Patents

Literature

731results about How to "Simplify construction steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carst region double-arch road tunnel construction method

ActiveCN101864960AReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

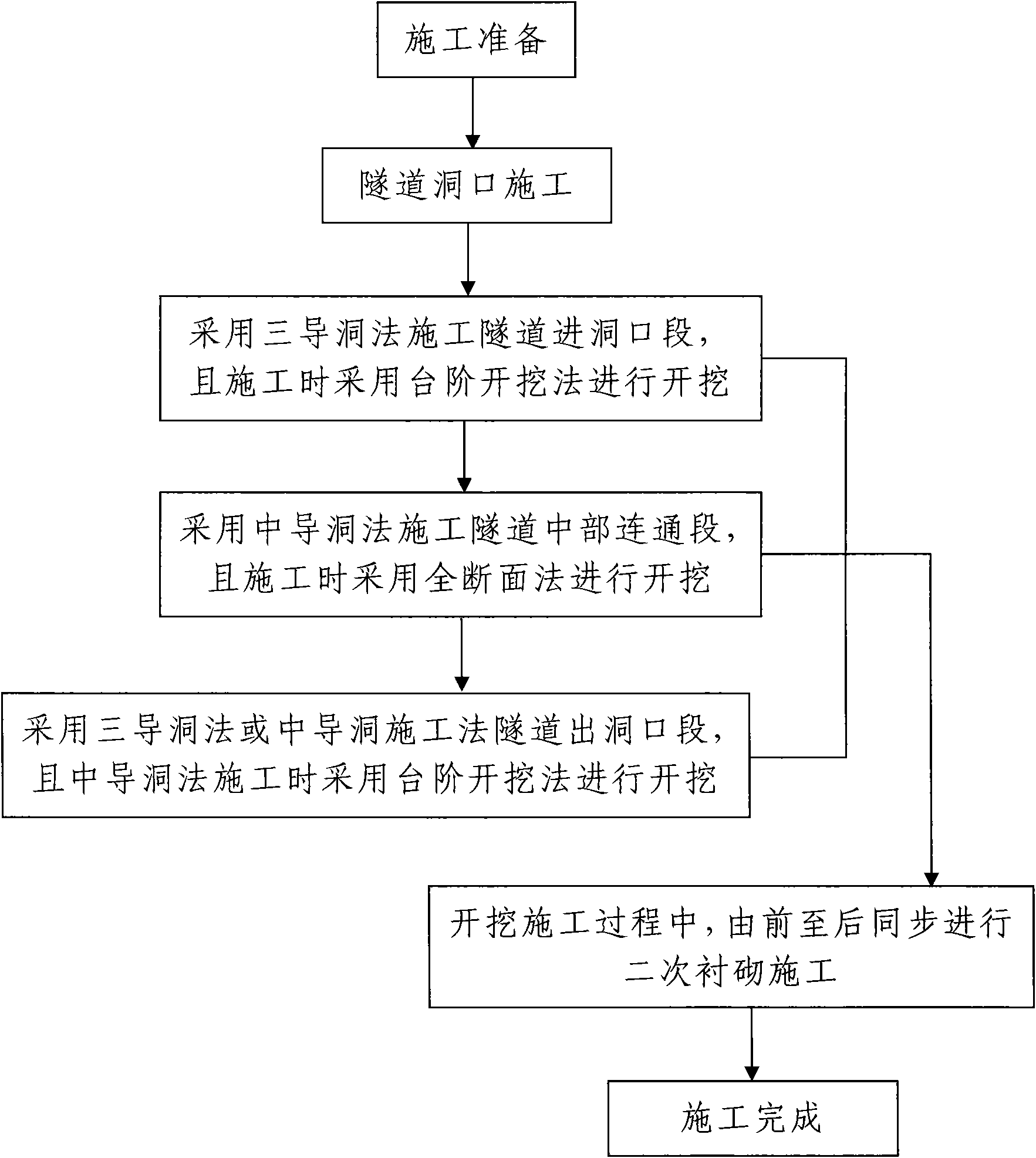

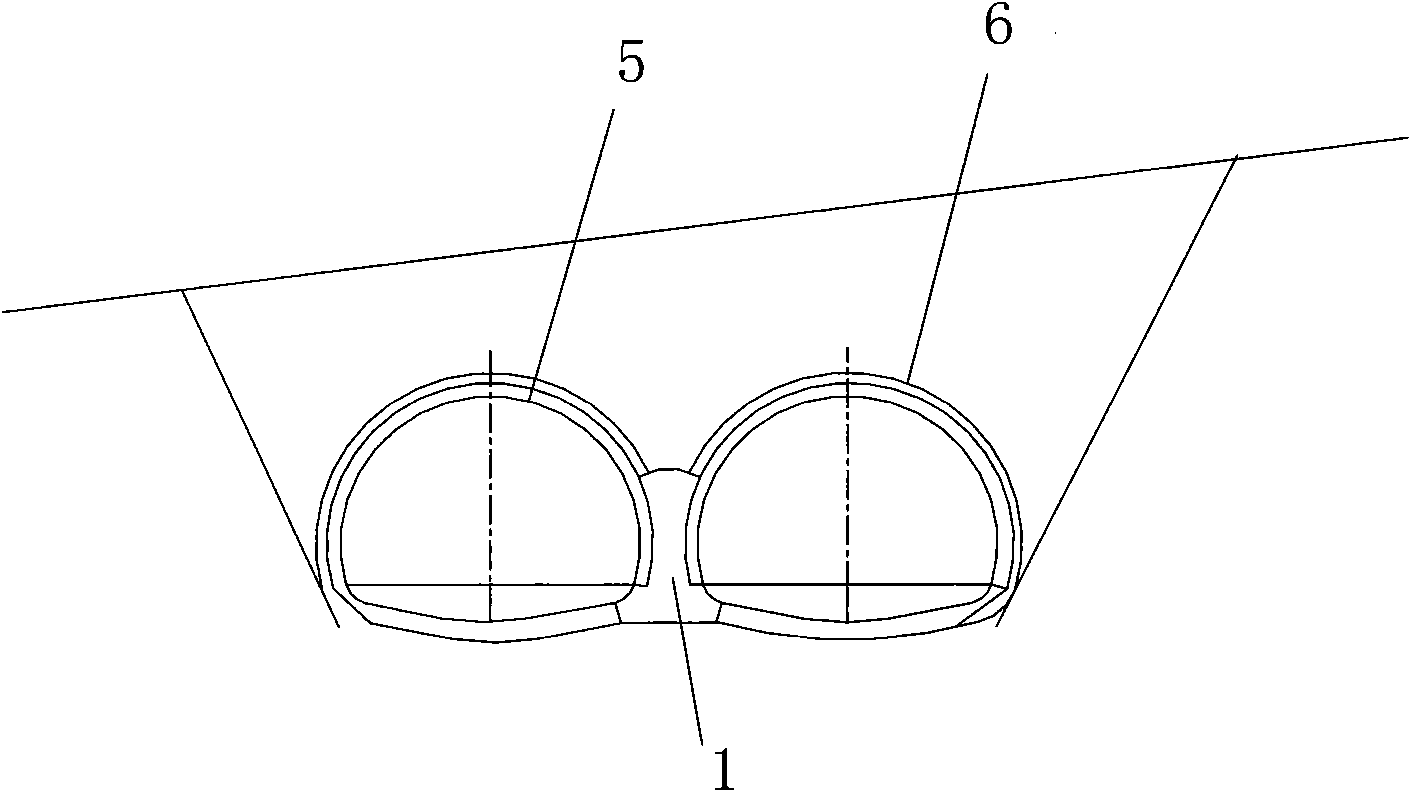

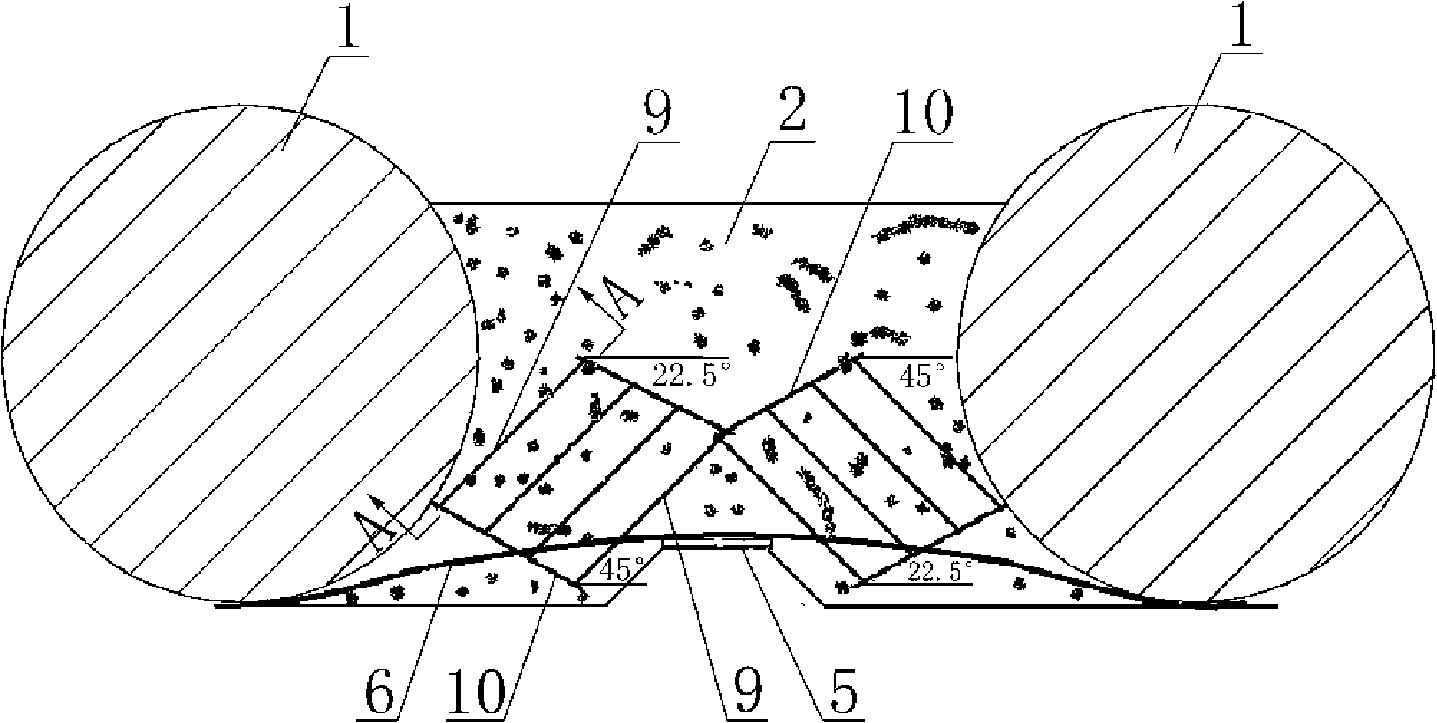

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

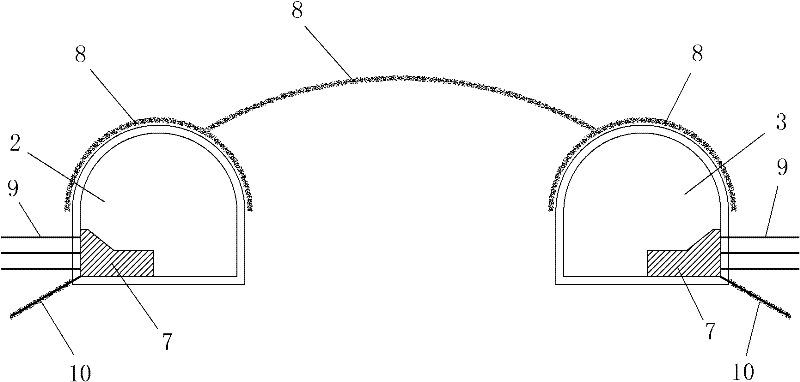

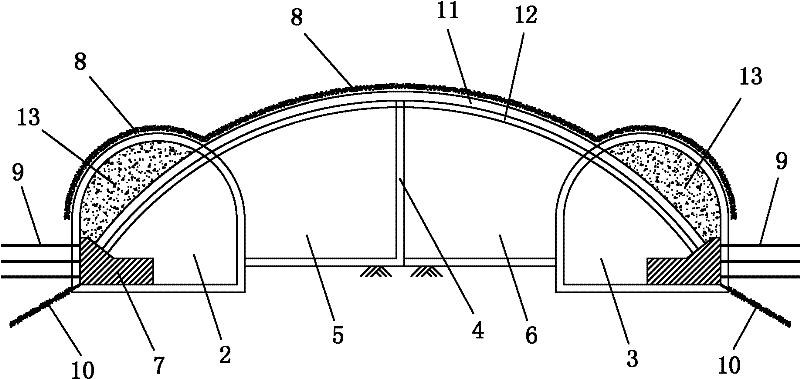

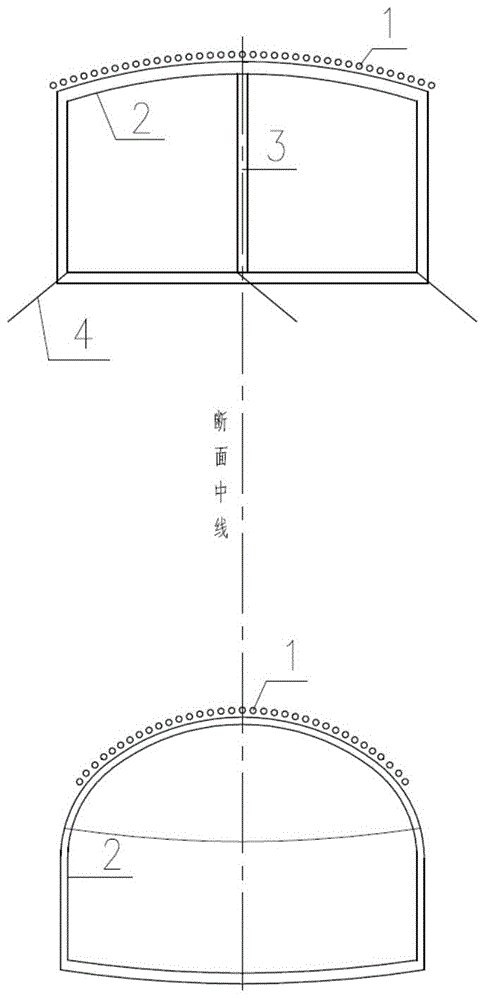

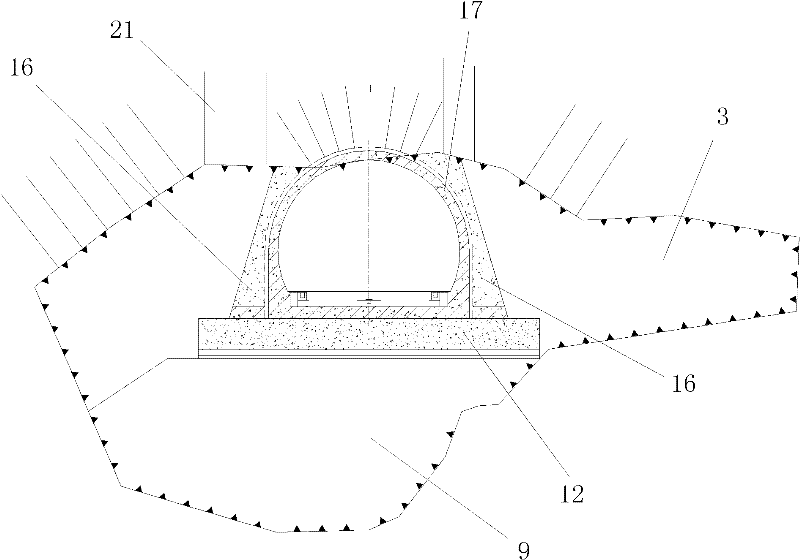

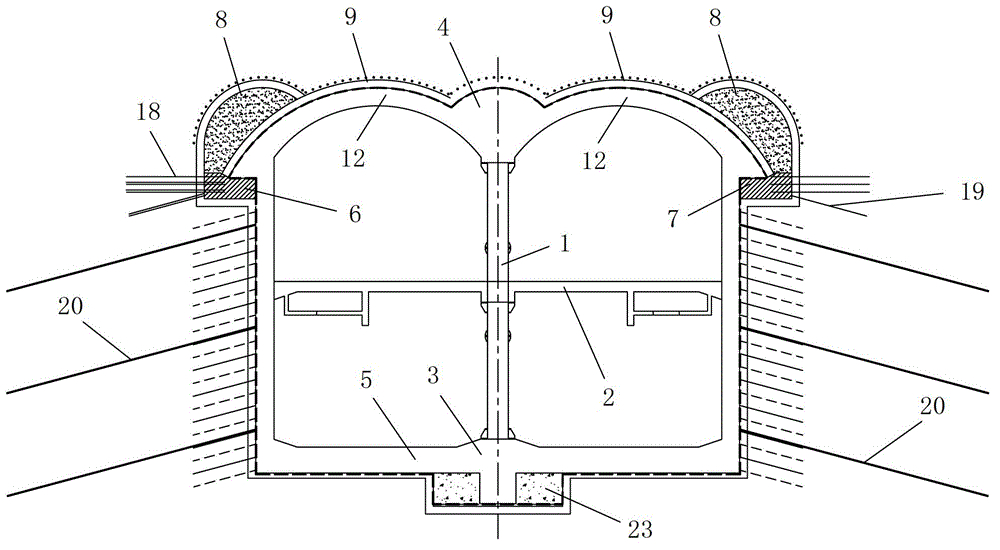

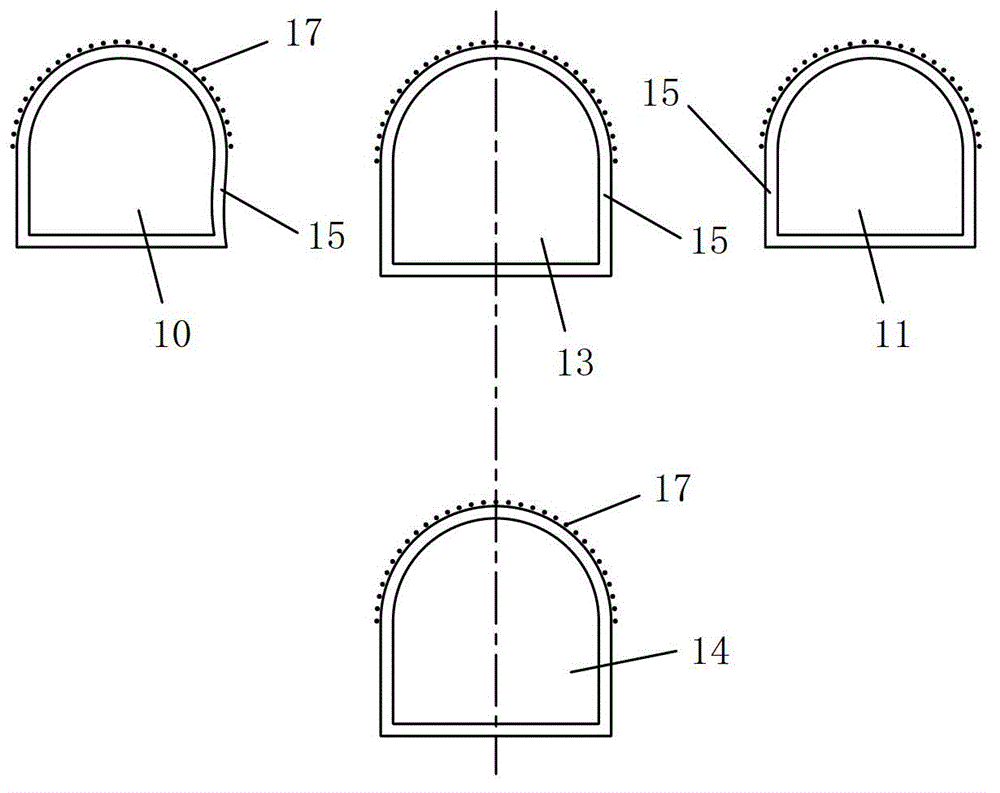

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

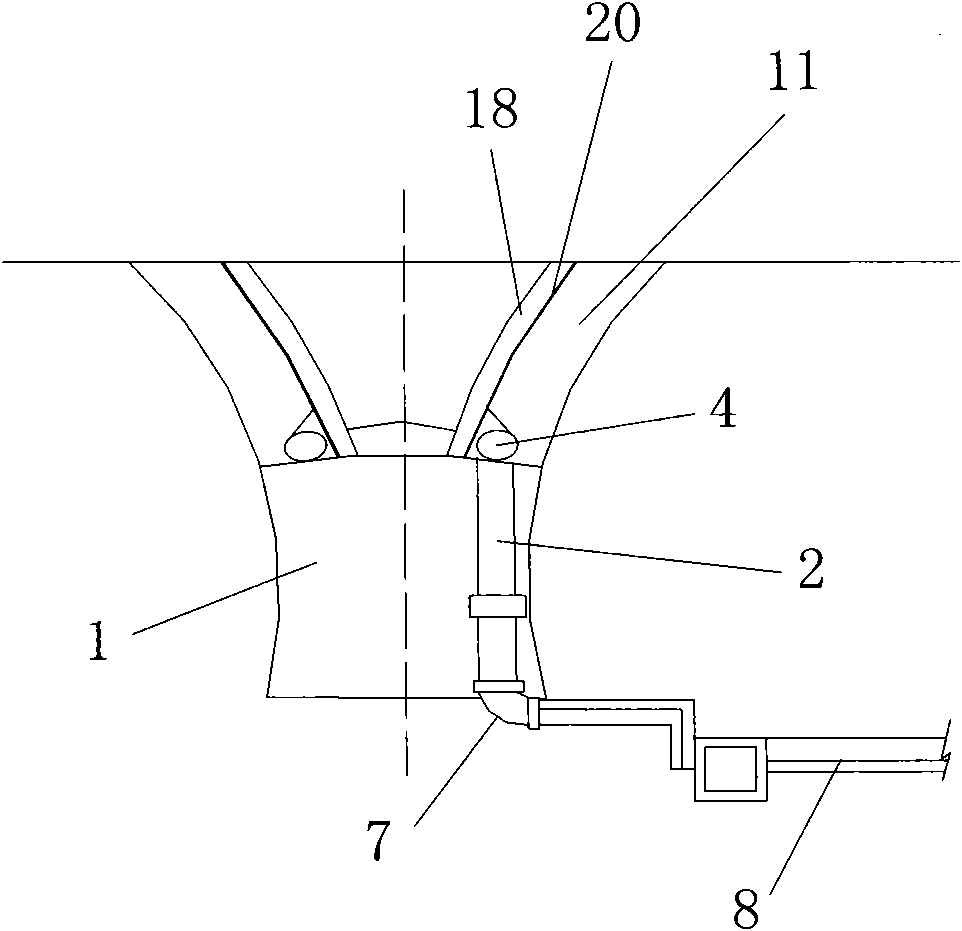

