Patents

Literature

147 results about "Low dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free resin composition and its application for copper clad laminate and printed circuit board

ActiveUS20130161080A1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyLow dissipation

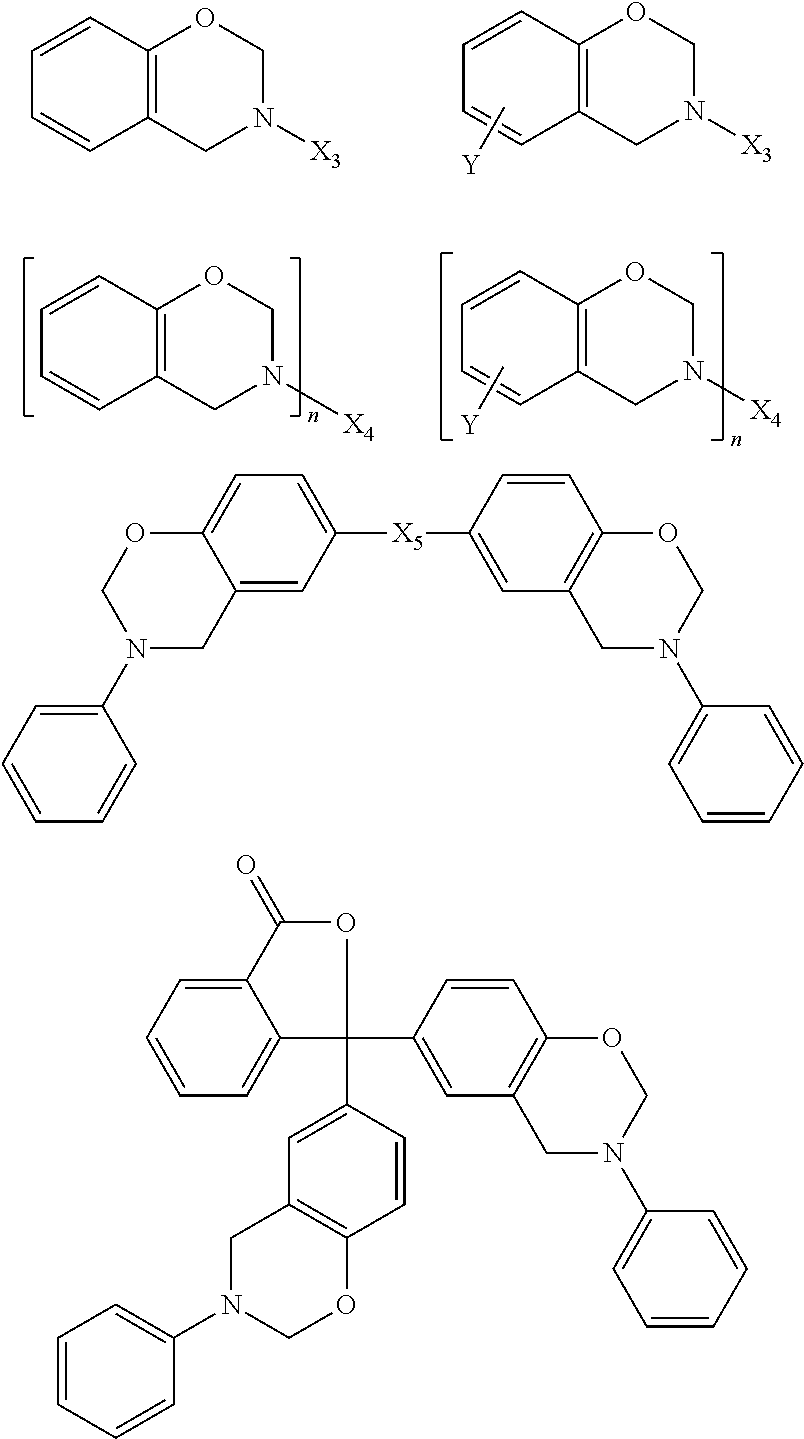

A halogen-free resin composition includes (A) 100 parts per hundred resin of epoxy resin; (B) 1 to 100 parts per hundred resin of benzoxazine resin; (C) 1 to 100 parts per hundred resin of styrene-maleic anhydride; (D) 0.5 to 30 parts per hundred resin of amine curing agent; and (E) 5 to 150 parts per hundred resin of halogen-free flame retardant. The composition obtains properties of low dielectric constant, low dissipation factor, high heat resistance and flame retardancy by specific composition and ratio. Thus, a prepreg or a resin film, which can be applied to a copper clad laminate and a printed circuit board, is formed.

