Composite microwave ceramic materials with dielectric adjustable and method for preparing same

A microwave ceramic and dielectric technology, applied in the field of microwave ceramic materials and their preparation, can solve the problems of undiscovered dielectric adjustability of low-fired microwave materials, inability to overcome high sintering temperature, and deterioration of dielectric adjustability rate, etc. Toxic and side effects, low cost, low sintering temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

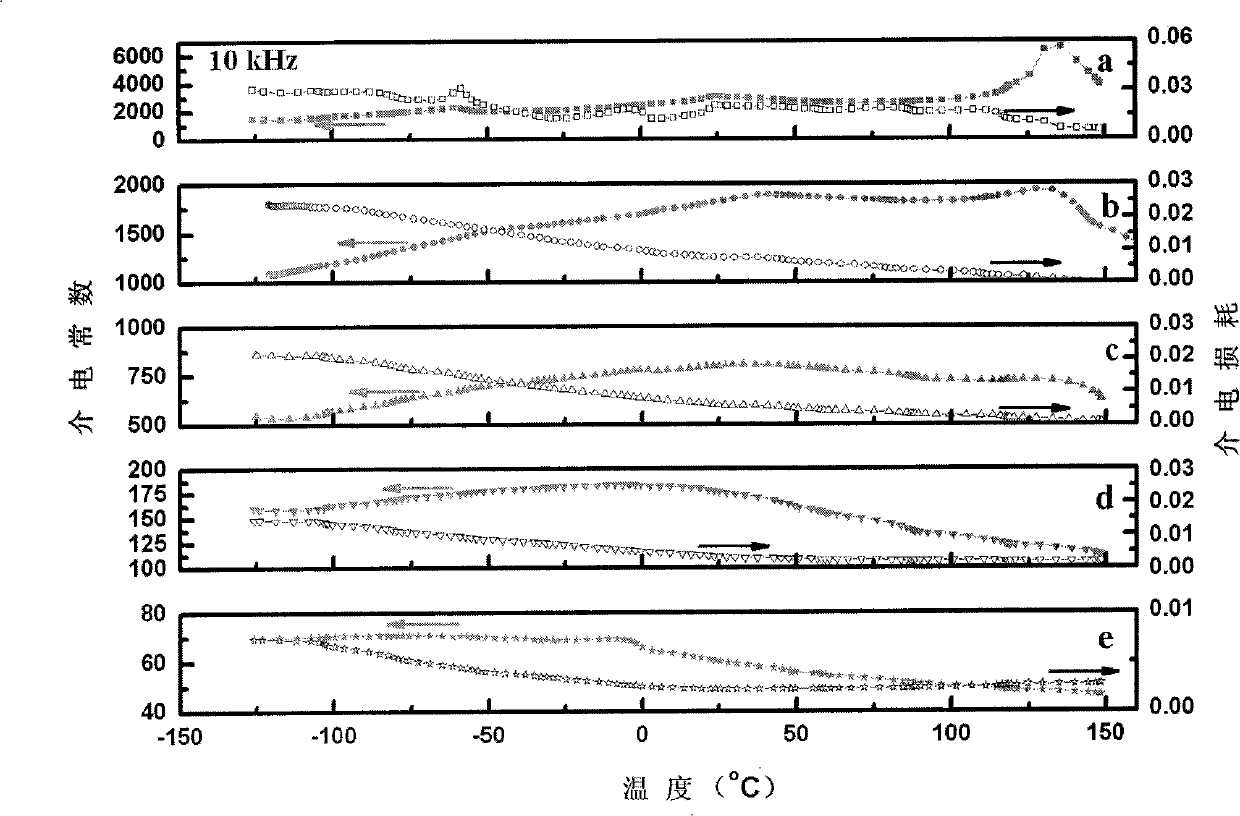

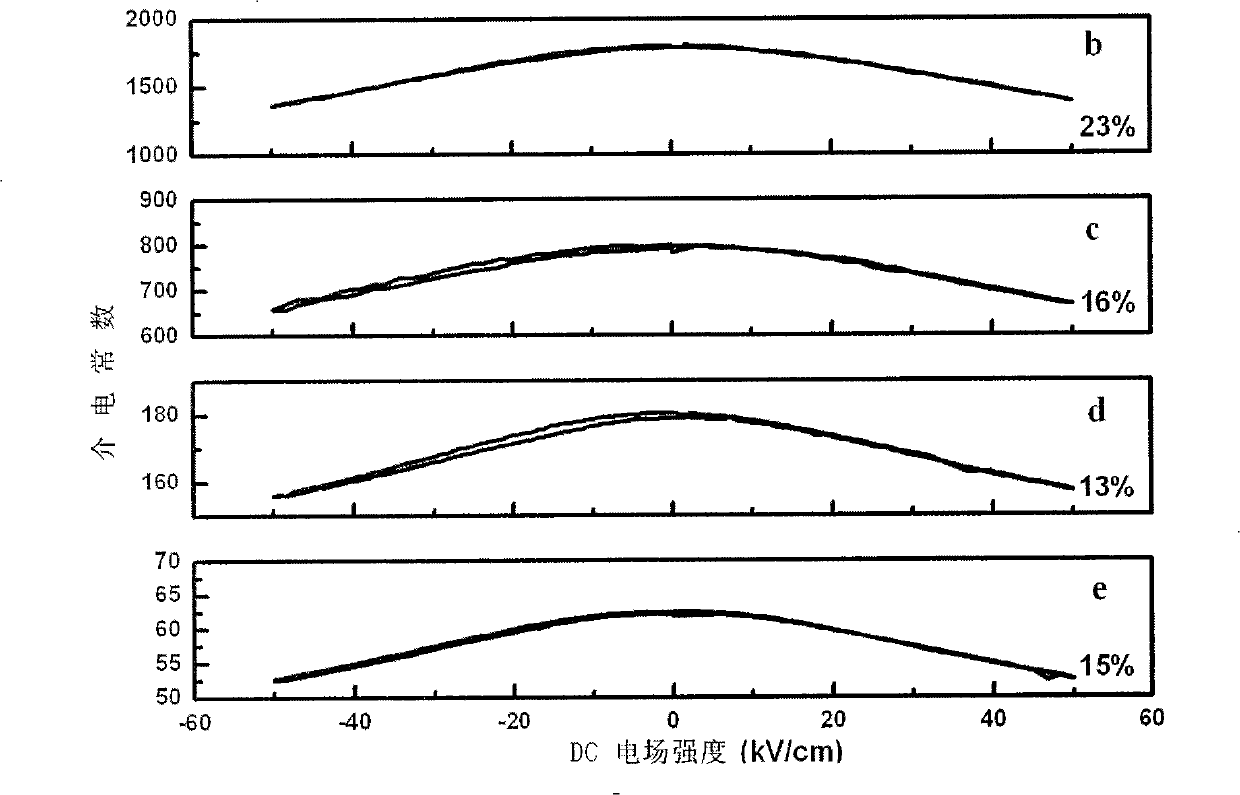

Image

Examples

preparation example Construction

[0034] BaTiO provided by the present invention 3 -AMP 2 o 7 The preparation method of dielectrically adjustable microwave composite ceramics specifically includes the following steps:

[0035](1) AMP 2 o 7 The powder is prepared by the traditional solid state reaction method. Choose CaCO 3 (purity 99.99%), SrCO 3 (99%), ZnO(99%), CuO(98%), (NH 4 ) 2 HPO 4 (98%) (its raw materials are all provided by Sinopharm Chemical Reagent Co., Ltd.) as the main raw material, according to a certain molar ratio of ingredients, the prepared raw materials are placed in the nylon ball mill tank, add zirconia balls and dehydrated alcohol or and remove Ionized water ball mill for 24 hours, after the discharge is dried, it is pre-fired at 550 ° C ~ 900 ° C for 1-5 hours, and AMP is obtained after grinding 2 o 7 Powder spare.

