Patents

Literature

306results about How to ""Good durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

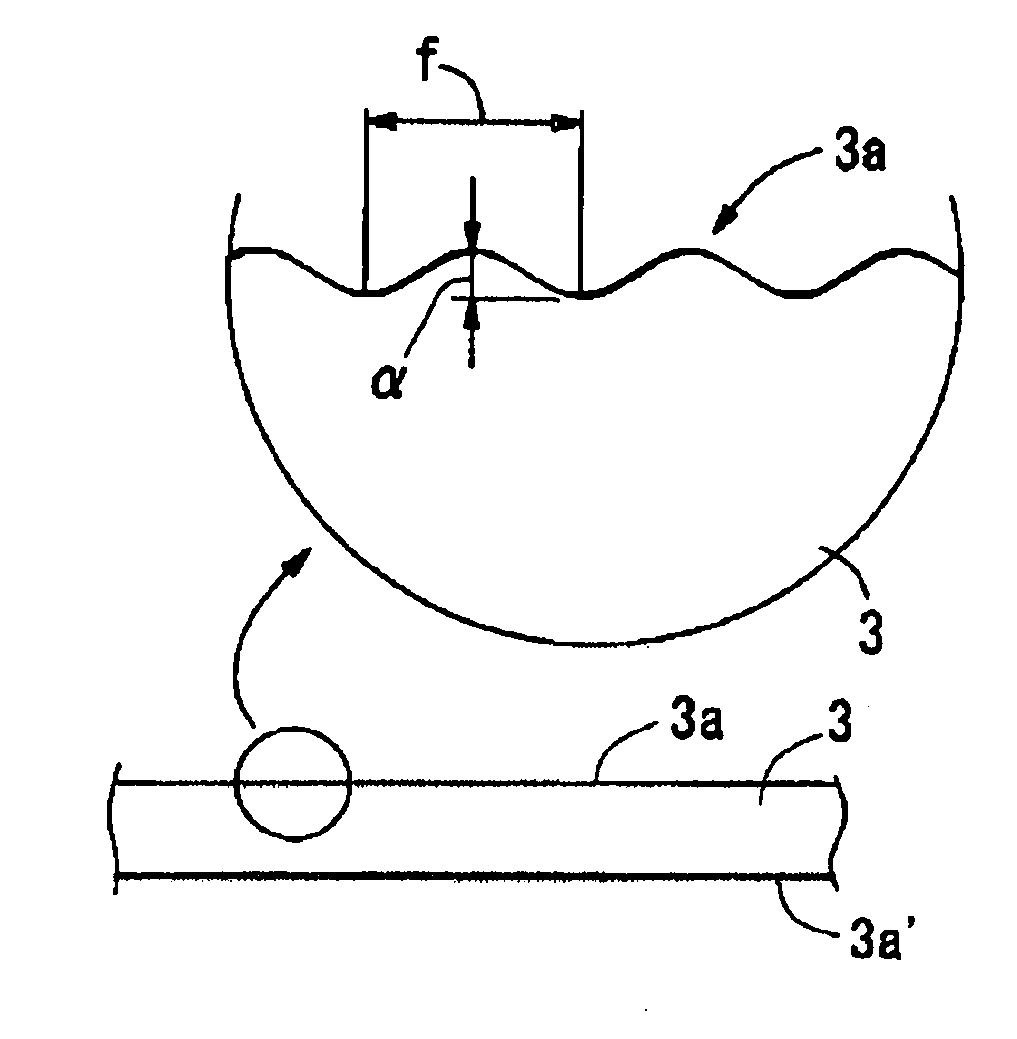

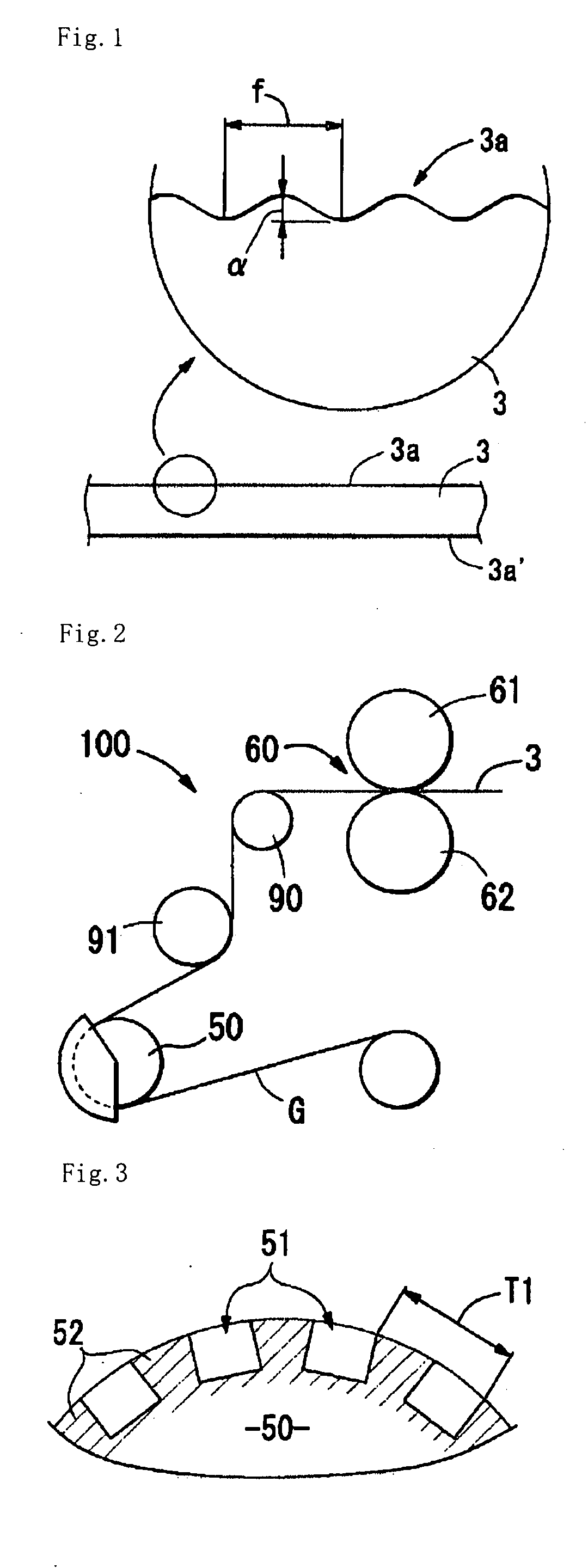

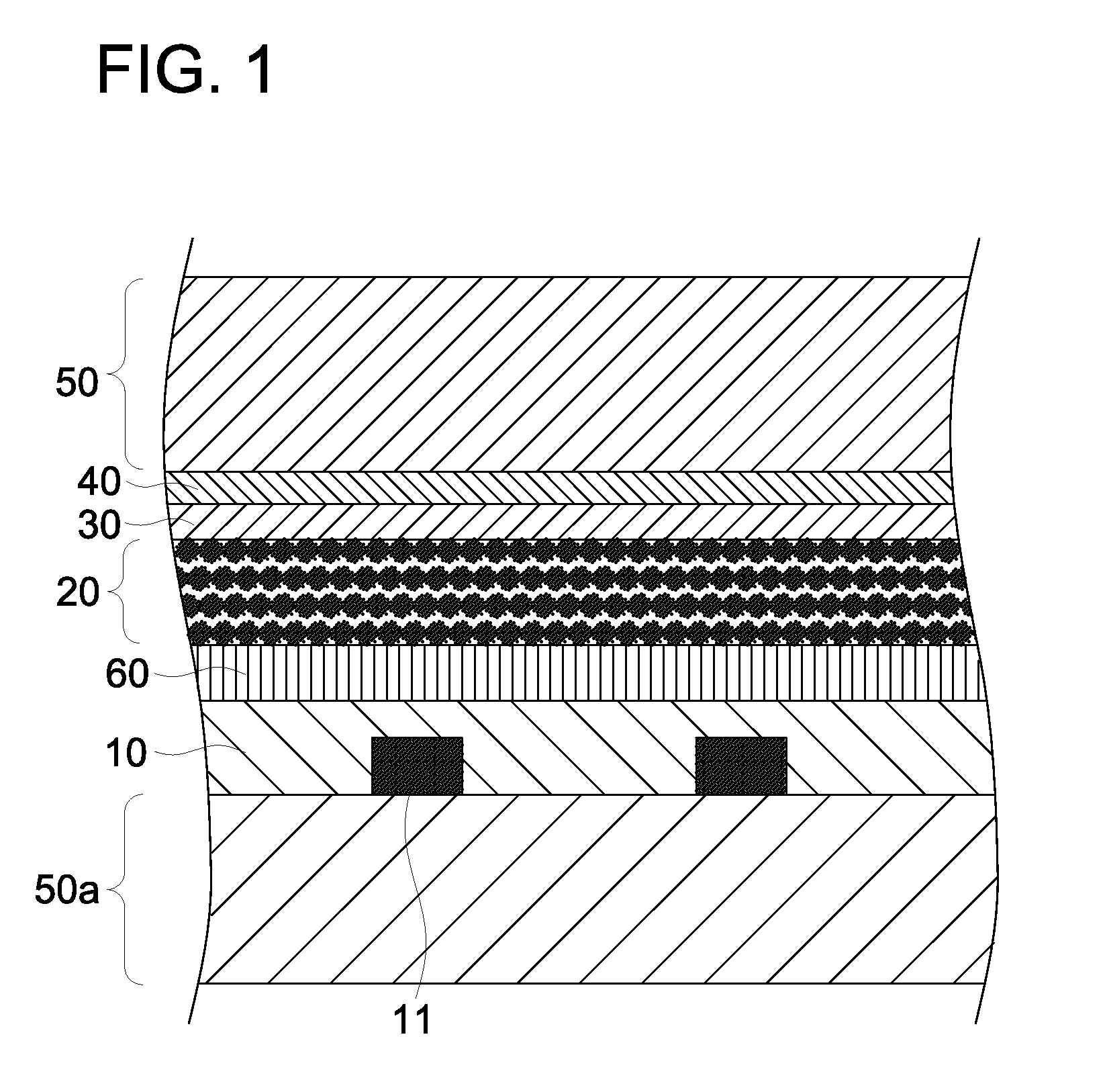

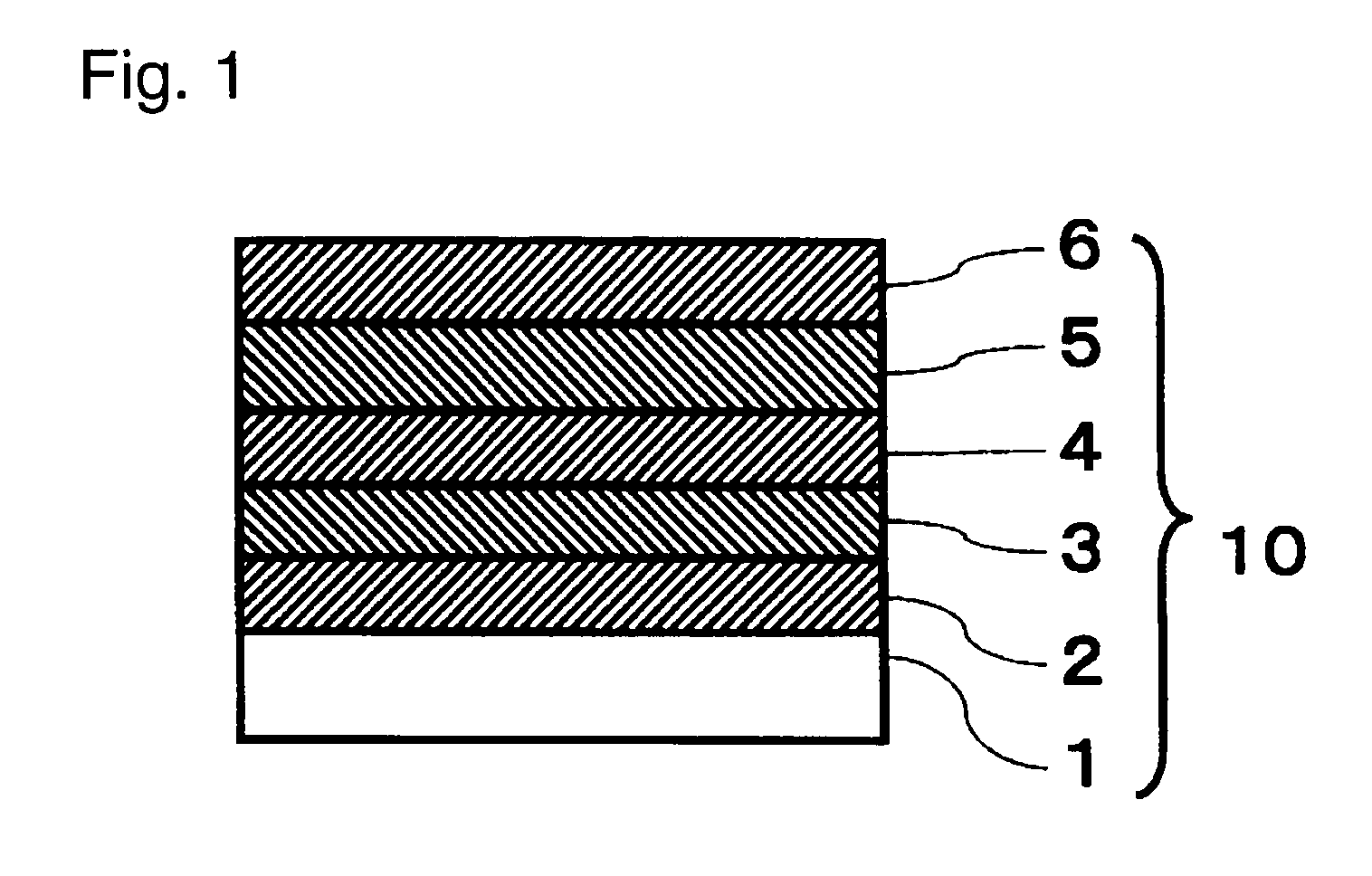

Magnetic tape

InactiveUS20050196645A1Excellent high record density characteristicGood durabilityManufacture head surfaceMagnetic materials for record carriersRecording densityMagnetic powder

A magnetic tape having excellent high recording density characteristics, good durability and good servo-tracking characteristics, which comprises a non-magnetic support, a magnetic layer formed on one surface of the non-magnetic support and containing a magnetic powder, a primer layer provided between the non-magnetic support and the magnetic layer and containing a non-magnetic powder, and a back coat layer formed on the other surface of the non-magnetic support, wherein the non-magnetic powder is goethite particles having an average particle size in a range of from 5 nm to 100 nm and the magnetic tape has an edge weave amount of 1.0 μm or less.

Owner:HITACHT MAXELL LTD

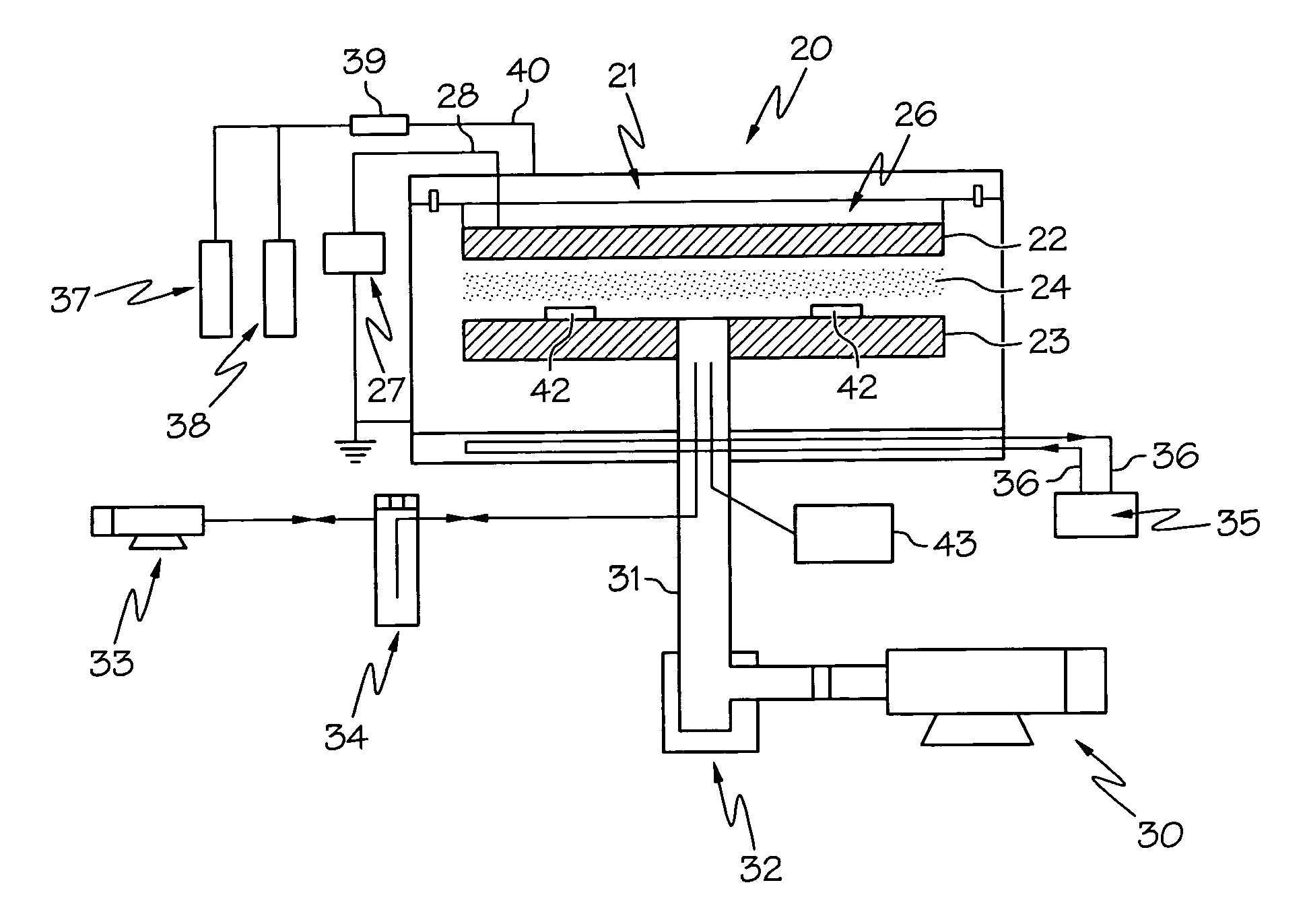

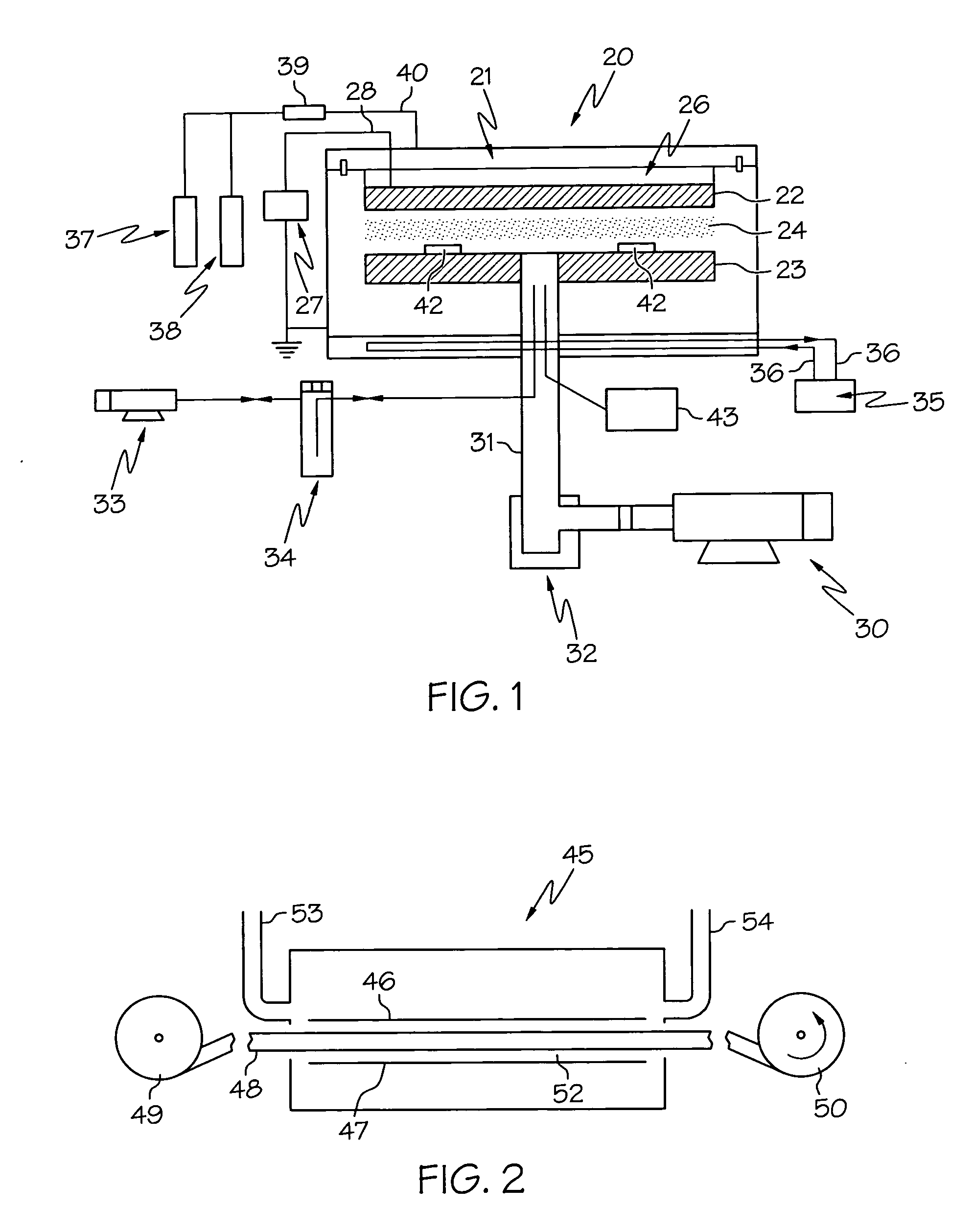

Medical devices coated with diamond-like carbon

InactiveUS20060079863A1Reduce slide resistanceGood durabilitySurgeryChemical vapor deposition coatingHydrocarbonPolymer

A medical device that has a sliding or peeling surface coated with diamond-like carbon (DLC) coating. The coating reduces sliding or peeling resistance. The coated substrates may be polymeric. The coating may be applied from a cold plasma of a hydrocarbon gas such as acetylene. Plasmas may be generated to deposit the coating on interior surfaces, exterior surfaces, or both.