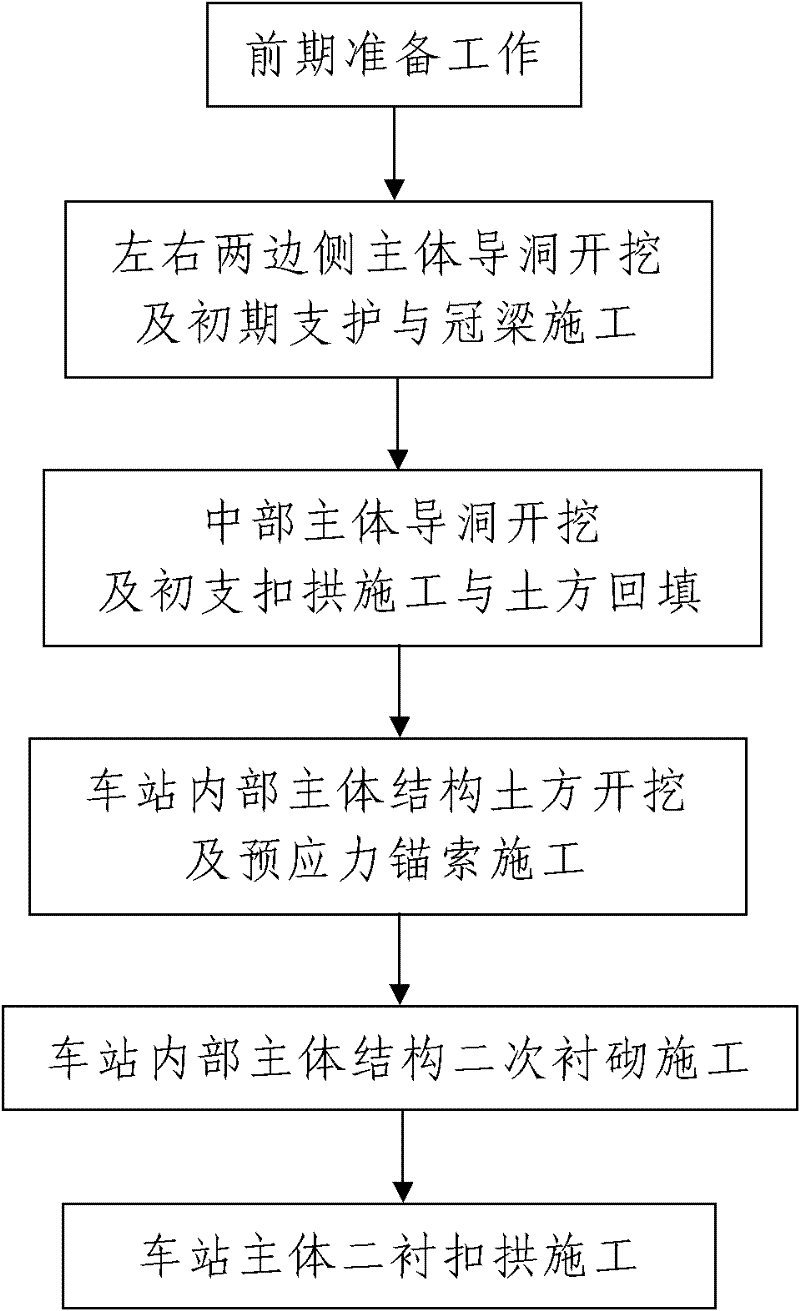

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

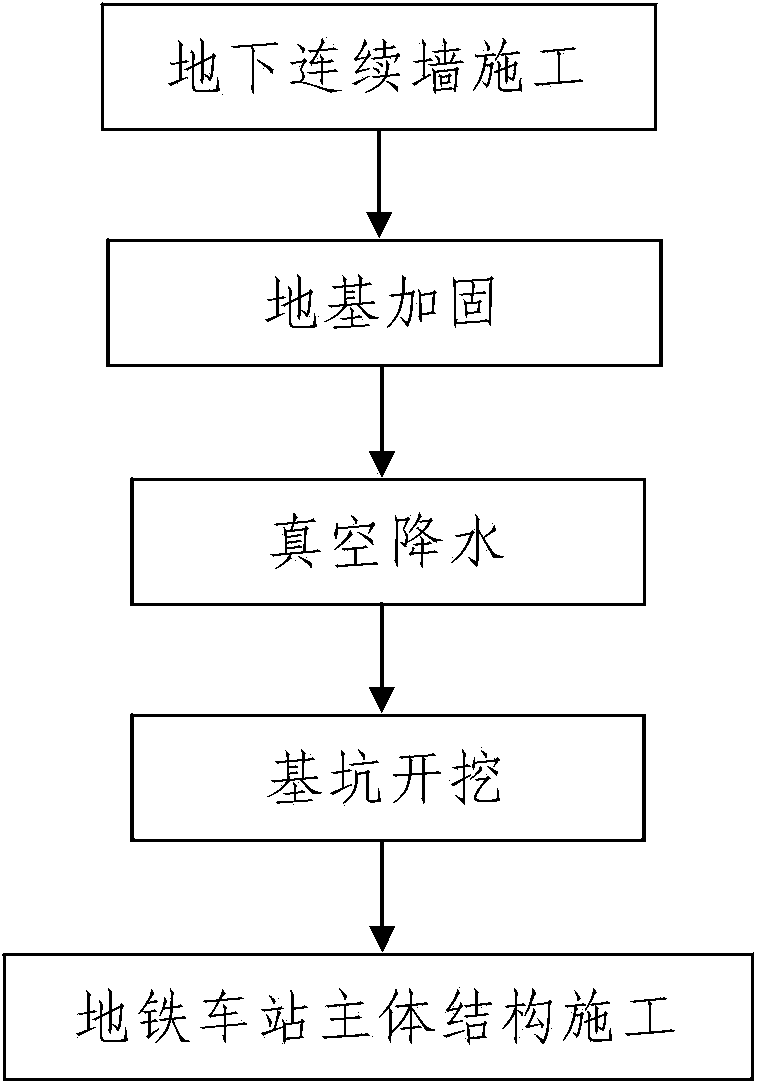

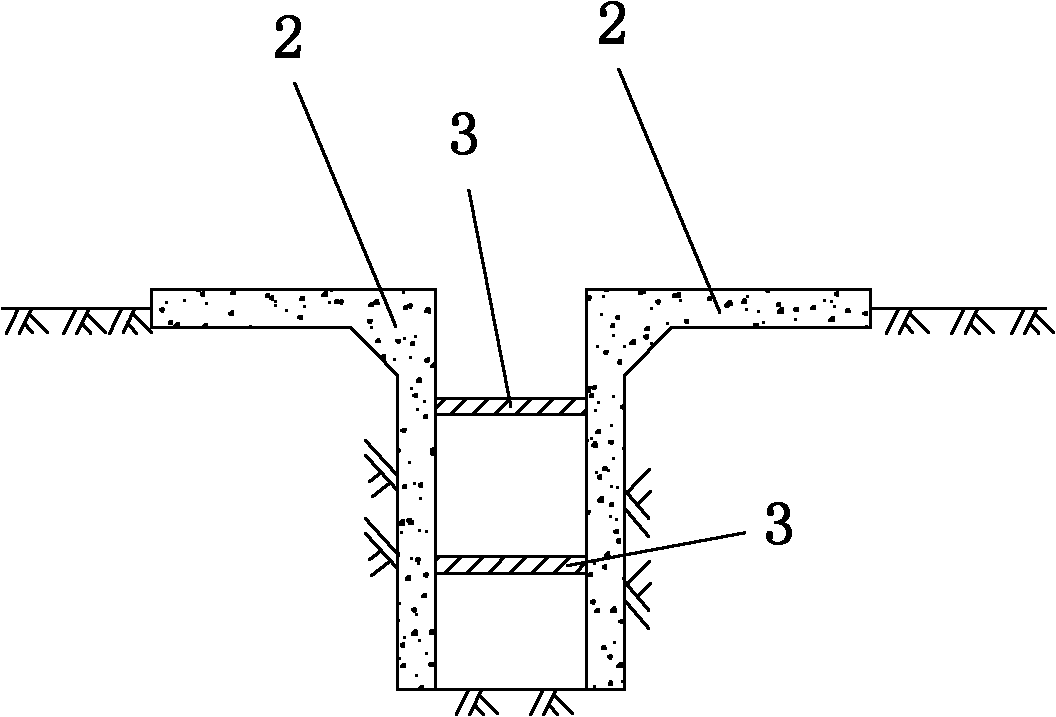

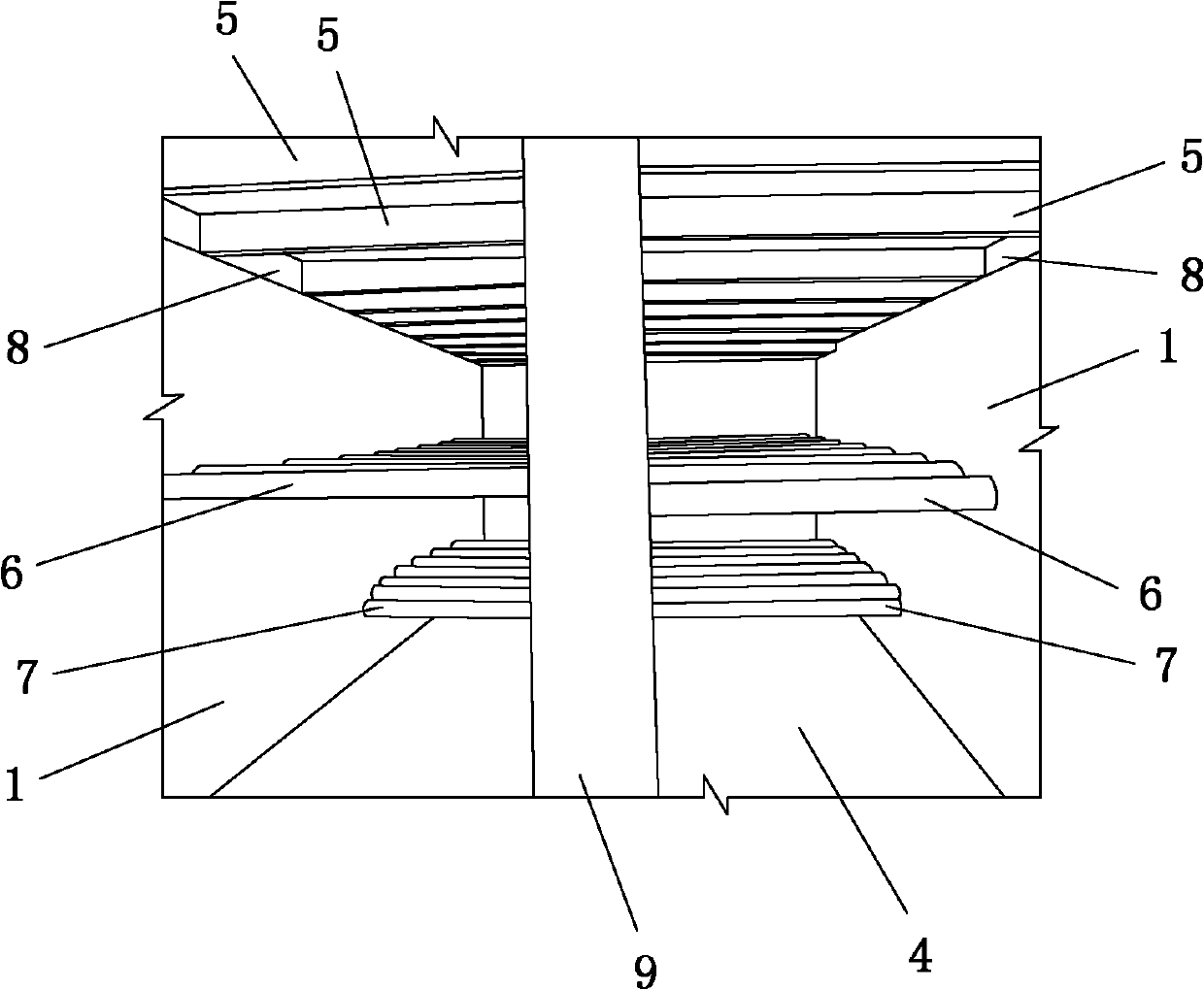

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

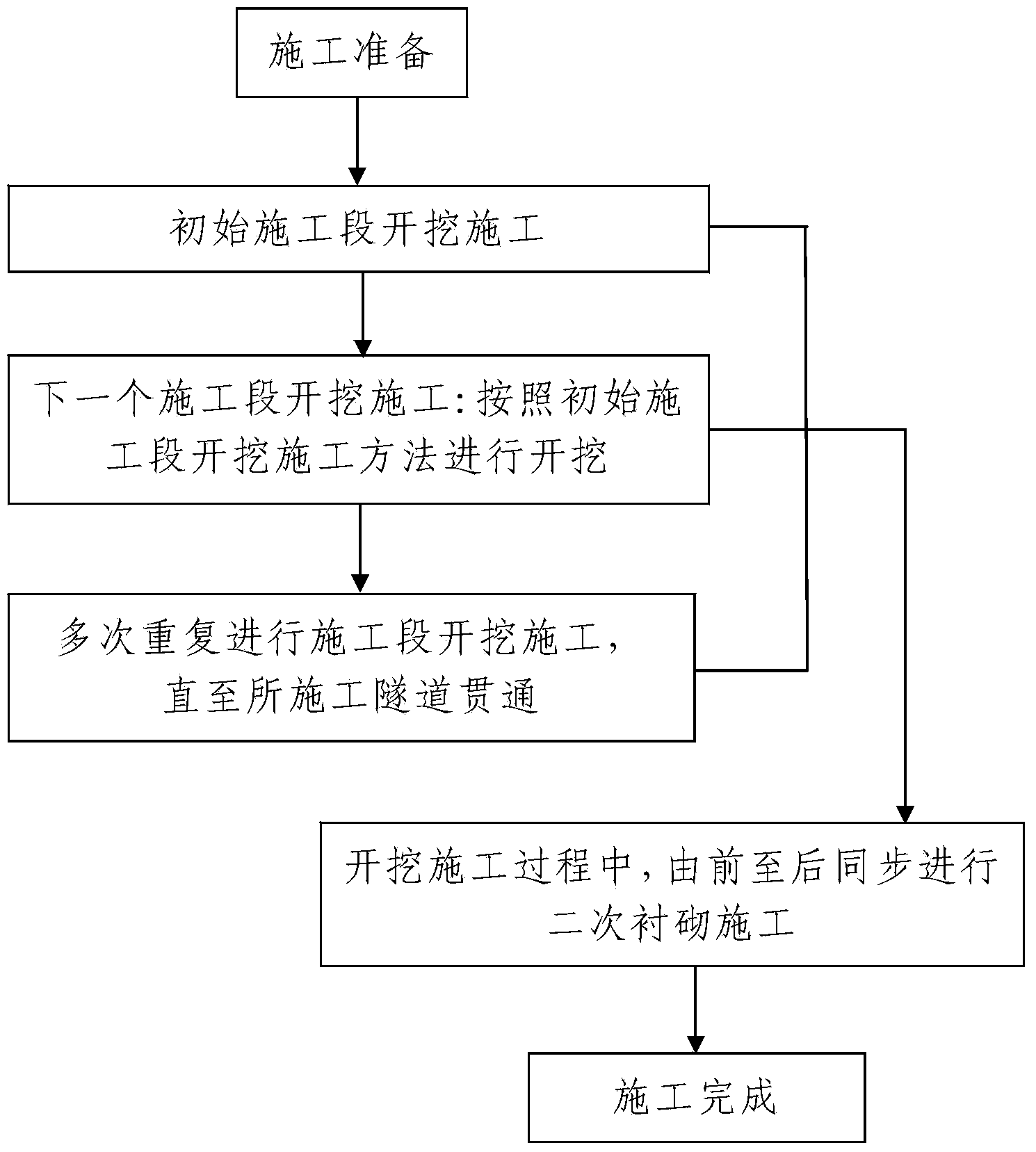

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

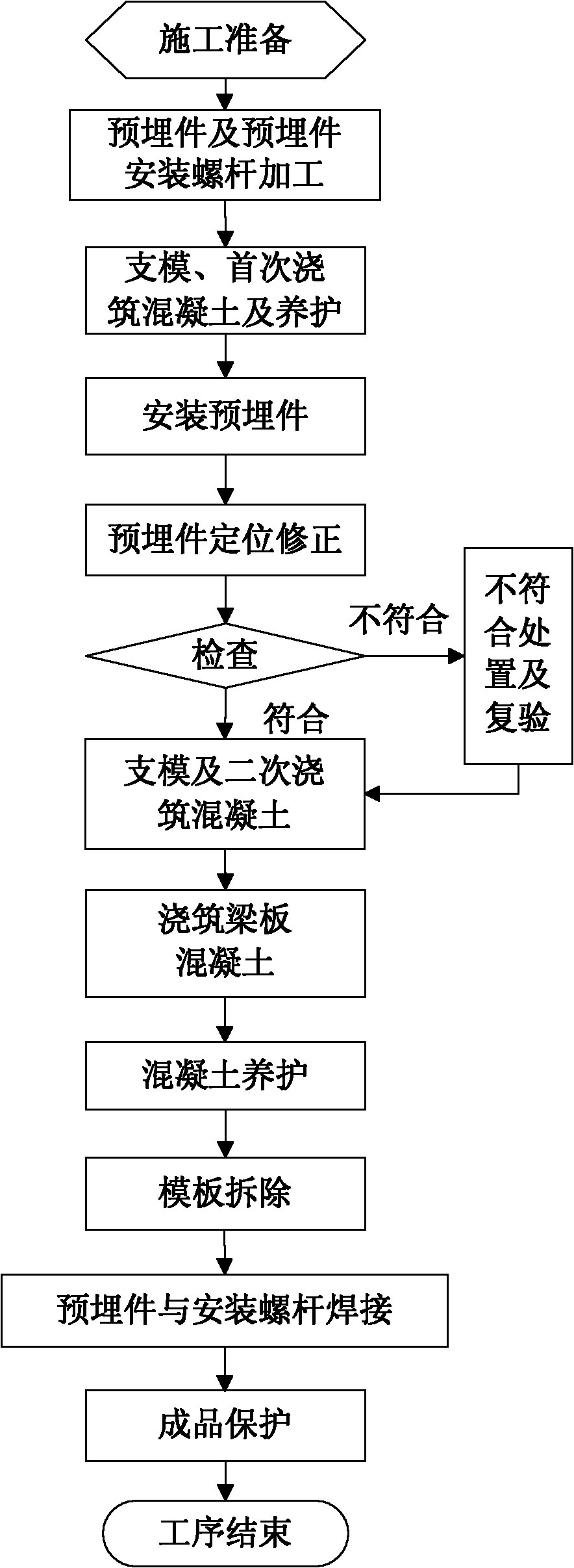

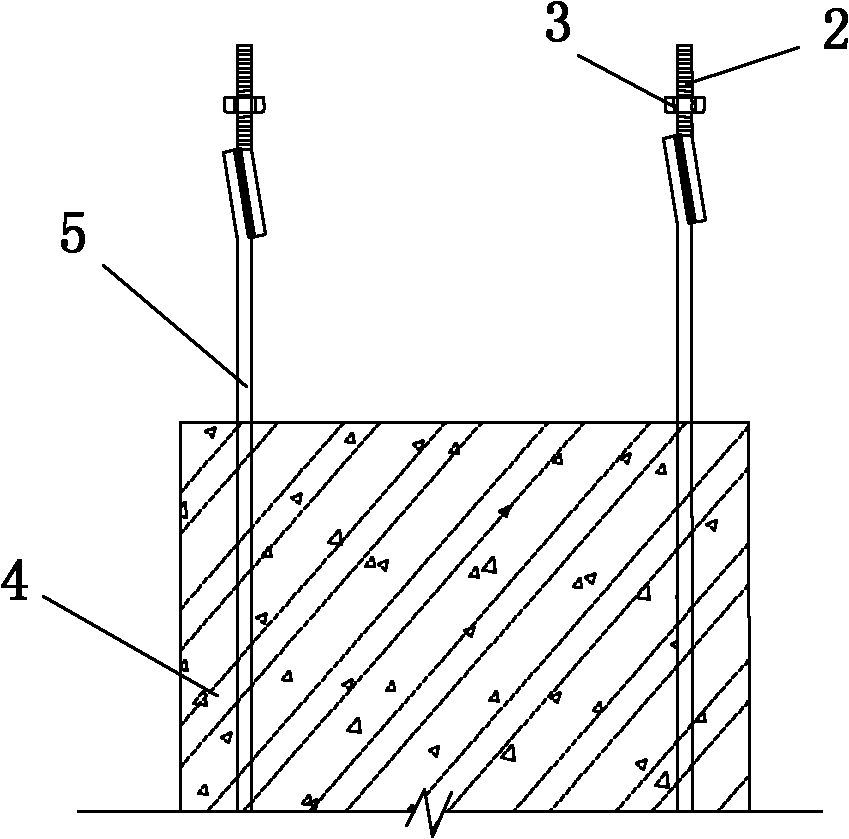

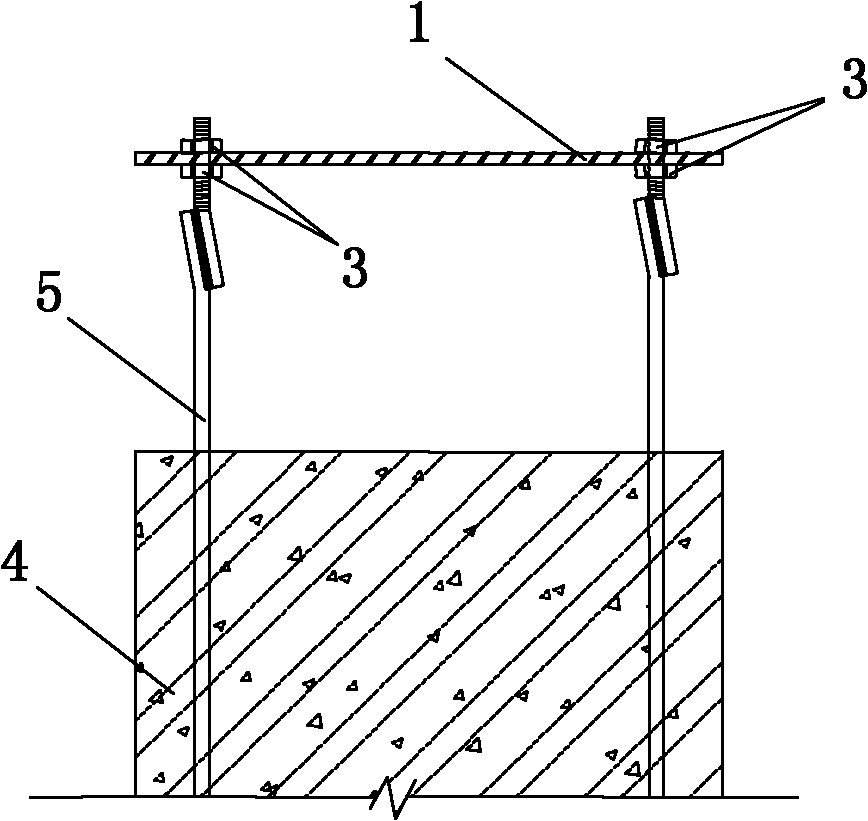

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879AReasonable designSimple construction stepsFoundation engineeringBuilding constructionsRebarReinforced concrete

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low, the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

