Patents

Literature

1151results about How to "Reduce construction procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

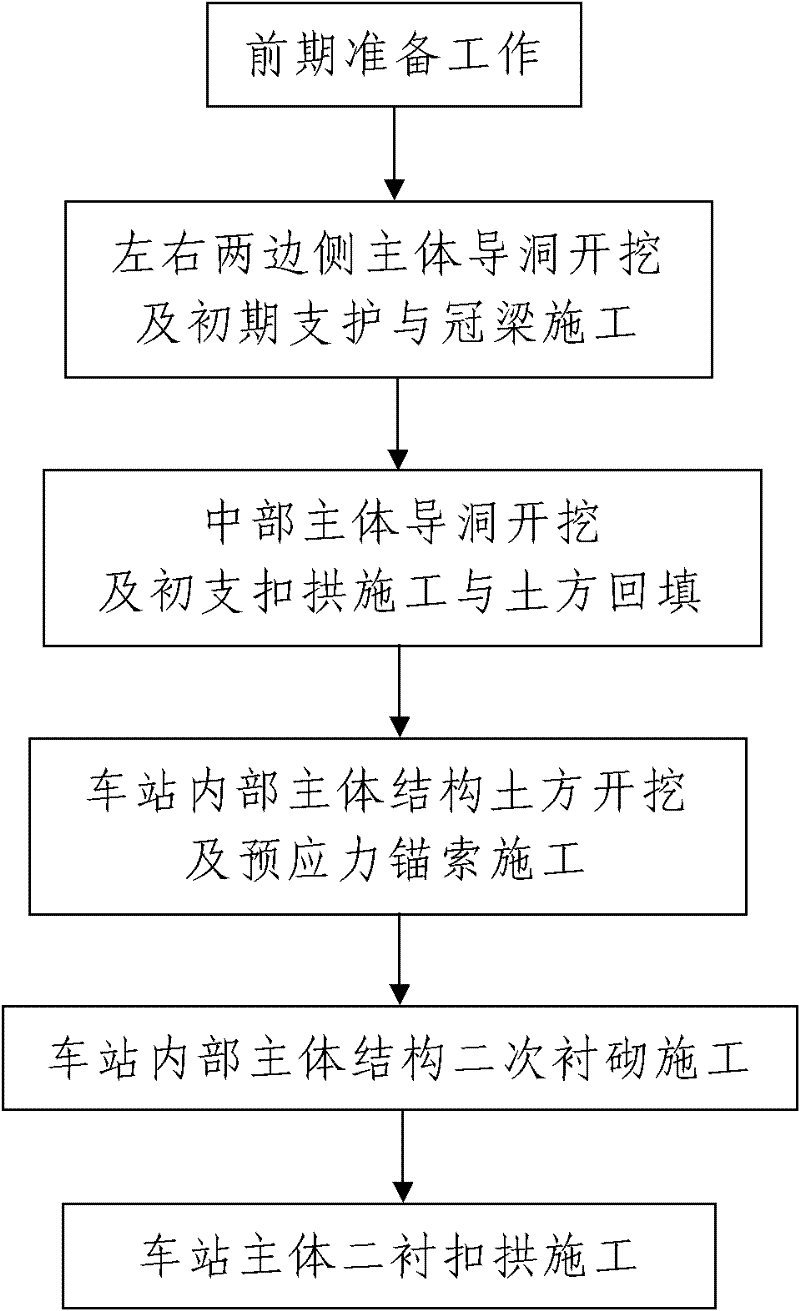

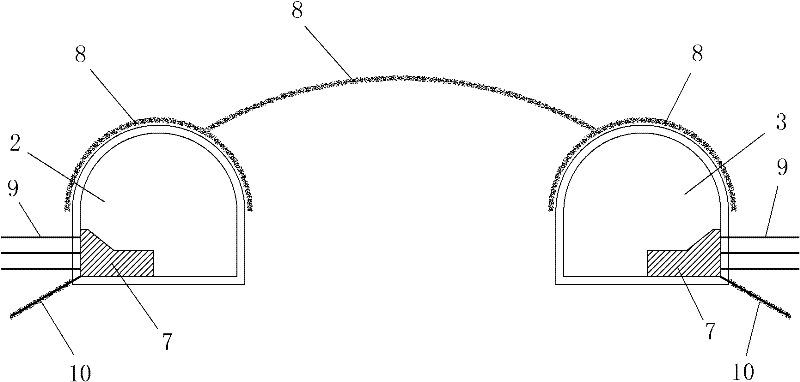

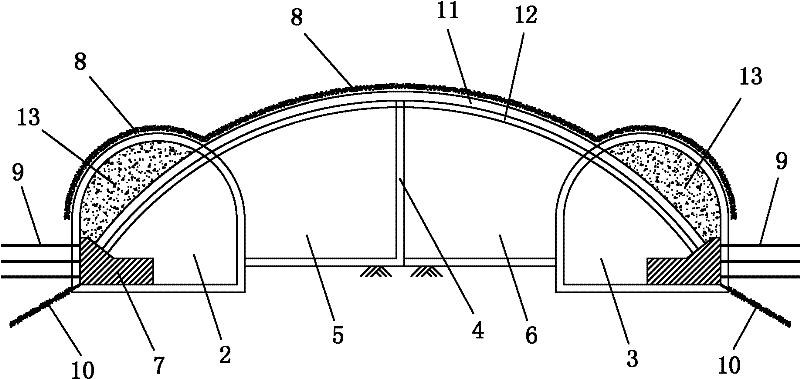

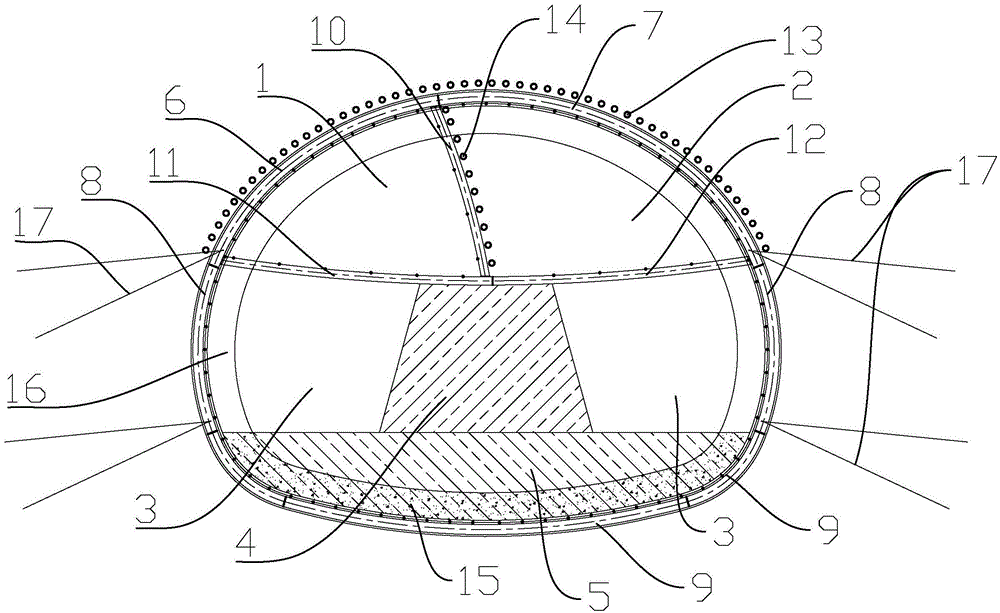

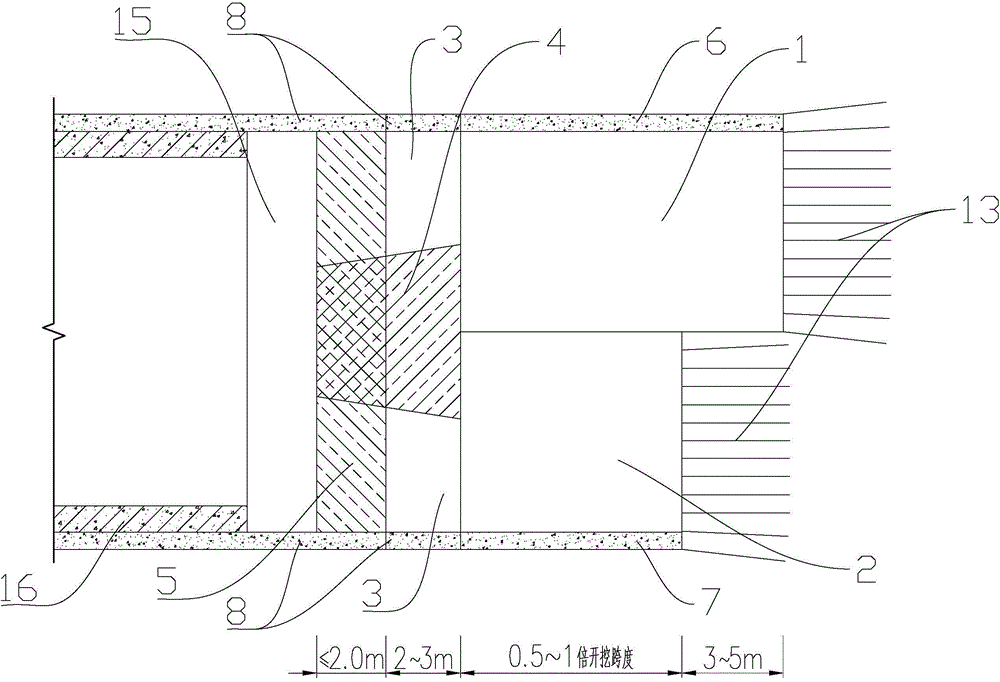

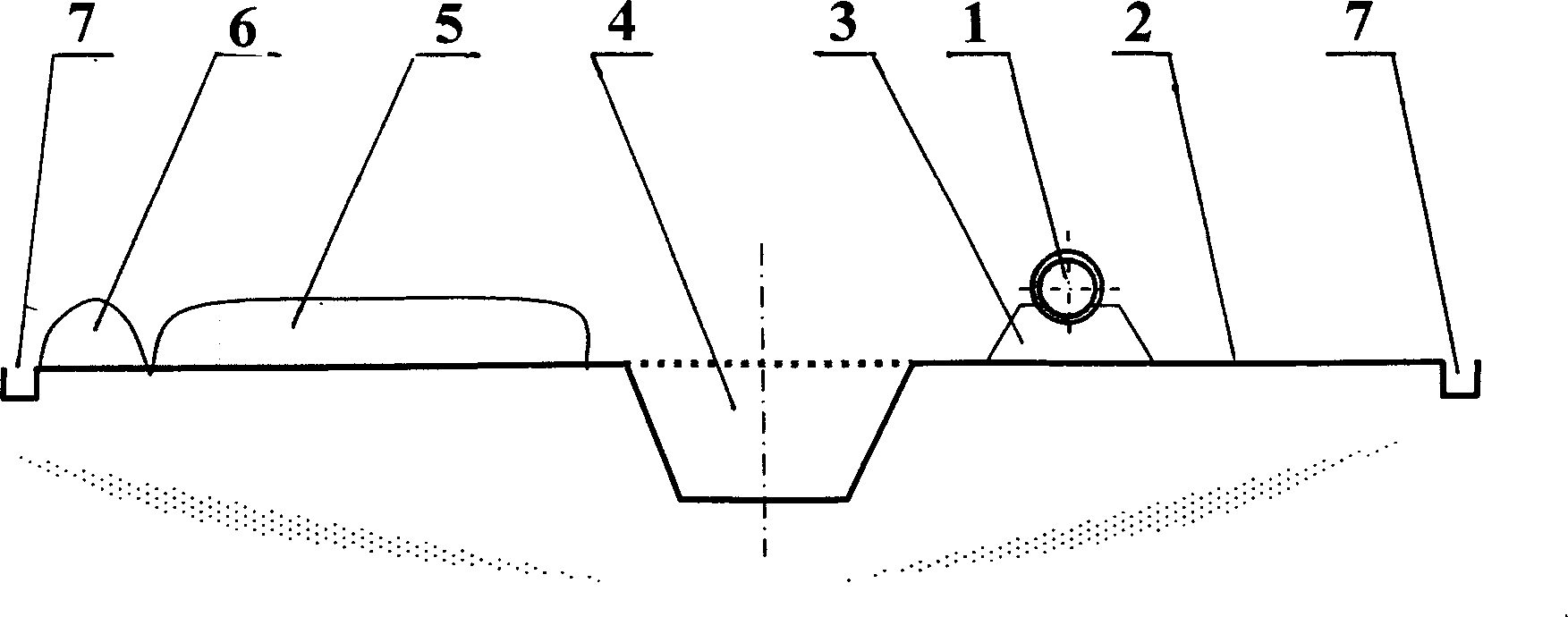

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

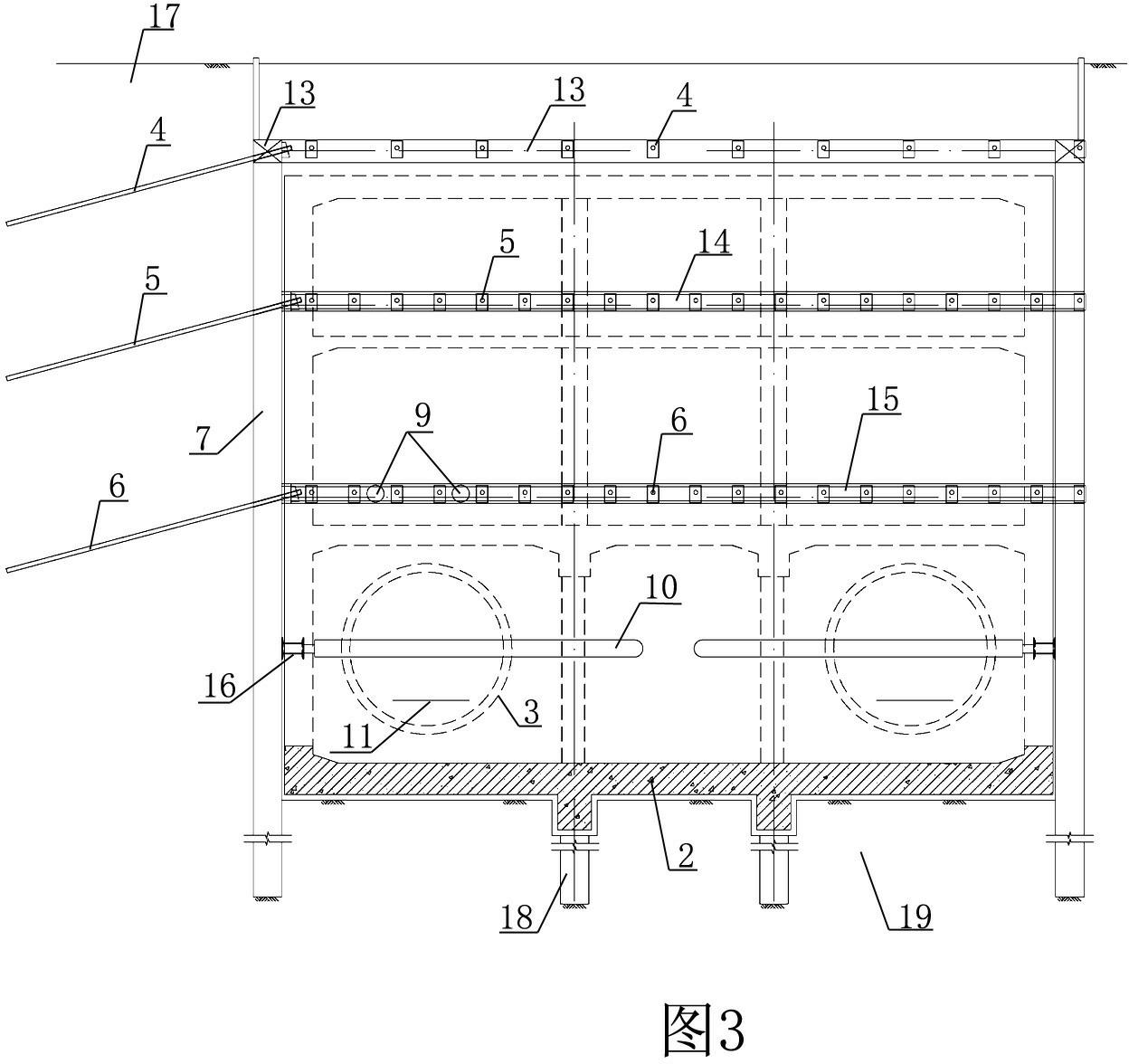

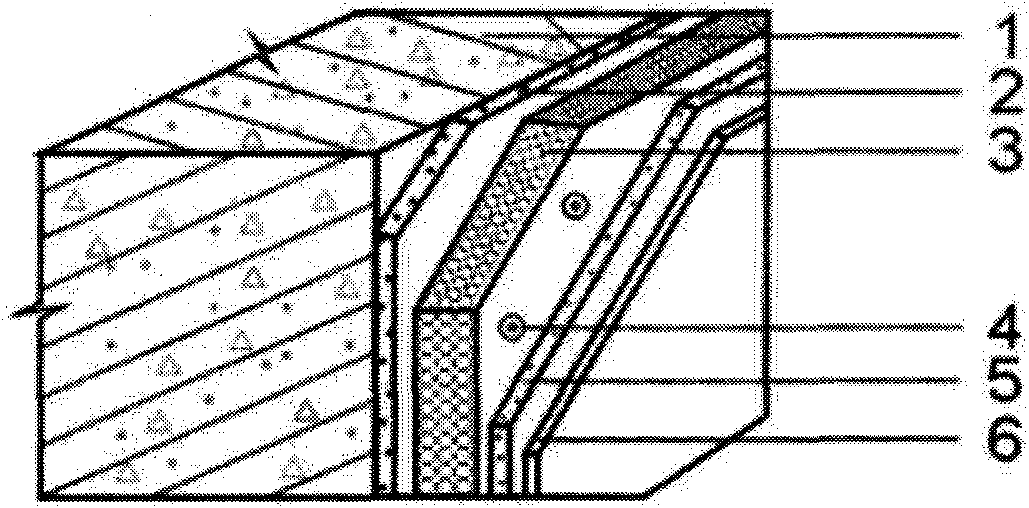

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

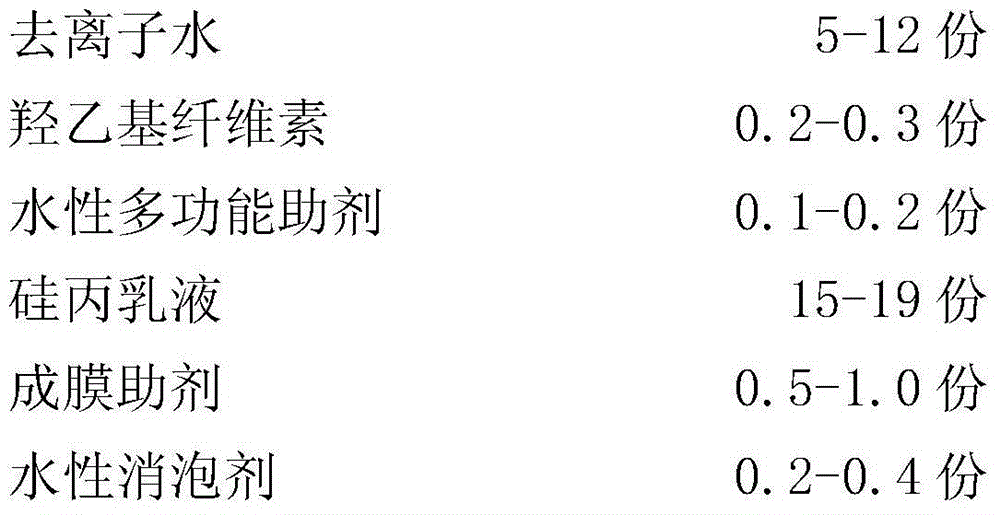

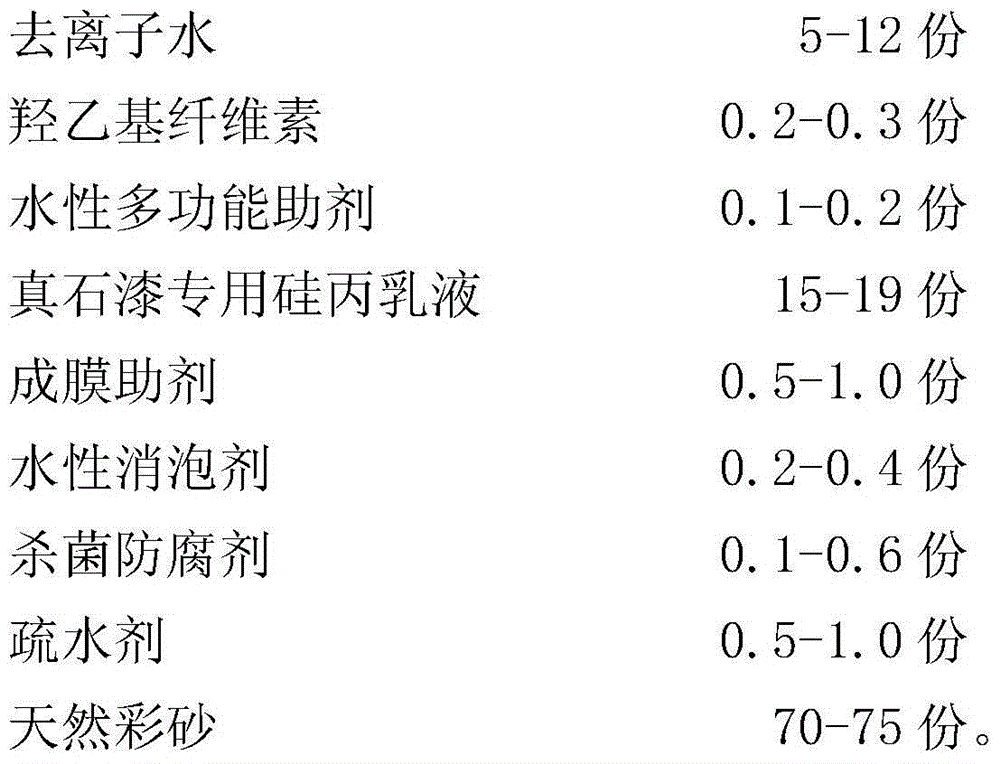

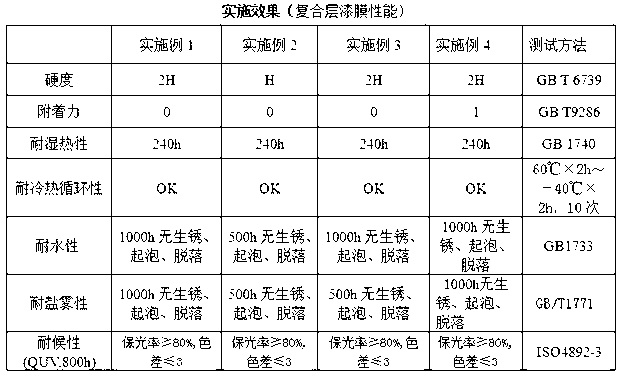

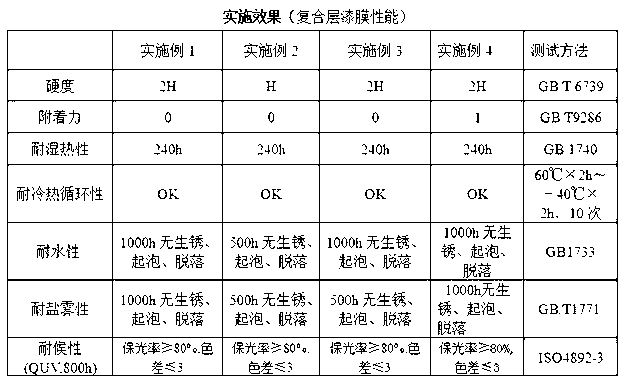

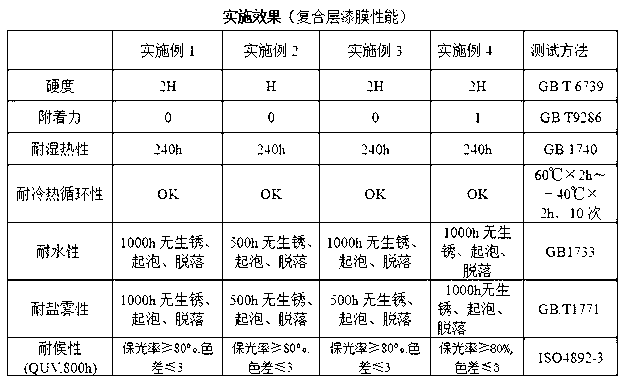

Functional real stone paint building exterior wall coating material and preparation method thereof

The invention relates to a functional real stone paint building exterior wall coating material and a preparation method thereof. The functional real stone paint building exterior wall coating material is composed of the following components in parts by weight: deionized water, hydroxyethyl cellulose, an aqueous multifunctional addition agent, a real stone paint special silicone acrylic emulsion, a coalescing agent, an aqueous defoamer, a sterilizing corrosion remover, a hydrophobing agent and natural colored sand. The functional real stone paint building exterior wall coating material prepared by the invention is formed with one construction process and strong in covering power with surface covering-free performance, simultaneously is excellent in water resistance, stain resistance and weather resistance performance.

