Patents

Literature

695results about How to "High thermodynamic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

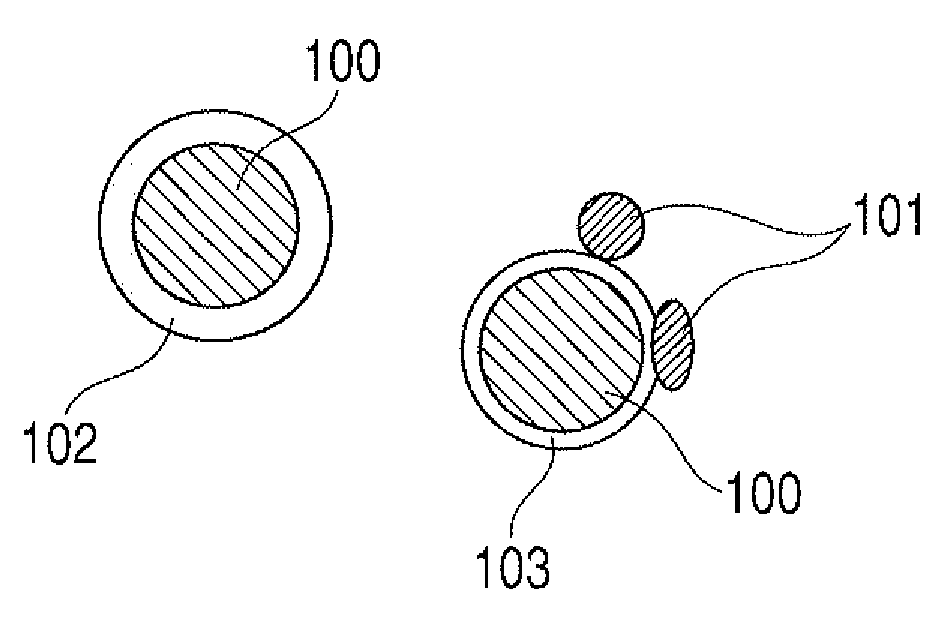

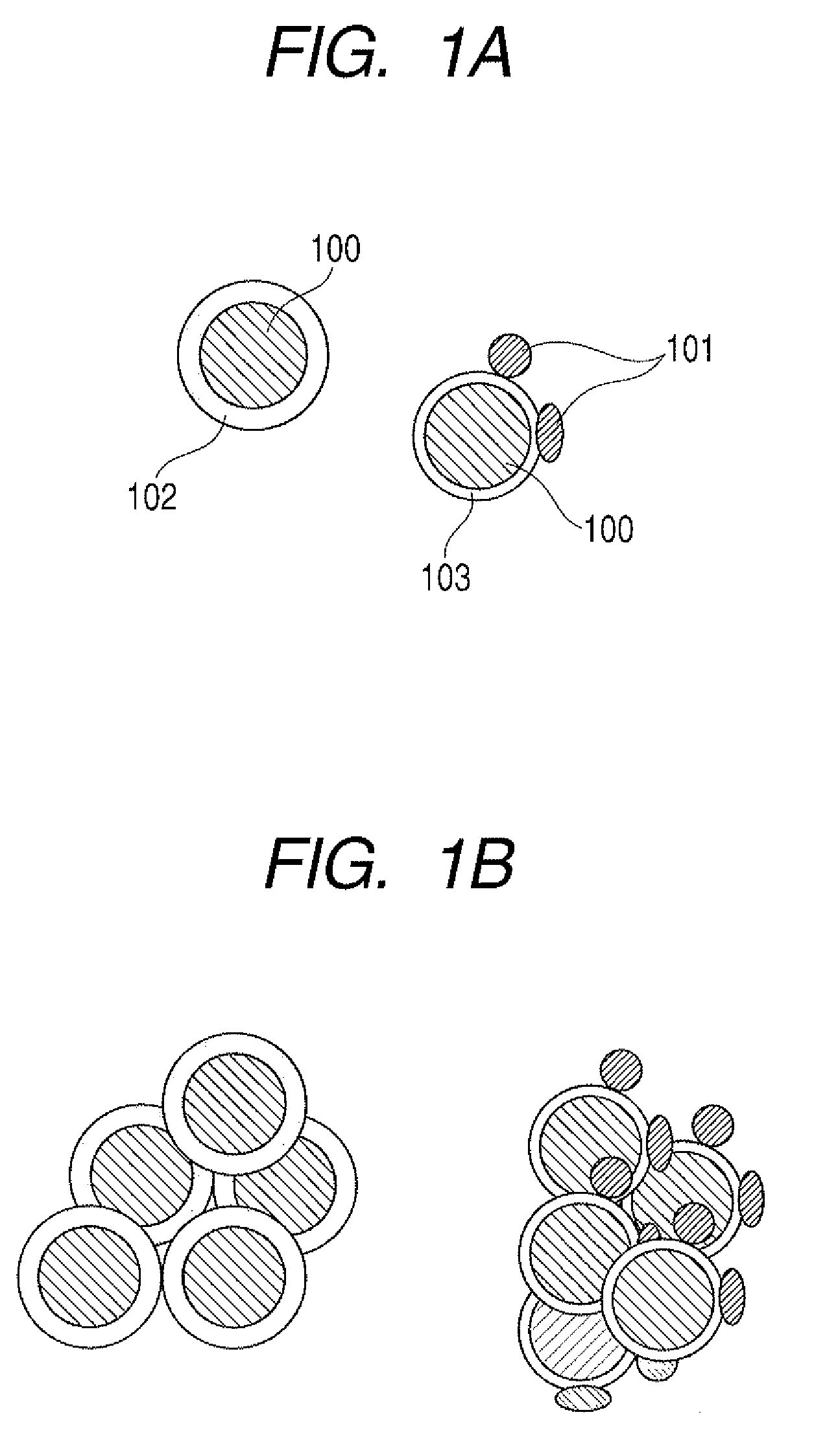

Method of producing lithium ion-storing/releasing material, lithium ion-storing/releasing material, and electrode structure and energy storage device using the material

InactiveUS20090162750A1Quickly chargeHigh charge and discharge efficiencyHybrid capacitor electrodesDouble layer capacitorsLithiumSilicon oxide

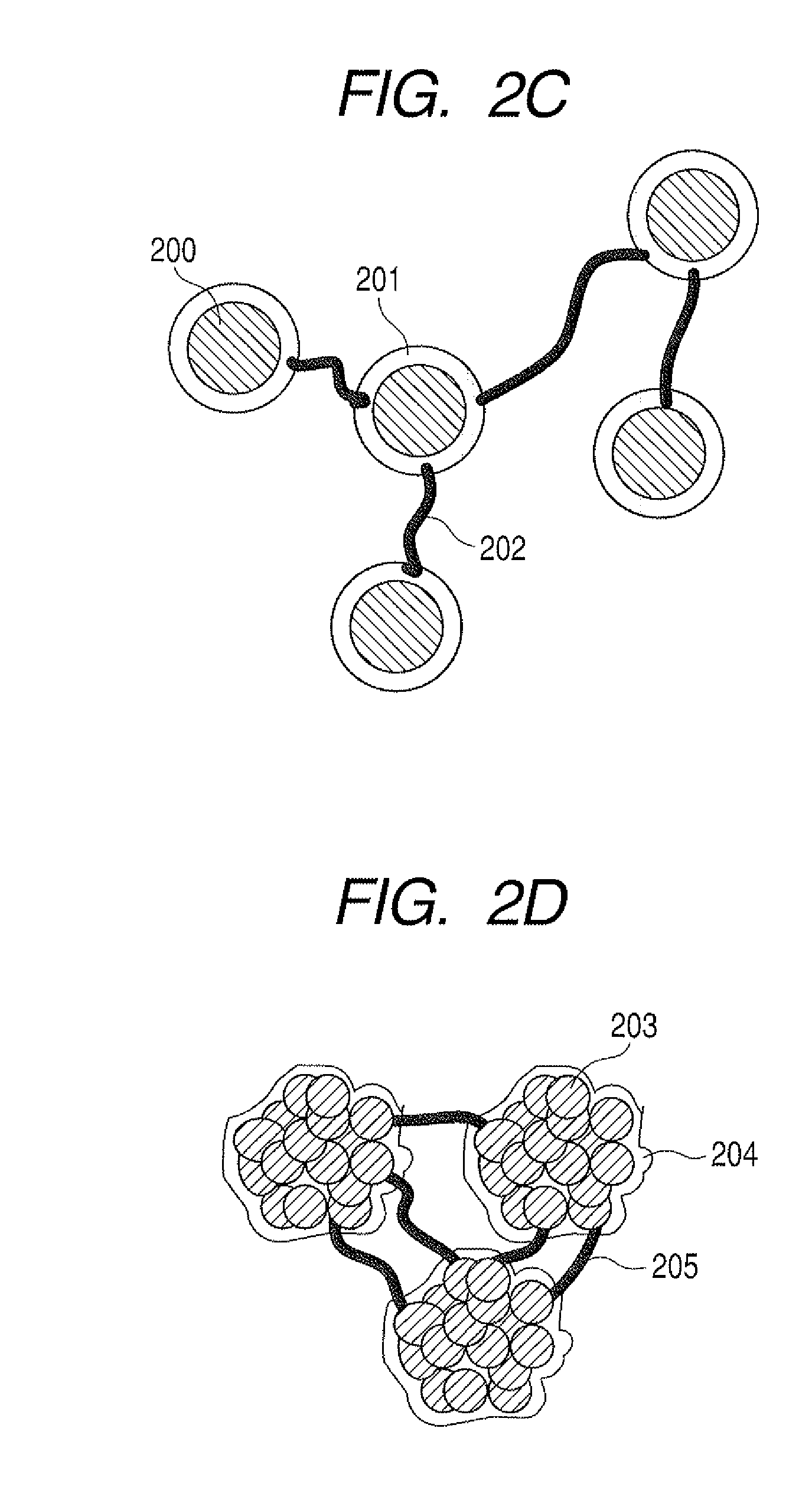

A method of producing a material capable of electrochemically storing and releasing a large amount of lithium ions is provided. The material is used as an electrode material for a negative electrode, and includes silicon or tin primary particles composed of crystal particles each having a specific diameter and an amorphous surface layer formed of at least a metal oxide, having a specific thickness. Gibbs free energy when the metal oxide is produced by oxidation of a metal is smaller than Gibbs free energy when silicon or tin is oxidized, and the metal oxide has higher thermodynamic stability than silicon oxide or tin oxide. The method of producing the electrode material includes reacting silicon or tin with a metal oxide, reacting a silicon oxide or a tin oxide with a metal, or reacting a silicon compound or a tin compound with a metal compound to react with each other.

Owner:CANON KK

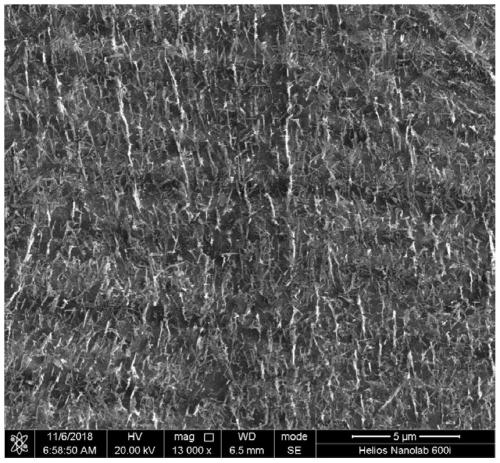

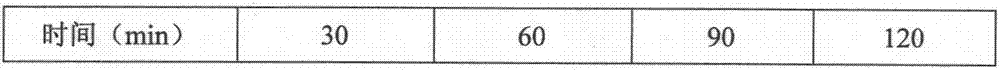

Metal organic framework/carbon nanofiber composite membrane material and preparation method thereof

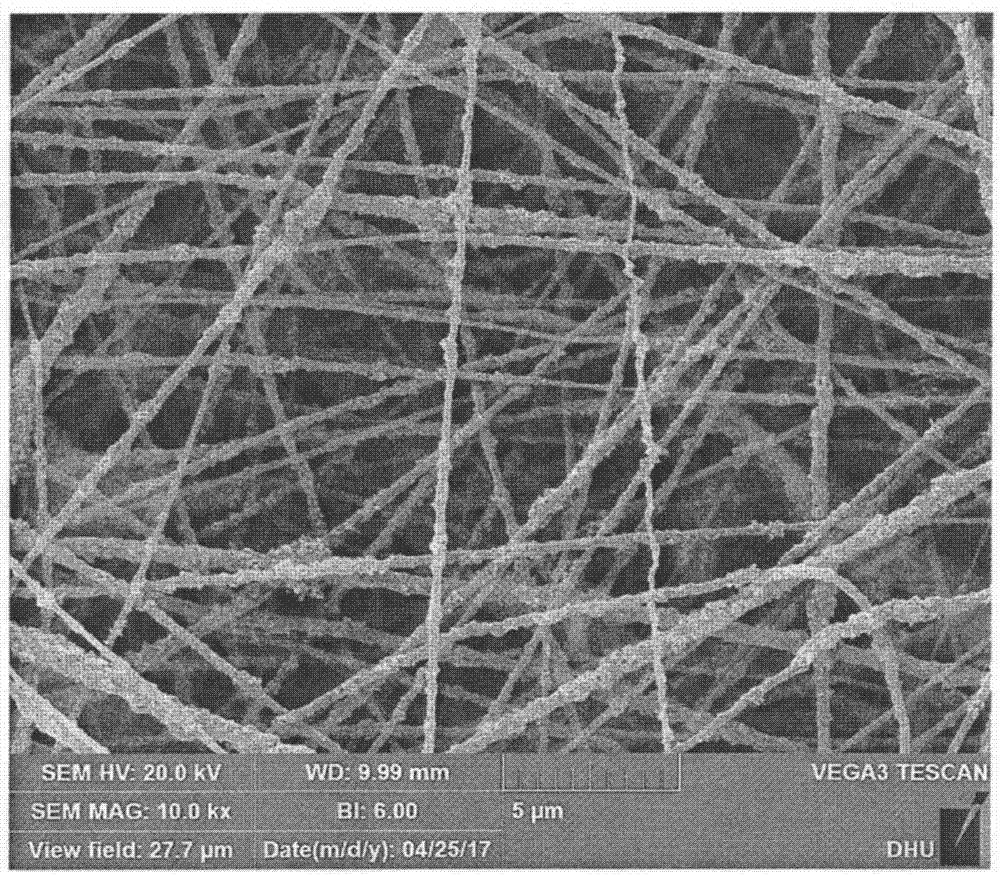

InactiveCN107201645AThe preparation process is simple and easy to operateEasy to recycleGas treatmentCarbon fibresCarboxylic groupMetal-organic framework

The invention provides a metal organic framework / carbon nanofiber composite membrane material and a preparation method thereof. The metal organic framework / carbon nanofiber composite membrane material is characterized by comprising a carbon nanofiber membrane, wherein a metal organic framework layer is grown on the nanofiber surface of the carbon nanofiber membrane. The preparation method comprises the following steps: first preparing a flexible carbon nanofiber membrane, oxidizing the flexible carbon nanofiber membrane by using nitric acid to form a carboxyl group-containing flexible carbon nanofiber membrane, putting the carboxyl group-containing flexible carbon nanofiber membrane into a precursor solution of a metal organic framework to grow the metal organic framework to obtain the metal organic framework / carbon nanofiber composite membrane material. The metal organic framework / carbon nanofiber composite membrane material prepared according to the preparation method provided by the invention has a great application potential in the fields of gas adsorption and separation, catalysts, sensors, electrode materials and the like.

