Patents

Literature

115results about How to "Reduce building height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

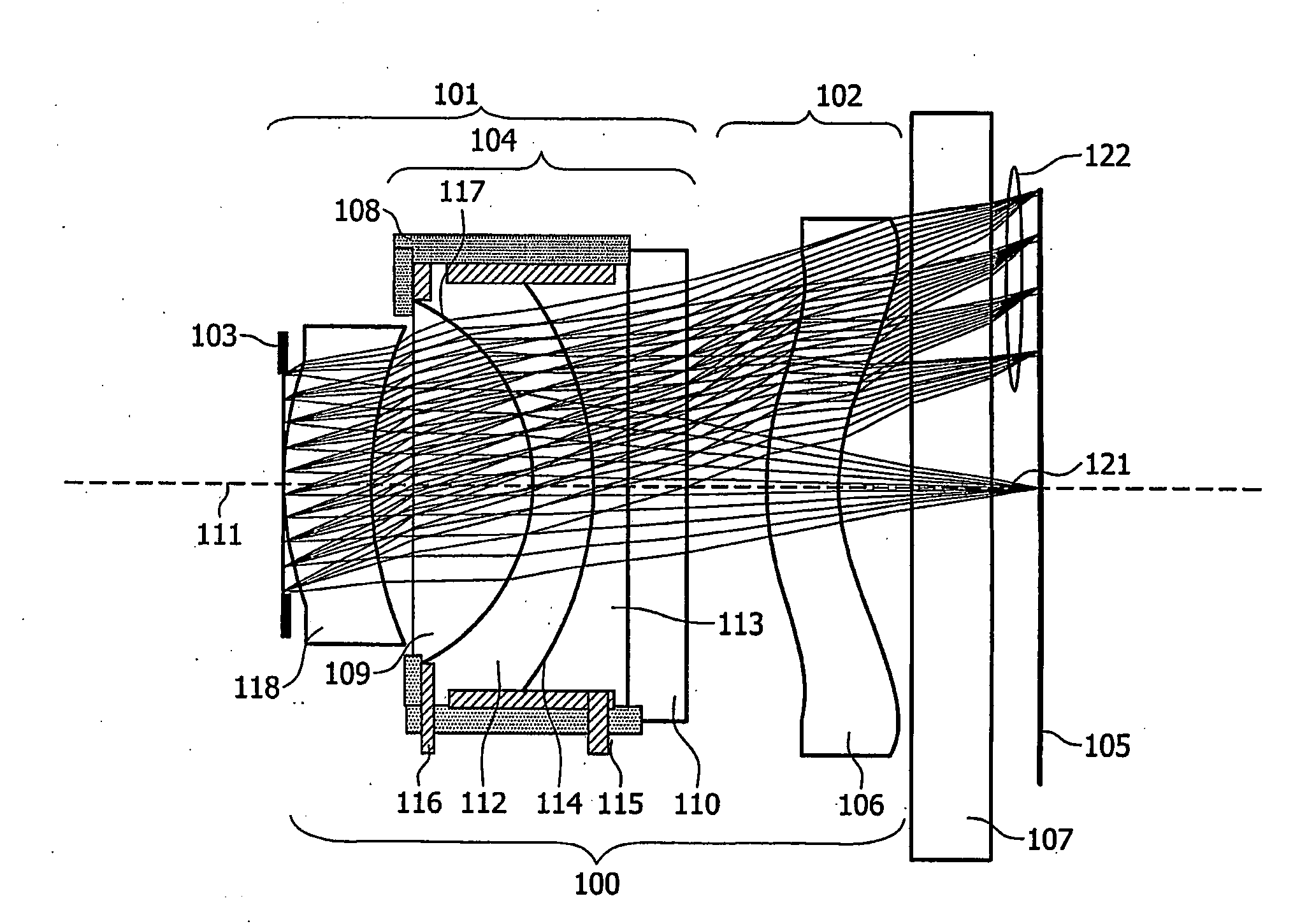

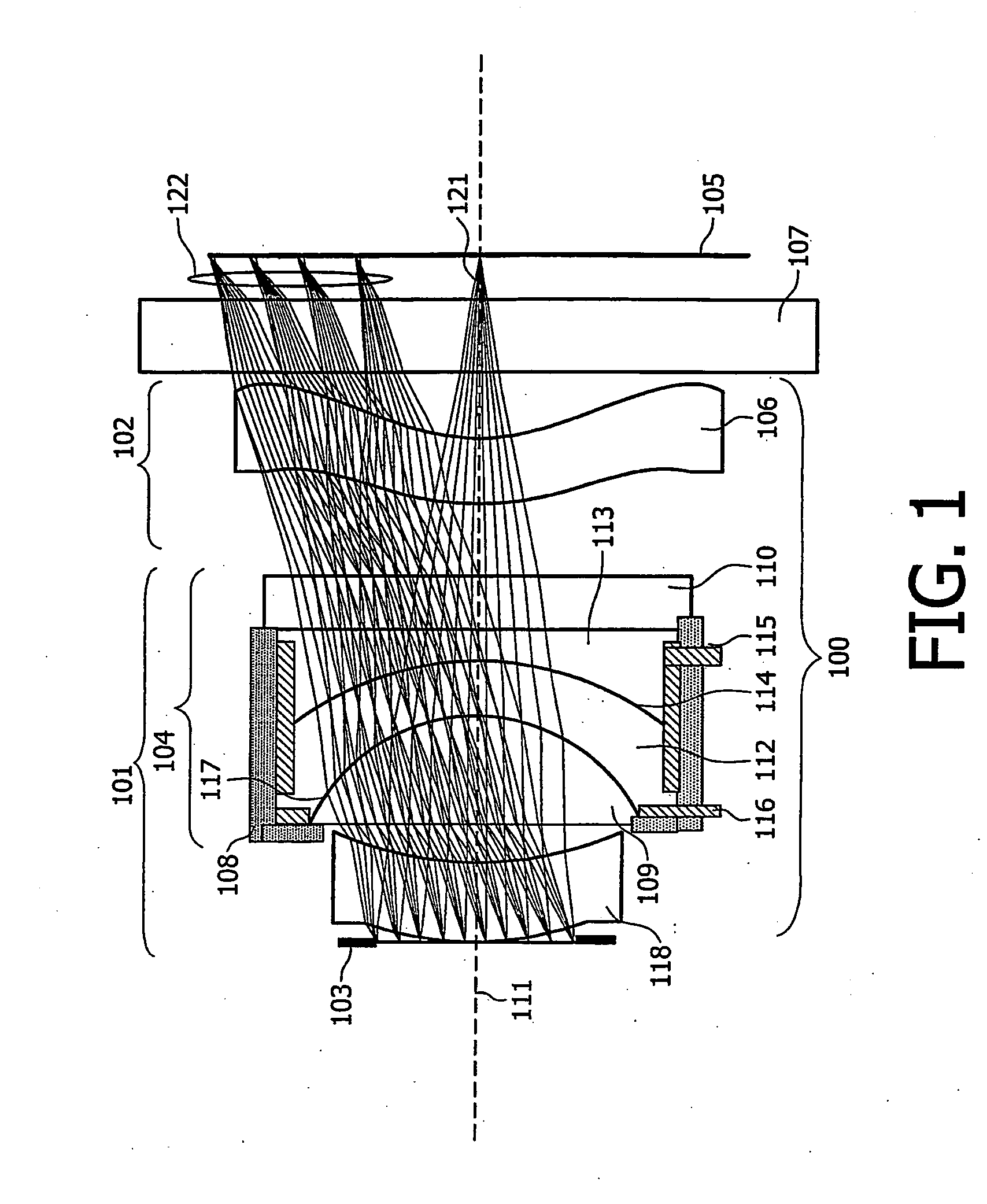

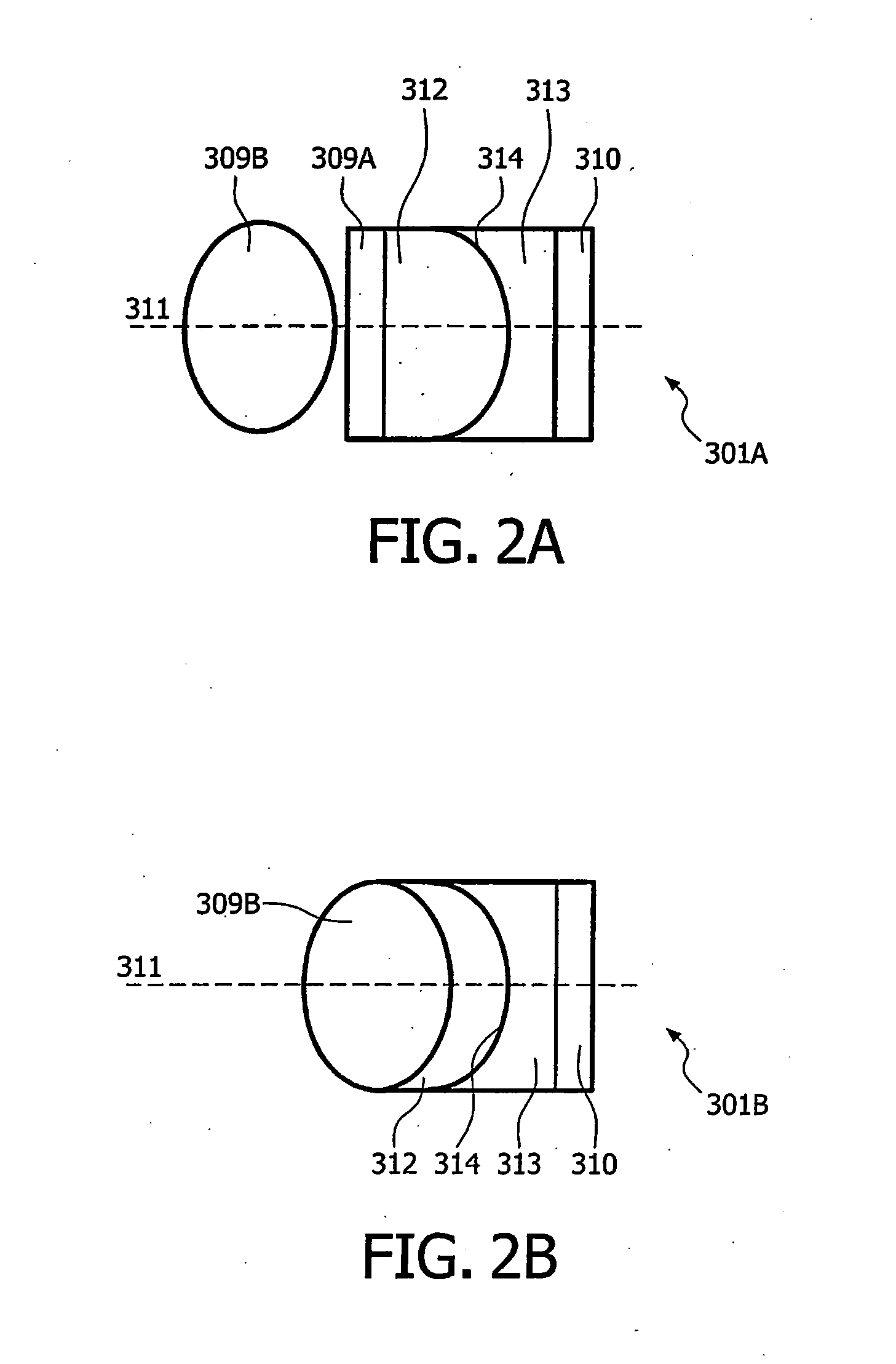

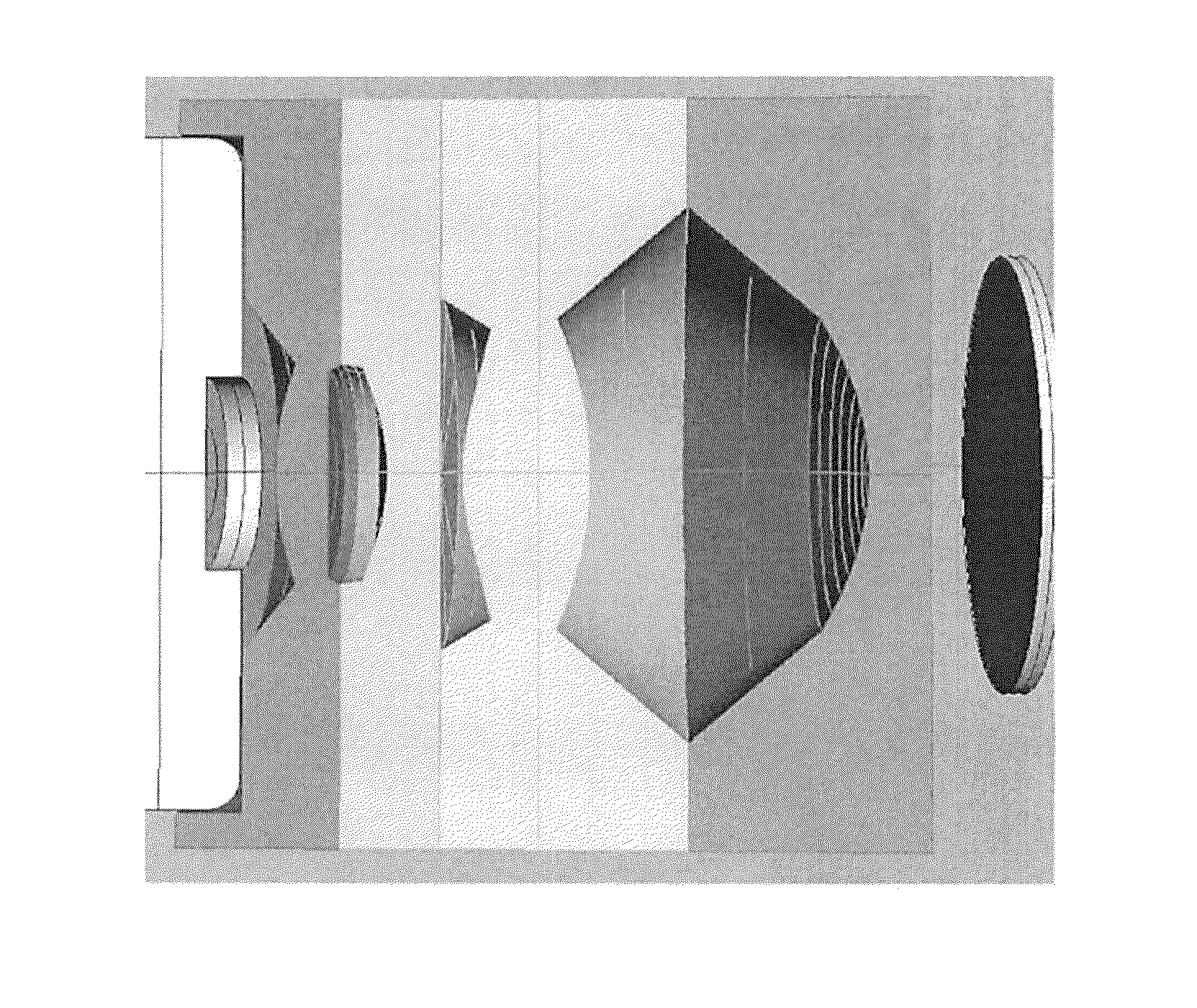

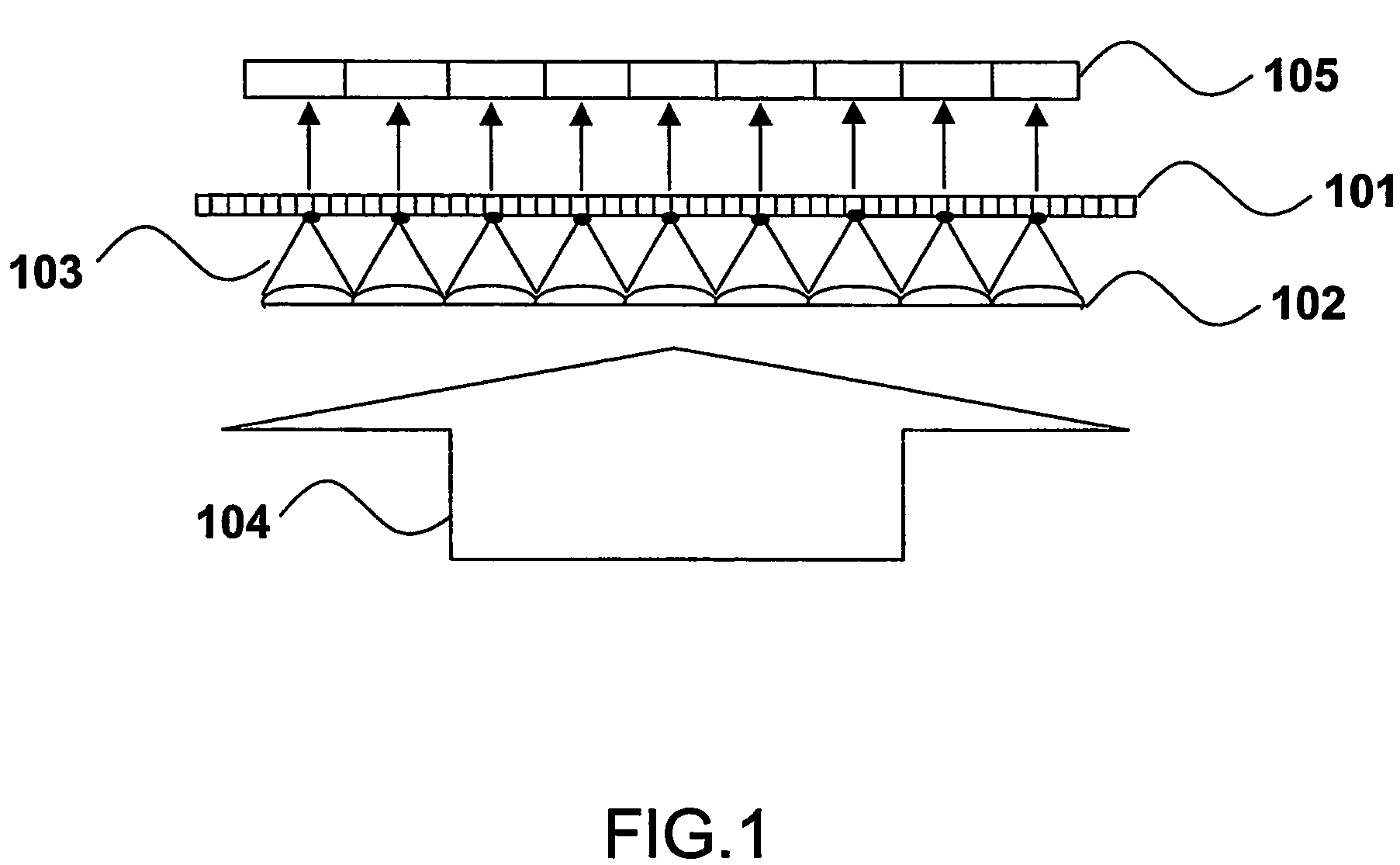

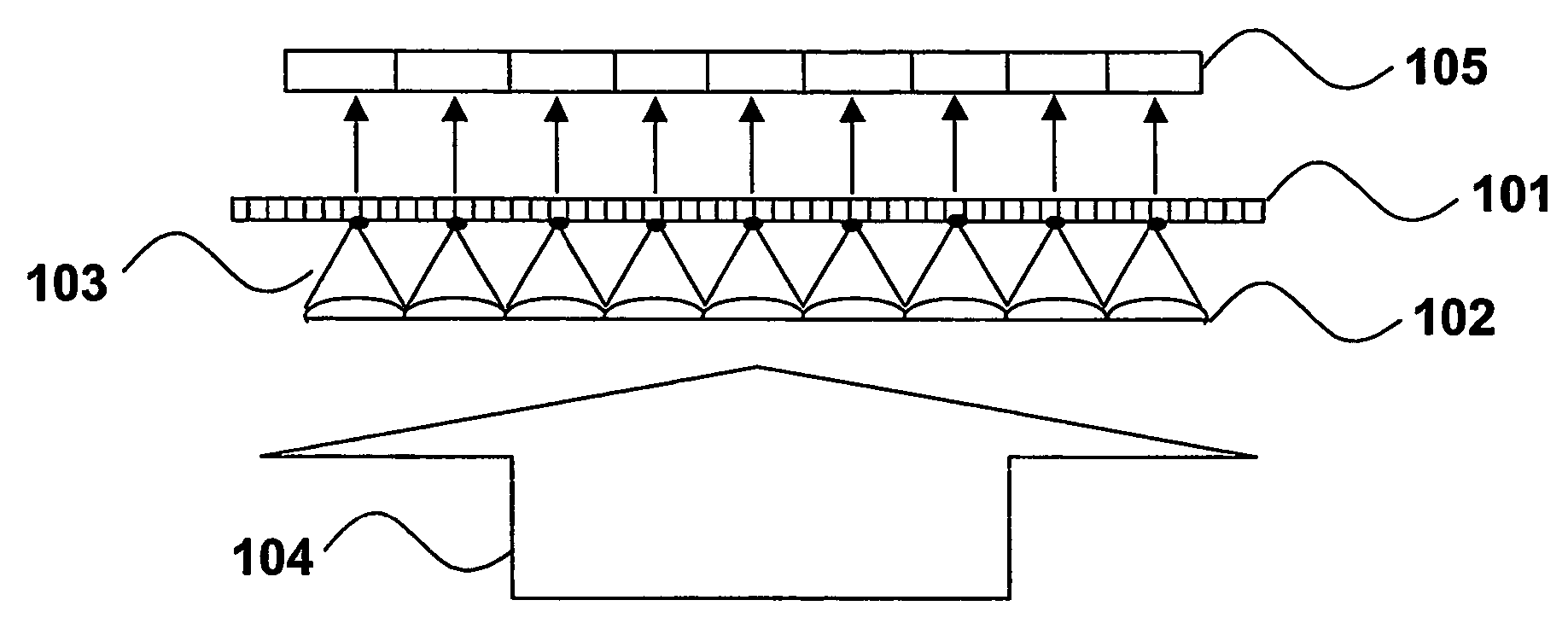

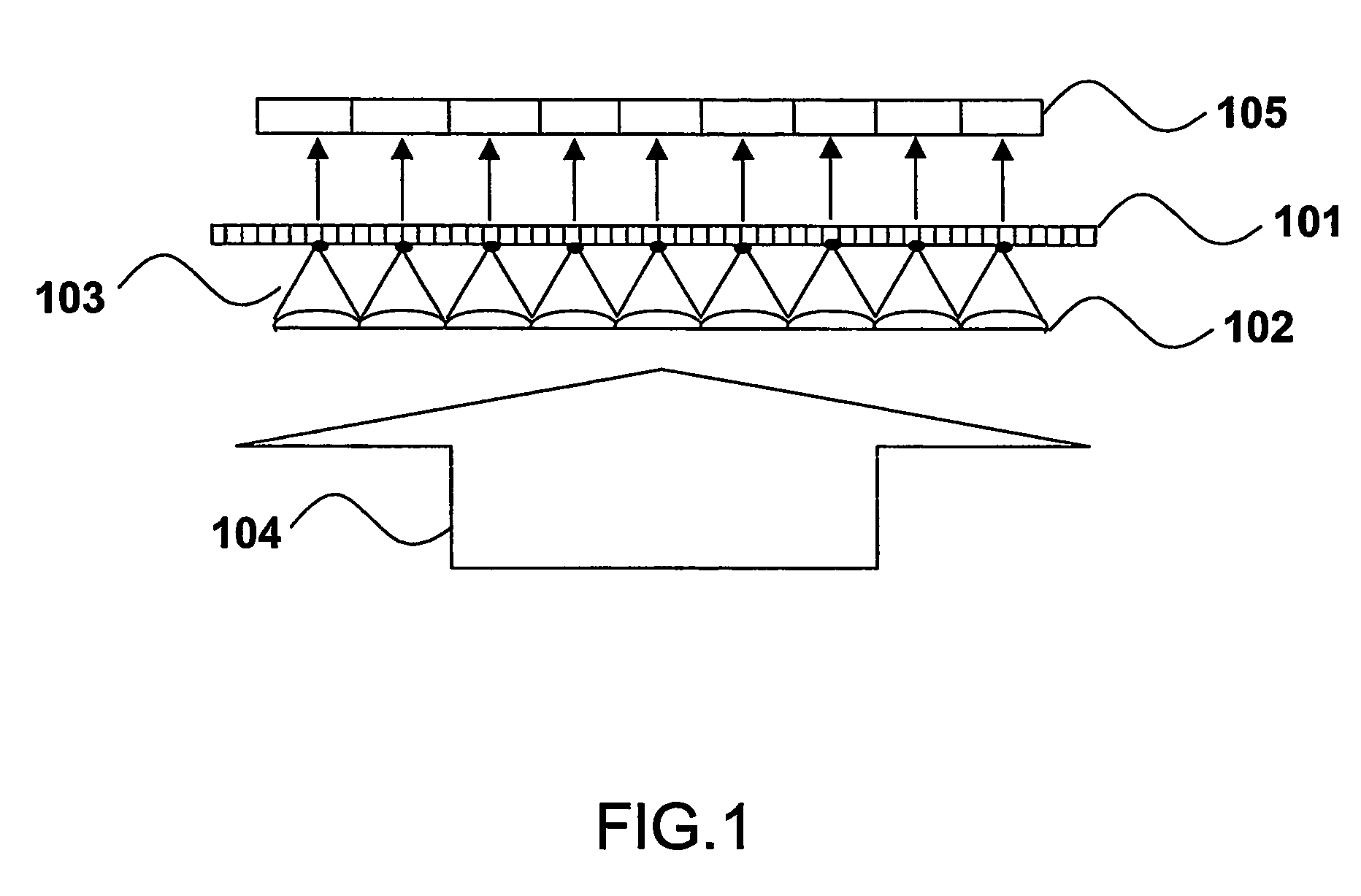

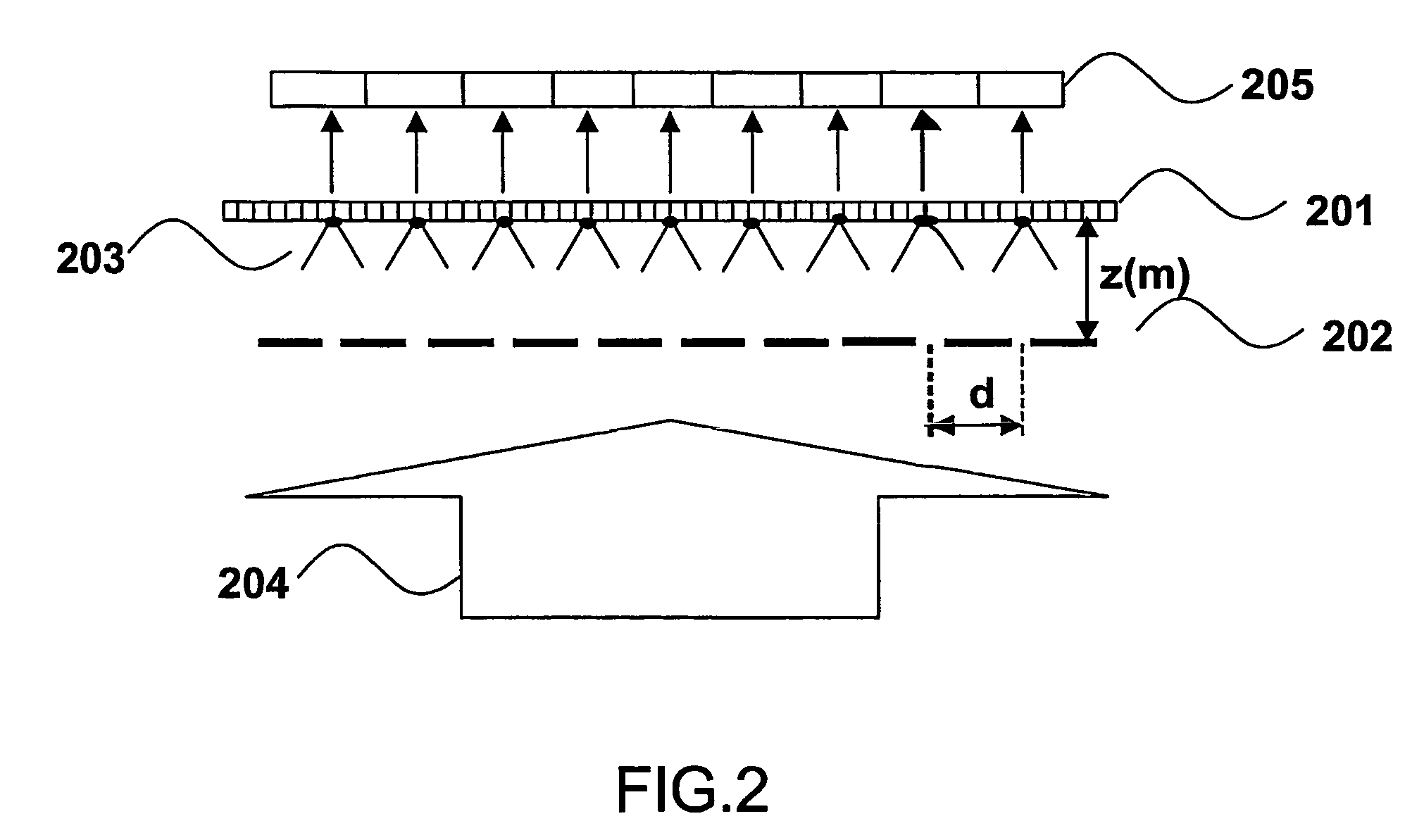

Variable Lens System

InactiveUS20080231966A1Reduce building heightLong focal lengthTelevision system detailsMountingsMaterials scienceOptics

