Patents

Literature

146 results about "Two phase composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-phase composite compact ceramic oxygen permeable membrane and method of preparing the same

InactiveCN101254421ALow costGood chemical stabilitySemi-permeable membranesDispersed particle separationFiberNon toxicity

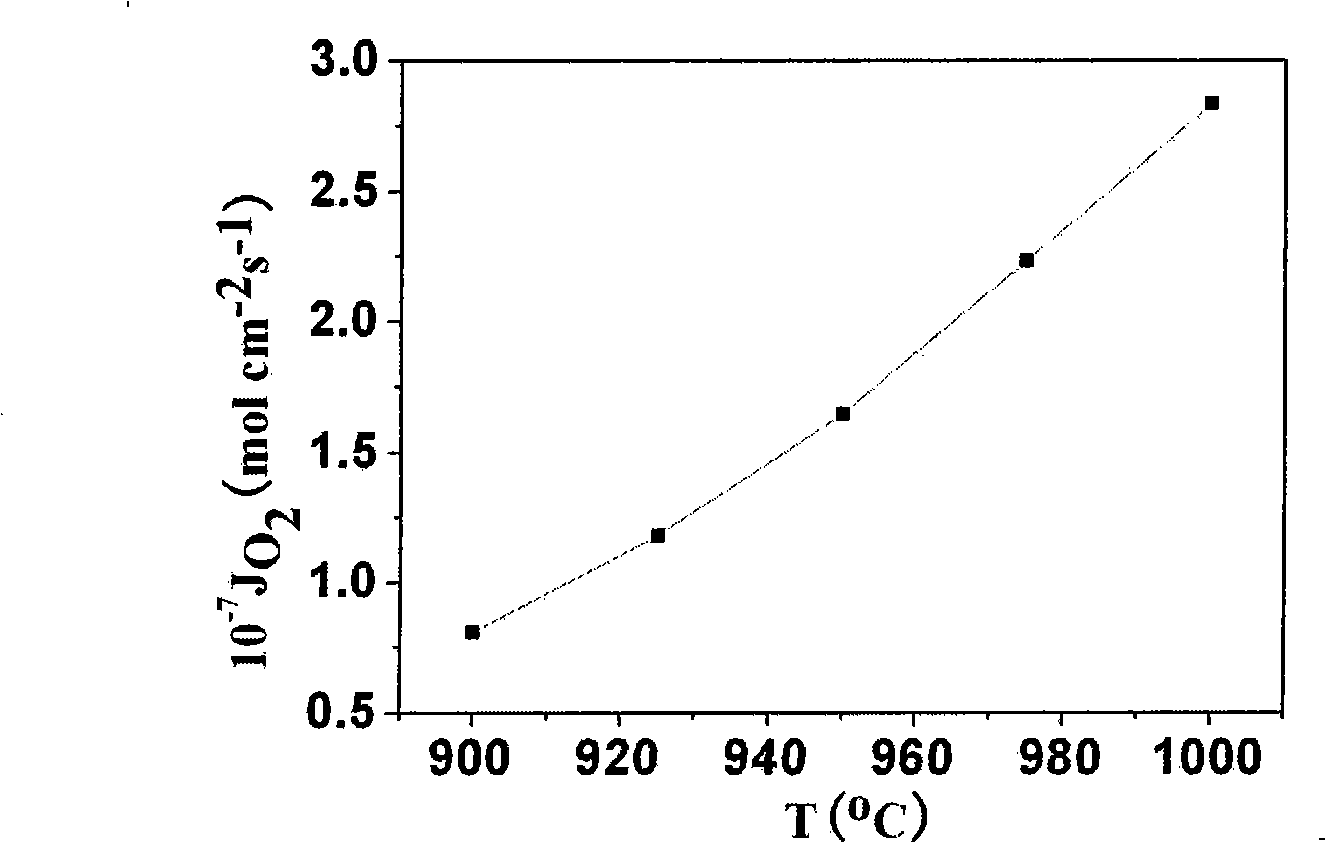

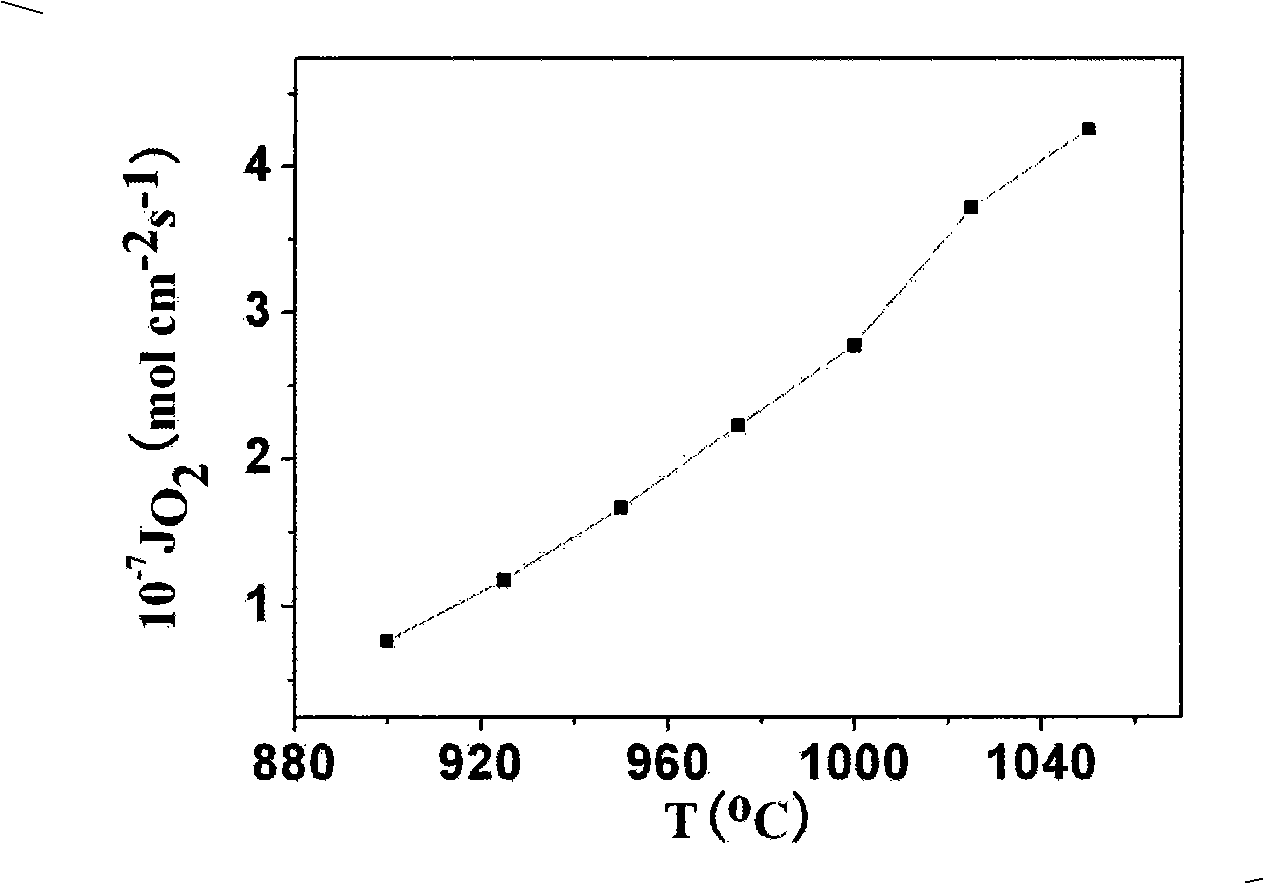

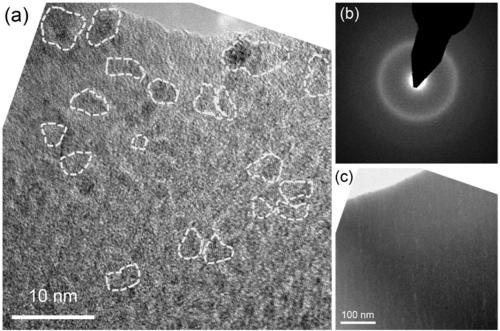

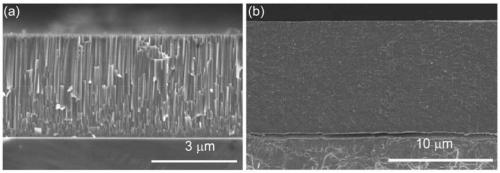

The invention provides a two-phase composite compact ceramic oxygen-permeable film and production method thereof. The invention is characterized in that: a perovskite-type lanthanum manganate-based composite oxide is mixed with a stabilized fluorite-type zirconium dioxide at a volume ratio of 0.6-1.8:1 to obtain a ceramic blank, the ceramic blank is further sintered to obtain a slab-like or a hollow fiber-like self-support compact ceramic oxygen-permeable film or porous support-loaded compact ceramic oxygen-permeable film with a thickness of 0.001-10 mm; the perovskite-type lanthanum manganate-based composite oxide is Ln1-xAx-yMnO3, wherein Ln is La, Pr, Nb, Ce, Gd, Dy, Sm or a mixture thereof, A is Sr or Ca, x is 0.1-0.4, y is 0-0.10; the stabilized fluorite-type zirconium dioxide is RzZr1-zO2, wherein R is Y, Sc, Yb, Er, Gd, Eu, Dy or a mixture thereof, and z is 0.10-0.26. The oxygen-permeable film is stable and kept in high oxygen permeability during long-term storage in the atmosphere of CO2 and H2O; and has the advantages of rich raw material, low price, non-toxicity and harmfulness, and environmental friendliness.

Owner:UNIV OF SCI & TECH OF CHINA

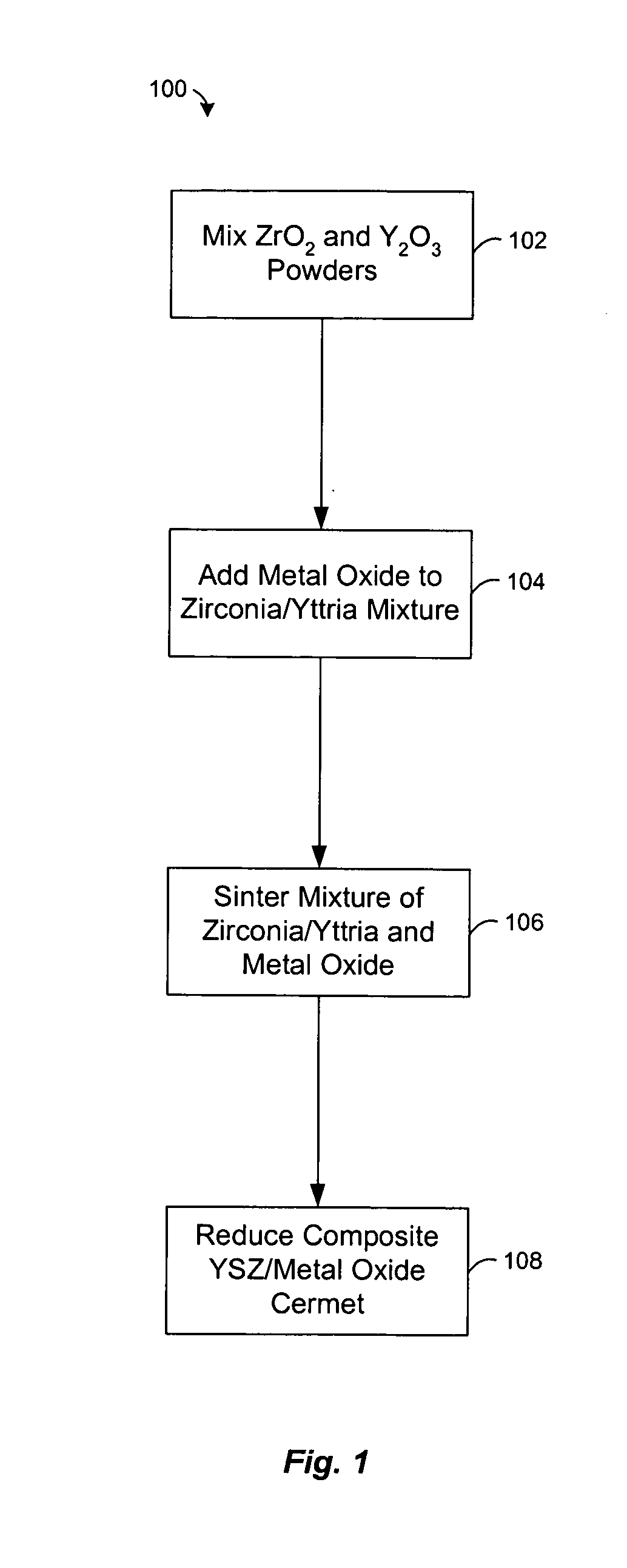

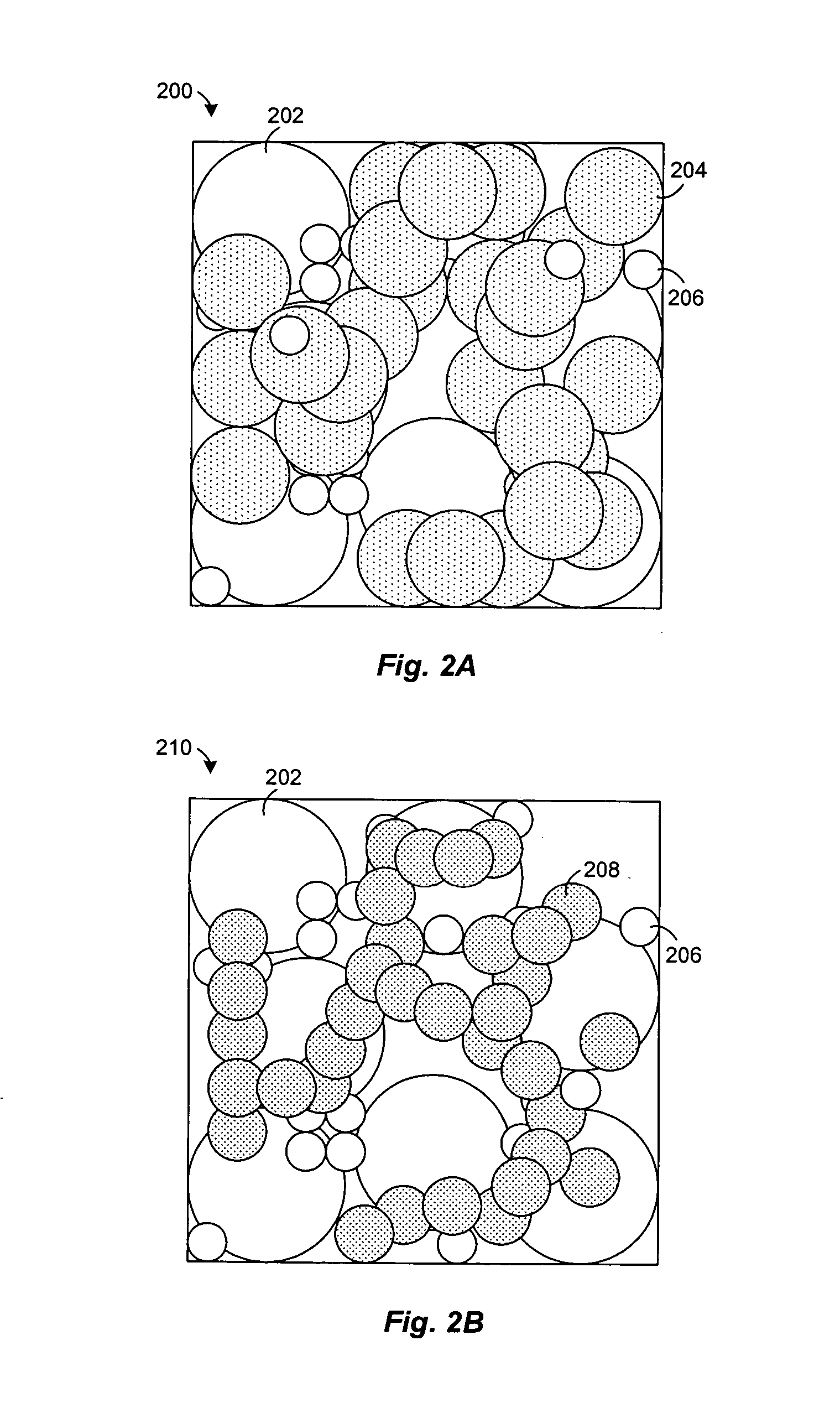

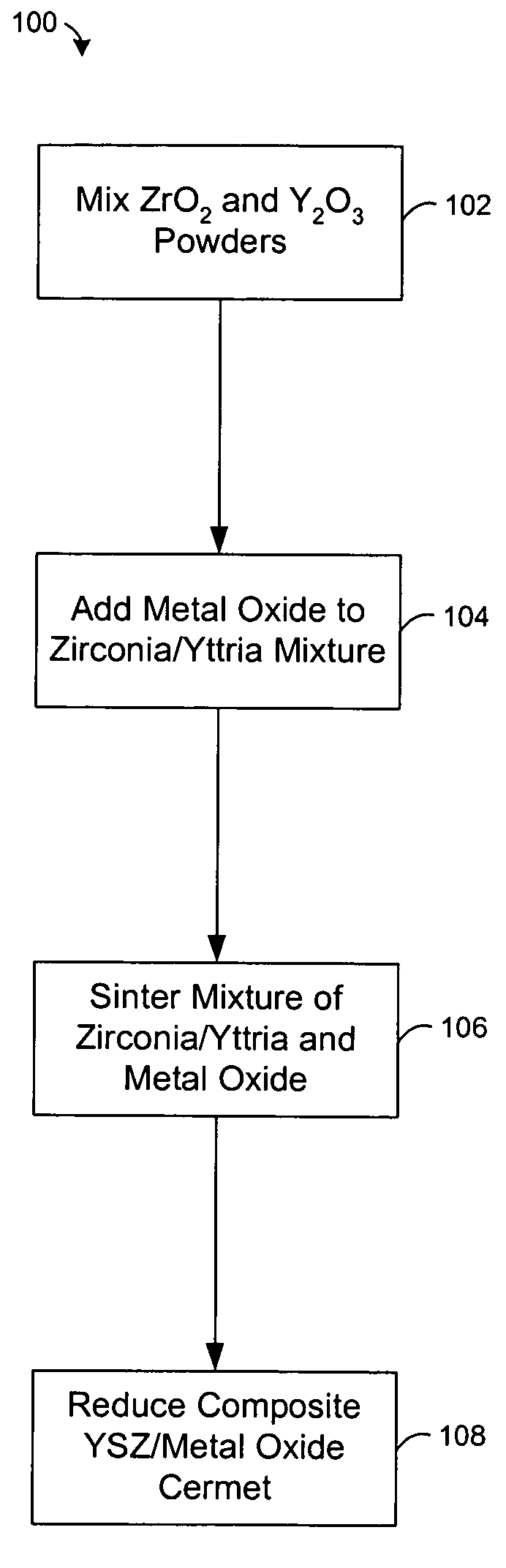

Preparation of yttria-stabilized zirconia reaction sintered products

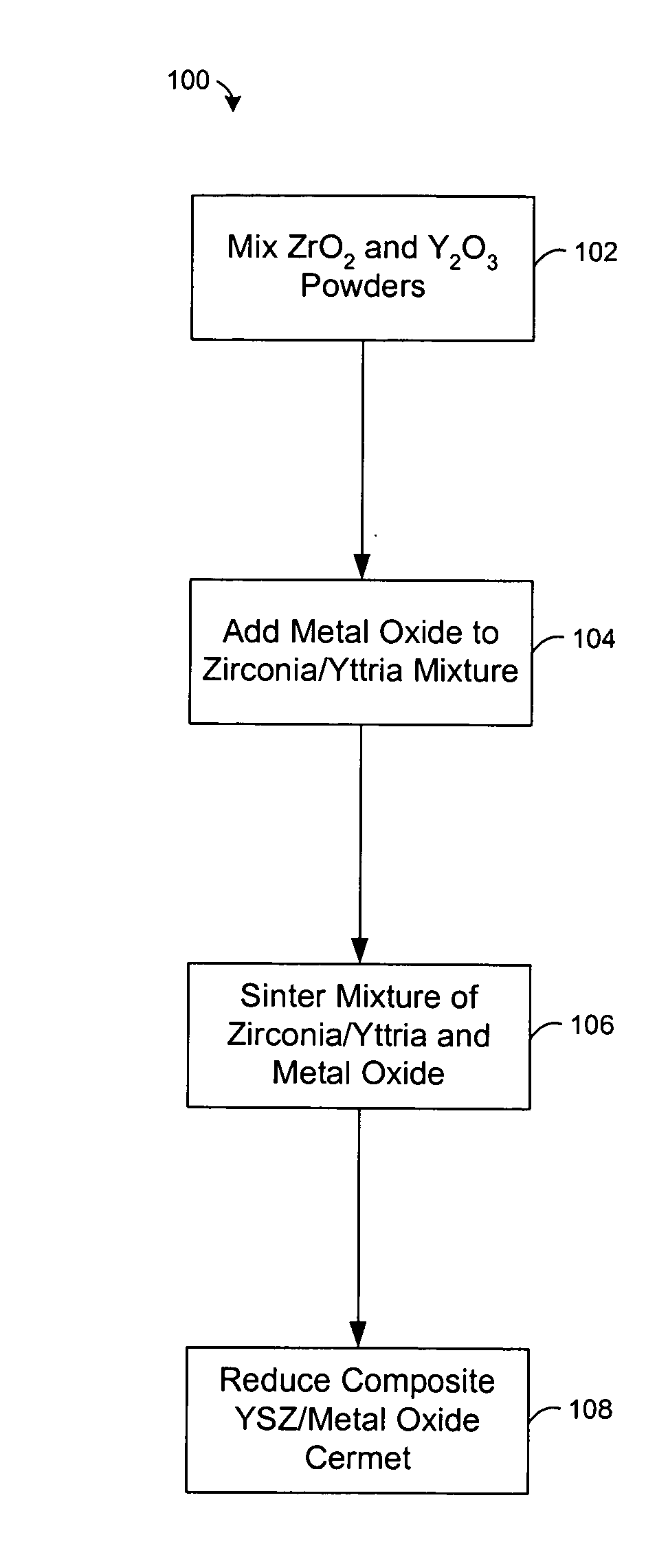

A method of making a solid electrolyte-YSZ product, where the method includes the step of providing a powdered mixture of zirconia, yttria and a metal oxide, where yttria-stabilized zirconia is not added to the mixture. The method also includes sintering the powdered mixture at about 1500° C. or less, for about 5 hours or less, to form a two-phase composite that includes cubic YSZ and the metal oxide. Also, a method of making a fuel cell electrode that includes the step of forming a green body that includes zirconia, yttria and a metal oxide, where yttria-stabilized zirconia is not added to the green body. The method also includes shaping the green body into a form of the electrode, and sintering the green body at about 1500° C. or less to form a two-phased sintered body that includes cubic yttria-stabilized zirconia and the metal oxide. The method may further include reducing the sintered body to form the electrode.

Owner:COORSTEK INC

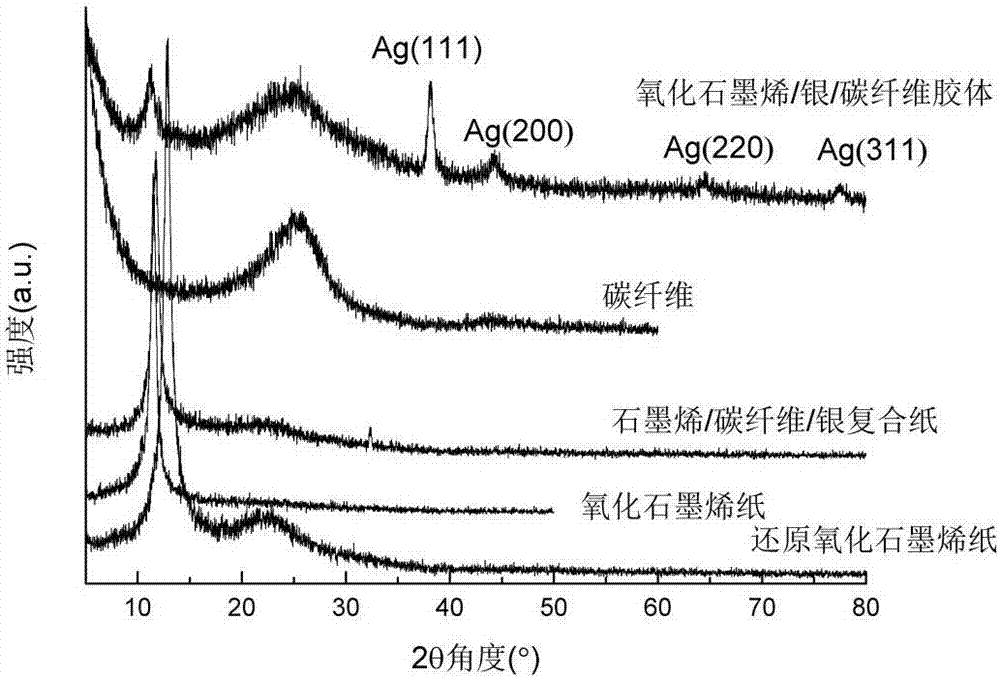

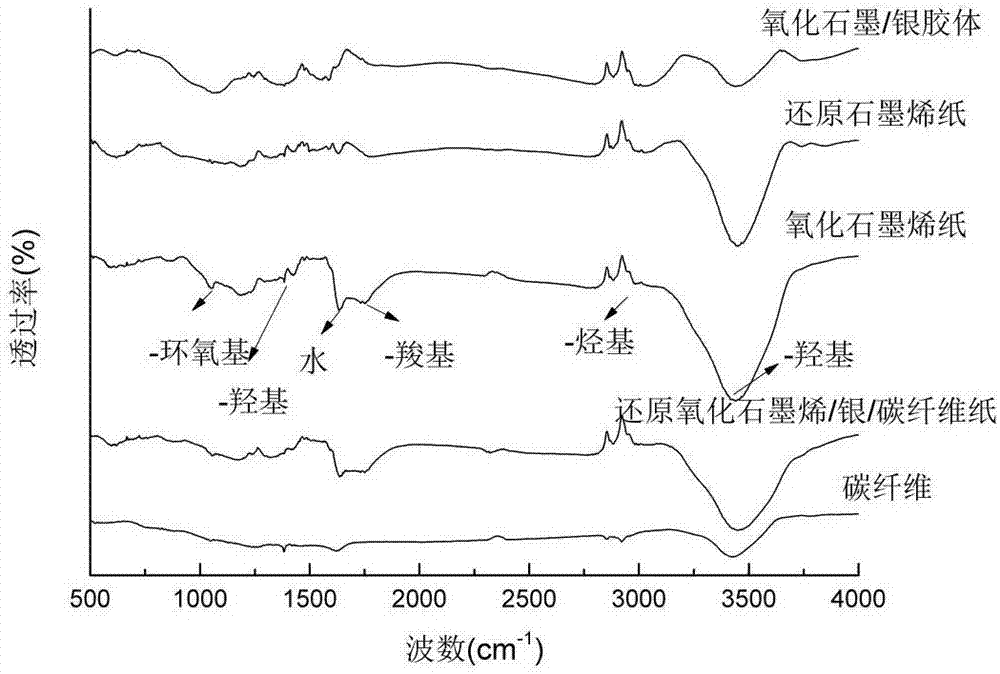

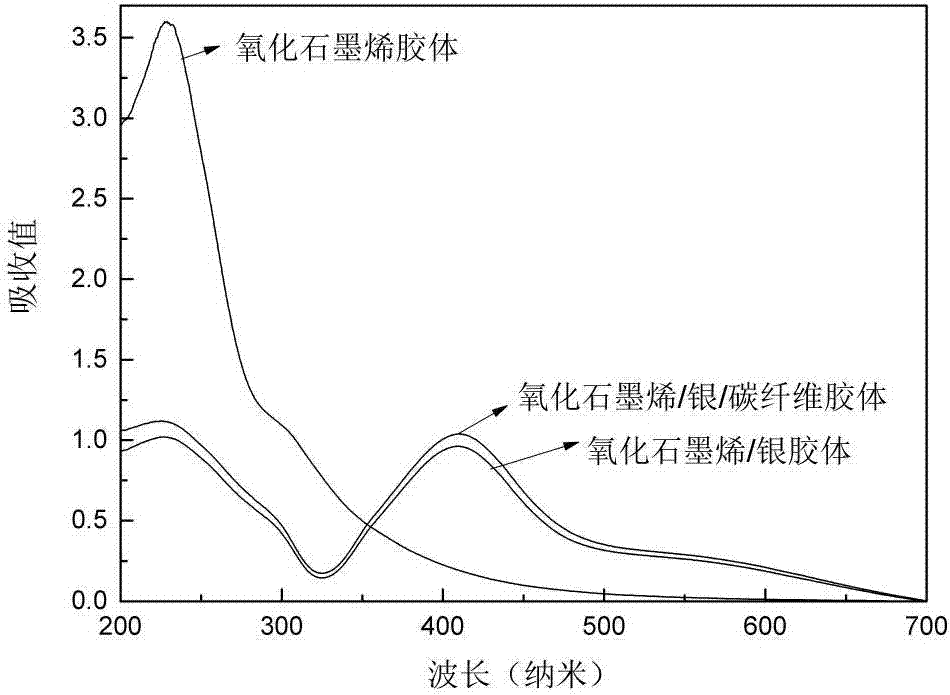

Preparation method of high strength graphene based composite paper

The invention relates to a preparation method of a high strength graphene based composite paper. Generally, the method includes: adopting a graphene oxide colloid and chopped carbon fiber mixed solution as the precursor to carry out hydrothermal reaction with a silver-ammonia solution, conducting in-situ one-step compounding of silver nanoparticles on the graphene oxide and carbon fiber surface, and then performing drying and low-temperature stepped heating reduction treatment so as to obtain a graphene / silver / carbon fiber three-phase composite paper. By controlling the ratio of the composite carbon fiber, the method provided by the invention synthesizes the graphene based three-phase composite paper with optimum mechanical properties and enhanced hydrophobicity and electrical conductivity. Compared with uncompounded graphene oxide paper, the electrical conductivity is increased by two orders of magnitude, and the hydrophobicity is strengthened. Compared with graphene / silver two-phase composite paper, the mechanical strength is increased by 80%. The composite paper can be used as a Raman enhanced substrate and a novel paper material. The method is simple and is easy for control, and is convenient for industrial production. The prepared self-support composite paper has broad application prospects in food safety, biomedicine, packaging materials and other fields.

