Patents

Literature

153results about How to "Speed up the construction progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

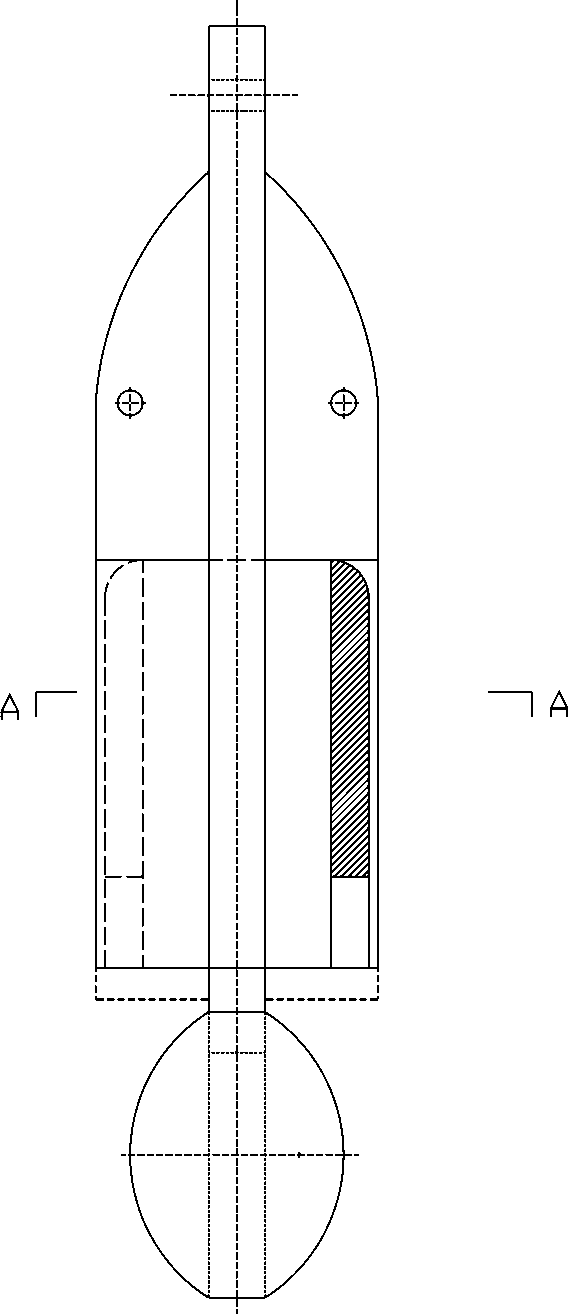

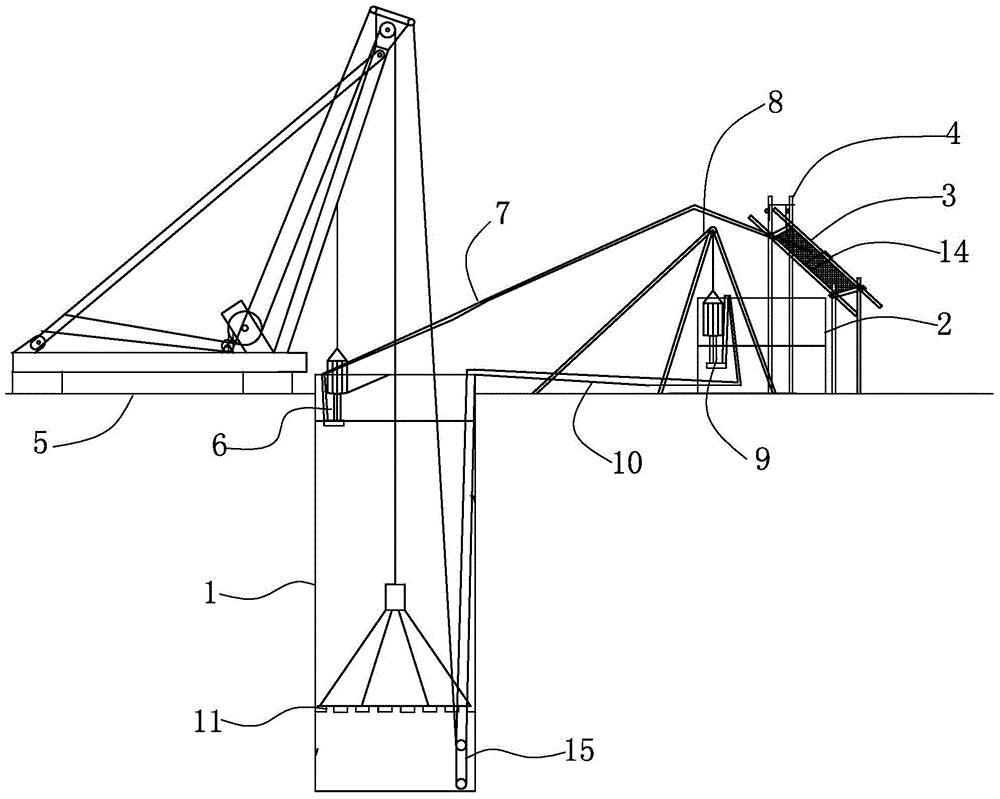

Upward moving type movable formwork for continuous box girder construction

InactiveCN105155423ALow costSpeed up the construction progressBridge erection/assemblyStructural stabilityEngineering

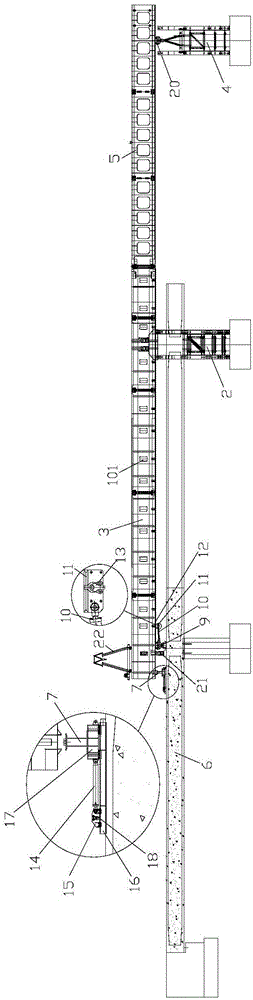

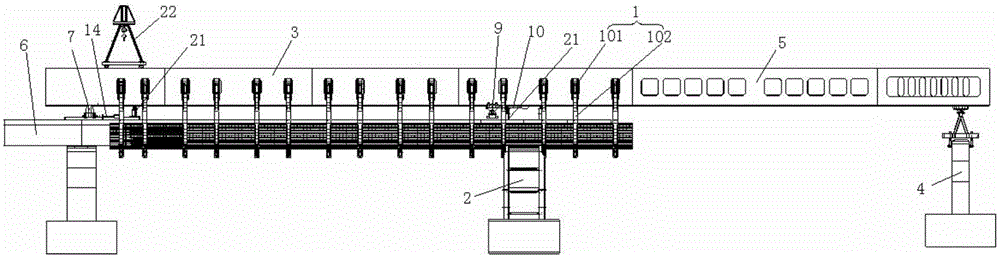

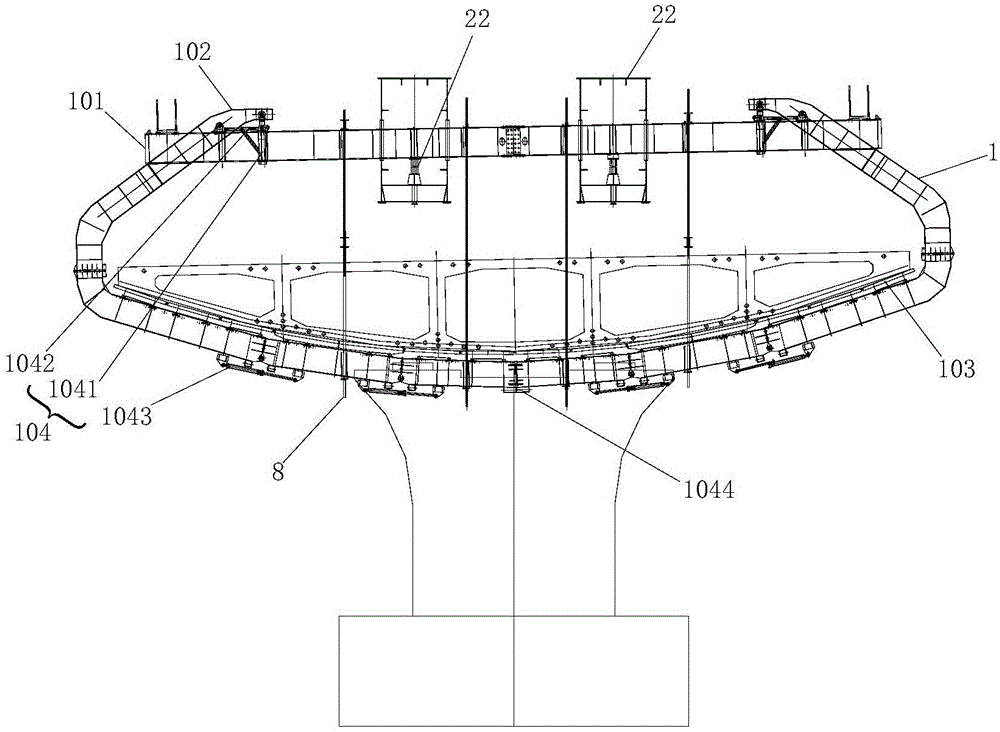

The invention discloses an upward moving type movable formwork for continuous box girder construction. The upward moving type movable formwork comprises a box girder body construction mold, a main beam, a nose beam and a rear sliding beam. The bottom of the box girder body construction mold is unfolded for box girder form removal or the bottom of the box girder body construction mold is closed so that a box girder can be poured. The main beam is supported on a middle supporting leg of the box girder and used for bearing the box girder body construction mold and driving the box girder body construction mold to move in the longitudinal direction of the box girder. The nose beam is supported on a front supporting leg of the box girder and used for guiding the main beam moving in the longitudinal direction of the box girder. The rear sliding beam is supported on the poured molded box girder and used for assisting the main beam in moving in the longitudinal direction of the box girder and being adjusted to be bent in the transverse direction of the box girder. The box girder body construction mold is suspended on the main beam, the nose beam is arranged at the advancing end of the main beam, and the rear sliding beam is arranged at the rear end of the main beam. Whole box girder pouring construction and mold movement are finished on the supporting legs and the poured molded box girder, the box girder body construction mold is opened from the bottom to form a folding span-crossing structure, and therefore the structural stability and safety of the whole formwork are guaranteed.

Owner:CCFEB CIVIL ENG

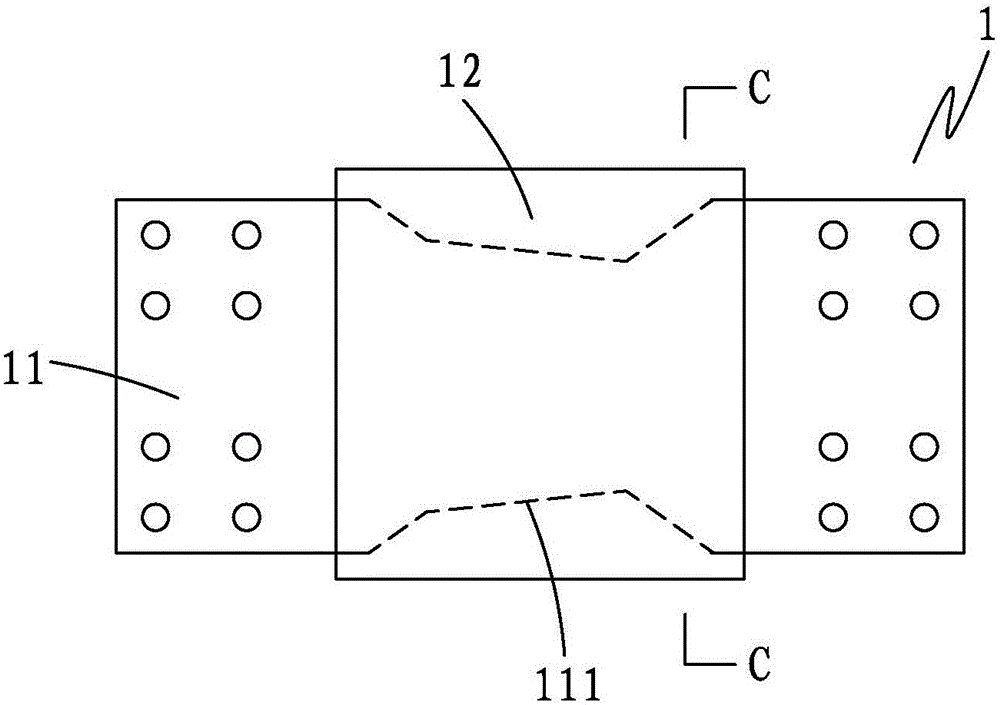

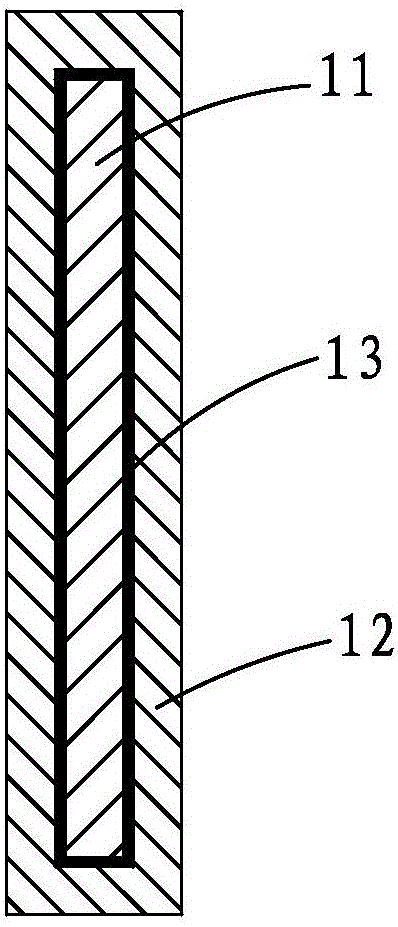

Fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint

InactiveCN105780960AAvoid wet workSpeed up the construction progressShock proofingPlastic propertyFlange

The invention provides a fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint which comprises two buckling-restrained flange metal plate energy-consuming dampers, two high-strength web connecting plates, a first pre-buried steel beam and a second pre-buried steel beam. One end of the first pre-buried steel beam is buried in a concrete column while the other end of the same outwards extends out of a column face, one end of the second pre-buried steel beam is buried in a concrete beam while the other end of the same outwards extends out of a beam end face, upper and lower flanges of the first pre-buried steel beam and the second pre-buried steel beam are connected through the buckling-restrained flange metal plate energy-consuming dampers, and two sides of the middles of the first pre-buried steel beam and the second pre-buried steel beam are connected through the high-strength web connecting plates. The fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint has the advantages that outward moving of a plastic hinge from the column beam can be realized through the buckling-restrained energy-consuming joint, so that damage to a core area of the buckling-restrained energy-consuming joint is reduced, and anti-seismic performance requirements on 'strong column and weak beam' and 'strong shearing and weak bending' are met.

Owner:FUJIAN UNIV OF TECH

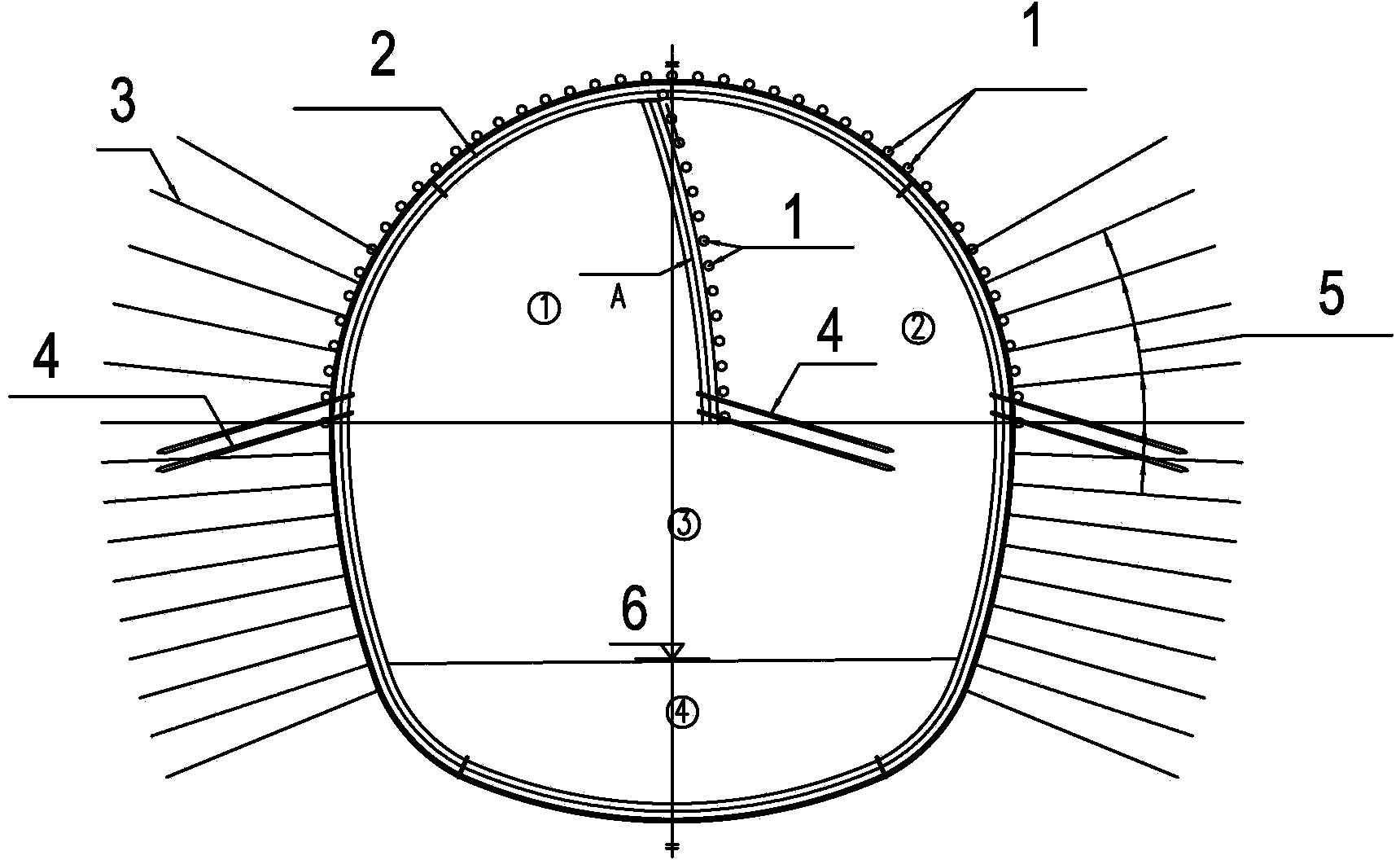

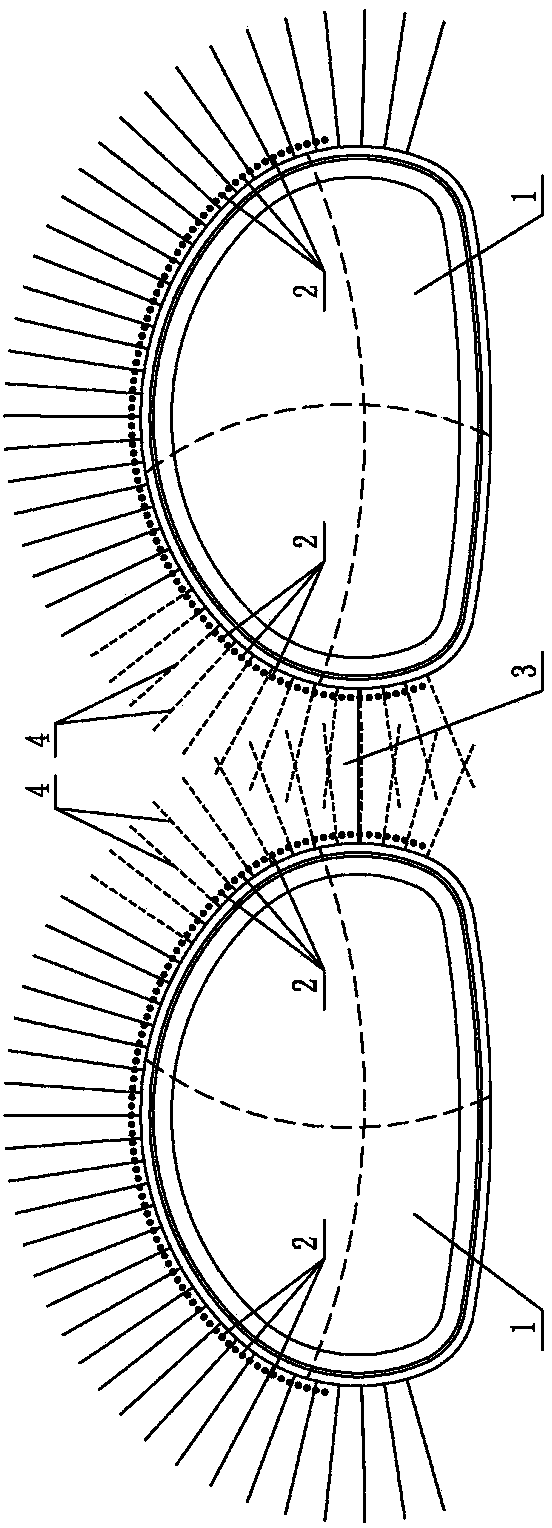

Construction method for excavating water-rich shallow underground excavation tunnel

InactiveCN104165056ASpeed up the construction progressImprove machine utilizationUnderground chambersTunnel liningTunnel constructionEngineering

The invention discloses a construction method for excavating a water-rich shallow underground excavation tunnel. The construction method includes the following steps that first, phi-42 advanced small pipes are constructed within the range of 180 degrees of the arch of the tunnel and the range of the top heading side wall through a steel frame erected in the last cycle, and advanced grouting supporting is performed; a first part is excavated; a preliminary support and a temporary support on the periphery of a heading of the first part are constructed, 4 cm thick concrete is sprayed preliminarily, a reinforcing mesh is installed, a steel frame and a temporary steel frame A are erected along with fluctuation of the rock face, and locking tremies are arranged; after holes are drilled and system anchor rods are arranged, concrete is sprayed again; second, a second part is excavated; 4 cm thick concrete is sprayed preliminarily on part of the periphery of the heading, and a reinforcing mesh is arranged; a steel frame on the periphery of a hole is lengthened through connection; after holes are drilled and system anchor rods are arranged, concrete is sprayed again; third, a third part is excavated in a blasting mode; fourth, a fourth part is excavated in a blasting mode. According to the construction method, the workloads for partition wall construction and removal are saved in construction, the tunnel construction progress is accelerated, the machine utilization rate is increased, energy waste is reduced, the construction period is short, and cost is low.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

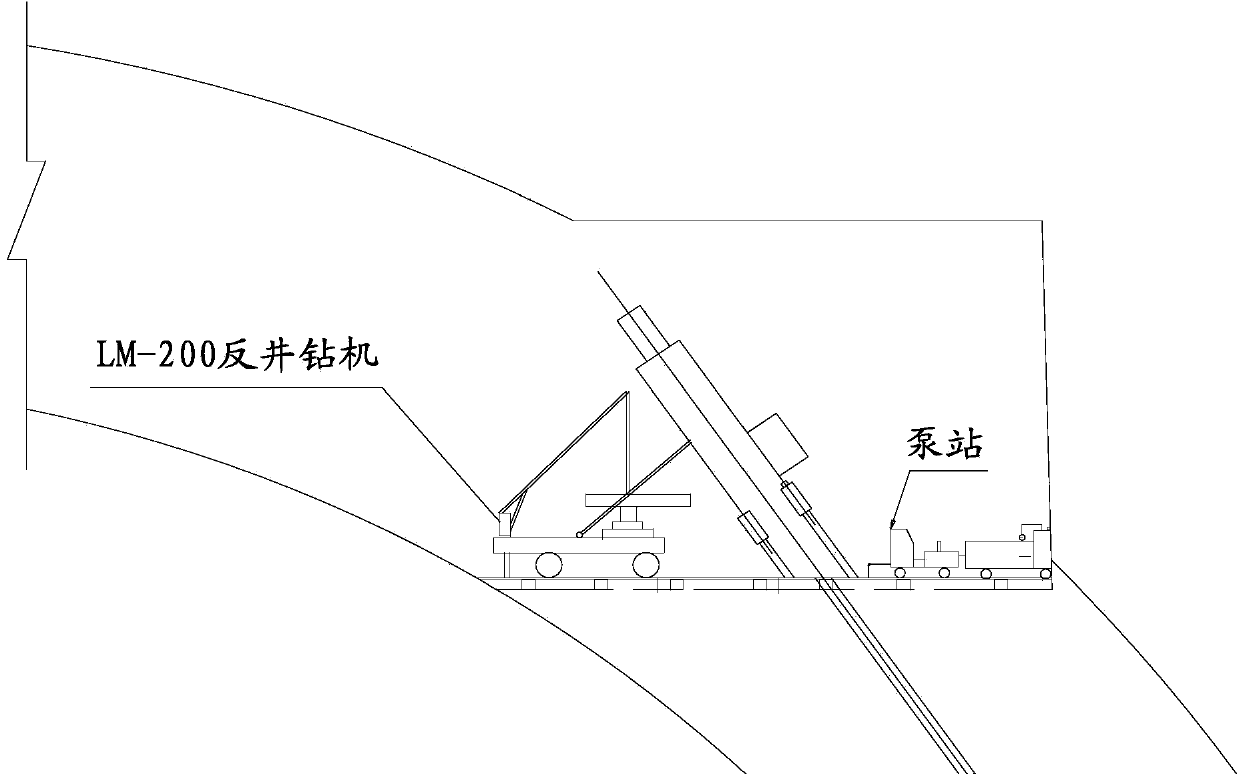

Method for carrying out construction in vertical shaft or inclined shaft through raise boring machine

InactiveCN104196442ASpeed up the construction progressGuarantee the quality of the projectDirectional drillingWork periodDrill bit

The invention relates to a method for carrying out construction in a vertical shaft or an inclined shaft through a raise boring machine. The construction method comprises the steps that the raise boring machine is used for downwards drilling a guide hole with the diameter of 216 mm in an upper horizontal plane excavation expanding area of an upper curved section in the axis direction of the inclined shaft, a drill bit of phi216 mm is replaced with an excavation expanding tool disc of phi1,400 mm on a lower curved section after the guide hole is formed, and then a slip slug pilot shaft with the diameter phi of 1,400 mm is formed in a counter pull excavation expanding mode from top to bottom. According to the method for carrying out construction in the vertical shaft or the inclined shaft through the raise boring machine, construction and shaft guide are carried out by the raise boring machine in the hydropower project, and safety accidents are avoided in the construction process. Excavation and supporting of the vertical shaft and the slow inclined shaft are smoothly completed during the joint work period, the investment of personnel and equipment is reduced, the construction schedule is accelerated, meanwhile, project quality is guaranteed, and economic benefits are increased for the project. The experience measures for controlling angle deviation in the construction process of the vertical shaft and the slow inclined shaft are grasped, and reference is provided for controlling hole direction deviation through the raise boring machine in the construction process of the vertical shaft and the slow inclined shaft later.

