Patents

Literature

250 results about "Polymer SMA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

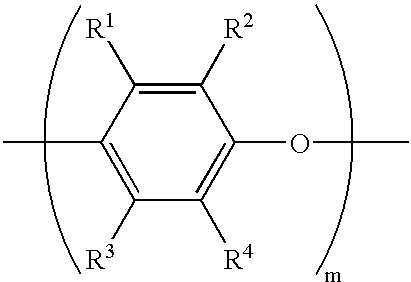

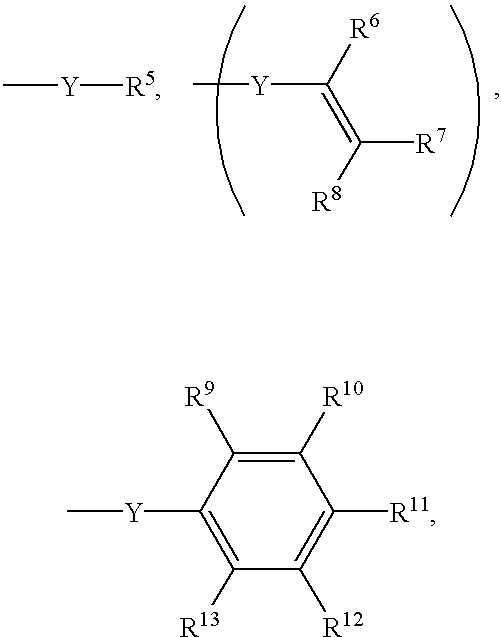

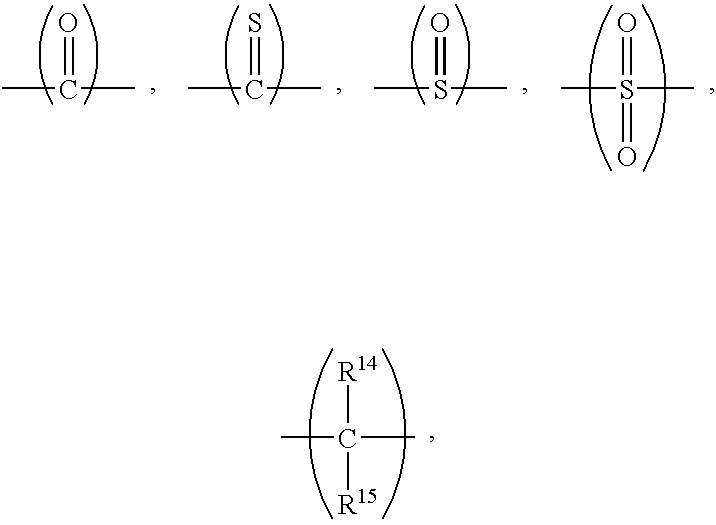

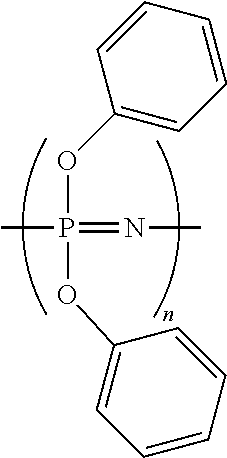

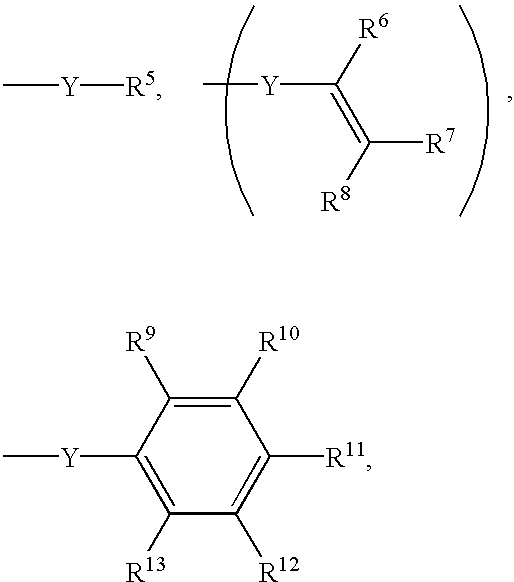

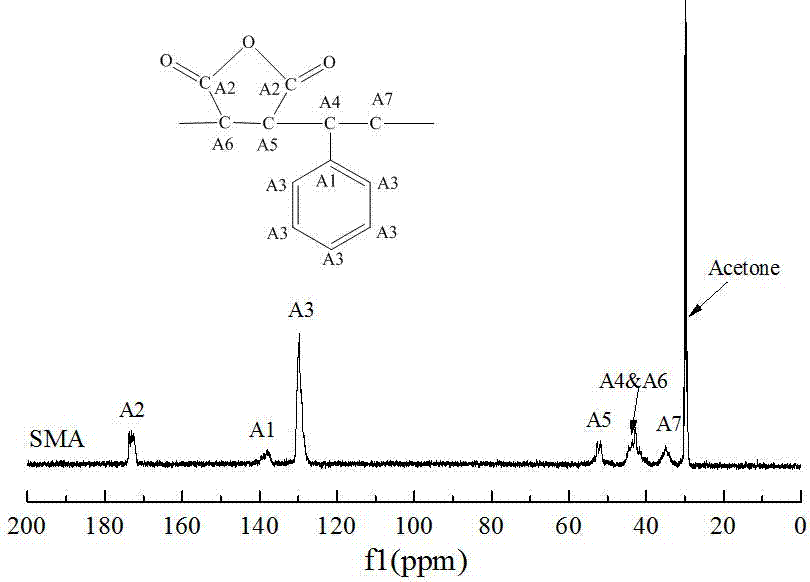

Styrene maleic anhydride (SMA or SMAnh) is a synthetic polymer that is built-up of styrene and maleic anhydride monomers. The monomers can be almost perfectly alternating, making it an alternating copolymer[citation needed], but (random) copolymerisation with less than 50% maleic anhydride content is also possible.

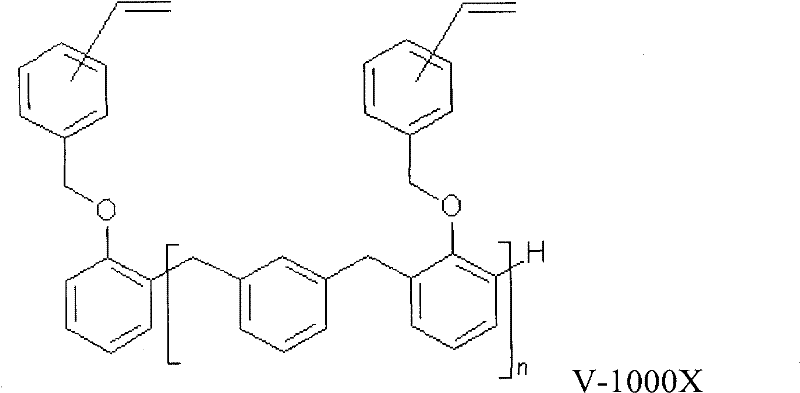

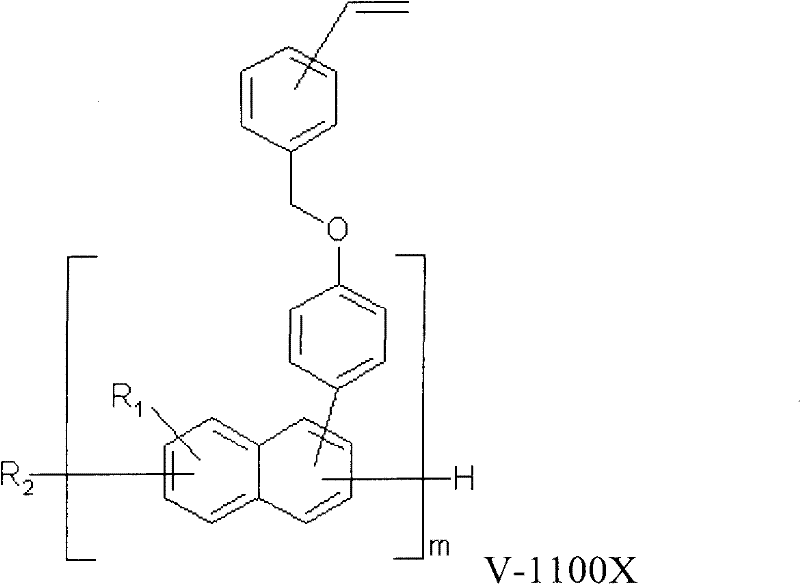

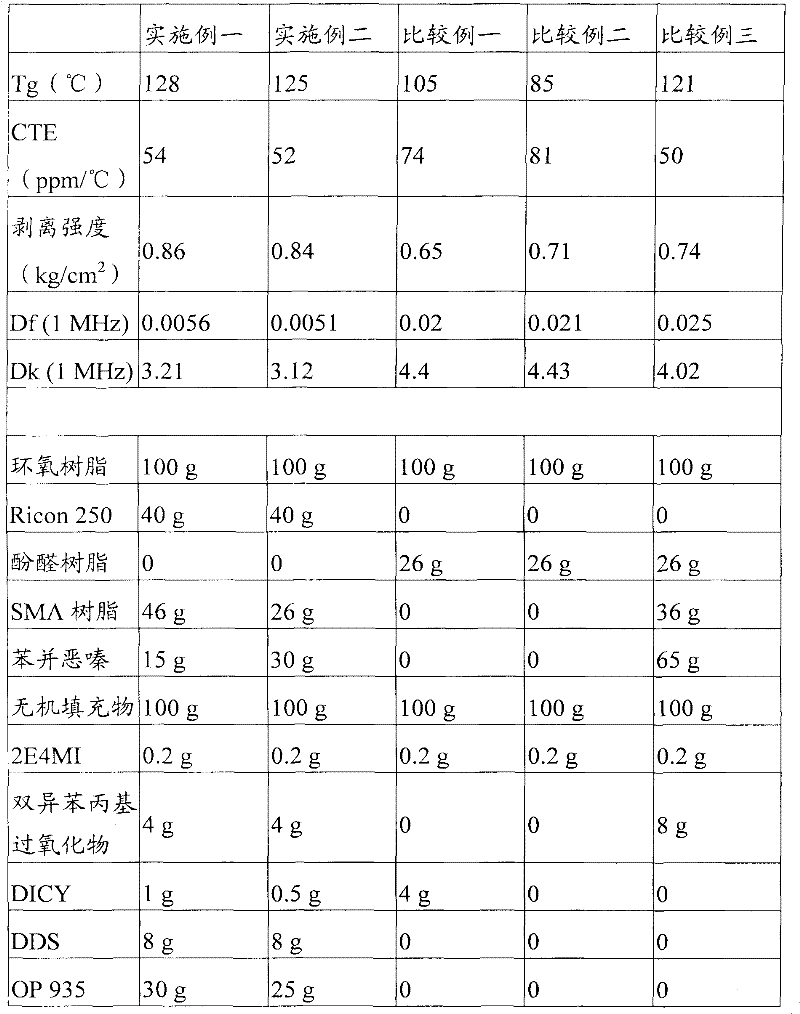

Thermoset composition, method, and article

InactiveUS20030215588A1Improve as-molded surface characteristics of polyReduce shrinkage on moldingSynthetic resin layered productsThin material handlingVinyl etherPolystyrene

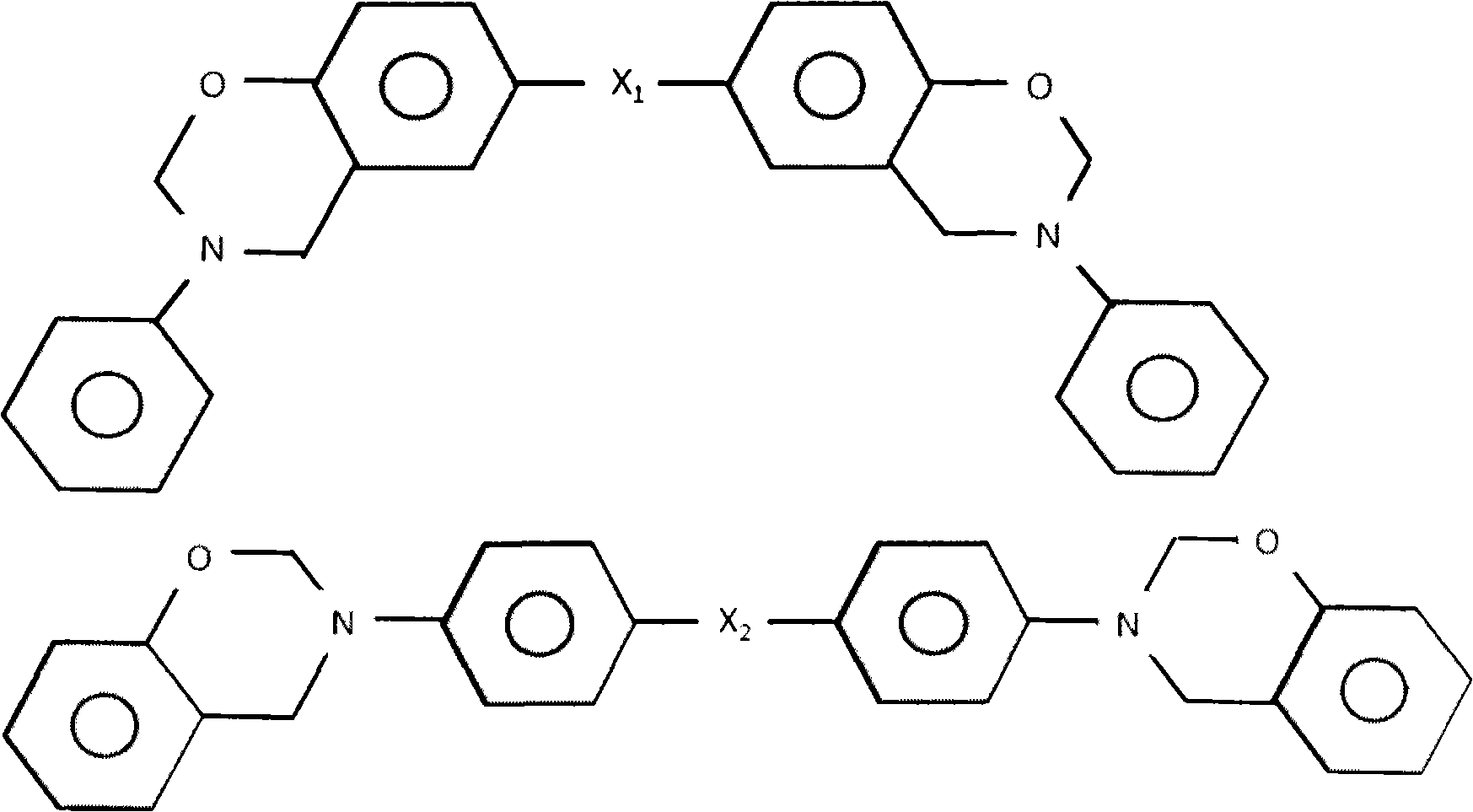

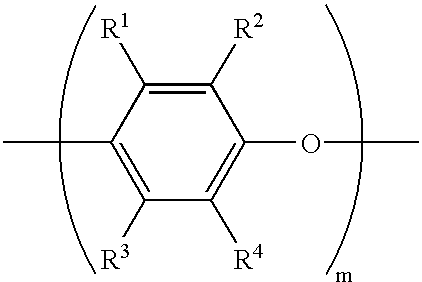

A curable composition includes a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a polymeric additive effective selected from polystyrene, poly(styrene-maleic anhydride), poly(styrene-methyl methacrylate), polybutene, poly(ethylene-butylene), poly(vinyl ether), poly(vinyl acetate), and combinations thereof. The composition exhibits low shrinkage on curing and improved surface smoothness. It is useful, for example, in the manufacture of automotive body panels.