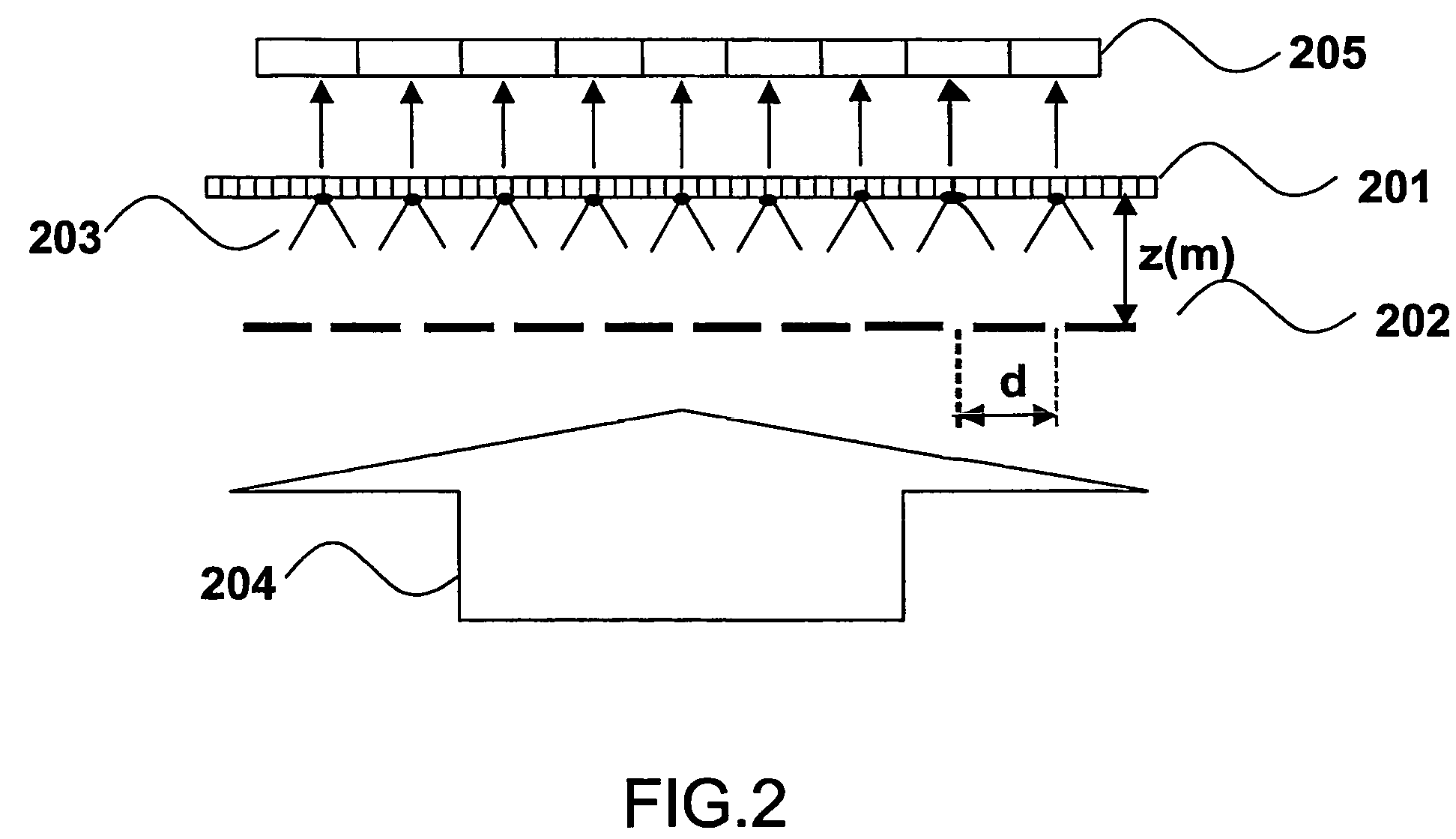

A compact and substantially achromatic optical lens system (100, 200) comprising an electrowetting lens (104, 204) is provided. The optical lens system is using an electrowetting lens in which at least one of the entrance window surface (117, 217) or exit window surfaces (219), being in contact with one of the fluids (112, 212, 113, 213), has a curvature. When the sign of the curvature of that surface has the same sign as the curvature of the meniscus when no voltage is applied, a low building height is achieved. The optical element (104, 204) not only acts as a focussing or zooming device, but that it also acts as an aberration reduction element for the other elements in the optical lens system (100, 200).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

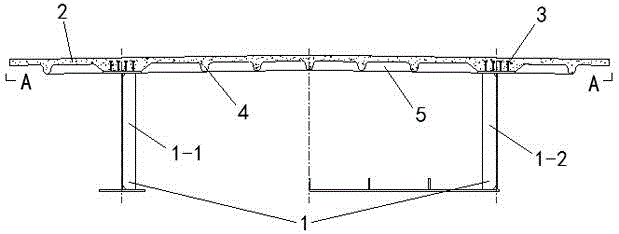

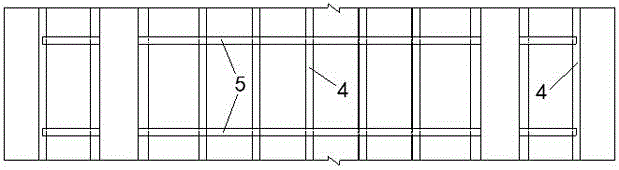

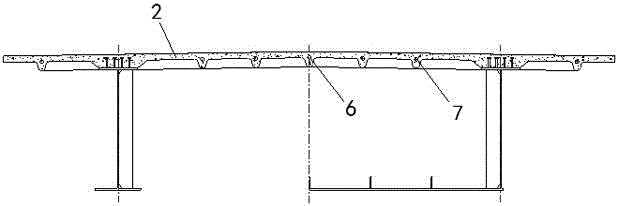

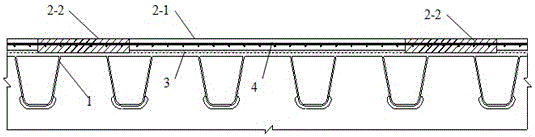

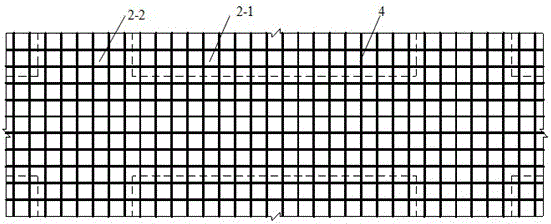

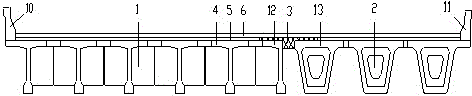

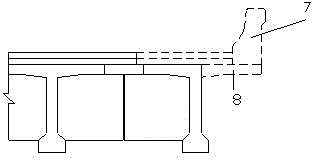

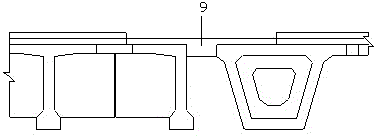

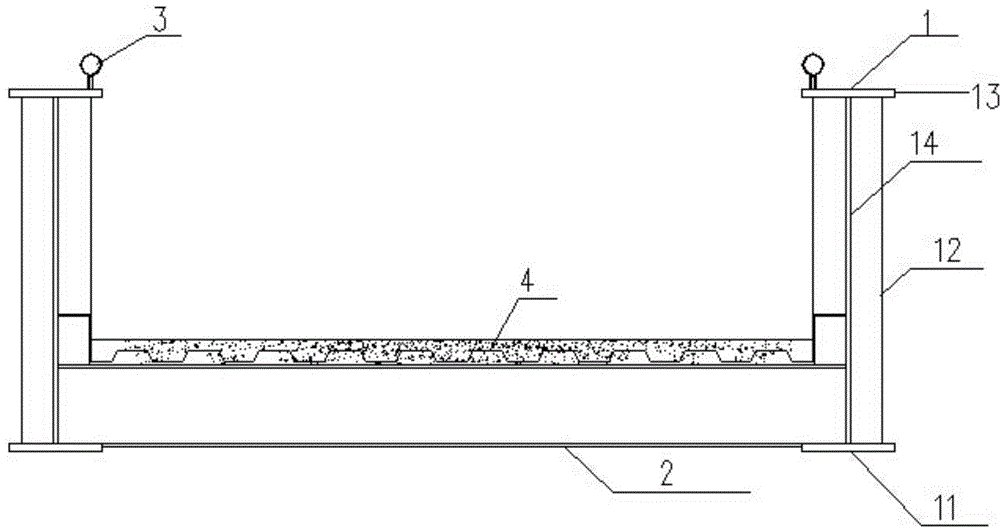

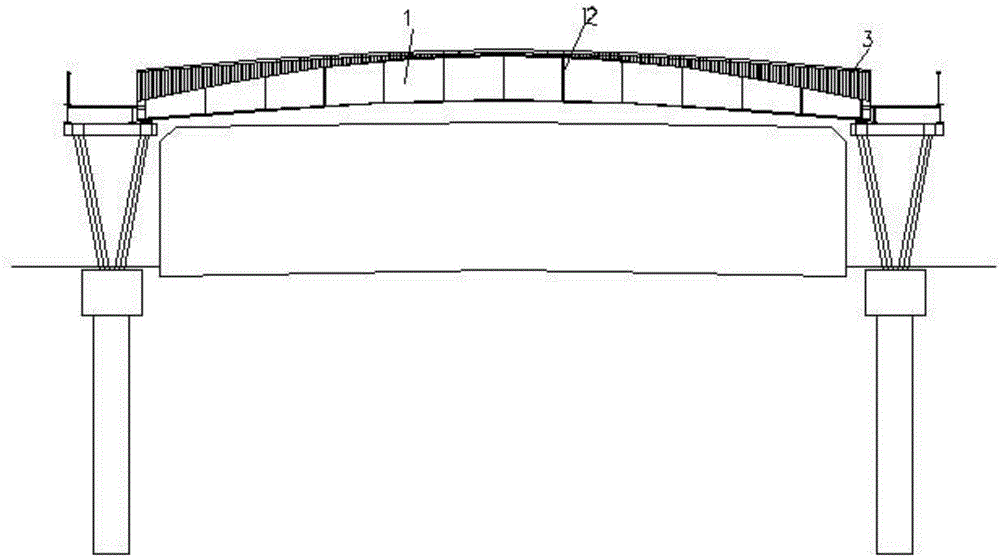

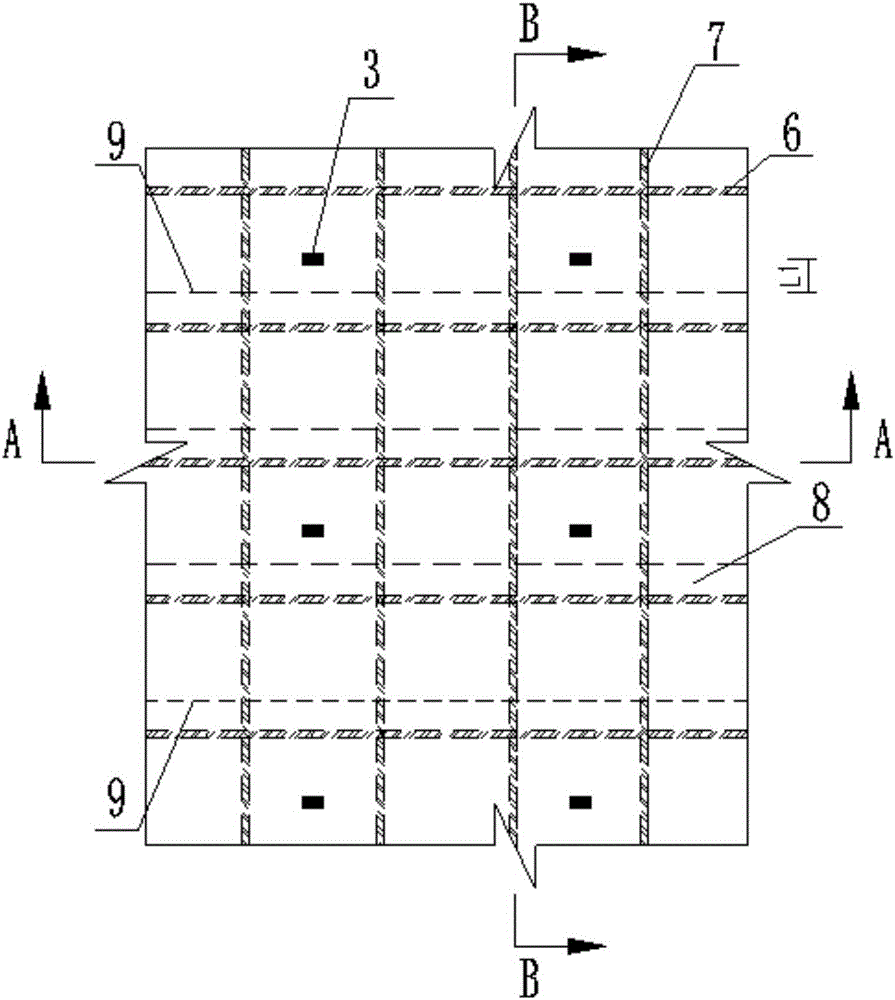

Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

InactiveCN104831617AReasonable forceHigh strengthBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a steel-super high performance concrete composite beam based on a ribbed plate type bridge deck and a construction method. The construction method includes the following steps that step1, steel beams are machined, manufactured and installed; step2, shearing force connecting parts are welded; step3, the super high performance concrete bridge deck is constructed; step4, a guardrail or an anti-collision wall is constructed; step5, bridge deck pavement is constructed, wherein the super high performance concrete bridge deck and the steel beams are fixed through the shearing force connecting parts, the cross section or / and the longitudinal section of the super high performance concrete bridge deck is / are of a ribbed plate structure, and pre-stressed reinforcements can be arranged on a longitudinal rib region or / and a transverse rib region. The composite beam is reasonable in stress, high in strength and capable of substantially reducing the structure dead weight, effectively avoiding defects at a hogging moment region of a composite continuous beam and bringing tensile strength, compressive strength and high durability of super high performance concrete into full play; the composite beam has the advantages of being small in building height, high in rigidity, small in dead weight, good in durability, crack resistance and fatigue resistance and the like, and has great practical value and good economic benefits.

Owner:FUZHOU UNIV

Steel and ultra-high performance concrete combined bridge deck structure

InactiveCN101858052AChange structureChange work statusBridge structural detailsBridge materialsBridge deckRebar

The invention relates to a bridge deck structure of a steel bridge, in particular to a steel and ultra-high performance concrete combined bridge deck structure, comprising a steel bridge deck, an ultra-high performance concrete layer is coated above the steel bridge deck, a bridge deck pavement layer is coated above the ultra-high performance concrete layer, and the ultra-high performance concrete layer is internally provided with reinforced bars. The steel and ultra-high performance concrete combined bridge deck structure has the advantages of small construction height, large stiffness, good binding performance between combined layers, good durability, good fatigue resistance, little vehicle impact and the like.

