Patents

Literature

5752 results about "Earthquake resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

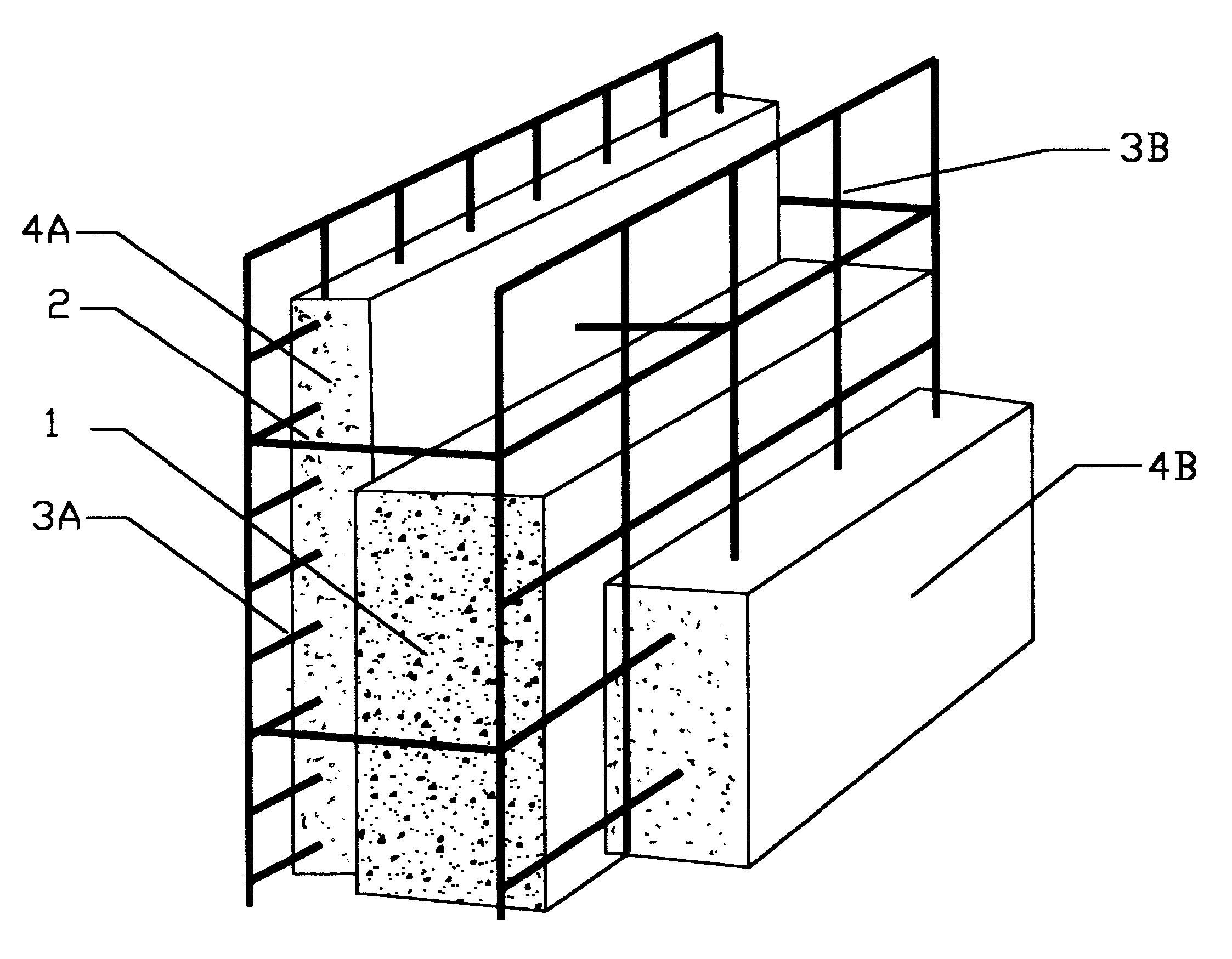

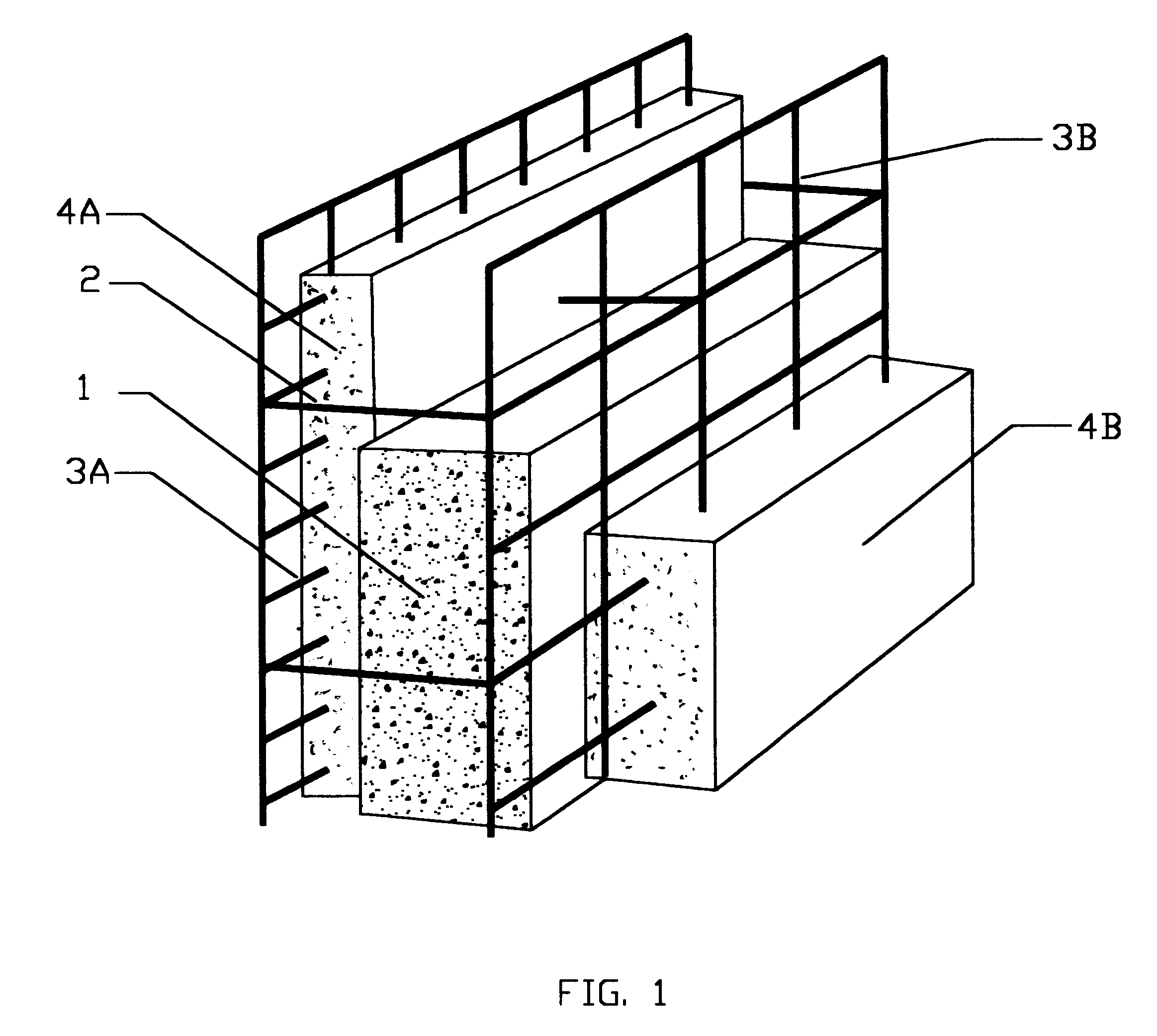

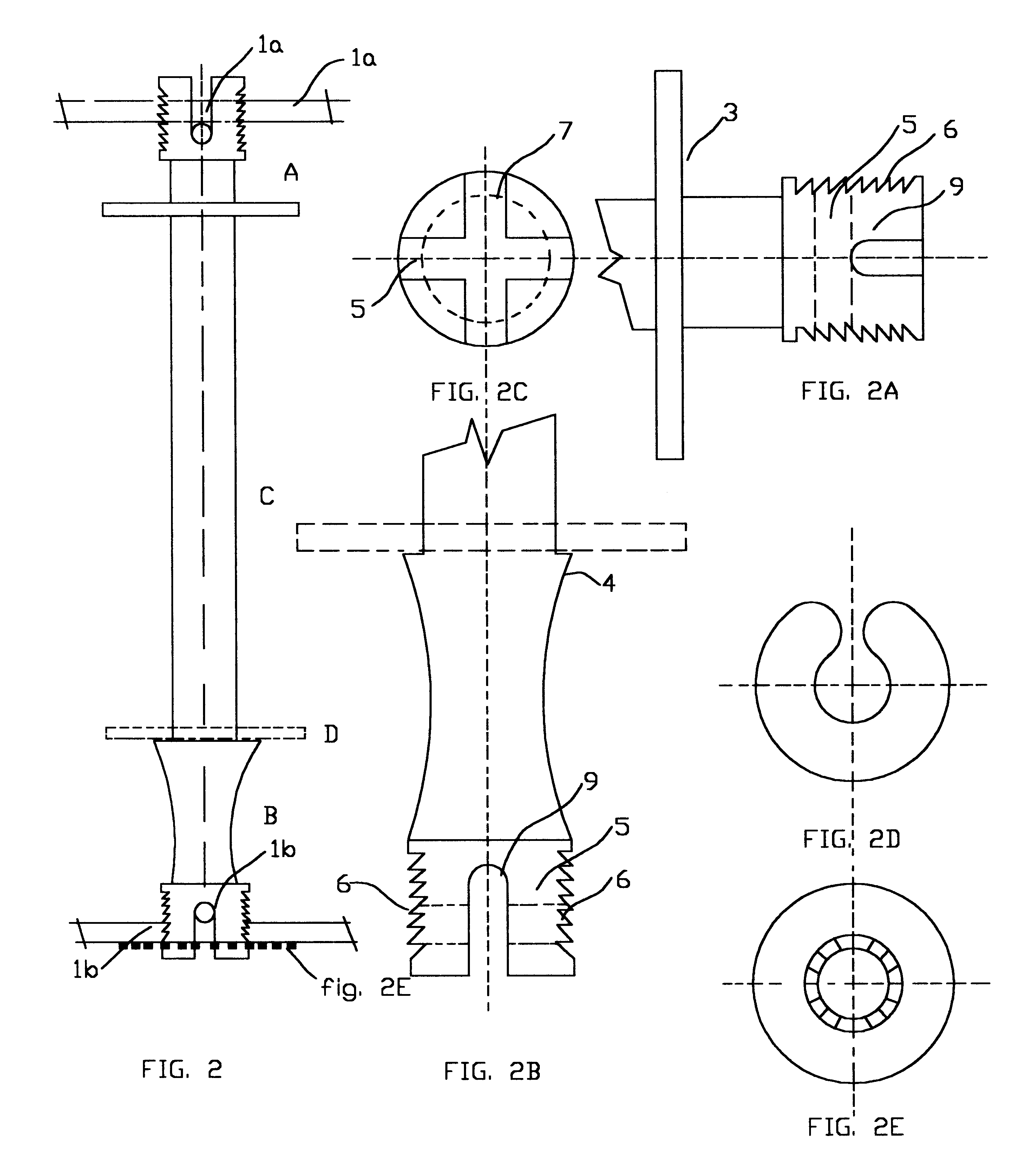

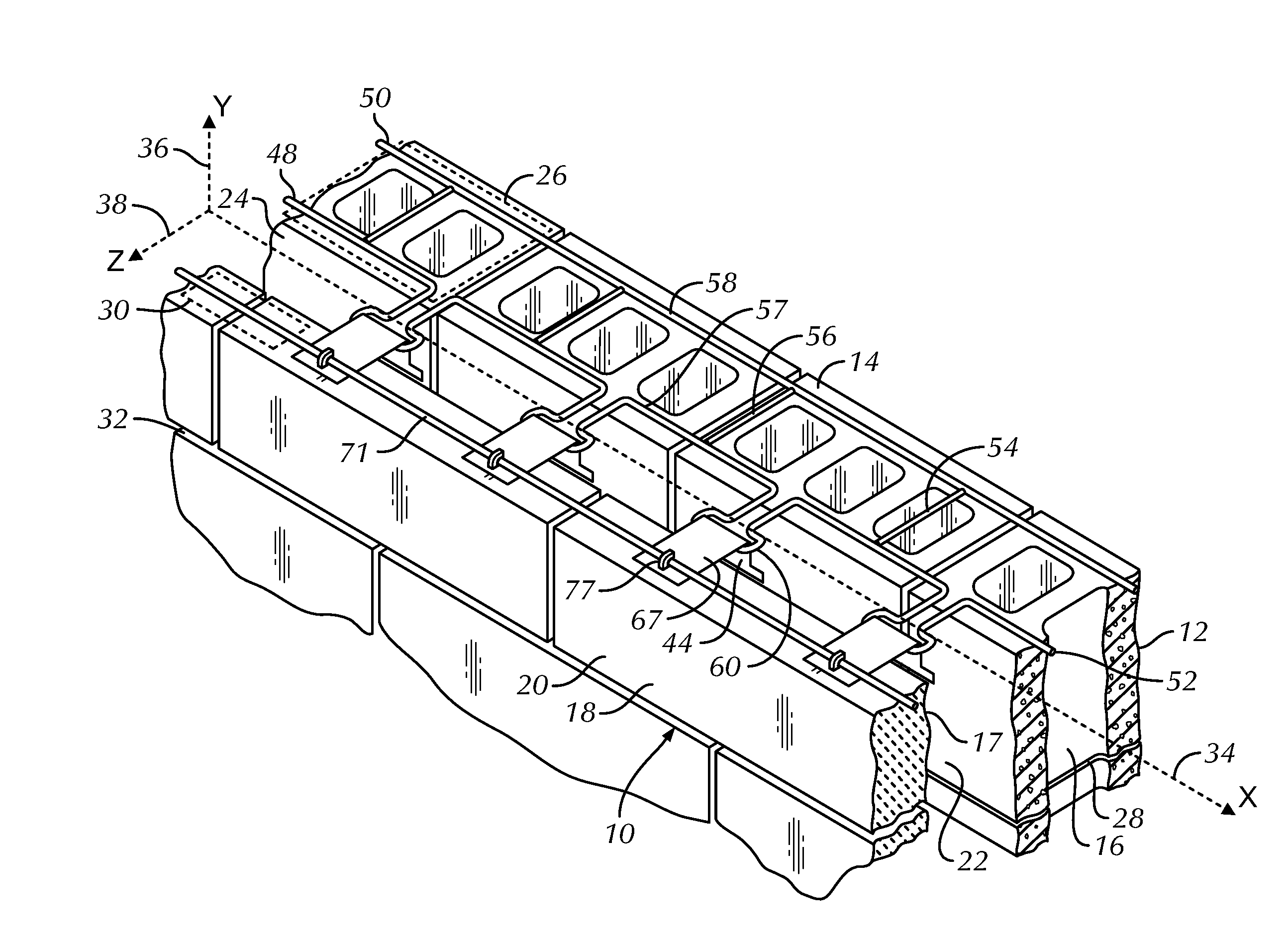

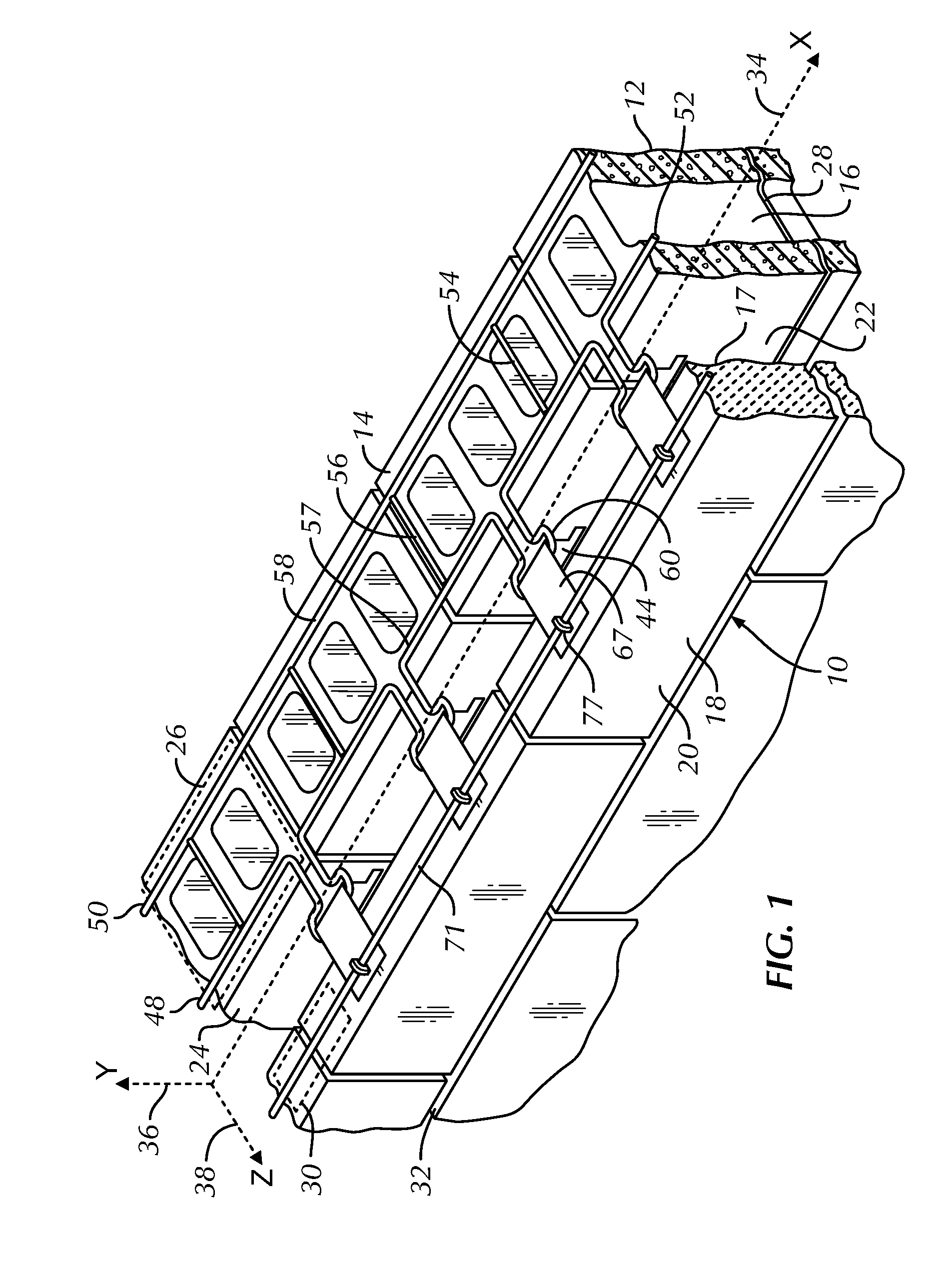

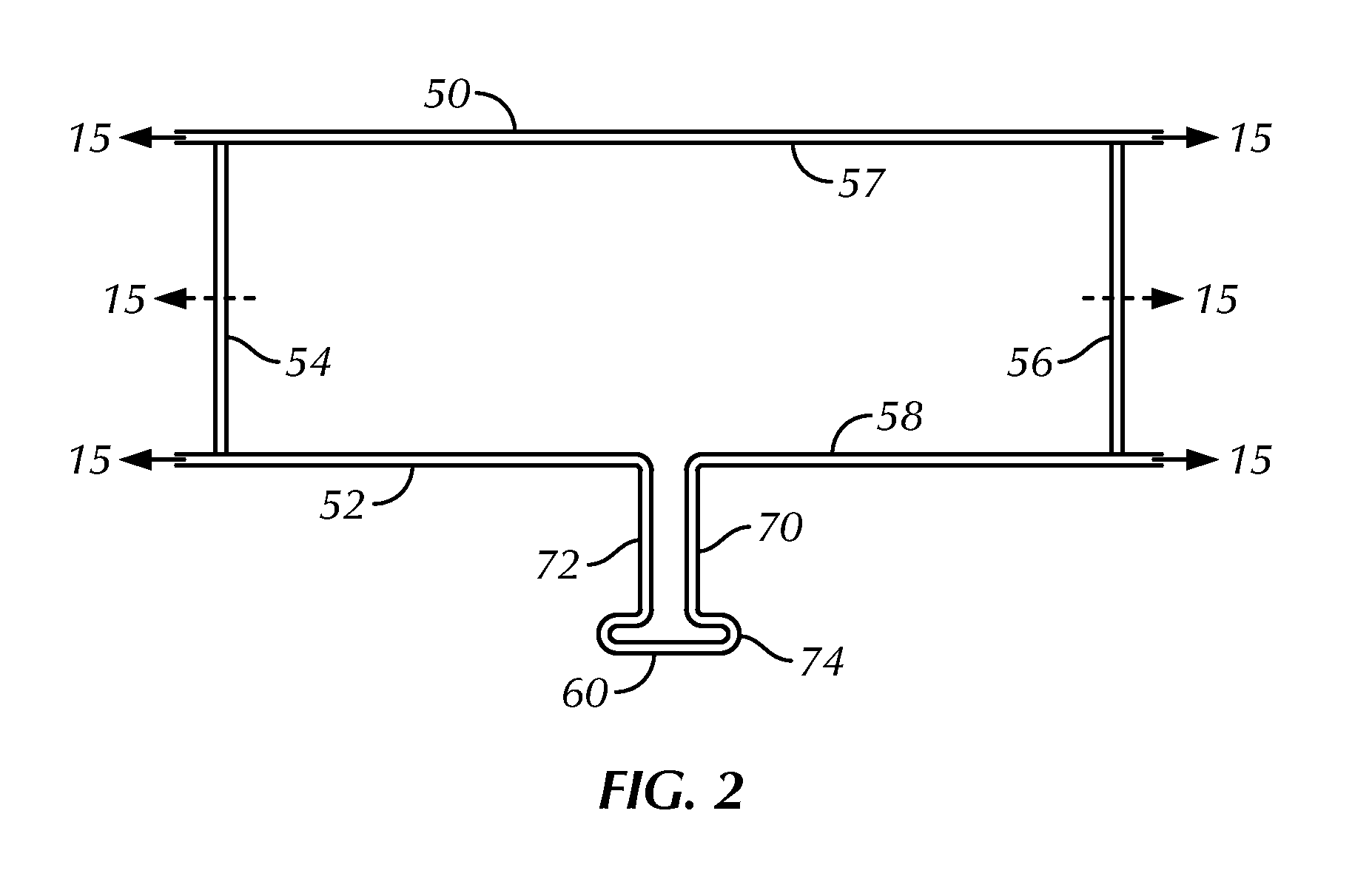

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

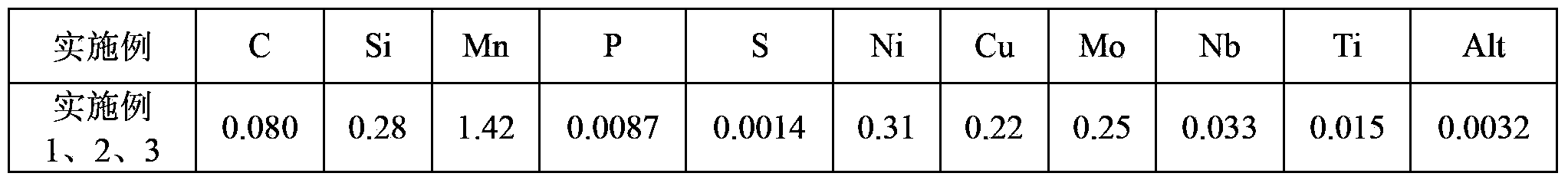

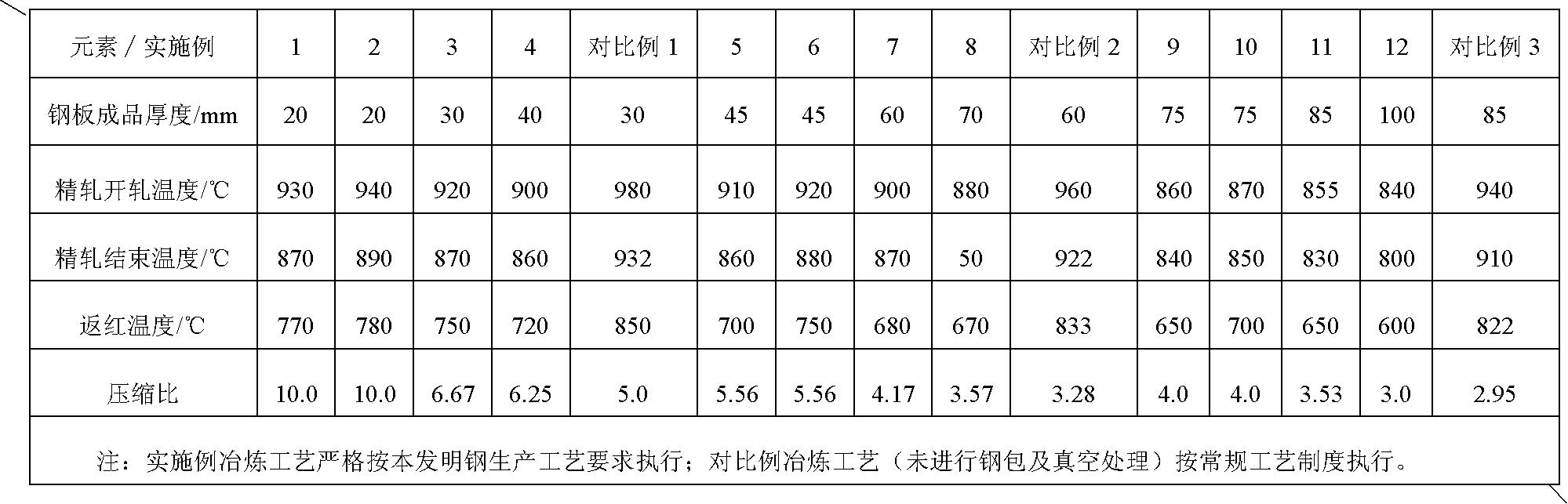

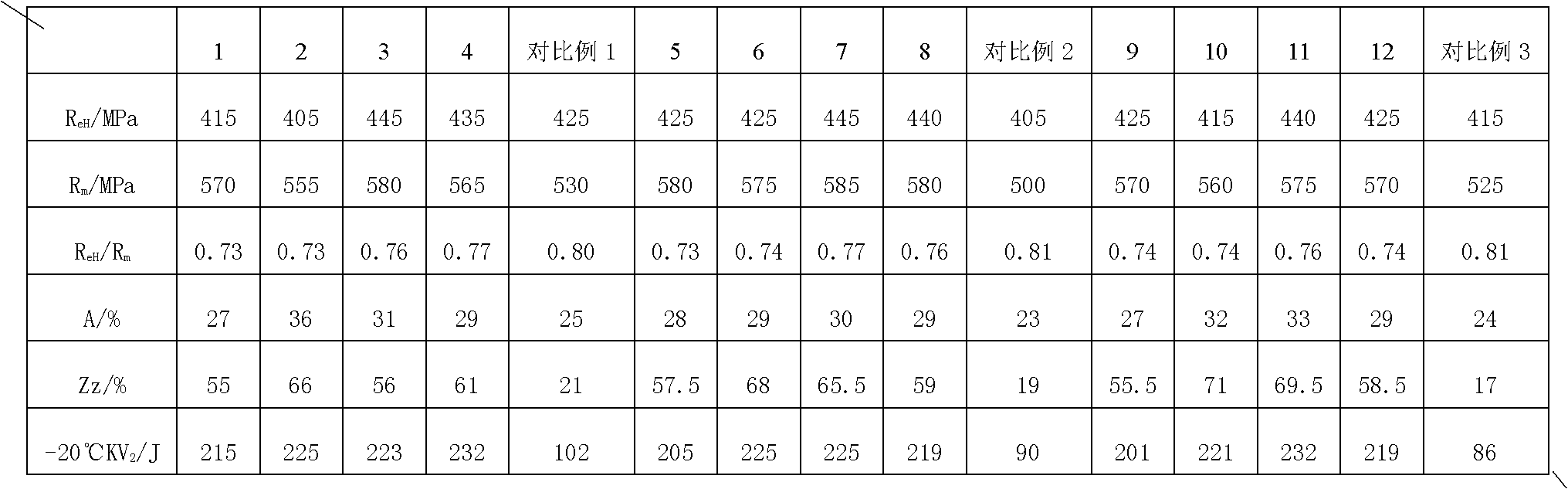

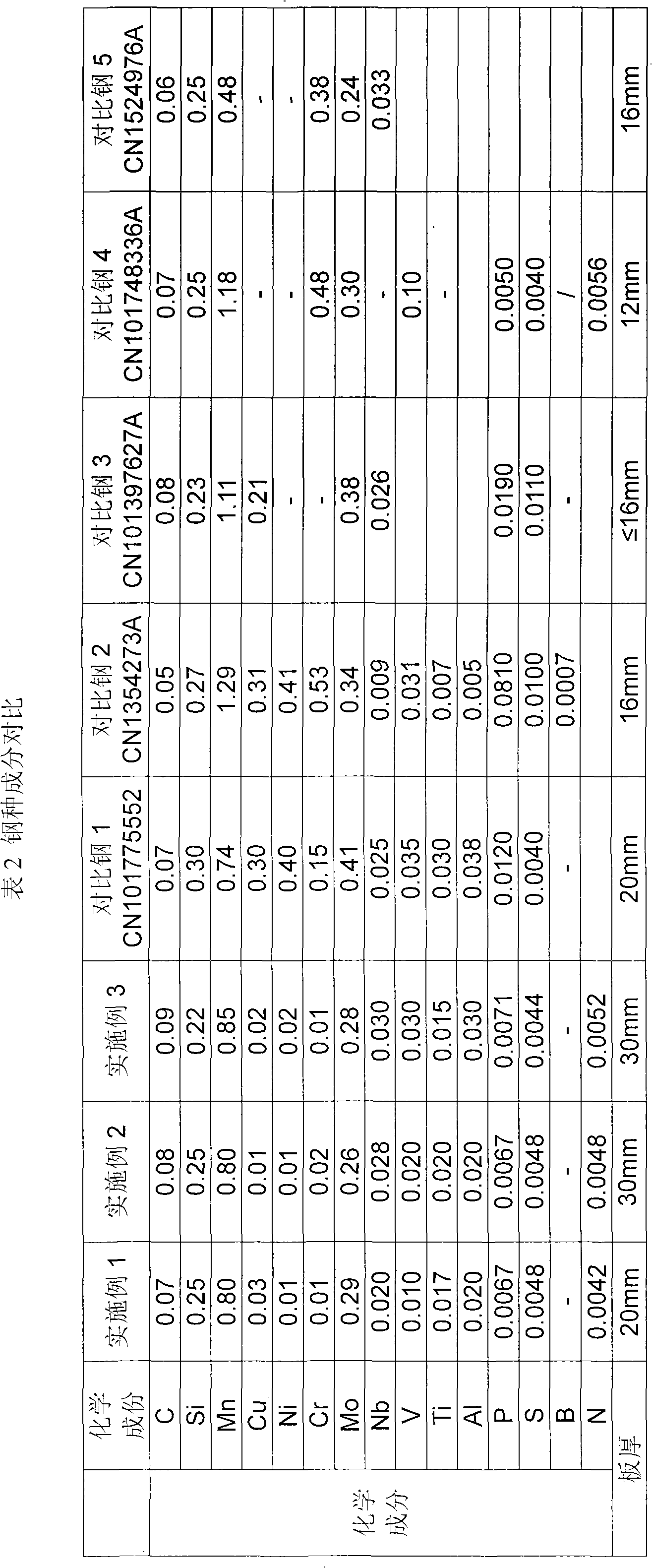

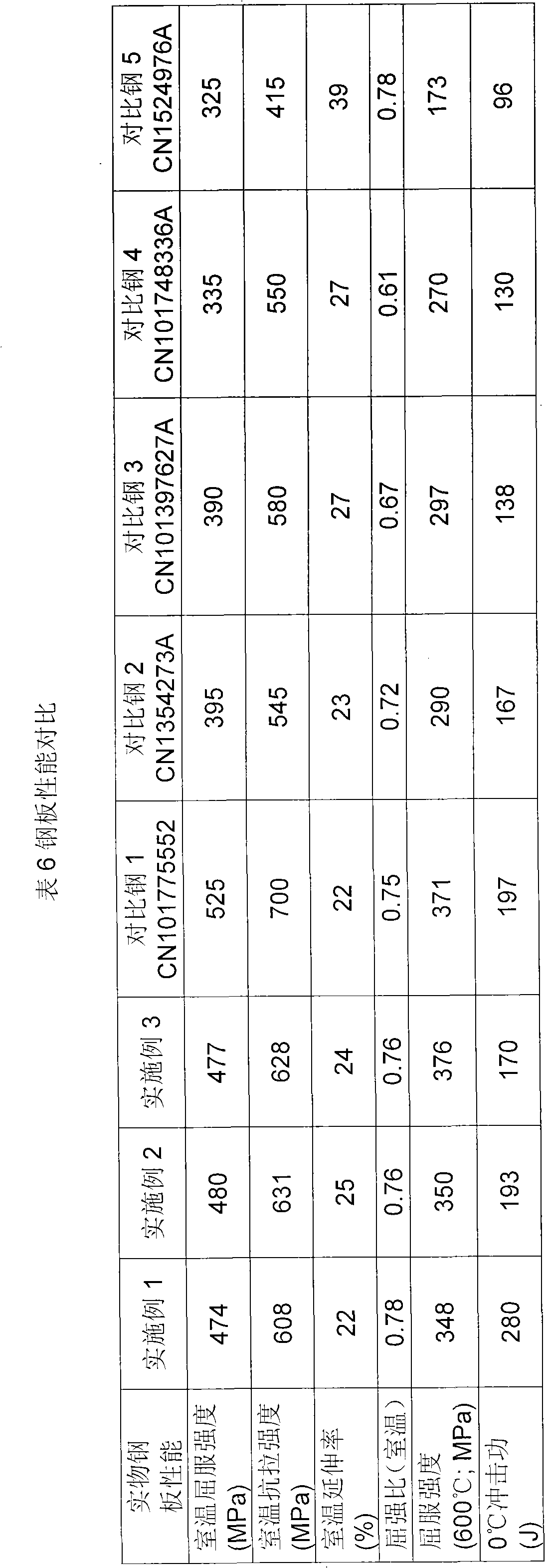

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

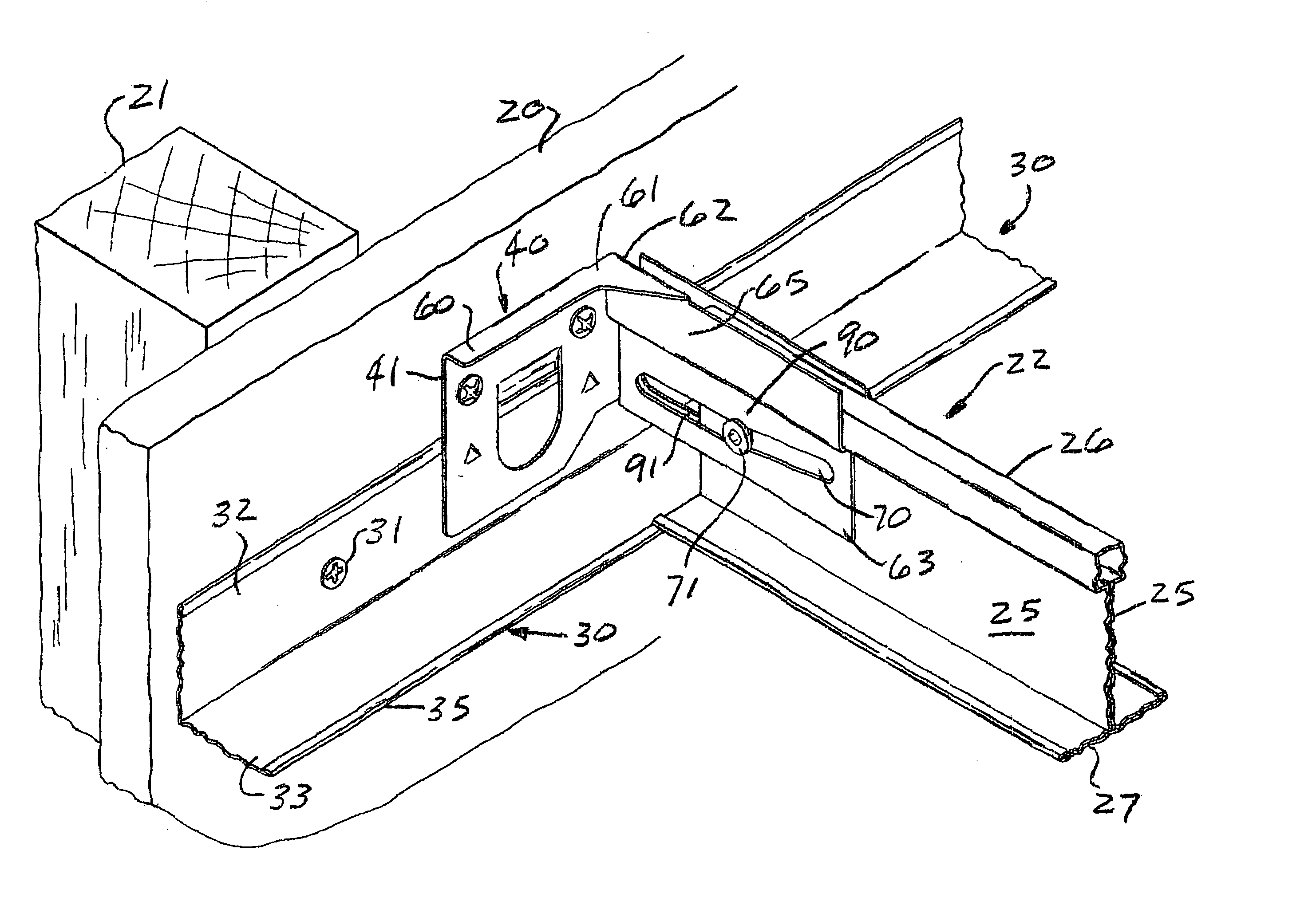

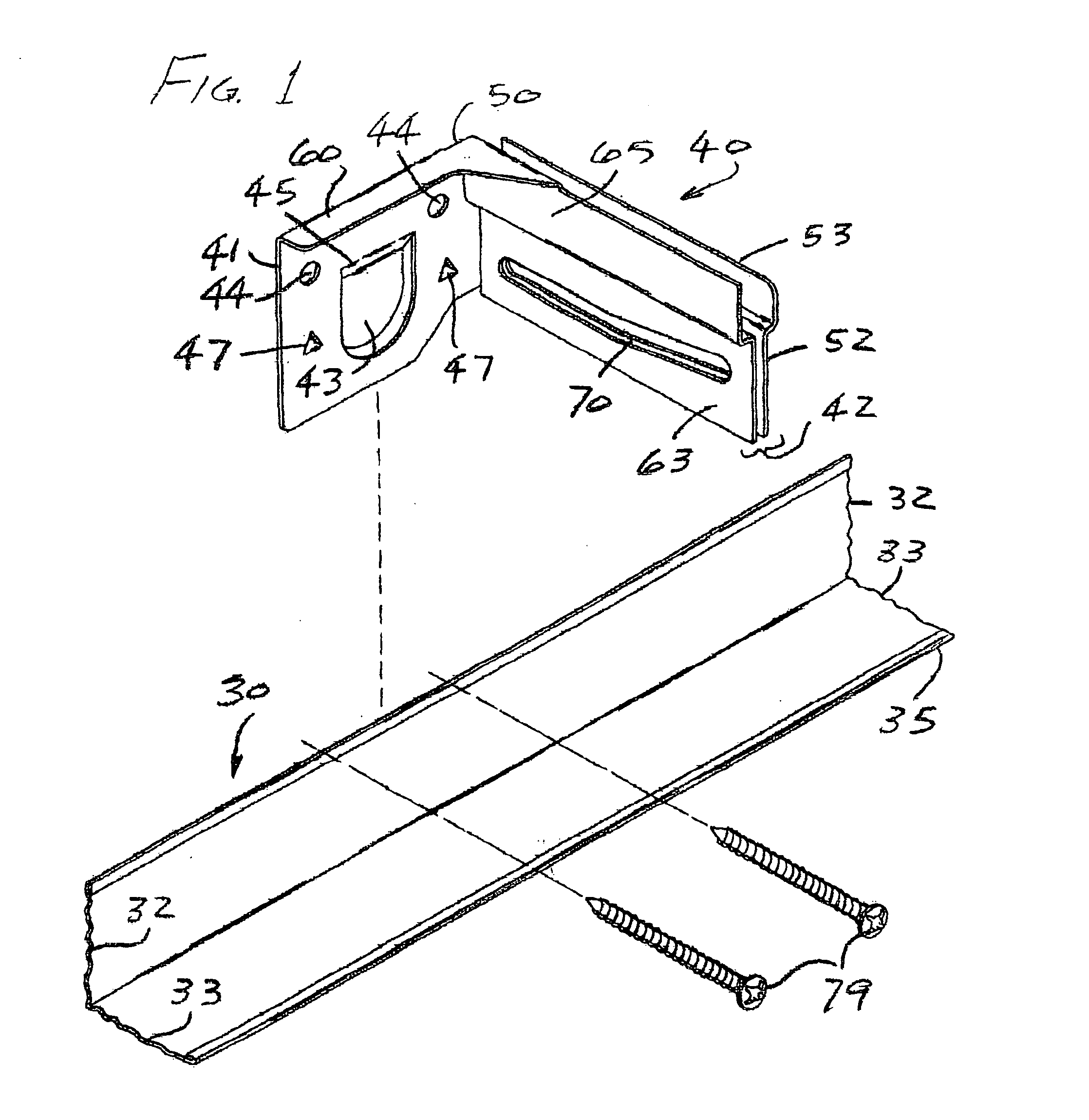

Perimeter clip for seismic ceilings

Owner:3DXLP LLC +1

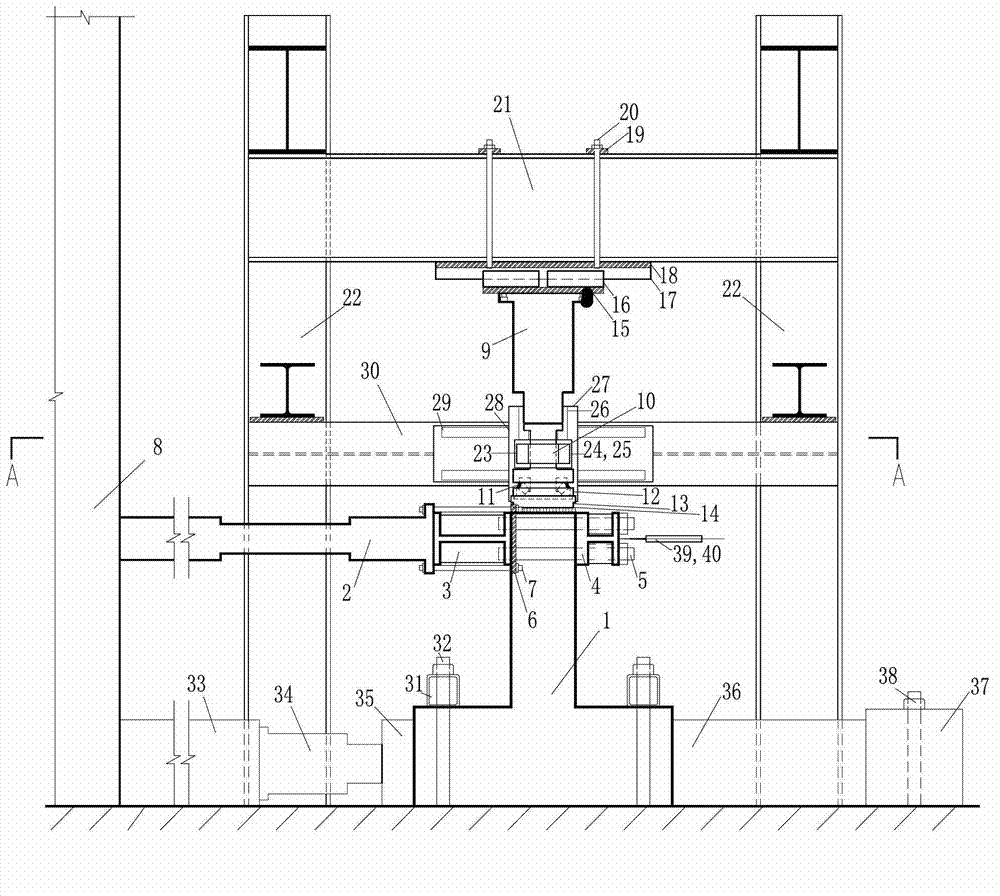

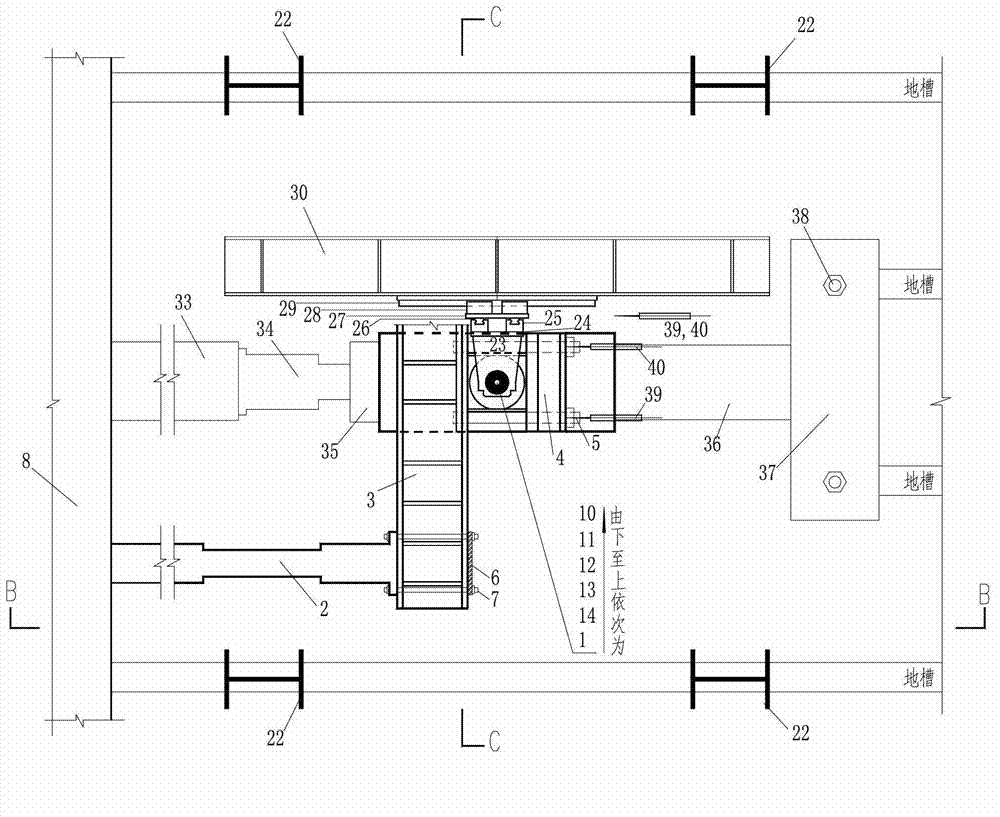

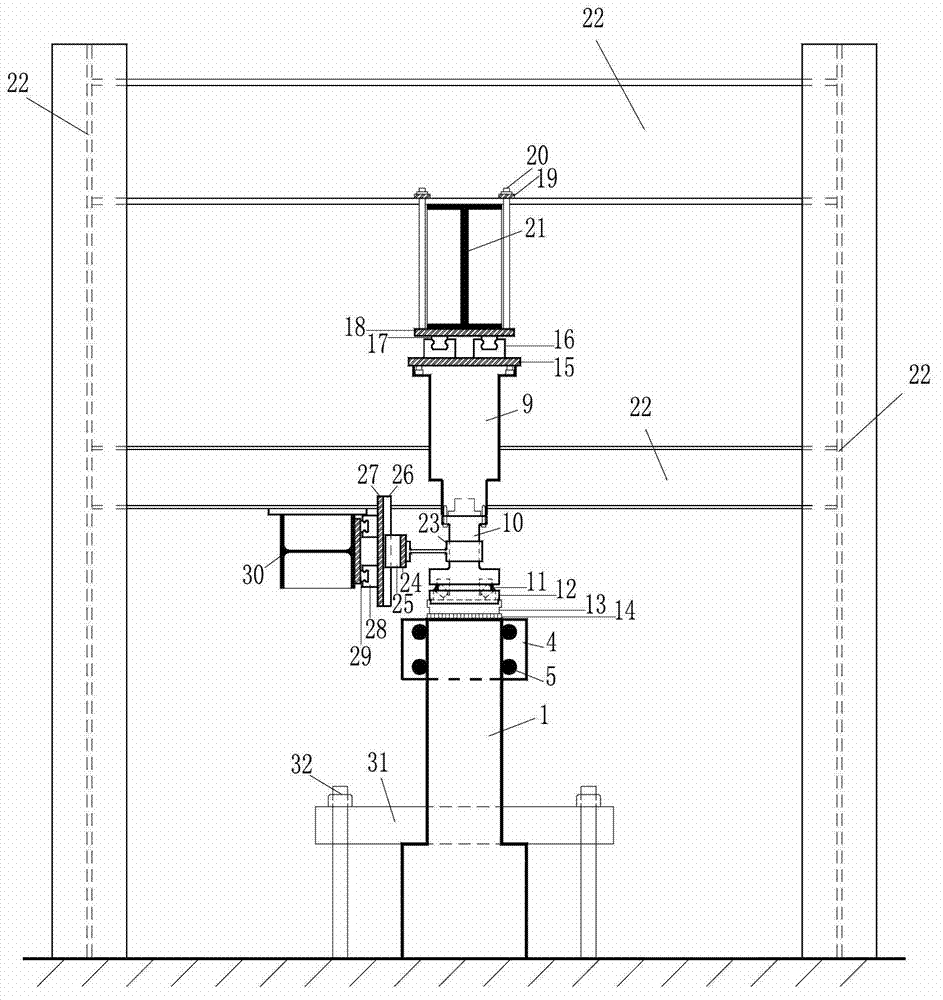

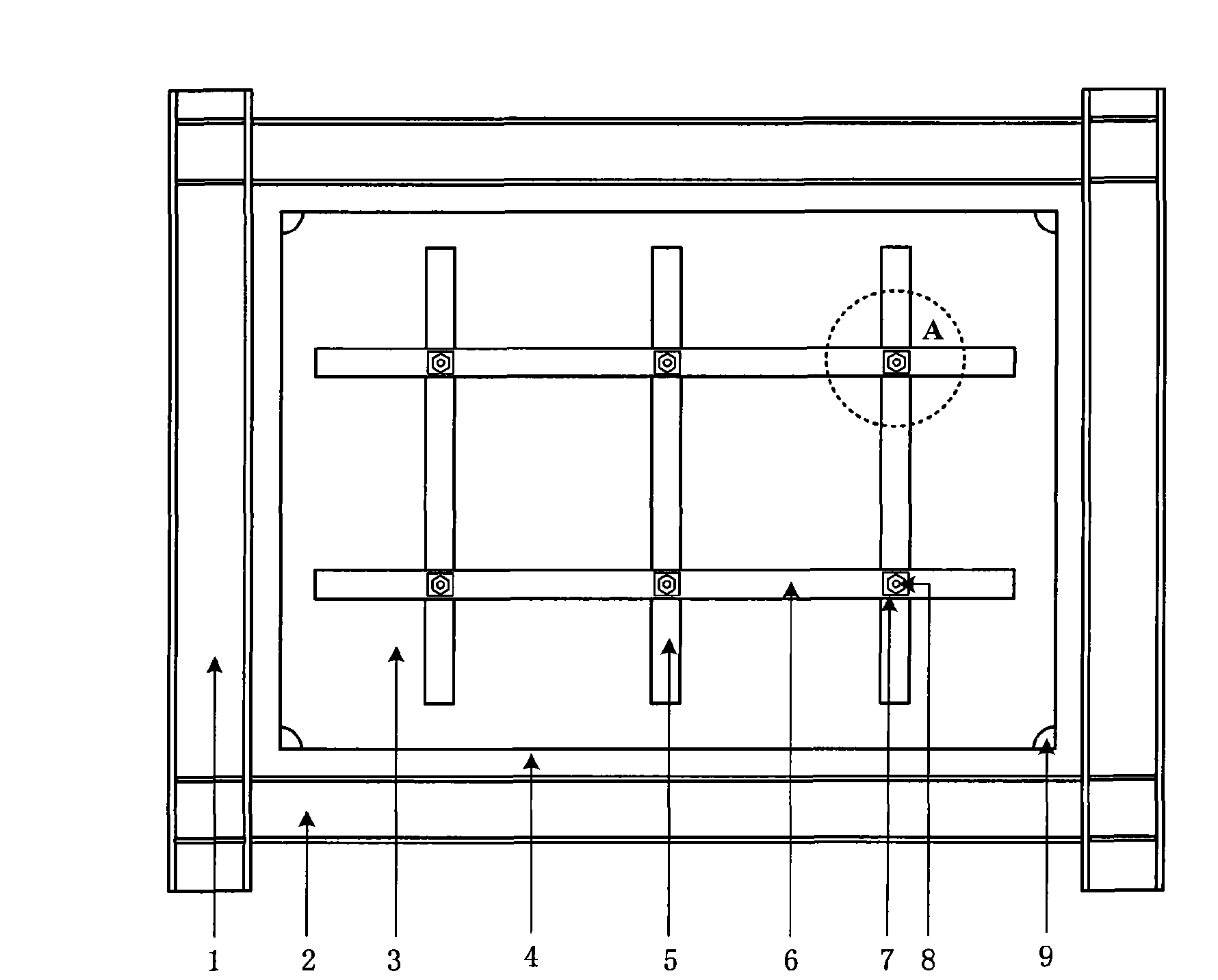

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

Thermal-insulation loading recycled concrete

The invention relates to a concrete commonly used in building materials, and especially relates to a thermal-insulation loading recycled concrete. A technical problem to be solved is to provide a recycled concrete which is an integration of thermal insulation, loading, quake resisting, and energy saving and emission reduction. A technical scheme adopted is characterized in that a weight ratio (kg / m<3>) of a composite lightweight aggregate admixture: cement: recycled fine aggregate: sand: recycled coarse aggregate: cobblestone: ceramsite: coal ash: water: additives is (5-250):(200-800):(20-500):(5-800):(30-600):(5-1400):(50-800):(10-600):(50-500):(0.1-200); the composite lightweight aggregate admixture is a mixture of glazed hollow beads and an aerogel, and the weight part ratio of the glazed hollow beads to the aerogel is 1:(0.7-1.5); and the additives comprise the following components, by weight, 10-150 parts of silica fume, 4-40 parts of an air entraining agent, 5-30 parts of a foaming agent, 3-30 parts of a water reducing agent, 1-30 parts of a polypropylene fiber, and 10-150 parts of waste slag. The technical scheme is used for making the recycled concrete.