Owner:SABIC INNOVATIVE PLASTICS IP BV

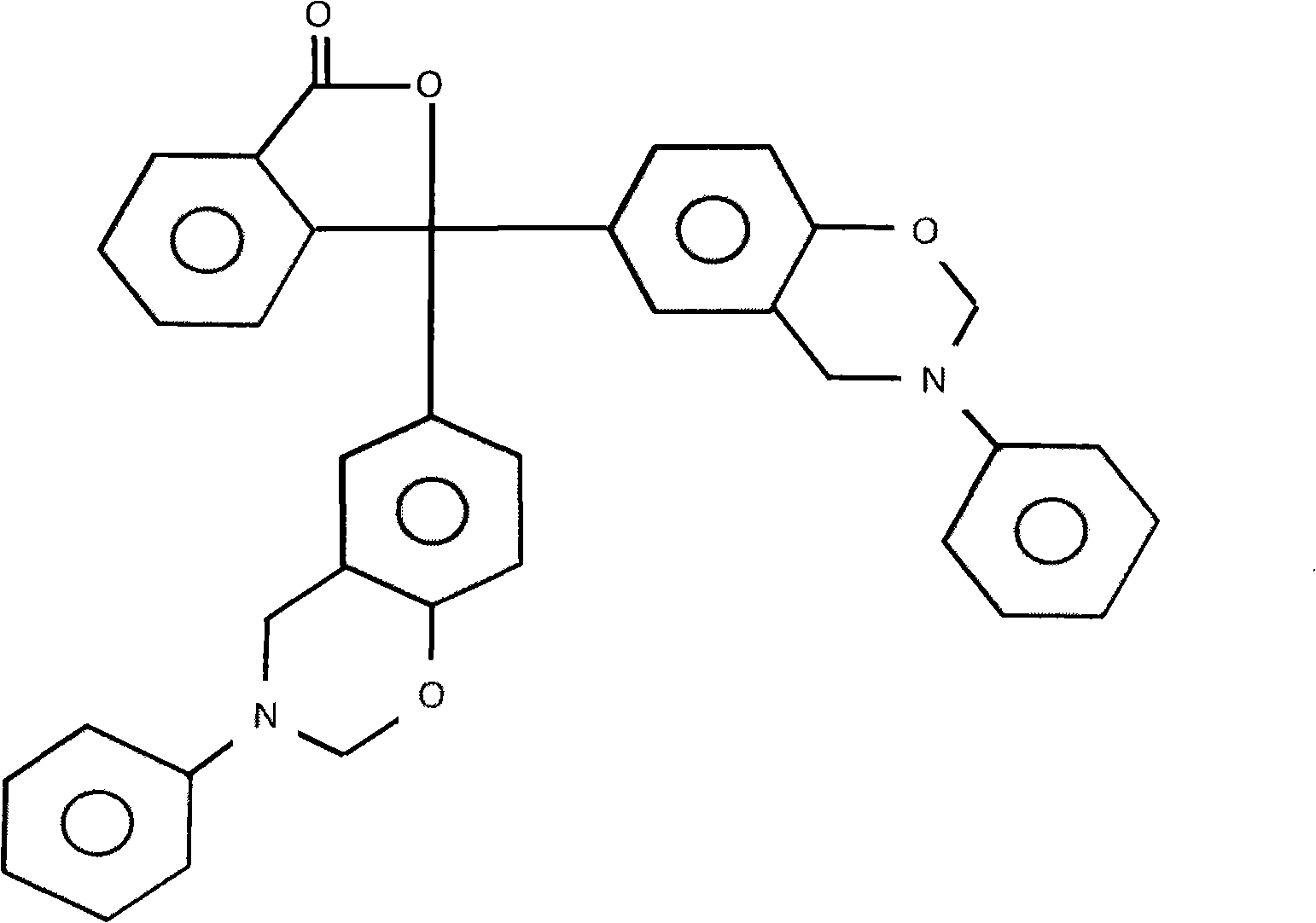

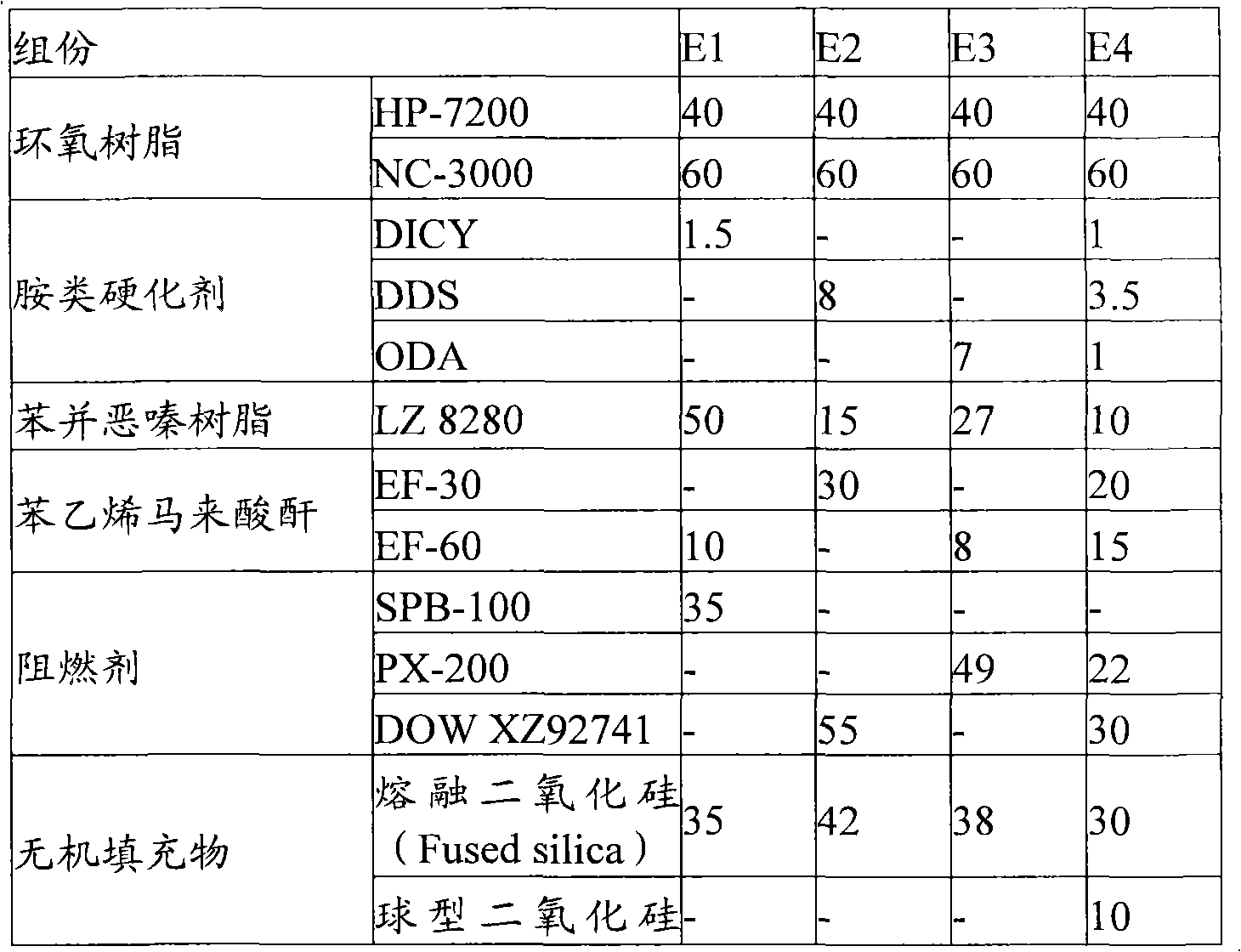

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

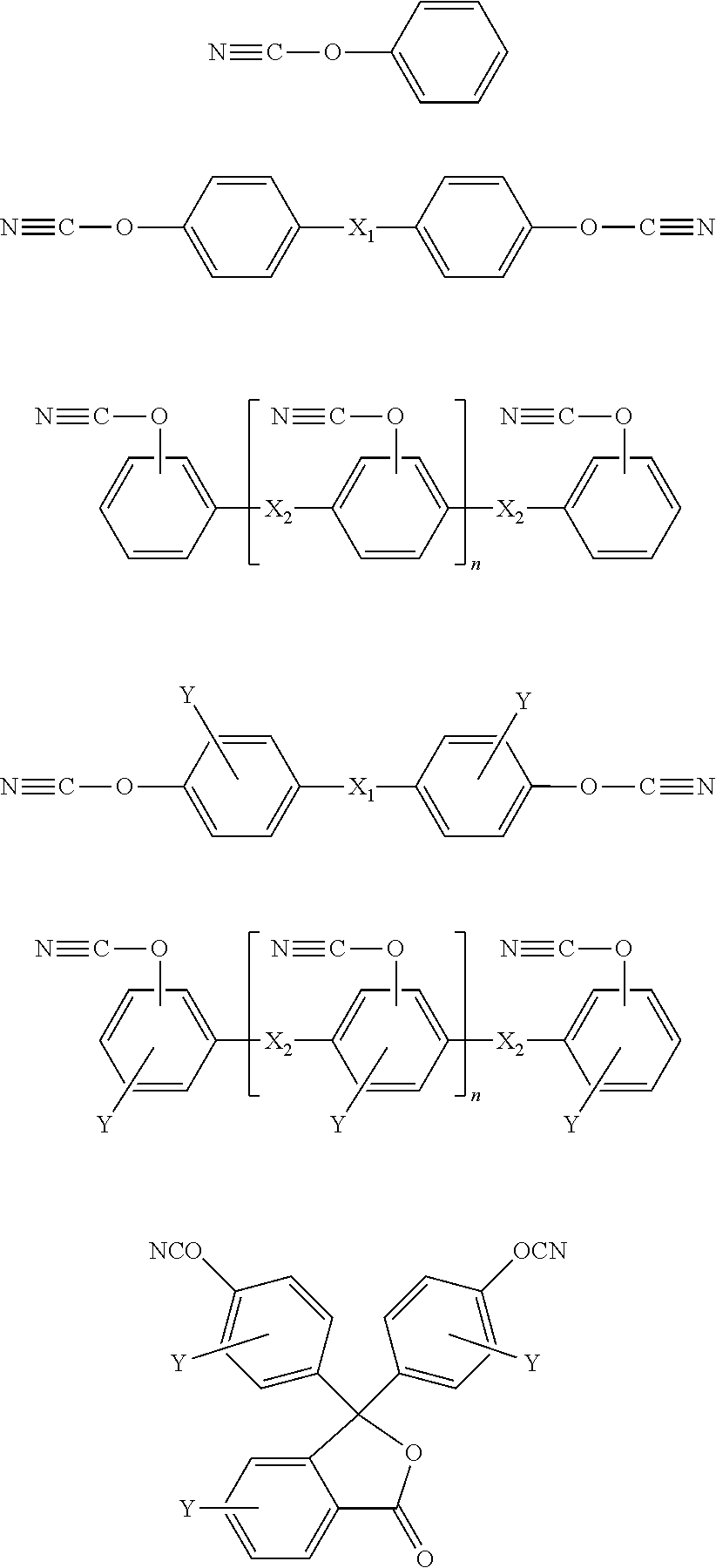

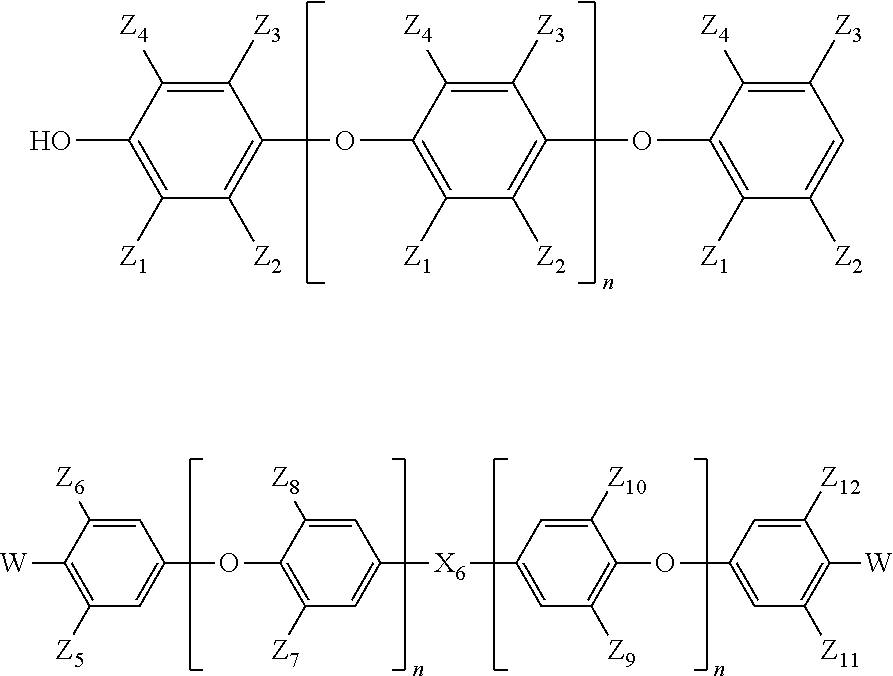

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

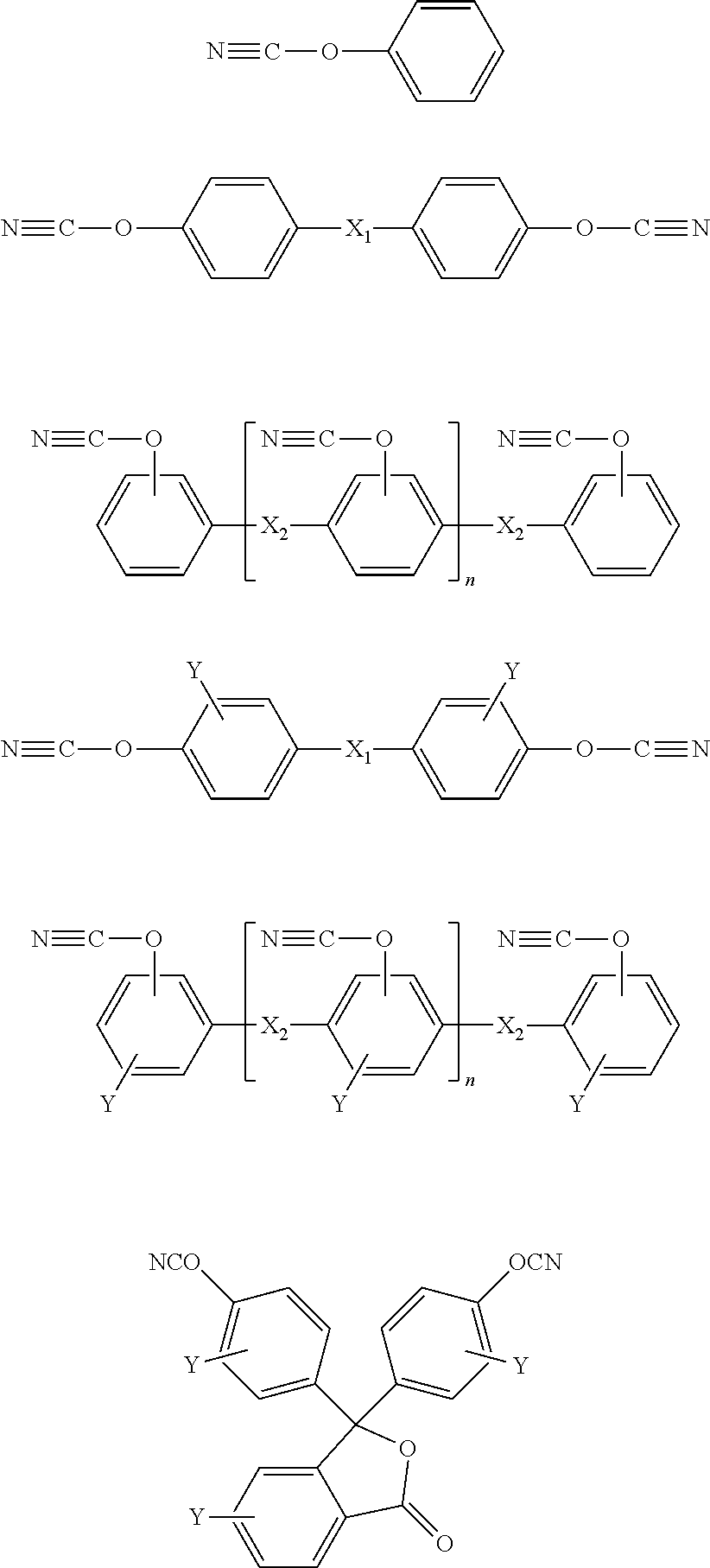

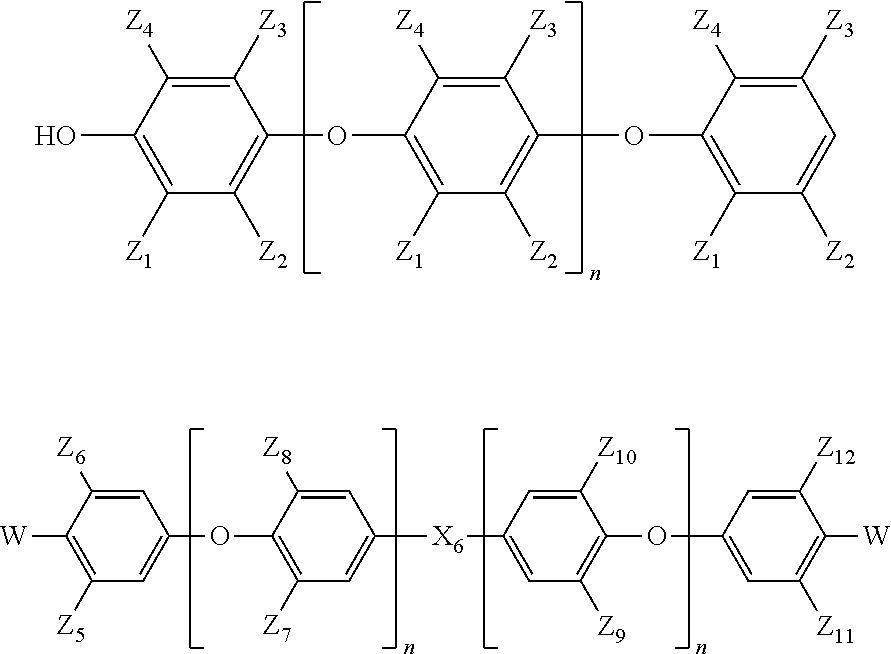

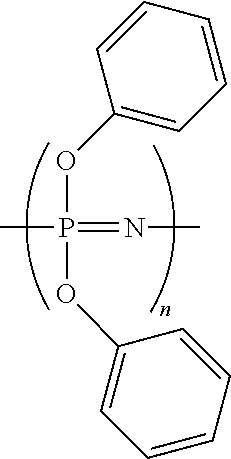

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

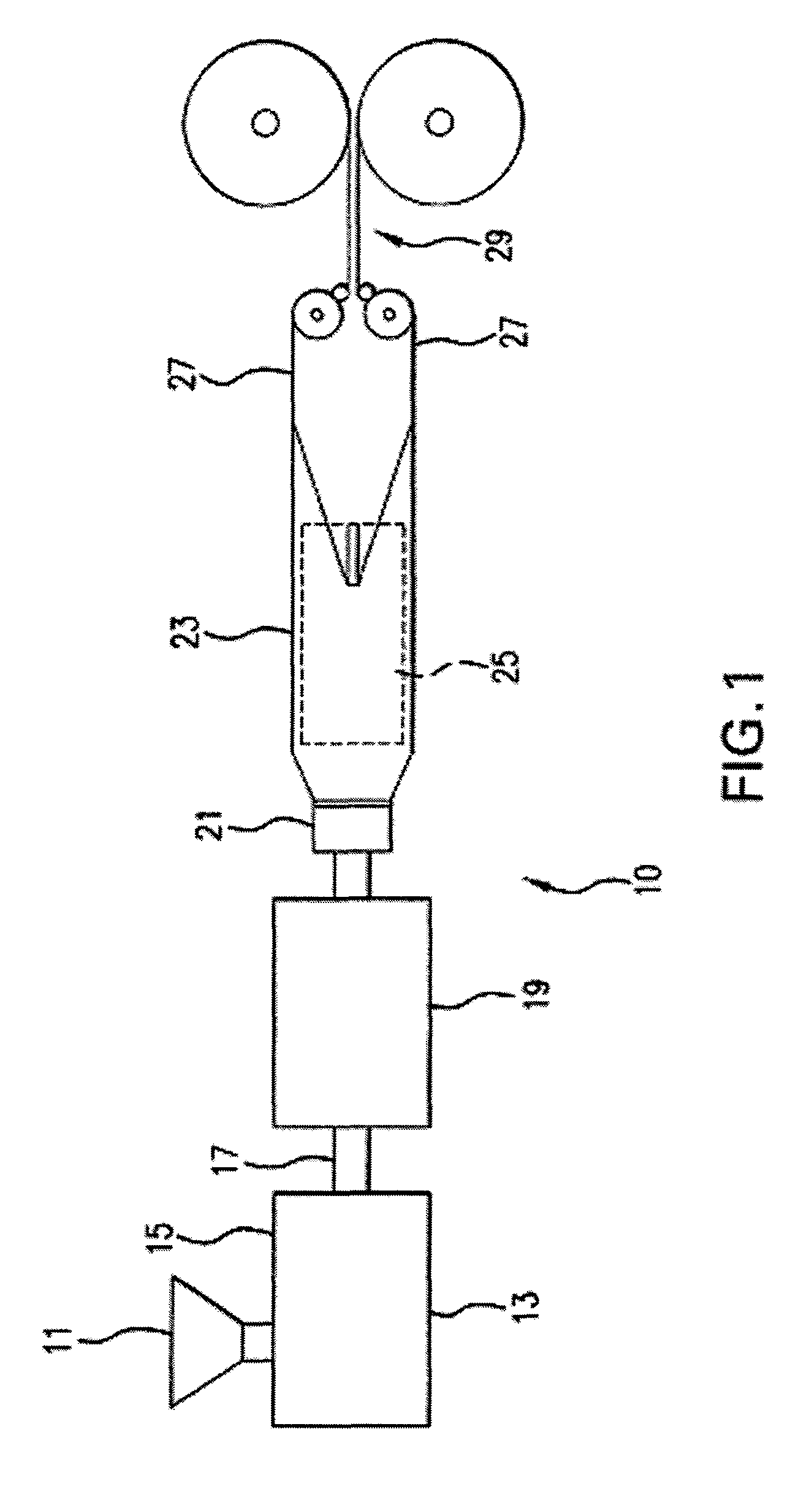

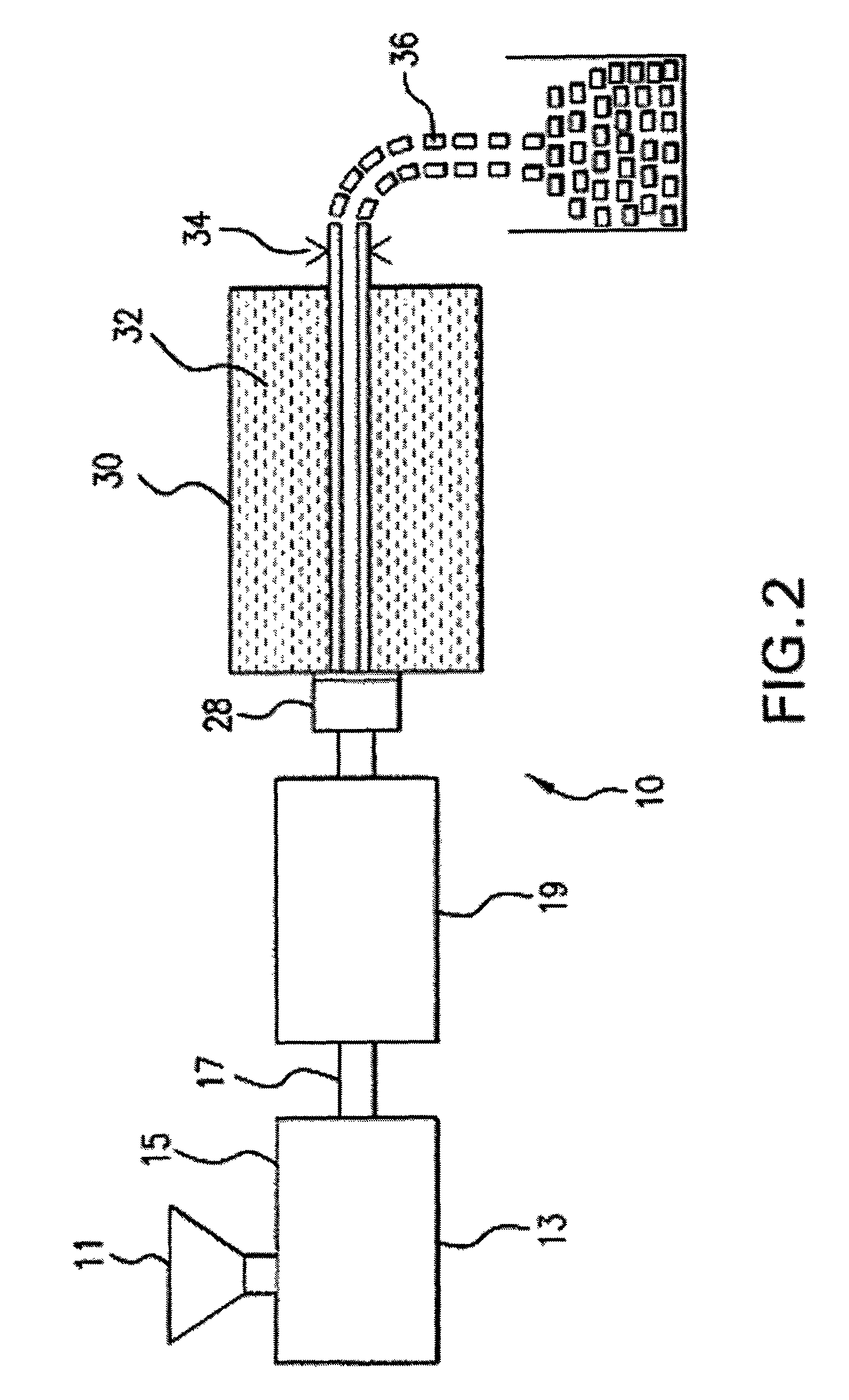

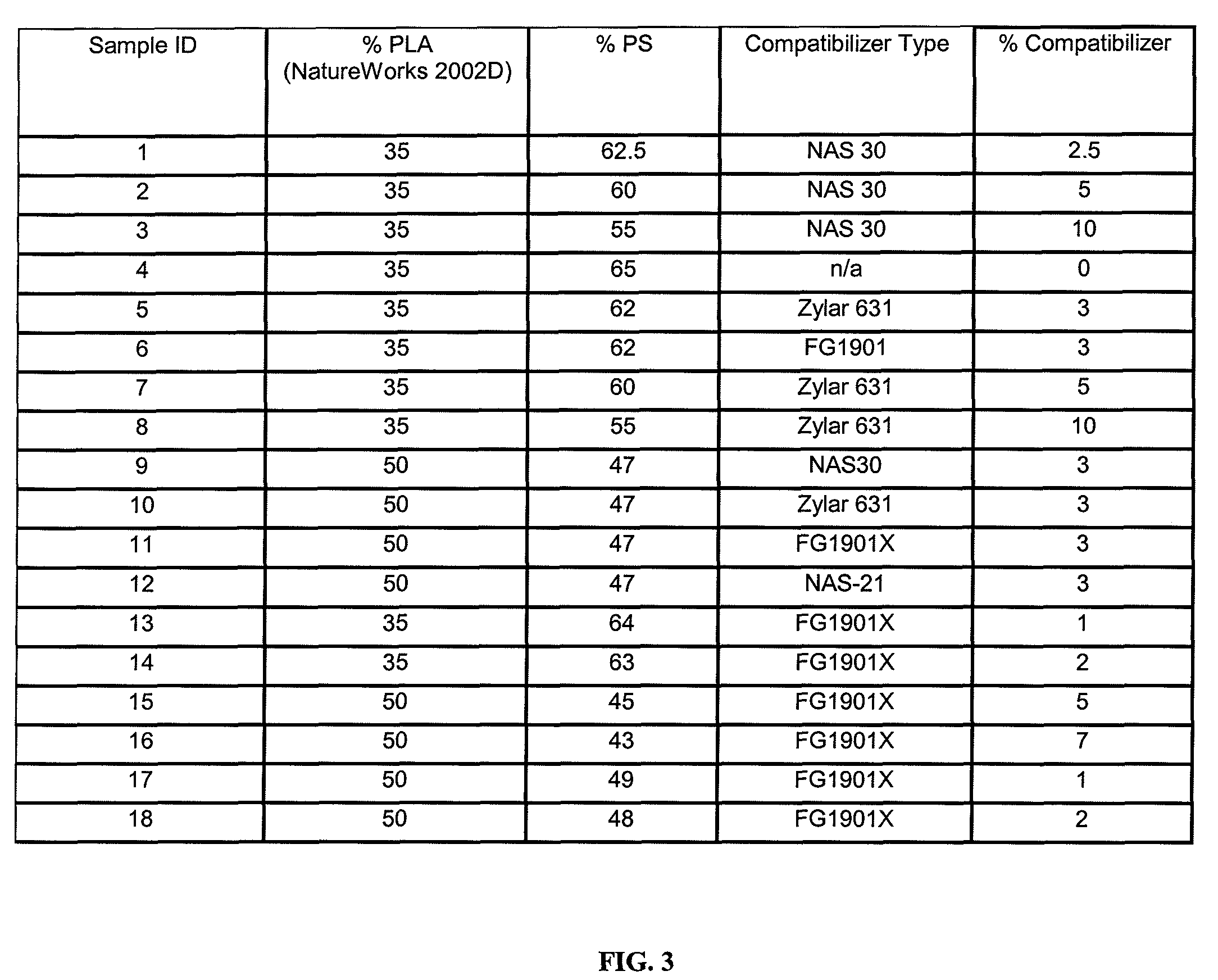

Polymer Blends Of Biodegradable Or Bio-Based And Synthetic Polymers And Foams Thereof

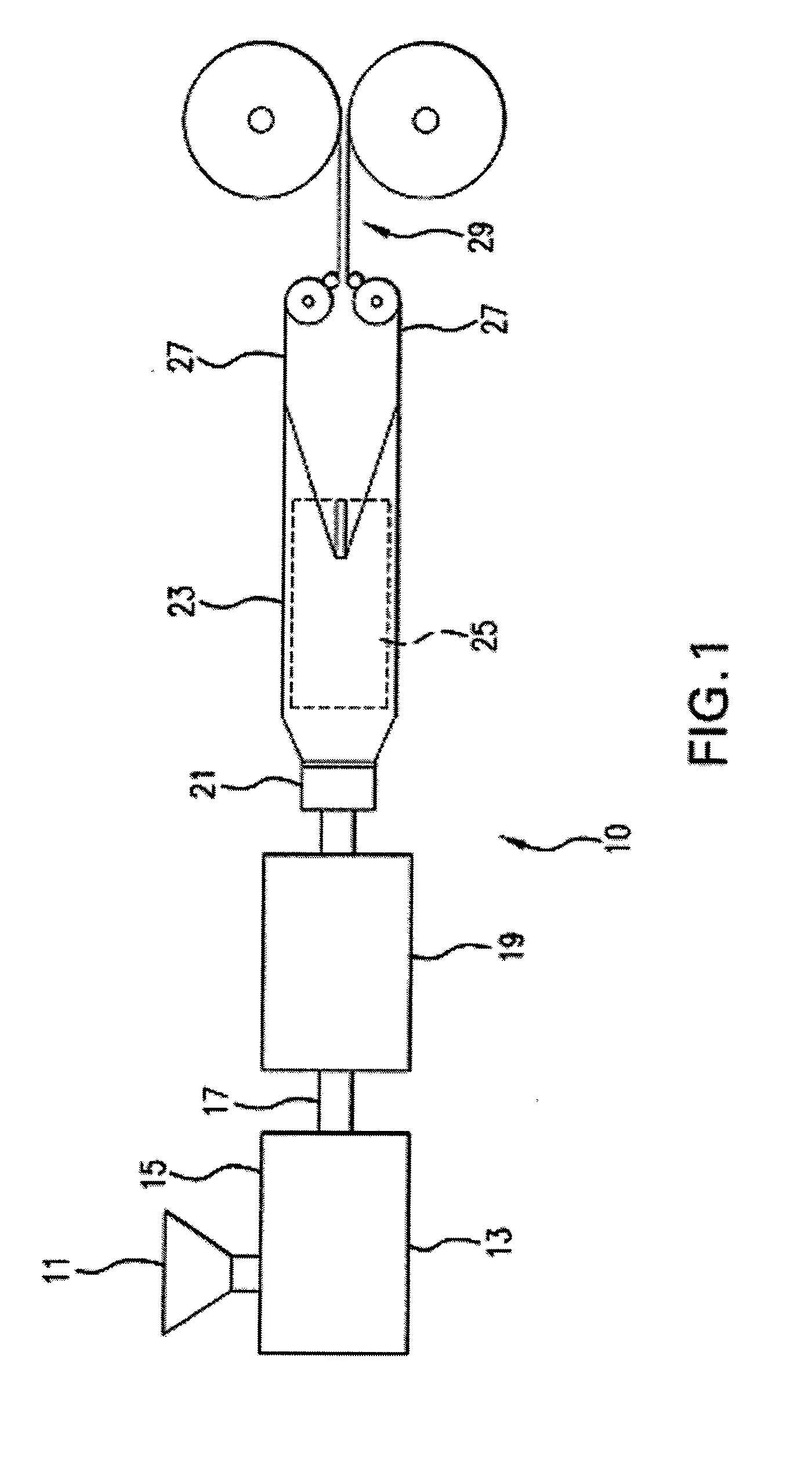

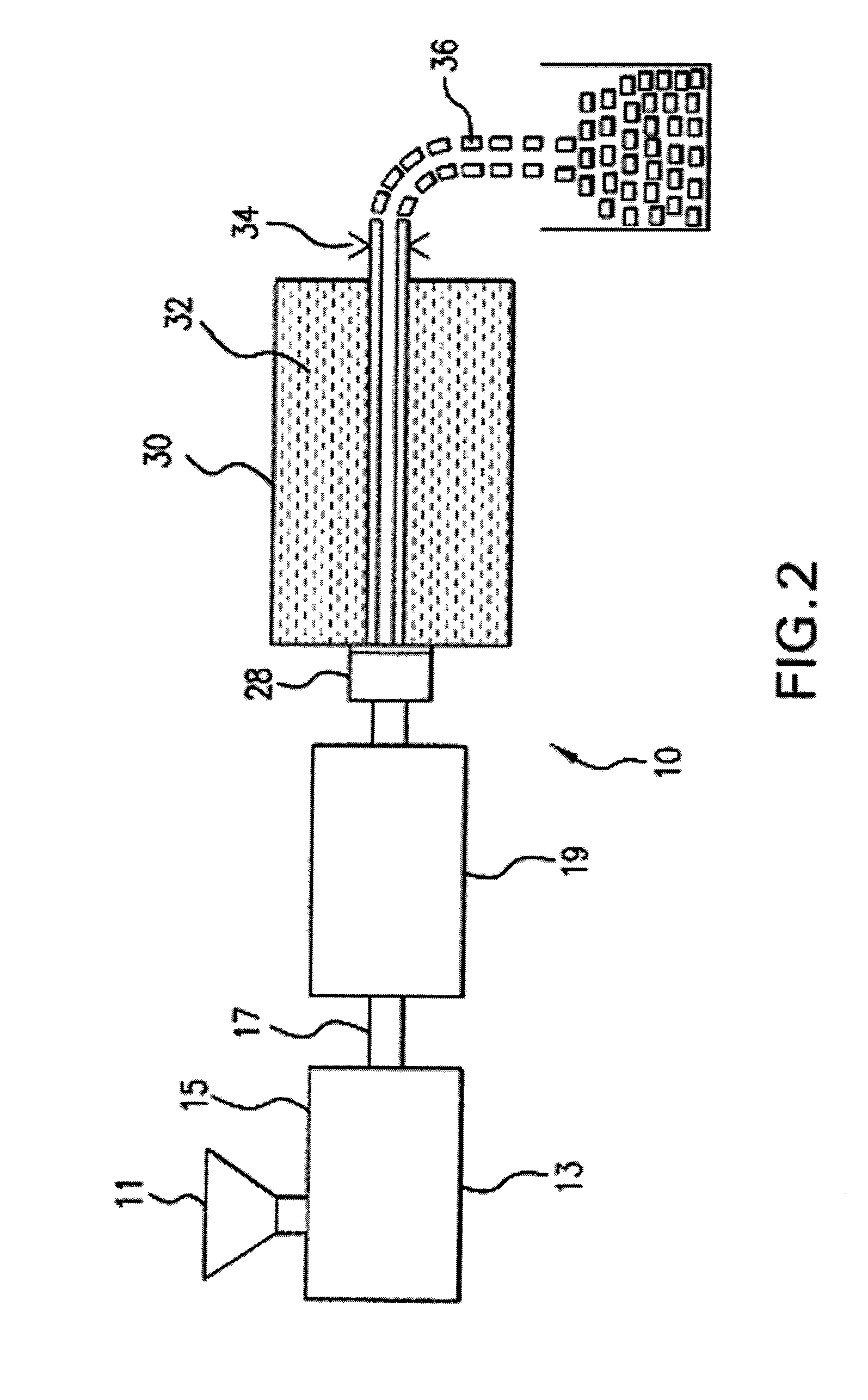