Owner:SKSHU PAINT

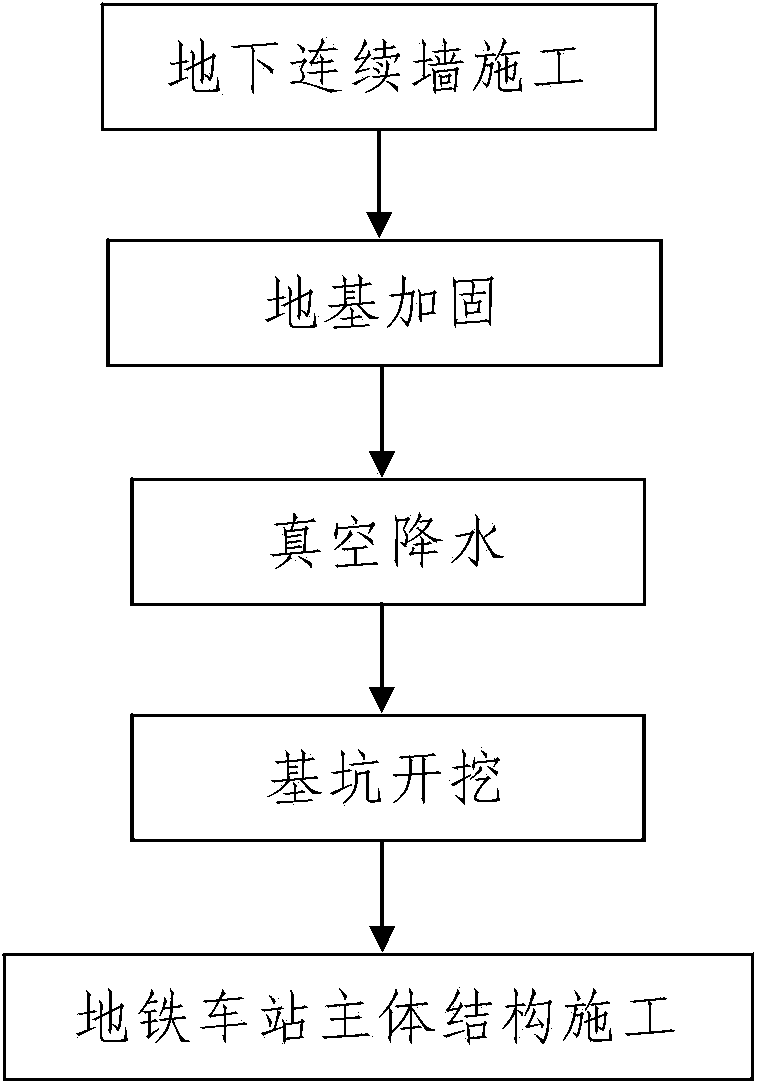

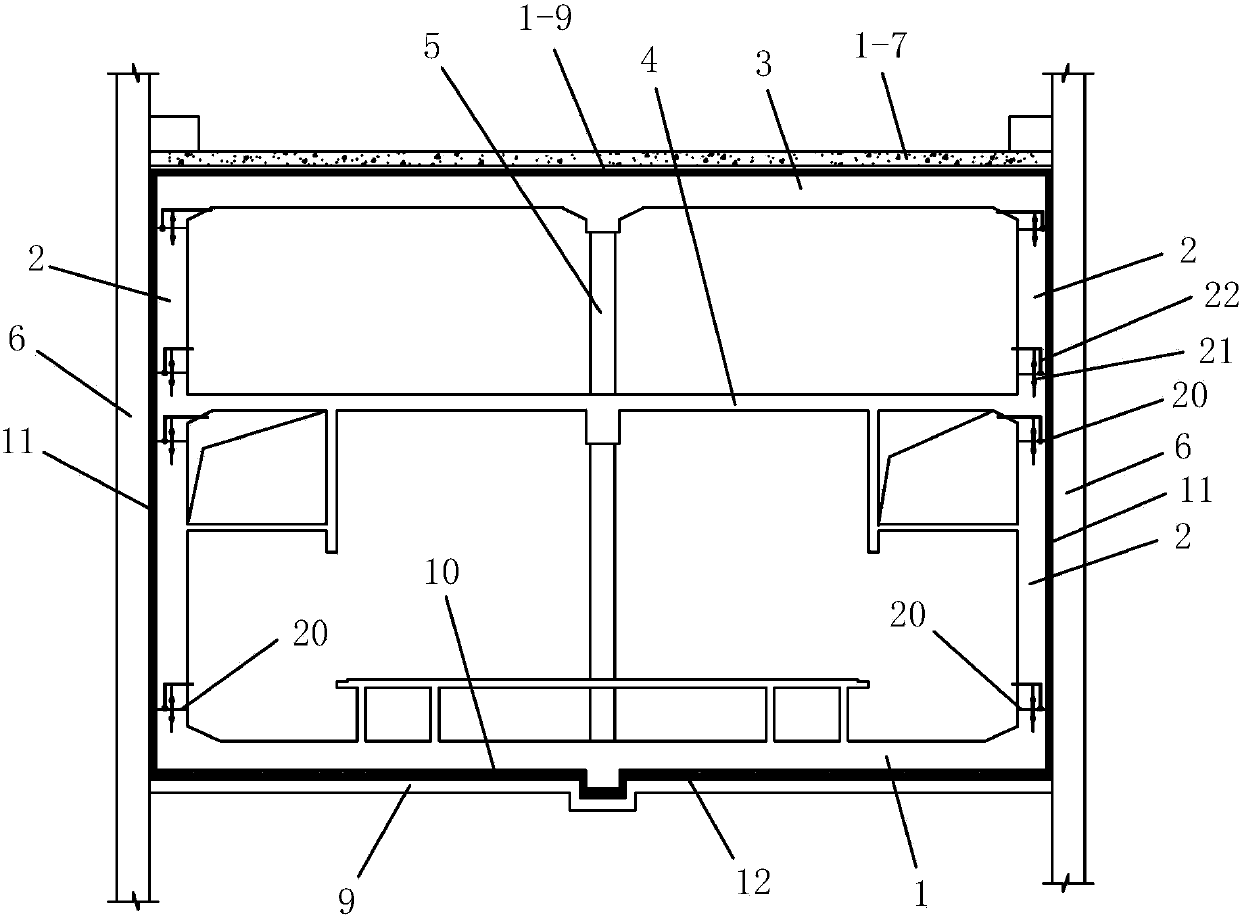

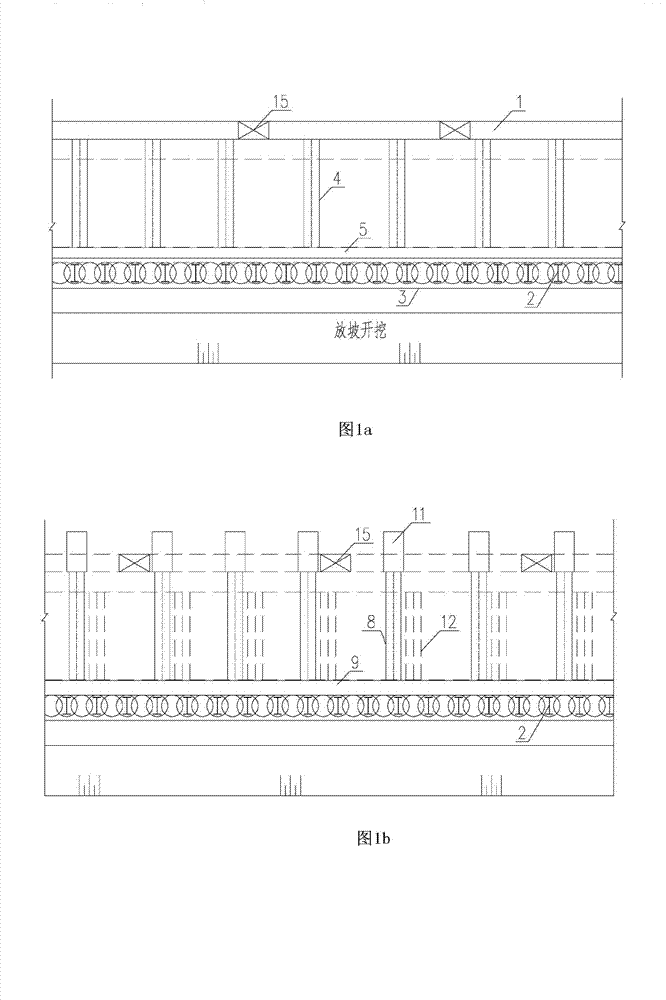

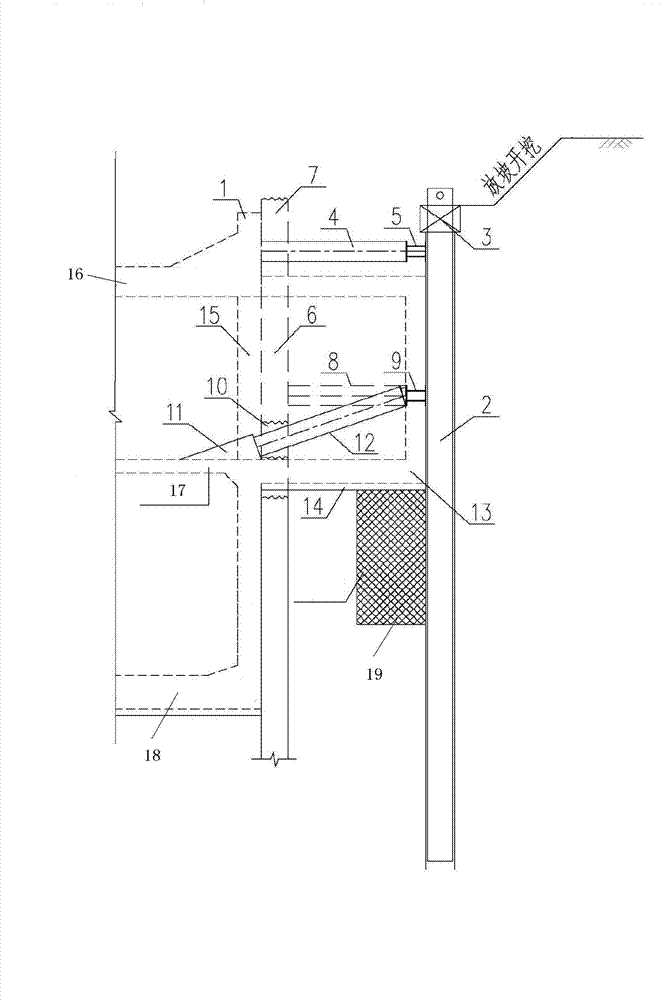

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

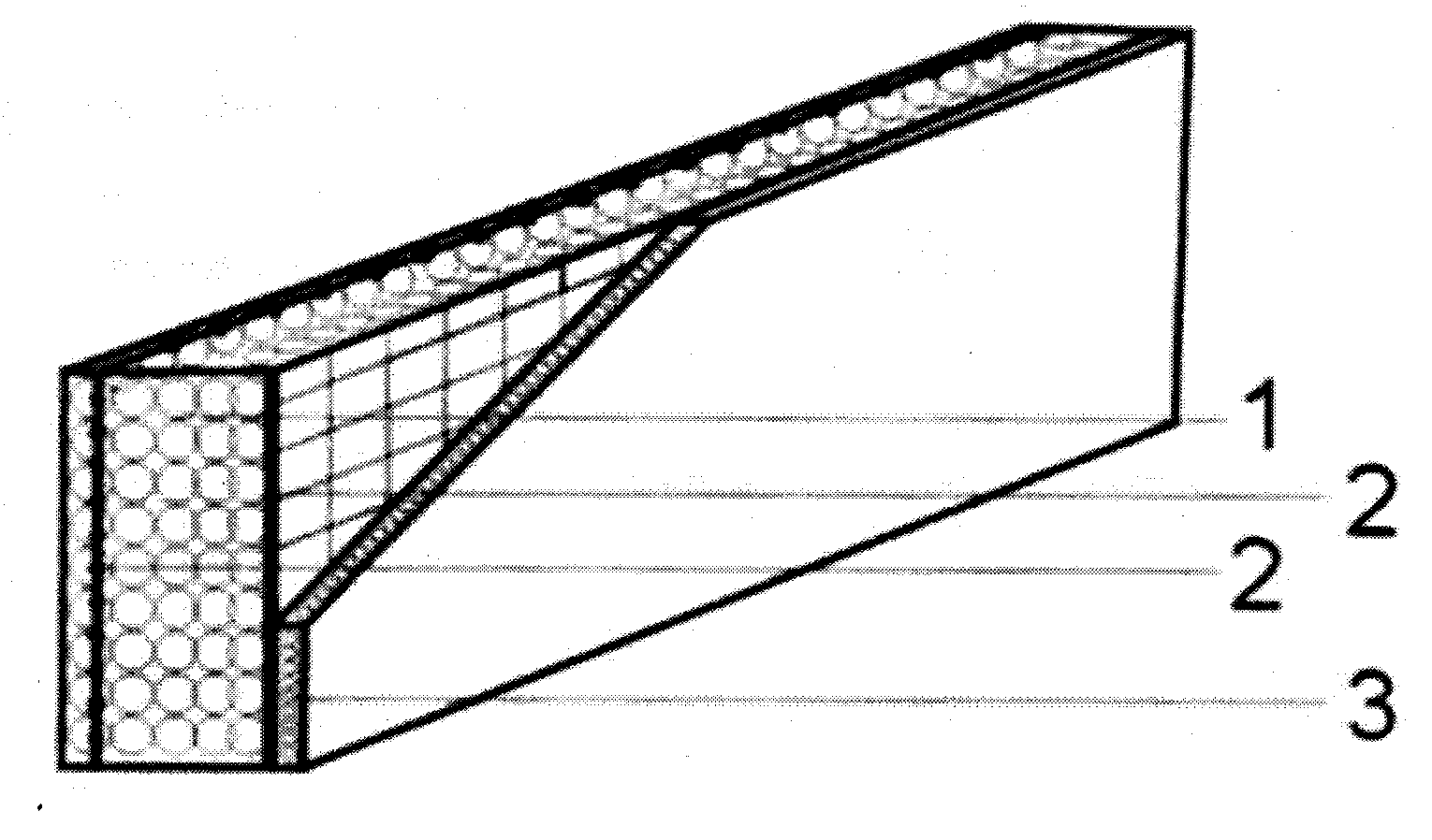

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501AReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