Owner:TAIYUAN UNIV OF TECH

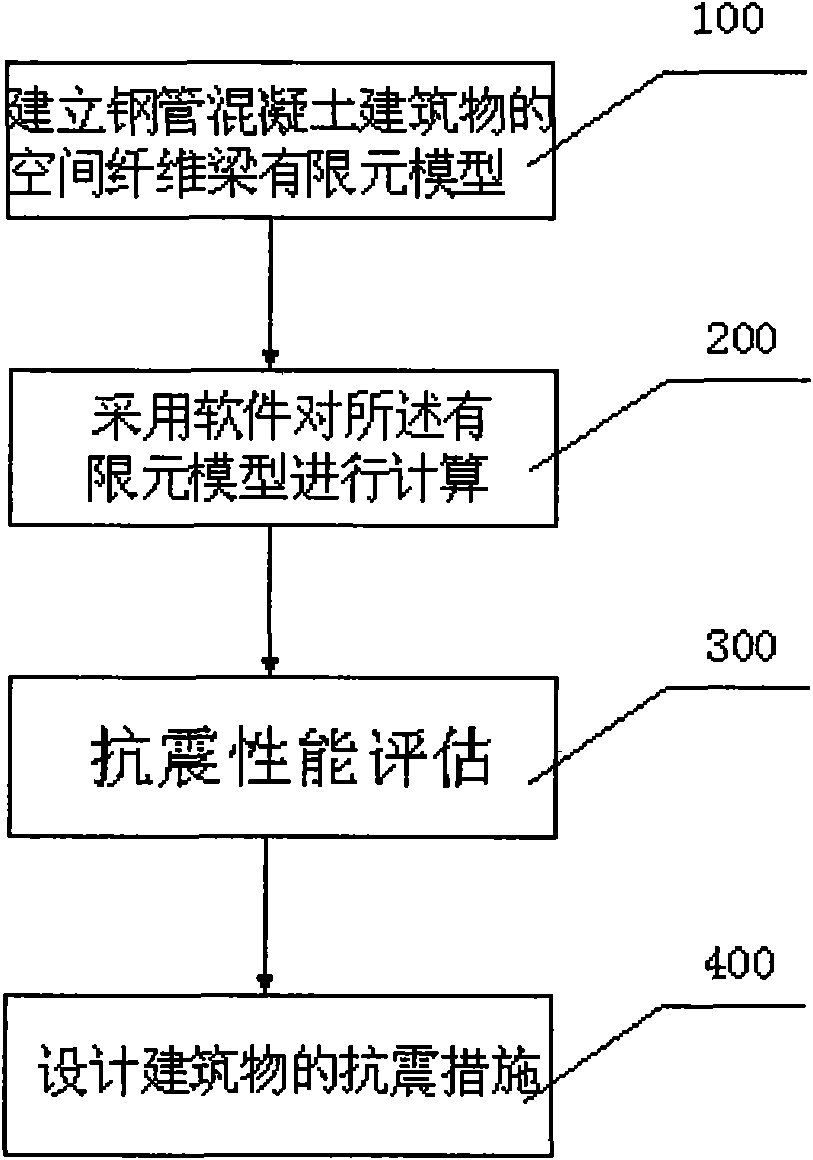

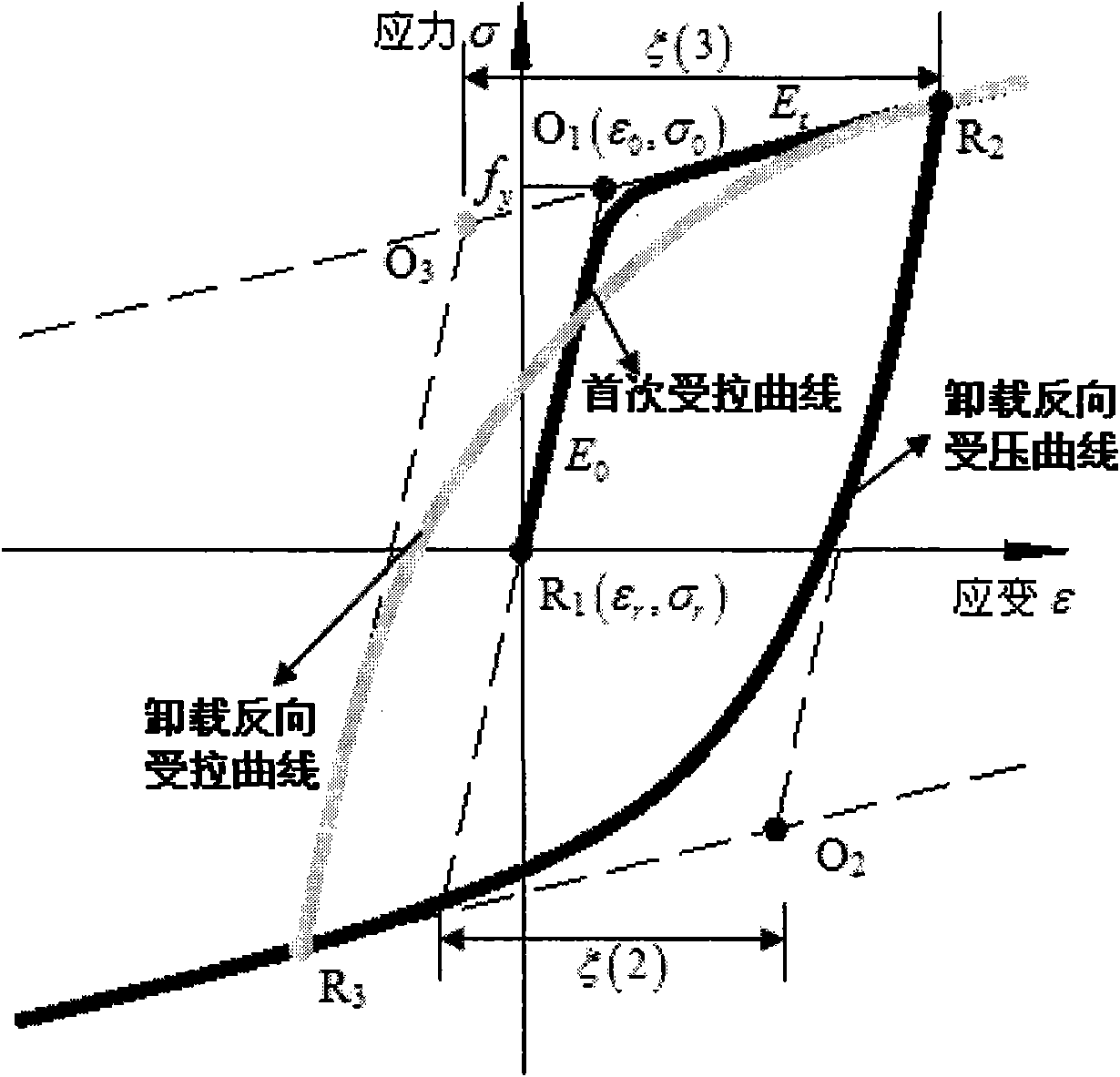

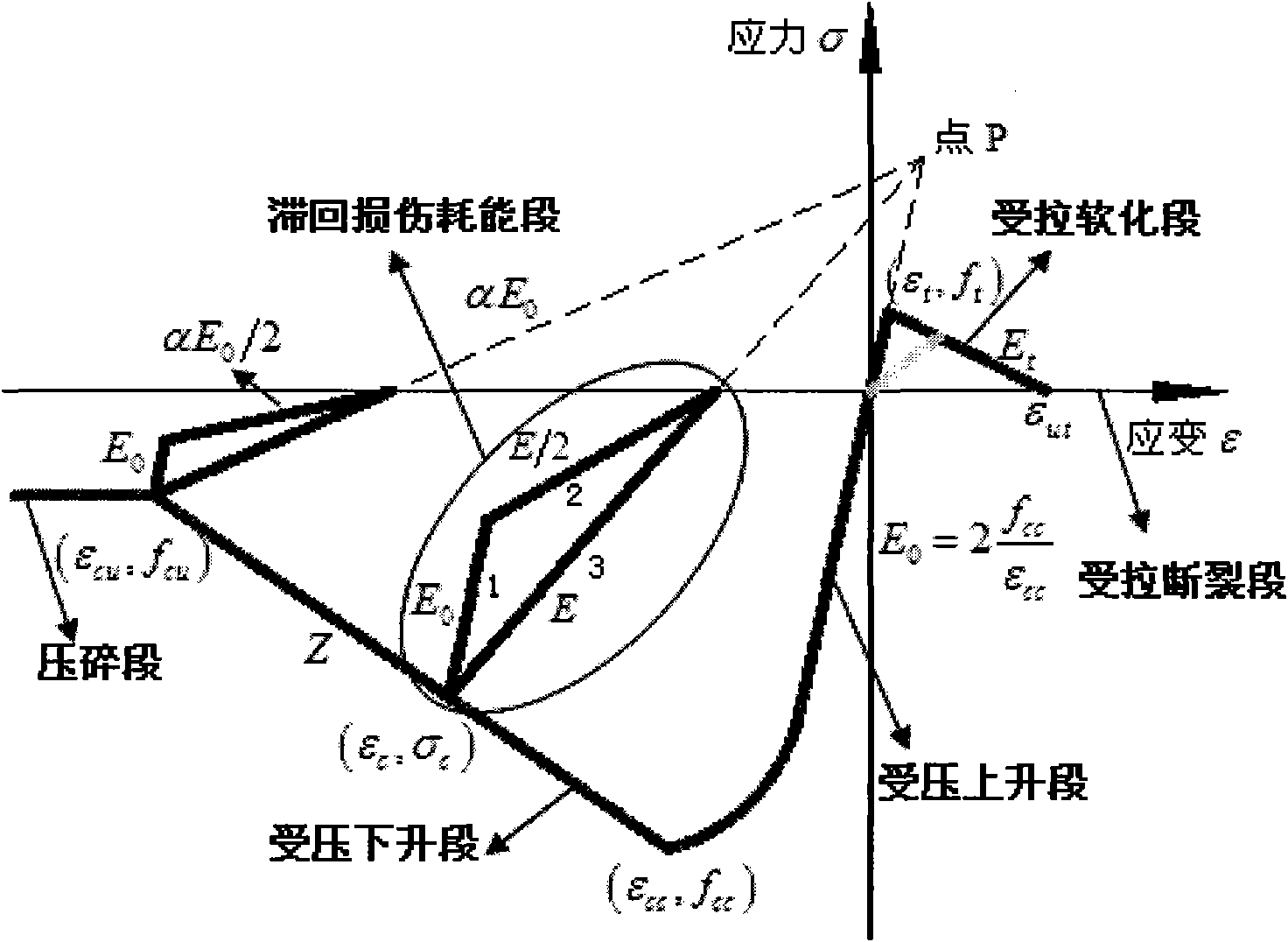

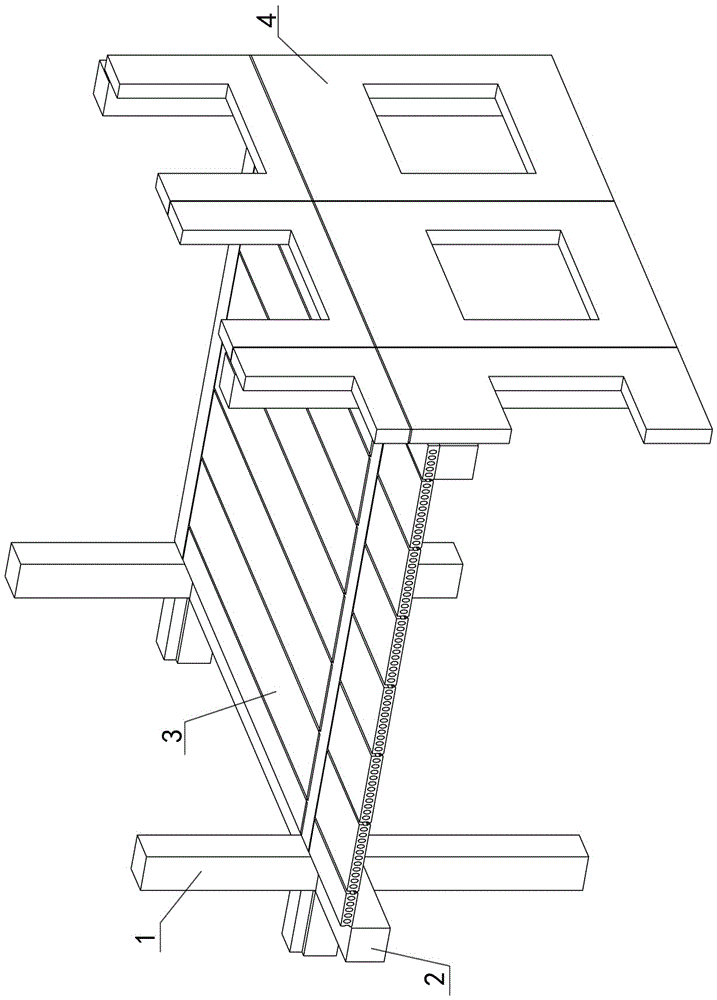

Evaluation method of earthquake resistant performance of steel tube concrete building and application

The invention relates to an evaluation method of earthquake resistant performance of a steel tube concrete building. A building support component is formed by steel tube concrete. The evaluation method comprises the following steps of establishing a space fiber beam finite element model of the steel tube concrete building, developing an analysis method suitable for a fiber beam, considering that the confinement effect and the material characteristic of the elasto-plasticity under earthquake cyclic loading damage a constitutive model and a corresponding subprogram, calculating the finite element model by adopting a software and combining with the material subprogram, evaluating the earthquake resistant performance, and designing the earthquake resistant measure of the building. In the provided evaluation method of the earthquake resistant performance of the steel tube concrete building, the earthquake resistant performance of the building is evaluated on the basis of the maximum inter-story displacement angle limit value required by a steel tube concrete structure by establishing the space fiber beam finite element model of the steel tube concrete building, developing the analysis method suitable for the fiber beam, considering that the confinement effect and the material characteristic of the elasto-plasticity under earthquake cyclic loading damage the constitutive model, calculating the finite element model by adopting the software and obtaining the maximum inter-story displacement angle of the building, and building earthquake resistant measures are planed according to the evaluation result of the earthquake resistant performance of the building.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

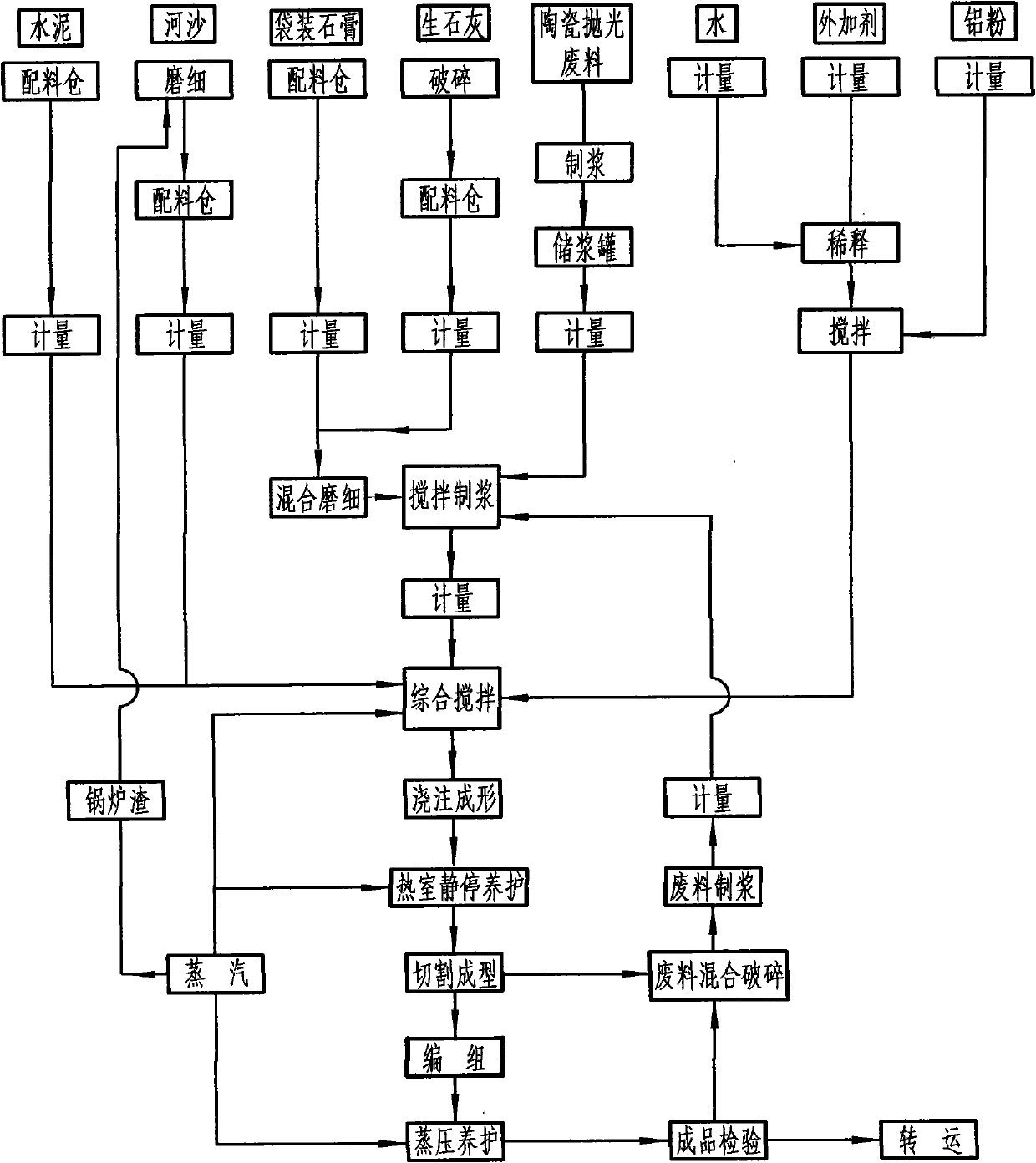

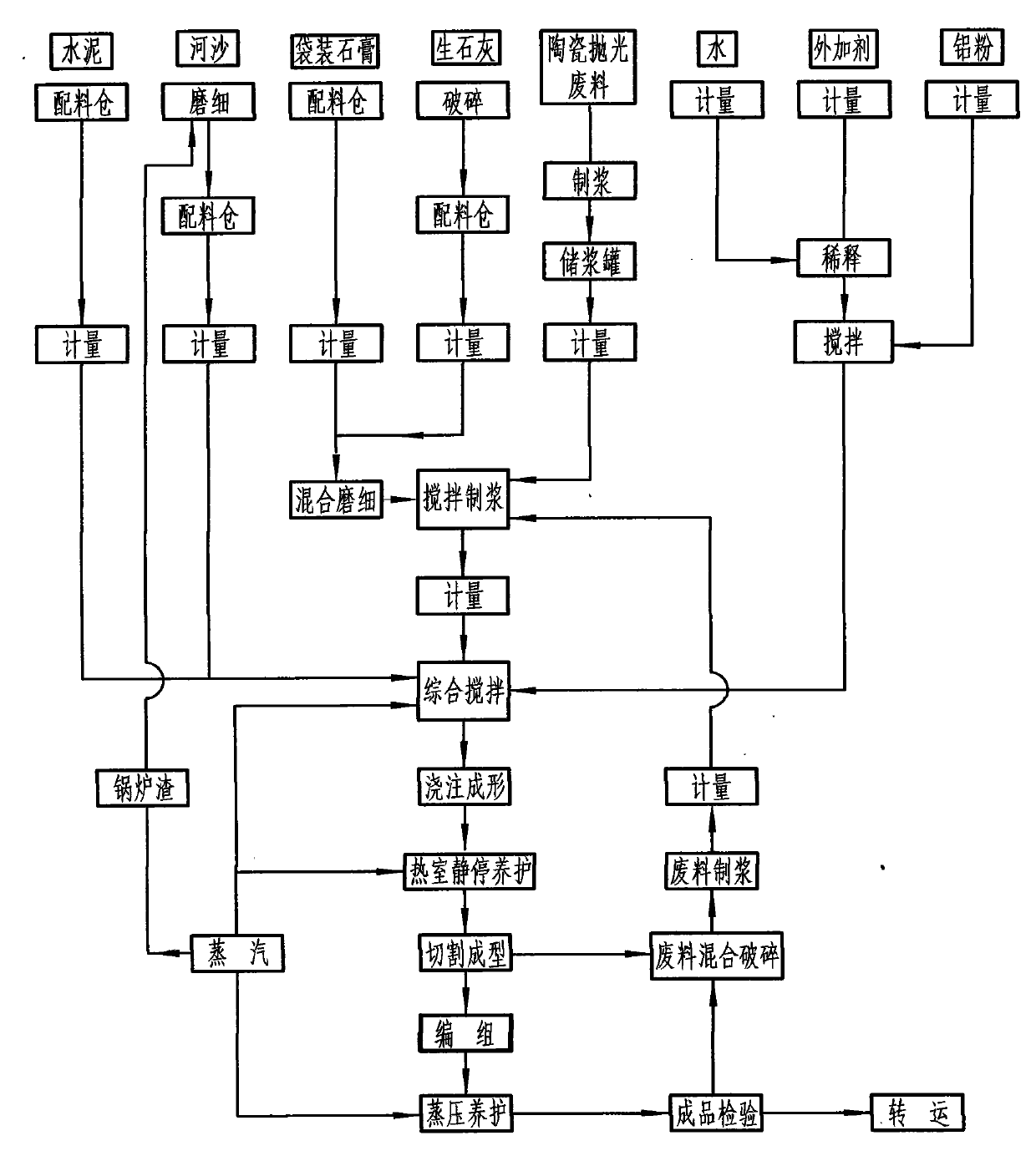

Autoclaved aerated concrete building block and preparation method thereof

The invention discloses an autoclaved aerated concrete building block, which is prepared by adding water into 50 to 55 weight parts of ceramic polishing waste, 10 to 15 weight parts of fine sand, 20 to 24 weight parts of calcined lime, 10 to 20 weight parts of cement, 0.05 to 0.09 weight part of aluminum powder and 3 to 5 weight parts of gypsum. The invention also discloses a preparation method for the autoclaved aerated concrete building block, which comprises the production processes of raw material fetching, slurry preparation, proportioning and pouring, standing and curing in a hot chamber, blank cutting, grouping, autoclaved maintenance, finished product inspection, recycle of waste liquid, waste slag and waste products and the like. The obtained autoclaved aerated concrete building block has the characteristics of high forming speed, light weight, high strength, heat insulation, sound insulation, good fireproof performance, low elasticity, seismic resistance, convenient construction and the like. The preparation method realizes utilization of the ceramic polishing waste, reduces the discharge of wastes of the ceramic industry, and is favorable for protection of ecological environment.

