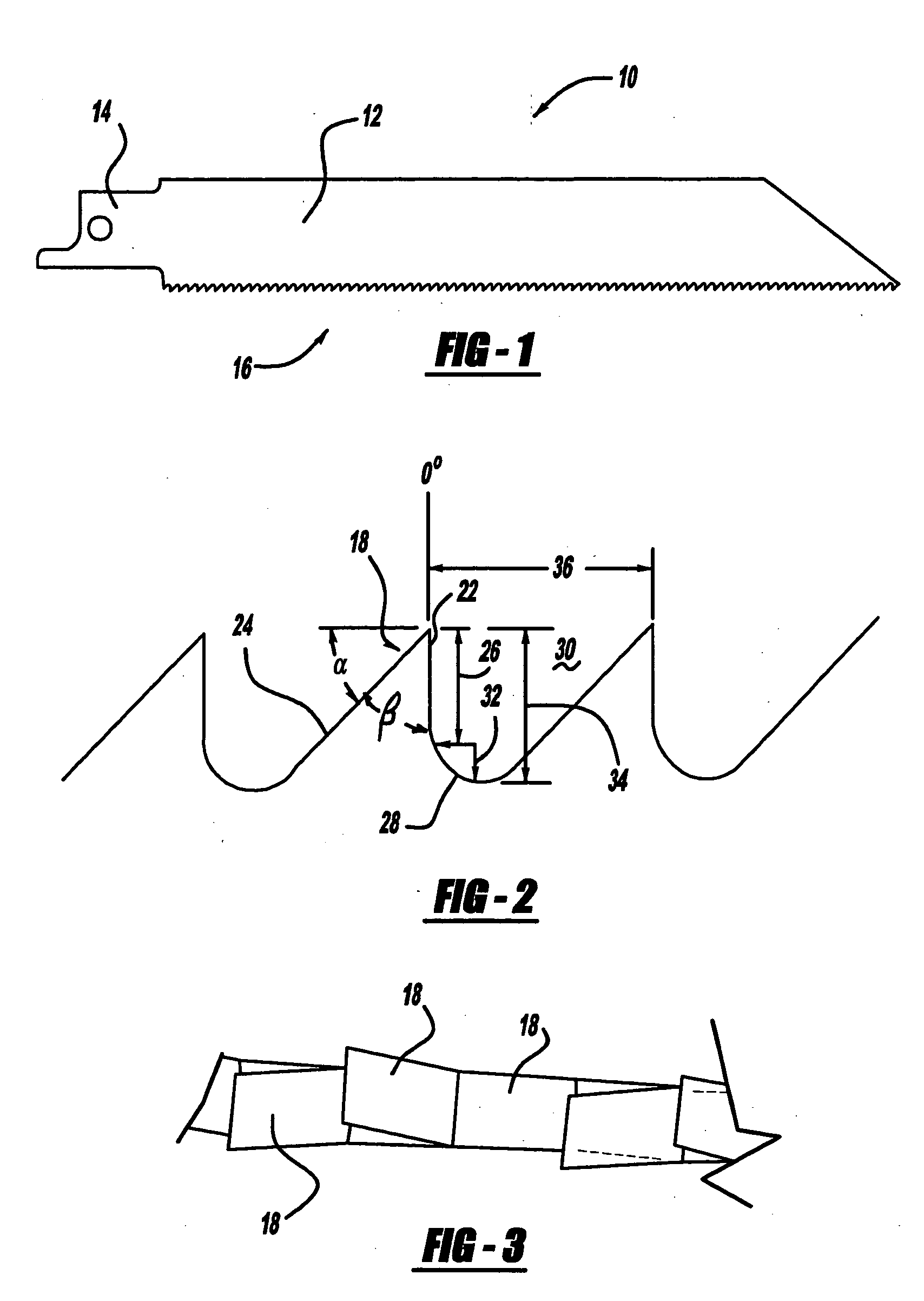

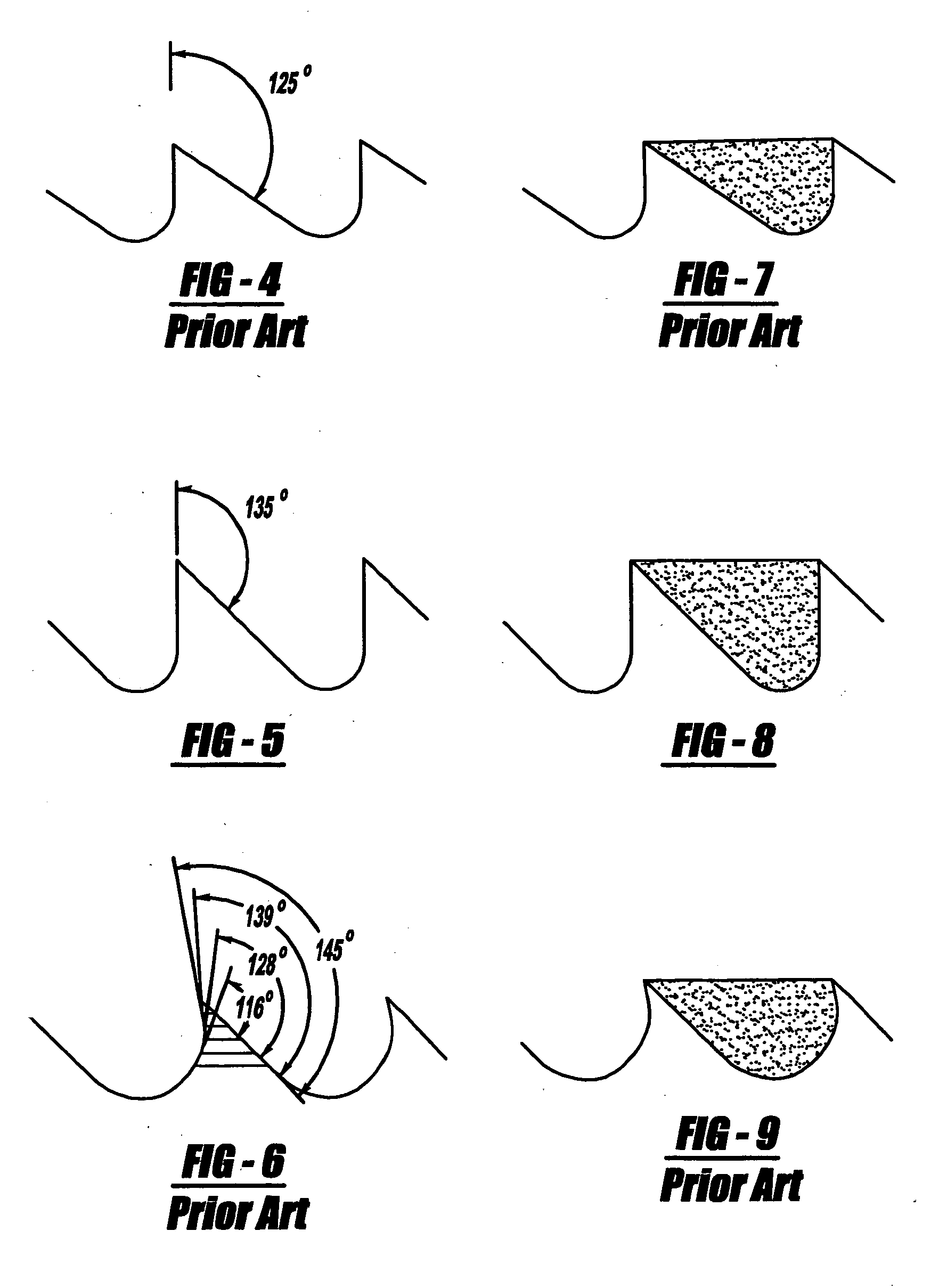

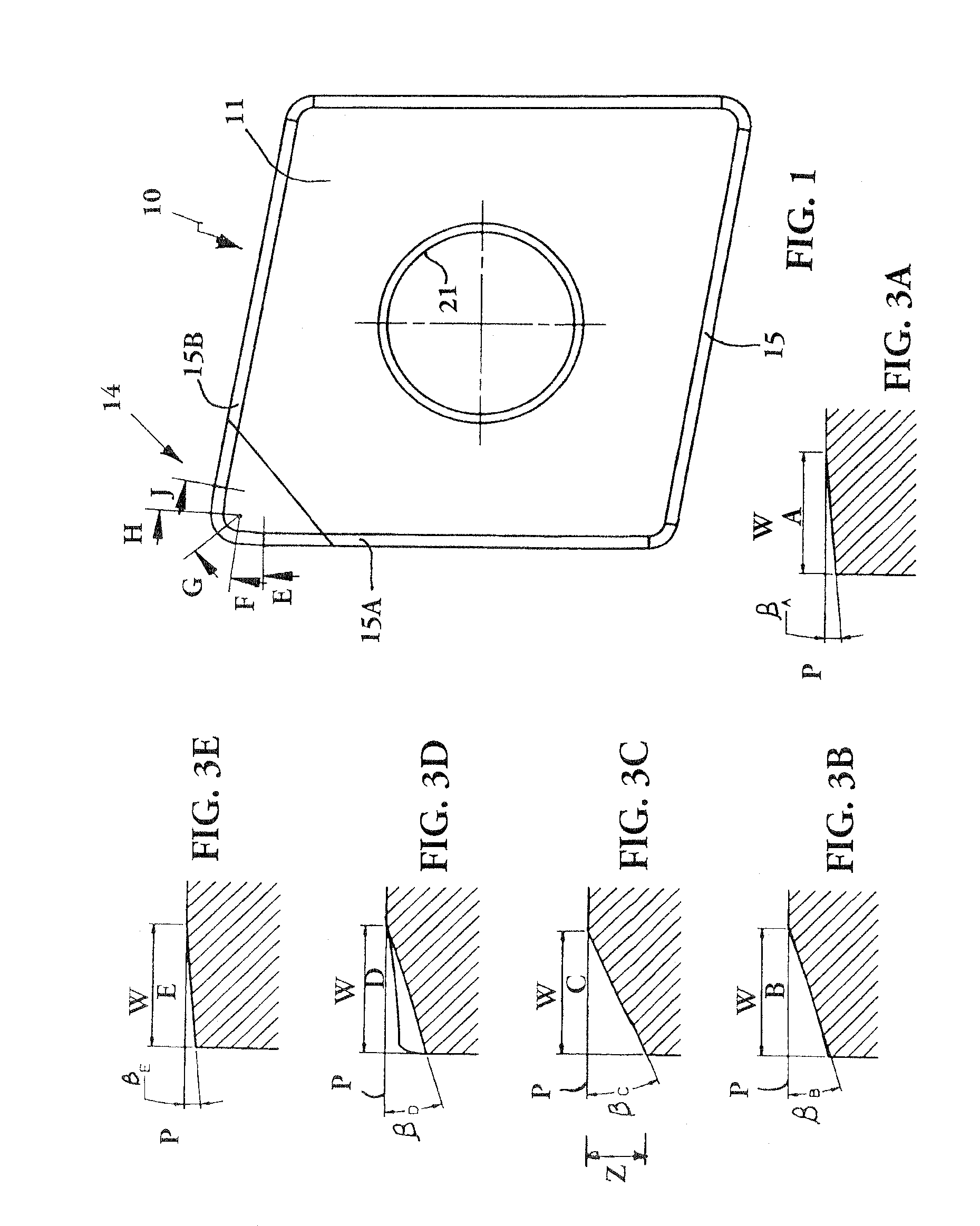

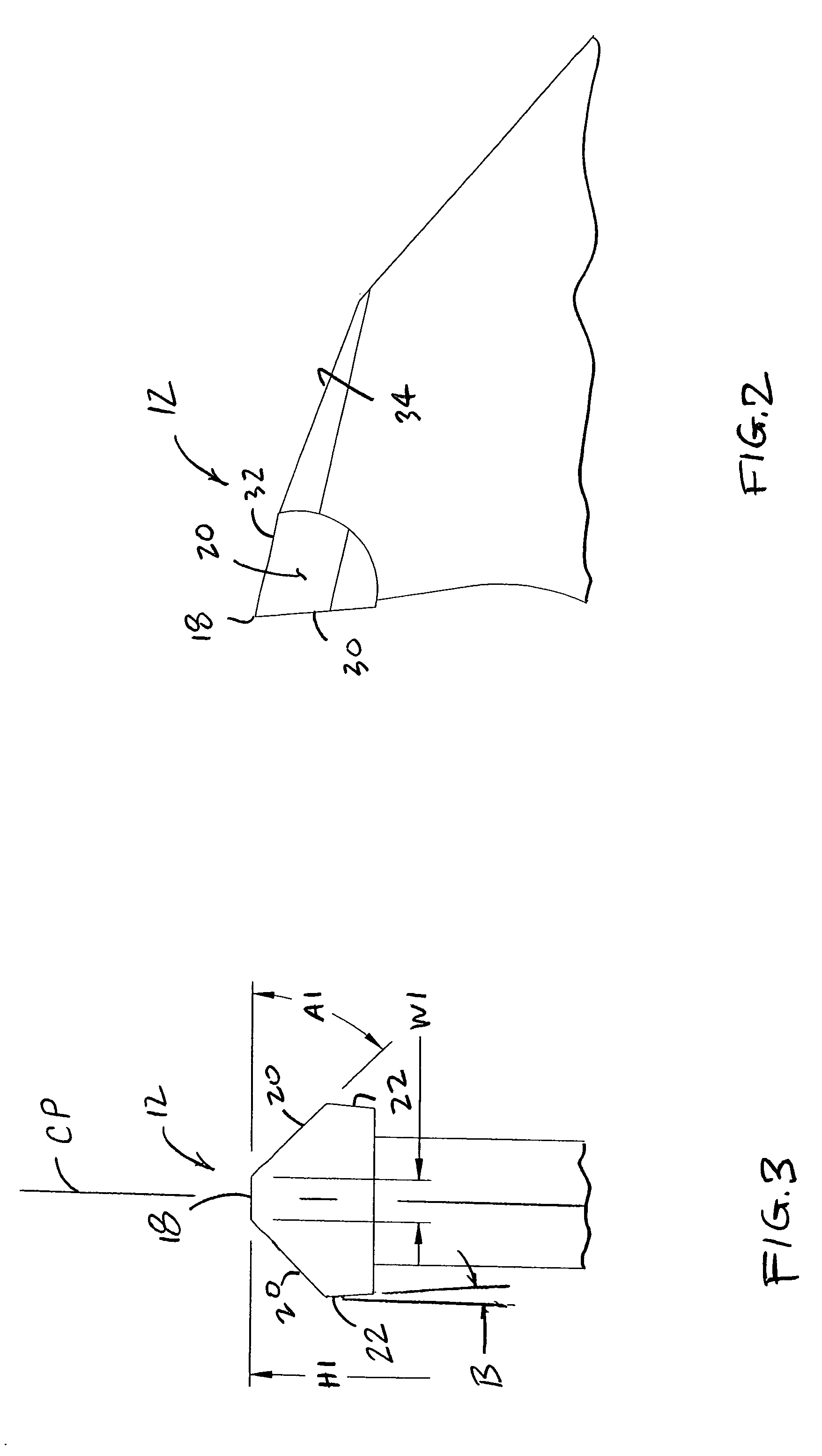

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

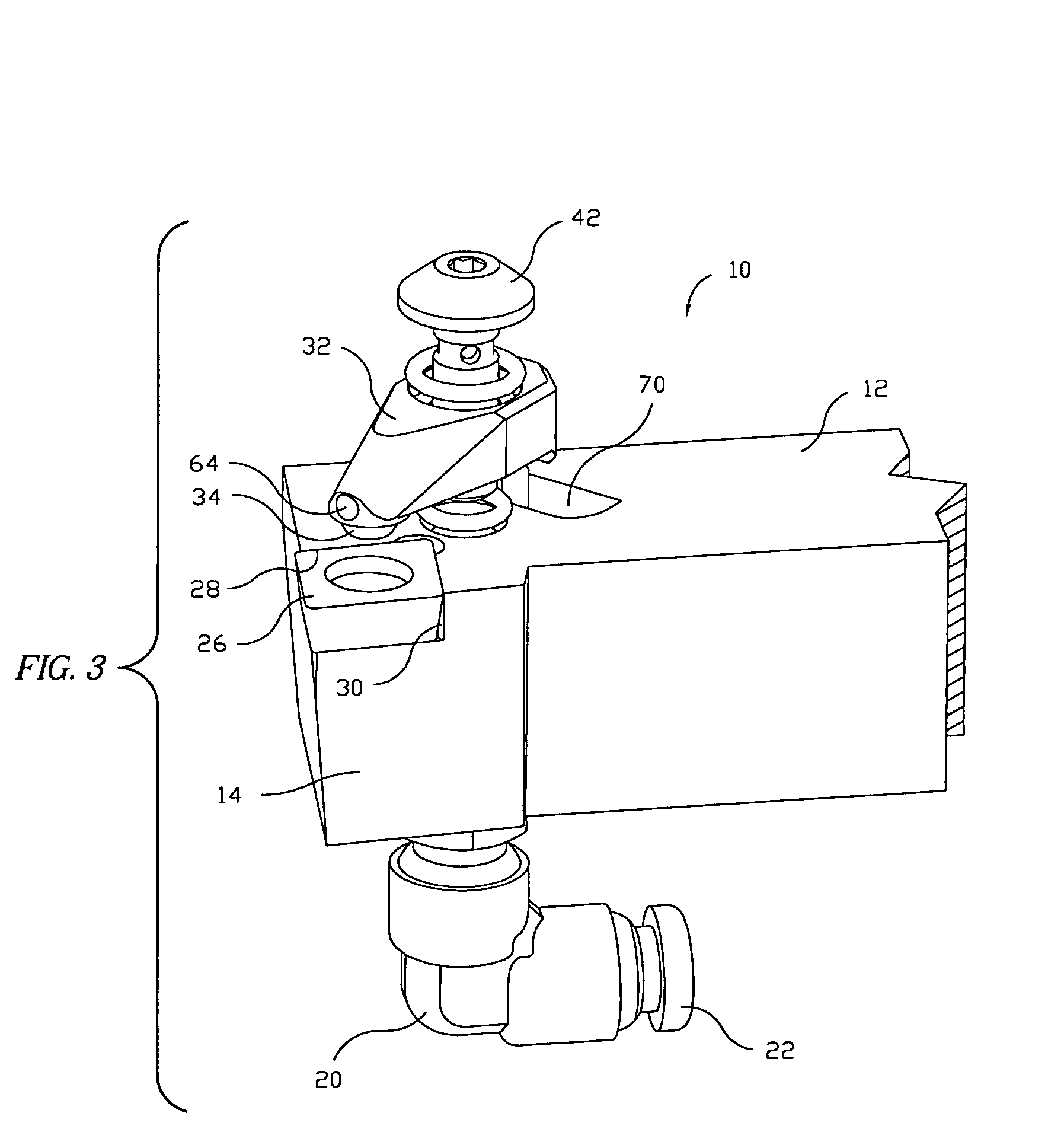

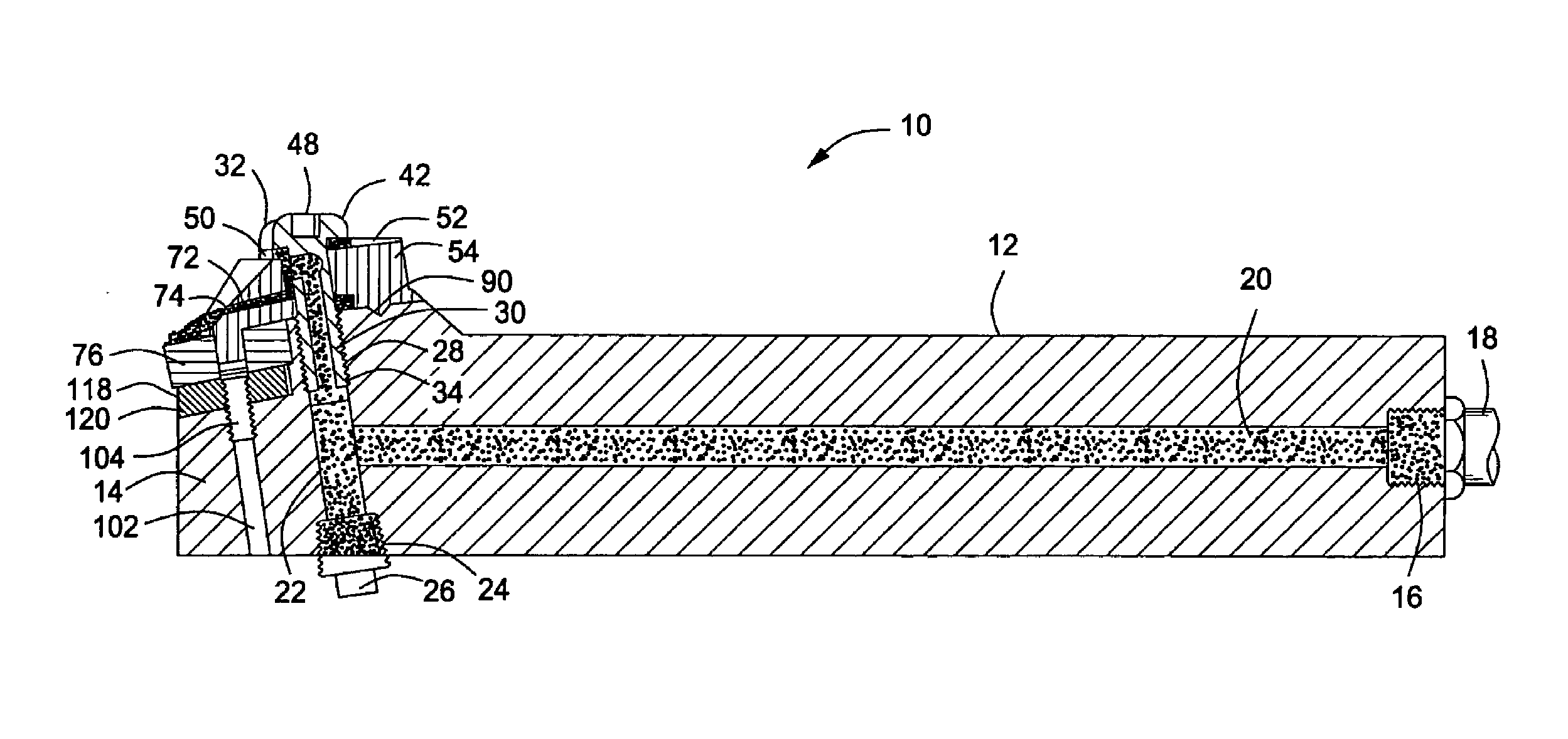

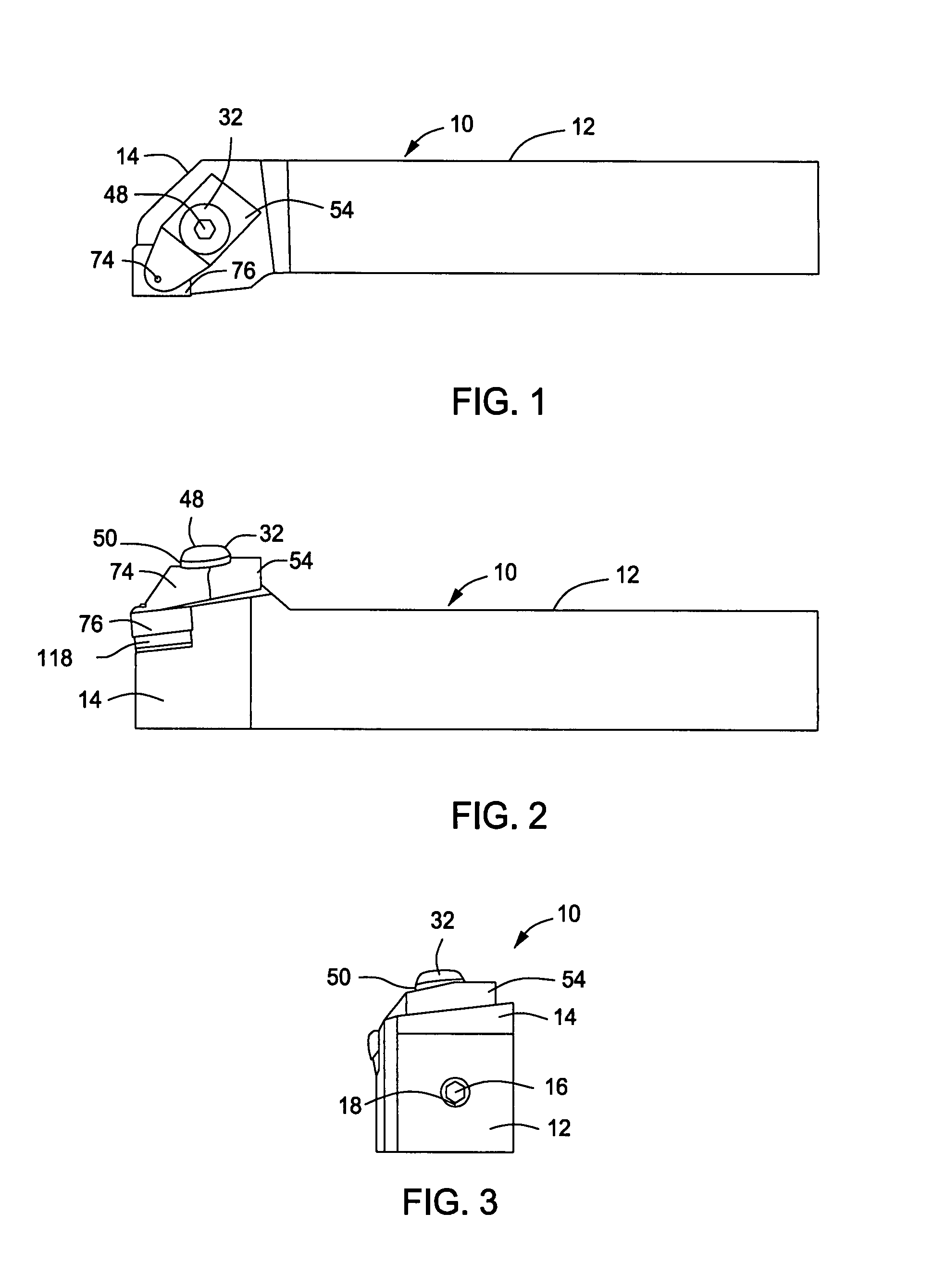

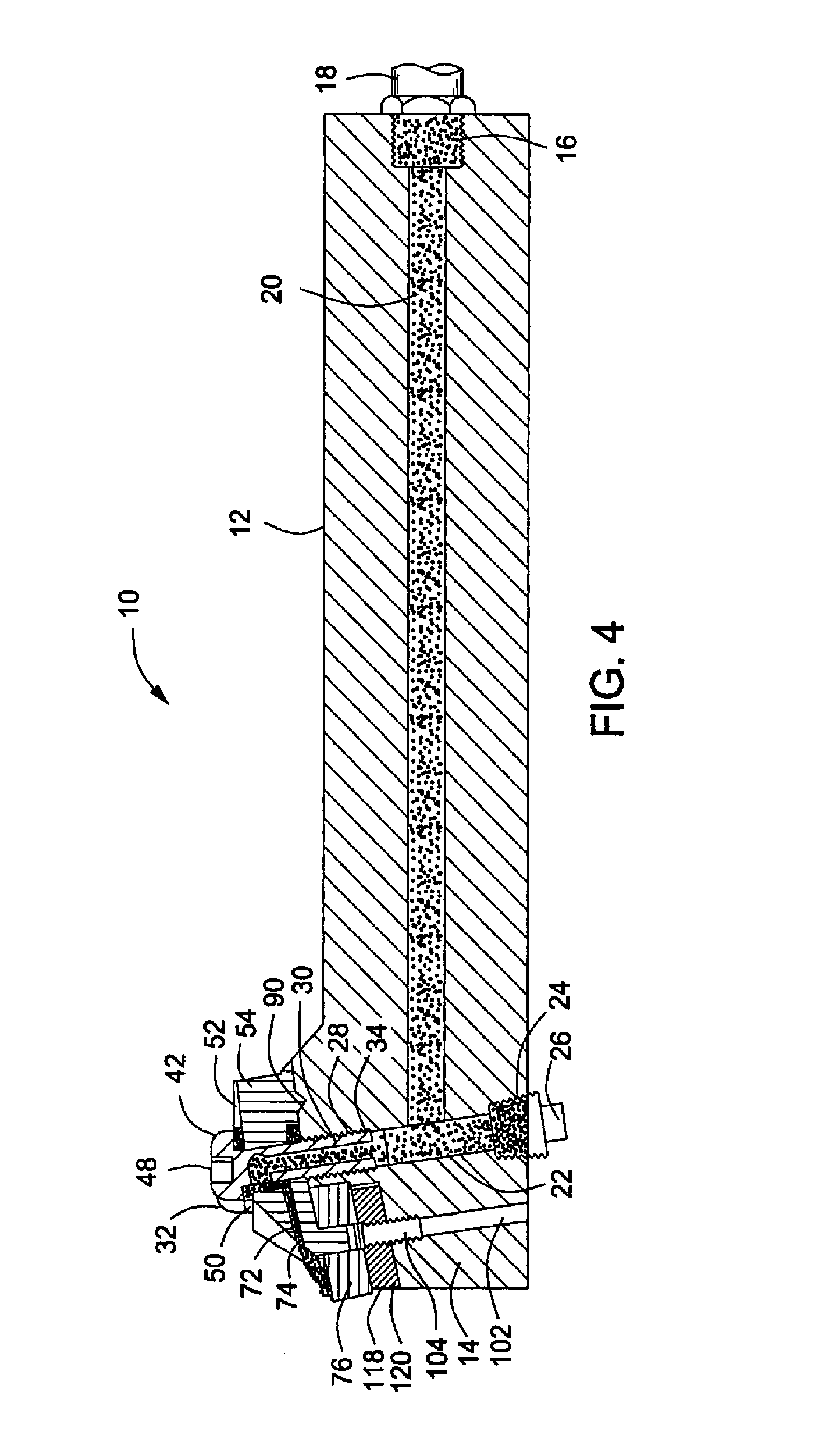

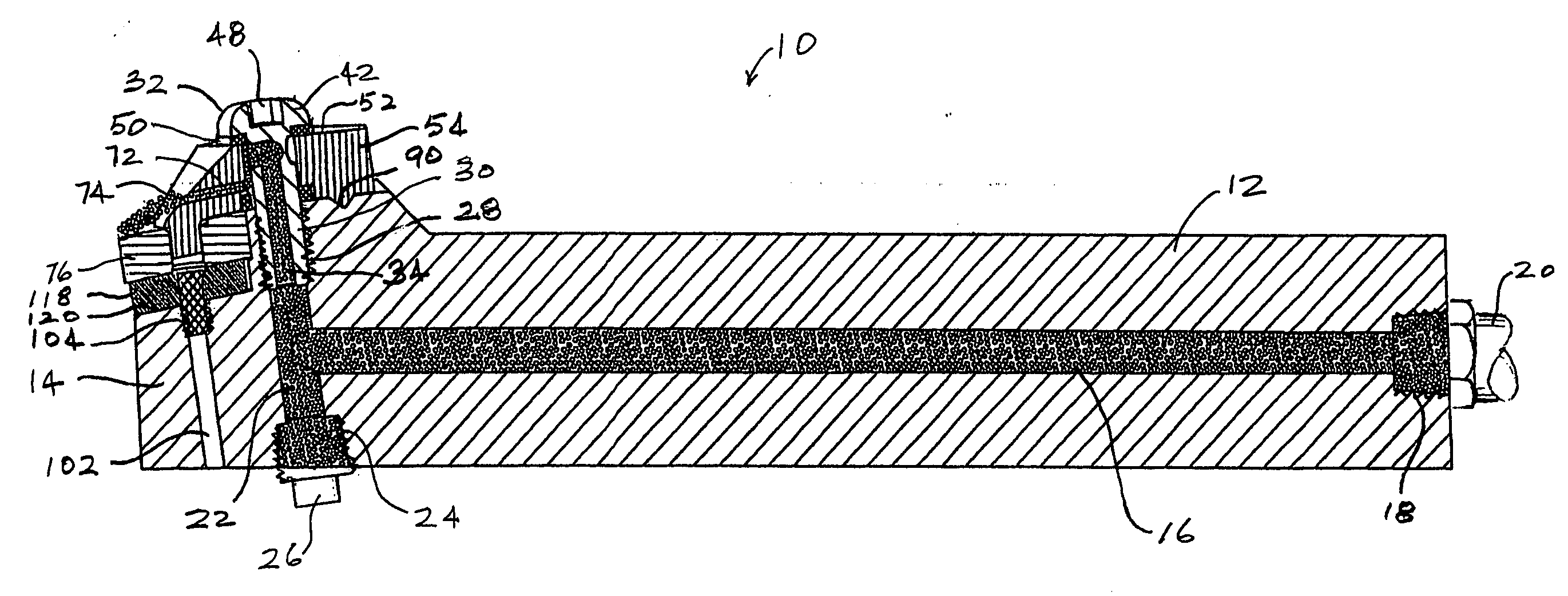

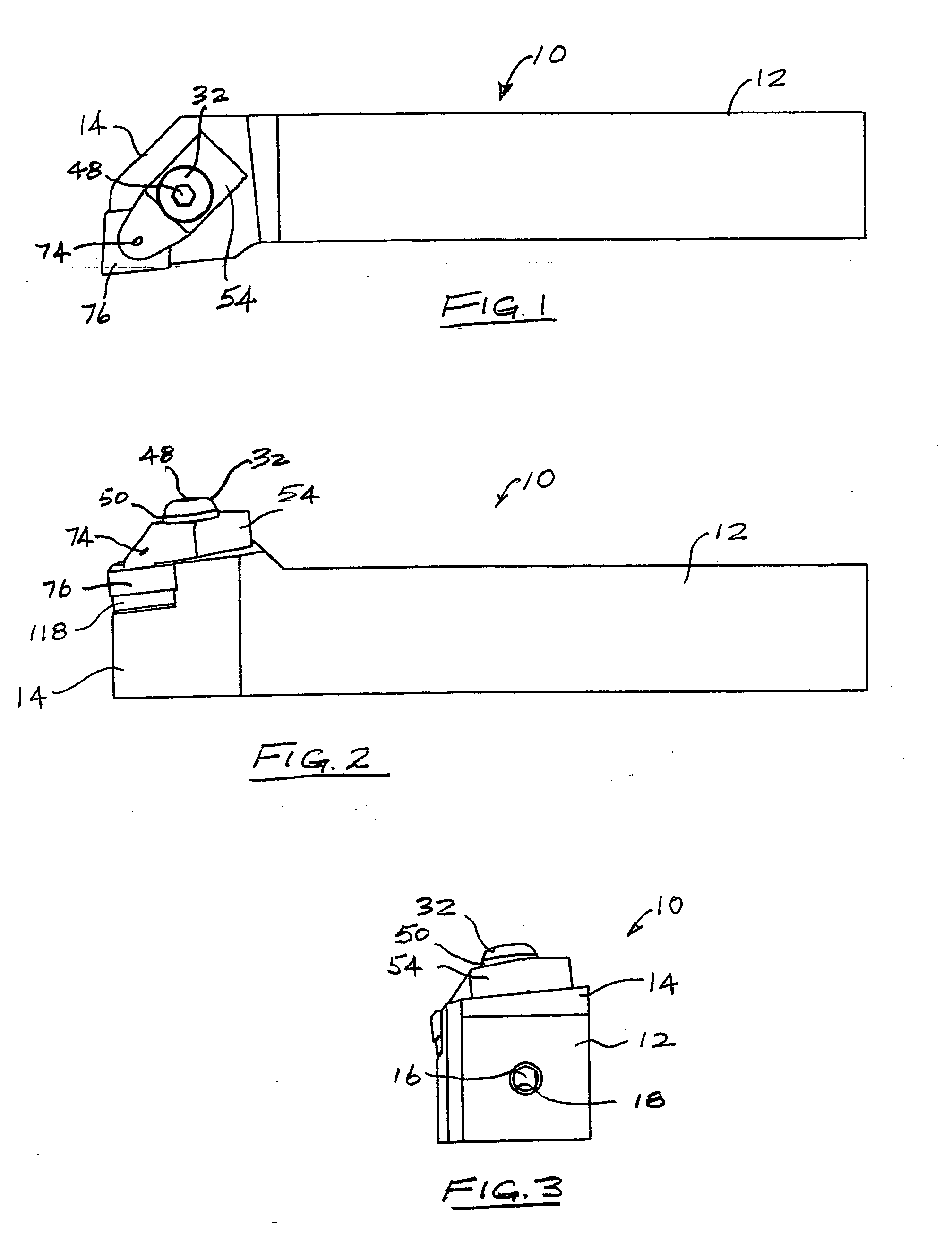

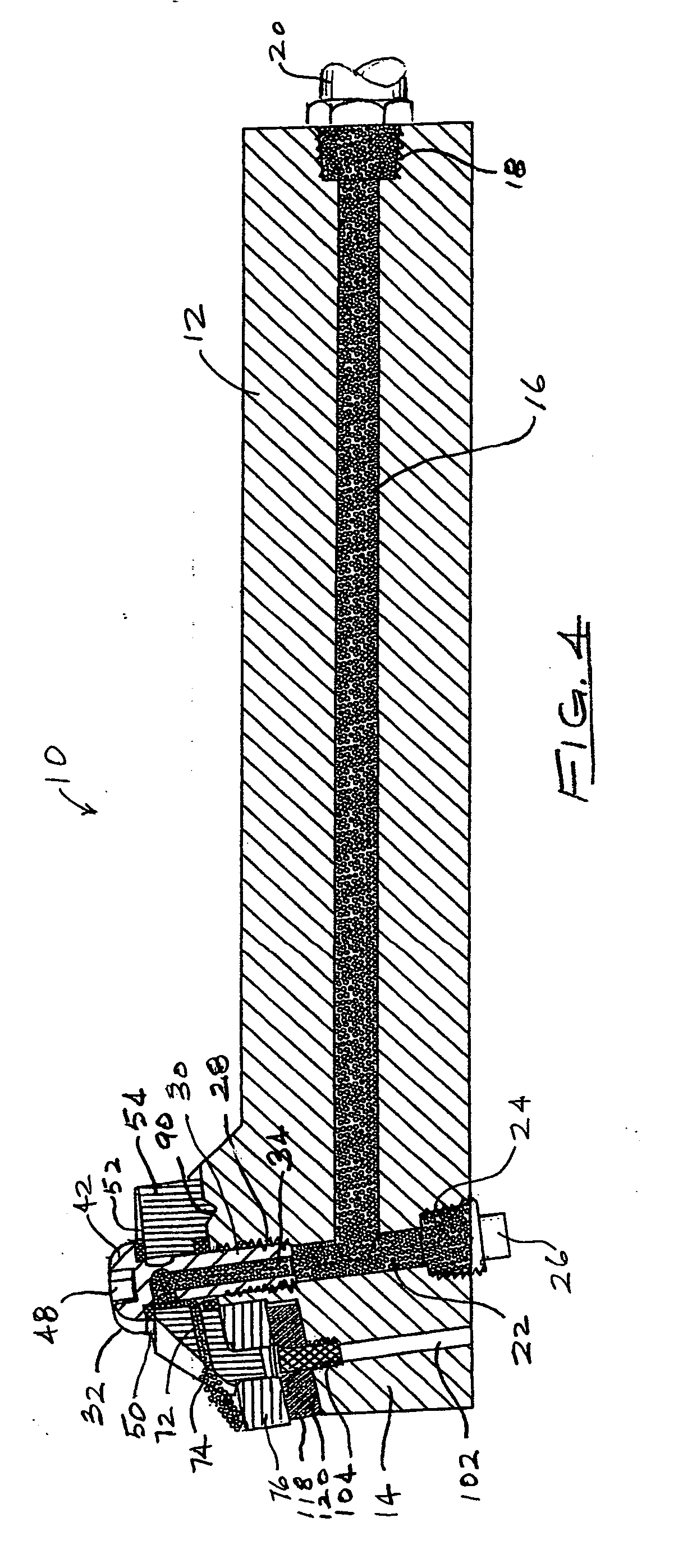

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

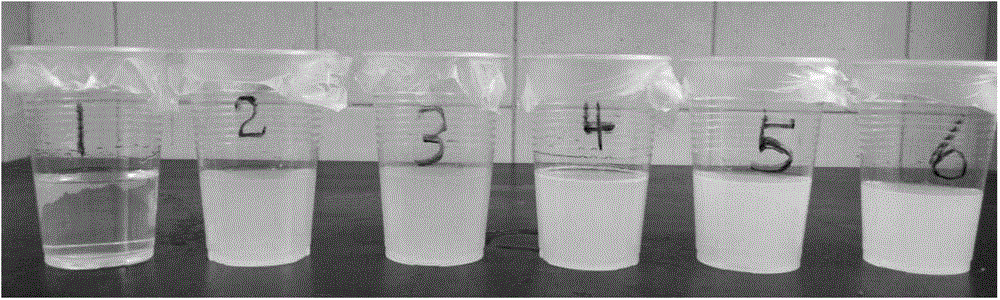

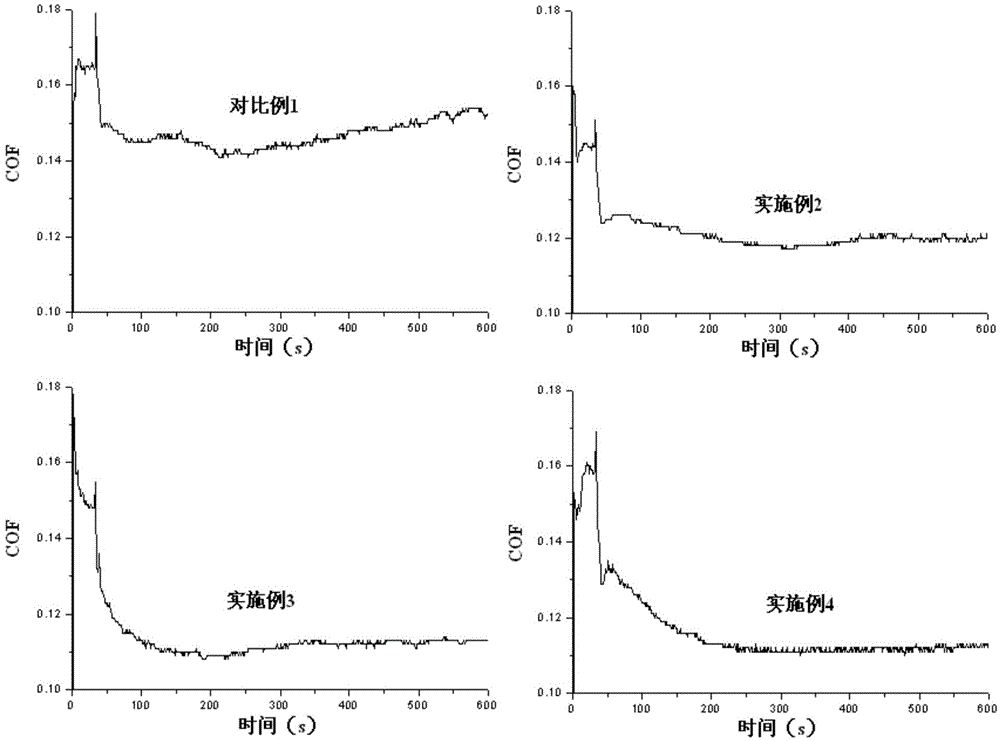

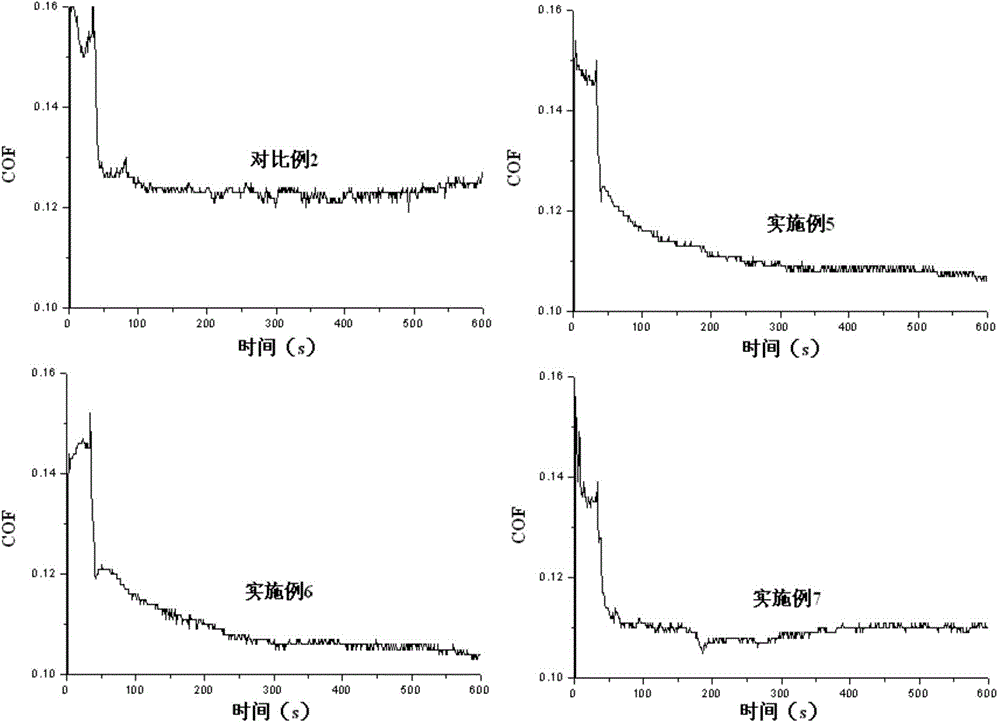

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