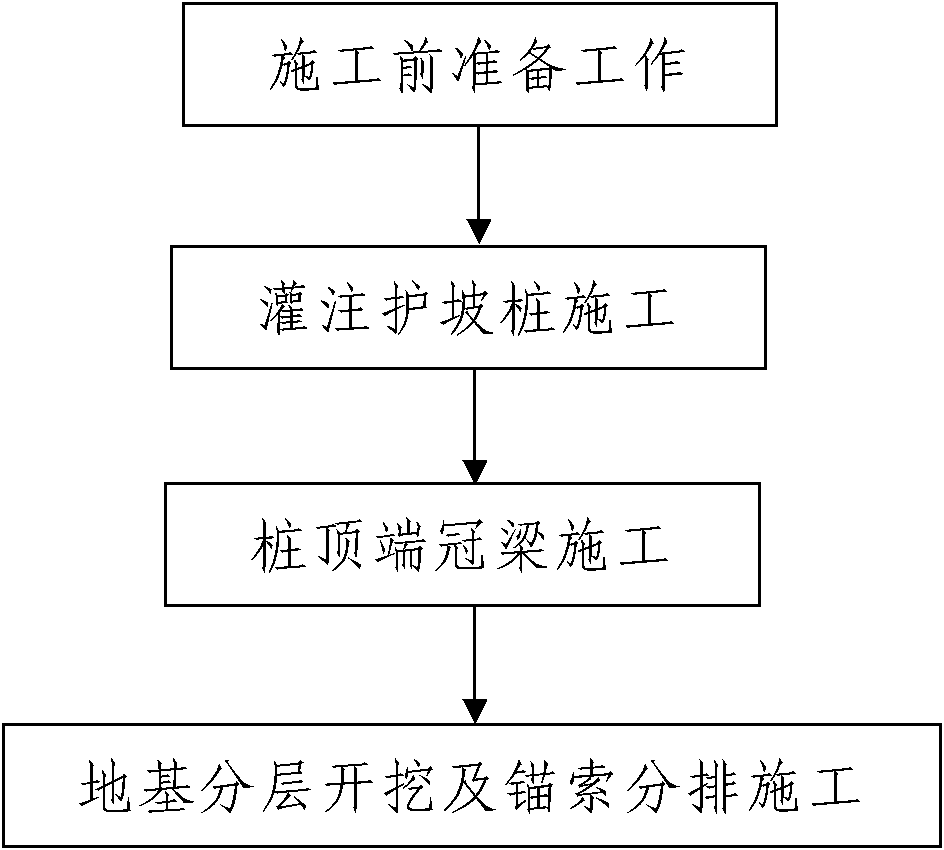

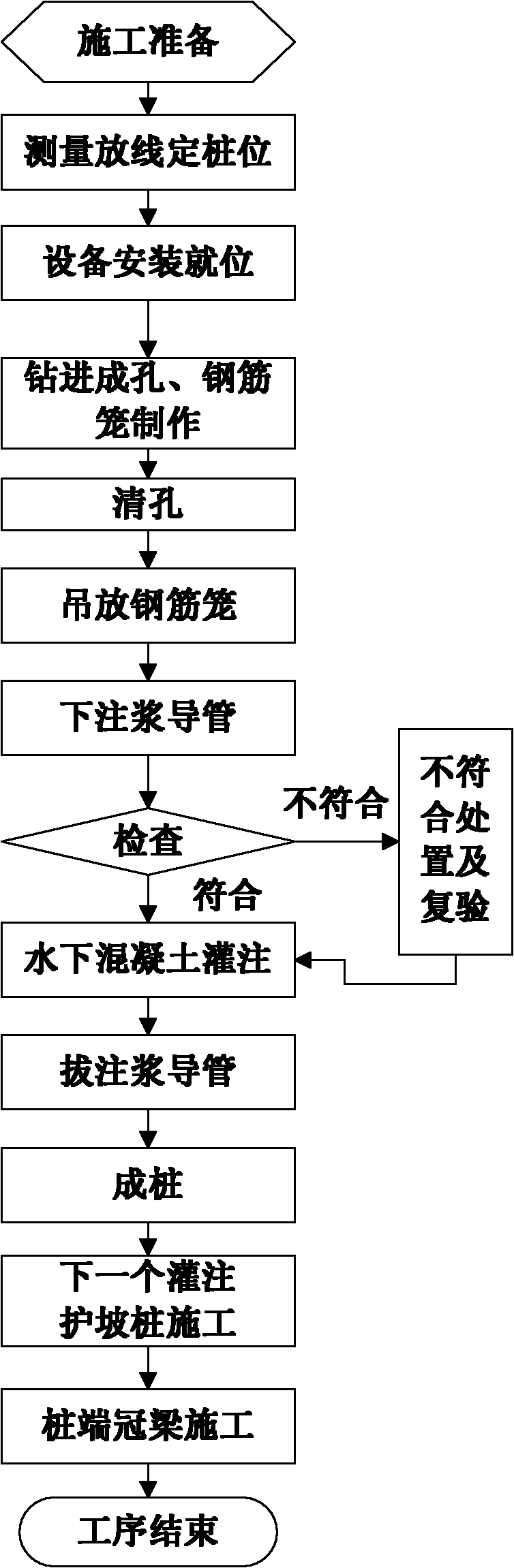

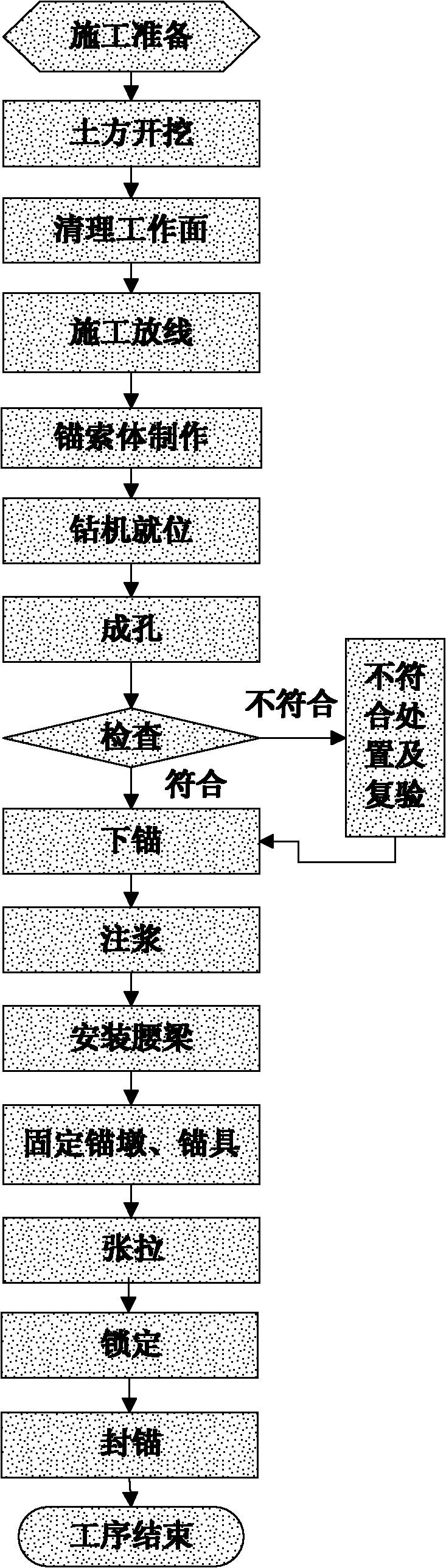

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

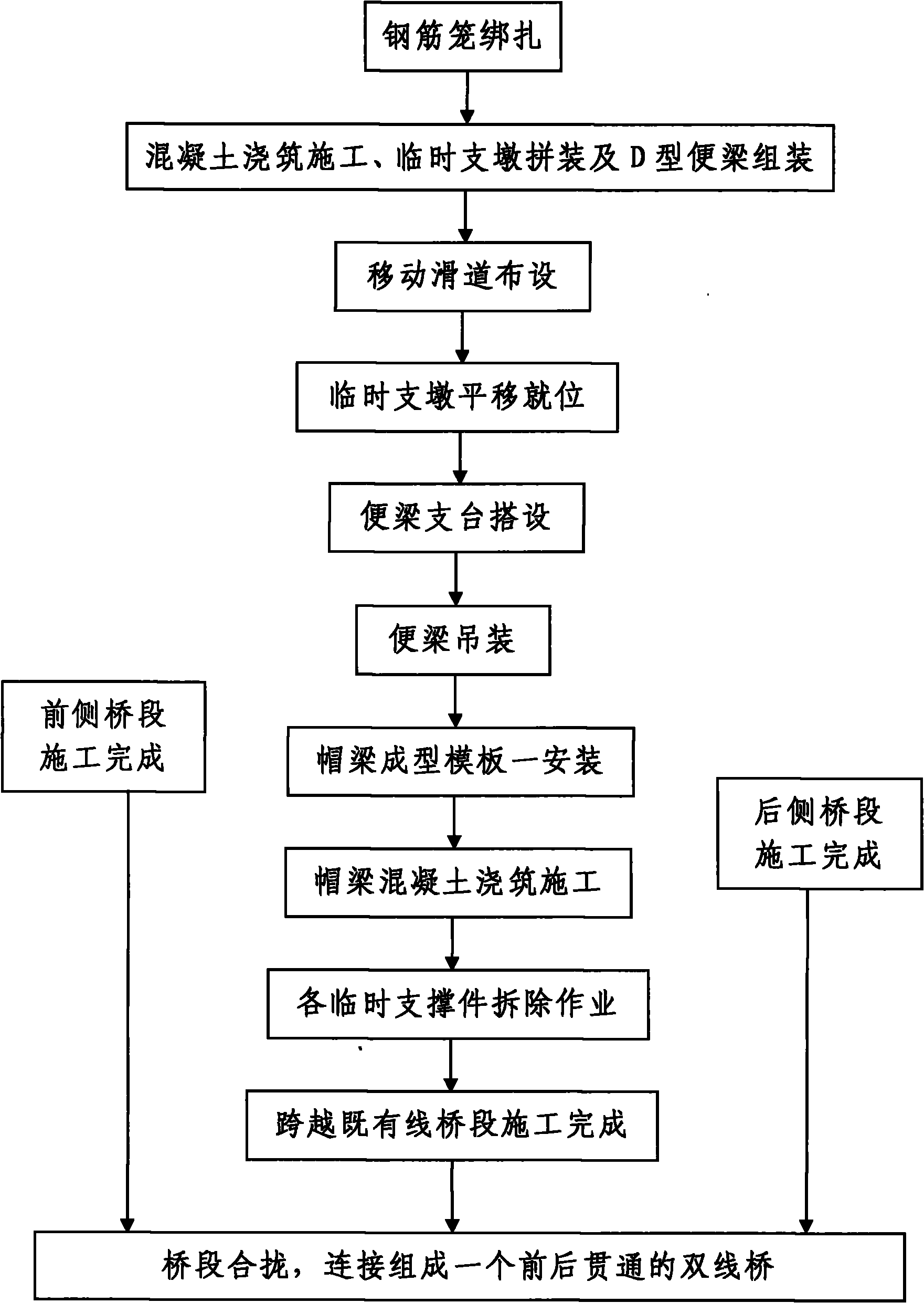

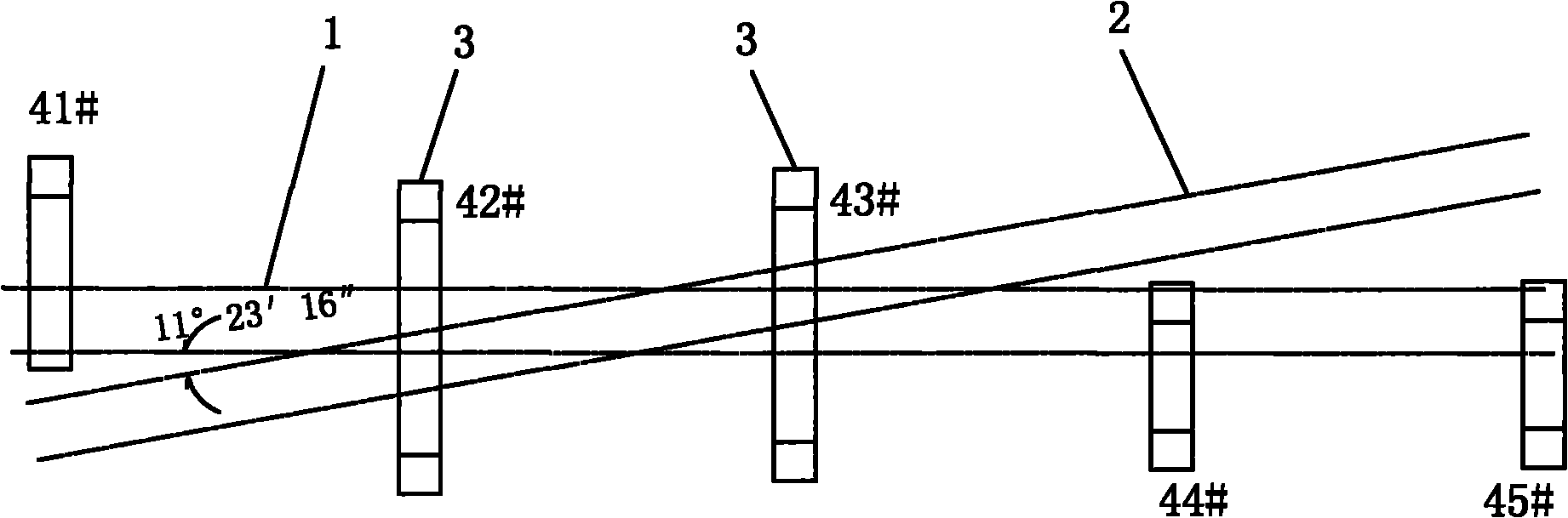

Double track bridge construction process crossing existing railway operational lines

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

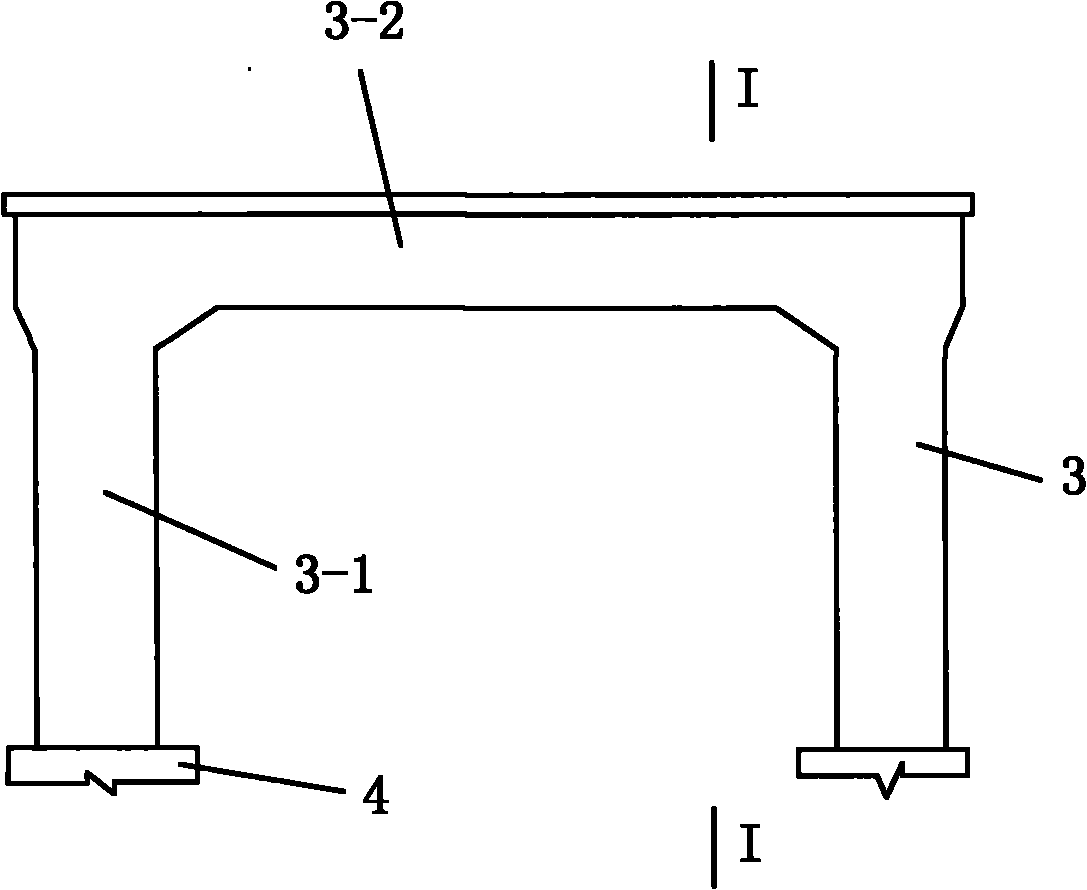

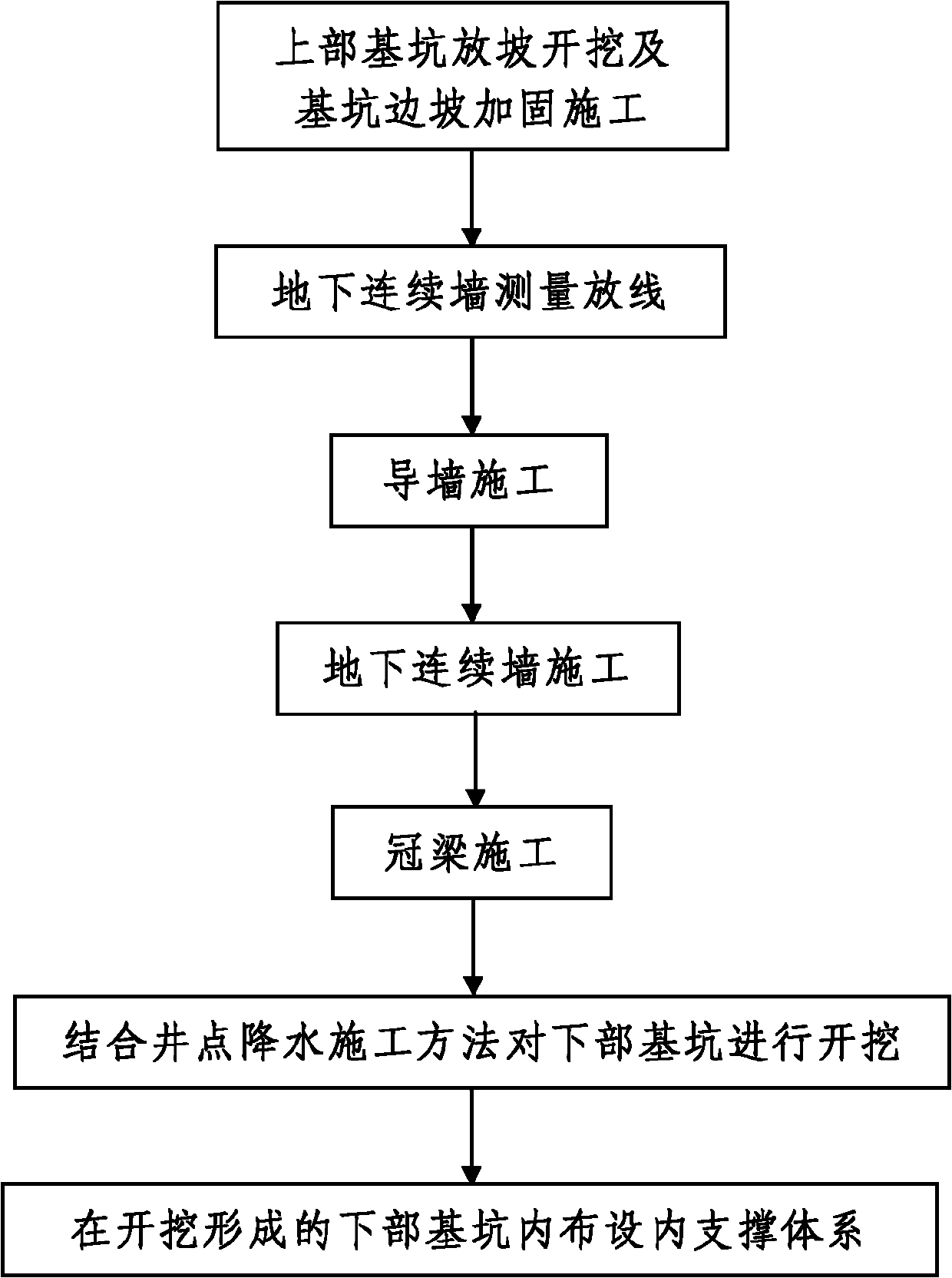

Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

InactiveCN102322064AReasonable designSimplify construction stepsArtificial islandsExcavationsSlurry wallSubway station

The invention discloses a construction method for an underground diaphragm wall of a deep foundation pit for a subway station in collapsible loess areas. The constructed station deep foundation pit for the subway station is divided into an upper-part foundation pit and a lower-part foundation pit from top to bottom; the building enclosure of the lower-part foundation pit is the underground diaphragm wall; and the upper-part foundation pit is a foundation pit formed by slope excavation. The construction method disclosed by the invention has the following steps of: (1) construction for upper-part foundation pit slope excavation and foundation pit slope reinforcement; (2) construction for lower-part foundation pit building enclosure: surveying and paying off, guide wall construction and underground diaphragm wall construction; and (3) construction for cap beam, and then carrying out excavation on the lower-part foundation pit through combining a well-point dewatering construction method and arranging a bracing system in the excavated lower-part foundation pit. The construction method disclosed by the invention has the advantages of reasonable design, simplicity and convenience for construction, safety and reliability for construction and good construction effect, high construction quality and capability of effectively solving the practical problems, such as high difficulty for construction, complicated construction procedure, difficulty for ensuring the construction quality of deep foundation pits and the like, in a process of constructing the deep foundation pits for subway stations in the collapsible loess areas.

Owner:CHINA RAILWAY 20 BUREAU GRP

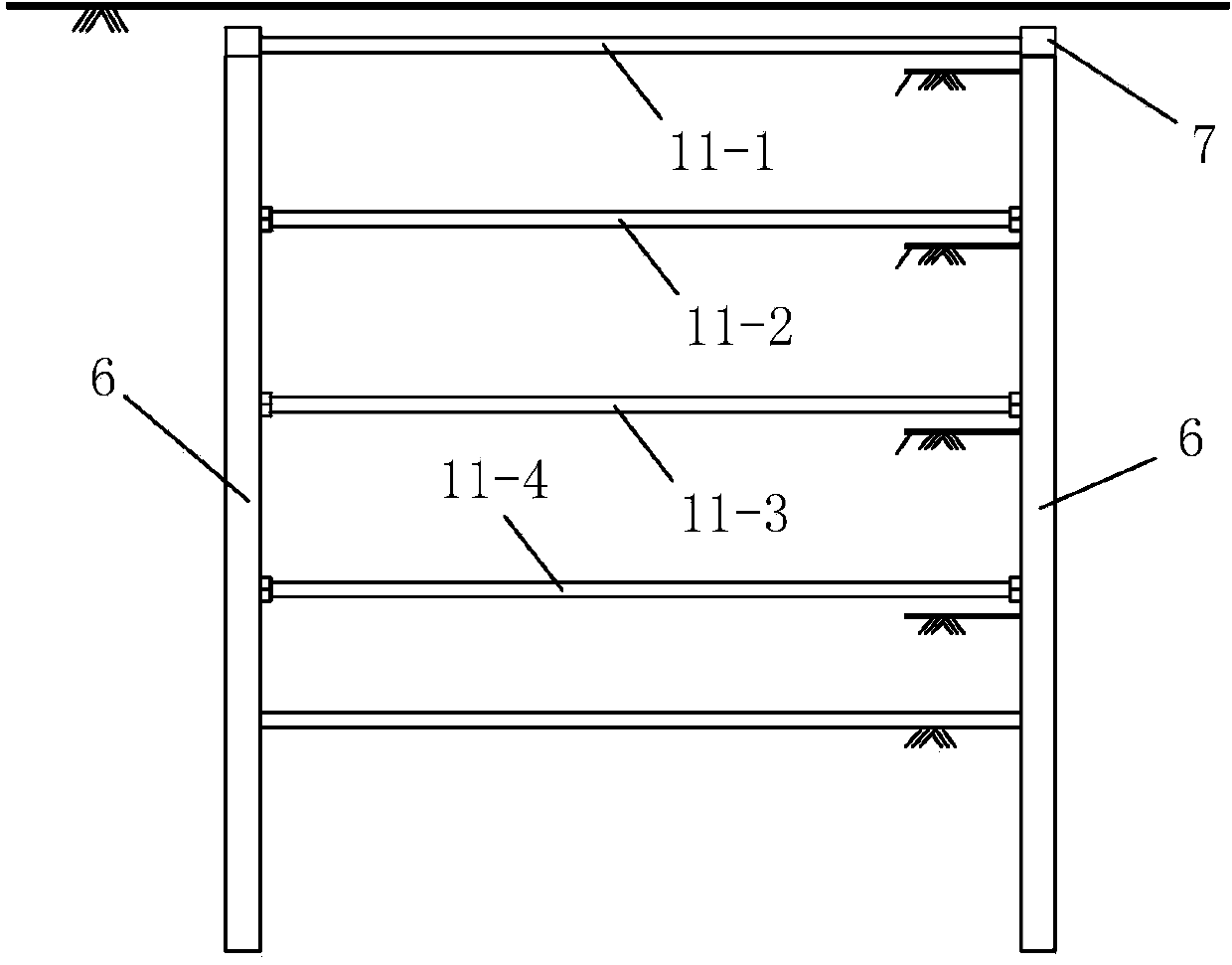

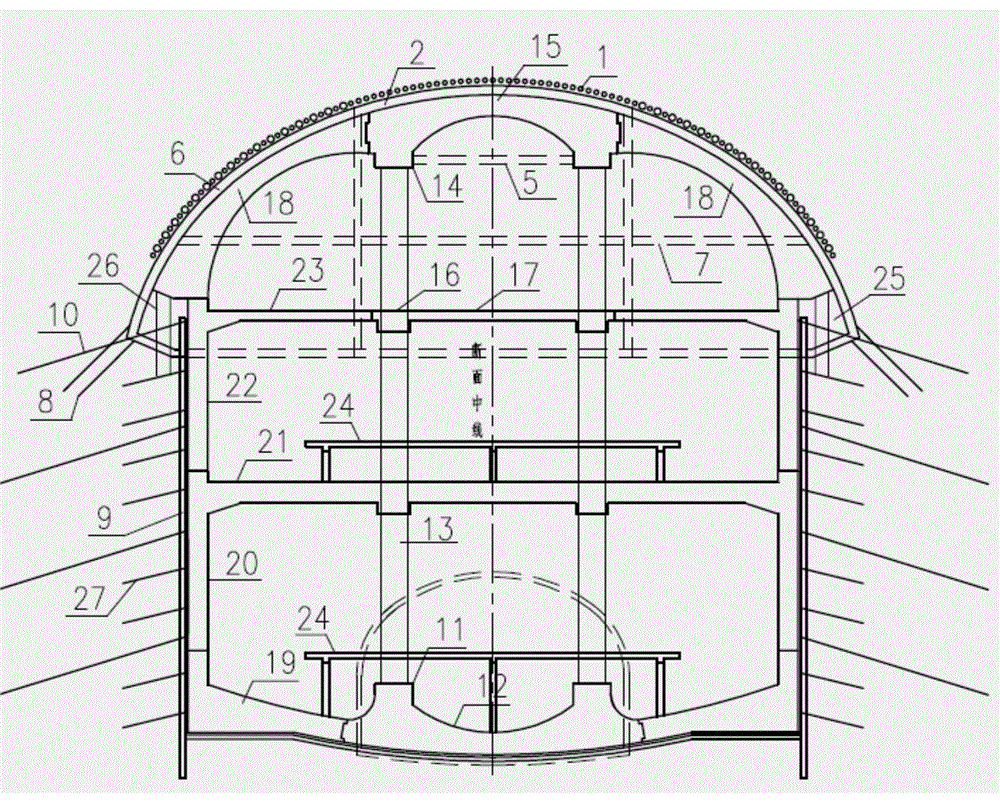

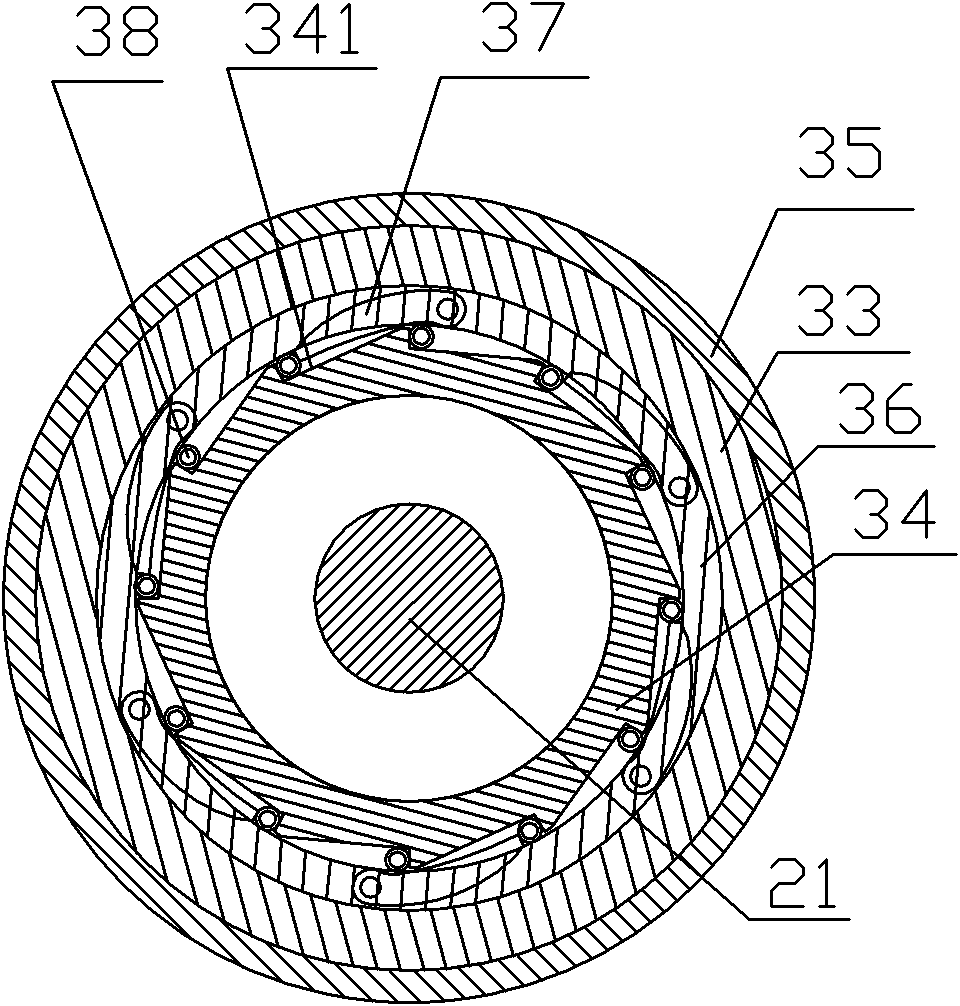

Rock stratum underground excavation three-story subway station umbrella cover structure and construction method thereof