Owner:ELITE MATERIAL

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

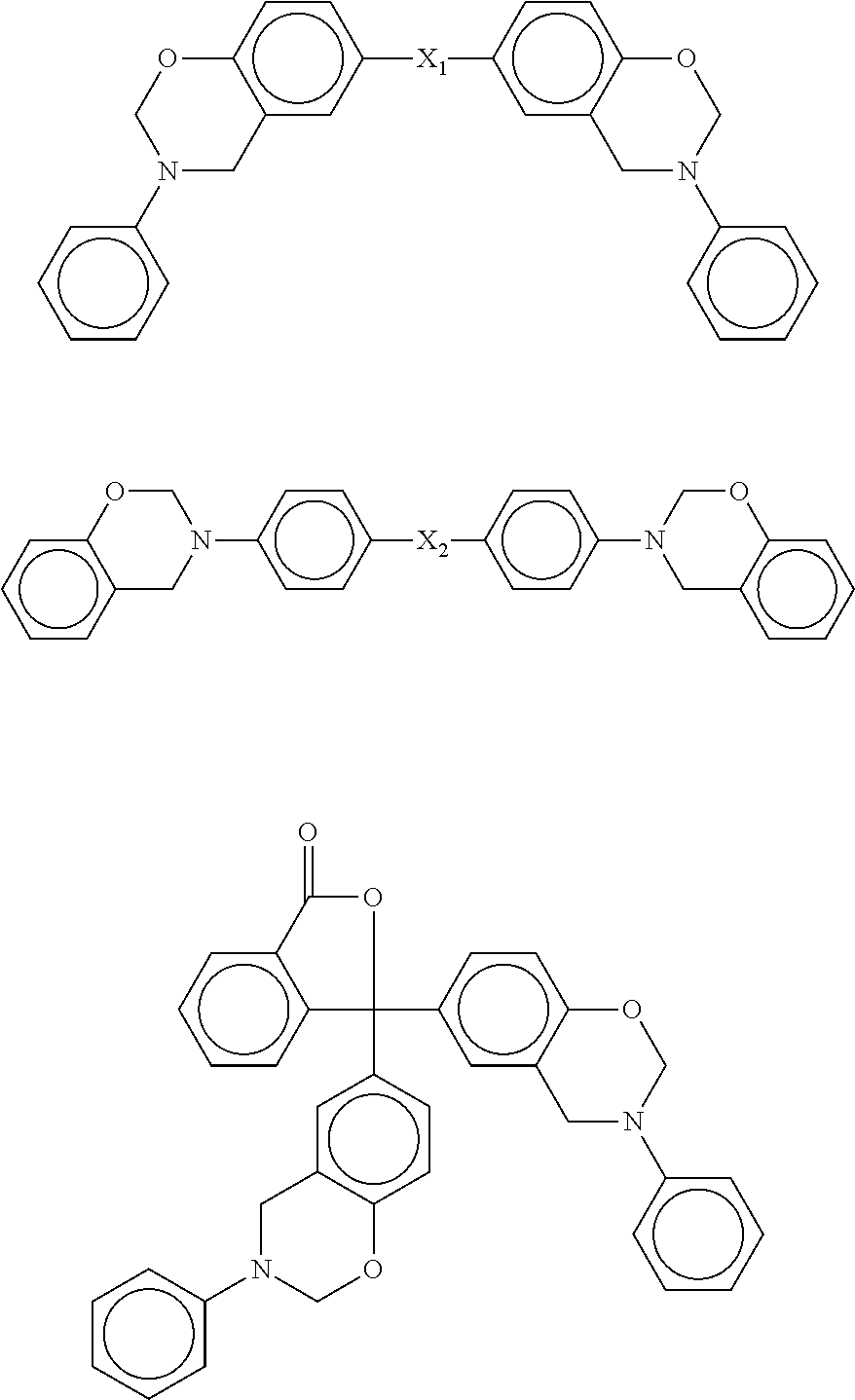

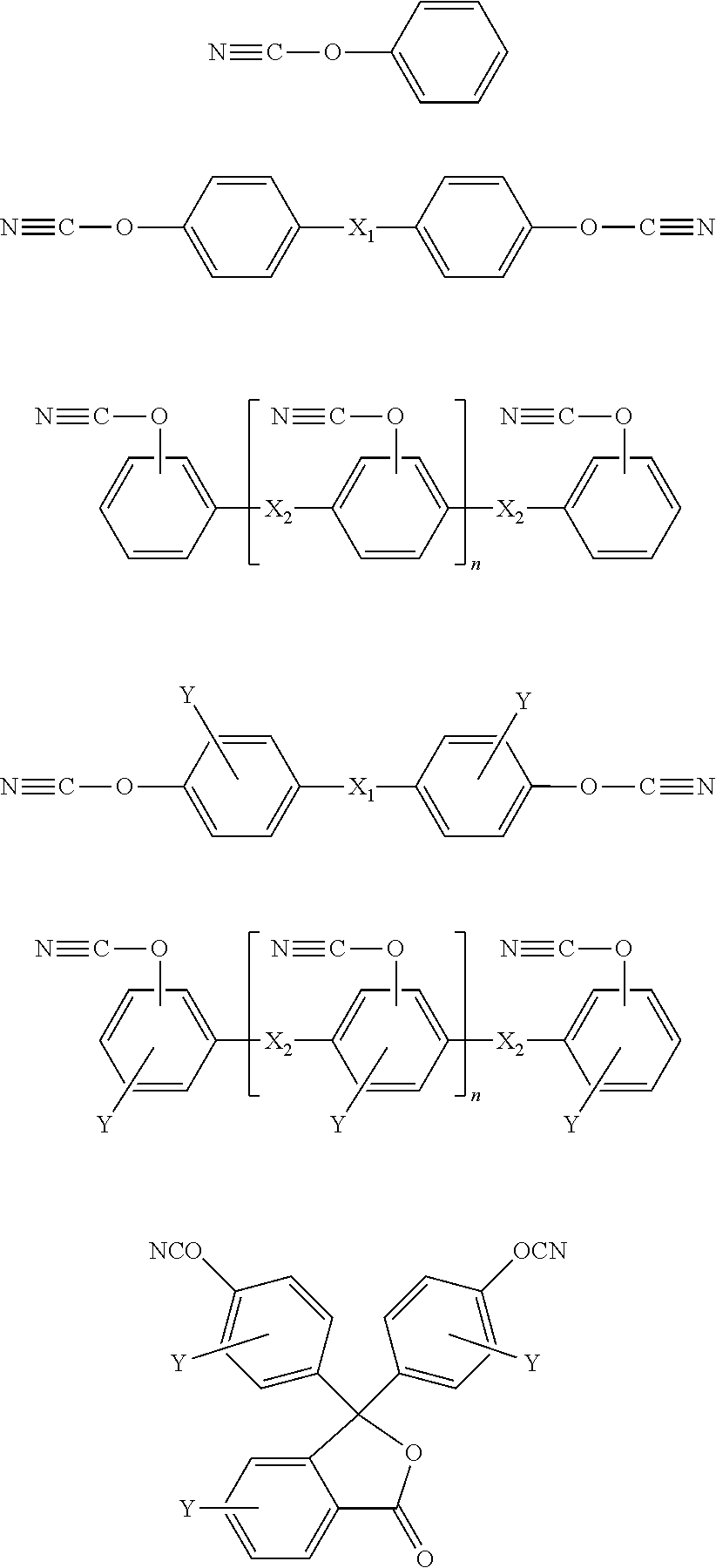

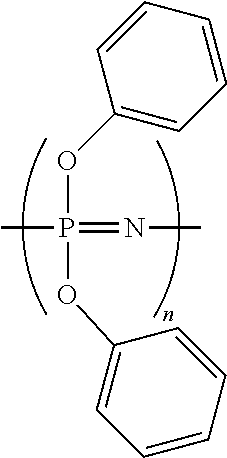

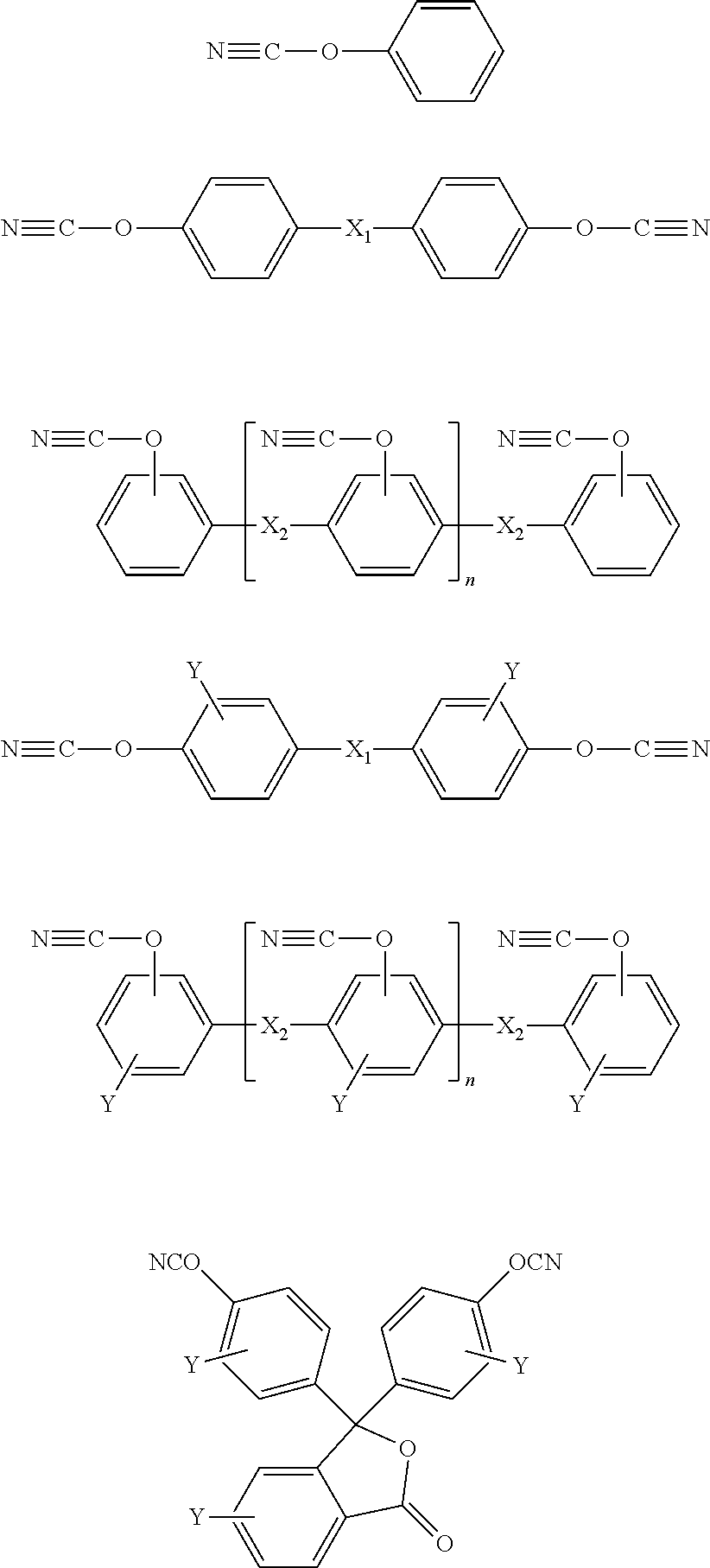

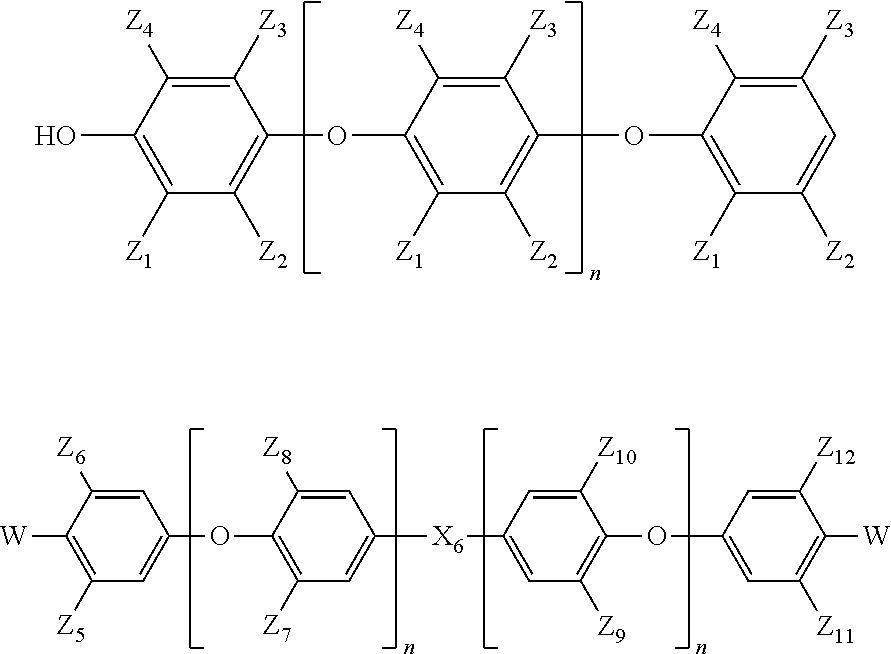

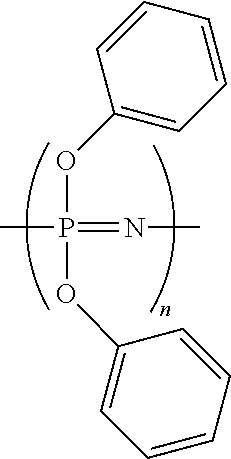

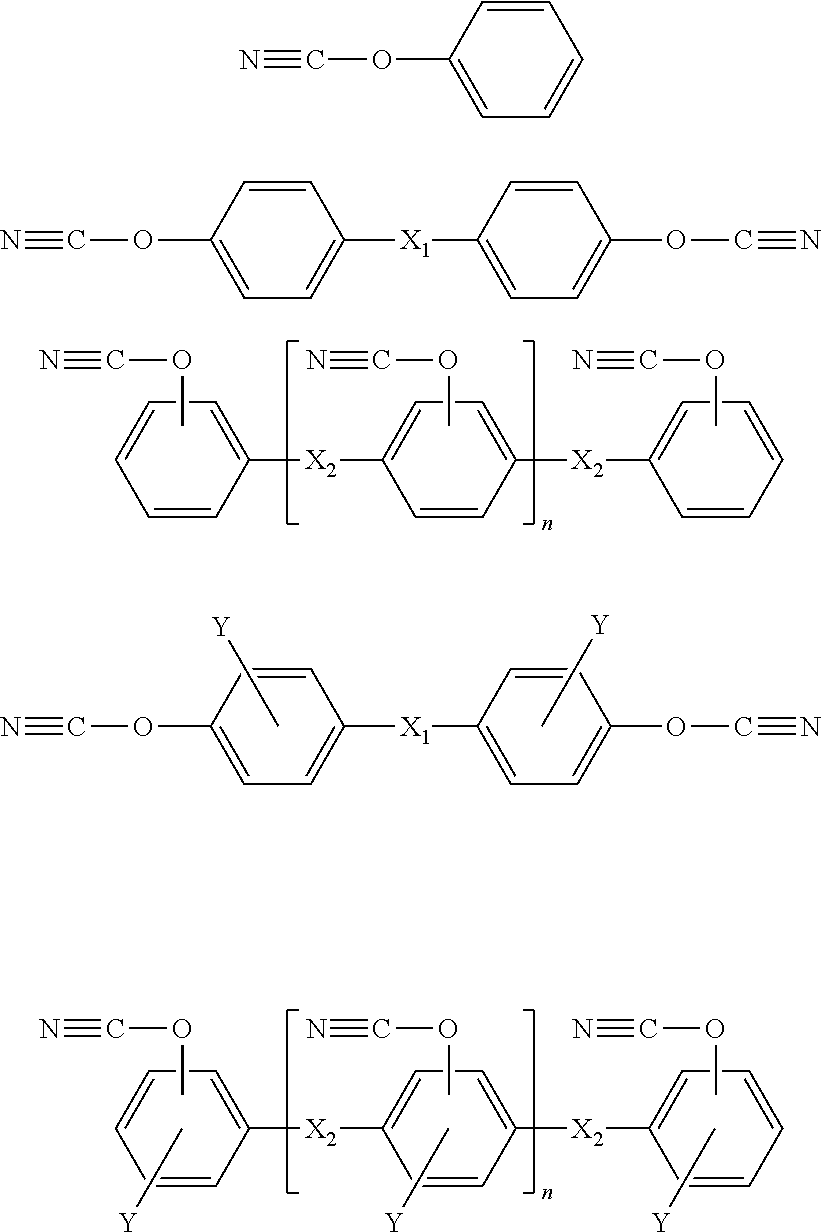

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

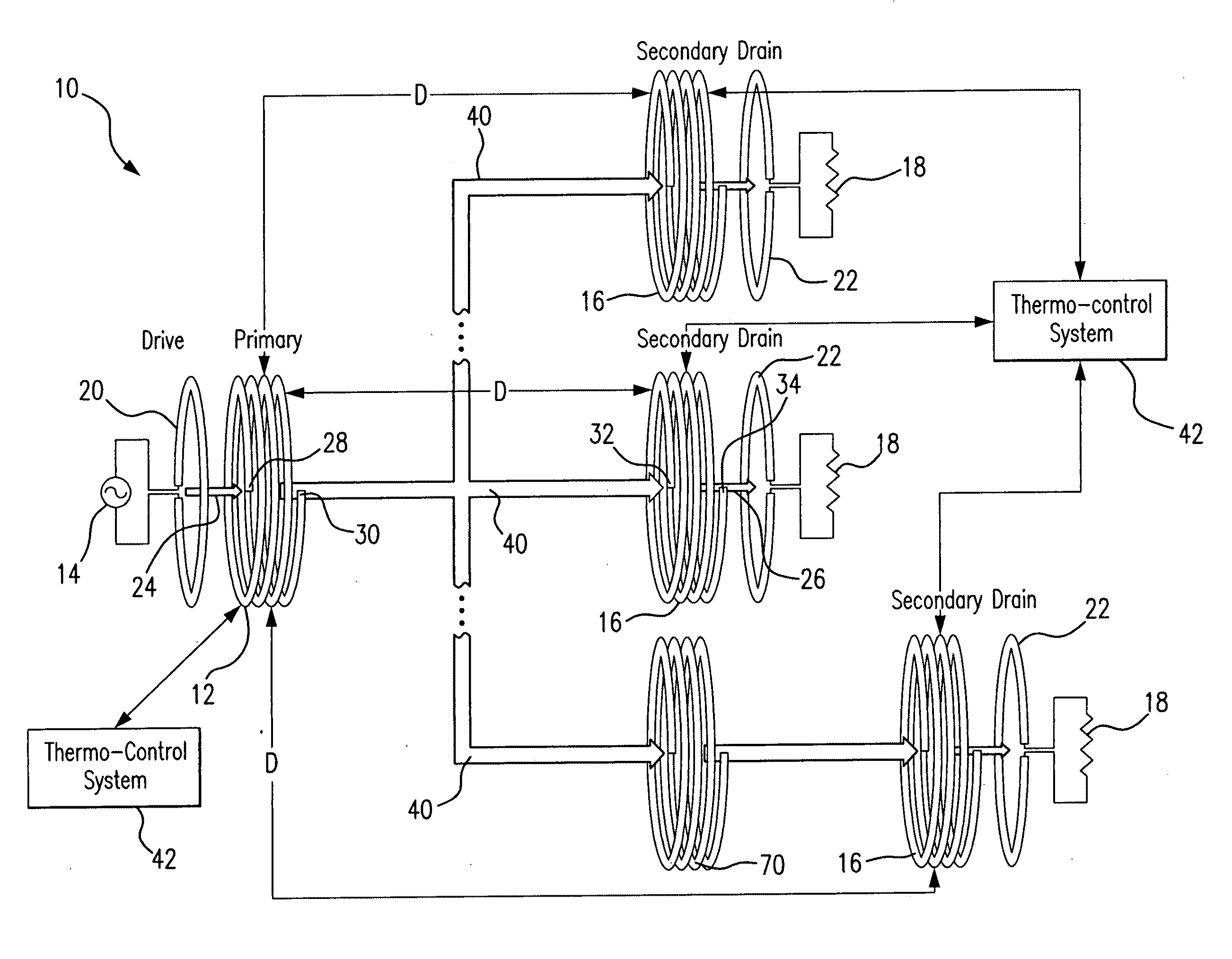

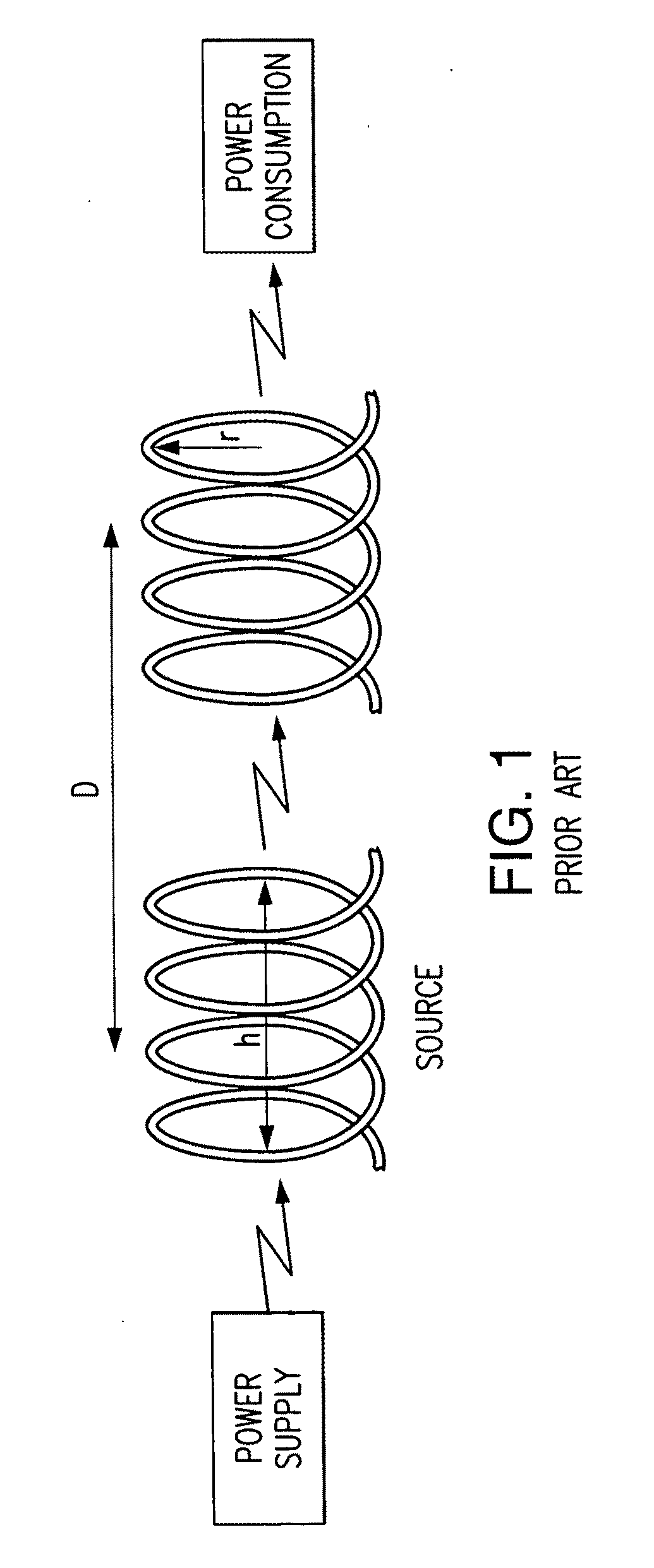

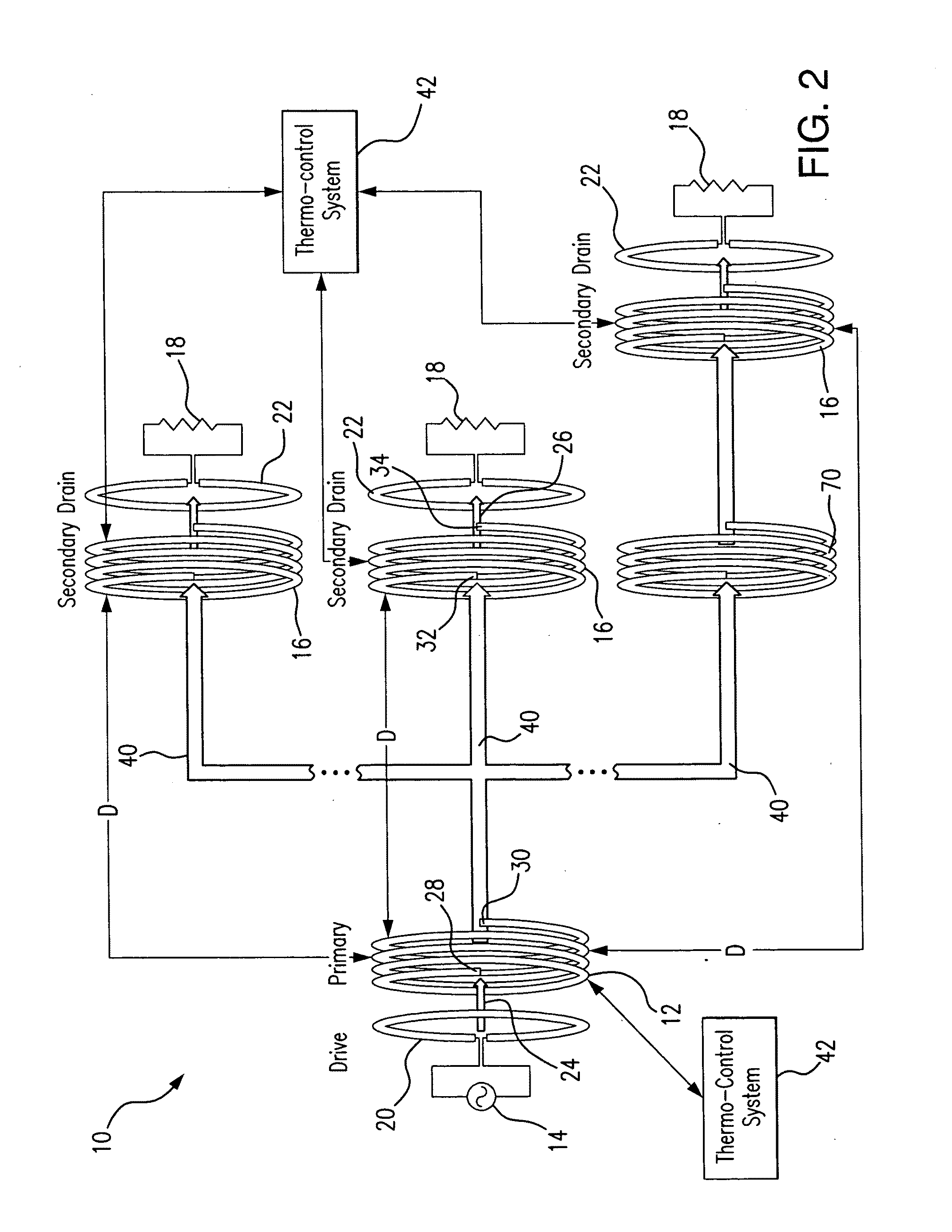

Method and system for long range wireless power transfer

ActiveUS20120010079A1Improve power transfer efficiencyReduce eliminateDc network circuit arrangementsElectromagnetic wave systemLow dissipationCapacitance

A wireless energy transfer system includes a primary and one (or more) secondary oscillators for transferring energy therebetween when resonating at the same frequency. The long range (up to and beyond 100 m) efficient (as high as and above 50%) energy transfer is achieved due to minimizing (or eliminating) losses in the system. Superconducting materials are used for all current carrying elements, dielectrics are either avoided altogether, or those are used with a low dissipation factor, and the system is operated at reduced frequencies (below 1 MHz). The oscillators are contoured as a compact flat coil formed from a superconducting wire material. The energy wavelengths exceed the coils diameter by several orders of magnitude. The reduction in radiative losses is enhanced by adding external dielectric-less electrical capacitance to each oscillator coil to reduce the operating frequency. The dielectric strength of the capacitor is increased by applying a magnetic cross-field to the capacitor to impede the electrons motion across an air gap defined between coaxial cylindrical electrodes.

Owner:MARYLAND UNIV OF

Dielectric compositions and methods to form the same

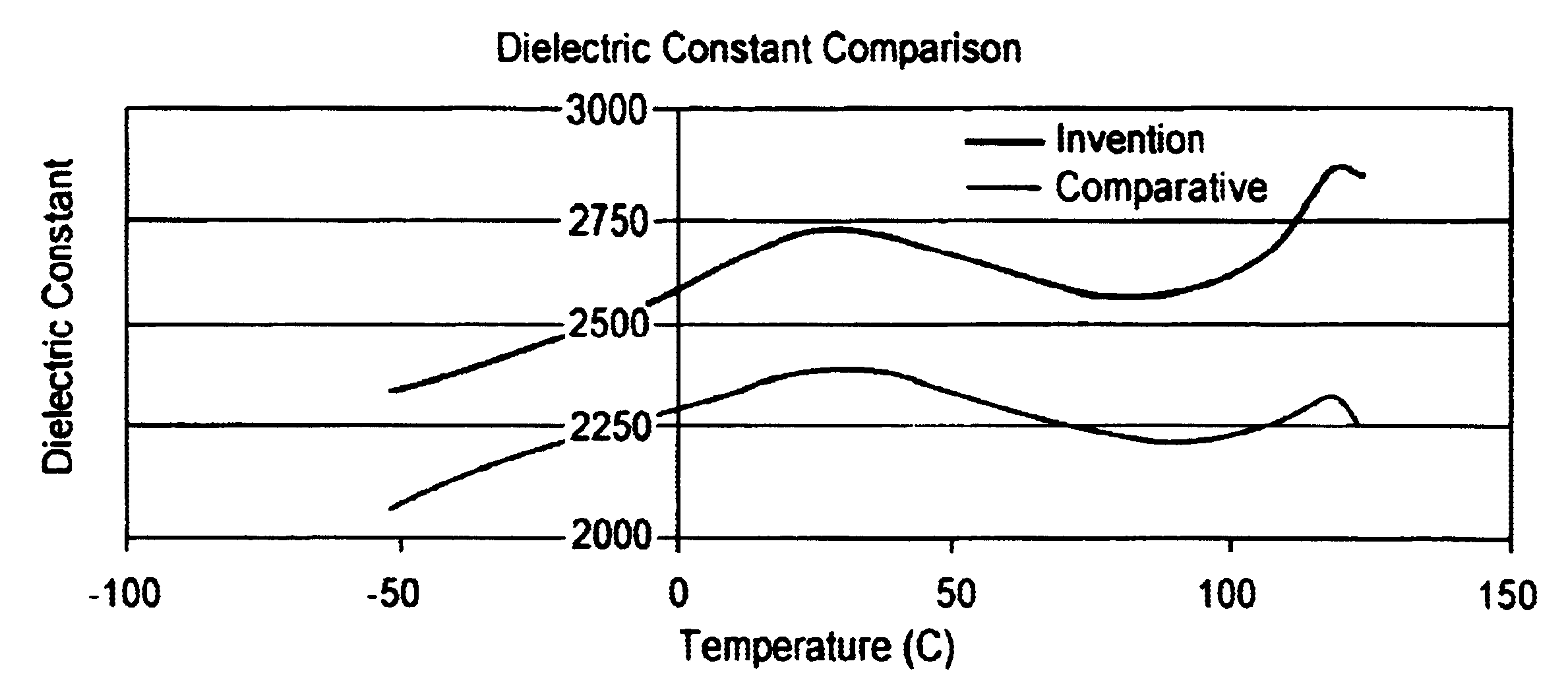

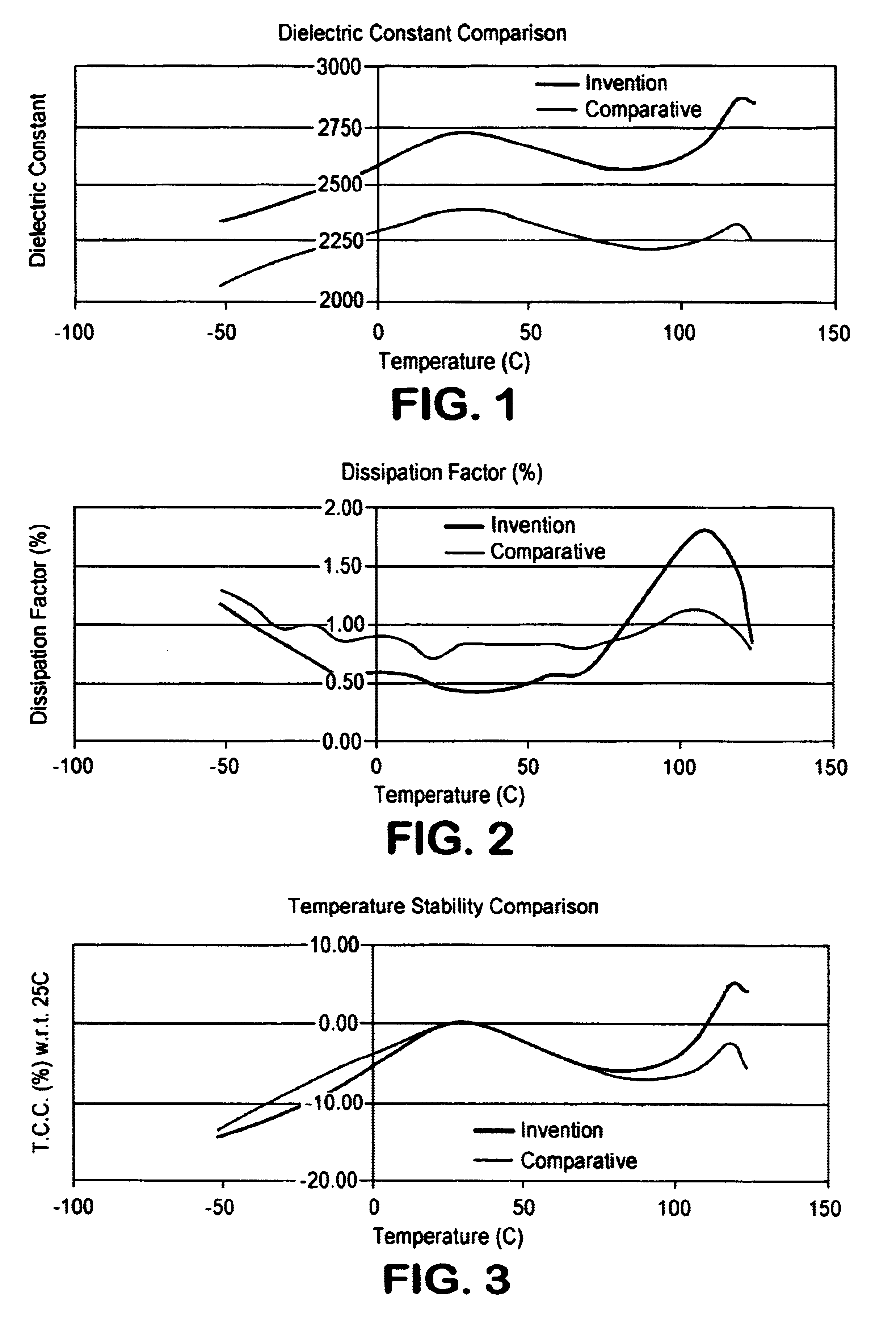

InactiveUS6673274B2Improve insulation performanceReduce dissipationLiquid organic insulatorsFixed capacitor dielectricLow dissipationDopant