Owner:DONGHUA UNIV

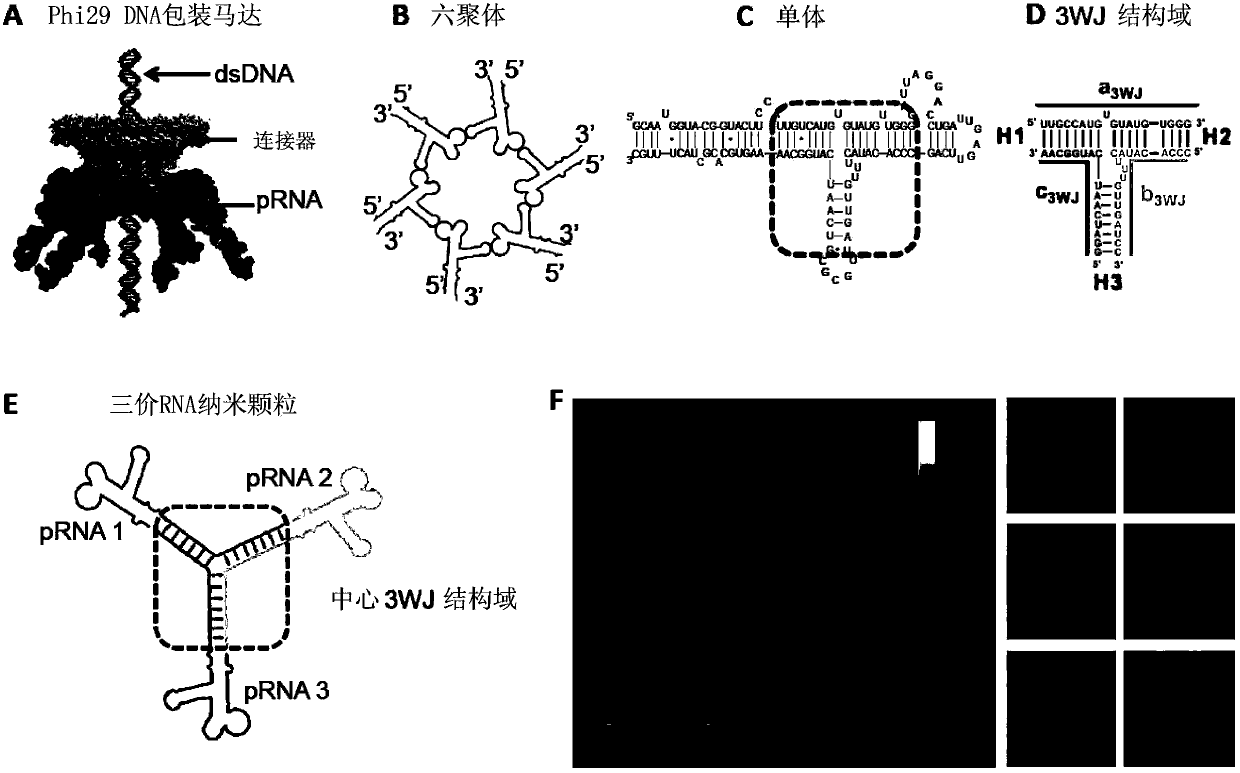

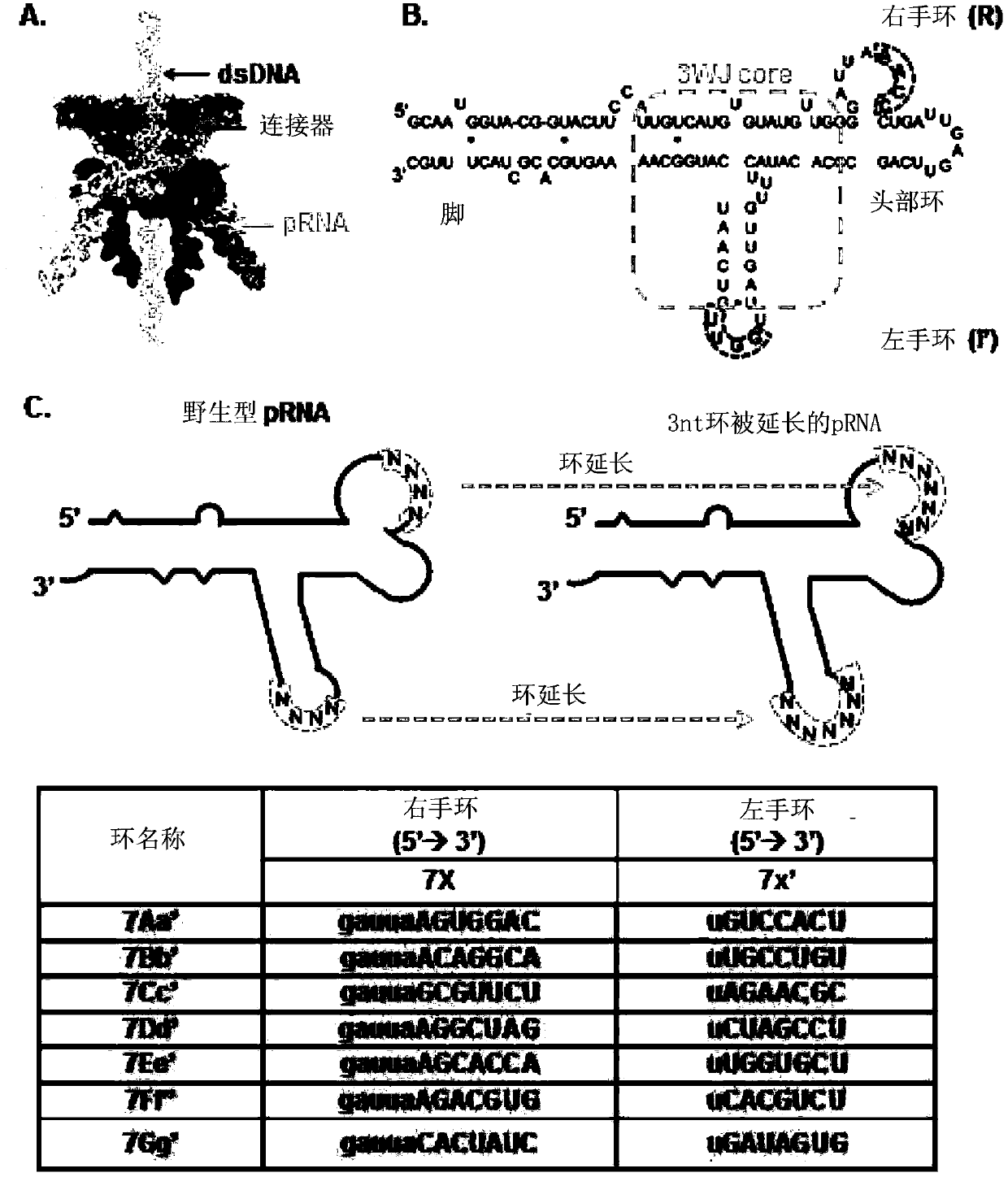

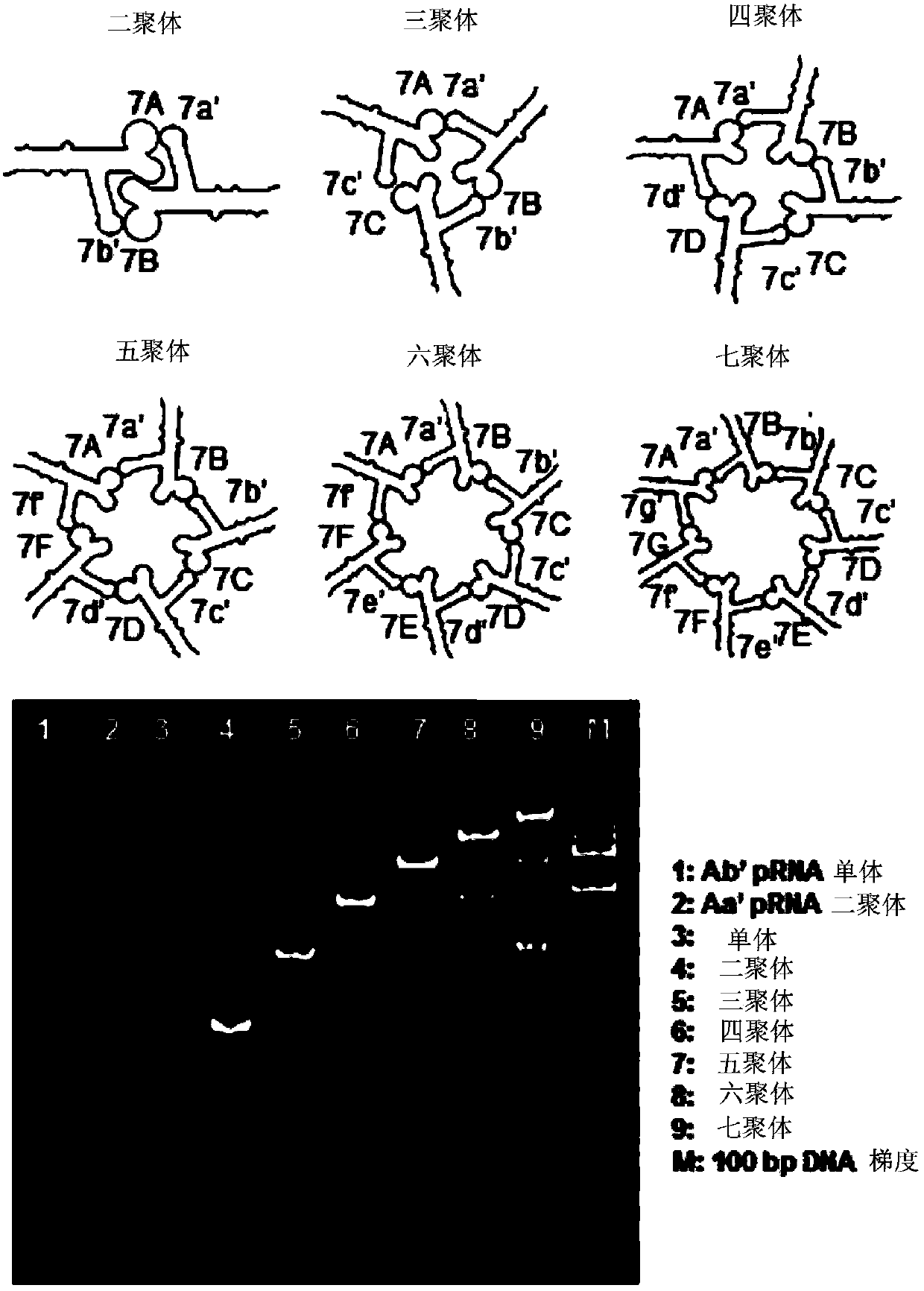

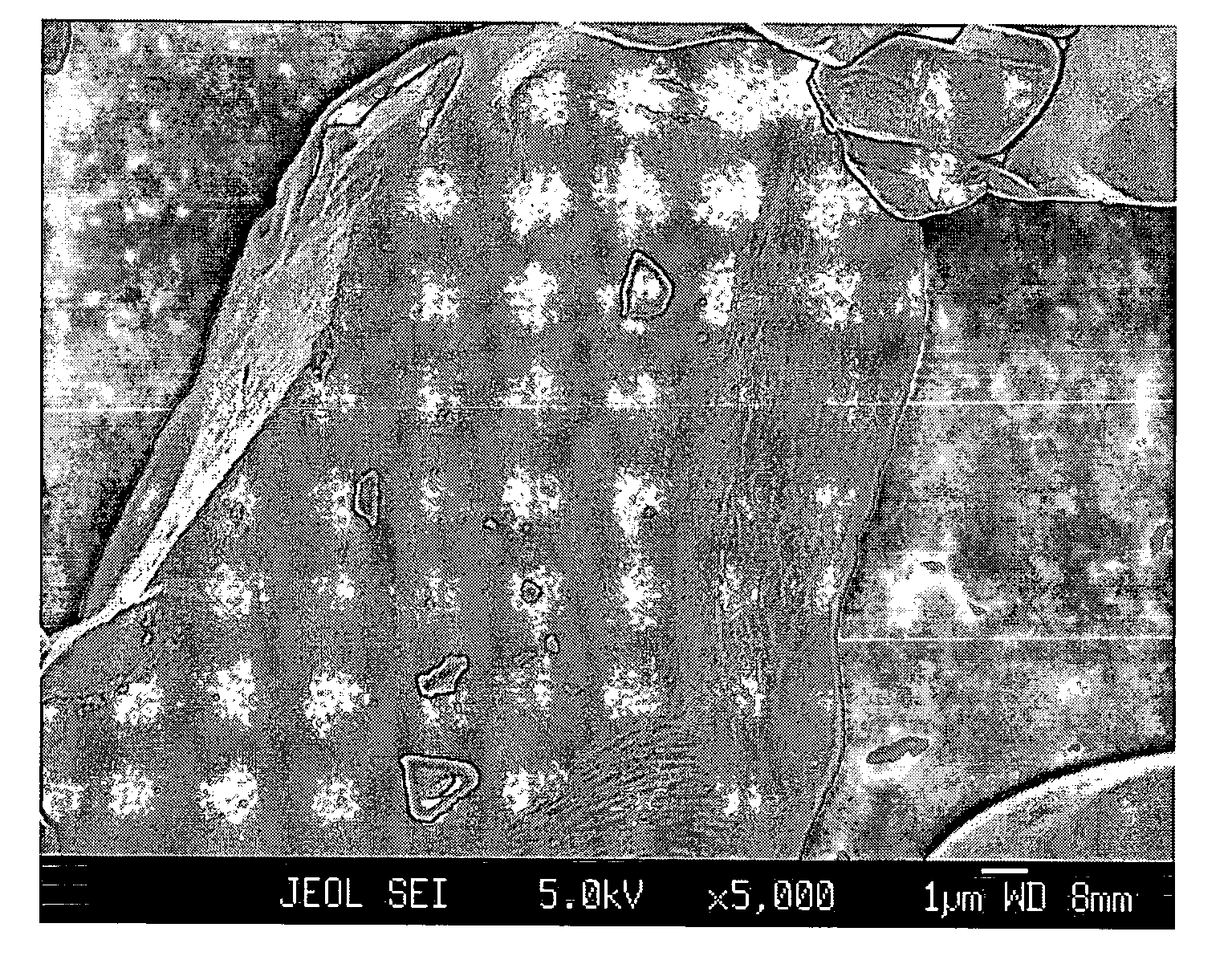

PRNA mutlivalent junction domain for use in stable multivalent RNA nanoparticles

ActiveCN103403189AStrong specificityImprove targetingMicrobiological testing/measurementDNA/RNA fragmentationDiagnostic agentNanoparticle

Trifurcate RNA junction domains derived from phi29 pRNA are described that assemble with high affinity and that are stable in vitro and in vivo. Further expansion of trifurcated RNA domains to multiple way junction scaffolds via creative designs enable an array of toolkit to construct nanoparticle architectures with diverse shapes and angles. The scaffolds can be used to form RNA nanoparticles having a wide variety of uses, including promotion of RNA crystallization, creation of RNA aptamer with high affinity to mimic antibody, delivery of therapeutic and / or diagnostic agents such as biologically active RNA-based moieties, including siRNA, ribozymes, aptamers, and others.

