High-quality ceramic dielectric material and preparation method thereof

A ceramic dielectric, high-quality technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of ceramic dielectric materials, the steps are as follows:

[0034] A. According to the structural formula BaTiO 3 The stoichiometric ratio of weighed electronic grade BaCO 3 、TiO 2 As a raw material, put the weighed raw material into a ball mill tank, add an appropriate amount of deionized water and zirconia balls to grind for 12 hours, discharge the material, dry it, grind it, and then calcinate it at 1250°C for 3.5 hours to synthesize BaTiO 3 (abbreviated as BT) burning block;

[0035] B. According to the structural formula Ca 0.8 Sr 0.2 (Zr 0.5 Ti 0.5 )O 3 The stoichiometric ratio of weighed electronic grade CaCO 3 , SrCO 3 、ZrO 2 、TiO 2 As a raw material, put the weighed raw material into a ball mill tank, add an appropriate amount of deionized water and zirconia balls to grind for 12 hours, and then calcine at 1250°C for 2.5 hours to synthesize Ca 0.8 Sr 0.2 (Zr 0.5 Ti 0.5 )O 3 (referred to as CSZT) burning block;

[0036] C. According...

Embodiment 2-12

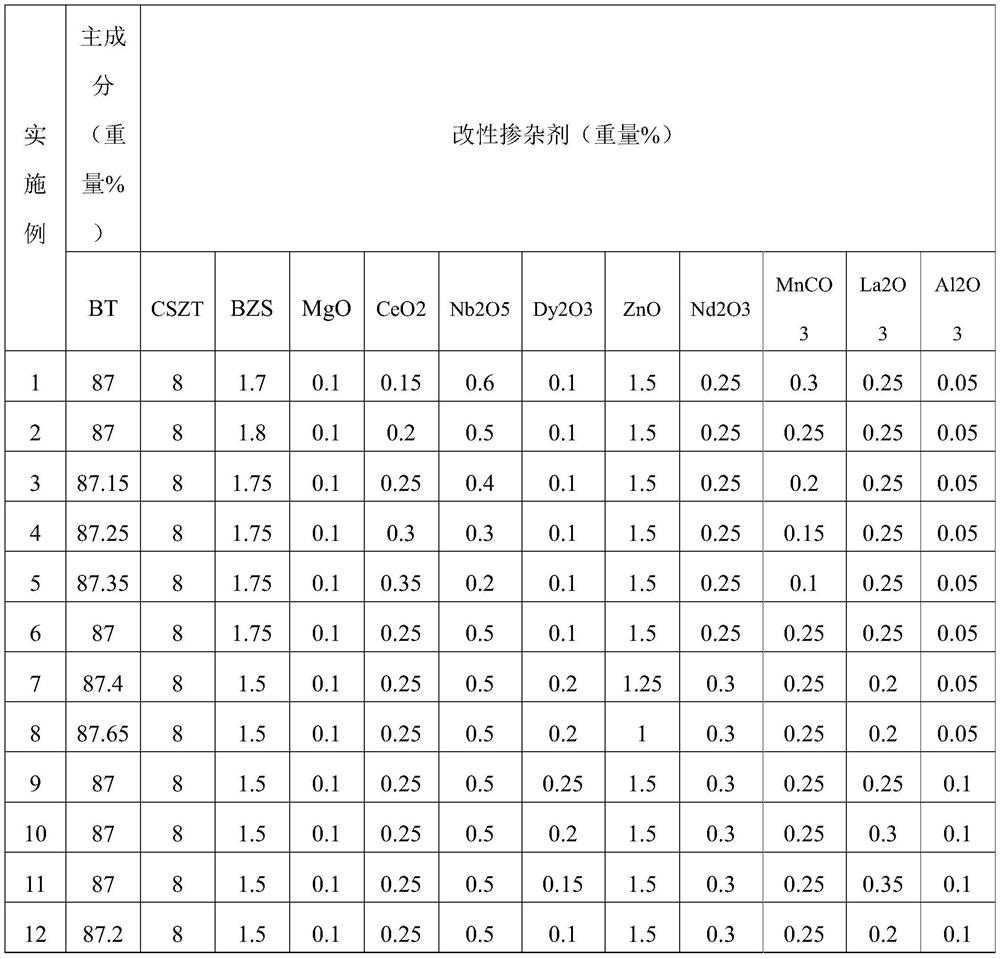

[0039] The materials were prepared with reference to the methods in the examples, the amounts of each substance are shown in Table 1, and the test results are shown in Table 2.

[0040] Table 1: Ceramic capacitor dielectric material composition table

[0041]

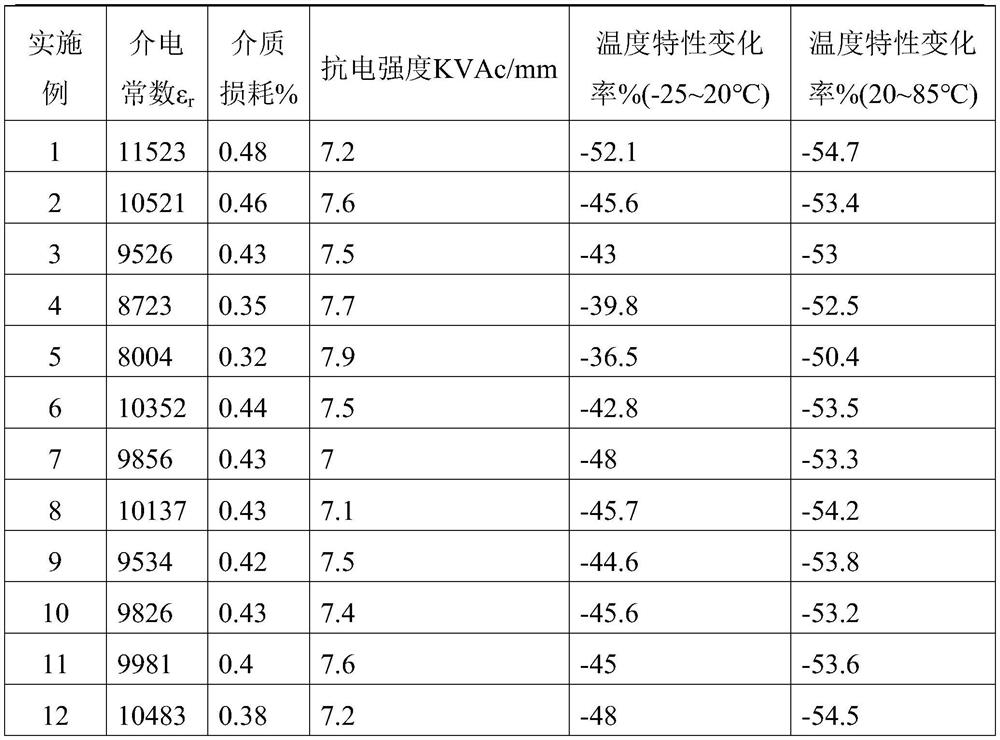

[0042] Table 2: Ceramic capacitor dielectric material performance table

[0043]

[0044] It can be seen from Table 2 that the dielectric constant of the high-quality ceramic dielectric material is adjustable from 7000 to 11000, the dielectric loss is ≦0.5%, and the dielectric strength is ≧7KV Ac / mm, the change rate of temperature characteristics conforms to the Y5U standard, and is suitable for making Y5U characteristic ceramic capacitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com