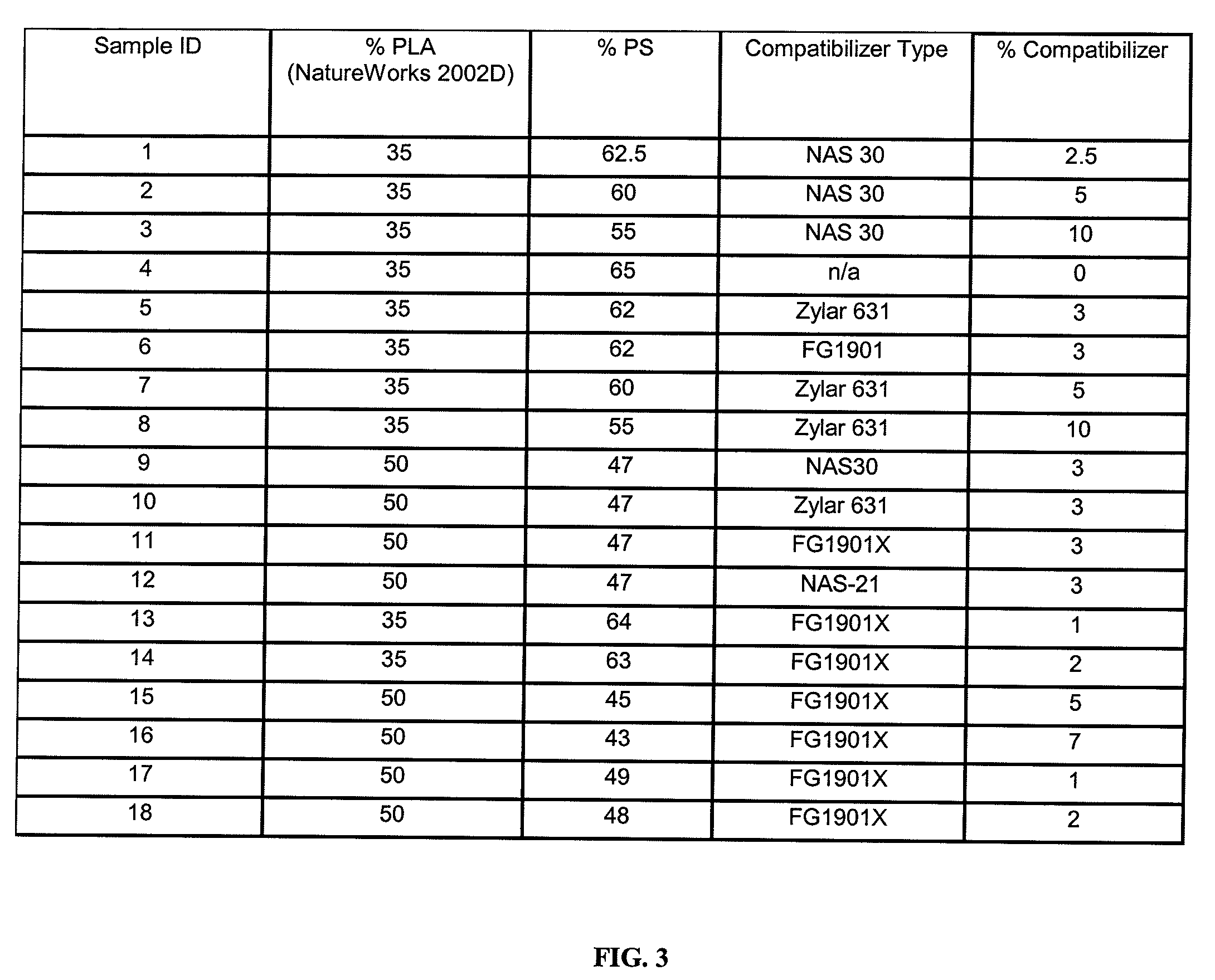

The present invention relates to compositions comprising blends of alkenyl aromatic polymers such as styrenic polymers (i.e. PS and HIPS) and bio-based or biodegradable polymers (i.e. PLA, PGA, PHA, PBS, PCL) compatibilized with styrene-based copolymers (i.e. styrene-ethylene-butylene-styrene (SEBS) block copolymers, maleated SEBS, styrene-maleic anhydride (SMA) copolymer, styrene-methyl methacrylate (SMMA) copolymer) or a mixture of two or more styrene-based copolymers such as SEBS and SMA. These novel compositions can be extruded and thermoformed to produce very low density food service and consumer foam articles such as plates, hinged lid containers, trays, bowls, and egg cartons with good mechanical properties.

