Patents

Literature

76results about How to "Moderate dielectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

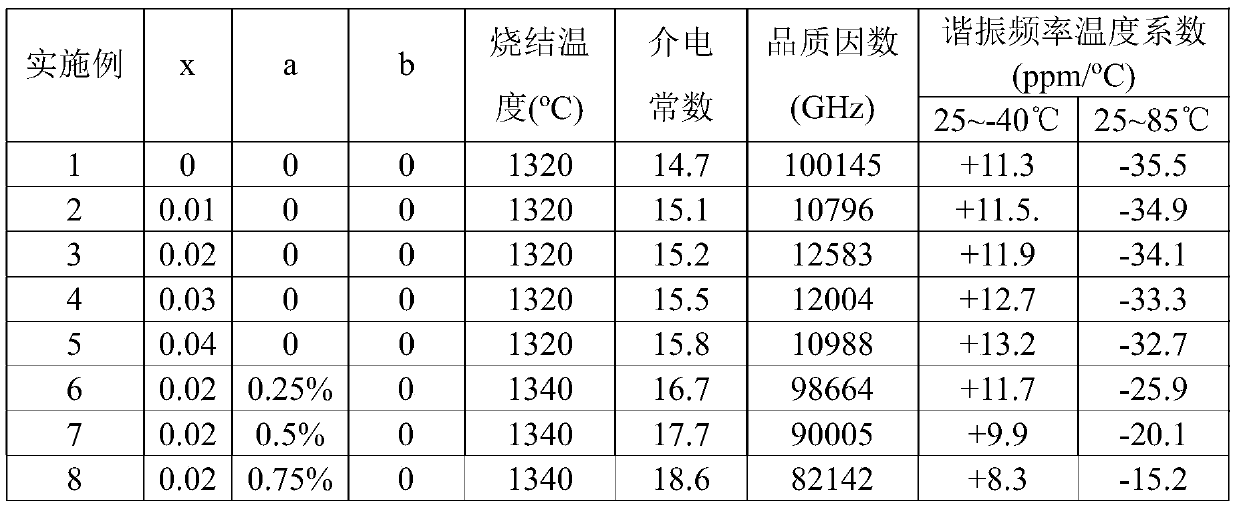

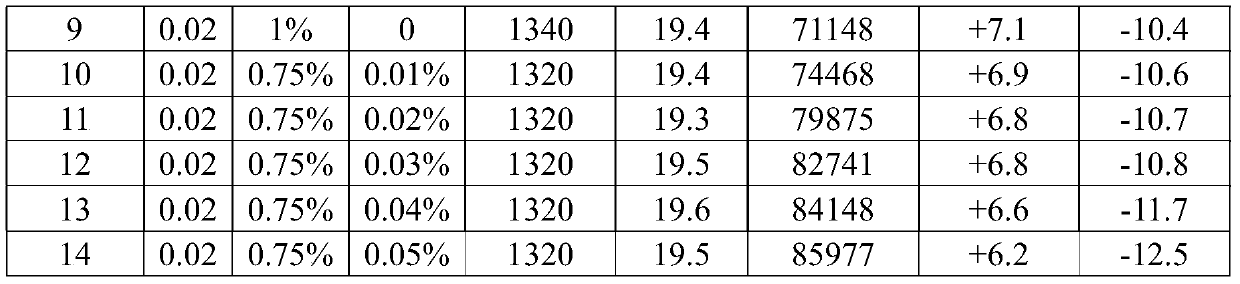

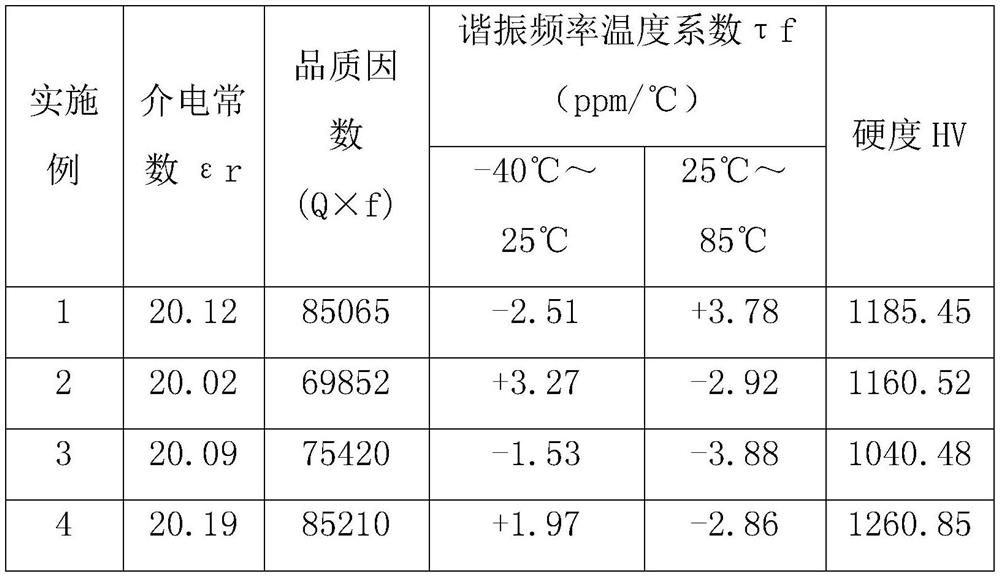

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material and a preparation method thereof, belonging to the technical field of electronic materials. The microwave dielectric ceramic material comprises the following components in percentage by mass: 25-35% of MgO, 60-68% of TiO2, 1-10% of CaO, 0-2% of SiO2, 0-2% of MnO2, 0-2% of Nb2O5 and 0-2% of CeO2; the microwave dielectric ceramic material is prepared by proportioning the MgO, TiO2, CaO, SiO2, MnO2, Nb2O5 and CeO2 according to the mass percentage of each component; performing ball milling and mixing; pre-calcining a mixture at a temperature in a range of 1050-1200 DEG C and sintering the mixture at the temperature in a range of 1250-1360 DEG C. In the invention, the microwave dielectric ceramic material is prepared by utilizing atraditional solid-phase sintering method, the process is simple and the cost is low; according to the prepared microwave dielectric ceramic material, the Q*f value is in a range of 63,000-83,000 GHz,the relative dielectric constant epsilon r is in a range of 20-22, and the temperature coefficient of resonance frequency is within + / -10 ppm / DEG C, so that the preparation requirements of a high-performance microwave device can be met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

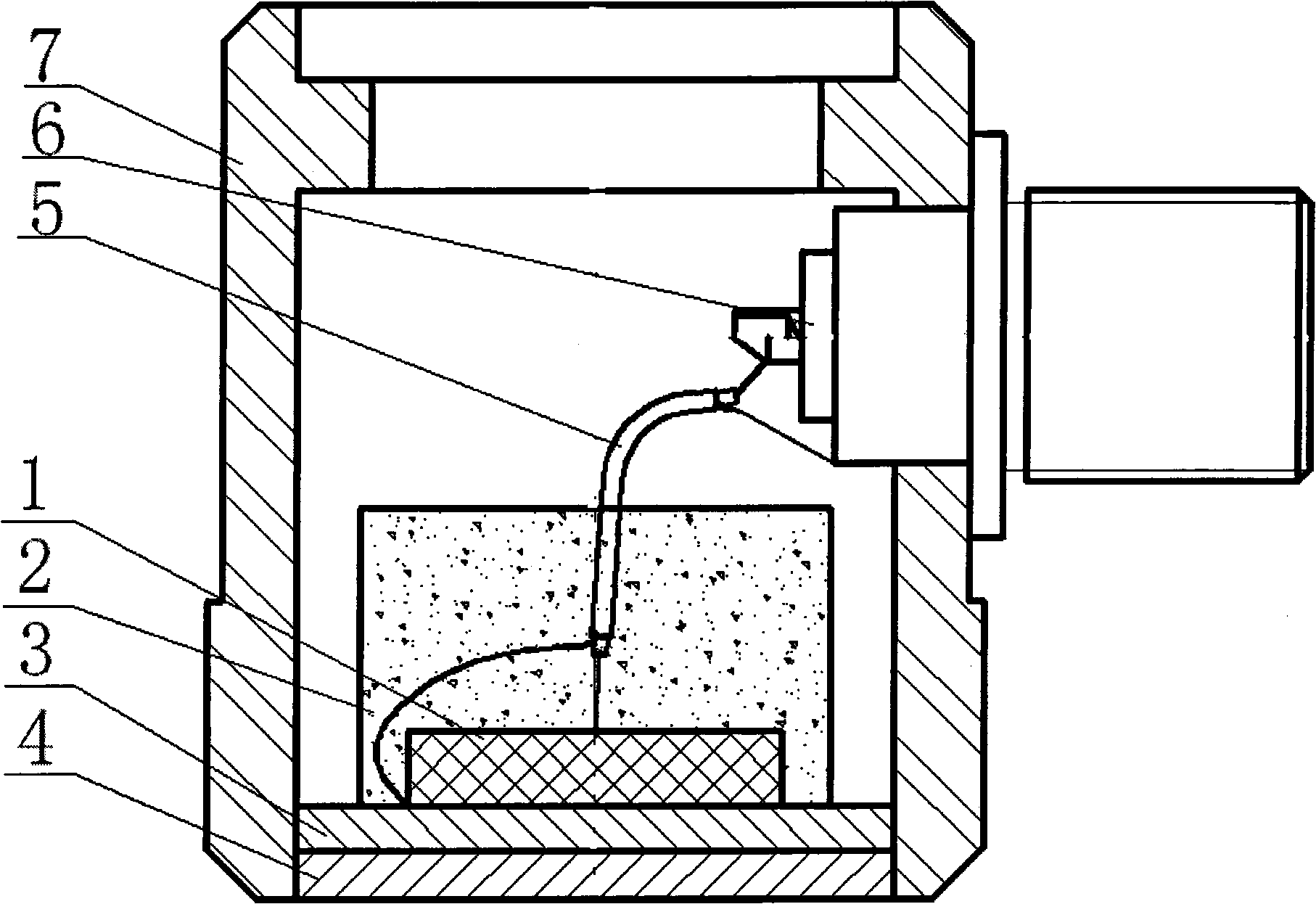

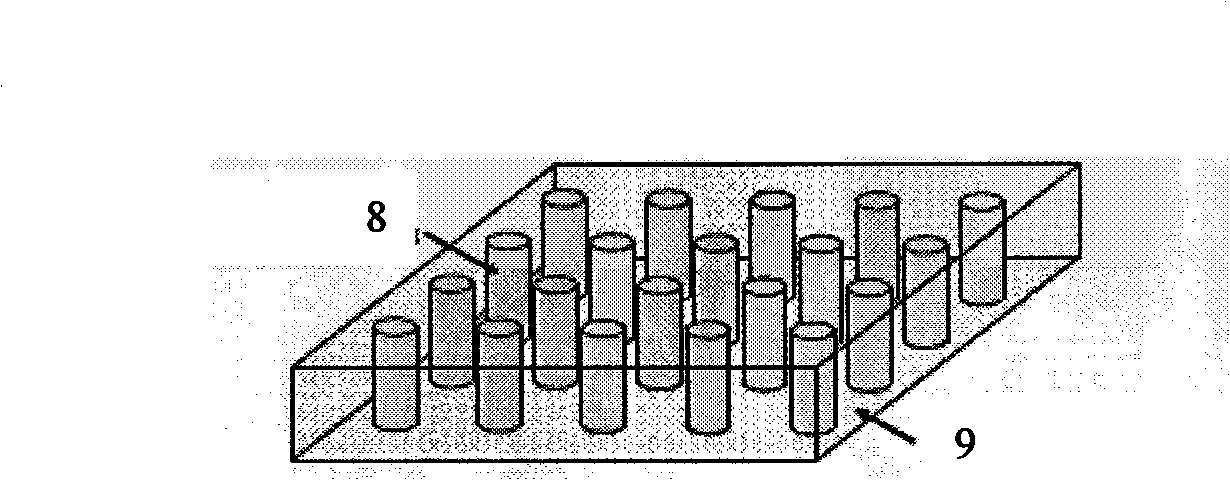

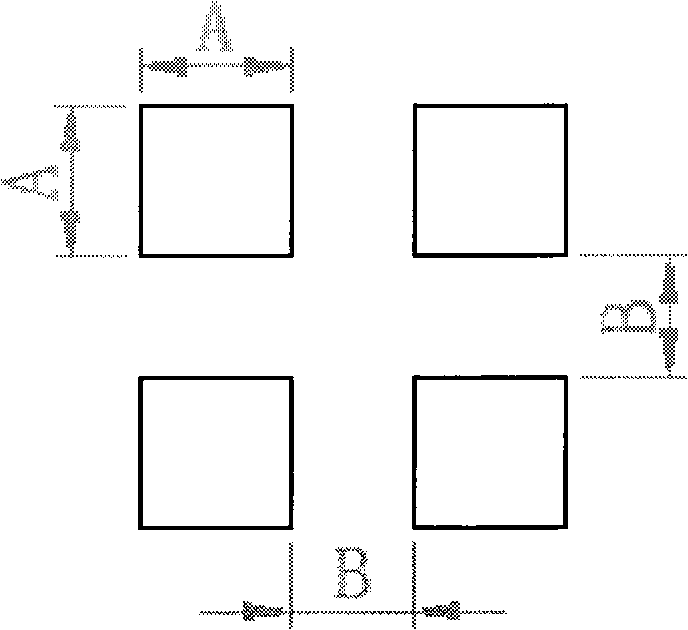

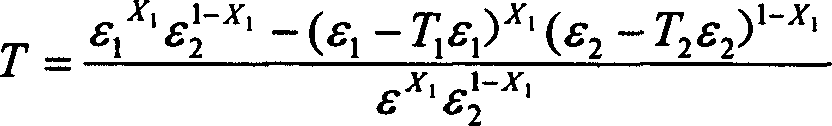

High-frequency ultrasonic transducer made of piezoelectric monocrystalline composite material as well as manufacturing method and application thereof

ActiveCN101524682AIncreased acoustic impedanceImprove electromechanical conversion efficiencyUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblySonificationUltrasonic sensor

The invention discloses a high-frequency ultrasonic transducer made of a piezoelectric monocrystalline composite material as well as a manufacturing method and an application thereof. The high-frequency ultrasonic transducer consists of a piezoelectric monocrystalline composite material wafer, a damping backing material, a first matching layer, a second matching layer, a coaxial electrode lead, a coaxial connector and a metal shell, wherein the second matching layer, the first matching layer, the piezoelectric monocrystalline composite material wafer and the damping backing material are bonded together in sequence; and the coaxial electrode lead is introduced from the positive electrode and the negative electrode of the piezoelectric monocrystalline composite material wafer to the coaxial connector which is fixed on the metal shell. The invention provides a method for manufacturing the transducer by matching acoustic characteristic based on a KLM model. The center frequency Fc of the obtained ultrasonic transducer is equal to 14.67MH, the bandwidth Bw can be up to 107 percent and the pulse echo sensitivity Sr can reach -30dB; and the ultrasonic transducer also has very high sensitivity on the premises of high frequency and large bandwidth. The ultrasonic transducer can be used for medical diagnosis, ultrasonic nondestructive detection and precise thickness measurement.

Owner:广州多浦乐电子科技股份有限公司

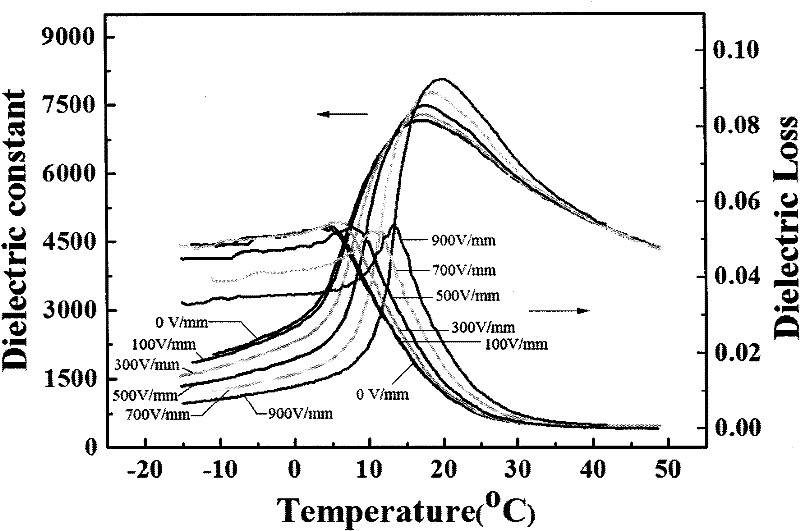

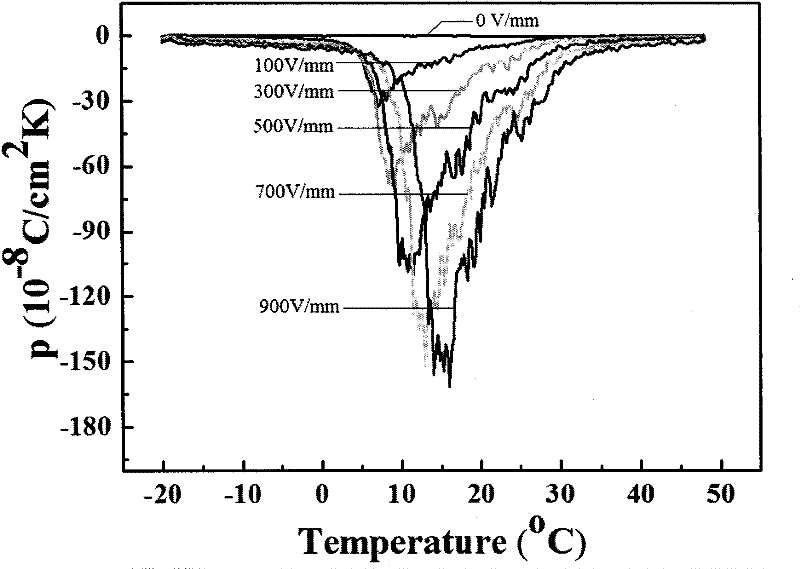

Composite microwave tuning strontium barium titanate ceramics

InactiveCN1453241AModerate dielectric constantLow dielectric lossCeramicsWaveguide type devicesStrontium titanateAlkaline earth metal

The composite microwave tuning strontium barium titanate ceramics consists of strontium barium titanate and low dielectric loss material. The low dielectric loss material is preferably one with perovskite structure, such as LaAlO3, NdGaO3, La(Mg1 / 2Ti1 / 2)O3, La(Zn1 / 2Ti1 / 2)O3, etc. The said perovskite structure material and the strontium barium titanate have similar lattice constant and thus are easy to form solid solution, and have no harmful second phase created, no degradation in microwave dielectric loss and high tuning rate of strontium barium titanate. The material of the present invention may be used in phase shifter, adjustable filter, delay line, vibrator, resonator, phase-controlled array antenna and other microwave devices.