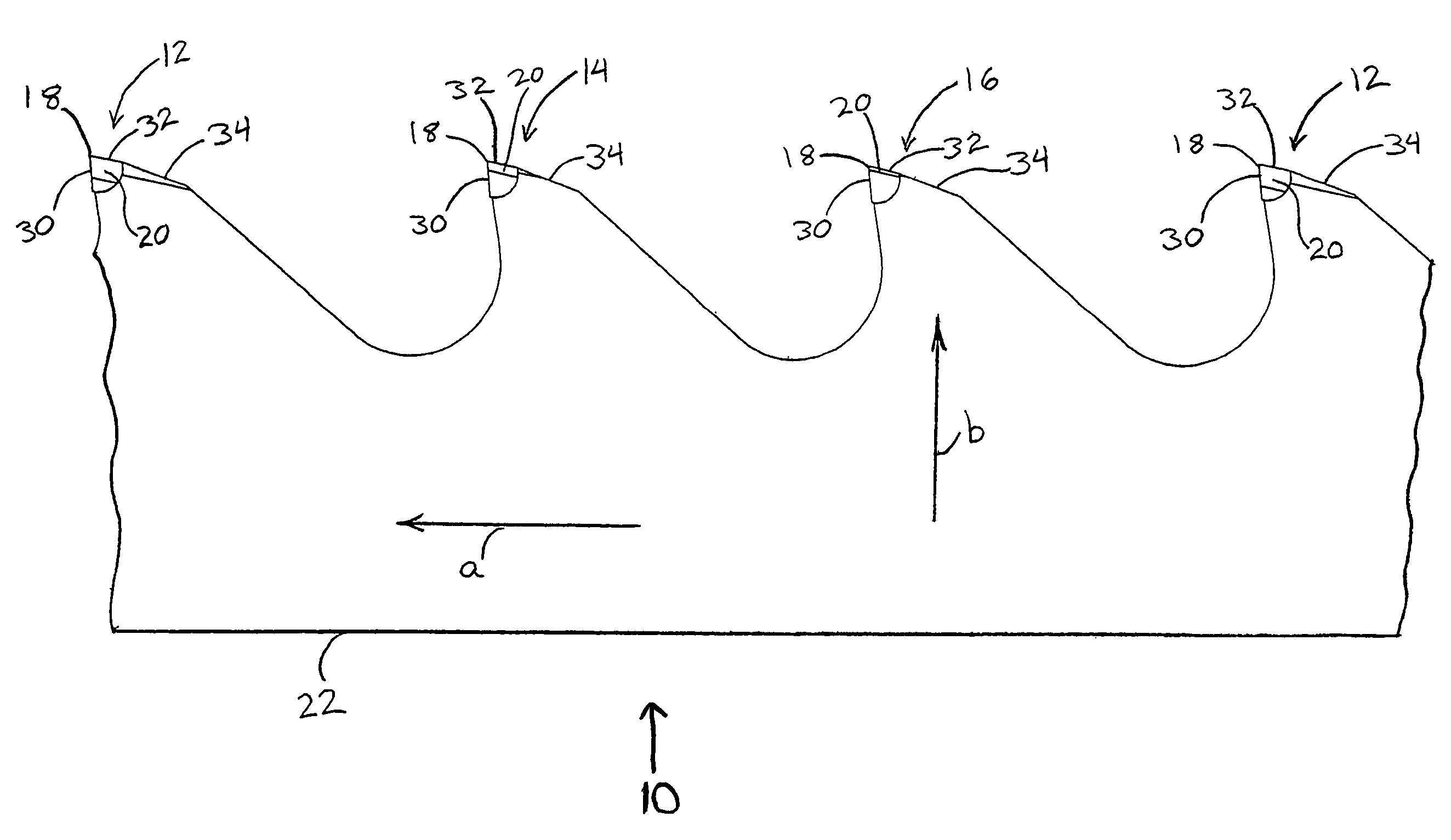

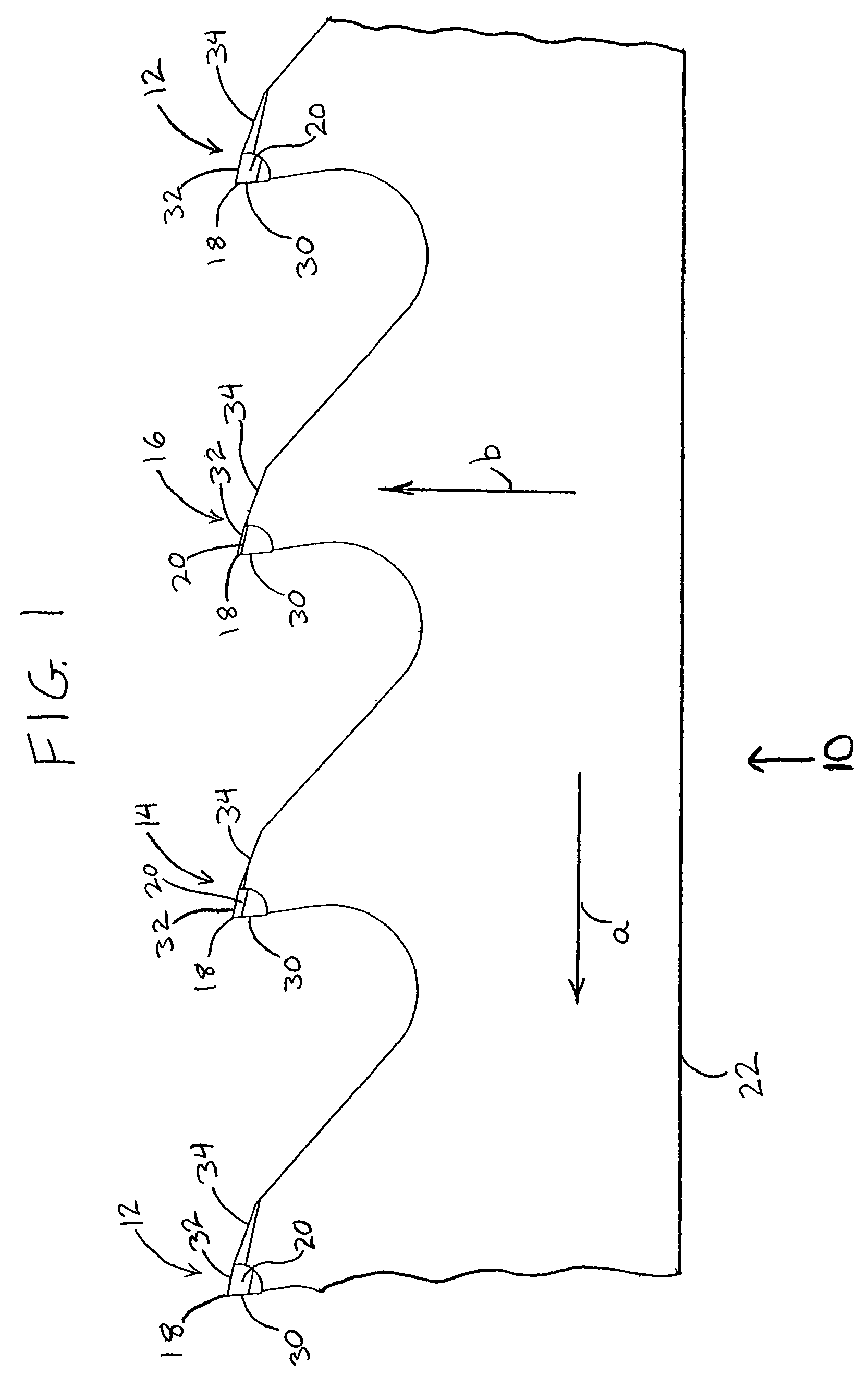

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

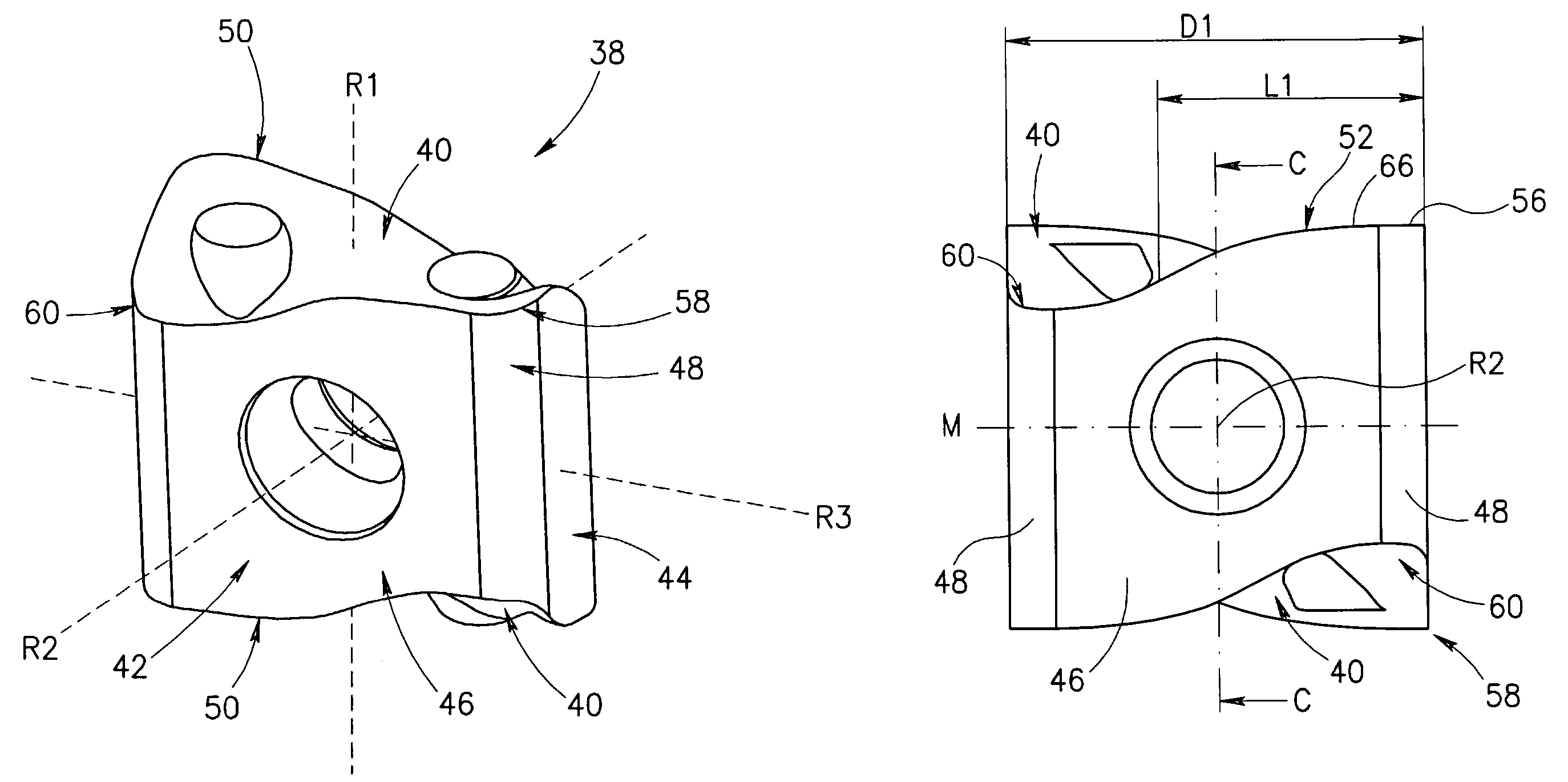

A cutting insert

ActiveUS20060228179A1Improve finenessLittle changeCutting insertsWorkpiecesEngineeringMechanical engineering

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with said upper surface, and at least three side surfaces extending between said upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert includes a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner includes at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is larger than the chamfer angle in a cross-section a distance away from the nose cutting edge.