Owner:PACTIV LLC

Polymer blends of biodegradable or bio-based and synthetic polymers and foams thereof

The present invention relates to compositions comprising blends of alkenyl aromatic polymers such as styrenic polymers (i.e. PS and HIPS) and bio-based or biodegradable polymers (i.e. PLA, PGA, PHA, PBS, PCL) compatibilized with styrene-based copolymers (i.e. styrene-ethylene-butylene-styrene (SEBS) block copolymers, maleated SEBS, styrene-maleic anhydride (SMA) copolymer, styrene-methyl methacrylate (SMMA) copolymer) or a mixture of two or more styrene-based copolymers such as SEBS and SMA. These novel compositions can be extruded and thermoformed to produce very low density food service and consumer foam articles such as plates, hinged lid containers, trays, bowls, and egg cartons with good mechanical properties.

Owner:PACTIV CORP

Thermoset composition, method, and article

InactiveUS20030220460A1Low viscosityFacilitating good glass carryHydrocarbonsHydrocarbon from saturated and unsaturated hydrocarbon additionVinyl etherPolystyrene

Owner:SABIC INNOVATIVE PLASTICS IP BV

Nucleating agent of polyethylene glycol terephthalate and preparation method thereof

InactiveCN102924641ASimple preparation processImprove thermal stabilityPolyethylene glycolPolymer SMA

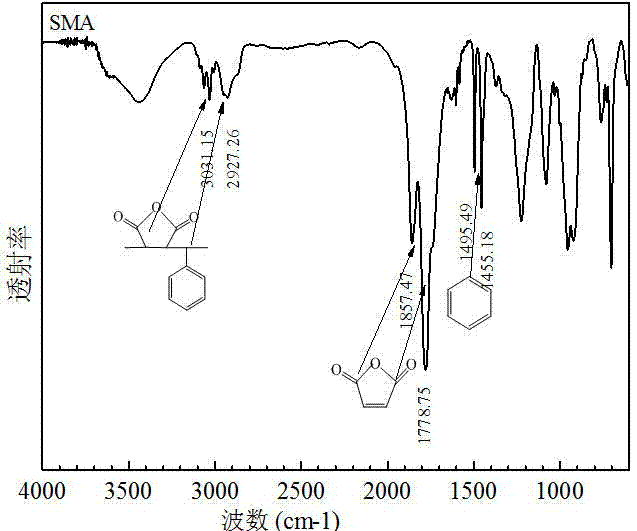

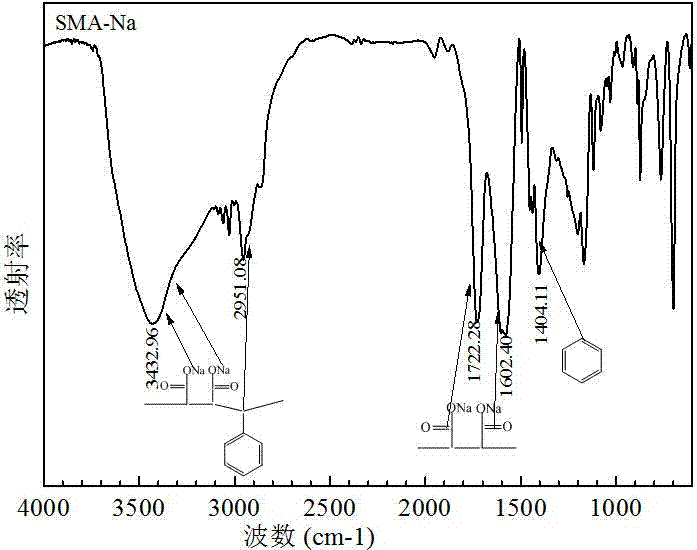

The invention belongs to the technical field of macromolecule materials, and particularly relates to a nucleating agent of the polyethylene glycol terephthalate and a preparation method thereof. The agent utilizes random copolymer or alternating copolymer of maleic anhydride and styrene as raw materials, and conducts hydrolysis, salinization and purification to obtain styrene-maleic anhydride ionomer. The styrene-maleic anhydride ionomer can serve as the nucleating agent of the polyethylene glycol (PET), increases crystallization temperature of the PET and increases crystallization rate. The nucleating agent is simple in preparation method, capable of adopting blending smelting reaction extrusion pelleting once process with the PET, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

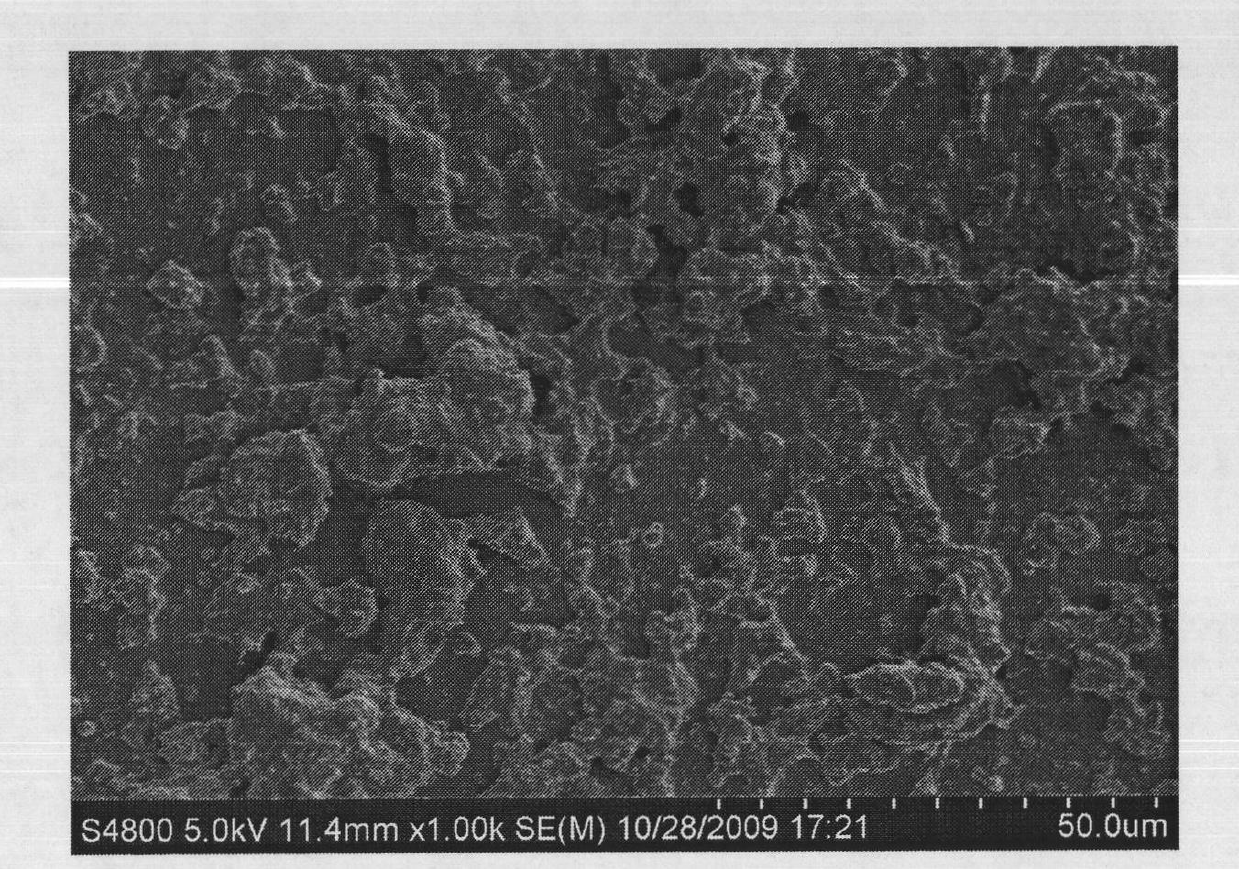

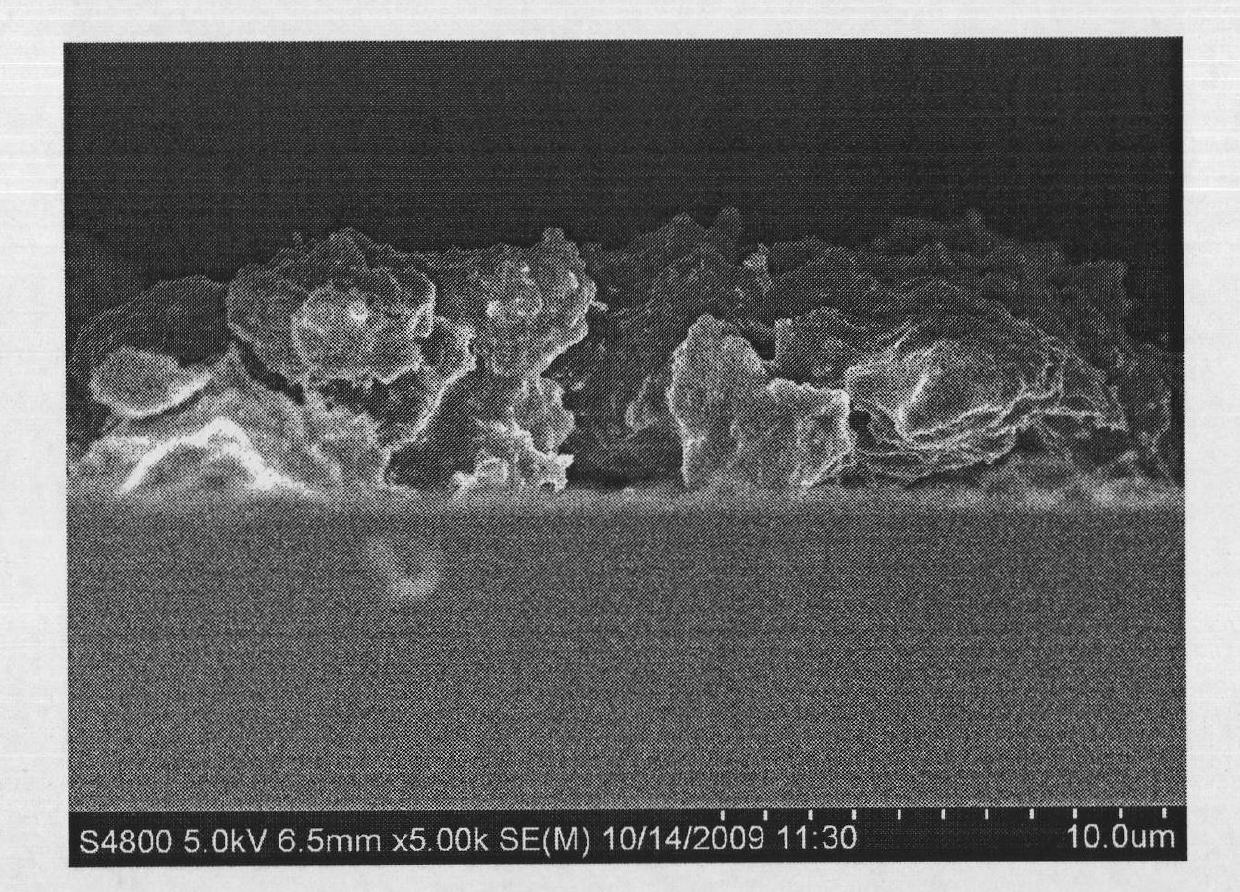

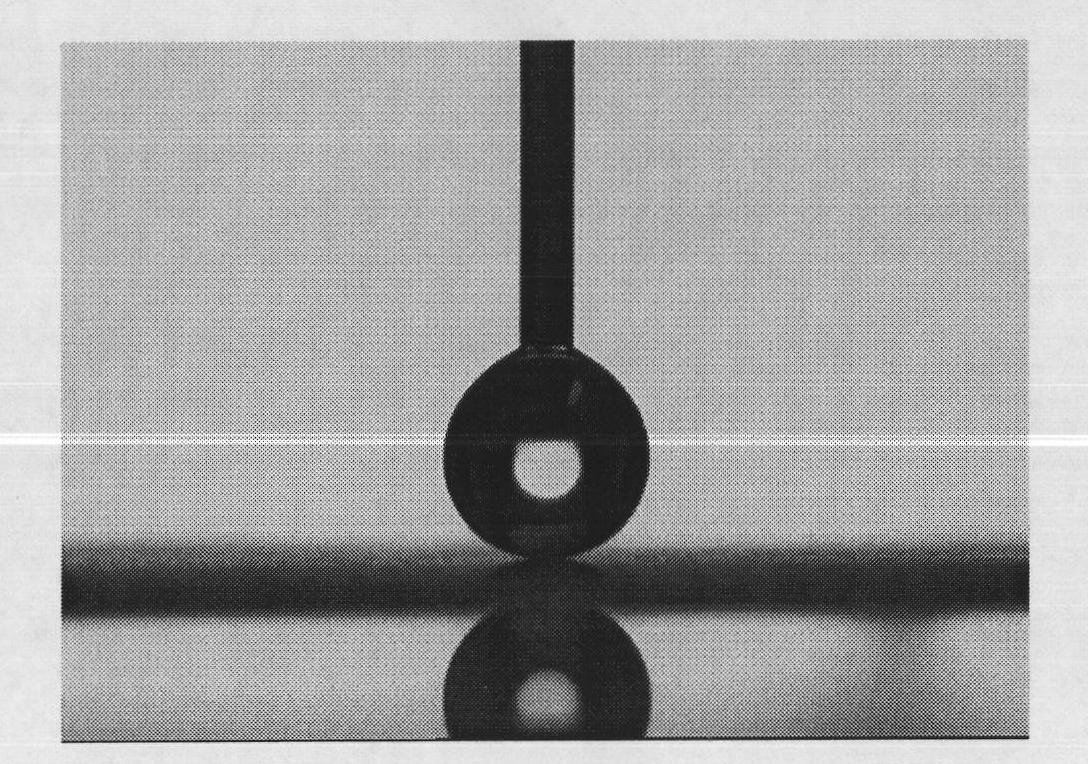

Preparation method for antistatic super hydrophobic composite coating

ActiveCN101792633ASimple and fast operationMild conditionsVegetal fibresElectrically-conductive paintsCarbon nanotubePolymer SMA

The invention discloses a preparation method for antistatic super hydrophobic composite coating, comprising the following steps: dissolving 0.2-2 parts of styrene-maleic anhydride alternate copolymer by weight into 20-1000 parts of solvent by weight, adding 1 part of carbon nanotube by weight and then evenly mixing, adding 0-26 parts of ammonia water and 0.2-2 parts of silicate ester or titanate compound by weight, stirring and mixing to enable silicate ester or titanate compound to perform hydrolysis reaction, adding 0.1-2 parts of silicate ester or titanate compound and 0.02-0.5 part of fluorine containing silane coupling agent by weight, evenly mixing and spraying on base materials, carrying out aging and thermal treatment to obtain stable antistatic super hydrophobic composite coating. The invention has simple operation and mild condition, the carbon nanotube can be directly used without the need of any chemical modification, the obtained composite coating has good hydrophobicity,the static contact angle and rolling angle between the composite coating and water are respectively larger than 150 degrees and less than 3 degrees, and the surface resistivity is 106-1011 omega, thus meeting the requirement of antistatic transparent coating and having wide application prospect.