Owner:HUAZHONG UNIV OF SCI & TECH

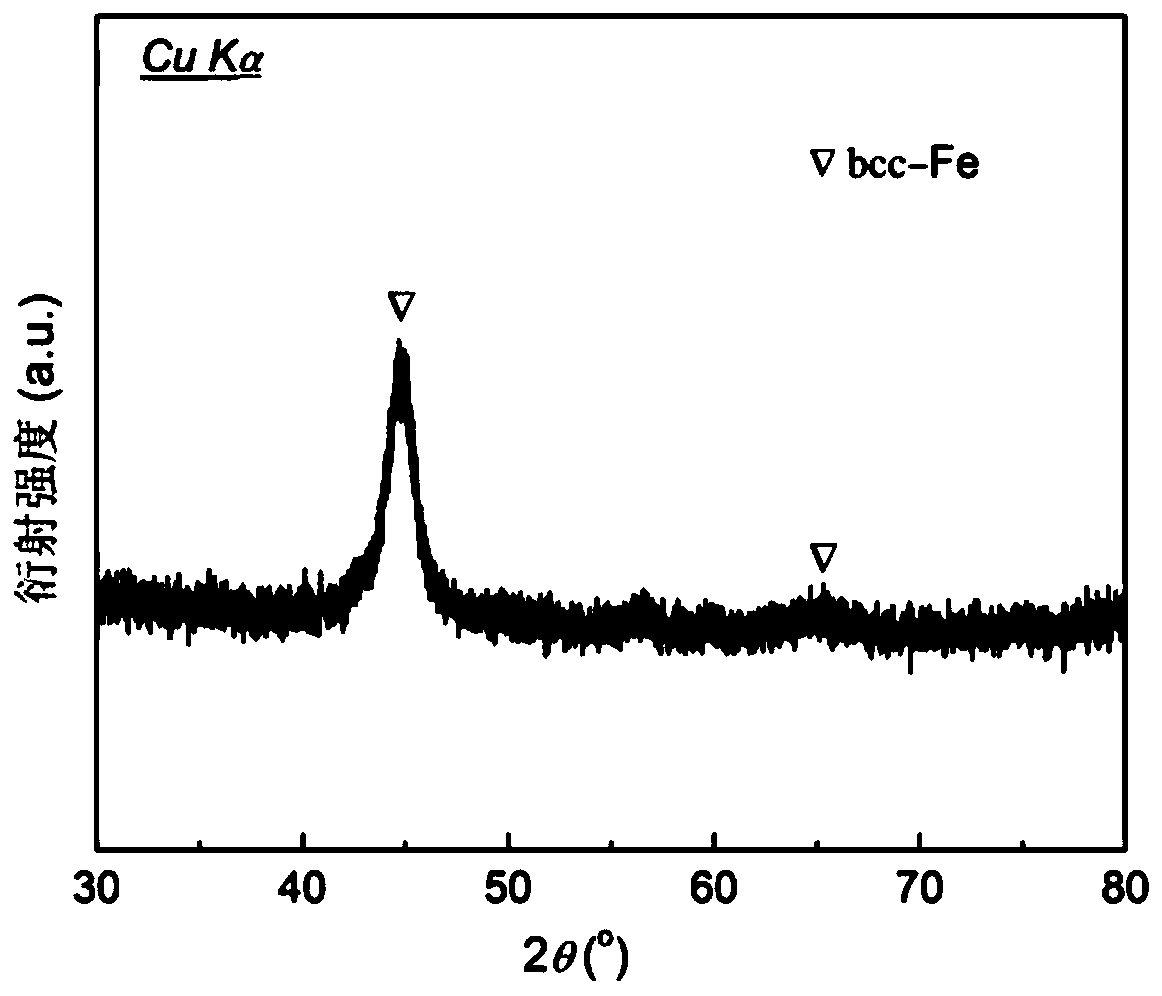

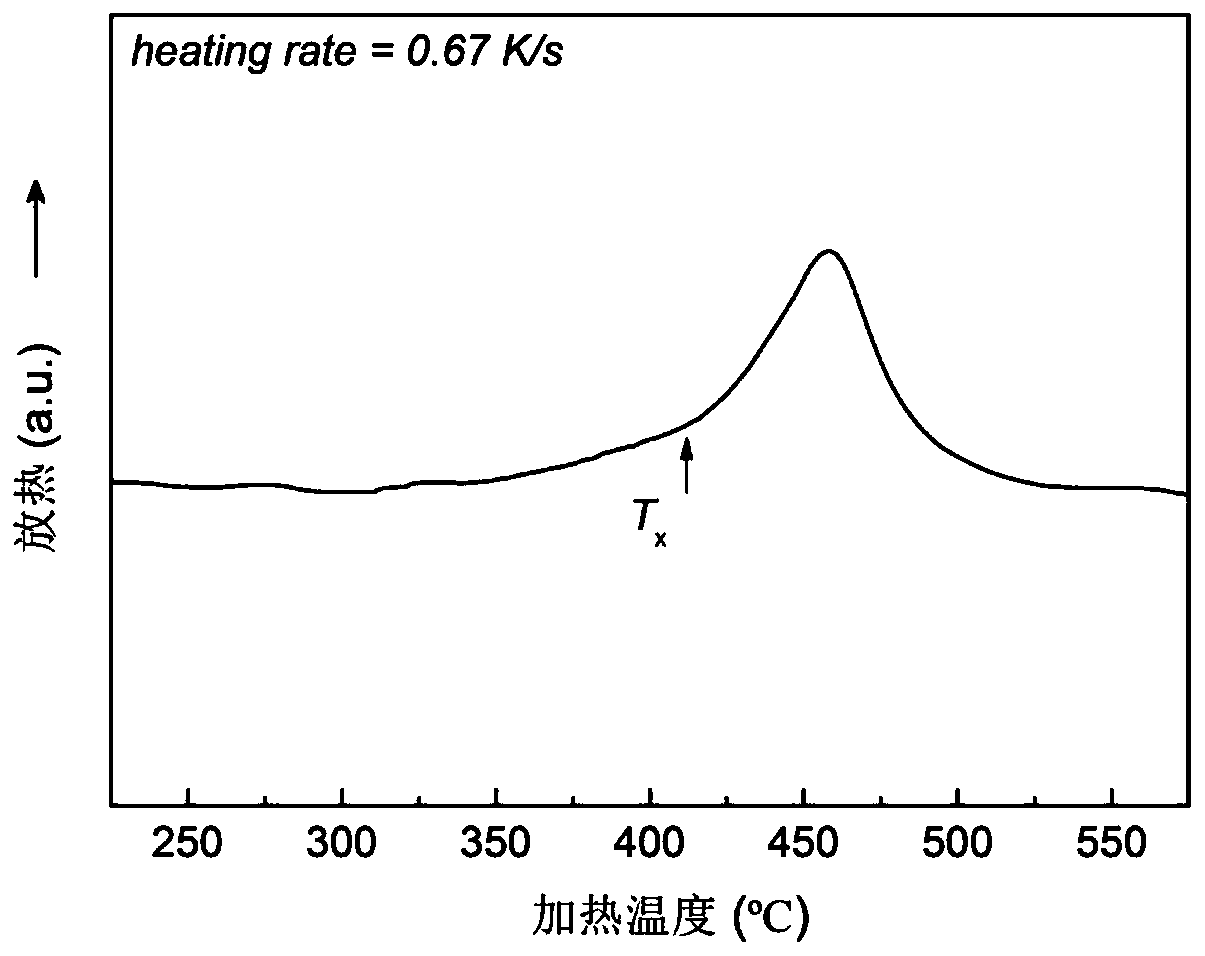

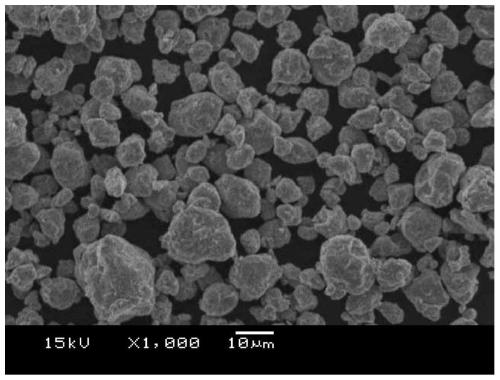

Iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent and preparation method thereof

ActiveCN109732078AHigh strengthImprove permeabilityMagnetic/electric field screeningNanocrystalNanocrystalline alloy

The invention provides an iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent. The component expression of alloy micropowder is FeaSibBcCudMe, wherein M is one or several of Al, Cr, Co, Ni, P and C elements; a, b, c, d and e respectively represent the atomic percent contents of corresponding components; a is not more than 90 and not less than 80; b is notmore than 15 and not less than 1; c is not more than 15 and not less than 3; d is not more than 2.5 and not less than 0; and e is not more than 5 and not less than 0. The invention further provides apreparation method of the iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent; and the preparation method comprises the following steps: (1) preparation ofraw materials for preparing alloy micropowder; and (2) preparation of nanocrystal alloy micropowder: the raw materials for preparing the alloy micropowder with diameters being less than 300 microns are selected to fill in a ball milling tank, inert gas is injected after vacuumizing for protection, and the alloy micropowder is prepared through ball milling. The iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent and the preparation method thereof solve the defects in a traditional electromagnetic wave absorbing agent and a preparation method thereof.

Owner:DALIAN UNIV OF TECH

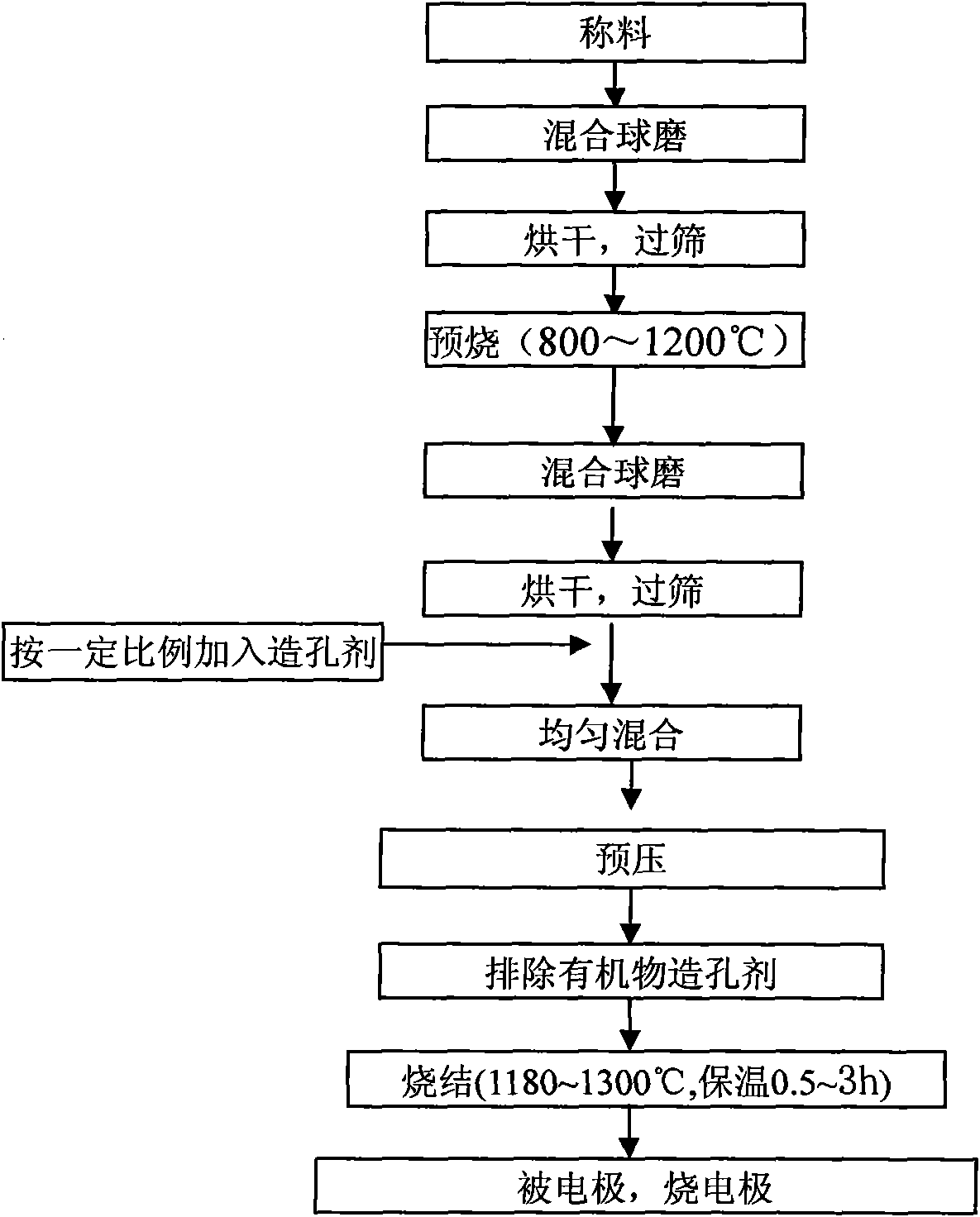

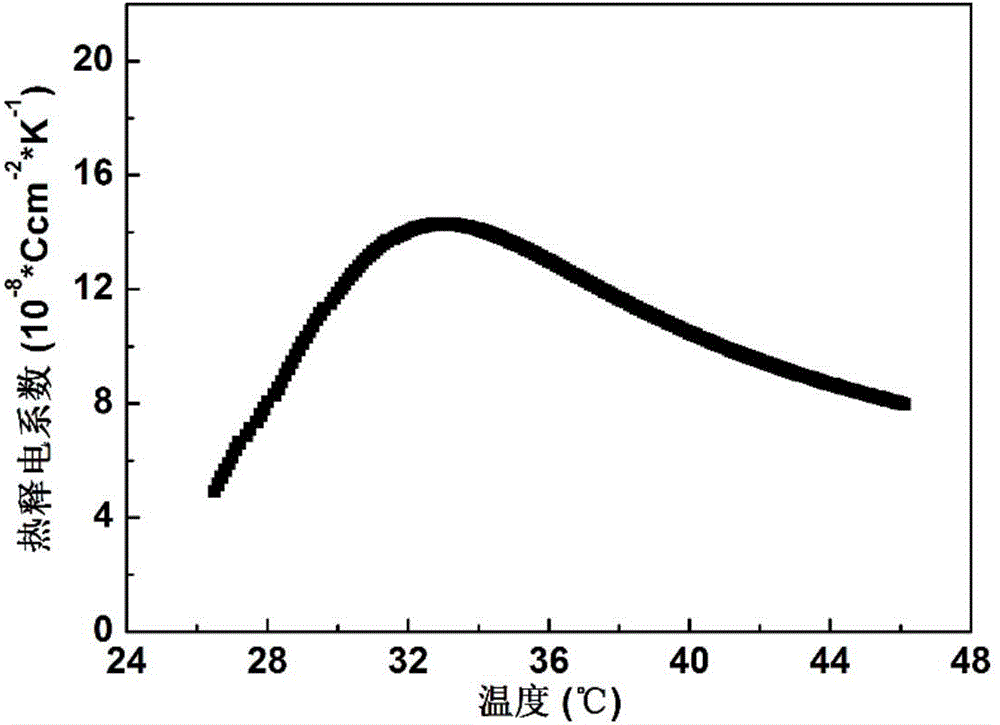

Preparation method of porous field pyroelectric ceramic material

InactiveCN101625268AHigh pyroelectric coefficientLow dielectric lossPyrometry using electric radation detectorsCeramicwareBarium strontium titanateDielectric loss

The invention discloses a method for preparing a porous barium strontium titanate field pyroelectric ceramic, comprising the following steps: firstly, mixing raw materials according to a stoichiometric ratio of respective chemical formula; pre-sintering the mixture at 800-1200 DEG C for 1-6 hours to obtain pre-sintered ceramic powder; then adding an organic substance pore-forming agent, mixing uniformly, tabletting and forming; heating again to remove organic substances; sintering, grinding, cleaning, adding an electrode and sintering the electrode. The porous BST field pyroelectric ceramic of the invention has the advantages of high pyroelectric coefficient, low dielectric loss, proper dielectric constant and excellent comprehensive pyroelectric property, and meets the requirements for manufacturing pyroelectric infrared detectors.