Owner:JILIN UNIV

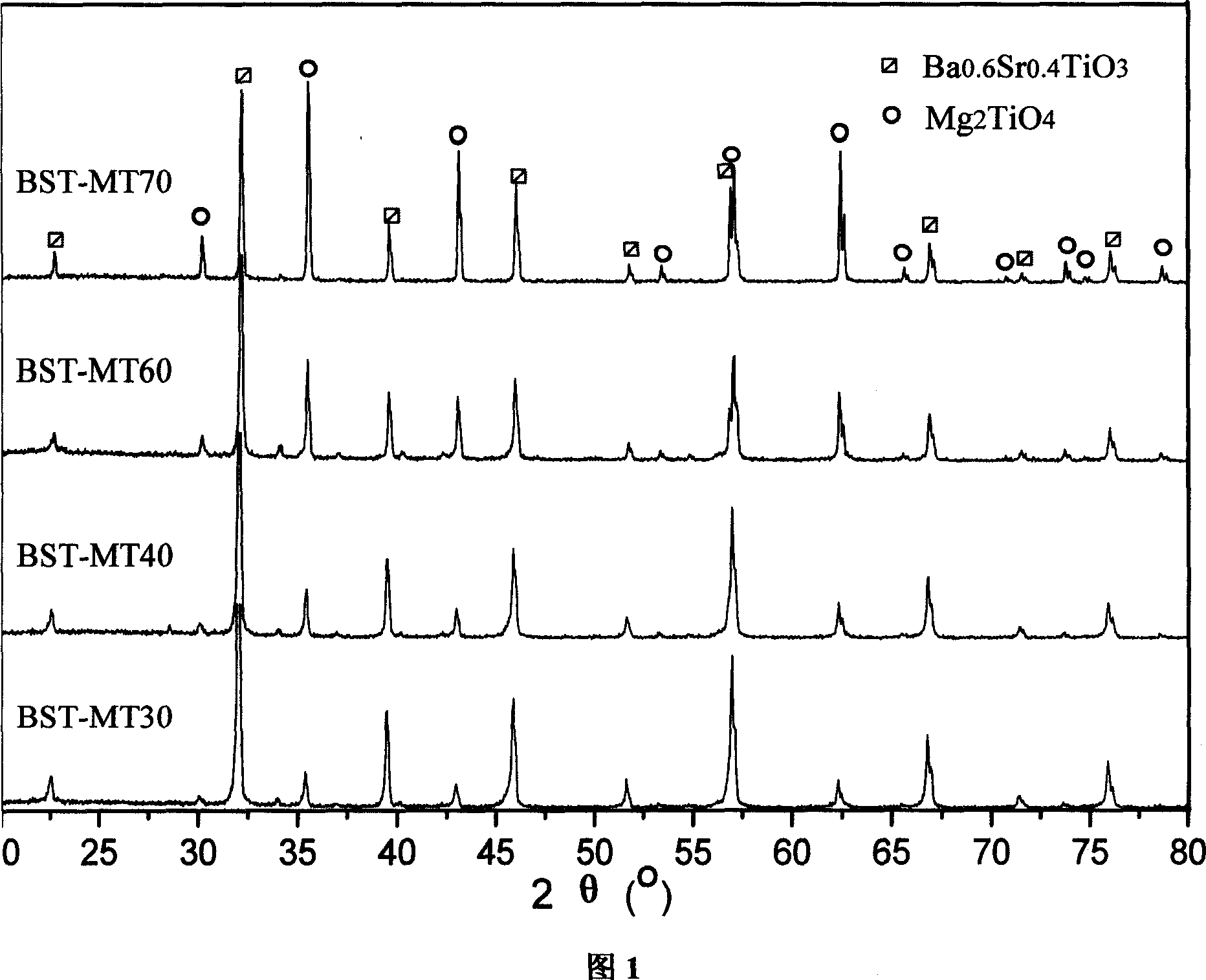

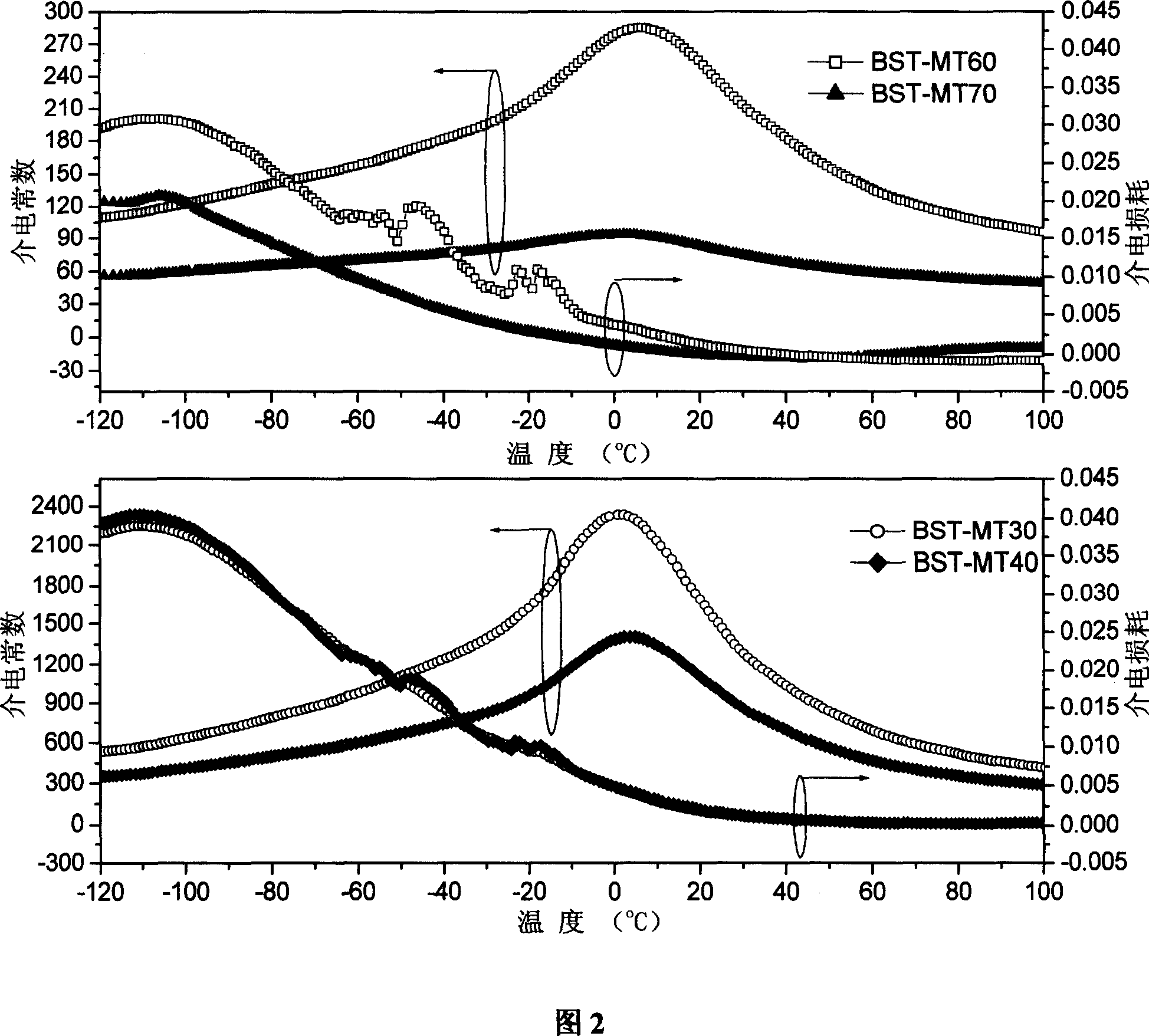

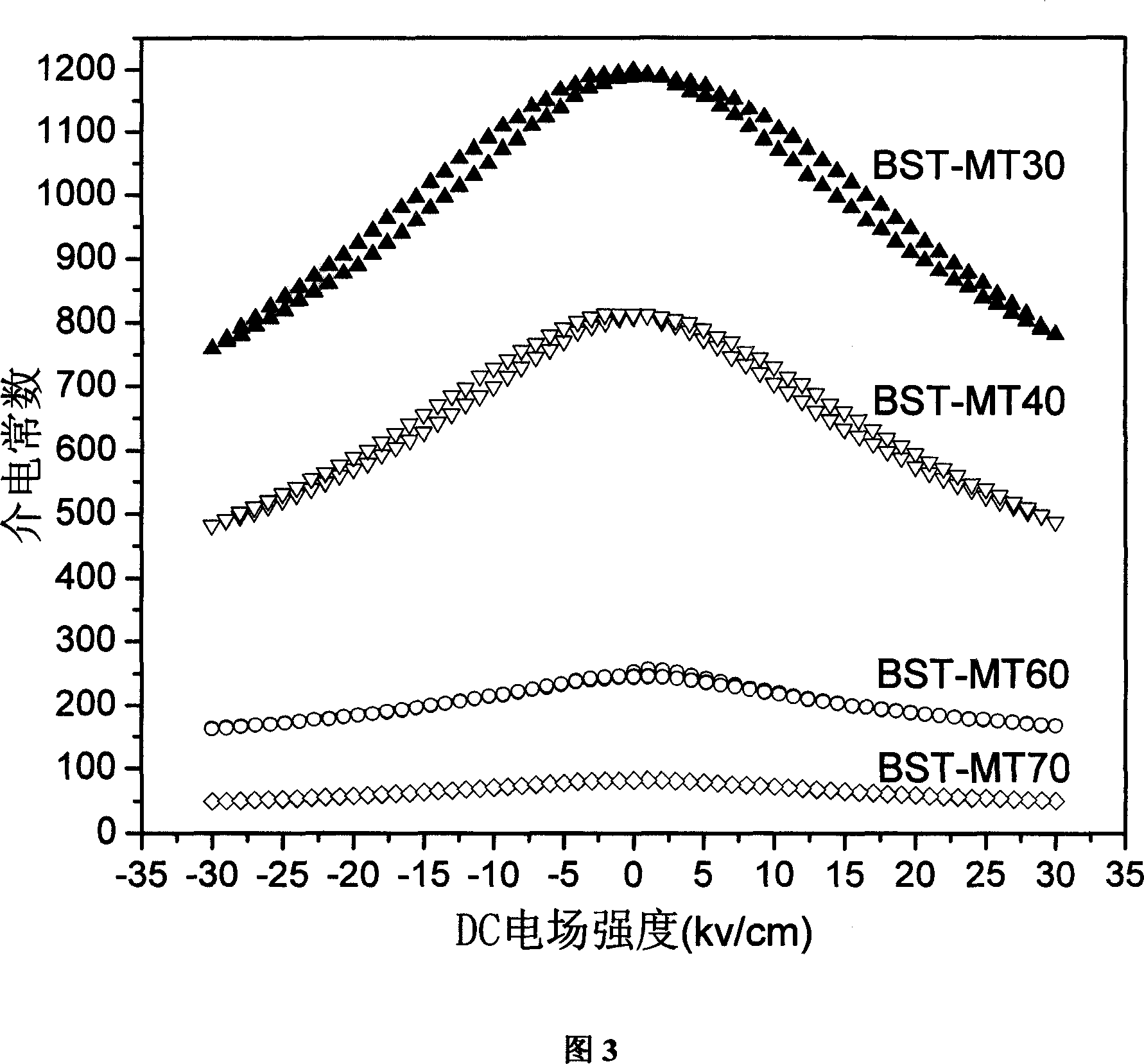

Ba1-xSrxTiO3-Mg2TiO4 two-phase composite ceramic material and its preparing process

InactiveCN101007736AExcellent dielectric propertiesHas dielectric tunable propertiesStrontium titanium oxideMicrowave

The invention discloses a two-phase composite ceramic material of being used to microwave modulator, which comprises 80.0-20.0wt% Ba(1-x)SrxTiO3(x=0.3-0.6) and 20.0-80.0wt% Mg2TiO4. The invention is characterizes by the following: adopting traditional electronic ceramic preparing craft; selecting microwave dielectric material normal magnesium titanate with good dielectric property; proceeding two-phase gradient composition with strontium titanate barium ferroelectric materials different Ba / Sr ingredient; getting the product.

Owner:TONGJI UNIV

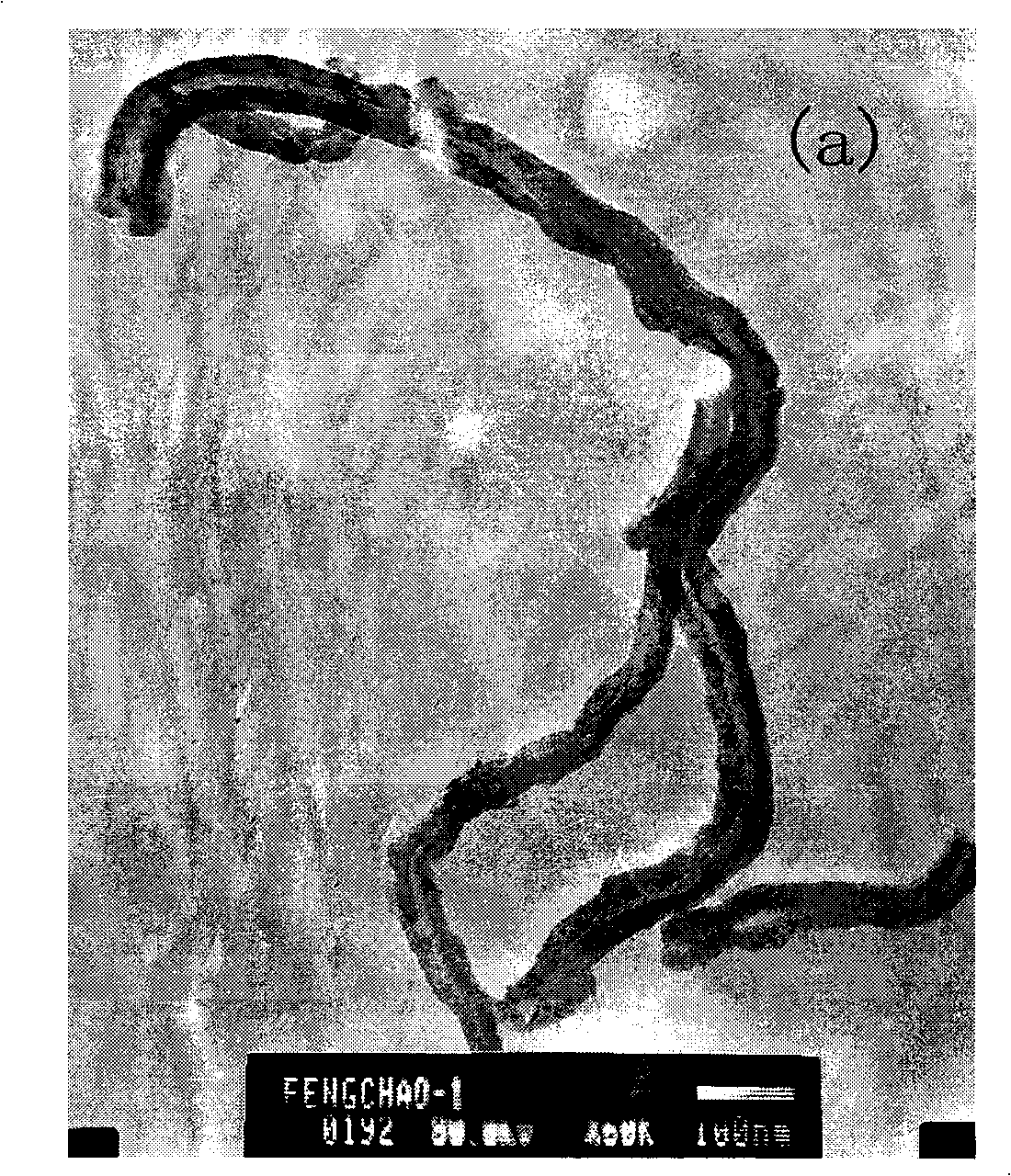

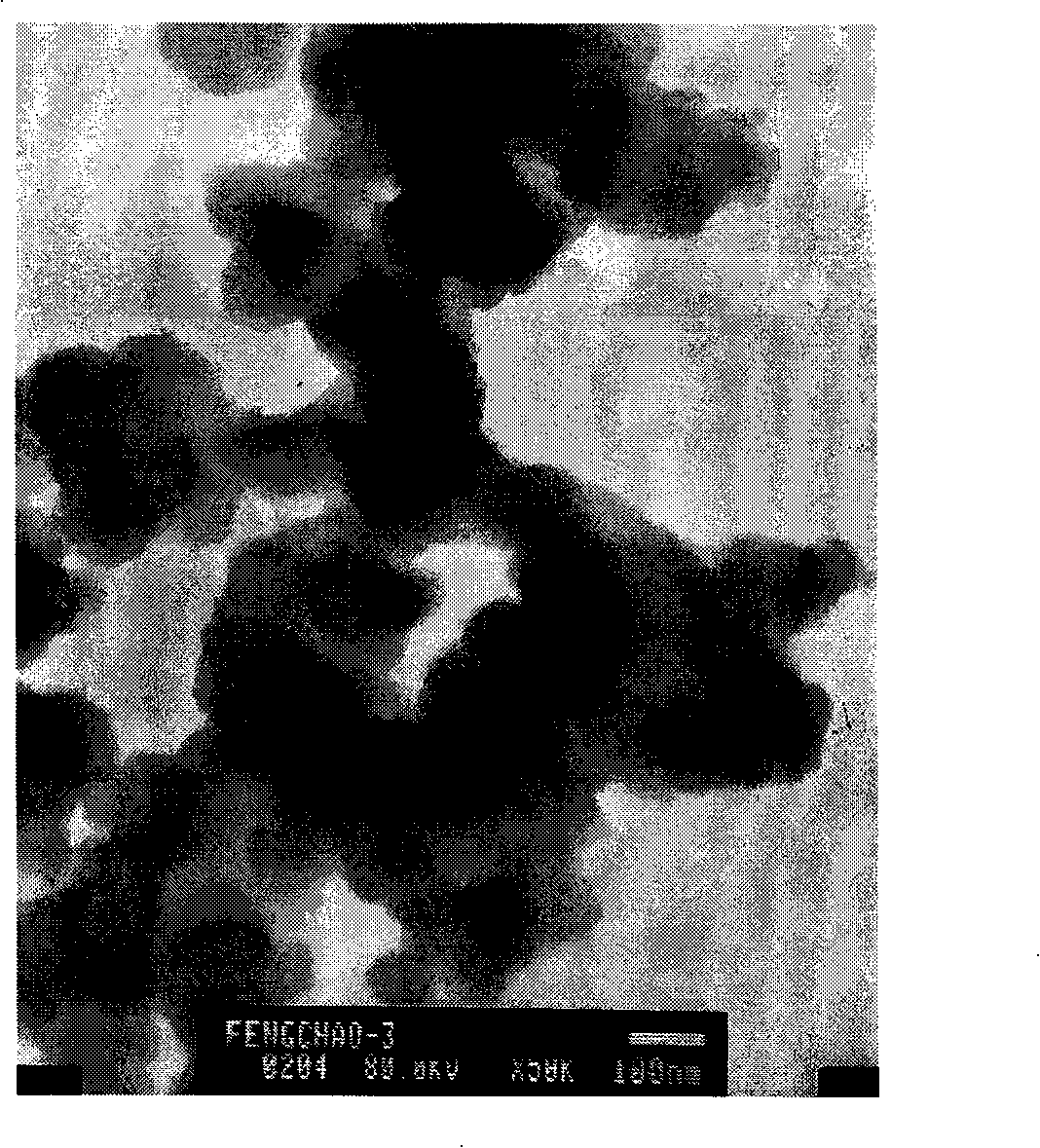

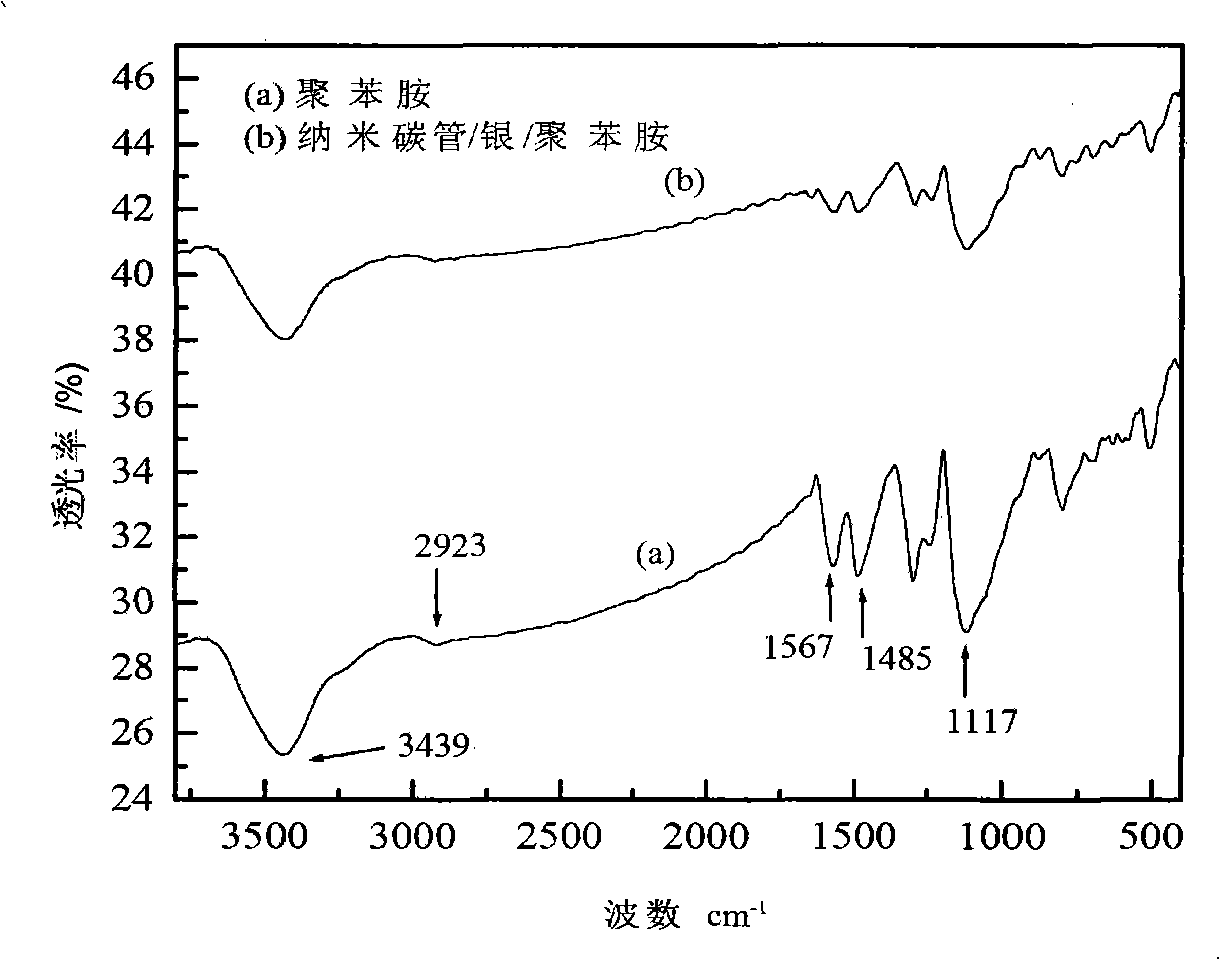

Polyaniline/carbon nano tube/nanometer silver particle conductive composite material and preparation method thereof

InactiveCN101525435AImprove conductivityHigh thermodynamic stabilityNon-conductive material with dispersed conductive materialCarbon nanotubeTwo phase composite

The invention provides a novel polyaniline / carbon nano tube / nanometer silver particle conductive composite material which belongs to the technical field of composite materials. The novel polyaniline / carbon nano tube / nanometer silver particle conductive composite material uses a two-phase composite material of carbon nano tube / nanometer silver particle as conductive filling and effectively utilizes the supersonic technology to lead the nanometer silver particle to uniformly disperse into polyaniline; the polyaniline grows on the surface of the carbon nano tube and completely covers the carbon nano tube. The invention solves the glomeration problem in aniline polymerization, can lead the nanometer silver particle to uniformly disperse into a polyaniline structure, effectively improves the conductive property and the thermodynamics stability of the polyaniline, and has simple process, convenient operation, mild reaction conditions, low production cost, high production efficiency, and better industrial production prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

