Patents

Literature

596 results about "Atmospheric corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochromic rearview mirror incorporating a third surface metal reflector

InactiveUS6064508AEconomical and reliableLow costMirrorsSolid-state devicesEpoxyElectrical conductor

An electrochromic variable reflectance mirror for a vehicle includes a reflector / electrode on the third surface of the mirror. This reflector / electrode forms an integral electrode in contact with the electrochromic media, and may be a single layer of a highly reflective material or may comprise a series of coatings. When a series of coatings is used for the reflector / electrode, there should be a base coating which bonds to the glass surface and resists any adverse interaction, e.g., corrosive action, with the constituents comprising the electrochromic media, an optional intermediate layer (or layers) which bonds well to the base coating and resists any adverse interaction with the electrochromic media, and at least one highly reflective layer which directly contacts the electrochromic media and which is chosen primarily for its high reflectance, stable behavior as an electrode, resistance to adverse interaction with the materials of the electrochromic media, resistance to atmospheric corrosion, resistance to electrical contact corrosion, the ability to adhere to the base or intermediate layer(s) (if present) and to the epoxy seal, and ease of cleaning. If a base layer is deposited it preferably covers the entire third surface; however, when this is done the highly reflective layer may optionally only coat the central portion of the third surface and not the perimeter edge portion. The third surface reflector / electrode provides of improved electrical interconnection techniques used to impart a voltage drive potential to a transparent conductor on the mirror's second surface.