Owner:HUAZHONG UNIV OF SCI & TECH

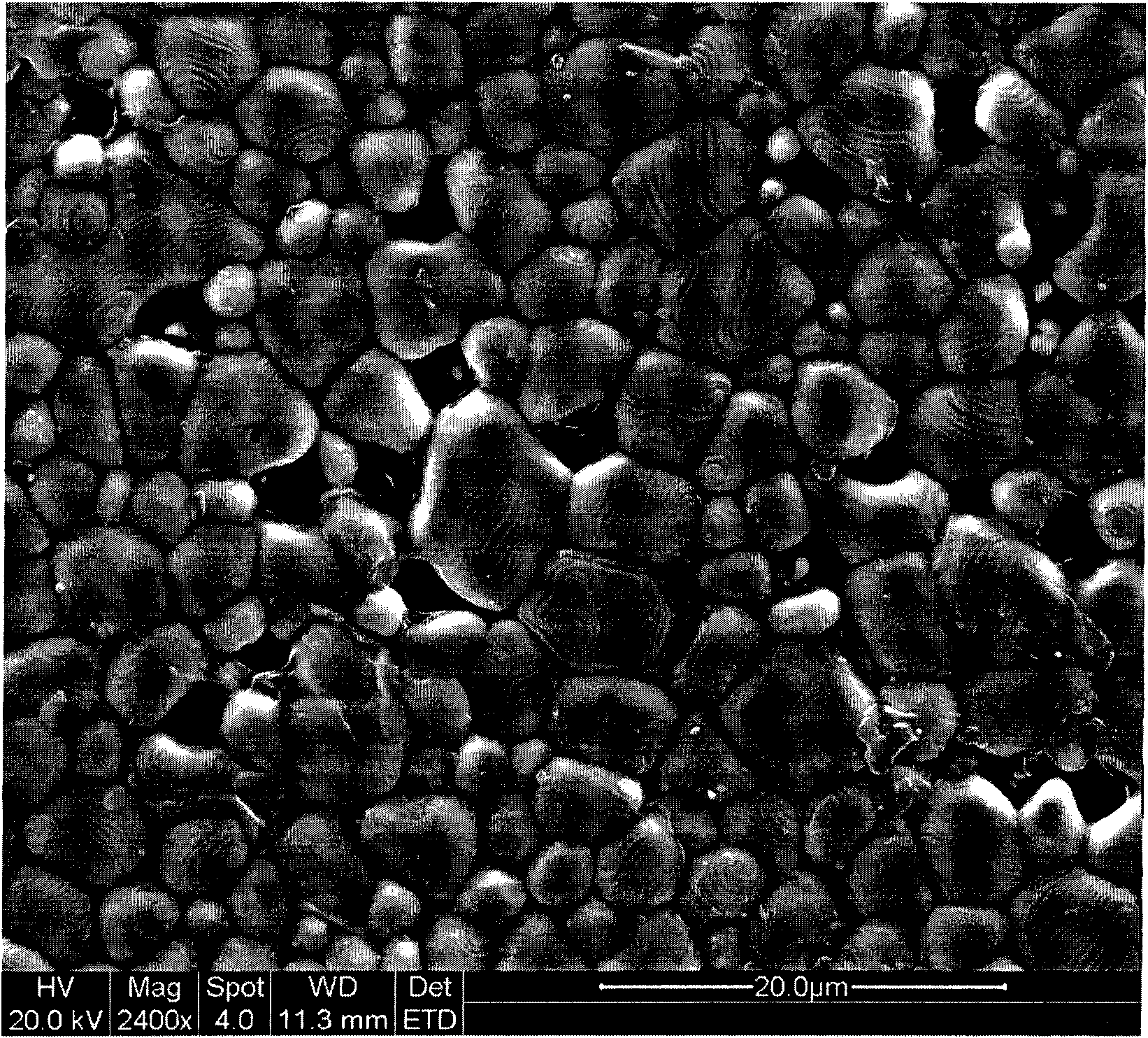

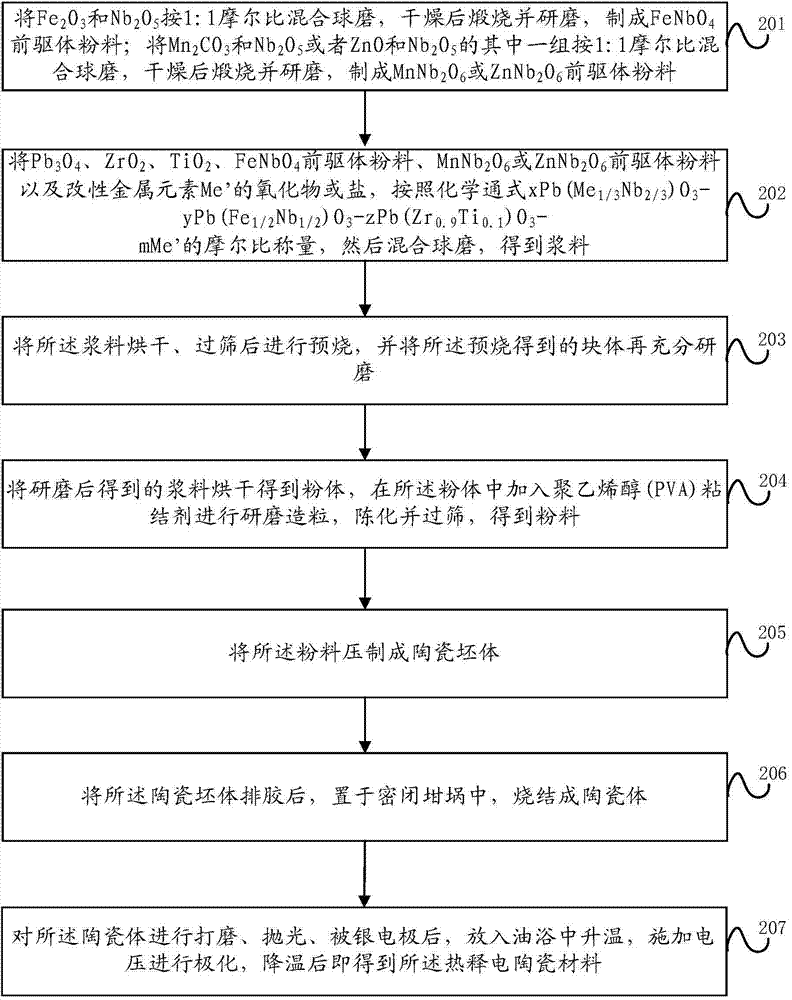

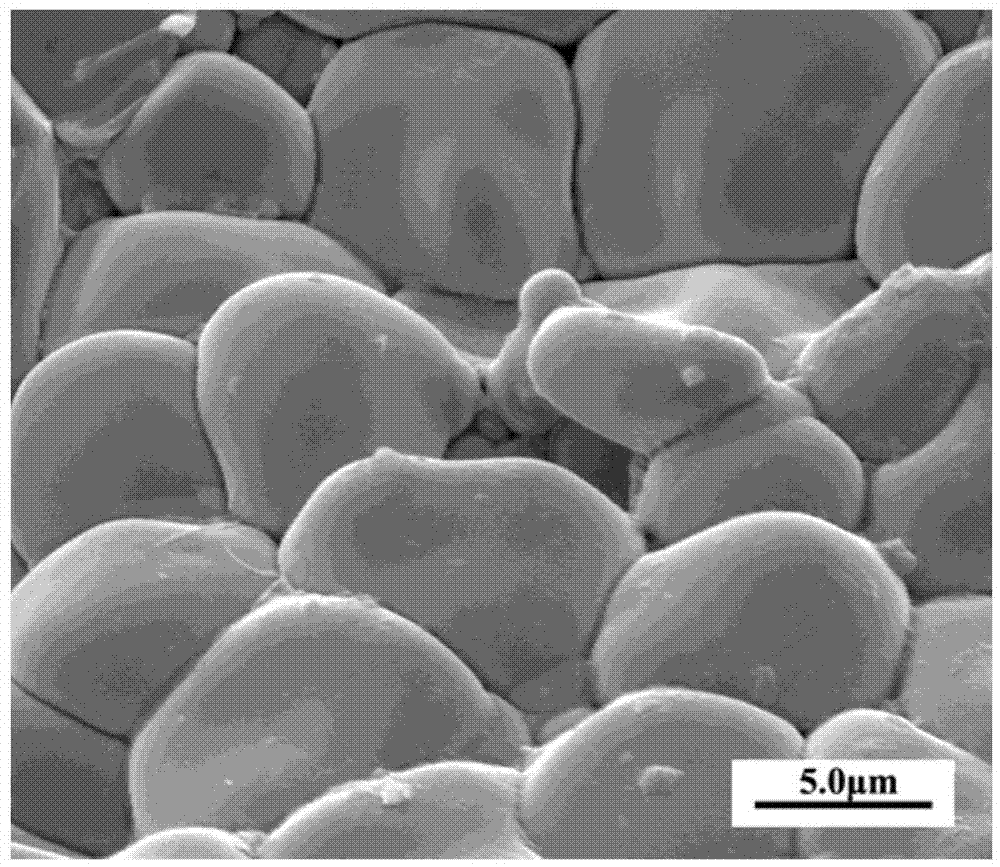

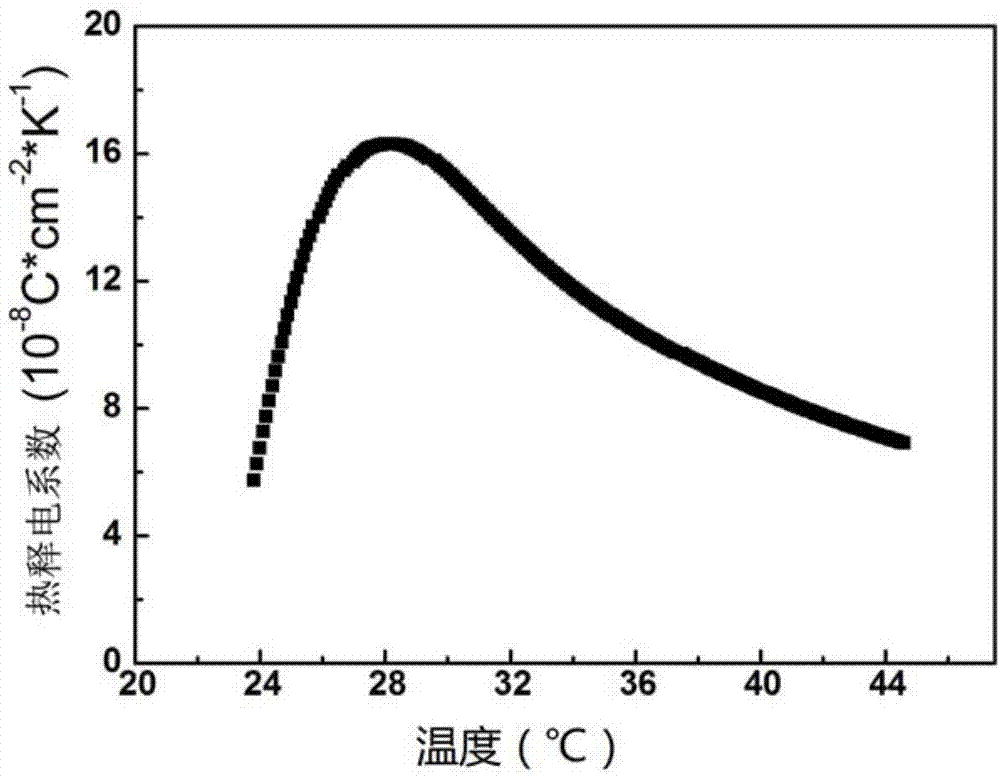

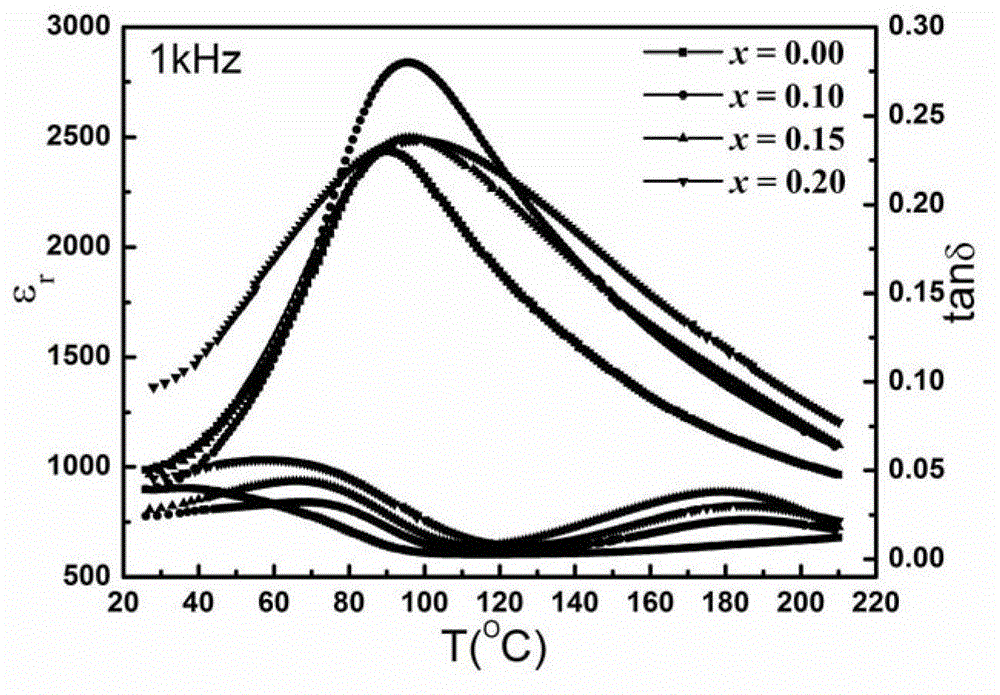

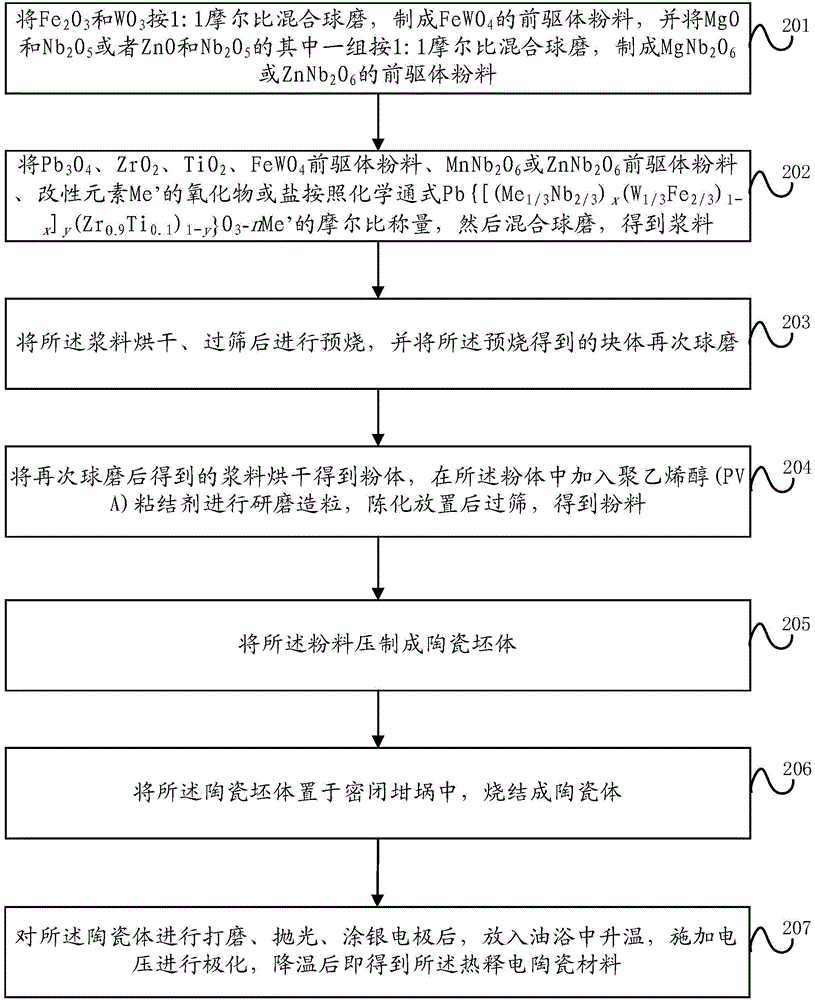

Multielement composite pyroelectric ceramic material and preparation method thereof

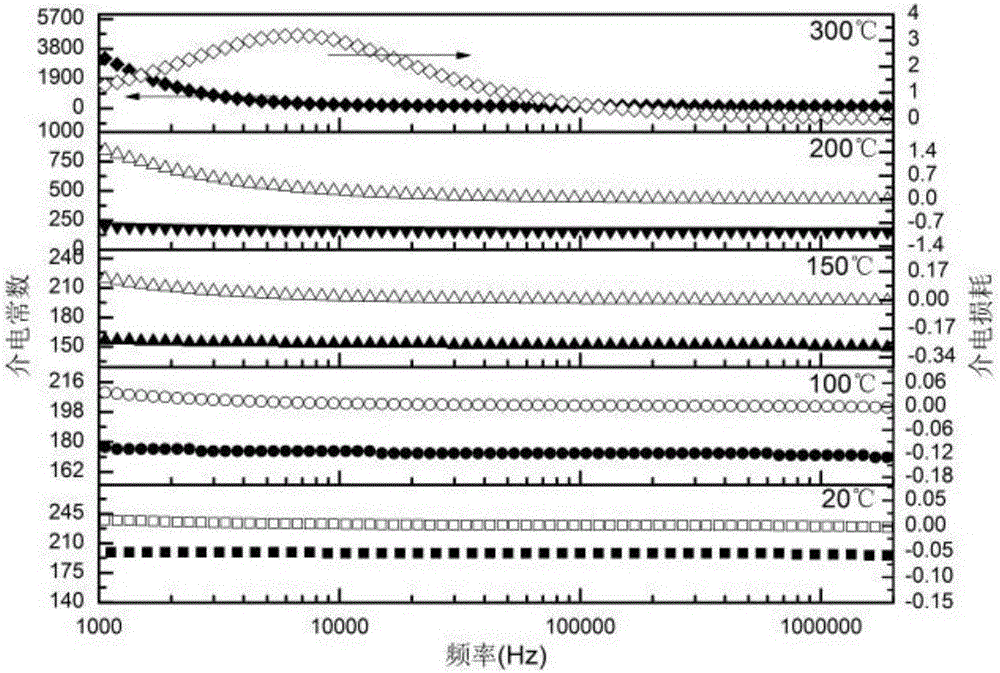

InactiveCN104725042AHigh pyroelectric coefficientModerate dielectric constantDielectric lossPyroelectric detectors

The invention discloses a multielement composite pyroelectric ceramic material and a preparation method thereof. The chemical general formula of the material is xPb(Me1 / 3Nb2 / 3)O3-yPb(Fe1 / 2Nb1 / 2)O3-zPb(Zr0.9Ti0.1)O3-mMe', wherein Me is one of Mn or Zn; x, y and z are respectively a mole coefficient, x is greater than or equal to 0.01 and less than or equal to 0.07, y is greater than or equal to 0.01 and less than or equal to 0.07, z is greater than or equal to 0.9 and less than or equal to 0.92, and x + y + z = 1; and Me' is a modifying metal element, m is a mole coefficient, and m is greater than or equal to 0 mol % and less than or equal to 5 mol %. The multielement composite pyroelectric ceramic material provided by the invention has a high pyroelectric coefficient, proper dielectric properties and a low dielectric loss, and the electrical properties can be adjusted, therefore, the multielement composite pyroelectric ceramic material has a good prospect in devices such as pyroelectric detectors and the like.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

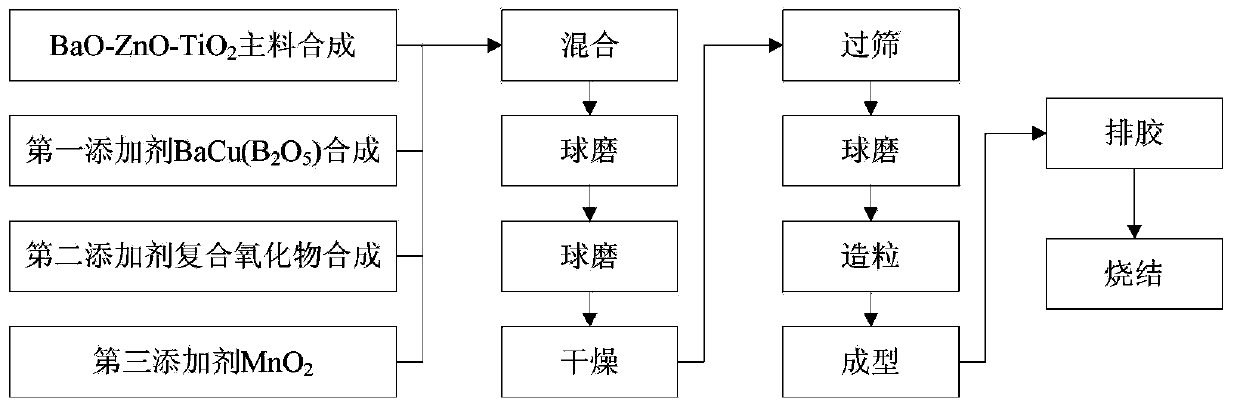

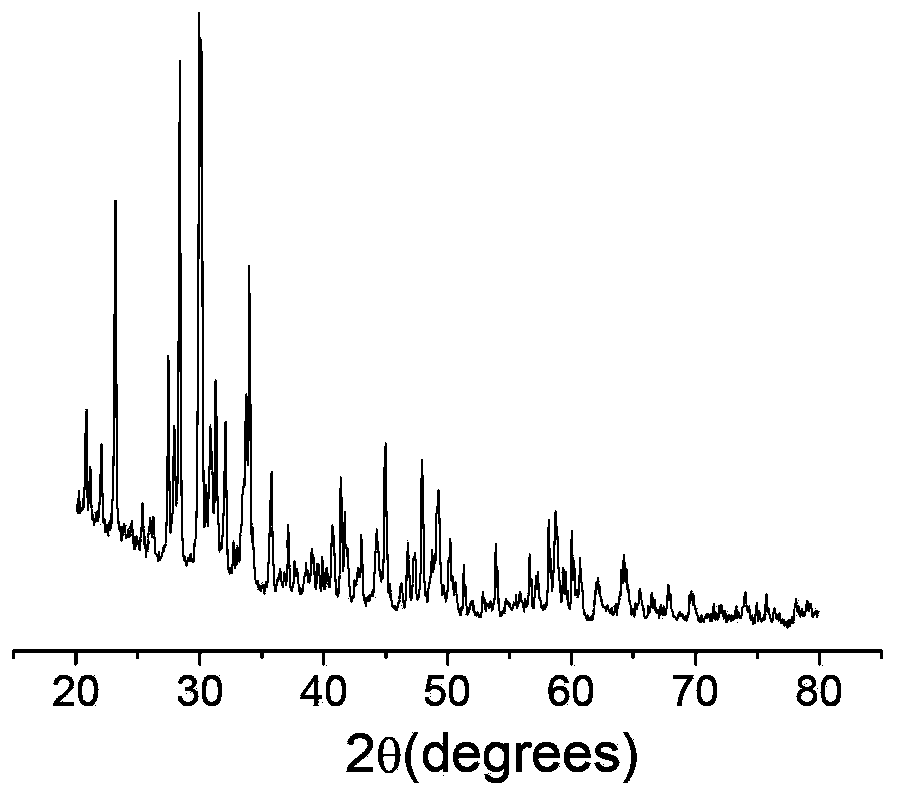

Low-temperature sintered microwave ceramic material and preparation method thereof

The invention discloses a low-temperature sintered microwave ceramic material and a preparation method thereof, and belongs to the technical field of materials. The low-temperature sintered microwave ceramic material comprises a main material-BaO-ZnO-TiO2, a first additive-BaCu(B2O5), a second additive-composite oxide and a third additive-MnO2. The preparation method comprises the following steps: taking BaCO3, ZnO and TiO2 as raw materials for synthesizing the main material-BaO-ZnO-TiO2, taking BaCO3, CuO and B2O3 as raw materials for synthesizing the first additive, taking BaCO3, ZnO, TiO2, SiO2 and B2O3 as raw materials for synthesizing the second additive, adding the first to third additives into the main material, performing ball-milling, drying, sieving, pelletizing, forming and rubber removing, and sintering in air at the temperature of 850-940 DEG C. The low-temperature sintered microwave ceramic material has the characteristics of high Q value, near-zero and serialized frequency temperature coefficient, moderate dielectric constant and good process stability through detection.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