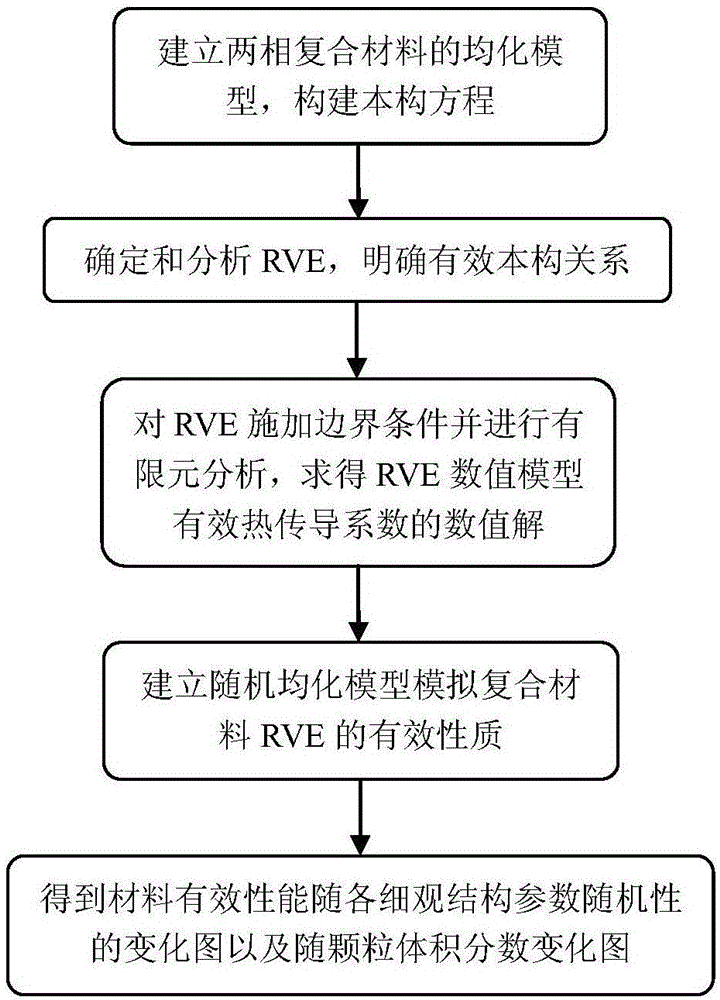

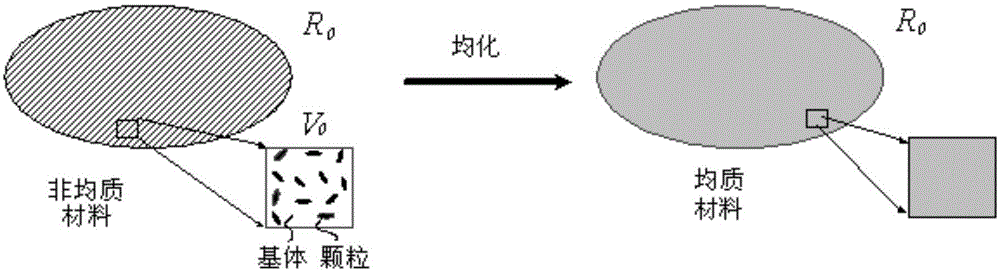

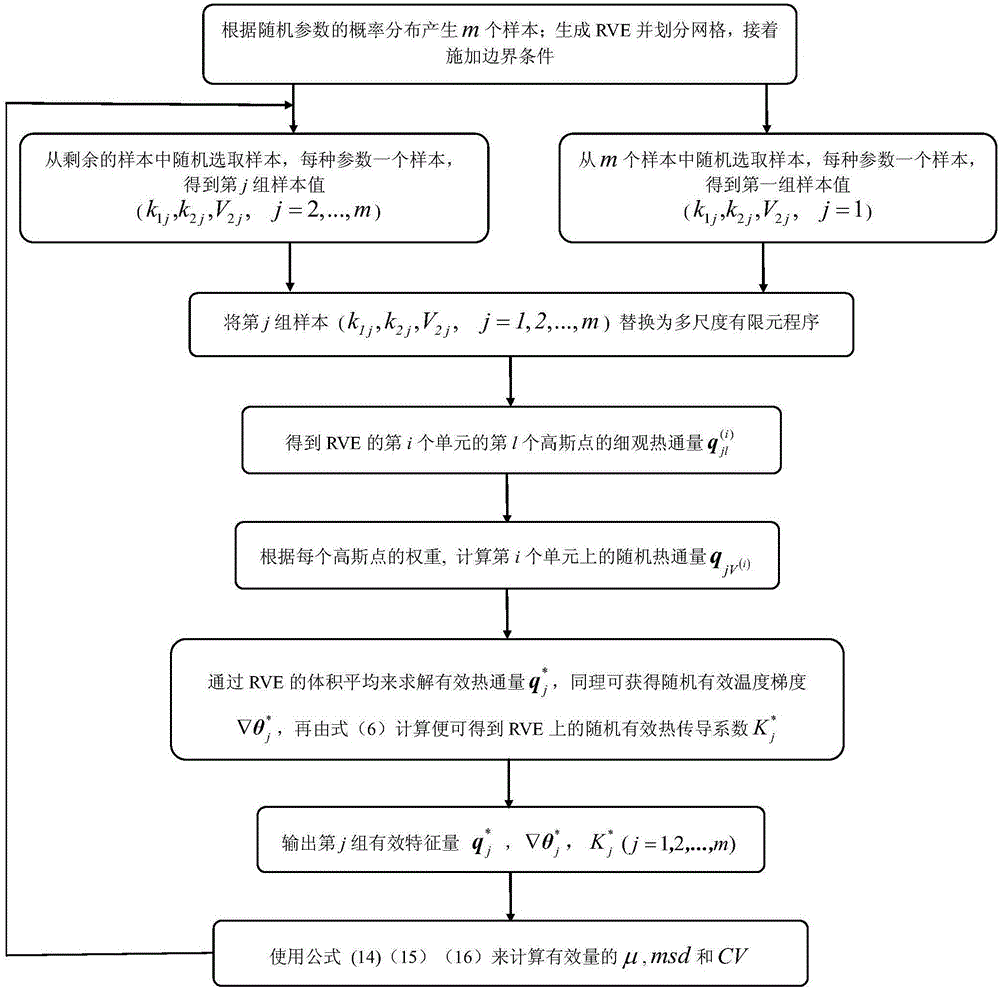

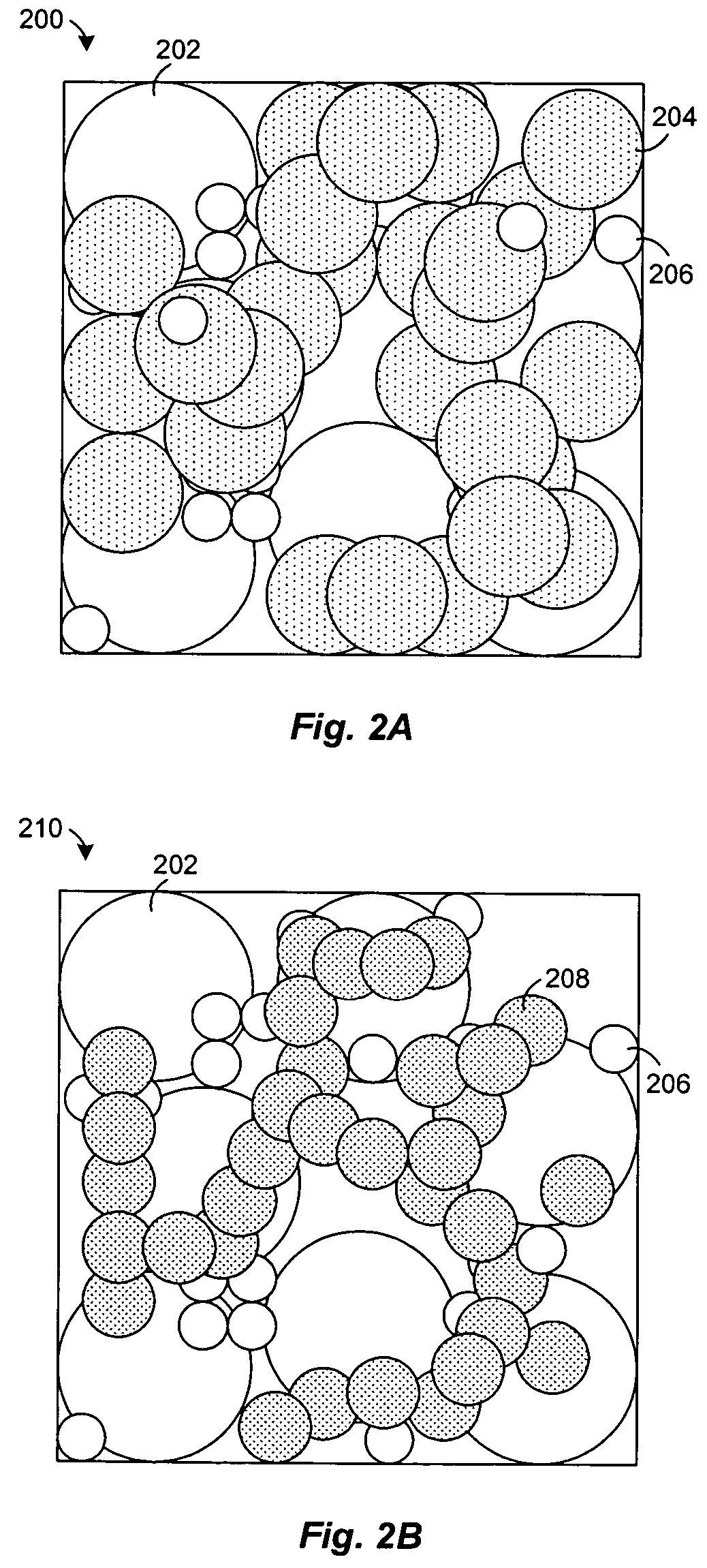

Random thermal homogenizing analysis method of two-phase composite material

ActiveCN105044146ASolving Numerical Modeling ProblemsMaterial heat developmentHeat fluxElement analysis

The invention discloses a random thermal homogenizing analysis method of a two-phase composite material. The method comprises the following steps: (1) establishing a corresponding microscopic homogenization model of a two-phase composite material composed of a matrix and particles, constructing constitutive equations, and calculating the thermal boundary values of the heterogeneous material; (2) determining and analyzing to obtain one RVE from the two-phase composite material, and determining the effective constitutive relationships among the effective heat conduction coefficient, the volumetric average temperature gradient and the volumetric average heat flux, wherein the volumetric average temperature gradient and the volumetric average heat flux are obtained from RVE; (3) applying boundary conditions on RVE, and at the same time carrying out finite element analysis and calculation to obtain the value of effective heat conduction coefficient of the RVE numerical model; (4) establishing a random homogenizing model to obtain the macroscopic effective quantity of the composite material. In the provided method, a finite element method and Matlab software are used to solve the problem of complicated RVE numerical modeling, the influences of parameter randomness of components of the composite material under three boundary conditions on the macroscopic thermal physical properties are taken into account comprehensively, and thus the provided method has an application value, a certain academic value, and theoretical significance.

Owner:XIDIAN UNIV

Preparation of yttria-stabilized zirconia reaction sintered products

Owner:COORSTEK INC

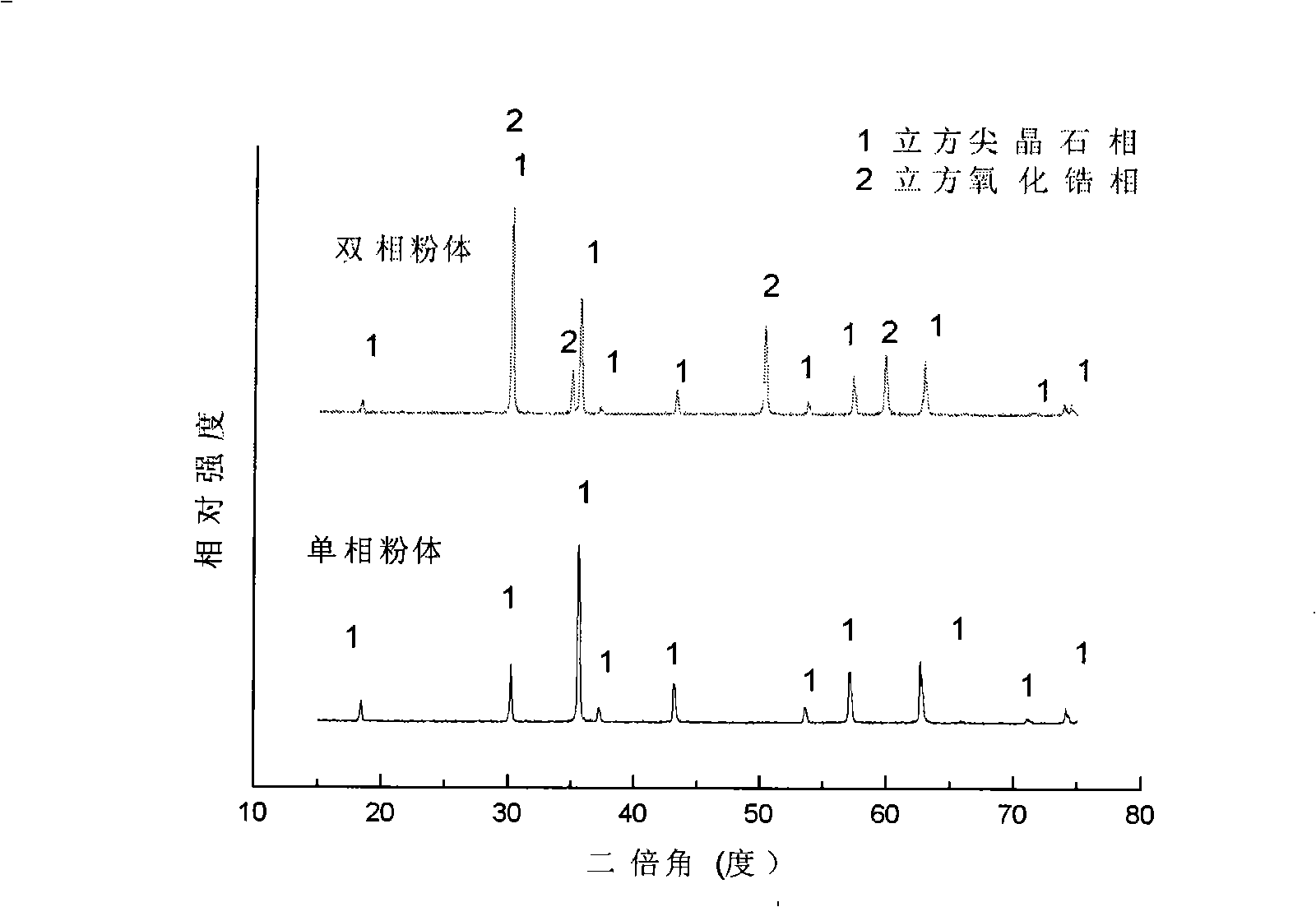

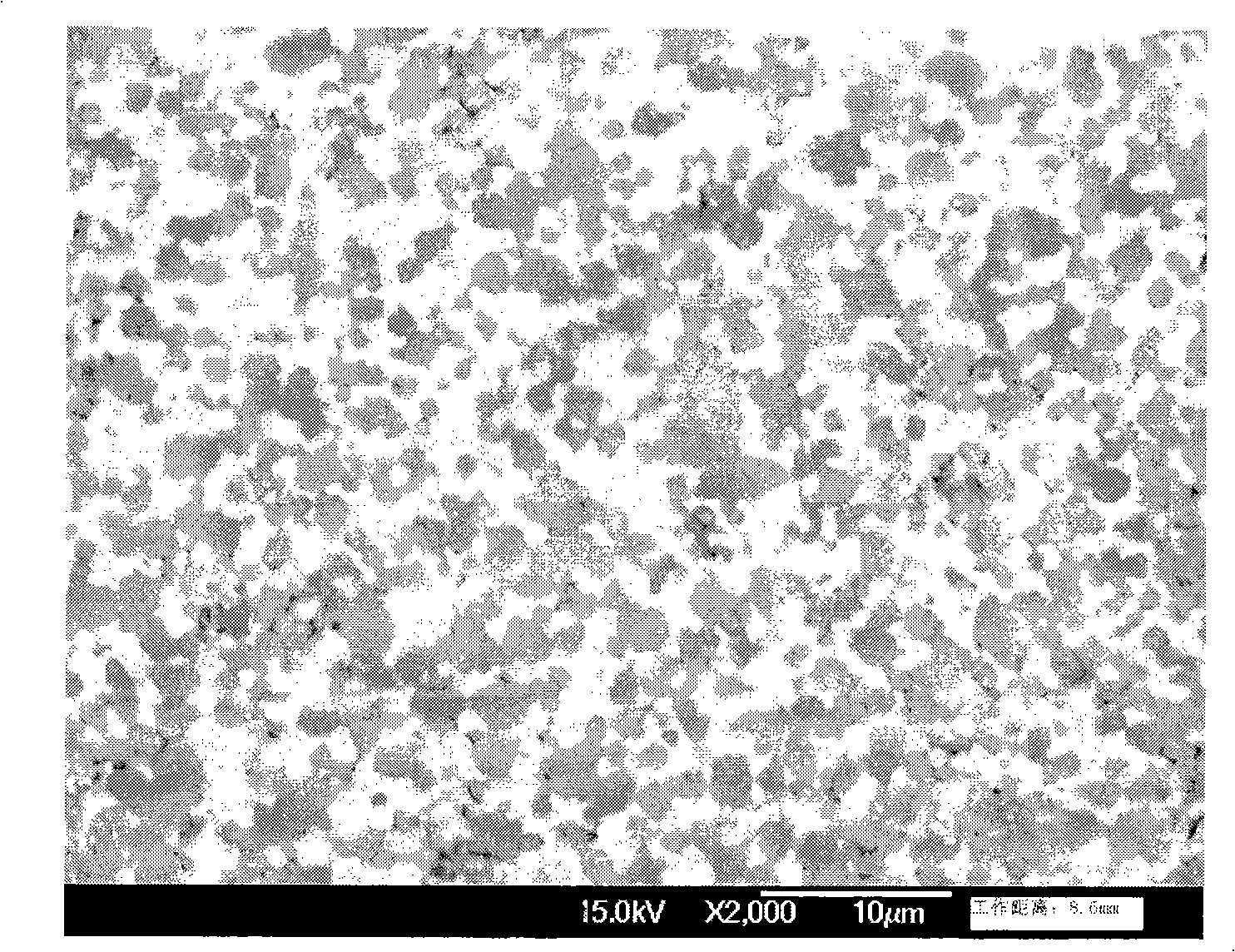

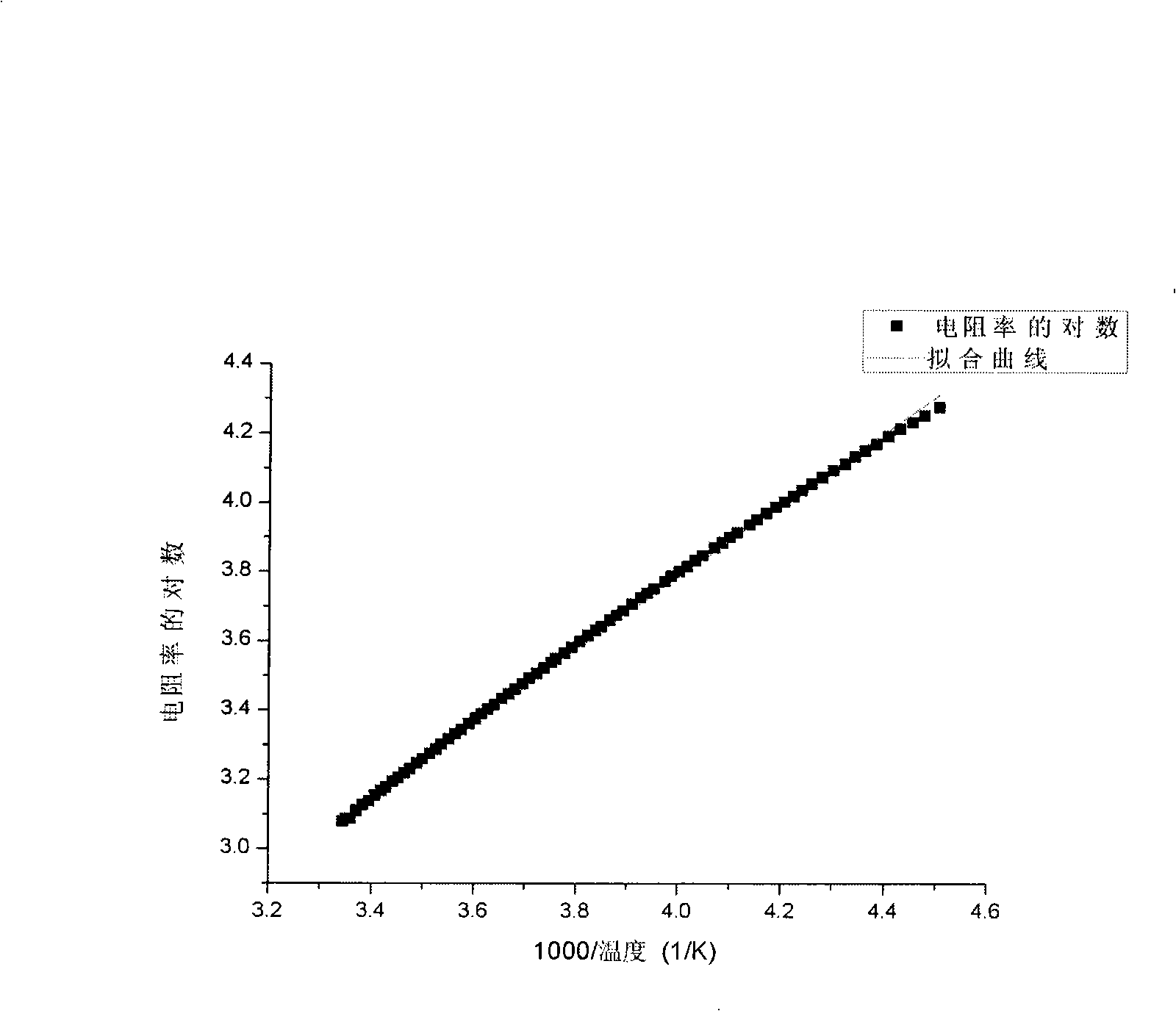

Negative temperature coefficient two-phase composite thermistor composition and preparation thereof

The invention discloses a negative temperature coefficient two-phase composite heat-sensitive material and a method for preparing the same characterized by mixing and milling the copper acetate, ferric oxalate, manganese acetate, nickel acetate and oxalate according to the mol ratio of 0.2-0.6: 1: 3.48-3.08: 1.32: 7.2, calcining the mixture after drying, mixing the prepared powder with partial stable cubic zirconia powder according to the mol ratio of 1: 1.5-4, getting two-phase composite powder after milling and drying, getting the negative temperature coefficient material with a relative density more than 94% after sintering. The material has a stable structure, a sintering temperature between 1200 and 1250 DEG C, a higher mechanical strength than the single-phase spinel ceramic, a B value less than 2800K, a resistivity of 1000omega.cm, a resistance drift less than 3% when accelerated ageing 1000 hours at 150 DEG C, a very good NTC property between -60 DEG C to +50 DEG C, and is suitable for the negative temperature coefficient heat sensitive sensor material in the modern aerostat.

Owner:HEFEI SENSING ELECTRONICS +1

Layered/acicular two-phase composite enhanced rare earth magnesium alloy and preparation technology thereof

The invention relates to a layered / acicular two-phase composite enhanced rare earth magnesium alloy and a preparation technology thereof, which belong to the technical field of magnesium alloy. The alloy comprises the following components by mass percentage: 6-25wt.% of Er, 4-10wt.% of Zn, and balance of Mg, wherein, mass proportion of Er / Zn is 1.5-3. The novel alloy is prepared by certain melting, a solid solution treatment technology is combined, and formation amount of the layered phase / acicular phase in the alloy can be controlled. Through the regulation and control technology, the hardness of the alloy is obviously changed.

