Low temperature sintering microwave ceramic material and preparation thereof

A microwave ceramic and low-temperature sintering technology, applied in ceramics, inorganic insulators, etc., can solve the problems of affecting the performance of dielectric tunable microwave ceramic materials, reducing the BST sintering temperature, and unstable dielectric properties, achieving excellent microwave performance, reducing Sintering temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

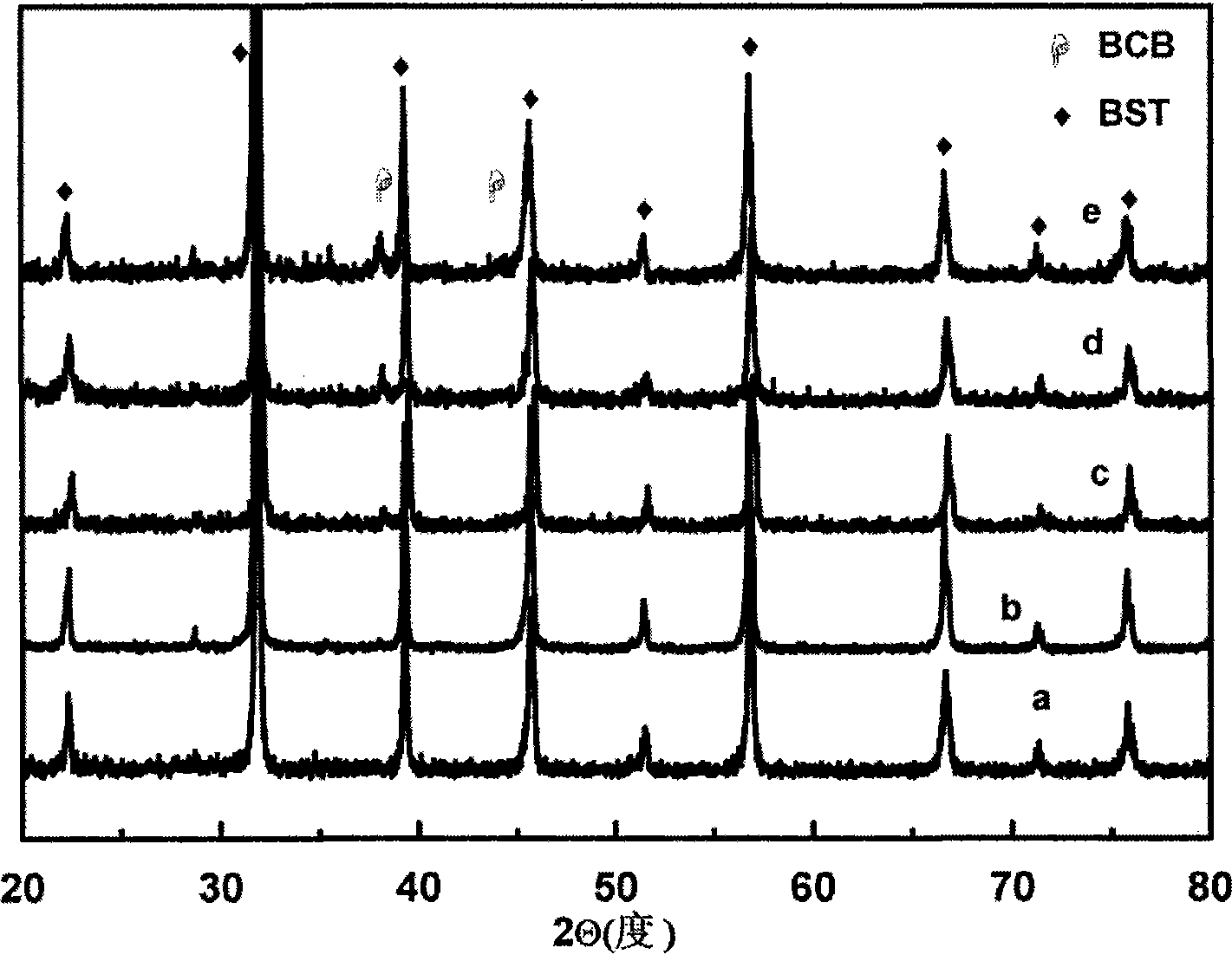

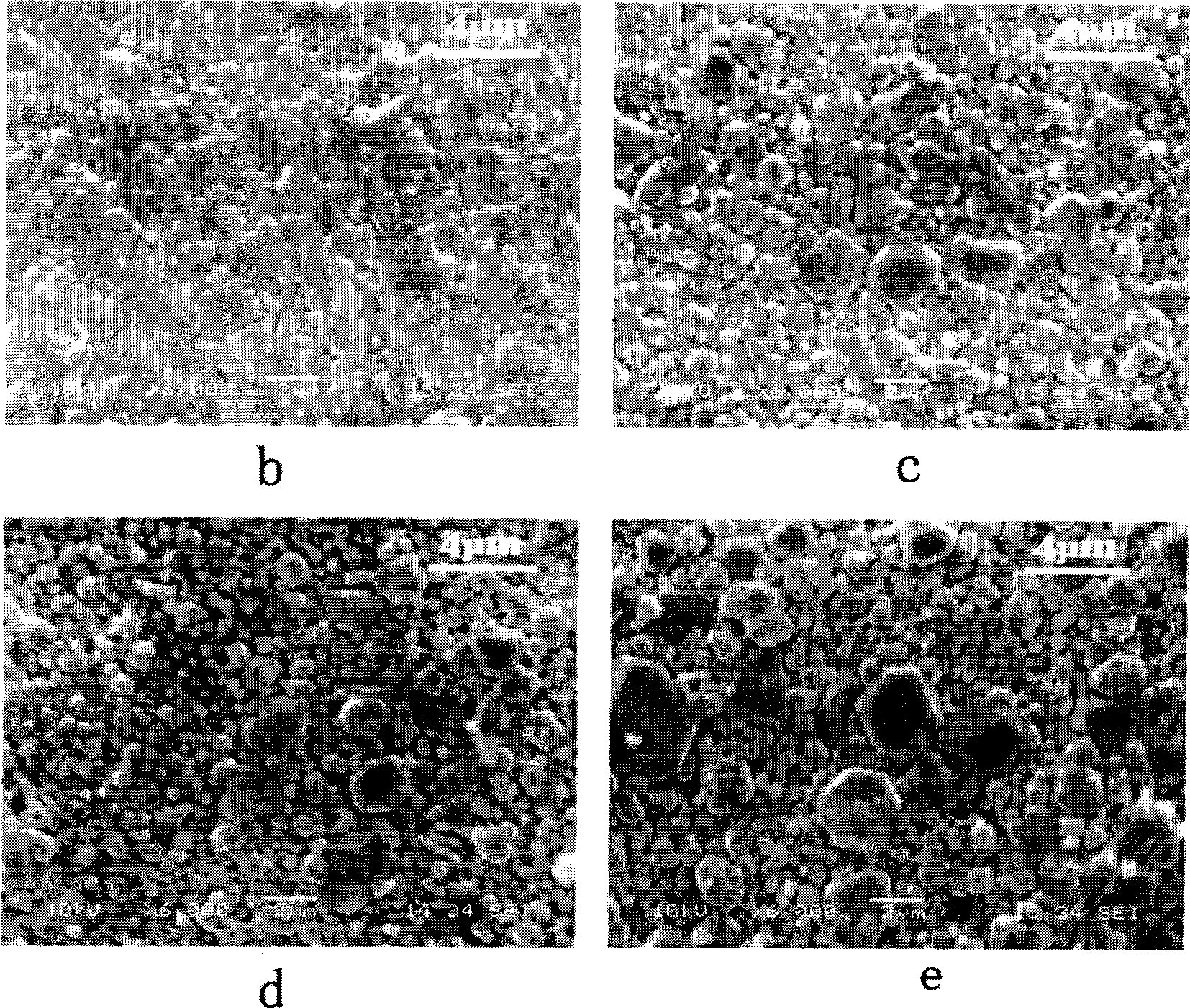

[0042] The preparation method of the BST-BCB low-temperature sintered dielectric adjustable microwave composite ceramic provided by the present invention specifically includes the following steps:

[0043] (1) BCB powder, a low-calorie additive, can be prepared by traditional electronic ceramic powder preparation methods and solid-state reaction methods: BaCO is selected 3 (99.99%), CuO (98%), H 3 BO 3 (99.5%) (its raw materials are all provided by Sinopharm Group Chemical Reagent Co., Ltd.) as the main raw material, according to the molar ratio batching in the molecular formula, the prepared raw materials are placed in the nylon ball mill jar, add zirconia balls and dehydrated alcohol or Ball mill with deionized water for 20-24 hours, and pre-calcine at 500°C-1050°C for 0.5-15 hours after discharge drying, more preferably at 700-900°C for 1-5 hours, and obtain BCB powder after calcining and grinding Material spare.

[0044] (2) Using high-purity BaTiO 3 , SrTiO 3 , mix t...

Embodiment 1

[0050] 1. Preparation of BST:

[0051] with Ba 0.40 Sr 0.60 TiO 3 as an example. Using high-purity BaTiO 3 , SrTiO 3 , mix the main ingredients, add deionized water according to the weight ratio of the mixture and deionized water 1:1, mix for 24 hours by wet ball milling, dry, place in a crucible, and pre-fire at 1000 ° C for 2 hours to obtain the final product The structure is Ba 0.40 Sr 0.60 TiO 3 . Ball mill again for 24 hours, after discharge, it is dried and ground into powder at 110°C, and passed through a 200-mesh sieve to obtain BST material.