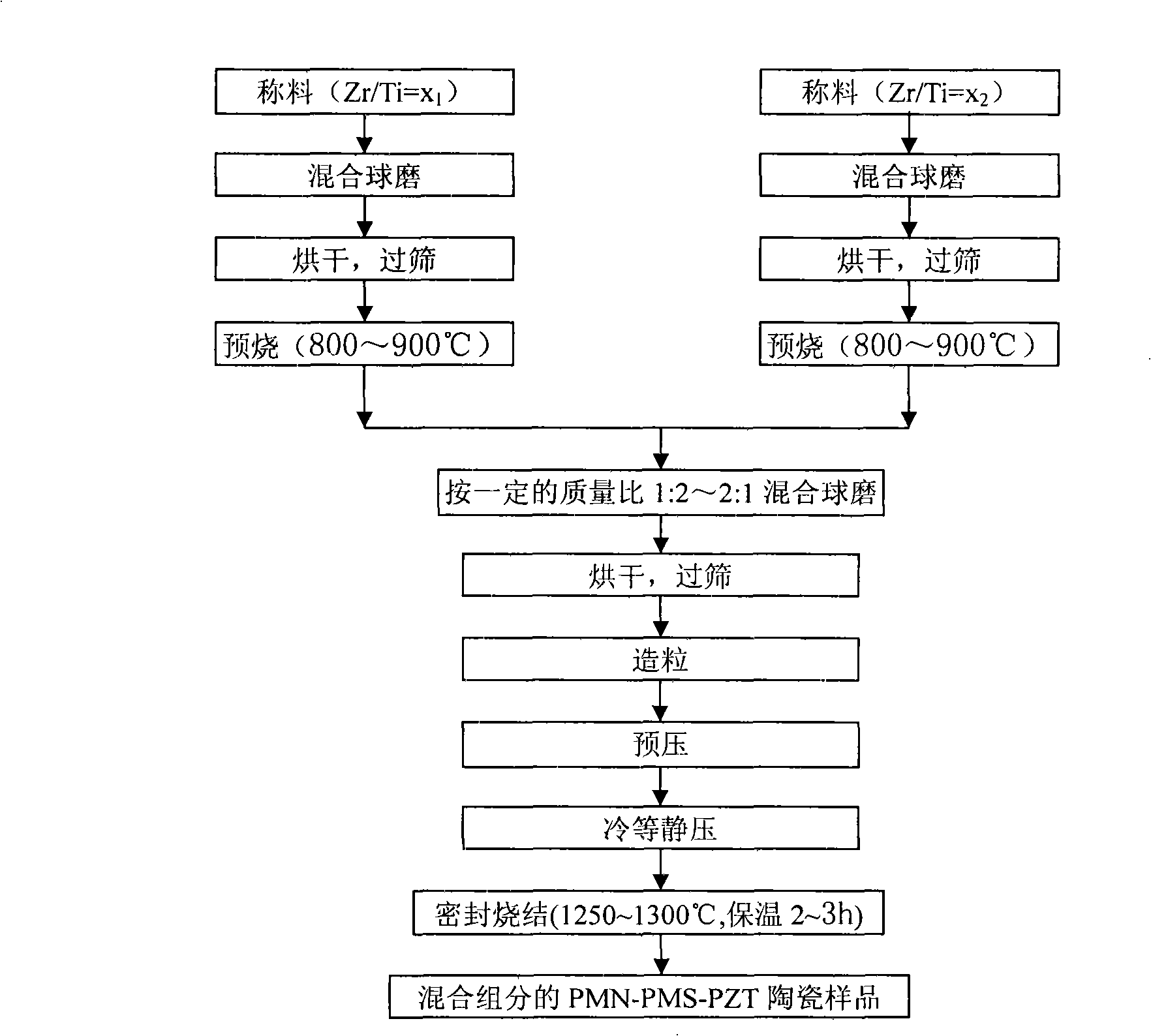

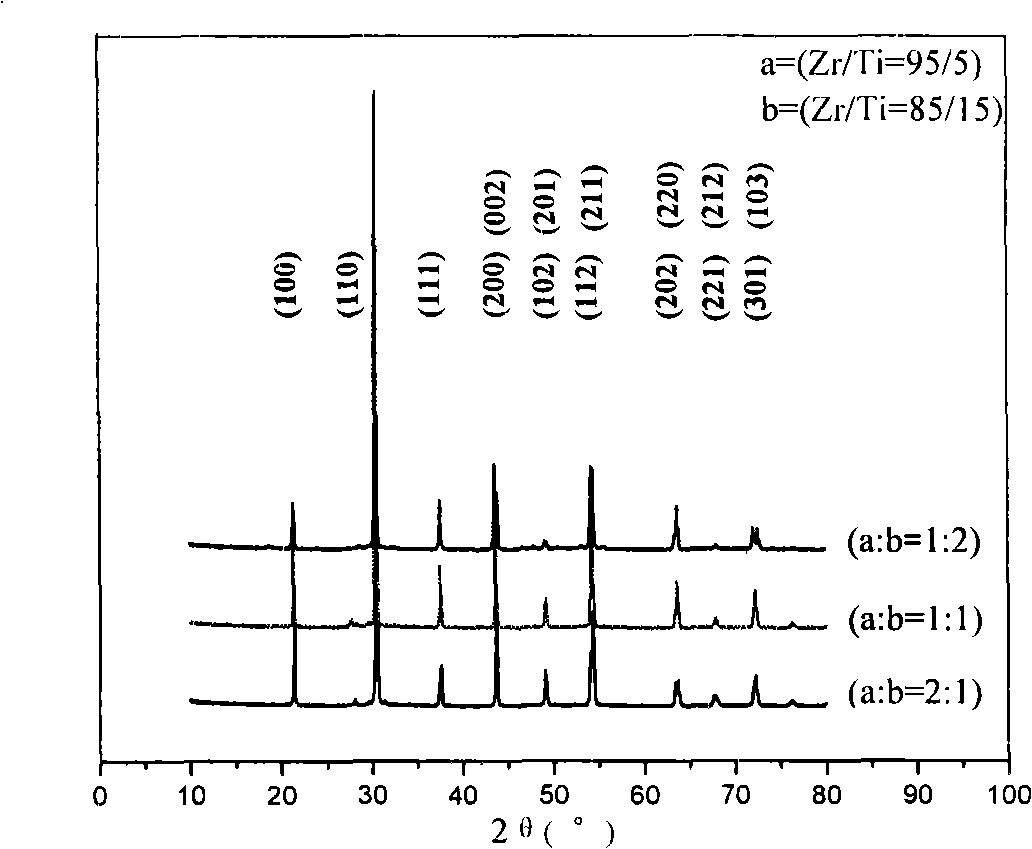

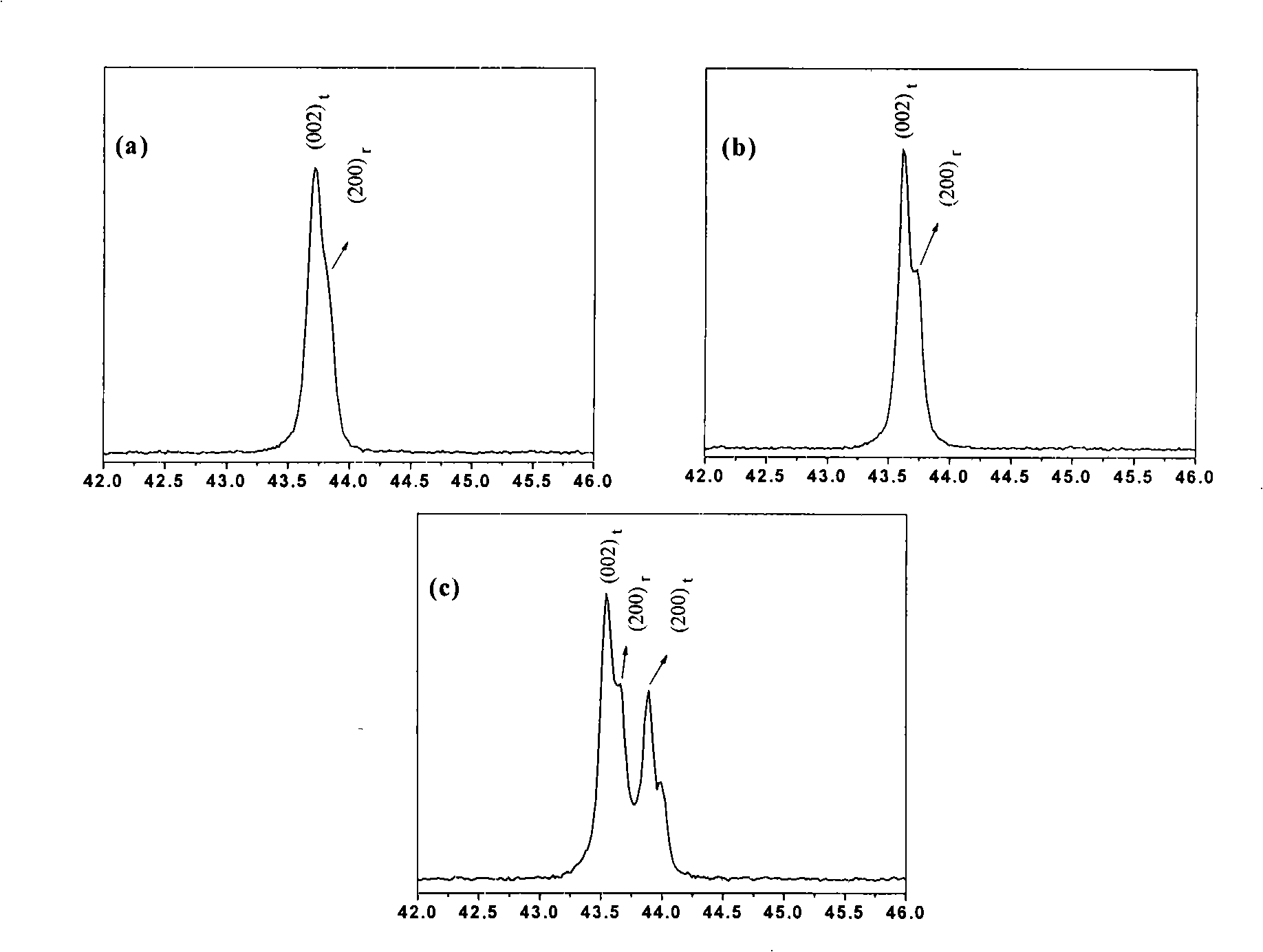

Method for preparing wide-temperature zone phase change type pyroelectric ceramic material

The invention discloses a preparation method for wide-temperature-range phase-transition pyroelectric ceramic materials, comprising the following steps: (1) based on the chemical formula Pb((Mn0.33Nb0.67) 0.5 (Mn0.33Sb0.67) 0.5)0.08 (ZrxTi1-x) 0.92O3, x stands for the molar fraction ratio between Zr and Ti and is greater than or equal to 0.80 but less than or equal to 0.98; selecting two different values in the value range of x; mixing PbO, ZrO2, TiO2, Nb2O5, Sb2O3 powder and Mn (NO3)2 based on the stoichiometric proportion in the respective chemical formula so as to get two mixtures; (2) insulating the two mixtures respectively for 4 to 6 hours at 800-900 DEG C to get pre-burning powder; (3) taking the pre-burning powder as base material and mixing the base material according to mass ratio of 1:2 to 2:1; molding the powder and insulating the powder for 2 to 3 hours at 1250-1300 DEG C for sintering; (4) grinding and washing the sintered material, then arranging and burning the electrodes; (5) after electrode burning, polarizing the material, and then retaining the voltage and cooling the material to room temperature. The mixed PMN-PMS-PZT pyroelectric ceramic prepared in the invention has high pyroelectric coefficient and good integrated pyroelectric performance in a wider temperature range, and is in line with the requirements of pyroelectric infrared detector production.

Owner:HUAZHONG UNIV OF SCI & TECH

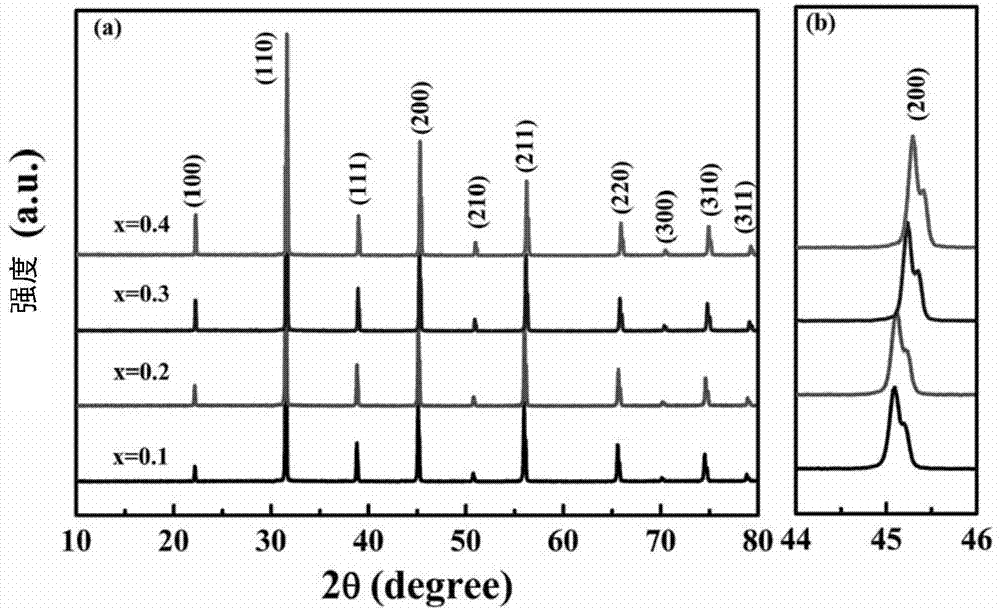

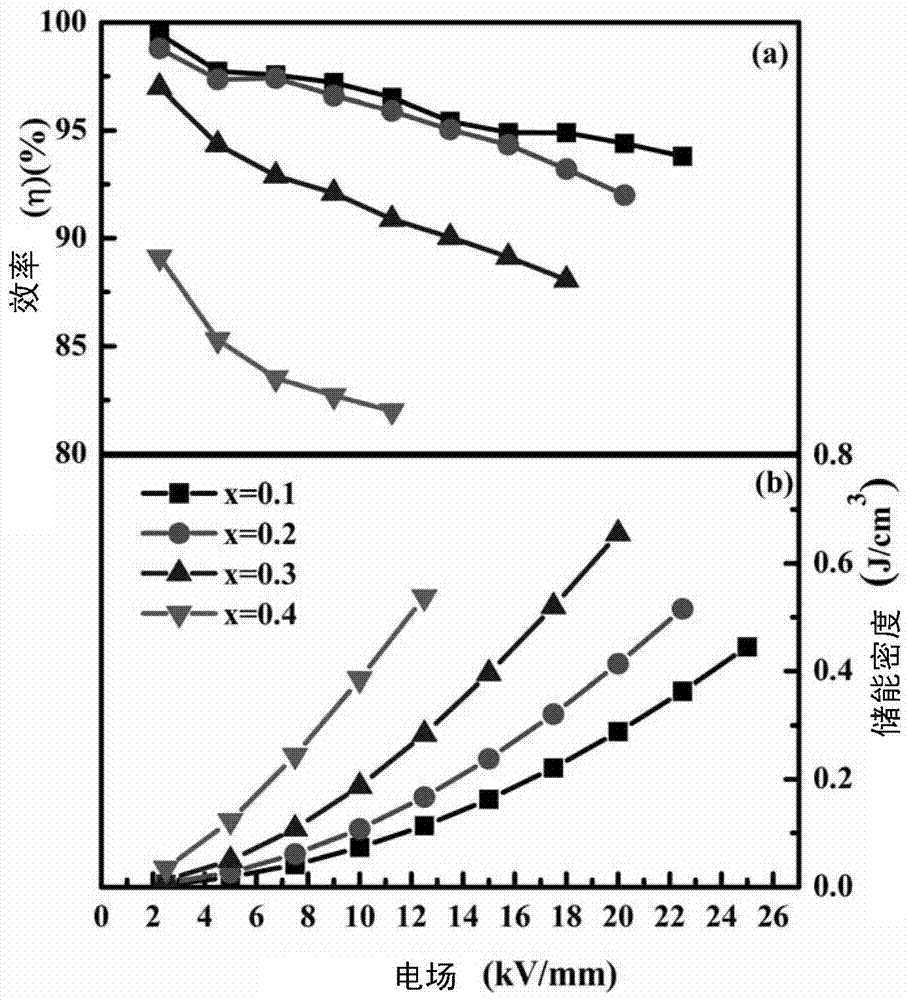

Novel BCZT-based energy storage ceramic material and preparation method and application thereof

ActiveCN107244912AHigh energy storage densityImprove energy storage efficiencyFixed capacitor dielectricStacked capacitorsBreakdown strengthDielectric loss

The invention relates to a novel BCZT-based energy storage ceramic material and a preparation method and application thereof. The BCZT-based energy storage ceramic material adopts the general formula as follows: (Ba0.85Ca0.15)(Zr0.10Ti0.90)1-x (NiyNbz)xO3, wherein x is greater than or equal to 0.1 and smaller than or equal to 0.8, y is greater than or equal to 0 and smaller than or equal to 1.0, and z is greater than or equal to 0 and smaller than or equal to 1.0. The (Ba0.85Ca0.15)(Zr0.10Ti0.90)1-x (NiyNbz)xO3 has high energy storage density, and further has the characteristics of low dielectric loss, a moderate dielectric constant, high breakdown strength, good temperature and frequency stability and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

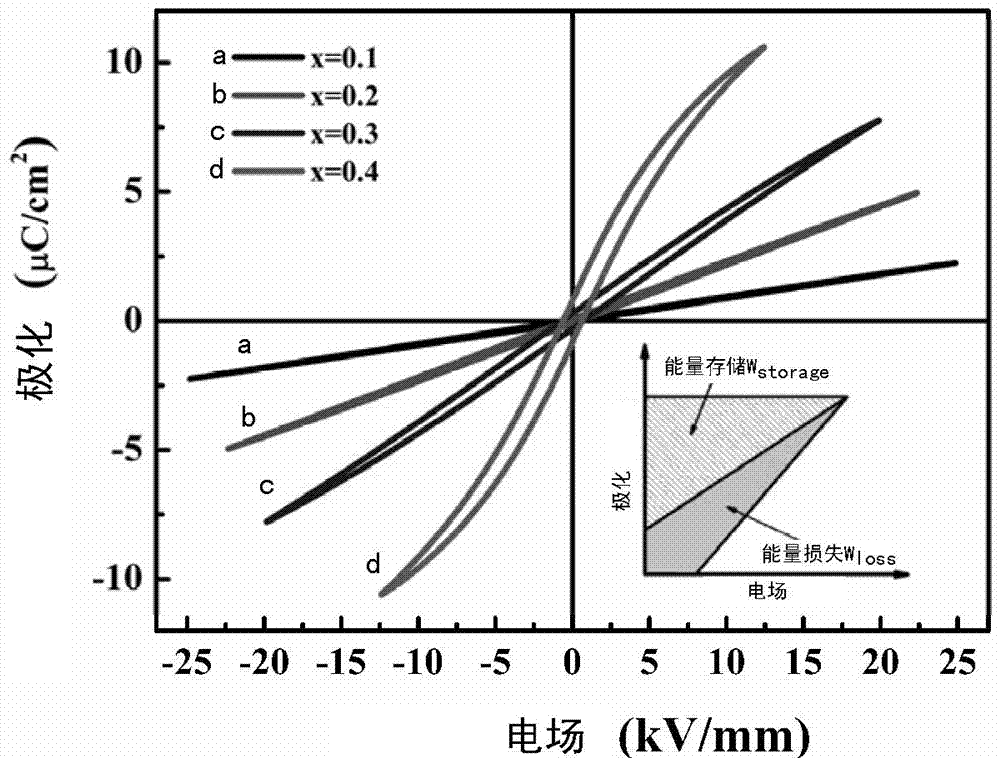

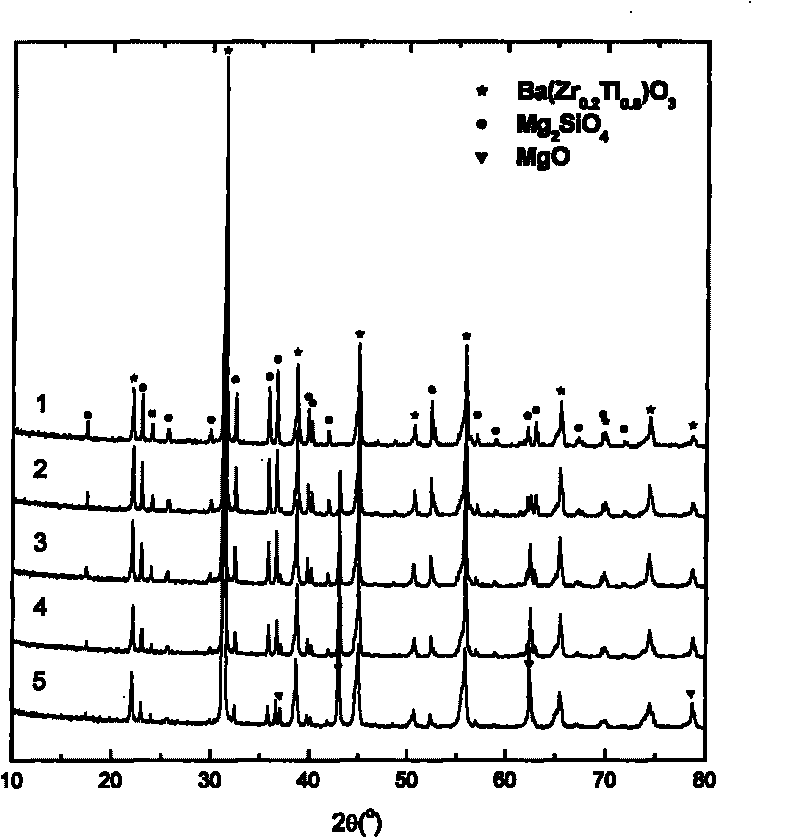

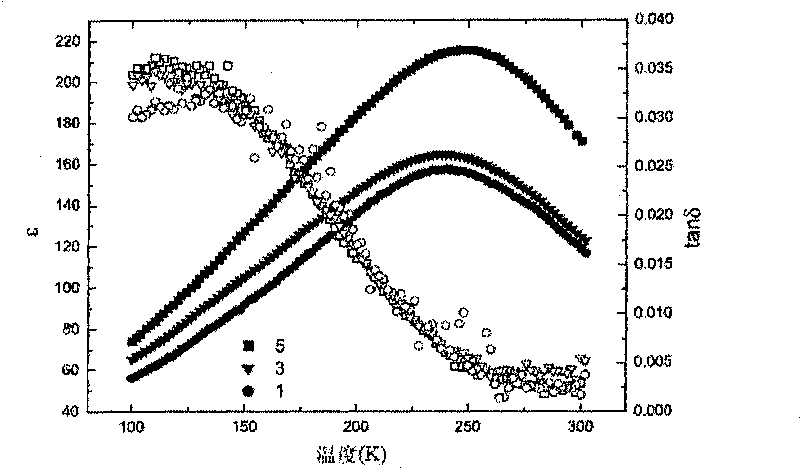

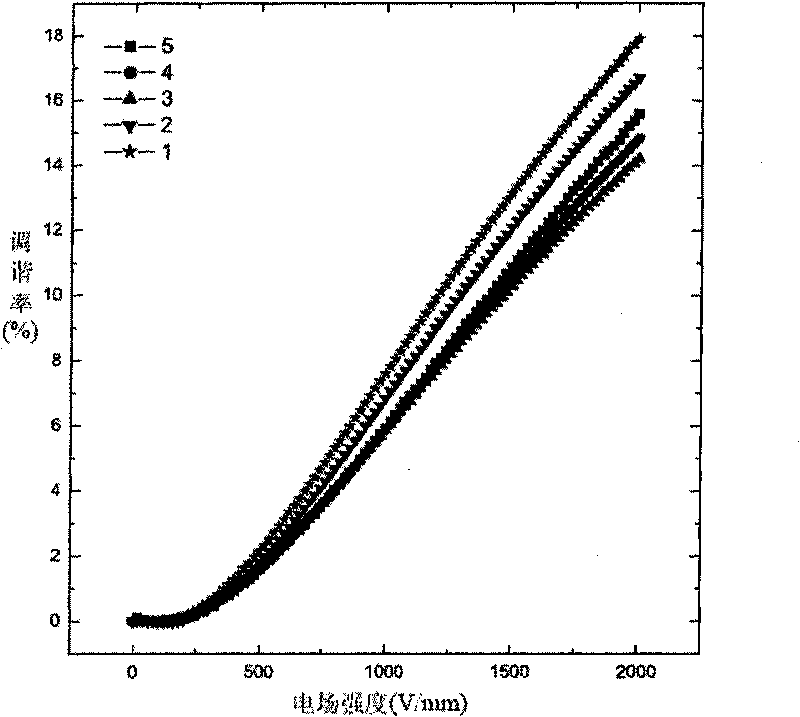

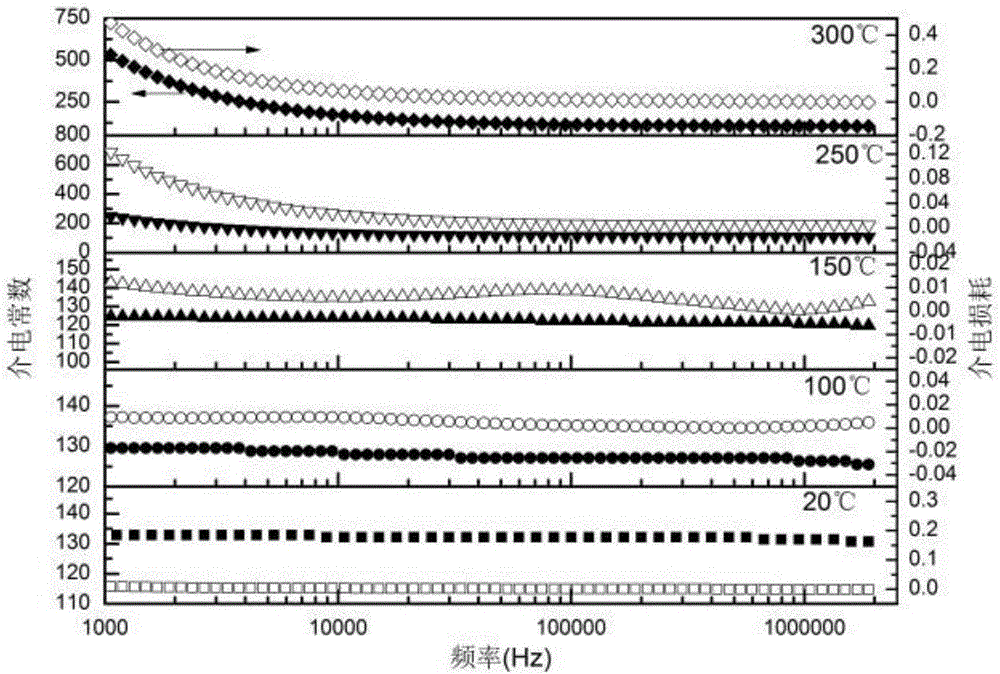

Microwave-tuned composite ceramic material and preparation method thereof

The invention discloses a microwave-tuned composite ceramic material and a preparation method thereof. The composite ceramic material consists of BaZrxTi1-xO3 and a mixture, wherein the BaZrxTi1-xO3 is 30 to 95 weight percent, and x is equal to 0.1 to 0.50; and the mixture consists of Mg2SiO4 and MgO, wherein the Mg2SiO4 in the mixture is 1 to 99 weight percent. The preparation method for the microwave-tuned composite ceramic material comprises the following steps: based on the stoichiometric proportion, preparing the BaZrxTi1-xO3 and the Mg2SiO4 respectively; obtaining the powder of the BaZrxTi1-xO3 and the powder of the Mg2SiO4 respectively by ball-milling, discharging, drying and presintering; doping the Mg2SiO4 and the MgO into the BZT powder according to the component design; and performing ball-milling, drying, pelleting, molding, batching out, then sintering at the furnace temperature if between 1,200 and 1,400 DEG C for 2 to 4 hours, and obtaining the needed material. The microwave-tuned composite ceramic material has the characteristics of proper dielectric constant, low dielectric loss, high tuning rate, and high performance and low sintering temperature. The microwave-tuned composite ceramic material can be applied to a phase shifter, an adjustable filter, a delay line, an oscillator, a resonator, a phased-array antenna, and other microwave devices.