Owner:BEIJING UNIV OF TECH

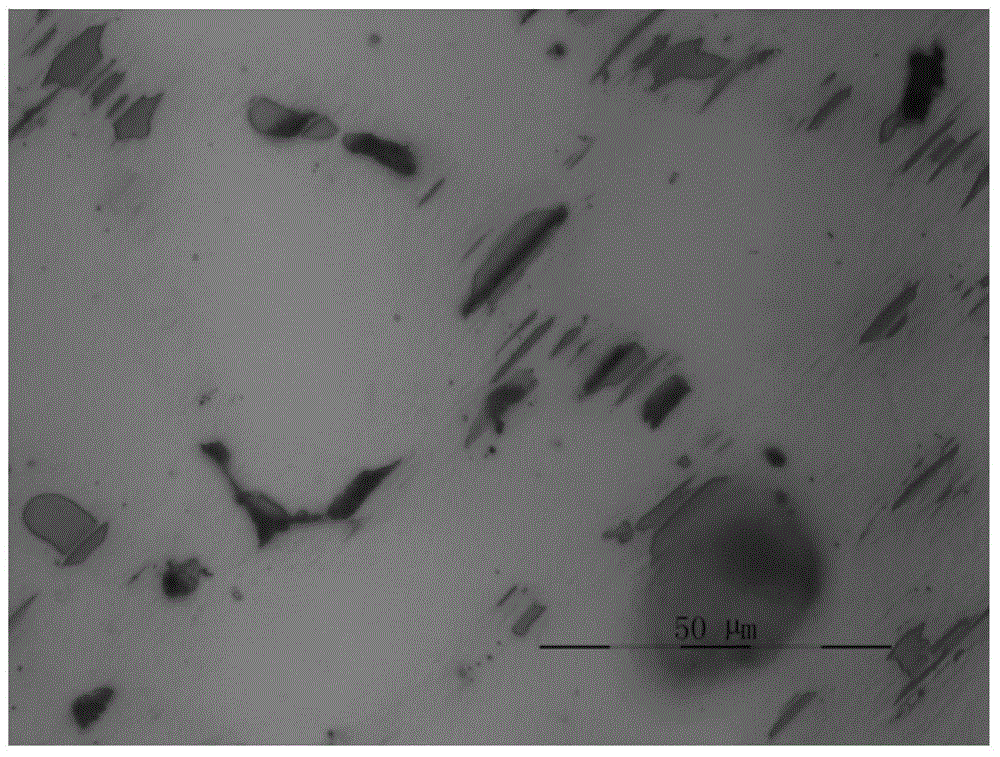

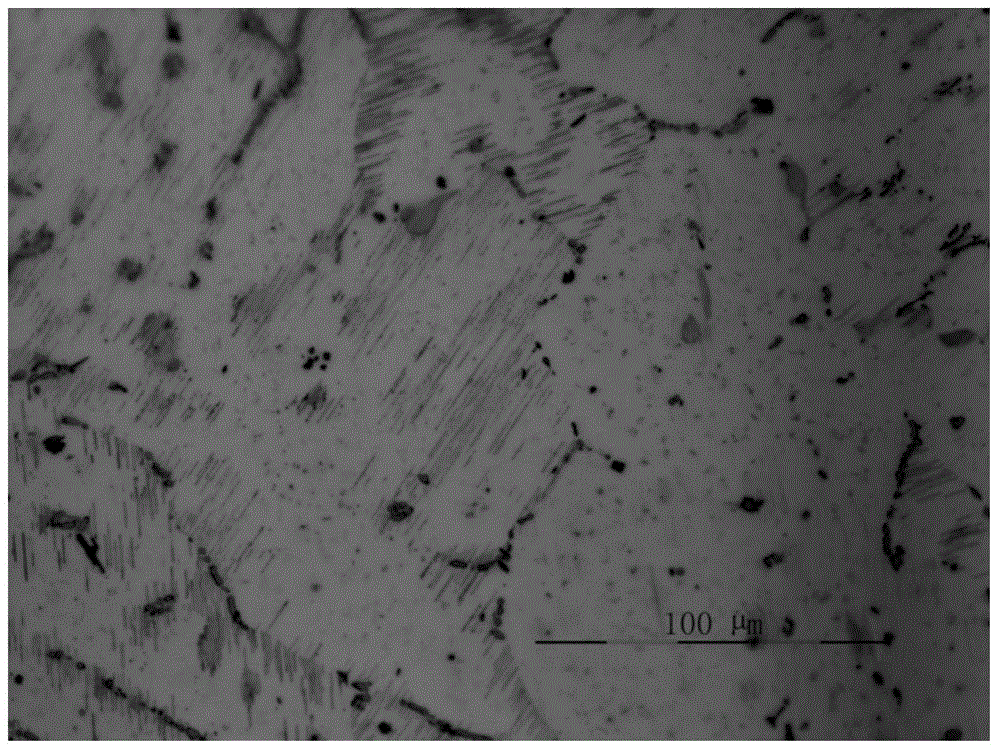

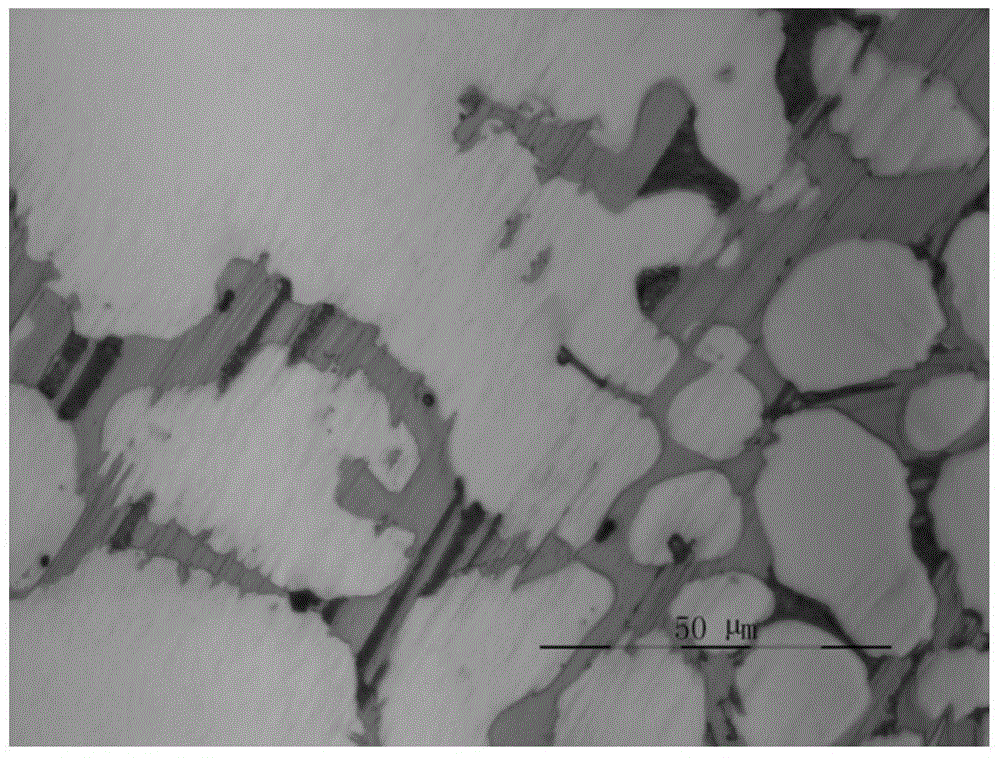

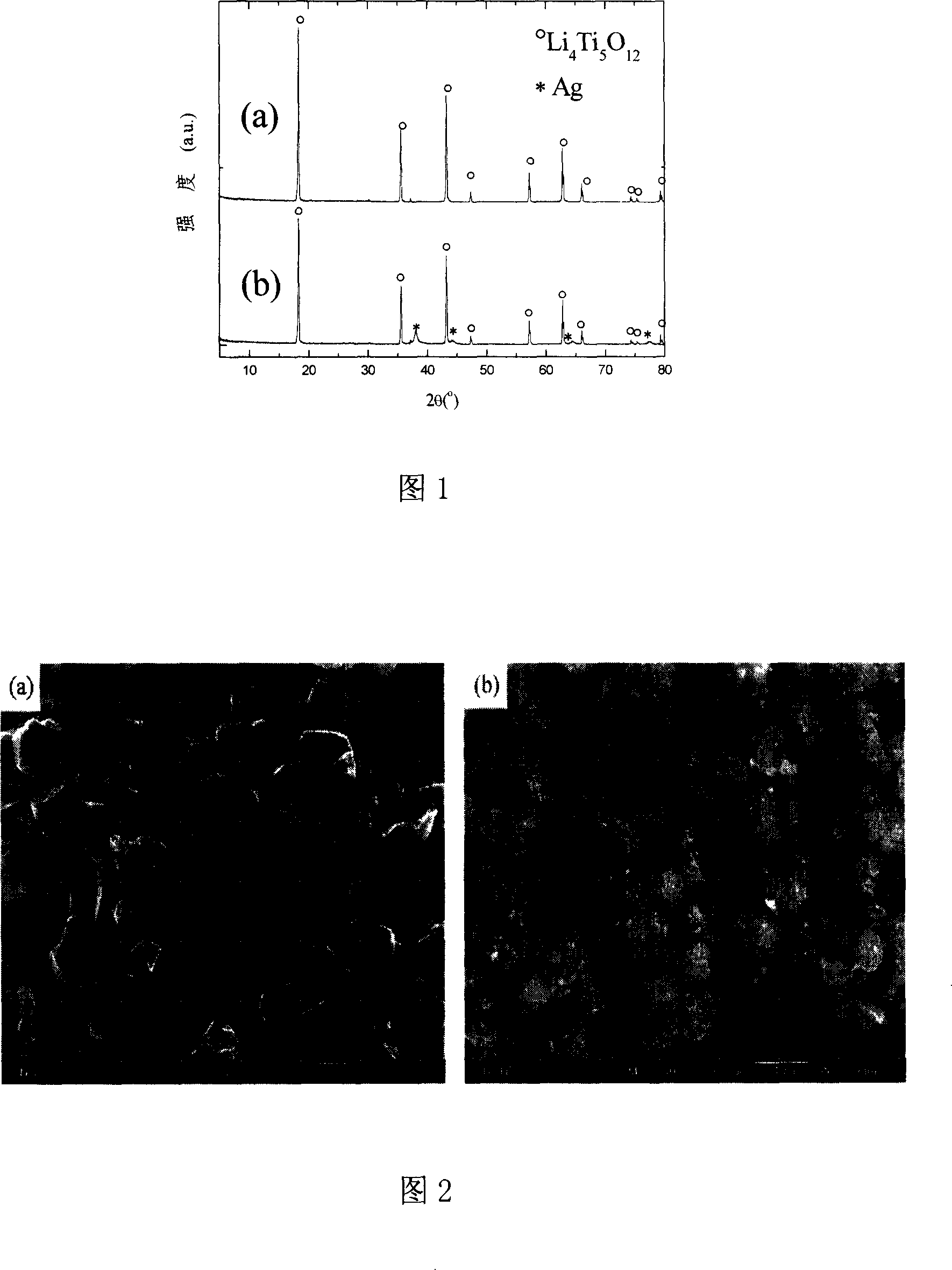

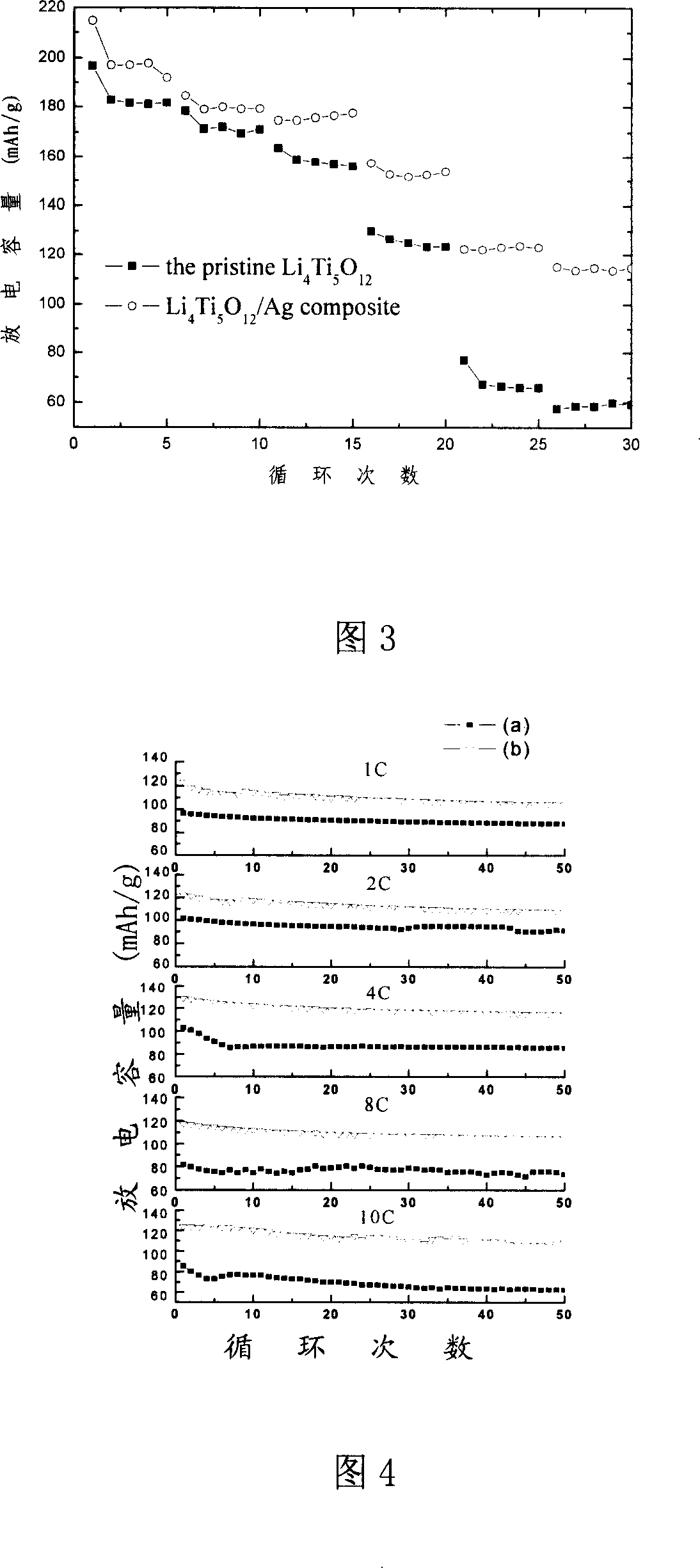

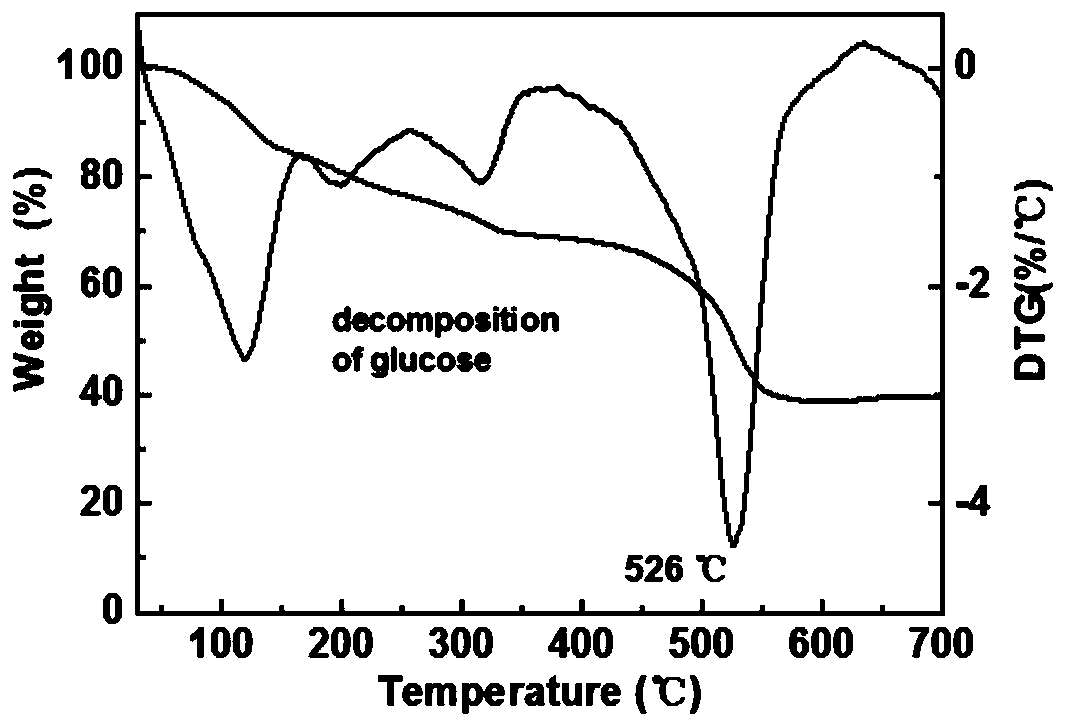

Silver electrode composite material of lithium secondary battery and low temp. preparation method thereof

InactiveCN101000956AStability is not affectedAvoid heterogeneous depositionElectrode manufacturing processesActive material electrodesSilver electrodeTwo phase composite

This invention relates to a sliver composite material for negative electrode of lithium secondary battery and its low-temperature preparation method, belonging to the field of electrochemical power. It is to mix NH4OH and AgNO3 solution to prepare [Ag(NH3)2]OH solution, then put up various electrode materials and [Ag(NH3)2]OH according to the composition formula to prepare solution, mix equally, and then infuse CH3CHO into it slowly until the response completes. The compositions of the invention is (100-y) electrode materials / y silver particles, in which, (100-y) / y is weight ratio, y = 0.1 ~ 20, and silver particle size is less than 20nm. Preparation of this invention is simple and low-cost. The first discharge capacity of the two-phase composite material is respectively 122.8 and 123.6mAh / g in 4.4-3V of 1C and 10C ratio.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

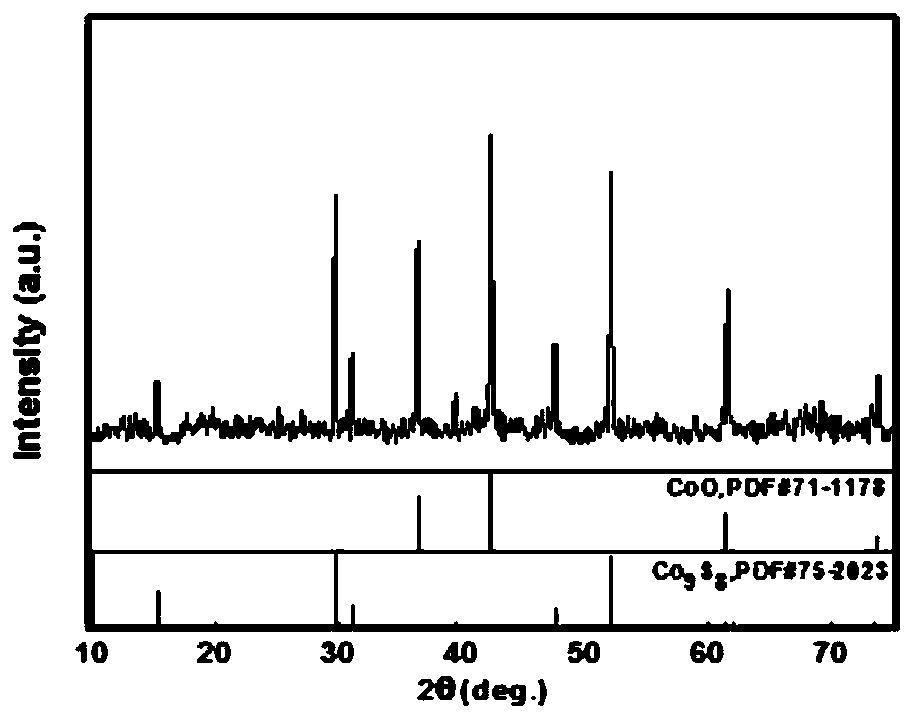

Heterojunction nano material diaphragm used for lithium-sulfur battery as well as preparation method thereof

ActiveCN109904369AImprove electrochemical reaction kineticsInhibition of the shuttle effectLi-accumulatorsCell component detailsHeterojunctionLithium–sulfur battery

The invention relates to a diaphragm used for a lithium-sulfur battery. The diaphragm comprises a diaphragm basal body and a modification layer covering the diaphragm basal body, and the diaphragm ischaracterized in that the modification layer adopts a graphene and heterojunction nano composite, wherein a heterojunction nano material is of a two-phase composite structure, the interior is a high catalytic phase, an outer layer is a strong adsorbed phase, the high catalytic phase is at least on of cobalt sulfide, nickel sulfide and iron sulfide, and the adsorbed phase is at least one of cobaltoxide, nickel oxide and iron oxide. The invention also provides a preparation method of the diaphragm. The prepared diaphragm can be used for making a lithium-sulfur battery with excellent performance.

Owner:TIANJIN UNIV

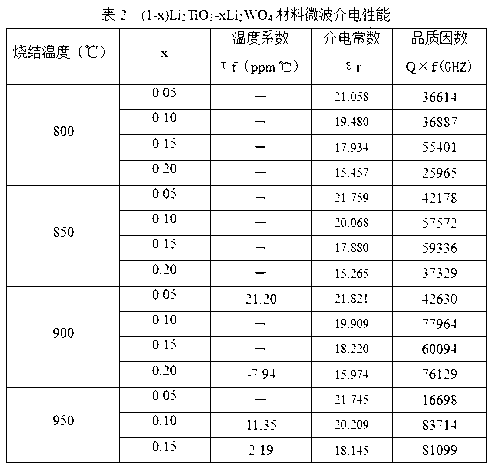

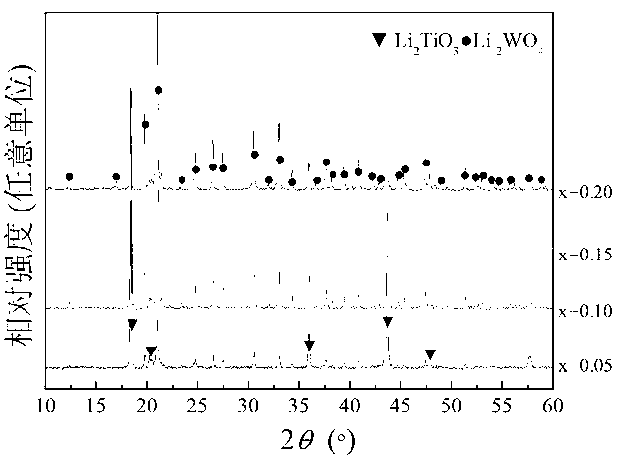

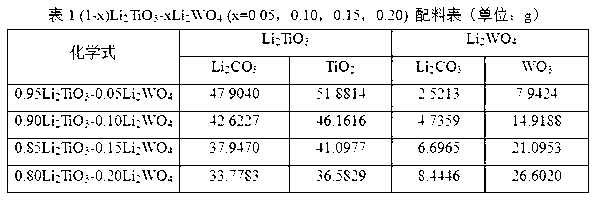

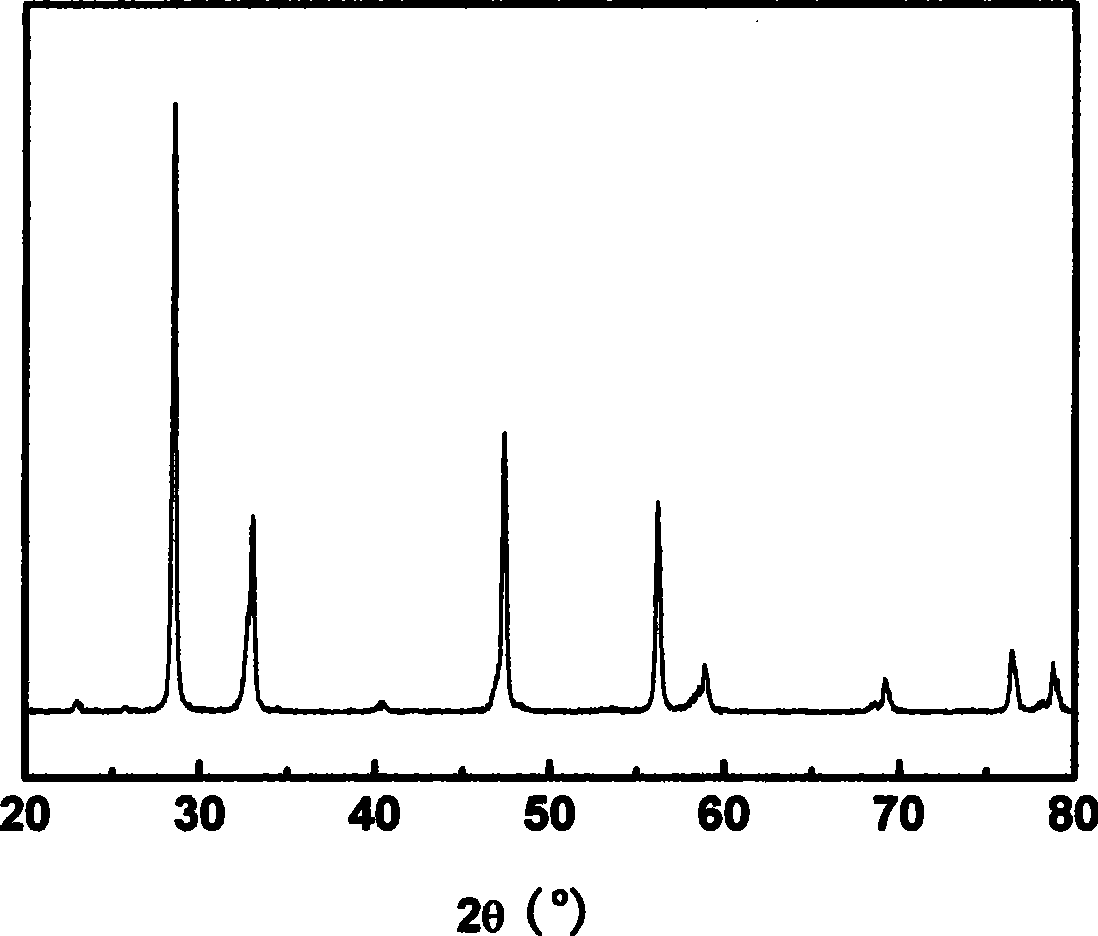

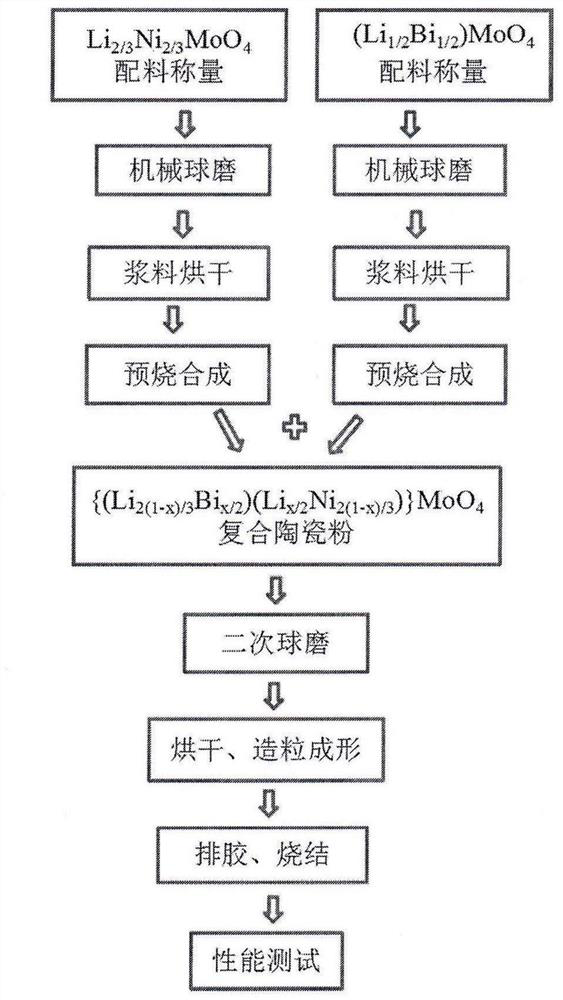

Preparation method of glass phase free two-phase composite microwave dielectric ceramic material Li2TiO3-Li2WO4

InactiveCN103274688ASmall dielectric lossAdjustable zero resonant frequency temperature coefficientTwo phase compositeDry pressing

The invention relates to a preparation method of a glass phase free two-phase composite microwave dielectric ceramic material Li2TiO3-Li2WO4, and belongs to the technical field of a special ceramic material process. The glass phase free microwave dielectric ceramic material provided by the invention is characterized by having the chemical formula show as (1-x)Li2TiO3-xLi2WO4, wherein x is mole fraction in chemometry and x is equal to 0.05-0.20. The process provided by the invention mainly comprises the following steps of: first, respectively synthesizing two single-phase ceramic powder; briquetting and calcining for 2 hours at 500-800 DEG C; then, grinding and sieving; weighing two single-phase powder according to two-phase composite proportion, and further ball-milling and sieving; then prilling and dry pressing; then, sintering for 2 hours at 800-950 DEG C; and finally preparing the two-phase composite microwave dielectric ceramic material.

Owner:SHANGHAI UNIV

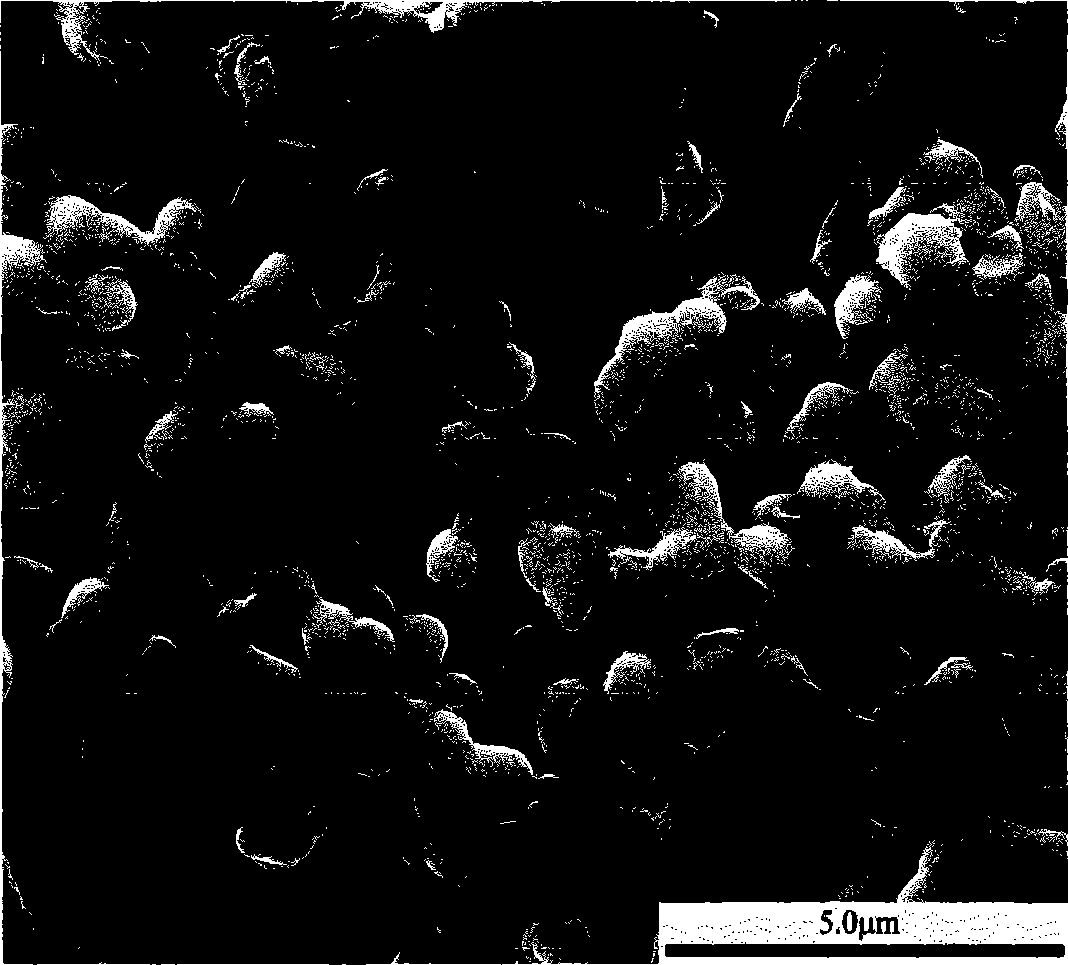

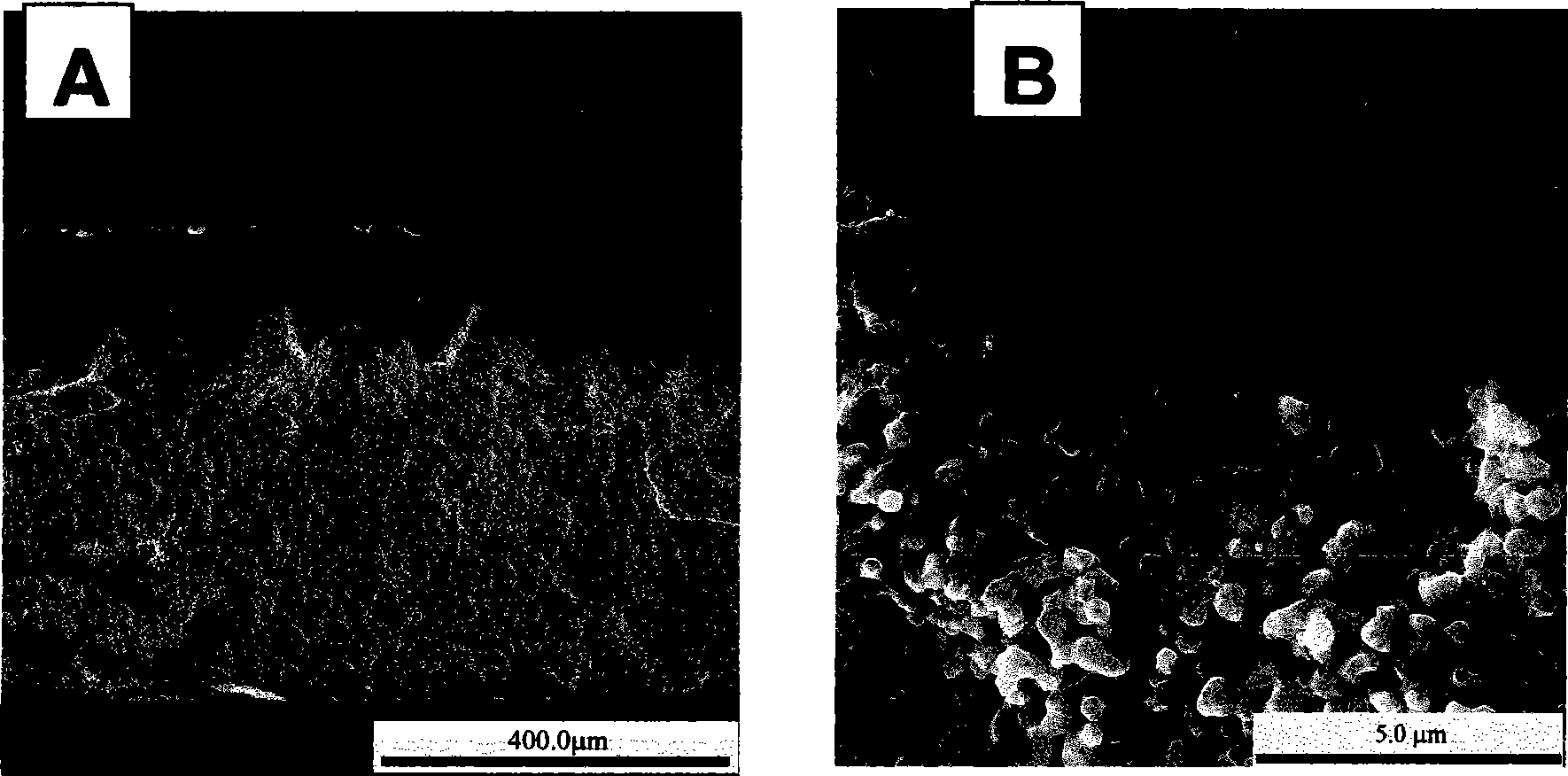

Method for preparing unsymmetrical biphase composite oxygen permeable membrane

ActiveCN101450861AExcellent oxygen permeabilityGood chemical stabilityVoid ratioElectrical conductor