Owner:BOSTON SCI SCIMED INC

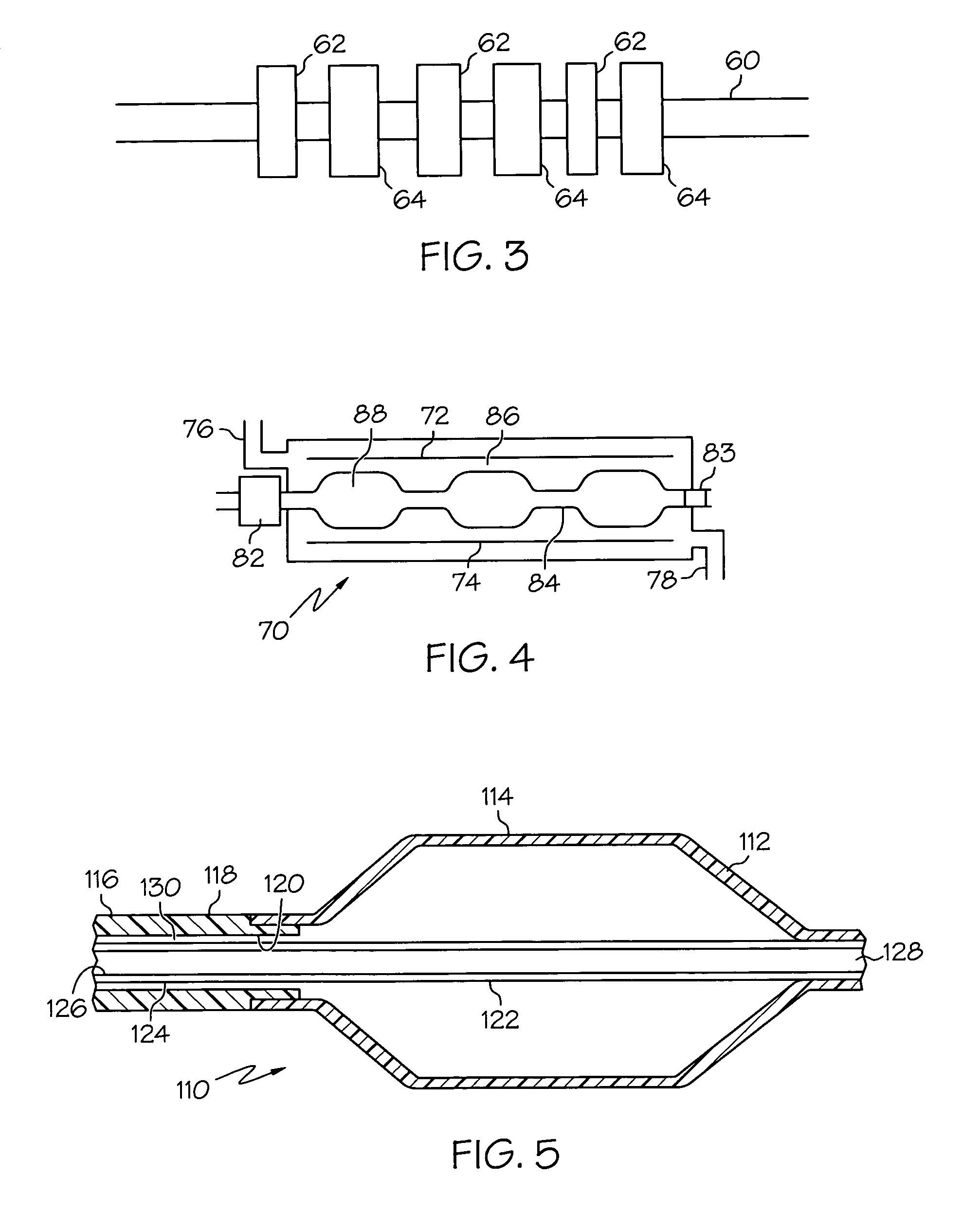

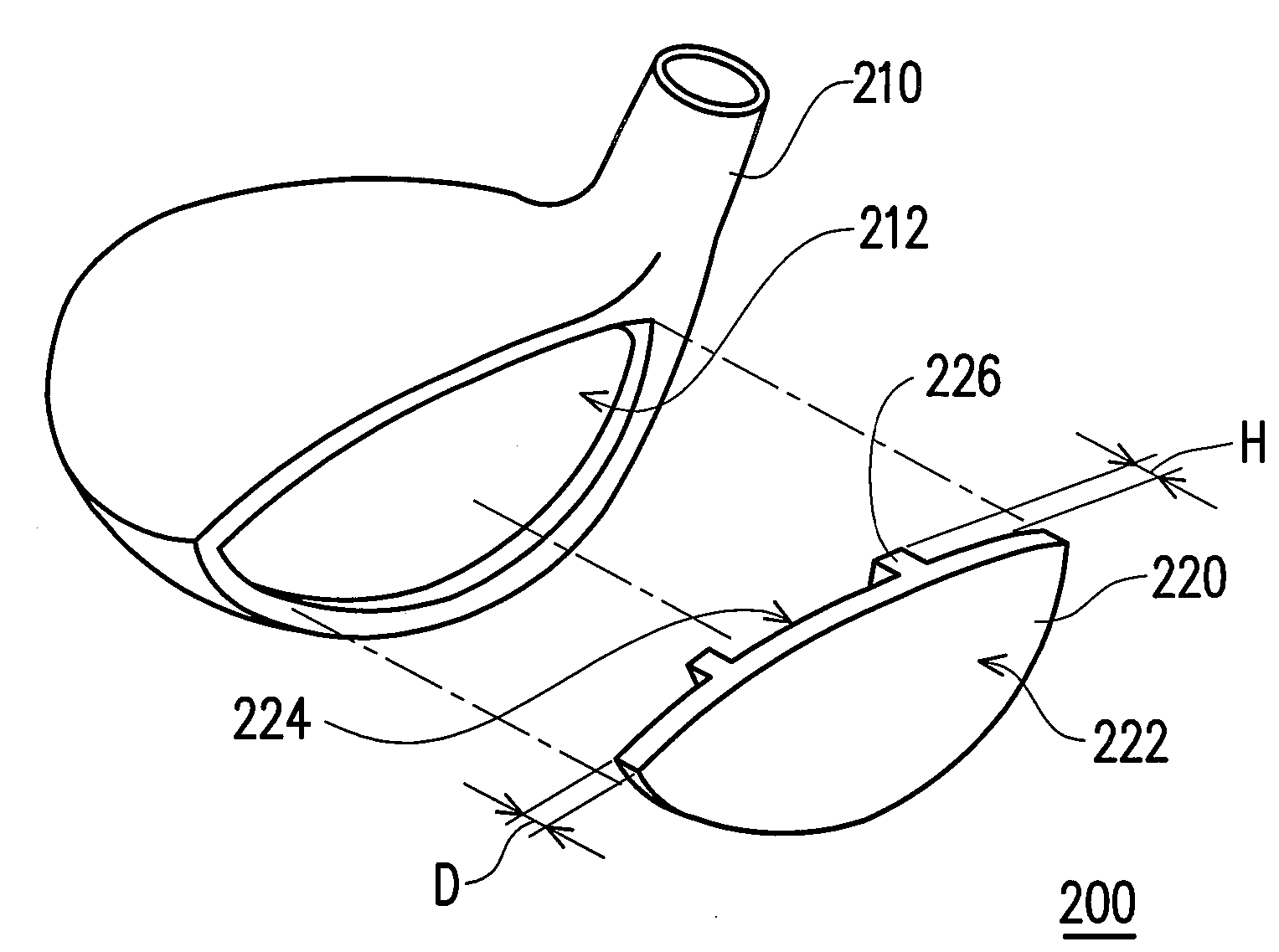

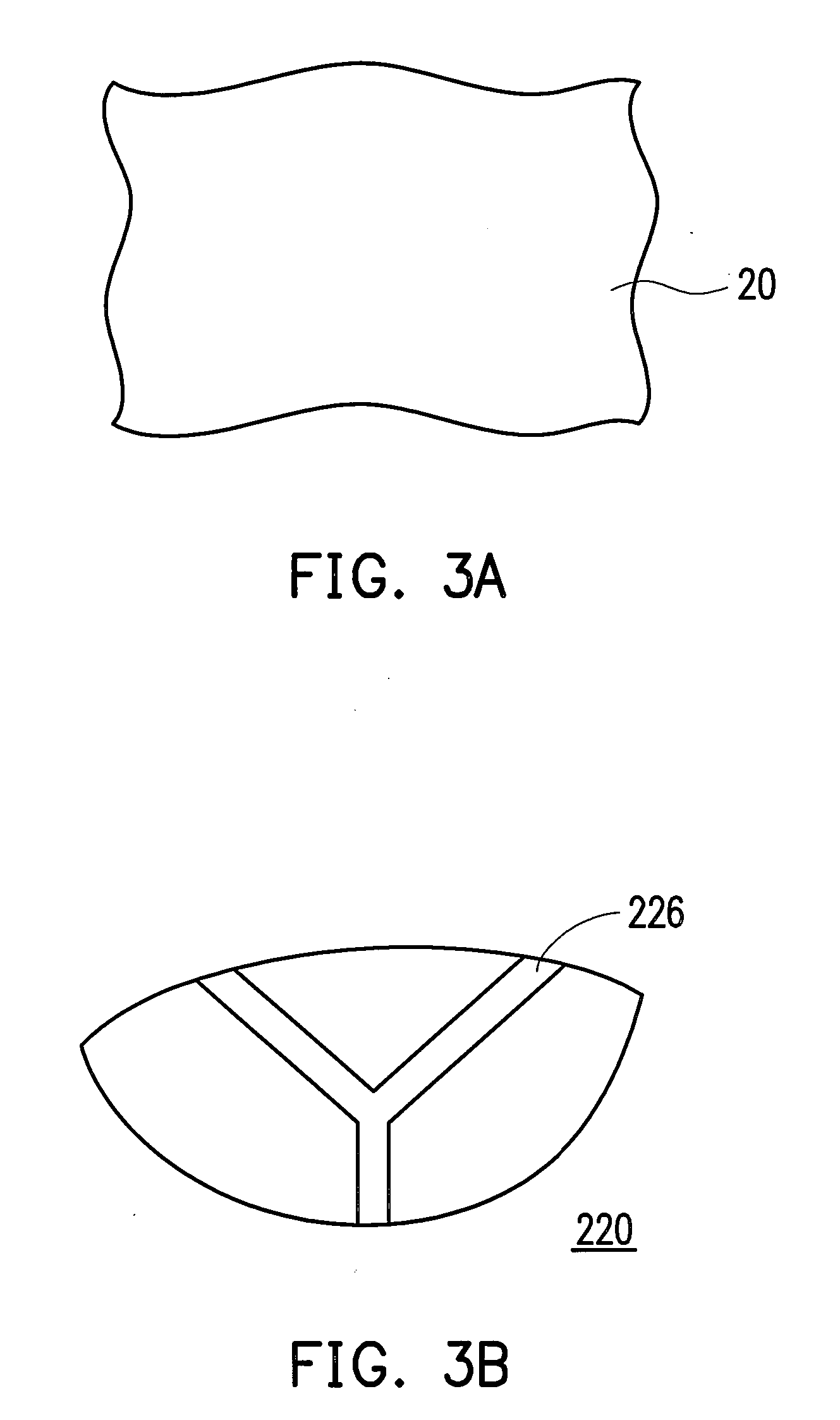

Golf club head

A golf club head including a body and a striking plate is provided. The body has an opening. The striking plate is disposed at the opening. The striking plate integrally formed has a striking surface exposed to the outside, a non-striking surface opposite to the striking surface, and multiple ribs spread on the non-striking surface. The thickness of the striking plate is between 1.5-4 mm. The thickness of each rib is between 0.1-3.5 mm. The ribs intersect in the region of which the center of a circle is the geometric center of the non-striking surface and of which the diameter is 20 mm.

Owner:FUSHENG IND CO LTD

Process for preparing water soluble epoxy resin grouting agent

The invention relates to a process for preparing water soluble epoxy resin grouting agent which consists of, introducing carboxyl radicals onto the molecular matrix of the epoxy resin, preparing water-based epoxy resin by neutralizing with neutralization agent, introducing double bonds to both ends of the molecular chain, employing water-soluble redox initiation system to produce water non-soluble gel through radical polymerization reaction. The invention can be applied to realize epoxide aquosity.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Cleaning blade, and image forming apparatus and process cartridge using the same

ActiveUS20110135361A1Good durabilityExcellent cleaning capabilityElectrography/magnetographyEngineeringImaging equipment

Owner:RICOH KK

Two-component macromolecular high elastic waterproof paint

InactiveCN104164143AGood durabilityTough and high strength coatingEpoxy resin coatingsPolyester coatingsWeather resistanceEmulsion

The invention discloses a two-component macromolecular high elastic waterproof paint, which is composed of the following components by weight: 20-30 parts of a high elastic acrylic emulsion, 25-35 parts of synthetic resin, 10-15 parts of aluminum sulfate salt cement, 12-18 parts of Portland cement, 5-10 parts of quartz powder, 8-13 parts of heavy calcium carbonate powder, 0.8-1.5 parts of a defoaming agent, 0.2-0.8 part of a dispersant, 0.3-0.6 part of dibutyl phthalate, 0.5-1.0 part of a thickening agent, and 0.4-1.0 part of a water reducing agent. The two-component waterproof paint formed by compounding of organic liquid and inorganic powder has the high elasticity of organic paint, and also has good durability and other advantages of inorganic materials. And the obtained coating is tough, and has high strength, good water resistance, weather resistance, and excellent durability.