Owner:UNIVERSITY OF CINCINNATI

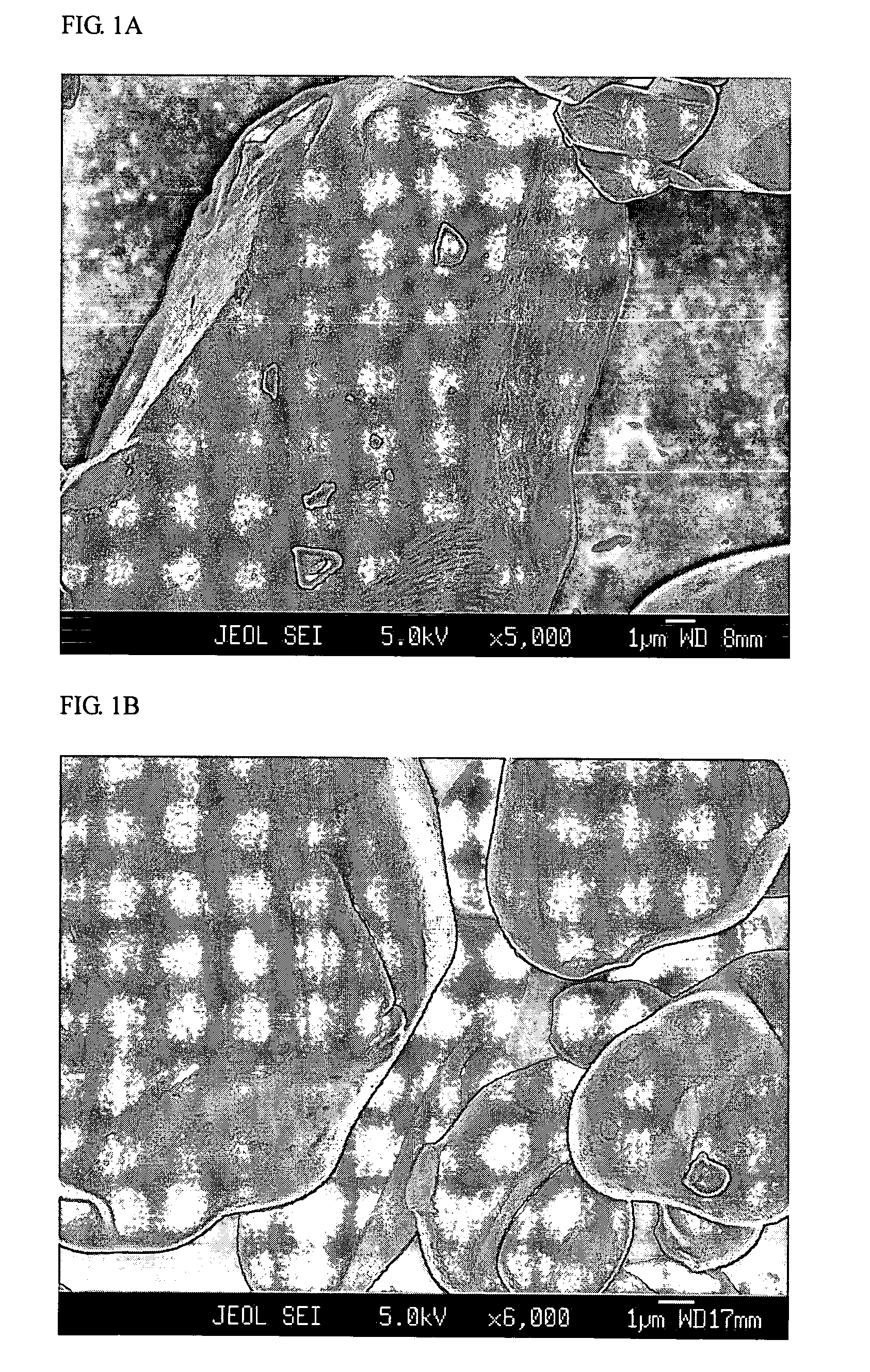

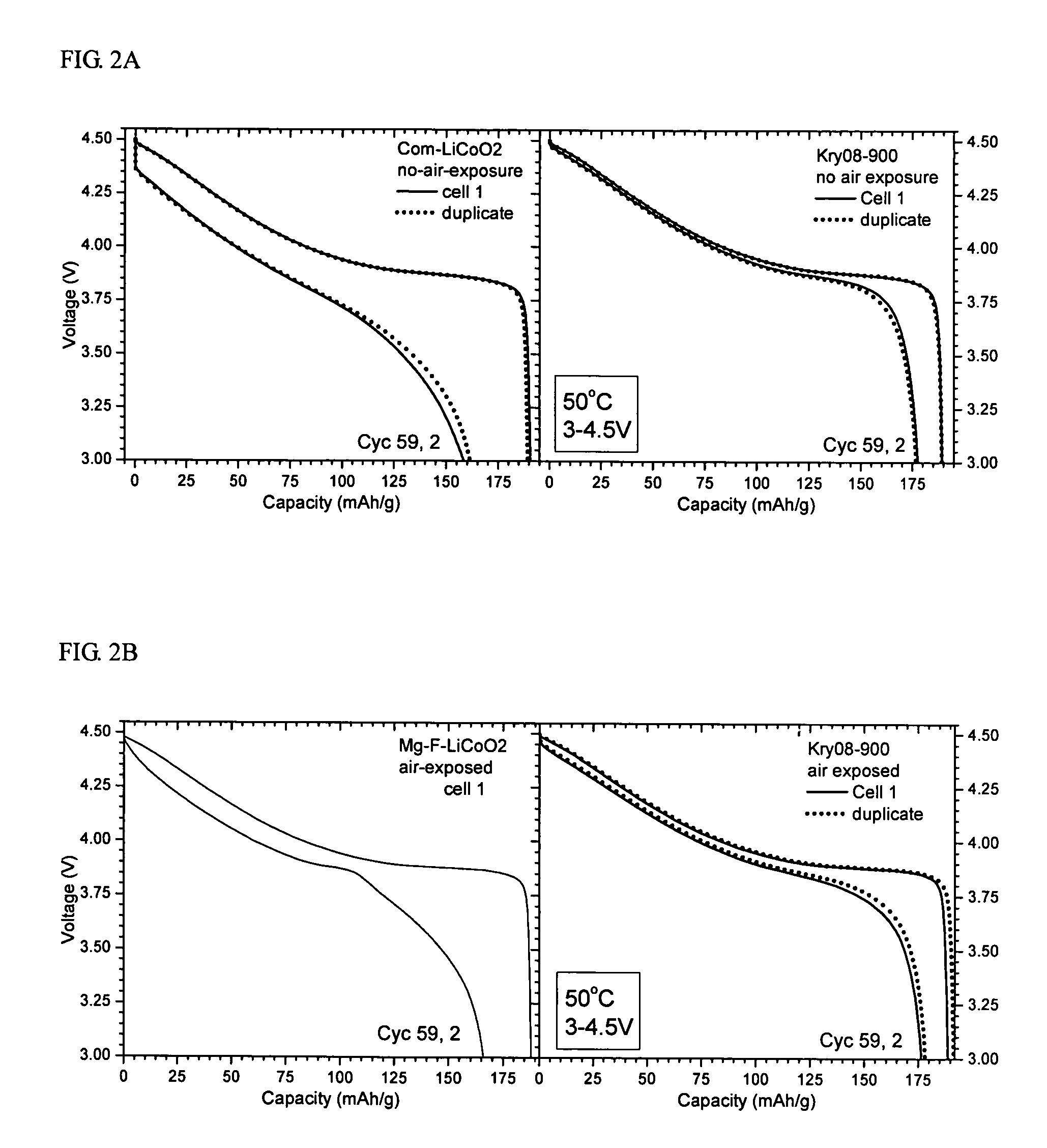

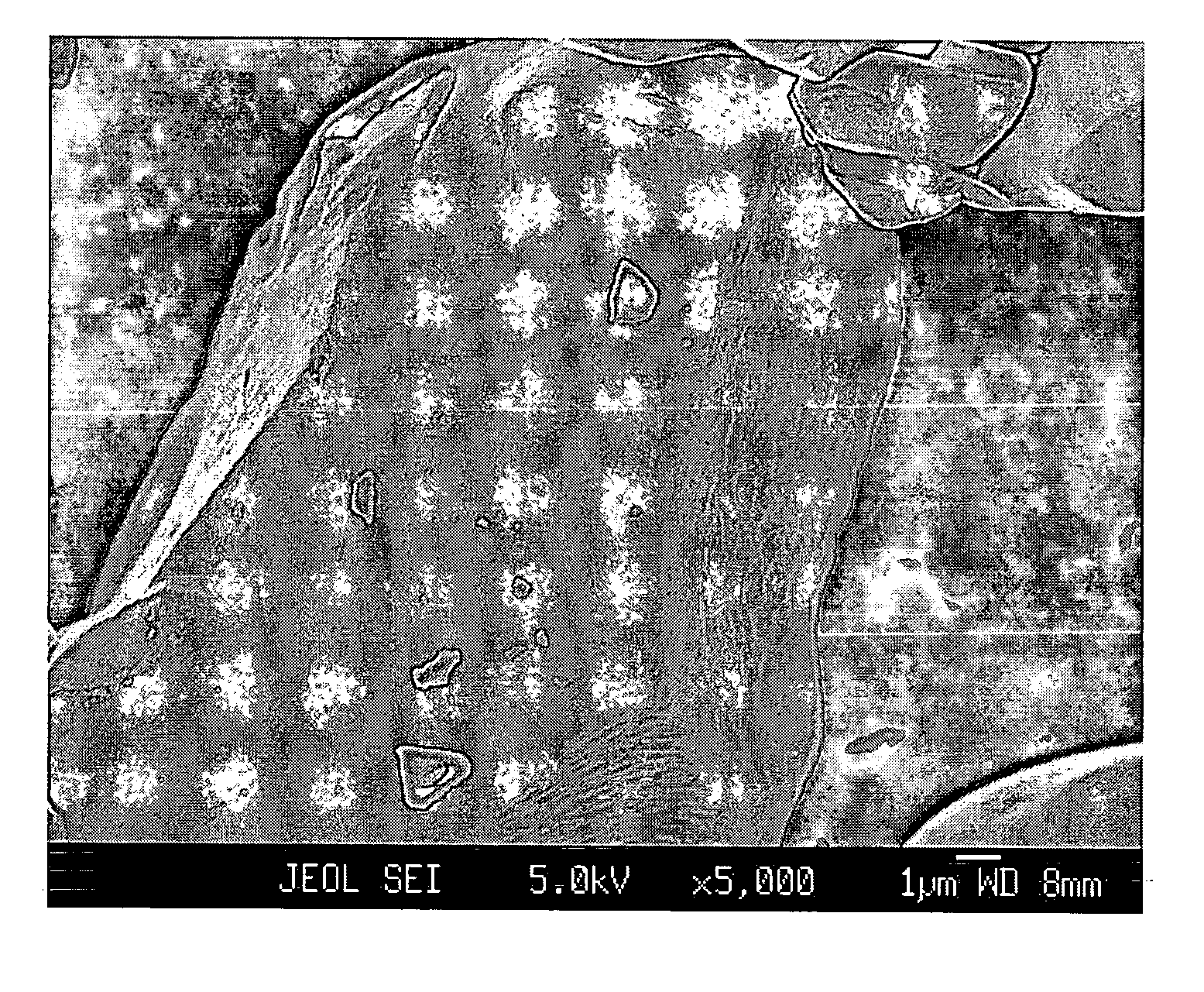

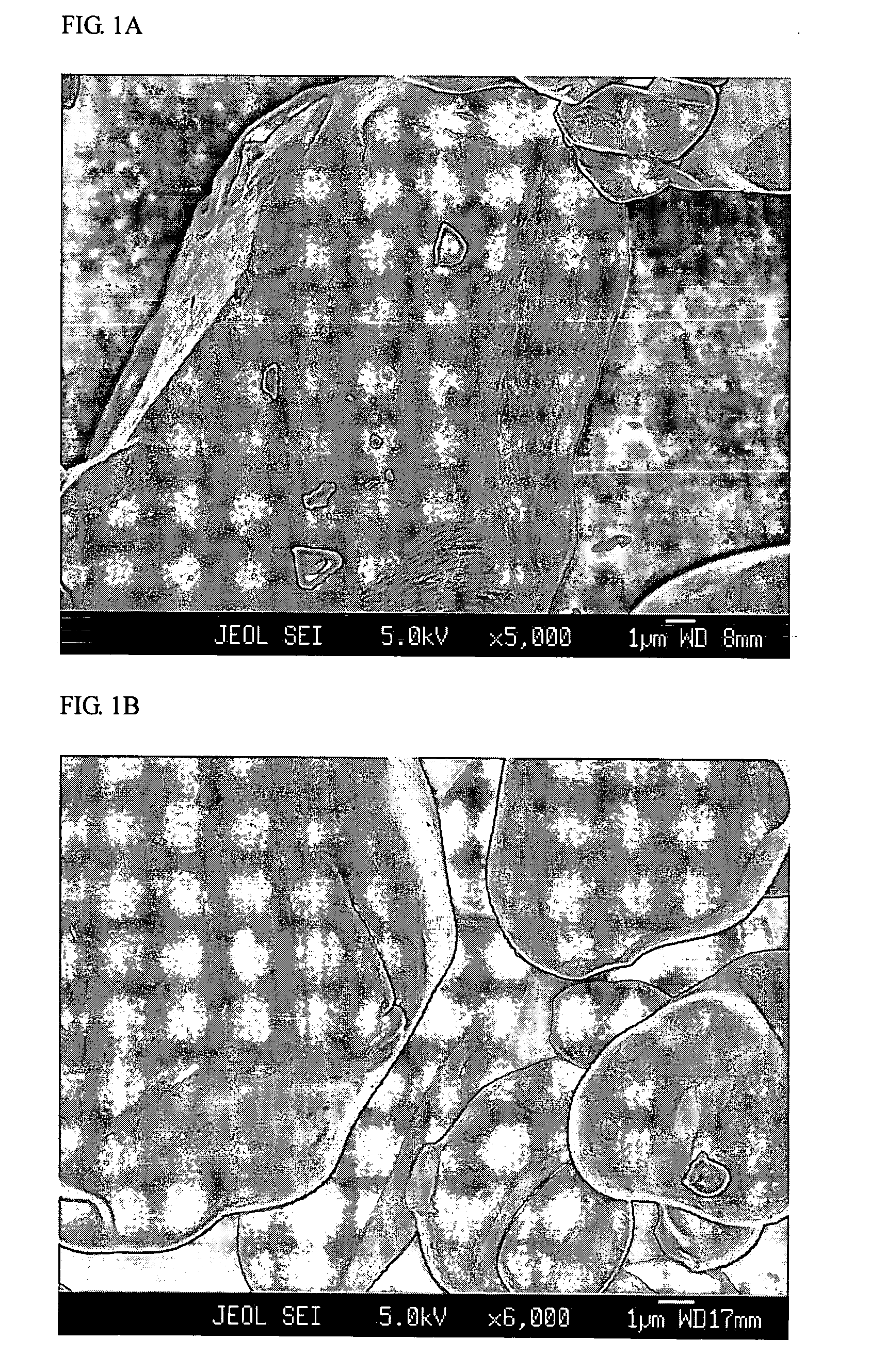

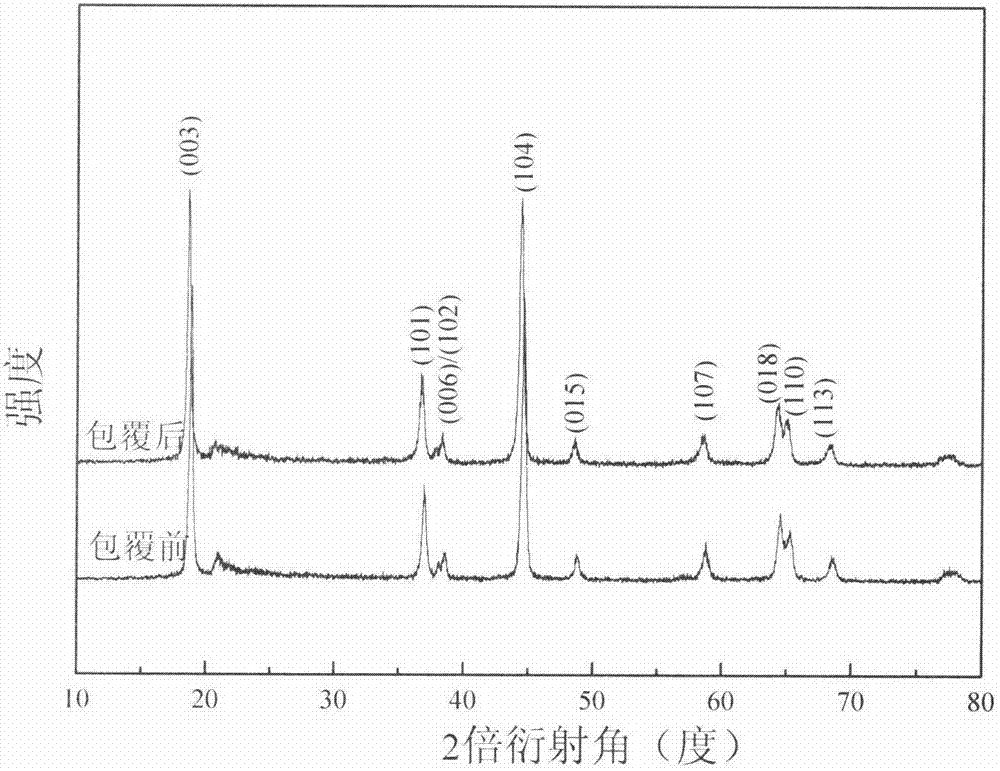

Powdered lithium transition metal oxide having doped interface layer and outer layer and method for preparation of the same

ActiveUS7364793B2Use of materialSimple processLiquid surface applicatorsElectrode thermal treatmentInterface layerMechanical stability

The present invention provides a powdered lithium transition metal oxide useful as a major component for cathode active material of rechargeable lithium batteries, comprising a lithium transition metal oxide particle, a doped interface layer formed near the surface of the particle, and a thermodynamically and mechanically stable outer layer, and a method of preparing the same.

Owner:LG ENERGY SOLUTION LTD

Melamine modified polyvinylalcohol formal foam, preparation and uses thereof

InactiveCN101508747AIncrease dosageImprove mechanical propertiesAbsorbent padsFiltration separationFoaming agentAdjuvant

The invention relates to a melamine modified polyvinyl formal foam material and a preparation method thereof. The foam material is prepared by proportionally mixing and reacting among polyvinyl alcohol, melamine, formaldehyde, an acidic catalyst, a basic catalyst, an emulsifier, a foaming agent, a pore former, an adjuvant and the like. The foam material has the advantages of simple preparation process, adjustable aperture ratio, high mechanical strength and good temperature resistance, and can be widely used as medical sponge, filtering material, sound insulation protection material, wiping and dedusting material and biological carrier material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Thin film dielectrics with perovskite structure and preparation thereof

InactiveUS20050136292A1High thermodynamic stabilityLow temperature reactionTantalum compoundsFixed capacitor dielectricDielectric layerCapacitor

Methods of making a ternary oxide and a perovskite-related ternary oxide structure are described. The methods include reacting a binary oxide with a metal oxide or a metal hydroxide to form a ternary oxide dielectric layer on a substrate. Powders, anodes, pressed articles, and capacitors including the ternary oxide or perovskite-related ternary oxide structure as a dielectric layer or other layers are further described.

Owner:CABOT CORP

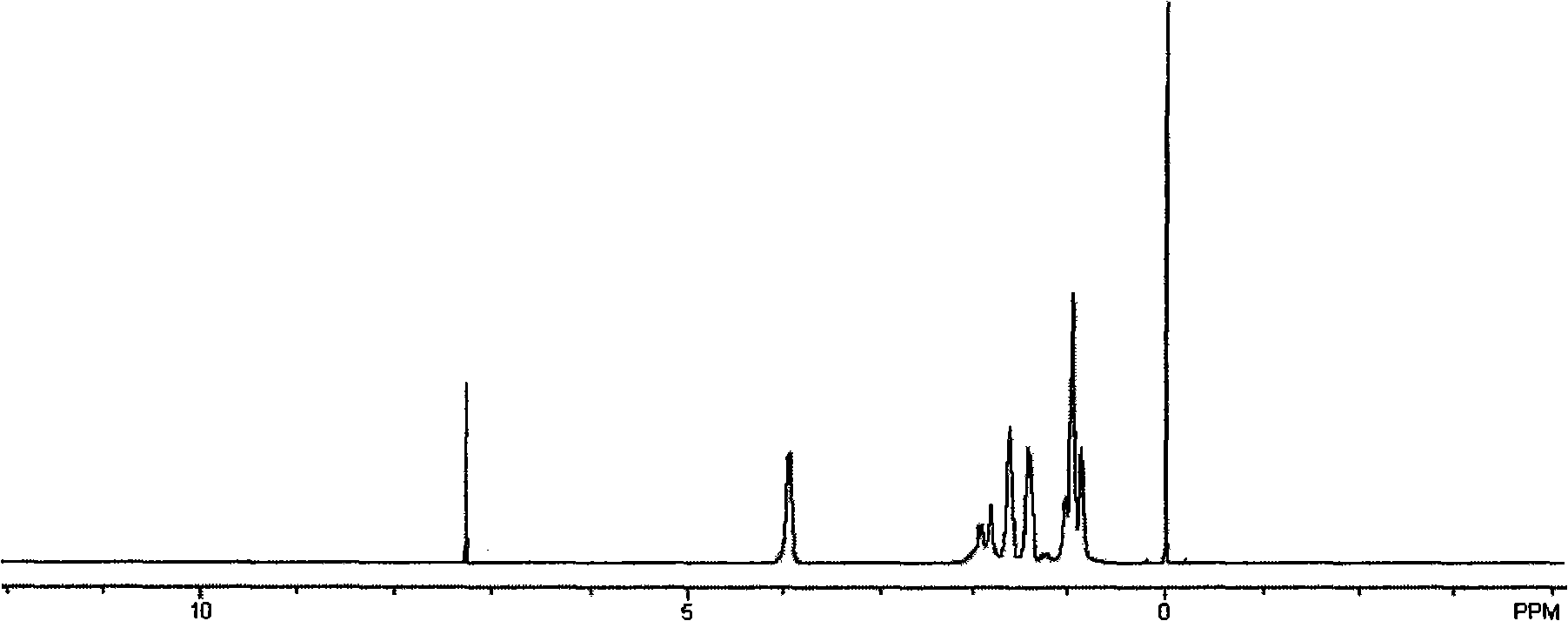

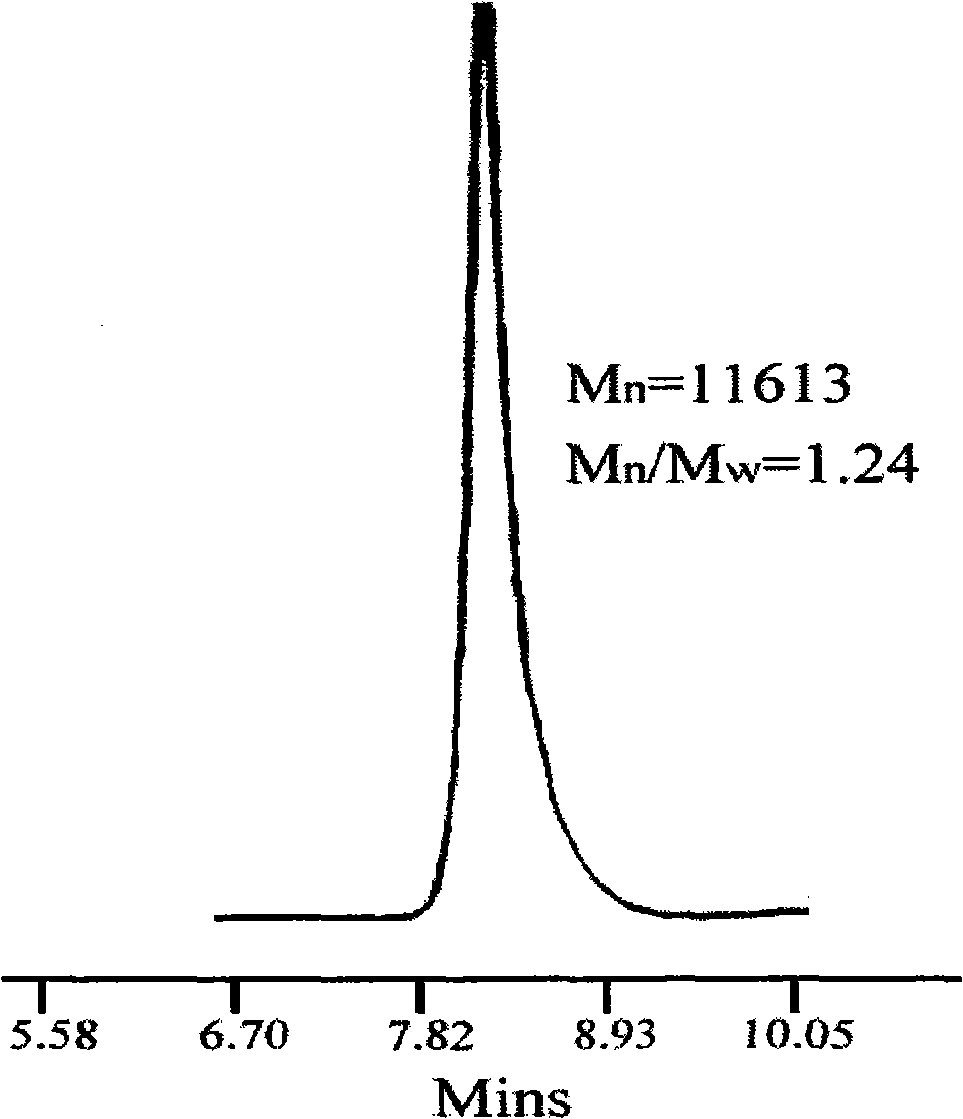

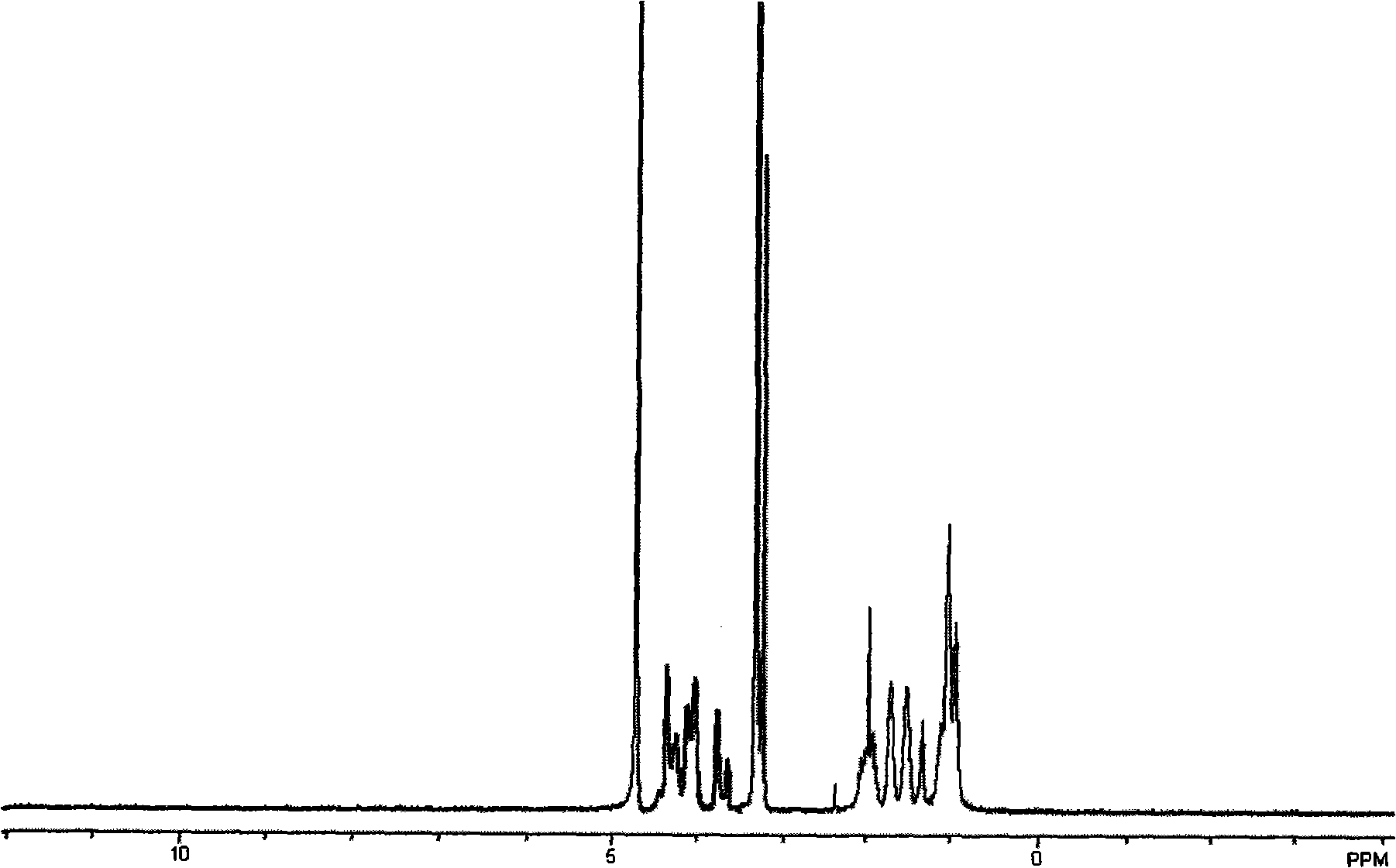

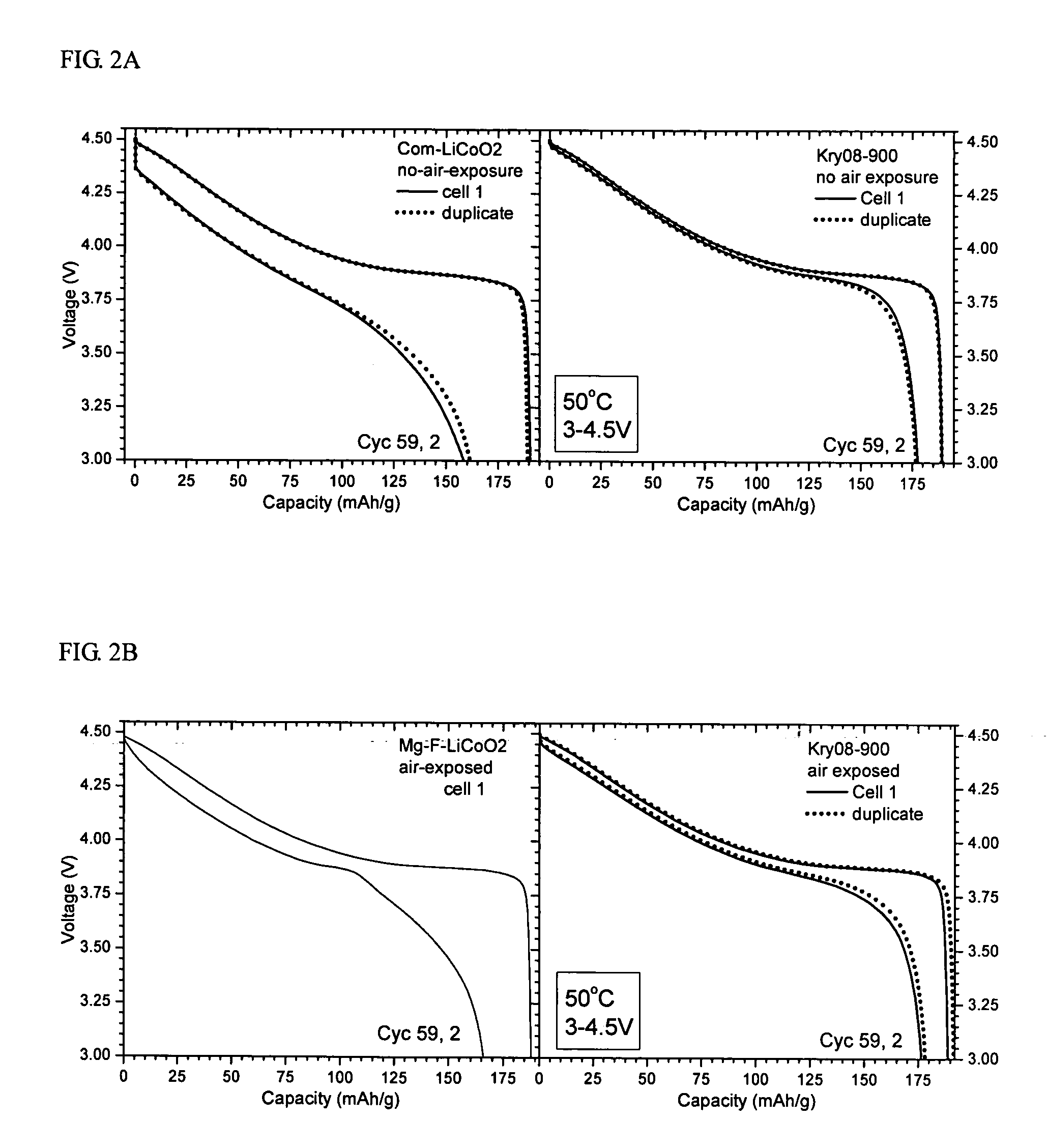

Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one

ActiveUS7268126B2Easy to manufactureHigh thermodynamic stabilityBiocideNervous disorderDiseasePhosphate

The present invention relates to novel polymorphic and amorphous forms of a phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-cd]indol-6-one, and to processes for their preparation. Such polymorphic forms may be a component of a pharmaceutical composition and may be used to treat a mammalian disease condition mediated by poly(ADP-ribose) polymerase activity including the disease condition such as cancer.

