Barium strontium titanate/zincum bismuth niobate heterogeneous structure material and preparation thereof

A technology of barium strontium titanate and zinc bismuth niobate, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of dielectric tunability and dielectric loss staying, without substantial improvement, and without sufficient potential Excavation and other problems to achieve the effect of high dielectric tunability and low dielectric loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

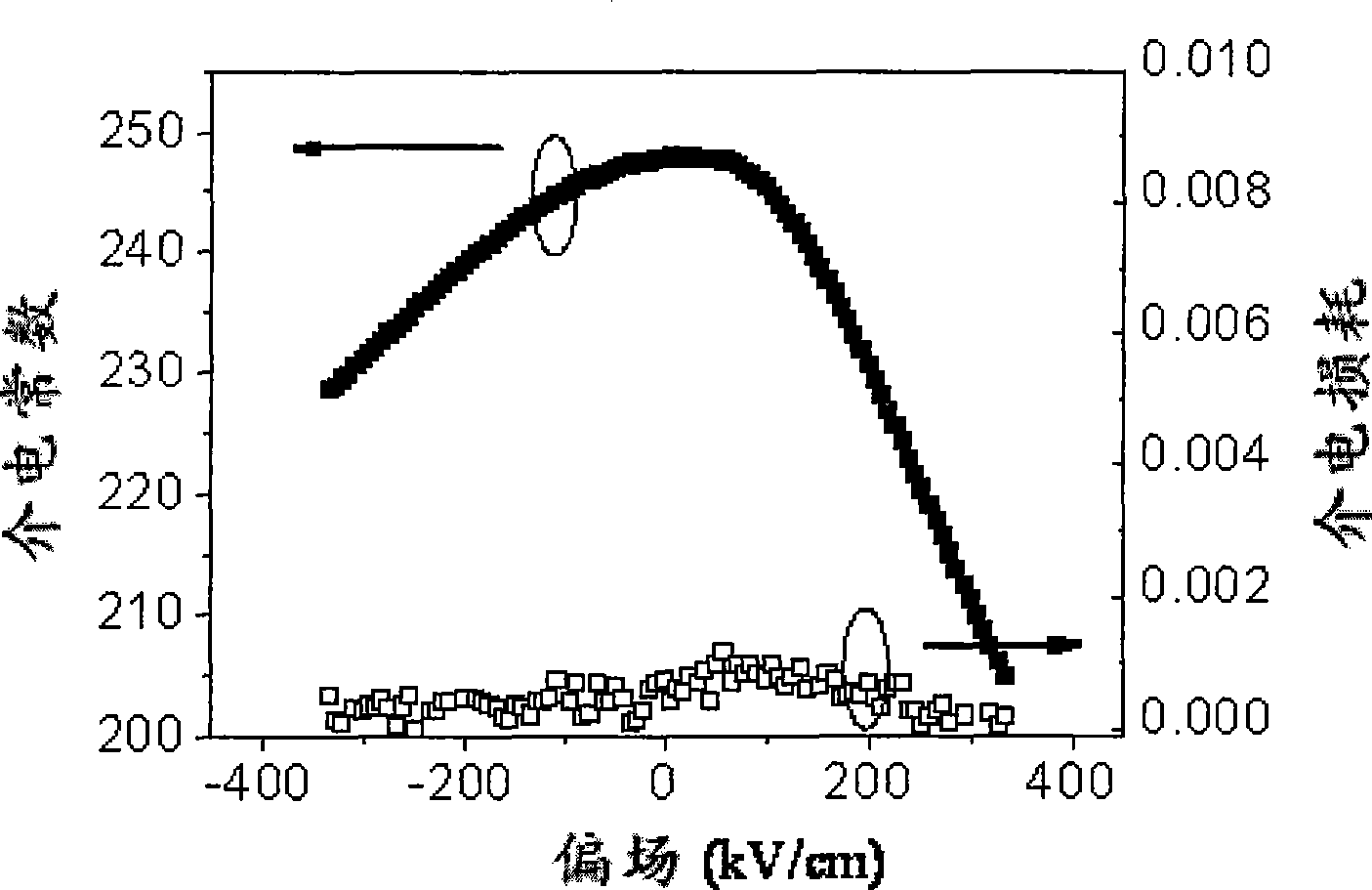

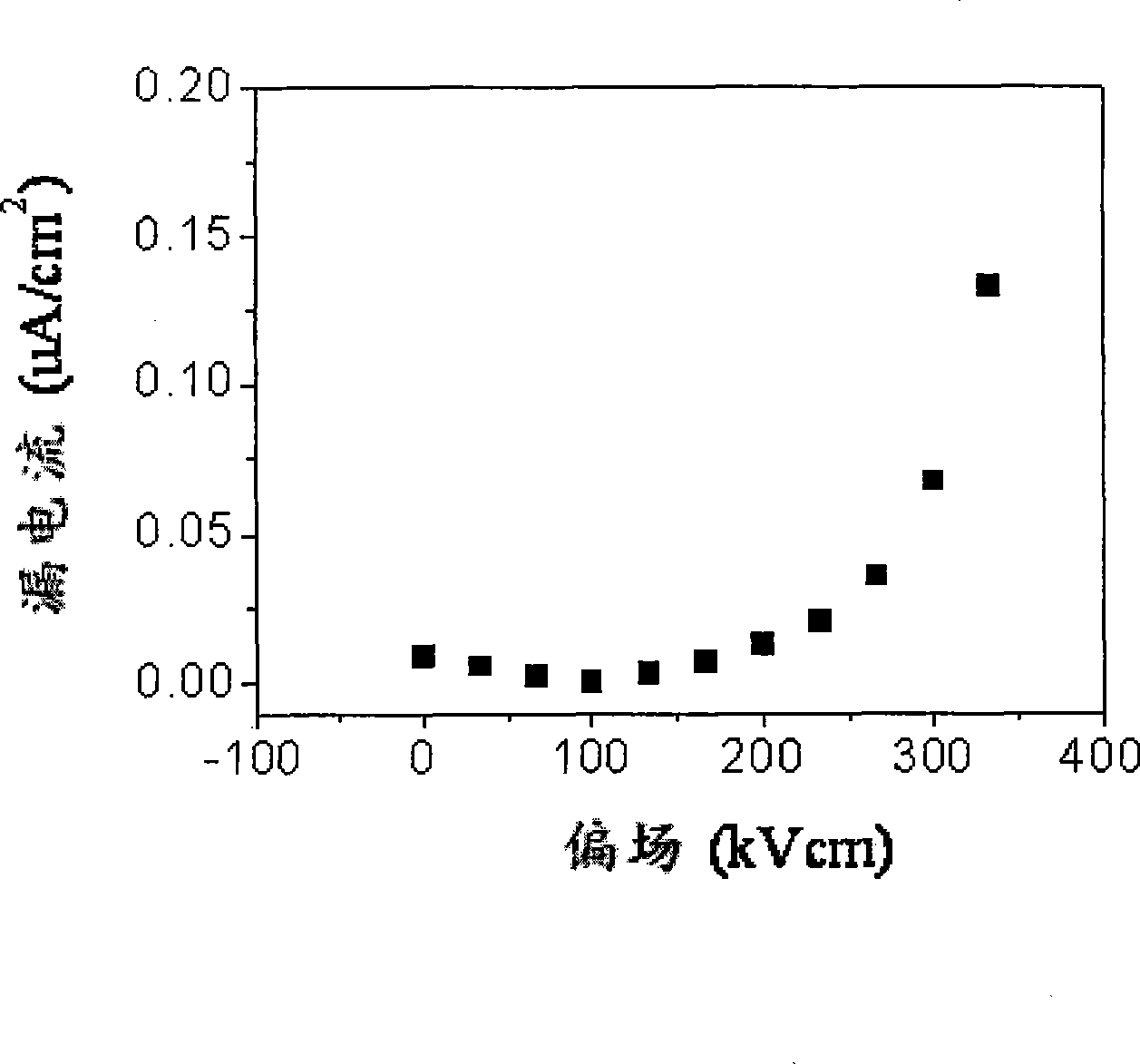

[0021] In the manganese-doped strontium barium titanate / zinc bismuth niobate heterostructure material in this embodiment, there is only one period of manganese-doped strontium barium titanate / zinc bismuth niobate structure, wherein the manganese-doped strontium titanate The thickness of the barium layer is 160nm, and the doping concentration of manganese is 2at%. The thickness of the zinc-bismuth niobate layer is 40nm. The thickness ratio of the two layers is manganese-doped strontium barium titanate:zinc-bismuth niobate=4:1. Its preparation method is as follows:

[0022] First, using pulsed laser deposition technology, a 160nm-thick manganese-doped strontium barium titanate layer was deposited on a silicon-platinum substrate at 900°C; then, the substrate temperature was lowered to 650°C, Then deposit a layer of zinc bismuth niobate with a thickness of 40nm to obtain a heterogeneous structure with a period of manganese-doped strontium barium titanate / zinc bismuth niobate; In-...

Embodiment 2