ActiveCN106337686AReasonable structural designImprove stabilityUnderground chambersTunnel liningReinforced concreteSubway station

The invention belongs to the technical field of design and construction of tunnel and underground engineering and especially relates to a rock stratum underground excavation three-story subway station umbrella cover structure and a construction method thereof. The structure comprises a main arc structure and a reinforced concrete inverted arch. an underground two-story side wall and an underground three-story side wall are installed between the main arc structure and the reinforced concrete inverted arch. The main arc structure comprises an arch portion second lining middle segment and arch portion second lining side segments; the arch portion second lining side segments are positioned at two sides of the arch portion second lining middle segment; the reinforced concrete inverted arch comprises an inverted arch second lining middle segment and inverted arch second lining side segments; the top of the inverted arch second lining middle segment is provided with two bottom girders; the bottom of the arch portion second lining middle segment is provided with two top girders; steel-pipe columns are installed between the top girders and the bottom girders. The structure and the method of the invention is suitable for supporting structure and construction of weak rock stratum dug three-story subway station and large sections of underground space; the structure has good stability and increased construction efficiency.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

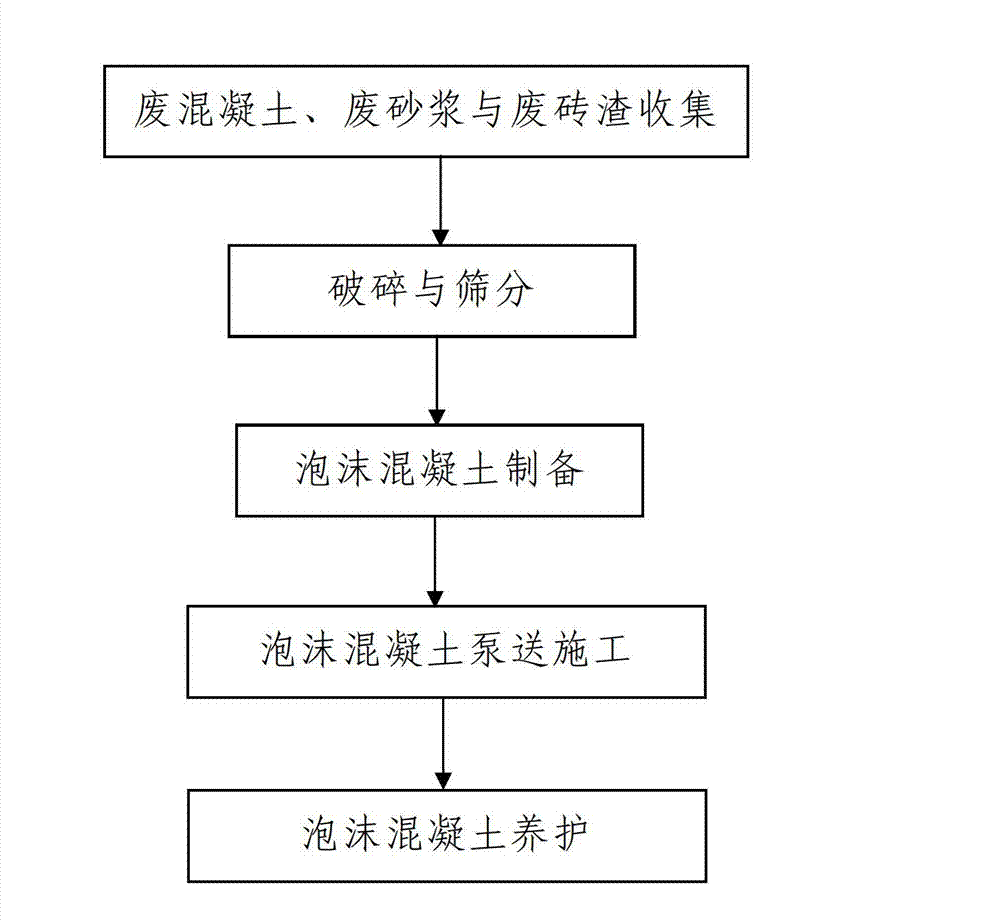

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

Putty for building external wall

InactiveCN101935196AStrong adhesionEasy constructionHydroxypropylmethyl celluloseCorrosion resistant

The invention discloses putty for a building external wall, which is made from the following raw materials in parts by weight: 20-40 of white cement, 5-10 of sierozem, 50-70 of powdered whiting, 5-10 of precipitated calcium carbonate, 0.2-0.3 of hydroxypropyl methylcellulose, 2-4 of re-dispersible latex powder, 0.1-0.3 of polypropylene staple fiber, 0.2-0.4 of moisture repellent and 0.3-0.5 of thixotropic lubricant. The putty is mainly used for direct renovation of an old finishing surface, and has high binding power and excellent water resisting property and ventilation property to a renovated substrate. The putty has the advantages of high strength, corrosion resistance, scrub resistance, high cracking resistance and convenient construction. All raw materials are non-volatile chemical substances, therefore, the putty is a comprehensive environment-friendly green product without toxicity or harms.

Owner:赵明

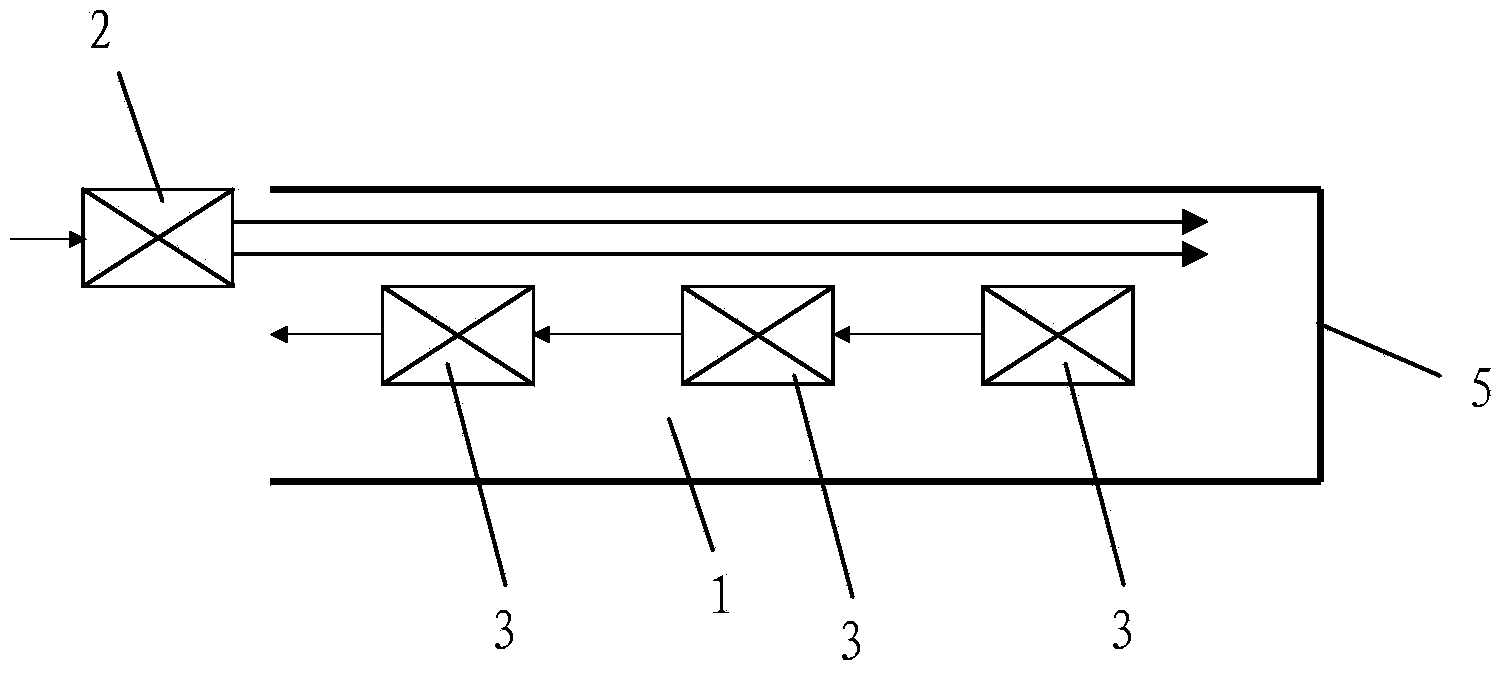

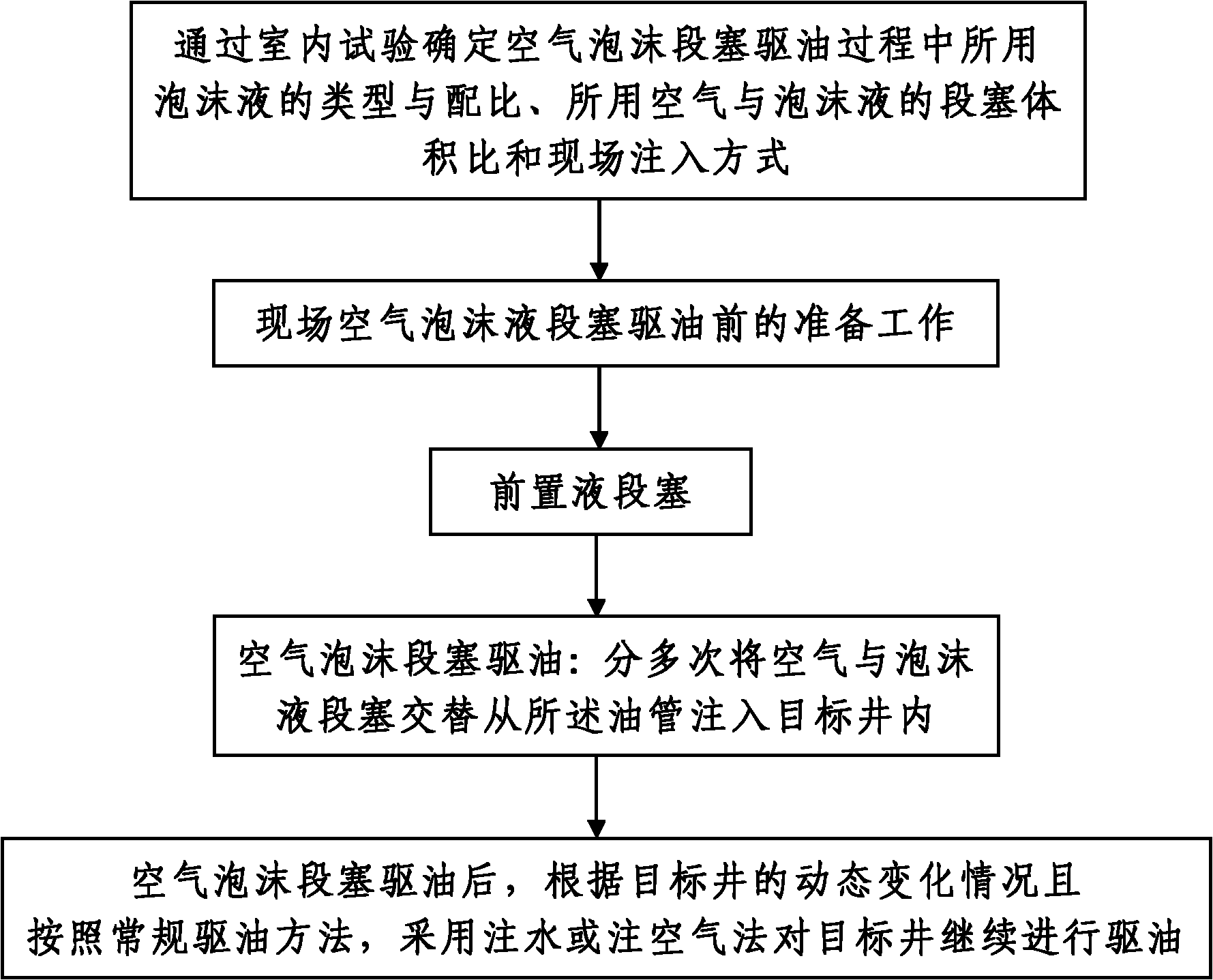

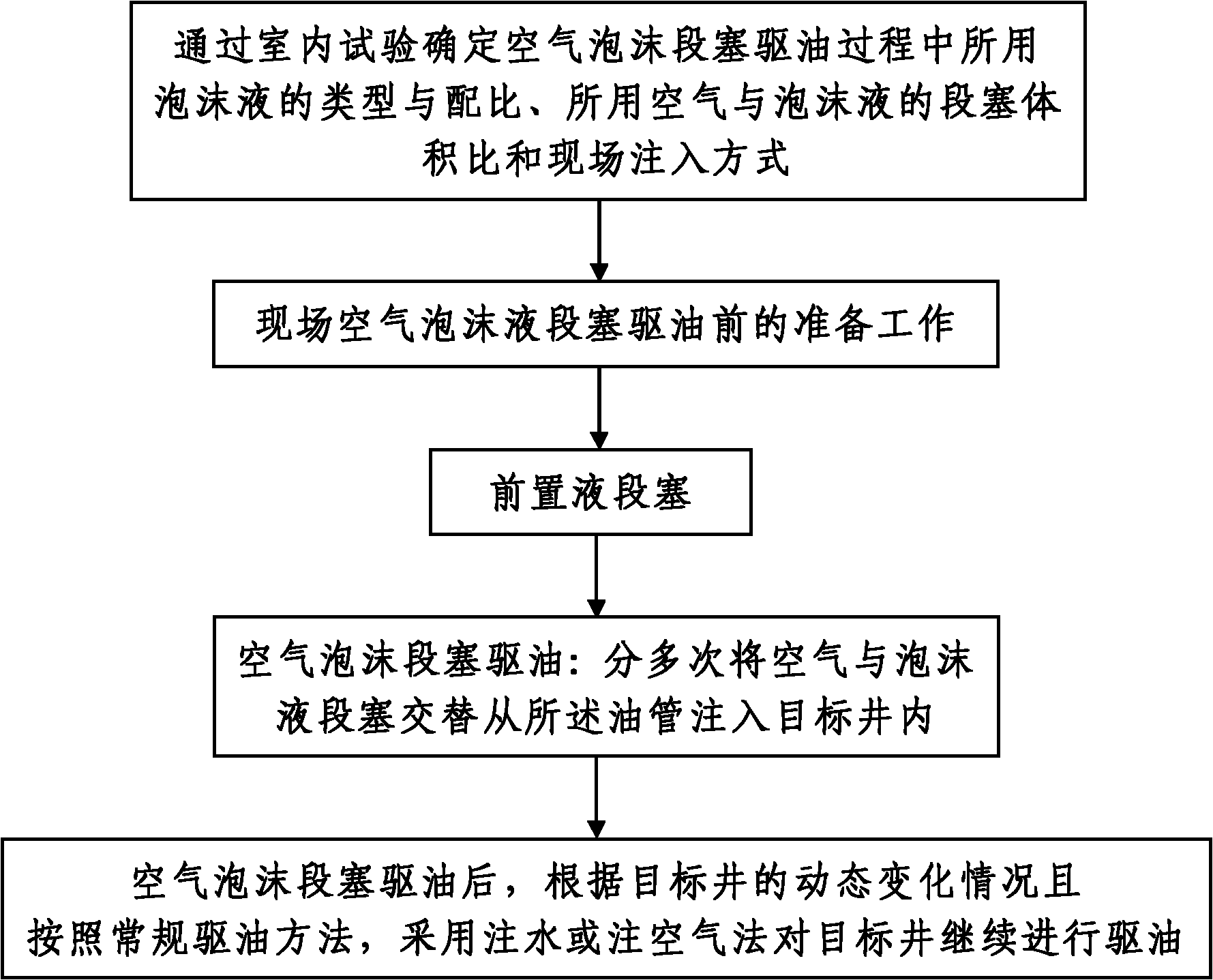

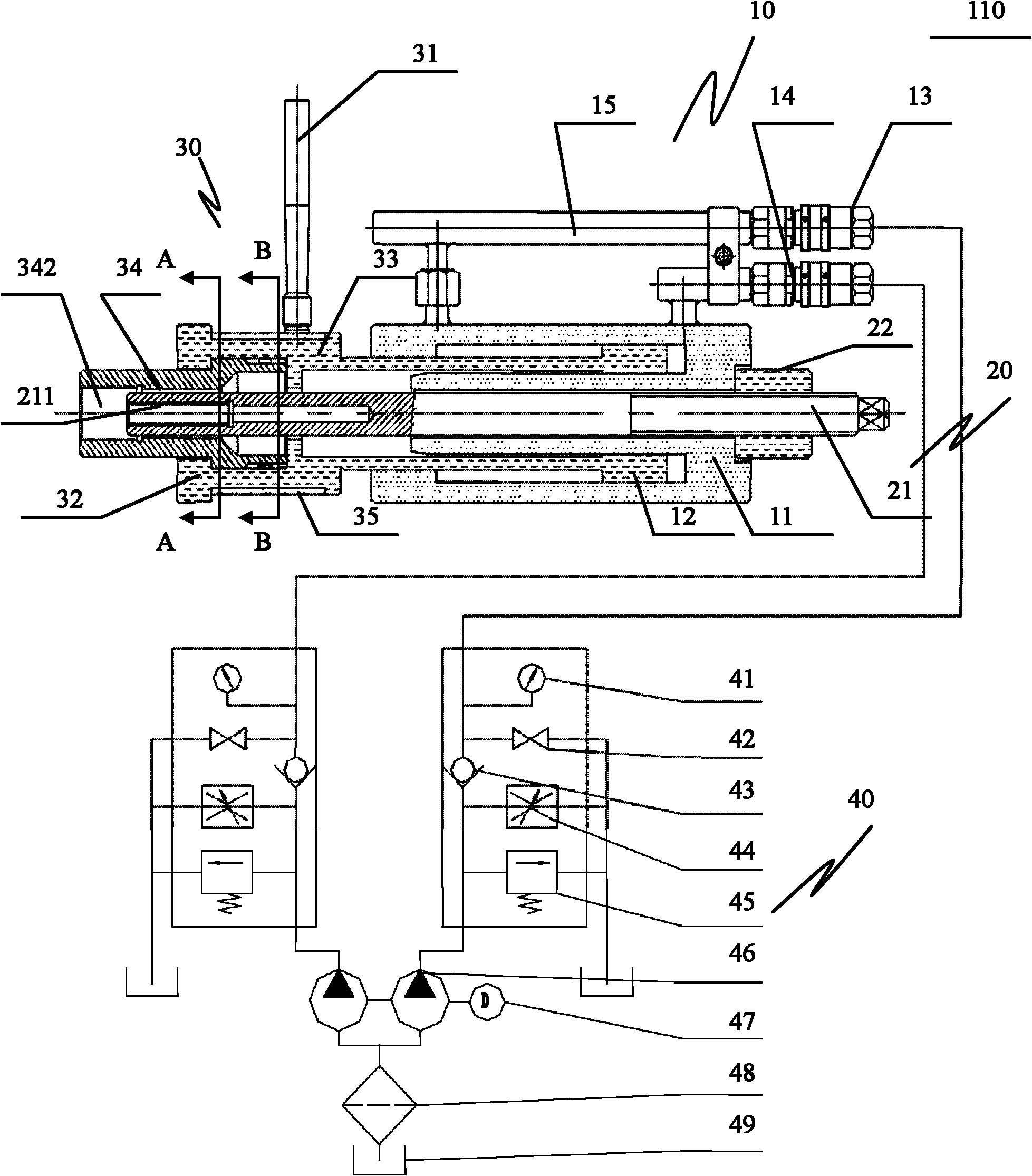

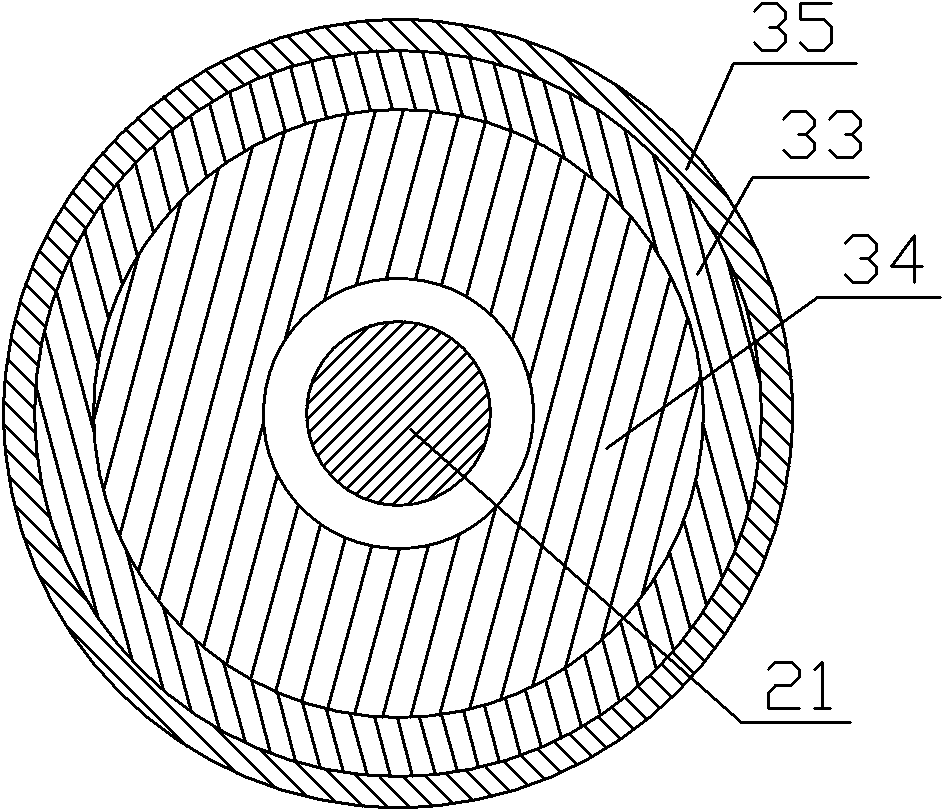

Air foam slug flow driving process for oil recovery of oil field

InactiveCN102061906ASimplify construction stepsEasy constructionFluid removalInjection airOil displacement

The invention discloses an air foam slug flow driving process for the oil recovery of an oil field, comprising the following steps of: 1 determining type and proportion of the used foam liquid, slug volume ratio and on-site injection manner of the used air and the foam liquid during the air foam slug flow driving by an indoor test; and 2 carrying out the air foam liquid slug flow driving on site,wherein the oil flow driving process comprises the following steps of: preparation before the oil flow driving; slugging a pad fluid; slugging the air foam; alternatively injecting the air and foam liquid slug from a specially manufactured device to a target well for many times; and continuously carrying out the oil flow driving on the target well by a water or air injection method according to the dynamic change condition of the target well and a conventional oil displacement method after the injection of the air foam slug is finished. The invention has the advantages of reasonable design, simple and convenient construction steps, good use effect and convenience of realizing, can effectively solve various practical problems of poor water injection effect, difficult improvement on the water injection capability, poor oil flow driving efficiency and the like during the ultralow reservoir waterflooding.

Owner:YANCHANG OIL FIELD

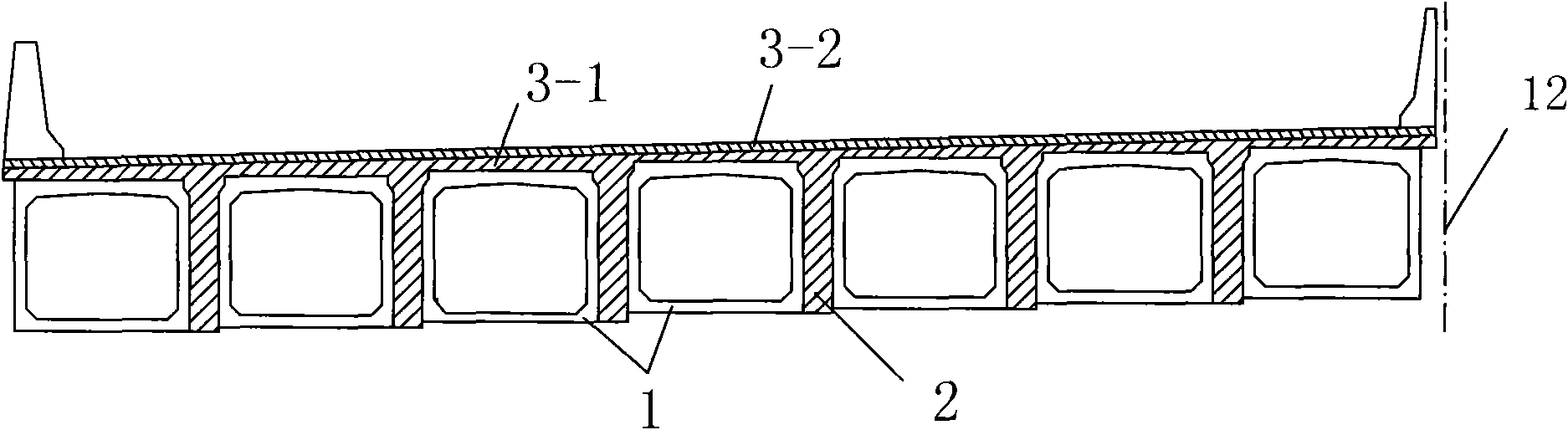

Prestress rib tensioning equipment, system and method and concrete continuous box girder

ActiveCN102182146AGuarantee the quality of the projectSimplify construction stepsBridge erection/assemblyBuilding material handlingPre stressLocking mechanism

The invention relates to prestress rib tensioning equipment, system and method and a concrete continuous box girder. A prestress rib is tensioned by using the tensioning equipment comprising a jack, a tensioning mechanism and a locking mechanism; the tensioning mechanism comprises a tensioning rod and a pressure-bearing member; the tensioning rod penetrates through a cylinder body of the jack and a rotating sleeve of the locking mechanism; one end of the tensioning rod is provided with a connecting part for being connected with the prestress rib, and the connecting part is positioned in the rotating sleeve; and the pressure-bearing member is arranged at the other end of the tensioning rod and abutted against the cylinder body. The invention realizes tensioning and anchoring by connecting the tensioning rod with the prestress rib and combining the jack and the locking mechanism, can realize tensioning and anchoring by one-step tensioning process, is convenient for the prestress application, simplifies the construction procedure of a railway bridge culvert and ensures the engineering quality.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

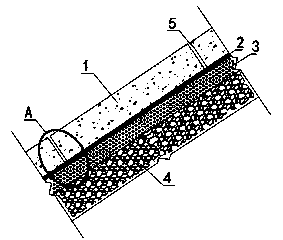

High rock-fill dam membrane anti-seepage body on deep coverage layer and construction method of high rock-fill dam membrane anti-seepage body

InactiveCN103643656AStrong adaptability to deformationNo crackEarth-fill damsRock-fill damsOverburdenFiber

The invention discloses a high rock-fill dam membrane anti-seepage body on a deep coverage layer and a construction method of the high rock-fill dam membrane anti-seepage body. The membrane anti-seepage body is composed of a concrete protection layer, a geomembrane anti-seepage layer, a flexibility cushion layer and a transition layer. The concrete protection layer is a cast-in-place fiber concrete layer for a reserved cross joint and a vertical joint and located on a surface layer to protect a geomembrane. The geomembrane anti-seepage layer is a two-cloth and one-membrane composite geomembrane and is located in the middle to play a role of preventing seepage. The flexibility cushion layer is a polyurethane pervious concrete layer and located at the bottom of the anti-seepage body to support the geomembrane and to transmit and disperse water loads. The rough granule transition layer is arranged between the flexibility cushion layer and a rock-fill dam body. The construction method comprises the technical steps of filling and building the transition layer, pouring the flexibility cushion layer, paving the composite geomembrane, pouring the concrete protection layer and the like. The membrane anti-seepage body can keep stable on a high rock-fill dam slope, the ability of adapting to deformation of a coverage layer dam foundation and the dam body is high, the structural form is simple, construction is fast, and the anti-seepage problem of the high rock-fill dam on the deep coverage layer can be effectively solved.