Owner:CANCER RES TECH LTD +2

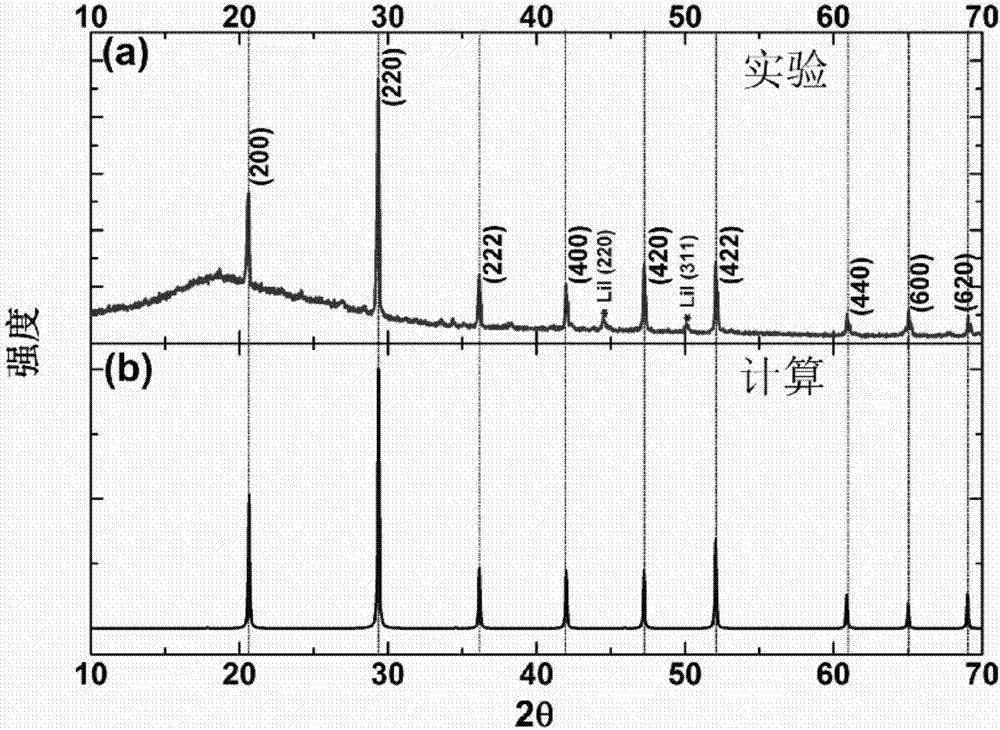

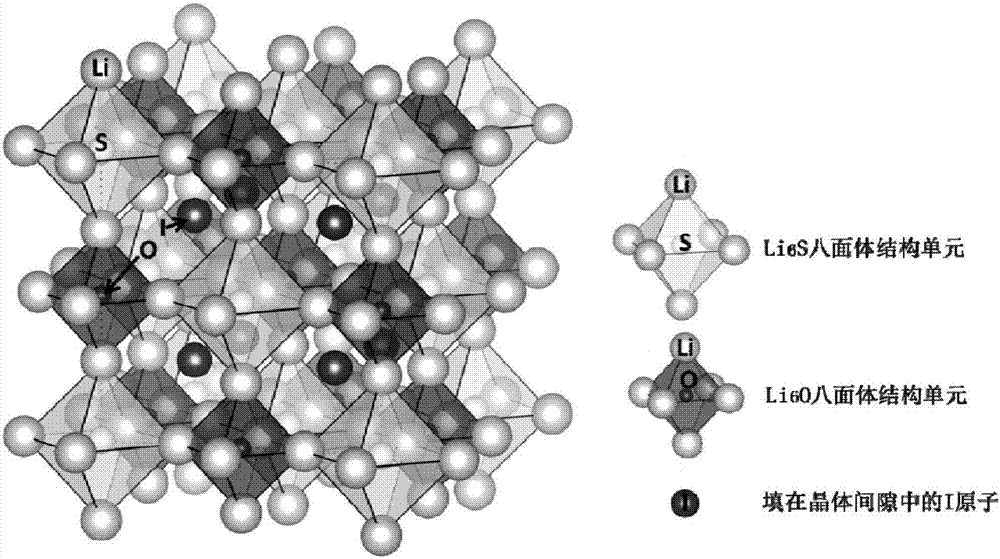

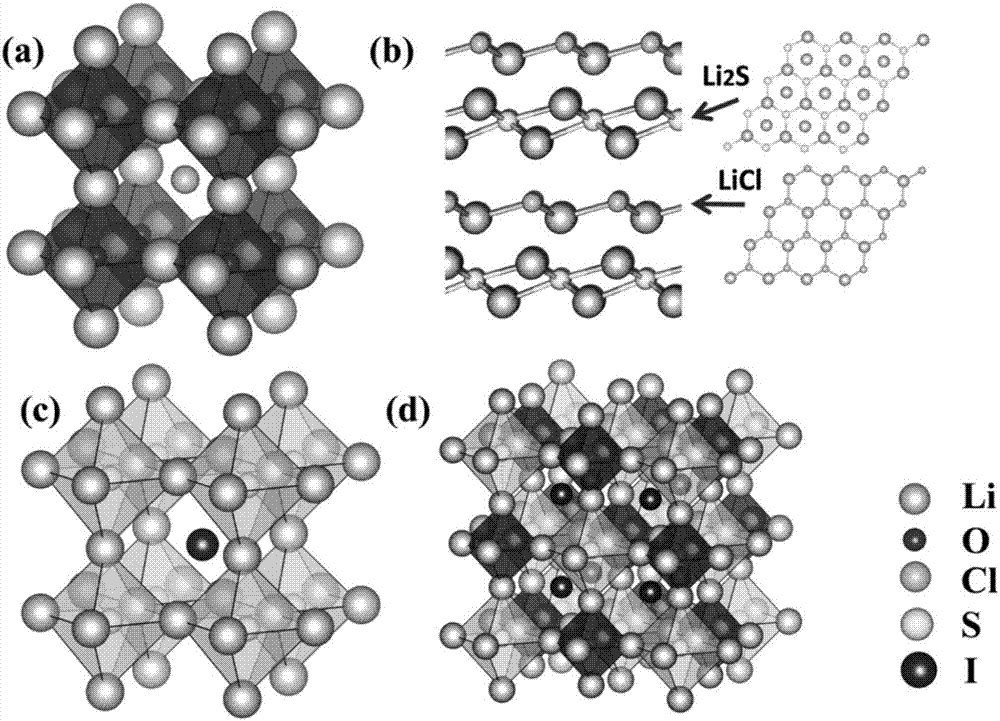

Lithium ion solid electrolyte and preparation method and application thereof

ActiveCN107425218AExcellent lithium ion conductivityHigh thermodynamic stabilityCell electrodesSecondary cellsHalogenPhysical chemistry

The invention relates to a lithium ion solid electrolyte and a preparation method application thereof, and belongs to the technical field of a lithium ion battery. The lithium ion solid electrolyte has the chemical formula shown as follows: Li<3+a>MA<m>B<n>Y<1-b>, wherein a is more than or equal to -0.25 but less than or equal to 0.25, b is more than or equal to 0 but less than or equal to 0.5, m is more than or equal to 0 but less than or equal to 1.25, n is more than or equal to 0 but less than or equal to 1.25, M is one of Ca, Ba, Mg, Al and Ti, A and B are separately selected from one of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I, and Y is one of halogen, minus monovalent ionic group or vacancy. The lithium ion solid electrolyte has a stable structure and favorable lithium ion transmission performance and has favorable electrochemical performance and safety performance when used as a solid electrolyte of the lithium ion battery.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

Powdered lithium transition metal oxide having doped interface layer and outer layer and method for preparation of the same

ActiveUS20060071198A1Efficient use ofSimple processLiquid surface applicatorsElectrode thermal treatmentLithiumInterface layer

The present invention provides a powdered lithium transition metal oxide useful as a major component for cathode active material of rechargeable lithium batteries, comprising a lithium transition metal oxide particle, a doped interface layer formed near the surface of the particle, and a thermodynamically and mechanically stable outer layer, and a method of preparing the same.

Owner:LG ENERGY SOLUTION LTD

Antiseptic wearable coat and coating method thereof

ActiveCN101191225ATo achieve the purpose of corrosion resistance and wear resistanceEasy to operateMetallic material coating processesRheniumThermal spraying

The invention discloses a corrosion and abrasion resistant coating and a coating method thereof, comprising: firstly, weight percentage of compositions of coating materials adopted is that: carbon: less than or equal to 0.5 percent; chromium: 16 to 26 percent; nickel: 3.5 to 9.5 percent; molybdenum: 1.0 to 4.0 percent; boron: 0.5 to 4.5 percent; silicon: 0.5 to 4.5 percent; copper: 1.0 to 4.0 percent; manganese: 0 to 2.0 percent; rare earth - rhenium: 0.01 to 1.5 percent; the residual is ferrum and inevitable impurities; secondly, pretreatment of the surface of a metallic matrix reaches technological demand; thirdly, thermal spraying is adopted on the matrix surface; a plurality of air cooling nozzles surrounding a spray gun which are in parallel with spraying flame velocity are arranged on the spray gun; travel rate of the spray gun is 150 to 400 millimeters per second; surface temperature of workpieces is controlled to be less than 150 DEG C; an amorphous stainless steel protective coating is formed on the matrix surface finally; fourthly, sundries on the coating surface are cleaned, and the coating is performed sealing treatment. The invention solves the protective problem of erosion-corrosion under the condition of acid humid environment and that Cl<-> ions and dust particles exist.

Owner:BAOSHAN IRON & STEEL CO LTD

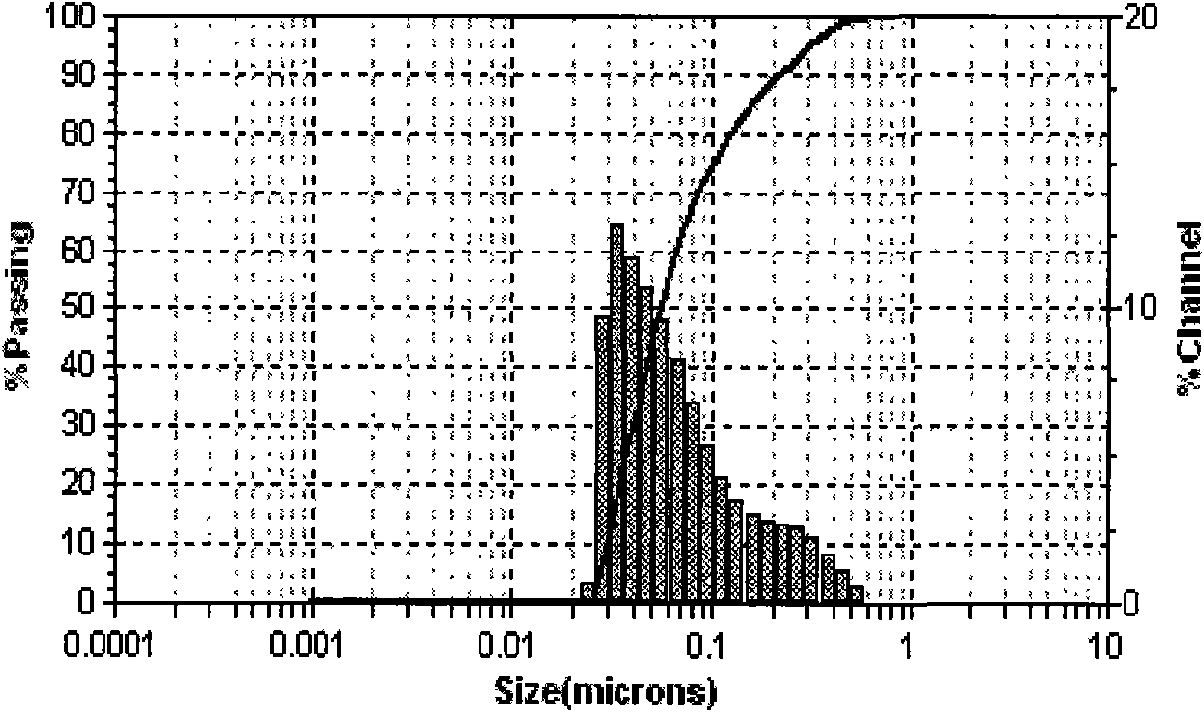

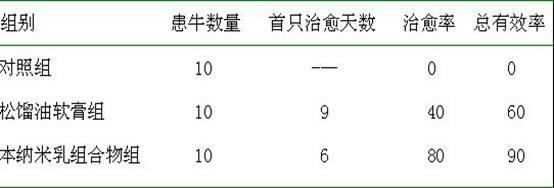

Nano-emulsion medicine for treating foot rot and preparation method thereof

InactiveCN102552339AHigh thermodynamic stabilityEasy to operateAntibacterial agentsHydroxy compound active ingredientsPropanoic acidCutin

The invention discloses a nano-emulsion medicine for treating foot rot. The grain diameter of the nano-emulsion is in a range of 1-100 nanometers and the nano-emulsion is composed of the following raw materials: 0.1-10.0% of pine tar, 0.1-6.0% of cinnamyl aldehyde, 0.1-6.0% of carvacrol, 0.1-5.0% of camphor oil, 0.01-0.1% of clobetasol propionate, 18.0-35.0% of surfactant, 0-7.0% of co-surfactant and residual amount of distilled water; and the sum of the mass percentages of the components is 100%. The nano-emulsion disclosed by the invention has the functions of dissolving cutin, relieving itching, diminishing inflammation, restraining, partially disinfecting and resisting corrosion, accelerating absorption and the like, and is mainly used for treating animal foot rot. According to the nano-emulsion medicine for treating the foot rot, the solubility of the medicine is increased, the medicinal stability and the biological utilization rate are improved, the dosage of the medicine is reduced, the skin transmission rate is higher than that of common preparations including a medicinal extract and the like, and the cost is low, so that the nano-emulsion medicine has a wide market prospect in a veterinary medicine field.

Owner:NORTHWEST A & F UNIV

Preparing cyclohexene catalyst and for benzene hydrogenation its manufacturing method

InactiveCN1597099AHas industrial application valueLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneCyclohexene

A catalyst for preparing cyclohexene from benzene by hydrogenating is prepared from metal Ru, one or two transition metals or RE elements, the hydroxide of alkali metal as precipitator, and hydrophilic indifferent oxide. It has high activity and selectivity.

Owner:ZHENGZHOU UNIV

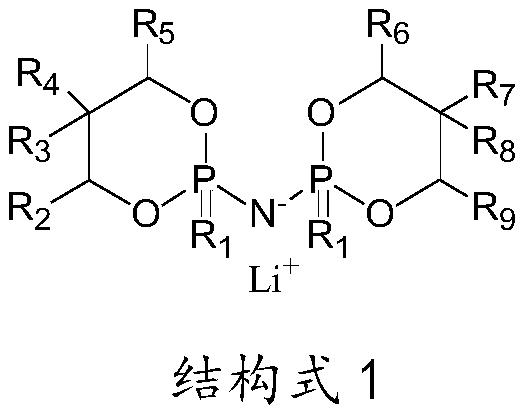

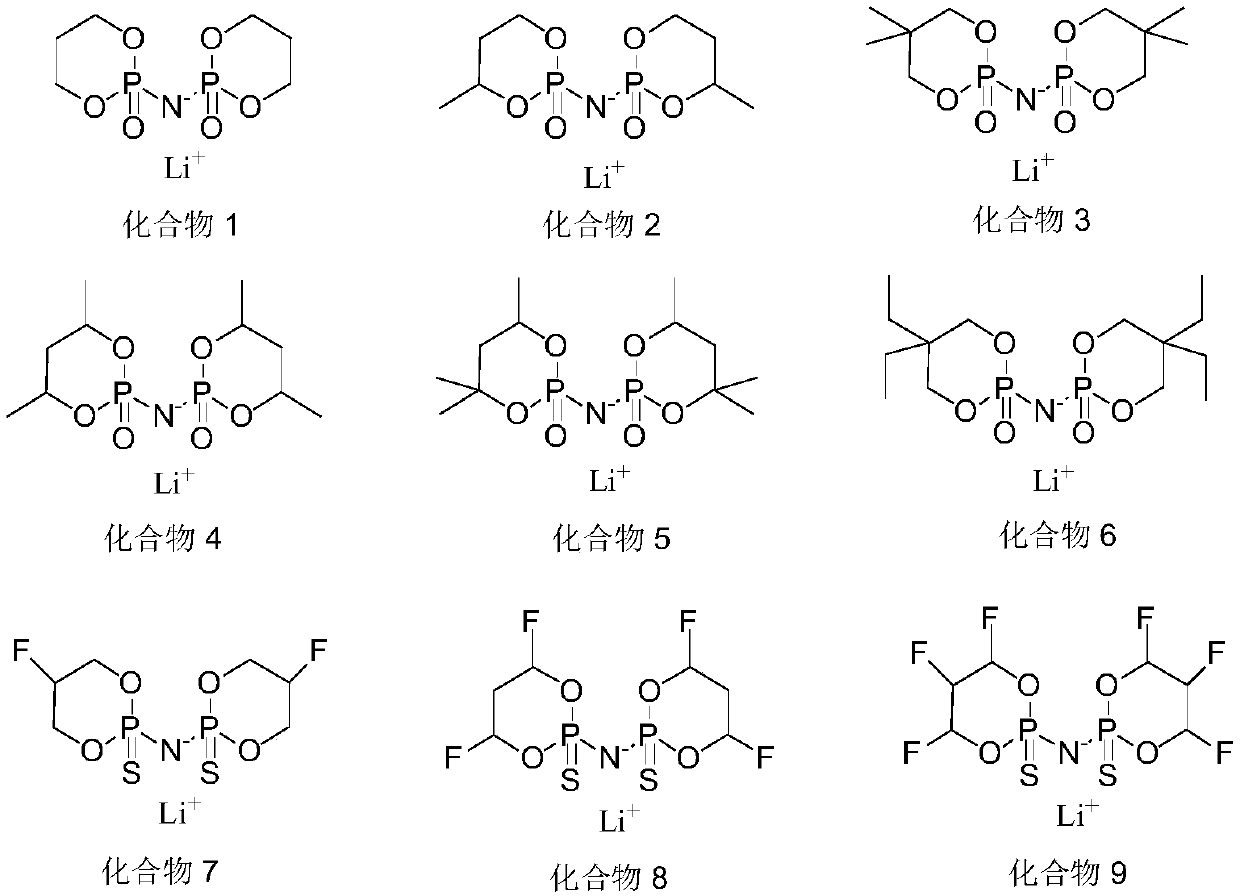

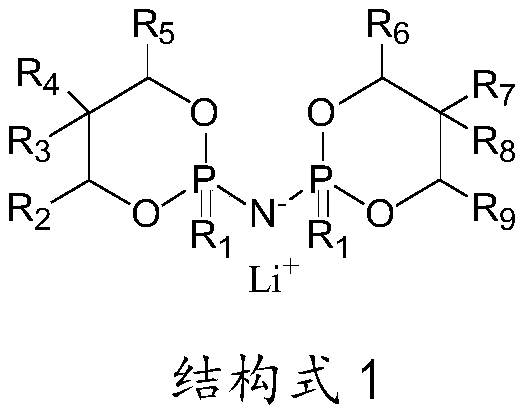

Novel lithium salt additive and non-aqueous electrolyte for lithium-ion batteries

ActiveCN110299562ALower oxidation potentialLower reduction potentialSecondary cellsOrganic electrolytesOrganic solventPhosphate

The invention provides a lithium-ion battery electrolyte, which is composed of an organic solvent, lithium salt, a novel additive and other conventional additives. The novel additive is a dicyclophosphimide lithium salt or lithium dicyclothiophosphimide lithium salt compound shown in a structural formula 1. The compound shown in structural formula 1 of the invention has a high reduction potentialwhen used as an electrolyte additive, so that the novel additive can participate in the formation of a solid electrolyte film on the surface of a negative electrode in preference to the conventional additives and improve the composition of the interfacial film. Because the additive has a cyclic phosphate structure, the phosphorus-oxygen bond is easy to break under high voltage, and the additive can participate in the formation of a positive electrolyte film and improve the interface stability of the positive electrode material. Therefore, the introduction of the additive can improve the high temperature performance, low temperature performance and cycle performance of lithium-ion batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