Owner:扬州豪扬新型建筑材料有限公司

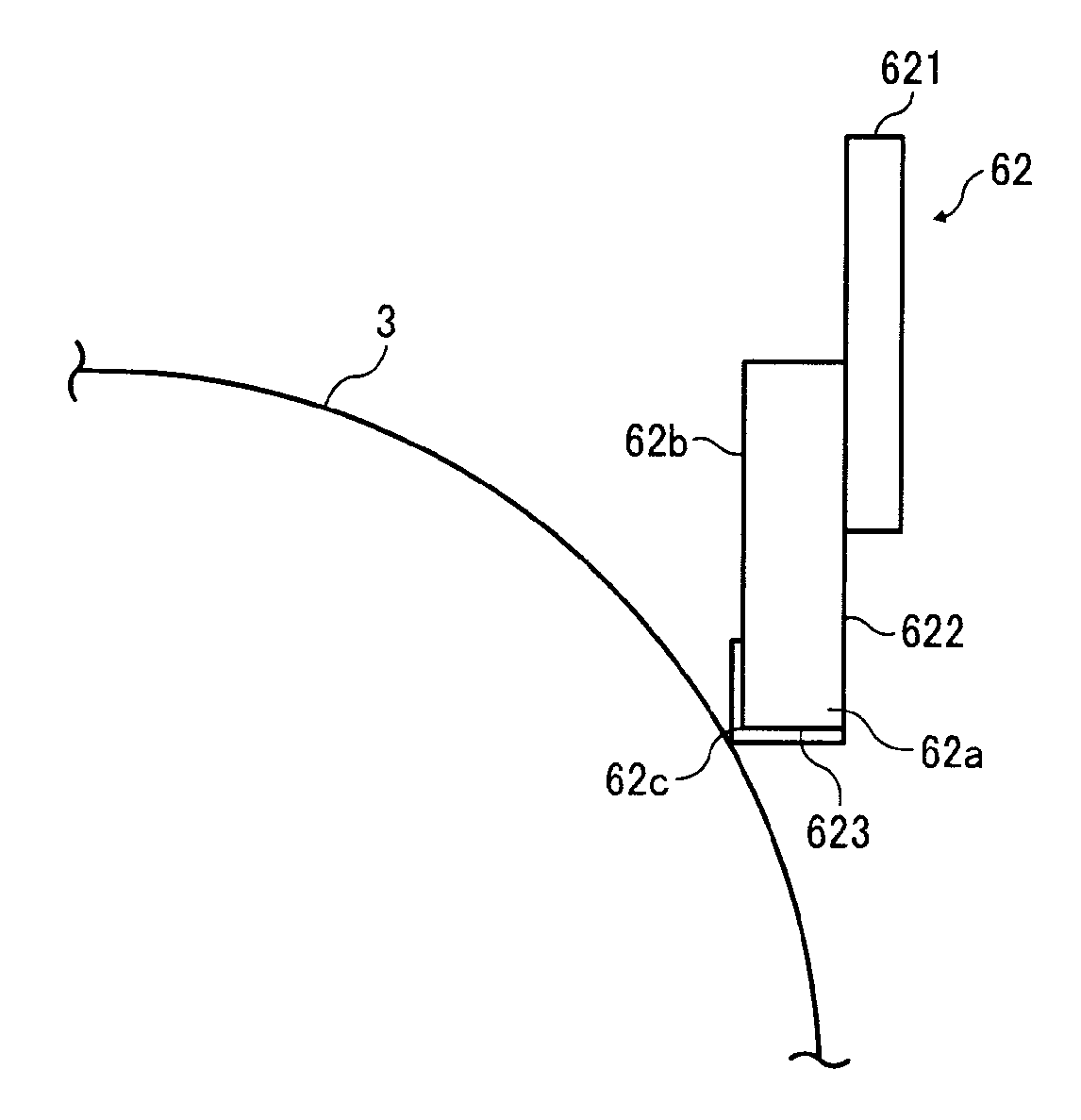

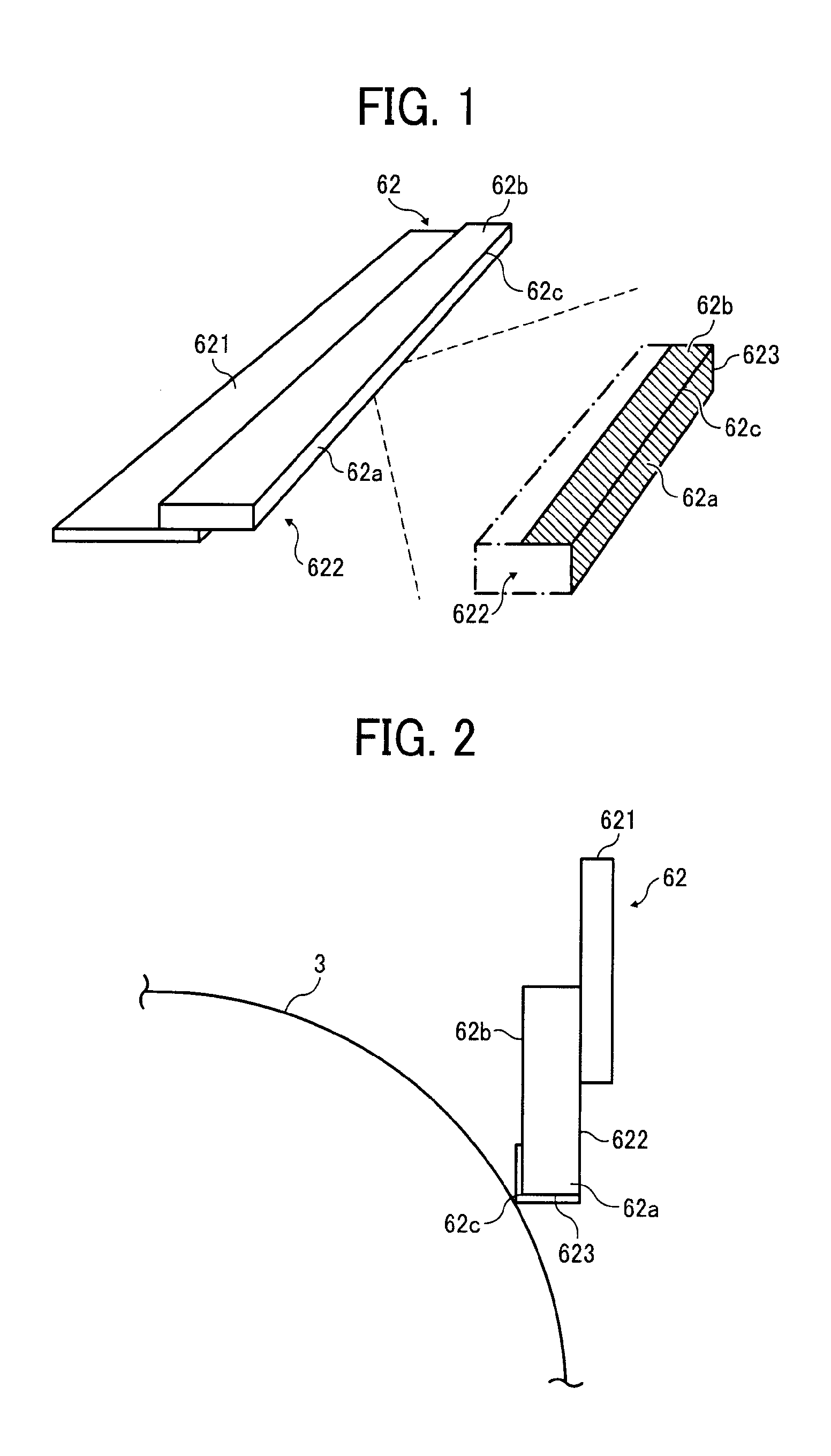

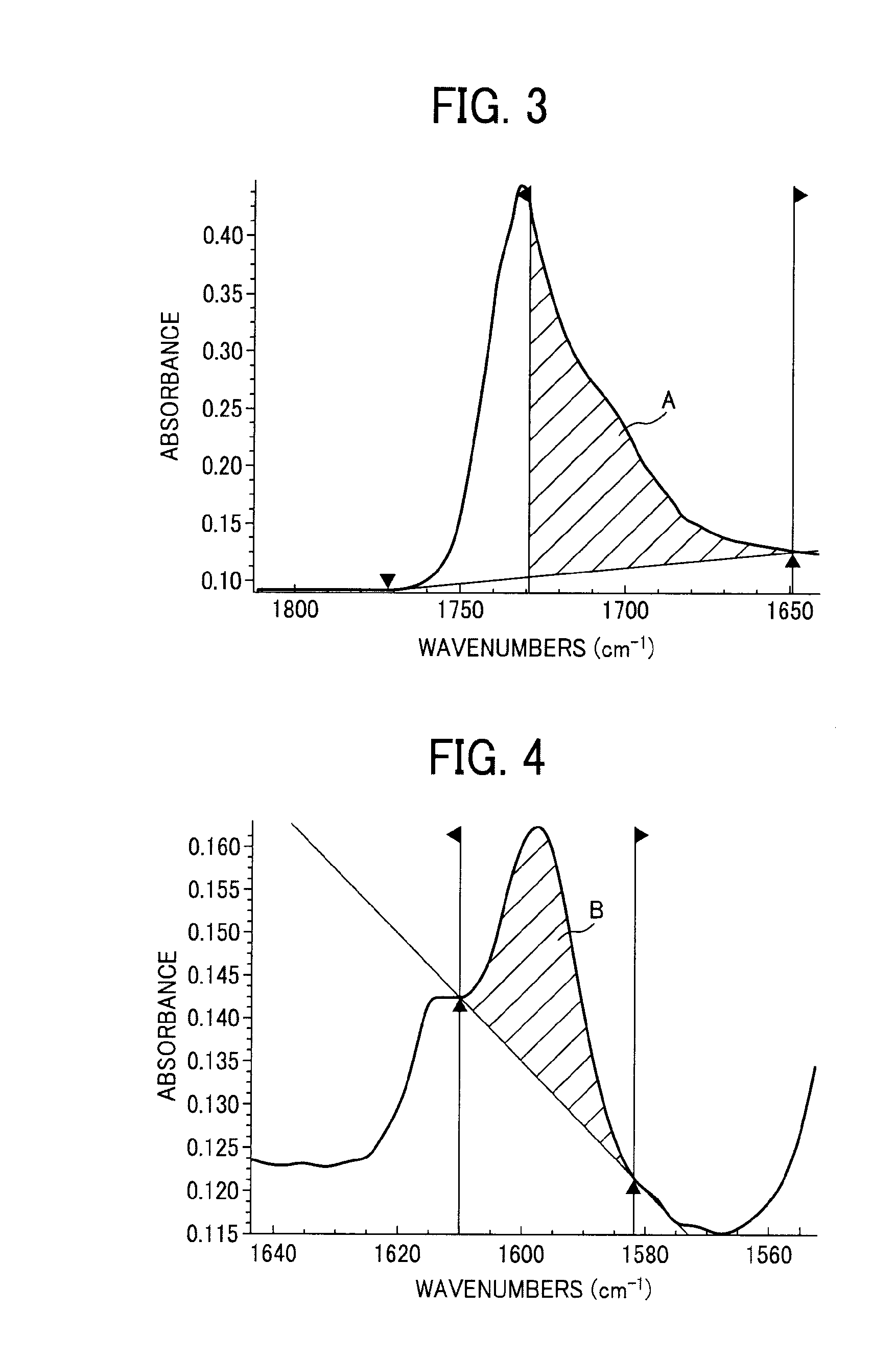

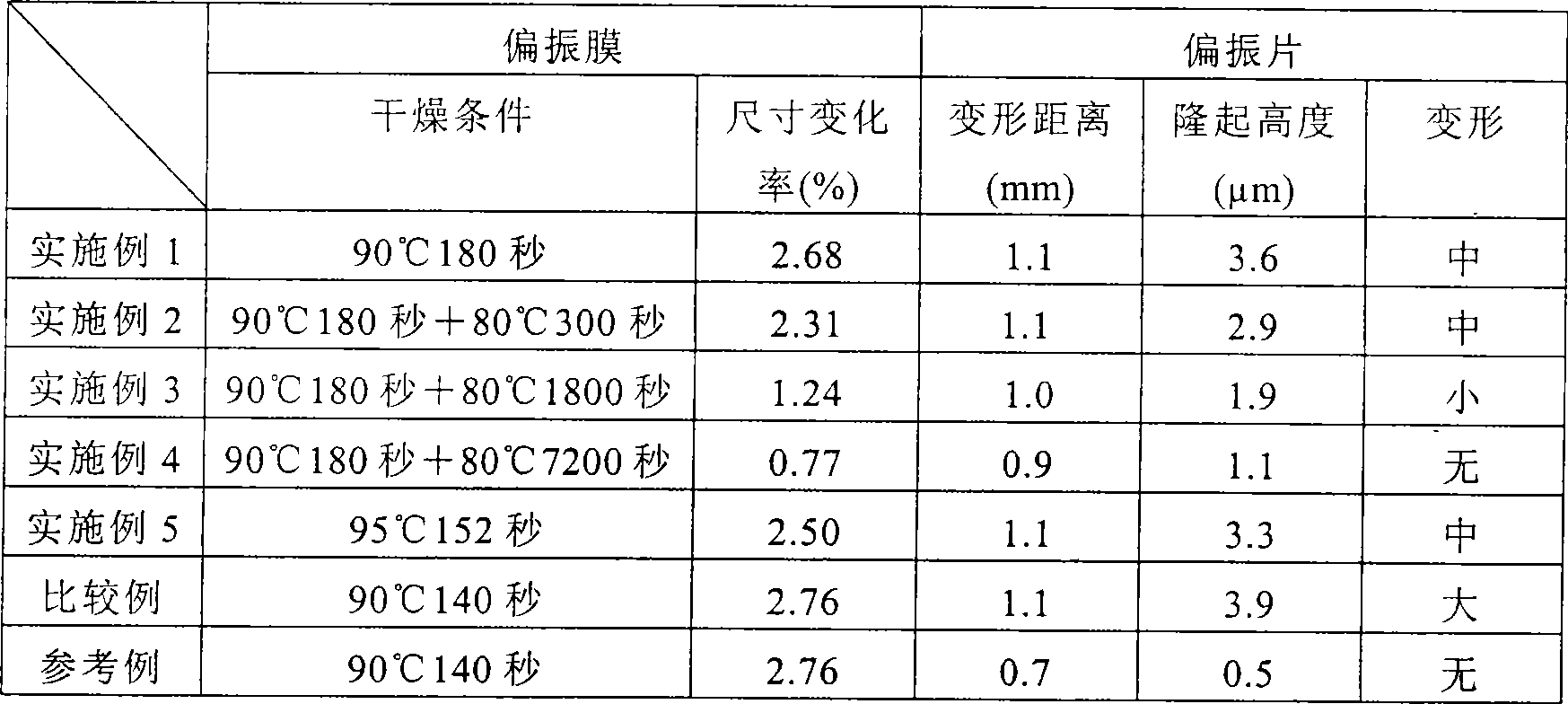

Method for preparing polaroid

InactiveCN101424766AThinningGood durabilitySynthetic resin layered productsPolarising elementsPolarizerCellulose acetate

The present invention provides a method for manufacturing a polarizing disc, wherein, a transparent protective film is laminated on only one surface of polarizing film which is formed by polyvinyl alcohol resin and has a dimension changing rate lower than 2.7through an adhesive layer. The transparent protective film is preferably cellulose acetate resin in the method for manufacturing a polarizing disc. Additionally, preferably the other surface of polarizing film is formed with an additive layer that is formed by acrylic resin.