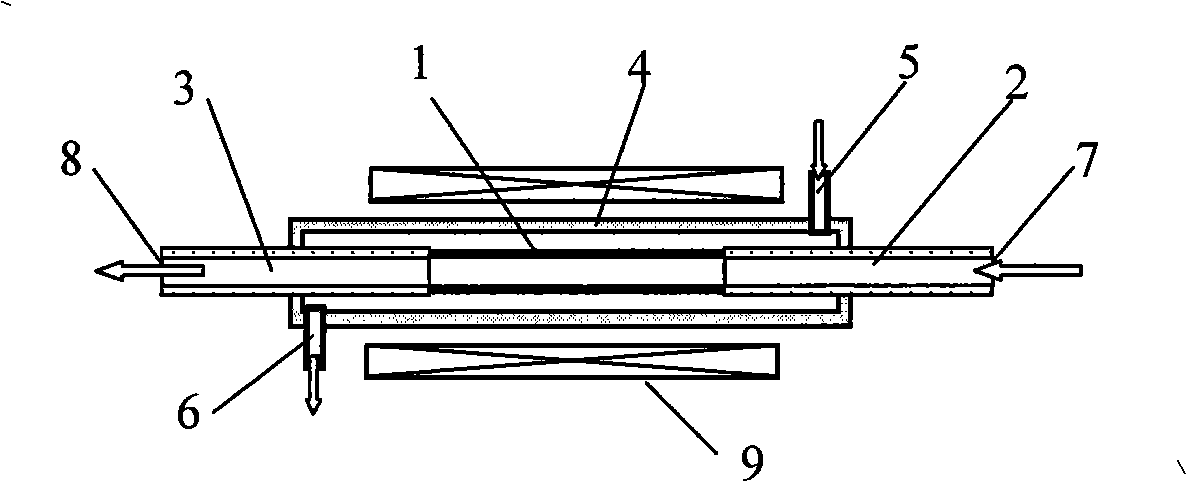

The invention provides a method for preparing an asymmetrical two-phase composite oxygen permeation membrane, which comprises the following processes: performing grinding, leveling, supersonic cleaning and drying on a two-phase composite oxygen permeation membrane which consists of an oxygen ion conductor and an oxygen ion-electron mixed conductor; protecting one surface of the oxygen permeation membrane, making the other surface of the oxygen permeation membrane exposed and placing the other surface of the oxygen permeation membrane into 1.0 to 50 percent of acid solution for soakage, wherein the soaking temperature is between 10 and 80 DEG C, and the soaking time is between 10 and 360 hours; and forming the asymmetrical two-phase composite oxygen permeation membrane. A porous carrier of the prepared asymmetrical two-phase composite oxygen permeation membrane has high voidage and centralized pore size distribution, and a porous carrier layer and an oxygen permeation membrane layer can be well fused and not separated. The asymmetrical two-phase composite oxygen permeation membrane has high oxygen permeability, and has high chemical stability and structural stability under reducing atmosphere. An asymmetrical composite oxygen permeation ceramic membrane prepared can be used for selecting and separating oxygen from oxygen-containing gas mixture and for converting natural gas into synthetic gas in a membrane reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

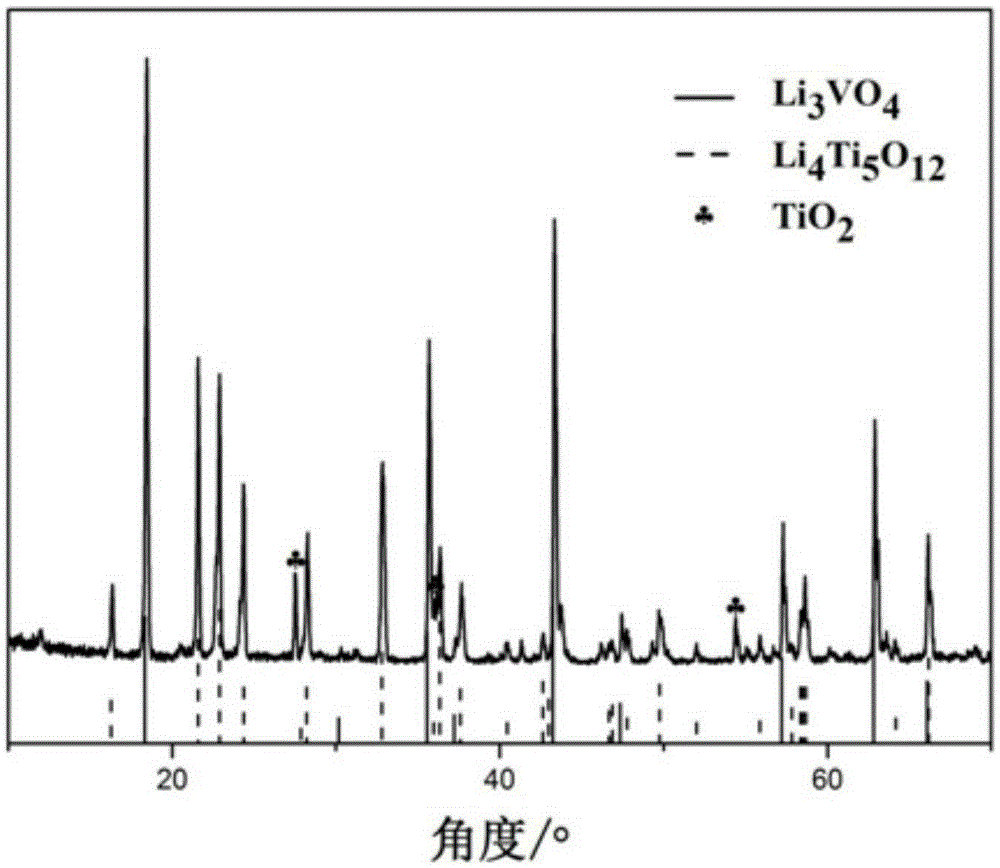

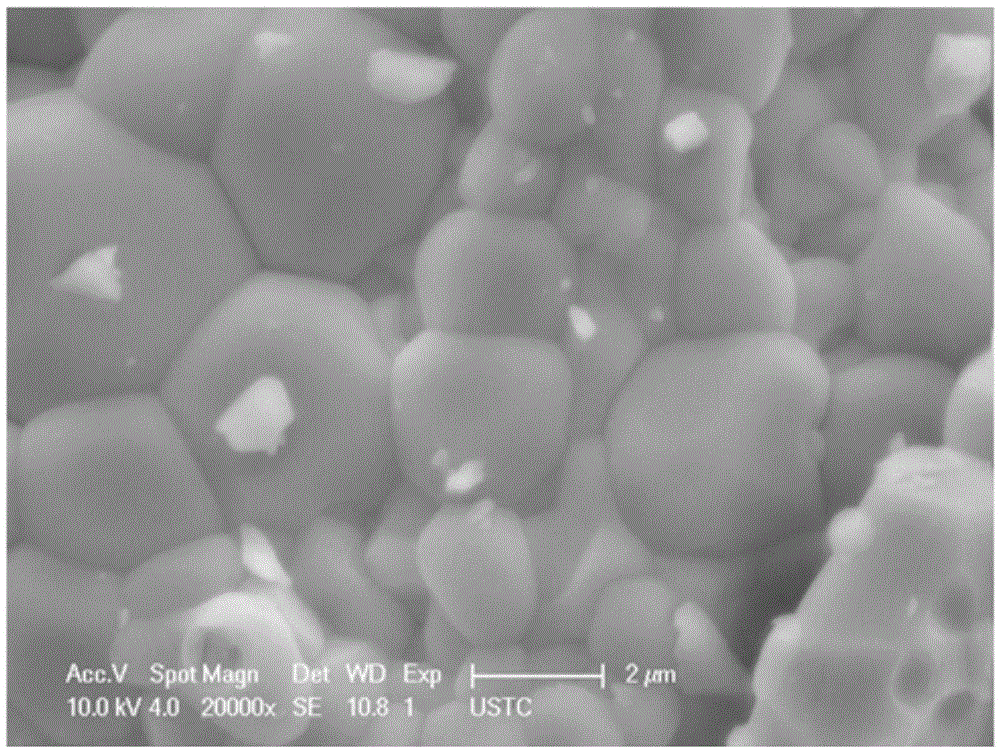

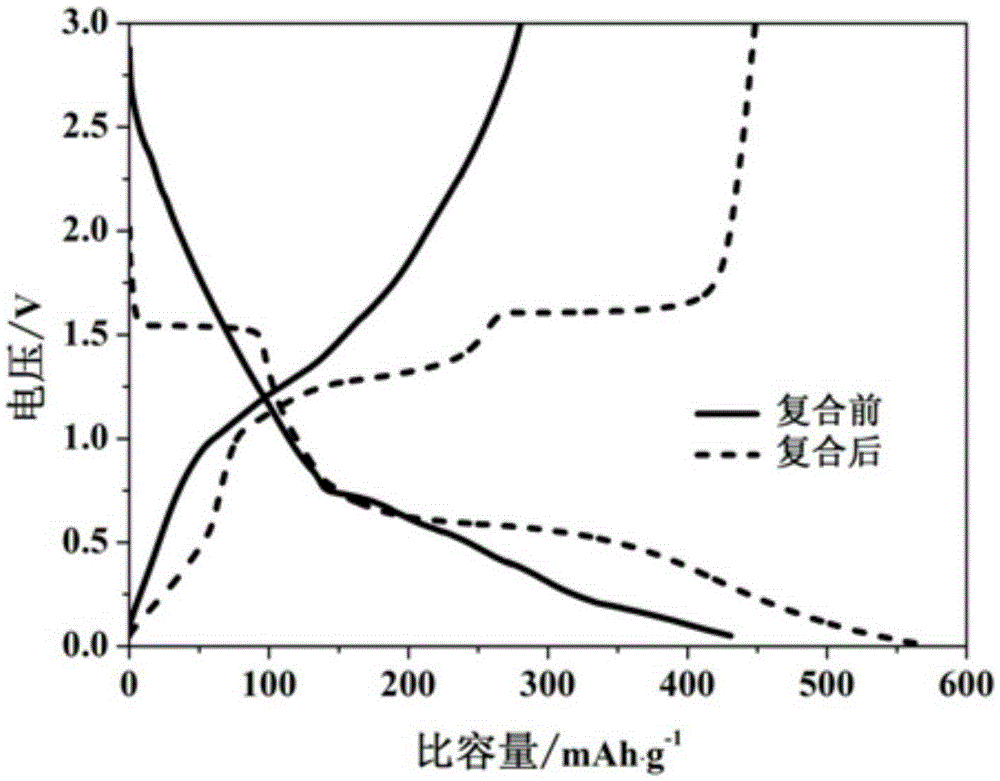

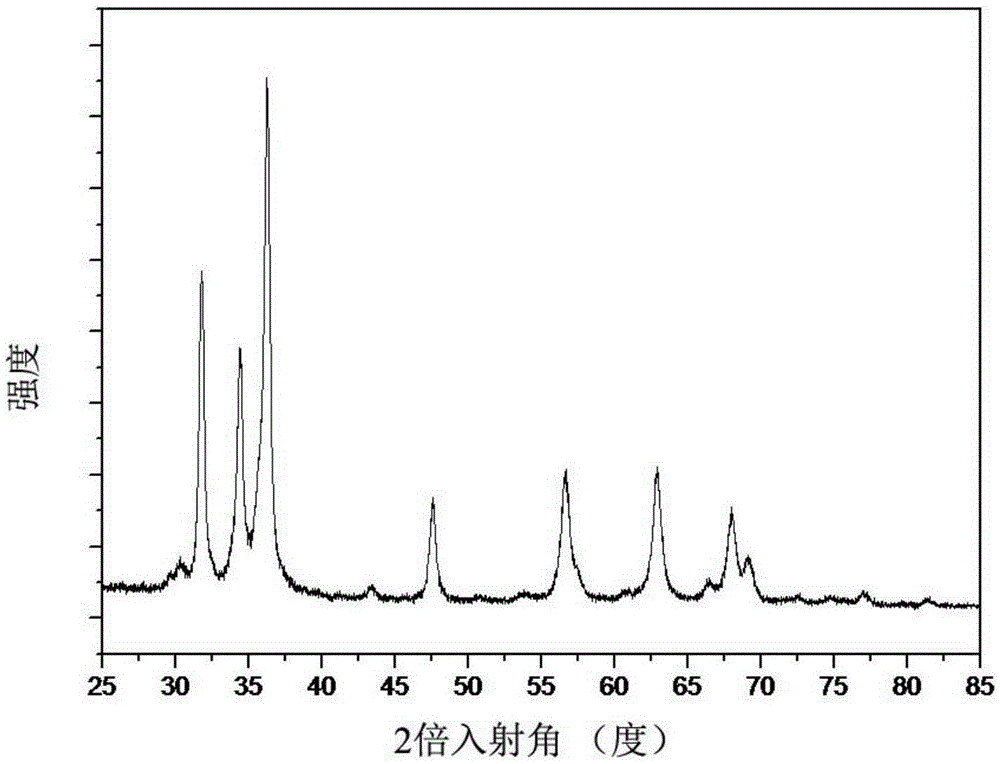

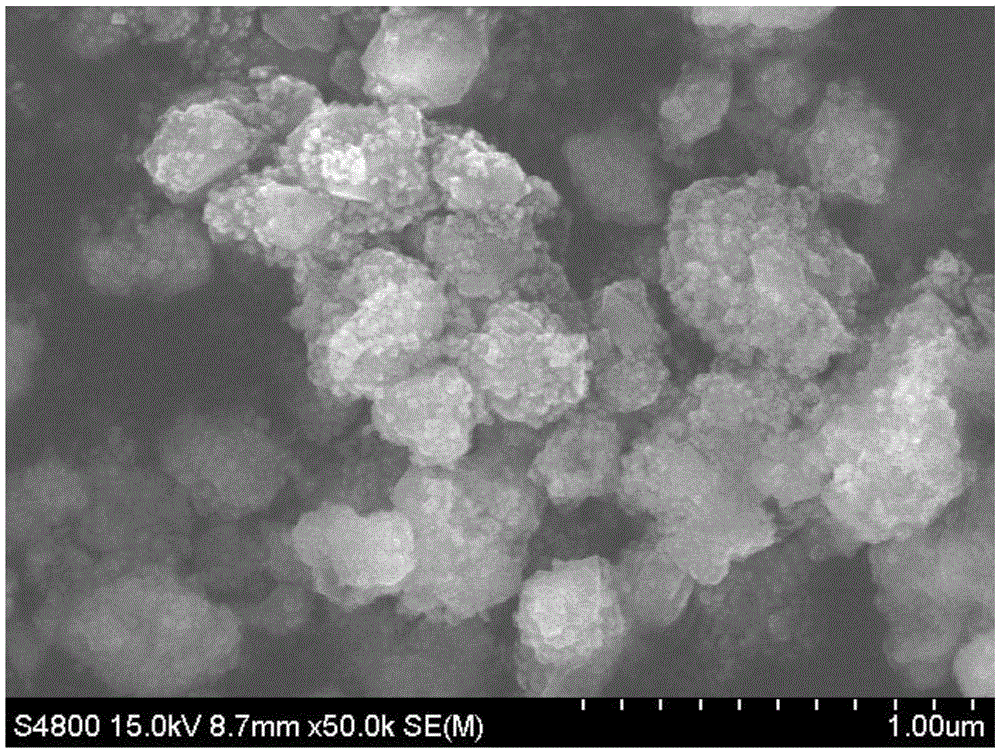

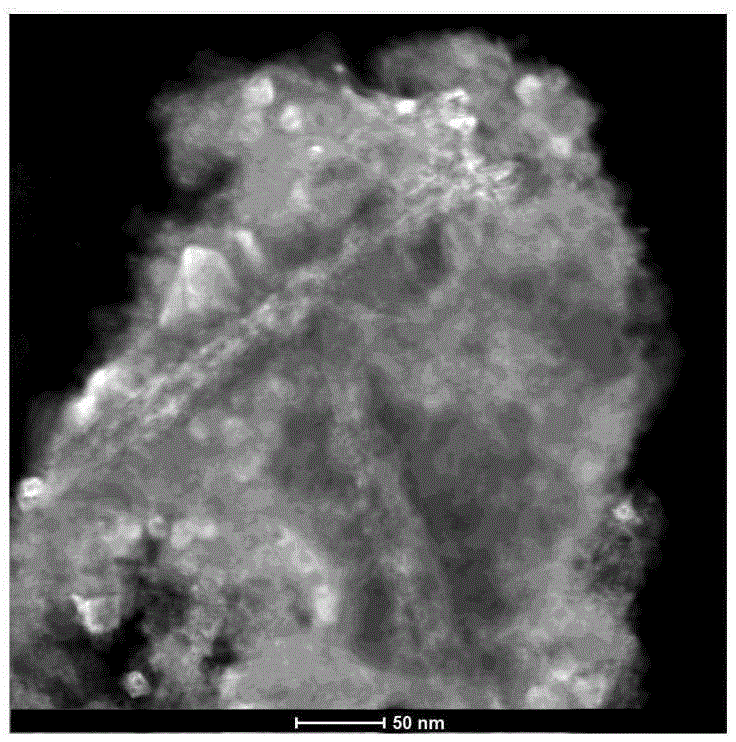

Negative composite material for lithium-ion battery and preparation method of negative composite material

ActiveCN105280895AImprove Coulombic efficiencyHigh specific capacityCell electrodesSecondary cellsSlurryTwo phase composite

The invention discloses a negative composite material for a lithium-ion battery and a preparation method of the negative composite material. The negative composite material for the lithium-ion battery is compounded according to the stoichiometric ratio of a chemical formula xLi<3>VO<4>.(1-x)Li<4>Ti<5>O<12> (wherein x is less than or equal to 1 and greater than or equal to 0.5). The preparation method comprises the following steps: weighing a lithium source and a vanadium source, adding an additive and a solvent or a complex agent and the solvent, and then forming a solution or slurry A; weighing the lithium source and a titanium source, adding the additive and the solvent or the complex agent and the solvent and then forming a solution or slurry B; and mixing the solution or slurry A with the solution or slurry B evenly through a liquid phase or solid phase method, and drying and sintering the mixture to obtain a Li<3>VO<4> or Li<4>Ti<5>O<12> two-phase composite material. With the obtained composite material as the negative material for the lithium-ion battery, the characteristics that lithium vanadate has proper intercalation / deintercalation potential and considerable capacity are fully utilized, so that the negative composite material for the lithium-ion battery has relatively high coulombic efficiency, relatively high specific capacity and good rate capability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing ZnO/ZnGaNO two-phase composite structure photocatalytic powder

ActiveCN105289694AImprove photocatalytic degradation efficiencyStrong decolorization abilityPhysical/chemical process catalystsNanoparticleTwo phase composite

The invention discloses a method for preparing ZnO / ZnGaNO two-phase composite structure photocatalytic powder. The method comprises the following steps: preparing a hydroxide precursor containing Zn and Ga ions in an aqueous solution by utilizing a co-precipitation method for reducing the pH value; nitriding the precursor, thereby obtaining the composite structure powder of which the interior is provided with ZnO nanosheets and the surface is provided with ZnGaNO solid solution nano particles. The powder is high in photocatalytic degradation efficiency of methylene blue aqueous solution under visible light and is high in decoloring power. The method disclosed by the invention is simple in process, low in cost and suitable for large-scale production.

Owner:XIAMEN UNIV OF TECH

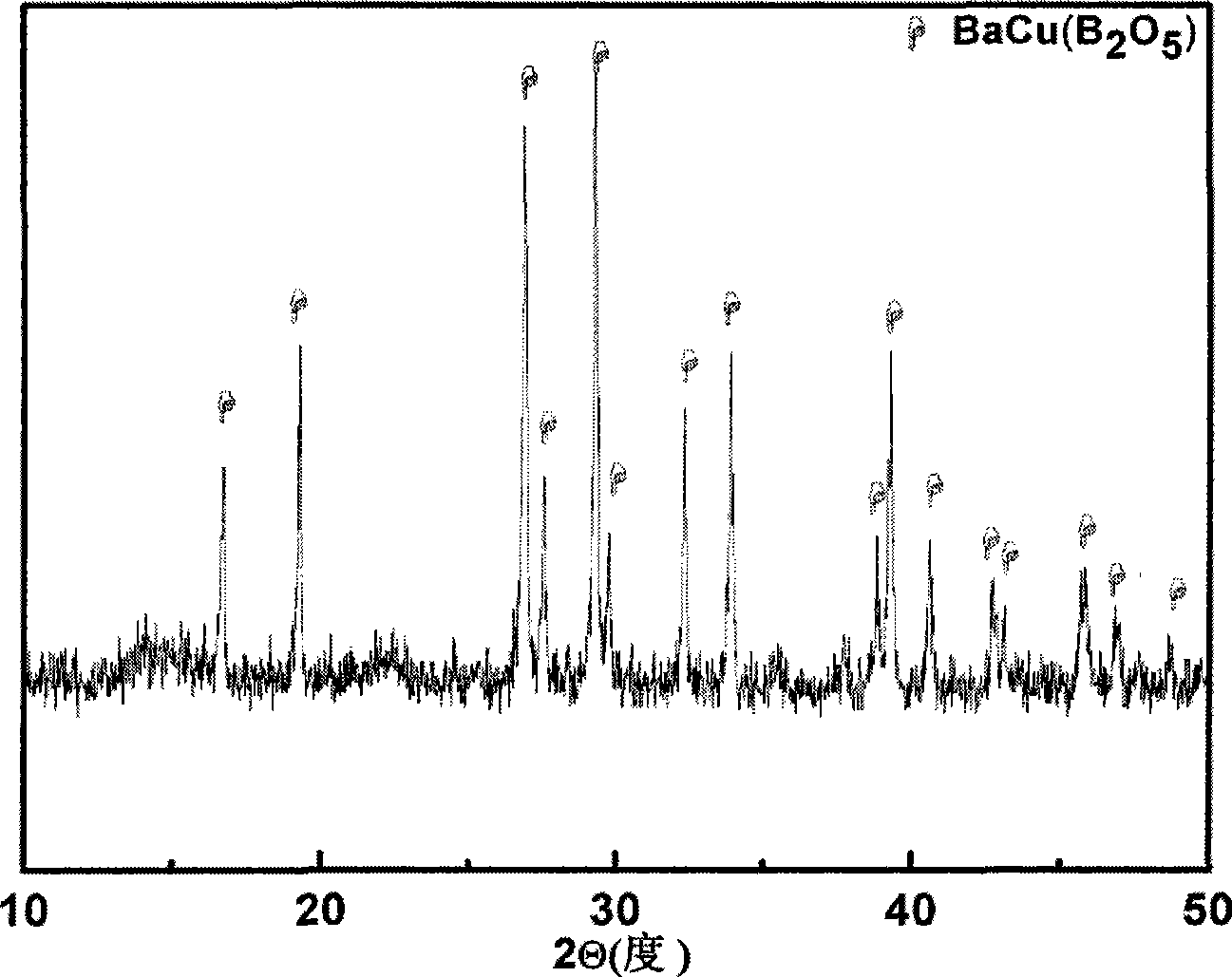

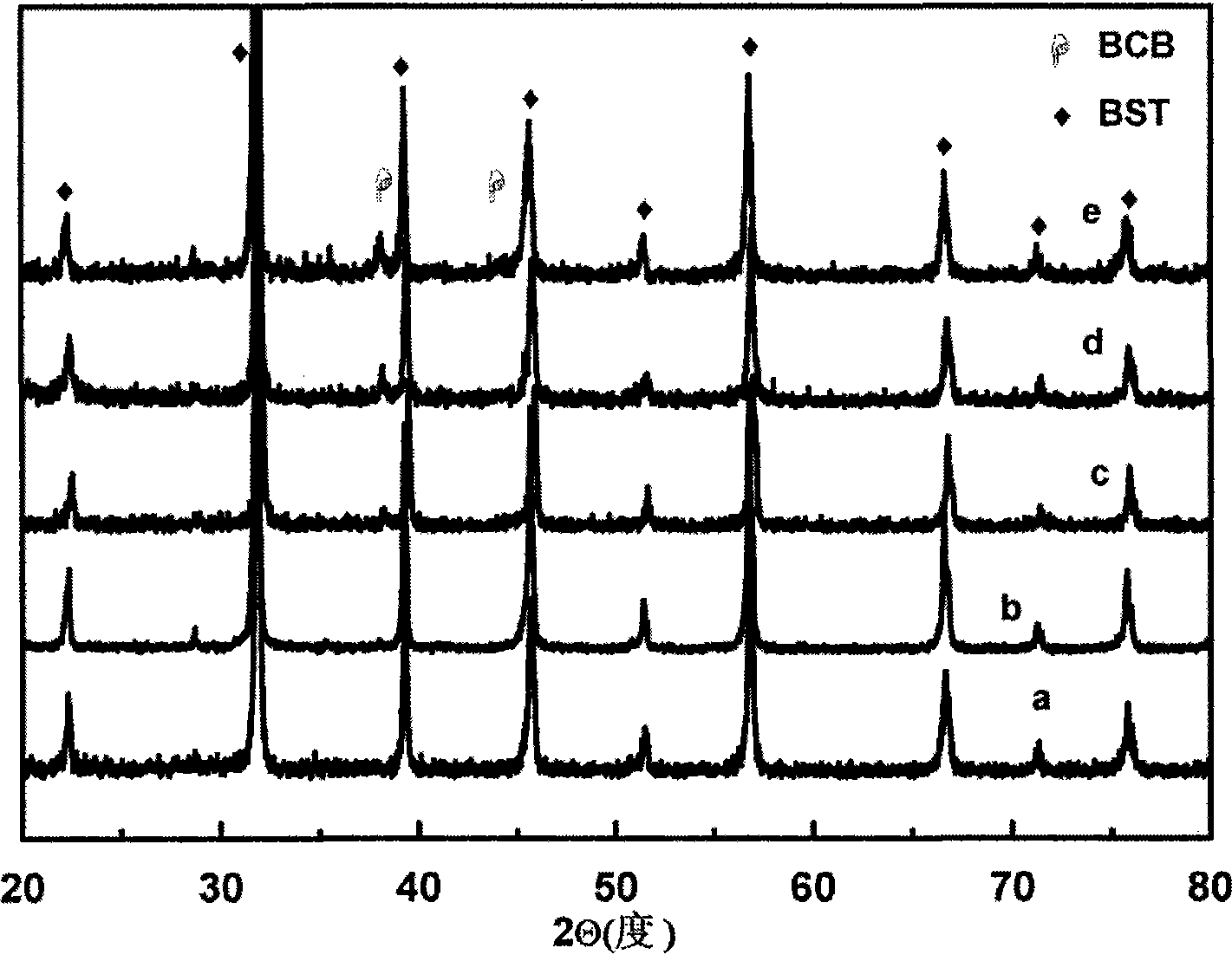

High-toughness electric conduction nylon composite material and preparation method thereof

The invention relates to a nylon composite material and particularly relates to a high-toughness electric conduction nylon composite material and a preparation method thereof. The composite material comprises raw materials of 50-80 wt.% of a polymer matrix, 10-20 wt.% of carbon black, 10-30 wt.% of maleic anhydride grafted polyolefin elastomer and 0.5-1.5 wt.% of liquid paraffin. The electric conduction performance of the obtained composite material is better than that of a carbon black / polymer two-phase composite material, and compared with impact strength of a pure matrix and the carbon black / polymer two-phase composite material, the impact strength of the obtained composite material is substantially improved; according to the high-toughness electric conduction nylon composite material and the preparation method thereof, a one-step method preparation process is used, so that industrialization production is easy to achieve, and the composite material is suitable for large-scale popularization and application; and the cheap foundation raw materials are used, so that costs are obviously reduced, and the composite material has a good price advantage.

