Patents

Literature

2718 results about "Hot stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot stamping or foil stamping is a printing method of relief printing in which pre-dried ink or foils are transferred to a surface at high temperatures. The non-polluting method has diversified since its rise to prominence in the 19th century to include a variety of colors and processes. After 1970s, hot stamping became one of the important methods of decoration on the surface of Plastic Products. Hot Stamping technology for plastic is now using for Electric Components (including TV frame, Audio components, Refrigerators etc.,) cosmetic containers (lipstick, cream, mascara, shampoo bottle etc), automobile parts (interior and exterior materials).

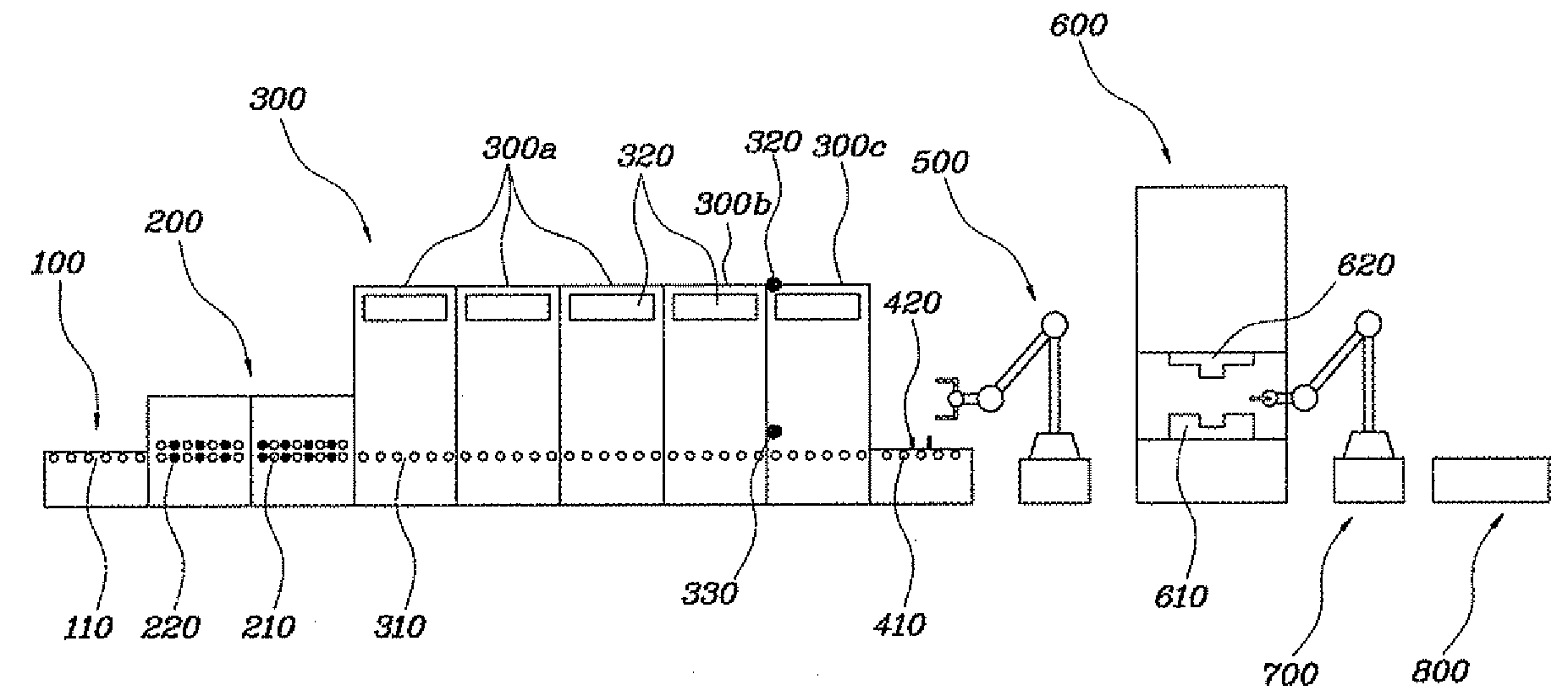

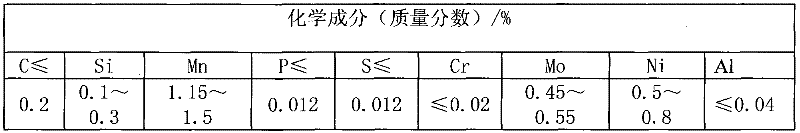

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

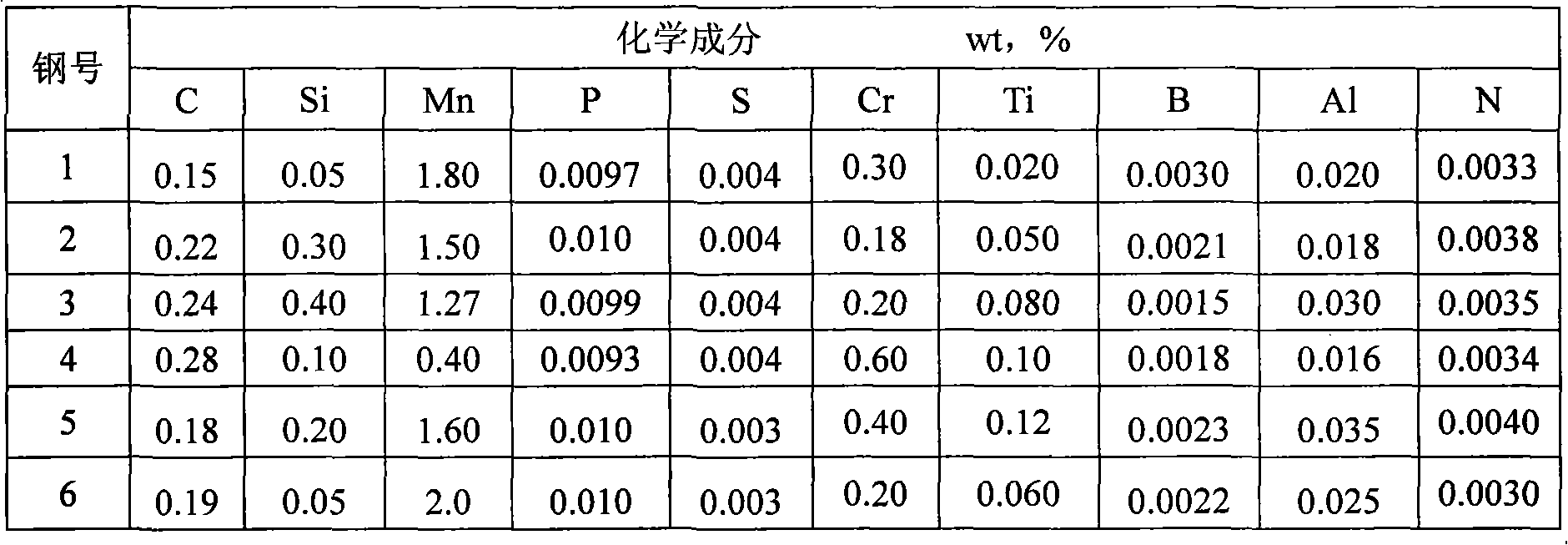

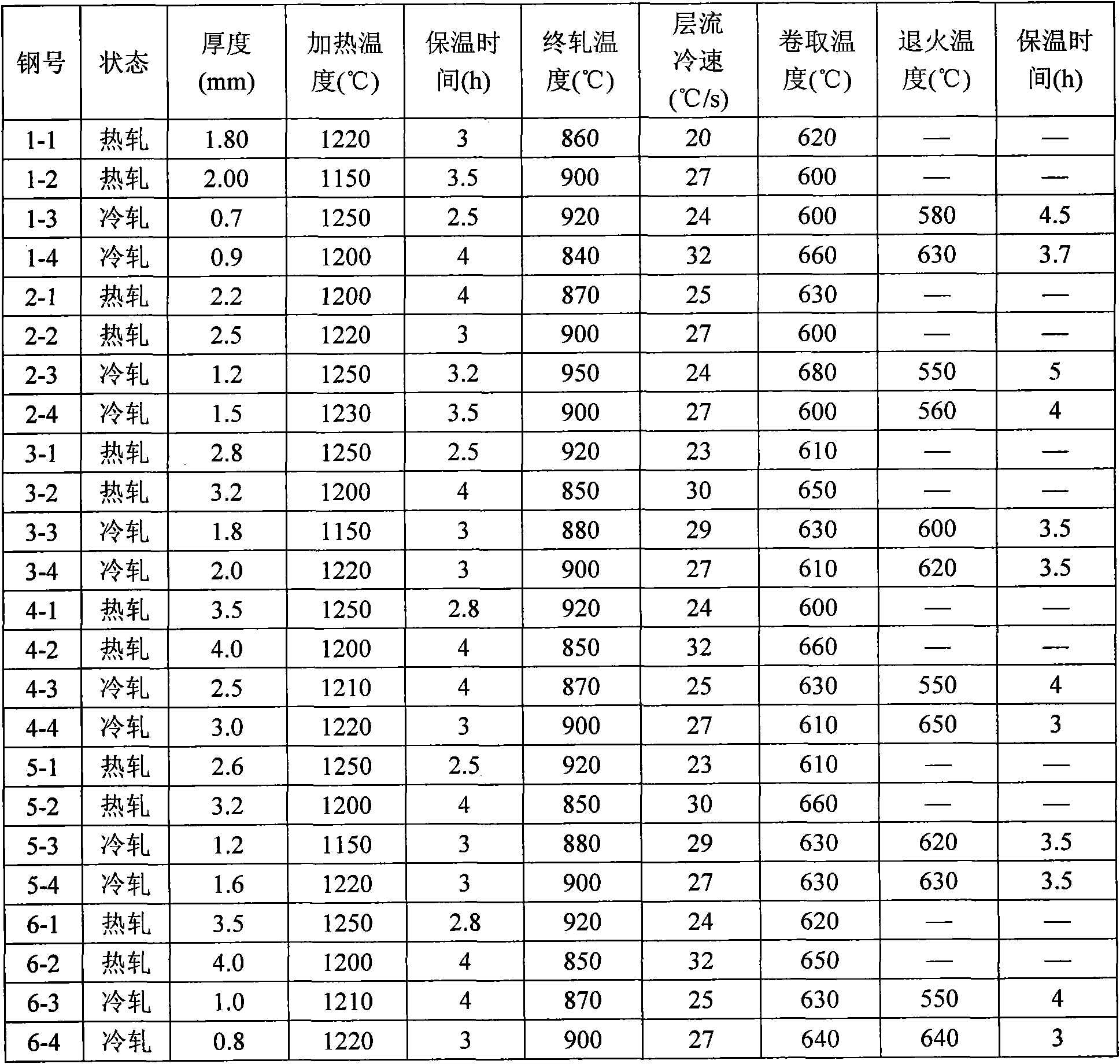

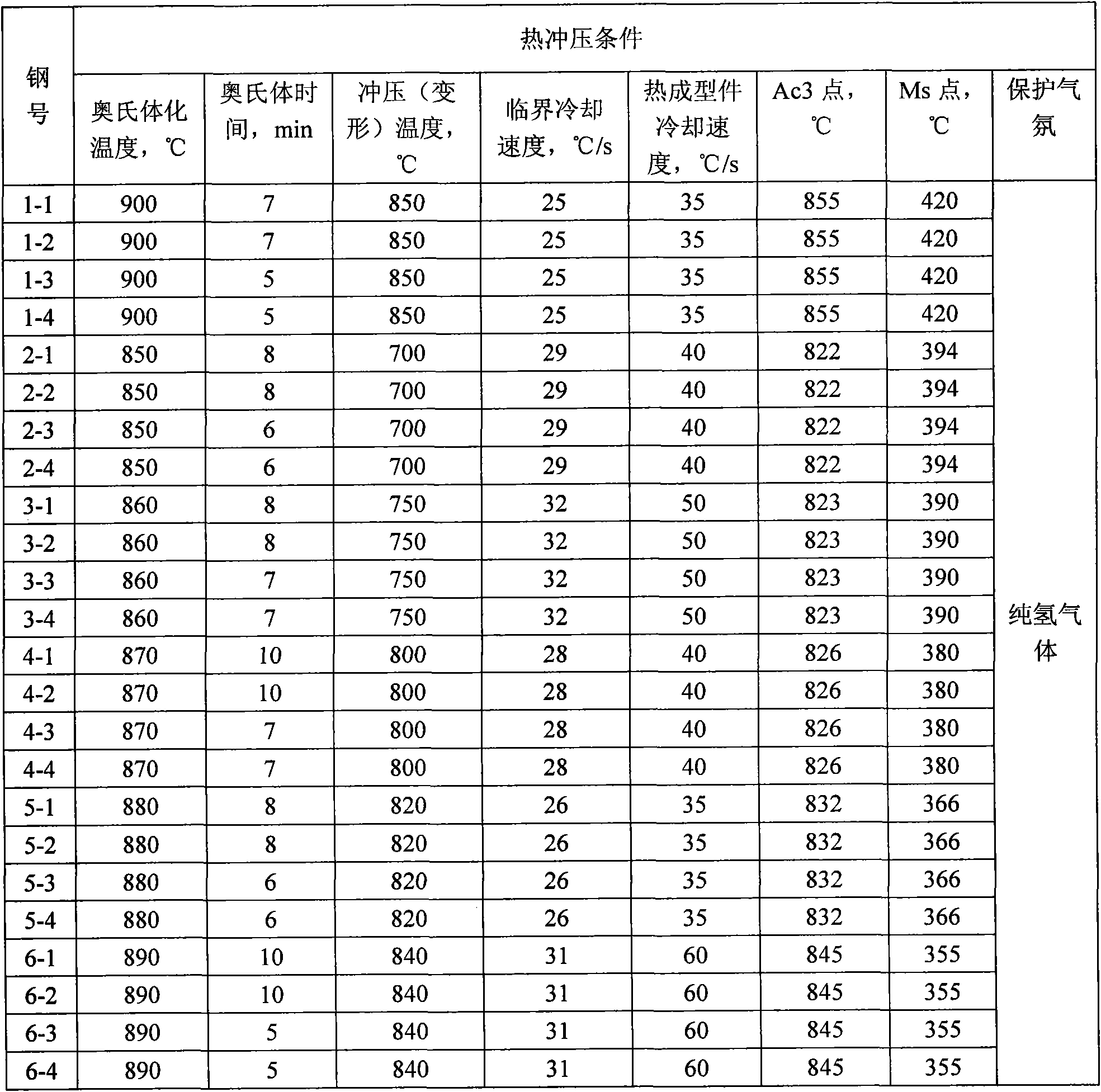

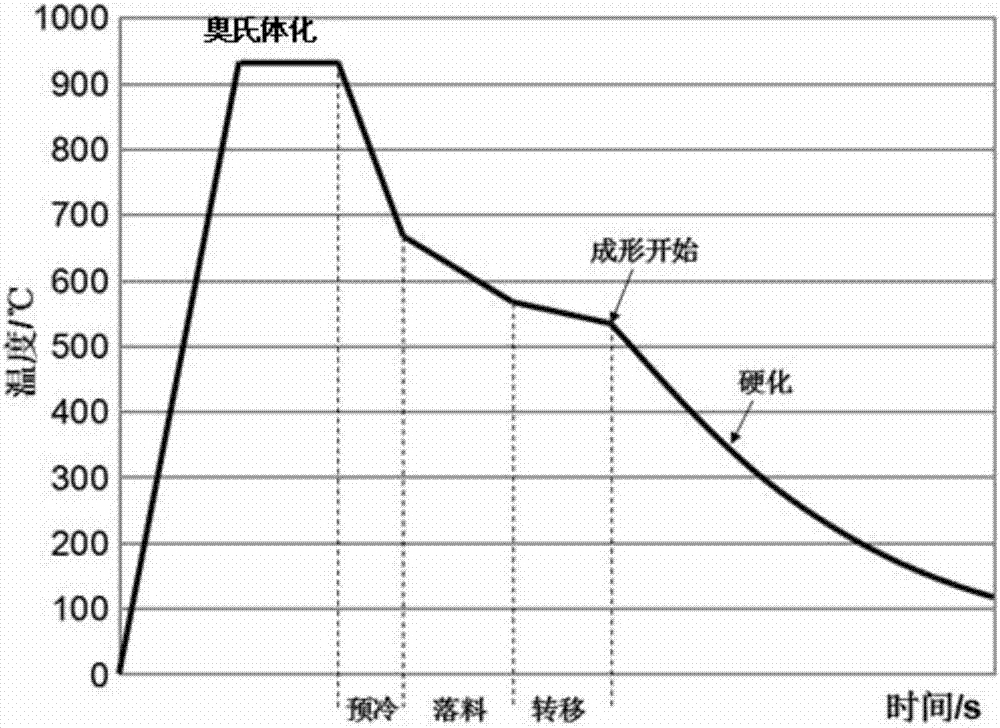

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

Steel plate for hot stamping, hot stamping process and hot-stamped member

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

Hot stamping and superplastic gas-bulging combined forming process

InactiveCN101786128ARelaxed Grain Size RequirementsLow costVehicle componentsQuality processHot stamping

The invention provides a new process of quick superplastic forming of automotive body parts of aluminum alloy automobiles, which is mainly characterized in that hot stamping is combined with superplastic gas-bulging forming, so that the advantages of the hot stamping and the superplastic gas-bulging forming are relatively complemented to achieve the aim of quick superplastic forming. The process reduces the requirements of the conventional superplastic forming on grain sizes of sheet materials, and allows for the use of ordinary commercial aluminum alloy sheet materials. Compared with a cold stamping process, the new process has the advantages of overcoming the drawbacks of cracks and large springback, along with fewer working procedures and high yield; and compared with the conventional superplastic forming process, the new process improves the forming speed obviously, and reduces the material cost. The new process eliminates the technical barriers in making light weight automobile bodies of the low and medium-grade automobiles by using aluminum alloy, and is an efficient and high-quality process for the mass production of the automobile bodies of the aluminum alloy automobiles.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

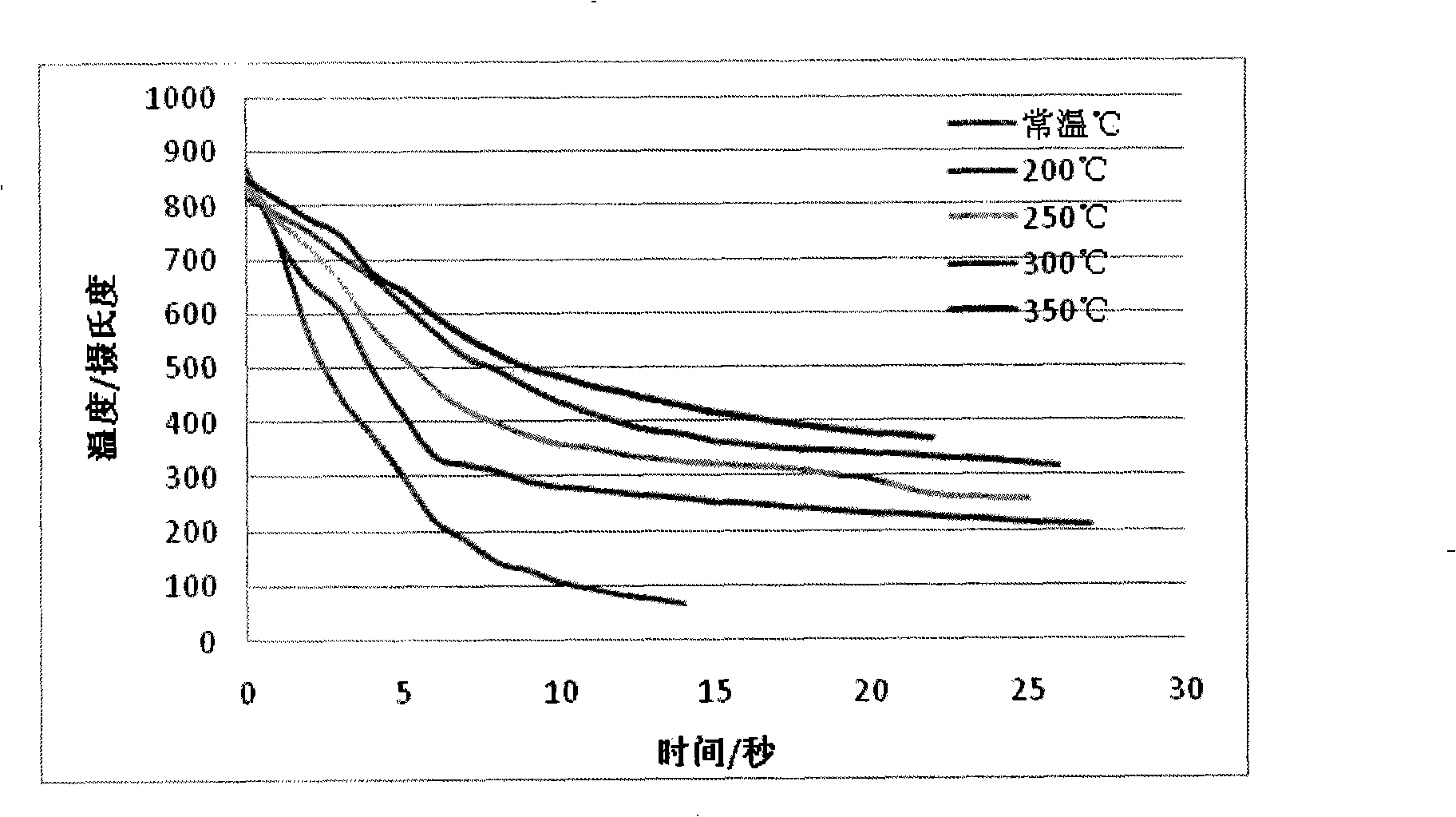

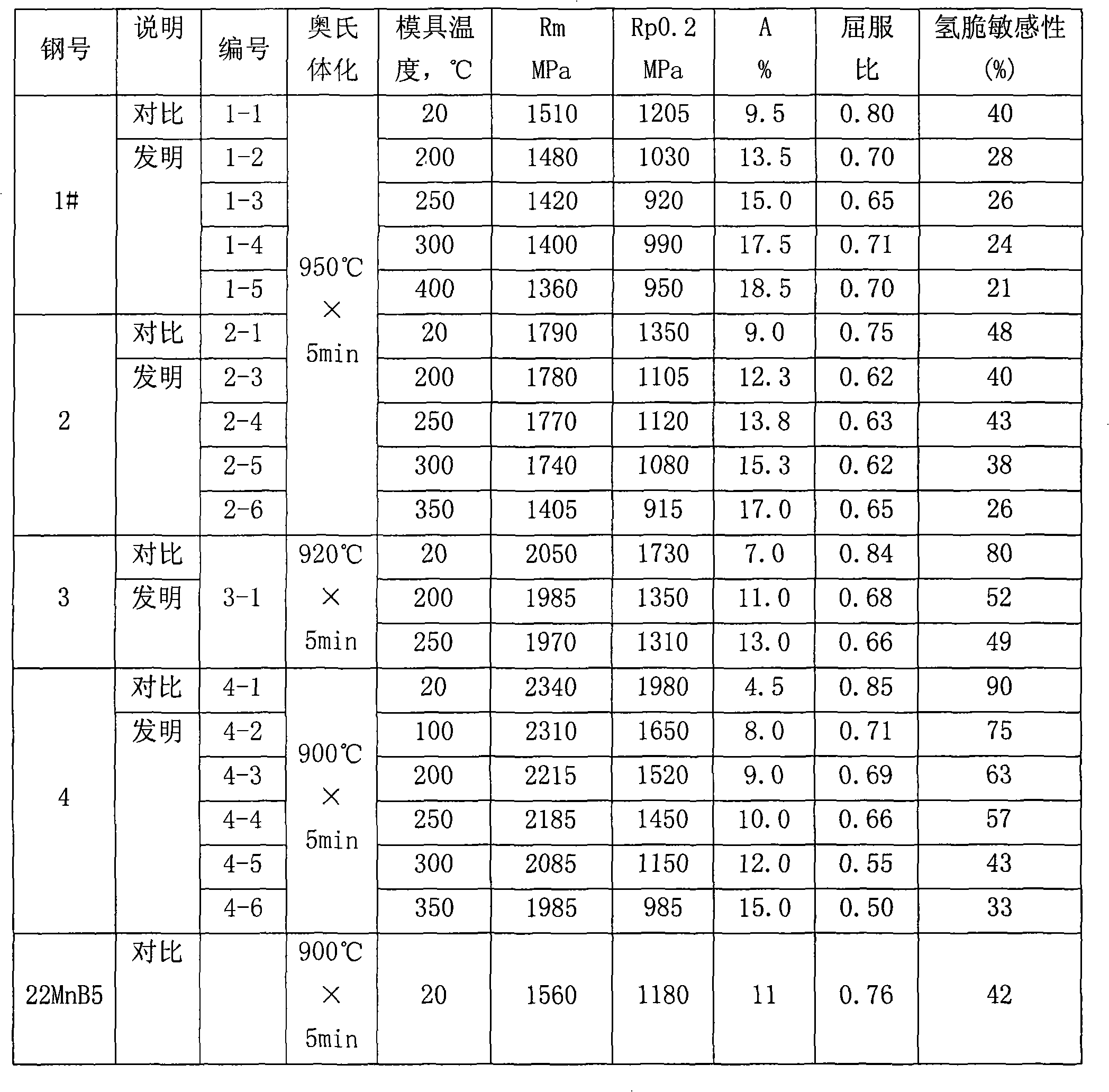

High-safe high-precision producing method of thermoforming martensitic steel parts

InactiveCN101280352AGuaranteed Hardenability RequirementsLow yield ratioShaping toolsHot stampingSheet steel

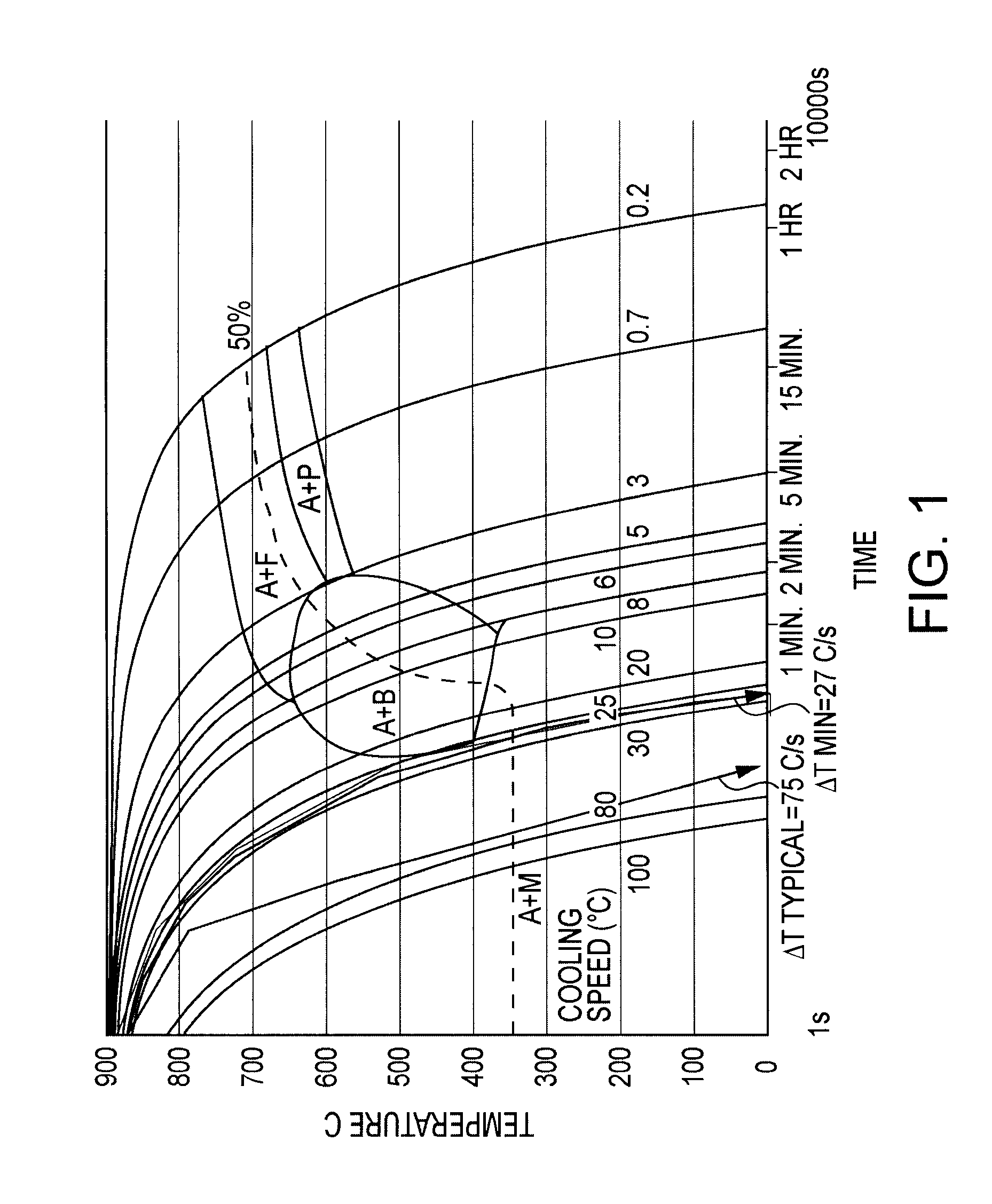

The invention provides a high security, high accuracy and thermal forming martensite steel part preparing method, which belongs to the field of obtaining controlling and cooling technology of the hot stamping forming part of the alloy steel plate, the martensite works as the matrix structure of the alloy steel plate. The method adopts the processes as follows: a steel plate is heated to 20 to 250 DEG C above the Ac3 temperature, therefore an austenite structure can be obtained, then the steel plate is transferred to the stamping die for forming by stamping; simultaneously, the temperature of the stamping die is controlled in a range of 100 to 400 DEG C, 5 to 60 seconds later after stamping forming, the formed component parts can be taken out of the stamping die. The method has the advantages that a well ductility and security can be obtained, and the anti-susceptibility of the steel can be greatly enhanced.