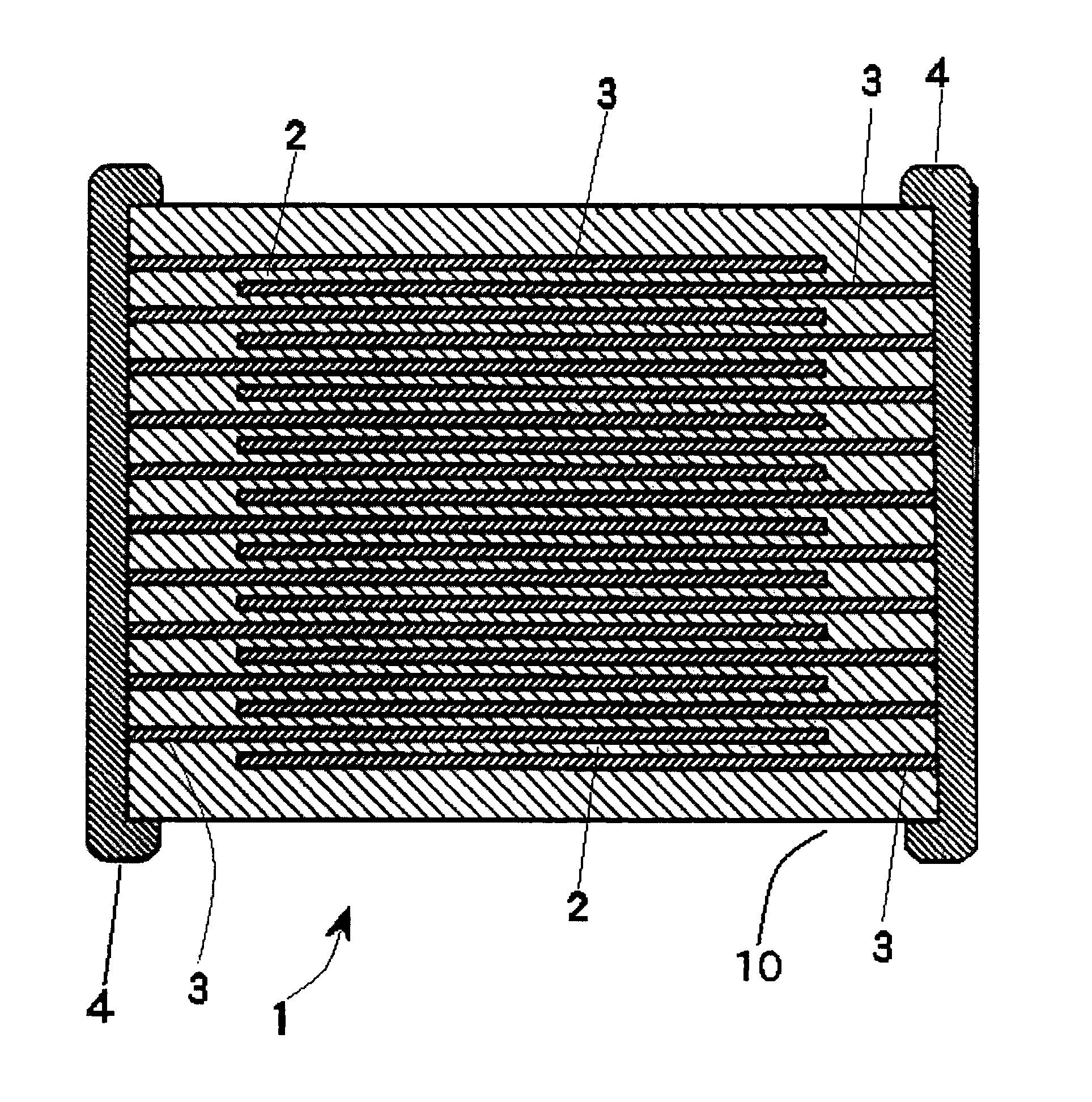

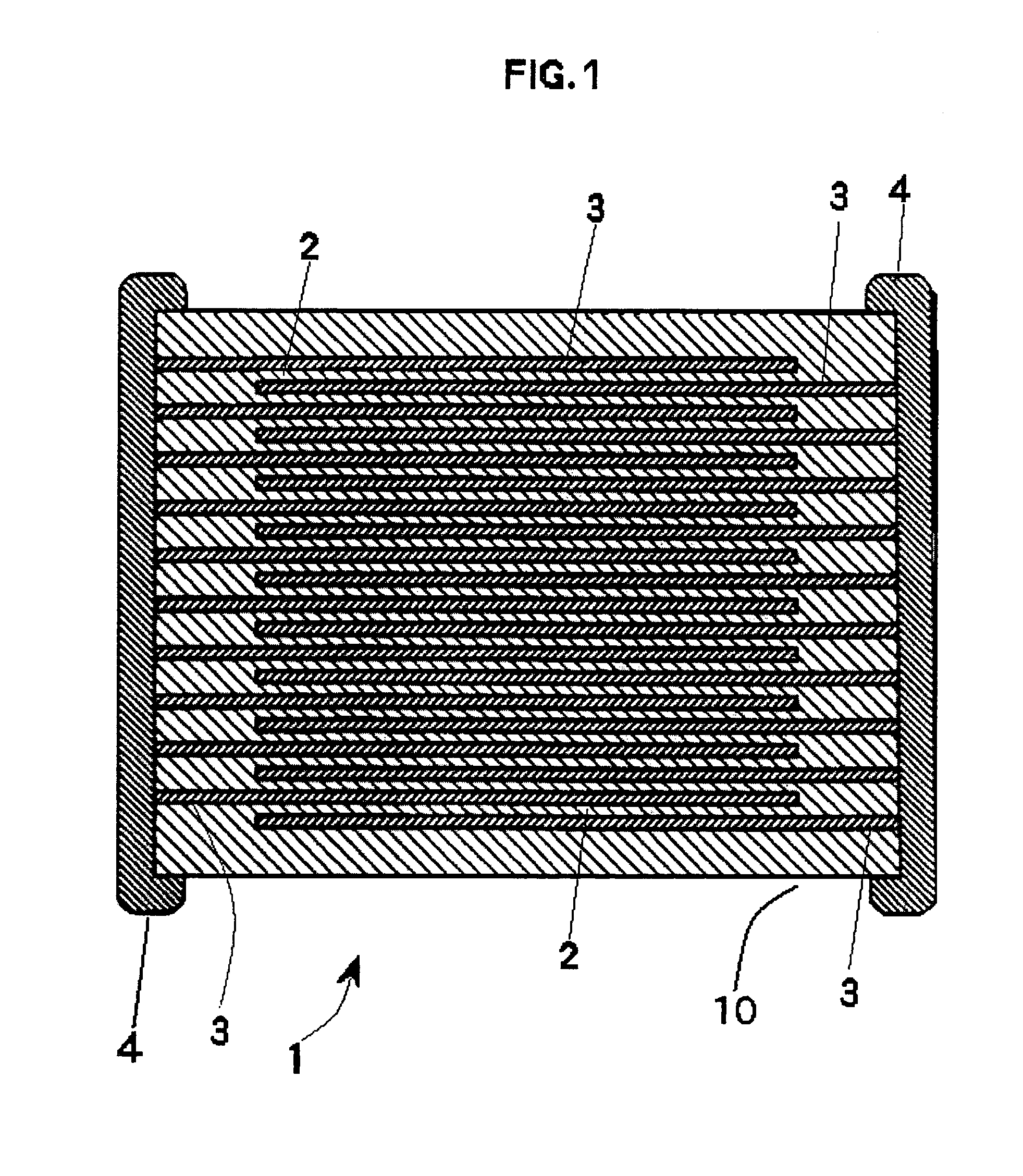

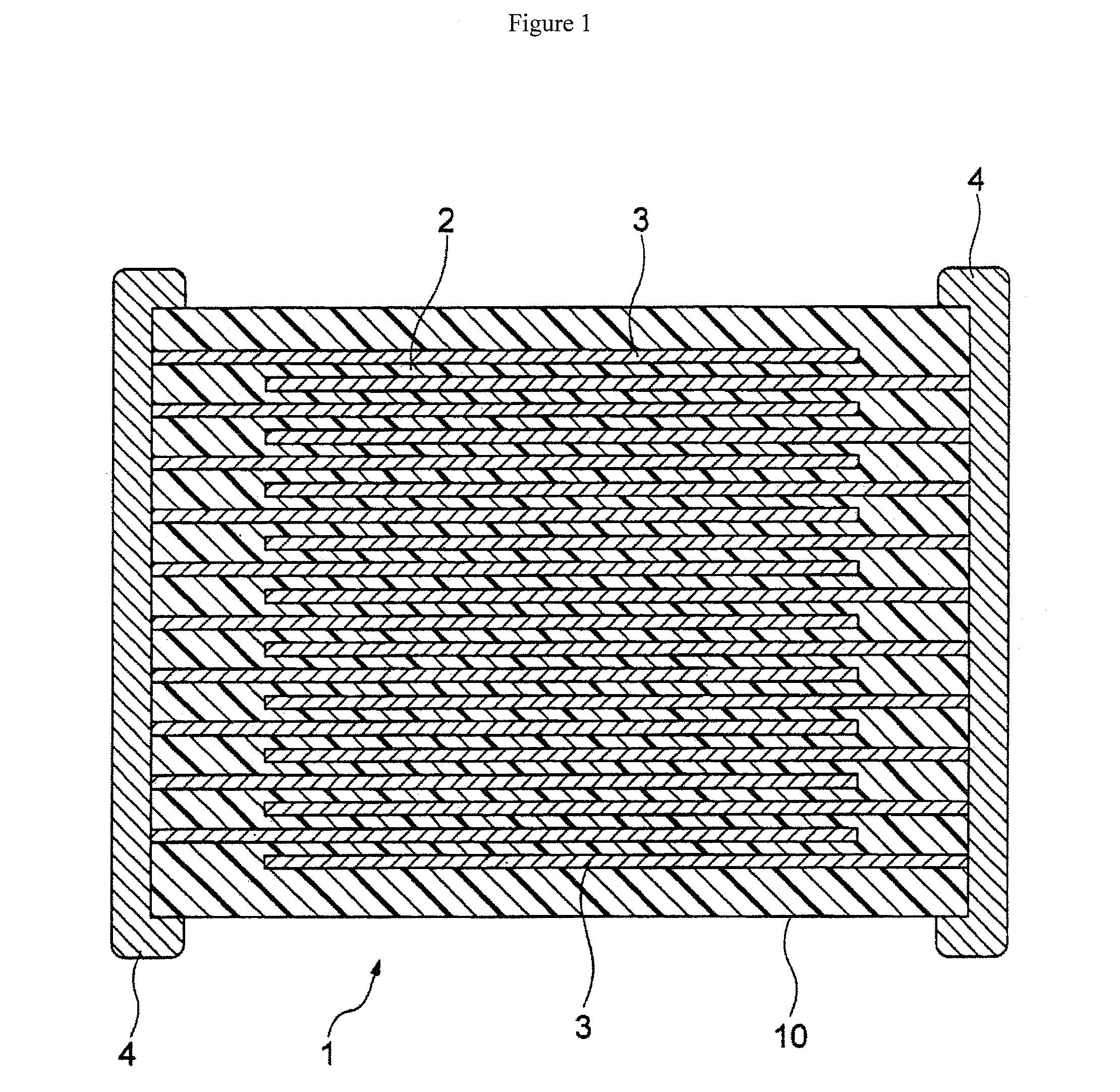

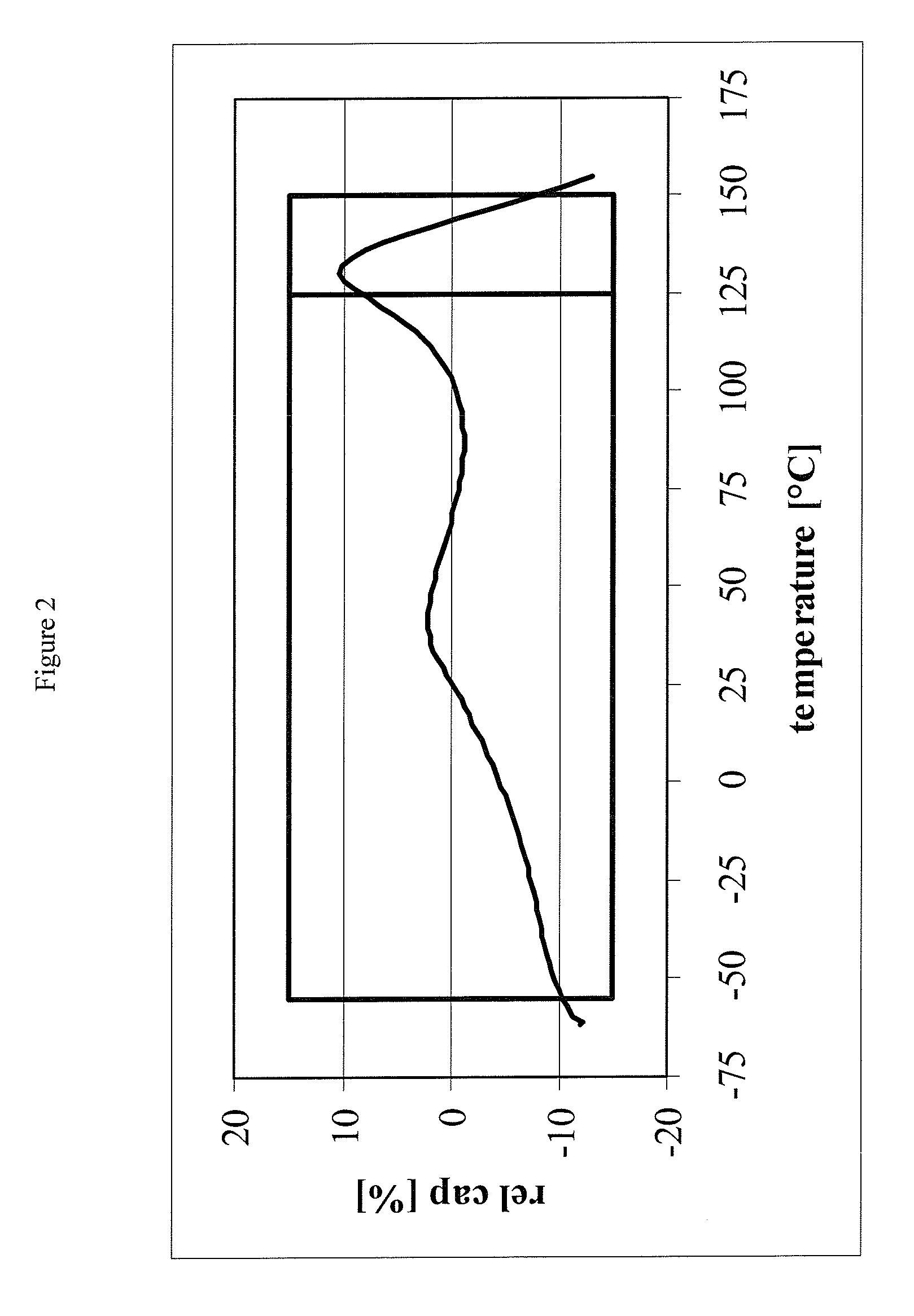

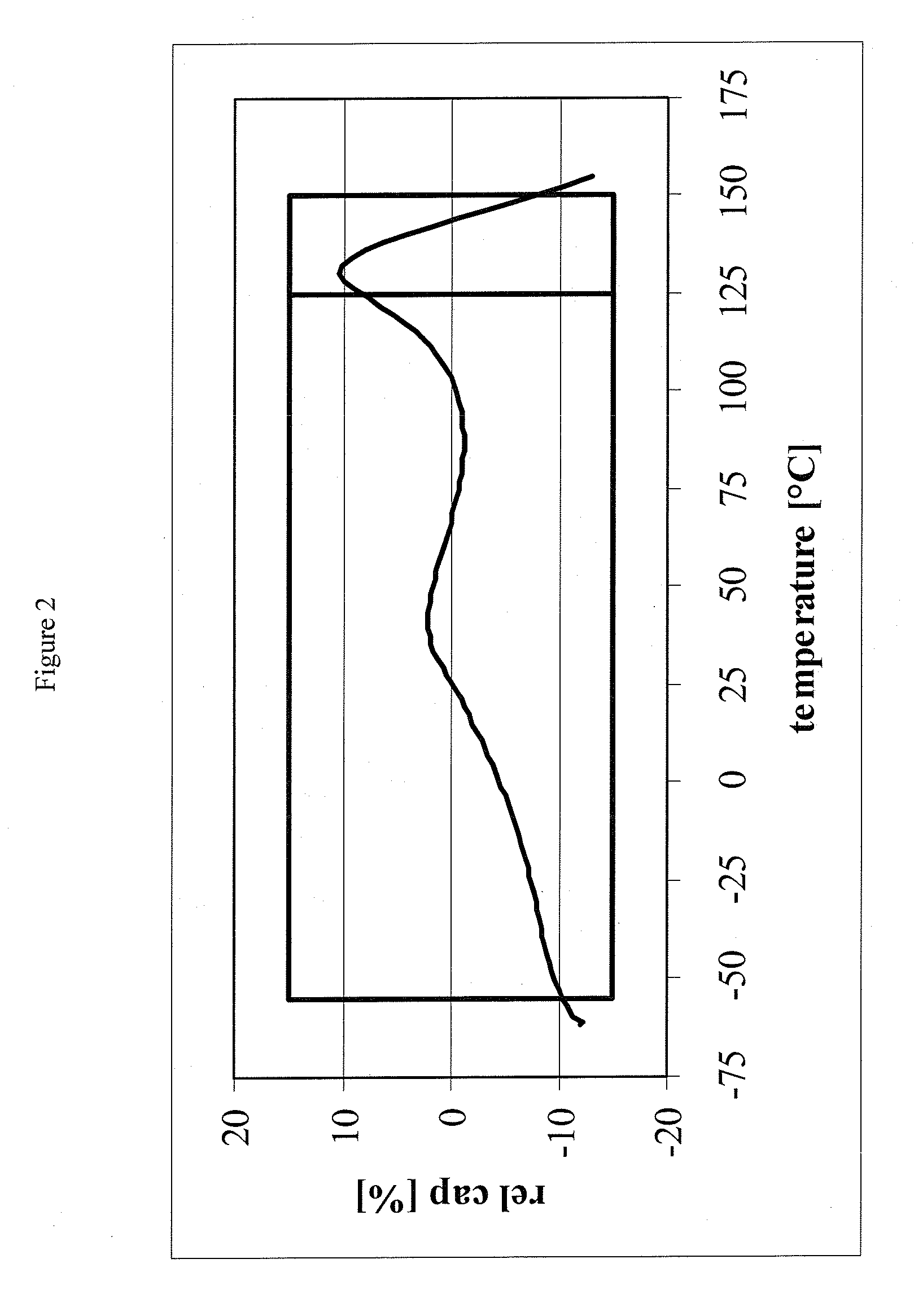

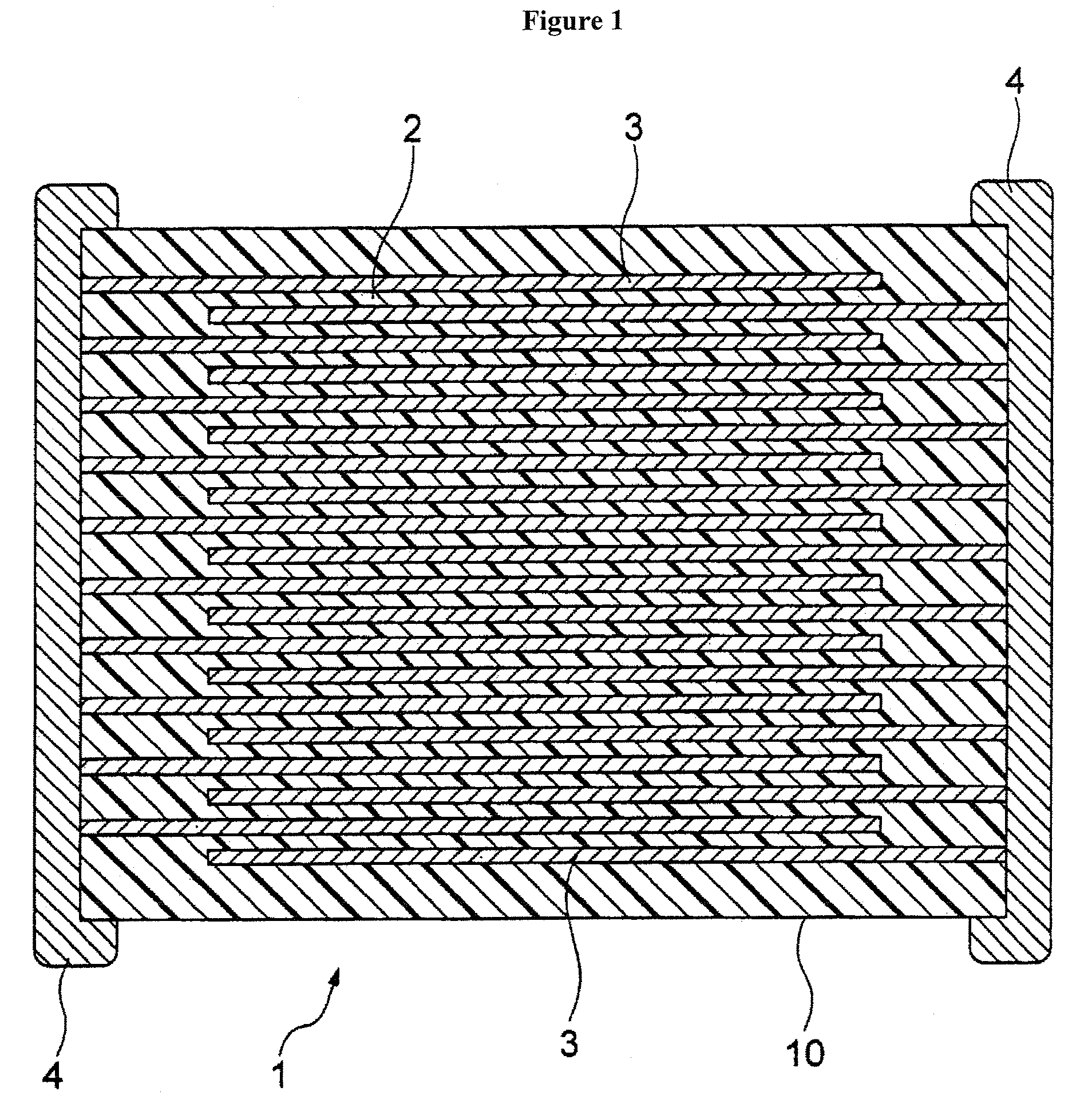

The invention provides dielectric compositions and methods of forming the same. The dielectric compositions may be used to form dielectric layers in electronic devices such as multilayer ceramic capacitors (MLCCs) and, in particular, MLCCs which include base metal electrodes. The dielectric compositions include a barium titanate-based material and several dopants. The type and concentration of each dopant is selected to provide the dielectric composition with desirable electrical properties including a stable capacitance over a temperature range, a low dissipation factor, and a high capacitance. Preferably, MLCCs including dielectric layers formed with the composition satisfy X7R and / or X5R requirements.

Owner:CABOT CORP

COG dielectric composition for use with copper electrodes

ActiveUS7161795B1Small dielectric lossImprove reliabilityFixed capacitor dielectricStacked capacitorsLow dissipationBarium titanate

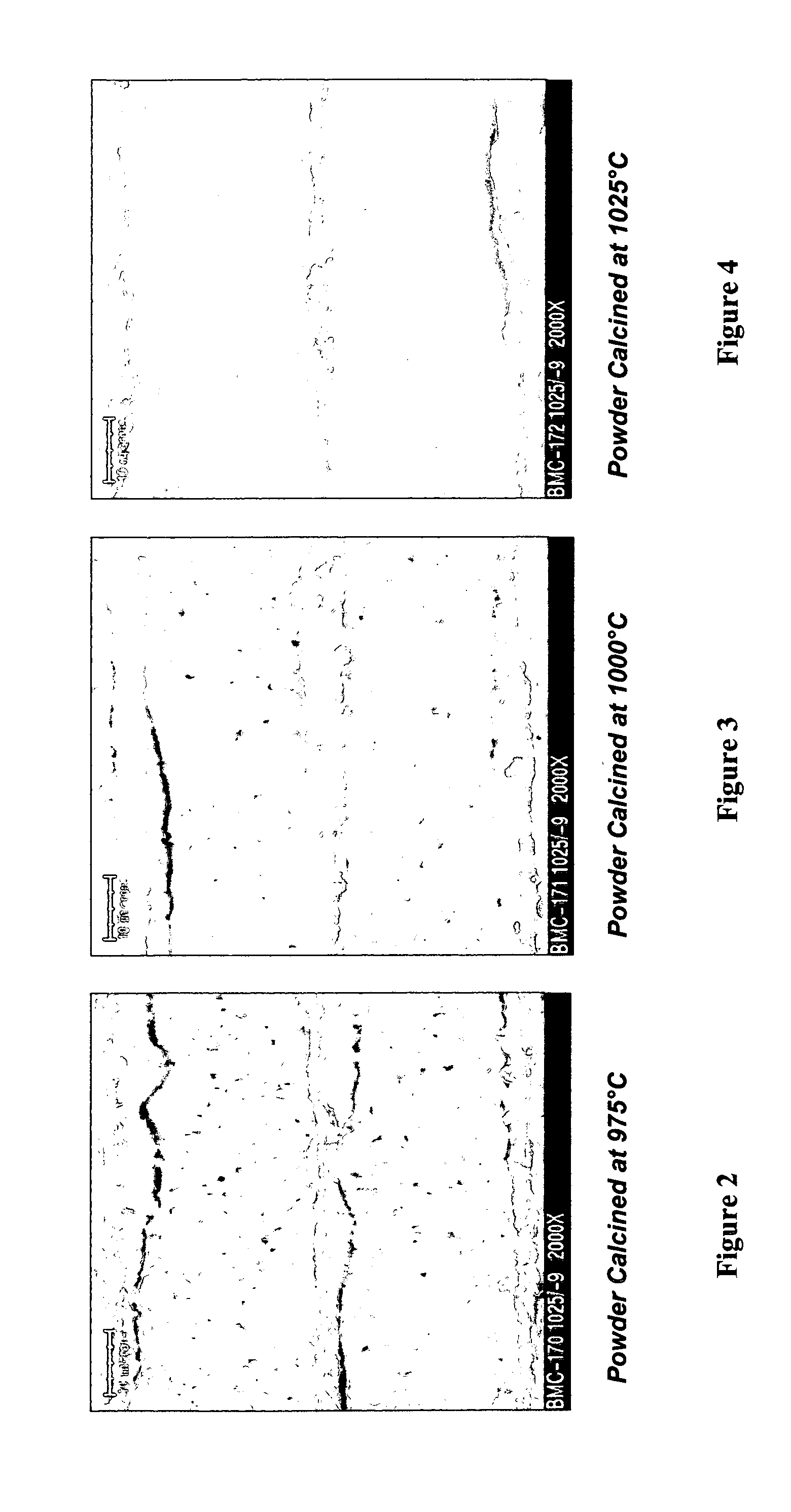

Multilayer ceramic chip capacitors which satisfy COG requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as copper and copper alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a composite oxide formed by calcining rare earth titanates, barium titanate, together with other metal oxides such as MgO, CaO, ZnO, MnO2, ZrO2, SiO2, Ga2O3, Nd2O3, Nb2O5, and Y2O3.

Owner:FERRO CORP

Lead And Cadmium Free, Low Temperature Fired X7R Dielectric Ceramic Composition And Method Of Making

ActiveUS20100220427A1Stable dielectric constantSmall dielectric lossFixed capacitor dielectricStacked capacitorsCeriumCadmium Cation

Multilayer ceramic chip capacitors (MLCC's) which satisfy X7R TCC requirements and which are compatible with silver-palladium internal electrodes. The MLCC's exhibit desirable dielectric properties—high capacitance, low dissipation factor, high insulation resistance, stable TCC—and excellent performance on highly accelerated life testing, and good resistance to dielectric breakdown. The dielectric layers comprise a lead-free and cadmium-free barium titanate base material doped with other metal oxides such oxides of zinc, boron, bismuth, barium, titanium, praseodymium, cerium, tungsten, neodymium, tungsten, tin, niobium, copper, and / or manganese in various combinations. The dielectric ceramic materials herein can be fired at less than 1150° C. with an inner electrode having 70 wt % or more Ag and 30 wt % or less Pd to form an MLCC.

Owner:FERRO CORP

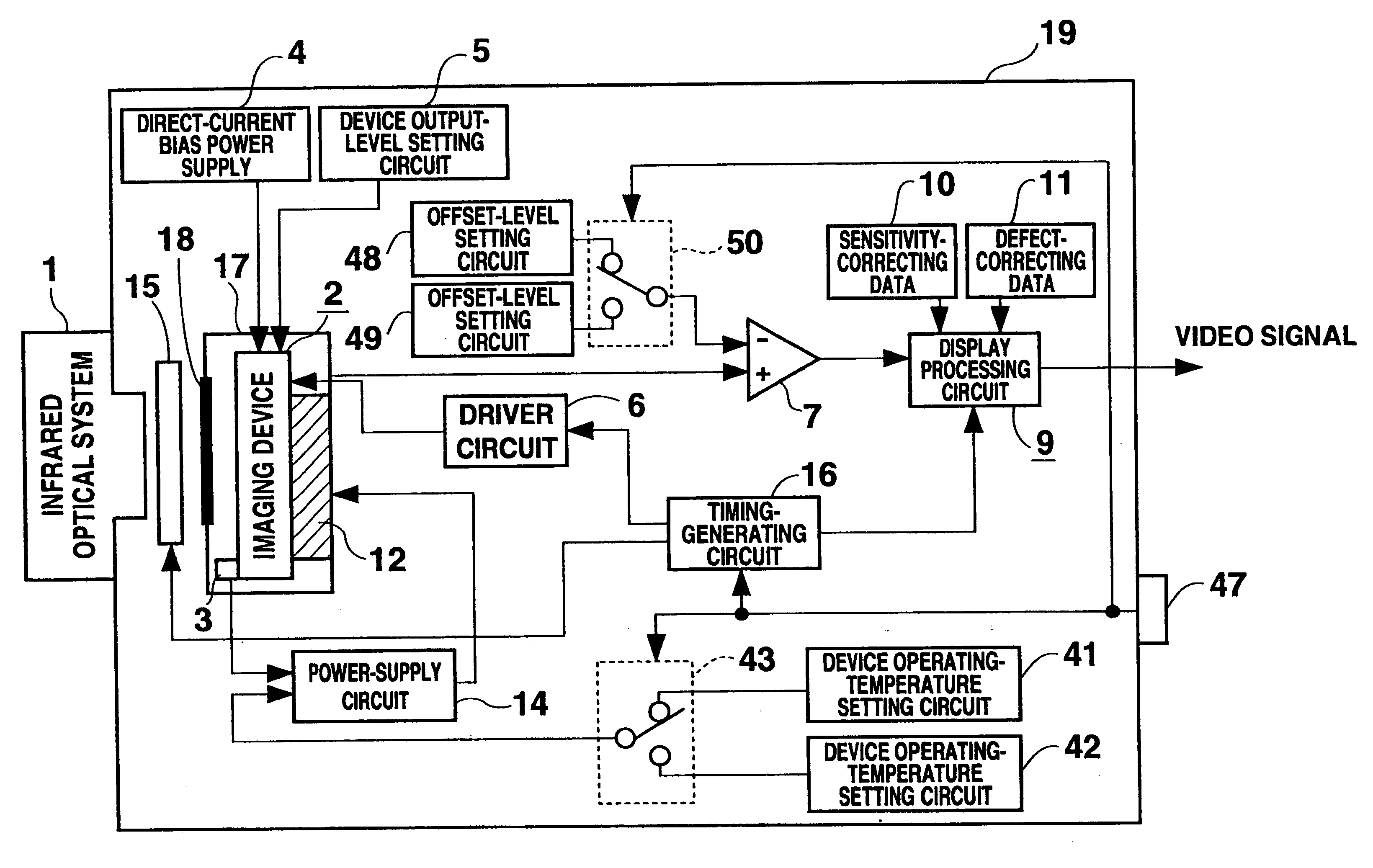

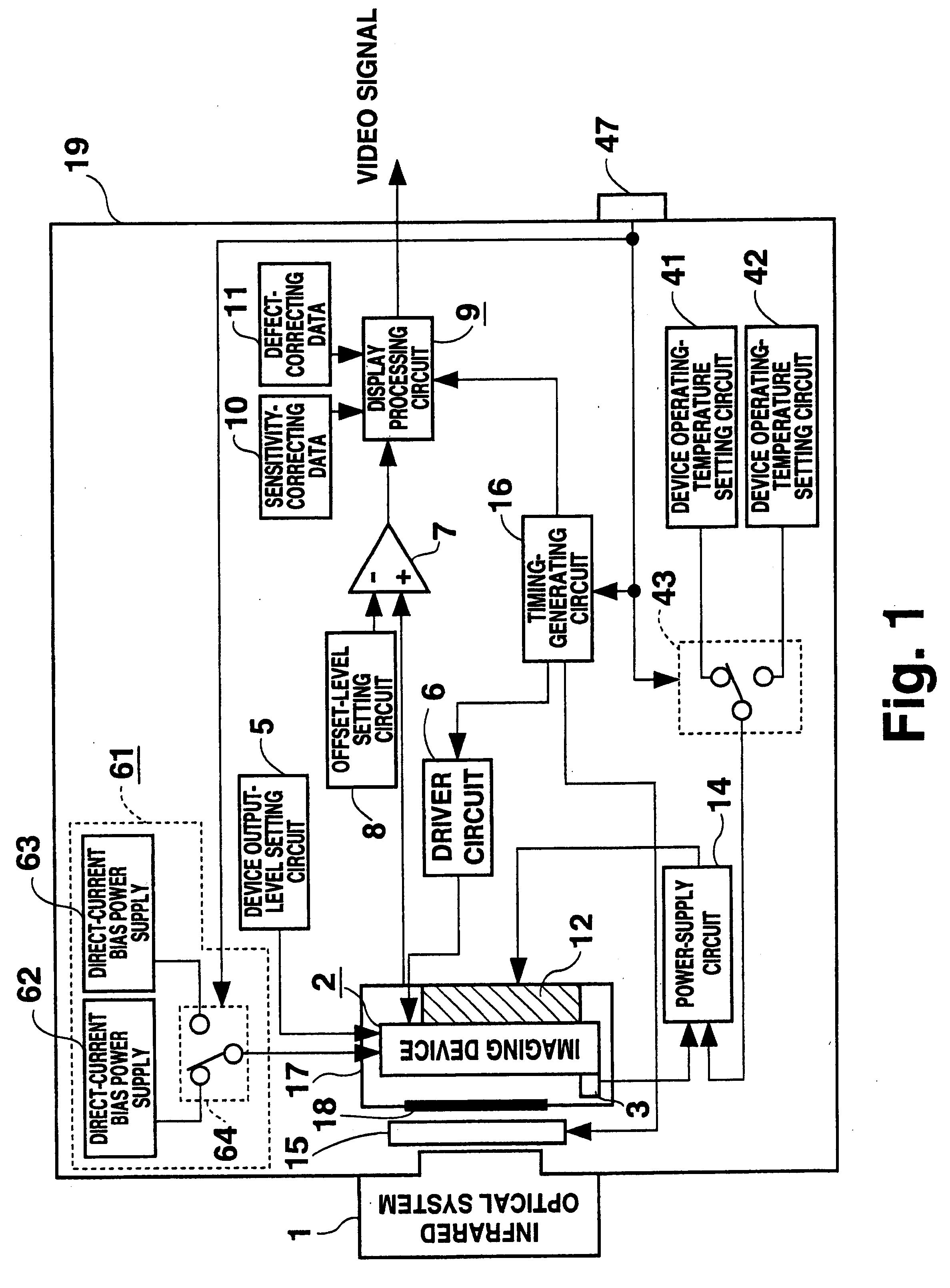

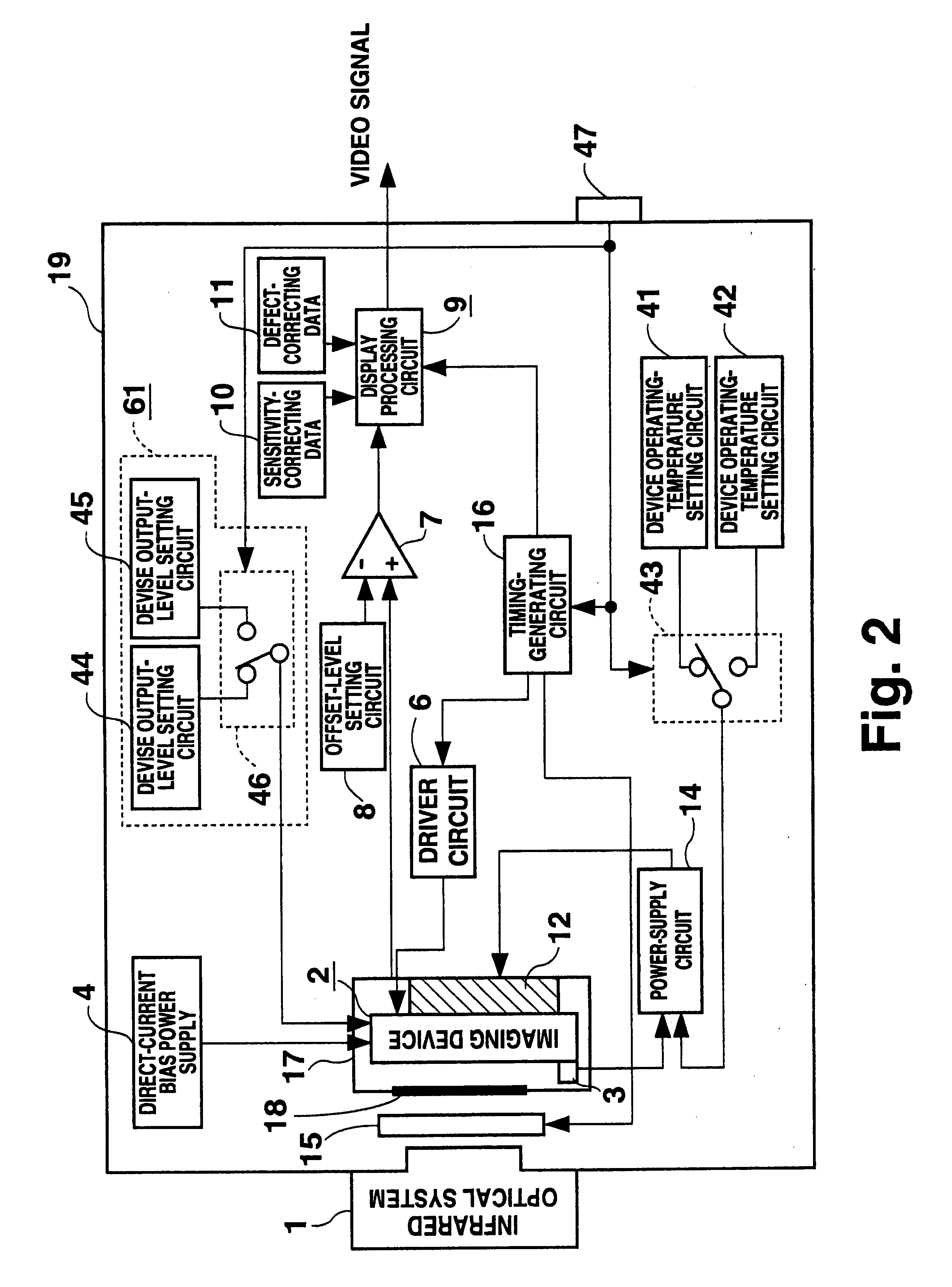

Infrared camera and infrared camera system having temperature selecting switch

InactiveUS6504155B1Low powerWide operating temperatureTelevision system detailsColor signal processing circuitsLow dissipationImaging equipment

An infrared camera with lower dissipation power, a wide range of operating environment temperature, and a shorter warmup is provided. The infrared camera includes a plurality of device operating-temperature setting circuits setting respective device operating temperatures different from one another, a device operating-temperature setting switch for selecting one of the output of the device operating-temperature setting circuits, and a temperature sensor, and performs imaging by switching the connection target of the device operating-temperature setting switch according to a measurement by the temperature sensor, that is to say, according to the temperature inside an enclosure and selecting an operating temperature for an imaging device among a plurality of device operating-temperature settings.