Owner:合肥市和裕达塑业有限公司

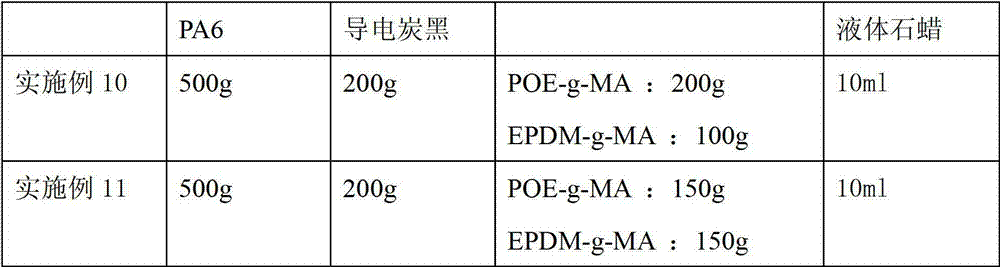

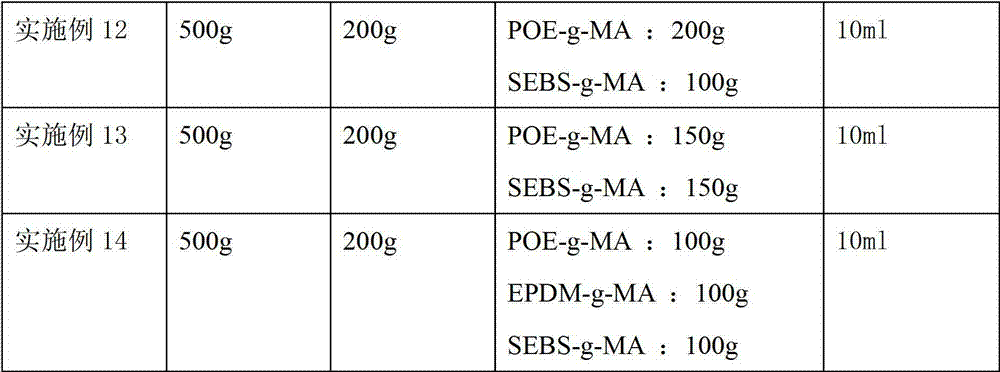

Low temperature sintering microwave ceramic material and preparation thereof

InactiveCN101486569ASerialization of dielectric constantLow dielectric lossCeramicsDielectric lossDouble phase

The invention belongs to the field of electronic material and apparatus, in particular relates to a low-temperature sintering microwave ceramics material and a preparation method thereof. The low-temperature sintering microwave ceramics material comprises components with the following molar percentage: 90.0 percent to 99.5 percent of Ba(1-x)SrxTiO3(x is equal to 0.2 to 0.7) as well as 0.5 percent to 10.0 percent of BaCu(B2O5). The invention develops a BST-BCB double-phase composite microwave ceramics material which has the advantages of dielectric constant seriation, low dielectric loss (high Q value) and higher modulation rate under a microwave frequency band and can be used on an adjustable microwave apparatus by carrying out composition to a microwave medium material BCB and a BST ferroelectric material.

Owner:TONGJI UNIV

Ba(1-x)SrxTiO3-BaX6Ti6O19(X=Mg, Zn) diphasic composite micro-wave ceramic material and preparation method thereof

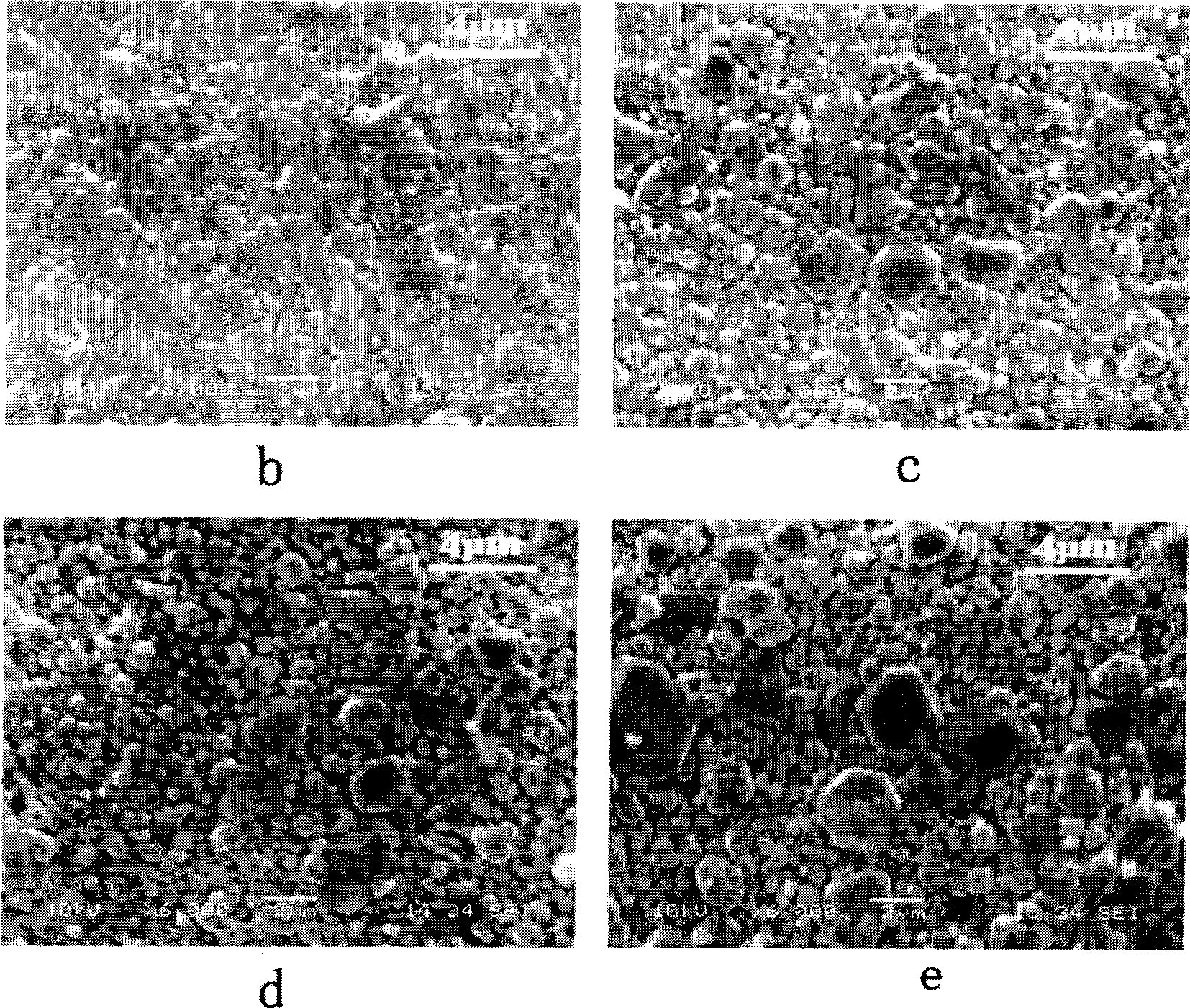

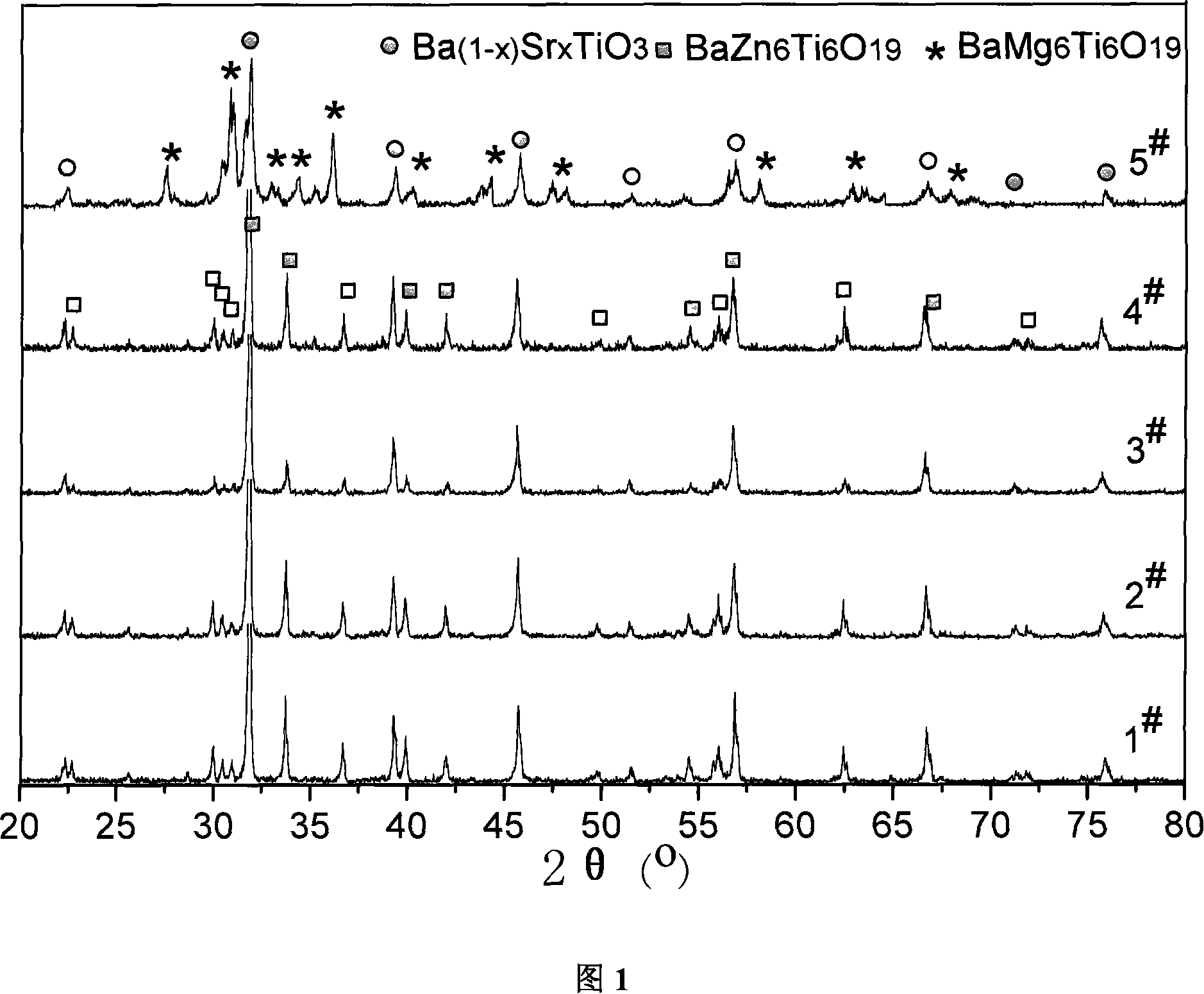

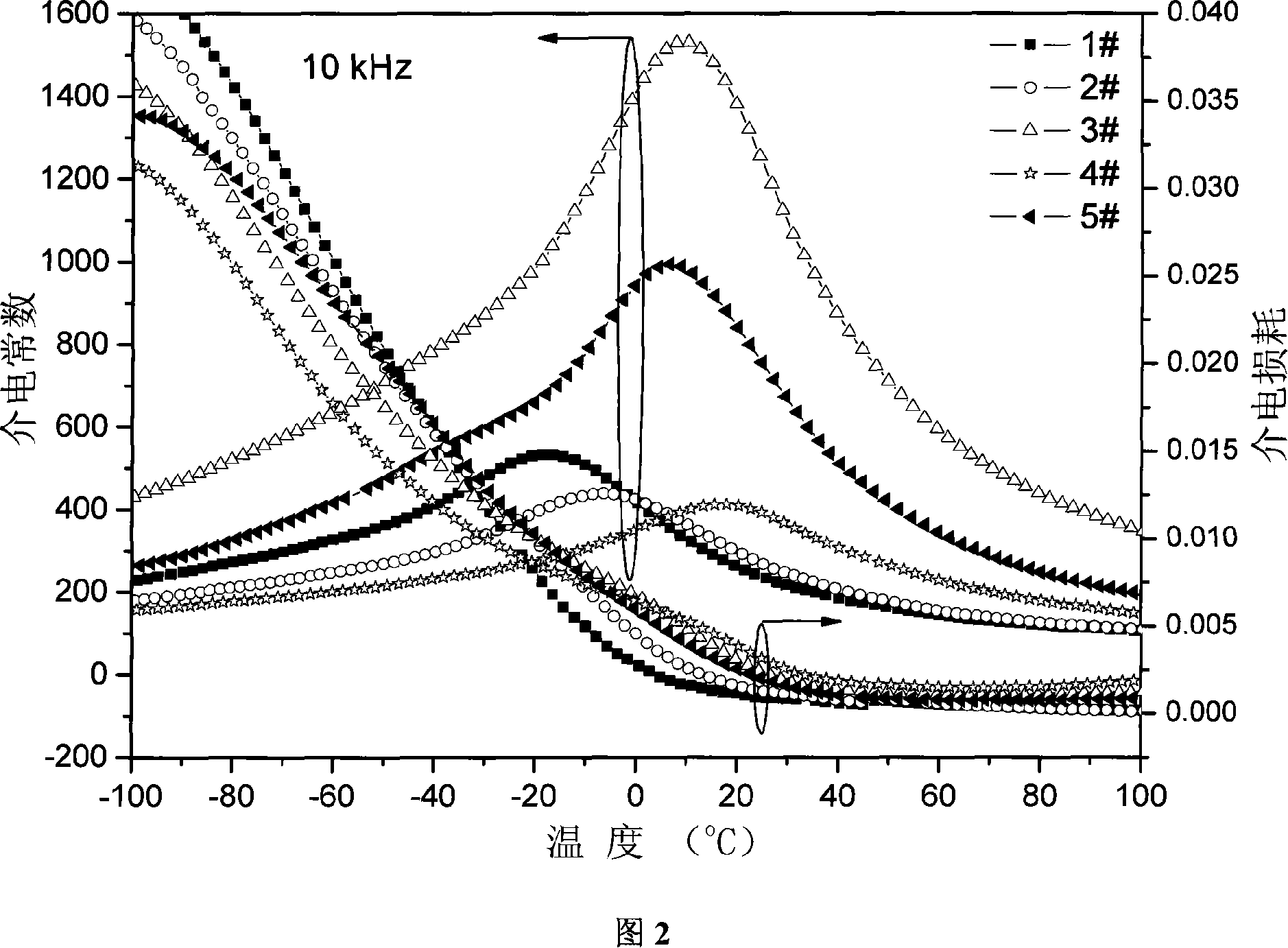

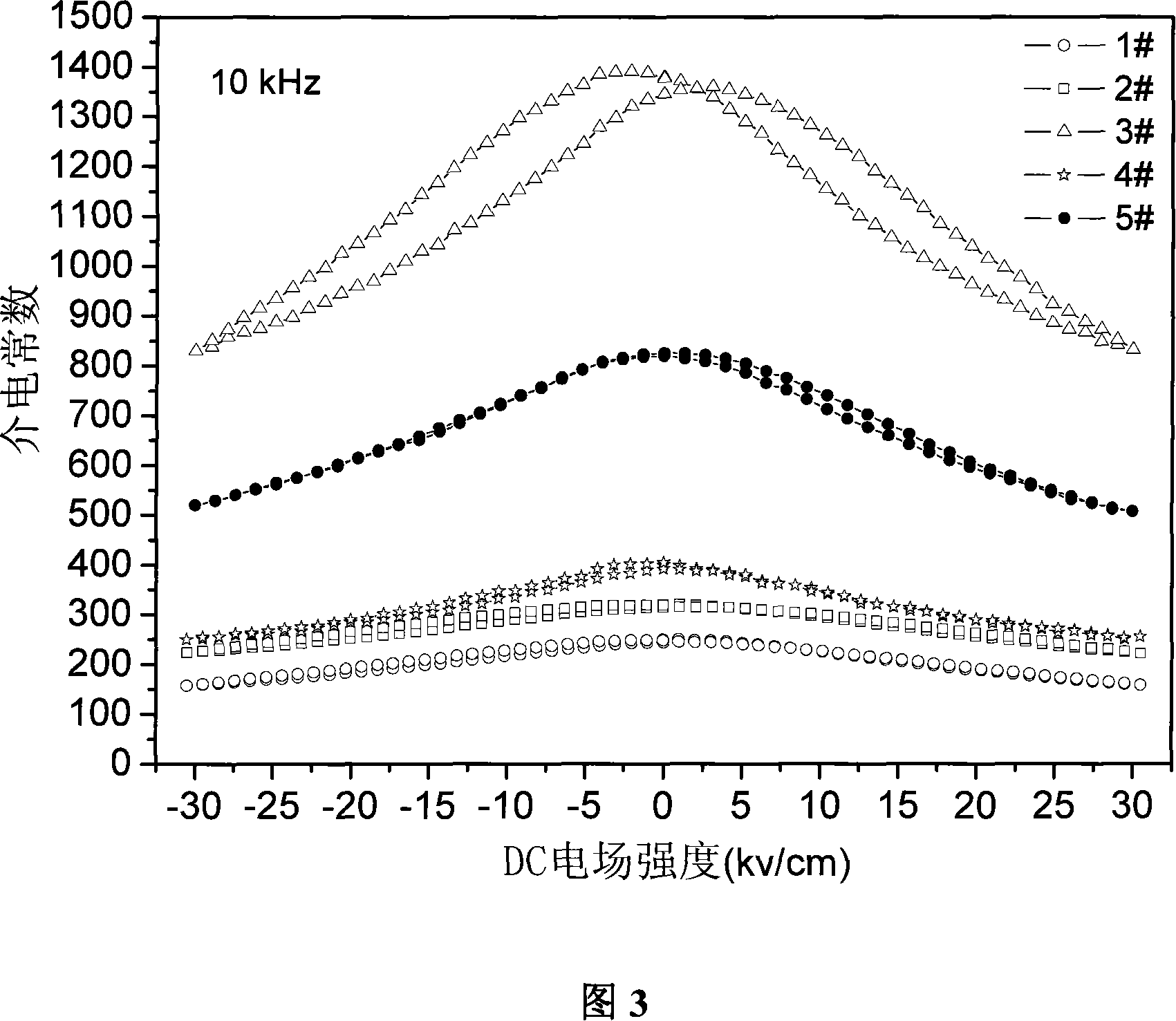

InactiveCN101117285AExcellent dielectric propertiesModerate dielectric propertiesCeramicsElectricityMicrowave

The invention relates to the two-phase composite microwave ceramics material technical field with controllable permittivity with the seriation of composition components and the high adjustability in imposed DC electric field. The Ba(1-x)SrxTiO3-BaX6Ti6O19(X=Mg, Zn) two-phased composite microwave ceramics material of the invention comprises: Ba (1-x)SrxTiO3(x=0.3-0.6) 80.0wt percent to 20.0wt percent and BaX6Ti6O19 20.0wt percent to 80.0wt percent. Adopting traditional electronic ceramics preparation process, the invention selects a low dielectric microwave dielectric material BaX6Ti6O19(X=Mg, Zn) with a high dielectric property and a barium strontium titanate ferroelectric materials of a different Ba / Sr components to be in two-phase gradient composite. The composite material produced has an appropriate permittivity, an electric adjustable property and is applicable to adjustable microwave elements and electric adjustable medium function modules.

Owner:TONGJI UNIV

Amorphous and nanocrystalline composite coating for zirconium alloy protection and preparation method of amorphous and nanocrystalline composite coating

ActiveCN109338303ANo penetrating voidCompact structureVacuum evaporation coatingSputtering coatingGas phaseWater vapor

The invention discloses an amorphous and nanocrystalline composite high hardness coating. The coating is composed of Cr<x>Al<y>Si<z>N<100-x-y-z>, wherein 52.0<=x<=55.5, 15.3<=y<=20.2, 3.3<=z<=6.7, thex, y, and z are atomic ratios, the high hardness protective coating is of a hexagonal AlN nanocrystalline and amorphous two-phase composite structure, the thickness of the high hardness protective coating is 8-12 [mu]m, and the density is 4.9-5.7 g / cm<3>; the coating is prepared through physical gas phase magnetron sputtering, when the vacuum degree is 3*10<-5> Pa or the less, the substrate surface is deposited by selecting a target material and adjusting the sputtering power density of the target material and the power density of an auxiliary plasma radio frequency power source, according tothe obtained protective coating, the hardness can reach 18-23 GPa, and can further resist water vapor oxidation at 800-1200 DEG C within a long time period.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

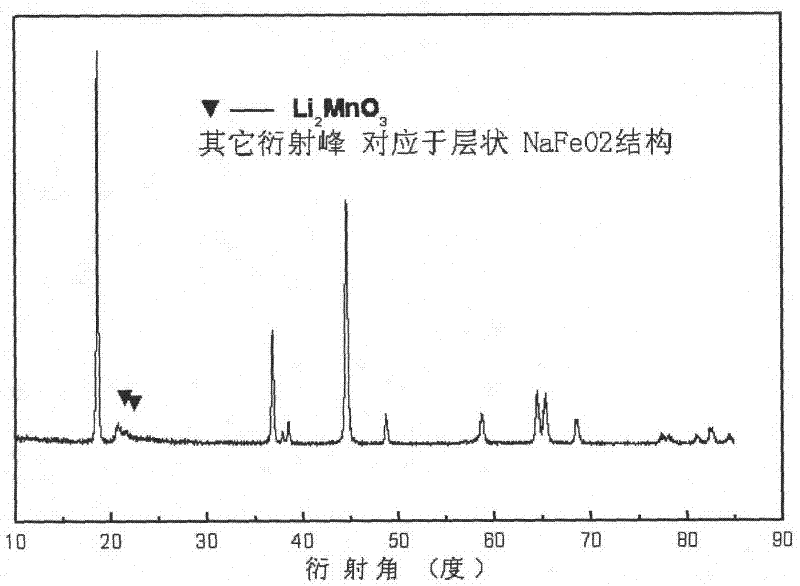

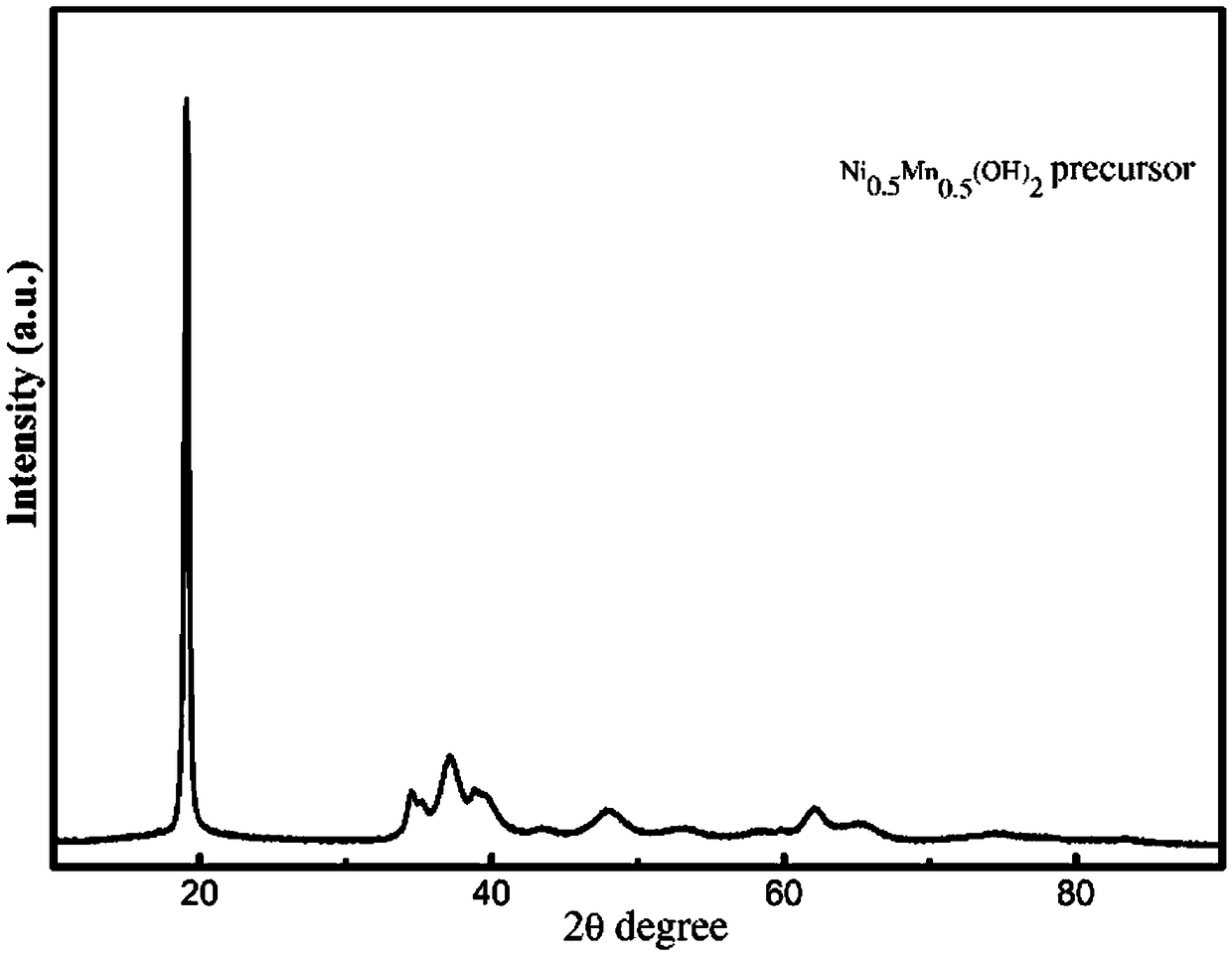

Multiphase Mn (manganese)-base anode material and preparation method thereof

ActiveCN102244258AIncrease capacityImprove the first Coulombic efficiencyCell electrodesManganeseMaterials science

The invention provides a multiphase Mn (manganese)-base anode material, which is of a three-phase composite structure comprising a kernel, an intermediate layer and a surface layer. The chemical formula of the anode material is shown as x(Li2MnO3).(LiNi0.3Mn0.7O2).y(MO), wherein x is more than or equal to 0.01 and less than or equal to 0.1, y is more than or equal to 0.01 and less than or equal to 0.1 and M is one selected from Cu, Zn or Mg. A preparation method of the anode material comprises the following steps: adopting a liquid phase precipitation reaction to prepare Ni0.3Mn0.7(OH)2 and precipitating the precursor of Mn(OH)2 on the surface of the Ni0.3Mn0.7(OH)2; mixing the precursor with lithium carbonate, and carrying out a solid-phase reaction to prepare a two-phase composite material x(Li2MnO3).(LiNi0.3Mn0.7O2); and finally adopting a liquid phase precipitation method to adhere a layer of metallic hydroxides to the surface of x(Li2MnO3).(LiNi0.3Mn0.7O2) and heating and decomposing to obtain MO. The preparation method is simple and convenient to operate; the components and the contents of the prepared multiphase Mn-base anode material can be controlled; the uniformity of the kernel components is good; and the prepared multiphase Mn-base anode material is high in capacity, first coulomb efficiency and safety and long in cycle life and is suitable for industrialization production.

