Bridge deck structure composed of prefabricated UHPC (Ultra High Performance Concrete) slabs and steel bridge deck and construction method thereof

A steel bridge deck and bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as easy shrinkage and cracking of ultra-high performance concrete, difficult maintenance of cast-in-place concrete, and shortened bridge deck pavement life. Achieve the effect of suitable factory construction, high rigidity and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

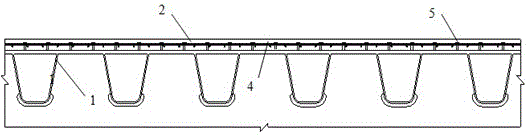

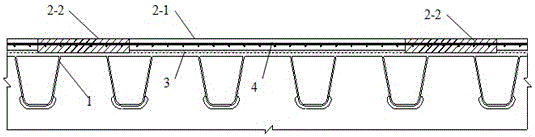

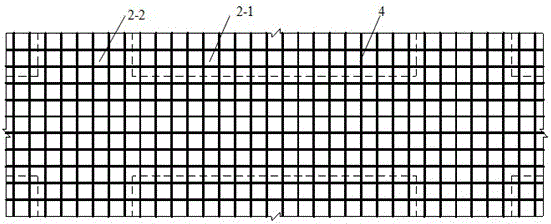

[0031] Such as Figure 2~7 As shown, a bridge deck structure composed of a prefabricated ultra-high performance concrete slab and a steel bridge deck includes a steel bridge deck 1 and an ultra-high performance concrete slab 2 covered on the steel bridge deck, and the ultra-high performance concrete slab 2 It is a prefabricated component, and the prefabricated slab 2-1 is connected into an integral ultra-high performance concrete slab 2 by the reserved cast-in-place belt 2-2, and then connected with the steel bridge deck 1 by cement-based adhesive 3 to form a composite bridge deck structure .

[0032] Wherein, the main material cement of the cement-based binder 3 can be ordinary Portland cement, sulphoaluminate cement, alkali-activated cement, magnesium cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com