Owner:HOHAI UNIV

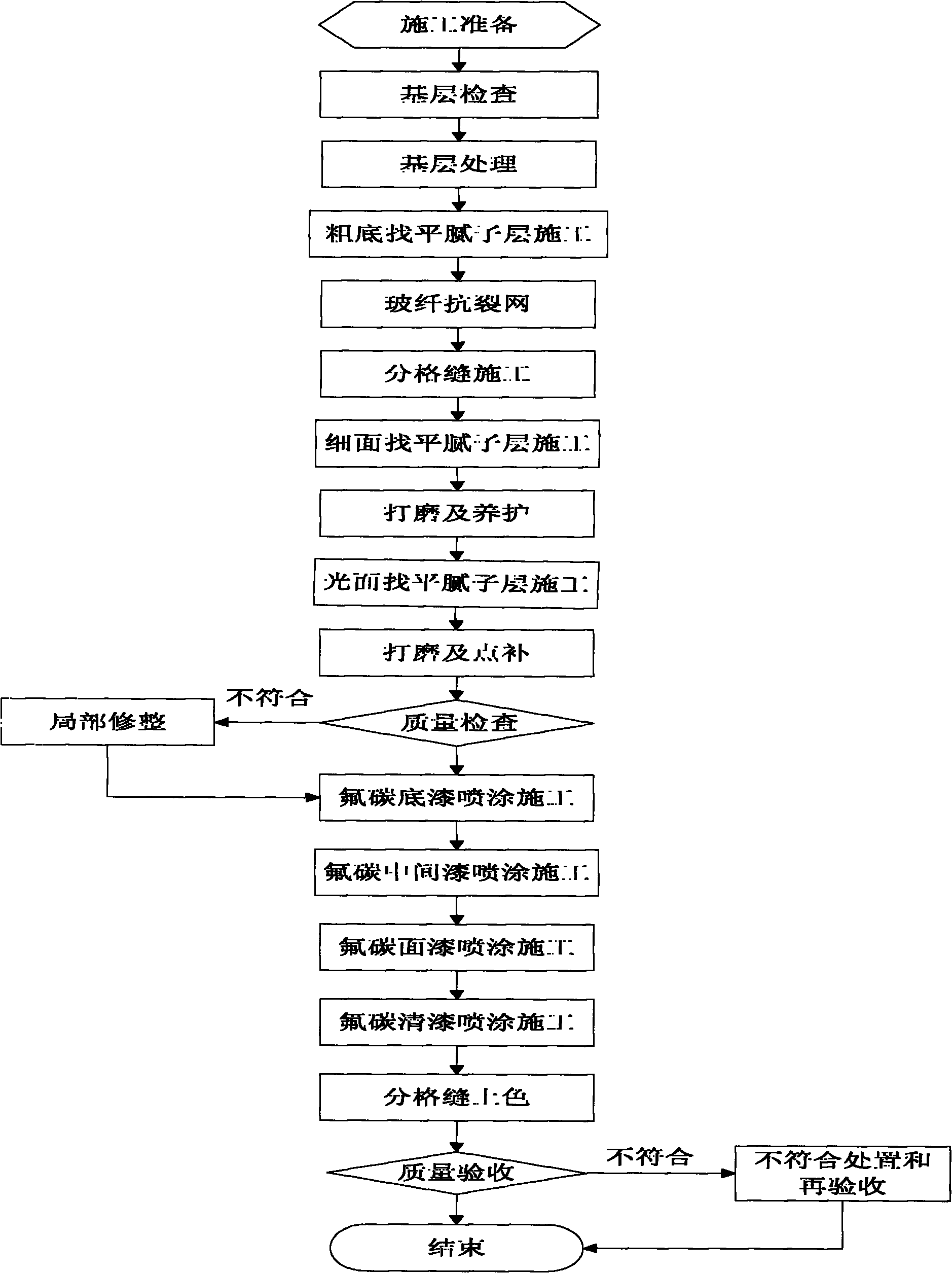

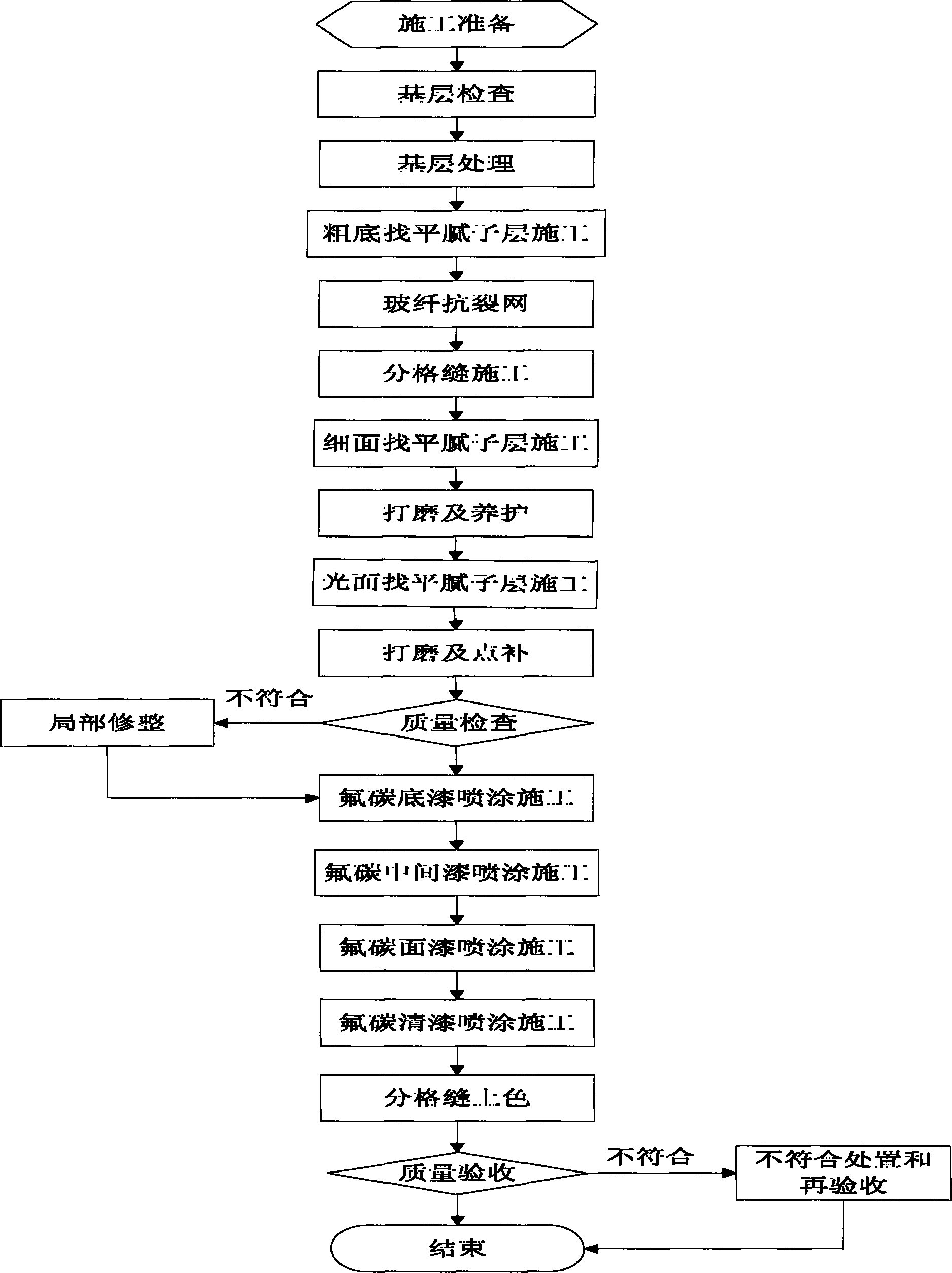

Construction process for outer wall metal fluorocarbon coating

InactiveCN101832015ASimplify construction stepsEasy to operateBuilding constructionsGlass fiberLacquer

The invention discloses a construction process for an outer wall metal fluorocarbon coating. The construction process comprises the following steps of: 1, checking a base layer; 2, treating the base layer; 3, performing coarse bottom leveling putty layer construction, wherein the used outer wall leveling coarse bottom putty is a finished putty special for the outer wall and a proper amount of quartz sand is added into the finished putty; 4, laying a glass fiber crack resistant net; 5, performing dividing joint construction; 6, performing fine surface leveling putty layer construction to ensure that the glass fiber crack resistant net is clamped between the coarse bottom leveling putty layer and the fine surface leveling putty layer; 7, polishing and maintaining; 8, performing polished side leveling putty layer construction; 9, performing fluorocarbon primer spraying construction; 10, performing fluorocarbon intermediate coating spraying construction; 11, performing fluorocarbon finish paint spraying construction; 12, performing fluorocarbon varnish spraying construction; and 13, coloring dividing joints. The construction process for the outer wall metal fluorocarbon coating has the advantages of simple construction steps, reasonable design, convenient operation, low construction cost, high construction quality, and excellent use efficiency, and can prevent the hollowness, delamination, crack and other quality defects on the surface of the outer wall metal fluorocarbon coating.

Owner:陕西建工第二建设集团有限公司

Shield synchronous grouting slurry prepared from shield waste slurry and construction method thereof

The invention discloses shield synchronous grouting slurry prepared from shield waste slurry and a construction method thereof, each cubic meter of the shield synchronous grouting slurry comprises the following components: 100-200kg of cement or 40-100kg of lime, 300-450kg of fly ash, 200-750kg of the waste slurry, 600-1300kg of sand, 0-450kg of water and 0-12kg of a water reducer. The waste slurry pollution problems can be alleviated, the amount of raw materials of mortar can be reduced, the shield waste slurry is mainly used in backwall grouting material for replacement of bentonite and arts of water in backwall grouting mortar, and the environmental pollution problems caused by the waste slurry can be reduced.

Owner:CCCC SECOND HARBOR ENG +2

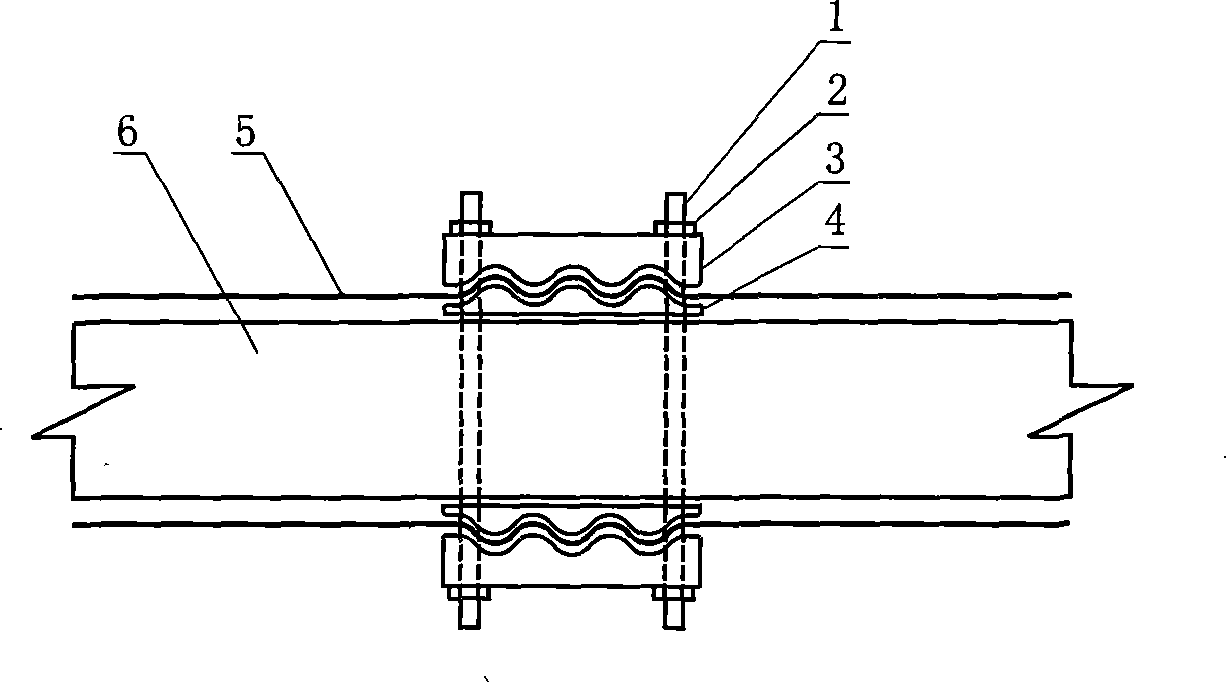

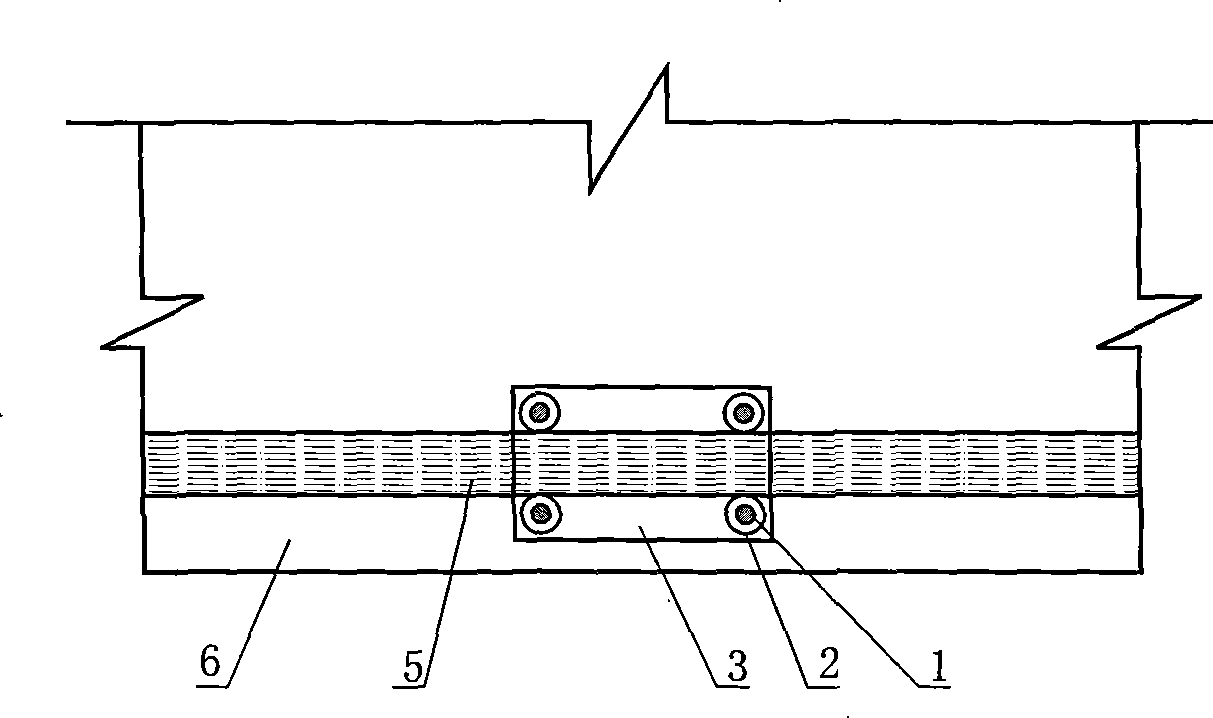

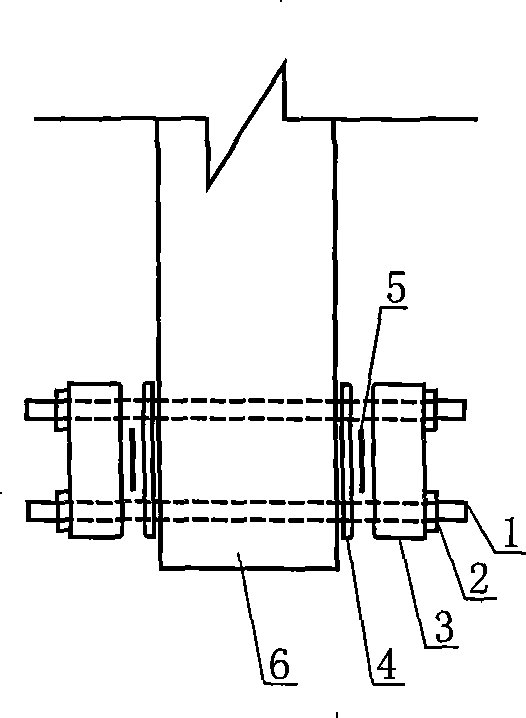

Construction method for two-side reinforcing engineering structure

InactiveCN101245668AEven by forceReduce design difficultyBuilding repairsBridge erection/assemblyShaped beamWave shape

The invention relates to a construction method for double-sided enhancement or reinforcement of the engineering structures, belonging to the technical field of enhancing or reinforcing the engineering structure through high-strength fibrous composites, which is characterized in that: holes are drilled on a surface of the enhanced or reinforced civil engineering structure, and longer screws are embedded in the holes to fix two pairs of wave-shaped gear-grip anchors at the same time, so that the high-strength fibrous composite sheets can be drawn and fixed by the anchors at the two sides of the engineering structure. The construction method for double-sided enhancement or reinforcement of the engineering structures has the advantages of definite and even stressing, simple path of force transfer, convenient construction and operation, high efficiency, improving the loading capacity of the civil engineering structures and extending the service life of the civil engineering structures, and is widely used in large-scale building structures of the civil engineering, especially in the construction, reconstruction and maintenance of the large-scale thin wall structures (like T-shaped beams, etc.).

Owner:李唐宁 +1

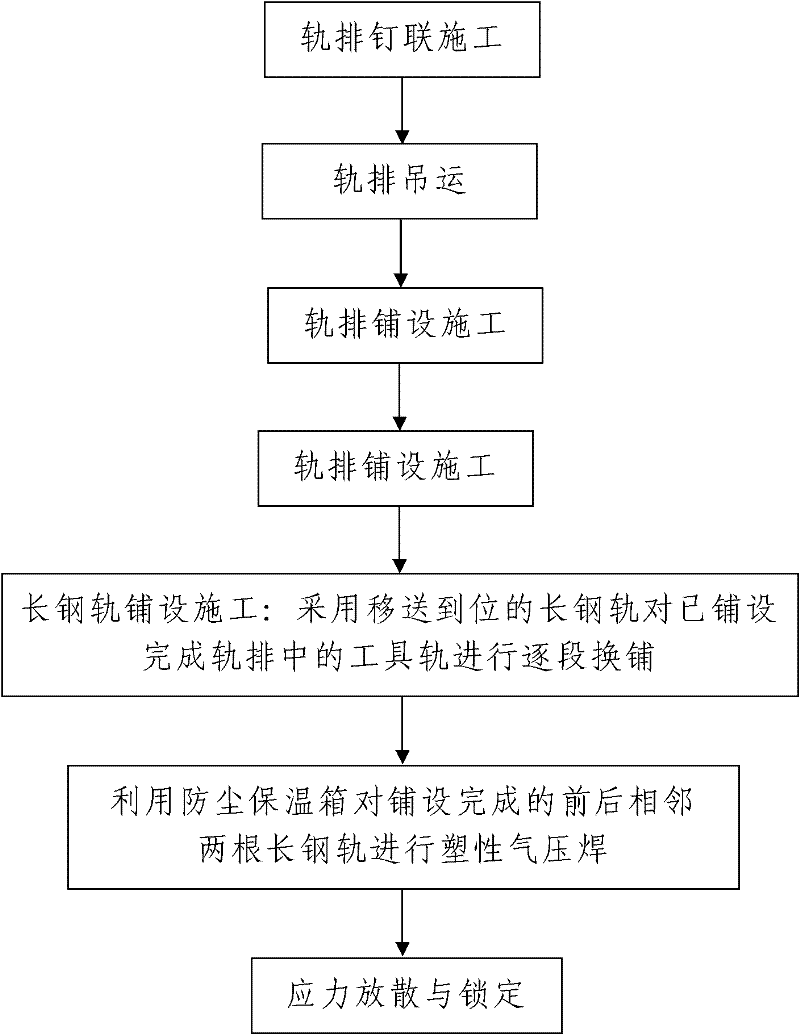

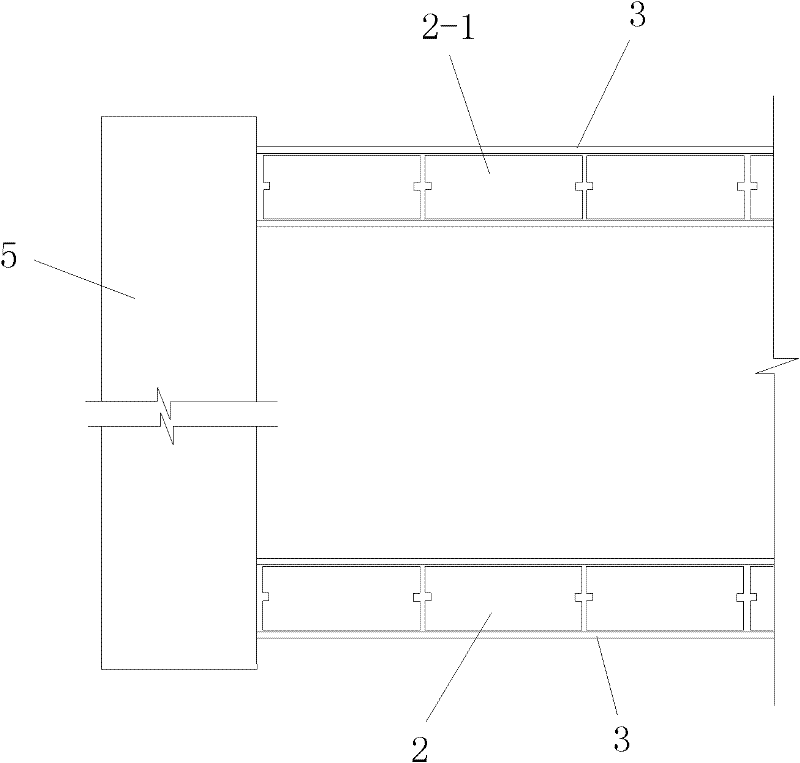

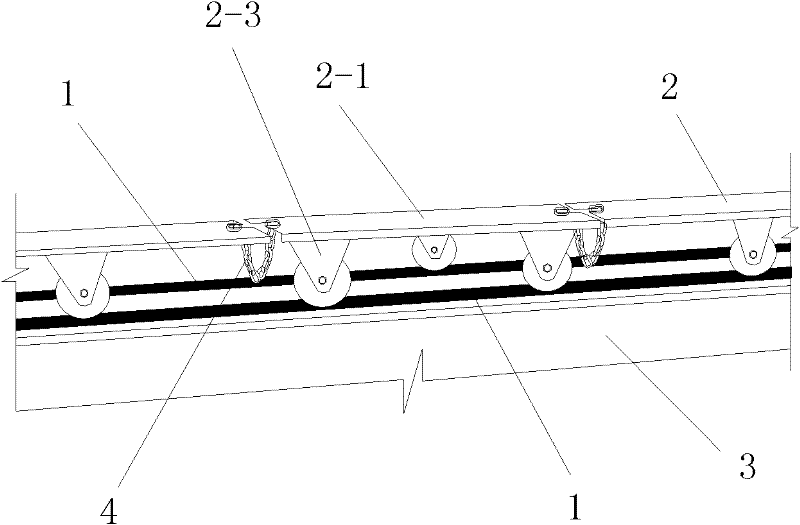

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

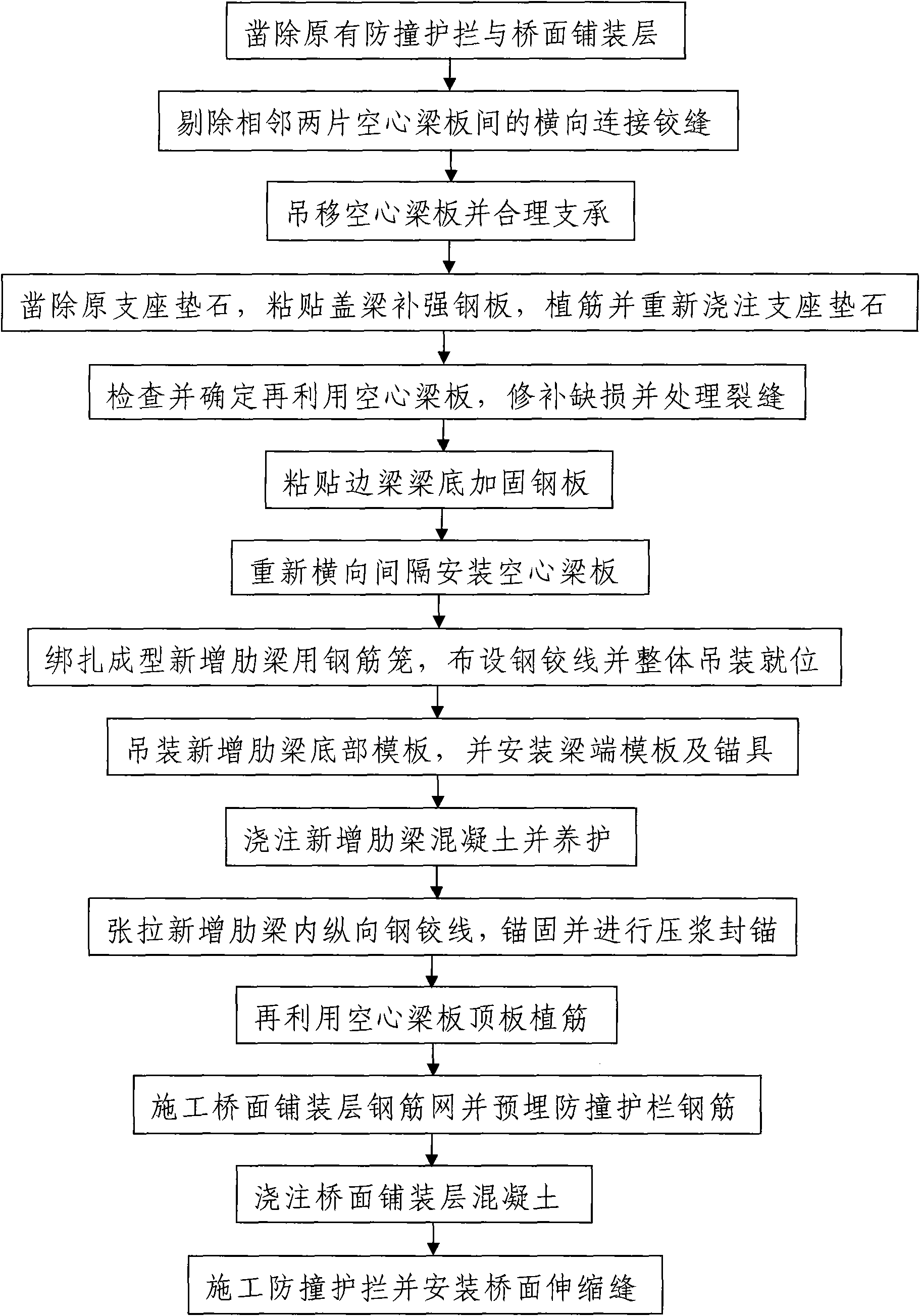

Beam-removing rib-increasing strengthening construction technology of highway bridge