Owner:CENT IRON & STEEL RES INST

Ultrahigh-strength steel laser tailor welded blank and forming process thereof

InactiveCN102162574AGood formabilityReduce weightSheets/panelsLaser beam welding apparatusHot stampingRoom temperature

The invention relates to an ultrahigh-strength steel laser tailor welded blank and a forming process thereof. The forming process provided by the invention comprises the following steps: carrying out the laser tailor welding on ultrahigh-strength steel and high-strength steel according to the needed shape; then, delivering the obtained welded blank to a furnace filled with a protective gas and heating to 920-940 DEG C to be continued for at least 5 minutes; fully austenitizing; transferring the austenitized welded blank to a press machine to be rapidly molded and formed; cooling to 100-150 DEG C through pressurization quenching; and cooling along room temperature to obtain the needed parts. The hot stamping process of the laser tailor welded blank provided by the invention has the double advantages of the forming and hot stamping forming of the laser tailor welded blank and simultaneously solves the problems that the ultrahigh-strength steel is difficultly applied to the production ofautomobile structural components / framework components in a laser tailor welded blank mode.

Owner:SHANDONG JIANZHU UNIV

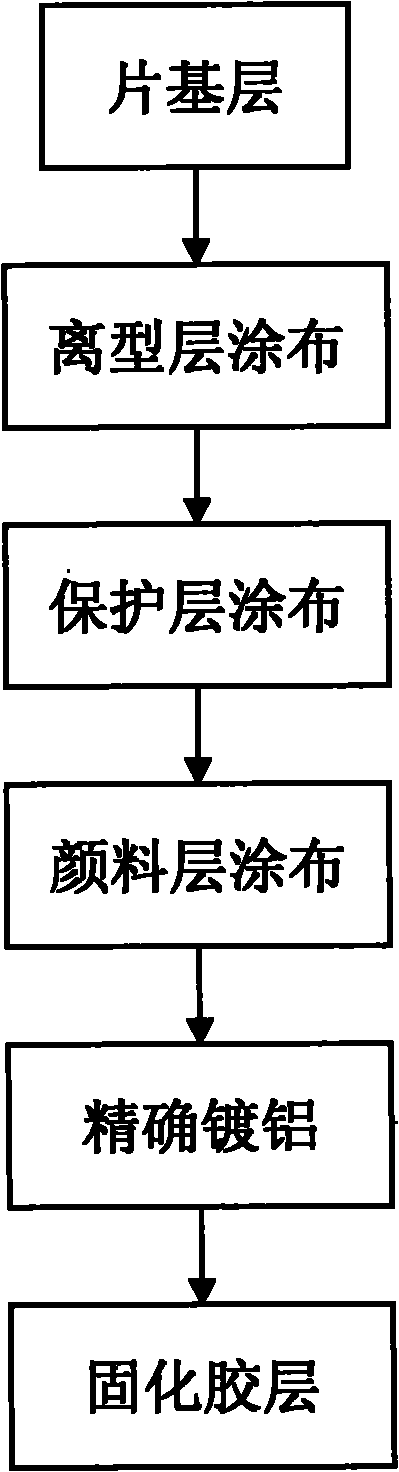

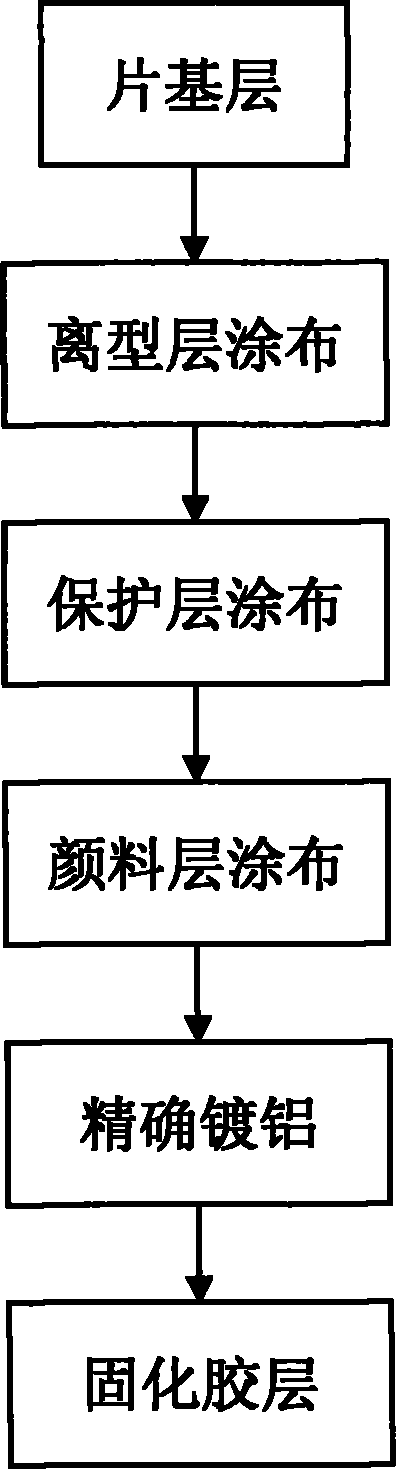

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

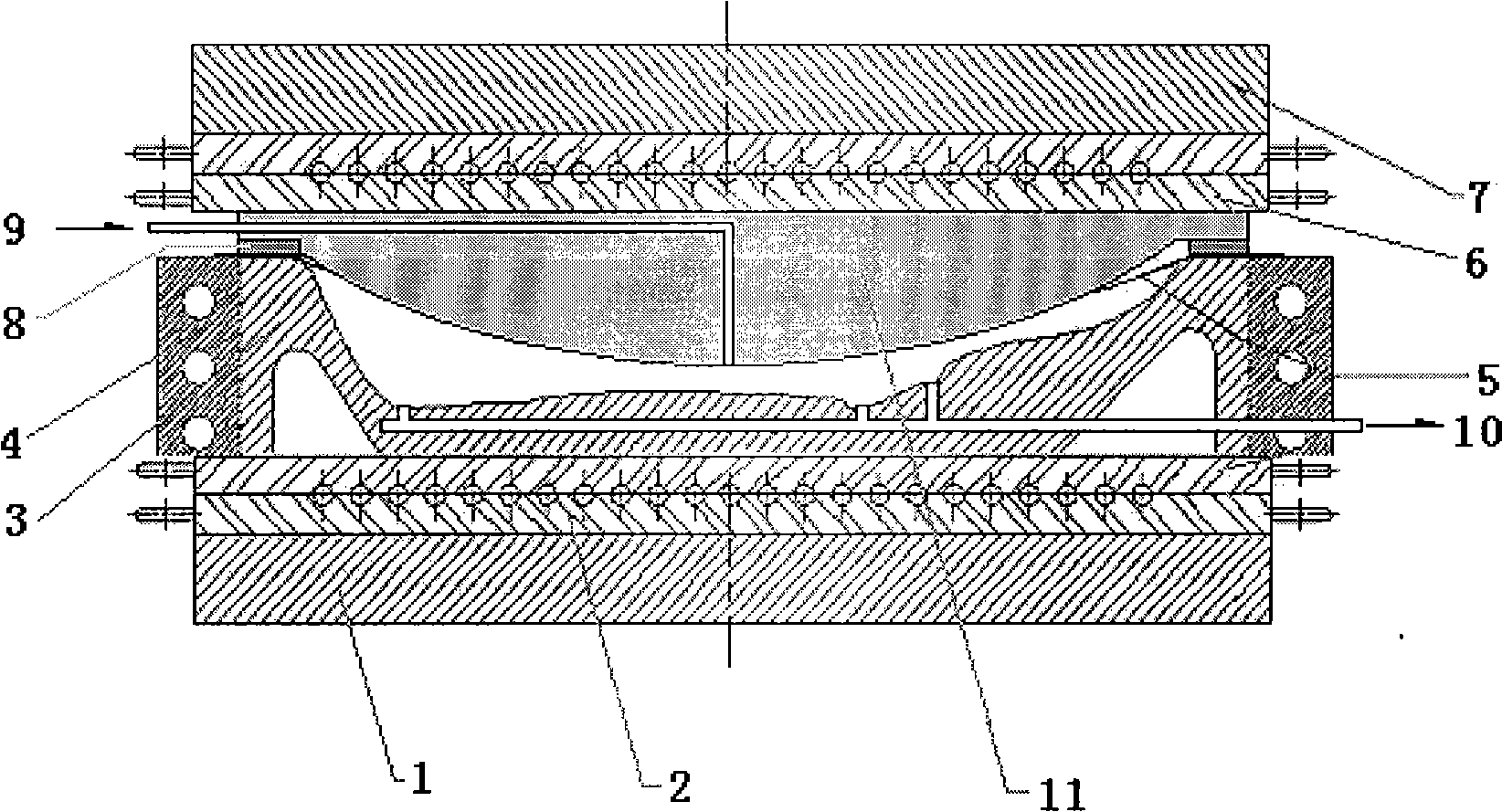

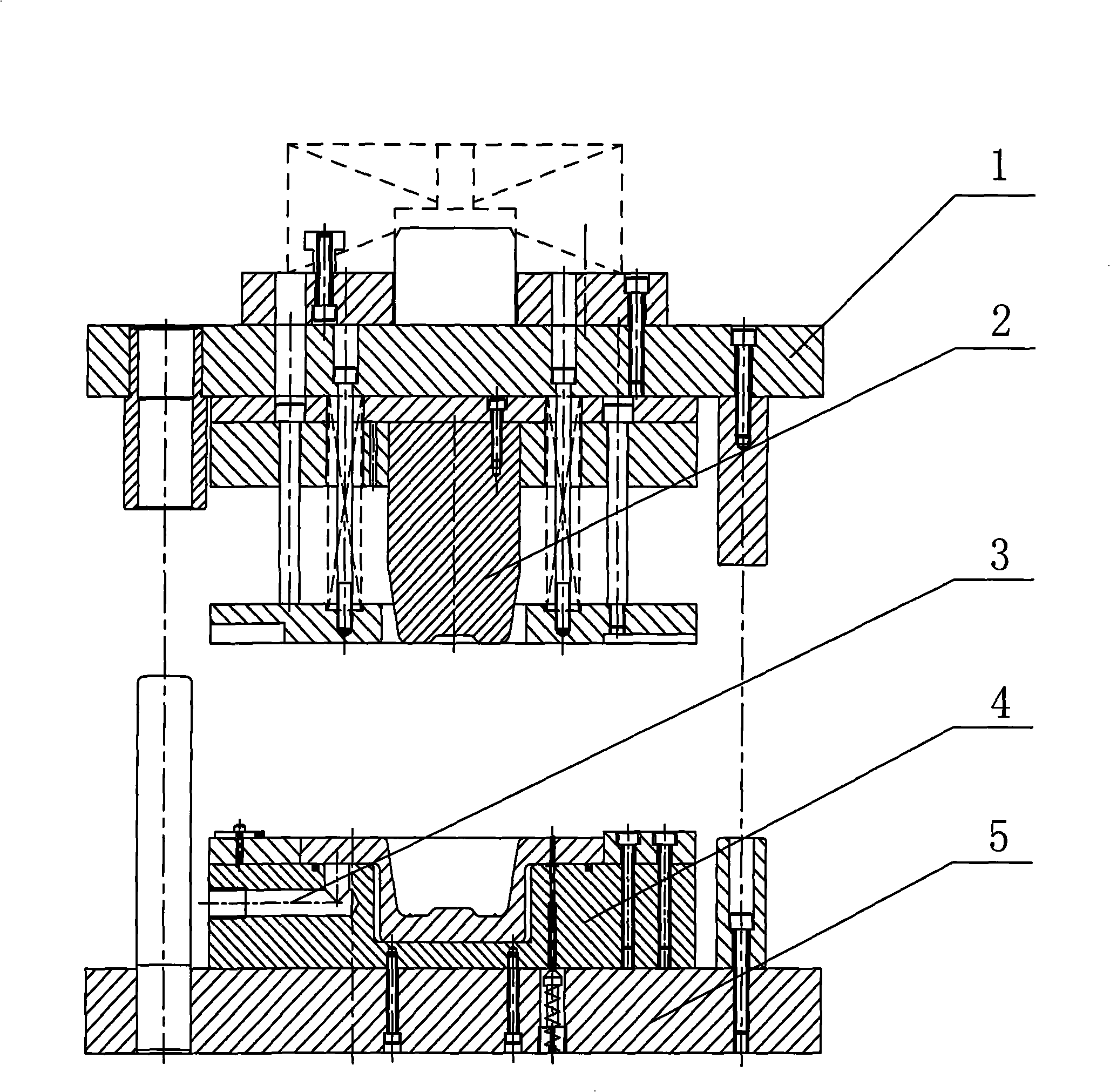

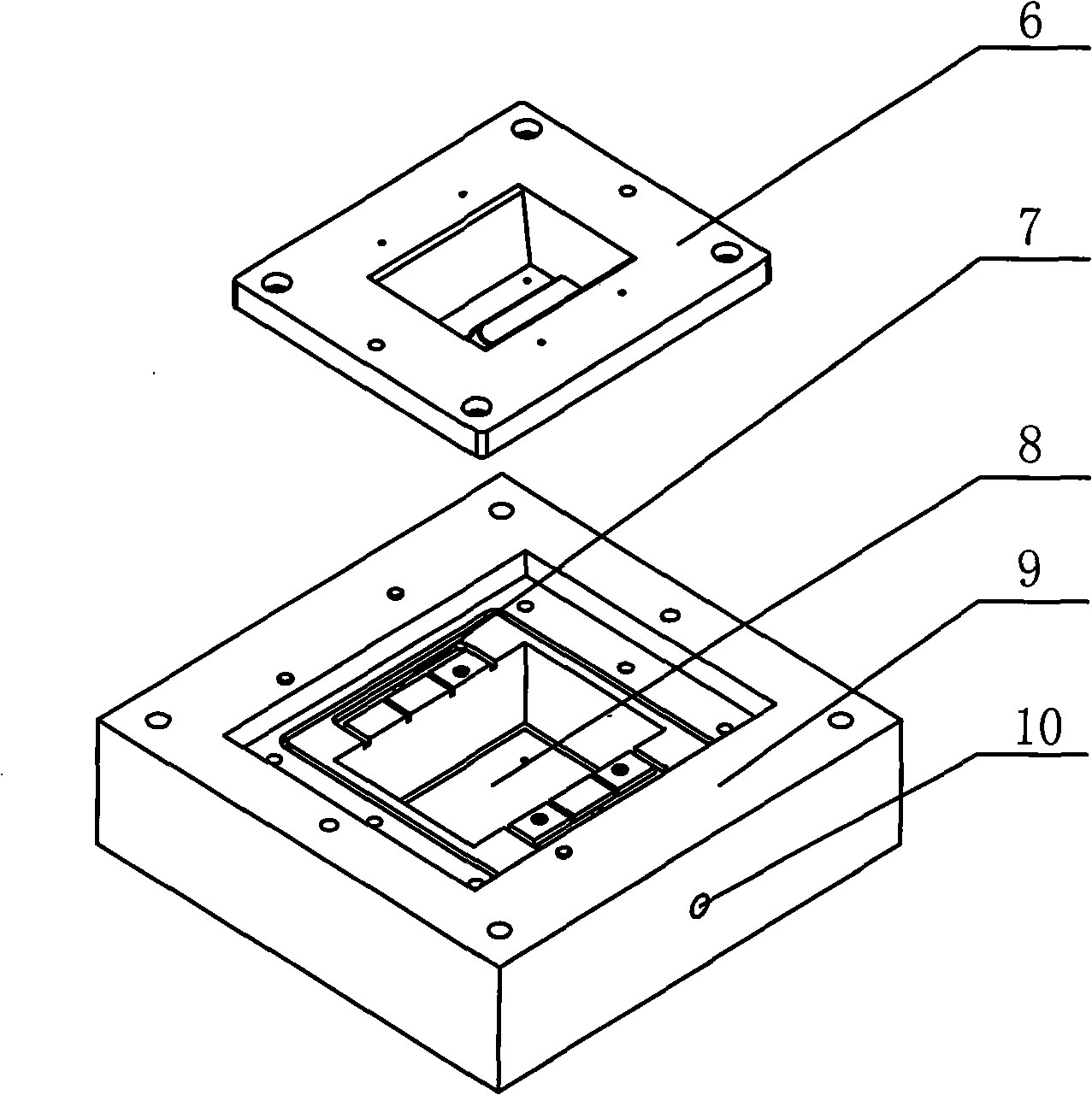

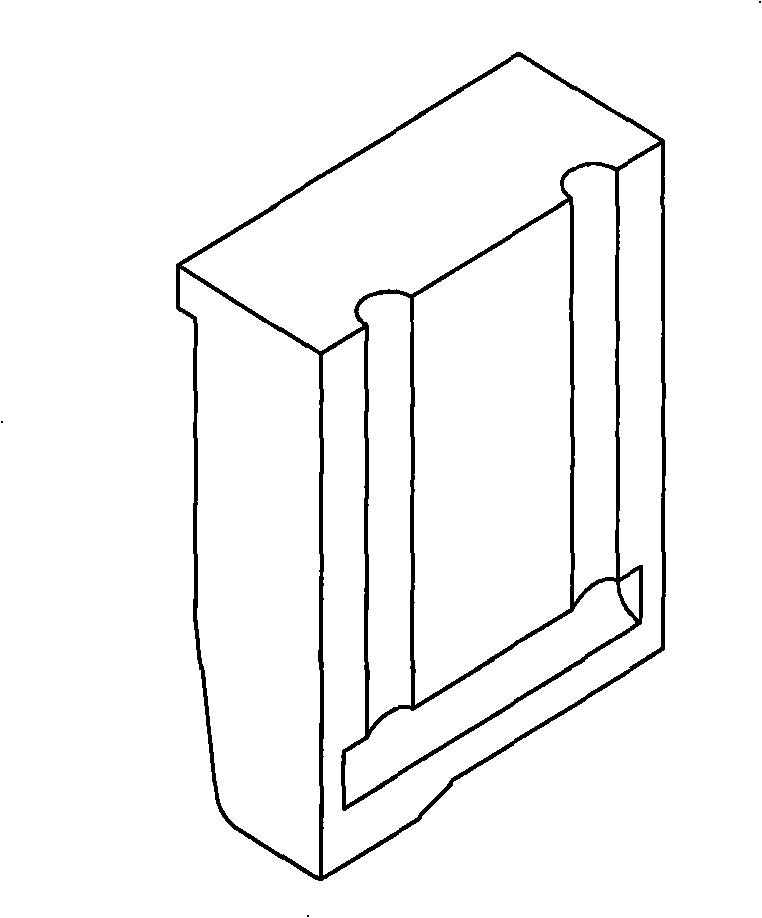

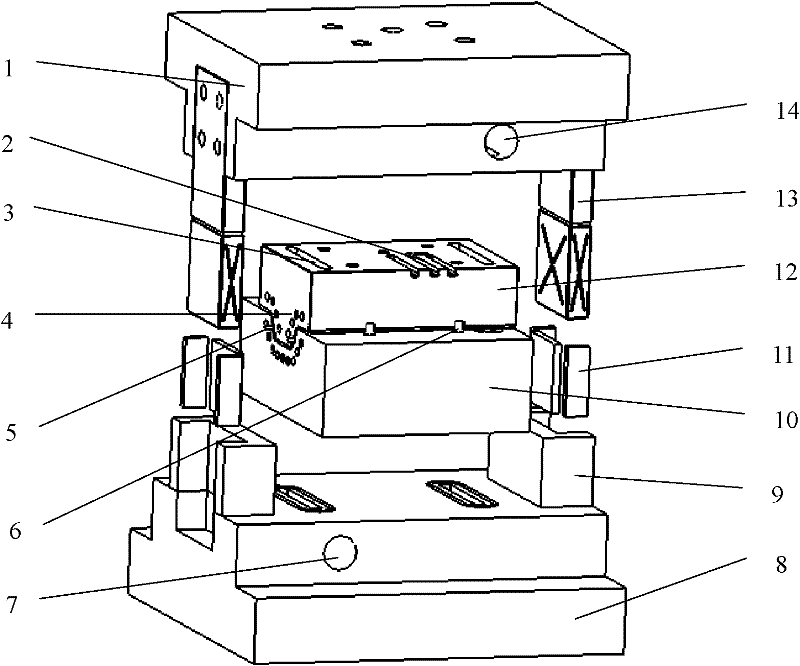

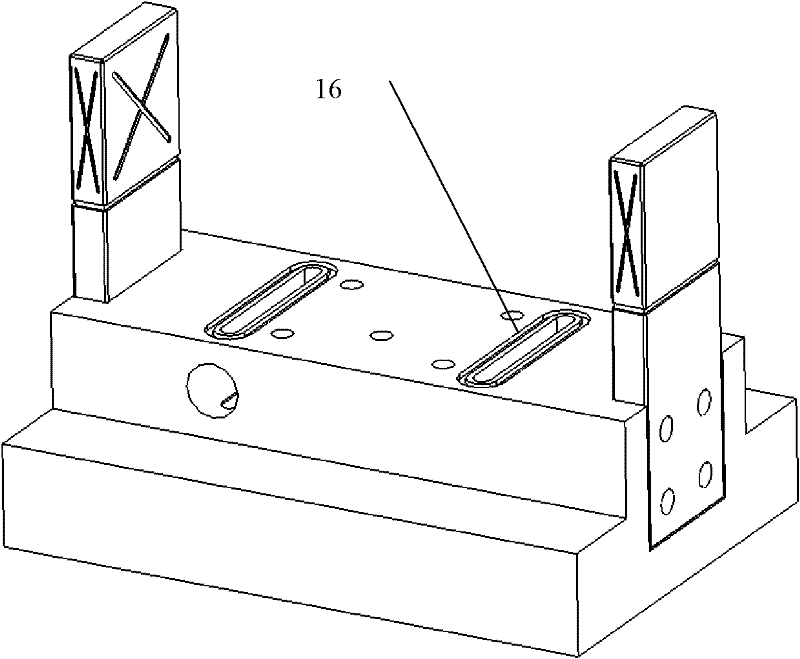

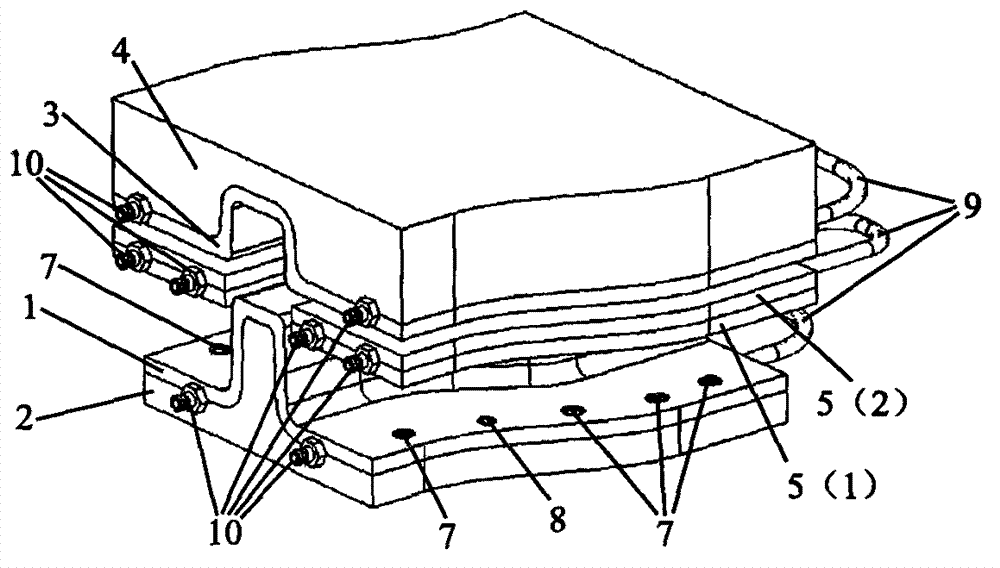

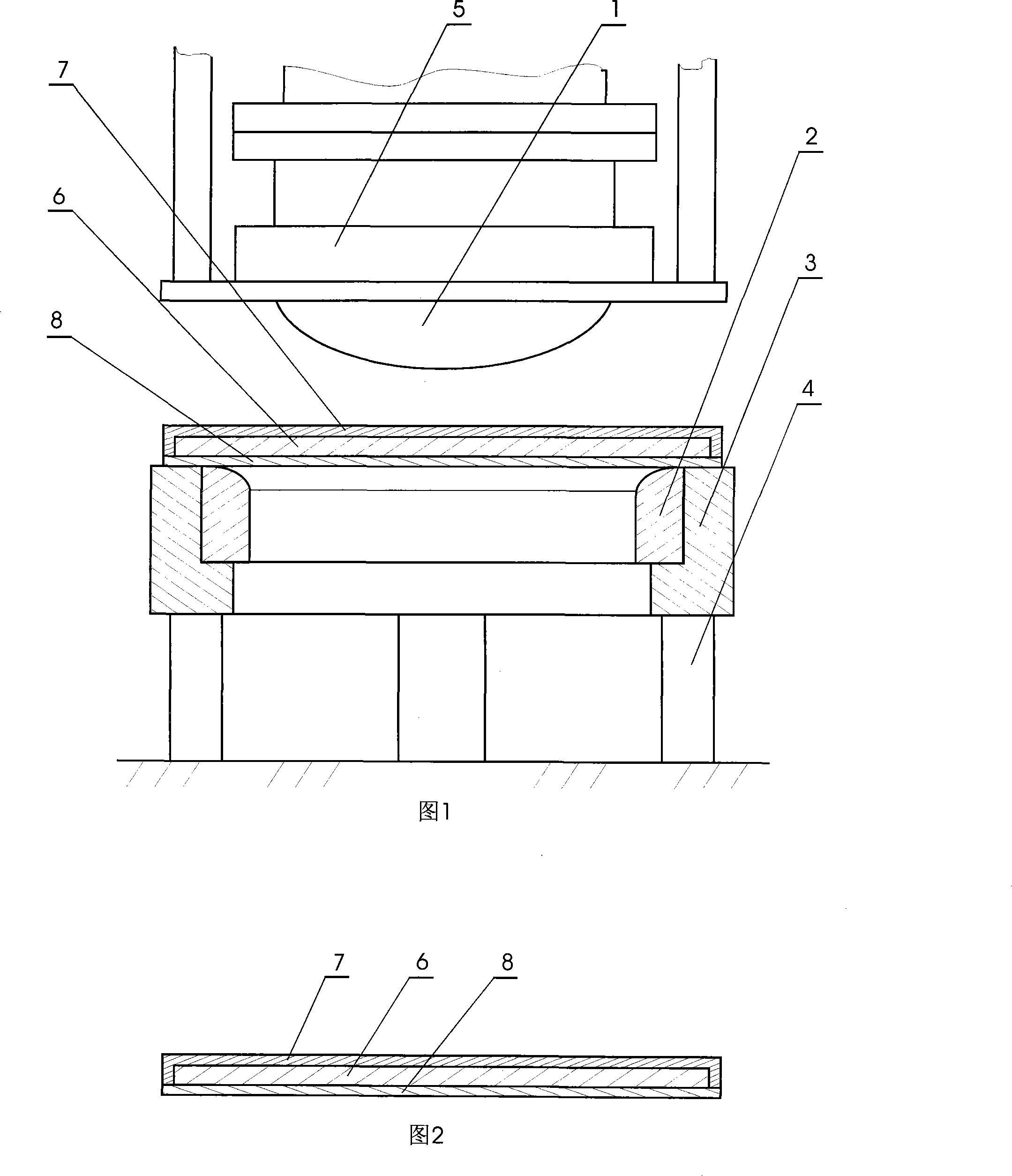

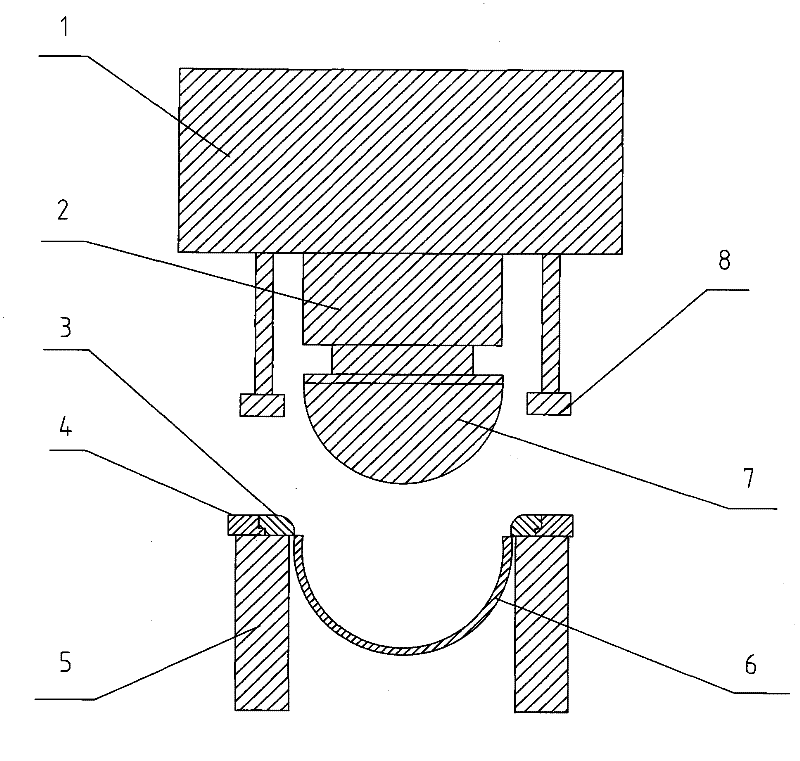

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

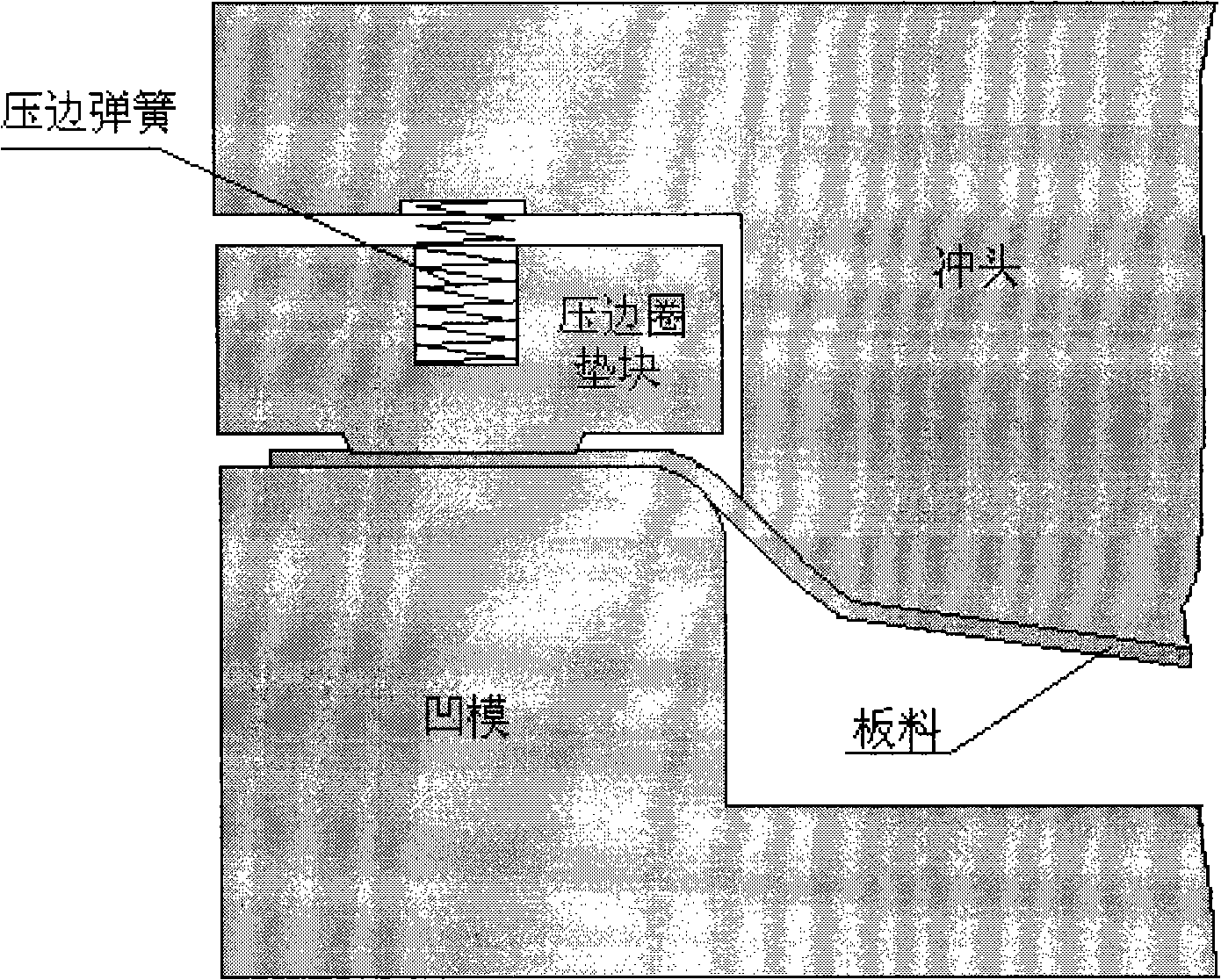

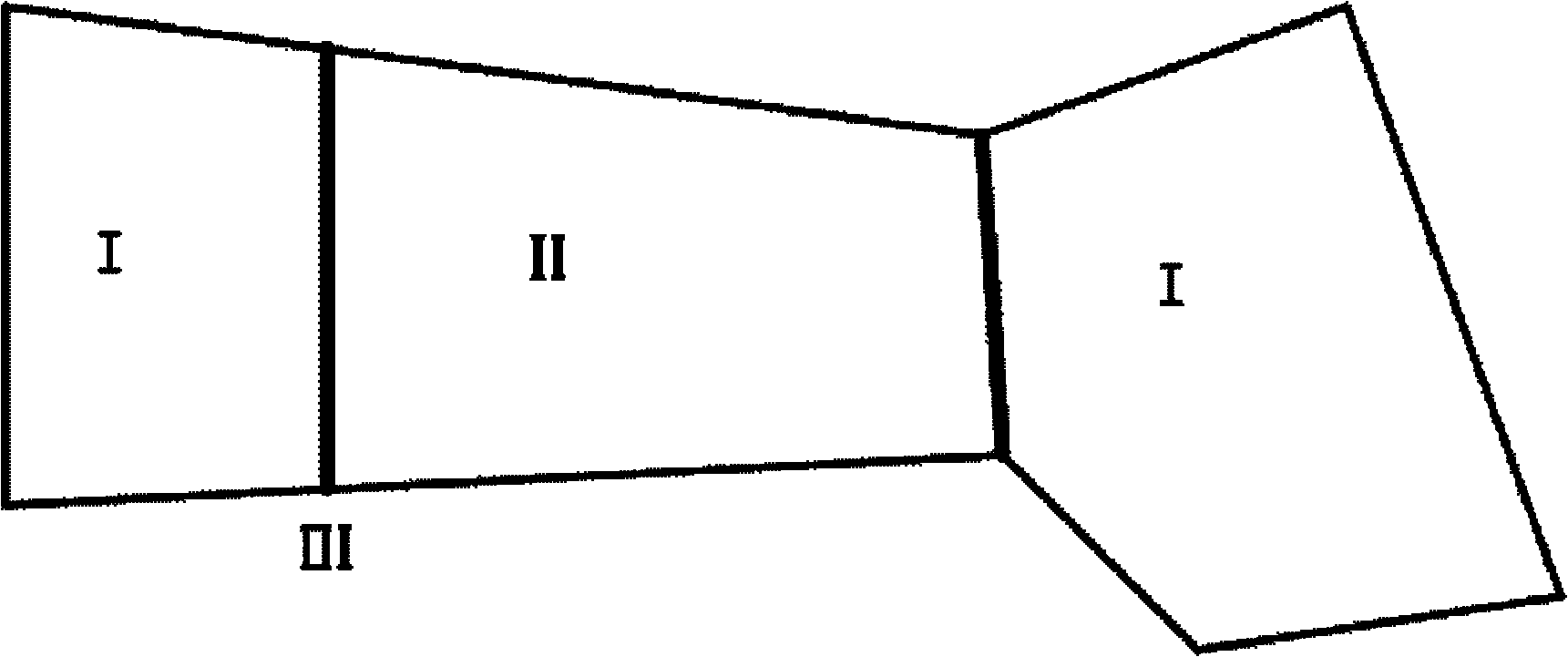

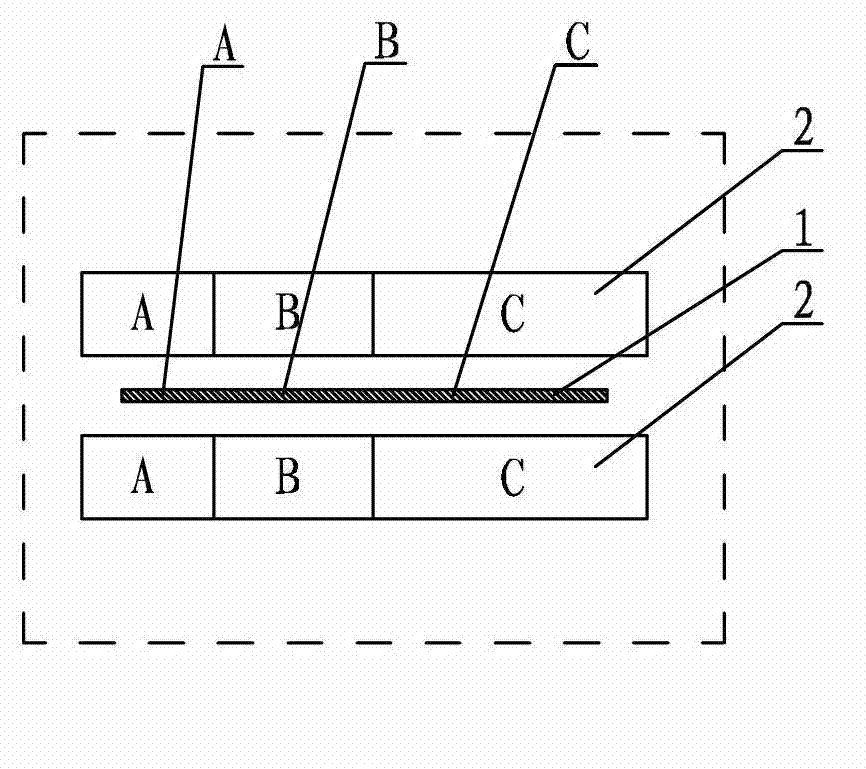

Hot stamping forming method for variable strength distribution strong-strength steel plate part

InactiveCN103028645AImprove efficiencyReasonable intensity distributionShaping toolsPressesHot stampingHeating time