Owner:HUNAN UNIV

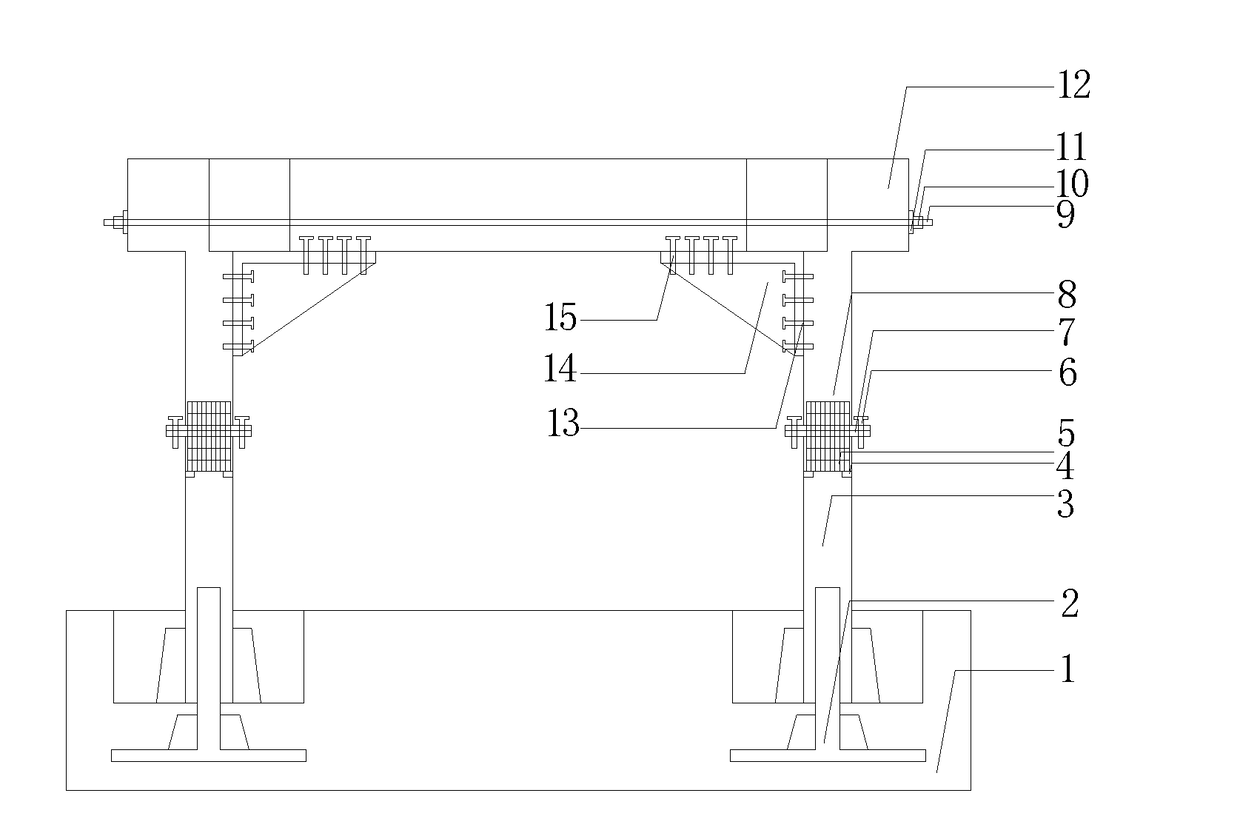

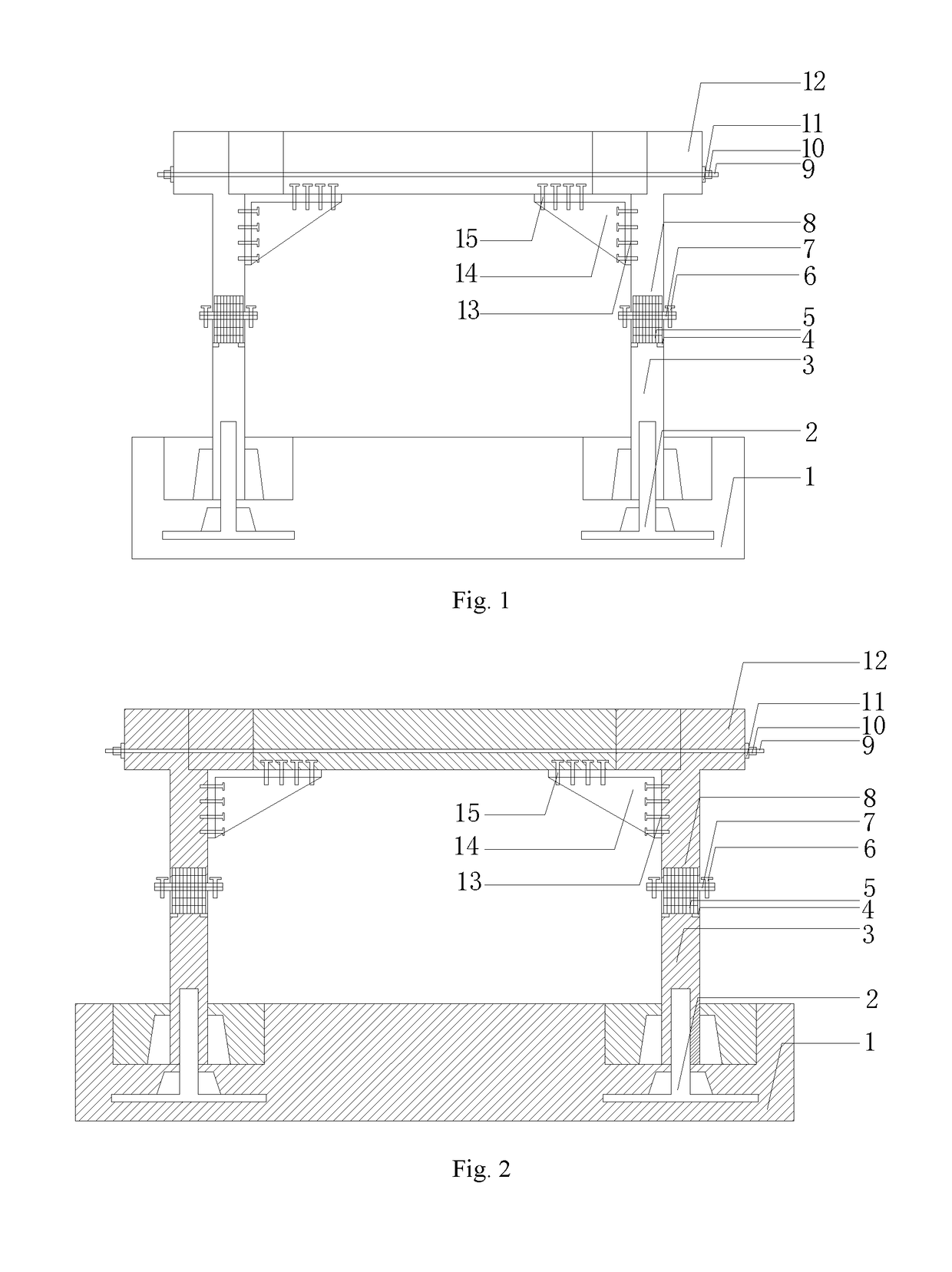

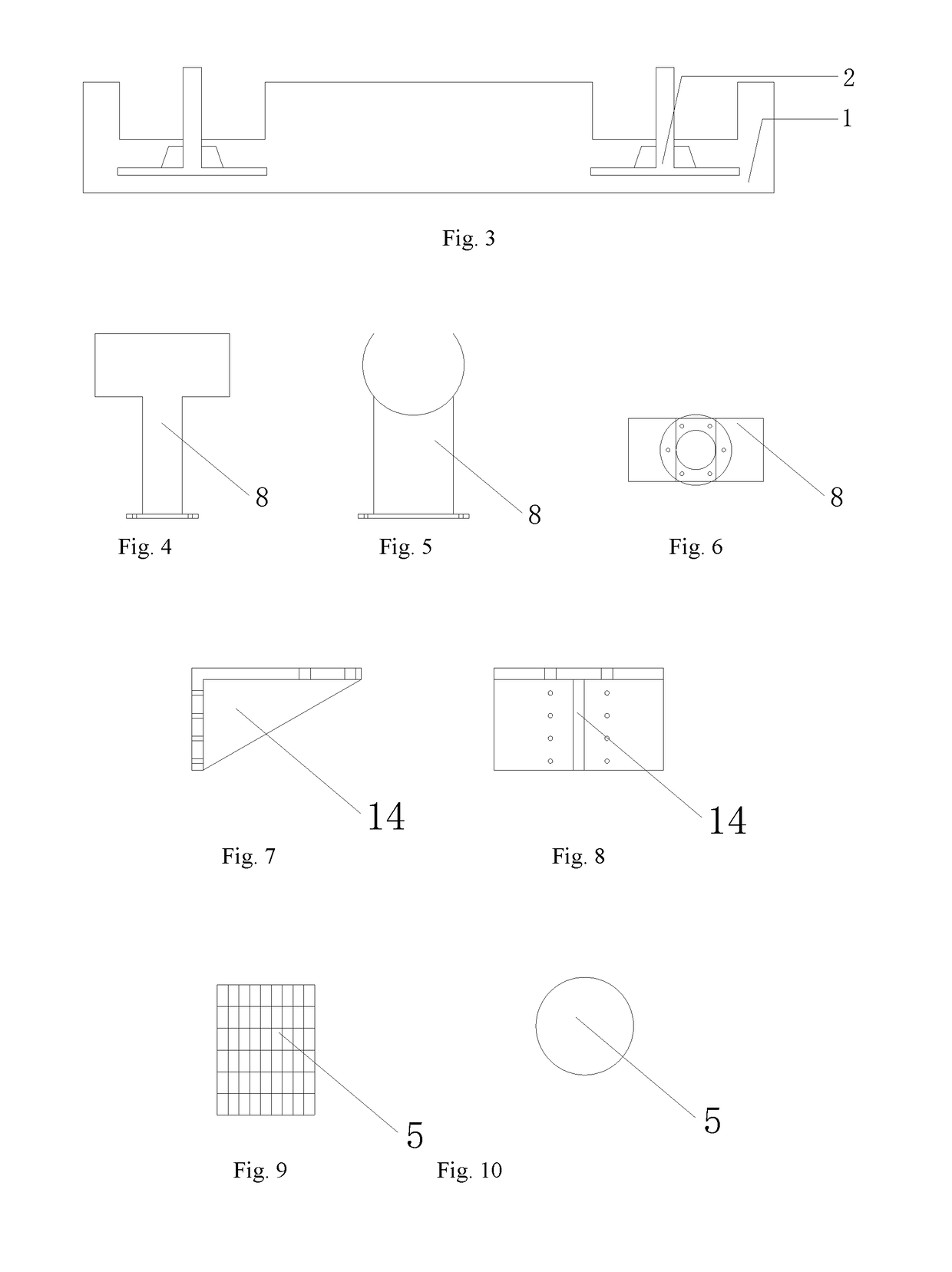

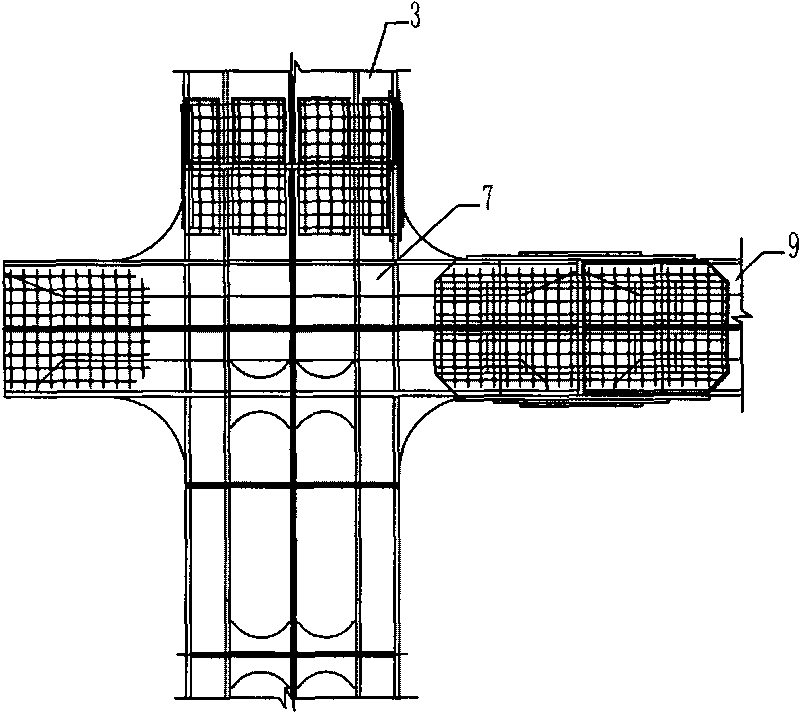

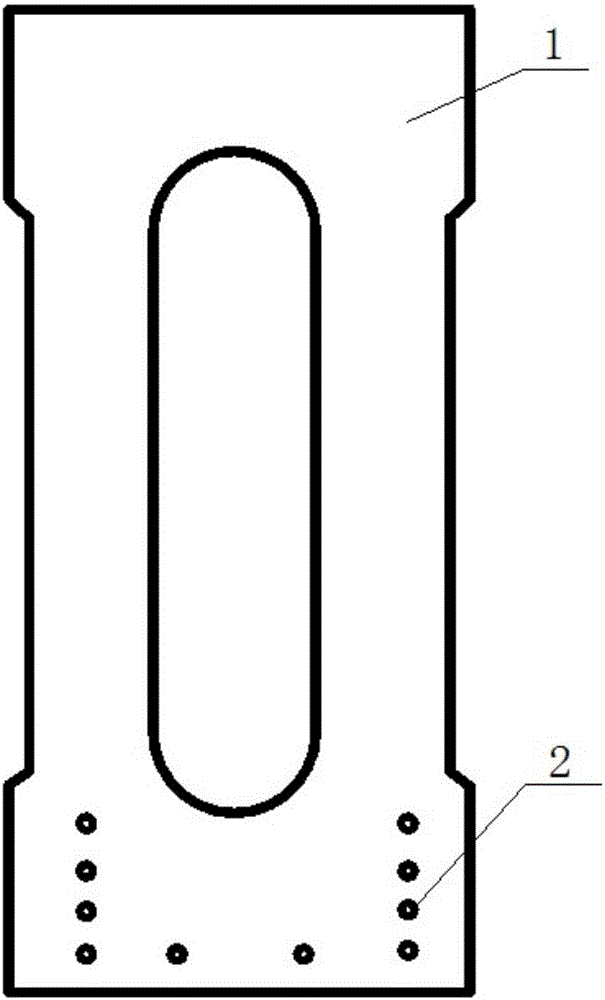

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

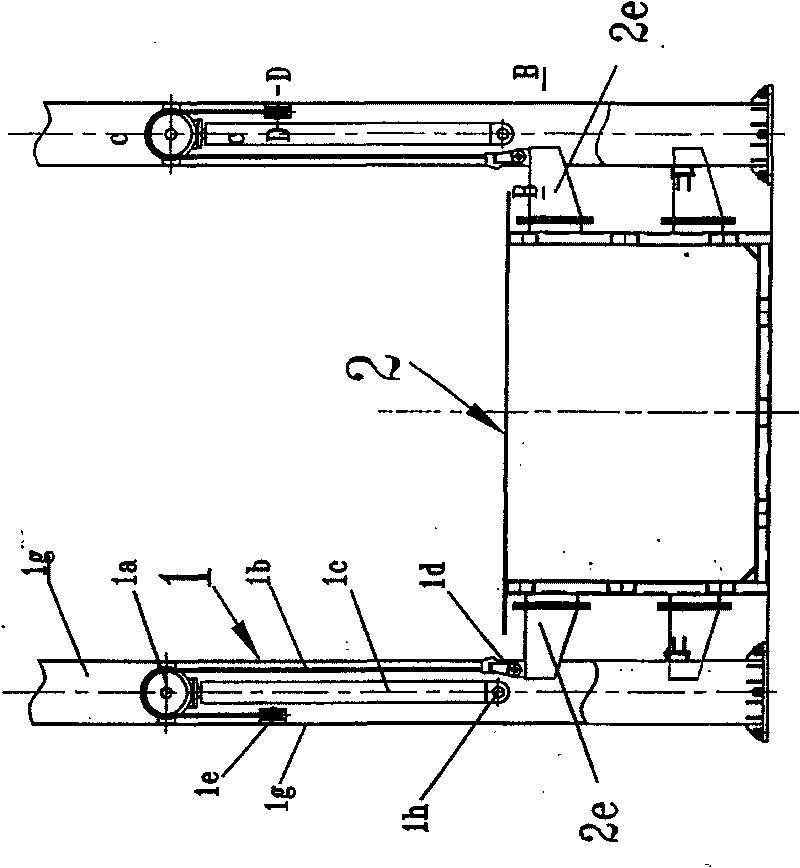

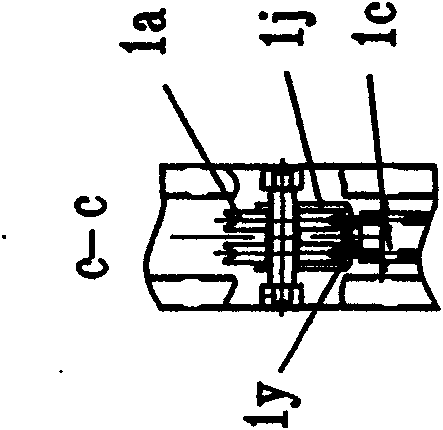

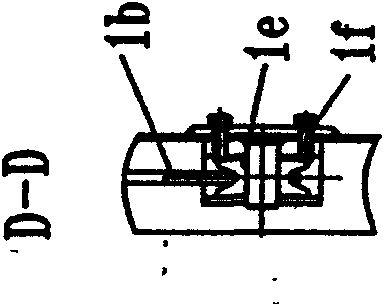

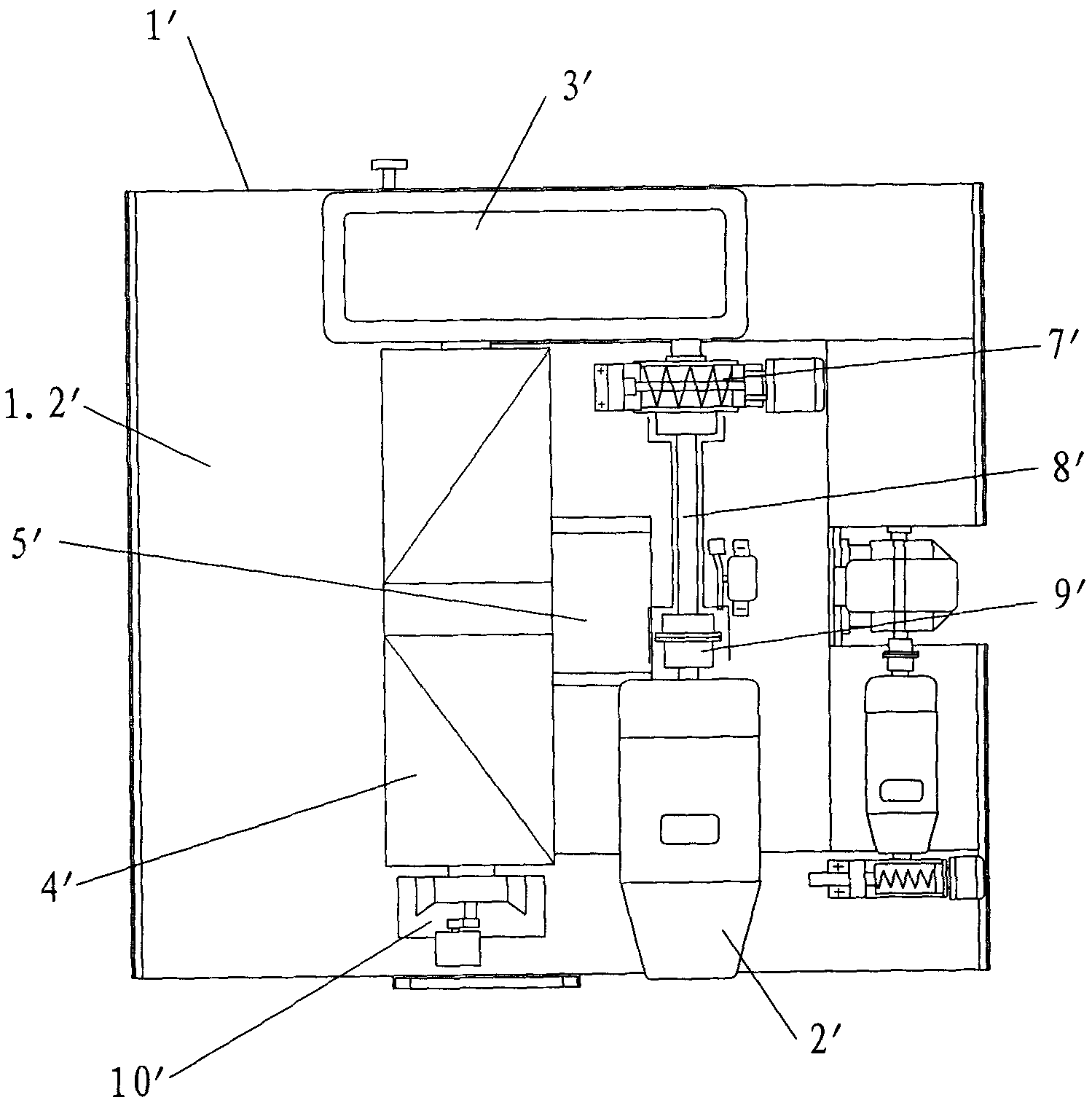

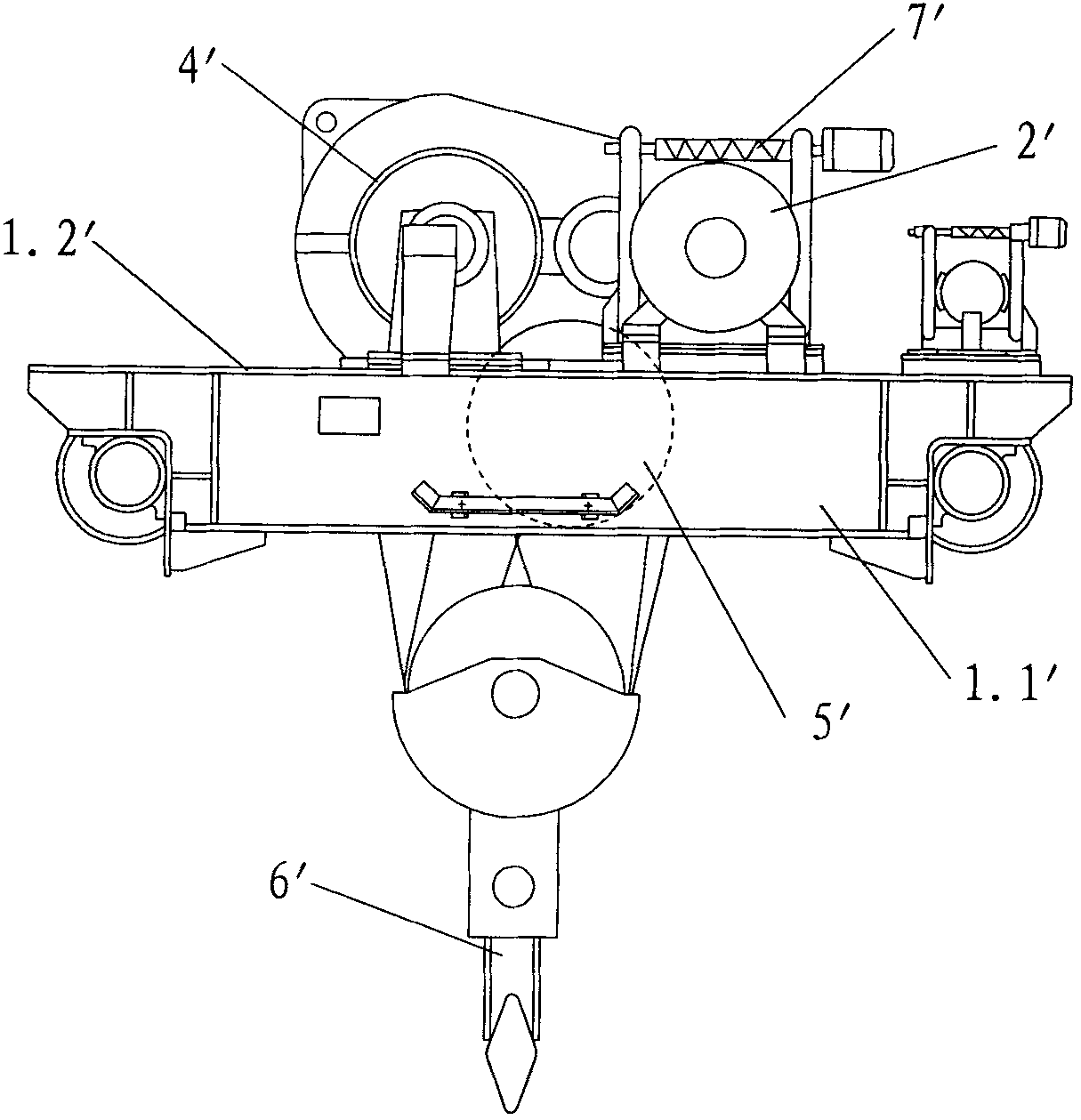

Lifting garbage compressor

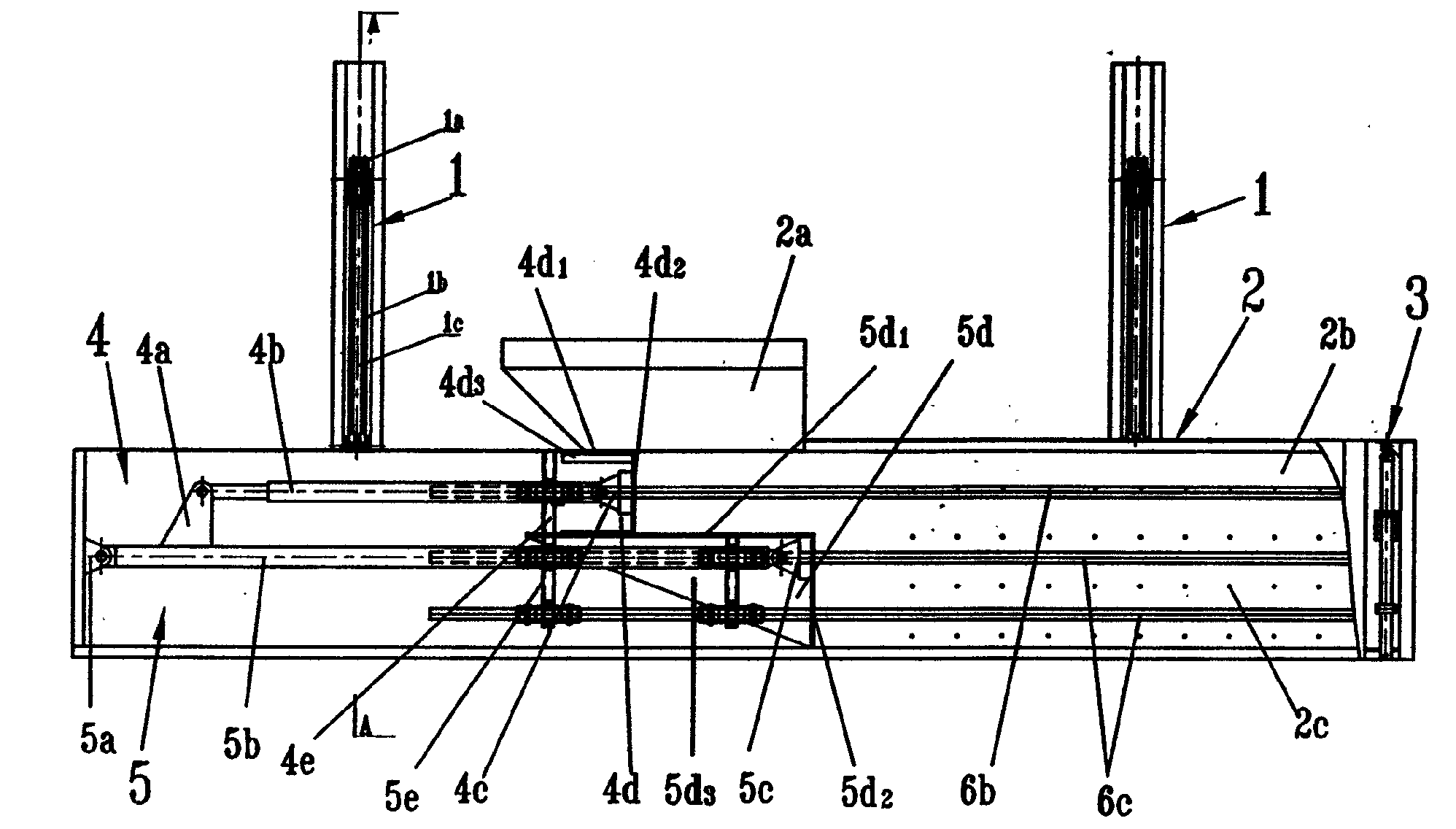

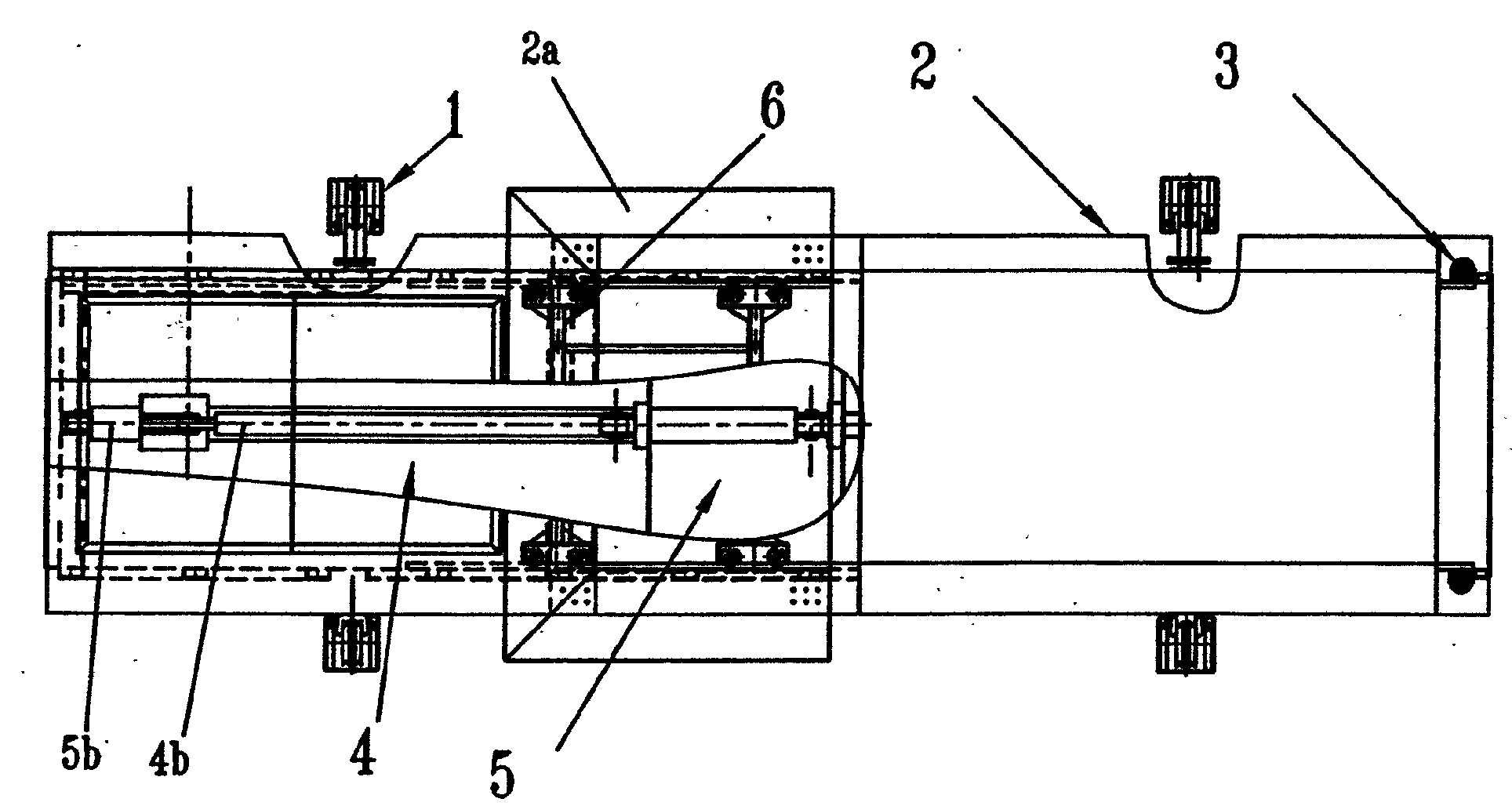

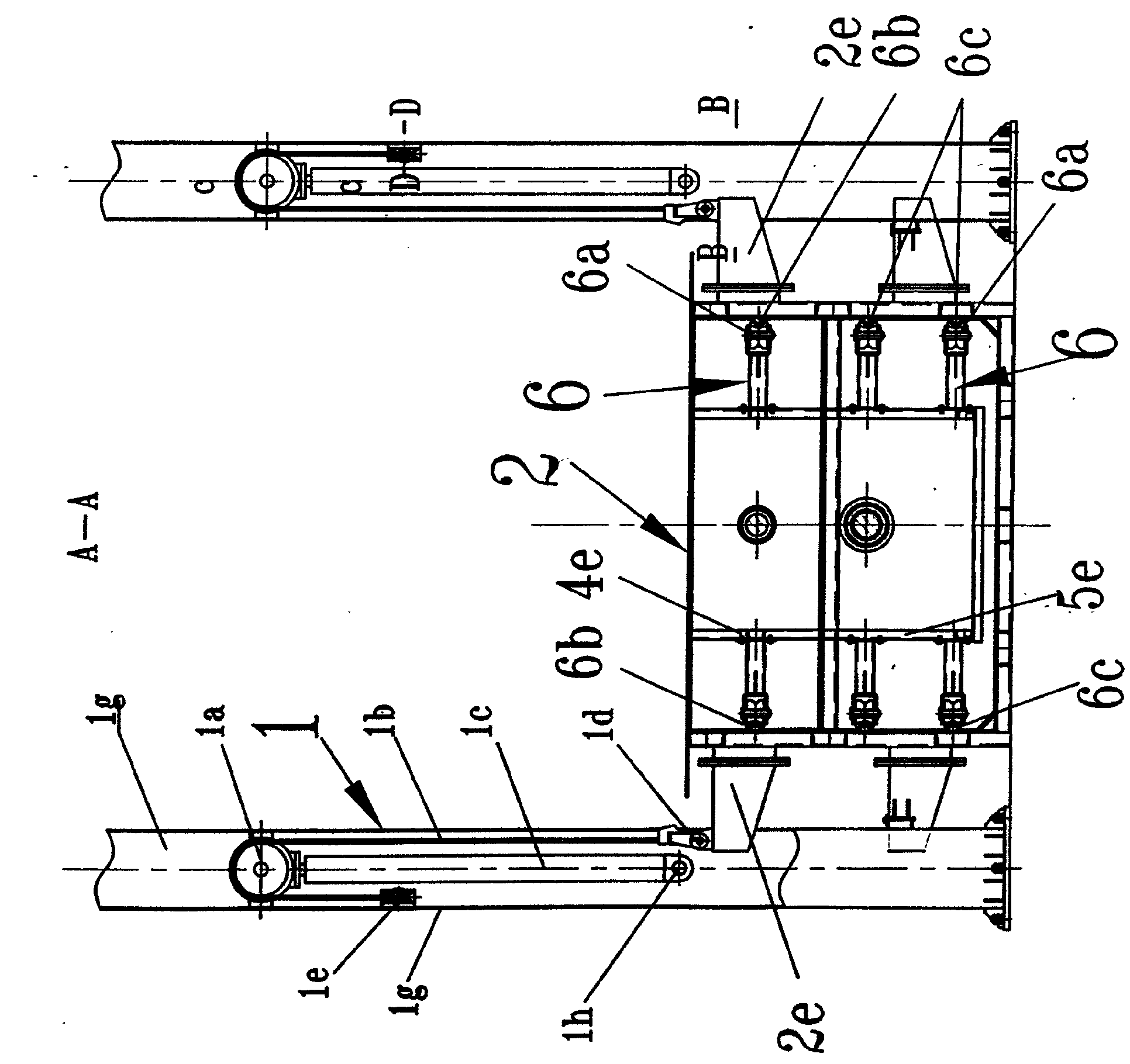

ActiveCN101653994AReduce power consumptionReduce building heightLifting devicesRefuse transferringPush outPiston

The invention relates to a lifting garbage compressor. The lifting garbage compressor comprises a lifting device 1, a gate mechanism 3, a garbage containing box 2, a garbage compressing mechanism 4 and a pushing mechanism 5. The invention is characterized in that: an upright column 1g of the lifting device has a dent hollow cross section and is provided with an opening, a built-in oil cylinder lifting mechanism and a pulley sliding-rope transmission mechanism; the lifting mechanism is composed of a lifting oil cylinder 1c, a piston 1y, a pulley base 1j and an oil cylinder base 1h; the pulley sliding-rope transmission mechanism is composed of a transmission pulley 1a, a sliding-rope 1b, a bearing pulley 1e and a bearing support 1f; the middle part of the sliding-rope is wound the bearing pulley; two parts of the sliding-rope are wound to the transmission pulley, and both ends of the sliding-rope are hinged on the cantilever beams 2e of the garbage containing box with the rope clamps 1d;a pushing-out mechanism 5 is placed at the back half part of the garbage containing box, and a compressing mechanism 4 is placed above the pushing-out mechanism 5. The lifting height of the lifting garbage compressor is two times of the oil cylinder stroke; the heights of the upright column and the workshop are reduced for more than 15%; and furthermore the compressing mechanism of the inventionhas the advantages of excellent compression effect and high efficiency.

Owner:吉林前沅专用汽车制造股份有限公司

Bridge deck structure composed of prefabricated UHPC (Ultra High Performance Concrete) slabs and steel bridge deck and construction method thereof

InactiveCN105064208AReduce building heightIncrease stiffnessBridge structural detailsBatch productionHigh performance concrete

The invention relates to a bridge deck structure composed of prefabricated UHPC (Ultra High Performance Concrete) slabs and a steel bridge deck and a construction method thereof. The bridge deck structure comprises the steel bridge deck and the UHPC slabs covering the steel bridge deck, wherein the UHPC slabs are arranged at intervals, UHPC cast-in-situ belts are arranged between adjacent UHPC slabs, and the bottoms of the UHPC slabs are connected with the steel bridge deck through cement based adhesives so as to form the composite bridge deck structure. Shear connectors can be appropriately arranged in the cast-in-situ belts so as to enhance the connecting effect of the prefabricated slabs and the steel bridge deck. The construction method of the structure comprises the following steps: constructing steel beams and the steel bridge deck; manufacturing and installing the UHPC slabs; constructing the UHPC cast-in-situ belts; and constructing the surface of the bridge deck. The structure is reasonable in stress, high in strength and stiffness, capable of effectively avoiding the generation of steel bridge deck defects, simple, capable of reducing relatively large shrinkage in a cast-in-situ process of UHPC, and easy to realize batch production in factories; and the structure has important practical values and favorable economic benefits.