Owner:SUMITOMO CHEM CO LTD

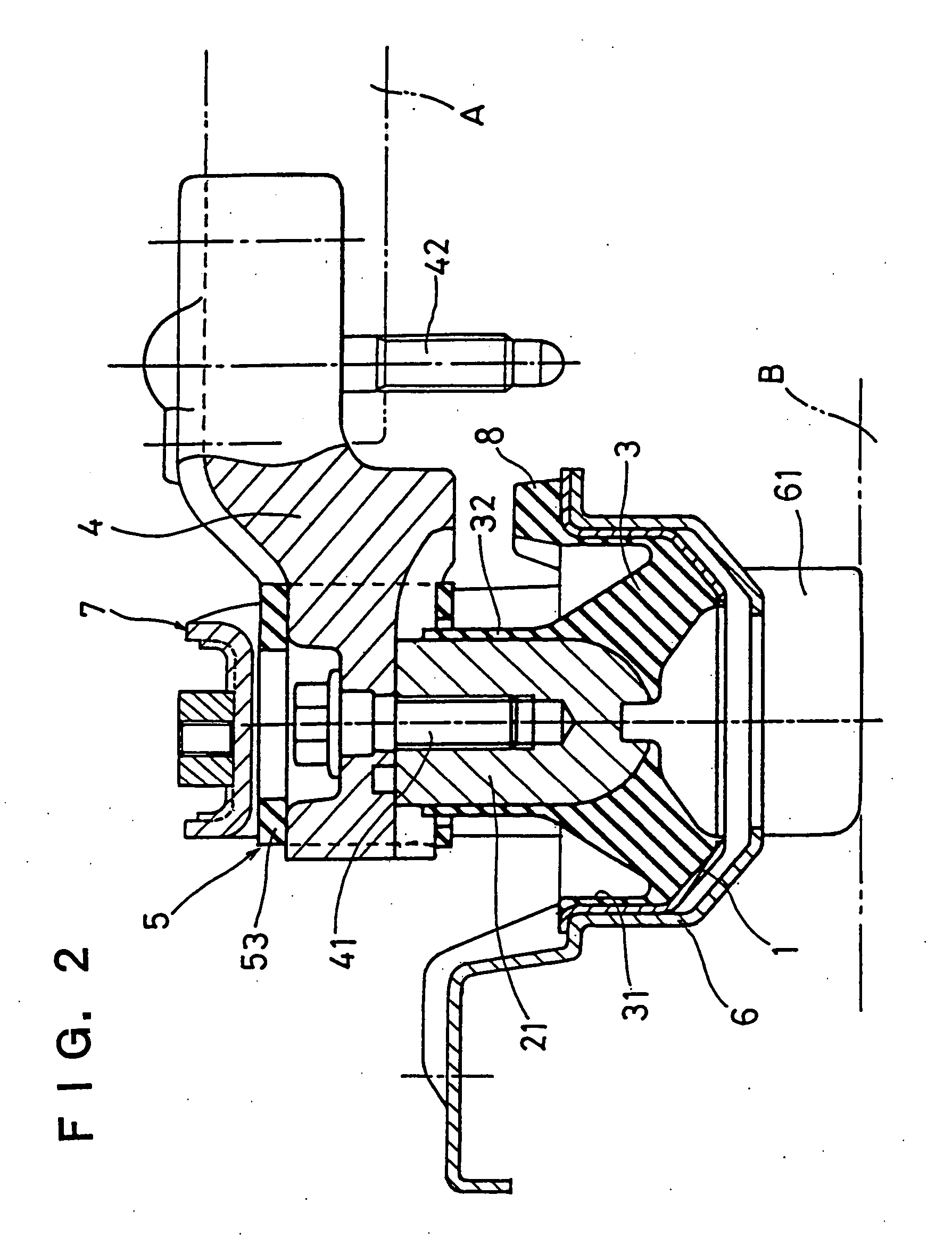

In-wheel motor drive device

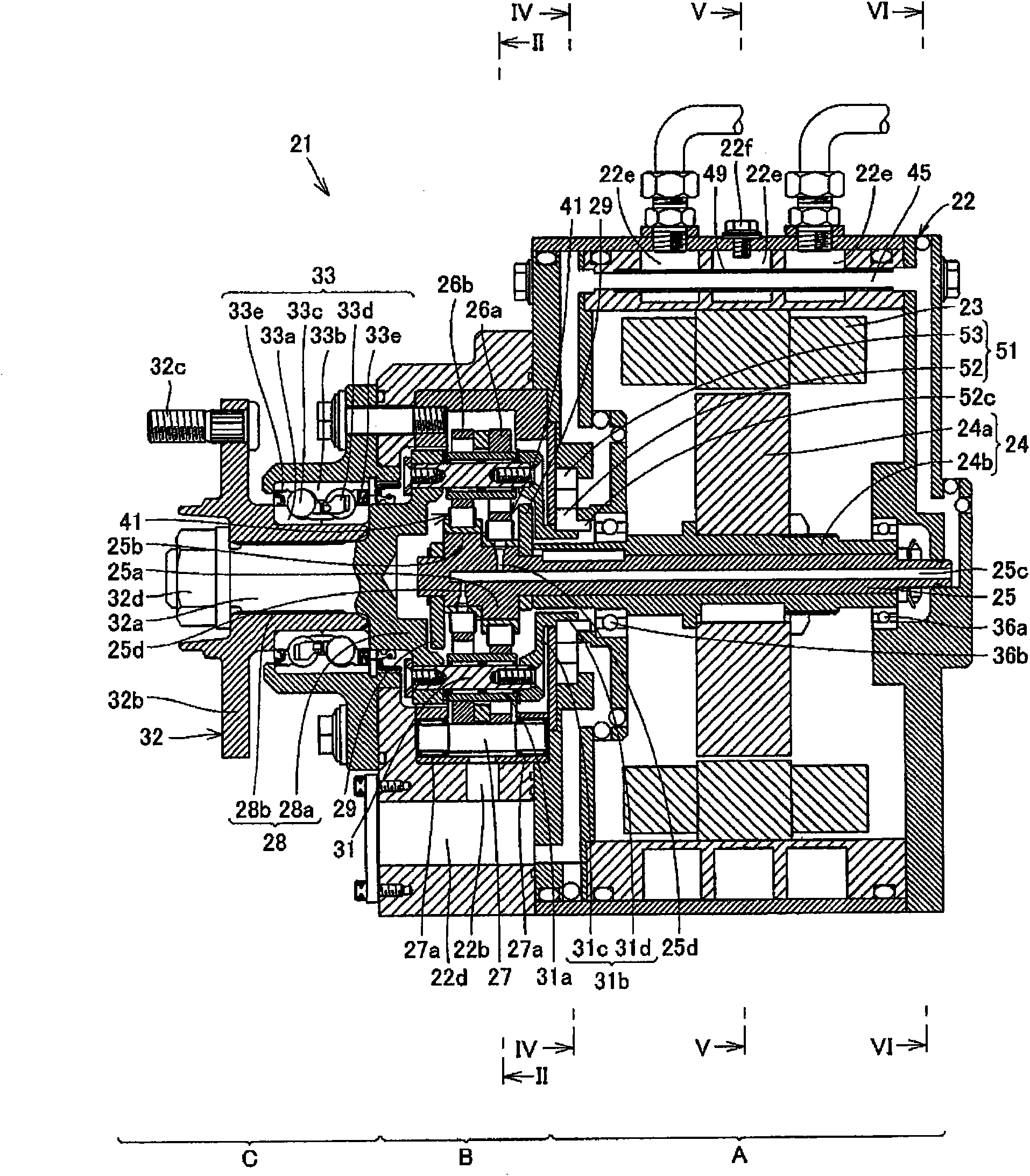

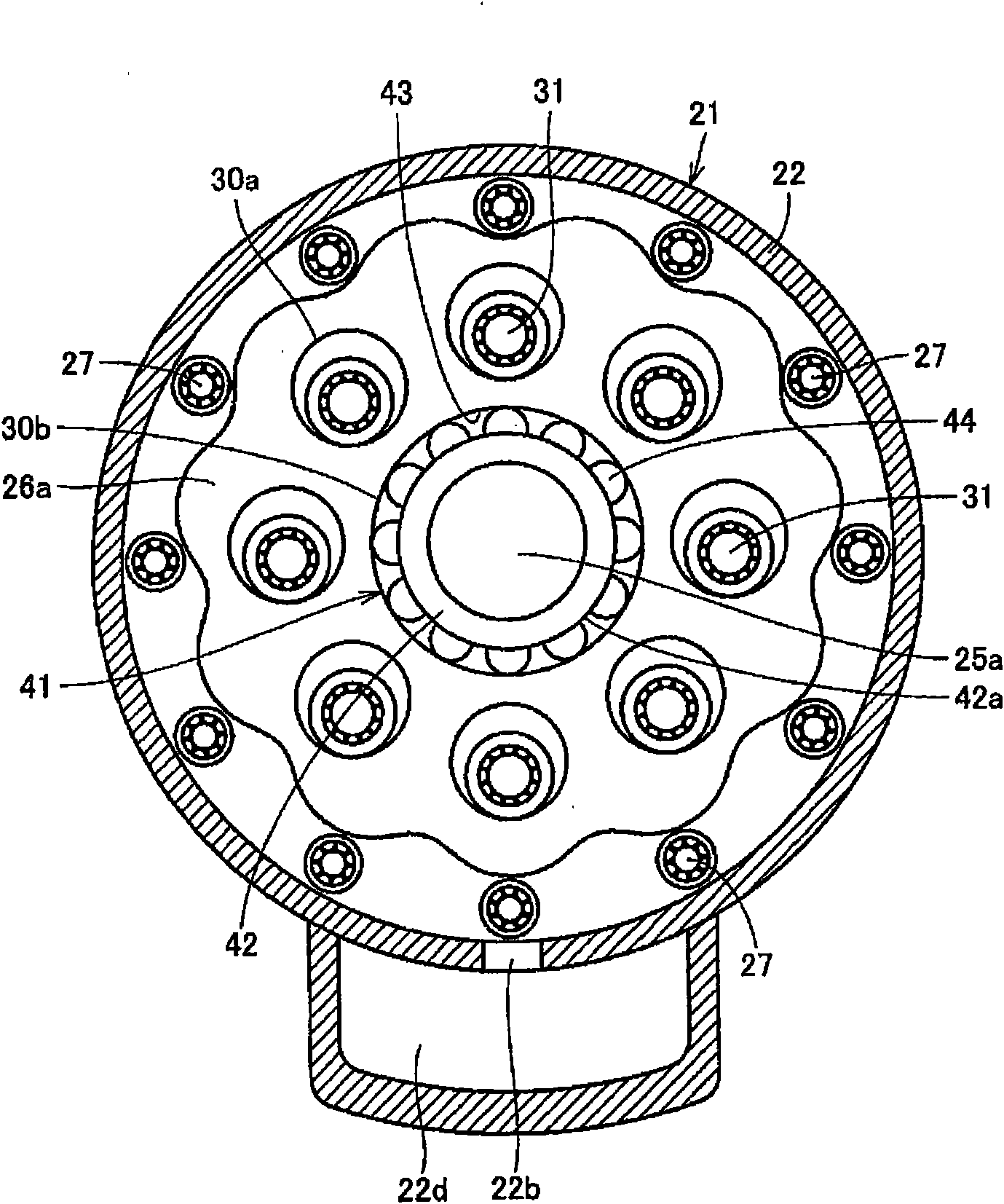

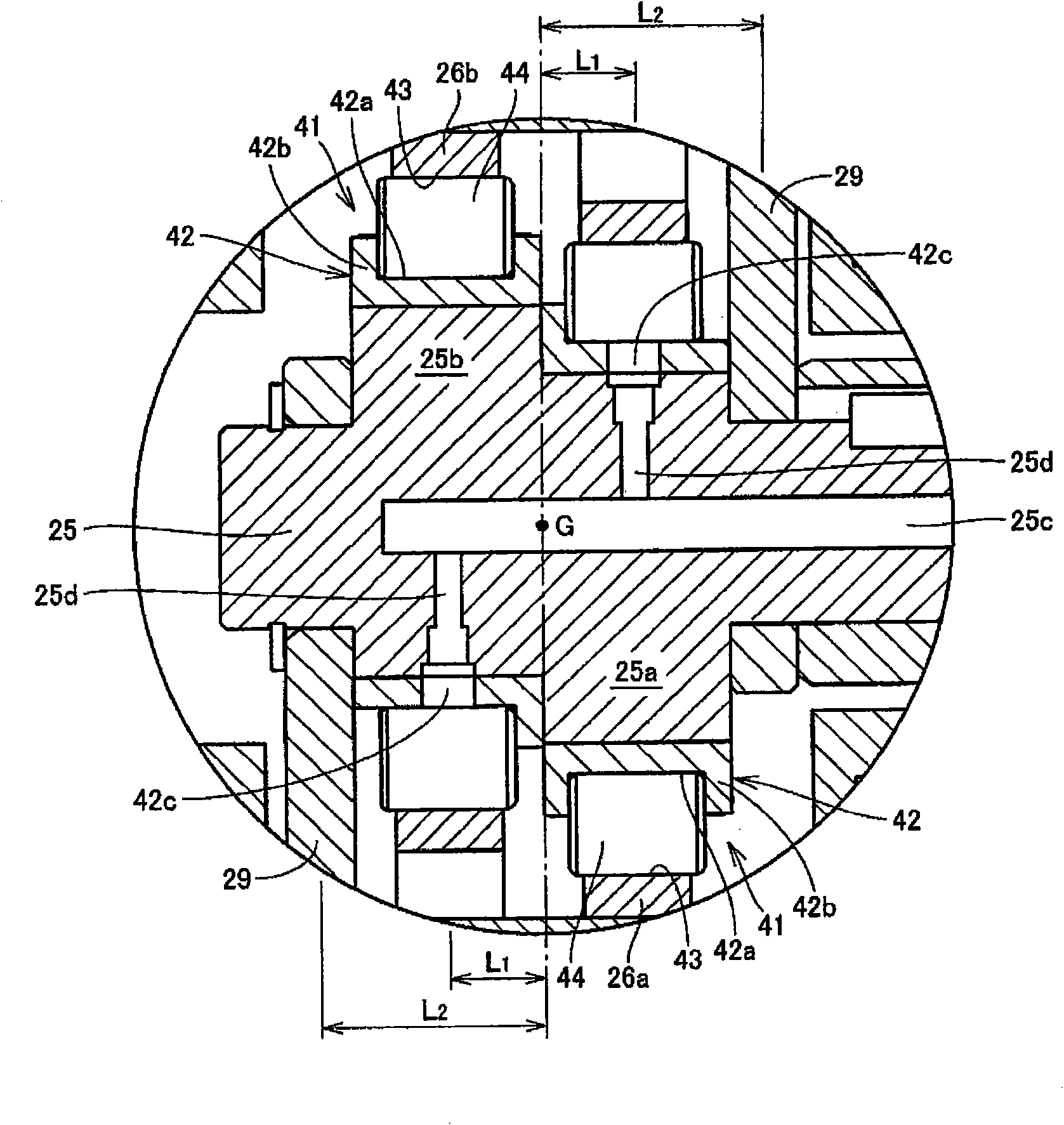

InactiveCN101965467AInhibit temperature riseGood durabilityGearboxesGear lubrication/coolingOil supplyElectric motor

An in-wheel motor drive device (21) has a motor section (A), a reduction section (B), a wheel hub (C), and a reduction section lubricating mechanism for supplying lubricating oil to the reduction section. The reduction section lubricating mechanism has a lubricating oil path (25c), a lubricating oil supplying opening (25d), a lubricating oil discharging opening (22b), a circulating oil path (45) passing through the inside of a casing (22) to interconnect the lubricating oil discharging opening (22b) and the lubricating oil path (25c) and circulating lubricating oil, which is discharged from the lubricating oil discharging opening (22b), to the lubricating oil path (25c), a cooling water path (22e) provided at that position in the casing (22) which is in contact with the circulating oil path (45) and cooling lubricating oil passing through the circulating oil path (45), and a partitioning member (49) mounted at a position at which the circulating oil path (45) and the cooling water path (22e) are in contact with each other and separating the paths from each other.

Owner:NTN CORP +1

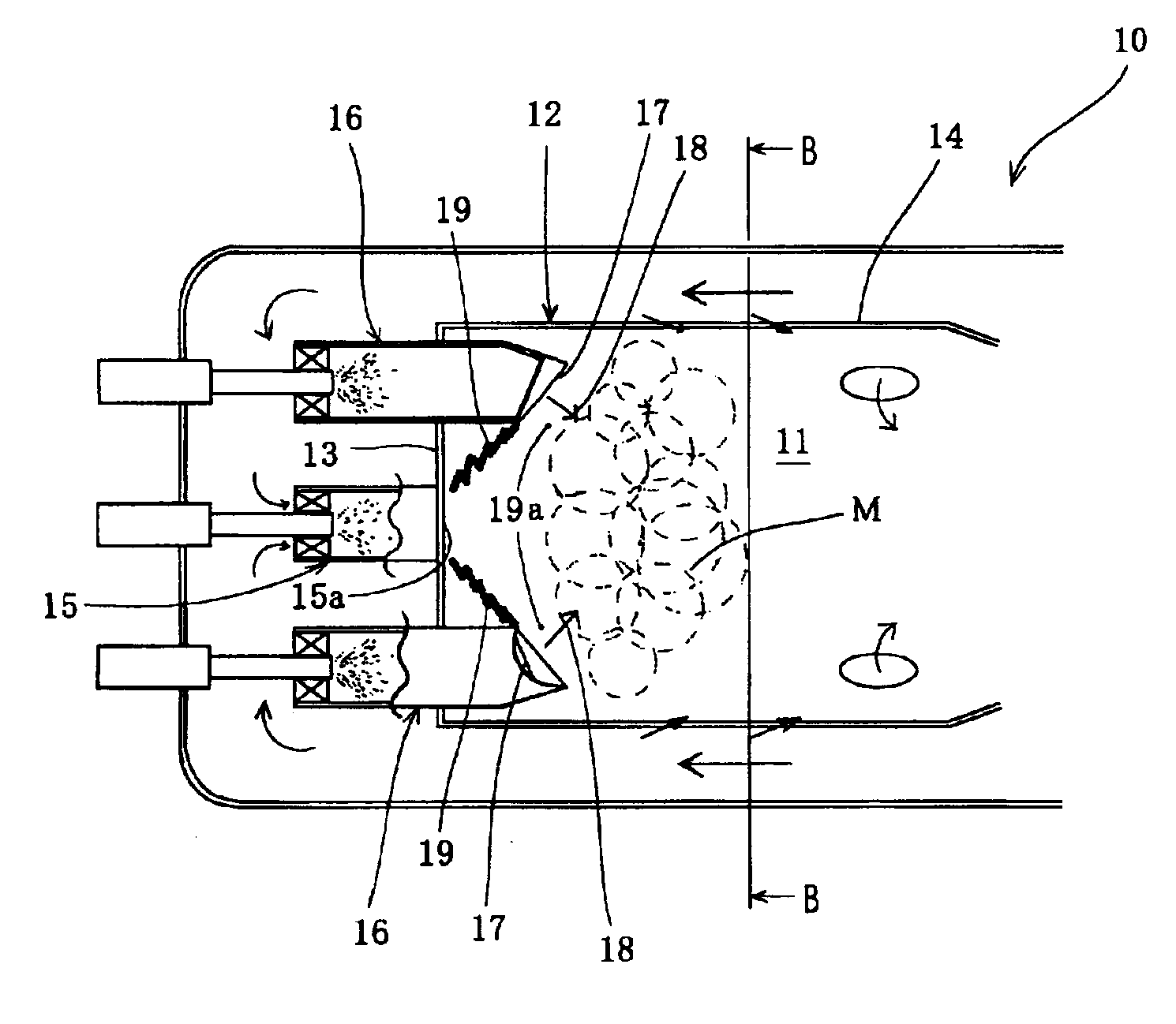

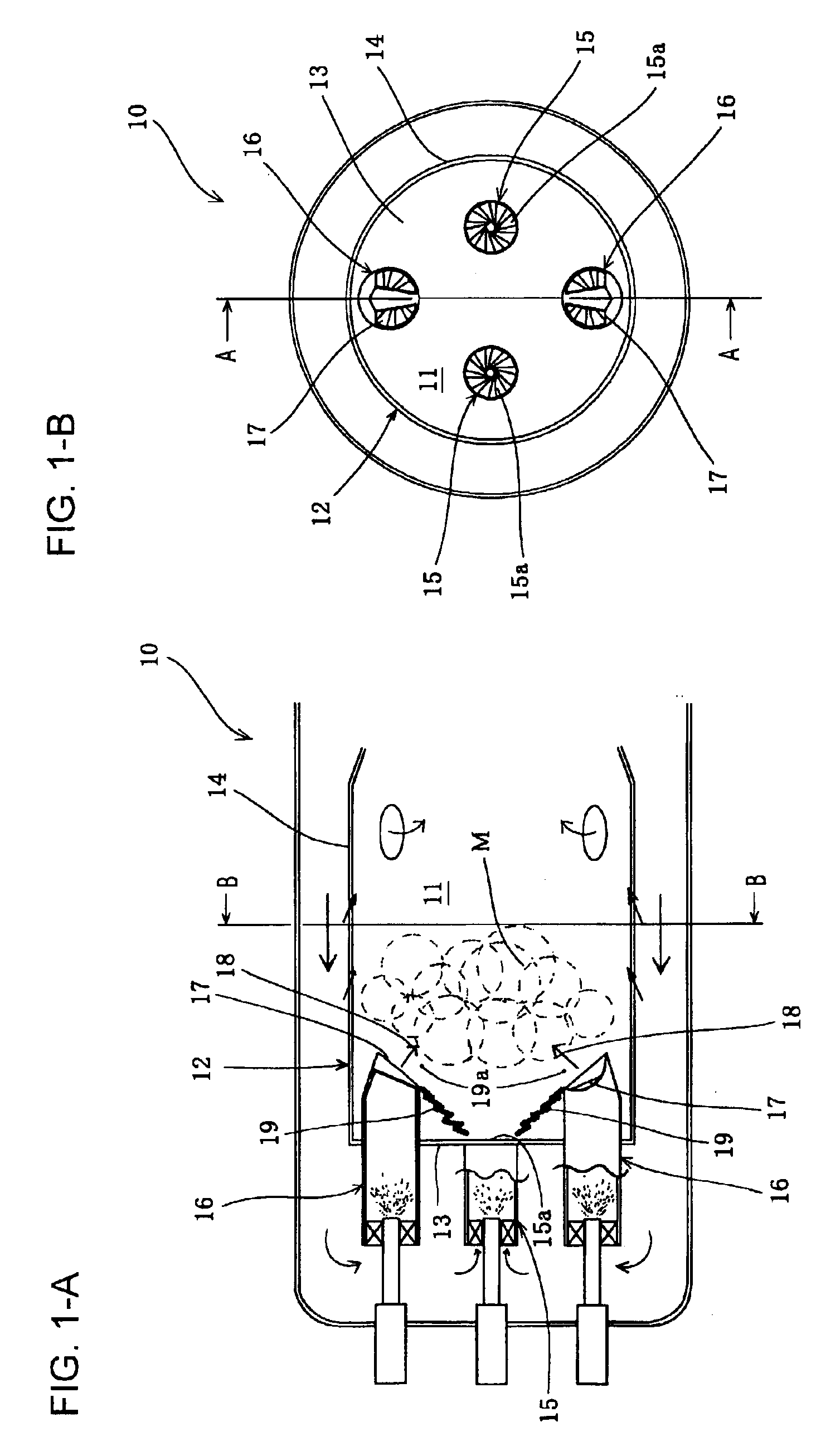

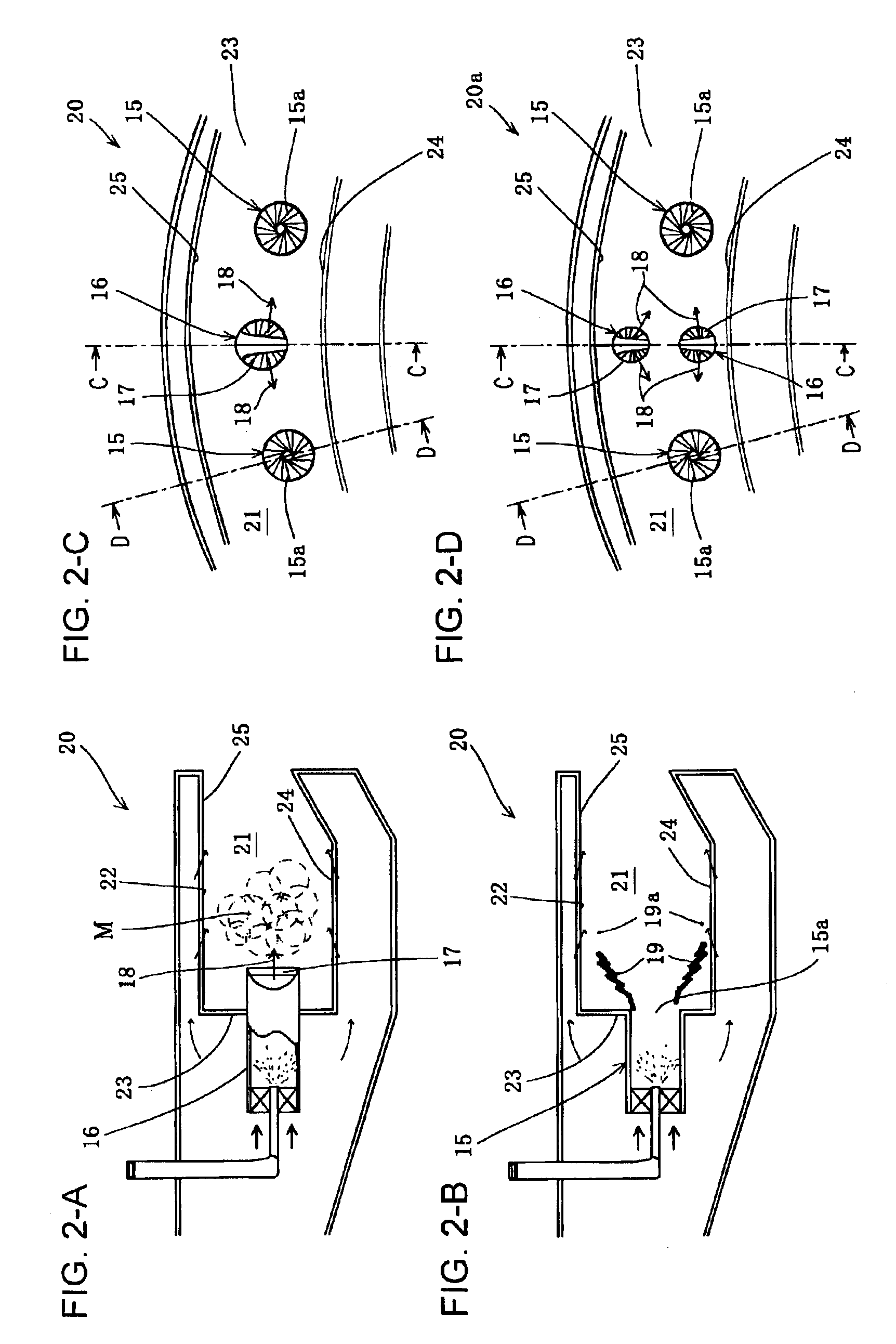

Gas turbine combustor

InactiveUS6889495B2Good durabilityReduce effectBurner safety arrangementsContinuous combustion chamberAutomotive engineeringGas turbines

The present invention provides a gas turbine combustor which makes it possible to achieve both a high combustion efficiency and low NOx emissions characteristics over a wide output power range without using a device that can vary the flow rate of the air used for combustion, by burning a lean mixture using high-temperature burned gas. The gas turbine combustor 10 comprises pre-mixture injection tubes 16 which conduct a mixture of fuel and air into a combustion chamber 11. The mixture from the pre-mixture injection tubes 16 is injected toward burned gas 19a present on the downstream side of the flame 19, which is injected from burners 15 that open into the combustion chamber 11, and this mixture is mixed with the burned gas 19a. Even in a mixture which is leaner than the lower limit of inflammability, the radicals in the burned gas 19a are effective in initiating reactions, so that the combustion of the mixture can be started. Since the burned gas has a lower oxygen concentration than fresh mixture, and since the pre-mixture is dispersed in space, the generation of NOx can be suppressed.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

