Mounting method of stayed cable of cable-stayed bridge

An installation method and technology of cable-stayed cables, applied to cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of prolonging the construction period of hanging cables, wasting construction time, increasing construction difficulty, etc., and reducing the number of times of wear , Save construction time and reduce the effect of construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is further described below with reference to the accompanying drawings and exemplary embodiments, wherein like numerals in the drawings refer to like parts throughout. Also, if a detailed description of known art is not necessary to illustrate the features of the present invention, it will be omitted.

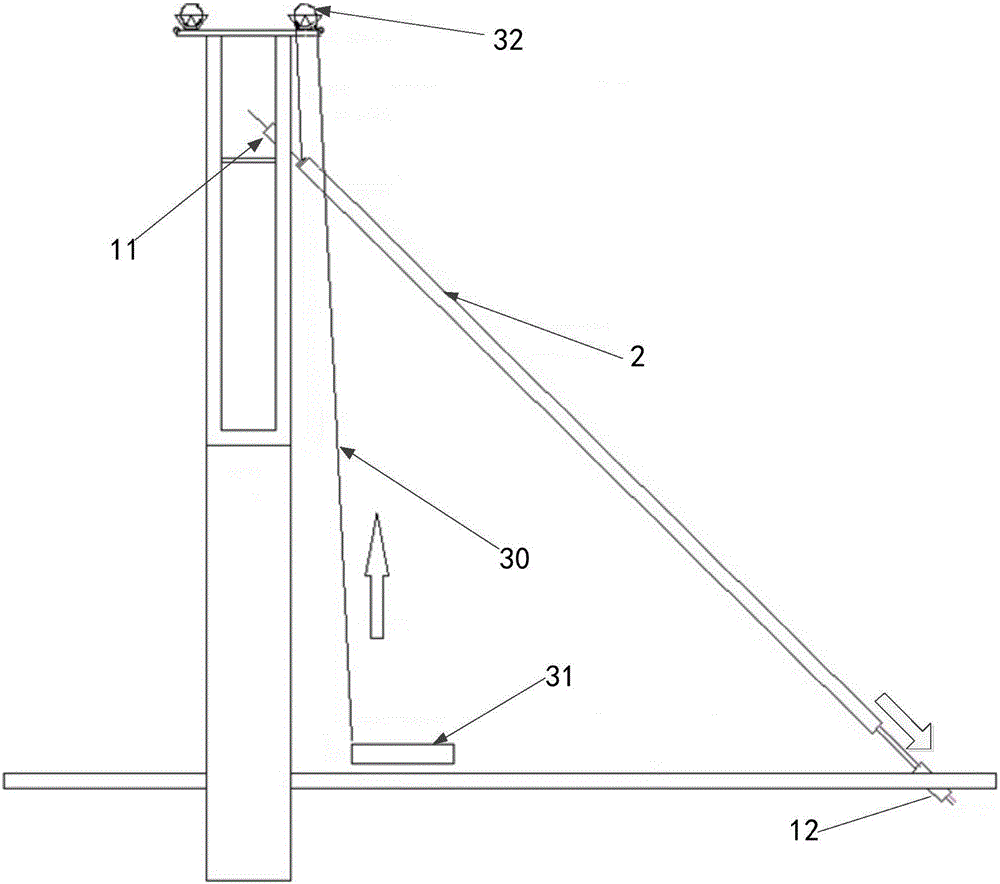