Owner:HUAZHONG UNIV OF SCI & TECH

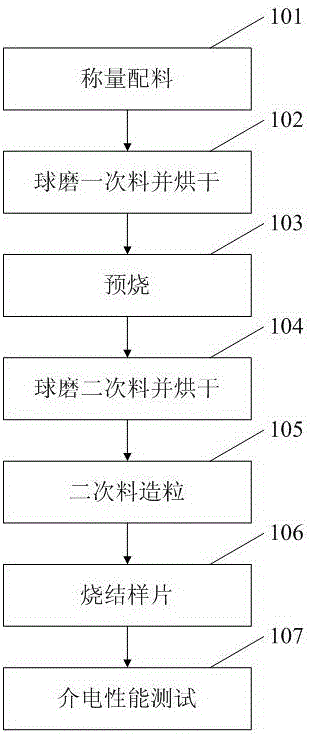

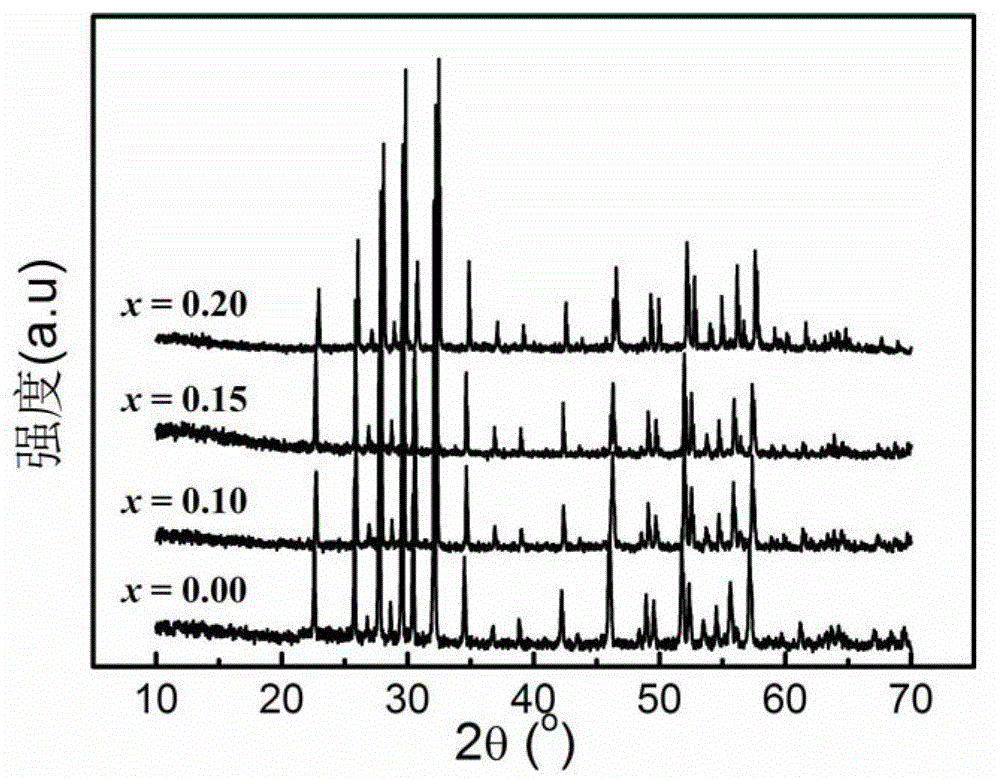

Novel CaTiO3-based linear energy-storage-medium ceramic material and preparation method thereof

The invention relates to a novel CaTiO3-based linear energy-storage-medium ceramic material and a preparation method thereof. The novel CaTiO3-based linear energy-storage-medium ceramic material is characterized in that the expression is ZnxCa(0.97-x)La0.03Ti0.97Al0.03O3, and x ranges from 0.01 to 0.2. The preparation method comprises steps as follows: CaCo3, TiO2, La2O3, Al2O3 and ZnO are taken as raw materials, weighed in the stoichiometric ratio according to the chemical formula ZnxCa0(0.97-x)La0.03Ti0.97Al0.03O3 with x ranging from 0.01 to 0.2, mixed, subjected to ball milling, dried, pre-sintered at the temperature of 1,000-1,150 DEG C and subjected to secondary ball milling, pre-sintered powder is obtained, the pre-sintered powder is sieved, mixed with an adhesive, granulated and formed, a ceramic body is obtained after dumping and sintered in air at the temperature of 1,200-1,300 DEG C, and the novel CaTiO3-based linear energy-storage-medium ceramic material is obtained. CaTiO3 ceramic is co-doped with Zn<2+> and La<3+> / Al<3+>, and the ZnxCa(0.97-x)La0.03Ti0.97Al0.03O3 linear energy-storage-medium ceramic material is obtained. The material has the characteristics of low dielectric loss, good frequency stability, moderate dielectric constant and relatively high breakdown strength.

Owner:WUHAN UNIV OF TECH

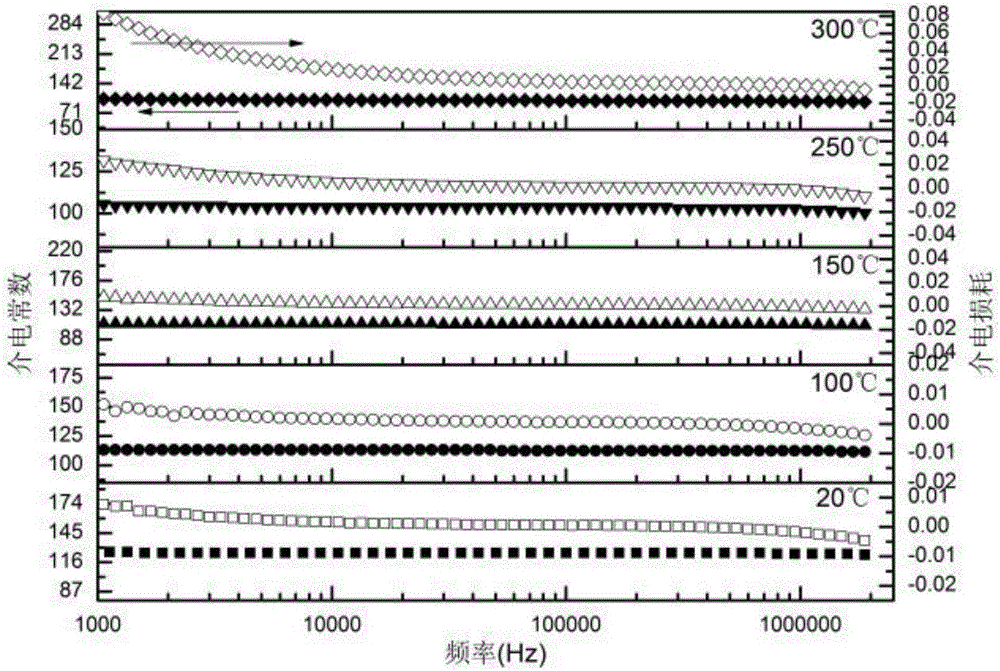

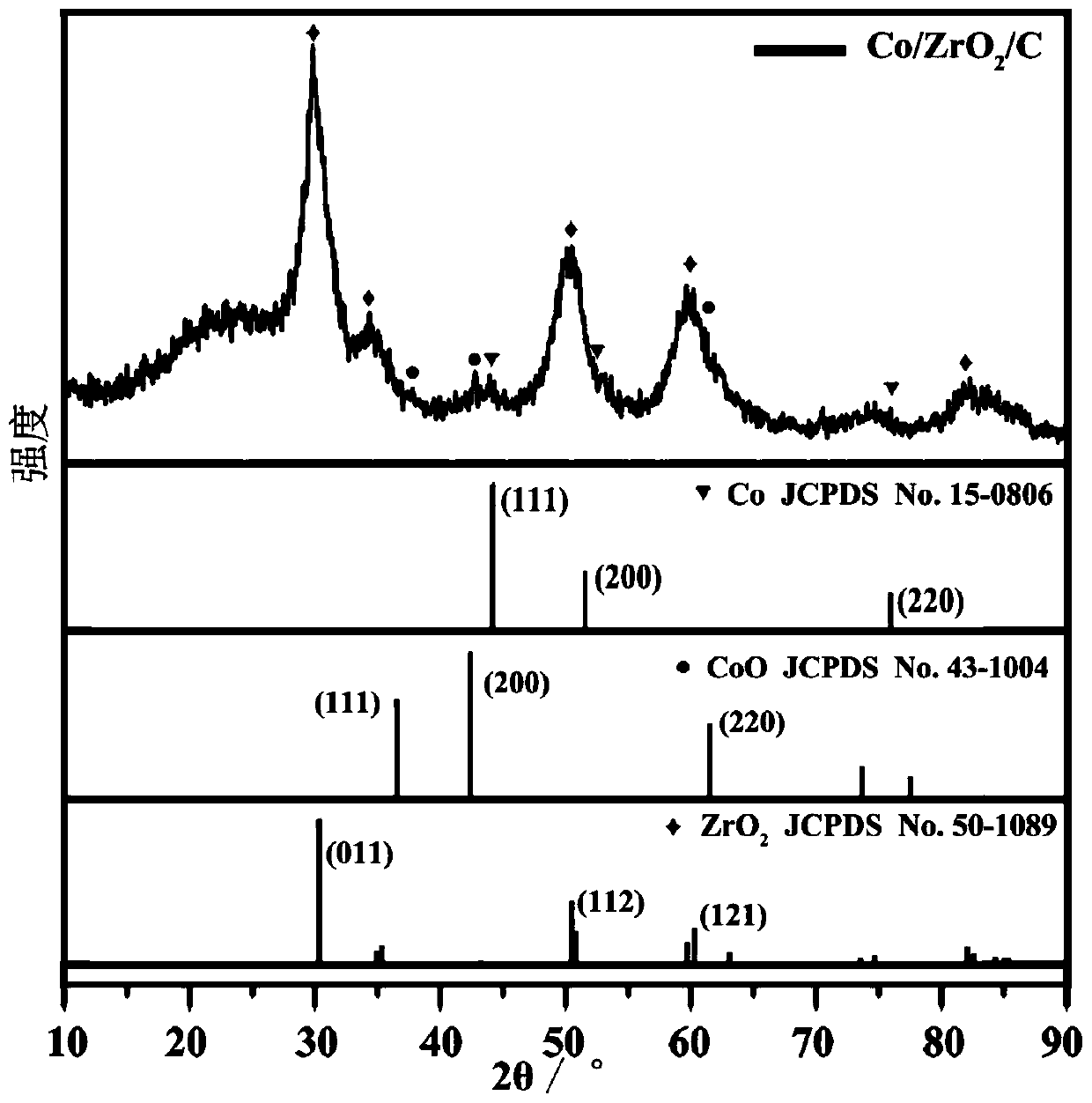

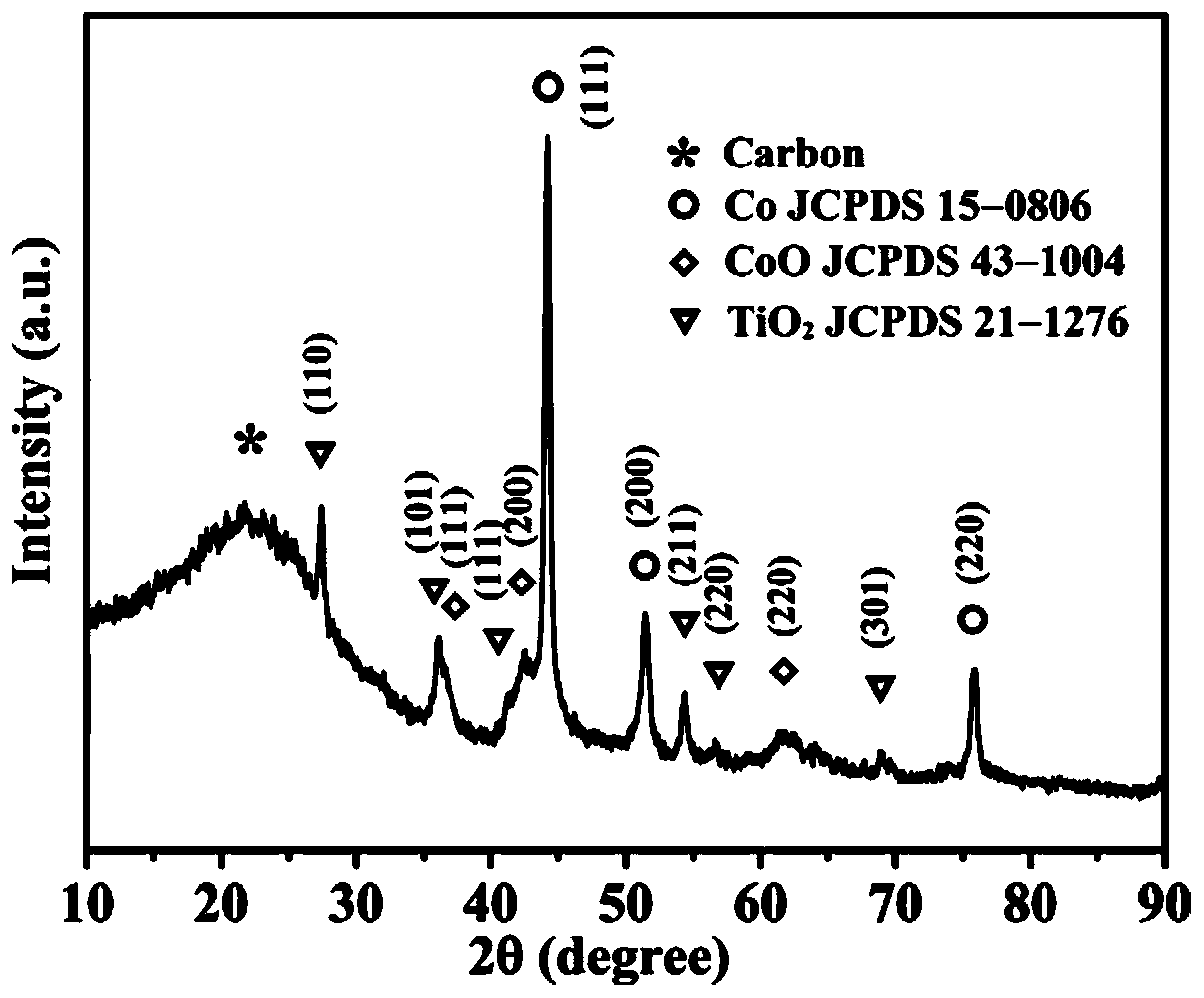

Co-modified metal organic framework-derived ZrO2/C electromagnetic wave absorbing material, and preparation method and application thereof

ActiveCN110437800AImproving Impedance MatchingUnique microstructureOther chemical processesFiberMetal-organic framework

The invention relates to a Co-modified metal organic framework-derived ZrO2 / C electromagnetic wave absorbing material, and a preparation method and an application thereof. The electromagnetic wave absorbing material is of a three-dimensional network structure formed by interweaving one-dimensional fibers. The fiber is composed of a carbonaceous matrix, ZrO2 and Co nanoparticles. The Co nanoparticles are embedded in the surface of the carbonaceous matrix uniformly distributed by ZrO2. The method comprises the steps that 1, a cobalt source, a zirconium source, an anhydrous acetic acid organic ligand and DMF are processed into a solvothermal solution, the organic ligand containing a carbon source, an MOF precursor is obtained after solvothermal reaction, the MOF precursor is washed and dried,then the MOF precursor is treated with the cobalt source, and cobalt source composite MOF is obtained; and (2) the compounded MOF precursor is placed in a protective atmosphere to convert cobalt ionsin a cobalt source into elemental cobalt, a zirconium source into ZrO2 and an organic ligand into a carbon matrix, thereby obtaining the catalyst. According to the preparation method disclosed by theinvention, ZrO2, Co and C are effectively subjected to nanoscale compounding, so that the prepared material has excellent performance.