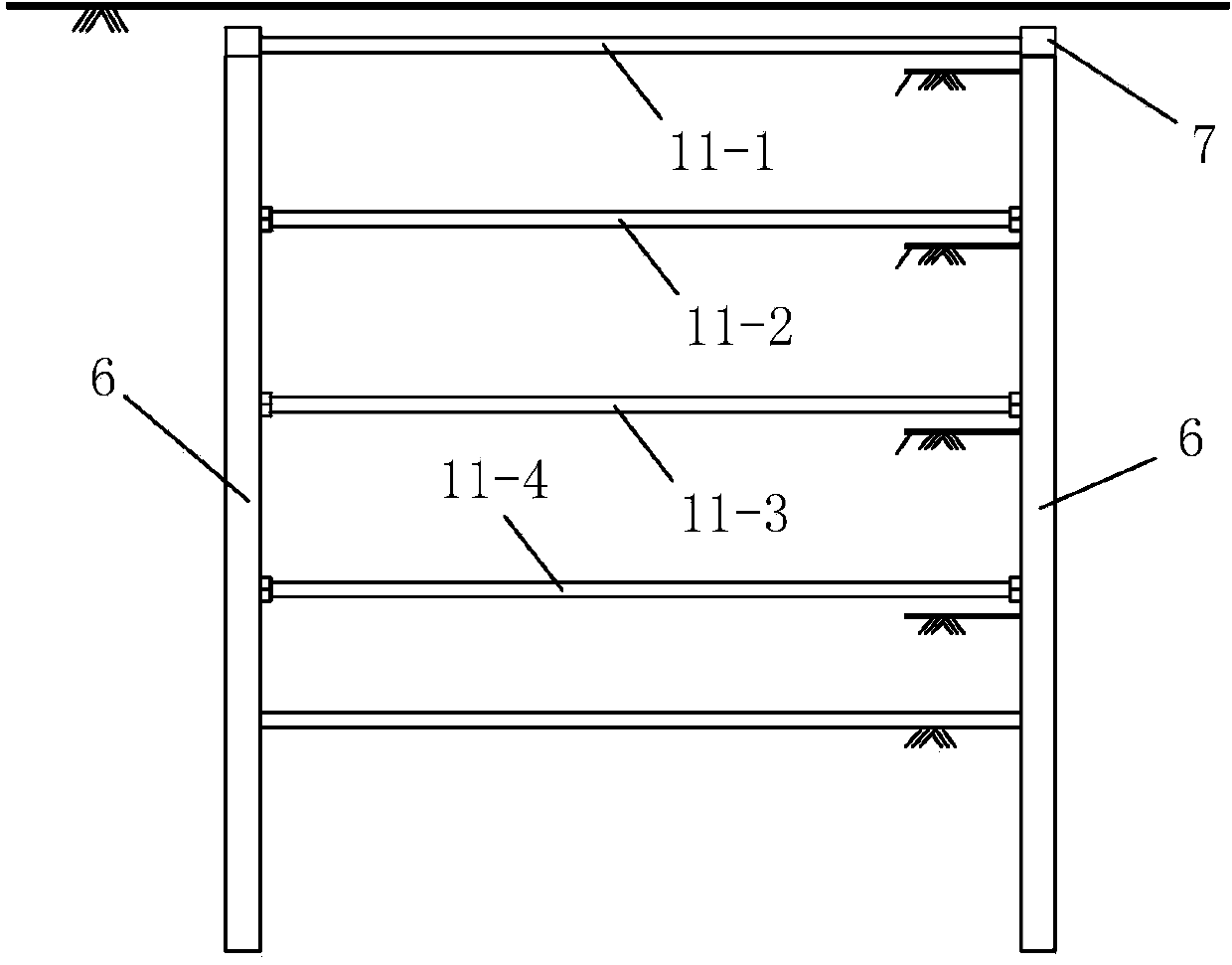

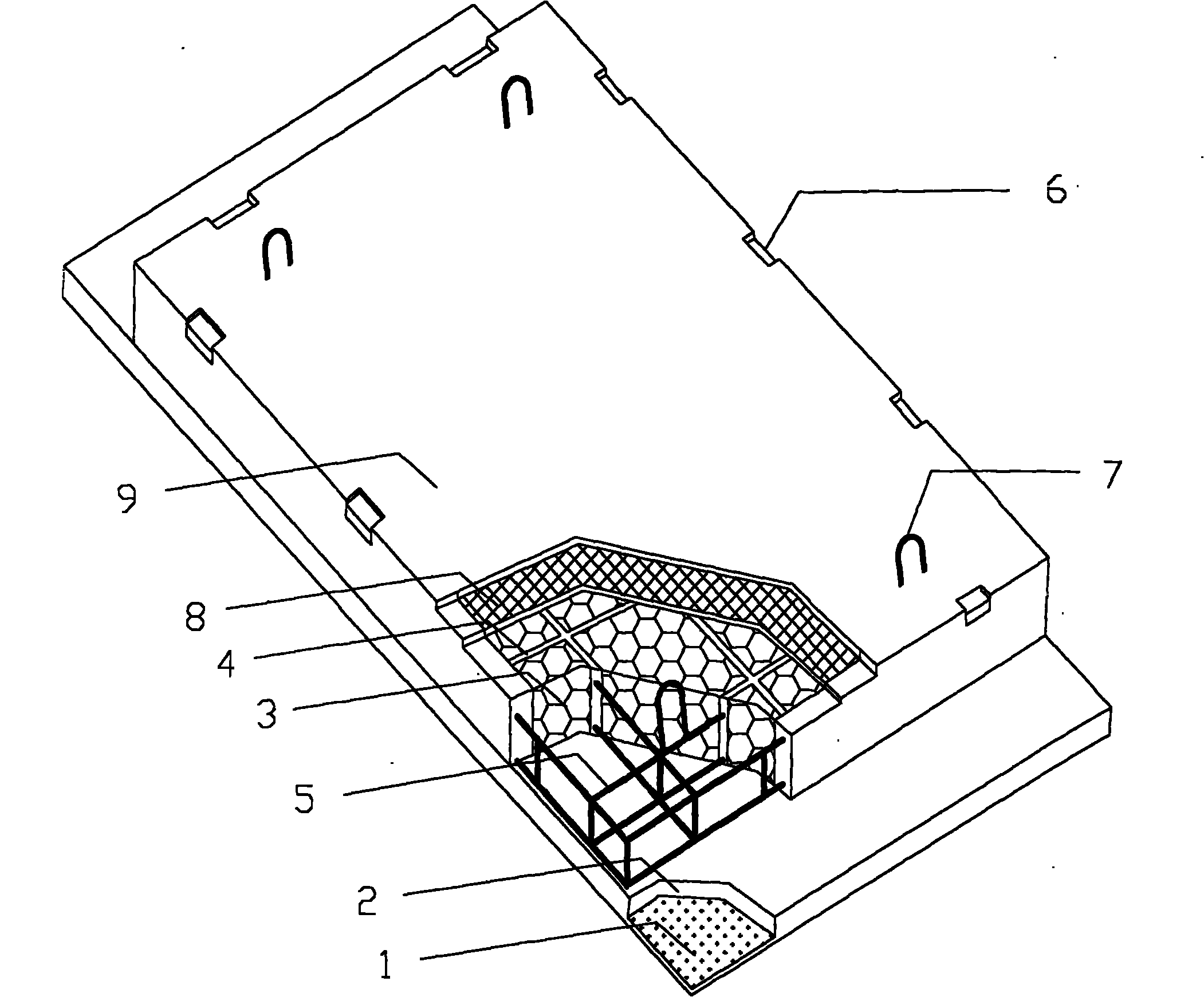

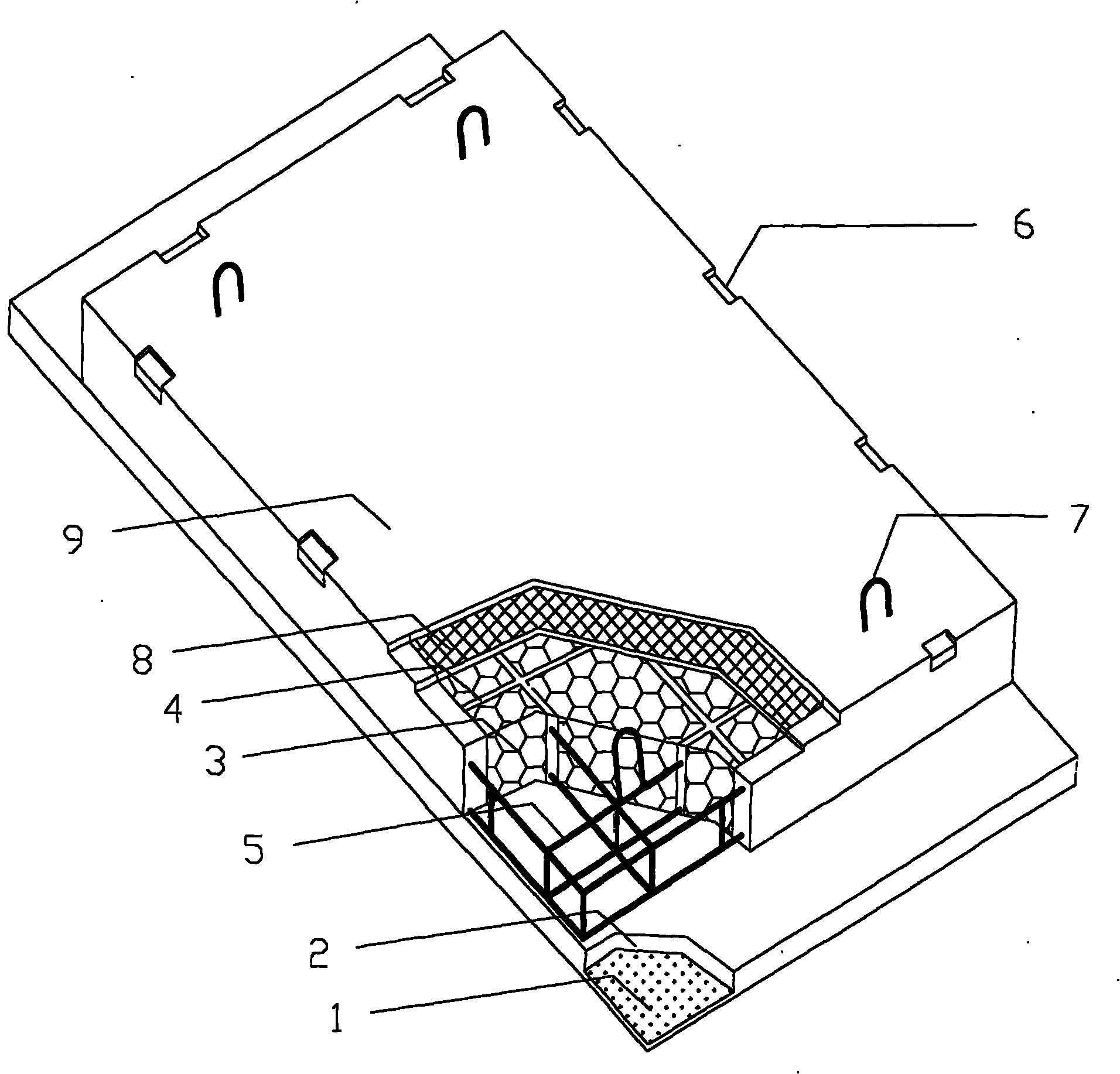

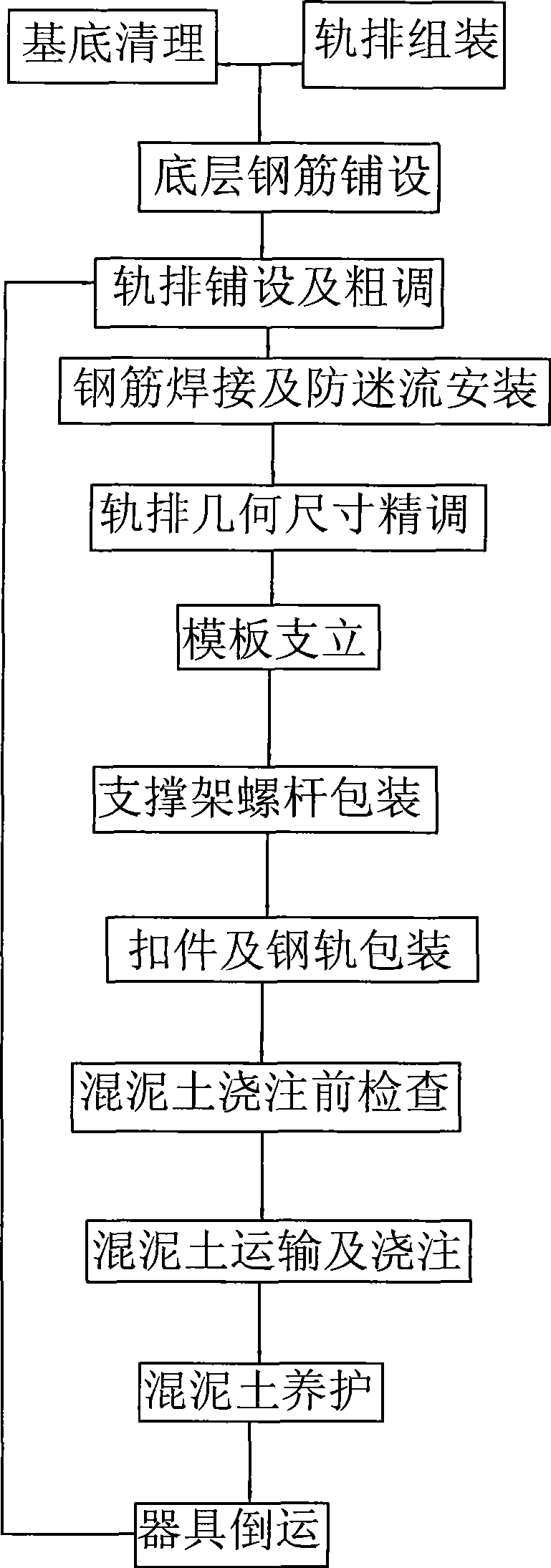

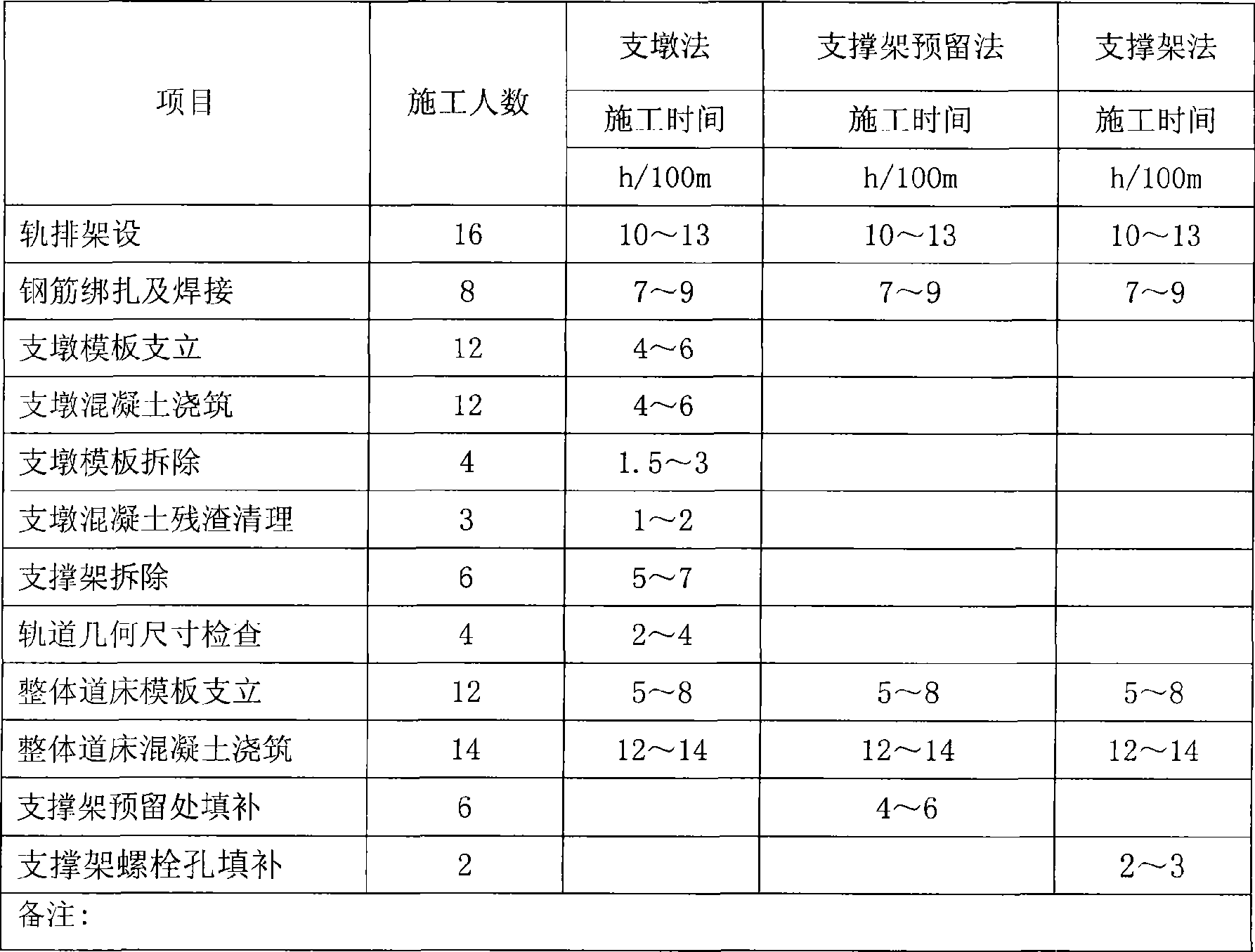

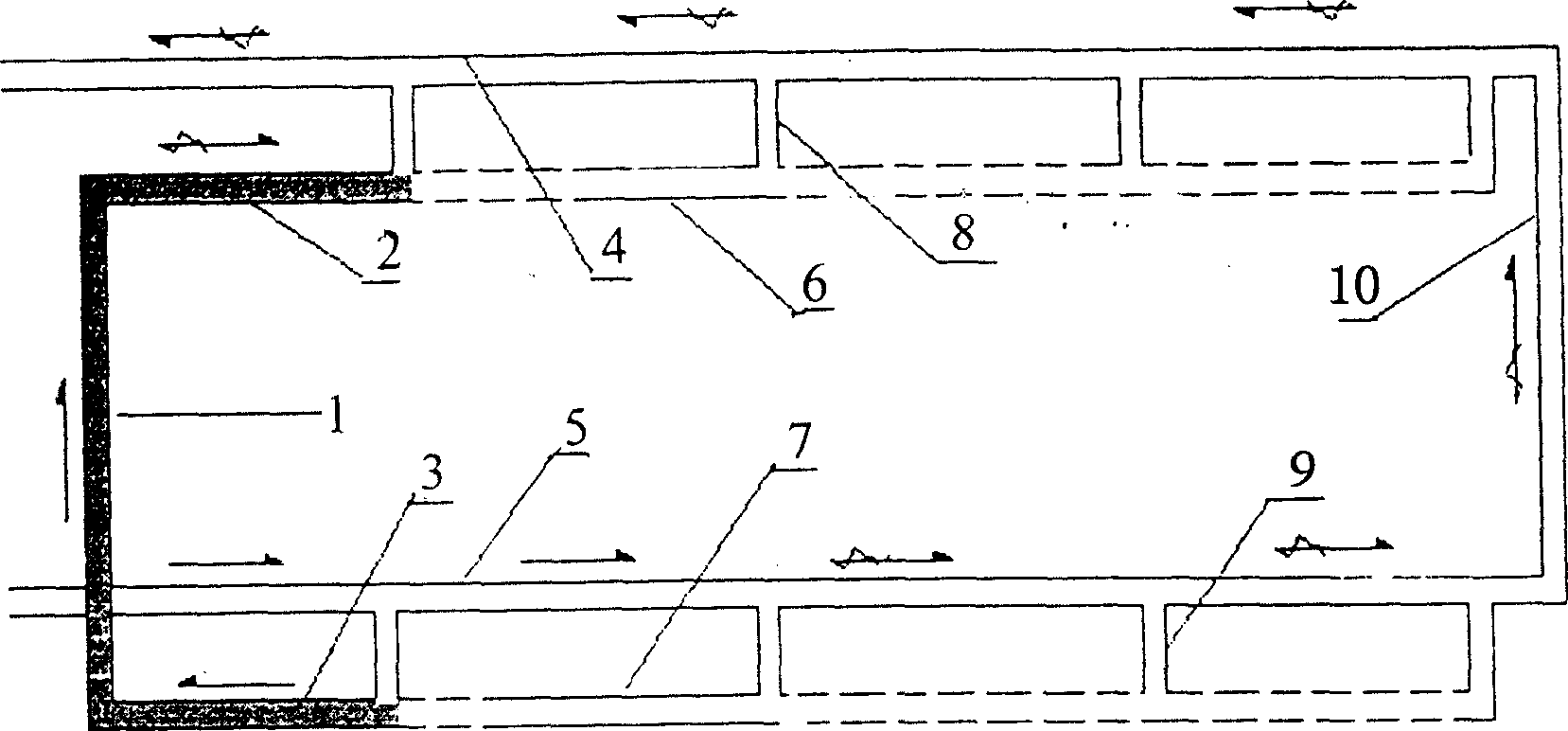

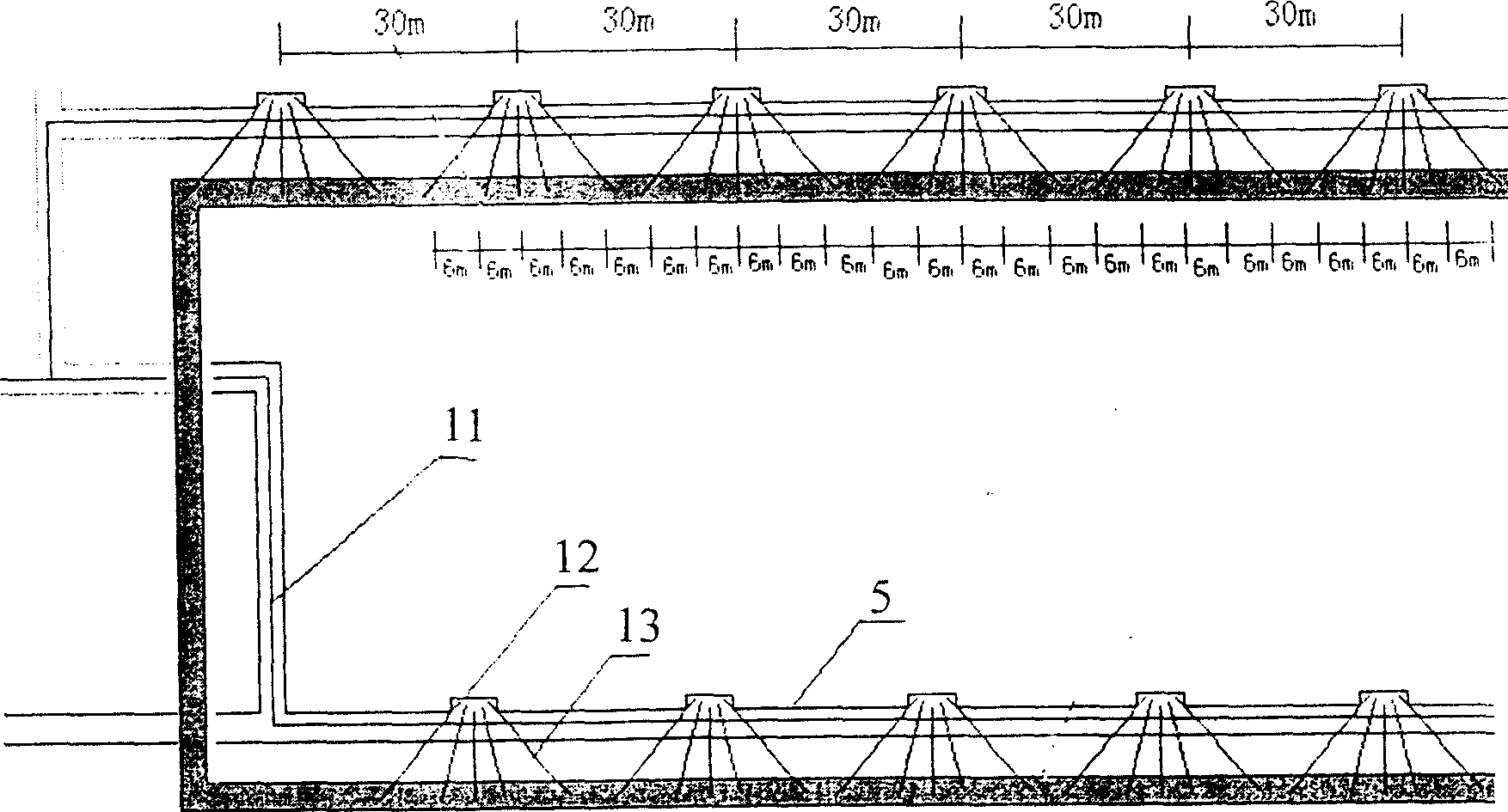

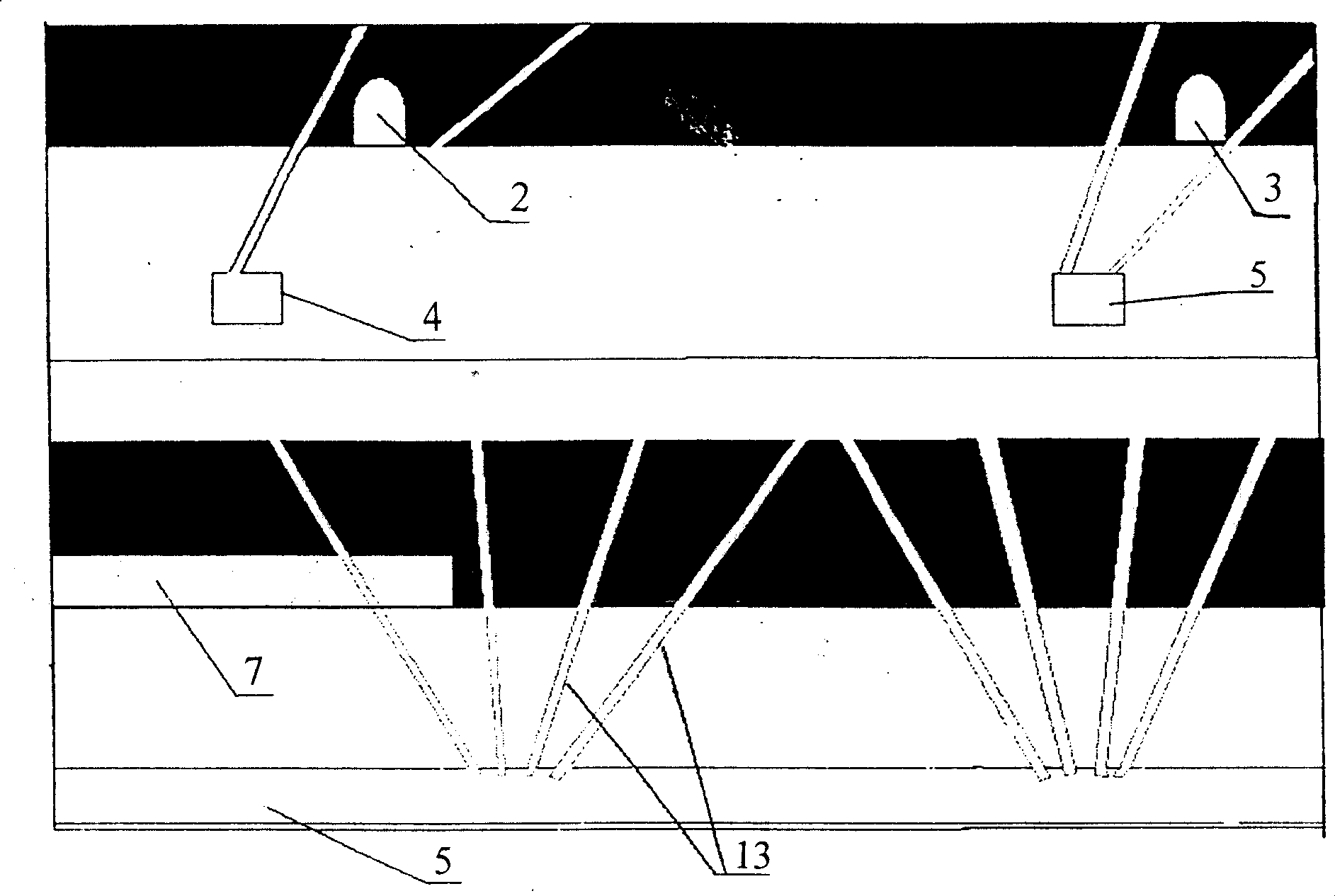

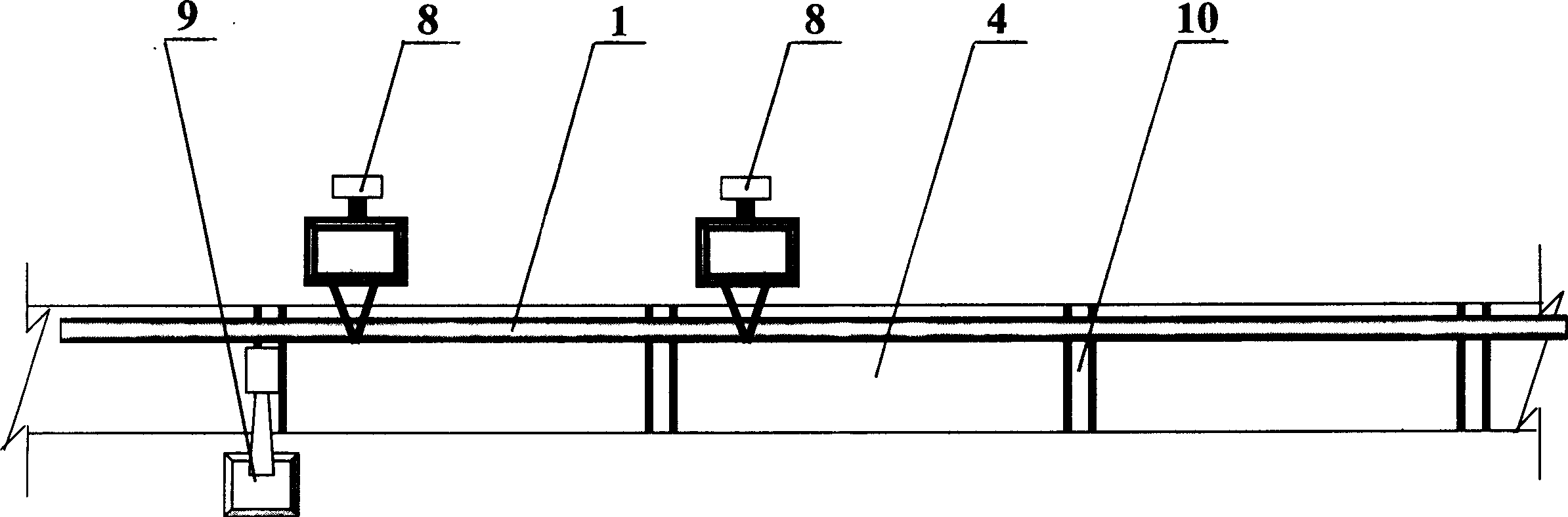

Construction method of monolithic road-bed in rail tunnel

ActiveCN101418535AReduce construction proceduresLow costRailway track constructionEngineeringLight rail