Owner:MITSUBISHI ELECTRIC CORP

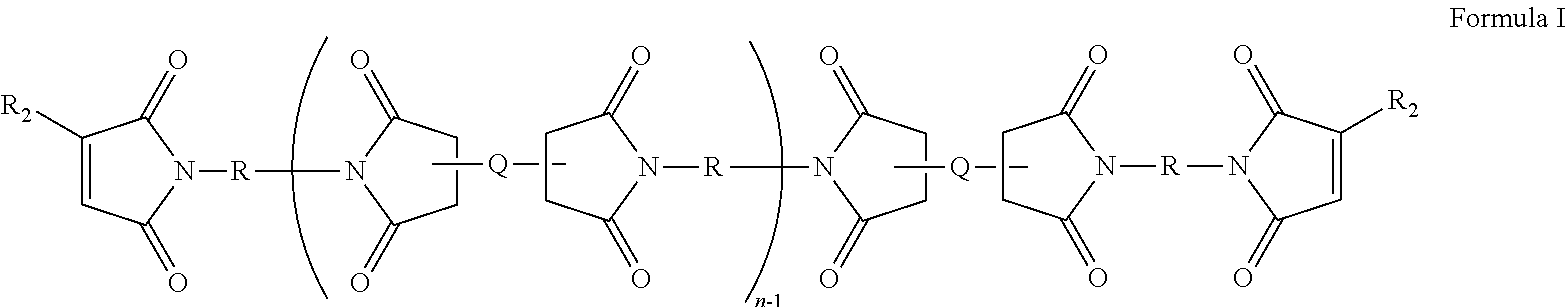

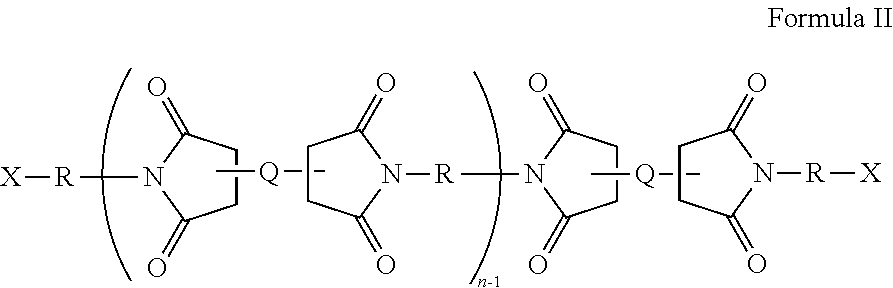

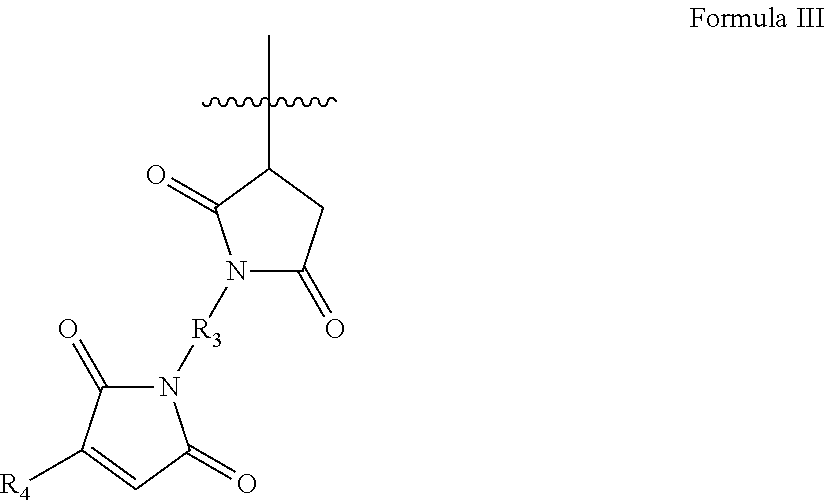

Low dielectric constant, low dielectric dissipation factor coatings, films and adhesives

Curable functionalized imide-linked polyimides compounds have been synthesized that have been found to possess very low dielectric constant and extremely low dissipation factor. These compounds also have a range of high to low modulus, extremely low moisture uptake and are very thermally stable. The combination of these materials in formulation along with functionalized polyethylene, polypropylene, polybutadiens have been found to be ideal for forming films and coatings for the microelectronic applications, multiplayer capacitors and interconnects, and high power cables and wire coatings. The addition of perfluorinated hydrocarbons, and POSS nanoparticles to the formulations have decreased the dielectric constant and dielectric dissipation factor further, and have also improved the flammability of the compositions.

Owner:MIZORI FARHAD G +1

Halogen-free resin composition, and copper clad laminate and printed circuit board using same

ActiveUS20130115472A1Group 5/15 element organic compoundsPrinted circuit aspectsLow dissipationHeat resistance

The halogen-free resin composition comprises (A) 100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 10 to 150 parts by weight of phosphazene; and (E) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Method for directly reducing ferronickel by tunnel kiln using laterite-nickel ore as raw material

InactiveCN101037713AReduce carbon contentIncrease concentrationRetort furnacesTunnel kilnLow dissipation

A method of using nickeliferous laterite to reduce ferronickel directly in tunnel kiln relates to a method of reducing ferronickel. Comparing with high furnace smelting ferronickel and electric furnace smelting ferronickel having problems such as great invest, high manufacturing cost and produced ferronickel with high carbon content, the method of the invention is finished as: selecting nickeliferous laterite as material, the nickeliferous laterite contains 0.75-2.60% by weight of nickel, 8.00-55.0% by weght of iron; adding weight ratio of nickeliferous laterite and reductant as 1.00:0.25-0.55 into reducing pot, then putting the reducing pot in tunnel kiln, through preheating and stoving, heating reducing, cooling, taking off to get qualified reduced directly nickeliferous laterite. The invention selects natural nickeliferous laterite as material to reduce nickeliferous laterite, having advantages such as technology which easy to control, simple operation, low dissipation of energy, environment protection without pollution, low manufacturing cost, low installion cost and produced ferronickel with low carbon content.

Owner:章宇

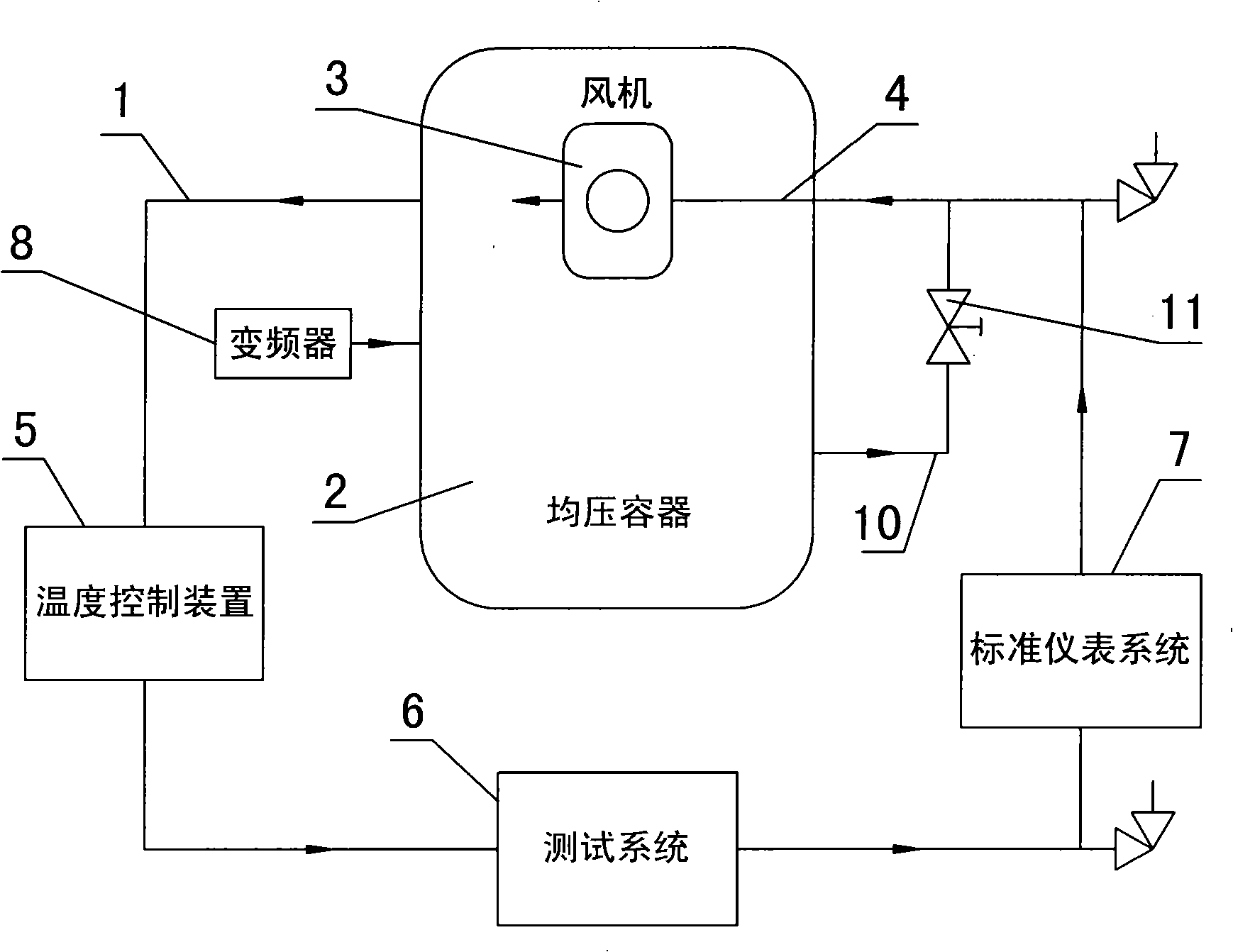

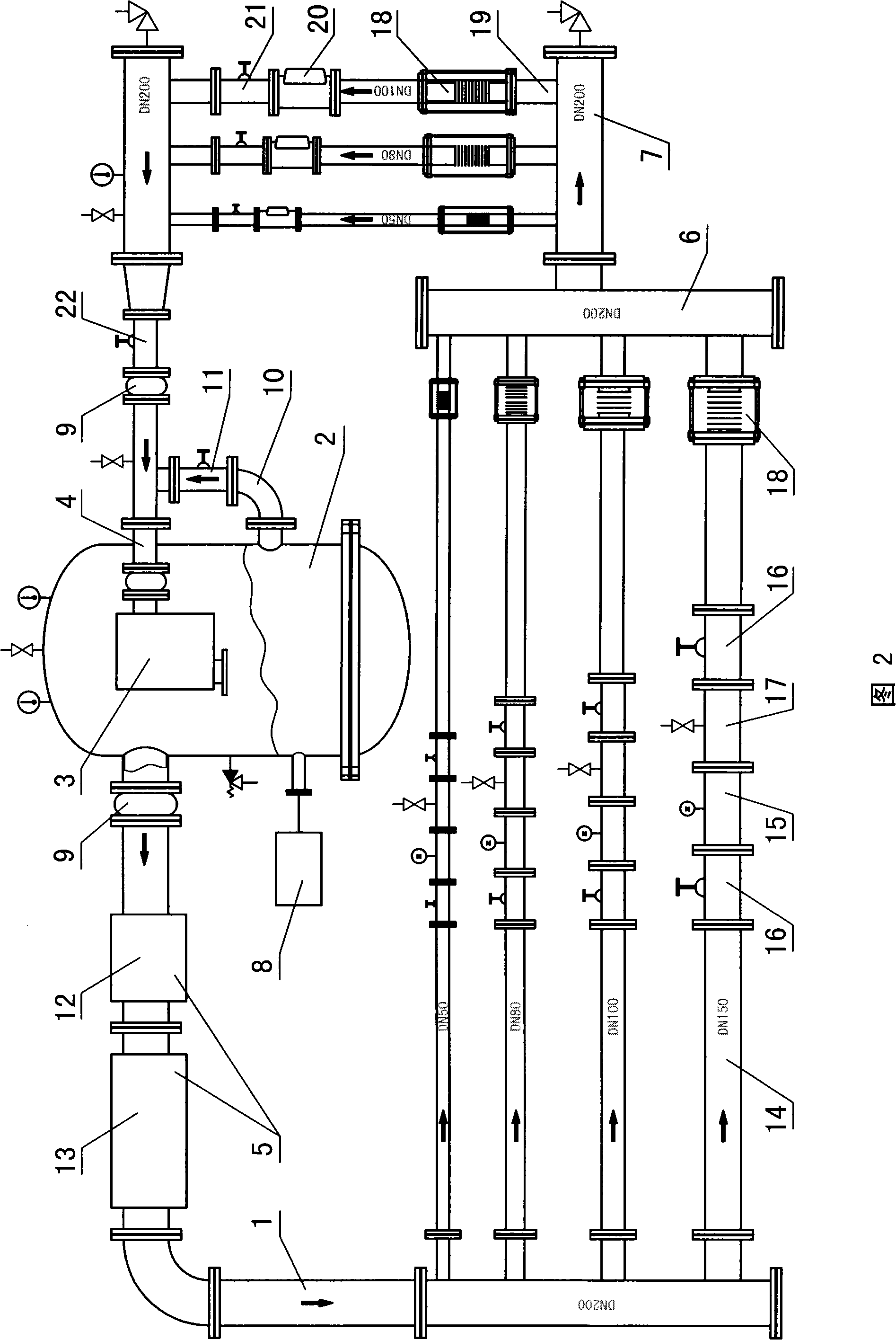

Actual flow circle calibrating apparatus for gas flowmeter and calibrating method thereof

InactiveCN101358871ASolve the costResolve accuracyTesting/calibration apparatusLow noiseTemperature control

The invention discloses a gas flow meter actual flow cycling detecting device and a detecting method thereof. A pipeline loop of the actual flow cycling detecting device is provided with a plurality of uniform voltage container sealing pots; a blower is arranged in the sealing pot; the air inlet of the blower penetrates out of the sealing pot to be connected with the upstream side of the pipeline loop; the air outlet of the blower is arranged in the sealing pot and the outlet of the sealing pot is connected with the downstream side of the pipeline loop; the sealing pot, a temperature controlling device, a testing system and a standard meter system are arranged in series. The invention effectively resolves the problem that the detecting condition is not consistent with the working condition to lead measurement error existing in the prior gas flow meter, breaks through the prior method which depends on a pipeline gas source or adopts compressor, has the advantages of small volume, low dissipation energy, high accuracy, and also has the characteristics of small investment, low noise, exchangeable gas and easy operation, is applicable to the testing of fuel gas and most industry gas and can be promoted and used in large range.

Owner:MEMSIC SEMICON WUXI

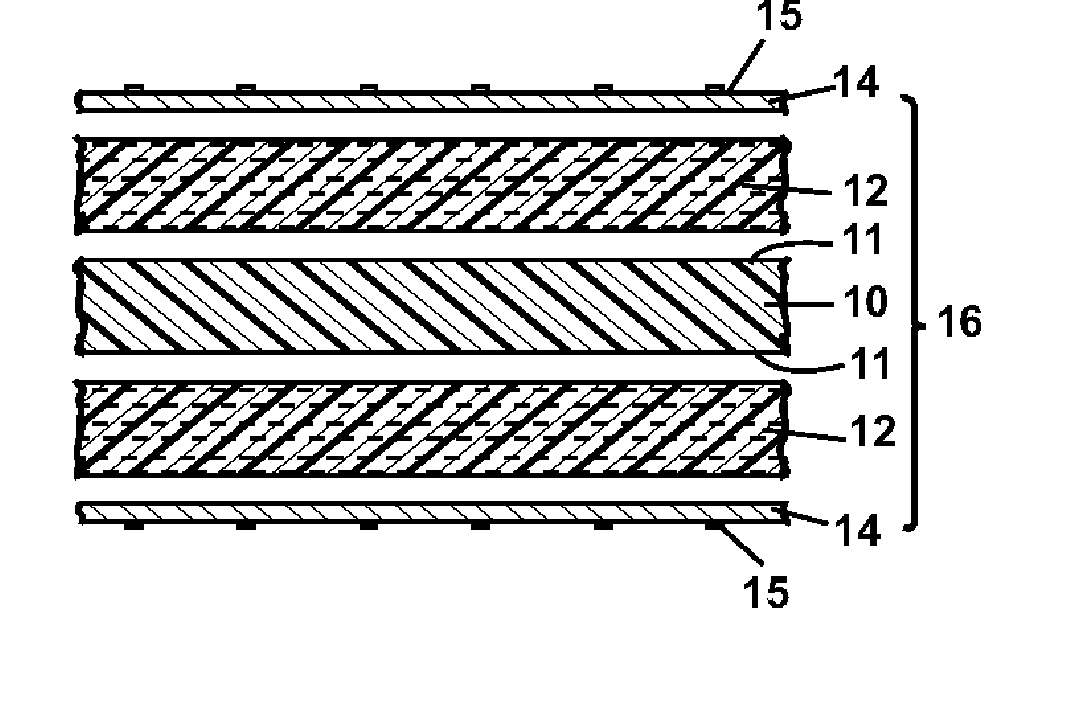

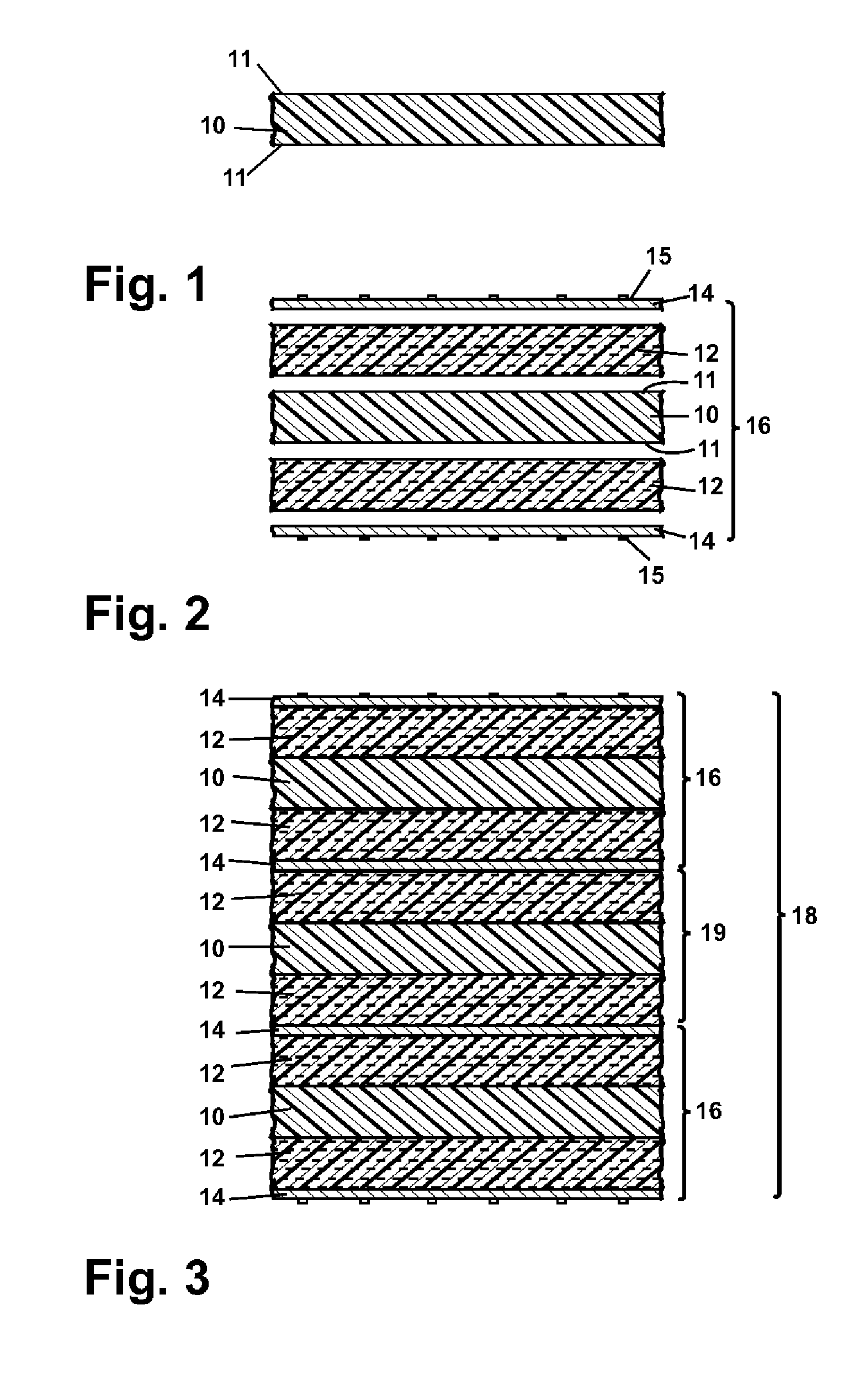

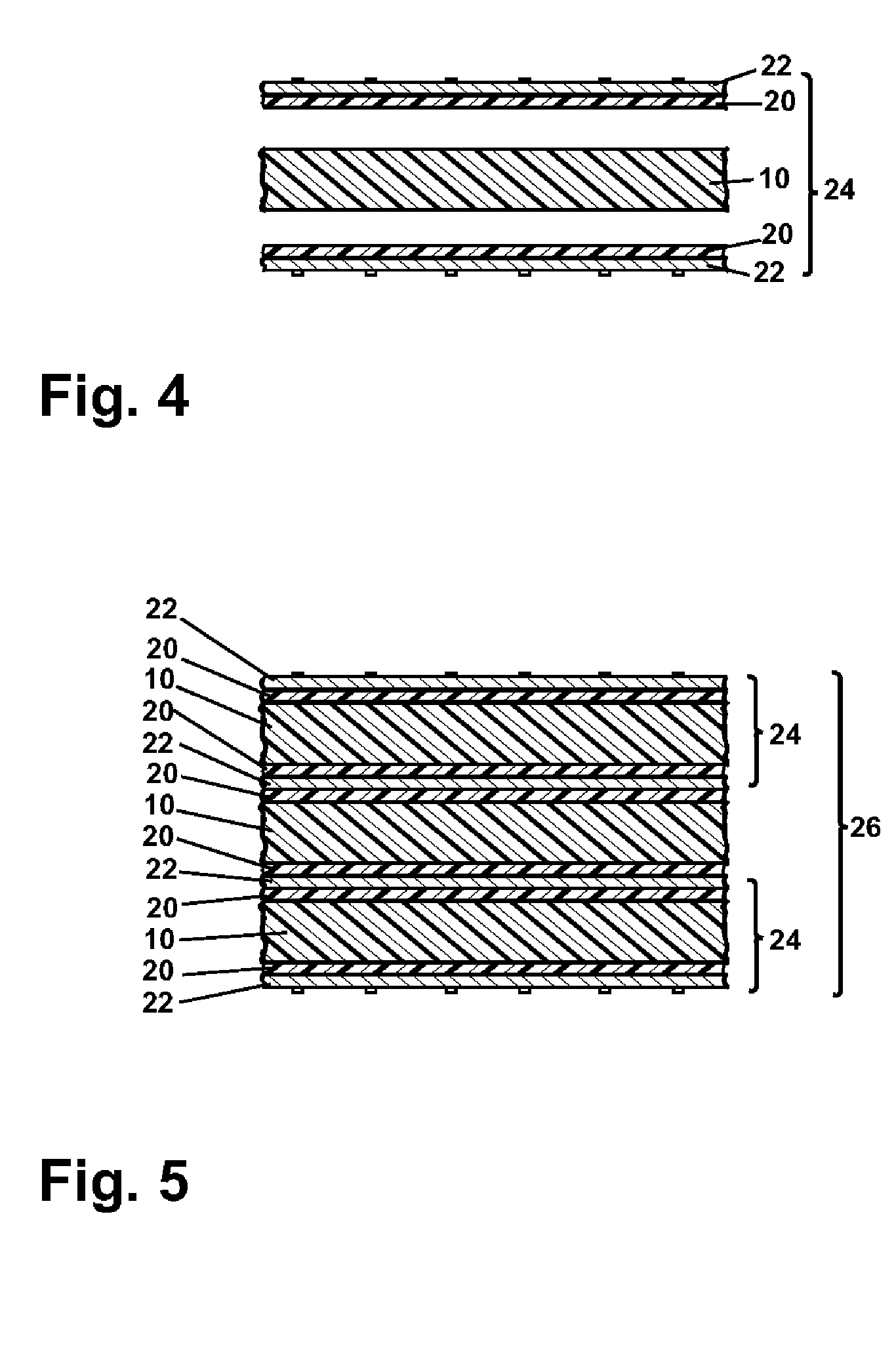

Laminates having a low dielectric constant, low disapation factor bond core and method of making same

InactiveUS20050121226A1Improve bindingLow dissipation factorInsulating substrate metal adhesion improvementDielectric materialsLow dissipationPolyetherimide

Laminates have at least one resin-system layer, a low dielectric, low dissipation factor bond core having at least one surface that is treated for adhesion, such as by etching, plasma or Corona discharge or mechanical roughing to facilitate bonding to the at least one resin system layer and a conductive metal cladding on the at least one resin system layer. The bond core can be a fluoropolymer film or a fluoropolymer prepreg, having at least one etched or Corona discharge treated surface. Alternately, the bond core can be a polyetherimide film or a polyetherimide prepreg, having at least one etched or Corona discharge treated surface. The laminates are used, for example, high performance, low loss printed circuit boards. The laminates have the desired dielectric properties inherent to fluoropolymer materials and can be produced using conventional printed circuit board manufacturing processes, materials, and equipment. Methods of producing laminates are disclosed.