Owner:周石镭 +3

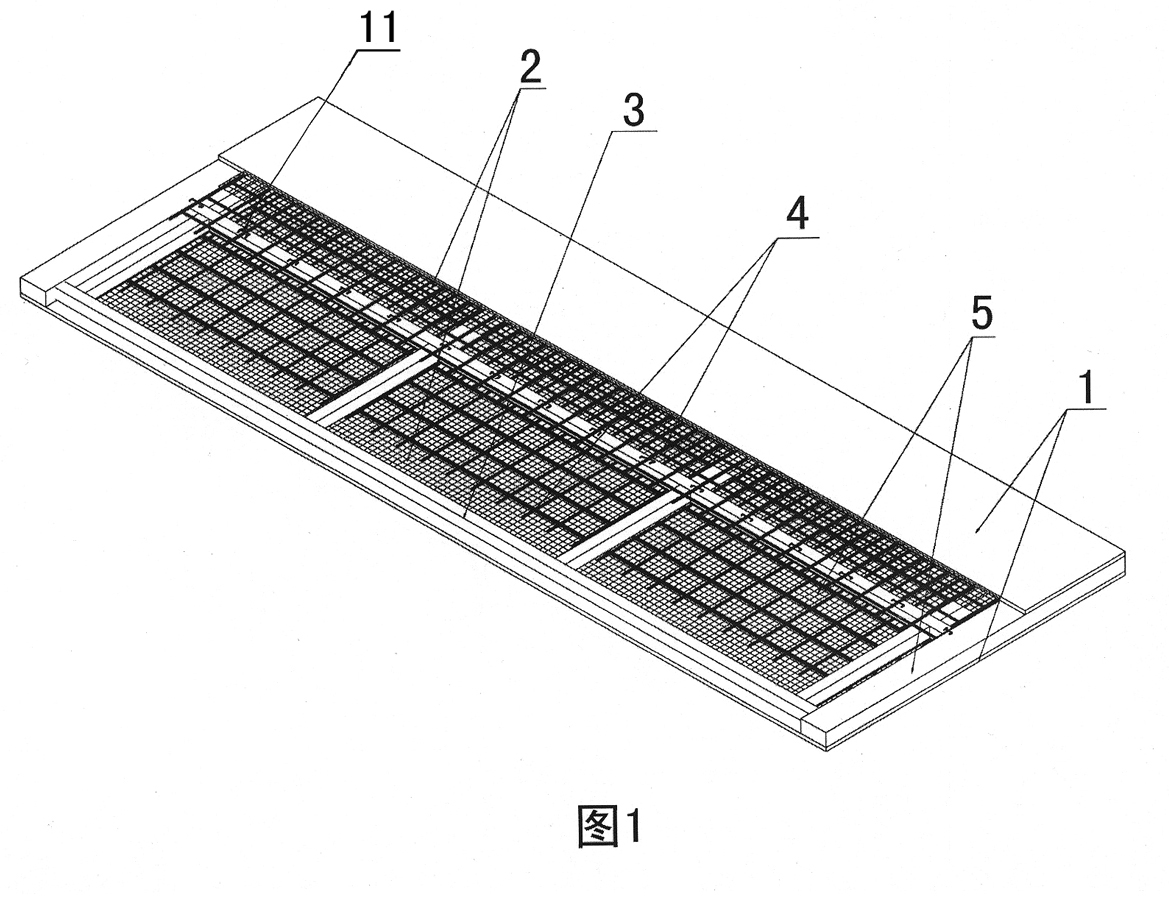

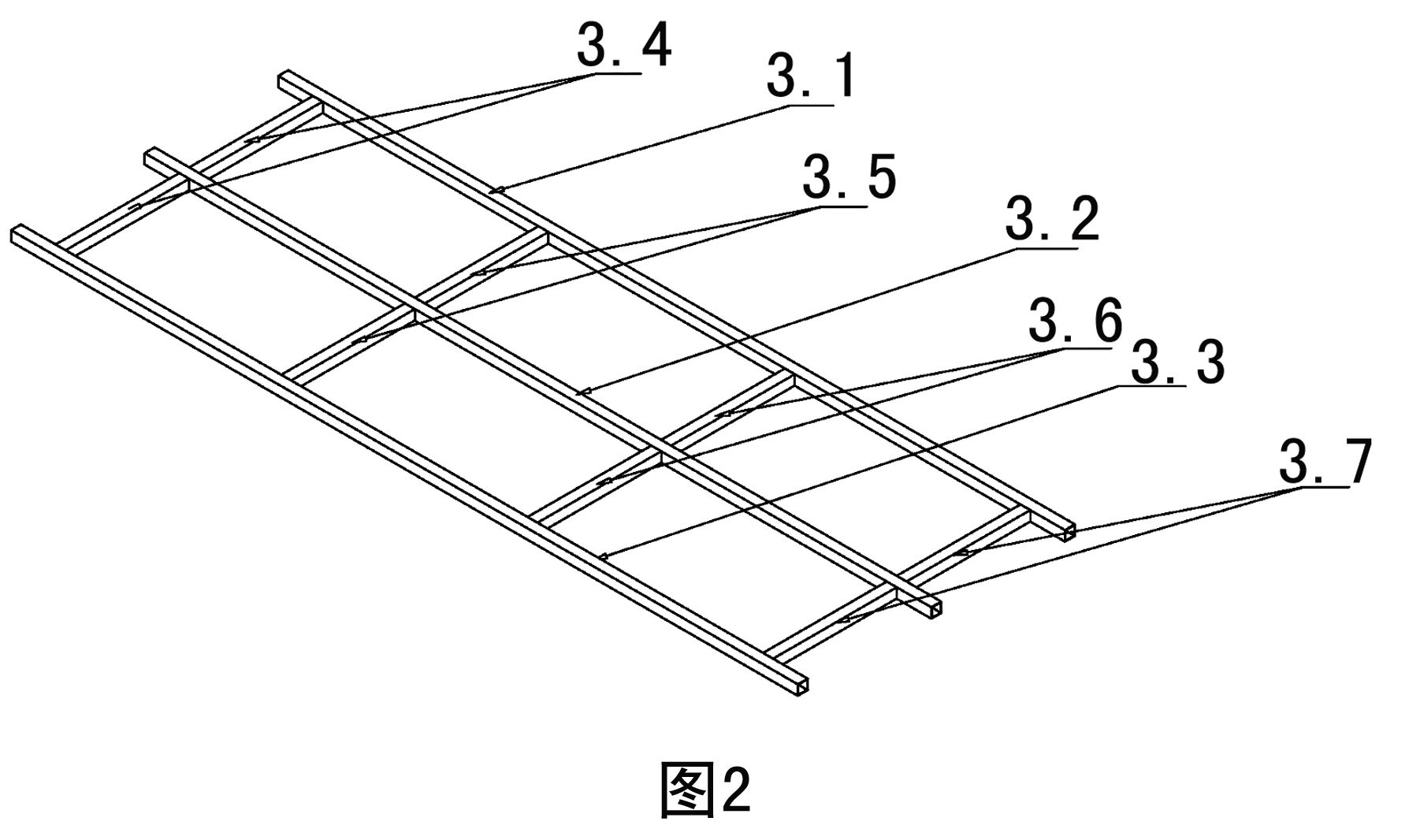

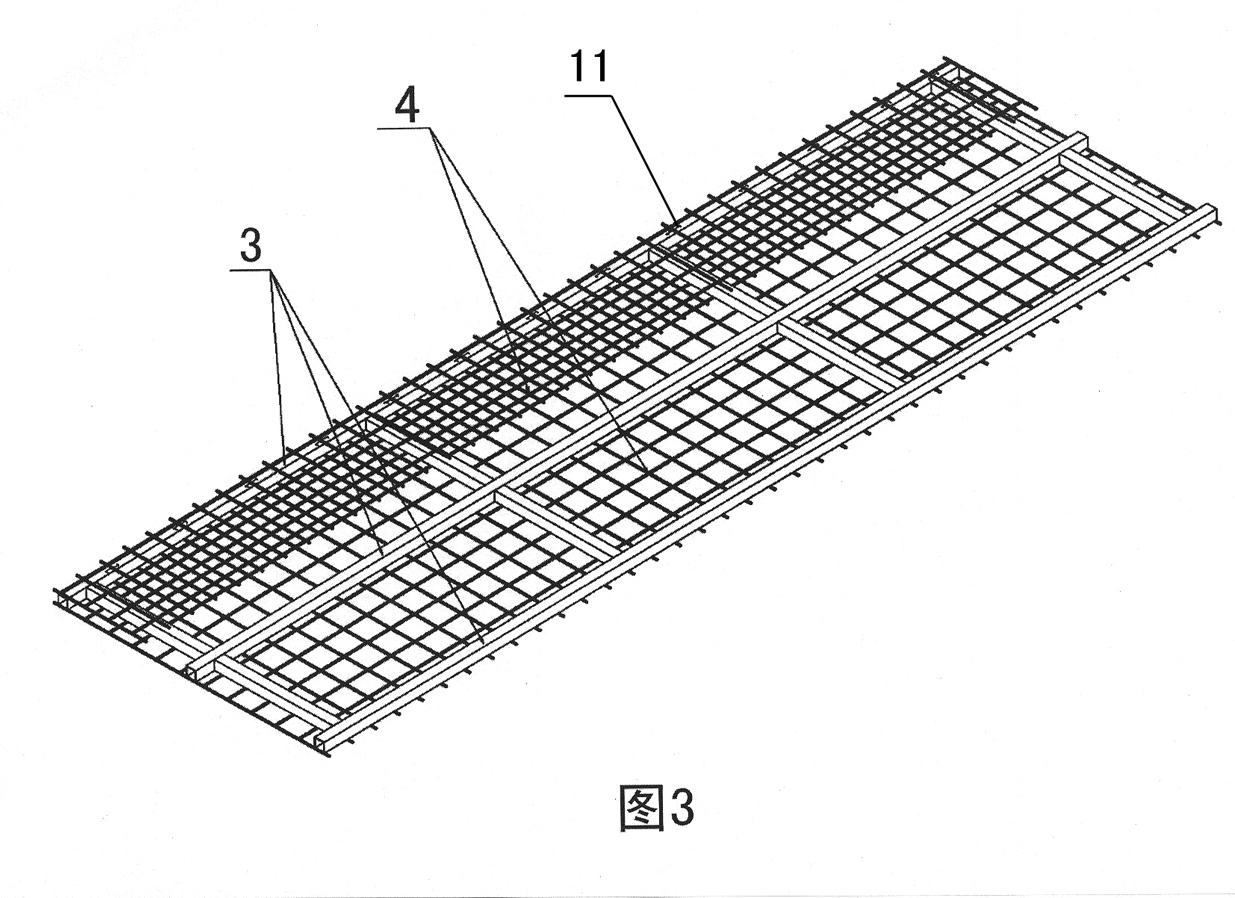

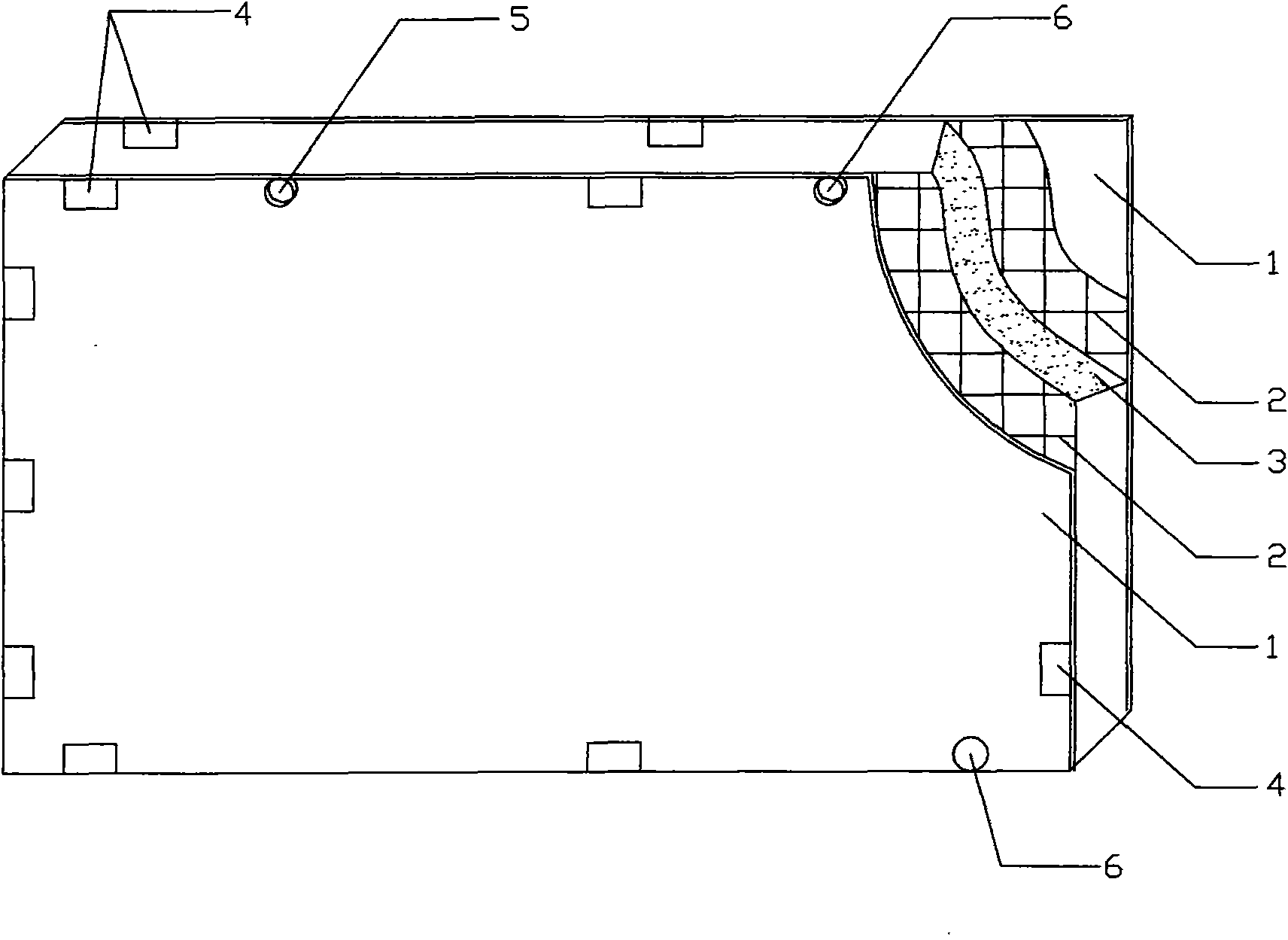

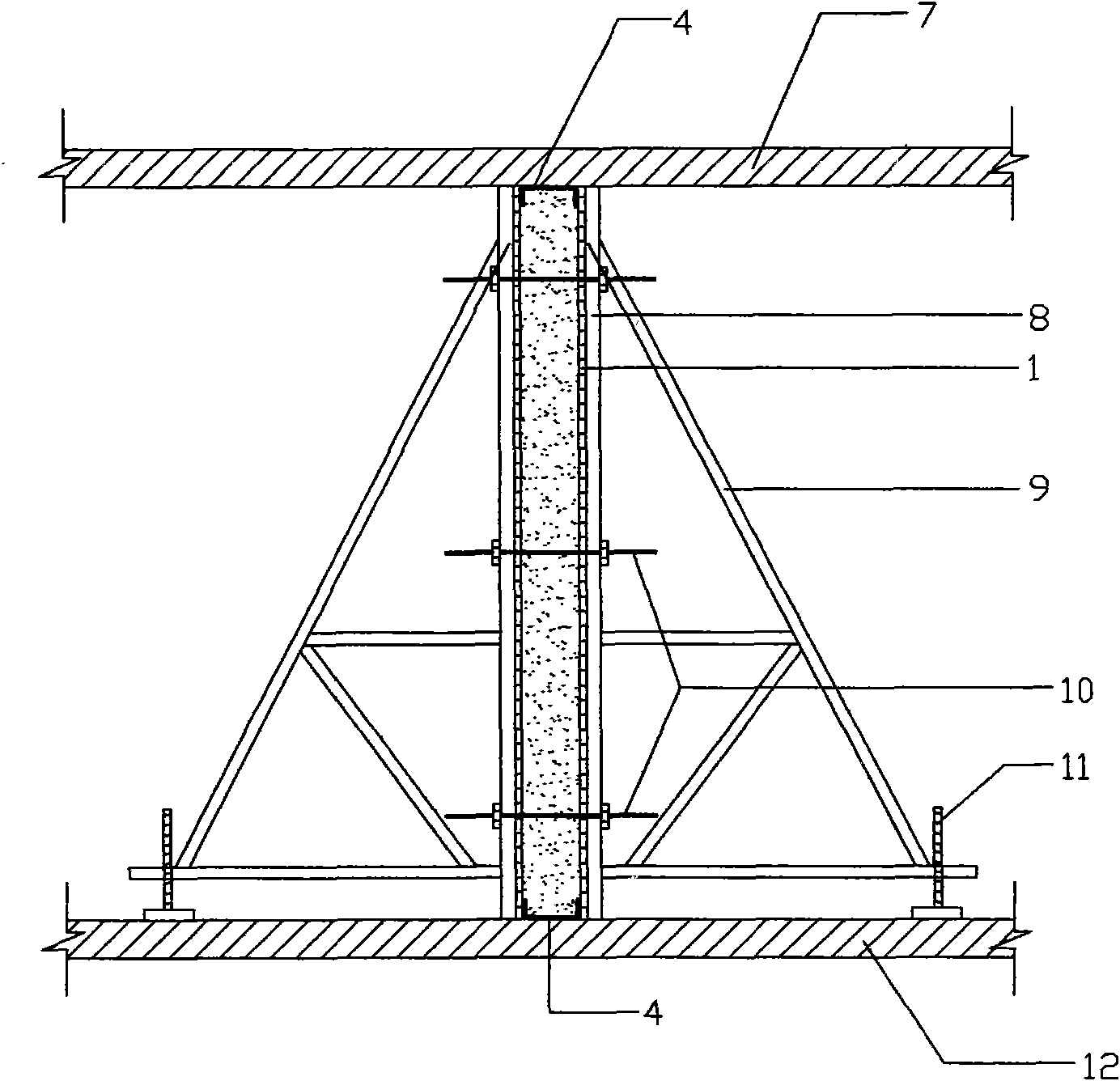

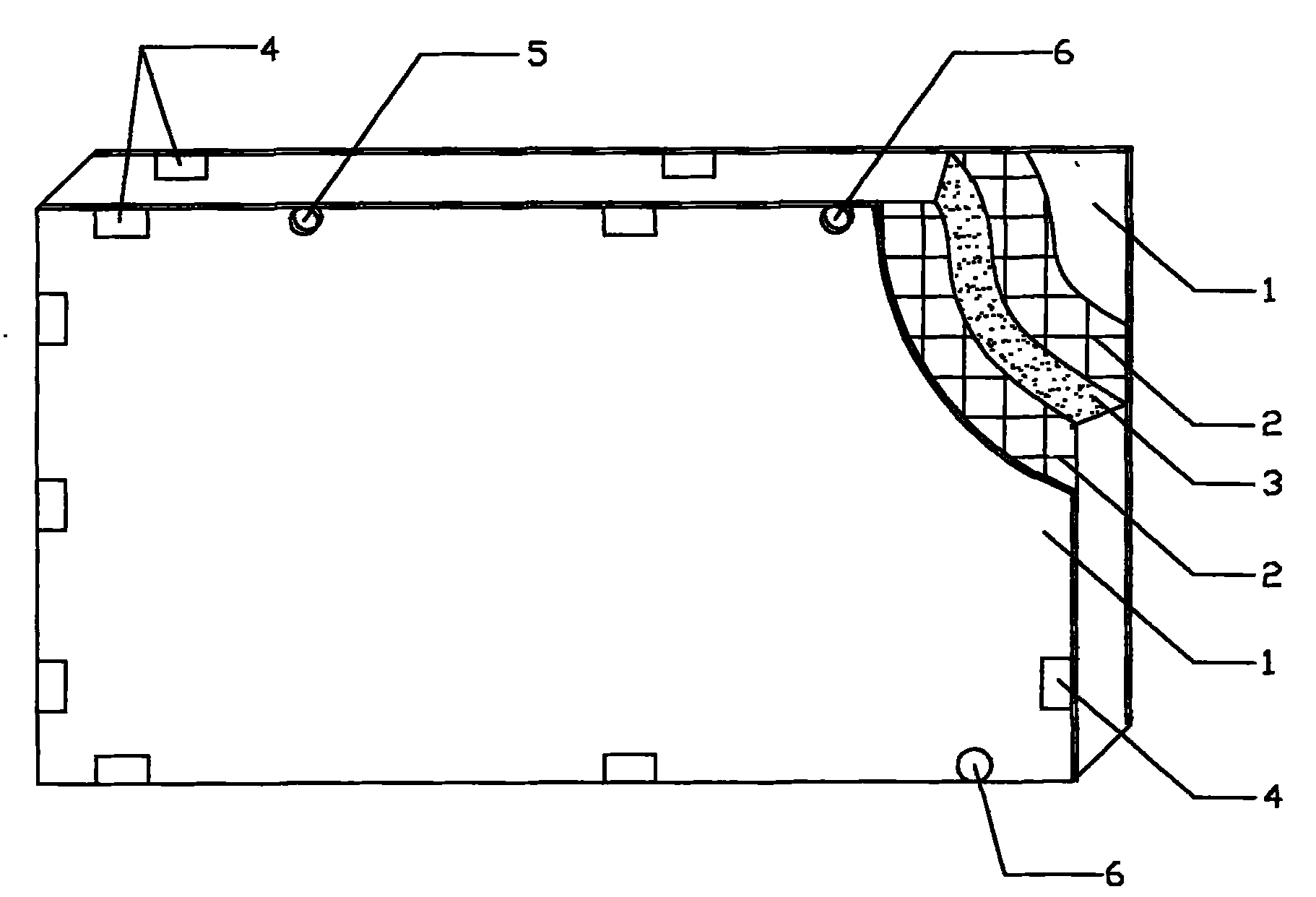

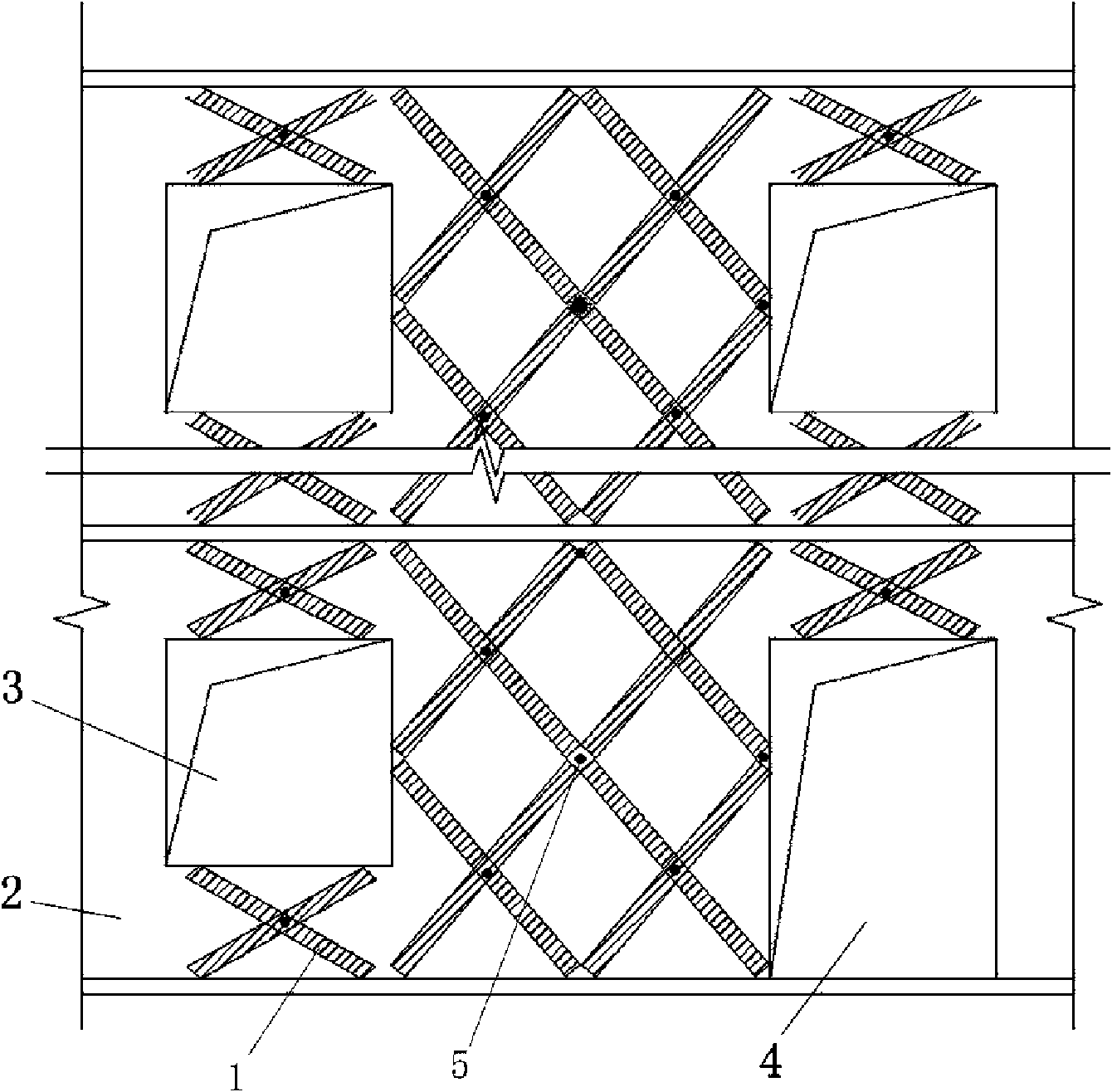

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

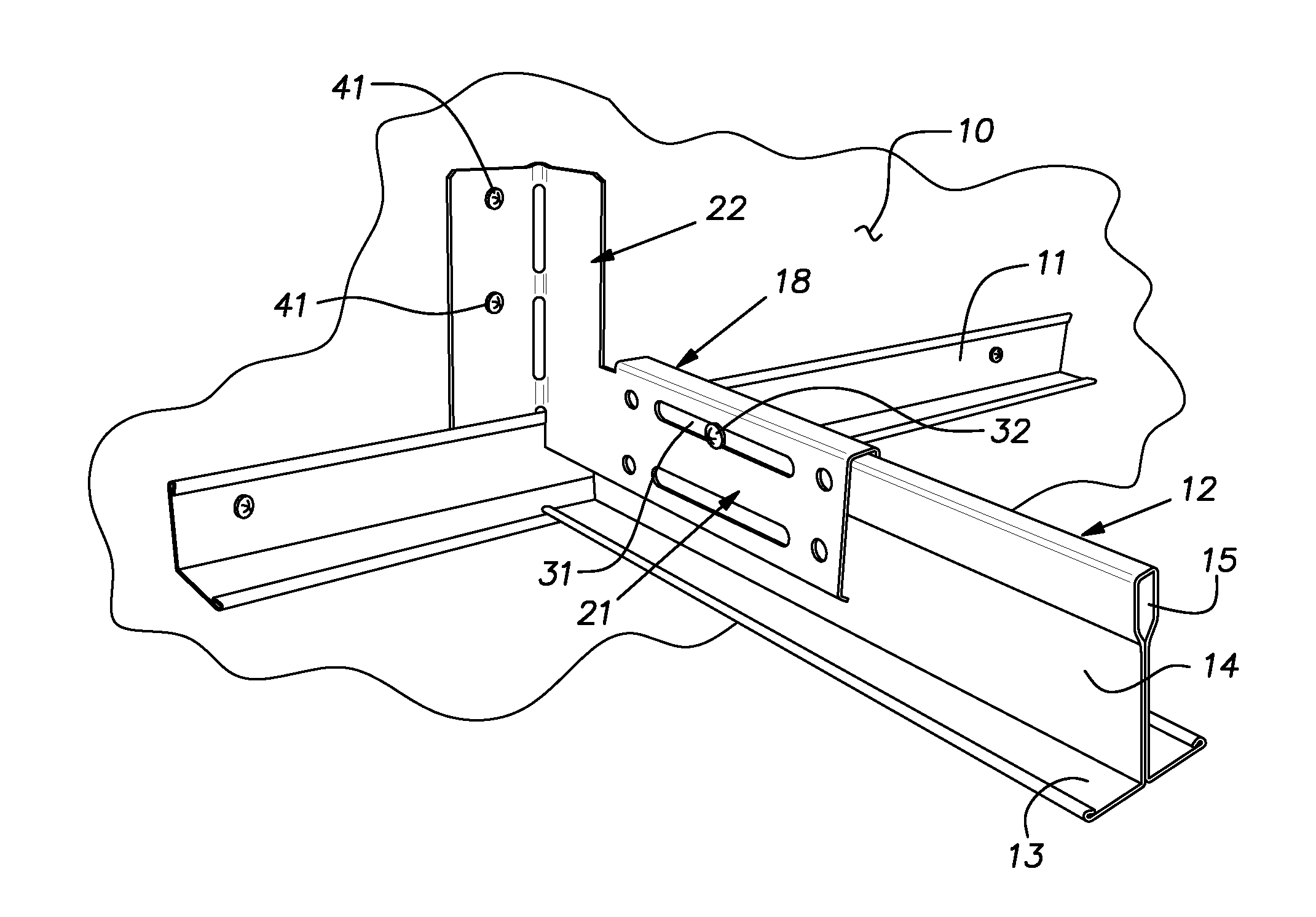

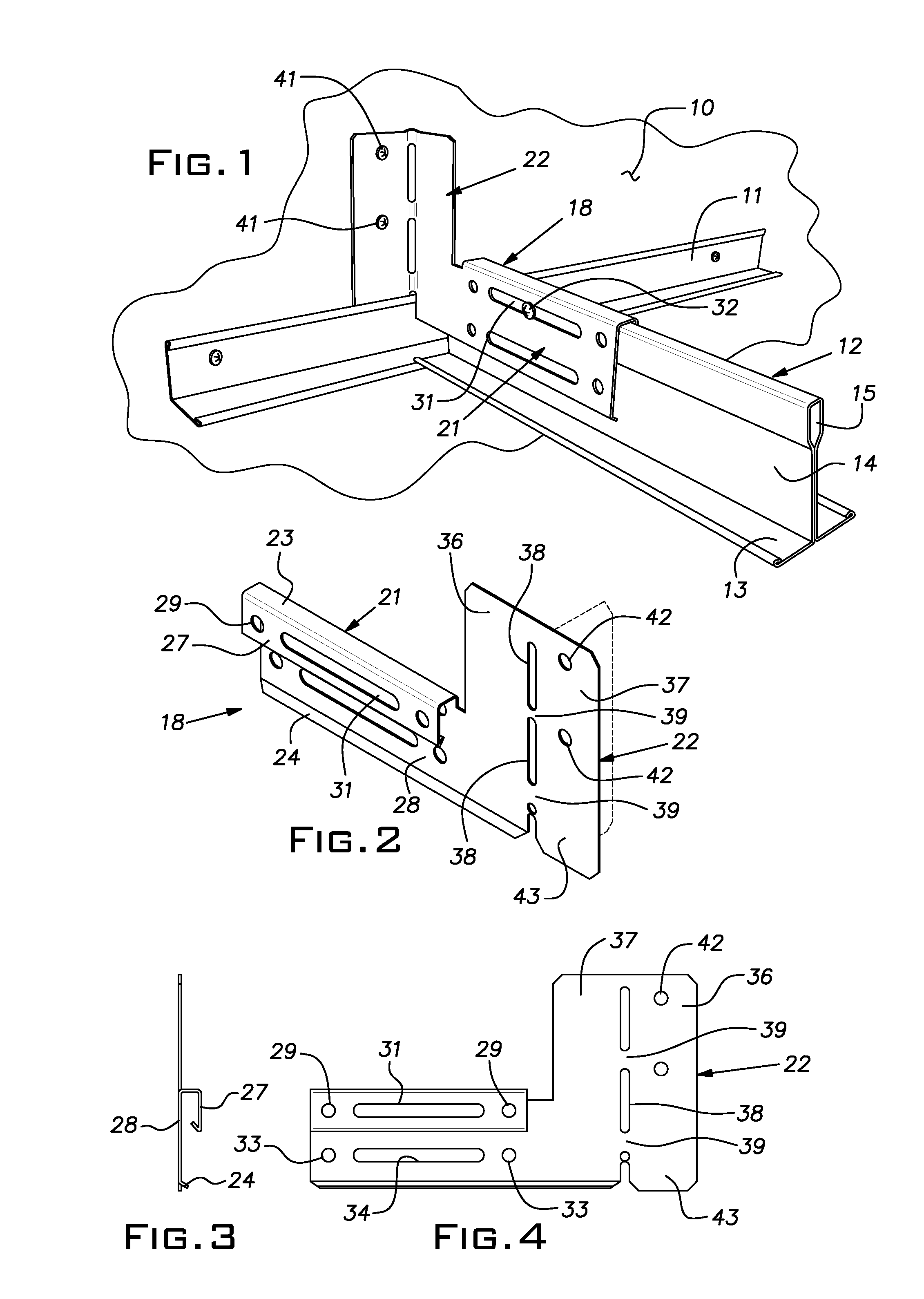

Backup wall reinforcement with t-type siderail

InactiveUS20130232893A1Improve protectionReduce manufacturing costStrutsWallsEarthquake resistant structuresStructural engineering

A backup wall reinforcement with T-type siderail anchoring system is described for use in masonry cavity walls. The reinforcement and integral anchor is hybrid device installed within the backup wall and interlocked with novel veneer ties. The novel veneer ties are manually connected through swinging or twisting the veneer ties until the veneer ties are interlocked with the anchor. Once interlocked, lateral and vertical veneer tie movement is limited strengthening the cavity wall structure. The inclusion of a reinforcement wire within the veneer ties and the exterior wall provides a seismic structure.

Owner:MITEK HLDG INC

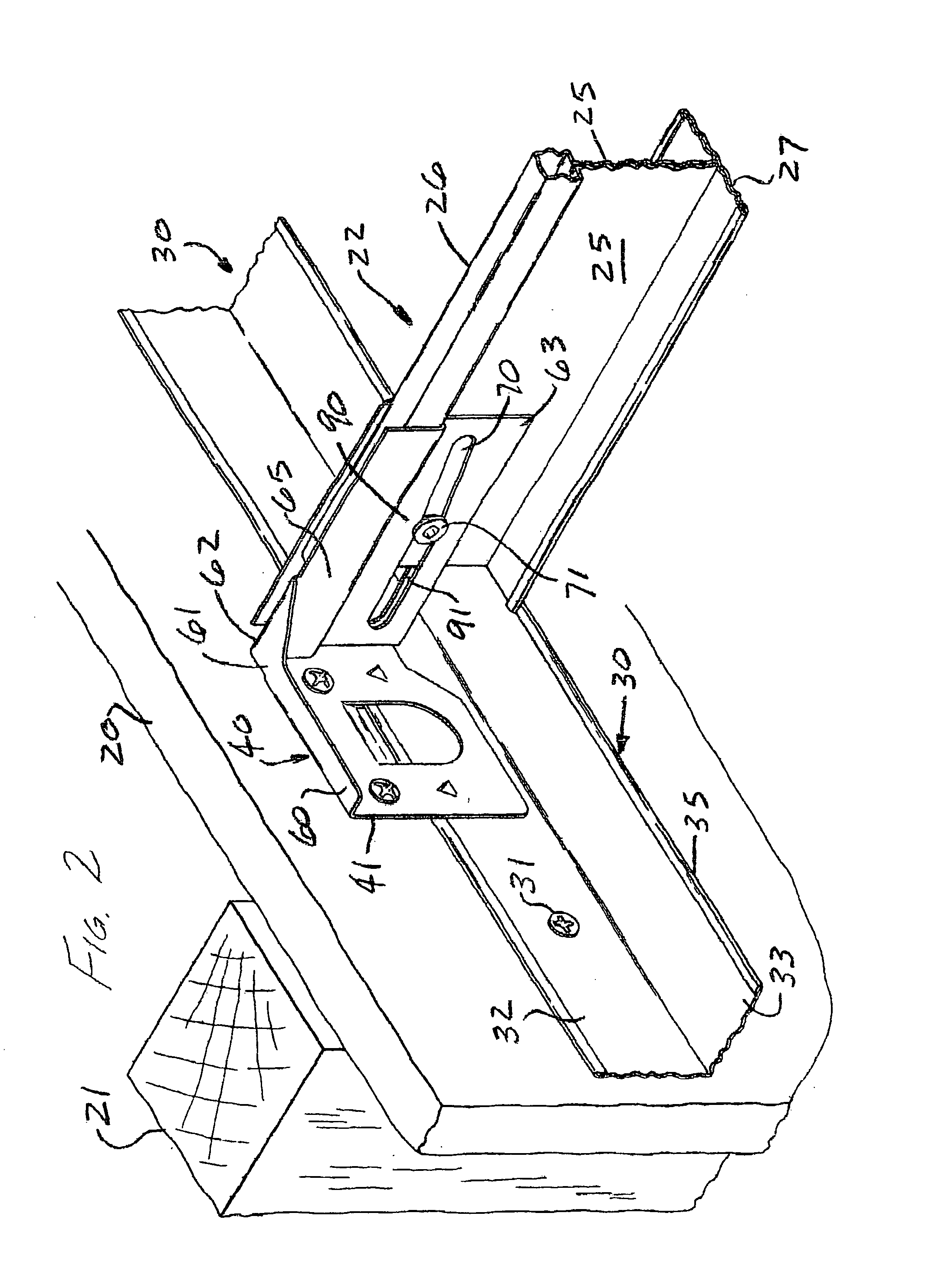

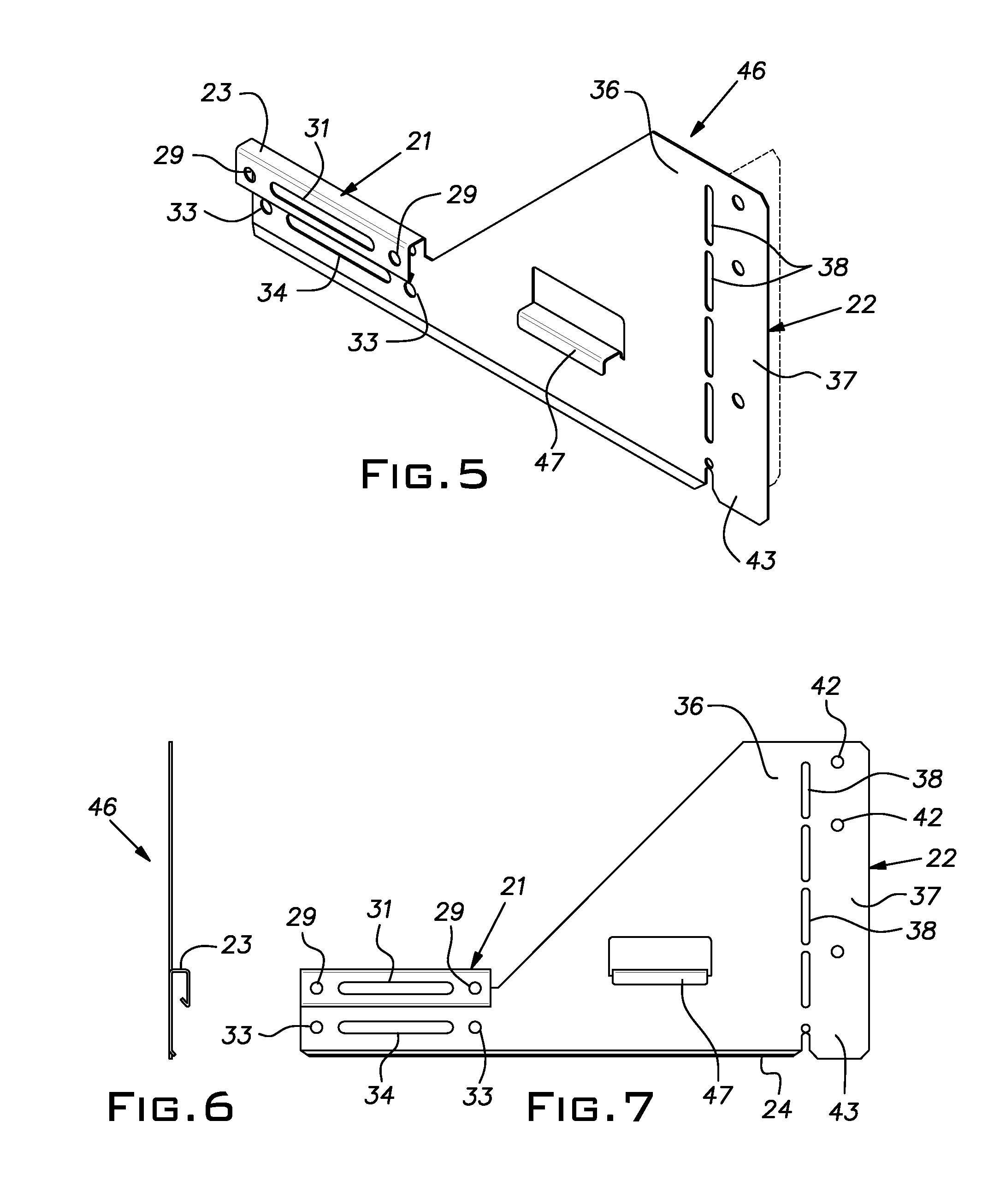

Seismic perimeter brace

InactiveUS20110283634A1Small volumeLimit horizontal movementCeilingsWallsEngineeringMechanical engineering

A seismic bracket for supporting ends of suspended ceiling grid runners from a wall comprising a stamped sheet metal body, the body having a horizontally extending portion and a vertically extending portion, the vertically extending portion, in its installed position, rising above the top of a standard grid runner a distance at least 1½ times the height of such standard grid runner, the vertically extending portion having two sections generally coextensive in the vertical direction, a first section being integral with the horizontally extending portion and a second section arranged to be in a vertical plane that intersects a vertical plane occupied by the horizontally extending portion, the horizontally extending portion being arranged to support a grid runner to move longitudinally a limited distance, the second section of the vertically extending portion having an aperture for securing the bracket to the wall at a location substantially above the grid tee.

Owner:USG INTERIORS LLC

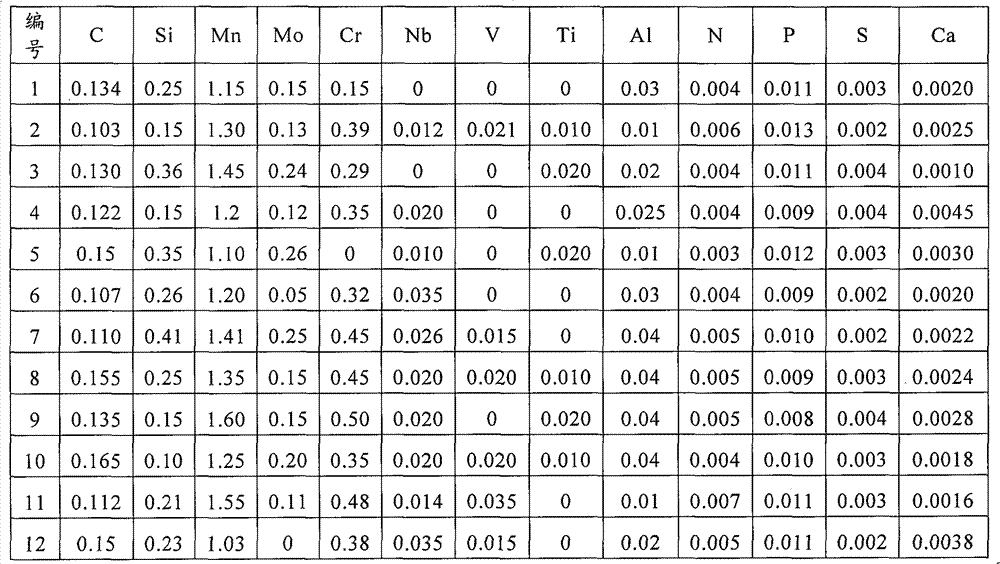

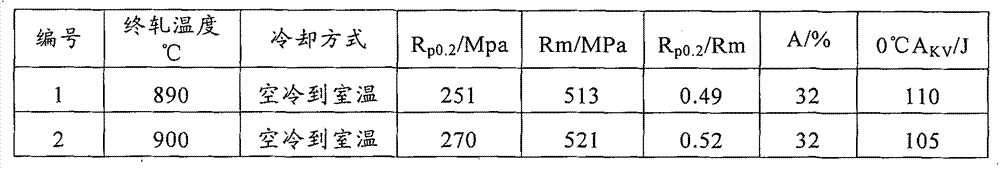

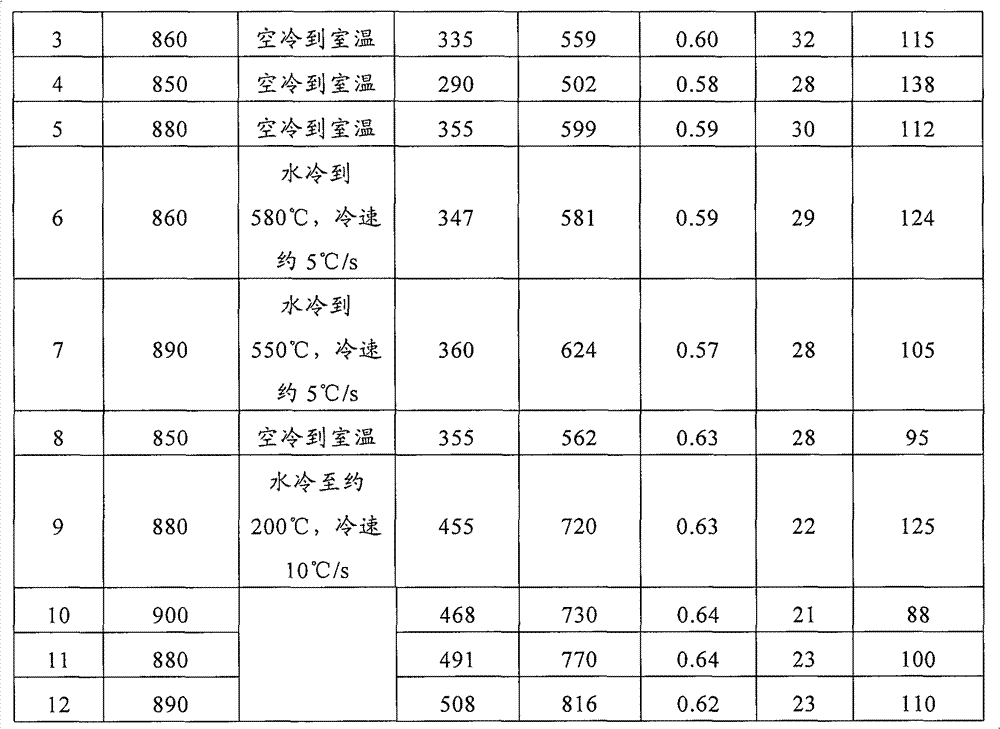

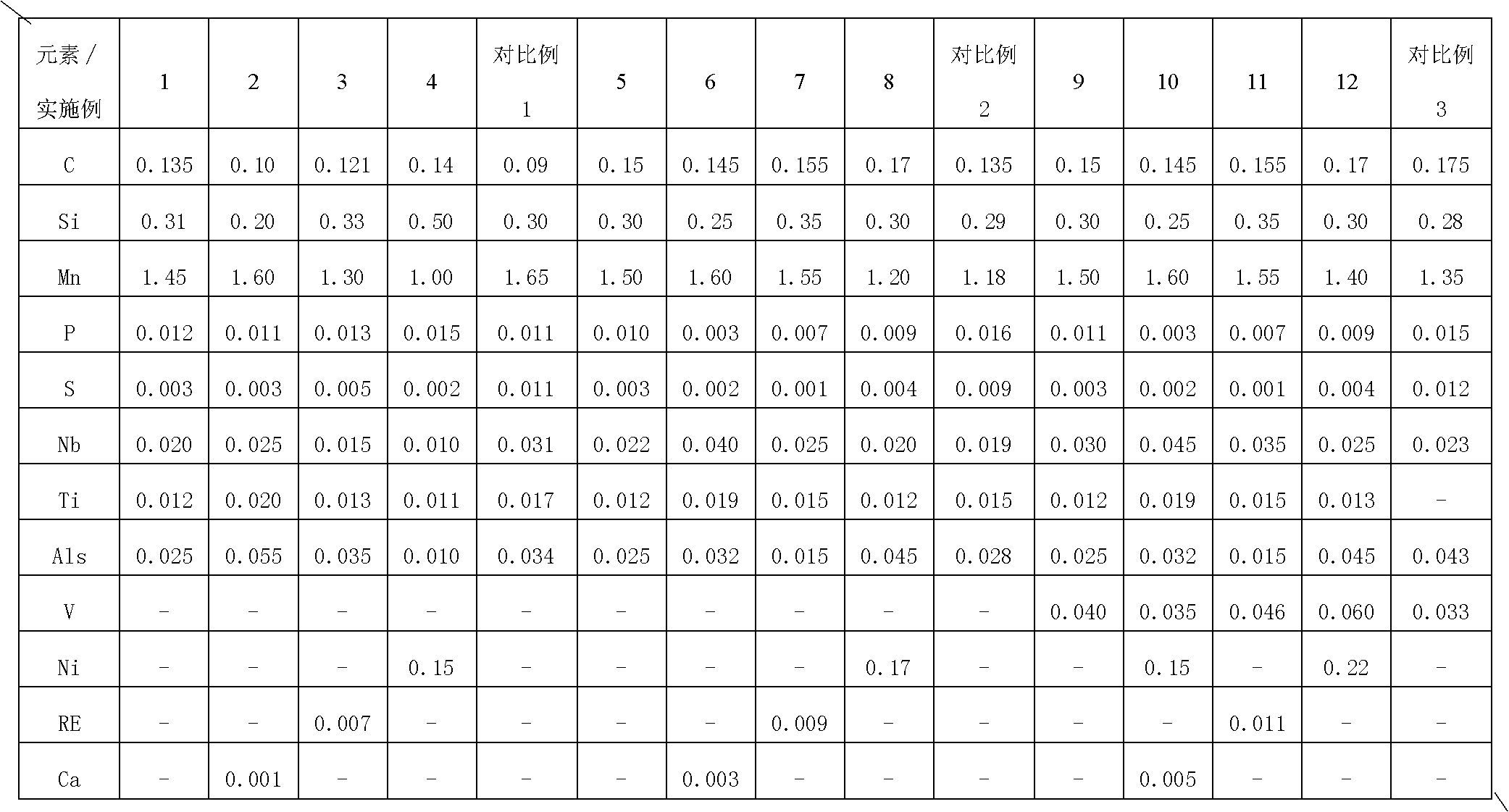

Fire-resistant and earthquake-resistant steel for construction and production method thereof