Owner:SECO TOOLS AB

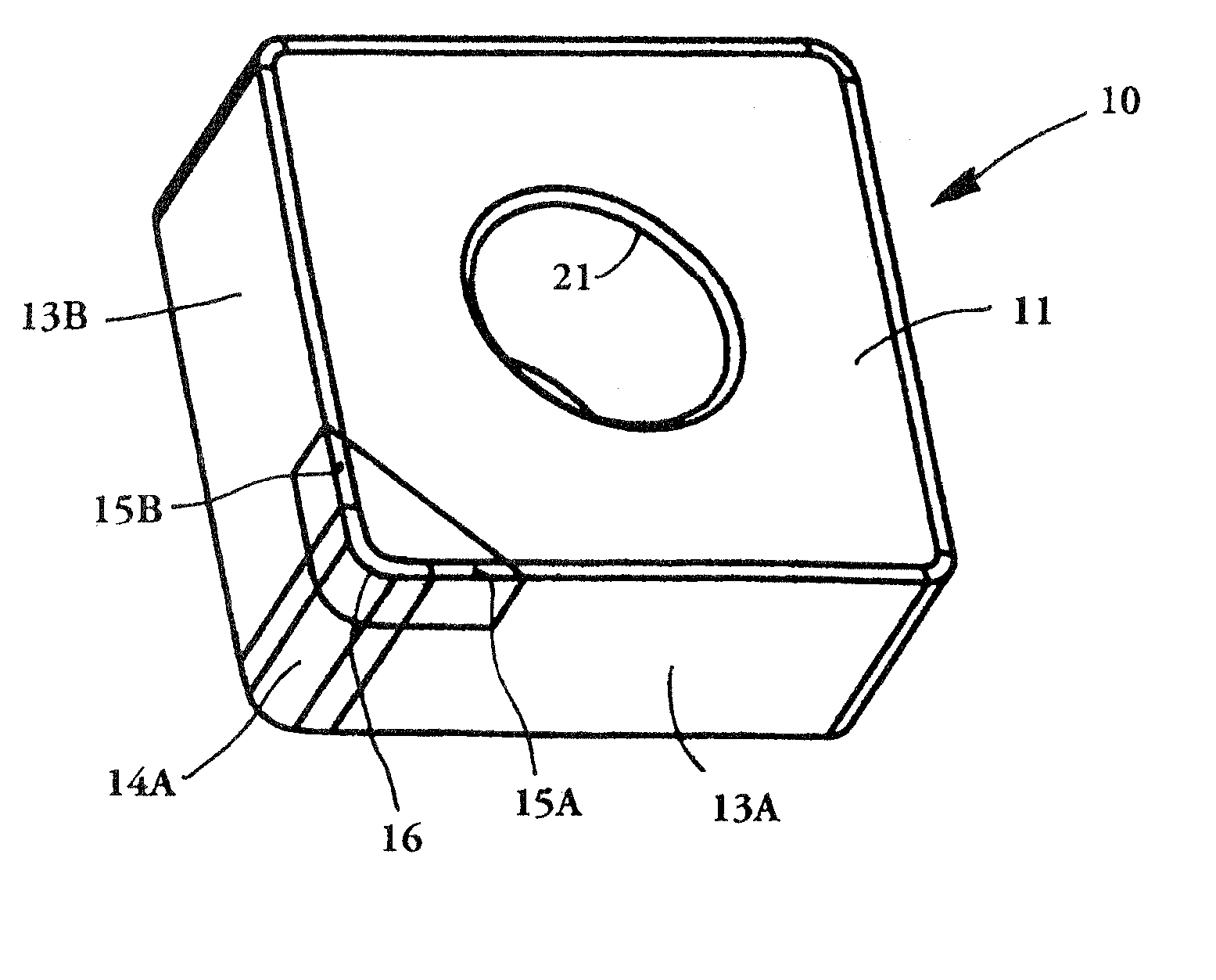

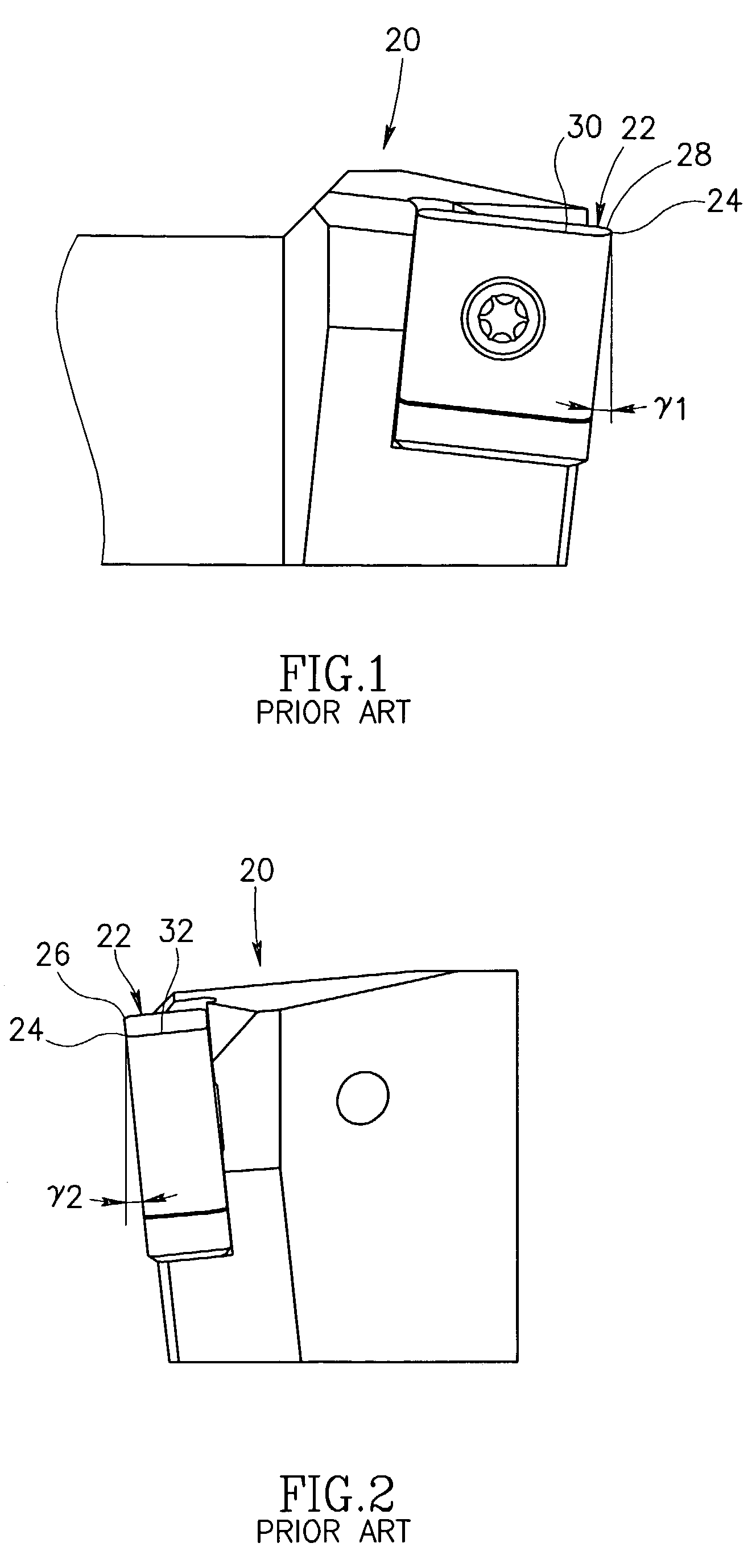

Tangential cutting insert and insert holder

A tangential indexable cutting insert can be used for metal cutting processes in general and for radial and axial turning of a stepped square shoulder in particular. The cutting insert exhibits 180° rotational symmetry about three mutually perpendicular axes. The cutting insert has generally “S”-shaped cutting edges extending between raised and lowered corners. The cutting edges and side surfaces are concave in an end view of the cutting insert. The cutting insert enables radial and axial turning operations of a square shoulder with unlimited depth of cut.

Owner:ISCAR LTD

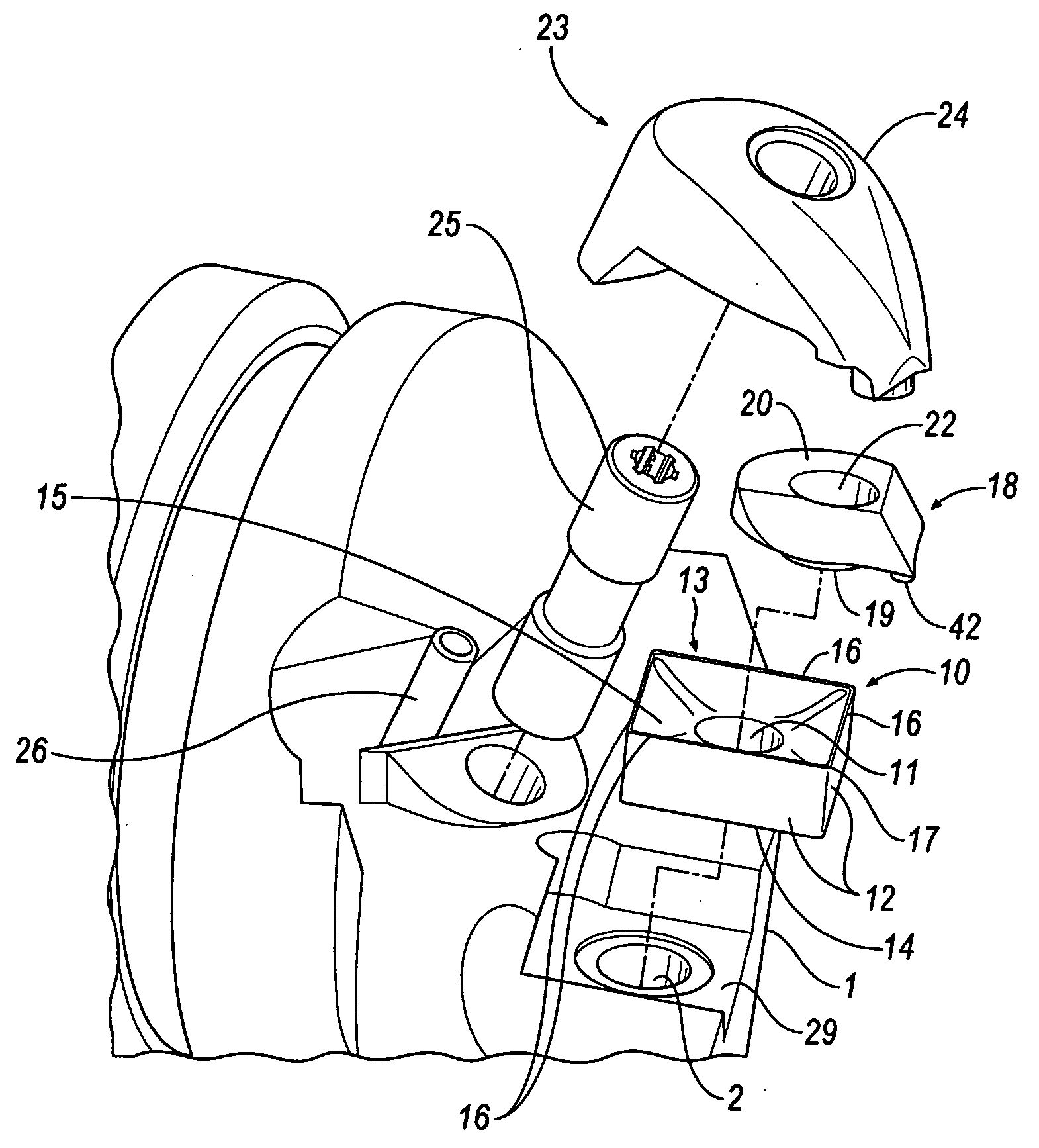

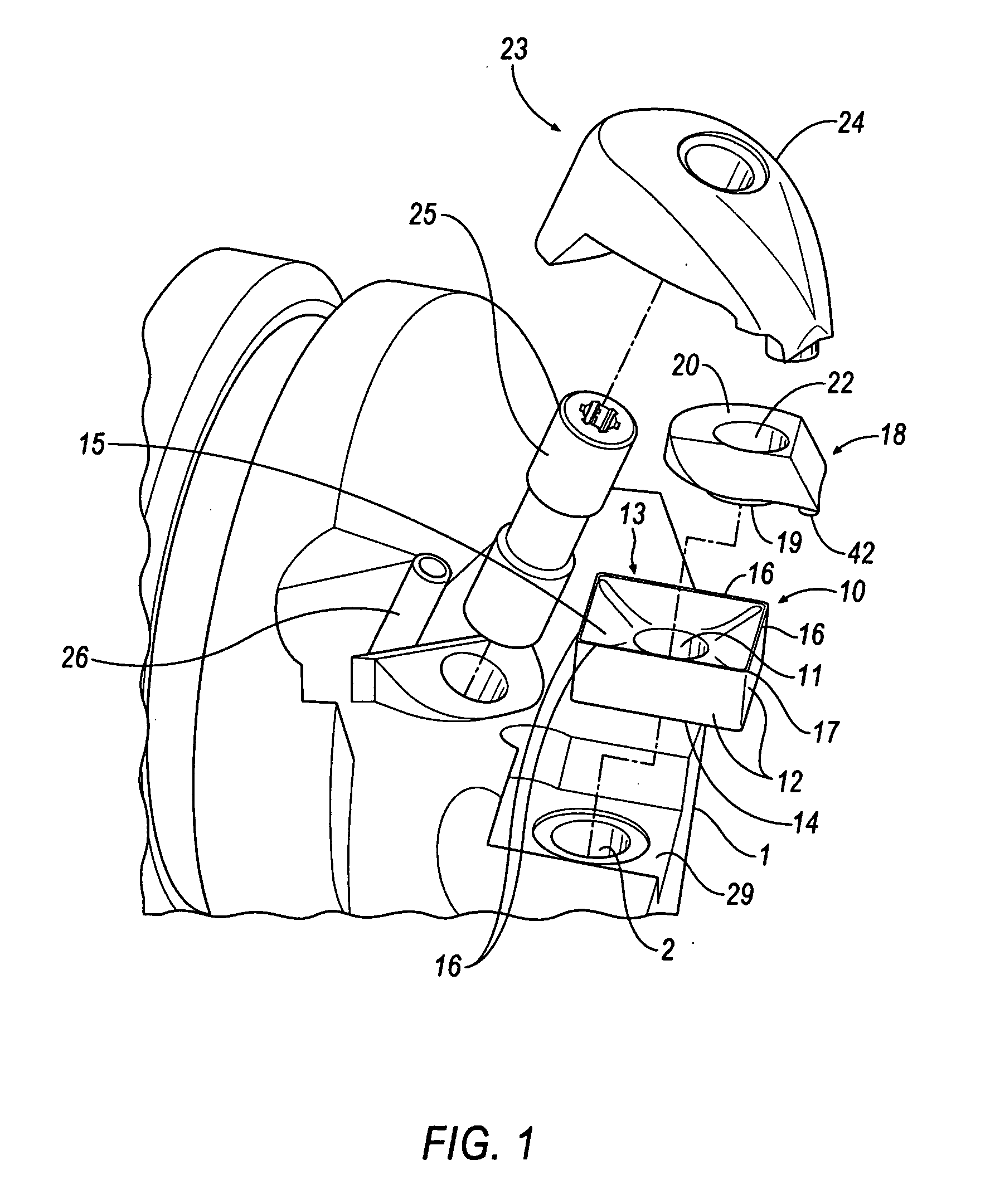

Metal cutting system for effective coolant delivery

A metal cutting system with a tool holder, a shim, an insert with a top depression, a top piece and a clamp. A rake face cooling channel for fluid delivery is formed between the top piece and the depression in the insert. A primary discharge slot at the end of the rake face cooling channel delivers fluid from below the cutting edge of the insert. A second cooling channel for delivery of fluid to the flank face is formed between the insert and the shim or is formed between the shim and the tool holder with a portion of the cooling channel passing through the shim.