The invention discloses a method for constructing an integrated road bed of a track traffic tunnel, which is a supporting frame method for short. Firstly, a finished track panel assembled on a base is hoisted to the constructed tunnel; and the track panel of sleepers with different forms is born through adopting a supporting frame of a lower bearing type track panel; secondly, the track panel in the construction working face is hoisted to the designed elevation; the supporting frame of the track panel is mounted to support the track panel; a transverse supporting lever is utilized to approximately fix the direction of the track panel; and finally, according to fiducial mark, the elevation of track surface, the direction of the track, level and height are adjusted to the designed positions; after the binding and welding of concrete reinforcing bars and the erection of a template of the road bed are sequentially completed, and the integrated road bed is finally subjected to concrete pouring to obtain the integrated road bed; and the steps are sequentially advanced to complete the whole construction. The method reduces control links and material waste, improves construction schedule, ensures construction quality and is mainly used for the structural construction of undergrounds, light rails, tunnels, bridges, large-scale vehicle fields and other integrated road beds.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

'Three-soft' low permeability high gas coal seam rapidly digging method

InactiveCN101382073AImprove parsing speedImprove the pumping effectUnderground miningSurface miningPunchingPressure controlled ventilation

The invention discloses a method for rapidly digging 'three soft' low permeability and high gas coal layer, which comprises the steps of arranging a stone head in a bottom plate rock under the coal layer, and constructing pre-extracted penetrating drill holes of gas in the bottom plate rock layer and pulling the bit back to the bottom plate of the coal layer after the bit penetrates the coal layer, and punching the drill holes by pressure water with the depth of the punching holes being less than or equal to three meters, and the control radius of the punching holes being from two to six meters to realize continuously, draining gas in the holes, and stopping draining while the gas draining amount is at 0.1 cubic meter per hour; injecting water to the coal layer by using the drained gas drill holes, with water injection pressure controlled between ten to fifteen Mpa, and stopping water injection when the water injection effect reaches the demands of construction in coal layer; and draining goaf by the drill holes after extraction in mining face. The digging method increases the resolving speed of the 'three soft' low permeability coal layer gas, improves the gas draining effect and realizes the low gas construction in the high gas coal layer and one hole for three purposes, not only ensures the safety during construction, but also improves the digging speed in the roadway maximally.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Large-span tunnel excavation method for upper soft and lower hard compound strata

ActiveCN104879131AStrong excavation applicabilityEnsure construction safetyUnderground chambersTunnel liningRoad surfaceGeotextile

The present invention relates to a large-span tunnel excavation method for upper soft and lower hard compound strata. The present invention aims at providing a large-span tunnel excavation method for upper soft and lower hard compound strata so as to ensure large-span tunnel construction safety for the upper soft and lower hard compound strata, accelerate the construction progress and shorten the construction period. The technical scheme is that a tunnel is divided into upper and lower steps for excavation by the method, and the steps are as follows: a, determining a boundary of the upper soft and lower hard strata of an excavation surface according to geological prospecting data; b, constructing the upper step by using the center diaphragm method; c, constructing the lower step by using the method of reserving core soil; d, lagging the lower step with 2-3m headings at two sides; e, arranging earthwork cloth and an EVA waterproof board on a surface of a lower step inverted arch preliminary bracing, and pouring an inverted arch second lining; and f, dismounting a center diaphragm temporary bracing of the upper step and a temporary inverted arch of the upper step with segments, and pouring a pavement lining close to a preliminary bracing of the upper step and preliminary bracings of the headings at the two sides of the lower step. The large-span tunnel excavation method is applied to the technical field of tunnel construction.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

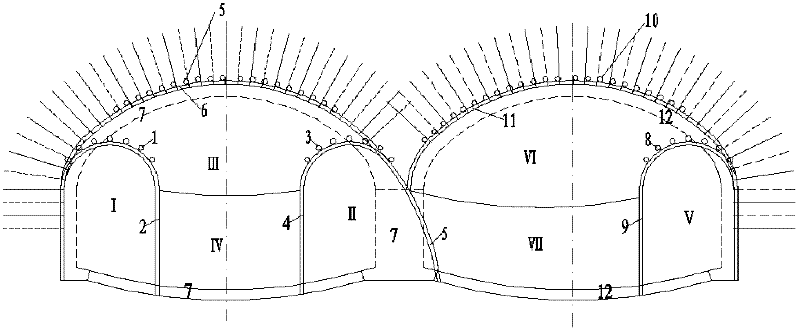

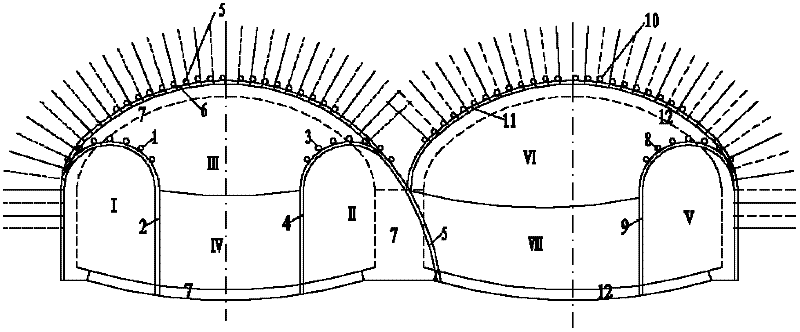

Rapid construction method of weak surrounding rock large-section multi-arc tunnel

InactiveCN102373930AImprove construction progressShorten the construction periodUnderground chambersTunnel liningStructure of the EarthRapid construction

The invention discloses a rapid construction method of a weak surrounding rock large-section multi-arc tunnel. According to the invention, in tunnel construction, the main tunnel on one side of the multi-arc tunnel and the place of a partition wall are synchronously excavated; the tunnel excavation is implemented by using a double side-wall heading method; then, a primary support and the partition wall are constructed before the secondary lining of the tunnel; and finally, the main tunnel on the other side of the multi-arc tunnel is excavated by using a single side-wall heading method, and a corresponding support structure is built. Compared with the traditional multi-arc tunnel construction method, the construction method disclosed by the invention does not need to cut through a middle guide tunnel and build the partition wall before excavating the main tunnels on the two sides, thereby greatly accelerating the construction of the multi-arc tunnel, shortening the construction period and properly lowering the construction cost.

Owner:CENT SOUTH UNIV

Construction method of railway tunnel lining side wall concrete

ActiveCN101586464ASimple structureQuality improvementUnderground chambersTunnel liningRailway tunnelHydraulic cylinder

The invention provides a construction method of railway tunnel lining side wall concrete. Firstly concrete for an inverted arch and the inner part of the inverted arch is constructed, then sleepers are placed, and a lining trolley traveling track is laid; a lining trolley is moved to a place to be lined, molding boards are connected to the top of a gantry, and end of hydraulic oil cylinders and jacks at two sides; the side hydraulic oil cylinders at two sides are started to regulate the molding boards at two sides of the lining trolley to the design positions, and all side jacks are locked to fix the side molding boards; short side wall molding boards at two sides of a tunnel are respectively mounted, the upper end heads of the short side wall molding boards are connected with the lower ends of arc-shaped molding boards at two sides to form a molding board assembly, and the molding board assembly is mounted at one end of the jack on a water groove side wall to be mounted with one side of the short side wall molding board; and then the concrete is cast and lined, and the cast lined concrete is dismounted with the mold after reaching the strength of mold removal. The construction method reduces procedures and shortens the erection time, saves the construction cost, and enhances the structure of the tunnel lining side wall and improves the external quality.

Owner:NO 1 ENG CO LTD OF CR11BG +1

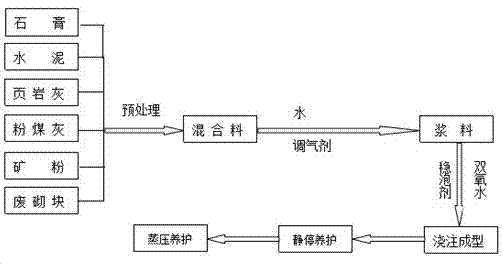

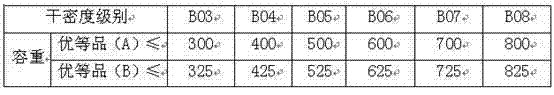

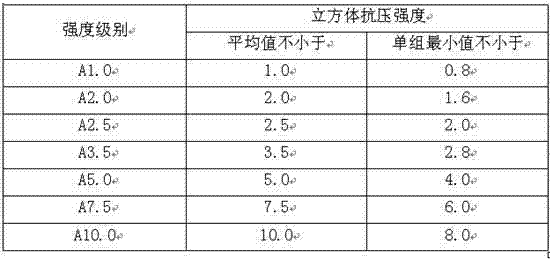

Aerated concrete block and preparation method thereof

The invention belongs to the technical field of building materials and particularly relates to an aerated concrete block and a preparation method thereof. The technical scheme is as follows: the aerated concrete block comprises the following components in parts by weight: 20-50 parts of cement, 20-55 parts of shale ash, 10-40 parts of mineral powder, 0.08-0.12 part of foam stabilizer, 0.5-3 parts of natural gypsum and 3-7 parts of hydrogen peroxide, wherein the ratio of water to material is 0.58-0.65. The heat self-preservation aerated concrete block prepared by the invention has the low volume weight of 200-500kg / m<3>, the heat conductivity coefficient of 0.06-0.12W / m.k and the compensative strength of 0.8-3MPa, and various indexes such as fire resistance, freezing resistance and the like of the aerated concrete block can be up to the national traditional autoclaved aerated concrete standard.

Owner:UNIV OF JINAN

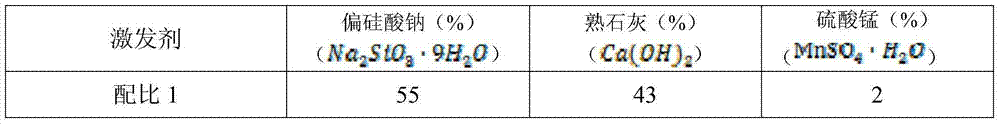

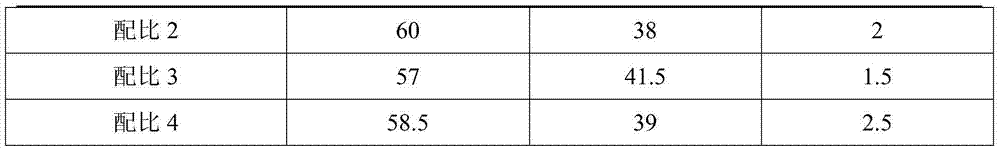

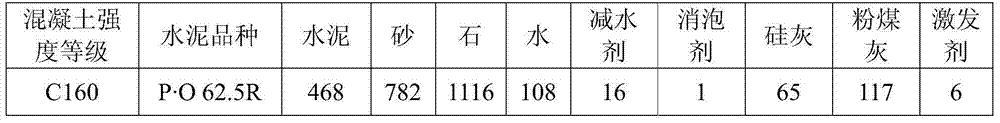

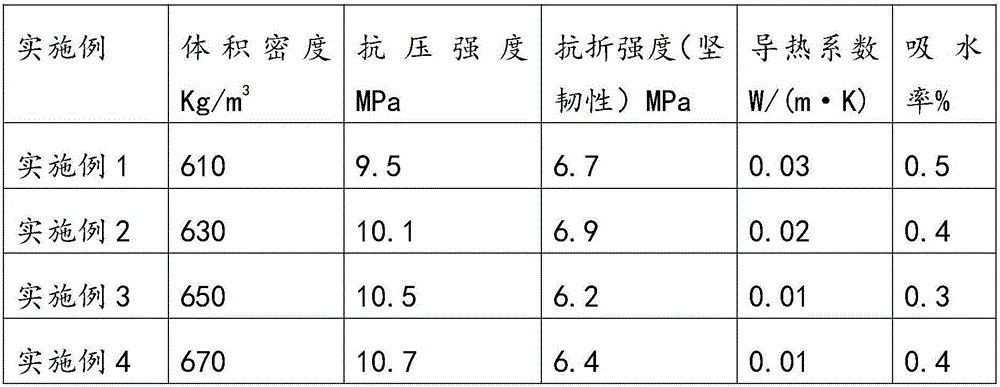

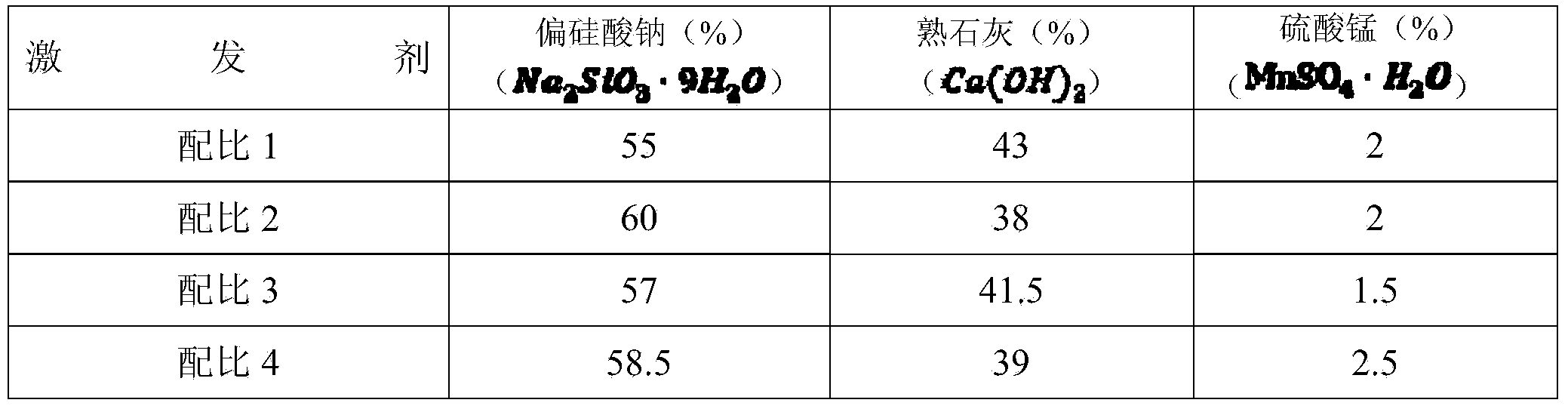

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

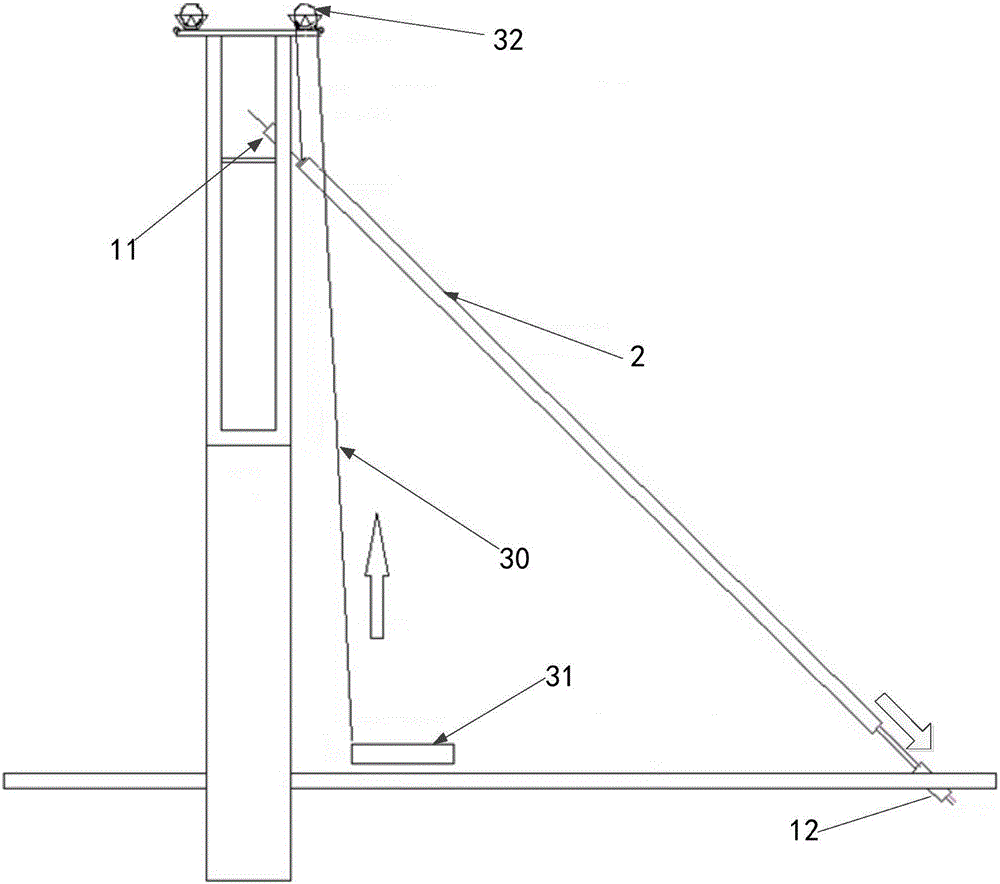

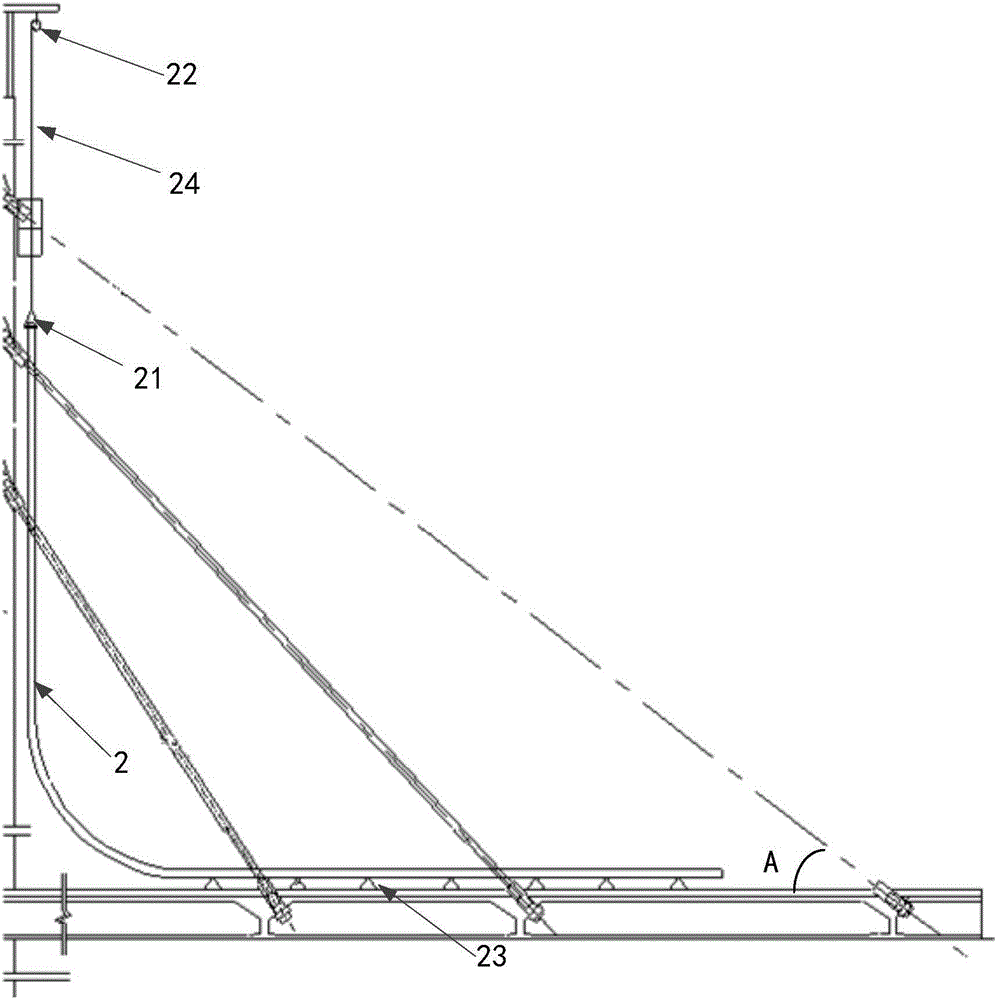

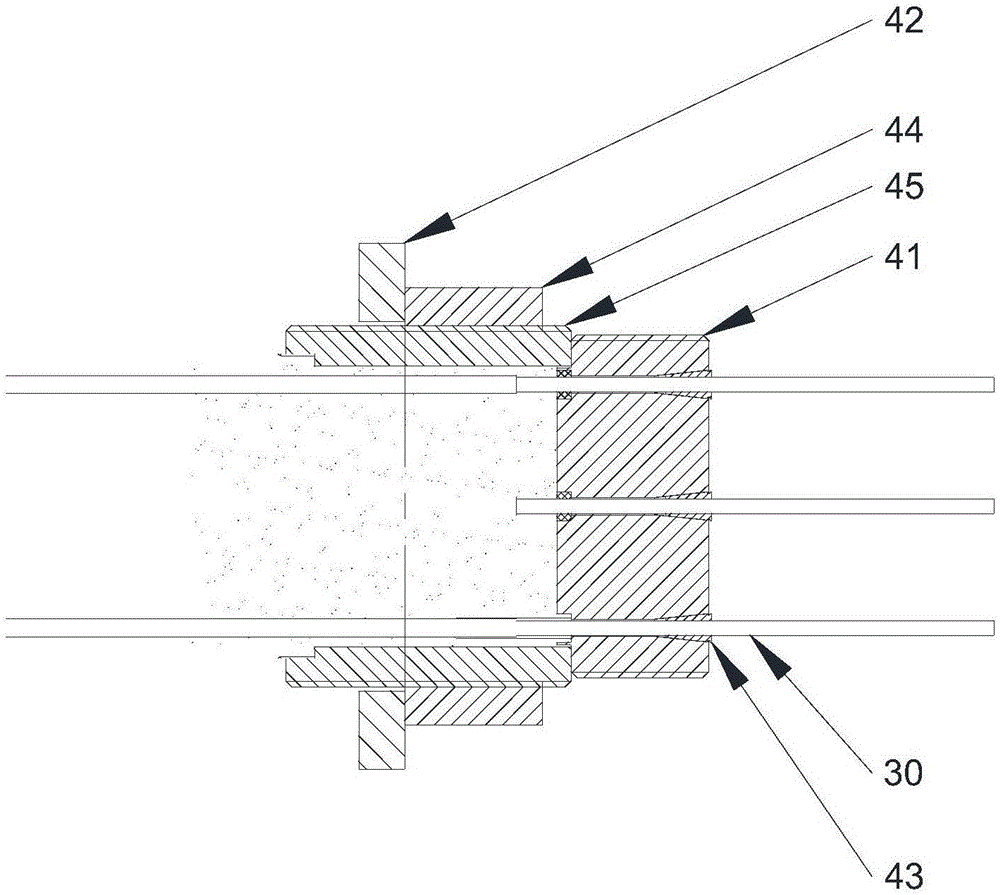

Mounting method of stayed cable of cable-stayed bridge

InactiveCN106592441AReduce loadReduce tractionCable-stayed bridgeBridge structural detailsCable stayedTower

The invention discloses a mounting method of a stayed cable of a cable-stayed bridge. The mounting method comprises the following steps that an under-girder anchoring device is mounted on a main girder section; a tower-end anchoring device is mounted on a cable bent tower; a stayed cable outer protection sleeve is hoisted and lifted and laid with a preset angle, and the stayed cable outer protection sleeve is collinearly arranged with the under-girder anchoring device and the tower end anchoring device which are relative to the stayed cable anchor; steel stranded wires penetrate through the outer protection sleeve one by one from the tower end to the beam end, and the two ends of each steel stranded wire are anchored on the under-girder anchoring device and the tower end anchoring device correspondingly; and the stayed cable is integrally tensioned. According to the explosive-removing unmanned aerial vehicle, the steel stranded wires penetrate through the outer protection sleeve from top to bottom, so that in the hoisting process of the steel stranded wires, the needed tractive force is reduced, construction procedures are reduced, construction time is saved, and meanwhile, abrasion to the outer protection sleeve is reduced.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Finishing compound foam ceramic based on granite tailings and preparation method of same

InactiveCN106187087AReduce construction proceduresReduce construction costsCeramic materials productionCeramicwareFritGranolithic

The invention discloses a finishing compound foam ceramic based on granite tailings and a preparation method of same. The finishing compound foam ceramic includes a finishing layer and foam ceramic, wherein the finishing layer includes: 55-85% of high-permeability frits, 5-20% of clay, and 0-10% of an inorganic pigment; the foam ceramic includes 60-90% of the granite tailings, 10-25% of clay, 1-10% of a fluxing agent, 1-10% of a foamer, 0.5-2% of a stabilizer and 0-2% of a peptizer. The preparation method includes the steps of: respectively preparing the finishing layer and the foam ceramic, and preparing the finishing compound foam ceramic through a reverse pavement method. The finishing layer and the foam ceramic are integrated, so that an extra decorative process after a heat insulation material is pasted onto external walls is avoided. The material not only reduces construction processes but also saves a large amount of cost, and greatly reduces construction cost and difficulty.