The invention discloses a hot stamping forming method for a variable strength distribution strong-strength steel plate part, relates to a hot-stamping forming method for a strong-strength steel plate part, and aims to solve the problems of difficulty in the effective adjustment of strength of different parts and incapability of obtaining rational strength distribution in a hot stamping forming process of a strong-strength steel plate. The method comprises the following steps of: 1, placing a strong-strength steel plate blank to be formed into a heater, and performing zonal control on first, second and third zones of the heater by correspondingly adopting different or the same heating temperature and different or the same heating time; 2, quickly transferring the heated strong-strength steel plate blank into a forming die within 3 to 5 seconds, quickly closing the forming die, and forming the strong-strength steel plate blank within 1 to 3 seconds; 3, keeping the forming die closed, and introducing cooling water into cooling holes in the forming die to reduce the temperature of the forming die to quench the strong-strength steel plate part; and 4, after the quenching is completed, opening the forming die, and taking out the obtained strong-strength steel plate part. The method is used for the hot forming of the strong-strength steel plate.

Owner:HARBIN INST OF TECH

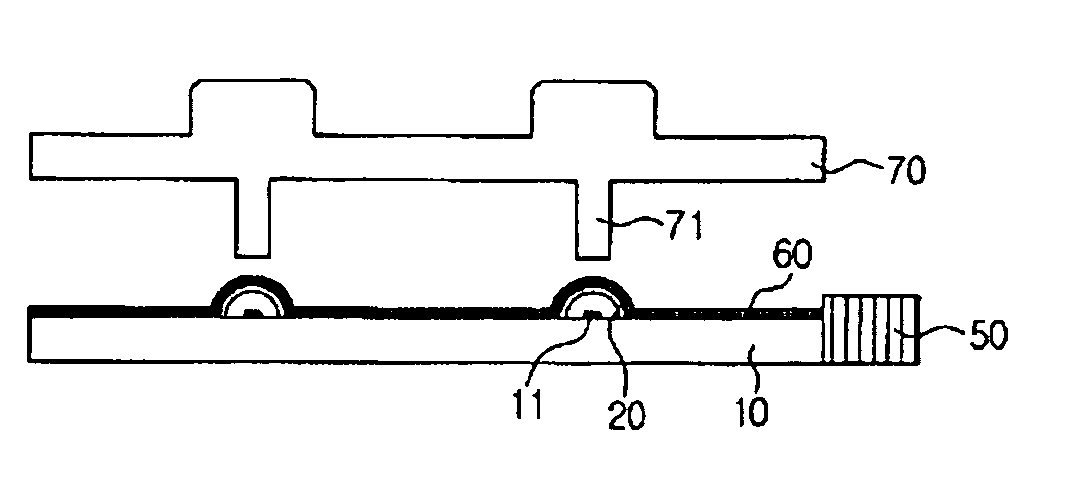

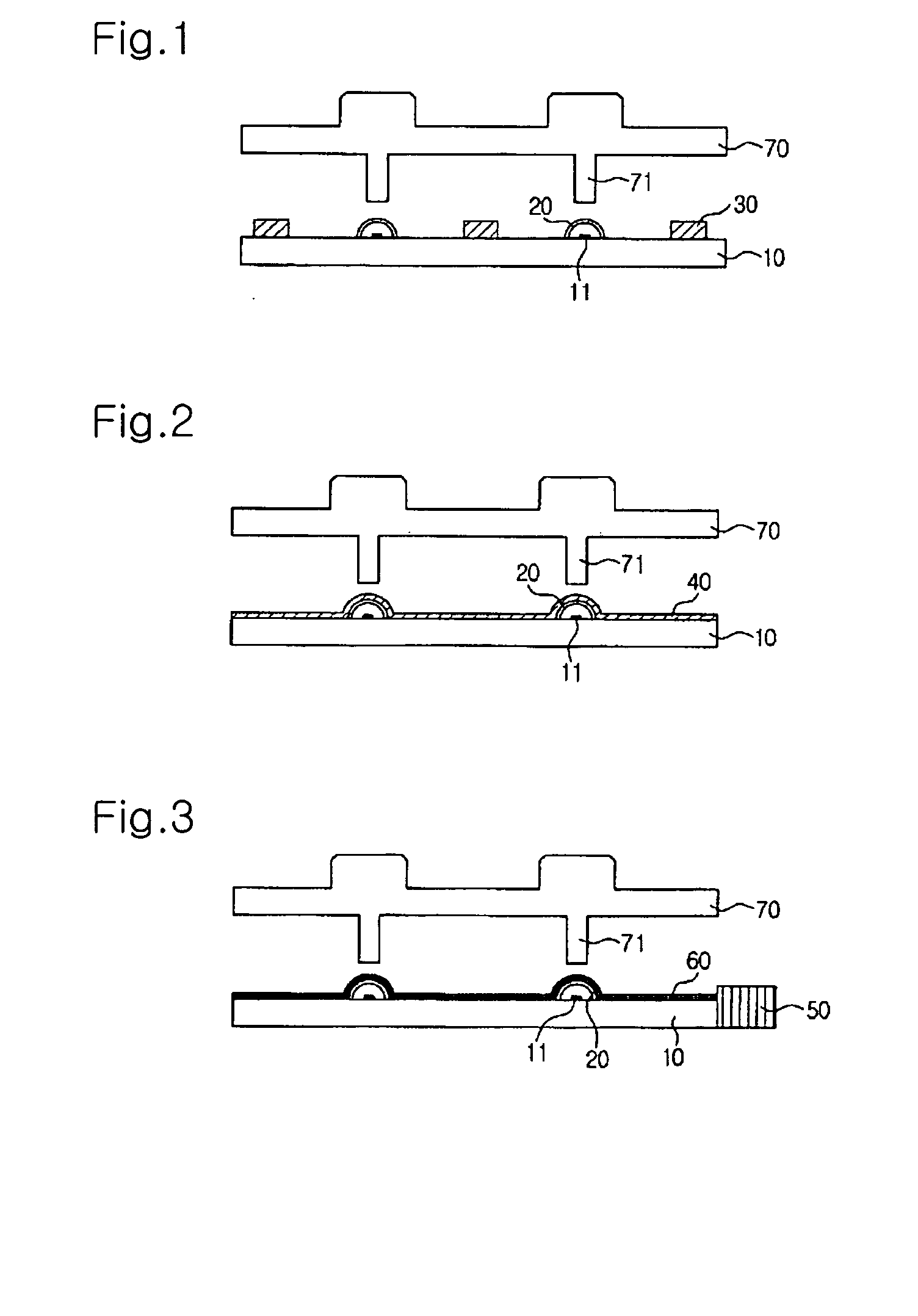

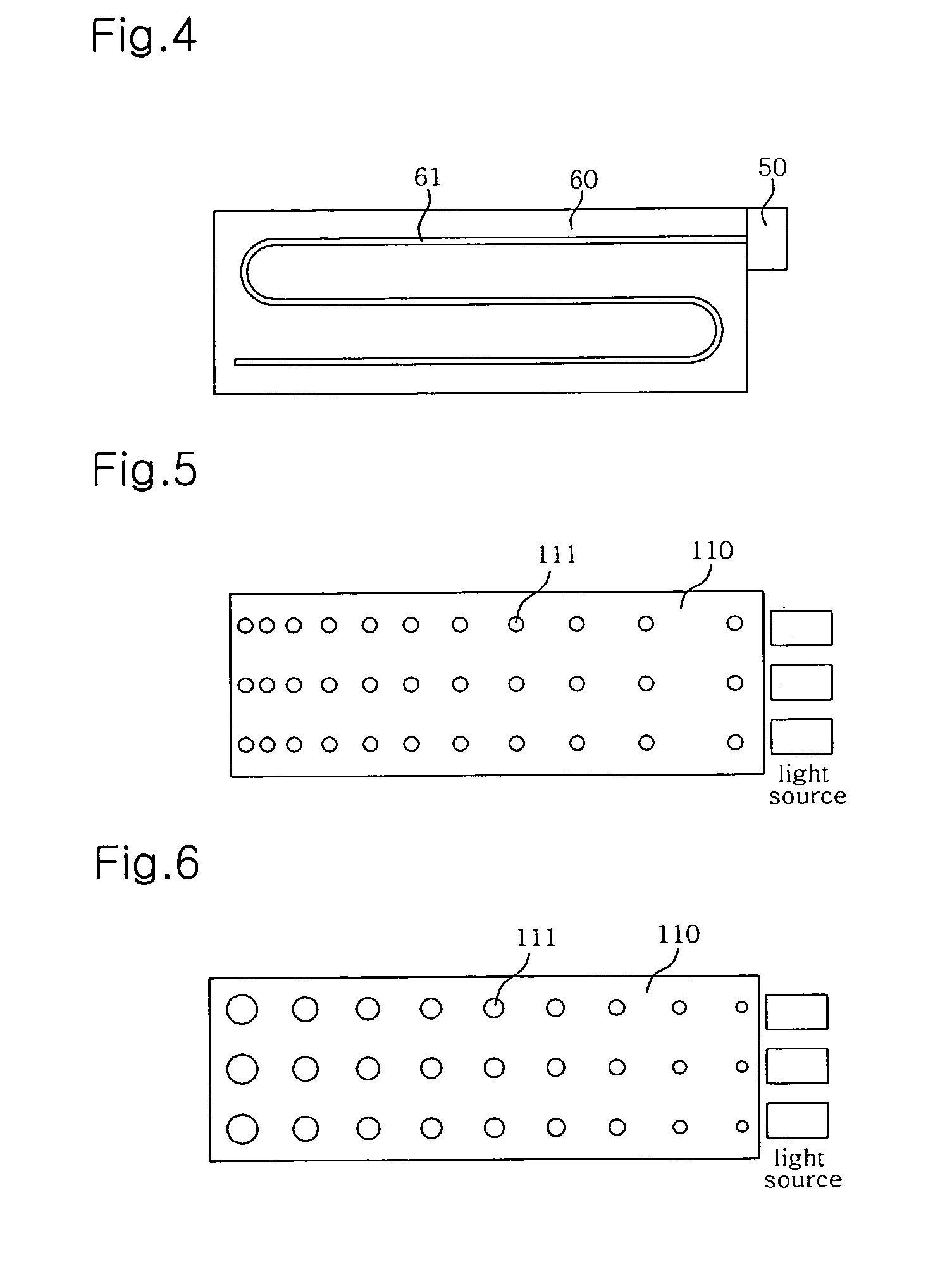

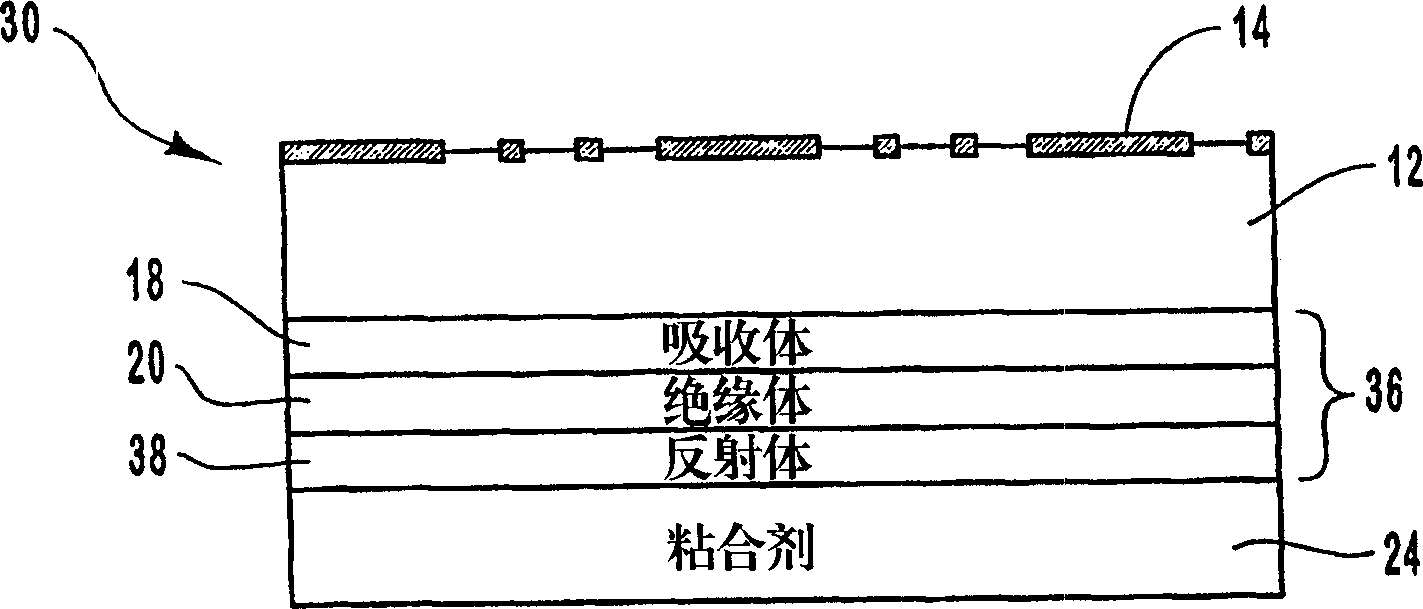

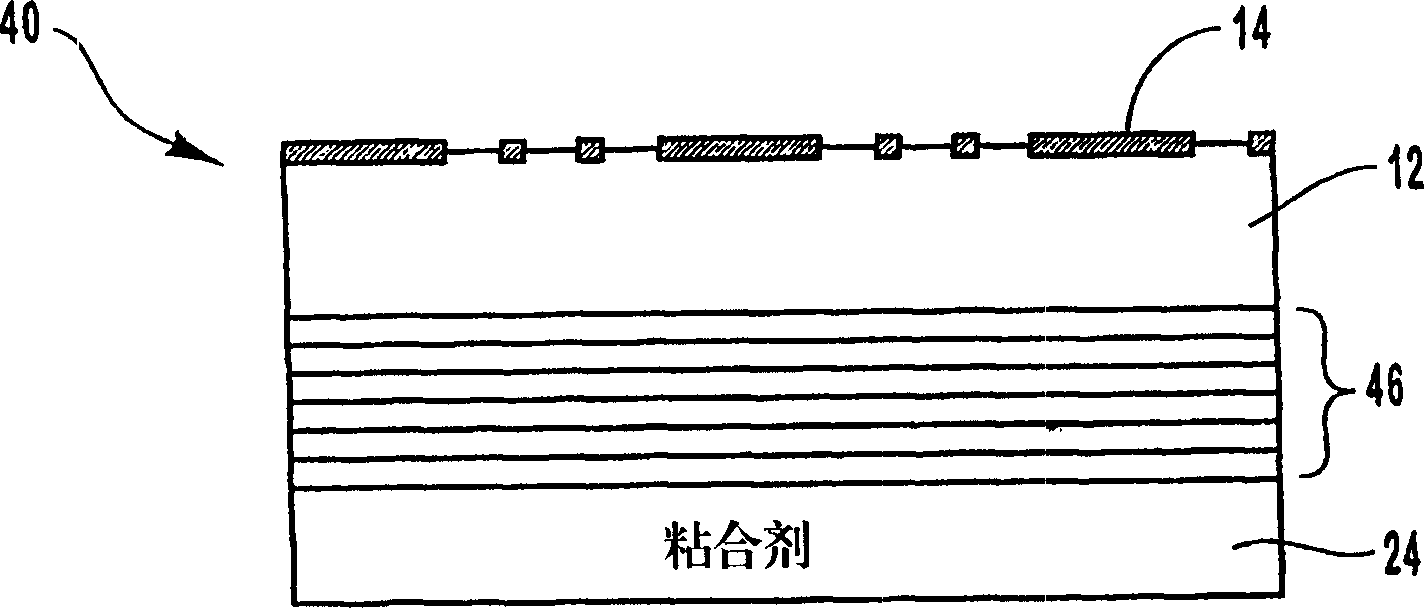

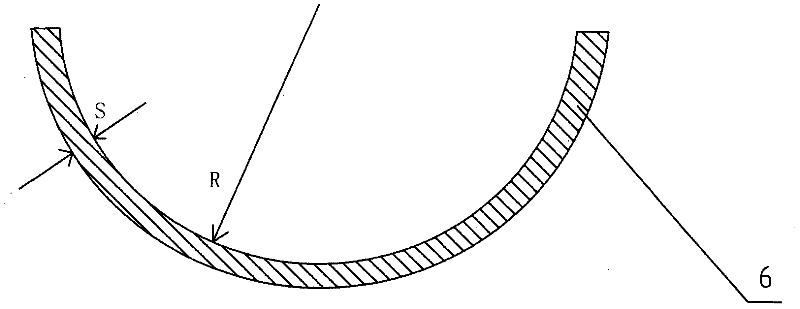

Light guide plate for keypad backlight panels and method of manufacturing the same

InactiveUS20070057031A1Increase brightnessThin structurePlanar/plate-like light guidesKeyboardsHot stampingLight guide

Disclosed herein is a light guide plate for keypad backlight panels, which is mounted at the rear of a keypad having numerals or characters printed thereon for supplying light emitted from a light source mounted at one side of the keypad to the keypad. The light guide plate is made of polycarbonate and is provided at the rear surface thereof with a concave-convex pattern, the density of which is increased as pattern elements of the pattern become more distant from the light source, such that light emitted from the light source is reflected and is uniformly supplied to the keypad, the pattern being formed on the light guide plate by hot stamping, injection molding, or micro blasting. The density of the pattern is adjusted by adjusting the distance between the pattern elements of the pattern or by adjusting the size of the pattern elements of the pattern. Consequently, it is possible to manufacture a keypad module in a slim structure or a curved structure. It is also possible to manufacture a keypad module that is capable of uniformly supplying light.