Owner:KENNAMETAL INC

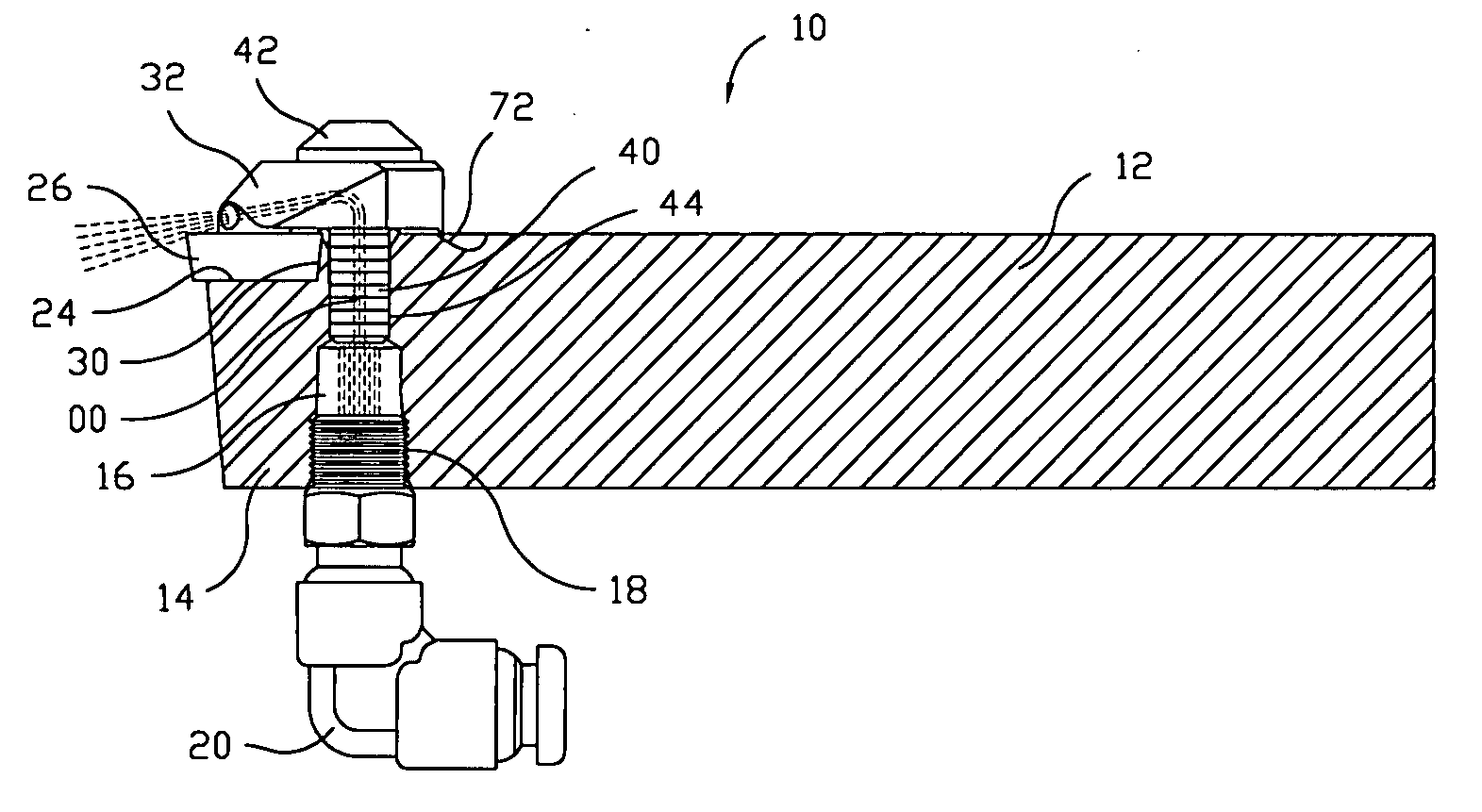

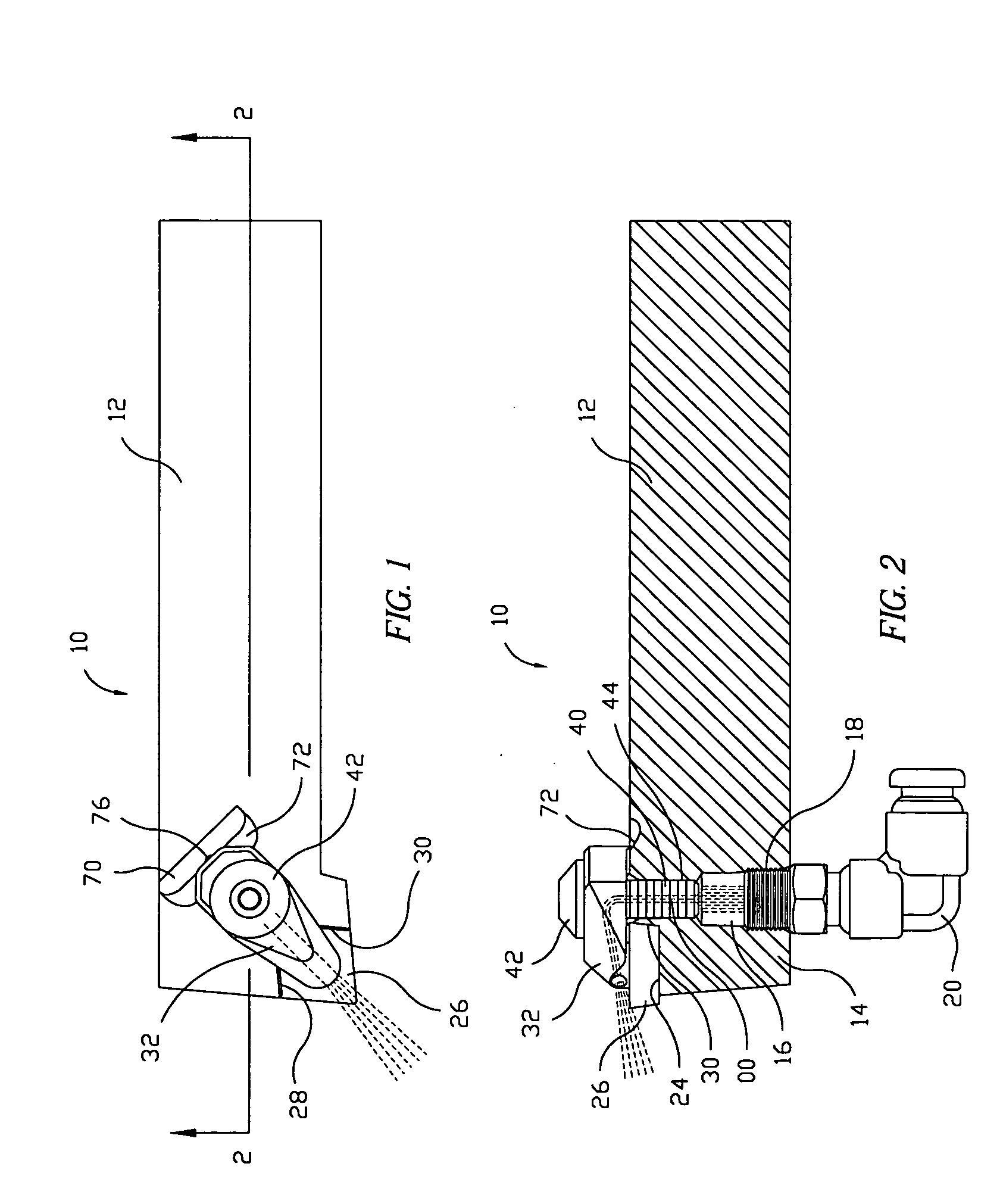

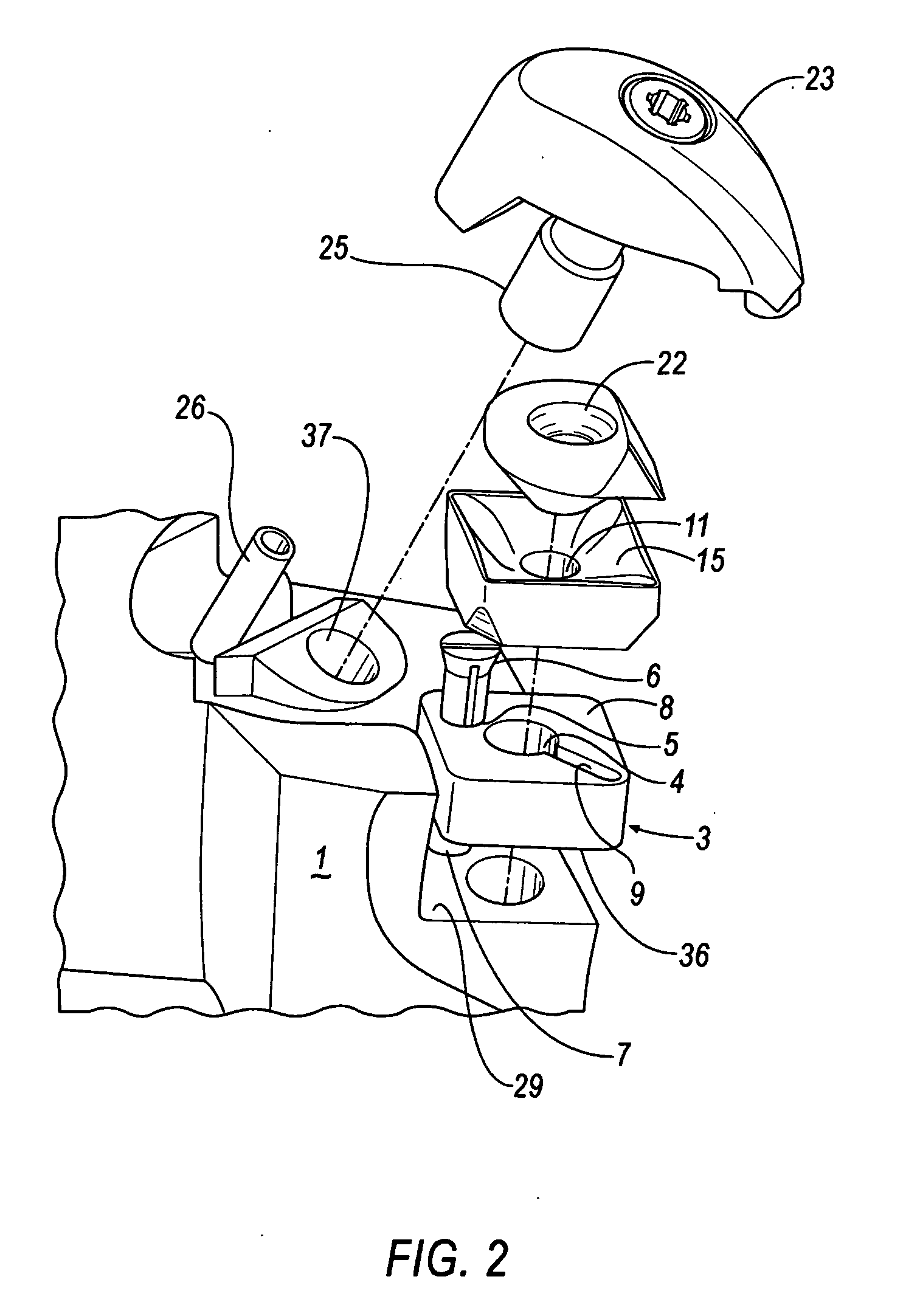

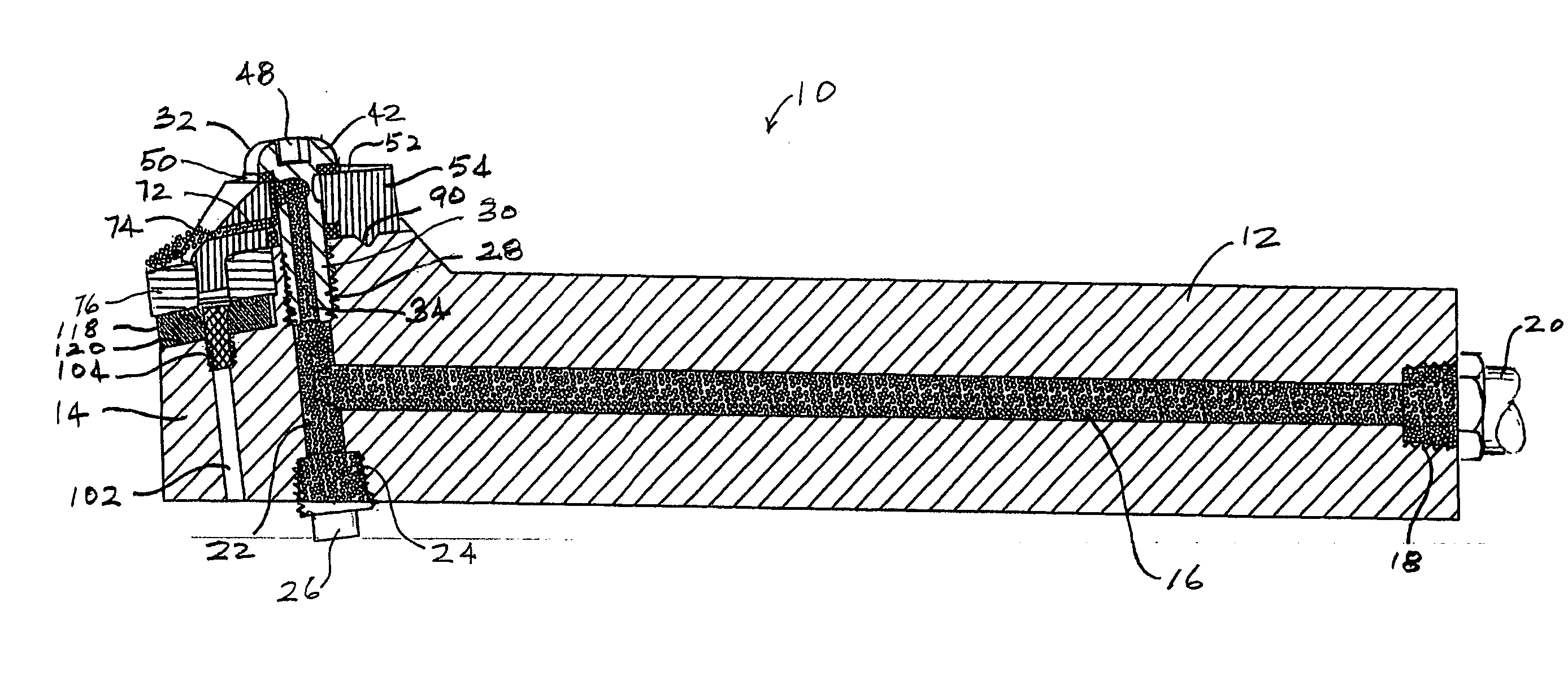

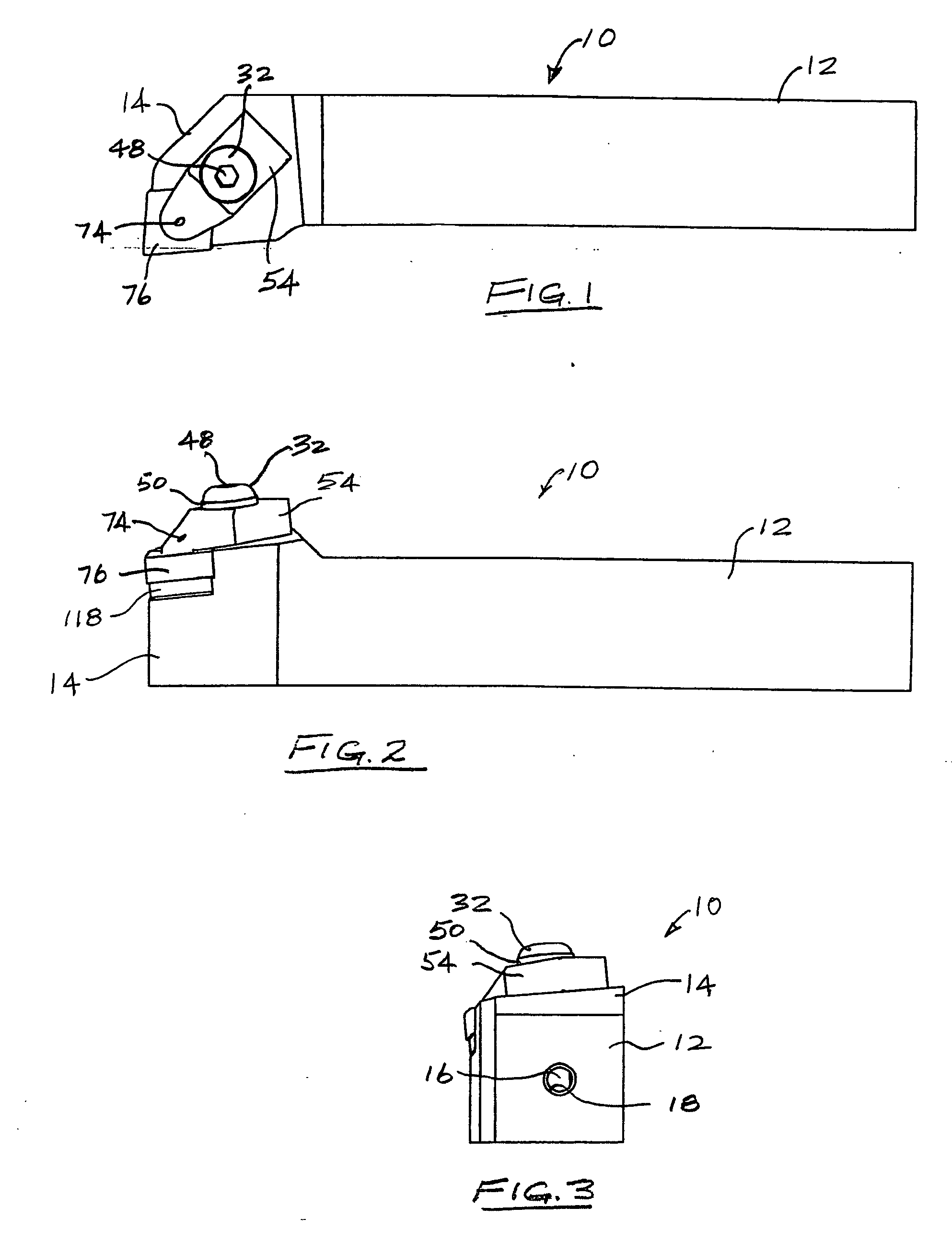

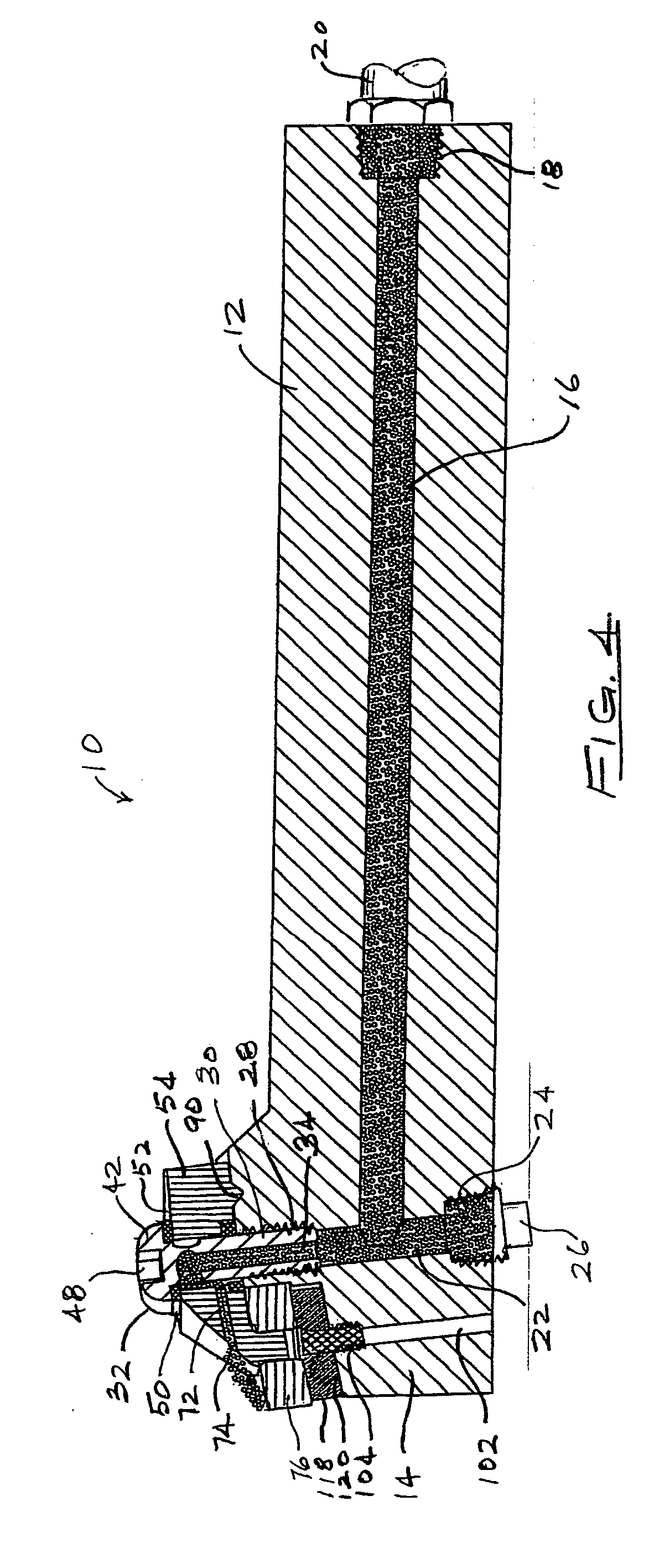

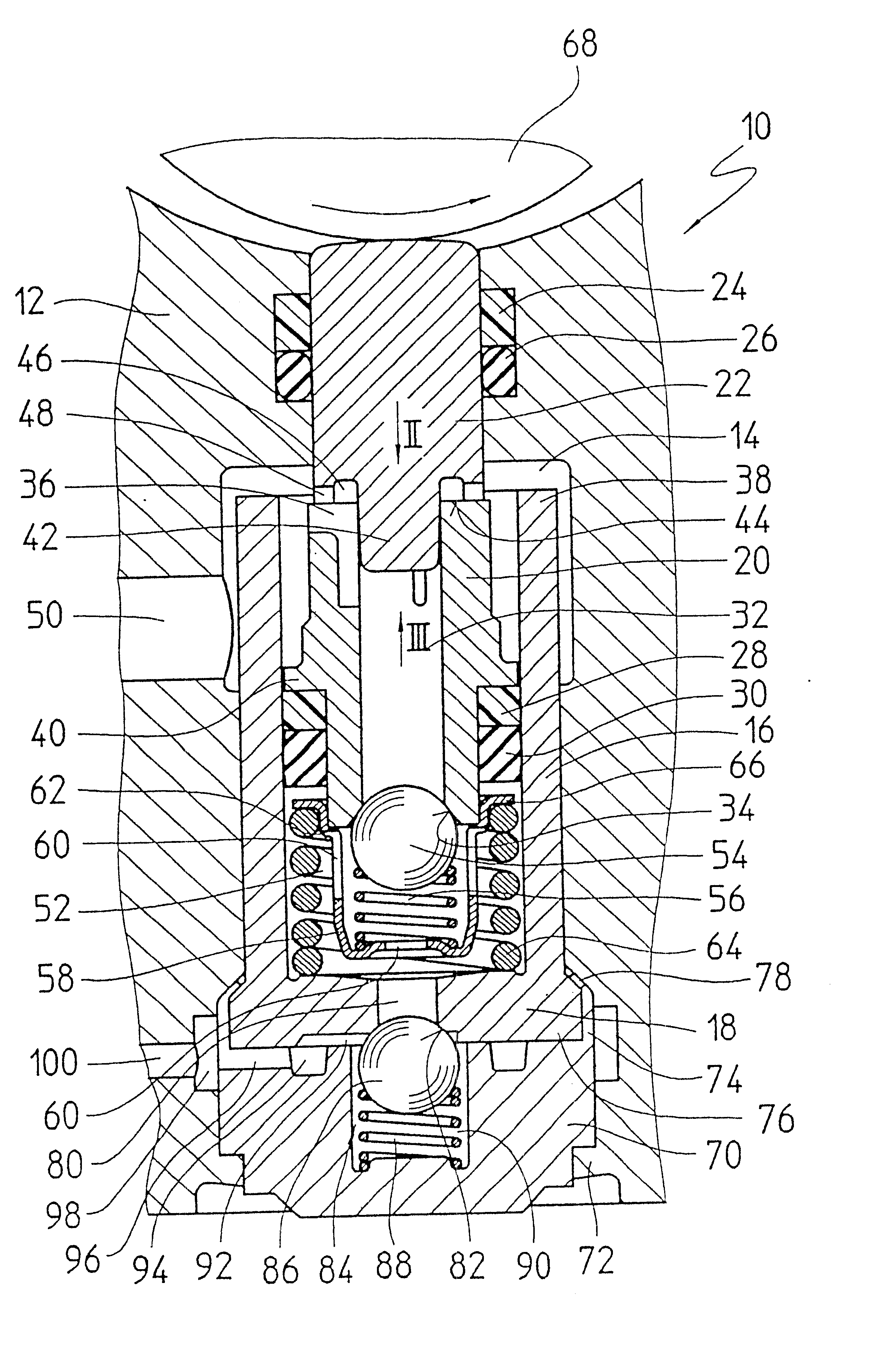

Boring bar having internal coolant supply

A boring bar has a shank having a cutter support head at one end. A flow passage extends longitudinally through the shank to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp member defines at least one coolant fluid flow passage having a discharge opening or openings each located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The clamp screw defines an internal passage that communicates with the transverse coolant fluid flow passage and conducts coolant fluid onto the metal cutting insert. Alternatively, an annular clearance is defined about the shank of the clamp screw and serves as a coolant flow passage which is in fluid communication with the internal coolant fluid discharge passage or passages of the clamp member.

Owner:GIANNETTI ENRICO R

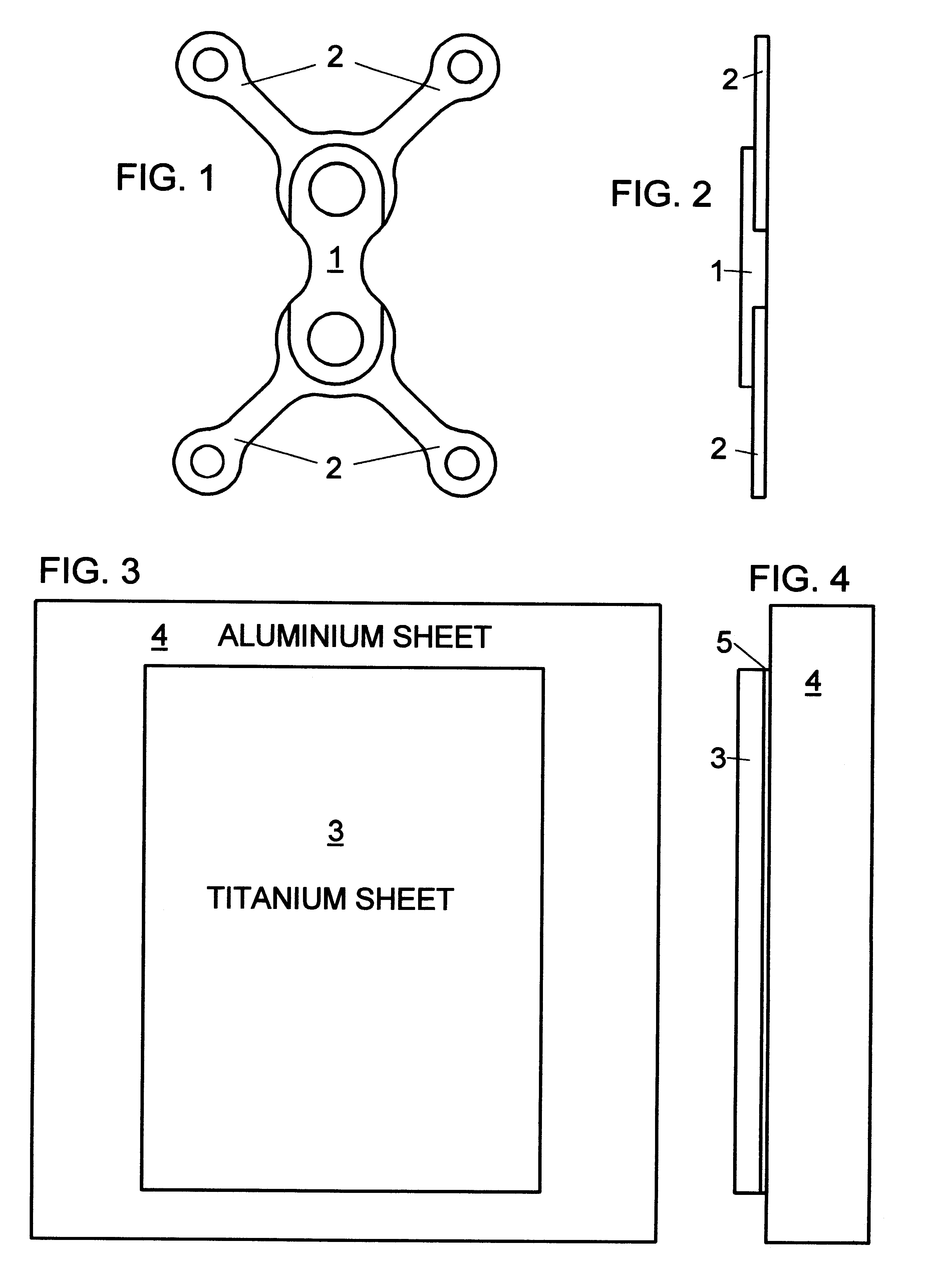

Production process of varying thickness osteosynthesis plates

InactiveUS6315852B1Improve thermal conductivityStress resistantLamination ancillary operationsInternal osteosythesisAdhesiveVarying thickness

The invention concerns a process for the production of osteosynthesis plates with a varying thickness to whatever degree. The plates are manufactured by a metal cutting process carried out on a composite structure made by a layer of the material which will form the osteosynthesis plate, bound through a layer of adhesive to a supporting layer with high thermal conductivity and mechanical strength. When the cutting process terminates, the osteosynthesis plate is separated from the supporting layer by heating the composite structure until the adhesive melts or by using a thinner suitable for the adopted adhesive.

Owner:MAGRINI ANNA

Boring bar having internal coolant supply

A boring bar has a shank having a cutter support head at one end. A flow passage extends longitudinally through the shank to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp member defines at least one coolant fluid flow passage having a discharge opening or openings each located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The clamp screw defines an internal passage that communicates with the transverse coolant fluid flow passage and conducts coolant fluid onto the metal cutting insert. Alternatively, an annular clearance is defined about the shank of the clamp screw and serves as a coolant flow passage which is in fluid communication with the internal coolant fluid discharge passage or passages of the clamp member.