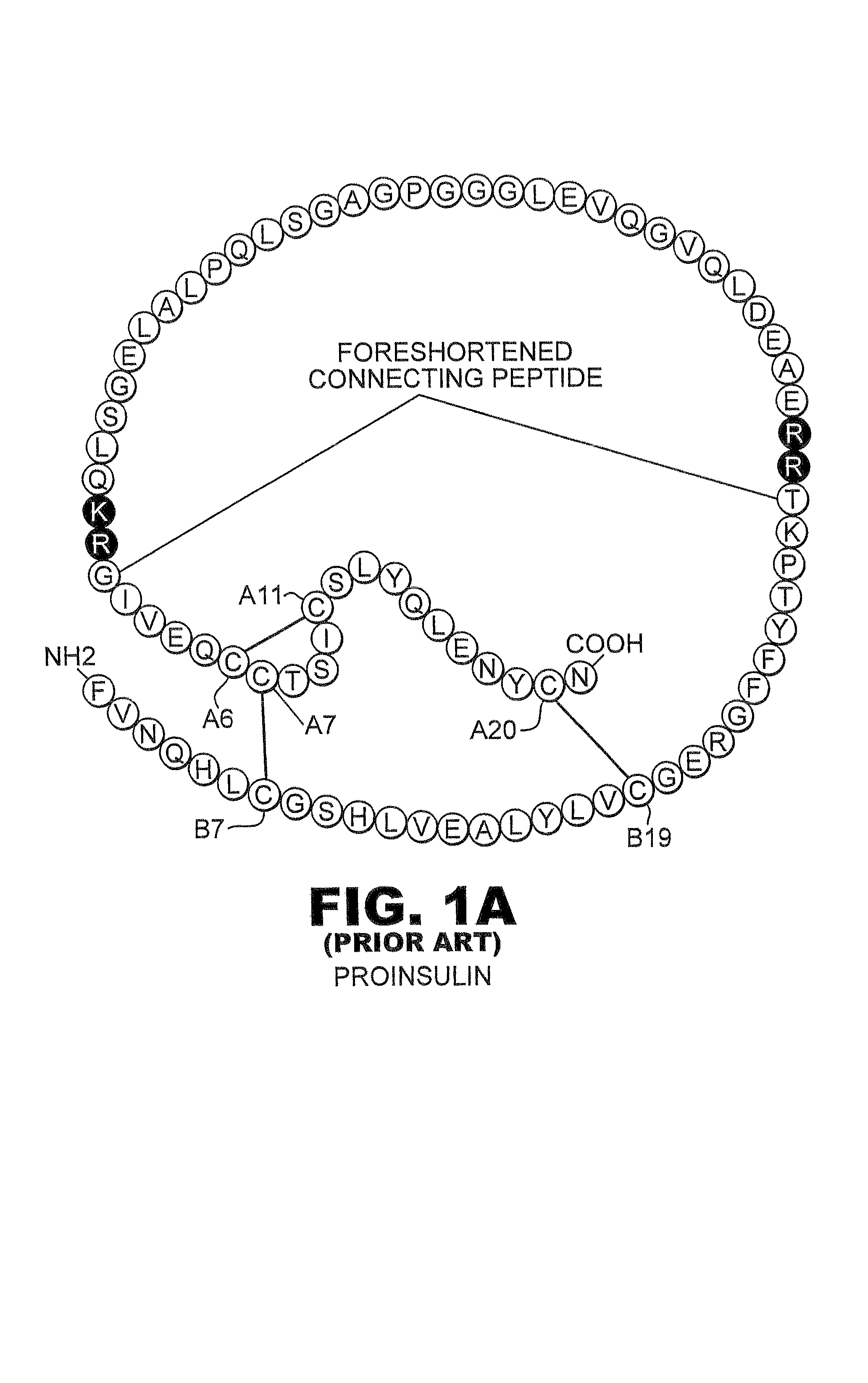

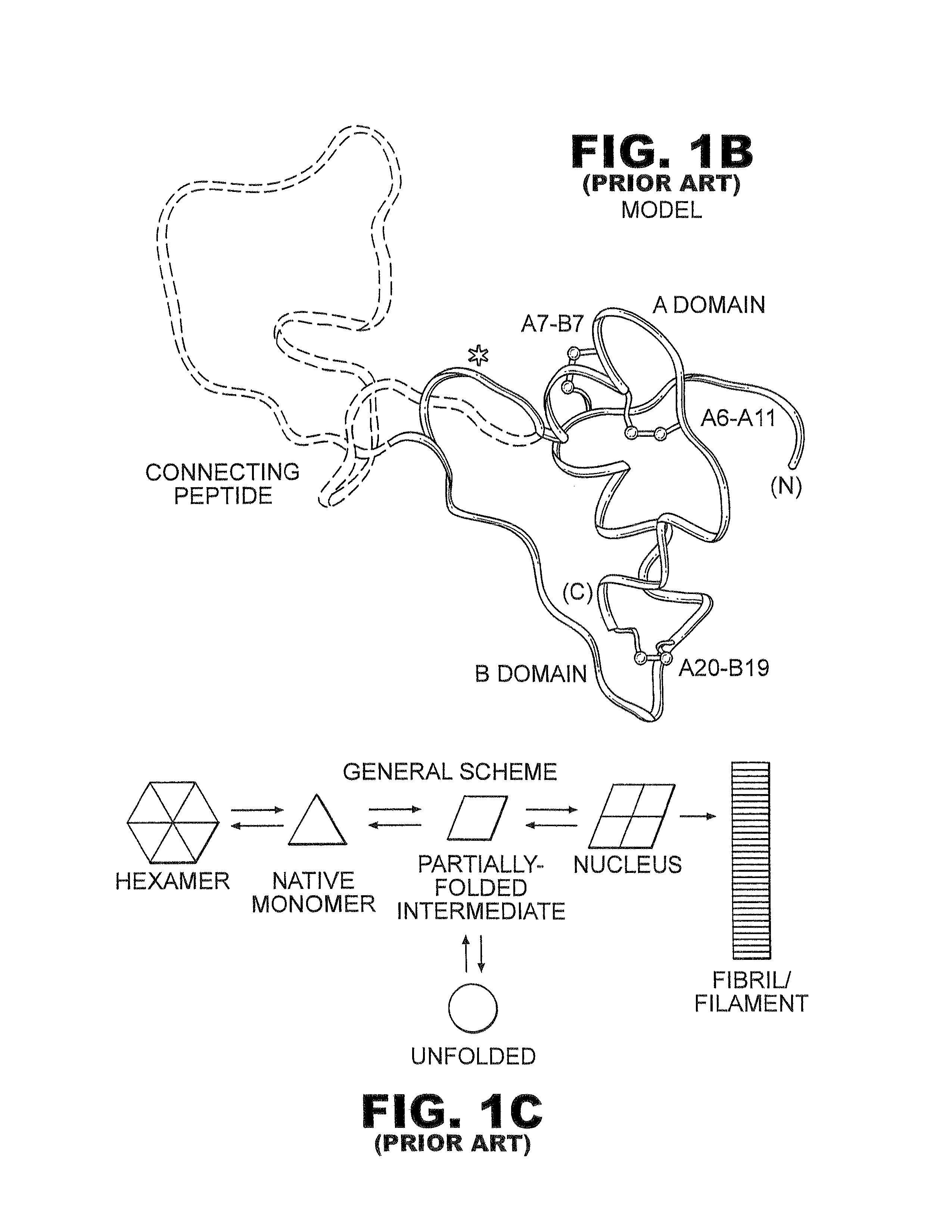

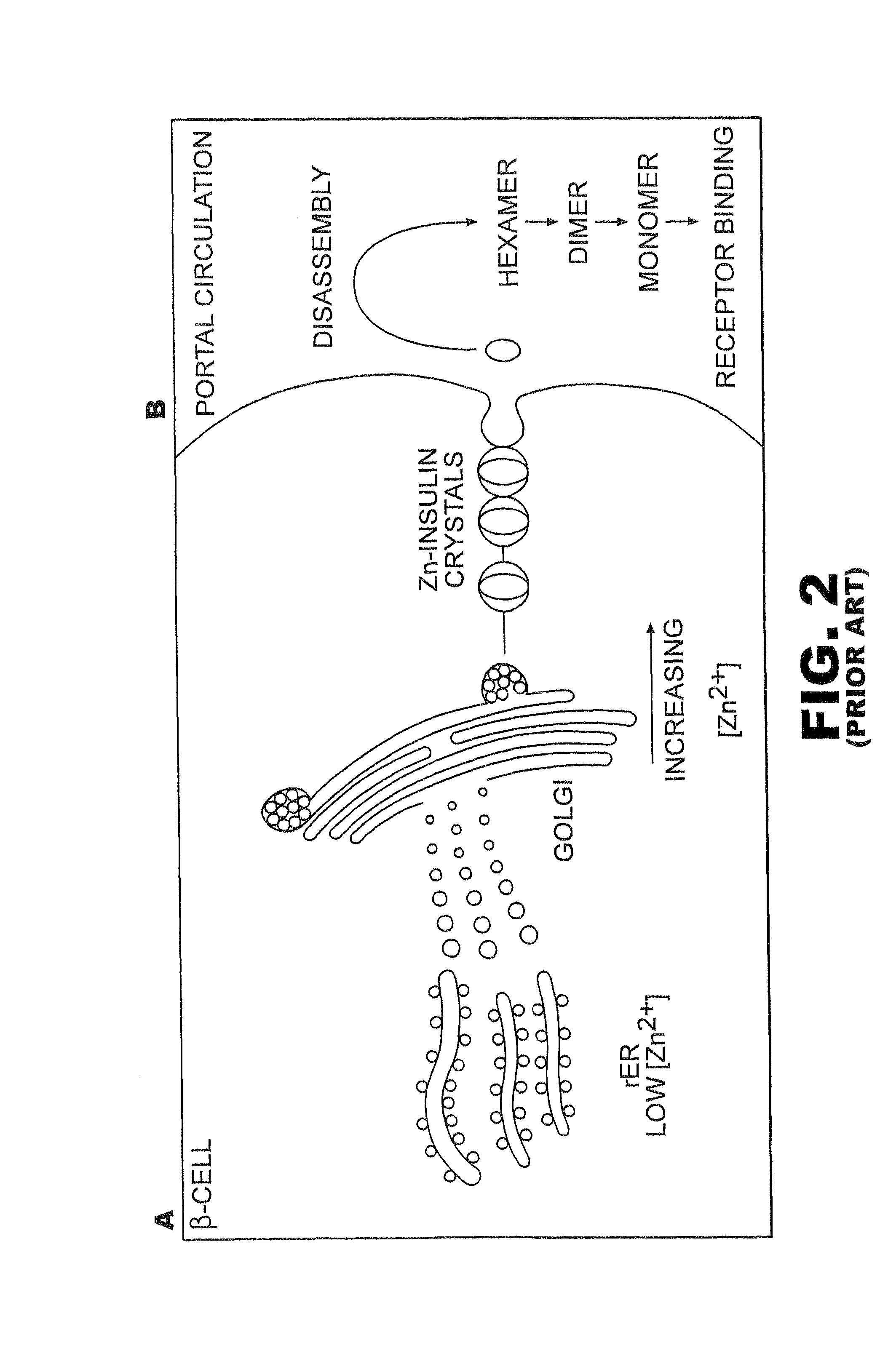

Fibrillation-resistant insulin and insulin analogues

InactiveUS8192957B2High thermodynamic stabilityMaintain biological activityBacteriaSugar derivativesInsulin A ChainNormal insulin

A fibrillation-resistant insulin analogue may be a single-chain insulin analogue or a physiologically acceptable salt thereof, containing an insulin A chain sequence or an analogue thereof and an insulin B chain sequence or an analogue thereof connected by a polypeptide of 4-10 amino acids. The fibrillation-resistant insulin analogue preferably displays less than 1 percent fibrillation with incubation at 37° C. for at least 21 days. A single-chain insulin analogue displays greater in vitro insulin receptor binding than normal insulin while displaying less than or equal binding to IGFR than normal insulin. The fibrillation-resistant insulin may be used to treat a patient using an implantable or external insulin pump, due to its greater fibrillation resistance.

Owner:CASE WESTERN RESERVE UNIV

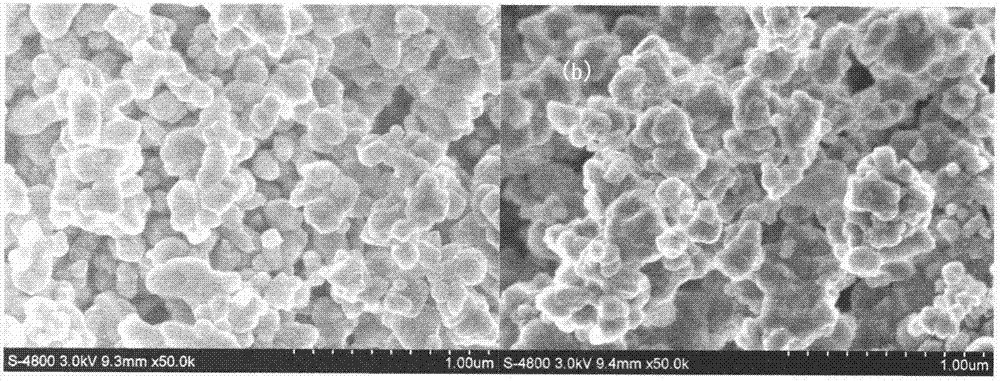

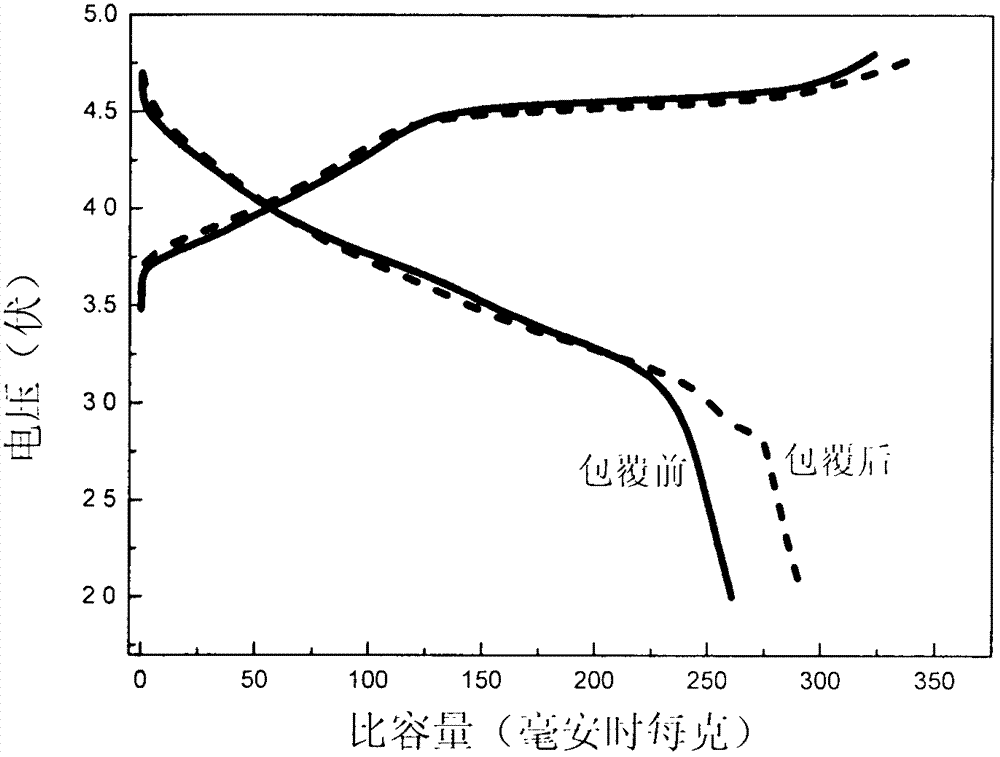

Lithium manganese phosphate clad lithium-rich layered oxide cathode material as well as preparation and application thereof

ActiveCN103035906AInhibition of dissolutionAvoid corrosionCell electrodesSecondary cellsManganesePhosphoric acid

The invention relates to a LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 (M is at least one of Ni or Co, wherein x is more than 0 and not less than 0.33) and a preparation method thereof. The Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is dipped in water solution containing Li, Mn and PO43- (the mol ratio is 1: 1: 1), is continuously stirred for 3-8 hours in an opening container at the temperature of 60-90 DEG C to prepare solid powder, then is dried for 2-24 hours at the temperature of 100 DEG C, and is roasted for 5-10 hours at the temperature of 300-600 DEG C to prepare the LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 cathode material, wherein the mass ratio of the LiMnPO4 to the Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is 3-10 wt%. The electrode material prepared by the method has the characteristics of high electrochemical capacity, good circulating stability, excellent rate capacity and the like, and has the advantages of simple preparation process, low cost and good reproducibility.

Owner:NANKAI UNIV

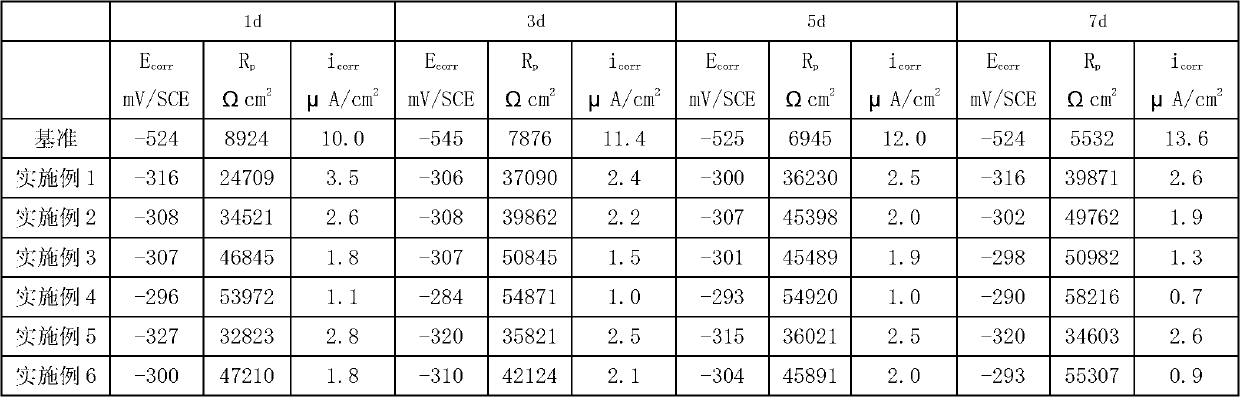

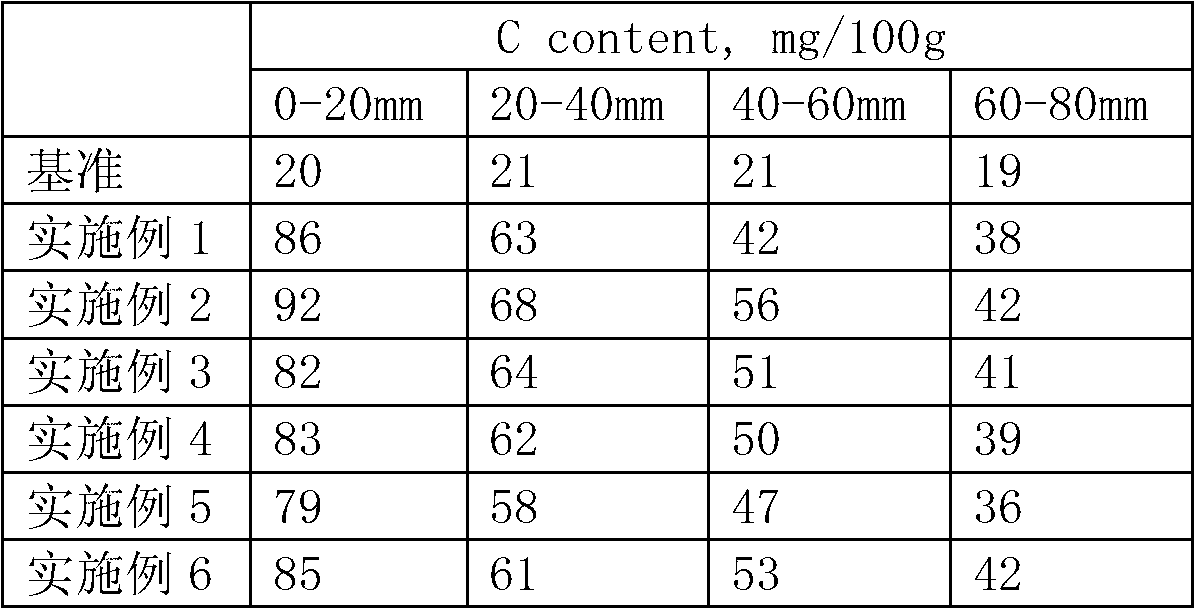

Surface coating type reinforced concrete corrosion inhibitor and preparation method thereof

ActiveCN102757197AModerate proportionPrevent and inhibit corrosionWater insolubleSurface-active agents

The invention relates to a surface coating type reinforced concrete corrosion inhibitor. The surface coating type reinforced concrete corrosion inhibitor comprises the components as follows: 15 to 40 wt% of a non-ionic surface active agent with HLB (Hydrophile Lipophile Balance) value more than 10, 5 to 30 wt% of a cosurfactant, 1 to 20 wt% of water insoluble organic inhibitor, and 20 to 50 wt% of water, wherein the cosurfactant is selected from organic alcohol or organic amine. The preparation method comprises the steps of mixing the non-ionic surface active agent, the cosurfactant and the water insoluble organic inhibitor, and agitating along with heating unit the mixture is completely molten, and then agitating along with water adding until the mixed liquid is turned into a clear state from a muddy state, thus obtaining the product. The preparation method provided by the invention is simple; the prepared product can be applied to surface treatment of the constructed concrete structure; and the prepared product has superior infiltration capacity, can effectively prevent the reinforcement surface from being eroded by chloride salt and sulfate, and has no adverse effect to the performance of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Lutein ester or lutein emulsion and preparation method of lutein ester or lutein emulsion

InactiveCN104366508AIncrease the amount of solubilizationPromote absorptionCosmetic preparationsSenses disorderSolubilityAdditive ingredient

The invention relates to lutein ester or lutein emulsion and a preparation method of the lutein ester or lutein emulsion, and aims at solving the problems that the stability and the water solubility of the lutein ester or lutein are poor, and the bioavailability is low. The emulsion is composed of the lutein ester or lutein, a solvent, an emulsifying agent, an auxiliary emulsifying agent, water and the like. The transparent or semi-transparent O / W type lutein ester emulsion is prepared by adopting a micro-emulsifying technology. The method is easy to operate and low in energy consumption, and is suitable for industrial production. The prepared lutein ester emulsion is uniform and has the strong stability, and can be diluted by adding the water at any ratio; and meanwhile, the system compatibility is good, and a plurality of beneficial components including amino acids, minerals, probiotics and the like can be compounded. The lutein ester or lutein emulsion can be widely applied to industries including health products, functional beverages, cosmetics, medicines and the like.

