Patents

Literature

945 results about "Continuous beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

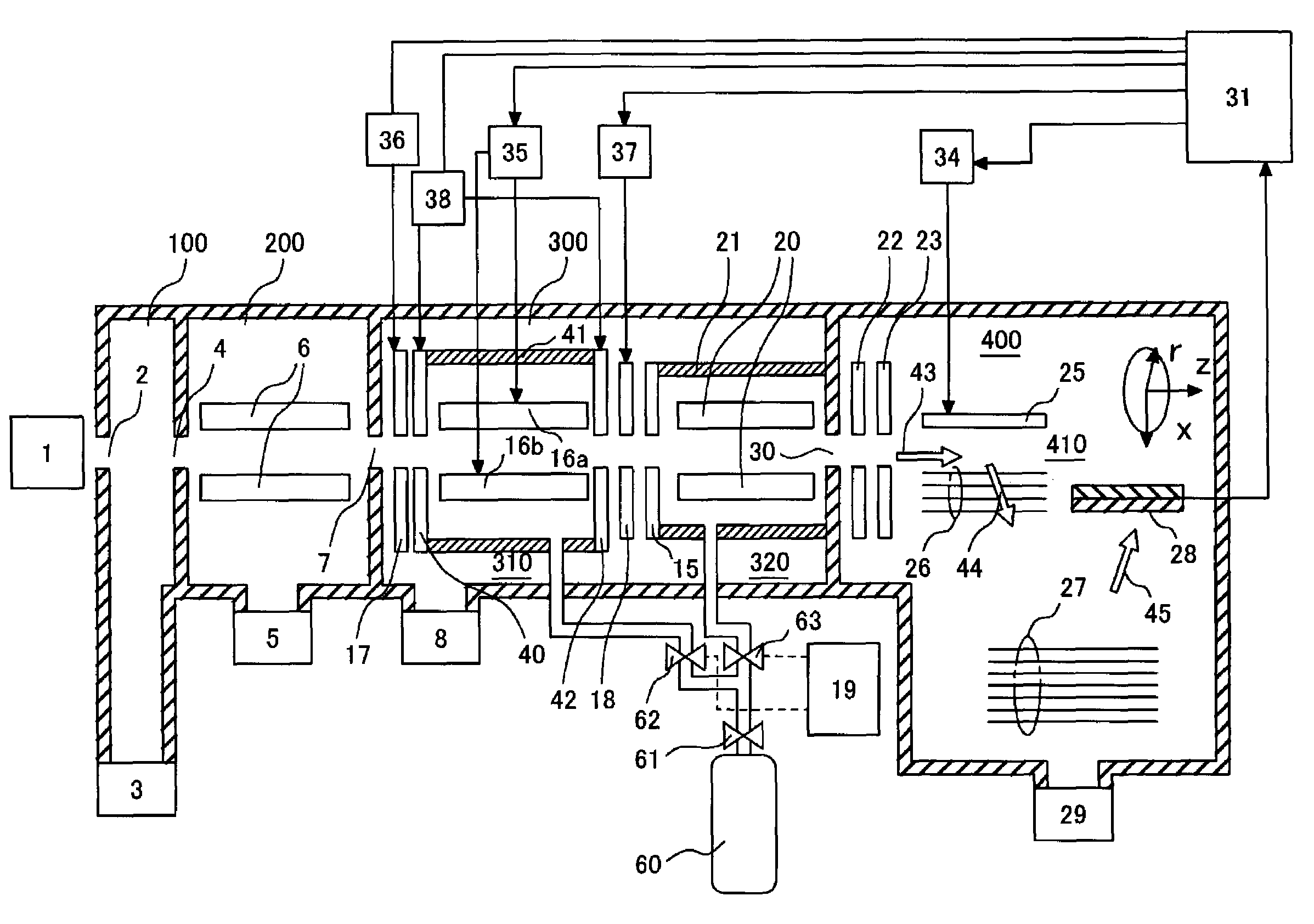

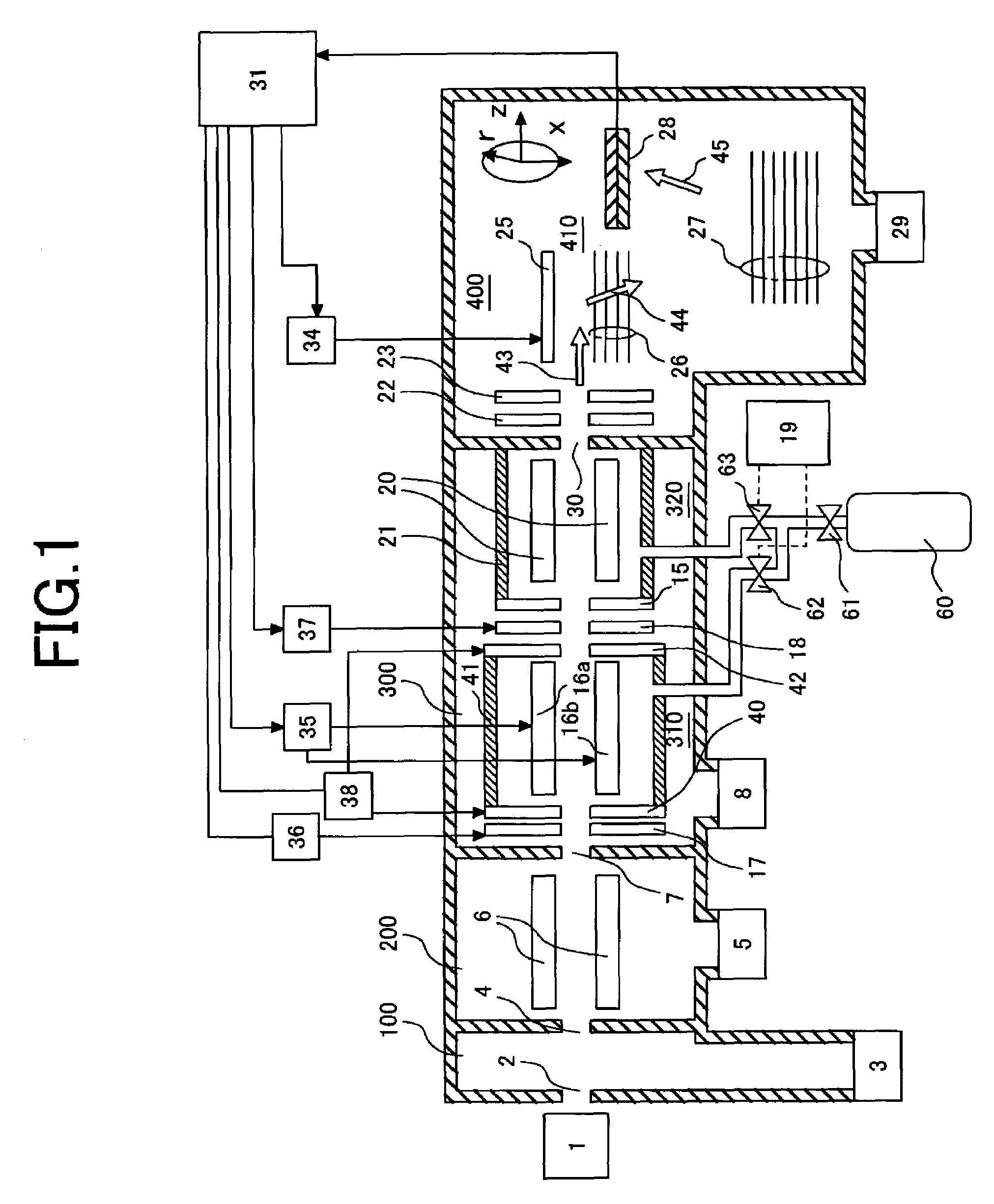

Illumination system with variable adjustment of the illumination

InactiveUS6658084B2Avoid lostSimple wayNanoinformaticsHandling using diffraction/refraction/reflectionGratingExit pupil

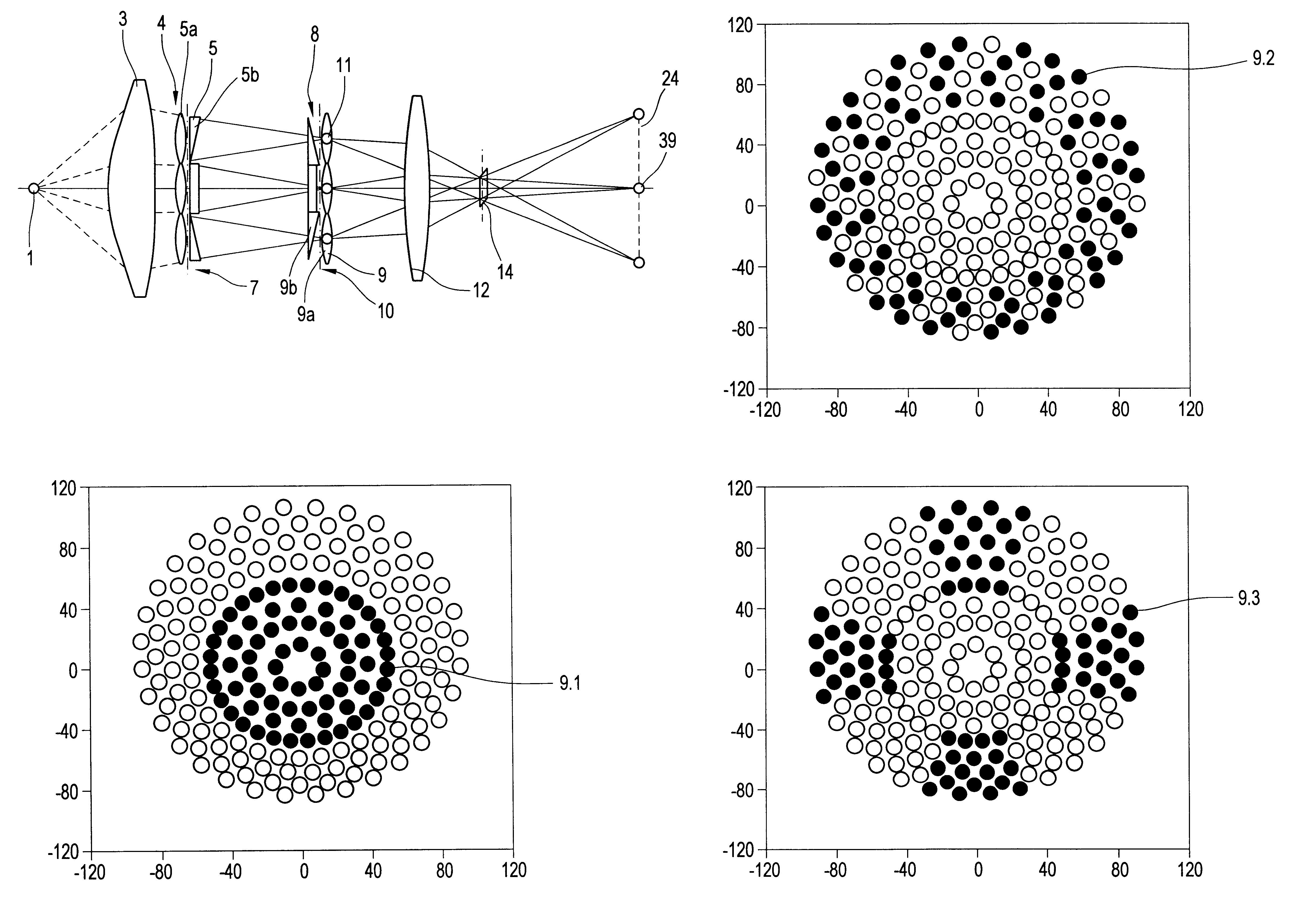

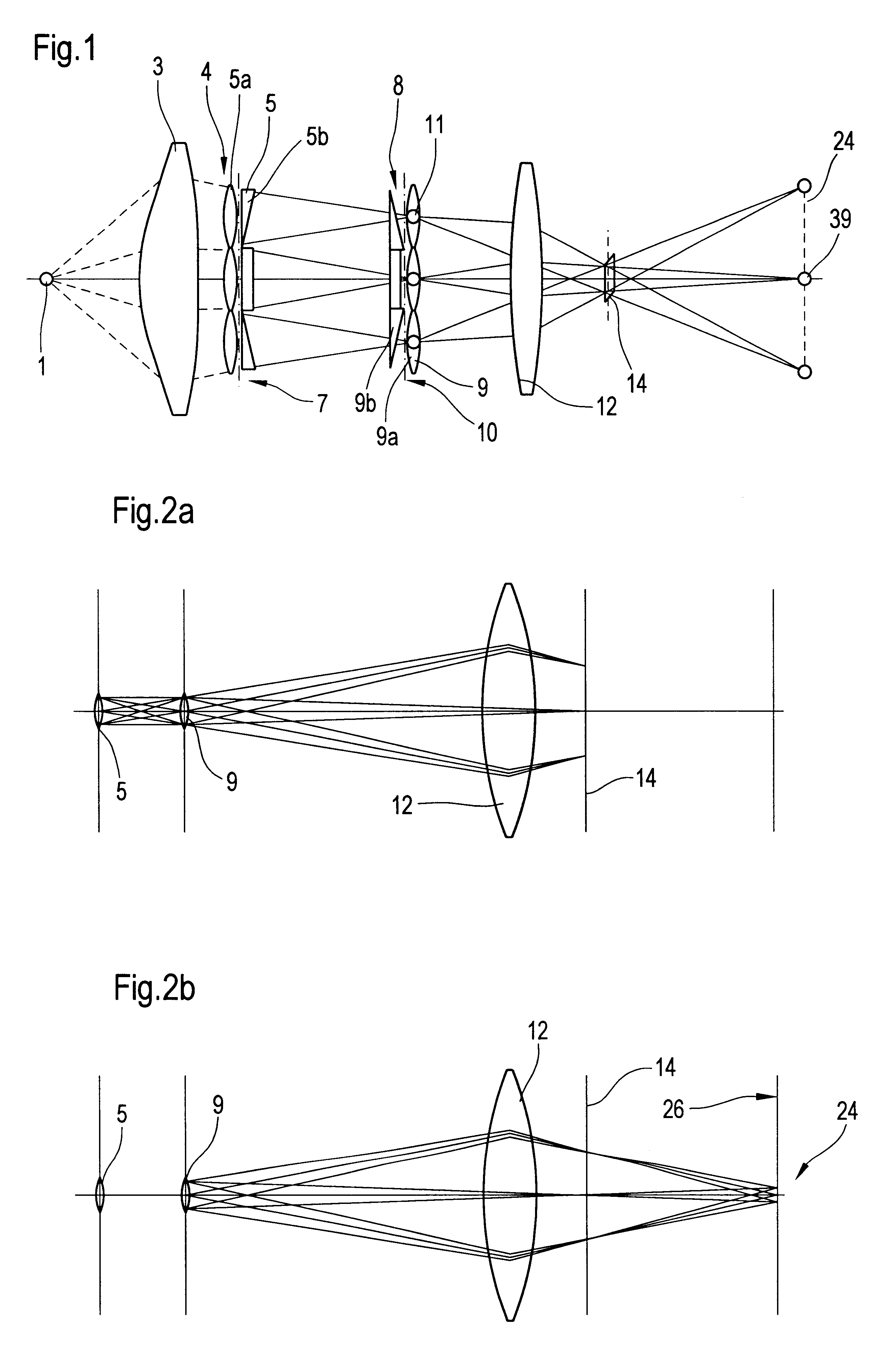

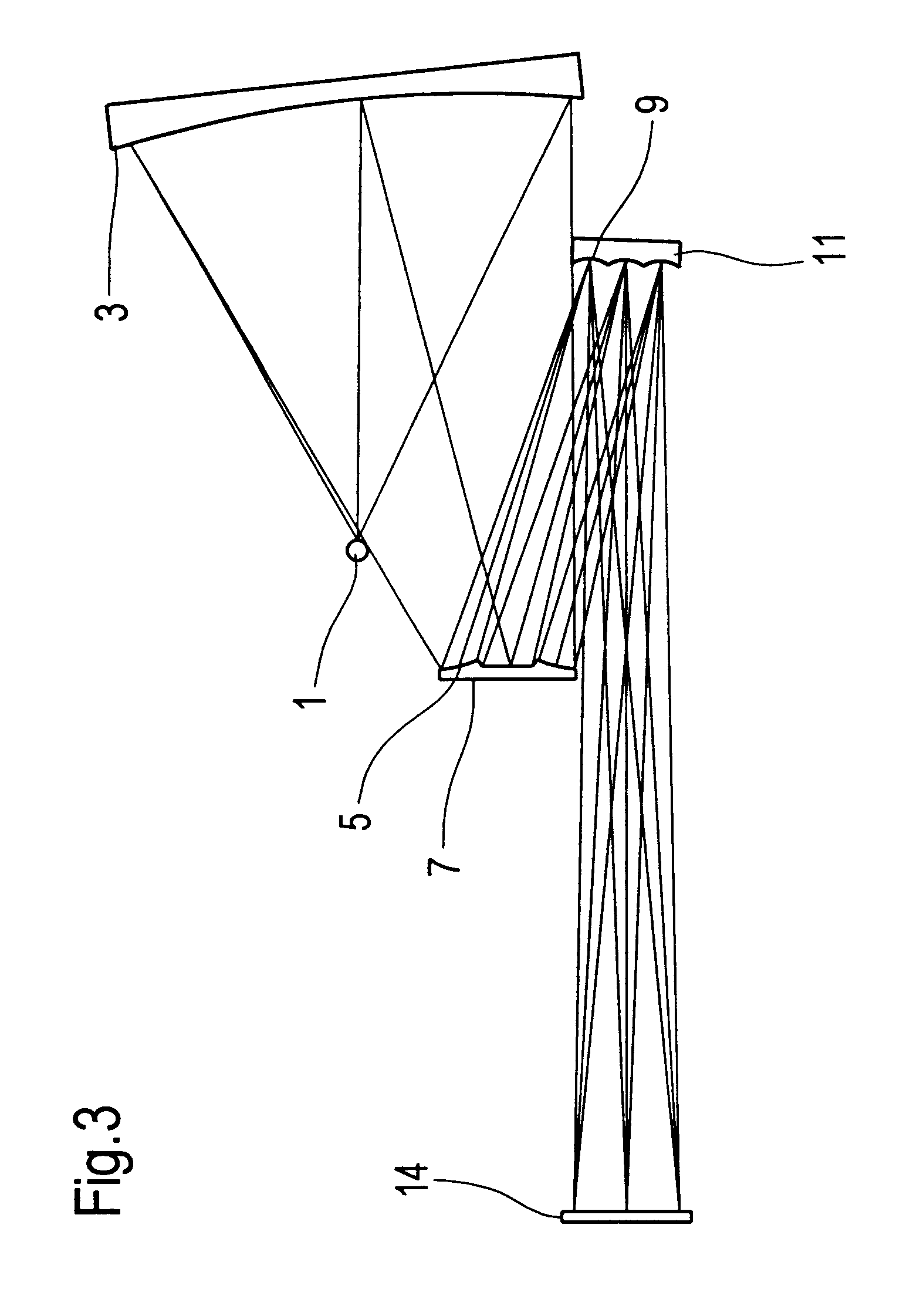

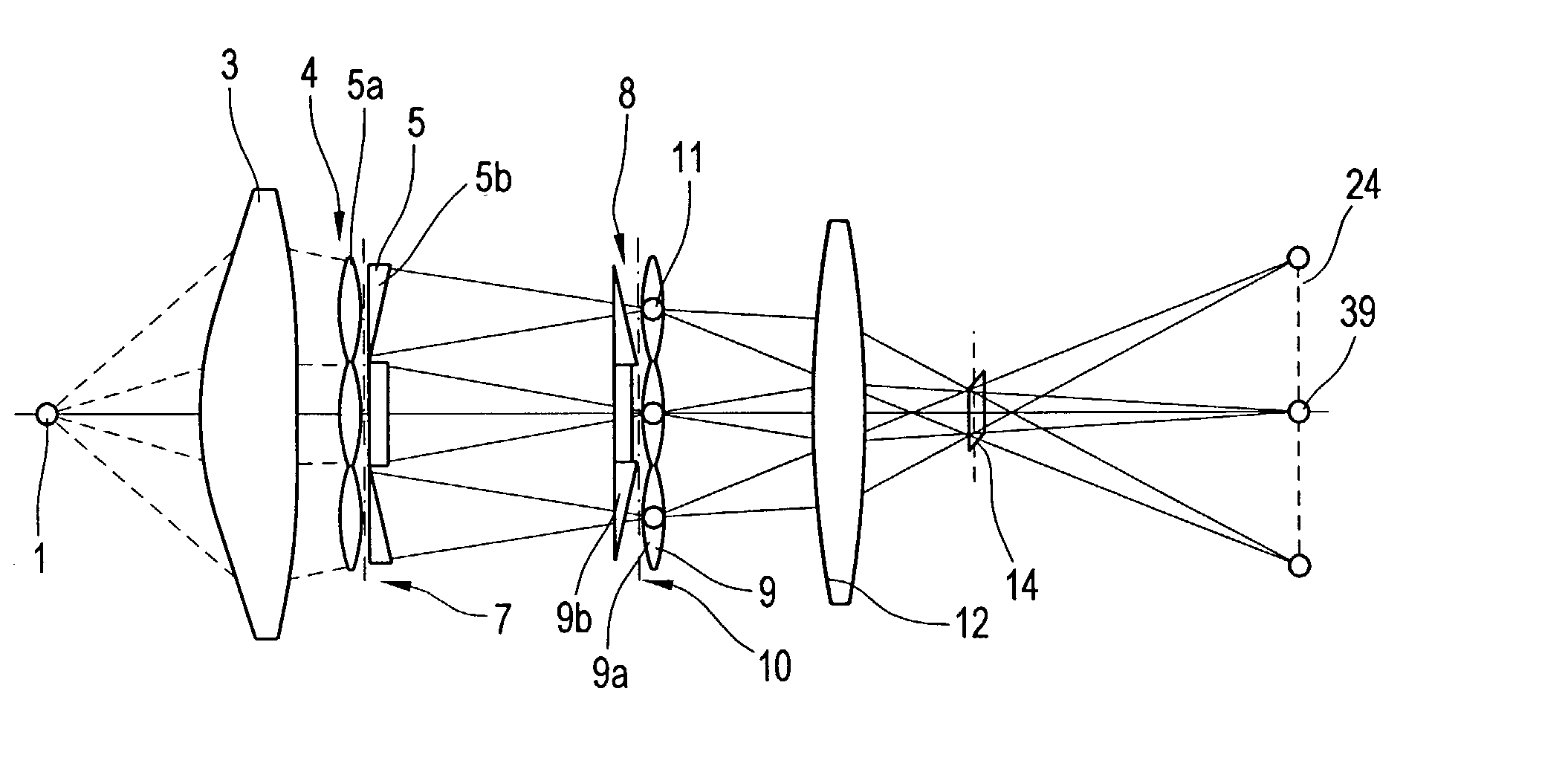

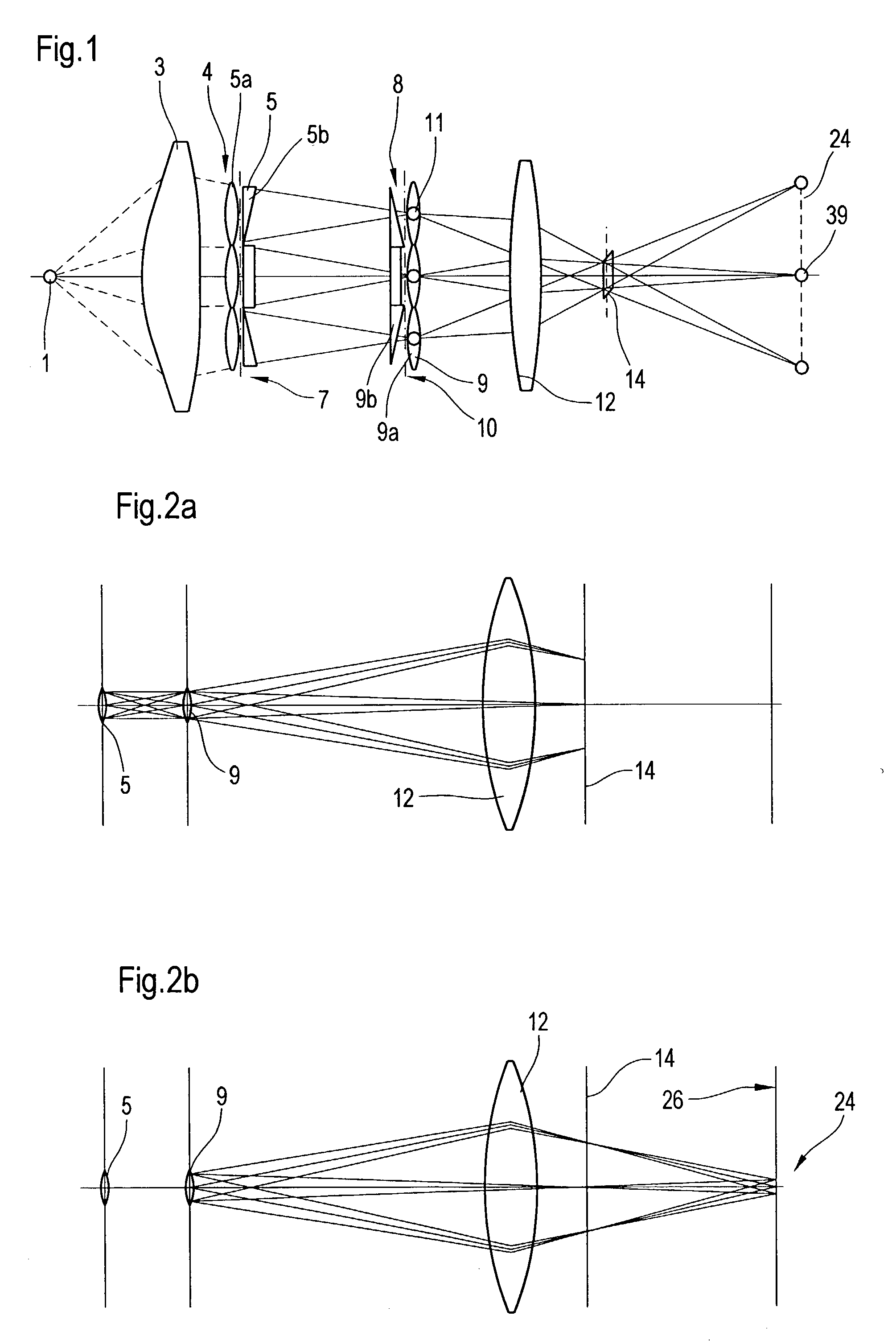

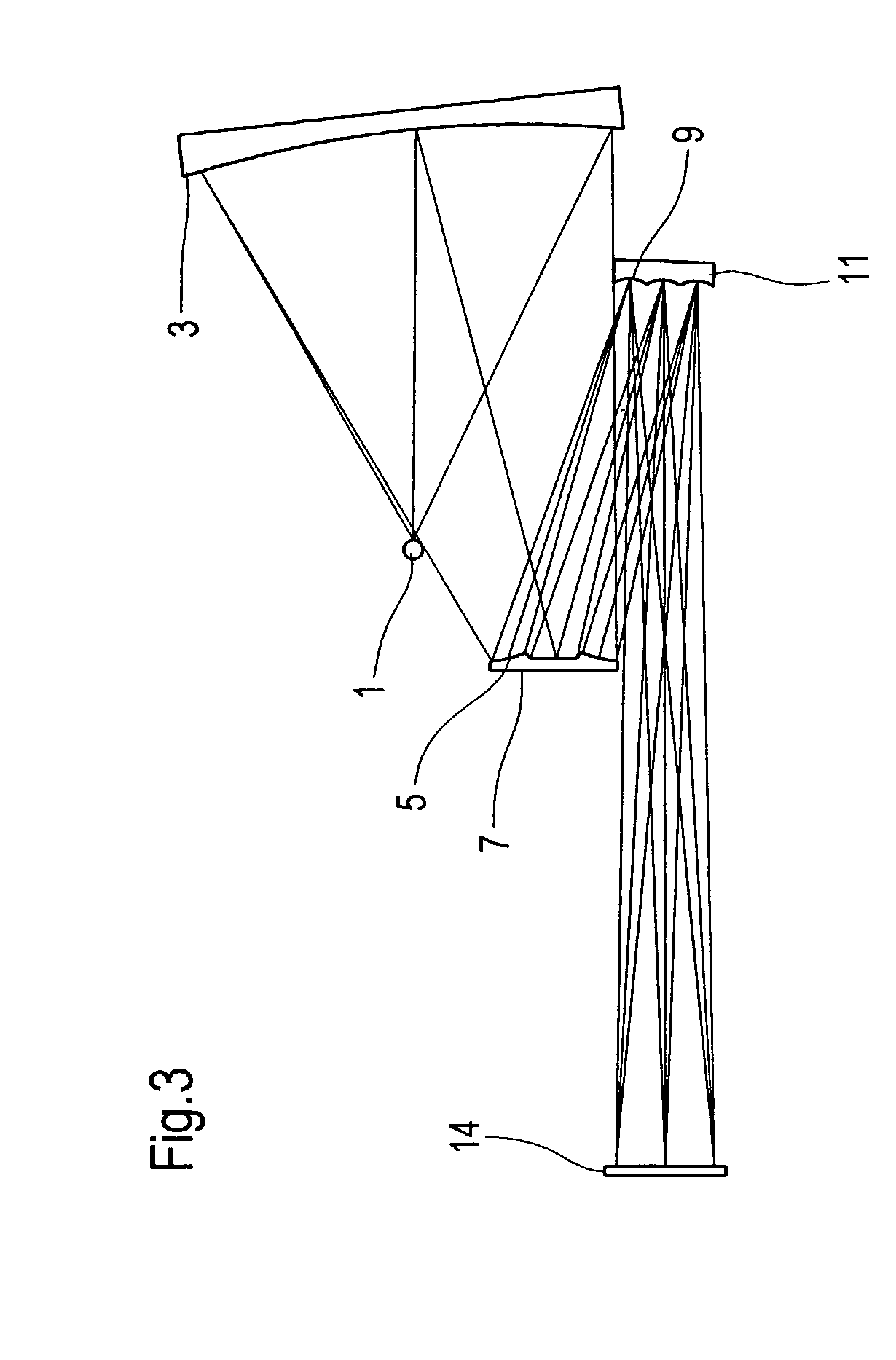

An illumination system comprises (a) a first optical element upon which a light beam impinges, where the first optical element has first raster elements that partition said light beam into light channels; (b) a second optical element that receives said light channels, where the second optical element has a second raster elements; (c) an object plane that receives said light channels via said second optical element; and (d) an exit pupil that is provided with an illumination via said object plane. The system is characterized by an assignment of a member of said first raster elements and a member of said second raster elements to each of said light channels to provide a continuous beam path from said first optical element to said object plane for each of said plurality of light channels. The assignment is changeable to provide an adjustment of said illumination in said exit pupil.

Owner:CARL ZEISS SMT GMBH

Illumination system with variable adjustment of the illumination

InactiveUS20020136351A1Avoid lostSimple wayNanoinformaticsHandling using diffraction/refraction/reflectionGratingExit pupil

An illumination system comprises (a) a first optical element upon which a light beam impinges, where the first optical element has first raster elements that partition said light beam into light channels; (b) a second optical element that receives said light channels, where the second optical element has a second raster elements; (c) an object plane that receives said light channels via said second optical element; and (d) an exit pupil that is provided with an illumination via said object plane. The system is characterized by an assignment of a member of said first raster elements and a member of said second raster elements to each of said light channels to provide a continuous beam path from said first optical element to said object plane for each of said plurality of light channels. The assignment is changeable to provide an adjustment of said illumination in said exit pupil.