Owner:GIANNETTI ENRICO R

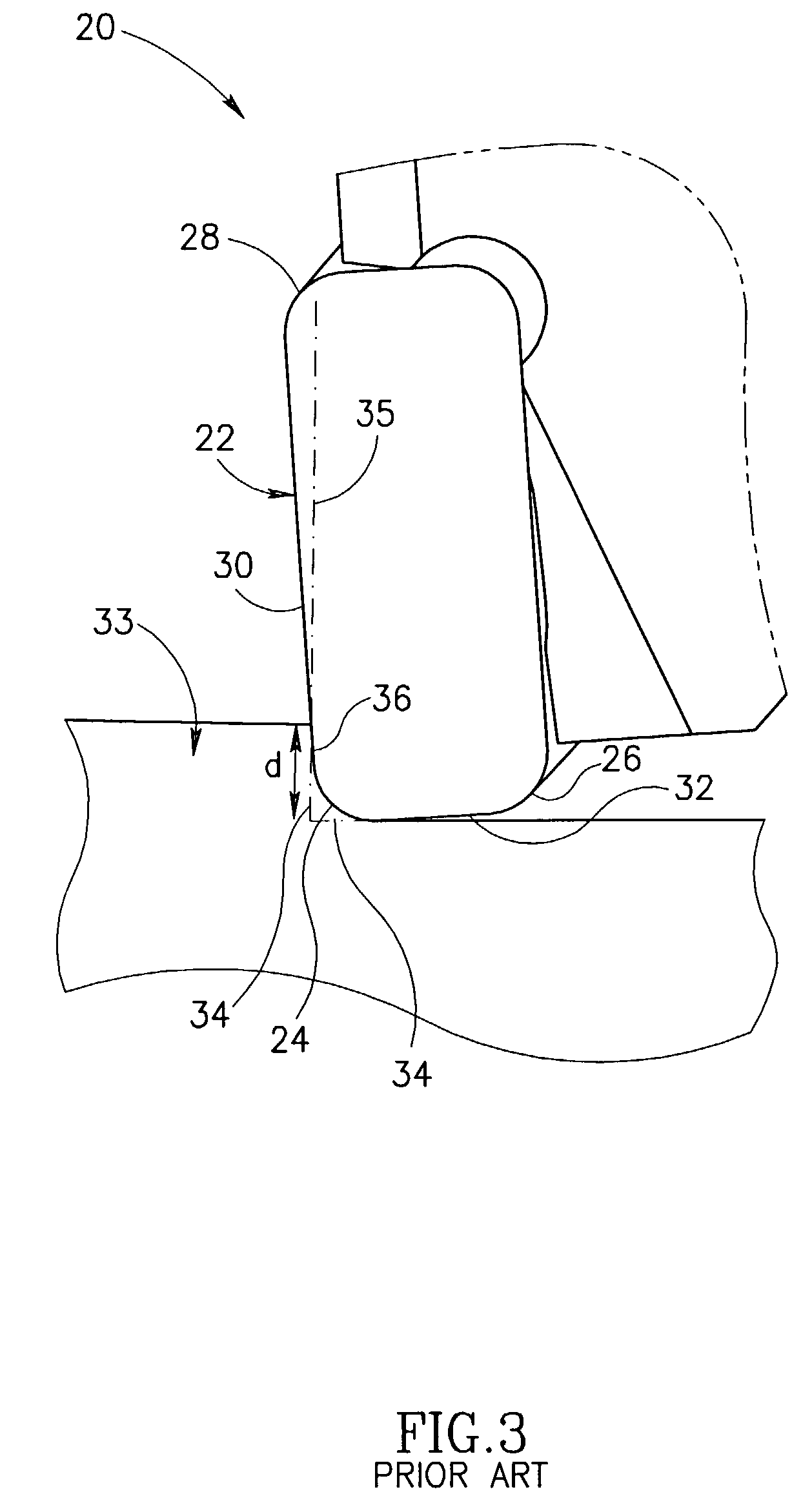

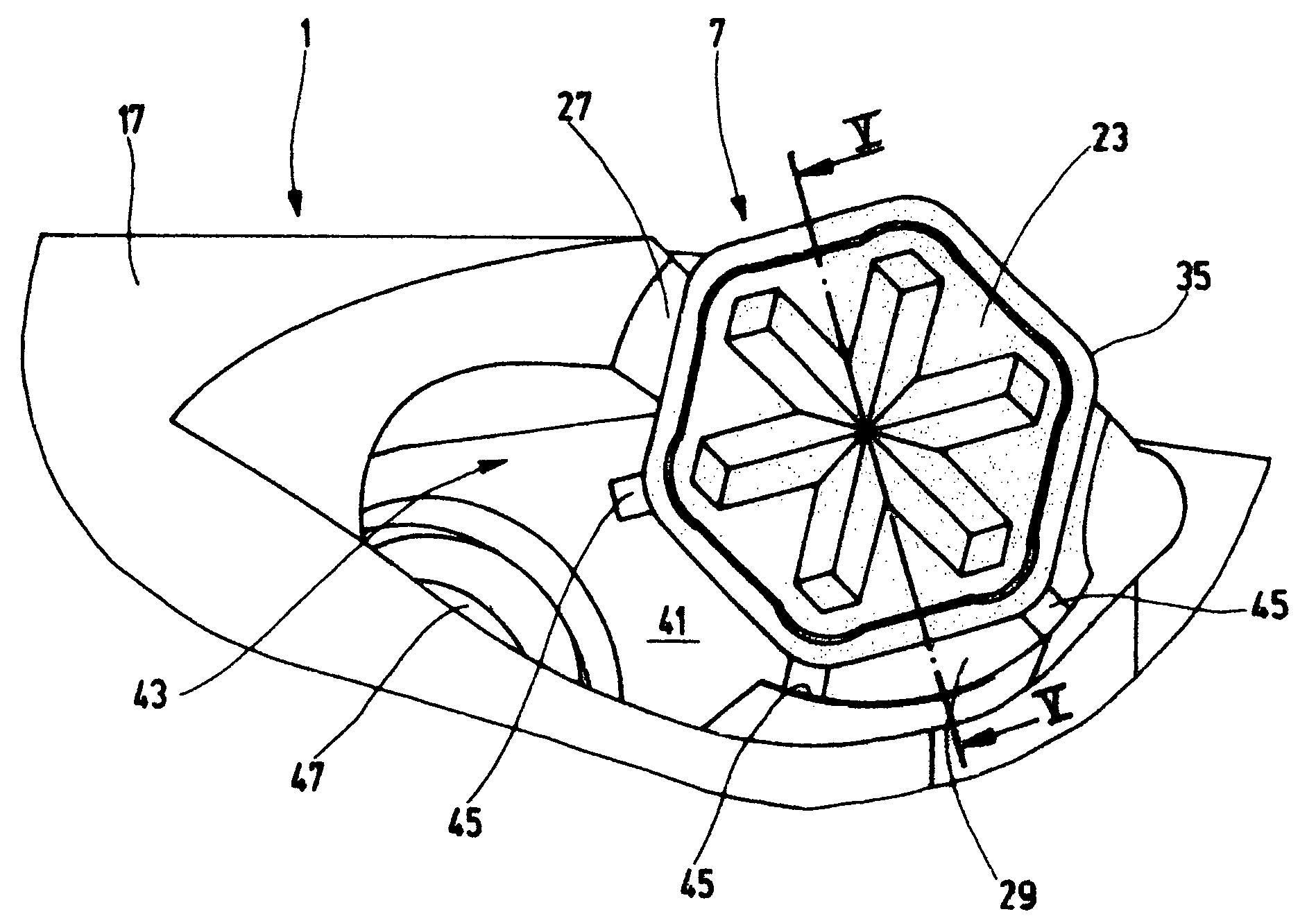

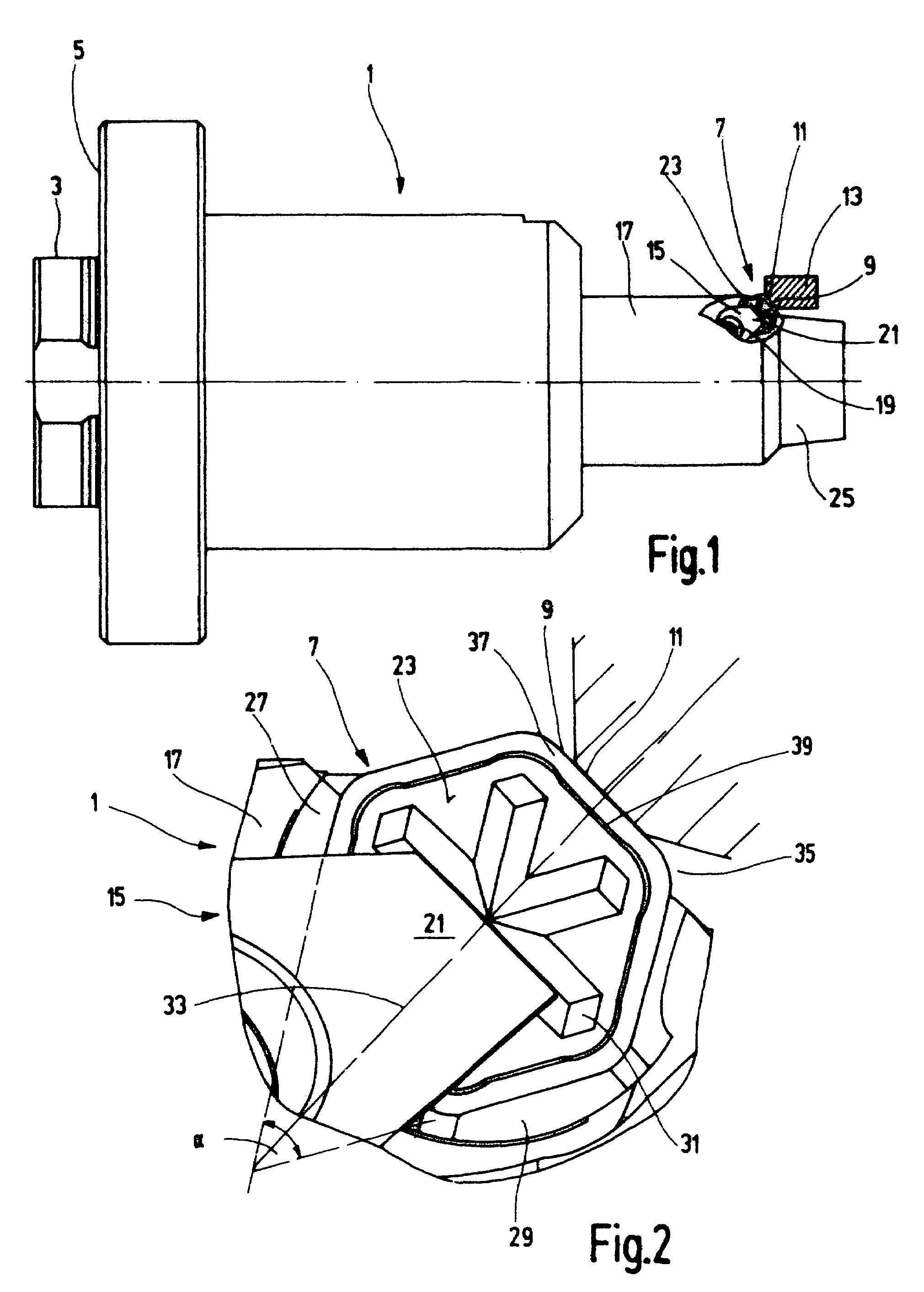

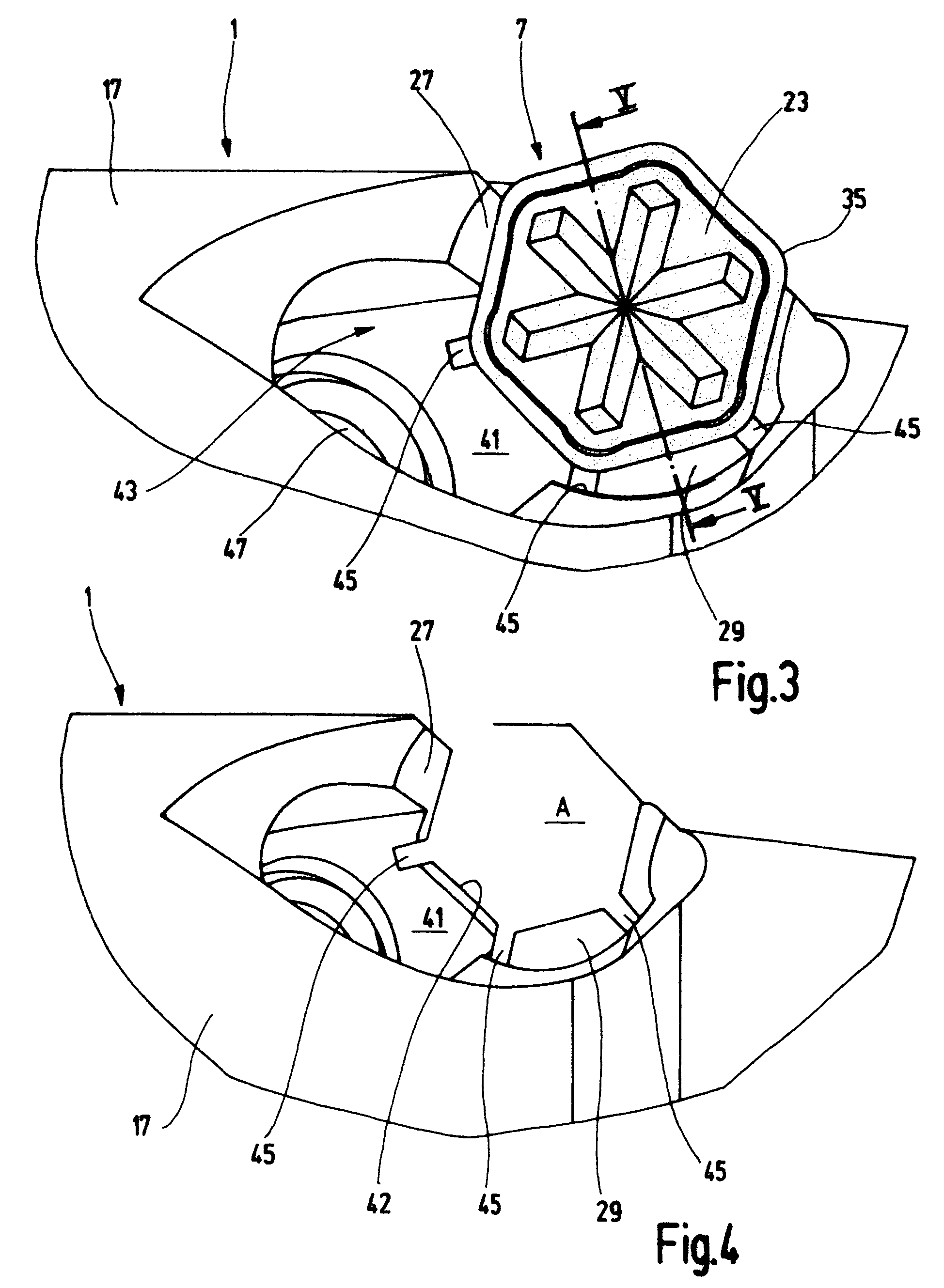

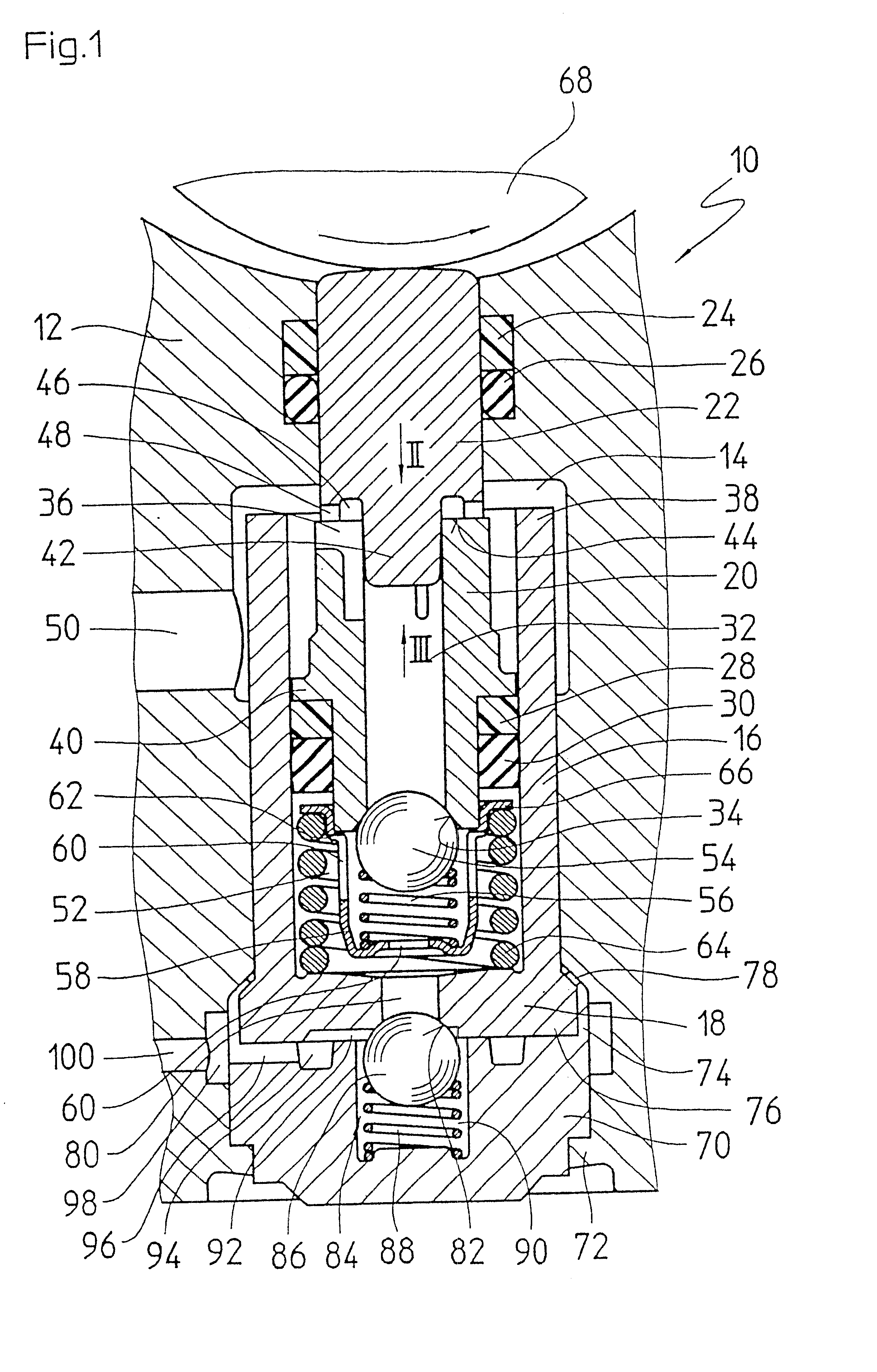

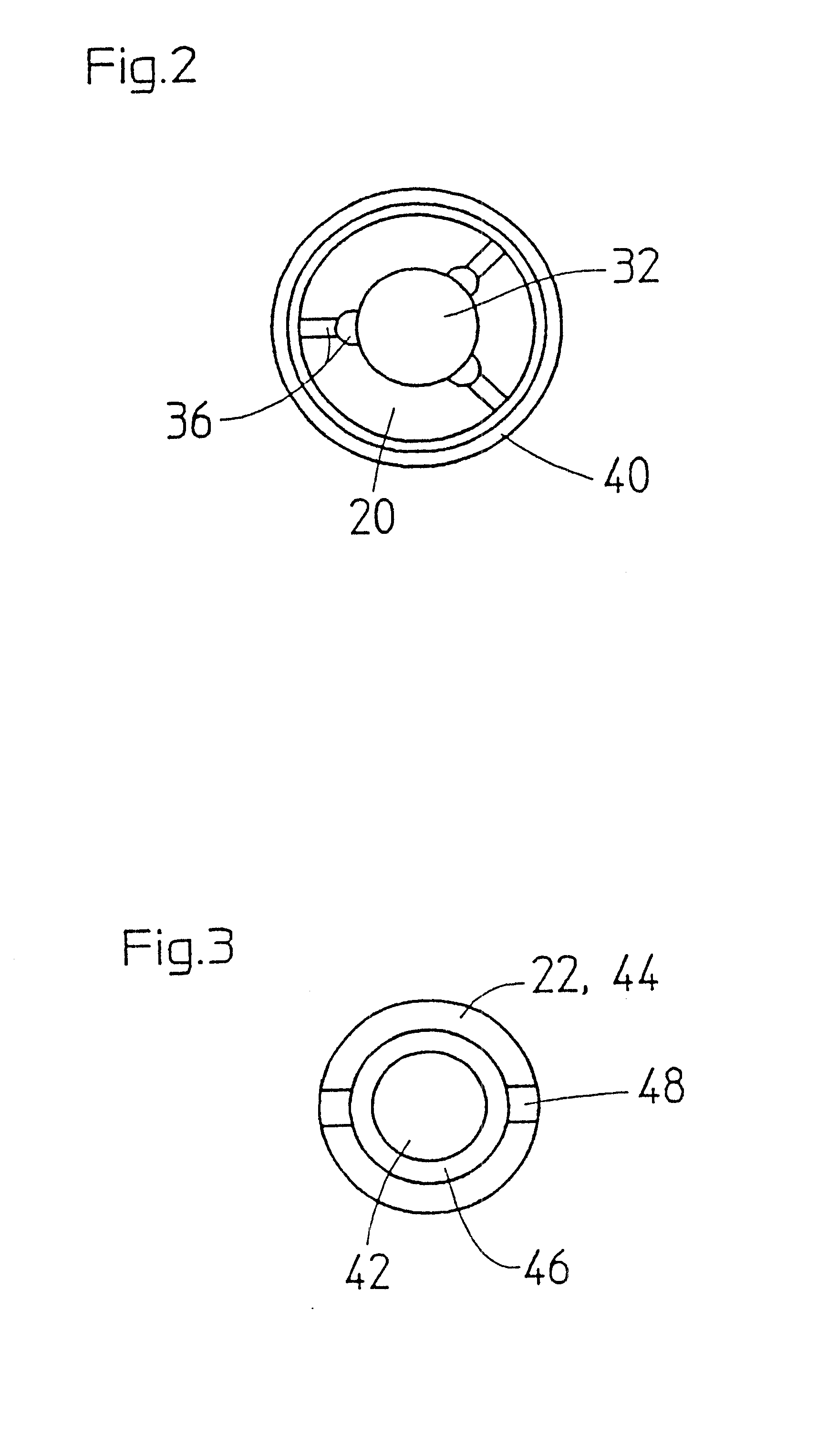

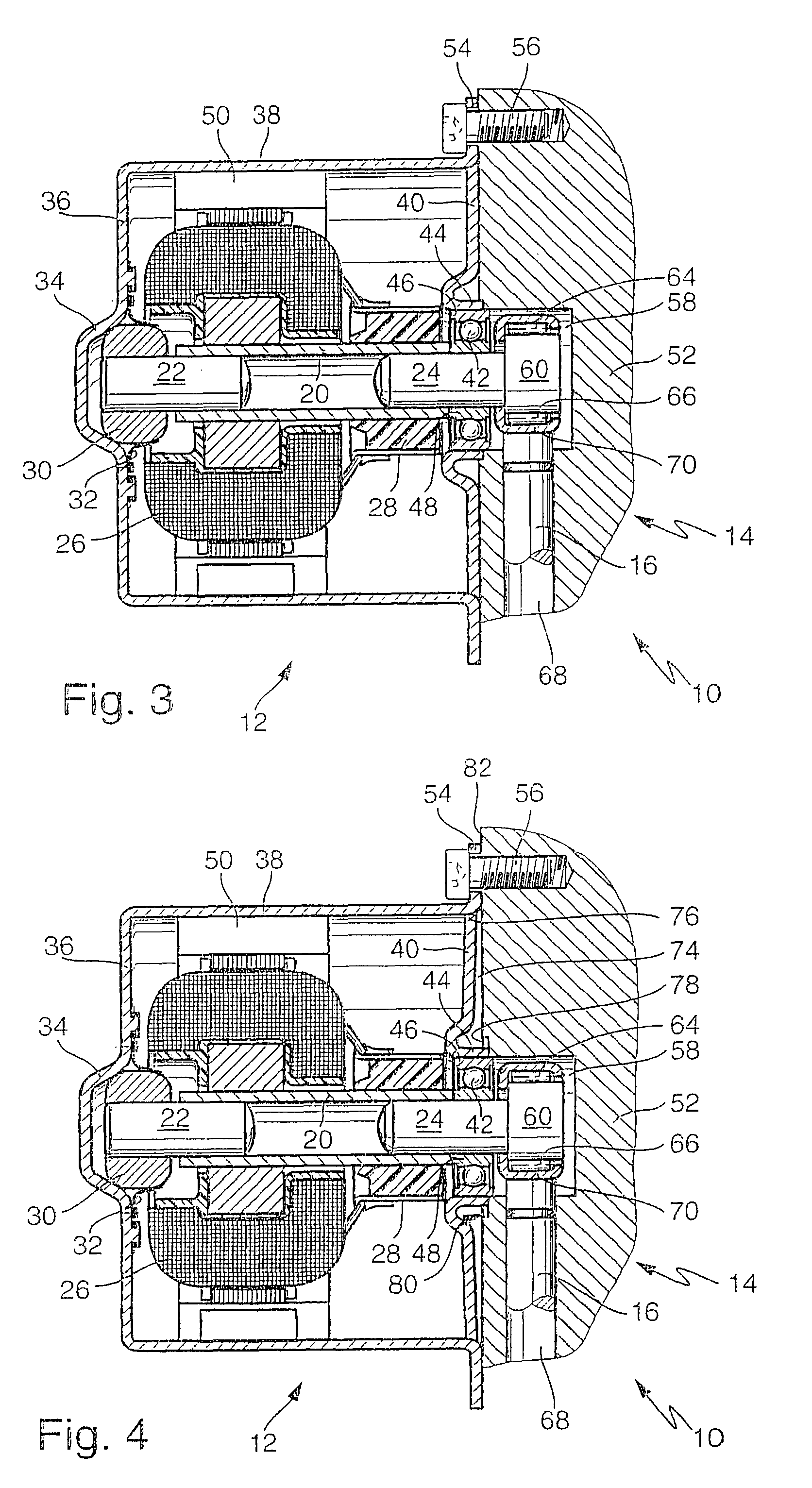

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

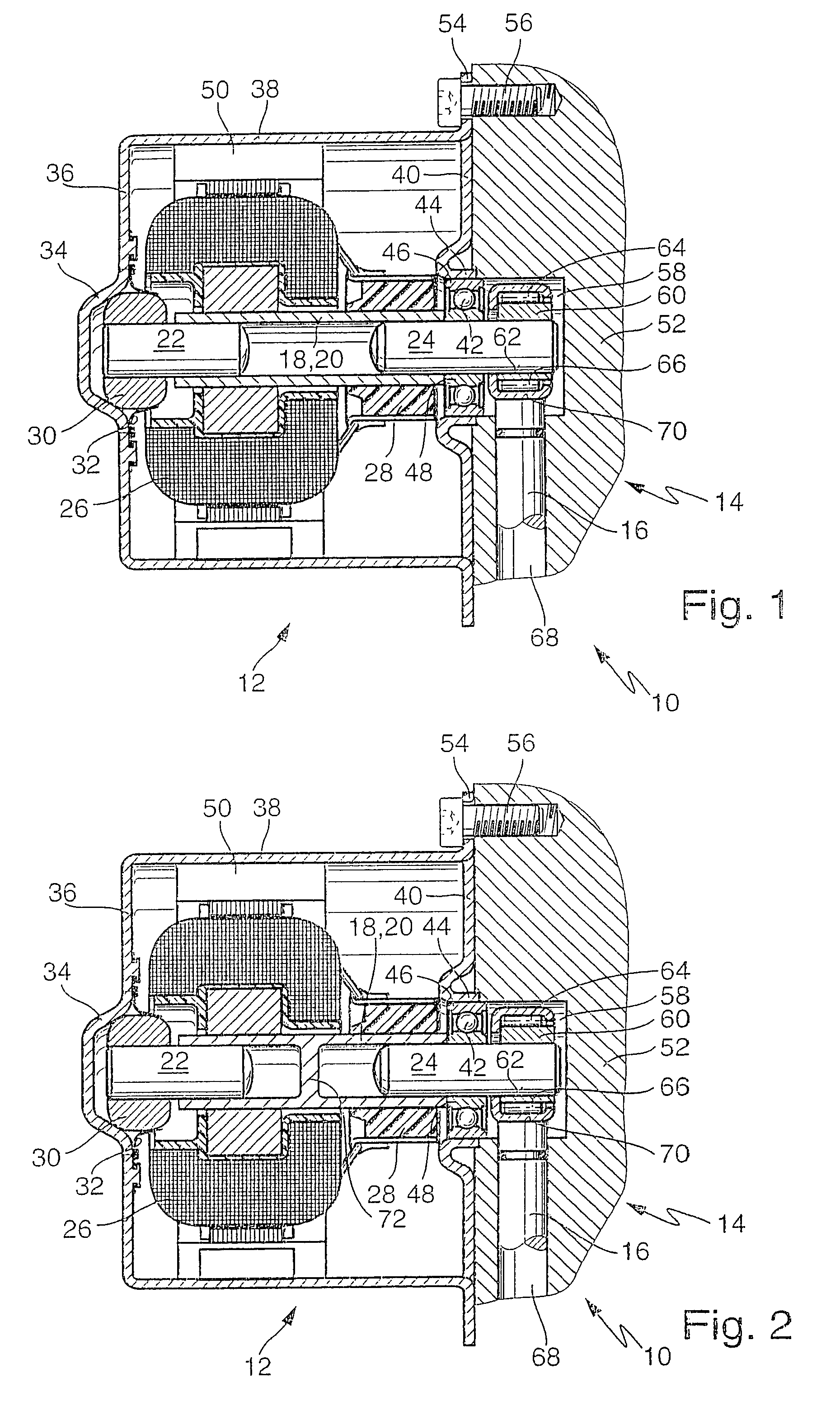

Piston pump for a vehicle brake system

InactiveUS6471496B1Positive displacement pump componentsBraking action transmissionEngineeringMechanical engineering

To enable economical production of a piston for a piston pump, the piston is made from a tubular deformed part and a closure plug, which is press-fitted with a protrusion into the deformed part. The piston has the advantage that the piston can be made without metal cutting in the form of deformed parts, for instance by extrusion, and hence can be produced quickly and economically.

Owner:ROBERT BOSCH GMBH

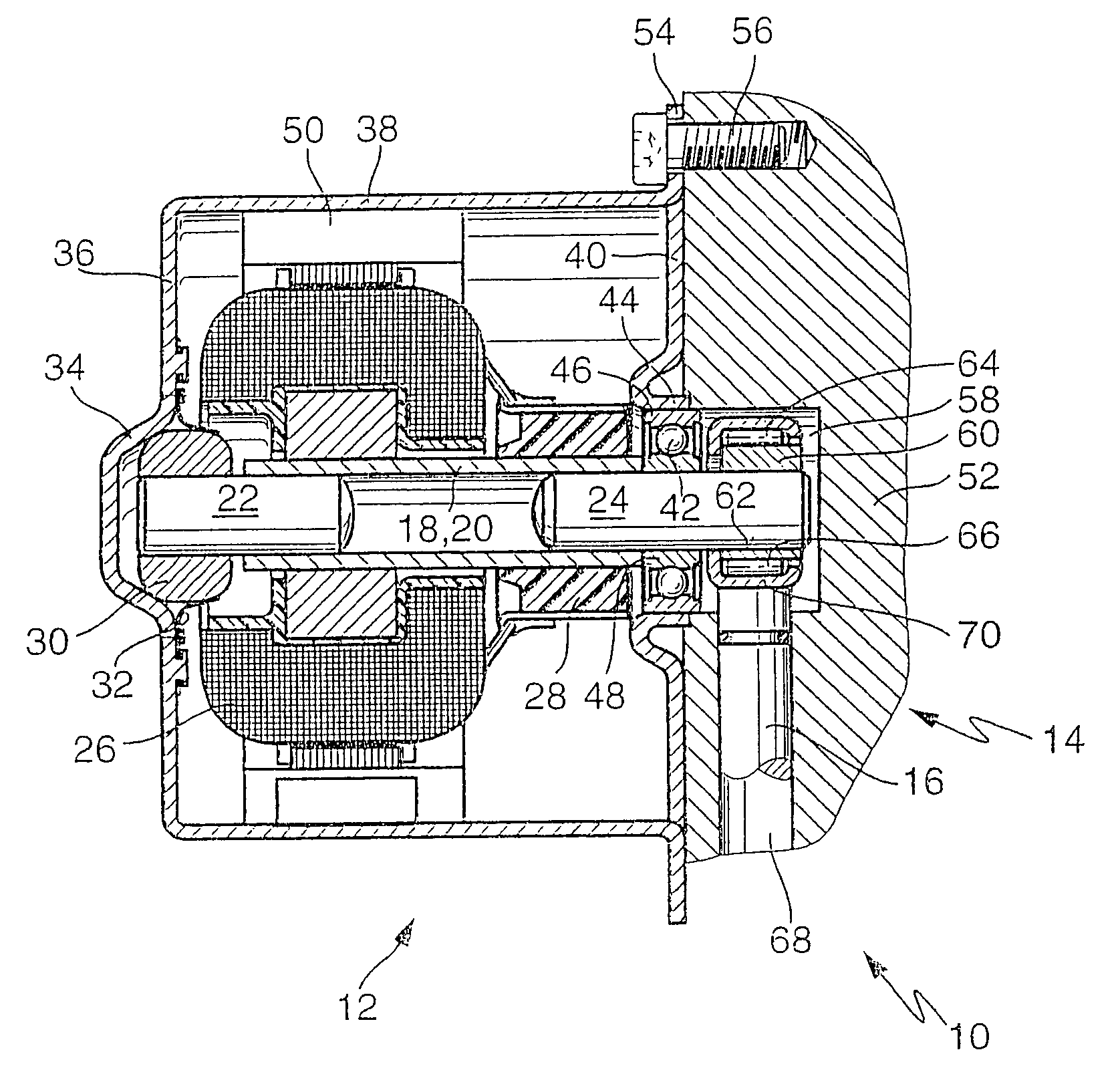

Pump aggregate for a hydraulic vehicle braking system

InactiveUS7168929B2Easy to bendImprove rigidityPositive displacement pump componentsBraking componentsRadial piston pumpTorsional strength

A pump unit for a hydraulic vehicle brake system with traction control has an electric motor driving a radial piston pump. A rotor shaft of the pump unit has a hollow shaft with two standardized, hardened cylindrical pins that are press-fitted into the ends of the hollow shaft. The rotor shaft can be produced simply, economically, and without metal-cutting machining. The hollow shaft has high bending and torsional strength. The rotor shaft has a small diameter at the bearing points, which makes a small bearing diameter and thus a small installation space for the pump unit possible.