Owner:SHANDONG UNIV

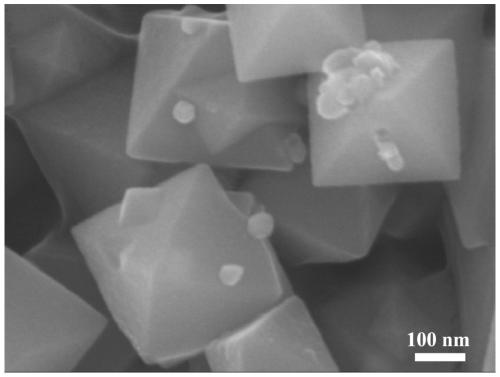

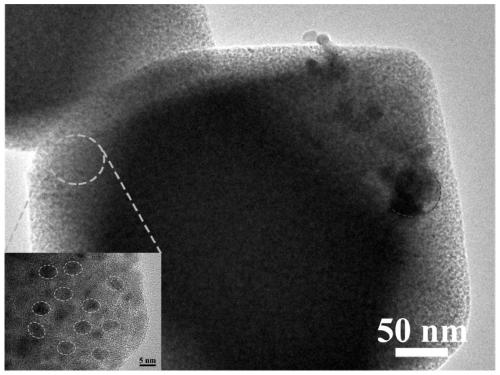

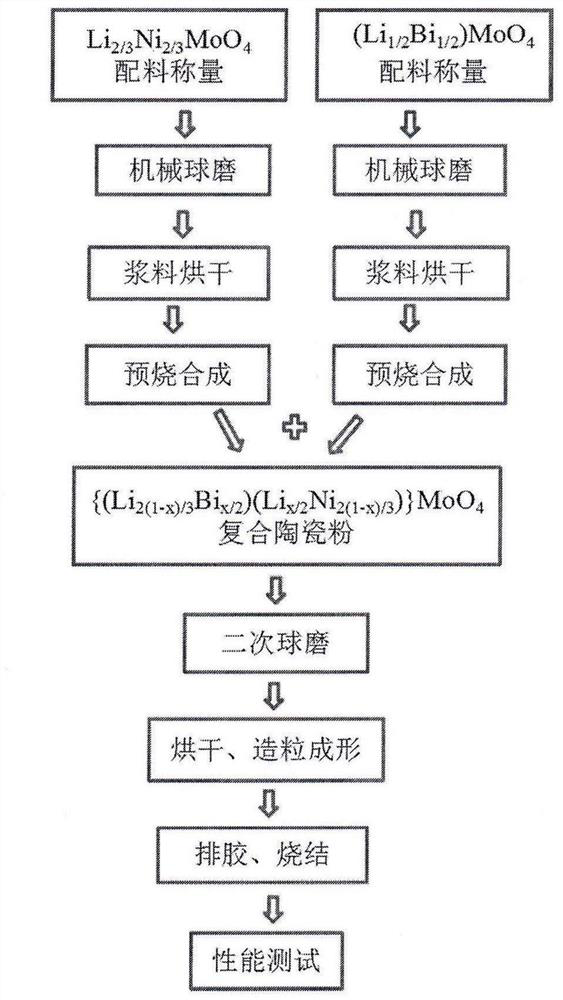

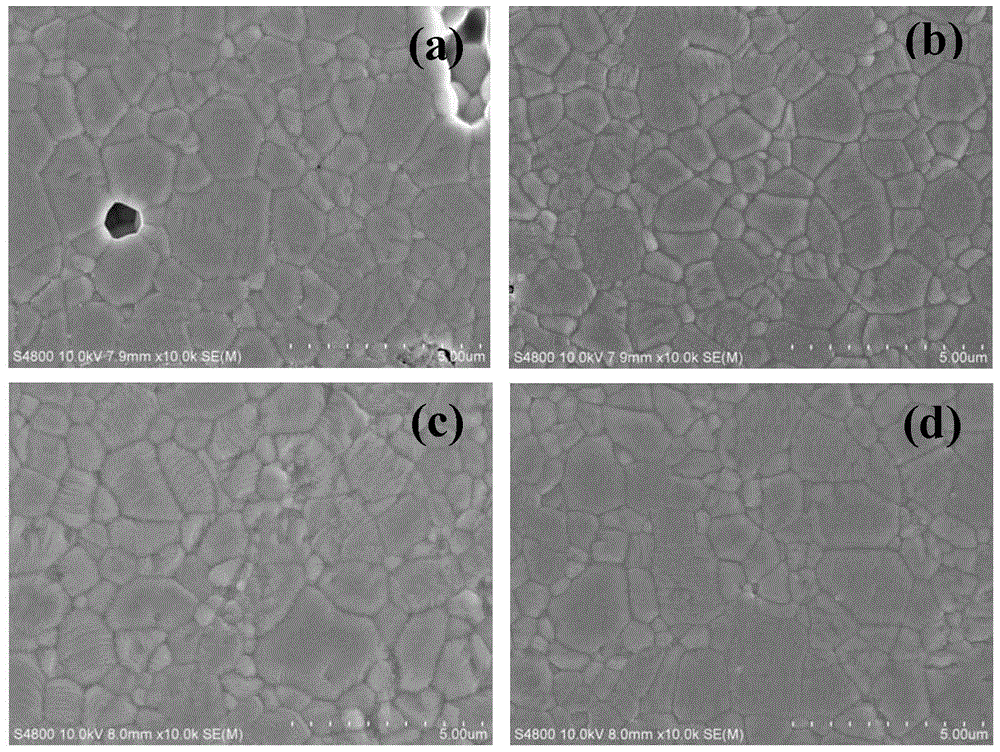

Low-temperature-sintered temperature-stable composite microwave dielectric ceramic and preparation method thereof

ActiveCN113149645ALower sintering temperatureImprove temperature stabilityChemical industryCeramic sinteringDielectric

The invention relates to a low-temperature-sintered temperature-stable composite microwave dielectric ceramic and a preparation method thereof. The composite microwave dielectric ceramic comprises the following components: a low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient and a low-temperature-sintered microwave dielectric ceramic material with a positive resonant frequency temperature coefficient. According to the invention, the low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient or the low-temperature-sintered microwave dielectric ceramic material with the positive resonant frequency temperature coefficient is used as a main material, a low-temperature-sintered microwave dielectric ceramic material with the same structure and an opposite resonant frequency temperature coefficient is added as an adjusting material through a two-phase compounding method, and compounding is conducted to form a multiphase ceramic material or a solid solution so as to obtain a low-temperature-sintered microwave dielectric ceramic material having a nearly-zero resonance frequency temperature coefficient. The problems that existing microwave dielectric ceramic is high in sintering temperature, and the temperature coefficient of resonance frequency changes greatly along with temperature are solved. The microwave dielectric ceramic material has a wide application scope in the LTCC low-temperature-sintered microwave dielectric ceramic materials.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

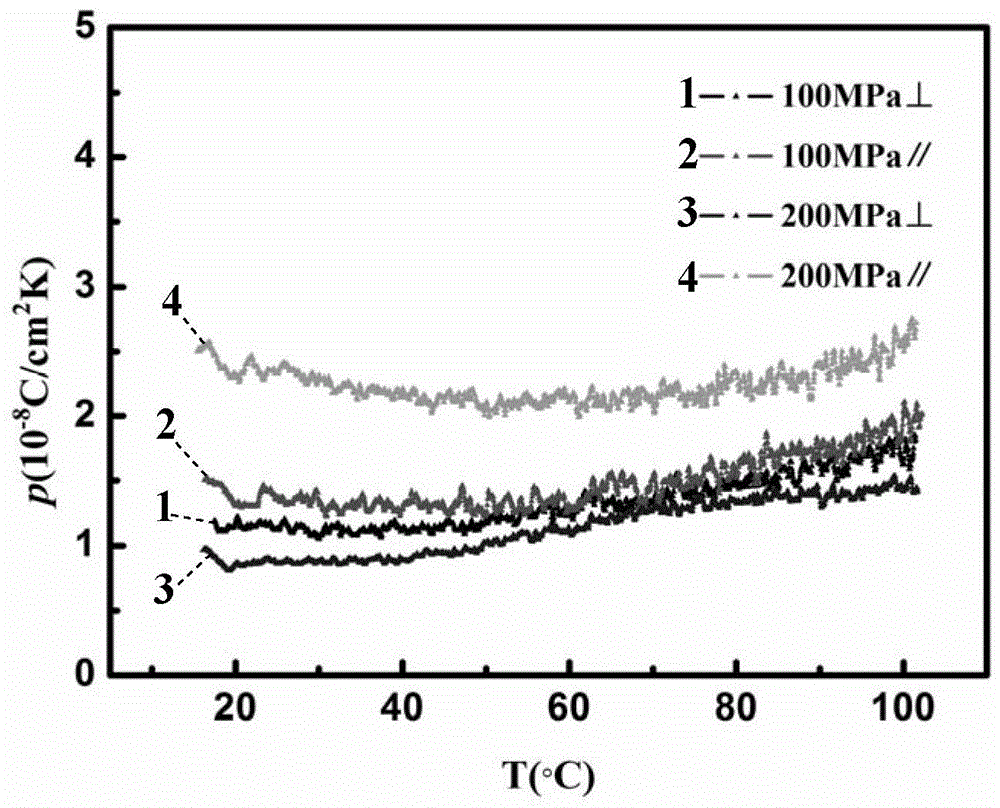

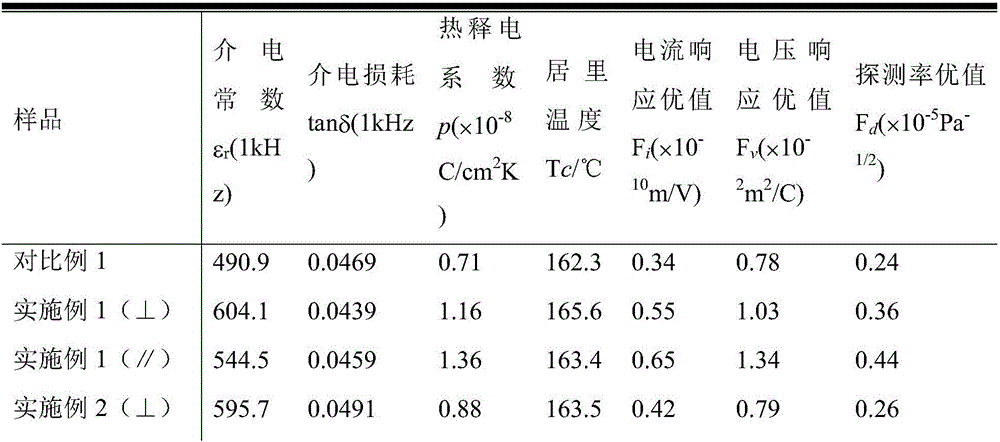

High-Curie-temperature strontium-barium niobate pyroelectric ceramic material and preparation method thereof

The invention relates to a high-Curie-temperature strontium-barium niobate pyroelectric ceramic material and a preparation method thereof. The material has the composition general formula of SrxBa1-xNb2O6, wherein x is larger than or equal to 0.25 and smaller than or equal to 0.35. The SBN ceramic material high in density and pyroelectric performance is obtained by preparing power through a solid phase method, preparing an SBN blank through cold isostatic pressing forming and other processes, putting the SBN blank in a mold, filling and covering the SBN blank with ZrO2 powder, raising the temperature to 1100-1150 DEG C, linearly and evenly pressurizing to 100-200 MPa with the axis of the mold as the hot-press axis, raising the temperature to 1200-1300 DEG C, keeping the temperature and the pressure for 2-4 h in the air atmosphere, and linearly depressurizing and cooling inside a furnace to the room temperature. The problem that high-Curie-temperature SBN components are poor in pyroelectric performance is solved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Bismuth silicate powder preparation method using stoichiometric ratio raw materials and sol-gel method

InactiveCN103949655AEase of mass productionLow dielectric constantPolycrystalline material growthFrom frozen solutionsSolid phasesSingle phase

The invention discloses a bismuth silicate powder preparation method using stoichiometric ratio raw materials and a sol-gel method. The preparation method comprises the following steps of S1, adding citric acid into mixed liquor of ethyl alcohol and water, then adding a proper amount of ethyl orthosilicate into the solution, and stirring until the solution is not layered, so that liquid A is prepared; S2, dissolving bismuth silicate into a proper amount of glycol, so that liquid B is prepared. According to the preparation method, the used raw materials are soluble bismuth salt and tetraethoxysilane liquid with stoichiometric ratio, purity levels are analyzed, purification can be performed by recrystallization, distillation and other methods, mass production is facilitated, single-phase powder is easy to obtain, and the cost is greatly lower than that of a traditional solid phase method; the composite powder can be used for crystal growth so that the quality of grown crystals is greatly superior to that of grown crystals prepared by the solid phase method; the composite powder can also be used for preparing microwave dielectric ceramic so that the prepared ceramic has the characteristics of moderate dielectric constant, low dielectric loss, low ceramic sintering temperature and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Intermediate temperature stable microwave dielectric ceramics and preparation method thereof

InactiveCN110143814AExcellent microwave dielectric propertiesHigh quality factorDielectric ceramicsHot Temperature

The invention discloses intermediate temperature stable microwave dielectric ceramics. The intermediate temperature stable microwave dielectric ceramics is formed by sintering a main material and auxiliary materials. The composition expression of the main material is aMgTil+xO3-bCaTiO3, wherein x is less than or equal to 0.05 and greater than or equal to 0; and a and b respectively represent molarratio, a is less than or equal to 0.95 and greater than or equal to 0.90, b is less than or equal to 0.1 and greater than or equal to 0.05, and a+b equals to 1. The auxiliary materials are La2O3 andZnO, wherein La2O3 accounts for 0-1 wt% of mass of the main material and ZnO accounts for 0-0.1 wt% of mass of the main material. The invention also discloses a preparation method of the intermediatetemperature stable microwave dielectric ceramics. The intermediate temperature stable microwave dielectric ceramics has excellent microwave dielectric properties, has good temperature stability at both high temperature and low temperature, and has a wide application prospect. In addition, raw materials for the preparation are nontoxic, the cost is low, and the preparation process is simple.

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

Preparation method of lead scandium tantalate pyroelectric ceramics

ActiveCN102219512AModerate dielectric constantLower sintering temperaturePyrometry using electric radation detectorsCeramicLead scandium tantalate

The invention belongs to the field of pyroelectric ceramics, and specifically relates to a preparation method of la ead scandium tantalate pyroelectric ceramics. The method comprises the following steps: first, weighing a PbO powder and a ScTaO4 powder according to stoichiometric ratio, adding an excess 2.5-7.5wt% PbO powder, and mixing by a wet ball milling method to obtain a Pb (Sc0.5Ta0.5)O3 powder; Then carrying out an insulation synthesis on the Pb (Sc0.5Ta0.5)O3 powder to obtain a Pb (Sc0.5Ta0.5) O3 solid solution powder; mixing the Pb (Sc0.5Ta0.5) O3 solid solution powder by ball milling, drying, adding a binder, and carrying out steps of aging, sieving and moulding, etc. to prepare a Pb (Sc0.5Ta0.5) O3 base substrate; at last, carrying out hot pressing sintering on the Pb (Sc0.5Ta0.5) O3 base substrate in an oxygen atmosphere to obtain the lead scandium tantalate pyroelectric ceramics. The preparation method provided by the invention enables a sintering temperature of the leadscandium tantalate to lower to 1290-1320 DEG C, and the lead scandium tantalate pyroelectric ceramics prepared through the method have high pyroelectric performance and can be applied to an uncooled infrared detector.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

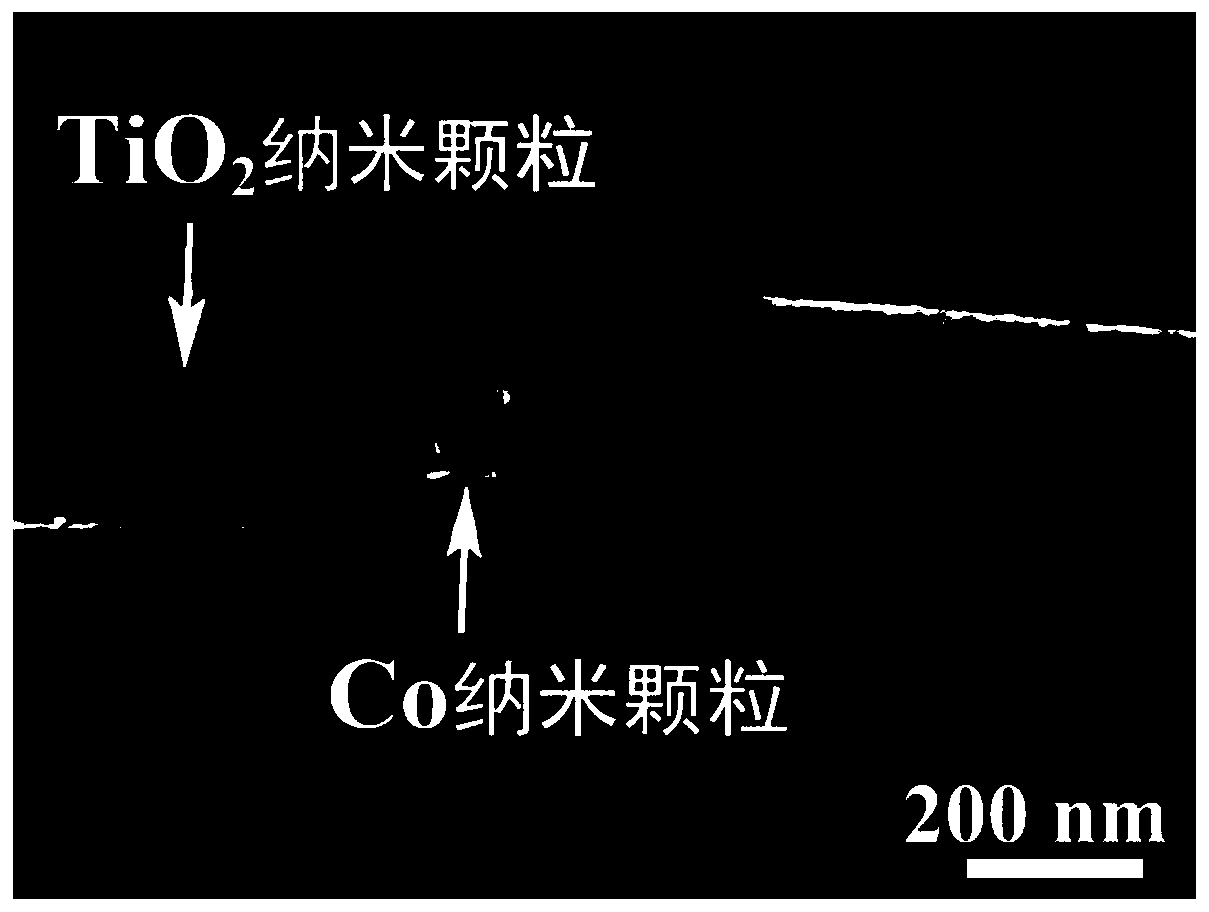

TiO2/Co-supported carbonaceous fiber electromagnetic wave absorbing material and preparation method and application thereof

ActiveCN110093686AImproving Impedance MatchingUnique microscopic morphologyArtifical filament manufactureFiberCarbon fibers

The invention belongs to the field of electromagnetic wave absorbing materials, and particularly relates to a TiO2 / Co-supported carbonaceous fiber electromagnetic wave absorbing material and a preparation method and application thereof. The electromagnetic wave absorbing material is of a three-dimensional network structure formed by interweaving one-dimensional fibers, the fibers are composed of acarbonaceous substrate and TiO2 and Co nanoparticles, wherein the TiO2 and Co nanoparticles are distributed in the carbonaceous substrate and the surface of the carbonaceous substrate. The method comprises the steps that (1) a cobalt source, an oxygen-containing organic titanium source and anhydrous acetic acid are prepared into an electrospinning viscous solution, wherein the electrospinning viscous solution comprises a carbon source, then spinning is performed on the viscous solution by adopting a high-pressure electrostatic spinning method to obtain nanofibers, and then the nanofibers aredried and pre-oxidized; (2) the pre-oxidized calcined nanofibers are placed in a protective atmosphere to convert cobalt ions in the cobalt source into elemental cobalt and convert the oxygen-containing organic titanium source into TiO2, and the TiO2 / Co-supported carbonaceous fiber electromagnetic wave absorbing material is obtained. The TiO2 / Co-supported carbonaceous fiber electromagnetic wave absorbing material and the preparation method and application thereof have the advantages that nanoscale composition is effectively performed on the TiO2, Co and carbon fibers, and the prepared materialhas excellent properties.

Owner:SHANDONG UNIV

Microwave ceramic SrO-ZnO(MgO)-TiO2 and preparation method thereof

The invention provides a microwave ceramic SrO-ZnO(MgO)-TiO2 and a preparation method thereof. The chemical formula of the microwave ceramic SrO-ZnO(MgO)-TiO2 is (1-z)[SrO-xZnO-yMgO]-zTiO2, wherein x is more than 0 and less than 1, x+y is equal to 1.0, and z is equal to 0.1-0.2 in molar ratio content; and SrO, ZnO, MgO and TiO2 are used as raw materials, and an auxiliary agent accounting for 2.5-5% of the mass of the raw materials is added according to a molar ratio of SrO:ZnO:MgO:TiO2 of (1-z):x(1-z):y(1-z):z to prepare the microwave ceramic. The ceramic provided by the invention is relatively low in sintering temperature, moderate in dielectric constant, relatively high in quality factor, and small and continuously adjustable in temperature coefficient of resonance frequency, and can be applied to microwave dielectric resonators and filters.