Owner:SINOHYDRO BUREAU 11 CO LTD

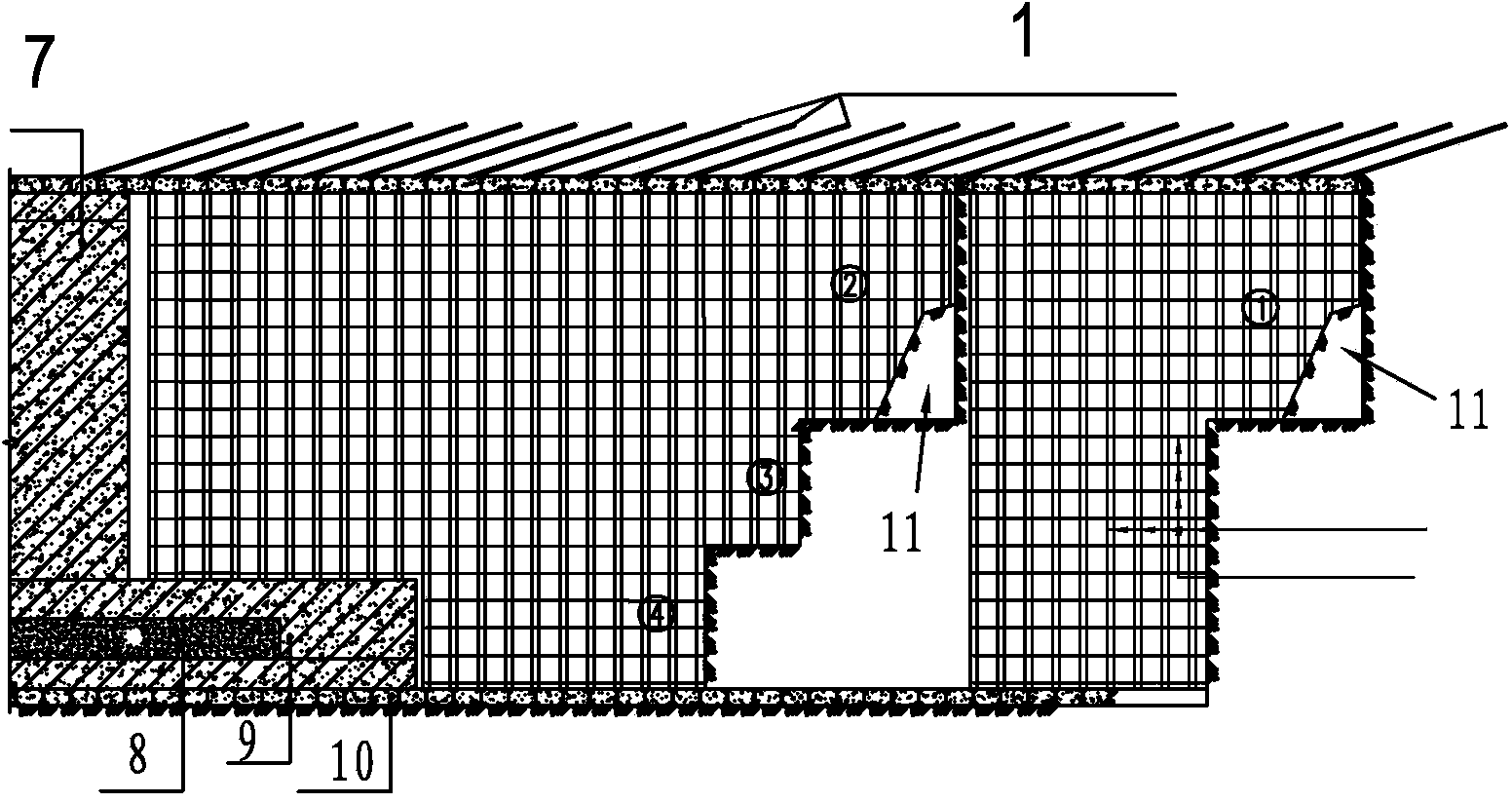

Neighborhood tunnel middle clamping rock strengthening method

ActiveCN103628884ASimple processSpeed up the construction progressUnderground chambersTunnel liningStructural engineeringSpandrel

The invention relates to a neighborhood tunnel middle clamping rock strengthening method to solve the problems that a traditional strengthening method is complex in processes and relatively slow in schedule. According to the technical scheme, the neighborhood tunnel middle clamping rock strengthening method is characterized by comprising the following steps that firstly, advance pipe-shed supports are established before a tunnel is excavated and are arranged inside a rock on the periphery of the tunnel, the advance pipe-shed supports extend to the arch springing position close to the middle clamping rock from the spandrel position far away from the middle clamping rock through the vault, and all large-pipe shed supports are arranged in the axial direction of the tunnel; secondly, the tunnel is partially excavated and supported, and before the soil body close to the middle clamping rock is excavated, small guiding pipes are filled with thick liquid, secondary reinforcing is carried out, and the small guiding pipes are located on one side, close to the middle clamping rock, of the tunnel and extend to the arch springing position form the spandrel position of the tunnel. The neighborhood tunnel middle clamping rock strengthening method is suitable for strengthening low-grade surrounding rock sections and neighborhood tunnel middle clamping rocks with the clear distance smaller than or equal to 6m.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

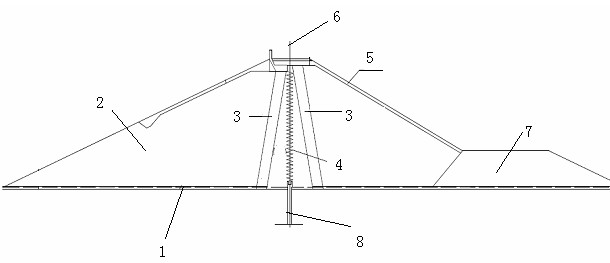

Method for realizing seepage prevention of bridge wall by means of polyvinyl chloride film

InactiveCN102660936AImprove construction efficiencySpeed up the construction progressEarth-fill damsRock-fill damsStructural engineeringEconomic benefits

The invention relates to a method for realizing seepage prevention of a bridge wall by means of a polyvinyl chloride film. The polyvinyl chloride film is arranged at the center of a bridge core wall, a sand mat layer is arranged at the bottom of the bridge wall, a polyvinyl chloride film seepage prevention wall is arranged in the middle of the bridge wall, transition material layers are arranged on two sides of the polyvinyl chloride film seepage prevention wall, a dam shell is arranged outside the transition material layers, a dry stone pitching is arranged on the surface of the dam shell, and the polyvinyl chloride film in the polyvinyl chloride film seepage prevention wall vertically ascends in a zigzag folded manner. A core wall type rockfill dam is effectively built in a place without proper impervious soil, the problem of settlement deformation of the core wall type rockfill dam built on a soft soil foundation is solved, cost is saved, construction period is shortened, and fine social and economic benefits are achieved. Combined positions of the polyvinyl chloride film and the top of the seepage prevention wall and two bank slopes are feeble in seepage prevention, the polyvinyl chloride film is fixed through a pressing plate by the aid of a concave groove, concrete is backfilled, and the seepage prevention effect of the combined positions is improved.

Owner:SINOHYDRO BUREAU 14 CO LTD

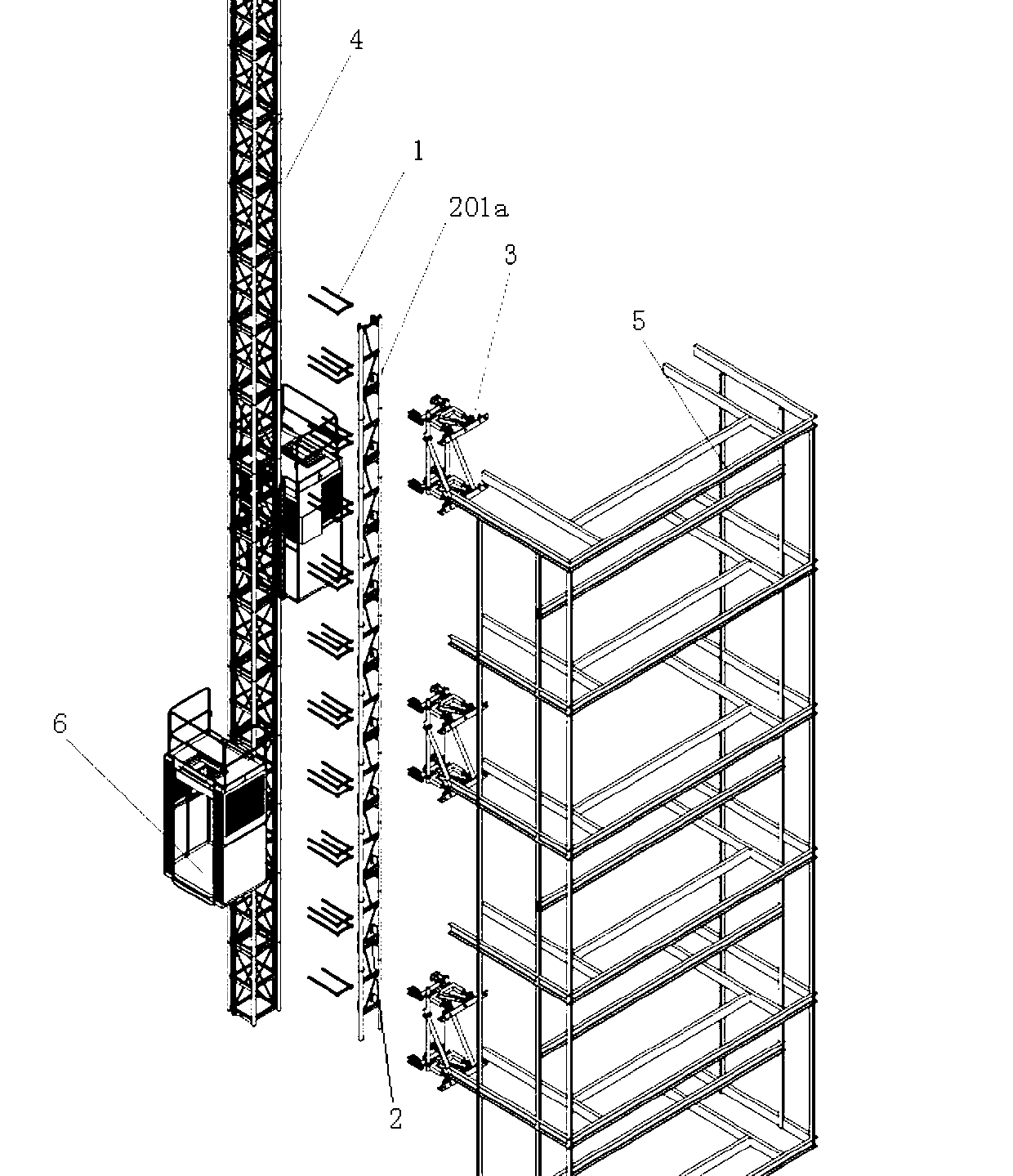

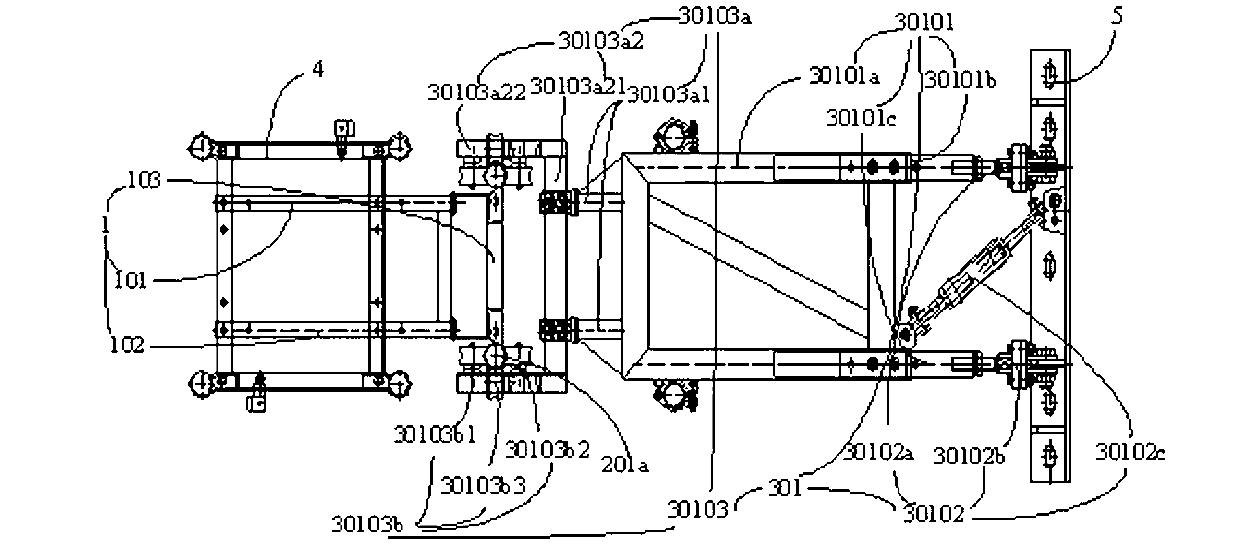

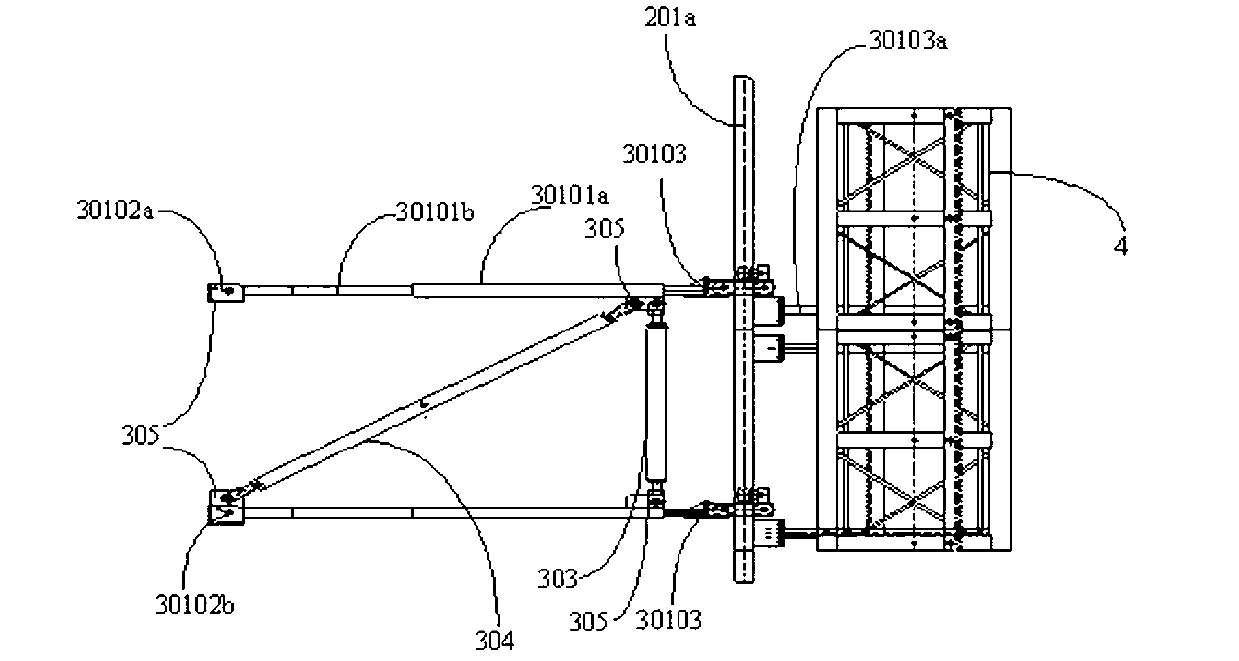

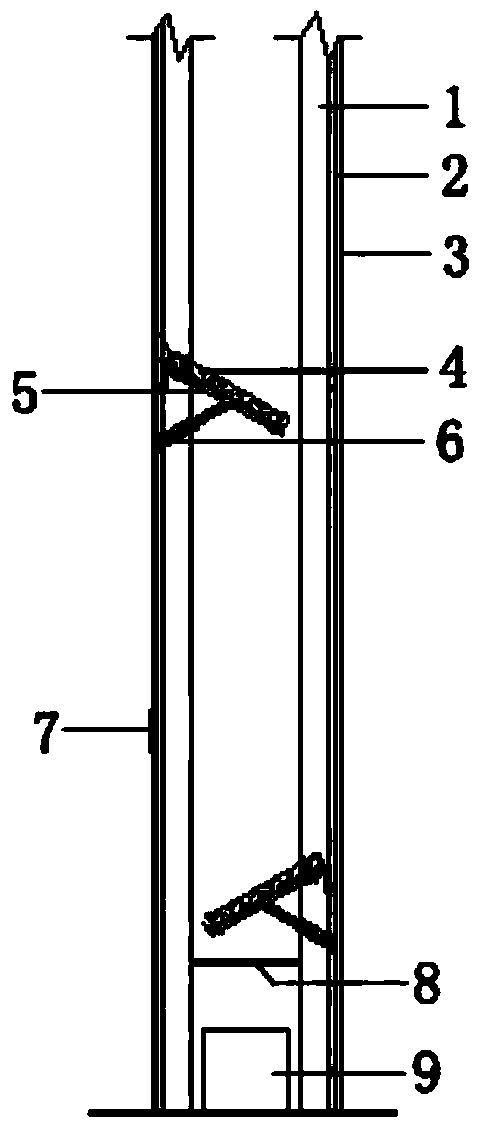

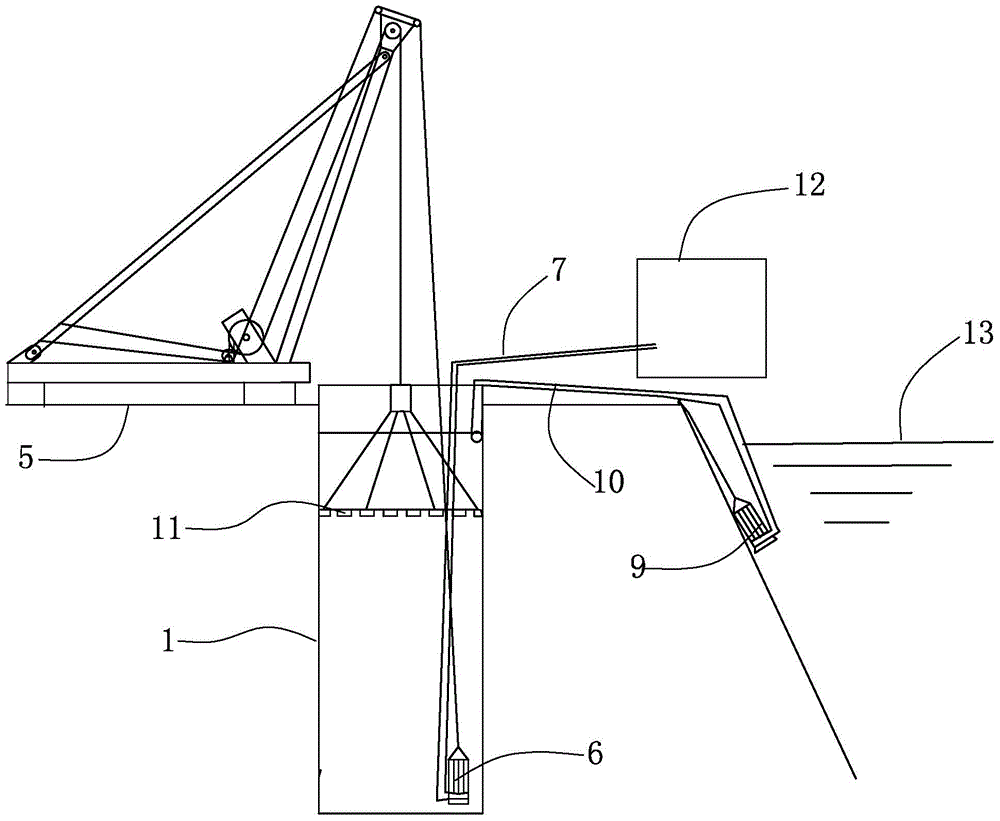

Attaching mechanism and ejecting method for super high-rise construction elevator

InactiveCN103342269AImprove installation efficiencySpeed up the construction progressElevatorsBuilding liftsEngineeringMechanical engineering

The invention discloses an attaching mechanism for a super high-rise construction elevator. The attaching mechanism comprises wall attaching parts, guiding rail parts and rolling parts. One end of each wall attaching part is fixedly connected with an elevator standard knot, and the other end of each wall attaching part is fixed with each guiding rail part through bolts. One end of each rolling part is fixedly connected with an inner frame of an ejecting formwork through bolts, and the other end of each rolling part is connected with each guiding rail part in a rolling mode. When the ejecting formwork ejects, the wall attaching parts and the guiding rail parts are fixed, the rolling parts roll on the guiding rail parts and eject along with the ejecting formwork, the construction elevator can rise to a top platform of the ejecting formwork at a time, and the elevator can operate normally in the ejecting process of the formwork. According to the attaching mechanism, the rolling parts do not need to be dismounted before and after the ejecting formwork ejects, only part of the wall attaching parts and the guiding rail parts needed by lifting at each time are transferred and installed again, installation efficiency is greatly improved, and construction progress is accelerated. The invention further provides an ejecting method for the super high-rise construction elevator.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