Owner:CARL ZEISS SMT GMBH

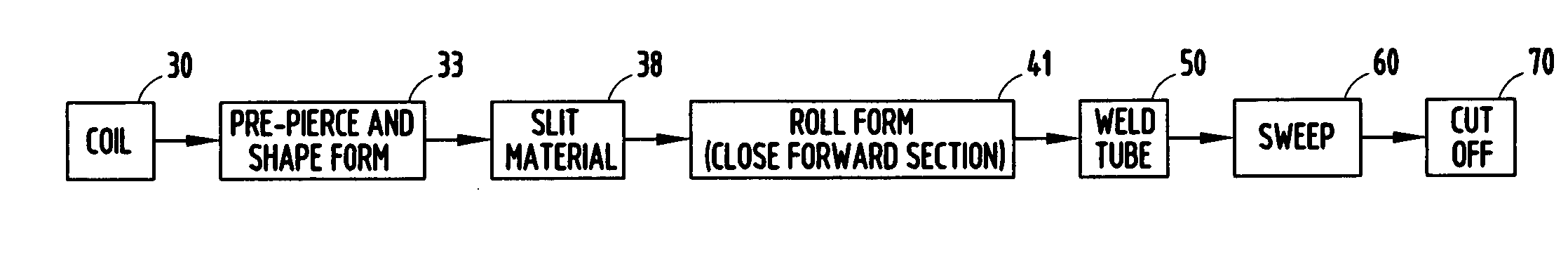

Continuous process of roll-forming stamped sheet

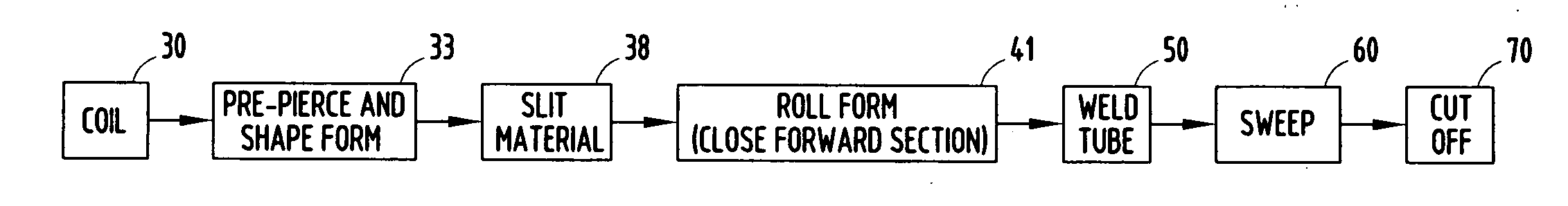

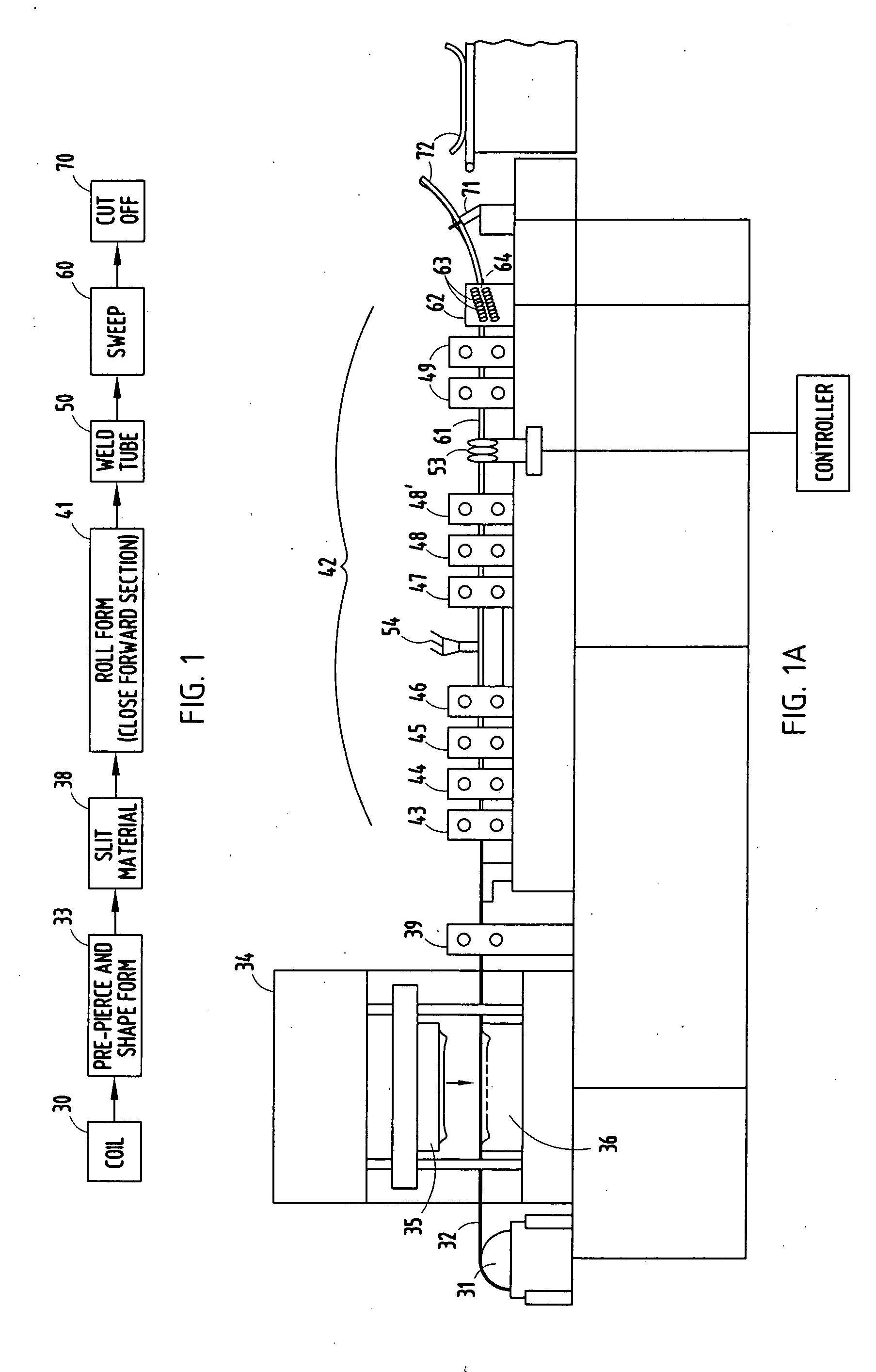

An apparatus includes a press with dies configured to deform a strip of material by drawing material primarily from a width direction, a slitter set to cut the deformed strip to a uniform desired width dimension, and a roll-former with rolls configured to shape linear portions of the deformed and now uniform-width strip into a continuous beam. The apparatus further includes a welder for welding abutting edges of the sheet together to form a permanent tube, a sweep station for imparting a longitudinal shape to the continuous beam, and a cut-off for cutting the continuous beam into segments useful as vehicle bumper beams. A controller controls timing of various components. The beam segments are optimized in specific regions for local strength and minimized weight, and features can be incorporated into the beam segments such as coplanar mounting surfaces.

Owner:SHAPE CORP

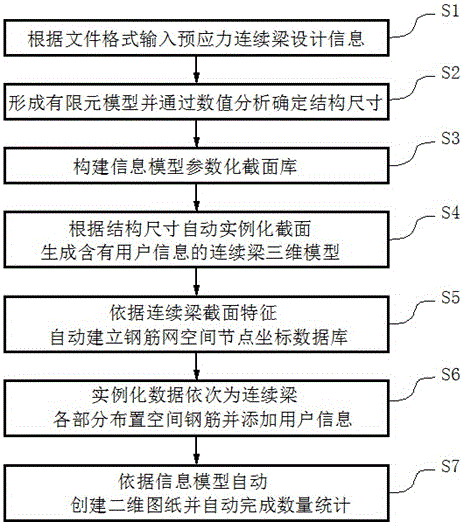

Pre-stressed continuous concrete beam design method based on BIM technology

ActiveCN106354968AAchieve integrationRealize automatic generationGeometric CADDesign optimisation/simulationElement modelContinuous beam

The invention discloses a pre-stressed continuous concrete beam design method based on the BIM technology. The pre-stressed continuous concrete beam design method includes the following steps that according to a file format, pre-stressed continuous beam design information is input; a finite element model is formed, and the structure size is analyzed and determined through the numerical value; an information-model parameterization cross section library is built; according to the structure size, a cross section is automatically instantiated to generate a continuous beam three-dimensional model containing user information; according to the characteristics of the cross section of the continuous beam, a reinforcing-steel-bar-net space node coordinate database is automatically built; instantiation data is sequentially comprises all parts of arrangement space reinforcing steel bars of the continuous beam, and user information is added; according to an information module, two-dimensional drawings are automatically established, quantity statistics is automatically completed. By means of the pre-stressed continuous concrete beam design method based on the BIM technology, rapid forming of universal data, the three-dimensional information model and the reinforcing-steel-bar drawings is achieved, and the pre-stressed continuous concrete beam design method has good popularization value and the good application value.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

