Patents

Literature

544 results about "Styrene maleic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

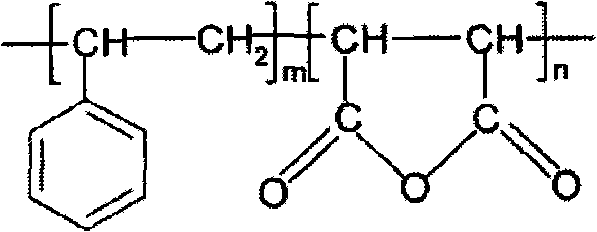

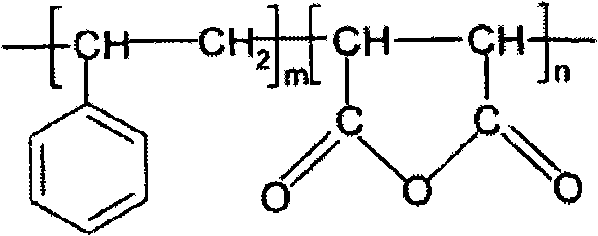

Styrene maleic anhydride (SMA or SMAnh) is a synthetic polymer that is built-up of styrene and maleic anhydride monomers. The monomers can be almost perfectly alternating, making it an alternating copolymer[citation needed], but (random) copolymerisation with less than 50% maleic anhydride content is also possible. The polymer is formed by a radical polymerization, using an organic peroxide as the initiator. The main characteristics of SMA copolymer are its transparent appearance, high heat resistance, high dimensional stability, and the specific reactivity of the anhydride groups. The latter feature results in the solubility of SMA in alkaline (water-based) solutions and dispersion.

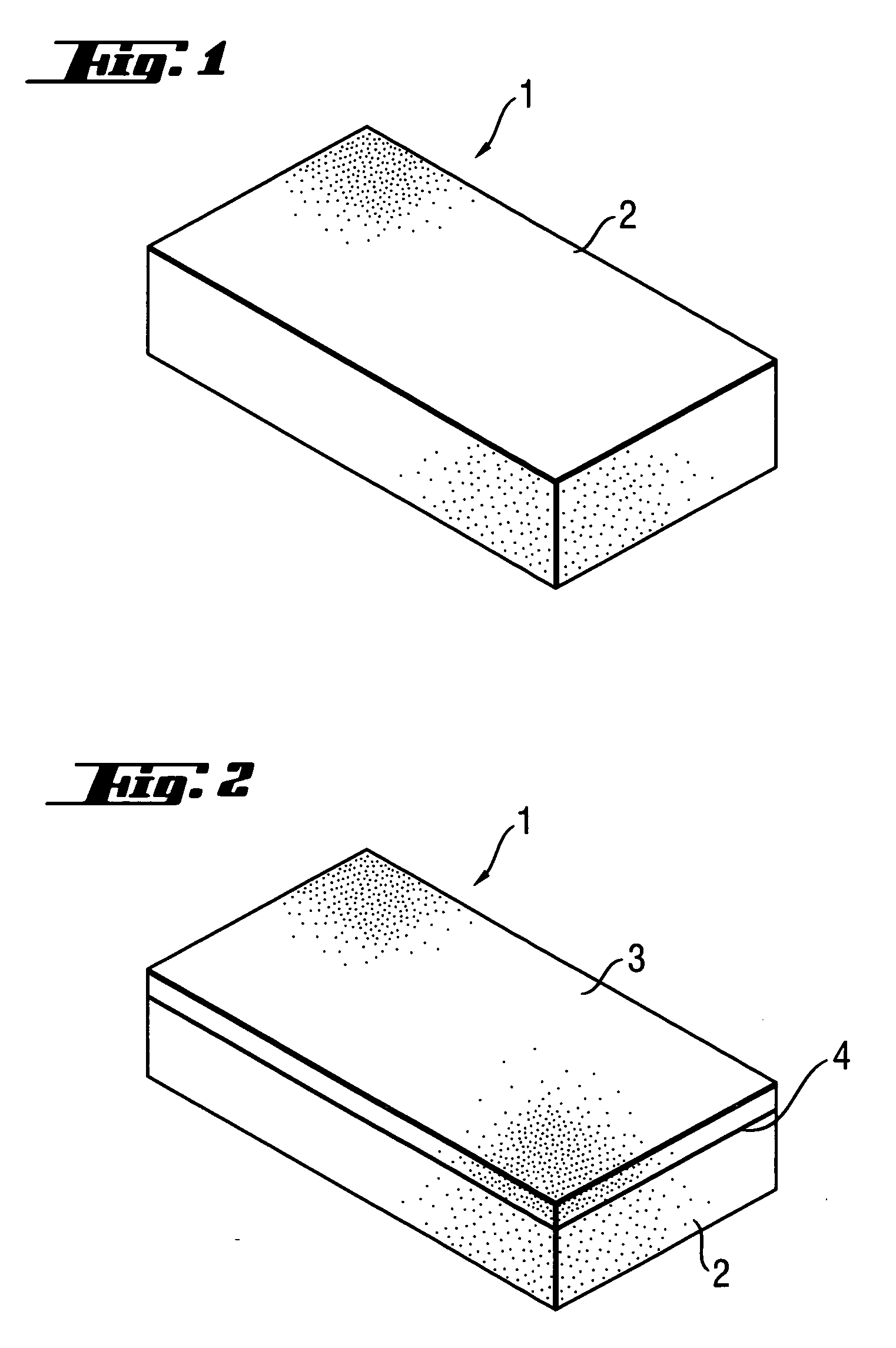

Halogen-free resin composition and its application for copper clad laminate and printed circuit board

ActiveUS20130161080A1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyLow dissipation

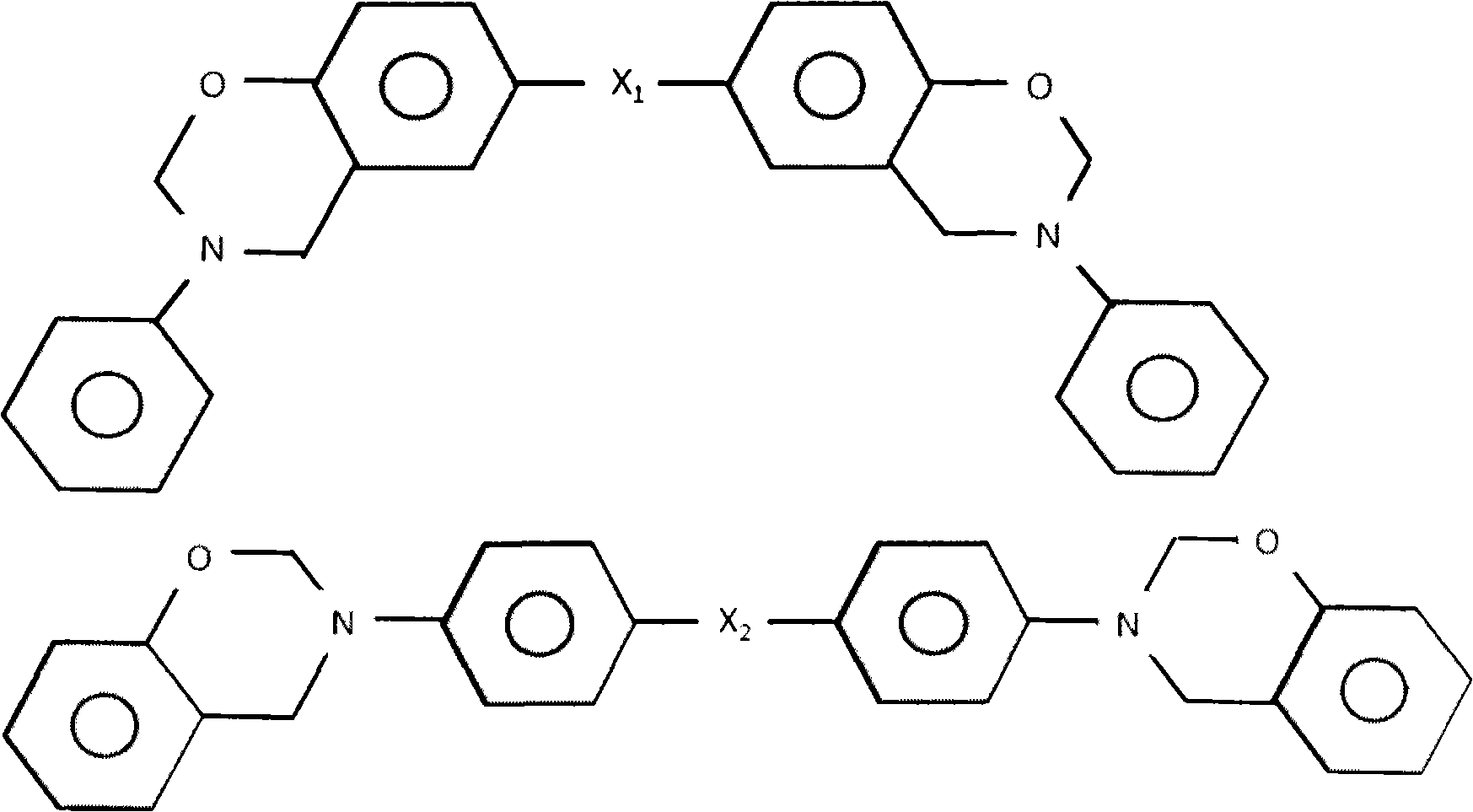

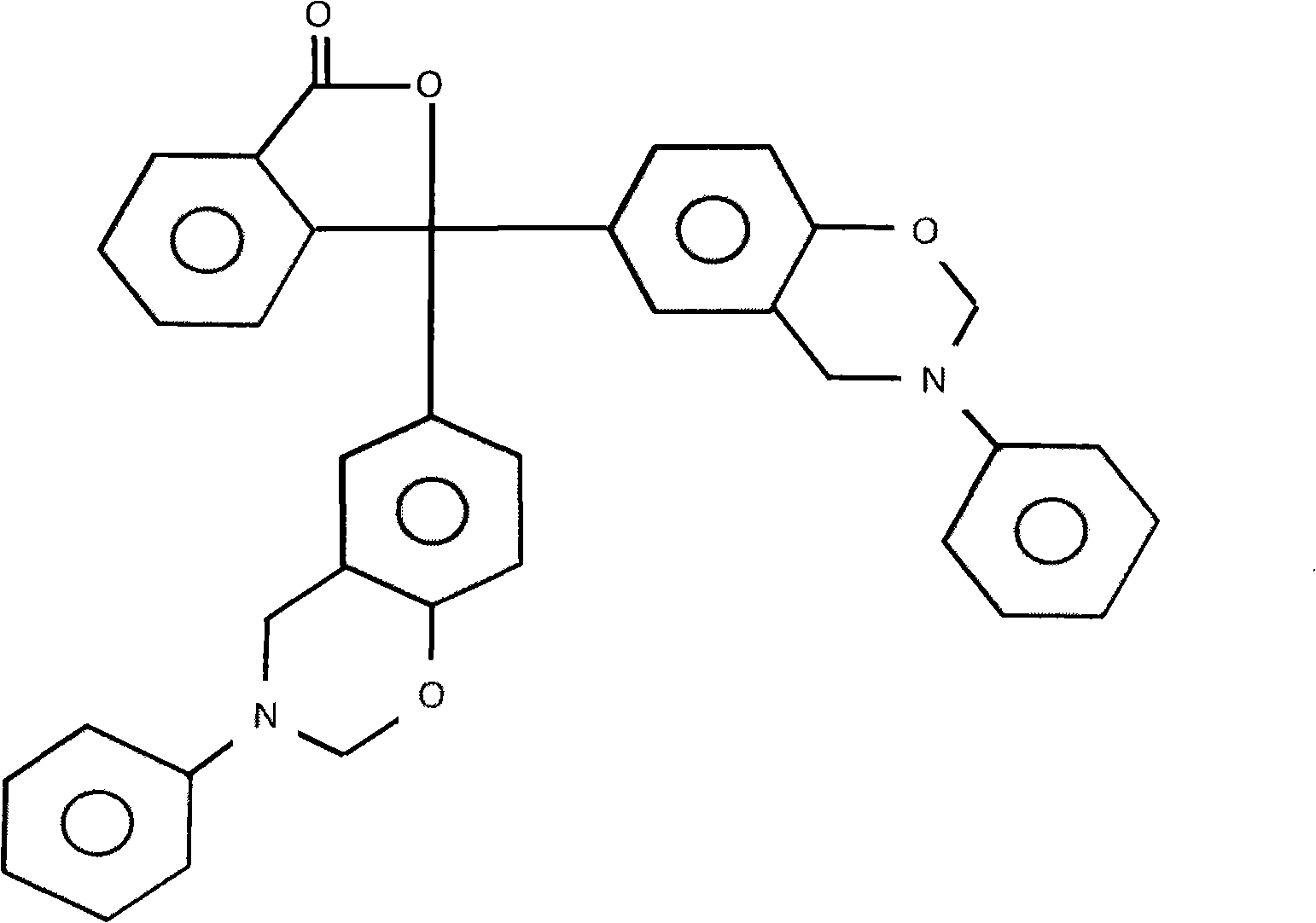

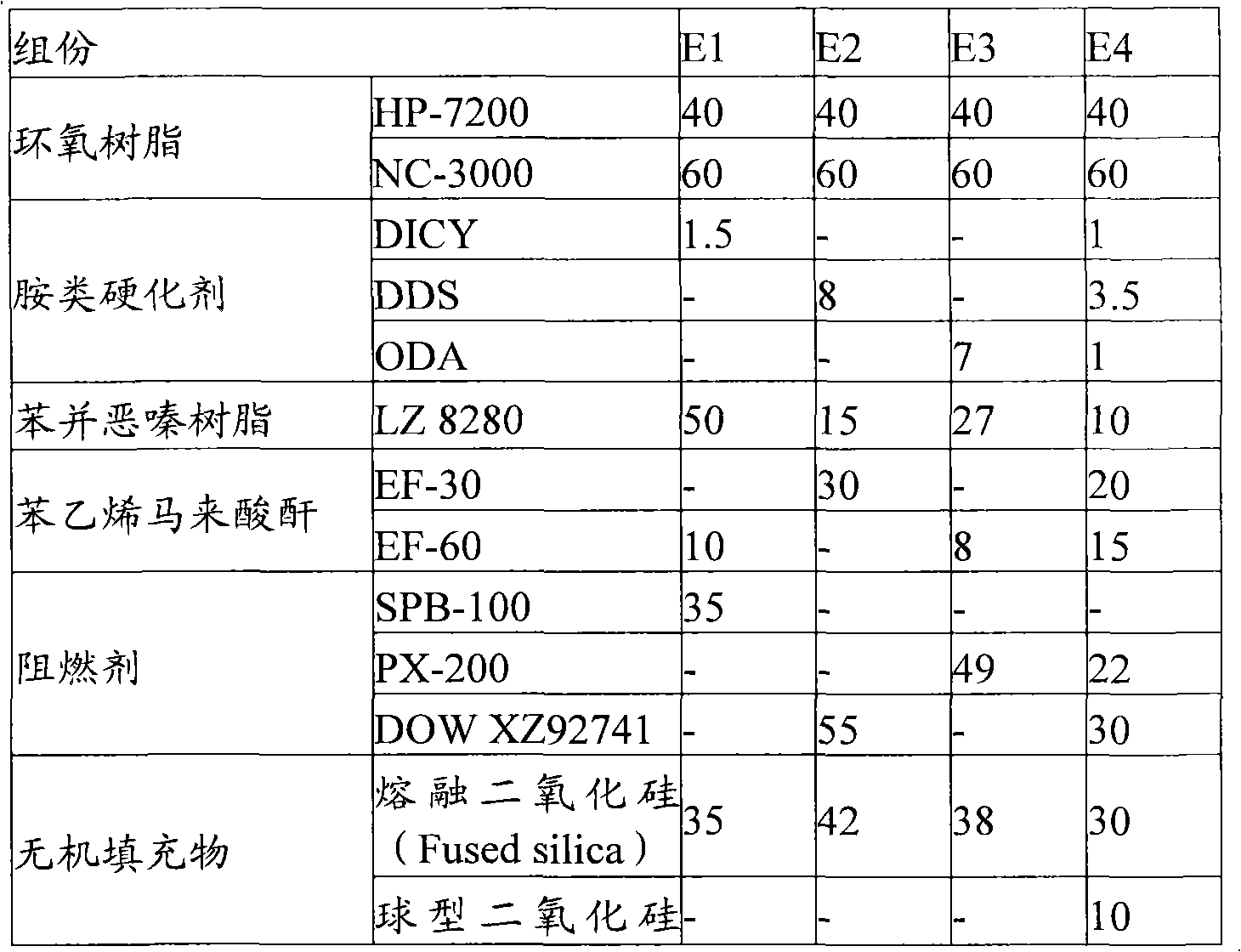

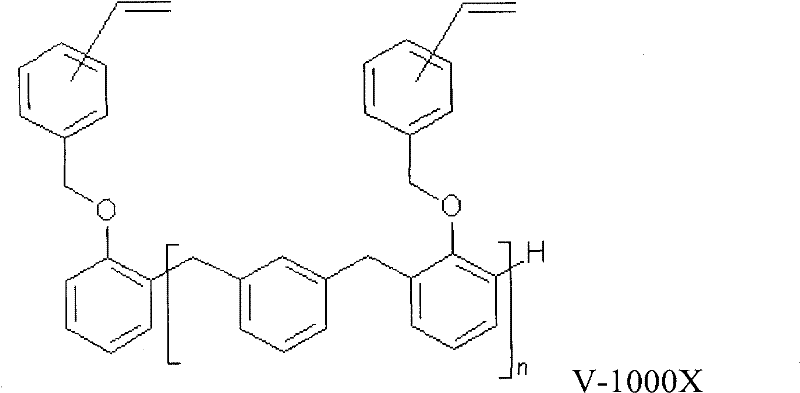

A halogen-free resin composition includes (A) 100 parts per hundred resin of epoxy resin; (B) 1 to 100 parts per hundred resin of benzoxazine resin; (C) 1 to 100 parts per hundred resin of styrene-maleic anhydride; (D) 0.5 to 30 parts per hundred resin of amine curing agent; and (E) 5 to 150 parts per hundred resin of halogen-free flame retardant. The composition obtains properties of low dielectric constant, low dissipation factor, high heat resistance and flame retardancy by specific composition and ratio. Thus, a prepreg or a resin film, which can be applied to a copper clad laminate and a printed circuit board, is formed.