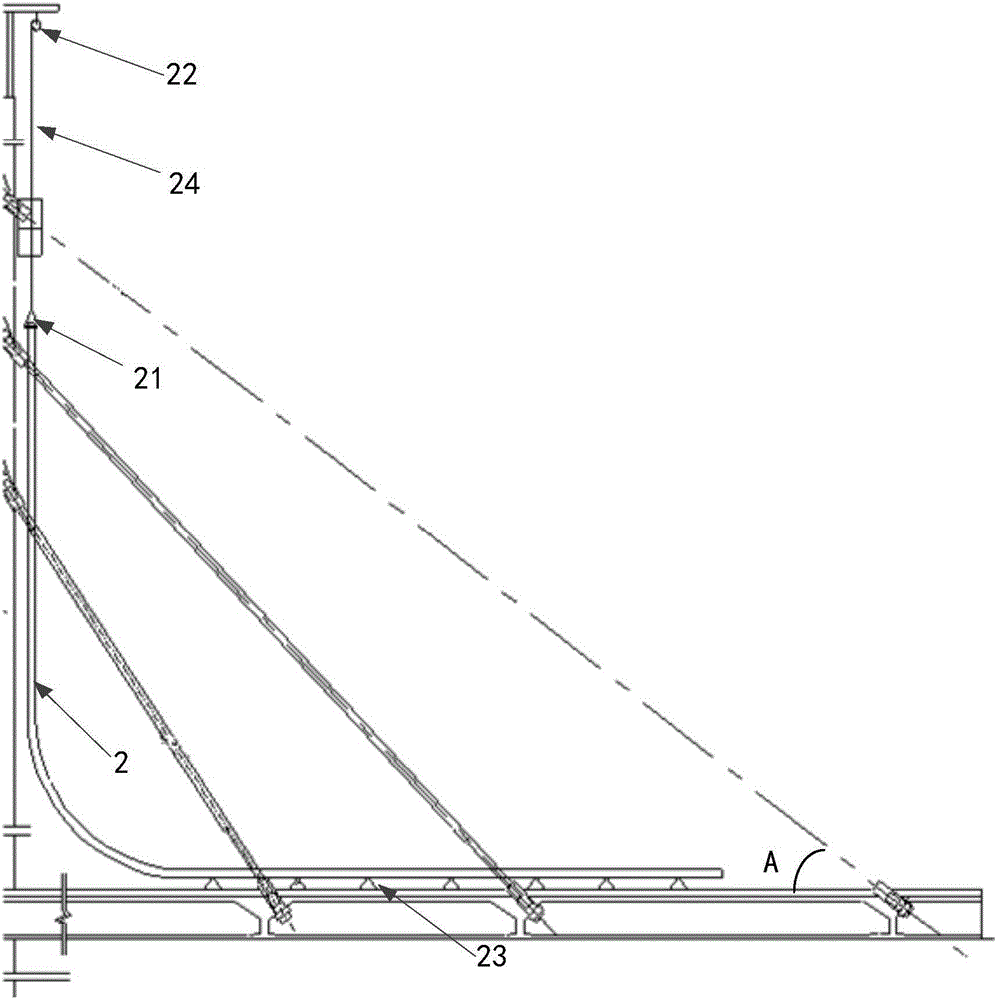

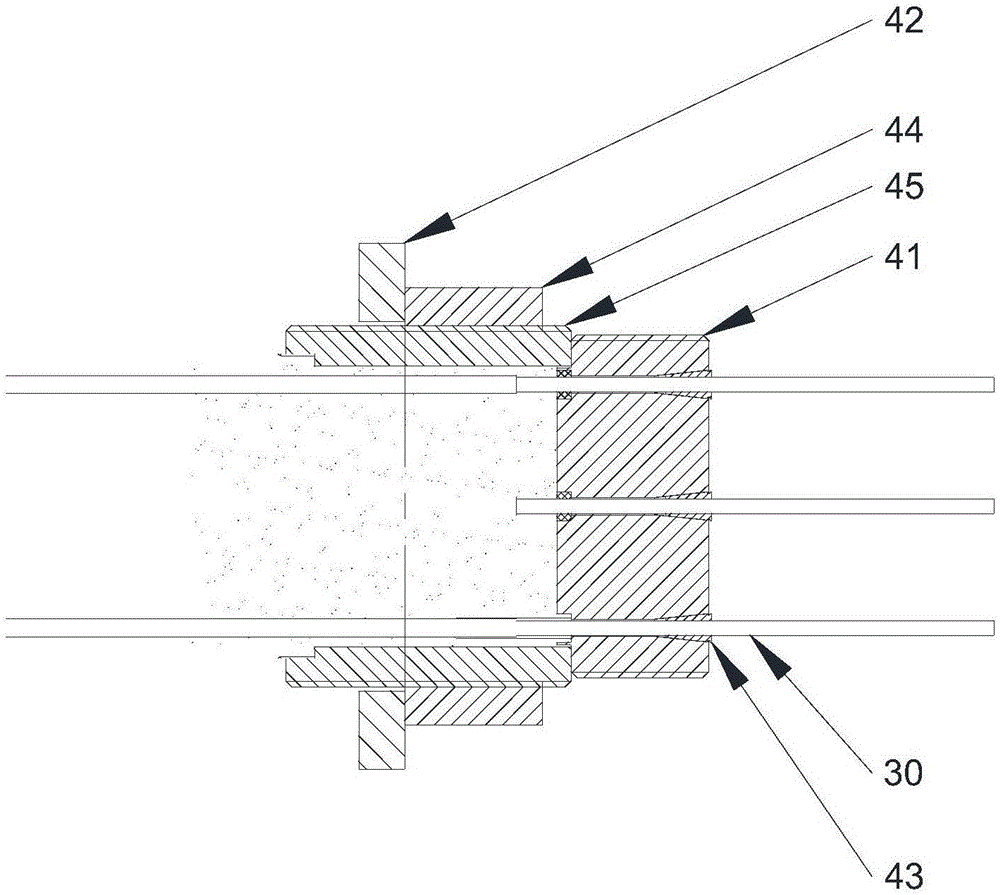

[0054] The cable-stayed cable installation schematic diagram of the cable-stayed cable installation method of the cable-stayed bridge disclosed in the present invention is as follows: figure 1 , the specific method is to install the lower beam anchoring device 12 on the main beam segment; install the tower end anchoring device 11 on the cable tower; lift the outer sheath tube 2 of the stay cable and arrange it at a preset angle to match the The anchoring device 12 under the beam and the anchoring device 11 at the tower end corresponding to the stay cables are arranged in line; Both ends of the cable are anchored and the stay cable is tensioned.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com