Owner:FUZHOU UNIVERSITY

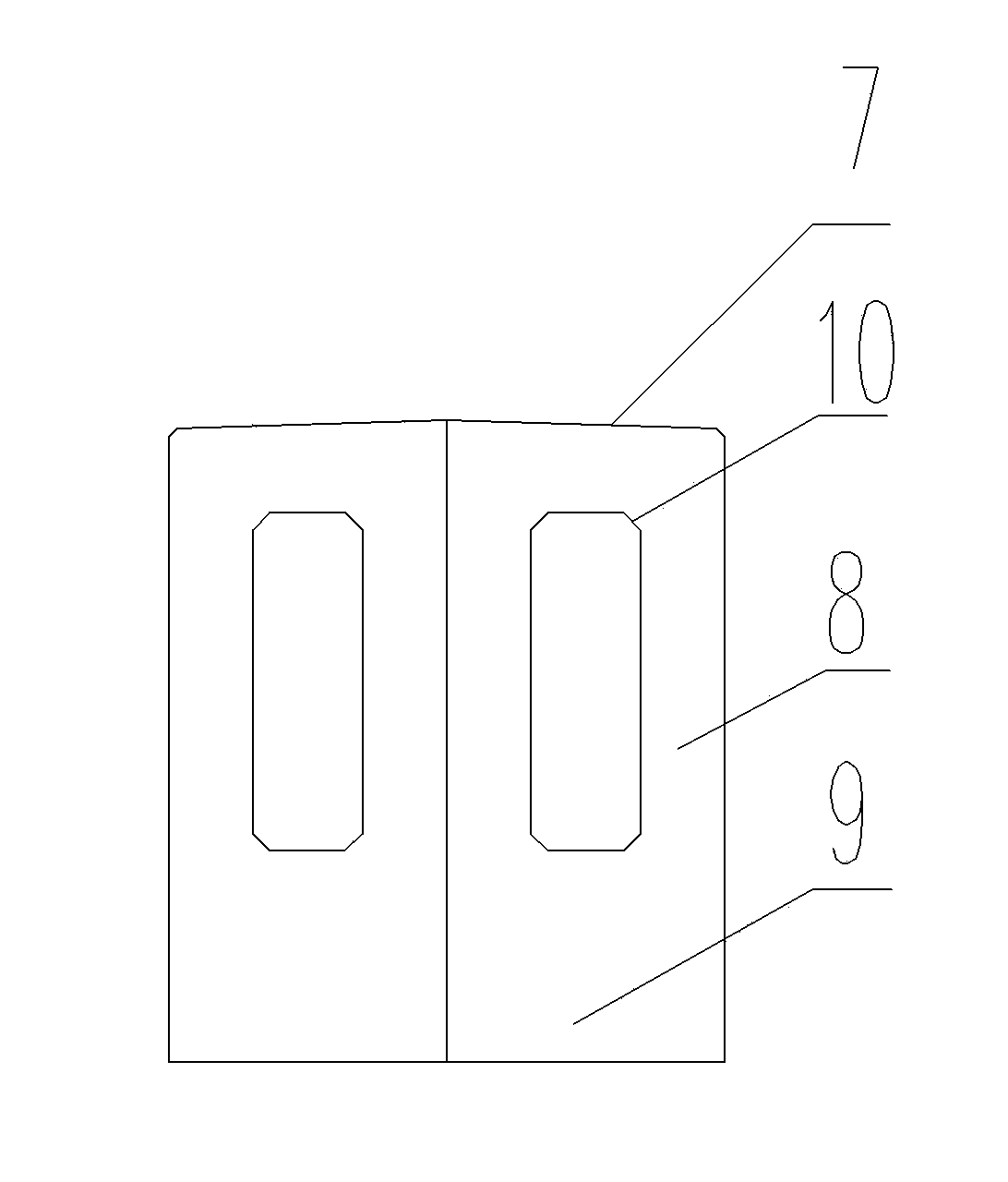

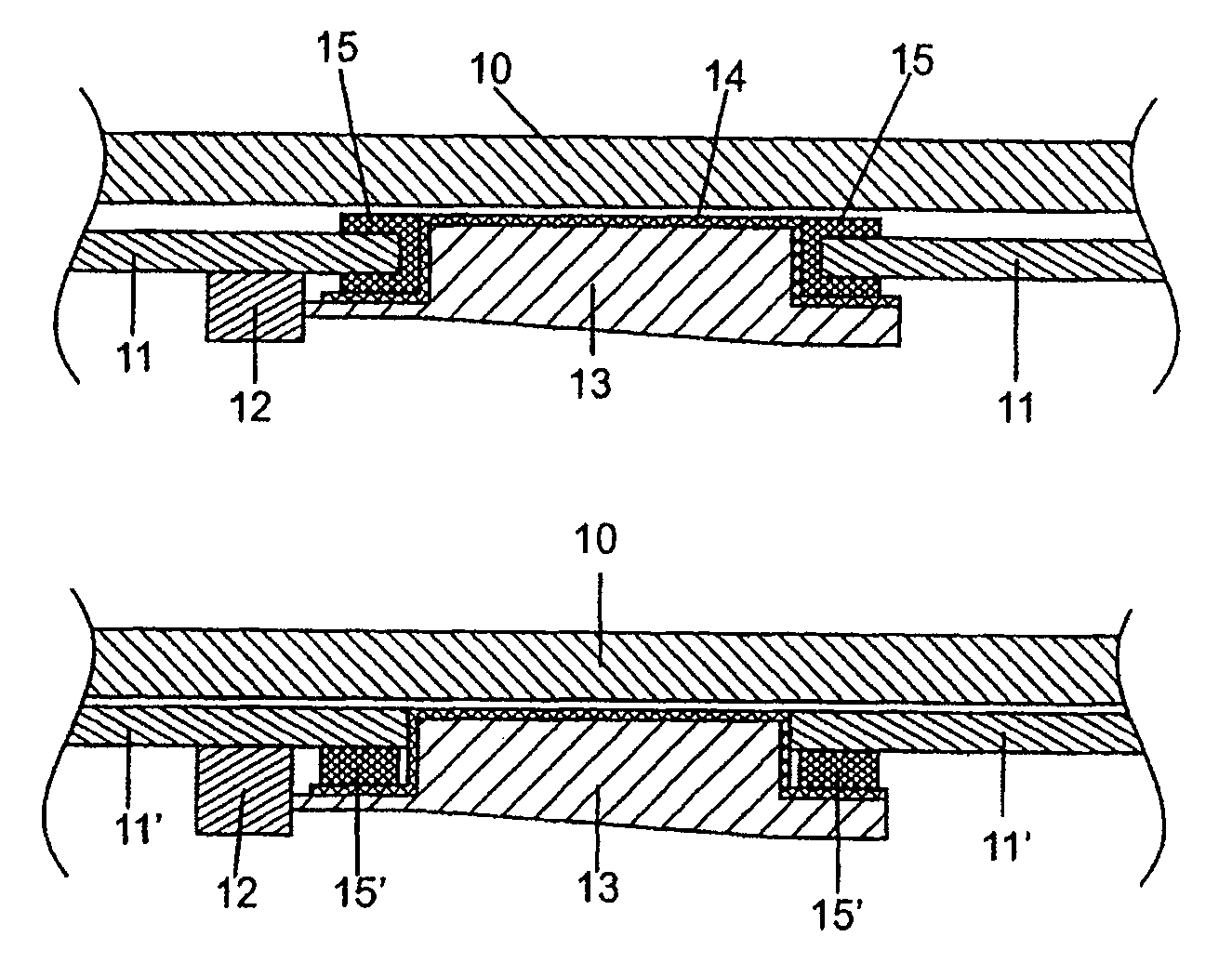

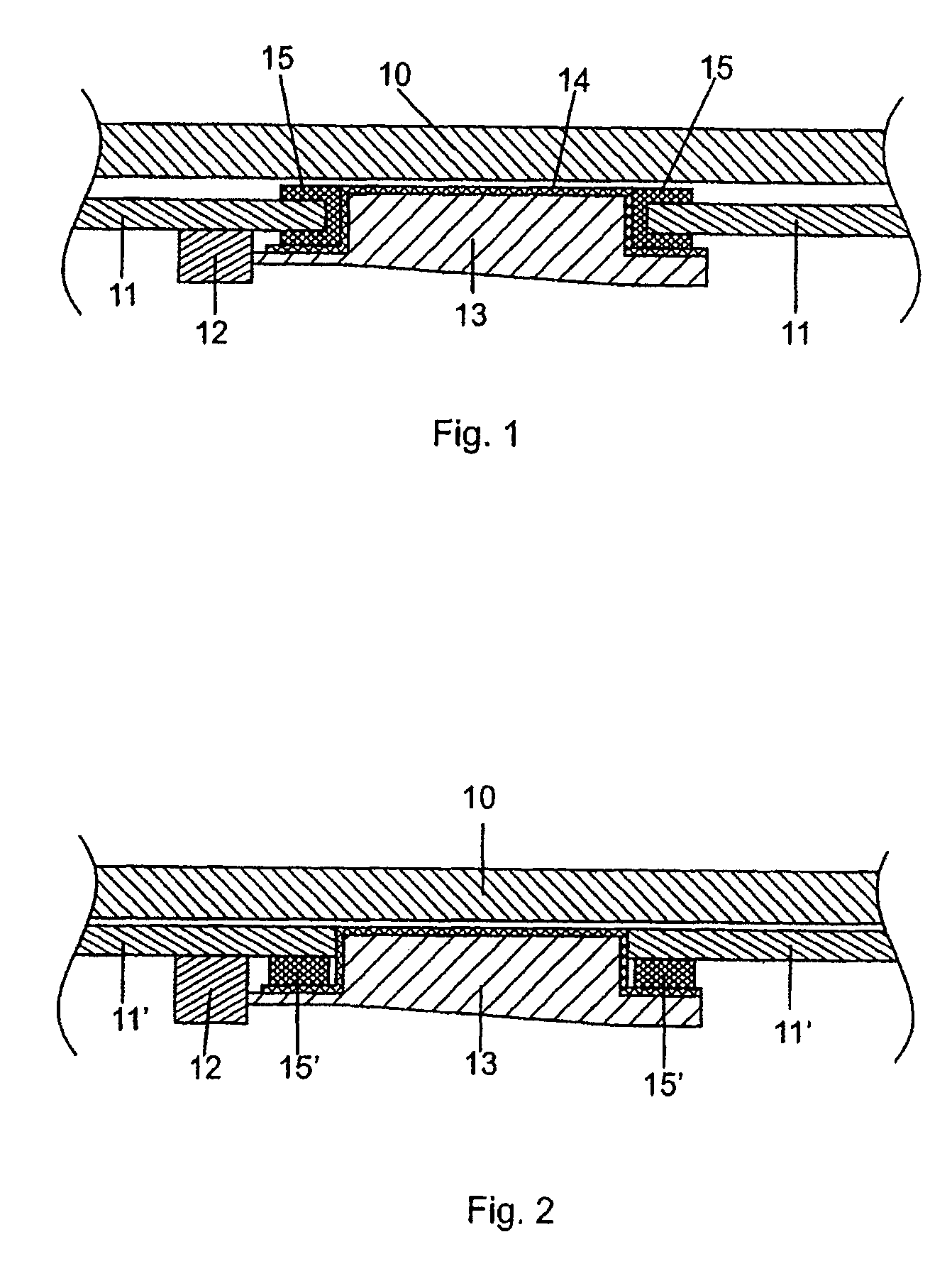

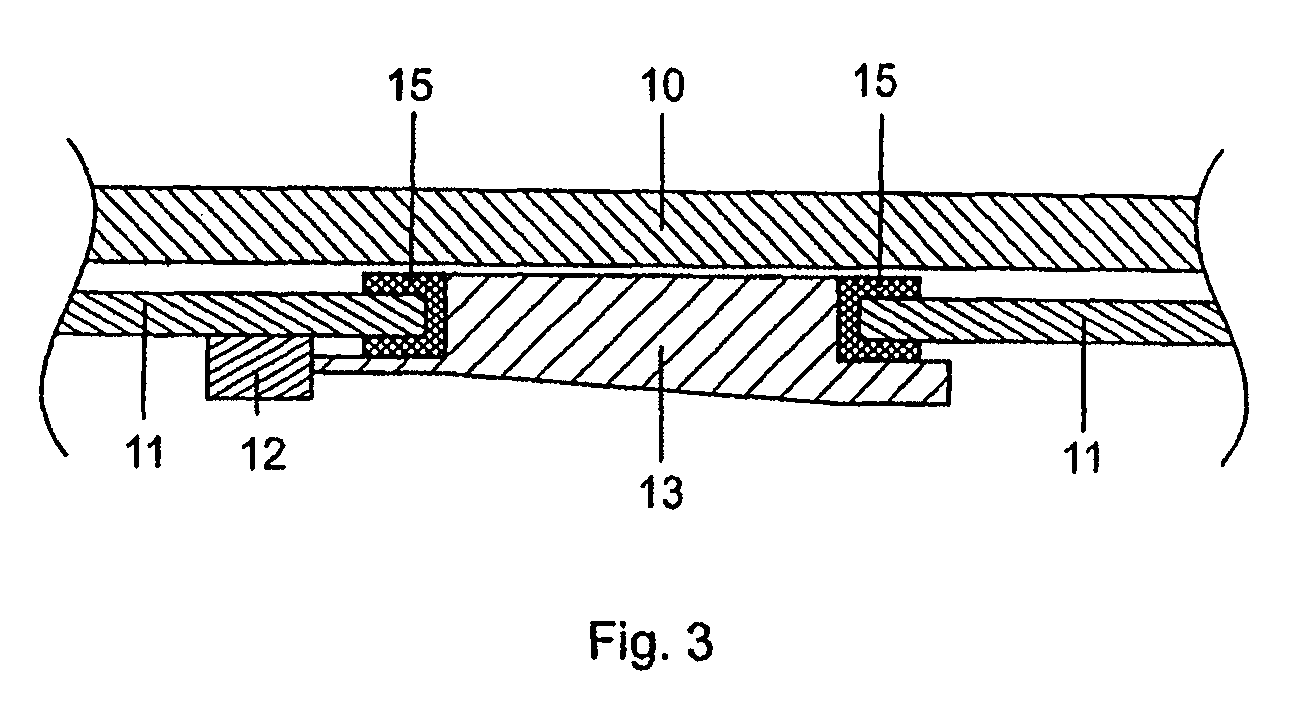

Control unit for domestic appliances

InactiveUS20090115645A1Reduce building heightEffective areaInput/output for user-computer interactionElectronic switchingCapacitanceLight guide

A control unit comprising a light guide is formed and positioned in a circuit board for providing visual indication to a user of an appliance, such as a cooktop. The light guide receives light from a source, typically in the form of an LED on the circuit board, typically positioned laterally to the light guide, and the light guide receives and directs the light to the user. In some embodiments, the light guide is positioned behind a cover, which may have indicia thereon for providing operating information to the user. Portions of the light guide may be coated with an electrically conductive coating so as to also form a portion of a capacitance touch switch for detecting user input for controlling operation of the appliance.

Owner:E G O ELEKTRO GERAETEBAU GMBH

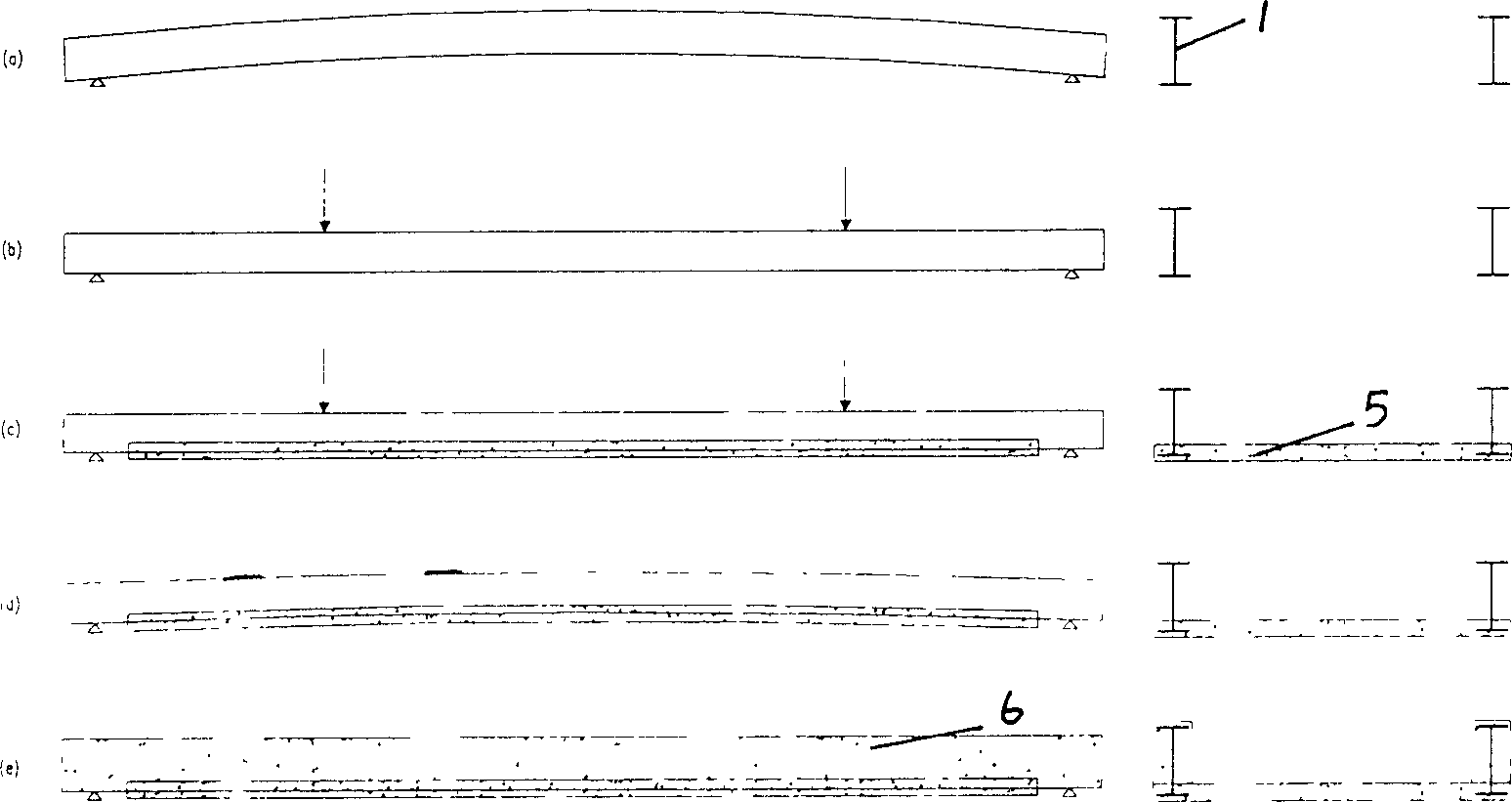

Preflex prestressed concrete channel beam and its making method

InactiveCN1730858AImprove fatigue resistanceImprove seismic performanceLoad-supporting elementsBuilding material handlingConcrete beamsPre stress

The present invention is one kind of pre-bent pre-stressed concrete channel beam and its making process, and features that the concrete beam in channel shape or U shape consists of bottom plate and two side web plates. The web plates are concrete coated steel beam with welded shear keys, and the web plate and the steel beam have I-shaped, rectangular or box cross section. The making process of the concrete channel beam includes the five steps of: making steel beam, pre-pressing the steel beam, depositing the first concrete layer, releasing pre-bending force, and depositing the second concrete layer. Compared with available technology, the present invention has the advantages of large span, low building height, easy construction, excellent fatigue and vibration resistance, etc. and is especially suitable for use in condition with limited building height.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Spliced girder bridge and construction method thereof

ActiveCN104480846AImprove carrying capacityReduce building heightBridge structural detailsBridge erection/assemblyPre stressConcrete beams

The invention discloses a spliced bridge and a construction method thereof. The spliced bridge comprises a fabricated prestressed concrete split small box girder bridge, a fabricated concrete T girder bridge and a cast-in-place connecting plate; a bridge which is spliced in different structural forms and is entirely stressed is formed by properly reconstructing an original structure, such as detaching an original bridge edge barrier, removing an asphalt pavement layer and a concrete pavement layer, and removing a flange plate and retaining transverse stressed steel bars, to meet requirements on splicing, binding steel bars distributed in the fabricated prestressed concrete split small box girder bridge and steel bars of an original structure integrally to form a steel bar framework, and pouring the cast-in-place connecting plate. The spliced bridge and the construction method thereof have the advantages that (1) the reconstructing mode of the original bridge is simple, and the cast-in-place connecting plate is simple in structure, reliable in connection and convenient to construct; (2) the bearing capacity of a newly built part is high, the building height is lower than that of the original bridge, and the structural design difficulty is reduced.

Owner:广东踏云智能科技有限公司

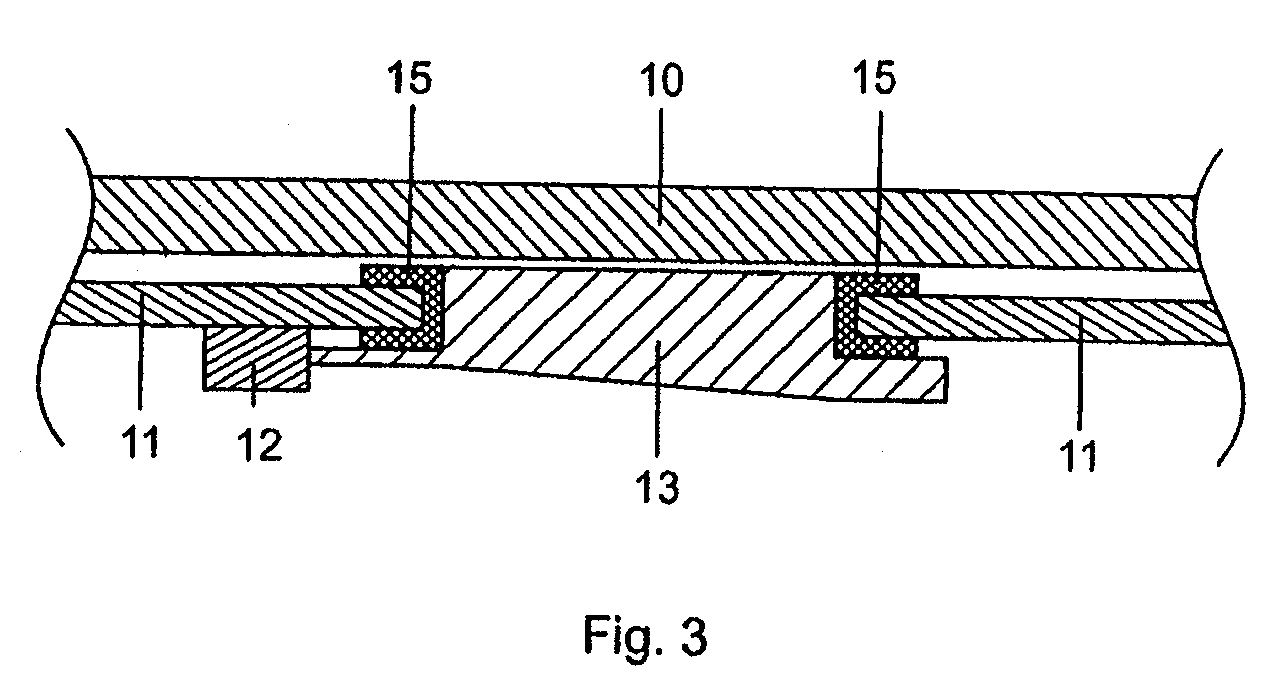

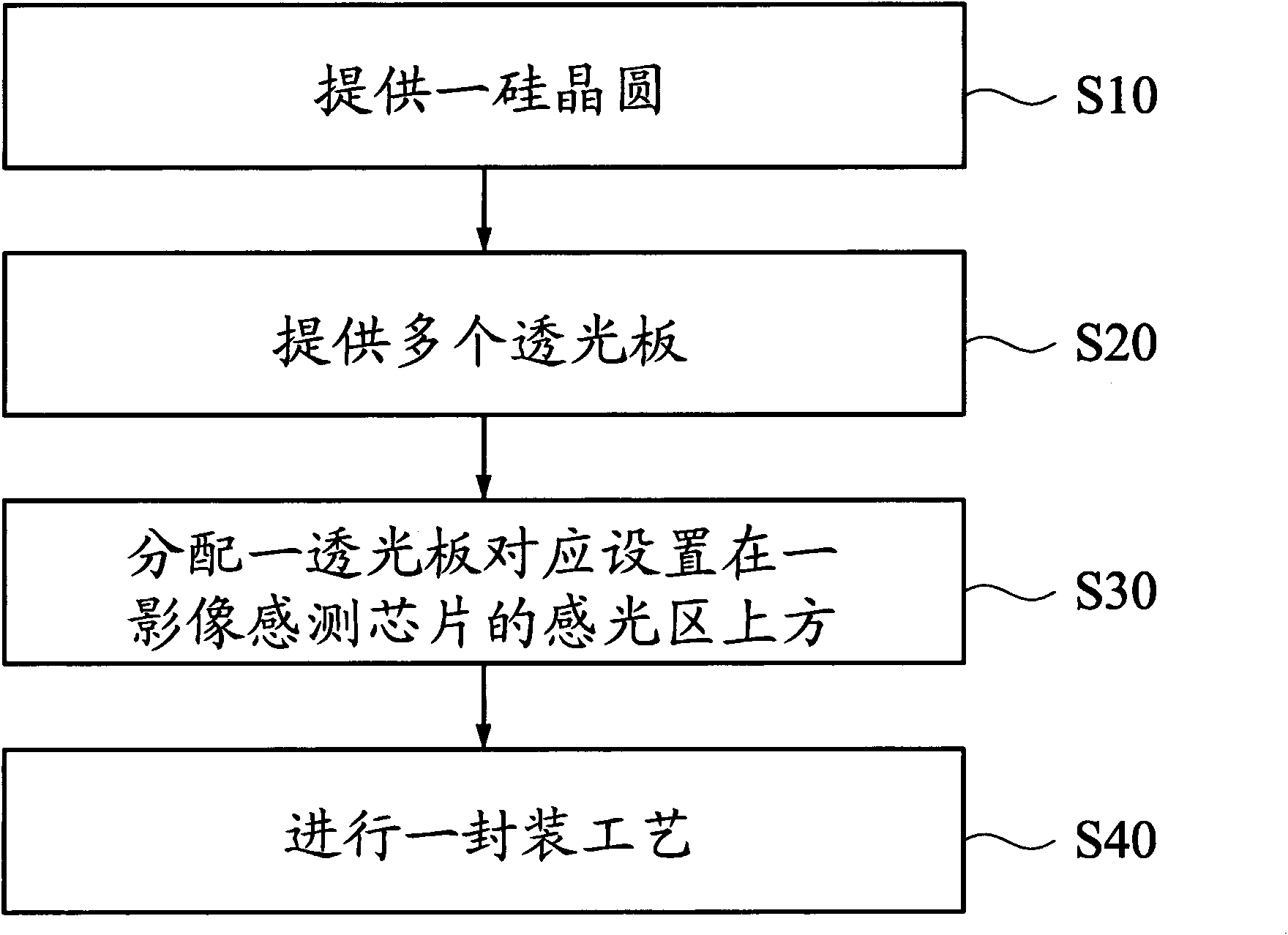

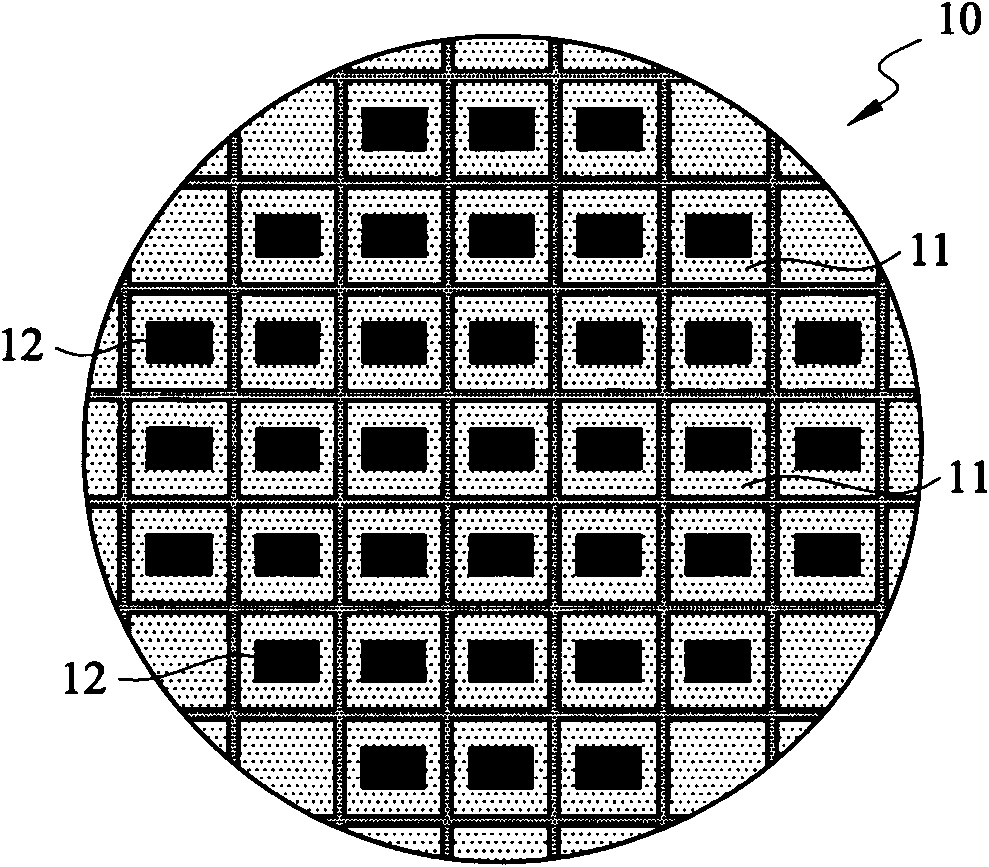

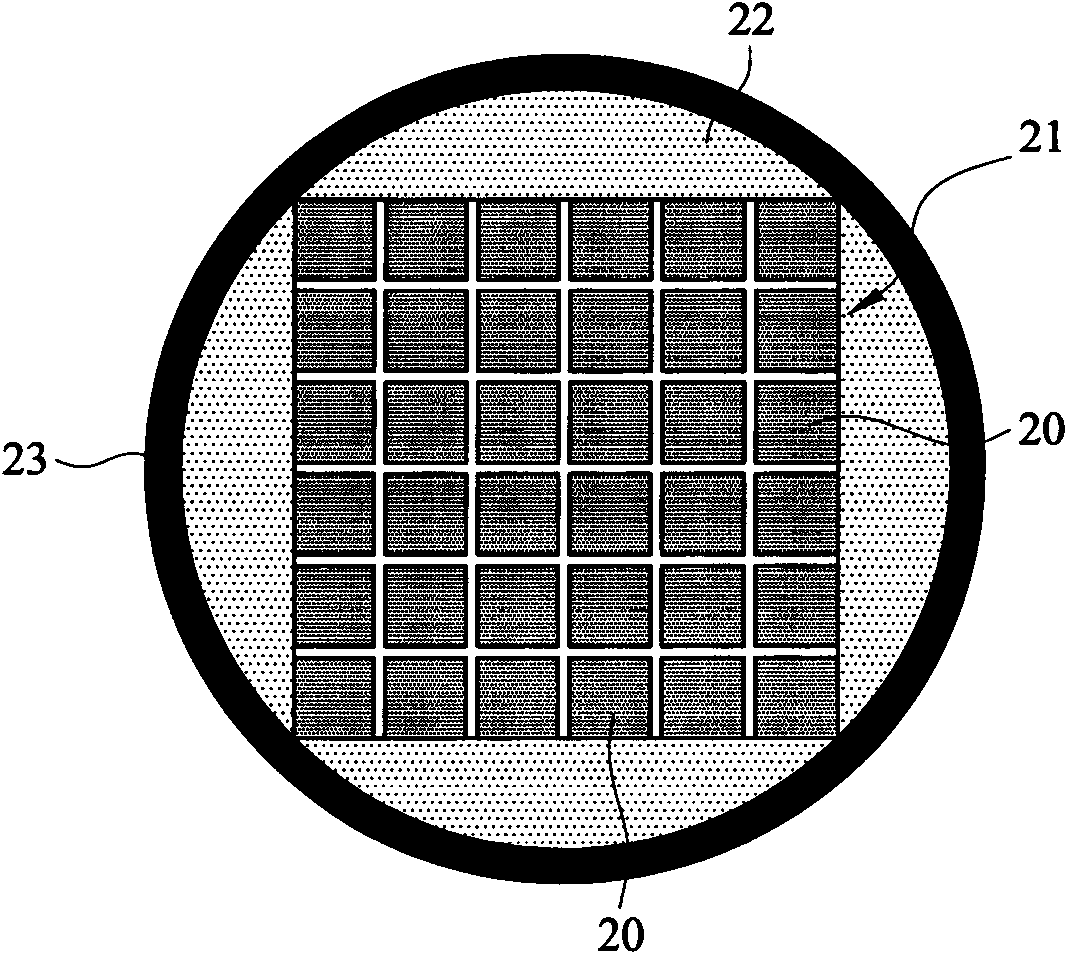

Wafer level image sensor packaging structure and manufacturing method thereof

ActiveCN102403323ASimplify the manufacturing processSmall structure sizeRadiation controlled devicesImage sensorEngineering

The invention relates to a wafer level image sensor packaging structure and a manufacturing method of the wafer level image sensor packaging structure, wherein the manufacturing method comprises the following steps of: providing a silicon wafer with an image sensor chip; providing a plurality of transparent boards; correspondingly arranging the distributed transparent boards above a photosensitive area of the image sensor chip; and packaging. The manufacturing method has the advantages of simplified manufacturing process, low manufacturing cost and high product yield; and as a plastic packaging material is arranged on the first surface of the image sensor chip and is coated on the peripheries of the transparent boards, the problem of side light leakage generated in a traditional chip size package (CSP) manner can be solved, and the image sensing efficiency of the wafer level image sensor packaging structure is further improved.

