Patents

Literature

941 results about "Dielectric strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

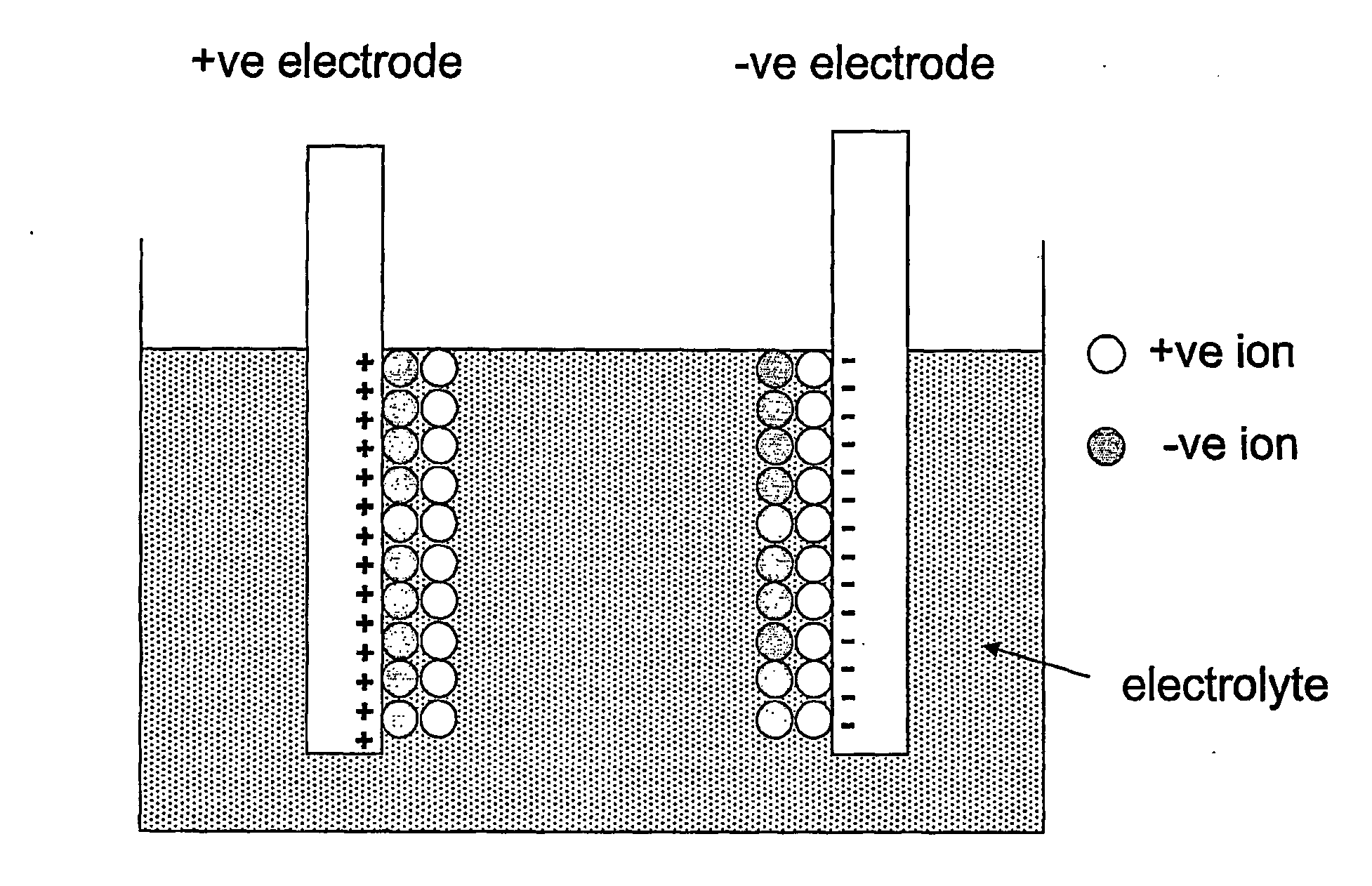

In physics, the term dielectric strength has the following meanings: Of an insulating material, the maximum electric field that a pure material can withstand under ideal conditions without breaking down. For a specific configuration of dielectric material and electrodes, the minimum applied electric field that results in breakdown. The theoretical dielectric strength of a material is an intrinsic property of the bulk material and is dependent on the configuration of the material or the electrodes with which the field is applied. The "intrinsic dielectric strength" is measured using pure materials under ideal laboratory conditions. At breakdown, the electric field frees bound electrons. If the applied electric field is sufficiently high, free electrons from background radiation may become accelerated to velocities that can liberate additional electrons during collisions with neutral atoms or molecules in a process called avalanche breakdown. Breakdown occurs quite abruptly, resulting in the formation of an electrically conductive path and a disruptive discharge through the material.

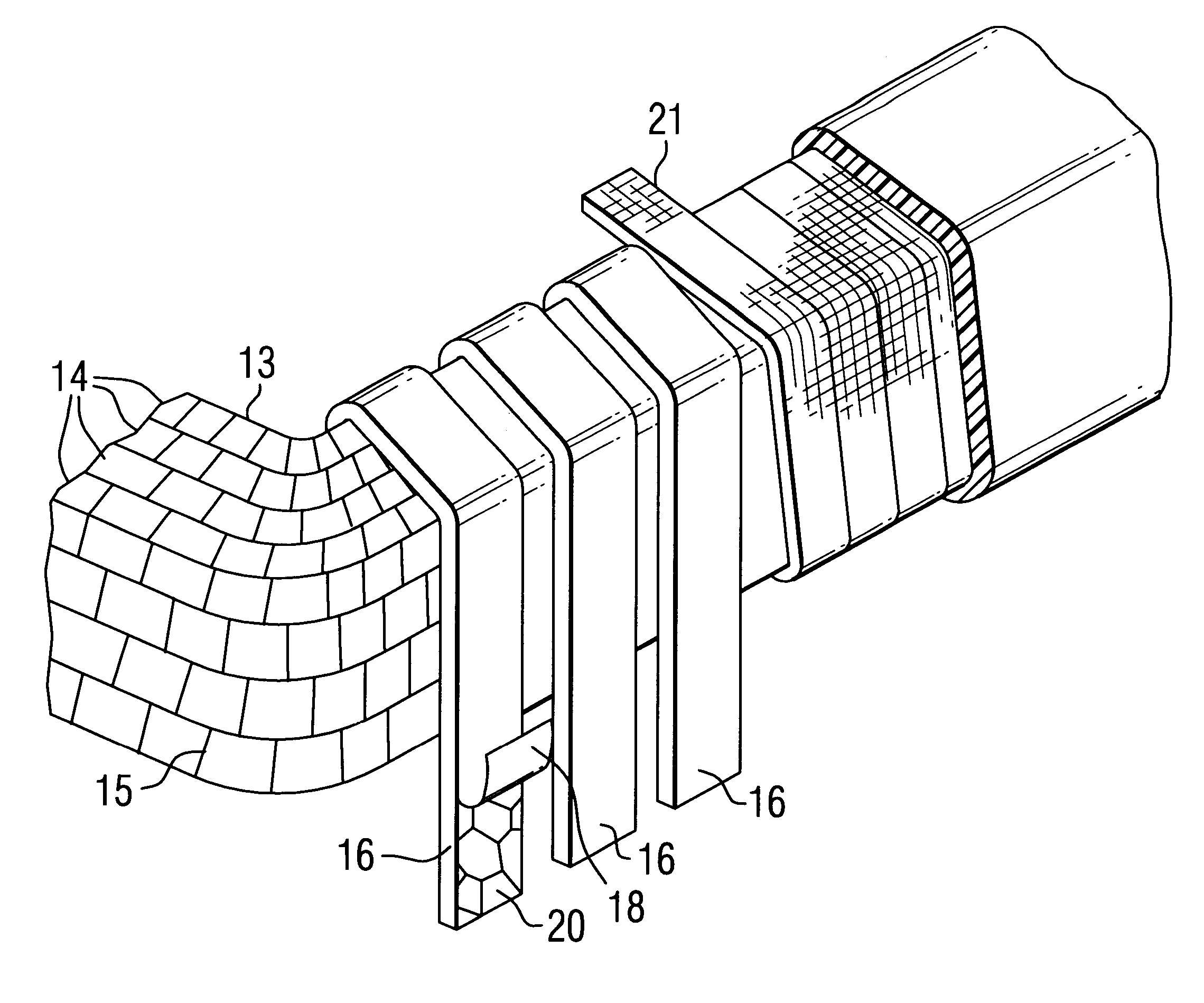

Enhanced dielectric strength mica tapes

InactiveUS6190775B1Low costHigh voltageWindings insulation materialSynthetic resin layered productsDielectric strengthMetal