Owner:深圳超超科技控股有限公司

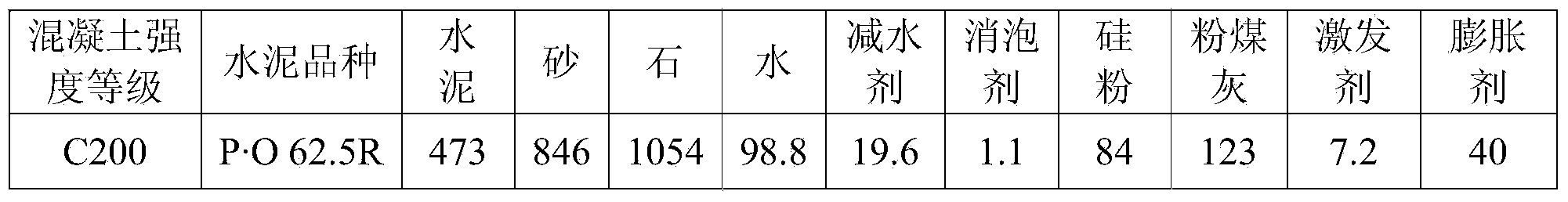

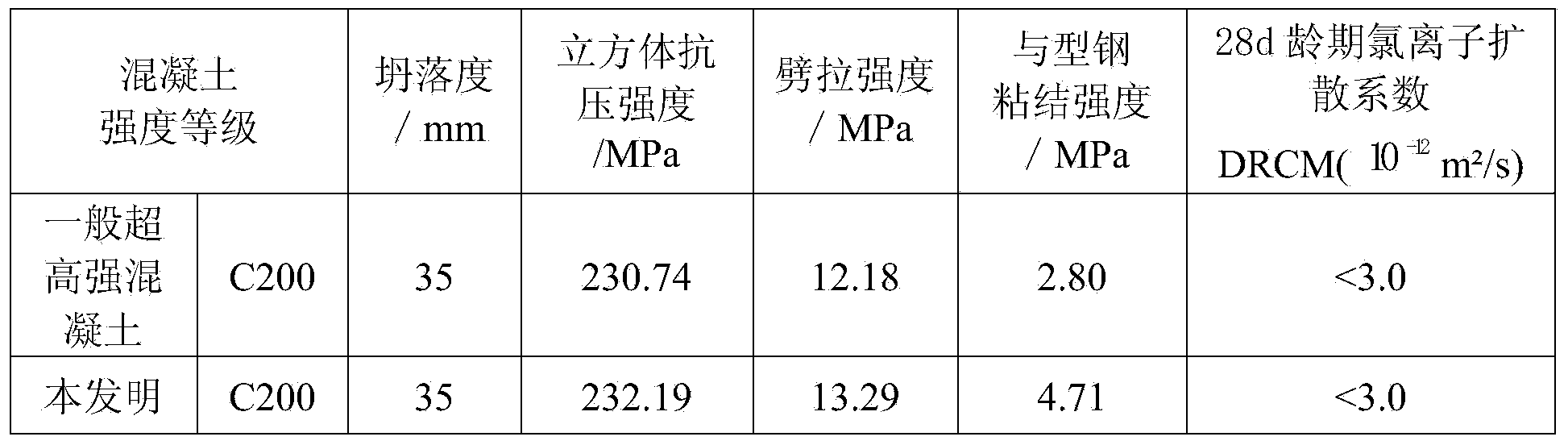

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

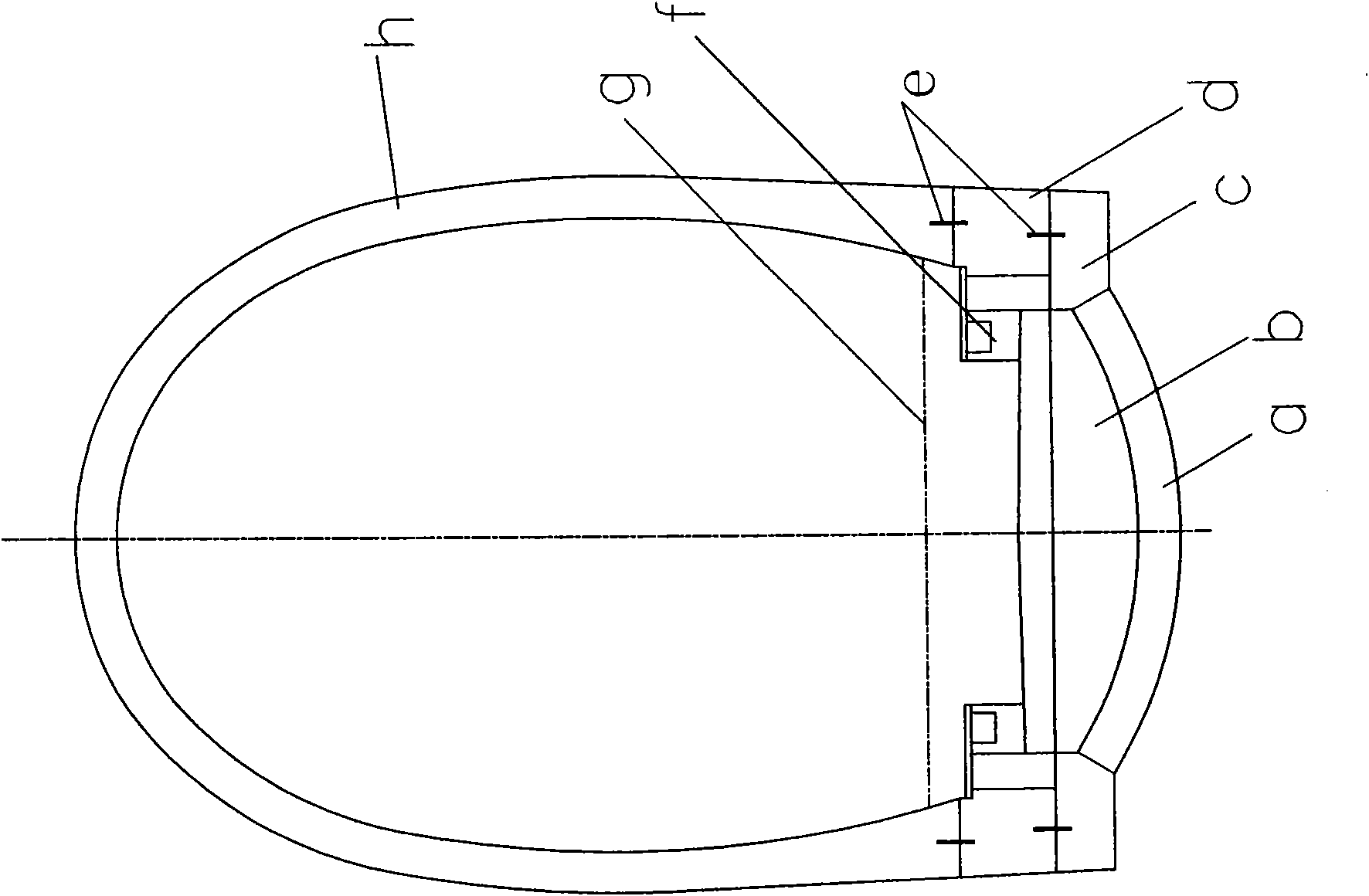

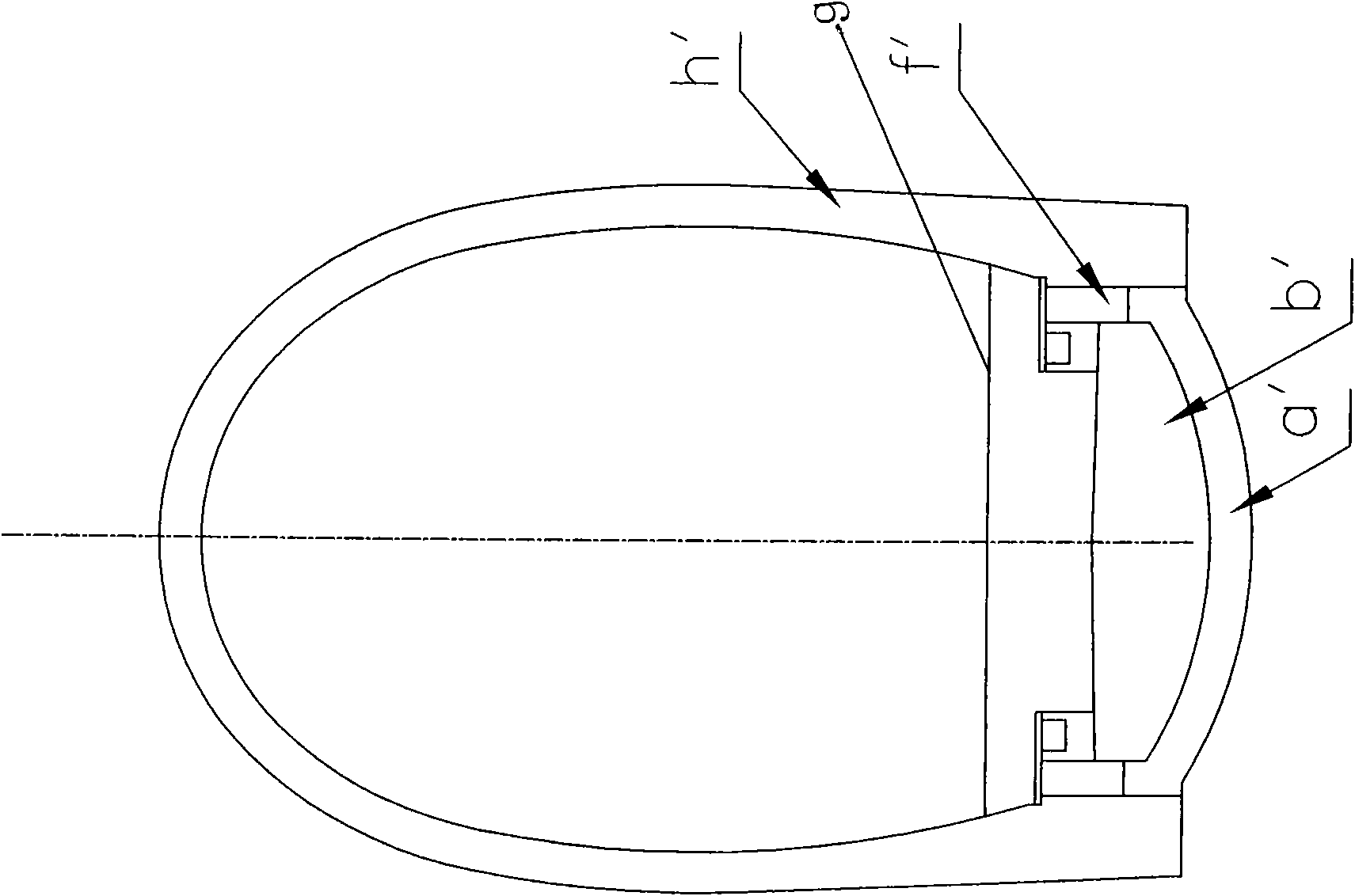

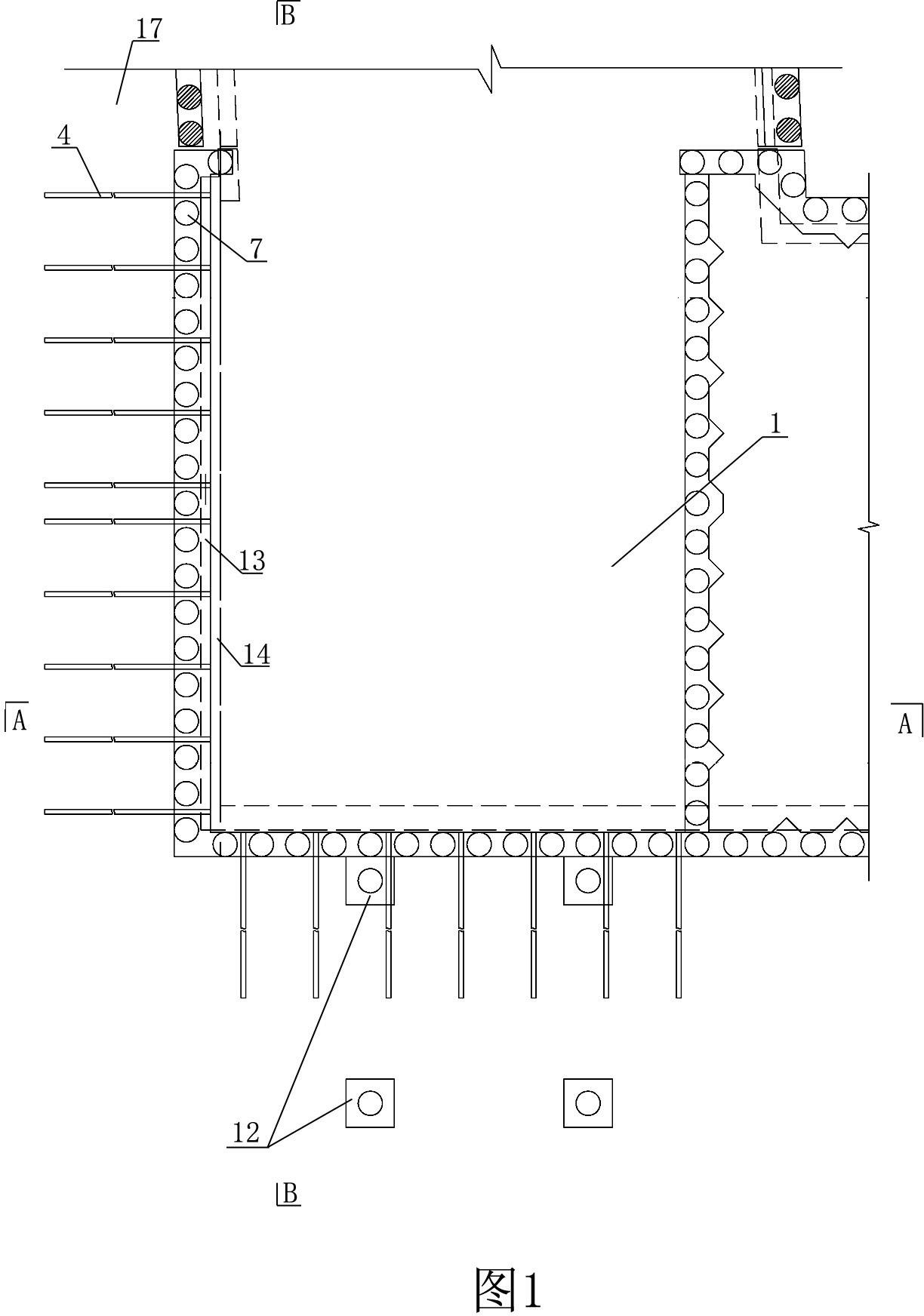

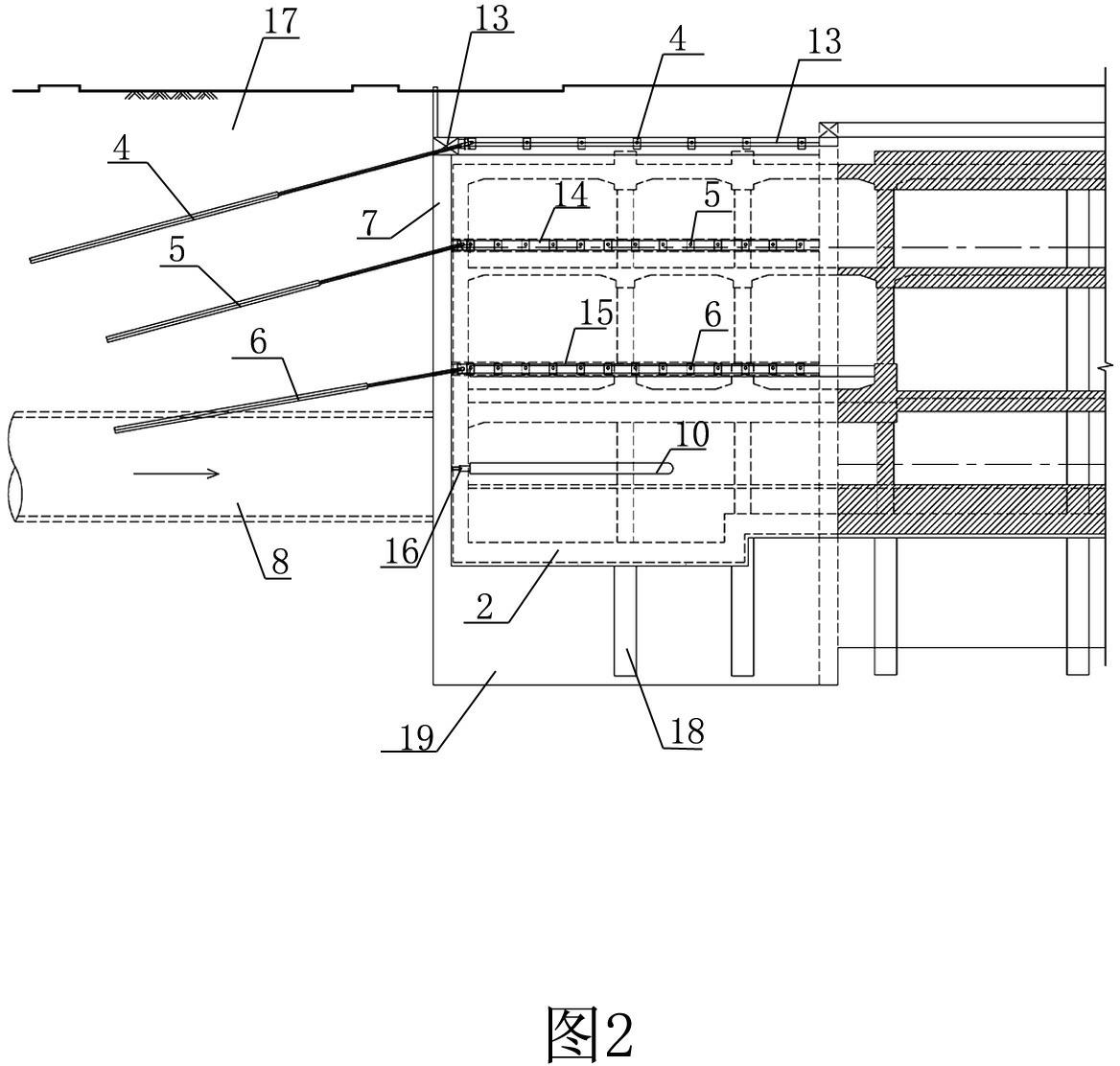

Super early receiving supporting structure of shield machine and super early receiving method

ActiveCN102322269AAchieve early receiptReduce construction proceduresTunnelsShield machineBuilding construction

The invention relates to a super early receiving supporting structure of a shield machine and a super early receiving method. The super early receiving supporting structure is characterized by comprising a receiving well foundation pit wall support, a bottom plate support and an outlet hole support, wherein the receiving well foundation pit wall support comprises a foundation pit envelope pile, at least two anchor cables and a steel pipe corner support; the outlet hole support is a temporary horizontal support; and the bottom plate support comprises an anti-pulling pile and a concrete bottom plate paved on a foundation pit bottom soil mass. By the super early receiving supporting structure and the super early receiving method, the construction problem that the shield machine cannot be received in advance when the shield machine arrives at a station in advance is successfully solved, the service life of the shield machine is prolonged, the construction cost of a shield interval is saved, and the construction period is shortened. The structure and the method can be applied to the advanced receiving of the shield machine when a receiving well structure is not completely constructed or finished.