Owner:ZHEJIANG UNIV

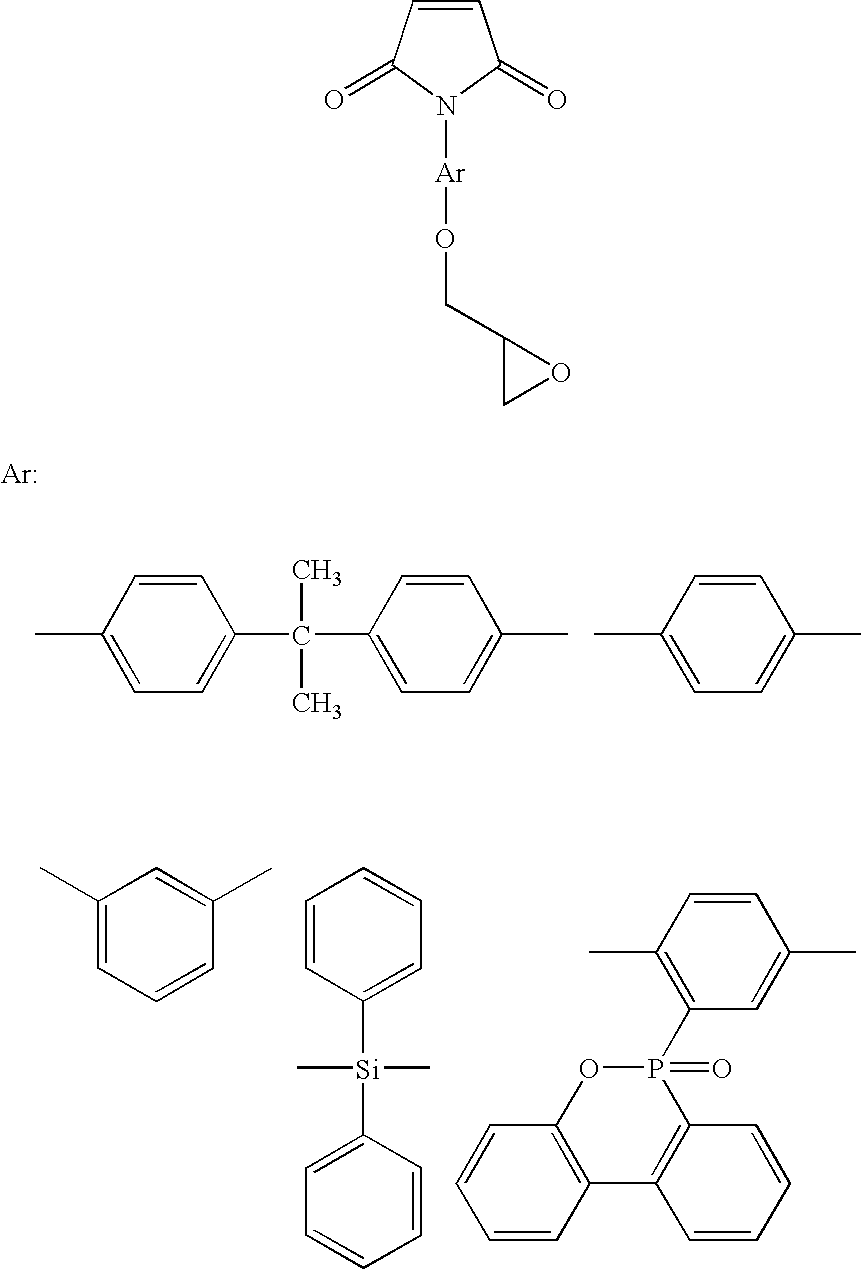

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS20030134978A1Avoid coatingSynthetic resin layered productsThin material handlingAcrylic resinPolymer SMA

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

Resin composition

The invention relates to a resin composition, mainly comprising the following components in parts by weight: (1) 100 parts of epoxy resin; (2) 20-100 parts of vinyl compound; (3) 10-50 parts of styrene maleic anhydride; (4) 5-50 parts of benzoxazine; (5) 0.5-5 parts of adherence promoter; (6) 10-150 parts of inorganic filler; (7) 0.2-25 parts of peroxide; (8) 10-250 parts of phosphorus-containing fire retardant; and (9) 0.01-10 parts of catalyst.

Owner:ELITE MATERIAL

Halogen-free resin composition, and copper clad laminate and printed circuit board using same

ActiveUS20130115472A1Group 5/15 element organic compoundsPrinted circuit aspectsLow dissipationHeat resistance

The halogen-free resin composition comprises (A) 100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 10 to 150 parts by weight of phosphazene; and (E) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

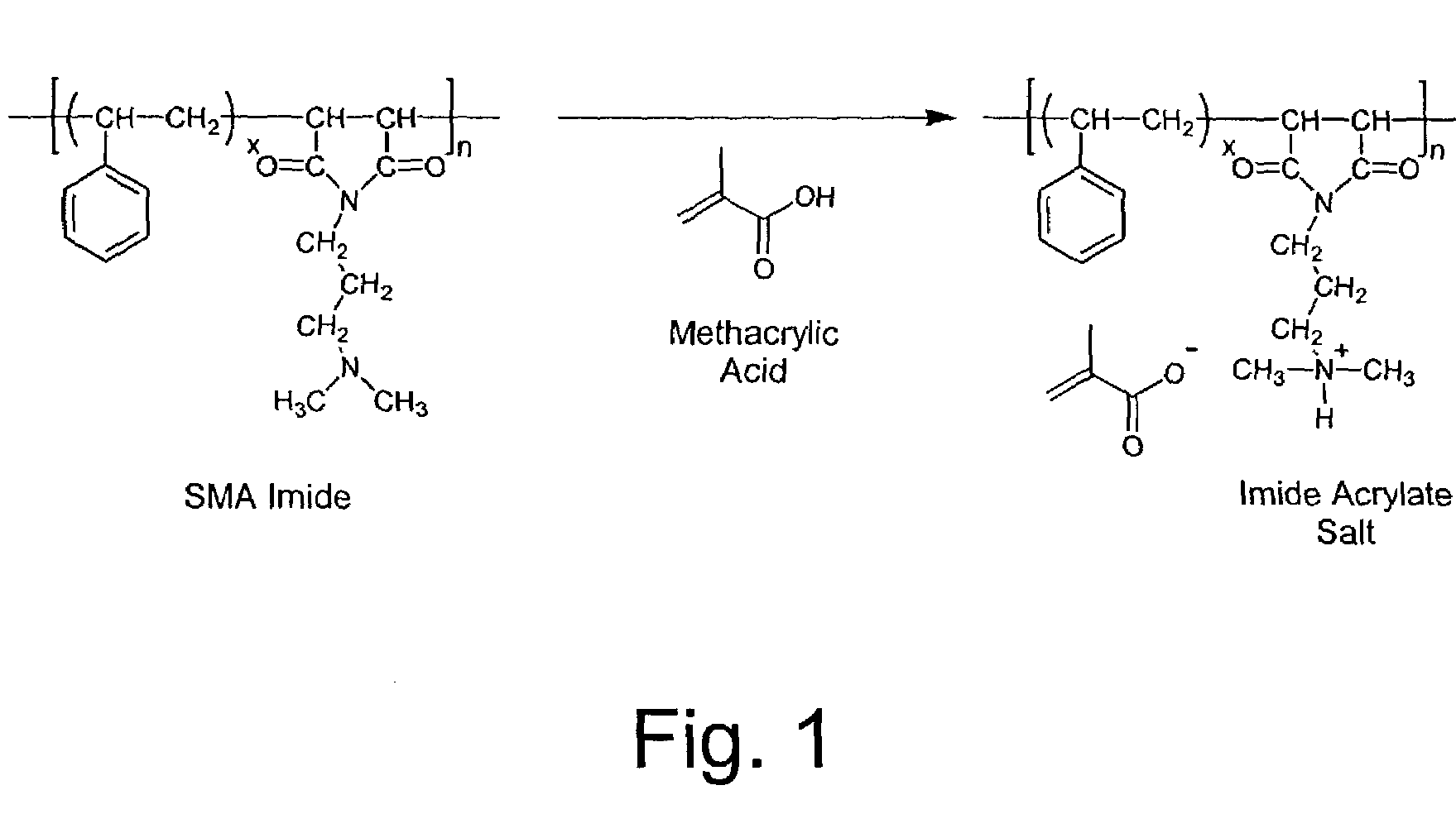

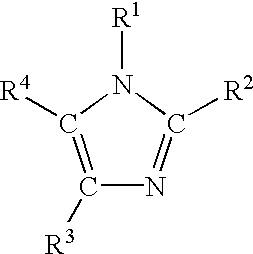

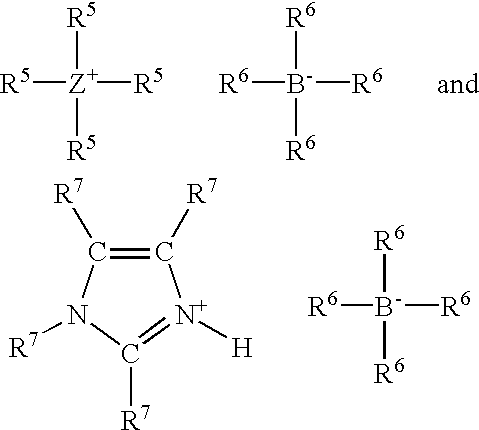

Acid salts of amine-functionalized SMA imide resins

Compositions comprising acid salts of amine-functionalized styrene-maleic anhydride resins are disclosed. The salts can be dissolved in organic solvents, UV / EB polymerizable monomers and / or oligomers, and / or water and act as a polymeric surfactants to disperse pigments or fillers, emulsifying agents, or hard resin additives in a variety of formulations. The compositions react under UV / EB cure conditions, and provide enhanced properties such as cure speed, hardness and adhesion to polymer compositions.

Owner:ARKEMA FRANCE SA

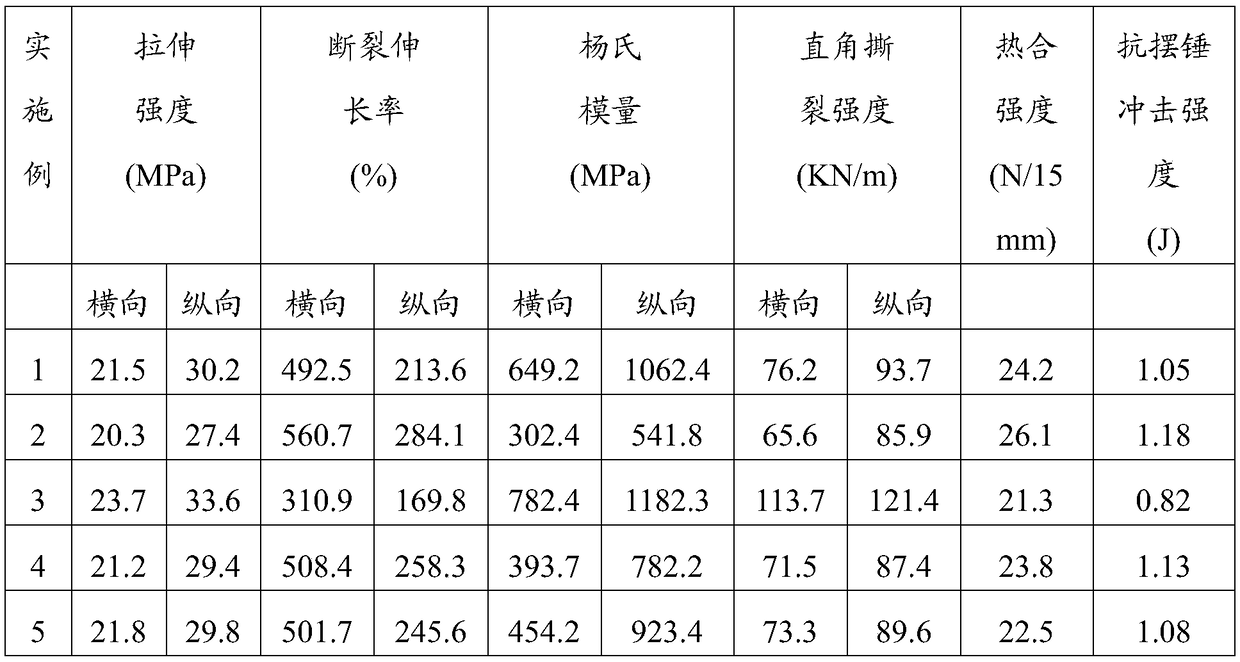

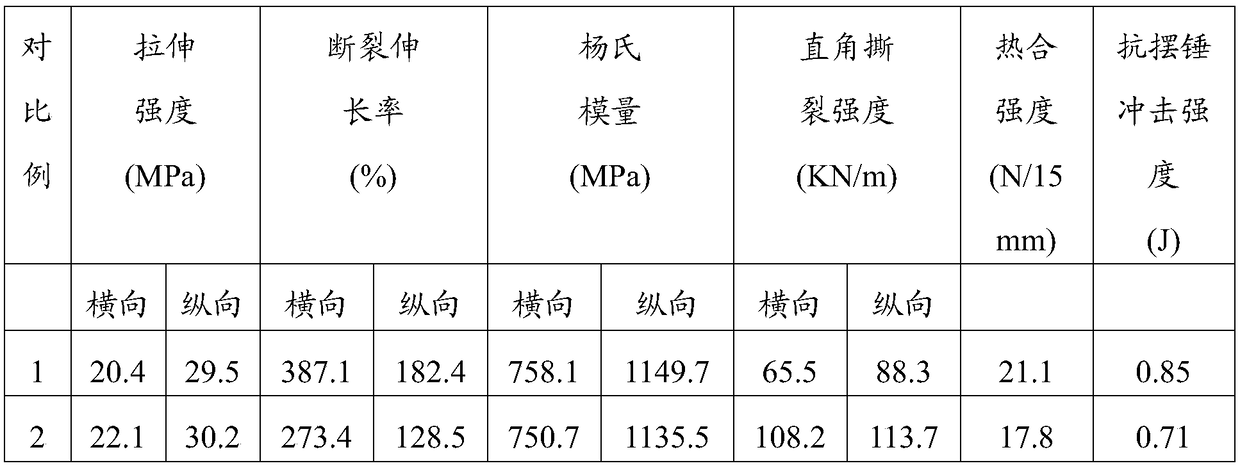

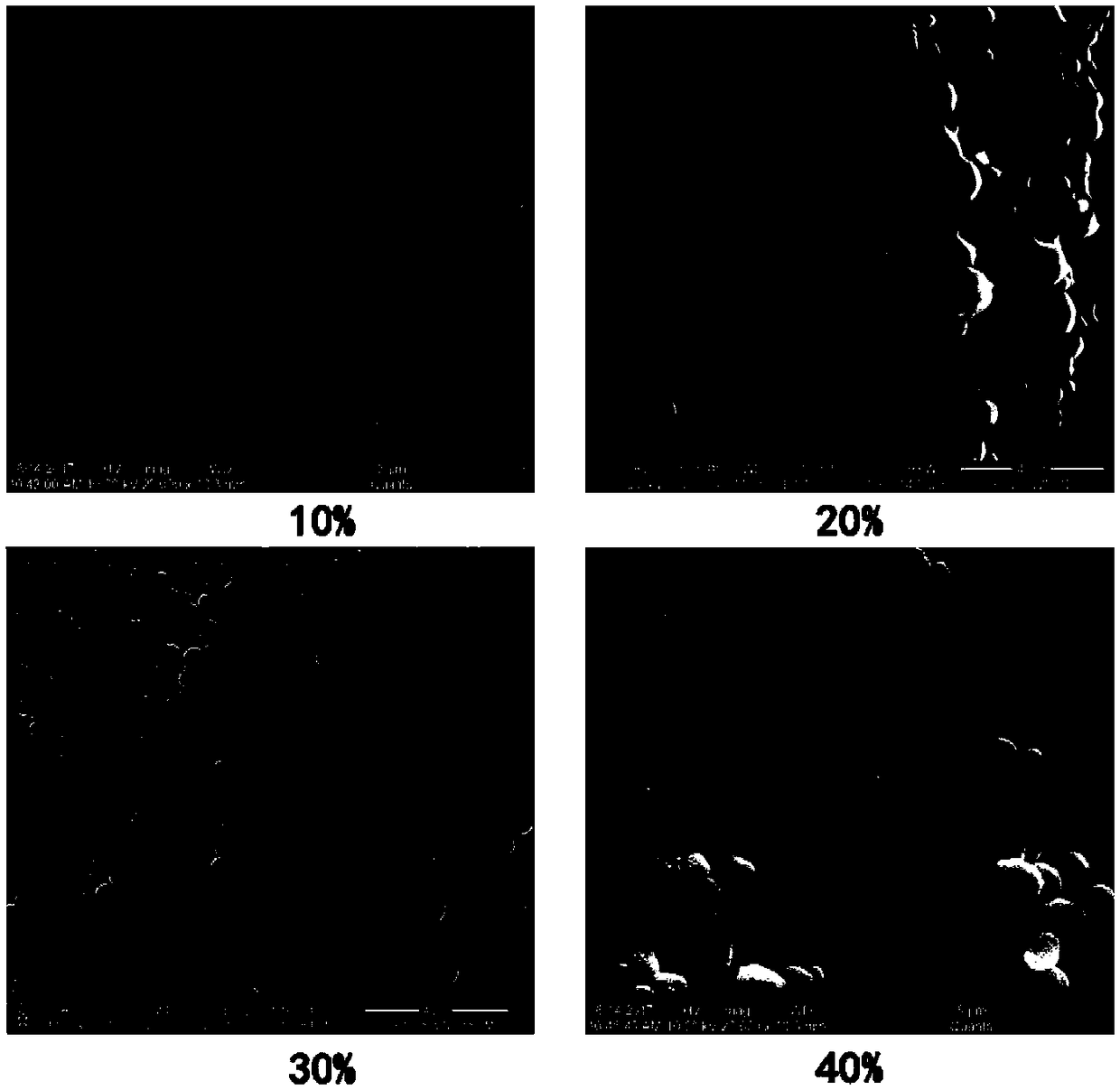

Completely-biodegradable blown film as well as preparation method and application of completely-biodegradable blown film

ActiveCN109177401AImprove melt strengthGood dispersionSynthetic resin layered productsFlat articlesMethacrylatePolymer science

The invention provides a completely-biodegradable blown film as well as a preparation method and application of the completely-biodegradable blown film. The film comprises an inner layer, a middle layer and an outer layer which are in contact in sequence; based on parts by weight, the inner layer comprises polylactic acid, poly(terephthalic acid)-adipic acid-butylene glycol ester, talcum powder, an antiblocking agent and carbon black; each of the middle layer and the outer layer comprises polylactic acid, poly(terephthalic acid)-adipic acid-butylene glycol ester and titanium dioxide; and eachof the three layers further comprises glycerol monooctadecanoate, acetyl tributyl citrate, ethylene bisstearamide and a chain extender; the antiblocking agent is erucylamide or oleamide; and the chainextender is a copolymer of styrene-acrylic acid-propylene oxide methacrylate and / or a copolymer of styrene-maleic anhydride-propylene oxide methacrylate. The film has relatively high tensile elongation at break, pendulum impact strength, tensile strength, Young modulus and heat sealing strength and keeps complete biodegradability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

