Laser electrolytic aluminum coating composition and preparation method thereof

A technology of anodized aluminum and composition, applied in the field of anodized aluminum coatings and their preparation, can solve the problems of high price, large profit margin, increased application amount, etc., and achieve the effects of high bronzing fineness, wide application range, and wide adaptability to temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

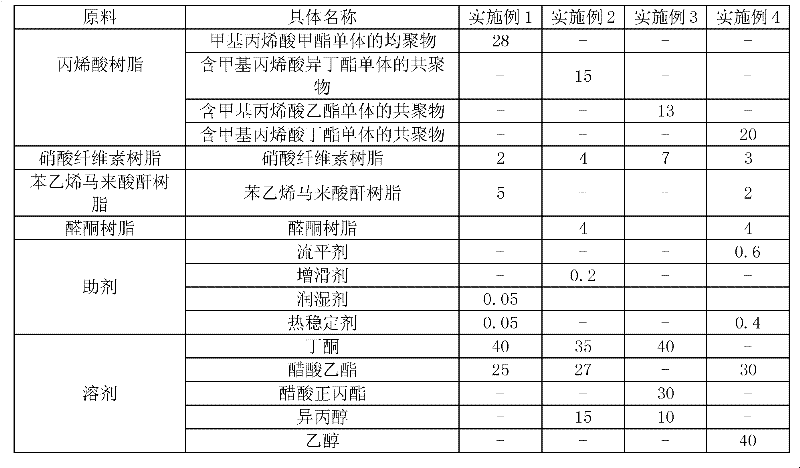

[0030] This embodiment provides a kind of anodized aluminum coating composition for bronzing, its composition and weight are as shown in Table 1, and its preparation method comprises the following steps:

[0031] (1) Put the solvent into the reaction kettle first, that is, 40 kilograms of butanone and 25 kilograms of ethyl acetate are put into the reaction kettle together, and heated to 70 ° C while stirring;

[0032] (2) 2 kilograms of nitrocellulose resin (viscosity is 1 / 16s) are dropped in the reactor, stirred for 0.5 hour;

[0033] (3) Add 28 kilograms of acrylic resin (weight-average molecular weight of 3 to 40,000) and 5 kilograms of styrene maleic anhydride resin into the above solution, and stir at high speed for 4 hours;

[0034] (4) After all the resin is completely dissolved, add 0.1 kg of additives and disperse at high speed for 1 hour;

[0035] (5) Stir slowly until the solution is cooled, then put it into the packaging barrel.

[0036] The paint obtained above ...

Embodiment 2

[0038] This embodiment provides a kind of anodized aluminum coating composition for bronzing, its composition and weight are as shown in Table 1, and its preparation method comprises the following steps:

[0039] (1) First put the solvent into the reactor, namely 35 kg of methyl ethyl ketone, 27 kg of ethyl acetate, and 15 kg of isopropanol, put them into the reactor together, and heat to 55 ° C while stirring;

[0040] (2) 4 kilograms of nitrocellulose resin (viscosity is 1 / 8s) are dropped in the reactor, stirred for 0.7 hours;

[0041] (3) Add 15 kg of acrylic resin (1.5-30,000 weight average molecular weight) and 4 kg of aldehyde and ketone resin into the above solution, and stir at high speed for 2 hours;

[0042] (4) After all the resin is completely dissolved, add 0.2 kg of additives and disperse at high speed for 1 hour;

[0043] (5) Stir slowly until the solution is cooled, then put it into the packaging barrel.

[0044] After the paint obtained above is coated, it i...

Embodiment 3

[0046] This embodiment provides a kind of anodized aluminum coating composition for bronzing, its composition and weight are as shown in Table 1, and its preparation method comprises the following steps:

[0047] (1) First put the solvent into the reactor, namely 40 kg of methyl ethyl ketone, 30 kg of n-propyl acetate, and 10 kg of isopropanol, put them into the reactor together, and heat to 40°C while stirring;

[0048] (2) 7 kilograms of nitrocellulose resin (viscosity is 5s) are dropped in the reactor, stirred for 1.0 hour;

[0049] (3) Add 13 kg of acrylic resin (weight average molecular weight: 0.5 to 15,000) into the above solution, and stir at high speed for 3 hours;

[0050] (4) Stir slowly until the solution is cooled, then put it into the packaging barrel.

[0051] The paint obtained above is low in cost and simple in operation process. After coating, it is tested by molding and hot stamping, and the molding temperature is low, and the fineness of hot stamping is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com