Owner:PARK ELECTROCHEMICAL CORP

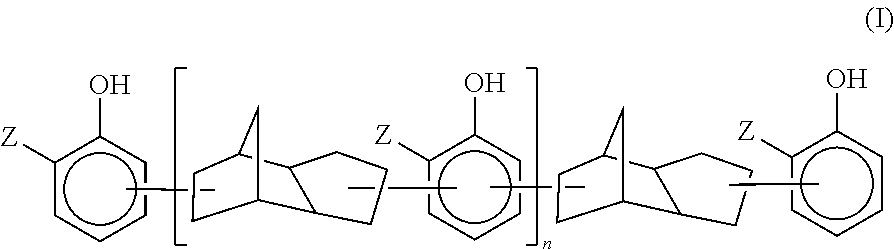

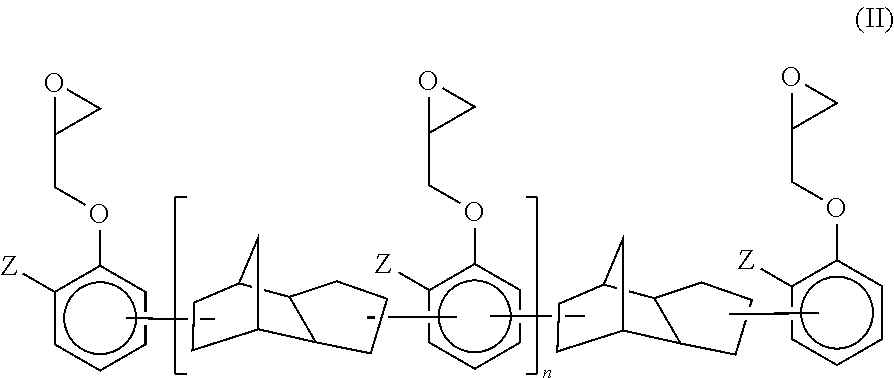

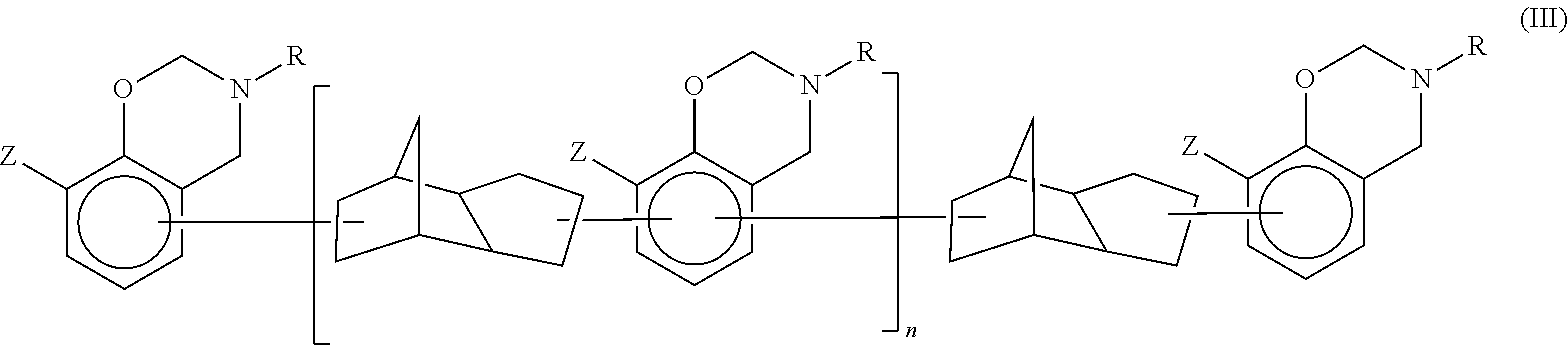

Novel low dielectric resin varnish composition for laminates and the preparation thereof

ActiveUS20110224345A1Improve featuresLow dielectric constantPlastic/resin/waxes insulatorsEpoxy resin coatingsLow dissipationMoisture absorption

This invention relates to a low dielectric resin varnish composition for laminated printed circuit boards, wherein the resin composition includes (A) Dicyclo-pentadiene-Phenolic Novolac resin (abbreviated as DCPD-PN); or (B) at least one kind of dicyclopentadiene Phenolic Novolac Epoxy resins(DCPD-PNE, referred to as Resin 1); or (C) a novel Dicyclopentadiene-Dihydrobenzoxazine resin (DCPD-BX, referred to as Resin 2); or the mixture of (B) and (C), and (D) Flame retardant agent, curing agent and accelerating agent solutions.Because all of component (A) DCPD-PN, component (B) DCPD-PNE and component (C) DCPD-BX in this resin varnish composition contain a saturated multi-cyclic structure of dicyclopentadiene, the resin varnish shows lower dipole, dielectric constant (Dk), dissipation factor (Df) and moisture absorption; and via adding a brominated or phosphorus flame retardant, the composition exhibits high thermal stability characteristic. The copper clad laminates obtained in accordance with the invention meet not only the demand of low dielectric constant (Dk<4.0 @ 1 GHz) and low dissipation factor (Df<0.009 @ 1 GHz), but also possesses high heat stability and low moisture absorption characteristics, thus are widely applied to high-performance electronic materials.

Owner:NANYA PLASTICS CORP

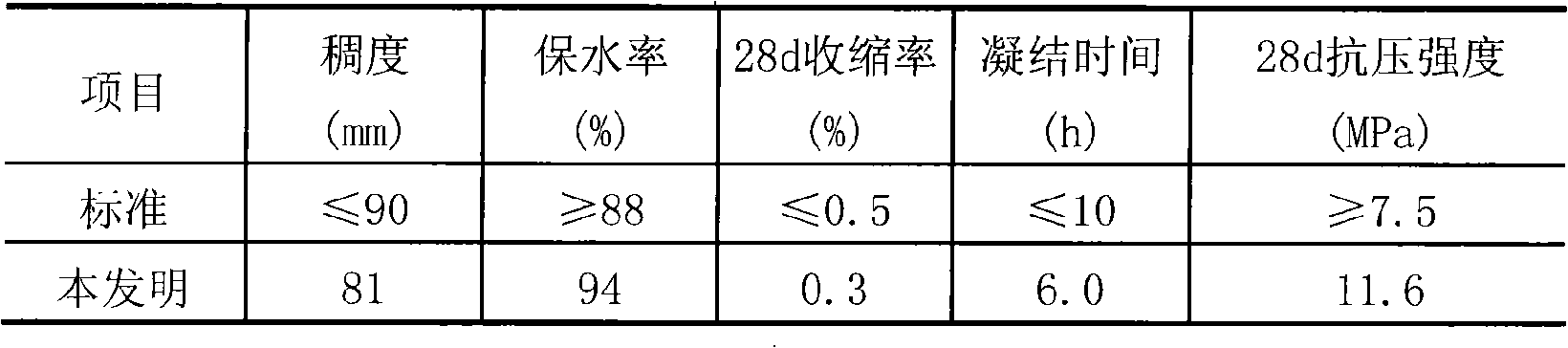

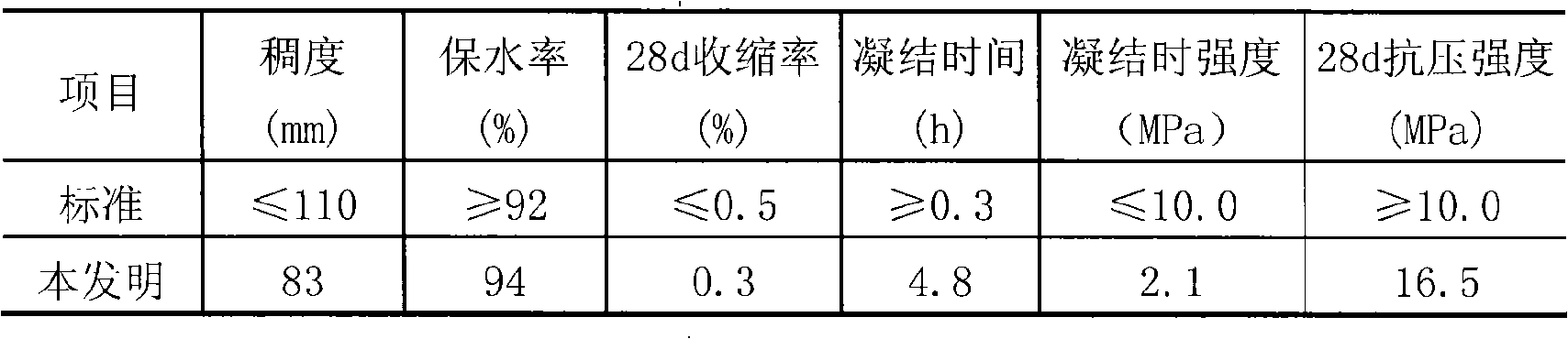

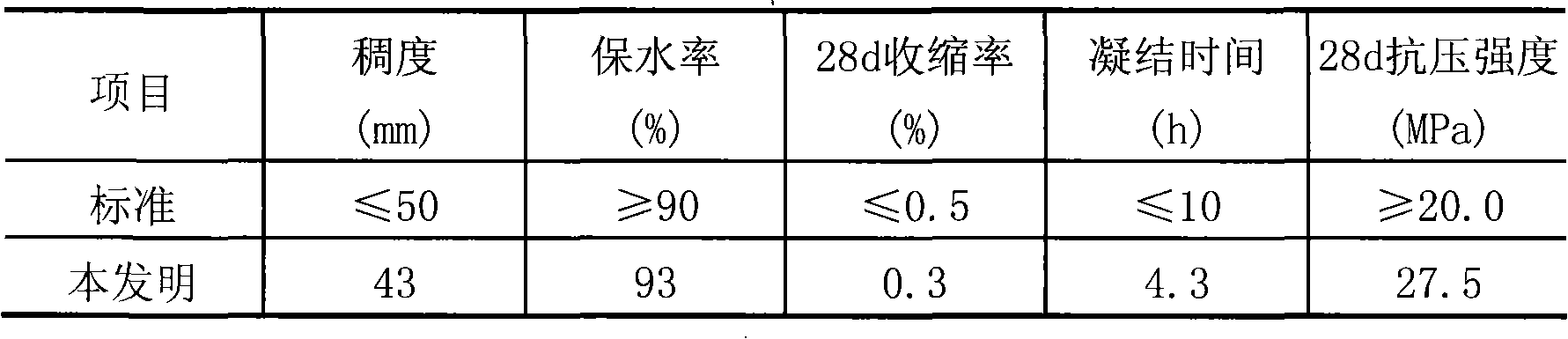

Building mortar and method for preparing same

The invention belongs to the technical field of a constructional material, in particular relates to building used mortar used for masonry and plastering of buildings and ground, and a preparation method thereof. The building mortar is characterized in that the building motor is prepared with a dry material and water though mixing according to the ratio of 1 to 0.03 to 0.35 by weight; the dry material is prepared with 60 to 80 percent of quartz sand, 7 to 30 percent of ground limestone, 1 to 20 percent of powdered industrial residue, 0.1 to 4 percent of land plaster, 0.1 to 8 percent of mineral admixture, and 0 to 0.1 percent of chemical additives by weight. The additive is any of or the mixture of a plasticizer and a gelatinizer at a discretionary ratio. The building mortar has the characteristics of low cost, high strength, and low dissipation of energy. The preparation method is operated easily.

Owner:WUHAN UNIV OF TECH +1

Halogen-free resin composition, copper clad laminate using the same, and printed circuit board using the same

ActiveUS20140023839A1Low dielectric constantImprove flame retardant performanceGroup 5/15 element organic compoundsSynthetic resin layered productsEpoxyLow dissipation

A halogen-free resin composition includes (A) 100 parts by weight of epoxy resin; (B) 10 to 100 parts by weight of benzoxazine resin; (C) 5 to 50 parts by weight of diallylbisphenol A resin; and (D) 0.05 to 20 parts by weight of an amine curing agent. The halogen-free resin composition includes specific ingredients and proportions thereof to attain low dielectric constant (Dk), low dissipation factor (Df), high heat resistance, and high flame retardation. The halogen-free resin composition is suitable for producing a prepreg or a resin film and thus applicable to copper clad laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Low-dielectric resin composition and copper-clad laminate and printed circuit board using the same

ActiveUS20150044485A1Low dissipation factorHigh frequencySynthetic resin layered productsPrinted circuit aspectsLow dissipationPrinted circuit board

The present invention provides a resin composition useful for a copper-clad laminate and a printed circuit board, wherein the resin composition comprises the following components: (A) 100 parts by weight of vinyl-containing polyphenylene ether resin; (B) 5 to 50 parts by weight of maleimide; (C) 10 to 100 parts by weight of styrene-butadiene copolymer; and (D) 5 to 30 parts by weight of cyanate ester resin. The present invention also provides a resin composition and an article made therefrom having low dissipation factor at high frequency and excellent thermal resistance and peeling strength and being useful for a copper-clad laminate and a printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Triphenyl phosphine oxide polymer capacitors

InactiveUS6493208B1Multiple fixed capacitorsFixed capacitor dielectricBreakdown strengthPolymer capacitor

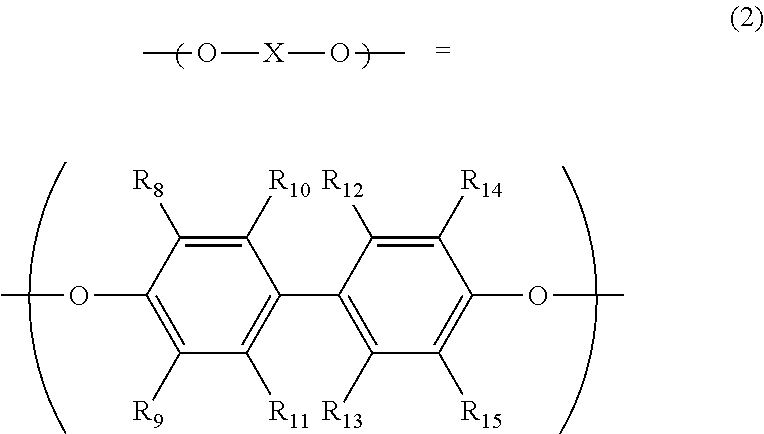

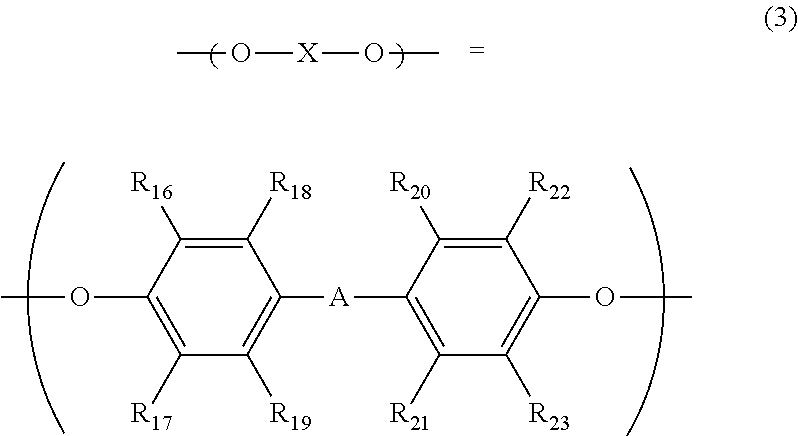

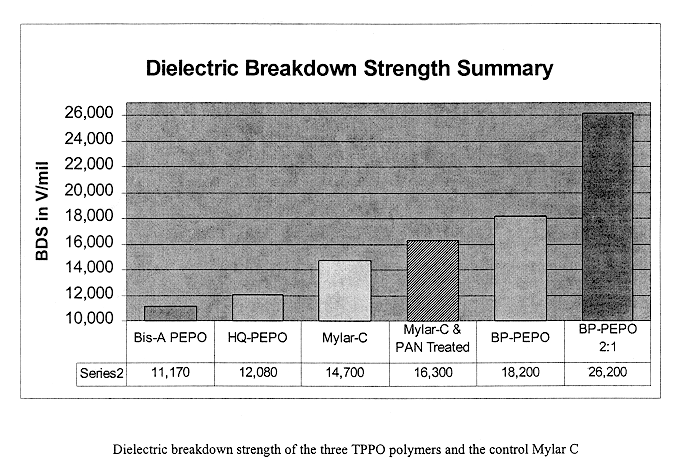

The present invention is a capacitor of a triphenyl phosphine oxide film as a base dielectric. More specifically, the base dielectric film is selected from the group consisting of Bisphenol-A (Bis-A PEPO). 4',4'-biphenol (BP-PEPO), and Hydroquinone (HQ-PEPO). TPPO based polymers have a very high breakdown strength, dielectric constant, low dissipation factor and high energy density. An ultra-thin coating can leverage the capabilities of this new dielectric, and potentially other commercial polymer films, to make possible energy storage in excess of 1 J / cc. The triphenyl phosphine oxide film can be fabricated containing a conducting PolyANiline (PAN) polymer layer located between the electrode and core polymer, or by being dip coated with PAN.

Owner:EIKOS

X8R dielectric composition for use with nickel electrodes

ActiveUS7541306B2Small dielectric lossImprove reliabilityStacked capacitorsSemiconductor/solid-state device manufacturingLow dissipationBarium titanate

Multilayer ceramic chip capacitors which satisfy X8R requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel and nickel alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a barium titanate base material doped with other metal oxides such as BaO, Y2O3, ZrO2, SiO2, MgO, MnO, MoO3, CaO, Lu2O3, Yb2O3, or WO3 in various combinations.