Owner:MYT INC

Hot stamping foil applied to overlapping hot stamping on gold stamping layer and preparation method of hot stamping foil

ActiveCN103465668AImprove trimming effectTransfer completelyDuplicating/marking methodsPolyurea/polyurethane coatingsHot stampingCellulose

The invention discloses a hot stamping foil applied to overlapping hot stamping on a gold stamping layer and a preparation method of the hot stamping foil. When overlapping hot stamping is carried out on an existing hot stamping foil, the defects that the transferring is incomplete, the hot stamping is not carried out on some portions due to omission, scumming is caused, powder falls off, and the edge of a hot stamping layer is not clear can happen. The hot stamping foil is composed of a base membrane layer, a release layer, a color coating layer, a vacuum aluminum coated layer and a gumming layer. The gumming layer is prepared by raw materials which comprise, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of polyvinyl alcohol, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. According to the hot stamping foil applied to the overlapping hot stamping on the gold stamping layer, the hot stamping foil has the good stamping performance and the good trimming performance, the overlapping hot stamping layer is complete in transferring, the edge is smooth and free of burrs, the adhesion is firm, the phenomena of dusting, powder falling and the like do not exist, the hot stamping effect is strong in third dimension, and the anti-fake performance is more outstanding.

Owner:云南玉溪东魅包装材料有限公司

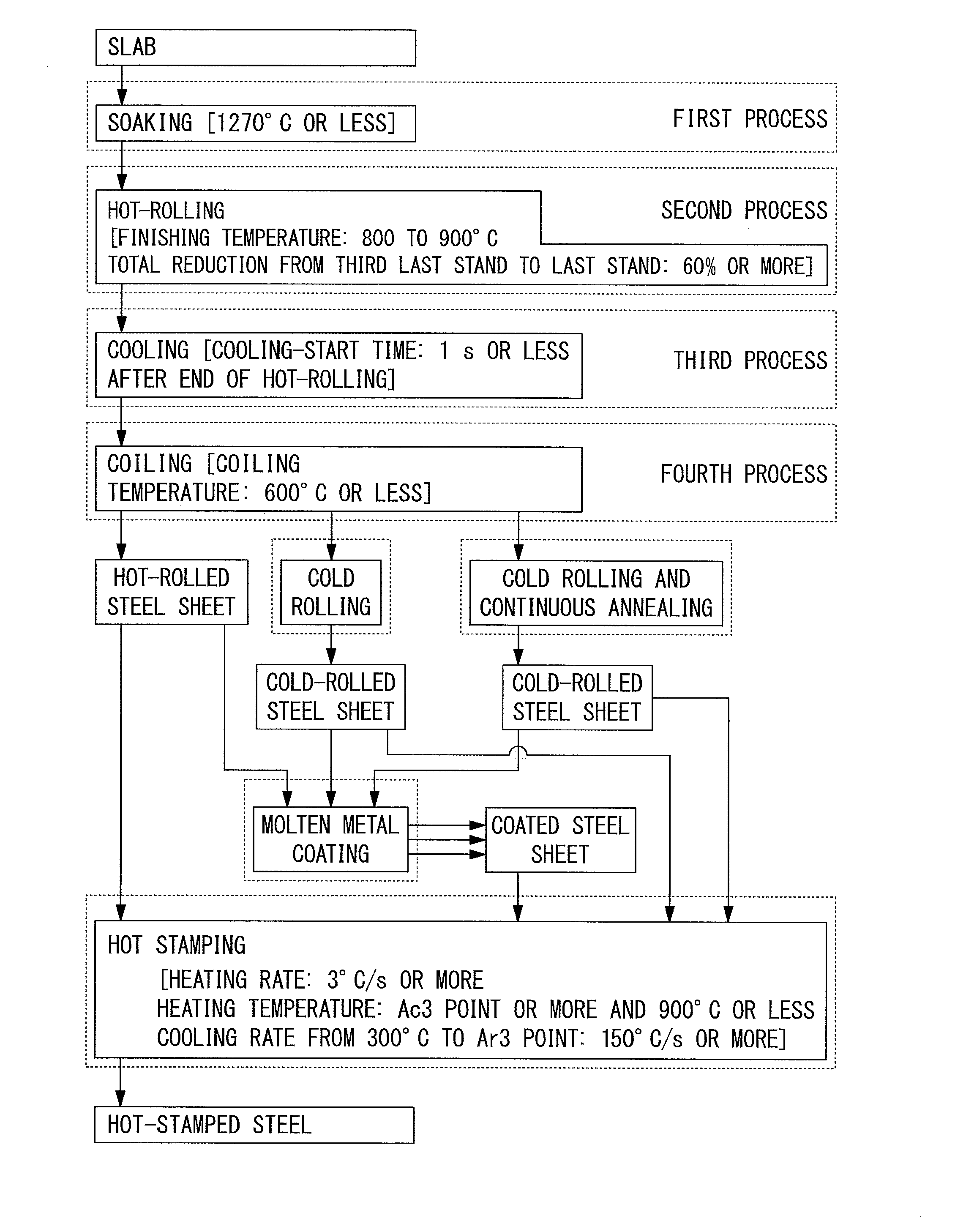

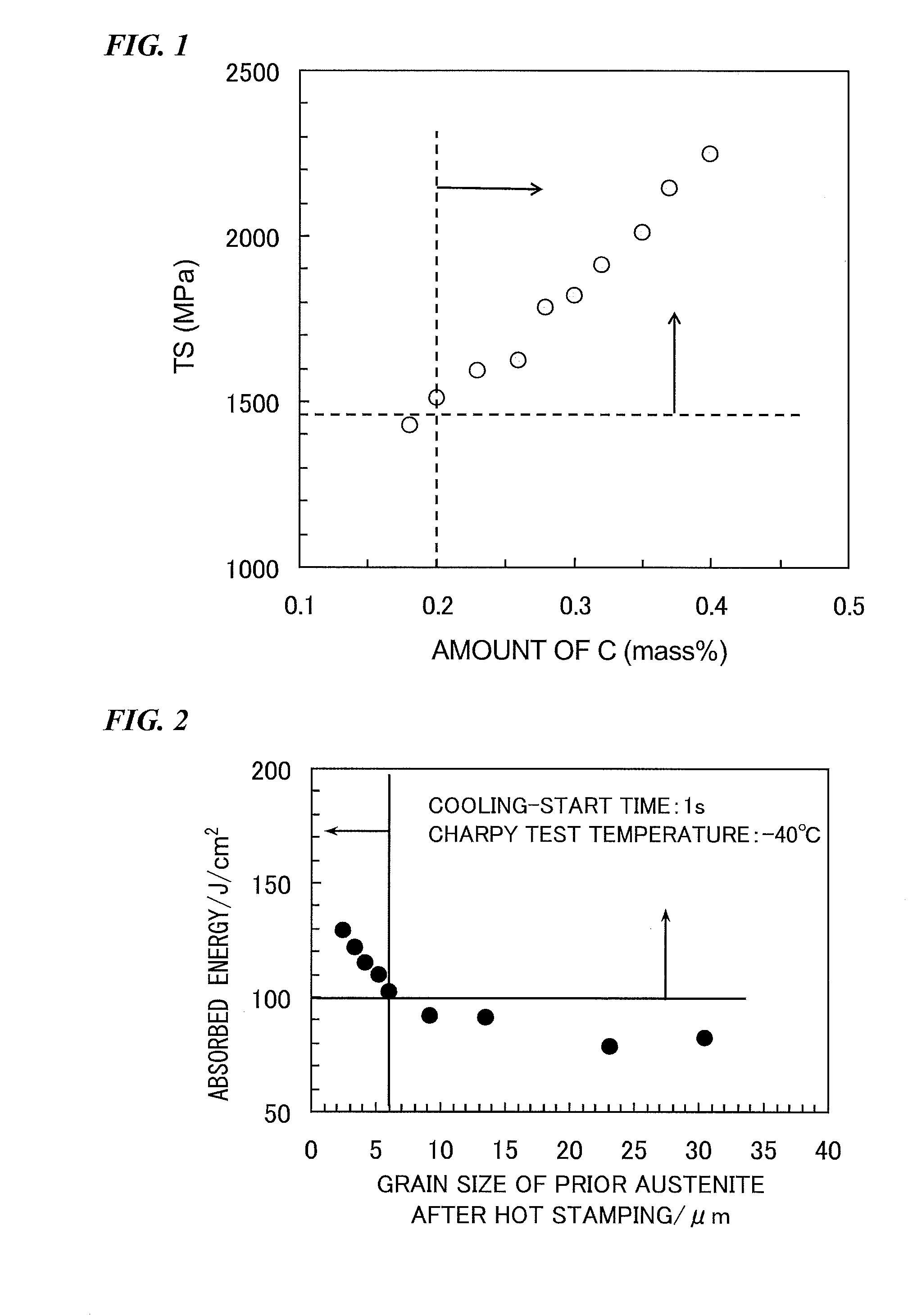

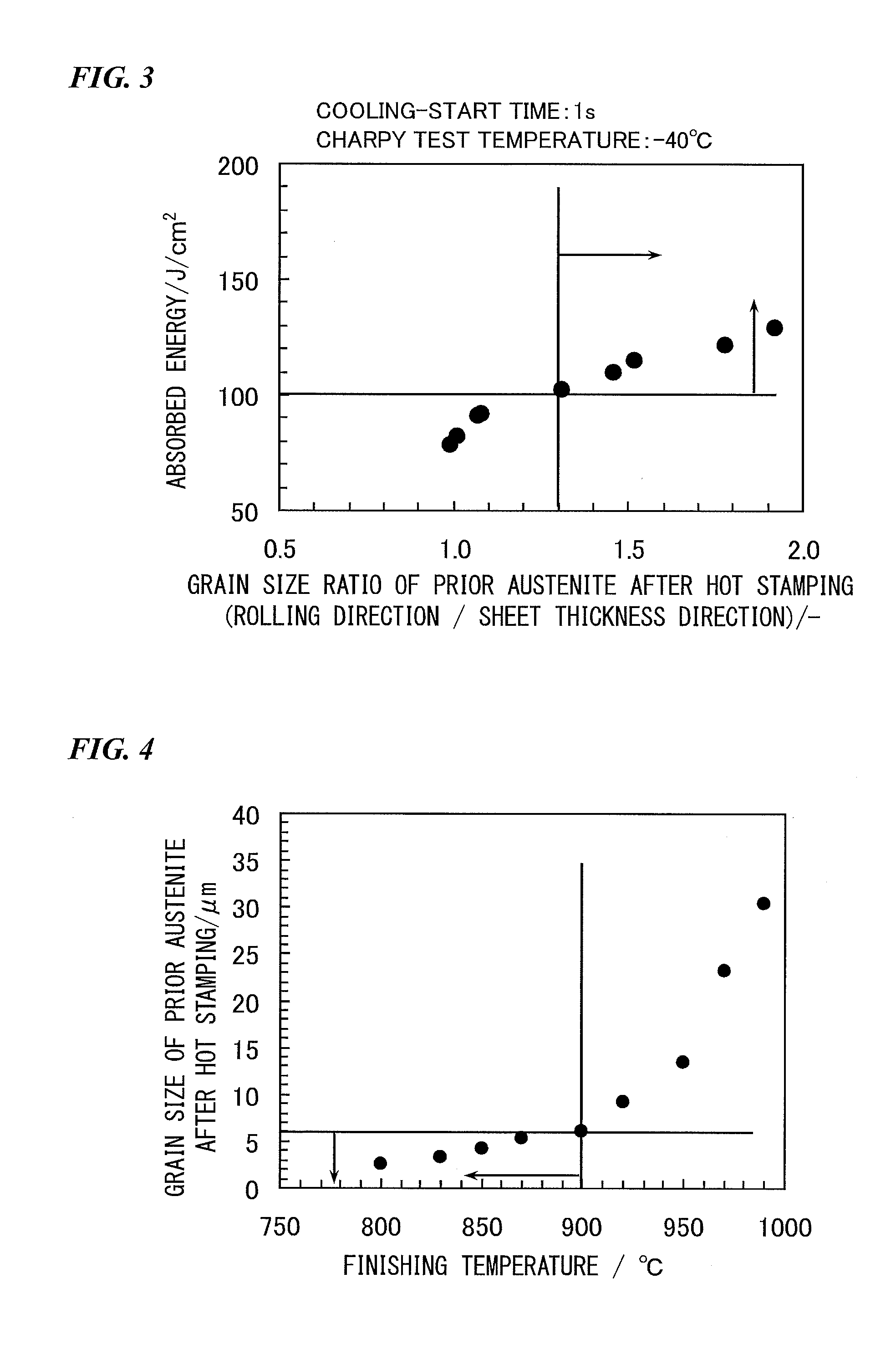

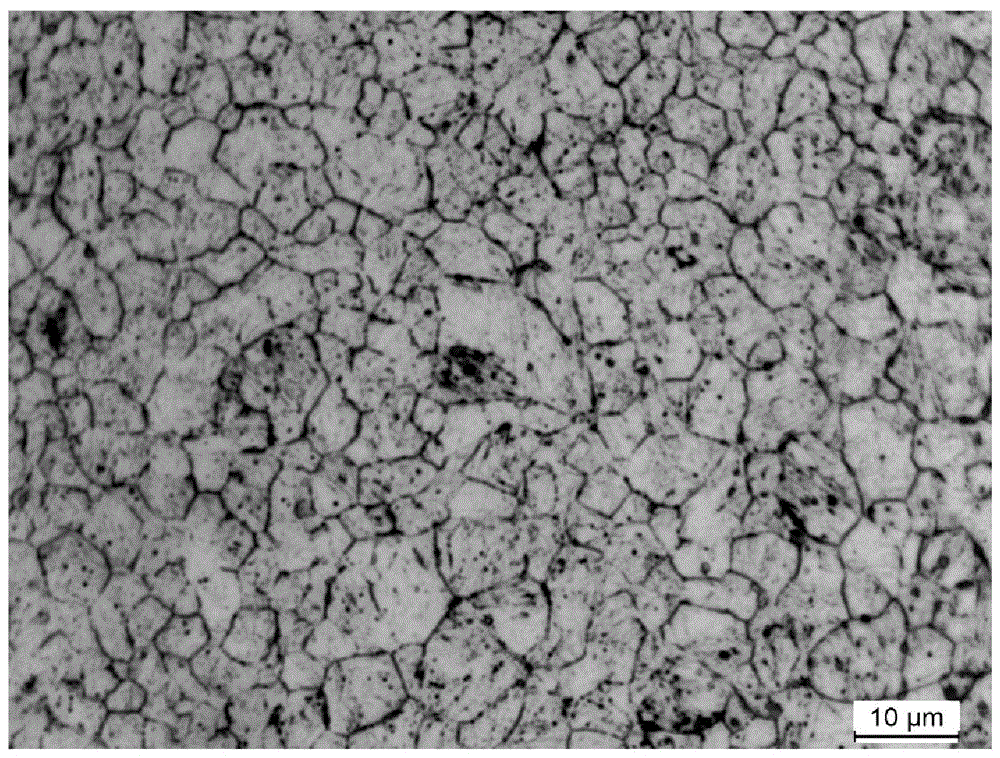

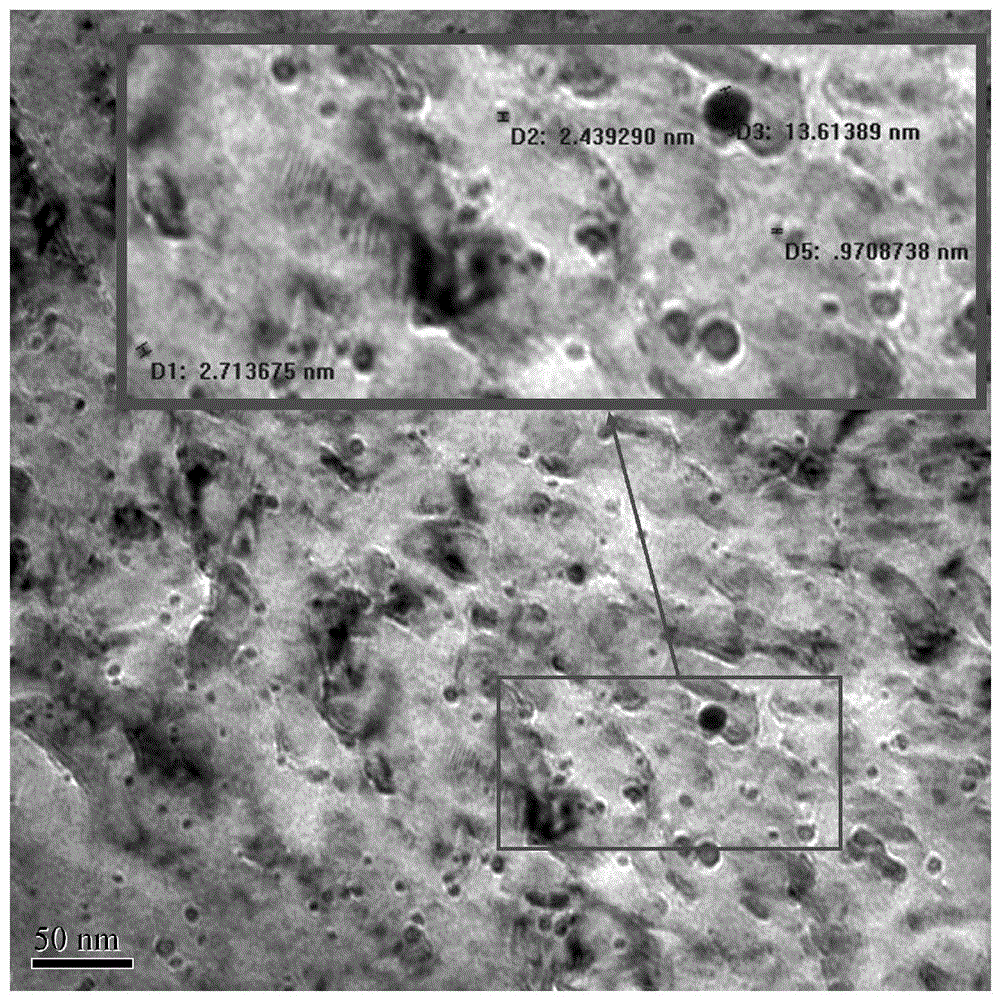

Hot-stamped steel, method of producing of steel sheet for hot stamping, and method of producing hot-stamped steel

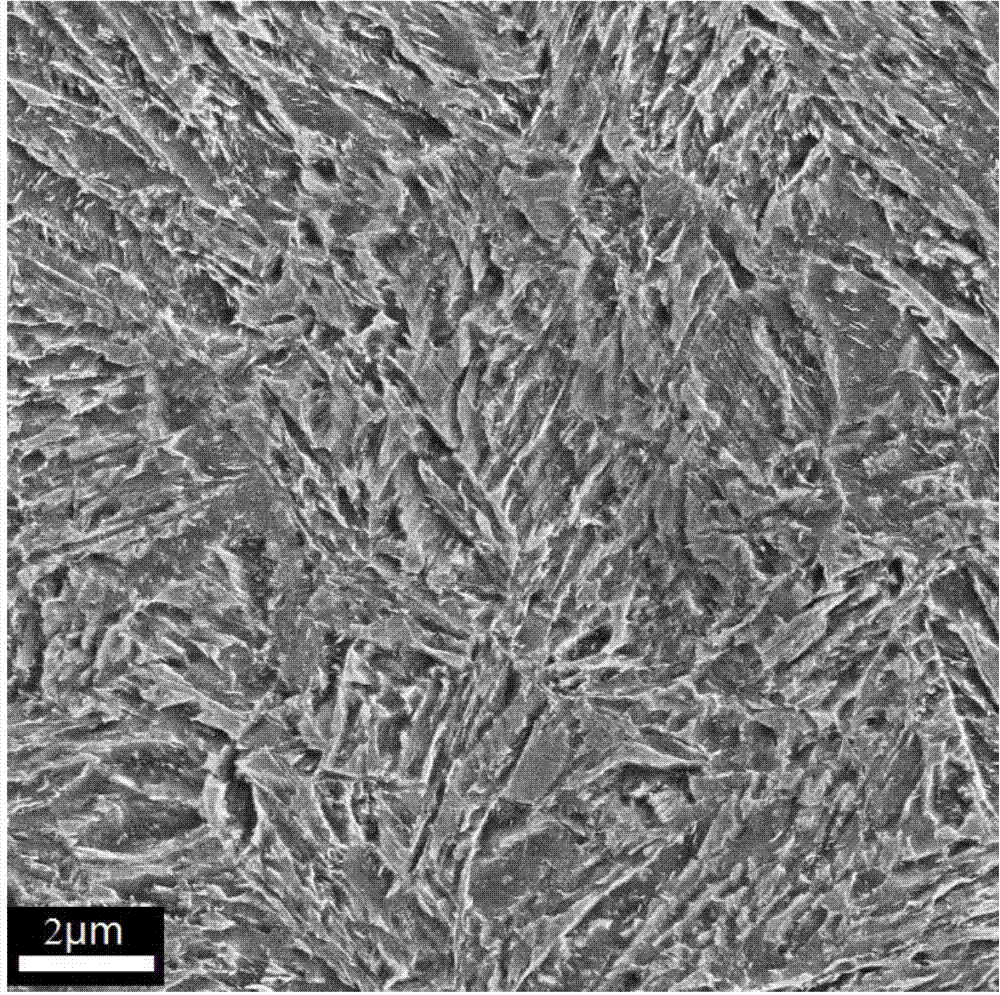

InactiveUS20130095347A1Process balanceImprove energy absorptionMetal rolling stand detailsFurnace typesHot stampingCrystallite