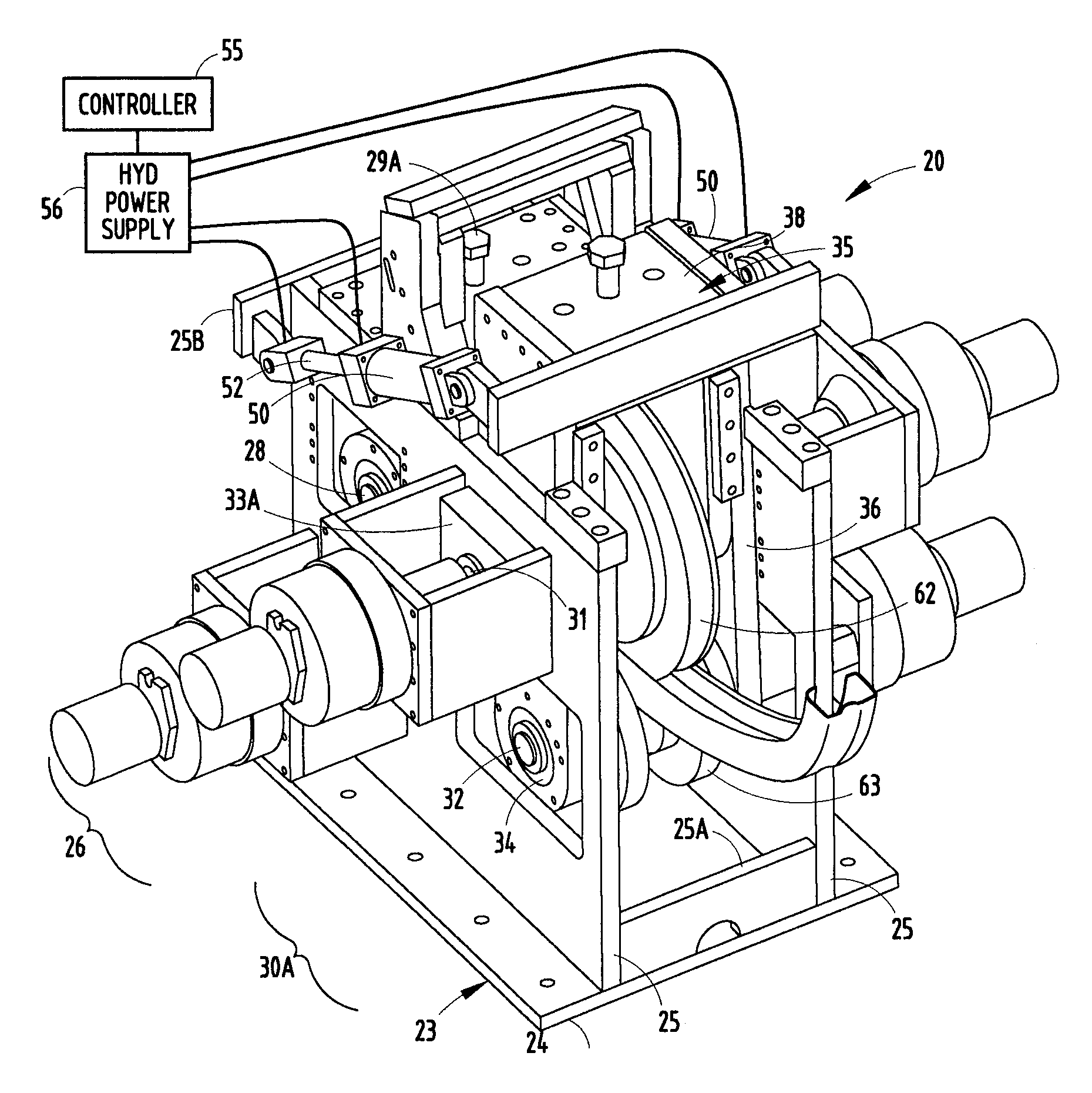

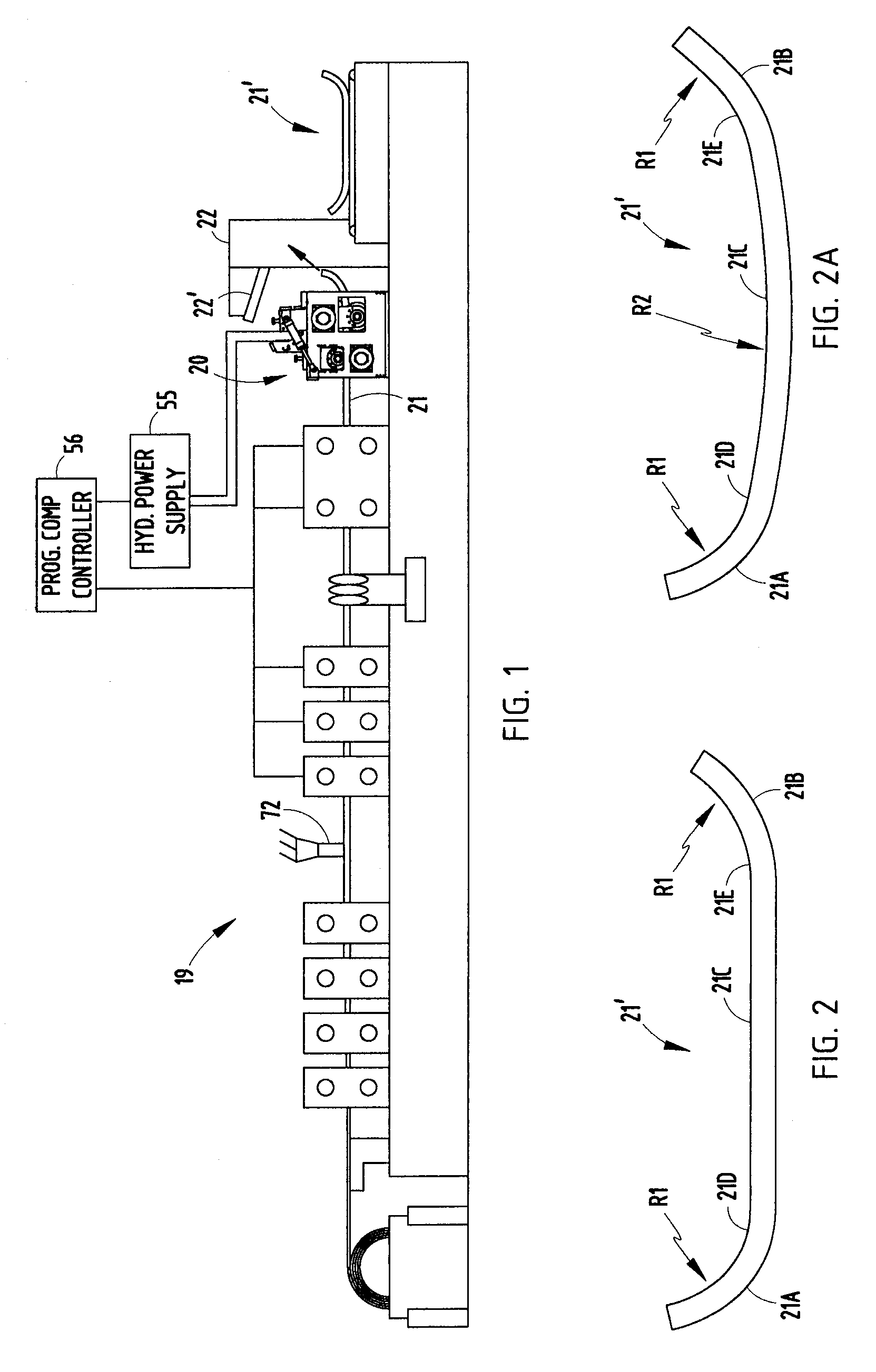

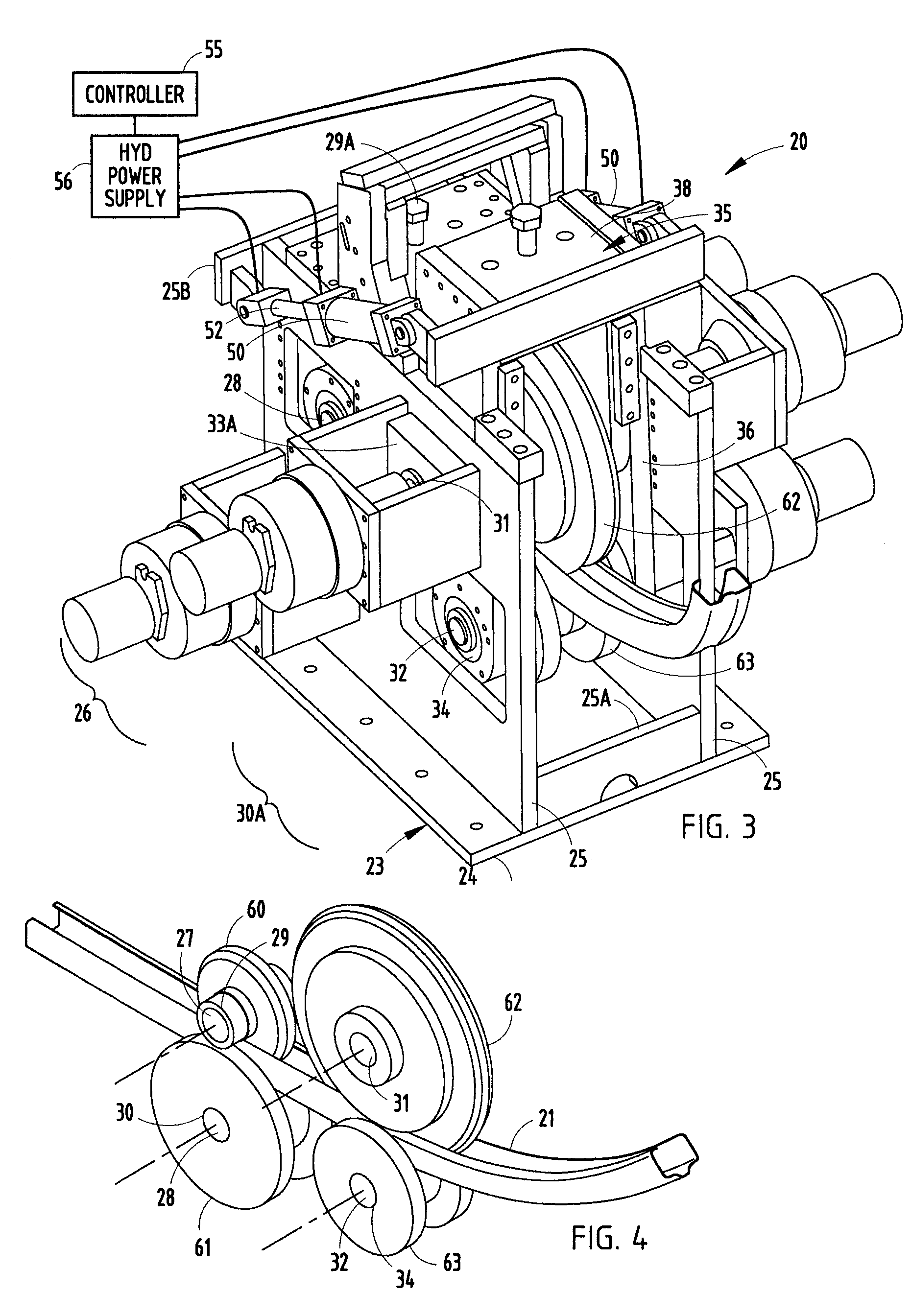

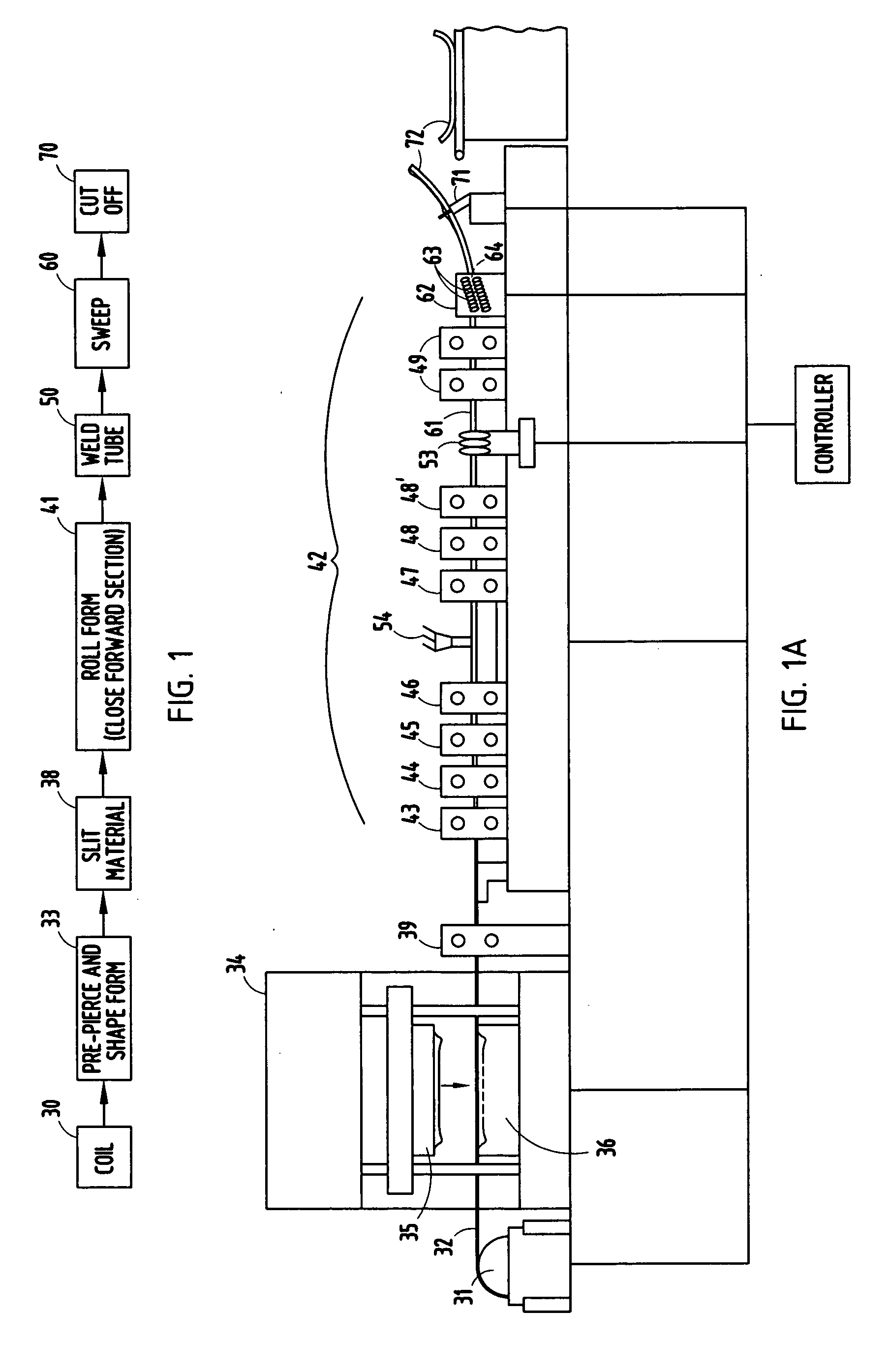

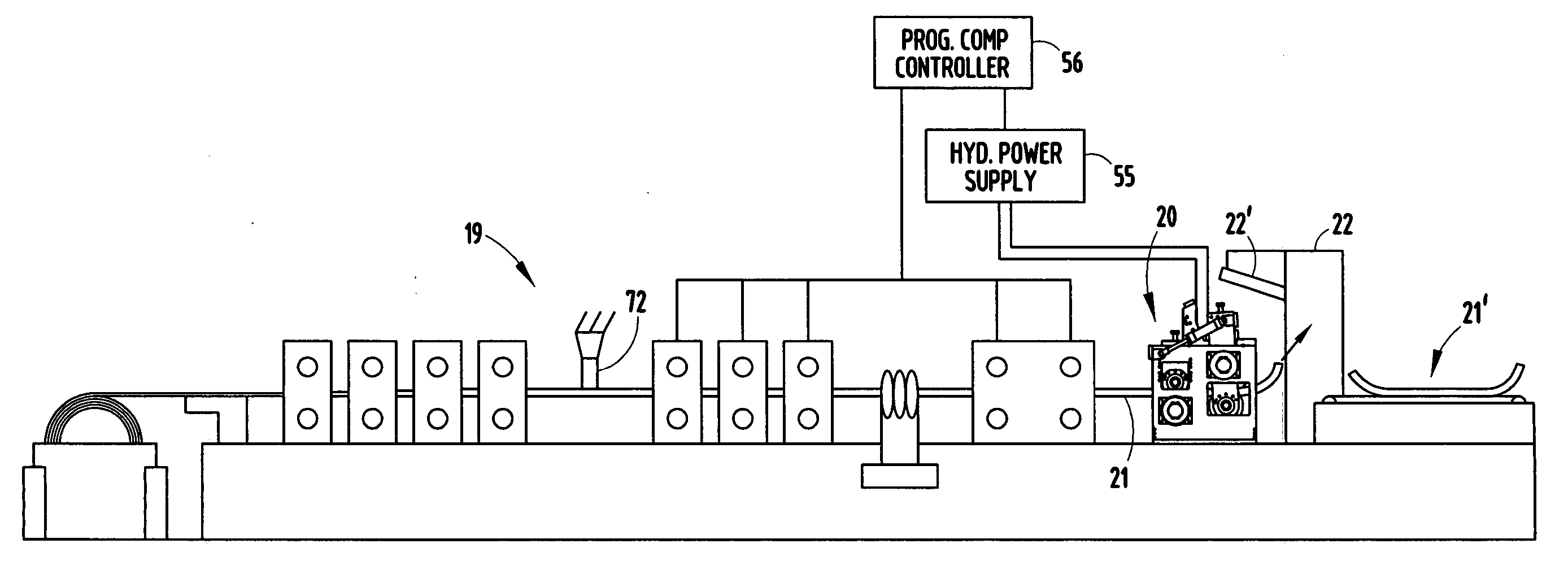

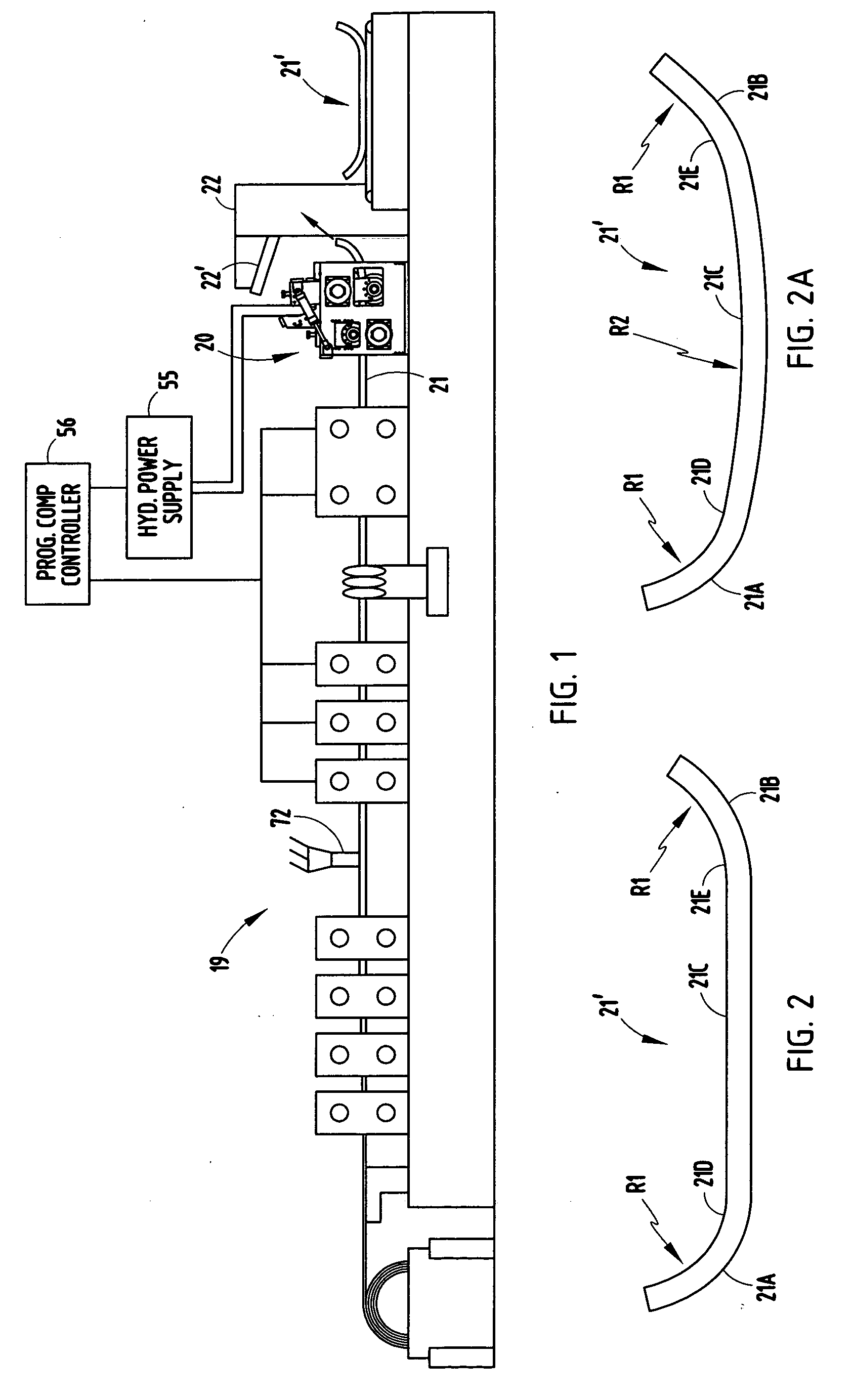

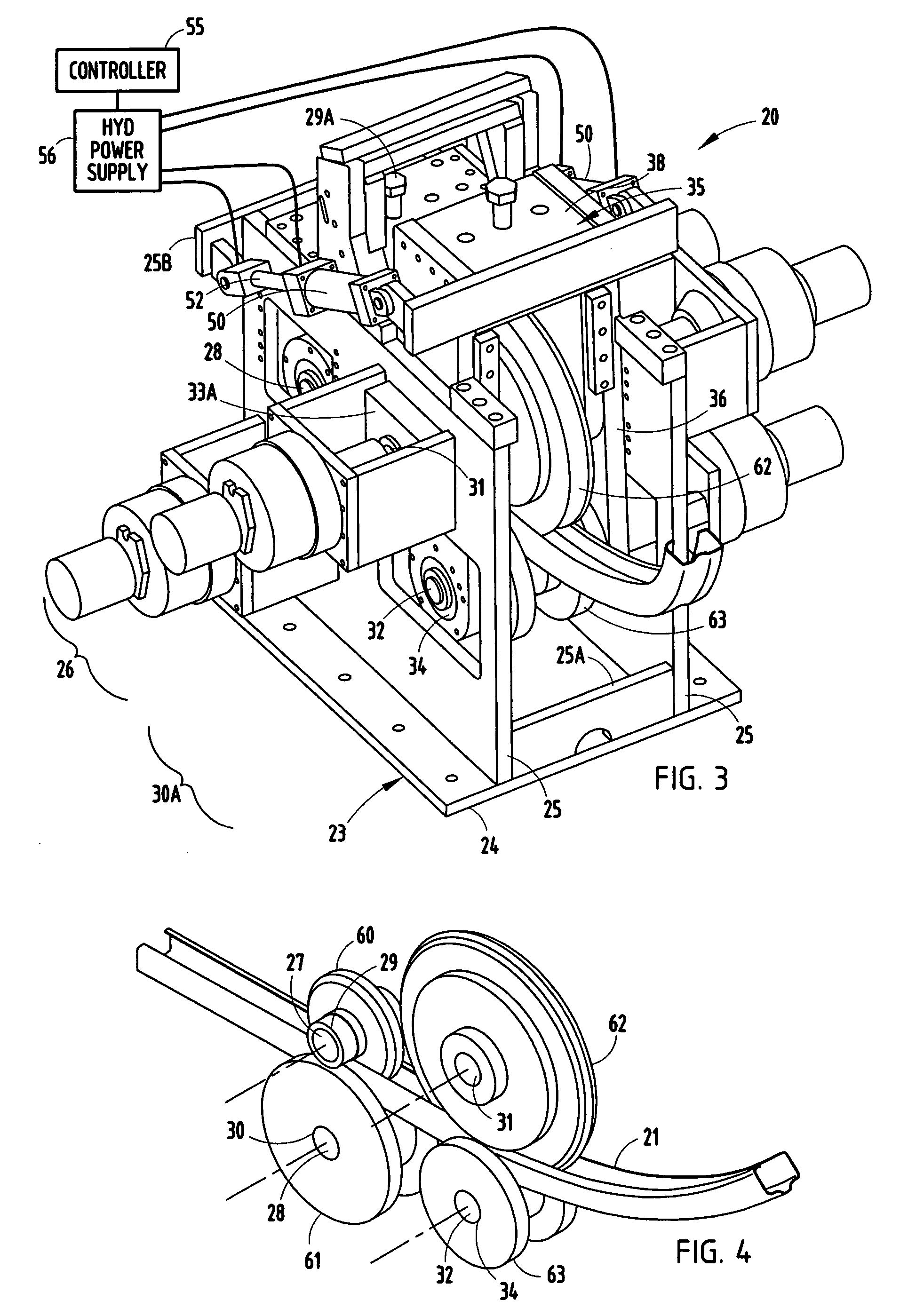

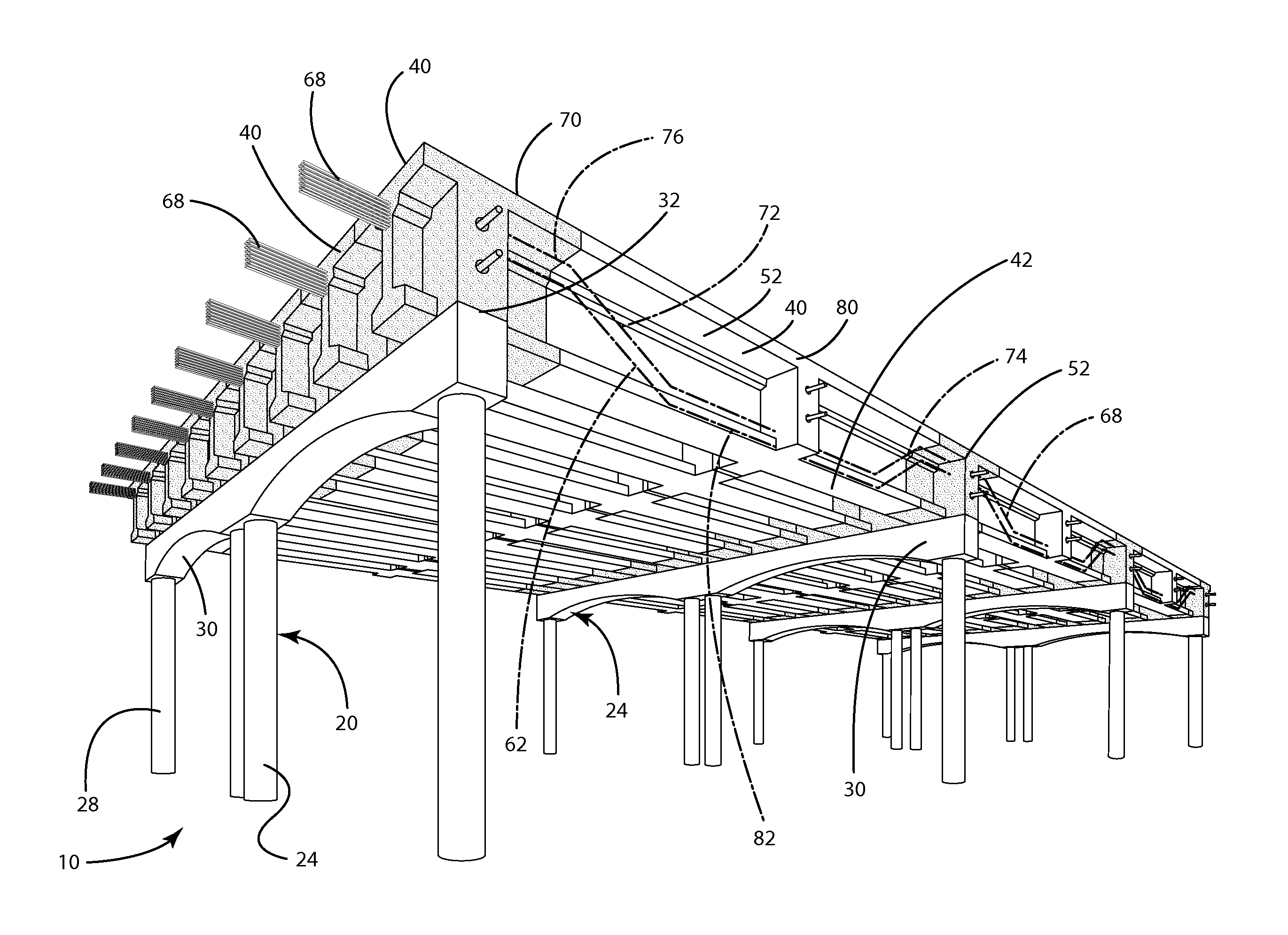

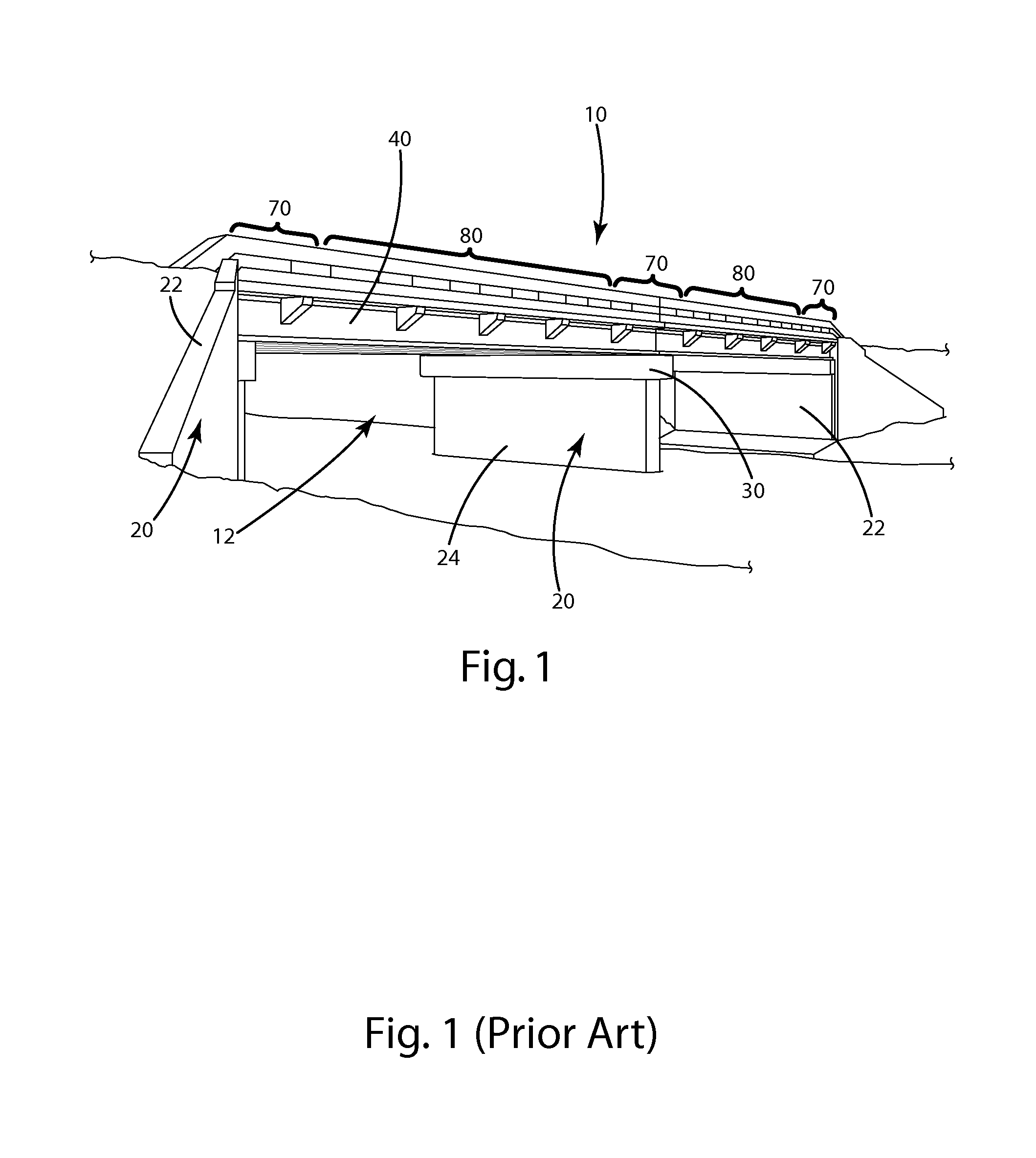

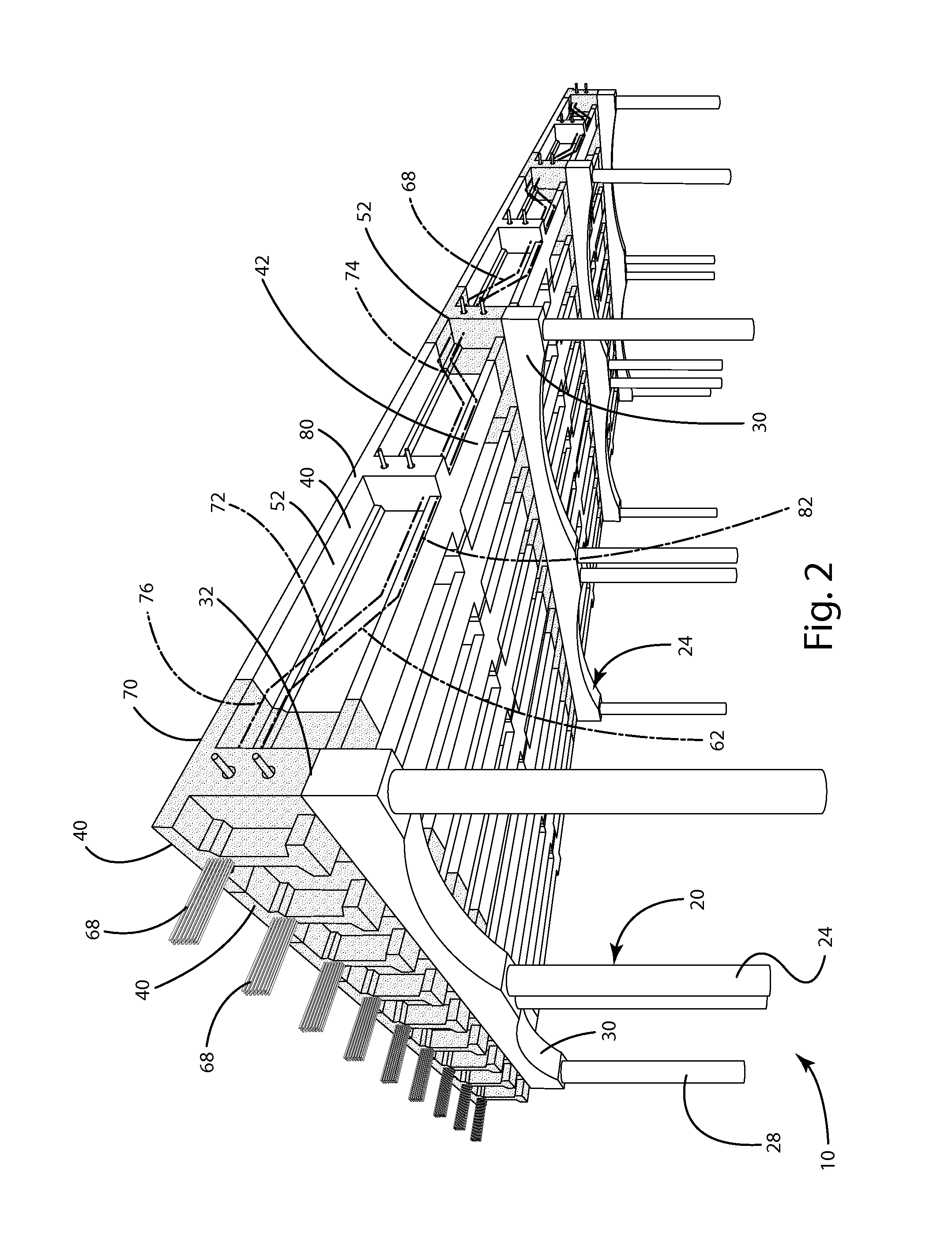

Roll-former apparatus with rapid-adjust sweep box

A computer controlled roll-forming apparatus is adapted to provide a repeating pattern of different longitudinal shapes to a continuous beam “on the fly” during the roll-forming process. A sweep station of the apparatus includes a primary bending roller tangentially engaging the continuous beam along the line level and an armature for biasing the continuous beam against the primary bending roller for a distance partially around a downstream side of the primary bending roller to form a sweep. Actuators adjustably move the armature partially around the downstream side of the primary bending roller between multiple positions for imparting a series of different longitudinal shapes. Internal and external mandrels control wall stability to allow even sharper sweeps. In one form, the apparatus also includes a coordinated cut-off, so that when separated into bumper beam segments, the ends of the individual beam segments have a greater sweep than their center sections.

Owner:SHAPE CORP

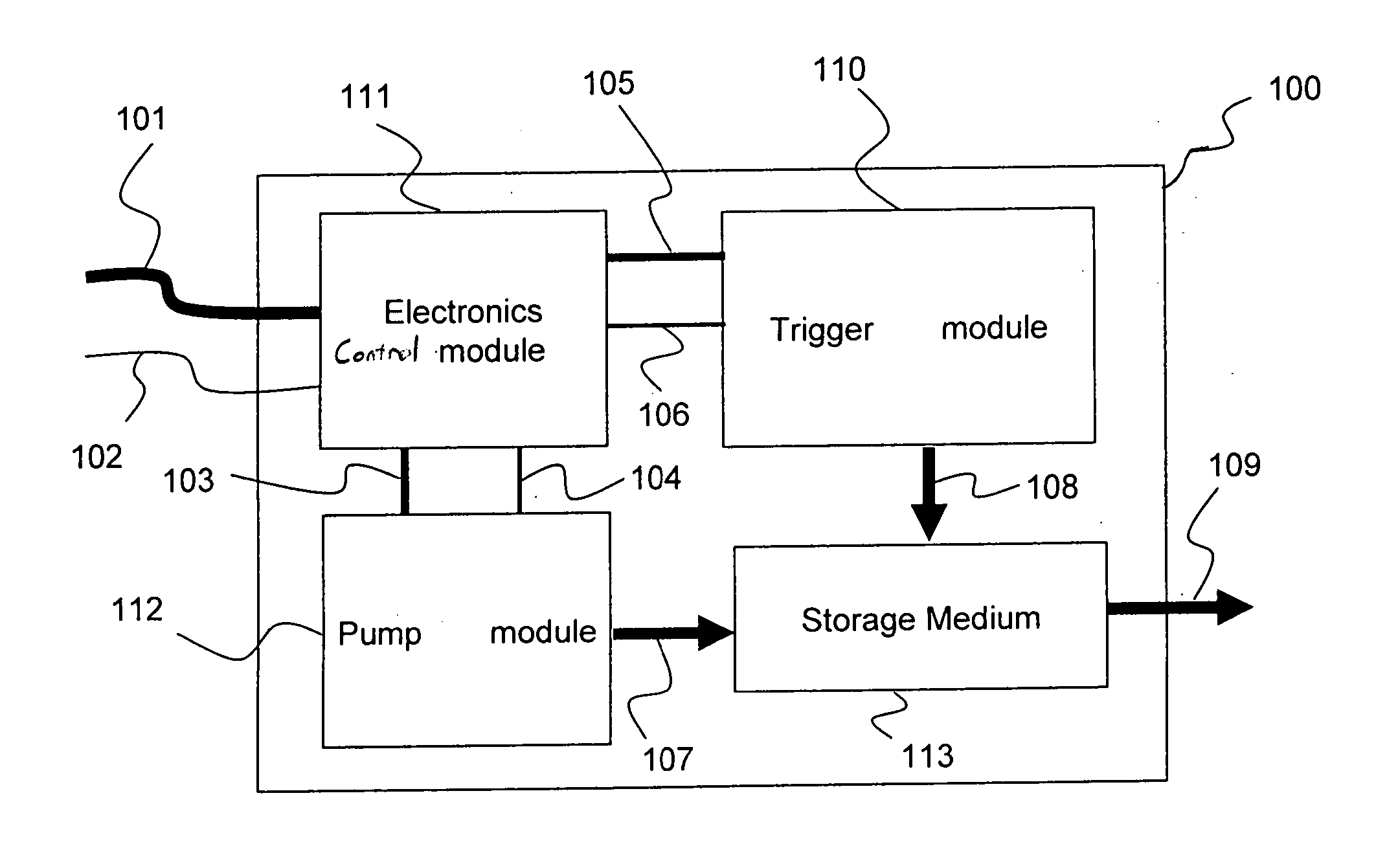

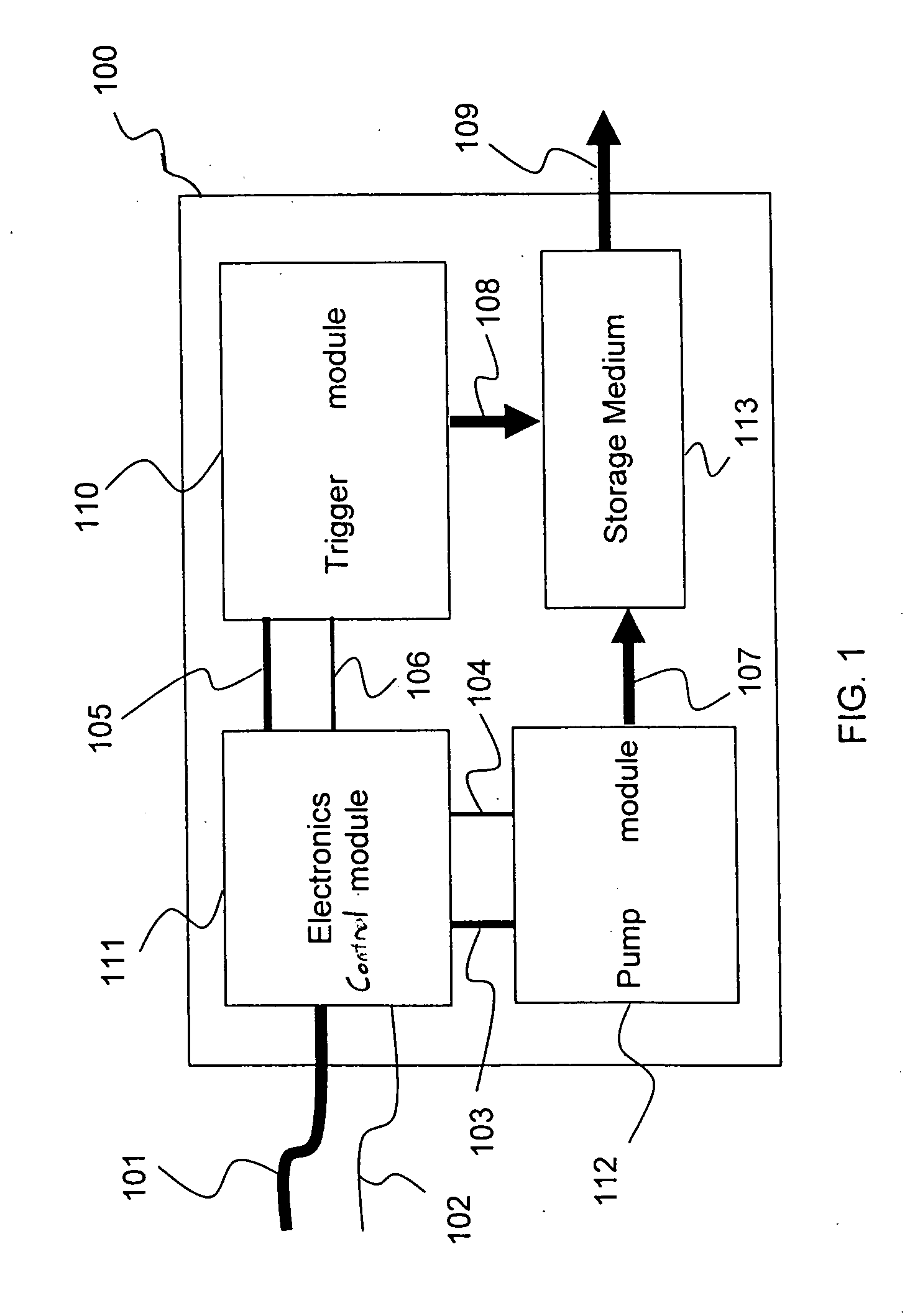

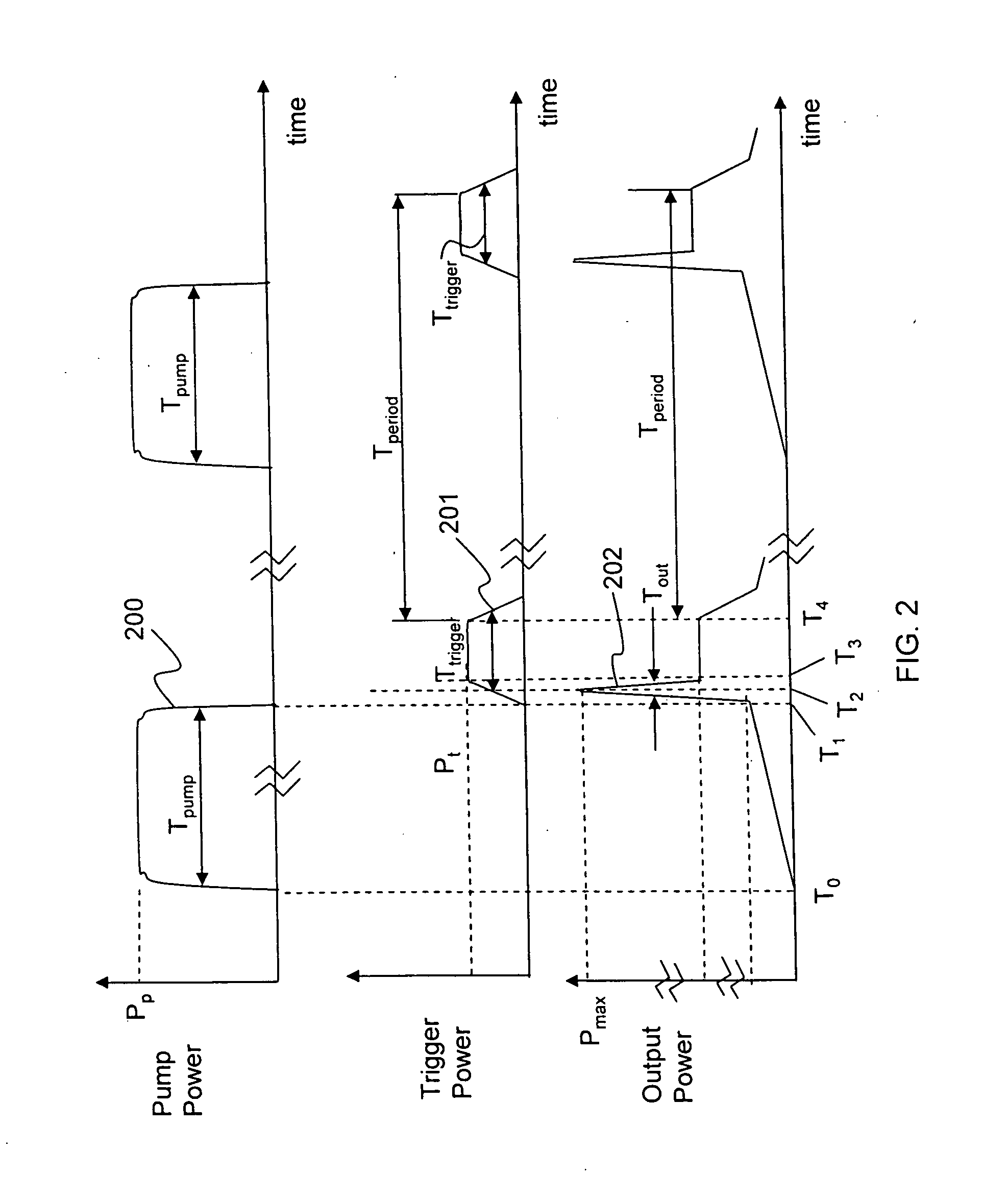

Apparatus and method for generating short optical pulses

An apparatus for generating short optical pulses is provided having a storage medium capable of storing optical energy, a first module for delivering pumping optical pulses or continuous beam into the storage medium to energize the storage medium, and a second module for delivering one or more trigger optical pulses to the optical storage medium. Each of the trigger optical pulses has a rising edge which causes a cascade release of the energy stored in the storage medium in an output optical pulse having a greater power and narrower in width or duration (at full width at half maximum) than the trigger optical pulse that caused the output pulse. A control module in the apparatus controls the operation of the pump module and trigger module so as to provide the desired characteristics of output optical pulses from the apparatus.

Owner:CLEAR ALIGN

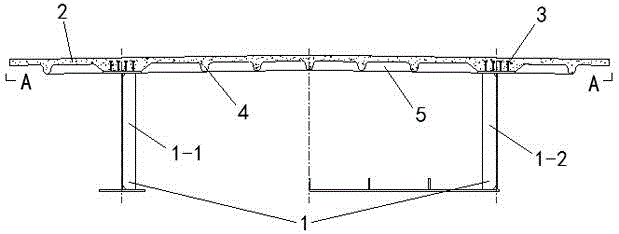

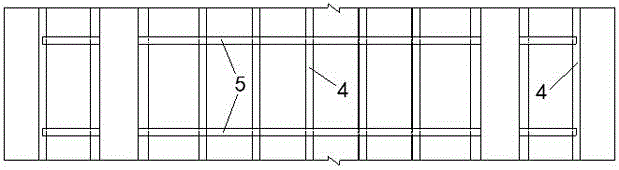

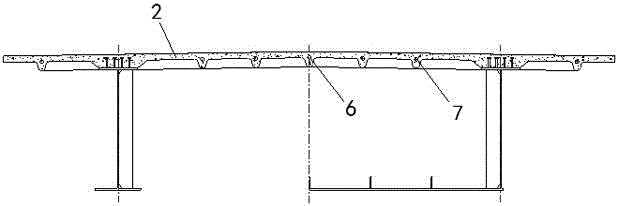

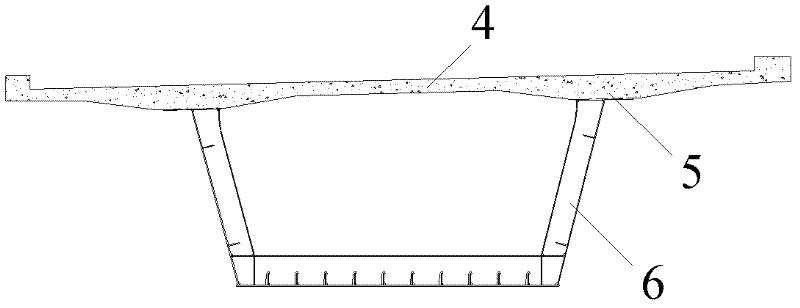

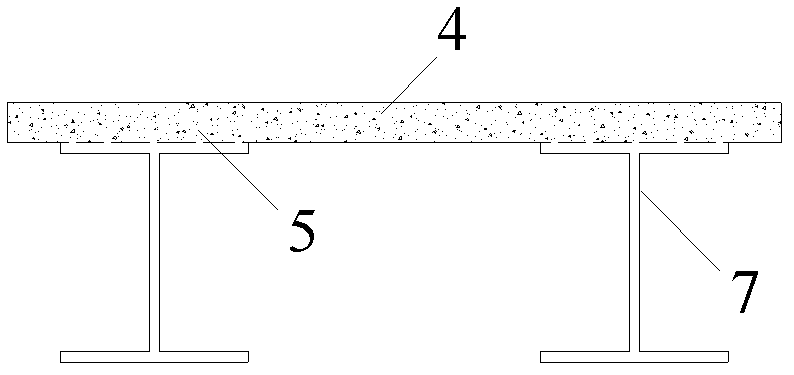

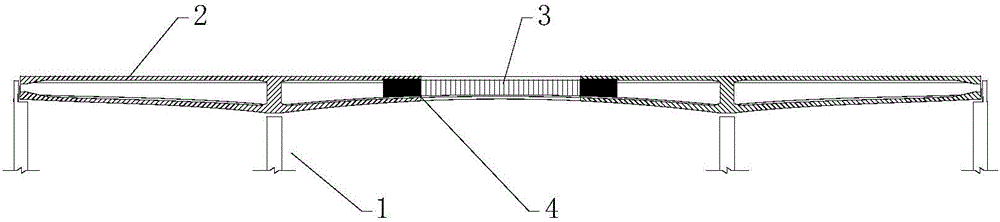

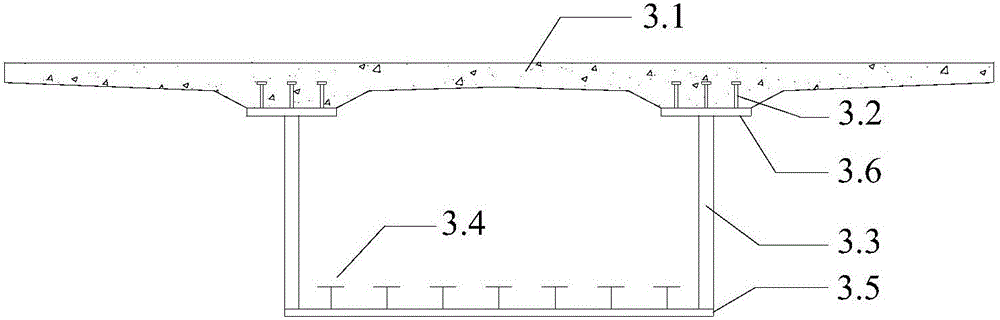

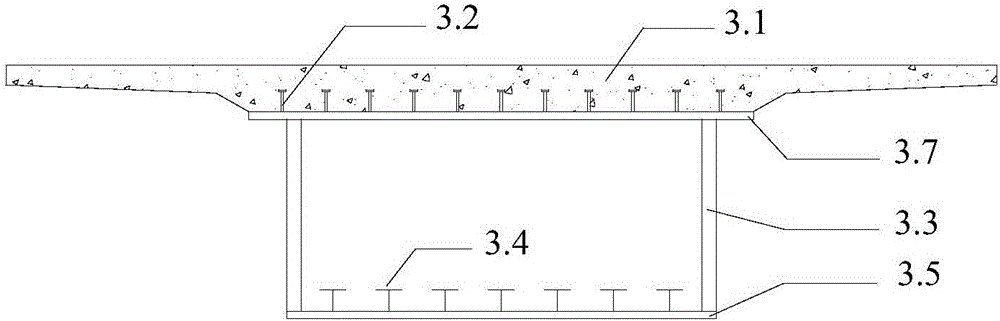

Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

InactiveCN104831617AReasonable forceHigh strengthBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a steel-super high performance concrete composite beam based on a ribbed plate type bridge deck and a construction method. The construction method includes the following steps that step1, steel beams are machined, manufactured and installed; step2, shearing force connecting parts are welded; step3, the super high performance concrete bridge deck is constructed; step4, a guardrail or an anti-collision wall is constructed; step5, bridge deck pavement is constructed, wherein the super high performance concrete bridge deck and the steel beams are fixed through the shearing force connecting parts, the cross section or / and the longitudinal section of the super high performance concrete bridge deck is / are of a ribbed plate structure, and pre-stressed reinforcements can be arranged on a longitudinal rib region or / and a transverse rib region. The composite beam is reasonable in stress, high in strength and capable of substantially reducing the structure dead weight, effectively avoiding defects at a hogging moment region of a composite continuous beam and bringing tensile strength, compressive strength and high durability of super high performance concrete into full play; the composite beam has the advantages of being small in building height, high in rigidity, small in dead weight, good in durability, crack resistance and fatigue resistance and the like, and has great practical value and good economic benefits.

