Prefabricated wall panel and connecting structure and construction method thereof

A technology of prefabricated wall panels and connecting structures, which is applied in building structures, building materials, buildings, etc., can solve the problems of affecting building seismic resistance, inconvenient operation, poor integrity, etc., and achieve efficient construction, fast and efficient installation, and reliable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

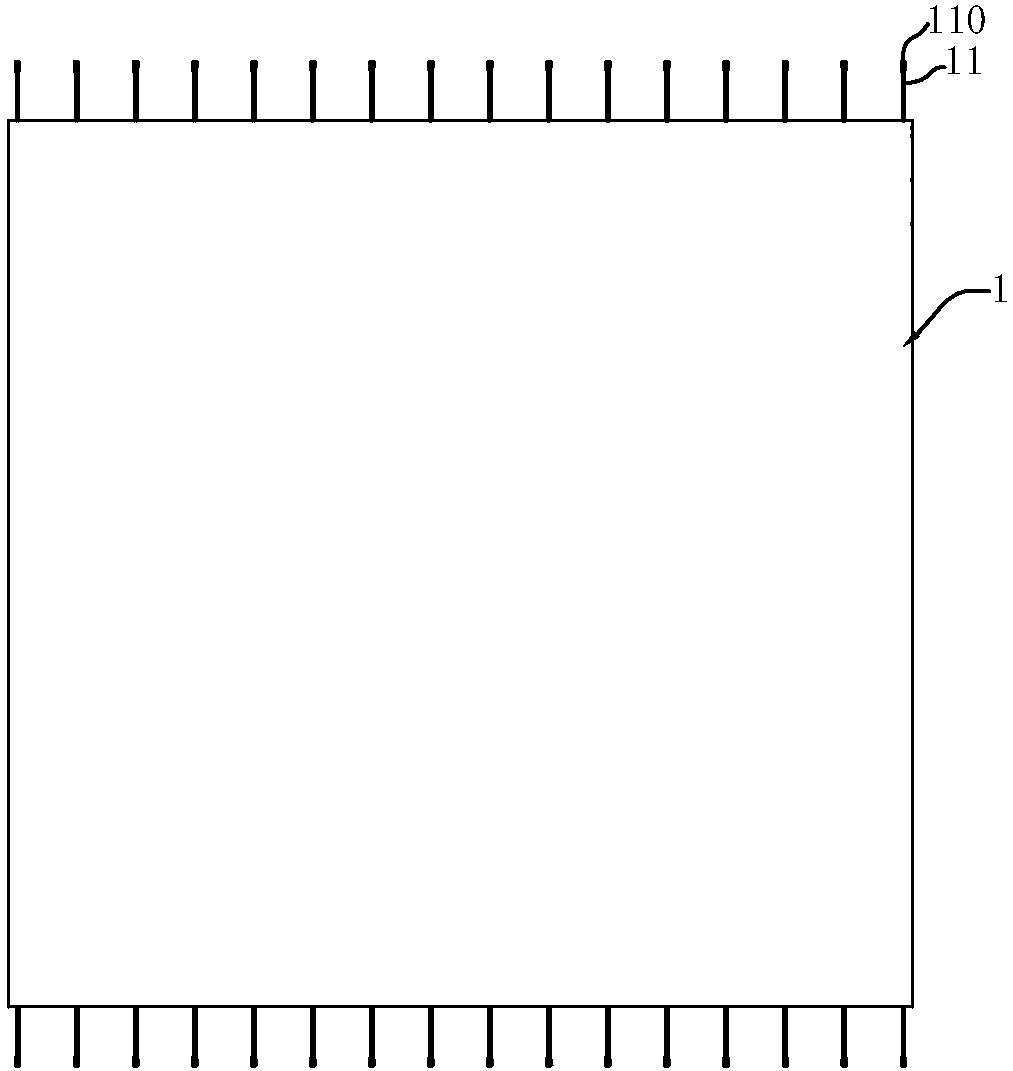

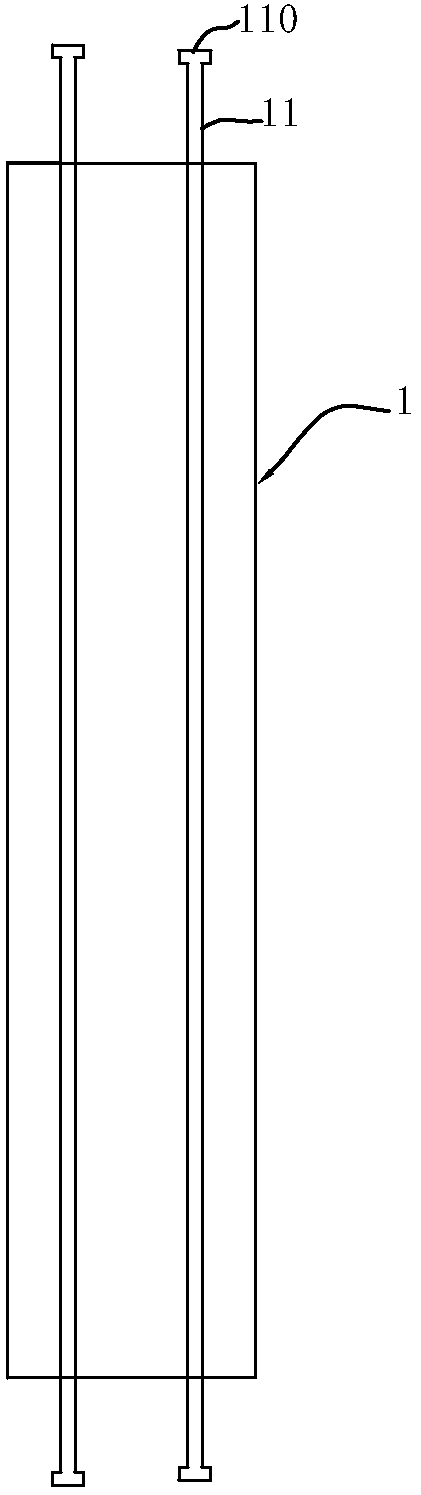

[0102] Embodiment one: if figure 1 and figure 2 As shown, a prefabricated wallboard is poured according to the actual situation according to the size of the mold to form a wallboard module 1 . The upper and lower end faces of the wallboard module 1 are pre-embedded connecting steel bars 11, and the connecting steel bars 11 extend out of the end of the wallboard module 1 to fix the expanding head 110. Modules 1 are spliced to form wall panels. The size of the expanding head 110 may be the diameter of the expanding head 110 .

[0103] The connecting steel bar 11 can be set through the wall panel module 1 through its entire length. The connecting steel bars 11 can be arranged in one or two layers in the thickness direction, and are regularly arranged in the wall panel module 1 .

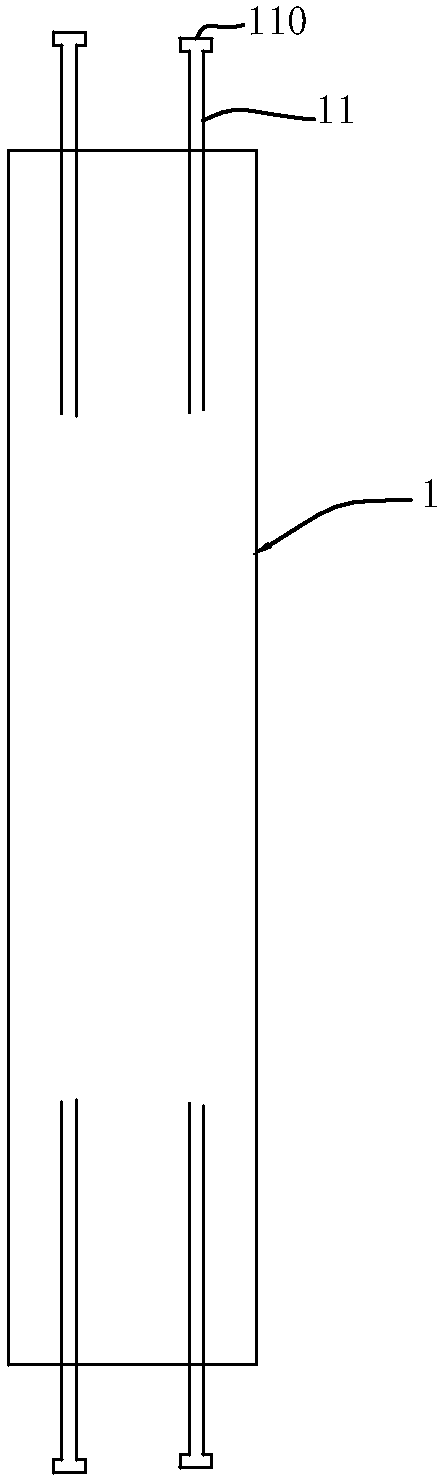

[0104] Such as image 3 Shown, connecting reinforcing bar 11 also can not be set in full length, and the pre-embedded part in wall panel module 1 can be straight bar or bent bar, also can connec...

Embodiment 2