Owner:天津禹王生物医药科技有限公司 +1

Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one

ActiveUS20060100198A1High thermodynamic stabilityEasy to manufactureBiocideNervous disorderDiseasePhosphate

The present invention relates to novel polymorphic and amorphous forms of a phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-cd]indol-6-one, and to processes for their preparation. Such polymorphic forms may be a component of a pharmaceutical composition and may be used to treat a mammalian disease condition mediated by poly(ADP-ribose) polymerase activity including the disease condition such as cancer.

Owner:CANCER RES TECH LTD +2

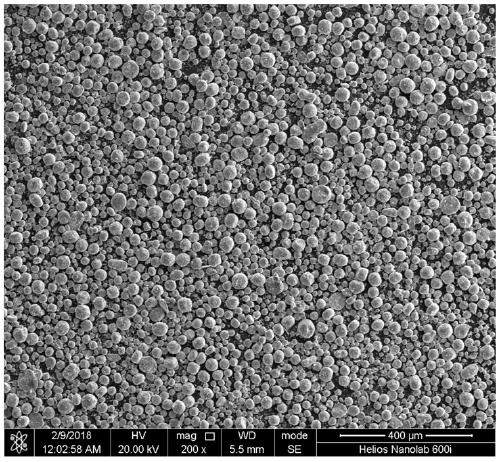

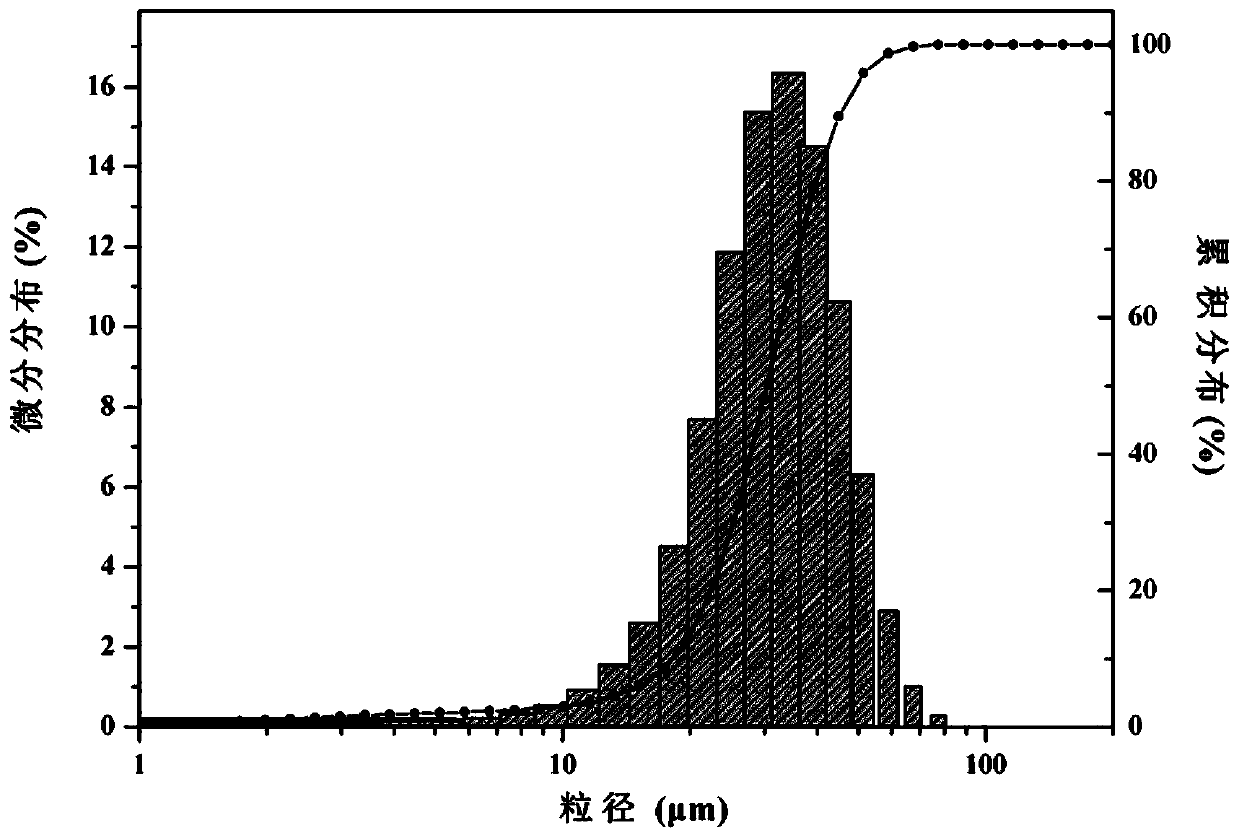

Nano hard alloy material containing spherical face-centered cubic structure cobalt powder and preparation process thereof

The invention provides a nano hard alloy material containing spherical face-centered cubic structure cobalt powder and a preparation process thereof and belongs to the technical field of hard alloy preparation. The method comprises the steps of using 12-14 wt.% of the spherical face-centered cubic structure cobalt powder with the average grain diameter in a range of 200-300nm, 65-70 wt.% of tungsten carbide with the average grain diameter in a range of 200-300nm, 16-23 wt.% of tungsten carbide-titanium carbide-vanadium carbide-tantalum carbide-chromium carbide solid solution powder with the average grain diameter in a range of 300-400nm and a proper amount of an active and surface dispersing agent, and combining with airtight inert gases to protect high-speed ball milling, spray drying and overpressure sintering, so that sintering bodies are compact to the maximum extent, grain growth is restrained, the high-temperature performance of an alloy is optimized, and finally the high-hardness high-strength hard alloy material is obtained. The process is optimal in technology, easy to operate and applicable to industrial production.

Owner:重庆金锐新材料技术研究院有限公司

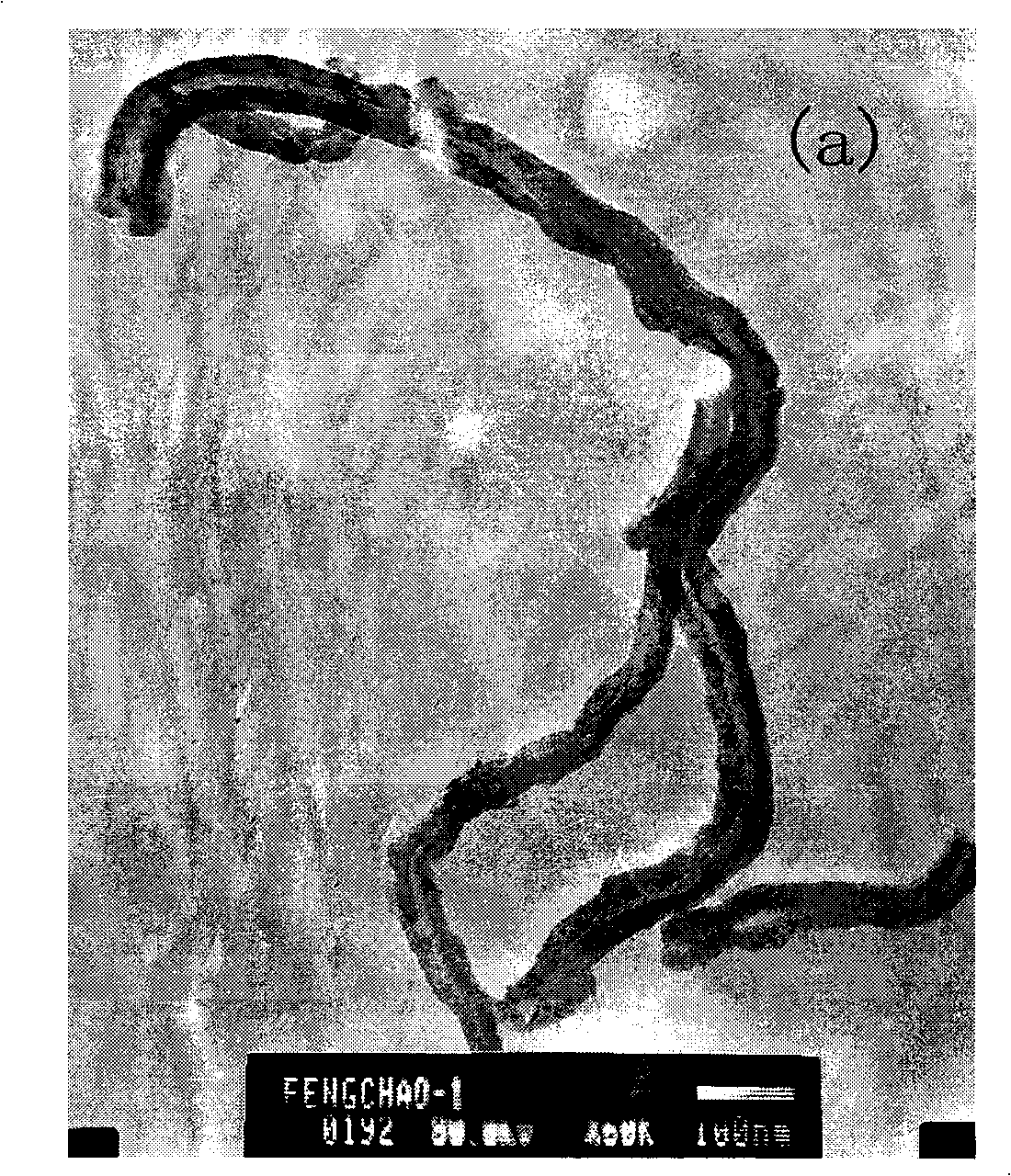

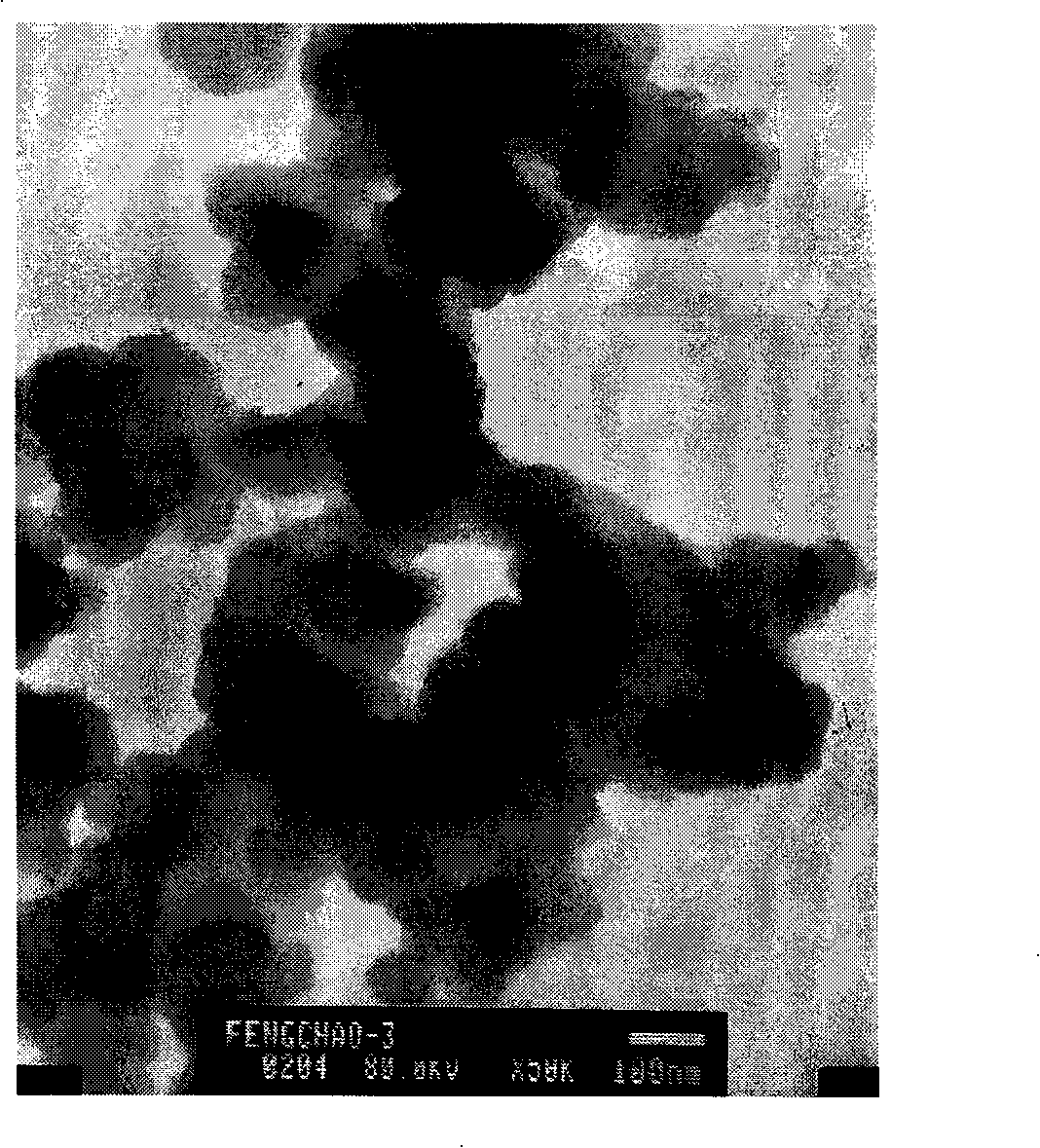

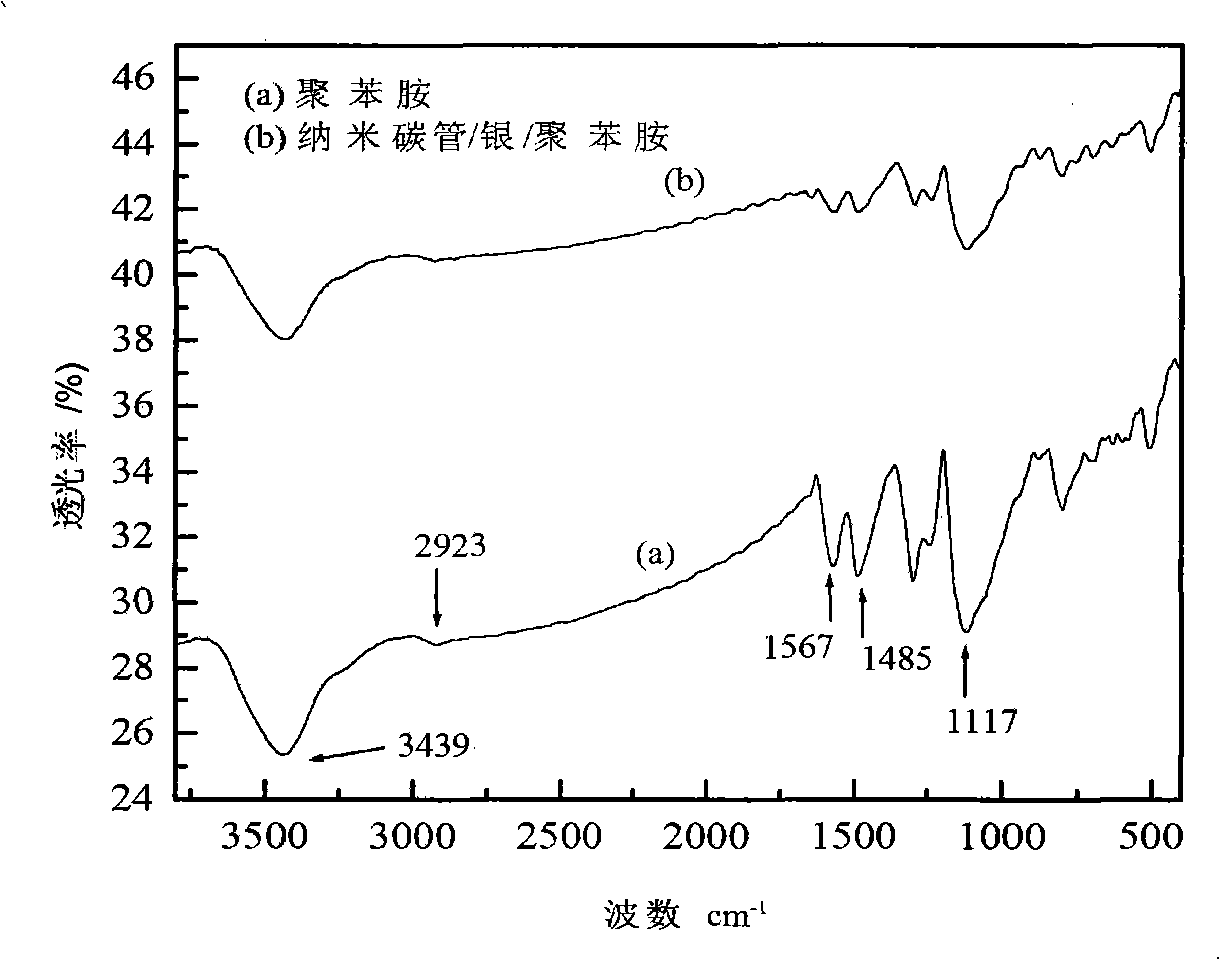

Polyaniline/carbon nano tube/nanometer silver particle conductive composite material and preparation method thereof

InactiveCN101525435AImprove conductivityHigh thermodynamic stabilityNon-conductive material with dispersed conductive materialCarbon nanotubeTwo phase composite

The invention provides a novel polyaniline / carbon nano tube / nanometer silver particle conductive composite material which belongs to the technical field of composite materials. The novel polyaniline / carbon nano tube / nanometer silver particle conductive composite material uses a two-phase composite material of carbon nano tube / nanometer silver particle as conductive filling and effectively utilizes the supersonic technology to lead the nanometer silver particle to uniformly disperse into polyaniline; the polyaniline grows on the surface of the carbon nano tube and completely covers the carbon nano tube. The invention solves the glomeration problem in aniline polymerization, can lead the nanometer silver particle to uniformly disperse into a polyaniline structure, effectively improves the conductive property and the thermodynamics stability of the polyaniline, and has simple process, convenient operation, mild reaction conditions, low production cost, high production efficiency, and better industrial production prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

