Dielectric adjustable two-phase composite microwave ceramic material and preparation thereof

A technology of microwave ceramics and ceramic powders, applied in ceramics, inorganic insulators, etc., can solve the problem of undiscovered dielectric tunability, and achieve the effects of environmental protection, no toxic side effects, widening the scope of application, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of BST:

[0044] Using high-purity BaTiO 3 , SrTiO 3 , mix the main ingredients, add deionized water according to the weight ratio of the mixture and deionized water 1:1, mix for 24 hours by wet ball milling, dry, place in a crucible, and pre-fire at 1200 ° C for 2 hours to obtain the final The product is (Ba 0.40 Sr 0.60 )TiO 3 . Ball milling again for 20h, drying and grinding at 110°C after discharge, and passing through a 100-mesh sieve to obtain (Ba 0.40 Sr 0.60 )TiO 3 Material.

[0045] 2. Preparation of ZST:

[0046] Choose high-purity ZrO 2 , SnO 2 ,TiO 2 , as the main raw material, according to a certain molar ratio, put the prepared raw materials in a nylon ball mill tank, add zirconia balls and absolute ethanol or deionized water ball mill for 24 hours, and pre-fire at 1100 ° C after drying 1 hour, Zr was obtained after grinding 0.8 sn 0.2 TiO 4 Powder spare.

[0047] 3, preparation preparation (Ba 0.4 Sr 0.6 )TiO 3 -(Zr 0.8...

Embodiment 2

[0051] 1. Preparation of BST:

[0052] Using high-purity BaTiO 3 , SrTiO 3 , mix the main ingredients, add deionized water according to the weight ratio of the mixture to deionized water 1:2, mix for 24 hours by wet ball milling, dry, place in a crucible, and pre-fire at 1200 ° C for 2 hours to obtain the final The product is (Ba 0.40 Sr 0.60 )TiO 3 . Ball mill again for 24h, after discharging, dry and grind at 300°C, and pass through a 200-mesh sieve to obtain (Ba 0.40 Sr 0.60 )TiO 3 Material.

[0053] 2. Preparation of ZST:

[0054] Choose high-purity ZrO 2 , SnO 2 ,TiO 2 , as the main raw material, according to a certain molar ratio, put the prepared raw materials in a nylon ball mill tank, add zirconia balls and absolute ethanol or deionized water ball mill for 24 hours, and pre-fire at 1500 °C after drying 5 hours, Zr was obtained after grinding 0.8 sn 0.2 TiO 4 Powder spare.

[0055] 3, preparation preparation (Ba 0.4 Sr 0.6 )TiO 3 -(Zr 0.8 sn 0.2 )...

Embodiment 3~8

[0059] 1. Preparation of BST:

[0060] Using high-purity BaTiO 3 , SrTiO 3 , mix the main ingredients, add deionized water according to the weight ratio of the mixture to deionized water 1:2, mix for 24 hours by wet ball milling, dry, place in a crucible, and pre-fire at 1200 ° C for 2 hours to obtain the final The product is (Ba 0.40 Sr 0.60 )TiO 3 . Ball mill again for 24h, after discharging, dry and grind at 300°C, and pass through a 200-mesh sieve to obtain (Ba 0.40 Sr 0.60 )TiO 3 Material.

[0061] 2. Preparation of ZST:

[0062] Choose high-purity ZrO 2 , SnO 2 ,TiO 2 , as the main raw material, according to a certain molar ratio, put the prepared raw materials in a nylon ball mill tank, add zirconia balls and absolute ethanol or deionized water ball mill for 24 hours, and pre-fire at 1500 °C after drying 5 hours, Zr was obtained after grinding 0.8 sn 0.2 TiO 4 Powder spare.

