Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

An ultra-high performance, concrete technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as weakening the effect of pre-compression stress of concrete slabs, adverse effects on durability, increasing the burden on steel beams, etc., to achieve good economic Benefit, avoid negative bending moment zone disease, reduce the effect of structure self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

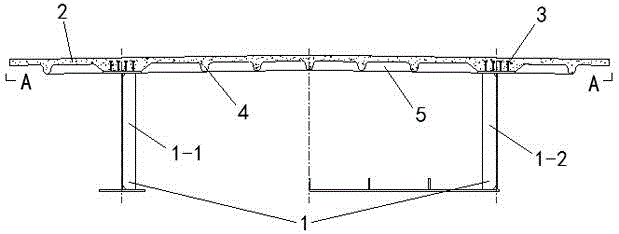

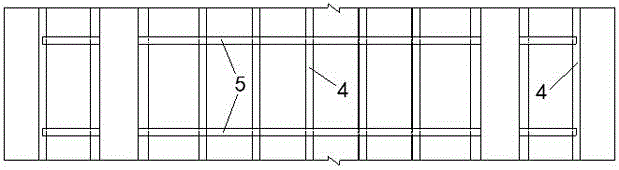

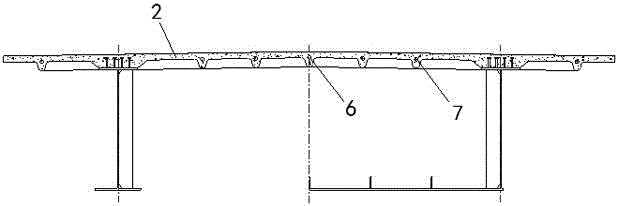

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0026] Such as Figure 1~3 As shown, a steel-ultra-high-performance concrete composite beam based on a ribbed bridge deck includes a steel girder 1 on which an ultra-high-performance concrete bridge deck 2 is placed, and the ultra-high-performance concrete bridge deck 2 The steel girder 1 is fixed together by the shear connector 3, and the ultra-high performance concrete bridge deck 2 is provided with a reinforcement mesh composed of steel bars criss-crossing. At least one of them is a rib structure to form a ribbed ultra-high performance concrete bridge deck 2 .

[0027] Wherein, the ultra-high-performance concrete bridge deck 2 is poured from ultra-high-performance concrete, and the ultra-high-performance concrete means that the components contain steel fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com