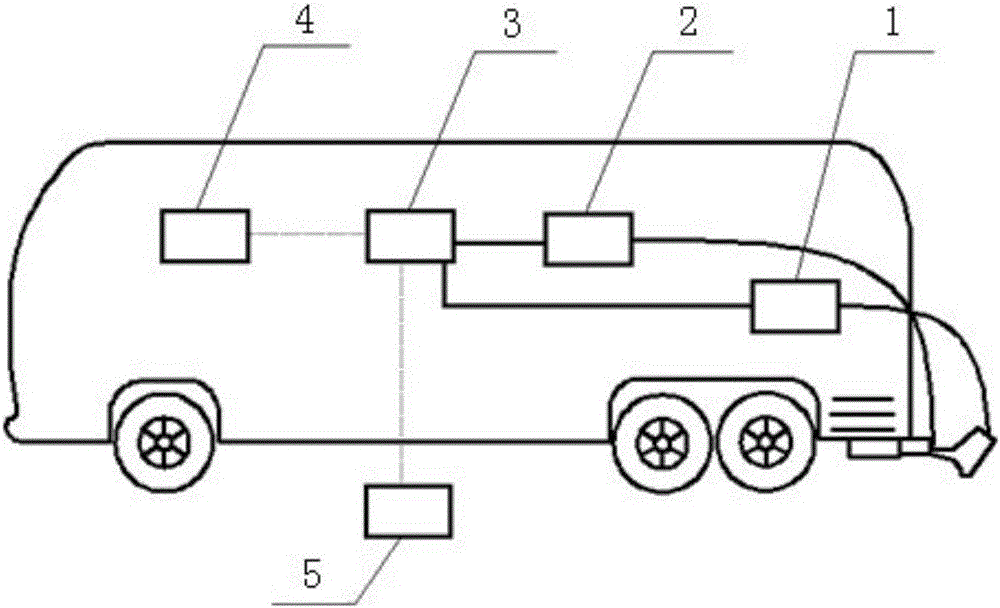

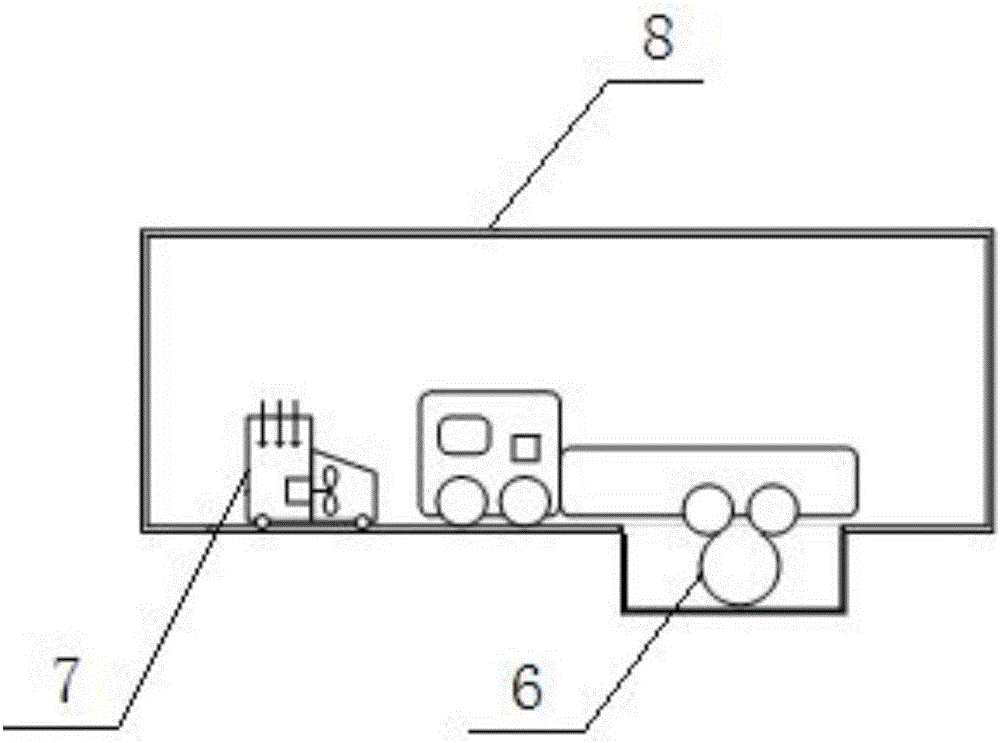

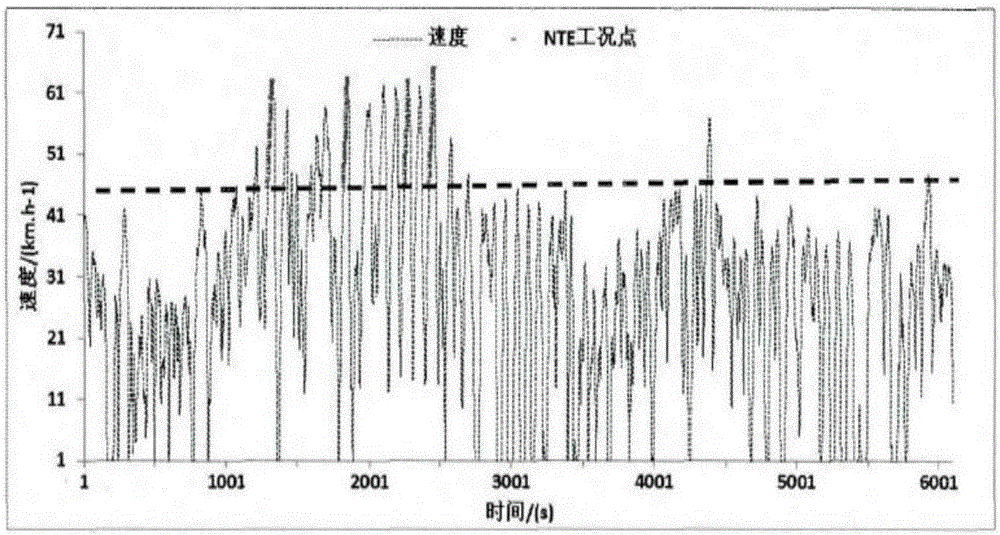

Vehicle-mounted emission testing device and testing method thereof

InactiveCN105806627AGood durabilityStrong expandabilityVehicle testingRelevant informationTest sample

The invention discloses a vehicle-mounted emission testing device and a testing method thereof. The vehicle-mounted emission testing device comprises an exhaust mass measurement unit, a pollutant sampling and analyzing unit, a master control unit, a fuel consumption measurement unit and a road load simulation loading device which are arranged on a tested sample vehicle. The exhaust mass measurement unit, the pollutant sampling and analyzing unit, the fuel consumption measurement unit and the road load simulation loading device are all connected with the master control unit. Compared with existing devices and methods in the industry, the vehicle-mounted emission testing device and the testing method can rapidly and efficiently perform vehicle emission testing without depending on relevant information of an electronic control unit of the tested vehicle, and accordingly obtain the emission performance condition of the tested vehicle.

Owner:NANJING AUTOMOBILE GROUP CORP

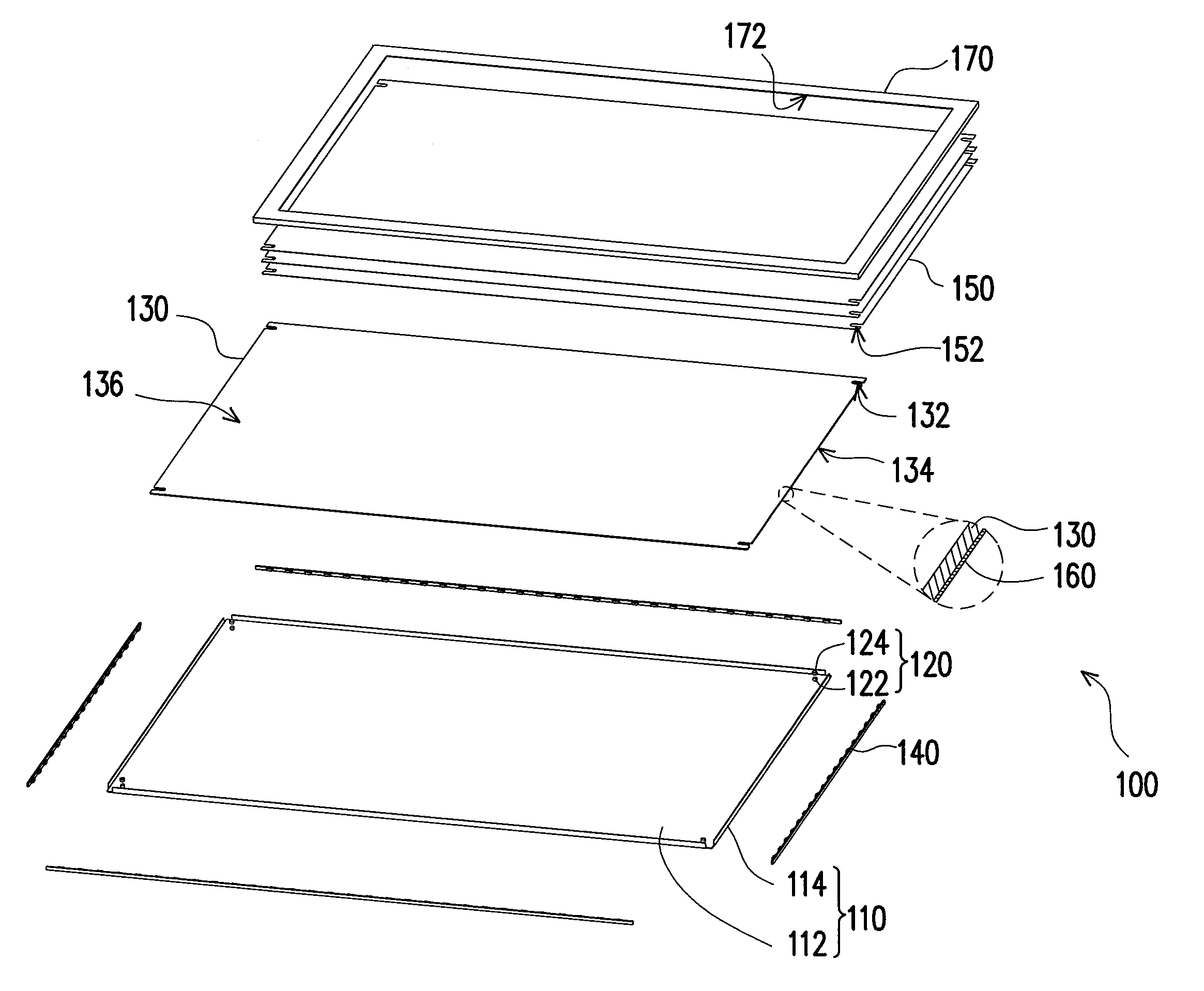

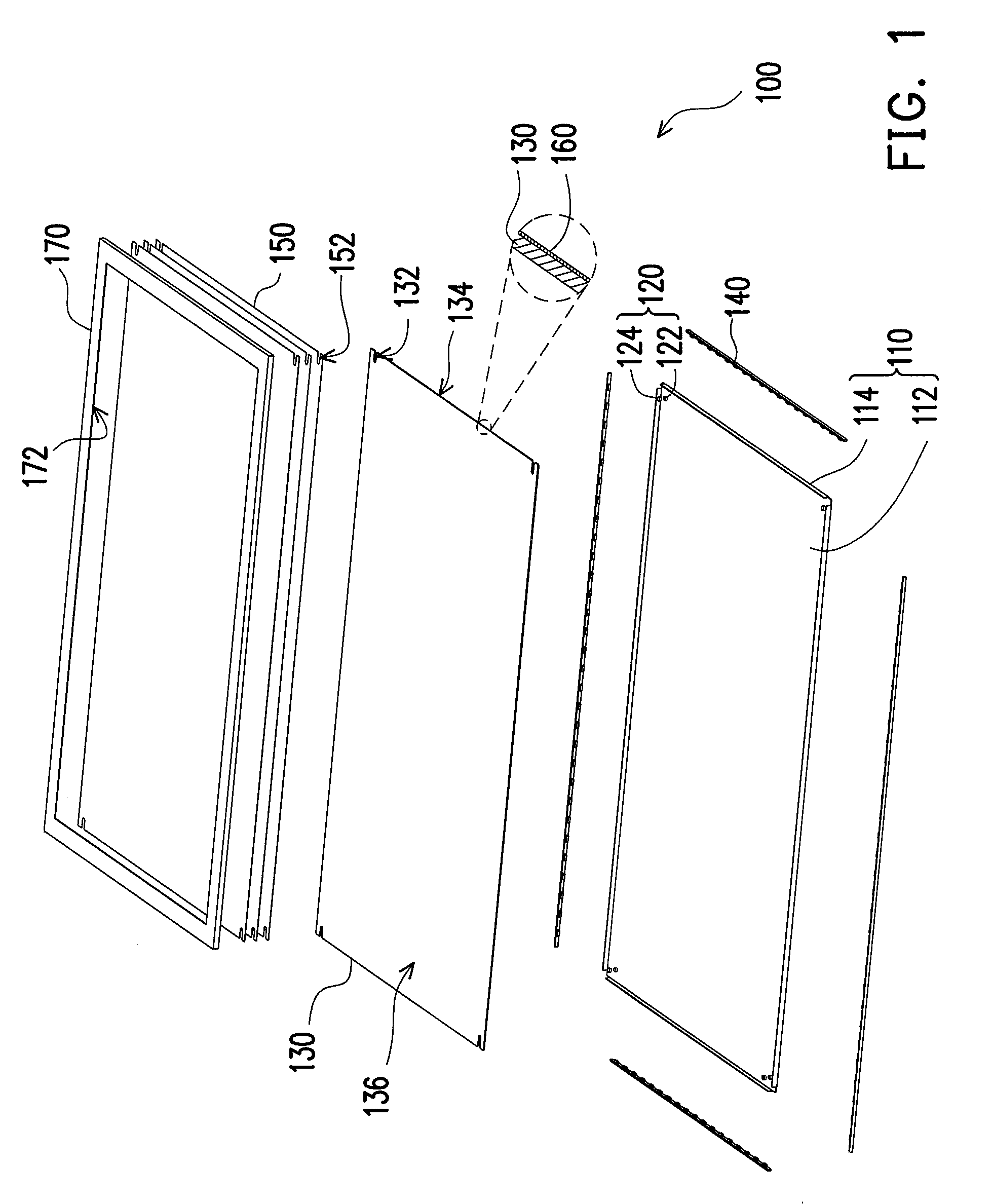

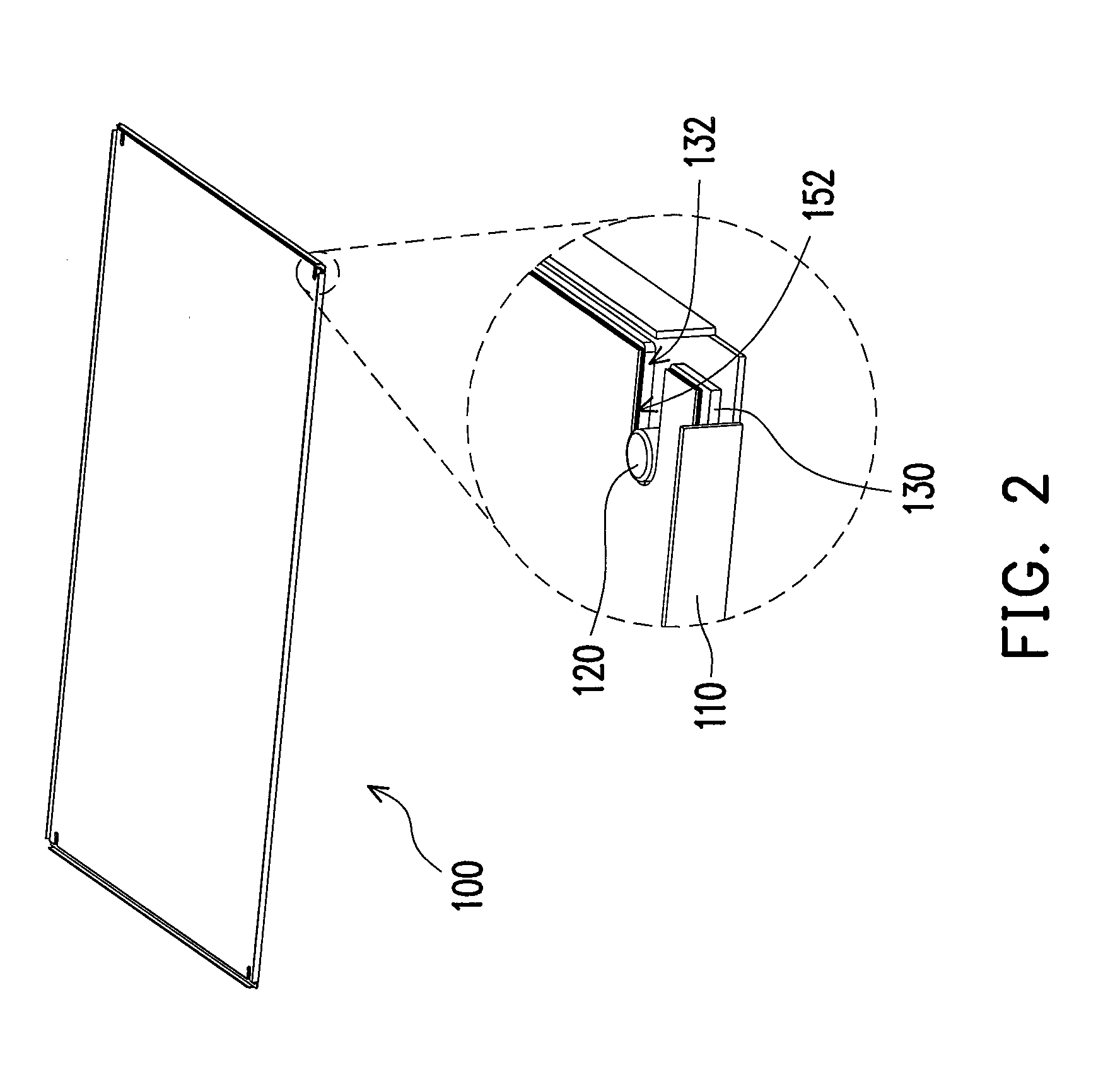

Backlight module

InactiveUS20110069509A1Good durabilityIncreased durabilityOptical light guidesNon-linear opticsBackplaneEngineering

A backlight module includes a back plate, a plurality of position limiting elements, a light guiding plate, and a light source. The position limiting elements are disposed on the back plate, and each of the position limiting elements includes a pillar and a cushion sheath covering the pillar. The light guiding plate is disposed on the back plate, and has a plurality of first position limiting portions. The first position limiting portions respectively contact the position limiting elements to position the light guiding plate on the back plate. The light source is disposed at a side of the light guiding plate.