Owner:北京城乡建设集团有限责任公司

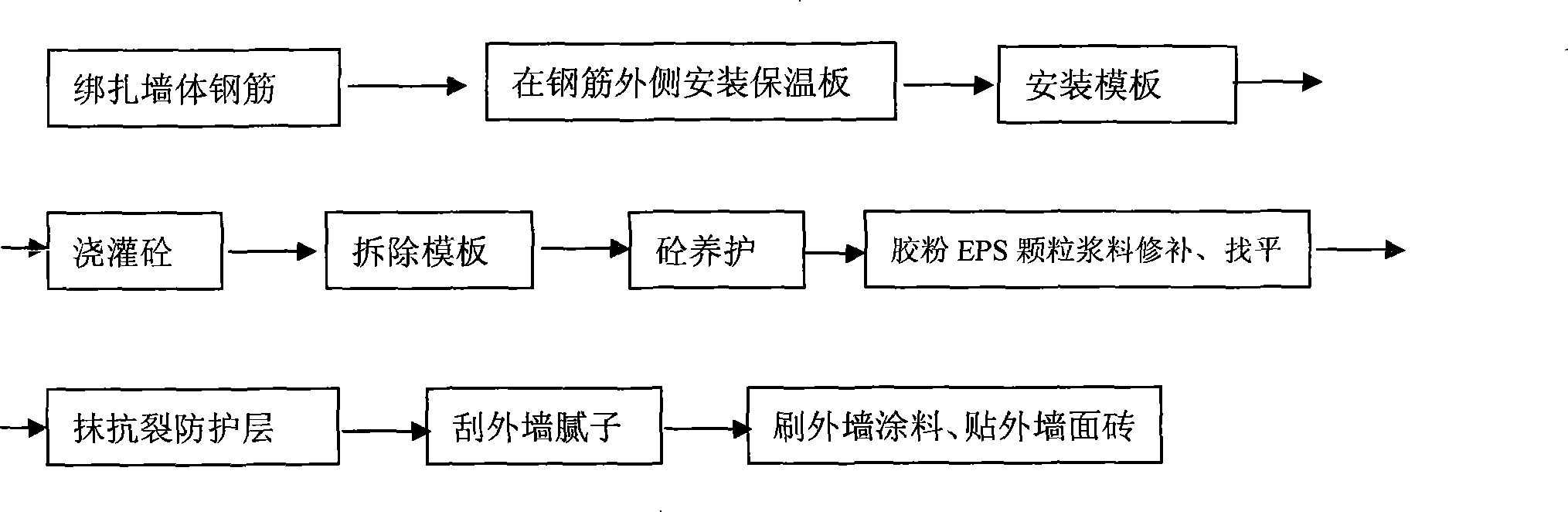

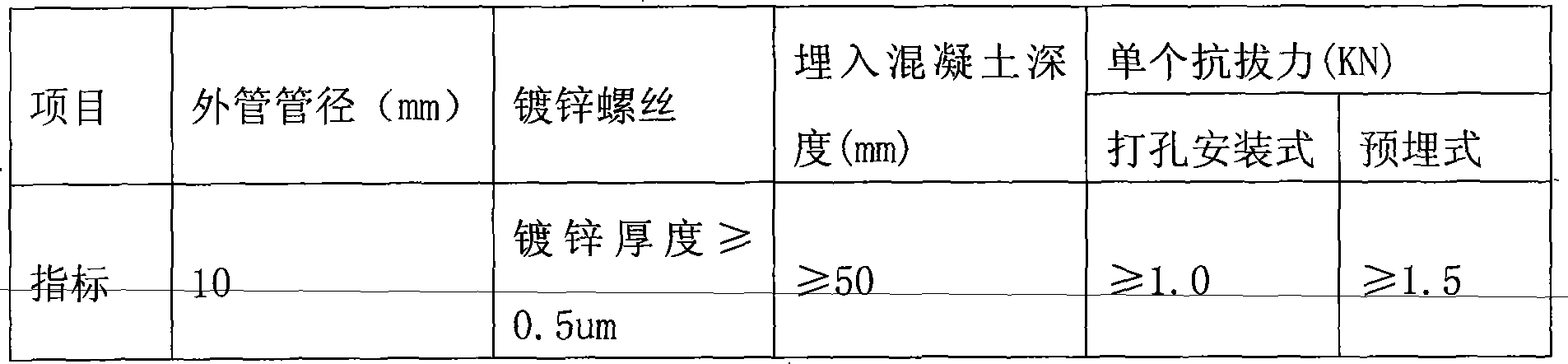

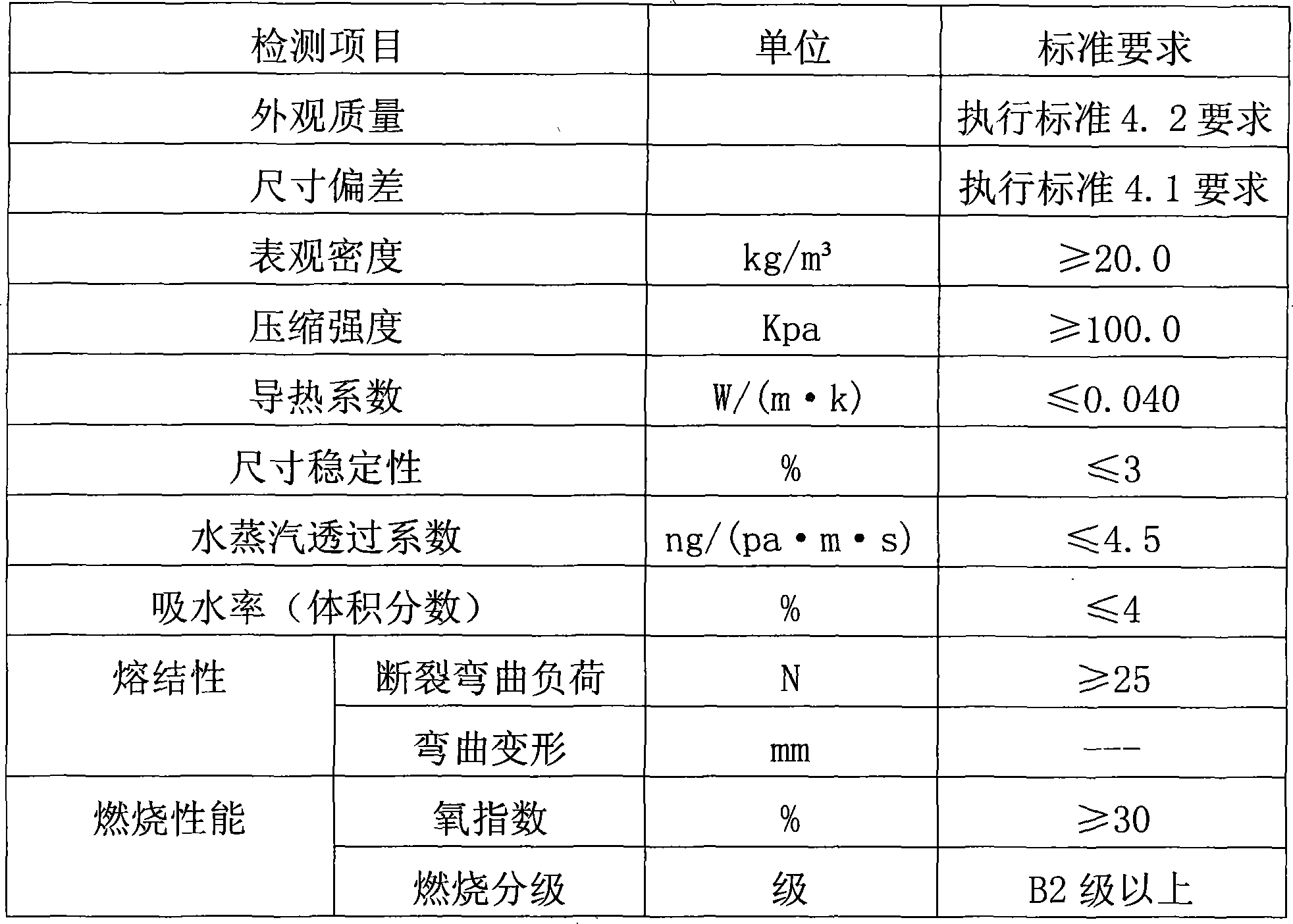

Non-net polyphenyl plate cast-in-place concrete exterior wall heat-preserving construction method

The invention relates to an exterior wall insulation construction method of composite cast-in-site concrete with non-reinforcing mesh polystyrene board, which can effectively solve the problems of the exterior walls with high quality, high speed, and low cost in the construction. The exterior wall insulation construction method is characterized in that: a flame retardant polystyrene board with concave and convex tooth sockets on one surface serves as the thermal insulation material for the cast-in-site concrete exterior wall; steel bars of the wall body are bundled; the polystyrene board is arranged on the outer side of the bundled steel bars of the wall body; an insulation board and a formwork are installed; the polystyrene board is penetrated by clips of the polystyrene board; the clips and the steel bars of the wall body are bundled and fixed by bundled iron wires; after the concrete is cast, dovetail grooves of the polystyrene board are fixedly combined with the concrete; after the formwork is removed, maintenance is carried out, and then repair and leveling are conducted through gelatin powder; after an anti-crack protection layer is coated and exterior wall putty is scraped, coating is made or face bricks of the exterior wall are constructed, so as to improve the application effect. As the polystyrene board and wall body are fixedly combined as a whole for once, the existing surface-sticking process for the insulation board and the wall body is omitted, thereby the construction procedure is reduced, the construction period is shortened, and the economic and social benefits are great.

Owner:HENAN GUOJI CONSTR GRP

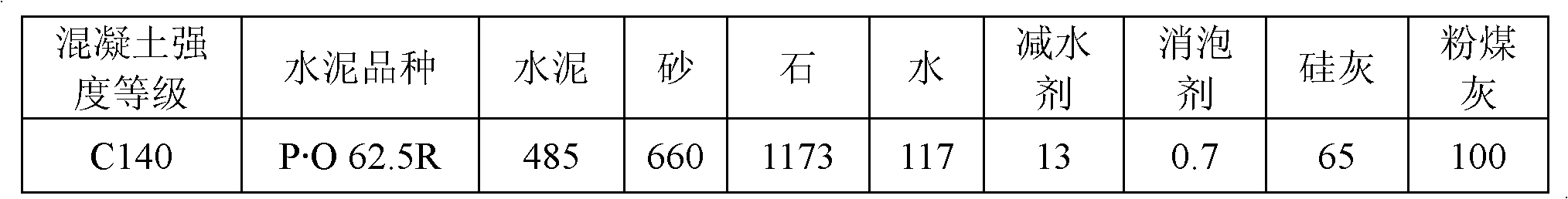

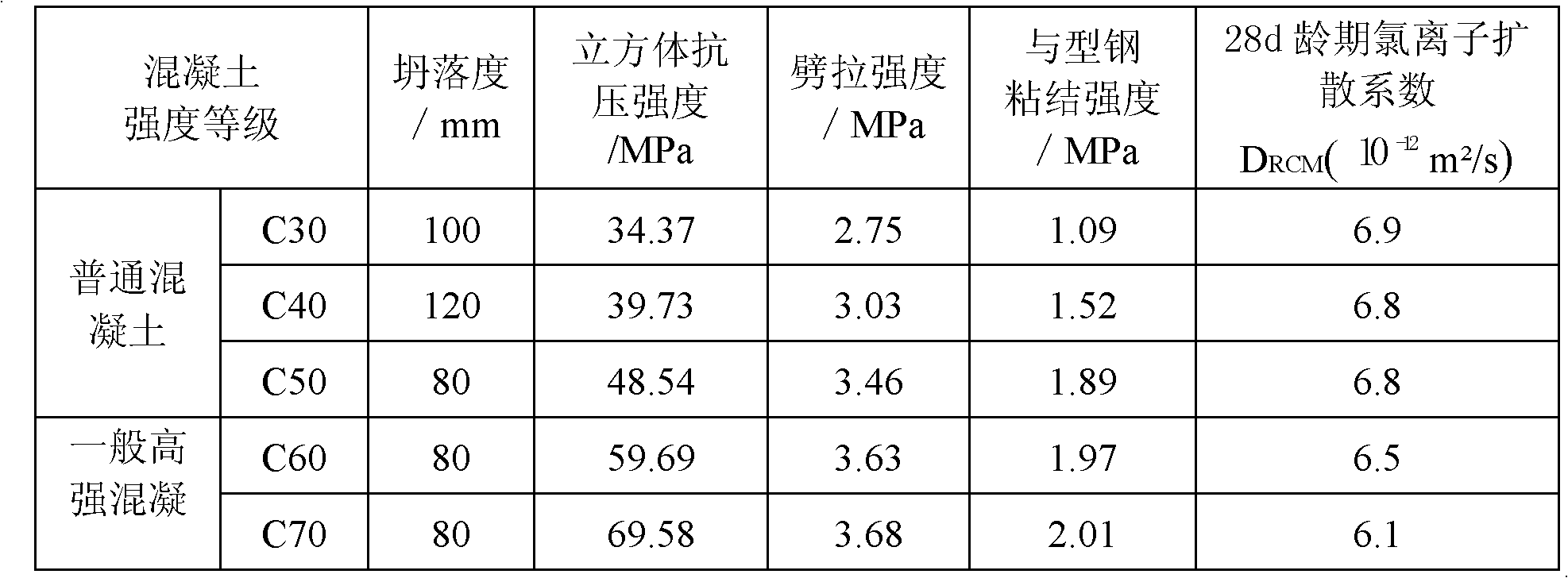

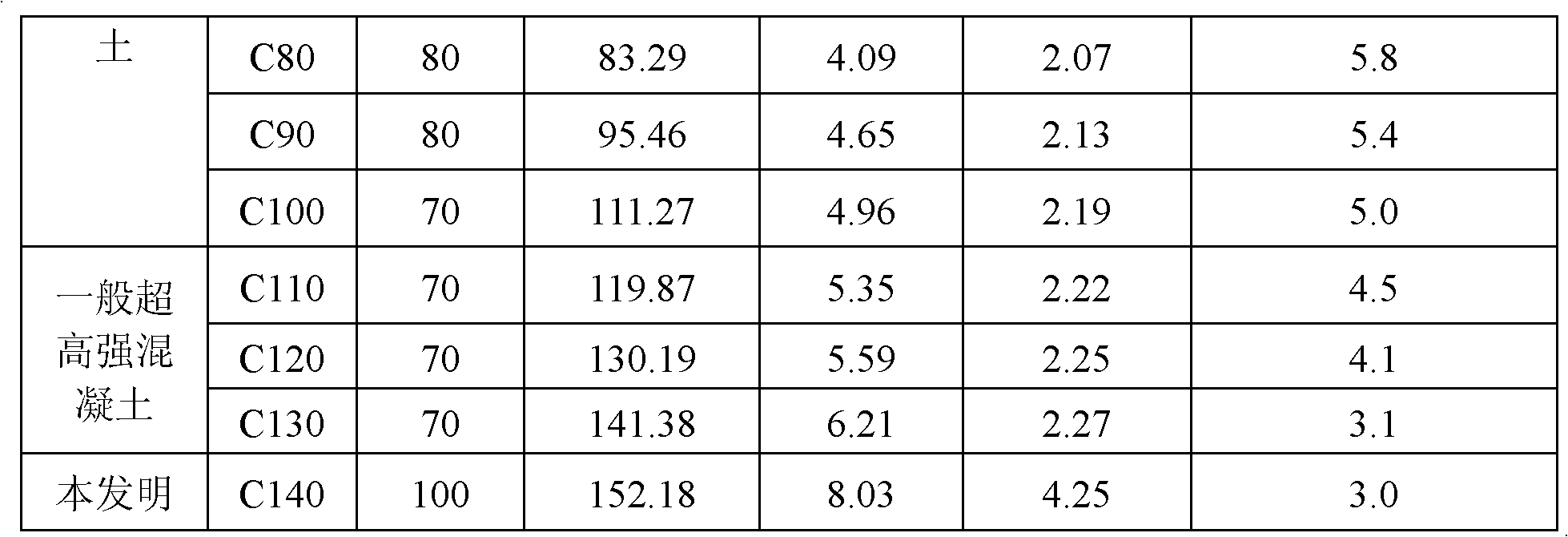

Concrete with strength grade of C140 used for profile steel-concrete composite structure

InactiveCN101913815AIncreased durabilityHigh Strength and DurabilitySolid waste managementCarrying capacityNatural state

The invention discloses concrete with strength grade of C140 used for a profile steel-concrete composite structure. The concrete is characterized by being prepared from cement, fine aggregate, coarse aggregate, water, a water reducing agent, an antifoaming agent, siliceous dust, coal ash(kg / m<3>) in a mixing proportion of 485:660:1,173:117:13:0.7:65:100. A preparation method of the concrete comprises the following steps of: adding the fine aggregate and the water in an amount of which is a half based on the total weight of the used water into a forced mixer according to the weight proportion in turn; uniformly stirring for 1 to 2 minutes; adding the coarse aggregate into the mixer; uniformly stirring for 2 to 4 minutes; adding the cement, the siliceous dust and the coal ash into the mixer; uniformly stirring for 2 to 3 minutes; adding the water reducing agent, the antifoaming agent and the rest water into the mixer; uniformly stirring for 2 to 5 minutes; and discharging to obtain a concrete mixture. The concrete can obviously improve the adhesive property between profile steel and the concrete in a natural state, effectively exert respective capacity and cooperative work performance of both materials, greatly improve the carrying capacity and performance of members, and improve the durability, high volume stability and economy of the members.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

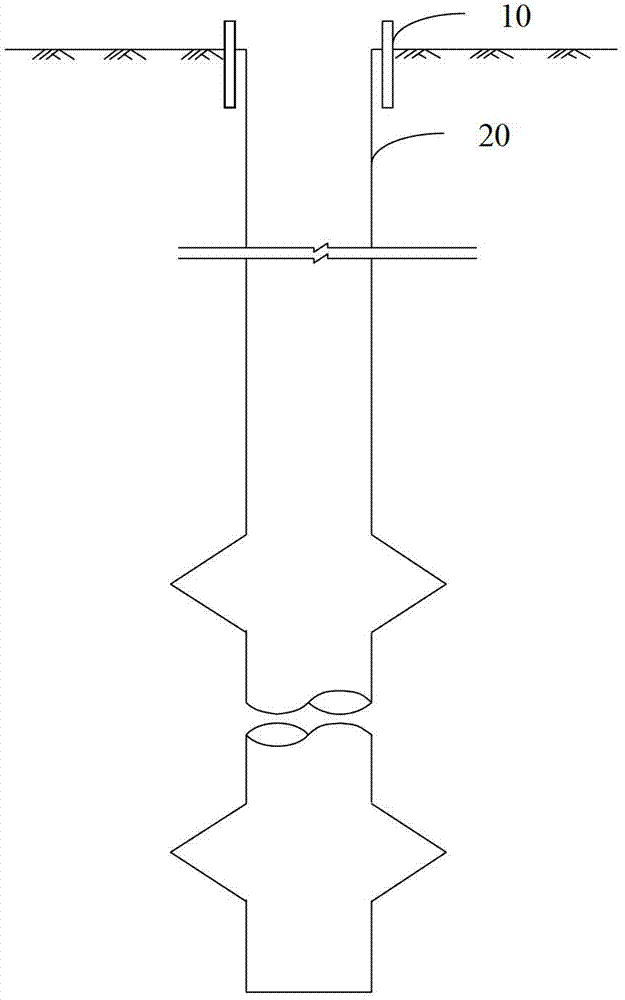

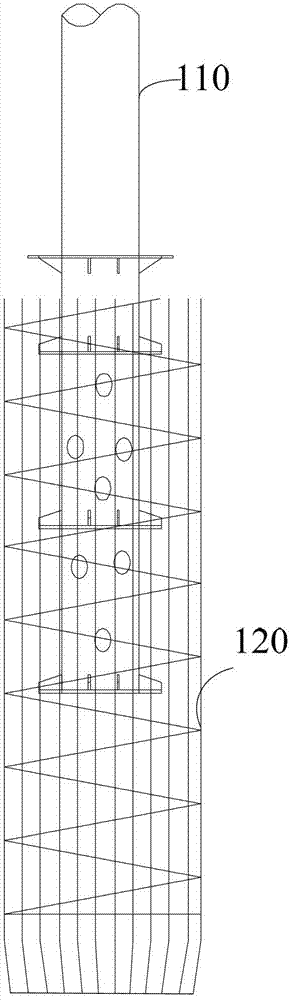

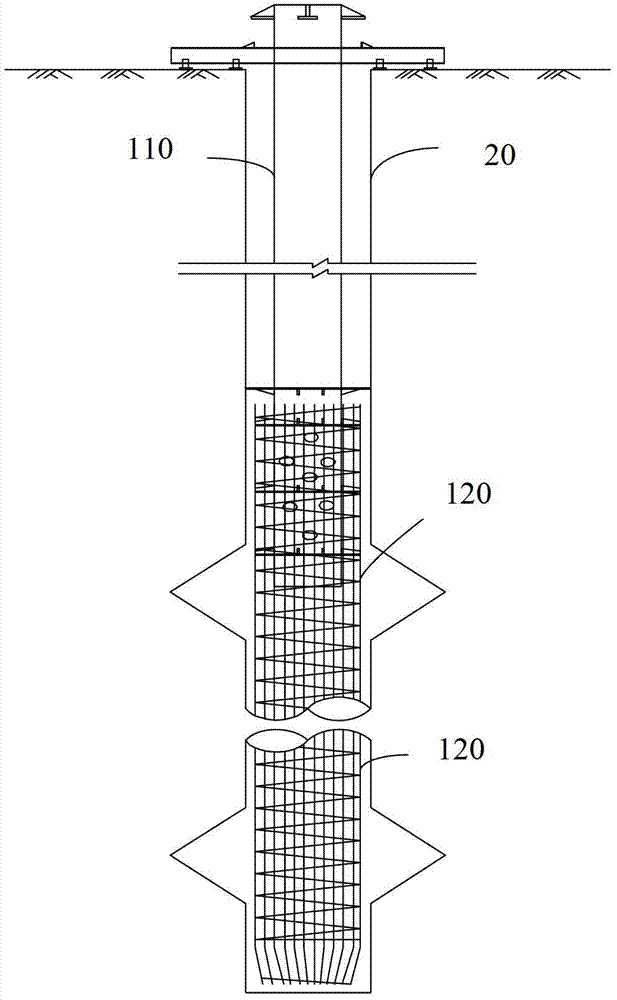

Cast-in-place pile construction method using steel pipe column splicing piles

The invention provides a cast-in-place pile construction method using steel pipe column splicing piles. The method includes: a) forming pile holes and forming slurry protecting walls automatically during formation of the pile holes; b) making the steel pipe column splicing piles which comprise steel tubes and reinforcing cages, and fixing the bottom ends of the steel pipes to the top ends of the reinforcing cages; c) lifting and positioning the steel pipe column splicing piles in the pile holes; d) pouring concrete into the pile holes through injection pipes on the steel pipe column splicing piles; and e) filling soil between the steel pipe column splicing piles and pipe hole walls. With the filling pile construction method, unity of cast-in-place piles is improved during the construction process of underground engineering, so that pipe formation quality of the cast-in-place piles is improved, and construction processes of cast-in-place piles are decreased.