Owner:FUZHOU UNIV

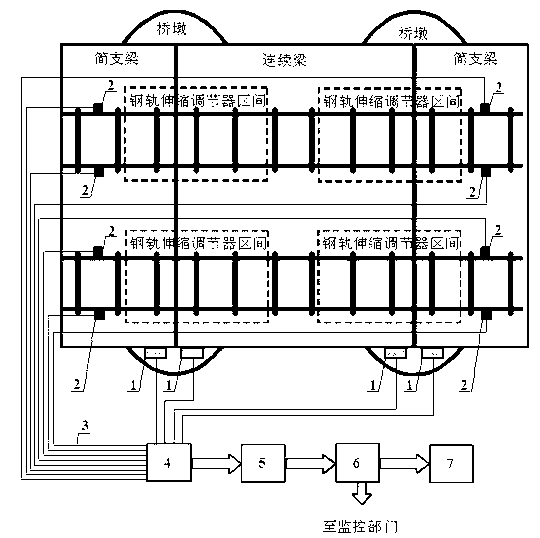

Method for dynamically monitoring health states of railway continuous-beam bridge and rail overlapping device

InactiveCN103215865AImprove long-term stabilityImprove anti-interference abilitySubsonic/sonic/ultrasonic wave measurementUsing optical meansGratingFiber Bragg grating

The invention provides a method for dynamically monitoring health states of a railway continuous-beam bridge and a rail overlapping device. Four fiber bragg grating vibrating sensors are arranged on the beam body end parts of a continuous beam and a simply supported beam; eight fiber bragg grating displacement sensors are arranged on a seamless rail, connected with the rail overlapping device, at a bridge seam joint; the vibrating sensors are used for performing vibration monitoring on a bridge seam body; the displacement sensors are used for performing continuous monitoring on the crawling displacement of the rail; and signals monitored by all the sensors are transmitted to a fiber splice box by virtue of a transmission fiber so as to be gathered, then are output to a demodulator so as to be demodulated and finally are transmitted to a data processing terminal so as to be processed and displayed, so that on-line dynamic monitoring is realized; by virtue of performing contrastive analysis on the historical change trend of data features and monitoring the health states of the railway continuous-beam bridge and the rail overlapping device, alarming is started if an alarm threshold value is exceeded, and the result is uploaded to a monitoring department in real time. The method can be used for dynamically monitoring the vibration of the bridge beam body and the displacement change of the rail in an on-line manner, prewarning in time and ensuring the heavy-load safe operation of a railway bridge.

Owner:WUHAN UNIV OF TECH

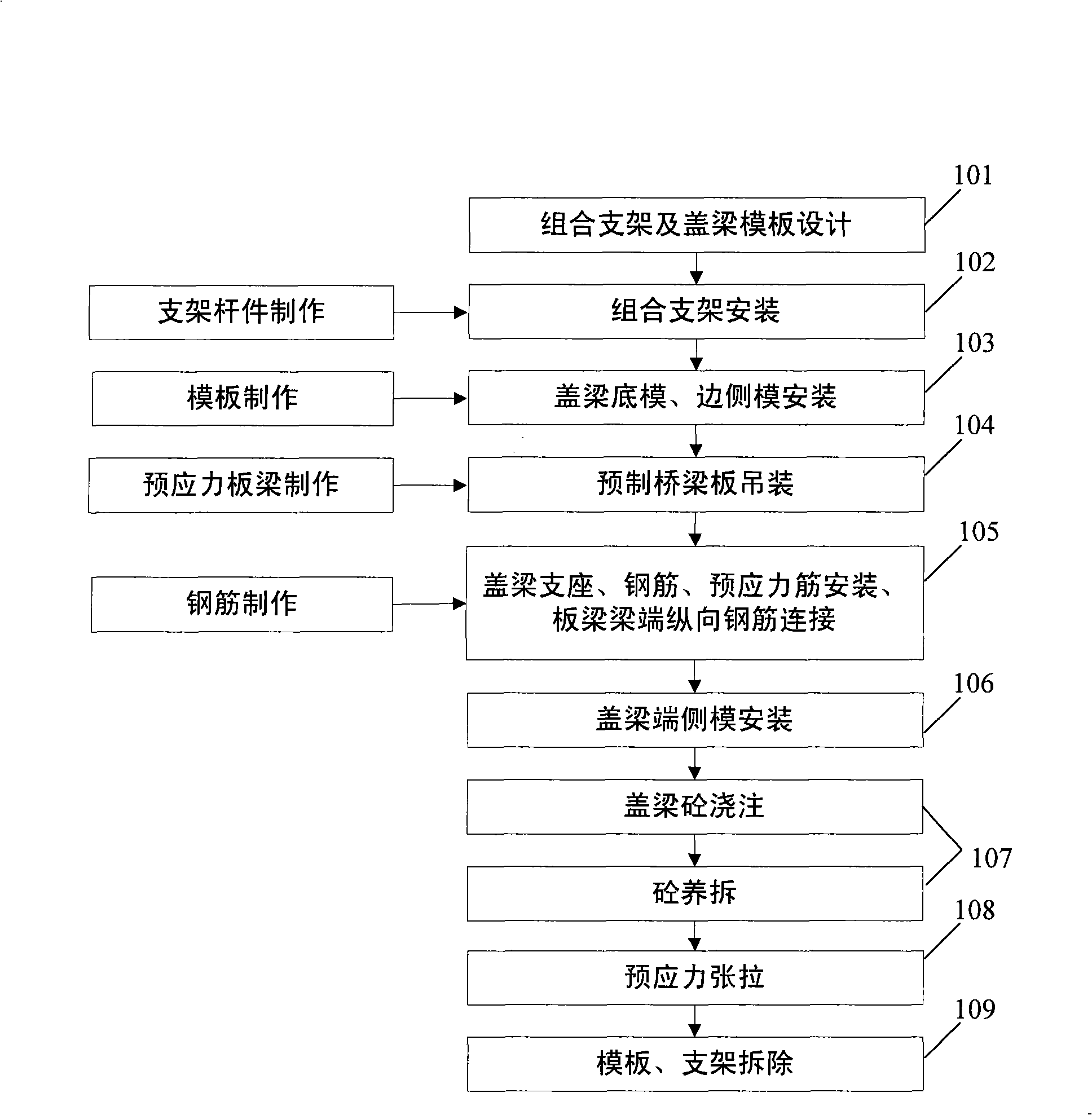

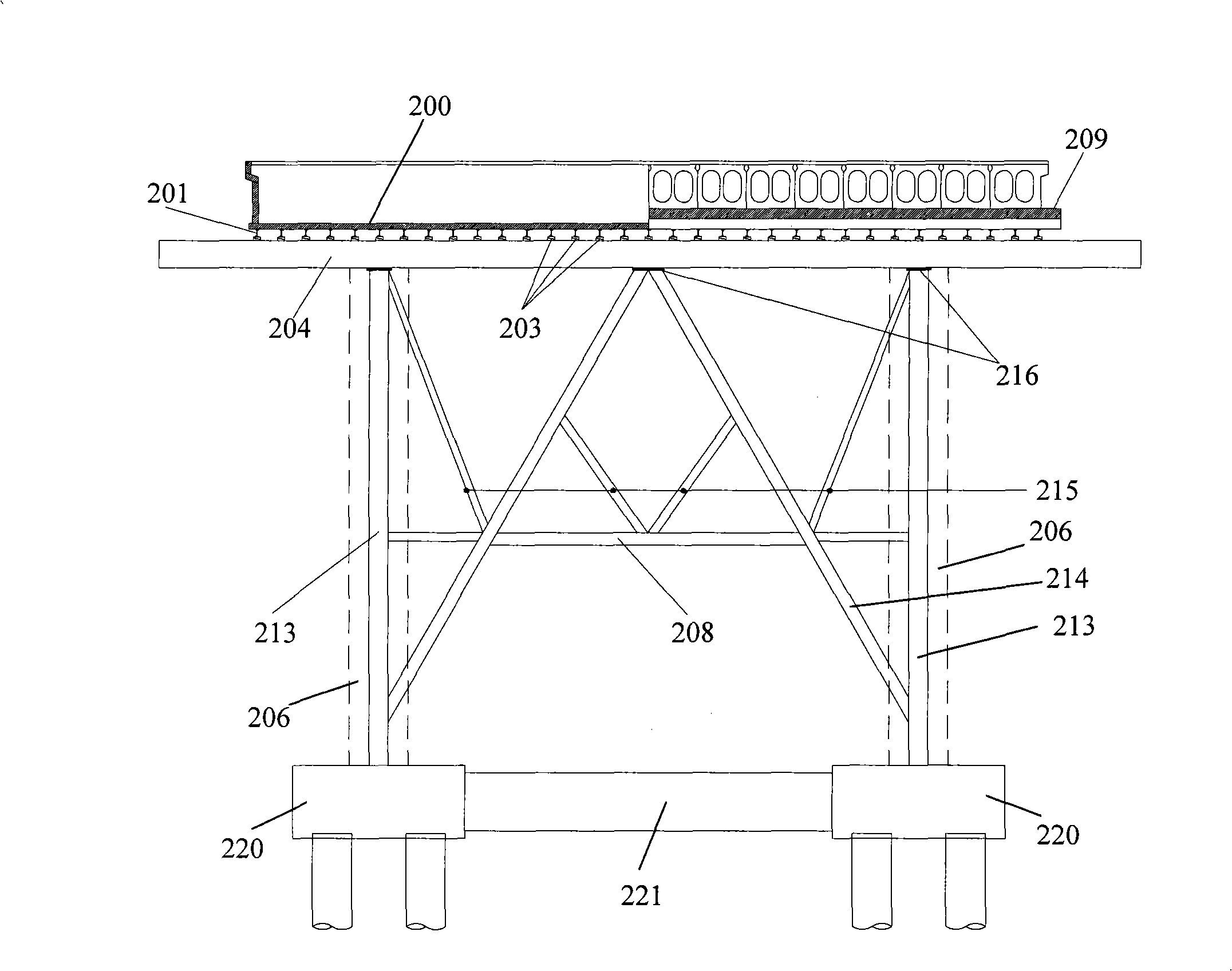

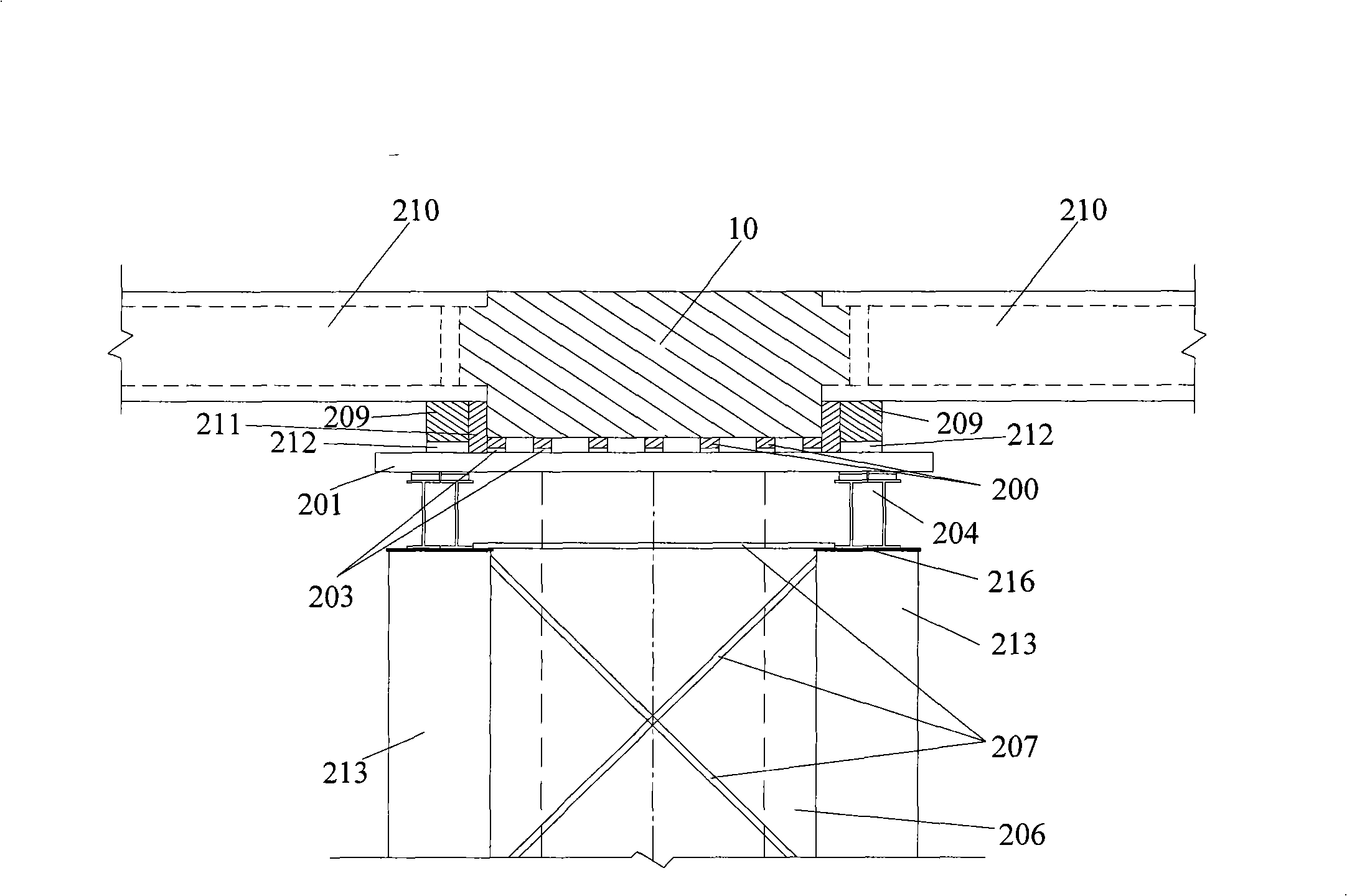

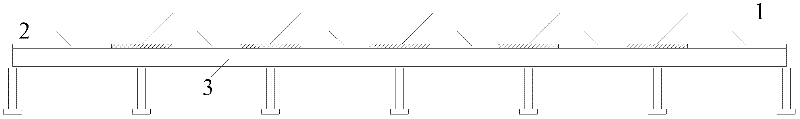

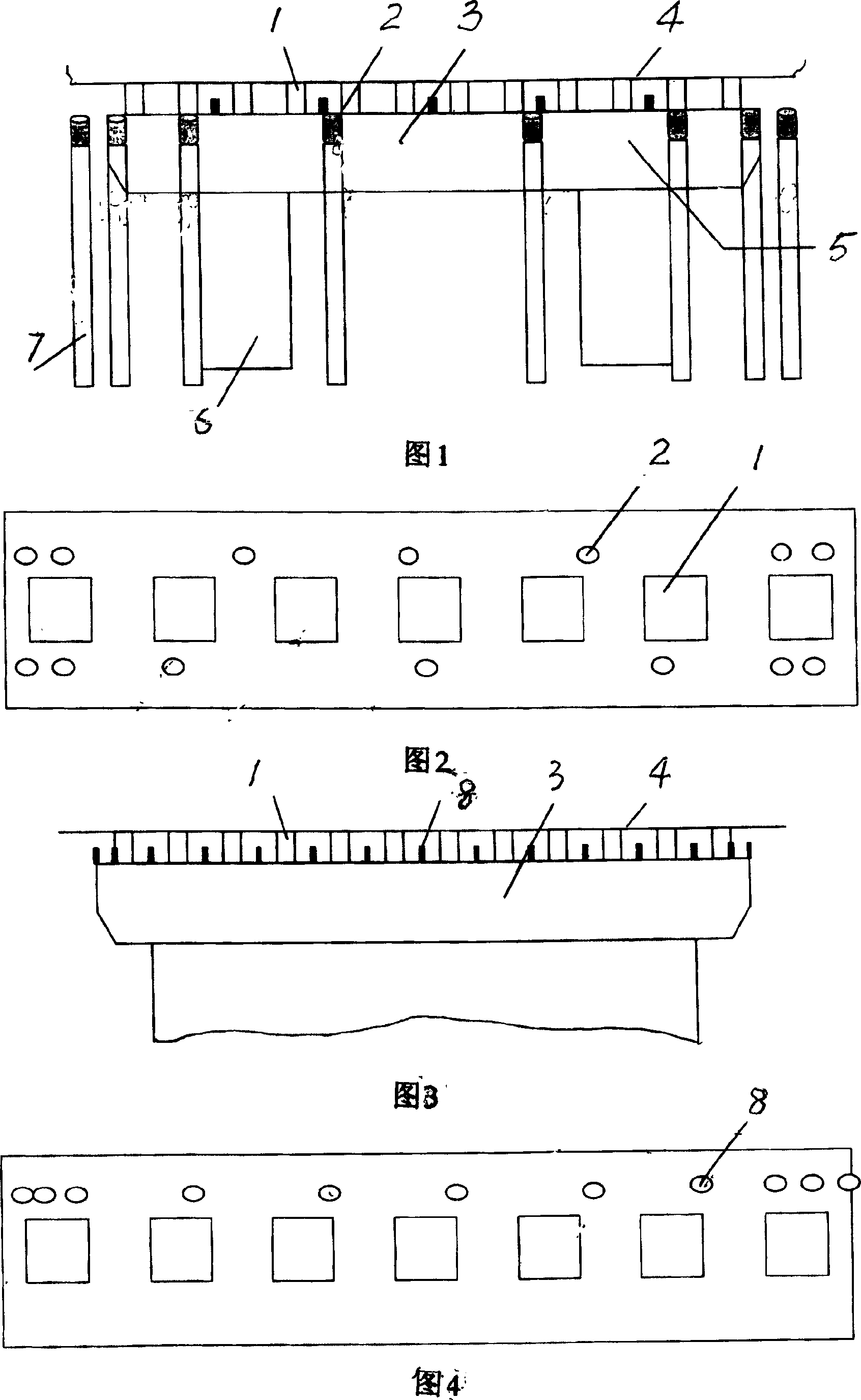

Post-poured hidden coping construction method for converting simply supported beams into continuous beams

ActiveCN101538831AAvoid harmLightweight componentsBridge erection/assemblyContinuous beamEngineering

The invention discloses a post-poured hidden coping construction method for converting simply supported beam into continuous beam. Plate girders are precast in a plant, are then connected with precast plate girders at two sides thereof via cast-in-situ copings so as to convert the precast plate girders into continuous beams, wherein the method of combining supports is adopted to carry out construction, in the method, a temporary support for installing the precast plate girders and a formwork support for installing the post-poured hidden copings are combined to be one, thus obtaining excellent effect.

Owner:HONGRUN CONSTR GROUP STOCK

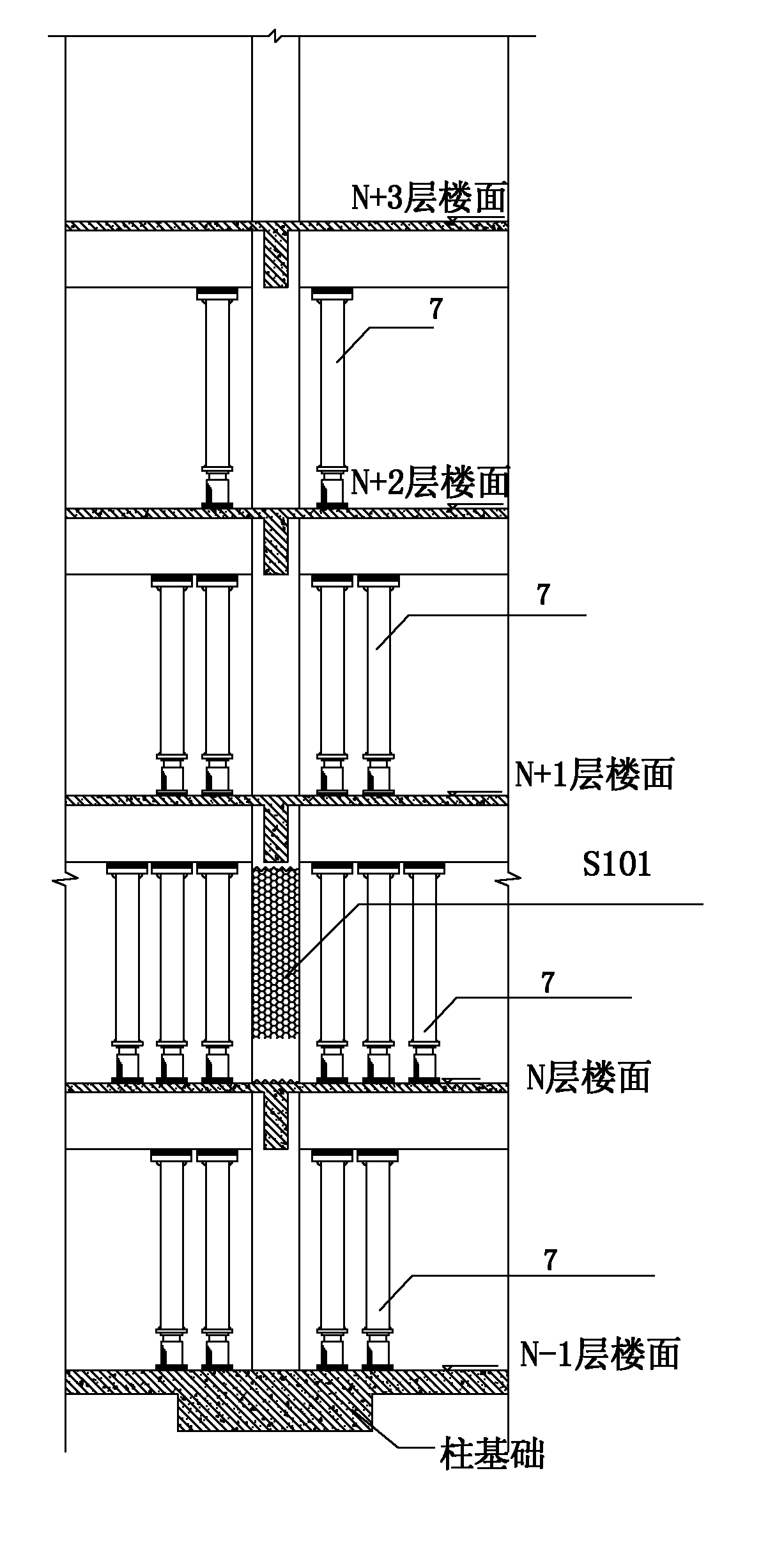

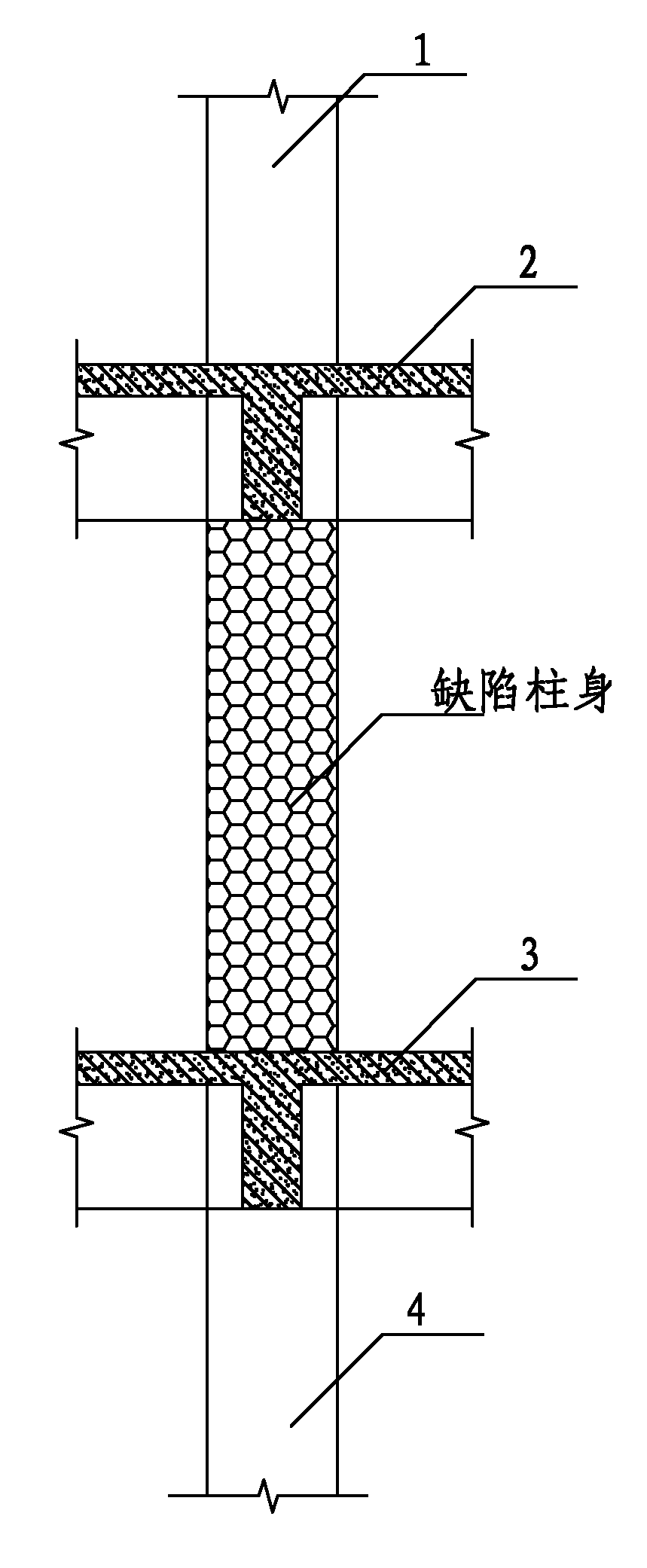

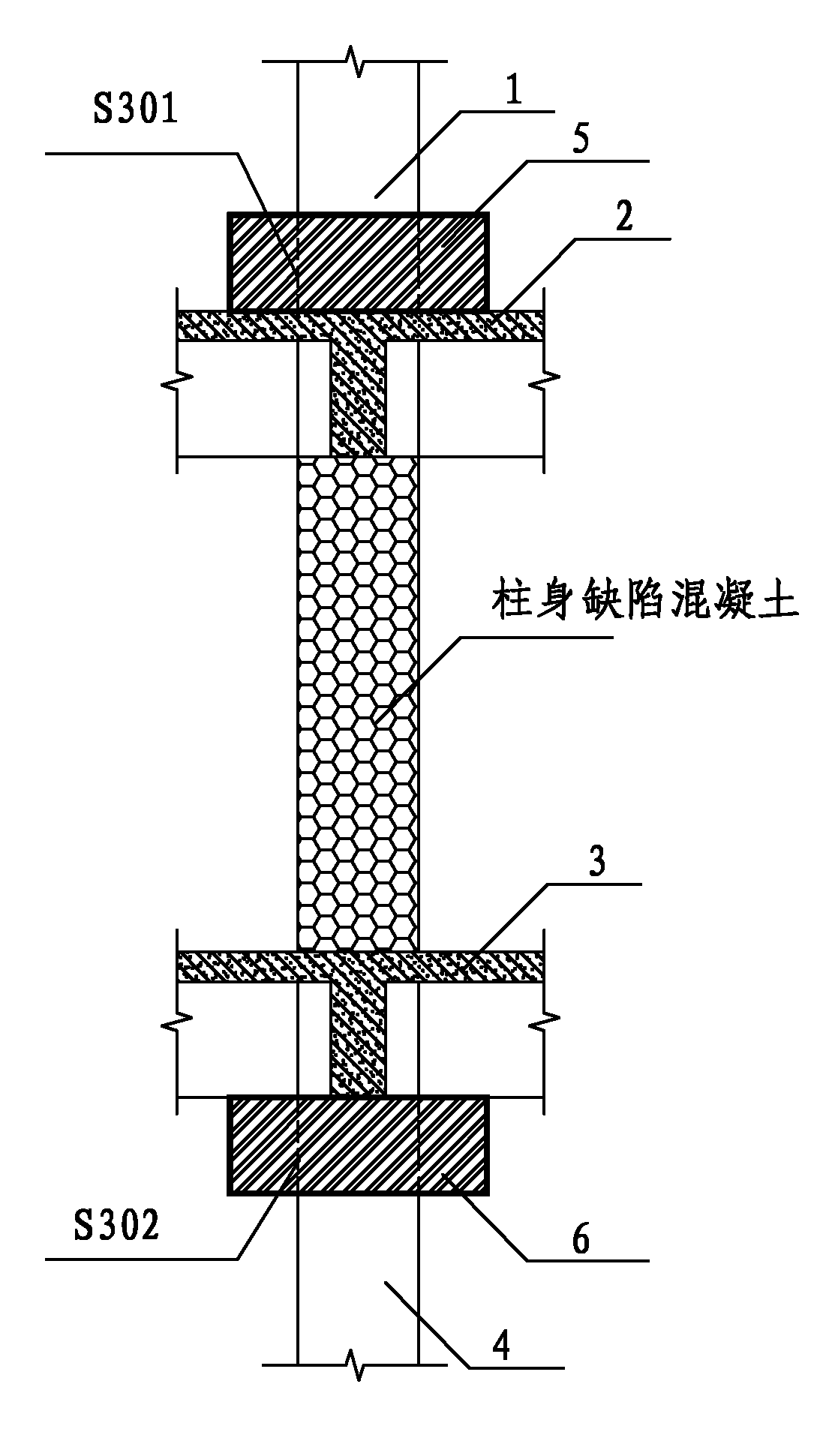

Displacement method of defective concrete of column body

InactiveCN102505866AThe way of power transmission is clearForce safe and reliableBuilding repairsStress conditionsReinforced concrete

The invention provides a displacement method of a defective concrete of a column body. The displacement method comprises the following steps of: respectively arranging displacement platforms on the upper end and the lower end of a column displacement layer as supporting ends of a steel pipe jack so as to carry out a disposable underpinned displacement of the defective concrete of a reinforced concrete frame column directly. In the displacement method, only the steel pipe jack support is arranged on the displacement layer, and multilayer continuous beam support of the steel pipe jack is unnecessary, the supporting load of the steel pipe jack is directly transmitted to the displacement platforms once, and the load is returned to an upper layer of the column body and a lower layer of the column body through the displacement platforms, so that a stress condition is clear and reasonable, the setting number of steel pipe jacks is reduced greatly; furthermore, a construction working face is small, so that the construction influence range is only located on the displacement layer, a layer on the displacement layer and a layer under the displacement layer. The displacement method of the defective concrete of the column body, provided by the invention, has the characteristics of simple design and construction, low construction cost, safety, reliability and the like.

Owner:广州华特建筑结构设计事务所

Construction method of swivel continuous beam for crossing railway bridges

The invention relates to a construction method of a swivel continuous beam when the existing railway bridges are crossed. The construction method is invented mainly to solve the existing problem that the construction method of bridge swivel can not be adopted when the distance between a pier body and the existing slope toe of the railway is short. The scheme adopted is that a center bearing rotates and a balanced supporting lug keeps stable as supplementary. The center bearing is taken as the swivel system and a swiveling system is arranged between the upper and lower cushion caps; a jack on both sides of a upper turntable is taken as a traction jack, another two jacks are arranged as start and boost jacks; a traction reaction base is arranged on the lower cushion cap, and the traction cable is placed on the concrete tray at the bottom of the upper cushion cap; after the completion of the box beam construction, the traction system is started, the overall formed by the upper cushion cap, pier body and box beam rotates around a hinge pin located in the center of the spherical hinge to get an angle, when the overall arrives at the location, the concrete is used for filling the gap between the upper and lower cushion caps for sealing and fixing the turntable, then the closure section is constructed. The advantage of the construction method of swivel continuous beam for crossing railway bridges is that it can be applied to the continuous box beam's construction when the distance between the pier body and the existing slope toe of the railway is short.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD +1

Simply supported-continuous construction method for bridge superstructure

The invention relates to a simply supported-continuous construction method for a bridge superstructure, The method comprises the following steps: firstly, prefabricating standard simply supported small box girders in batch; installing temporary steel brackets at two sides of a bracket steel tube column that is erected on each cushion cap, installing a temporary support with adjustable elevation at the tops of the steel brackets, and lifting the prefabricated simply supported small box girders on the temporary supports arranged on the steel brackets; after that, arranging a transverse prestressed reinforcing steel at the cross beam position between the simply supported small box girders, arranging longitudinal hogging moment bundles through reserved holes arranged at the top surfaces of the simply supported small box girders; pouring concrete into cross beams; and stretching and drawing by use of prestress after the concrete reaches the designed strength to form a two-way prestress continuous beam system. The simply supported-continuous construction method provided by the invention has the characteristics that the simply supported box girder has low manufacturing cost and a simple structure and facilitates industrialized production and lifting work, and a continuous bridge is good in integrity and reasonable in stress, so that the disadvantages that inclined section cracks occur at ends of the simply supported box girders, the bridge surface continuation is liable to damage, and the continuous bridge has high requirement on a foundation and supports and has a complex structure and long construction period can be avoided.