Owner:ROBERT BOSCH GMBH

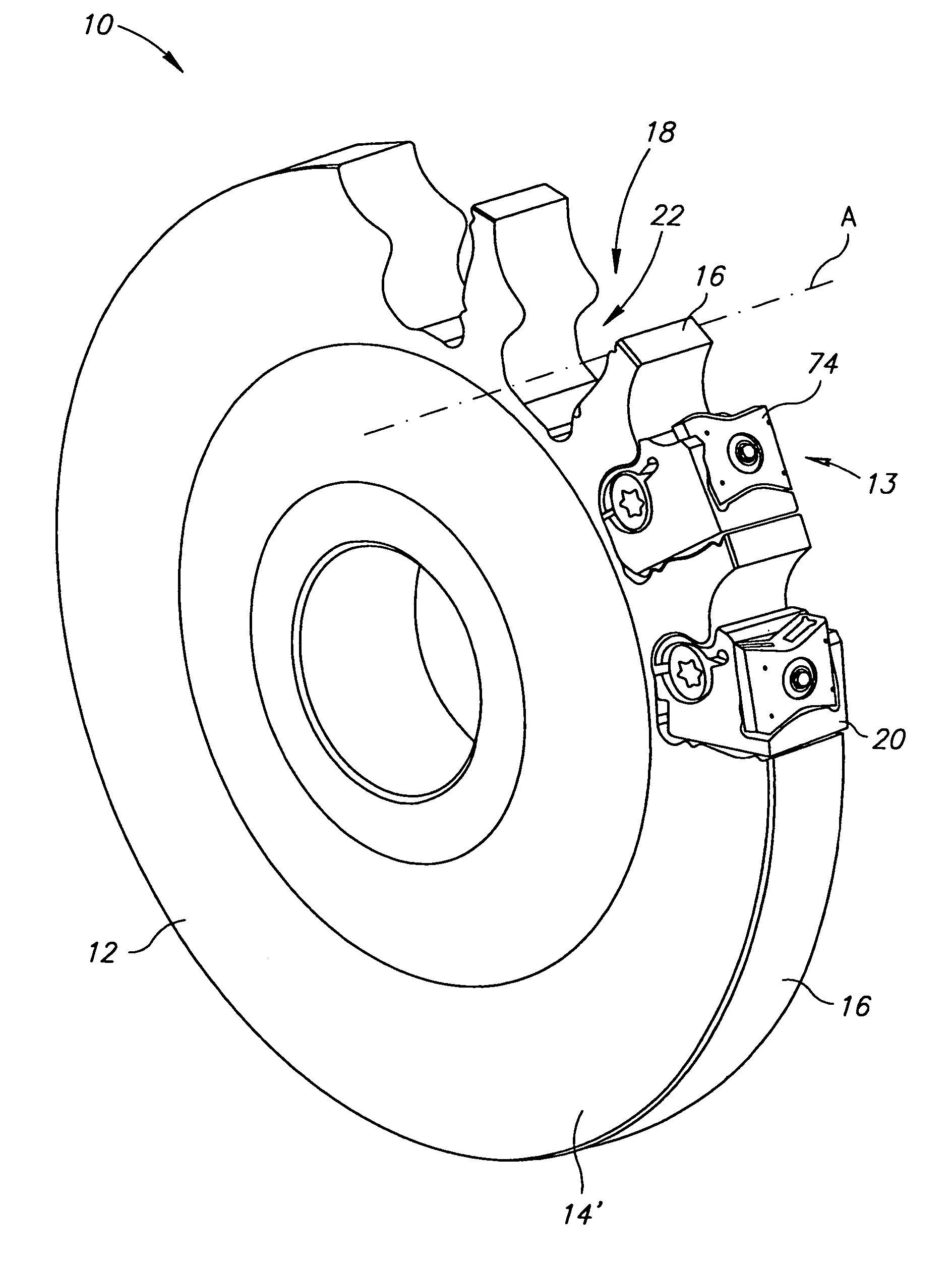

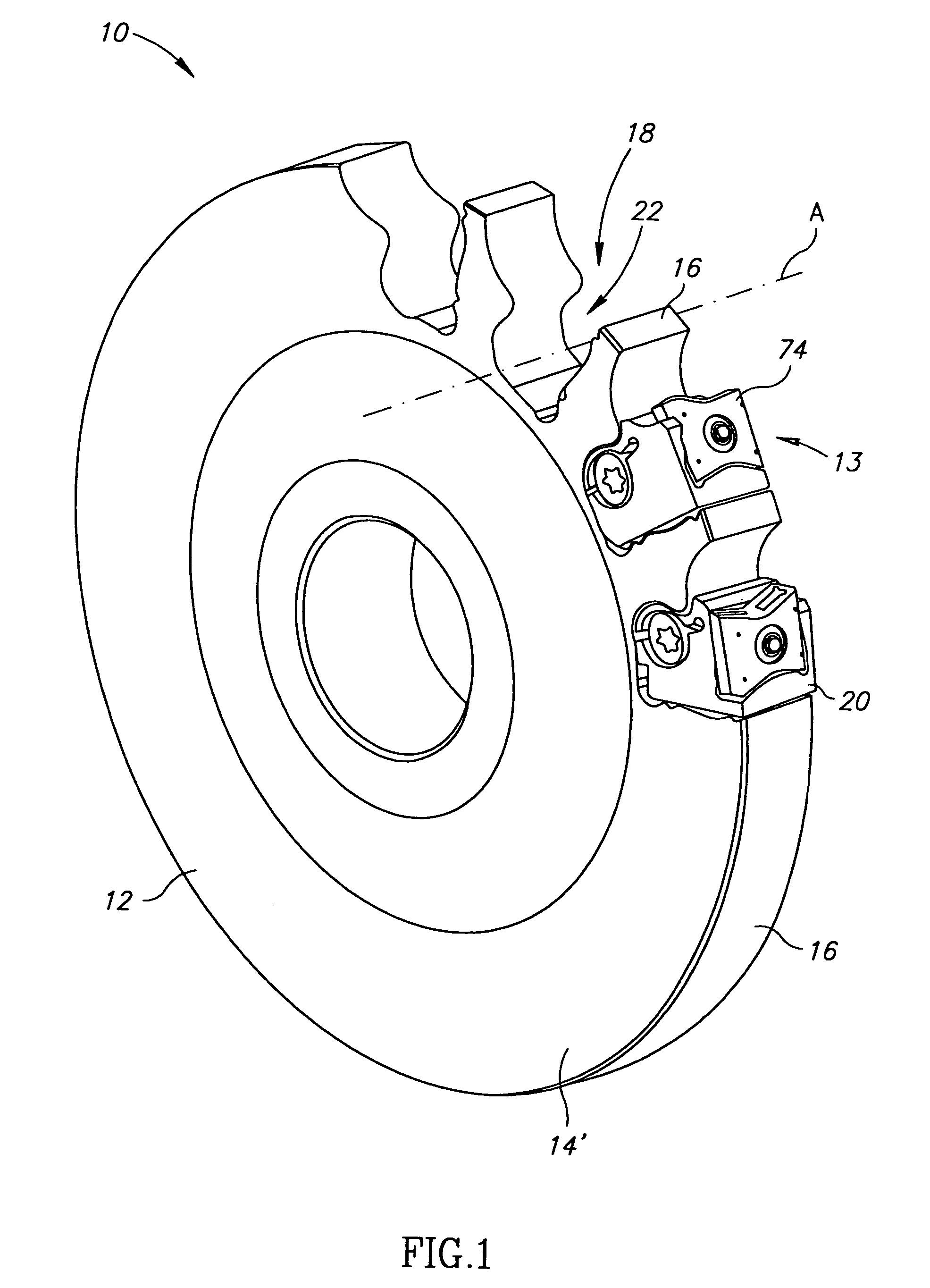

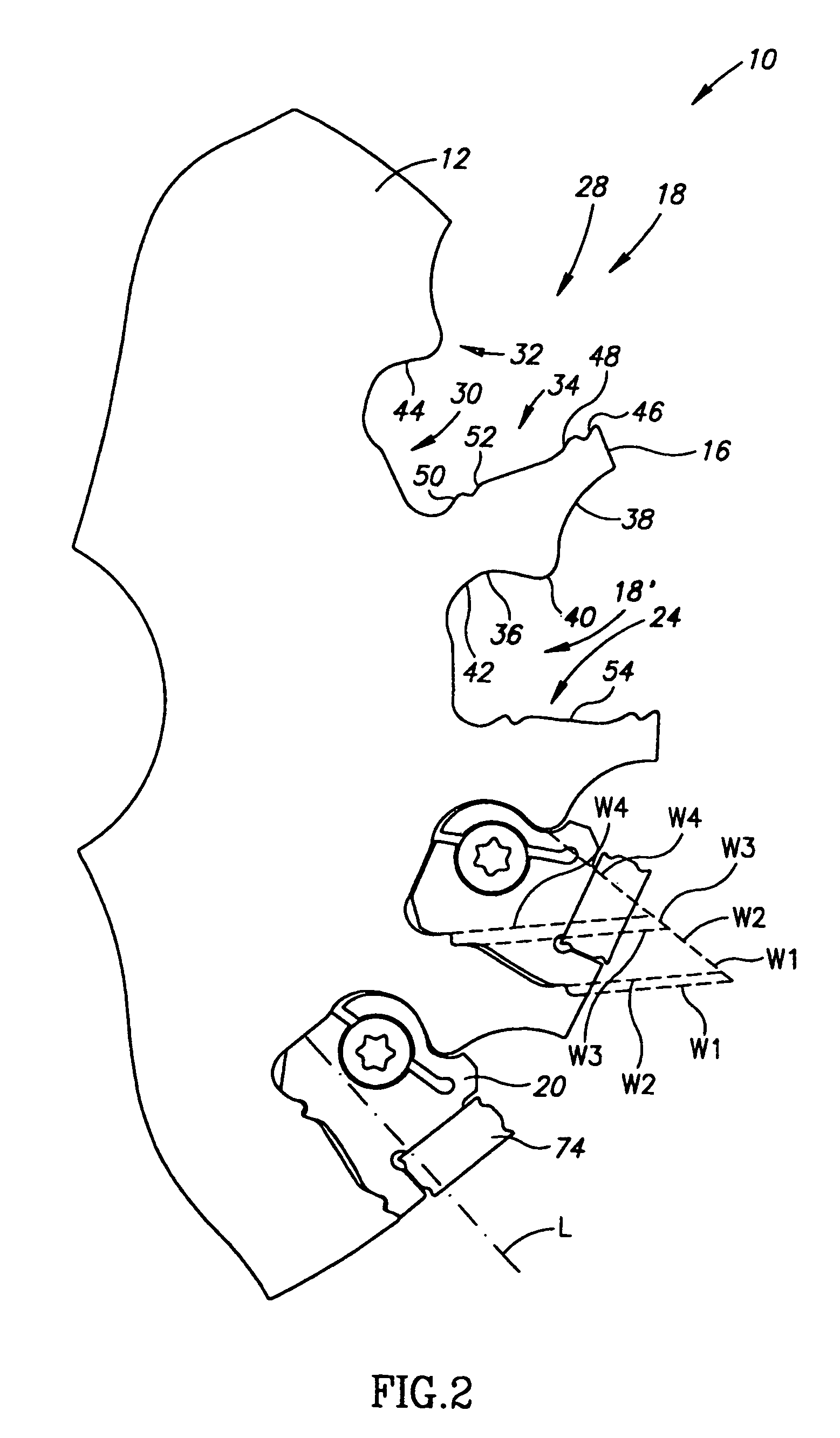

Cutting tool and cartridge therefor

A. cutting tool for metal cutting operations employing detachable cutting insert secured to cartridges. The cartridges have a clamping portion that is resiliently transformable between a normally non-expanded state and a biased expanded state by means of a clamping screw received in a through bore in the cartridge. The clamping portion is slidably insertable into the cartridge pocket when in the normally non-expanded state, and is securely retained in the cartridge pocket when in the biased expanded state.

Owner:ISCAR LTD

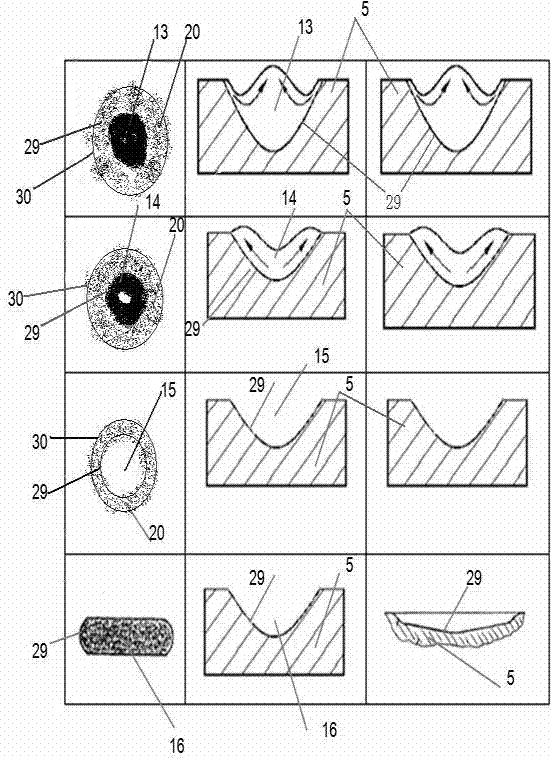

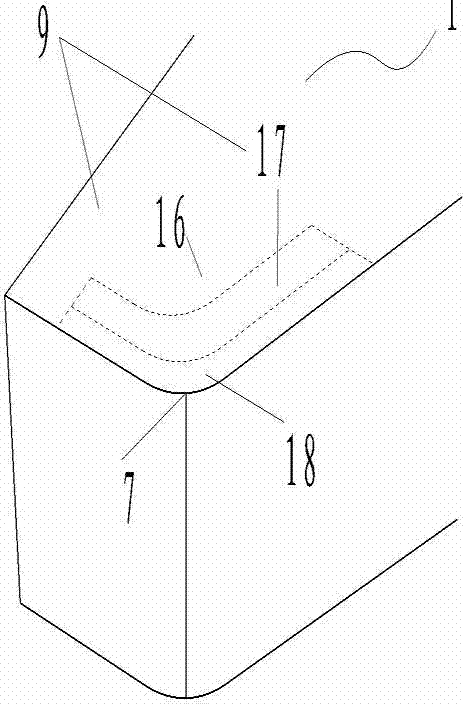

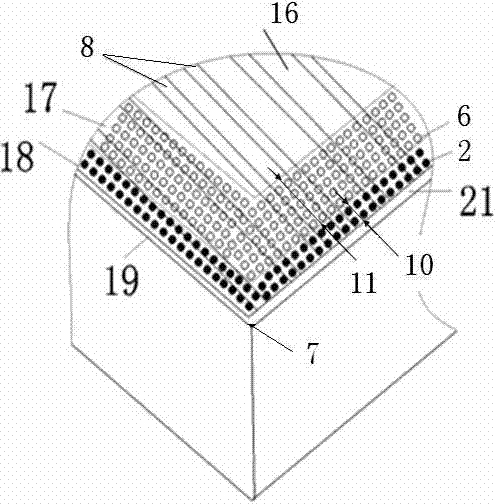

Compound model processing method and device for cutter

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

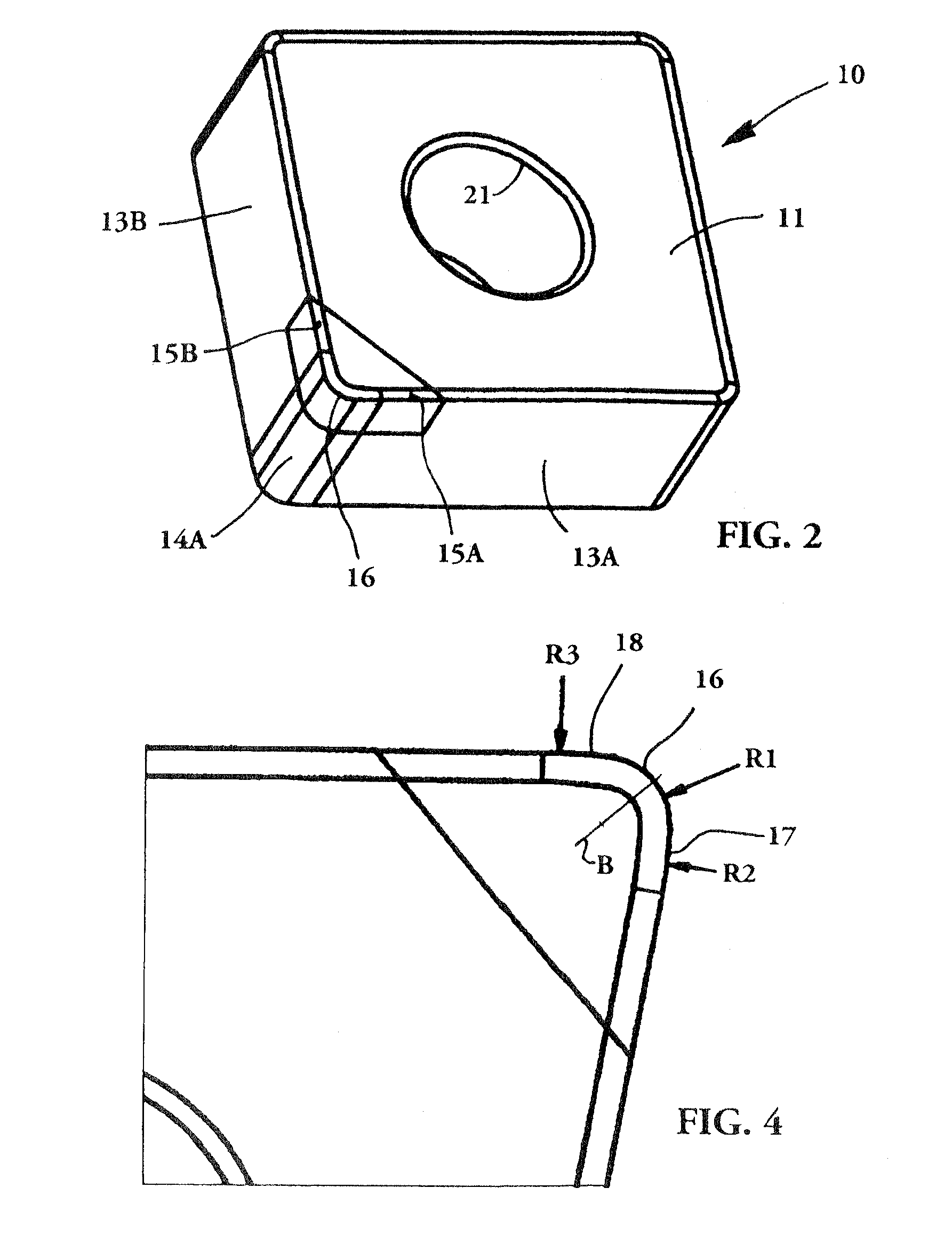

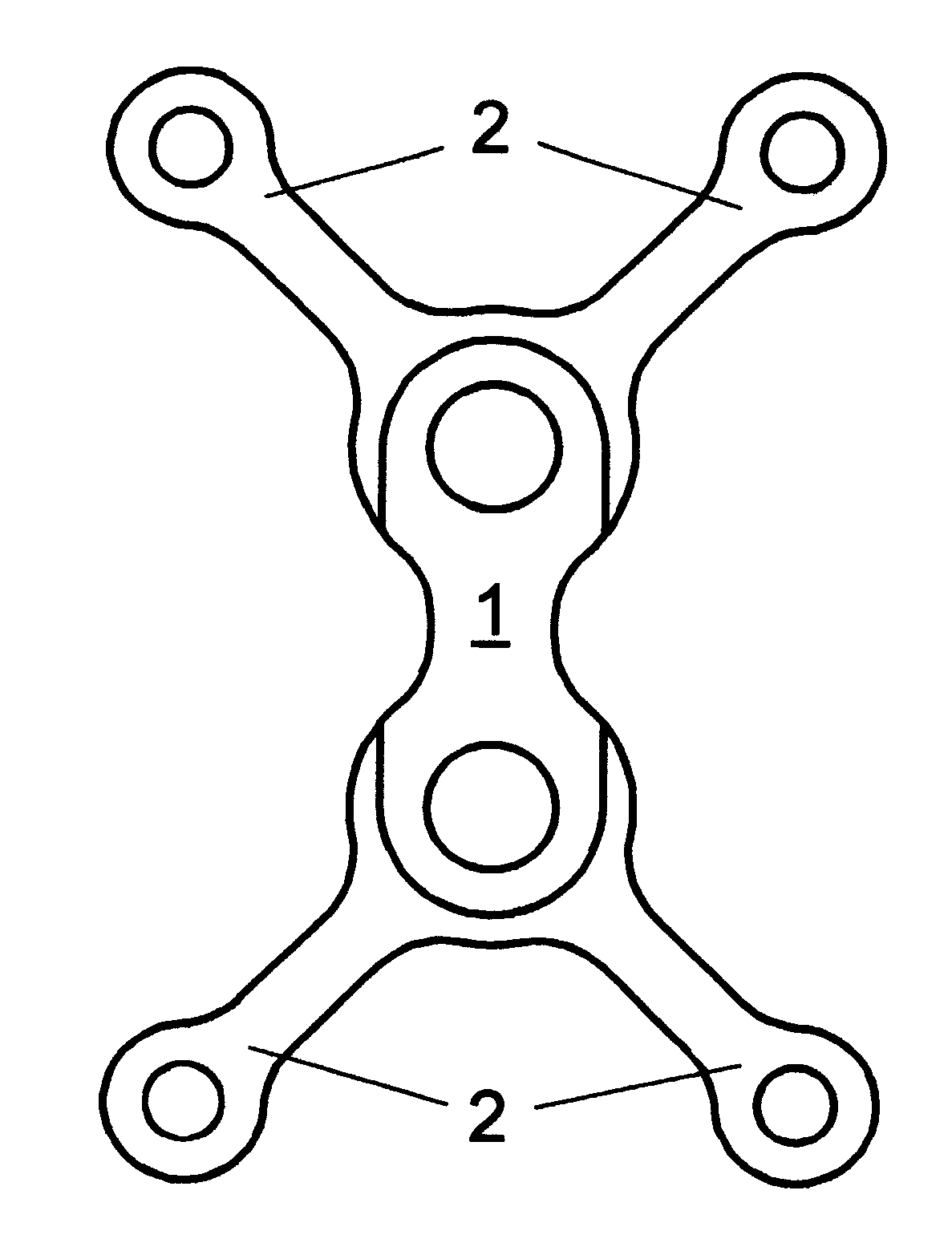

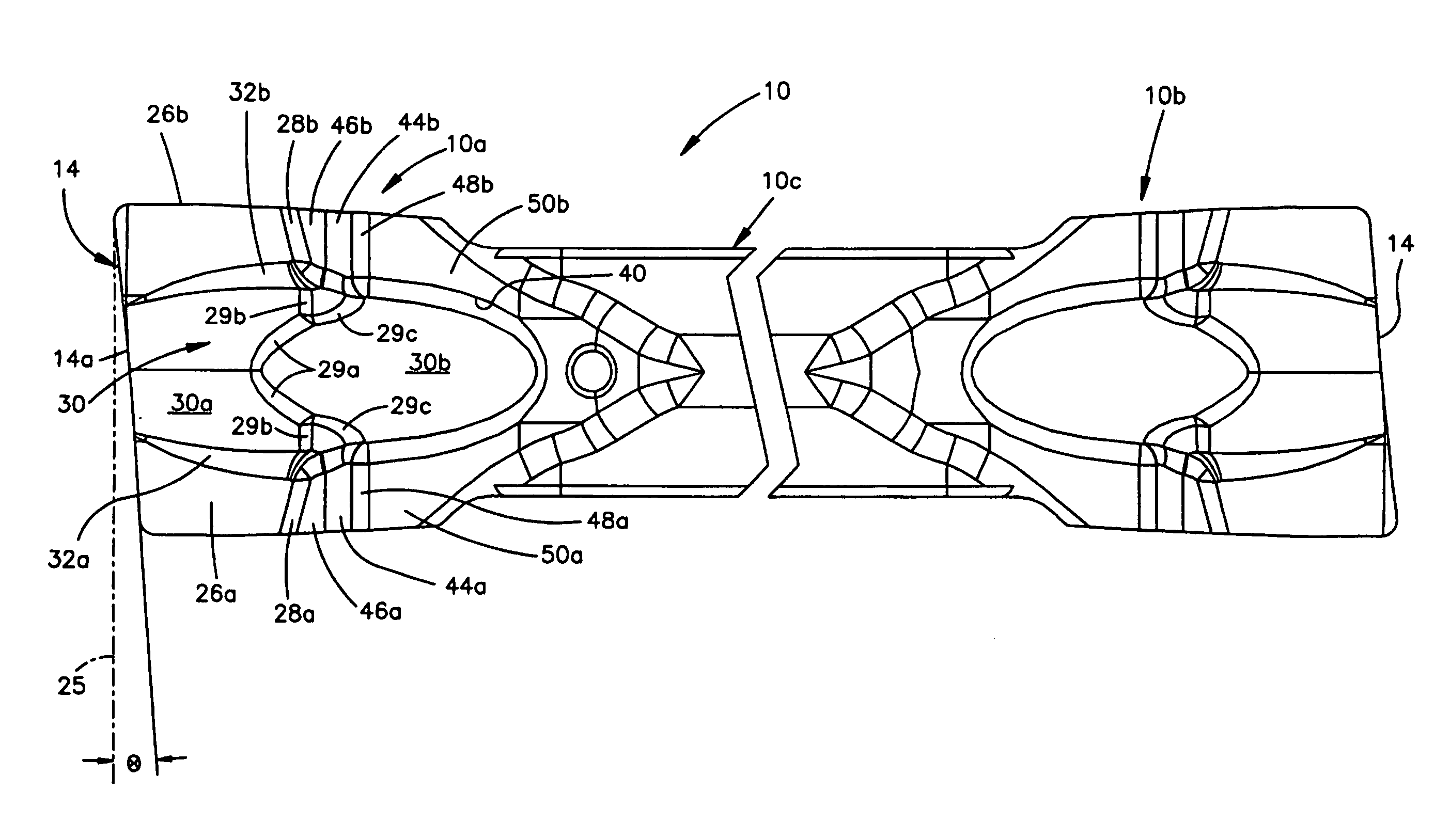

Tool holder and metal cutting insert with chip breaking surfaces

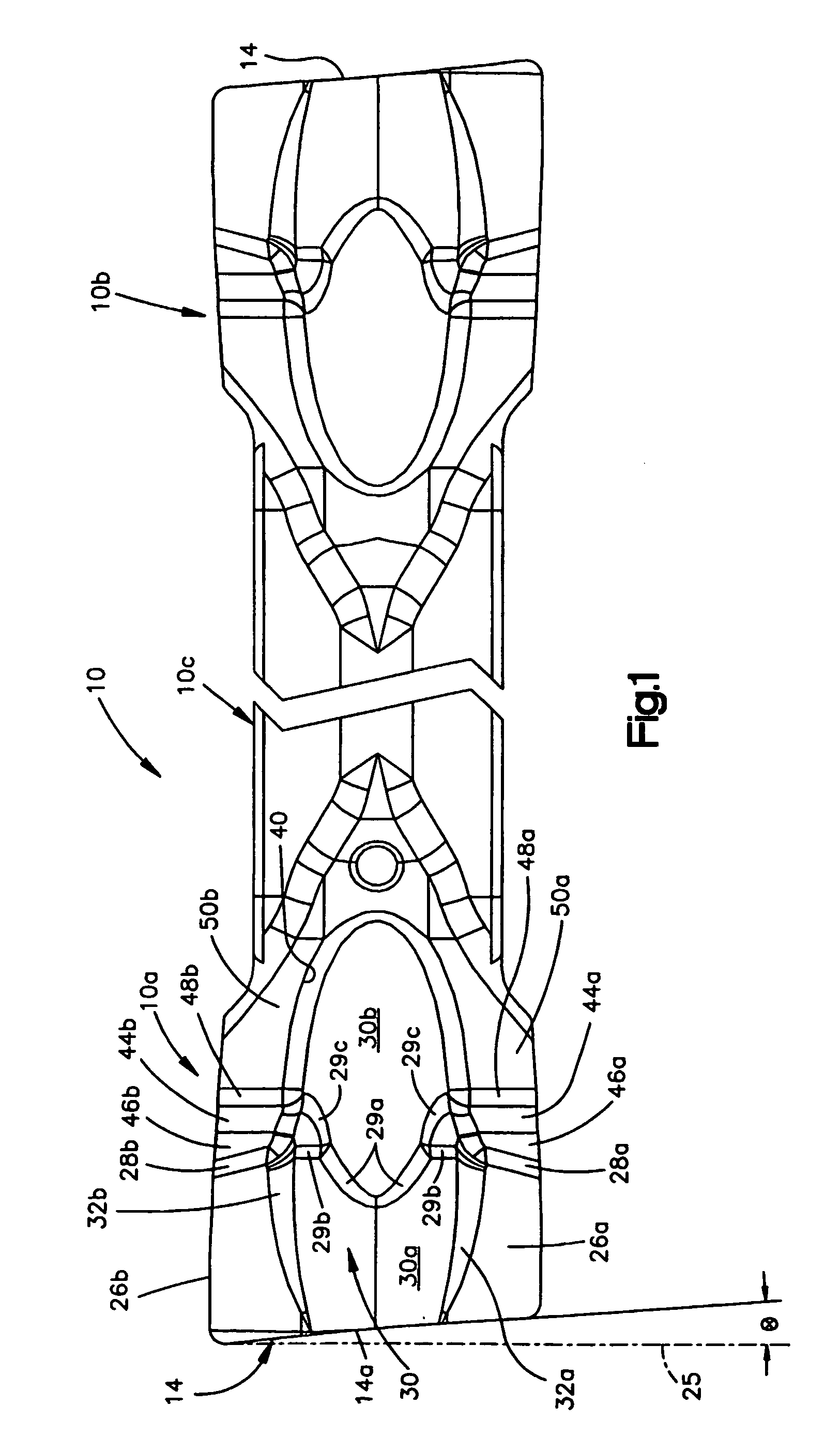

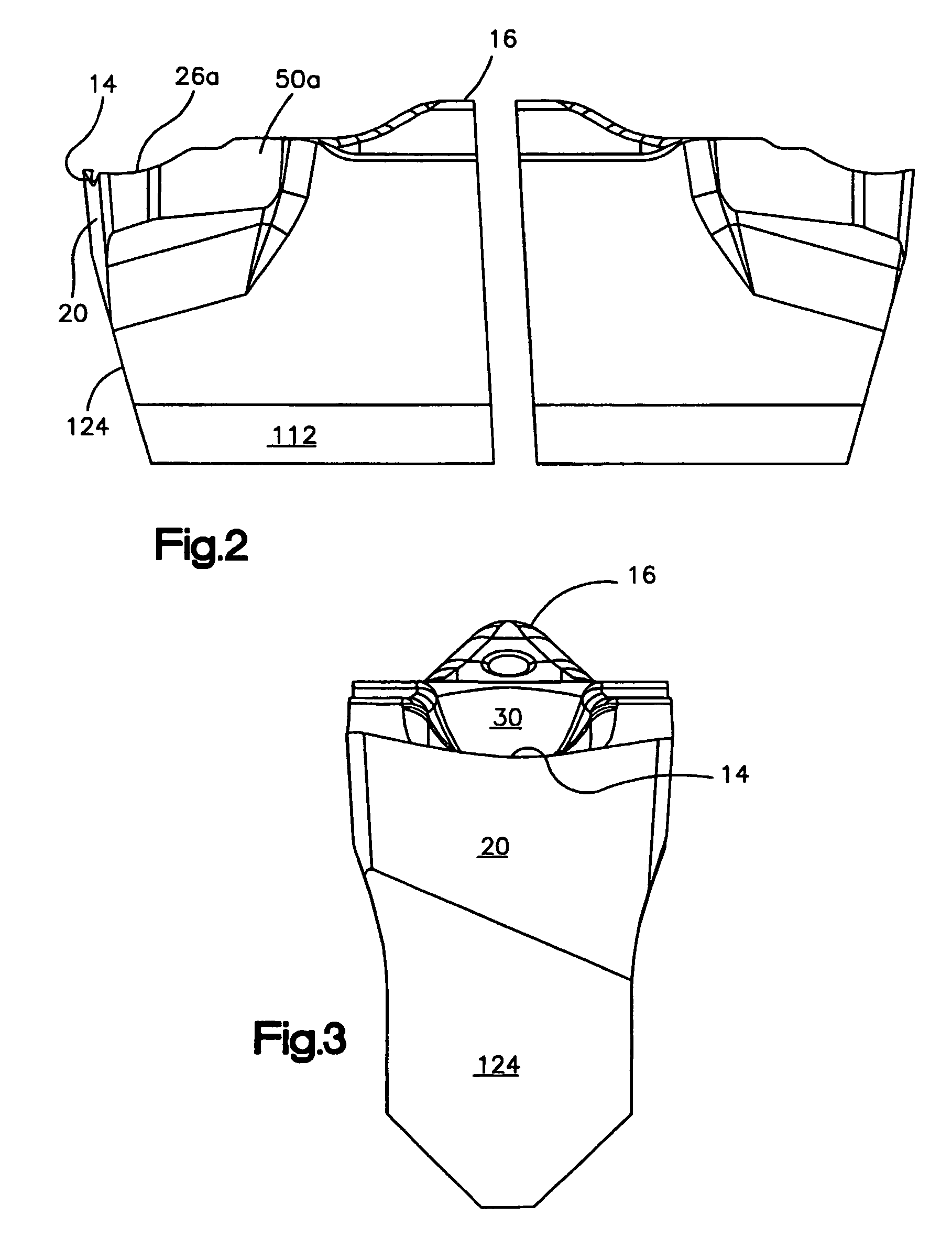

A metal cutting insert (10) having a pair of cutting portions (10a, 10b) disposed on either end of a shank portion (10c), each cutting portion having a front clearance face (20), the upper boundary of which defines a cutting edge (14). A pair of spaced apart chip breaking surfaces (26a, 26b, 28a, 28b) commence at or near the cutting edge and extend away from the cutting edge. A pair of secondary chip breaking surfaces (44a, 44b, 46a, 46b, 48a, 48b, 50a, 50b) are located downstream of the first chip breaking surfaces and are interconnected with associated first chip breaking surfaces by transition surfaces. A center channel (30) is located between the chip breaking surfaces and includes an entry portion (30a). A tool holder (100) includes a base (102) and clamping arm (104) which together define a gap (106) for receiving one of the cutting portions of the insert.