Owner:ELITE MATERIAL

Thermoset composition, method, and article

InactiveUS20030215588A1Improve as-molded surface characteristics of polyReduce shrinkage on moldingSynthetic resin layered productsThin material handlingVinyl etherPolystyrene

A curable composition includes a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a polymeric additive effective selected from polystyrene, poly(styrene-maleic anhydride), poly(styrene-methyl methacrylate), polybutene, poly(ethylene-butylene), poly(vinyl ether), poly(vinyl acetate), and combinations thereof. The composition exhibits low shrinkage on curing and improved surface smoothness. It is useful, for example, in the manufacture of automotive body panels.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

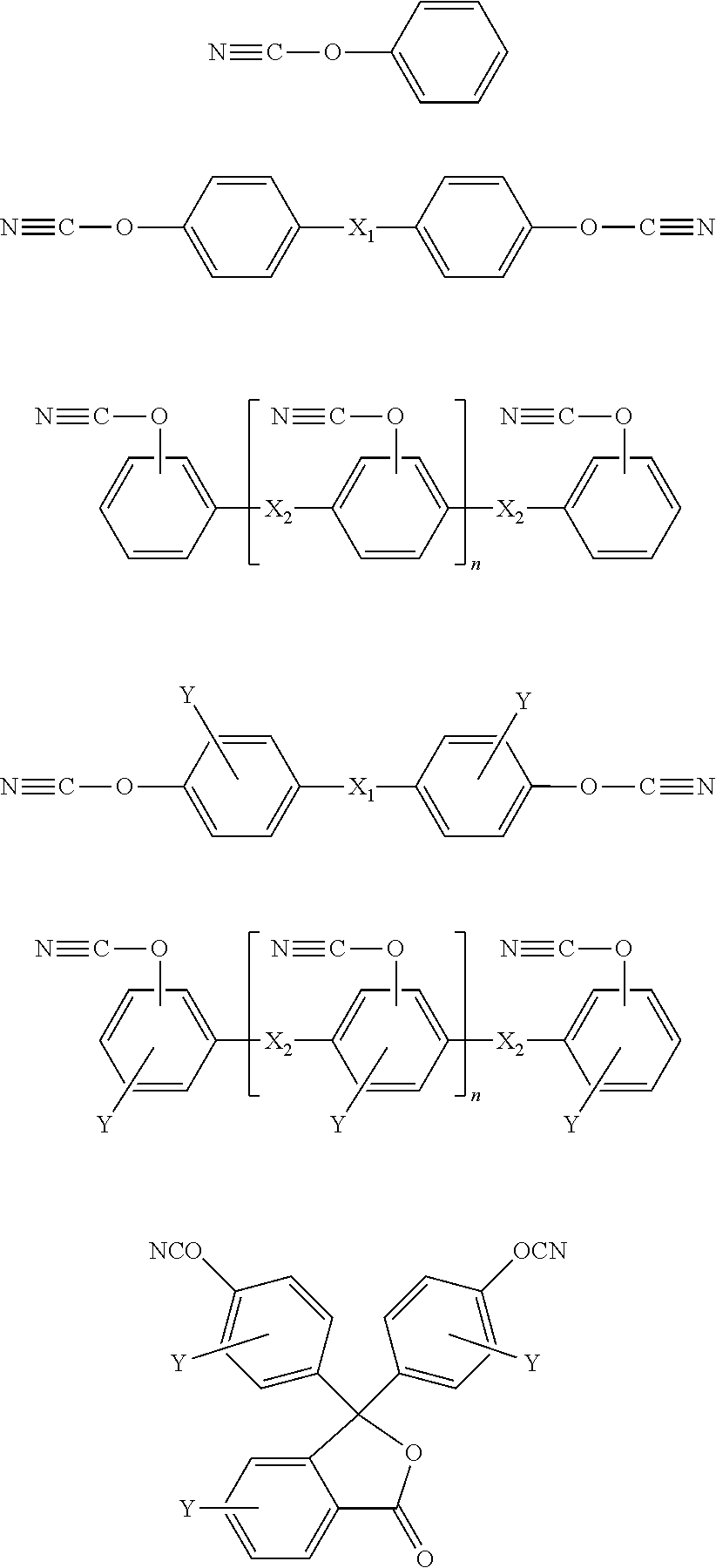

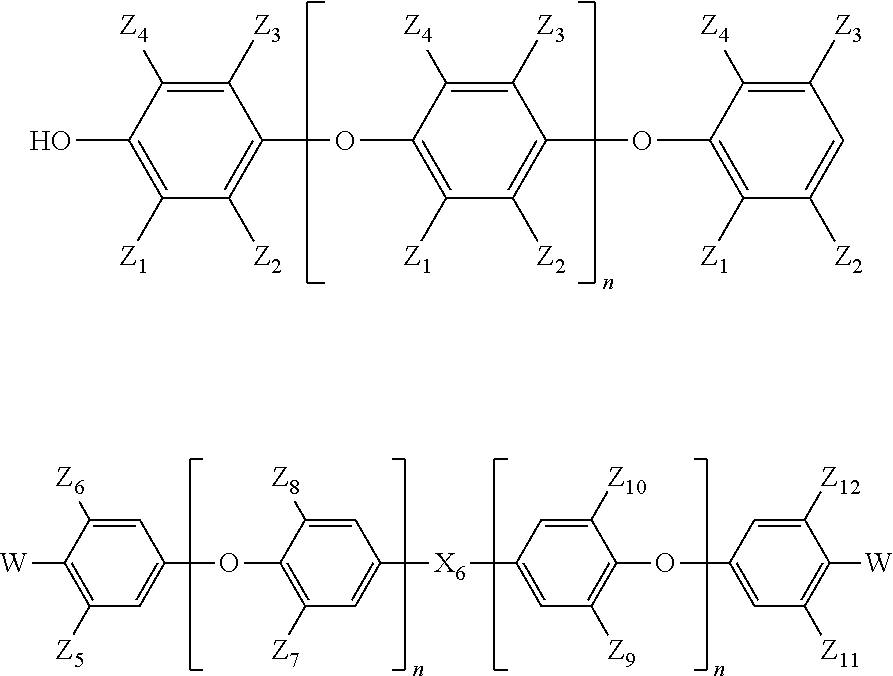

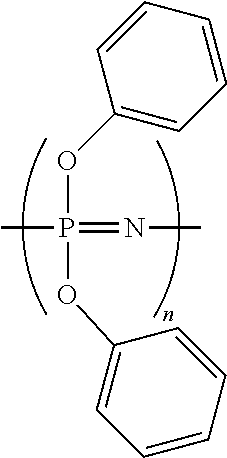

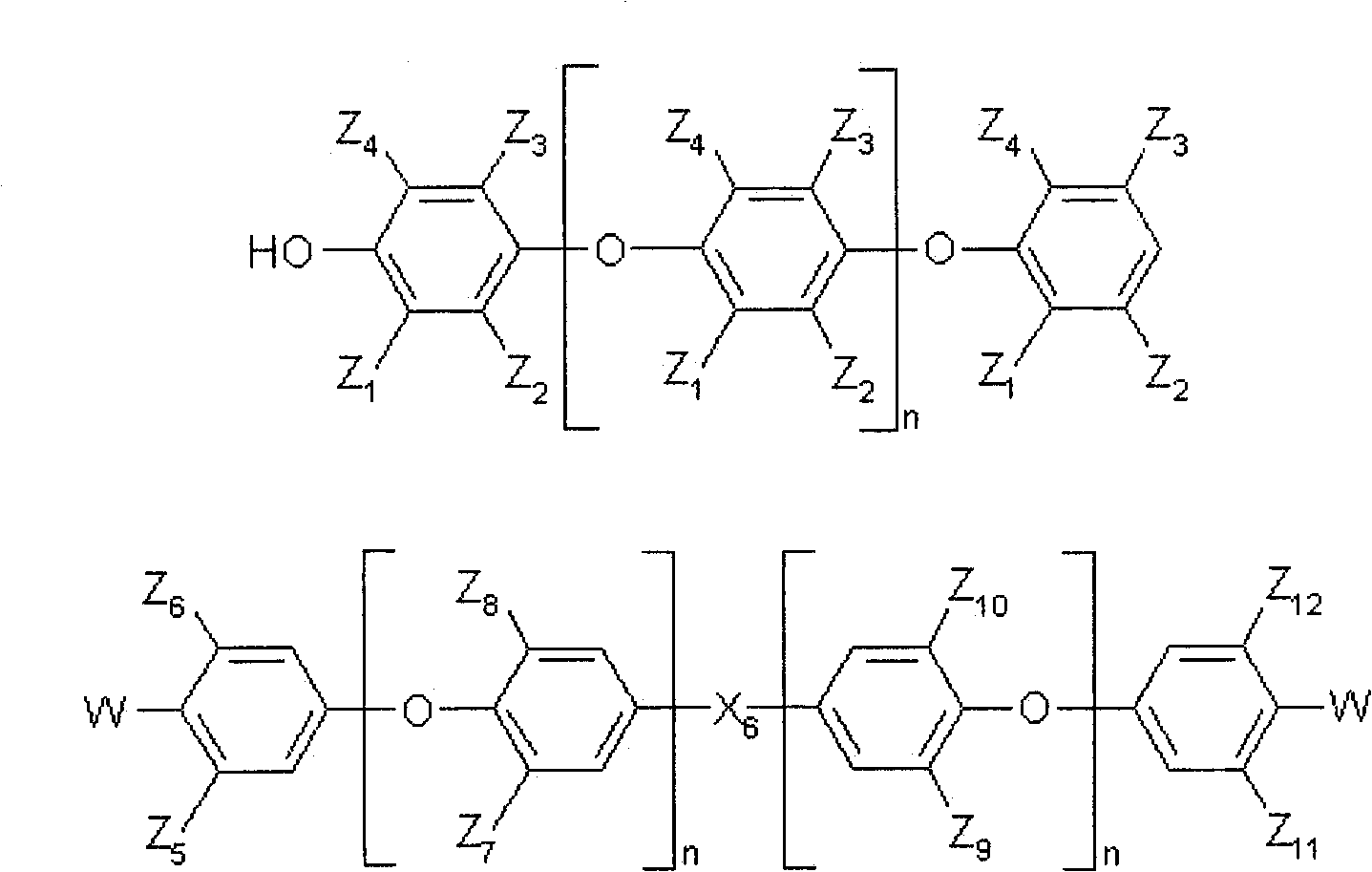

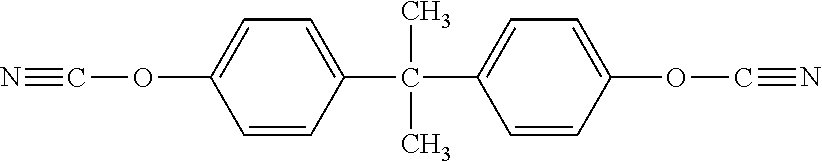

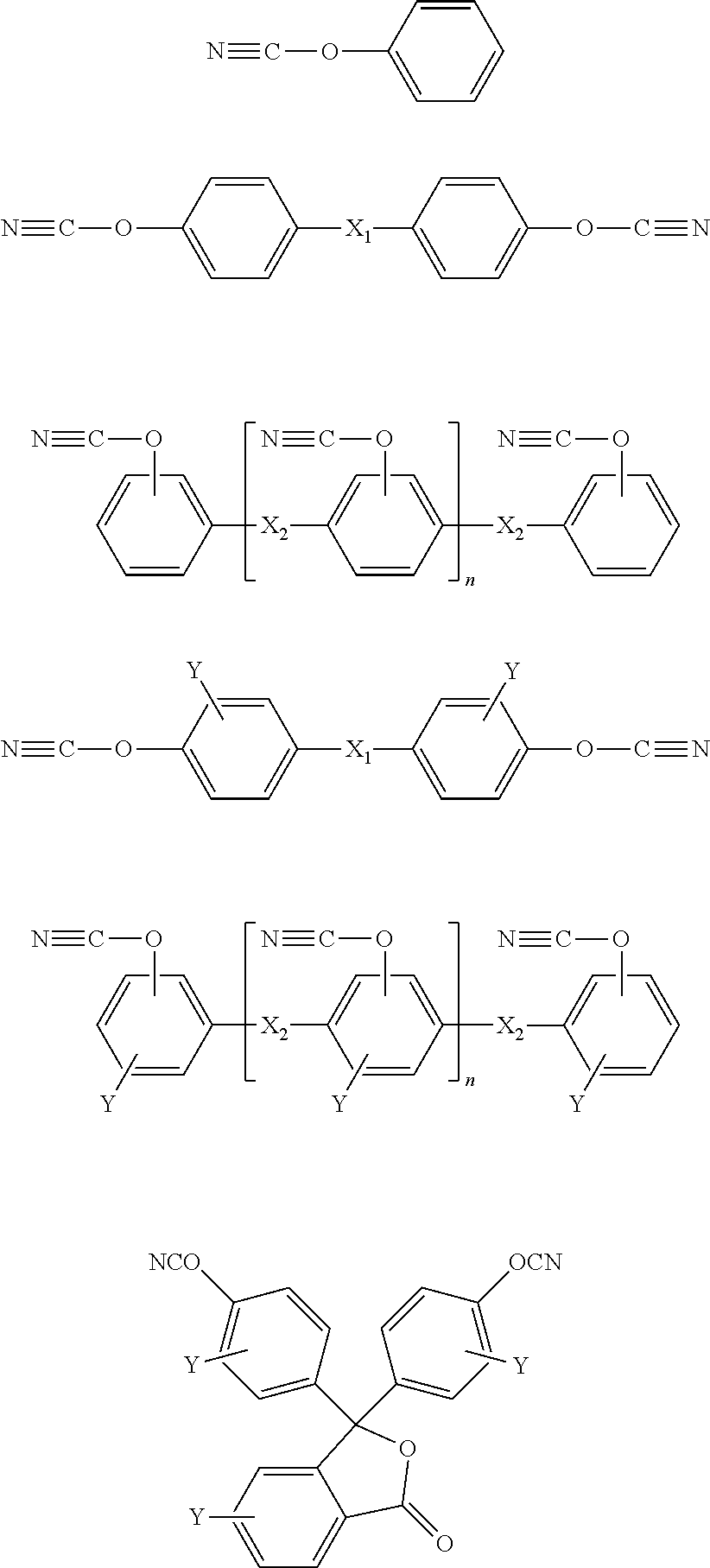

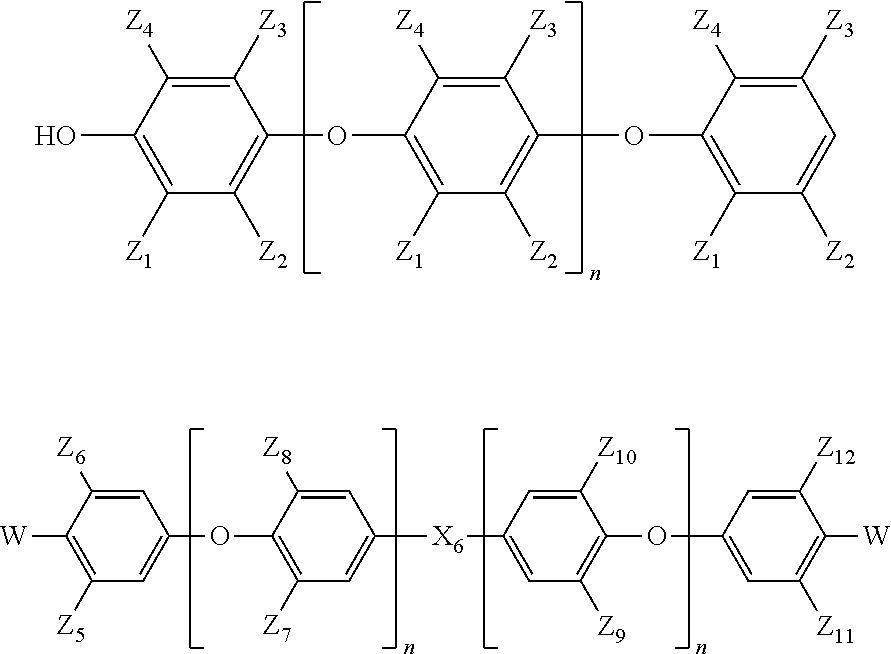

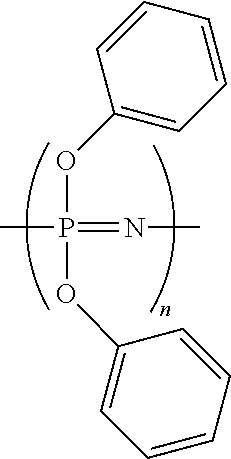

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Halogen-less high frequency resin composition, and prepreg and laminate manufacturing by using same

ActiveCN101684191ALow heat resistanceImprove heat resistanceSynthetic resin layered productsWoven fabricsStyrene maleic anhydrideAbsorbance

The invention relates to a halogen-less high frequency resin composition, and a prepreg and a laminate manufactured by using the same. The halogen-less high frequency resin composition comprises the following components based on weight part of the organic solids: (A) 10 to 50 parts of styrene-maleic anhydride oligomer; (B) 10 to 50 parts of at least one compound containing dihydro-benzoxazine ring; (C) 10 to 50 parts of at least one polyepoxide; and (D) 5 to 30 parts of at least one phosphorus-containing flame retardant. The prepreg and the laminate manufactured by using the halogen-less highfrequency resin composition has low dielectric constant, low dielectric loss factor, high glass transition temperature, good heat resistance, low water absorbance, and simple and convenient technological operation.