Owner:SHANGHAI NO 4 CONSTR

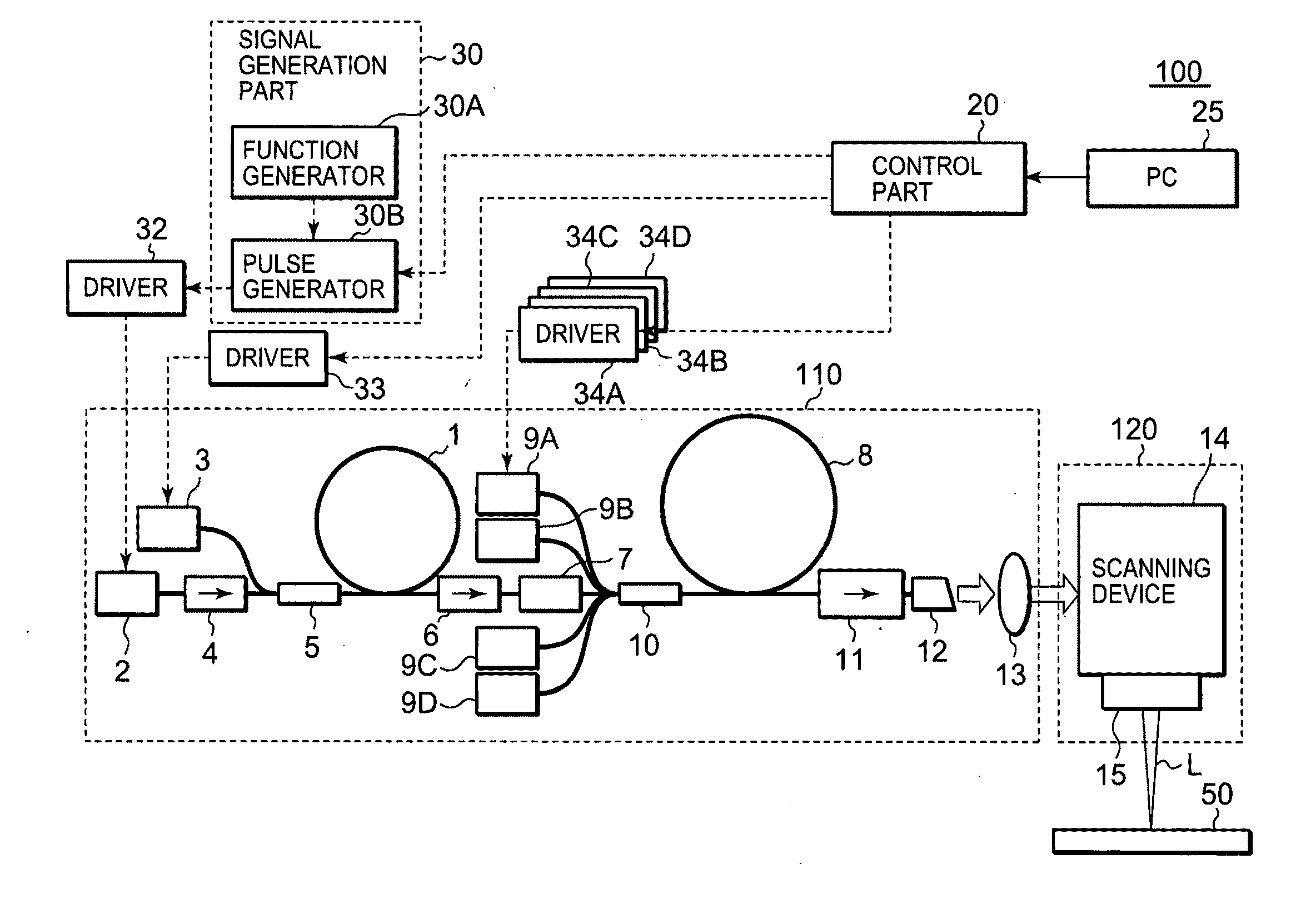

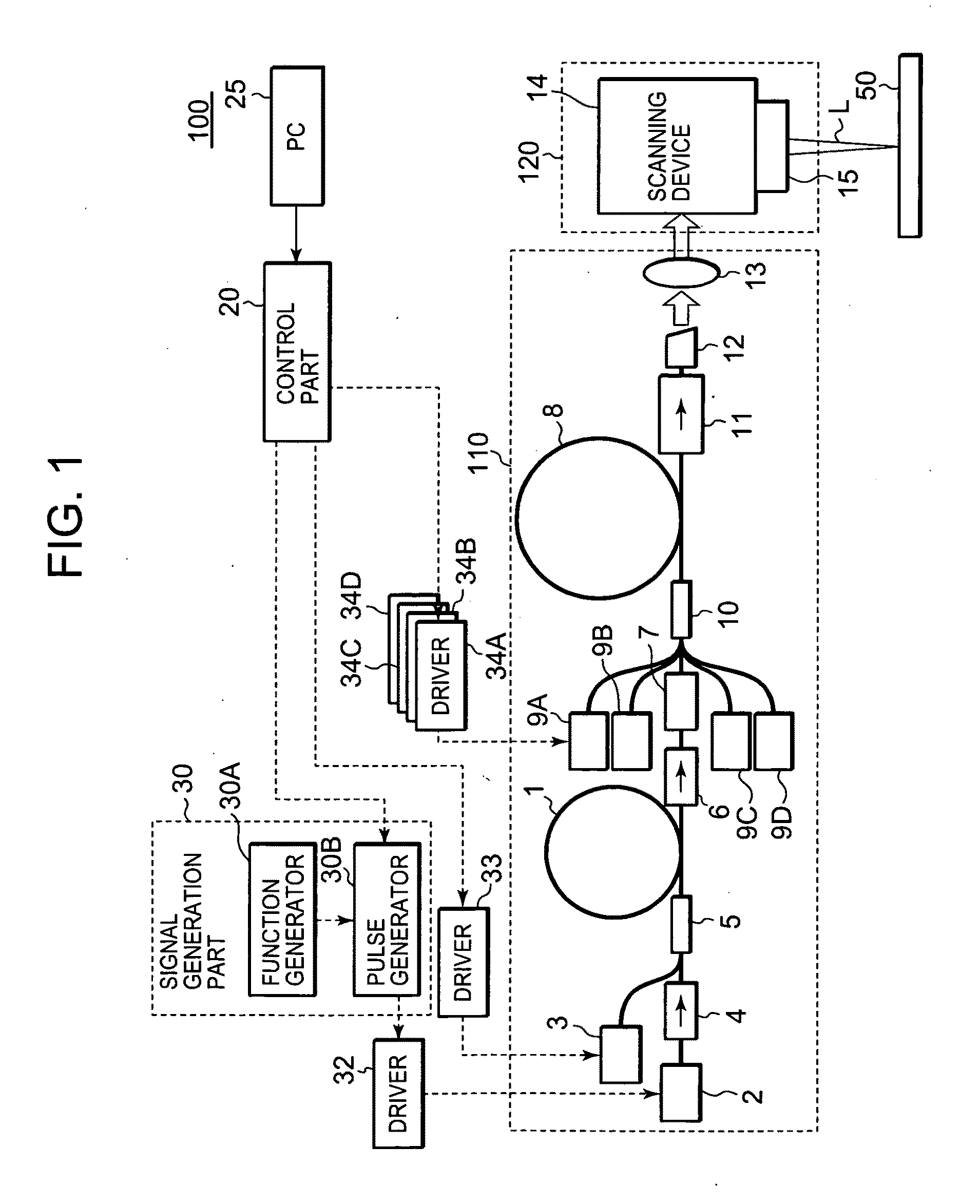

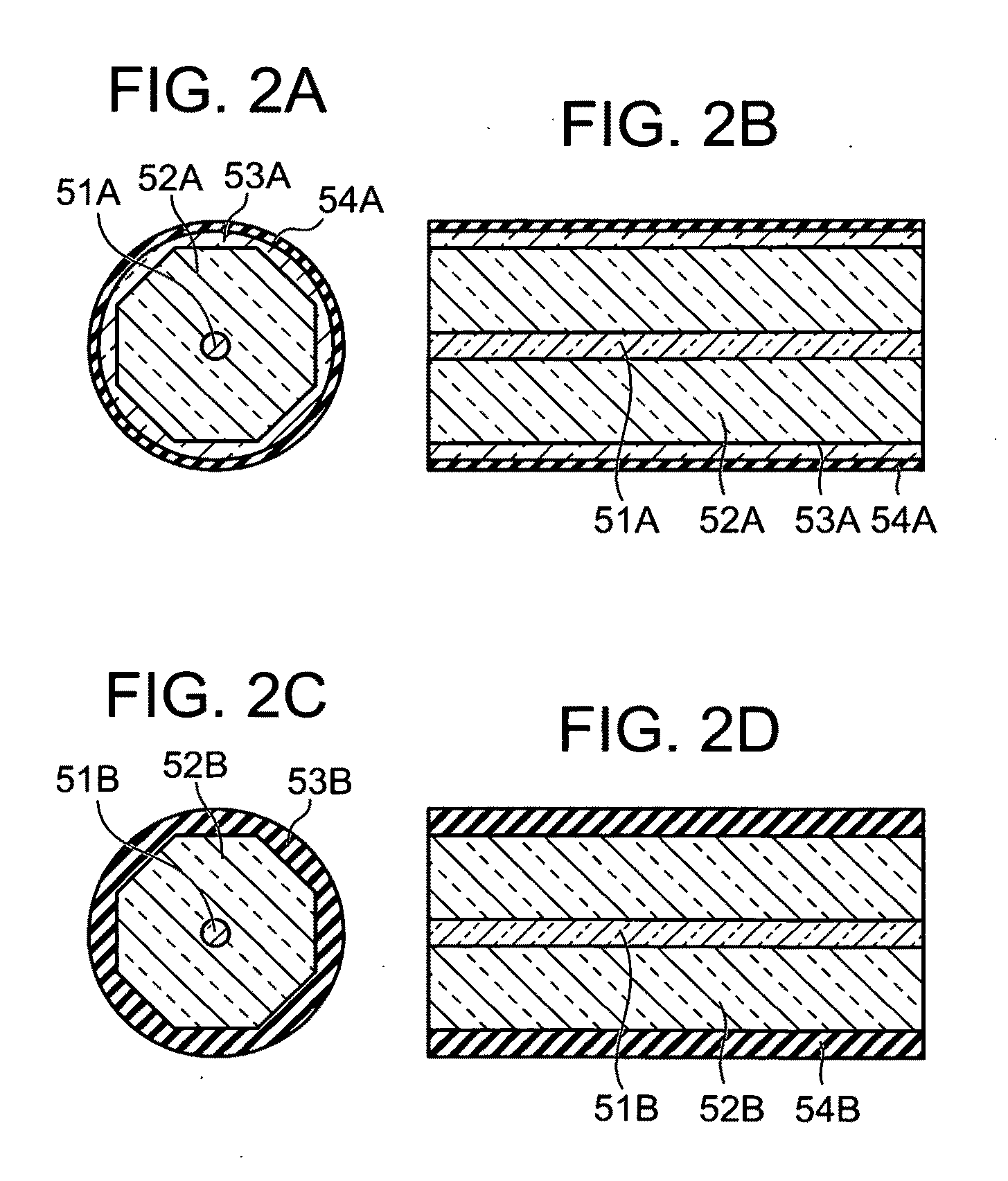

Laser source device and laser processing device

InactiveUS20100183040A1High peak powerLaser arrangementsWelding/soldering/cutting articlesPulse beamLaser processing

A laser source device includes an optical amplifier having an optical amplifying medium that is configured to amplify a seed beam when the seed beam and an exciting beam are entered, a seed beam source for emitting a laser beam as the seed beam, and an exciting beam source for emitting an exciting beam. The seed beam source emits a pulse beam as the seed beam during a predetermined principal irradiation period. The seed beam source emits a substantially continuous beam as the seed beam, having a smaller power than a peak power of the pulse beam during a supplemental irradiation period different from the principal irradiation period. The exciting beam source emits the exciting beam such that the power of the exciting beam is smaller during the supplemental irradiation period than the power of the exciting beam during the principal irradiation period.

Owner:ORMON CORP

Anti-cracking steel-concrete combined continuous girder bridge of negative moment region

ActiveCN102505624AOptimize layoutHigh tensile strengthBridge structural detailsBridge materialsFiberCrack resistance

The invention relates to an anti-cracking steel-concrete combined continuous girder bridge of a negative moment region. A main girder of the bridge girder is of a steel structure; a bridge deck is of a concrete structure; and the main girder and the bridge deck are connected through shear nails, wherein the main steel girder structure and the shear nails are made of a steel product with a standard model; the bridge deck is made of two concrete materials; a base material of the negative moment region of the bridge deck is made of high-strength organic polymer fiber concrete of which the dry apparent density is not less than 2400 kg / m<3>; the base material of the other region of the bridge deck is made of high-strength common concrete of which the dry apparent density is not less than 2400 kg / m<3>, and prestressed reinforcements are arranged in the negative moment region of the bridge deck. The cracking resistance of the negative moment region of the bridge is improved and the technical problem of low anti-cracking ability of the bridge deck in the negative moment region of the steel-concrete combined continuous girder bridge can be solved by using material characteristics, such as high tensile strength and shearing strength (over 20% greater than those of common high-strength concrete) of the high-strength organic polymer fibre concrete and optimizing the arrangement mode of prestressing tendons.

Owner:WUHAN UNIV OF TECH

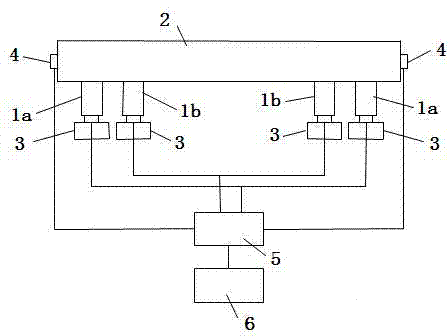

Slope-variable proportional alternate jacking construction method for continuous beam bridges

ActiveCN103205940AEliminate compressionEliminate height differenceBridge erection/assemblyBridge strengtheningHydraulic pumpContinuous beam

The invention discloses a slope-variable proportional alternate jacking construction method for continuous beam bridges. The slope-variable proportional alternate jacking construction method includes setting two groups of jacks capable of actively applying jacking force at the bottom of a bridge structure corresponding to fronts and backs of a pier and an abutment; enabling a control panel to control a hydraulic pump station to drive the two groups of jacks to carry out slope-variable proportional alternate jacking; and plugging temporary steel support cushion blocks at bottoms of one group of jacks when the other group of jacks performs jacking so as to eliminate height differences among various support points. The slope-variable proportional alternate jacking construction method has the advantages that the safety of the bridge structure is effectively guaranteed in a jacking procedure; and the requirement on a design gesture of an existing beam is met by the continuous slope-variable proportional alternate jacking method, and accordingly the purpose of modifying an existing bridge is achieved.

Owner:CHENGDU CONSTR ENG GROUP CORP

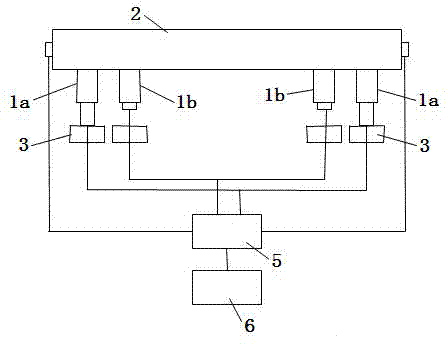

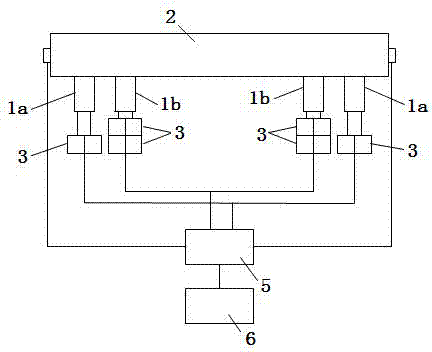

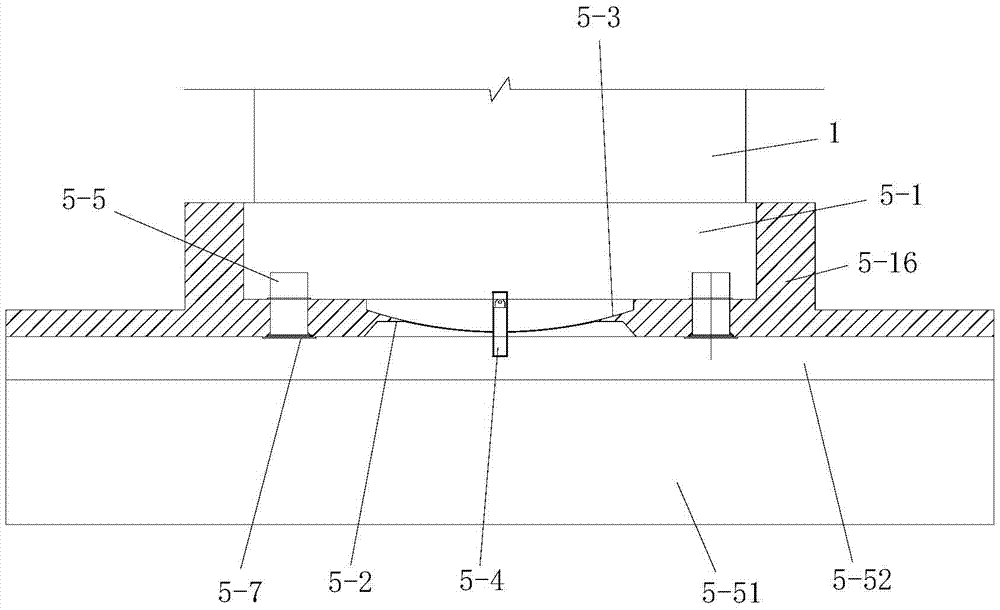

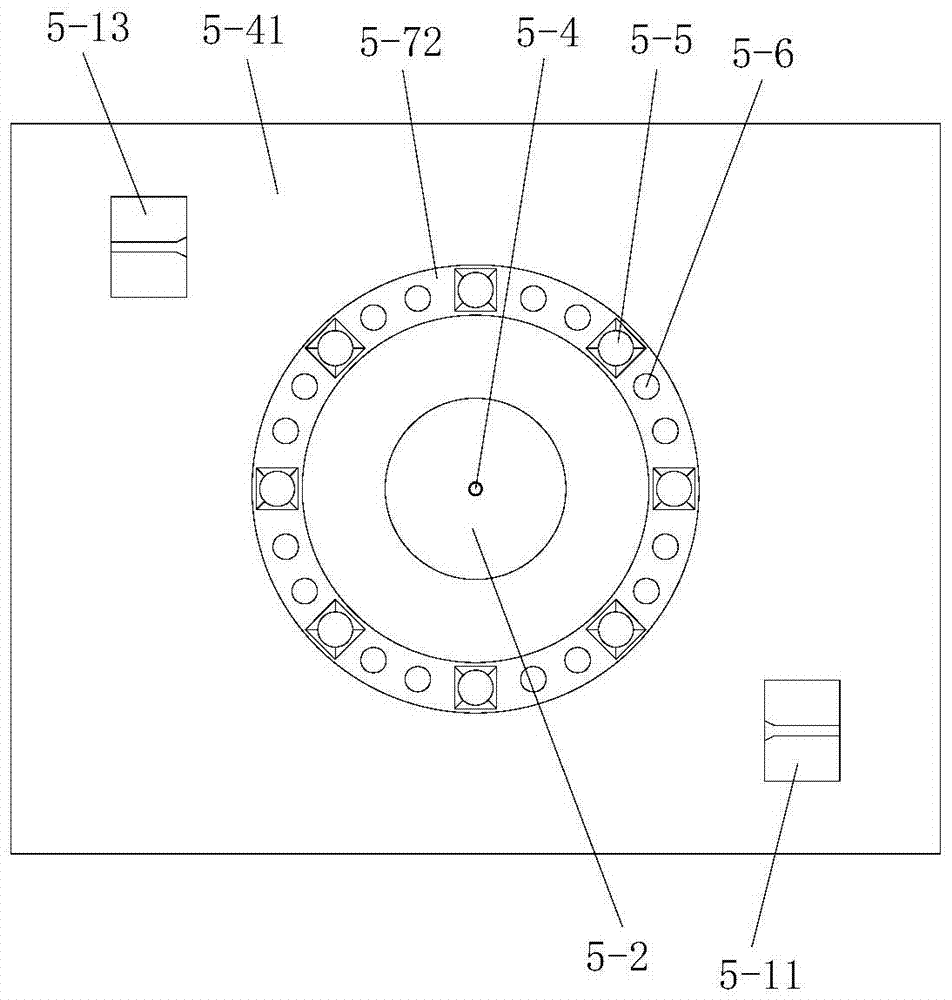

Swivel system for long-span continuous beam span existing station swivel construction and construction method

ActiveCN105442459ASimple structureReasonable designBridge erection/assemblyReinforced concreteTraction system

The invention discloses a swivel system for long-span continuous beam span existing station swivel construction and a construction method. The swivel system comprises a lower supporting disk, an upper rotating disk, a bridge swivel spherical hinge mounted between the lower supporting disk and upper rotating disk and a swivel traction system driving the upper rotating disk to rotate, wherein the lower supporting disk and the upper rotating disk are each of a reinforced concrete structure and are both arranged horizontally, and the swivel traction system is connected with the upper rotating disk; multiple supporting legs are arranged at the bottom of the upper rotating disk, and an annular slide way where the supporting legs slide is arranged on a lower bearing table. The construction method of the swivel system comprises the steps of erection of a lower bearing table forming formwork, concrete pouring construction of a bottom bearing table, installation of a lower spherical hinge and the annular slide way, concrete pouring construction of an upper bearing table, hoisting of an upper spherical hinge, installation of the supporting legs, erection of an upper rotating disk forming formwork and concrete pouring construction. The swivel system is reasonable in design, easy and convenient to construct and good in use effect, the swivel construction process of a long-span continuous beam can be completed easily and conveniently, and the swivel process is stable.