Owner:KENNAMETAL INC

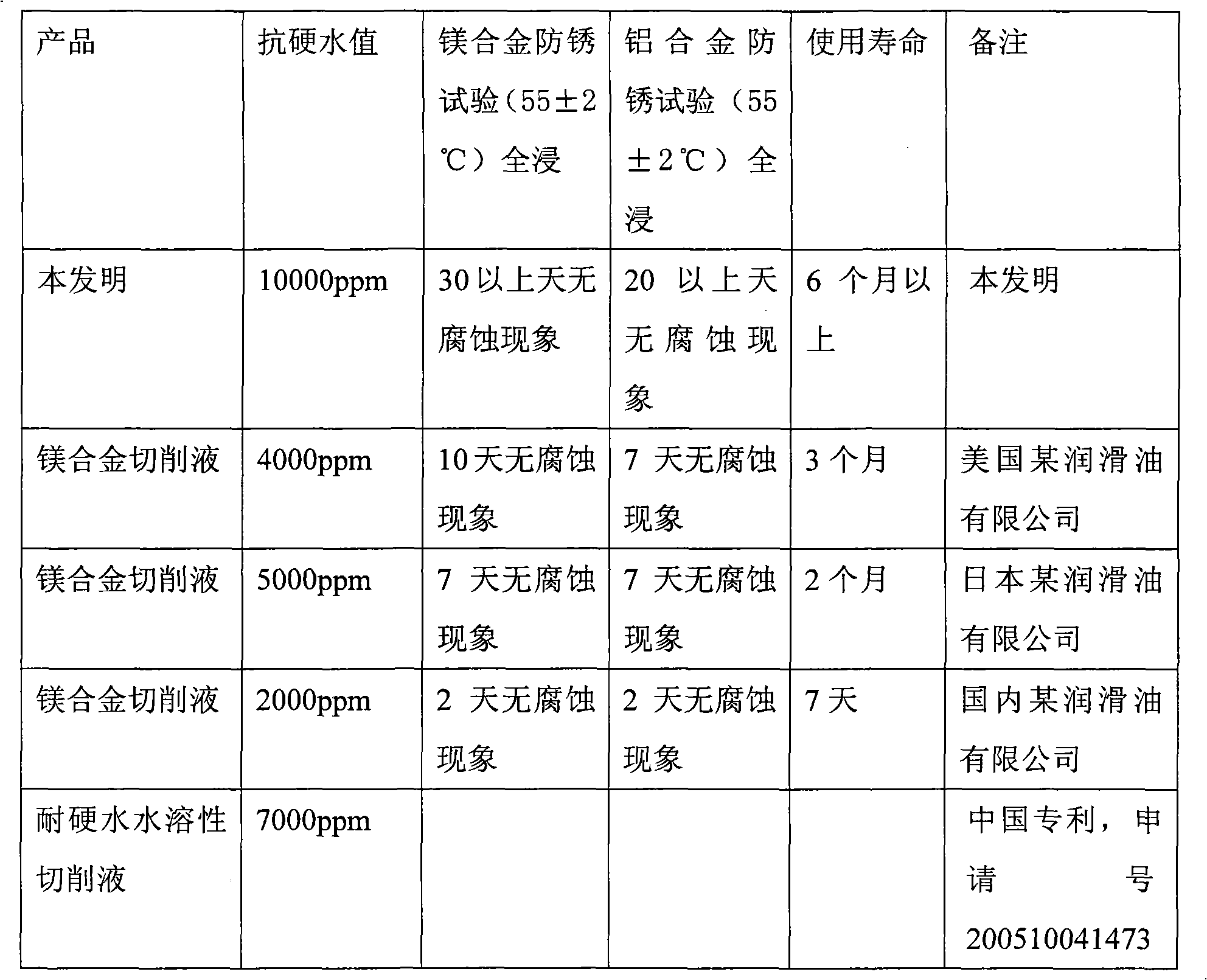

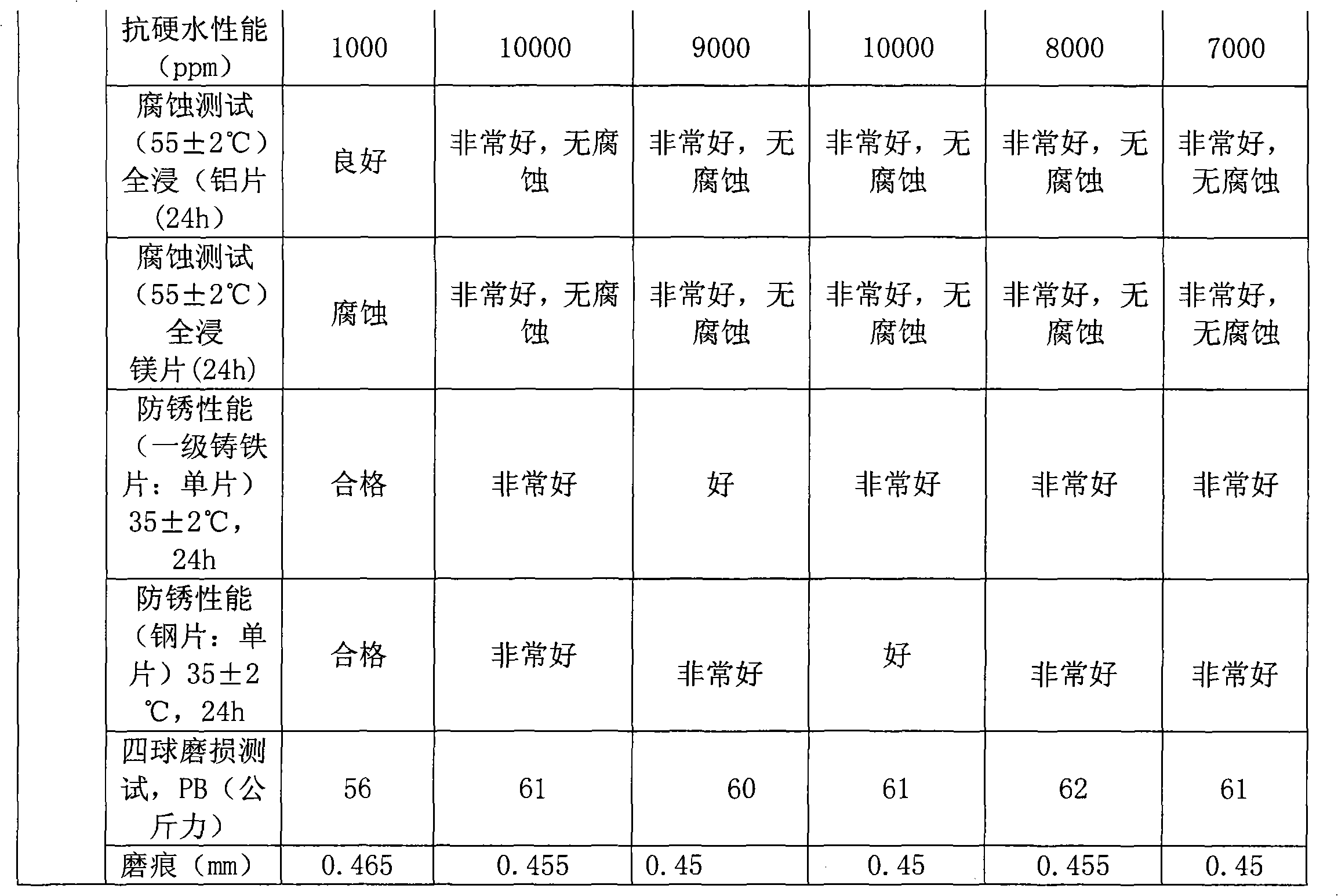

Magnesium alloy cutting liquid

ActiveCN101870909AImprove rust resistanceInhibition of hydrogen evolutionAdditivesColor changesCast iron

The invention relates to metal cutting liquid, in particular to magnesium alloy cutting liquid, which comprises basic oil, nonionic surfactants, anionic surfactants, antirust agents, lubricating agents, coupling agents, corrosion inhibitors and bactericide raw materials. The unique recipe in the invention has the advantages that magnesium alloy can no generate color change corrosion phenomena after being continuously soaked for more than 30 days at 55 DEG C in 5 percent diluent, the hydrogen release phenomenon of the magnesium alloy in water can be effectively inhabited, in addition, the hardwater resistance of the product is as high as 10000 ppm, and in addition, the work liquid can be used for more than half a year. At the same time, the invention has excellent performance such as rust prevention, lubrication, cooling and the like. In addition, the cutting liquid can be used for processing the magnesium alloy, and can also be used for processing metals such as aluminium alloy, cast iron, stainless steel and the like.

Owner:东莞太平洋博高润滑油有限公司

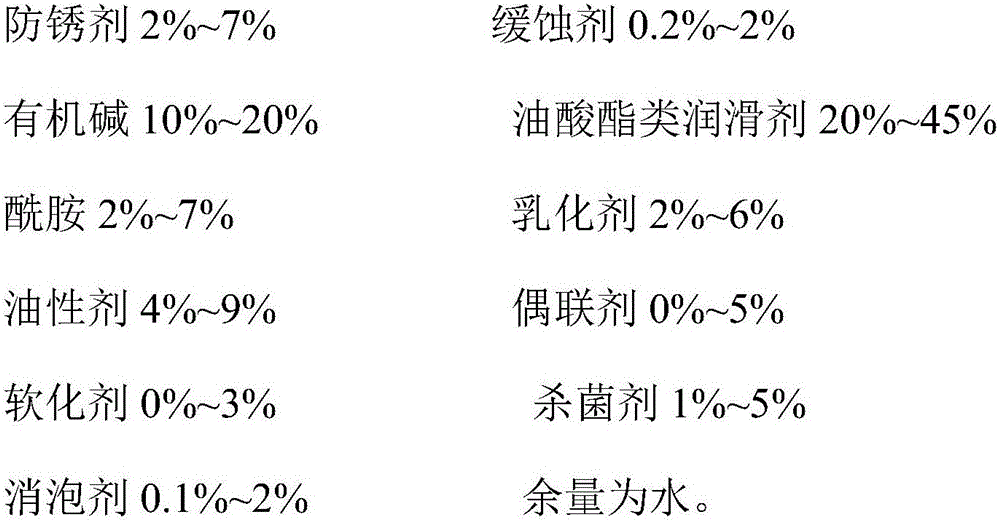

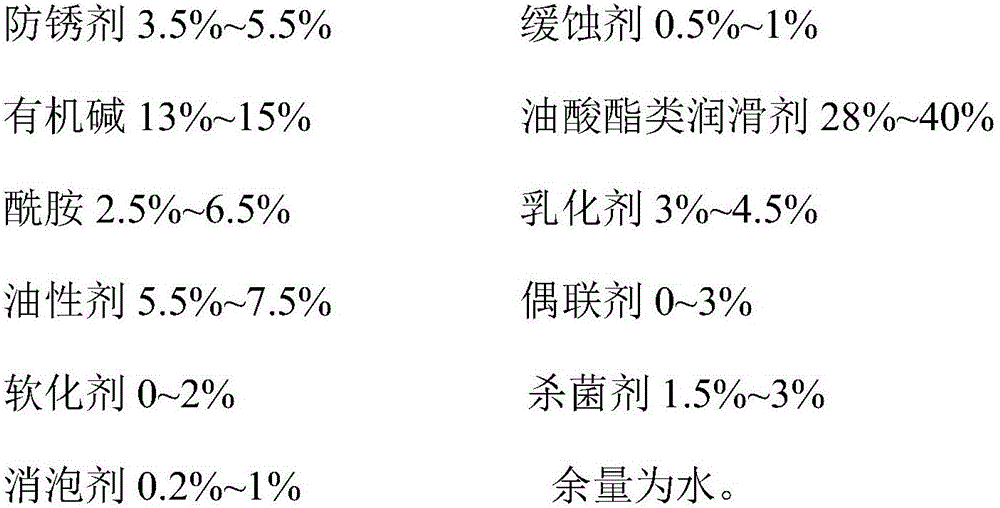

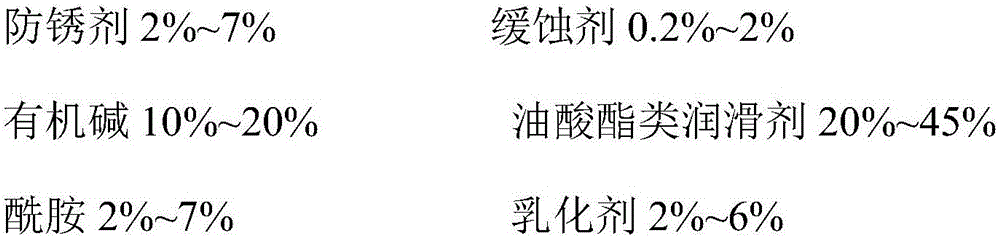

Water-based metal cutting liquid

InactiveCN106479654AGood compatibilityStrong synergistic functionLubricant compositionWater basedSulfur

The invention discloses a water-based metal cutting liquid. The water-based metal cutting liquid is prepared from raw materials in percentage by mass as follows: 2%-7% of an antirust agent, 0.2%-2% of a corrosion inhibitor, 10%-20% of organic alkali, 20%-45% of an oleate lubricant, 2%-7% of amide, 2%-6% of an emulsifier, 4%-9% of an oiliness agent, 0%-5% of a coupling agent, 0%-3% of a softener, 1%-5% of a sterilizing agent, 0.1%-2% of a defoaming agent and the balance of water. The water-based metal cutting liquid provided by the invention contains no sulfur, phosphorus, chlorine or boric acid and is efficient, environment-friendly and recyclable.

Owner:深圳市宏达威表面处理技术有限公司

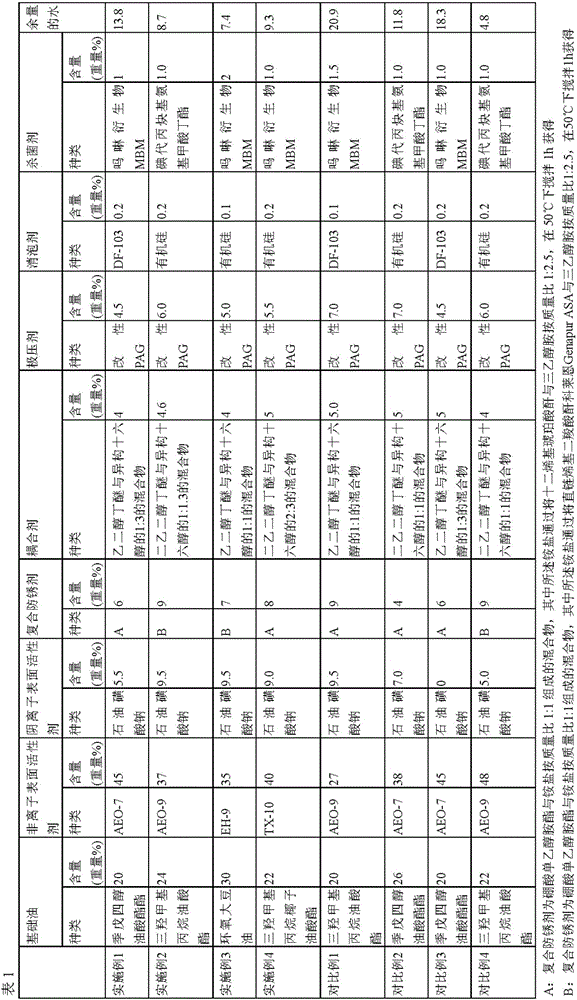

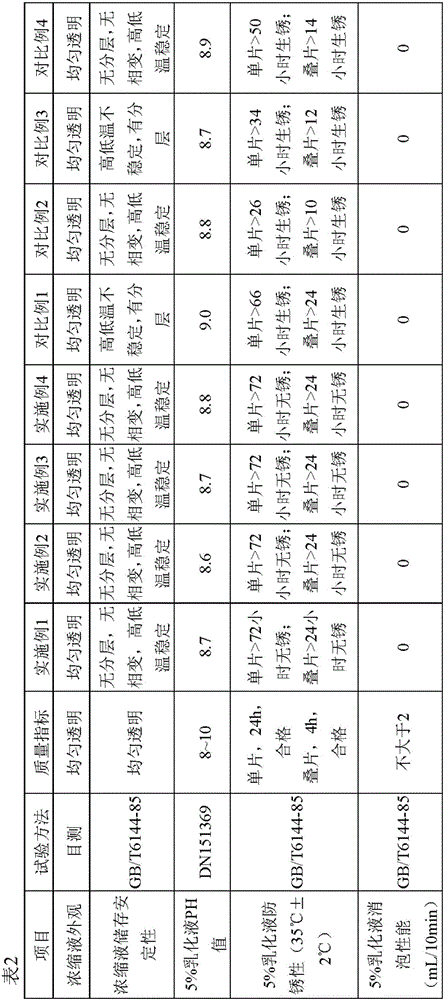

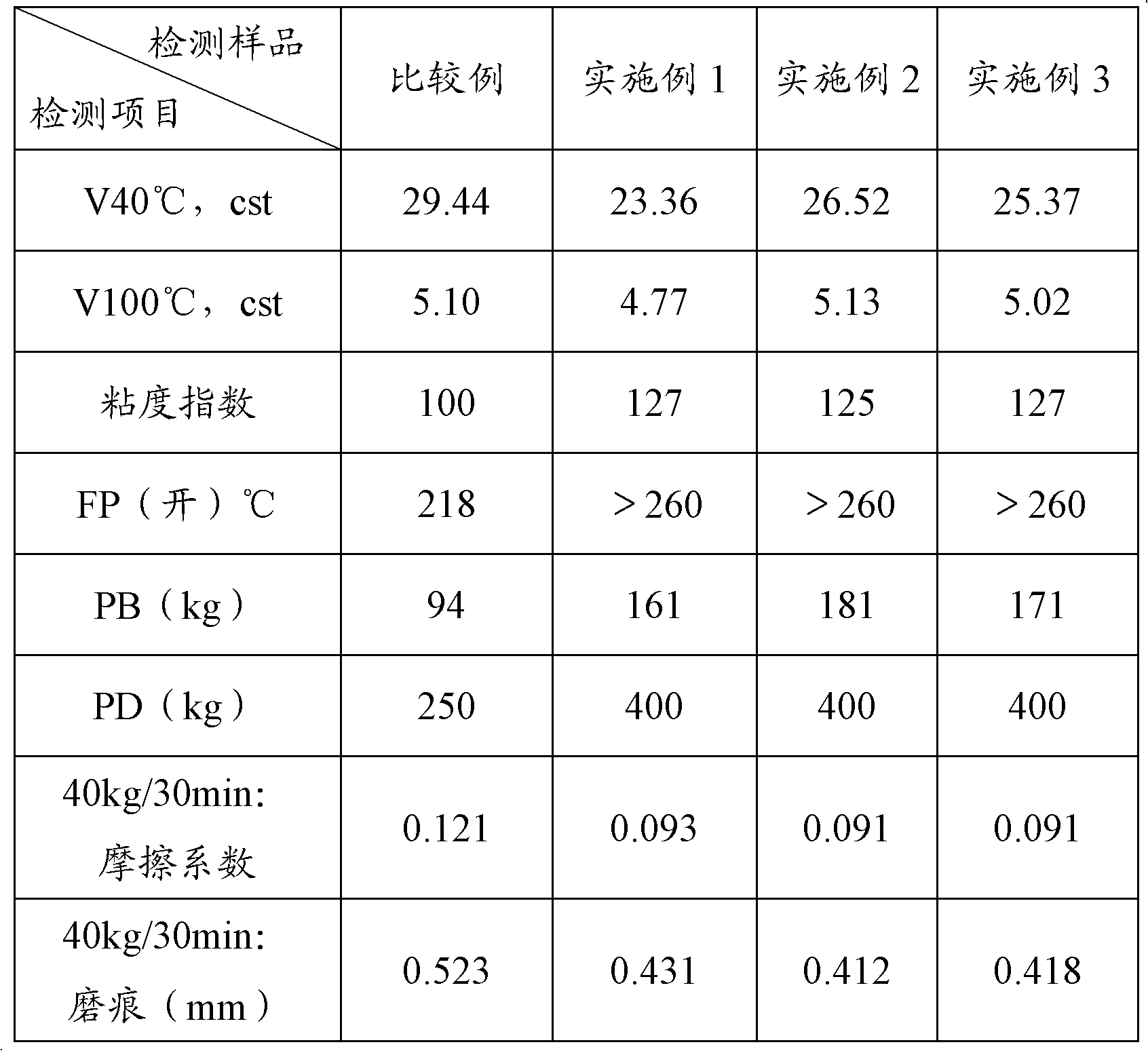

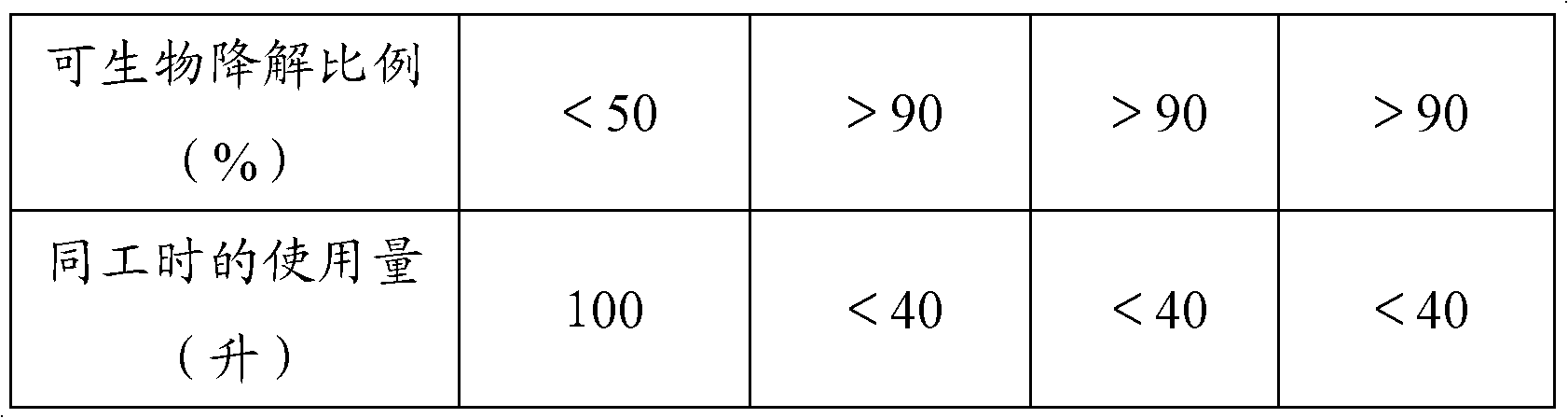

Environment-friendly metal cutting liquid and preparing method thereof

The invention relates to environment-friendly metal cutting liquid and a preparing method thereof. The environment-friendly metal cutting liquid contains, by weight, 18-30% of base oil, 30-45% of non-ionic surfactant, 5.0-10.0% of anionic surfactant, 6-11% of composite antirust agent, 3.6-5% of coupling agent, 4.5-7% of extreme pressure agent, 0.1-0.2% of defoamer, 0.8-2.5% of bactericide and the balance water. The environment-friendly metal cutting liquid does not contain nitrite, heavy metal or toxic solvent and is an environment-friendly product, has excellent cleaning ability, anti-rust property, emulsion stability and defoaming property and has unique advantages in lubrication and bacteriostasis, and liquid waste is easy to treat and can be treated like general industrial wastewater after demulsification.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Metal cutting solution of green semi-synthesis double-base oil and preparation method thereof

InactiveCN101531946ASuitable for cuttingSuitable for grindingBase-materialsFoaming agentActive agent

The invention relates to a metal cutting solution of green semi-synthesis double-base oil, which comprises the following components in percentage by weight: 0 to 30 percent of mineral oil, 0 to 30 percent of synthetic ester, 5 to 10 percent of anionic surfactant, 5 to 10 percent of non-ionic surfactant, 5 to 15 percent of anti-rust agent, 0 to 15 percent of extreme pressure agent, 1 to 3 percent of de-foaming agent and 0 to 2 percent of bactericide, and the balance being water. A preparation method for the metal cutting solution comprises the following steps: firstly, heating the mineral oil to about 50 DEG C, adding the synthetic ester into the mineral oil, and stirring the mixture evenly to form a double-base oil system; and then adding the anti-rust agent, the extreme pressure agent, the de-foaming agent and the bactericide into the water respectively, and using the anionic surfactant and the non-ionic surfactant to regulate the system to balance so as to form the metal cutting solution of the green semi-synthesis double-base oil. Because the synthetic ester is added in the preparation process to form the double-base oil system, the biodegradability, oxidative stability and flash point are improved; and the method meets the requirement of environmental protection, and is applicable to cutting, grinding and processing various mechanical parts.

Owner:SHANGHAI INST OF TECH

Multi-chip facet cutting saw blade and related method

ActiveUS7131365B2Improved blade life and straightness of cutHigh rateMetal sawing devicesMetal sawing toolsAcute angleKnife blades

A metal cutting band saw blade has a plurality of cutting teeth defining a cutting direction, and a repeating tooth pattern of between 3 and 7 teeth. Each tooth defines a laterally-extending upper surface having a width and a height with respect to the back edge of the blade, and side surfaces extending laterally and downwardly on opposite sides of the upper surface relative to each other at acute angles relative to the upper surface. The teeth located rearwardly of the first tooth with respect to the cutting direction of the saw blade define progressively lower heights and progressively smaller acute angles of the side surfaces, and the widths of the upper surfaces of these teeth are greater than the width of the upper surface of the respective first tooth.