Owner:FERRO CORP

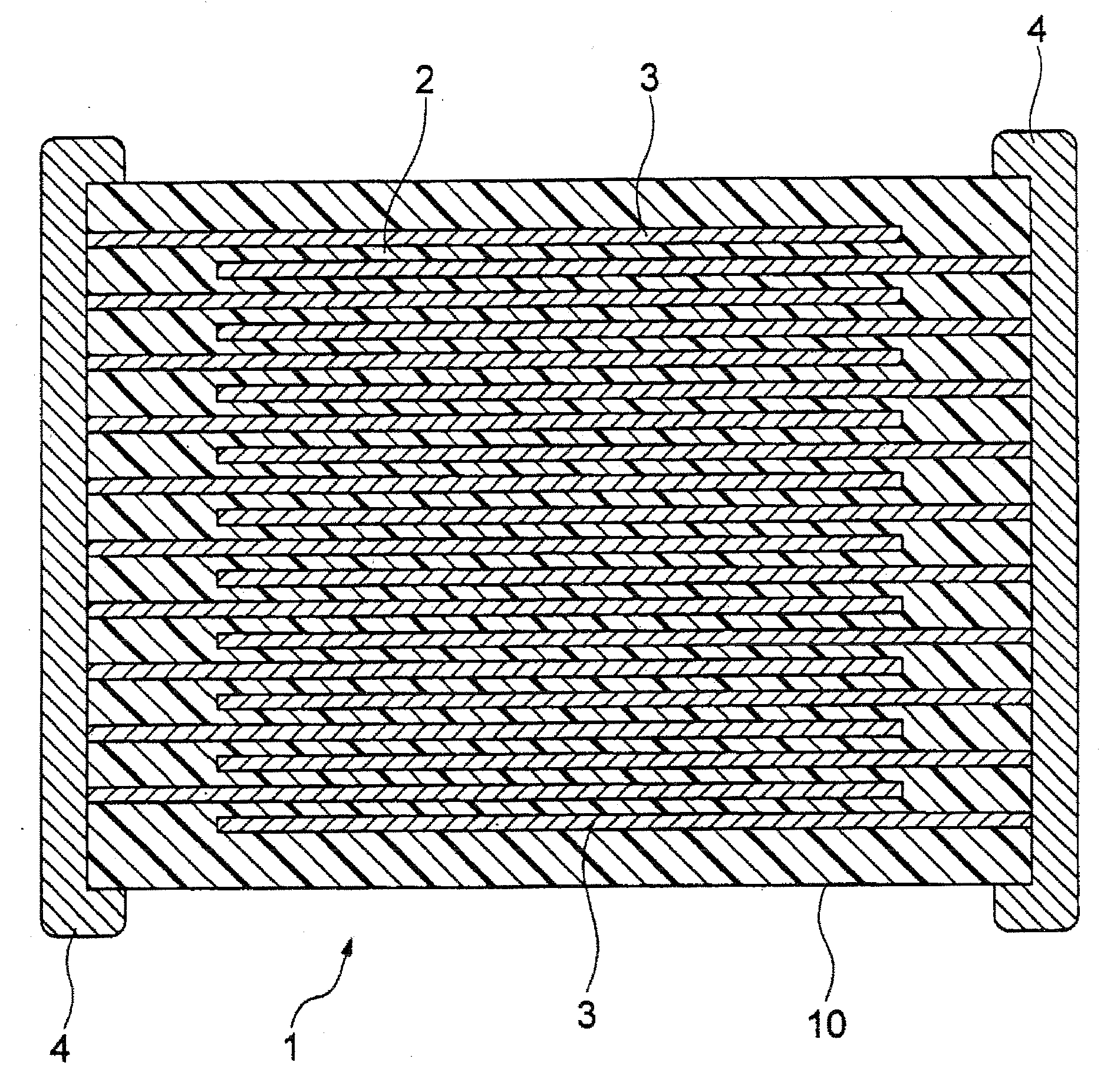

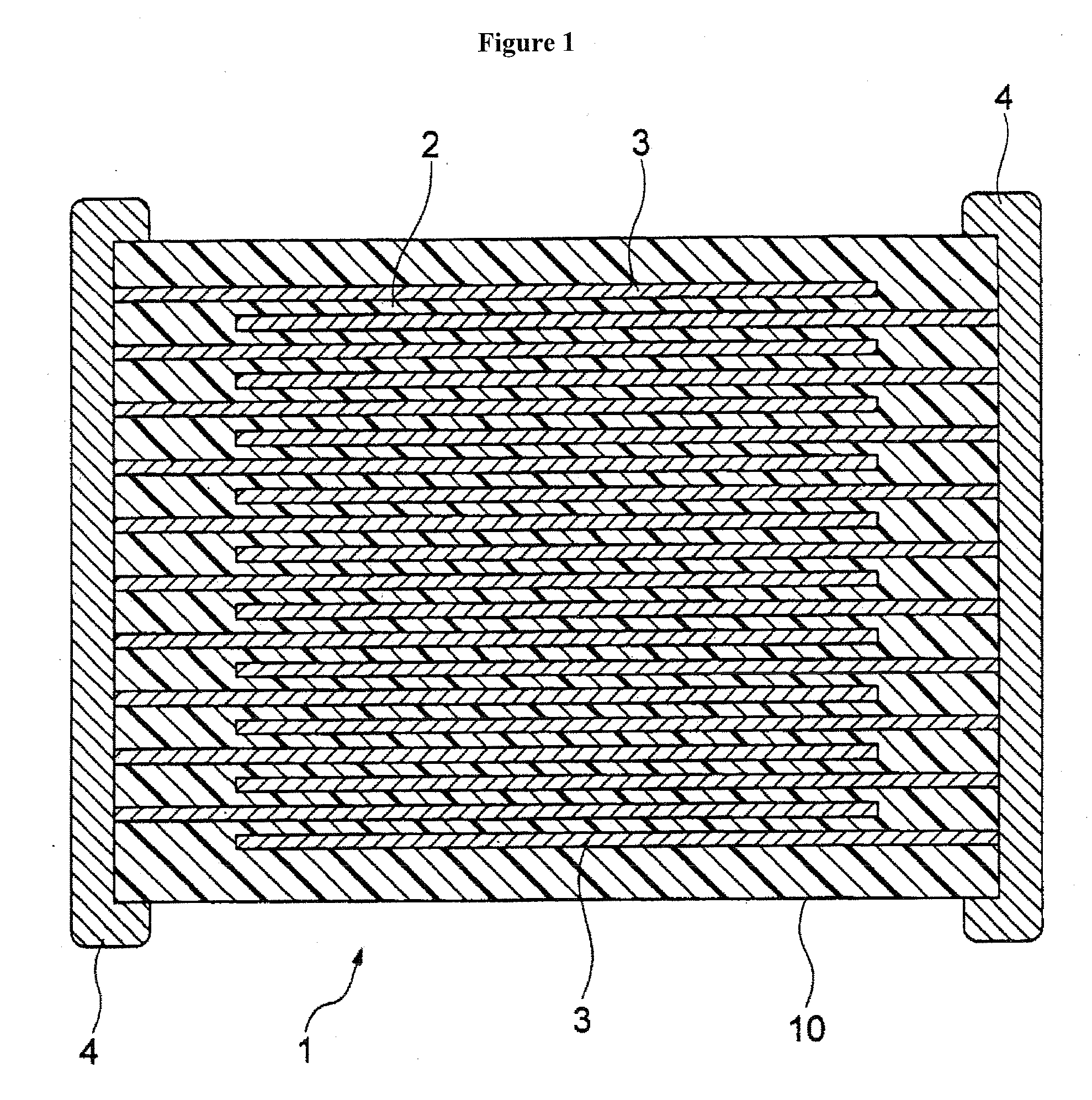

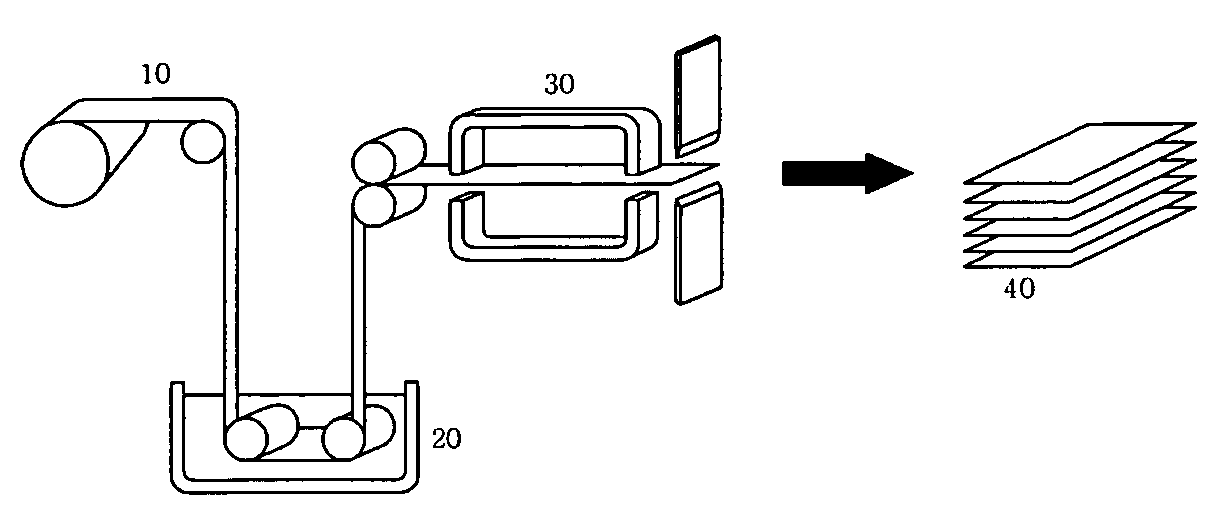

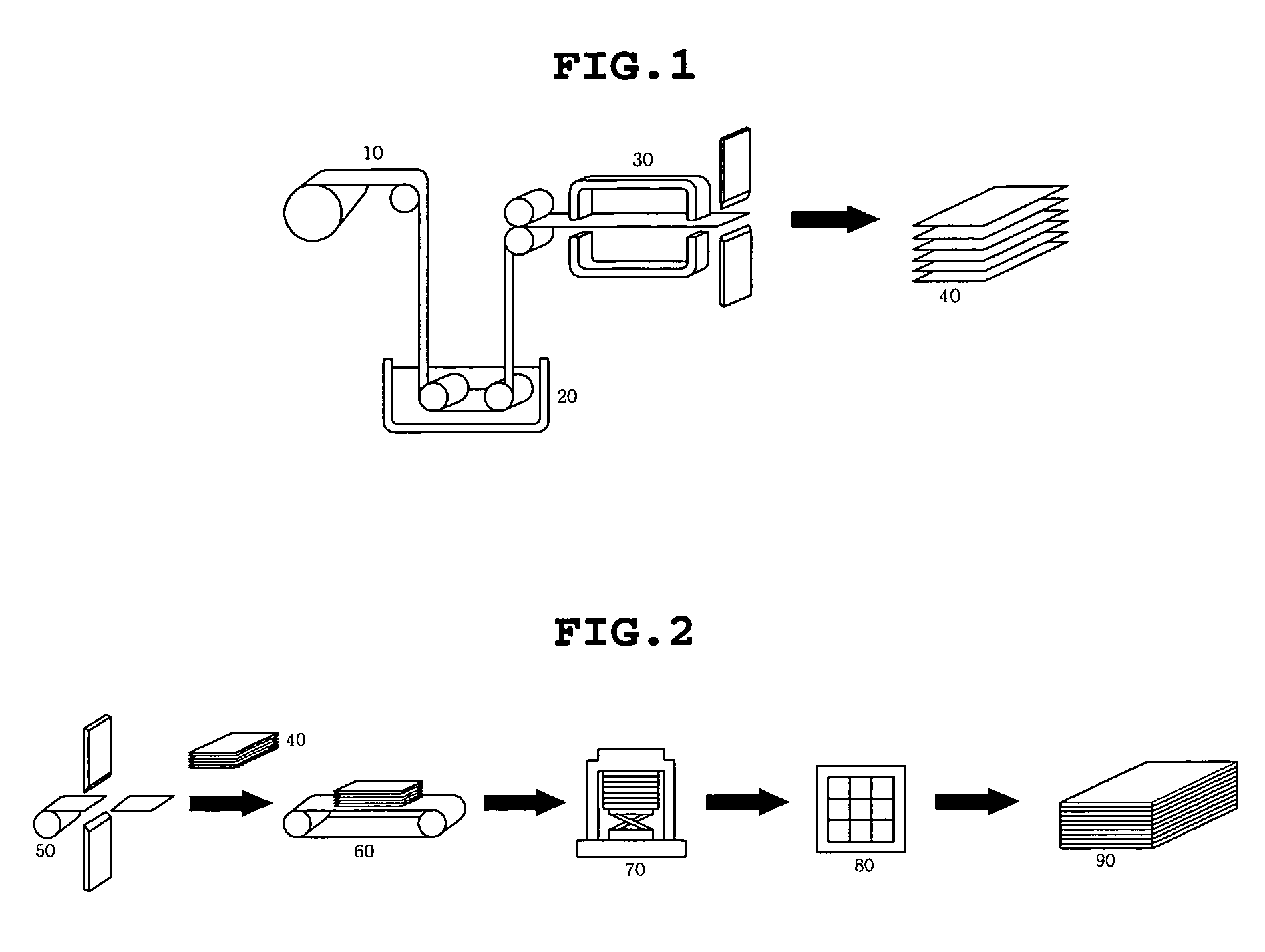

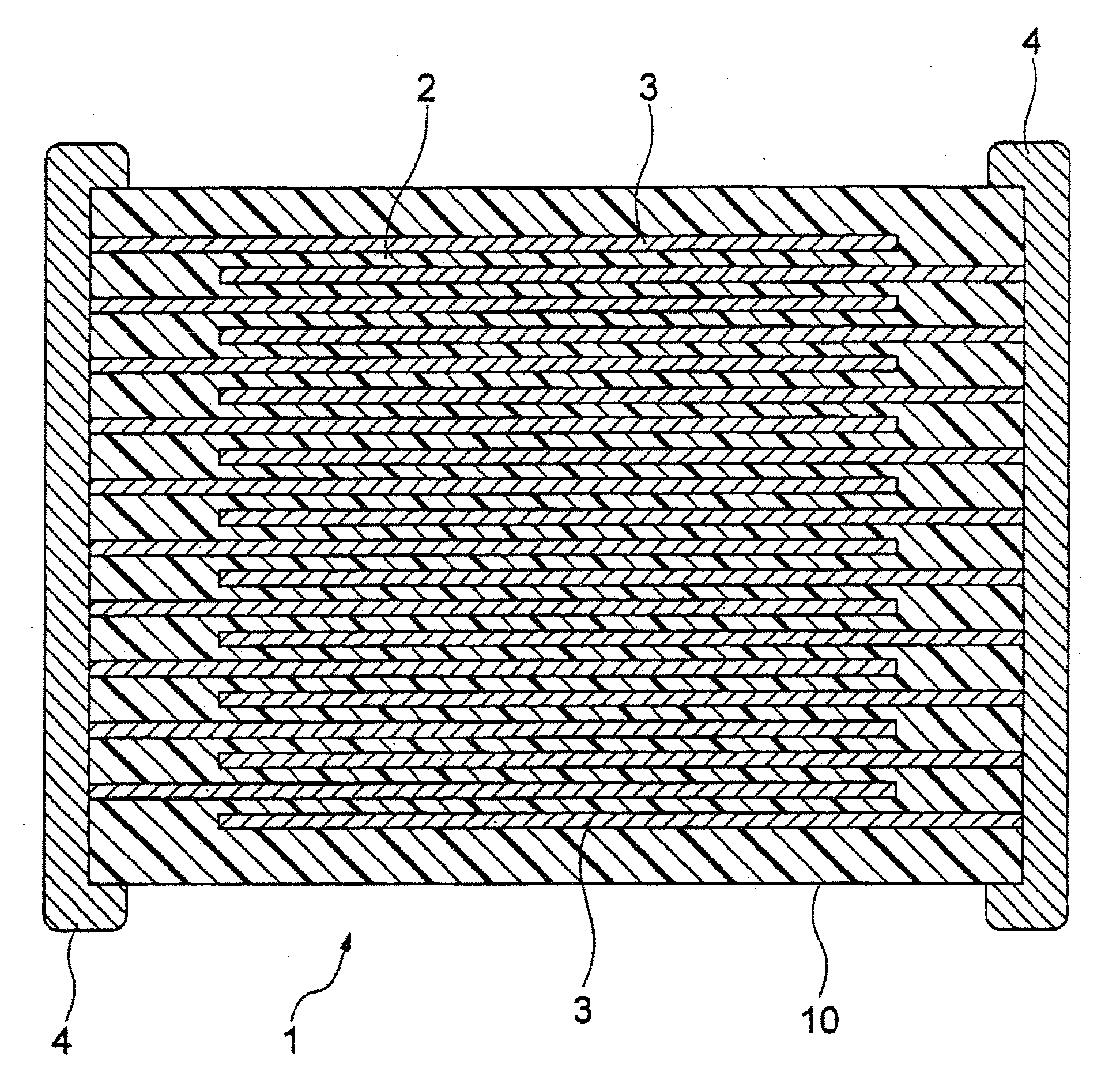

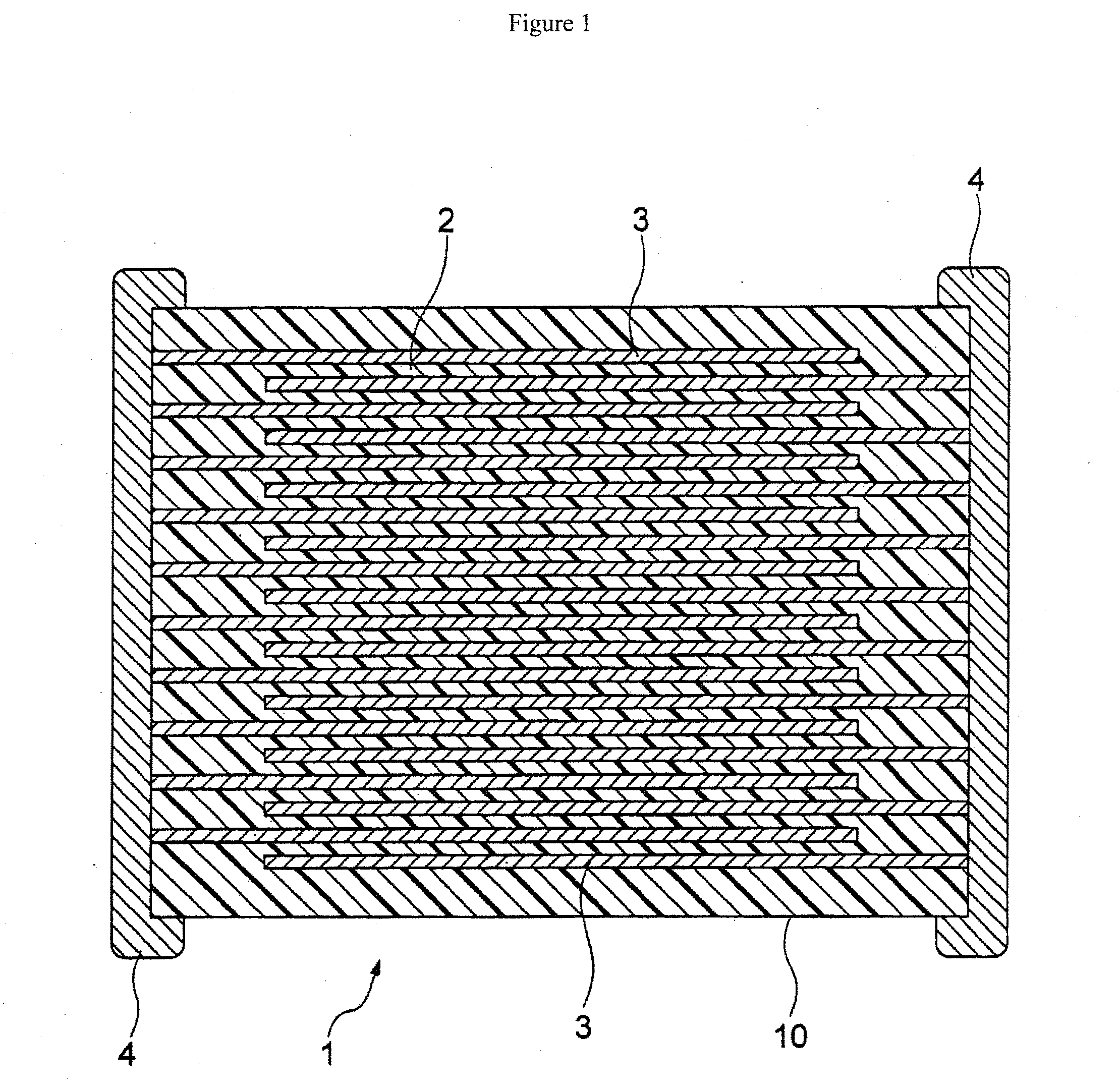

Laminate for printed circuit board and method of manufacturing the same

InactiveUS20060257622A1Low stiffnessMaximize advantageLamination ancillary operationsLayered product treatmentLow dissipationEngineering

The present invention relates to a laminate for a printed circuit board, which is manufactured by incorporating woven fabric or nonwoven fabric formed of liquid crystal polyester fibers into a liquid crystal polyester resin, thus having a low dielectric constant and a low dissipation factor, suitable for use in the high frequency range (GHz or more), and exhibiting excellent thermal properties and high reliability, resulting in high processability.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

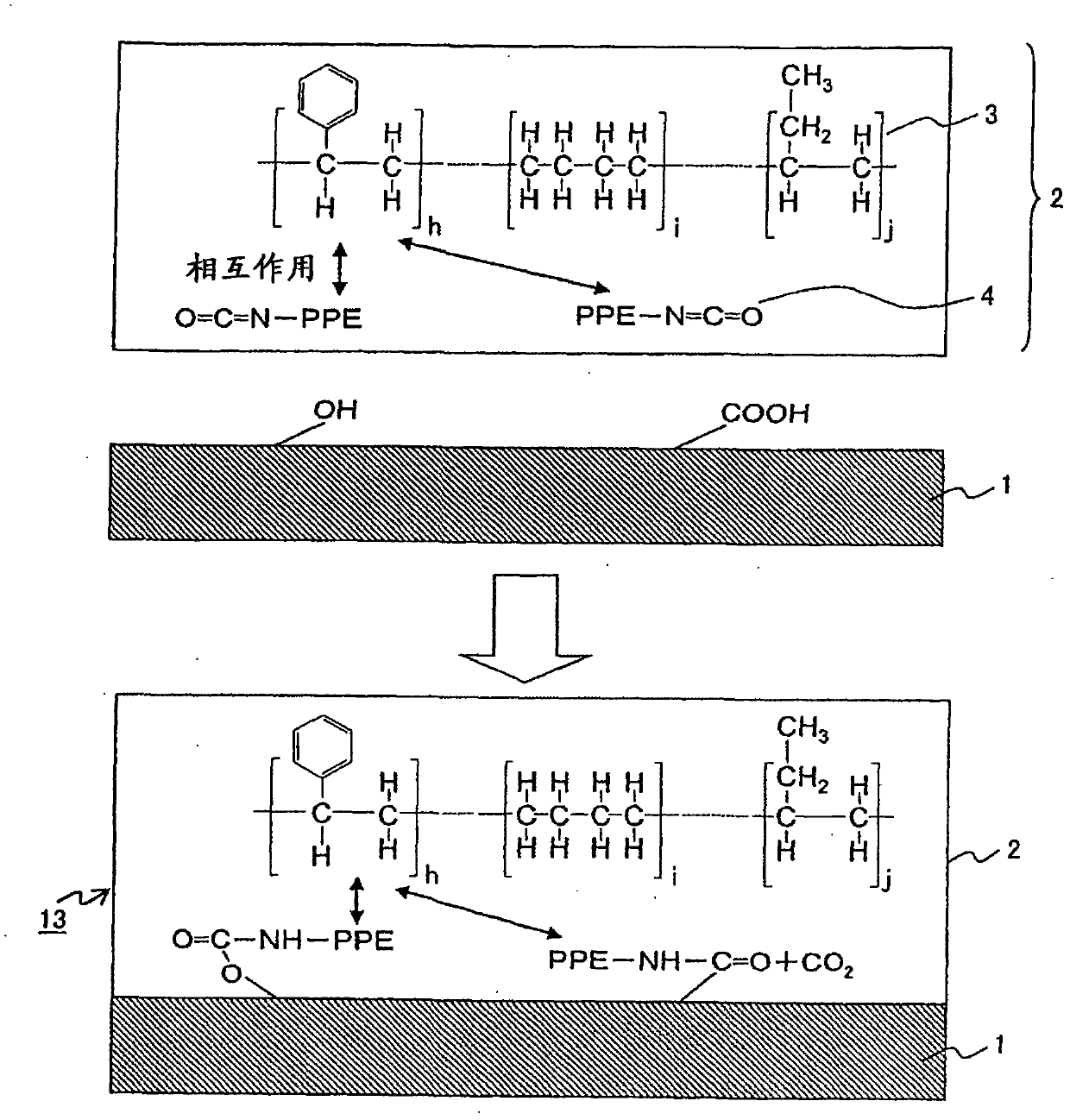

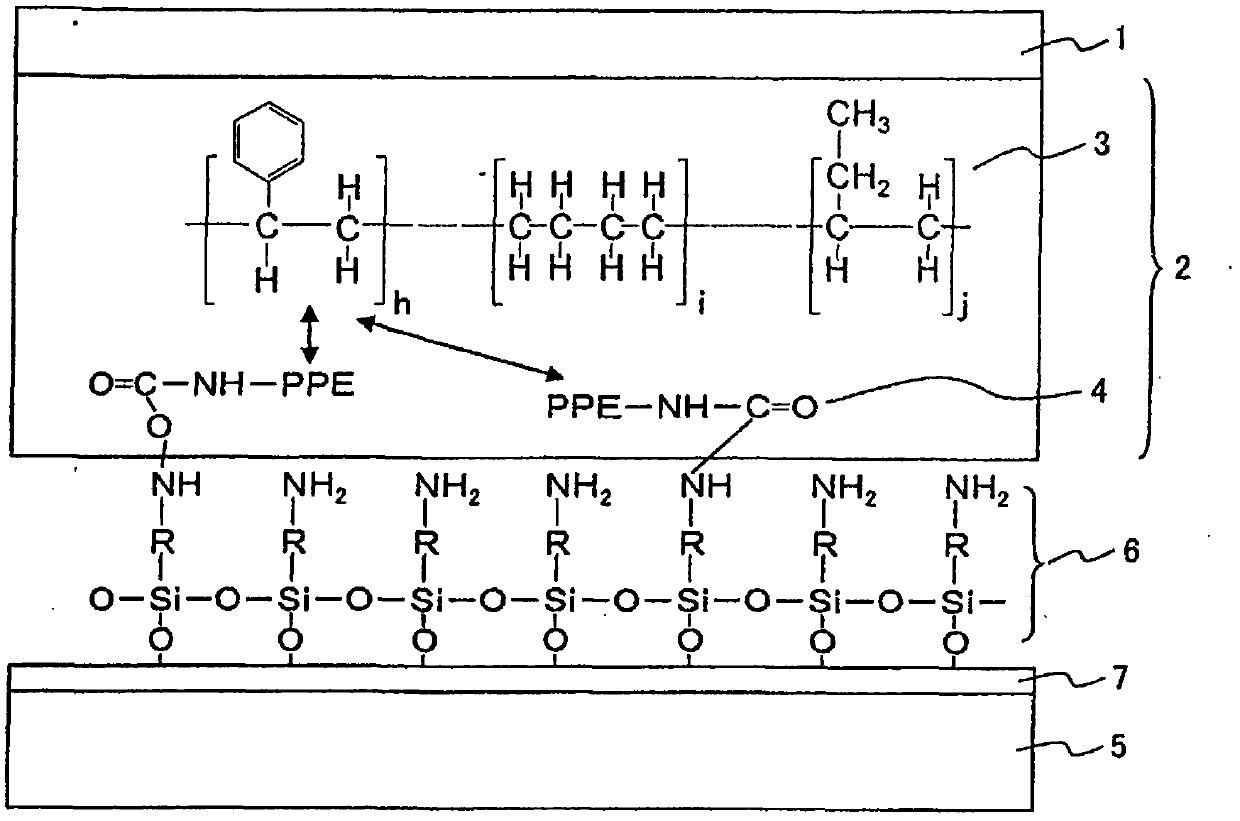

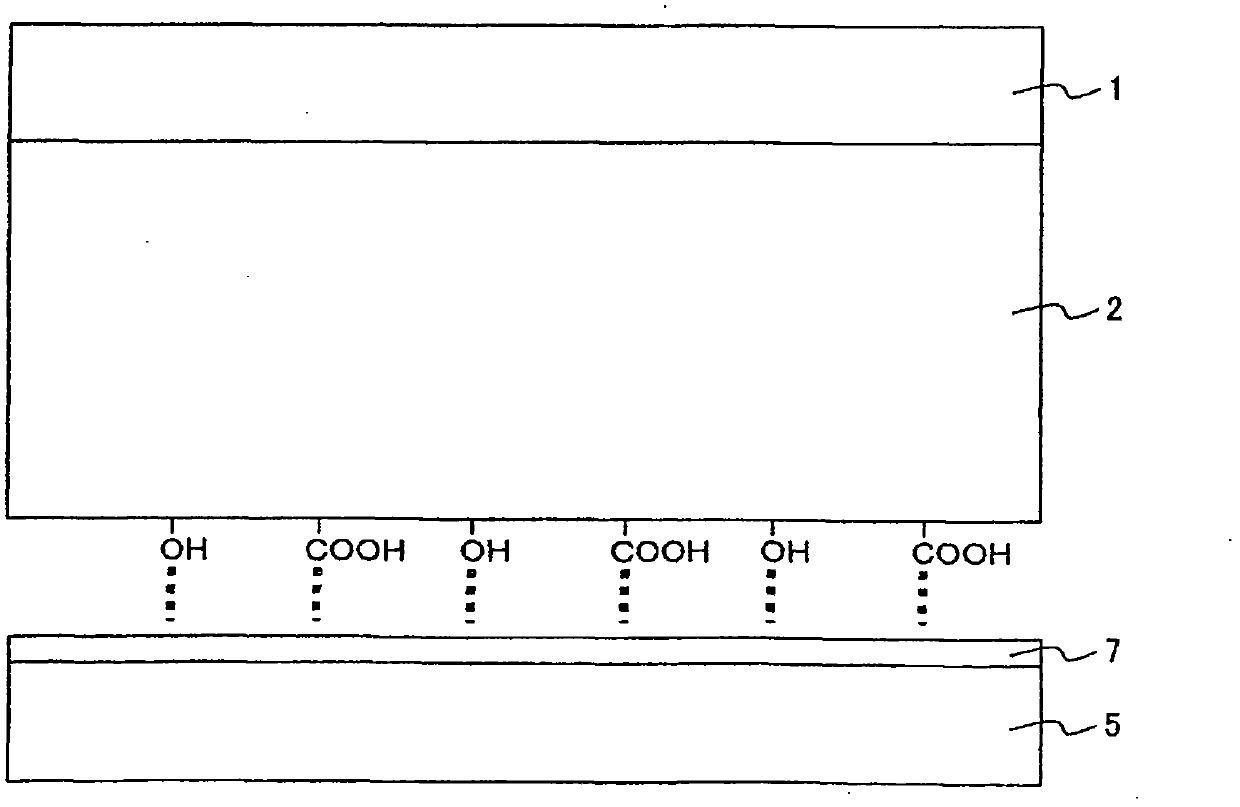

Thermoplastic resin composition, adhesive film and wiring film using the same

InactiveCN102382382AImprove adhesionImprove bond reliabilityFilm/foil adhesivesAdhesive articlesLow dissipationElastomer

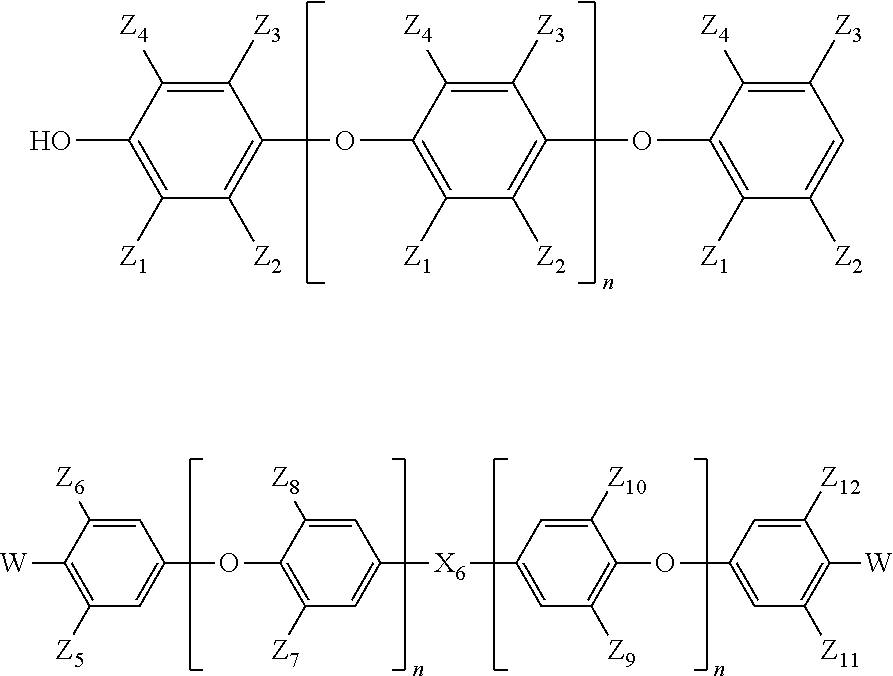

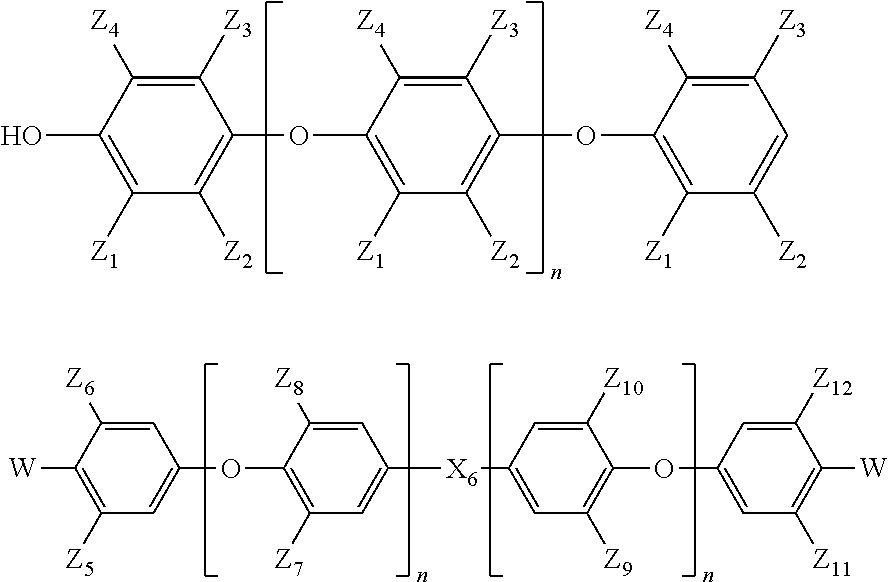

The present invention relates to a thermoplastic resin composition having a low dielectric constant, a low dissipation factor and excellent adhesiveness to a substrate film or a conductor wiring, an adhesive film and a wiring film using the same. The thermoplastic resin composition includes a polyphenylene ether-based polymer having hydroxyl groups in its chemical structure and having 2,6-dimethylphenylene ether as a repeating unit, an isocyanate compound having a plurality of isocyanate groups in its structure; or a reaction product of the polyphenylene ether-based polymer having 2,6-dimethylphenylene ether as a repeating unit and the isocyanate compound having a plurality of isocyanate groups in its structure; and a hydrogenated styrene-based elastomer. .

