Microfluidic chip preparation method capable of realizing microsphere discretization

A microfluidic chip and discretization technology, which is applied in the photoplate making process of patterned surface, manufacturing tools, welding equipment, etc., can solve the problems of high cost, temperature, and high electric field intensity, and achieve the effect of less investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

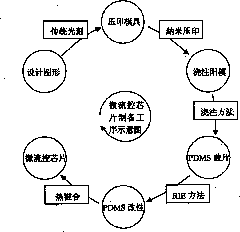

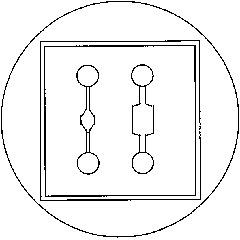

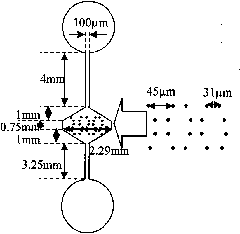

[0024] Embodiment: A kind of microfluidic chip preparation method that realizes microsphere discretization according to the present invention comprises the following steps (see figure 1 , Figure 4 ):

[0025] ① Use the IntelliMask module in the MEMS special design software IntelliSuite simulation software to design the layout for plate making, and hang-coat the photoresist (positive resist used in the experiment) on the two-inch silicon wafer with a thickness of 1 μm.

[0026]②Place the silicon wafer coated with photoresist in a vacuum drying oven for 10 minutes before drying at a temperature of 90°C. Photolithography was performed with extreme ultraviolet light, the exposure time was 8s, and then developed in a NaOH solution with a concentration of 0.6% for 40s, and the developed silicon wafer was post-baked and pre-baked for 15 minutes at a temperature of 120°C.

[0027] ③Use Oxford Plasmalab 80plus reactive ion etching machine to adjust the residual glue thickness after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com