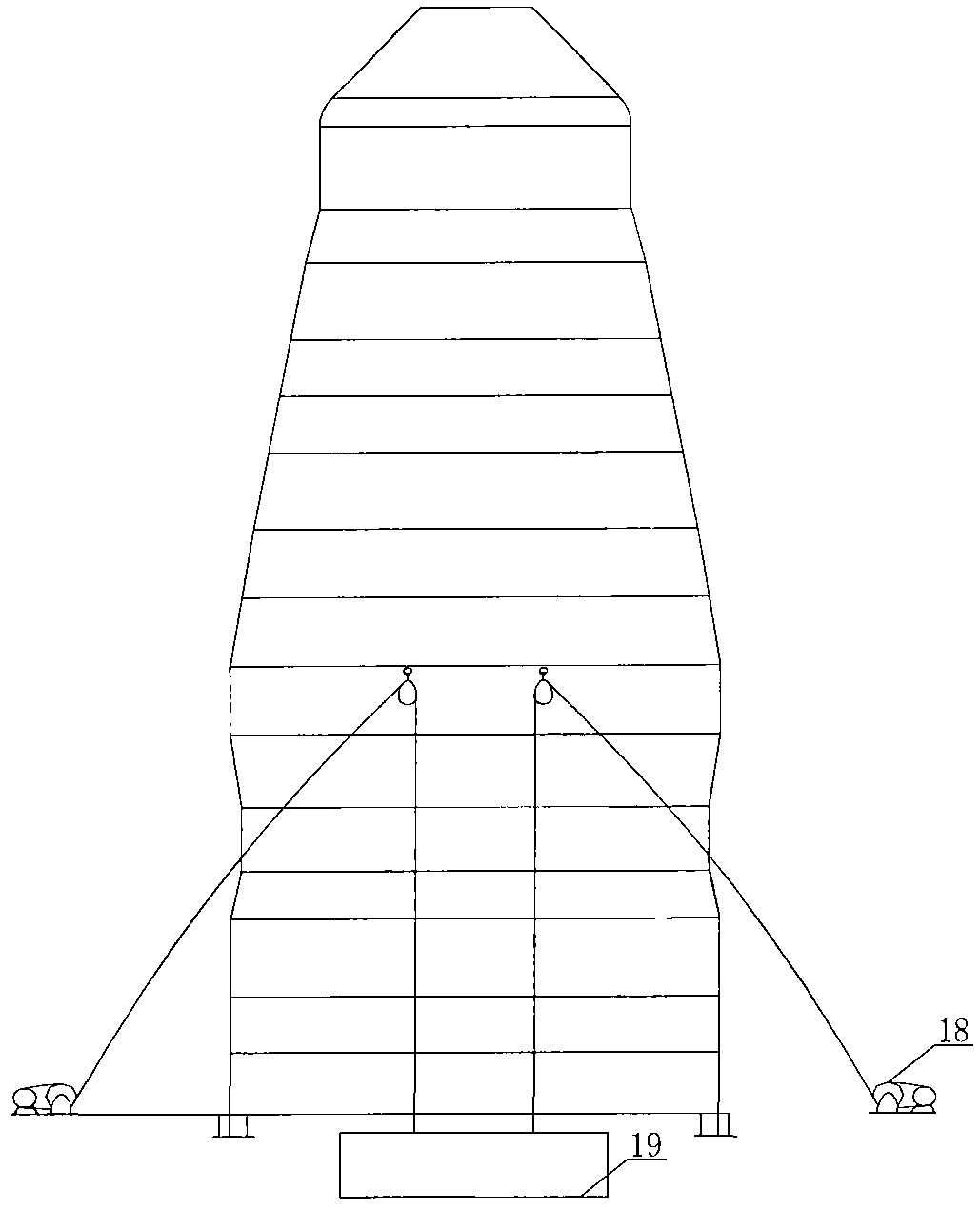

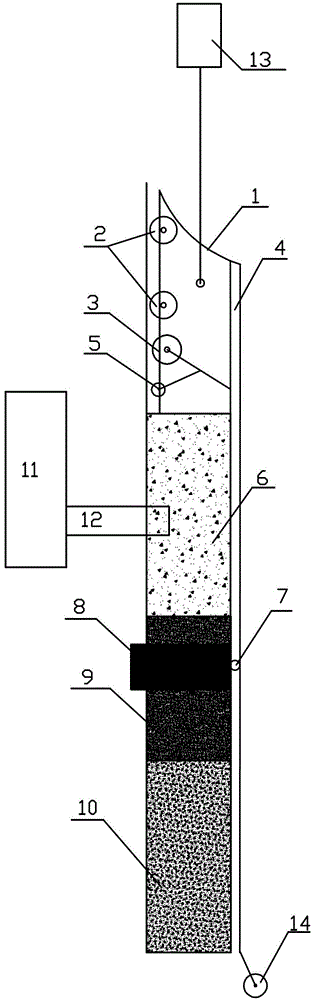

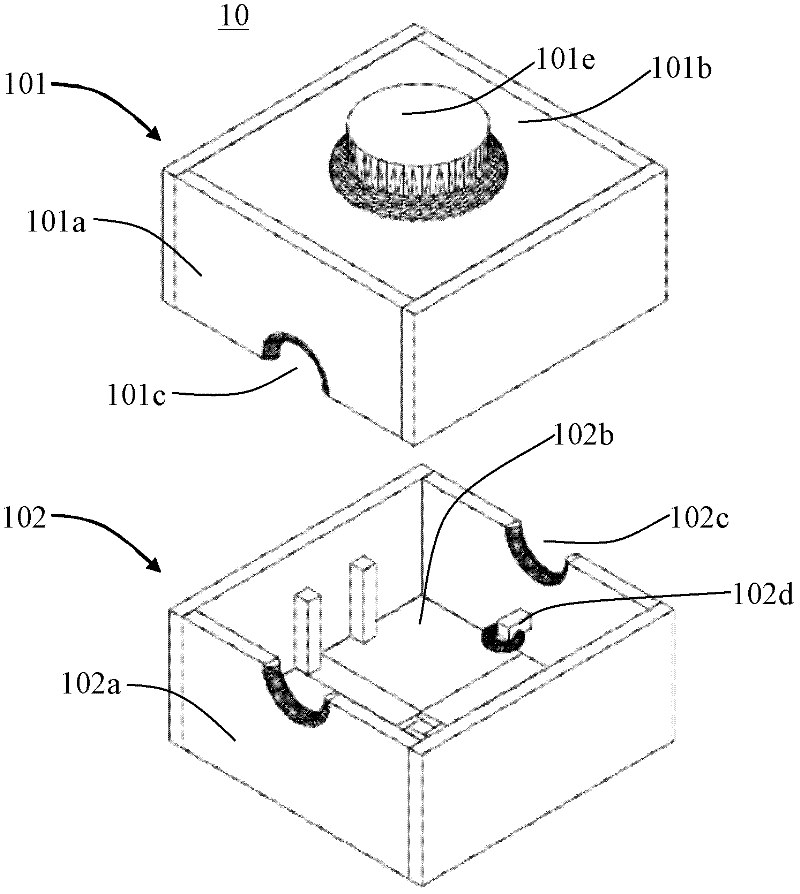

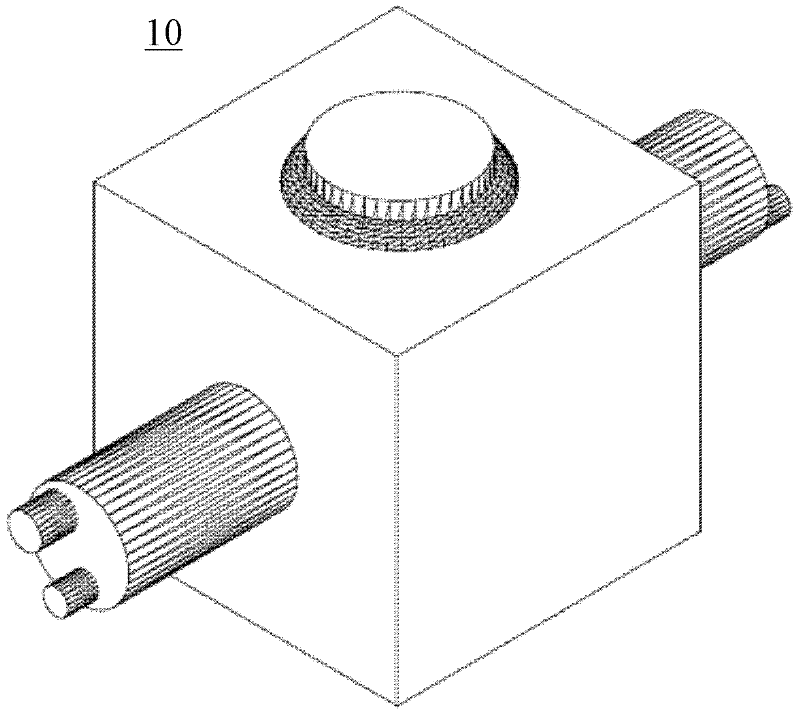

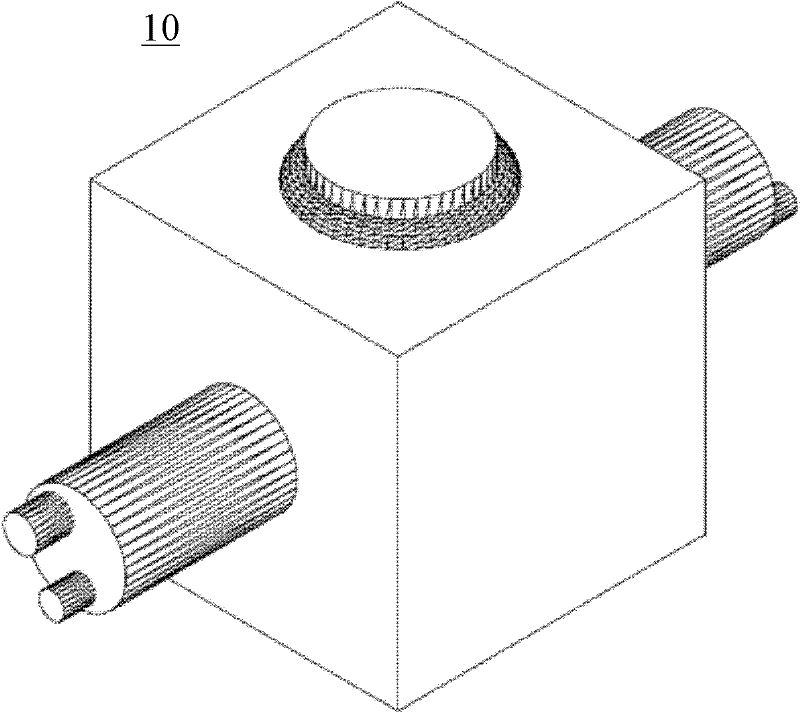

High-rise building garbage transportation system

ActiveCN103790364ASpeed up the construction progressImprove construction efficiencyVertical ductsBatch productionCost savings

The invention discloses a high-rise building garbage transportation system, relates to the technical field of garbage transportation, and aims to provide a high-rise building garbage transportation system which is capable of improving construction efficiency, free of leaving and spilling and raising dust, high in economic benefit and cost saving. The system comprises a special garbage bin arranged in a vertical opening of a tower core tube, a slowing-down device arranged on the inner wall of the special garbage bin, a weight limiter (8) arranged at the bottom end of the special garbage bin and a garbage classification recycling device arranged at the position of a garbage outlet on the first floor. By the system, construction progress is accelerated greatly, construction efficiency is improved, and construction time and space for main construction work are prevented from being occupied. Meanwhile, a closed system is adopted in the whole process, classified packing is realized, classified transportation and transfer of garbage are achieved, leaving and spilling and raising dust are avoided, and on-site civilized construction is guaranteed. In addition, the system after being optimized is capable of realizing batch production, becomes a standardized system, and is popularized and applied for providing a powerful efficient convenient mode for super high-rise building garbage transfer.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

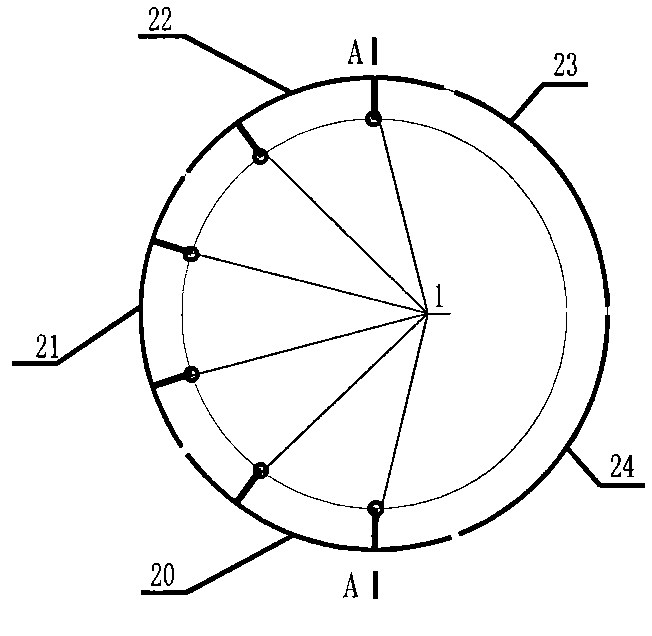

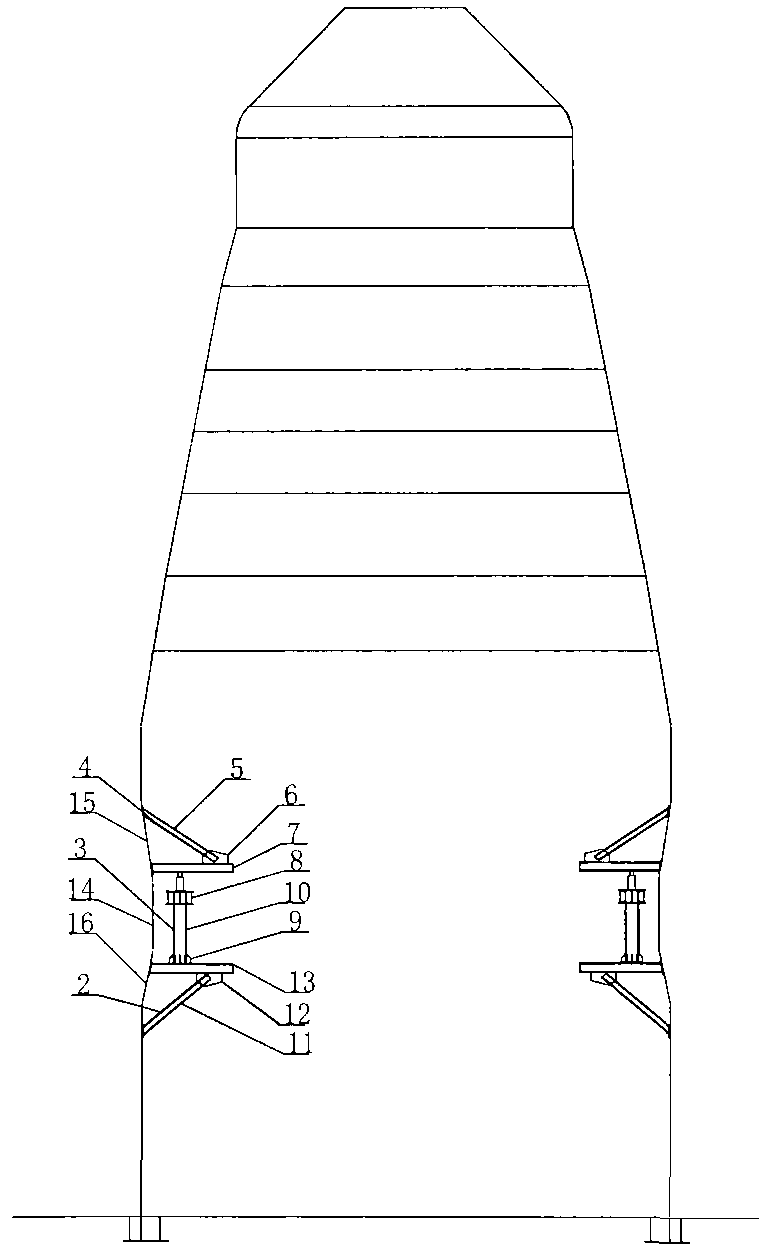

Installation method for quickly removing and replacing middle-section furnace casing of large blast furnace

ActiveCN101984078AReduce material usageSpeed up the construction progressBlast furnace componentsBlast furnace detailsMaterial consumptionStructural engineering

The invention relates to an installation method for quickly removing and replacing a middle-section furnace casing of a large blast furnace, belonging to the field of installation and construction of a metallurgical construction engineering metal structure. The invention provides a construction method for quickly removing and replacing the middle-section furnace casing after the installation of the entire blast furnace is finished, which comprises the following steps: dividing the furnace casing to be replaced into five sheets, manufacturing six temporary supports 1 before the replacement, and installing the six temporary supports 1 at three adjacent furnace casing sheets to be replaced (20, 21 and 22), wherein each furnace casing sheet to be replaced is provided two temporary supports 1; firstly replacing the first and the second furnace casing sheets (20 and 21), removing the two temporary supports 1 positioned at the first furnace casing sheet 20 after installation and fixation, and installing the two temporary supports 1 at a fourth furnace casing sheet 23 to be replaced, wherein the third and the fourth furnace casing sheets 22 and 23 are replaced simultaneously while the temporary supports are removed and installed; and replacing a fifth furnace casing sheet 24 without moving the temporary supports. The method does not destroy the overall stability of the structure, realizes the safe and reliable construction operation, has low material consumption for the temporary supports and ensures that the whole process can be finished in seven days, thereby achieving the effects of shortening the construction period and lowering the construction cost.

Owner:CHINA MCC 2 GRP CO LTD

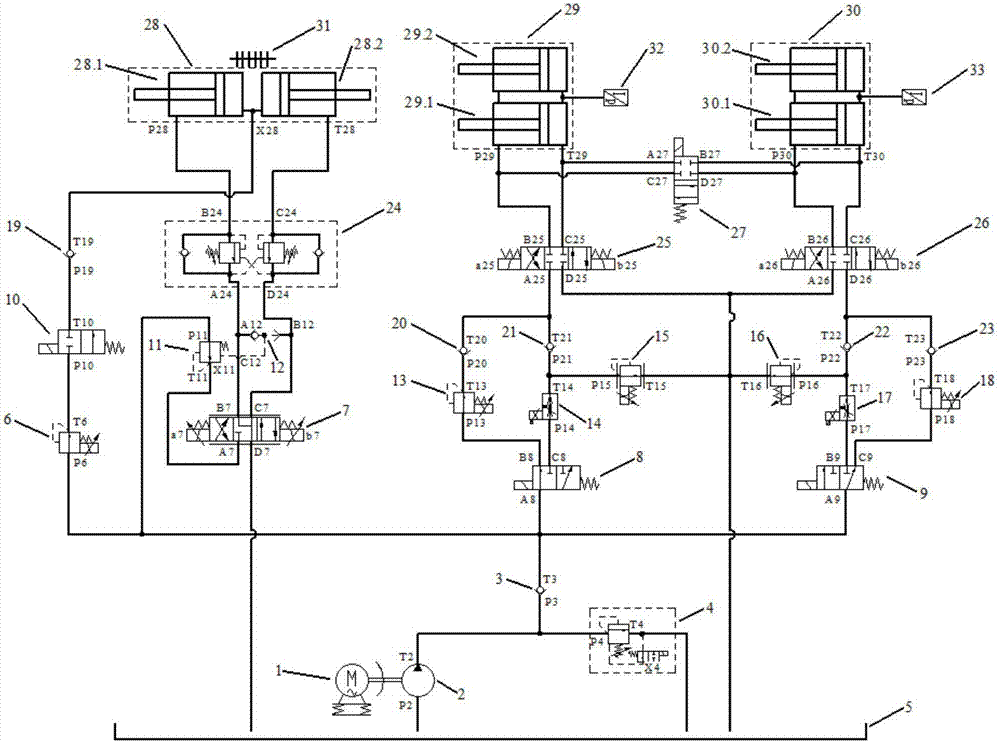

Hydraulic system for adjustment of level posture of hard-rock heading machine

ActiveCN107060797AImprove molding qualitySpeed up the construction progressFluid-pressure actuator testingServomotor componentsElectric machineryFuel tank

The invention discloses a hydraulic system for adjustment of a level posture of a hard-rock heading machine. The hydraulic system comprises a motor, a high-pressure pump, an electromagnetic unloading valve, six one-way valves, three proportional pressure reducing valves, a three-unit-four-passage electromagnetic proportional directional valve, two two-unit-three-passage electromagnetic directional valves, a two-unit-two-passage electromagnetic directional valve, a uniform-pressure-drop valve, a shuttle valve, two compensated flow control valves, two proportional overflow valves, a balance valve, two three-unit-four-passage electromagnetic directional valves, a two-unit-four-passage electromagnetic directional valve, a displacement sensor, two pressure sensors, six hydraulic cylinders and a fuel tank. According to the hydraulic system for adjustment of the level posture of the hard-rock heading machine, the influence of loading pressure surge on the displacement of the boot-supporting hydraulic cylinders can be reduced, the deviation of a track posture can be rectified rapidly, and the disturbing force of the hard-rock heading machine is reduced when the level posture is adjusted; and the problem that a tunnel deviates a preset track is solved, the forming quality of the tunnel is improved, and the construction progress is accelerated.