Owner:MCC COMM CONSTR GRP CO LTD

Method for supporting foundation pit next to established underground structure

ActiveCN103590404AEasy and fast conversionReduce construction riskArtificial islandsProtective foundationReinforced concreteAxial force

The invention discloses a method for supporting a foundation pit next to an established underground structure. The method is characterized in that one end of a supporting member of the foundation pit built after underground structure establishment is supported on a vertical or horizontal member of an established body structure, supporting axial force is directly transferred to the member of the established body structure, one end of the supporting member can be supported on the established body structure by changing supporting after the foundation pit built after underground structure establishment is excavated to the pit bottom, and then base plate water-proof layer and reinforced concrete base plate construction, side wall water-proof layer and reinforced concrete side wall construction and top plate reinforced concrete and water-proof layer construction are sequentially performed. The method has the advantages that on the premise that engineering construction, operation safety and engineering quality are ensured, the engineering construction is simple, quick and convenient, construction risk is reduced, construction joints and construction processes are decreased, a construction period is shortened, and the construction cost is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

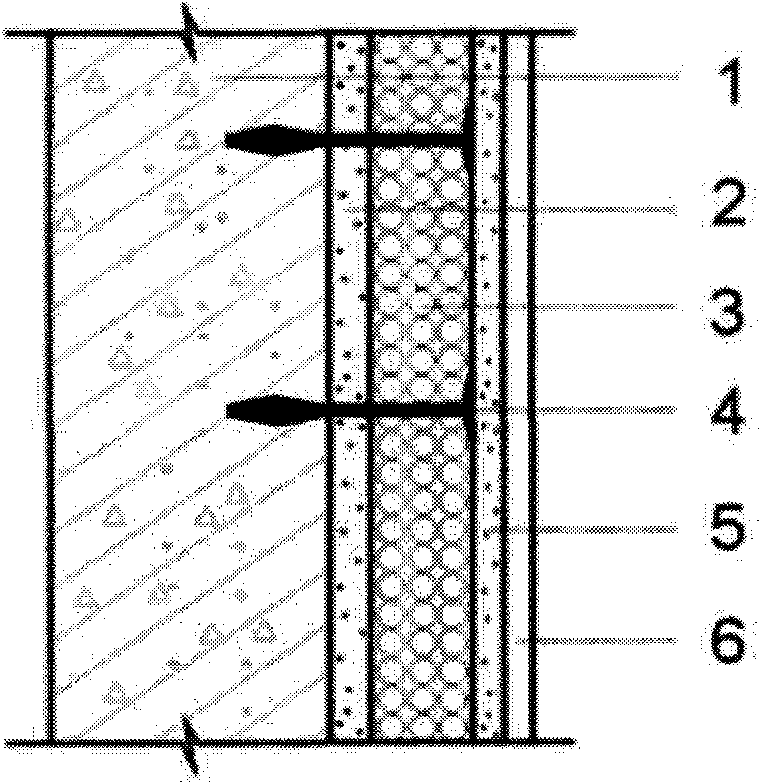

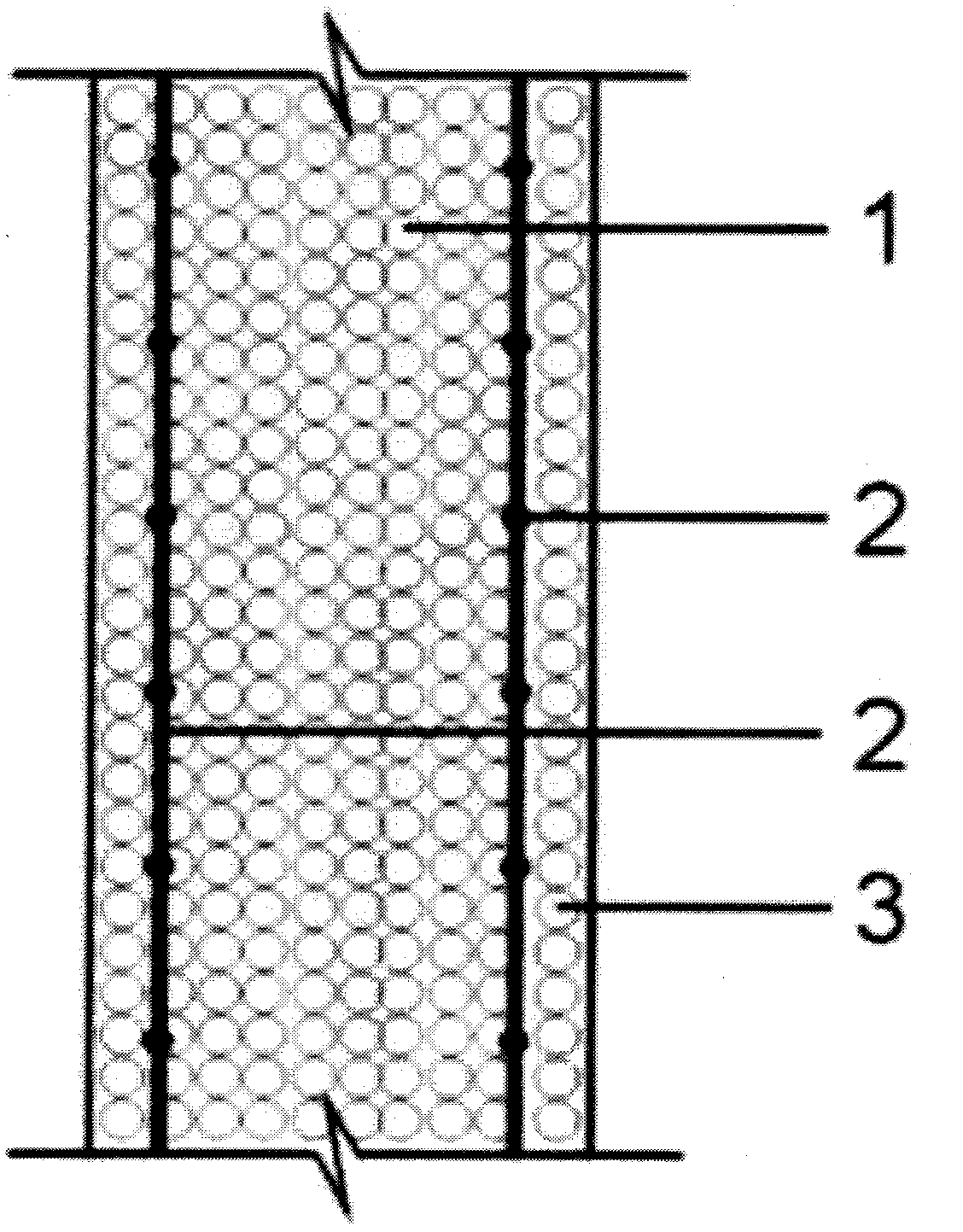

Outer thermal insulation wall with mechanically anchored metal mesh reinforced polystyrene boards

InactiveCN101806105AReduce construction procedures and construction periodSimple construction processWallsHeat proofingThermal insulationMetal mesh

The invention relates to an outer thermal insulation wall with metal mesh reinforced polystyrene boards anchored by a mechanical fixing device. By utilizing the leveling and binding layer on the foundation wall, before the leveling layer is dried, the metal mesh reinforced boards for thermal insulation are bound on the leveling layer to perform the functions of auxiliary connection and stabilization, thereby ensuring the flatness of the polystyrene boards. Holes are drilled in the board surface, and the metal mesh reinforced polystyrene boards for thermal insulation are directly fixed on the foundation wall through plastic expansion anchor bolts, so that all the load on the outer thermal insulation system is completely borne by the fixing anchor bolts and transferred to the foundation structural wall. The organic combination of the anchor bolts and the reinforced polystyrene boards can perform the auxiliary stabilizing function on the load on the leveling layer of the wall. Therefore, the outer thermal insulation wall is especially suitable for outer thermal insulation energy-saving modification works on outer walls of buildings, and can well solve the technical problems of low bearing capacity and difficult surface treatment in the old foundation of the outer wall.

Owner:周金烈 +1

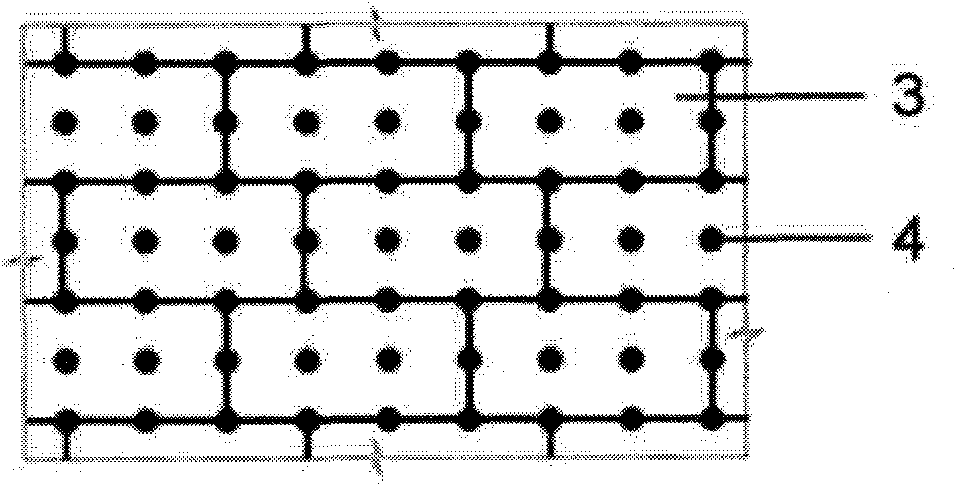

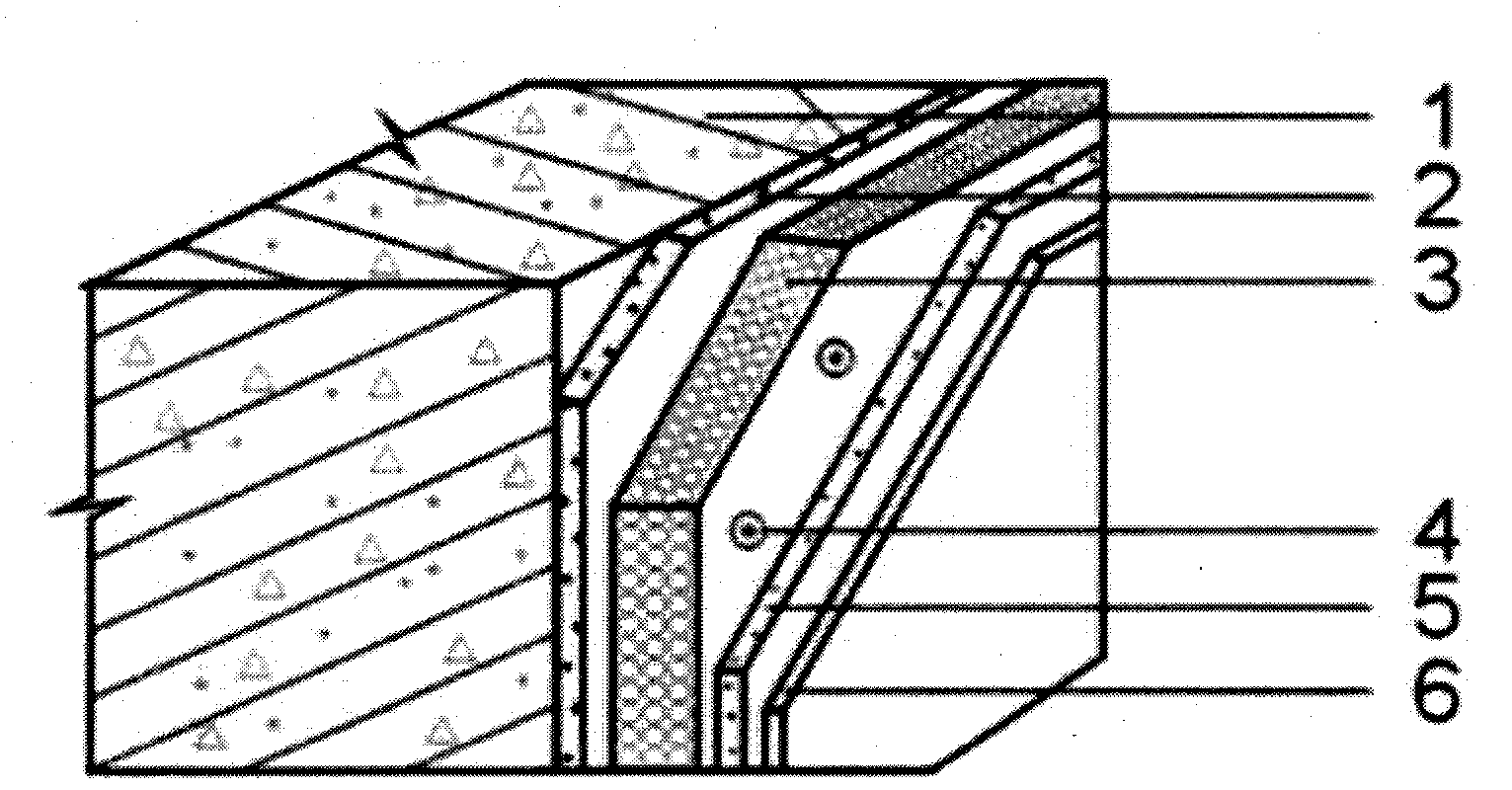

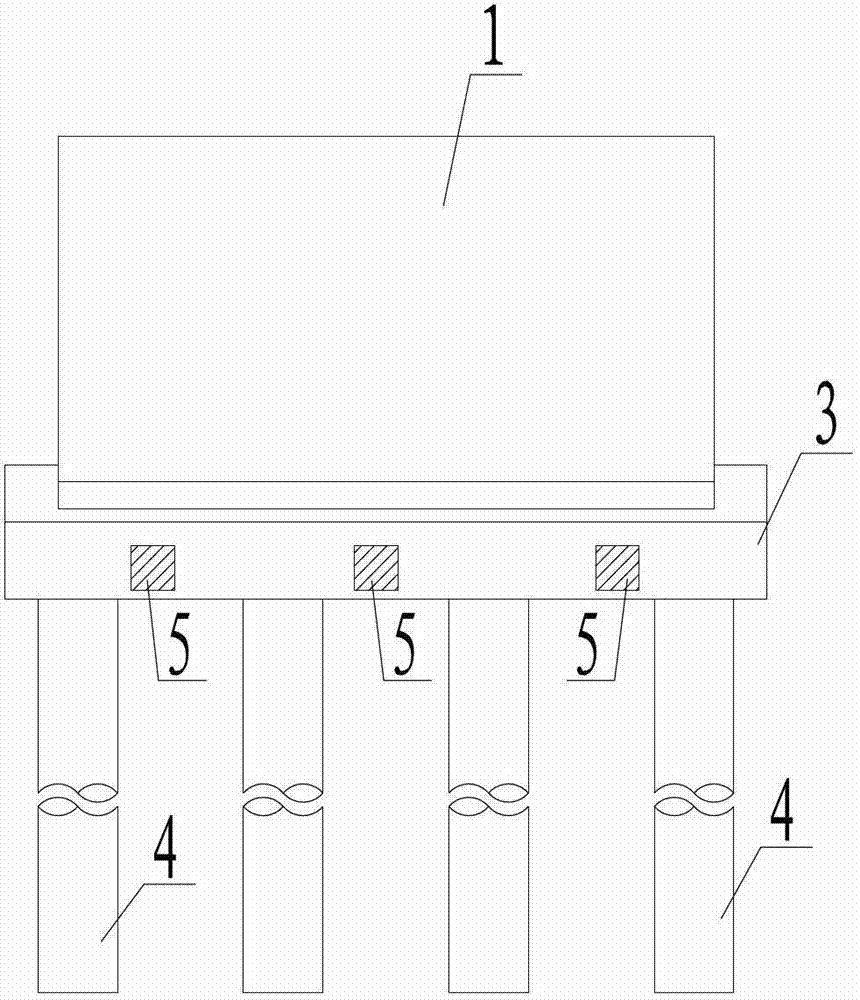

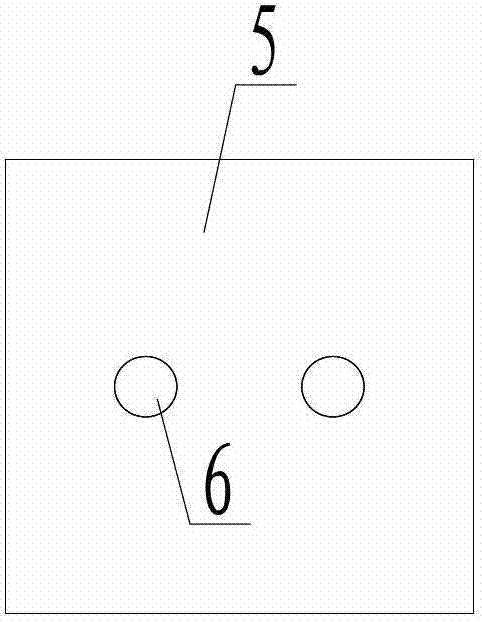

External thermal-insulation wall of mechanical anchoring gridding reinforcing rib inorganic modified foam thermal-insulation board

ActiveCN103174226AGuaranteed flatnessHigh tensile strengthCovering/liningsWallsSurface layerThermal insulation

The invention discloses an external thermal-insulation wall of a mechanical anchoring gridding reinforcing rib inorganic modified foam thermal-insulation board. The external thermal-insulation wall is sequentially composed of a base layer wall body 4, a leveling and binding layer 5, a gridding reinforcing rib inorganic modified foam thermal-insulation board 6, plastic expansion anchor bolts 7, a thin troweling protective surface layer 8 and a surface detective layer 9 on the base wall body from inside to outside. The external thermal-insulation wall is characterized in that the leveling and binding layer 5 is adopted to bond the base layer leveling and the gridding reinforcing rib inorganic modified foam thermal-insulation board 6 in an auxiliary mode in one step, the bonding is only used for ensuring planeness during installation of an external thermal-insulation system, then the plastic expansion anchor bolts 7 are used for anchoring the gridding reinforcing rib inorganic modified foam thermal-insulation board 6, and all loads of the external thermal-insulation system are enabled to completely borne by the plastic expansion anchor bolts 7 and are directly transferred to the base layer wall body 4. Through combination of the gridding reinforcing rib inorganic modified foam thermal-insulation board 6 and the plastic expansion anchor bolts 7, tensile strength, anti-bending strength and stability of a thermal-insulation layer are largely improved.