Owner:HITACHI CABLE

X8R Dielectric Composition For Use With Nickel Electrodes

ActiveUS20080169530A1Small dielectric lossImprove reliabilityStacked capacitorsSemiconductor/solid-state device manufacturingLow dissipationBarium titanate

Multilayer ceramic chip capacitors which satisfy X8R requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel and nickel alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a barium titanate base material doped with other metal oxides such as BaO, Y2O3, ZrO2, SiO2, MgO, MnO, MoO3, CaO, Lu2O3, Yb2O3, or WO3 in various combinations.

Owner:FERRO CORP

Resin composition and prepreg, laminate and circuit board thereof

A resin composition comprises (A) 100 parts by weight of cyanate ester resin; (B) 5 to 25 parts by weight of nitrogen and oxygen containing heterocyclic compound; (C) 5 to 75 parts by weight of polyphenylene oxide resin; and (D) 5 to 100 parts by weight of oligomer of phenylmethane maleimide. By using specific components at specific proportions, the resin composition of the invention offers the features of low dielectric constant and low dissipation factor and can be made into prepreg that may be used in printed circuit board.

Owner:ELITE MATERIAL

Perfluoropolymers

InactiveUS20070292685A1Surprising melt-extrudabilityImprove the level ofEnvelopes/bags making machinerySpecial surfacesLow dissipationHalocarbon

Perfluoropolymer made without ionic species, initiator and without halocarbon solvent polymerization medium and dispersing agent is beneficially useful in liquid contact or food contact applications, for high-speed melt extrusion wire coating, and to produce insulated wire exhibiting low dissipation factor at high signal frequencies.

Owner:EI DU PONT DE NEMOURS & CO

Low dielectric resin composition, and resin film, prepreg, printed circuit board made thereby

ActiveUS20150353730A1Easy to storeExtension of timePrinted circuit aspectsCircuit susbtrate materialsLow dissipationHeat resistance

A resin composition, including (A) a polyimide resin; (B) a pre-polymerised maleimide resin; (C) a thermosetting resin; and (D) a flame retardant. The reactants for use in synthesizing the polyimide resin include an acid anhydride and a diamine, with the diamine including 4,4′-diaminodiphenylmethane and its analogous compounds and polyetherdiamines. The resin composition has the following advantages, a resin film or a prepreg is manufactured from the resin composition comprises a polyimide resin synthesized from a diamine of a specific structure and a pre-polymerised maleimide resin, so as to achieve satisfactory characteristics of circuit laminates, such as a low dielectric constant, a low dissipation factor, high heat resistance, and high adhesiveness, so as to be for use in the manufacturing of metal clad laminates and printed circuit boards.

Owner:ELITE MATERIAL

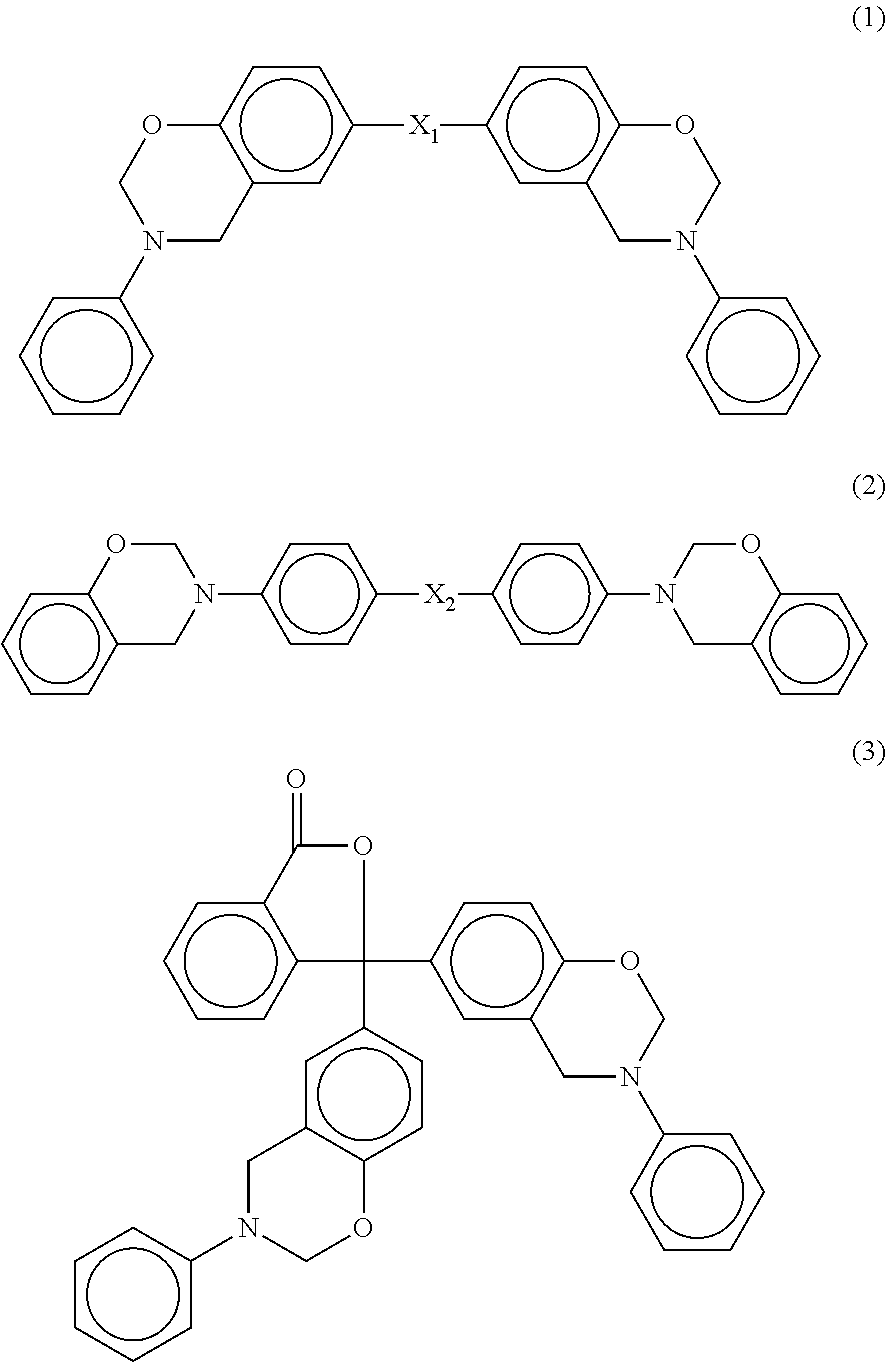

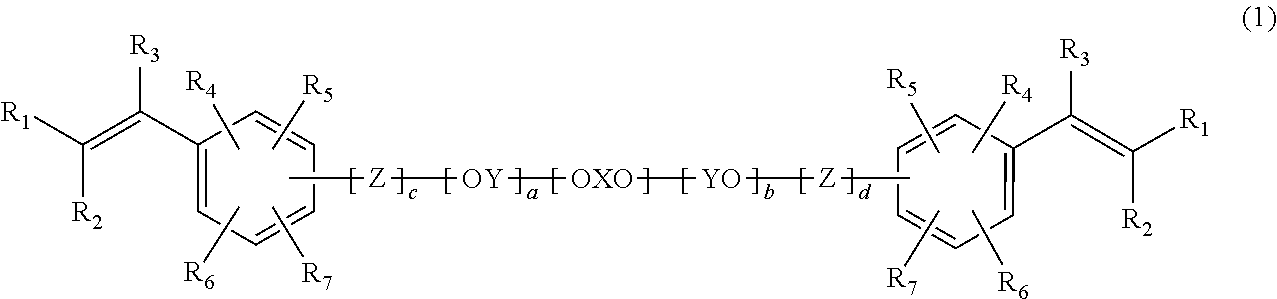

Process for Making Ethylene-Based Polymers Using Hydrocarbon Initiators

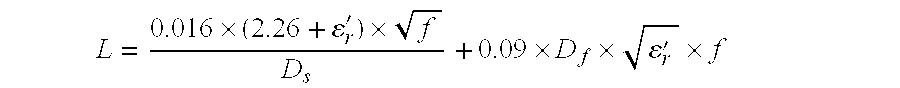

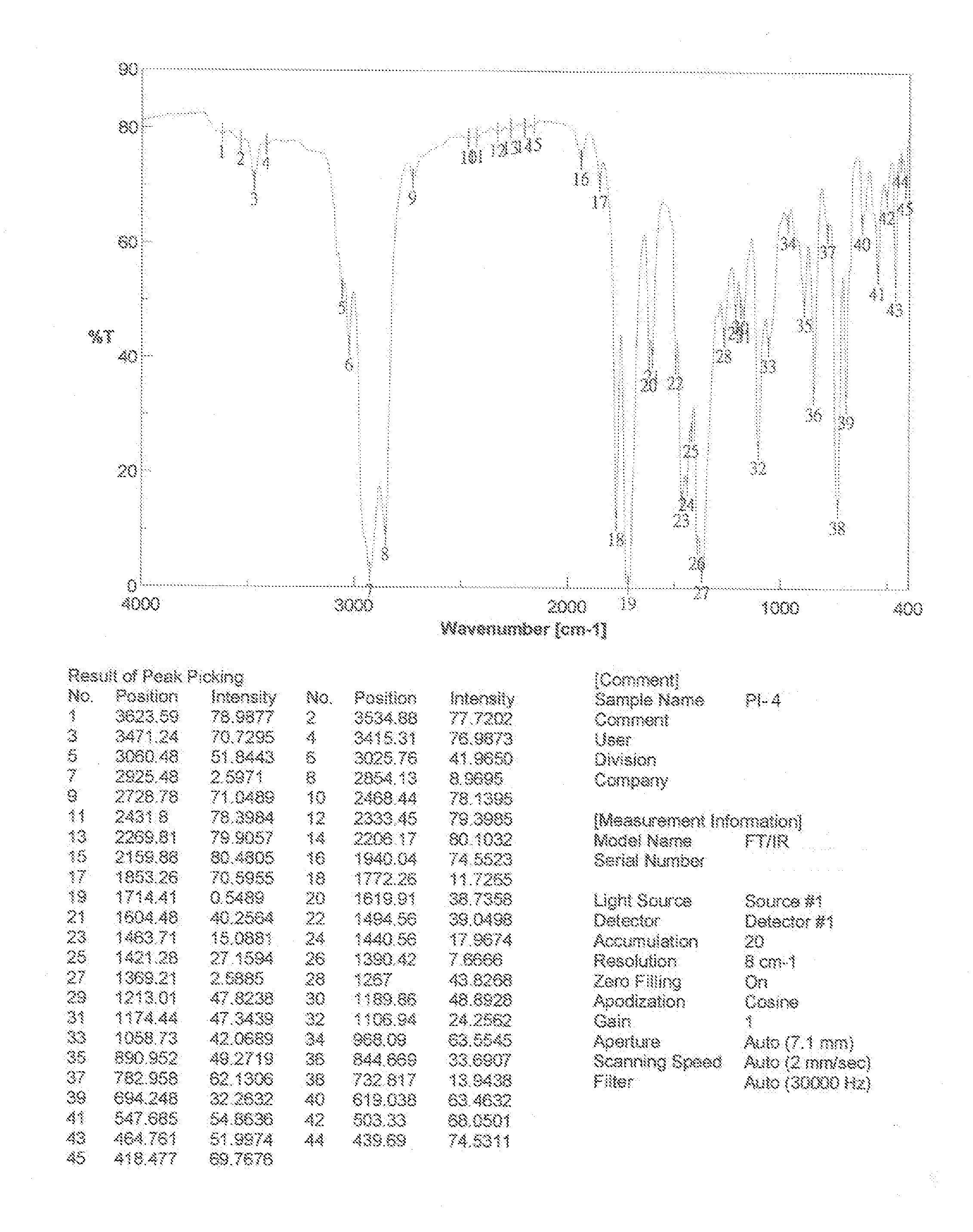

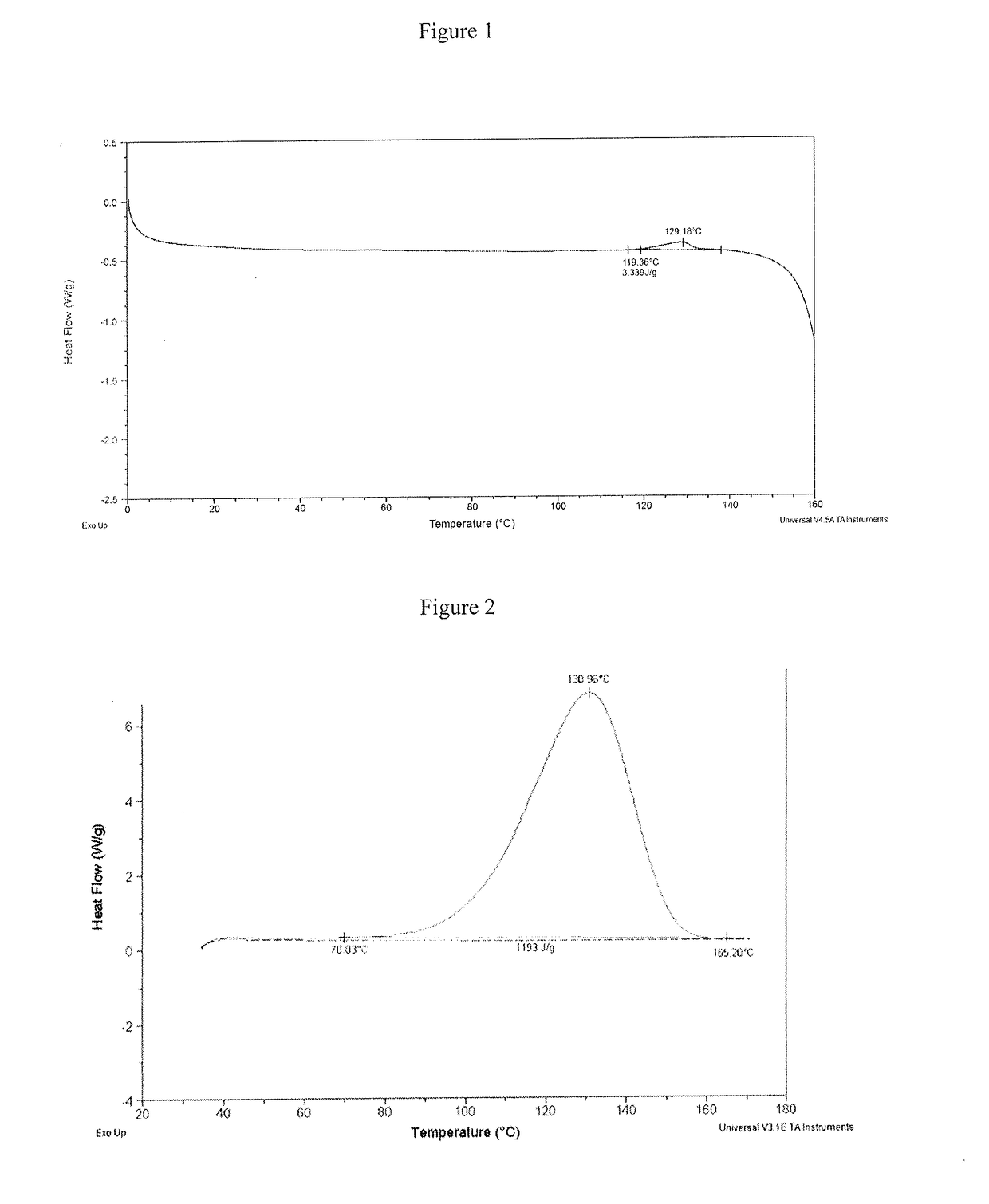

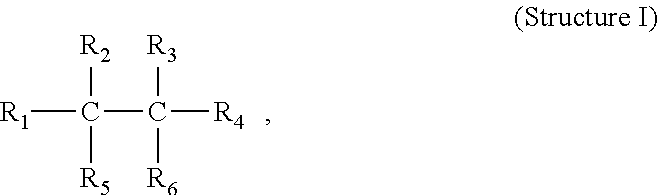

An ethylene-based polymer, e.g., LDPE, with a low dissipation factor is made by a process comprising the step of contacting at polymerization conditions ethylene and, optionally, one or more comonomers, e.g., an alpha-olefin, with at least one carbon-carbon (C—C) hydrocarbyl, free-radical initiator of Structure 1: wherein R1, R2, R3, R4, R5 and R6, are each, independently, hydrogen or a hydrocarbyl group and wherein, optionally, two or more R groups (R1, R2, R3, R4, R5 and R6) form a ring structure, with the provisos that at least one of R2 and R5, and at least one of R3 and R6 is a hydrocarbyl group of at least two carbon atoms, e.g., an alkaryl of at least seven carbon atoms.

Owner:DOW GLOBAL TECH LLC

Ultra low temperature fixed X7R and BX dielectric ceramic composition and method of making

ActiveUS7521390B2Small dielectric lossFixed capacitor dielectricStacked capacitorsCeriumCeramic capacitor

Multilayer ceramic chip capacitors which satisfy X7R and BX requirements and which are compatible with silver-palladium internal electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a lead-free and cadmium-free barium titanate base material doped with other metal oxides such oxides of zinc, boron, bismuth, cerium, tungsten, copper, manganese, neodymium, niobium, silver, barium, silicon and nickel in various combinations. The dielectric ceramic materials herein can be sintered together (fired) at less than 1000° C. with an inner electrode having more than 80 wt % Ag and less than 20 wt % Pd to form a multilayer ceramic capacitor (MLCC).

Owner:FERRO CORP

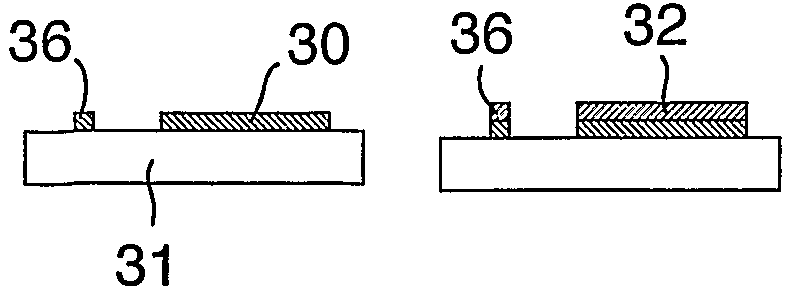

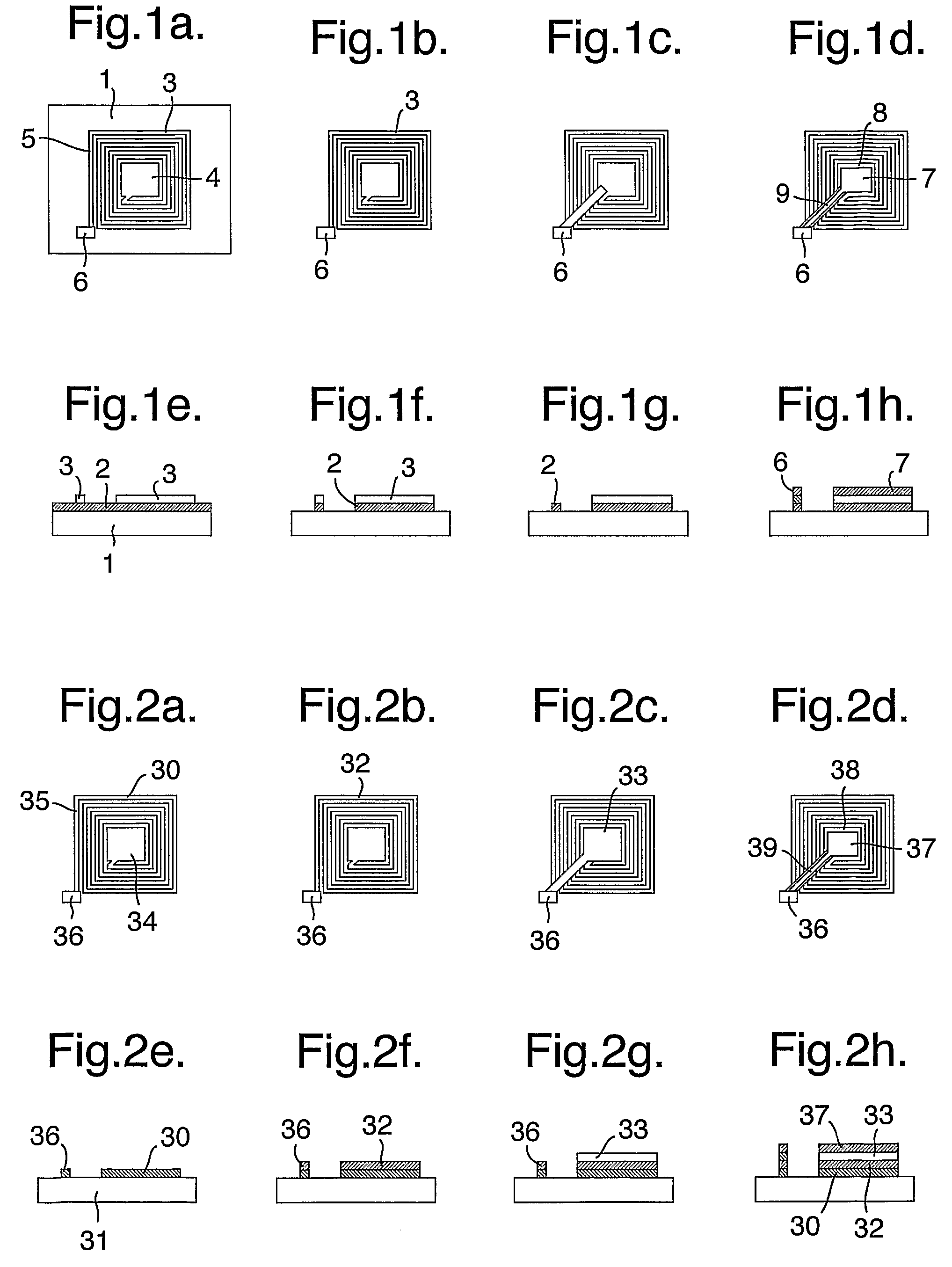

RF tags

InactiveUS7683785B2Costly stepsTime costlyWave amplification devicesBurglar alarm by hand-portable articles removalLow dissipationElectricity

A single sided RF tag suitable for use for electronic article surveillance comprises a tuned circuit formed on one side of a substrate. Provided by a deposited first conducting layer which comprises an inductive coil, which behaves as an antenna and is electrically connected to a first capacitor plate and a connection means to connect to a second conducting layer. A low dissipation factor dielectric layer is deposited onto said first conducting layer. A second conducting layer comprising at least one capacitor and a connection means to electrically connect to the first conducting layer is deposited on the dielectric layer. The second capacitor plate is substantially co-located above the first capacitor plate, to form the capacitor. The capacitor and coil together form a resonant circuit. The circuit pattern for the first and second layer may be formed by known metal printing techniques, such as, for example the use of a catalytic seed layer which is deposited by a pattern transfer mechanism into the circuit pattern. Alternatively the circuit pattern may be formed by standard photo-lithography etch techniques to reveal a circuit pattern from a metallised surface. The tag will preferably incorporate known methods of fusing to deactivate or detune the tag, to permit removal of articles from an enclosed area. The substrate may further include a second RF tag tuned to an alternative frequency on the opposite side of the substrate. Alternatively a plurality of tags may be built up in successive layers on one or both sides of the tag.