ActiveCN102952994AImprove fire resistanceSimple mechanical propertiesReduction rateEarthquake resistance

The invention relates to a fire-resistant and earthquake-resistant steel for construction. The steel comprises the following components by weight percent: 0.1-0.18 % of C, 0.1-0.50 % of Si, 1-1.80 % of Mn, less than or equal to 0.025 % of P, less than or equal to 0.015 % of S, less than or equal to 0.50 % of Cr, less than or equal to 0.30 % of Mo, less than or equal to 0.04 % of Al, less than or equal to 0.007 % of N, less than or equal to 0.006 % of Ca, one or two or more of less than or equal to 0.050 % of Nb, less than or equal to 0.055 % of V and less than or equal to 0.035 % of Ti, with Nb+V+Ti being <= 0.055 %, and the balance being Fe and unavoidable impurities. A production method comprises heating under a temperature of 1180 DEG C, insulating for 3 hours, rolling with a starting temperature of not less than 1180 DEG C, an accumulated reduction rate of last three controlled rolling being not less than 35 %, and a terminating temperature of 860 to 900 DEG C, and then directly air-cooling to a room temperature or cooling with a rate of 5 to 15 DEG C per second to the room temperature. The obtained steel is excellent in fire resistance, low in yield ratio (Rp0.2 / Rm <= 0.75), and good in earthquake-resistance performance, with Rp0.2 (yield strength at 600 DEG C) / Rp0.2 (yield strength at the room temperature) >= 2 / 3.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

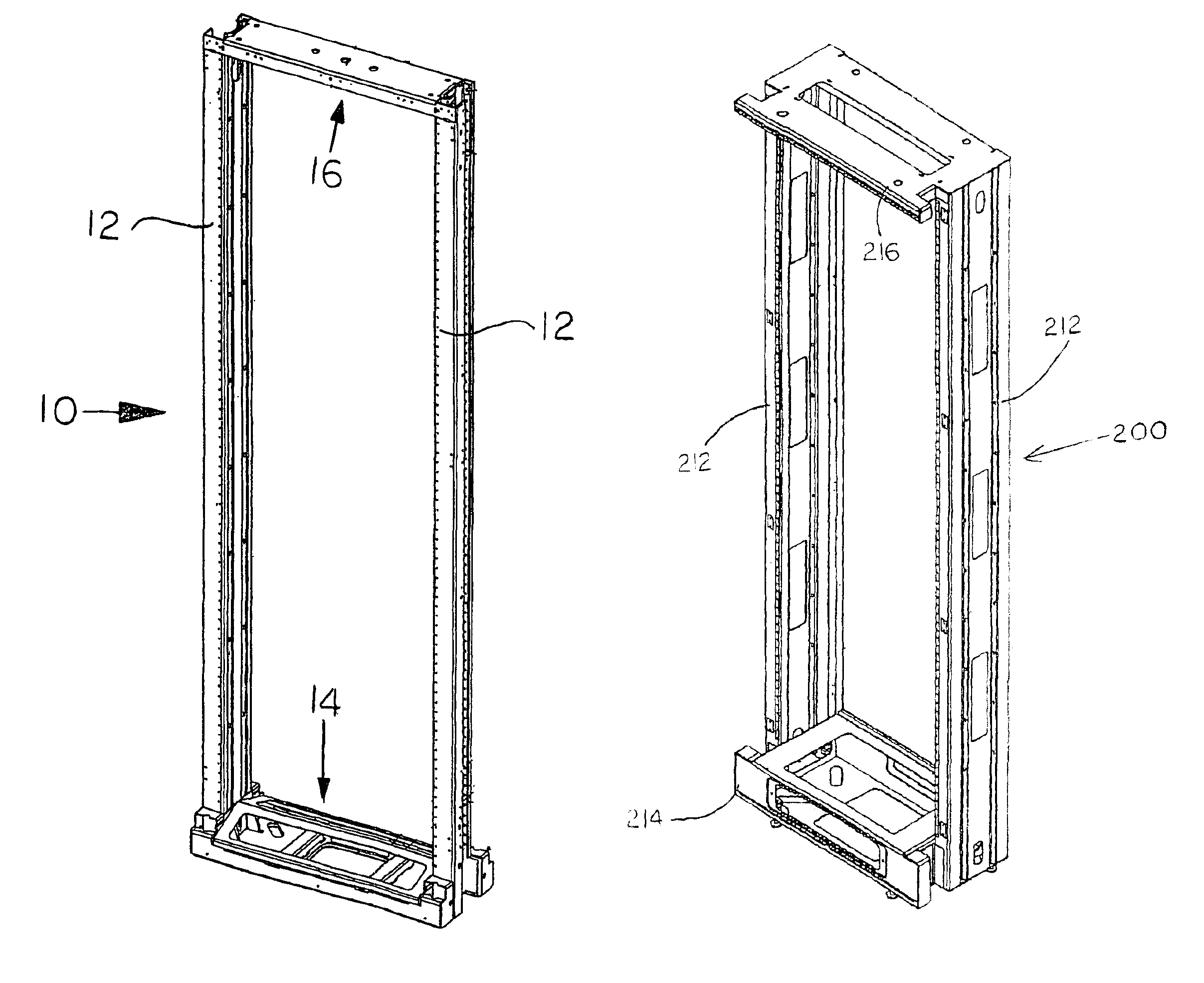

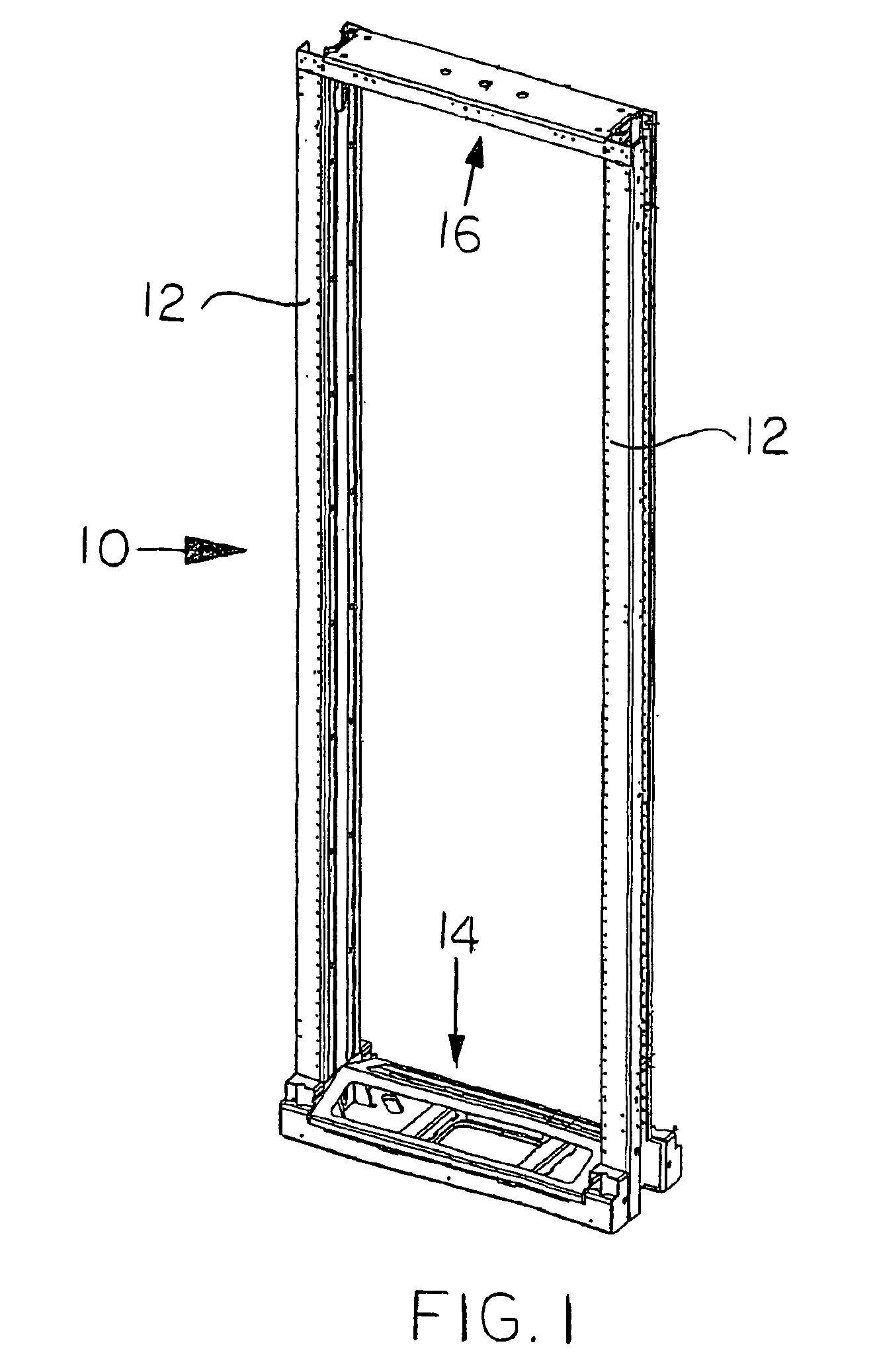

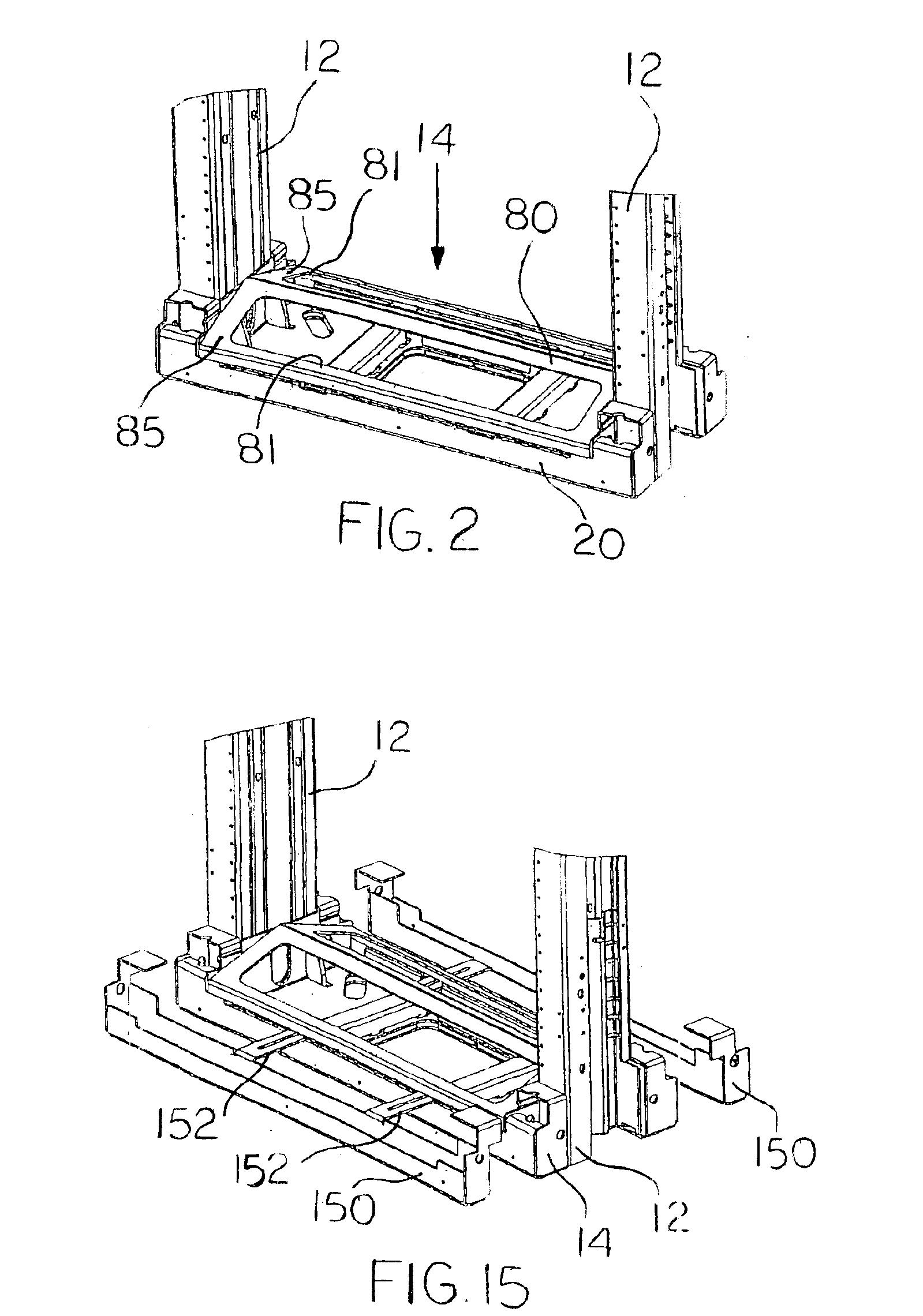

Earthquake resistant equipment rack

InactiveUS6951288B2High strengthIncrease costSubstation/switching arrangement casingsAnti-seismic devicesEngineeringMechanical engineering

An earthquake resistant equipment rack that includes multiple methods for reinforcing the equipment rack to resist seismic forces. The side rails can include two inwardly projecting V portions extending the length of the rails to diffuse seismic forces by deflecting seismic forces vertically. The base and top are preferably formed from multiple components formed from sheet metal and having both over-lapping multiple thickness of sheet metal and multiple box structures. A cover is non-removably attached to the base. In one embodiment, the cover has a dog house shape with inclined roof like surfaces.

Owner:CK ACQUISITION HLDG INC

Section steel concrete- punched steel plate-concrete combined shear wall and method for producing the same

InactiveCN101457560AIncreased shear capacityIncrease the usable areaWallsShock proofingRebarSteel plates

The invention relates to a shear wall, in particular to a profile steel concrete-punching steel plate-concrete combined shear wall and a manufacturing method thereof. The shear wall is limited by a profile steel concrete column and formed by a steel plate combination structure which is covered with concrete outside and provided with holes; the shear wall is provided with the steel plate, and then two sides of the steel plate are configured with a reinforcing mesh formed by reinforcing steel bars which are distributed transversely and longitudinally, and a drawknot rib that passes through the holes is used for connecting the reinforcing meshes at the two sides of the steel plate together; finally, the concrete is poured. The profile steel concrete-punching steel plate-concrete combined shear wall can improve the carrying capacity, reduce the attenuation speed of rigidity and carrying capacity, lead the later period shakeproof performance of the wall to be relative stable, and weakens the damage caused by cutting and gliding at the bottom.

Owner:BEIJING UNIV OF TECH

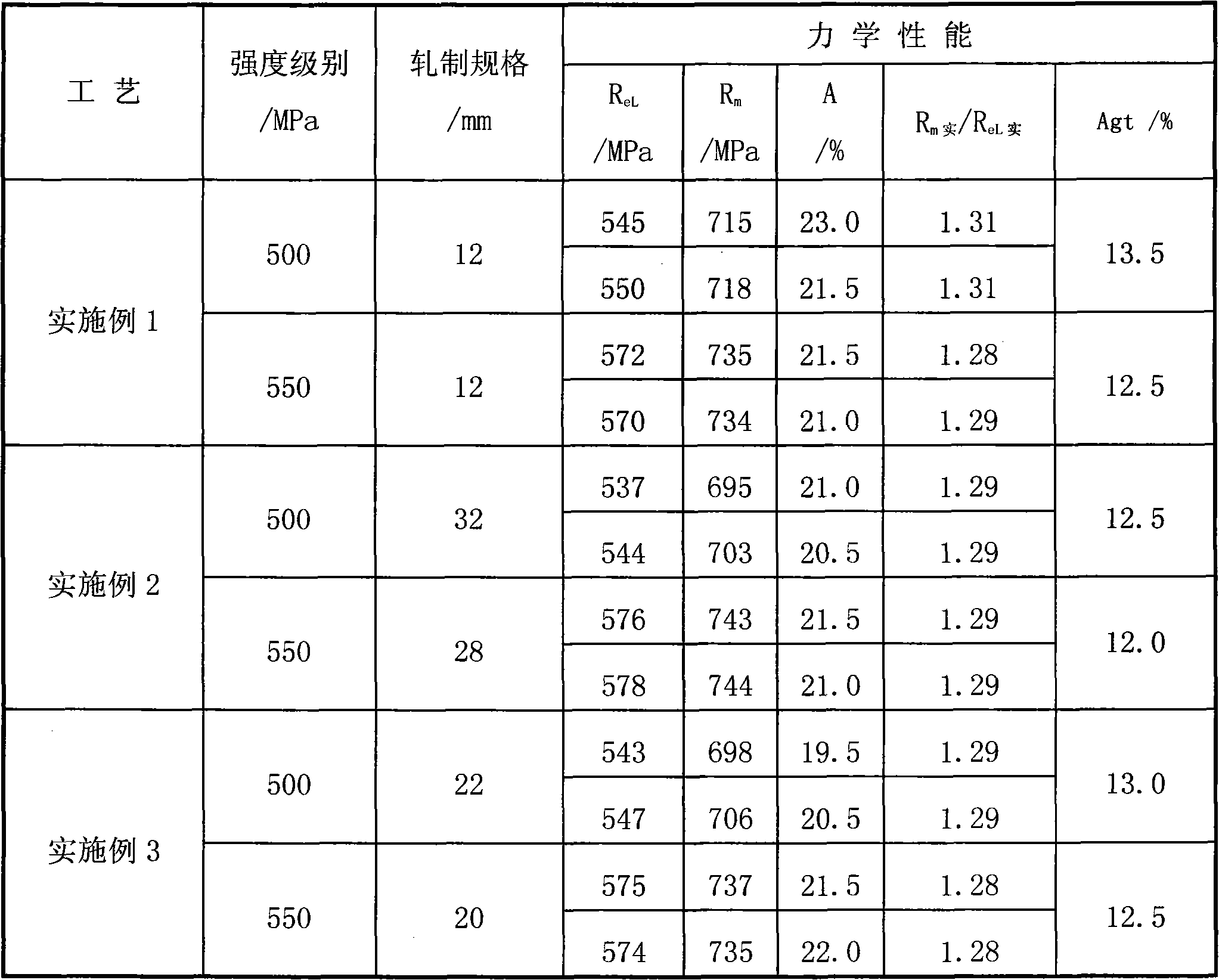

Nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and melting method

ActiveCN102071357AIncrease supersaturationIncrease the number ofManufacturing convertersNiobiumAdditive ingredient

The invention provides a nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and a melting method. The high-intensity aseismic reinforcing steel bar comprises the following ingredients in percentage by mass: 0.20 to 0.25 wt percent of C, 0.35 to 0.55 wt percent of Si, 1.35 to 1.58 wt percent of Mn, 0.013 to 0.025 wt percent of V, 0.019 to 0.032 wt percent of Nb, 0.065 to 0.085 wt percent of N, at most 0.040 wt percent of S, at most 0.040 wt percent of P and the balance Fe and unavoidable impurities. The reinforcement effect of microalloy V and Nb is sufficiently exerted through increasing the N and decreasing the V and the Nb, the addition of the ferrocolumbium and vanadium nitrogen alloy is reduced, and the addition of noble alloy issaved. Compared with the traditional vanadium nitrogen alloy microalloying 500MPa high-intensity reinforcing steel bar , the nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar provided by the invention has the advantages that the alloying cost of the process is reduced by 65 to 75 Yuan / t steel over the same periods, the economic benefit is obvious, the process production cost is low, the applicability and the controllability are high, the produced 500MPa and 550MPa high-intensity reinforcing steel bar is widely applicable to highrise andlarge-scale constructional engineering, and the aseismic performance and the welding performance of the reinforcing steel bar are good.

