Method of making coated stamped parts and parts made therefrom

A manufacturing method and component technology, applied in the field of hot stamping components, can solve problems such as weak adhesion of stamping components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

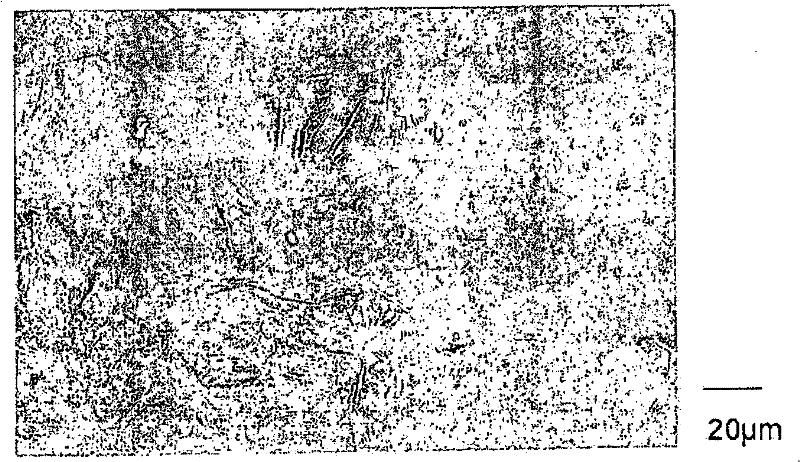

[0082] Cold-rolled steel sheets of thickness 1 and 2 mm are supplied with a steel composition comprising the following by weight: 0.22% C, 1.2% Mn, 0.2% Si, 0.2% Cr, 0.040% Al, 0.003% B, 0.030 %Ti, 0.0002% S, 0.020% P, and the remainder is iron and impurities inherent in processing. The microstructure consists of ferrite-pearlite. At this stage, the lack of martensite makes it easy to further cut, drill or stamp the sheet.

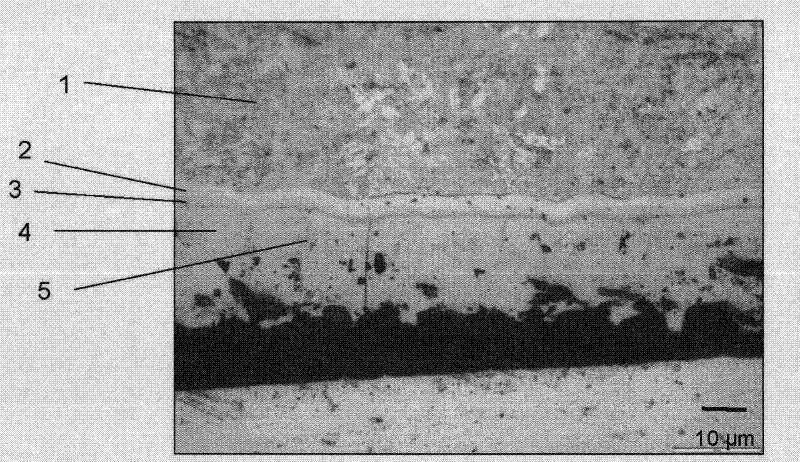

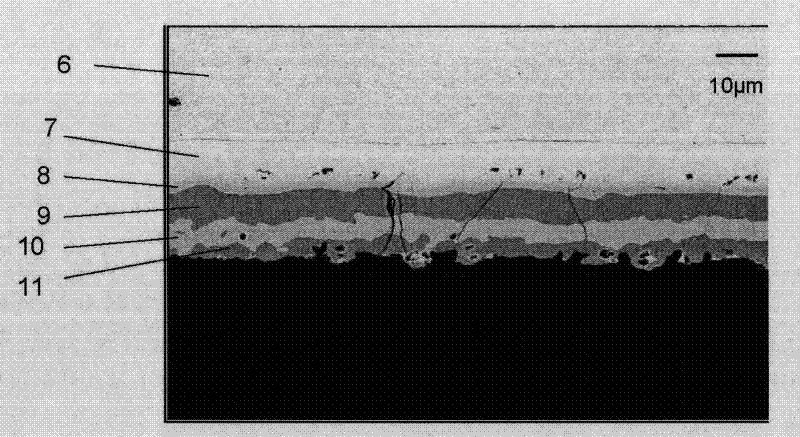

[0083] These panels have been pre-coated by successive immersion of the panels in an Al-Si liquid bath. A precoat is thus obtained, the thickness of which is 27 micrometers, comprising by weight 9% Si, 3% Fe, the remainder being aluminum and impurities inherent in processing. This pre-coat consists of the following layers:

[0084] - FeAl in direct contact with the steel substrate 3 and Fe 2 Al 5 thin layer (less than 1 micron).

[0085] - On top of this layer, a hexagonal, 5 micron thick intermetallic τ 5 layer;

[0086] - On top of this layer, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com