[0120] A connection structure of prefabricated wall panels is formed by splicing the prefabricated wall panels in the first embodiment. Such as Figure 18 As shown, the first layer of wall body 2 is built on the foundation in advance, the prefabricated wall panels 21 extend along the horizontal direction, and two adjacent prefabricated wall panels 21 are spliced in a straight line. At the corner position, two adjacent prefabricated wall panels 21 are arranged vertically and spliced in an L-shape to form a corner. When the wall body and the interior wall are spliced, two prefabricated wall panels 21 spliced in a straight line and another prefabricated wall panel 21 are spliced in a T-shaped manner. When dividing the indoor area, the four prefabricated wall panels 21 can be spliced in a cross-shaped manner to divide the space into four parts.

[0121] Here, the connection method of two adjacent prefabricated wall panels 21 is taken as an example for illustration. Su...

Embodiment 3

[0128] A connection structure of prefabricated wall panels is formed by vertical splicing of the prefabricated wall panels 21 in the first embodiment. Such as Figure 27 As shown, the adjacent prefabricated wall panels 21 in the vertical direction are spliced with each other, and the joints of the prefabricated wall panels 21 form a horizontal post-casting belt 24; Offer two mounting holes 31 matching the outer diameter of the connecting steel bar 11 on the 3.

[0129] Such as Figure 28 As shown, when the prefabricated wallboard 21 is provided with a vertical hollow hole 13, the concrete poured in the hollow hole 13 is connected with the horizontal post-casting belt 24 as a whole, thereby further strengthening the connection between the upper and lower layers of the prefabricated wallboard 21.

[0130] Further, as Figure 29 As shown, the vertical direction in the hollow hole 13 is provided with shear reinforcement 25, and one end of the shear reinforcement 25 extends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com