Owner:YOUNG LIGHTING TECHNOLOGY INC

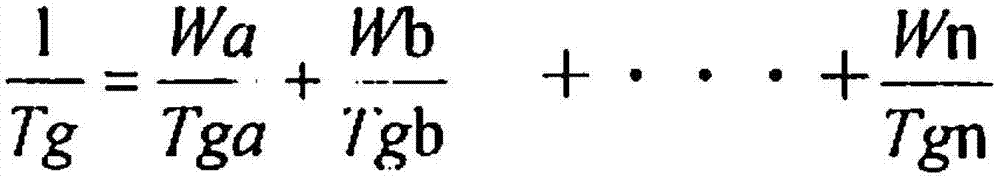

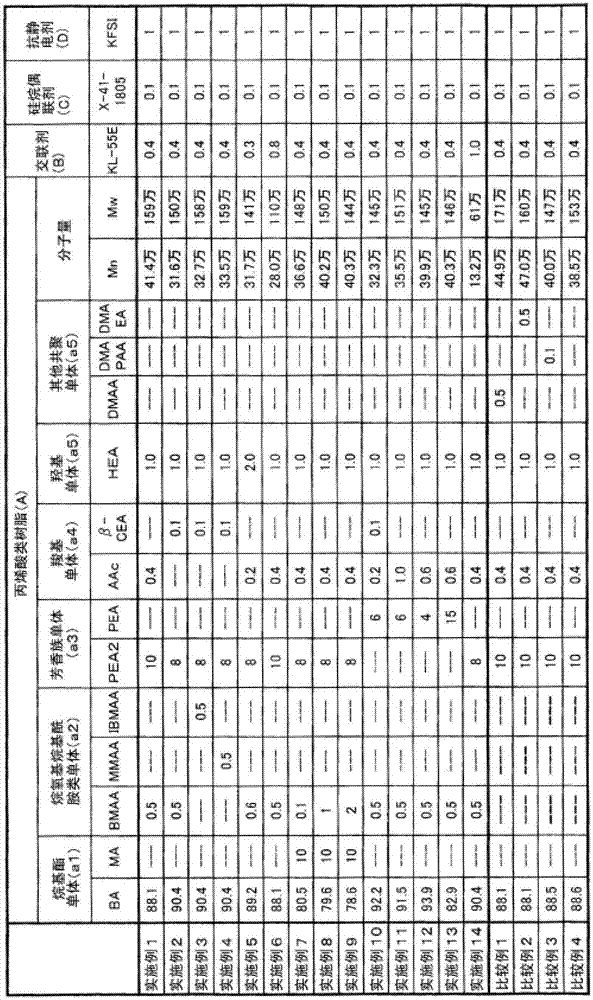

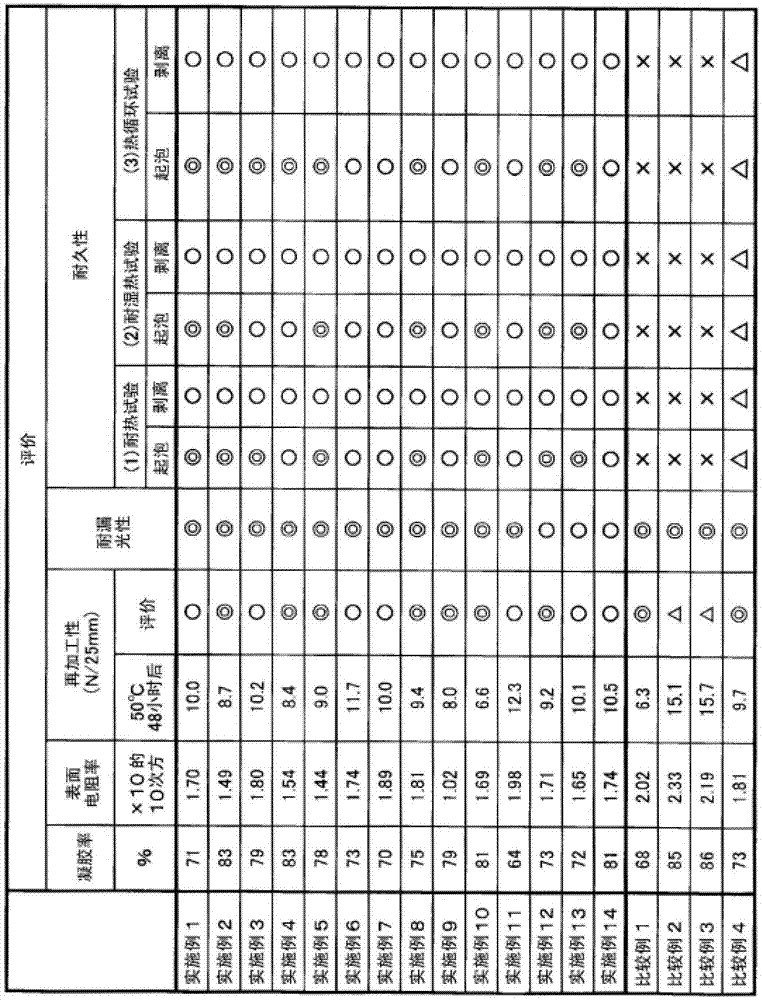

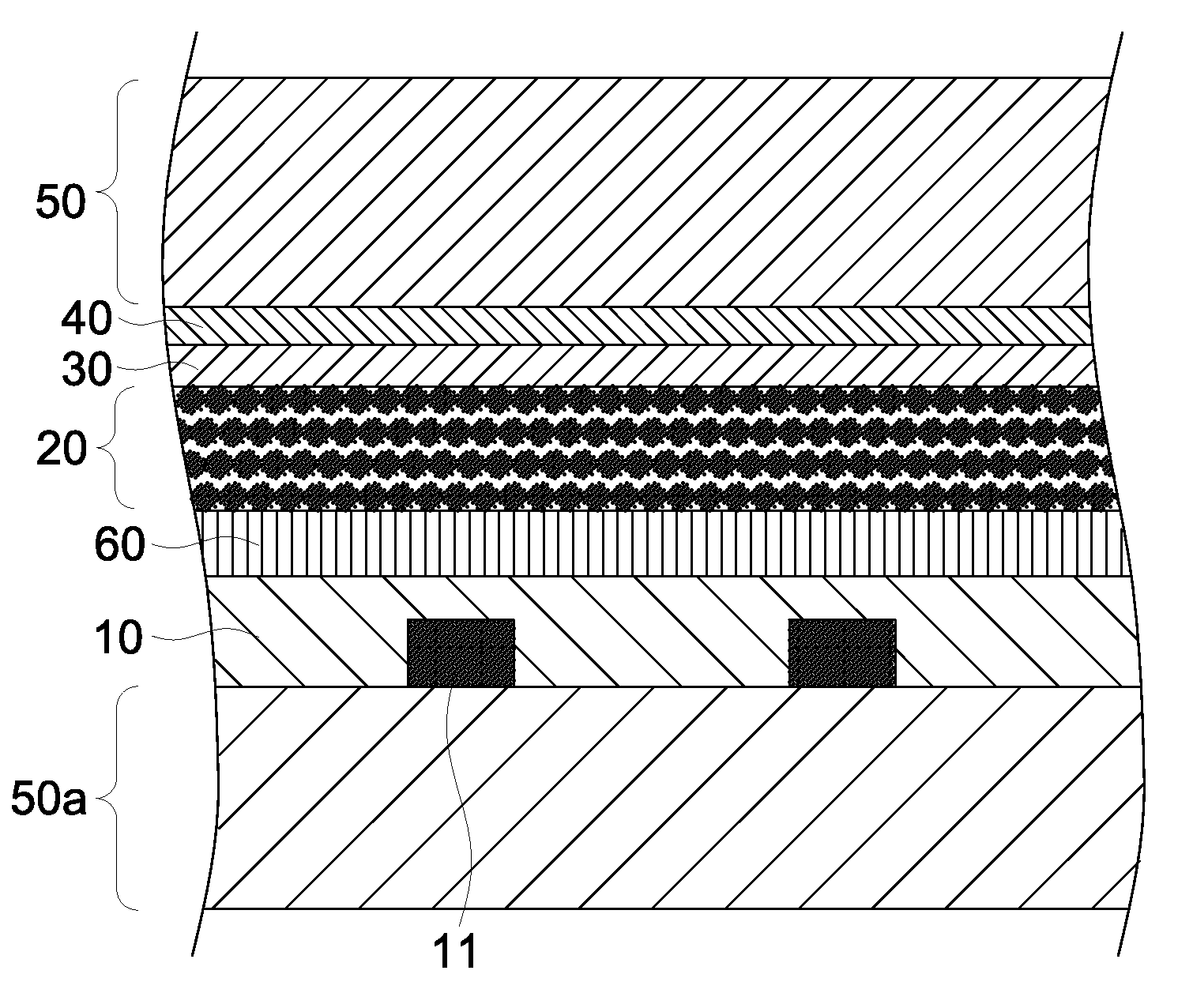

Adhesive composition for optical components, adhesive for optical components, optical component with adhesive layer, and image display device

ActiveCN103168083AExcellent reworkabilityGood durabilityNon-macromolecular adhesive additivesPolarising elementsChemistryLiquid-crystal display

The present invention provides an adhesive composition for optical components that is capable of achieving both reworkability and durability and that is capable of inhibiting unevenness in color and light leakage when applied to image display devices such as liquid crystal display panels. The present invention relates to an adhesive composition for optical components that contains an acrylic resin (A) obtained by copolymerizing a copolymerization component [I] containing, as the principal component thereof, an alkyl (meth)acrylate ester monomer (a1), wherein the adhesive composition is characterized by containing a N-(alkoxyalkyl)(meth)acrylamide monomer (a2) as the copolymerization component [I].

Owner:MITSUBISHI CHEM CORP +1

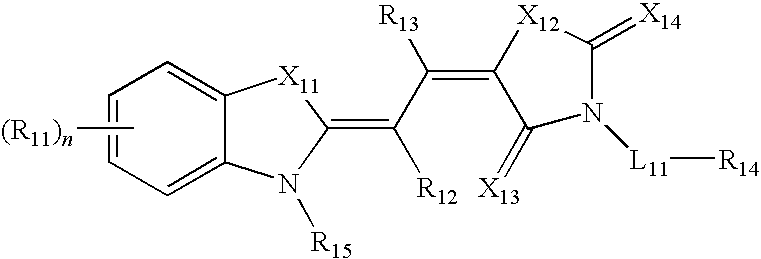

Dye-sensitized solar cell

InactiveUS20100300529A1Good photoelectric conversion efficiencyGood durabilityElectrolytic capacitorsSolid-state devicesOxide semiconductorChemistry

Disclosed is a dye-sensitized solar cell which can simultaneously realize an excellent photoelectric conversion efficiency and excellent durability. The dye-sensitized solar cell is also suitable when a resin film is used as a base material. The dye-sensitized solar cell comprises an electroconductive base material, and a metal oxide semiconductor layer formed of a semiconductor film with a dye adsorbed on the surface thereof, a charge transfer layer, and a counter electrode provided in that order on the electroconductive base material and is characterized in that a metal oxide intermediate layer formed of fine particles of a metal oxide is provided between the electroconductive base material and the metal oxide semiconductor layer and the electroconductive base material comprises a transparent base material, and a metallic current collecting layer formed of metallic fine wires and an electroconductive polymer-containing transparent electroconductive layer provided on the transparent base material.

Owner:KONICA MINOLTA INC

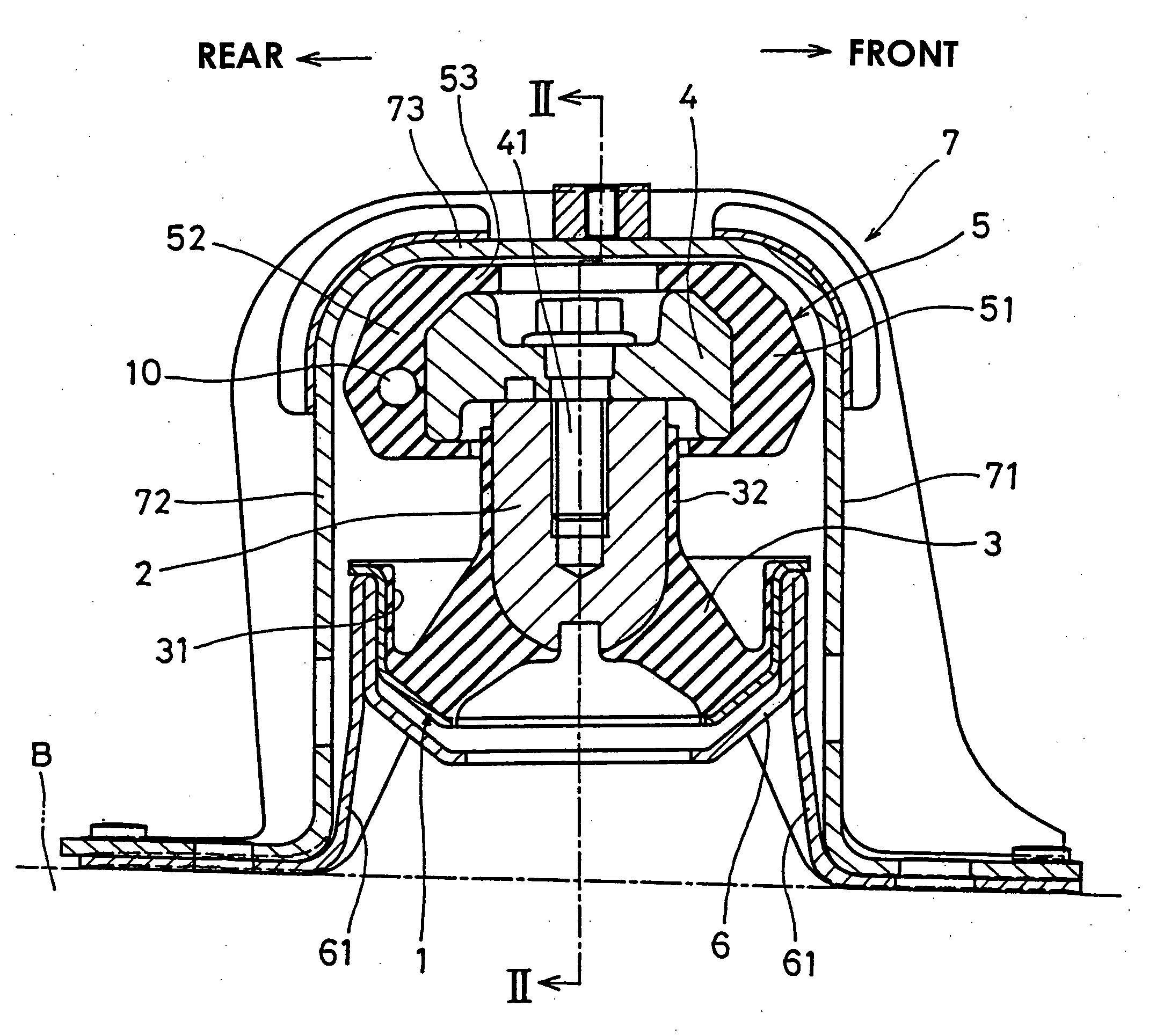

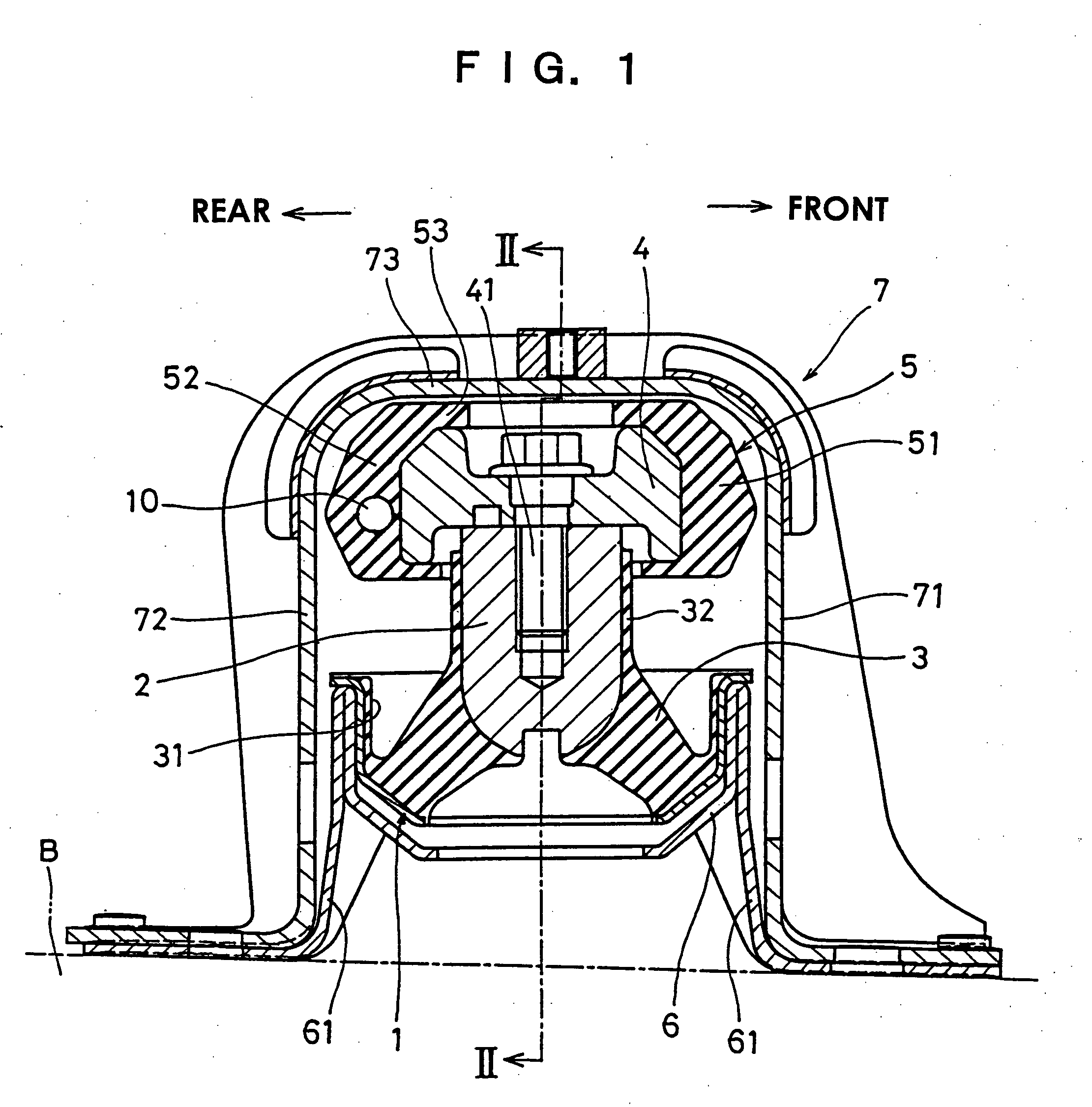

Vibration isolating device

InactiveUS20050242481A1Diminish dynamic spring constantGood durabilityMachine framesNon-rotating vibration suppressionMechanical engineeringElastomer

To provide a vibration isolating device that can reduce the dynamic spring constant in the fore-and-aft direction of a vehicle and can reduce effectively the indoor noise upon acceleration and running at high speed. The device has a cylindrical main body fitting to be fixed to a vehicle body side, a boss fitting to be coupled to a vibration generator side, a rubber elastomer as a vibration isolator interposed between both, front and rear stopper rubber portions attached to a coupling member secured to an upside of the boss fitting, and a stopper member disposed in front of and in the rear of the stopper rubber portions and to be fixed to a vehicle body side, wherein a small cavity is provided in at least one of the front and rear stopper rubber portions.

Owner:TOYO TIRE & RUBBER CO LTD

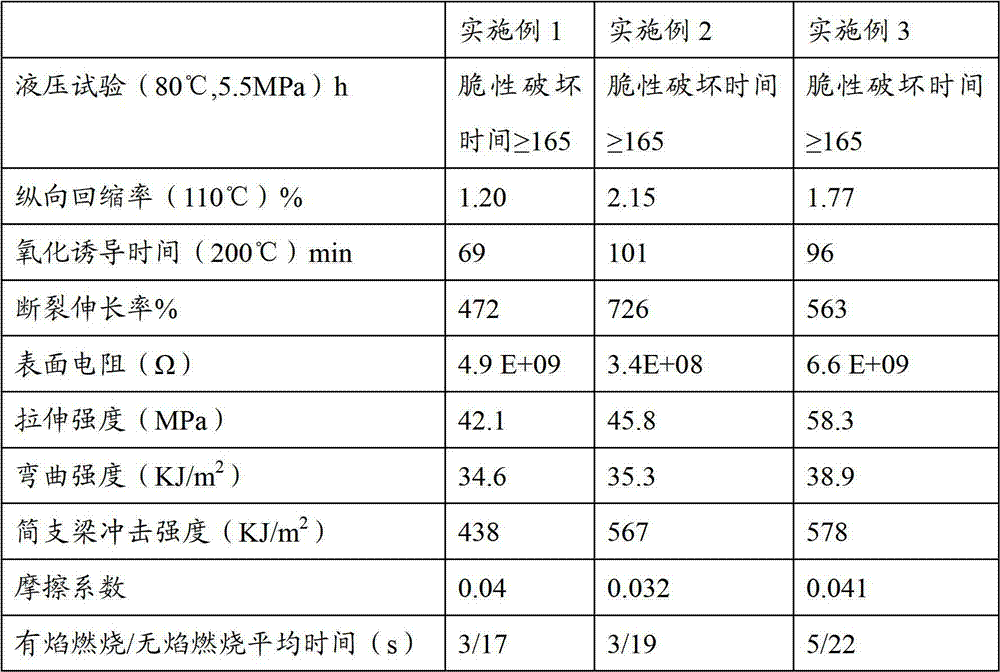

Carbon-nano-tube-reinforced polyethylene tube

The invention relates to a carbon-nano-tube-reinforced polyethylene tube which comprises, by weight, 70-100 parts of high-density polyethylene and 1-10 parts of carbon nano tubes. The carbon-nano-tube-reinforced polyethylene tube has the advantages that the carbon-nano-tube-reinforced polyethylene tube has excellent suppleness and formability; the carbon nano tubes are uniformly distributed and basically consistent in orientation in a polyethylene matrix so as to be firmly combined with the matrix, free from scattering and loss due to friction and good in durability; and the carbon nano tubes are conflict-free with other auxiliaries and good in synergy, and the antistatic performance, the mechanical strength and the thermal ageing performance are improved.