Owner:WUKUN STEEL

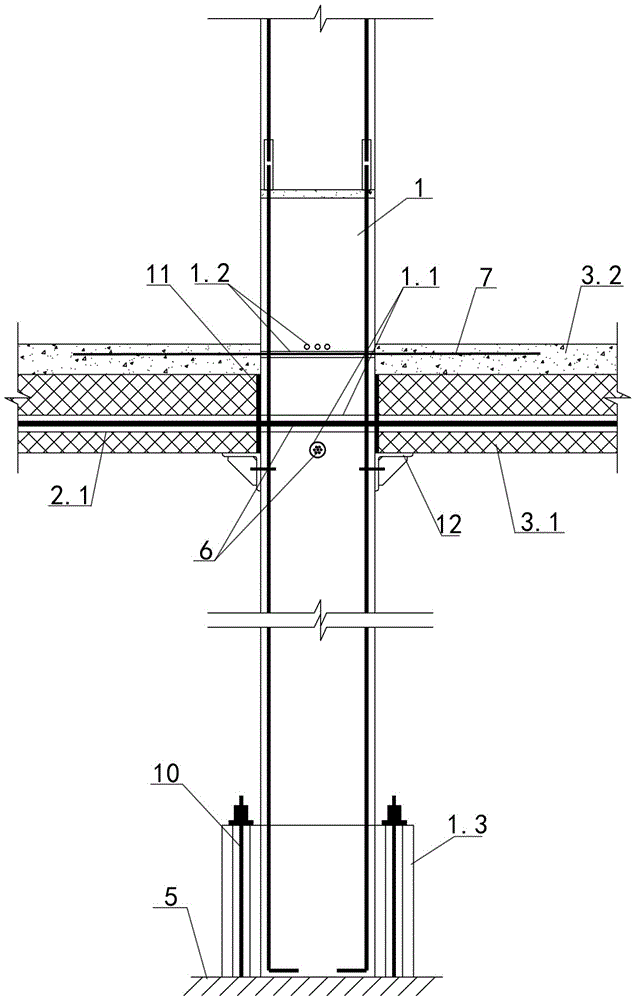

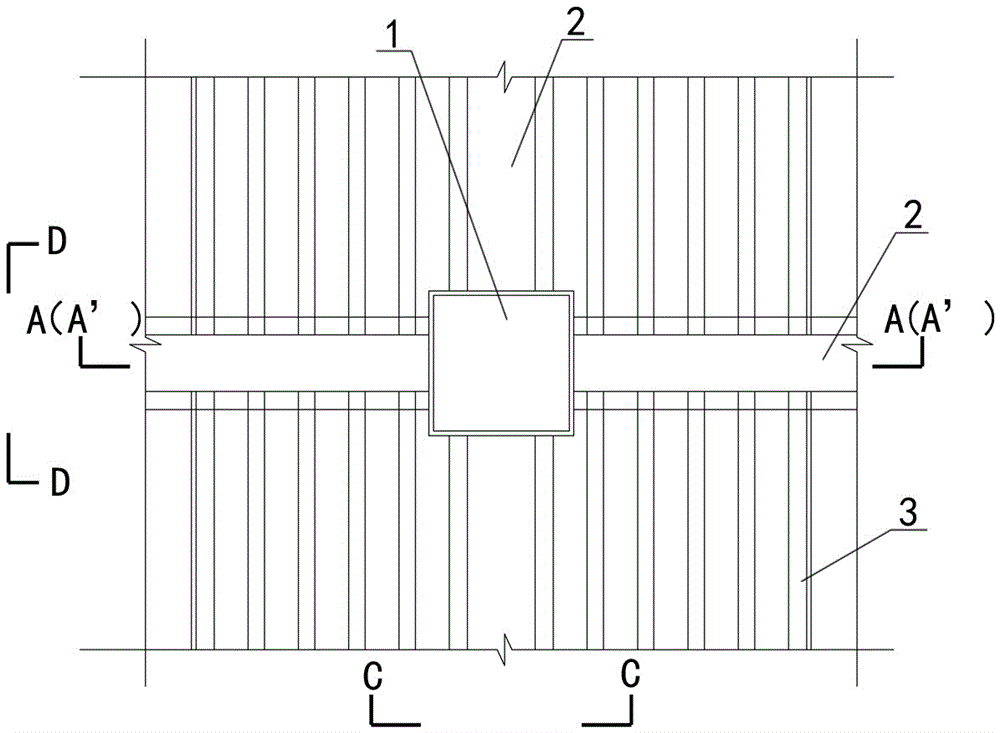

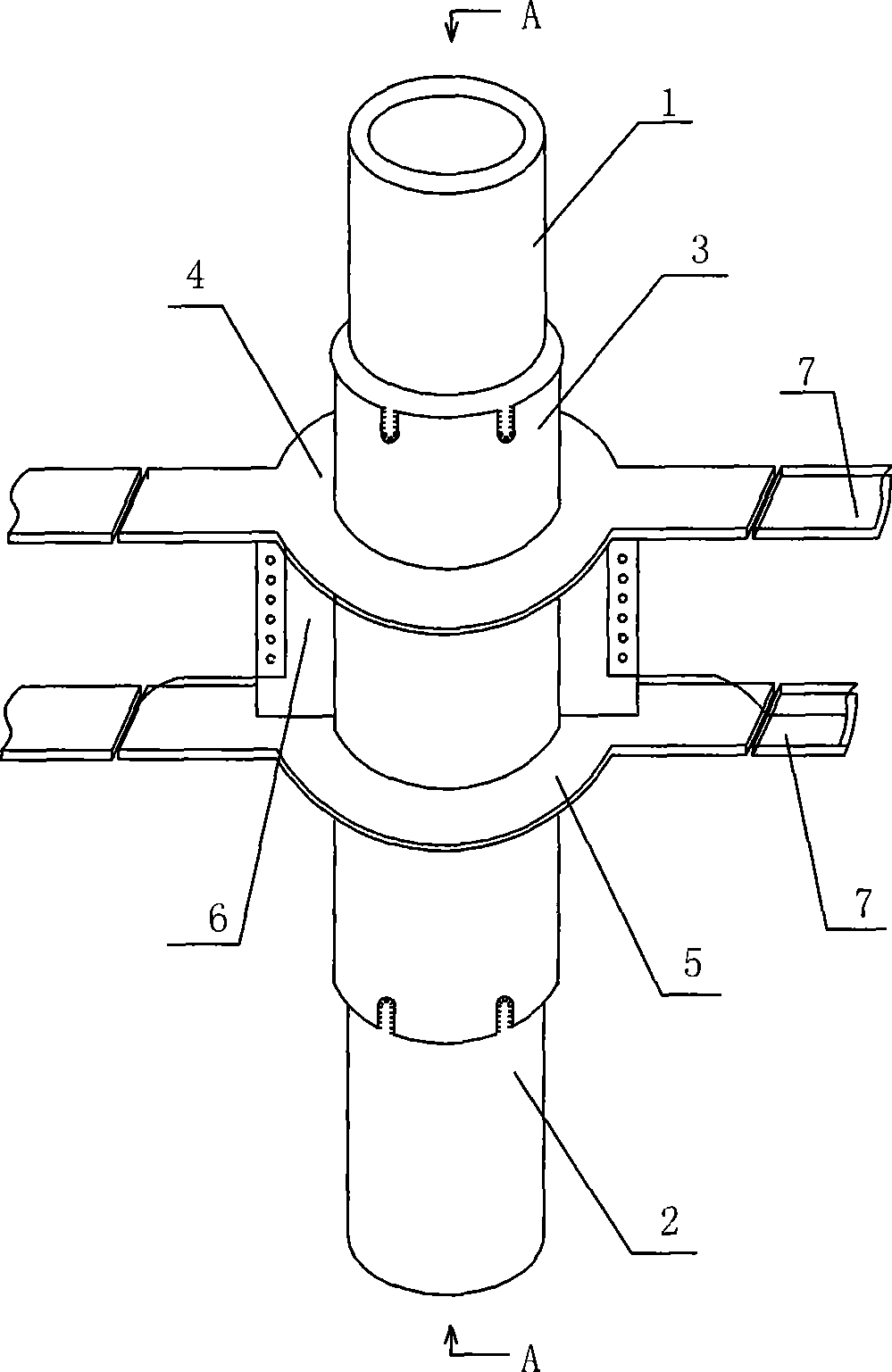

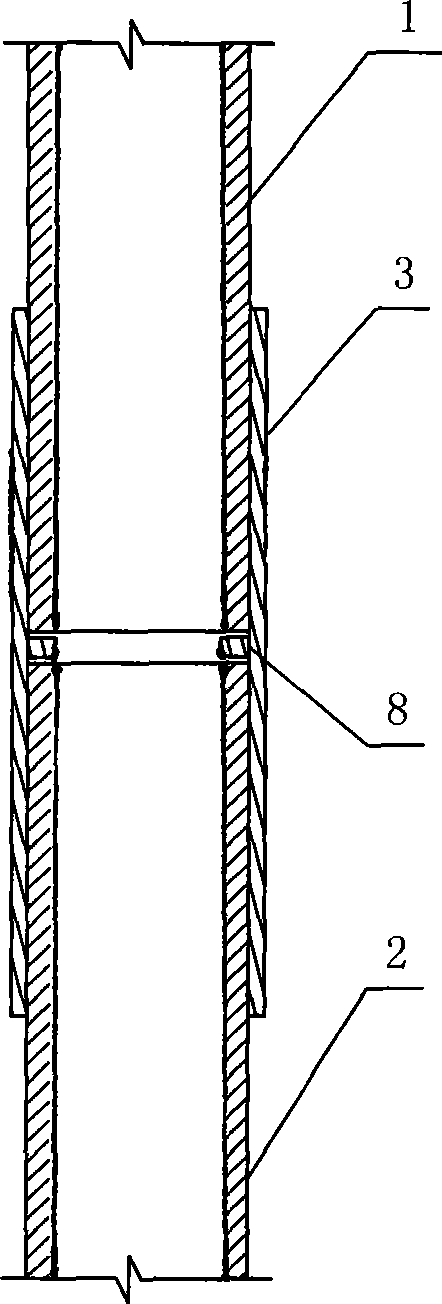

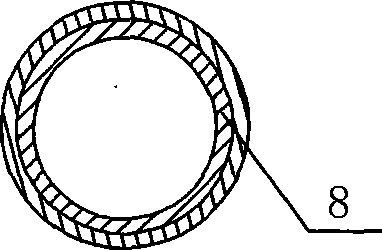

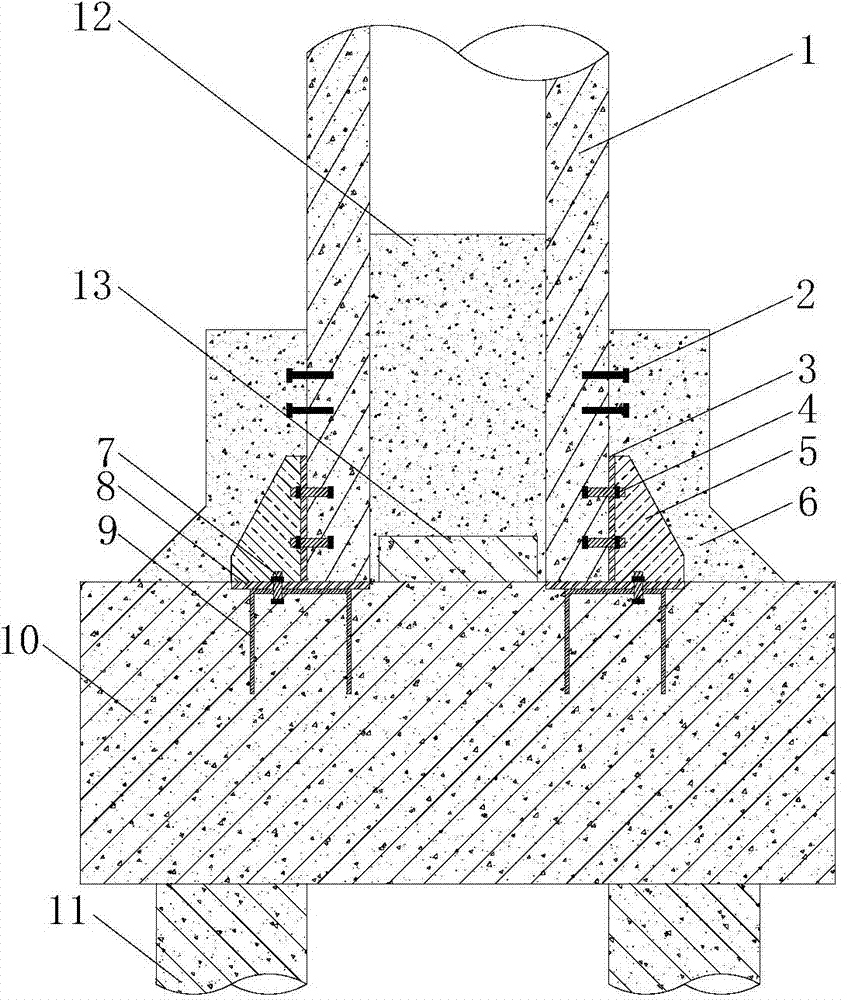

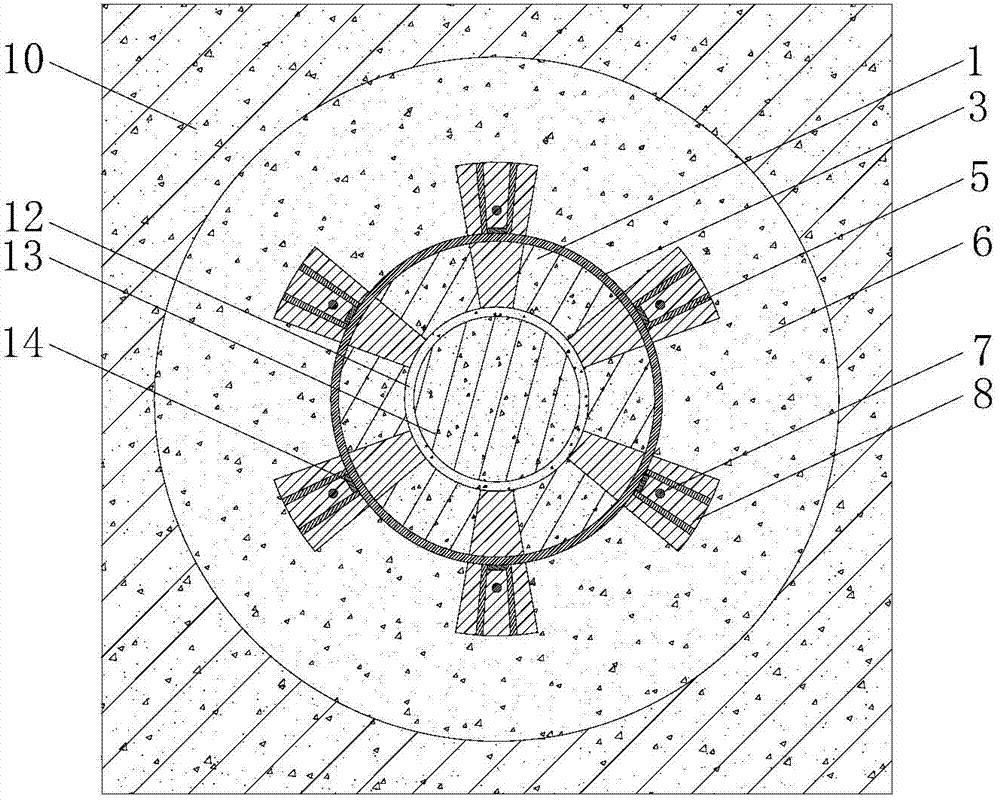

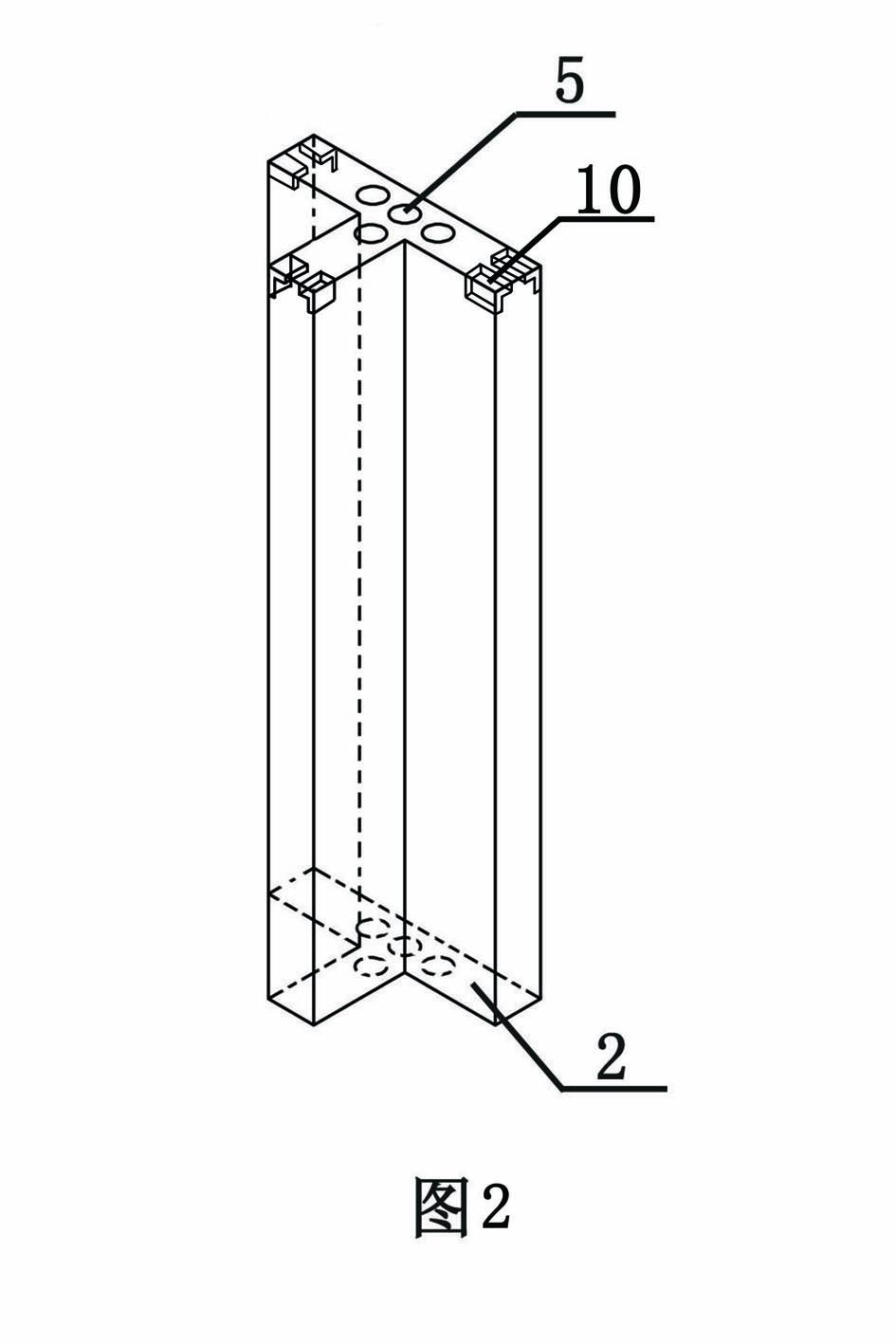

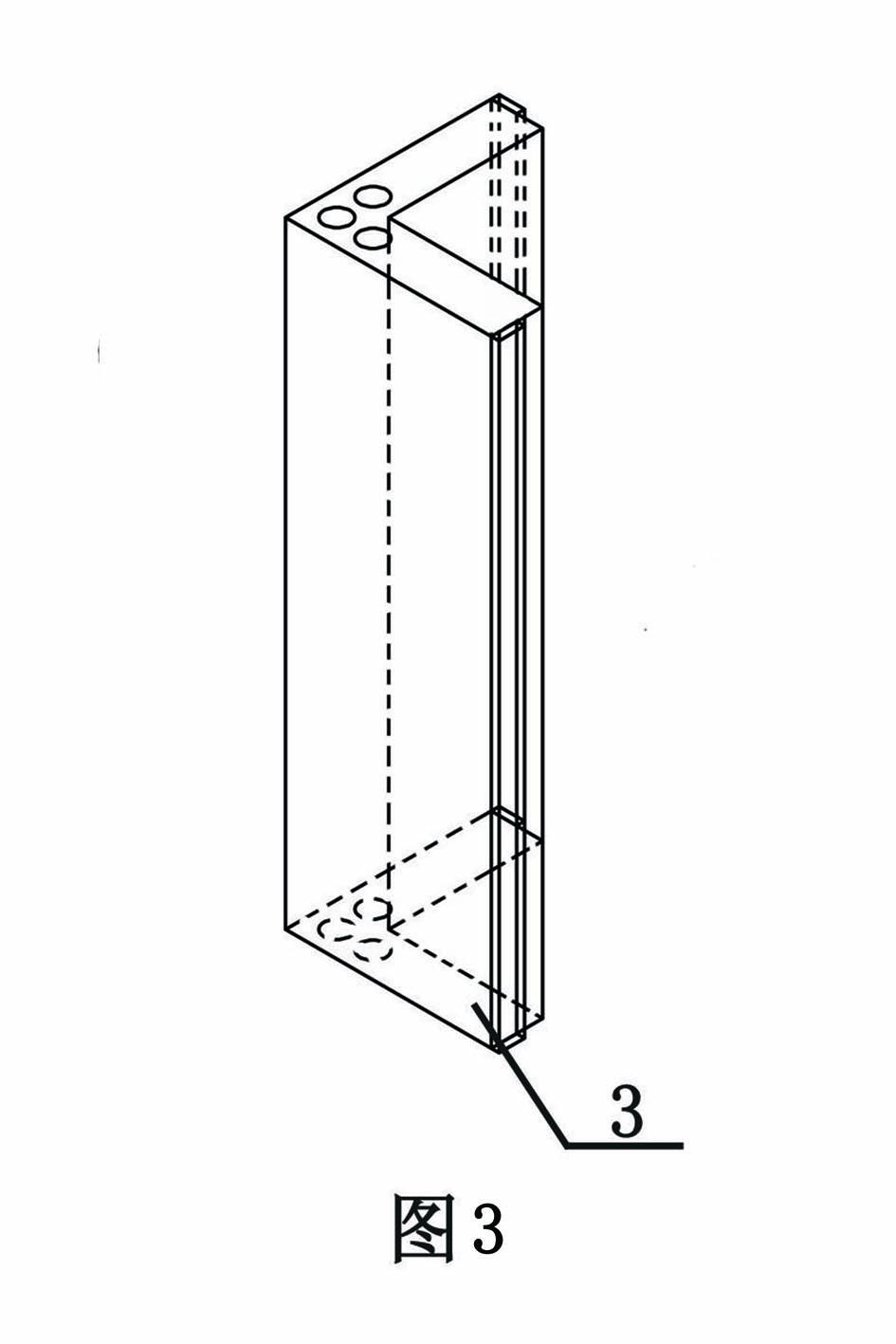

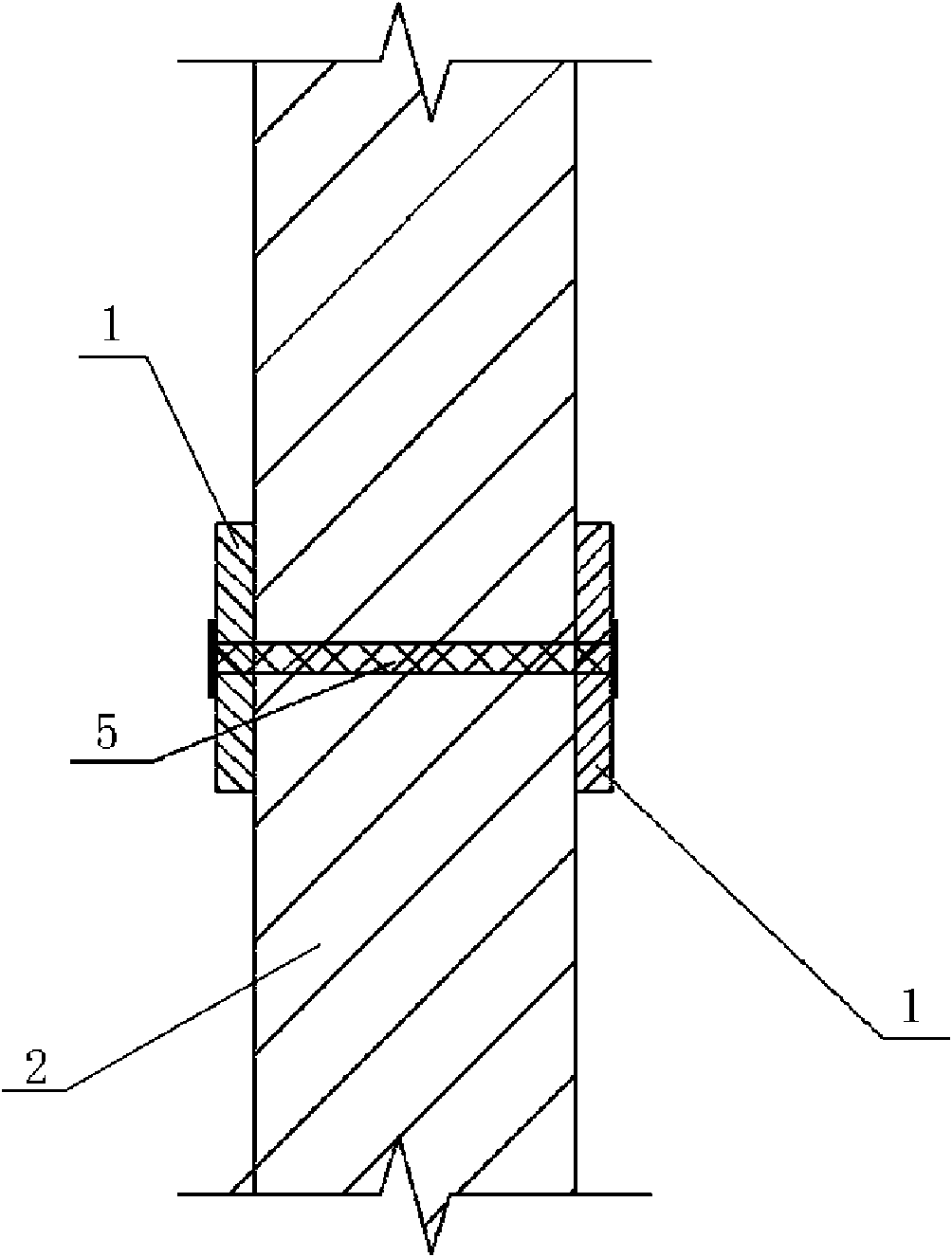

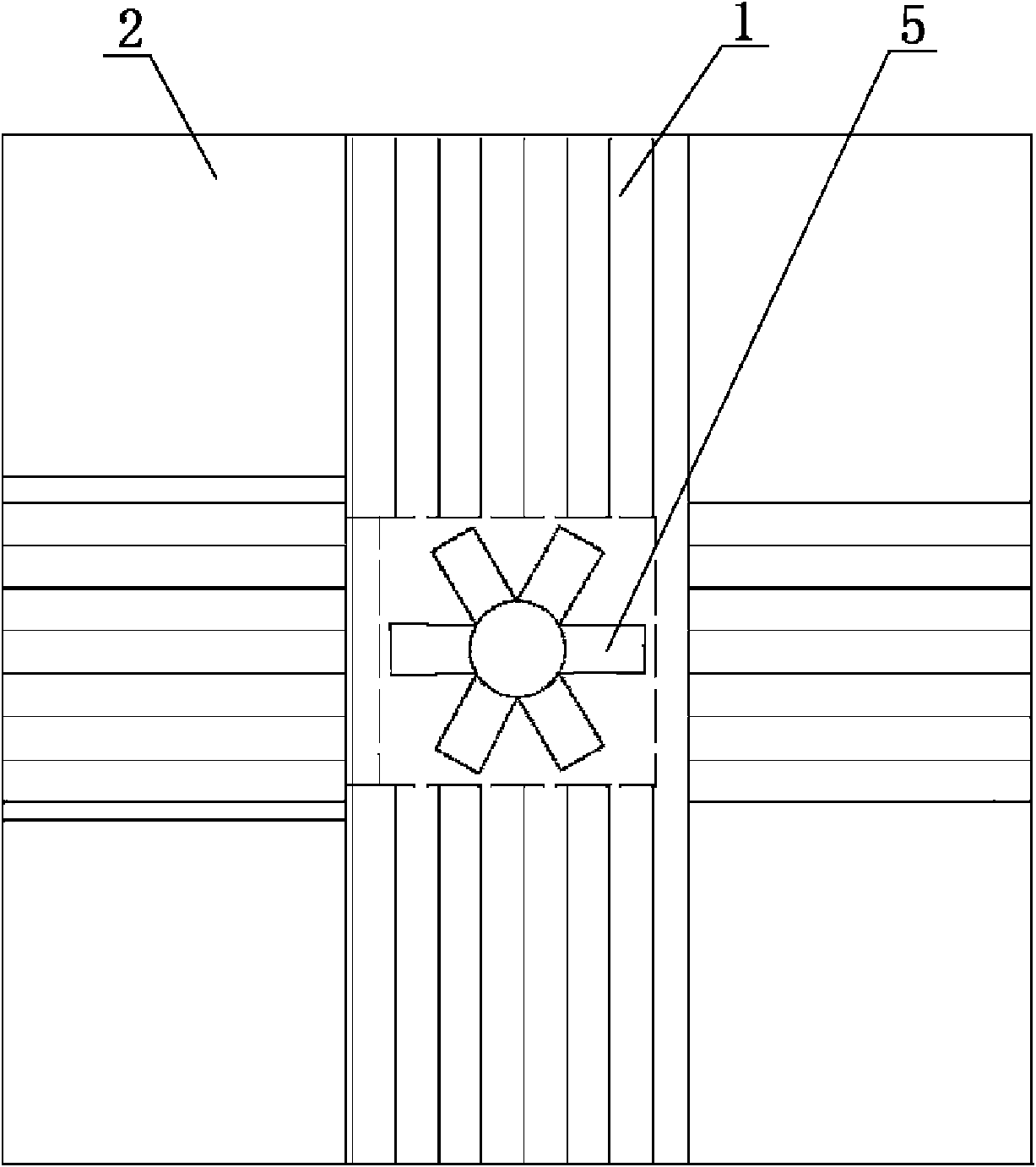

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

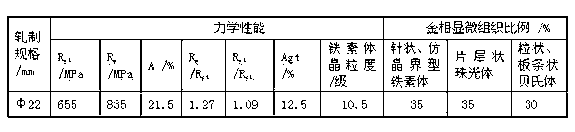

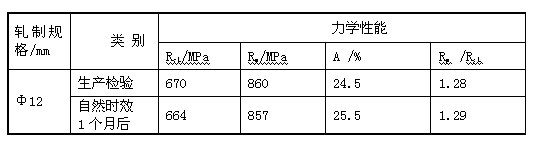

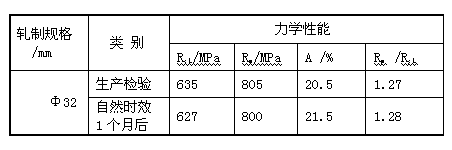

Niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production thereof

ActiveCN102796962ALow strain agingIncreased strain agingProcess efficiency improvementNiobiumTitanium

The invention provides a niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production of the niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar. Through molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling, the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar is produced and comprises the following chemical constituents according to mass ratio: 0.14-0.18% of C, 0.30-0.50% of Si, 0.50-0.75% of Mn, 0.50-0.70% of Cr, 0.030-0.050% of Nb, 0.0015-0.0030% of B, 0.020-0.040% of Ti, no more than 0.045% of S, no more than 0.045% of P and the balance of Fe and unavoidable impurities. The niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar has the characteristics of low production cost, technological applicability, strong controllability and the like, the steel microstructure is uniformly distributed and has good form, the refining effect of ferrite is obvious, and the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcement has good low-strain timeliness, high strength, good toughness, good welding performance, excellent aseismic performance and excellent combination property.

Owner:WUKUN STEEL

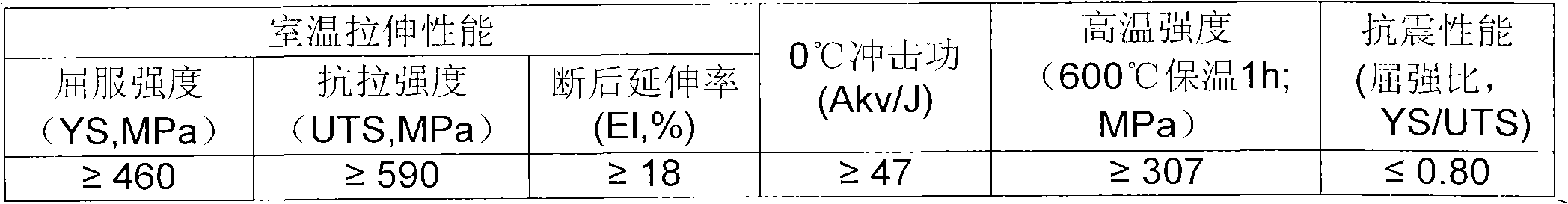

Low-cost high-strength high-toughness shock-proof refractory steel and preparation technique thereof

ActiveCN102181792AReduce contentLow costRoll mill control devicesMetal rolling arrangementsShock resistanceImpact toughness

The invention relates to a low-cost high-strength high-toughness shock-proof refractory steel and a preparation technique thereof. The steel comprises the following components in percentage by weight: 0.05-0.09% of C, 0.10-0.30% of Si, 0.60-1.00% of Mn, 0.20-0.40% of Mo, less than 0.10% of Cr, less than 0.10% of Cu, less than 0.10% of Ni, 0.02-0.04% of Nb, 0.01-0.04% of V, 0.01-0.04% of Ti, 0.02-0.04% of Al, at most 0.006% of N, at most 0.010% of P, at most 0.006% of S, and the balance of Fe and impurities. The preparation technique sequentially comprises the steps of temperature keeping, two-stage rolling and cooling. The steel provided by the invention adopts an Mo+Nb alloy system, and has the advantages of simple composition, low content of precious alloy elements, low alloy cost, highyield strength, favorable shock resistance and favorable impact toughness; and due to the adoption of the advanced controlled rolling and controlled cooling technologies, the cost of the technique islow.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

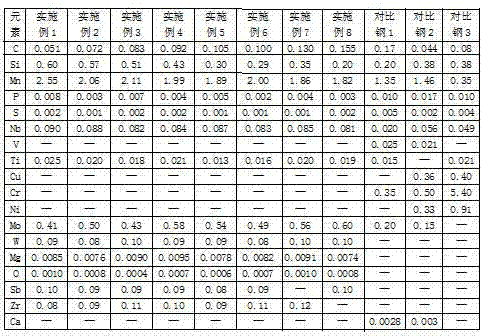

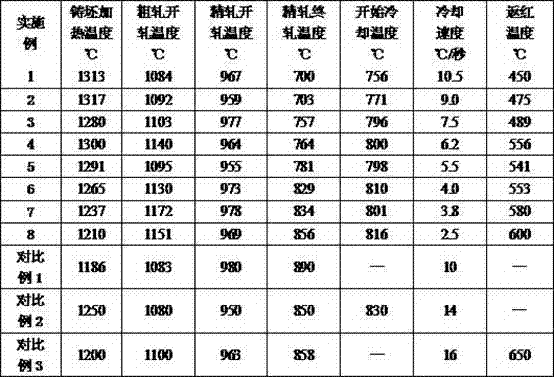

690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695773AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.051-0.155% of C, 0.20-0.60% of Si, 1.82-2.55% of Mn, at most 0.008% of P, at most 0.002% of S, 0.081-0.090% of Nb, 0.010-0.025% of Ti, 0.41-0.60% of Mo, 0.08-0.10% of W, 0.0071-0.0095% of Mg and at most 0.0010% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 690-850MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