Owner:KINGPAK TECH INC

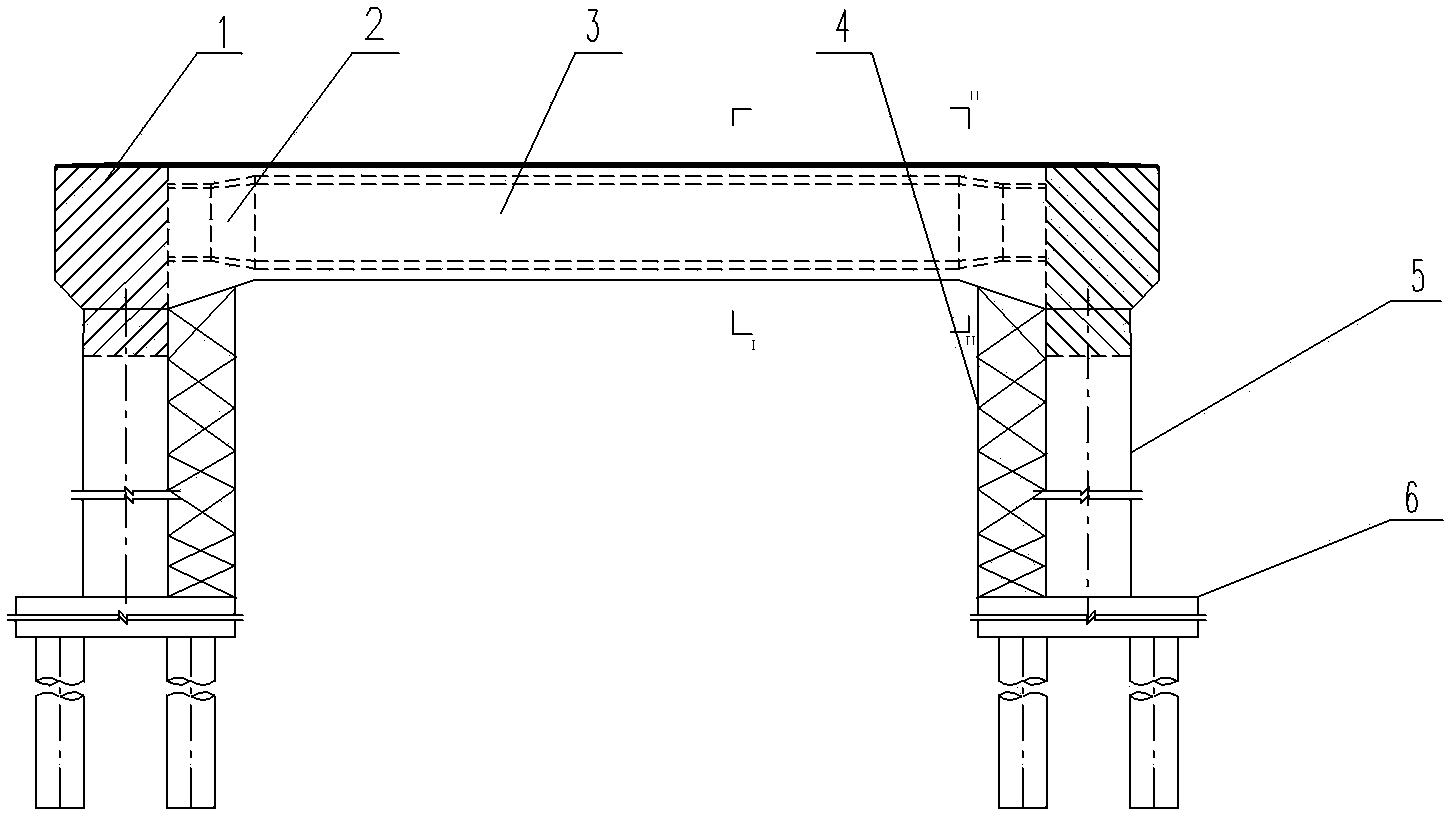

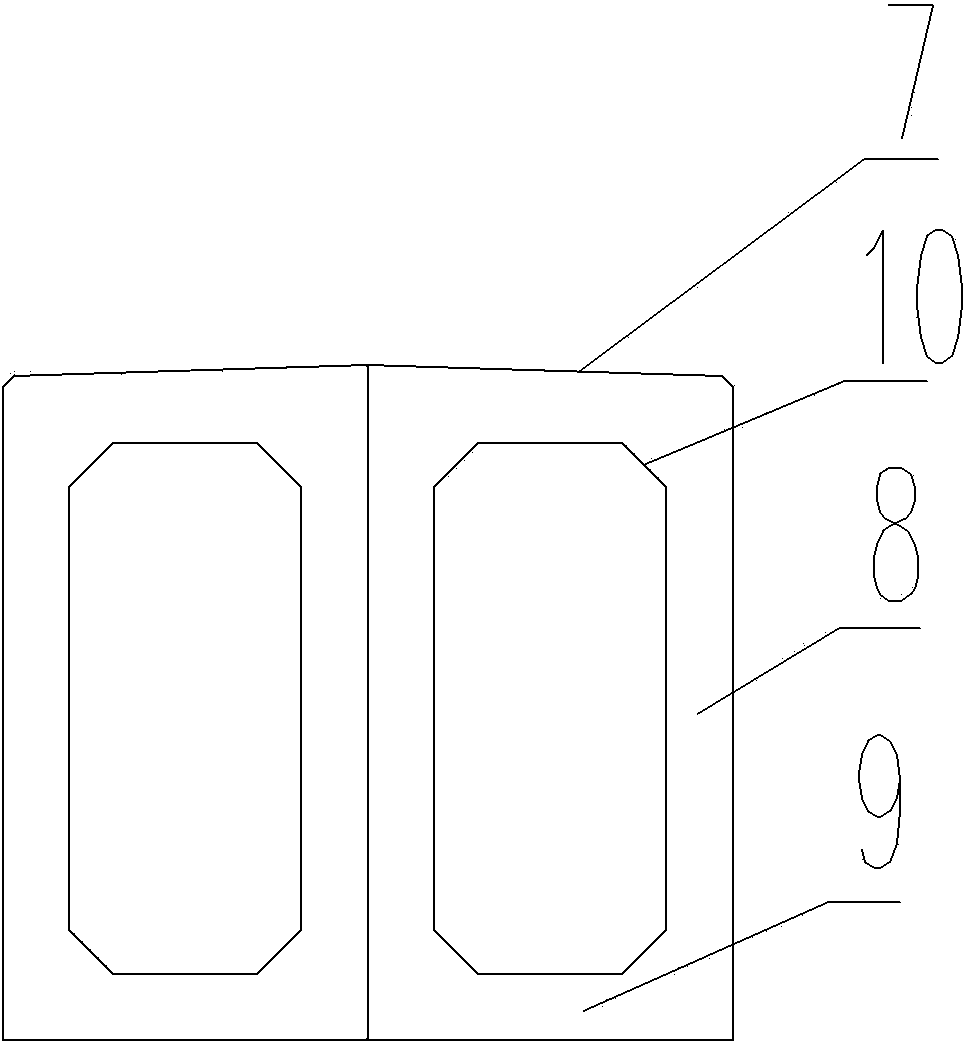

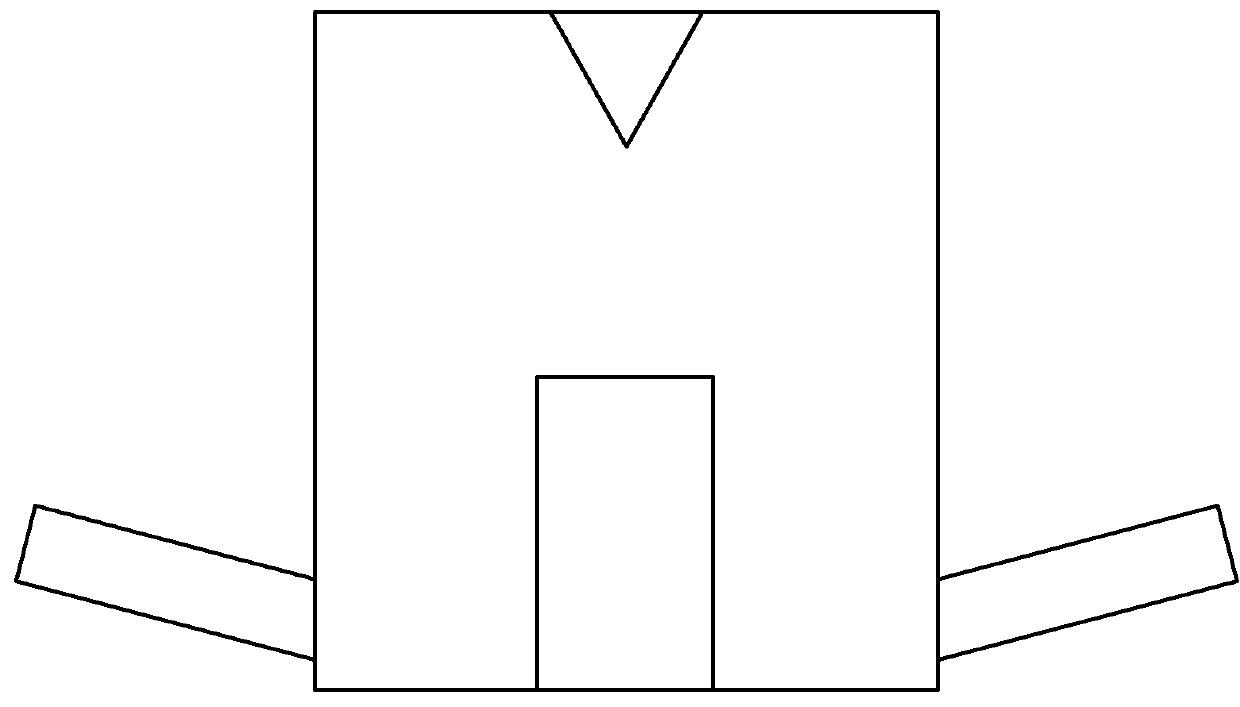

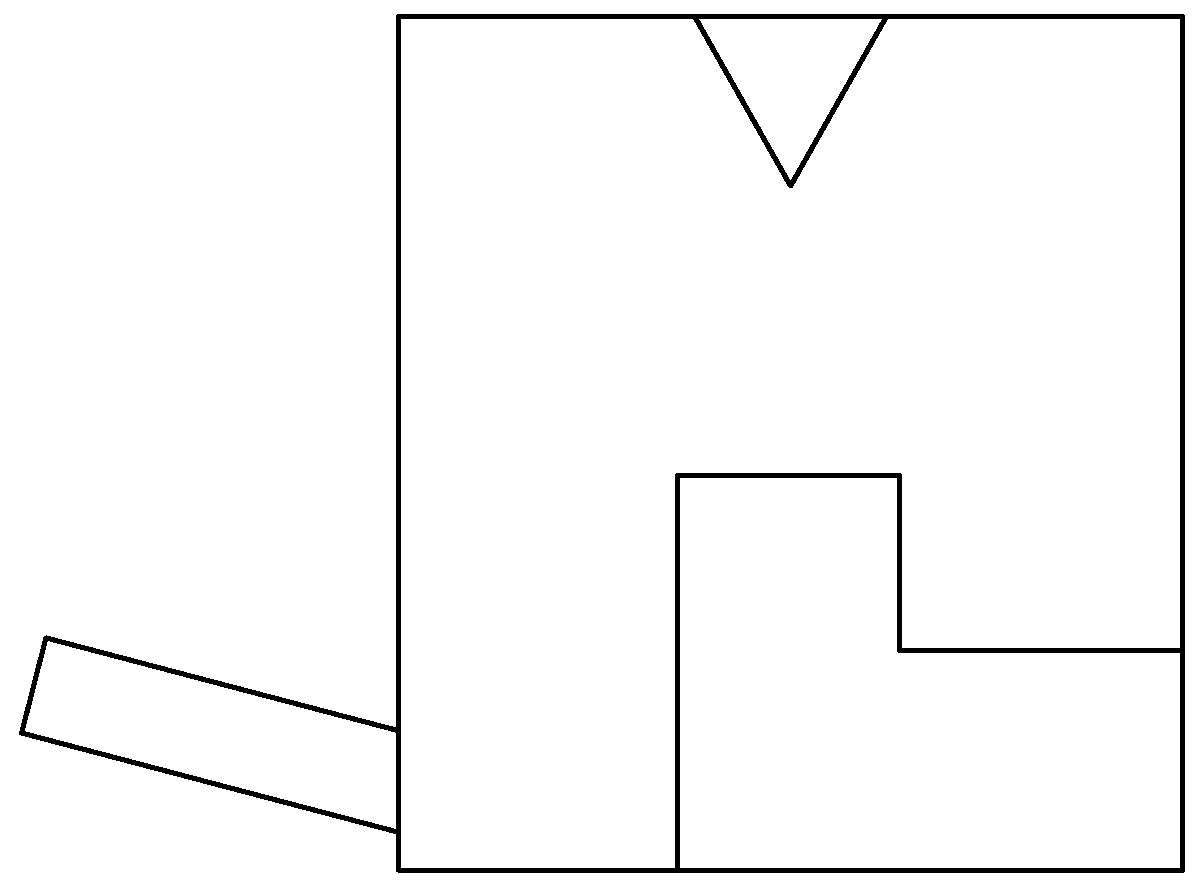

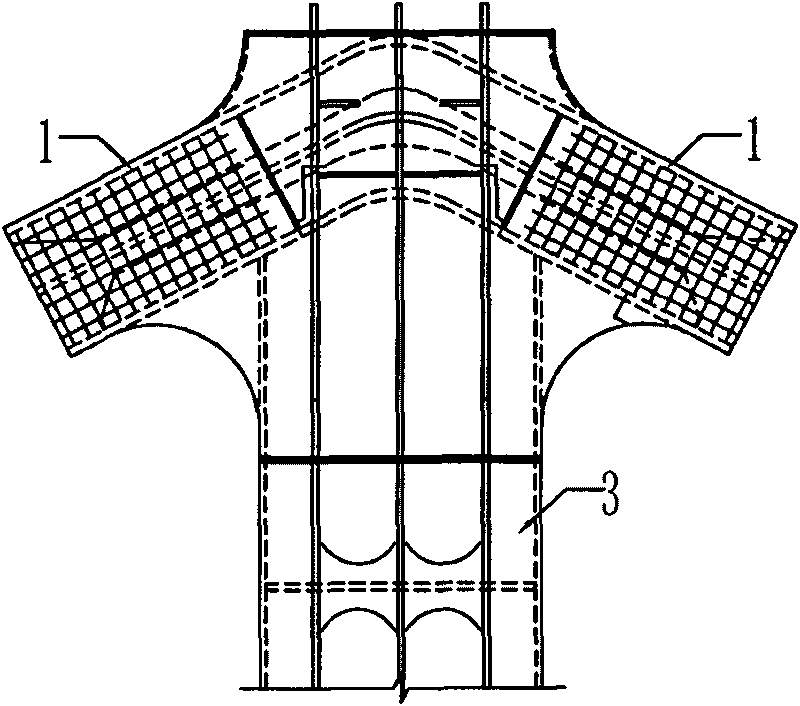

Prefabricated assembled combination type door-shaped pillar and construction method thereof

ActiveCN103981803AReduce operational disruptionShorten the construction periodBridge structural detailsBridge erection/assemblyArchitectural engineeringSteel frame

The invention relates to a prefabricated assembled combination type door-shaped pillar. Most of traditional door-shaped pillars are in rectangular solid concrete structures or box-shaped steel cover beam structures, door-shaped pillars in the rectangular solid concrete structures are large in masonry amount, high in dead weight and can only be constructed by a spot support cast-in-place scheme, and the door-shaped pillars in the box-shaped steel cover beam structures are high engineering cost, large in maintenance workload in late period and difficult to inspect and maintain. The prefabricated assembled combination type door-shaped pillar comprises bearing platforms and pillar columns on two sides, cast-in-place solid anchoring sections are arranged above the pillar columns, a cover beam formed by abreast splicing of a normal box beam section and box beam transition sections is connected between the two cast-in-place solid anchoring sections, all the normal box beam section and the box beam transition sections are in hollow structures, the normal box beam section is composed of a top plate, two lateral webs and a bottom plate, chamfers are arranged between the webs and between the bottom plate and the webs, and temporary supports which are grid-shaped steel frames are arranged between the box beam transition sections and the bearing platforms. The prefabricated assembled combination type door-shaped pillar in a concrete structure has the advantages that simplicity and convenience in designing and construction are facilitated, construction period can be shortened, engineering investment can be saved greatly and significantly, workload and difficulty in maintenance in the later period are lowered, and economy and reasonability are achieved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Control unit for domestic appliances

InactiveUS8462022B2Reduce building heightEffective areaInput/output for user-computer interactionElectronic switchingCapacitanceUser input

Owner:E G O ELEKTRO GERAETEBAU GMBH

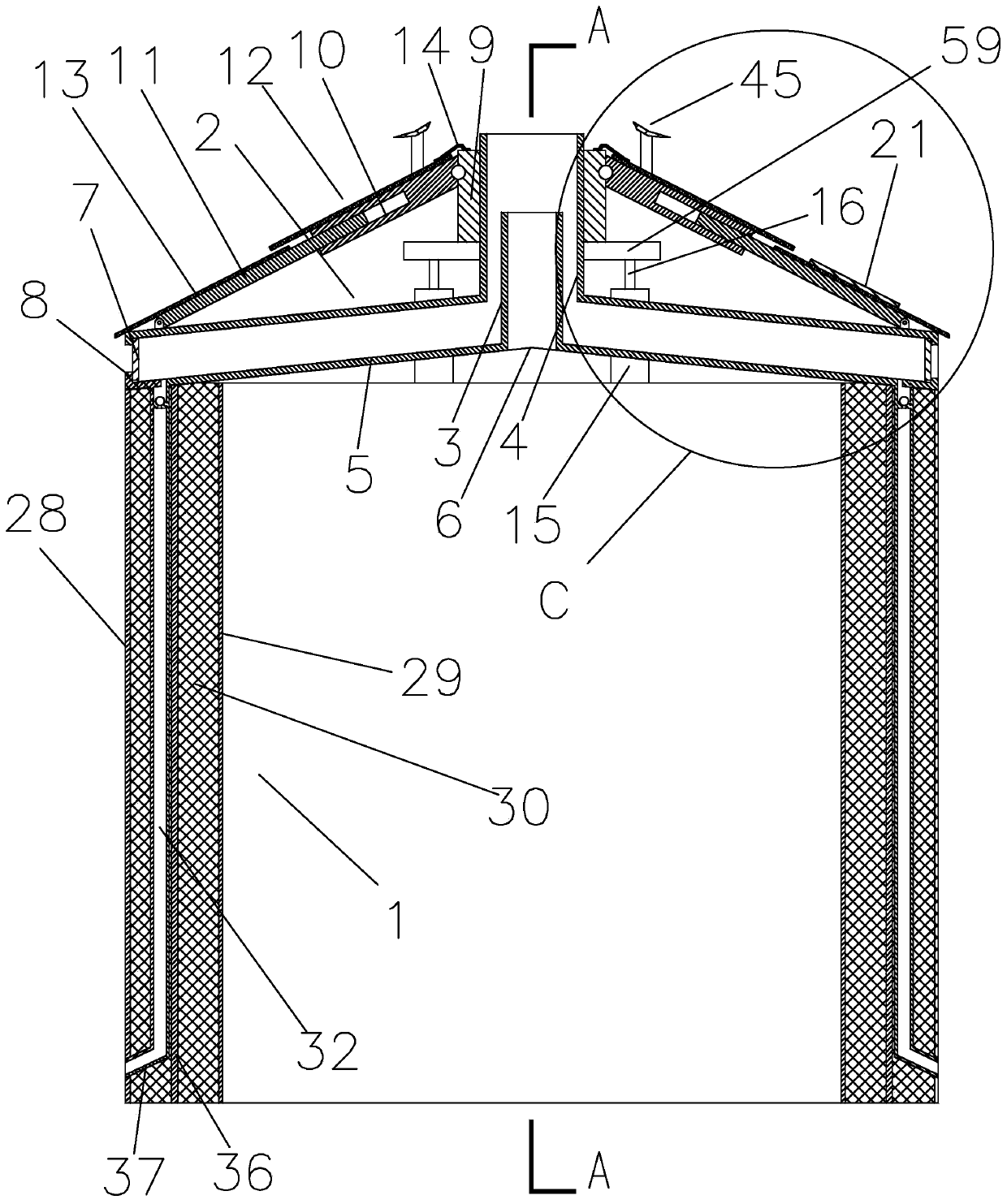

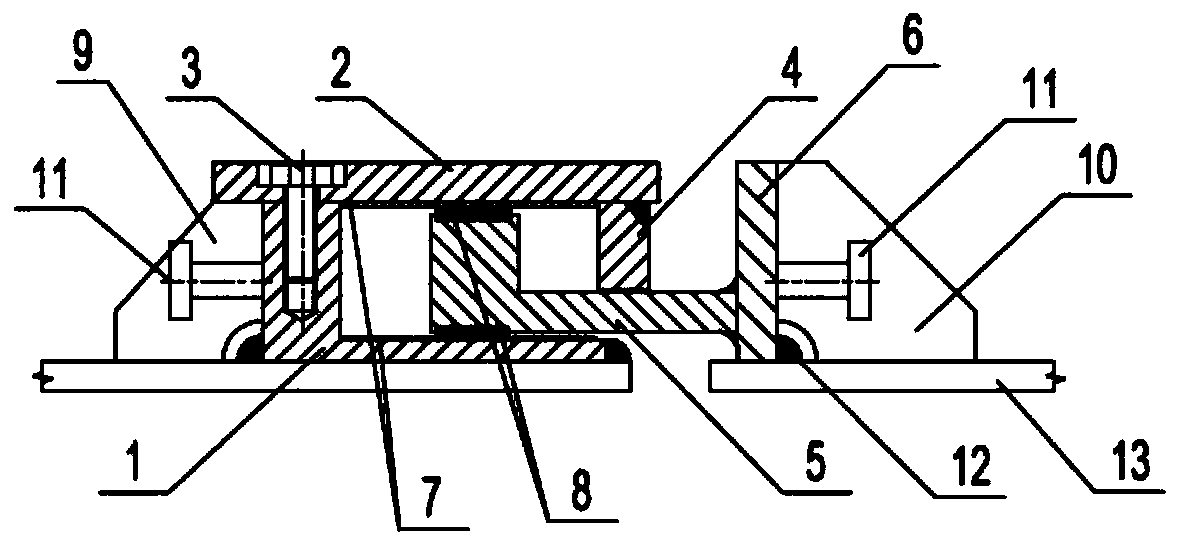

Lifting device used on rubbish compression machine (station)

InactiveCN101691169ALower the altitudeReduce building heightRefuse transferringLoading/unloadingEngineeringCantilever

The invention particularly relates to a lifting device used on a rubbish compression machine (station), which comprises a lifting device 1 and a rubbish volume box 2, and is characterized in that: a cantilever beam 2e is fixed on the rubbish volume box 2; the lifting device 1 comprises a stand column 1g, an oil cylinder lifting mechanism, a pulley and sliding rope transmission gear; the cross section of the stand column 1g is in a sunken shape and hollow and provided with an opening, and the oil cylinder lifting device and the pulley and sliding rope transmission gear are arranged in the stand column 1g; the lifting mechanism consists of a lifting oil cylinder 1c, a piston 1y, a pulley base 1j and an oil cylinder base 1h, the pulley and sliding rope transmission gear is composed of a driven pulley 1a, a sliding rope 1b, a bearing pulley 1e and a bearing support 1f; the middle of the sliding rope is wound in a bearing pulley, two sides are wound on the driven pulley, two ends are hinged on the cantilever beam 2e by a rope clip 1d. The lifting height and lifting speed of the invention is twice as that of the oil cylinder, the height of the stand column and factory buildings is reduced by more than 15%, the structure is simple and the efficiency is high.

Owner:吉林前沅专用汽车制造股份有限公司

Steel plate girder pedestrian overbridge

InactiveCN104452568ASmall amount of workSimple structureBridge structural detailsShaped beamSheet steel

The invention discloses a steel plate girder pedestrian overbridge. The steel plate girder pedestrian overbridge comprises a bridge and ladder ways arranged at the two ends of the bridge; the bridge is of a through type structure of open type longitudinal and cross beams formed by splicing and welding I-shaped steel; the longitudinal and cross beams are fixedly connected to form a main ladder-shaped beam; two I-shaped steel beams formed by welding steel boards are adopted as stress longitudinal beams; the two longitudinal beams are connected through multiple small I-shaped steel cross beams; a profiled steel sheet concrete combined bridge panel is laid on the cross beams and used for transmitting live loads of bridge surface crowds. The steel plate girder pedestrian overbridge has the advantages of being simple in structure, reasonable in stress, easy to build, comfortable to use, small in work amount, low in manufacturing cost, economical, convenient to maintain, attractive in modeling and the like.

Owner:林同棪国际工程咨询(中国)有限公司

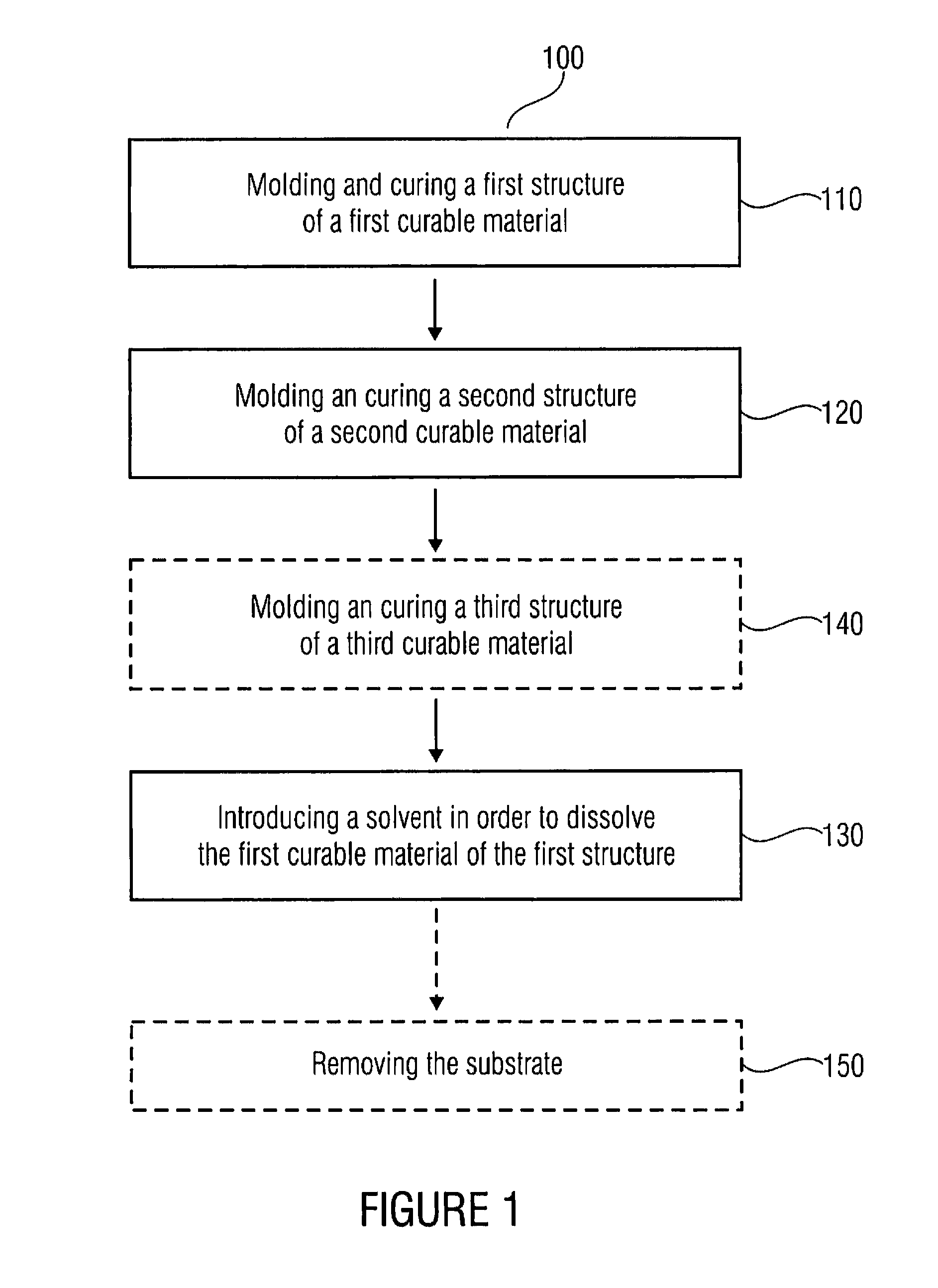

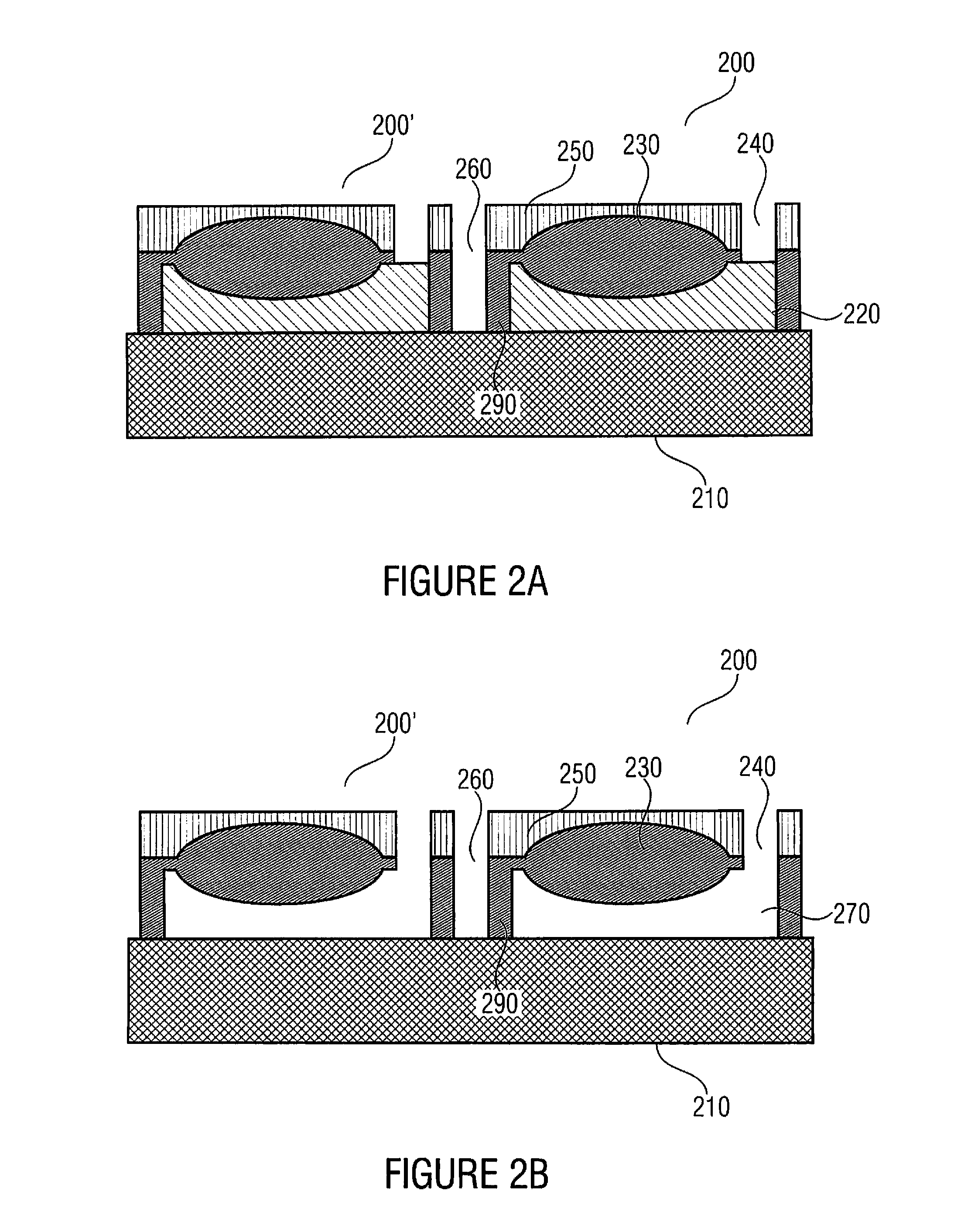

Method for Manufacturing a Structure, Optical Component, Optical Layer Stack

In a method for manufacturing a structure of curable material, a first structure from a first curable material is molded and cured on a substrate, and a second structure of a second curable material is molded and cured on a first surface of the first structure facing away from the substrate, so that at the first surface of the first structure a boundary surface forms between the first and second structures so that the first structure is not covered by the second structure in a passage area. A solvent is introduced into the passage area to dissolve the first curable material of the first structure so that a cavity forms between the second structure and the first surface of the substrate. After curing, the first curable material is soluble and the second curable material is insoluble for the solvent. An optical component and an optical layer stack are made of curable material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

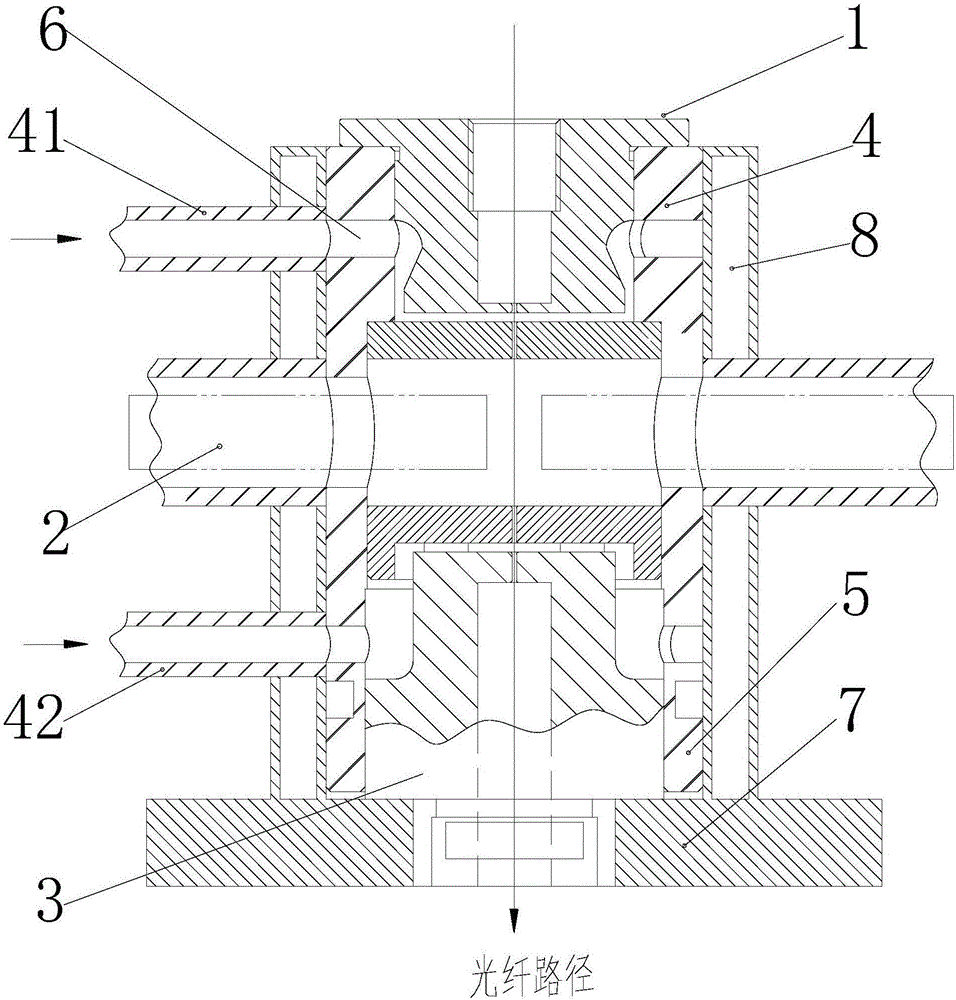

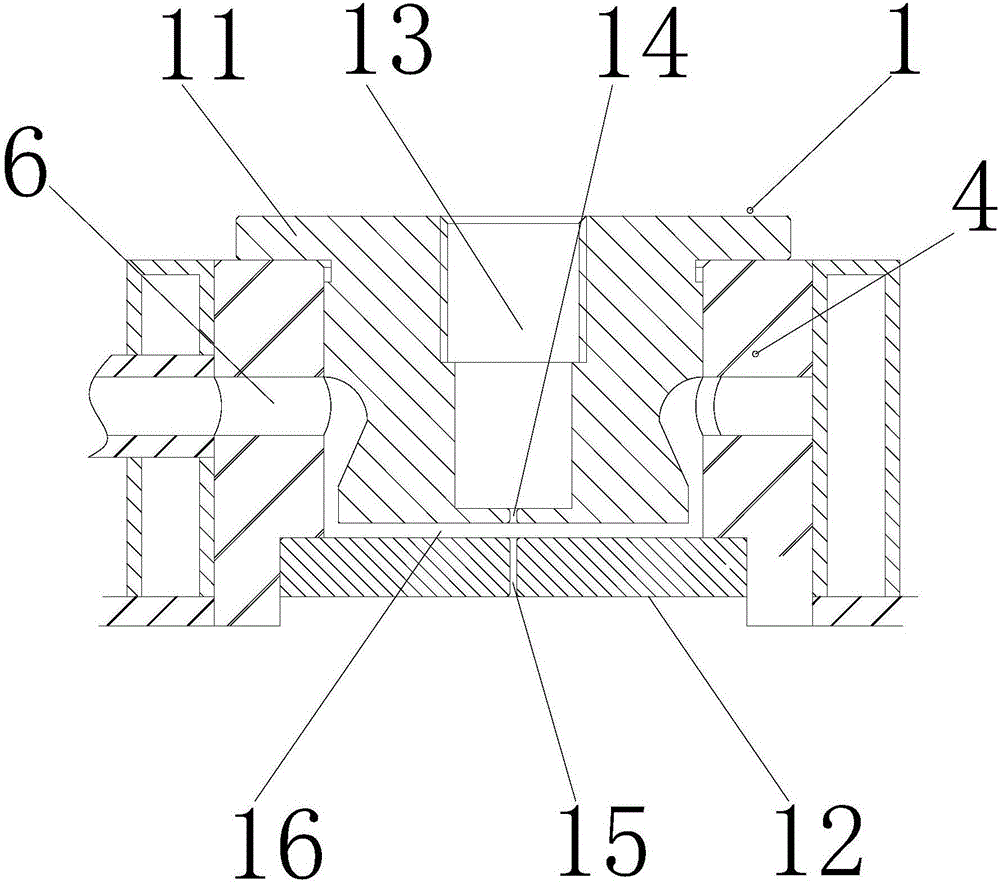

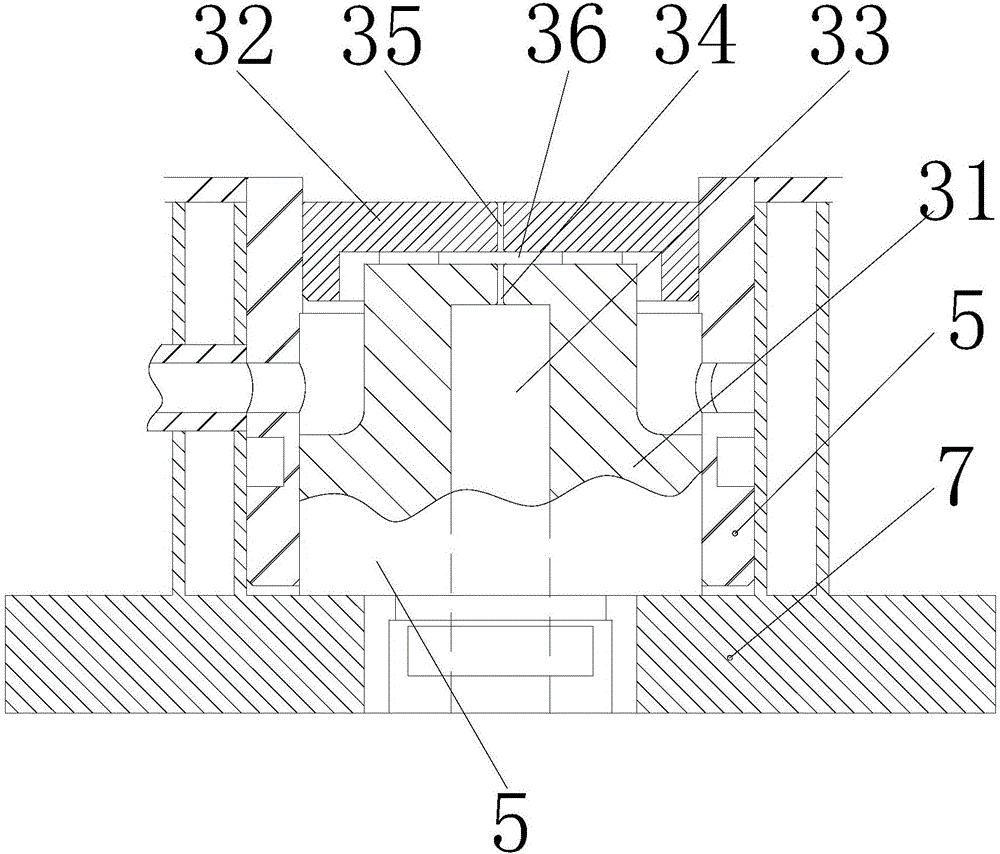

Optical fiber coating device

The invention discloses an optical fiber coating device which includes a primary coating mold and a secondary coating mold, and a UV curing apparatus arranged therebetween. The primary coating mold, the UV curing apparatus and the secondary coating mold are arranged along the path of an optical fiber from top to bottom to assemble an integrated mold. In the optical fiber coating device, primary coating and secondary coating are integrated in one mold, so that the path of coating process is effectively reduced, and further building height of an optical fiber drawing tower is reduced and building cost of the device is reduced. The primary coating and the secondary coating are completed synchronously, so that coating quality is convenient to control. Concentricity of a produced optical fiber is excellent, consumption on resin is effectively reduced and production cost is reduced.