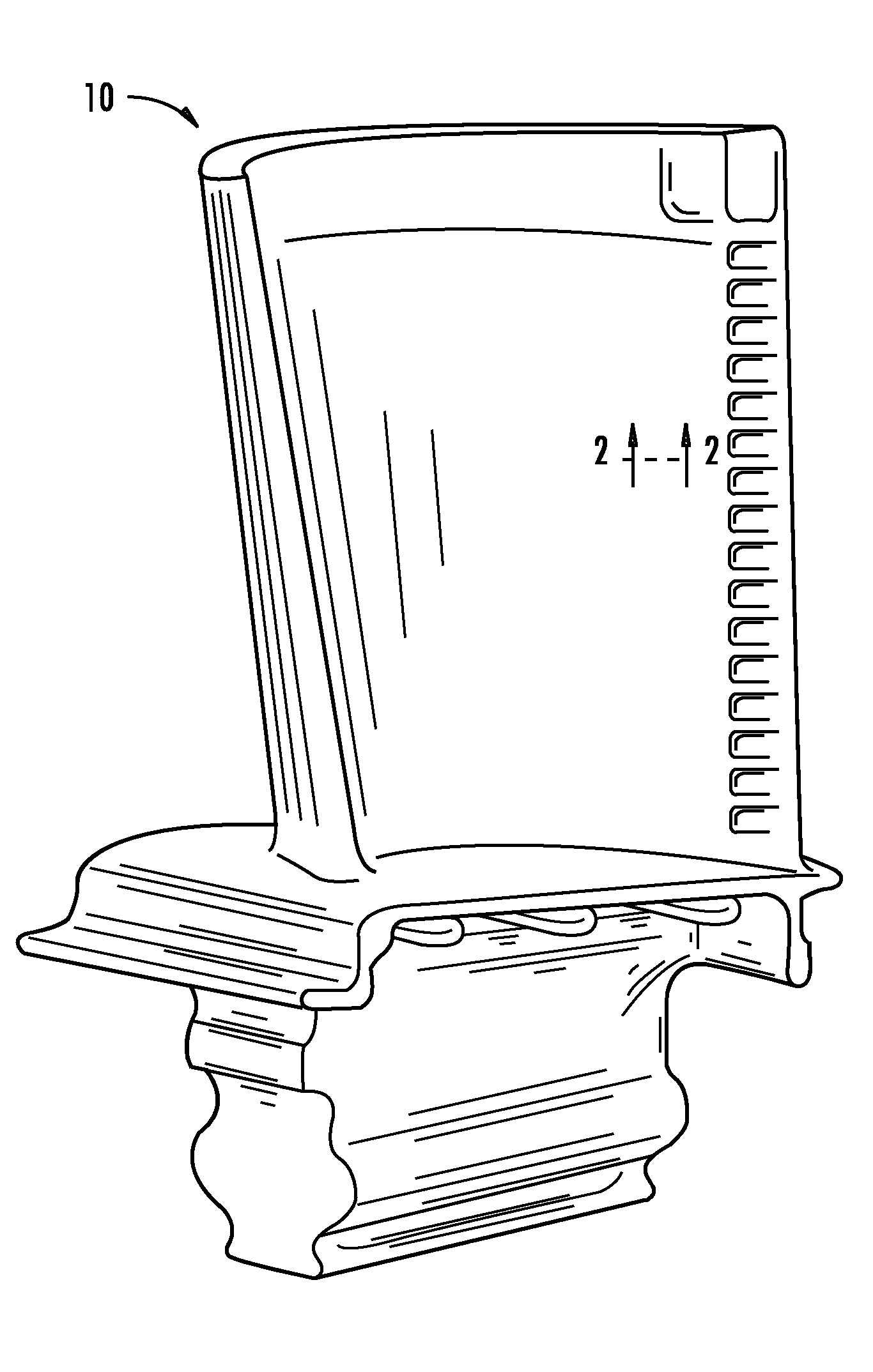

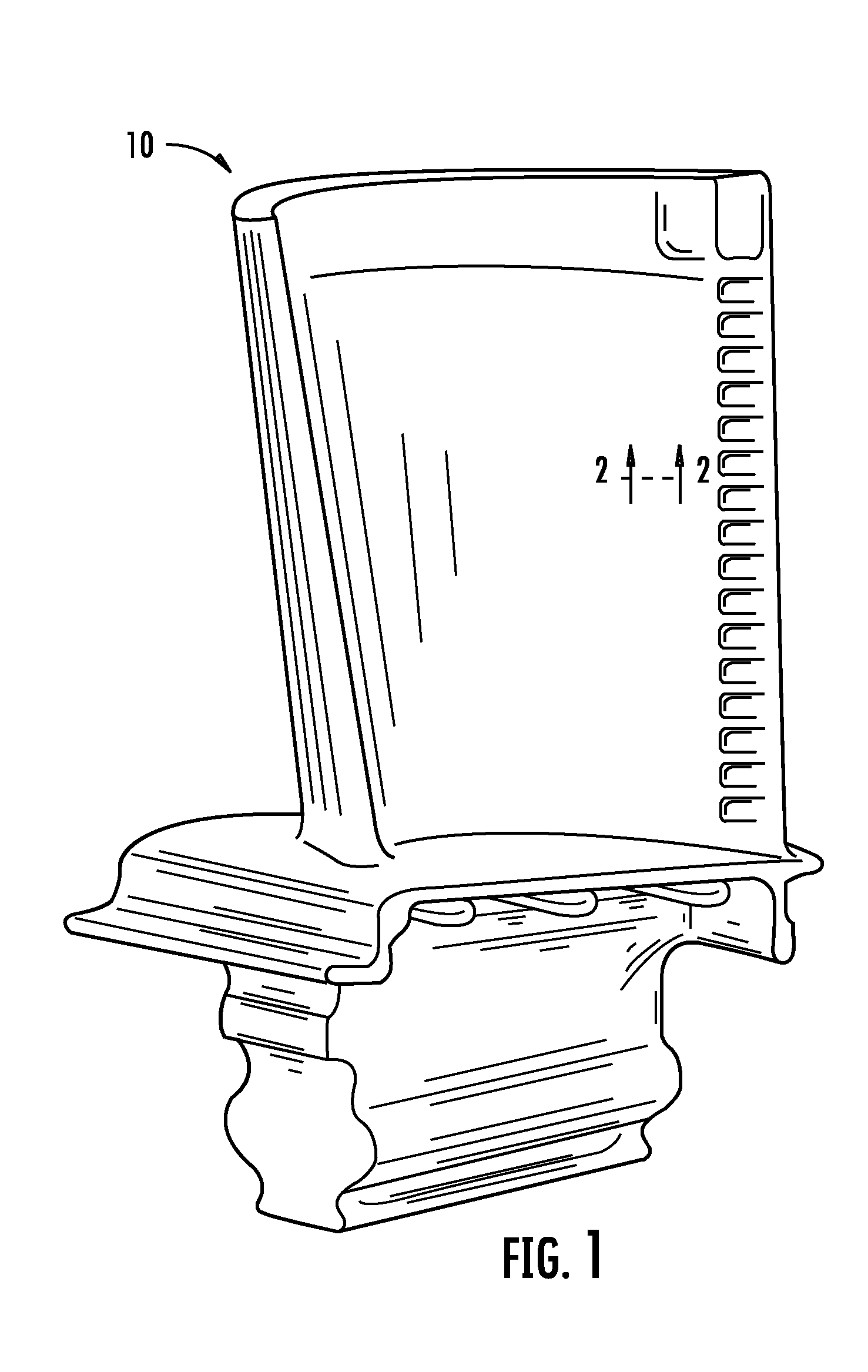

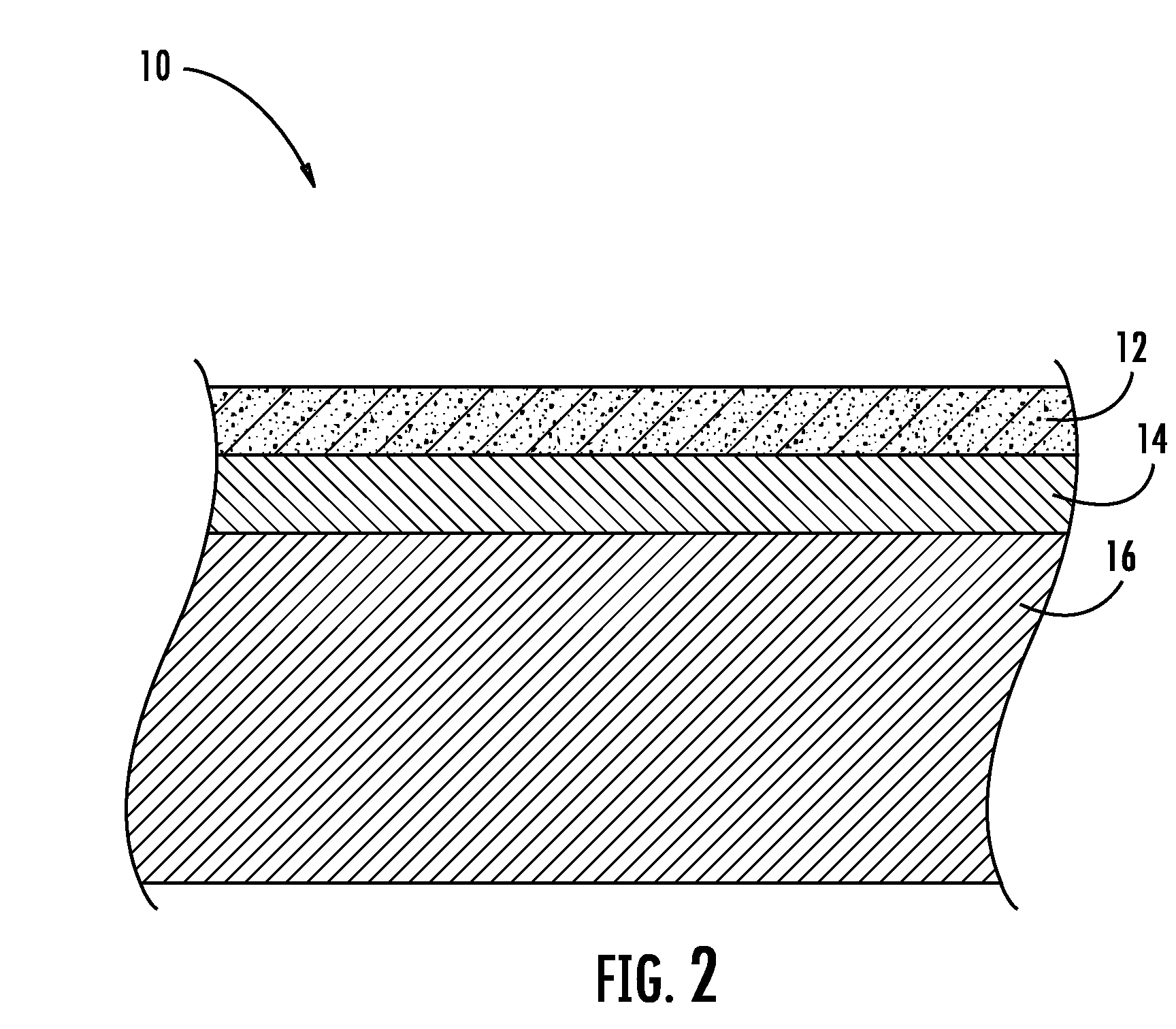

Combustion Turbine Component Having Rare Earth CoNiCrAl Coating and Associated Methods

ActiveUS20090075101A1Improved high-temperature oxidation resistanceImprove creep resistanceLiquid surface applicatorsMolten spray coatingRare-earth elementNichrome

A combustion turbine component (10) includes a combustion turbine component substrate (16) and an alloy coating (14) on the combustion turbine component substrate. The alloy coating (14) includes a first amount, by weight percent, of cobalt (Co) and a second amount, by weight percent, of nickel (Ni), the first amount being greater than the second amount. The alloy coating further includes chromium (Cr), aluminum (Al), at least one rare earth element, and an oxide of the at least one rare earth element.

Owner:SIEMENS ENERGY INC

Biocompatibile monodisperse nano polymer carrier and its preparation and medicine-carrying method

InactiveCN101259279AGood biocompatibilityGood blood compatibilityOrganic active ingredientsPharmaceutical non-active ingredientsPhosphorylcholineCarrier system

The invention relates to a monodisperse nano-polymer carrier with biological compatibility and a method for preparation and carrying drug thereof. Firstly, a reversible addition fragmentation chain transfer (RAFT) polymerization method is used for preparing amphiphilic block copolymers with smaller polydispersity index, wherein the hydrophilic segment is methylacryoyloxyethyl phosphorylcholine (MPC) and the hydrophobic segment is n-butyl methacrylate (BMA). Then through the method of solvent evaporation, the amphiphilic block copolymers are used for preparing nano-polymer micelle, drugs are encapsulated in the micelle through physical action, thus obtaining the monodisperse nano-polymer carrier system with good biological compatibility.

Owner:SOUTHEAST UNIV

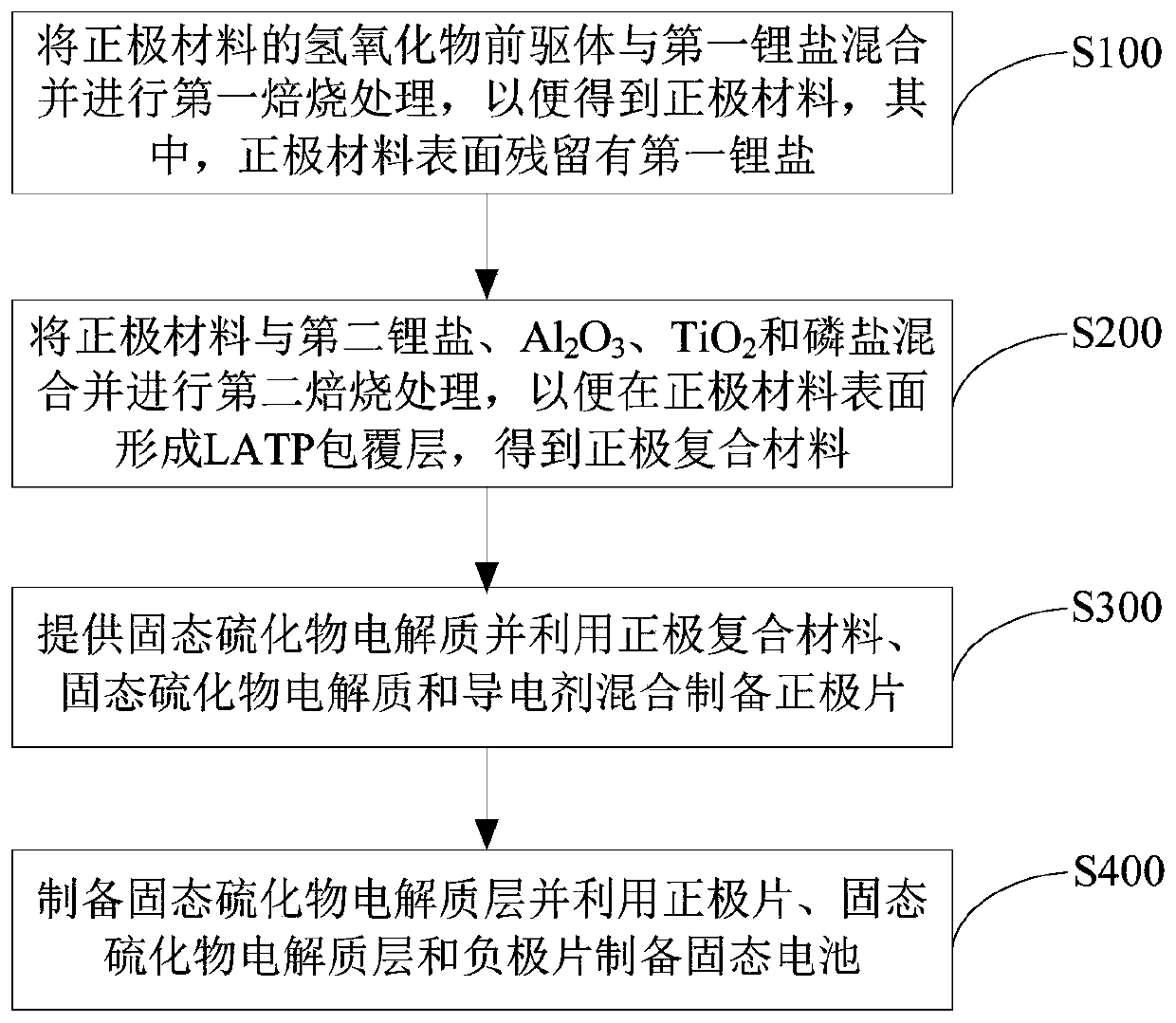

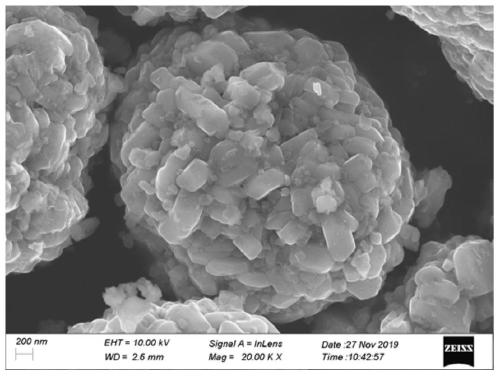

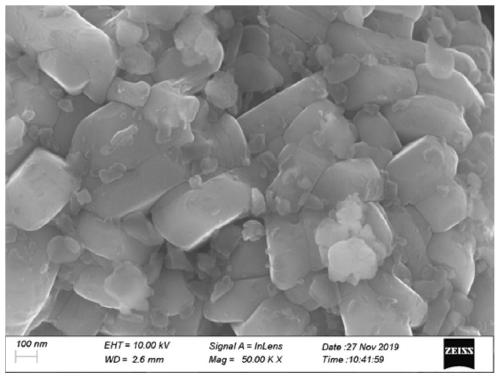

Solid-state battery and preparation method and application thereof

InactiveCN111430688AHigh charge and discharge capacityImprove the first effectSolid electrolytesCell electrodesPhysical chemistrySulfide compound

The invention discloses a solid-state battery and a preparation method and application thereof. The solid-state battery comprises a positive plate, a solid-state sulfide electrolyte layer and a negative plate. The positive plate comprises a positive composite material, a solid-state sulfide electrolyte and a conductive agent, the positive composite material comprises a positive material and an LATP coating layer formed on the surface of the positive material, and the solid sulfide electrolyte layer is arranged between the positive plate and the negative plate, wherein the LATP coating layer isobtained by taking the residual lithium salt on the surface of the positive electrode material as a guiding agent and the lithium source and inducing the lithium source, an aluminum source, a titanium source and a phosphorus source through an in-situ synthesis method. The solid-state battery has better rate capability and cycle performance at room temperature and a high temperature (70 DEG C).

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Method for preparing titanium-based nano composite material based on selective laser melting 3D printing

InactiveCN109943786ALight in massHigh thermodynamic stabilityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingTitanium matrix composites

The invention discloses a method for preparing a titanium-based nano composite material based on selective laser melting 3D printing, relates to a method for preparing the titanium-based nano composite material, and aims at solving the problem of poor cutting processing performance of titanium and the titanium-based composite material. The method comprises the steps that preparation is conducted,wherein composite powder is prepared through ball milling, and the content of B4C powder in the composite powder is (0.5-1) wt%; selective laser melting 3D printing is utilized for shaping. The methodhas the advantages that the mass of the prepared composite material is light, the thermodynamic stability is high, the strength is high, the wearing resistance is high, fixture tools or molds are notneeded in the shaping process, 'near net shape forming' is easily achieved, the composite material can be massively prepared in a short time, and sources of raw materials are wide; substrate crystalline grains of the prepared composite material are significantly fined, in-site generated complete nano scale TiB whiskers are diffusely distributed on boarders of substrate crystalline grains, an obvious enhancing effect on the composite material is achieved, the mechanical performance is significantly improved, and the method is suitable for preparing the titanium-based nano composite material through 3D printing.

Owner:HARBIN INST OF TECH

Ivermectin nanoemulsion drug combination and preparation method thereof

ActiveCN101623256AHigh thermodynamic stabilityGood storage stabilityOrganic active ingredientsPharmaceutical non-active ingredientsDistilled waterBioavailability

The invention discloses an ivermectin nanoemulsion drug combination. Oil-in-water type nanoemulsion consisting of ethyl oleate, Tween-80, 1,2- propylene glycol and ivermectin is prepared from being diluted by double distilled water. The ivermectin nanoemulsion drug combination greatly improves the effect of ivermectin in resisting parazoon, enhances the dissolubility, safety and bioavailability and is a high-efficiency antiparasitic nano level medicinal preparation with convenient use and wide ways of administration.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

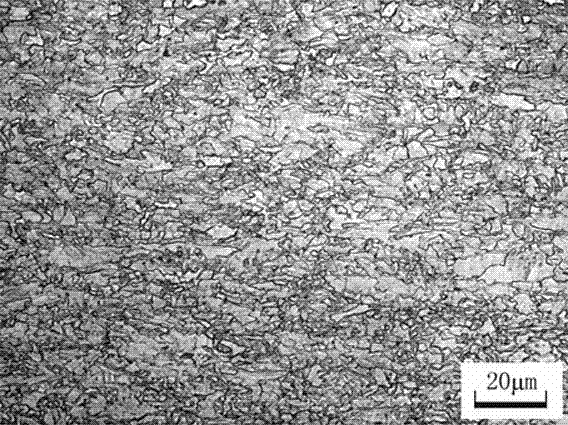

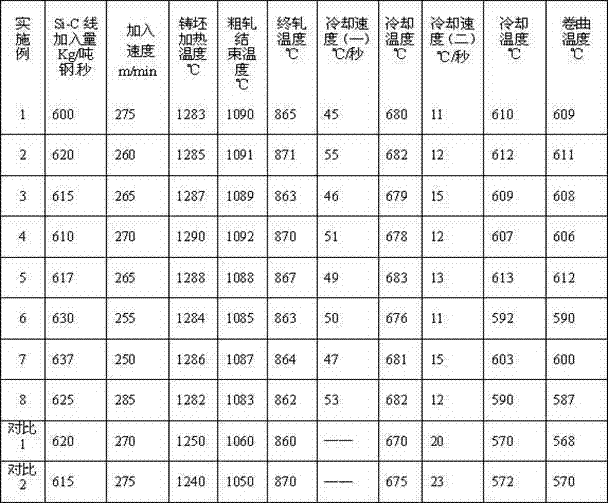

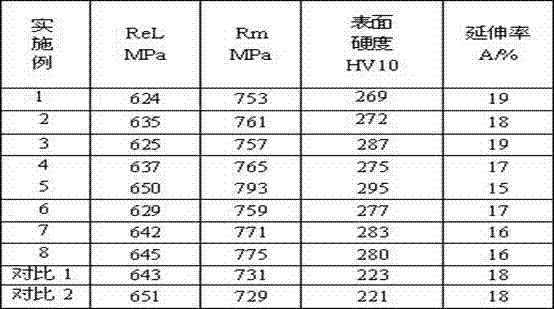

Hot rolled steel used for stirrer in automotive stirring tank and production method thereof

ActiveCN102776442AImprove corrosion resistanceImprove wear resistanceTemperature control deviceAfter treatmentChemical composition

The invention relates to a hot rolled steel used for a stirrer in an automotive stirring tank with tensile intensity of 750 MPa and a production method thereof. The hot rolled steel comprises the following chemical components by weight: 0.13-0.18% of C, not more than 0.15% of Si, 1.20-1.70% of Mn, 0.016-0.025% of P, not more than 0.008% of S, 0.035-0.070% of Als, 0.07-0.10% of Ti, 0.035-0.055% of Nb and 0.20-0.33% of Cu. The process comprises the following steps: smelting in a converter; treating in an LF furnace (ladle furnace); continuously casting to a blank and heating the cast blank; rolling in a segmental manner; cooling at variable speed and carrying out laminar flow cooling; coiling; and finishing and carrying out an after treatment process. According to the invention, an Rm average value is 780-800 MPa, elongation A is not less than 14%, the surface hardness HV10 reaches 260-300, in comparison with the conventional intensity steel with the same level, the surface hardness is at least improved for 20%, a plate form is easy to control, the surface quality is high, copper is particularly added, and the wear resistance and the anti-corrosion performance of a steel product are greatly improved.