Owner:SHANGHAI ONE GOLD ENERGY SAVING TECH

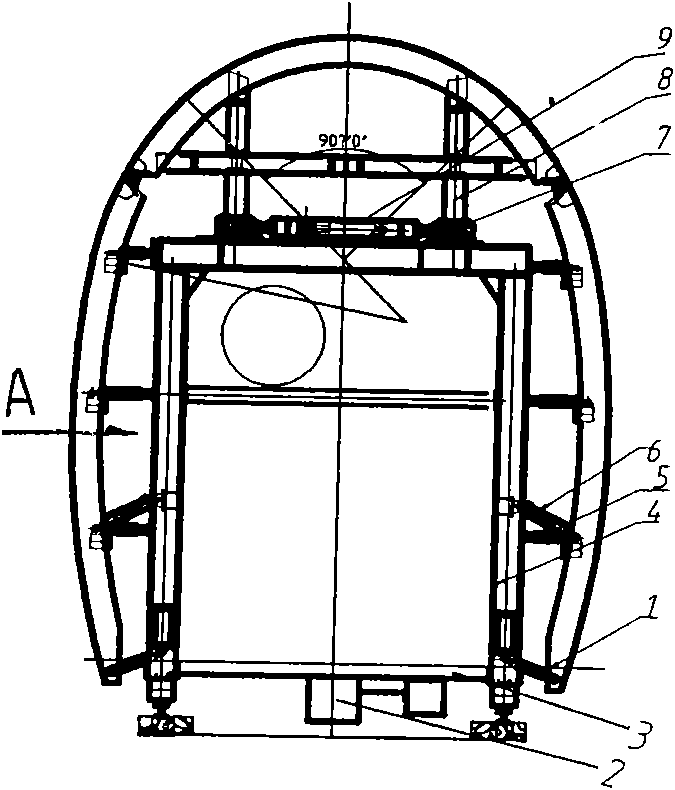

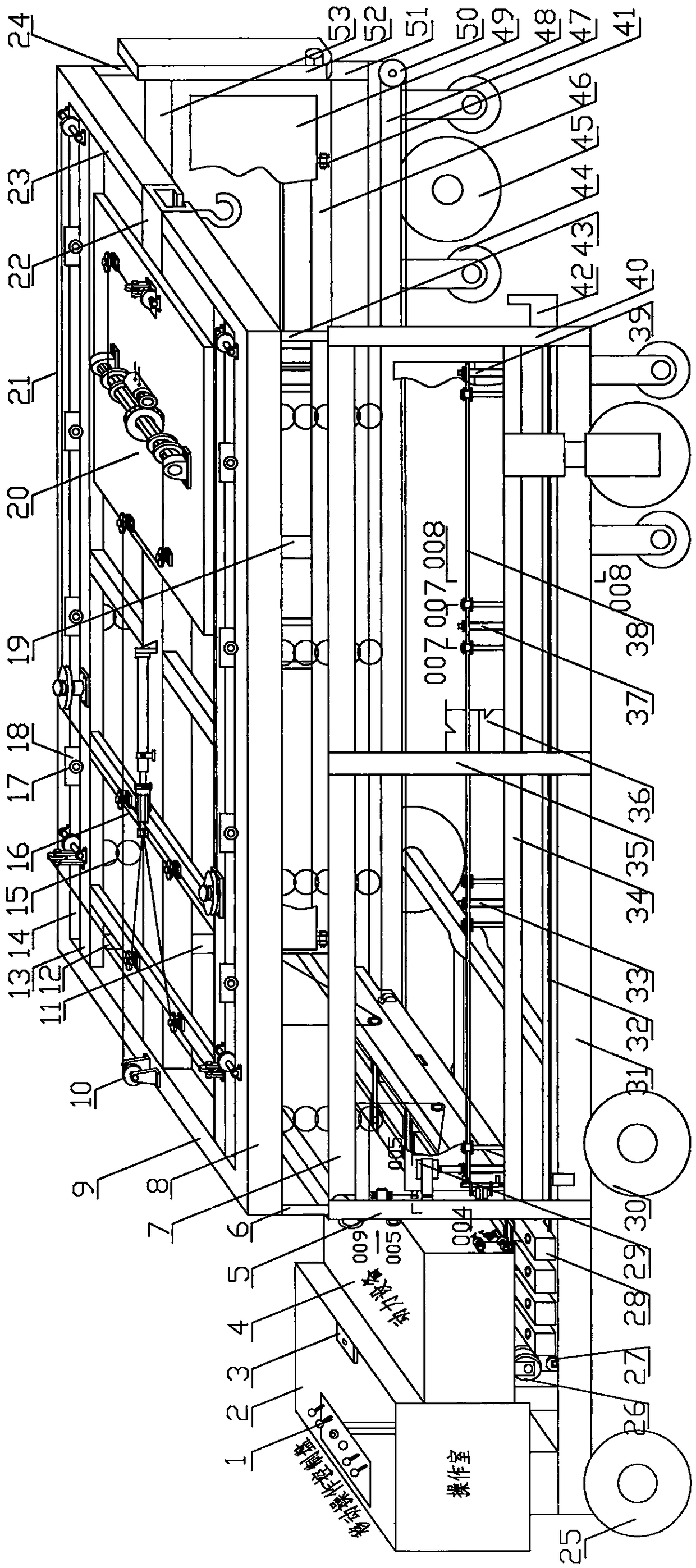

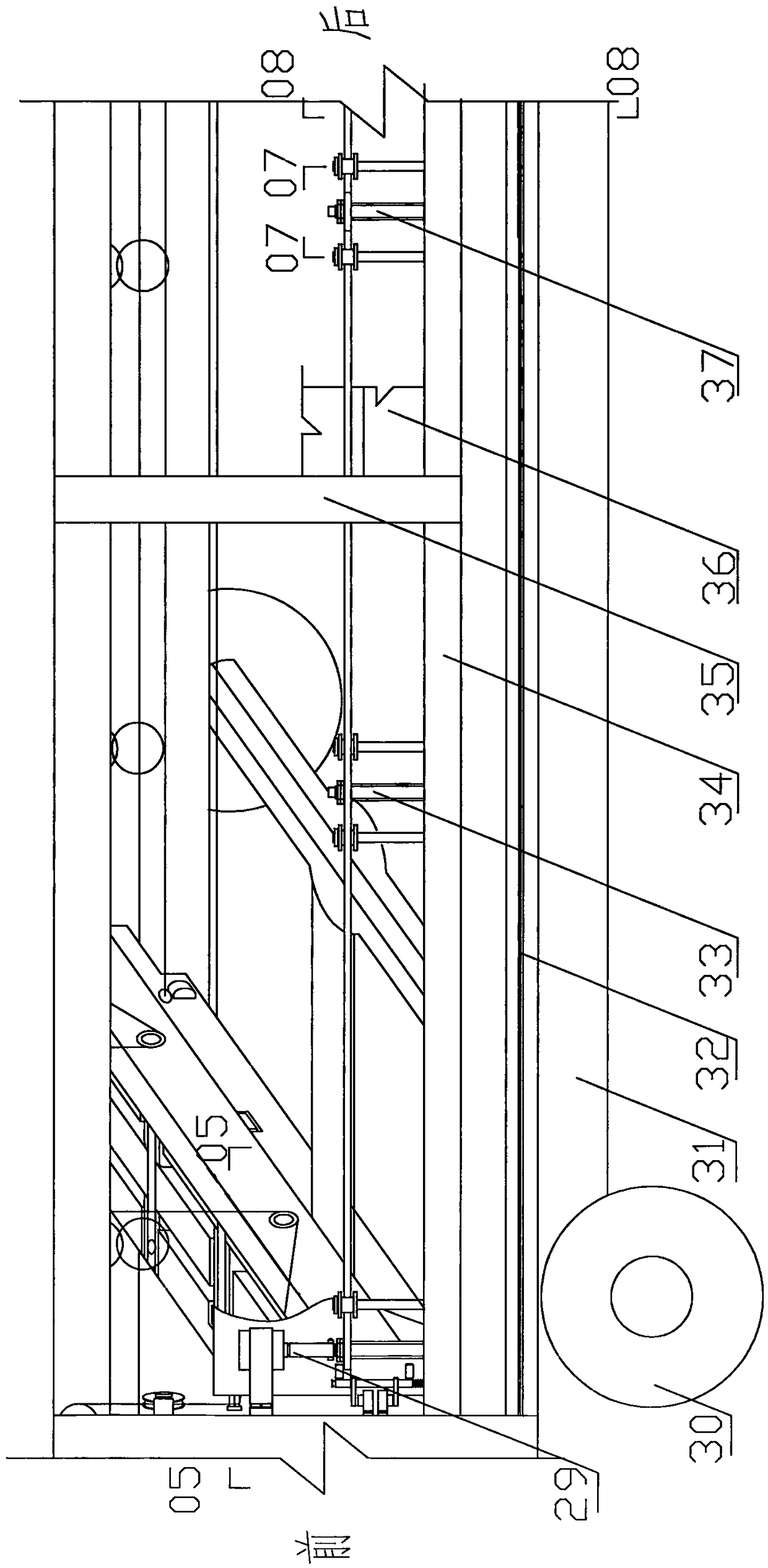

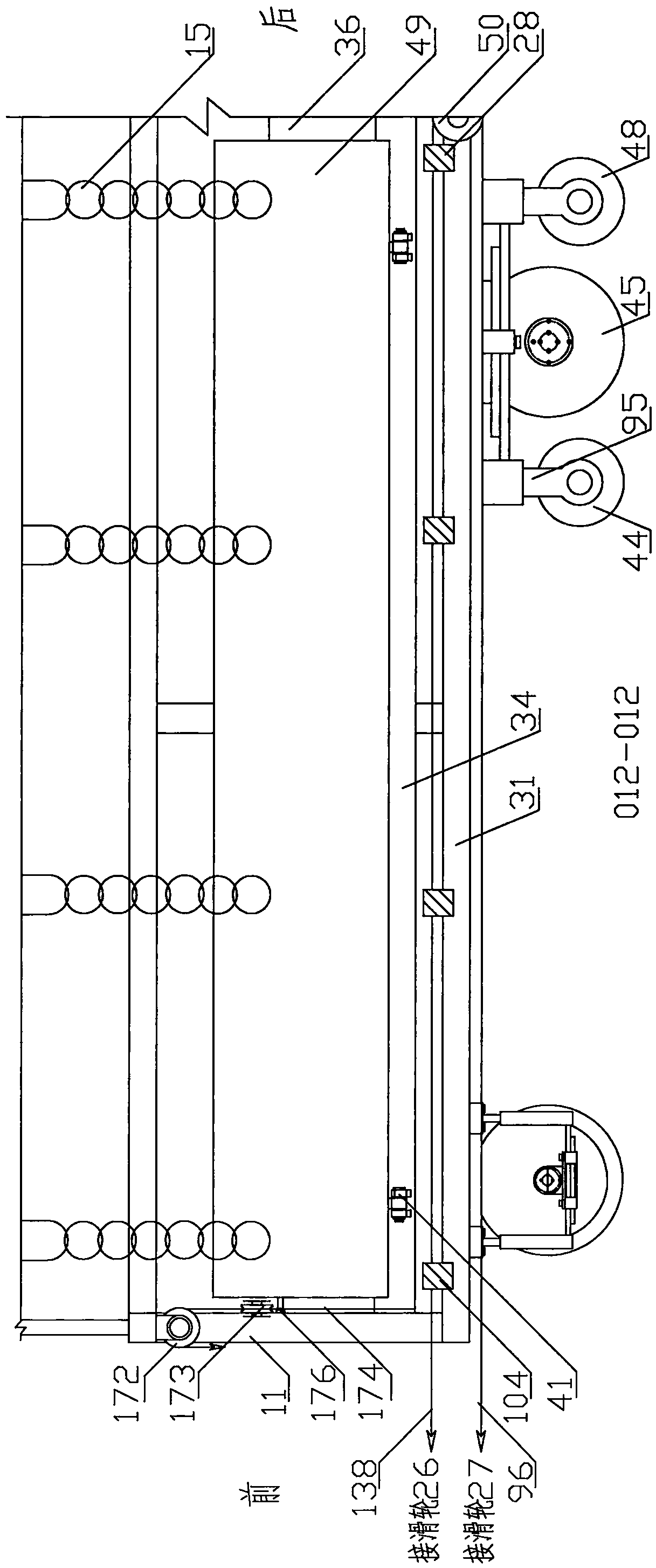

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

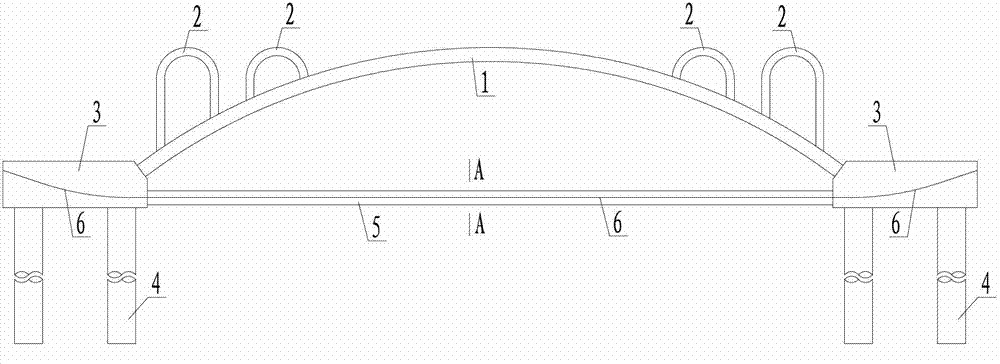

Deck type open shoulder arch bridge and constructing method thereof

InactiveCN103088749ASmall water blocking areaReduce weightBridge erection/assemblyArch-type bridgePrestressed concreteSpandrel

The invention belongs to the bridge technical field and relates to a deck type open shoulder arch bridge. The deck type open shoulder arch bridge comprises a main arch ring 1, upper spandrel arches 2, a bearing platform 3 and a pile foundation 4, wherein the upper spandrel arches 2 are arranged on both sides of the main arch ring 1, and arch feet of the main arch ring 1 are arranged in the bearing platform 3. The deck type open shoulder arch bridge further comprises a plurality of prestressed concrete pull-pressing rods 5. A prestressed wire 6 penetrates through each prestressed concrete pull-pressing rod 5, and two ends of the prestressed wire 6 are respectively anchored in the bearing platform 3 which is on the same side of the prestressed wire 6. The main arch ring 1, the pile foundation 4 and the prestressed concrete pull-pressing rods 5 are connected to form a whole through the bearing platform 3. Meanwhile, the invention provides a constructing method of the deck type open shoulder arch bridge. Prestressed steel beams in the prestressed concrete pull-pressing rods 5 can be once tensioned in place in constructing process, and no construction passageway is need to leave to conduct tension step-by-step.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Composite thermal insulation steel skeleton concrete integration construction structure and construction process thereof

InactiveCN1570304ARealize factory constructionBuild Quality Precisely ControlledWallsFloorsFloor slabReinforced concrete

One kind of compound heat preservation reinforced concrete integration construction structure and the construction craft, its foundation each one with buries in the concrete foundation from the laying aside steel, in the assembly wall and the floor section skeleton, with lays aside the section skeleton the steel buries in advance in the foundation a permanent connection; Its wall the steel bar coagulation dirt wall main body which first hands over by the polystyrene heat preservation wall template and the template interior bonds becomes, the polystyrene heat preservation wall template has two polystyrene heat preservations board parallel relative establishment, two between has two distinguishes to bury in advance pulls in its in steel skeleton combination ties becomes, under the polystyrene heat preservation board two side buddhist priest separately has the raised saw notch; Its floor because archery target heat preservation template and cast-in-place the steel bar layer of concrete duplicate synthesizes a body, keeps warm the template is passes long by the polystyrene thermal insulation material in sets at the section to become spongy the composition, keeps warm the template with cast-in-place the steel bar layer of concrete between has the concave-convex joint face. Compared to traditional construction working procedure few, time limit for a project short, construction cost low, the craft is simple, is suitable for much, the high-rise construction.

Owner:朱秦江

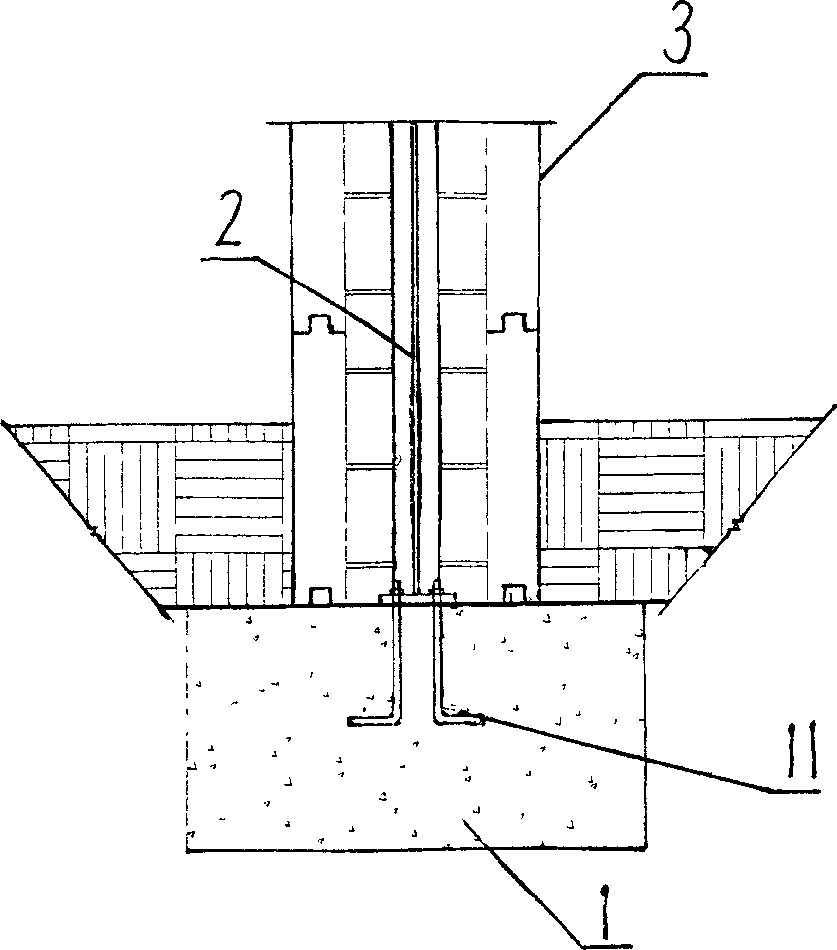

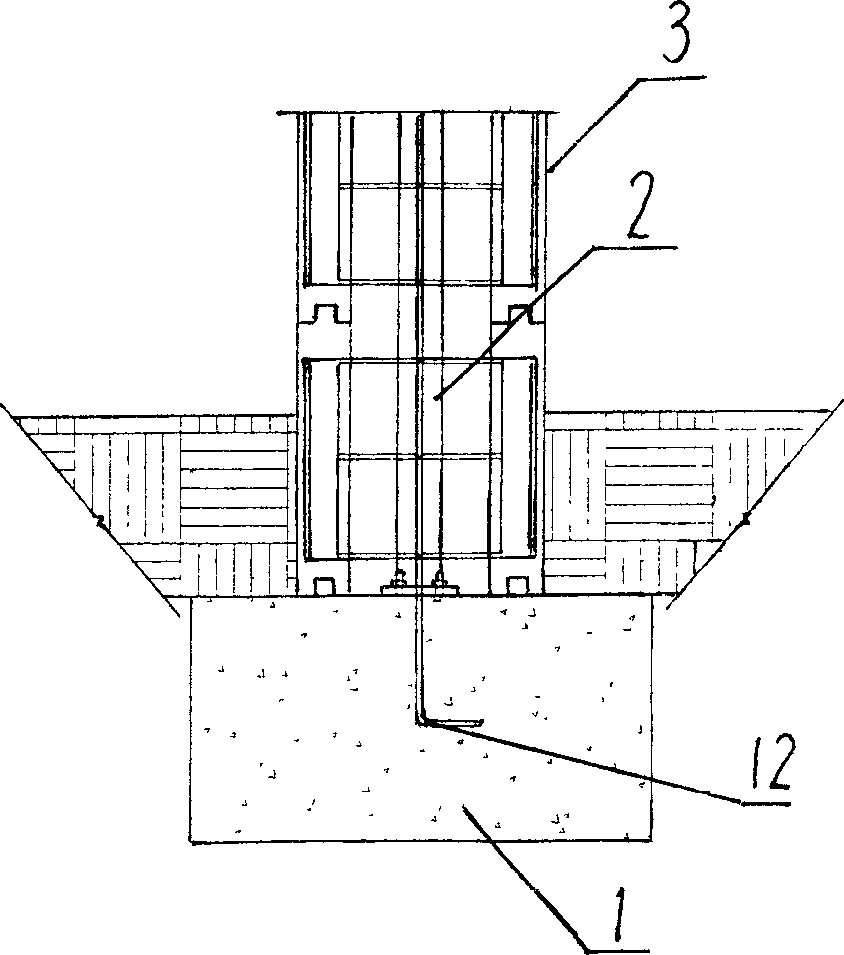

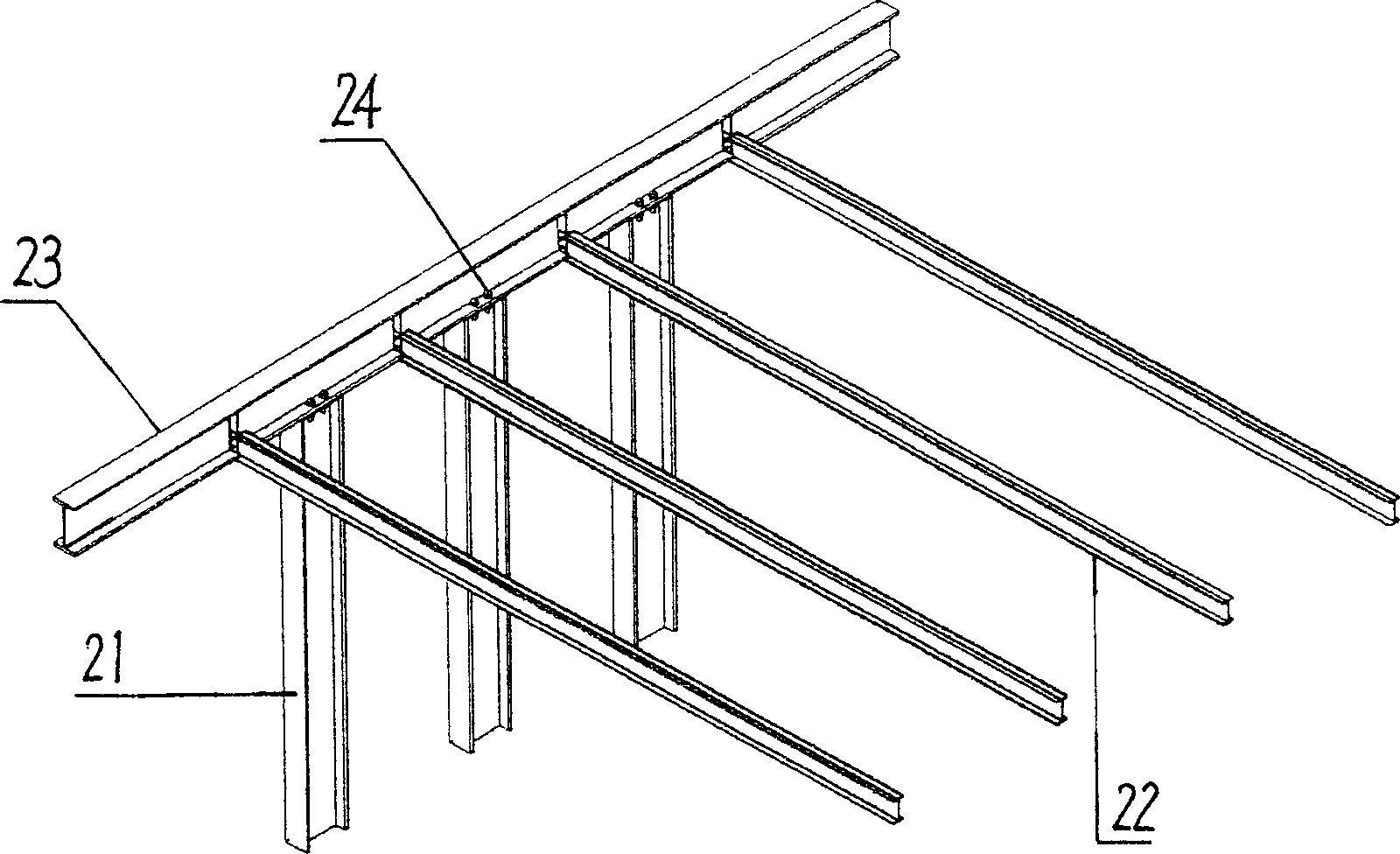

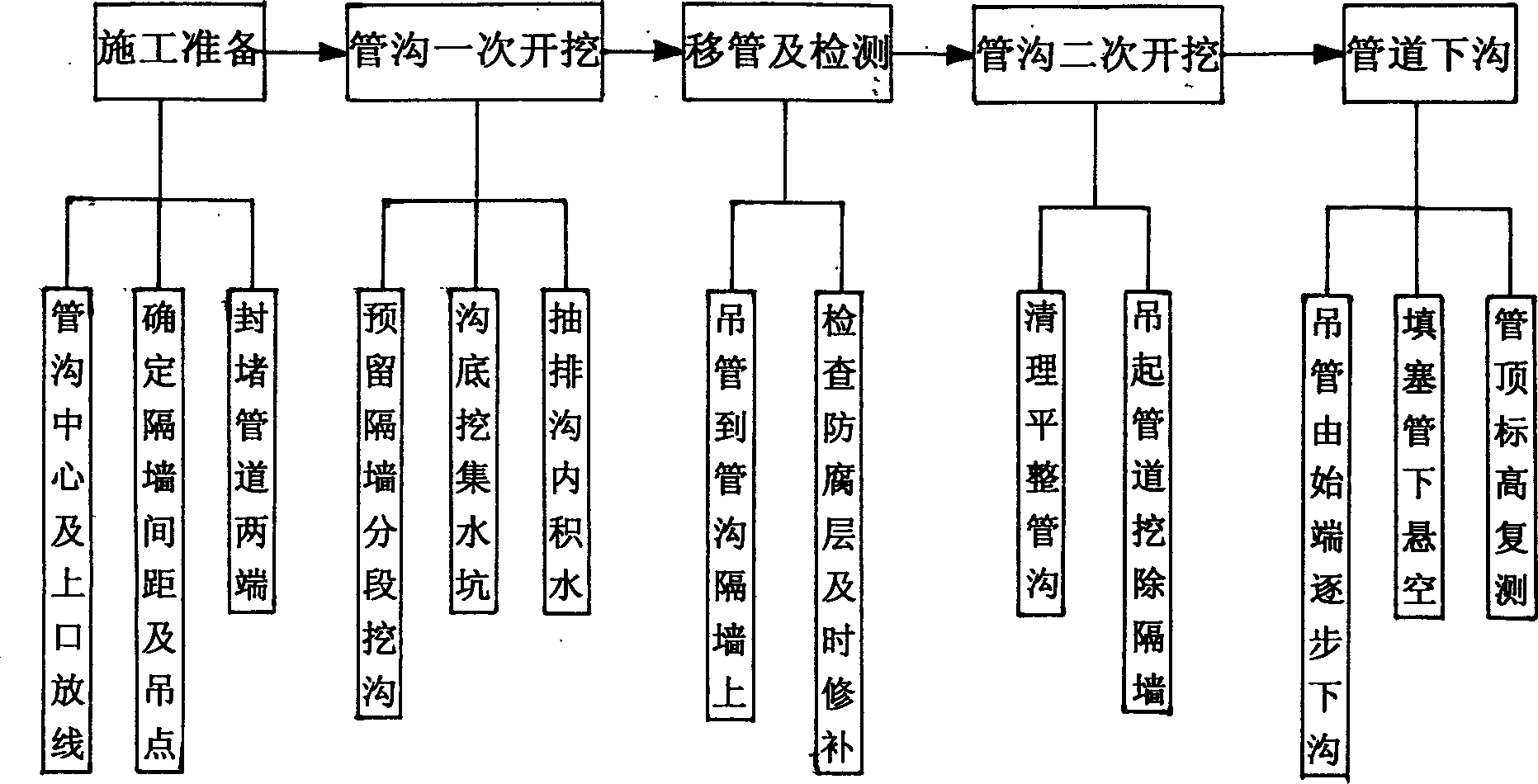

Down-ditch construction method for laying heavy caliber pipeline

InactiveCN1558130AAvoid tipping accidentsGuarantee the quality of workPipe laying and repairDitchPipe layer

The present invention is the construction process of laying wide bore pipe into pipe canal and relates to one important pipeline construction step. The present invention features that during excavating pipe canal, one soil partition wall is preserved in each certain distance; the pipe is first hoisted with two pipe layers and settled on the partition walls, and the initial end of the pipe is lifted before the soil partition wall is dug out with excavator and then settled slowly into the pipe canal; and all the partition walls are dug out successively and the pipes are settled in the pipe canal. The construction process includes the main steps of: preparation, the first pipe canal excavation, shifting pipes and detection, the second pipe canal excavation, and laying the pipes. The main advantages includes using two pipe layers only, low cost, low power consumption, simplified construction process, short construction period, etc.

Owner:NO 3 BRANCH OF SHENGLI PETROCHEM BUILDING CO LTD SHENGLI OIL FIELD

Coating process applying water-based paint to metal parts of engineering machinery

InactiveCN102974522AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyEngineering

The invention discloses a coating process applying water-based paint to metal parts of engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery enables the water-based paint to be correctly used for the coating of the metal parts of the engineering machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and physical and chemical performance coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Novel heat-insulation dry powder mortar

InactiveCN101723639AHigh bond strengthEarly strength fastSolid waste managementBuilding materialCellulose

The invention belongs to the technical field of building materials, and discloses novel heat-insulation dry powder mortar. The mortar consists of portland cement, fly ash, vitrified beads, floating beads, heavy calcium, cellulose, latex powder and the like. Compared with conventional heat-insulation mortar, the novel heat-insulation dry powder mortar provided by the invention has the advantages of high strength, light weight, high bond strength and the like.

Owner:何林道 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com