Owner:CHENGDU SEI FUTONG OPTICAL CABLE +1

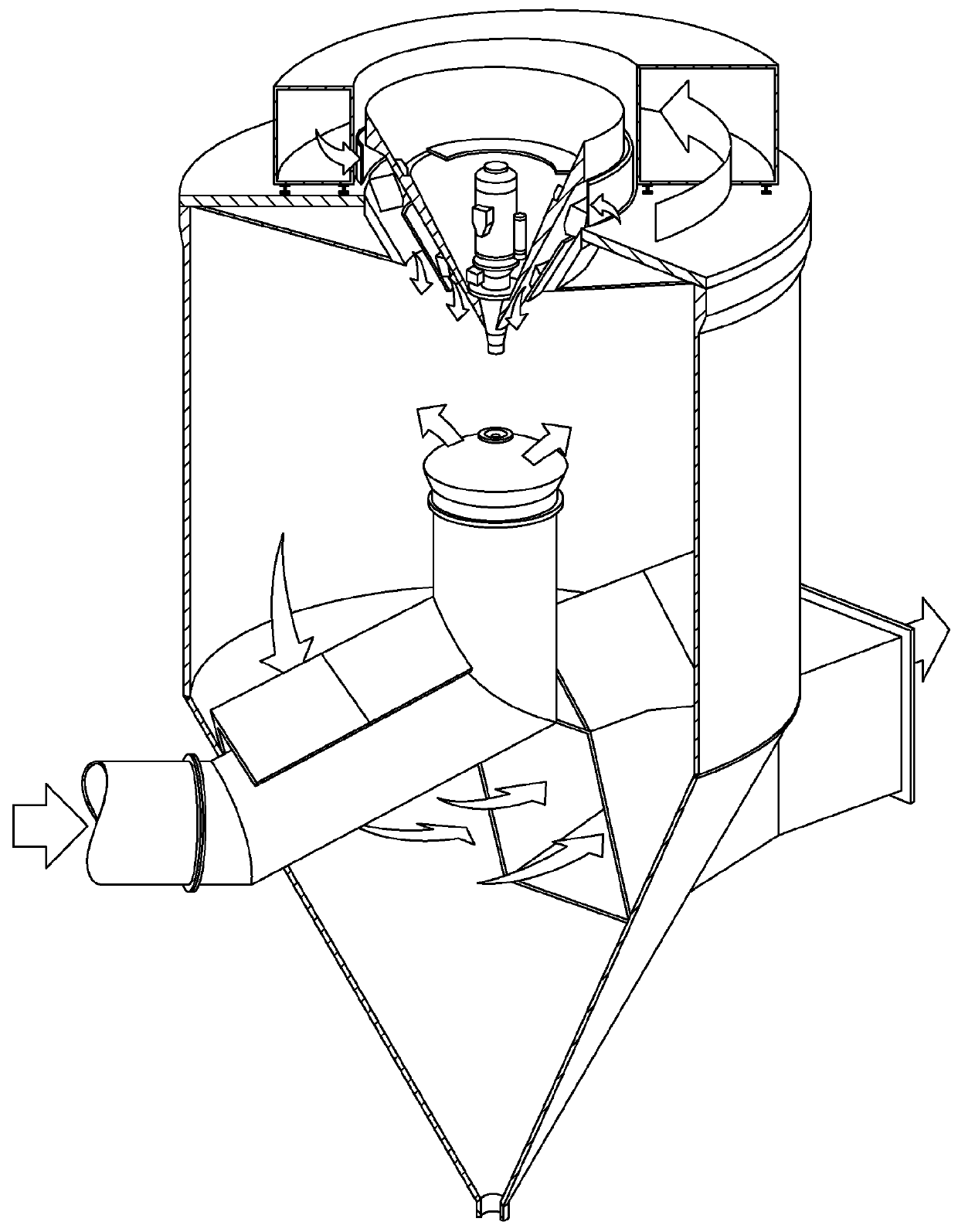

Spray dryer absorption apparatus with flat-bottomed chamber

ActiveUS9227157B2Reduced support structureAvoid excessive heightCombination devicesGas treatmentParticulatesChemical reaction

In the application a spray dryer absorption apparatus for treating a stream of flue gas containing acidic components is disclosed. The apparatus comprises a chamber having vertical cylindrical walls, said chamber comprises (i) an inlet for a flue gas stream containing an acidic component, (ii) an atomizer for spraying droplets of an absorbent slurry into said flue gas stream to effect a chemical reaction between the droplets and the acidic component of the flue gas, thereby forming a particulate reaction product, and (iii) an outlet for the treated flue gas and entrained particulate reaction product, wherein the bottom of the chamber having vertical cylindrical walls is substantially horizontal and impervious to gases. The apparatus of the invention has the advantage of a simplified geometry accounting for lower building and maintenance costs.

Owner:GEA PROCESS ENG

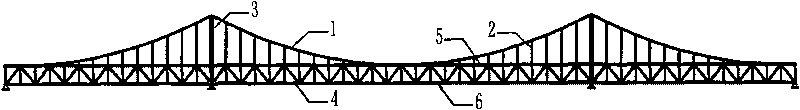

Double-deck continuous steel girder bridge for rigid suspended cable stiffening

InactiveCN101709565AReduce truss heightReasonable forceSuspension bridgeBridge materialsTerrainLand resources

The invention discloses a double-deck continuous steel girder bridge for rigid suspended cable stiffening, relating to a double-deck continuous steel girder bridge. Lower ends of rigid suspenders and lower ends of pivot stand columns are connected with primary truss joints; upper ends of the rigid suspenders and upper ends of pivot stand columns are connected with stiffened chord joints of rigid suspended cables; and when stiffened chords are adopted, vehicles are allowed to travel on both an upper bridge surface and a lower surface of a primary truss. In the invention, the stiffening suspender stiffened chords can load force together with the primary truss at a dead load state; the primary truss has short girders and low steel consumption; approach bridges can be shortened and cross connecting systems can be vacantly arranged or less arranged so as to save construction cost; with a space above, the primary truss can be used as a double-deck bridge and provided with multiple lanes in a stereoscopic way, thereby further saving cost and land resources; when constructing, special equipment and technology are not needed, and the double-deck continuous steel girder bridge can be manufactured, installed uniformly with simple construction; moreover, the rigid suspended cable stiffening chords have attractive curve appearance; and the double-deck continuous steel girder bridge has no anchorage free in bridge type, and has reasonable force-loading, low requirements on geology and terrain, and wider adaptability.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Environment-friendly energy-saving fabricated steel structure factory building structure

ActiveCN111472585AReduce the maximum bending momentReduce the cross-sectional areaRoof covering using slabs/sheetsBuilding roofsArchitectural engineeringMechanical engineering

The invention discloses an environment-friendly energy-saving fabricated steel structure factory building structure, and relates to the technical field of energy-saving environment-friendly buildings.The environment-friendly energy-saving fabricated steel structure factory building structure comprises walls, a plurality of air exhausting steel beams erected on the two opposite sides of the walls,and a roof located above the air exhausting steel beams. Each air exhausting steel beam comprises a ventilating pipe erected on the walls, an outer barrel with the lower end communicating with the ventilating pipe, and an inner barrel located in the outer barrel. The lower end of each inner barrel is fixedly connected with the lower side wall of the corresponding ventilating pipe, and ventilatingholes are formed in the positions, corresponding to the inner barrels, of the lower side walls of the ventilating pipes. According to the environment-friendly energy-saving fabricated steel structurefactory building structure, hot air in a factory building is taken away through natural air; and on the other hand, the interference of the natural air with a ground operation area in the factory building is avoided, and operation garbage on the ground cannot be blown; and the characteristics of saving energy and being environmentally friendly are achieved.

Owner:ZHEJIANG DADI STEEL STRUCTURE

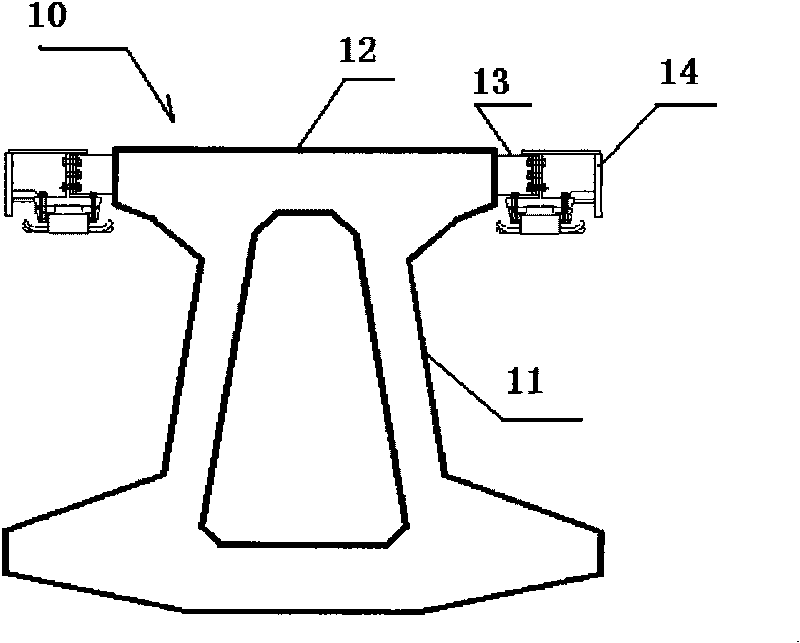

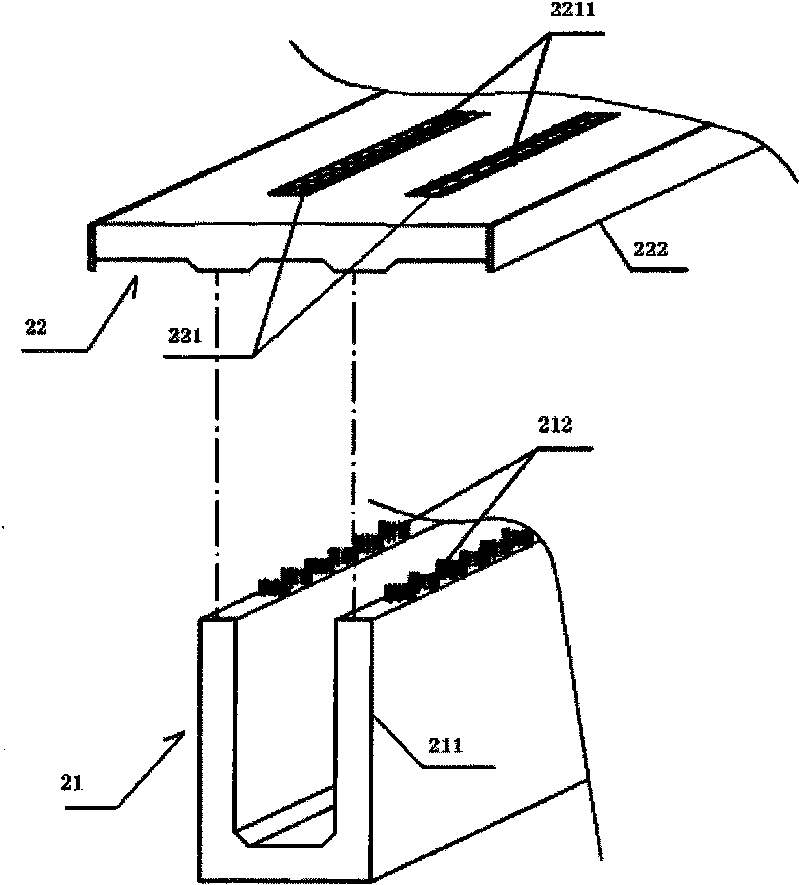

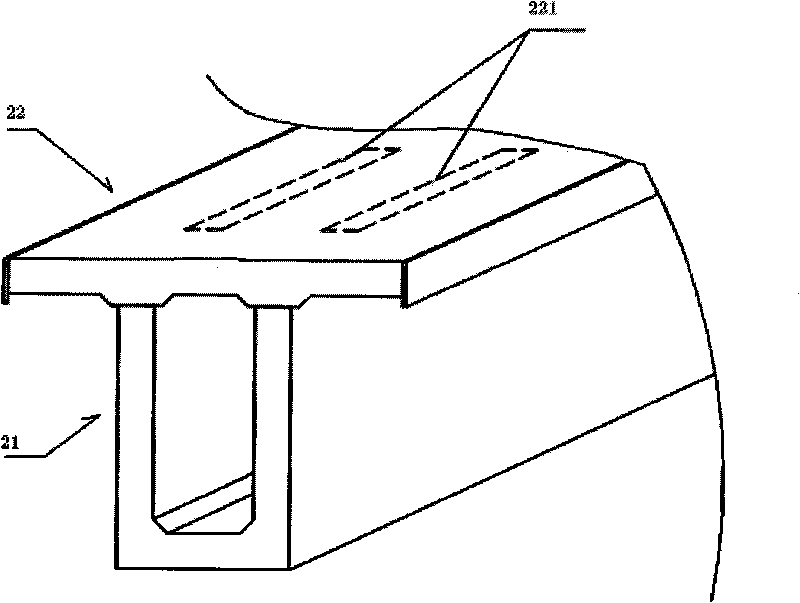

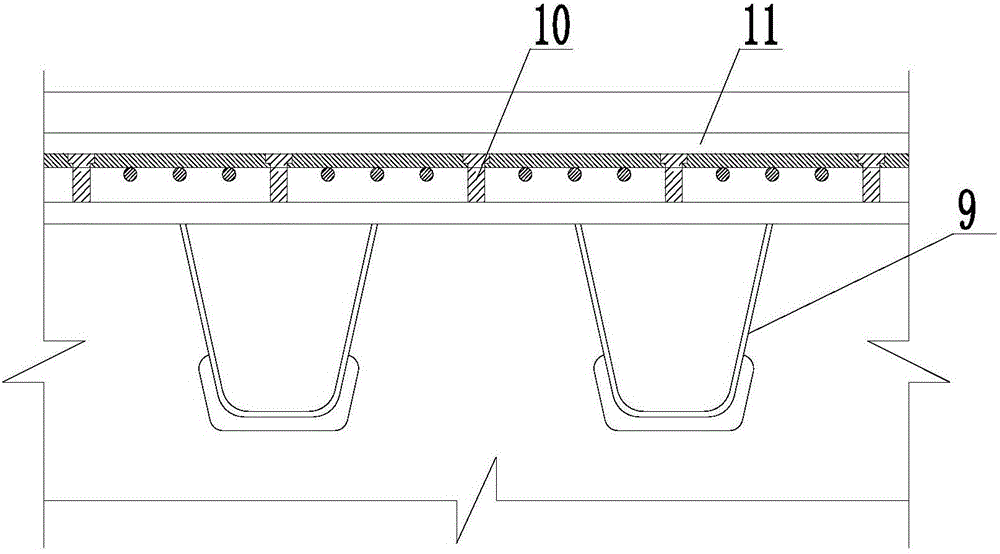

Prefabricated track slab combined track beam

InactiveCN101725107ALow equipment requirementsLower Shipping RequirementsBridgesShaped beamEngineering

The invention relates to a prefabricated track slab combined track beam which comprises a track slab and a support beam; a notch is preserved on the track slab, and a grid type steel bar is exposed in the notch; the support beam is a U-shaped beam, a web plate of the support beam is arranged below the track slab, and a plurality of vertical dowel bars are vertically arranged at the top end of the web plate; and the track slab is arranged on the support beam, the web plate is used for positioning the notch, the plurality of vertical dowel bars on the web plate are anchored in the grid type steel bar of the notch of the track slab, and concrete is used for filling the notch of the track slab, thereby solidifying the track slab and the support beam into a whole. The track slab and the support beam are separately manufactured in the prefabricated track slab combined track beam, the field positioning, the splicing and the pouring of the concrete are sequentially carried out, and the whole is finally formed, thereby limiting the part which needs to be processed at the track slab, greatly reducing the requirements on processing equipment and transportation, simultaneously preserving the notch on the track slab, adopting the way of inserting the track slab into the U-shaped beam and further reducing the construction height.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD +1