Owner:GUANGDONG SHENGYI SCI TECH

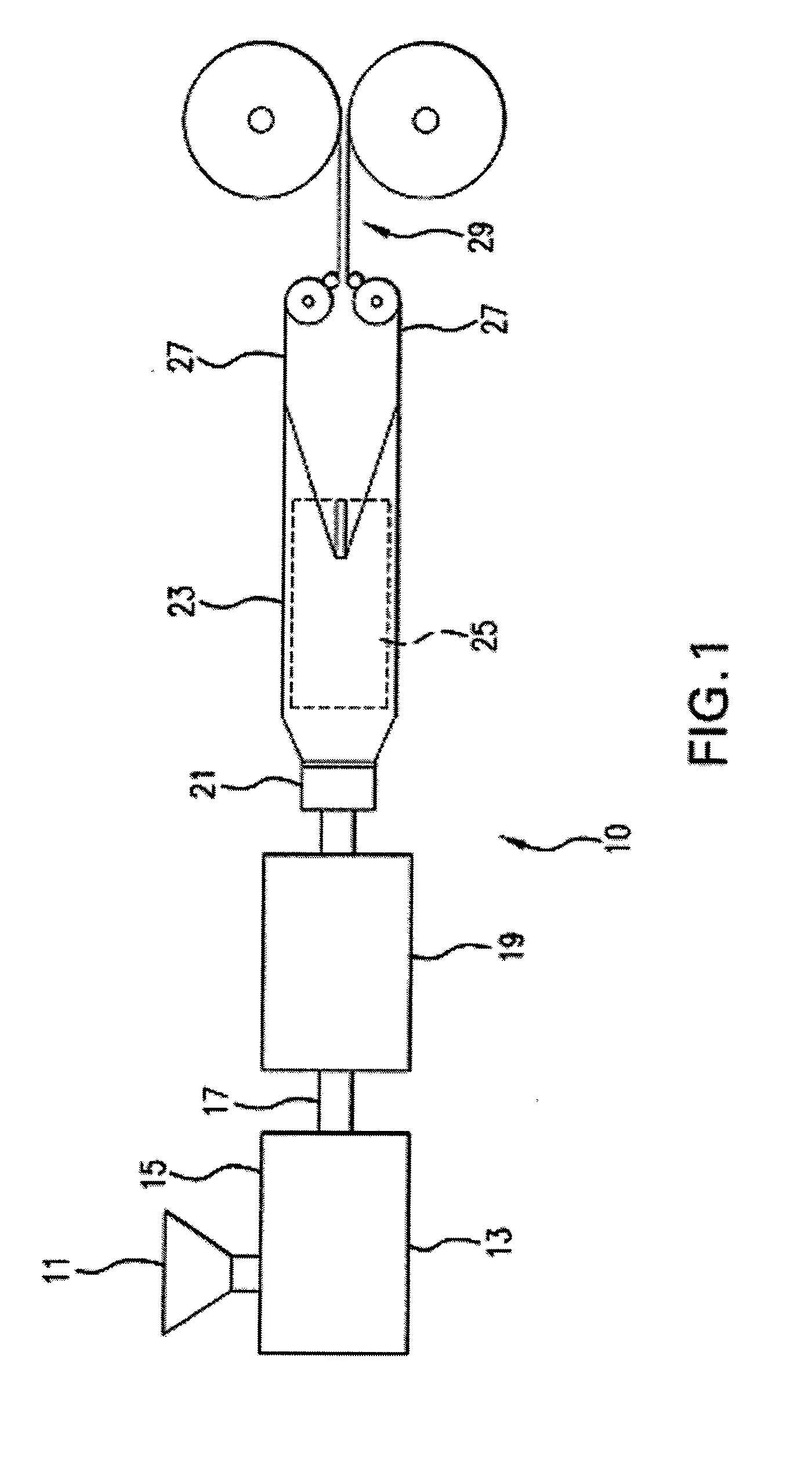

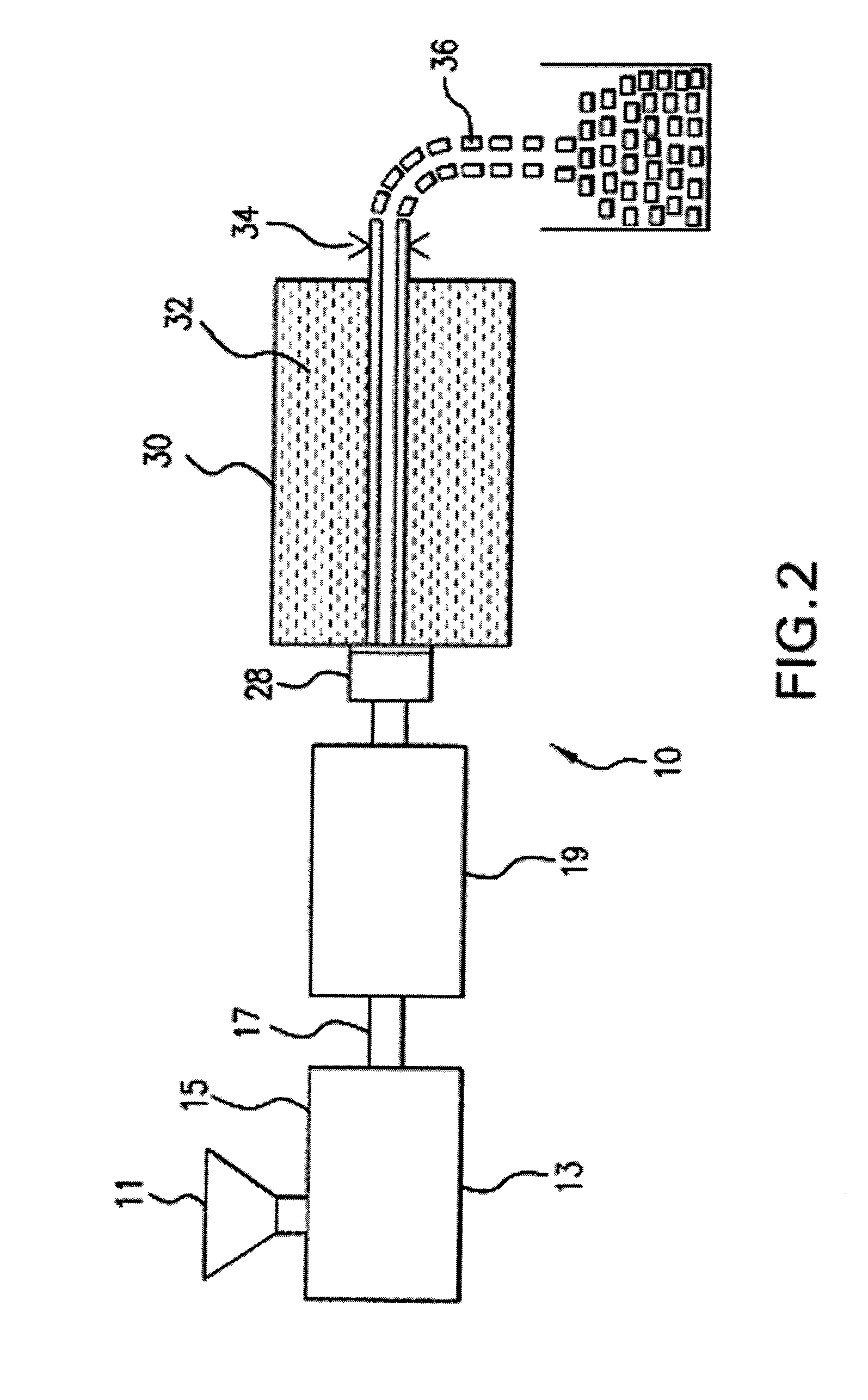

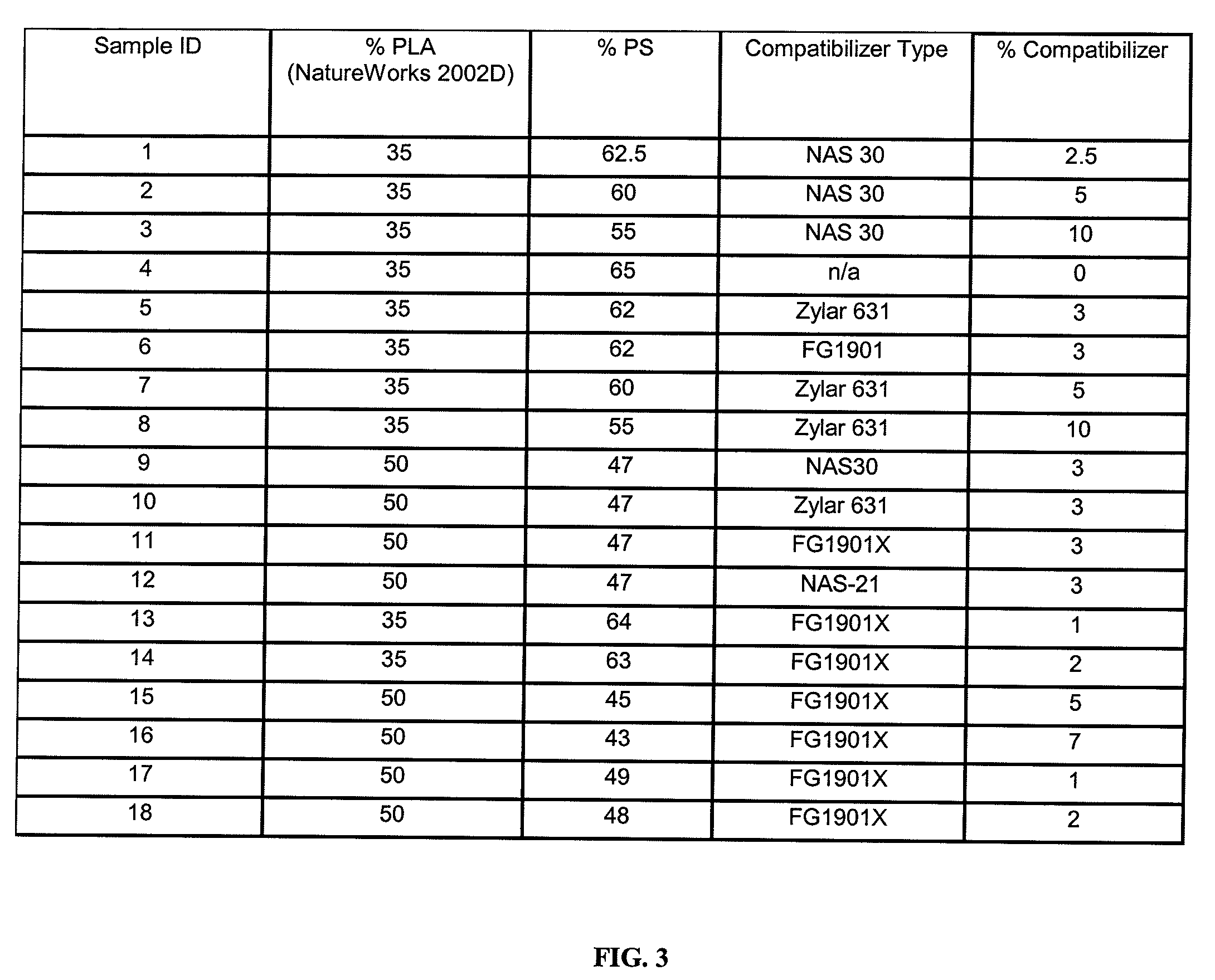

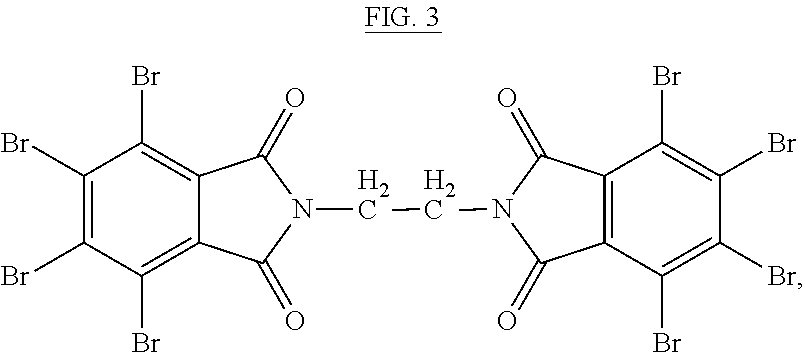

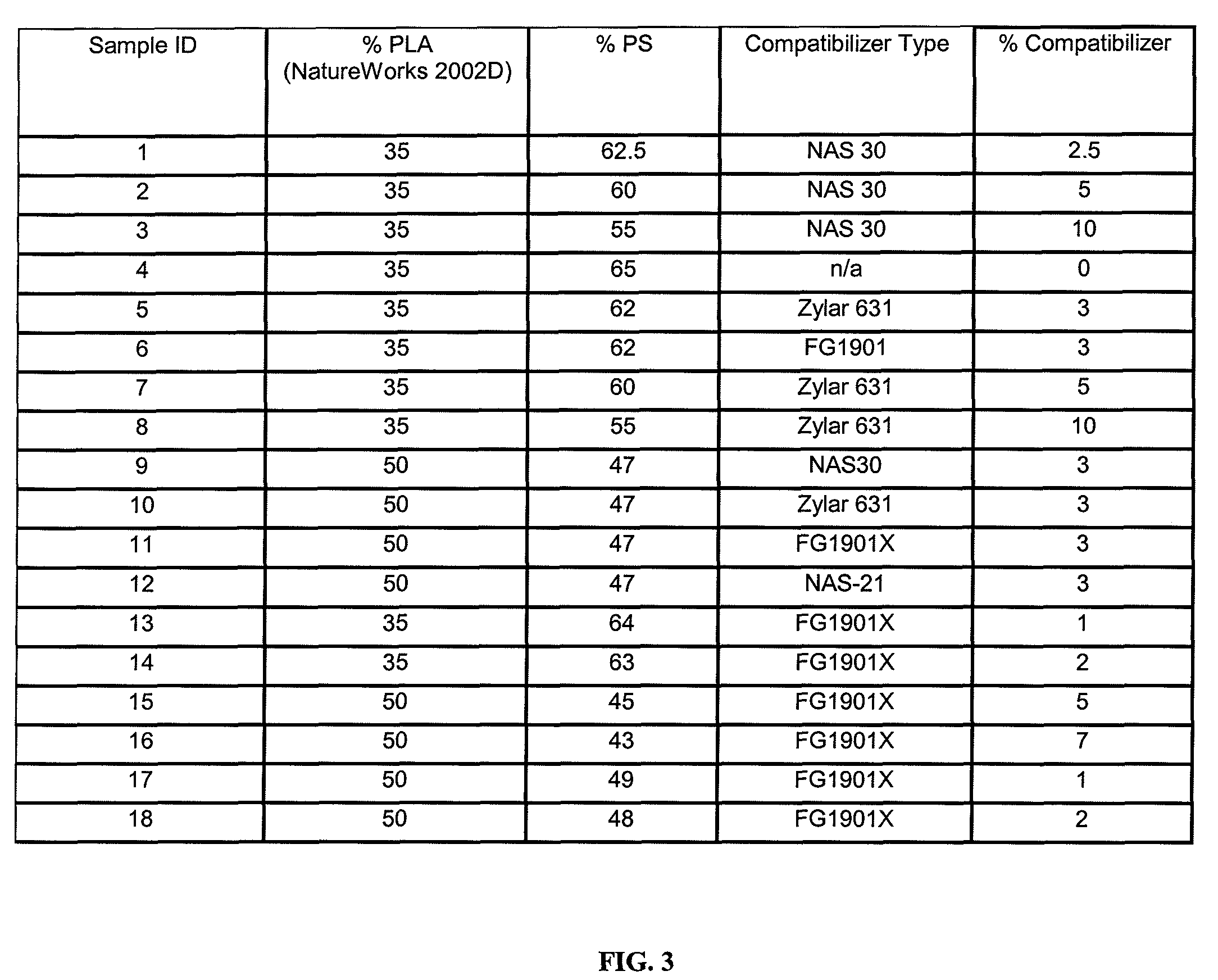

Polymer Blends Of Biodegradable Or Bio-Based And Synthetic Polymers And Foams Thereof

The present invention relates to compositions comprising blends of alkenyl aromatic polymers such as styrenic polymers (i.e. PS and HIPS) and bio-based or biodegradable polymers (i.e. PLA, PGA, PHA, PBS, PCL) compatibilized with styrene-based copolymers (i.e. styrene-ethylene-butylene-styrene (SEBS) block copolymers, maleated SEBS, styrene-maleic anhydride (SMA) copolymer, styrene-methyl methacrylate (SMMA) copolymer) or a mixture of two or more styrene-based copolymers such as SEBS and SMA. These novel compositions can be extruded and thermoformed to produce very low density food service and consumer foam articles such as plates, hinged lid containers, trays, bowls, and egg cartons with good mechanical properties.