Owner:SIEMENS ENERGY INC

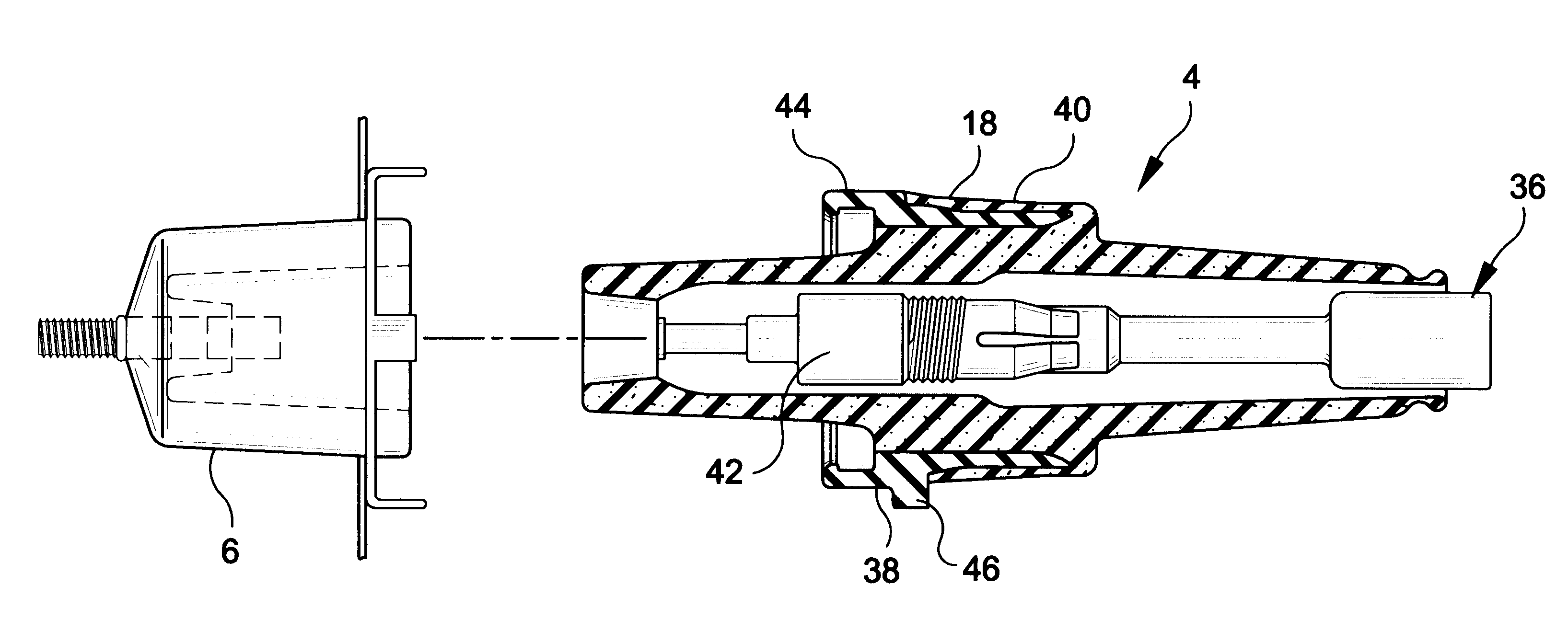

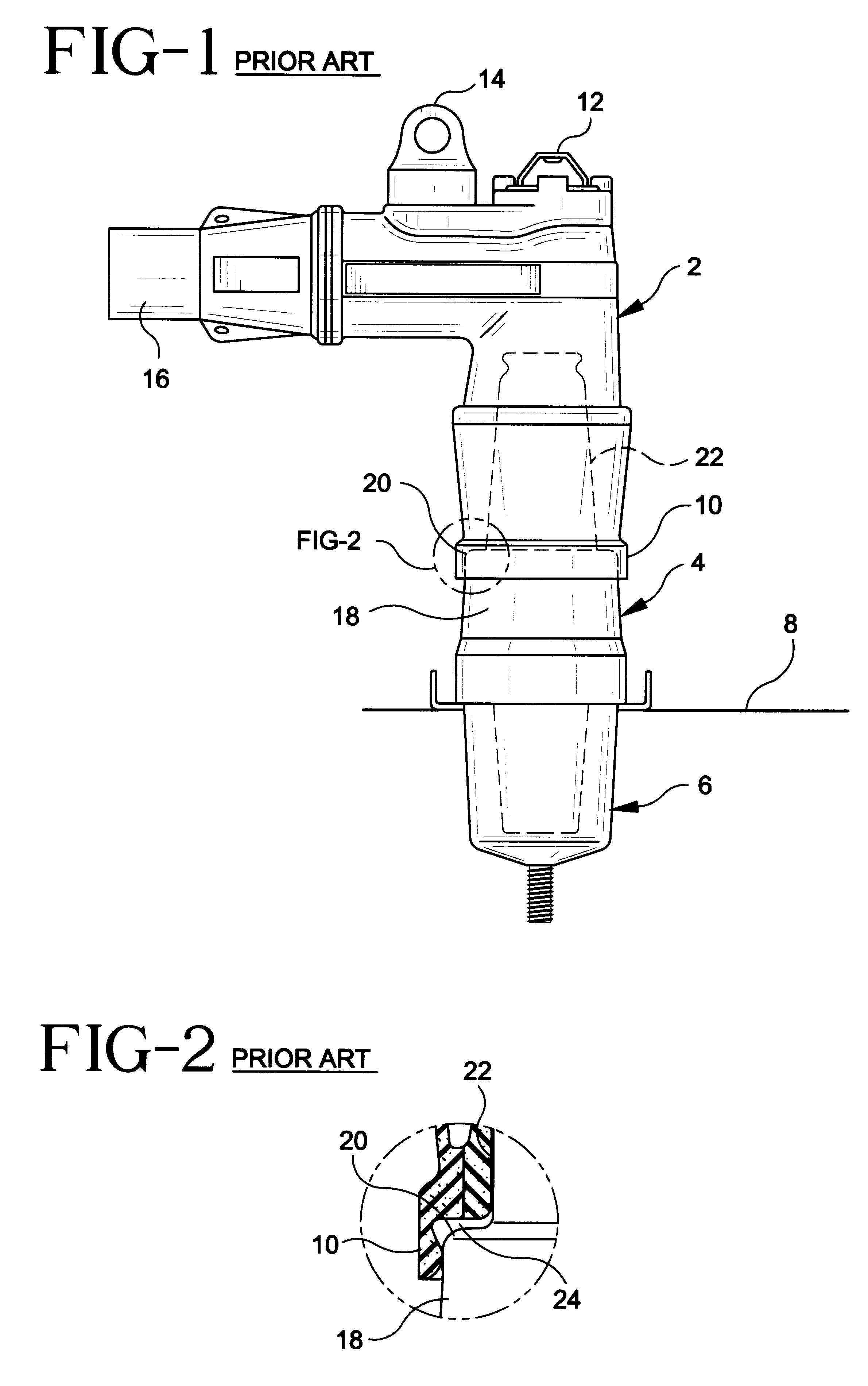

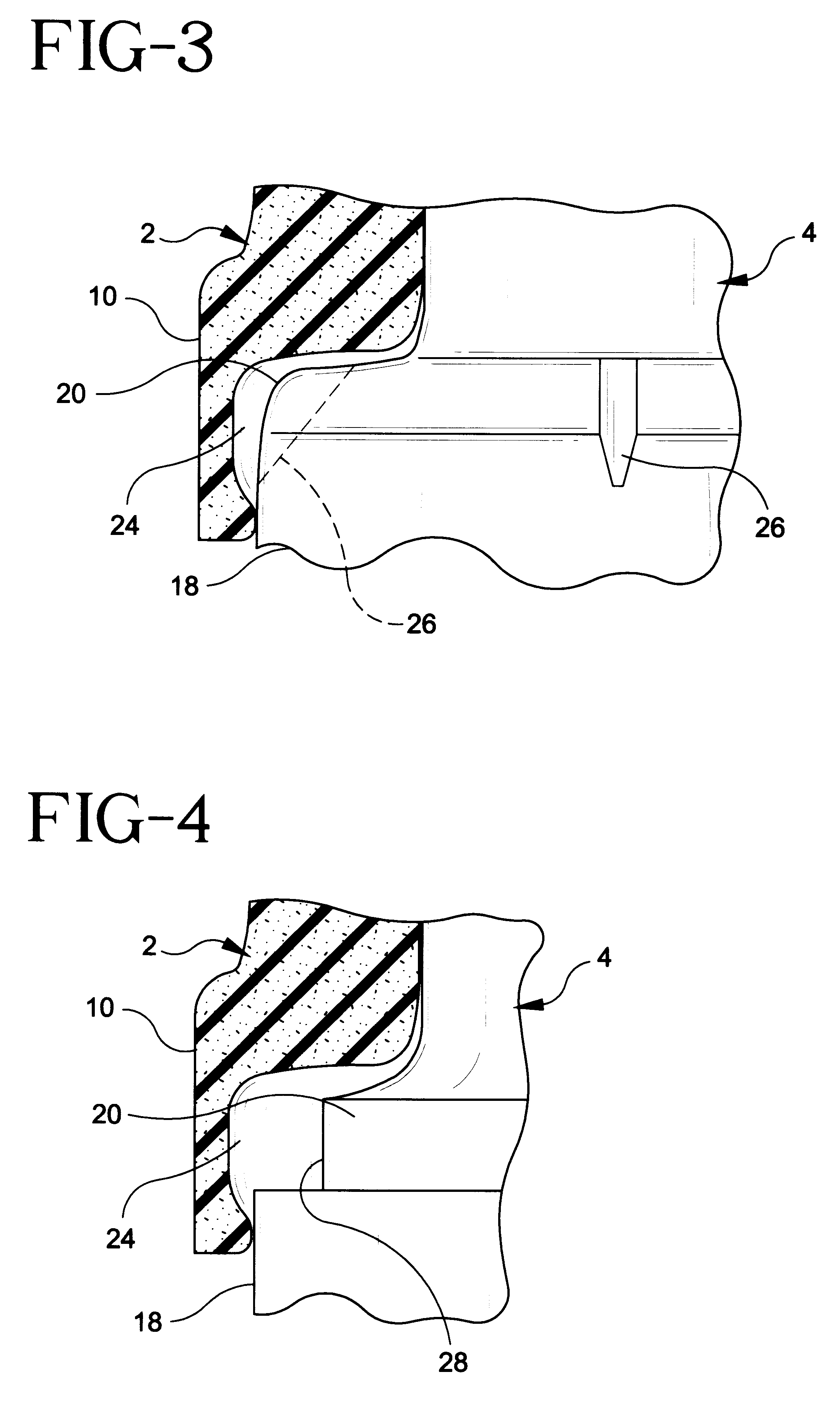

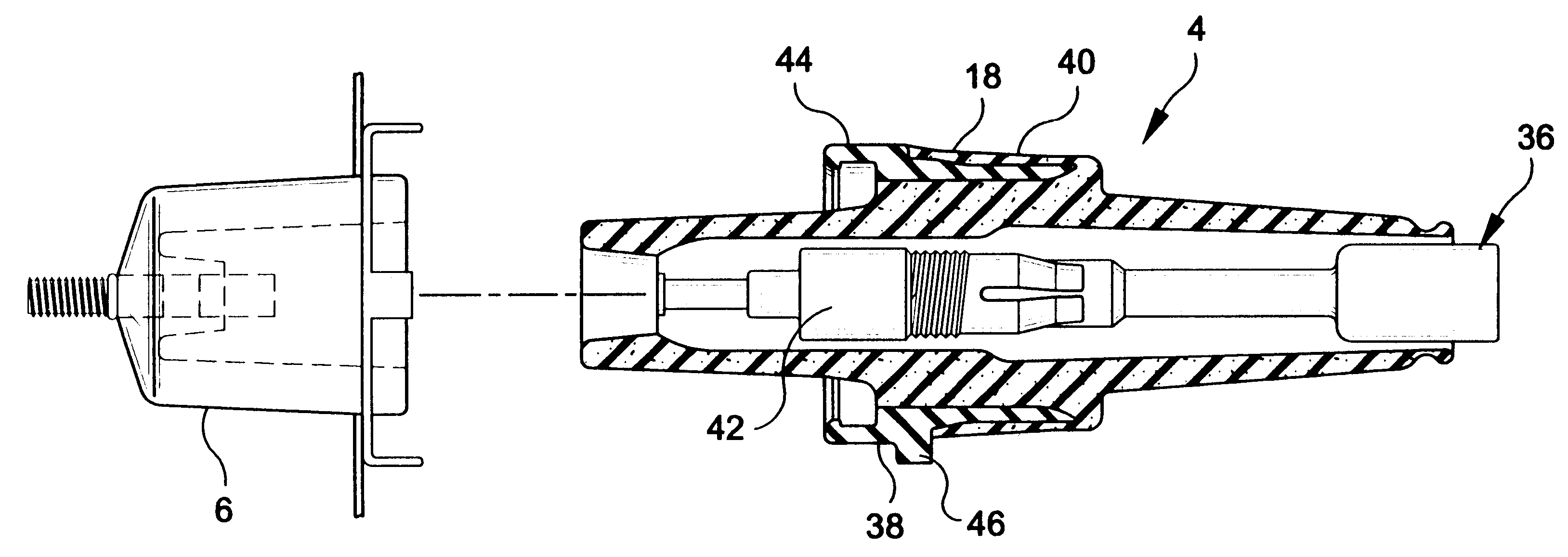

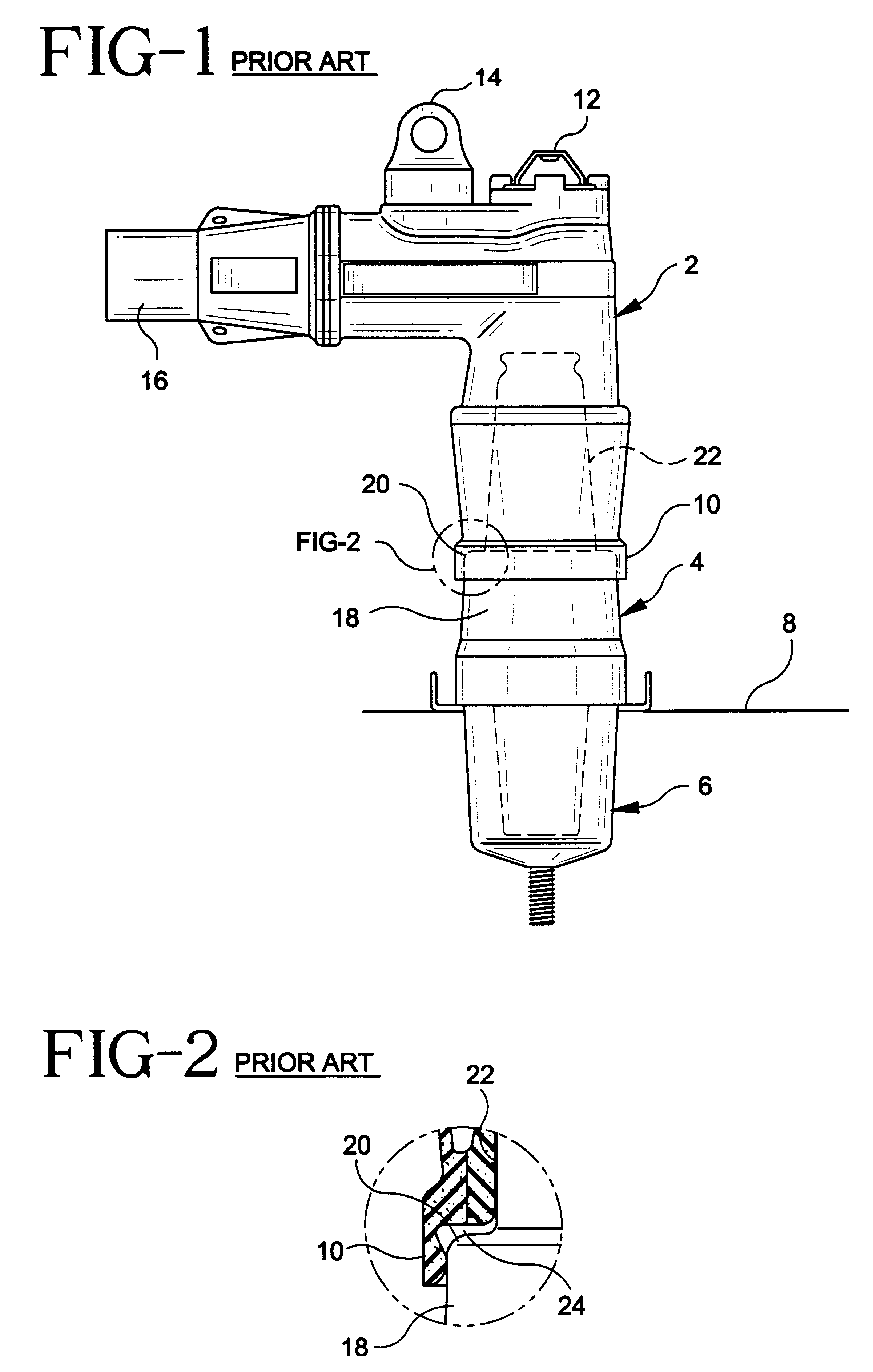

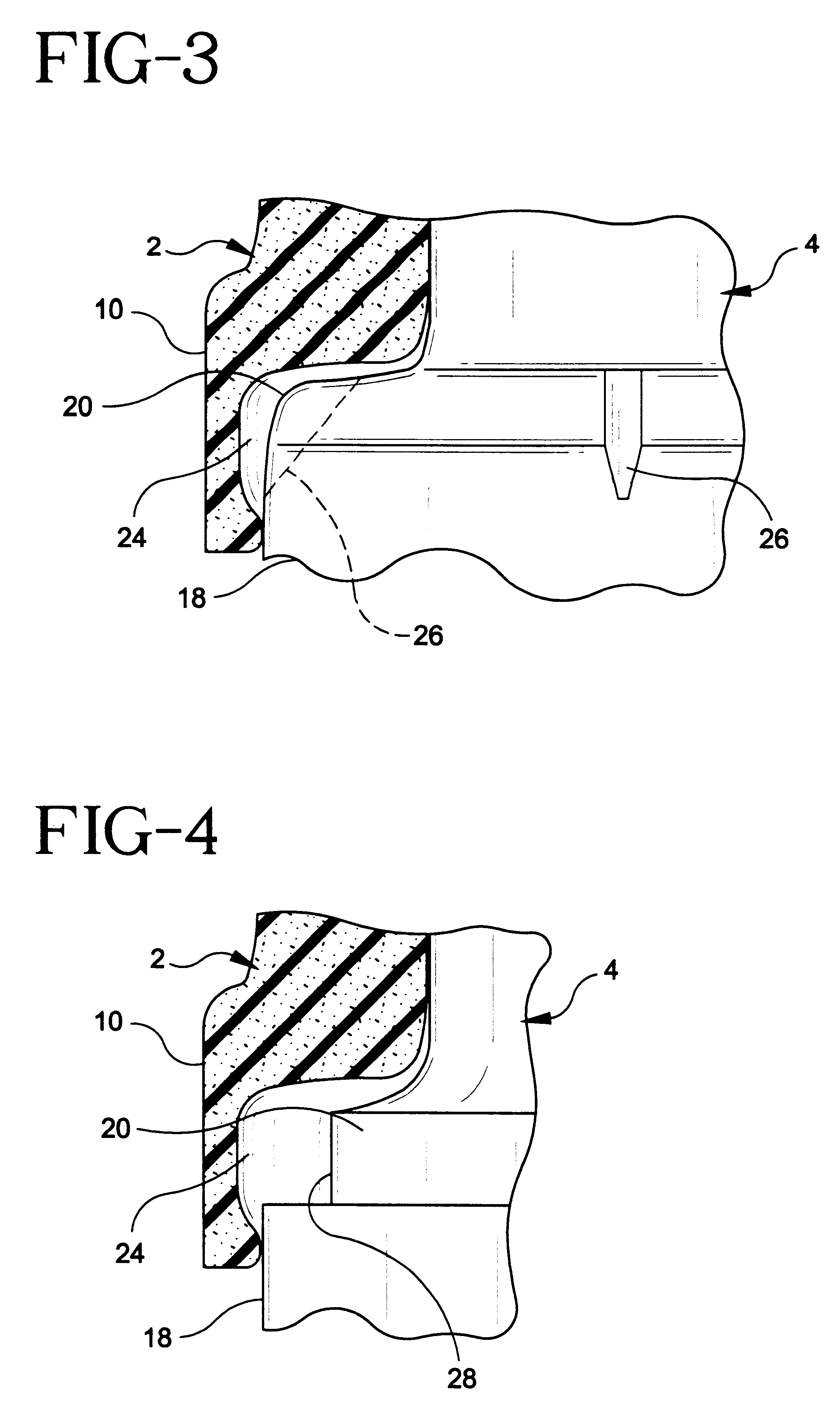

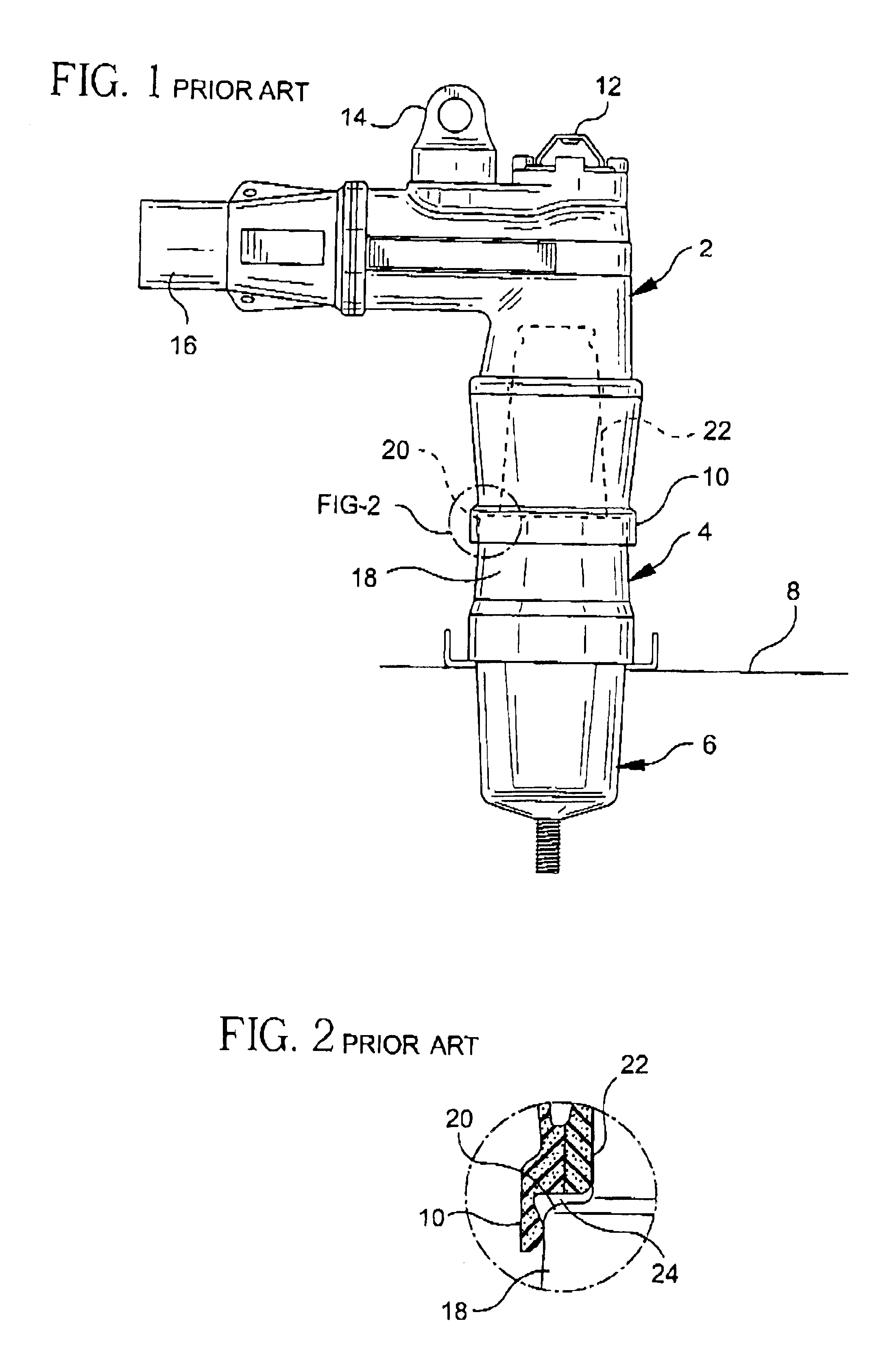

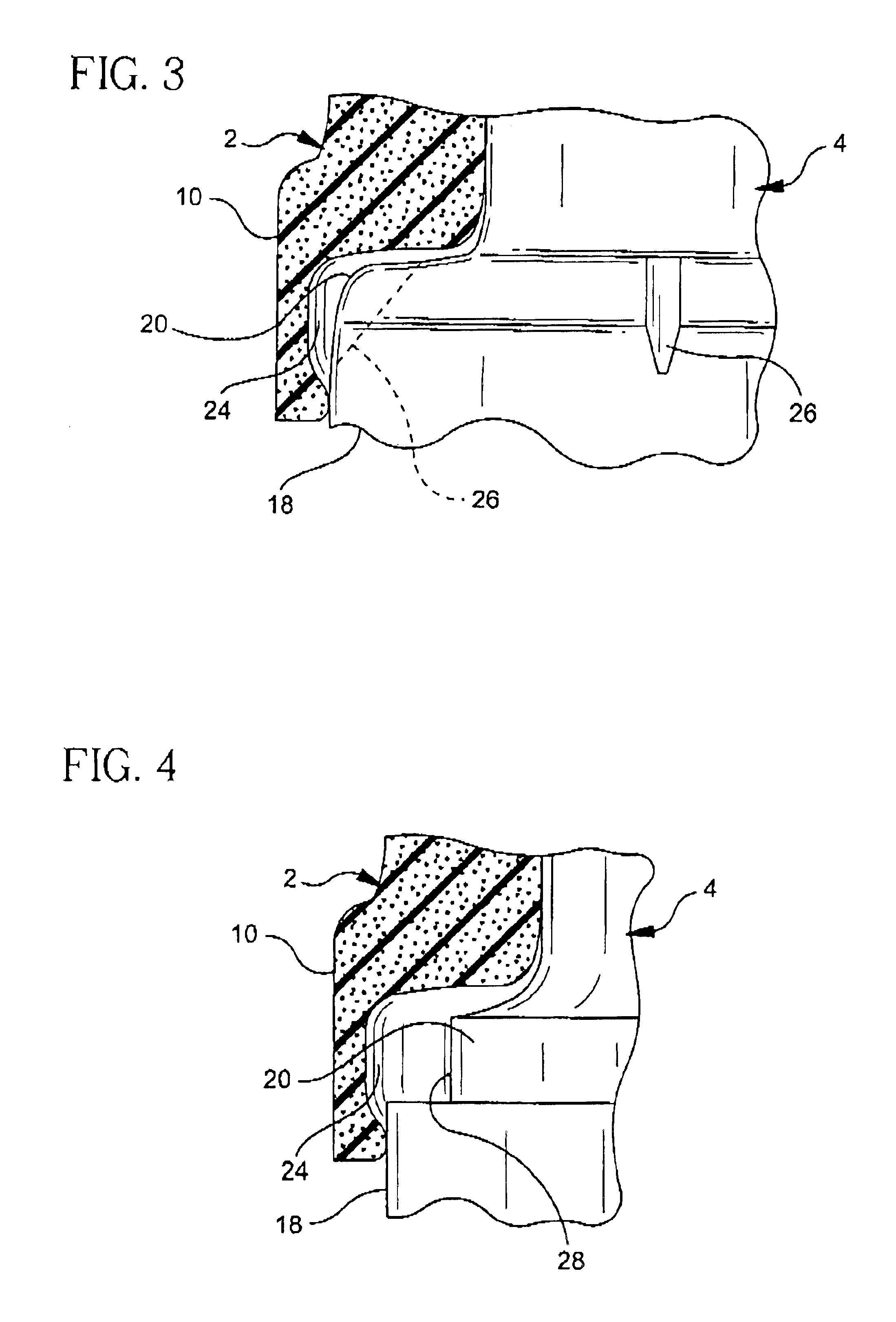

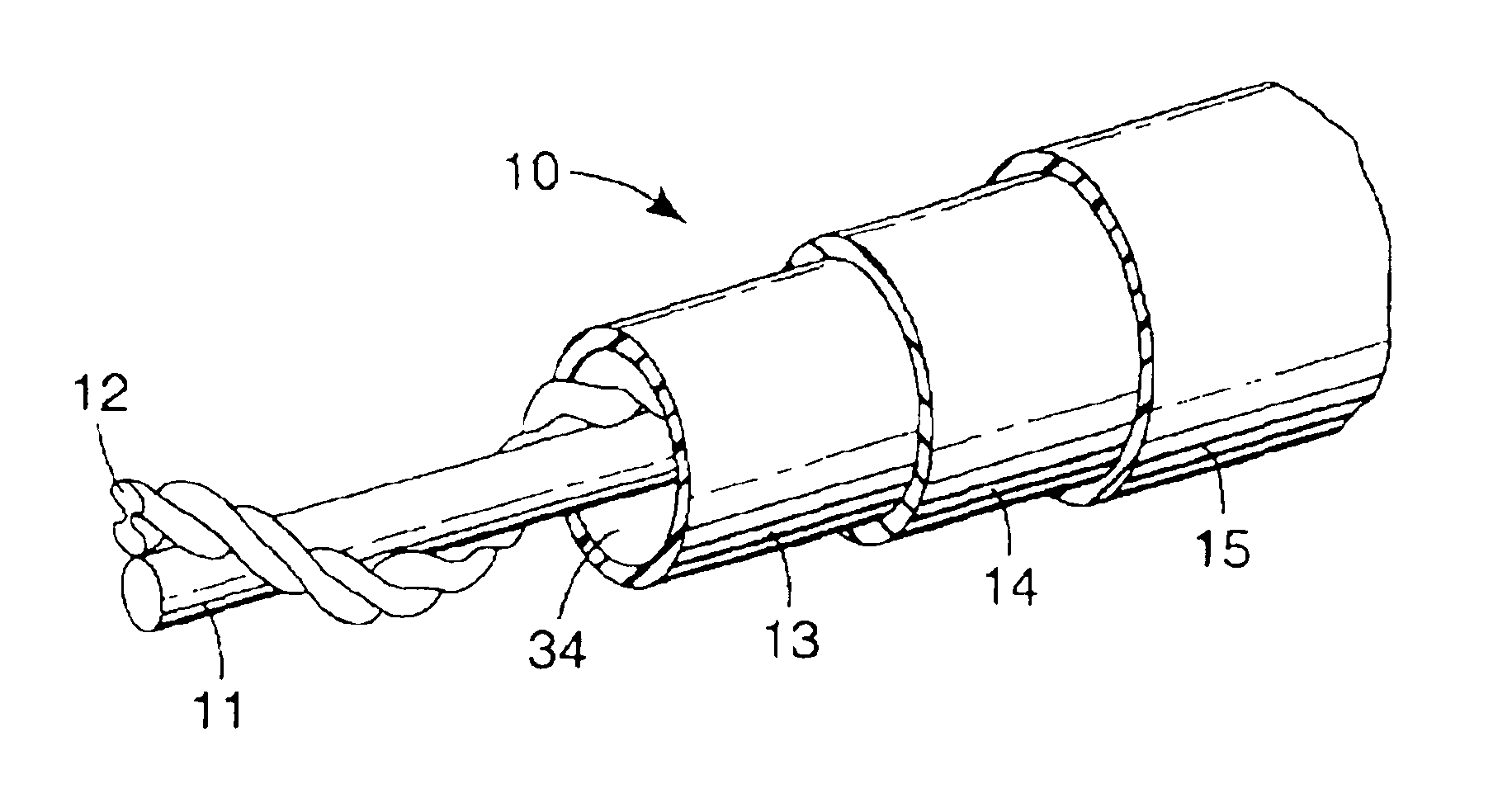

Loadbreak connector assembly which prevents switching flashover

InactiveUS6168447B1Avoid flashoverIncrease distanceOne pole connectionsCouplings bases/casesInterference fitPower cable

Loadbreak connectors which are modified to reduce the probability of flashover upon disassembly operation of a loadbreak bushing insert from a power cable elbow connector. The loadbreak bushing insert and power cable elbow connector are mated with an interference fit between an elbow cuff and a transition shoulder portion of the loadbreak bushing insert. The bushing insert is provided with vents to vent a cavity formed between the elbow cuff and the transition shoulder portion of the bushing insert with ambient air to avoid a decrease in pressure within the connection region and avoid a decrease in the dielectric strength of the air therein thus preventing flashover. Preferably, the vents are provided on an elbow seating indicator band formed of a bright contrasting color on the bushing insert which, in addition to venting the cavity, serves to indicate whether the loadbreak connector is improperly assembled.

Owner:THOMAS & BETTS INT INC

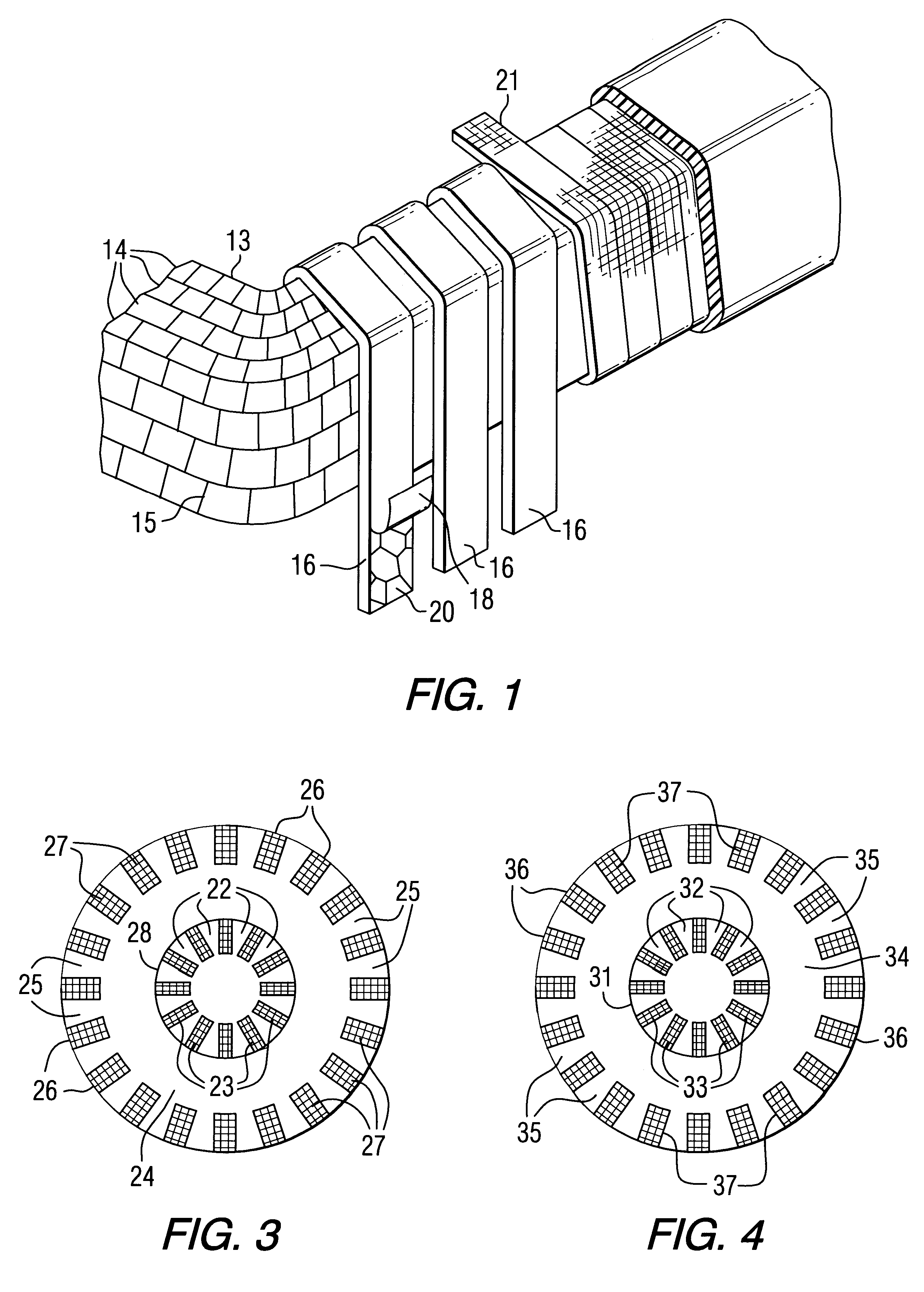

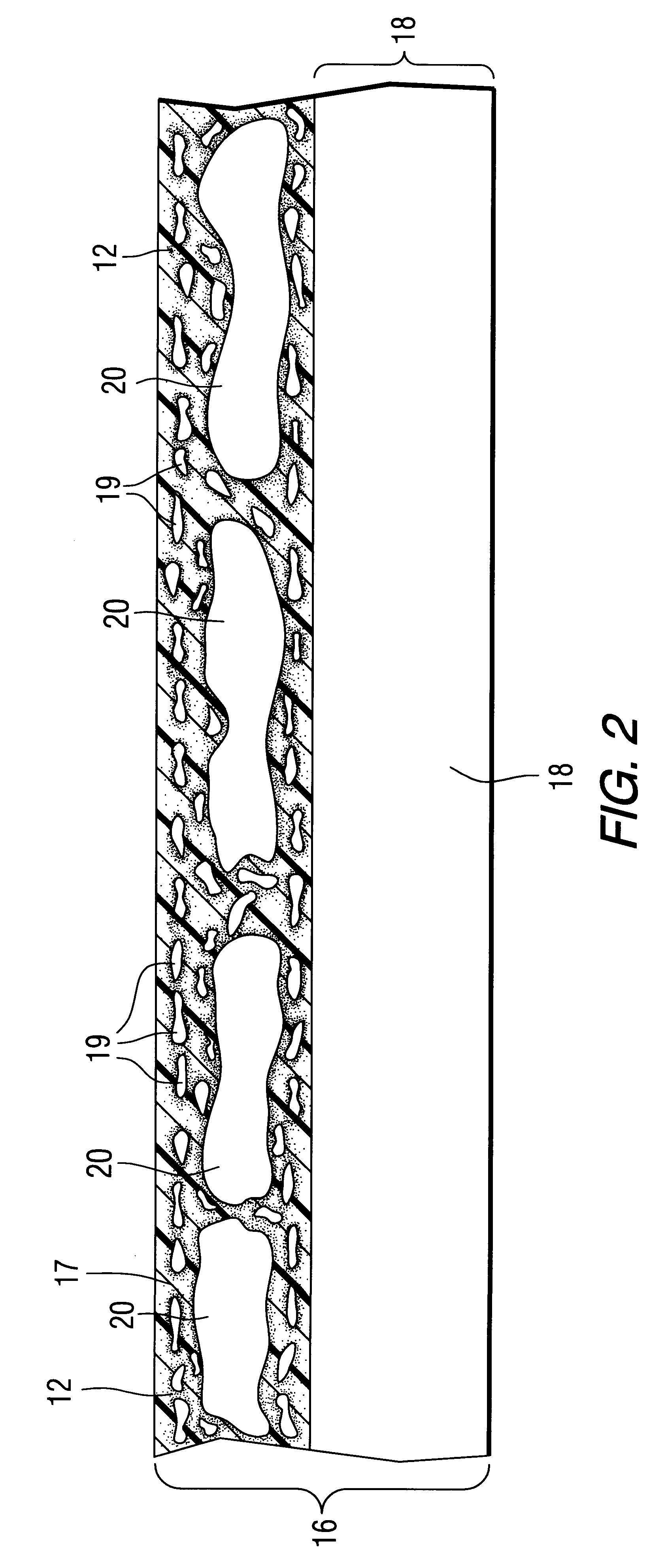

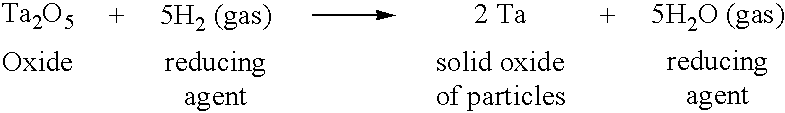

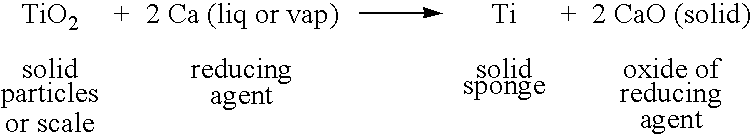

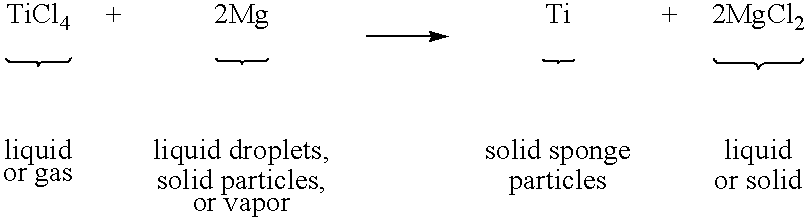

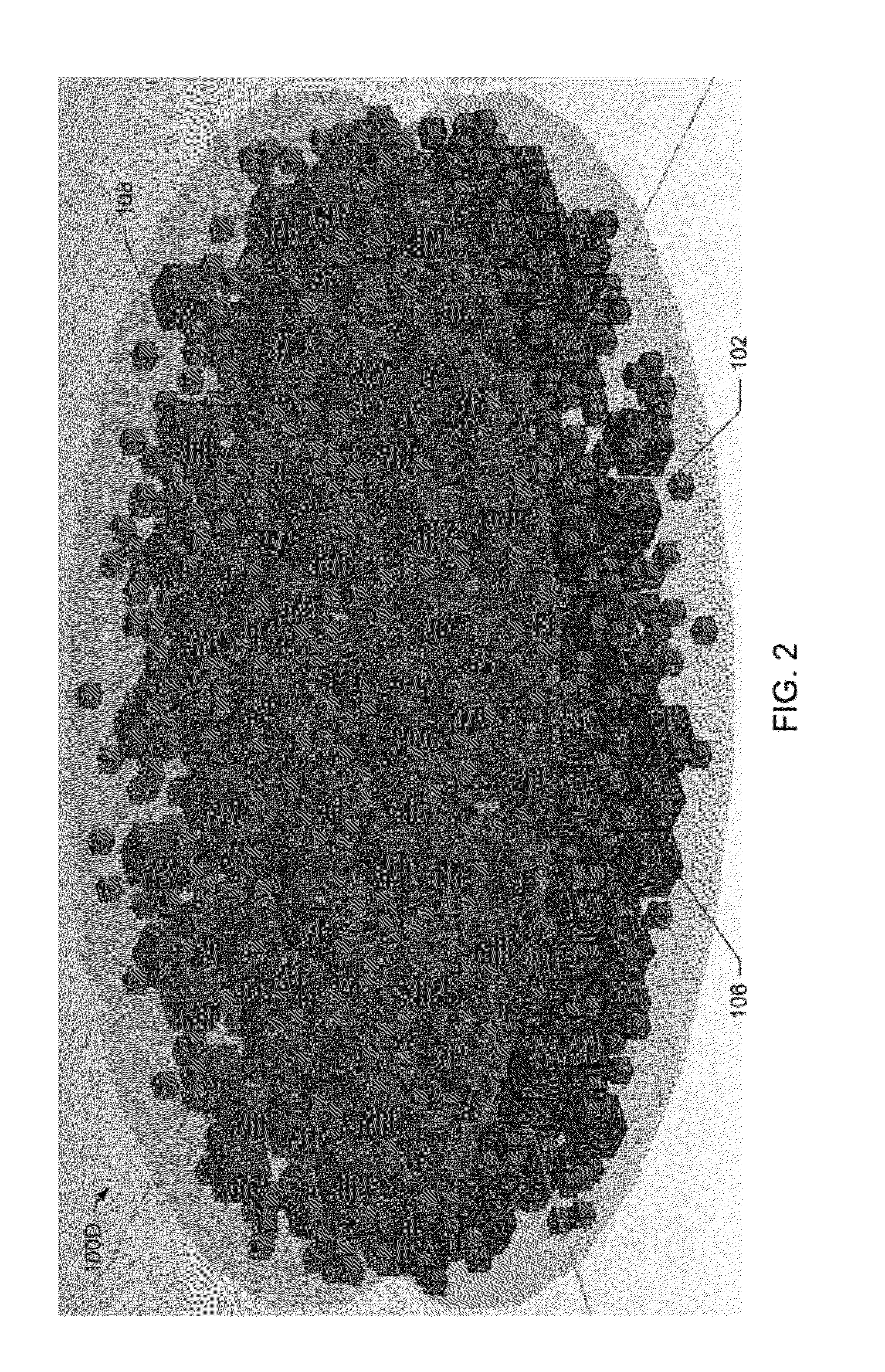

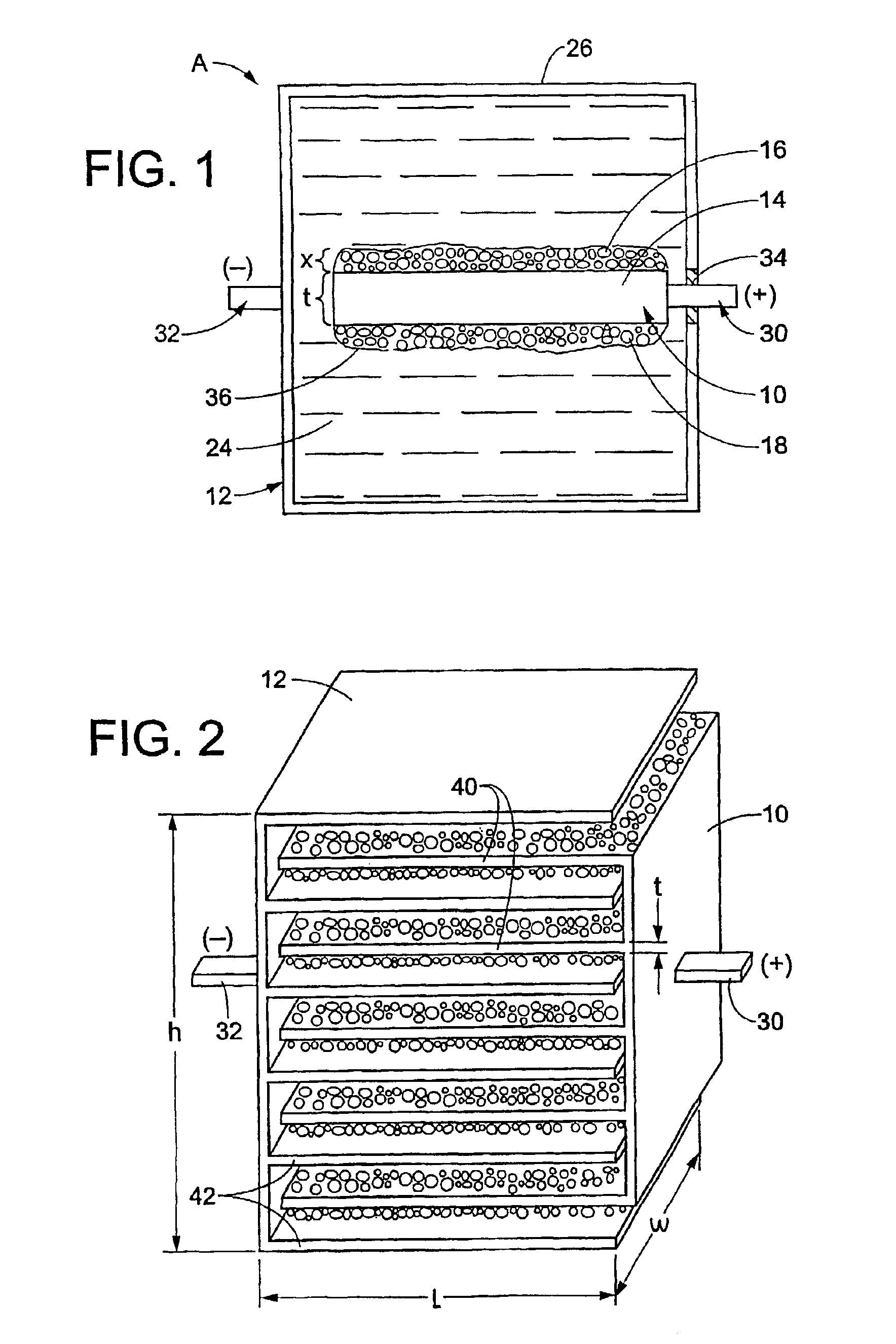

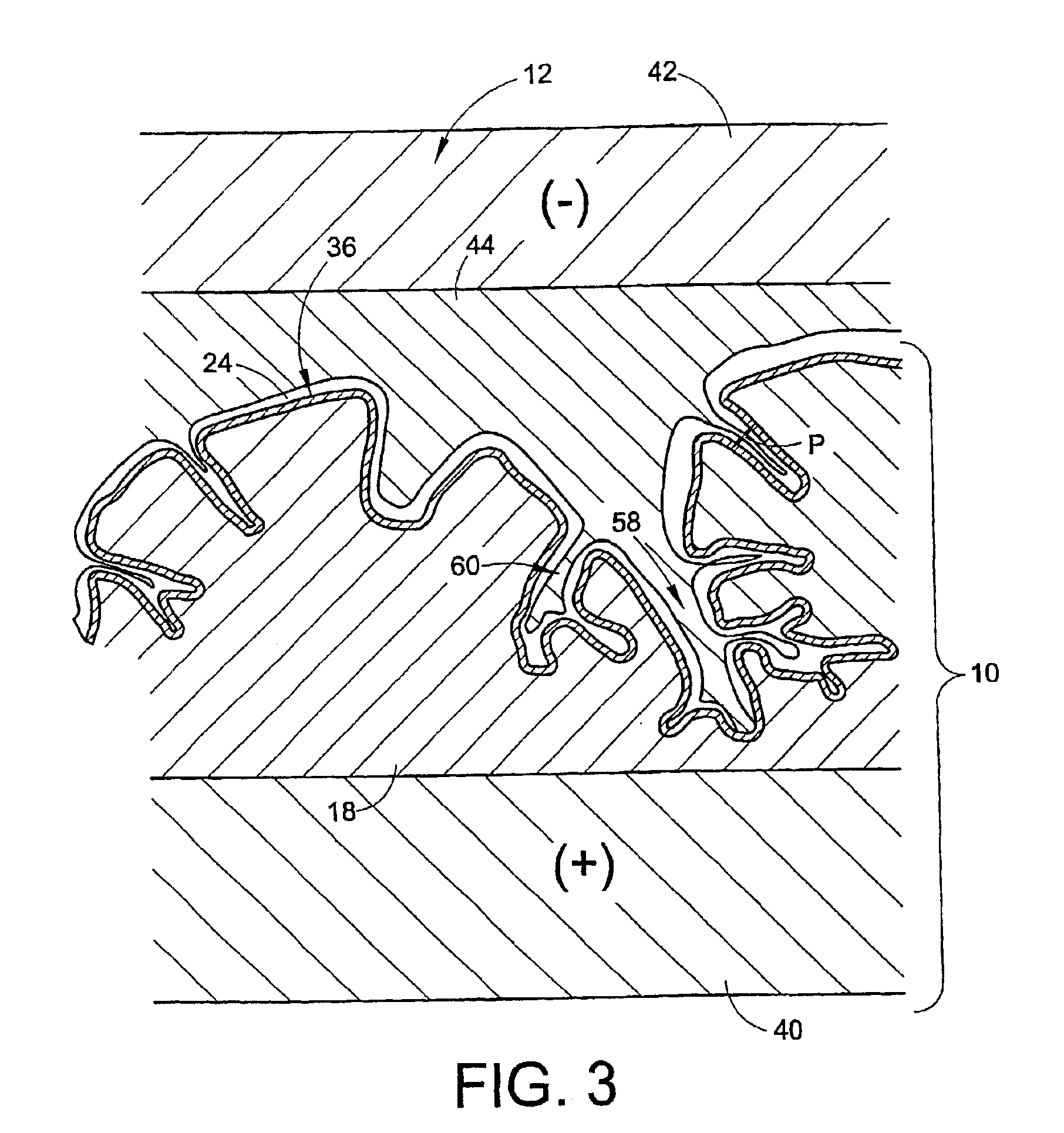

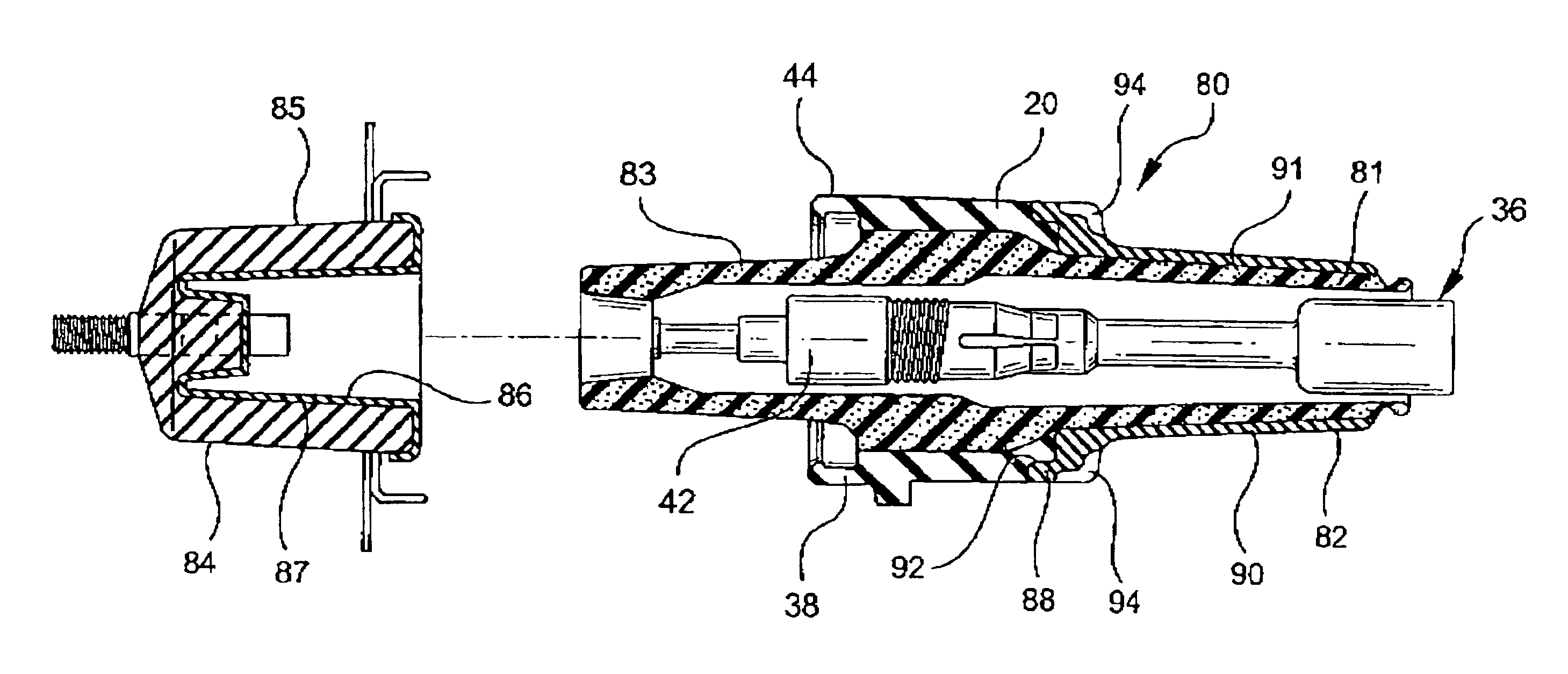

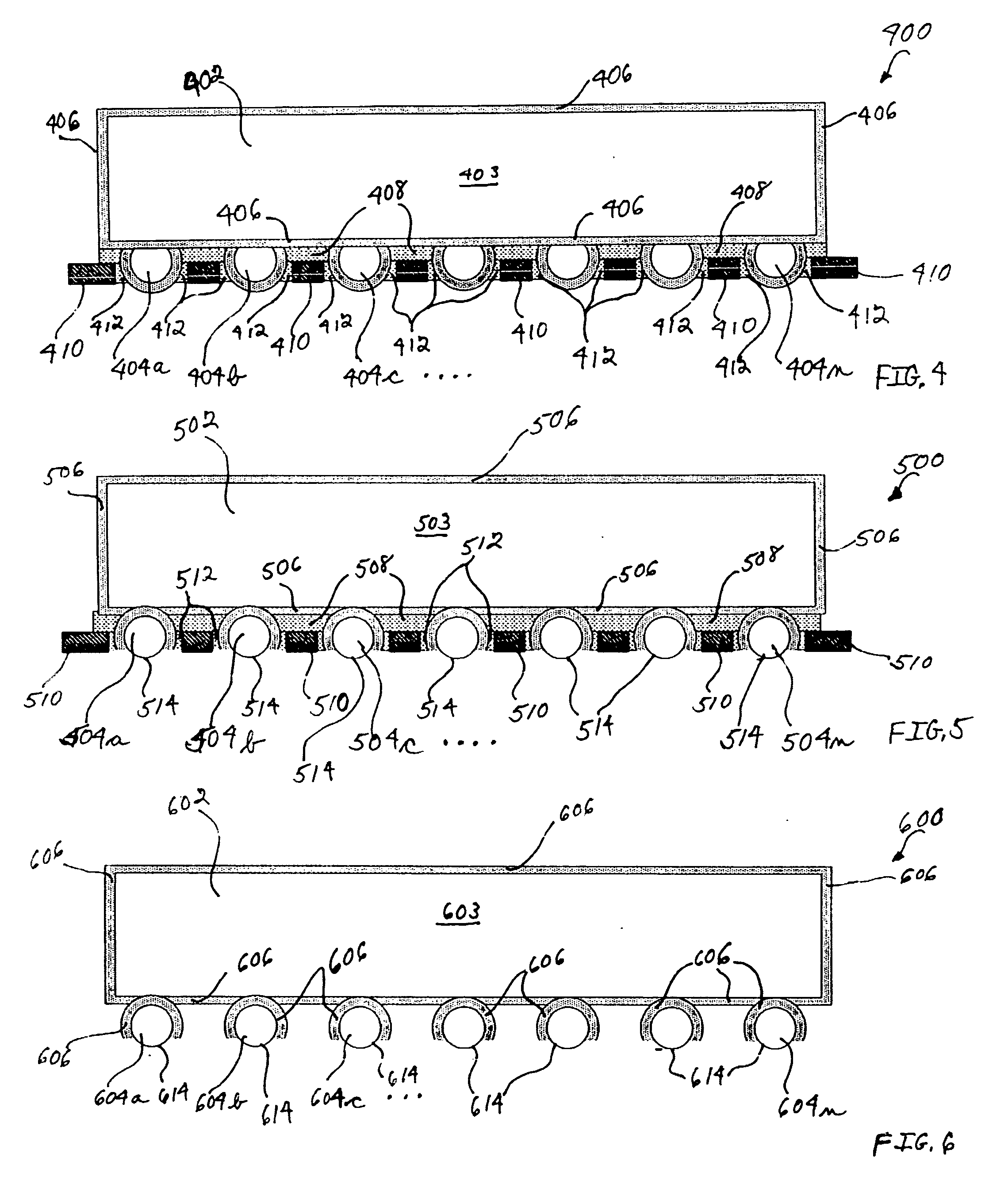

High power capacitors from thin layers of metal powder or metal sponge particles

InactiveUS20030169560A1Increase surface areaSmall sizeFixed capacitor dielectricSolid-state devicesDielectric strengthHigh surface area

An anode (14, 208, 410) and / or cathode (12, 212, 420) of a capacitor has a large surface area. The high surface area of the anode is provided by forming the anode from a thin, electrically conductive layer (16) formed from metal particles (18) or an electrically conductive metallic sponge (416). These materials provide a porous structure with a large surface area of high accessibility. The particles are preferably directional or non-directional sponge particles of a metal, such as titanium. The conductive layer hasa dielectric film (36, 236, 414) on its surface, formed by anodizing the particle surfaces. The dielectric film has a combination of high dielectric constant and high dielectric strength. The cathode (12, 212, 420) of the capacitor is either a conventional solid material or, more preferably, has a large surface provided by forming the surface from a sponge or particles analogously to the anode. The high dielectric strengths obtainable from the capacitor allow for extreme miniaturization, making the capacitor particularly suited for integrated circuit applications.