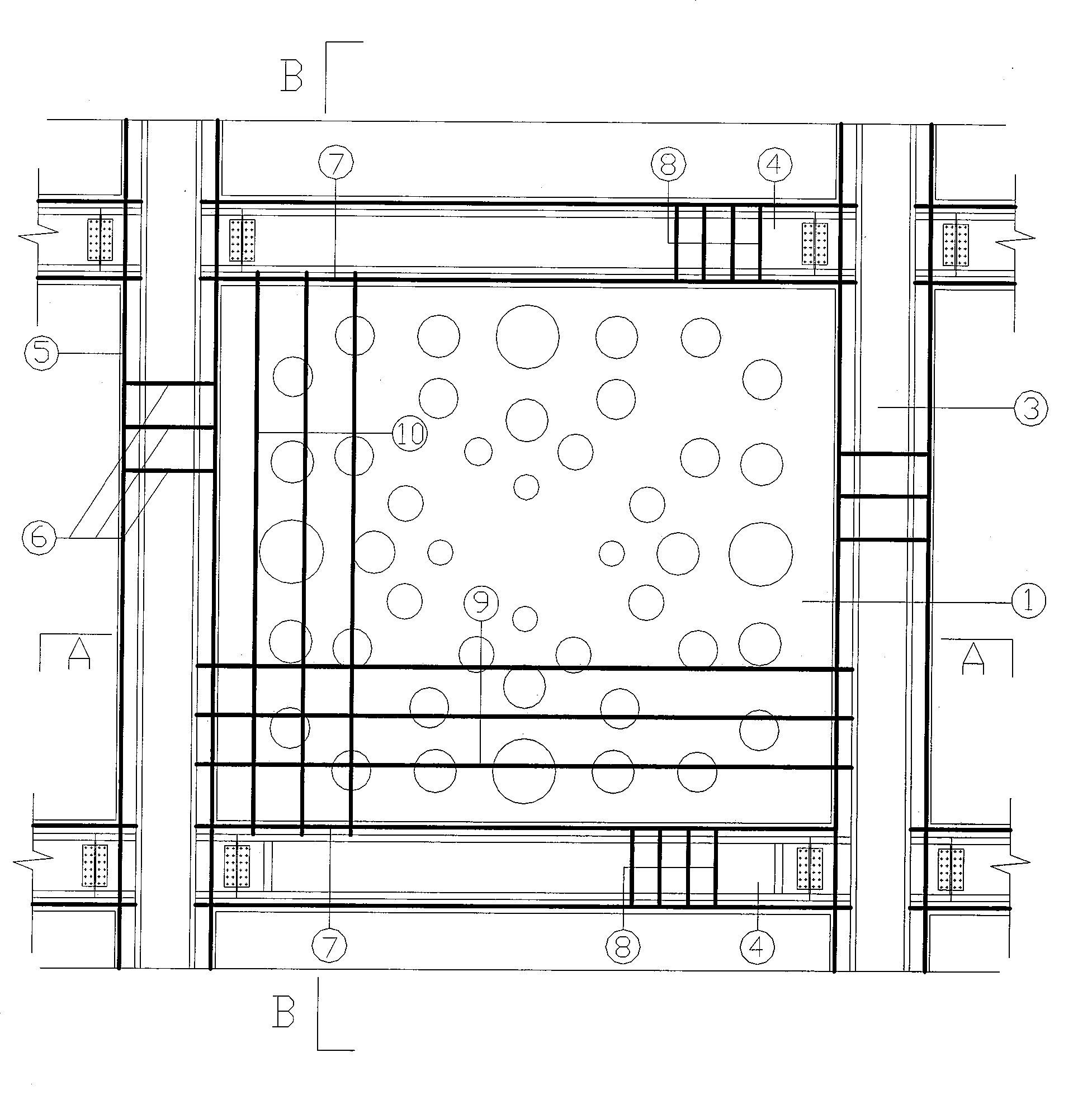

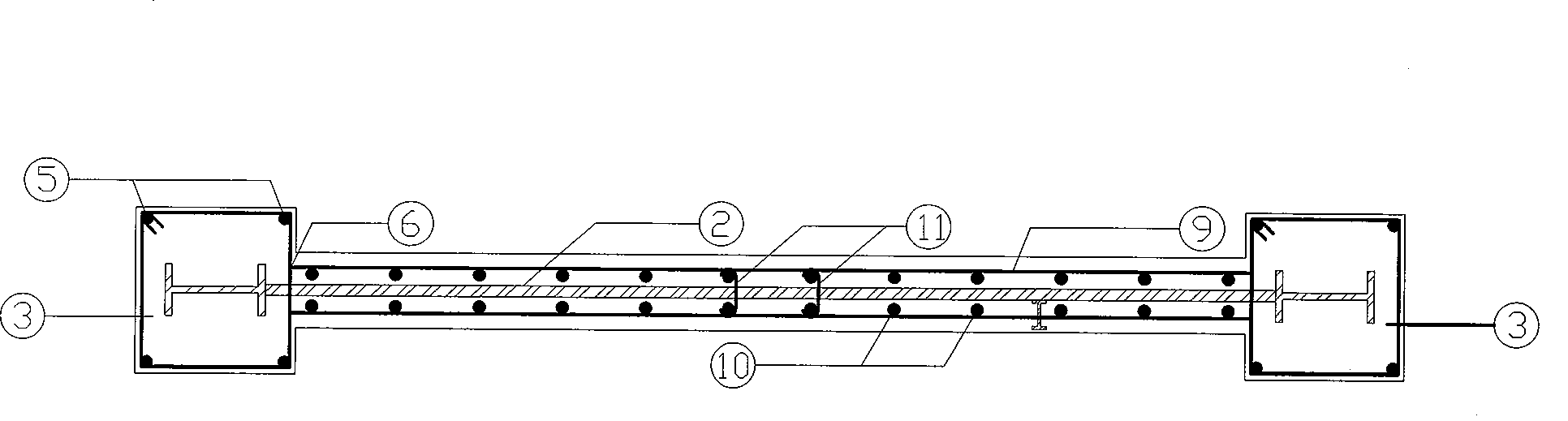

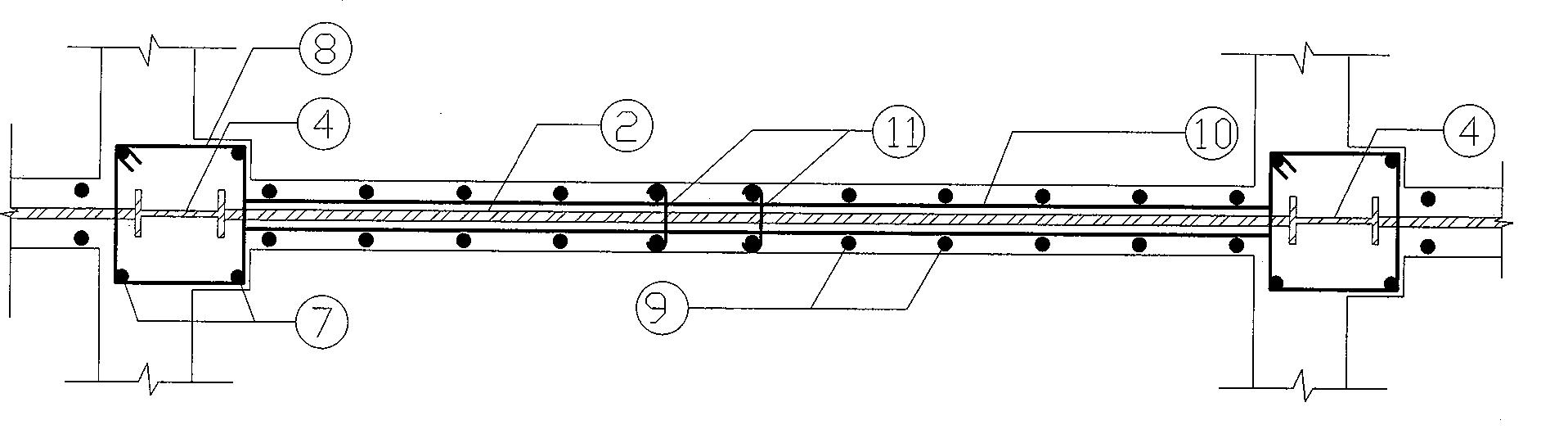

Bridge prefabricated hollow pier column post-poured connecting structure and construction method

InactiveCN104746422AGood connection performanceFast constructionBridge structural detailsFoundation engineeringEarthquake resistanceArchitectural engineering

The invention relates to a bridge prefabricated hollow pier column post-poured connecting structure. The bridge prefabricated hollow pier column post-poured connecting structure is characterized by comprising a prefabricated hollow pier column, a pier column foundation and a post-poured concrete pier wall, wherein connecting steel plates are pre-buried in the top surface of the pier column foundation, and an installation limiting block limiting the installation position of the prefabricated hollow pier column is arranged at the center of the pier column foundation; the prefabricated hollow pier column is fixed on the pier column foundation through the connecting steel plates; the prefabricated hollow pier column is wrapped by a steel protecting barrel, and a steel rib plate is arranged on the outer wall of the steel protecting barrel; the concrete pier wall is poured on the periphery of the bottom of the prefabricated hollow pier column, and the hollow position in the prefabricated hollow pier column is filled with a concrete filling core section formed by micro-expansion concrete. As the prefabricating process is adopted for the structure, the construction speed is high, connection strength is high, overall stress performance is good, anti-seismic performance is strong, and technological and economical benefits are good. The invention further discloses a construction method for the bridge prefabricated hollow pier column and foundation connecting structure.

Owner:柳州市建筑工程集团有限责任公司

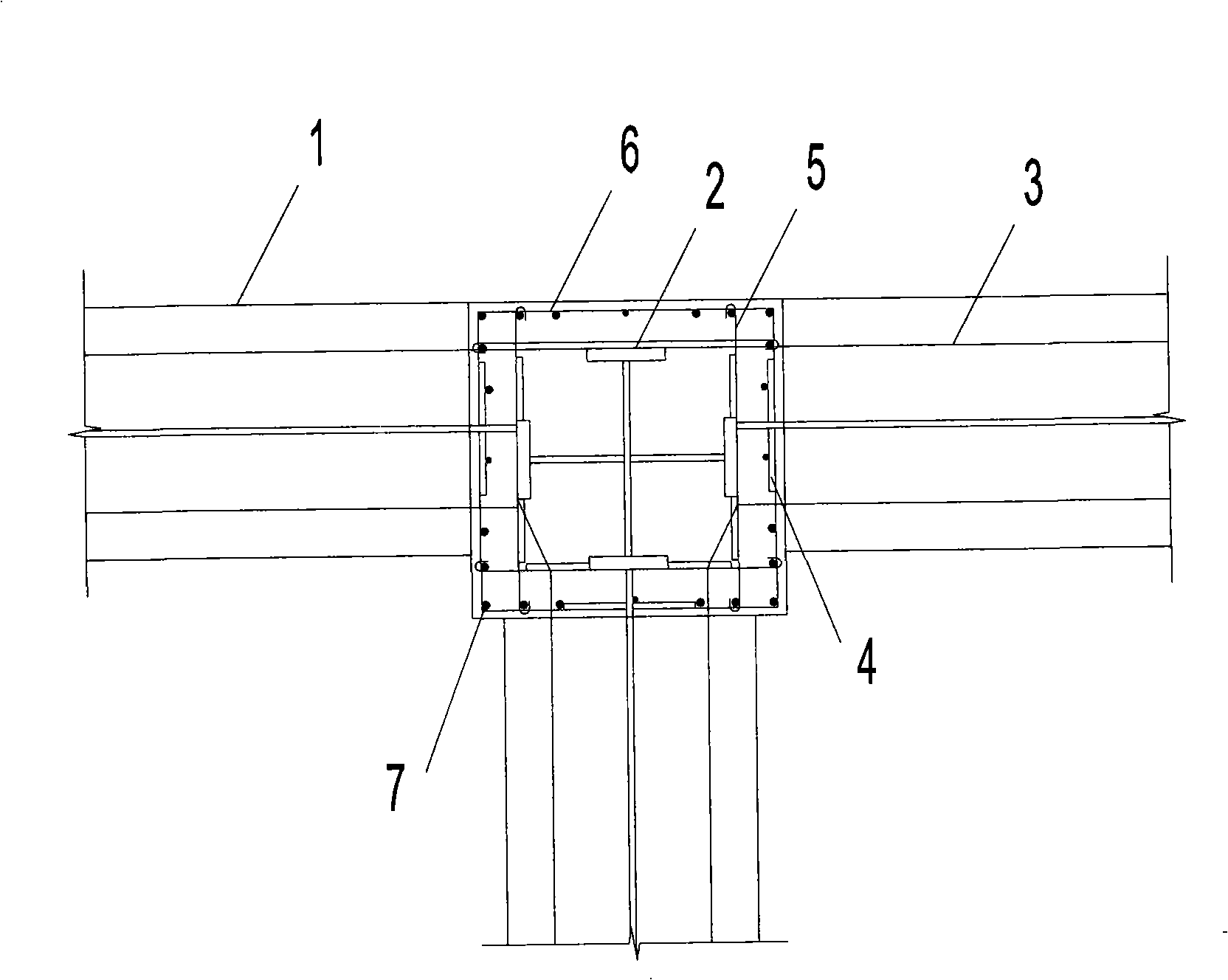

High-rise building frame supported sectional steel concrete girder-like structural transfer floor construction method

InactiveCN101333825ASolve the difficulty of tyingSolve the problem of binding difficultiesBuilding constructionsConcrete beamsRebar

Disclosed is a construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings, which relates to the high-rise building structural transferring technology. Reinforced plates are welded on a profiled steel girder column flange plate and a profiled steel column flange plate; a profiled steel column stirrup is machined to an open stirrup which is welded on the reinforced plate. A perforation hole used for the stirrup to be inserted into is preset on the web plate of the profiled steel column; an angle table is welded on the profiled steel column flange plate; reinforced steel bars are in lap welding with the angle table. In the intersection of a non-frame girder and the profiled steel girder, the reinforced steel bars disconnect a bent anchor on the profiled steel girder web plate; wall body reinforced plates are generally welded on the upper flange wall body of the profiled steel girder; both sides of the wall body reinforced steel bars are welded on the wall body reinforced plates. Perforation holes used for the stirrup to be inserted into are prearranged on the upper flange of the profiled steel girder for the reinforced steel bar parts of the upper column and the concealed column of the profiled steel concrete girder; tie bars are welded with the tie bar reinforced plates. Spilt bolts are welded on both sides of the profiled steel web plate to reinforce the profiled steel concrete girder mould plate. The construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings has the advantages that the important technical problem the support frame steel concrete girder structure transfer floor in the construction process of the high-rise buildings is solved; the intensity, rigidity and the vibration resistance of the profiled steel concrete girder are reinforced.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

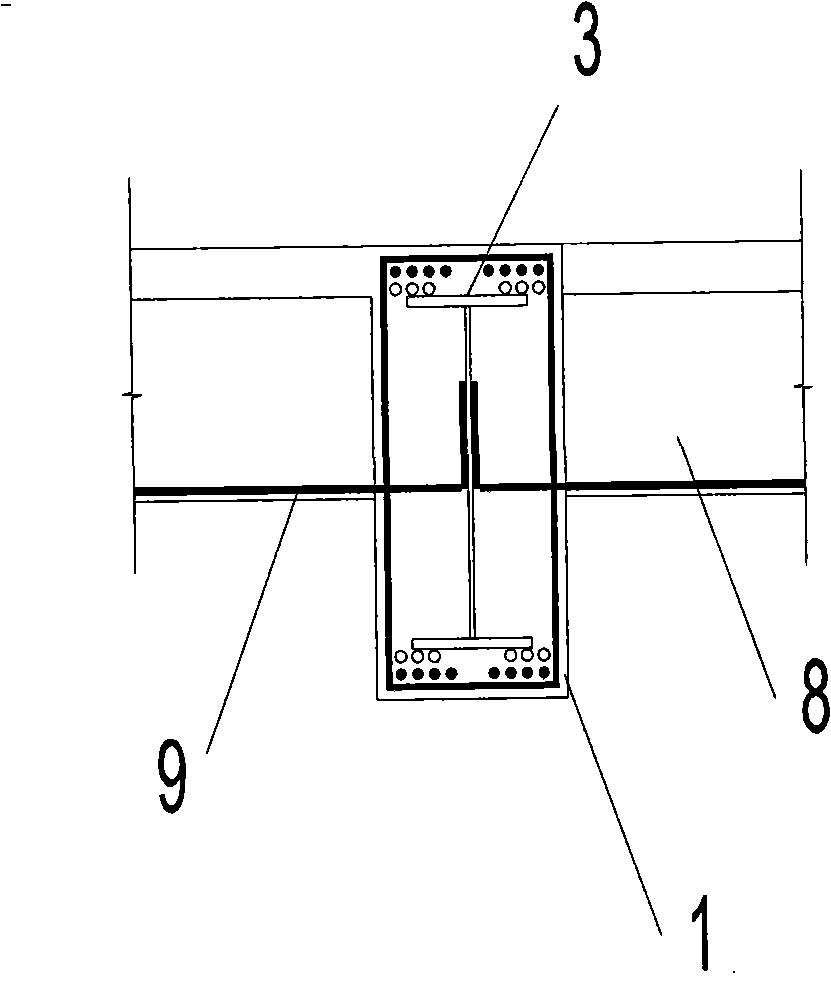

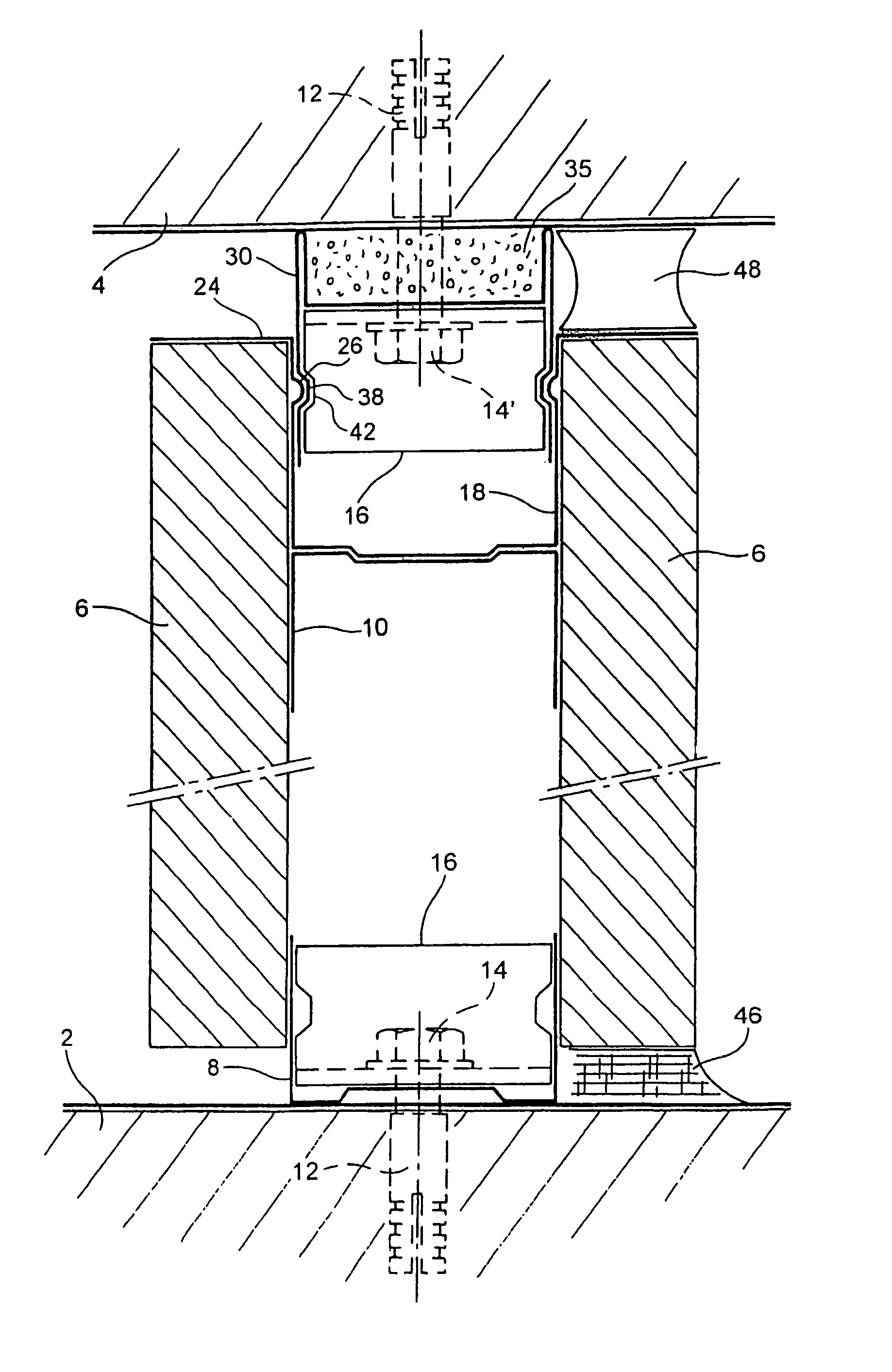

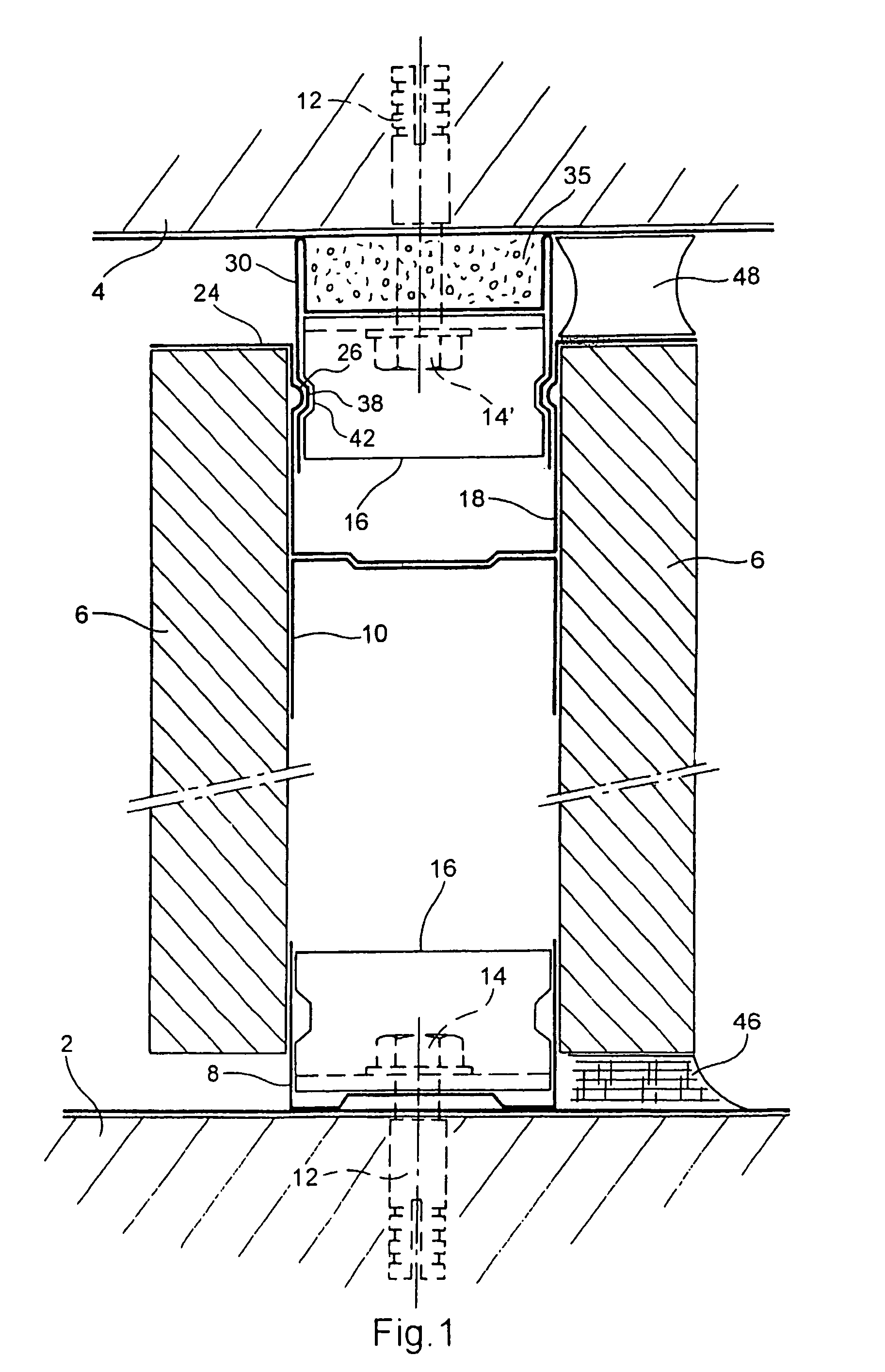

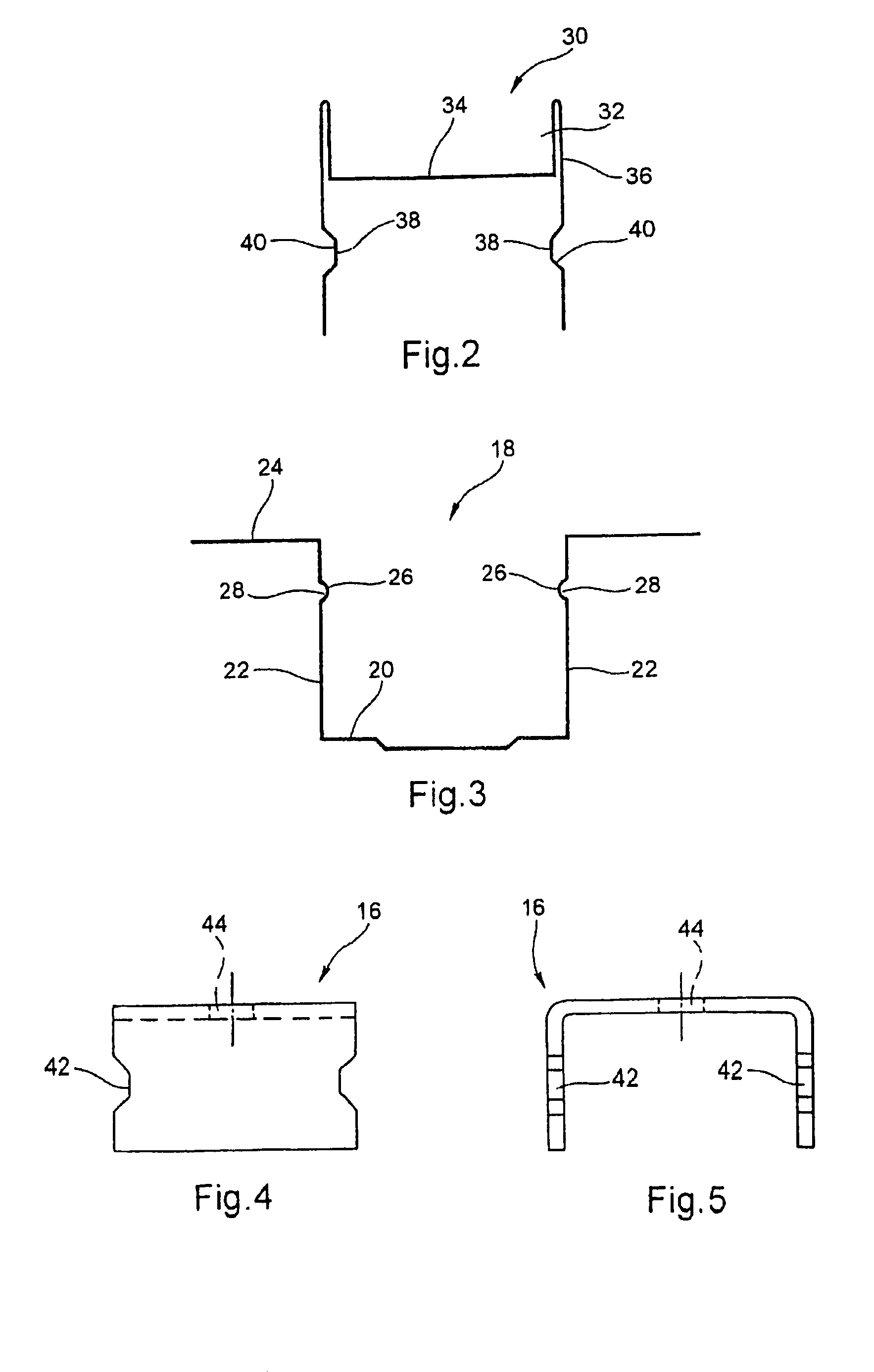

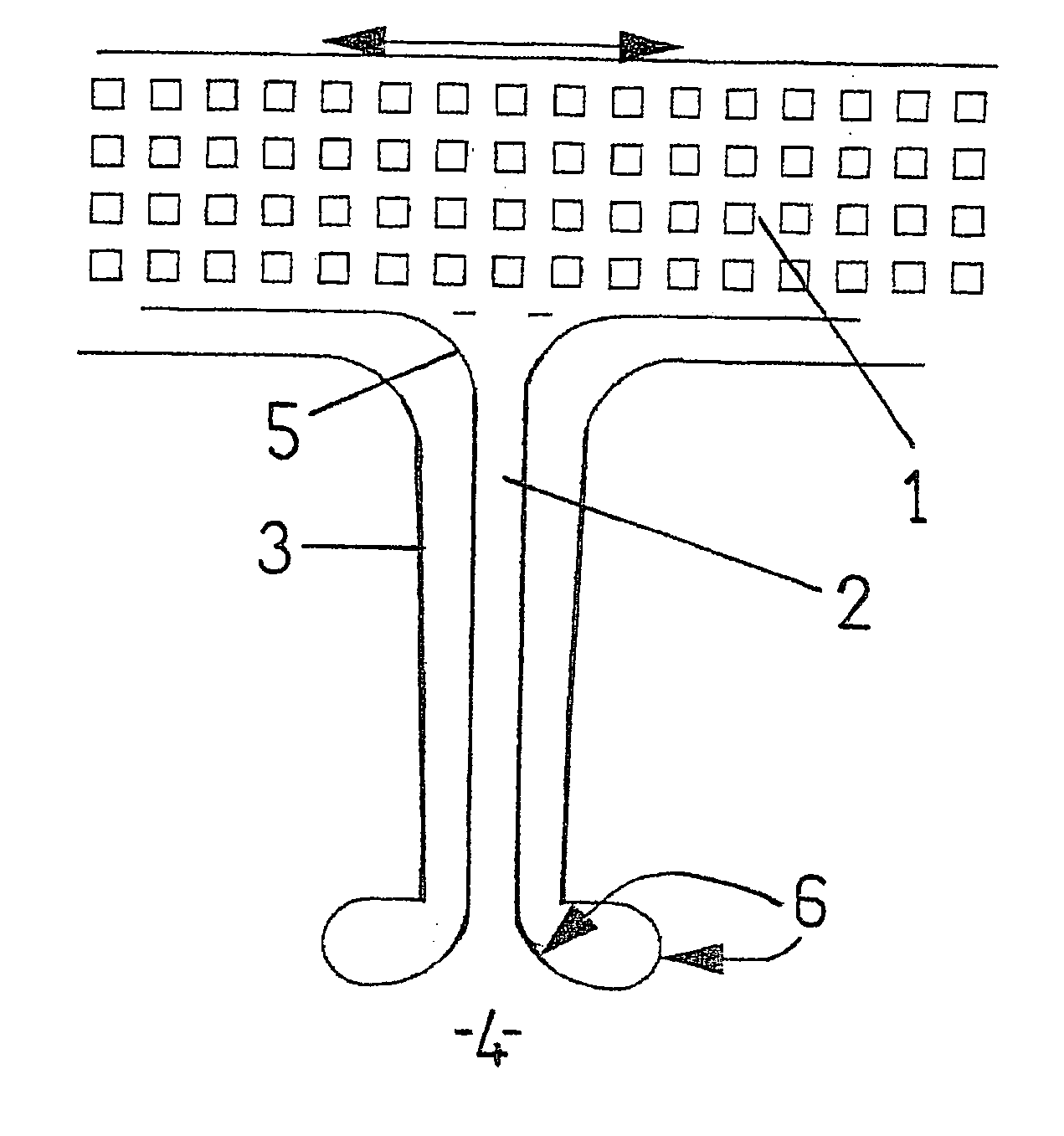

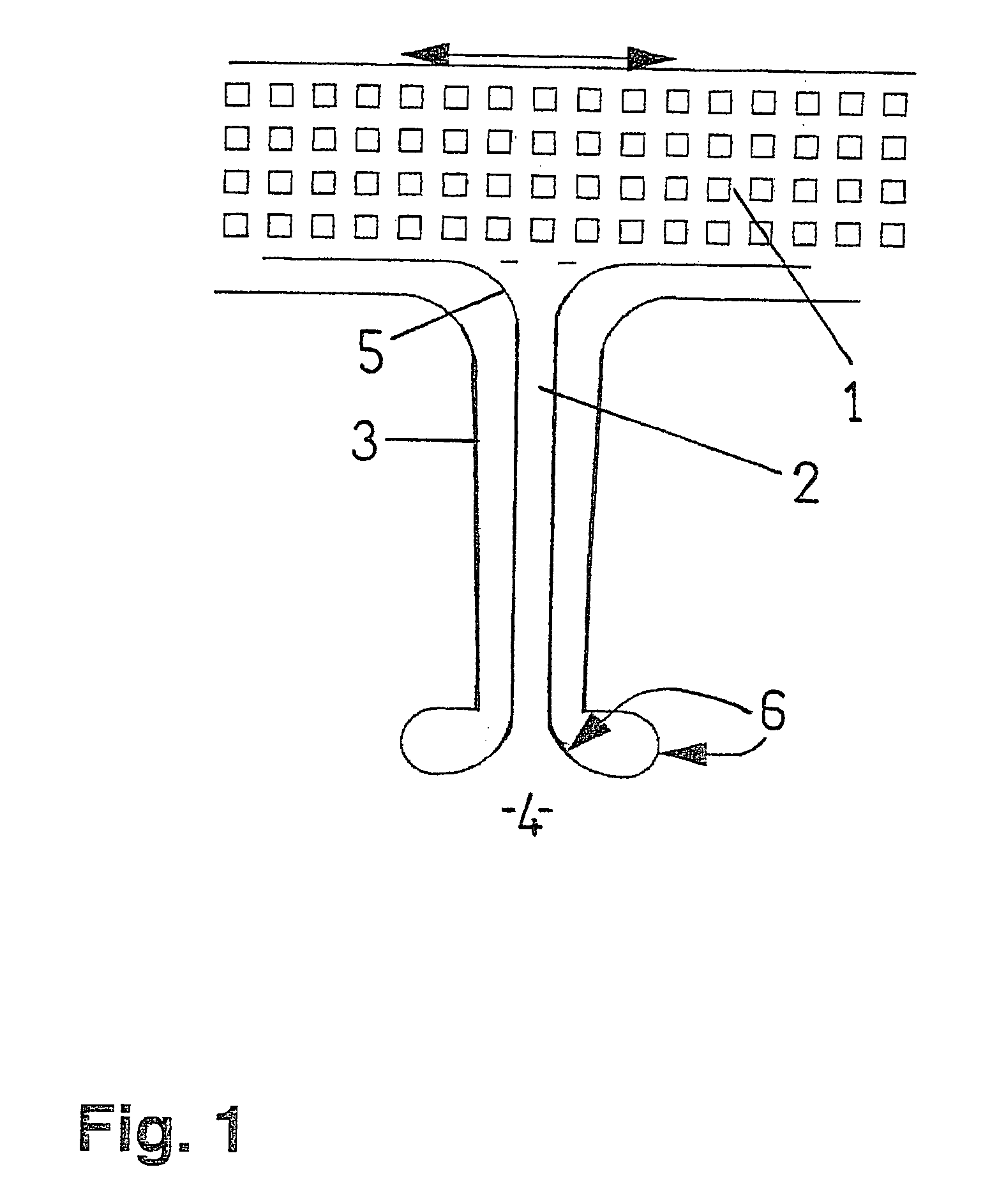

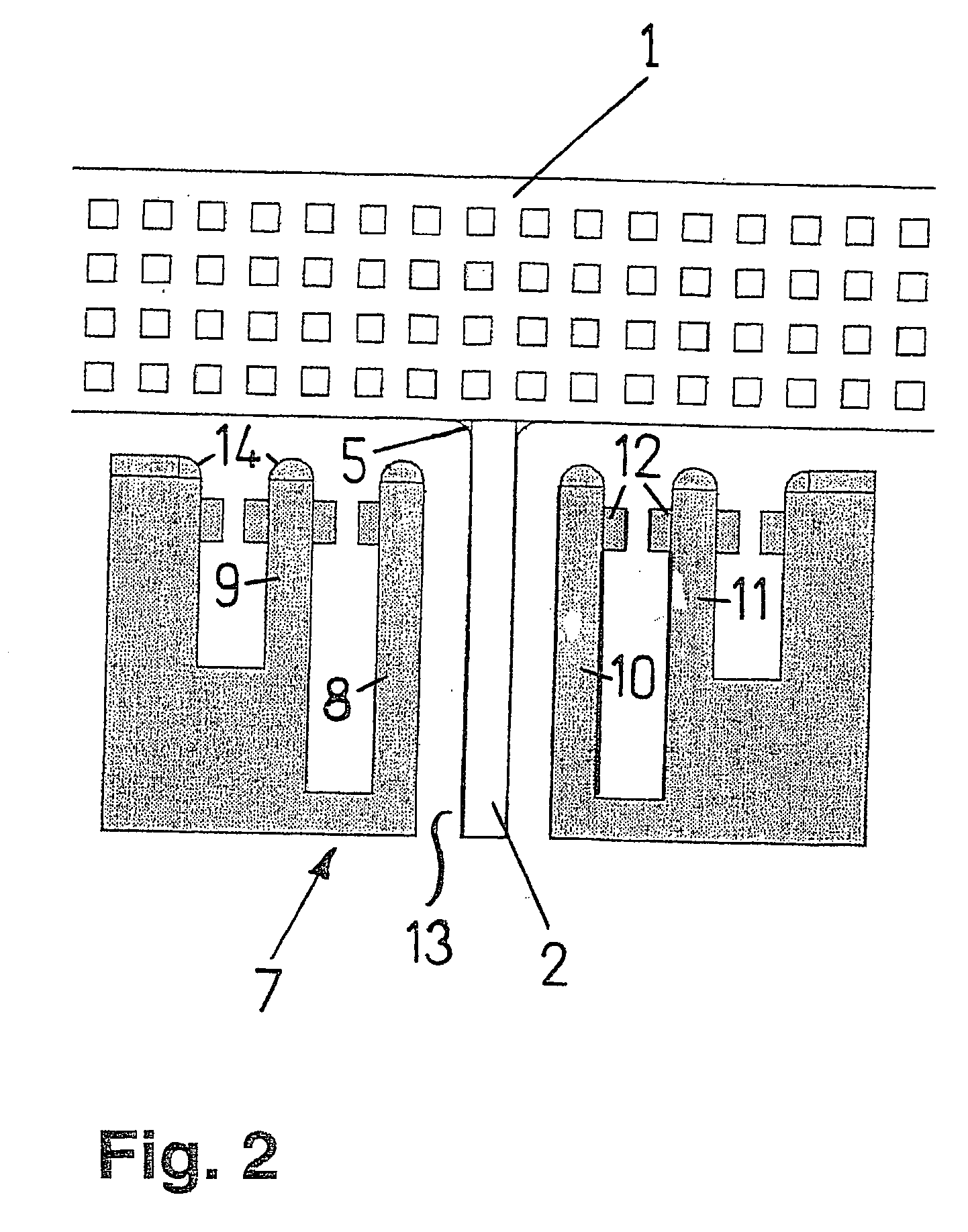

Device for the earthquake-resistant mounting of a partition

ActiveUS7966778B2Additional cost of device is limitedEasy to installWallsProtective buildings/sheltersMechanical engineeringCoating