Owner:PACTIV LLC

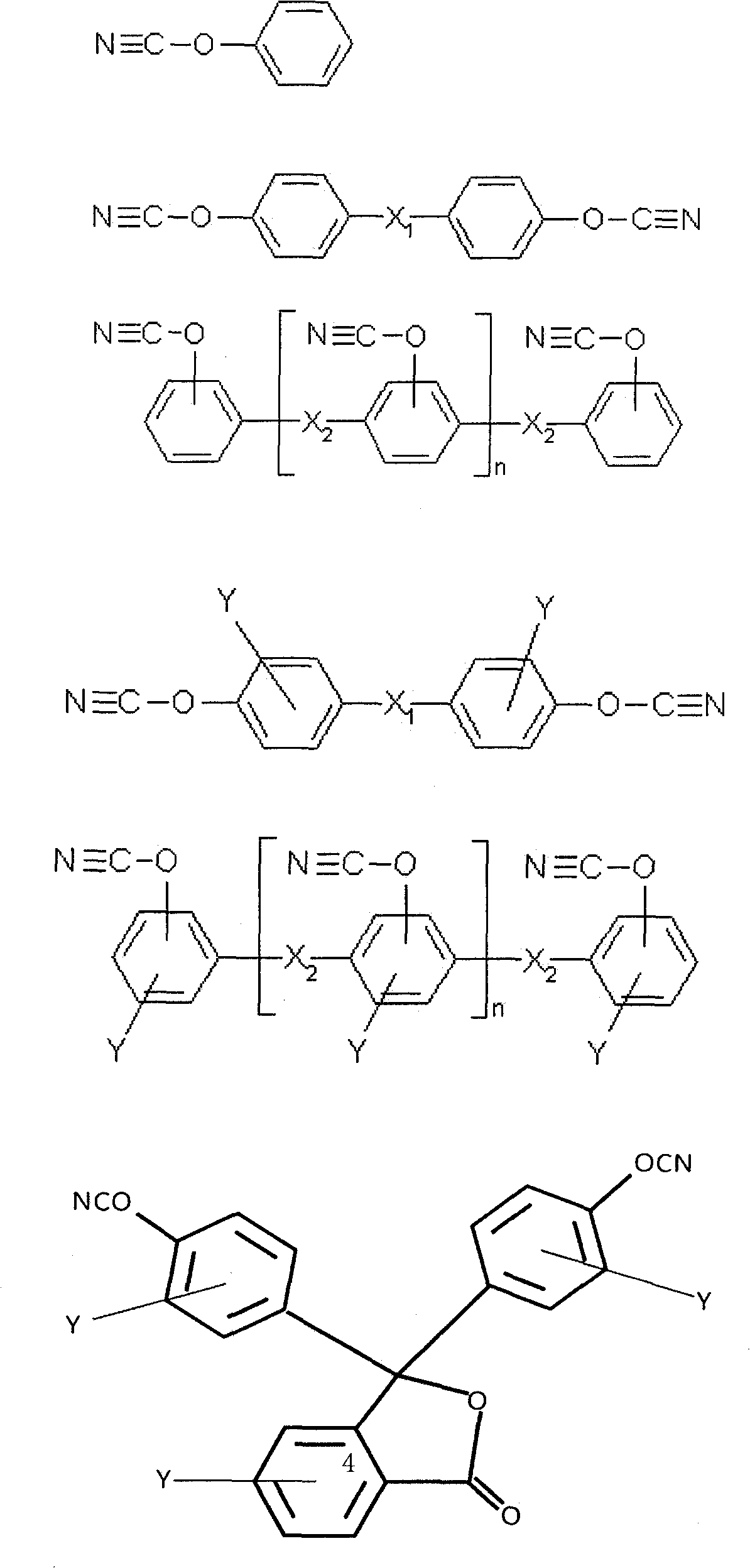

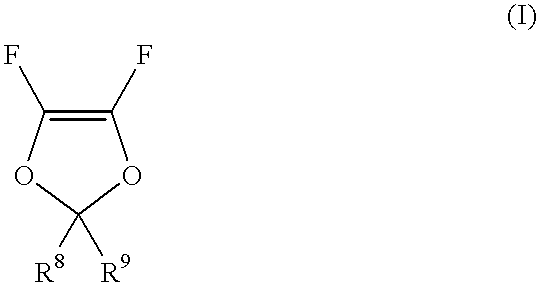

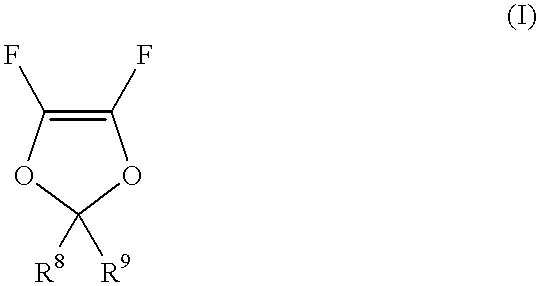

Copolymers of maleic anhydride or acid and fluorinated olefins

Novel copolymers of fluorinated olefins and maleic anhydride, maleic acid, dichloromaleic anhydride or dichloromaleic acid may be made by using as solvents for the maleic anhydride or acid a perfluorinated alkyl carboxylic acid, or liquid or supercritical hexafluoropropylene or carbon dioxide. The resulting polymers are useful as adhesives or compatibilizing agents for fluoropolymers, and in coatings.

Owner:THE CHEMOURS CO FC LLC

Thermosetting resin composition and use thereof

The present invention discloses a thermosetting resin composition comprising: a bifunctional or multifunctional epoxy resin, a styrene-maleic anhydride (SMA) copolymer with a styrene / maleic anhydride molar ratio of 5-12:1 as a curing agent, a BPA epoxy resin with a low or high bromine content or tetrabromobisphenol A as a flame retardant agent, an accelerator and a solvent. The cured resin composition of the invention has a very low dielectric property, improved thermal reliability and better toughness. A copper clad laminate made of the resin composition and a reinforced material such as glass fiber cloth has a very low dielectric constant and dissipation factor, high Td, better toughness and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs and also applied to the common use of epoxy resins, such as molding resins, and composite materials for construction, automobiles and aviation.

Owner:ITEQ DONGGUAN +1

Polymer blends of biodegradable or bio-based and synthetic polymers and foams thereof

The present invention relates to compositions comprising blends of alkenyl aromatic polymers such as styrenic polymers (i.e. PS and HIPS) and bio-based or biodegradable polymers (i.e. PLA, PGA, PHA, PBS, PCL) compatibilized with styrene-based copolymers (i.e. styrene-ethylene-butylene-styrene (SEBS) block copolymers, maleated SEBS, styrene-maleic anhydride (SMA) copolymer, styrene-methyl methacrylate (SMMA) copolymer) or a mixture of two or more styrene-based copolymers such as SEBS and SMA. These novel compositions can be extruded and thermoformed to produce very low density food service and consumer foam articles such as plates, hinged lid containers, trays, bowls, and egg cartons with good mechanical properties.

Owner:PACTIV CORP

Halogen-free resin composition as well as copper foil substrate and printed circuit board applying same

ActiveCN103013110AWith flame retardant functionWon't happenCircuit susbtrate materialsSheet filmCopper foil

The invention provides a halogen-free resin composition which comprises (A) 100 parts of cyanate ester resin, (B) 5-50 parts of styrene maleic anhydride, (C), 5-100 parts of polyphenyl ether resin, (D) 5-100 parts of maleimide resin, (E) 10-150 parts of nitrogenous compound, and (F) 10-1000 parts of inorganic filler. As the composition comprises components in special proportion, the halogen-free resin composition is low in dielectric constant, low in dielectric loss, high in heat resistance and high in flame resistance. The halogen-free resin composition can be prepared as a semi-cured film or a resin film, so that the composition can be applied to a copper foil substrate and a printed circuit board.

Owner:ELITE MATERIAL

Copolymers of maleic anhydride or acid and fluorinated olefins

Novel copolymers of fluorinated olefins and maleic anhydride, maleic acid, dichloromaleic anhydride or dichloromaleic acid may be made by using as solvents for the maleic anhydride or acid a perfluorinated alkyl carboxylic acid, or liquid or supercritical hexafluoropropylene or carbon dioxide. The resulting polymers are useful as adhesives or compatibilizing agents for fluoropolymers, and in coatings.