Owner:TITANIUM POWER TECH

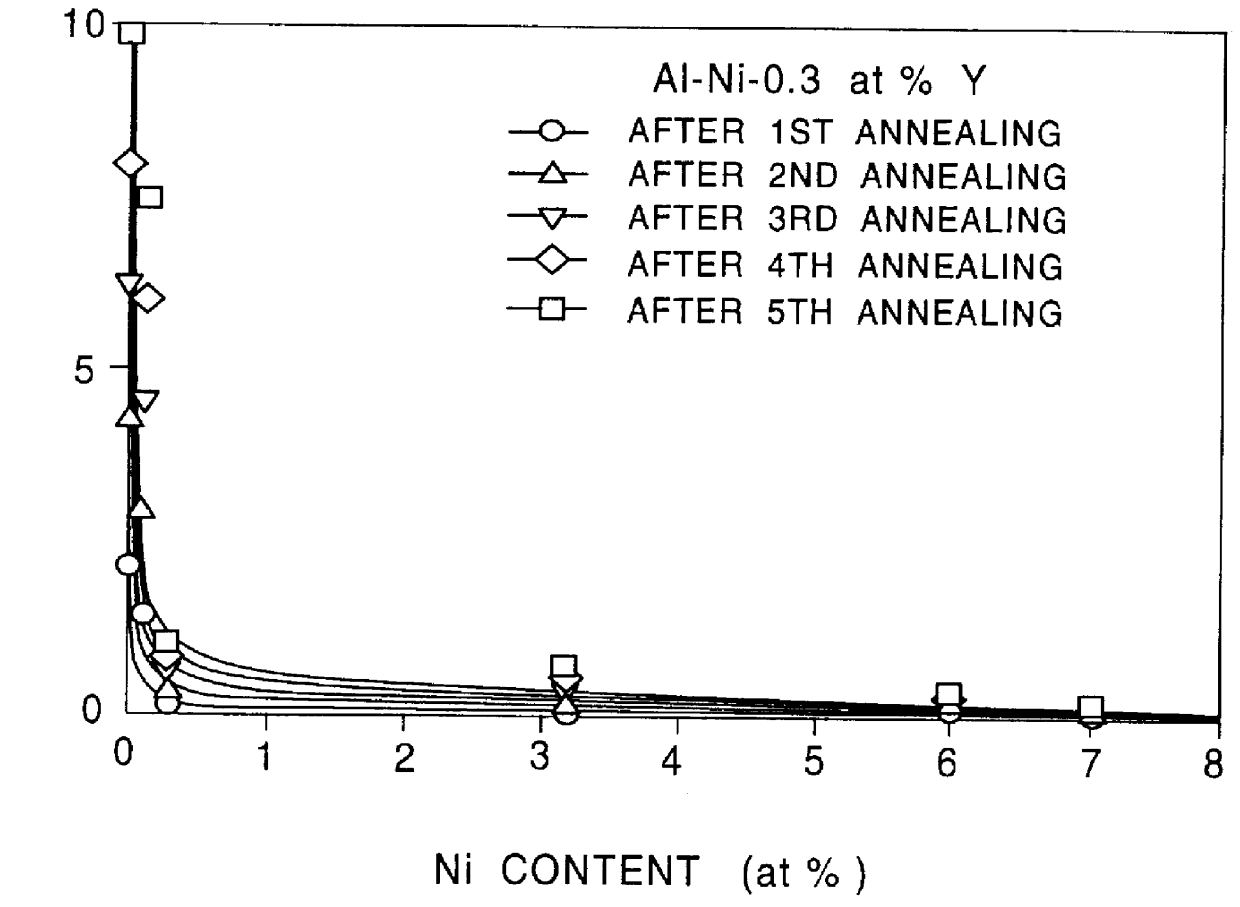

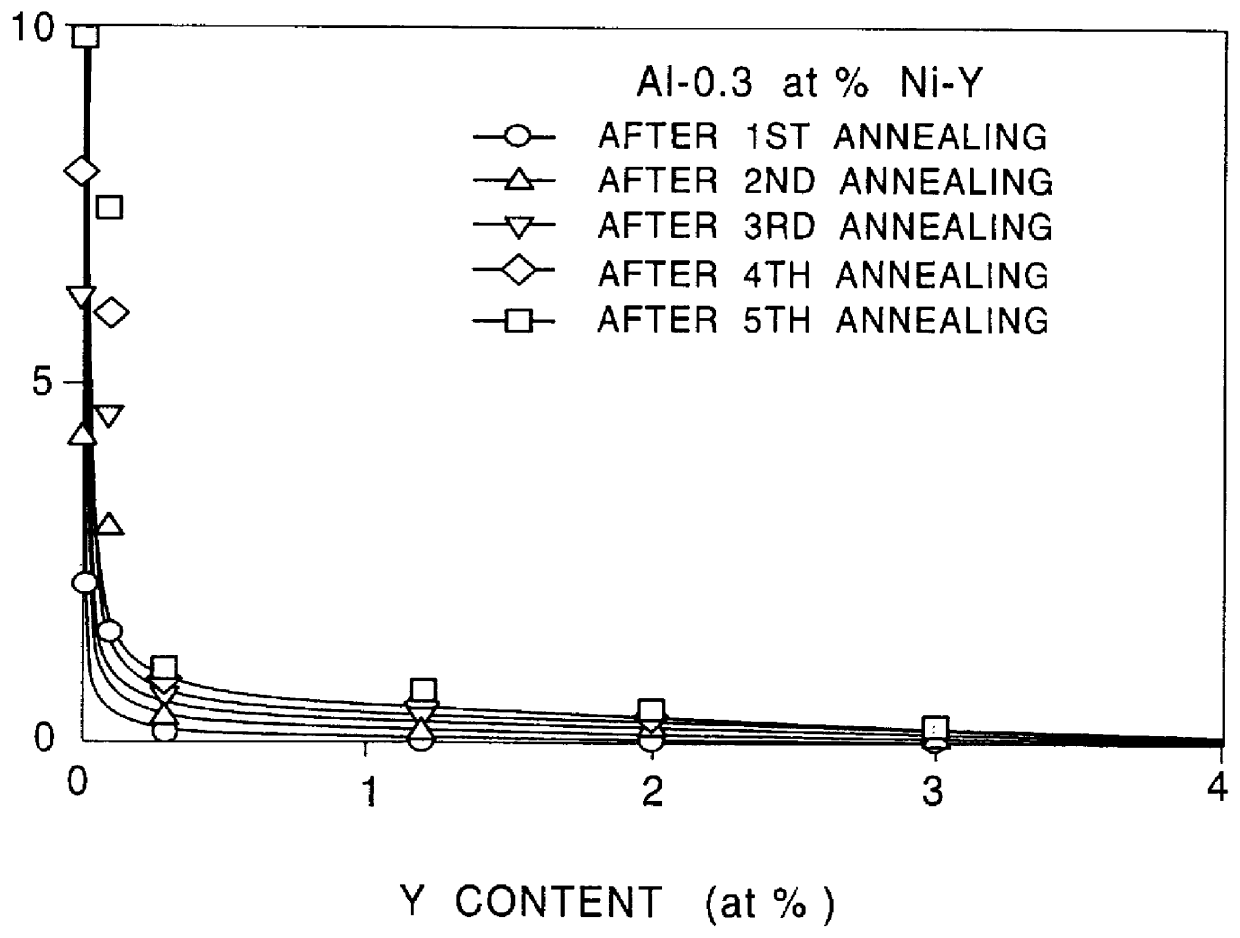

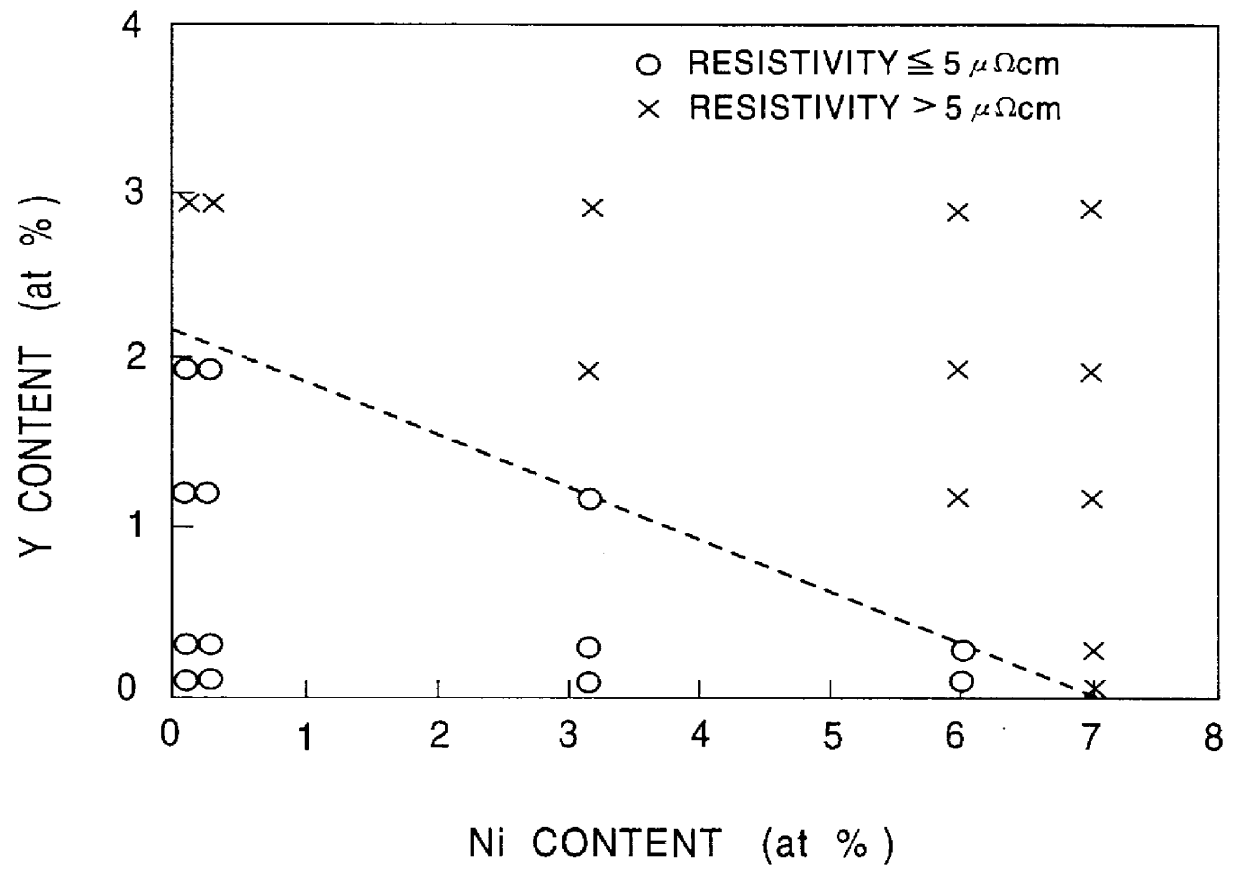

A1-N1-Y alloy films for electrodes of semiconductor devices and sputtering targets for depositing the A1-N1-Y alloy films

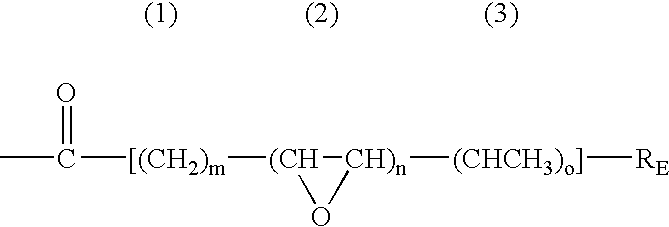

The invention provides an Al alloy film for use as an electrode of a semiconductor device and also provides an Al alloy sputtering target used to produce such an Al alloy film wherein the Al alloy film has not only a low resistivity equal to or less than 5 mu OMEGA cm and a high hillock resistance (property of hillock suppression) but also a high dielectric strength when it is anodized into an anodic oxide film and wherein the Al alloy film has a composition such that the Ni content is equal to or greater than 0.3 at % and the Y content is equal to or greater than 0.3 at % and such that 0.22 CNi+0.74 CY<1.6 at % where CNi denotes the Ni content (at %) and CY denotes the Y content (at %) and further wherein, in order to deposit the Al alloy film by sputtering, a spray forming Al alloy target containing Ni and Y is used.

Owner:KOBE STEEL LTD

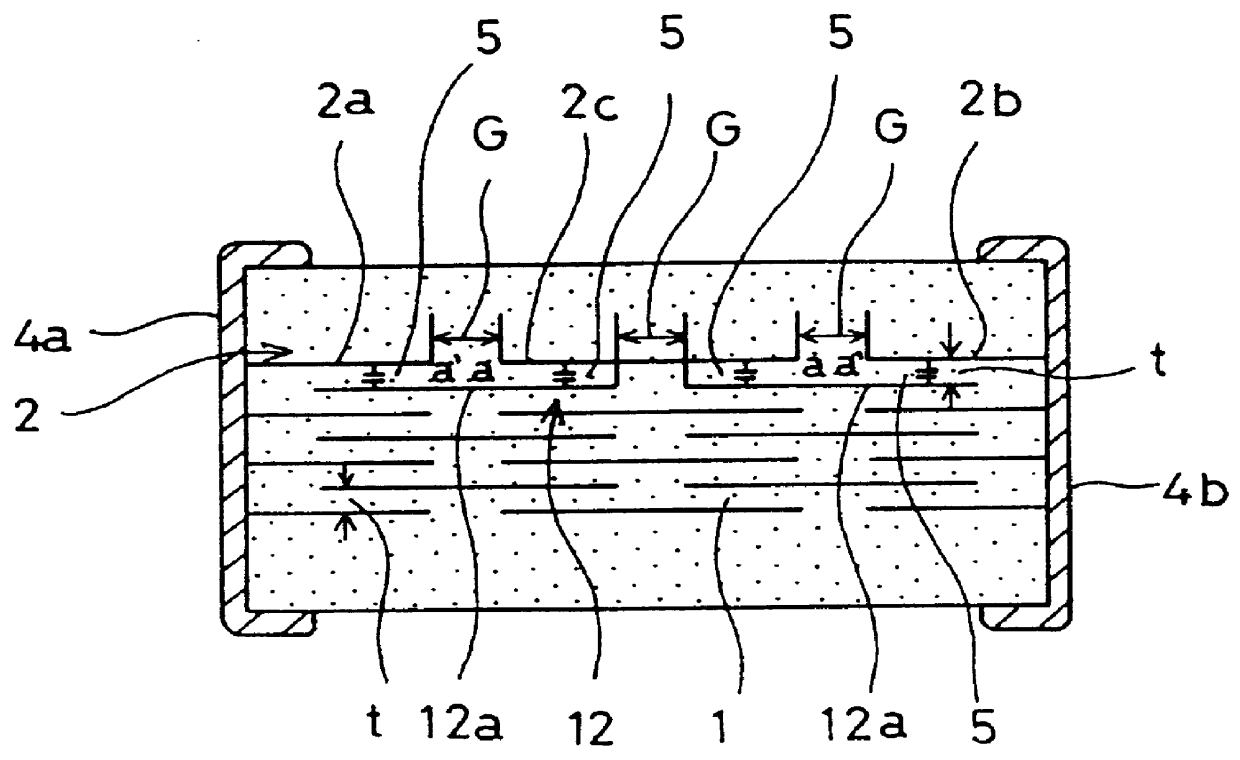

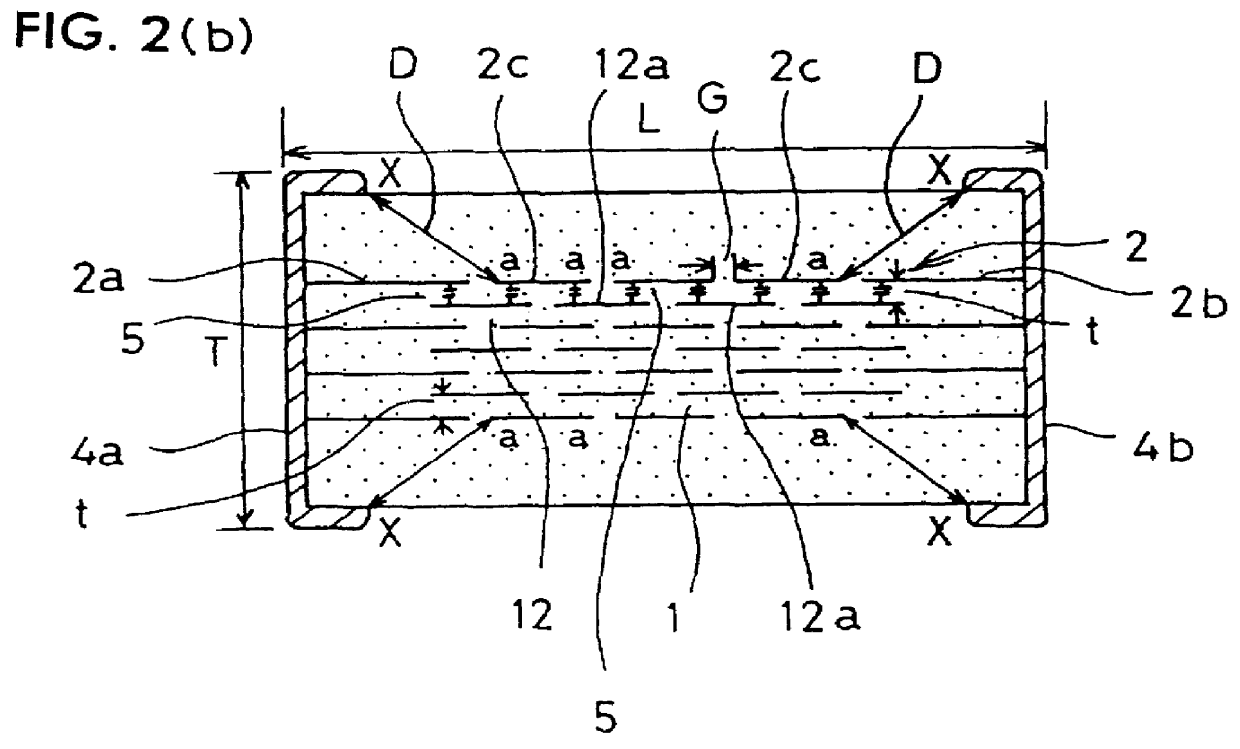

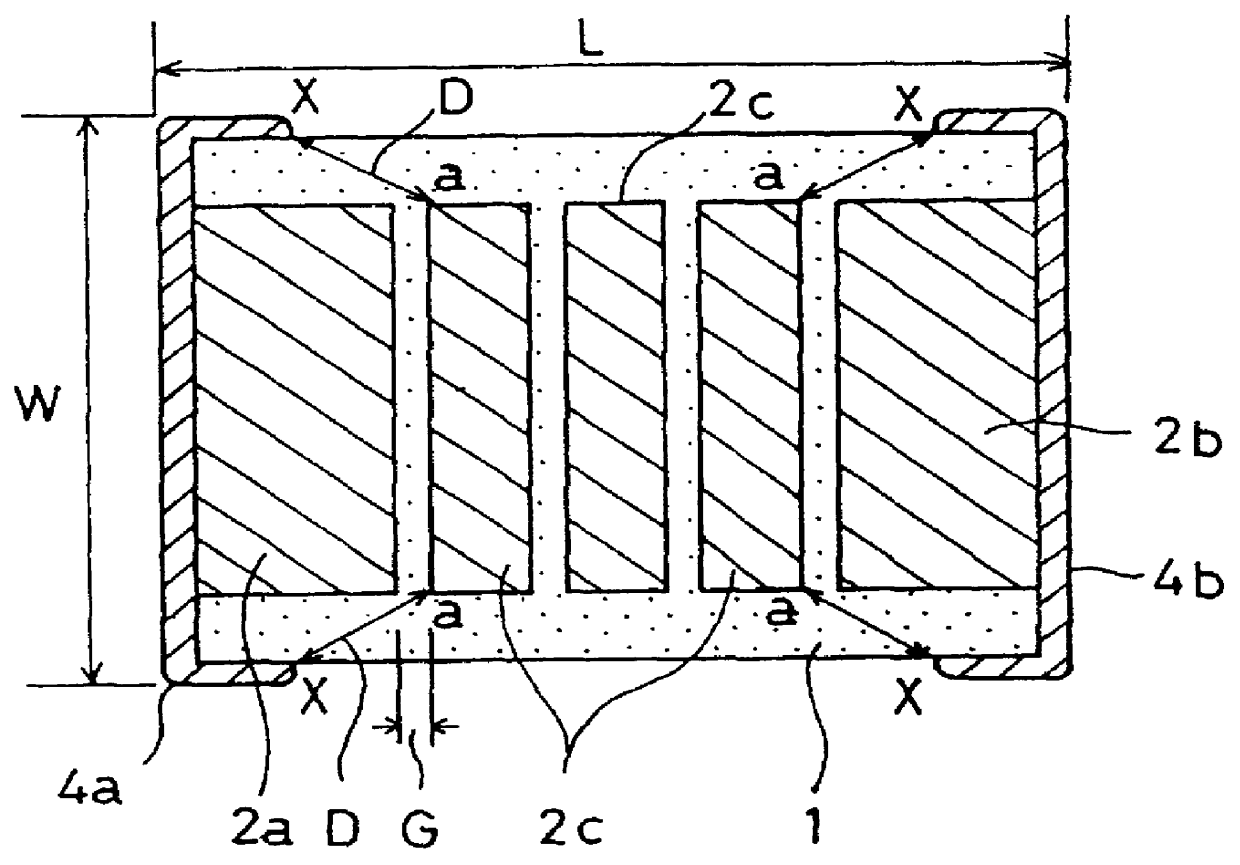

Laminated capacitor

A laminated capacitor that can be made small in size, that can prevent flashover, has excellent dielectric strength performance and a large capacitance is disclosed. Each gap between internal electrodes in the same plane is set at 2.7 to 20 times a thickness (element thickness) of a dielectric layer positioned between first and second internal electrode groups which face each other and a distance between an edge of the external terminal and an edge of the floating internal electrode closest to the external terminal among floating internal electrodes of the internal electrode group of the outermost layer is set at 0.4 mm to 1.4 mm.

Owner:MURATA MFG CO LTD

Thermally conductive polyimide film composites having high thermal conductivity useful in an electronic device

InactiveUS20060127686A1Excellent dielectric propertiesImprove thermal conductivityPrinted circuit aspectsConductive materialUltimate tensile strengthDielectric layer

In electronic devices, heat removal is an important consideration of any device designer. Thermally conductive, high-temperature polyimide composites are disclosed herein which are generally useful as a dielectric layer in an electronic device, or a precursor metal-laminate, where the dielectric is layered on one side (or on both sides) with a metal. The polyimide composites of the present invention contain dispersed therein thermally conductive filler particles at a weight percent between 40 and 85 % weight percent. These film composites have good dielectric strength, good thermal conductivity, and optionally good adhesivity.

Owner:EI DU PONT DE NEMOURS & CO

Loadbreak connector assembly which prevents switching flashover

InactiveUS6585531B1Avoid flashoverIncrease distanceOne pole connectionsCouplings bases/casesInterference fitPower cable

Loadbreak connectors which are modified to reduce the probability of flashover upon disassembly operation of a loadbreak bushing insert from a power cable elbow connector. The loadbreak bushing insert and power cable elbow connector are mated with an interference fit between an elbow cuff and a transition shoulder portion of the loadbreak bushing insert. The bushing insert is provided with vents to vent a cavity formed between the elbow cuff and the transition shoulder portion of the bushing insert with ambient air to avoid a decrease in pressure within the connection region and avoid a decrease in the dielectric strength of the air therein thus preventing flashover. Preferably, the vents are provided on an elbow seating indicator band formed of a bright contrasting color on the bushing insert which, in addition to venting the cavity, serves to indicate whether the loadbreak connector is improperly assembled.

Owner:THOMAS & BETTS INT INC

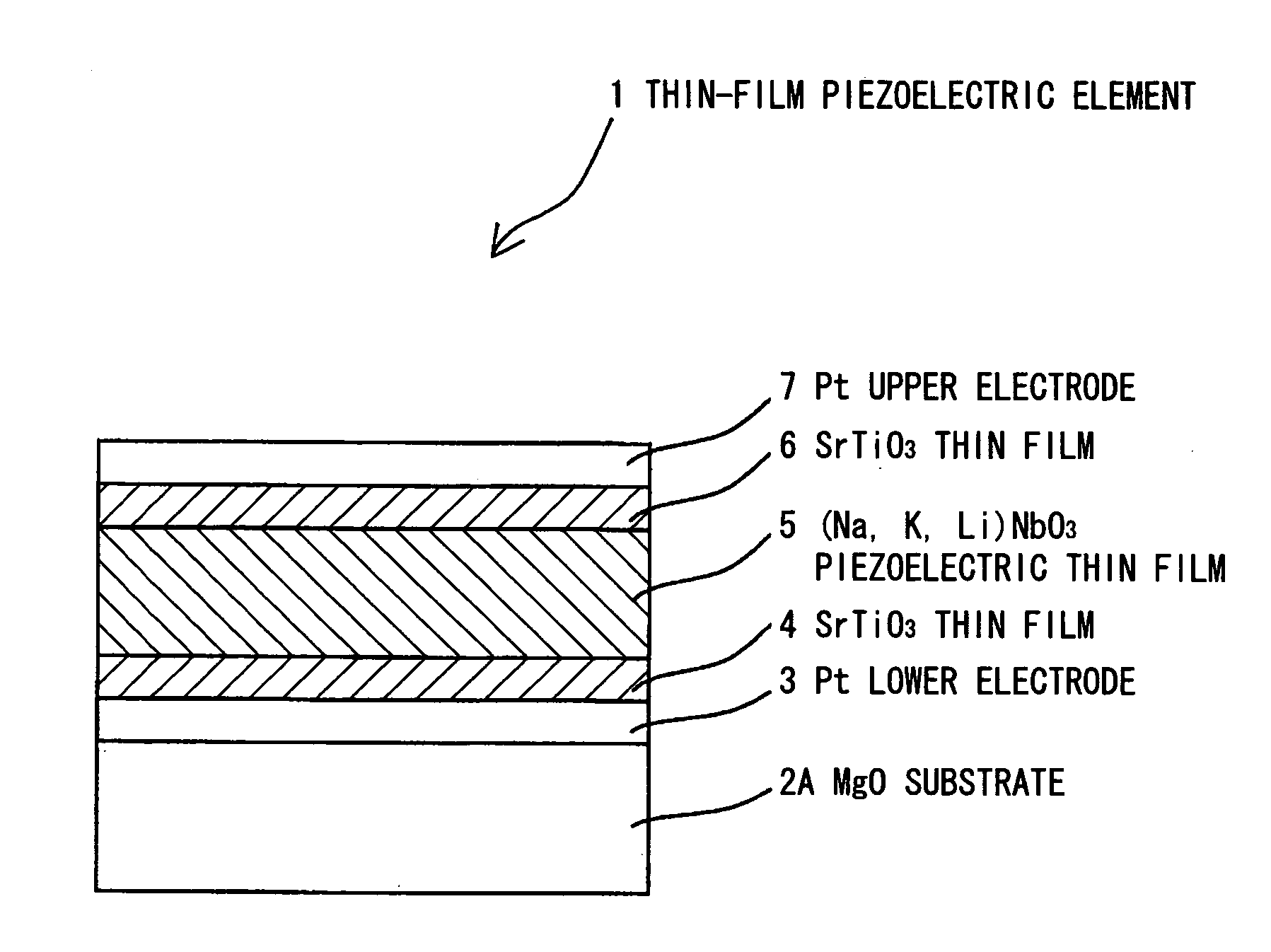

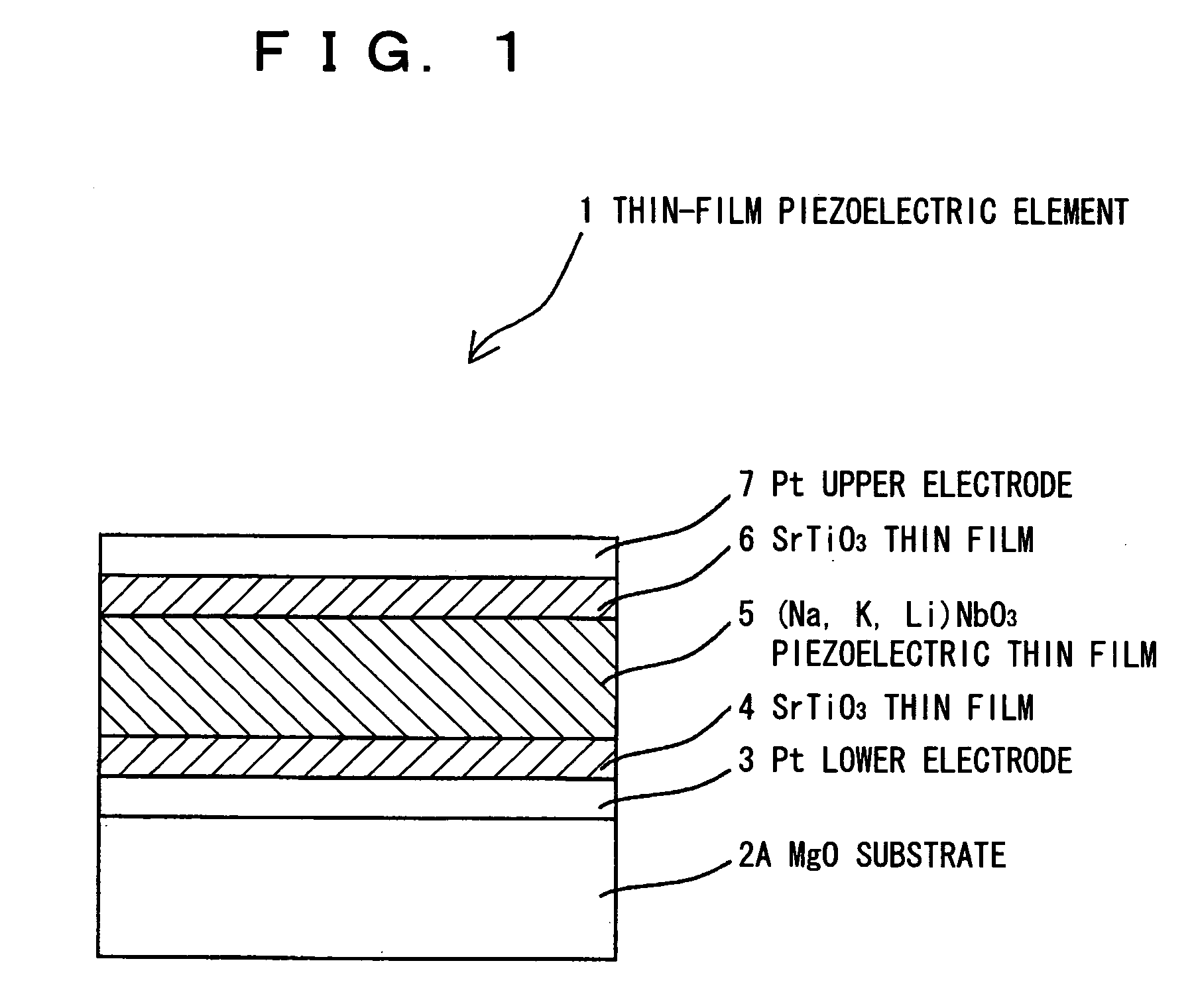

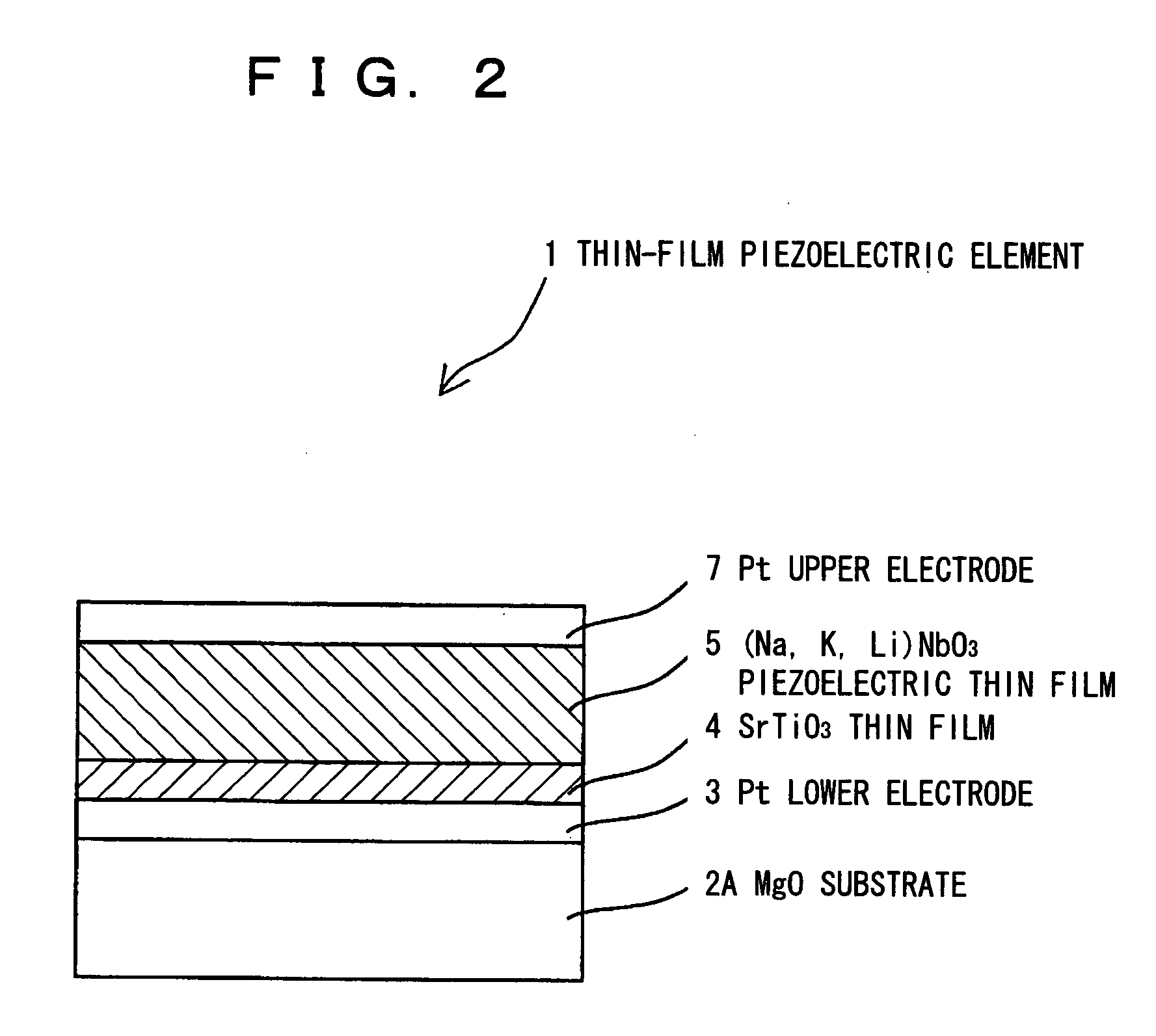

Piezoelectric thin film element

InactiveUS20070024162A1Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric strengthDielectric thin films

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

Coatings for Electrowetting and Electrofluidic Devices

ActiveUS20130171546A1Low surface energy polymersHigh dielectric strengthElectrostatic separatorsSludge treatmentGas phaseUltimate tensile strength

Electrowetting devices coated with one or more polymeric layers and methods of making and using thereof are described herein. The coatings may be formed in a single layer or as multiple layers. In one embodiment the first layer deposited serves as an insulating layer of high dielectric strength while the second layer deposited serves as a hydrophobic layer of low surface energy. These materials may themselves be deposited as multiple layers to eliminate pinhole defects and maximize device yield. In one embodiment the insulating layer would be a vapor deposited silicone polymeric material including, but not limited to, polytrivinyltrimethylcyclotrisiloxane or polyHVDS. In another embodiment the insulating layer may be a vapor deposited ceramic such as SiO2 with very little carbon content. In a further embodiment the insulating layer may be composed of alternating layers of a siloxane material and a ceramic material.

