Nucleating agent of polyethylene glycol terephthalate and preparation method thereof

A technology of polyethylene terephthalate and nucleating agent is applied in the field of nucleating agent of polyethylene terephthalate and its preparation, and can solve the problems of difficulty in finding a compatibilizer, complicated operation process, and difficulty in Industrialization and other problems, to achieve the effect of accelerating the crystallization rate, simple preparation process, and increasing the melting crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

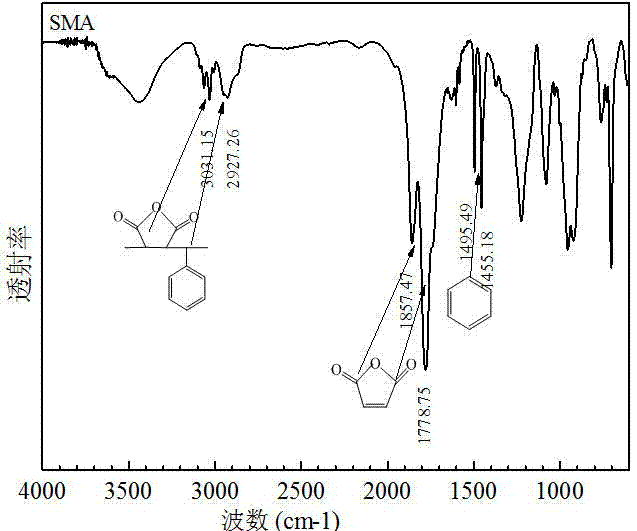

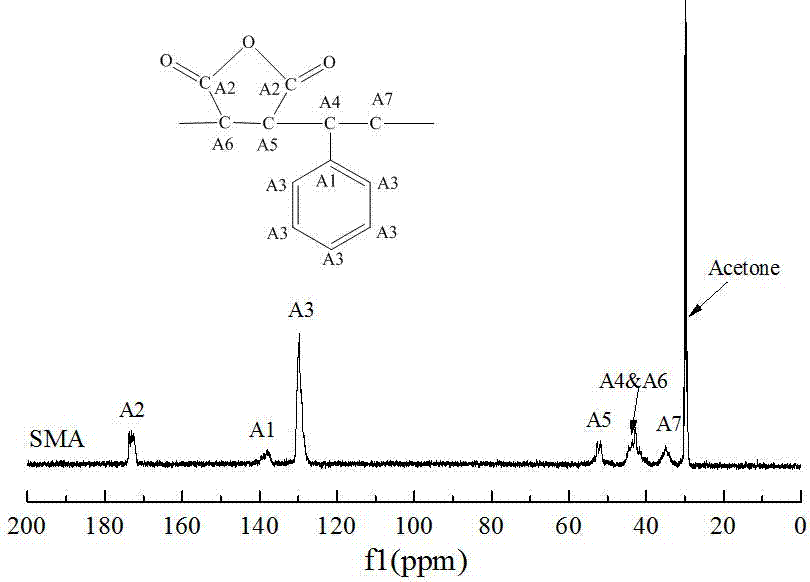

[0026] (1) Synthesis of styrene-maleic anhydride copolymer

[0027] Mix 9.8g of maleic anhydride monomer, 10.4g of styrene monomer, 0.0242g of benzoyl peroxide and 200ml of cyclohexanone, and heat the reaction at 80°C for 1 hour in a nitrogen atmosphere. Precipitate from the solvent solution, purify, and vacuum dry.

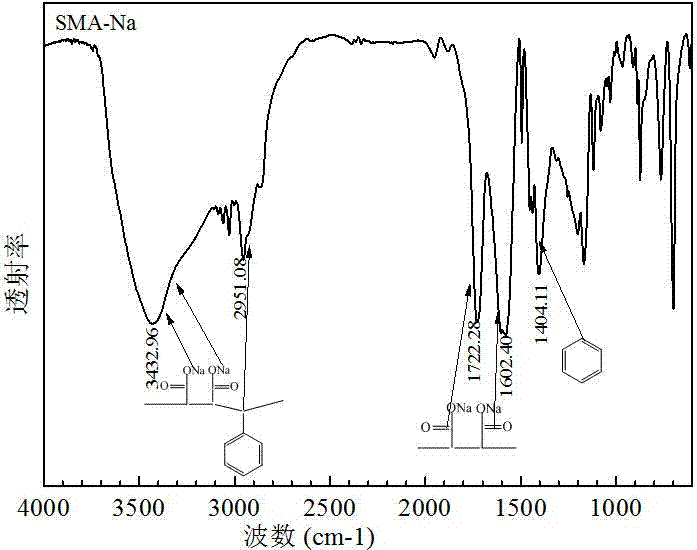

[0028] (2) Preparation of styrene-maleic anhydride ionomer

[0029] Dissolve the dried styrene maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of sodium hydroxide in methanol, the generated ionomer will precipitate from the solution, vacuum pump Filtration yielded an ionomer solid. The obtained ionomer solid is purified and vacuum-dried to finally obtain a pure styrene-maleic anhydride ionomer.

Embodiment 2

[0031] (1) Synthesis of styrene-maleic anhydride copolymer

[0032] Mix 9.8g of maleic anhydride monomer, 55g of styrene monomer, 0.0242g of benzoyl peroxide and 200ml of cyclohexanone, and heat the reaction at 80°C for 1.5 hours in a nitrogen atmosphere. solution, purified and dried.

[0033] (2) Preparation of styrene-maleic anhydride ionomer

[0034] Dissolve the dried styrene-maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of barium hydroxide in methanol, the generated ionomer will precipitate out of the solution, vacuum pump Filtration yielded an ionomer solid. The obtained ionomer solid is purified and vacuum-dried to finally obtain a pure styrene-maleic anhydride ionomer.

Embodiment 3

[0036] (1) Synthesis of styrene-maleic anhydride copolymer

[0037] Mix 9.8g of maleic anhydride monomer, 10.4g of styrene monomer, 0.0484g of benzoyl peroxide and 200ml of cyclohexanone, and heat the reaction at 80°C for 1.5 hours in a nitrogen atmosphere. solution, purified and dried.

[0038] (2) Preparation of styrene-maleic anhydride ionomer

[0039] Dissolve the dried styrene maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of sodium hydroxide in methanol, the generated ionomer will precipitate from the solution, vacuum pump Filtration yielded an ionomer solid. The obtained ionomer solid is purified and vacuum-dried to finally obtain a pure styrene-maleic anhydride ionomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com