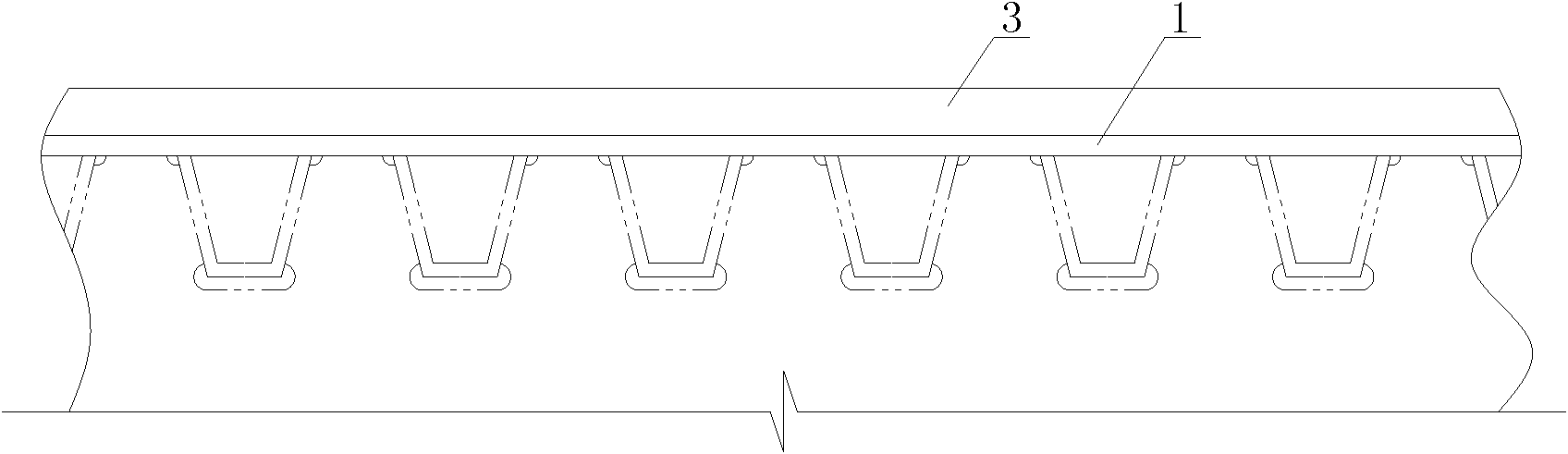

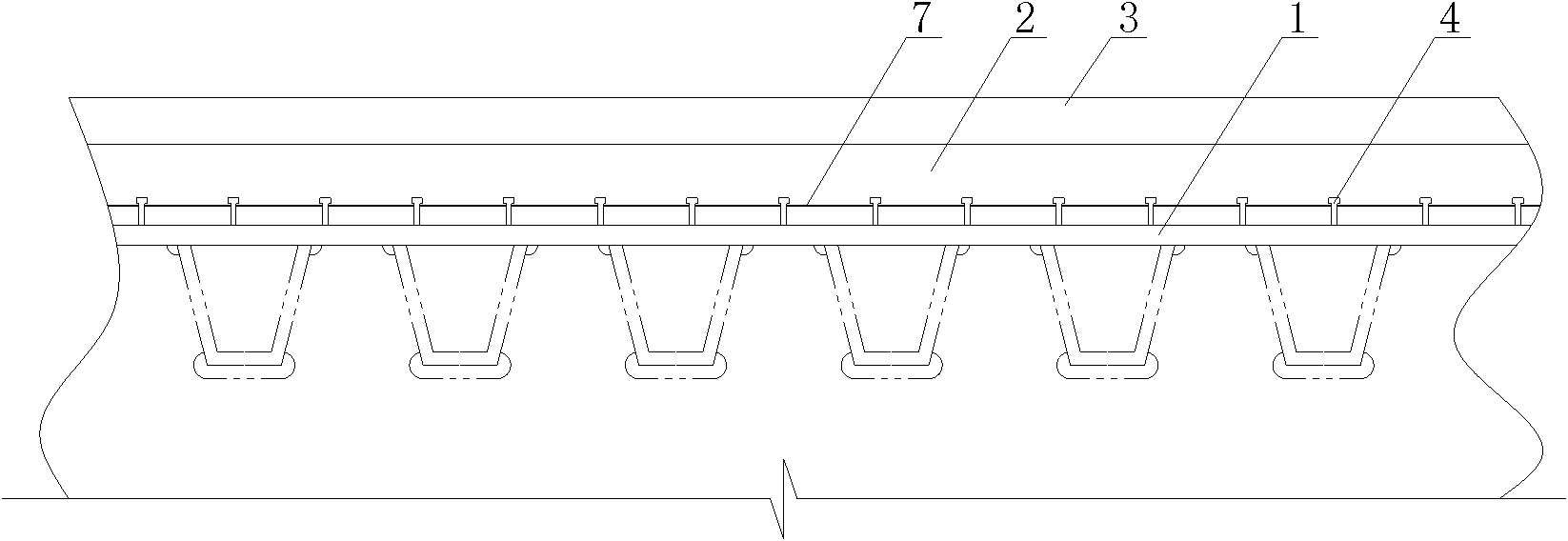

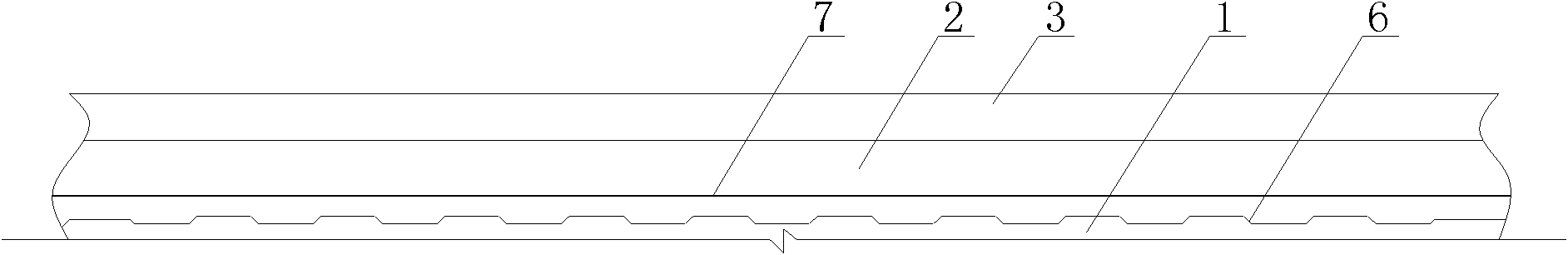

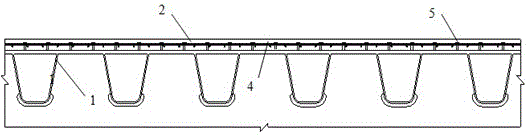

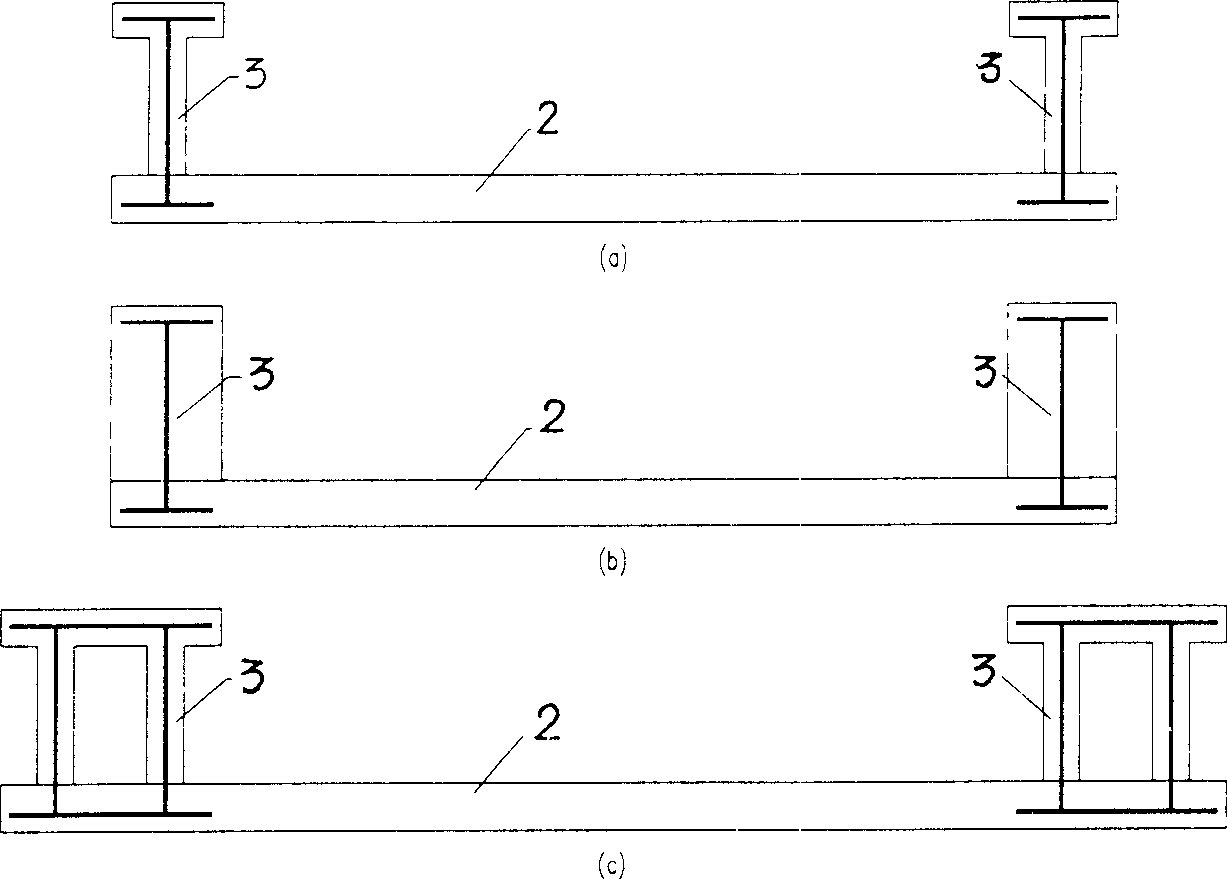

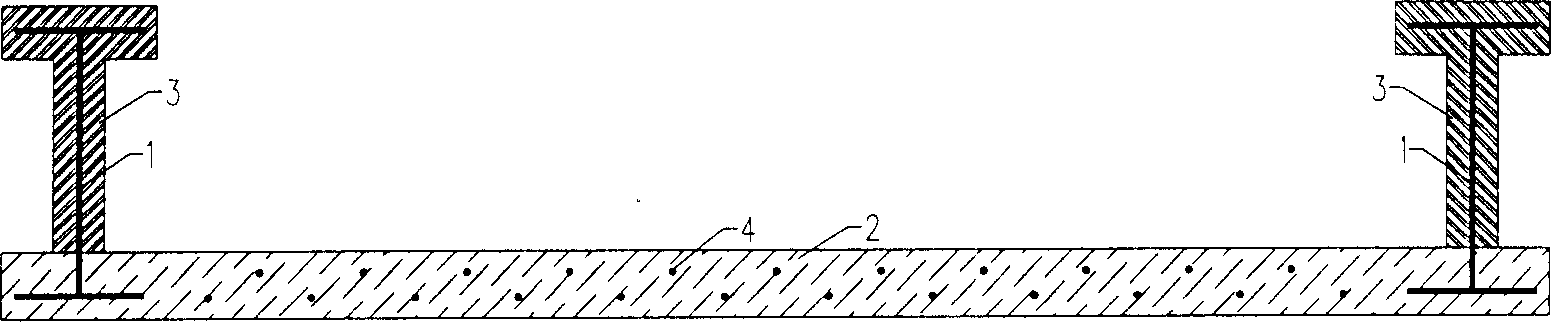

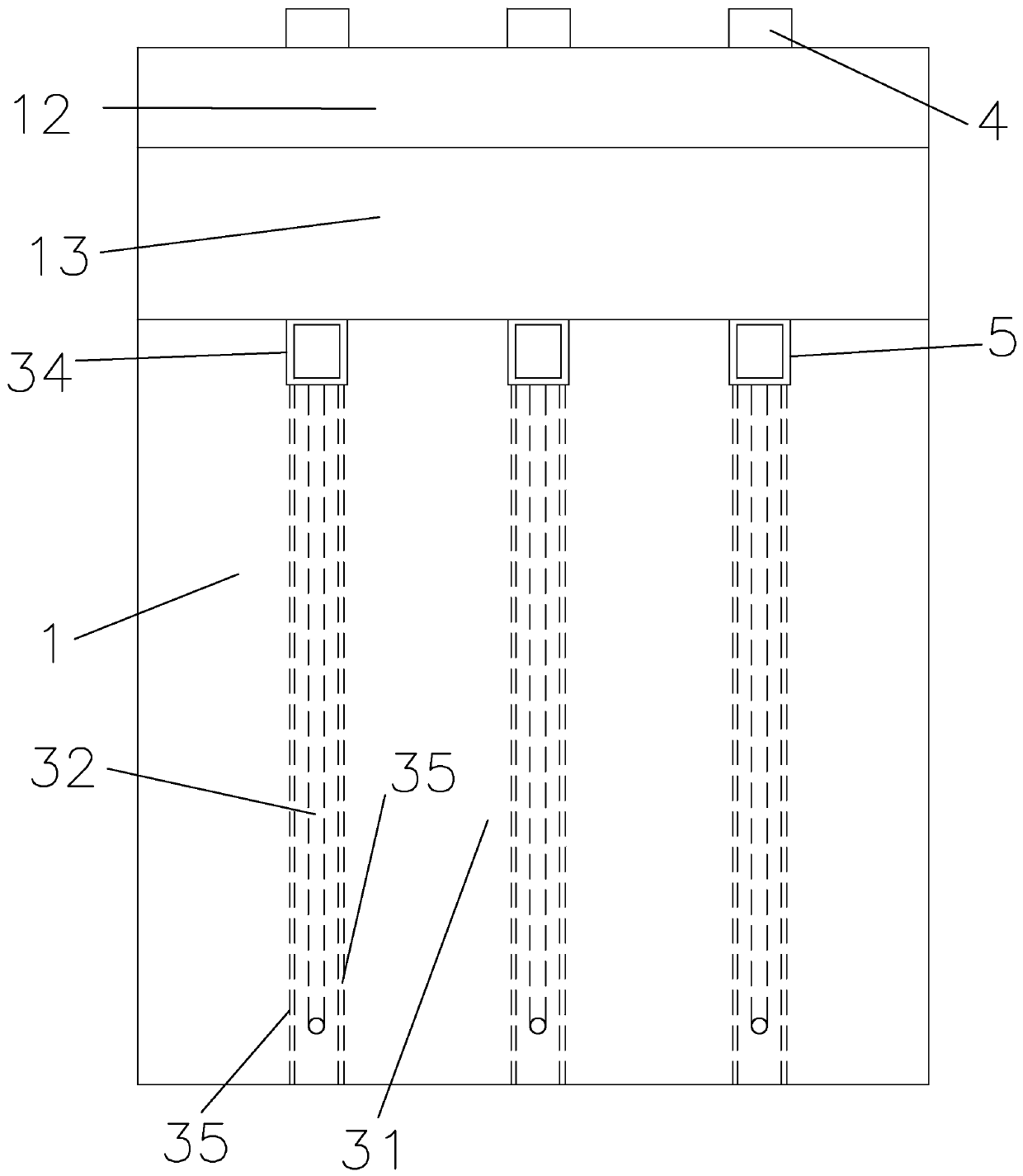

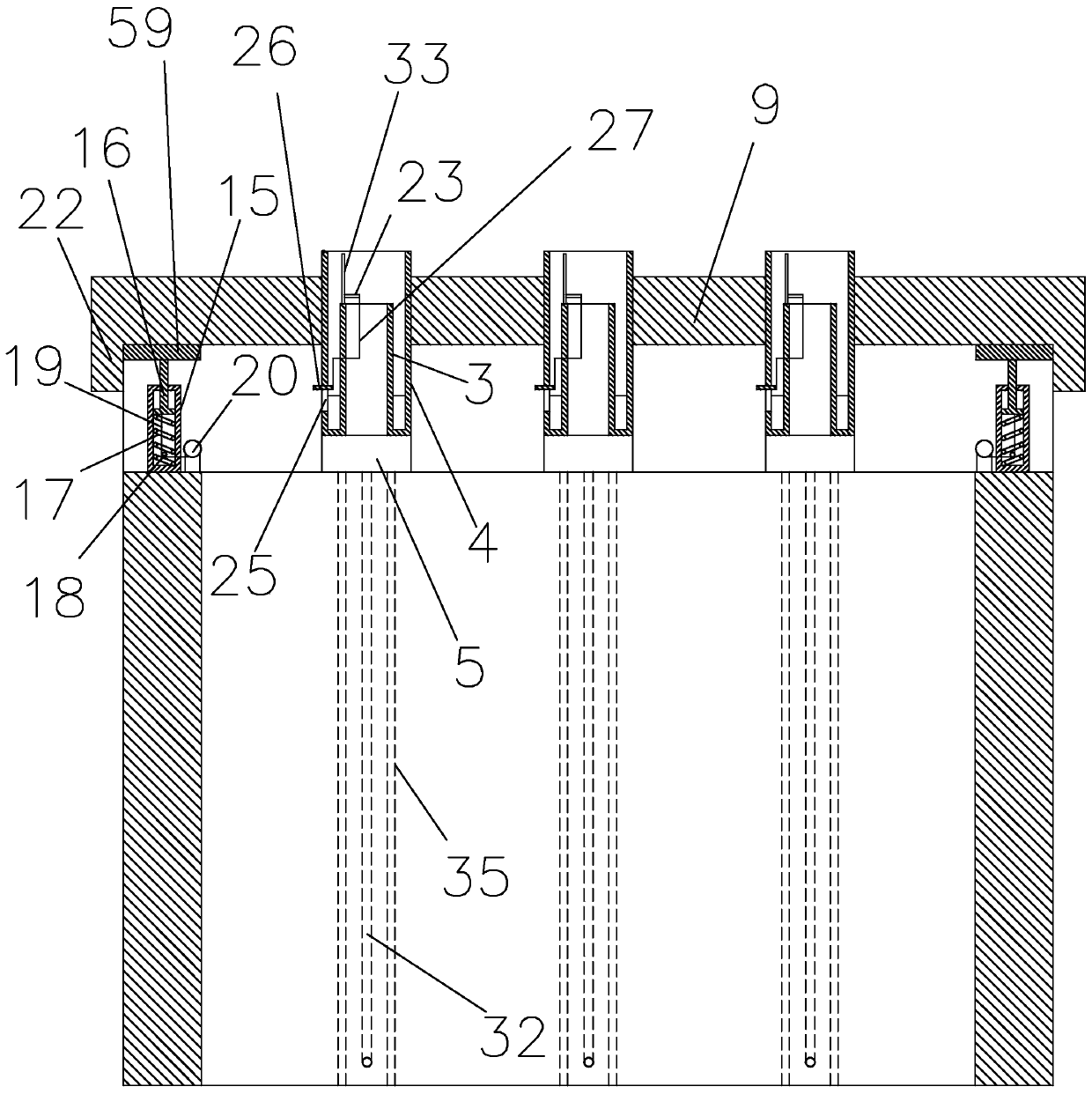

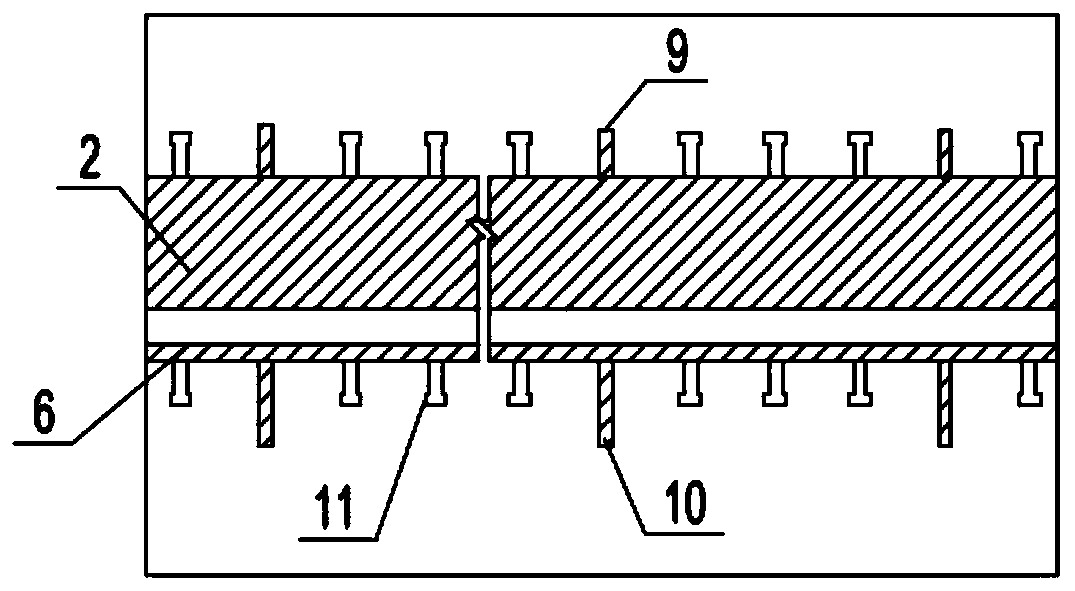

Steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and construction method thereof

ActiveCN106638306ALow construction heightIncreased shear strengthBridge structural detailsBridge materialsRebarHigh performance concrete

The invention discloses a steel-ultrahigh performance concrete combined bridge deck structure with short-steel-bar anti-shear structures and a construction method thereof. The combined bridge deck structure comprises a steel bridge deck layer (1) and an ultrahigh performance concrete layer (2) poured on the steel bridge deck layer (1). The steel bridge deck layer (1) is fixedly connected with the short-steel-bar anti-shear structures, each short-steel-bar anti-shear structure comprises a plurality of short steel bars (3) fixedly connected to the upper surface of the steel bridge deck layer (1), wherein the short steel bars (3) are horizontally arranged in the longitudinal bridge direction. The short-steel-bar anti-shear structures are wrapped in the ultrahigh performance concrete layer (2). According to the steel-ultrahigh performance concrete combined bridge deck structure with the short-steel-bar anti-shear structures, the thickness of the ultrahigh performance concrete layer can be reduced, the weight of a bridge deck can be lowered, the shear key structure is small in size and simple in construction process, and the steel-ultrahigh performance concrete combined bridge deck structure is especially suitable for large-span flexible bridges which are sensitive in bridge weight.

Owner:HUNAN UNIV

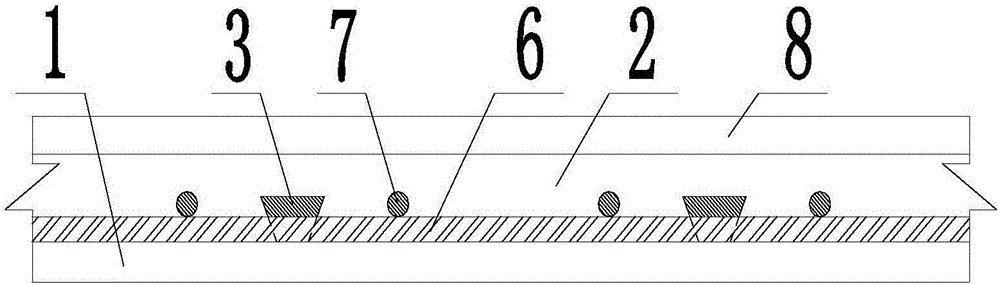

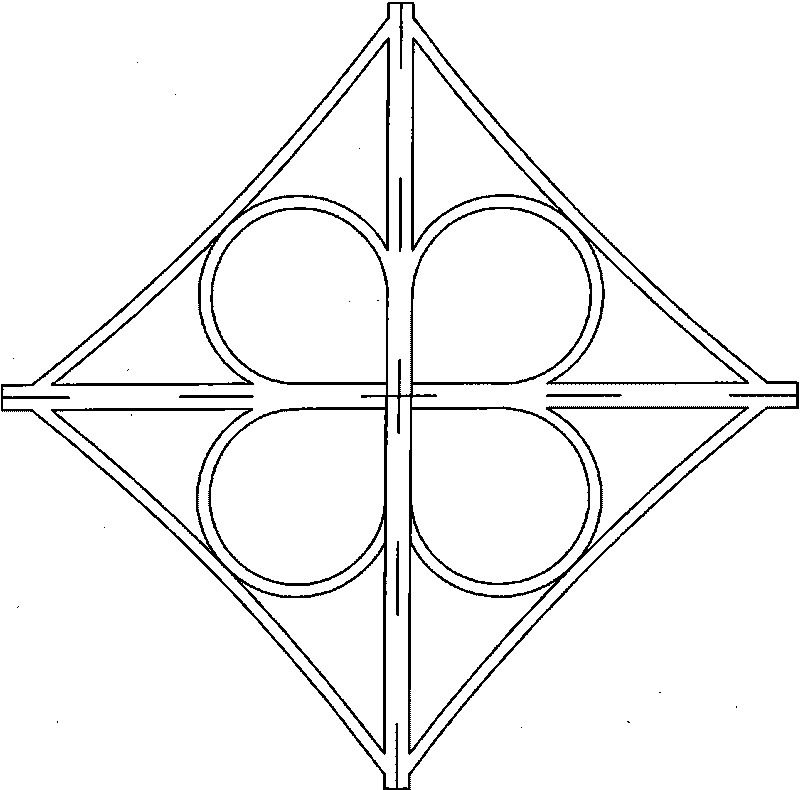

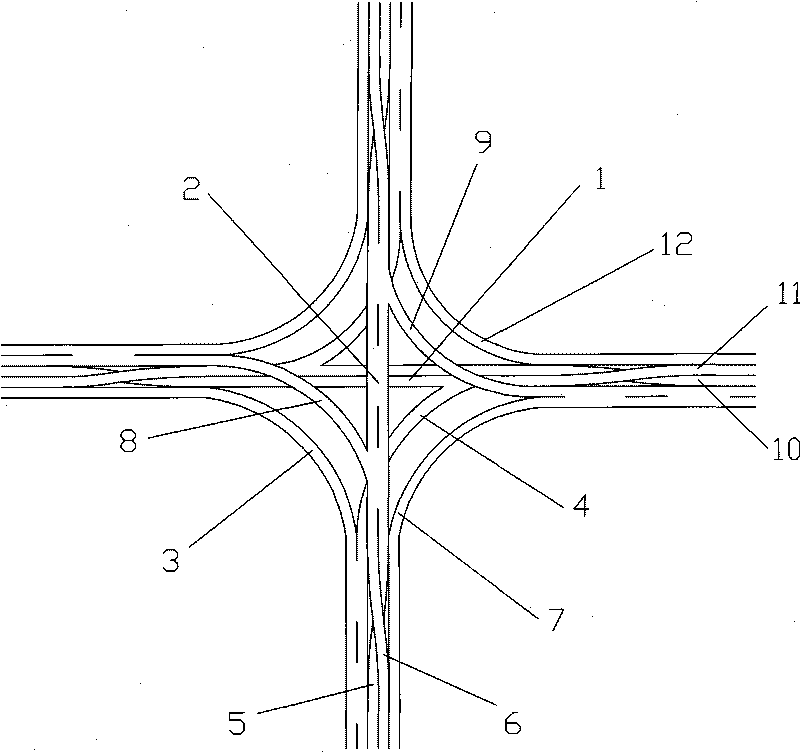

Single-layer full interchange viaduct

The invention discloses a single-layer full interchange viaduct, which comprises an east-west ground artery, a south-north overhead artery and four road junctions, wherein each road junction has five running lanes and one left-right lane change viaduct; a southwest bend, a southeast bend and east-south bend are all ground roads; a north-south straight lane is connected with an east running lane of the south-north overhead artery through an approach bridge; a south-north straight lane is connected with a west running lane of the south-north overhead artery after the left-right lane change viaduct spans the north-south straight lane, and is connected with a south-west bend through the south-north overhead artery; the running lane of the north road junction is in inverse symmetry with the running lane of the south road junction; the running lane of the east road junction is similar to that of the south road junction, but the straight lane of the east road junction is connected with the east-west ground artery; and the running lane of the west road junction is in inverse symmetry with the running lane of the east road junction. The single-layer full interchange viaduct realizes right passing when turning right and left passing when turning left so that vehicles can pass naturally, smoothly and quickly during turning left and turning right, the occupied area is small, and the building height is low.

Owner:DALIAN MARITIME UNIVERSITY

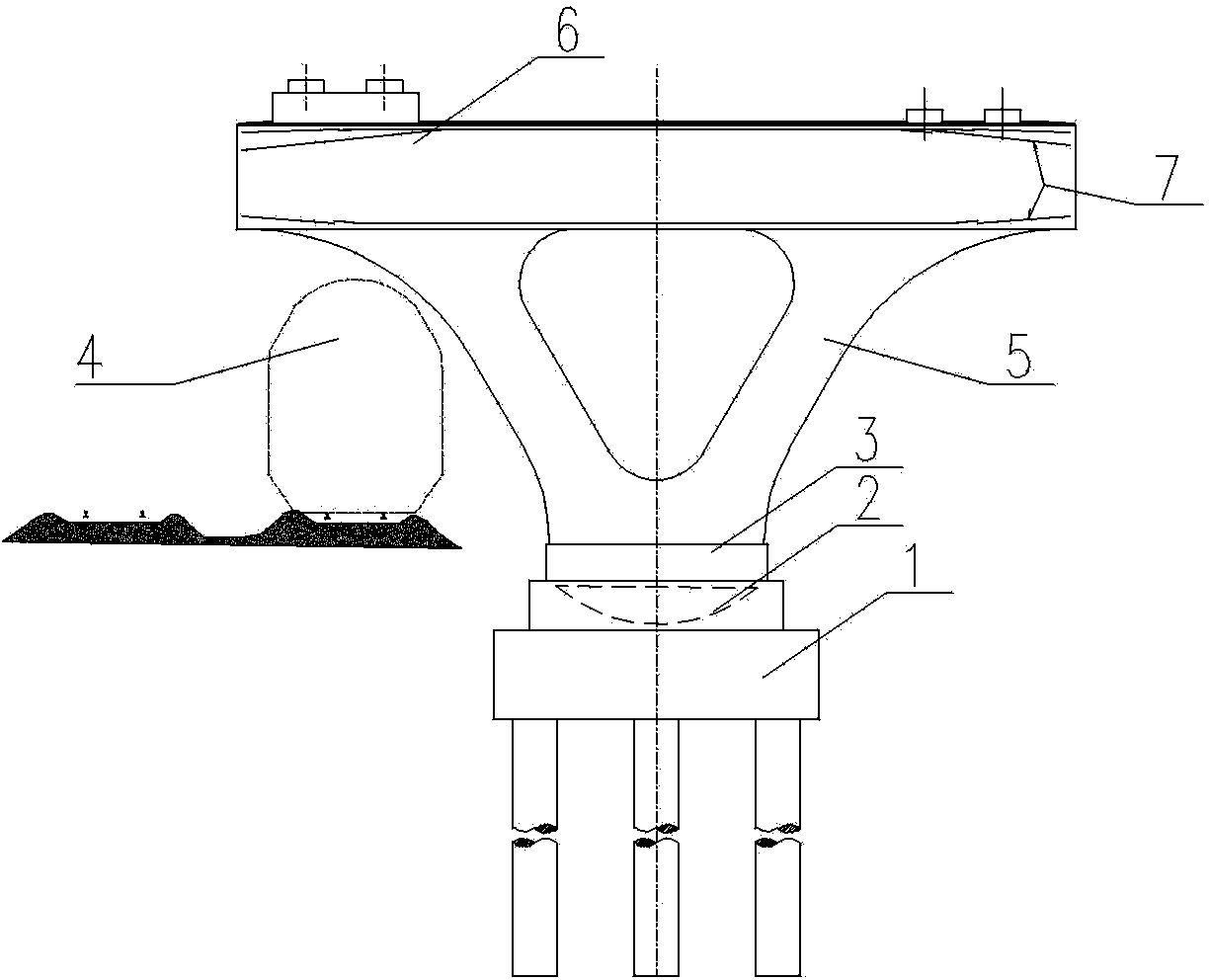

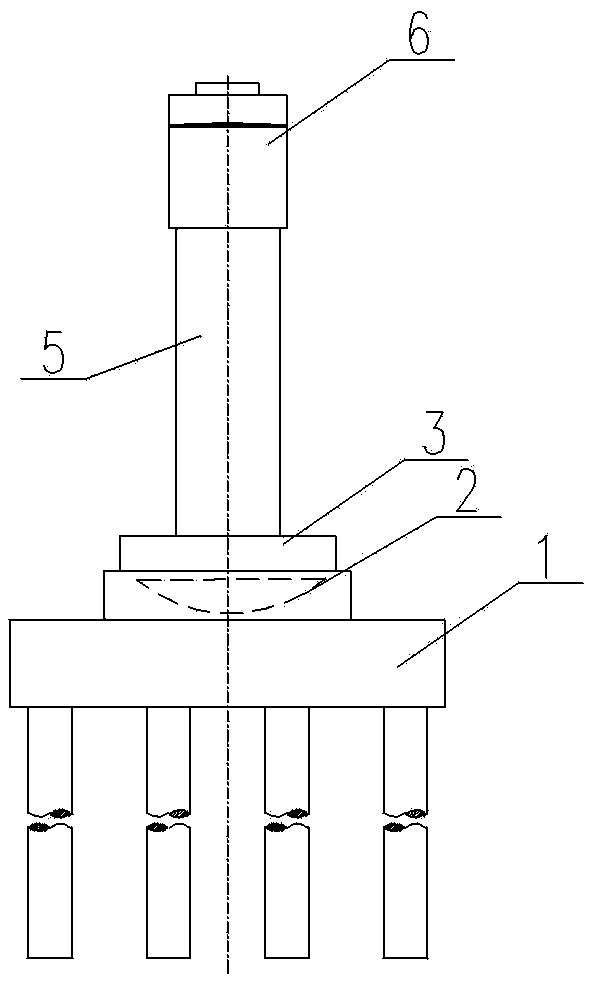

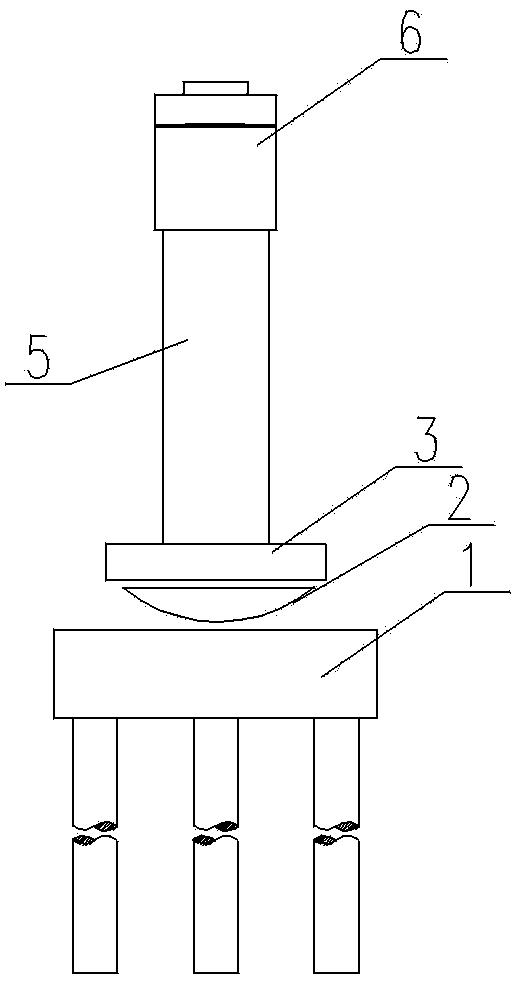

Rotation V-type T-structure bridge pier and construction thereof

ActiveCN104213504AShorten the construction periodReduce operational disruptionBridge structural detailsFoundation engineeringArchitectural engineeringUrban area

The invention relates to a rotation V-type T-structure bridge pier and a construction thereof. When an included angle formed between a line and an existing busy trunk line through vertical crossing is smaller, cross-hole arrangement of a bridge is more difficult. The bridge pier is constructed on one side of the existing trunk line, and comprises a pile foundation, a supporting platform, pier arms and a cover beam from bottom to top, wherein the supporting platform is divided into a lower rotary table and an upper rotary table from bottom to top; a rotary spherical hinge is arranged between the upper rotary table and the lower rotary table; during line operation skylight time, the upper rotary table and the structure rotate to a designed position by taking the rotary spherical hinge as the center, concrete on the outer side of the rotary spherical hinge is poured to form a solid stage, and the lower rotary table and the upper rotary table are fixedly connected together to complete construction. Due to the adoption of a rotation V-type T-structure scheme, the construction only needs to be performed on one side of the existing line, requirements for roads and construction sites on the other side are reduced, the conditions that houses on two sides of the existing line in an urban area are dense and are difficult to remove are facilitated, the removal cost is greatly reduced, and the construction period is guaranteed; meanwhile, due to the adoption of rotation construction, the influence on operation of the existing line is minimized.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

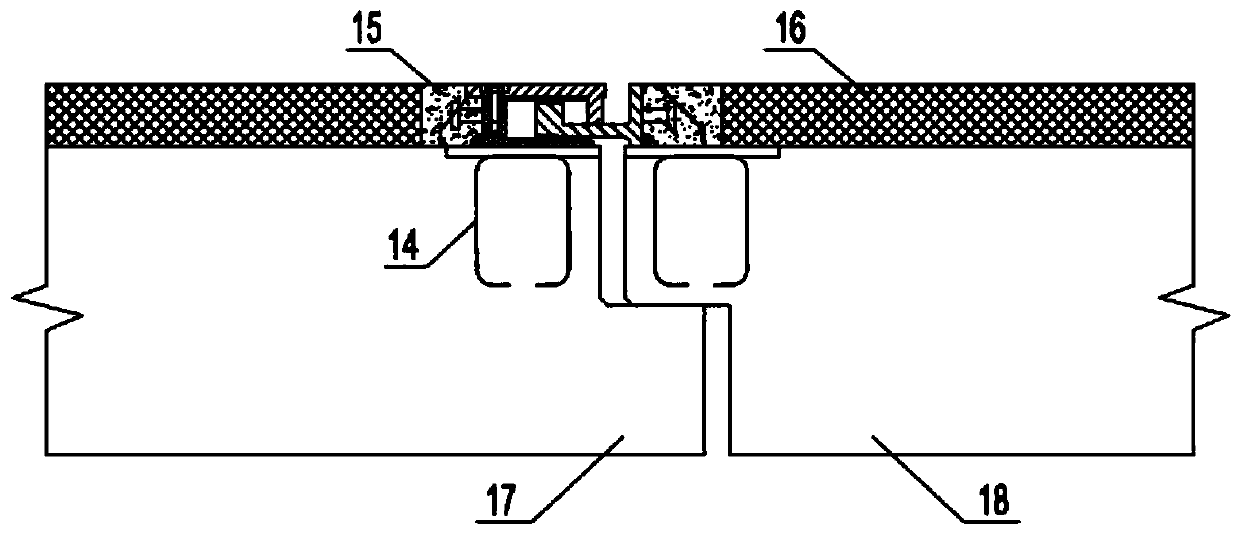

Low-height bridge bracket dual-way limiting telescopic device

The invention discloses a low-height bridge bracket dual-way limiting telescopic device. The low-height bridge bracket dual-way limiting telescopic device is located on beam plates on two sides of a bridge bracket beam line, and is composed of a fixed end, a sliding end and an anchorage system, embedded steel plates are embedded on the top faces of the beam plates on the two sides of the bracket beam line, embedded reinforcing steel bars are welded to the bottom faces of the steel plates, the steel plates are firmly anchored into the beam plates, and an anchorage system is formed; the fixed end is arranged on a bridge left bracket, and the sliding end is arranged on a bridge right bracket; vertical limiting is achieved, the beam plates on the two sides of the brackets are displaced in a coordinated manner, the vehicle impact is reduced to the maximum degree, and safety and durability of the bridge brackets can be improved; longitudinal limiting is achieved, when the bridge suffers theearthquake and other extreme conditions, the telescopic device carries out effective limiting on the longitudinal displacement of the beam plates on the two sides of the bridge brackets, the risk of beam falling caused by too large longitudinal displacement of the bridge brackets during the earthquake can be prevented, the structure is simple, the building height is small, mounting is firm, the beam plates do not need to be slotted, and construction is facilitated.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

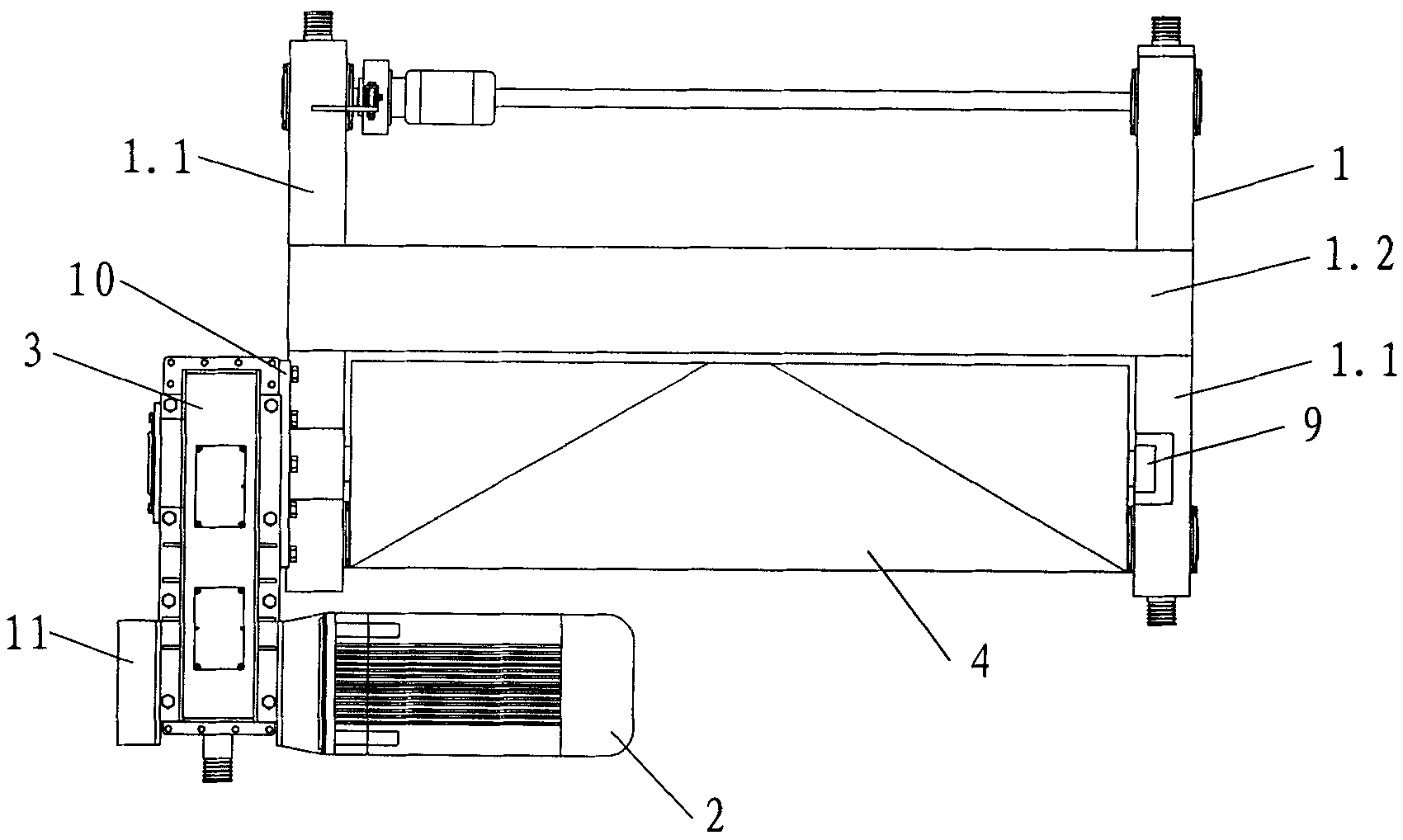

Dolly for overhead and gantry cranes

The invention discloses a dolly for overhead and gantry cranes. A hoisting mechanism comprises a car frame (1), a motor (2), a speed reducer (3), a winding drum (4), a fixed pulley group (5) and a lifting hook (6); the car frame (1) comprises two end beams (1.1) and a main beam (1.2); the end beams (1.1) and the main beam (1.2) form a framework structure; the winding drum (4) is positioned in theframework structure; the winding drum (4) is rotationally installed on the two end beams (1.1); the speed reducer (3) is installed on the side wall of one of the end beams (1.1); a low-speed shaft ofthe speed reducer (3) is connected with the end part of the winding drum (4) installed on the end beam (1.1); the motor (2) is installed on the side wall of the speed reducer (3); and an output shaftof the motor (2) is connected with a high-speed shaft of the speed reducer (3). The dolly has low height, is convenient to maintain, and has light weight and low energy consumption.