Owner:GVD CORP

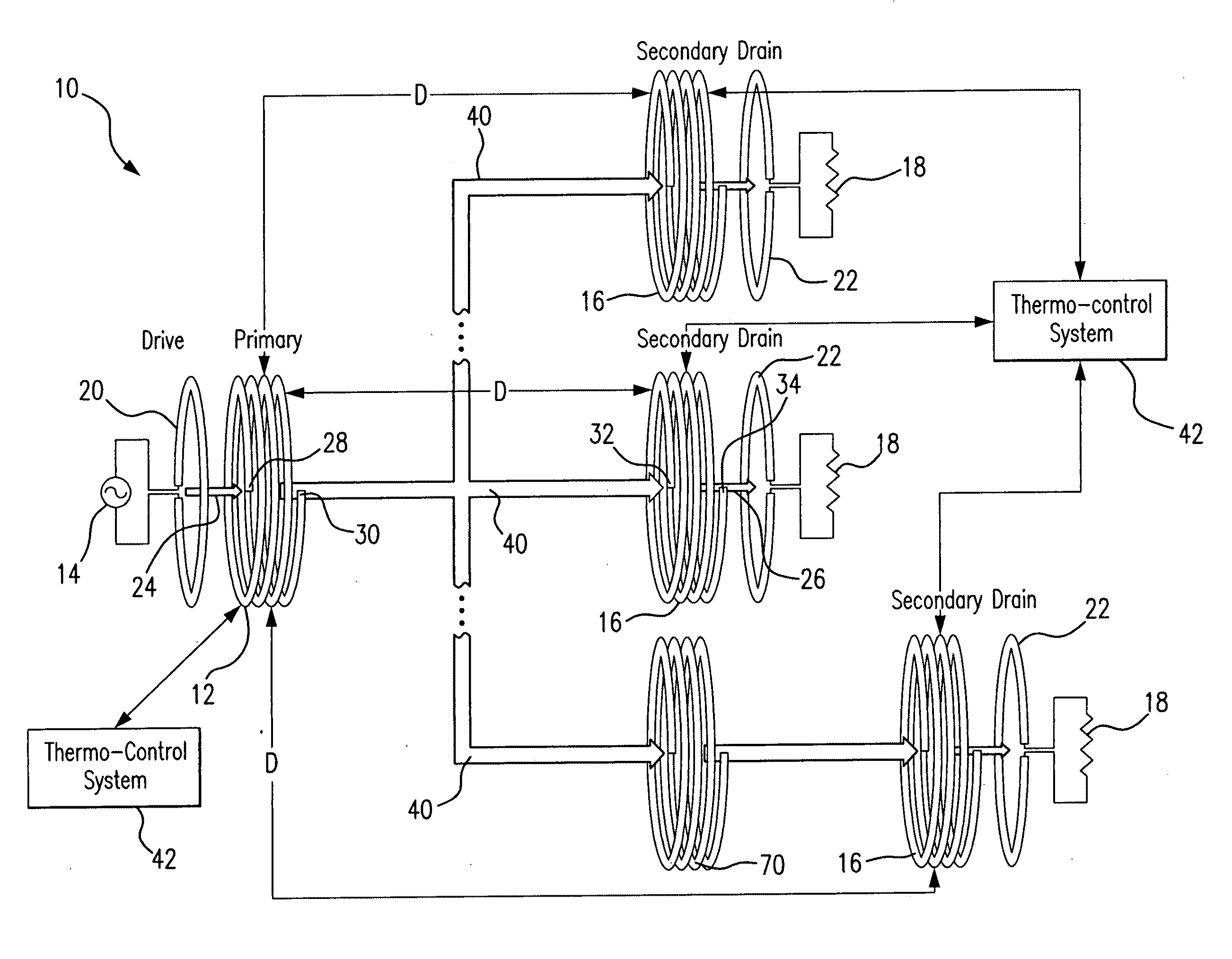

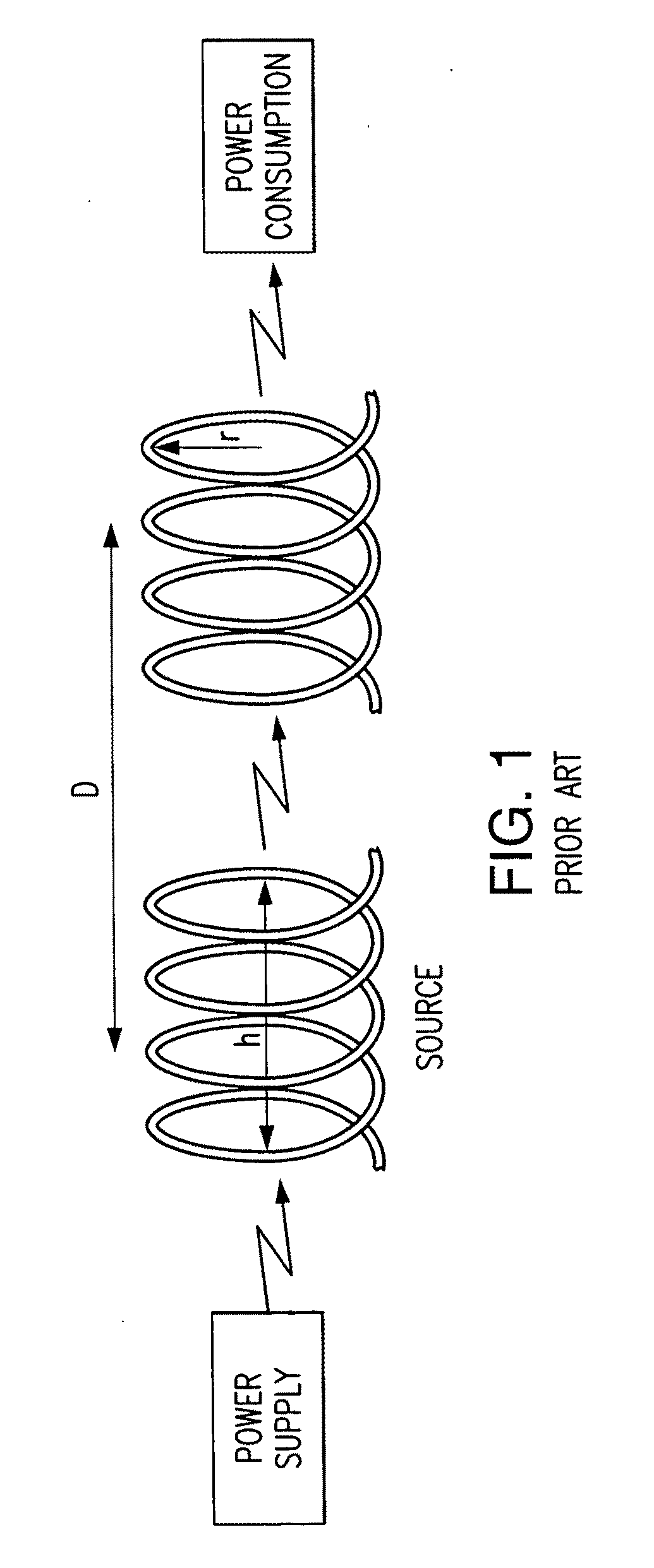

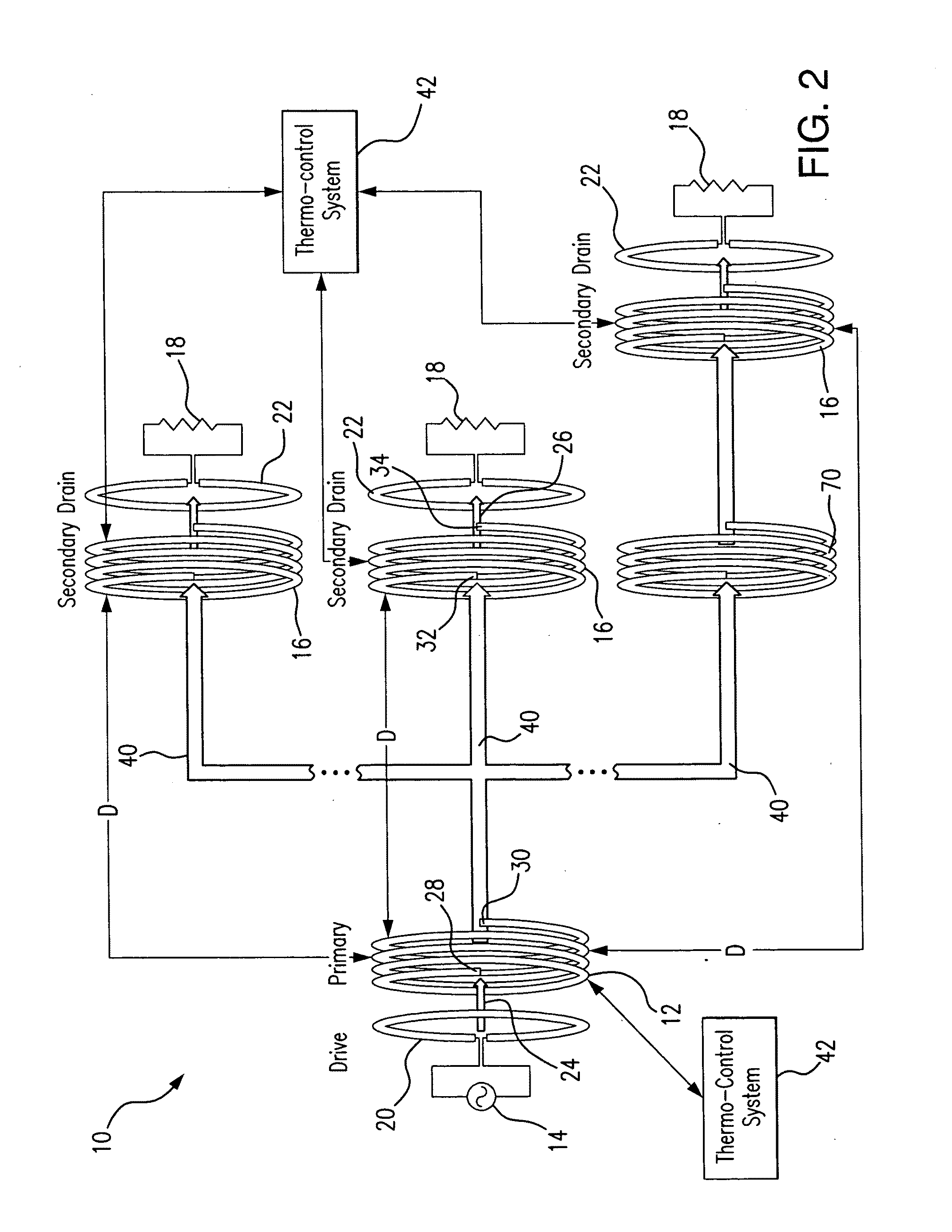

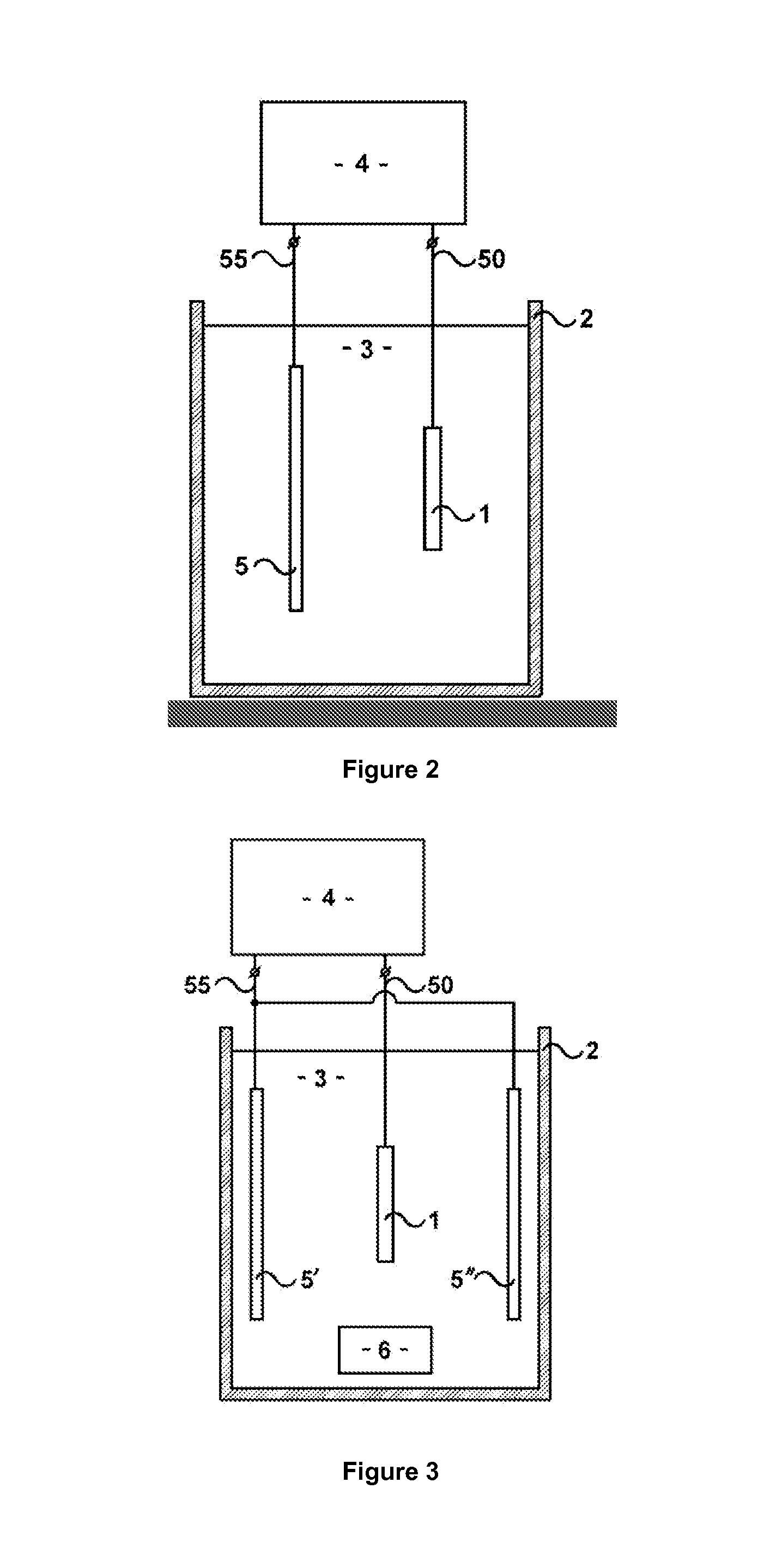

Method and system for long range wireless power transfer

ActiveUS20120010079A1Improve power transfer efficiencyReduce eliminateDc network circuit arrangementsElectromagnetic wave systemLow dissipationCapacitance

A wireless energy transfer system includes a primary and one (or more) secondary oscillators for transferring energy therebetween when resonating at the same frequency. The long range (up to and beyond 100 m) efficient (as high as and above 50%) energy transfer is achieved due to minimizing (or eliminating) losses in the system. Superconducting materials are used for all current carrying elements, dielectrics are either avoided altogether, or those are used with a low dissipation factor, and the system is operated at reduced frequencies (below 1 MHz). The oscillators are contoured as a compact flat coil formed from a superconducting wire material. The energy wavelengths exceed the coils diameter by several orders of magnitude. The reduction in radiative losses is enhanced by adding external dielectric-less electrical capacitance to each oscillator coil to reduce the operating frequency. The dielectric strength of the capacitor is increased by applying a magnetic cross-field to the capacitor to impede the electrons motion across an air gap defined between coaxial cylindrical electrodes.

Owner:MARYLAND UNIV OF

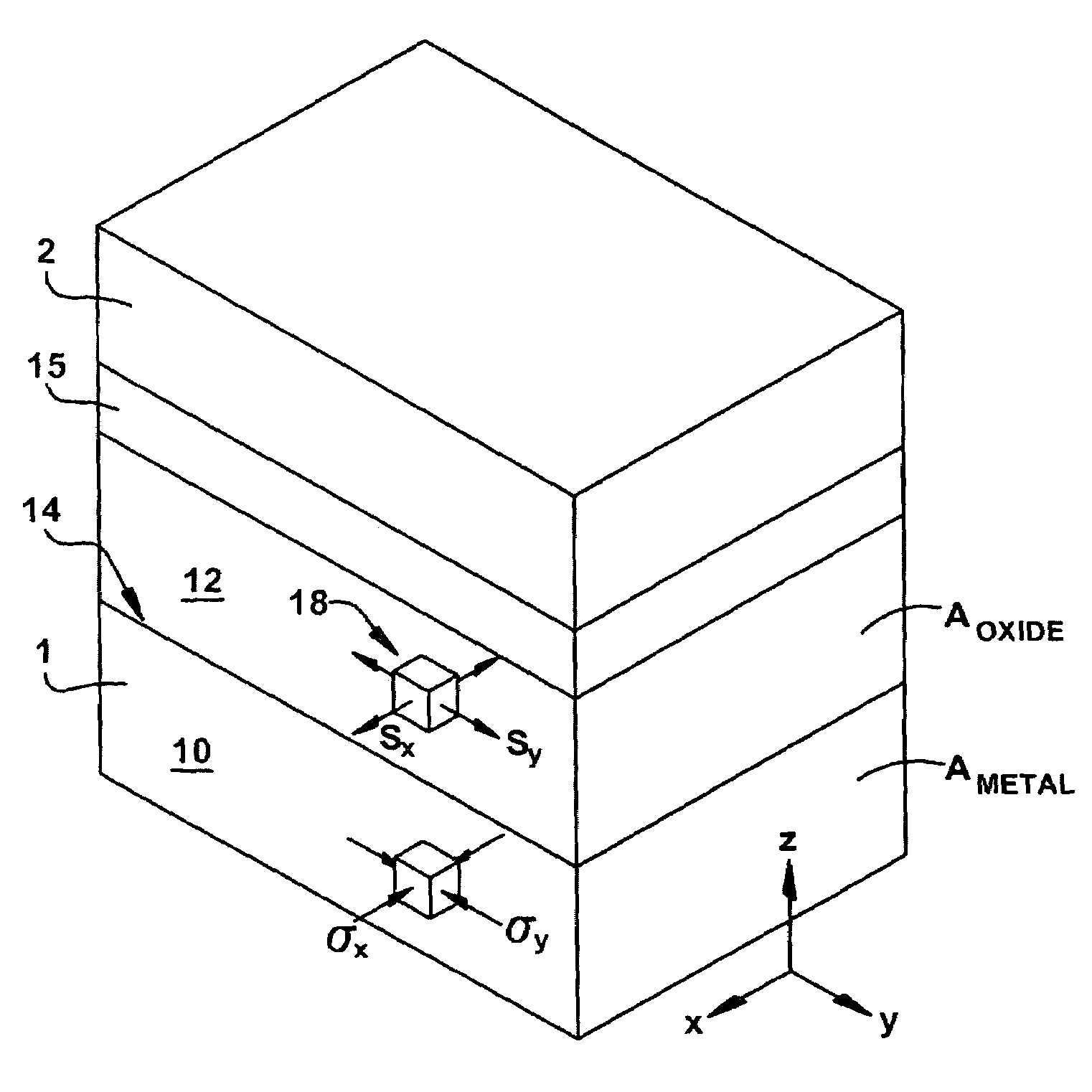

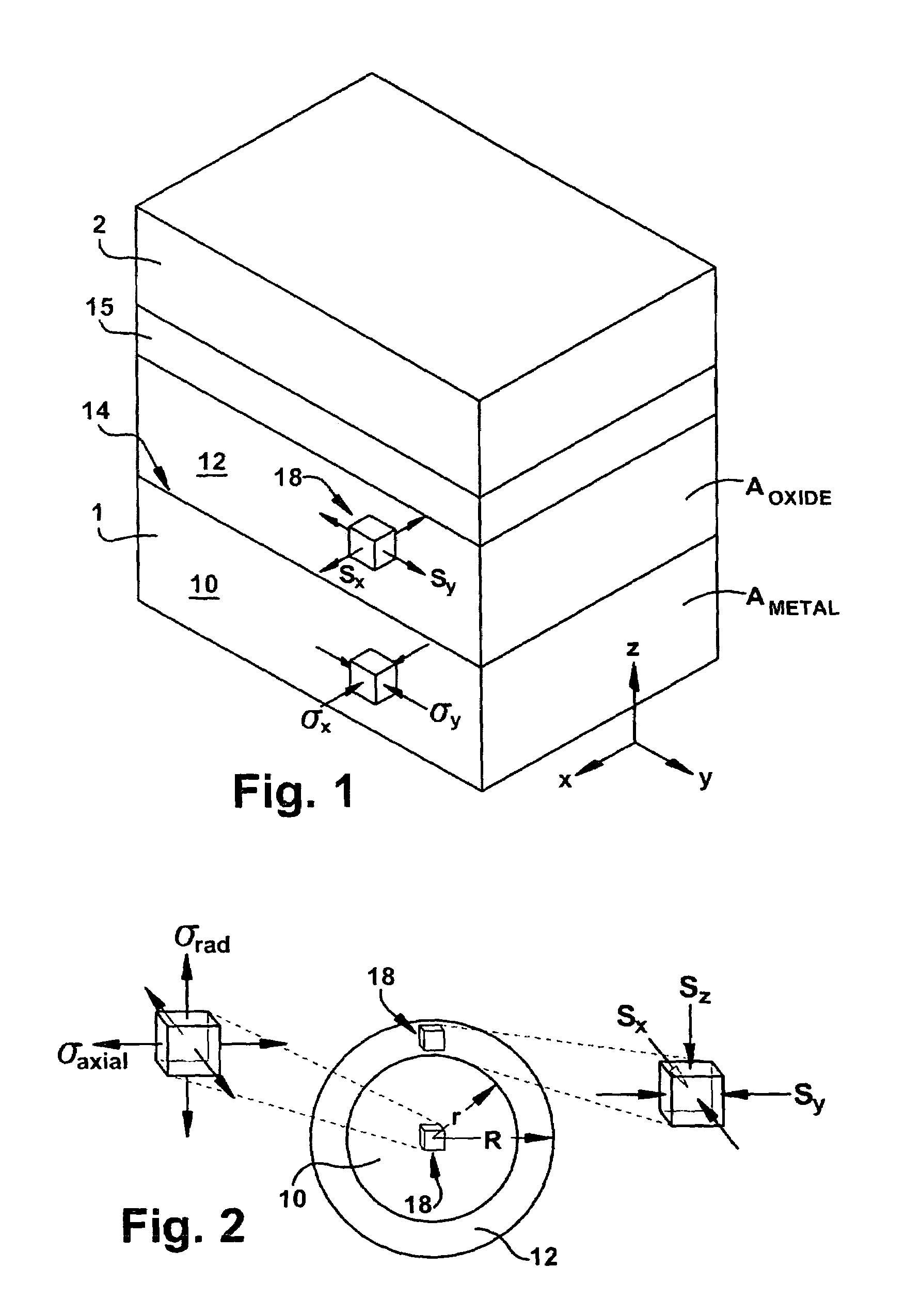

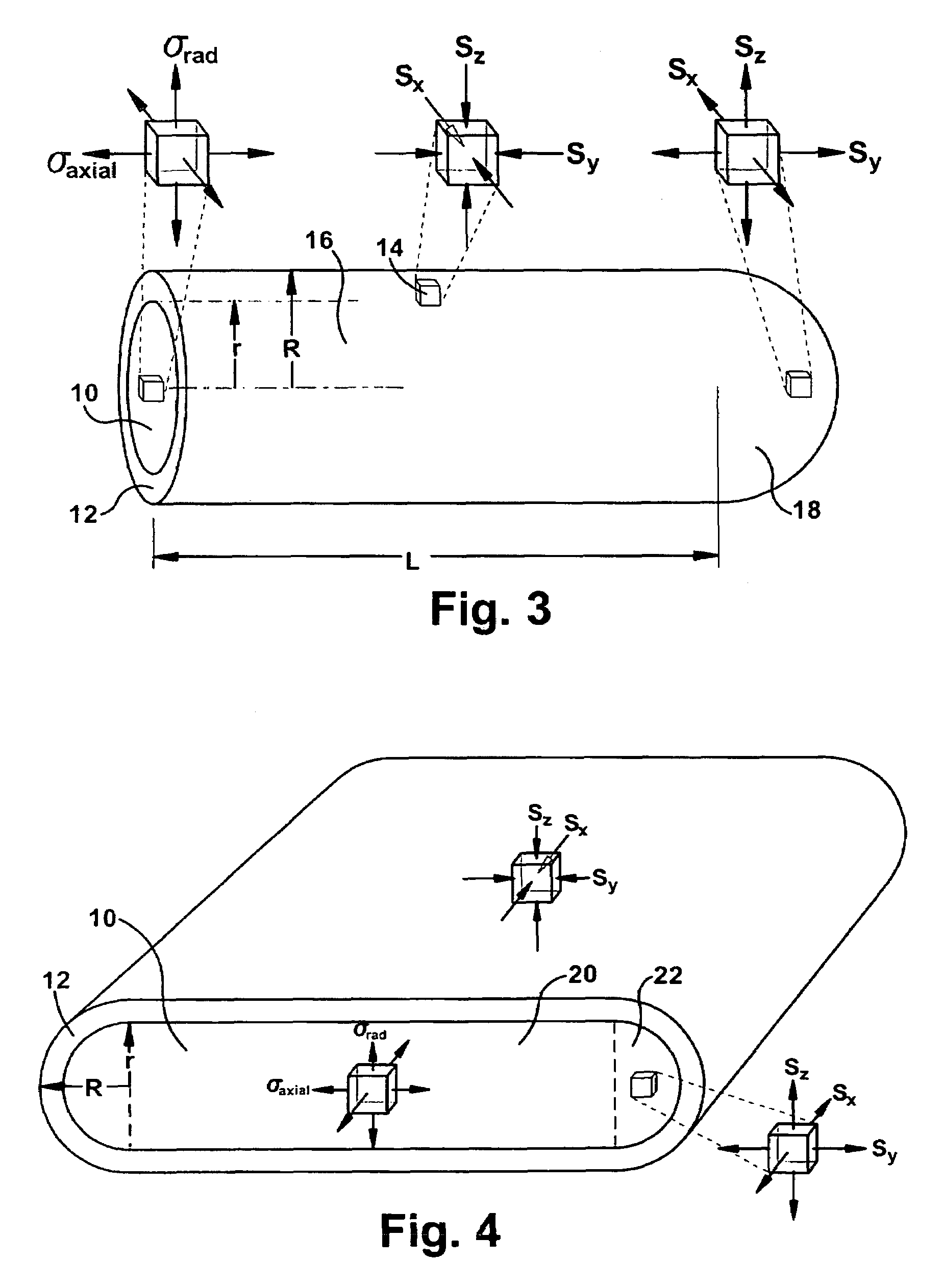

Strong substrate alloy and compressively stressed dielectric film for capacitor with high energy density

A capacitor anode (1) includes a substrate (10) which is formed from an alloy, metal, or metal compound which has a high tensile yield strength and high elastic modulus. The material has a composition which can be anodized, yielding an adherent and compressively stressed dielectric film (12) of pure, mixed, alloyed, or doped oxide that has a high usable dielectric strength (e.g., over 50 V / μm) and high dielectric constant (e.g., 20 to over 10,000). A capacitor formed from the anode has a high energy density.