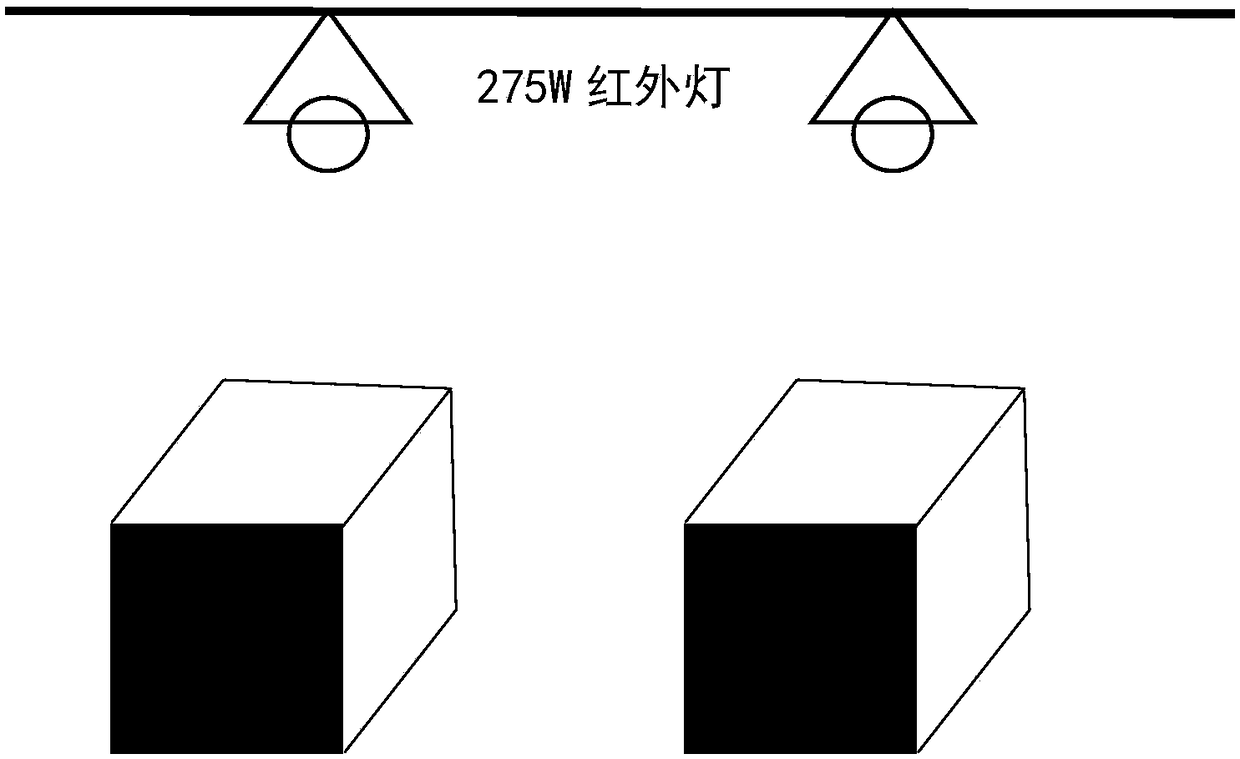

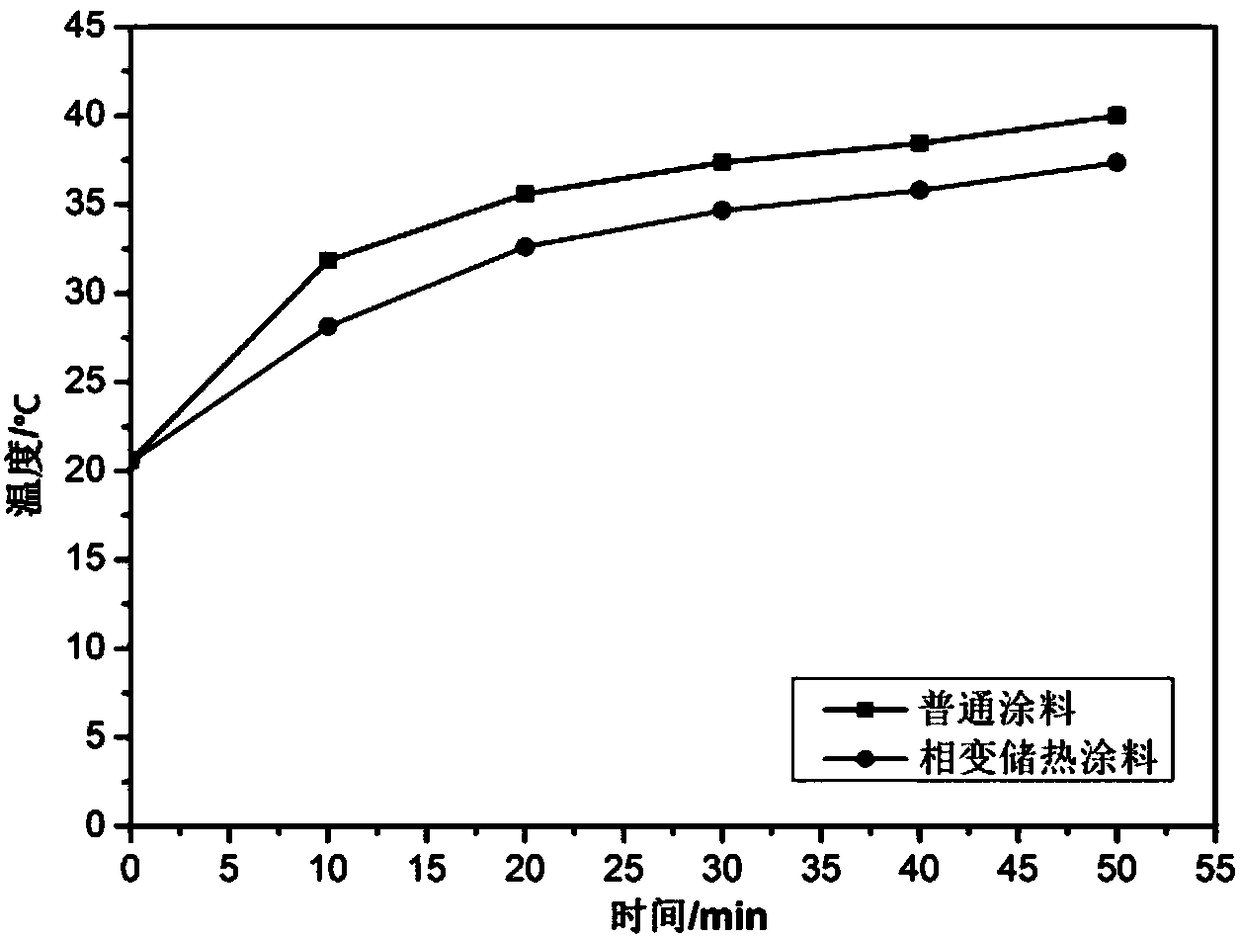

Phase change heat storage coating, and preparation method and application thereof

InactiveCN108192467AGood capacity storage performanceHigh heat storage efficiencyHeat-exchange elementsEpoxy resin coatingsWater basedPolymer science

The invention belongs to the field of new energy materials, and particularly relates to a phase change heat storage coating, and a preparation method and application thereof. The preparation method ofthe phase change heat storage coating comprises the following steps: (1) taking graphene oxide-modified melamine resin as a wall material, taking dodecanol as a core material, taking styrene maleic anhydride sodium salt as an emulsifying agent, and preparing phase change micro-capsules through an in-situ polymerization method; (2) taking water-based emulsion as a film forming matter, taking the phase change micro-capsules as filler, adding a suitable amount of water, a dispersing agent, a defoaming agent, a thickening agent and a coalescing agent in sequence, mixing uniformly, and finally, adding the thickening agent to adjust viscosity to prepare the phase change heat storage coating. The phase change heat storage coating prepared by the preparation method is used for an inner wall of abuilding, can show excellent temperature regulating performance, is low in cost, easy to prepare, can effectively improve the thermal comfort of the building and reduce the energy consumption of the building.

Owner:邹元月

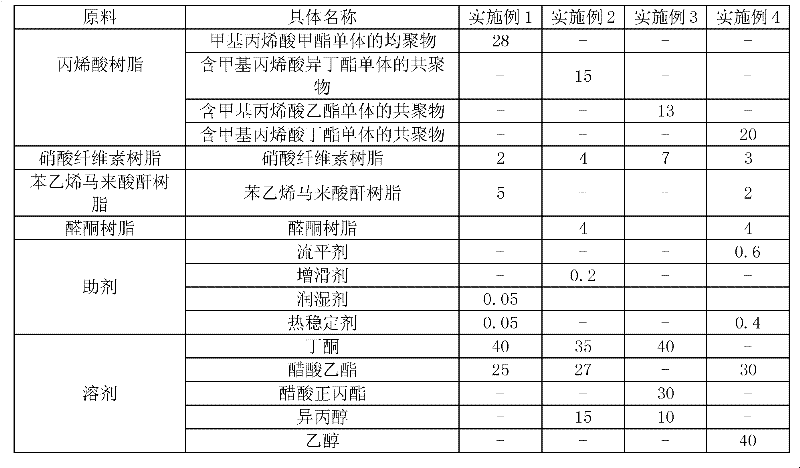

Laser electrolytic aluminum coating composition and preparation method thereof

The invention discloses a laser electrolytic aluminum coating composition and a preparation method thereof. The laser electrolytic aluminum coating comprises the following components by weight percent: 13-28% of acrylic resin, 2-7% of nitrocellulose resin, 0-5% of styrene maleic anhydride resin, 0-4% of aldehyde ketone resin, 0-1% of auxiliary agent and 65-80% of solvent. The preparation method comprises the steps of: putting the solvent into a reaction kettle, and heating to 40-70 DEG C when stirring; putting the nitrocellulose resin into the reaction kettle, and stirring; sequentially putting the rest resins into the reaction kettle, and further stirring; after all the resins which are put into the reaction kettle are completely dissolved, putting the auxiliary agent into the reaction kettle, and cooling after dispersing to obtain the laser electrolytic aluminum coating. Compared with the prior art, the laser electrolytic aluminum coating disclosed by the invention is environment-friendly, low in cost, good in application adaptability and excellent in performance.

Owner:SHANGHAI WEIKAI CHEM +1

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS6905778B2Synthetic resin layered productsThin material handlingAcrylic resinStyrene maleic anhydride

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

Maleic anhydride copolymers as soluble support material for fused deposition modelling (FDM) printer

ActiveUS20130317164A1Avoid accumulationImprove adhesionOrganic dyes3D object support structuresState of artStyrene maleic anhydride

The invention relates to a novel support material for the fused deposition modelling process for producing three-dimensional objects. The invention relates more particularly to a 3D printing process involving support materials which are easier to remove than in the prior art. The support materials according to the invention are styrene-maleic anhydride copolymers for example.

Owner:EVONIK OPERATIONS GMBH

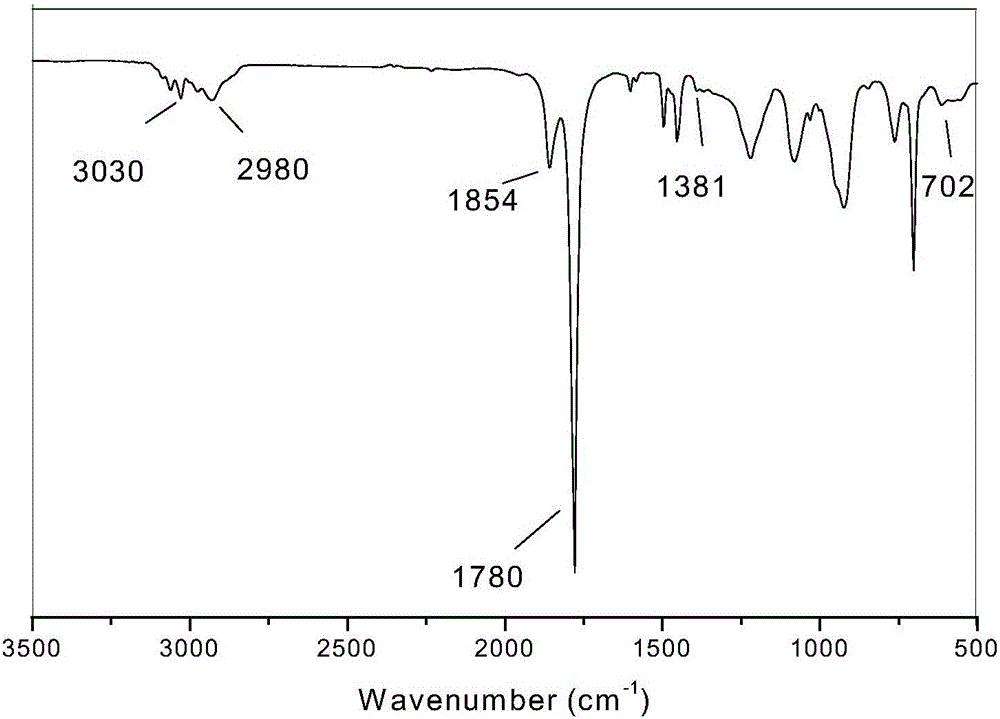

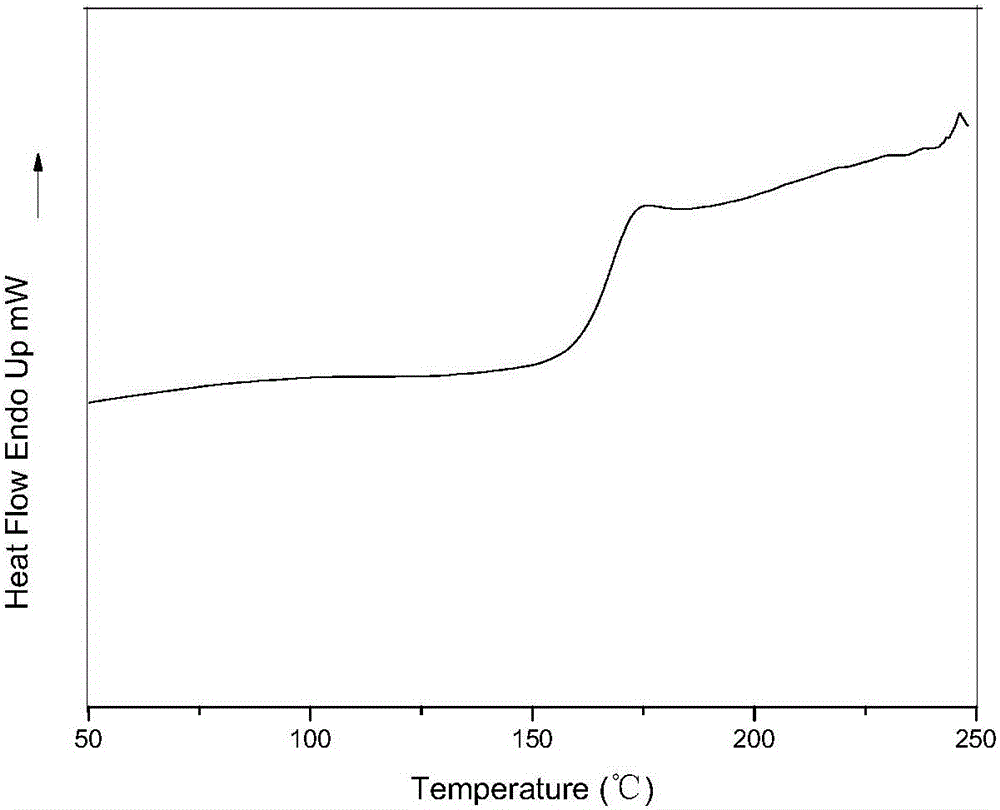

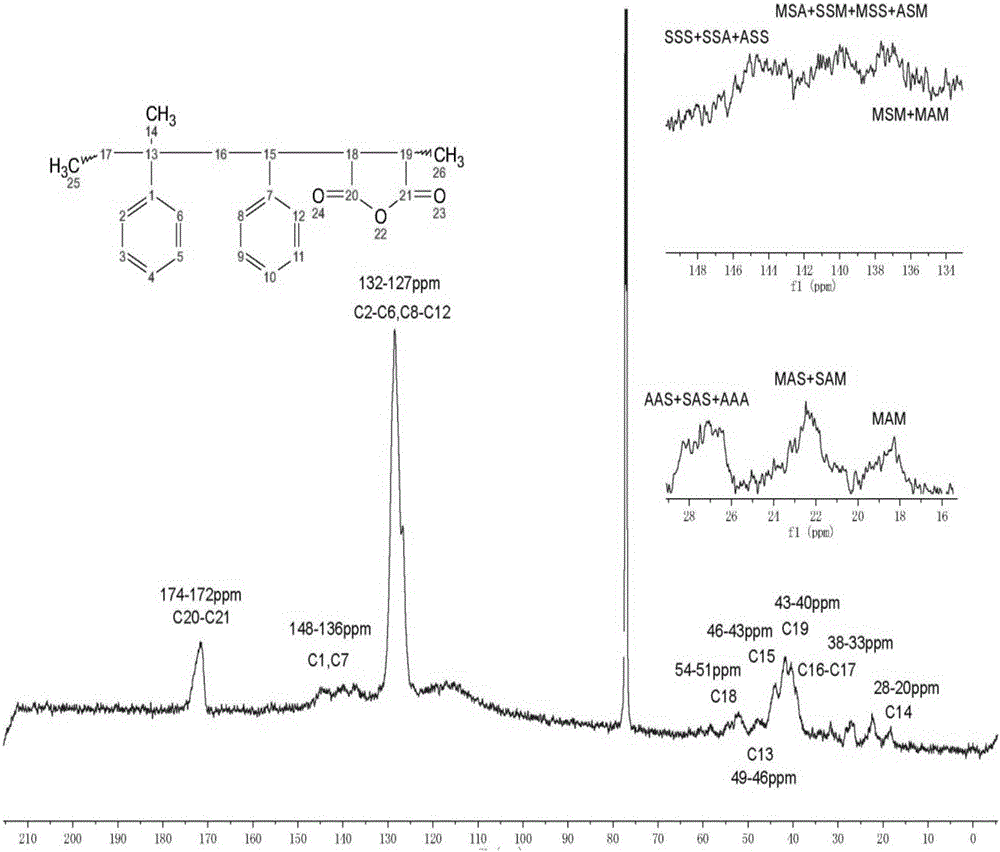

Alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer and preparation method thereof

The invention discloses an alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer and a preparation method thereof, and belongs to the field of macromolecular polymerization.The preparation method comprises the steps that firstly, a monomer alpha-vinyltoluene, styrene and an initiator are added to a solvent to be dissolved, and the solution is heated to 80 DEG C to 110 DEG C; then, a semicontinuous sample introduction method is adopted for dropwise adding a solution containing maleic anhydride to a reaction system for 1 h to 3 h, and the reaction continues to be carried out for 30 min to 60 min after the solution is dropwise added; after the reaction is finished, the system is subjected to methyl alcohol precipitation, suction filtration and drying, and the alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer is obtained.The prepared alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer has the advantages that the content of maleic anhydride is high, and the glass transition temperature is low (low Tg facilitates machine shaping); meanwhile, an alpha-vinyltoluene structural unit is contained in the polymer chain of the ternary random copolymer, depolymerization occurs at high temperature to generate free radicals, and the alpha-vinyltoluene-styrene-maleic anhydride ternary random copolymer can be used as a macroinitiator to be applied to polyolefin grafting and polyolefin melt blending modification.