Owner:SHANDONG UNIV OF SCI & TECH

Leadless pyroelectric ceramic material and preparation method thereof

InactiveCN104098332AModerate dielectric constantExcellent intrinsic pyroelectric performanceSolid phasesElectricity

The invention discloses a leadless pyroelectric ceramic material and a preparation method thereof. The leadless pyroelectric ceramic material has the following general formula: Cax(Sr0.5Ba0.5)1-xNb2O6, wherein x is equal to 0-0.20. The provided leadless pyroelectric ceramic material can be prepared by employing a conventional solid-phase powder preparation method and an air sintering technology. The prepared leadless pyroelectric ceramic material has the advantages of small crystal grain size, moderate dielectric constant and typical ferroelectric phase at room temperature, also has excellent intrinsic pyroelectric performance, and the pyroelectric coefficient of the leadless pyroelectric ceramic material at room temperature is capable of rivaling that of PZT serial lead-containing pyroelectric ceramic. Additionally, the preparation method has the advantages of simple technology, no special equipment, low cost and the like, is suitable for large-scale production and accords with industrialized production requirements.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

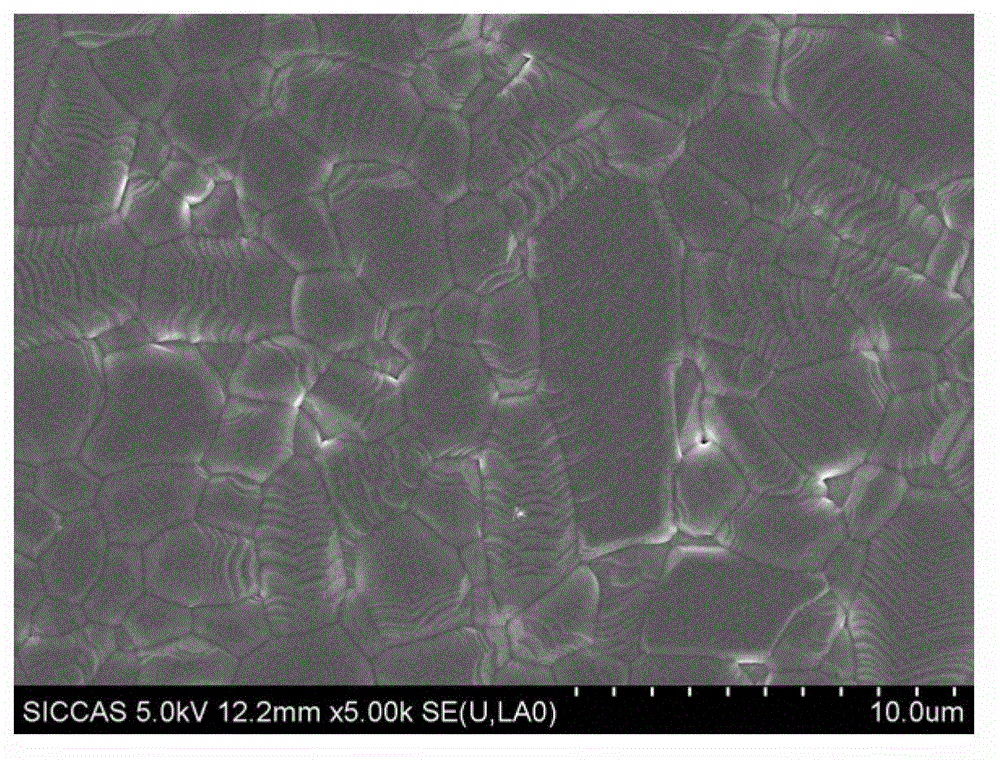

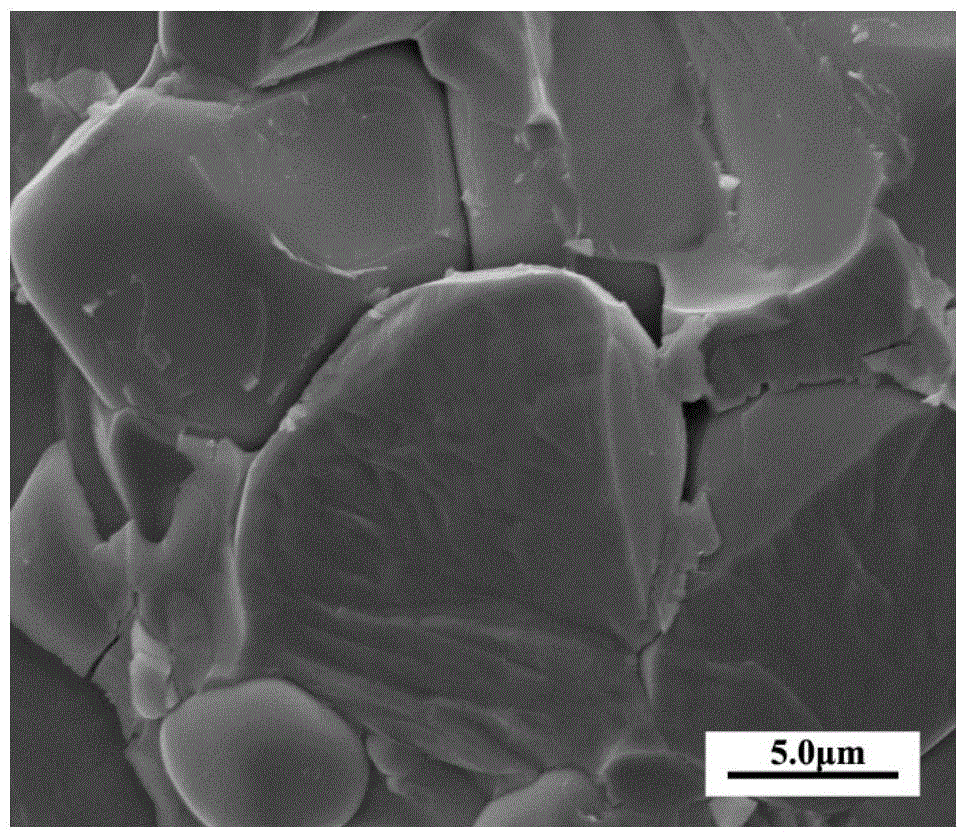

Composite pyroelectric ceramic material and preparation method thereof

InactiveCN104557038AHigh pyroelectric coefficientModerate dielectric constantMetallurgyPyroelectric detectors

The invention discloses a composite pyroelectric ceramic material and a preparation method thereof. The chemical general formula of the material is Pb {[(Me1 / 3Nb2 / 3)x(W1 / 3Fe2 / 3)1-x]y(Zr0.9Ti0.1) (1-y) }O3-nMe', wherein Me is Mg or Zn; x and y represent a mole fraction respectively, x is larger than or equal to 0.125 and smaller than or equal to 0.875, and y is larger than or equal to 0.08 and smaller than or equal to 0.11; Me' is a modified element and is one or more of Li, La and Sb, and the molar ratio range n is larger than or equal to 0 mol% and smaller than or equal to 5 mol%. The composite pyroelectric ceramic material has a higher pyroelectric coefficient and adjustable dielectric property, thereby having a better application prospect in various pyroelectric detectors.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

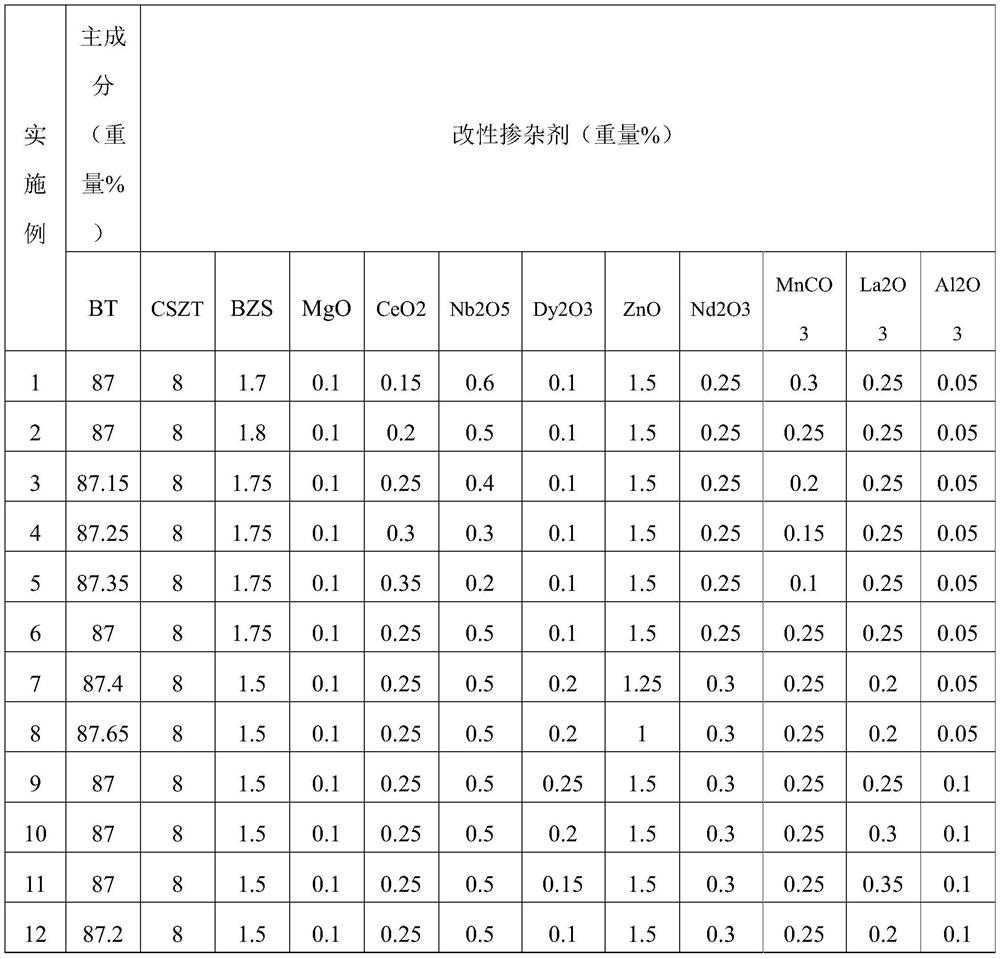

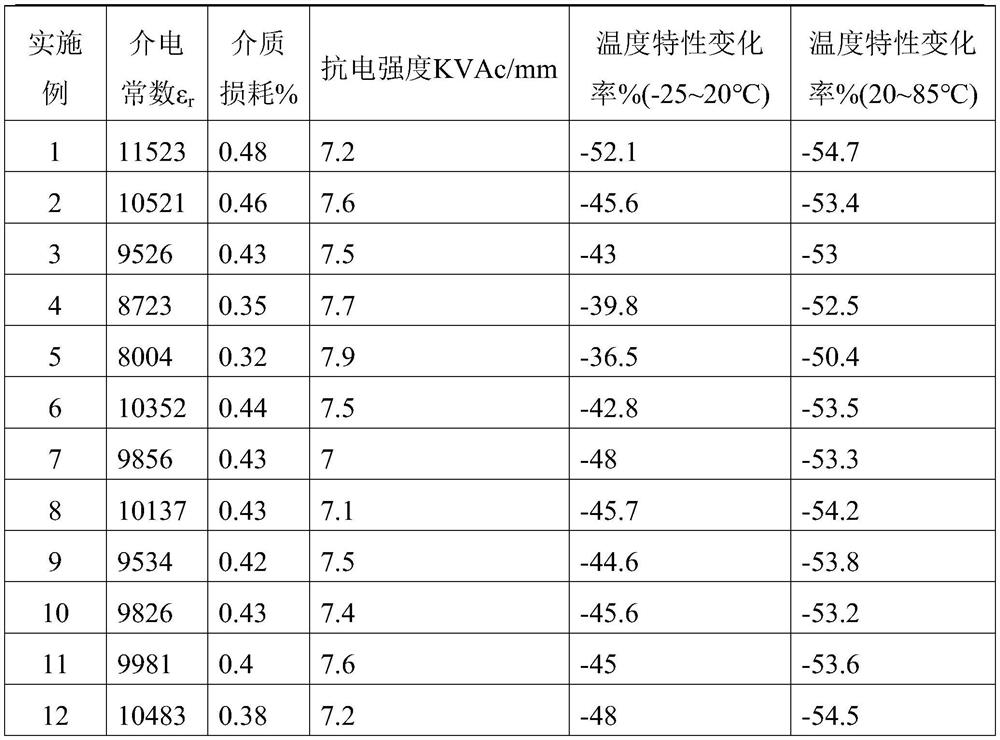

High-quality ceramic dielectric material and preparation method thereof

InactiveCN112408977AGood reproducibilityMeet environmental protection requirementsFixed capacitor dielectricDopantDielectric loss

The invention relates to a high-quality ceramic dielectric material and a preparation method thereof, the high-quality ceramic dielectric material is composed of a main component and a modified dopingagent and the main component is BaTiO3; wherein the modified doping agent comprises Ca<x>Sr<1-x>(Zr<y>Ti<1-y>) O<3>, x is equal to 0.2 to 0.8, y is equal to 0.1 to 0.8, Bi<2> (ZrSn<1-p>) O<7> andp is equal to 0.2 to 0.8, and the modified doping agent further comprises three or more of the following components: MgO, CeO2, ZnO, Al2O3, Nb2O5, La2O3, Nd2O3, Dy2O3 or MnCO3. The firing temperatureof the high-quality ceramic dielectric material is 1250-1320 DEG C, the dielectric constant is adjustable in a range of 7000-11000, the dielectric loss is less than or equal to 0.5%, the dielectric strength is greater than or equal to 7KVAc / mm, the temperature characteristic change rate is less than +20-55% (-25 to 85 DEG C), and the high-quality ceramic dielectric material is suitable for manufacturing Y5U characteristic ceramic dielectric capacitors.

Owner:厦门三行电子有限公司

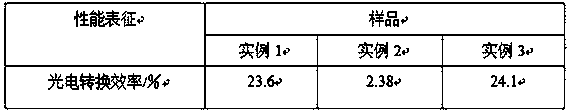

Preparation method of CIGS solar cell film buffer layer material

InactiveCN109285919AHigh quality factorLow dielectric lossFinal product manufacturePhotovoltaic energy generationElectronic band structureFilm material

The invention relates to a preparation method of a CIGS solar cell film buffer layer material, and belongs to the technical field of cell materials. The technical scheme of the invention adopts a sol-gel method, and a buffer layer is introduced on the surface of a CIGS film. Meanwhile, a role of resistance is played through reducing the interface state, so that internal short circuit of the cell is prevented, and the dielectric performance and photoelectric conversion efficiency of the film material are effectively improved. In addition, the CIGS solar cell film buffer layer material adopts the buffer layer and is coated by a precursor gel structure and dried, so that the bonding strength of the material on the surface is effectively improved. Through the mutual matching of an energy bandstructure between the buffer layer material and an absorption layer, a film with moderate thickness is formed on the basis. The damage imposed on the absorption layer by the preparation of a subsequent window layer material is reduced through improving the number of photons of the absorption layer, so that the surface conductivity and photoconductivity of the buffer layer material are effectivelyimproved, and photon-generated carriers are enabled to be outputted to an external circuit in time.

Owner:王敏

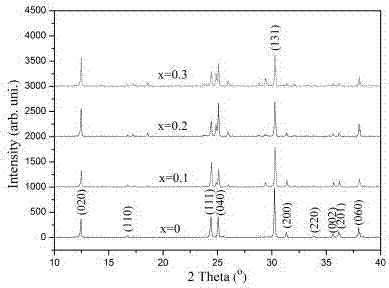

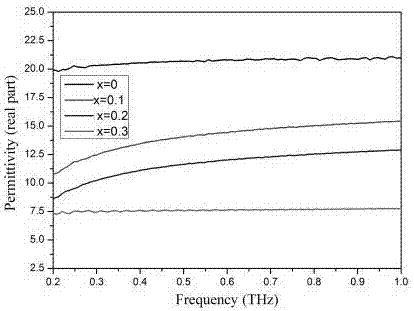

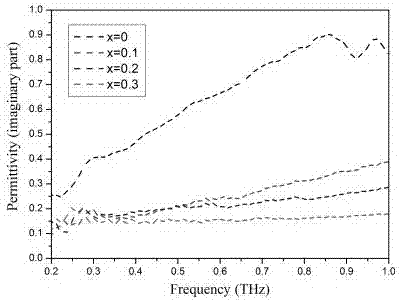

Terahertz waveband medium material, preparation method and method of preparing dielectric medium therefrom

InactiveCN107879738AControl the sintering temperatureRegulate sintered densityDielectric lossNanotechnology

The invention discloses a terahertz waveband medium material, a preparation method and a method of preparing a dielectric medium therefrom. The chemical formula of the medium material is [(Mg<1 x>Al<2 / 3x>)<1 / 3>Nb<2 / 3>]O<2> + y wt% ABSMV, 0<=x<=0.3, and y=1 or 2. The medium material has the advantages of low sintering temperature, low dielectric loss, and moderate dielectric constant.

Owner:LIUPANSHUI NORMAL UNIV

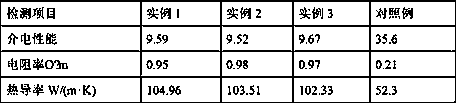

Microwave attenuation ceramic and preparation method thereof

InactiveCN108516837AHigh thermal conductivityHigh resistivityWaveguide type devicesHigh resistivityBoron nitride

The invention relates to microwave attenuation ceramic and a preparation method thereof and belongs to the technical field of wave absorption materials. By ball-milling aluminum nitride powder and dispersing the powder into interlayers of nano-lamella boron nitride to form contact points, a framework material, which has high heat conductivity, moderated dielectric constant, excellent chemical andthermal stabilities and very high resistivity, can be formed; meanwhile, because molybdenum has excellent heat and electric conductivities and is approximate to aluminum nitride in expansion coefficient, dielectric loss of the material can be increased by uniformly distributing electric conductive granules such as molybdenum in the ceramic material, so that the material has excellent thermal performances, such as high heat conductivity, low elasticity modulus and low heat-expansion coefficient, thereby preparing the novel microwave attenuation material having excellent comprehensive performances. The ceramic is sintered compactly and hardly has pores. When being acted with microwave, the material having irregular crystalline grain appearance can increase absorption and scattering area andimprove the microwave attenuation performance.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Method for stabilizing Zn2TiO4 spinel microwave dielectric ceramics and improving quality factor of Zn2TiO4 spinel microwave dielectric ceramics

InactiveCN104341147ALower sintering temperatureImprove Microwave PerformanceCompression moldingChemical composition

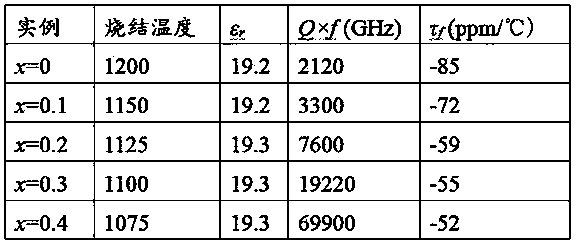

The invention discloses a method for stabilizing Zn2TiO4 spinel microwave dielectric ceramics and improving a quality factor of the Zn2TiO4 spinel microwave dielectric ceramics. The chemical composition formula of a microwave dielectric ceramic material is (1-x)Zn2TiO4-xLi4 / 3Ti5 / 3O4, wherein x is not smaller than 0.1 and not greater than 0.4. The method comprises the following steps of firstly, weighing and dispensing Li2CO3, ZnO and TiO2 raw materials with the purity of over 99 percent according to the composition of the (1-x)Zn2TiO4-xLi4 / 3Ti5 / 3O4; secondly, performing wet ball milling and mixing on the raw materials in the first step for 4 hours, and preburning in the atmosphere of 900DEG C for 8 hours after drying, wherein a ball milling medium is ethanol; thirdly, adding a binding agent in powder obtained in the second step and granulating, performing compression molding, and finally, sintering the mixture in the atmosphere of 1,078-1,200DEG C for 4 hours, wherein the binding agent is polyvinyl alcohol solution with the mass concentration of 5 percent, and the dose accounts for 7 percent of the total mass of the powder. According to the method disclosed by the invention, a Zn2TiO4 spinel structure can be remarkably stabilized; the quality factor Q*f value of the Zn2TiO4 spinel structure can be improved from 2120 to 69900GHz.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-performance ceramic dielectric material and preparation method thereof

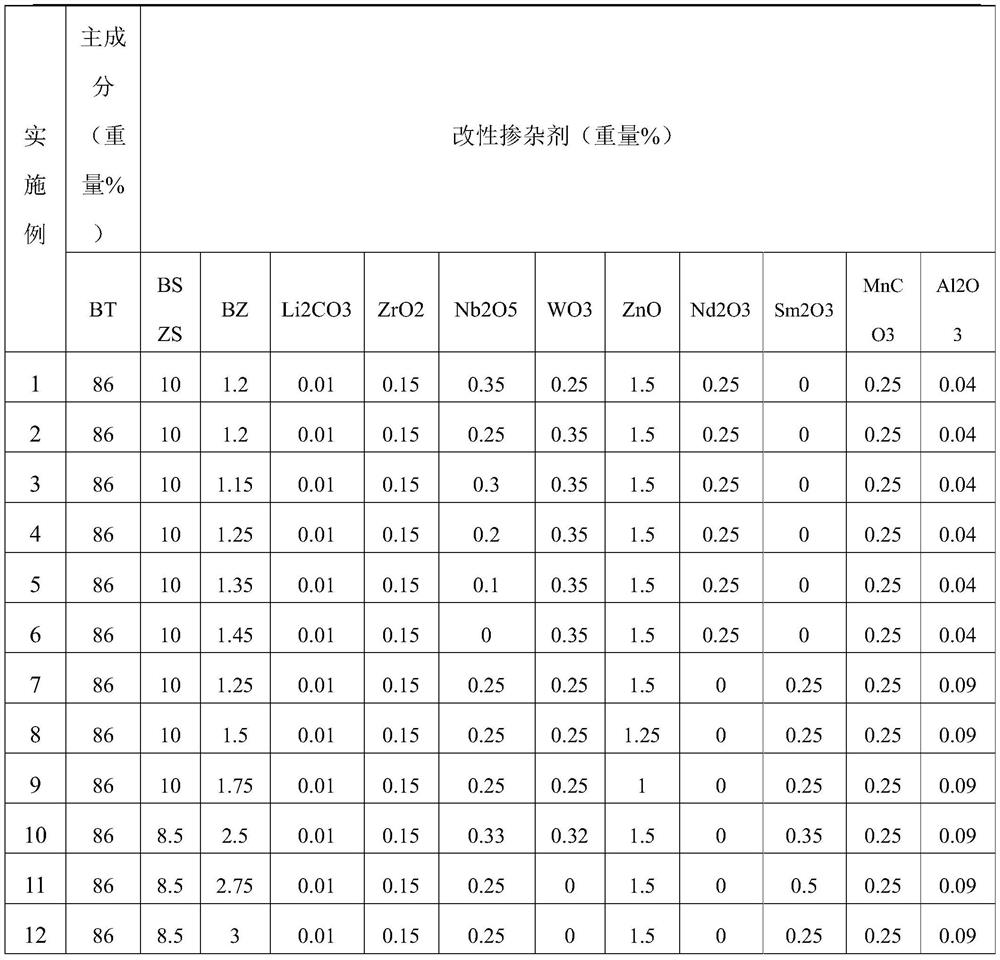

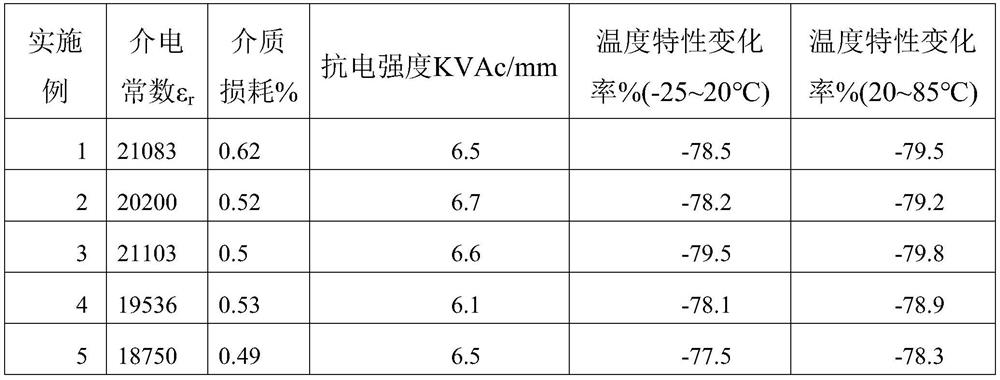

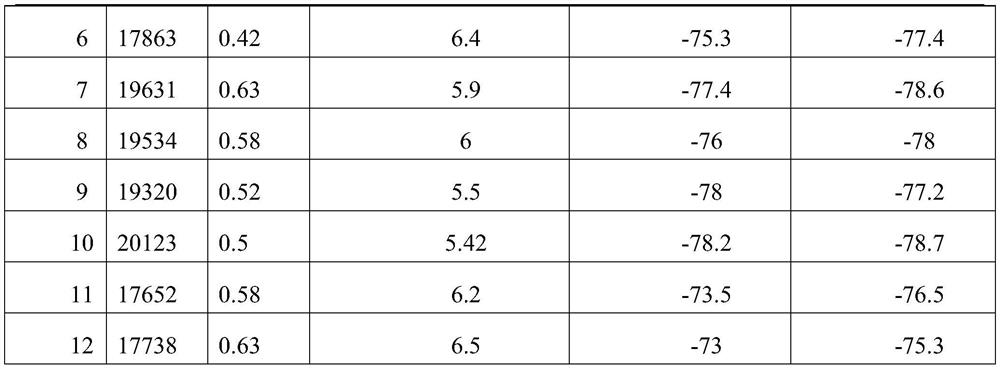

ActiveCN112299845AGood reproducibilityMeet environmental protection requirementsDopantDielectric loss

The invention relates to a high-performance ceramic dielectric material and a preparation method thereof, the high-performance ceramic dielectric material is composed of a main component and a modified doping agent, and the main component is BaTiO3; the modified doping agent comprises BaxSr1-x (ZrySn1-y) O3, x is equal to 0.2 to 0.9, y is equal to 0.1 to 0.8, and Bi2Zr2O7, and further comprises three or more of the following components: ZnO, Al2O3, WO3, Nb2O5, ZrO2, Li2CO3, Nd2O3, Sm2O3 or MnCO3. The sintering temperature of the high-performance ceramic dielectric material is 1250-1320 DEG C,the dielectric constant is adjustable within 15000-21000, the dielectric loss is less than or equal to 0.75%, the dielectric strength is greater than or equal to 5KVAc / mm, the temperature characteristic change rate is less than + 20-80% (-25-85 DEG C), and the material is suitable for manufacturing Y5V characteristic ceramic dielectric capacitors.