Owner:CASE WESTERN RESERVE UNIV

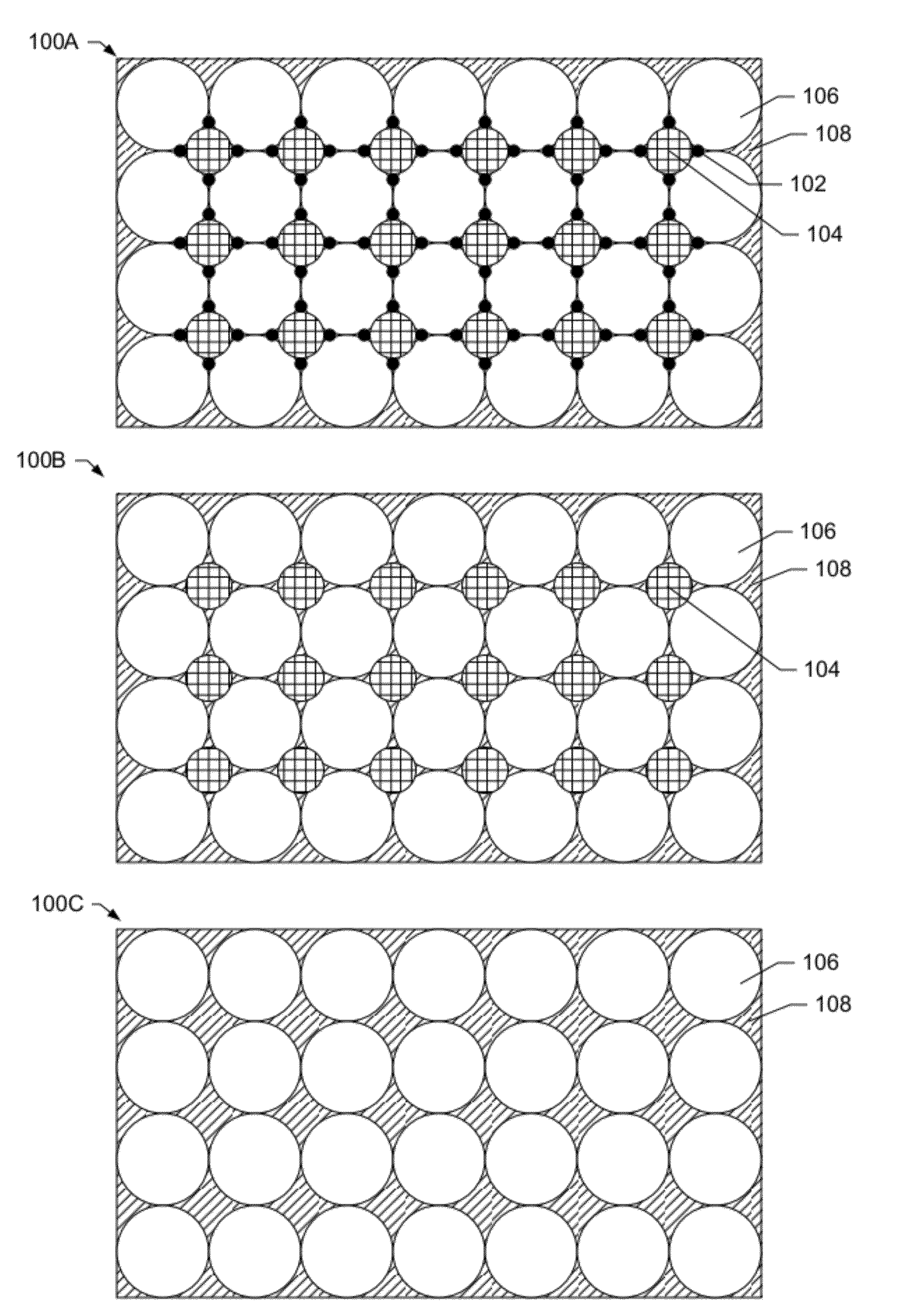

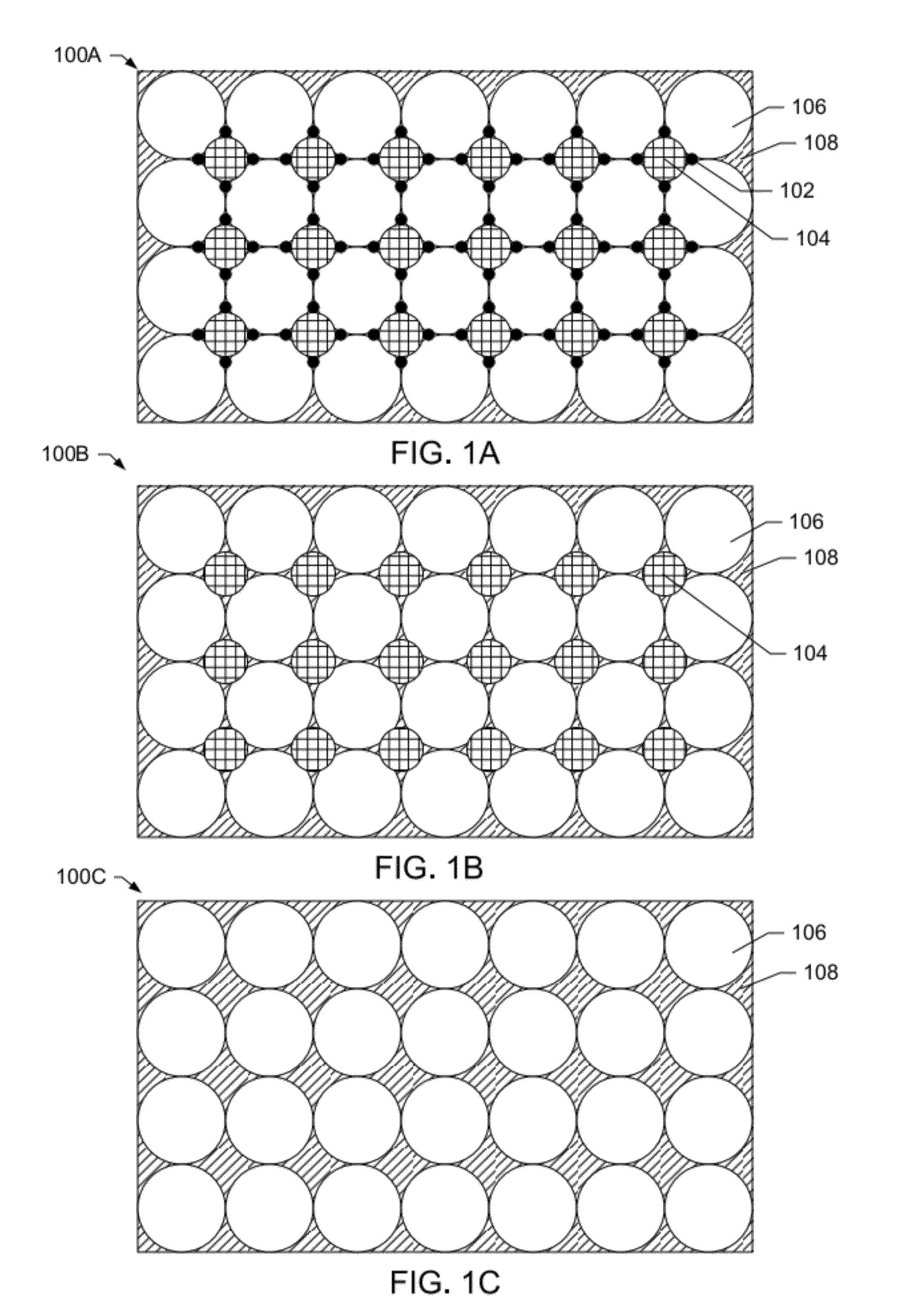

High dielectric constant composite materials and methods of manufacture

ActiveUS20120245016A1High composite strengthHigh dielectric constantMaterial nanotechnologyLiquid surface applicatorsBarium strontium titanateBarium titanate

The present invention relates to composite materials with a high dielectric constant and high dielectric strength and to methods of producing the composite materials. The composite materials have high dielectric constants at a range of high frequencies and possess robust mechanical properties and strengths, such that they may be machined to a variety of configurations. The composite materials also have high dielectric strengths for operation in high power and high energy density systems. In one embodiment, the composite material is composed of a trimodal distribution of ceramic particles, including barium titanate, barium strontium titanate (BST), or combinations thereof and a polymer binder.

Owner:UNIVERSITY OF MISSOURI

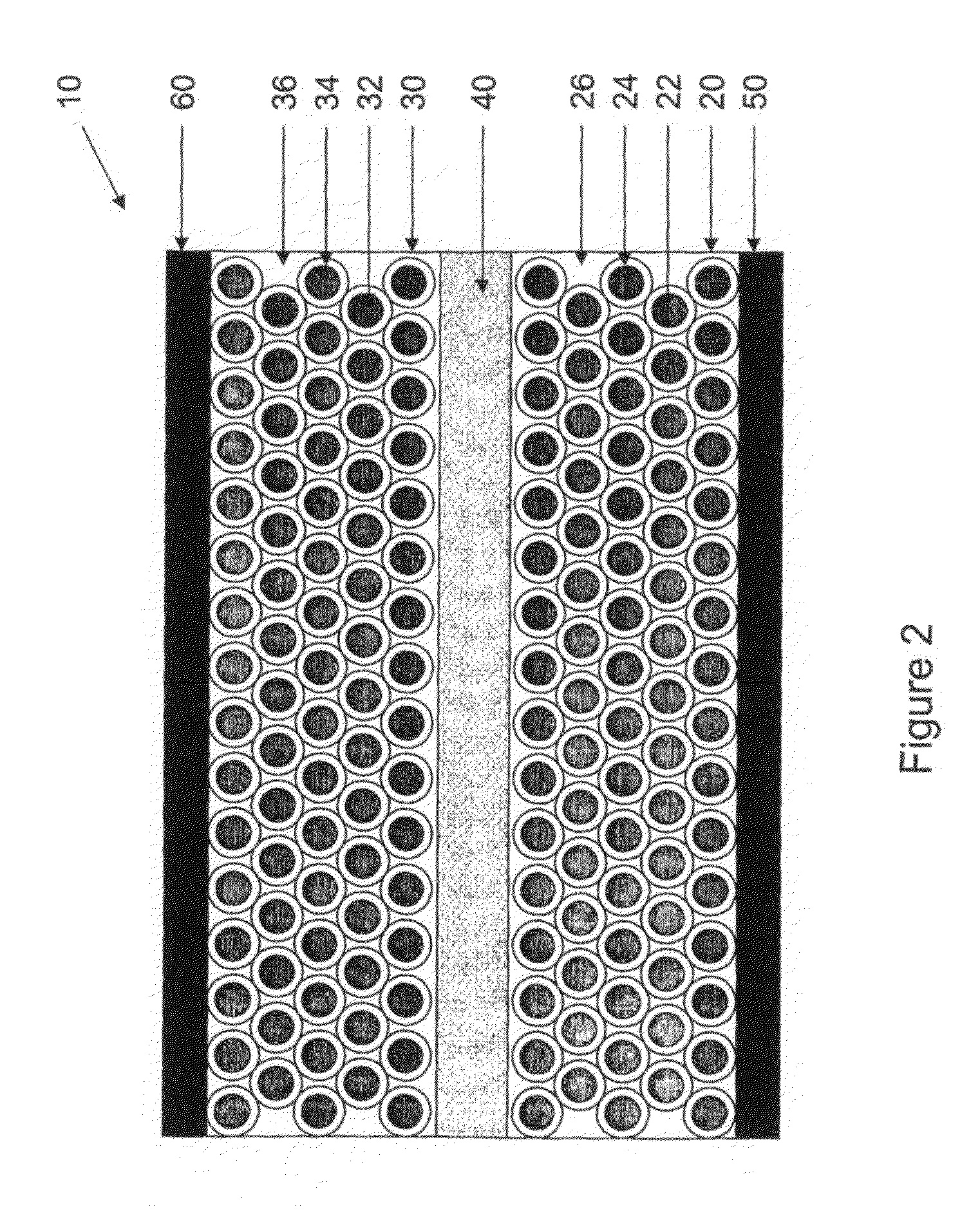

High power capacitors from thin layers of metal powder or metal sponge particles

InactiveUS6914769B2Increase surface areaSmall sizeLiquid electrolytic capacitorsFixed capacitor dielectricMetal particleDielectric strength

An anode (14, 208, 410) and / or cathode (12, 212, 420) of a capacitor has a large surface area. The high surface area of the anode is provided by forming the anode from a thin, electrically conductive layer (16) formed from metal particles (18) or an electrically conductive metallic sponge (416). These materials provide a porous structure with a large surface area of high accessibility. The particles are preferably directional or non-directional sponge particles of a metal, such as titanium. The conductive layer has a dielectric film (36, 236, 414) on its surface, formed by anodizing the particle surfaces. The dielectric film has a combination of high dielectric constant and high dielectric strength. The cathode (12, 212, 420) of the capacitor is either a conventional solid material or, more preferably, has a large surface provided by forming the surface from a sponge or particles analogously to the anode. The high dielectric strengths obtainable from the capacitor allow for extreme miniaturization, making the capacitor particularly suited for integrated circuit applications.

Owner:TITANIUM POWER TECH

Loadbreak connector assembly which prevents switching flashover

InactiveUS6939151B2Avoid flashoverReduced strengthOne pole connectionsElectric discharge tubesPower cableEngineering

Owner:THOMAS & BETTS INT INC

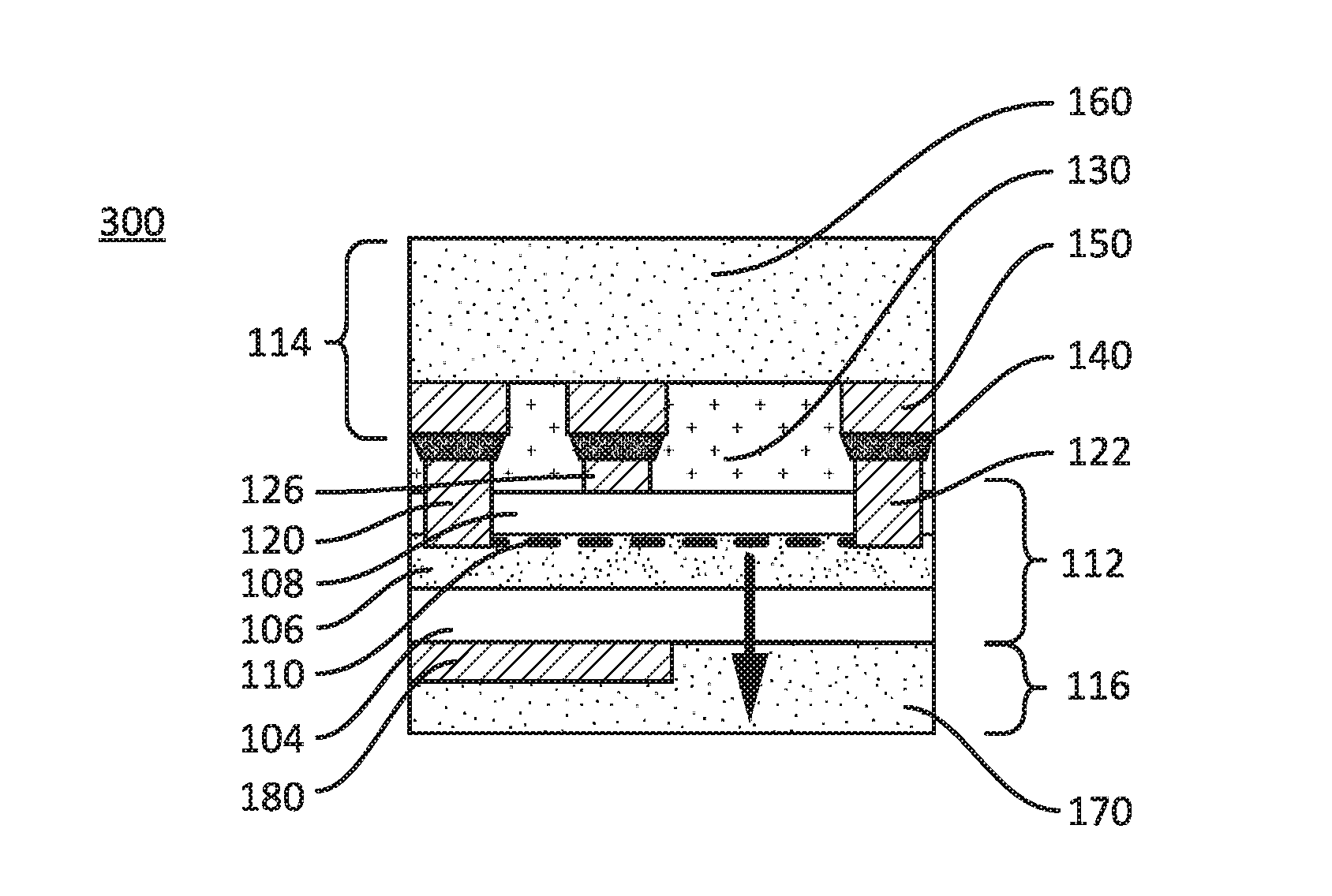

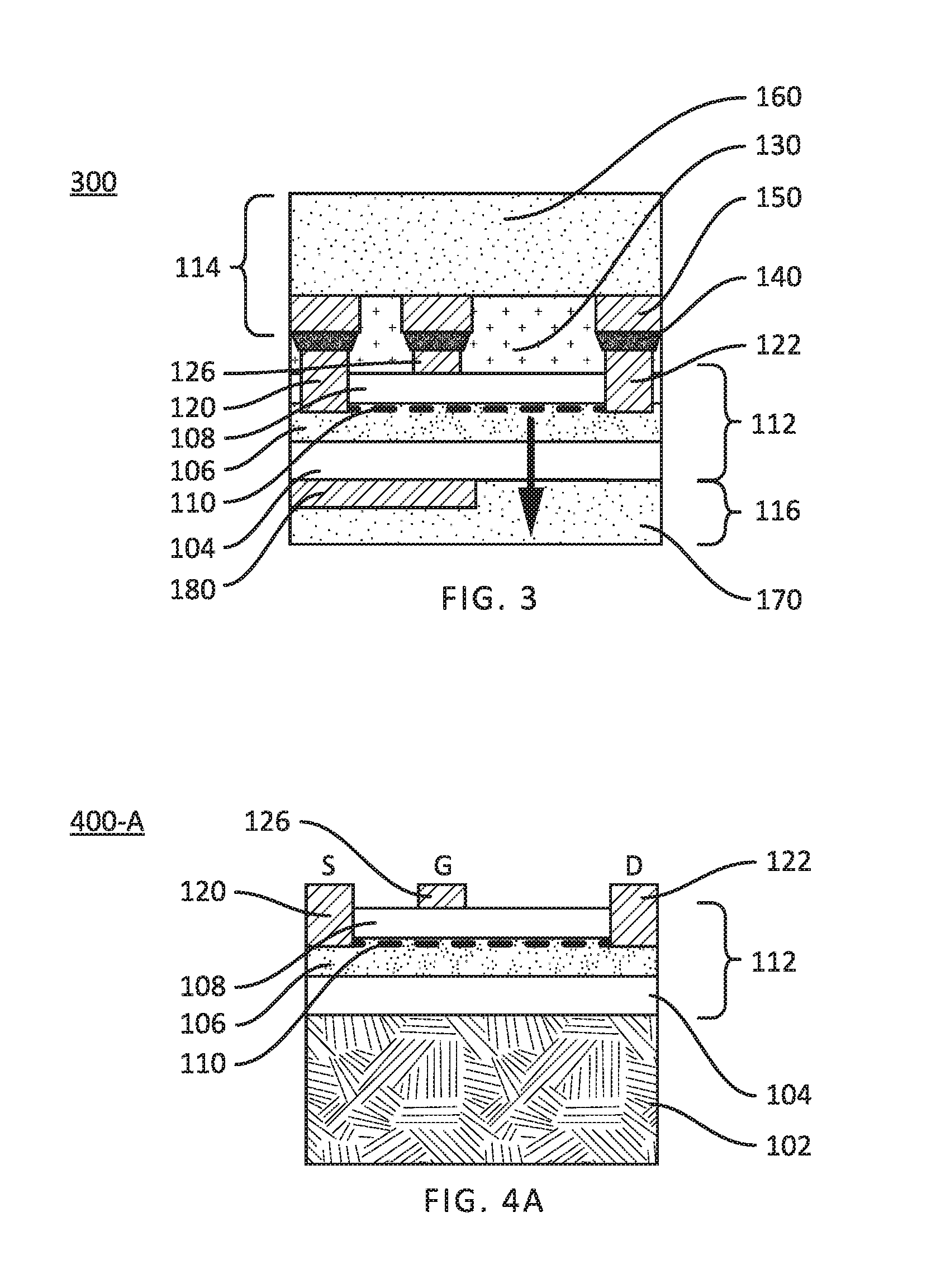

GaN SEMICONDUCTOR DEVICE STRUCTURE AND METHOD OF FABRICATION BY SUBSTRATE REPLACEMENT

ActiveUS20160380090A1Increased vertical breakdown resistanceImprove cooling effectTransistorSemiconductor/solid-state device testing/measurementContact padDevice material

Devices and systems comprising high current / high voltage GaN semiconductor devices are disclosed. A GaN die, comprising a lateral GaN transistor, is sandwiched between an overlying header and an underlying composite thermal dielectric layer. Fabrication comprises providing a conventional GaN device structure fabricated on a low cost silicon substrate (GaN-on-Si die), mechanically and electrically attaching source, drain and gate contact pads of the GaN-on-Si die to corresponding contact areas of conductive tracks of the header, then entirely removing the silicon substrate. The exposed substrate-surface of the epi-layer stack is coated with the composite dielectric thermal layer. Preferably, the header comprises a ceramic dielectric support layer having a CTE matched to the GaN epi-layer stack. The thermal dielectric layer comprises a high dielectric strength thermoplastic polymer and a dielectric filler having a high thermal conductivity. This structure offers improved electrical breakdown resistance and effective thermal dissipation compared to conventional GaN-on-Si device structures.

Owner:GAN SYST

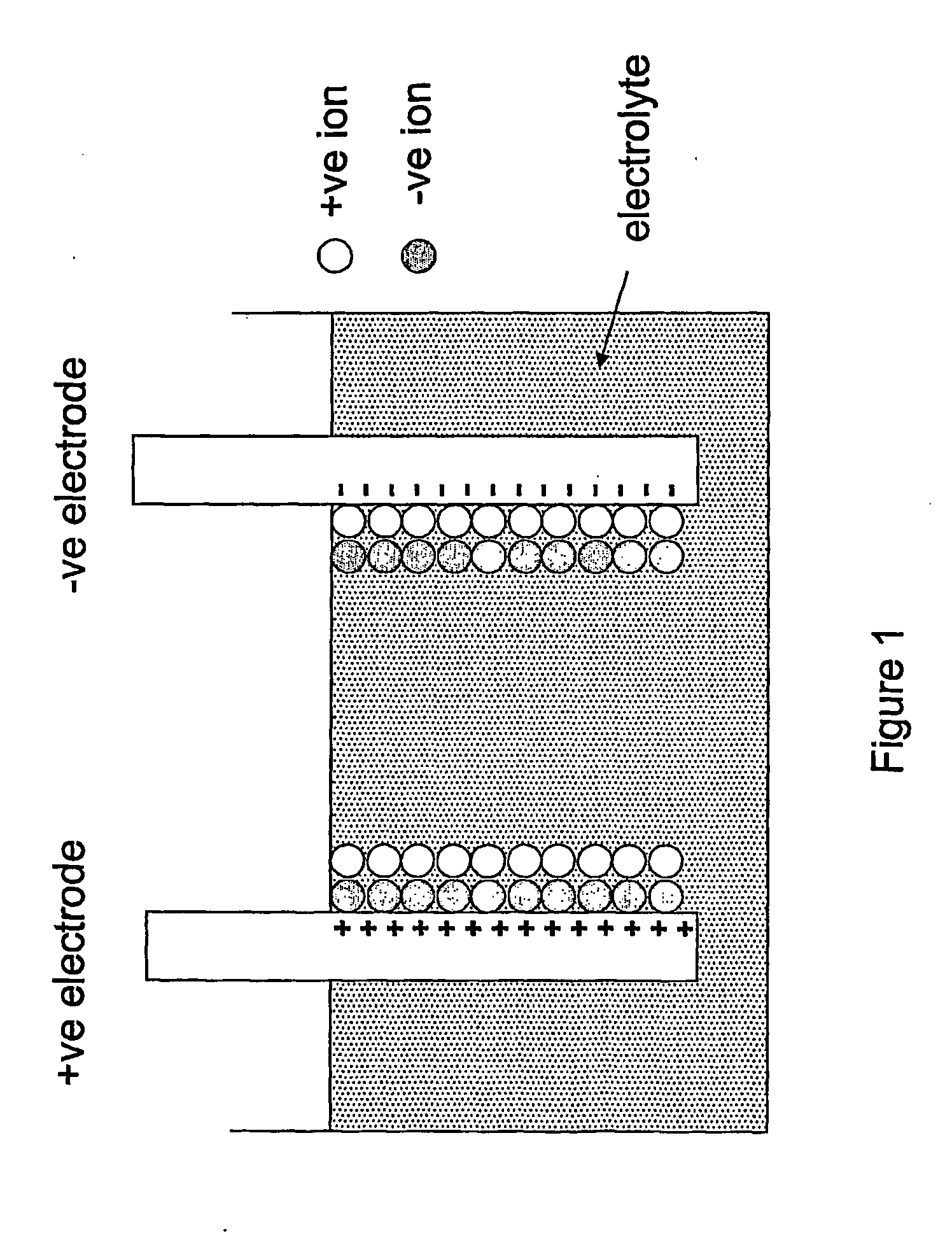

Core-shell nanoparticles in electronic battery applications

InactiveUS20130078510A1Shorten cycle lifeCompromise capacitanceMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesCore shell nanoparticlesCore shell

The present invention provides an improved supercapacitor-like electronic battery comprising a conventional electrochemical capacitor structure. A first nanocomposite electrode and a second electrode and an electrolyte are positioned within the conventional electrochemical capacitor structure. The electrolyte separates the nanocomposite electrode and the second electrode. The first nanocomposite electrode has first conductive core-shell nanoparticles in a first electrolyte matrix. A first current collector is in communication with the nanocomposite electrode and a second current collector is in communication with the second electrode. Also provided is an electrostatic capacitor-like electronic battery comprising a high dielectric-strength matrix separating a first electrode from a second electrode and, dispersed in said high-dielectric strength matrix, a plurality of core-shell nanoparticles, each of said core-shell nanoparticles having a conductive core and an insulating shell.

Owner:OERLIKON ADVANCED TECH +1

High oleic acid oil compositions and methods of making and electrical insulation fluids and devices comprising the same

InactiveUS7048875B2Fatty acid chemical modificationOther chemical processesTriglycerideHigh oleic acid

High oleic acid triglyceride compositions that comprise fatty acid components of at least 75% oleic acid, less than 10% diunsaturated fatty acid component; less than 3% triunsaturated fatty acid component; and less than 8% saturated fatty acid component; and having the properties of a dielectric strength of at least 35 KV / 100 mil gap, a dissipation factor of less than 0.05% at 25NC, acidity of less than 0.03 mg KOH / g, electrical conductivity of less than 1 pS / m at 25NC, a flash point of at least 250NC and a pour point of at least −15NC are disclosed. Electrical insulation fluids comprising the triglyceride composition are disclosed. Electrical insulation fluids that comprise the triglyceride composition and a combination of additives are disclosed. Electrical apparatuses comprising the electrical insulation fluids and the use of electrical insulation fluids to provide insulation in electrical apparatuses are disclosed. A process for preparing the high oleic acid triglyceride composition is disclosed.

Owner:ABB TECH AG

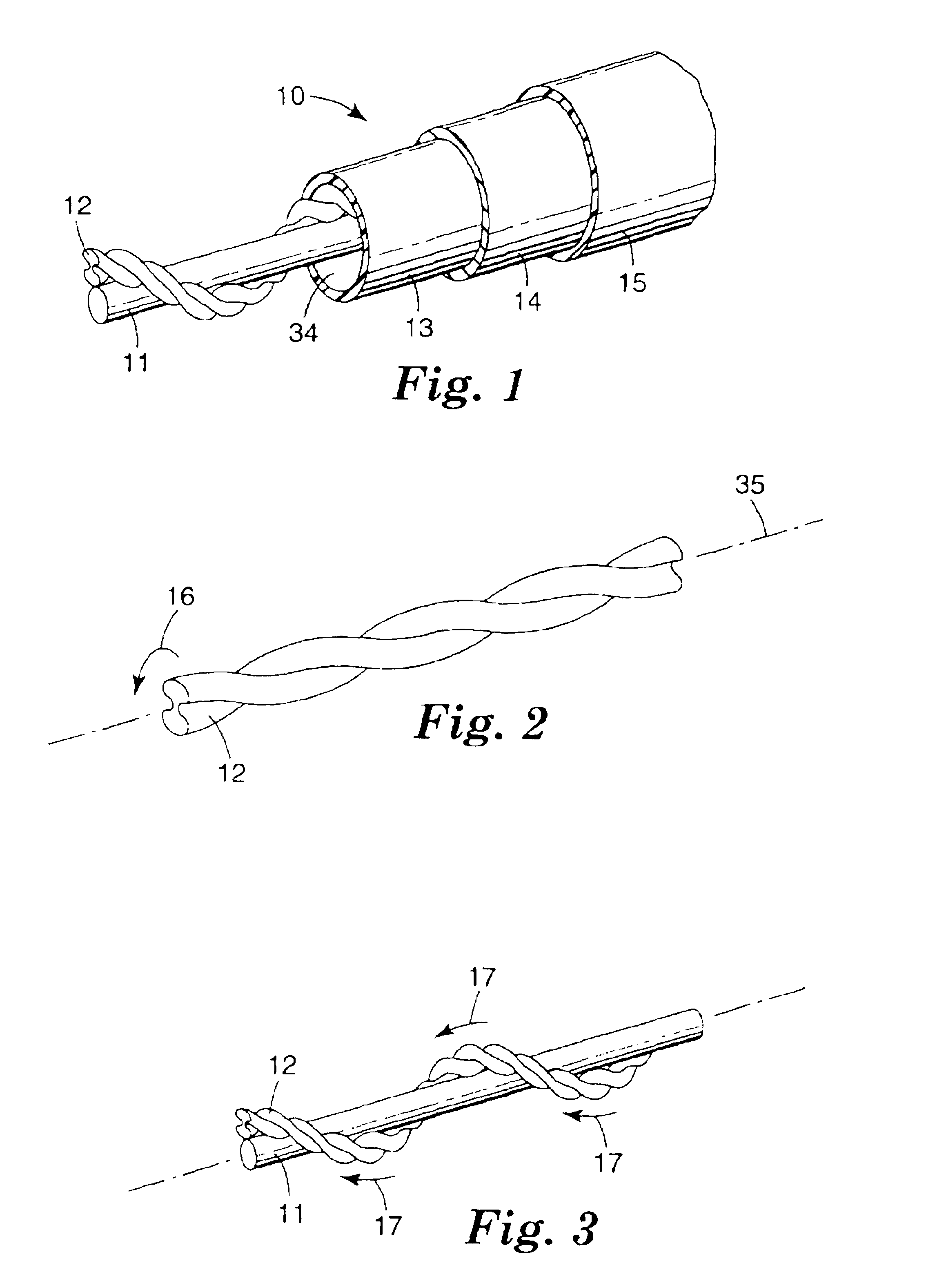

High propagation speed coaxial and twinaxial cable

InactiveUS6849799B2Low dielectric constantReduce morbidityCable insulation constructionInsulated cablesElectrical conductorEngineering