Owner:宁波风盛新材料科技有限公司

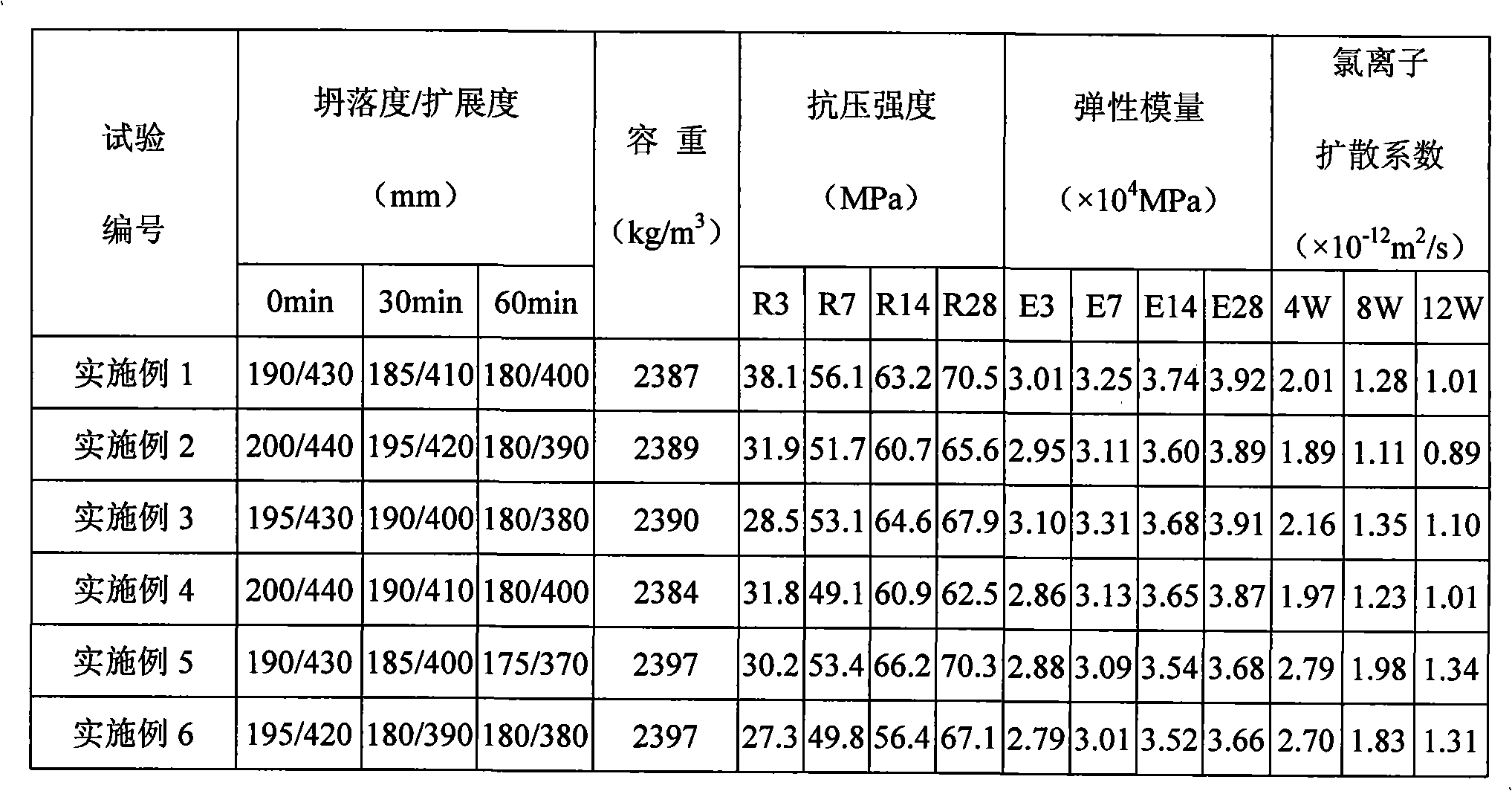

Maritime work concrete and construction method

InactiveCN101269937AGood durabilityImprove anti-segregation performanceSolid waste managementBridge erection/assemblyCorrosionMoisture

The present invention discloses maritime-works concrete and a method for constructing the maritime-works concrete, which is mainly composed of cement, blast-furnace slag powder, fly ash, sand, crushed stone, additive and water, and has favorable durance, and can meet the requirements of the ocean large engineering project on the favorable durance of the concrete system, and can effectively avoid the corrosion of the steel bar during the service life, and can maintain the favorable appearance. The construction method of the maritime-works concrete comprises adopting the mixing factory-orientation production, the integrated material supply, the conveying pump and the tank cart to transport the concrete to the pouring site, and adopting the material rod to distribute the materials, thus can effectively control the feeding point, the feeding quantity and the feeding speed, and can guarantee the concrete to meet the working indexes required for the construction such as the uniformity and the stipulated collapsed degree while effectively improving the construction progress, and can promote the successful completion of the engineering project. The moisture-preservation and temperature-preservation maintenance is adopted for the initial maintenance of the beam body, thereby improving the initial strength, accelerating the turnover of the beam holder and the die, and reducing the beam-making cost.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

Polishing pad

ActiveUS20100029182A1Good durabilityPoor durabilityPolishing machinesAbrasion apparatusMetallurgyCell diameter

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

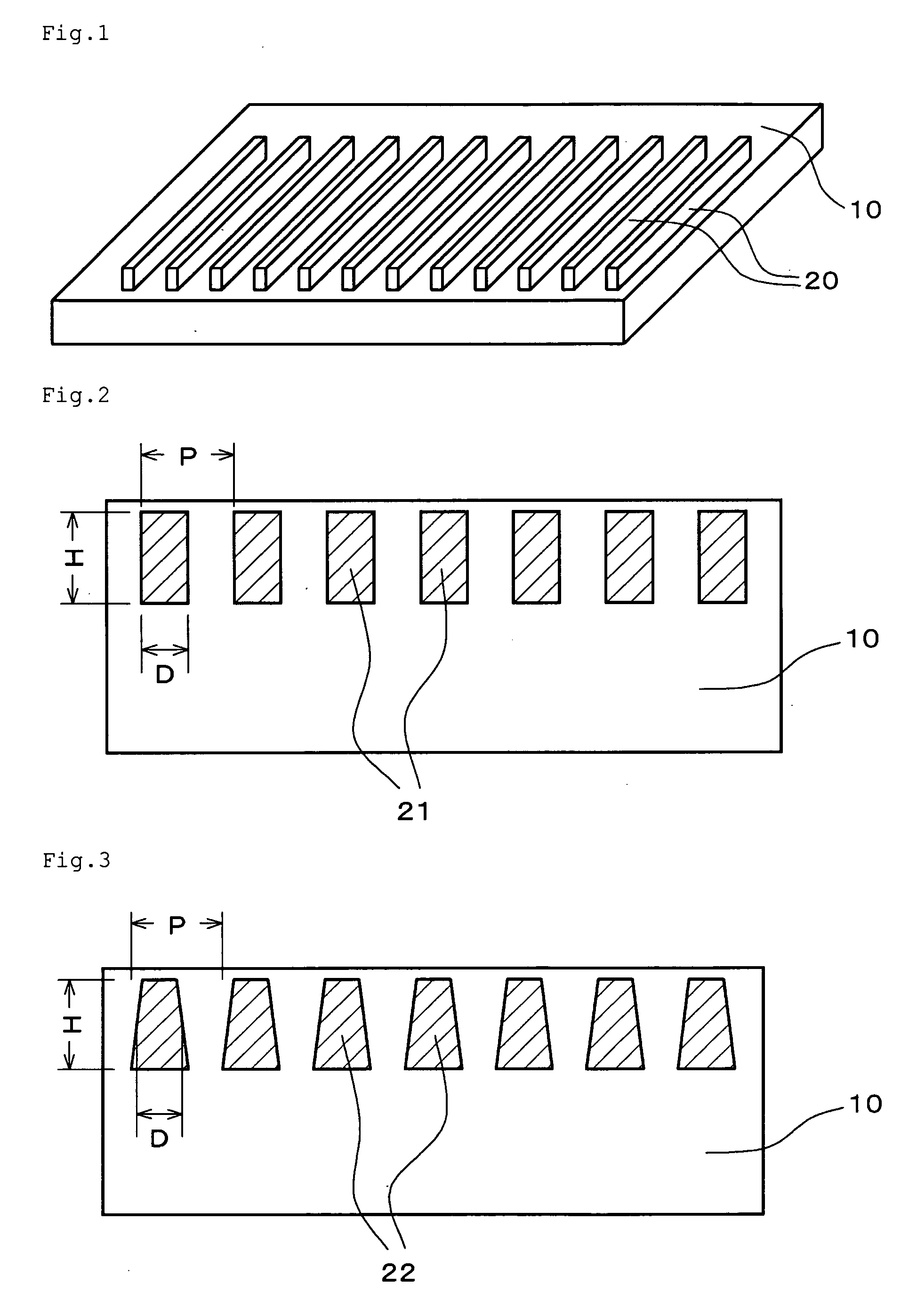

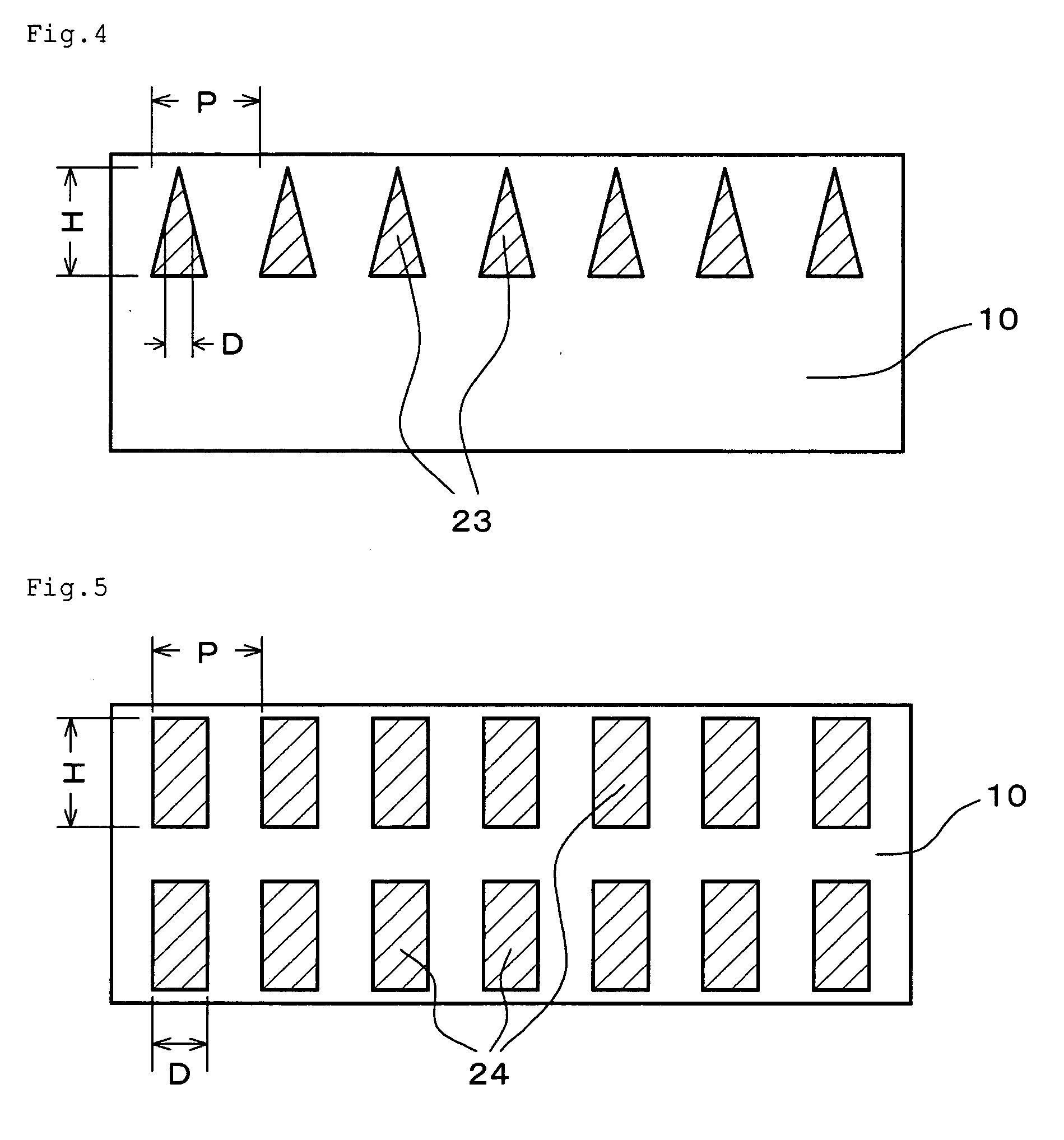

Polarized light separating element embedded with thin metallic wire

InactiveUS20060039069A1Stable structureGood durabilityPolarising elementsNon-linear opticsOptoelectronicsOxide

An object of the present invention is to provide a high-performance polarized light separating element having stable structure and superior durability, whose product with a large area can easily be manufactured. There is provided a polarized light separating element comprising a plurality of thin metallic wires 21, 21 embedded and arrayed in a planar substrate 10 so as to be parallel to each other, wherein the pitch (P) of the wires 21, 21 is 100 to 300 nm, the ratio (D / P) of the width (D) of the wires 21, 21 to the pitch (P) of the wires is 0.1 to 0.6, and the height (H) of the wires 21, 21 in a cross section orthogonal to a lengthwise direction of the wires is 50 to 500 nm. With regard to the wires 21, 21, a surface thereof may be covered with a metallic oxide film. The substrate 10 is preferably a polymeric resin film.

Owner:SUMITOMO CHEM CO LTD

Method for making composite type nucleated glass from flyash used in building

InactiveCN1433980AHigh strengthGood durabilityCovering/liningsSolid waste disposalIndustrial wasteSurface layer

The present invention relates to a method for making composite flyash building nucleated glass, and is characterized by that in the course of production the nucleating agent beta-CaO. SO2 or microcrystalline kaolin can be added before the flux is water-quenched, also can be added after the flux is water-quenched, the toughening agent is ZrO2 or ZrO2, the flyash can be substituted with industrial wastes and discards material containing SiO2 and Al2O3, and its sandwich layer is filled with colour glass powder, inorganic pigment or light-storing luminescent material, the bottom portion of the melting furnace is equipped with bottom slope with 5-8 deg. and in the course of sintering the base glass, surface layer composite glass and sandwich layer are simultaneously sintered.

Owner:DALIAN UNIV OF TECH

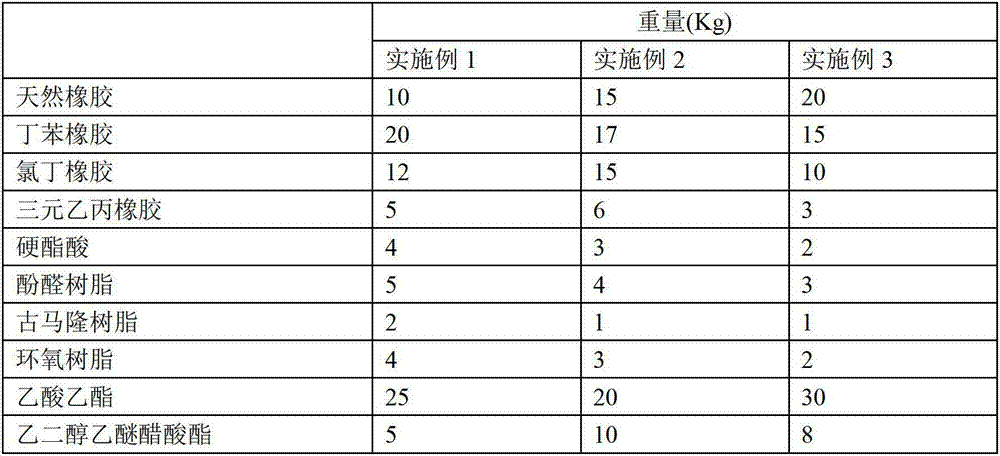

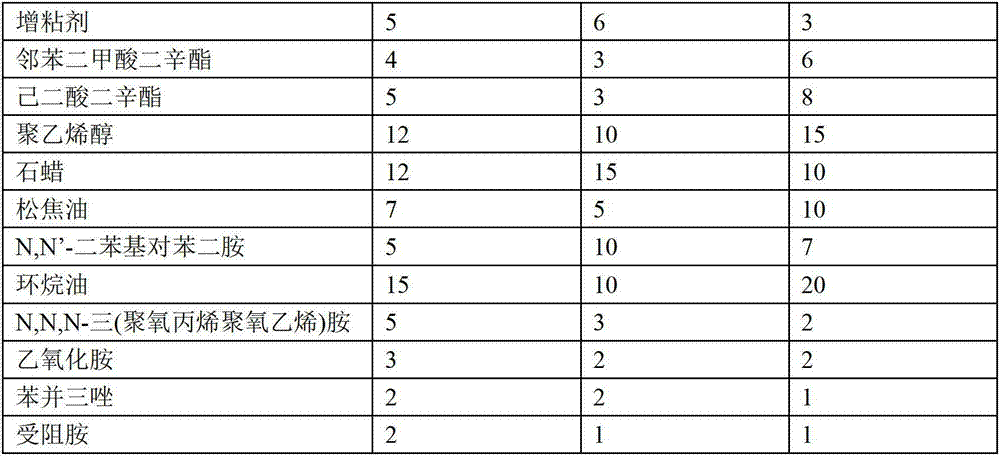

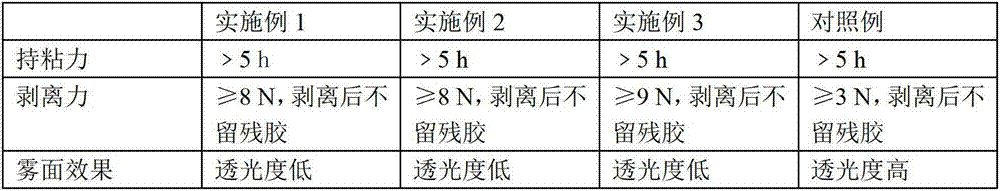

Durable pressure-sensitive adhesive

ActiveCN102876256AStrong adhesionGood durabilityNatural rubber adhesivesNon-macromolecular adhesive additivesParaffin waxTar

The invention provides a rubber-type pressure-sensitive adhesive. The rubber-type pressure-sensitive adhesive comprises the following components in part by weight: 10-20 parts of natural rubber, 15-20 parts of styrene-butadiene rubber, 10-15 parts of chloroprene rubber, 3-6 parts of ethylene-propylene-diene monomer, 2-4 parts of stearic acid, 3-5 parts of phenolic resin, 1-2 parts of coumarone resin, 2-4 parts of epoxy resin, 20-30 parts of ethyl acetate, 5-10 parts of glycol ether acetate, 3-6 parts of tackifier, 3-6 parts of dioctyl phthalate, 3-8 parts of hexyldioctyl ester, 10-15 parts of polyvinyl alcohol, 10-15 parts of paraffin wax, 5-10 parts of pine tar, 5-10 parts of N,N'-diphenyl-p-phenylenediamine, 10-20 parts of naphthenic oil, 2-5 parts of N,N,N-tri (polyoxypropylene polyoxyethylene) amine, 2-3 parts of ethoxylate amine, 1-2 parts of benzotriazole and 1-2 parts of hindered amine. The rubber-type pressure-sensitive adhesive is strong in adhesion and good in durability; and after thermal aging, an adhesion test shows that the adhesion still lasts more than four hours and a release force test shows that the release force lasts more than 7 hours.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

Cushion for engine suspension system and preparation method thereof

InactiveCN103772758AGood durabilityExcellent thermal and oxygen aging resistanceSilane couplingActive agent

The invention provides a cushion for an engine suspension system and a preparation method thereof. The cushion comprises the following rubber materials in parts by weight: 60-80 parts of natural rubber, 20-40 parts of cis-polybutadiene, 5-8 parts of inorganic active agent, 1-3 parts of organic active agent, 1-3 parts of paraffin, 2-3 parts of age resister A, 1-1.5 parts of age resister B, 1-2 parts of heat stabilizer, 1-3 parts of antifatigue, 1-2 parts of silane coupling agent, 5-10 parts of white reinforced material, 10-30 parts of fast compression reinforced material, 30-40 parts of semi reinforced material, 5-10 parts of softener, 1.5-2.0 parts of vulcanizing agent and 1-2 parts of vulcanizing aid. The cushion for an engine suspension system has excellent endurance quality and outstanding heat / oxygen aging resistance and also has remarkable anti-fatigue performance under a dynamic condition.