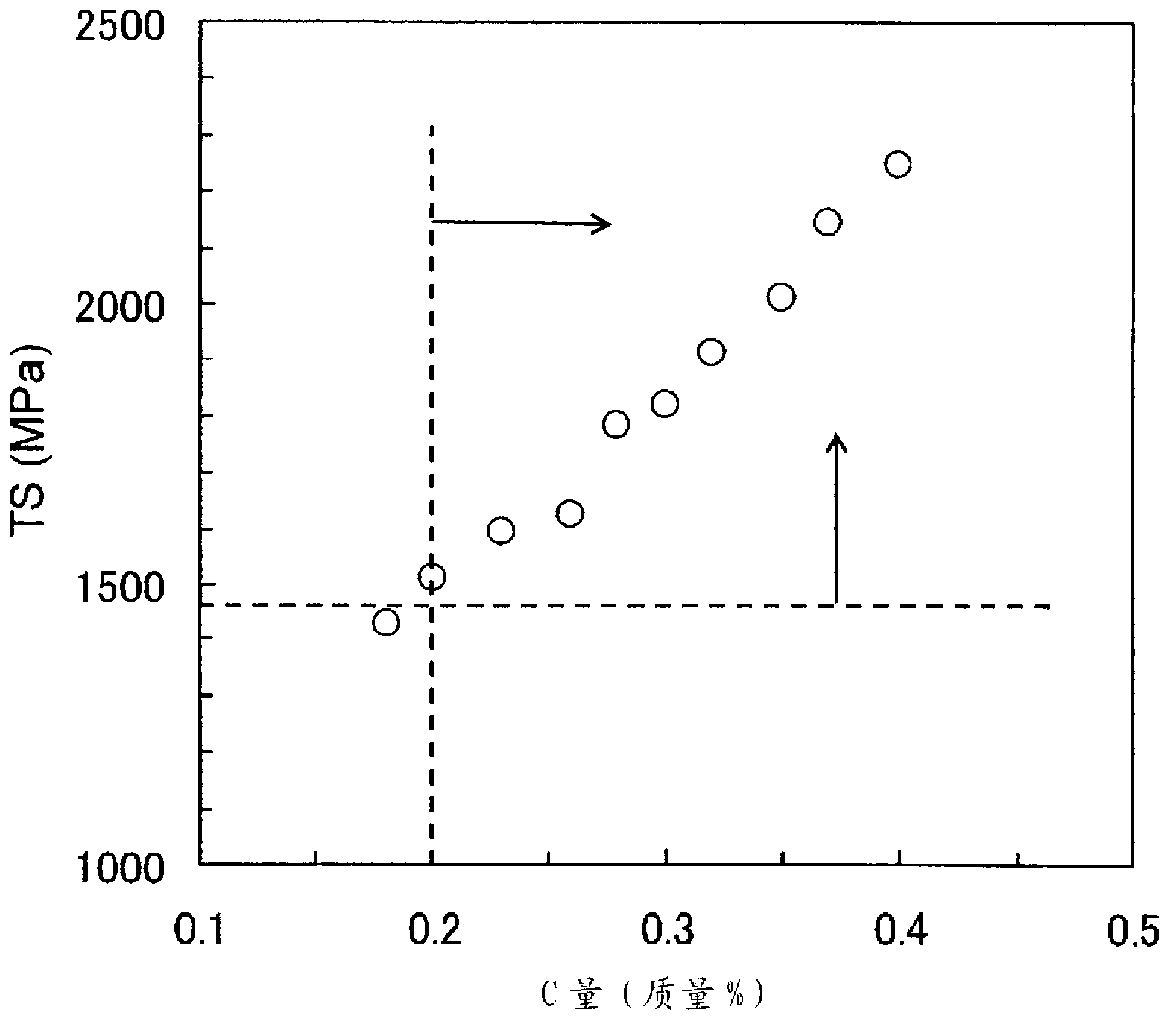

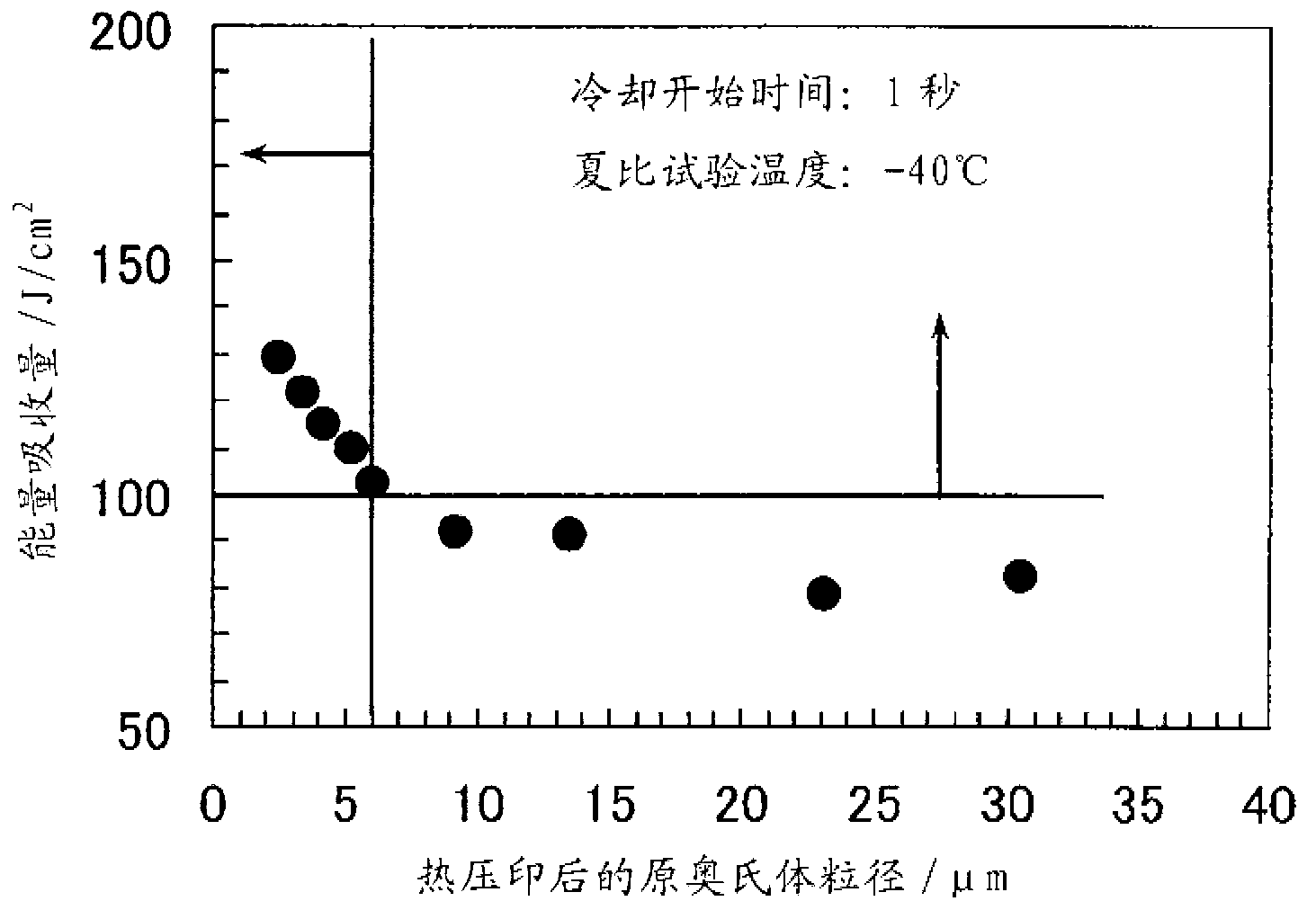

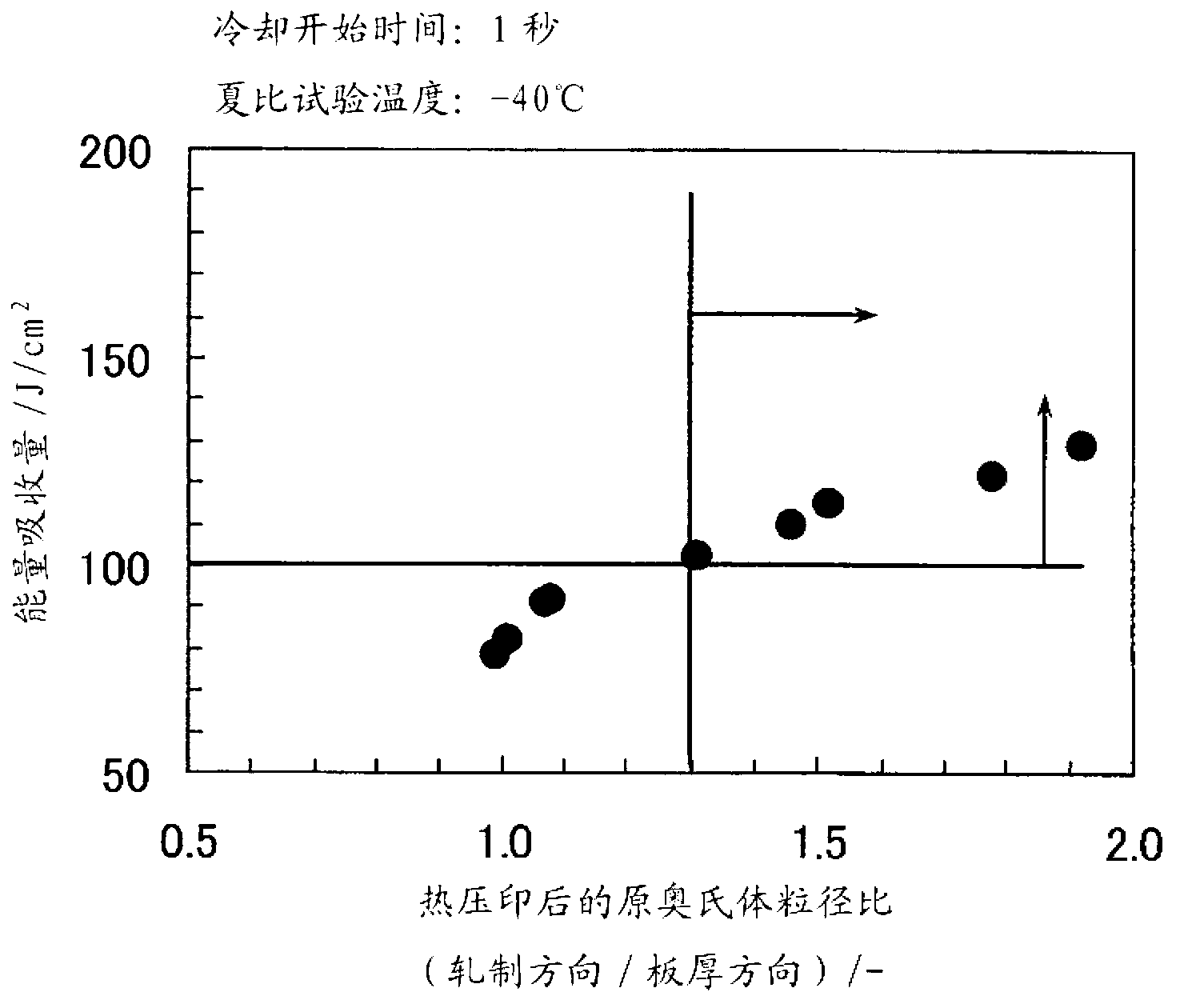

A hot-stamped steel according to the present invention includes, by mass %, C: 0.20% to 0.35%, Si: 0.1% to 0.5%, the total of at least one selected from Mn and Cr: 1% to 3%, Al: 0.005% to 0.06%, Ti: 0.002% to 0.1%, Nb: 0.002% to 0.1%, O: 0.003% to 0.007%, and a balance of iron and inevitable impurities, wherein P is limited to 0.015% or less, S is limited to 0.01% or less, N is limited to 0.004% or less, the dimensional ratio of the lengths of prior austenite grains in a rolling direction to the lengths of the prior austenite grains in the sheet thickness direction is 1.3 to 2.5, the average grain size of the prior austenite grains is 6 μm or less, the microstructure includes 98% or more of martensite, and the tensile strength is 1470 MPa or more.

Owner:NIPPON STEEL CORP

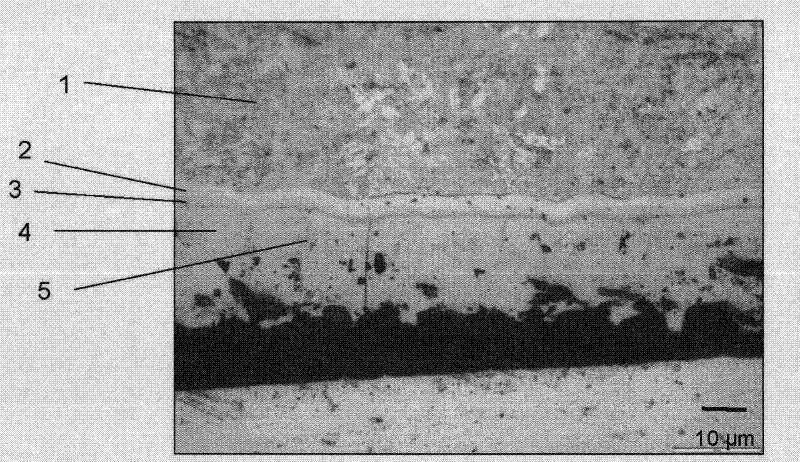

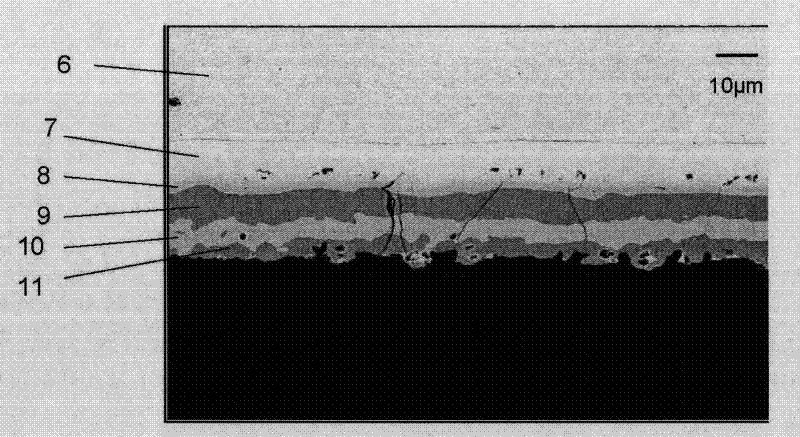

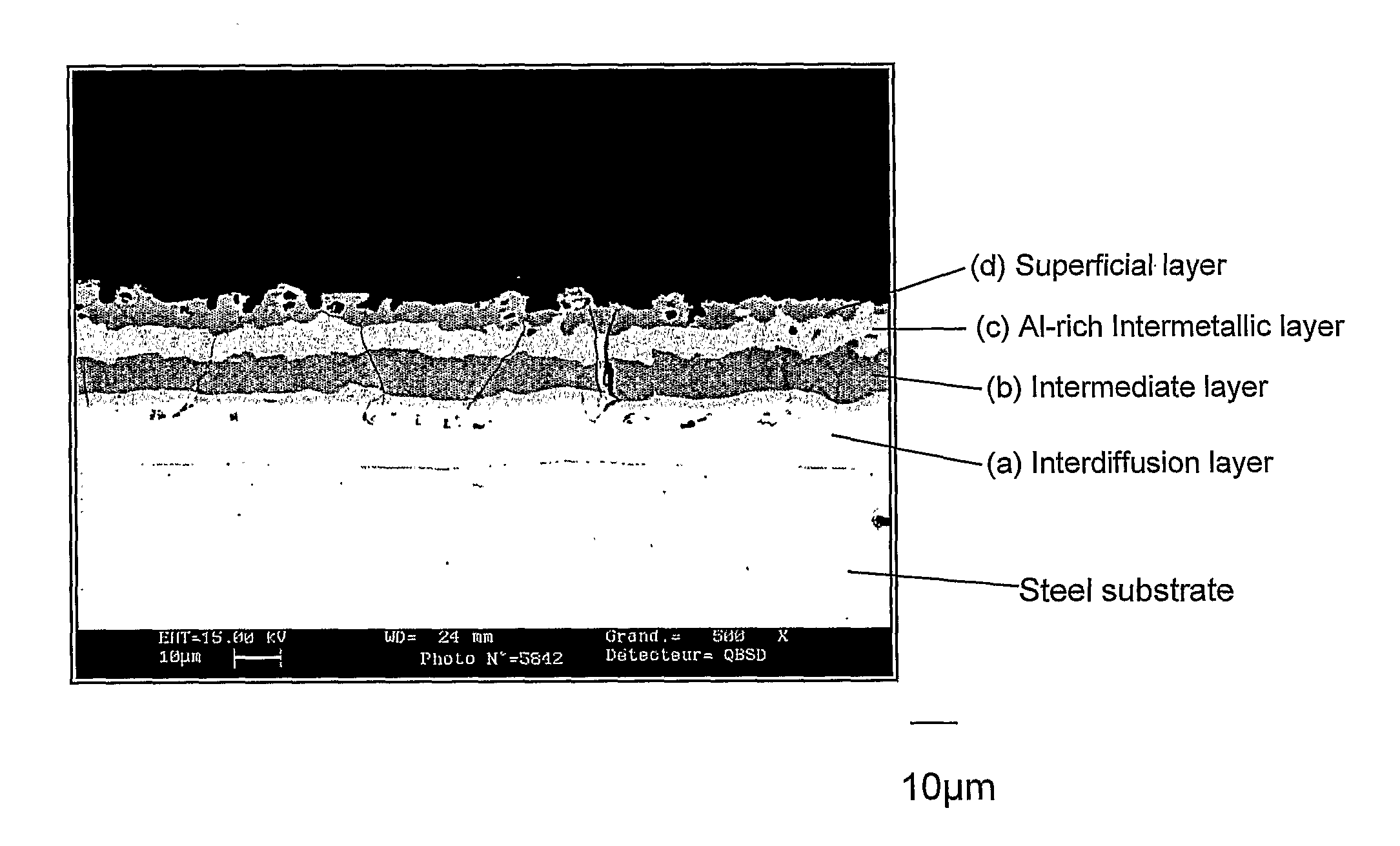

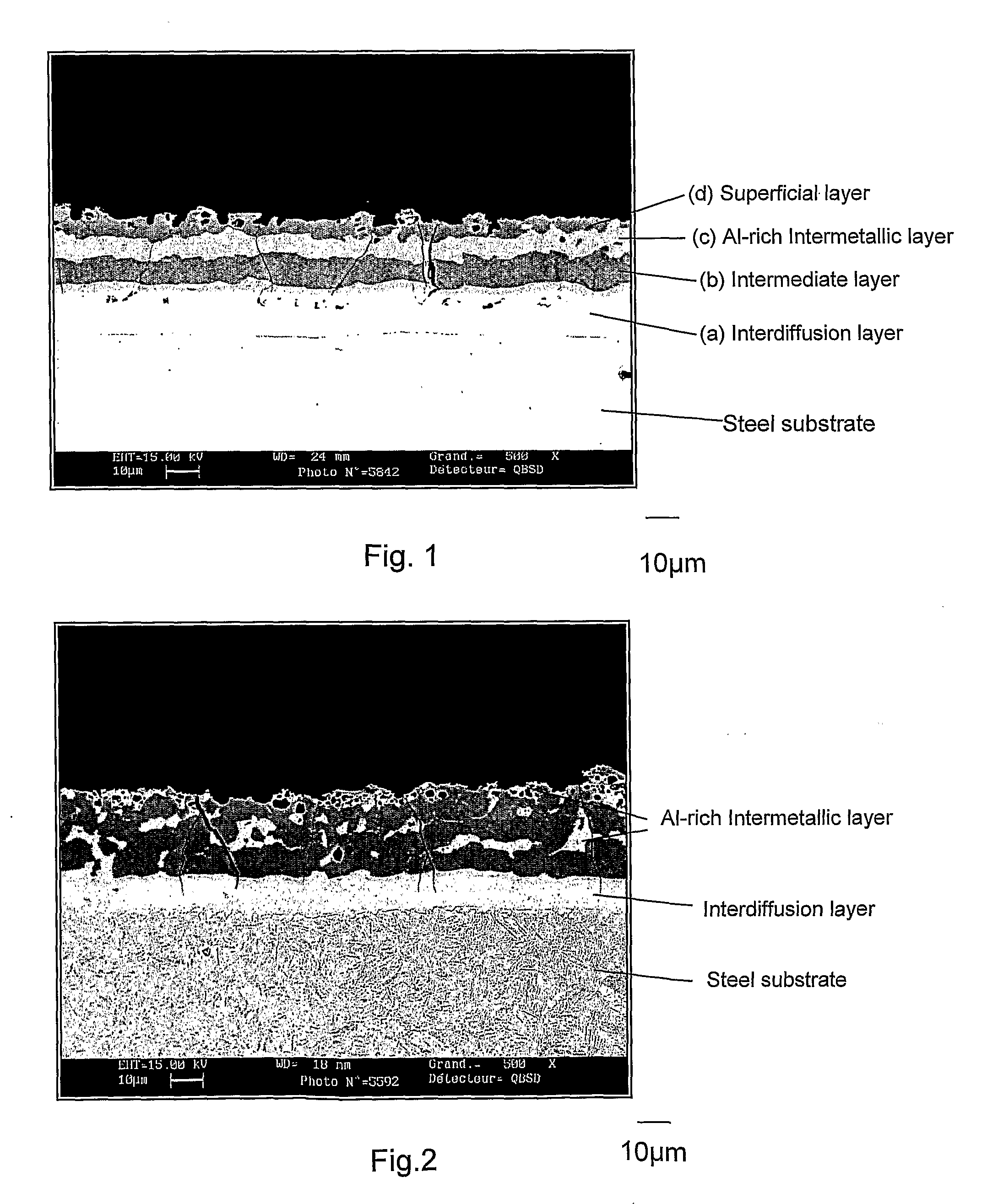

Method of making coated stamped parts and parts made therefrom

The present invention relates to a method for manufacturing hot stamped coated parts, which method includes the following consecutive steps, in order: providing a hot-rolled or cold-rolled steel plate including a steel substrate and an aluminum-silicon alloy precoat, the precoat containing Greater than 50% free aluminum and with a thickness of 15 to 50 microns; the steel plate is then cut to obtain a pre-coated steel blank; the blank is then heated in a non-protective atmosphere to a temperature Ti of Te-10°C to Te, Te is the eutectic or solidus temperature of the precoat; the billet at temperature Ti is then heated to 840 to 950°C in a non-protective atmosphere at a heating rate V of 30°C / s to 90°C / s The temperature Tm of the coated heated blank is obtained, and V is the heating rate from the temperature Ti to the temperature Tm; then the coated heated blank is soaked at the temperature Tm for a time tm of 20s to 90s; and then hot stamped. The blank is obtained to obtain a hot stamped coated part; the stamped part is then cooled at a cooling rate to form a microstructure including at least one component selected from martensite or bainite in the steel substrate.

Owner:安赛乐米塔尔研究发展有限公司 +2

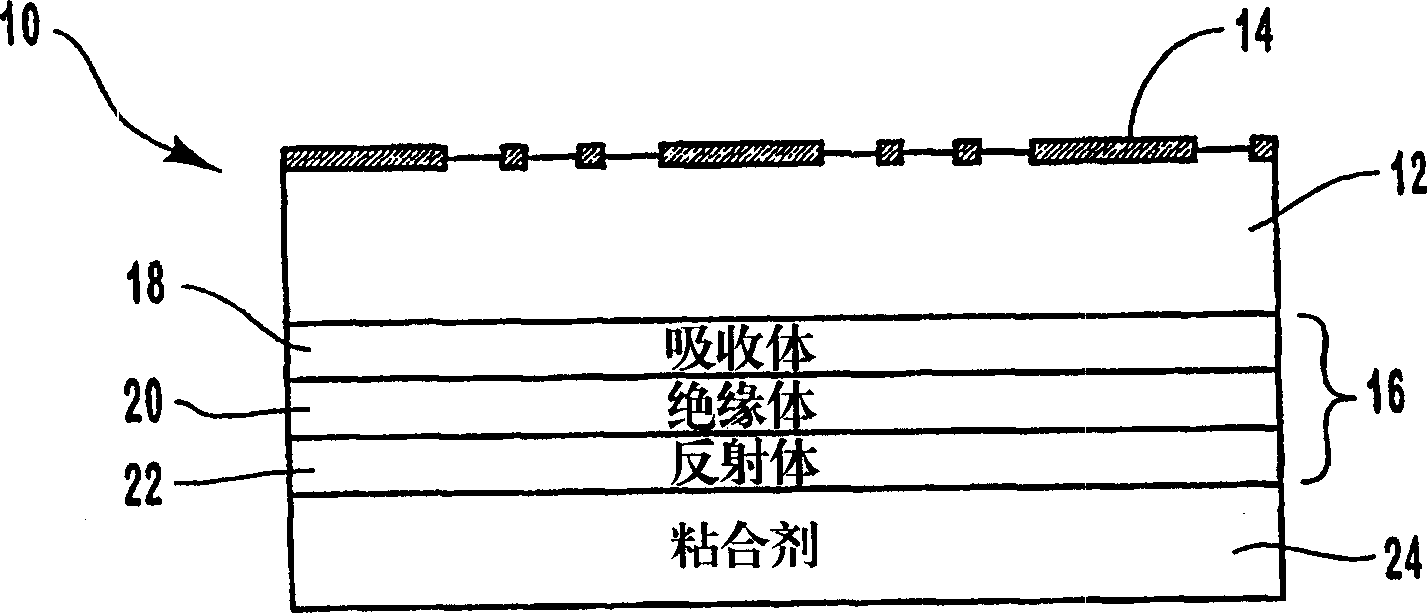

Uptically variable security devices

InactiveCN1423598AGood anti-counterfeiting measuresOther printing matterSynthetic resin layered productsHot stampingEngineering

A security article (10) includes a light transmissive substrate (12) having a first surface and an opposing second surface, with the first surface having an optical interference pattern (14) such as a holographic image pattern or an optical diffraction pattern thereon. A color shifting optical coating (16) is formed on the substrate such as on the interference pattern or on the opposing second surface of the substrate, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. Various processes can be utilized to form the security article (10), such as vacuum coating processes, lamination, laser scribing, and laser imaging. The security article (10) can be affixed to a variety of objects through various attachment mechanisms, such as pressure sensitive adhesives or hot stamping processes, to provide for enhanced security measures such as anticounterfeiting.

Owner:光学涂层实验公司

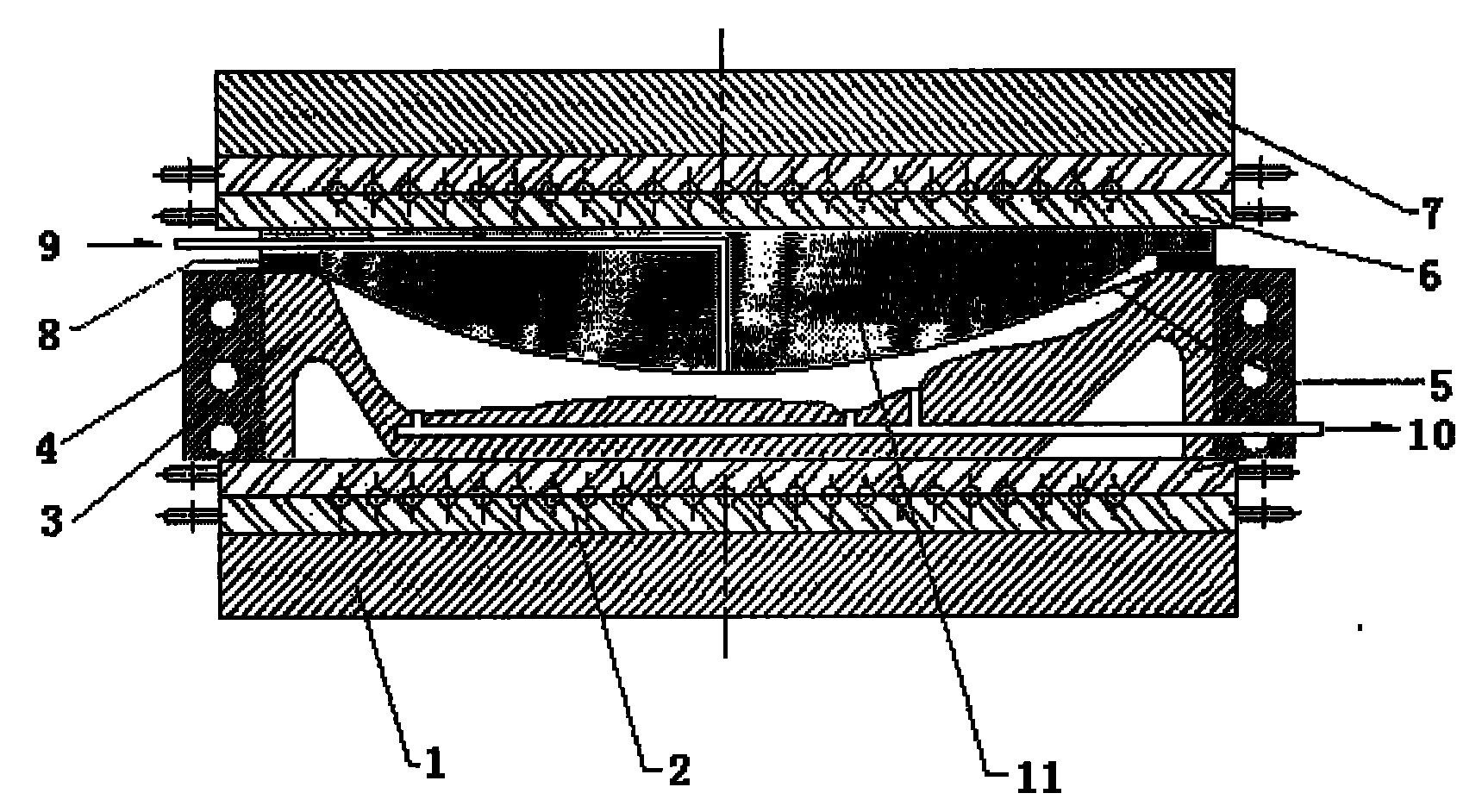

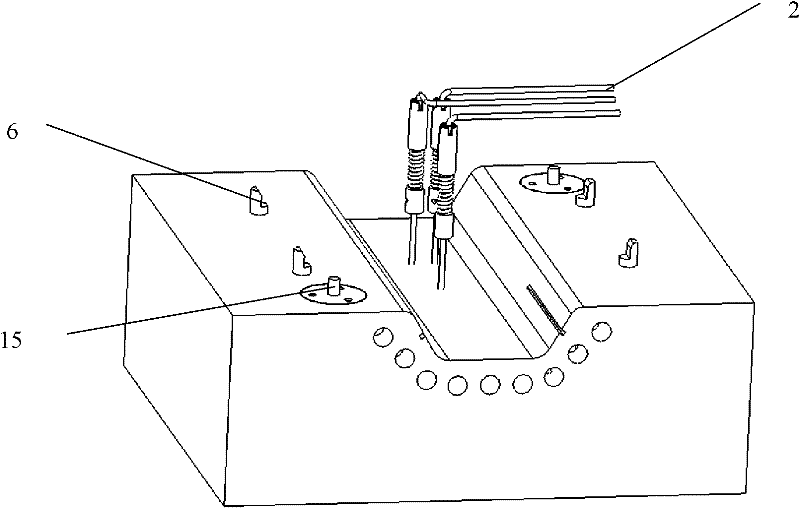

Hot stamping mould with temperature measuring system

InactiveCN102172719ARealize full cycle temperature monitoringAvoid cycleShaping toolsMetal working apparatusHot stampingTemperature curve

The invention discloses a hot stamping mould with a temperature measuring system. The hot stamping mould comprises a concave mould, a convex mould, a plate support and positioning device, a mould built-in cooling system, a mould built-in temperature measuring system and an external temperature recording device, and is characterized in that: the concave mould and convex mould are provided with a molded surface corresponding to the workpiece shape respectively; cooling pipelines are staggered in the concave mould and convex mould, and connected with a water inlet and a water outlet through a diversion groove; and multiple thermocouples are pre-embedded on specific positions on the surface of the concave mould as well as on the surface and inside of the convex mould, and connected with the multi-channel temperature recording device. The hot stamping mould disclosed by the invention realizes full-period temperature monitoring, can directly judge and predict the product quality according to a temperature curve so as to eliminate unqualified products immediately, shortens the inspection cycle and lowers the production cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Holography positioning alumite high speed thermoprint back glue and preparation method

ActiveCN101343522AGood chemical propertiesGood weather resistancePolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesHot stampingPrinting ink

The invention discloses a high-speed hot stamping gum used for holographic positioning electrochemical aluminium and the preparation method. The gum prepared through the formulation and the method of the invention can achieve good adhesive effect under the appropriate temperature and pressure, and the appropriate release coating is added, thus the holographic image information of the holographic electrochemical aluminium can be stripped and cemented on the surface of the scalded object at the high speed. The fragileness of the gum is moderate, therefore, the trimming performance of the holographic image is good in the hot stamping process, the gum is particularly applied to high-speed hot stamping on the surface of the sheet paper and the printing ink with which the density and the hardness are big, the surface energy is low, the surface wettability is poor, and the general coating liquor is difficult to be transferred and cemented on.