Owner:3M INNOVATIVE PROPERTIES CO

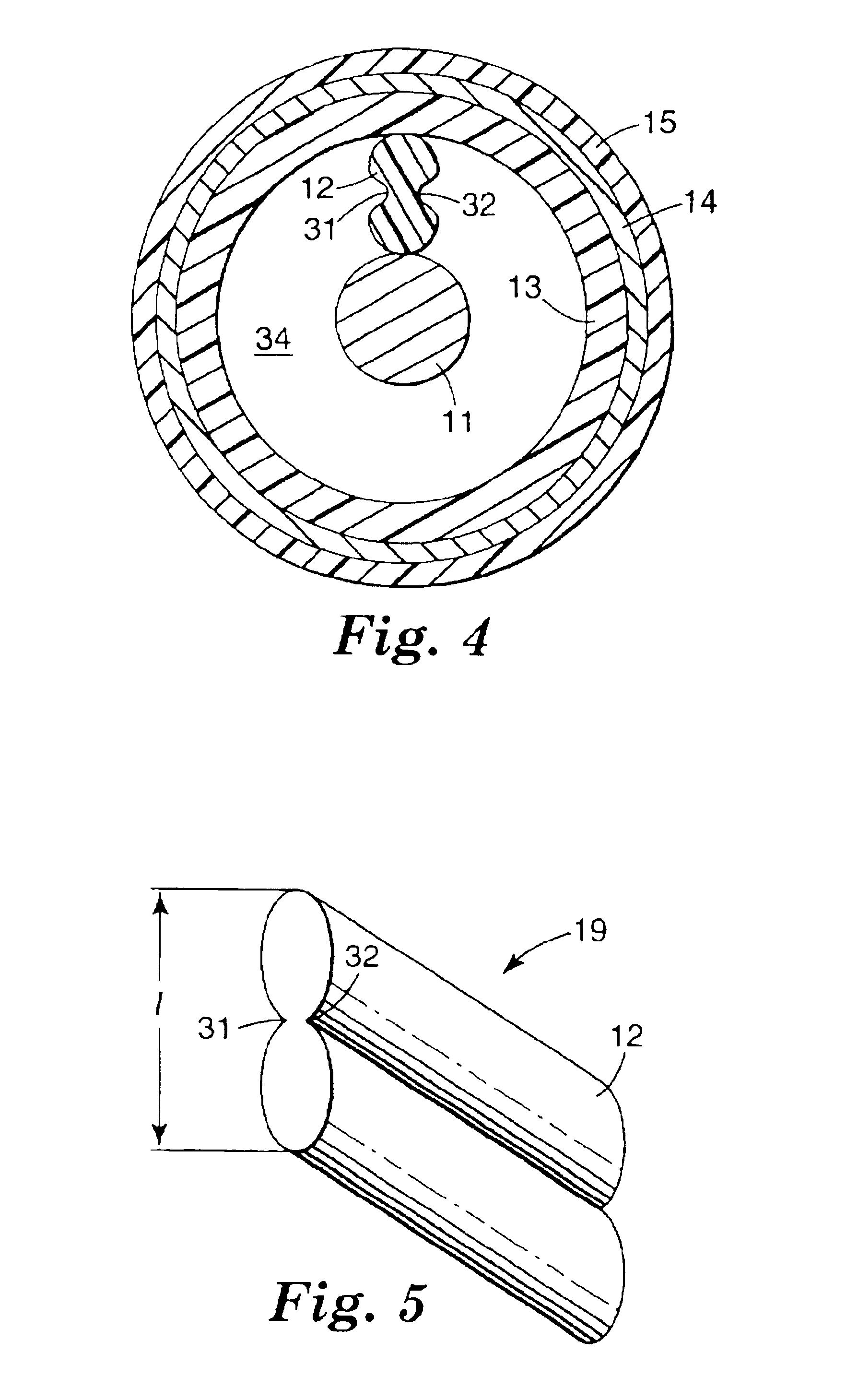

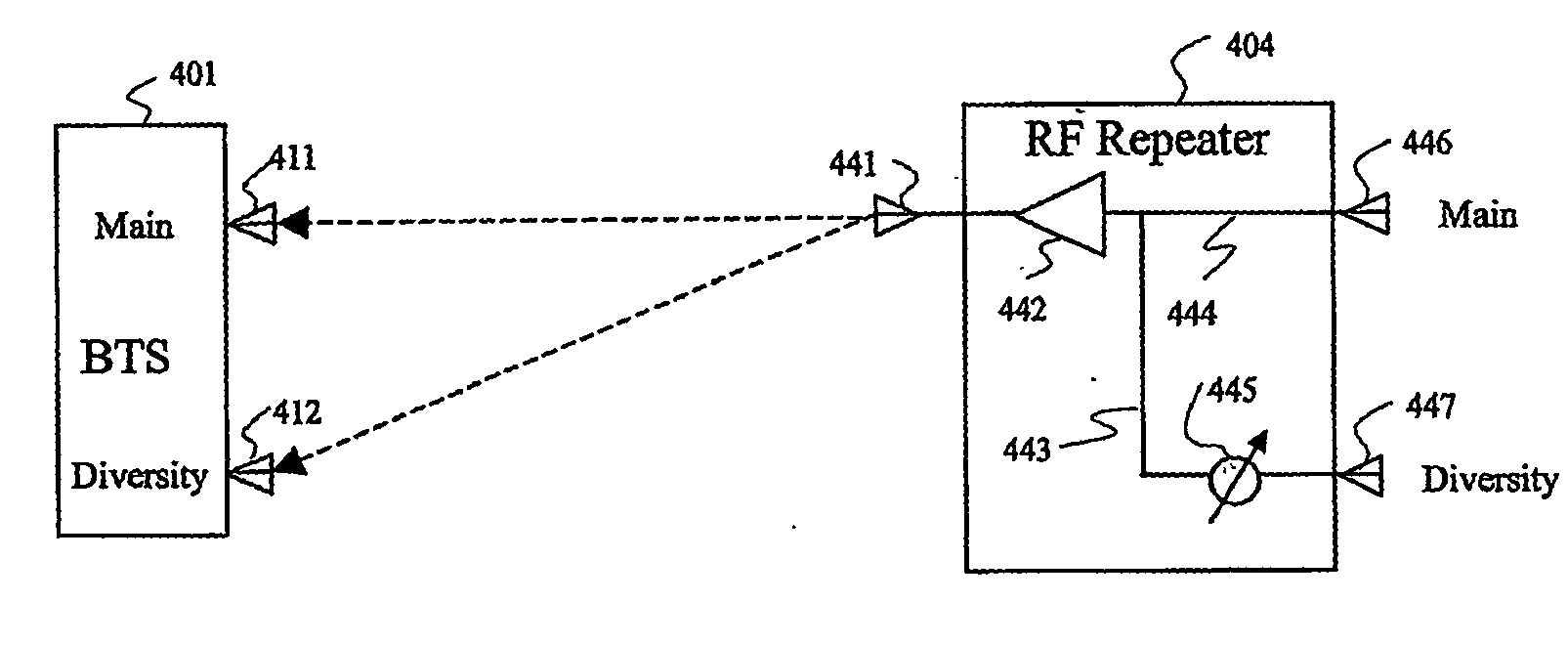

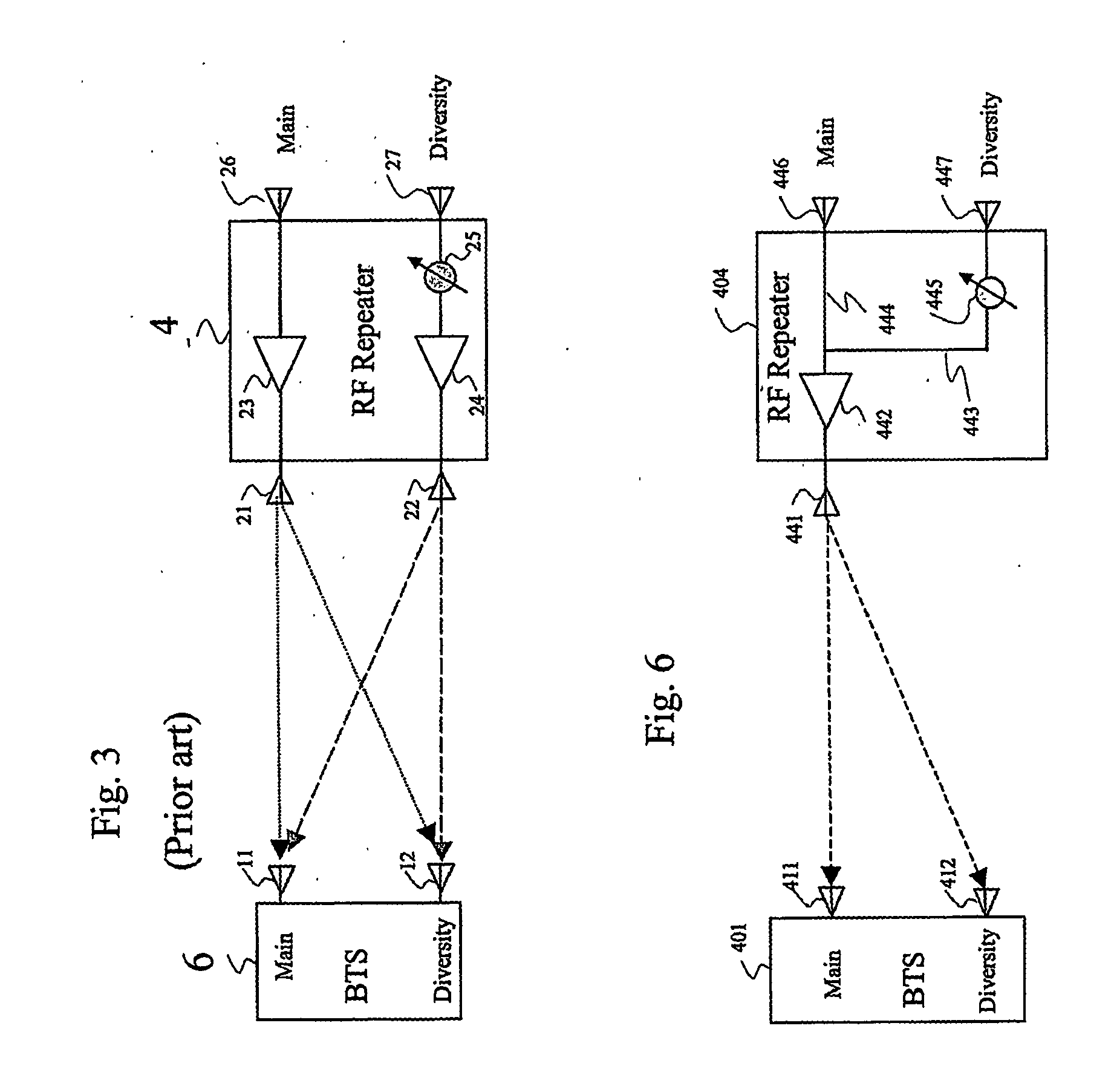

Phase sweeping methods for transmit diversity and diversity combining in bts sector extension and in wireless repeaters

InactiveUS20060172710A1Spatial transmit diversityElectromagnetic wave modulationEngineeringWireless repeater

Apparatus for inserting transmit diversity into an RF signal for transmission, comprises: an RF splitter for splitting the RF signal to be transmitted into two signal parts, and a non-linear phase modulator which applies a non-linear phase modulation to one of the two signal parts, thereby to provide transmit diversity between the first signal part and the second signal part. One of the ways of inserting a non-linear phase modulation into the RF signal is to use a spinning disc with tracks of different dielectric strength. The apparatus is useful in cellular telephony for supplying repeaters and base station extensions with diversity capability.

Owner:CELLETRA

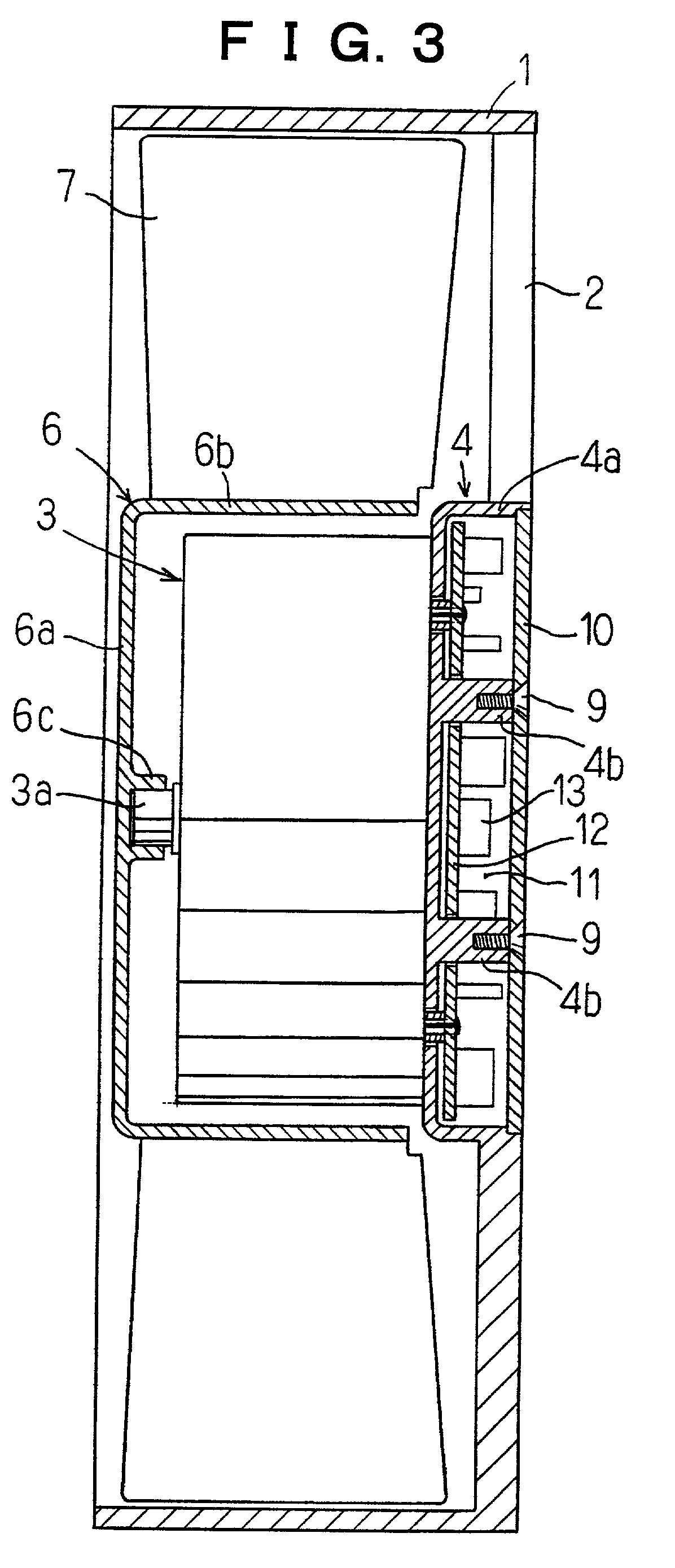

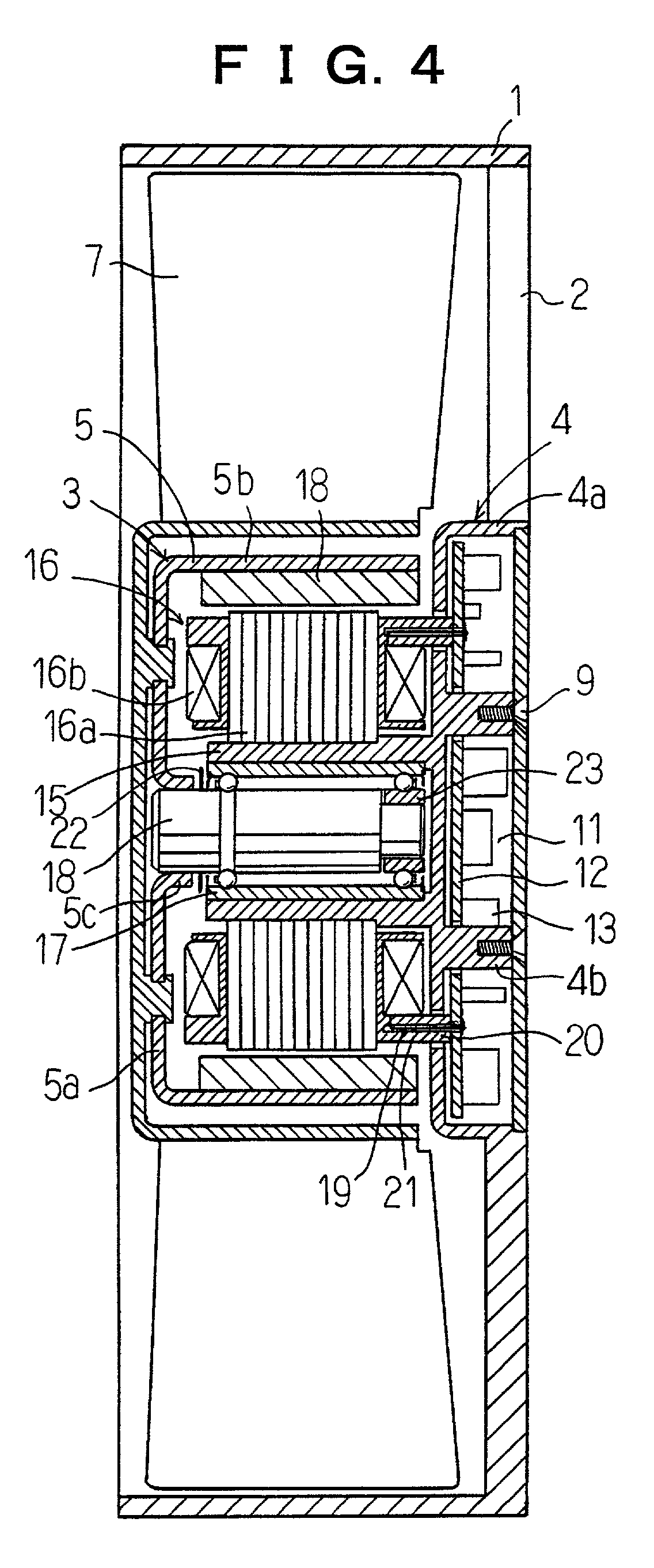

Switch gear and method of manufacturing thereof

InactiveUS6897396B2Reduce the number of partsEconomical and efficientContact mechanismsSubstation/switching arrangement cooling/ventilationMan-hourMechanical engineering

By molding a plurality of vacuum valves (7), (13) having differing functions together with an input member (3) and an output member (21) en bloc in a resin layer (23) to form a switch gear (1), the present invention seeks to achieve dielectric strength without resorting to the use of SF6 gas, while rendering the whole device more compact and reducing both the number of parts and the man hours required for molding.

Owner:KK TOSHIBA

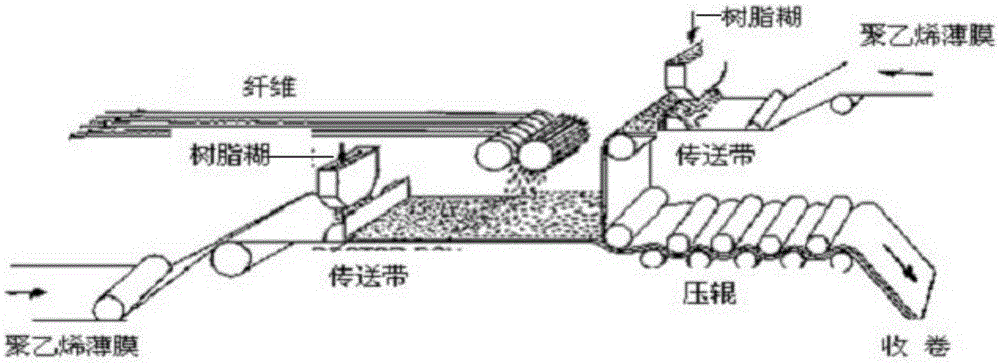

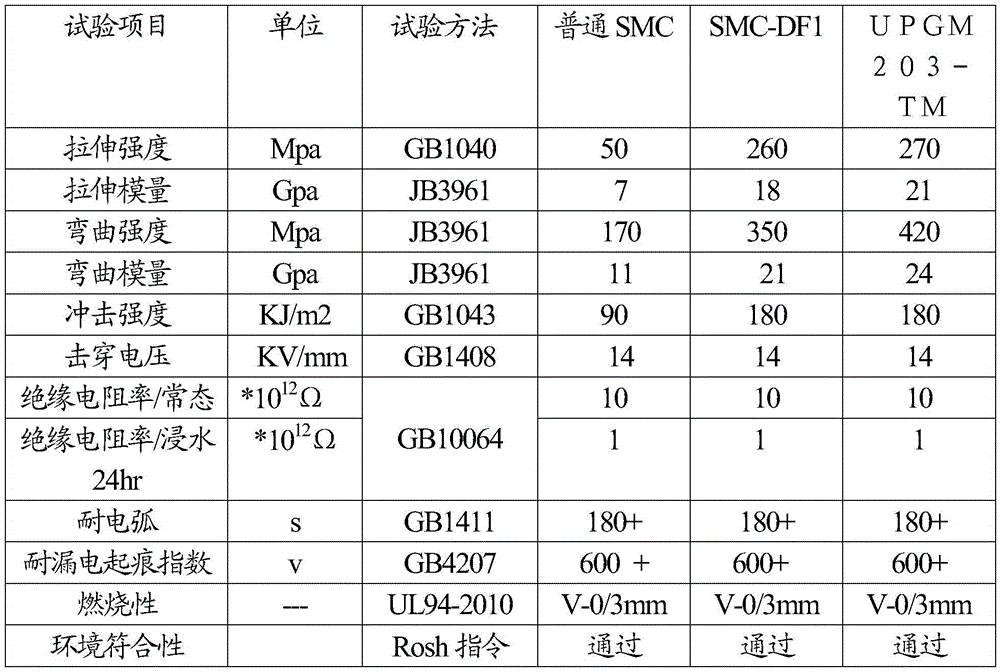

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

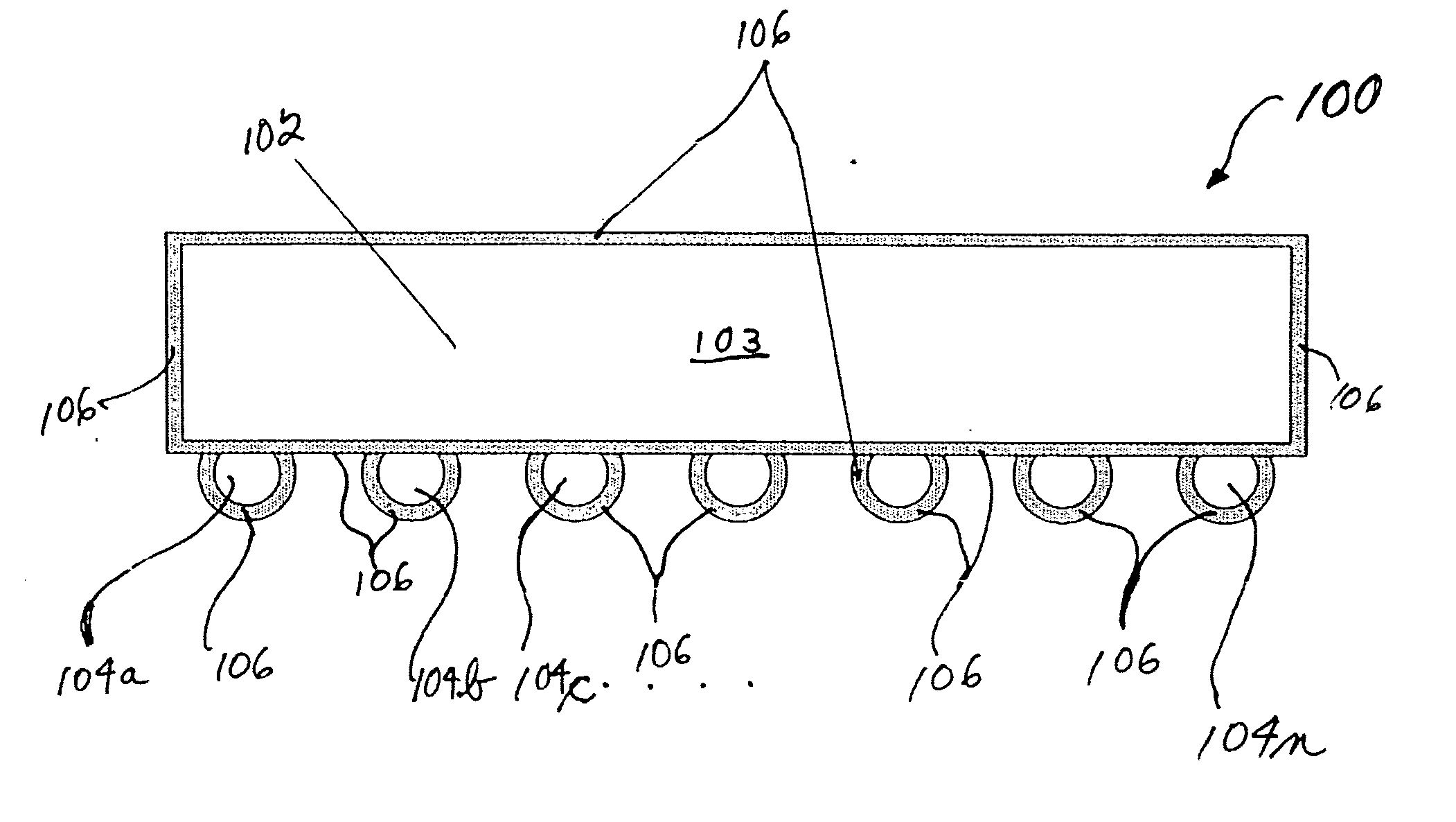

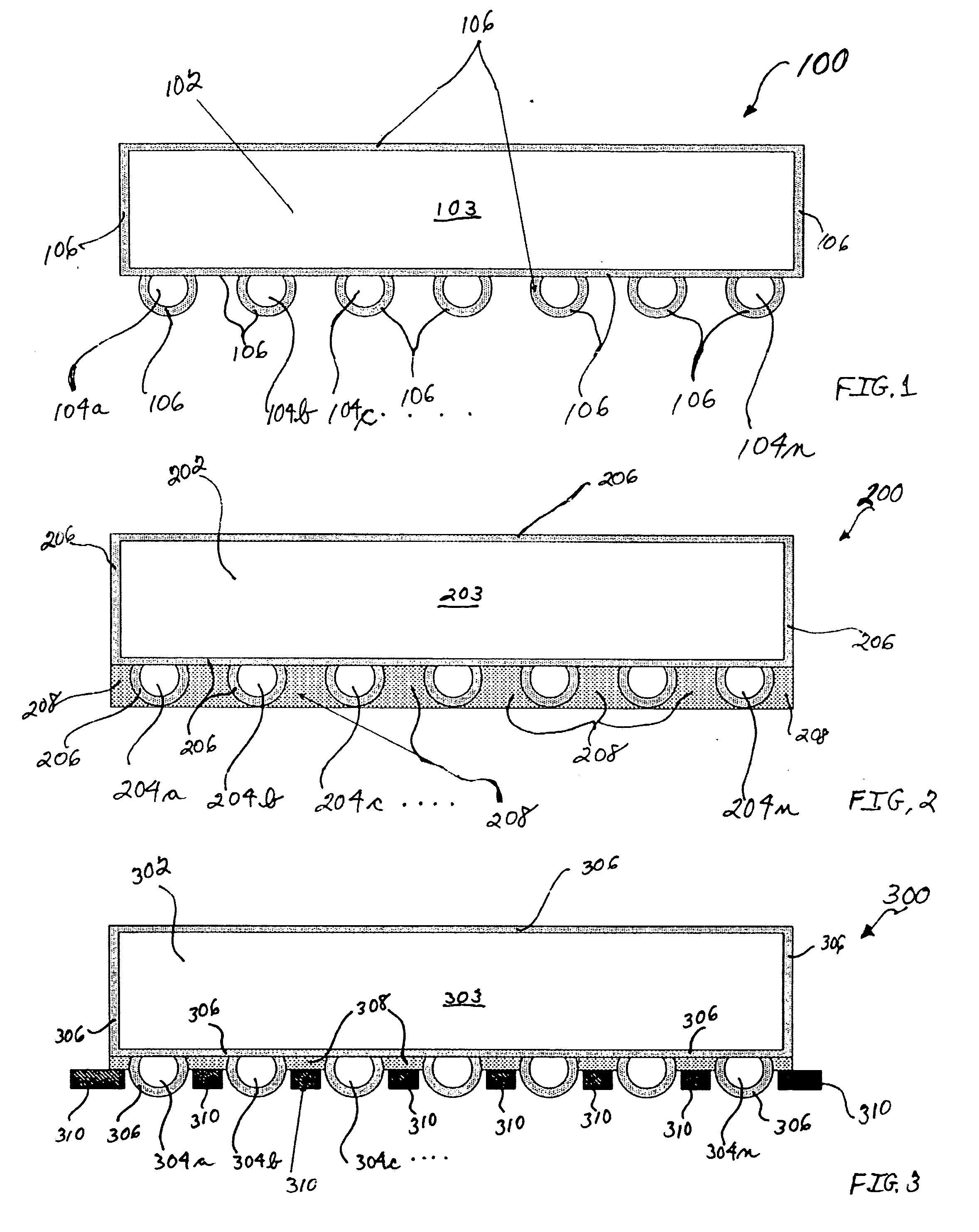

Method and apparatus for applying external coating to grid array packages for increased reliability and performance

InactiveUS20060278971A1Improve electrical performanceImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsParylene coatingEngineering

A method and apparatus are disclosed for selective removal of a conformal coating from the solder balls of grid array packages such that the benefits of the coating are realized. An ancillary benefit of the invention is improved process-ability of the grid array package by improving the mechanical containment of the solder during the reflow process and improved electrical isolation between the individual solder attachment points. For example, a method for coating a ball grid array is provided, which includes coating the ball grid array with a thin layer of parylene. Next, the solder ball side of the part is butter smeared or squeegeed with a water soluble coating and assembled wet. A mask having holes in the same pattern as the balls in the grid, and a thickness that is about 80% of the height of the balls, is applied to the solder ball side of the part. This side of the part is then butter smeared again with the water soluble coating, and the entire assembly is allowed to dry. At this point, about 20% of each parylene-coated solder ball protrudes higher than the surface of the mask. The solder ball side of the part is then grit blasted with an abrasive material. The extent that the abrasive material removes the parylene coating from the solder balls is limited by the mask and the layer of water soluble coating. Therefore, the grit blasting removes the parylene coating from only the protruding areas (e.g., about top 20%) of the solder balls. Water is then used to remove the water soluble coating, and the parylene coated part is baked to remove moisture. Thus, a parylene coated ball grid array (or column grid array) is provided that is highly impervious to moisture, has a very high dielectric strength, and thereby improves the electrical performance and reliability of the surface mounted part.