Owner:BEIJING UNIV OF CHEM TECH

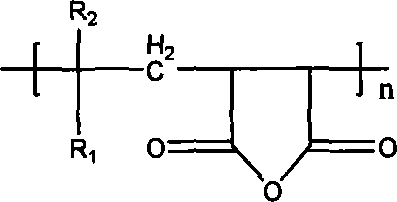

Esterified object of maleic anhydride of styrene, preparation method, and application

This invention relates to a method for preparing styrene-maleic anhydride esterification product. The method comprises: dissolving styrene-maleic anhydride copolymer in solvent, adding alcohol, adding basic catalyst, reacting, purifying the product, and refining. The product can be used as controlled release agent aid for pH-sensitive drugs, paint dispersant, high-efficiency water-reducing agent, polyelectrolyte and phase-separating material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

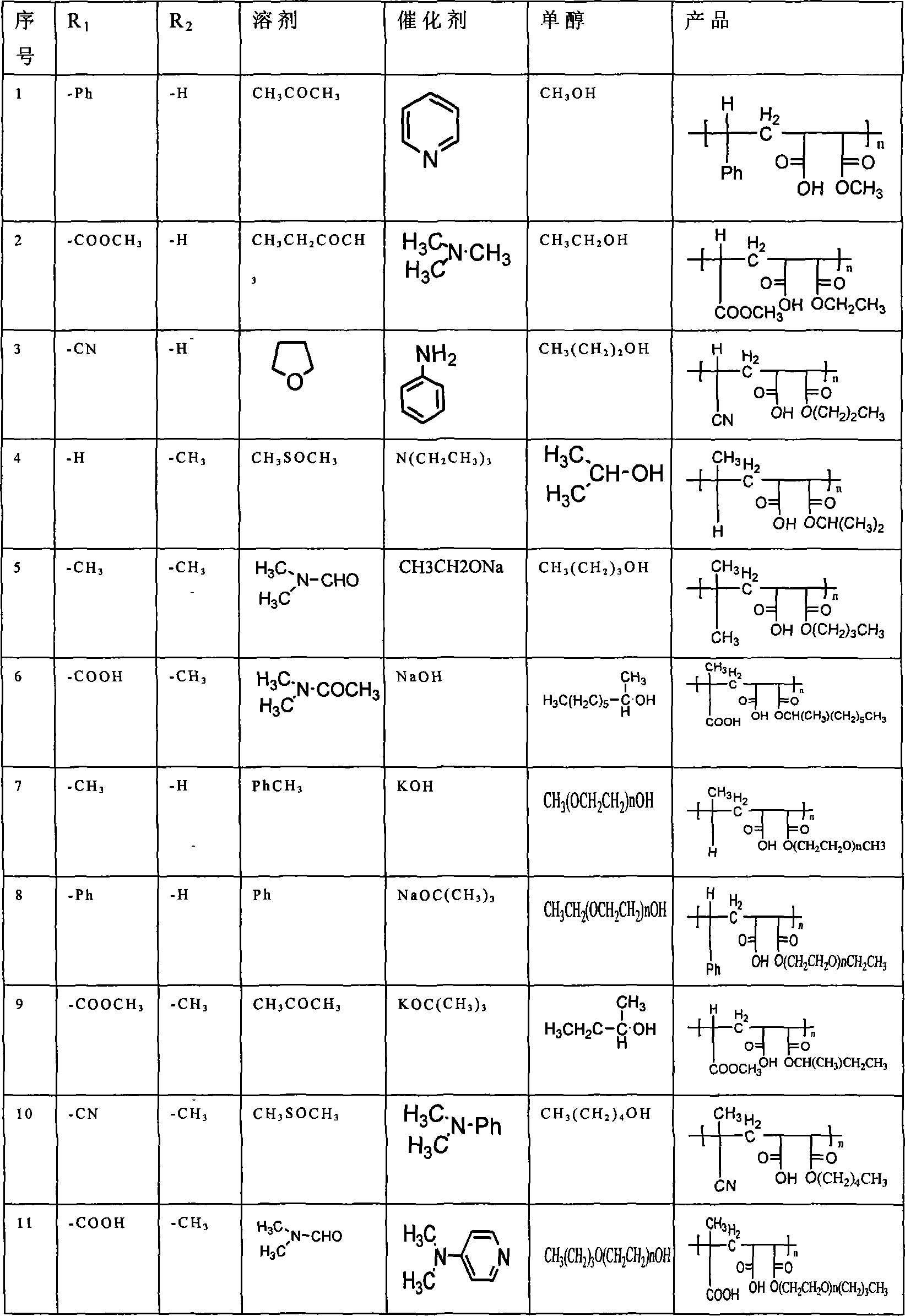

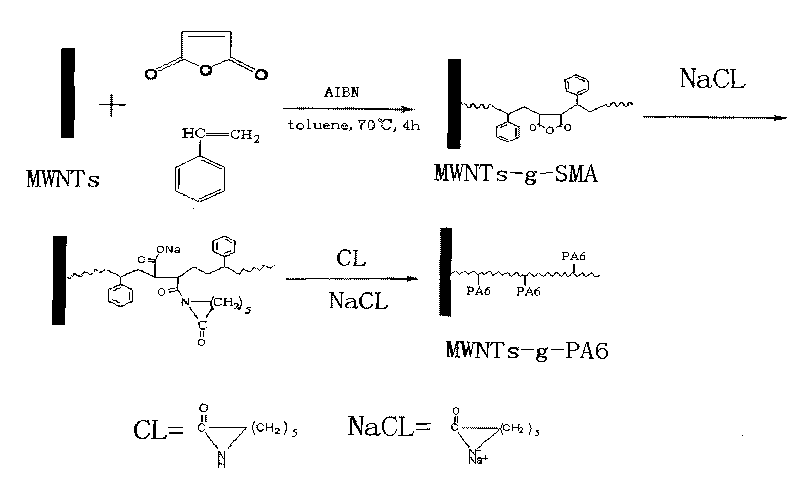

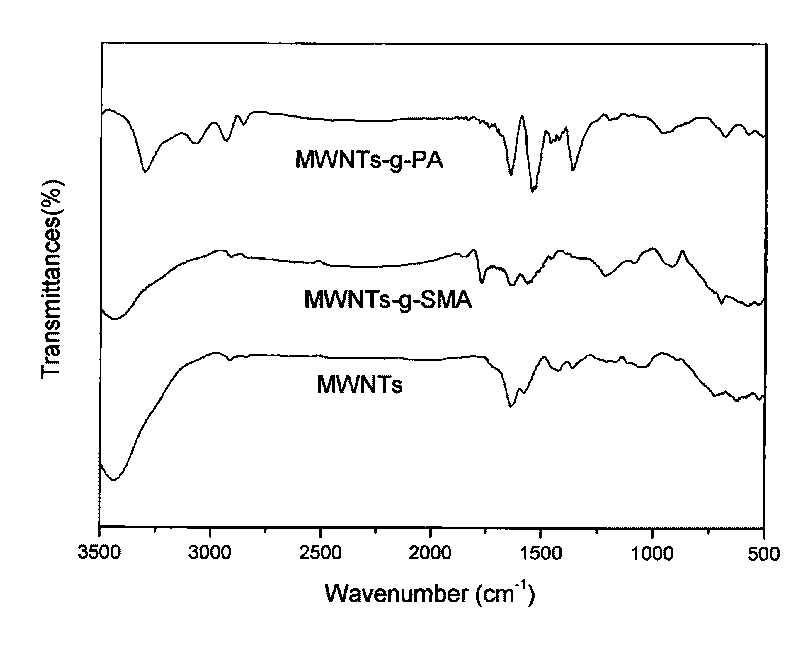

Preparation method of nylon-6 grafting modified carbon nano tubes

The invention relates to a preparation method of nylon-6 grafting modified carbon nano tubes, which comprises the following steps: adding multi-wall carbon nano tubes, styrene and maleic anhydride into phenylmethane to carry out a free radical polymerization, then obtaining styrene maleic anhydride grafting multi-wall carbon nano tubes; and adding the styrene maleic anhydride grafting multi-wall carbon nano tubes into caprolactam monomer as a macromolecule cocatalyst for anion ring-opening polymerization, then obtaining the nylon-6 grafting modified carbon nano tubes. Compared with the prior method, the invention grafts PA6 molecular chains on the surface of the multi-wall carbon nano tubes, so that the multi-wall carbon nano tubes can be uniformly dispersed in various solvents, and meanwhile, the PA6 molecular chains can be used as a good macromolecule compatilizer to improve the dispersibility of MWNTs in various polyamides. The invention prevents the structure of the carbon nano tubes from being destroyed since the carbon nano tubes are oxidized by strong acid, and avoids using lots of virulent phenylmethane 2,4-diisocyanate. Thus, the method is convenient and safe.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

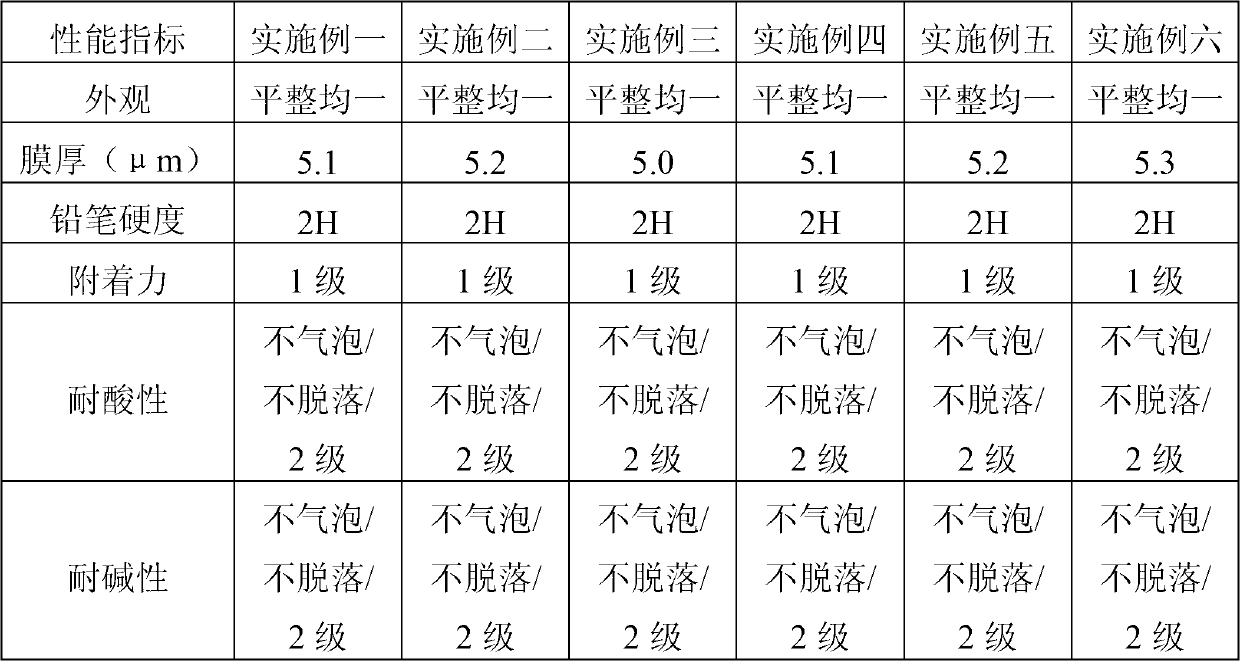

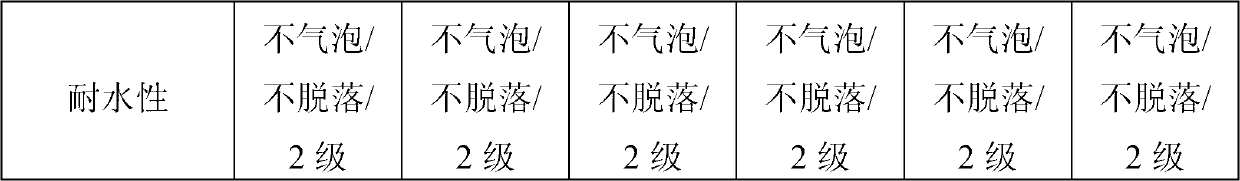

Finish paint for plastic

InactiveCN102775902AGood spray viscositySave electricityPolyurea/polyurethane coatingsPaints with free metalsCelluloseLacquer

The invention discloses a finish paint for plastics. The finish paint comprises the following components in percentage by weight: 5-10% of aliphatic polyurethane acrylate, 10-15% of aromatic polyurethane acrylate, 0-2% of high polymer containing paint affinity group, 0-0.3% of unsaturated polyamic acid homo-polymer, 0-0.2% of organic silicon, 10-35% of cellulose ester, 2-10% of mixture of pearl powder, aluminum silver powder and paint, 3-5% of nano filler, 10-20% of hydroxy acrylic resin, 5-10% of styrene maleic anhydride modified chloride resin vinegar, 5-10% of poly-functional-group reactive diluent, 2-5% of dual-functional-group reactive diluent, 3-5% of three-functional-group reactive diluent, 1-3% of crack-type photo-initiator, and 0.5-1% of acyl phosphine oxide photo-initiator. The curing time of the finish paint for plastics is only 3min to 4min, so a large amount of power is saved; and the finish consumption of each electric car is respectively reduced by 48% and 53%. With the adoption of the combination of the polyurethane acrylates and the hydroxy acrylic resin, the problem on adhesion among three layers of plastic substrate, finish paint and priming paint is solved.

Owner:KUSN WANSHENG CHEM

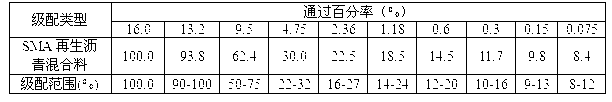

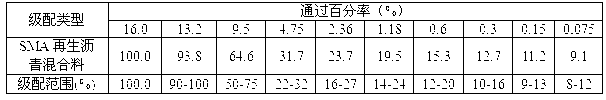

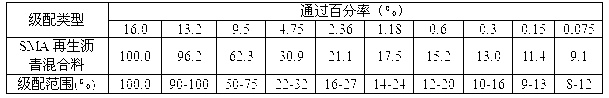

SMA (styrene maleic anhydride) on-site thermal regenerated asphalt mixture

The invention discloses an SMA (styrene maleic anhydride) on-site thermal regenerated asphalt mixture and a preparation method thereof. Raw materials of the SMA on-site thermal regenerated asphalt mixture adopt SMA asphalt pavement milling and planning materials and comprise a regenerated old material and newly added asphalt mixture as well as an additive, wherein the regenerated old material adopts the SMA asphalt pavement milling and planning materials; the additive is SBS (styrene butadiene styrene) modified asphalt, an asphalt regenerating agent or a mixture of SBS modified asphalt and the asphalt regenerating agent; and the newly added asphalt mixture comprises SBS modified asphalt, cellulose fibers and mineral aggregates. According to the preparation method, the SMA asphalt pavement milling and planning materials are taken as raw materials, resource is saved, and environmental pollution is avoided; and the prepared mixture can be applied to an SMA asphalt pavement again, each technical requirement can be met, and preparation cost is reduced.

Owner:JSTI GRP CO LTD

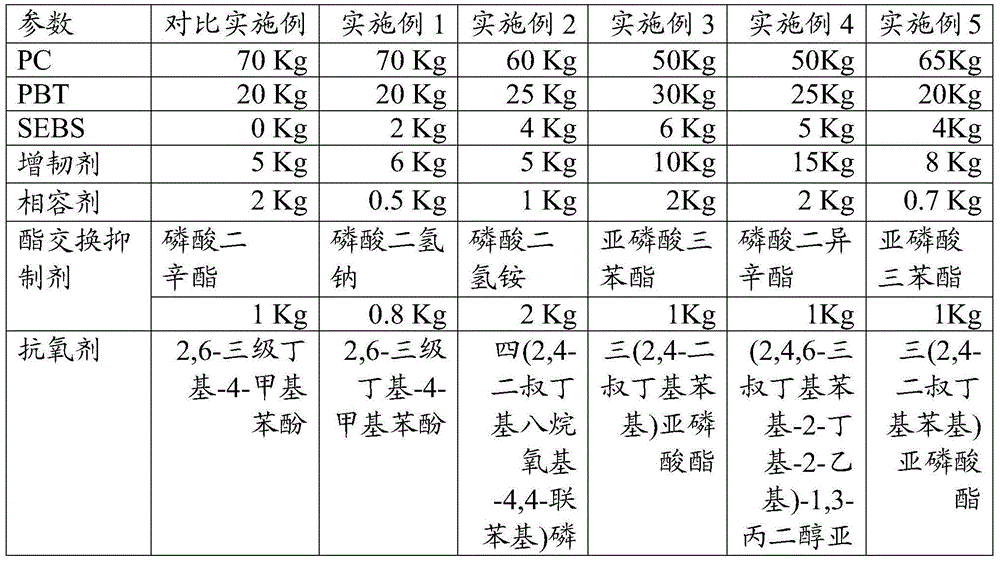

PC/PBT alloy material as well as preparation method and application thereof

The invention discloses a PC / PBT alloy material as well as a preparation method and application thereof. The PC / PBT alloy material comprises the following components in parts by mass: 50-70 parts of PC (polycarbonate), 20-30 parts of PBT (polybutylene terephthalate), 2-6 parts of SEBS (styrene-ethylene / butylene-styrene block polymer), 5-15 parts of toughening agent, 0.5-2 parts of compatilizer, 0.8-2 parts of ester exchange inhibitor, 0.1-1 part of antioxidant and 0.1-1 part of lubricant, wherein the toughening agent is polysiloxane-methyl methacrylate copolymer, the compatibilizer is SBS-MAH (styrene butadiene styrene-maleic anhydride), the ester exchange inhibitor is phosphate type ester exchange inhibitor, the antioxidant is hindered phenol antioxidant or phosphite antioxidant, and the lubricant is silicone powder. The PC / PBT alloy material has stable performance. Moreover, the invention further provids a preparation method and application of the PC / PBT alloy material.