Owner:厦门三行电子有限公司

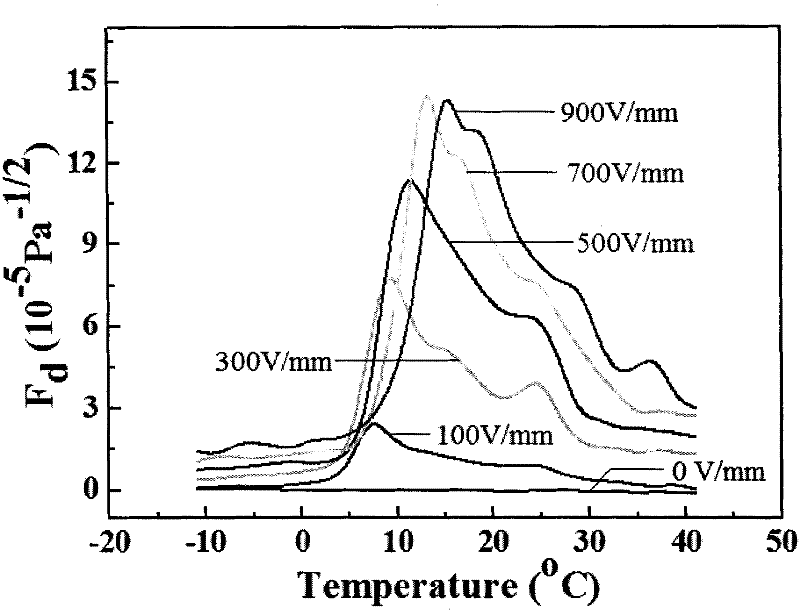

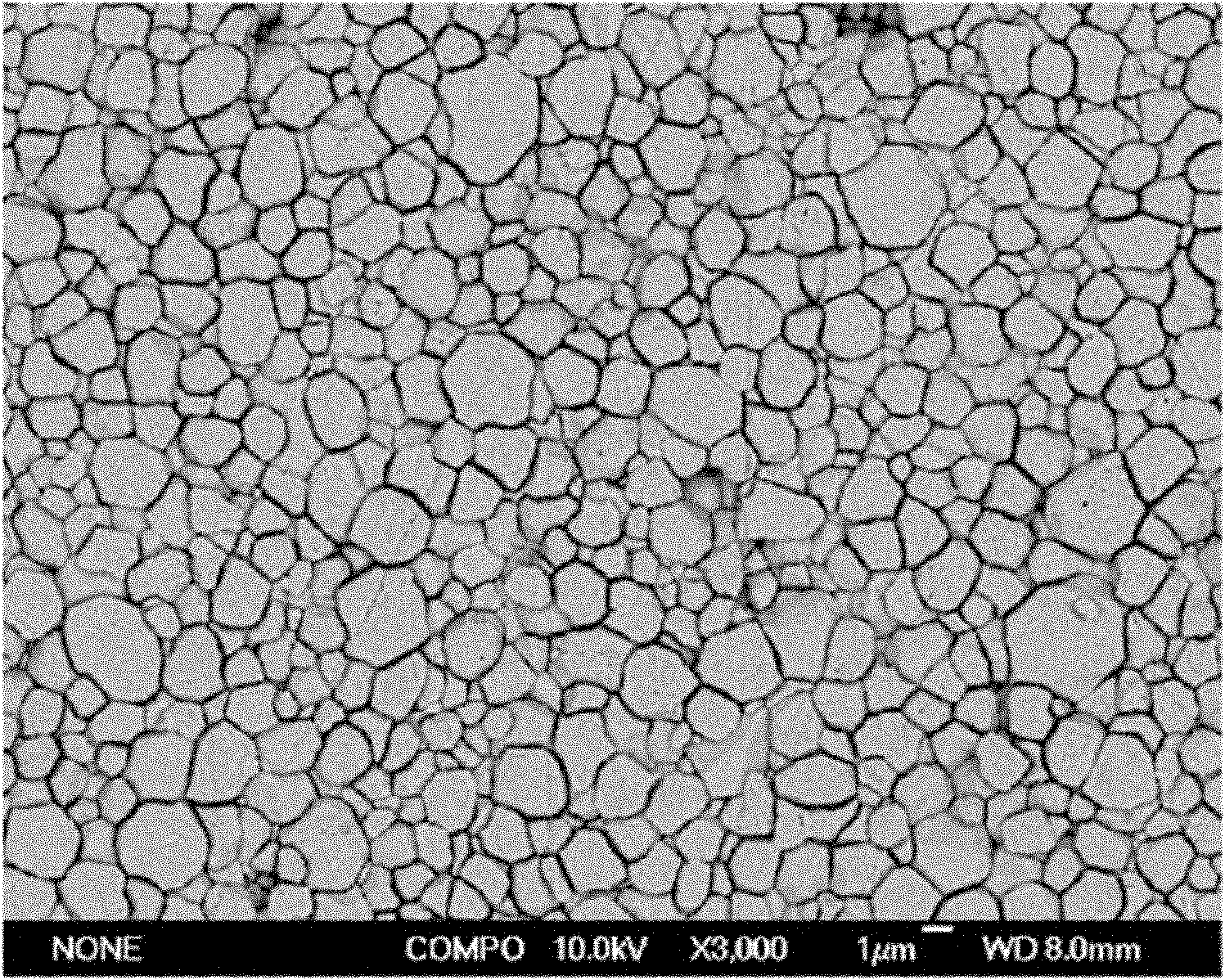

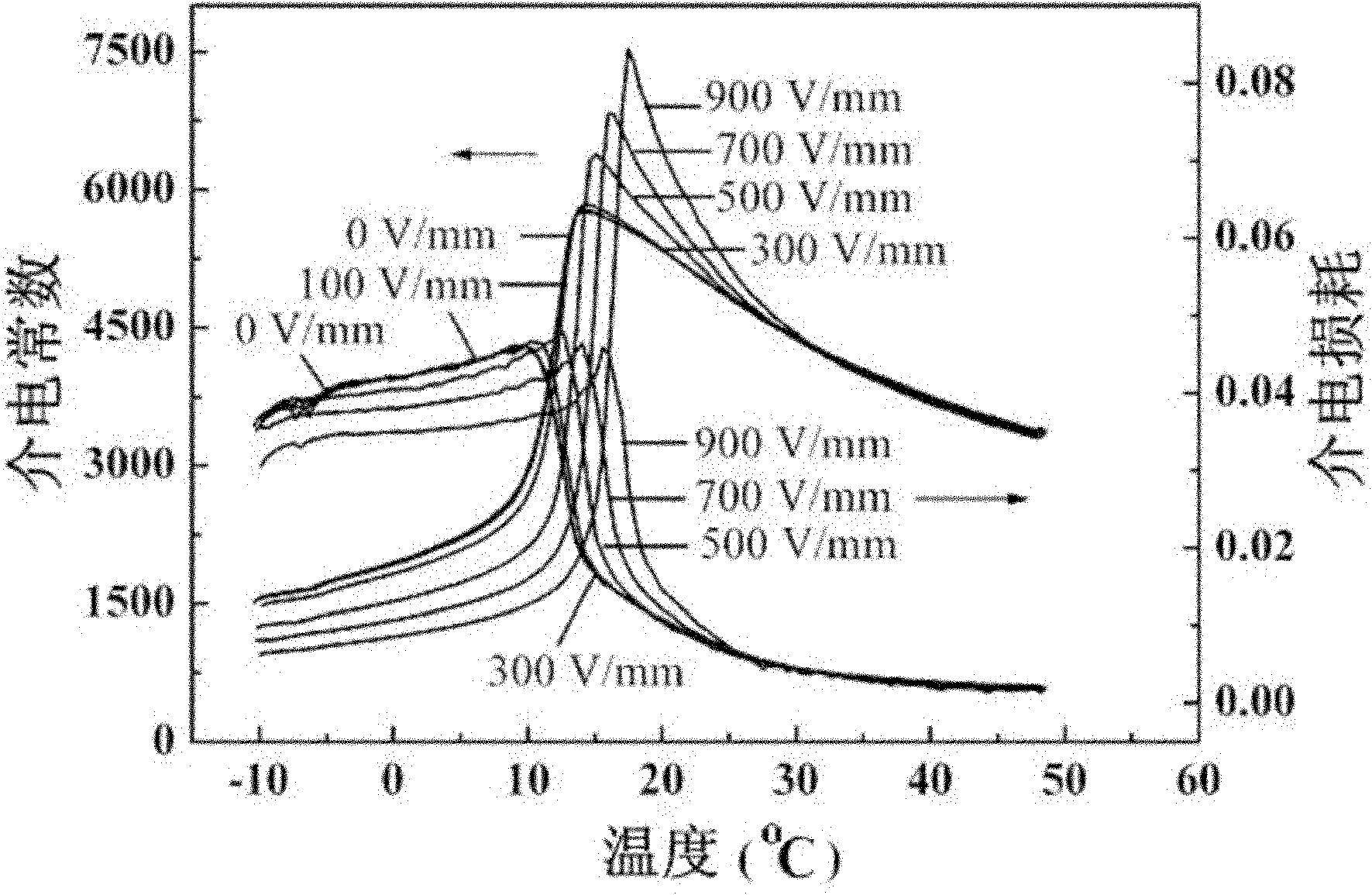

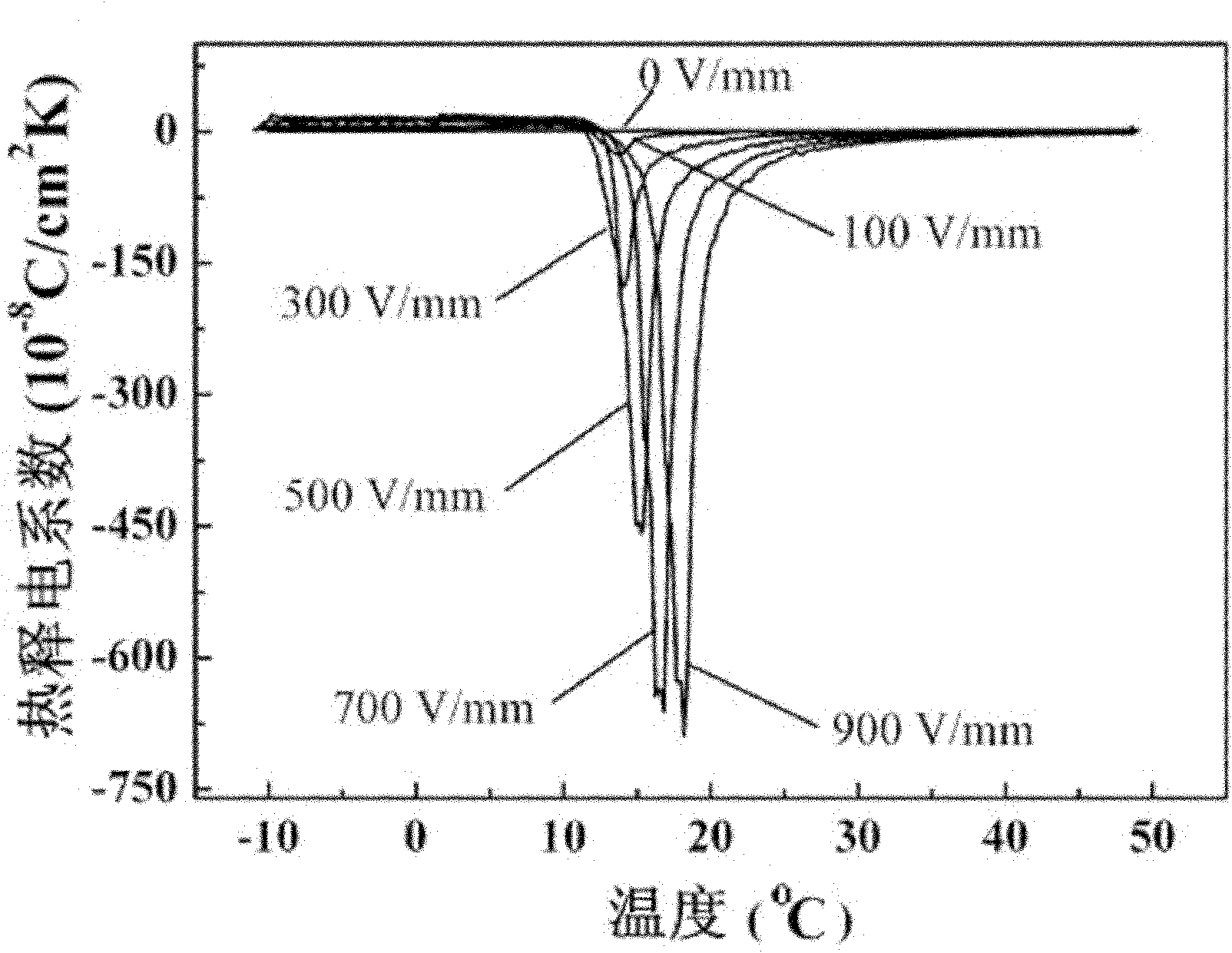

Method for preparing fine-grain lead scandium tantalate pyroelectric ceramic material

The invention discloses a method for preparing a fine-grain lead scandium tantalate pyroelectric ceramic material by a liquid-phase method for preparing powder and a two-step sintering process. The method comprises the following steps of: preparing Pb(Sc0.5Ta0.5)O3 powder by a liquid-phase method; ball-milling the powder and drying; adding an adhesive and then performing aging, sieving, forming and the like to prepare a blank; and finally sintering the blank by a two-step method. The method for preparing the material has the advantages of simple process, no need of special equipment, low costand the like, is suitable for mass production and can meet industrial requirements. The prepared lead scandium tantalate pyroelectric ceramic material has the advantages of high compactness, fine grains, moderate dielectric constant, high pyroelectric coefficient and the like; and a pyroelectric detectivity optimal value of a sample can reach 72.9*10<-5>Pa<-1 / 2> in an offset electric field of 700V / mm, so the performance requirement of applying the material to an uncooled infrared focal plane array detector can be met.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

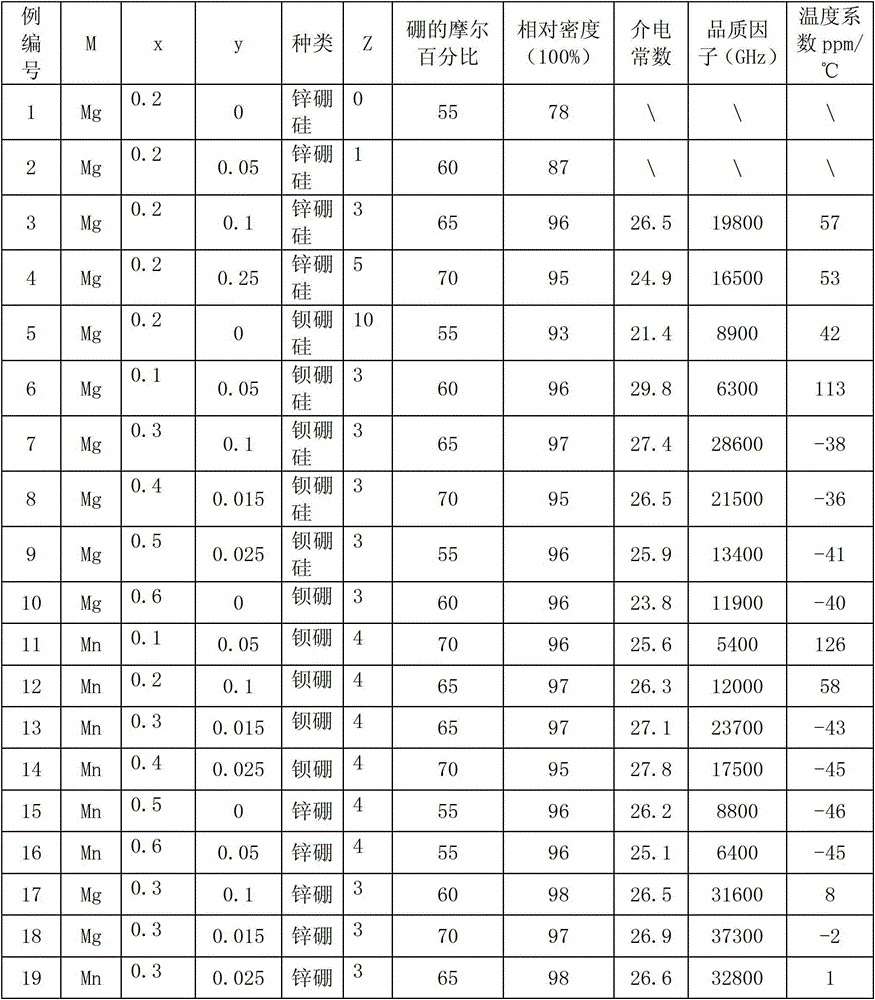

Microwave dielectric materials capable of burning with copper electrodes together, preparation method and application thereof

ActiveCN103146345AModerate dielectric constantHigh quality factorOther chemical processesDielectricCopper electrode

The invention discloses microwave dielectric materials capable of burning with copper electrodes together, a preparation method and application thereof. The microwave dielectric materials comprise: (1-z) wt% ((ZnxM (1-x) (Til-y / 2Mgy) O3)) + zwt% low-melting-point glass, wherein the M is magnesium or manganese; 0<x <=0.6, 0<y <=0.1, 0<z <=10. According to the microwave dielectric material, dielectric constant is moderate, a quality factor is high, temperature coefficient of resonance frequency is adjustable, burning with the copper electrodes can be achieved. Ceramic materials are insoluble in solvents such as water and ethanol and do not occur gelation reaction with binders such as poly vinyl alcohol (PVA) and polyvinyl butyral (PVB), and ceramic diaphragm with high density can be obtained, and firing density of ceramic can not be reduced, the direction of microwave communication frequency developing to higher frequency can be satisfied. The microwave dielectric materials capable of burning with the copper electrodes together is low in cost and suitable for multi-layer microwave medium components and industrialization production of base plates.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Microwave dielectric ceramic and preparation method thereof

InactiveCN113354409AExcellent microwave dielectric propertiesHigh quality factorChemical compositionPhysical chemistry

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is RO doped magnesium-calcium-titanium system ceramic, and the chemical composition expression of the microwave dielectric ceramic is aMgTiO3-bCaTiO3-RO. The magnesium-calcium-titanium system ceramic is a main material, the chemical expression of the magnesium-calcium-titanium system ceramic is aMgTiO3-bCaTiO3, a and b respectively represent molar ratios, a is more than or equal to 0.90 and less than or equal to 0.99, b is more than or equal to 0.01 and less than or equal to 0.1, and a + b is equal to 1; the RO is a sintering aid, and comprises at least one of MnO2, Fe2O3, ZnO, SiO2, Nb2O5, Cr2O3, La2O3, NiO, ZrO2 and Nd2O3. According to the microwave dielectric ceramic, the RO doped magnesium-calcium-titanium system ceramic serving as the sintering aid is used for forming the microwave dielectric ceramic, and the microwave dielectric ceramic has the advantages of excellent microwave dielectric property, high quality factor, moderate dielectric constant, better temperature stability, excellent mechanical property, wide application prospect, simple preparation process, convenience in operation and good repeatability.

Owner:臻金新材(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com