[0028] The manganese-doped strontium barium titanate / zinc bismuth niobate heterostructure material in this embodiment includes two manganese-doped strontium barium titanate layers with a thickness of 300 nm, and the manganese doping concentration is 0.1 at%. There is a zinc bismuth niobate layer with a thickness of 100nm between the manganese-doped strontium barium titanate layers, and the thickness ratio is manganese doped strontium barium titanate: zinc bismuth niobate=3:1, and its preparation method is as follows:

[0029] First, using pulsed laser deposition technology, a layer of manganese-doped barium strontium titanate with a thickness of 300nm was deposited on a silicon platinum substrate at 700°C; the substrate temperature was lowered to 600°C, and a Zinc-bismuth niobate layer with a thickness of 100nm; then raise the substrate temperature back to 700°C and turn the target in situ to deposit a layer of 300nm-thick manganese-doped strontium titanate barium layer to obta...

Embodiment 3

[0031] In the manganese-doped barium strontium titanate / zinc-bismuth niobate heterostructure material in this embodiment, there are 10 cycles of manganese-doped barium strontium titanate / zinc-bismuth niobate structures, in which each layer of manganese-doped strontium titanate The thickness of barium is 40nm, the doping concentration of manganese is 6at%, the thickness of each layer of zinc bismuth niobate is 20nm, and the thickness ratio of the two layers is manganese-doped strontium barium titanate:zinc bismuth niobate=2:1. Its preparation method is as follows:

[0032] First, manganese-doped barium strontium titanate (thickness 40nm) and zinc bismuth niobate (thickness 20nm) were alternately deposited on a Pt-coated sapphire substrate at 700°C and 600°C by radio frequency magnetron sputtering deposition technology. Finally, a manganese-doped strontium barium titanate / zinc bismuth niobate heterostructure with 10 cycles was finally obtained, with a total thickness of 600nm; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com