Owner:THE CHEMOURS CO FC LLC

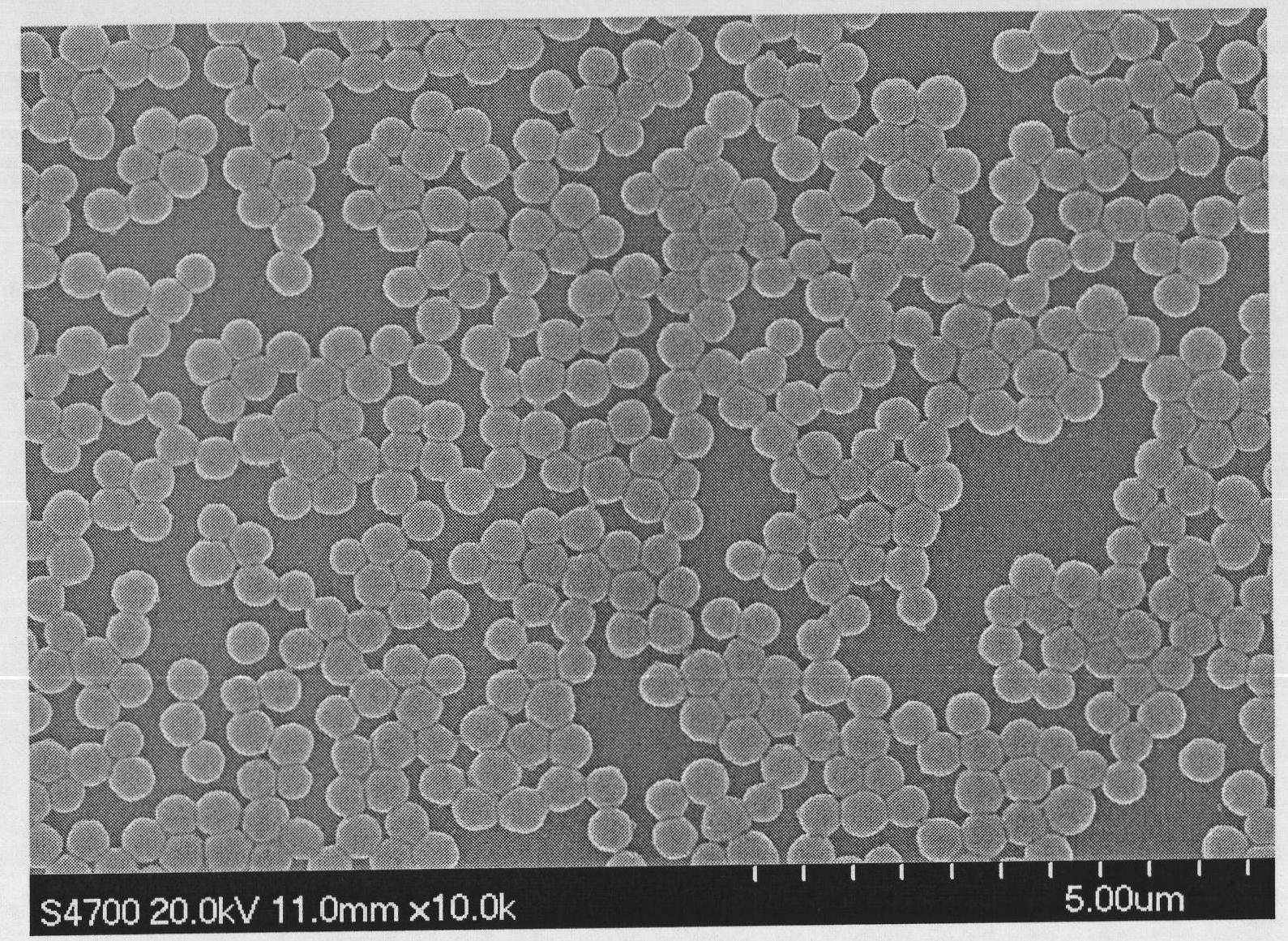

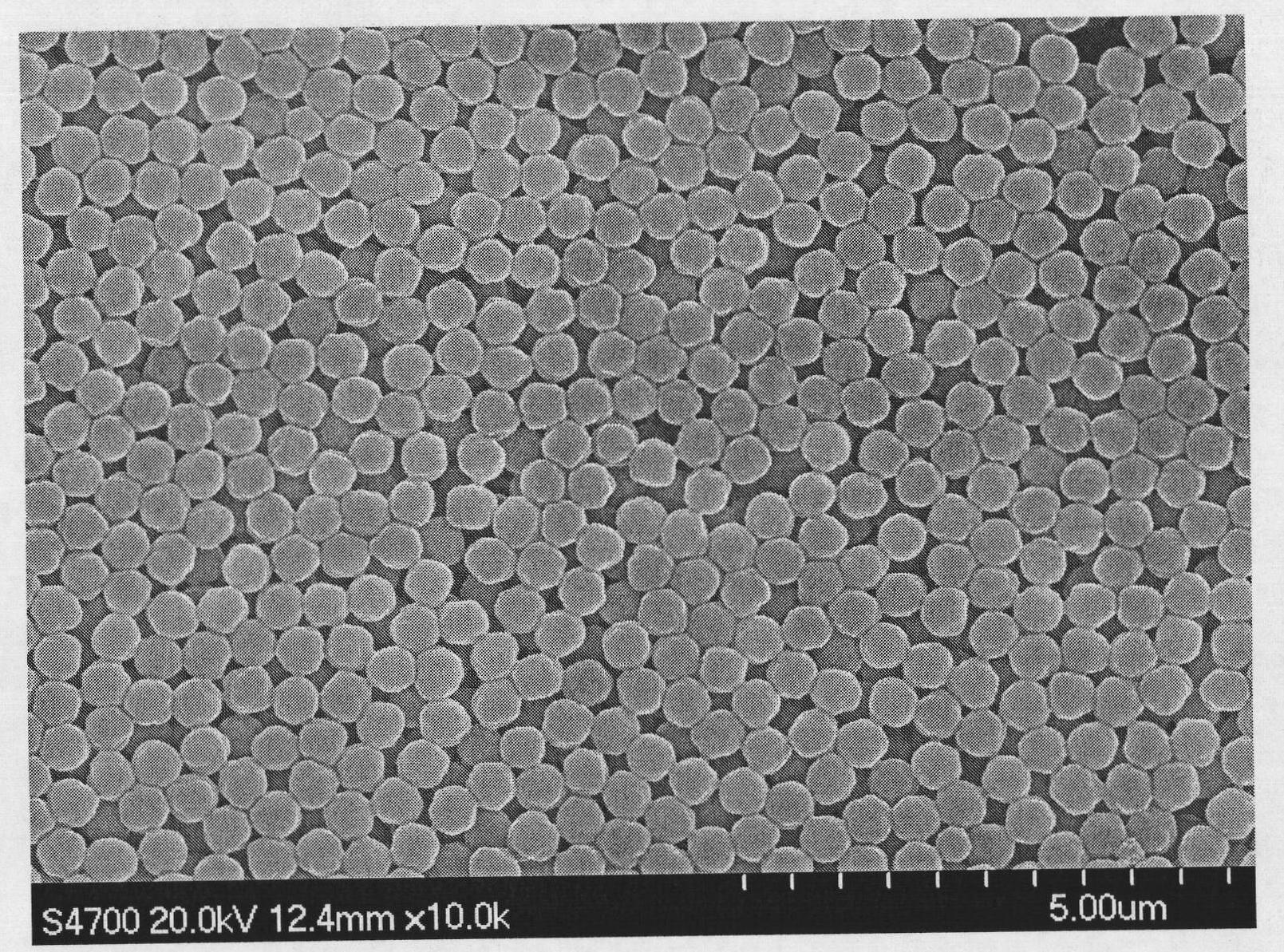

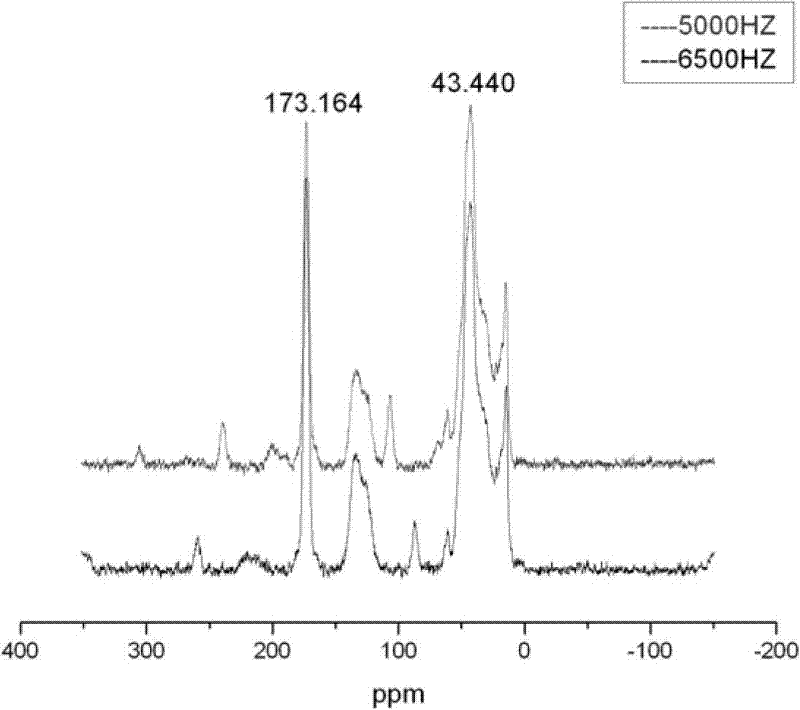

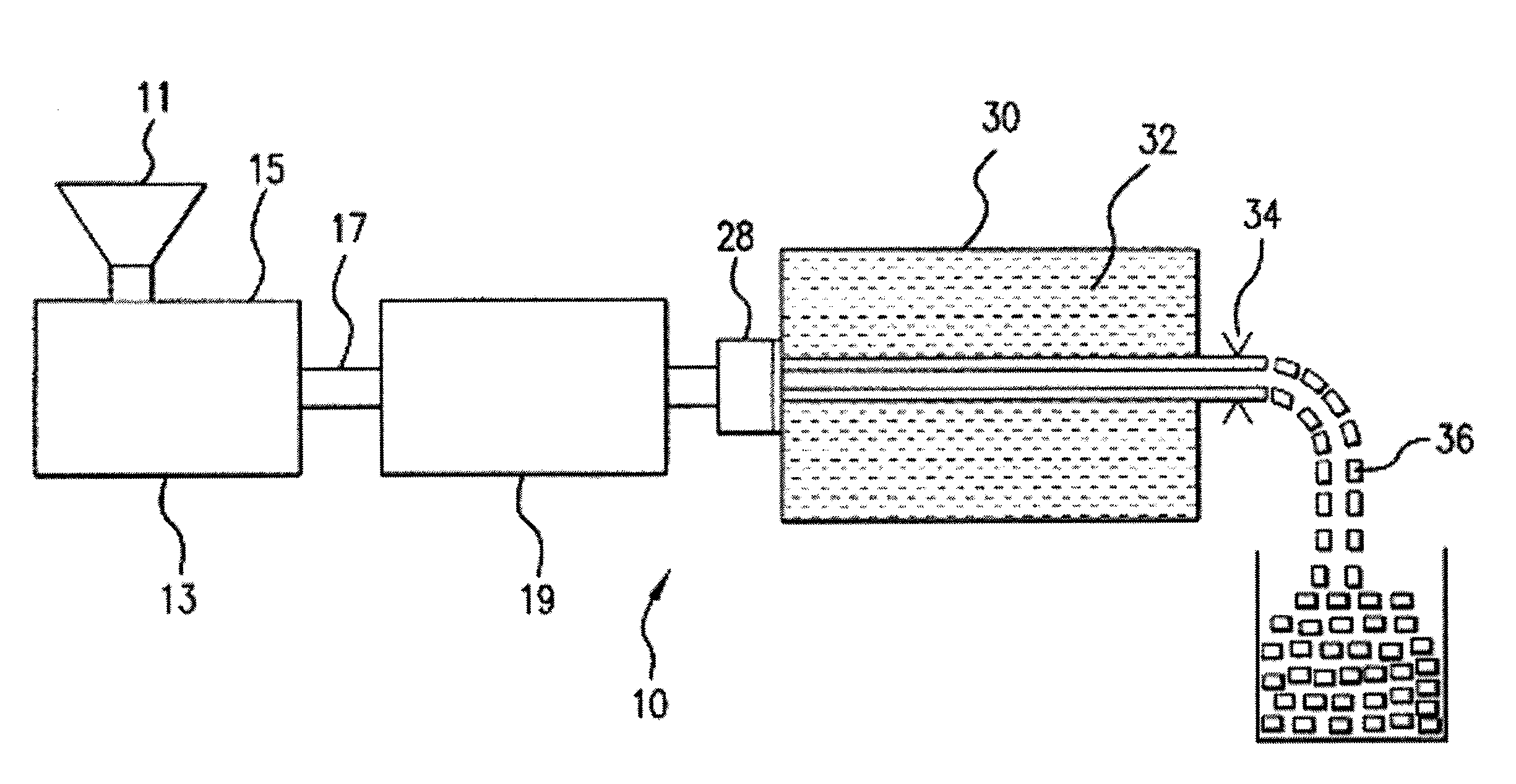

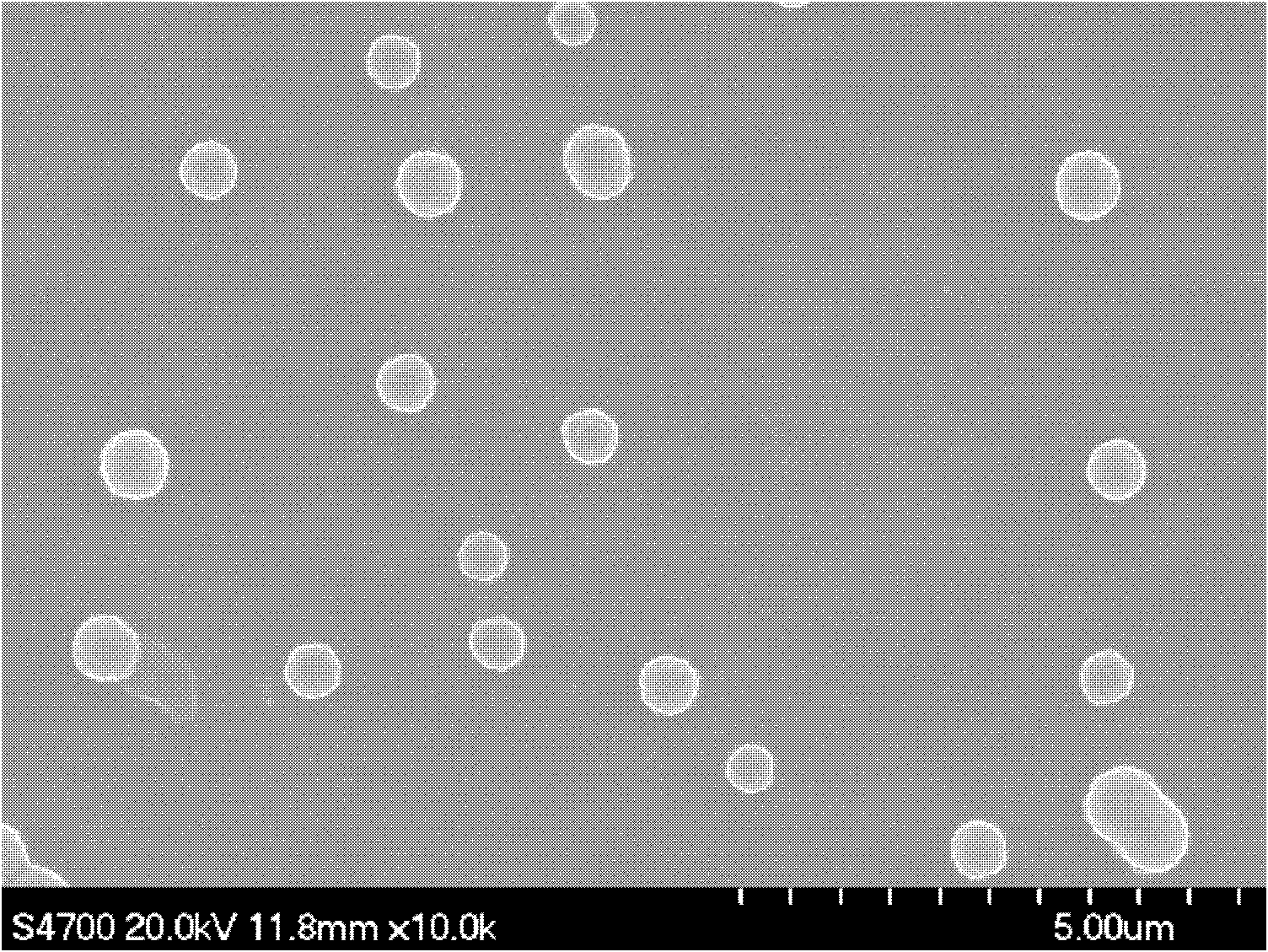

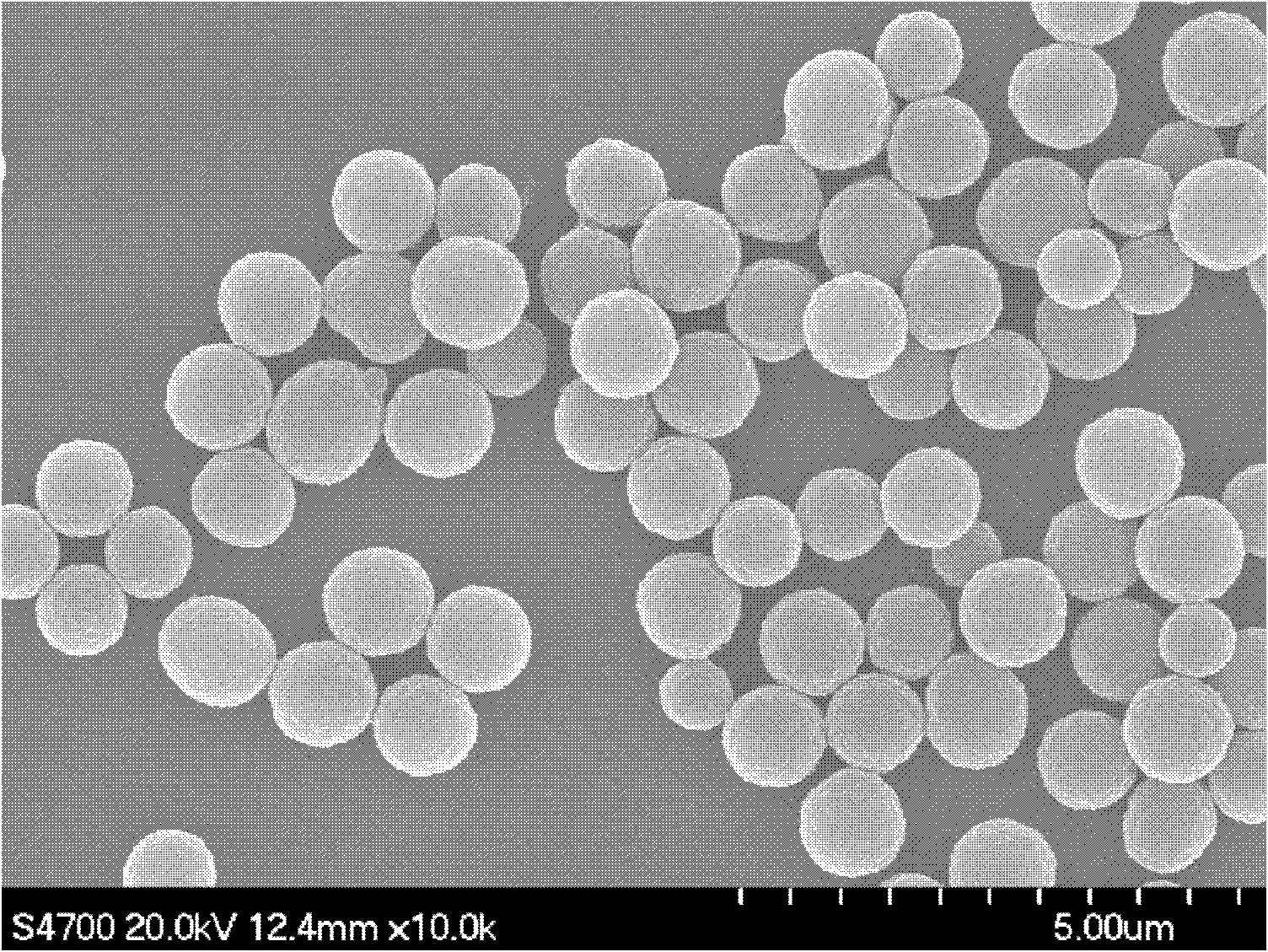

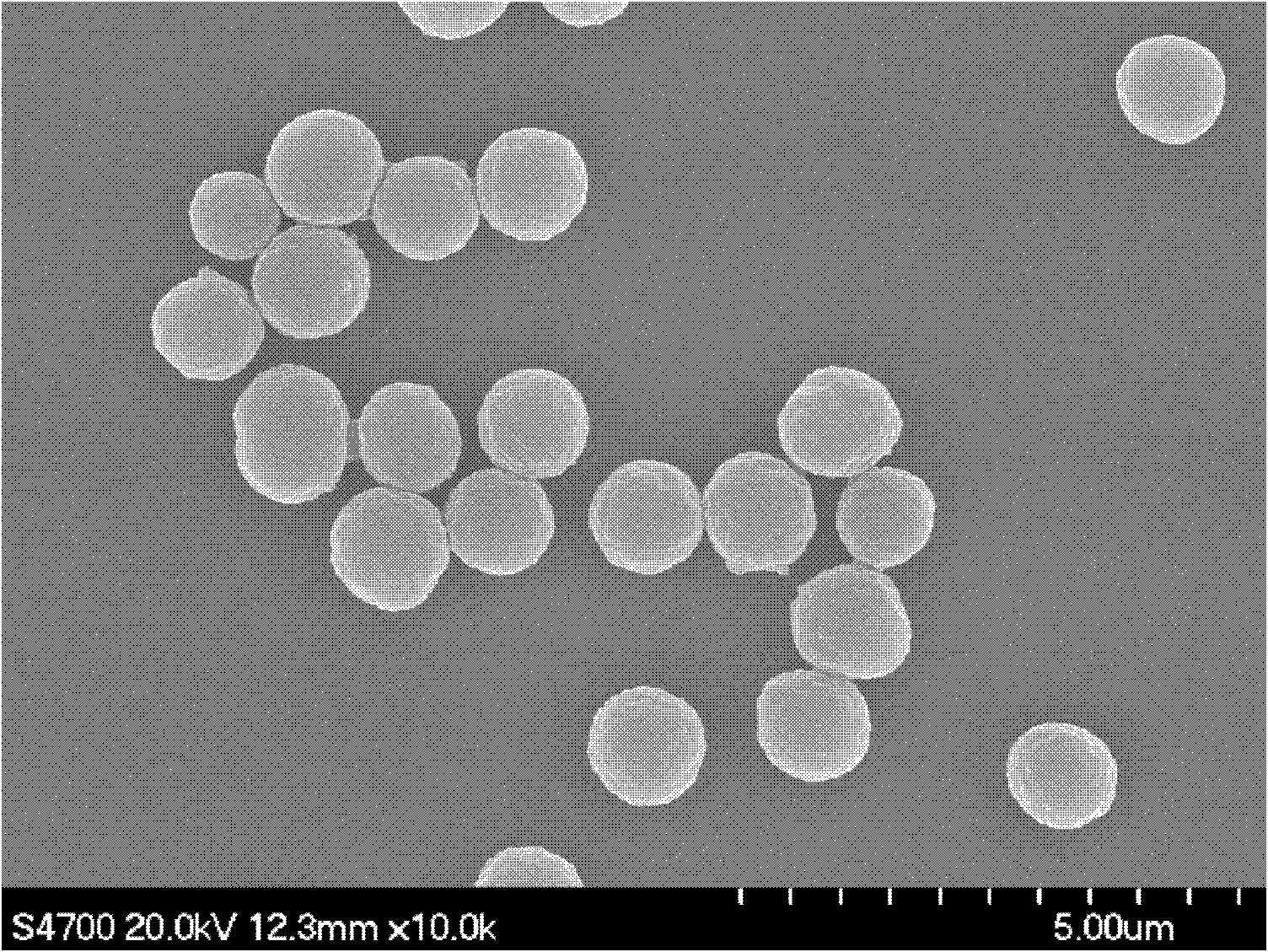

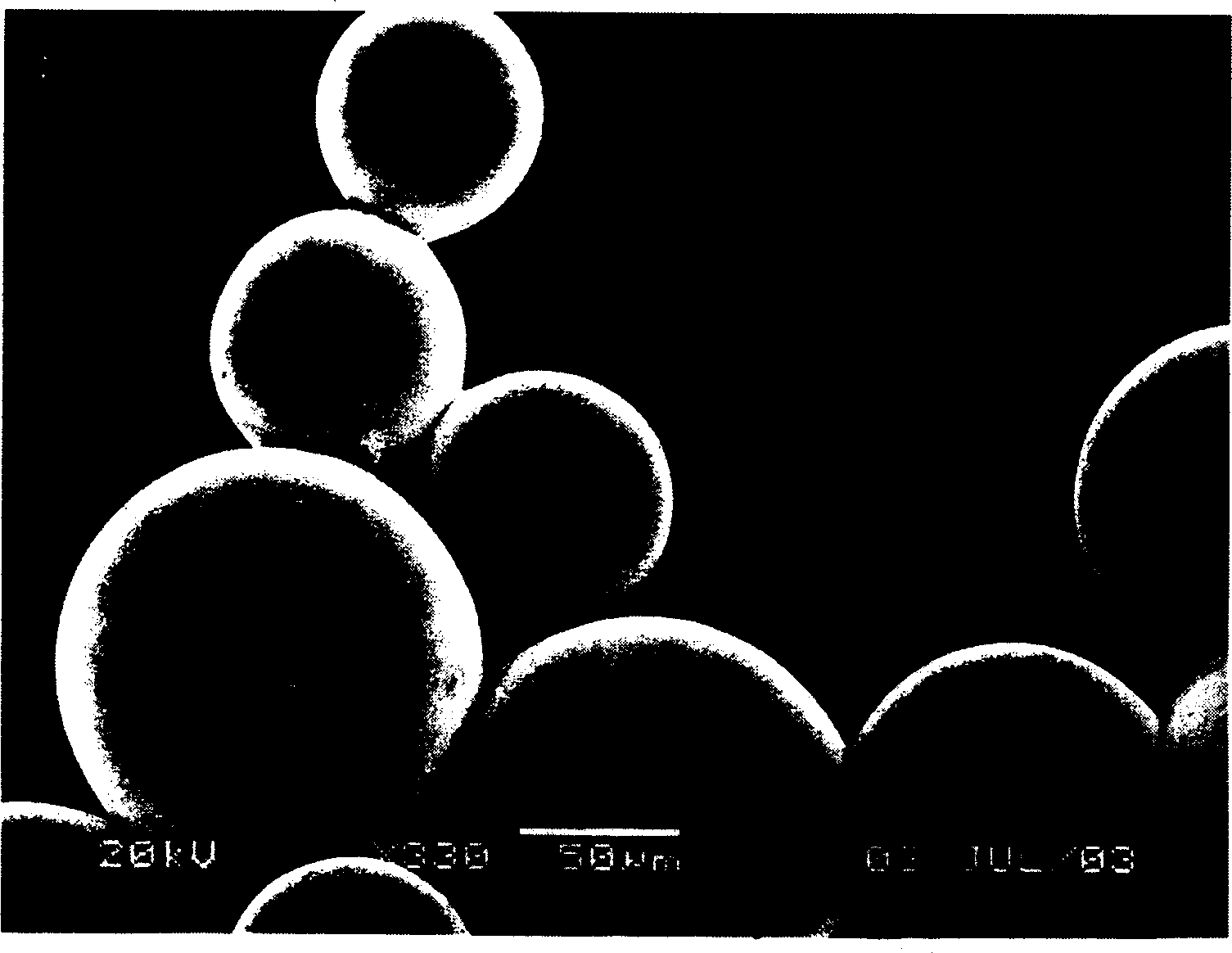

Method for copolymerization of maleic anhydride/conjugated diene

The invention discloses a method for copolymerization of maleic anhydride / conjugated diene, relating to the field of high polymer self-stable precipitation polymerization. The invention comprises the following steps: under the protection of nitrogen, adding the monomer maleic anhydride and initiators into medium to dissolve fully; after that, adding the monomer conjugated diene into the system, dissolving, and reacting for 0.5-73h at 50-90 DEG C to obtain a disperse system of copolymer microspheres of the maleic anhydride and the conjugated diene; then obtaining a white solid of the copolymer of the maleic anhydride and the conjugated diene through centrifugation and vacuum drying. The invention has the advantages of simple process, simple post-treatment to the synthesized copolymer, low cost, environmental friendliness, etc.