Owner:武汉钢铁有限公司

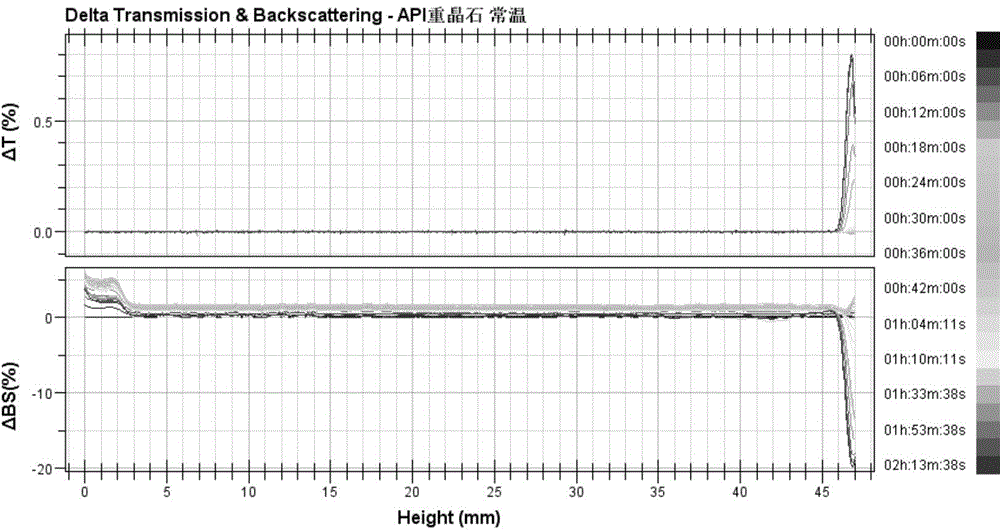

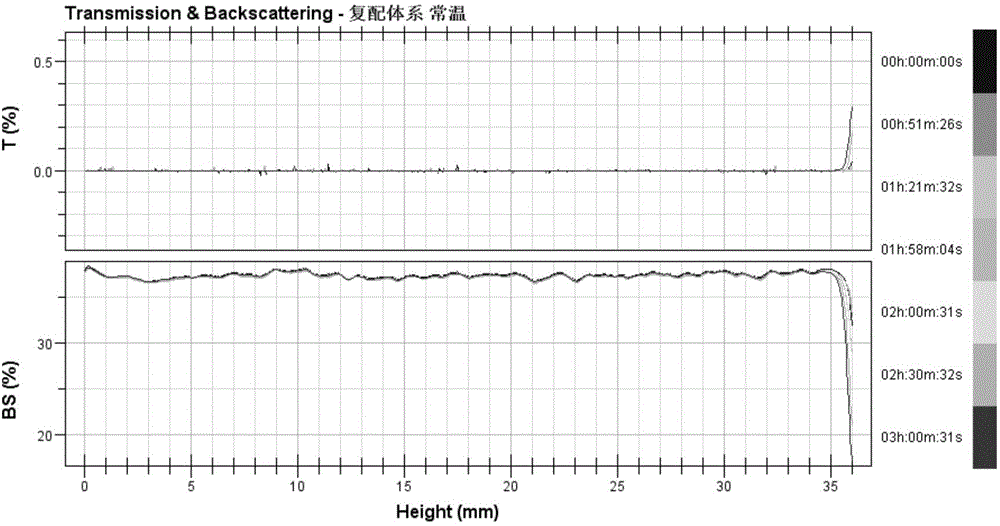

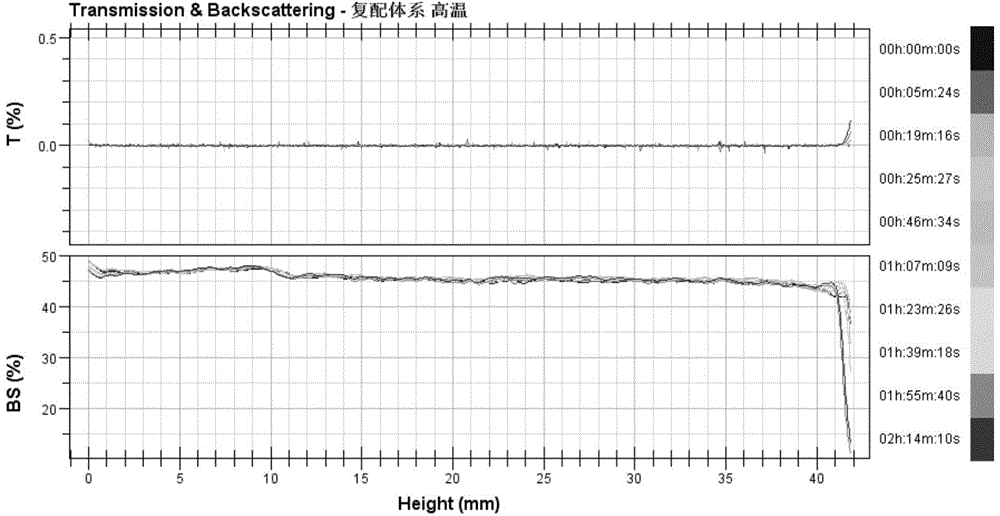

Superfine oil-base drilling fluid used for high temperature high temperatur high pressure superdeep well and preparation method thereof

ActiveCN104610946AIncreased steric hindranceOvercoming the tendency to coalesceDrilling compositionFiltrationHigh pressure

The invention provides a superfine oil-base drilling fluid used for a high temperature high pressure superdeep well, the superfine oil-base drilling fluid contains the following raw materials by weight: 20-40 parts of water, 250-500 parts of diesel, 2-10 parts of an emulsifier, 3-15 parts of a wetting agent, 2-8 parts of organic soil, 15-25 parts of a filtrate loss agent, 5-10 parts of calcium chloride, 5-10 parts of calcium oxide, 450-800 parts of API barite, and 350-660 parts of an ultra aggravating material. The oil-base drilling fluid is weighted by compounding superfine mineral powder and ordinary barite, the superfine high density oil-base drilling fluid density can reach 2.8g / cm<3>, has better settling stability and high temperature and high pressure filtration loss compared with that of ordinary barite weighted drilling fluid, and can meet drilling of deep wells, superdeep wells and composite salt formations.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

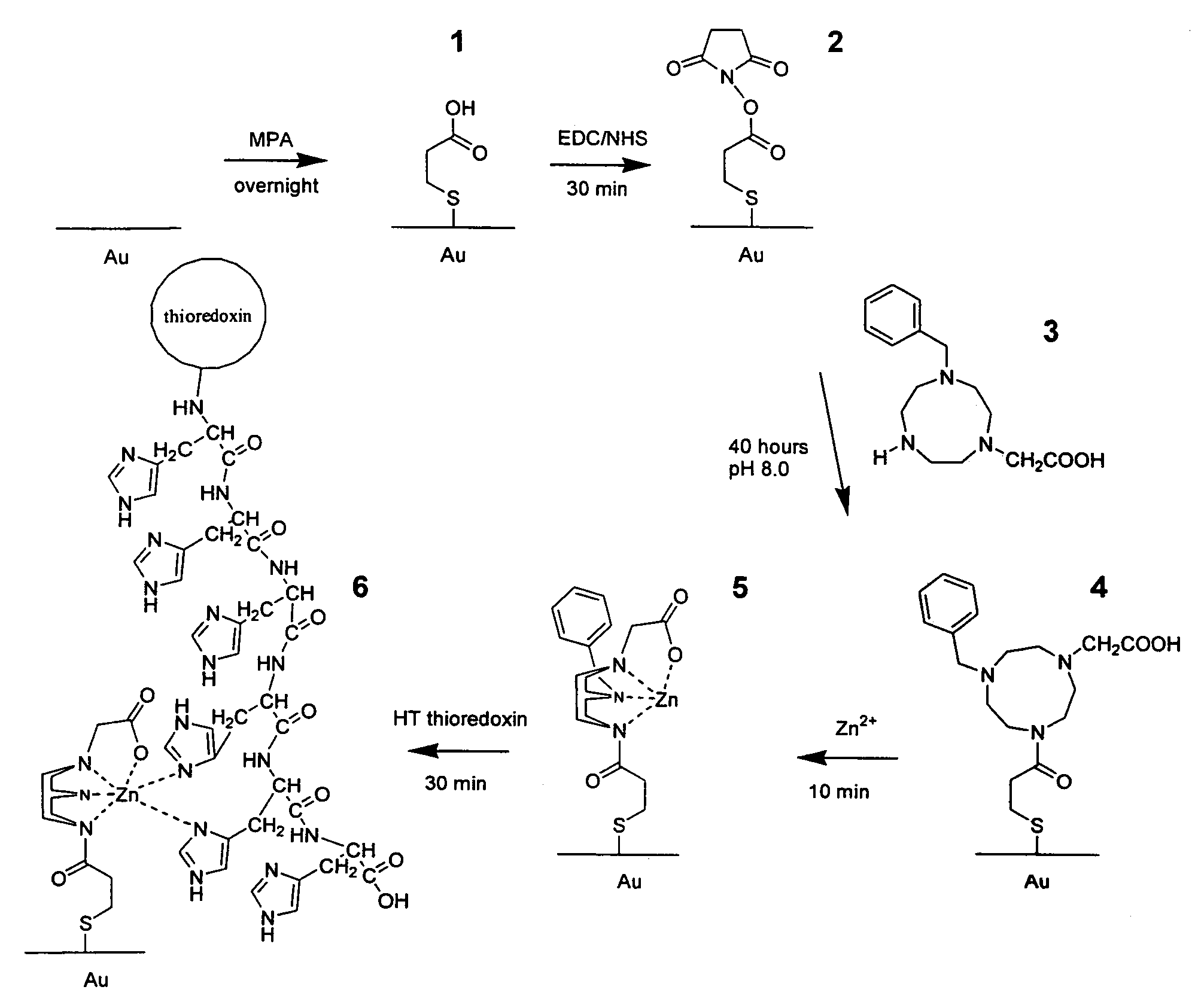

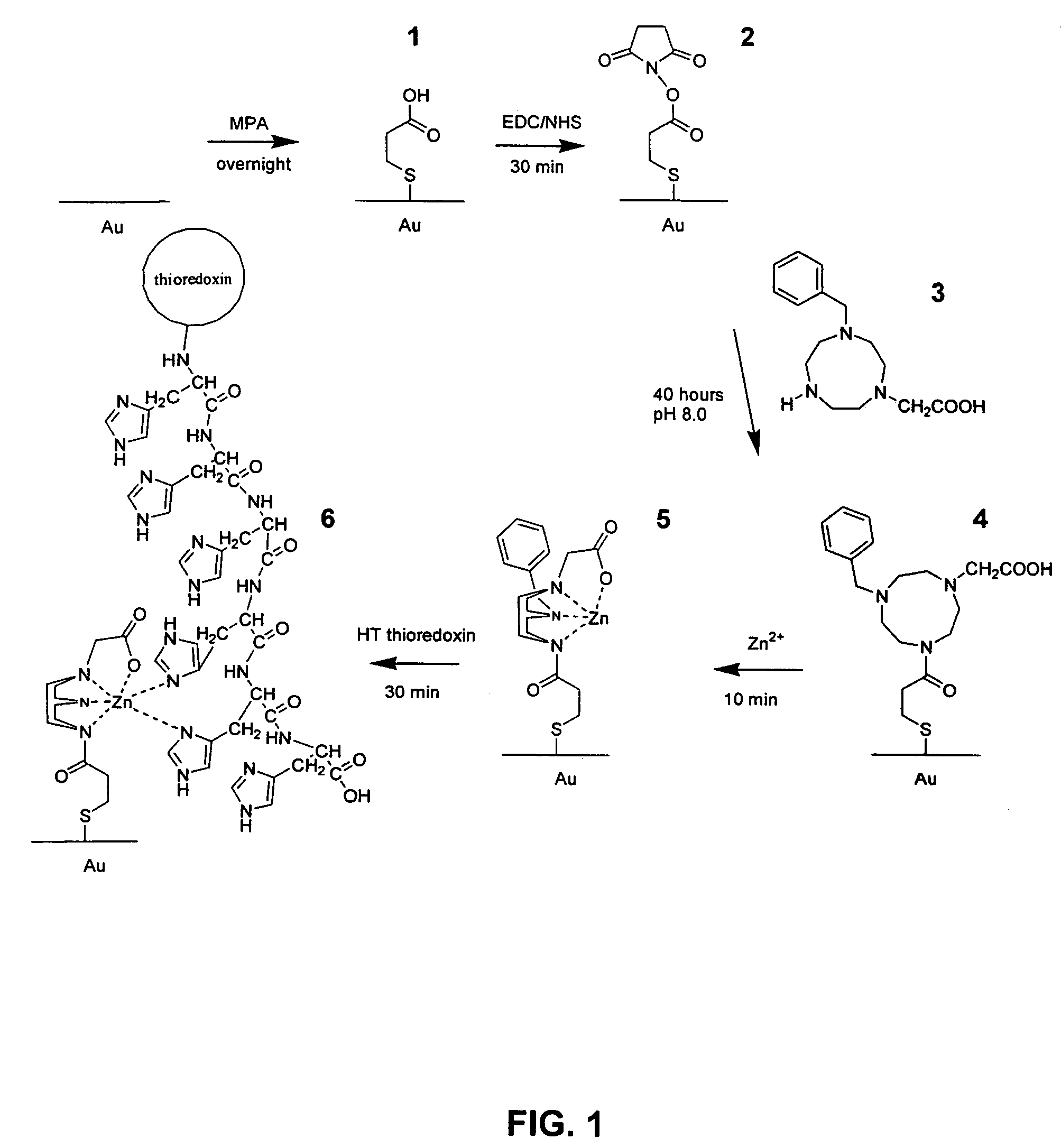

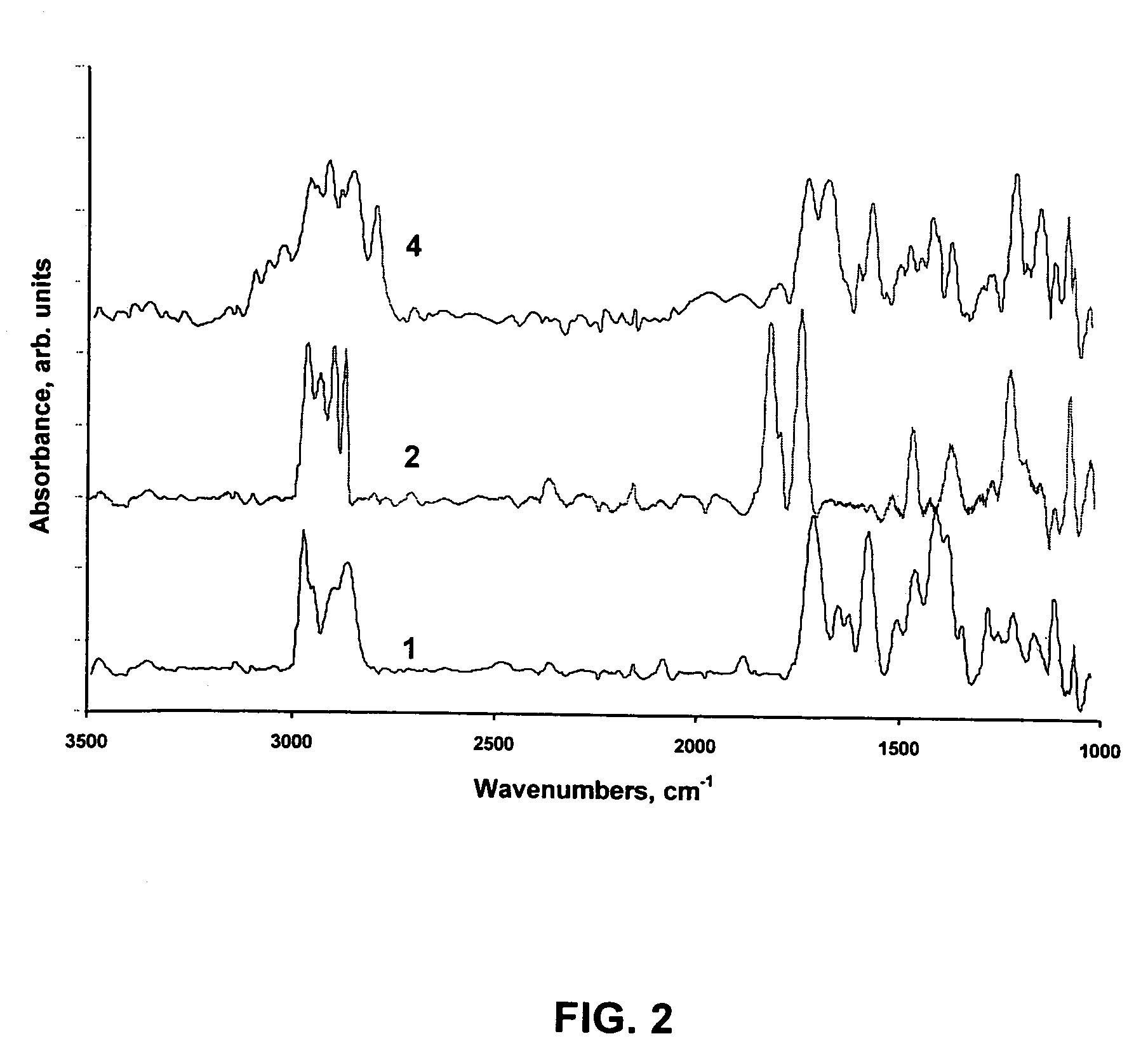

Sensor chips

InactiveUS7759114B2Improve efficiencyIncrease rangeBioreactor/fermenter combinationsMaterial nanotechnologyCombinatorial chemistryMetal ion sequestering

A method for selectively orienting molecules on a surface of a solid support. The method includes the steps of: (a) attaching a linker molecule to the surface of the solid support, the linker molecule including a head group that is capable of binding to the solid support, and a tail group that is capable of chelating to a metal ion; (b) subsequently treating the solid support with a solution containing the metal ion; (c) attaching a metal ion chelating tag to the molecules to form tagged molecules; and (d) capturing the tagged molecules on the solid support by contacting it with the tagged molecules to form a monolayer of molecules on the surface of the solid support in which a majority of the molecules are held in the same orientation with respect to the surface. The invention also provides a sensor chip formed using the methods of the invention.

Owner:TACNIA

High temperature resistant anticorrosion modified epoxy organosilicon coating

InactiveCN101486875AImprove corrosion resistanceImprove temperature resistanceAnti-corrosive paintsEpoxyPhosphate

The invention relates to a high-temperature resistant anti-corrosion modified epoxy organic silicon coating and a preparation method. The coating uses organic phosphate and fluoropolymer to modify epoxy organic silicon resin which originally has excellent high-temperature resistant and anti-corrosion properties; with organic phosphate group introduced, not only the high-temperature resistance of resin is improved, but also the later anticorrosion property of the coating can be improved to certain extent. In the film forming process of the coating, the organic phosphate group and substrate metal form a compact phosphate protective film, thus passivating metal surface, preventing water molecules and salt ions from being contacted with metal and further leading the coating to have excellent anticorrosion function. With the fluoropolymer with high-temperature resistance and chemical corrosion resistance introduced, the polymerization between the fluoropolymer and active organic silicon group can distinctly improve the high-temperature resistance of resin. The matched use of the modified epoxy organic silicon resin and a high-temperature resistant pigment can lead the coating to not only maintain proper physical mechanical property, but also have excellent anticorrosion performance under the high temperature condition of 350 DEG C.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

Grain refiner for synthesis of aluminium alloy by laser ignited self-propagation and method for preparing the same

InactiveCN1789448AHigh thermodynamic stabilityStrong resistance to grain refinement recession5052 aluminium alloyMetal

The invention relates grain refiner used for synthesizing aluminum alloy by laser firing and preparing method. The grain refiner comprises Al, Ti and B. The method comprises the following steps: mixing the Al, Ti, B and TiH2 powers with blending attachment, adding the powders into die and pressing them to preformed sample, after evacuating and filling argon gas, utilizing the laser to carry out self-propagating reaction of preformed sample and get grain refiner. The grain refiner possesses good refining effect and decline-resistant capability. The invention suits for aluminum alloy handling field.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/1bab3e8f-b3b0-4729-9aa3-b9a10476b72a/US07268126-20070911-D00001.png)

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/1bab3e8f-b3b0-4729-9aa3-b9a10476b72a/US07268126-20070911-D00002.png)

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6H-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/1bab3e8f-b3b0-4729-9aa3-b9a10476b72a/US07268126-20070911-D00003.png)

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/8b5d2cdc-ff64-424a-85ec-9c92a1b51edf/US20060100198A1-20060511-D00001.png)

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/8b5d2cdc-ff64-424a-85ec-9c92a1b51edf/US20060100198A1-20060511-D00002.png)

![Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one Polymorphic and amorphous forms of the phosphate salt of 8-fluoro-2-{4-[(methylamino)methyl]phenyl}-1,3,4,5-tetrahydro-6h-azepino[5,4,3-ce]indol-6-one](https://images-eureka.patsnap.com/patent_img/8b5d2cdc-ff64-424a-85ec-9c92a1b51edf/US20060100198A1-20060511-D00003.png)