Owner:湖北省葛店开发区晨光实业有限公司 +1

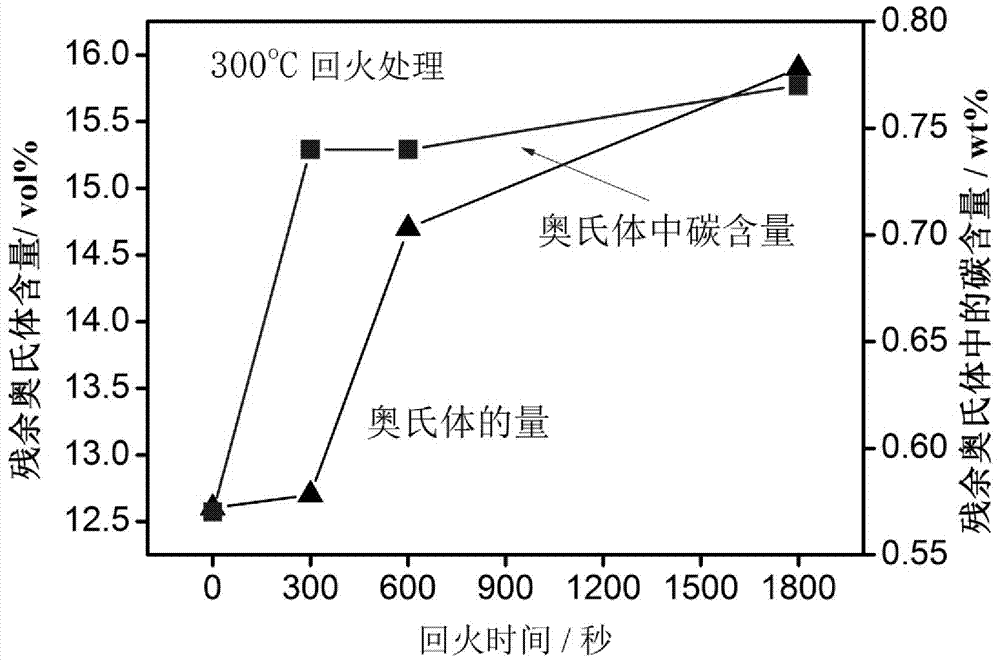

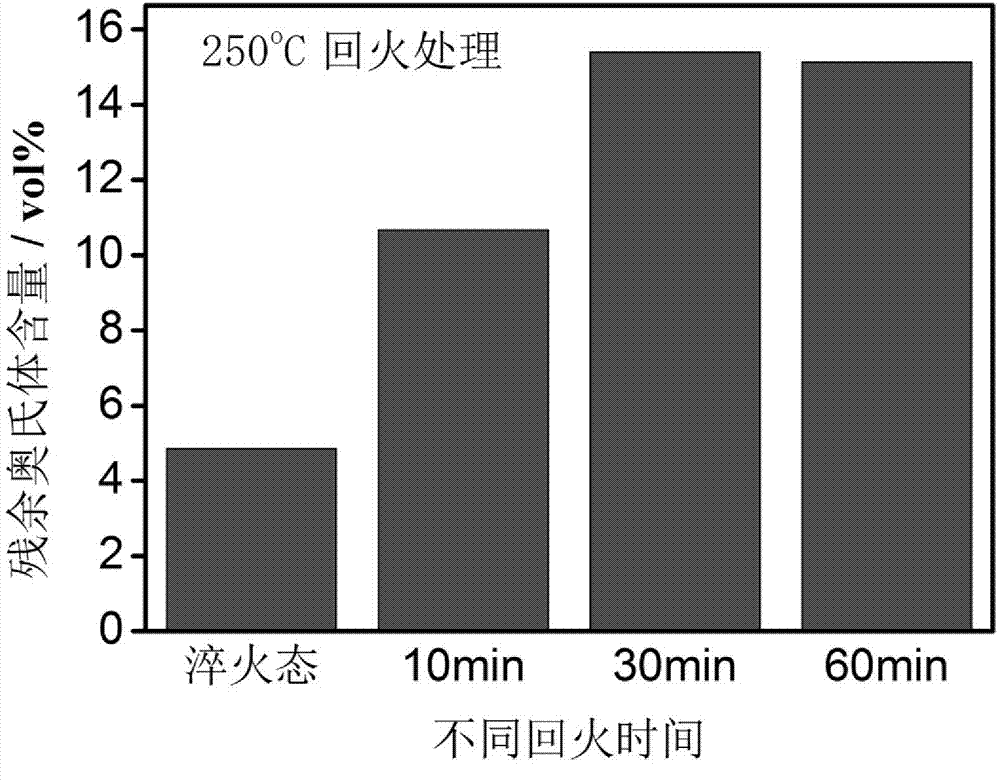

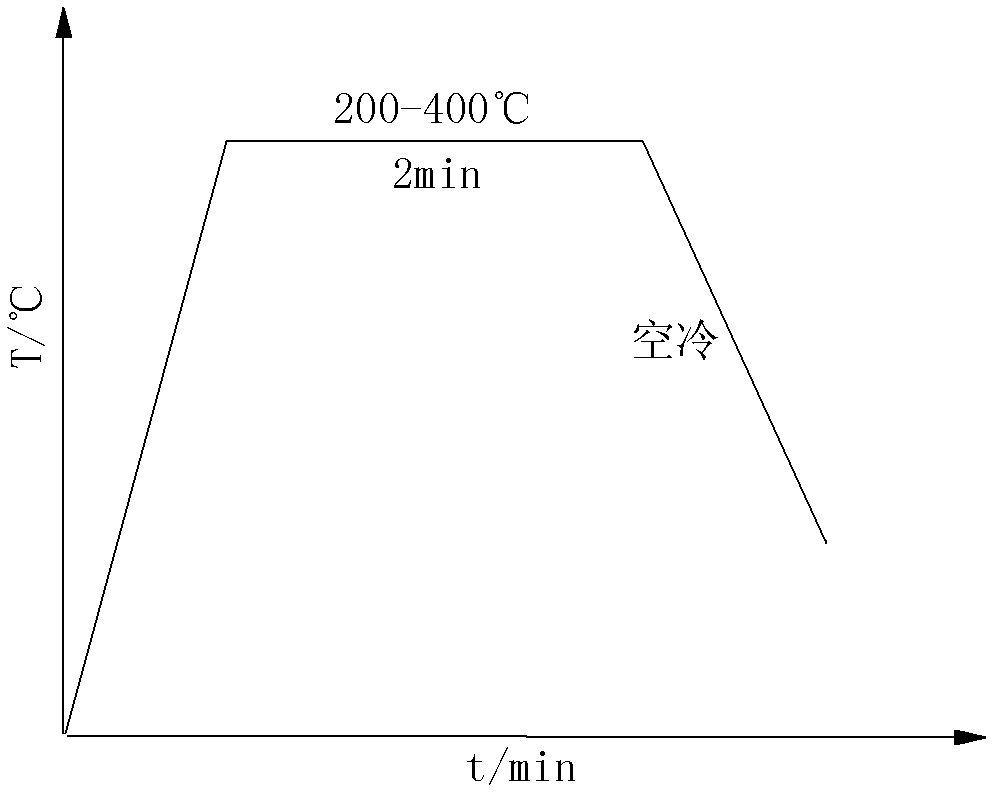

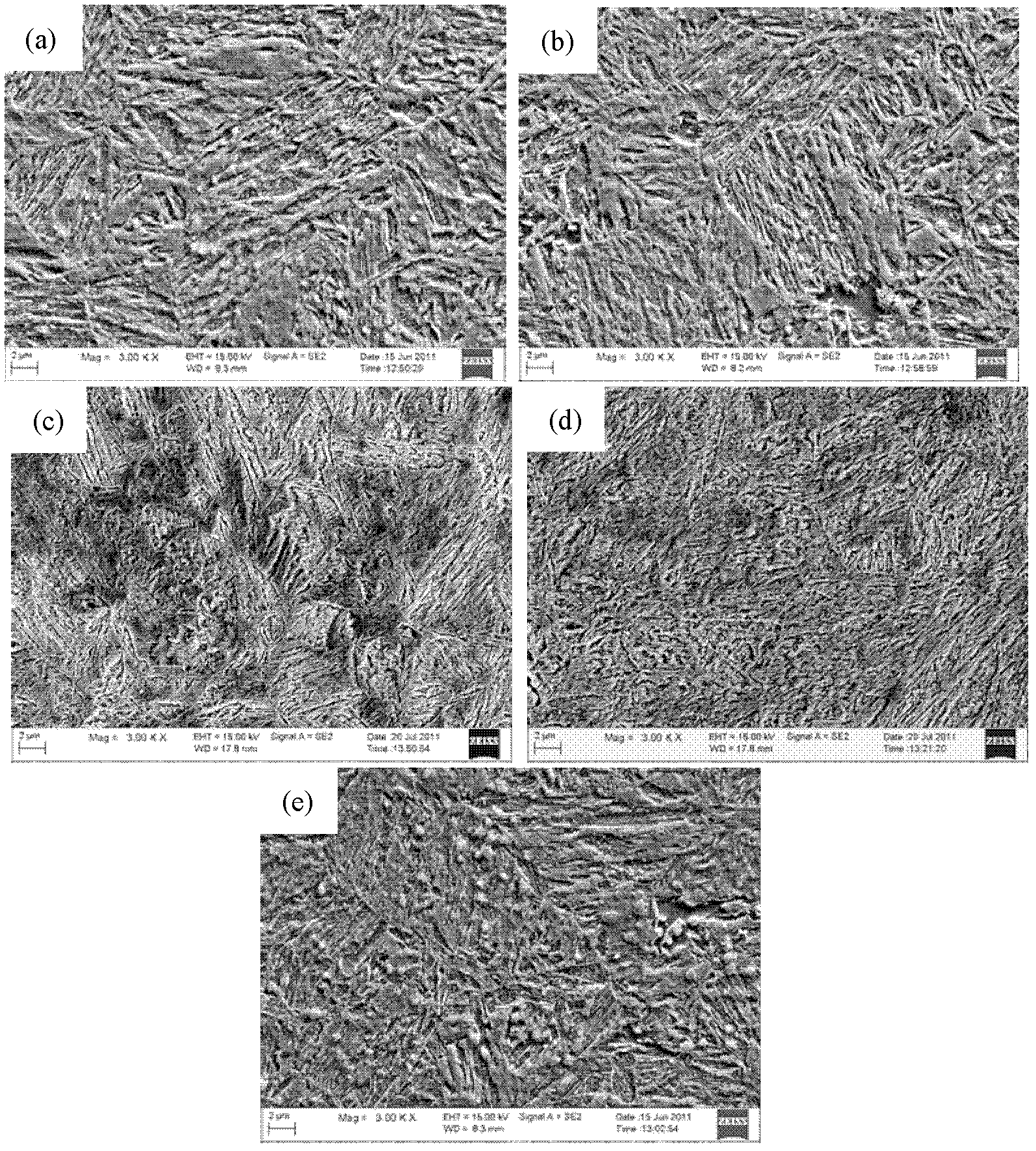

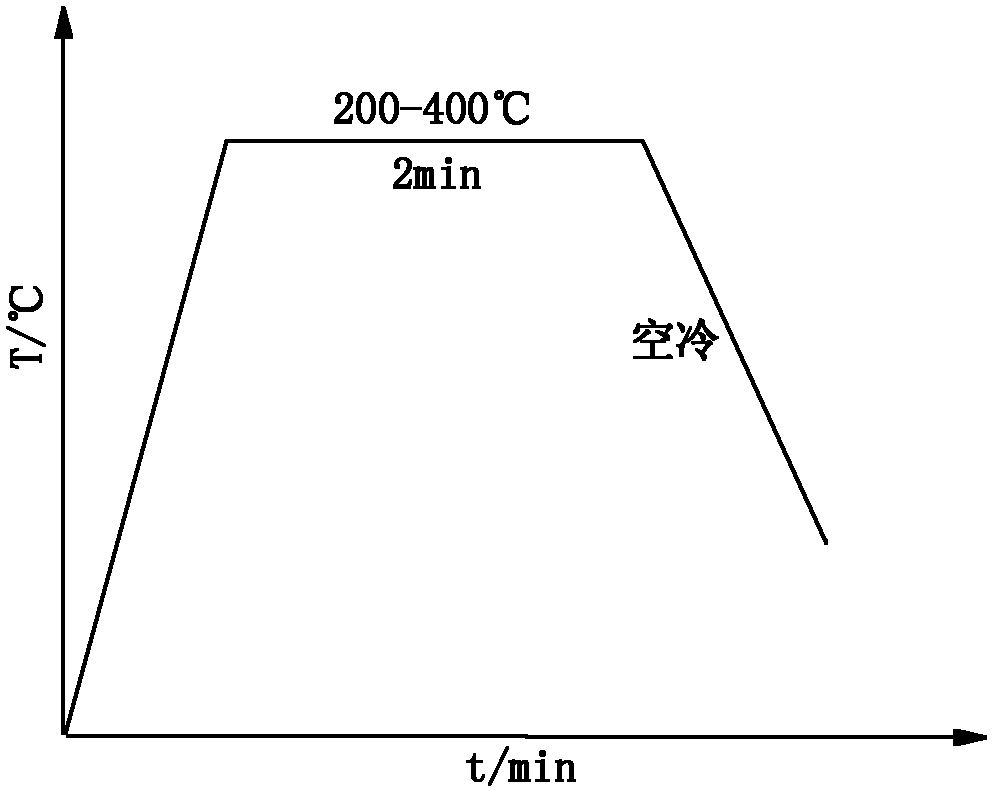

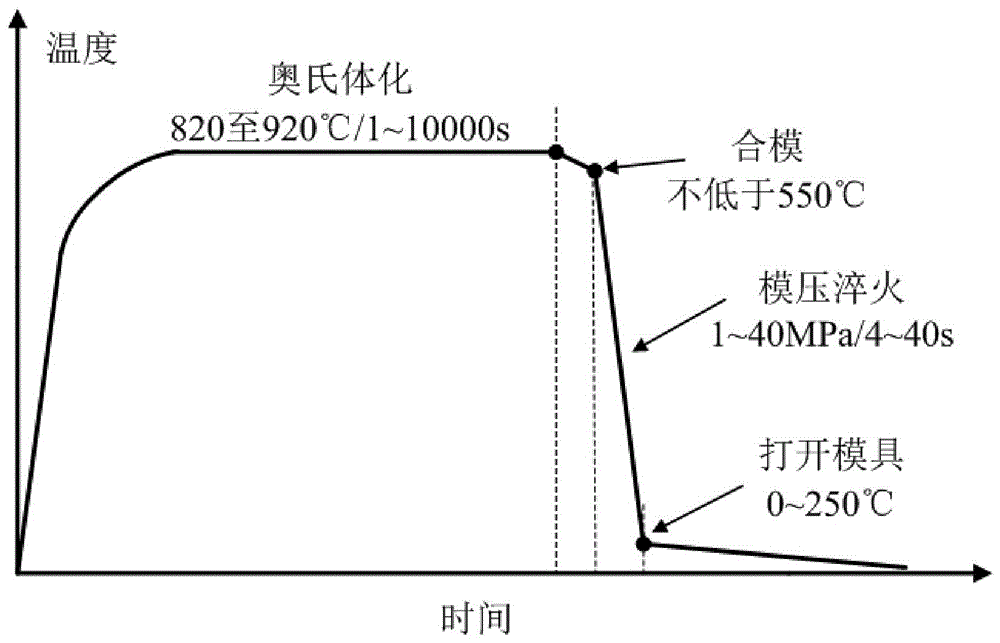

A heat treatment method for high-strength and toughness hot-formed steel sheets for automobiles

The invention provides a heat treatment method for high-strength and toughness hot-formed steel plates for automobiles, which belongs to the technical field of high-strength steels for automobiles, and aims to solve the problems of high strength but poor plasticity of steel plates for hot-formation at present. Technical measures to solve the problem: the mass percentage of the components is: C: 0.2~0.4%, Si: 0.1-0.5%, Mn: 1.0~2.0%, Cr: 0.1~0.5%, B: 0.001-0.005%, Ti : 0.01~0.05%, Al: 0.01-0.1%, P: <0.02%, S: <0.01%, N: <0.01%, and the balance is iron and unavoidable impurities. In the range of ~500℃, tempering treatment is carried out for 1-5min. The invention has the advantages that after the tempering treatment, the plasticity of the hot-formed steel is significantly improved while the strength is slightly reduced, and the toughness of the steel plate after hot stamping is improved.

Owner:UNIV OF SCI & TECH BEIJING

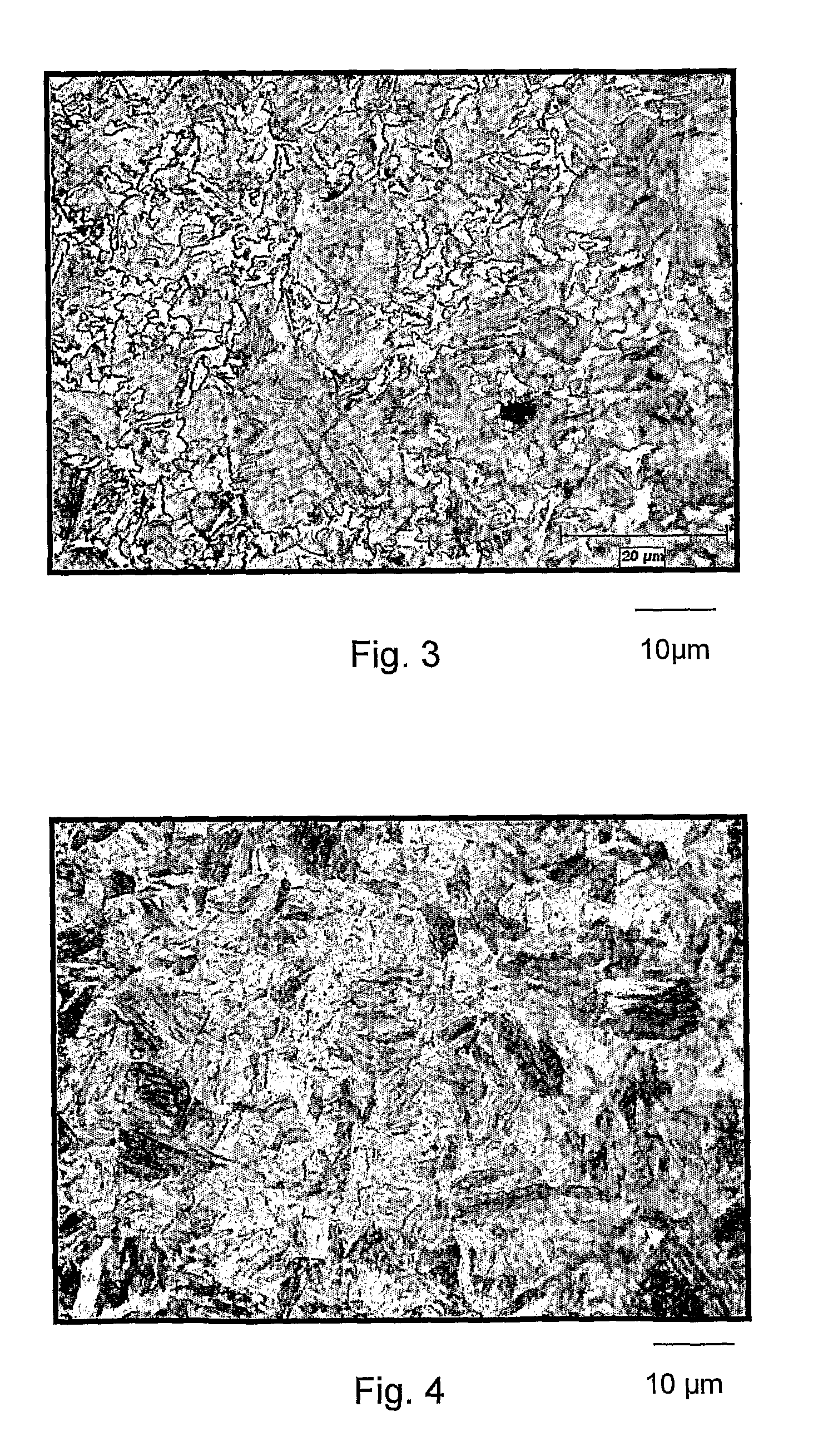

Hot-stamp-molded article, process for production of steel sheet for hot stamping, and process for production of hot-stamp-molded article

ActiveCN102939399AAchieve lightweightHigh strengthHot-dipping/immersion processesFurnace typesHot stampingAustenite grain

A hot-stamp-molded article comprises, in mass%, 0.20 to 0.35% of C, 0.1 to 0.5% of Si, at least one element selected from Mn and Cr in the total amount of 1 to 3%, 0.005 to 0.06% of Al, 0.002 to 0.1% of Ti, 0.002 to 0.1% of Nb, 0.003 to 0.007% of O, 0.015% or less of P, 0.01% or less of S, 0.004% or less of N, and a remainder made up by Fe and unavoidable impurities, wherein the dimensional ratio of the length of a prior austenite grain in the rolling direction to that in the thicknesswise direction is 1.3 to 2.5 inclusive, the prior austenite grain has an average particle diameter of 6 [mu]m or less, martensite is contained at a proportion of 98% or more, and the tensile strength is 1470 MPa or more.

Owner:NIPPON STEEL CORP

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

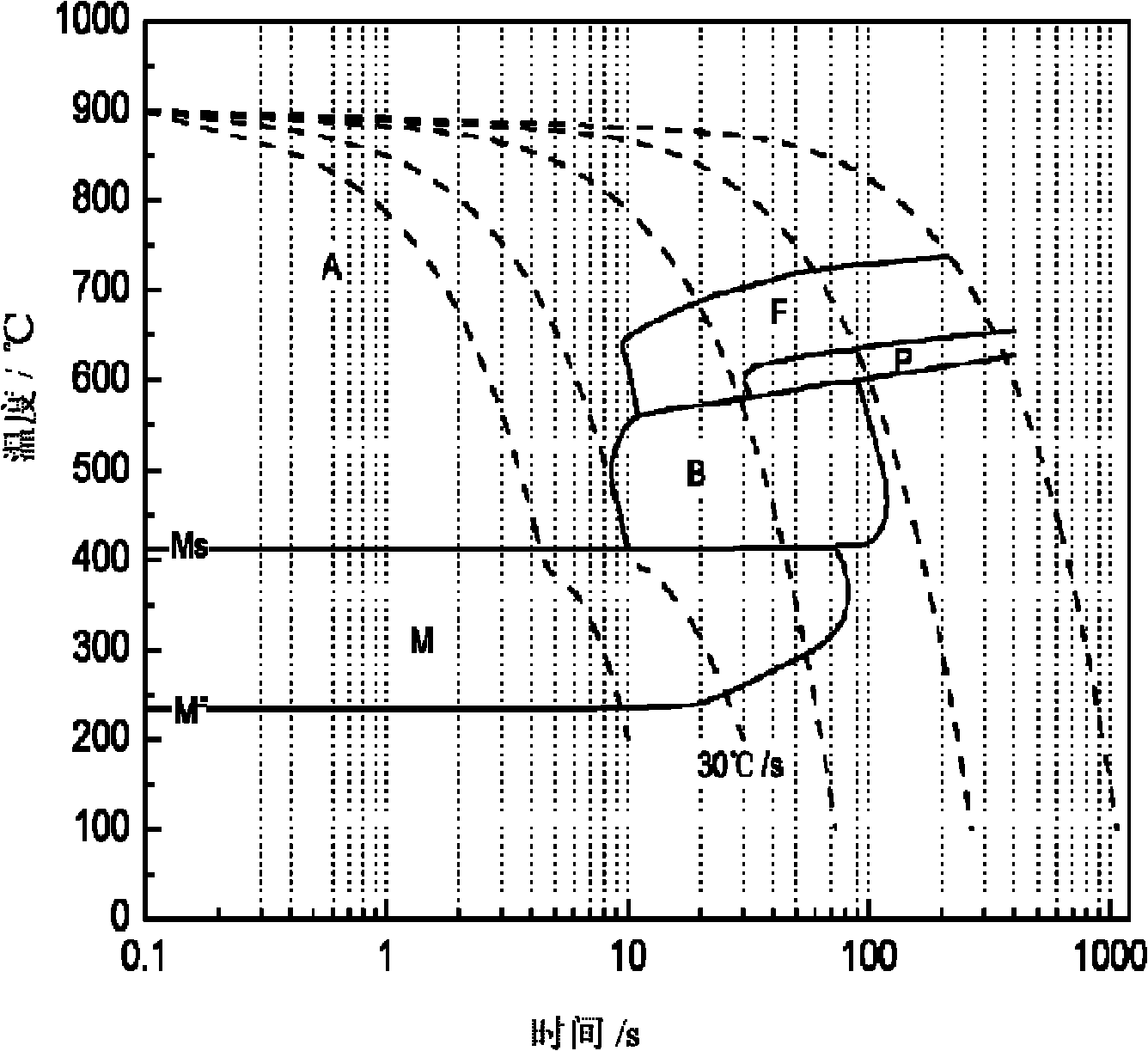

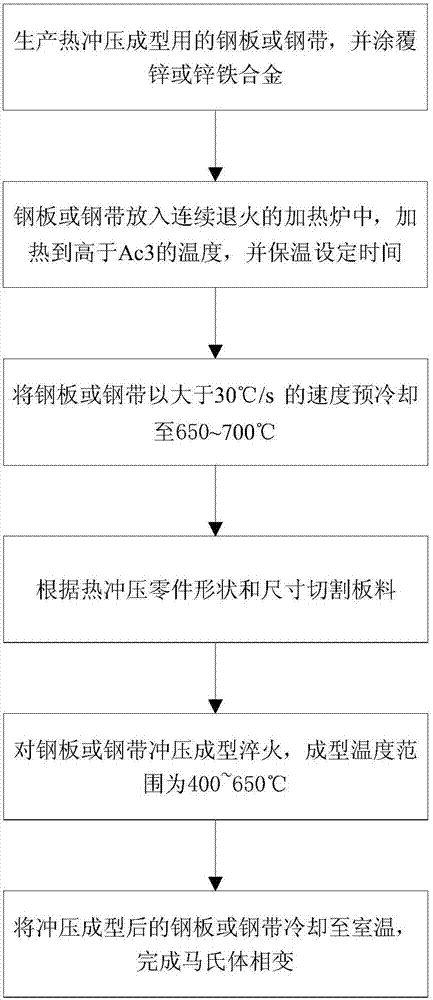

Hot-stamping forming method for zinc plating steel plate or steel strip

ActiveCN107127238ALow heating temperatureShort holding timeShaping toolsHot-dipping/immersion processesHot stampingSheet steel

The invention relates to a hot-stamping forming method for a zinc plating steel plate or a steel strip. According to the hot-stamping forming method, the steel plate or the steel strip is conveyed into a vertical heating annealing furnace, the temperature is kept for a certain time, the steel plate is completely austenitized, a pre-cooling device is used when the steel plate leaves the annealing furnace, the steel plate is cooled to 650-700 DEG C at the cooling rate higher than 30 DEG C / s, then blanking is performed according to the part shape and size, then the steel plate is quickly transferred into a mold for hot-stamping forming, the steel plate is hardened at the speed higher than 30 DEG C / s, and the hot-stamping forming temperature is kept between 400 DEG C and 650 DEG C. Base plate cracks caused by partial stress and liquid metal embrittlement (LME) can be avoided, and the method is used for solving the problem that the base plate cracks cannot be avoided for existing zinc-based hot-stamping formed steel.