Owner:BEIJING UNIV OF CHEM TECH

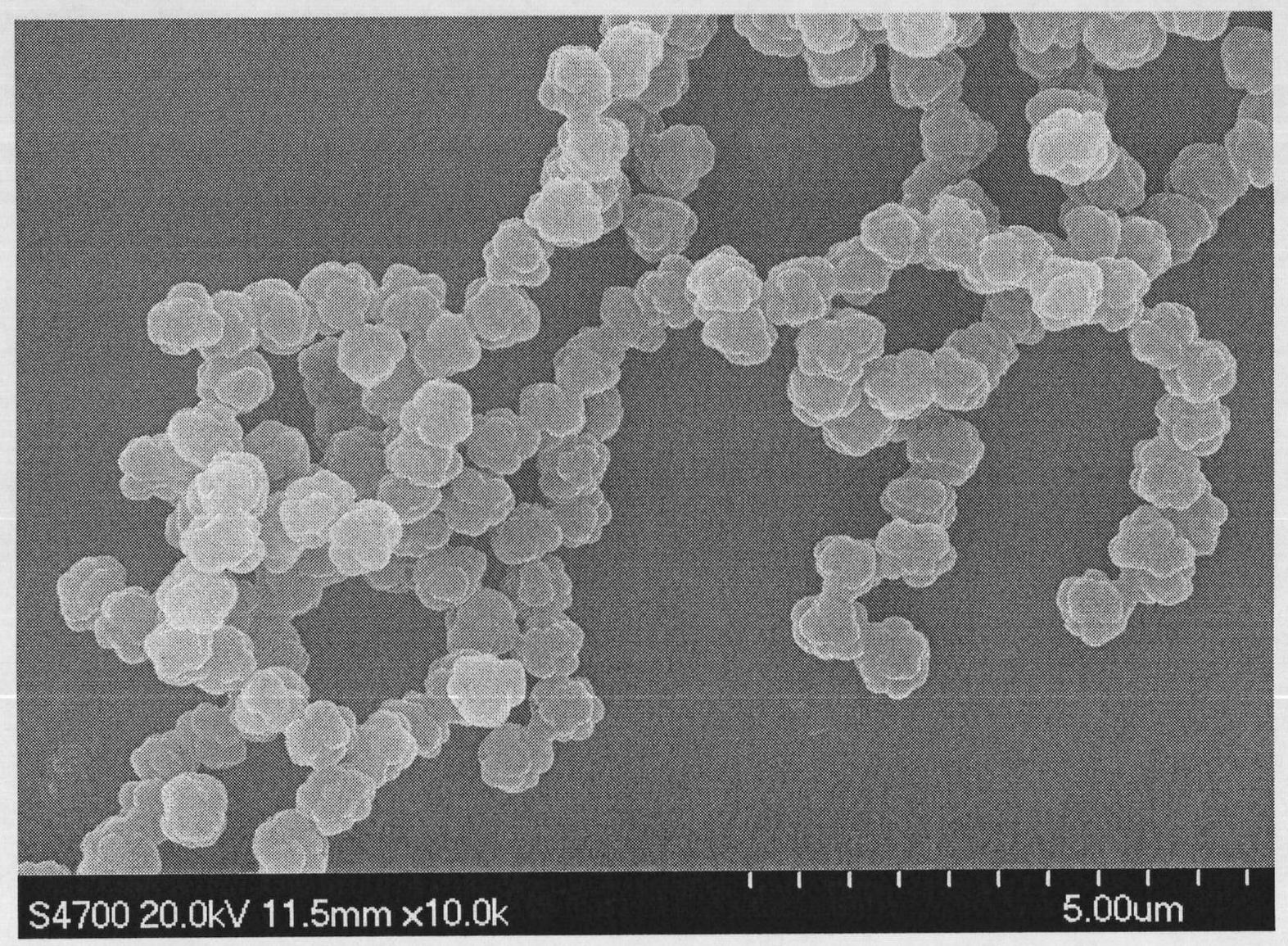

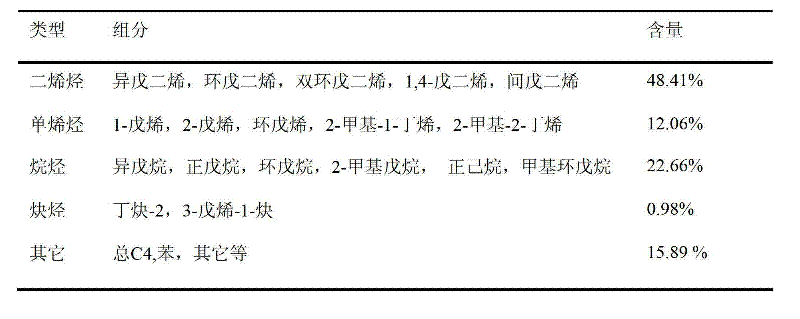

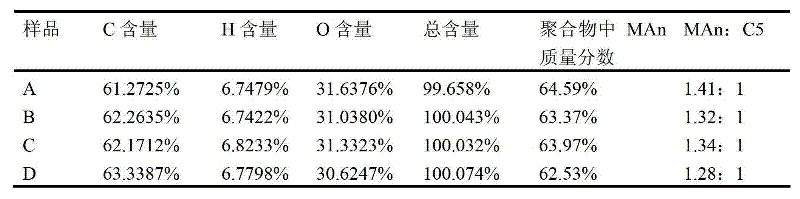

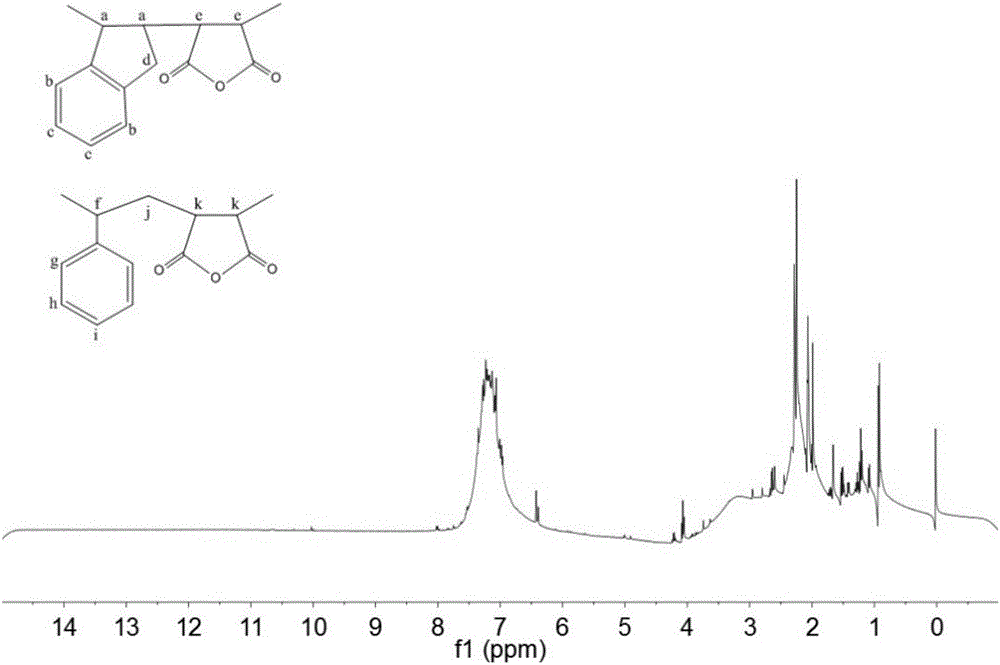

Copolymer containing functional group and prepared by C5 mixture and maleic anhydride, and preparation of copolymer

The invention provides a copolymer containing a functional group and prepared by a C5 mixture and maleic anhydride and a preparation of the copolymer, belonging to the field of applications of C5 resource. The preparation method comprises the following steps of: adding monomer maleic anhydride and initiator azobisisobutyronitrile (AIBN) into ester medium under the protection of nitrogen, dissolving completely, adding C5 mixture into the system, and dissolving, wherein the mol ratio of the maleic anhydride and the C5 is 1:1, reacting for 0.05-7 hours at 50-90 DEG C so as to obtain a milky and stable solid-liquid disperse system of the copolymer of C5 and maleic anhydride, centrifugally separating and drying at vacuum condition so as to obtain the white solid powder of copolymer of C5 and maleic anhydride. According to the invention, the C5 mixture is directly used as the raw material to prepare the highly crosslinked copolymer containing the functional group in one-step reaction, in this way, the C5 resource is used reasonably and effectively.

Owner:BEIJING UNIV OF CHEM TECH

Polyether graft poly-carboxylic acid concrete water reducer preparation

Production of polyether graft poly-carboxylic acid concrete water reducer is prepared by sulfonating styrene-anhydride multipolymer with anhydride content 10í½50 mol% and relative molecular mass 2000í½20000 from sulfonating agent of non-destructive acid anhydride group, esterifying grafting polyether side chain on acid anhydride key, and dissolving in water. Its advantages include simple process, no catalyst, higher fluidity of cement concrete and compression strength.

Owner:海南中科翔新材料科技有限公司

Thermoset composition, method, and article

InactiveUS20030220460A1Low viscosityFacilitating good glass carryHydrocarbonsHydrocarbon from saturated and unsaturated hydrocarbon additionVinyl etherPolystyrene

Owner:SABIC INNOVATIVE PLASTICS IP BV

Composition of modified maleic anhydride and epoxy resin

ActiveUS20110092640A1Increase heatIncrease temperatureSynthetic resin layered productsThin material handlingEpoxyHeat resistance

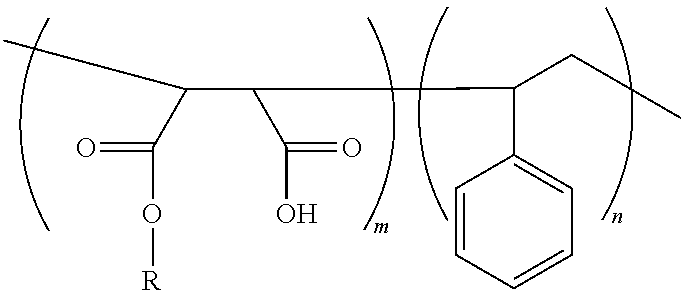

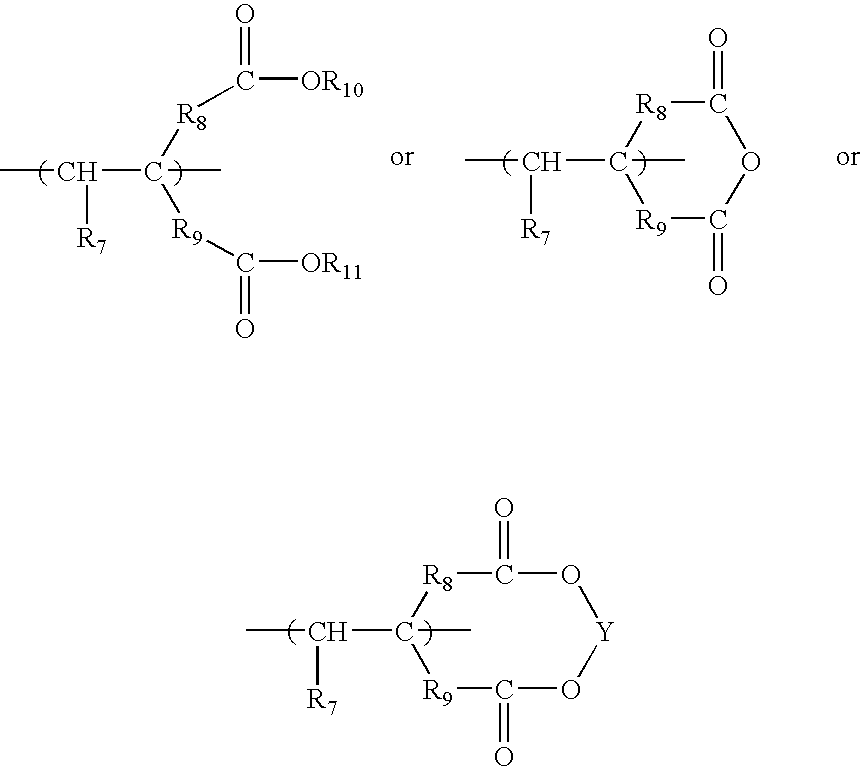

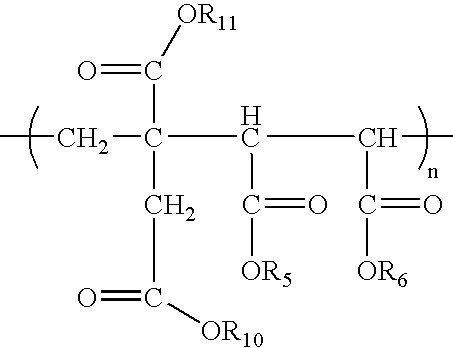

The present invention provides a composition of the modified maleic anhydride and the epoxy resins, including (A) one or more of the epoxy resin mixtures, (B) a modified maleic anhydride copolymer, (C) additives and (D) inorganic filler materials, wherein component (A) the epoxy resin mixture accounts for 35%˜56% by weight of the composition solids, component (B) the modified maleic anhydride copolymer accounts for 44%˜65% by weight of the composition solids, based on 100% by weight of total components (A), (B) and (C). According to the present invention, the modified maleic anhydride copolymer curing agent is prepared by reacting styrene / maleic anhydride copolymer with a modifier having hydroxy groups (OH), wherein the modifier having hydroxy groups (OH) can be a brominated, phosphorus-based or halogen-free material; the epoxy resin composition of the present invention shows good heat resistance and outstanding electrical properties, is suitable for the production of prepreg material, bonding films and copper clad laminates, thus can be used in the field of the general or high-frequency printed circuit boards.

Owner:NANYA PLASTICS CORP

Hydrophobic cationic dispersions stabilized by low molecular weight maleimide copolymers, for paper sizing

InactiveUS6830657B1Promote resultsImprove hydrophobicityNatural cellulose pulp/paperSpecial paperMean diameterImide

The invention concerns a method for obtaining an aqueous dispersion of hydrophobic polymers dispersed in the form of particles with mean diameter less than 100 nm stablized soley with a macromolecular surfactant based on low molecular weight styrene / maleic anhydride imide copolymer. The invention also concerns the use of said dispersion for treating and sizing paper.

Owner:FINA TECH

Nucleating agent of polyethylene glycol terephthalate and preparation method thereof

InactiveCN102924641ASimple preparation processImprove thermal stabilityPolyethylene glycolPolymer SMA

The invention belongs to the technical field of macromolecule materials, and particularly relates to a nucleating agent of the polyethylene glycol terephthalate and a preparation method thereof. The agent utilizes random copolymer or alternating copolymer of maleic anhydride and styrene as raw materials, and conducts hydrolysis, salinization and purification to obtain styrene-maleic anhydride ionomer. The styrene-maleic anhydride ionomer can serve as the nucleating agent of the polyethylene glycol (PET), increases crystallization temperature of the PET and increases crystallization rate. The nucleating agent is simple in preparation method, capable of adopting blending smelting reaction extrusion pelleting once process with the PET, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