Owner:ZHEJIANG UNIV

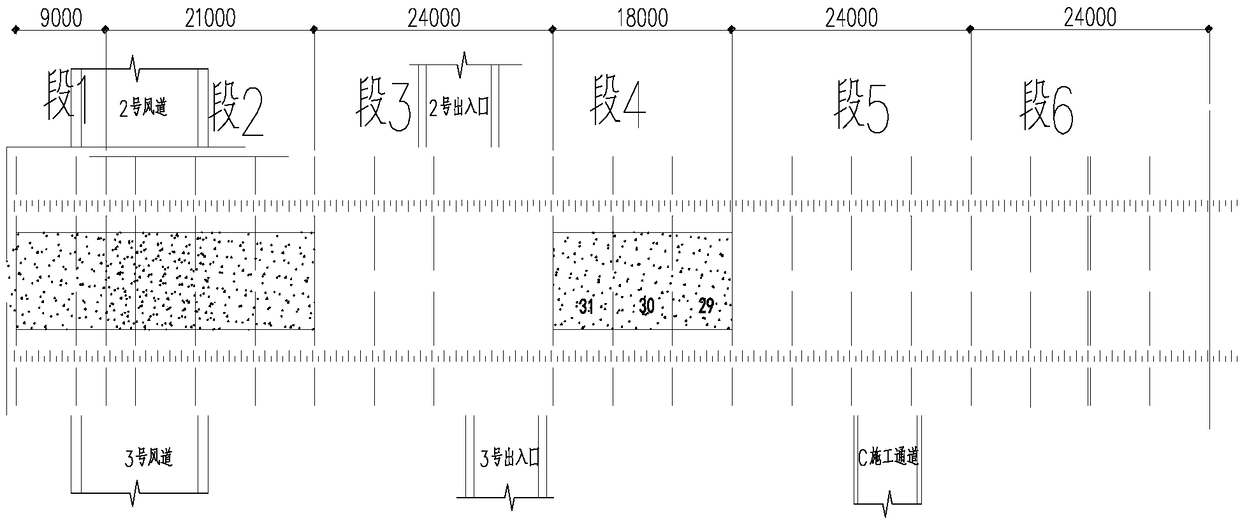

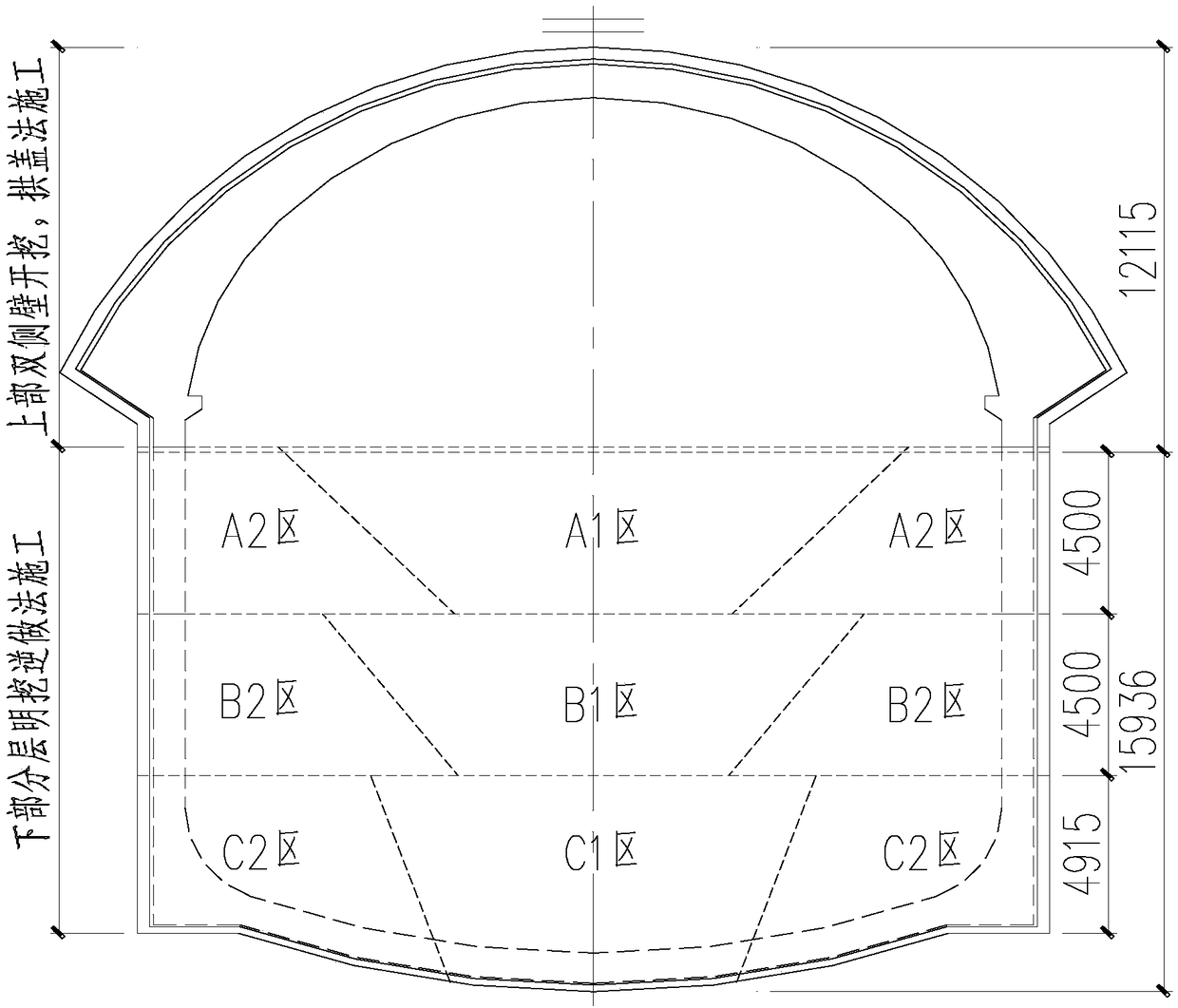

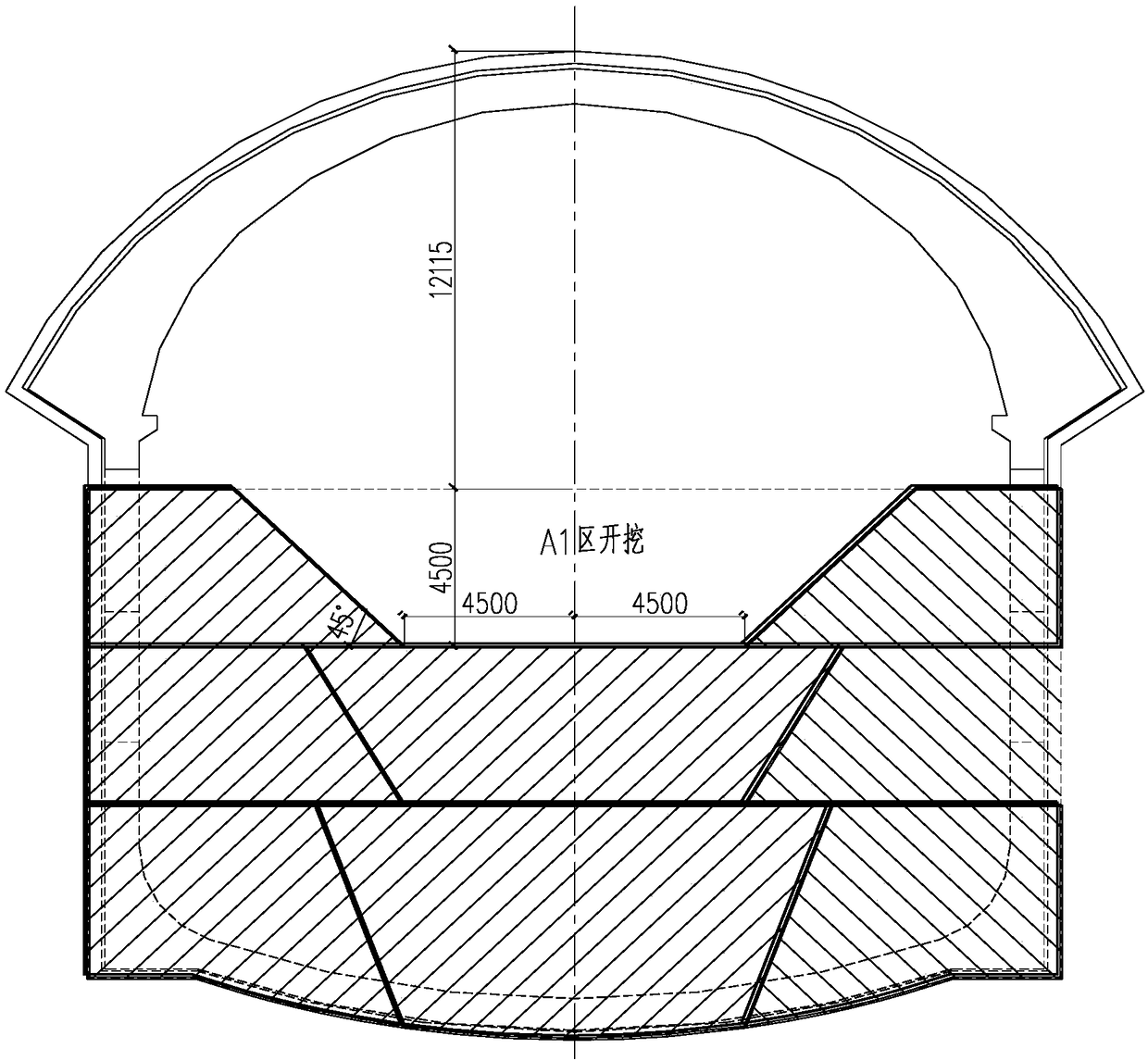

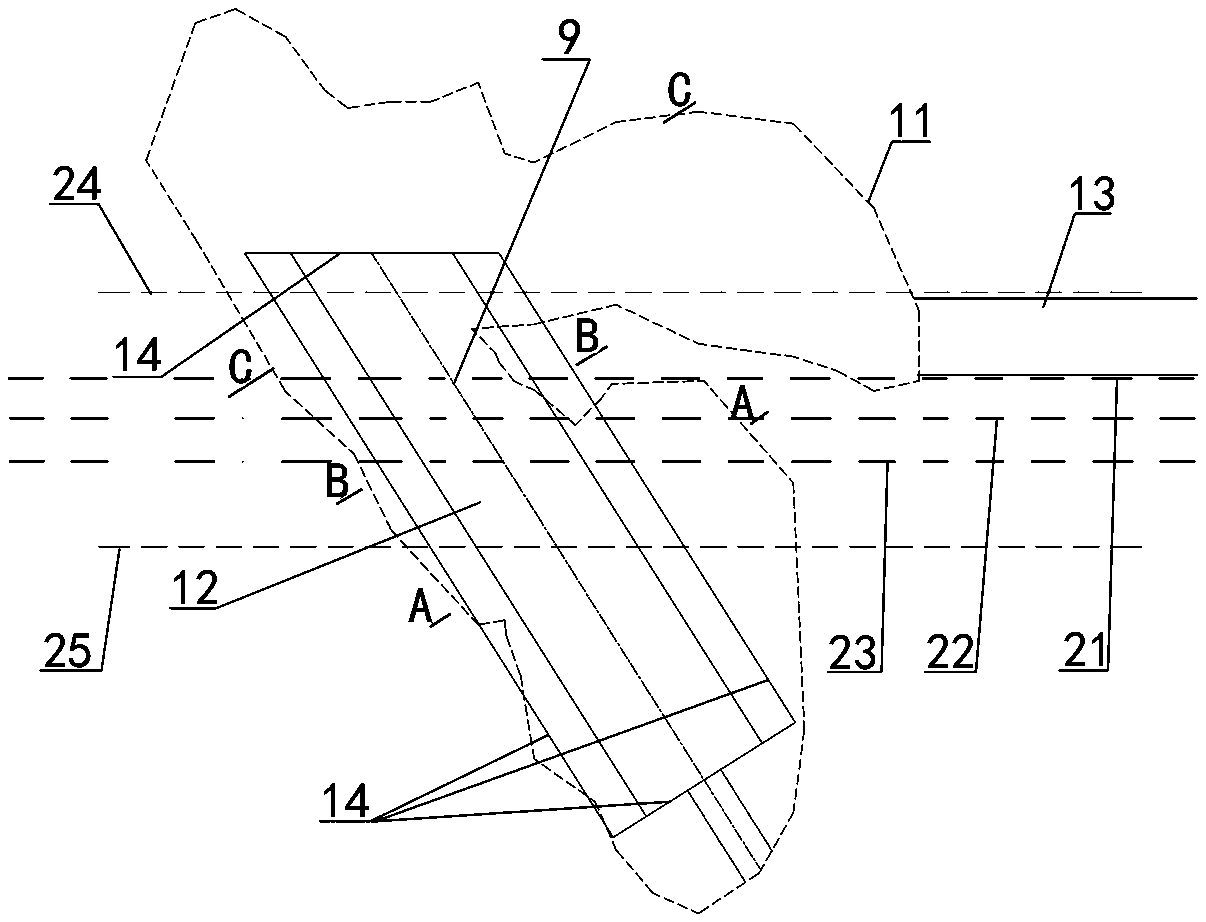

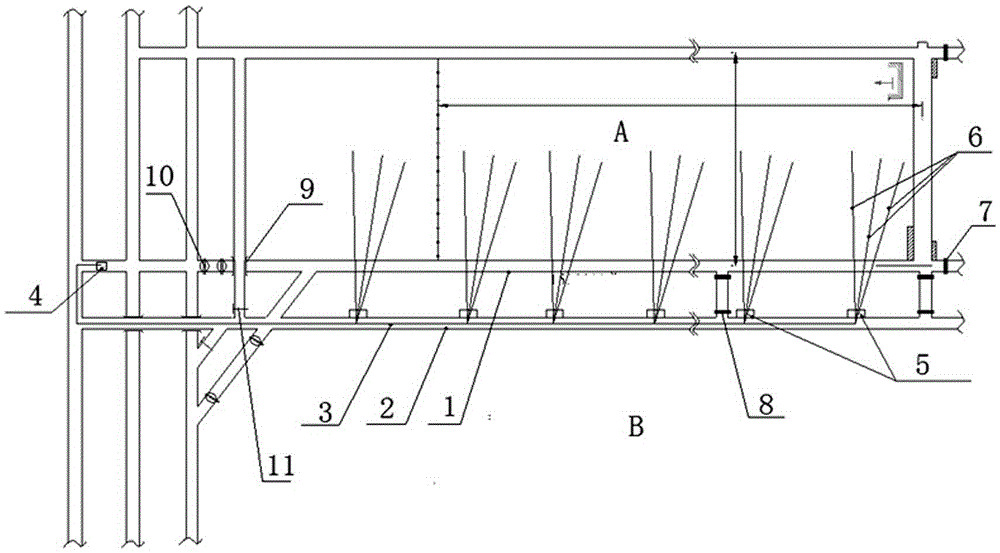

Rapid construction method for excavation of lower portion of ultra-large cross-section metro station through large arch cover method

InactiveCN108266209AEnsure construction safetySpeed up the construction progressUnderground chambersTunnel liningMetro stationEngineering

The invention discloses a rapid construction method for excavation of the lower portion of an ultra-large cross-section metro station through a large arch cover method. After an arch cover secondary lining is constructed, the middle and lower portion of the station are constructed by adopting a layered and sectioned quit excavation sequential-excavation mode. The method comprises the specific construction steps that (1), according to the length of the station, the station is divided into multiple sections, and according to the height, the middle and lower portion of the station are divided into multiple layers; (2), a first-layer middle trough is pulled in the first layer of the first section, a first horse mouth quit trough is excavated, then soil on the two sides of the first-layer middle trough are excavated, preliminary supports and side wall secondary linings are constructed, steel supports are erected on the first layer, and construction as that of the first layer is conducted onthe other layers located under the first layer till the first section is excavated to the bottom; and (3), construction of the other sections is conducted as the step (2). According to the method, sectioned quit excavation is conducted, a plurality of operation faces are simultaneously constructed, the construction progress is stepped up while the construction safety is ensured, meanwhile reversely-constructed construction seams are reduced, and the waterproof quality at structural construction seams is ensured.

Owner:RANKEN RAILWAY CONSTR GROUP

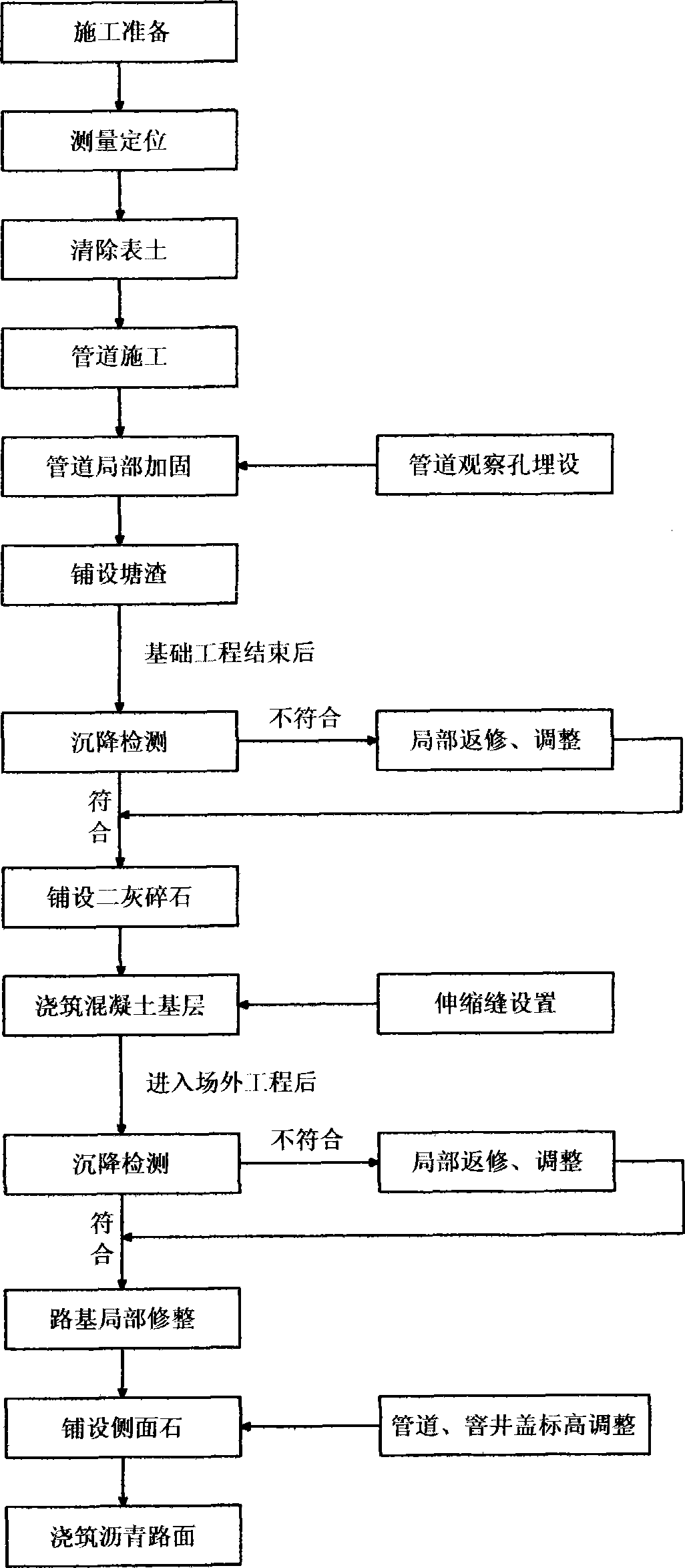

A single time construction method for temporary and permanent roads

InactiveCN101424063ALow costSpeed up the construction progressIn situ pavingsTopsoilRoad construction

The invention discloses a one-time construction method for temporary and permanent roads, which comprises the concrete steps of: construction preparation, survey positioning, topsoil removal, pipeline construction, local pipeline reinforcement, roadbed paving, local roadbed dressing, side stone paving, and asphalt pavement pouring. The method has the characteristics of saving materials, saving energy, accelerating construction progress, saving the time for repeated road construction, and reducing the pollution caused by secondary excavation.

Owner:浙江中联建设集团有限公司

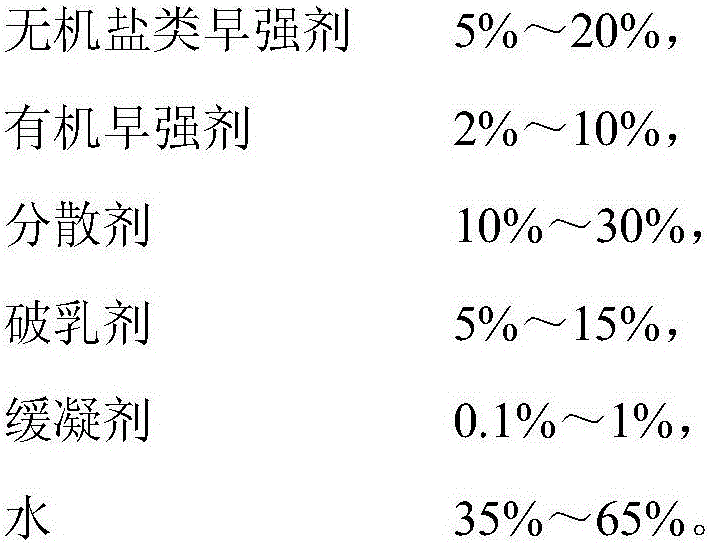

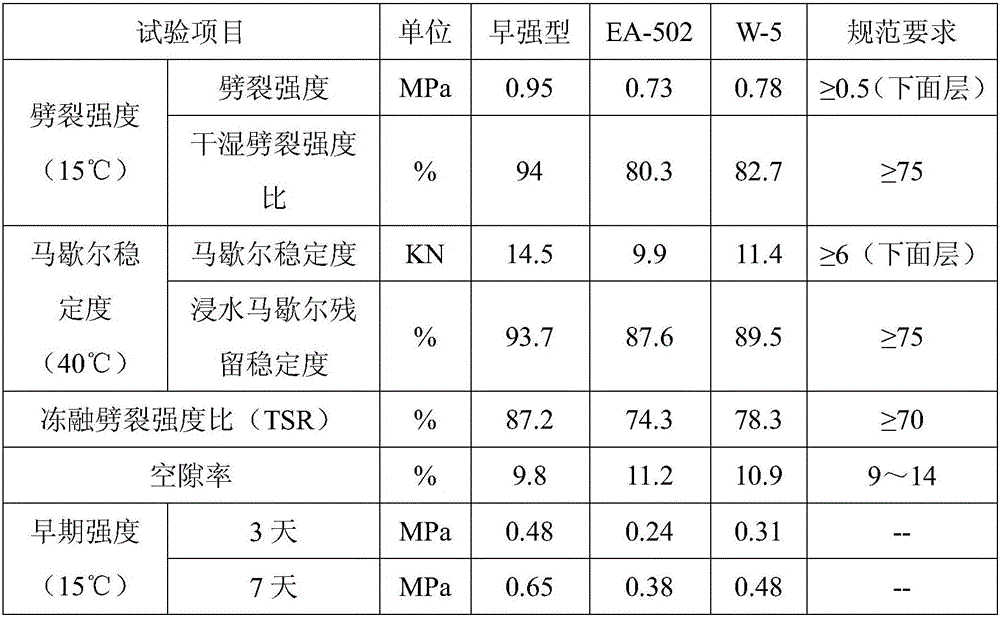

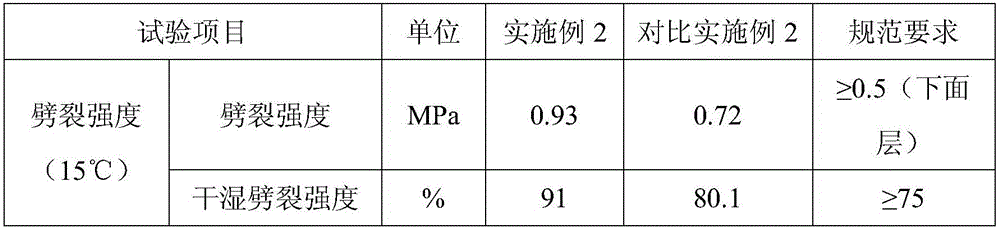

Compound early strength agent for cold-recycling of emulsified asphalt and preparation method and application of compound early strength agent

ActiveCN105713402ASpeed up the construction progressGood for promotion and applicationBuilding insulationsInorganic saltsAsphalt

The invention discloses a compound early strength agent for cold-recycling of emulsified asphalt. The compound early strength agent for cold-recycling of emulsified asphalt is prepared from, by mass, 5-20% of an inorganic salt type early strength agent body, 2-10% of an organic early strength agent body, 10-30% of a dispersing agent, 5-15% of demulsifier, 0.1-1% of retarder and 35-65% of water. According to the complex early strength agent, early strength improvement of a cold recycled mixture of emulsified asphalt is accelerated in two directions of acceleration of hydration of cement and promotion of demulsification of asphalt, the improvement extent can reach 1-3 times, the construction progress can be greatly accelerated, and it is beneficial to apply and popularize a cold-recycling technology emulsified asphalt; raw materials are chemical accessories commonly used in engineering, extremely easy to obtain and moderate in price, a compounding technology is simple, and large-scale production and application can be met; the long-term strength, volume index and water stability of the prepared cold recycled mixture of emulsified asphalt are greatly improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

Method for reinforcing assembly type multilayer brick-concrete structure

ActiveCN103352583ASpeed up the construction progressShorten the construction periodBuilding repairsProtective buildings/sheltersSteel tubeEngineering

The invention relates to a method for reinforcing an assembly type multilayer brick-concrete structure, and belongs to the technical field of seismic strengthening. The assembly type multilayer brick-concrete structure comprises an original multilayer brick-concrete structure and further comprises a square steel concrete constructional column, a steel channel ring beam and a flat steel drawing rod. The square steel concrete constructional column is arranged outside the original multilayer brick-concrete structure, the outer side of the longitudinal wall, the outer side of the gable wall and the crossed intersection point of the longitudinal wall and the transverse wall, and a constructional column foundation is arranged on the lower portion of the square steel concrete constructional column. The steel channel ring beam is arranged on the square steel concrete constructional column along the floor height, and the square steel concrete constructional column and the steel channel ring beam are connected together through an external-added clapboard supporting beam bolt. The prestress flat steel drawing rod is arranged on the transverse wall inside the original multilayer brick-concrete structure. The method effectively overcomes the defects in the original reinforcing method, improves the construction speed, increases structural safety, and has significance for further researching and implementing seismic strengthening of the existing house of the brick-concrete structure, comprehensively reconstructing the old house and perfecting and improving a seismic strengthening method.

Owner:亚都建设集团有限公司

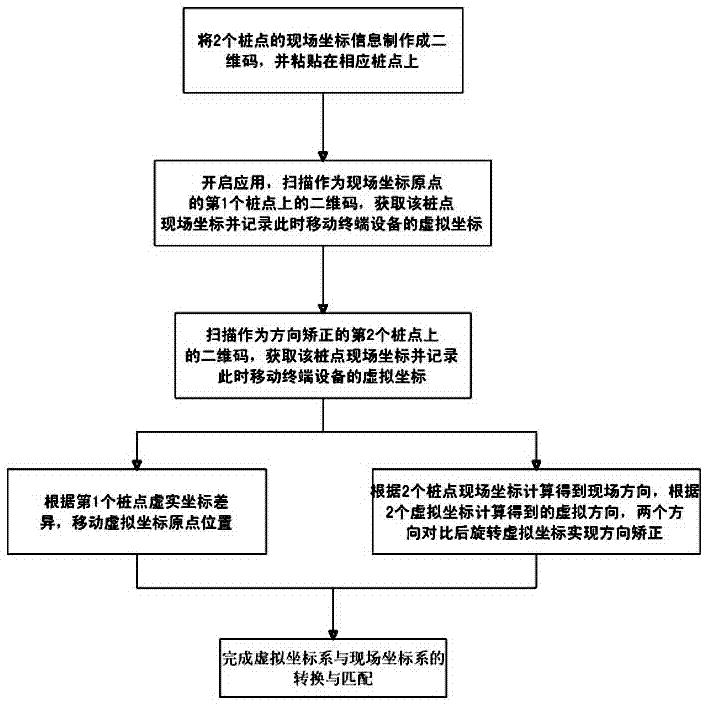

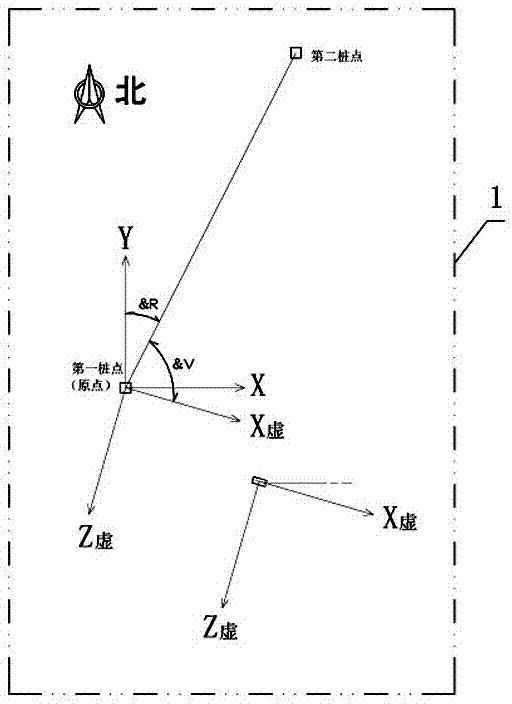

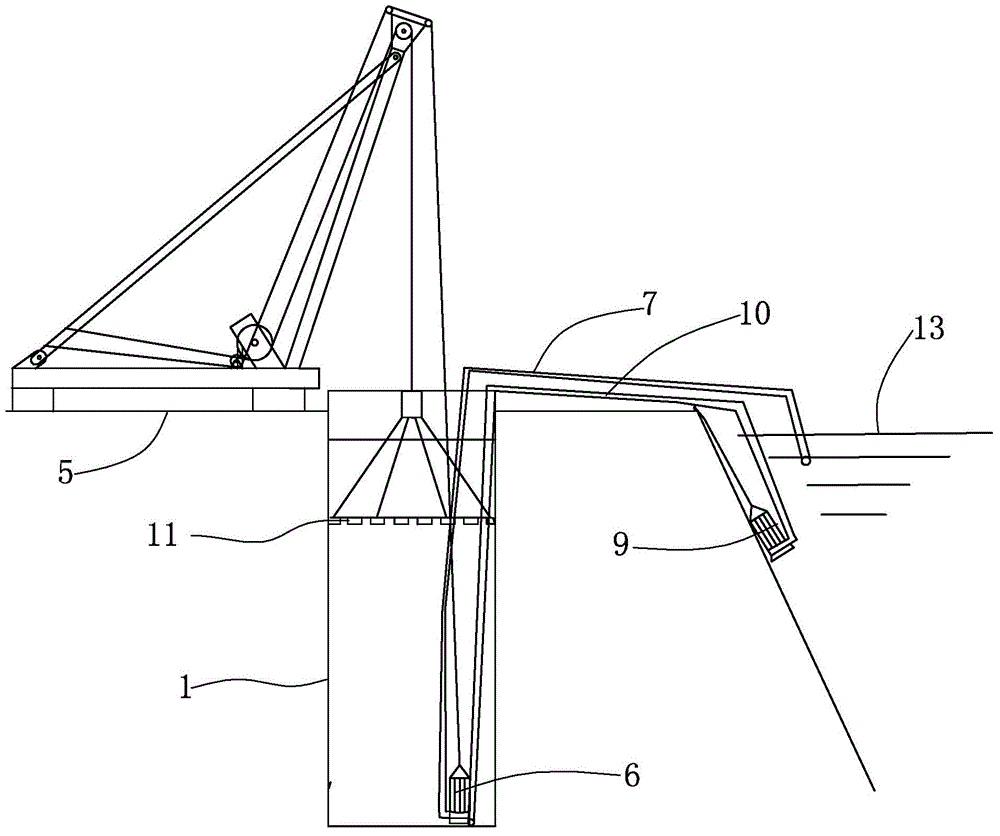

Mobile augmented reality matching method for virtual coordinates and construction field coordinates

ActiveCN107958491ASpeed up the construction progressLess investmentGeometric CADData processing applicationsVirtual coordinatesVirtual coordinate systems

The invention discloses a mobile augmented reality matching method for virtual coordinates and construction field coordinates. The method includes I, establishing an application system developed basedon an Arkit interface; II, pasting a two-dimensional code with pile point field coordinate information on two pile points in a construction field; III, placing a mobile terminal device exactly abovethe first pile point as an origin of coordinates and scans the two-dimensional code on the first pile point, acquires the field coordinates of a field coordinate system of the pile point, and acquiresthe virtual coordinates of the mobile terminal device in the virtual coordinate system synchronously, and modifying the position of the origin of coordinates of the virtual coordinate system; IV, through scanning the two-dimensional code on the second pile point, acquiring the field coordinates of the second pile point in the field coordinate system and the virtual coordinates of the mobile terminal device in the virtual coordinate system, and implementing the matching of virtual coordinates and field coordinates finally.