Owner:东莞市科罗威新型材料有限公司

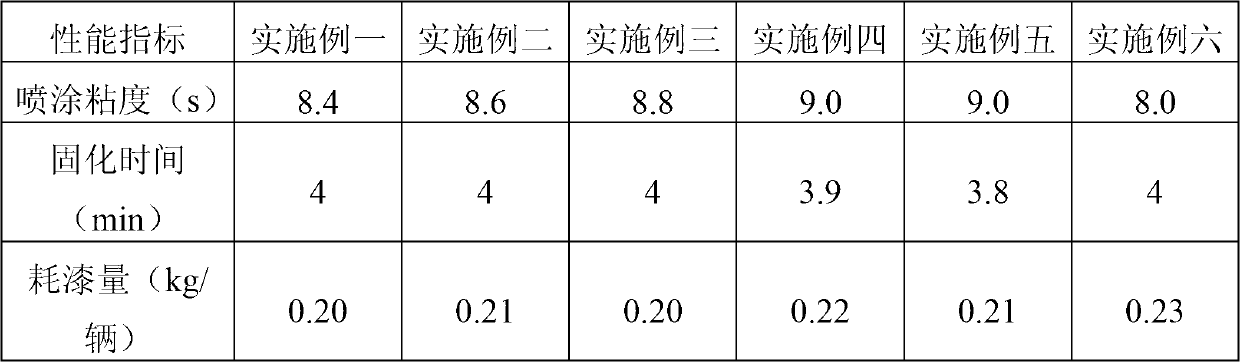

Naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and preparation method thereof

InactiveCN103045014AFast developingImprove imaging clarityInksPhotosensitive materials for photomechanical apparatusCelluloseCooking & baking

The invention discloses a naturally dried photosensitive acid-corrosion-resistant electroplating printing ink and a preparation method thereof. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink comprises the following components in parts by weight: 50-80 parts of alkali soluble photosensitive resin, 0-5 parts of cellulose used for coating, 2-10 parts of active diluents, 2-8 parts of photosensitizer, 10-40 parts of filler, 0.5-1 part of pigment, 5-15 parts of solvent and 0.5-3 parts of auxiliaries, wherein the alkali soluble photosensitive resin is prepared from the following components in parts by weight: 40-60 parts of mixture consisting of 20-30 parts of n-butyl acetate, 0-30 parts of methyl isobutyl ketone, 0-20 parts of methylbenzene and 0-20 parts of propylene glycol monomethyl ether acetate, 25-40 parts of styrene-maleic anhydride resin, 15-20 parts of acrylic acid monomer, 0.1-1.0 part of catalyst and 0.1-1.0 part of polymerization inhibitor. The naturally dried photosensitive acid-corrosion-resistant electroplating printing ink disclosed by the invention does not need baking, is dried naturally after being diluted and is energy-saving and is resistant to acid and electroplating, and a film formed after the electroplating printing ink sprayed and dried naturally is high in adhesive force, high in hardness, quick in development, capable of obtaining clear images and resistant to acid corrosion.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

Transparent impact-resistance polystyrene and preparation method thereof

The invention relates to a transparent impact-resistance polystyrene and a preparation method thereof, particularly a transparent high-impact-resistance polystyrene and a preparation method thereof. The polystyrene comprises the following components in percentage by weight: 25-40% of GPPS (general purpose polystyrene), 50-70% of K gum, 0.5-1% of SMA (styrene maleic anhydride), 5-10% of toughener, 0.2-0.5% of lubricant, 0.1-0.3% of coupling agent and 0.1-0.3% of antioxidant, totaling 100%. The preparation method comprises the following steps: proportionally and uniformly mixing the materials with a high-speed mixer, and extruding and granulating with a double screw extruder. The polystyrene has the advantages of high transparency, favorable product formability, favorable dimensional stability, high bending resistance and high tear resistance.

Owner:DONGGUAN DECHENG PLASTIC TECH

Textile auxiliary containing antibiotic constituents and preparation method thereof

InactiveCN105714558AImprove antibacterial propertiesWith anti-fouling functionBiochemical fibre treatmentPolymer sciencePyrrolidinones

The invention discloses a textile auxiliary containing antibiotic constituents. The textile auxiliary comprises, by weight parts, 50-60 parts of sodium diethylhexyl sulfosuccinate, 45-55 parts of polyvinyl pyrrolidone, 40-50 parts of sodium dodecyl sulfonate, 30-40 parts of hydroxyethyl sulfonate, 30-40 parts of 2-hydroxyethyl salicylate, 25-35 parts of lupenyl palmitate, 25-35 parts of styrene maleic anhydride resin, 15-25 parts of trichloro-sym-diphenylurea, 15-25 parts of ethyl vanillin, 5-10 parts of zinc oxide, 5-10 parts of cross-linking agent and 5-10 parts of softening agent. The textile auxiliary containing the antibiotic constituents improves antibiotic effects of textile, and further has antifouling function. A corresponding preparation method is further disclosed.

Owner:WUJIANG FUHUIYUAN HOME TEXTILES CO LTD

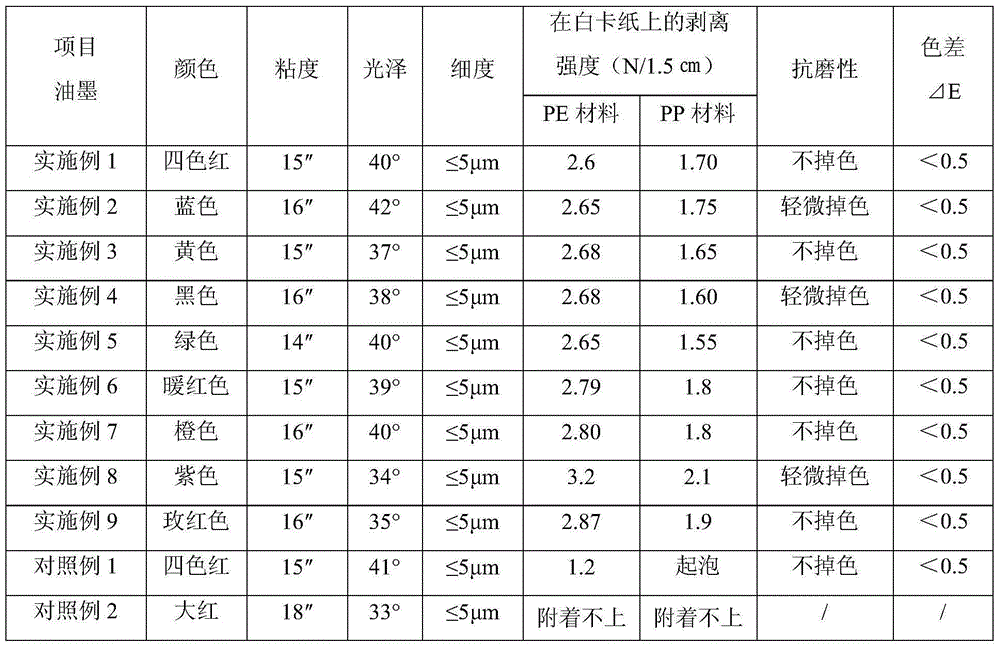

Water-based inner printing ink coated with PE and PP and preparation method thereof

The invention provides water-based inner printing ink coated with PE and PP and a preparation method thereof. The water-based inner printing ink coated with the PE and the PP contains, by weight, 25-30 parts of varnish, 65-75 parts of water-based color paste and 0.1-0.3 part of defoaming agent, wherein the varnish contains, by weight, 50-70 parts of styrene-acrylate non-film-forming emulsion, 20-35 parts of acrylic resin solution or styrene-maleic anhydride resin solution, 1-3 parts of wax emulsion, 3-8 parts of coalescing agent, 0.1-0.5 part of organic amine, 0.5-1 part of wetting agent, 0.1-0.3 part of defoaming agent and 0.05-0.15 part of preservative, and the Tg value of the styrene-acrylate non-film-forming emulsion is greater than or equal to 85 DEG C. The water-based color paste contains, by weight, 20-25 parts of acrylic resin solution, 1-2 parts of wetting dispersant agent, 25-35 parts of deionized water, 40-45 parts of pigment, 0.1-0.3 part of defoaming agent and 0.05-0.15 part of preservative. The water-based inner printing ink is resistant to high temperature and abrasion, is small in chromatic aberration after being coated with PE and PP films, is high in peel strength on a basic material and can well meet the requirement of a spraying process.

Owner:山东布瑞特油墨有限公司

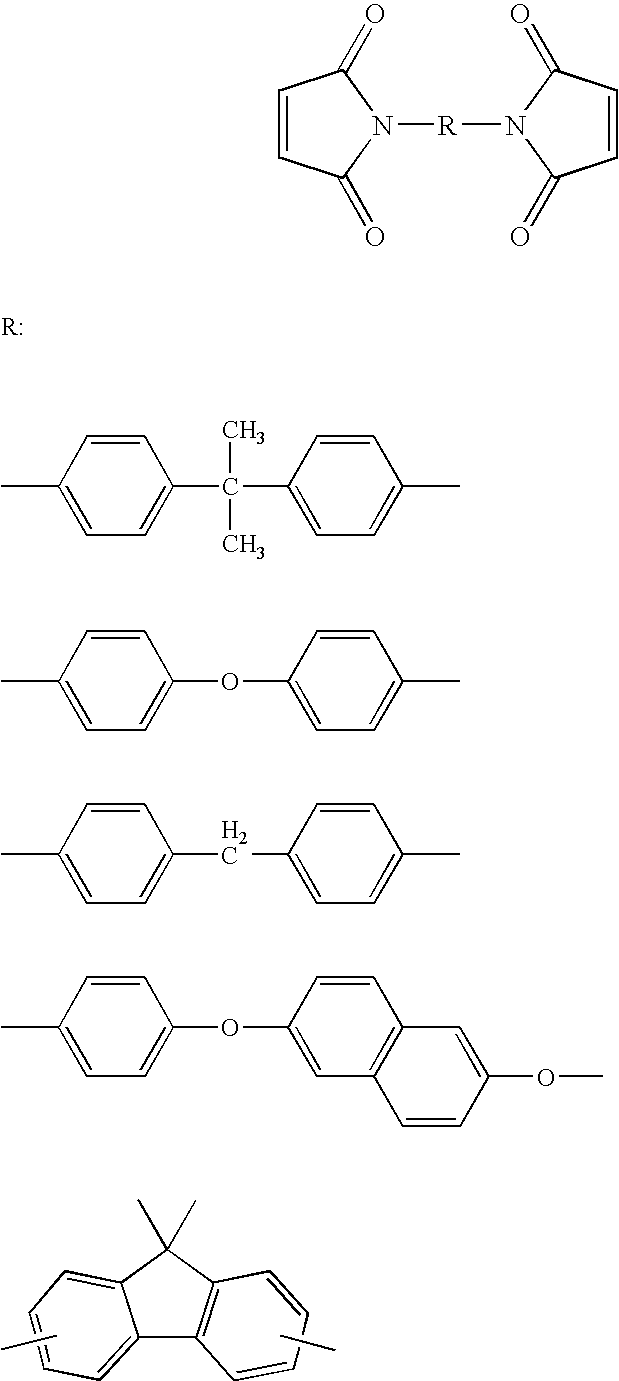

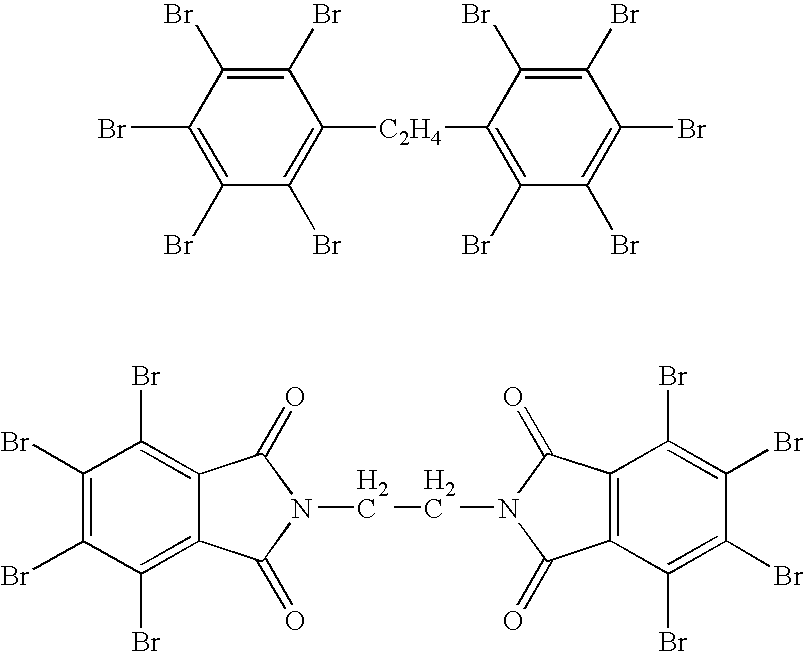

Thermosetting resin composition

InactiveUS20090292062A1Excellent dielectric propertiesLow water absorptionOrganic dyesPrinted circuitsHigh resistanceEpoxy

The present invention discloses a thermosetting resins composite, composed of: epoxy resin which can have a total polymerization with bismaleimide, occupying 1.75%-18.0% solids weight of the composite; bismaleimide compounds, occupying 0.15%-12.5% solids weight of the composite; free radical initiator, its mole fraction of which its addition accounts for reaction monomer total is 0.01%-0.15%; inhibitor, whose amount is the half to double of the initiator; styrene-maleic anhydride oligomers, occupying 17.5%-47.0% solids weight of the composite; filler, occupying 20%-60% solids weight of the composite; solvent, occupying 30%-50% solids weight of the composite; flame retardant which can be used in CCL industries. The composite provided in the present invention can form homogeneous solution in the low boiling point solvents, and the manufactured CCL has high vitrification transition temperature, excellent dielectric properties, low coefficient of expansion, low water absorption rate, high resistance to heat impact and excellent thermal conductivity and other properties.

Owner:ITEQ DONGGUAN +1

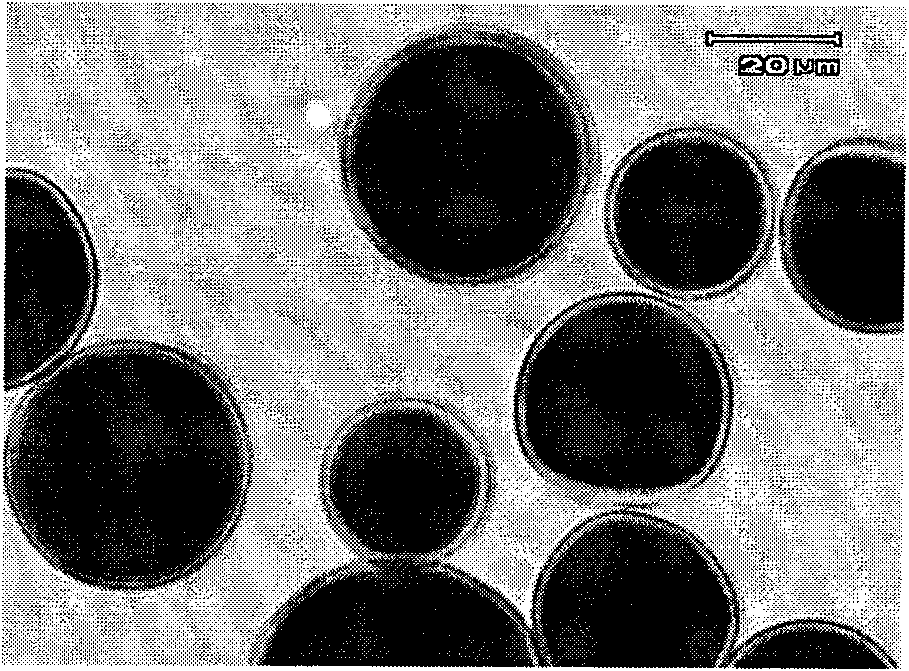

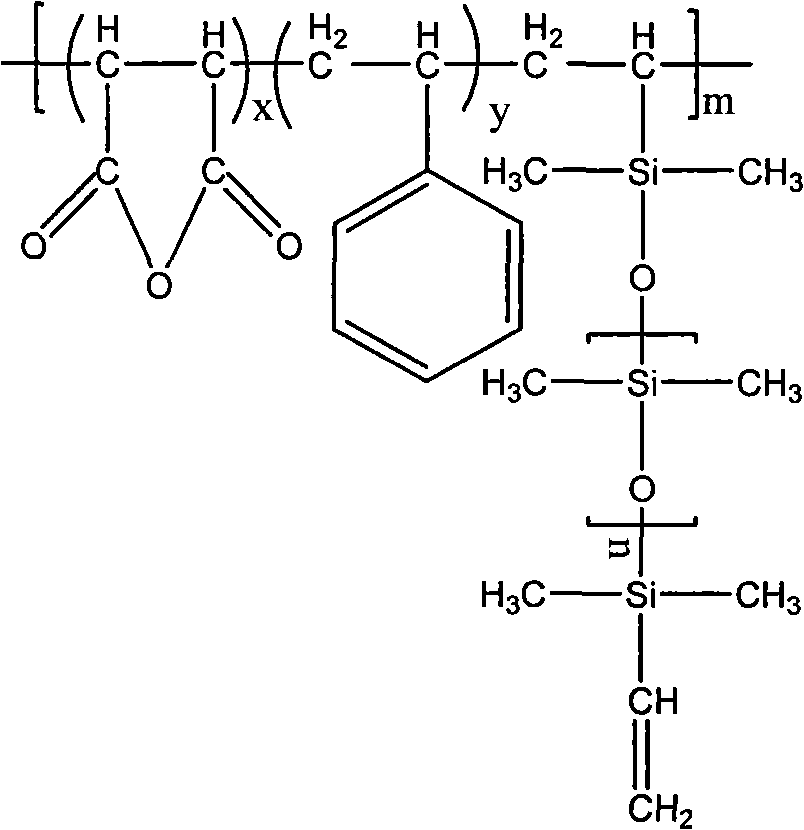

Preparation method of electrophoretic display microcapsule containing organic silicon

ActiveCN101642694AImprove barrier propertiesImprove sealingMicroballoon preparationNon-linear opticsHydrolysatePolymer SMA

The invention discloses a preparation method of electrophoretic display microcapsule containing organic silicon. The microcapsule is prepared by complex coacervation of gelatin and hydrolysate of vinyl-silicone oil-styrene-maleic anhydride terpolymer. Through appropriate technology, encysted object is firstly emulsified in aqueous solution of vinyl-silicone oil-styrene-maleic anhydride terpolymer,gelatin is added, and complex coacervation is carried out by adding acid and / or water. The invention induces organic silicon component into microcapsule wall by providing synthetic macromolecule vinyl-silicone oil-styrene-maleic anhydride terpolymer and utilizes the characteristics of stability and low surface energy of organosilicon chemistry to improve separating capability of the microcapsuleto electrophoretic medium, thus improving storing and working stability of the electrophoretic microcapsule. And stable and sealed spherical microcapsule is prepared by appropriate raw material formula and technology.

Owner:CHANGSHU CHANGJI CHEM

Styrene-maleic anhydride based dispersant in a coating or ink

The invention relates to a composition containing a particulate solid, an organic or aqueous medium, and a copolymer containing less than 25 mol % of residues of monomers comprising a dicarboxylic acid, or anhydride thereof. The invention further relates to novel copolymers, and the use of the copolymers as a dispersant.

Owner:LUBRIZOL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com