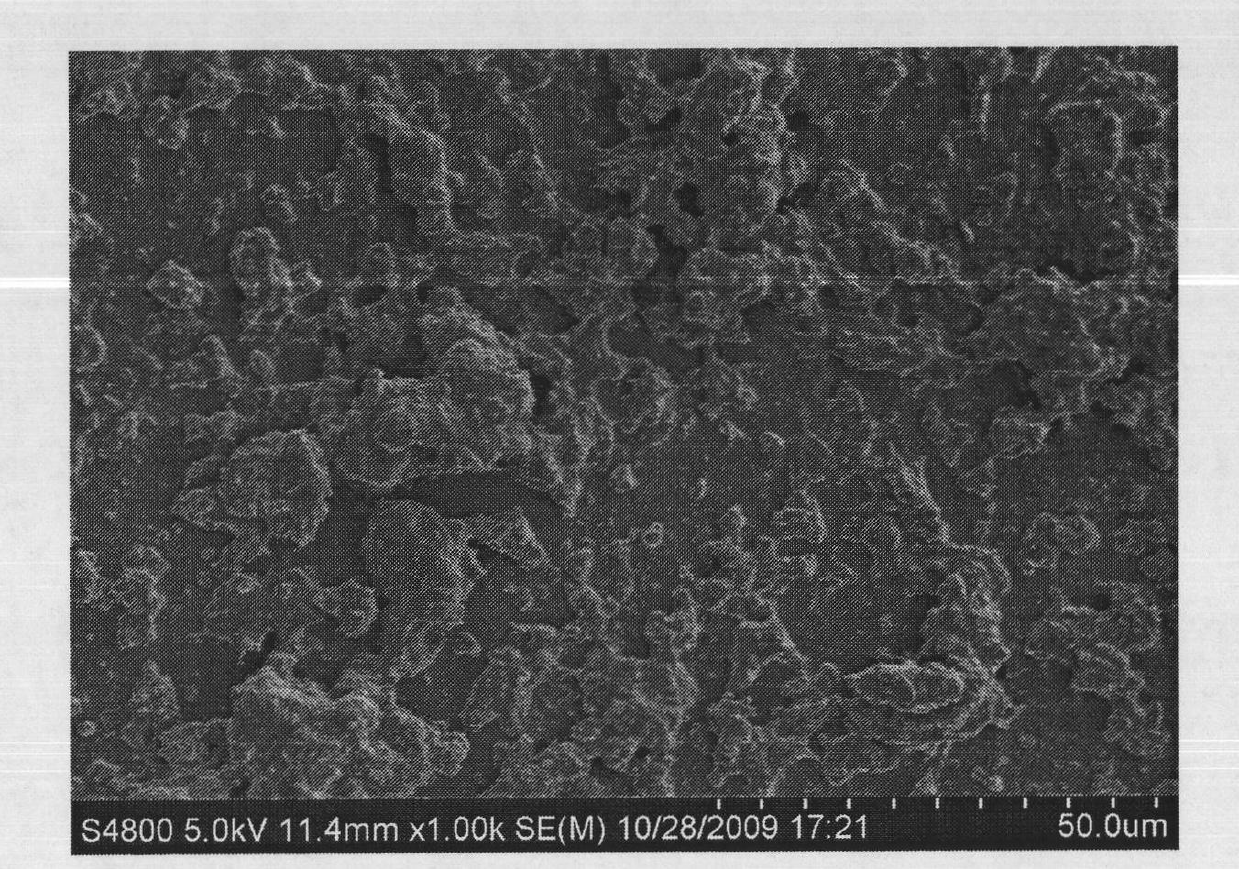

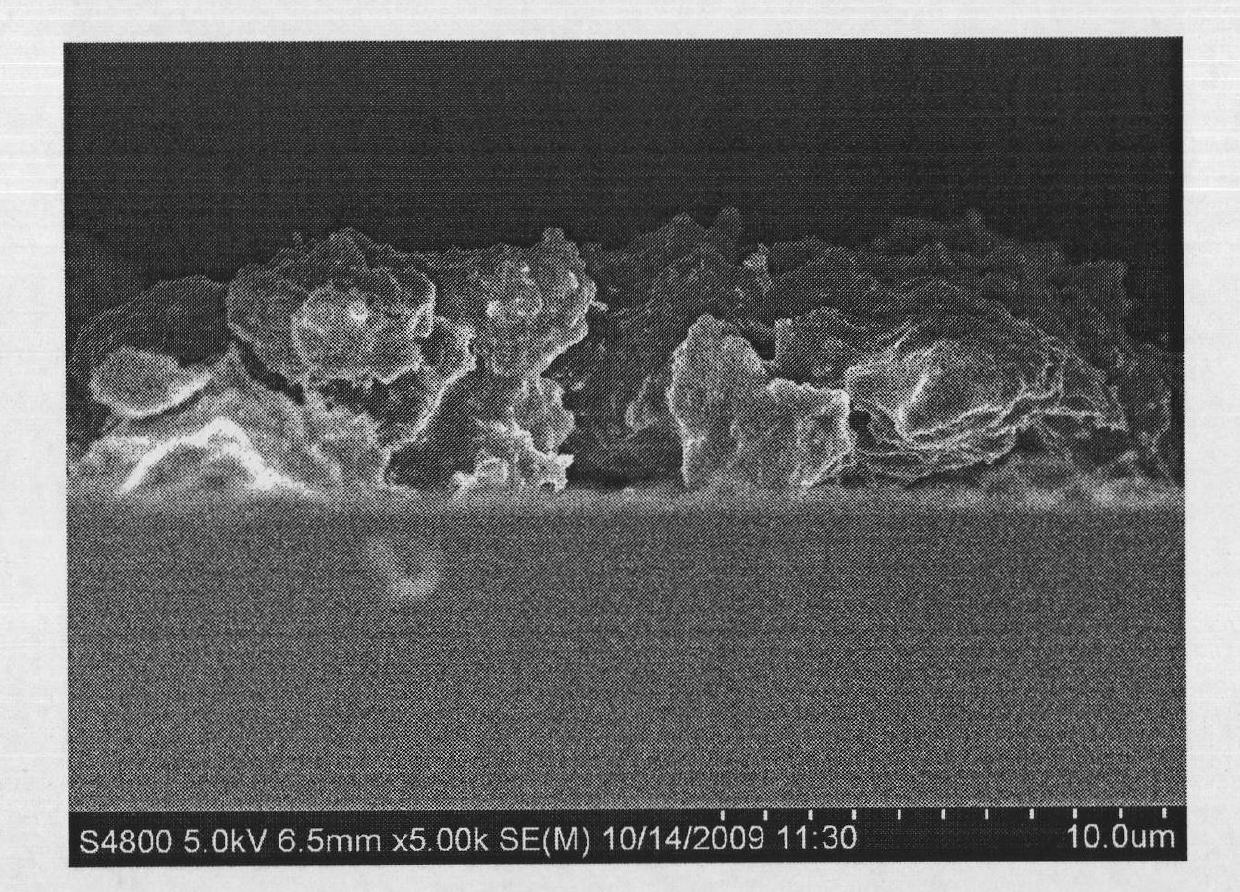

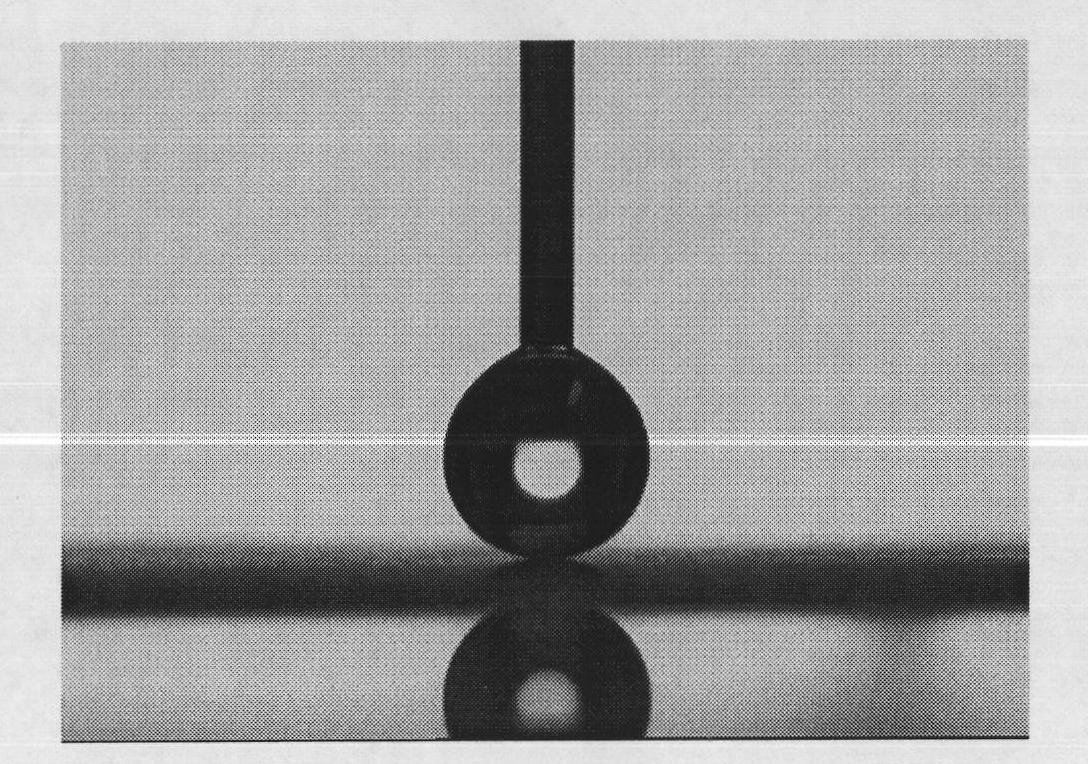

Preparation method for antistatic super hydrophobic composite coating

ActiveCN101792633ASimple and fast operationMild conditionsVegetal fibresElectrically-conductive paintsCarbon nanotubePolymer SMA

The invention discloses a preparation method for antistatic super hydrophobic composite coating, comprising the following steps: dissolving 0.2-2 parts of styrene-maleic anhydride alternate copolymer by weight into 20-1000 parts of solvent by weight, adding 1 part of carbon nanotube by weight and then evenly mixing, adding 0-26 parts of ammonia water and 0.2-2 parts of silicate ester or titanate compound by weight, stirring and mixing to enable silicate ester or titanate compound to perform hydrolysis reaction, adding 0.1-2 parts of silicate ester or titanate compound and 0.02-0.5 part of fluorine containing silane coupling agent by weight, evenly mixing and spraying on base materials, carrying out aging and thermal treatment to obtain stable antistatic super hydrophobic composite coating. The invention has simple operation and mild condition, the carbon nanotube can be directly used without the need of any chemical modification, the obtained composite coating has good hydrophobicity,the static contact angle and rolling angle between the composite coating and water are respectively larger than 150 degrees and less than 3 degrees, and the surface resistivity is 106-1011 omega, thus meeting the requirement of antistatic transparent coating and having wide application prospect.

Owner:ZHEJIANG UNIV

Polymer Blends Of Biodegradable Or Bio-Based And Synthetic Polymers And Foams Thereof

InactiveUS20090123728A1Layered productsThin material handlingPolymer scienceStyrene maleic anhydride

The present invention relates to compositions comprising blends of alkenyl aromatic polymers such as styrenic polymers (i.e. PS and HIPS) and bio-based or biodegradable polymers (i.e. PLA, PGA, PHA, PBS, PCL) compatibilized with styrene-based copolymers (i.e. styrene-ethylene-butylene-styrene (SEBS) block copolymers, maleated SEBS, styrene-maleic anhydride (SMA) copolymer, styrene-methyl methacrylate (SMMA) copolymer) or a mixture of two or more styrene-based copolymers such as SEBS and SMA. These novel compositions can be extruded and thermoformed to produce very low density food service and consumer foam articles such as plates, hinged lid containers, trays, bowls, and egg cartons with good mechanical properties.

Owner:PACTIV CORP

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS20030134978A1Avoid coatingSynthetic resin layered productsThin material handlingAcrylic resinPolymer SMA

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

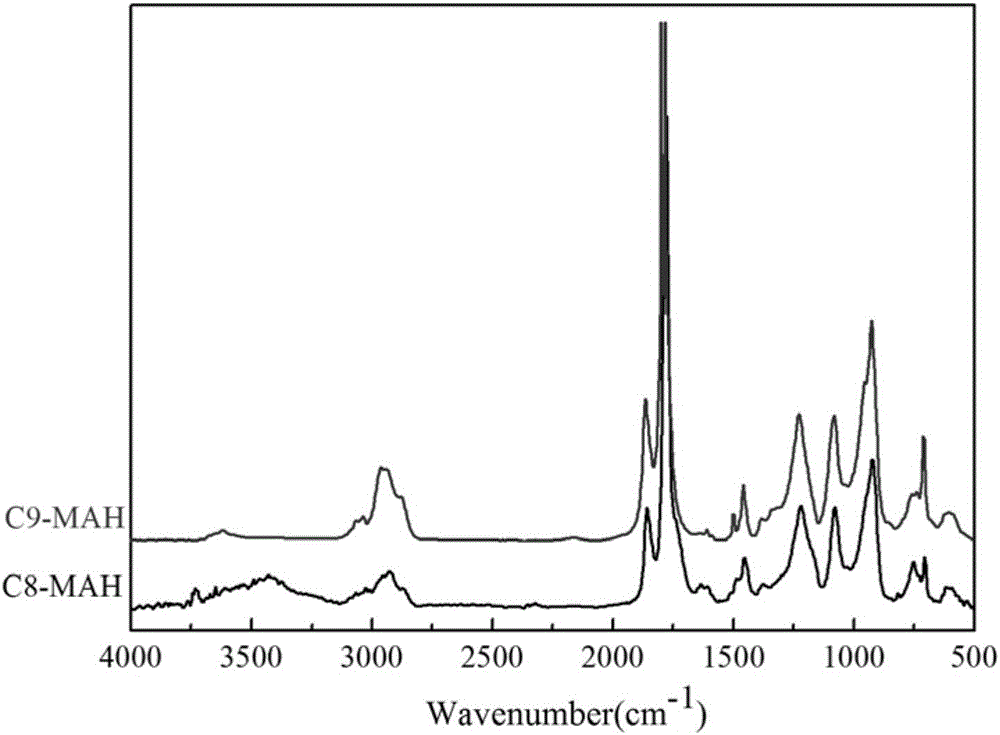

Functional copolymer directly prepared from higher olefin mixture and preparation method

ActiveCN105949388AOvercome difficultyOvercoming issues that limit its applicationHydrocarbon mixturesNitrogen

The invention relates to a functional copolymer directly prepared from higher olefin mixture and a preparation method, and belongs to the field of application of petroleum resources. The preparation method includes: under the condition of nitrogen protection, adding one or more of MAH (maleic anhydride), maleimide and derivatives thereof and itaconic anhydride as well as oil soluble free radical initiator into selected solvent to be fully dissolved, then adding one or more of C8 and C9 fraction and light fraction of coal tar into the system to be mixed evenly, performing reaction at the temperature of 60-120 DEG C, and after reaction is finished, performing separating and drying to obtain the functional copolymer formed by copolymerization of olefin components and maleic anhydride in the mixture. C8 and C9 fraction and light fraction of coal tar are taken raw materials directly to be subjected to one-step reaction for preparing the copolymer comprising functional radicals, the process is simple, reaction conditions are mild, preparation efficiency is high, the prepared copolymer and non-polymerization components are easy to separate, the copolymer is high in functional radical content, and resources of C8 and C9 fraction and light fraction of coal tar can be utilized reasonably and effectively.

Owner:BEIJING UNIV OF CHEM TECH

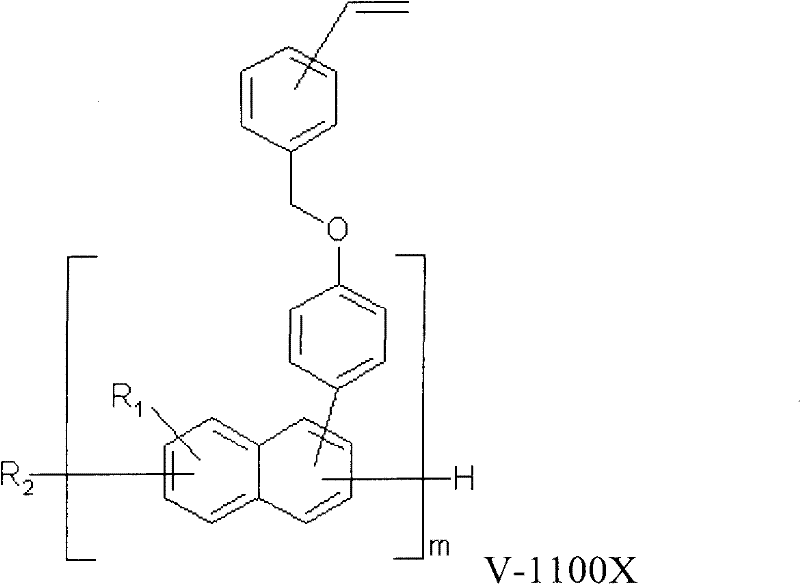

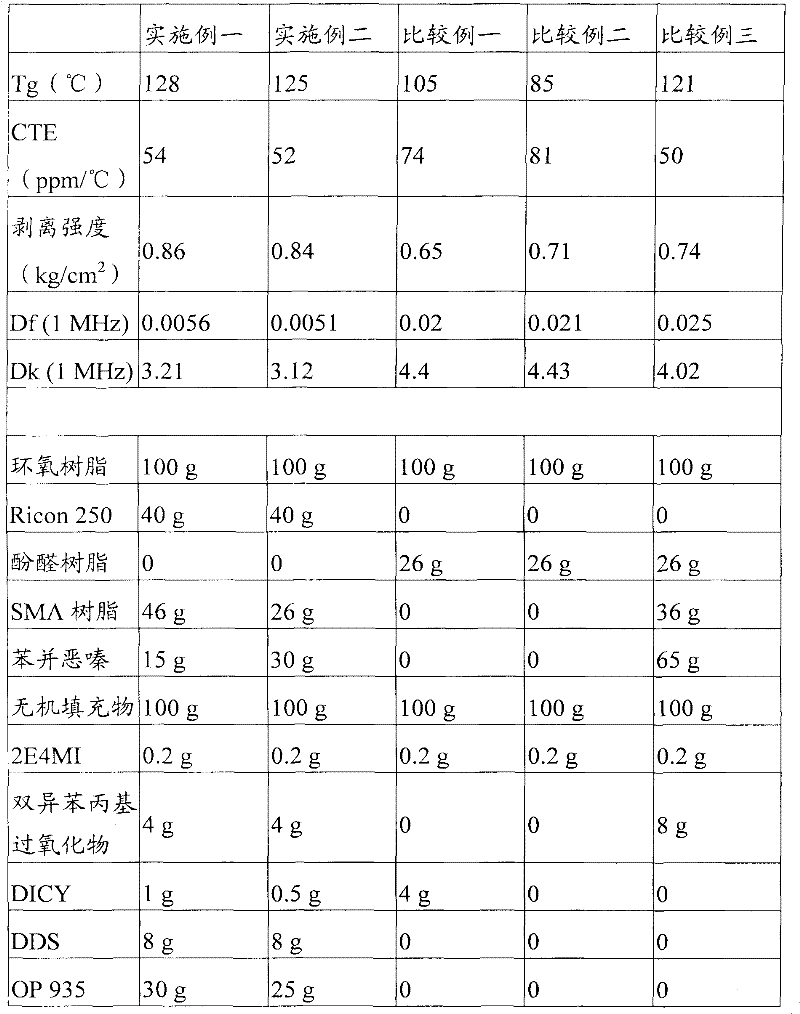

Resin composition

The invention relates to a resin composition, mainly comprising the following components in parts by weight: (1) 100 parts of epoxy resin; (2) 20-100 parts of vinyl compound; (3) 10-50 parts of styrene maleic anhydride; (4) 5-50 parts of benzoxazine; (5) 0.5-5 parts of adherence promoter; (6) 10-150 parts of inorganic filler; (7) 0.2-25 parts of peroxide; (8) 10-250 parts of phosphorus-containing fire retardant; and (9) 0.01-10 parts of catalyst.