Owner:NO 1 ENG LIMITED OF CR20G

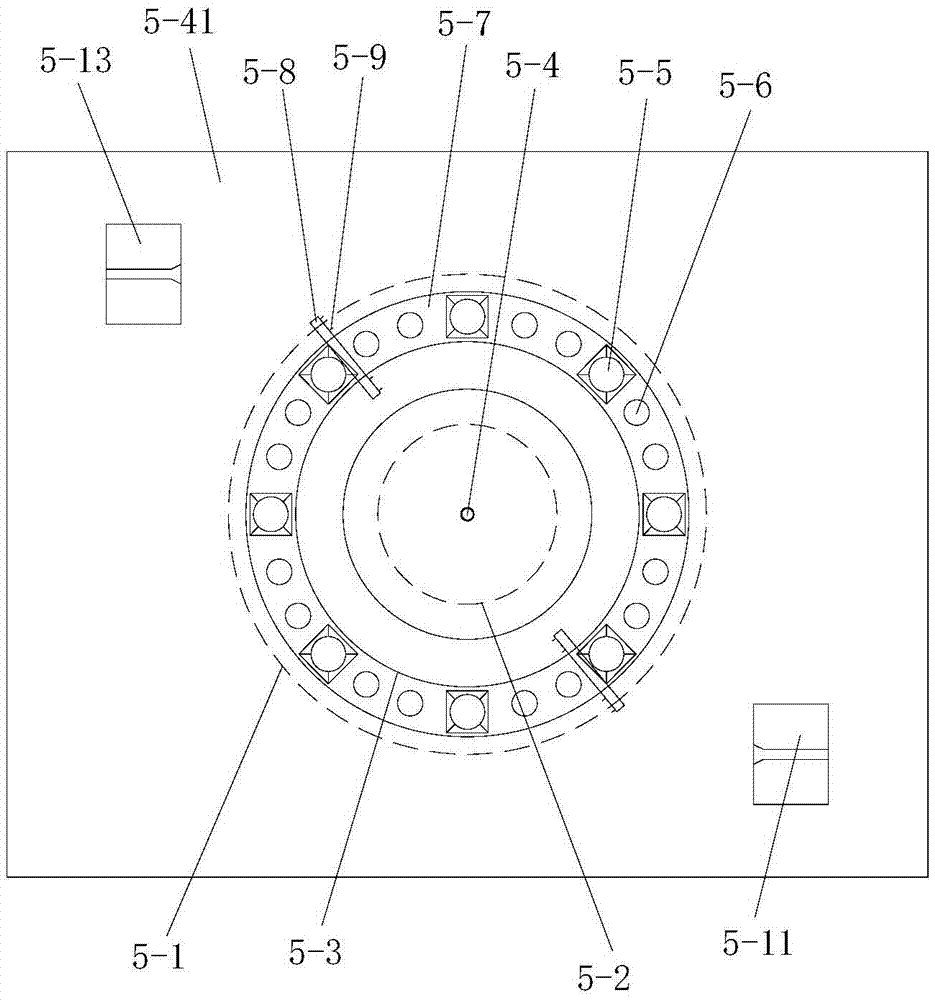

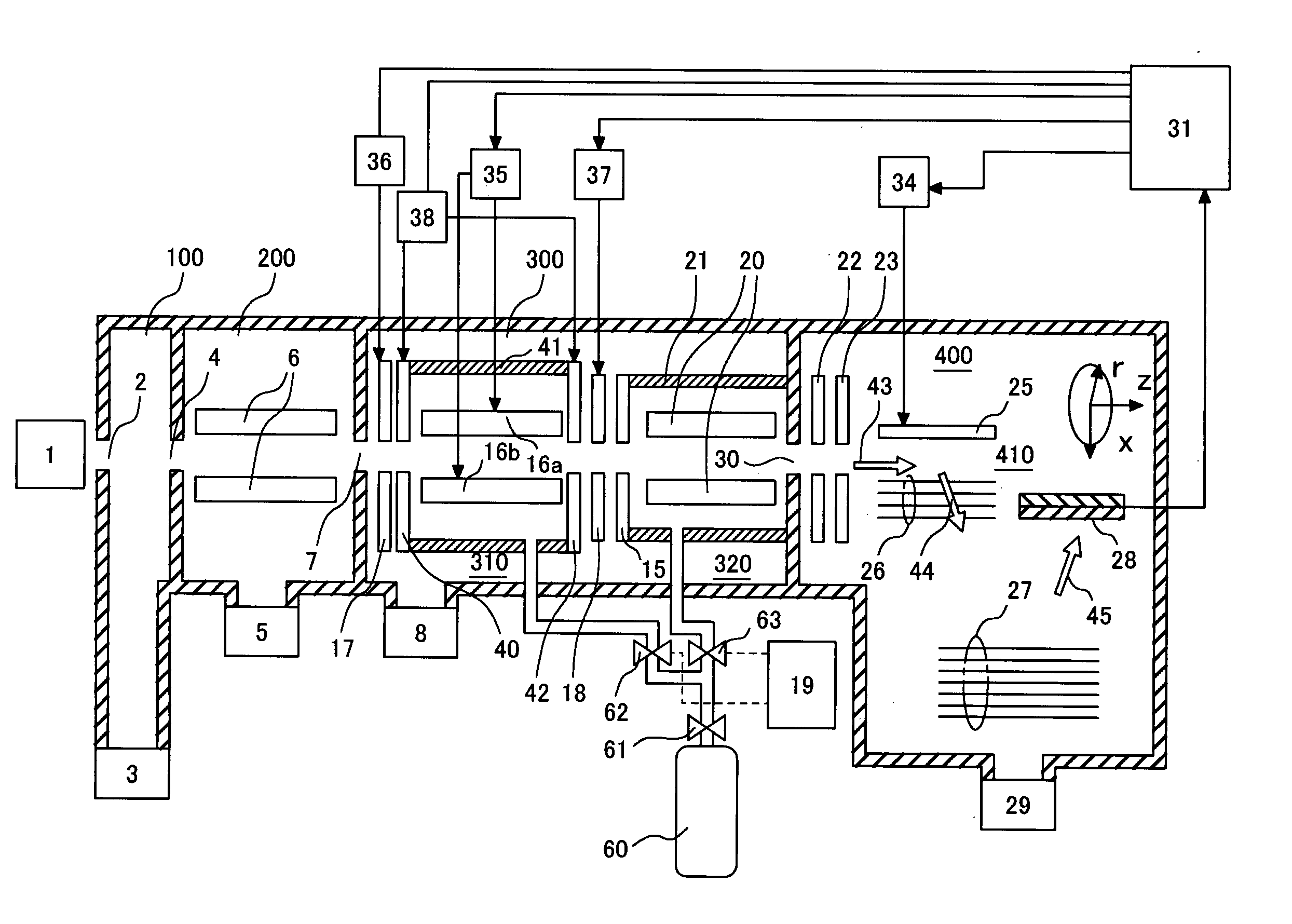

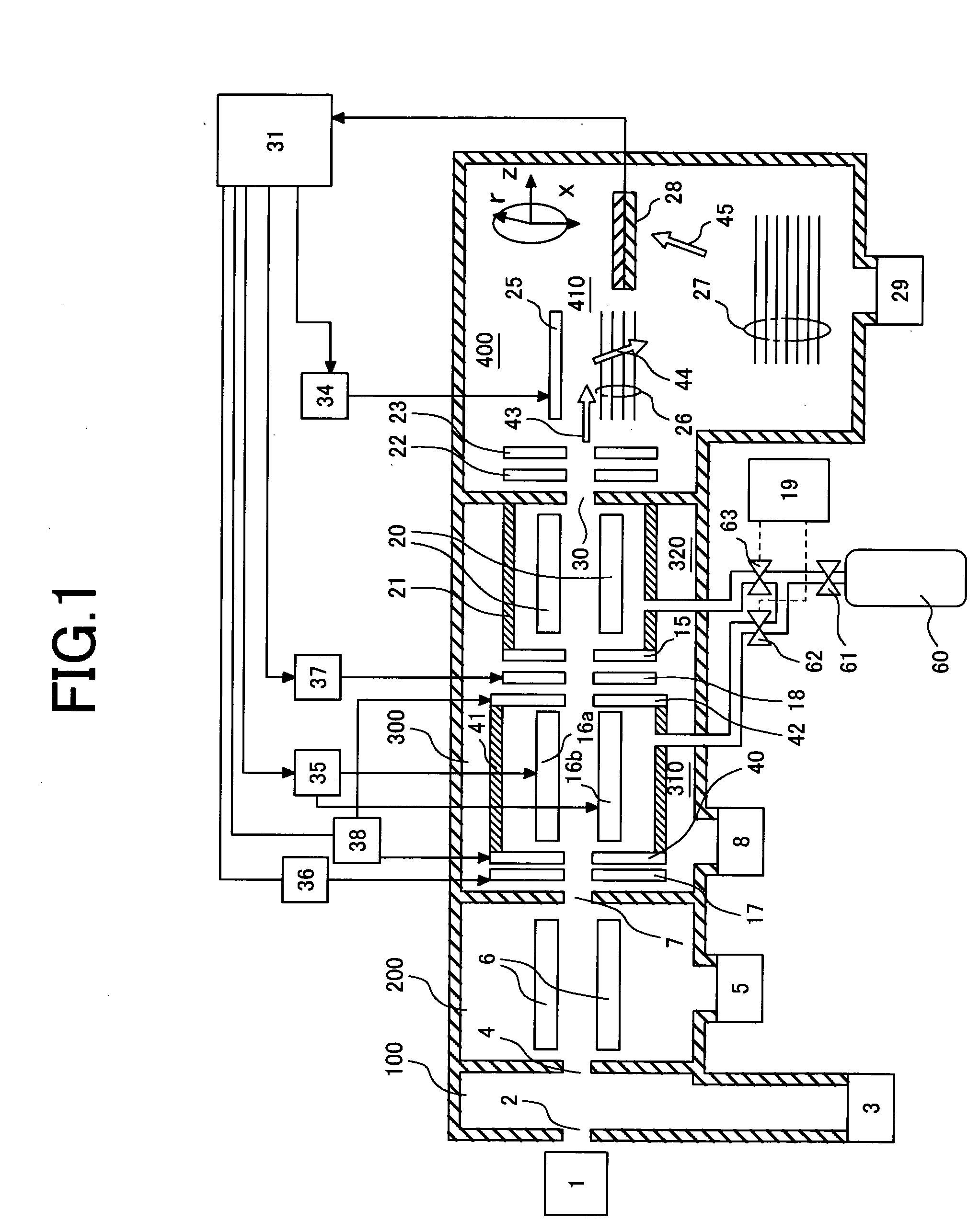

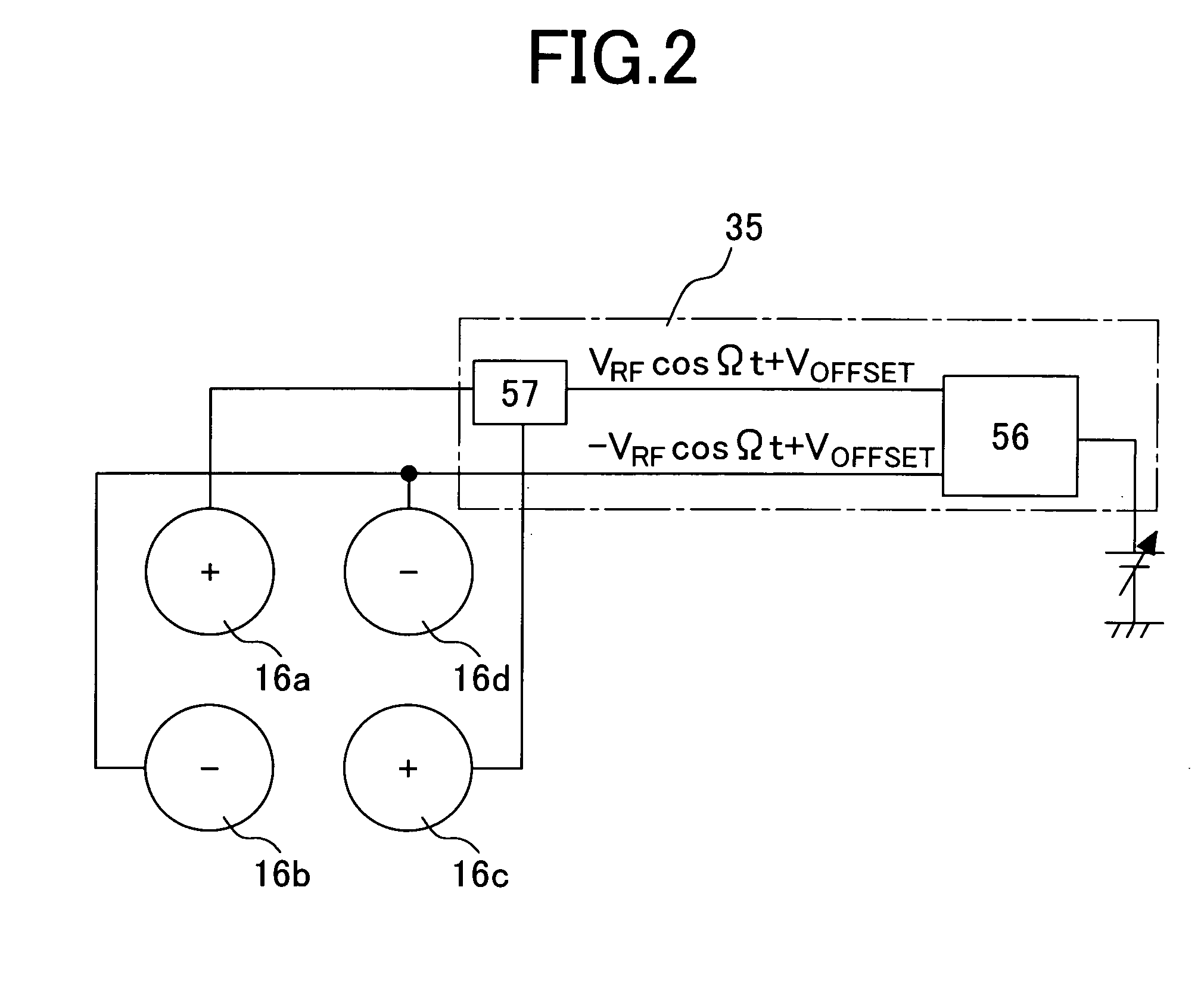

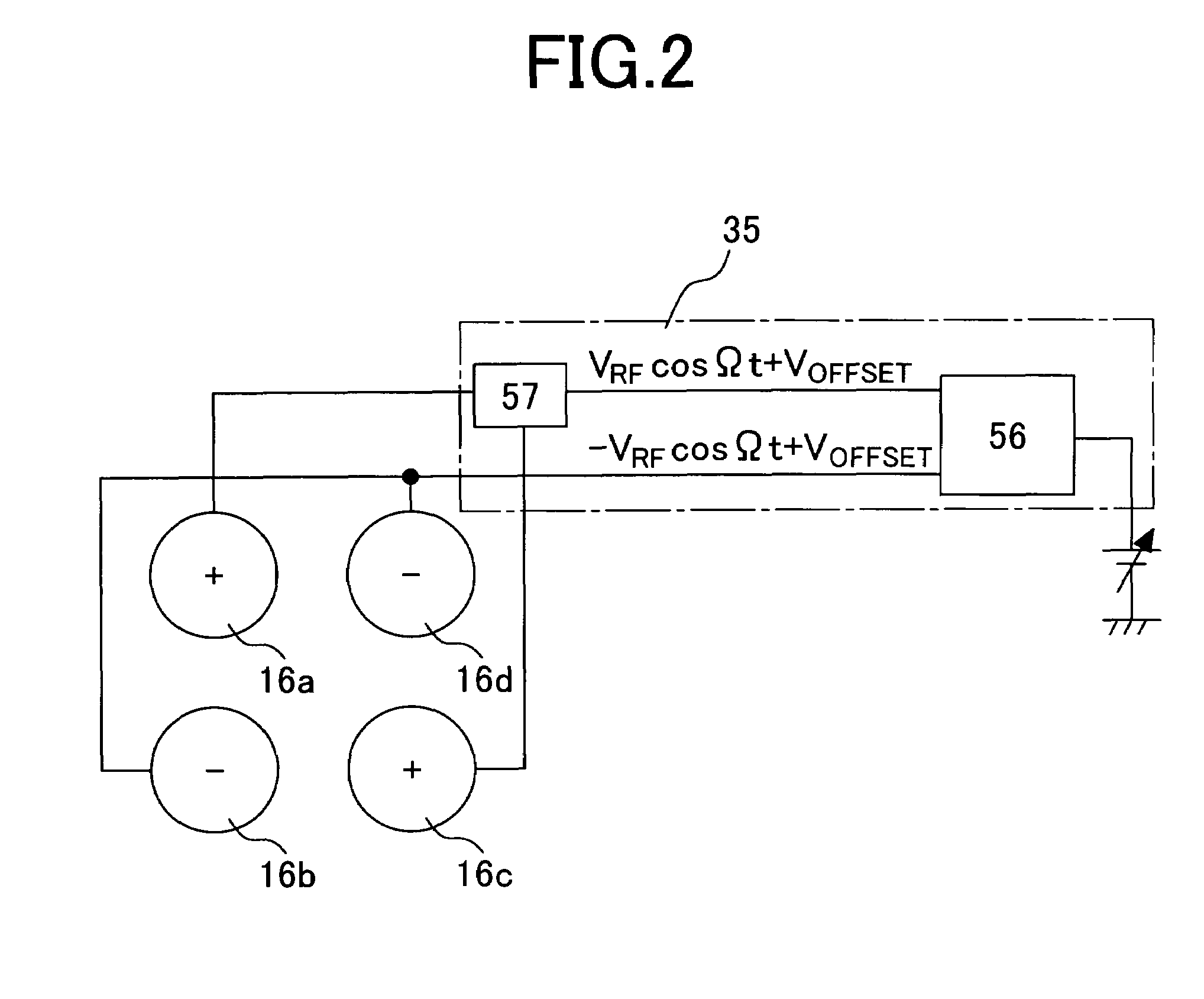

Mass spectrometer

ActiveUS20050023452A1High sensitivityStability-of-path spectrometersTime-of-flight spectrometersSpectroscopyContinuous beam

An ion mass spectrometer comprising an ionization source for generating ions, a linear trap region for accumulation and dissociation of ions, and a time-of-flight mass spectrometer for mass spectroscopy of ions based on the flying time, and having a collision damping region introduced with a buffer gas for reducing the kinetic energy of ions ejected from the linear trap region and converting the ion packet into continuous beam and provided with plural electrodes for generating multipole electric fields in the inside between the linear trap region and the time-of-flight mass spectrometer, and having an ion transmission control mechanism for allowing or inhibiting incidence of ion from the linear trap region to the collision damping region between the linear trap region and the collision damping region.

Owner:HITACHI HIGH-TECH CORP

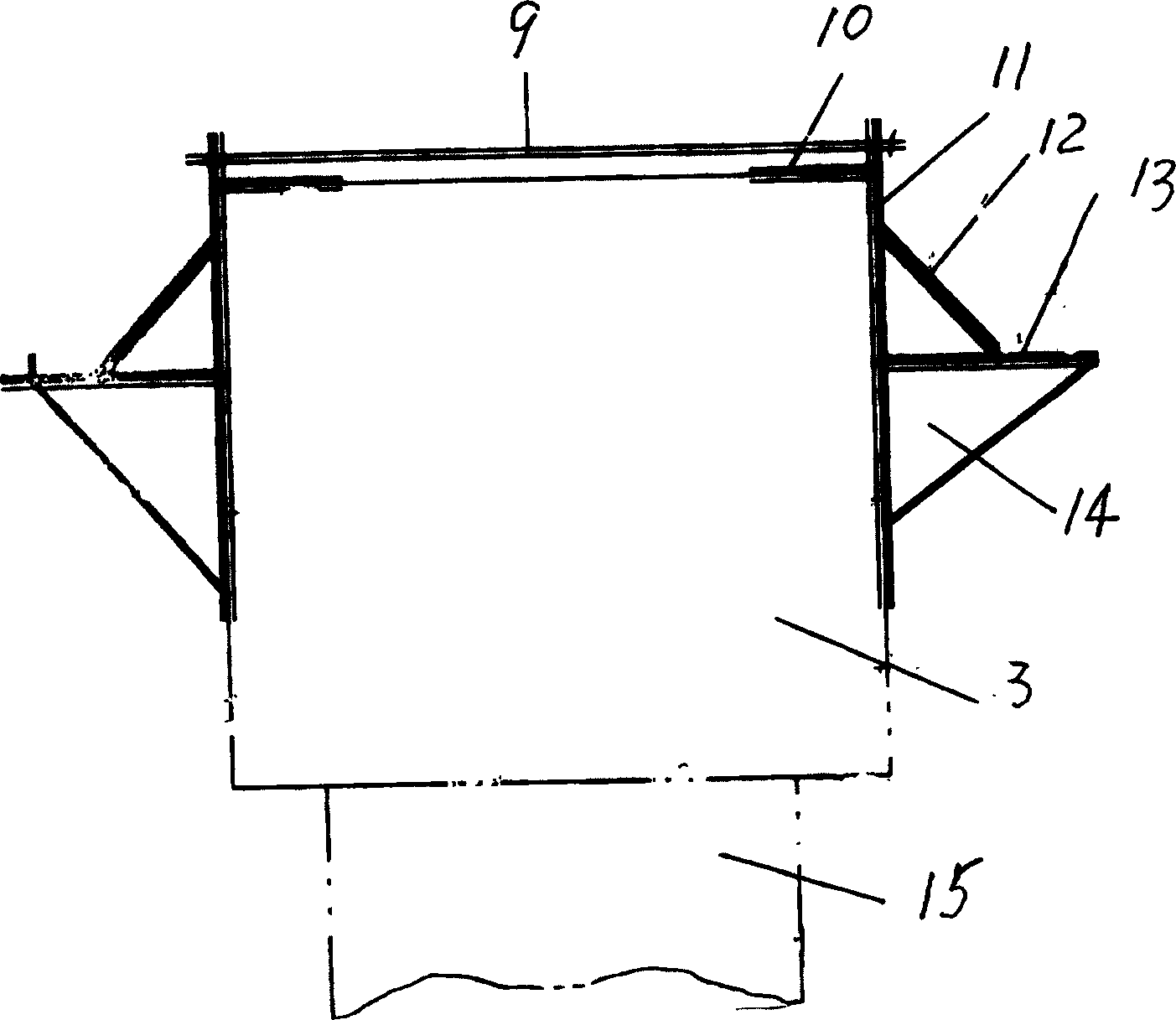

Method for casting concrete 0# block support by continuous beam cantilever

The invention relates to a method for casting concrete 0# block support by a continuous beam cantilever, comprising the following steps: (1) a triangular bracket is manufactured, and each triangular bracket is composed of a horizontal rod, an inclined strut, a channel steel shore, a channel steel inclined strut, a reinforced steel plate and a reinforced steel plate I; 2) the support is pre-casted:each group of support is composed of a pre-cast steel plate, a smooth plate, three vertical steel plates, an embedded bar and a reinforced bar fabric; 3) finishing screw threaded steel bars are pre-casted: every four finishing screw threaded steel bars are one group, a PVC pipe is sheathed outside each finishing screw threaded steel bar, and two ends of each finishing screw threaded steel bar areprovided with a steel box and a reinforced steel plate II and are fixed by blind nuts, four groups of the finishing screw threaded steel bars are arrayed horizontally and are pre-casted in pier cap concrete; 4) the triangular bracket is mounted: the horizontal rod of the triangular bracket is respectively welded on the steel box and the reinforced steel plate II, the inclined strut thereof is welded on the smooth plate in the support; the method has the advantages that: the method does not occupy the space under the bridge, the used material is less compared with a steel pie bracket, the structure is simple, and assembly and disassembly are convenient.