Owner:QINETIQ LTD

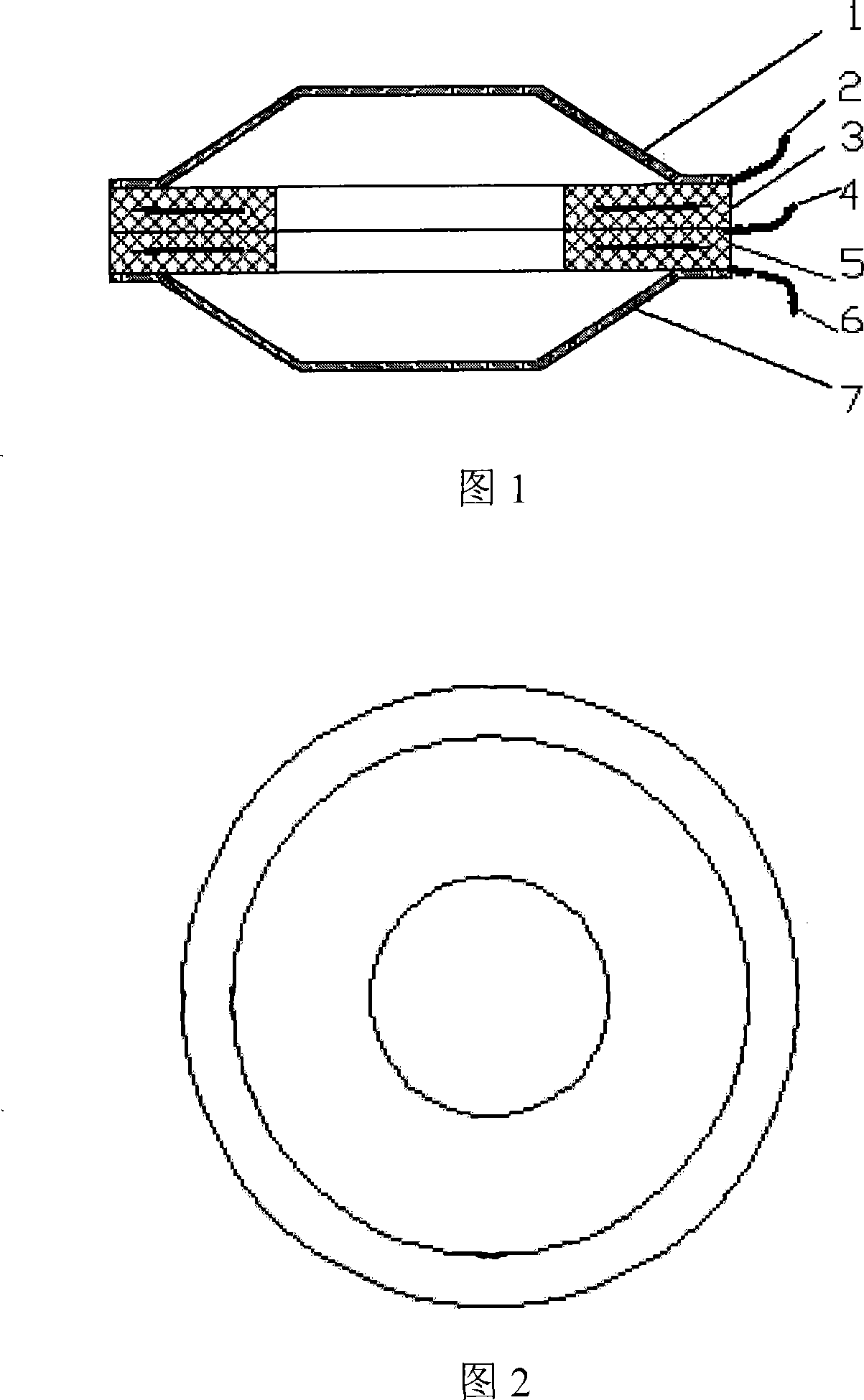

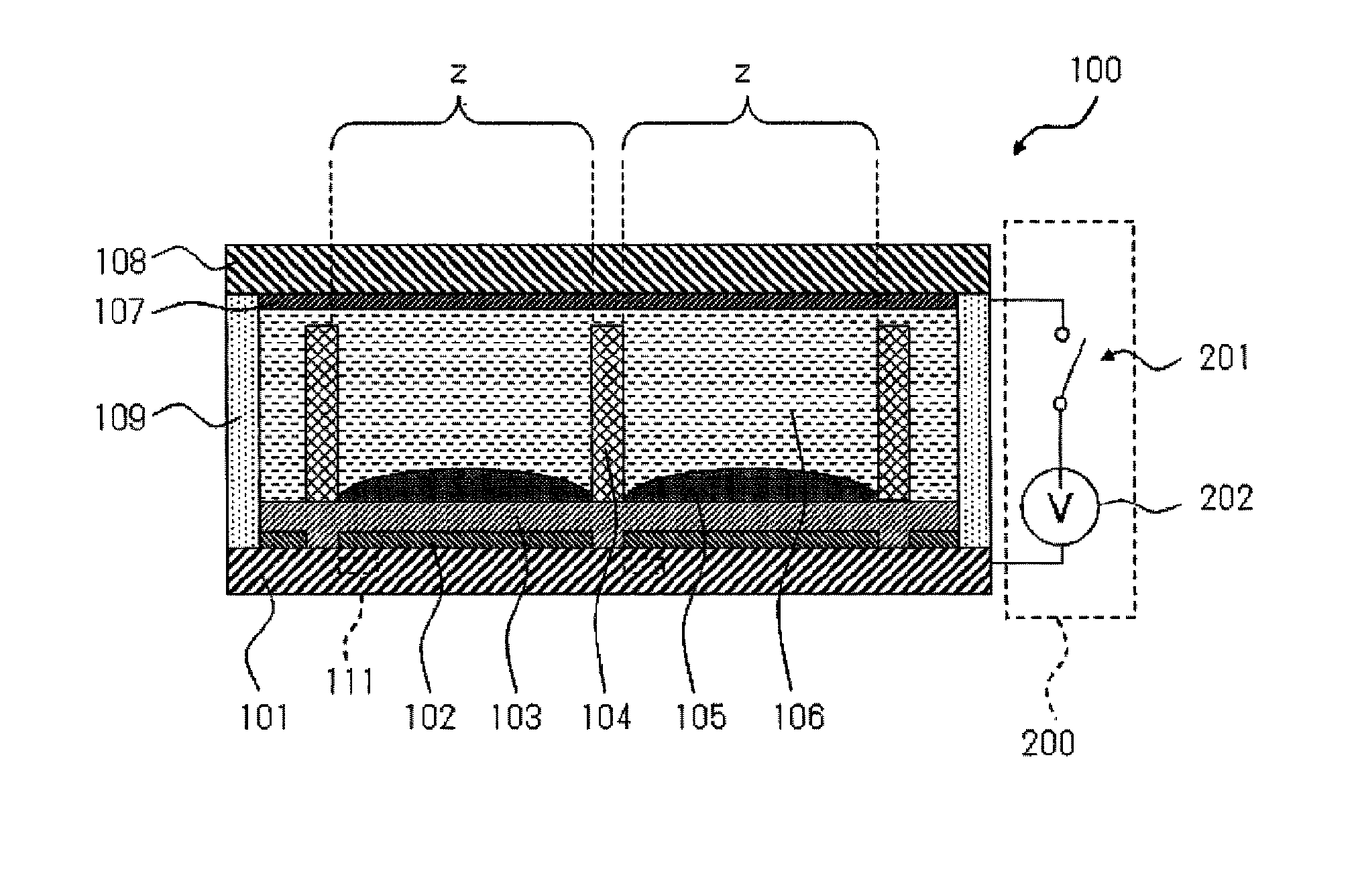

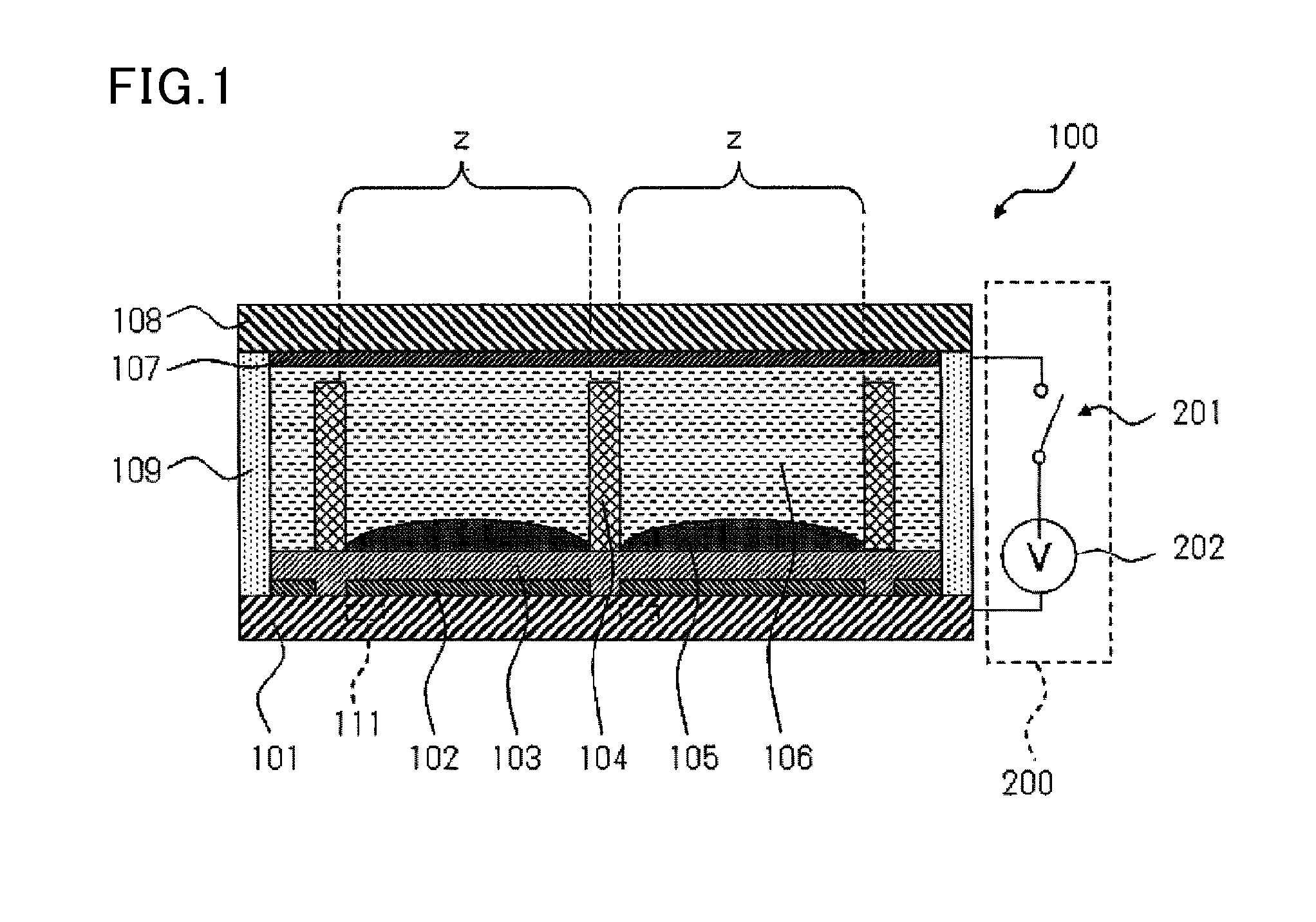

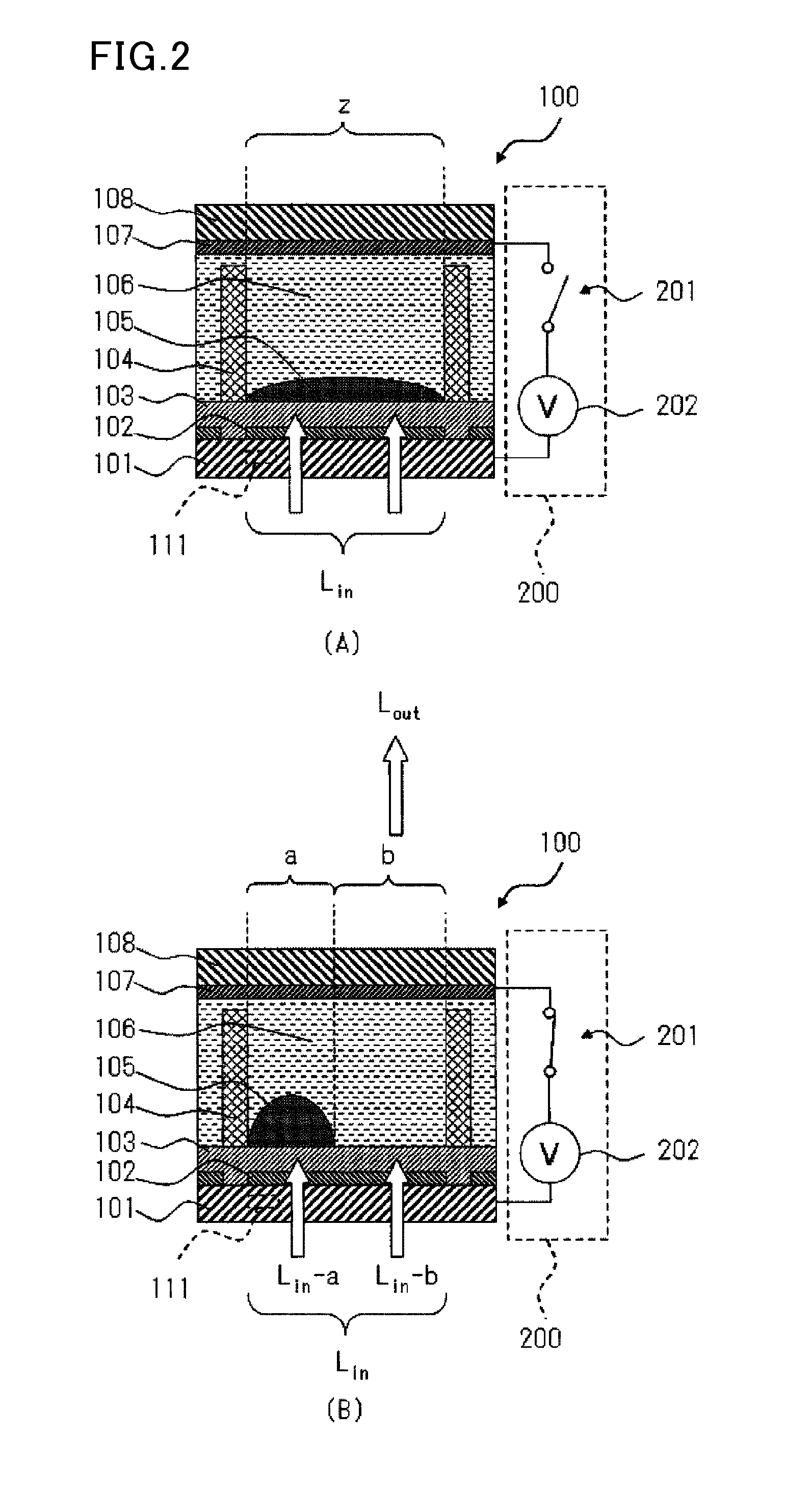

Cymbals driver based on tangential distortion and its driving method

InactiveCN101123404ALarge axial displacement outputHigh piezoelectric conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesElastomerLow dissipation

The invention discloses a cymbal-shaped driver based on tangential deformation, which comprises a piezoelectric element, an upper metal elastomer and a lower metal elastomer. The piezoelectric element is in double-deck toroidal structure. The metal elastomer is in semi-cymbal shape. The upside of the piezoelectric element is connected with the bottom of the upper metal elastomer. The underside of the piezoelectric element is connected with the bottom of the lower metal elastomer. Signal input lines are connected between the double rings of the piezoelectric element. An earth wire is connected between the piezoelectric element and the upper metal elastomer; another earth wire is connected between the piezoelectric element and the lower metal elastomer. The invention also discloses a drive method of the cymbal-shaped driver. Regarding the driver, the traditional displacement driving power section and actuator are manufactured into one piece. The utility model has the advantages of large displacement, high rigidity, working safely, simple structure, compactness, minitype and thinness, light weight, low dissipation of energy, no noise, no electromagnetic interference, high precision and high resolution and so on, and is applicable for mechanical systems of optics and electronics and so on requiring precise displacement.

Owner:SOUTH CHINA AGRI UNIV

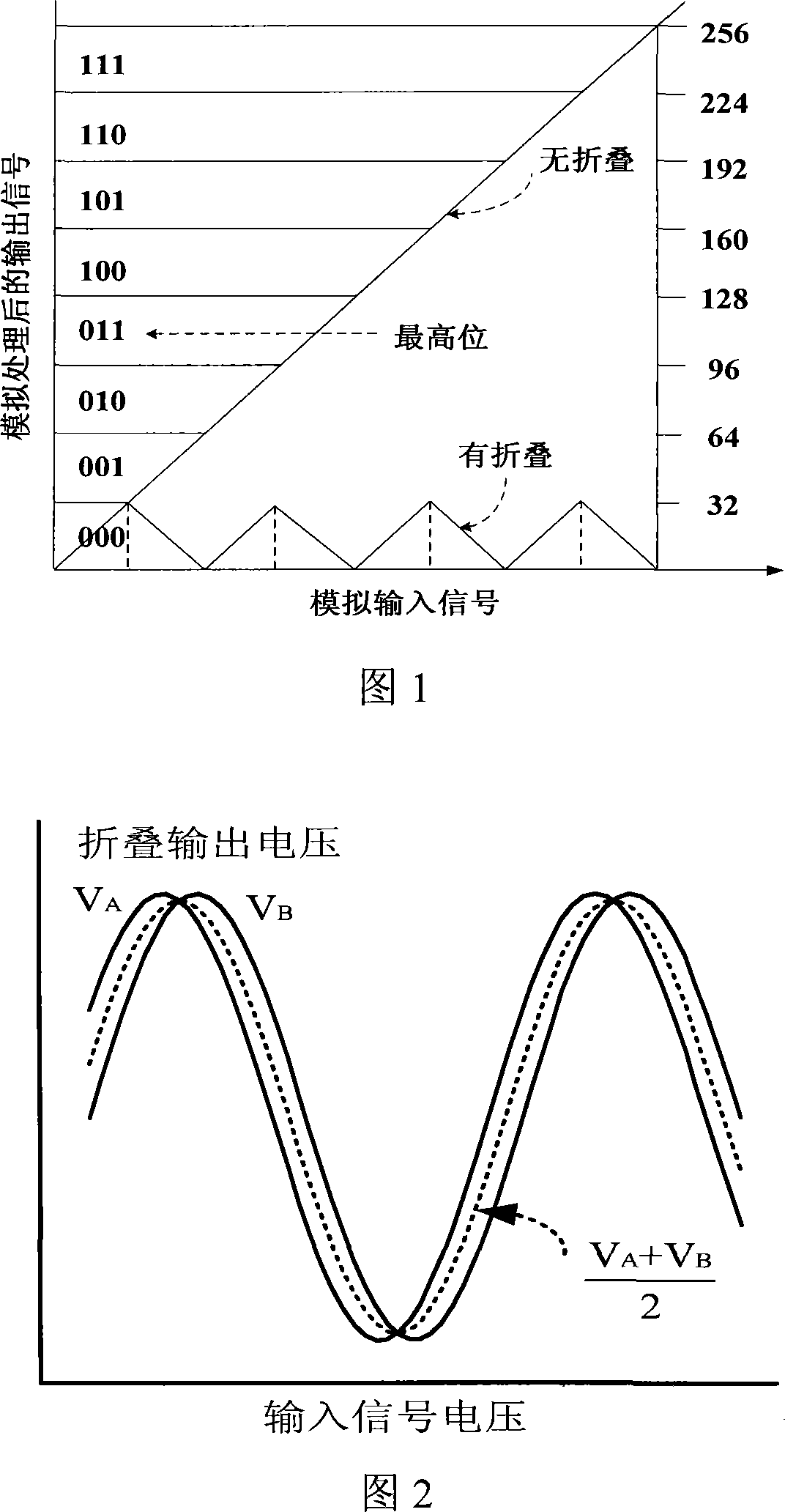

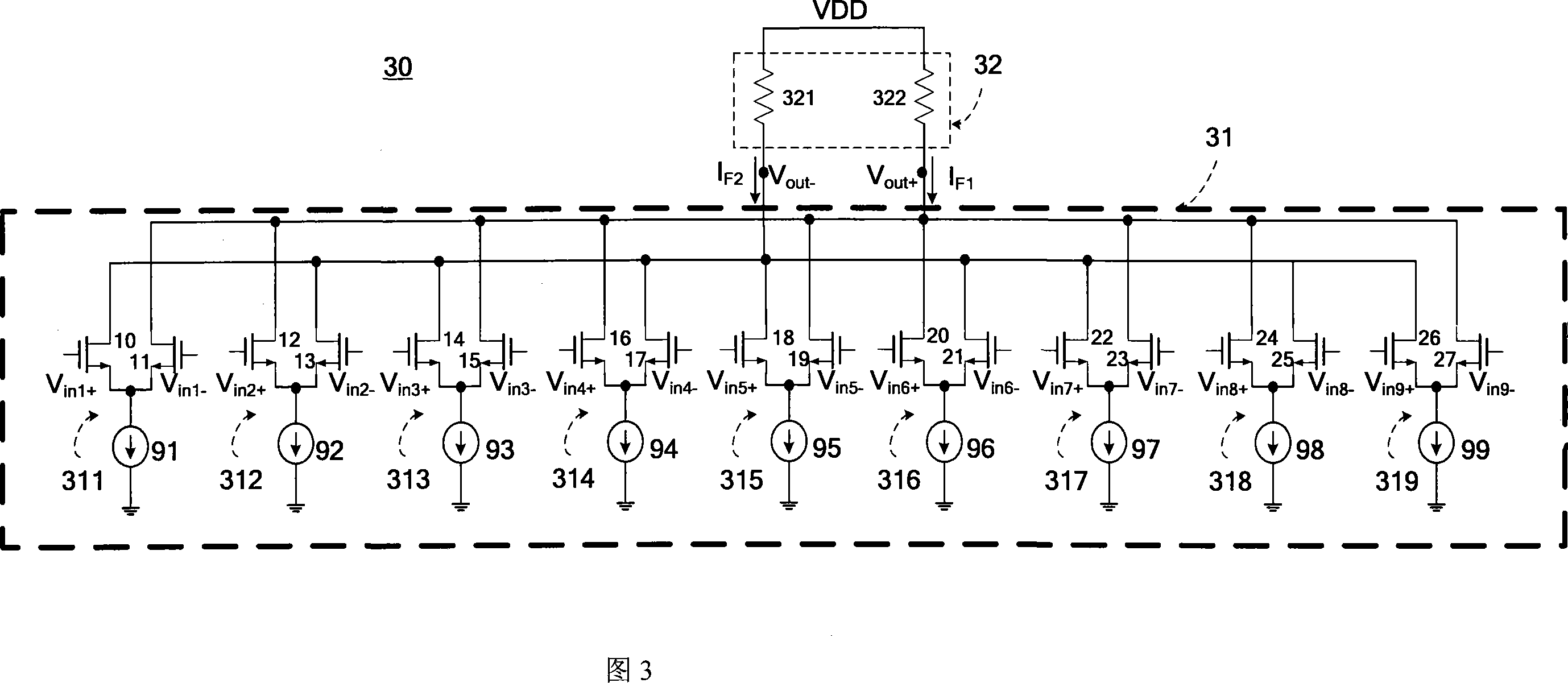

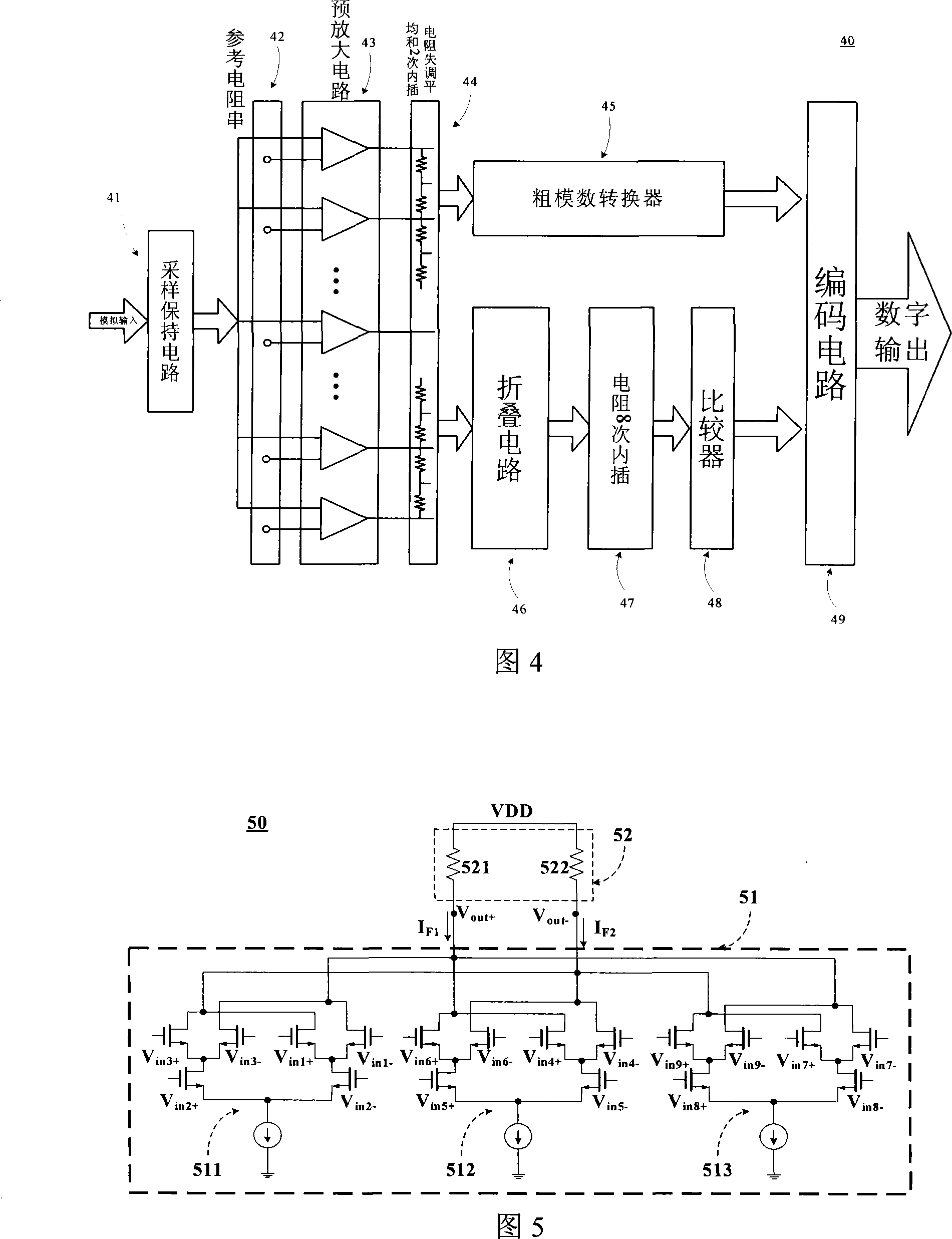

An A/D converter adopting mixed type dual-layer folding circuit

InactiveCN101217282AReduced number of current sourcesReduced parasitic gate-to-drain capacitanceAnalogue/digital conversionElectric signal transmission systemsLow dissipationElectrical resistance and conductance

The invention belongs to the integrated circuit technical field, in particular to a mixed type double-layer folding circuit analog-to-digital converter. The invention consists of a single sample-hold circuit, a reference resistance string, premagnification, resistance offset averaging and twice interpolating circuit, a rough analog-to-digital converter, a folding circuit, an resistance eight-time interpolating circuit, a comparator and a code circuit, etc.; wherein, the folding circuit consists of an amplifying circuit and an outputting circuit and makes improvement of high-speed and low-dissipation to the amplifying circuit which comprises double-layer amplifying units which are same with the number being M and leads 3 multiplied by M pairs of differential input voltage to be amplified. In the invention, the consumption of the circuit is reduced greatly and the speed is raised greatly.

Owner:FUDAN UNIV

High dielectric film

InactiveUS20150368413A1Low dissipation factorHigh dielectric constantFixed capacitor dielectricSolid ballsTetrafluoroethyleneLow dissipation

The present invention aims to provide a film having a high dielectric constant and a low dissipation factor. The high dielectric film of the present invention includes a vinylidene fluoride / tetrafluoroethylene copolymer (A) with a mole ratio (vinylidene fluoride) / (tetrafluoroethylene) of 95 / 5 to 80 / 20. The film includes an β-crystal structure and a β-crystal structure. The ratio of the β-crystal structure is 50% or more.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com