Owner:河南省水利勘测设计研究有限公司

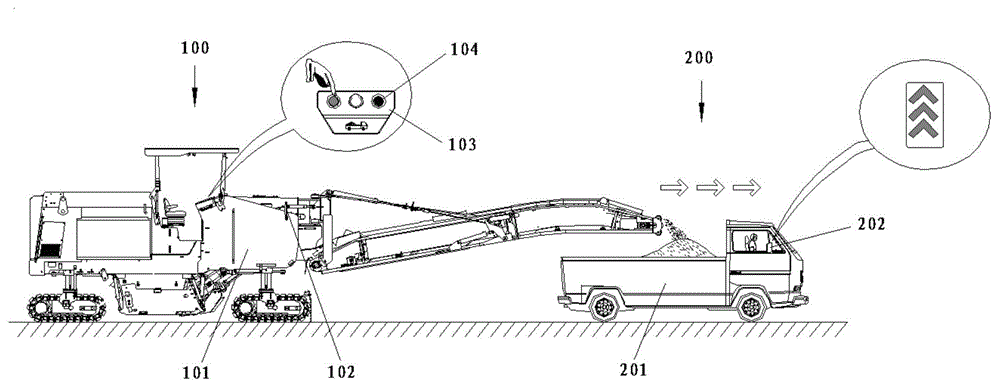

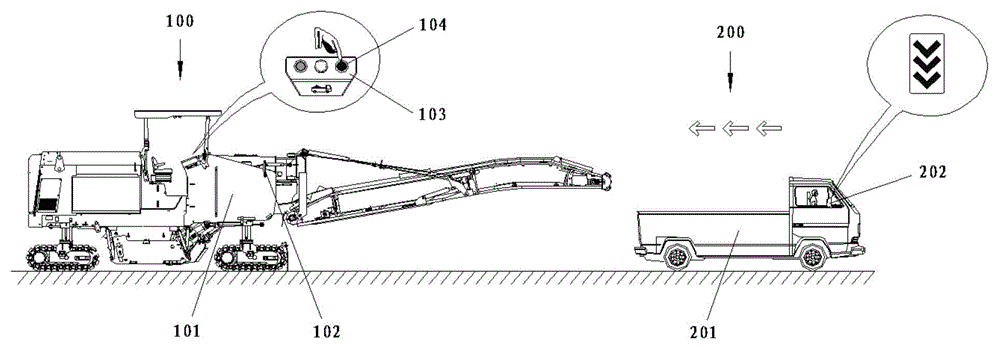

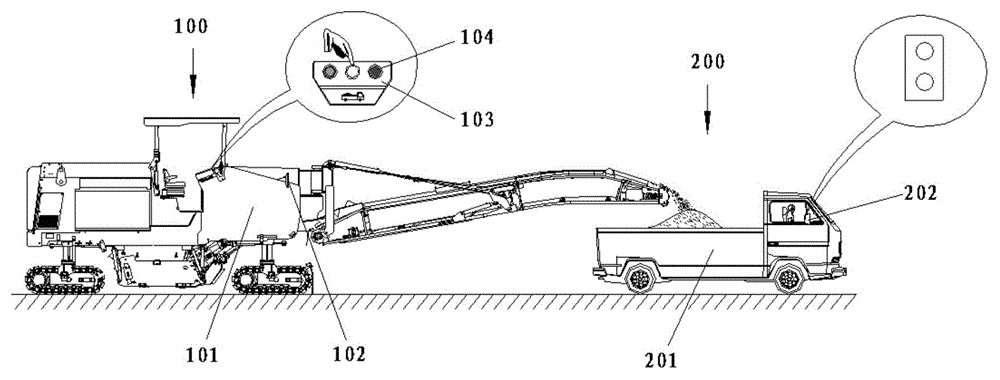

Pavement milling machine

InactiveCN104153282ASpeed up the construction progressImprove construction progressRoads maintainenceDriver/operatorPavement milling

The invention discloses a pavement milling machine which includes a cab, a display screen and a controller of the display screen. The display screen is disposed in the front side of the cab and is towards the front. The controller is disposed in the cab and can allow a corresponding command signal to be displayed on the display screen. Because the position of the cab in the pavement milling machine is high, an operator of the pavement milling machine can operate the controller in the cab according to a situation of a material transportation vehicle so that the corresponding command signal can be displayed on the display screen. A driver of the material transportation vehicle, when observes the command signal by observing the display screen through a rearview mirror of the material transportation vehicle, can move the material transportation vehicle according to the command signal. The operator of the pavement milling machine can send an accurate command signal to the material transportation vehicle, and the driver of the material transportation vehicle, by observing the rearview mirror of the material transportation vehicle, can effectively receive the command signal and then move the material transportation vehicle. By means of the pavement milling machine, the command signal can be sent to the material transportation vehicle effectively so that the material transportation vehicle can be moved timely and a construction progress of the pavement milling machine can be fastened.

Owner:SHANTUI CONSTR MASCH CO LTD

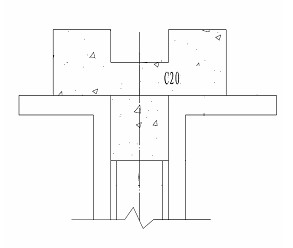

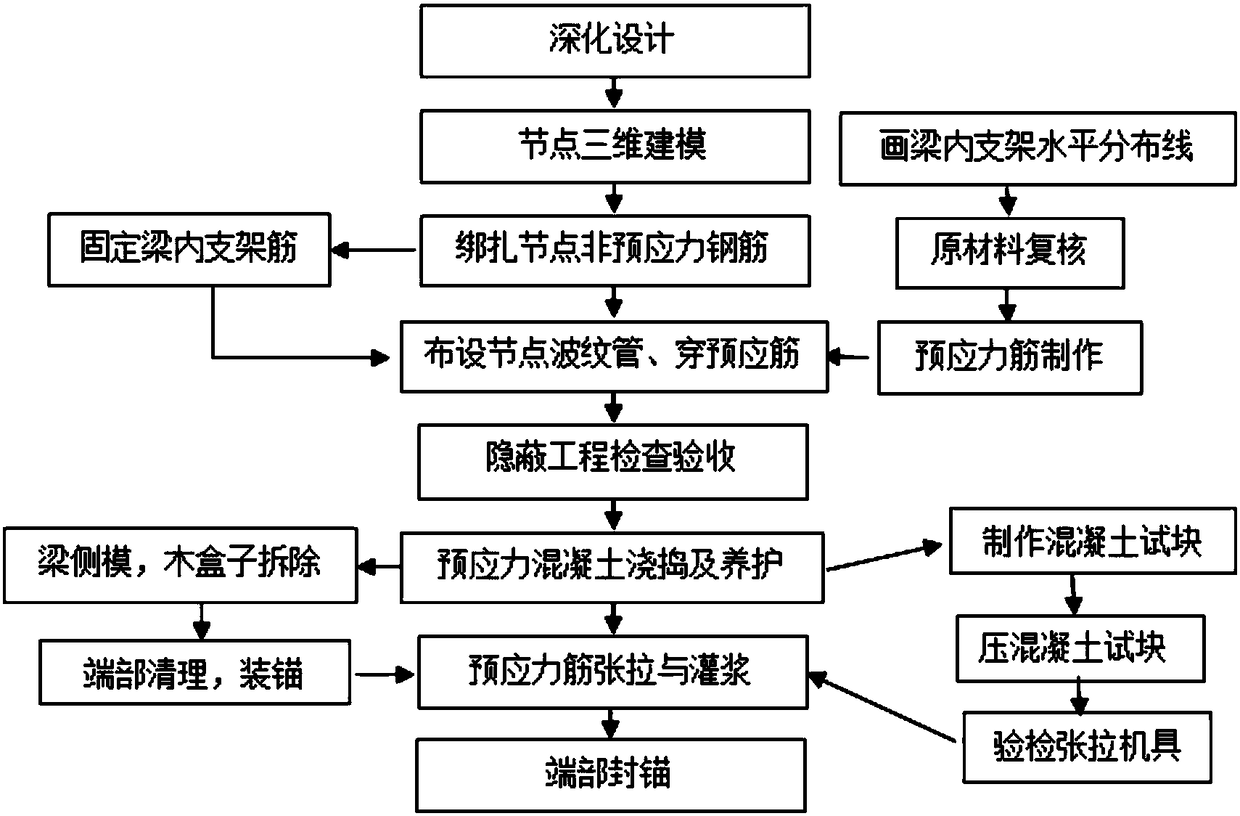

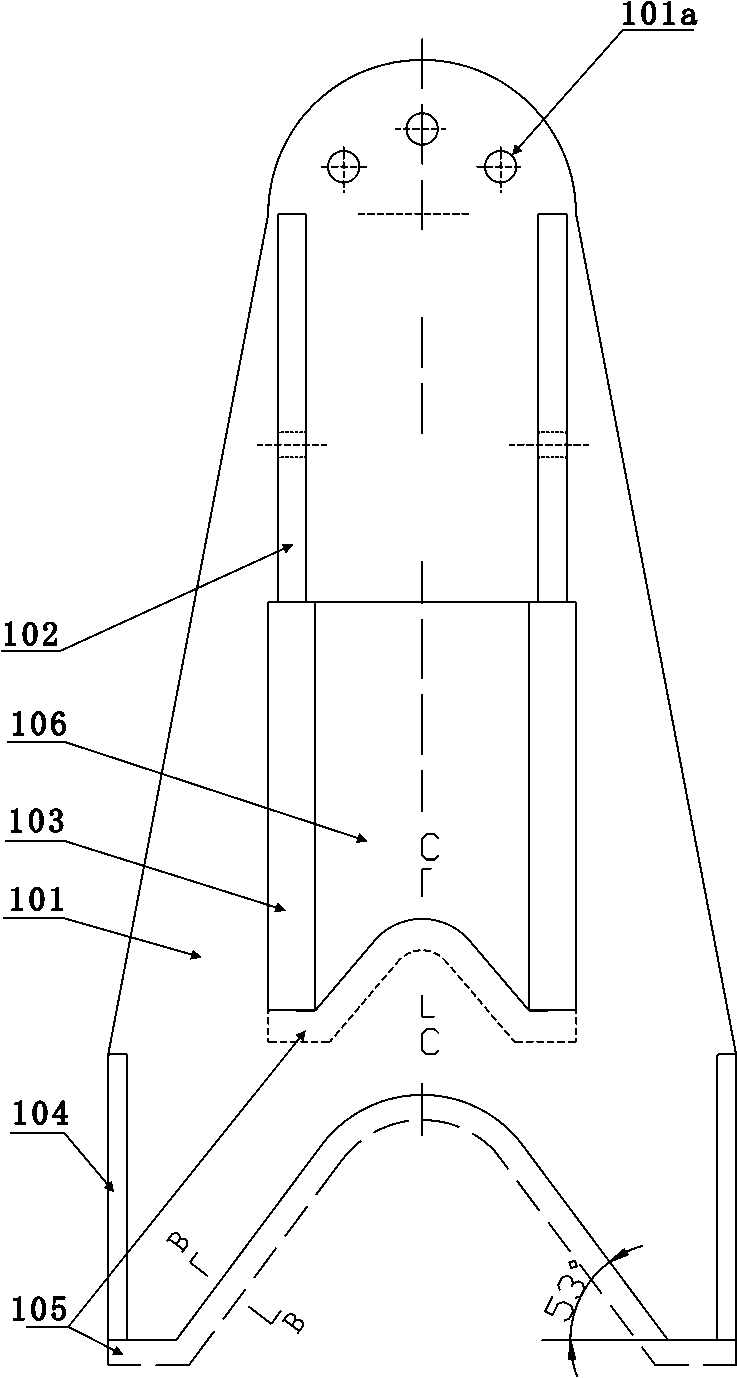

Construction method for haunching bi-directional tension prestressed concrete complex beam-column joints

InactiveCN108343150ASpeed up the construction progressShorten the construction periodBuilding constructionsRebarEngineering

The invention provides a construction method for haunching bi-directional tension prestressed concrete complex beam-column joints. The construction method includes the steps of deepening design, three-dimensional modeling, joint non-prestressed steel bars binding, joint corrugated pipe arrangement, concealed engineering inspection and acceptance, concrete pouring and tamping and maintenance, performing of a prestressed tendon tensioning method, performing of tensioning sequence, end portion sealing anchorage and the like. The construction method for the haunching bi-directional tension prestressed concrete complex beam-column joints accelerates the construction progress, saves the construction period, and ensures the engineering quality of the beam-column joints and the bearing capacity ofjoint areas.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

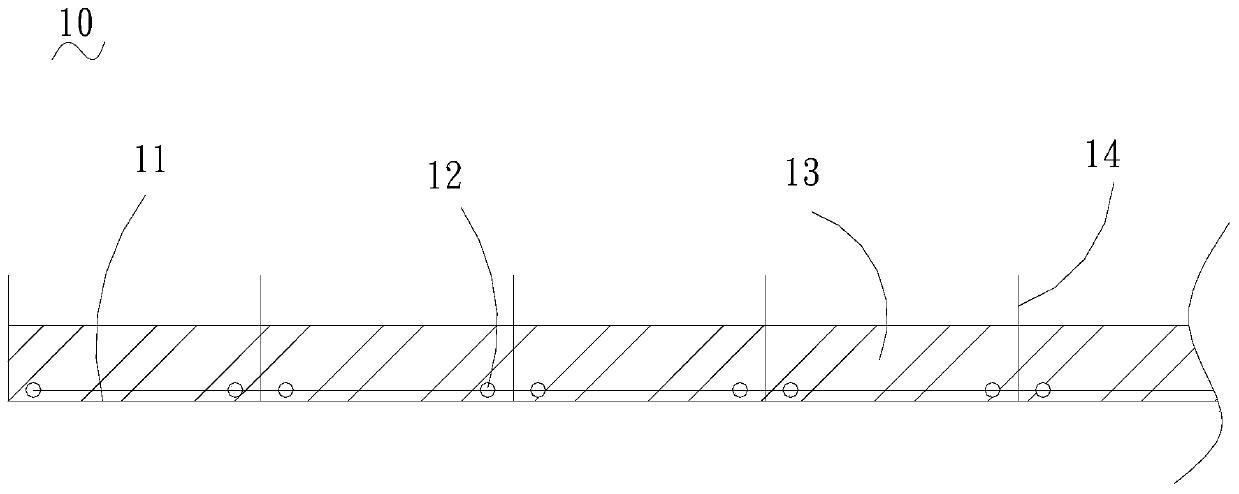

Heavy hammer for excavating rock formation and welding processing method

ActiveCN103225480APreserve qualitySpeed up the construction progressDrill bitsArc welding apparatusSteel platesSpecial design

The invention discloses a heavy hammer for excavating a rock formation. The heavy hammer is characterized by comprising a heavy hammer body, wing plates and a heavy hammer appendage, wherein the heavy hammer body is an integral steel plate; and two pairs of wing plates are added at the tail part of the heavy hammer body, so that the phenomenon that turbulence from the wall of a slotted hole enables the heavy hammer to be tilted when the heavy hammer drops can be overcome, directional striking is realized, the quality of the slotted hole is guaranteed; and four wing plates and the heavy hammer body are symmetrically welded, so that a guiding function is achieved; holes for steel ropes to achieve hoisting are formed in the upper part of the heavy hammer body, concaves formed by colliding and cracking of rock are formed in the front side of the heavy hammer body, and an abrasion-resistant alloy is bead-welded to the concave position for enhancing the abrasion resistance; and two vertical plates are welded on the heavy hammer body, the heavy hammer appendage is welded to the heavy hammer body, and a baffle is welded to the heavy hammer body and used for preventing crushed blocks and uncrushed blocks from flying out when the heavy hammer crushes the rock, and the rock is further crushed until the rock can be lifted. The strength of a hammer head is guaranteed, and at the same time, by means of a special design of the hammer body, shaping recovery of the whole hammer can be guaranteed during striking. Directional striking can be achieved when the hammer strikes the rock formation, so that the working efficiency is improved, and the construction period is shortened.