Owner:宁波市凹凸重工有限公司

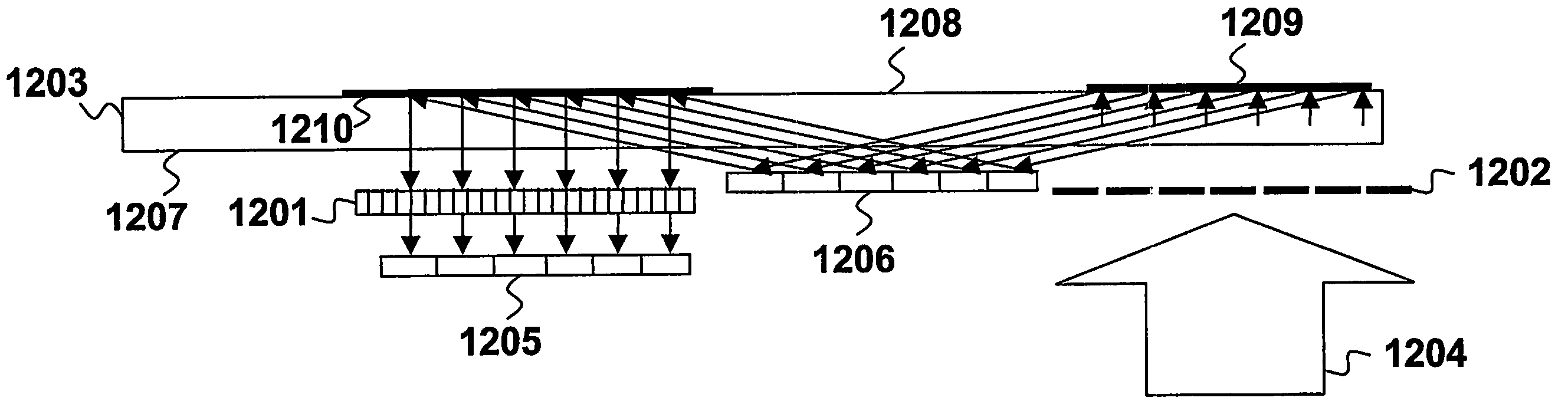

System for reading data stored on an information carrier

InactiveUS7308172B2Easy to implementReduce building heightIntegrated optical head arrangementsRecord information storageLight beamOptical storage

The invention relates to a system for reading data stored on an information carrier. The system comprises a waveguide (1203) which allows displacing laterally the different components in exploiting the reflection of the light beams between a first surface (1207) and a second surface (1208) of said wave guide (1203). Use: Optical storage.

Owner:KONINK PHILIPS ELECTRONICS NV

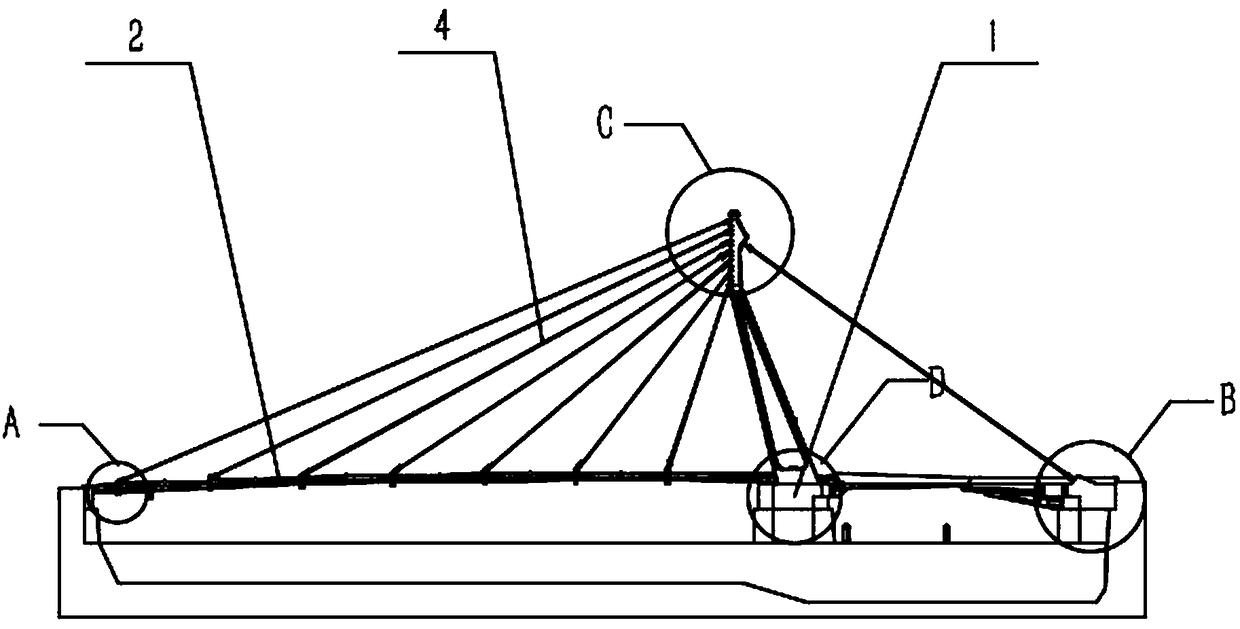

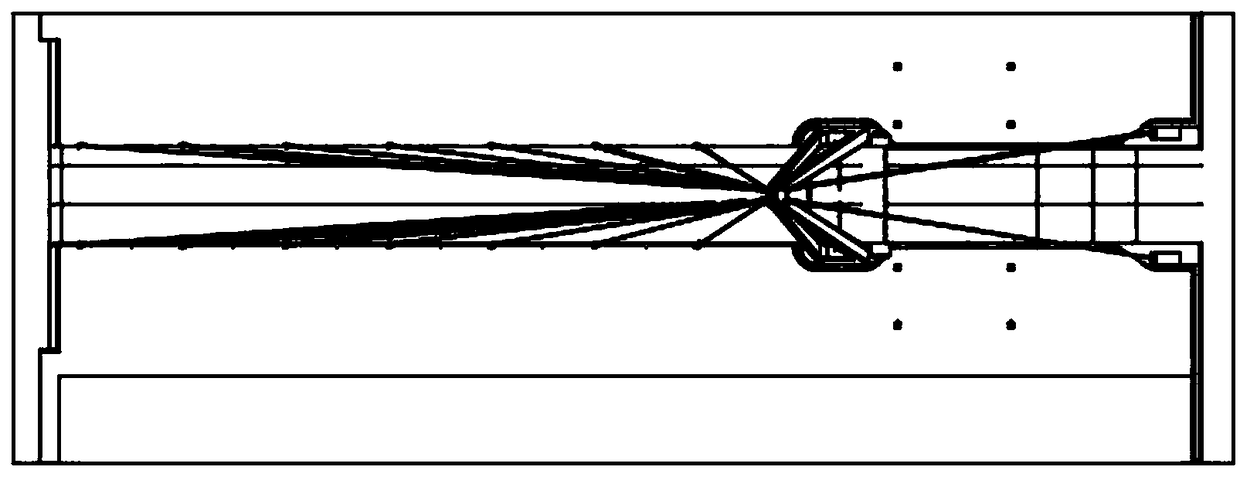

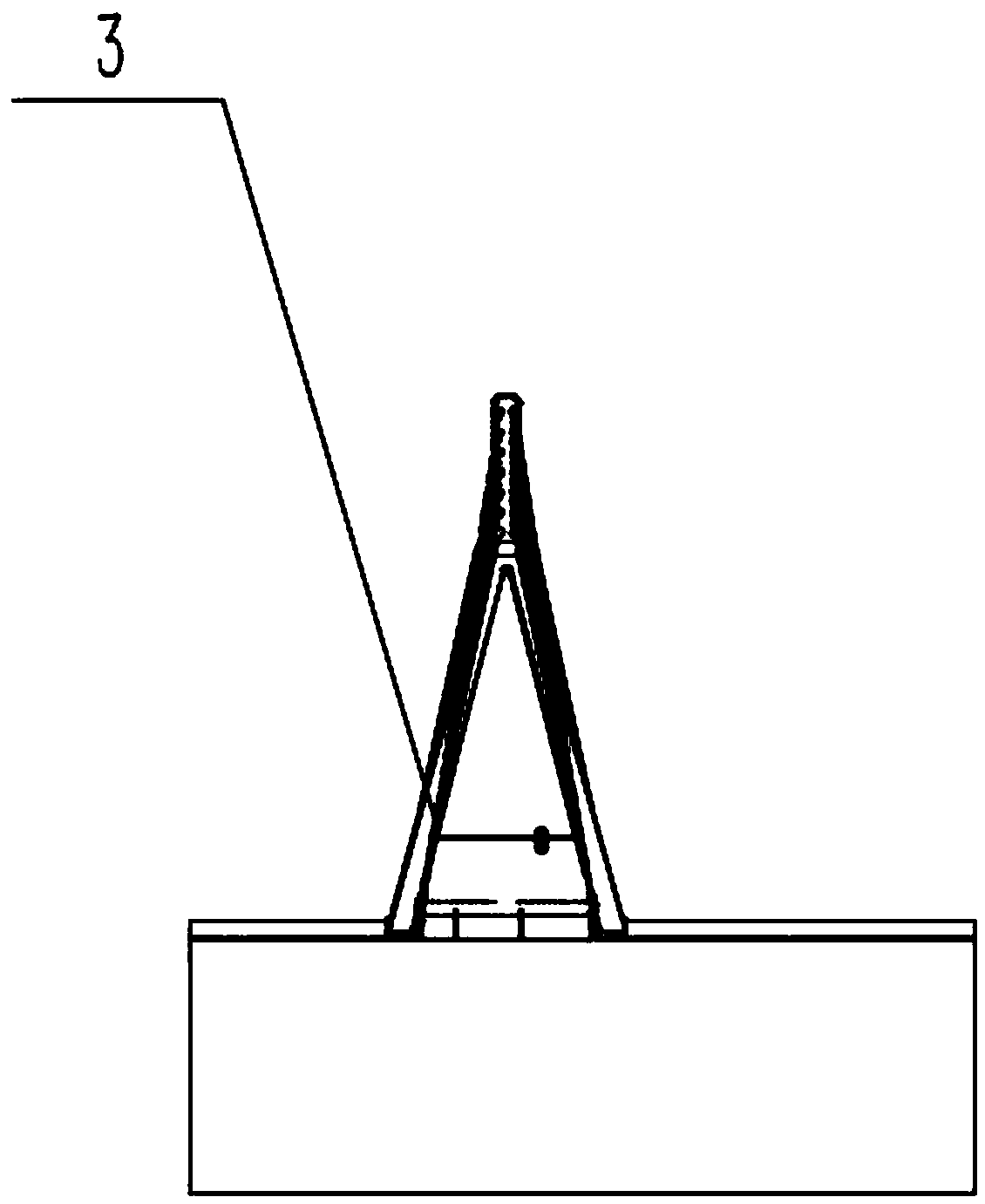

A construction method of a cable-stayed bridge

InactiveCN108999088AReduce building heightReduce structural weightCable-stayed bridgeBridge structural detailsCable stayedMaterial consumption

The invention discloses a construction method of a cable-stayed bridge, which mainly solves the problems in the prior art that the bridge body is large in weight, and the material consumption is largeand the cost is high. The cable-stayed bridge adopts the form of single pylon and double cable planes, and the main girder is directly pulled on the pylon by a plurality of stay cables, and the staycables replace the multi-span elastic support continuous girder of the pier, so that the problems existing in the prior art can be overcome, the building height can be reduced, the weight of the structure can be lightened, the material can be saved, and the bridge has good popularization and utilization value.

Owner:张家港市欧微自动化研发有限公司

Straddle type monorail prestressing reactive powder concrete track beam

InactiveCN106758576AImprove fatigue resistanceImprove seismic performanceRailway tracksBridge materialsPre stressStraddle

The invention discloses a straddle type monorail prestressing reactive powder concrete track beam. The cross section of the track beam is a hollow I-shaped cross section. The bottom of the track beam is provided with a plurality of prestressing tendons. The prestressing tendons extend in the length direction of the track beam. The prestressing tendons are distributed in a U-shaped manner at the cross section of the track beam. The span of the track beam is 30-40m. According to the reactive powder concrete track beam, the disadvantages that a PC track beam is short in economic span and poor in endurance are overcome, and the problems that for a steel track beam, the amount of steel used is large, vibration noise is high and skid resistance performance is poor are also solved.

Owner:中交铁道设计研究总院有限公司

System for reading data stored on an information carrier

InactiveUS20070104406A1Reduce heightFacilitate implementationIntegrated optical head arrangementsRecord information storageOptical storageWaveguide

The invention relates to a system for reading data stored on an information carrier. The system comprises a waveguide (1203) which allows displacing laterally the different components in exploiting the reflection of the light beams between a first surface (1207) and a second surface (1208) of said wave guide (1203). Use: Optical storage

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

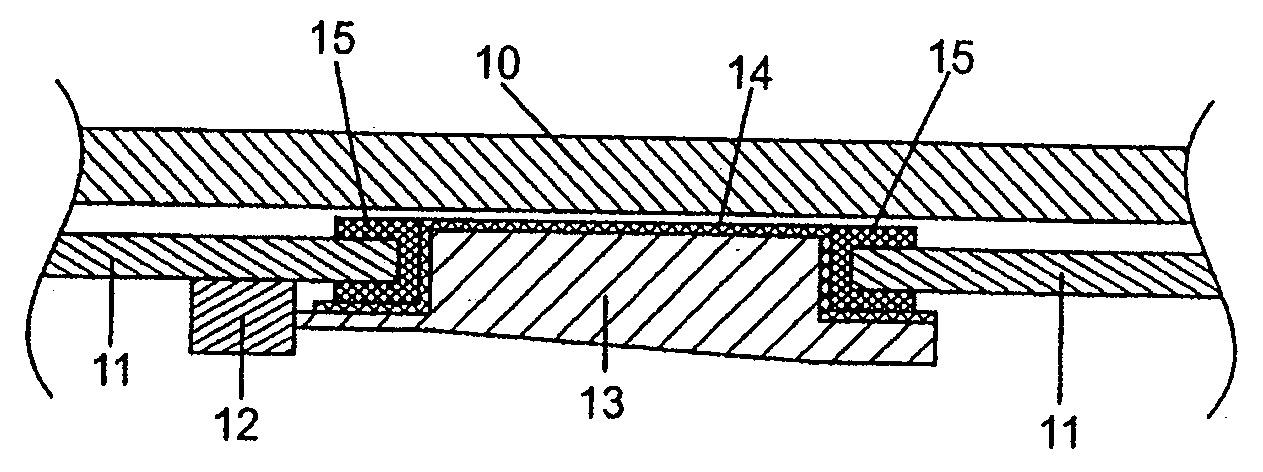

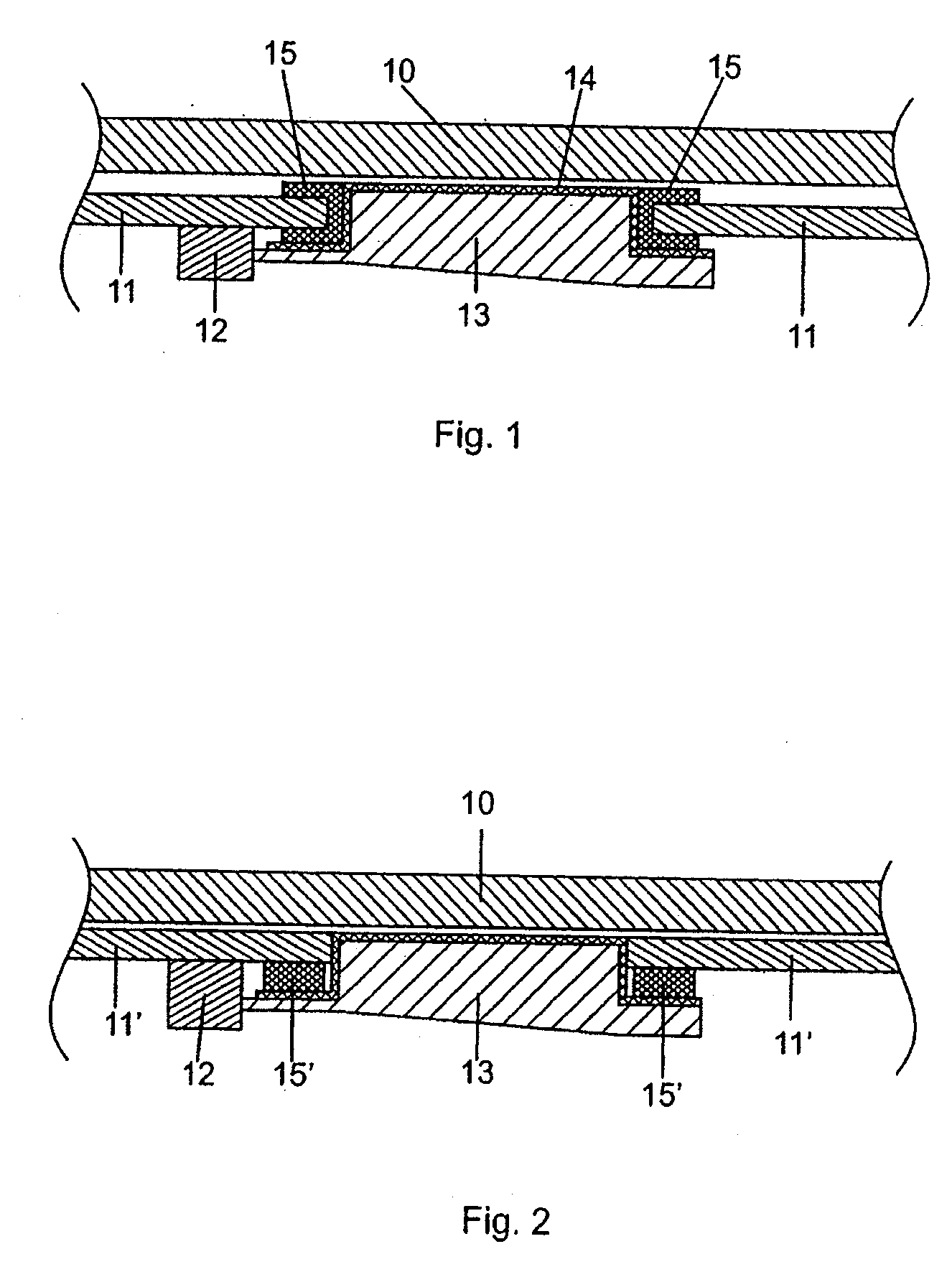

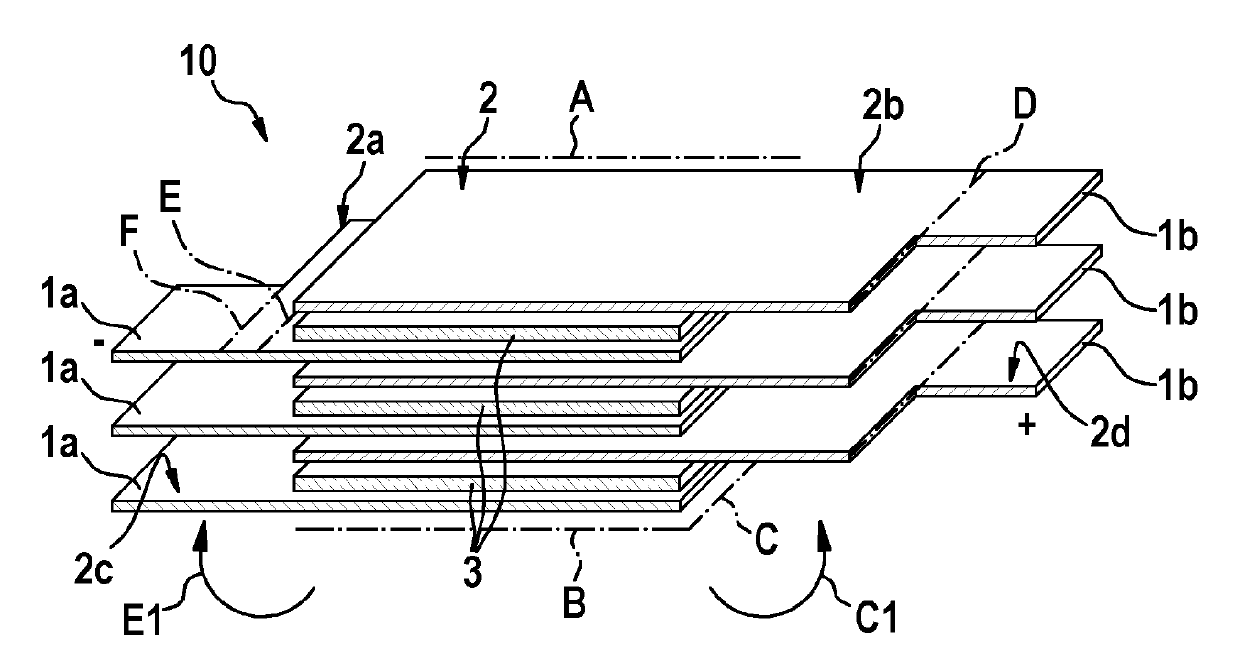

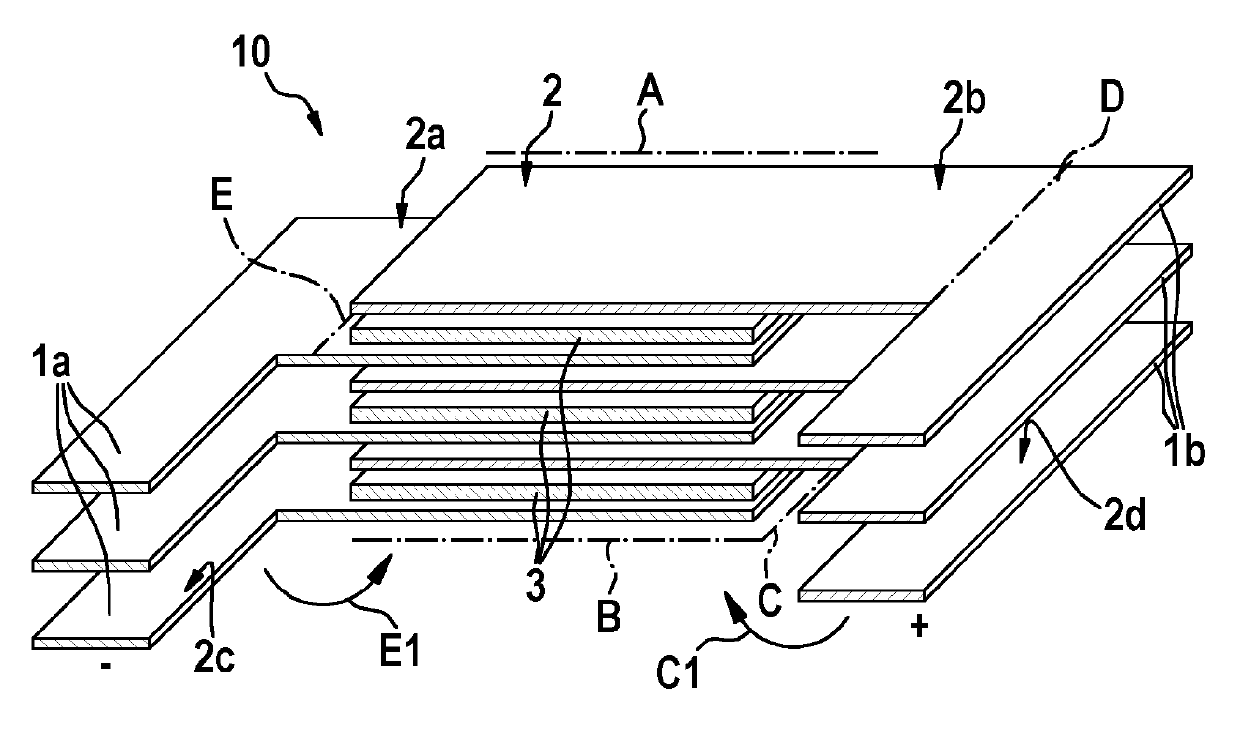

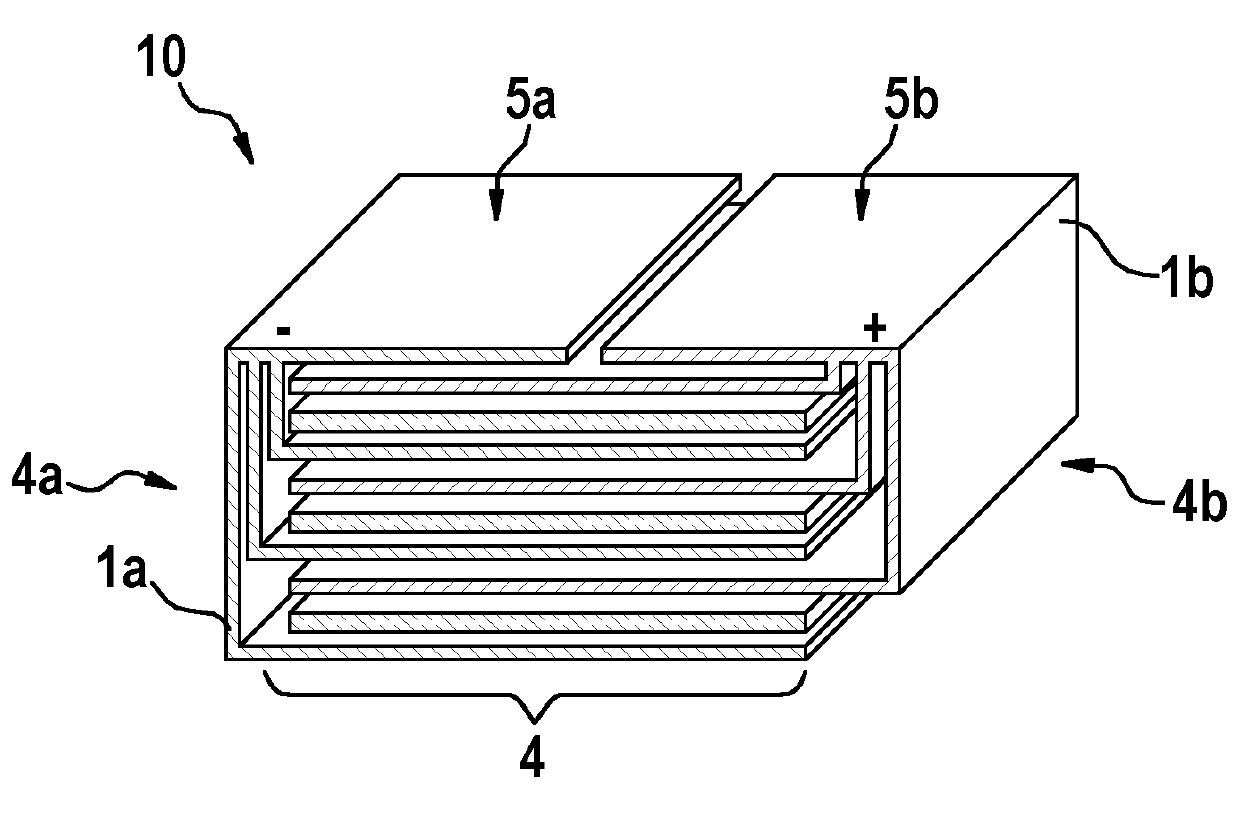

Electrical energy storage cell, electrical energy storage module and method for producing an electrical energy storage cell

ActiveCN104584274AReduce energy lossBattery inductance decreasesLarge-sized flat cells/batteriesFinal product manufactureStorage cellPlane parallel

The invention relates to an electrical energy storage cell (10) with a plurality of planar anode foils (1a) which have first storage sections (2) and first arrester sections (2a), and with a plurality of planar cathode foils (1b) which have second storage sections (2) and second arrester sections (2b), the anode foils (1a) and the cathode foils (1b) being stacked plane-parallel relative each other such that the first and section storage sections (2) overlap alternately and form a storage cell stack (4), the first arrester sections (2a) projecting by a first overhang length over a first side face (4a) of the storage cell stack (4) and the second arrester sections (2b) projecting by a second overhang length over a second side face (4b), opposite the first side face (4a), of the storage cell stack (4). The first arrester sections (2a) are folded relative the first storage sections (2) about a first fold line (E) and are oriented in parallel along the first side face (4a) of the storage cell stack (4). The second arrester sections (2b) are folded relative the second storage sections (2) about a second fold line (C) and are oriented in parallel along the second side face (4b) of the storage cell stack (4).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com