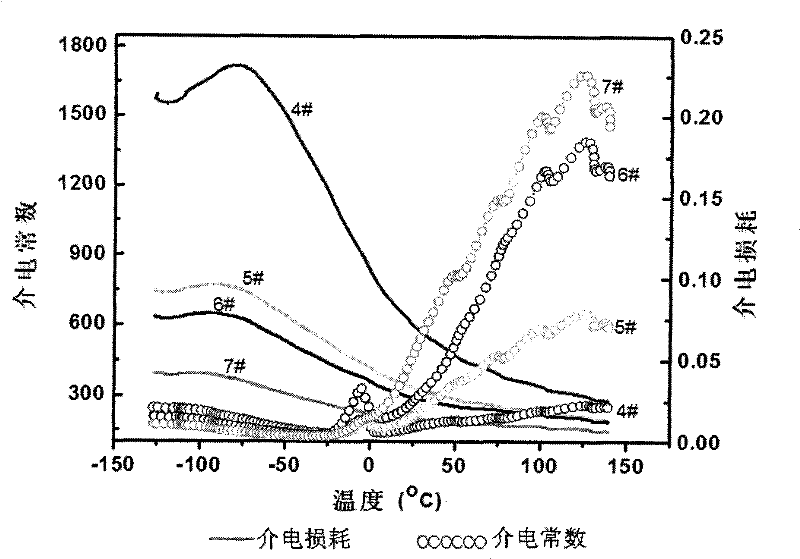

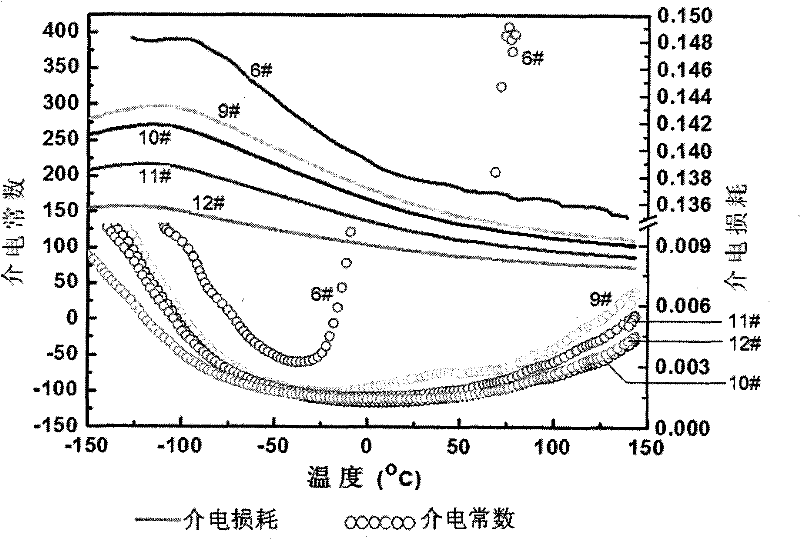

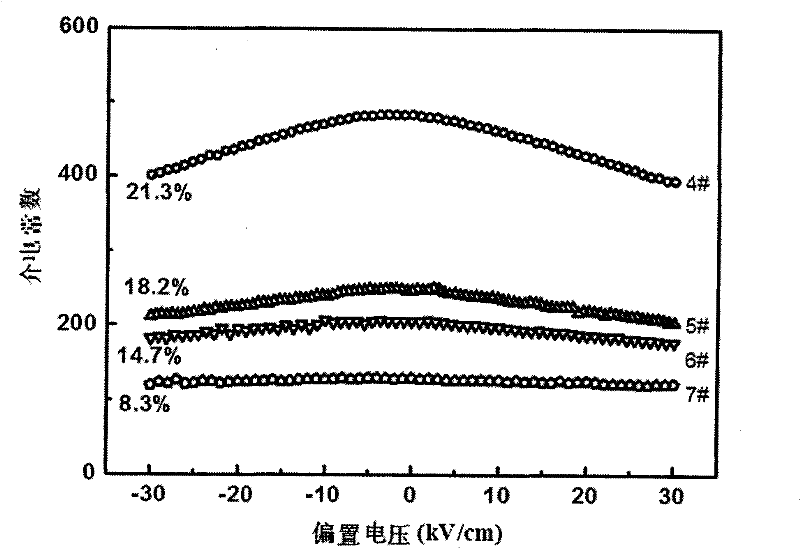

[0063] 3, preparation (Ba 0.4 Sr 0.6 )TiO 3 -(Zr 0.8 sn 0.2 )TiO 4 Compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com