Owner:BLACK & DECKER INC

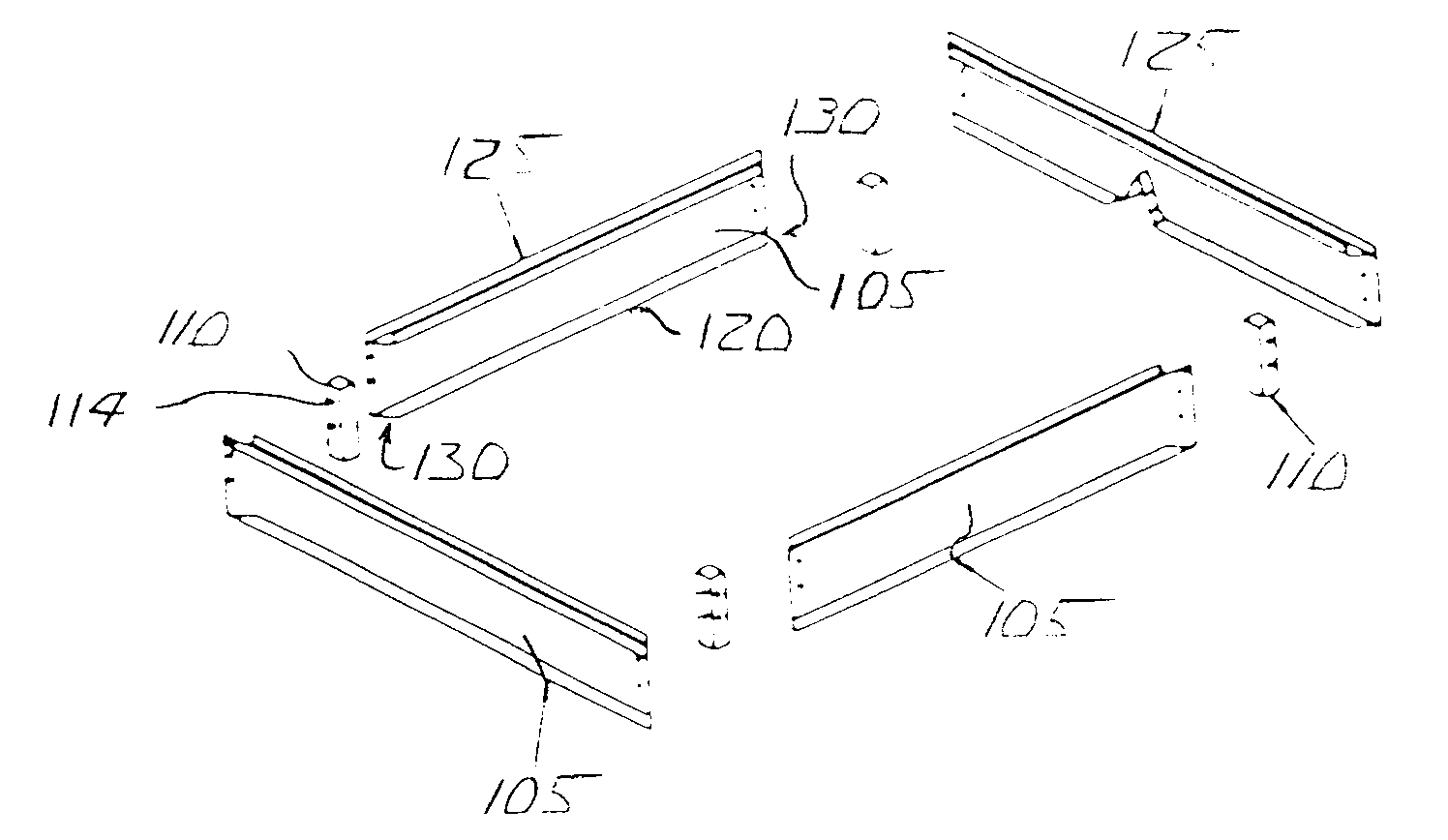

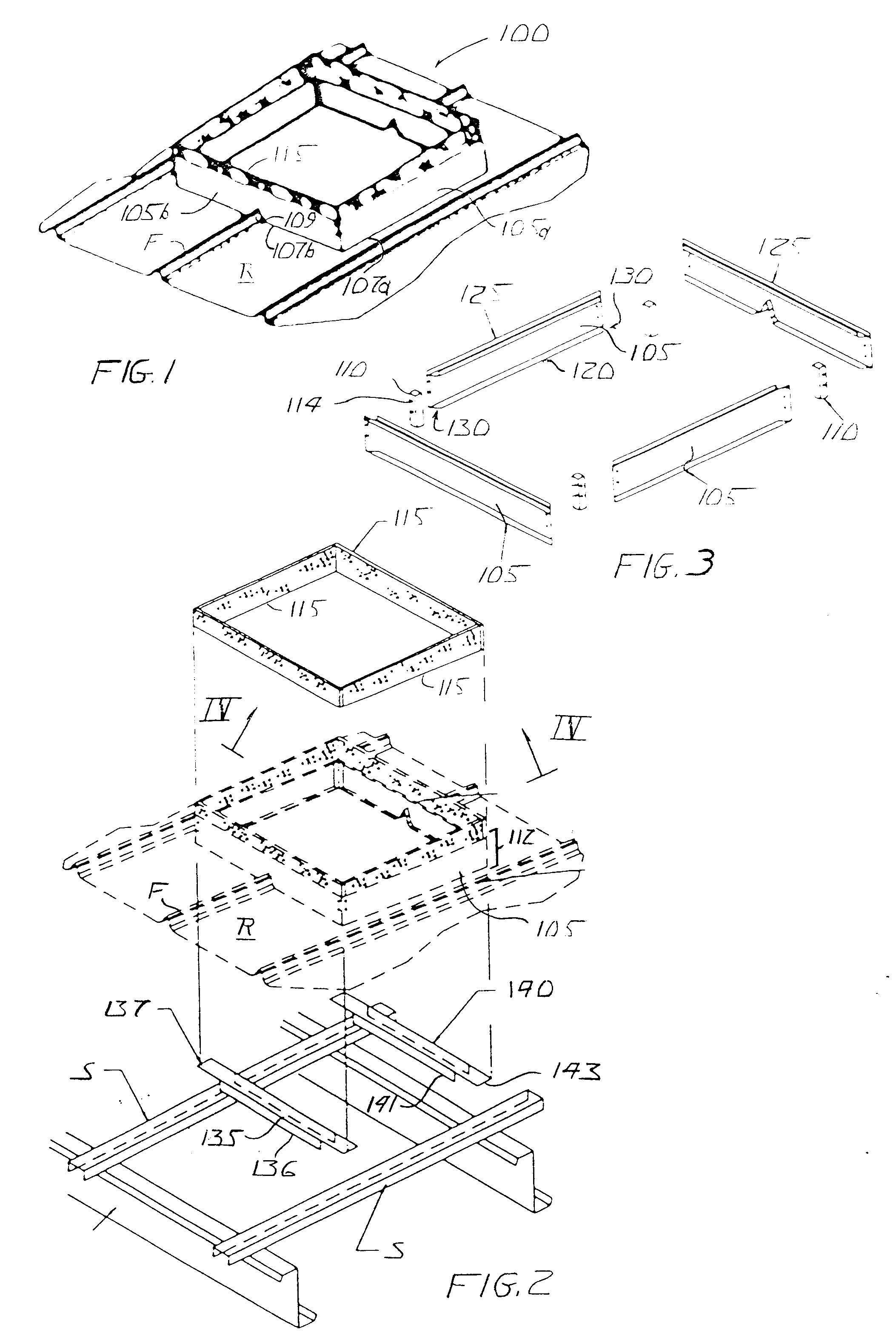

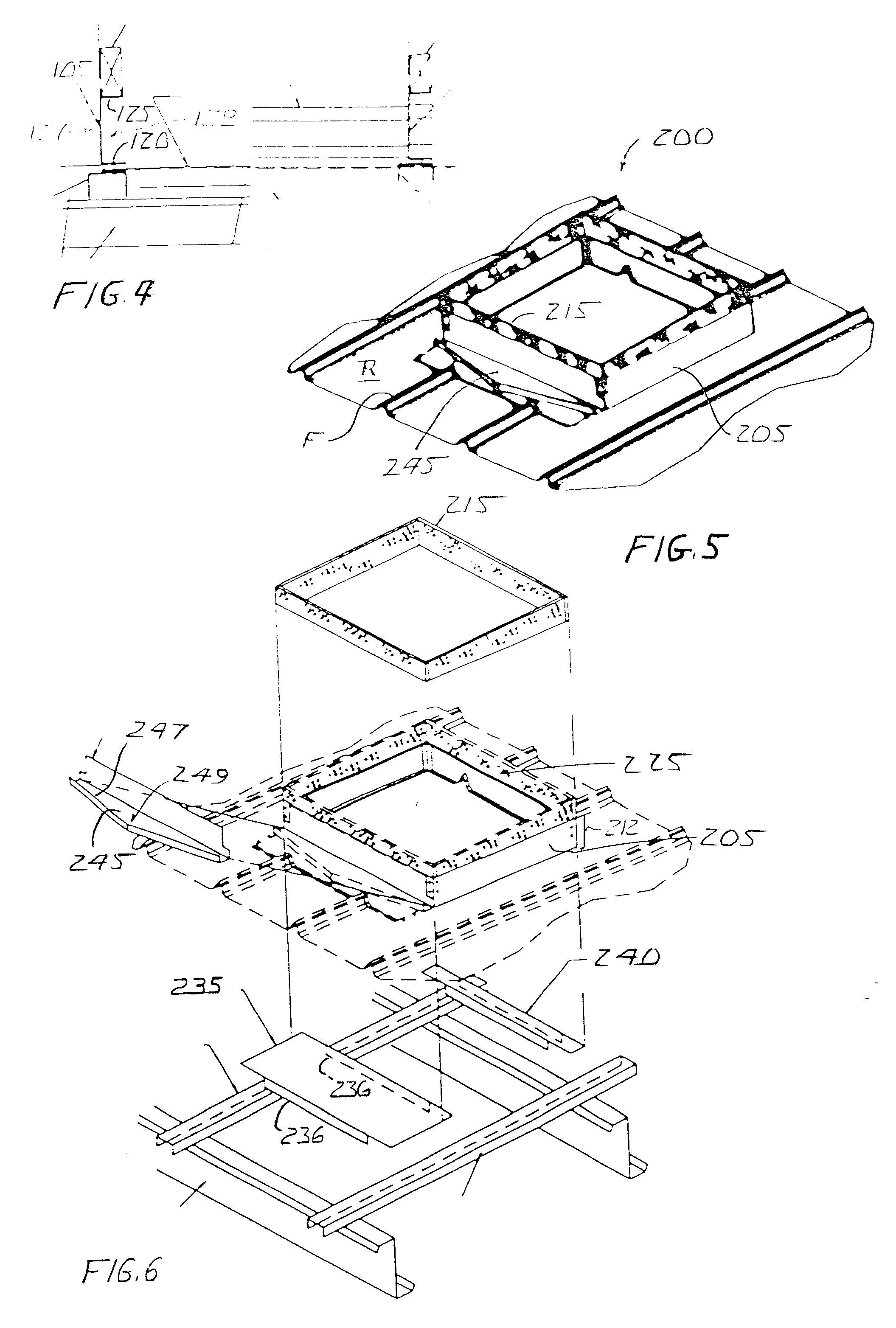

Knock-Down Roof Curb

InactiveUS20070094984A1Inexpensive, dependable and effectiveBuilding roofsRoof coveringStructural engineeringMetal cutting

A roof curb is shipped in a disassembled state to an installer who assembles, sizes, locates and configures the curb to accommodate slope on any roof without welding or metal cutting. The curb includes an aluminum walls, each having a channel for receiving the bottom edge of a board, which may be taper cut according to the pitch of the roof to provide a level surface for supporting an appliance. Methods of making and installing the roof curb also are disclosed.

Owner:BLUESCOPE BUILDINGS NORTH AMERICA

Boring bar having internal coolant supply and cutter retaining nozzle

InactiveUS20070286689A1Minimizes heat induced wearMinimizes deteriorationCutting insertsTurning toolsCoolant flowEngineering

A boring bar has a shank having a cutter support head at one end. A flow passage extends longitudinally through the shank to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp member defines at least one coolant fluid flow passage having a discharge opening or openings each located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The clamp screw defines an internal passage that communicates with the transverse coolant fluid flow passage and conducts coolant fluid onto the metal cutting insert. Alternatively, an annular clearance is defined about the shank of the clamp screw and serves as a coolant flow passage which is in fluid communication with the internal coolant fluid discharge passage or passages of the clamp member.

Owner:GIANNETTI ENRICO R

Cutting oil and preparation method thereof

InactiveCN102031190AImprove low temperature performanceImprove filtering effectBase-materialsEcological environmentEnvironmental index

The invention provides environmentally-friendly efficient atomization cutting oil, which comprises the following components in percentage by weight: 20 to 40 percent of synthetic ester, 60 to 80 percent of vegetable oil, 0 to 3 percent of antioxidant, 0 to 2 percent of anti-rusting agent, 0 to 5 percent of extreme pressure abrasion-resistant agent and 0 to 1 percent of metal passivator. The synthetic ester and the vegetable oil are matched and used base oil, so the cutting oil has the advantages of good lubricating property and biodegradability, resource recycle, no toxicity and the like, has low toxin and low harm to the human body and the ecological environment, meets the requirements of related environmental indexes, has good low-temperature performance and oxidation stability and strong universality, is suitable for metal cutting and processing of most materials, is particularly special cutting oil for modern advanced semi-dry and trace lubrication processing and development, and is mainly used for oil mist lubrication; and the gas and liquid two-phase oil mist can play a role in lubricating, take away a large amount of heat, reduce the consumption of cutting fluid, lower the cost and reduce the discharge of waste solution, and is favorable for environmental protection.

Owner:东莞太平洋博高润滑油有限公司

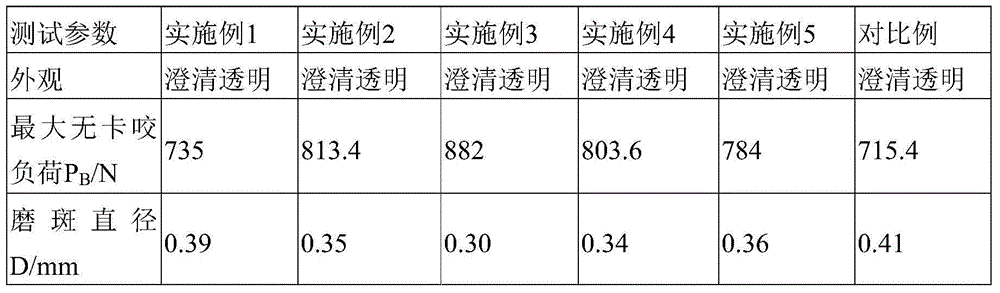

Metal cutting fluid containing graphene dispersion solution and preparation method thereof

The invention relates to a metal cutting fluid containing a graphene dispersion solution and a preparation method thereof. The metal cutting fluid is composed of the following raw materials: 0.2-2.0% of lubricating additive, 5-7% of rust inhibitor, 0.2-0.5% of corrosion inhibitor, 0.05-0.15% of hard water resisting agent, 15-20% of lubricant and the balance of water. The lubricating additive is the graphene dispersion solution. The metal cutting fluid has favorable lubricating property and antirust property; by using the water base as the carrier, the metal cutting fluid is free of base oil; and the production process has the advantages of low energy consumption and low production cost, and is simple to operate.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

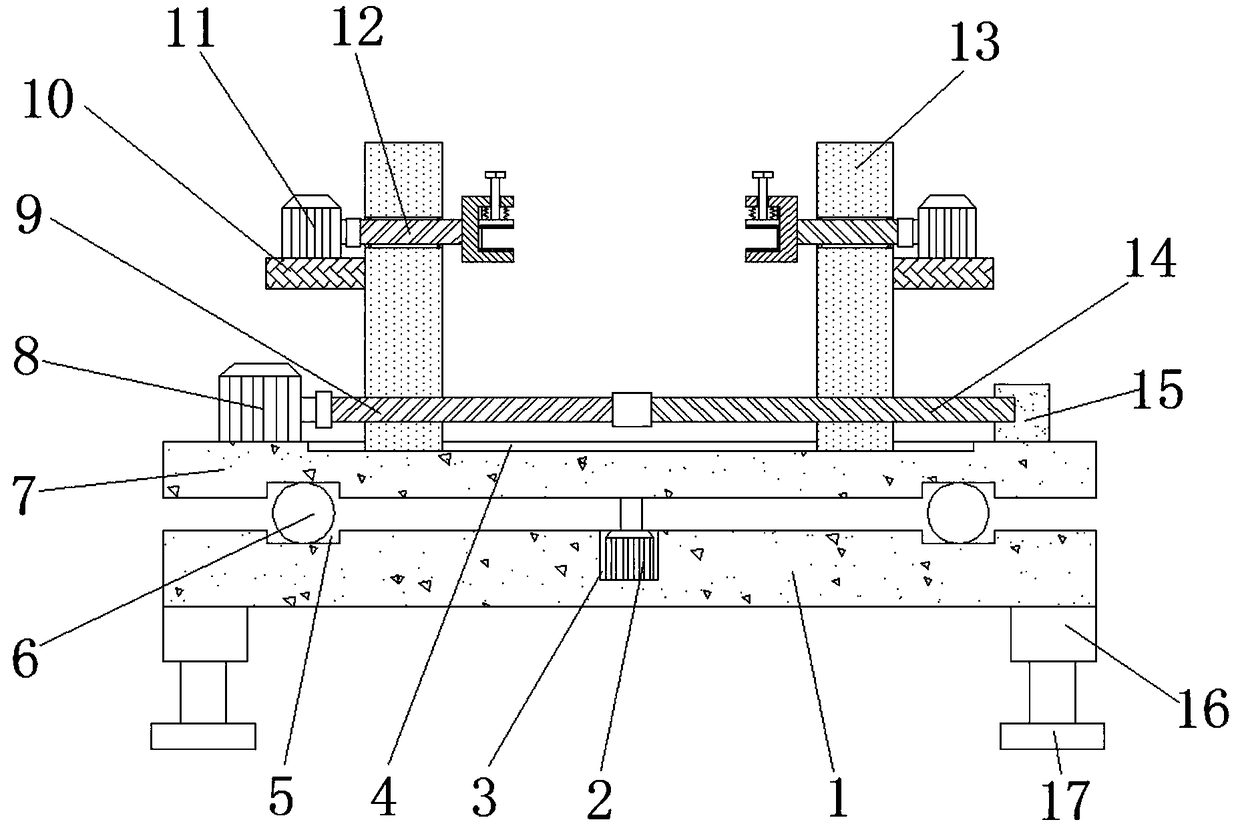

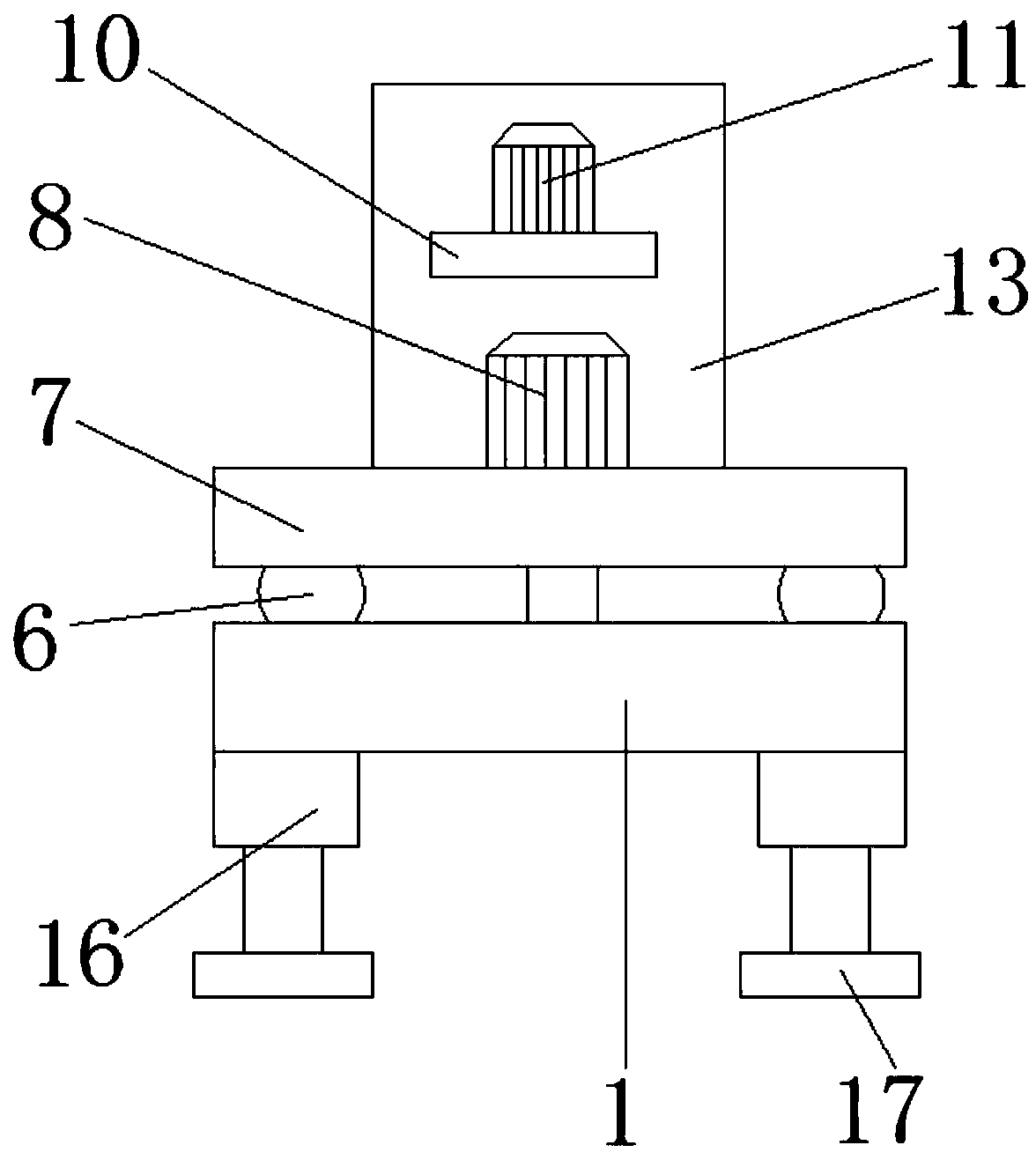

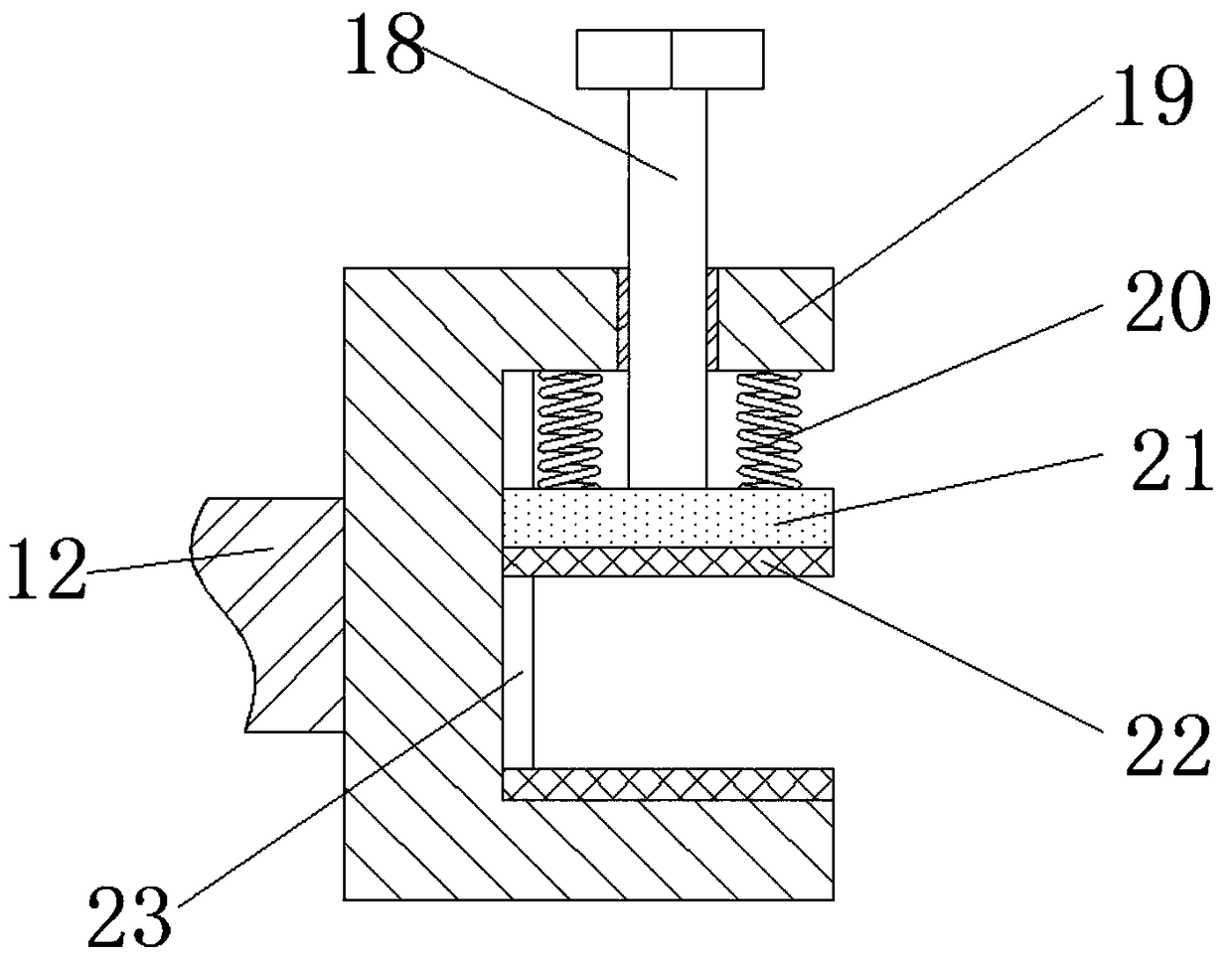

Metal piece clamping device for metal cutting machine tool machining

InactiveCN108655782AEasy to holdIncrease flexibilityLarge fixed membersPositioning apparatusHydraulic cylinderEngineering

The invention discloses a metal piece clamping device for metal cutting machine tool machining. A base and a rotating table are included, and the dead corners of the bottom outer wall of the base areeach fixedly provided with a hydraulic cylinder through a screw; the outer walls of the sides, away from the base, of the four hydraulic cylinders are each fixedly provided with a supporting leg through a screw; the center axis position of the top outer wall of the base is provided with an installing groove; the inner wall of the bottom of the installing groove is fixedly provided with a first servo motor through a screw; an output shaft of the first servo motor is fixed to the center axis position of the bottom outer wall of the rotating table through a screw; the outer walls of the oppositesides of the base and the rotating table are each provided with an annular groove; and the inner walls of the two annular grooves are connected with same rolling balls in an equal-distance uniform rolling manner. According to the metal piece clamping device for metal cutting machine tool machining, the height and the angle of the device can be adjusted, so that the device conveniently clamp metalpieces, and the distance between two adjusting blocks can be adjusted according to the size of the metal pieces so that the device can be used for clamping the metal pieces in different sizes.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

Semi-synthetic metal cutting fluid

InactiveCN104830513AImprove cooling effectGood anti-corrosion and anti-rustAdditivesCarboxylic saltEngineering

The invention relates to cutting fluid, in particular to semi-synthetic metal cutting fluid. The semi-synthetic metal cutting fluid is prepared by methyl levulinate, (R)-(+)-2,4-dyhydroxy-N-(3-hydroxypropyl)-3,3-dimethylbutyramide, 2-oxo-1,5-disoidum glutarate dihydrate, 4-piperidone-3-carboxylate hydrochloride and trimethylsilylketene. The semi-synthetic metal cutting fluid has good cooling, anticorrosion, antirust and lubricating performance, service life of a knife can be prolonged effectively, and excellent machining accuracy can be realized; the semi-synthetic metal cutting fluid can play a role in safely and reliably protecting and inhibiting corrosion of nonferrous metal like aluminum and steel and ferrous metal, so that time and cost for subsequent treatment can be omitted; the semi-synthetic metal cutting fluid is suitable for being widely popularized and applied in the field of the cutting fluid.

Owner:烟台顺隆化工科技有限公司

Aluminium alloy cutting liquid with long service life and preparation method thereof

ActiveCN106118834AReduce dosageExtended service lifeLubricant compositionDefoaming AgentsMineral oil

The invention relates to the field of metal cutting liquids, in particular to an aluminium alloy cutting liquid with a long service life and a preparation method thereof. The semi-synthetic cutting liquid provided by the invention is prepared from 10 to 30 percent of mineral oil, 5 to 15 percent of alcohol amine, 5 to 12 percent of an emulsifying agent, 3 to 8 percent of an anti-rusting agent, 3 to 10 percent of a lubricating agent, 1 to 4 percent of a corrosion inhibitor, 1 to 4 percent of an extreme pressure agent, 0.5 to 1 percent of a defoaming agent, and 1 to 3 percent of a sterilizing agent. According to the formula of the aluminium alloy cutting liquid, conventional monoethanolamine, diethanol amine and triethanolamine serving as pH regulating agents are abandoned, and through a special compounding mode, the aluminium alloy cutting liquid has higher stability, and the cost is reduced. Secondly, the using amount of the extreme pressure agent is reduced by regulating the using amounts of various raw materials; moreover, excellent corrosion preventing and lubricating effects of the cutting liquid are maintained; the cutting liquid can be used for a long time; the replacement period of the cutting liquid provided by the invention is about one year; the cutting liquid is environment-friendly and has extremely low damage to a human body.

Owner:东莞市科泽润滑油有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com