Owner:CHINA RAILWAY NO 9 GRP

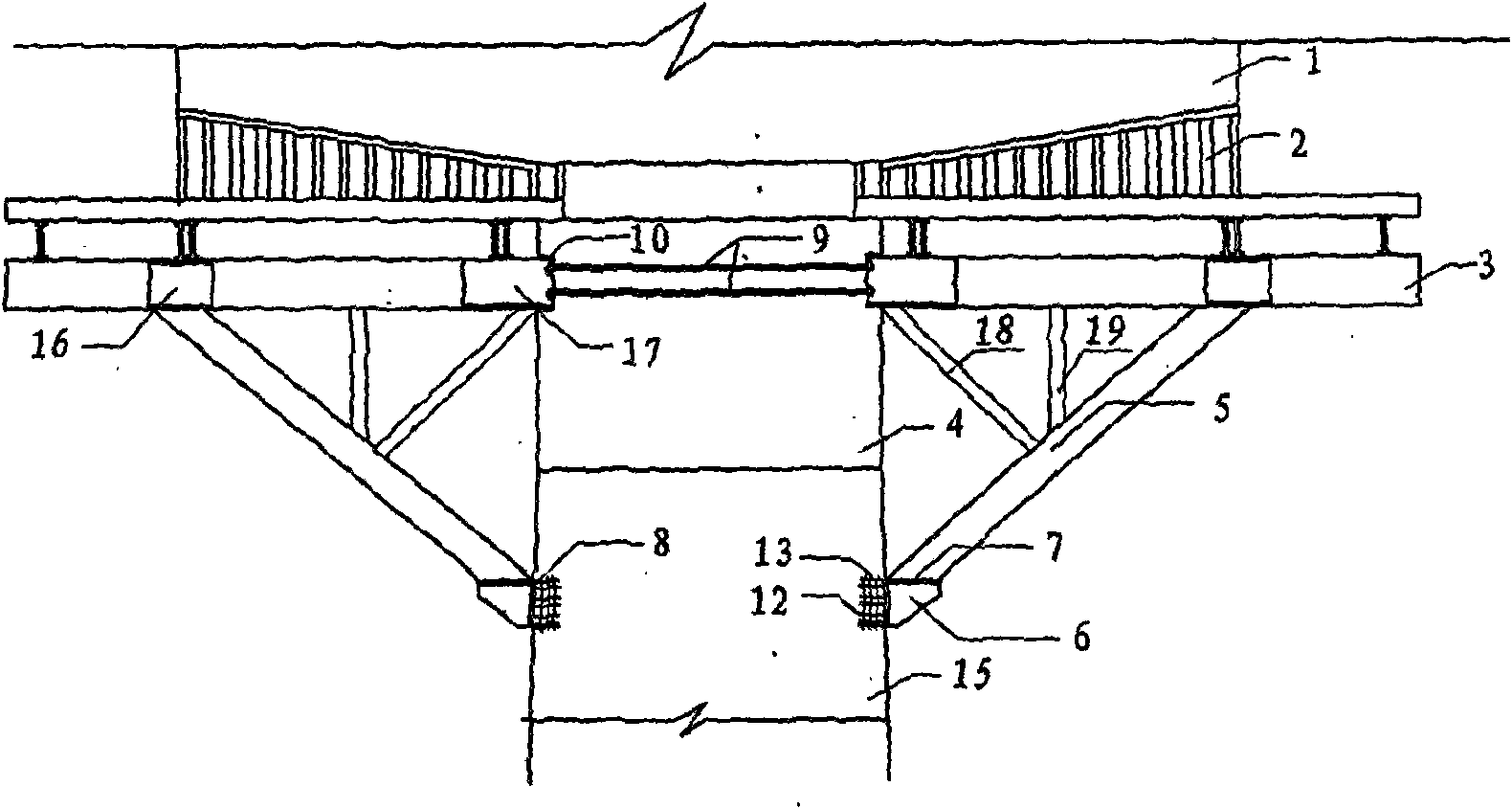

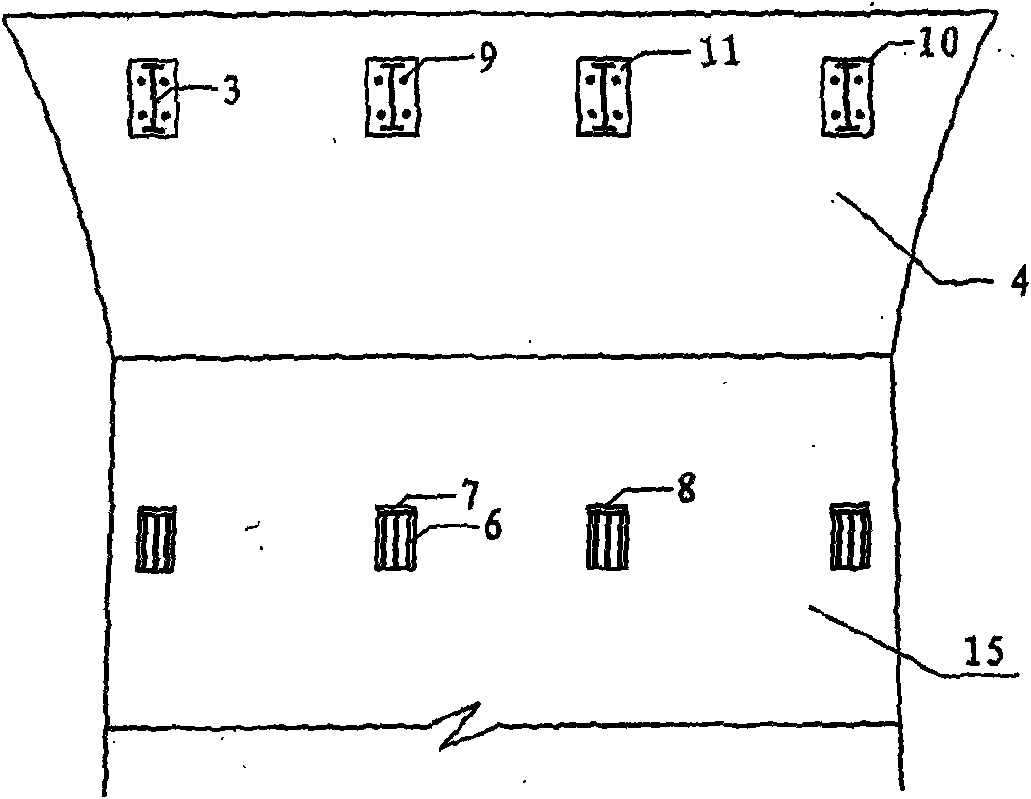

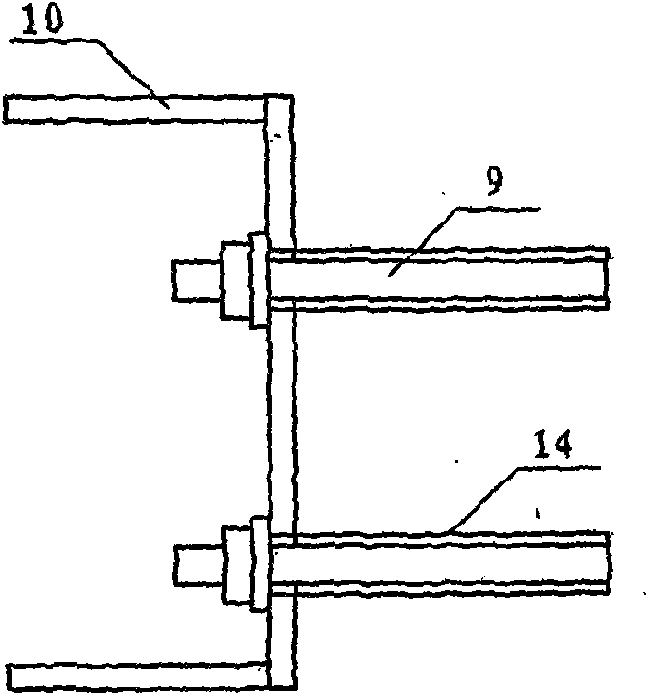

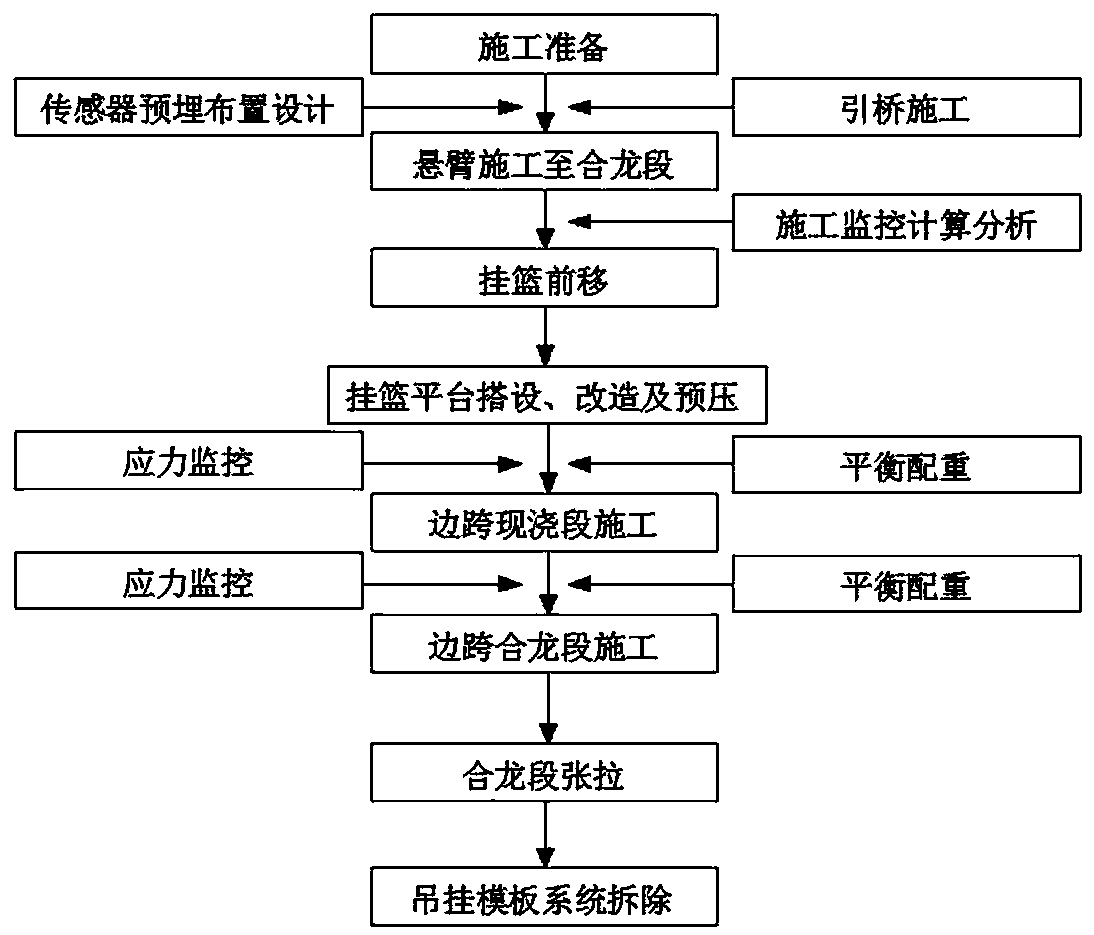

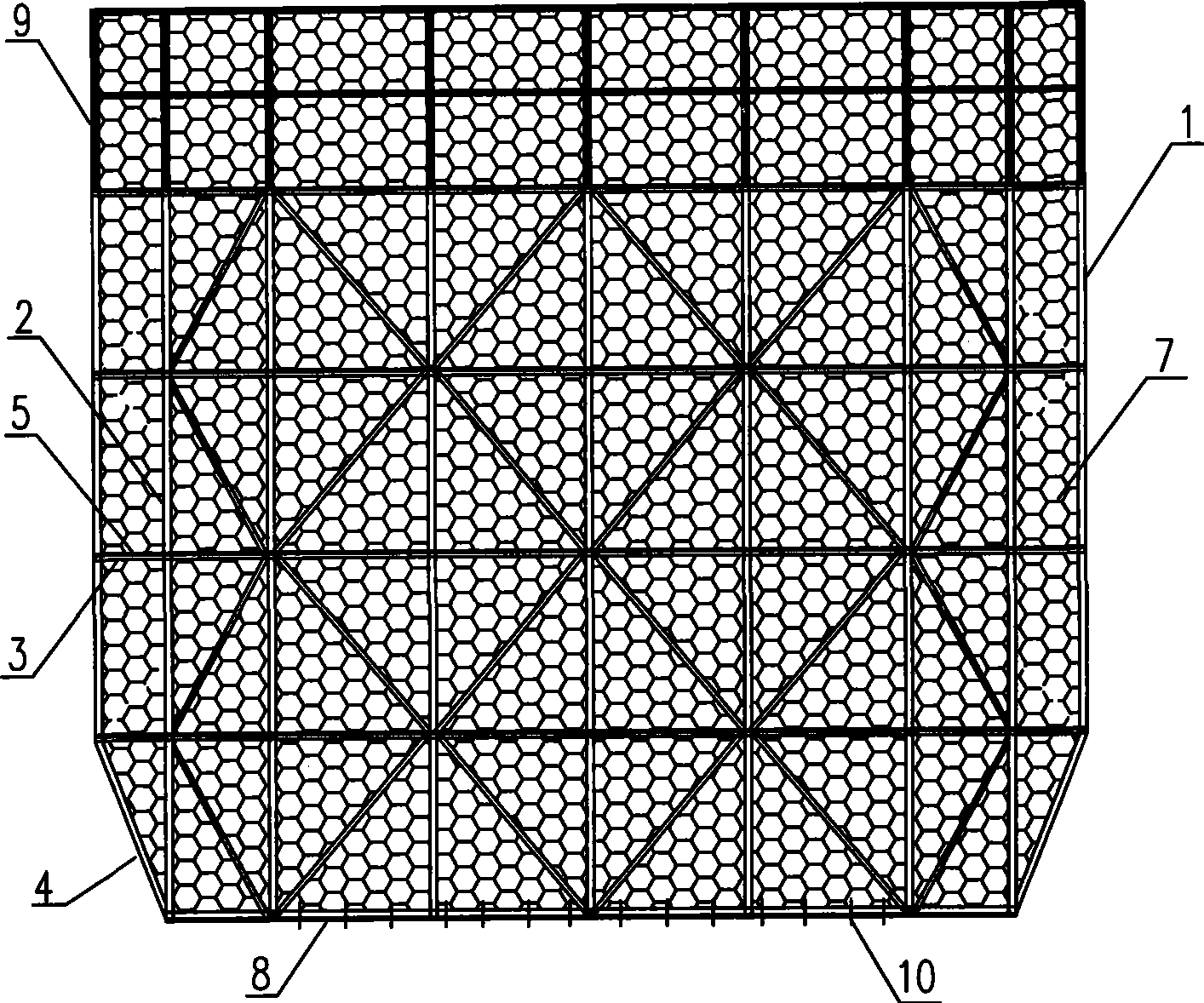

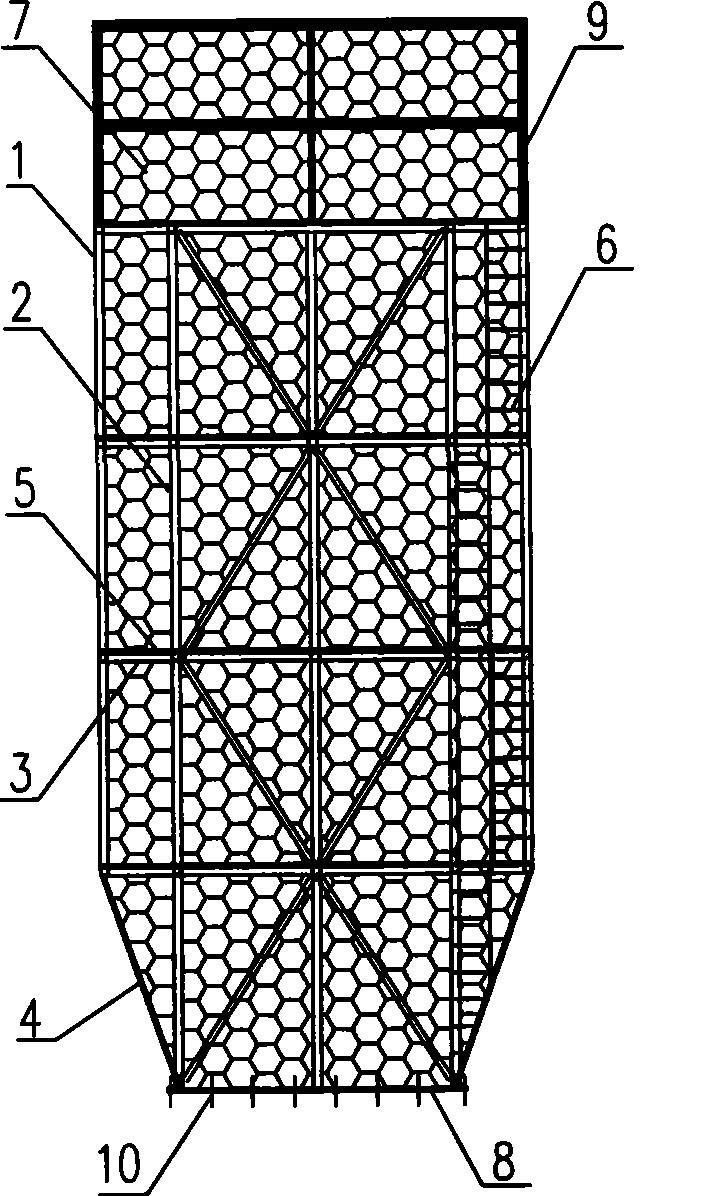

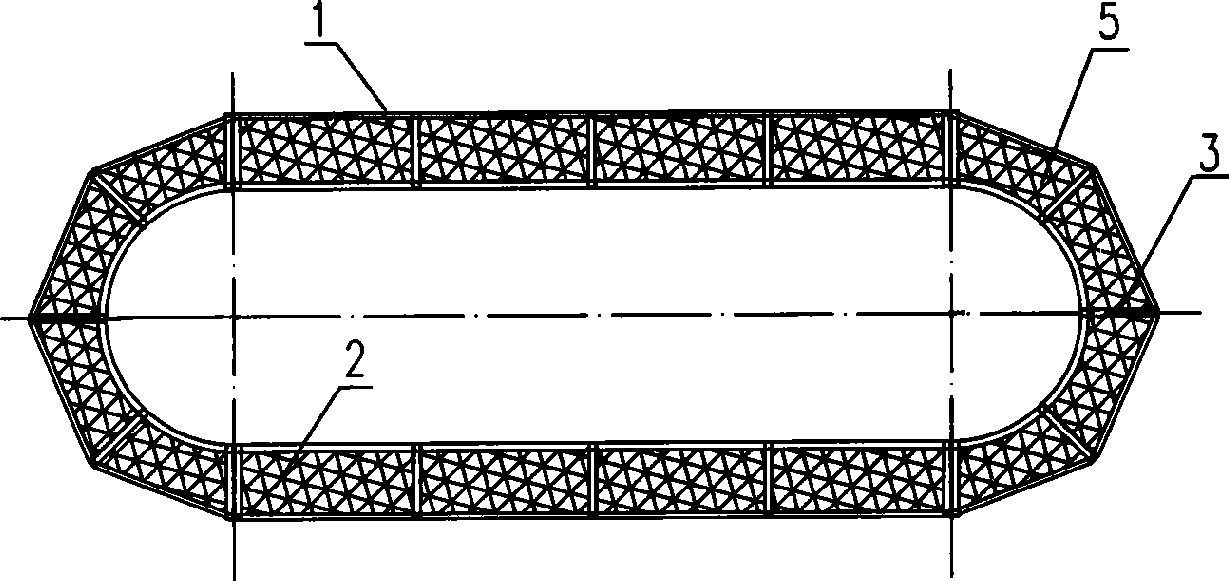

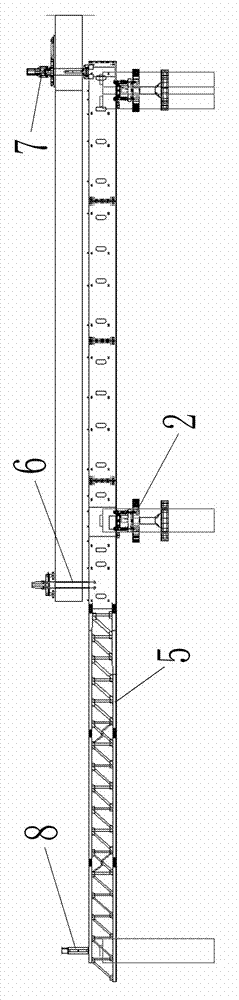

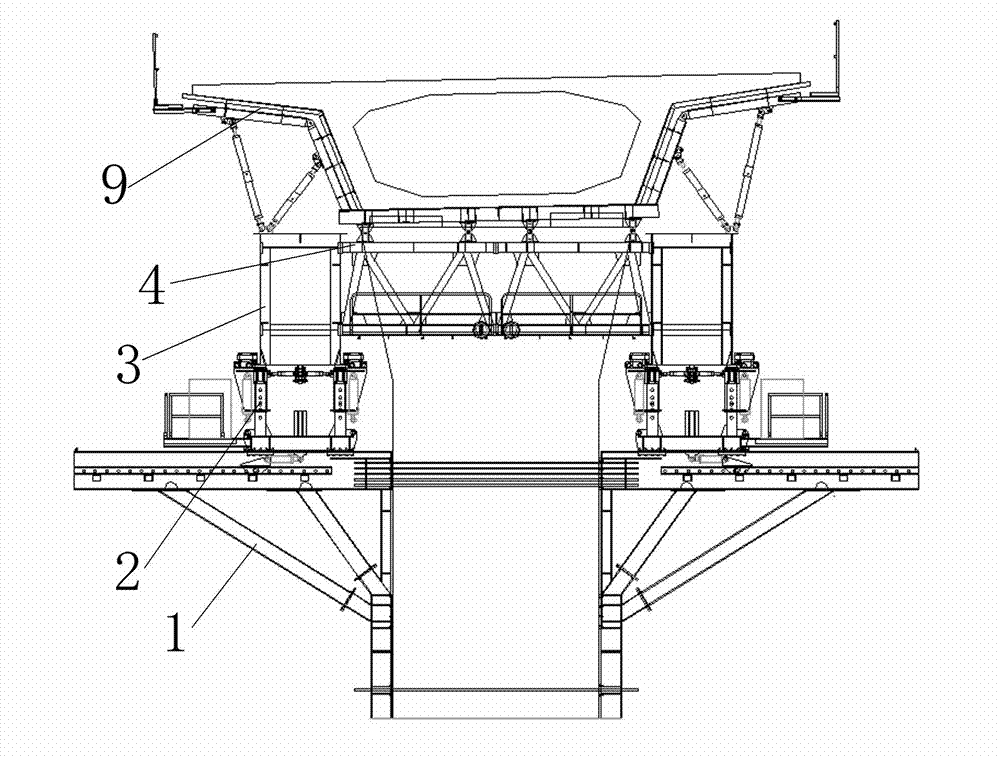

High pier continuous beam side span cast-in-place section and closed section integrated construction system and construction method

PendingCN109944170ASolve the erection problemAvoid constructionBridge erection/assemblyContinuous beamHanging basket

The invention relates to the technical field of building construction, in particular to a high pier continuous beam side span cast-in-place section and closure section integrated construction system and construction method, the construction method comprises the following steps of: construction preparation; construction monitoring calculation analysis; cantilever construction to the closure sectionand bridge approach construction; basket forward movement and basket platform reconstruction; pre-pressing; side span cast-in-place section construction; side span cast-in-place section construction;side span closure section construction; side span closure section tensioning; and lifting platform system dismantling. Compared with a prior method, the method effectively solves the problem of highpier support erection, avoids a large number of support erection construction, adopts the stress of the hanging system of the hanging basket, has simple construction technology, reduces the use amountof materials, reduces the use of large-scale hoisting equipment, has the obvious advantages of cost saving, construction period saving, better technical economy and the like aiming at the work of possibly prior support treatment and the like, avoids the prior construction support erection, avoids the work of a large number of basic treatment and the like, and has obvious construction period saving.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

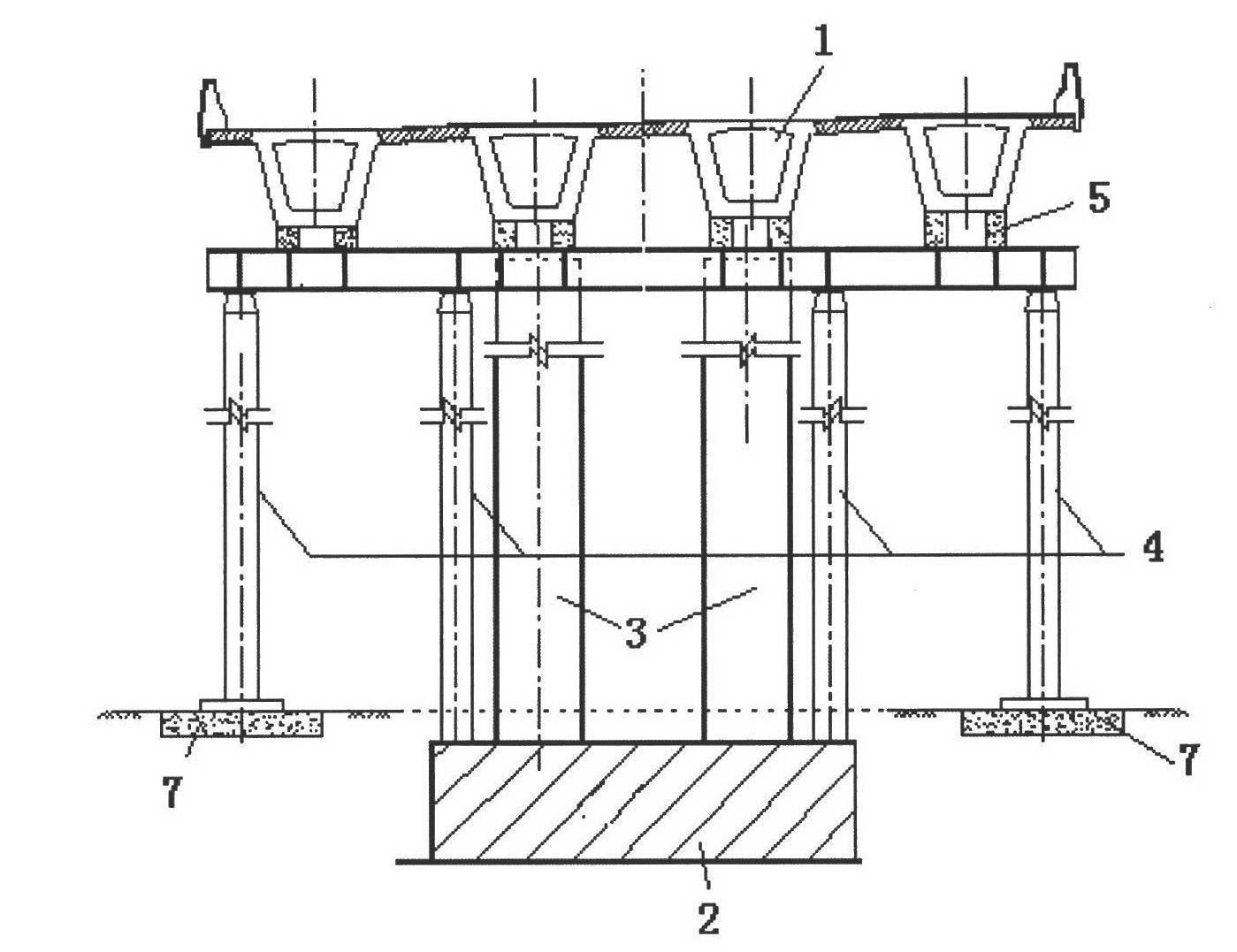

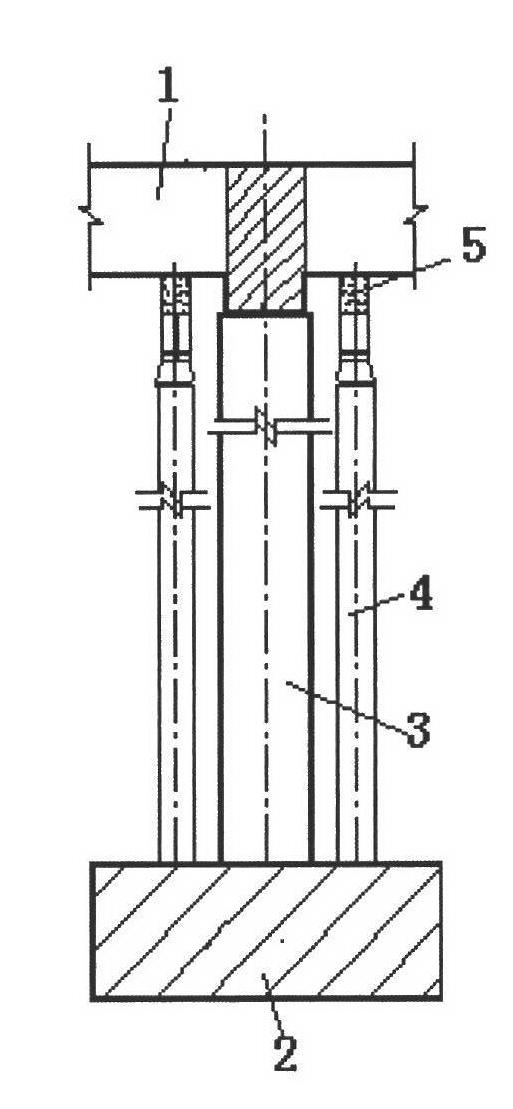

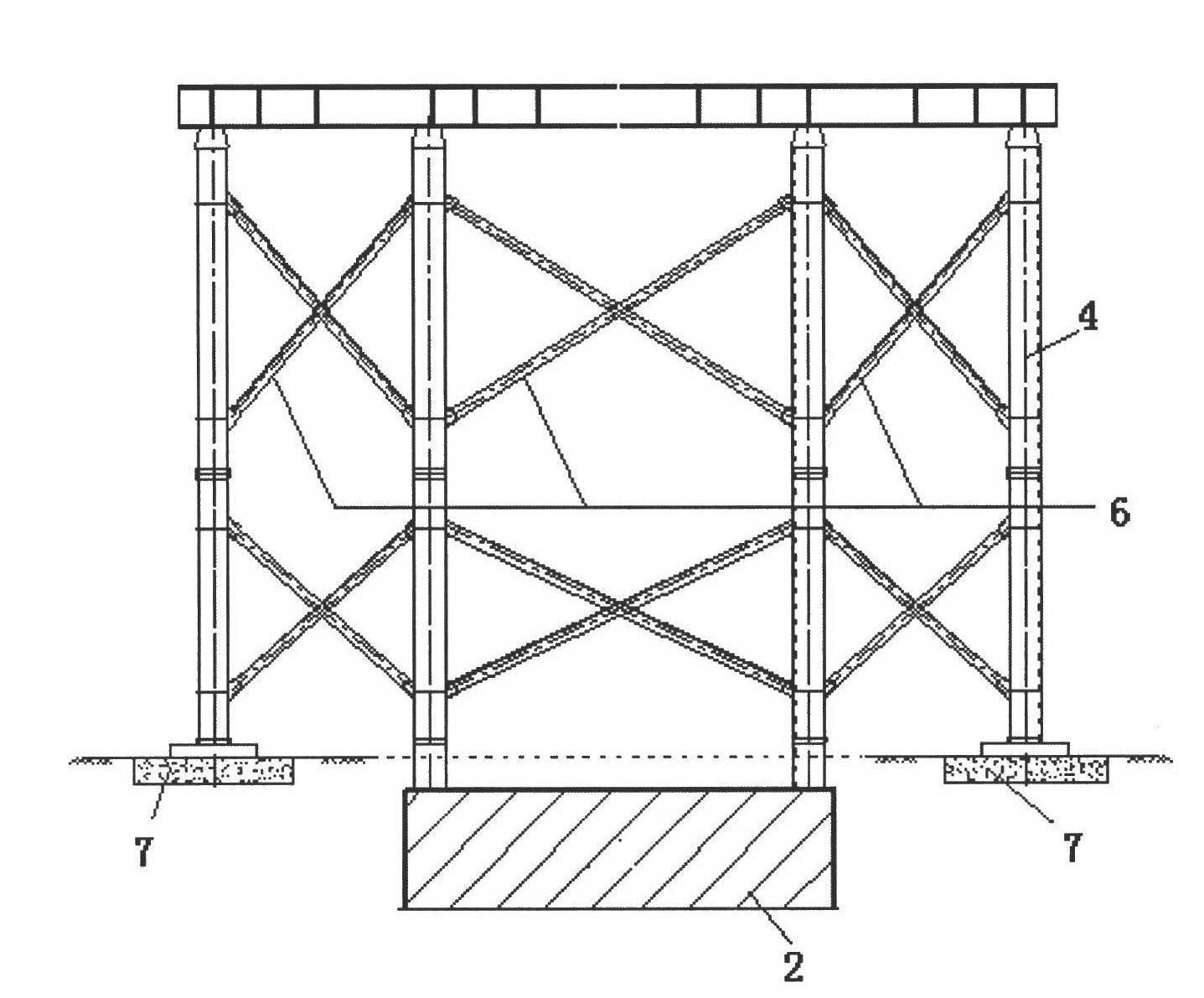

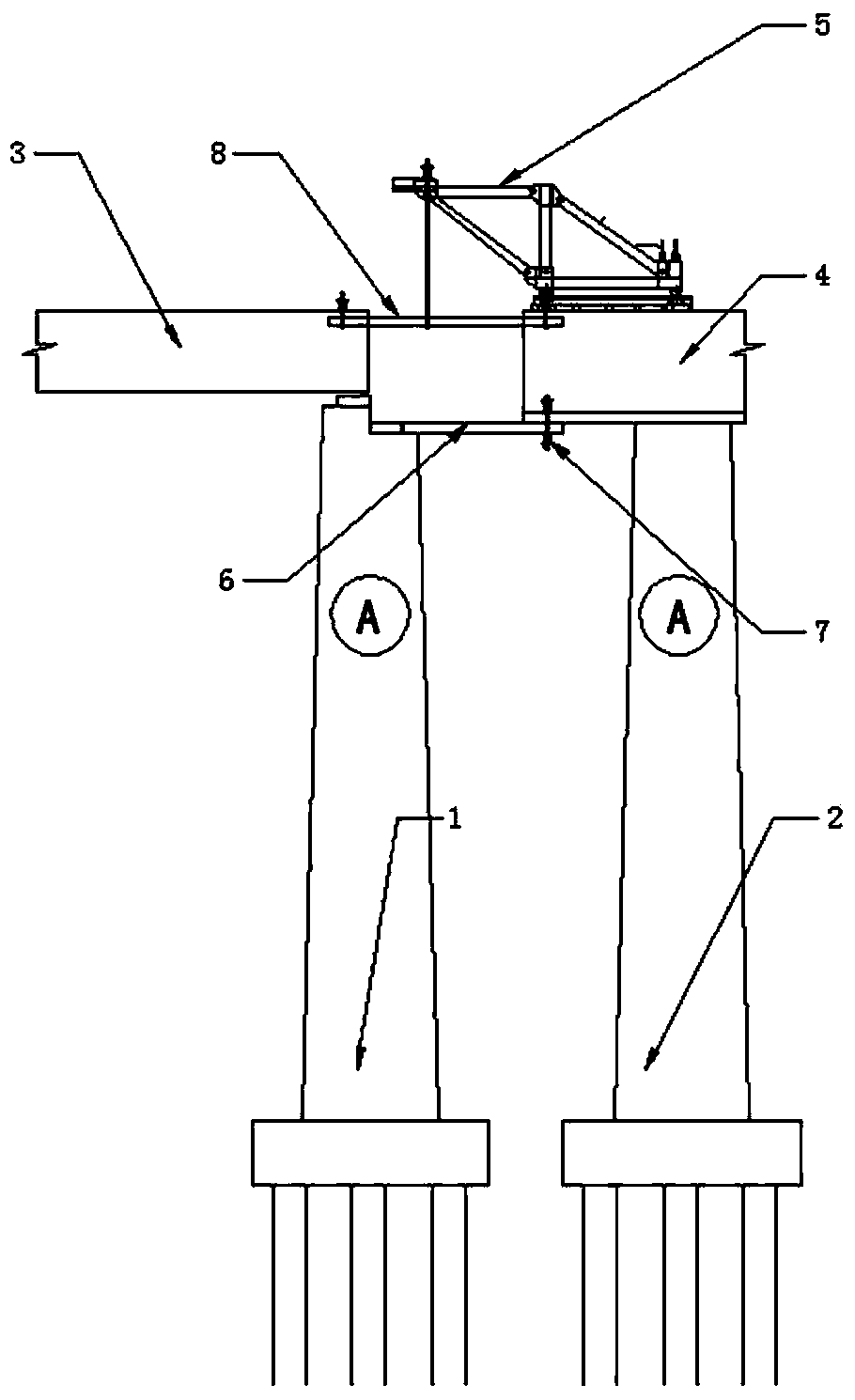

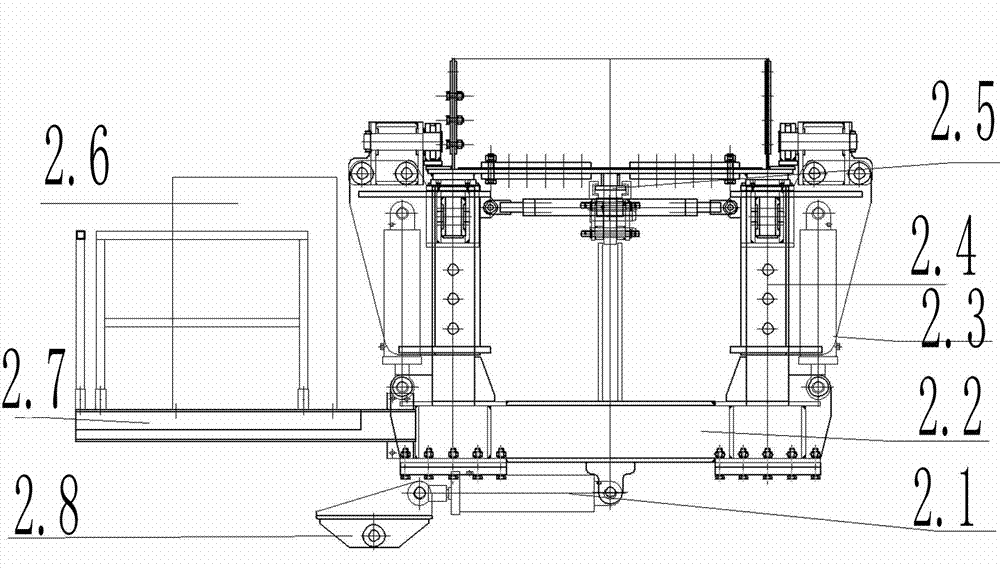

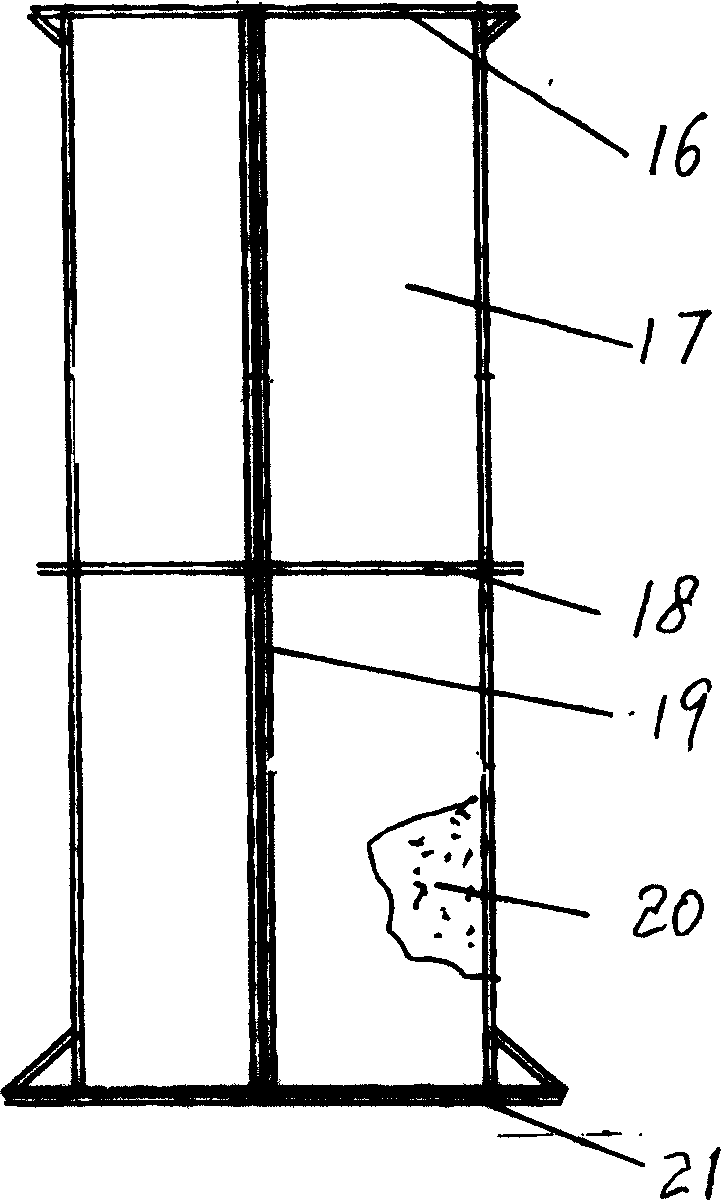

Method for mounting high pier, tower over-form construction reinforced bar and movable support thereof

InactiveCN101481944AEnsure safetyLow costForms/shuttering/falseworksBuilding reinforcementsRolloverReinforced concrete

The invention relates to a method for installing reinforcing steel for the rollover construction of a high pier and a tower and a moveable bracket thereof. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower has the construction steps as follows: (1) according to the characteristics of the sections of the pier and the tower, a moveable bracket (2) matched with a pier body and a tower body is designed and processed, a movable bracket (3) and reinforcing steel (4) are installed, the moveable brackets are dismounted, a pier body moulding board or a tower body moulding board is installed, concrete (5)for the section of a pier body or the section of a tower body on which the reinforcing steel is bound is cast, hoisting equipment is used for installing the moveable brackets, and finally, the installation and the construction of the next section of reinforcing steel are carried out. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower and the moveable bracket thereof greatly reduce the construction cost and the security risk, and have obvious efficiency of accelerating the engineering speed. The invention provides the method for installing the reinforcing steel and the moveable bracket, which are safe, reliable, economic and convenient, for the construction of the high pier and the tower with the constant section and variable section reinforced concrete used for a suspension bridge, a cable stayed bridge, a continuous rigid frame bridge, a continuous girder bridge and bridges of other types.

Owner:SICHUAN ROAD & BRIDGE GRP

Descending bracket self-mobile model framework bridge fabrication machine

The invention discloses a descending bracket self-mobile model framework bridge fabrication machine, and relates to a bridge fabrication machine. A middle lifting point cross beam takes place and finishes primary blanking together with a C beam and a traveling trolley system, so that conversion of a stressing system from the lower part to the upper part is realized. The front end of a nose bridge is driven by a front supporting cross beam system to be jacked in place. A bracket is driven by the traveling trolley system to move out transversely, move longitudinally to travel and move transversely to take place. The middle lifting point cross beam and the C beam together finish secondary blanking, a middle lifting point cross beam lifting rod is removed, the mobile die framework moves transversely to open, moves longitudinally to travel, moves transversely to close and jacks in place, and the C beam 7 is removed; and finally concrete is poured. Thus, through stressing system conversion of the bracket, the traveling trolley system, the middle lifting point cross beam and the C beam, the use at construction sites of continuous beams at sites of intertidal zones, canyons, urban viaducts, river-crossing bridges and cross-sea bridges with limited construction conditions and high construction difficulty, where the auxiliary hoisting equipment cannot reach, can be realized.