Device for the earthquake-resistant mounting of a partition between a floor (2) and a ceiling (4). The partition includes: a frame having (i) a lower runner (8) and an upper runner (10) which are essentially horizontal, and (ii) essentially-vertical studs which connect the upper and lower runners; and a coating (6) which is fixed to the frame. The device includes: a contoured slide (18) which is intended to be solidly connected to the upper runner (10) and which has an essentially-U-shaped cross-section, and a top rail (30) which is intended to be fixed to the ceiling (4) and partially housed in the slide (18) between the arms of the U-shaped section thereof. The slide (18) and the top rail (30) are mounted such that they can move vertically in relation to one another. In addition, reversible detent elements are also provided between the slide (18) and the top rail (30).

Owner:PLACOPLATRE SA

High-performance weather-resisting anti-seismic steel for building and production method thereof

The invention relates to low alloyed steel used for building and a production method thereof, aiming at solving the defects that the prior building steel has atmospheric corrosion resisting property and does not consider the shock resistance problem. The invention adopts the measures that the low alloyed steel contains components by weight of 0.05-0.16 percent of C, 0.10-0.50 percent of Si, 0.60-1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15-0.60 percent of Cu, 0.25-0.80 percent of Cr, 0.10-0.50 percent of Ni, 0.01-0.10 percent of V, 0.005-0.030 percent of Ti at least one component of 0.010-0.040 percent of Nb, 0.010-0.050 percent of Als, 0.0010-0.0060 percent of Ca and 0.0010-0.020 percent of RE, and the rest of Fe and unavoidable impurities; and the production method comprises the following steps of molten iron desulphurizing and RH degassing, heating to 1150-1310 DEG C, rough rolling with the temperature being controlled at 1100-1200 DEG C and finishing rolling, wherein the beginning temperature of the finishing rolling is 880-980 DEG C, the rolling reduction ratio of each step is 15-30 percent, the final temperature of the finishing rolling is 800-900 DEG C, and the accumulated rolling reduction ratio of three steps of 35-50 DEG C.

Owner:WUHAN IRON & STEEL (GROUP) CORP

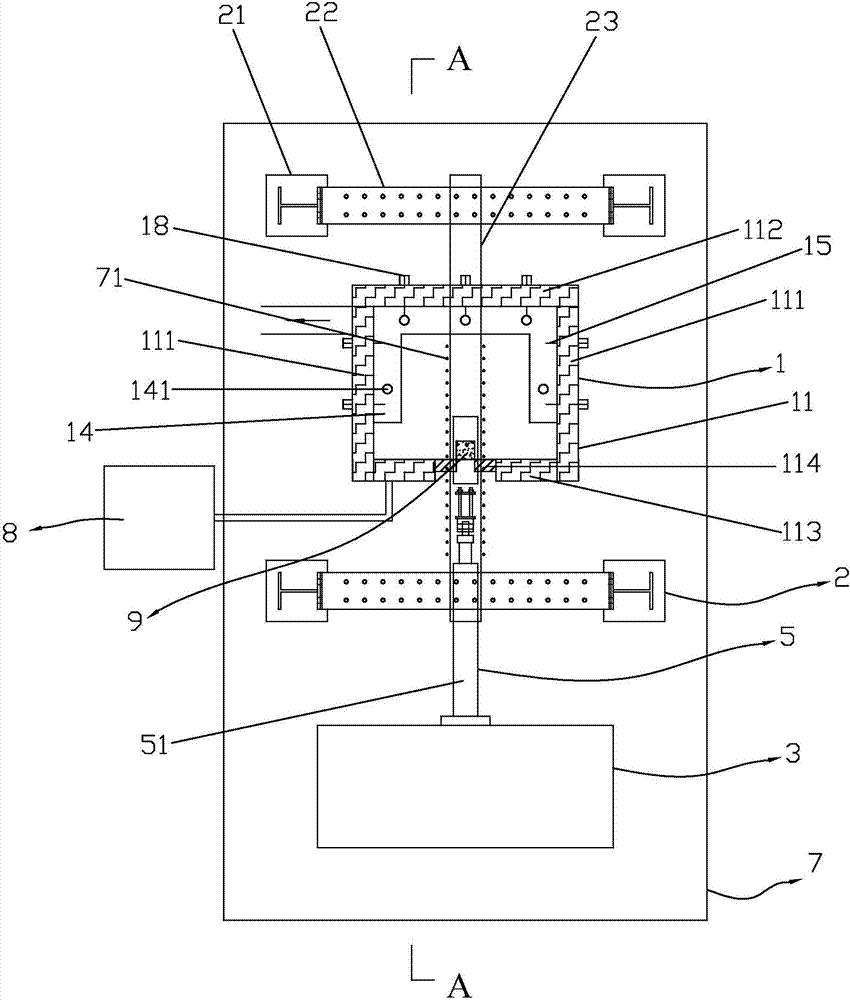

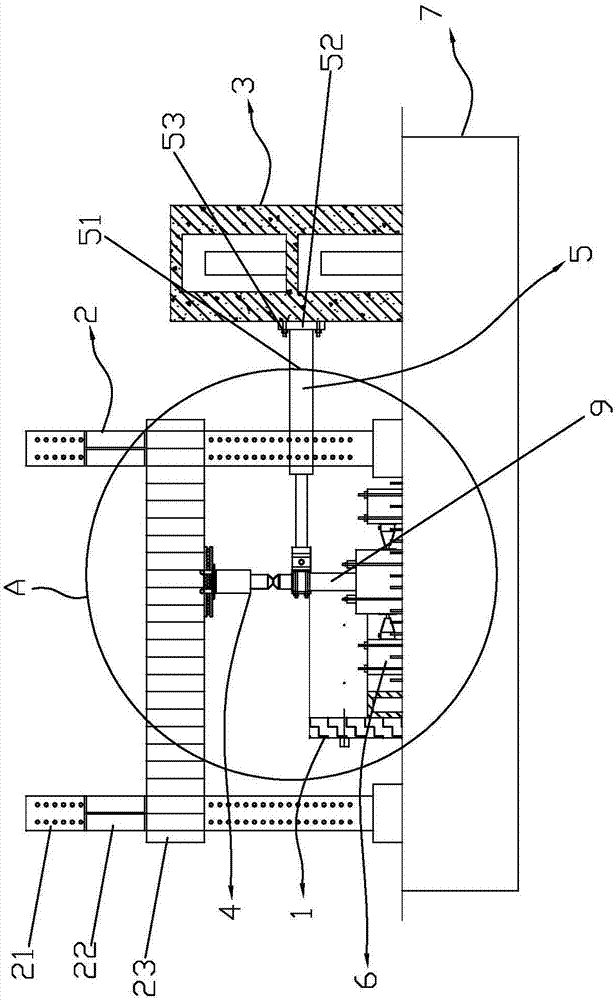

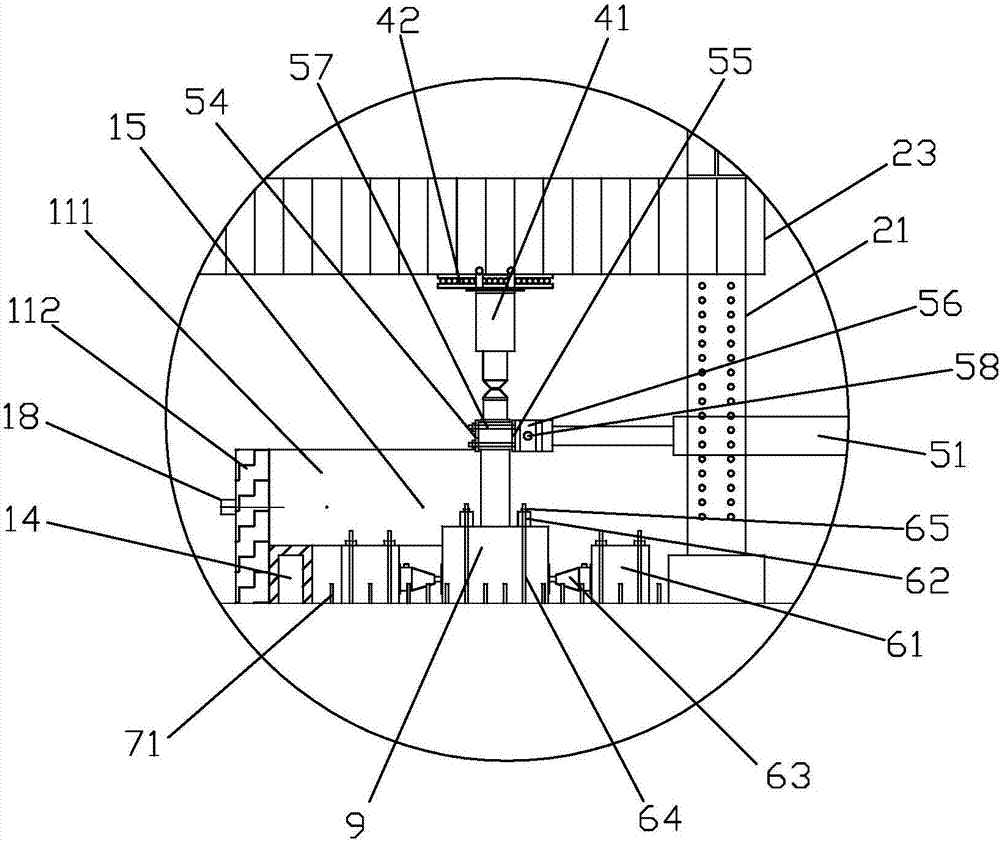

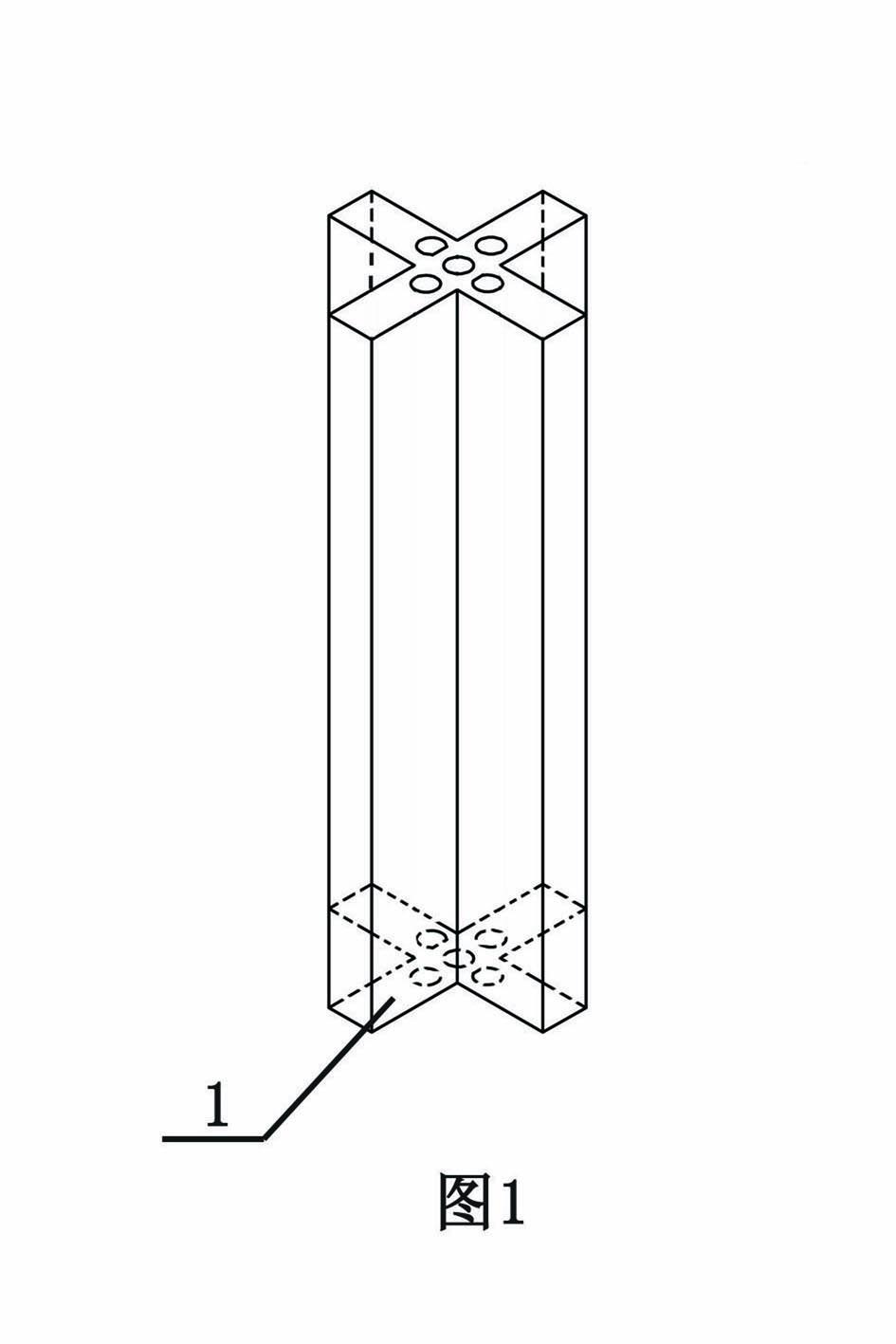

Pseudo-static testing device for concrete columns after non-peripheral fire exposure and implementation method thereof

ActiveCN107167368AThe test data is accurate and reliableRealize automatic controlVibration testingStrength propertiesFire testArchitectural engineering

The invention provides a pseudo-static testing device for concrete columns after non-peripheral fire exposure and an implementation method thereof. According to the fire exposure of a concrete column, two movable stove walls plus a temporary filling wall built in the middle opening are combined to form a fourth stove wall of a stove of the testing device. The stove is arranged in the body of a reaction frame, and a vertical load application unit is mounted on the bottom of a middle horizontal steel beam to apply vertical load on the concrete column; and a horizontal tension-compression servo loading unit is mounted on a horizontal reaction wall, and can apply pushover load and low-cycle horizontal reversed load on the concrete column specimen. The testing device first carries out a fire test under non-peripheral fire exposure on a loaded concrete column, and then carries out a pseudo-static test after fire extinguishment and cooling, and a data acquisition system is used for acquiring air pressure, temperature, displacement and load at each measuring point. The invention is applicable to the experimental study on the fire resistance and post-fire anti-seismic performance of concrete columns under non-peripheral (such as three-side, two-neighboring-sides and single-side) fire exposure.

Owner:HUAQIAO UNIVERSITY

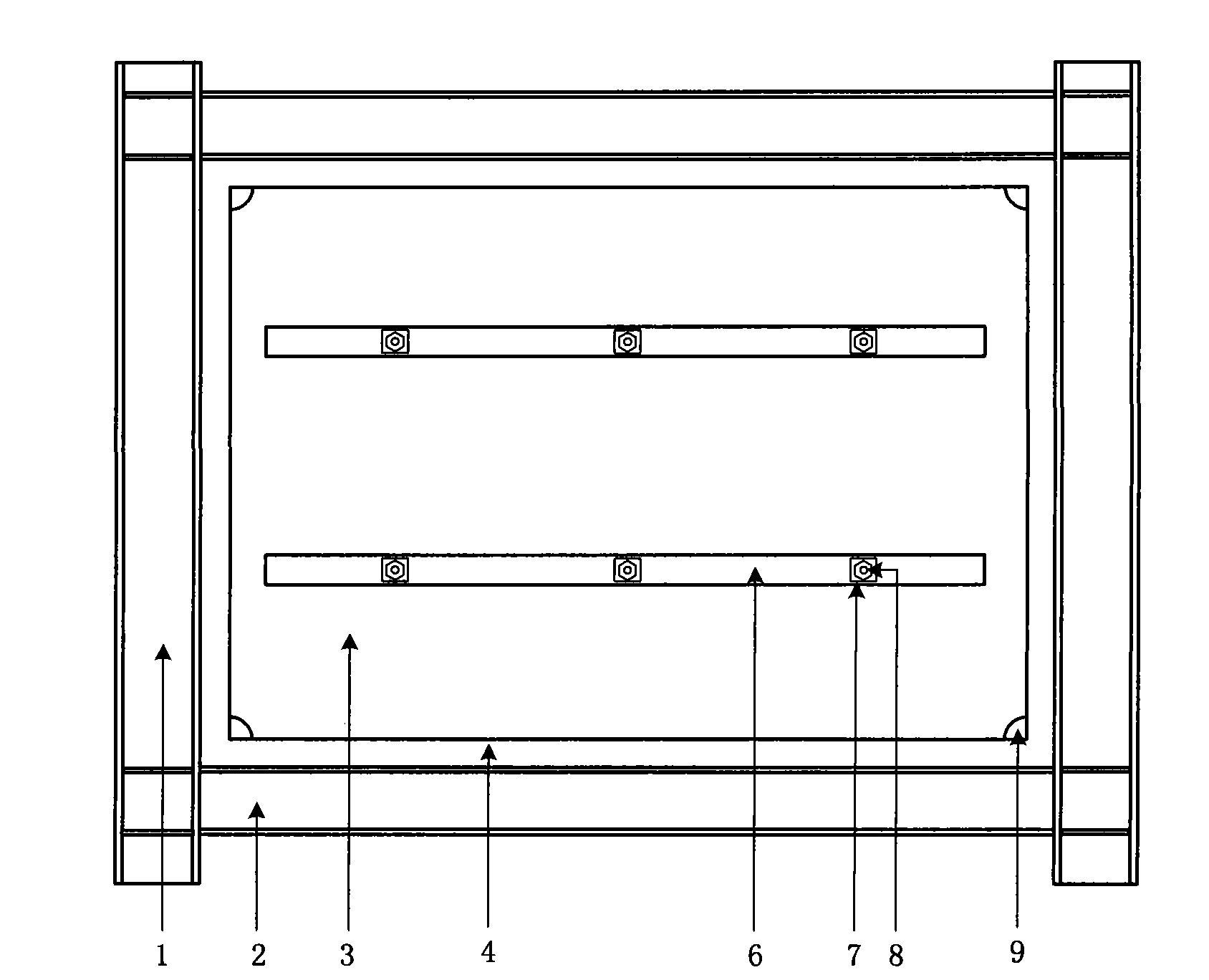

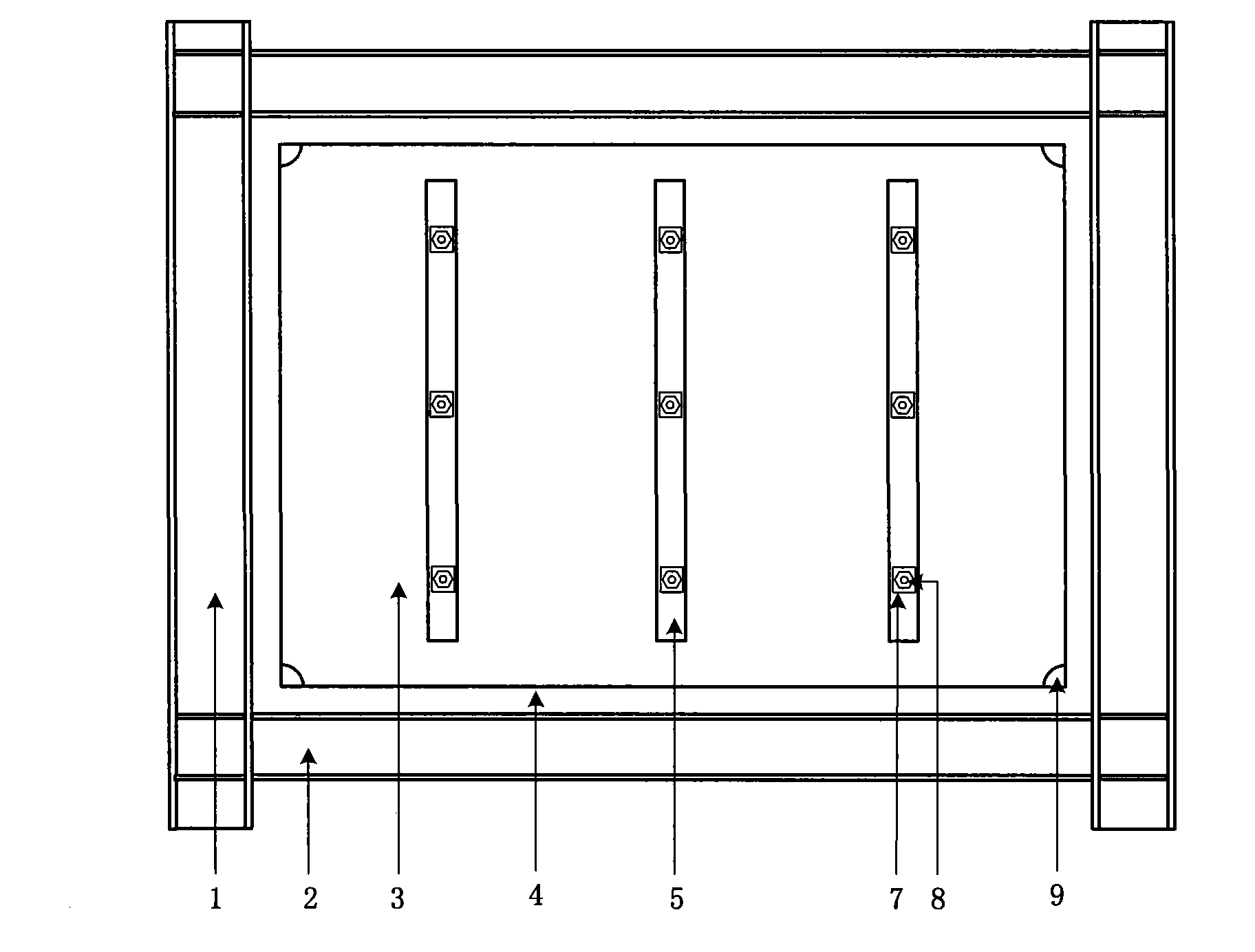

Prefabricated column of reserved concealed column channel, concealed column type complete assembled earthquake-resistant building and its method

InactiveCN102493603AReduce usageShorten the construction periodStrutsPillarsFloor slabArchitectural engineering

The invention relates to a concealed column type complete assembled earthquake-resistant building and its method, the concealed column type complete assembled earthquake-resistant building comprises a base, a prefabricated column, a prefabricated beam, a prefabricated wall panel, a prefabricated floor slab and a prefabricated stair, at least one reserved concealed column channel with continuous length used for passing through a steel bar, casting the concrete and constructing the concealed column is provided on a core part of the prefabricated column along the direction of column length, a beam of concealed column steel bar is passed through in the reserved concealed column channel, and solidified with a casted fine aggregate concrete to form the concealed column in the column, the upper part of the prefabricated column of the reserved concealed column channel is connected to a beam column edged steel plate. According to the invention, the products can solve the technical problem that the assembly of nodes can not reach the earthquake-resistant requirements or installation requirements in a traditional assembly type building, and solve the technical problem that production with complete prefabrication and complete assembly of columns, beams and wall panels of the building can be simultaneously realized under the prerequisite that the tradition assembly type building can not guarantee the earthquake-resistant requirements.

Owner:王夏静 +1

Bending restraining type shear wall with slideable stiffening shaped steel and internally embedded steel plate

InactiveCN101672077AImprove ductilityImprove seismic performanceWallsShock proofingSheet steelHigh intensity

The invention provides a bending restraining type shear wall with a slideable stiffening shaped steel and an internally embedded steel plate, belonging to the technical field of structural engineering. The shear wall consists of the internally embedded steel plate, a stiffening rib of the shaped steel, a fishplate and an edge component. The internally embedded steel plate adopts a thin steel platerolled by high-extensibility steel material; the edge component consists of an edge pillar and an edge beam; the stiffening rib of the shaped steel adopts the shaped steel in the forms of an I-shape,a box shape, a C-shape, an L-shape, a brim-curling shape or the other sections; the internally embedded steel plate is provided with arc notches at a quarter of four corners; the internally embeddedsteel plate is connected with the edge component by the fishplate; and the internally embedded steel plate is connected with the stiffening rib of the shaped steel with a high-intensity bolt which penetrates therethrough. The bending restraining type shear wall with the slideable stiffening shaped steel and the internally embedded steel plate can be taken as a novel lateral force-resistant component of a high rise building steel structure or other structures of the novel lateral force-resistant components, has the advantages of good earthquake-resistant performance, high extensibility, convenient construction and cost saving, and is a predominant earthquake-resistant energy-dissipating component.

Owner:TSINGHUA UNIV

Method and structure for enhancing brickwork structure and improving earthquake resistant performance of structure by using carbon fiber

InactiveCN101672110AImprove the state of stressAvoid sudden destructionBuilding repairsFiberCarbon fibers

The invention relates to a method and a structure for enhancing a brickwork structure and improving earthquake resistant performance of the structure by using carbon fiber. The method comprises the following steps of: step one, determining a part to be enhanced and reconstructed and pre-treating the surfaces of a brickwork; step two, coating binder on the surfaces of the brickwork; step three, sticking carbon fiber cloth tapes on the surfaces of the brickwork in a gridding shape and in a double-surface symmetrical manner; step four, drilling a through hole; step five, using a carbon fiber pinto pass through the through hole, infusing glue in the through hole and sticking the carbon fiber pin with the brickwork; step six, dispersing the two ends of the carbon fiber pin which are exposed from the brickwork in a strip shape, and respectively sticking and fixing the two ends with the carbon fiber cloth tapes on the two surfaces of the brickwork in a petal shape; and step seven, additionally sticking a piece of glue-coated carbon fiber cloth in an each area in which strips are stuck. The method solves the technical problem that the carbon fiber cloth tapes on the two surfaces of the brickwork lack organic linkage and can not ensure the cooperative work of the carbon fiber cloth tapes and the brickwork structure. The adoption of the method can effectively enhance the whole earthquake resistant performance of the brickwork structure. Meanwhile, the method also has the advantages of simple and convenient construction, short construction period, no original space occupation, no load added to the structure or a foundation and low investment.

Owner:BEIJING ZHUFU ARCHITECTURE AFFAIRS CO LTD

Sensor

InactiveUS20040129077A1Vibration measurement in solidsAcceleration measurement using interia forcesSeismic massEngineering

For a sensor whose sensor structure is implemented in a micromechanical structural component and which has parts which are movable in relation to the stationary substrate of the structural component, and which also includes an unsupported seismic mass (1), a spring system having at least one spring (2), the seismic mass (1) being connected to the substrate through the spring system, an overload protection to limit the deflection of the spring system and the seismic mass (1) in at least one direction, and means for detecting the deflections of the spring system and the seismic mass (1), design measures are proposed whereby the impact forces may be reduced to prevent conchoidal breaks and resulting incipient damage to the sensor structure, as well as formation of particles. To that end, at least one two-dimensional stop (3) for at least one moving part of the sensor structure is provided as overload protection. Alternatively or in addition thereto, at least one spring stop (7) for at least one moving part of the sensor structure is provided according to the present invention as overload protection.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com