BRB inclined and X-shaped arranged dry-type connection fabricated reinforced concrete frame structure

A reinforced concrete and frame structure technology, applied in the direction of building components, building types, building structures, etc., can solve problems such as easy damage, and achieve the effects of easy assembly, accelerated construction progress, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

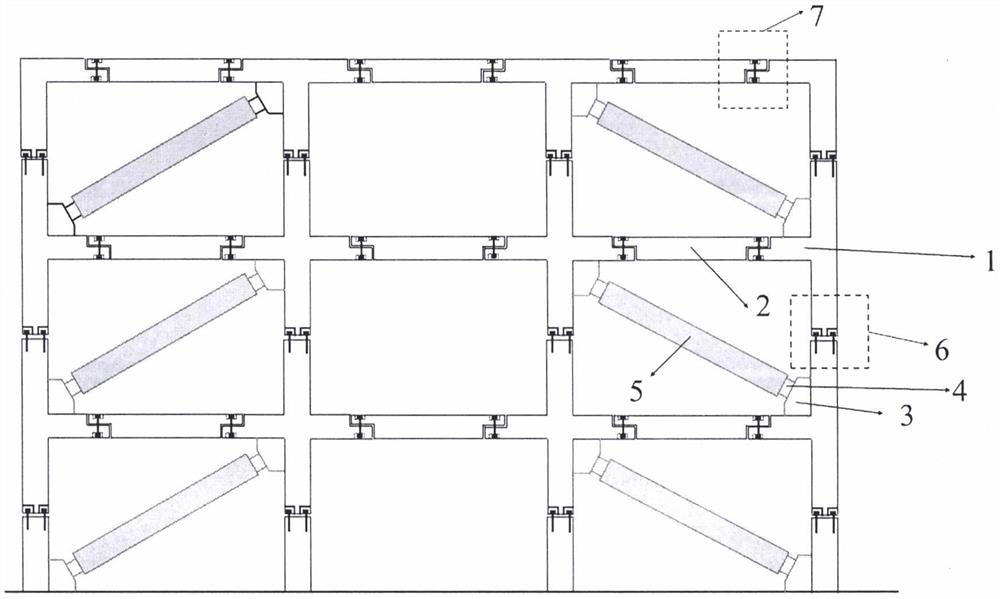

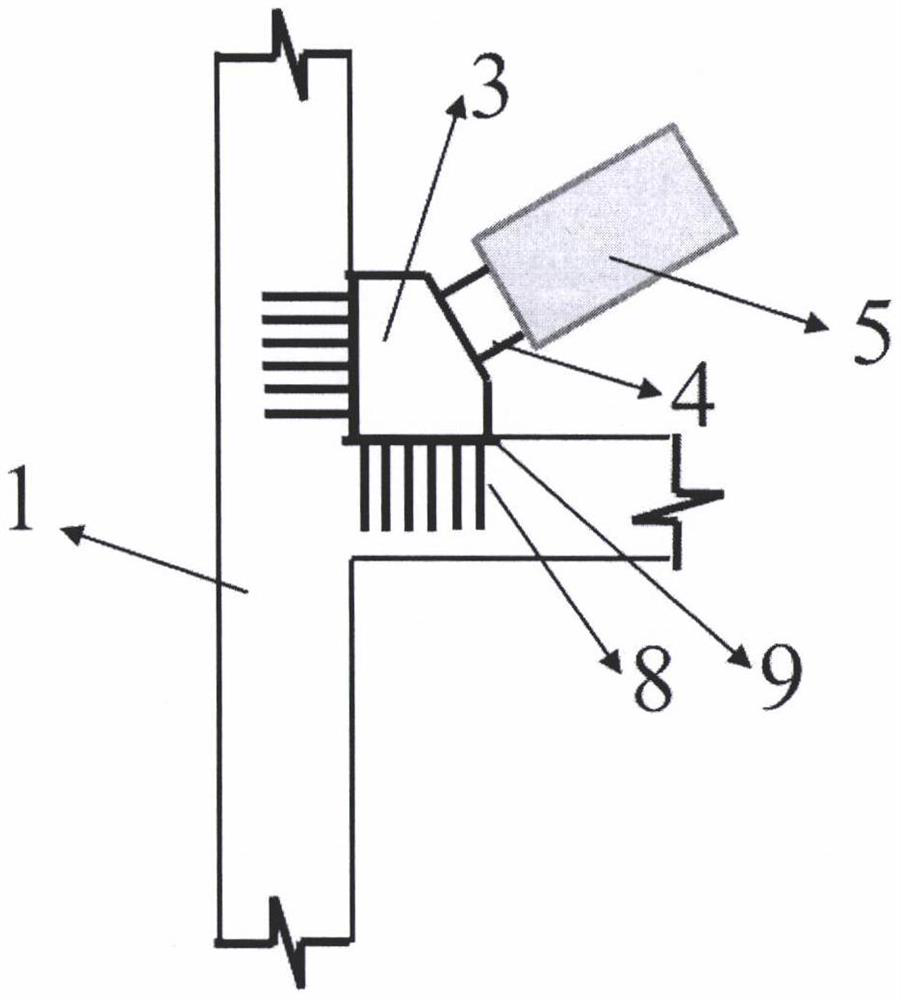

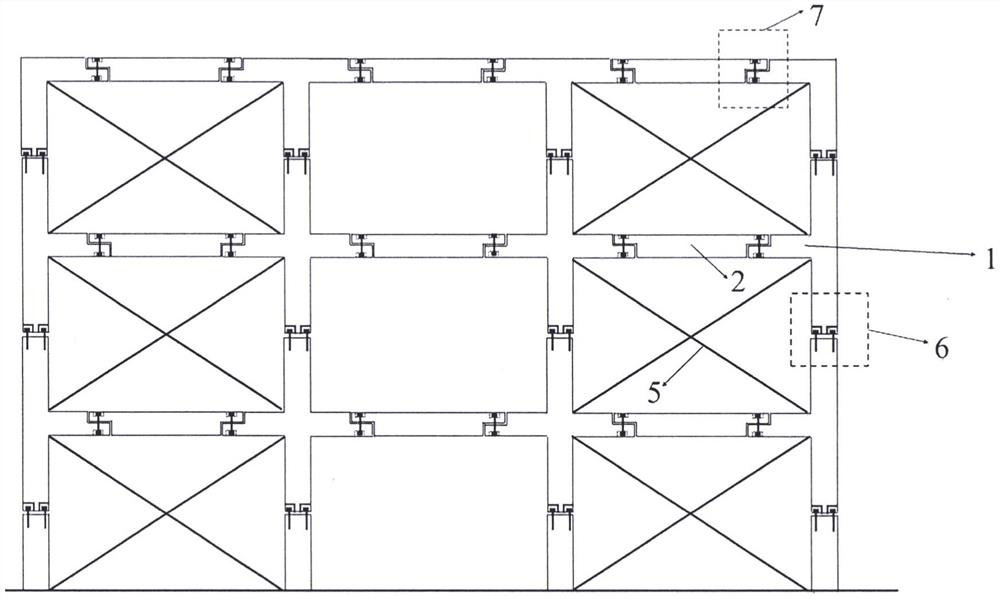

[0019]Such asFigure 1-Figure 4As shown, the present invention proposes a dry-connected assembled reinforced concrete frame structure with anti-buckling support oblique and X-shaped arrangement, consisting of prefabricated beam-column combined members 1, prefabricated beams 2, pre-embedded connecting plates 3, anti-buckling Support end 4, anti-buckling support 5, column-column connection node 6, beam-beam-column combined component connection node 7, embedded reinforcement 8, embedded welding plate 9 and anti-buckling support connection plate 10, which The characteristic is that the prefabricated beam-column combined member 1 and the prefabricated beam 2 and the beam-column combined member 1 are all connected by dry connection nodes 6 and 7 to form a fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com