Owner:CENT SOUTH UNIV

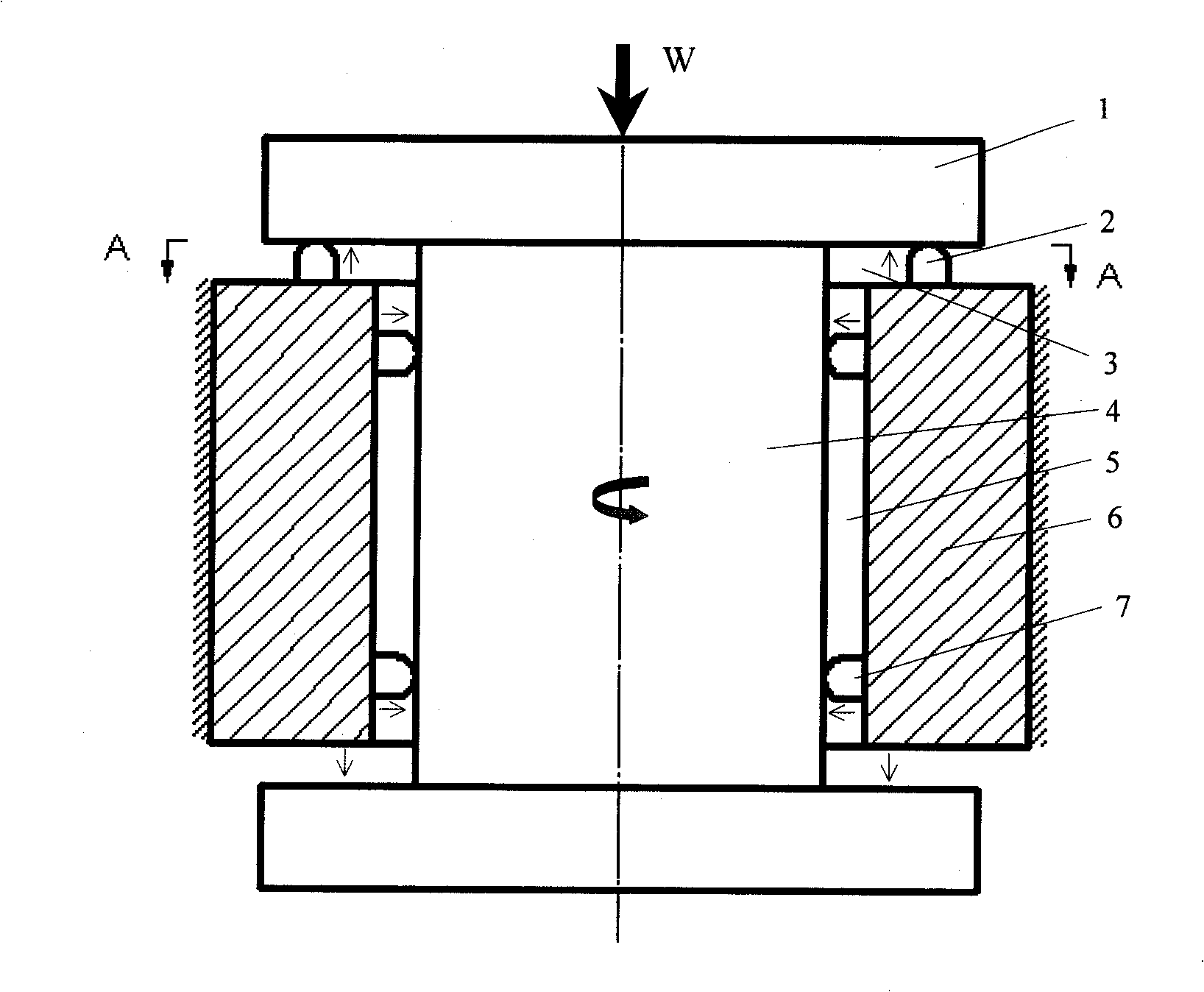

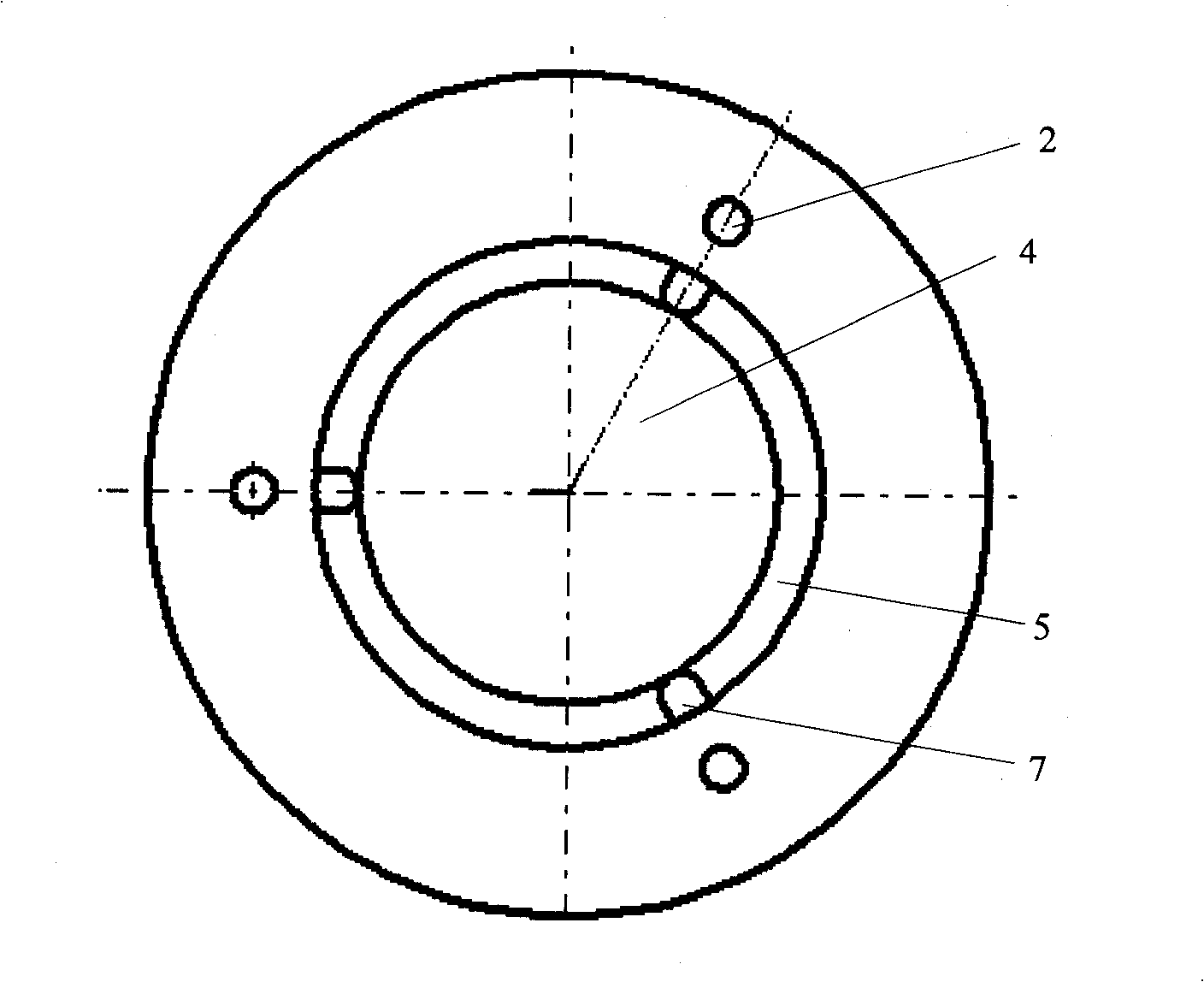

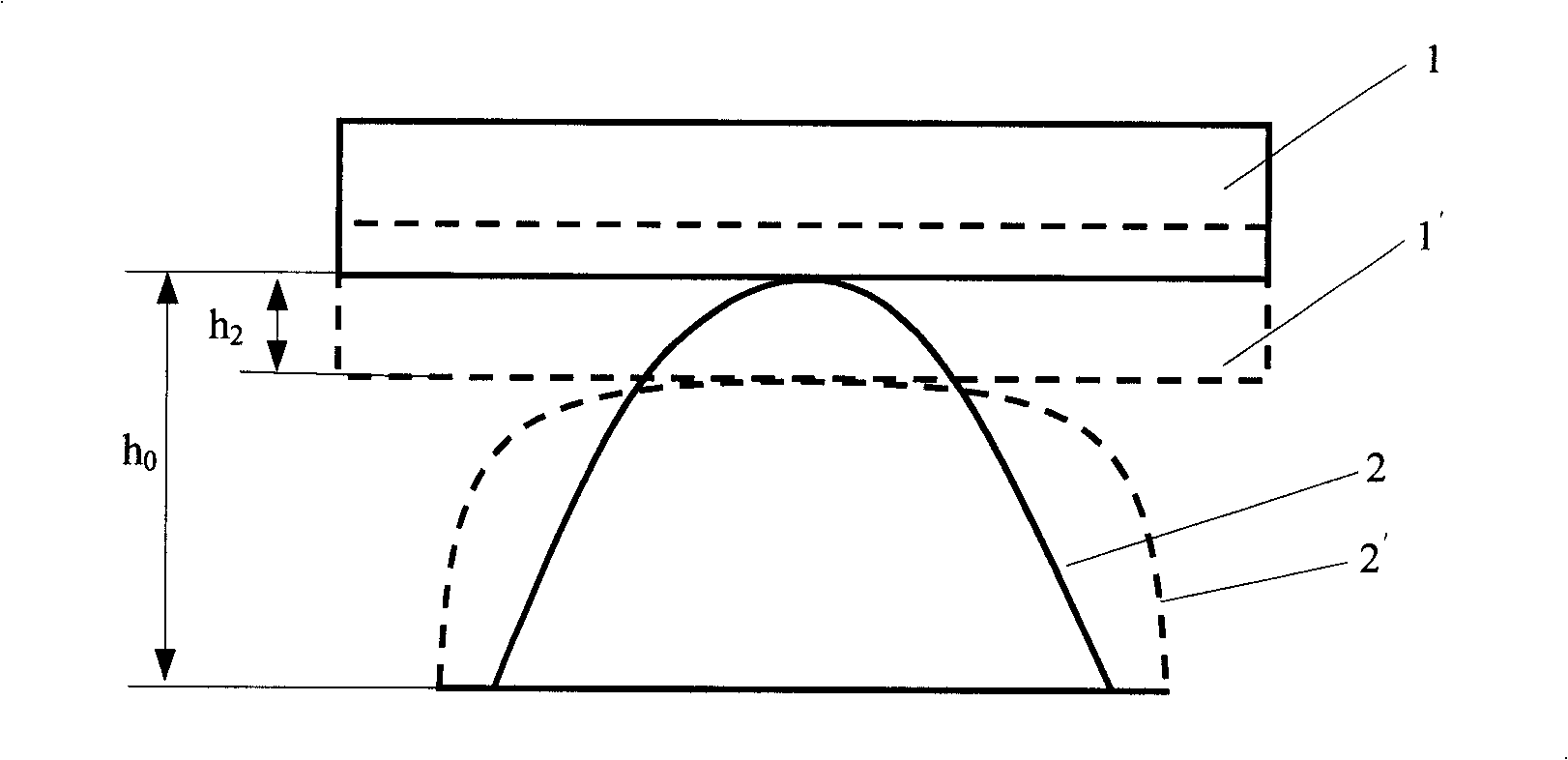

Gas/ solid two-phase composite gyration basic method and device

InactiveCN101338790AOvercome the shortcomings of not being able to take care of these features at the same timeImprove carrying capacityBearingsGas lubricationGas phase

The present invention relates to a gas phase / solid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas lubricating and error averaging technology and the solid supporting and damping technology, the method applies axial solid support in the axial anti-thrust gaseous film of a gas-floated shafting to form a composite supporting mode with the primary solid support and the subsidiary gas support or the primary gas support and the subsidiary solid support or the gas support and the solid support which are the equivalent in order to notably enhance the axial rigidity and bearing capacity of the gas-floated shafting. Applying radial solid support in the radial gaseous film of the gas-floated shafting, the method utilizes the slight elastic deformation of elastic elements to dissipate the medium / high-frequency micro-vibration energy of a mainshaft and the stored deformation energy and static friction characteristic of the elastic elements to enhance positioning damp in order to increase positioning precision. In the device, the solid elastic elements are respectively assembled in the axial anti-thrust gaseous film and the radial gaseous film. The method can establish a gyration benchmark which also takes high precision, high rigidity, high support, low vibration and high displacement sensitivity into consideration.

Owner:HARBIN INST OF TECH

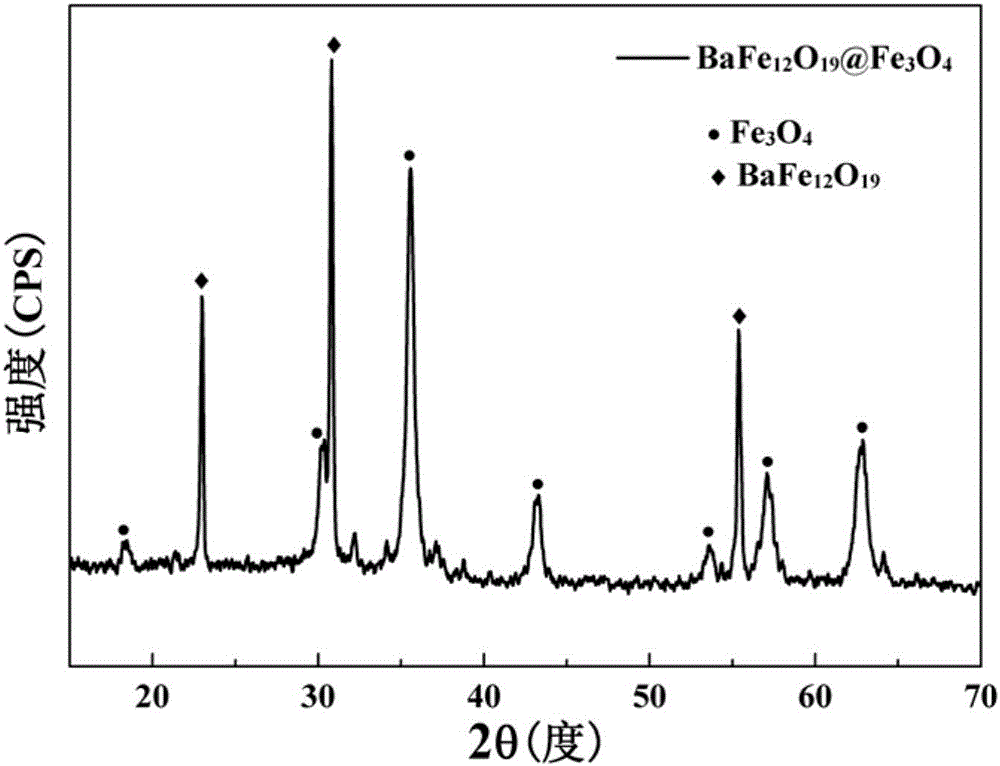

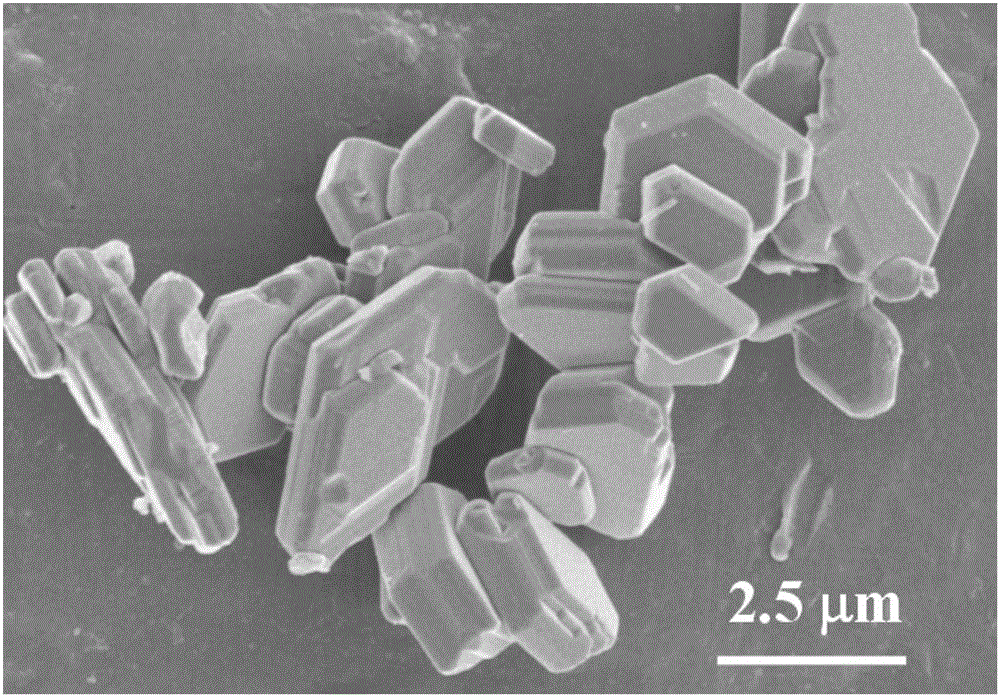

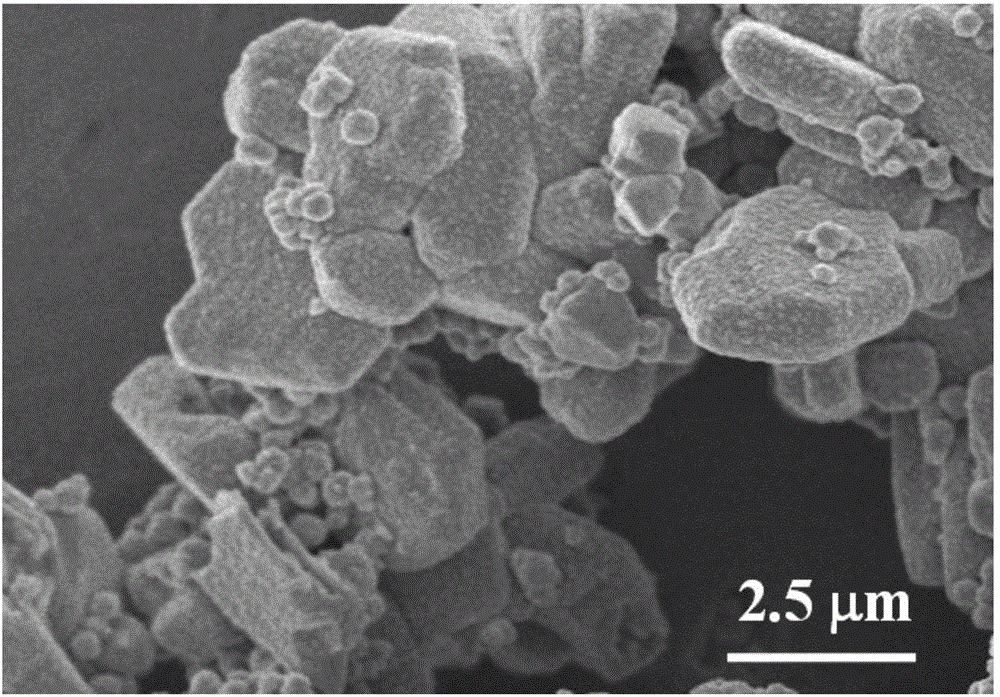

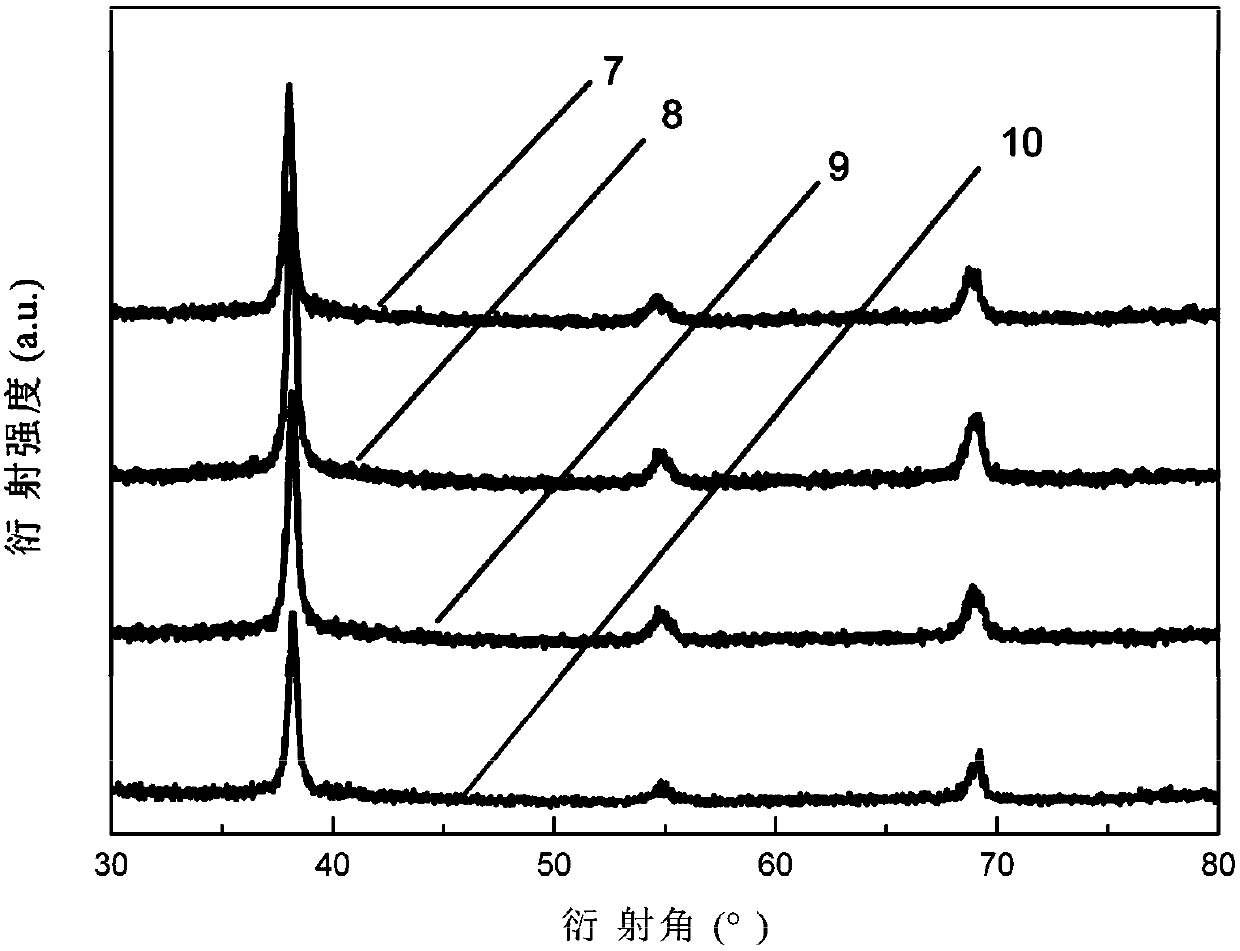

Preparation method of barium ferrite-ferroferric oxide composite wave-absorbing material

ActiveCN106587167AImprove absorbing performanceShort preparation cycleOther chemical processesFerroso-ferric oxidesMicrowaveMolten salt

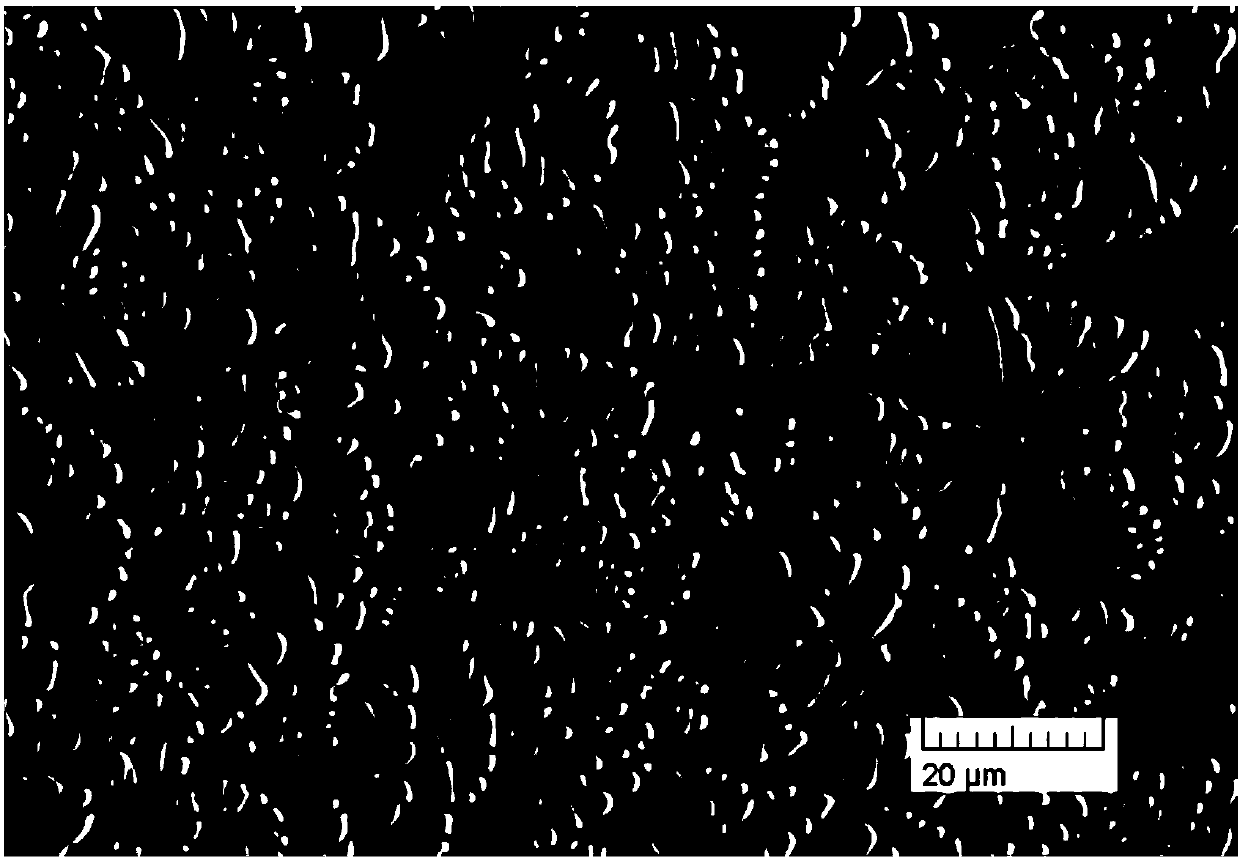

The invention discloses a preparation method of a barium ferrite-ferroferric oxide composite wave-absorbing material. The preparation method comprises the following steps: preparing a (001) direction-oriented BaFe12O19 flaky powder by virtue of a molten salt method first, and then enabling Fe3O4 to grow on the BaFe12O19 which is used as a matrix by adopting a hydrothermal method, thereby preparing the barium ferrite-ferroferric oxide two-phase composite wave-absorbing material. The preparation process provided by the invention is simple in operation and short in period, the diameter of the prepared flaky barium ferrite-ferroferric oxide is about 2[mu]m, the size is uniform, and the microwave absorptivity of the flaky barium ferrite-ferroferric oxide has certain improvement.

Owner:SHAANXI UNIV OF SCI & TECH

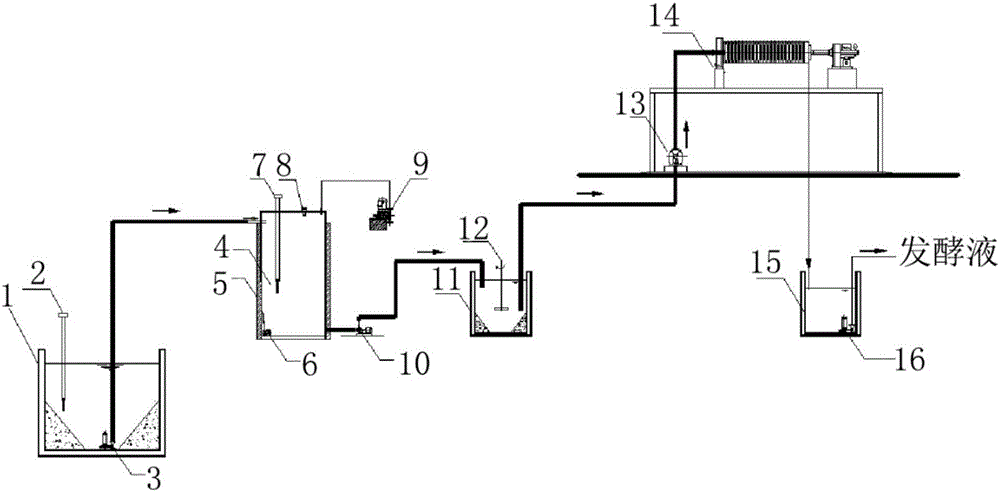

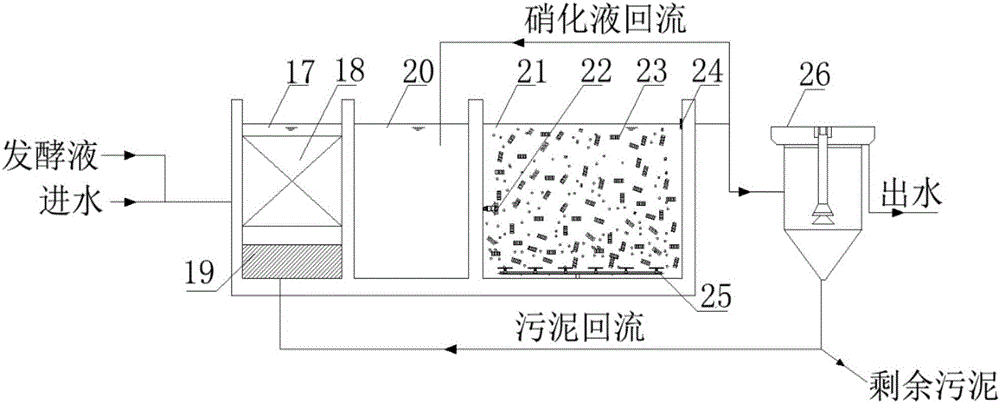

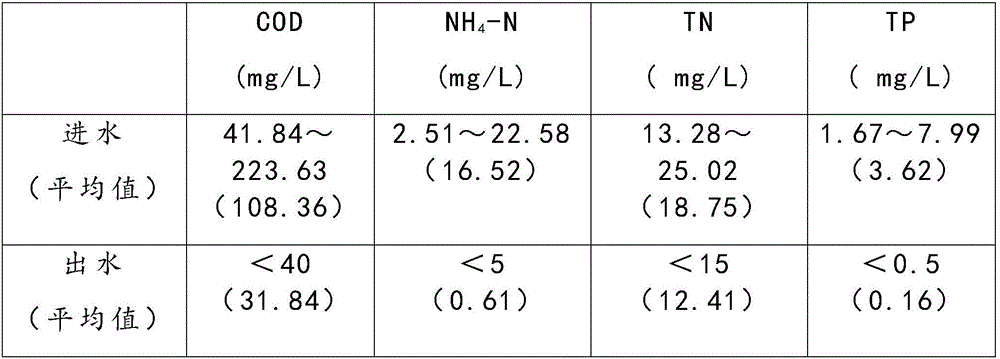

Coupling anaerobic sludge acidogenesis mud-film two-phase composite A/A/O system and technology

InactiveCN105906052AIncrease CODIncrease chemical oxygen demand)Treatment with aerobic and anaerobic processesEmission standardLiquid storage tank

The invention discloses a coupling anaerobic sludge acidogenesis mud-film two-phase composite A / A / O system and technology. The system comprises an anaerobic sludge acidogenesis subsystem and a Hybrid-A / A / O subsystem. The anaerobic sludge acidogenesis subsystem comprises a sludge thickening tank, an anaerobic sludge acidogenesis tower, a medicine adding mixing tank, a sludge filter press and a liquid storage tank. The Hybrid-A / A / O subsystem comprises an anaerobic tank, an anoxia tank, an aerobic tank and a sedimentation tank, wherein biological stuffing in the anaerobic tank is solid biological stuffing; biological stuffing in the aerobic tank is suspended biological stuffing; the liquid storage tank is communicated with the anaerobic tank; the sedimentation tank is communicated with the sludge concentration tank through a pipeline. According to the coupling anaerobic sludge acidogenesis mud-film two-phase composite A / A / O system and technology, carbon source distribution and complementation, sludge reduction and nitrogen and phosphorus removal performance are intensified and organically combined, the problems that the outlet water quality is not stable, the excess sludge yield is large and the processing cost is high are solved, and the outlet water obtained after low-carbon-source urban sewage treatment stably reaches the emission standard.