InactiveCN101644032AAvoid damageImprove bearing capacityBridge erection/assemblyBridge strengtheningBridge deckEngineering

The invention discloses a beam-removing rib-increasing strengthening construction technology of a highway bridge. A bearing beam of a strengthened bridge comprises a plurality of hollow beam plates. The technology comprises the following steps: chiseling and removing an original collision prevention guardrail and a bridge face laying layer; eliminating a transverse connection hinge seam between the two adjacent hollow beam plates; hanging and moving the hollow beam plates and supporting reasonably; embedding ribs and pouring the pad stone of a supporting seat anew; checking, determining, recycling the hollow beam plates, repairing defects and processing cracks; sticking the beam bottoms of edge beams and strengthening steel plates; anew installing the hollow beam plates transversely at intervals; constructing rib beams which are added newly; constructing a steel bar net of the bridge face laying layer and embedding the steel bar of the collision prevention guardrail in advance; pouringthe concrete of the bridge face laying layer; and constructing the collision prevention guardrail and installing bridge face expansion joints. The invention has reasonable design, smaller execution difficulty, simple construction steps and low construction cost, has small damage to the original hollow beam plates, can enhance the bearing capacity of an original structure of a hollow plate bridge,has very good strengthening effect and can effectively solve the strengthening problem of the hollow plate bridge.

Owner:ZHONGJIAO TONGLI CONSTR

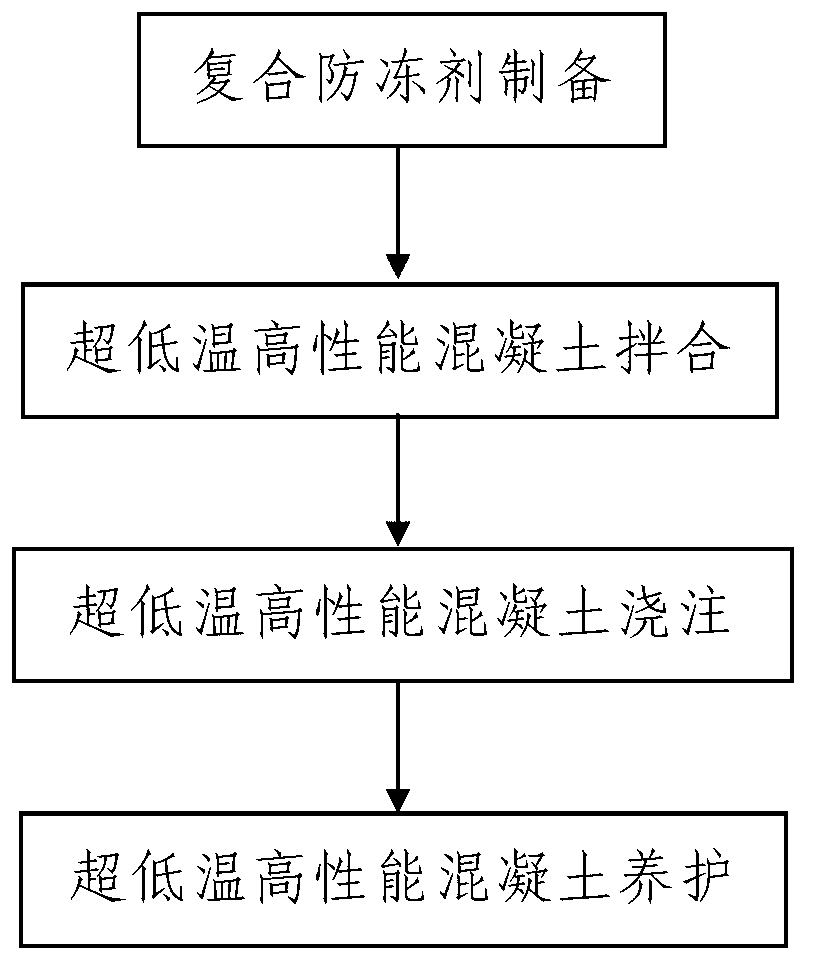

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

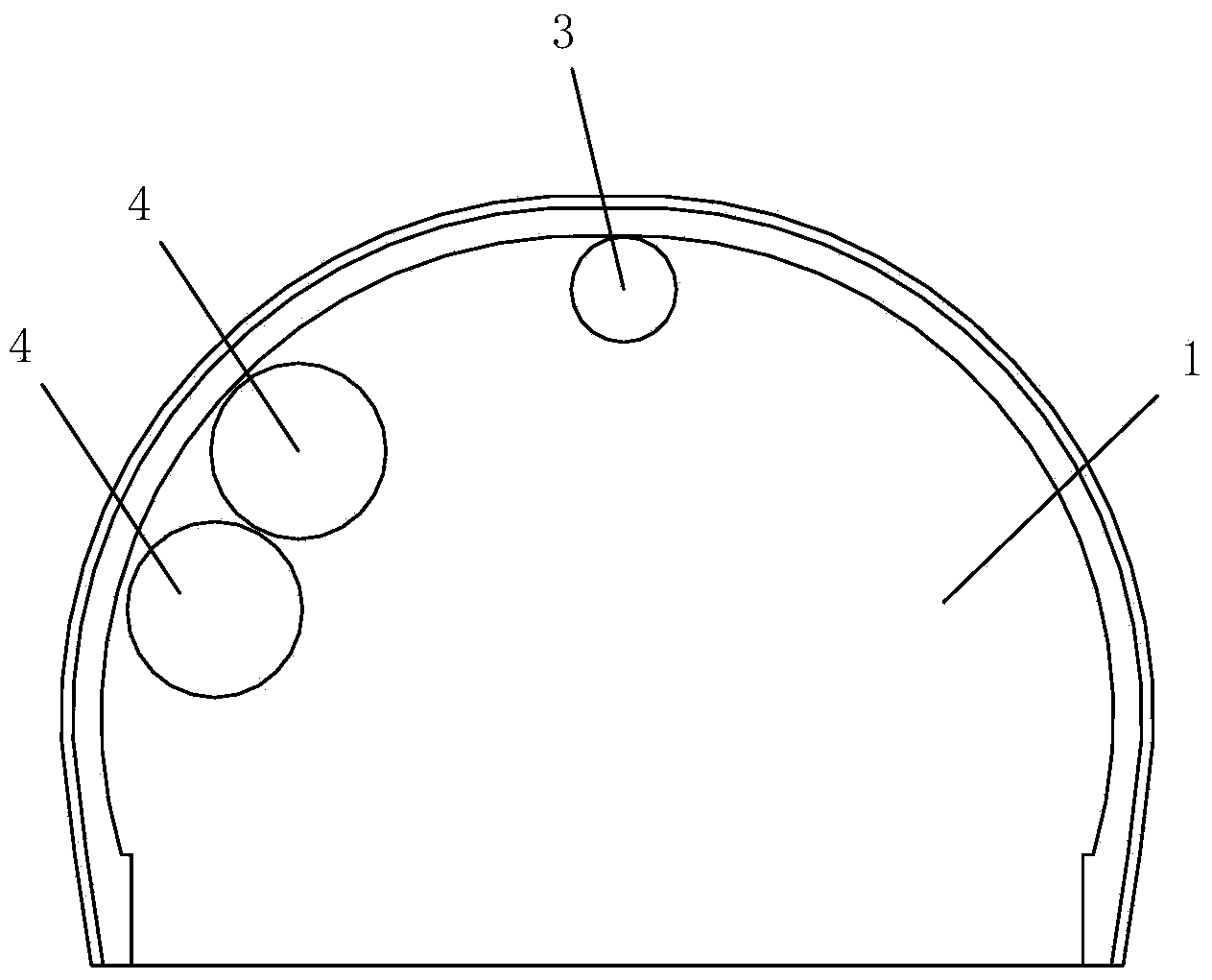

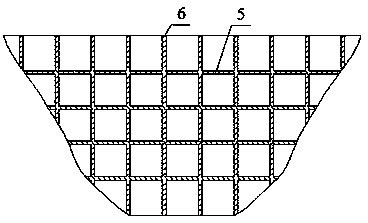

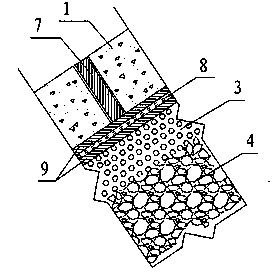

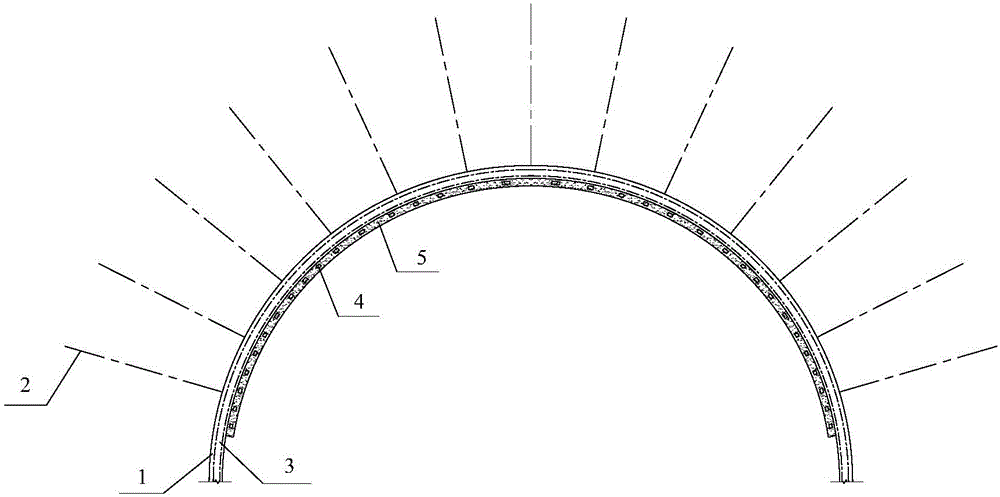

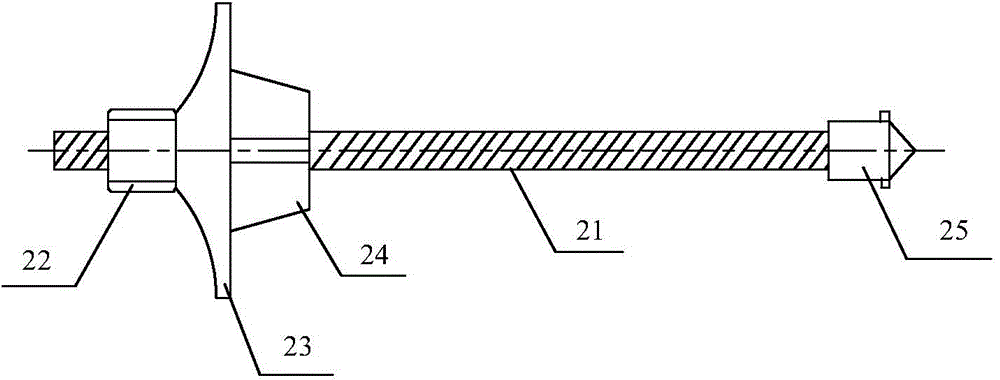

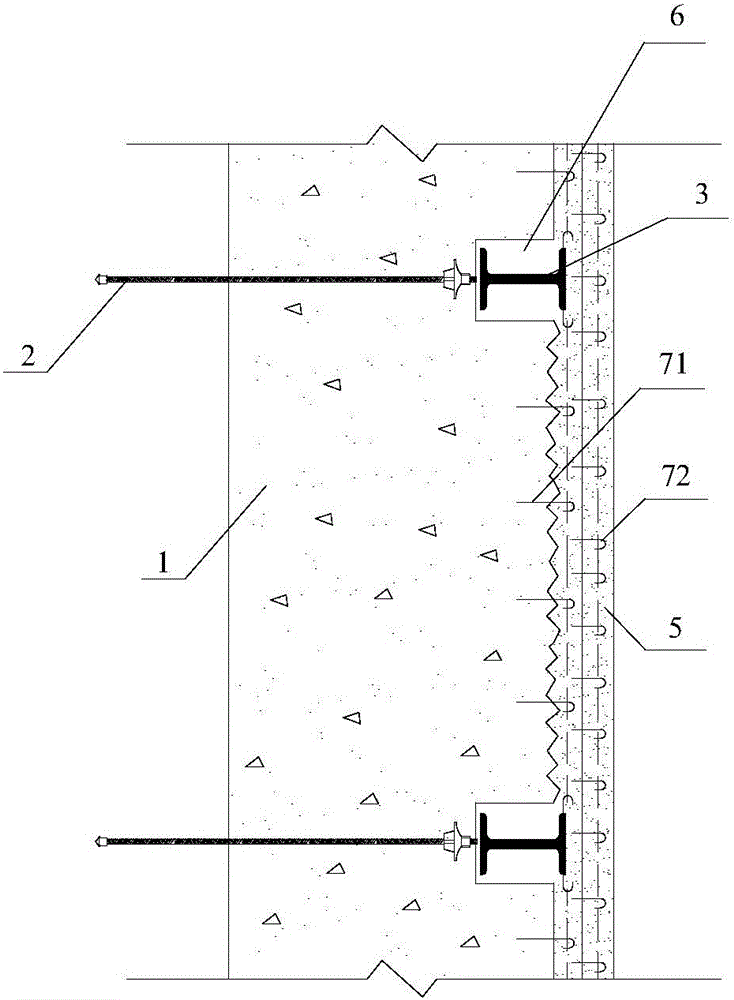

Tunnel lining rapid repair structure based on carbon fiber woven mesh and repair method thereof

ActiveCN104895581AImprove bearing capacityReduce external water pressureUnderground chambersTunnel liningFiberJoist

The invention relates to a tunnel lining rapid repair structure based on a carbon fiber woven mesh and a repair method thereof. The tunnel lining rapid repair structure based on the carbon fiber woven mesh comprises self-propelled hollow grouting anchors, joist steel, the carbon fiber woven mesh, U-shaped hooks and a composite mortar layer. The joist steel is arranged on a tunnel lining to be repaired, one end of each self-propelled hollow grouting anchor stretches into the tunnel lining to be repaired in the radial direction of the tunnel lining to be repaired, the other end of each self-propelled hollow grouting anchor is connected with joist steel, the carbon fiber woven mesh is laid on the inner wall of the tunnel lining to be repaired and connected with the joist steel through the U-shaped hooks, and the composite mortar layer is sprayed on the inner surface of the carbon fiber woven mesh. The tunnel lining rapid repair structure based on the carbon fiber woven mesh and the repair method thereof aims to solve the problems existing in the existing tunnel lining reinforcing technology, the structure is reasonable in design, the mechanical property is good the steps of the method is simple, the operability is high, and the project cost is low.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

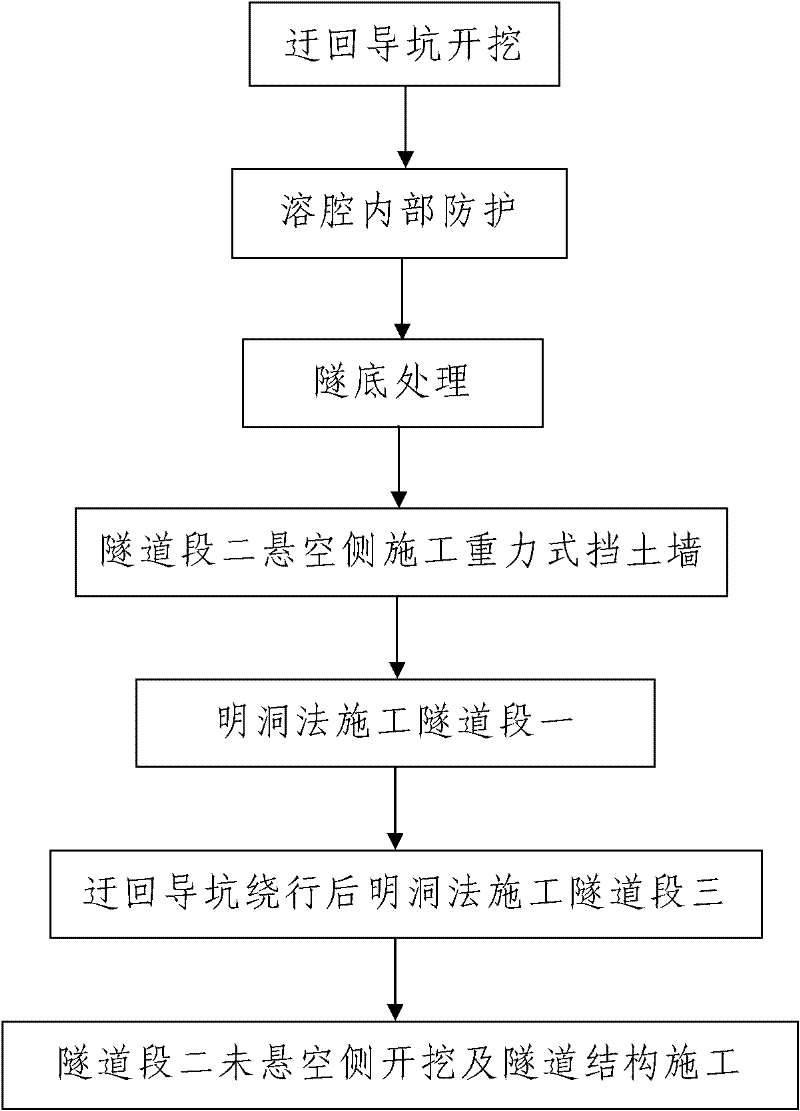

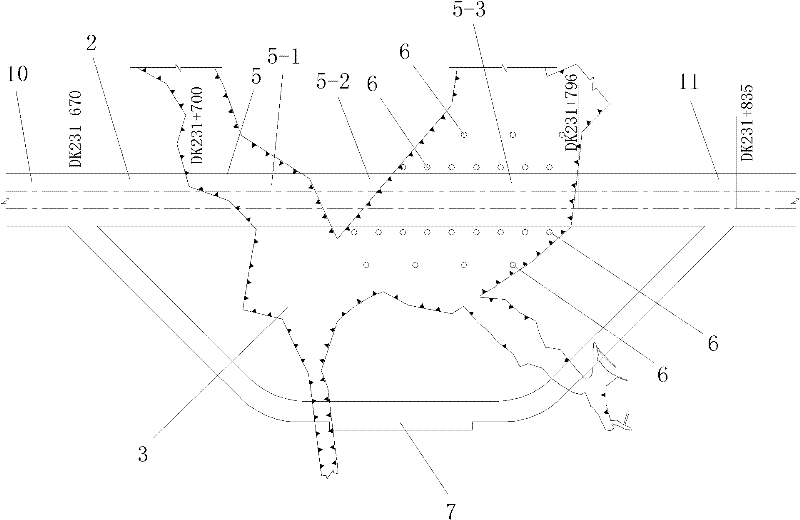

A large-scale solution cavity treatment method for karst tunnels

ActiveCN102296961AReasonable designSimplify construction stepsUnderground chambersTunnel liningLarge distanceKarst tunnel

The invention discloses a karst tunnel large-scale cavern processing method. A cavern traversing tunnel section penetrating through a cavern comprises a tunnel section I, a tunnel section II and a tunnel section III according to the distribution positions, wherein two sides of the tunnel section I are suspended in midair and the top of the tunnel section I is at a smaller distance away from a cavern top plate, one side of the tunnel section II is suspended in midair, and two sides of the tunnel section III are suspended in midair and the top of the tunnel section III is at a larger distance away from the cavern top plate. The processing method comprises the steps of: 1, excavating a bypass pilot tunnel; 2, protecting inside of the cavern; 3, processing the bottom of the tunnel: filling the cavern below the tunnel section I with rock residues and grouting for reinforcing, and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section III with concrete and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section II with hard fillers; 4, constructing a gravity retaining wall at the suspending side of the tunnel section II; 5, constructing the tunnel section I with an open cut tunnel process; 6, constructing the tunnel section III with the open cut tunnel process after the bypass pilot tunnel bypasses; and 7, constructing the tunnel section II. The karst tunnel large-scale cavern processing method has the advantages of reasonable design, convenience for construction, safe and reliable construction process and short construction period, good processing effect on the large-scale cavern.