Owner:BAOSHAN IRON & STEEL CO LTD

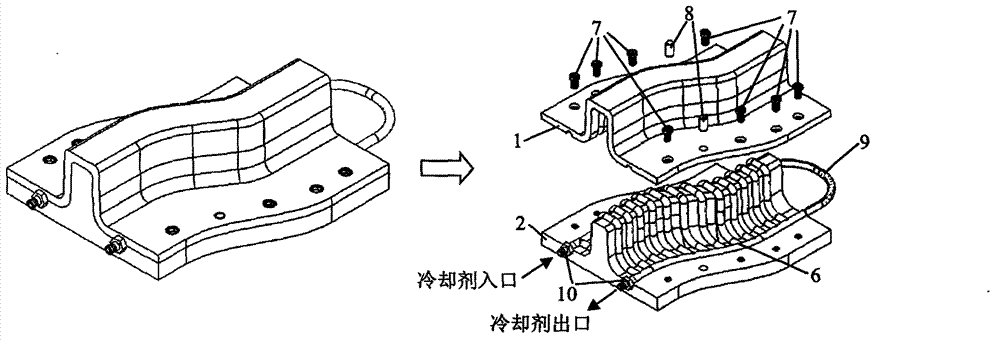

High strength steel plate hot stamping die for automobile parts

The invention discloses a high strength steel plate hot stamping die for automobile parts. The high strength steel plate hot stamping die for the automobile parts mainly consists of a male die body (a male die and a male die connecting fixing plate), a female die body (a female die and a female die connecting fixing plate), blank holders, cooling pipelines, connecting devices, positioning devices, U-shaped connecting hoses and pipe joints. The male die, the male die connecting fixing plate, the female die, the female die connecting fixing plate and the blank holders are respectively manufactured, and grooves used for fixing the cooling pipes are respectively processed. The cooling pipelines are manufactured into shape-following cooling pipelines which are consistent with the shape trends of the parts by adopting copper pipes, are respectively arranged in the grooves respectively arranged in the male die body, the female die body and the blank holders, and are externally connected with a master cooling pipeline through the U-shaped connecting hoses and the pipe joints to form a cooling closed loop. The hot stamping die disclosed by the invention is simple and compact in structure and convenient in maintenance, is reliable and practical, can be used for evenly and rapidly cooling the parts during a stamping process and is in favor of enhancing the working stability per se and prolonging the service life per se.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

A processing method of titanium alloy closing end

InactiveCN101157175AImprove molding qualityHigh precisionRocket engine plantsHot stampingTitanium alloy

The invention discloses a processing method of a titanium alloy end socket. The invention is characterized in that a stamping component is protected by utilizing a clamping plate, a suitable ram head and a suitable lift-ring are selected, and the specified stamping temperature, the stamping speed and the stamping times are given to perform hot stamping processing to a work piece, and an inner profile and an outer profile of the product after the hot stamping is ensured to meet the requirement of subsequent processing; the hot processing is performed after the stamping. The invention mainly used for the processing of the titanium alloy end socket of the casing of a satellite tank, the end socket material processed is smooth, the shape is well, and the percent of pass is high.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

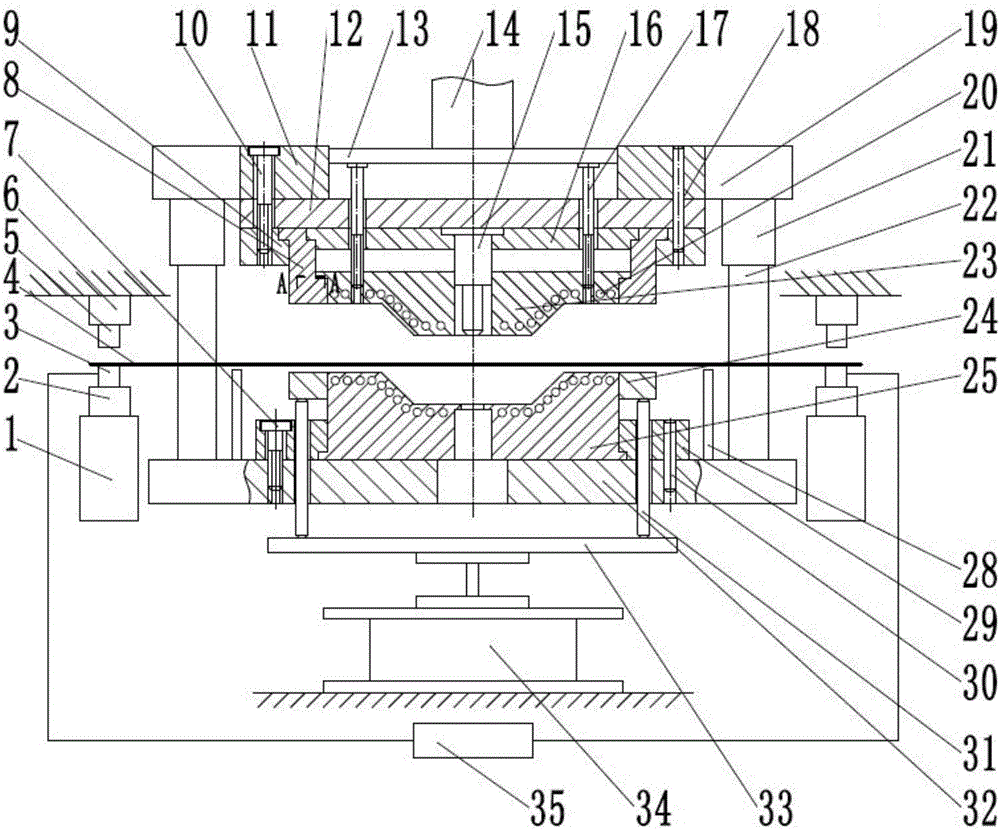

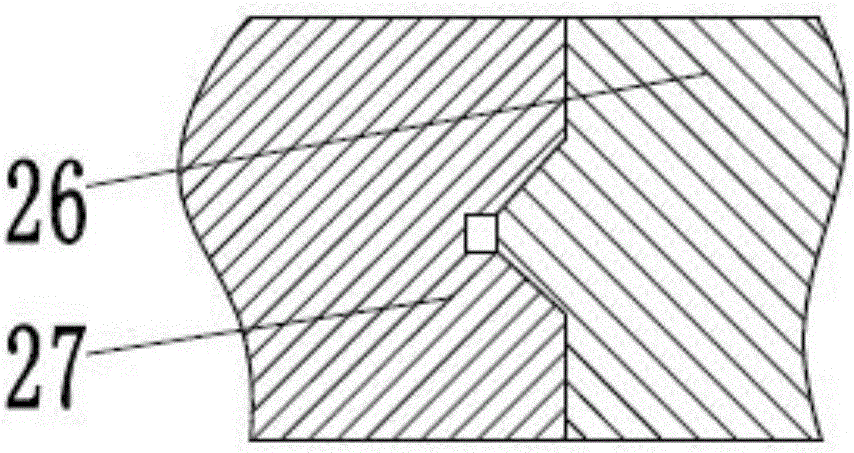

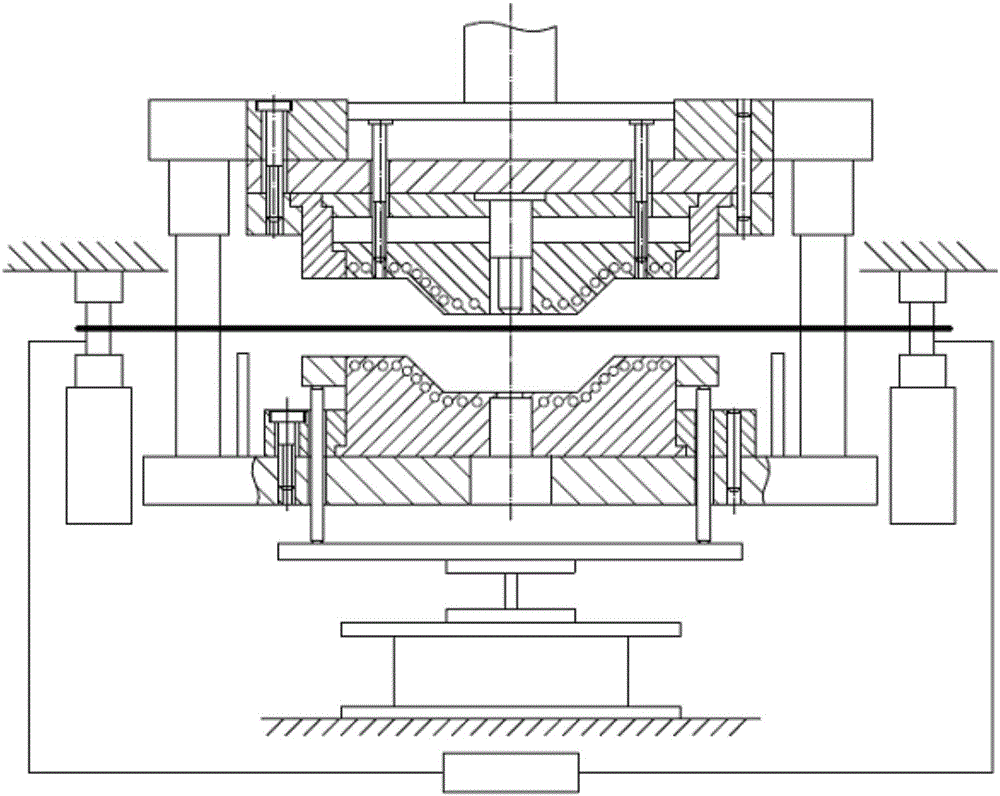

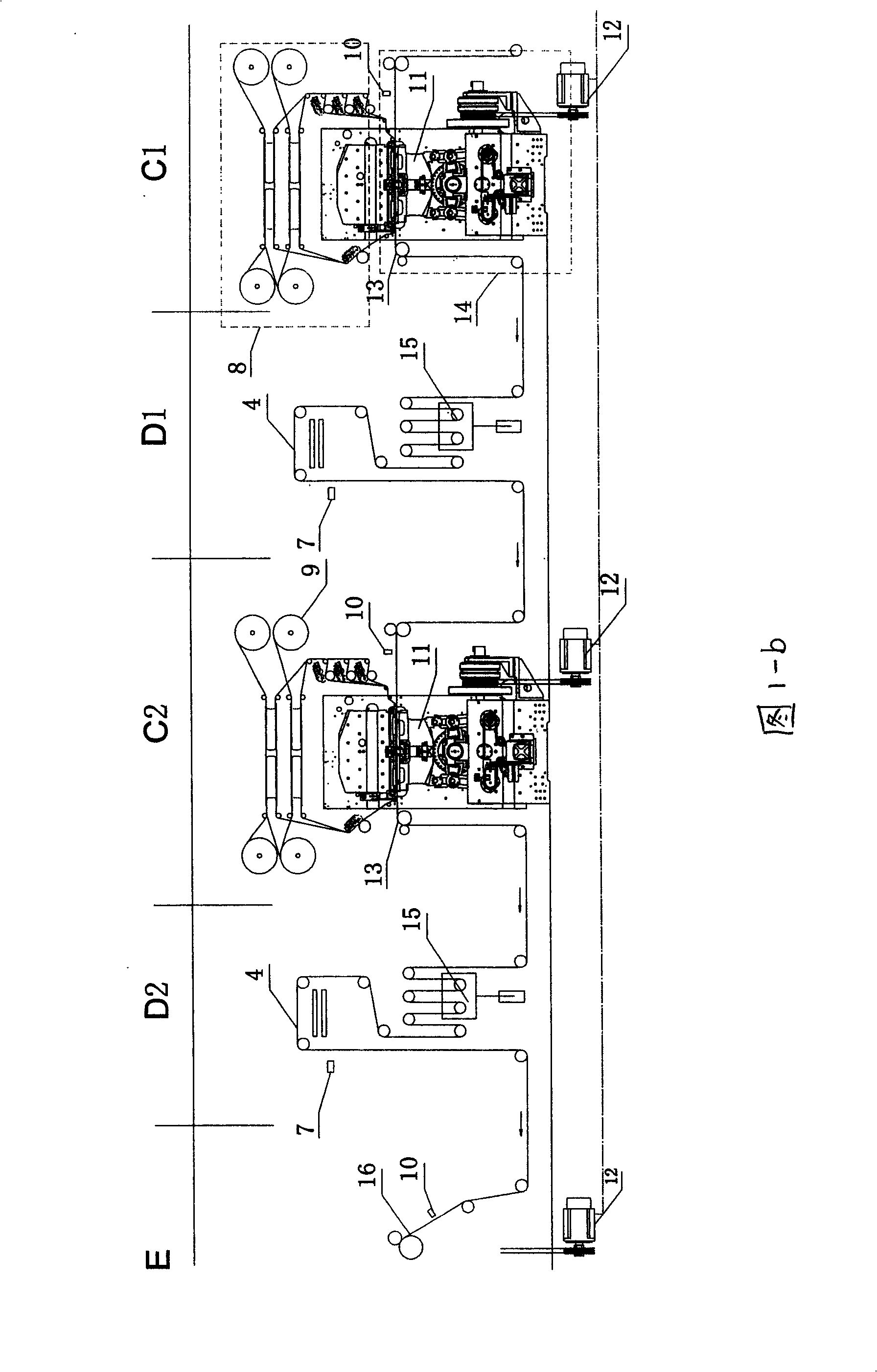

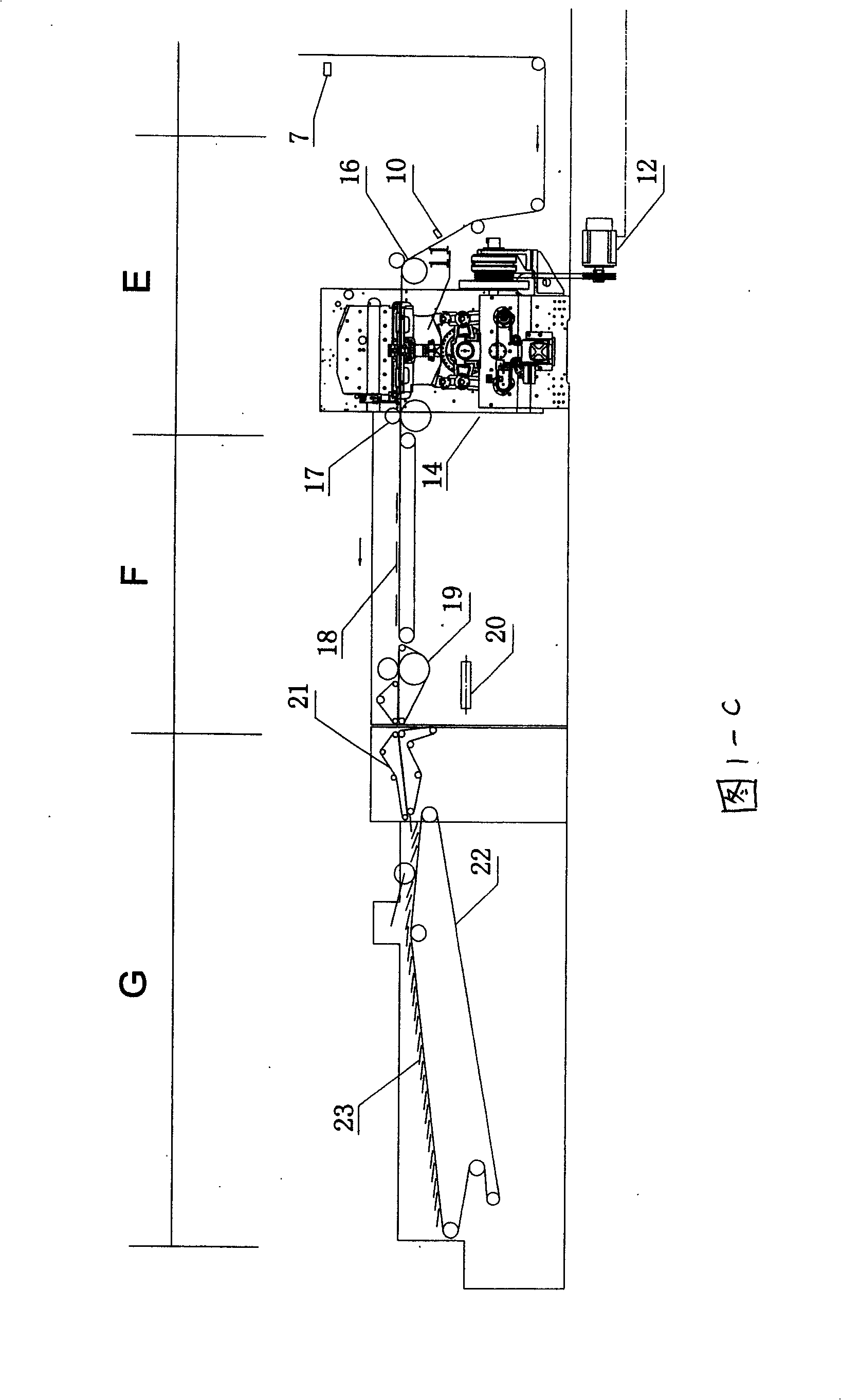

Continuous hot stamping device and technology

The invention discloses a continuous hot stamping device and technology. The device comprises a composite die and an electric heating mechanism. The composite die is mounted on a double-action press and comprises an upper die body and a lower die body which are oppositely arranged. The upper die body comprises an upper die base, a forming male die, an edge cutting female die and a piercing male die. The lower die body comprises a lower die base, a forming female die, an ejector plate, an elastic cushion and material supporting racks. The forming female die is fixedly mounted on the lower die base. The ejector plate is arranged under the edge cutting female die. The bottom of the ejector plate is fixedly connected with the elastic cushion through an ejector rod. The material supporting racks are mounted at the two ends of the lower die base. The electric heating mechanism comprises a power source, a movable electrode, a fixed electrode and a lifting assembly. By means of the continuous hot stamping device and technology, fast heating, drawing forming, pressurizing and quenching, edge cutting and piercing can be completed continuously, production efficiency is improved, and the transportation process before a hot blank is stamped is omitted.

Owner:WUHAN UNIV OF TECH

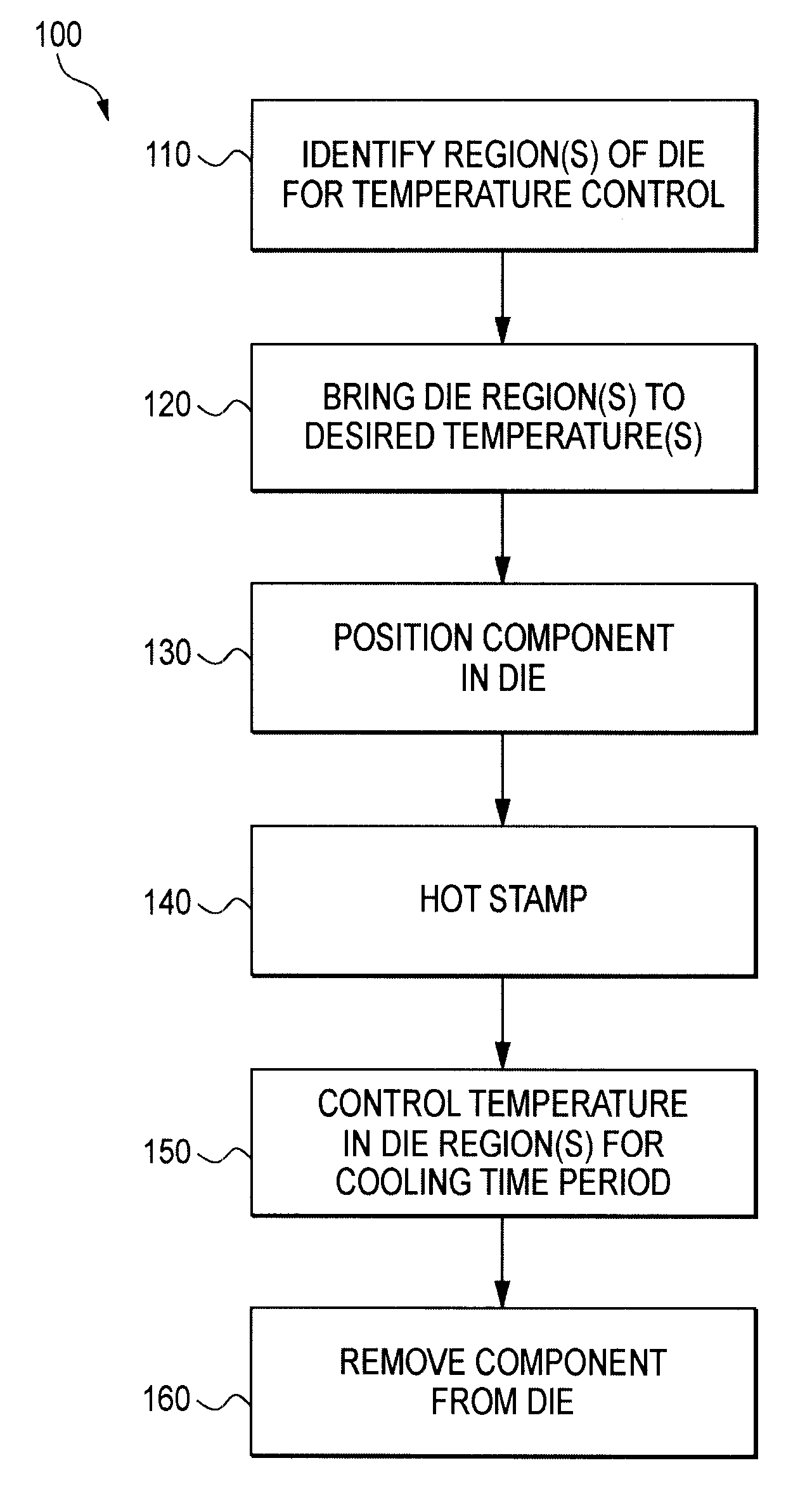

Microstructural optimization of automotive structures

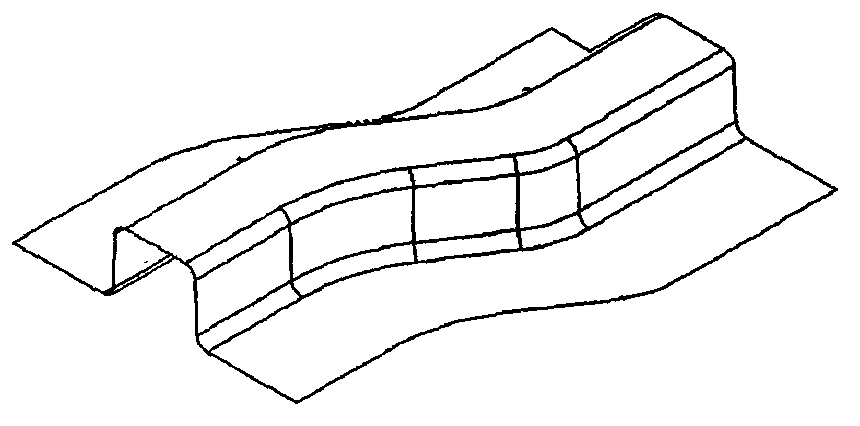

A process for hot stamping a steel component is described. The hot stamping process enables the formation of one or more regions of the component to exhibit specific physical properties different than other regions of the component. The various processes are particularly well suited for forming a variety of automobile structural members.

Owner:HONDA MOTOR CO LTD

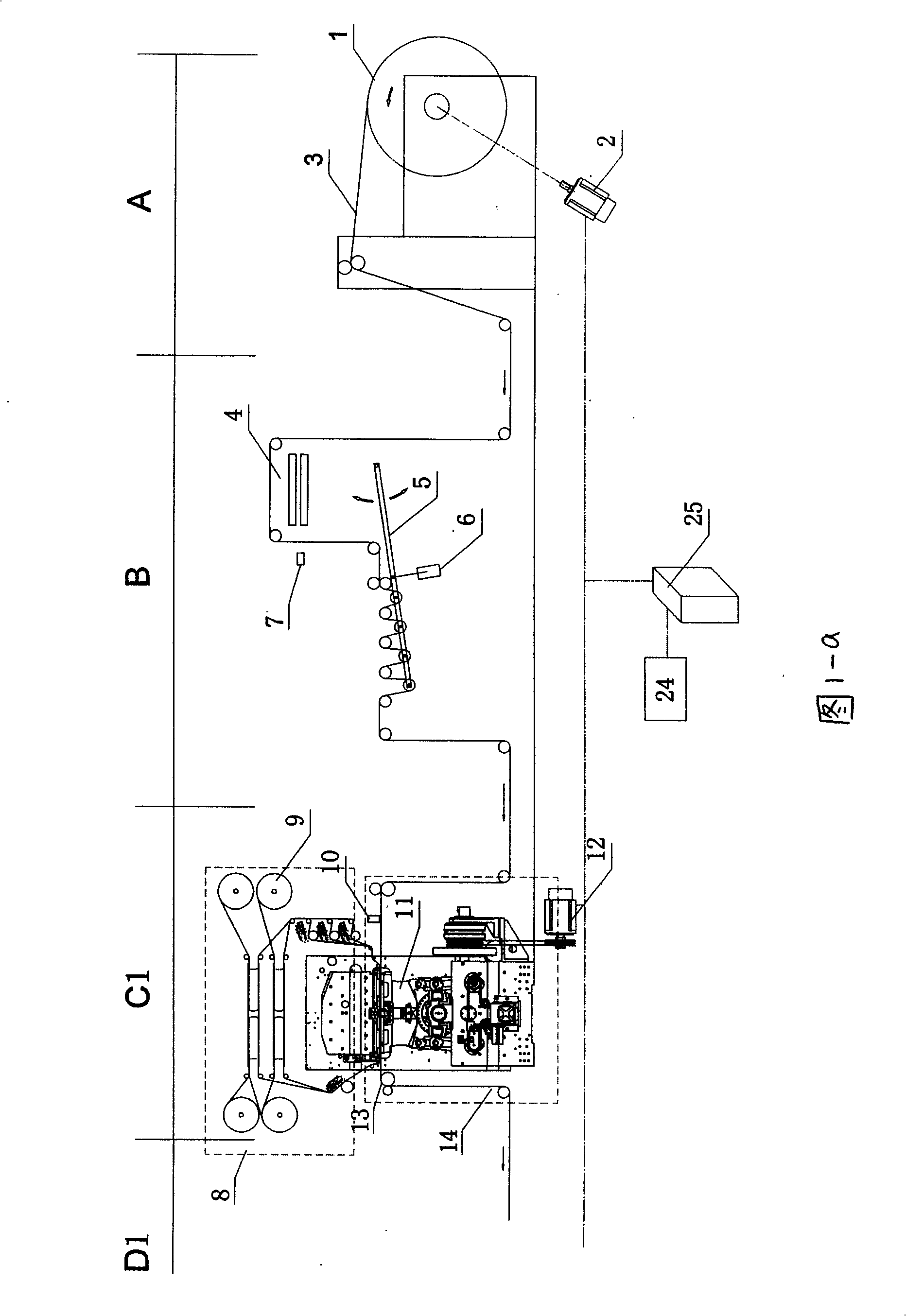

Unit type mold cutter for reeled paper

ActiveCN101407127AProduction effectively adapts toProduction adaptationTransfer printingPlaten pressesHot stampingRolling paper

The invention relates to a roll paper unit-type die cutting machine. The machine consists of a roll paper releasing and winding device, a paper storage device, a hot stamping unit, a tensile force control device, a die cutting unit and a waste cleaning device, wherein the roll paper releasing and winding device consists of roll paper, a motor and paper, the paper storage device consists of a deviation rectifying device, a swinging rod, a constant-force device and a detection sensor of the deviation rectifying device, the hot stamping unit consists of an aluminum foil conveying device, aluminum foil, a sensor, a moving platform, a motor, a paper drawing device and a press mould device, the tensile force control device consists of a deviation rectifying device, a detection sensor of the deviation rectifying device and a constant-force device, the die cutting device consists of a sensor, a motor, a press mould device, a paper drawing device and a paper receiving device, the waste cleaning device consists of paper, waste cleaning device and a slitter edge conveying device, and a sheet material collecting device consists of a paper separating and conveying device, a conveyor belt and paper.

Owner:MASTERWORK GROUP CO LTD

Steel for hot stamping forming, hot stamping forming process and hot stamping forming component

ActiveCN106399837AReach yield strengthReach tensile strengthHot-dipping/immersion processesUnderstructuresHot stampingUltra fine

The invention relates to steel which is provided with ultra-fine grains and used for hot stamping forming, a manufacturing process of the steel, a hot stamping forming process and a hot stamping forming component. The steel comprises, by weight, 0.27%-0.40% of C, 0.2%-3.0% of Mn, 0.11%-0.4% of V, 0-0.8% of Si, 0-0.5% of Al, 0-2% of Cr, 0-0.15% of Ti, 0-0.15% of Nb, 0-0.004% of B, less than 2% of the total content of Mo, Ni, Cu and other alloy elements beneficial to improve the hardenability of the steel and other impurity elements.