Owner:柳州日高汽车减振技术有限责任公司

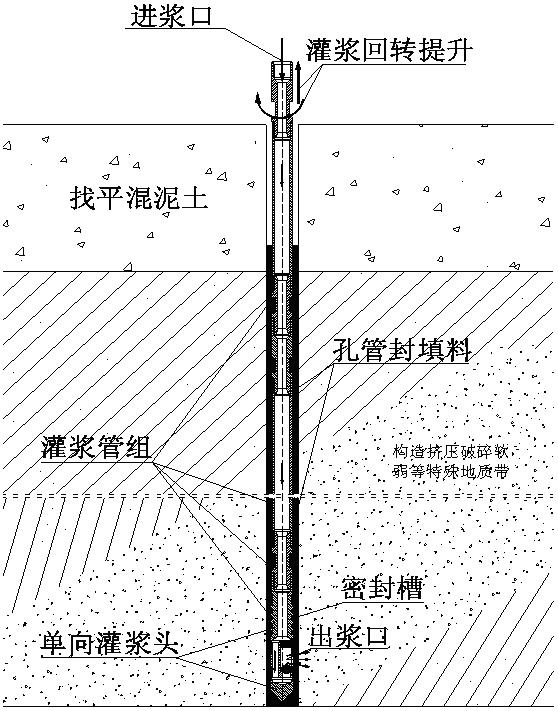

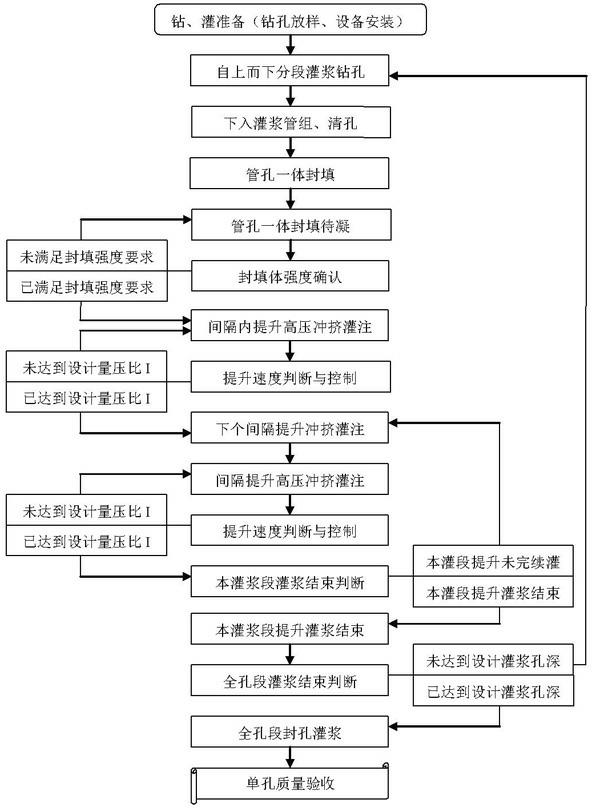

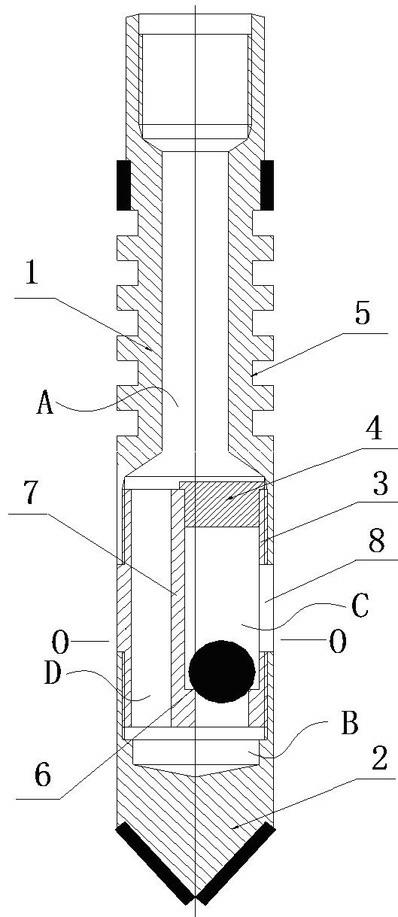

Pored-tube filling and high-pressure impacting extruding grouting method

Owner:POWERCHINA ZHONGNAN ENG

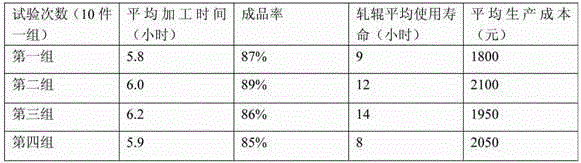

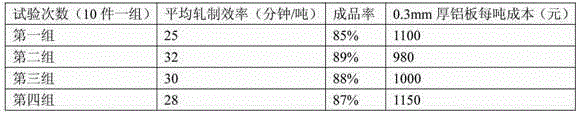

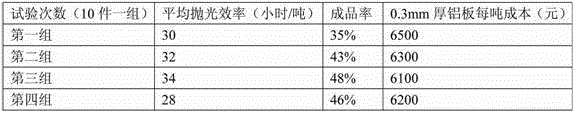

Mirror-surface roller processing method and method for processing mirror-surface aluminum board by utilizing mirror-surface roller

InactiveCN105215791AAvoid polishing corrosionGood durabilityMetal rolling arrangementsCorrosionRolling mill

The invention provides a mirror-surface roller processing method and a method for processing a mirror-surface aluminum board by utilizing the mirror-surface roller. A grinding machine is utilized to grind roller blank into a finished product mirror-surface roller with roughness smaller than or equal to 0.006 microns; and then, a rolling mill with the finished product mirror-surface roller is utilized to roll aluminum board blank into the mirror-surface aluminum board with roughness smaller than 0.006 microns. According to the invention, the mirror-surface roller is processed by virtue of a grinding process, and the mirror-surface roller is grinded on the grinding machine until the roughness is smaller than or equal to 0.006 microns, so that a complex process of grinding and then polishing in the prior art is replaced. The grinding process does not use a polishing machine, so that the grinding time of the mirror-surface roller is shortened to be about 6 hours, and therefore, polishing corrosion is avoided; the yield of the mirror-surface roller is higher than 85%; compared with a polished mirror-surface roller, the grinded mirror-surface roller has better durability, a long service life and lower cost. The rolling mill with the mirror-surface roller is utilized to roll out the mirror-surface aluminum board, and an original manufacturing method for polishing on the polishing machine is replaced, so that various quality problems, caused by the defects of the polishing process, of the mirror-surface aluminum board, are effectively avoided.

Owner:张红超

A laser marking method on wafer surface

InactiveCN101533771AEasy to operateGood durabilitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsMaterials science

A laser marking method on wafer surface includes: production of marking films, wherein, the matrix for marking films is glass sheets capable of permeating the laser, a metallic film layer with a certain thickness is formed on the single side surface of the glass sheet, the laser irradiates on the metallic film layer, and is blocked and accumulated by the metallic film layer, the thickness of the metallic film layer can ensure that the metallic film layer can be melted through by the laser irradiated by the laser marking machine; jointing of the marking film and the wafer surface, so that the metallic film layer surface on the marking film are jointed together with the position on the wafer surface required to mark; laser marking, using laser marking machine to irradiate laser to the position of the wafer required to mark from one side of the marking film without metallic film layer, the irradiated laser is blocked by the metallic film layer and accumulated at the metallic film layer, the accumulated laser can melt through the metallic film layer to ablate the wafer surface, for forming making on the wafer surface. So that three-dimensional effect makings can expediently be marked at wafer surfaces with various characteristics.

Owner:ZHEJIANG CRYSTAL OPTECH

SBR modified road bitumen

ActiveCN101012338AImprove high temperature stabilityGood anti-rutting ability at high temperatureBuilding insulationsTarColloid

Owner:QINGHAI HONGCHUAN XINYUAN INDAL

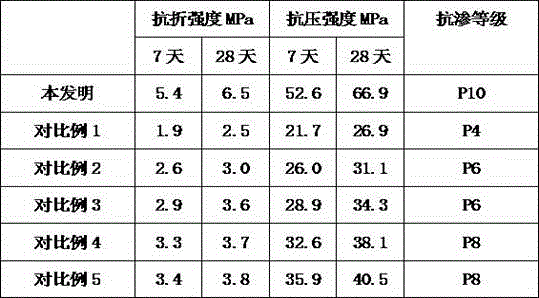

Modified asphalt concrete

The invention discloses a modified asphalt concrete. The modified asphalt concrete is prepared from a binding material, sand, gravel, cocoanut active charcoal, superfine slag powder, waste rubber powder, modified asphalt, hydrotalcite, an additive, an adjuvant and a proper amount of water. The binding material can adsorb stone sand in mortar, a network structure can be formed after gel absorption, all the ingredients can be well bound under the situation of little water, and the situations of separation and water seepage can be reduced. The additive and the adjuvant are added into the concrete formula, the proportion of all the ingredients is adjusted so as to improve the comprehensive performance of the concrete, and the requirements of most buildings can be met. By preparing the modified asphalt concrete with the modified asphalt, the comprehensive performance of the concrete can be further improved, the compressive strength and the flexural strength are improved by 10% or above, the salt resistance and the seepage resistance of the concrete are further improved, development of micro-cracks inside the concrete can be impeded, and the concrete is reinforced and toughened.

Owner:安徽金丰新型建材有限公司

Waterproof thermal insulation and insulating integral material for building roof and construction method of integral material

ActiveCN102808482ALow costGood durabilityRoof improvementClimate change adaptationThermal insulationBuilding material

The invention discloses a waterproof thermal insulation and insulating integral material for a building roof and a construction method of the integral material, and belongs to the technical field of building materials. The integral material comprises cement, sand, lightweight aggregates, waterproof gel, fibers and water. The construction method comprises the steps as follows: forming a bonding waterproof layer, a waterproof insulation sloping layer, a waterproof insulation layer and a waterproof protection layer in the preparation and construction processes respectively by configuring different proportions, and carrying out layering construction to realize the integration of a waterproof function and an insulation function. The invention has the advantages as follows: the complex method for the conventional insulation and waterproof construction processes is avoided; the inconveniences caused by cross construction are avoided; the method is easily constructed and hardly influenced by outside climate; the fire protection level of the waterproof thermal insulation and insulating material reaches A1; and the roof with a ladder is directly formed and is good in durability and easy and convenient to repair.

Owner:BEIJING ACAD OF BUILDING ENG

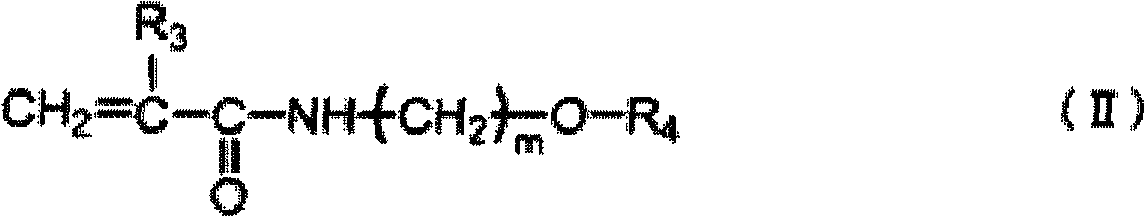

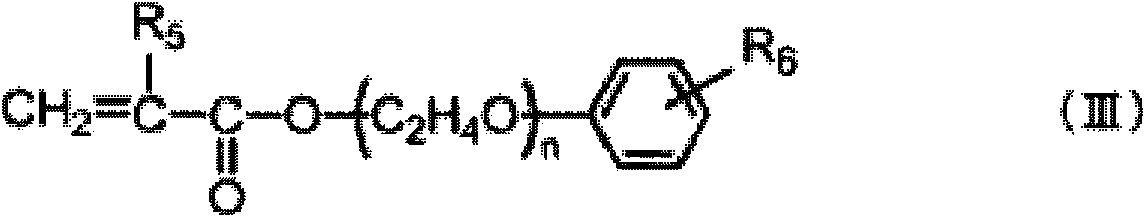

Optical film having adhesive agent, and optical laminated body in which same is used

ActiveCN103403117AInhibit electrificationGood durabilityNon-macromolecular adhesive additivesSynthetic resin layered productsAcrylic acidOptical film

The present invention provides an optical film having an adhesive agent, the optical film being provided with an adhesive agent layer obtained using a composition in which 0.3 to 12 parts by weight of an ionizable compound and 0.1 to 5 parts by weight of a cross-linking agent are compounded with 100 parts by weight of an acrylic copolymer of a monomer mixture comprising 80 to 96 wt% of (A-1), 1 to 15 wt% of (A-2), 0.1 to 5 wt% of (A-3), and 0.5 to 5 wt% of (A-4). (A-1) is a compound of formula (I) (R1 is a hydrogen or methyl, and R2 is a C1-14 alkyl), (A-2) is an unsaturated monomer having an aromatic ring, (A-3) is a compound of formula (II) (R3 is a hydrogen or methyl, R4 is an alkyl, and m is 1 to 8), and (A-4) is an unsaturated monomer having a polar functional group.

Owner:SUMITOMO CHEM CO LTD

Special antimicrobial mould-proof low-odor regenerative polypropylene modified material for automobile instrument desk and preparation method thereof

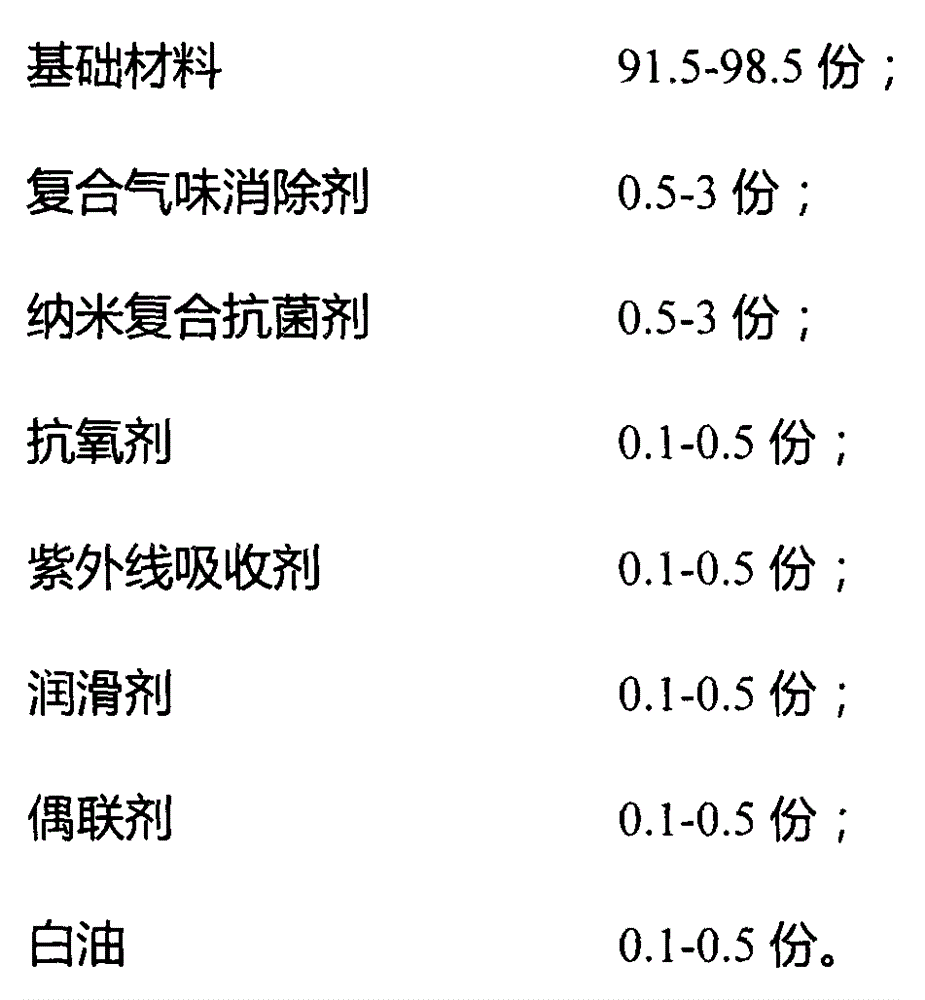

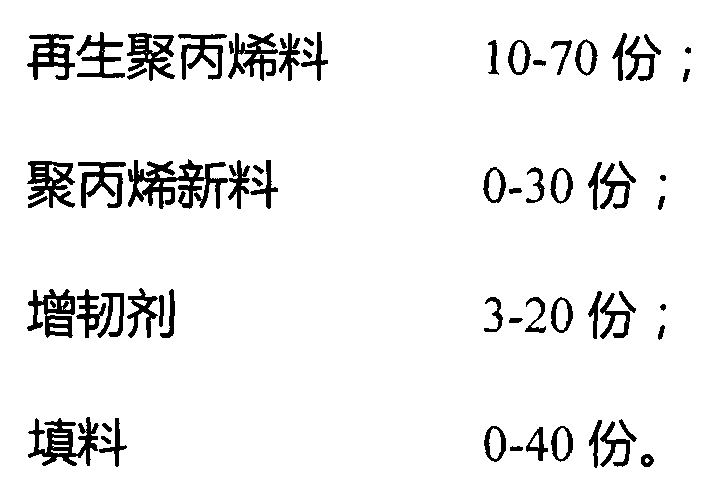

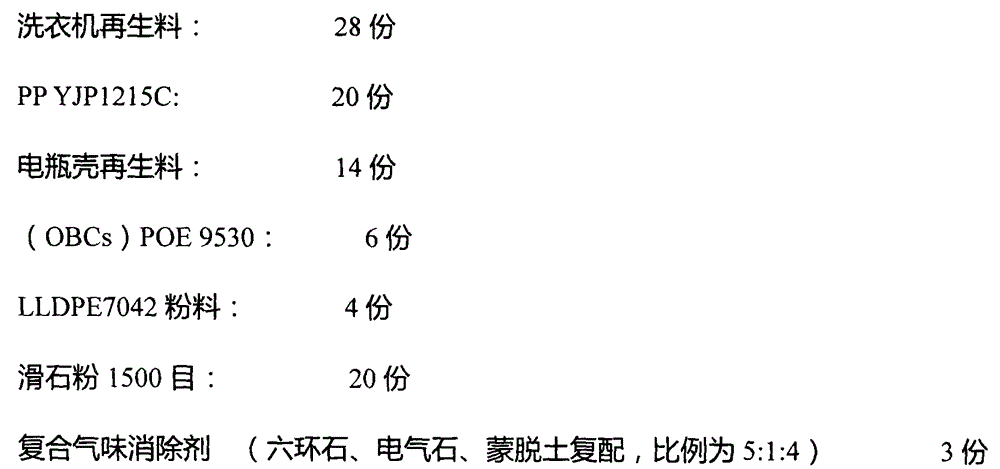

The invention relates to a special antimicrobial mould-proof low-odor regenerative polypropylene modified material for an automobile instrument desk. The special antimicrobial mould-proof low-odor regenerative polypropylene modified material is characterized by comprising the following components in parts by weight: 91.5 to 98.5 parts of base material, 0.5 to 3 parts of composite odor eliminating agent, 0.5 to 3 parts of nano composite antimicrobial agent, 0.1 to 0.5 part of antioxidant, 0.1 to 0.5 part of ultraviolet absorption agent, 0.1 to 0.5 part of lubricating agent, 0.1 to 0.5 part of coupling agent and 0.1 to 0.5 part of white oil. The base material comprises the following components in parts by weight: 10 to 70 parts of regenerative polypropylene material, 0 to 30 parts of polypropylene fresh material, 3 to 20 parts of flexibilizer and 0 to 40 parts of filler. The invention also provides a preparation method of the special antimicrobial mould-proof low-odor regenerative polypropylene modified material. The special antimicrobial mould-proof low-odor regenerative polypropylene modified material for the automobile instrument desk is low in odor, good in antimicrobial durability and safe to use; the utilization rate of the regenerative material is greatly increased, a good circulating system is formed, and the environment can be improved. The preparation method is simple and easy and high in practical value.

Owner:CHANGZHOU PLASKING POLYMER TECH

Laminate for reflection film

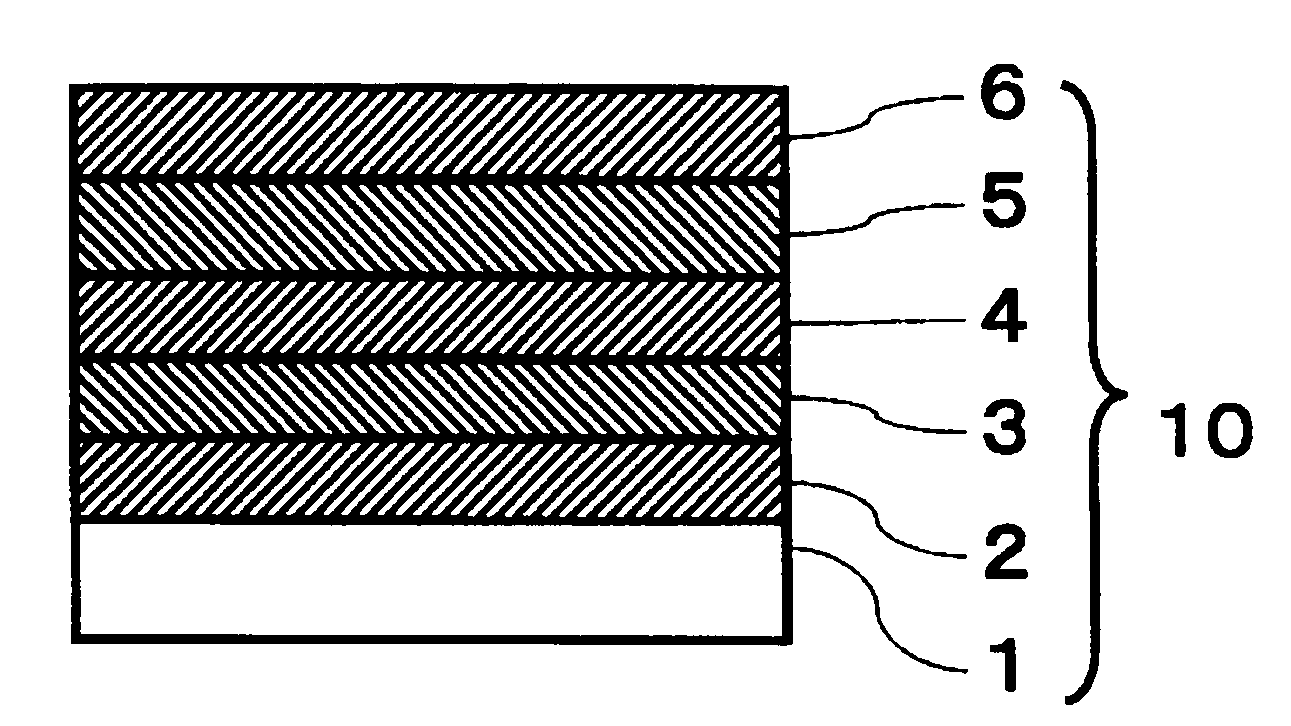

InactiveUS20080131693A1Increased reflectanceGood durabilityMirrorsRecord information storageHigh reflectivityRadio frequency sputtering

To provide a laminate having a high reflectance in the entire visible region and having excellent durability such as moisture resistance and salt water resistance.A laminate comprising a substrate, and a silver film, an adhesion-improving film, a low refractive index film and a high refractive index film formed in this order on the substrate, wherein at least a layer on the adhesion-improving film side in the low refractive index film is formed by a radio frequency sputtering method by means of an oxide target using a sputtering gas containing nitrogen, the adhesion improving film has an extinction coefficient of at most 0.1 and has a thickness of from 0.5 to 4 nm, the low refractive index film has an extinction coefficient of at most 0.01, and the high refractive index film has an extinction coefficient of at most 0.01.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com