Owner:SHANDONG LUQIAO GROUP

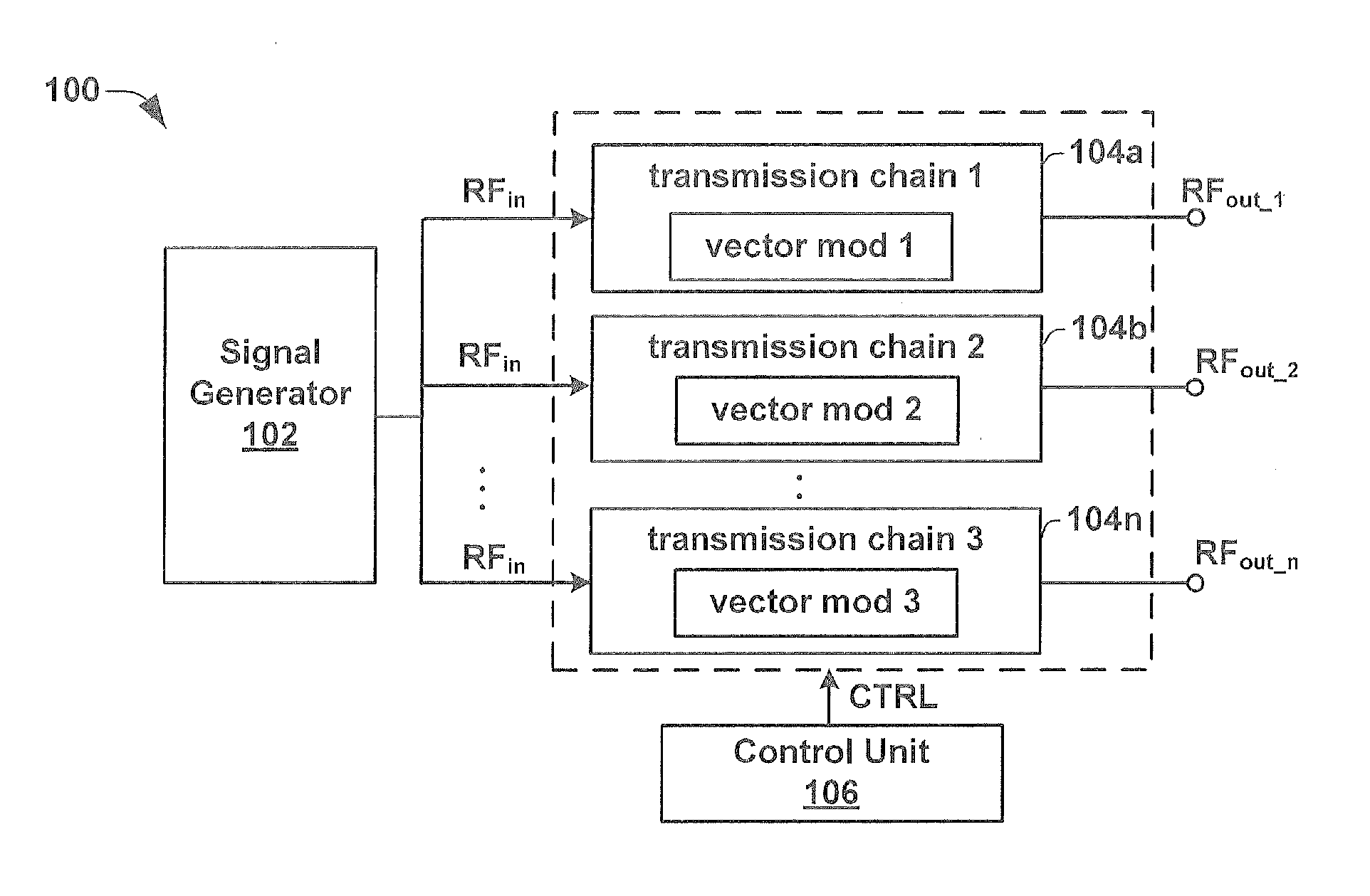

Automotive Radar Transmitter Architecture

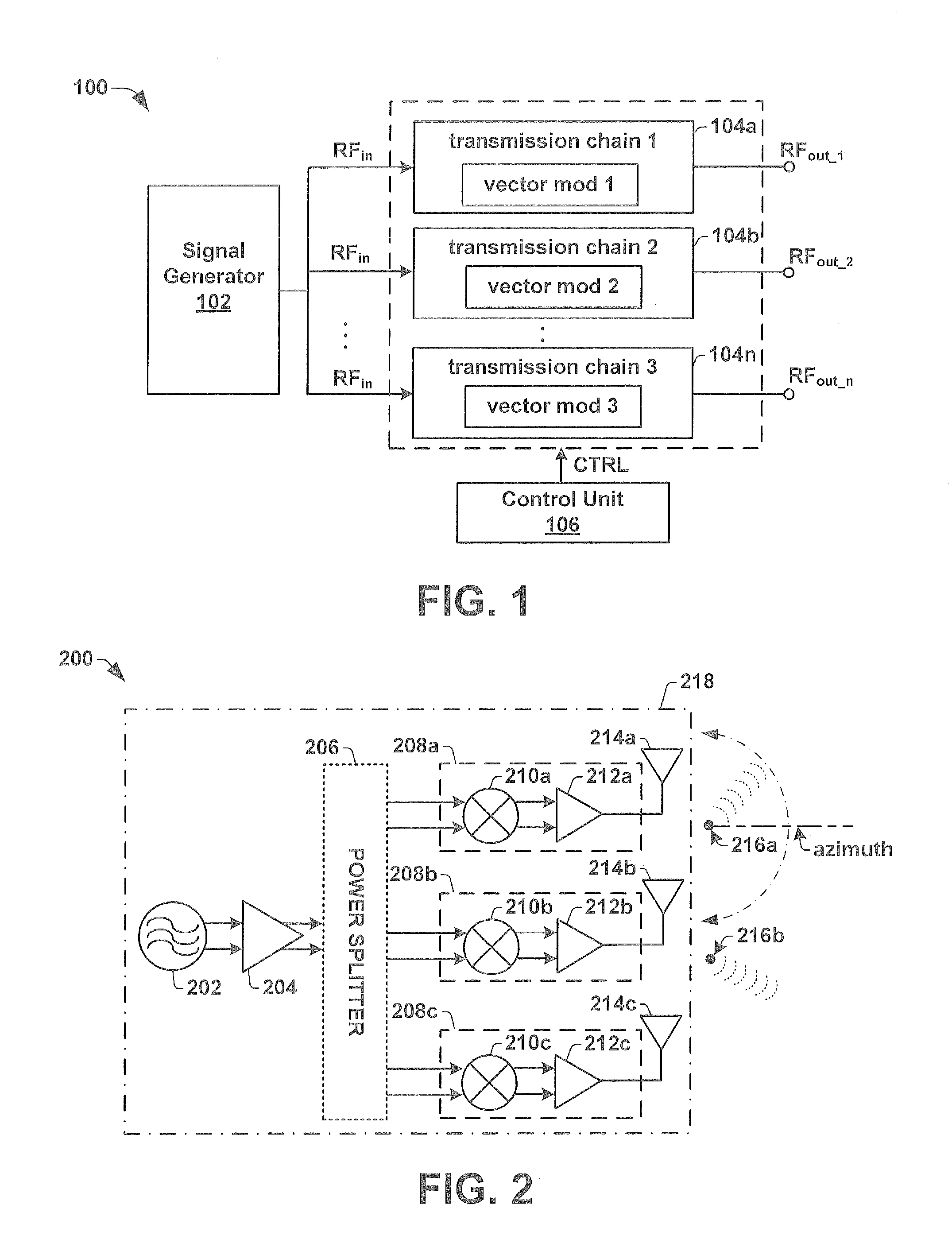

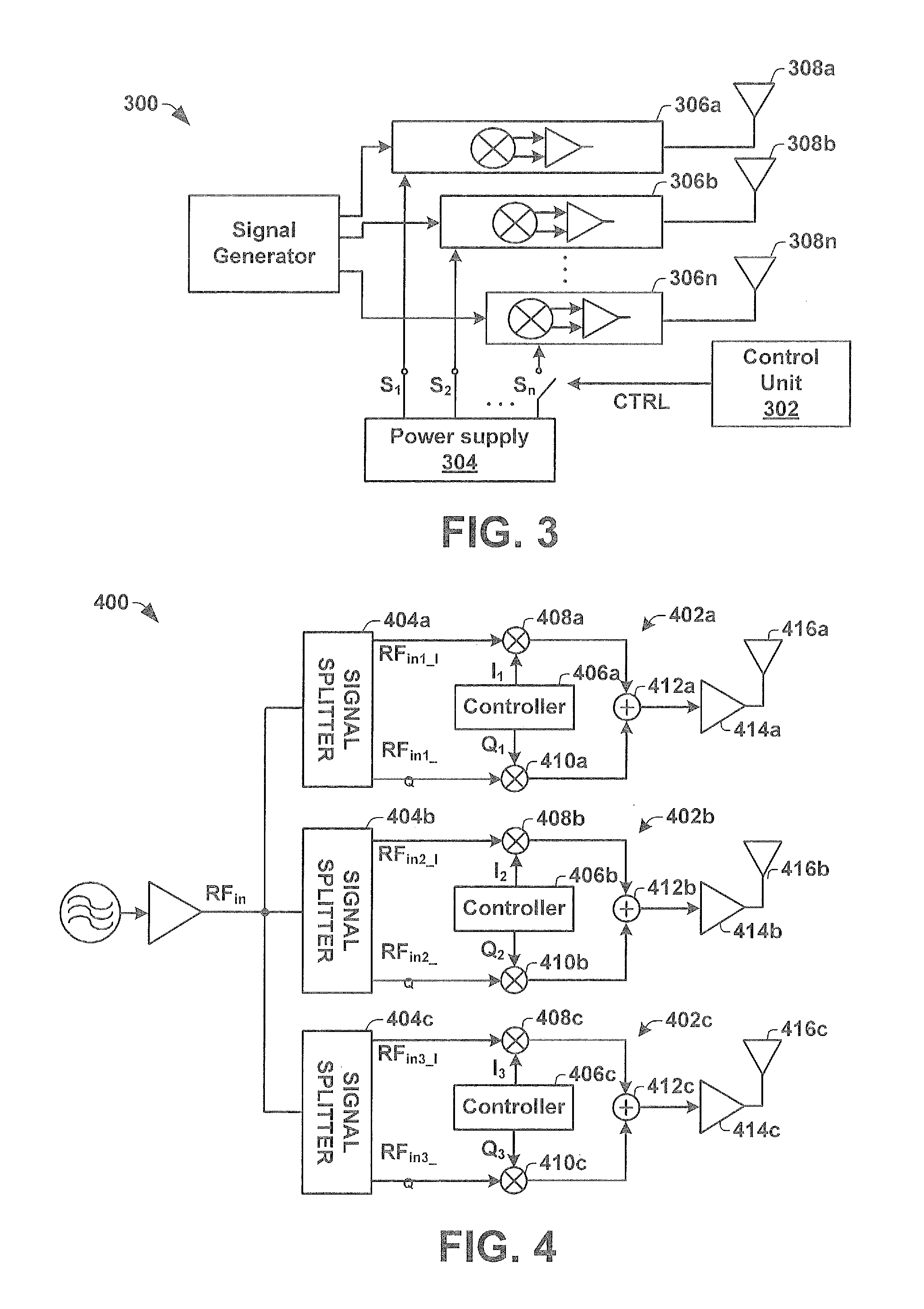

ActiveUS20130088383A1Radio transmissionIndividually energised antenna arraysBeam steeringEngineering

One embodiment of the present invention relates to a radar transmitter comprised within a single integrated chip substrate, which is capable of continuous beam steering of a transmitted radar beam as well as an option to change the physical position of the origin of the transmit radar beam. The radar transmitter has a signal generator that generates an RF signal. The RF signal is provided to a plurality of independent transmission chains, which contain independently operated vector modulators configured to introduce an individual phase adjustment to the high frequency input signal to generate separate RF output signals. A control unit is configured to selectively activate a subset of (e.g., two or more) the independent transmission chains. By activating the subset of independent transmission chains to generate RF output signals with separate phases, a beam steering functionality is enabled. Furthermore, the subset defines a changeable position of the transmitted radar beam.

Owner:INFINEON TECH AG

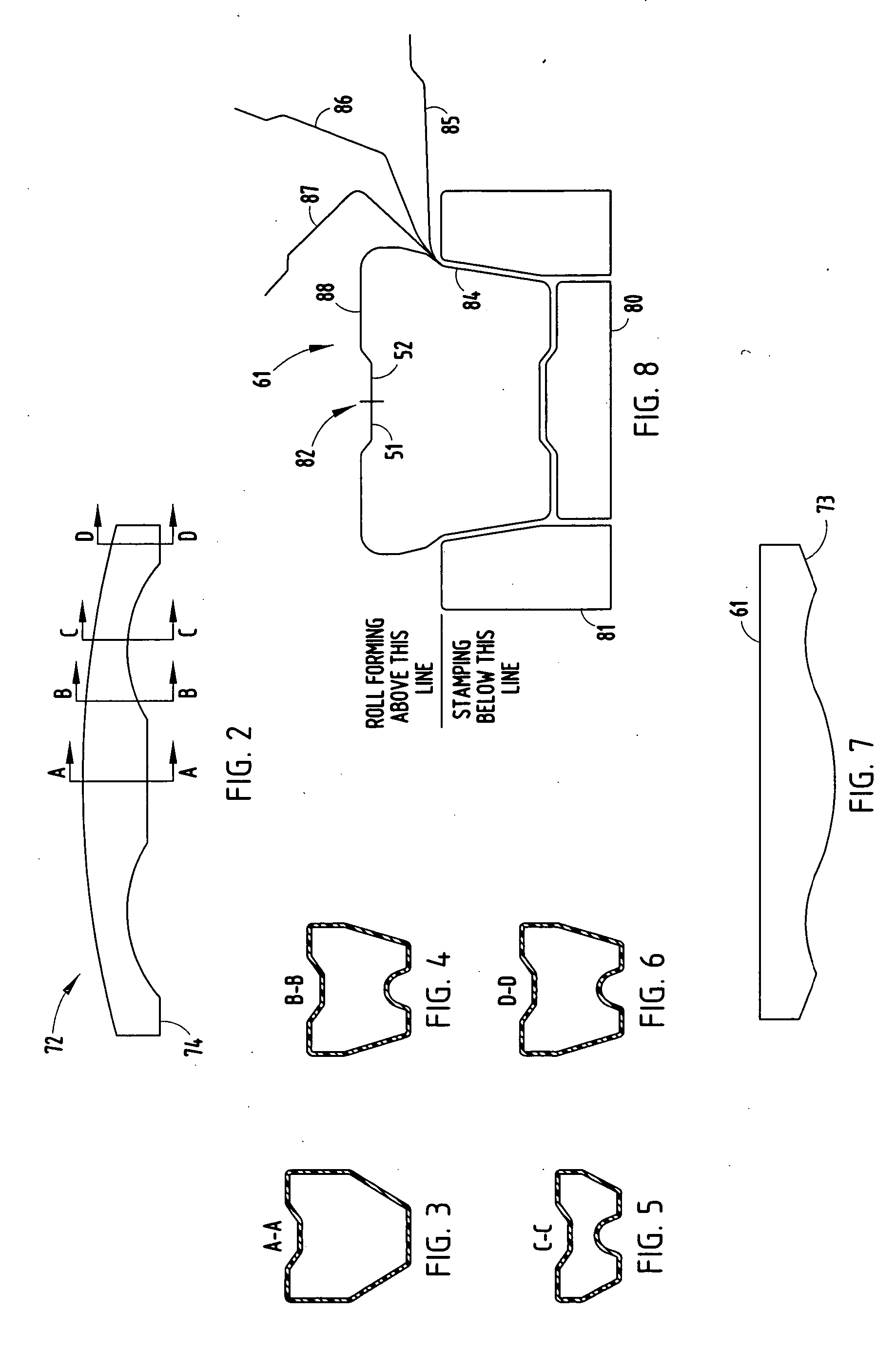

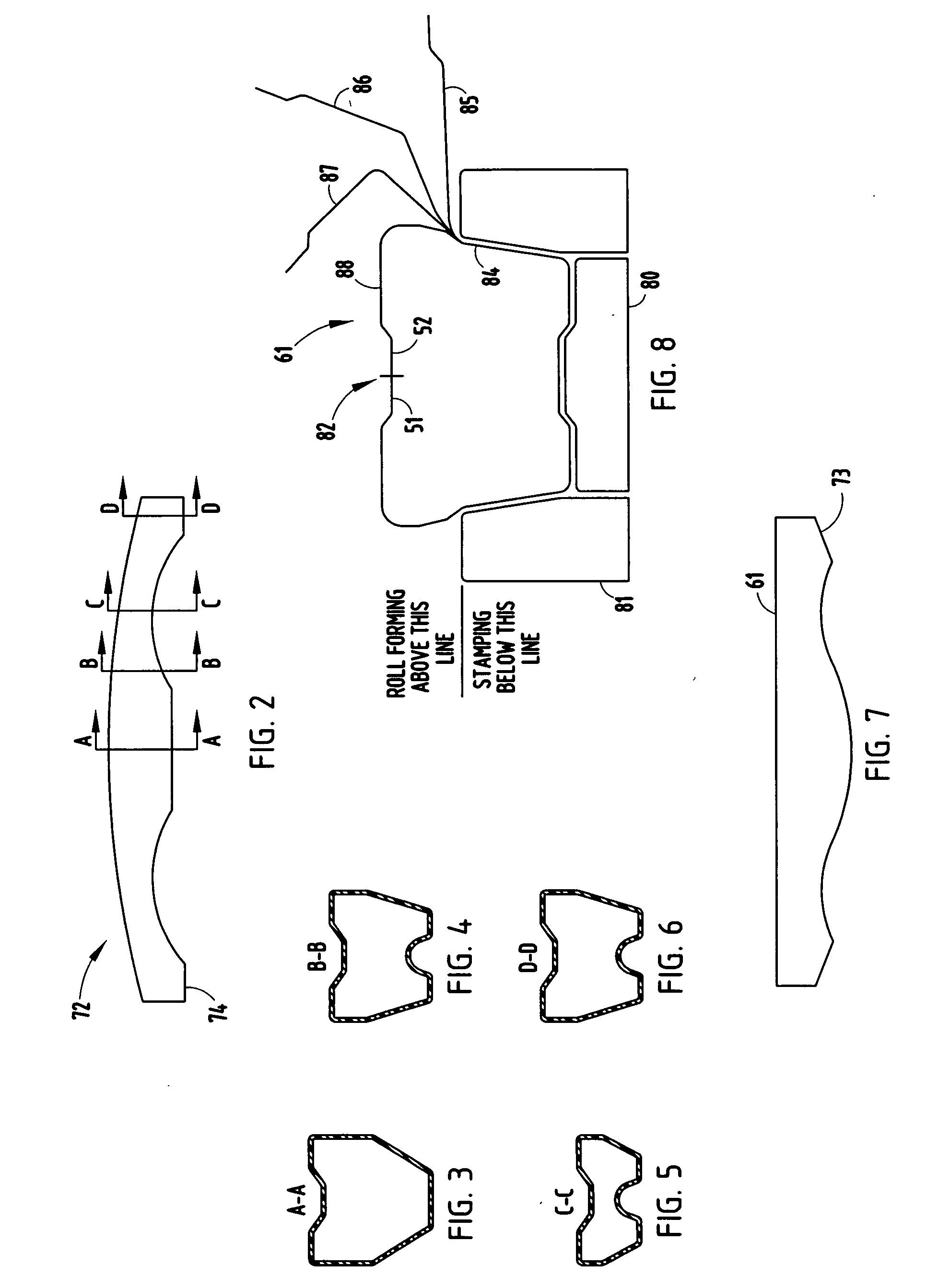

Continuous process of roll-forming pre-stamped varying shapes

An apparatus includes a press with dies configured to deform a strip of material by drawing material primarily from a width direction, a slitter set to cut the deformed strip to a uniform desired width dimension, and a roll-former with rolls configured to shape linear portions of the deformed and now uniform-width strip into a continuous beam. The apparatus further includes a welder for welding abutting edges of the sheet together to form a permanent tube, a sweep station for imparting a longitudinal shape to the continuous beam, and a cut-off for cutting the continuous beam into segments useful as vehicle bumper beams. A controller controls timing of various components. The beam segments are optimized in specific regions for local strength and minimized weight, and features can be incorporated into the beam segments such as coplanar mounting surfaces.

Owner:SHAPE CORP

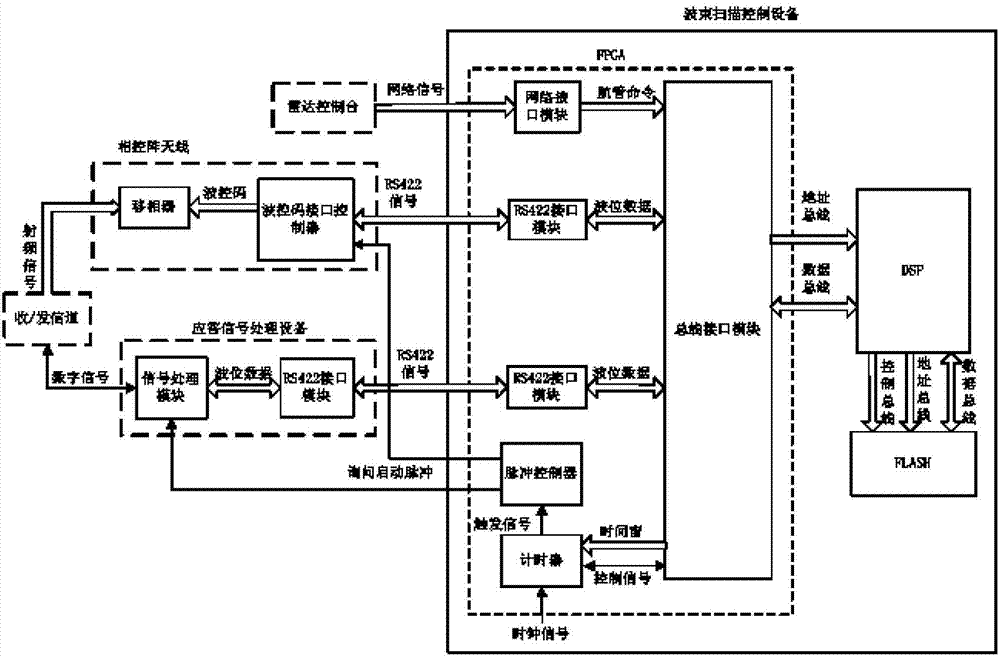

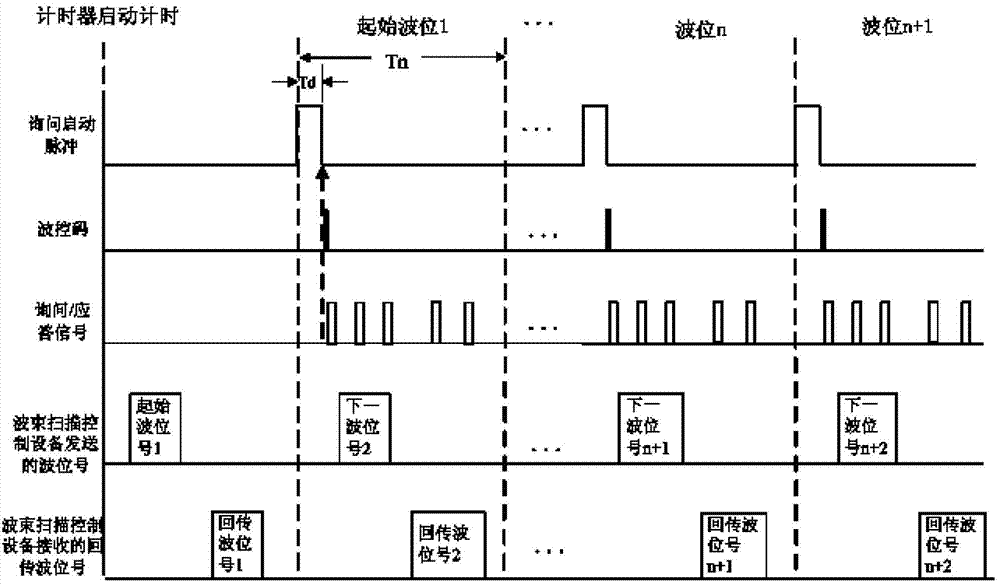

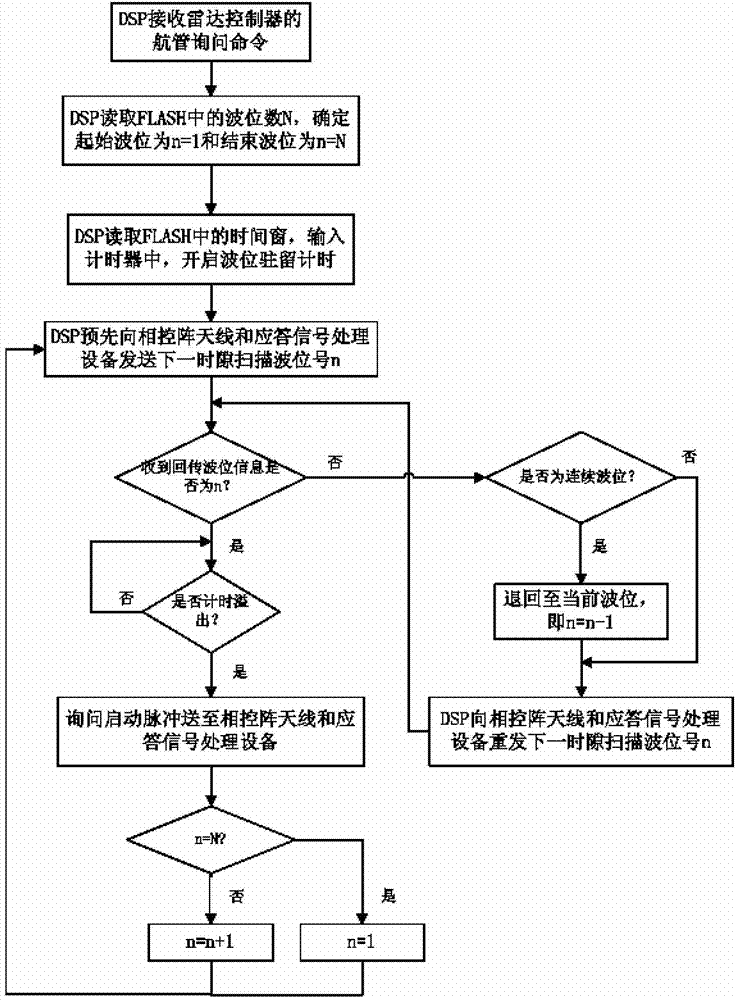

Time control method of navigation management beam scanning

ActiveCN103092113AShorten the inquiry cycleImprove reliabilityProgramme controlComputer controlStopwatchRadar systems

The invention provides a time control method of navigation management beam scanning. The time control method of the navigation management beam scanning solves the problems that the enquiry circle is prolonged and the time usage ratio is low when the secondary radar system navigation management monitoring function is compatible with other inquiring functions. According to the technical scheme, in a navigation management beam scanning time system, a navigation management monitoring airspace is evenly divided into a plurality of continuous beam positions; when a navigation management control command of a radar control table is sent to a digital signal processor (DSP) through a field programmable gate array (FPGA), the DSP reads a beam position dividing parameter from the FLASH and enables a FPGA timer to start beam position lingering time slot timing, and in each time slot, the DSP sends a scanning beam number of the next time slot to a beam control code connector controller of a phased-array antenna and an RS422 connector module of an answering signal processing device through the FPGA, and when time hopping happens, a pulse controller of the FPGA is controlled by the timer to generate an enquiry starting pulse; and the DSP judges the veracity of beam position switch according to the beam position number passed back from the phased-array antenna and the answering signal processing device.

Owner:10TH RES INST OF CETC

Roll-former apparatus with rapid-adjust sweep box

ActiveUS20060277960A1Consistent shapeVehicle componentsMetal rolling arrangementsContinuous beamEngineering

A computer controlled roll-forming apparatus is adapted to provide a repeating pattern of different longitudinal shapes to a continuous beam “on the fly” during the roll-forming process. A sweep station on the apparatus includes a primary bending roller tangentially engaging the continuous beam along the line level and an armature for biasing the continuous beam against the primary bending roller for a distance partially around a downstream side of the primary bending roller to form a sweep. Further, actuators adjustably move the armature at least partially around the downstream side of the primary bending roller between at least first and second positions for imparting multiple different longitudinal shapes into the continuous beam. In one form, the apparatus also includes a coordinated cut-off, so that when separated into bumper beam segments, the ends of the individual beam segments have a greater sweep than their center sections.

Owner:SHAPE CORP

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

Mass spectrometer

ActiveUS6967323B2Stability-of-path spectrometersTime-of-flight spectrometersSpectroscopyMass analyzer

An ion mass spectrometer comprising an ionization source for generating ions, a linear trap region for accumulation and dissociation of ions, and a time-of-flight mass spectrometer for mass spectroscopy of ions based on the flying time, and having a collision damping region introduced with a buffer gas for reducing the kinetic energy of ions ejected from the linear trap region and converting the ion packet into continuous beam and provided with plural electrodes for generating multipole electric fields in the inside between the linear trap region and the time-of-flight mass spectrometer, and having an ion transmission control mechanism for allowing or inhibiting incidence of ion from the linear trap region to the collision damping region between the linear trap region and the collision damping region.

Owner:HITACHI HIGH-TECH CORP

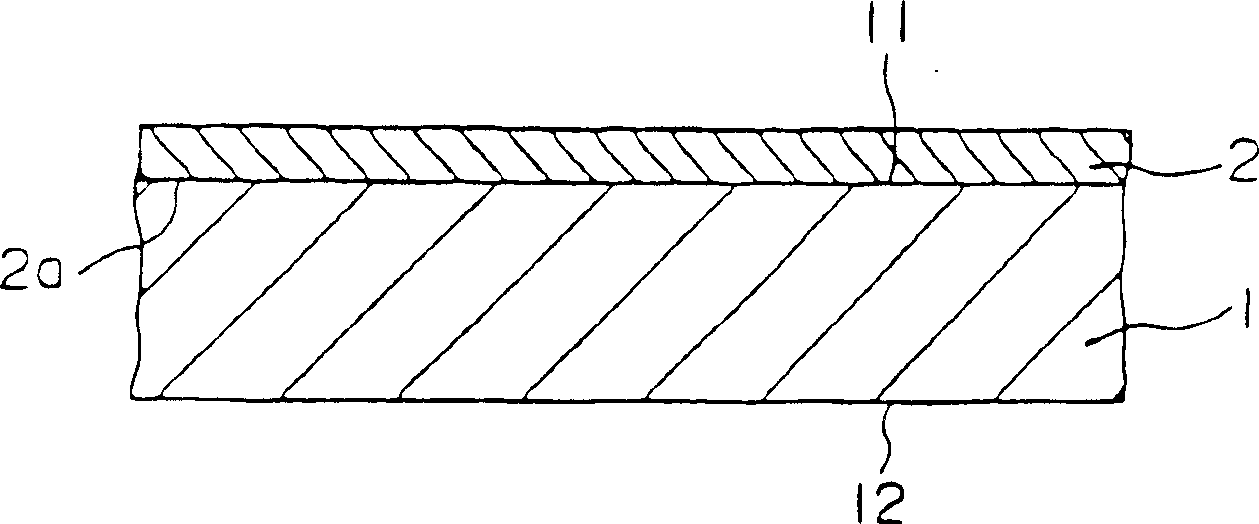

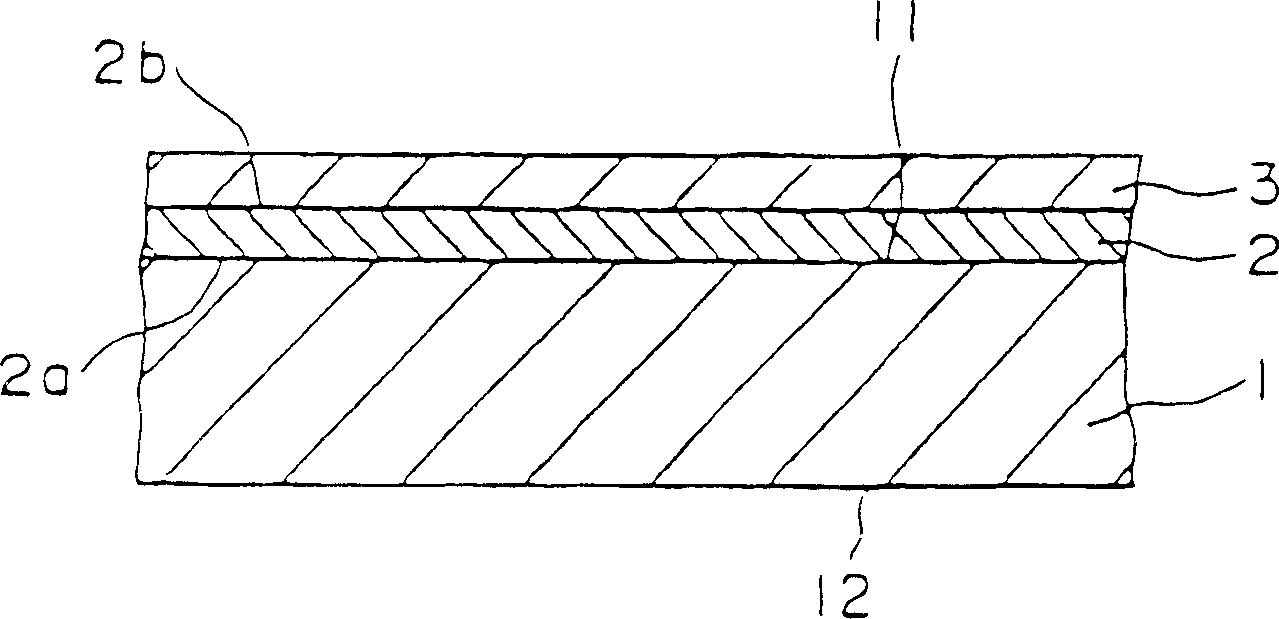

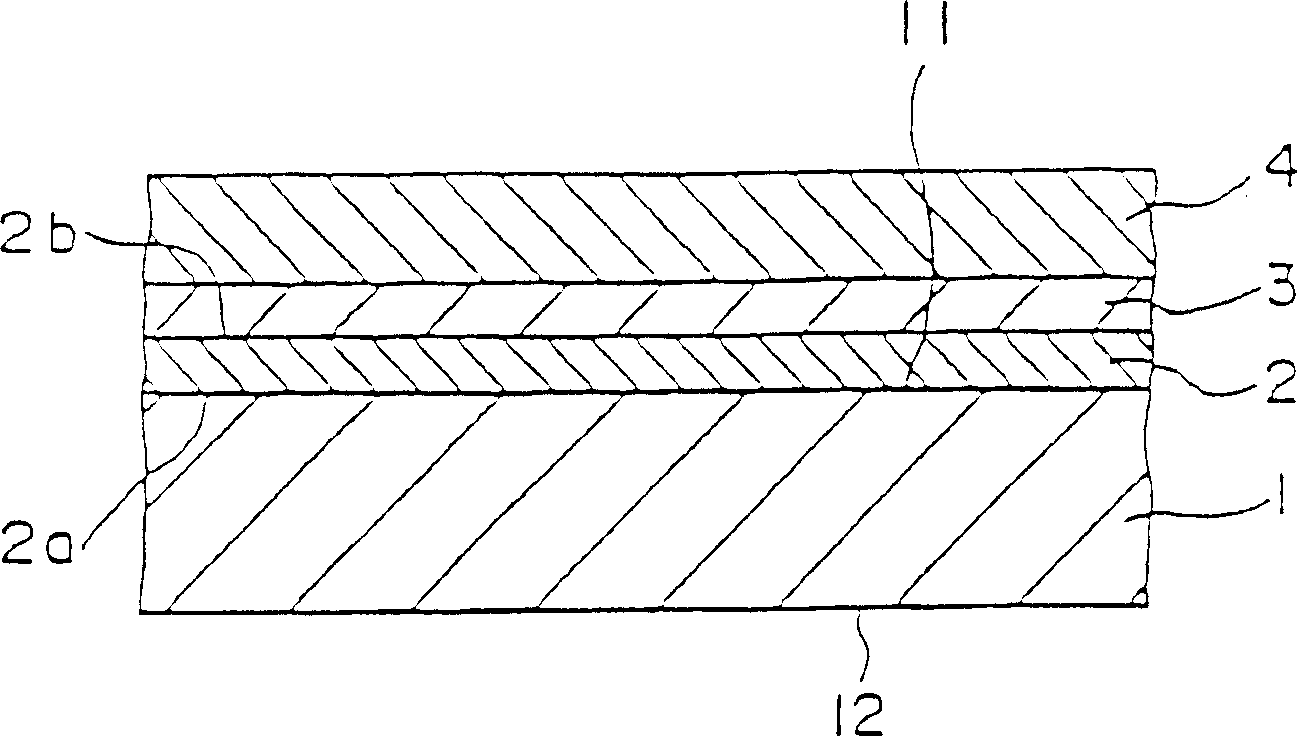

Transferring method

InactiveCN1897219AAvoid damageSmall conduction currentSemiconductor/solid-state device manufacturingNon-linear opticsContinuous beamIrradiation

Owner:SAMSUNG ELECTRONICS CO LTD

Technique for replacing supporters for continuous beam without breaking off traffic

ActiveCN1696407AShort construction periodLess investmentBridge structural detailsBridge erection/assemblyRoad traffic controlIt equipment

The present invention relates to a continuous bridge bearing replacement technique under the condition of non-stopping traffic, beloning to the method for maintaining and strengthening existent bridge or field of its equipment technology. It is characterized by that it adopts a multipoint synchronous jack up control equipment to make the whole continuous bridge system be synchronously lifted under the action of large multipoint jack-up force, and can simultaneously replace old bearings of bridge with new bearings of bridge.

Owner:河北道桥工程检测有限公司

Continuous CFRP Decked Bulb T Beam Bridges For Accelerated Bridge Construction

A pre-stressed concrete bridge using longitudinal load members of a single continuous beam including at least two types of concrete, one of which is ultra-high-performance concrete (UHPC) mix with a compressive strength exceeding 20 ksi and tensile strength exceeding 1.5 ksi in a region proximate to the support structure.

Owner:LAWRENCE TECHNOLOGICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com