Owner:滕州方冠企业管理咨询有限公司

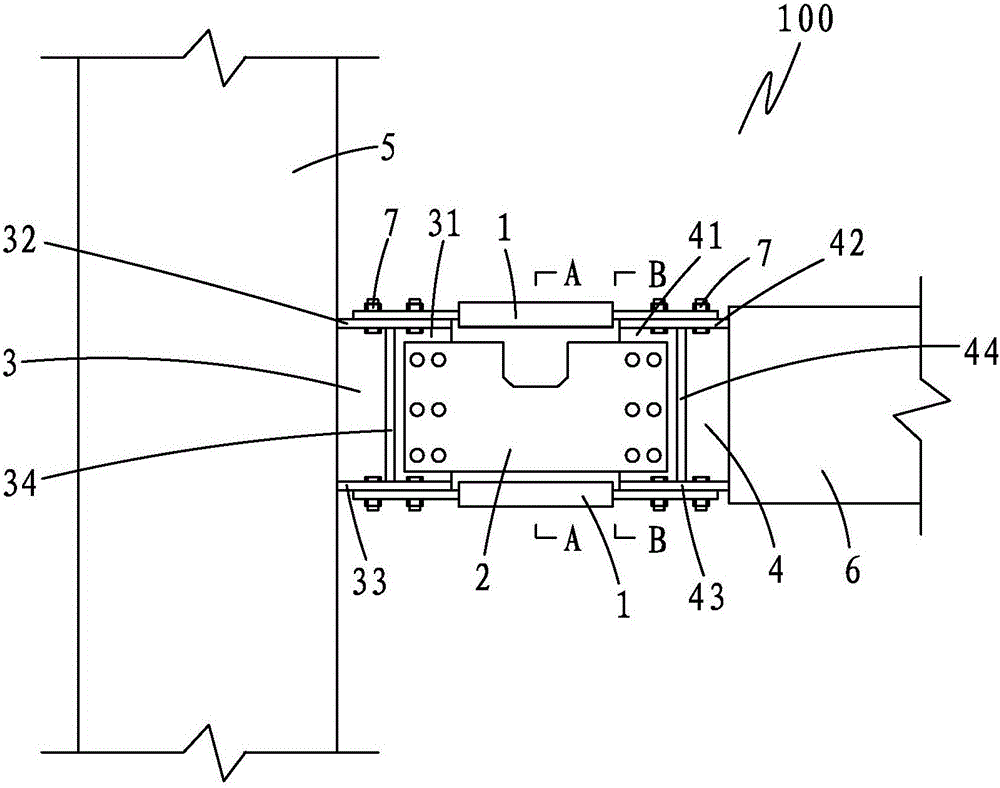

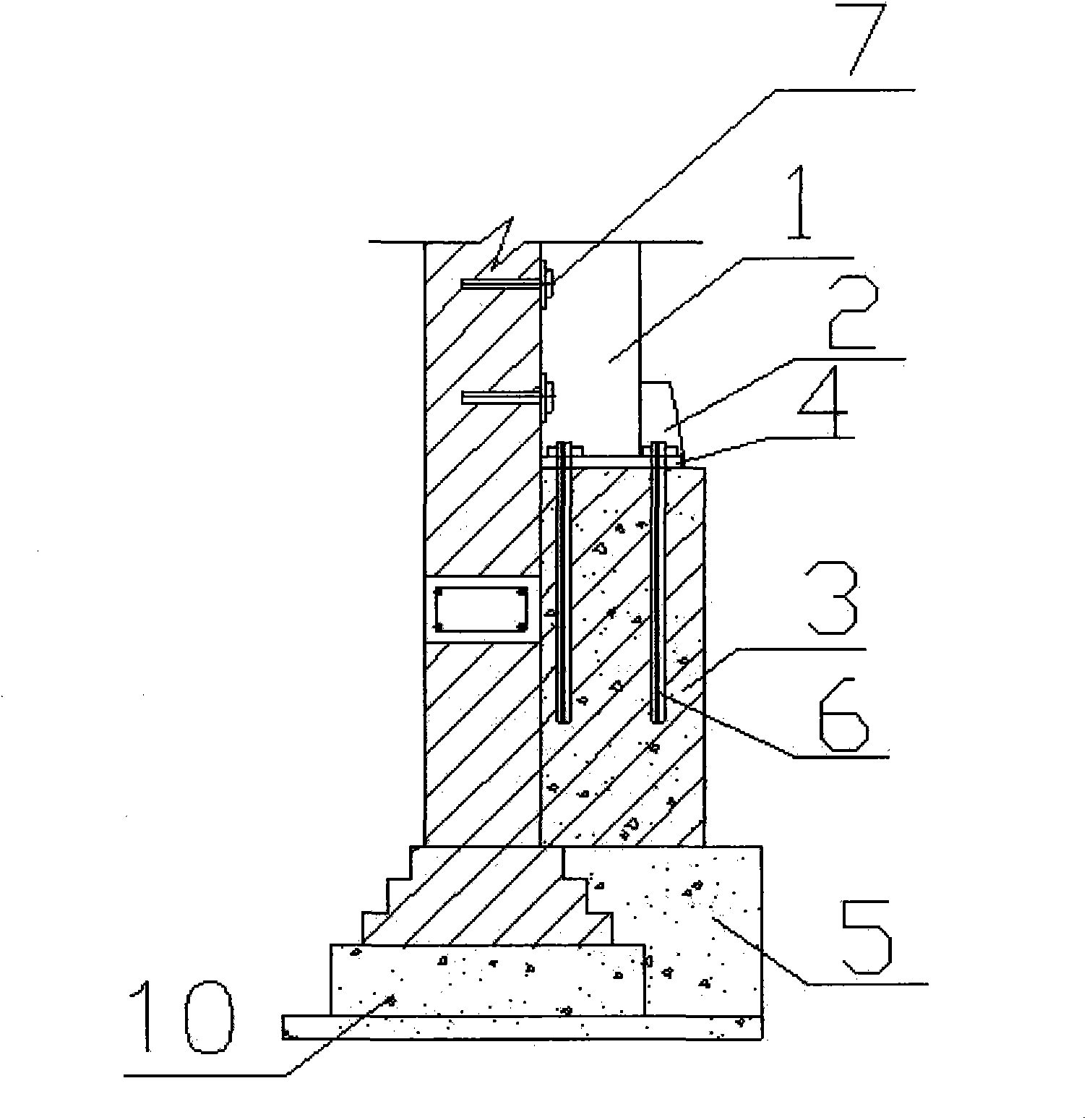

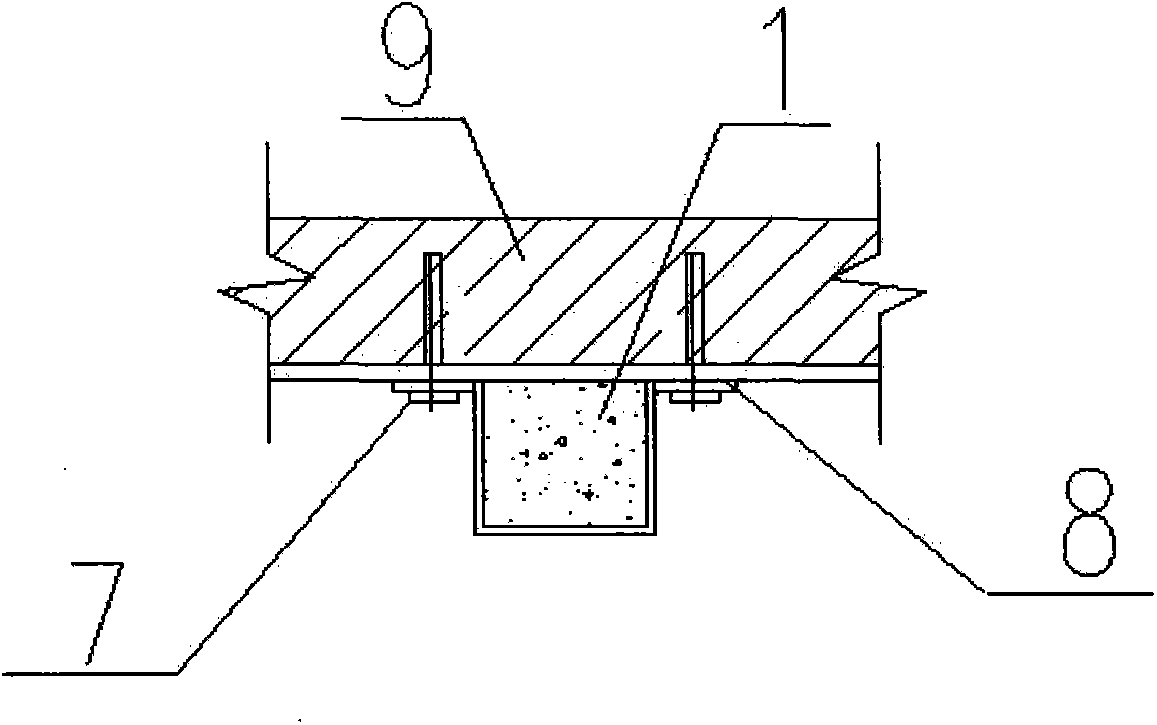

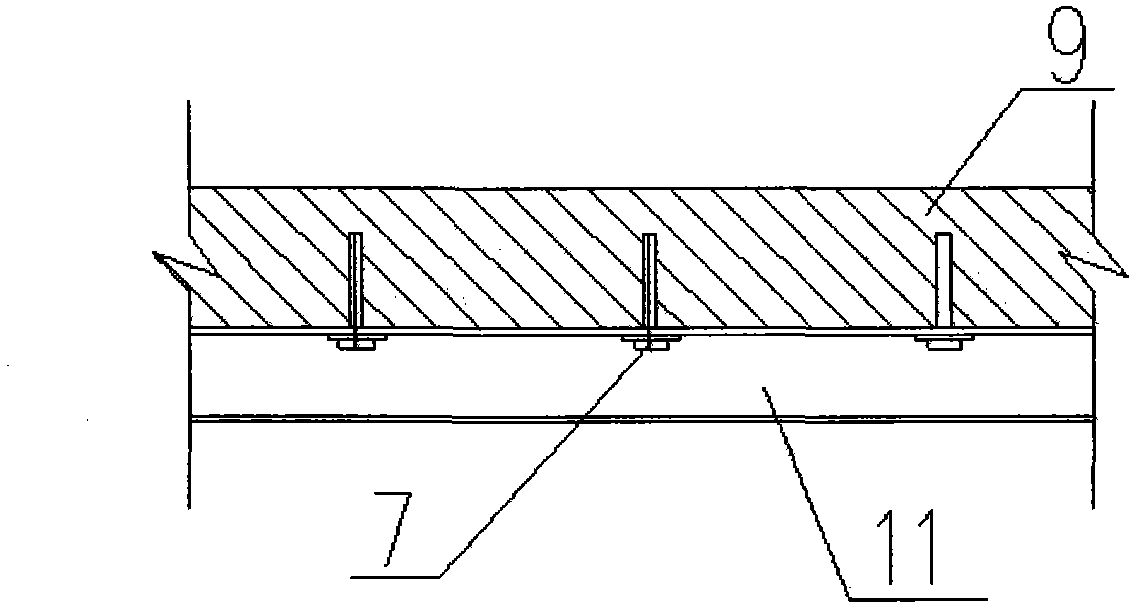

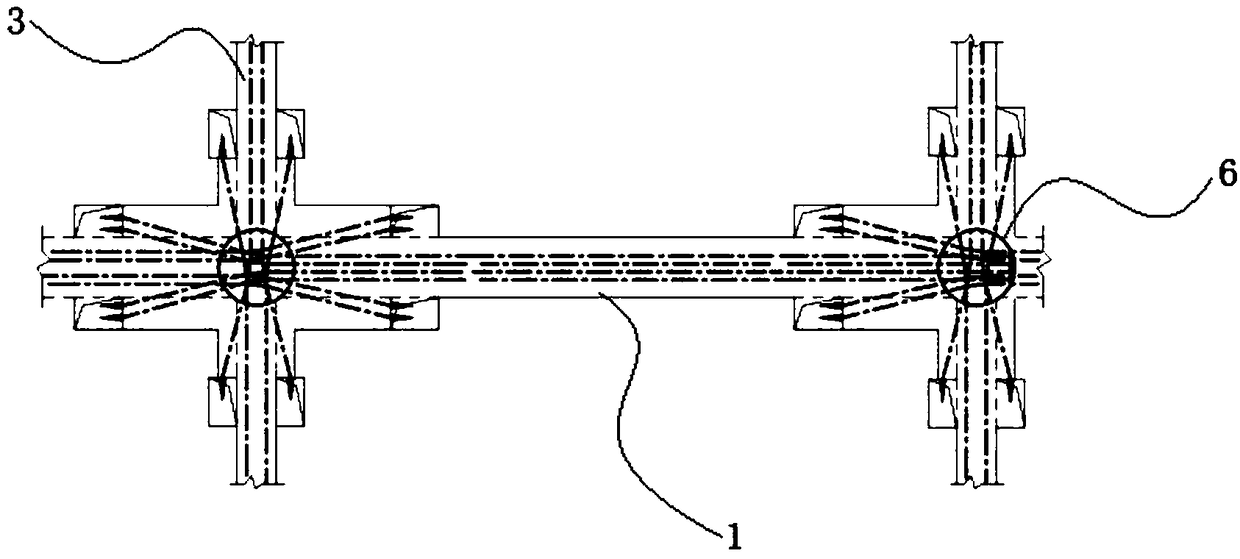

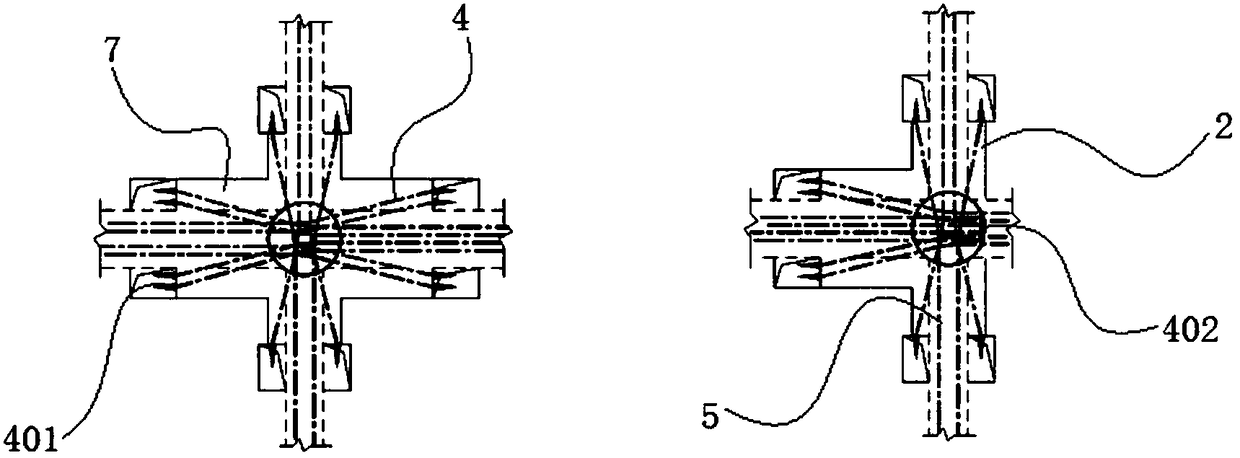

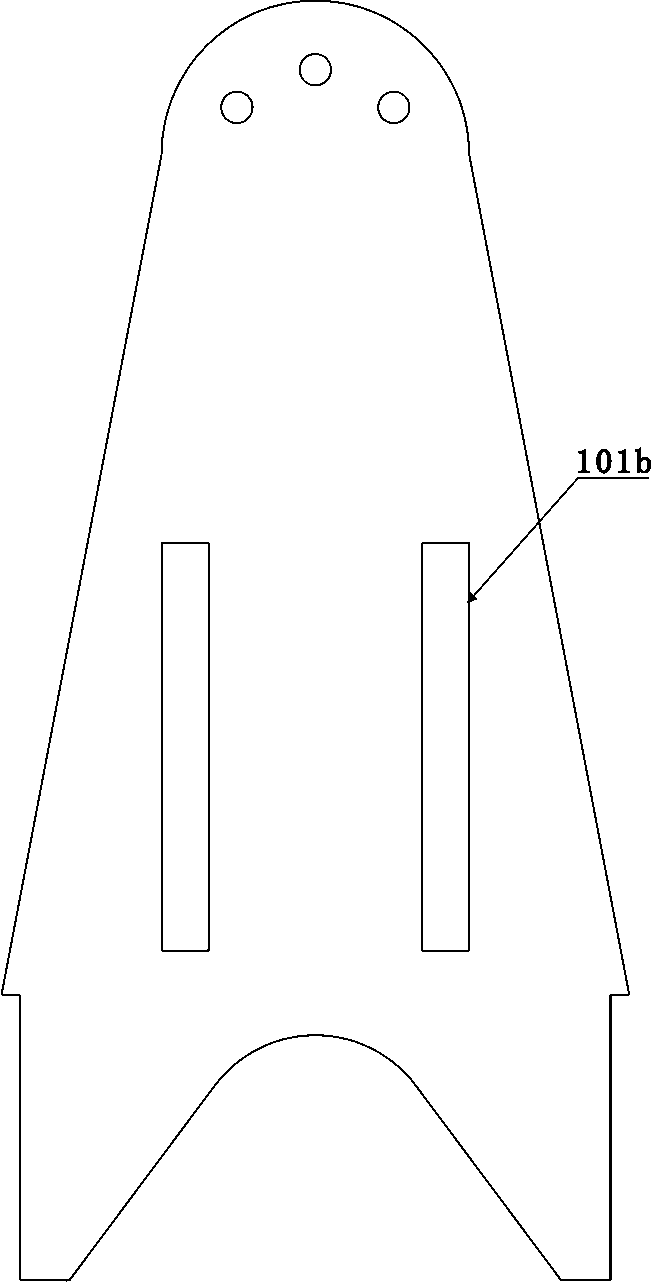

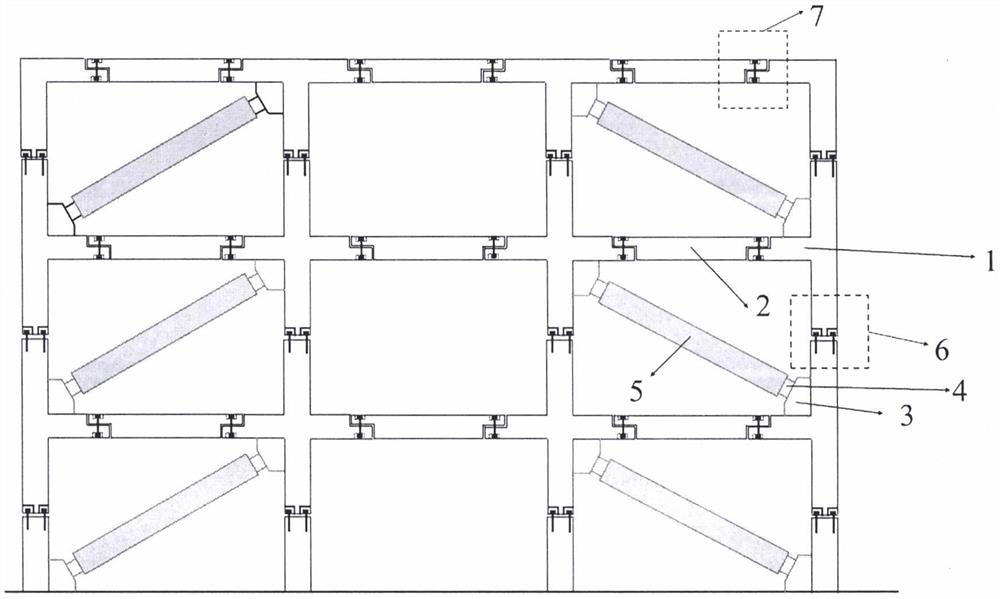

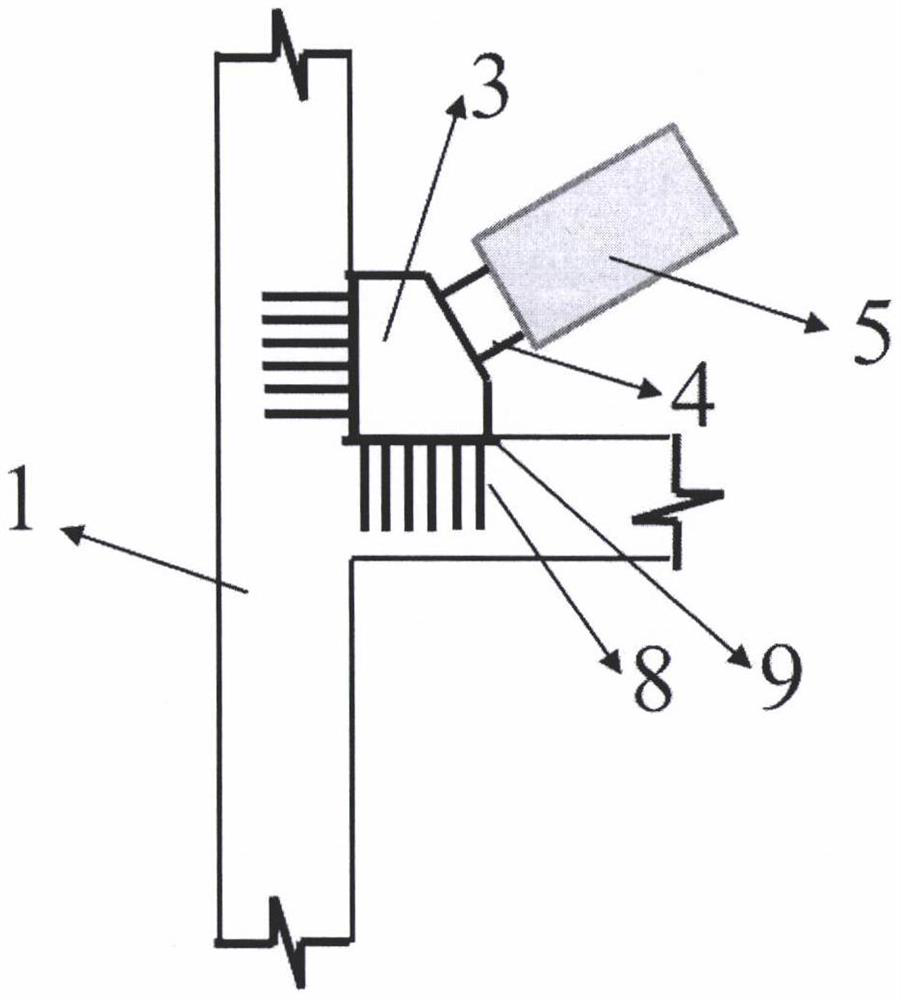

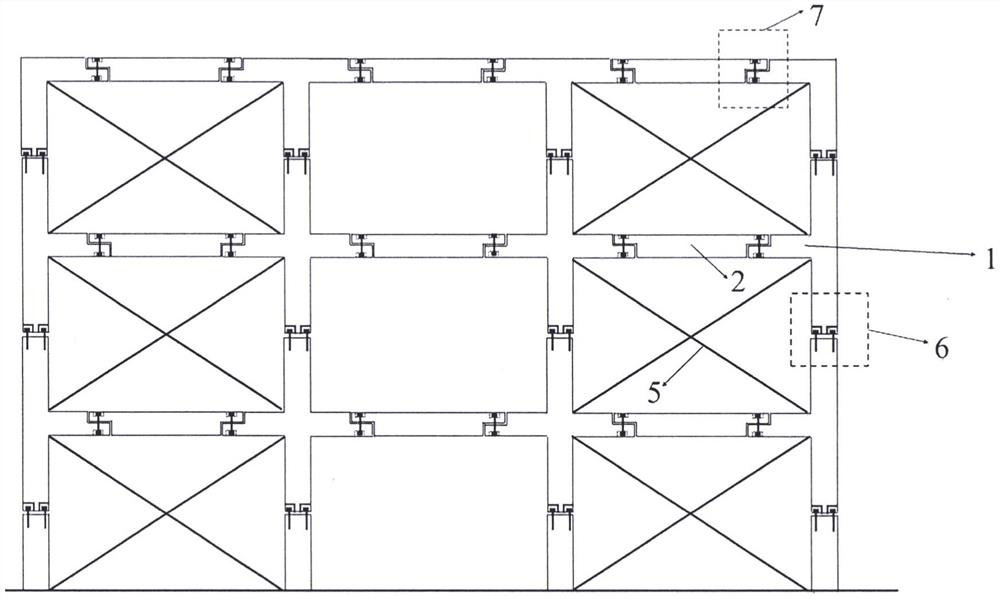

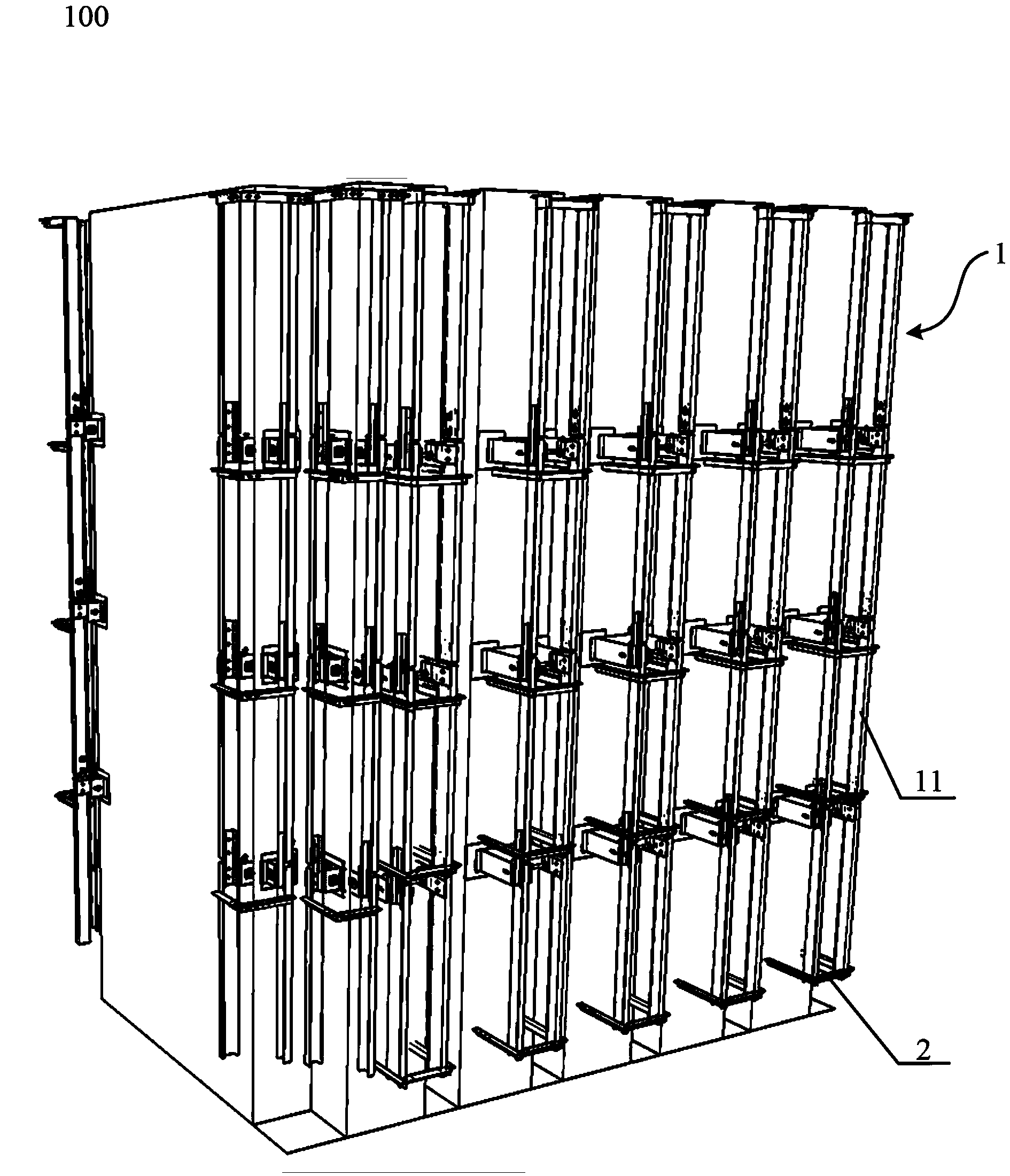

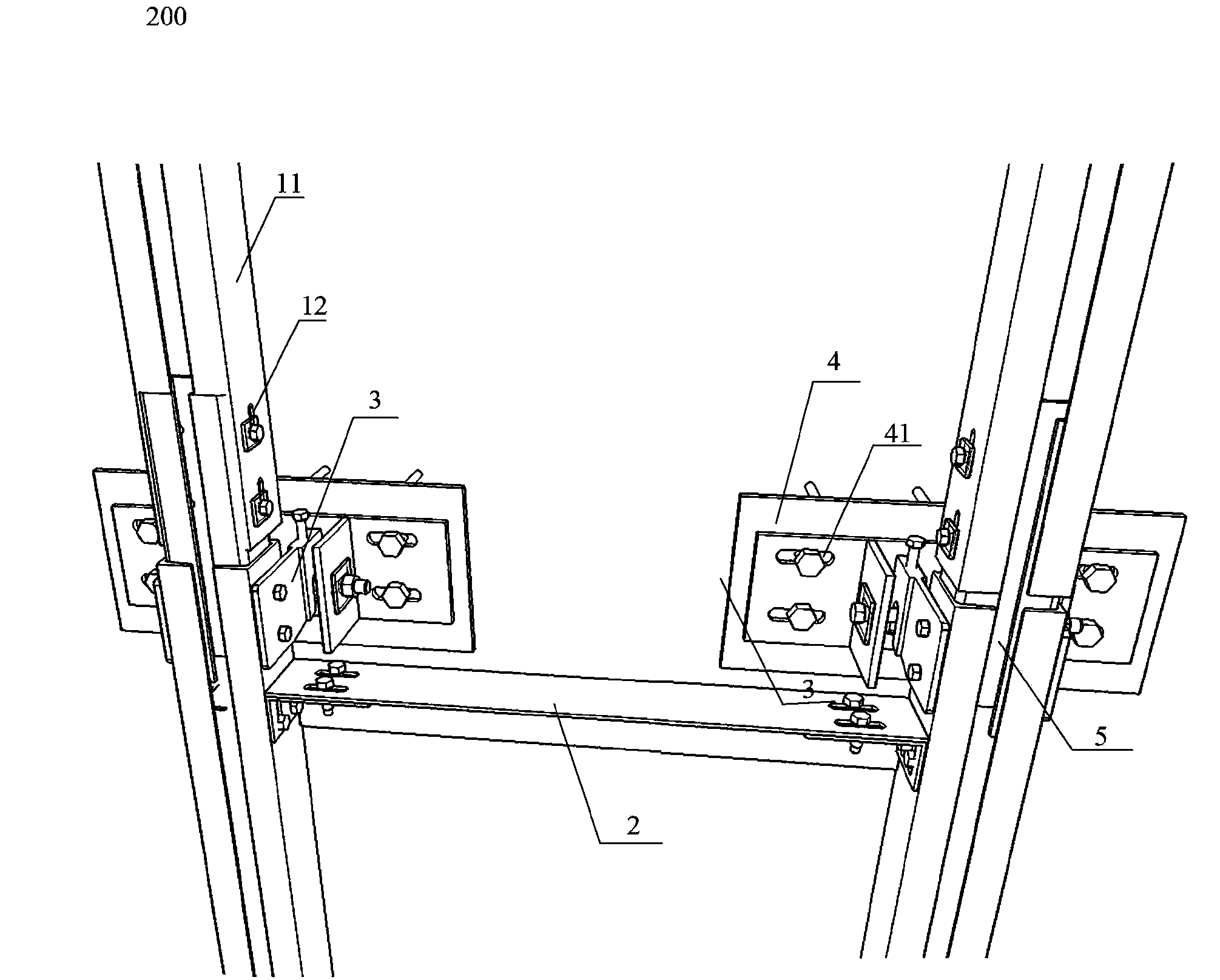

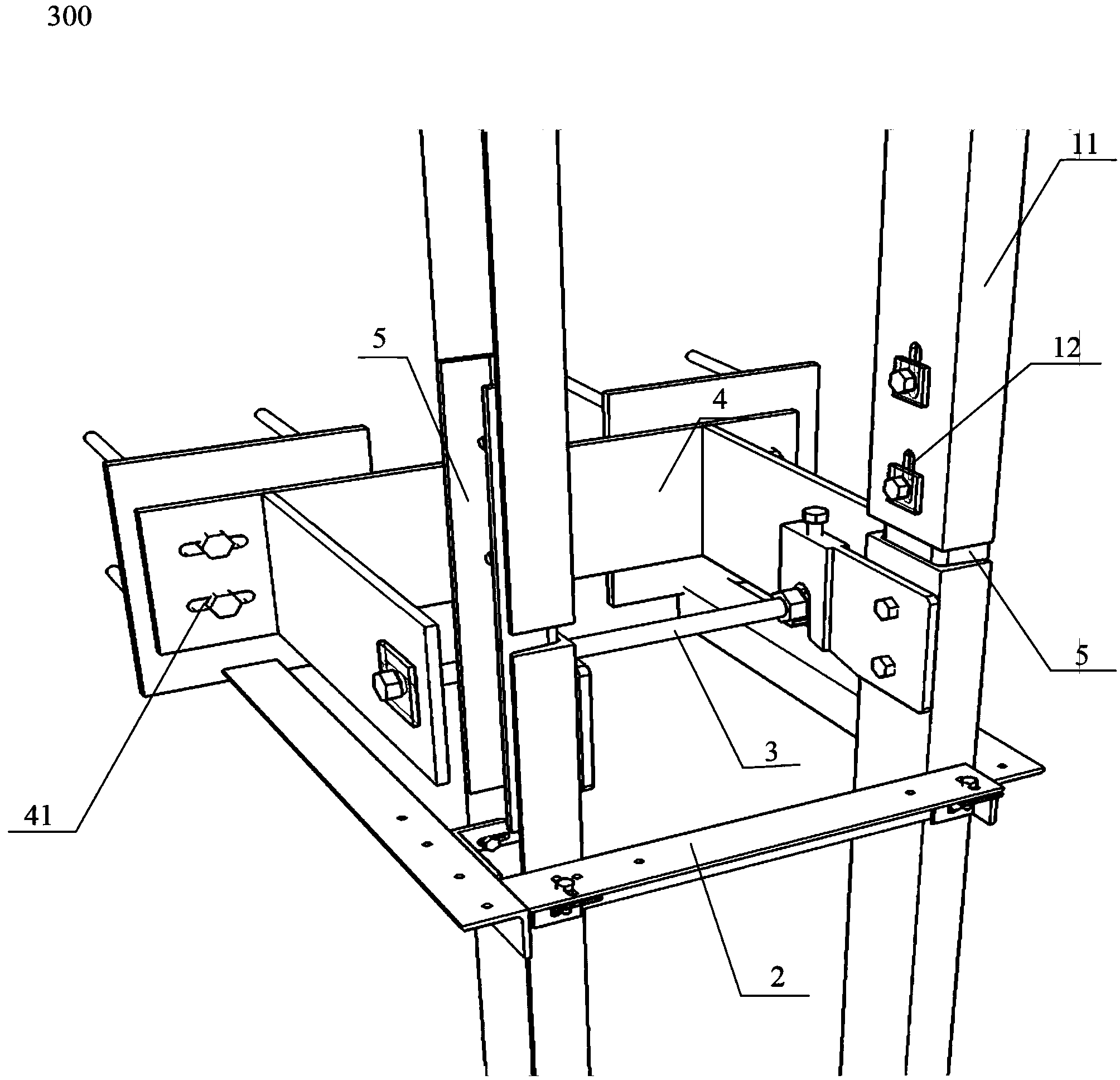

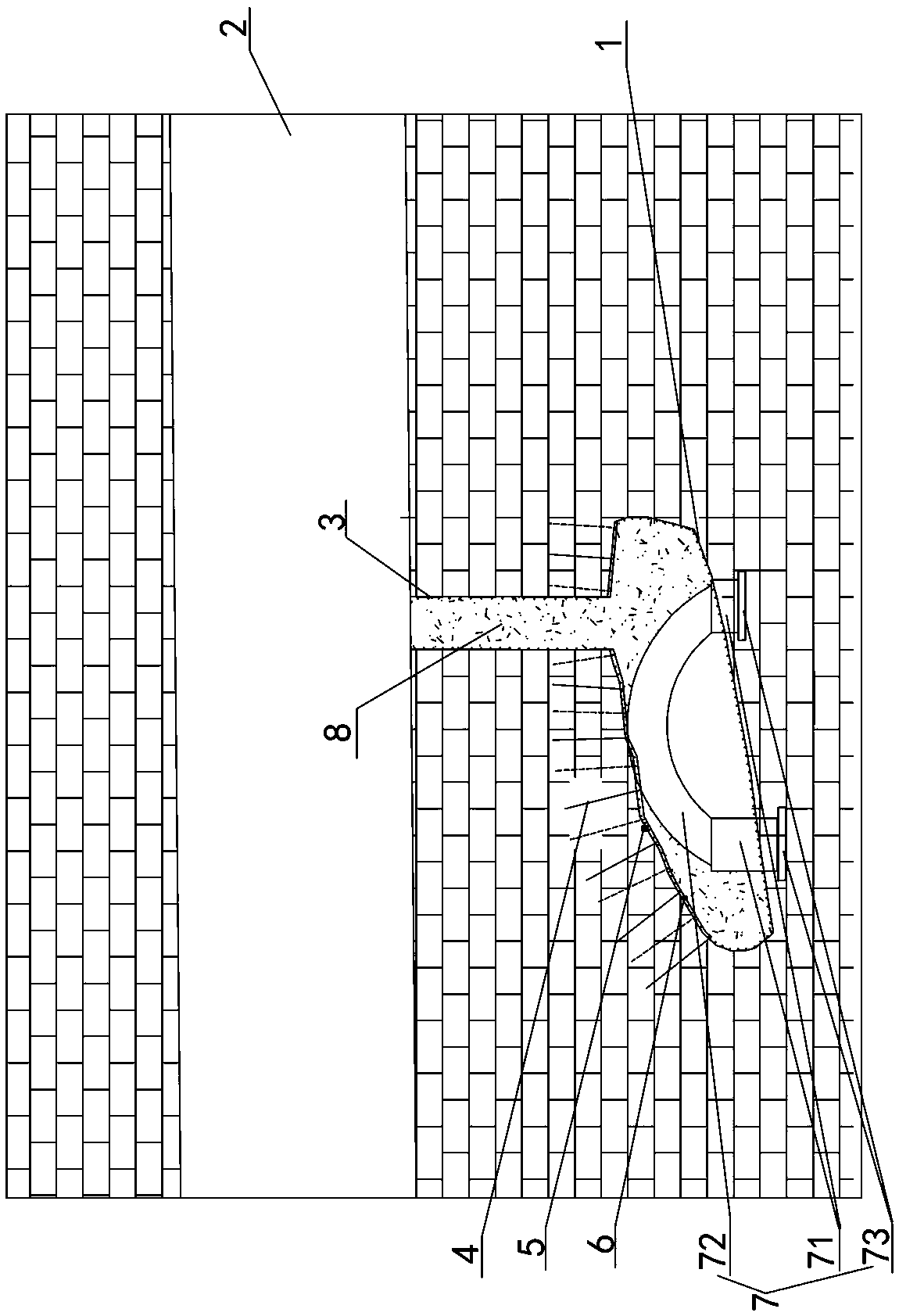

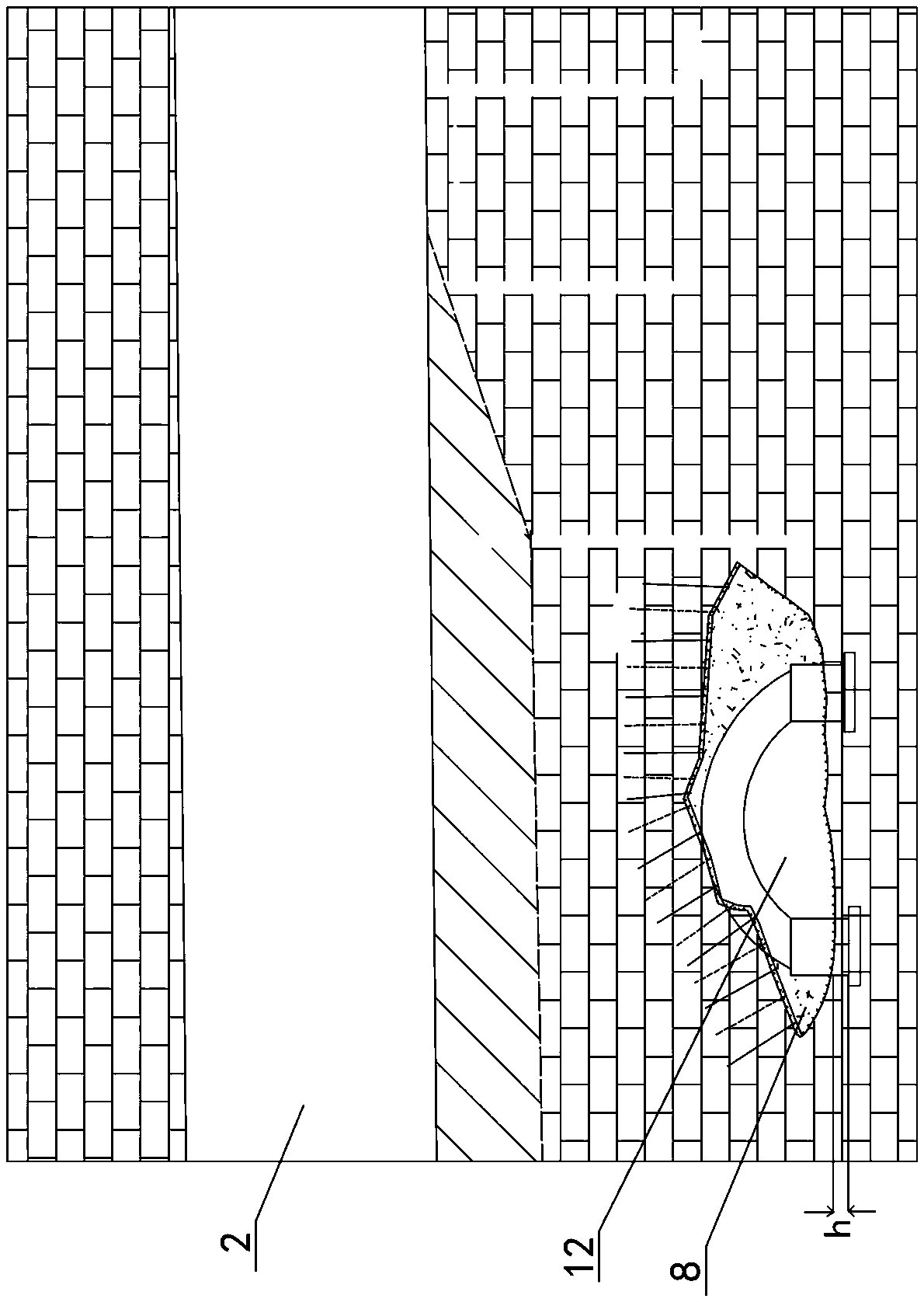

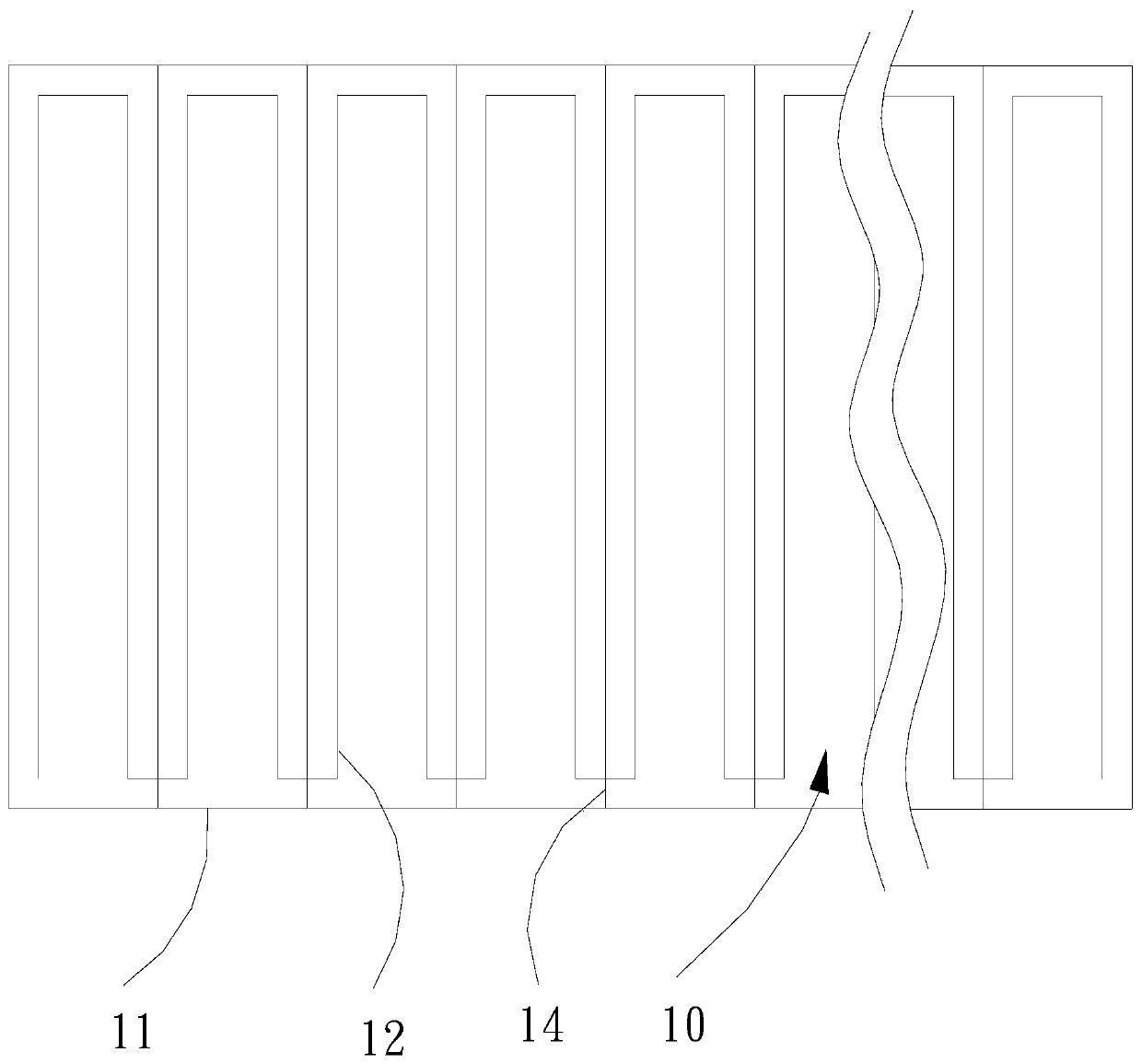

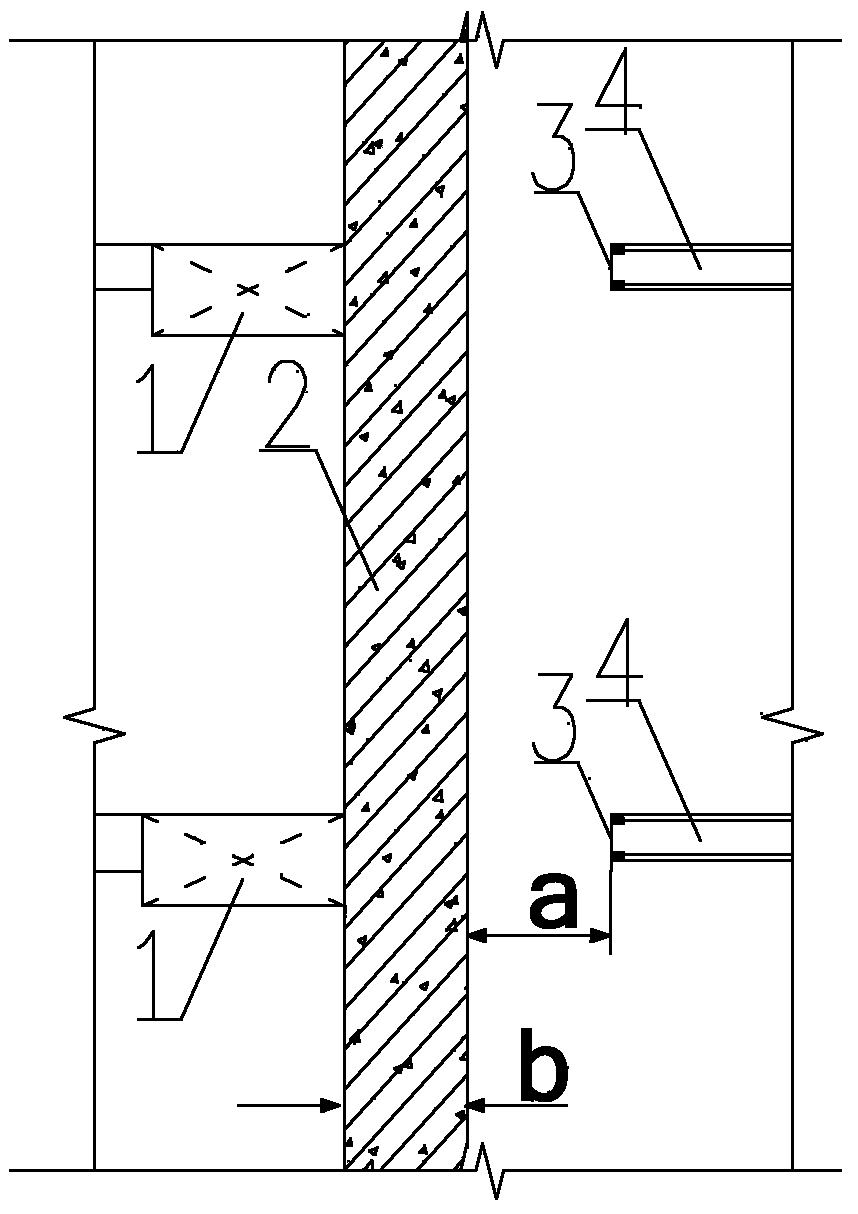

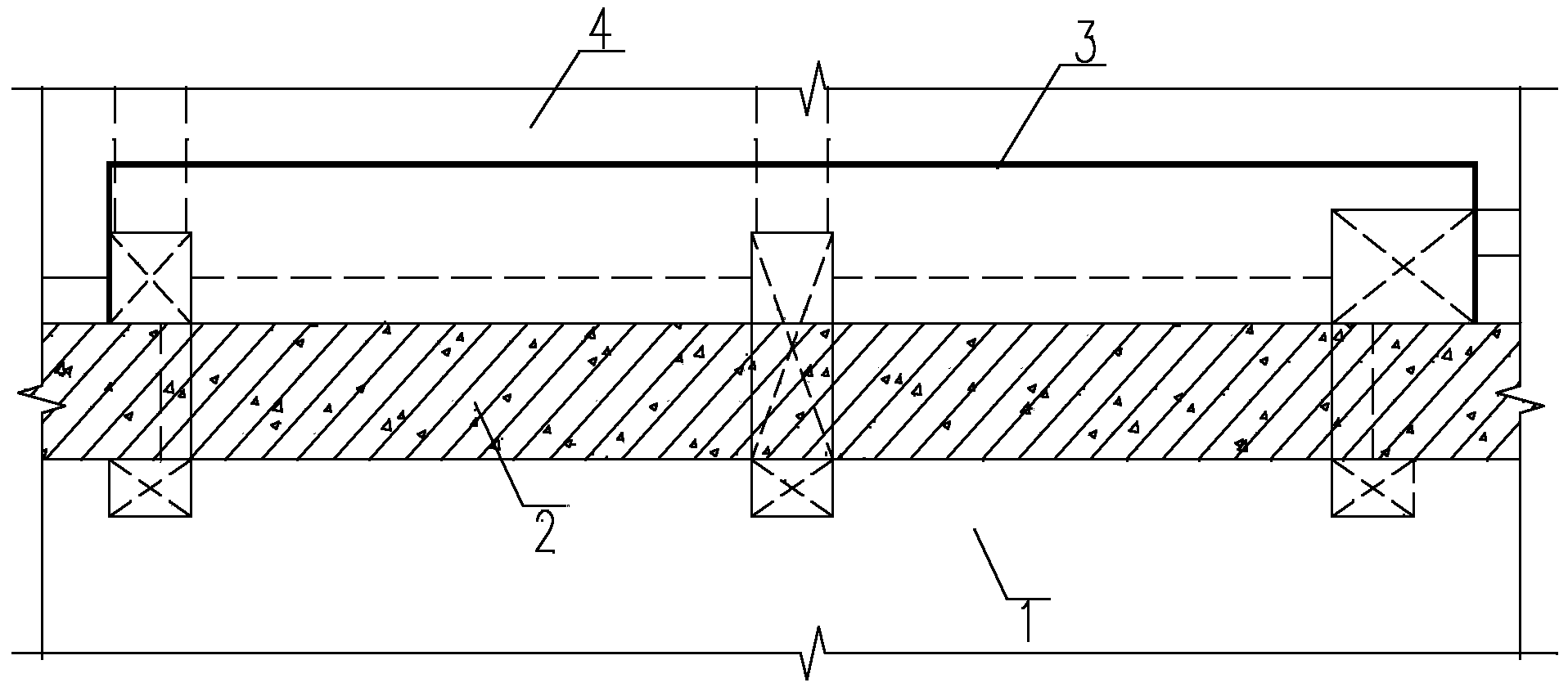

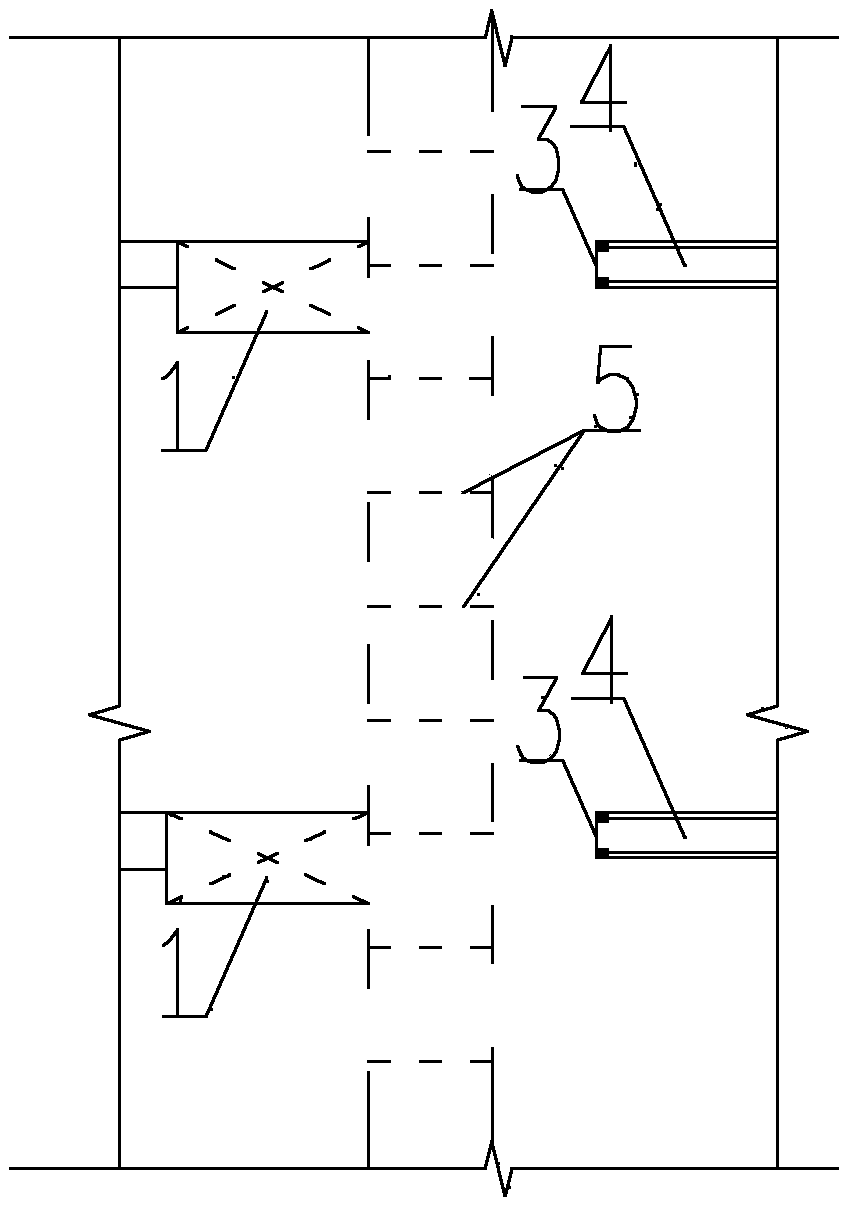

BRB inclined and X-shaped arranged dry-type connection fabricated reinforced concrete frame structure

PendingCN112196098AEasy to assembleSpeed up the construction progressProtective buildings/sheltersShock proofingRc framesRebar

The invention provides a BRB inclined and X-shaped arranged dry-type connection fabricated reinforced concrete frame structure. The structure is formed by combining a prefabricated beam-column combined component (1), a prefabricated beam (2), an embedded part connecting plate (3), an anti-buckling support end part (4), an anti-buckling support BRB (5), a column-column connecting joint (6) and a beam-column combined component connecting joint (7). The BRB inclined and X-shaped arranged dry-type connection fabricated reinforced concrete frame structure is characterized in that the prefabricatedbeam-column combined component (1) and the prefabricated beam (2) are connected through the dry-type connecting joint (6), and the prefabricated beam-column combined component (1) and the beam-columncombined component (1) are connected through the dry-type connecting joint (7), so that the fabricated reinforced concrete frame structure is formed; and on the basis, the anti-buckling support (5) isarranged and combined with the fabricated reinforced concrete frame structure into a whole through the embedded part connecting plate (3) and the anti-buckling support end part (4). According to theBRB inclined and X-shaped arranged dry-type connection fabricated reinforced concrete frame structure, the defect that a dry-type connecting joint in an existing fabricated damping structure is proneto being damaged under a strong earthquake is overcome, and the bearing capacity of the damping component BRB and the energy dissipation capacity in the earthquake are fully exerted; and meanwhile, the damping component BRB can be replaced after the earthquake and has the function recoverability, so that the provided structure has the advantages of being easy to assemble, replaceable, good in anti-seismic property and the like, and further development of the fabricated concrete structure can be promoted.