[0036] (2) Weigh BaTiO 3 (99.90%, 100nm, provided by Shandong Guoci Functional Ceramic Material Co., Ltd.) powder, AMP 2 o 7 Powder, after mixing, put it in a...

Embodiment 1

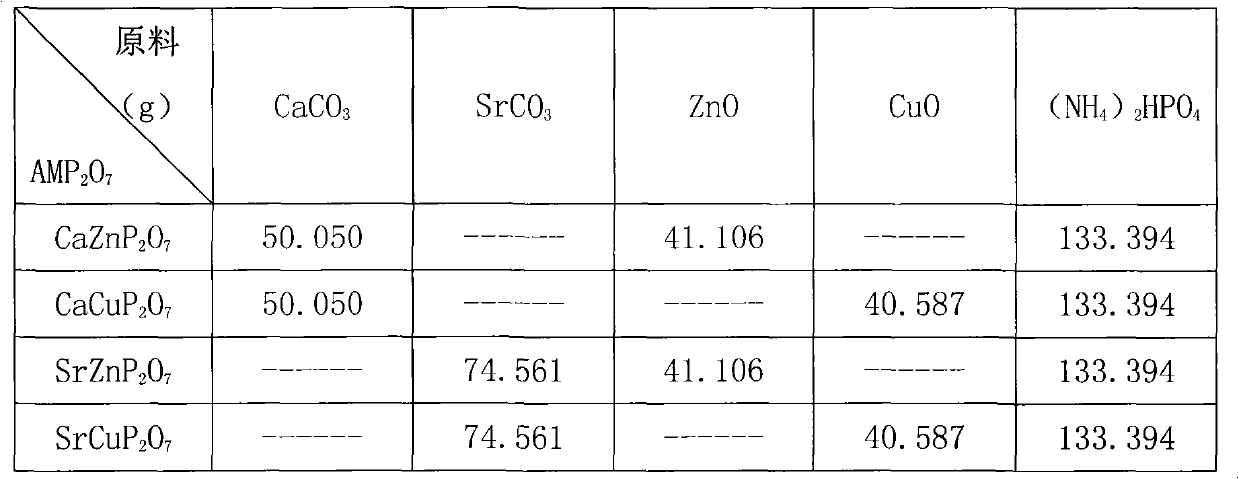

[0040] Example 1AMP 2 o 7 preparation of

[0041] According to the molecular formula, according to the ingredients in the following table, weigh CaCO 3 , SrCO 3 , ZnO, CuO, (NH 4 ) 2 HPO 4 , put the prepared raw materials in a nylon ball mill tank, add zirconia balls and absolute ethanol or deionized water ball mill for 24 hours, and pre-calcine at 550°C to 880°C for 1-5 hours after discharging the material, after grinding get AMP 2 o 7 , the weight (g) of each raw material that participates in reaction and the corresponding reaction product that obtains are listed in table 1:

[0042] Table 1

[0043]

Embodiment 2~9

[0044] Embodiment 2~9 prepares BaTiO 3 -AMP 2 o 7 (A=Sr, M=Cu) composite ceramics

[0045] Weigh the BaTiO respectively according to the composition ratio in the formula in Table 2 3 , SrCuP 2 o 7 Powder. Put the mixture of each formula in the embodiment into a nylon ball mill jar, add zirconia balls and absolute ethanol ball mill for 24 hours, and after drying, the powder passes through a 200-mesh sieve. According to the traditional electronic ceramic preparation process, use 8% Polyvinyl alcohol (PVA) is used as a binder for granulation, and under a pressure of 10MPa, it is dry-pressed into a diameter green sheet and h=5mm, h=7mm, h=9mm, h = 12mm cylinder, after 550 ° C debonding treatment, the sample is sintered in the air atmosphere, the sintering temperature is in the range of 950 ° C - 1300 ° C, after holding for 2 hours, BaTiO is obtained 3 -AMP 2 o 7 (A=Sr, M=Cu) two-phase composite ceramic samples.

[0046] Table 2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com