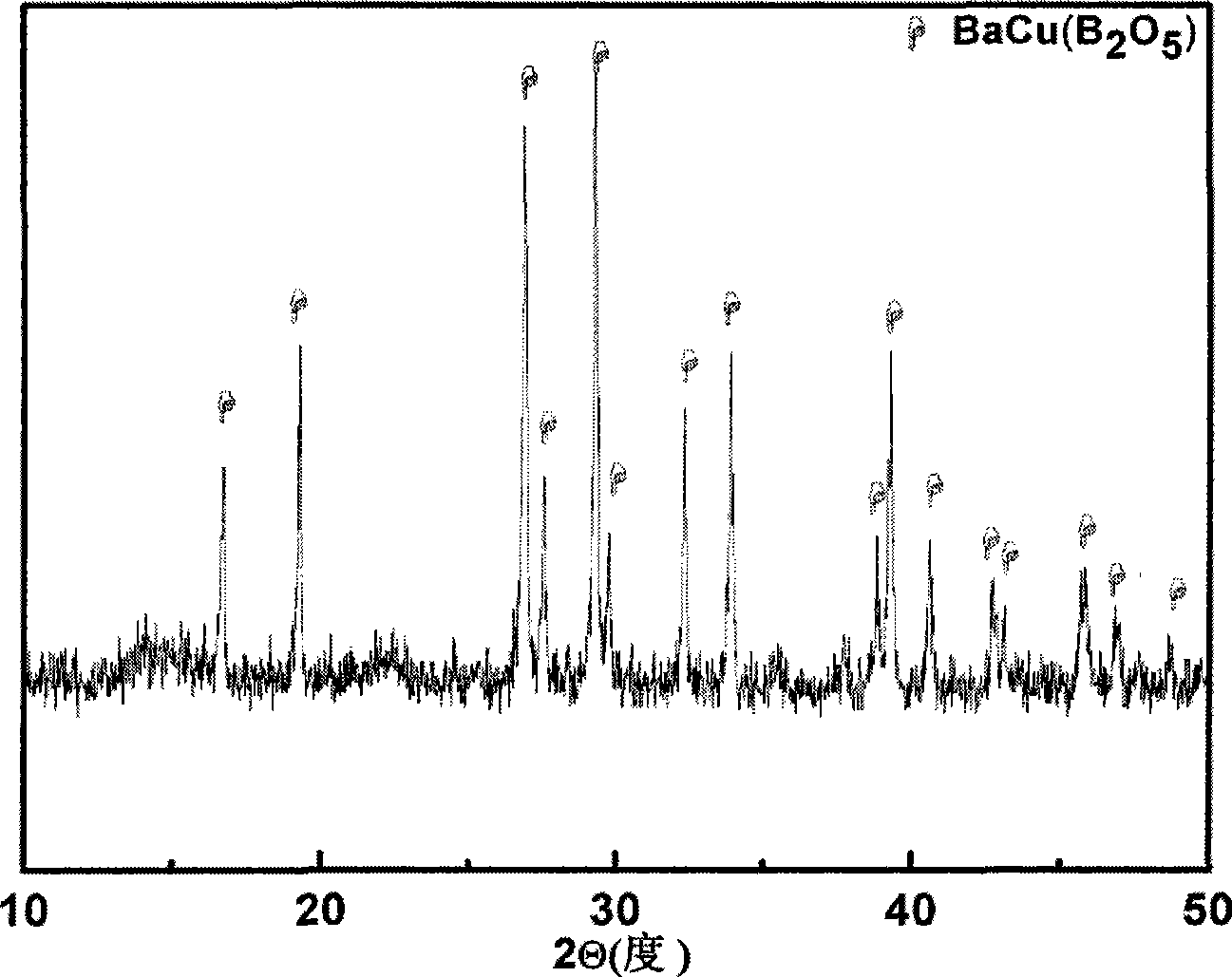

[0052] 2. Preparation of BCB:

[0053] According to the molecular formula, according to a certain molar ratio, weigh the BaCO 3 , CuO, H 3 BO 3 As the main raw material, the prepared raw material is placed in a nylon ball mill tank, and zirconia balls and absolute ethanol or deionized water are added to ball mill for 20 hours. After the discharge is dried, it is pre-calcined at 900°C for 5 hours, and BCB is obtained...

Embodiment 2

[0071] 1. Preparation of BST:

[0072] with Ba 0.40 Sr 0.60 TiO 3 as an example. Using high-purity BaTiO 3 , SrTiO 3 , mix the main ingredients, add deionized water according to the weight ratio of the mixture to deionized water 1:2, mix for 24 hours by wet ball milling, dry, place in a crucible, and pre-fire at 1300 ° C for 8 hours to obtain the final product The structure is Ba 0.40 Sr 0.60 TiO 3 . Ball mill again for 24 hours, after discharging, it is dried and ground into powder at 300°C, and passed through a 100-mesh sieve to obtain BST material.

[0073] 2. Preparation of BCB:

[0074] According to the molecular formula, according to a certain molar ratio, weigh the BaCO 3 , CuO, H 3 BO 3 As the main raw material, put the prepared raw material in a nylon ball mill jar, add zirconia balls and absolute ethanol or deionized water balls for 20 hours, and pre-calcine at 700°C for 0.5 hours after discharging the material, and grind to obtain BCB. According to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com