Owner:NANJING FORESTRY UNIV

Keel for dry hanging stone curtain wall and mounting method of keel

ActiveCN103541477AShorten the construction periodSpeed up the construction progressWallsBuilding material handlingSteel frameArchitectural engineering

The invention provides a keel for a dry hanging stone curtain wall and a mounting method of the keel, and solves the problem of large high-altitude electric welding operation volume in the mounting process of a traditional dry hanging stone curtain wall keel. The keel for the dry hanging stone curtain wall comprises a plurality of steel frame units and a plurality of dry hanging connectors, the steel frame units and the dry hanging connectors are manufactured in a factory, each steel frame unit comprises at least one steel channel, each dry hanging connector stretches across the adjacent steel channels and is fixedly connected with the steel channels, each steel frame unit is fixedly connected with an embedded part on a building wall through a horizontal tie part, the steel frame units and the embedded parts are fixedly connected with the horizontal tie parts through bolts, every two longitudinally adjacent steel frame units are connected through a sleeve core, and the sleeve cores are fixedly connected with the steel frame units through bolts. By the aid of the keel for the dry hanging stone curtain wall, construction cycle can be effectively shortened, mounting quality is improved, and potential safety hazards of construction sites can be greatly reduced.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Shear wall structural wall and slab integral pouring construction method

InactiveCN103206088AImprove integritySpeed up the construction progressBuilding material handlingRebarEngineering

The invention discloses a shear wall structural wall and slab integral pouring construction method. The method includes the construction steps of reinforcing bar engineering, formwork engineering, concrete engineering and the like. By the method, building structural integrity is improved remarkably, construction progress of integral engineering is accelerated, flexural capacity, shear capacity, waterproofness, anti-permeability and safety of the integral structure are improved greatly, and the method has wide development space and application prospect.

Owner:NANTONG ZHUOQIANG CONSTR GRP +1

Reinforcing structure of high-speed rail tunnel bottom water passing karst cave and construction method of reinforcing structure

ActiveCN107905799AShort construction periodSpeed up the construction progressUnderground chambersTunnel liningRebarEngineering

The invention discloses a reinforcing structure of a high-speed rail tunnel bottom water passing karst cave and a construction method of the reinforcing structure. The reinforcing structure comprisesthe karst cave, a construction slope channel, a deslagging vertical shaft, a shotcrete-bolting-mesh supporting layer and an arch culvert. The shotcrete-bolting-mesh supporting layer comprises an anchor rod, a rebar hanging net and a concrete jetting layer, the arch culvert comprises an arch culvert foundation, an arch culvert side wall and an arch culvert arch ring, and the construction slope channel, the deslagging vertical shaft and a culvert body in the outer portion of the arch culvert are compacted by adopting backfilled concrete. The construction method comprises the steps of karst caveexcavation, karst cave cleaning, deslagging vertical shaft excavation, deslagging construction, arch culvert construction, karst cave backfilling and the like. According to the reinforcing structure,the structure is stable and reliable, the water draining effect is good, the construction safety can be ensured, and the reinforcing structure is suitable for high-speed rail tunnel bottom water passing type karst treatment, particularly karst with water and a certain size and scale.

Owner:中国建筑土木建设有限公司

Hole-cleaning method for washing pile hole and pumping sand

ActiveCN104695879ASpeed up the construction progressGuarantee the construction qualityConstructionsFlushingEngineeringCrushed stone

Owner:CCCC FOURTH HIGHWAY ENG

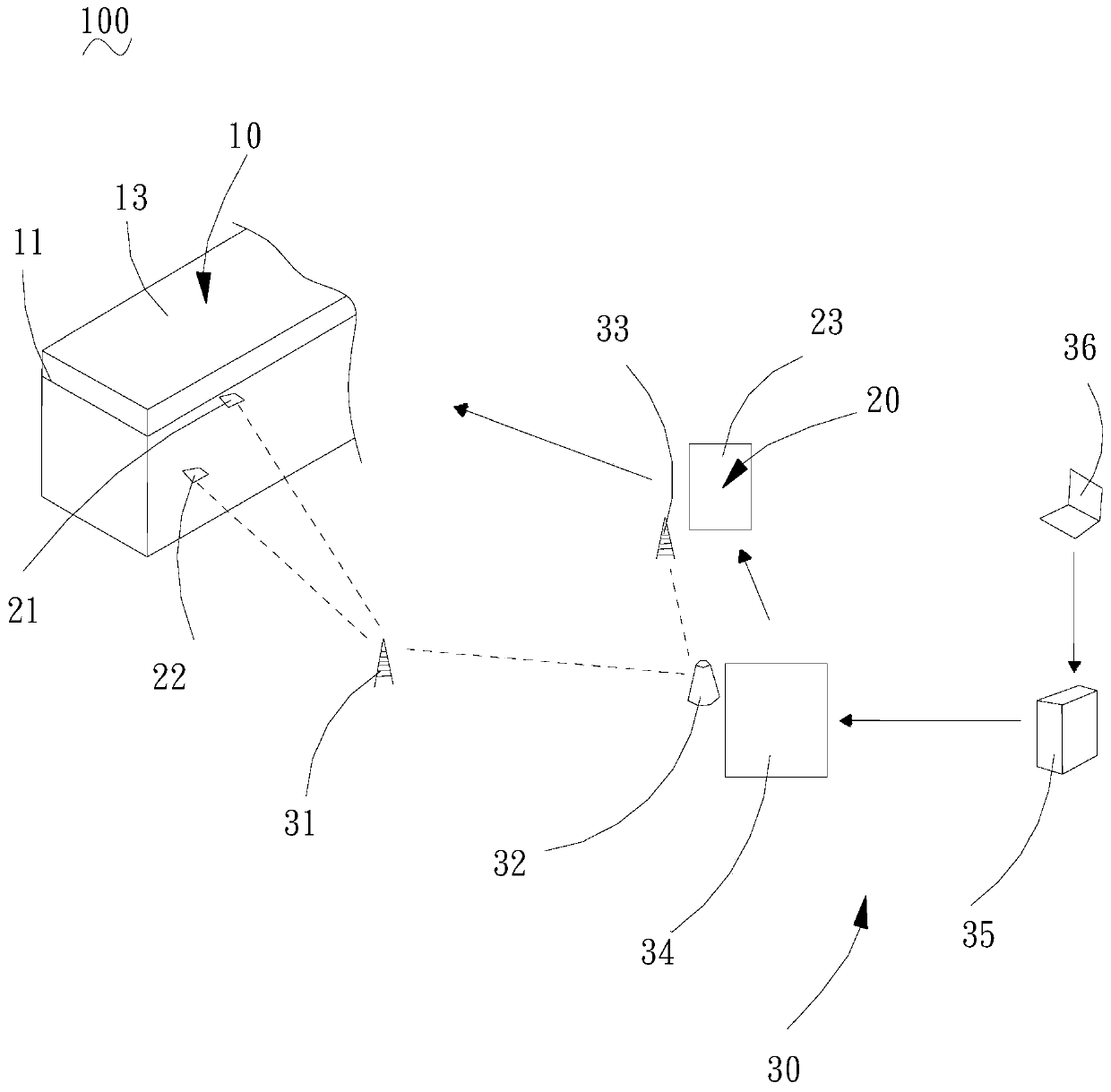

Electric heating system for concrete curing

InactiveCN110328745AGuaranteed structural crack resistanceSpeed up the construction progressCeramic shaping apparatusAutomatic controlElectric heating

The invention relates to an electric heating system for concrete curing. The electric heating system for concrete curing comprises a curing mechanism and a temperature control mechanism connected withthe curing mechanism, wherein the curing mechanism comprises a mold plate, a heating element connected with the mold plate, and a heat insulating layer connected with the heating element; the temperature control mechanism comprises a first temperature detector connected to the surface of concrete, a second temperature detector connected to the inner part of the concrete, and a temperature controller; the temperature controller is connected with the first temperature detector and the second temperature detector; and the temperature controller is used for controlling the heating element to workaccording to the information fed back by the first temperature detector and the second temperature detector. According to the system, the temperature of the surface of the concrete and the temperature of the inner part of the concrete are acquired in real time through the first temperature detector and the second temperature detector, and the temperature controller controls the heating element towork in real time after carrying out data analysis according to the information fed back by the first temperature detector and the second temperature detector, so that intelligent temperature controland concrete curing are realized, and a structure crack-resisting ability of the concrete is ensured. The system has the functions of data acquisition, data analysis and automatic control, the construction progress is accelerated, and the engineering cost is reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Method for dismantling division wall between foundation pits in semi-reversed construction mode

ActiveCN103726494AReduce construction costsSpeed up the construction progressEmbankmentsExcavationsStructural engineeringBuilding construction

The invention provides a method for dismantling a division wall between foundation pits in a semi-reversed construction mode. The method is used for dismantling the division wall between an early-constructed foundation pit structure and a post-constructed foundation pit structure. The method includes the steps that the early-constructed foundation pit structure is constructed firstly; after earth excavation of the post-constructed foundation pit is completed, the structure is reconstructed upwards from a base plate structure, and the vertically-interpenetrating post-pouring belt space is reserved between each layer of the post-constructed foundation pit structure and the division wall from the base plate structure; the division wall is cut into concrete blocks convenient to hoist from bottom to top, and then a crane is utilized to directly hoist the concrete blocks out of the post-pouring belt space of the post-constructed foundation pit structure. Through the arrangement of the post-pouring belt space, the method has the advantages that the method enables the division wall to be dismantled more conveniently, effectively reduces construction cost, accelerates construction progress, saves resources, and has the effect of low-carbon construction.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Machine for casting curbs in situ and use method thereof

InactiveCN102912713AEliminates the process of linear adjustmentSpeed up the construction progressRoads maintainenceSteel platesPlough

The invention discloses a machine for casting curbs in situ and a use method thereof, wherein the machine comprises a machine main body and a drawing device, wherein the machine main body comprises a plough-shaped shovel; the width of the plough-shaped shovel is 2-3 cm less than that of the curb; the outer edge of the plough-shaped shovel is welded with a machine external template in a full-length way; not less than two guide wheels are arranged on the internal side of the front end of the machine; a bottom steel plate is arranged at the bottom of the front end of the machine main body; the bottom steel plate is welded with the bottom edge of the plough-shaped shovel and the bottom edge of the machine external template in a full-length way; a film lamination roller I, which is 5-10 cm higher than the curb, is arranged on the back side of the guide wheel; a film pressing roller is arranged on the back side of the film lamination roller I; a vibrating rod sleeve is placed outside the machine external template corresponding to a concrete casting area; and the vibrating rod sleeve is provided with a vibrating rod. According to the invention, the cast-in-situ molding of the concrete curbs can be achieved, a linear adjusting procedure can be omitted, the construction progress is accelerated and labors are saved.

Owner:SHANDONG HI SPEED QINGDAO HIGHWAY +1

Construction method for straight manhole

InactiveCN102392459ASpeed up the construction progressReduce construction costs and expensesArtificial islandsUnderwater structuresSUSPENDING VEHICLEBuilding construction

Owner:SHANGHAI TELECOMM ENG

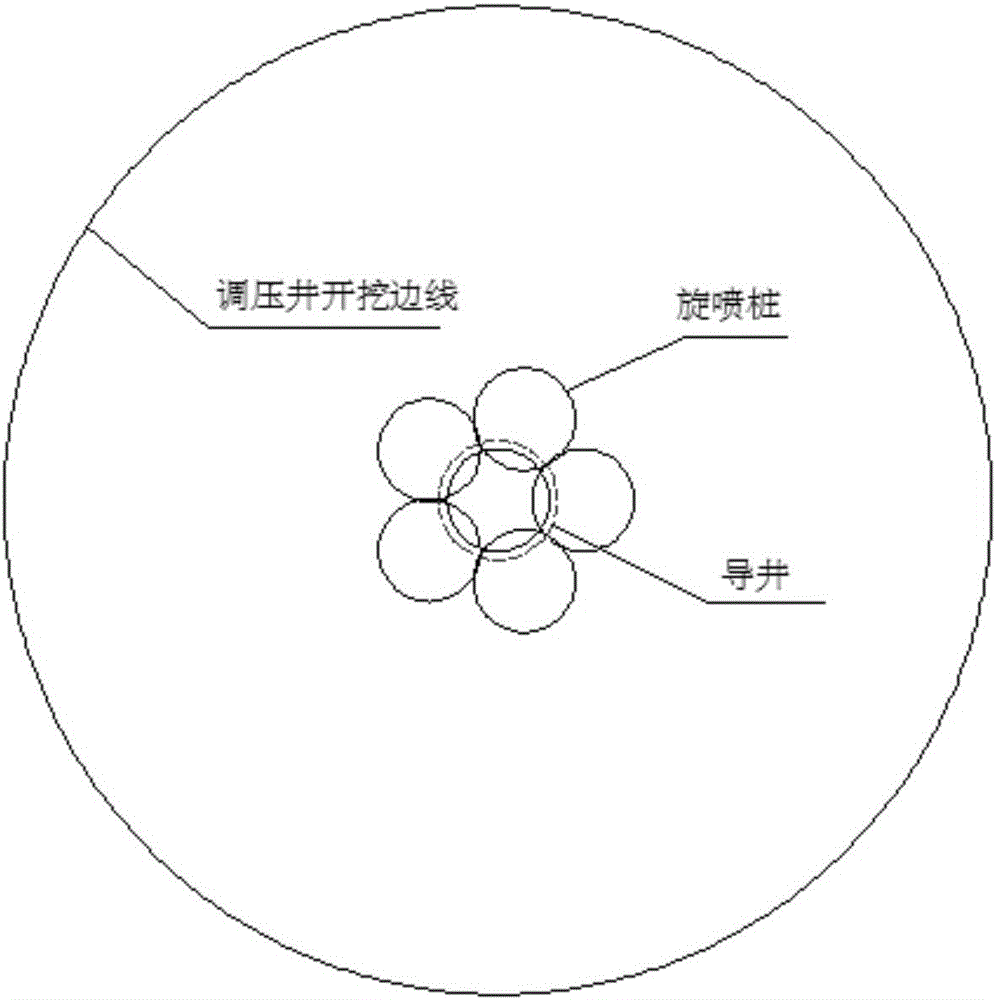

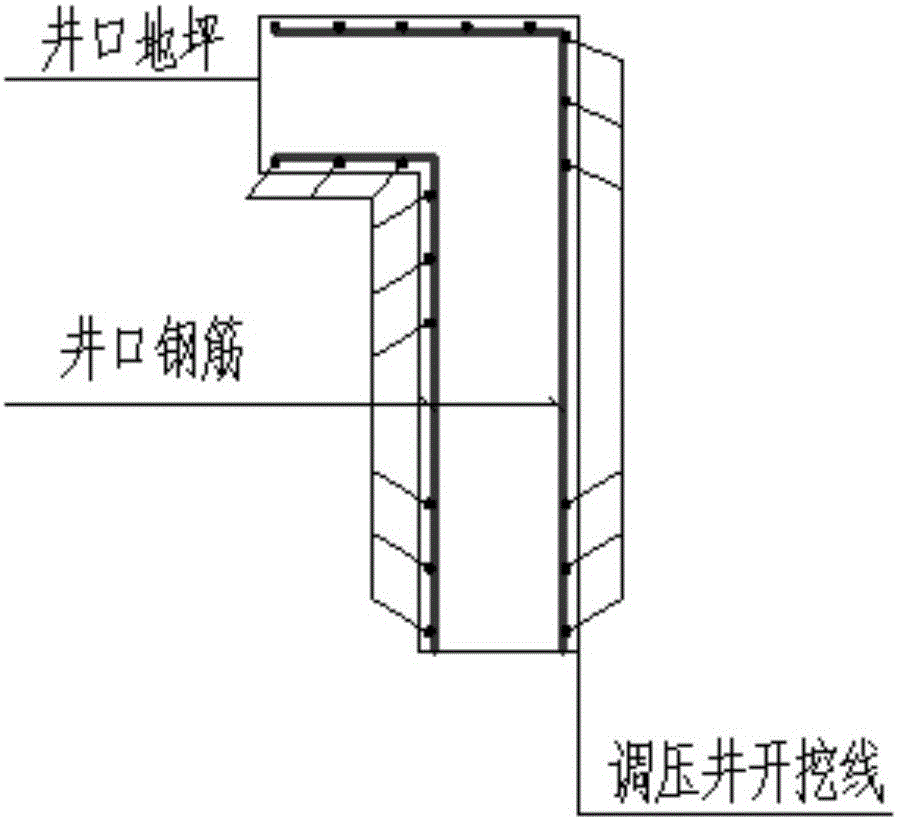

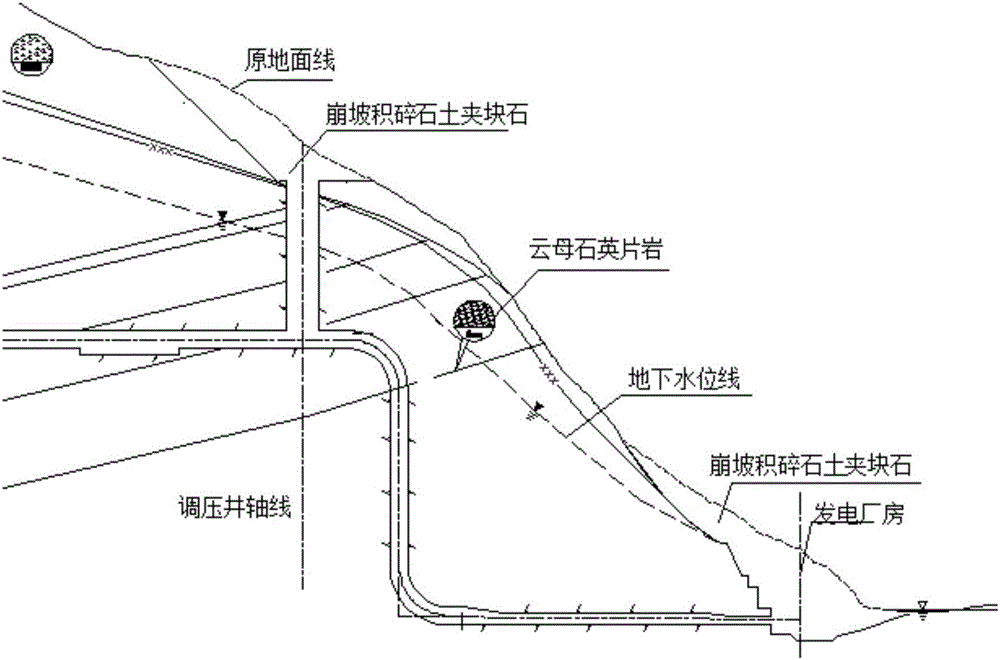

Excavating construction method for surge shaft in gravel and sandy soil layer

InactiveCN105714748ASpeed up the construction progressDifficult to remove slagWater-power plantsHydro energy generationSlagHigh pressure

The invention relates to an excavating construction method for a surge shaft in a gravel and sandy soil layer. The method comprises steps as follows: construction of rotary jet grouting combined cylinder piles, construction of raise-boring machine platform concrete, construction of a raise-boring machine as well as excavation and supporting of a sandy soil layer shaft body section. According to the method, high-pressure rotary jet grouting pile combined pile cylinders are used as raise-boring machine pilot shaft construction areas for the surge shaft in the gravel and sandy soil layer, annular steel arches are adopted for lower part layer-by-layer supporting under protection of a shaft top ring beam, excavation and deslagging are performed by the aid of a pilot shaft, vertical transport and hoisting equipment for excavating slag is not required to be mounted additionally, and the construction progress is greatly accelerated. For completion of excavation and supporting construction of the gravel and sandy soil layer with the depth being 15 m and the excavation diameter being 11.6 m, at least 60 days are required if the conventional drop shaft sinking method and the vertical excavation and wall protection method are adopted, the deslagging difficulty is very large, and the cost is very high; however, with the adoption of the method, the construction task can be completed within 42 days, and the grouting reinforcement effect of high-pressure rotary jet grouting piles in a colluvial gravel soil and rock block covering layer mainly comprising the gravel and sandy soil layer is good.

Owner:SINOHYDRO BUREAU 11 CO LTD

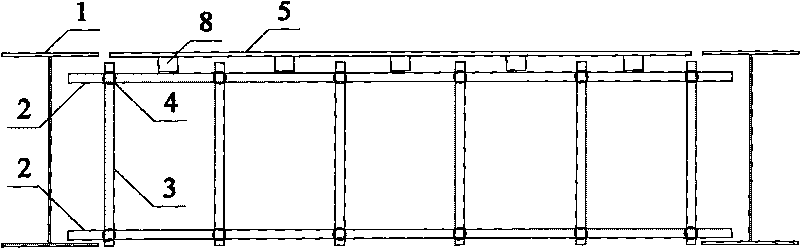

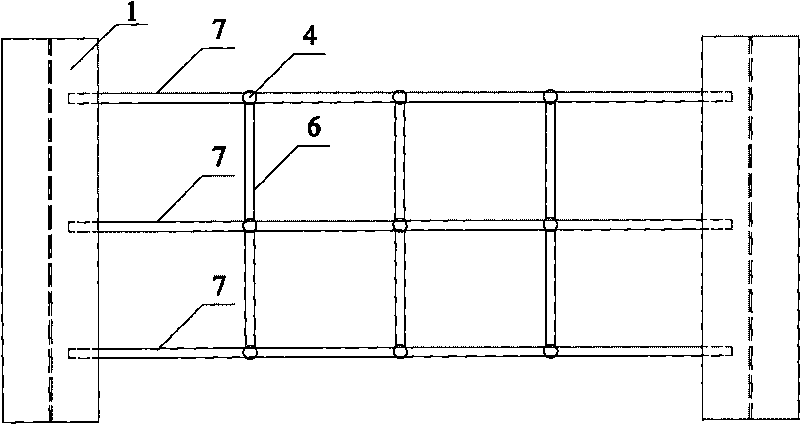

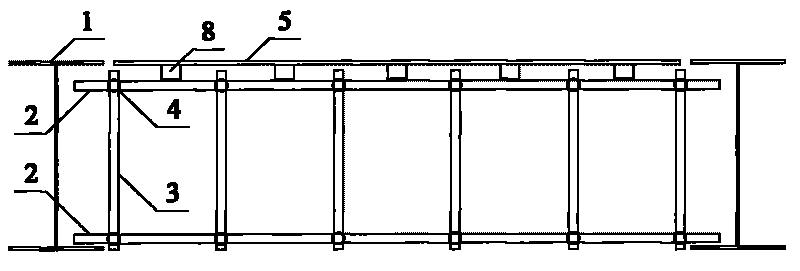

Formwork support system for steel frame structure cast-in-place concrete floorslabs

InactiveCN101694127AReduce on-site workloadSpeed up the construction progressForms/shuttering/falseworksSteel tubeFloor slab

The invention discloses a formwork support system for steel frame structure cast-in-place concrete floorslabs. The formwork support system comprises I-shaped section beams, horizontal scaffold steel pipes, vertical scaffold steel pipes, steel pipe fasteners, timber formworks, tie bar steel pipes and battens; two horizontal scaffold steel pipes and a plurality of vertical scaffold steel pipes are connected by the steel pipe fasteners to form scaffold steel pipe trusses; more than two scaffold steel pipe trusses are connected with more than two tie bar steel pipes by the steel pipe fasteners; the lower ends of the scaffold steel pipe trusses are arranged on the lower flanges of the I-shaped section beams, the battens are arranged on the upper ends of the scaffold steel pipe trusses, and the timber formworks are arranged on the battens. Compared with the background art, the invention has the advantages: 1) the timber formworks are used for freely fabrication and assembly; 2) steel pipe top bracings are avoided, thereby reducing the site work load; and 3) the formworks are supported on the lower flanges of the beams, thereby providing wide working platforms for the operations of all types of work, and realizing multilayer stereo operation to further accelerate the construction progress.

Owner:ZHEJIANG UNIV

Method for performing extraction treatment on corner gas on work faces of adjacent roadways

InactiveCN105401973ASpeed up the construction progressImprove construction progressGas removalCoalEngineering

The invention relates to a gas treatment method, in particular to a method for performing extraction treatment on the corner gas on the work faces of adjacent roadways. The problems that according to existing treatment on corner gas on the work faces, the tunneling workload is large, cost is high, and an extraction pipeline is prone to damage are solved. After an air returning gate roadway of a coal face A is finished, a return airway of a next work face B is arranged in advance at 30-meter interval, the gas extraction pipeline is arranged in the return airway, a gas extraction drill site is arranged in the return airway every 80 meters, drilling is constructed in the gas extraction drill sites to extract the corner gas on the coal face A, and after the coal face A is extracted, holes towards the coal face B are drilled in the drill sites for gas extraction. The method has the beneficial effects that the purpose that the extraction pipeline is arranged on one roadway and the two adjacent work faces are commonly used is achieved, the project of repeated construction of the gas extraction drill sites in the two roadways is avoided, and the construction progress is greatly increased.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com