Owner:GUANGDONG ENG TECH INST

Low-cobalt doped spinel-layered structure lithium nickel manganate two-phase composite cathode material preparation method

ActiveCN109088067AInhibition of shufflingImprove conductivityCell electrodesSecondary cellsNickel saltHigh rate

The invention discloses a low-cobalt doped spinel-layered structure lithium nickel manganate two-phase composite cathode material preparation method. The preparation method comprises the following steps: 1) preparing a nickel-manganese precursor with spinel structure and a nickel-manganese precursor with layered structure by using a nickel salt and a manganese salt; 2) uniformly mixing the nickel-manganese precursor with spinel structure, the nickel-manganese precursor with layered structure, the lithium source and the cobalt source, and then calcining to obtain the composite cathode material.The invention utilizes the spinel phase to enhance the stability of the layered structure, and conversely, the low Li + migration activation barrier of the layered structure lithium nickel manganategives the composite material the possibility of high rate performance. A small amount of cobalt doped into the composite can partially enter the transition metal layer, which can inhibit the Ni / Li mixing and enhance the conductivity of the composite. The composite cathode material prepared by the method has the characteristics of high energy density, excellent cycling and rate performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

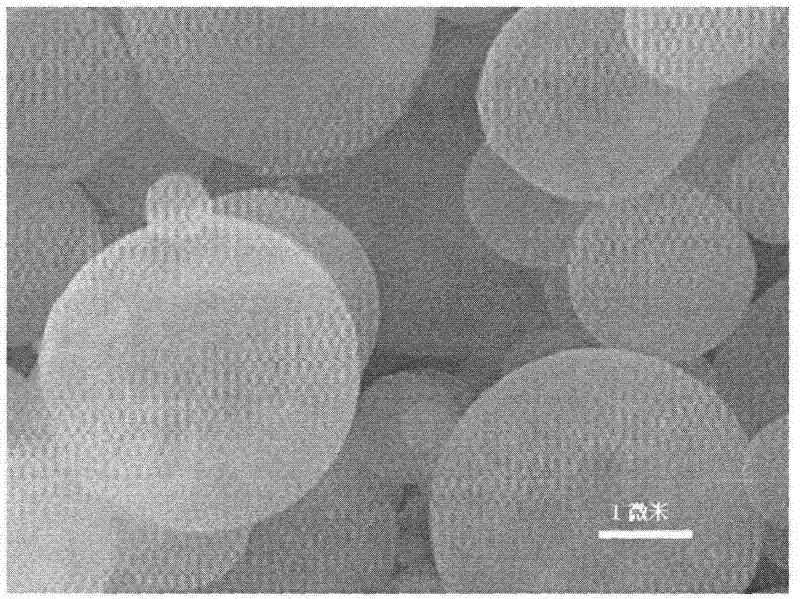

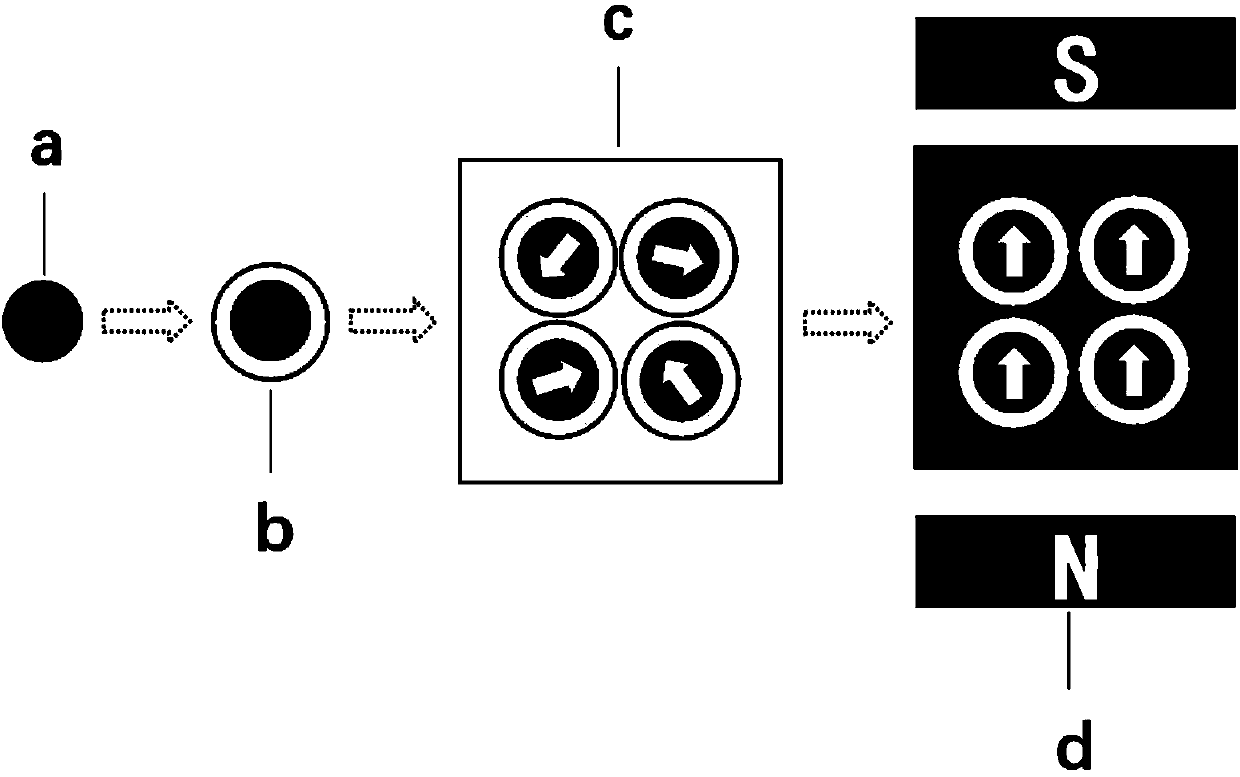

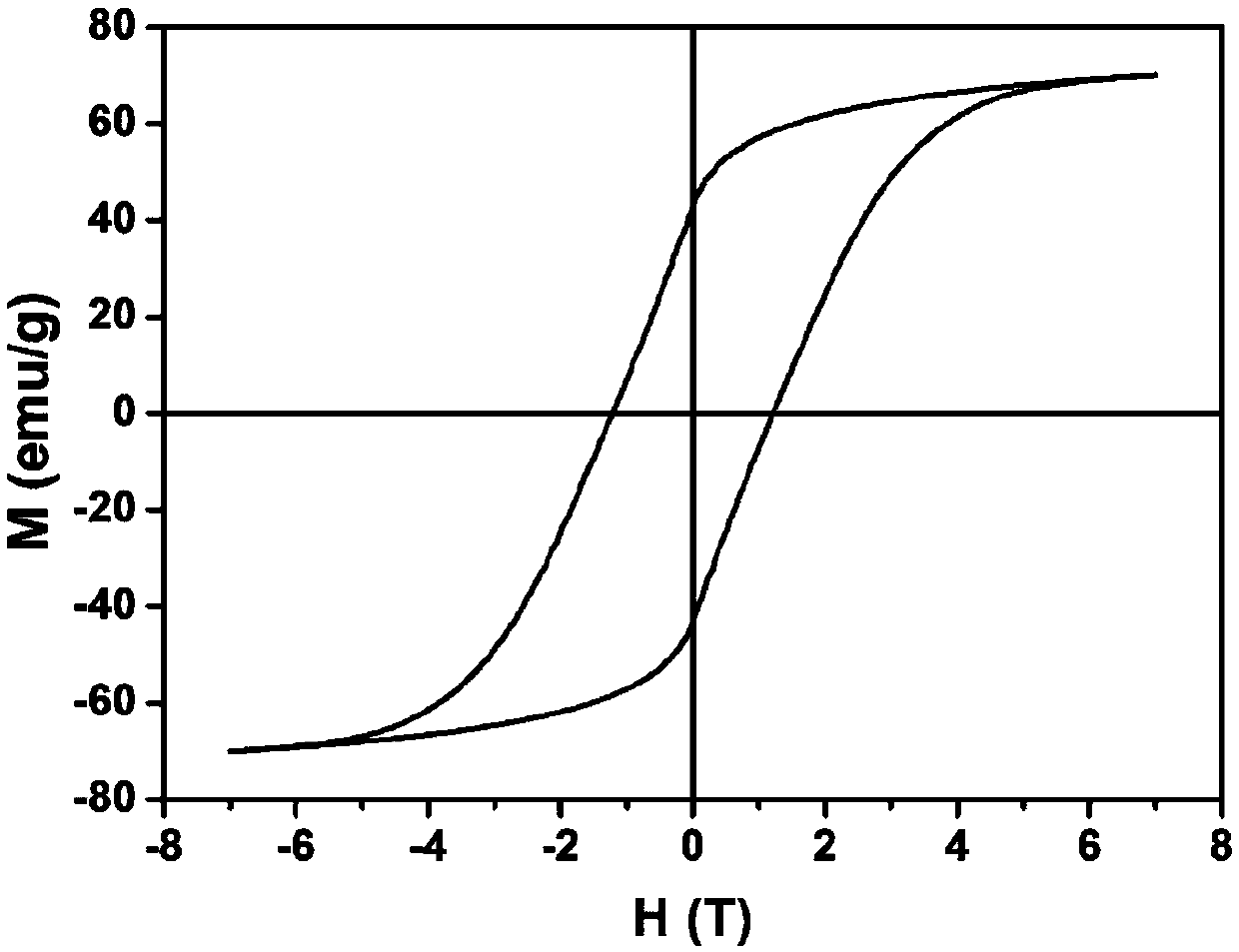

Nano-particle-based anisotropic two-phase composite magnet and preparing method

ActiveCN107564643APrecise control of coercivityPrecise control of saturation magnetizationMaterial nanotechnologyInductances/transformers/magnets manufactureEpoxyMagnetic phase

The invention provides a nano-particle-based anisotropic two-phase composite magnet and a preparing method. The nano-particle-based anisotropic two-phase composite magnet is characterized in that thetwo-phase magnet is made of nano particles which are of a core-shell structure and formed by hard magnetic phase inner cores and soft magnetic phase shells; orientation is conducted on the nano particles of the core-shell structure by applying a high-intensity magnetic field, and the nano particles of the core-shell structure obtained after orientation are cured with epoxy resin to obtain the nano-particle-based anisotropic two-phase composite magnet. The preparing method is simple in process, convenient to operate and does not need complex equipment. The particle size of the hard magnetic phase inner cores and the thickness of the soft magnetic phase shells can be adjusted in a wide range, and therefore the coercivity, saturation magnetization intensity, maximum magnetic energy product and other properties are adjusted and controlled. The nano two-phase composite magnet is excellent in performance, the ratio of residual magnetization intensity to saturation magnetization intensity (namely the remanence ratio) can reach 0.85, and the maximum magnetic energy product can reach 20 MG Oe.

Owner:苏州航大新材料科技有限公司

Zirconia nano ceramic material

The invention discloses a zirconia nano ceramic material simply prepared by conventional low-temperature sintering. The material can be sintered and densified without pressure at the temperature of lower than 1,000 DEG C, and has a two-phase composite structure consisting of a single oblique phase and a square phase; and the grain sizes of the two phases are less than 100 nanometers. The material has the characteristics of simple preparation process, small sintered grains and high compactness.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

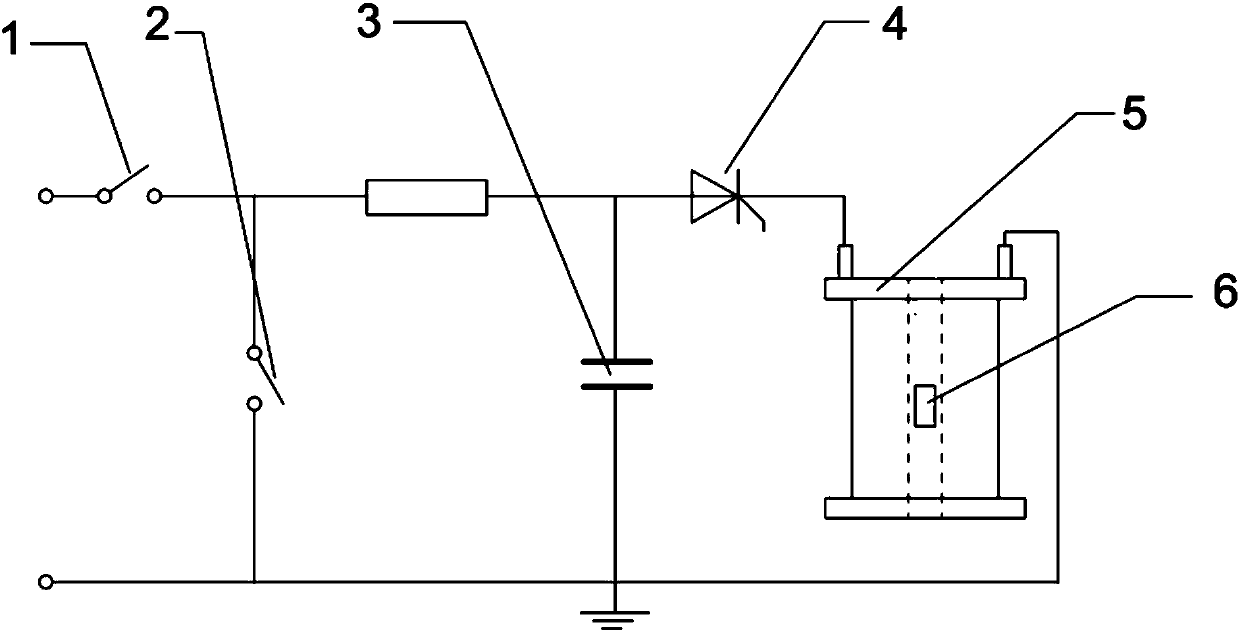

Method for improving mechanical property of Ti48Zr20Nb12Cu5Be15 by using magnetic field

Disclosed is a method for improving mechanical properties of Ti48Zr20Nb12Cu5Be15 by using a magnetic field. By disconnecting an energy releasing switch and a discharging switch of an electromagnetic field device, a charging capacitor is made to output an impulse current to an electro-magnetic induction coil so that a pulsed magnetic field is formed in the center position of the interior of the electro-magnetic induction coil and pulsed magnetic field treatment for one time is conducted on a Ti-based amorphous composite material positioned in the interior of the electro-magnetic induction coil.After repeating the pulsed magnetic field treatment process of charging, discharging and energy releasing for 5-20 times and carrying out the pulsed magnetic field treatment to the existing Ti 48 Zr20Nb12Cu5Be15 Ti-based amorphous composite material, the Ti-based amorphous composite material after treatment still presents as a two-phase composite structure of beta dendritic crystal and an amorphous basal body. Meanwhile, the magnetic field treatment can not change the dendritic crystal volume fraction and the dendritic crystal morphology of the original Ti-based amorphous composite material.According to the method for improving the mechanical property of the Ti48Zr20Nb12Cu5Be15 by using the magnetic field, yield strength of the Ti-based amorphous composite material is improved and meanwhile plasticity of the material is not sacrificed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-temperature-sintered temperature-stable composite microwave dielectric ceramic and preparation method thereof

ActiveCN113149645ALower sintering temperatureImprove temperature stabilityChemical industryCeramic sinteringDielectric

The invention relates to a low-temperature-sintered temperature-stable composite microwave dielectric ceramic and a preparation method thereof. The composite microwave dielectric ceramic comprises the following components: a low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient and a low-temperature-sintered microwave dielectric ceramic material with a positive resonant frequency temperature coefficient. According to the invention, the low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient or the low-temperature-sintered microwave dielectric ceramic material with the positive resonant frequency temperature coefficient is used as a main material, a low-temperature-sintered microwave dielectric ceramic material with the same structure and an opposite resonant frequency temperature coefficient is added as an adjusting material through a two-phase compounding method, and compounding is conducted to form a multiphase ceramic material or a solid solution so as to obtain a low-temperature-sintered microwave dielectric ceramic material having a nearly-zero resonance frequency temperature coefficient. The problems that existing microwave dielectric ceramic is high in sintering temperature, and the temperature coefficient of resonance frequency changes greatly along with temperature are solved. The microwave dielectric ceramic material has a wide application scope in the LTCC low-temperature-sintered microwave dielectric ceramic materials.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

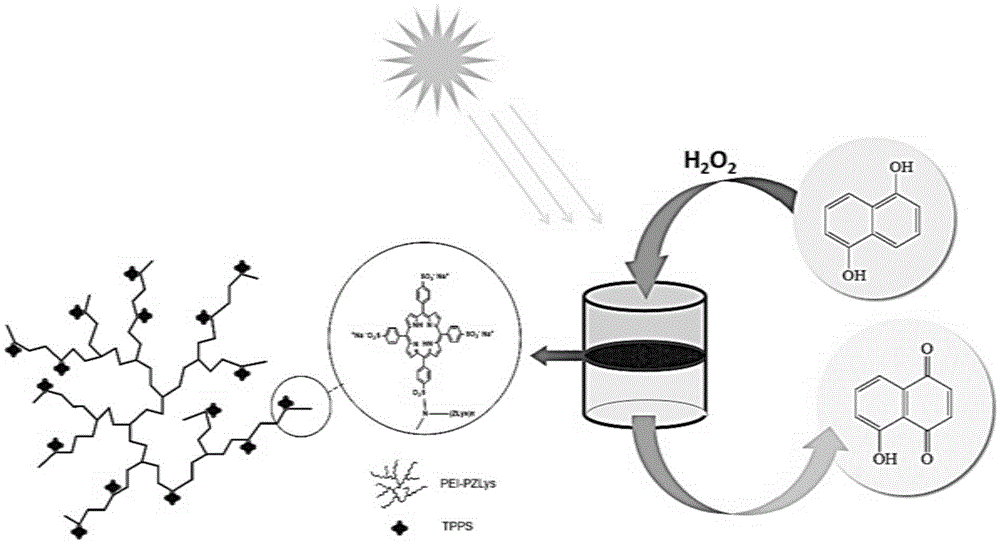

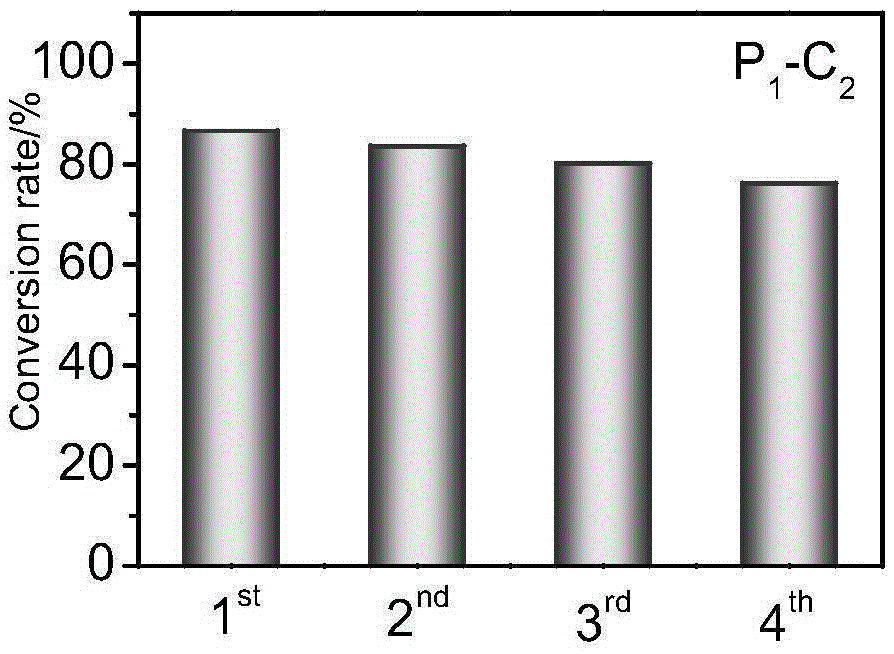

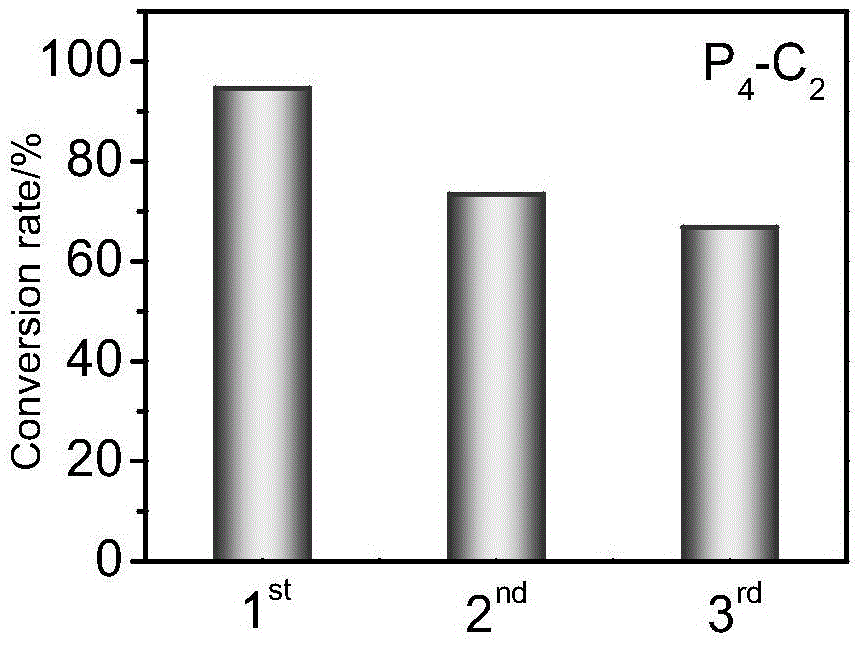

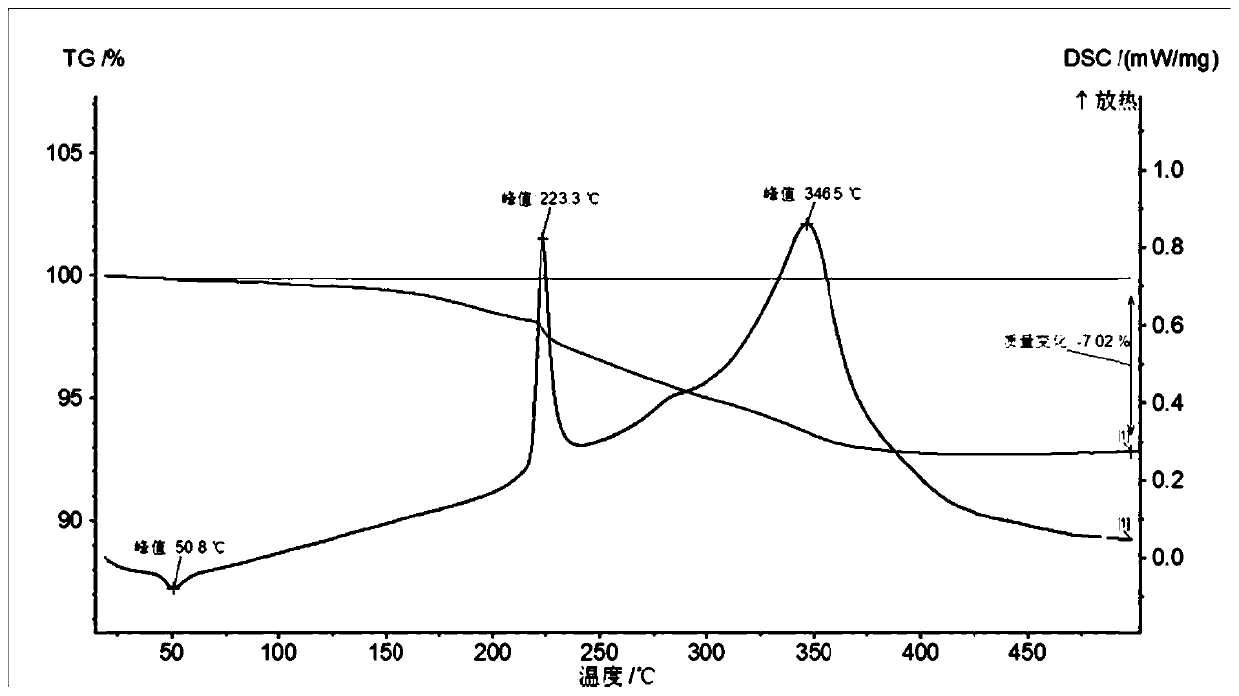

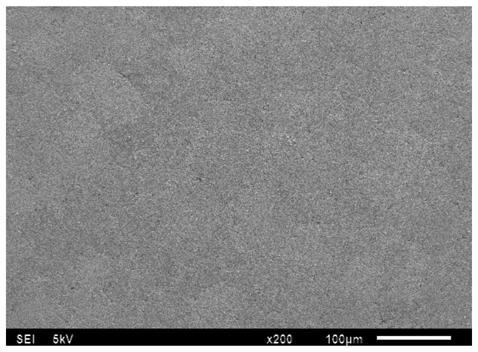

Water-soluble porphyrin sulfonate-hyperbranched polymer two-phase composite catalyst and preparation and application thereof

InactiveCN105642354AEasy to synthesizeLow costOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPorphyrinWater soluble

The invention provides a water-soluble porphyrin sulfonate-hyperbranched polymer two-phase composite catalyst and preparation and application thereof. The catalyst is used for the oxidation catalysis of 1,5-naphthalenediol two-phase interface catalytic system. The catalytic system comprises 0.1000% -0.1018% of a main catalyst, 0.0112%-0.1120% of an oxygen source and 0.003193% -0.003196% of a substrate. The catalytic system is simple for preparation and low in cost, has good catalytic stability; and after four rounds of experiments, the catalytic system still reaches a conversion rate of higher than 75%, and can effectively achieve the separation and recovery of the catalyst.

Owner:SHANGHAI JIAO TONG UNIV

Two-phase composite microwave dielectric ceramic material for filter and preparation method thereof

The invention belongs to the technical field of microwave dielectric ceramic materials, particularly relates to a two-phase composite microwave dielectric ceramic material for a filter, and further discloses a preparation method of the two-phase composite microwave dielectric ceramic material. According to the two-phase composite microwave dielectric ceramic material disclosed by the invention, Mg2TiO4 is used as a main crystal form structure, Ca and Co elements are used for doping, and functional aids and / or sintering aids such as TiO2 and CaTiO3 are further added, so the microwave performance of the material is further optimized effectively. The composite microwave dielectric ceramic material is high in quality factor and has a dielectric constant of 18-23; the value of f*Q at 25 DEG C is larger than 60000; the value of the temperature coefficient of resonance frequency is close to zero, and use requirements of the filter can be met; meanwhile, the material also has relatively good dielectric property in a millimeter wave frequency band; and the sintering temperature of the material is only 1200-1300 DEG C, so low-temperature sintering performance is greatly improved, and large-scale stable production can be achieved.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com