Owner:HONEYWELL INT INC

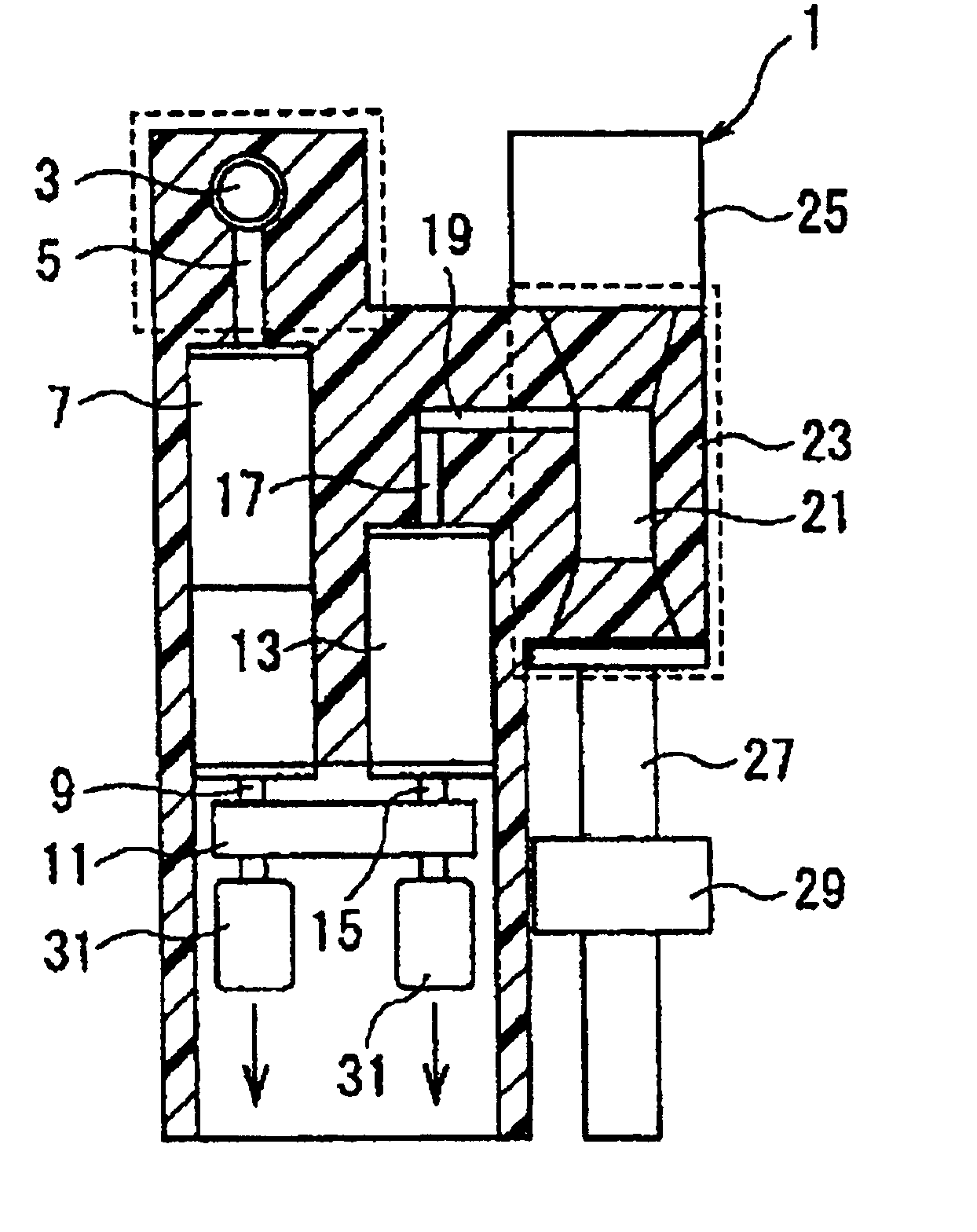

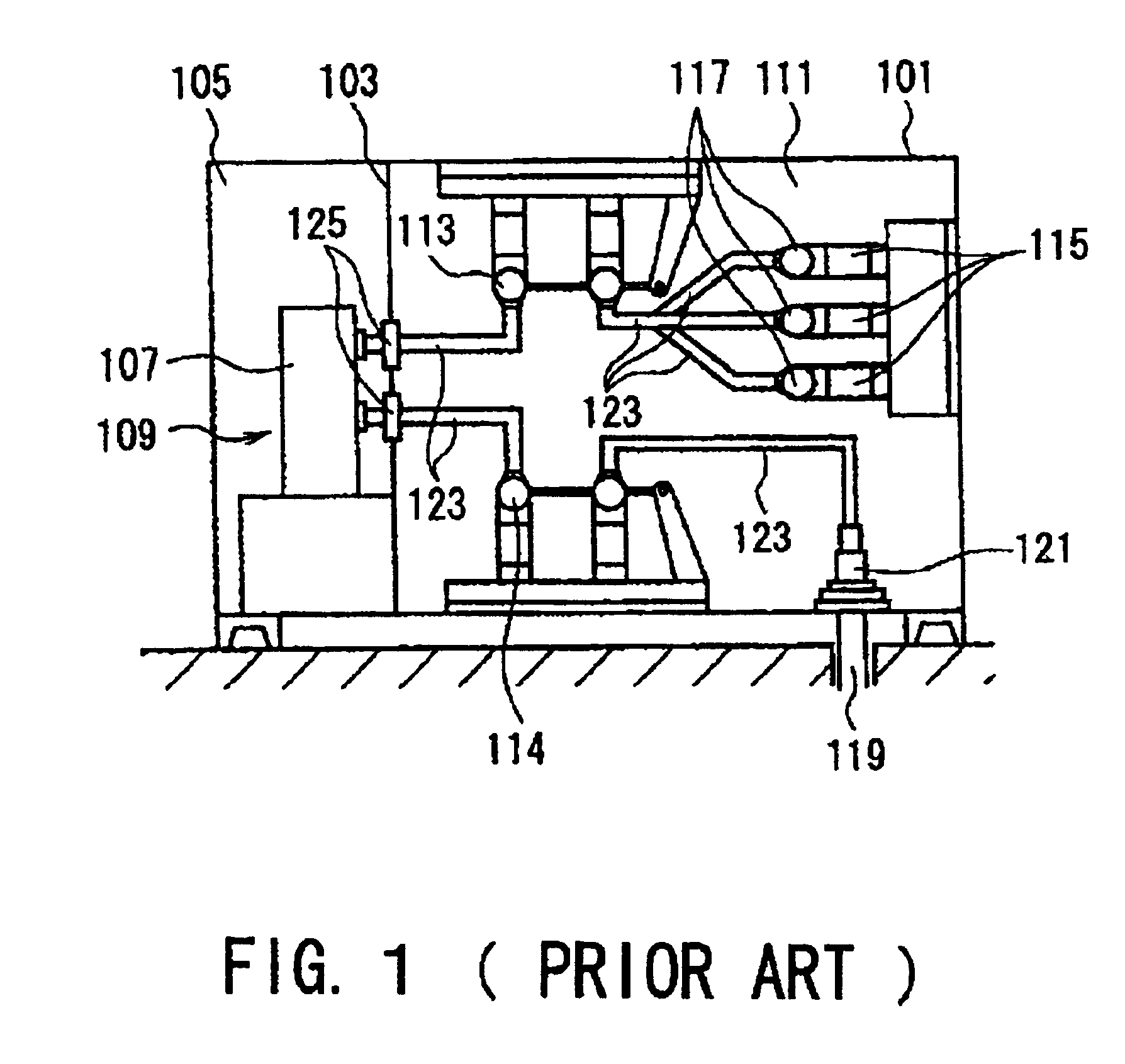

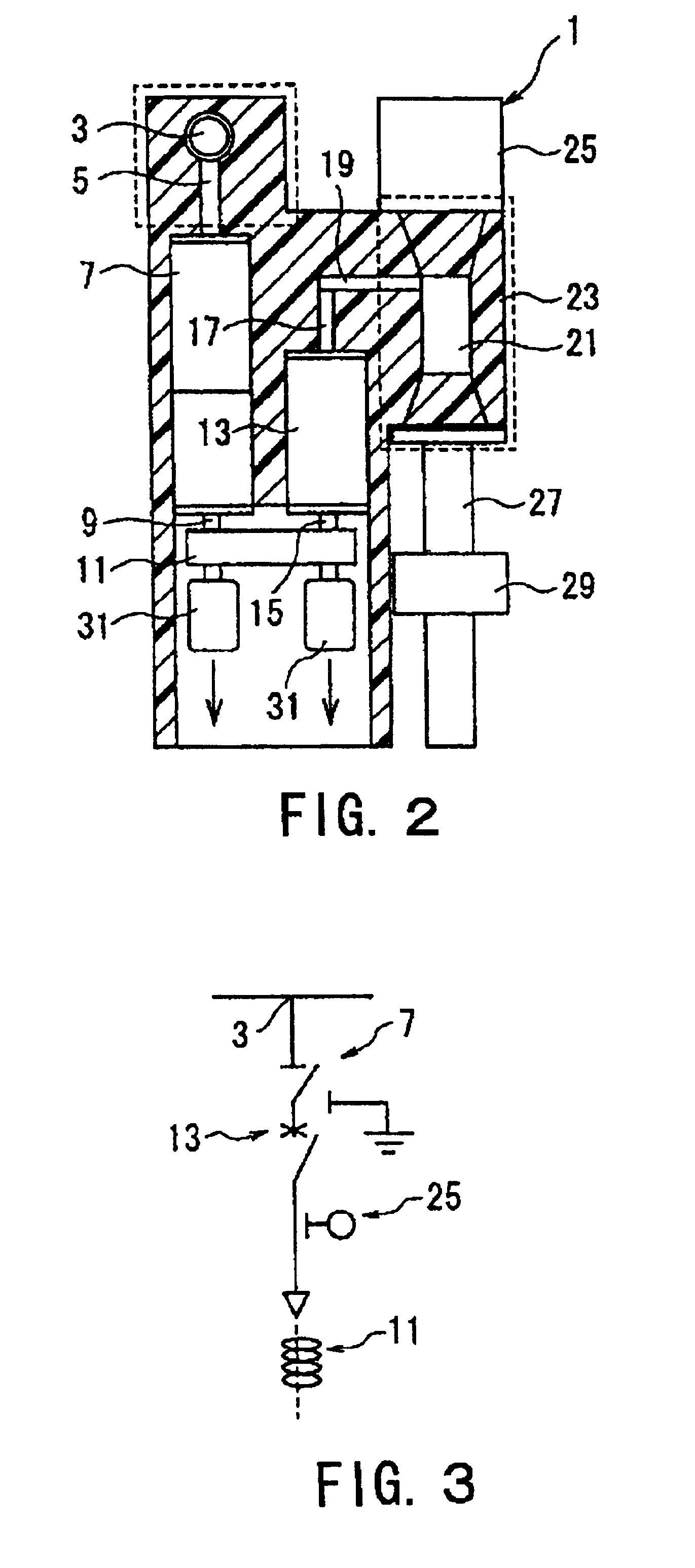

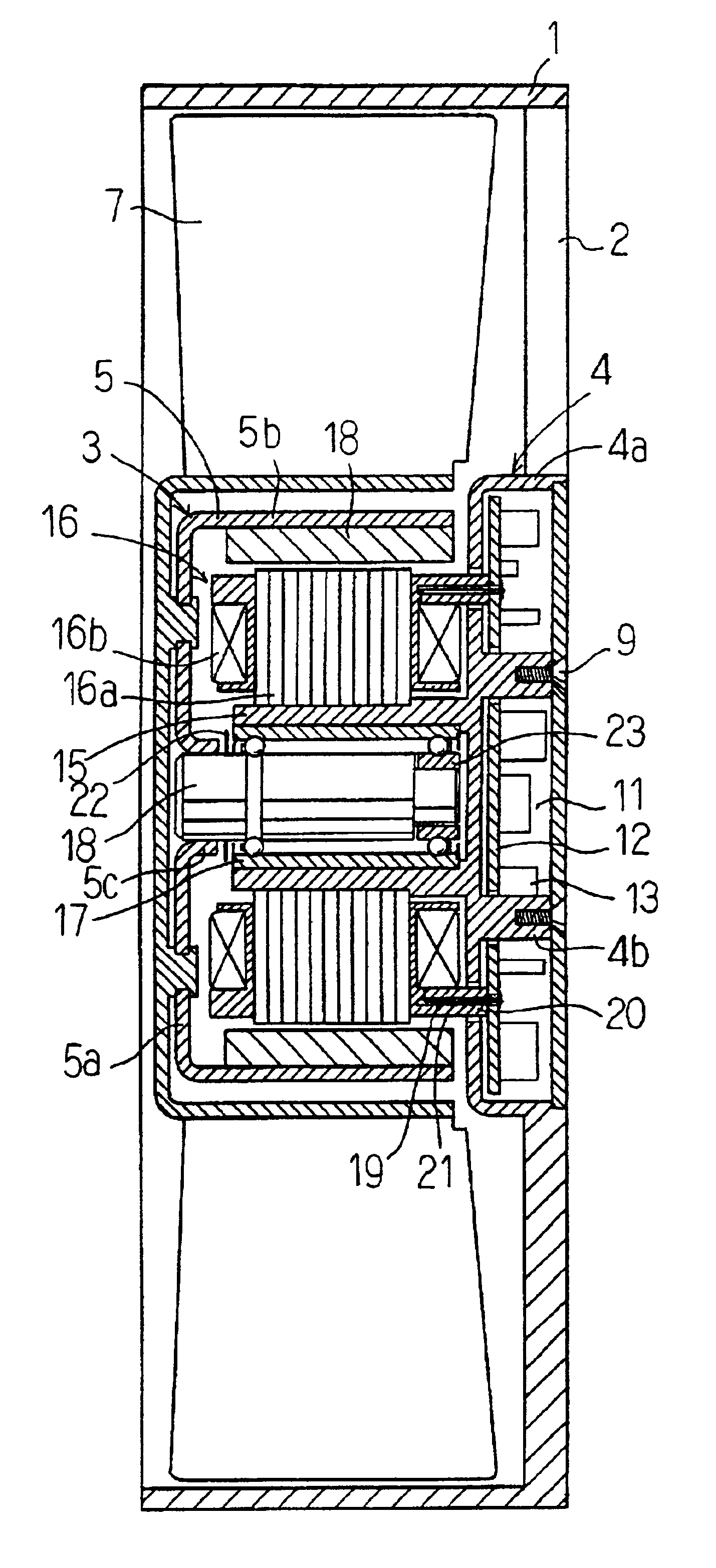

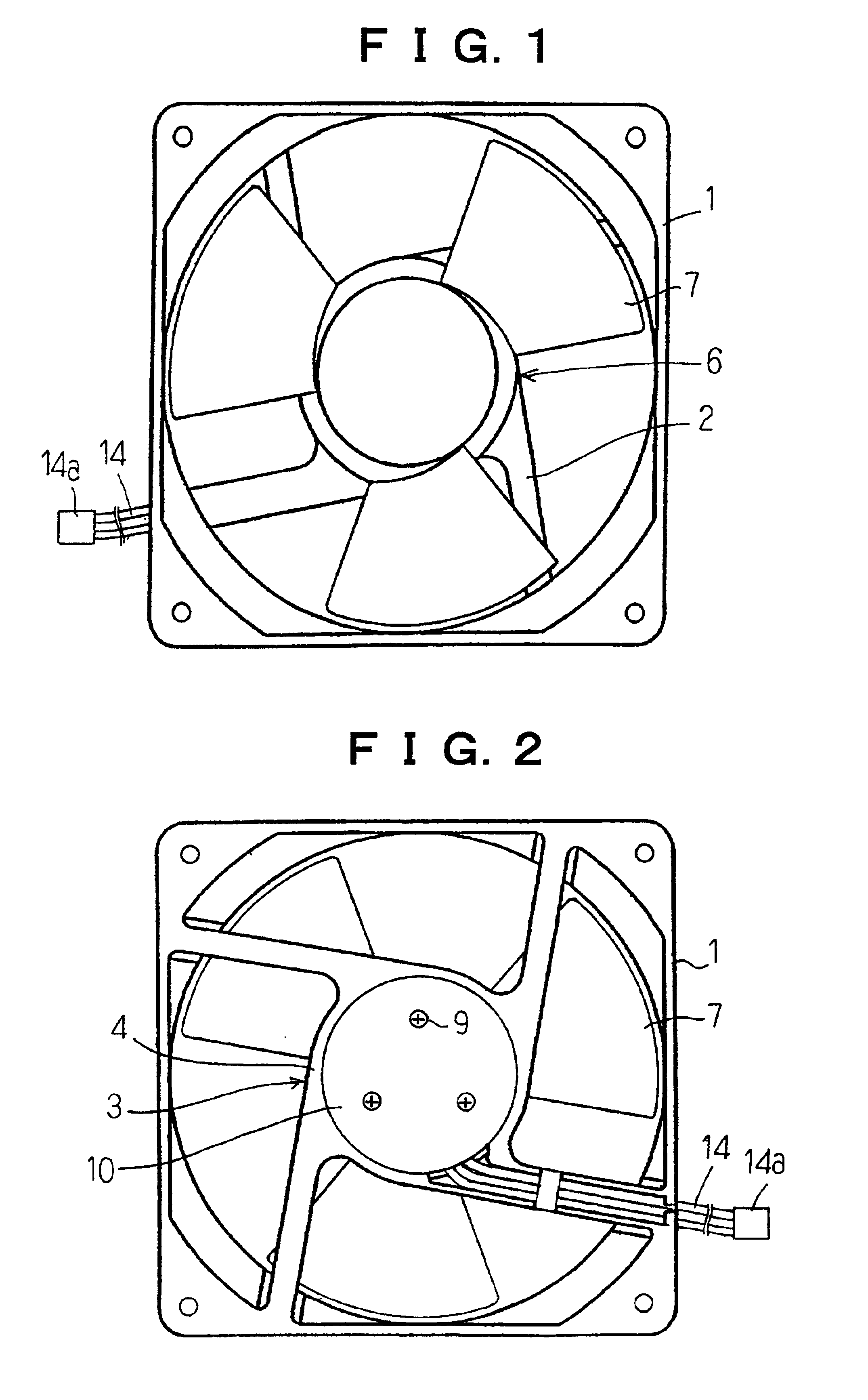

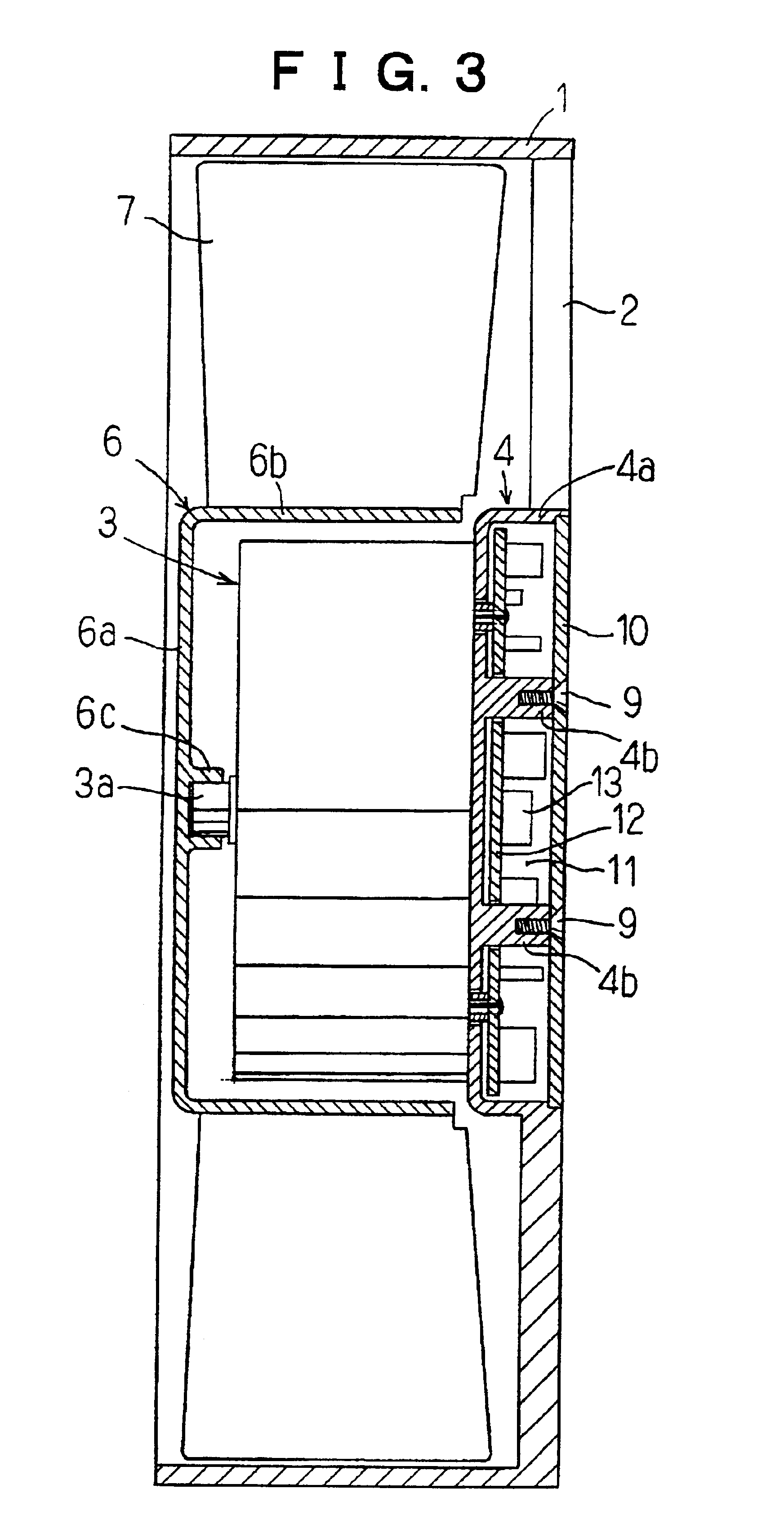

Axial electric fan blower with electric components housing sealed from moisture, dirt and dust or other harmful gas

The object of the present invention is to provide a blower in which electrical components such as printed circuit board or electronic parts are isolated from the wind flowing through the blower to protect these components from moisture, dirt, dusts, or other harmful gas or substance contained in the wind, and to prevent the degradation of the insulating property such as the electric insulation or dielectric strength.A blower having an impeller 6 adapted to be rotated by means of a motor 3 comprises a base 4 for supporting the motor 3, the base is provided and supported at the central portion of a frame 1 through stays 2, a chamber 11 for accommodating electrical components formed in the base, the back portion of the chamber is adapted to be sealed by a removable cover 10, wherein the chamber for accommodating electrical components is formed by the base 4 having a flange 4a extending backward from the outer periphery thereof to form a cylindrical body with a bottom, the chamber has an opening at the rear thereof, and the rear opening of the base is occluded by the cover 10 detachably mounted by screws on the base 4.

Owner:MINEBEA CO LTD

White opaque film having low transparency and improved dielectric strength

InactiveUS20060275593A1Good orientationLow indexSignboardsSynthetic resin layered productsPolyesterThermoplastic

Owner:SANDIA +1

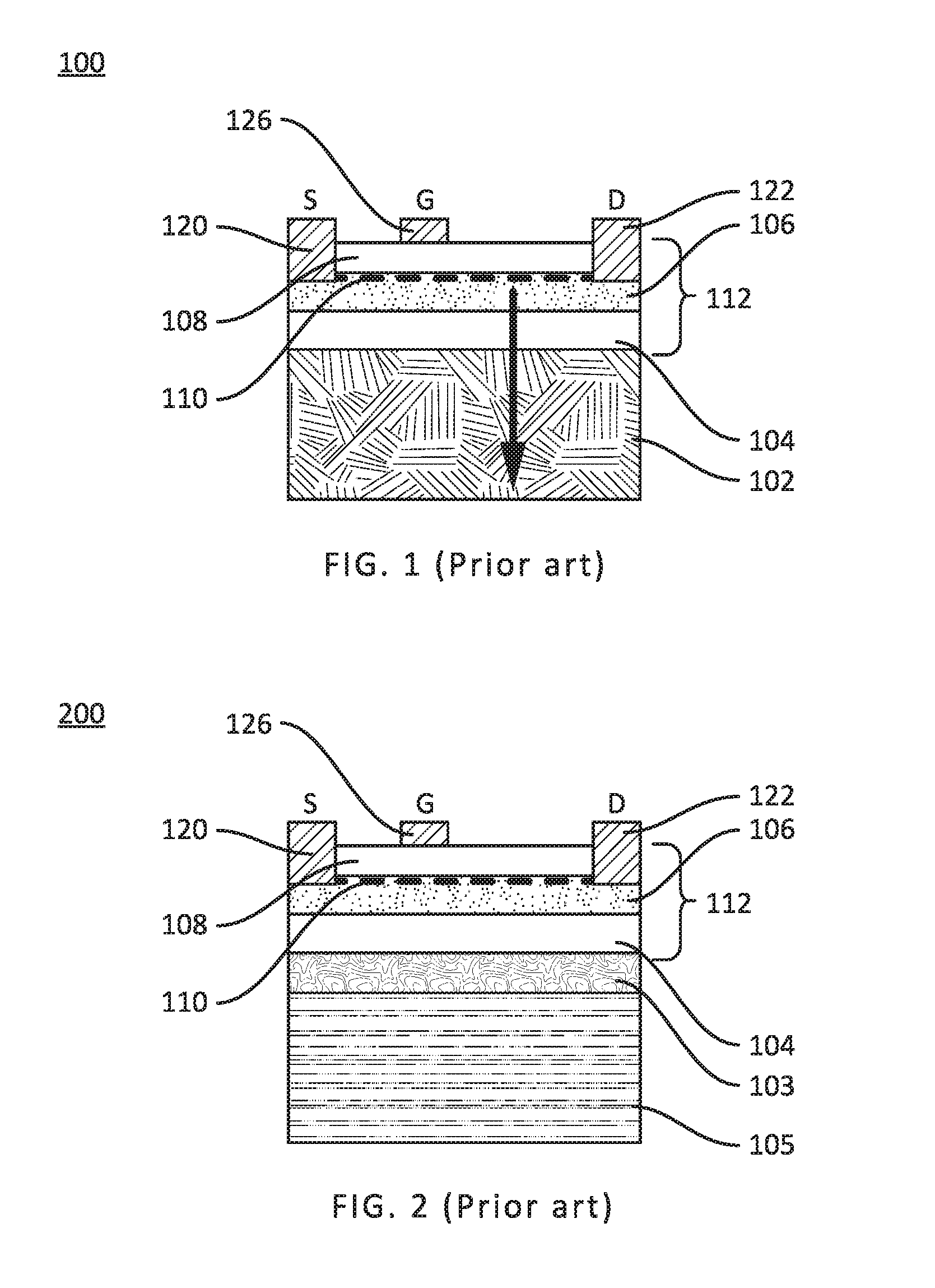

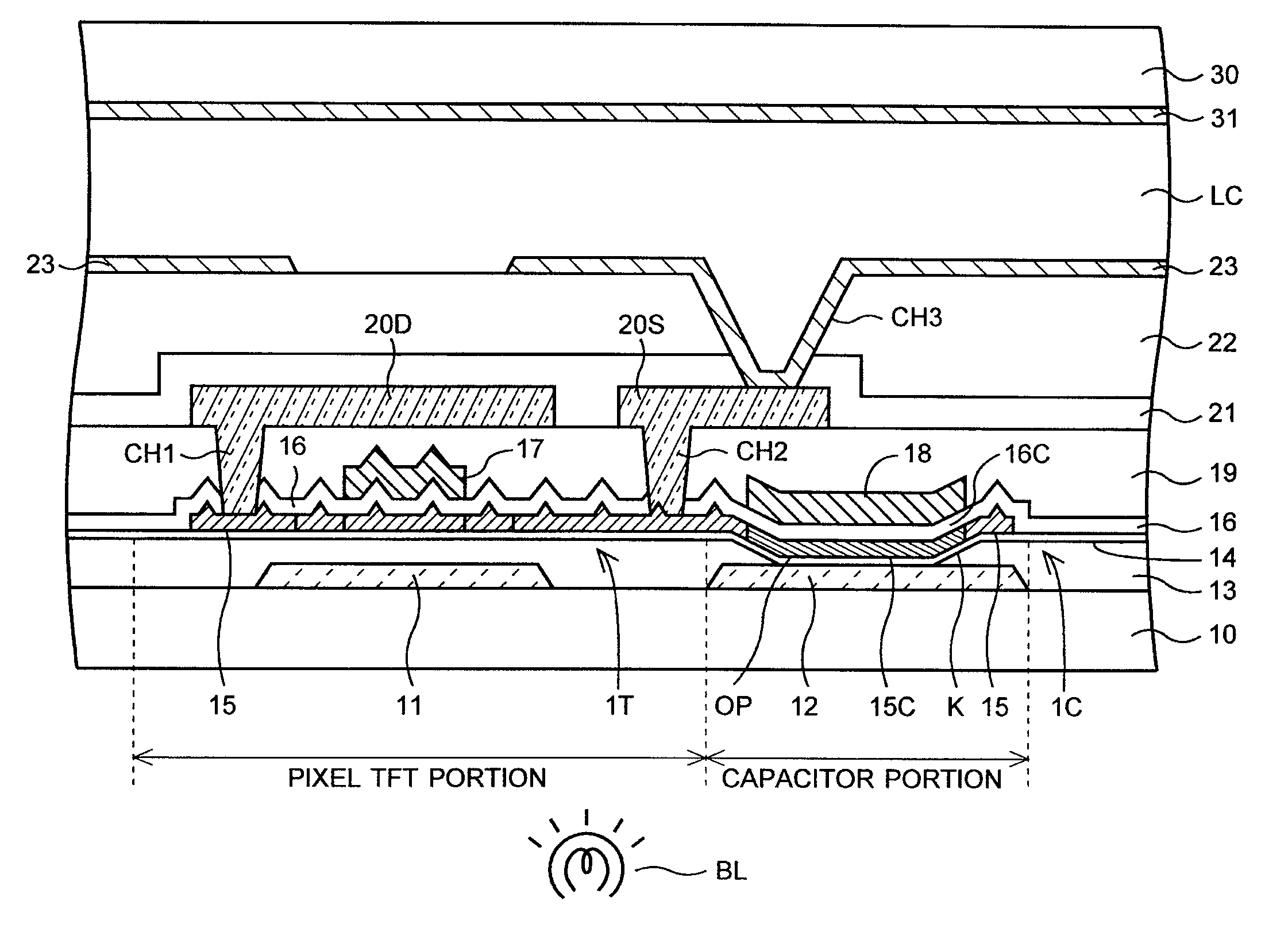

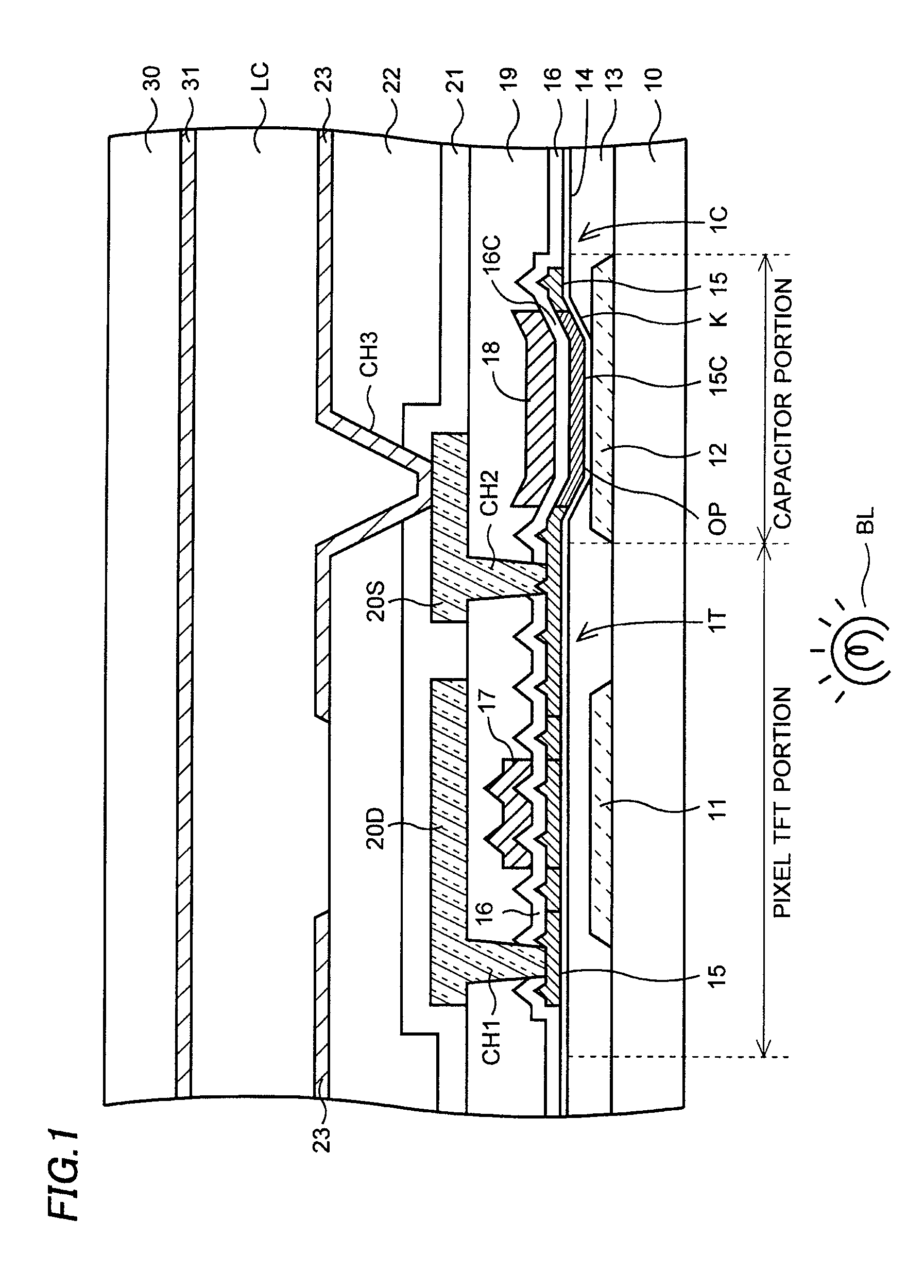

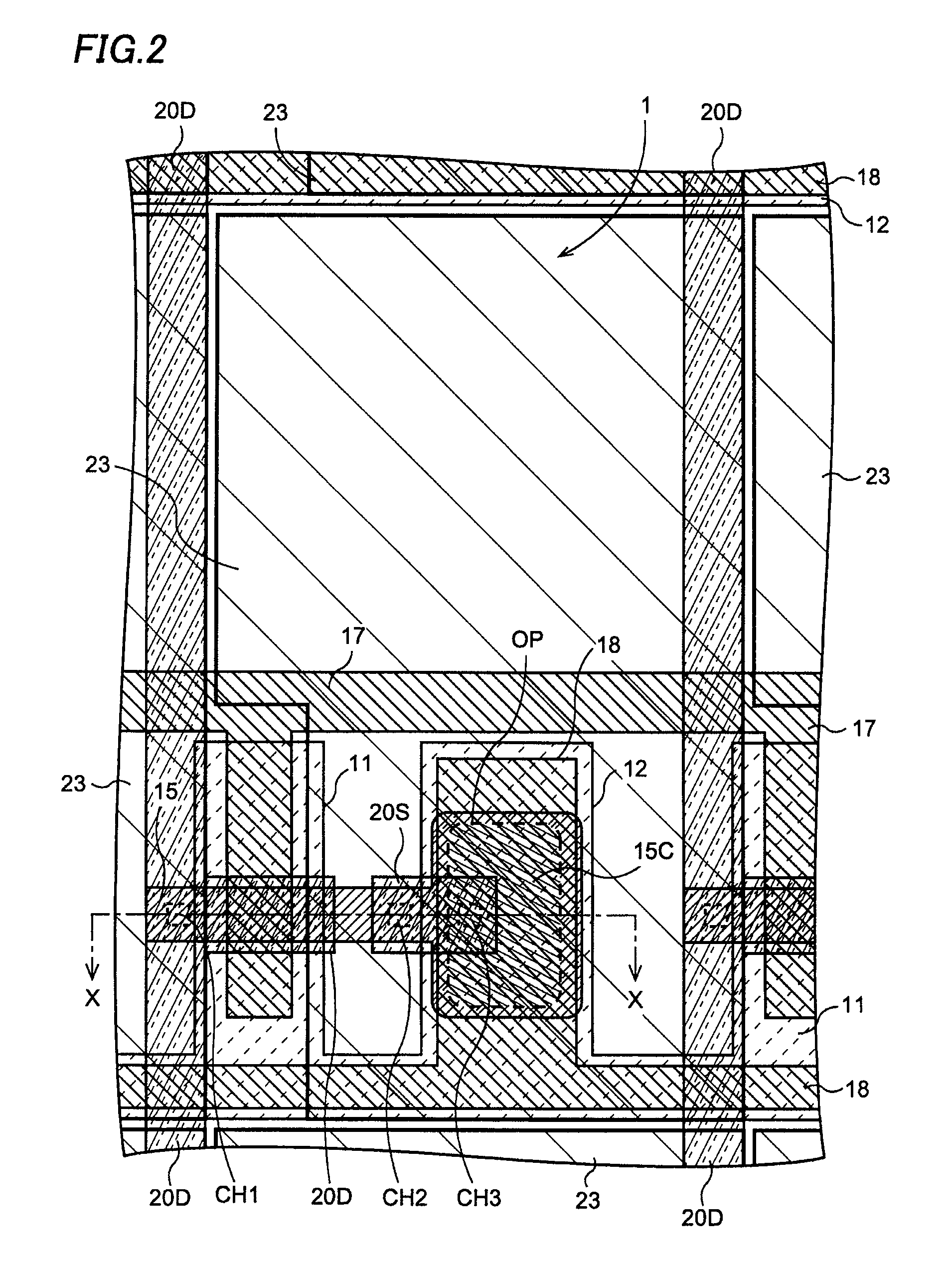

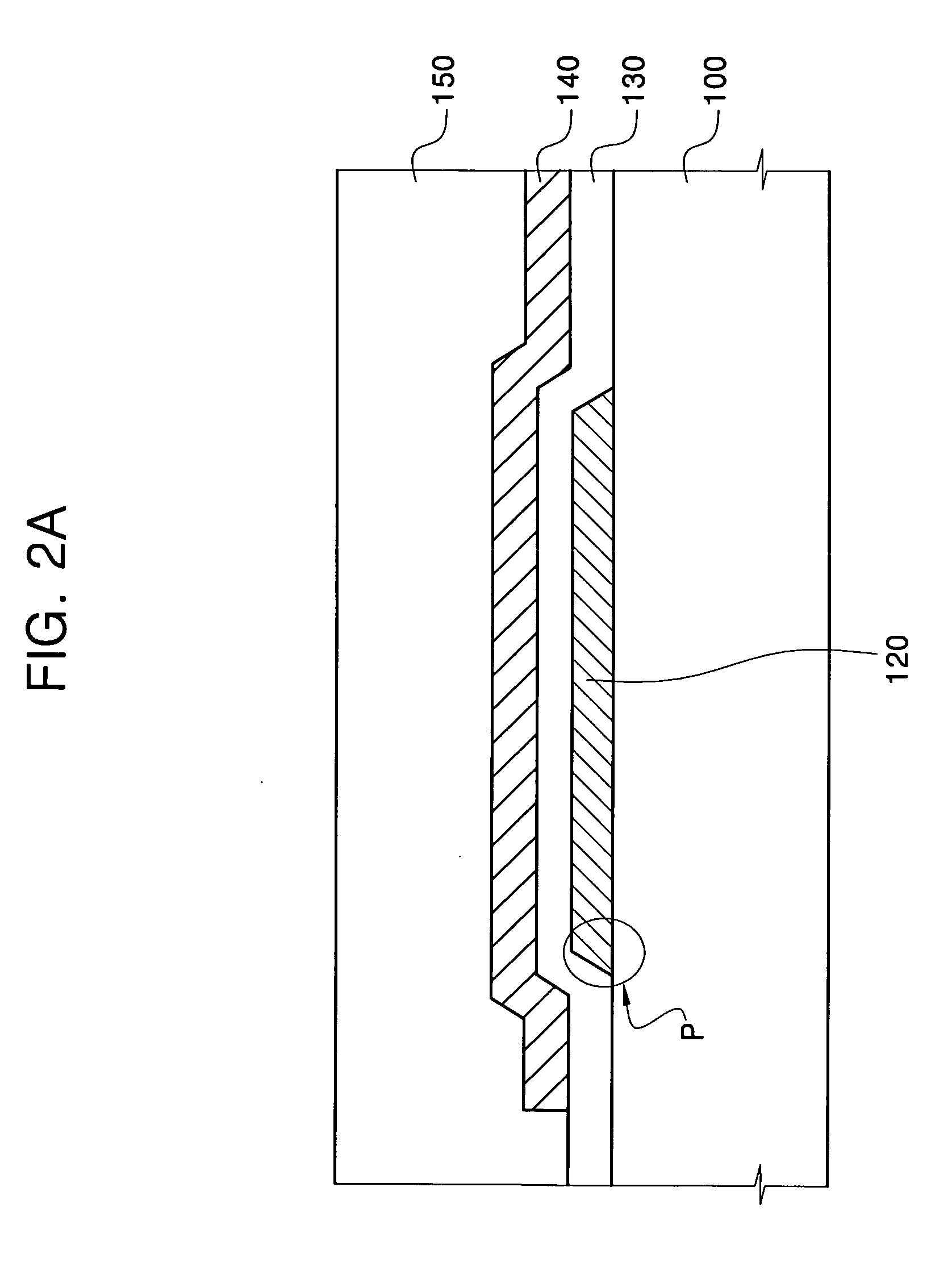

Display device and method of manufacturing the same

ActiveUS20080067519A1Reduce contact resistanceReduce peripheral resistanceTransistorSolid-state devicesDisplay deviceCapacitor

The invention provides a display device having a thin film transistor and a storage capacitor storing a display signal applied to a pixel electrode through this thin film transistor on a substrate, where dielectric strength between electrodes forming the storage capacitor is enhanced for increasing the yield. In the storage capacitor, a lower storage capacitor electrode, a thin lower storage capacitor film, a polysilicon layer, an upper storage capacitor film and an upper storage capacitor electrode are layered. The polysilicon layer is formed by crystallization by laser annealing. The polysilicon layer of the storage capacitor is microcrystalline and thus the flatness of its surface is enhanced. The pattern of the polysilicon layer (storage capacitor electrode) is formed larger than the bottom portion of an opening, and the edge of its peripheral portion is located on a buffer film on the slant portion of the opening or on the buffer film on the outside of the opening.