Owner:NORTHEASTERN UNIV +1

Coated steel strips, methods of making the same, methods of using the same, stamping blanks prepared from the same, stamped products prepared from the same, and articles of manufacture which contain such a stamped product

ActiveUS20110165436A1Improve cohesionGood formabilityShaping toolsHot-dipping/immersion processesHot stampingPolymer science

Coated steel having a well defined and uniform thickness is useful and advantageous for preparing products by hot stamping. Products prepared by hot stamping such a steel are particularly advantageous when subjected to a subsequent spot welding step.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

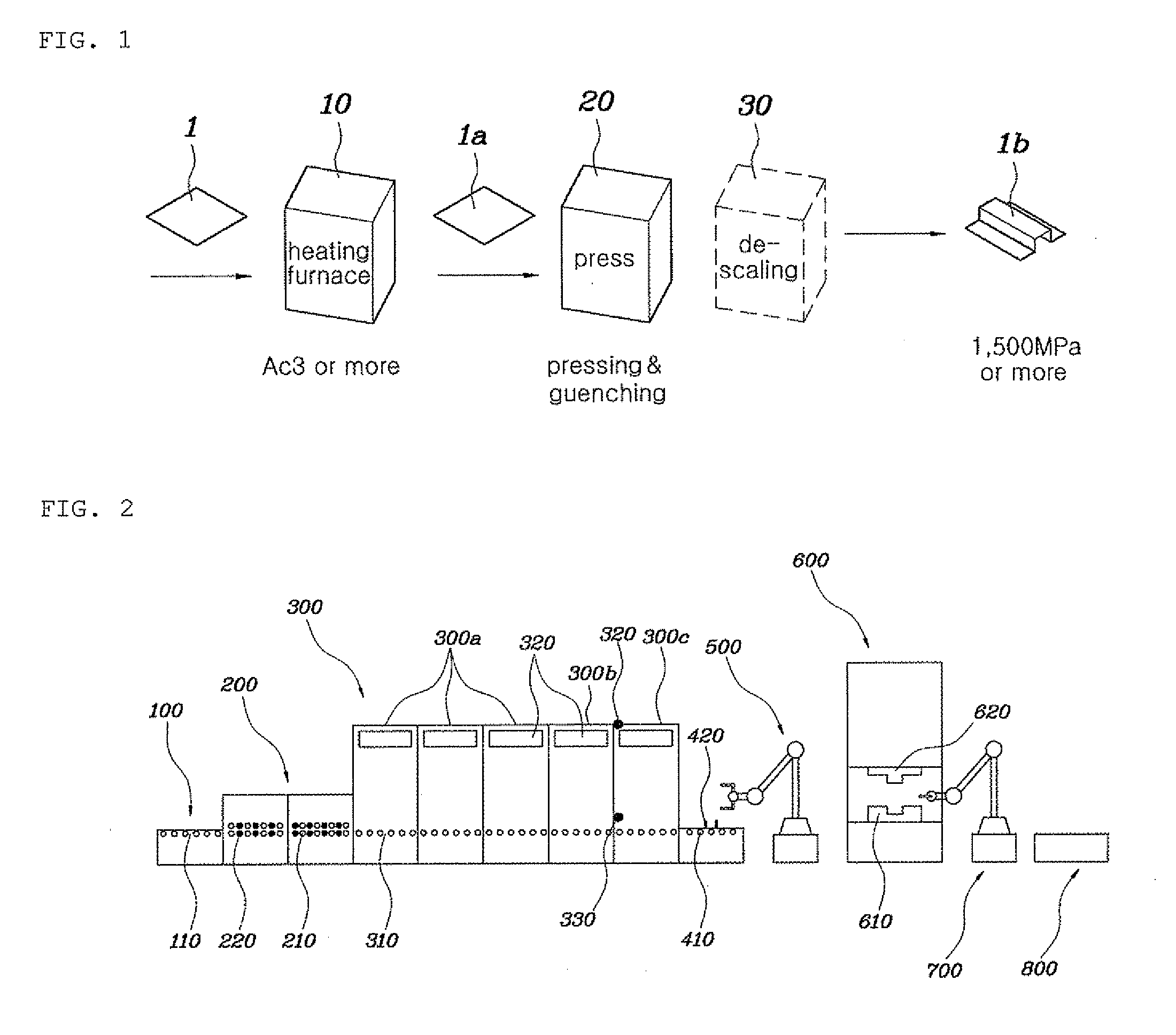

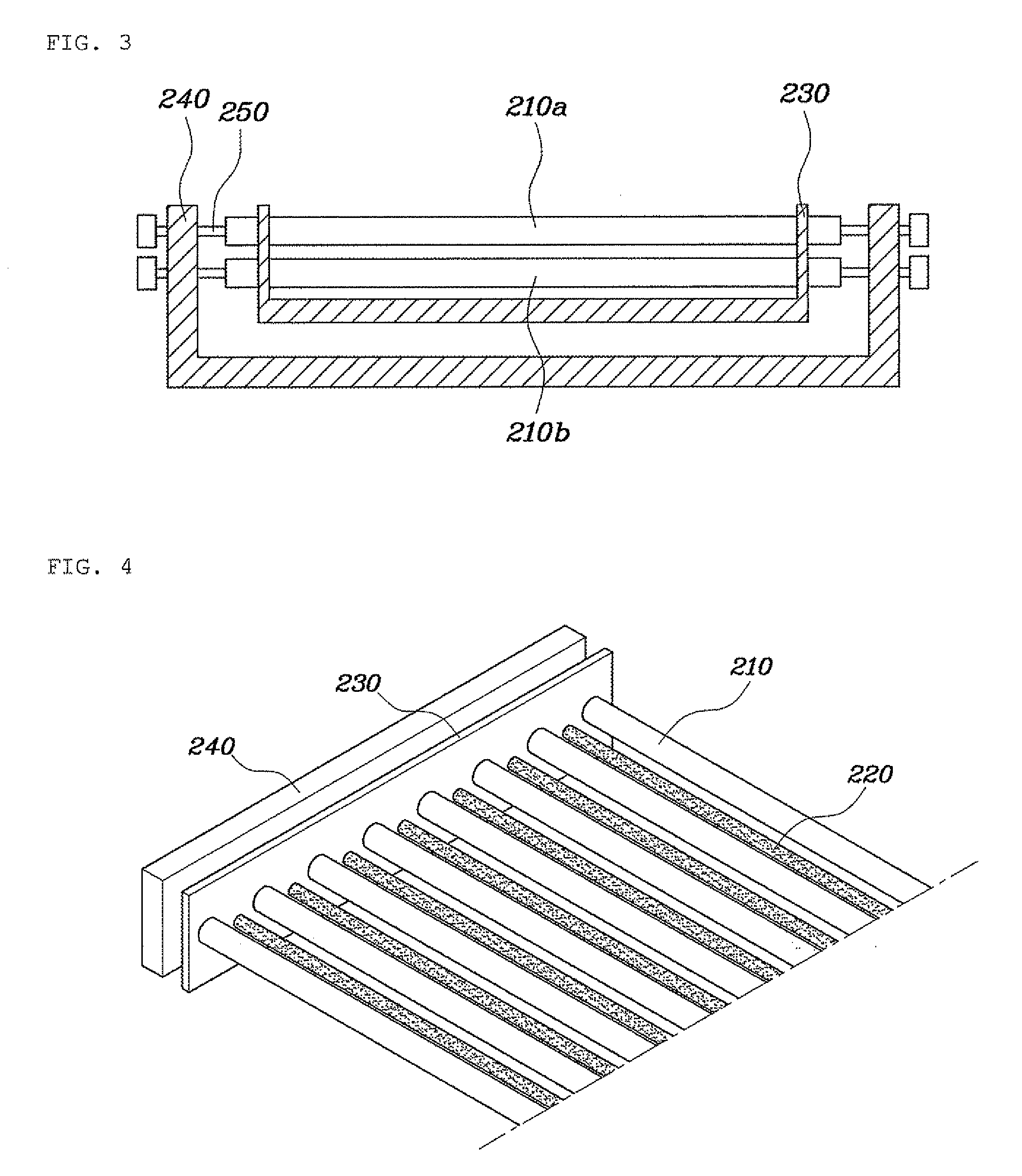

Heating Furnace System for Hot Stamping

ActiveUS20100086002A1Reduce spacingFuel costFurnace componentsElectrical apparatusHot stampingElectric arc furnace

Disclosed is a heating furnace system for hot stamping. A first heating furnace has a plurality of pairs of upper and lower rolls arranged in a lengthwise direction thereof in order to transfer a steel plate, and high-frequency coils alternately arranged with the pairs of upper and lower rolls in the lengthwise direction thereof. A second heating furnace continuously transfers the steel plate from the first heating furnace during heating the steel plate at temperature of Ac3 or more, and has a plurality of transfer rollers arranged in a lengthwise direction thereof. The second heating furnace includes an electric furnace or a gas furnace. This heating furnace system can reduce space required for facilities by 50% or more compared to the related art.

Owner:MYUNGSHIN IND CO LTD +1

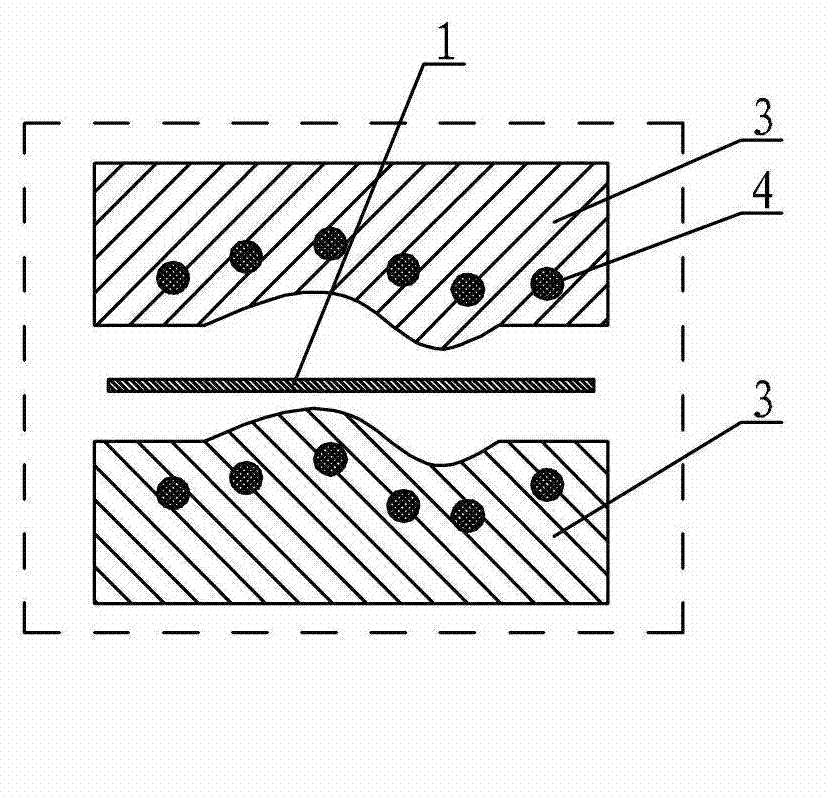

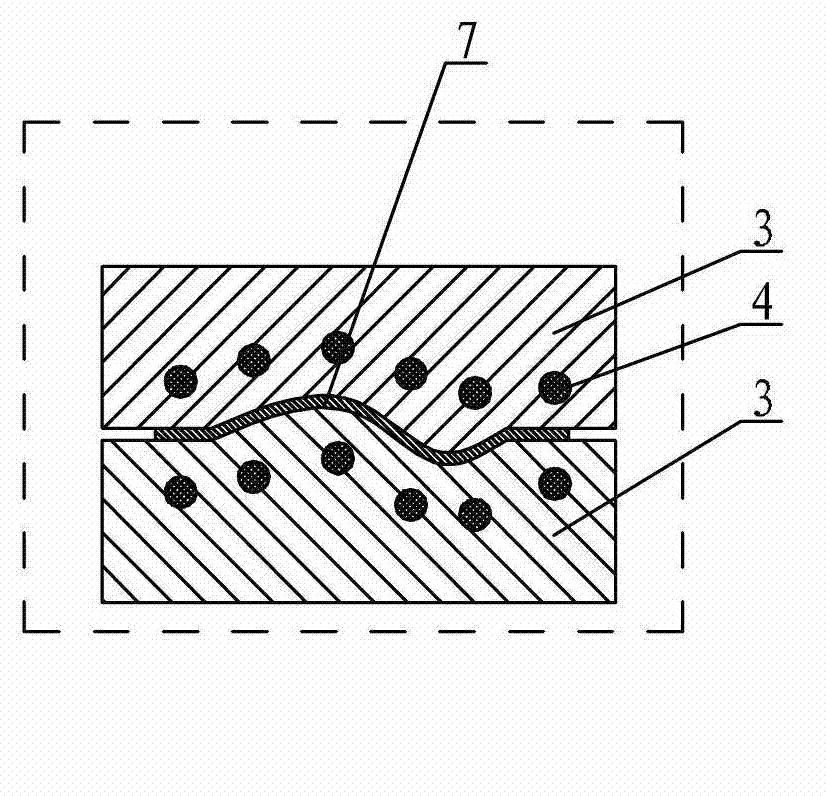

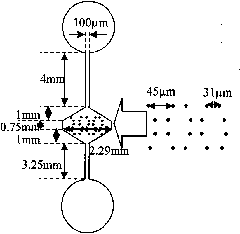

Microfluidic chip preparation method capable of realizing microsphere discretization

InactiveCN102190283AReduce investmentSimple processPrecision positioning equipmentDecorative surface effectsHot stampingGlass cover

The invention discloses a microfluidic chip preparation method capable of realizing microsphere discretization, comprising the following steps: manufacture of microfluidic chip die: manufacturing a glass-base metal mask plate to obtain a microfluidic chip pattern, transferring the pattern to a substrate which is spin-coated with photoresist by photoetching, and obtaining the microfluidic chip die with a cylindrical pattern on the substrate by dry etching; preparation of polydimethylsiloxane (PDMS) microfluidic chip substrate: polymerizing molten PDMS in situ in the convex microfluidic chip die, curing, and stripping to obtain a PDMS substrate with the pattern; and bonding of glass cover plate and PDMS substrate: etching the glass cover plate and the PDMS substrate by O2 reaction ions, and aligning and sealing the glass cover plate and the PDMS substrate. The preparation method has the advantages that the microfluidic chip prepared on the basis of the nanometer hot stamping method can be used for manufacturing casting male dies with higher bench height only by stamping the die once. The method has the advantages of low investment and simple process.

Owner:CHINA NAT ACAD NANOTECH & ENG

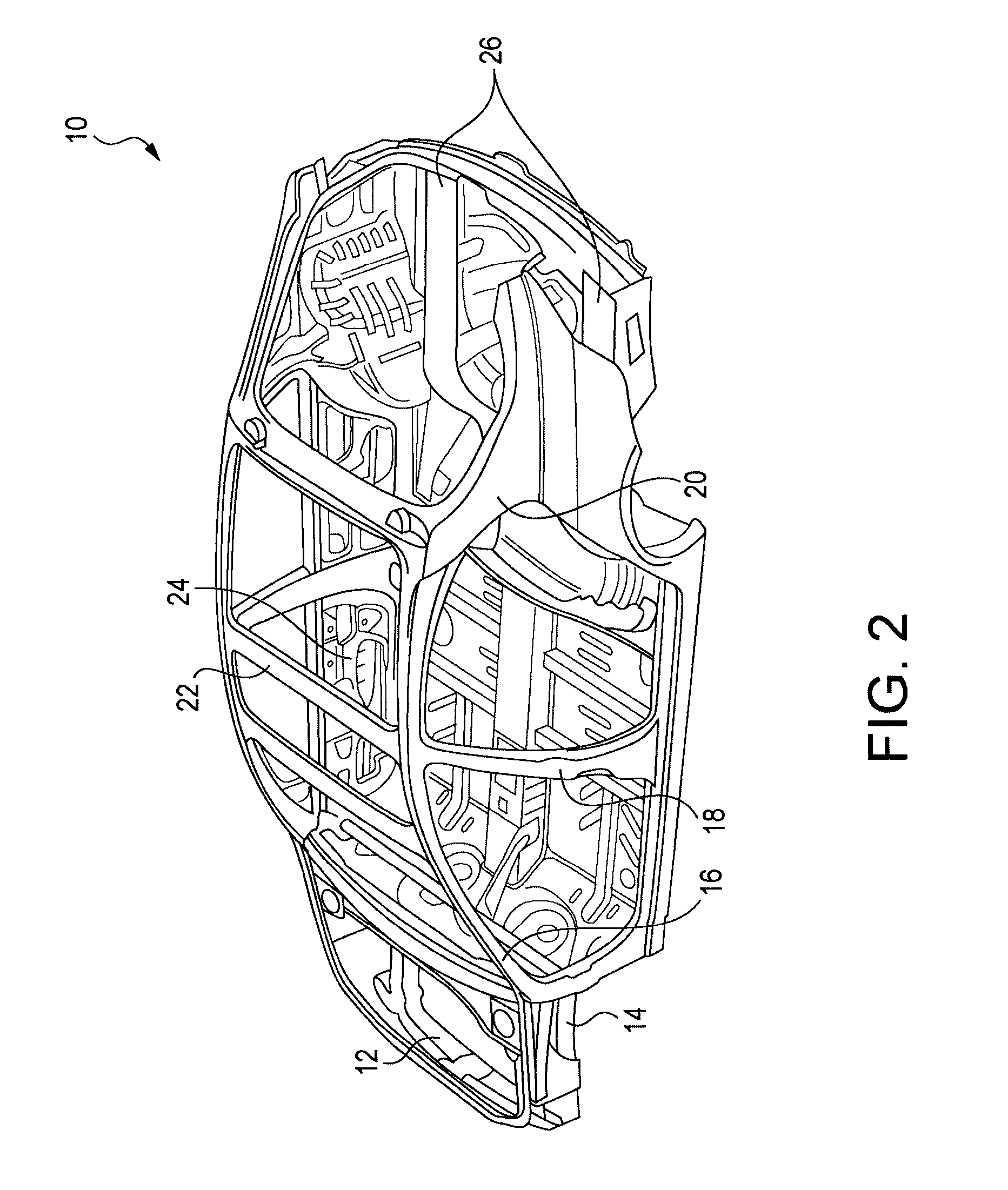

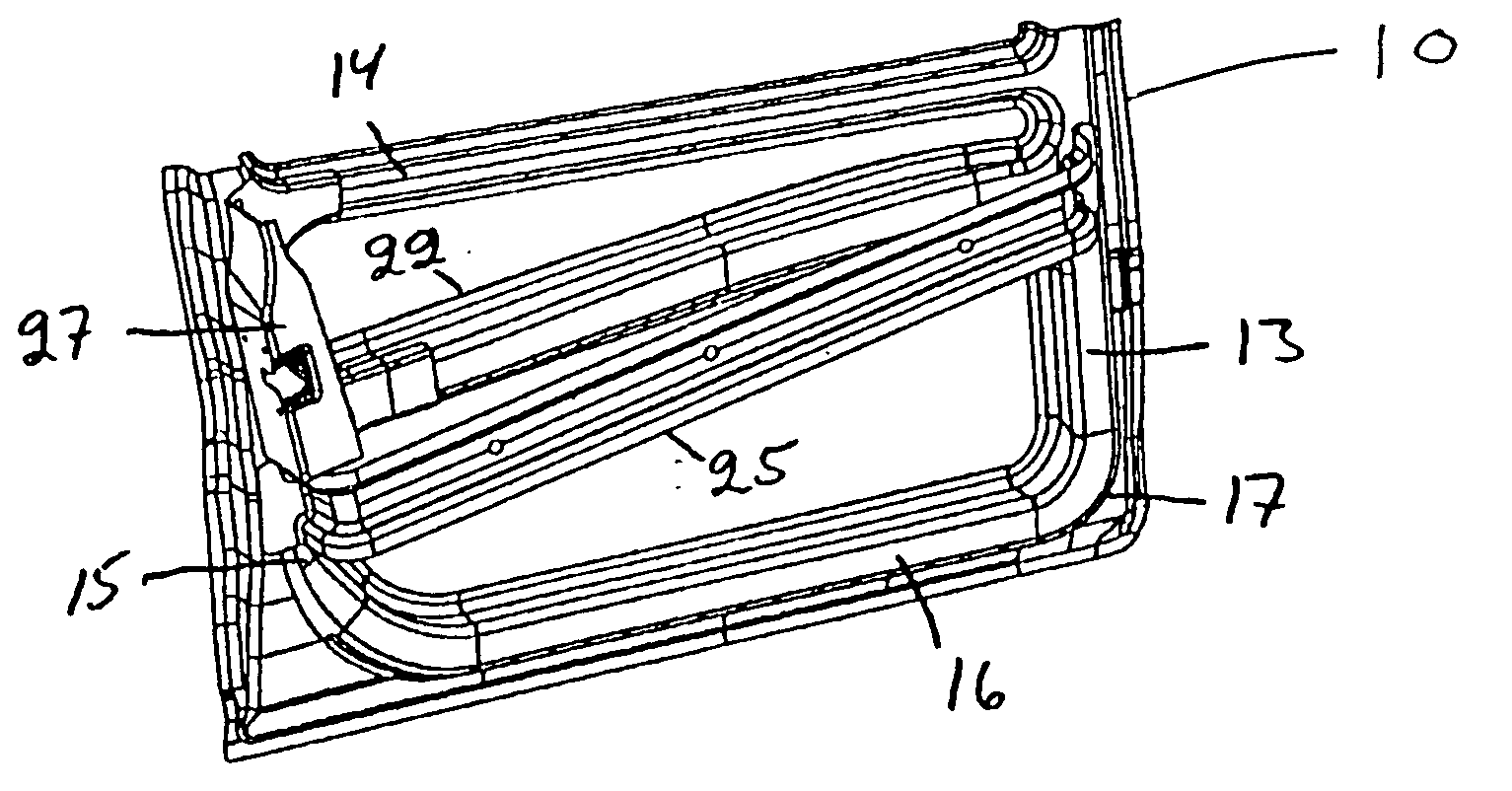

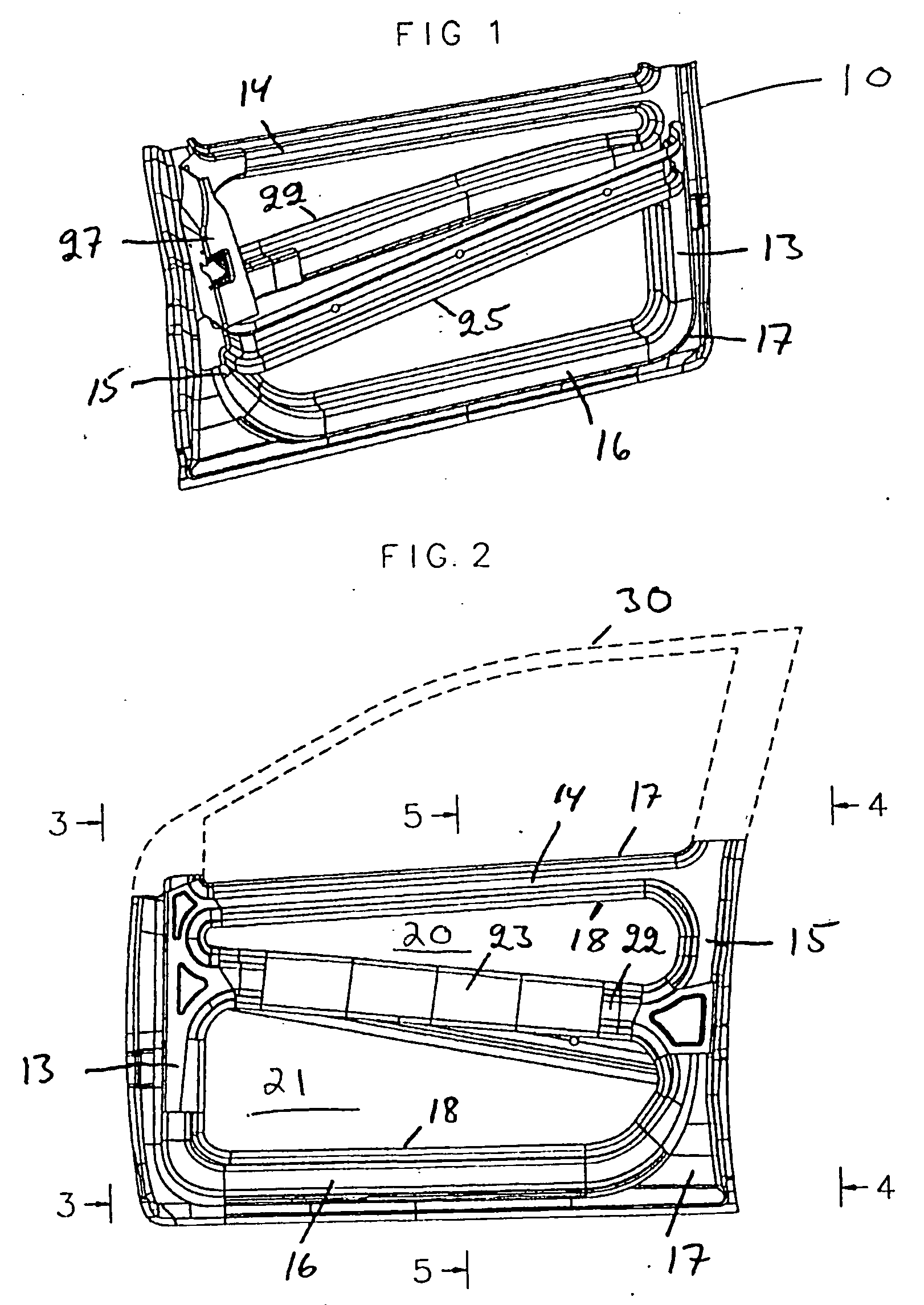

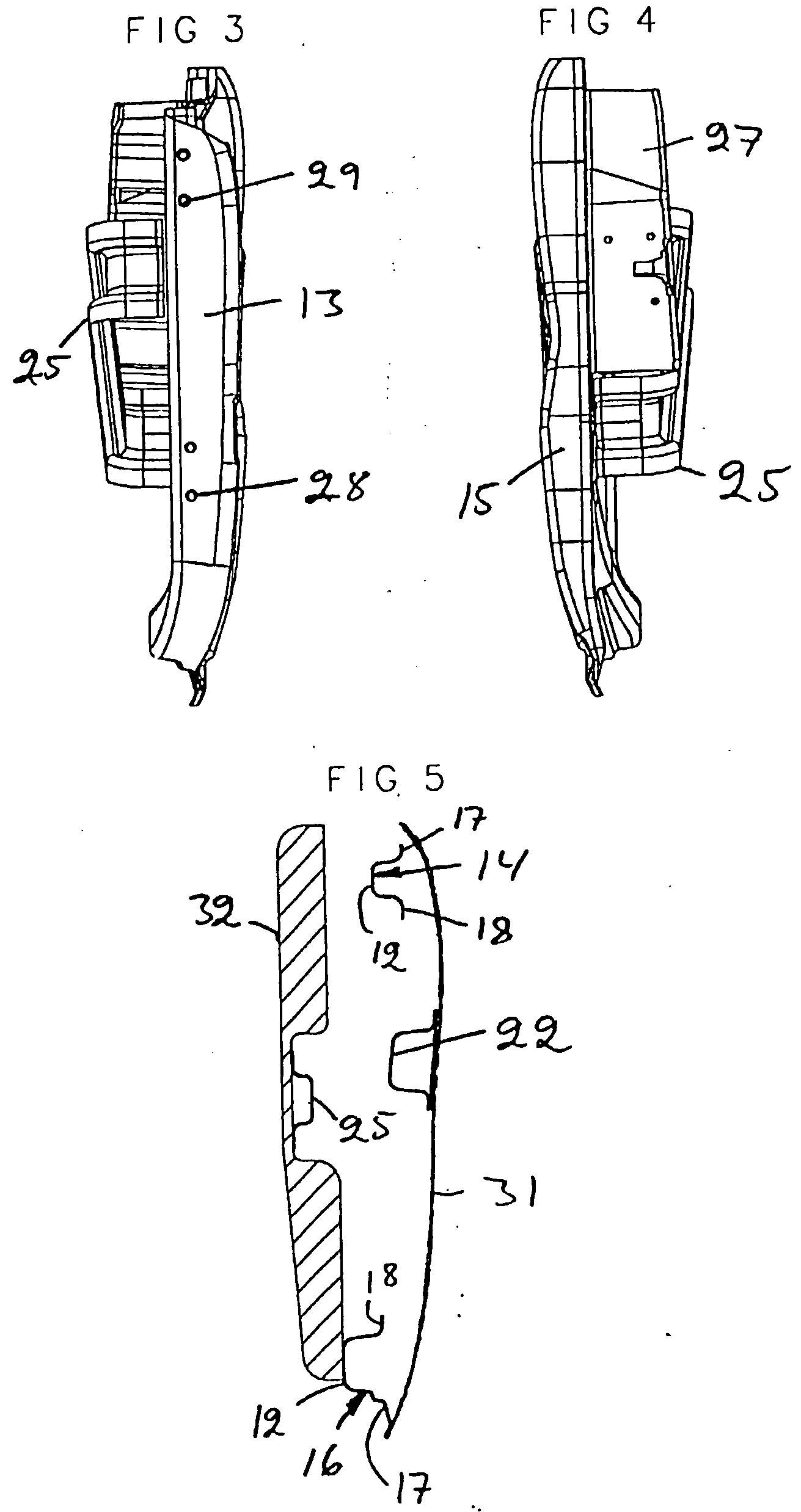

Vehicle door and a method to make such a door

InactiveUS20070102955A1Easy to installEasy accessMonocoque constructionsVehicle bodiesHot stampingSheet steel

A vehicle door has a supportive frame (10). A waist rail (14) and a side impact guard beam (22) are formed integrally with the supportive frame. The entire frame is made of high strength sheet steel. The door is produced by hot stamping a steel sheet blank into the shape of a supportive door frame that includes an integral waist rail (14) and a side impact guard beam (22), and hardening the shaped door frame while the frame remains in the shaping tools, and fastening an outer panel (31) to the finished door such that the side collision guard beam (22) of the frame will lie close to the outer panel (31).

Owner:GESTAMP HARDTECH AB

Method for manufacturing end socket of voltage stabilizer for nuclear power

ActiveCN102248362ASize qualifiedQualified shapeFurnace typesHeat treatment furnacesHot stampingNuclear power

The invention discloses a method for manufacturing an end socket of a voltage stabilizer for nuclear power. The integral end socket is subjected to hot stamping deep drawing by a 16MND5 low-alloy steel plate, and is subjected to heat treatment of normalizing and tempering to form the end socket, which is reliable in quality, accurate in size and high in mechanical property, of the voltage stabilizer for nuclear power. In the method, the weight of the end socket manufactured by the low-alloy steel plate can be reduced by about half compared with that of the end socket manufactured by forging piece materials, the manufacturing period is short and the cost is reduced greatly.

Owner:泰安东润核电装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com