Maritime work concrete and construction method

A kind of marine concrete and concrete technology, which is applied in the field of concrete, can solve the problems of not forming a reasonable, economical and effective marine durable concrete construction method, unsuitable early strength of concrete structure, copying concrete formula, etc., to achieve good appearance, Avoid steel corrosion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

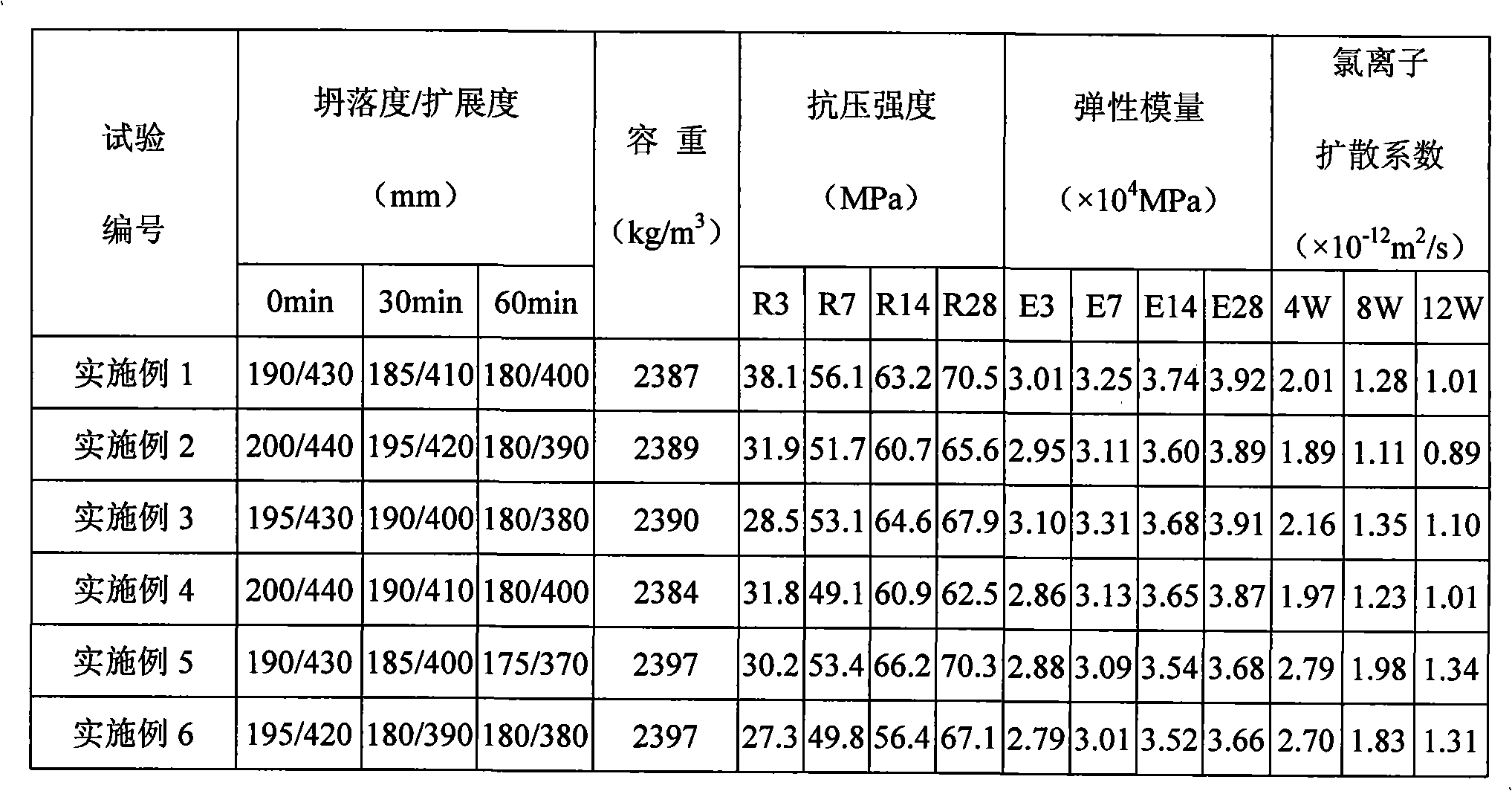

Examples

Embodiment 1

[0038] A kind of marine concrete, which is a mixture composed of cement, blast furnace slag fine powder, fly ash, sand, gravel, admixture and water in proportion. The weight ratio of each component in the mixture is (unit: kg ):

[0039] Cement 202, blast furnace slag fine powder 217, fly ash 56, sand 695, gravel 1086, water 152, admixture 4.5.

[0040] The cement described in this embodiment is Portland cement, and its quality index meets the requirements of "Portland cement, ordinary Portland cement" GB175-1999, and its performance parameters are: density is 3.16g / cm3; specific surface area is 308m 2 / kg; the setting time is, the initial setting is 2:25h, the final setting is 3:15h, the flexural strength is: the 3d flexural strength is 5.8MPa, the 28d flexural strength is 9.3MPa, the compressive strength is, the 3d compressive strength is 26.9MPa, 28d compressive strength is 55.6MPa.

[0041] The blast furnace slag fine powder and fly ash are waste residues from iron and ...

Embodiment 2

[0046] A kind of marine concrete, which is a mixture composed of cement, blast furnace slag fine powder, fly ash, sand, gravel, admixture and water in proportion. The weight ratio of each component in the mixture is (unit: kg ):

[0047] Cement 218, blast furnace slag fine powder 201, fly ash 56, sand 695, gravel 1087, admixture 4.5, water 152.

[0048] The cement is Portland cement; the blast furnace slag fine powder and fly ash are waste residues from iron and steel plants, power plants, etc.; the sand is river sand with a fineness modulus of 2.6; the particle size of the gravel is 5-25mm, wherein the ratio of gravel with a particle size of 5-15mm to gravel with a particle size of 15-25mm is 2:8; the admixture is a polycarboxylate water reducer Rheoplus325, and its water-reducing rate is 28.9%, bleeding ratio 40.1%, air content 3.0%, initial setting time difference +98min, final setting time difference +113min; 1d compressive strength ratio 186%, 3d compressive strength rat...

Embodiment 3

[0050] A kind of marine concrete, which is a mixture composed of cement, blast furnace slag fine powder, fly ash, sand, gravel, admixture and water in proportion. The weight ratio of each component in the mixture is (unit: kg ):

[0051] Cement 218, blast furnace slag fine powder 196, fly ash 56, sand 694, gravel 1086, admixture 4.2, water 152.

[0052] The cement is Portland cement, the blast furnace slag fine powder and fly ash are waste residues from iron and steel plants, power plants, etc., the sand is river sand with a fineness modulus of 2.6, and the particle size of the crushed stone is 5-25 mm, wherein the ratio of crushed stones with a particle size of 5-15 mm to crushed stones with a particle size of 15-25 mm is 2:8, and the additive is polycarboxylate water reducer ADVA152.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com