Owner:JAPAN DISPLAY WEST

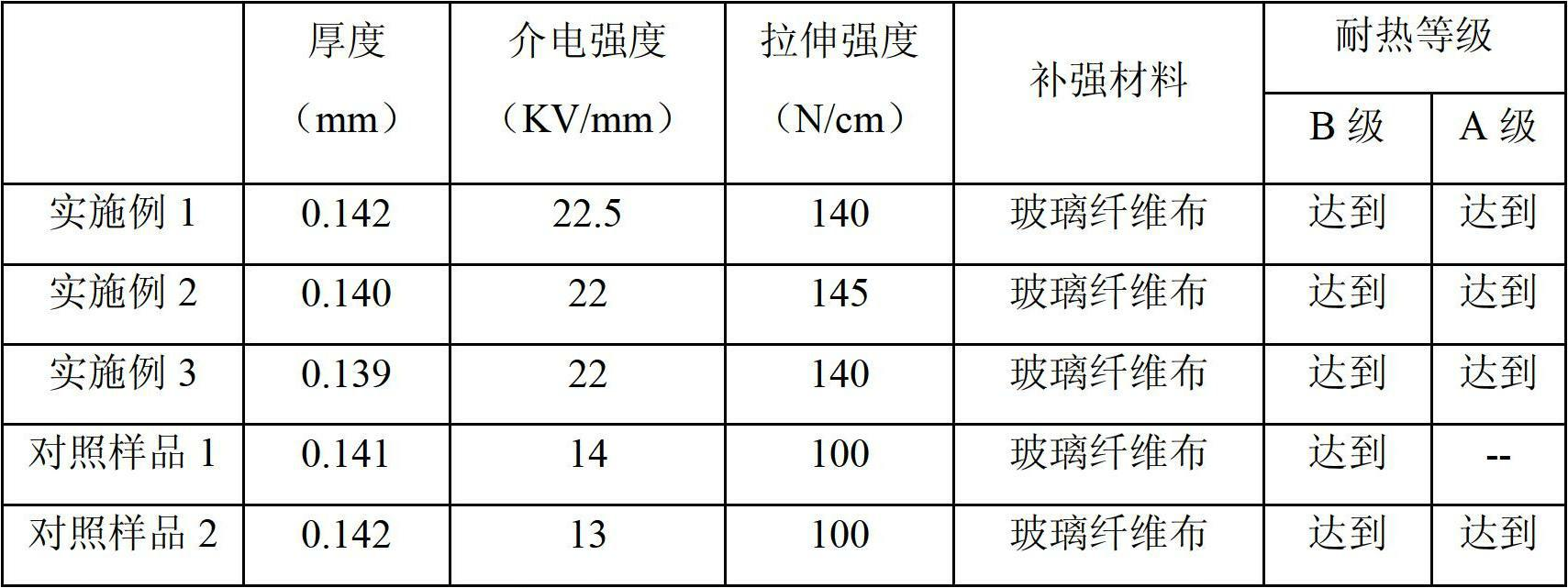

Method for manufacturing calcined high-temperature and high-pressure resistant mica paper tape

InactiveCN102651262AHigh dielectric strengthGuarantee product qualityInsulating bodiesPapermakingHigh pressure

The invention belongs to the field of insulating materials, particularly relating to a method for manufacturing a calcined high-temperature and high-pressure resistant mica paper tape, and aiming to solve the technical problem that the traditional mica paper tape is easily broken down due to the low dielectric strength. The method for manufacturing the calcined high-temperature and high-pressure resistant mica paper tape comprises the following steps of: a. selecting a mica raw material; b. calcining; c. preparing pulp; d. papermaking; and e. compounding. The mica paper tape manufactured by the method provided by the invention has high dielectric strength, and is suitable for both a B-grade cable and an A-grade cable.

Owner:SICHUAN MEIFENG MICA IND

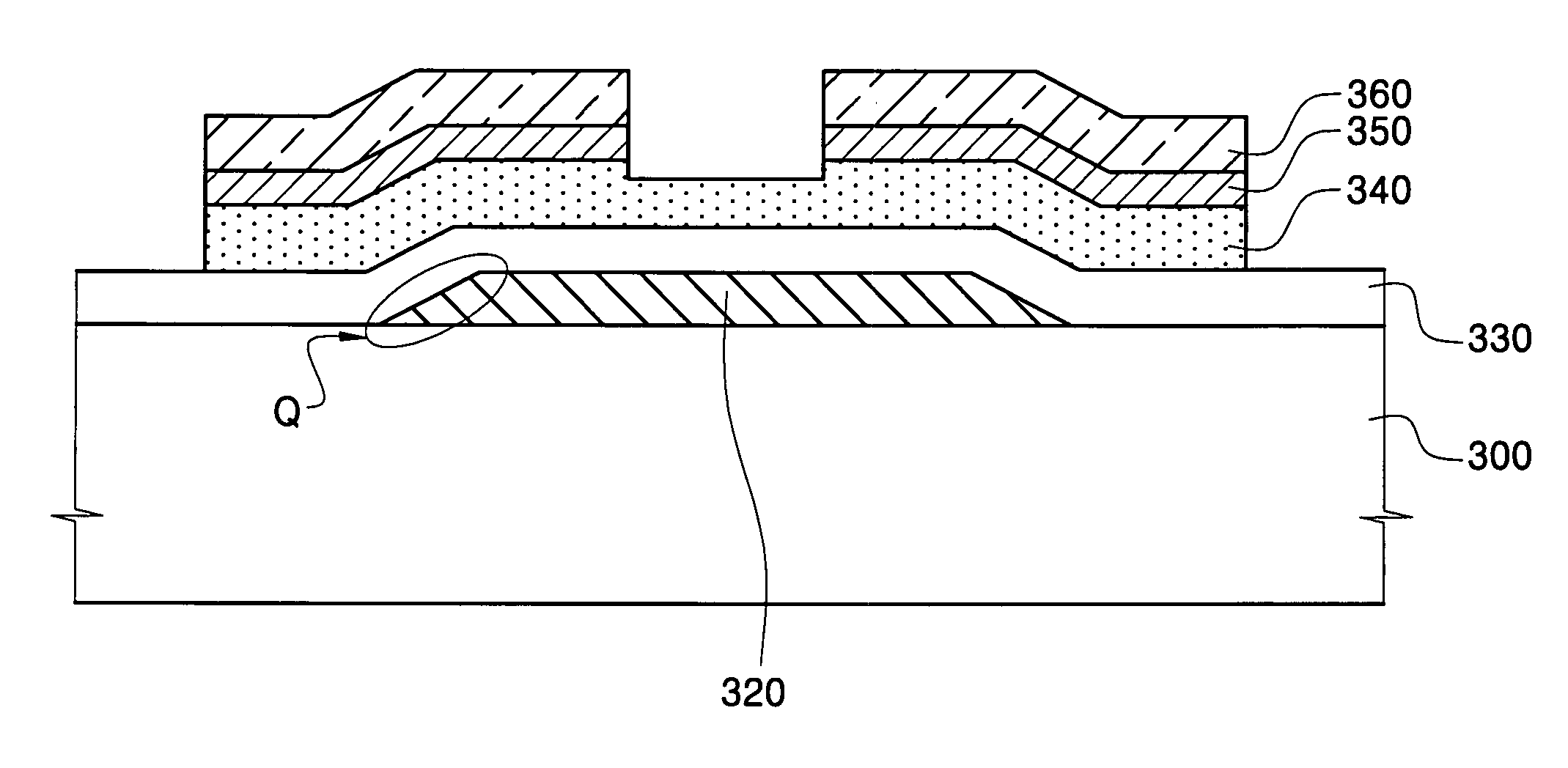

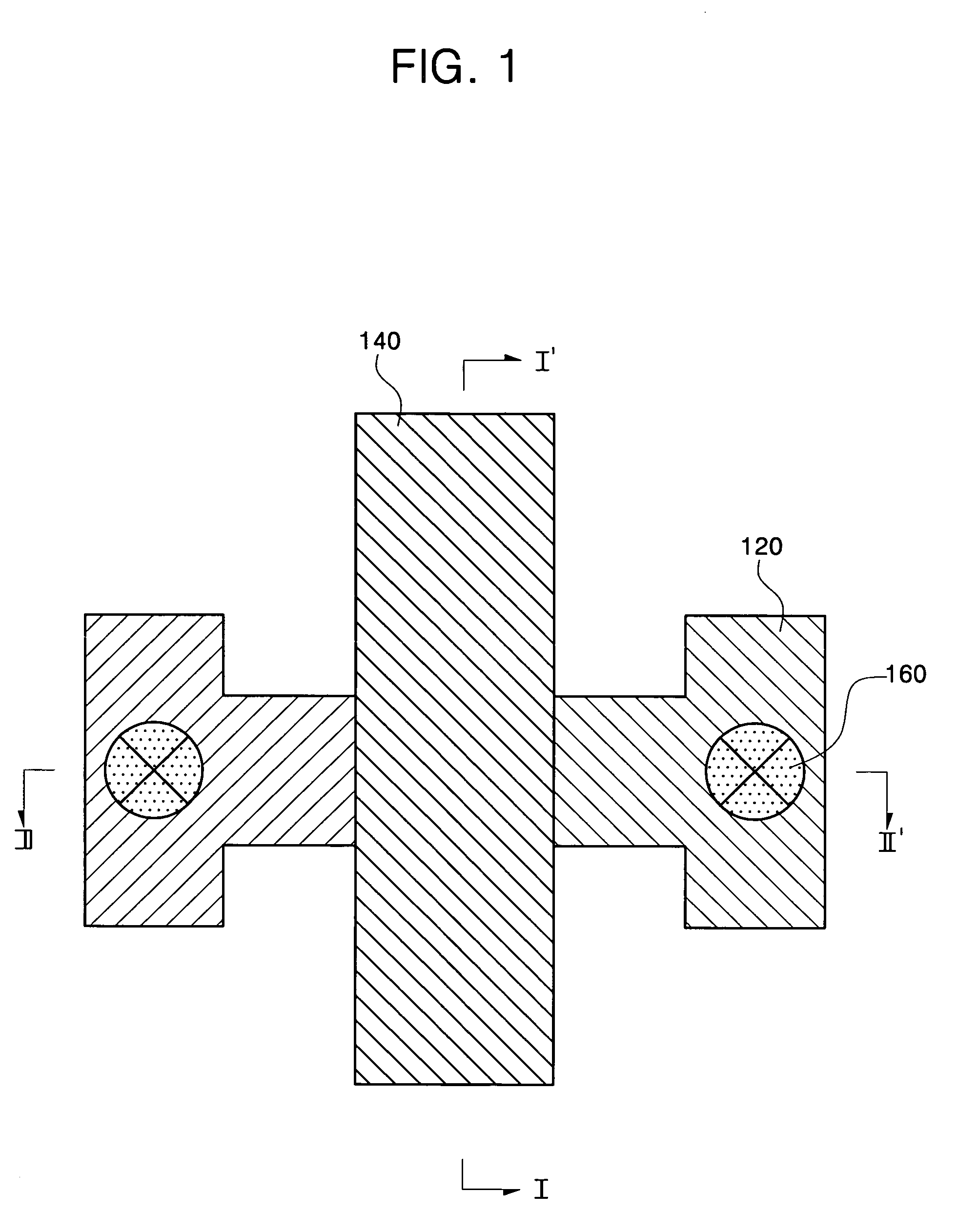

Thin film transistor

InactiveUS20050116305A1High dielectric strengthTransistorSolid-state devicesDielectric strengthTransistor

A thin film transistor according to the present invention may include a gate insulating layer; and a lower pattern placed below the gate insulating layer to contact therewith and having an edge with a taper angle of at most about 80°. With this design, dielectric strength of the gate insulating layer can be enhanced. The lower pattern can be a gate electrode layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Insulated metal substrate

InactiveUS20140293554A1Improve propertiesSmall sizeCell electrodesSurface reaction electrolytic coatingCeramic coatingUltimate tensile strength

An insulated metal substrate (IMS) for supporting a device comprises a metallic substrate having a ceramic coating formed at least in part by oxidation of a portion of the surface of the metallic substrate. The ceramic coating has a dielectric strength of greater than 50 KV mm−1 and a thermal conductivity of greater than 5 Wm−1K−1.

Owner:CAMBRIDGE NANOTHERM

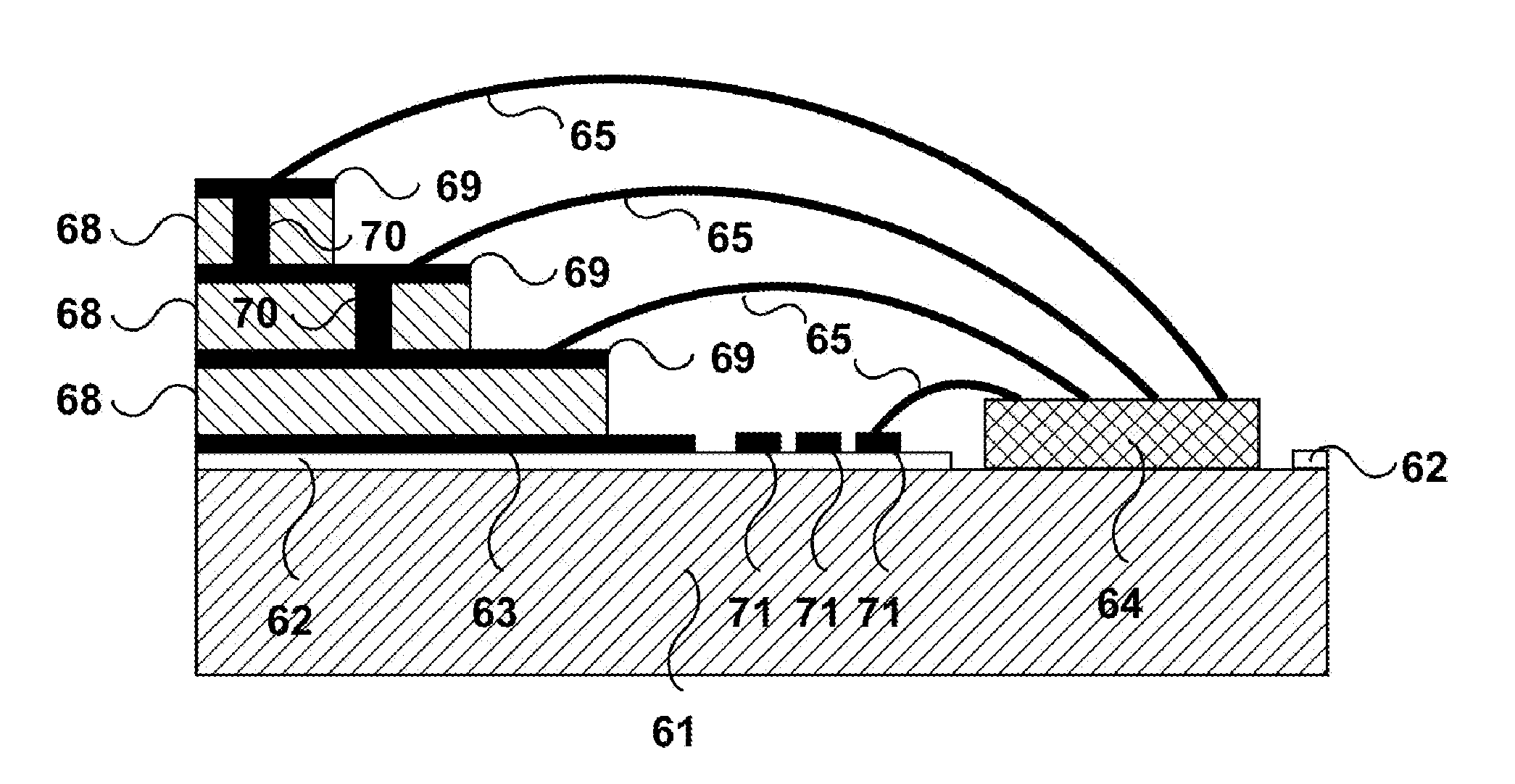

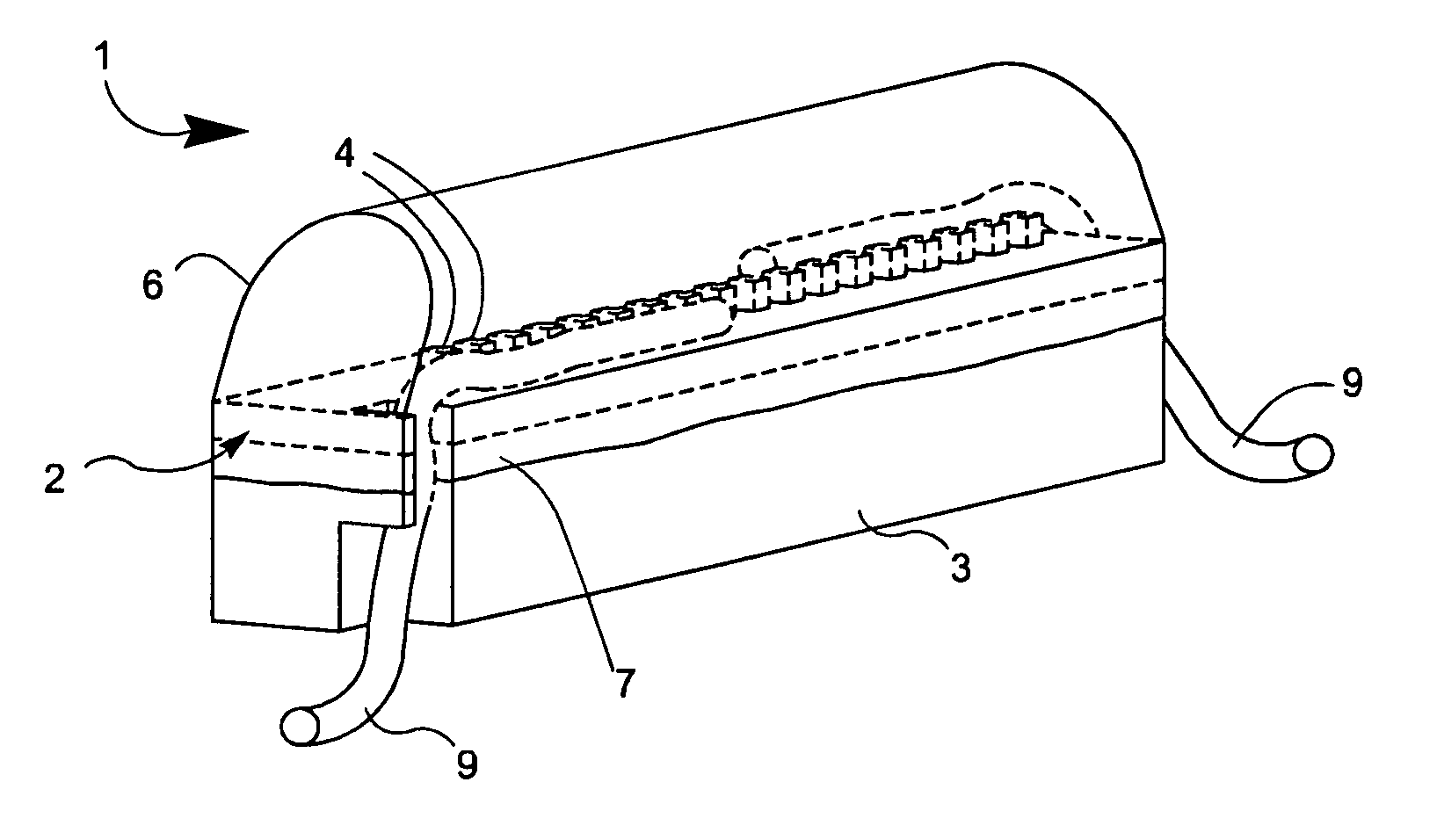

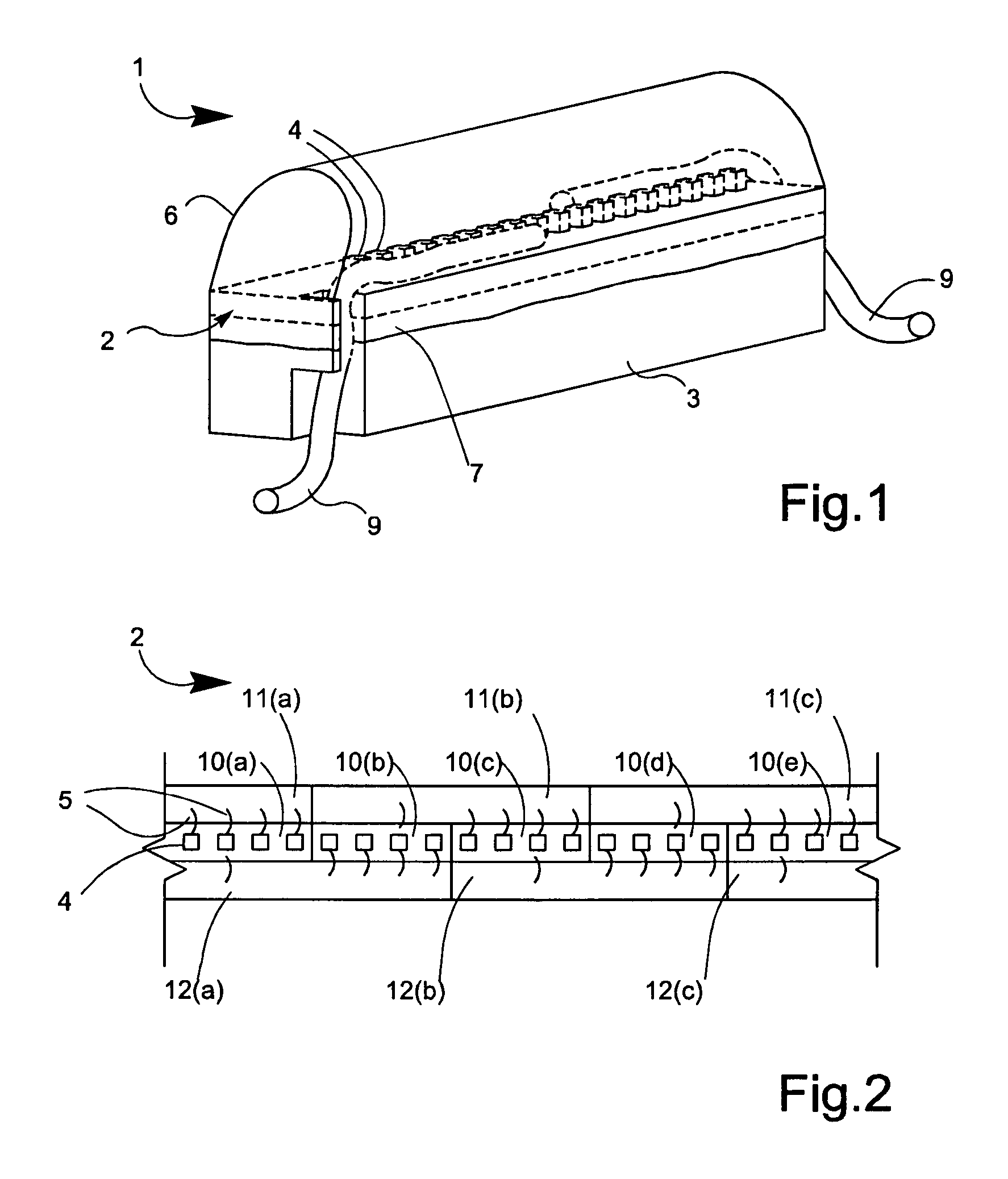

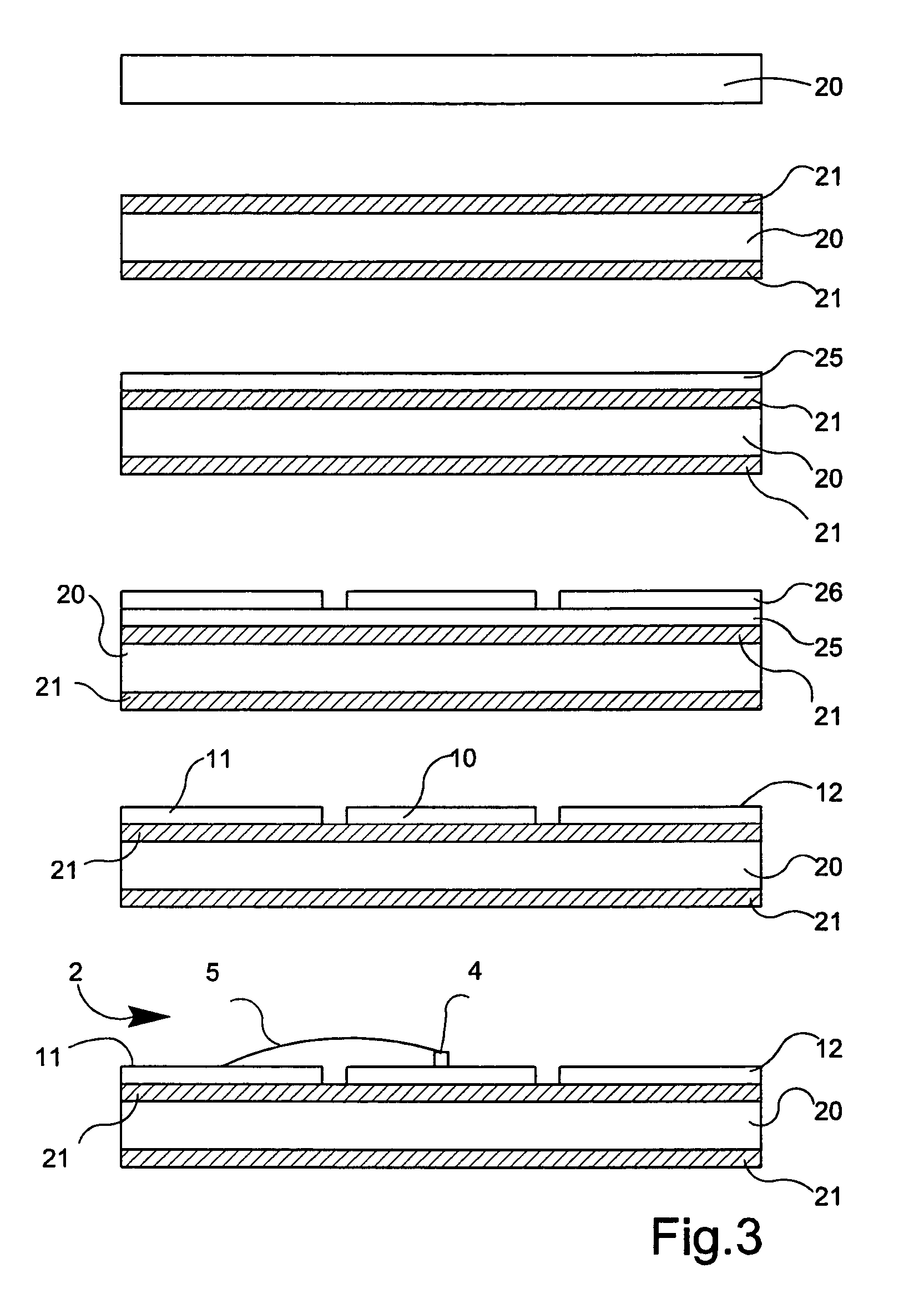

Illuminator

InactiveUS6995405B2Non-electric lightingPoint-like light sourceElectrical connectionLight reflection

An illuminator (1) comprises a substrate (2) supporting light source dies (4) driven via wire bonds (5). The substrate (2) comprises a silicon strip (20) in direct contact with a brass heat sink (3), thus providing for excellent heat transfer away from the die (4). Pads (10, 11, 12) of Ni, Ti, and Ag sub-layers support the die (4) and the wire bonds (5). These both provide electrical connections for the die (4) and also light reflection upwardly because the Ag sub-layers of the pads (10, 11, 12) are evaporated over a thermally grown oxide layer (21) on the Si (20). The oxide has a very high dielectric strength, thus maintaining excellent electrical insulating properties over a large voltage range.

Owner:LUMOS SOLUTIONS

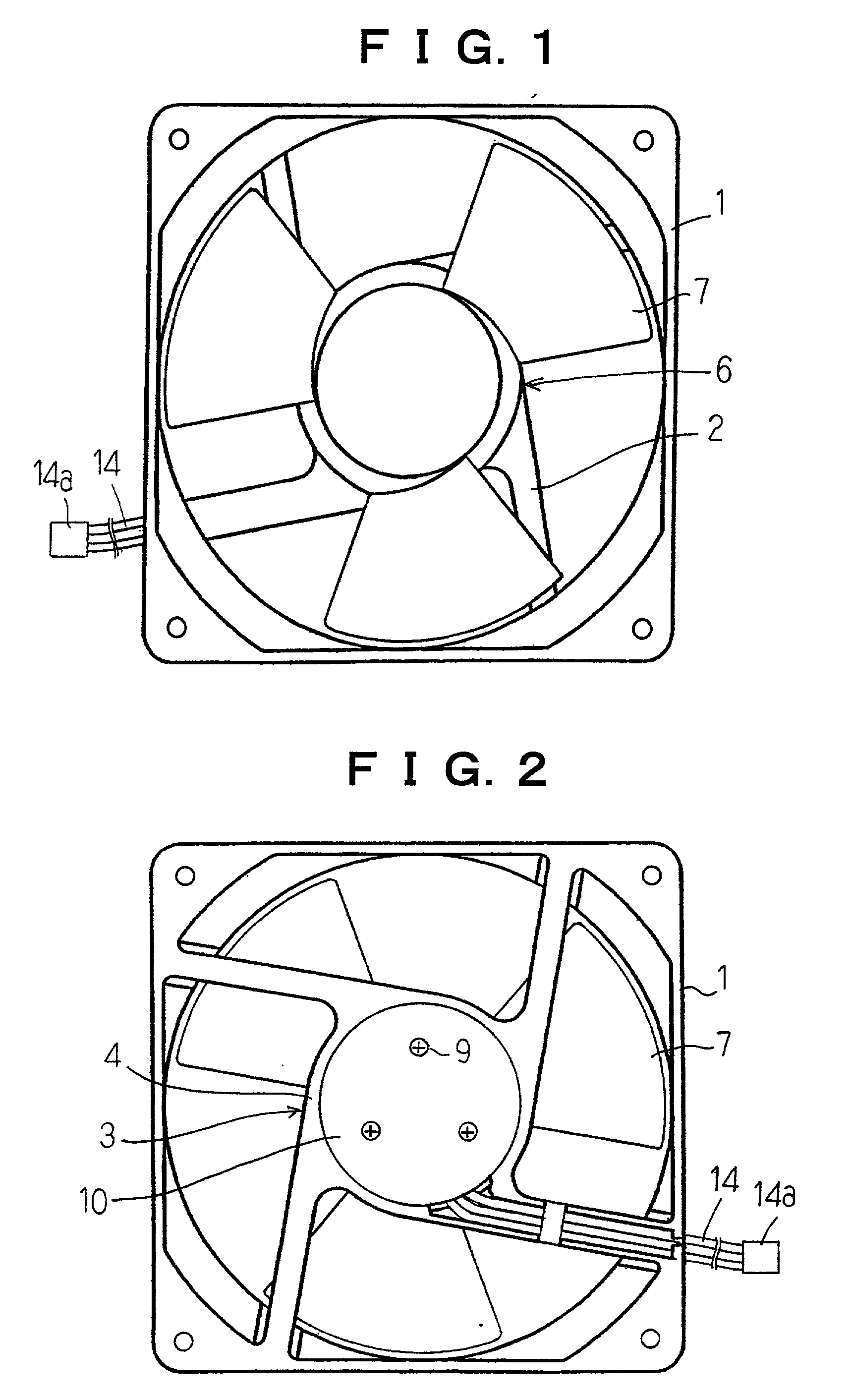

Blower

The object of the present invention is to provide a blower in which electrical components such as printed circuit board or electronic parts are isolated from the wind flowing through the blower to protect these components from moisture, dirt, dusts, or other harmful gas or substance contained in the wind, and to prevent the degradation of the insulating property such as the electric insulation or dielectric strength. A blower having an impeller 6 adapted to be rotated by means of a motor 3 comprises a base 4 for supporting the motor 3, the base is provided and supported at the central portion of a frame 1 through stays 2, a chamber 11 for accommodating electrical components formed in the base, the back portion of the chamber is adapted to be sealed by a removable cover 10, wherein the chamber for accommodating electrical components is formed by the base 4 having a flange 4a extending backward from the outer periphery thereof to form a cylindrical body with a bottom, the chamber has an opening at the rear thereof, and the rear opening of the base is occluded by the cover 10 detachably mounted by screws on the base 4.

Owner:MINEBEA CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com