Owner:ELITE MATERIAL

Halogen-free resin composition, and copper clad laminate and printed circuit board using same

ActiveUS20130115472A1Group 5/15 element organic compoundsPrinted circuit aspectsLow dissipationHeat resistance

The halogen-free resin composition comprises (A) 100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 10 to 150 parts by weight of phosphazene; and (E) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

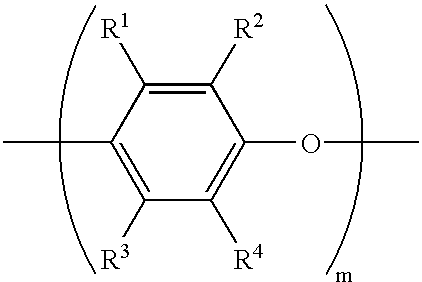

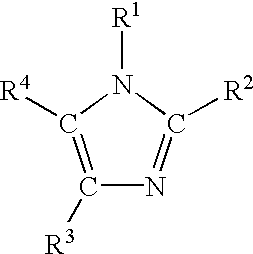

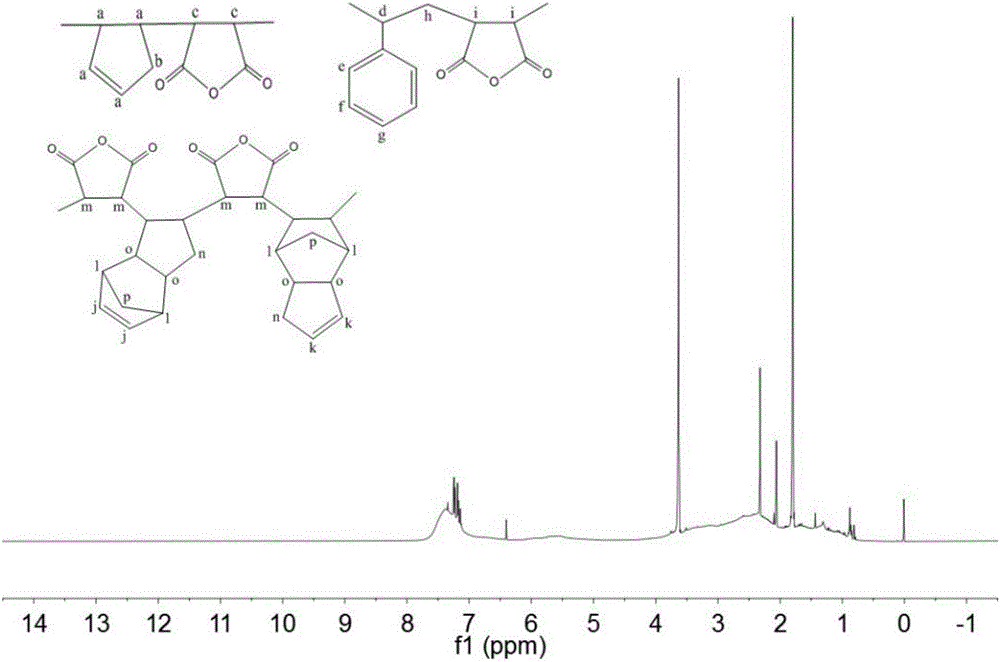

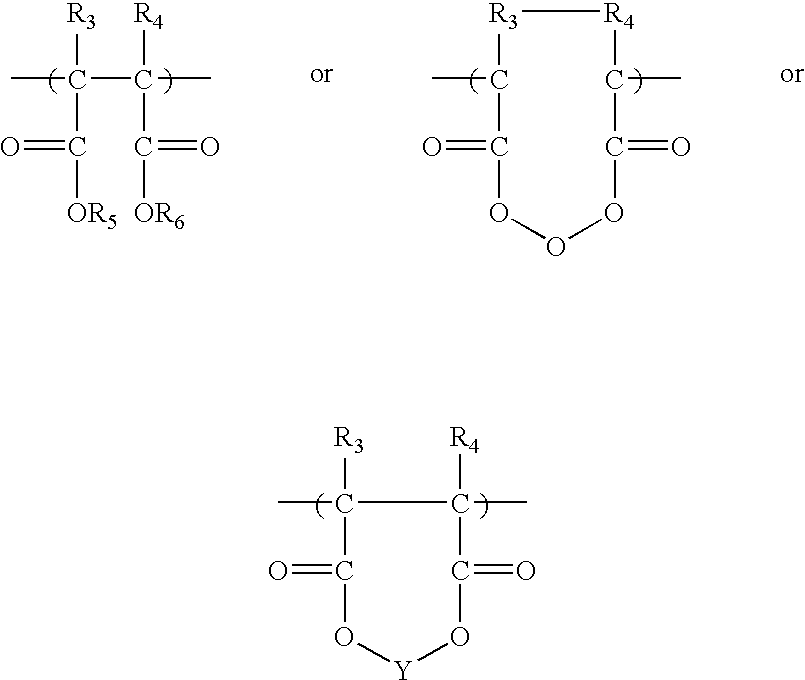

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

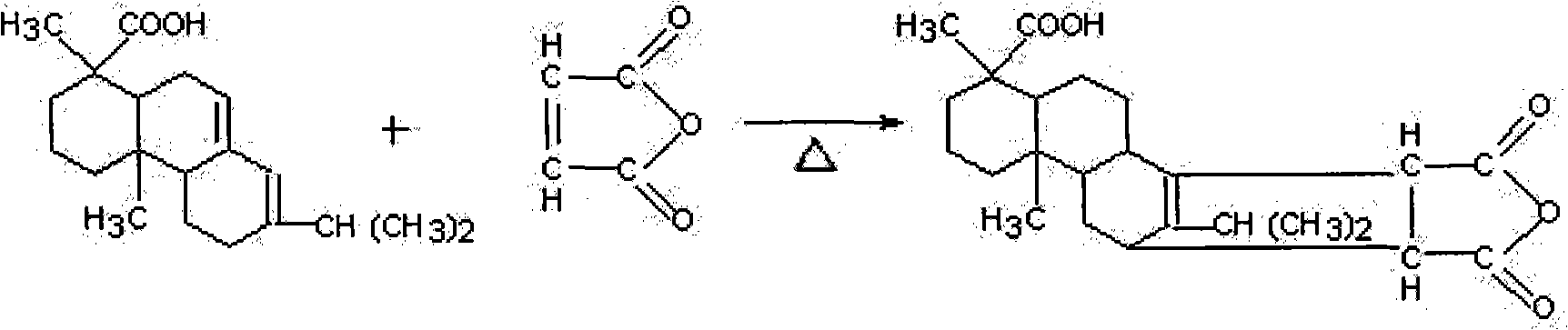

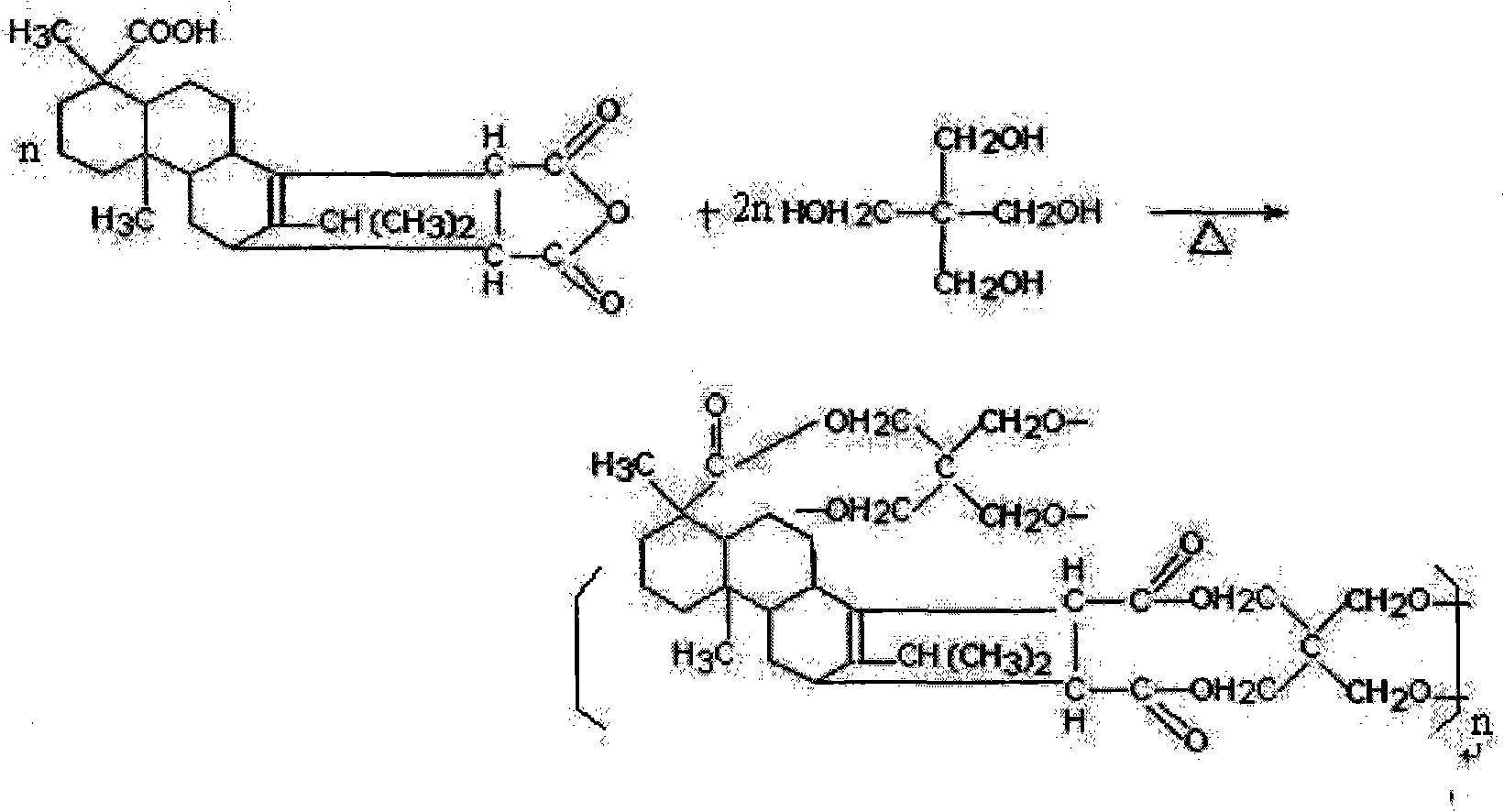

Production method of abietic maleic anhydride resin

InactiveCN102010503AExemption from releaseProtect physical and mental healthInksNatural resin chemical modificationSolubilityReaction temperature

The invention relates to a production method of abietic maleic anhydride resin, comprising the following two reaction steps of: 1, carrying out addition reaction on abietyl and maleic anhydride to generate an abietic maleic anhydride addition product; and 2, carrying out esterification reaction on the abietic maleic anhydride addition product and pentaerythritol to generate the abietic maleic anhydride resin. The production method is easy and convenient to operate, has the advantages of large temperature control range, high operability, small investment and stable product quality and is a method suitable for industrialized production; in the production method, appropriate process conditions including raw material proportion, reaction temperature, reaction time, catalysts, and the like, are adopted, thereby the acid value and the molecular weight range of a resin product can be effectively controlled; in addition, the resin product obtained with the production method has higher acid value of 150-170 mg KOH / g, reasonable softening point at 140-155 DEG C and good water solubility and is suitable for producing water-based ink, and a formed coating film has toughness and better after-tackiness resistance, water resistance and alkali resistance.

Owner:上海华谊精细化工有限公司上海南大化工厂

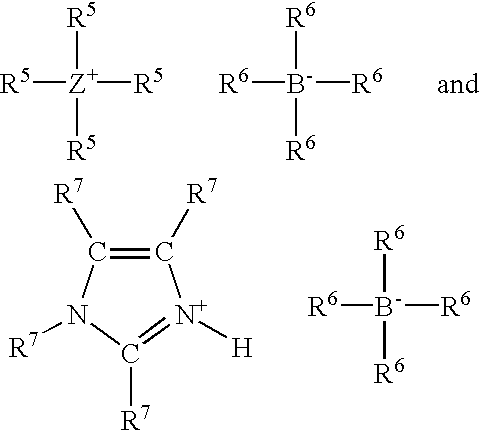

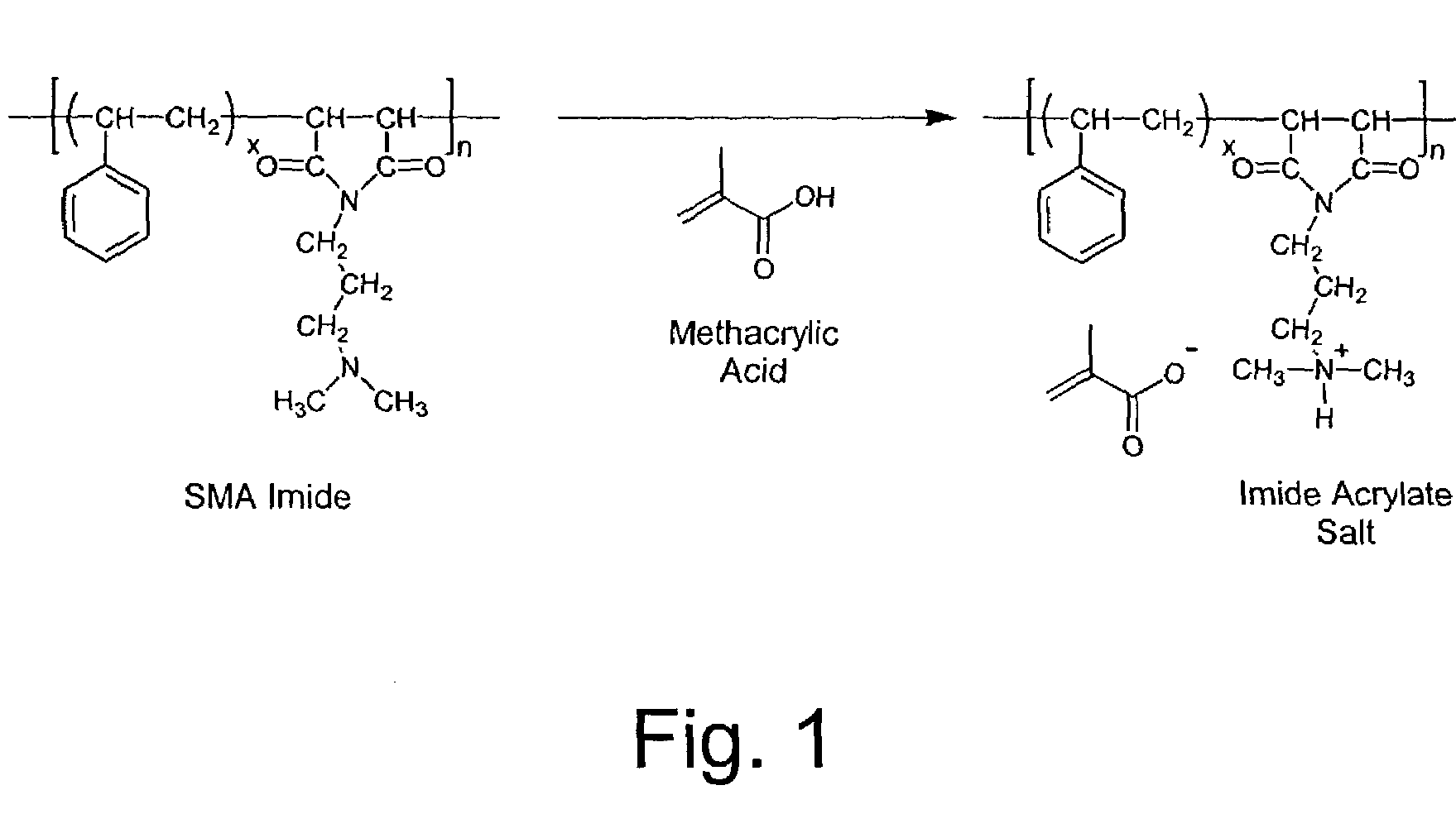

Acid salts of amine-functionalized SMA imide resins

Compositions comprising acid salts of amine-functionalized styrene-maleic anhydride resins are disclosed. The salts can be dissolved in organic solvents, UV / EB polymerizable monomers and / or oligomers, and / or water and act as a polymeric surfactants to disperse pigments or fillers, emulsifying agents, or hard resin additives in a variety of formulations. The compositions react under UV / EB cure conditions, and provide enhanced properties such as cure speed, hardness and adhesion to polymer compositions.

Owner:ARKEMA FRANCE SA

Cleaning implement comprising a modified open-cell foam

A cleaning implement comprises a modified open-cell foam with a density in the range from about 5 to about 1,000 kg / m3 and with an average pore diameter in the range from about 1 μm to about 1 mm, comprising an amount in the range from about 1 to about 2,500% by weight, based on the weight of the unmodified open-cell foam, of at least about one water-insoluble polymer (b), selected from polystyrene, styrene copolymers, polybutadiene, butadiene copolymers, polyvinylesters, polyvinylethers, copolymers from (meth)acrylic acid with at least one (meth)acrylate, and polyurethanes, with the proviso that styrene-acrylonitrile-C1-C10-alkyl (meth)acrylate terpolymers, styrene-butadiene-n-butyl acrylate terpolymers, and styrene-maleic anhydride copolymers are excluded.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of microcapsule for electrophoretic display

InactiveCN1544141AOvercoming performance shortcomingsUniform particle size distributionMicroballoon preparationNon-linear opticsHydrolysateElectrophoresis

The invention discloses an electrophoresis-displaying microcapsule and its preparing method, which recondenses hydrolysate of styrene-maleic anhydride copolymer and glutin to prepare the microcapsule. By the proper technique, it firstly emulsifies the encapsulated matter in the styrene-maleic anhydride copolymer solution, adds in the gultin, and then recondenses them by adding acid and / or water. Its advantages: provision of synthetic high-molecular styrene-maleic anhydride copolymer overcomes the disadvantage that the natural gum Arabic high molecule is easy to degrade so as to affect performance of the microcapsule, and reduces the cost. And by proper technique, it can prepare circular microcapsules which are stable, sealed and have more uniform particle size distribution.

Owner:ZHEJIANG UNIV

Anionic polymers composed of dicarboxylic acids and uses thereof

InactiveUS20040226331A1Good effectDry weight increaseBiocideAlkali orthophosphate fertiliserStyrene maleic anhydrideCarboxylic acid

Biodegradable anionic polymers are disclosed which include recurring polymeric subunits preferably made up of dicarboxylic monomers such as maleic anhydride, itaconic anhydride or citraconic anhydride. Free radical polymerization is used in the synthesis of the polymers. The polymers may be complexed with ions and / or mixed with fertilizers or seeds to yield agriculturally useful compositions. The preferred products of the invention may be applied foliarly or to the earth adjacent growing plants in order to enhance nutrient uptake by the plants.

Owner:SPECIALTY FERTILIZER PROD LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com