Owner:CHINA RAILWAY 20 BUREAU GRP

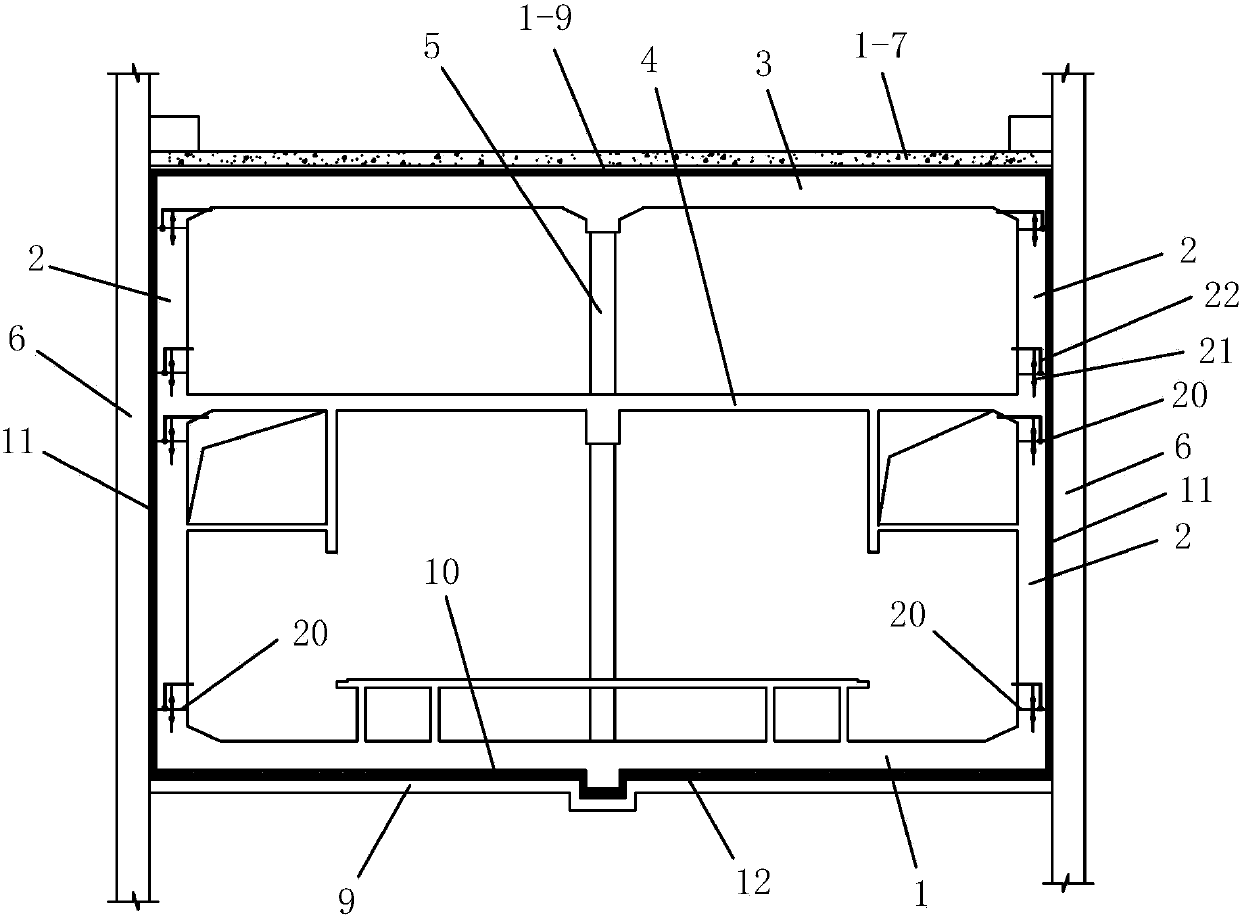

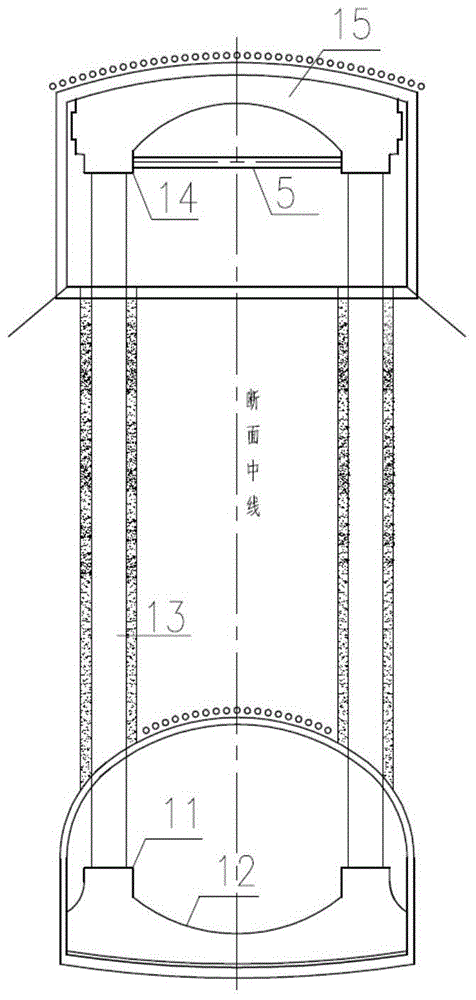

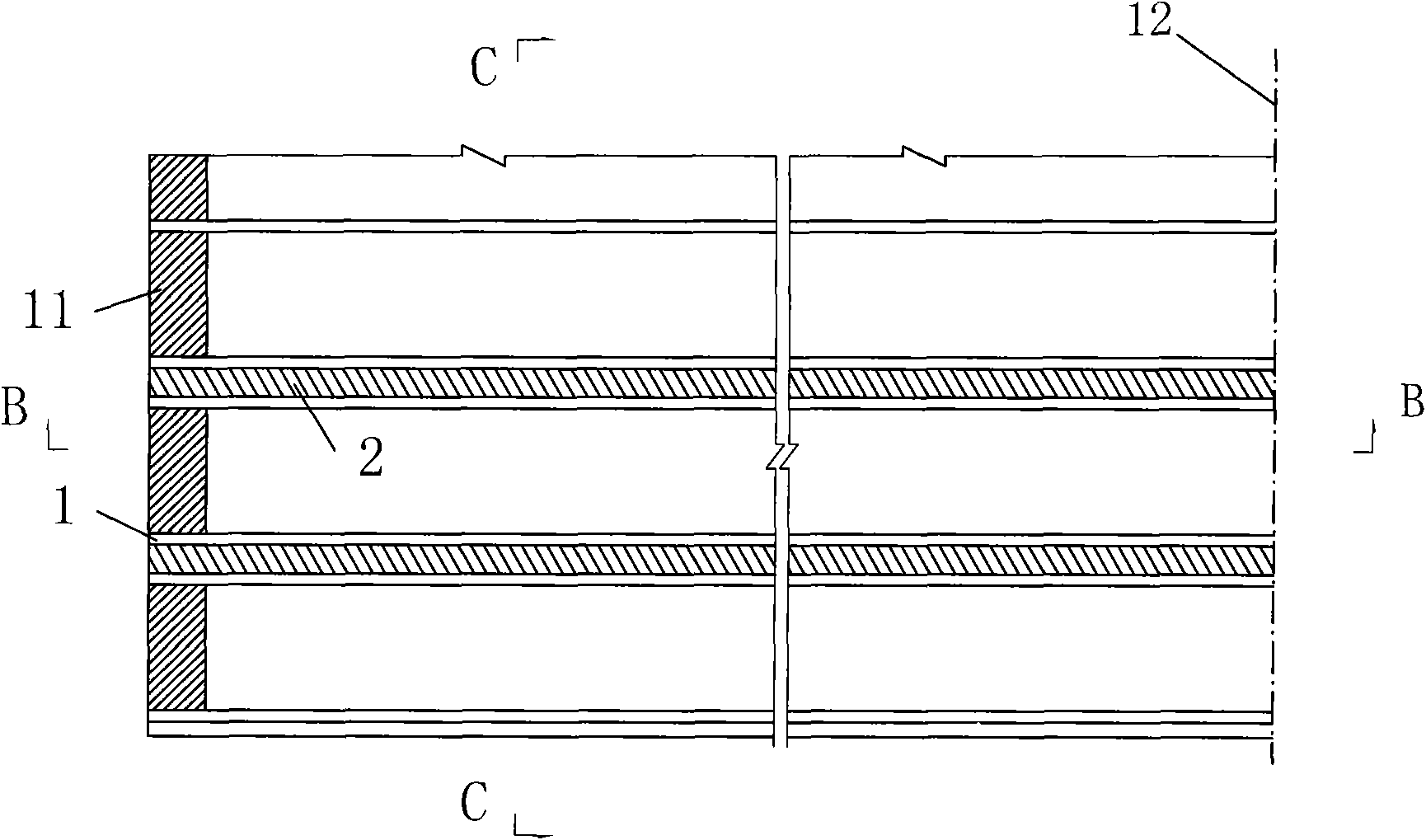

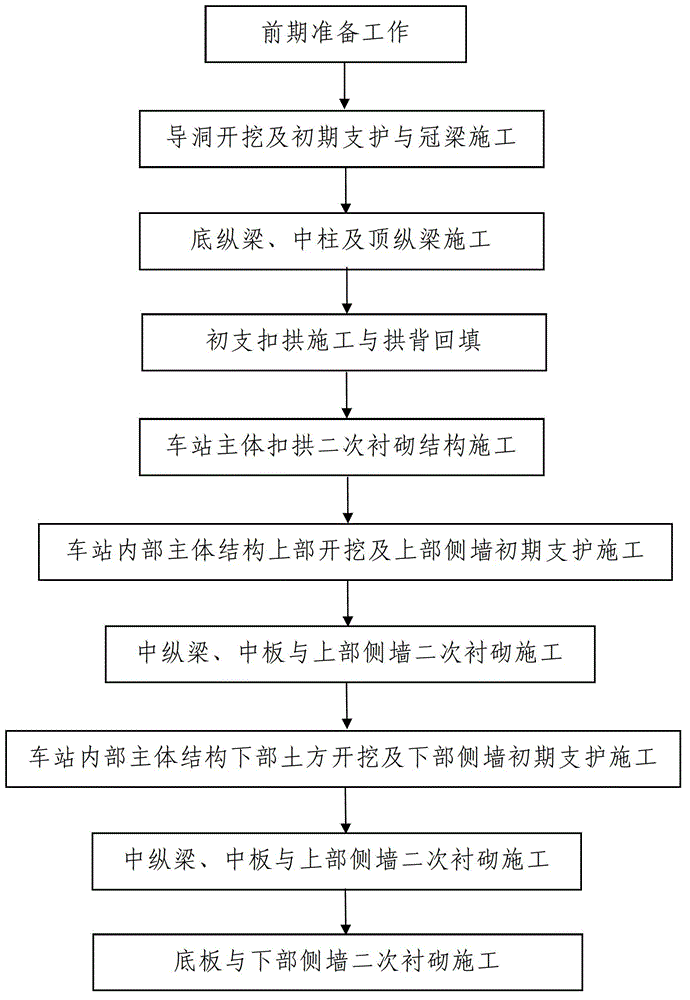

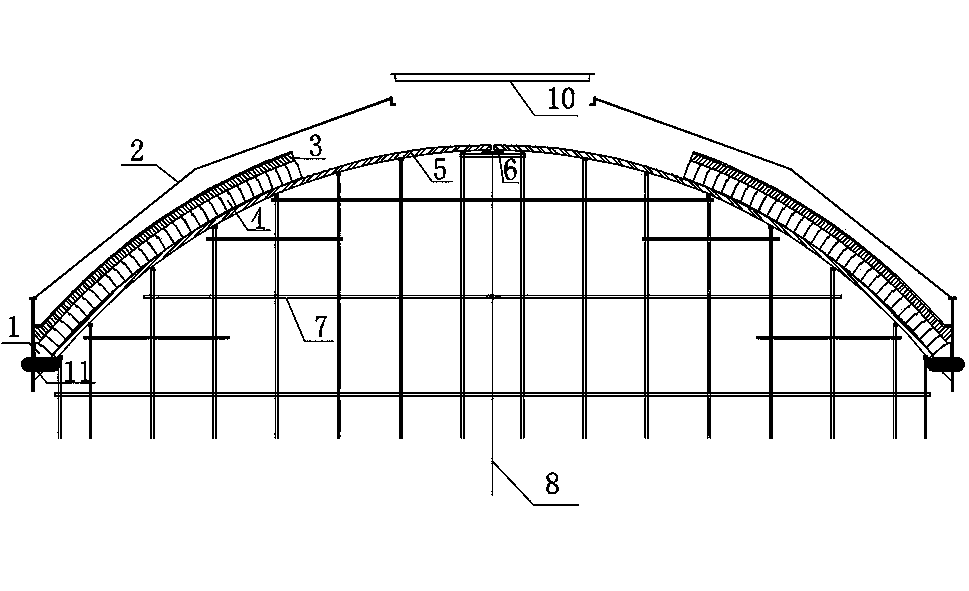

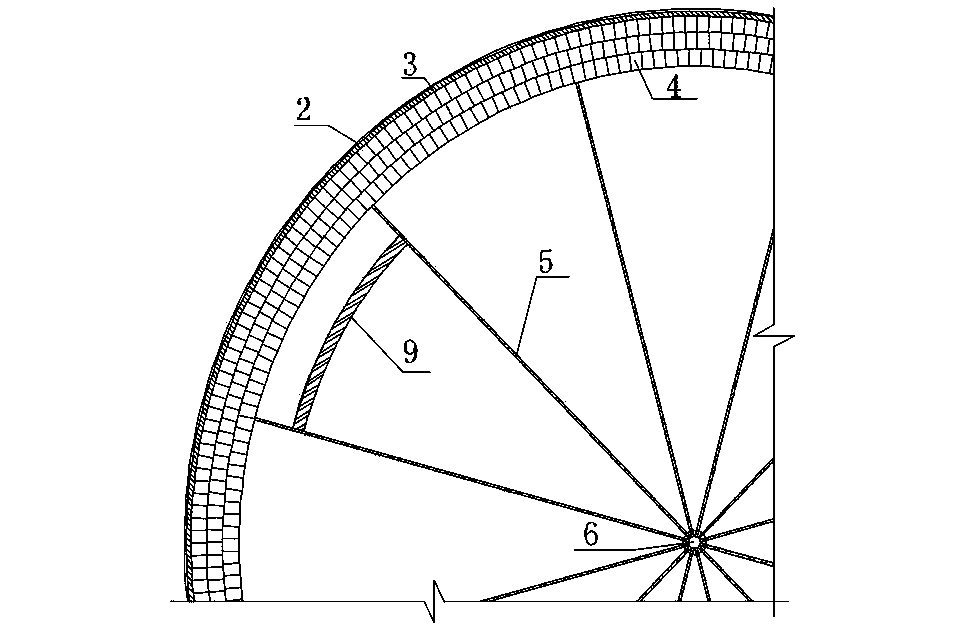

Main structure for metro long-span station and pillar arching construction method thereof

ActiveCN102748040AEasy constructionSimplify construction stepsUnderground chambersEngineeringLong span

The invention discloses a main structure for a metro long-span station and a pillar arching construction method thereof. The main structure comprises a station interior main structure, a plurality of middle pillars, a middle plate and a main arch part, wherein the station interior main structure is dug; the middle plate is located on the middle pillars; the main arch part is located right above the main structure; a bottom longitudinal beam is arranged at the bottom of the station interior main structure; a top longitudinal beam is arranged on the main arch part; and a middle longitudinal beam is arranged between adjacent middle pillars. The construction method comprises the following steps: 1) preparing in earlier stage; 2) digging a guiding hole and performing primary bracing and bridging construction; 3) constructing the bottom longitudinal beam, the middle pillars and the top longitudinal beam; 4) constructing a primary branch arch and refilling an arch back; 5) performing arch secondary lining construction; 6) digging the upper part of the main structure and constructing a primary branch of a side wall of the upper part; 7) performing secondary lining construction of the middle longitudinal beam, the middle plate and the side wall of the upper part; 8) digging the lower part of the main structure and constructing the primary branch of the side wall of the lower part; and 9) performing secondary lining construction for a base plate and the side wall of the lower part. The construction method provided by the invention has the advantages of reasonable design, simple construction step, convenience in realizing, small construction difficulty and high construction speed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

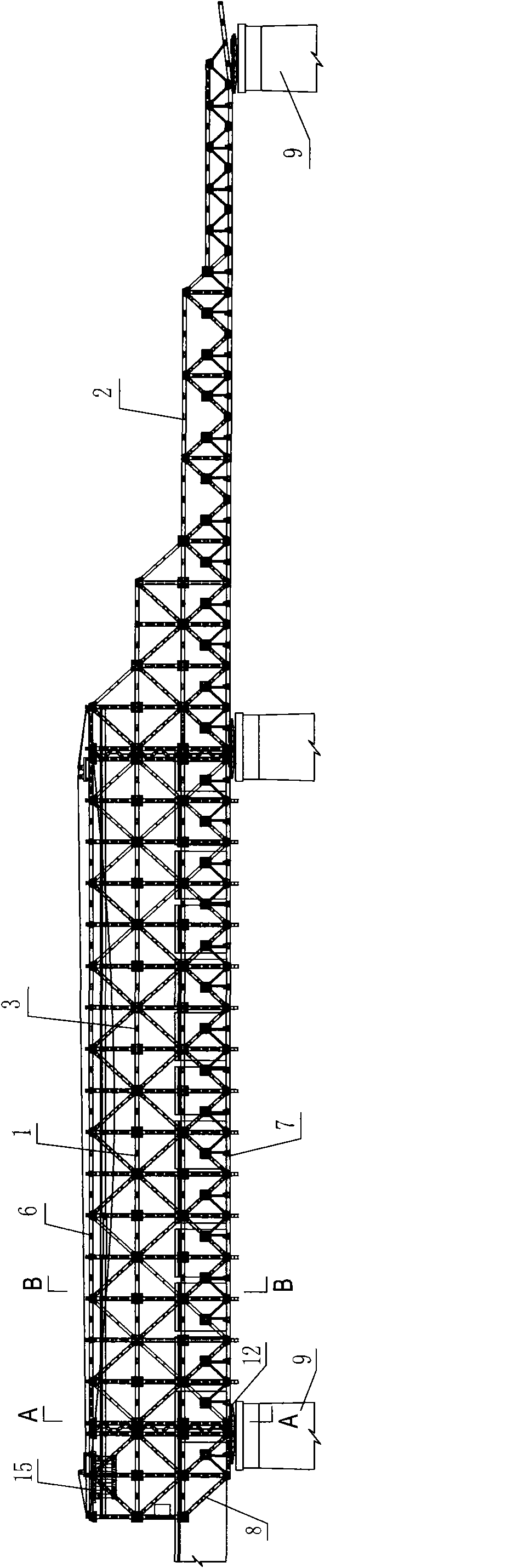

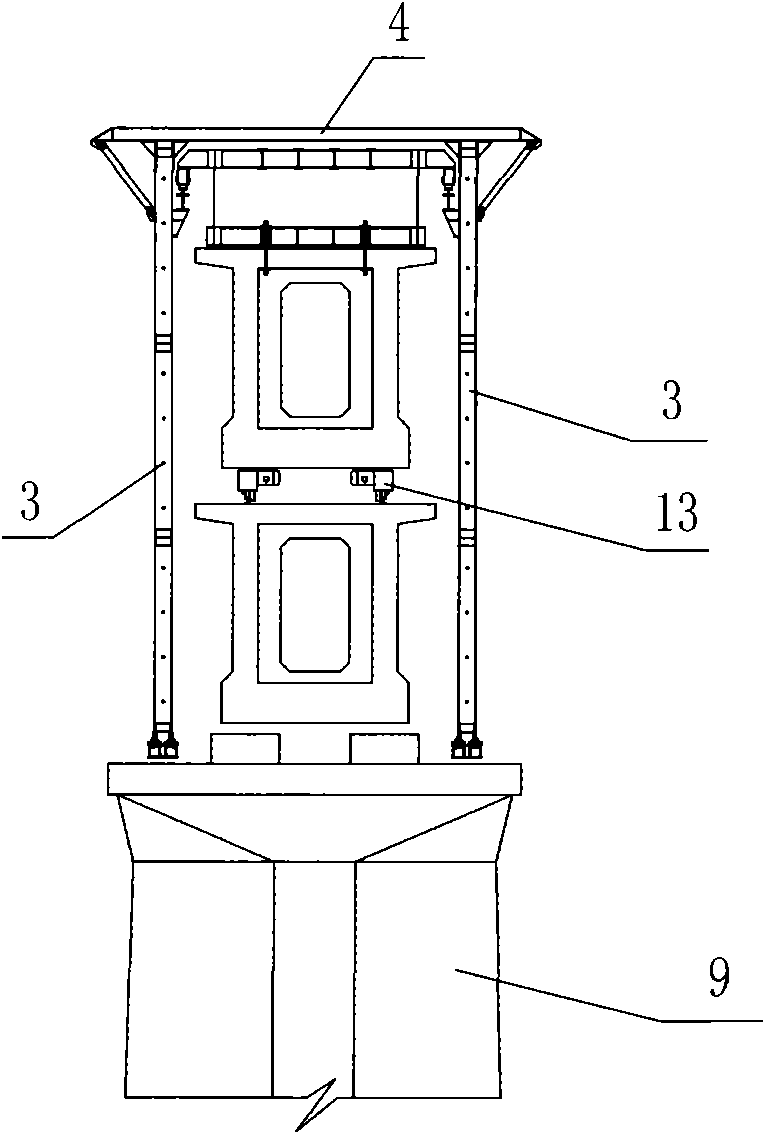

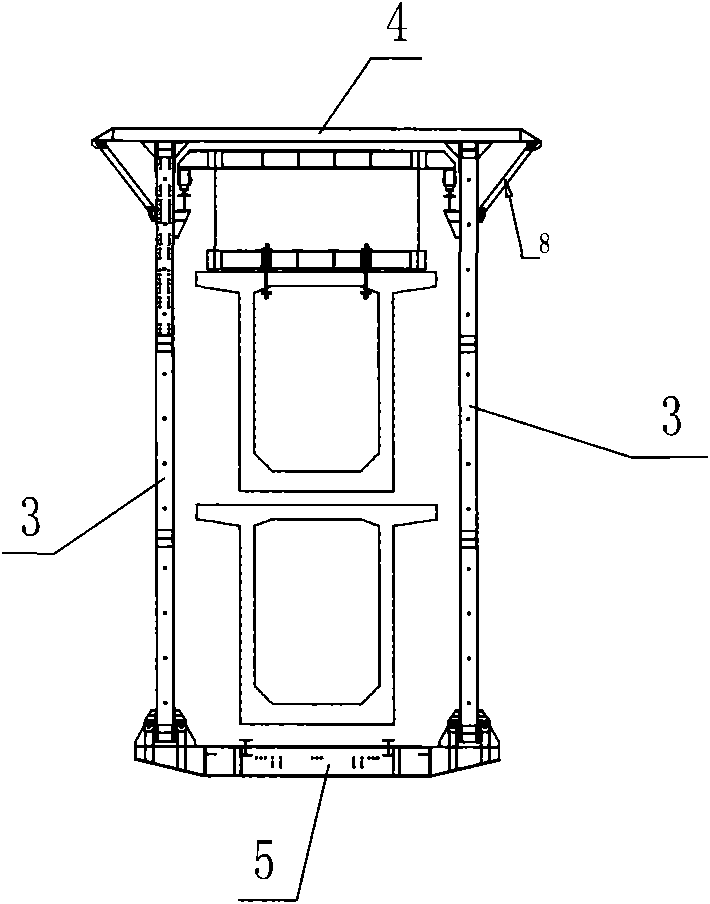

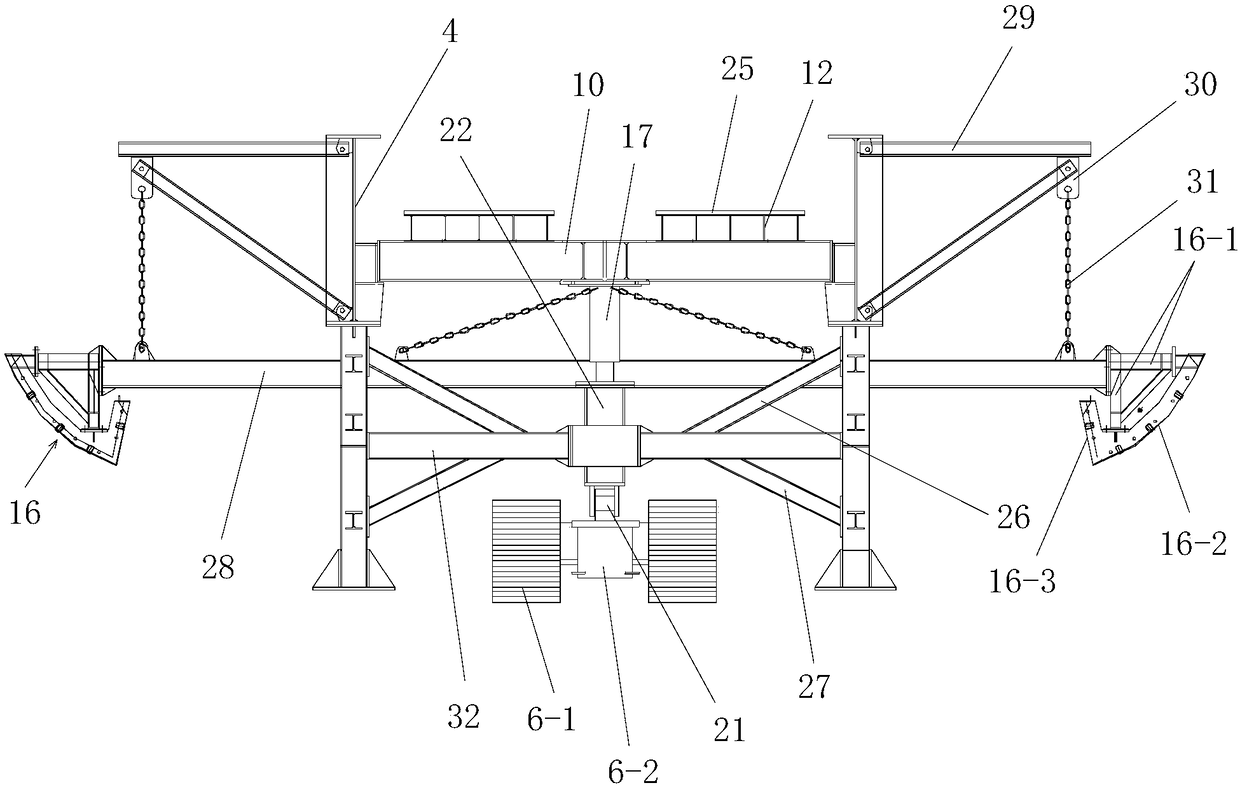

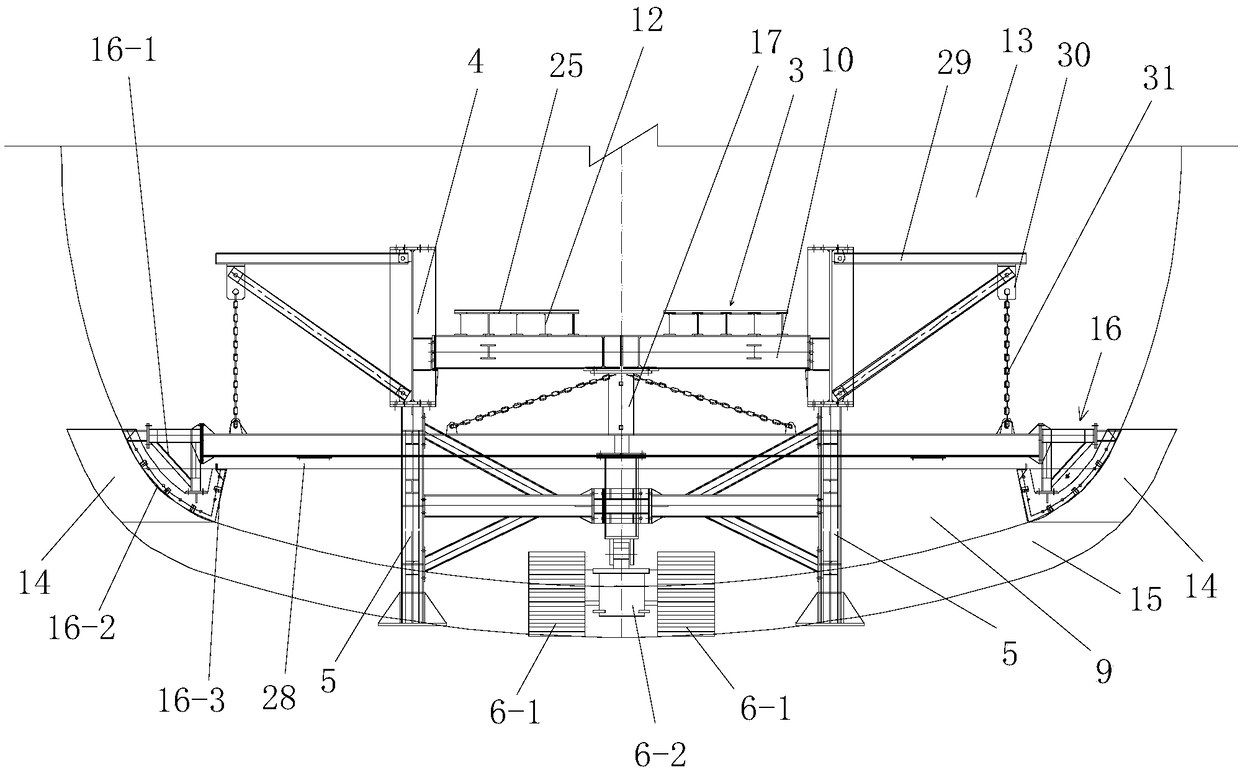

Large-span section assembling bridge manufacturing machine and assembling construction process thereof

ActiveCN101787678AReasonable structural designLarge spanBridge erection/assemblyStructural engineeringInvestment cost

The invention discloses a large-span section assembling bridge manufacturing machine and an assembling construction process thereof. The bridge manufacturing machine comprises a bridge manufacturing machine main body structure, a crown block system and a forward moving system, wherein the bridge manufacturing machine main body structure comprises a left main truss, a right main truss, an upper lateral brace and a lower lateral brace; the two main trusses comprise a main beam and a guide beam, and the guide beam has a three-layer step type truss structure; and a plurality of connecting rods comprise 87 type military beams and heterogenic rods. The assembling construction process comprises the following steps of: 1. assembling and constructing a first hole beam of a single-hole beam or a porous beam; forwards shifting the bridge manufacturing machine main body structure to construct the next hole beam across the hole; and repeatedly constructing till the integral construction of a constructed bridge is finished and the bridge manufacturing machine main body structure is disassembled. The bridge manufacturing machine has reasonable structural design, large span, convenient processing, manufacture, assembly and installation, strong weight capacity and low investment cost; and the used assembling construction process is simple, is convenient for realization and can be effectively suitable for the assembling construction process of bridge sections with the span of 64m and below 64m.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

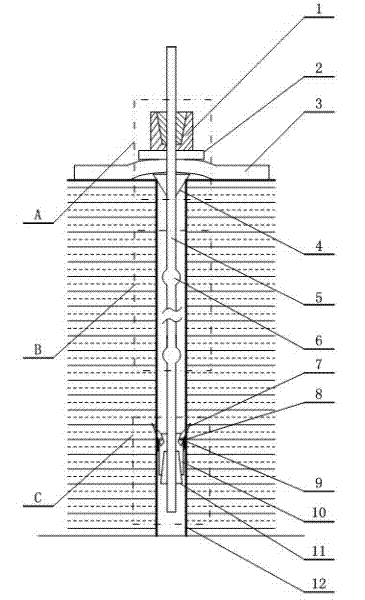

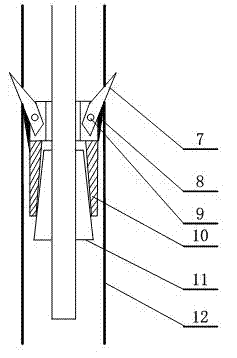

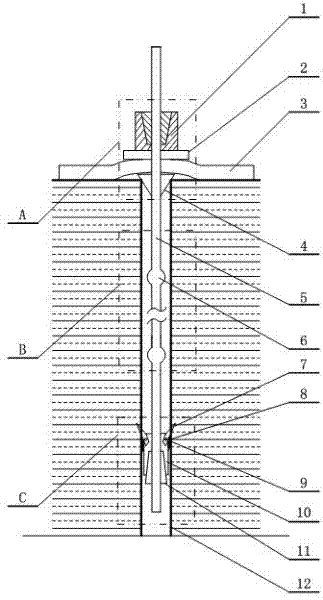

Large-aperture pretension base plate hollow grouting device

InactiveCN102418536ASolve the problem of less groutingSolve the easy plugging holeUnderground chambersTunnel liningRock boltRock body

The invention relates to a large-aperture pretension base plate hollow grouting device, which comprises a fastening section A, a grouting section B and an anchoring section C. In the large-aperture pretension base plate hollow grouting device, a mechanical anchoring mode is adopted; by using a structural characteristic of a pouring bayonet nail that the pouring bayonet nail can be opened or closed and can only move forward instead of moving backward according to a diameter of an anchoring rod hole, an anchoring rope can be effectively anchored; meanwhile, pretension can be applied before grouting. The device has a simple structure and lower cost, is accepted by the market easily, is easy to install mechanically or manually. By adoption of the device, the fastening efficiency and the reliability of rock bodies can be effectively improved; and an important technical insurance is provided to support and protect deep soft rock alleys easily and to realize safety production in mines; furthermore, the method is simple and is easy to implement; time and labor are saved; the efficiency is high; and the large-aperture pretension base plate hollow grouting device has a wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Pit pile anchor breast wall concrete breast beam structure and construction method thereof

InactiveCN101280564AReduce processing costsChange the situationExcavationsBulkheads/pilesPre stressRock bolt

Disclosed is a concrete middle beam structure with foundation pit piles and anchor breast wall and the construction method thereof. Prestressed anchor rods are fixed between slope protection piles towards the soil between piles, and side wall of the foundation pits is also provided with transverse concrete middle beams which are between concrete slope protection piles and are in casting connection with the prestressed anchor rods; the outer lateral surface of the transverse concrete middle beams is as parallel and level as the sheath of the pile bodies of the concrete slope protection piles; the inner lateral surface is close to the inner end of the pile bodies of the concrete slope protection piles, and the inner part close to the outer lateral surface is distributed with reinforced nets which are coated at the outer lateral surface of the pile bodies of the row of the concrete slope protection piles and connected with anchor plates of the prestressed anchor rods; the prestressed anchor rods are embedded into the soil between piles from the side wall of the foundation pits, wherein, the anchor heads are positioned in the inner side of the connecting surface at the outer lateral surface of the row of the concrete slope protection piles. The structure of the invention changes the middle beams of section steel and the state that the prestressed anchor heads extrude the pile bodies, can reduce the excavation volume of foundation pits and needs no hoisting equipment to lift section steel middle beam, thereby greatly shortening construction time, simplifying construction steps and reducing construction cost.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

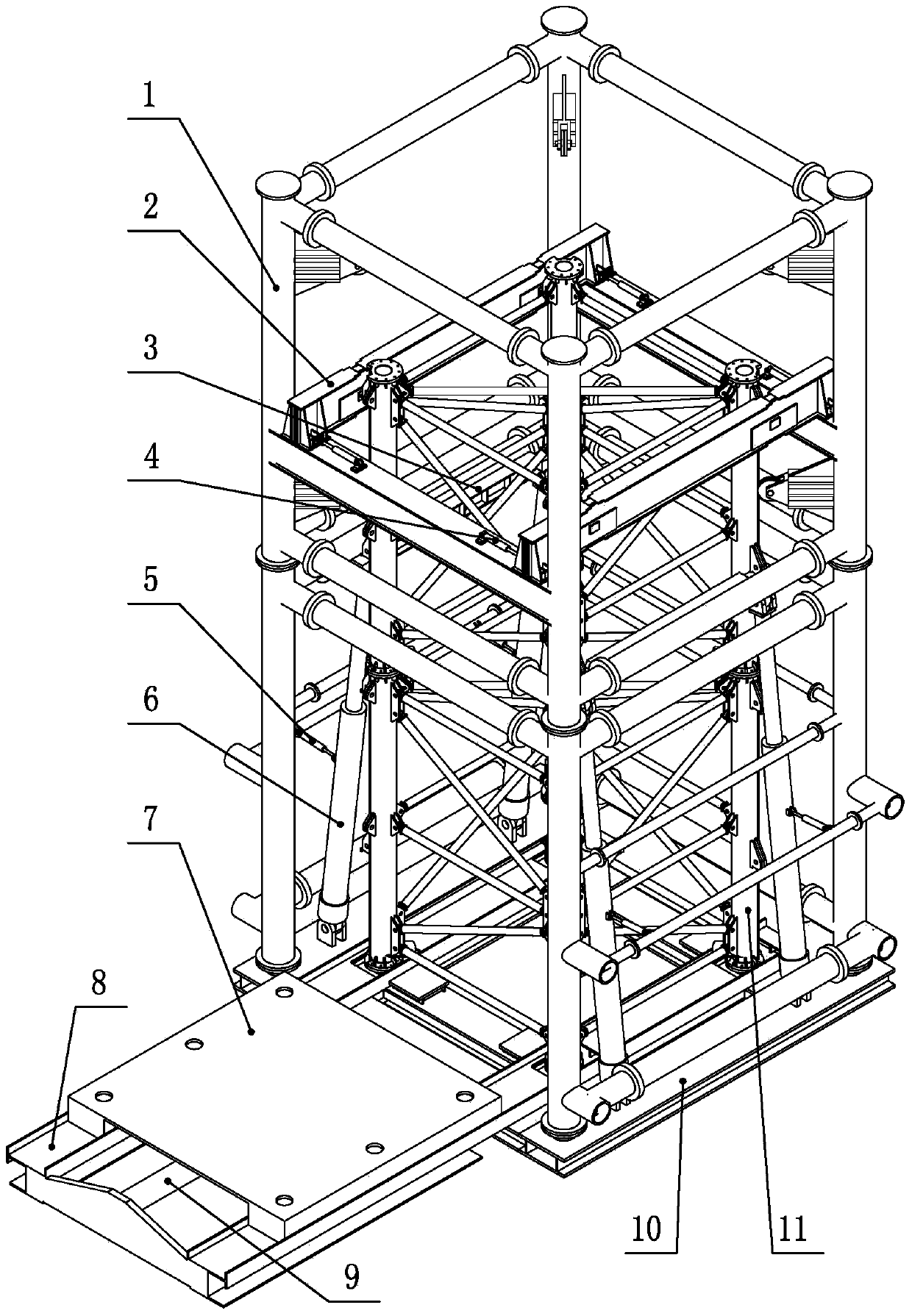

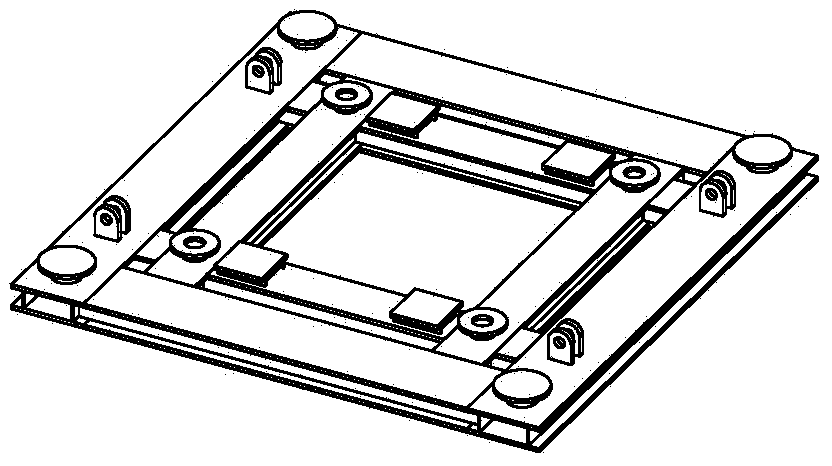

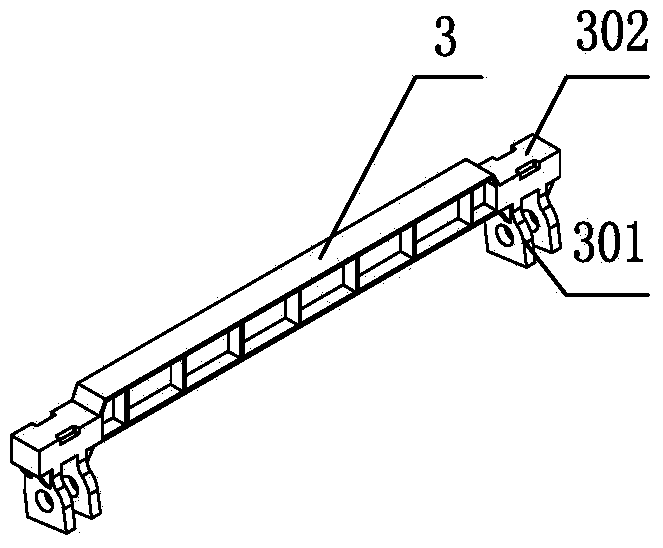

Standard knot jacking device and construction method for continuously and automatically jacking standard knots thereof

A standard knot jacking device comprises a sleeve frame, a conversion beam, a force bearing beam, a conversion beam jack, an amplitude variation jack, a jacking jack, a feeding platform, a guide rail, a feeding jack and a base. The sleeve frame is installed on the base, two ends of the conversion beam are installed on the beam of the sleeve frame, connection lugs at two ends of the force bearing beam are hinged to a piston head installed on the jacking jack through pin rolls in a hinge mode, one end of the jacking jack is fixed on the base in a hinge mode through a pin roll, and the other end of the jacking jack is fixed on a force bearing beam lug plate at two ends of the force bearing beam through a pin roll. During jacking operation, the jacking device is matched with a small crane to hoist the standard knots on the feeding platform, the feeding jack jacks the feeding platform to the jacking position of the standard knots, a control device is adopted to control action of the jacking jack, the amplitude variation jack and the conversion beam jack to achieve automatic jacking of a standard knot steel frame for a journey, the jacks conduct jacking again through load conversion, the small-journey jacking jack can jack higher standard knots, and the whole construction process is simple and easy to operate.

Owner:LIUZHOU OVM MASCH CO LTD

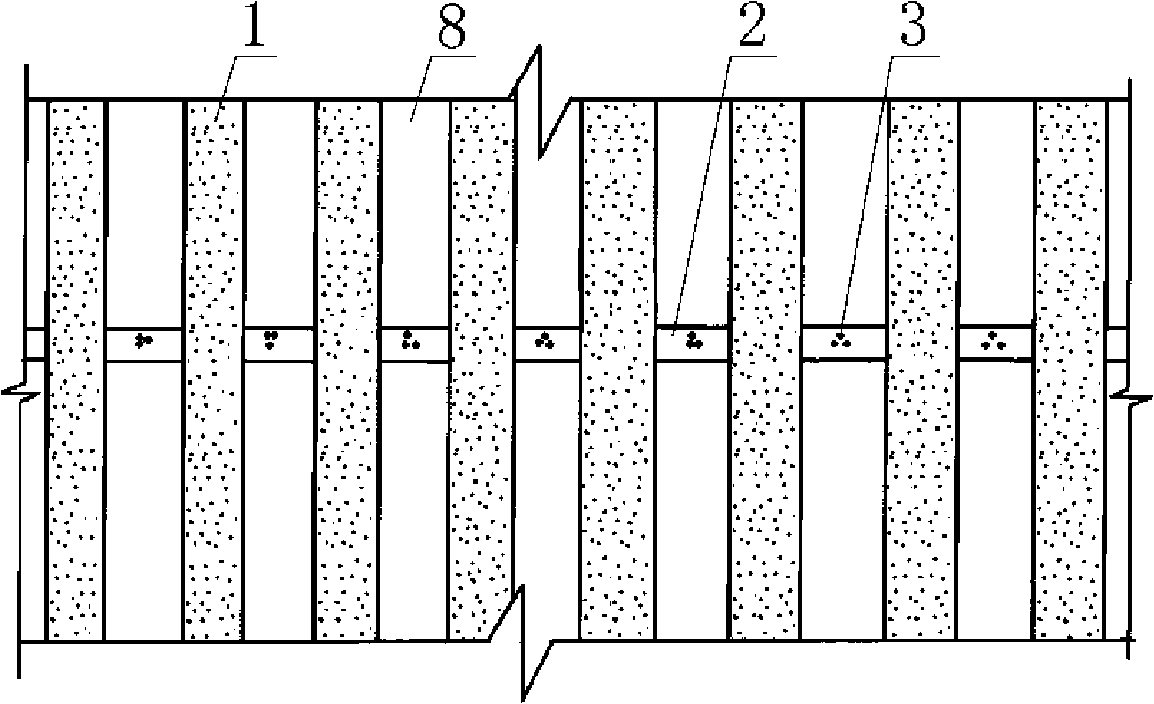

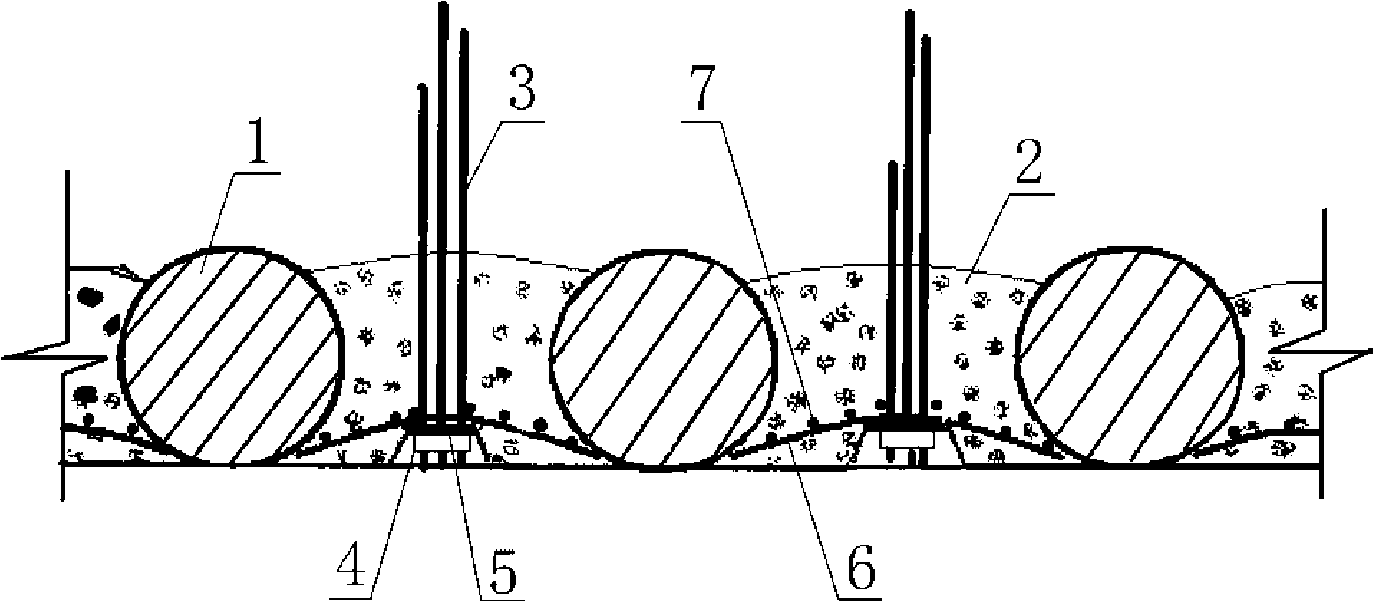

Prefabricated wall panel and connecting structure and construction method thereof

The invention relates to a prefabricated wall panel and a connecting structure and a construction method thereof. The prefabricated wall panel comprises a wall panel die block, connecting steel bars are pre-embedded in the upper and lower end surfaces of the wall panel die block, expanded feet are fixed at the ends, extending out of the wall panel die block, of the connecting steel bars, and the sizes of the expanded feet are greater than the outer diameters of the connecting steel bars. The prefabricated wall panels, adjacent to each another in the horizontal direction, of the multiple prefabricated wall panels are spliced to form to be in the shape of a line, T, L or cross, and vertical post-pouring belts are formed at the joints of the prefabricated wall panels. The construction methodcomprises the steps that lower prefabricated wall panels are pre-installed, the lower precast wall panels are installed, supported and located, so that horizontal post-pouring belt space is reserved between the upper and lower prefabricated wall panels; the connecting steel bars of the upper and lower prefabricated wall panels are connected with sleeves; and horizontal post-pouring concrete is poured, so that cement slurry flows into the sleeves. The prefabricated wall panel obtained by the construction method has good connecting integrity and high seismic resistance.

Owner:李藏柱

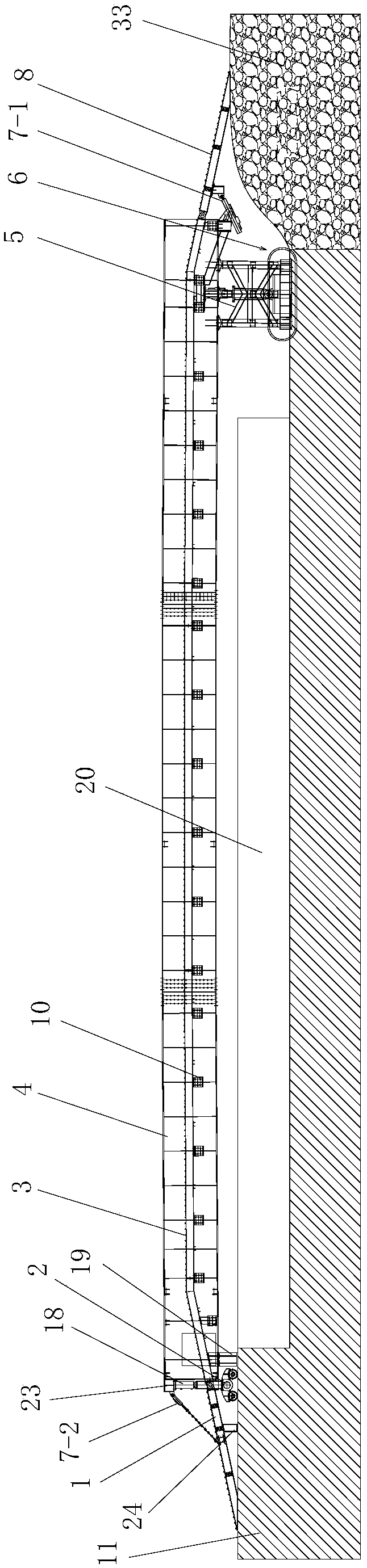

Full-hydraulic crawler-type self-propelled trestle and construction method thereof

ActiveCN109505630ASimple structureReasonable designUnderground chambersTravelling bridgesTunnel constructionBuilding construction

The invention discloses a full-hydraulic crawler-type self-propelled trestle and a construction method thereof. The trestle comprises a main bridge, a front approach bridge and a rear approach bridge,and further comprises two short-side walls symmetrically arranged at the left and right and an inverted arch backfill construction template, wherein the main bridge comprises two main beams symmetrically arranged at the left and right, a plurality of distributive girders and a bridge floor structure, and the short-side walls and the inverted arch backfill construction template comprise forming templates and template supporting frames; when a tunnel is constructed, the full-hydraulic crawler-type self-propelled trestle is used for constructing the tunnel bottom lining and inverted arch backfill layer of the constructed tunnel from back to front separately by multiple tunnel sections. The full-hydraulic crawler-type self-propelled trestle and the construction method thereof have the advantages that the design is reasonable, the construction is simple and convenient, the use effect is good, self-propelled stable walking can be performed in the tunnel by adopting a crawler-type walking mechanism, the synchronous construction of the tunnel inverted arch, short-side walls and inverted arch backfill can be achieved, tunnel digging and deslagging construction can be simultaneously performed, the tunnel construction efficiency can be greatly improved, the construction quality of the tunnel inverted arch, short-side walls and inverted arch backfill can be ensured, and the construction process is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Construction method for spherical furnace top of industrial furnace

ActiveCN103673621AReduce cleanup workloadReduce usageLinings repairFurnace crowns/roofsMetallurgyFire brick

The invention discloses a construction method for a spherical furnace top of an industrial furnace. Firstly, a steel furnace shell is mounted, the elevation and the like of steel supporting plates at the arch springing positions of a globe-roof are rechecked, a vertical control line is arranged from the center of the furnace bottom to the center of the furnace top in a drawn mode, a supporting frame is erected in a furnace body, and a round top plate is arranged in the center of the top; multiple vertical arc plates are then manufactured and are fixed on the round top plate and the supporting frame, and the elevation and the radius of each layers of refractory bricks are marked on the corresponding vertical arc plates; multiple horizontal arc plates are manufactured; the refractory bricks at the arch springing positions are constructed first, the refractory bricks are constructed upwards in sequence, the vertical radian and the elevation of the refractory bricks are controlled by using the vertical arc plates, and the horizontal radius of the refractory bricks is controlled by using the horizontal arc plates; one heat preservation brick layer is constructed after one certain layer of the refractory bricks are constructed, and the construction is carried out in the way until the construction of all the refractory brick layers and the construction of all the heat preservation brick layers are completed; a steel cover plate of the furnace top is mounted in a hanging mode to seal the steel furnace shell. The construction method for the spherical furnace top of the industrial furnace has the advantages of being economical in used material, simple in working procedure, low in cost and the like, and can ensure construction quality more easily.

Owner:五矿二十三冶建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com