Owner:GENTEX CORP

Weather resistant thick steel plate and manufacturing method thereof

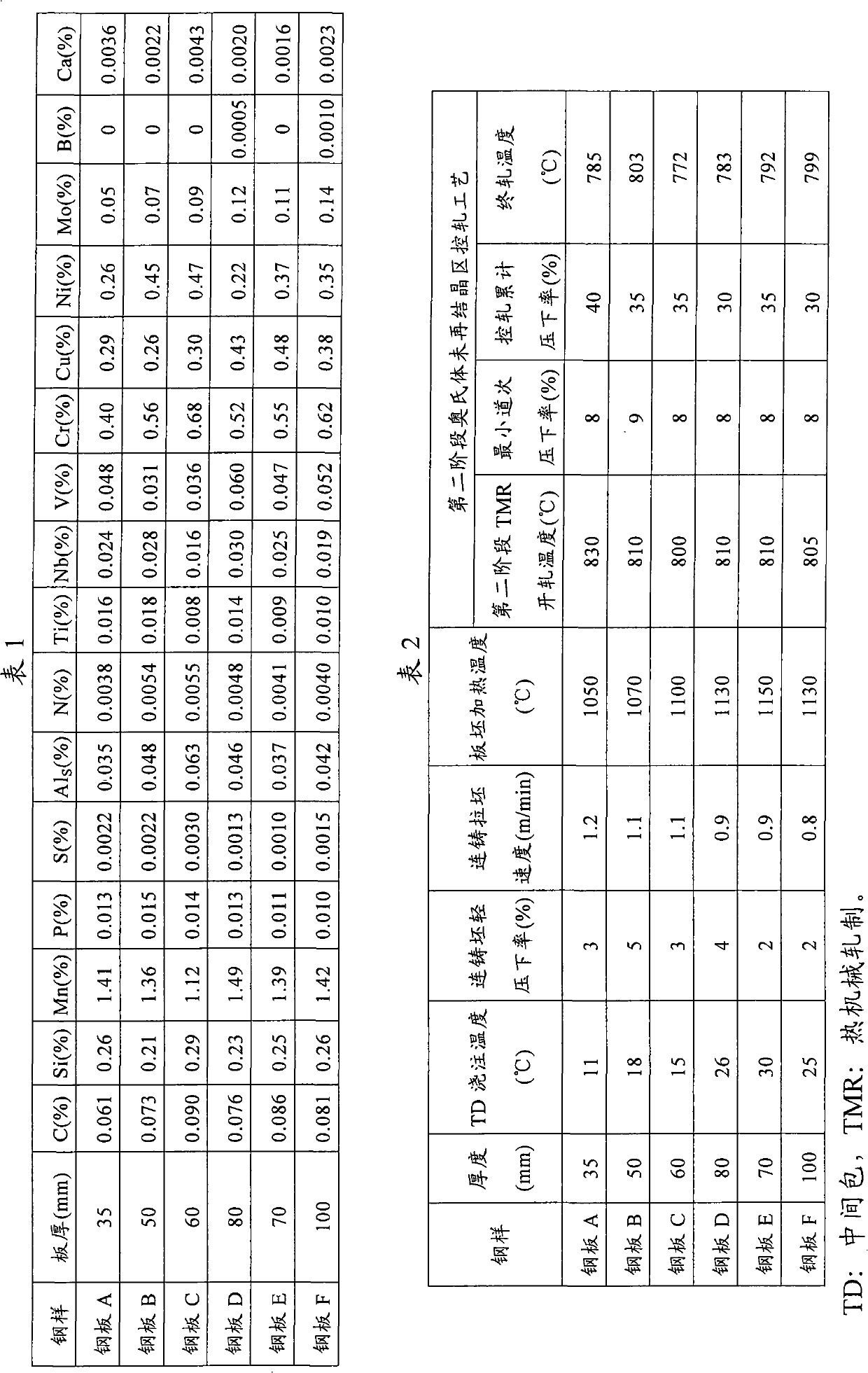

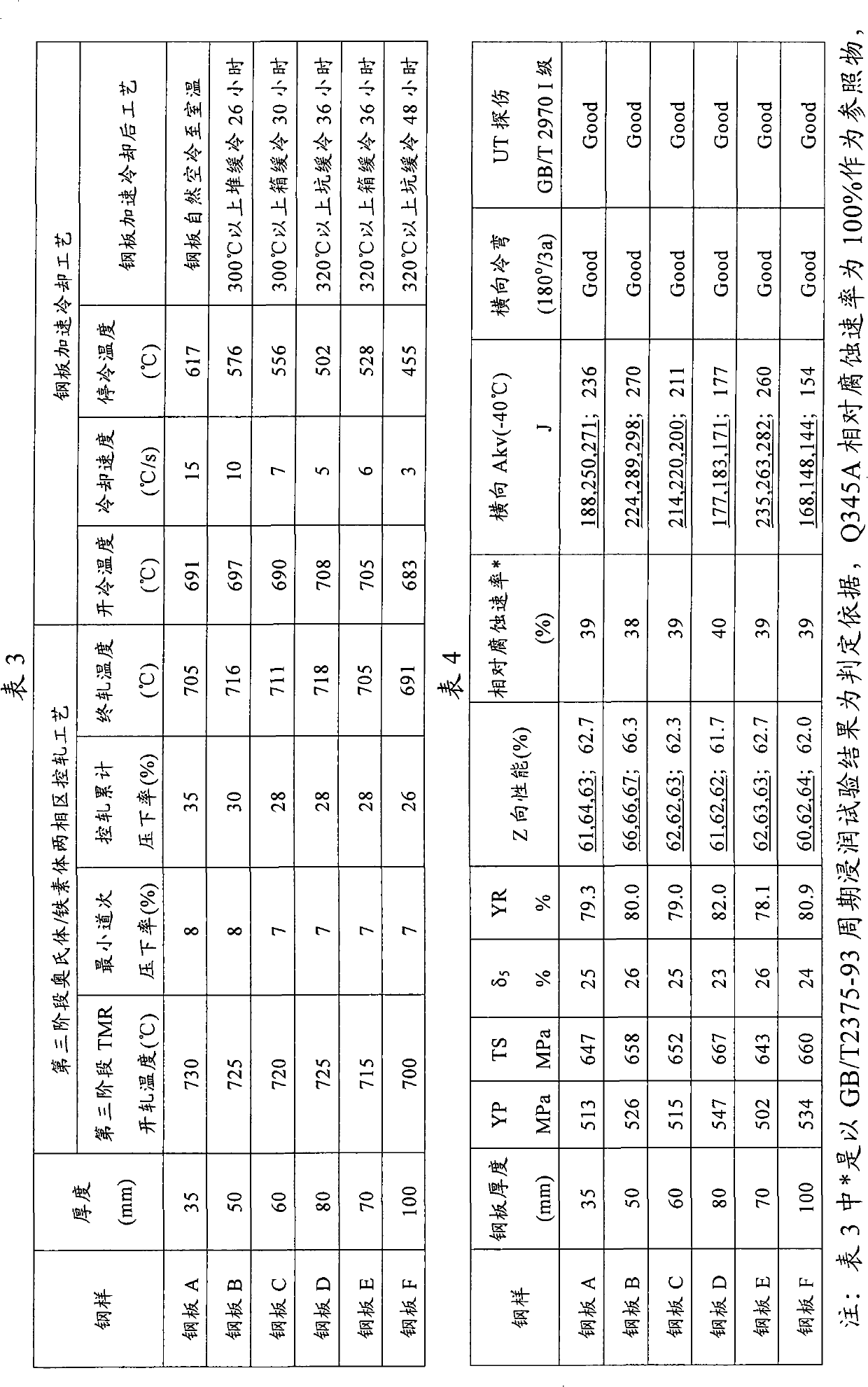

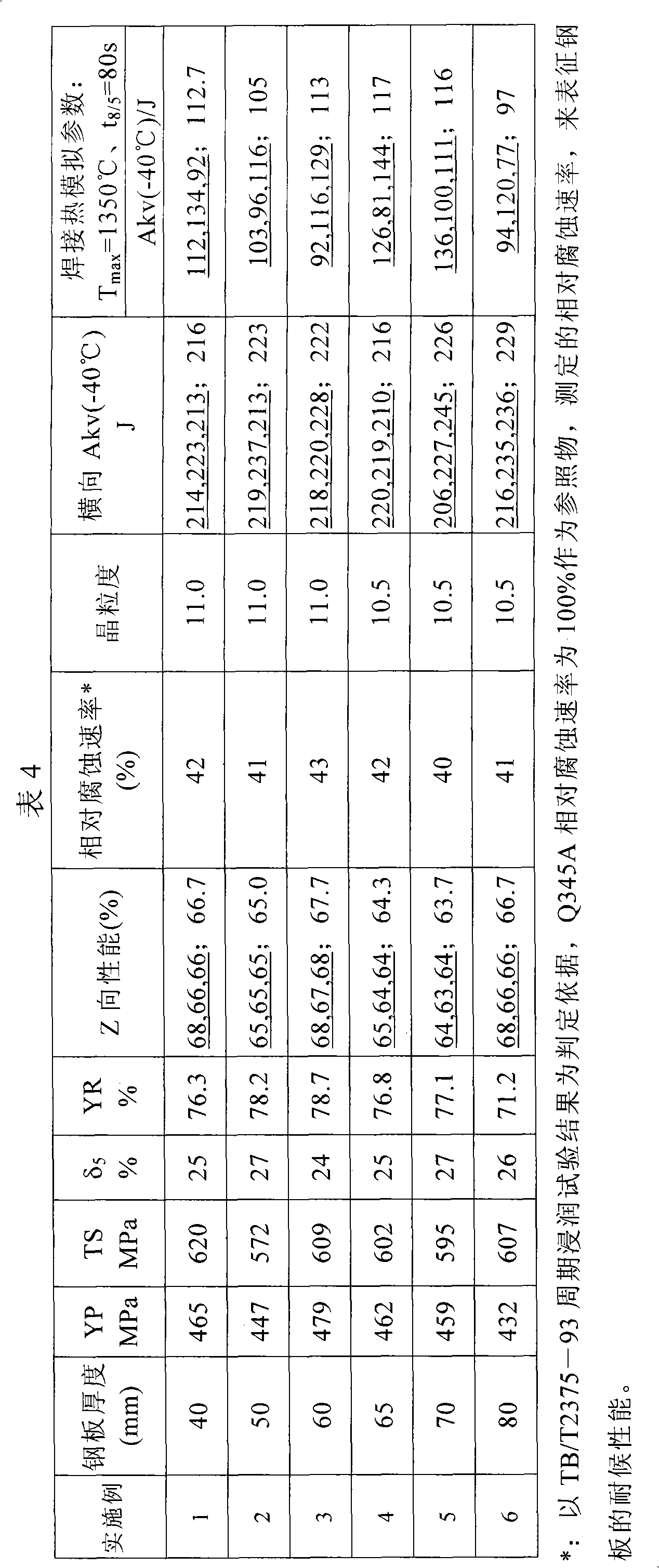

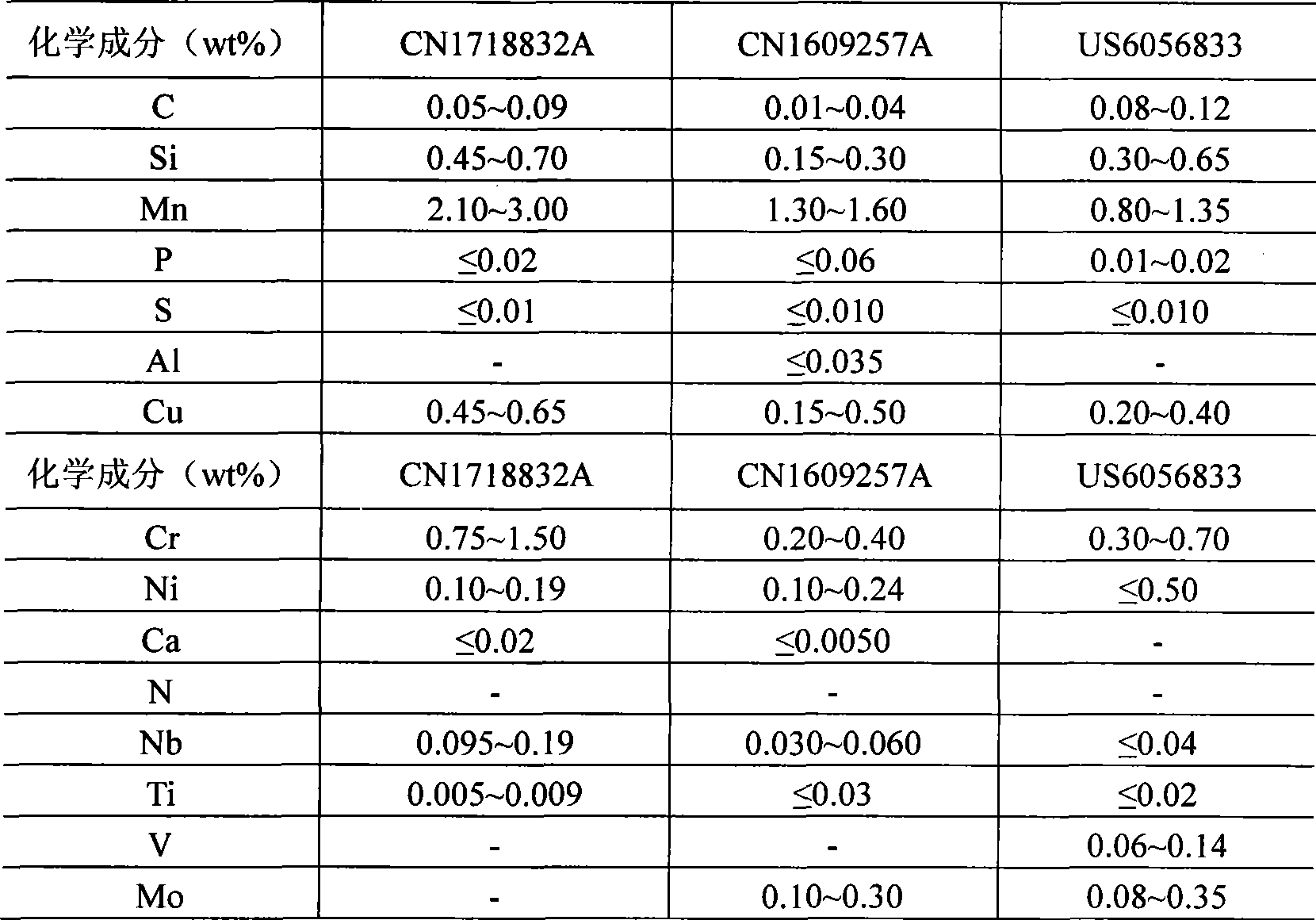

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

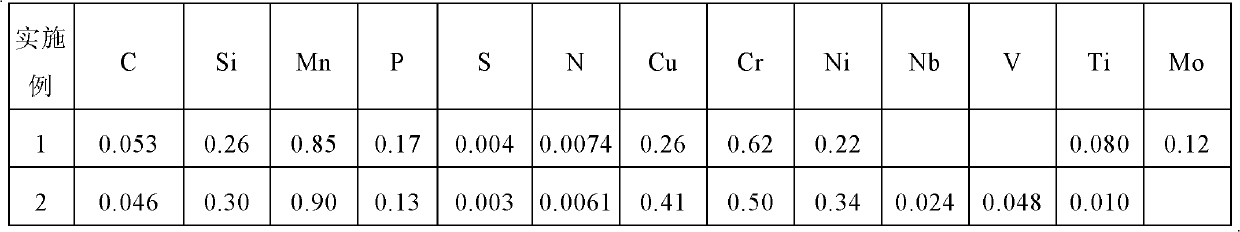

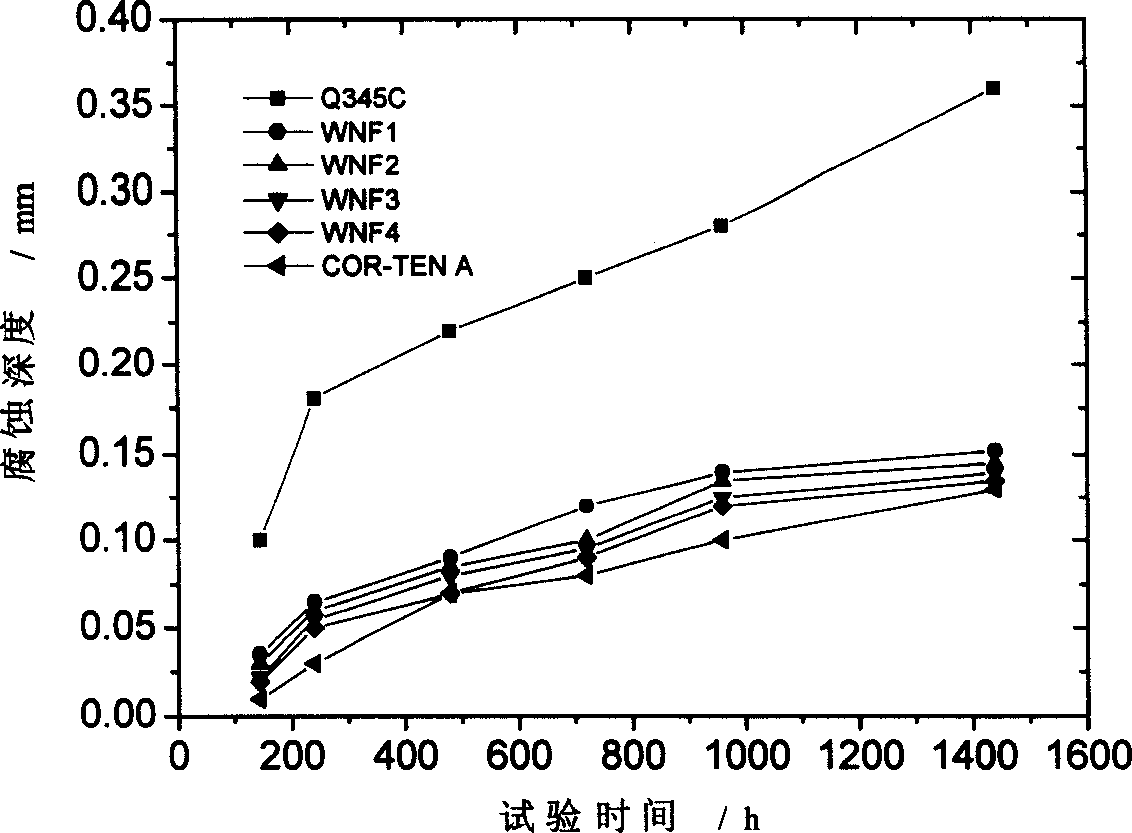

High-strength easy-formation atmospheric corrosion resisting steel

The invention relates to high strength easily forming atmospheric corrosion resistant steel. The invention provides the high strength easily forming atmospheric corrosion resistant steel aiming at the problems in existing steel that the weatherability is bad and the service life is lowered under the condition that the thickness is thinned. The high strength easily forming atmospheric corrosion resistant steel is composed of components of following weight percent: C: 0.04-0.09%, Si: 0.10-0.50%, Mn: 1.20-1.70%, P: <=0.020%, S: < =0.010%, Cu: 0.20-0.60%, Cr: 0.40-0.80%, Ni: 0.20-0.50% and Nb: 0.03-0.07%, and also comprises one or a plurality of Mo: <=0.20%, Ti: <=0.03% and Als: <=0.035%, and allowance is Fe and unavoidable impurity. The yield strength of the steel of the invention is more than or equal to 550MPa, the tensile strength is more than or equal to 650MPa, the percentage elongation is more than or equal to 18%, the corrosion resistance is equivalent to SPA-H steel which is used for previous containers, and the steel has excellent welding performance, cold roll forming performance and low temperature impact toughness, which is beneficial for extending and applying.

Owner:武钢集团有限公司

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance weather-proof building structural steel and manufacturing method thereof

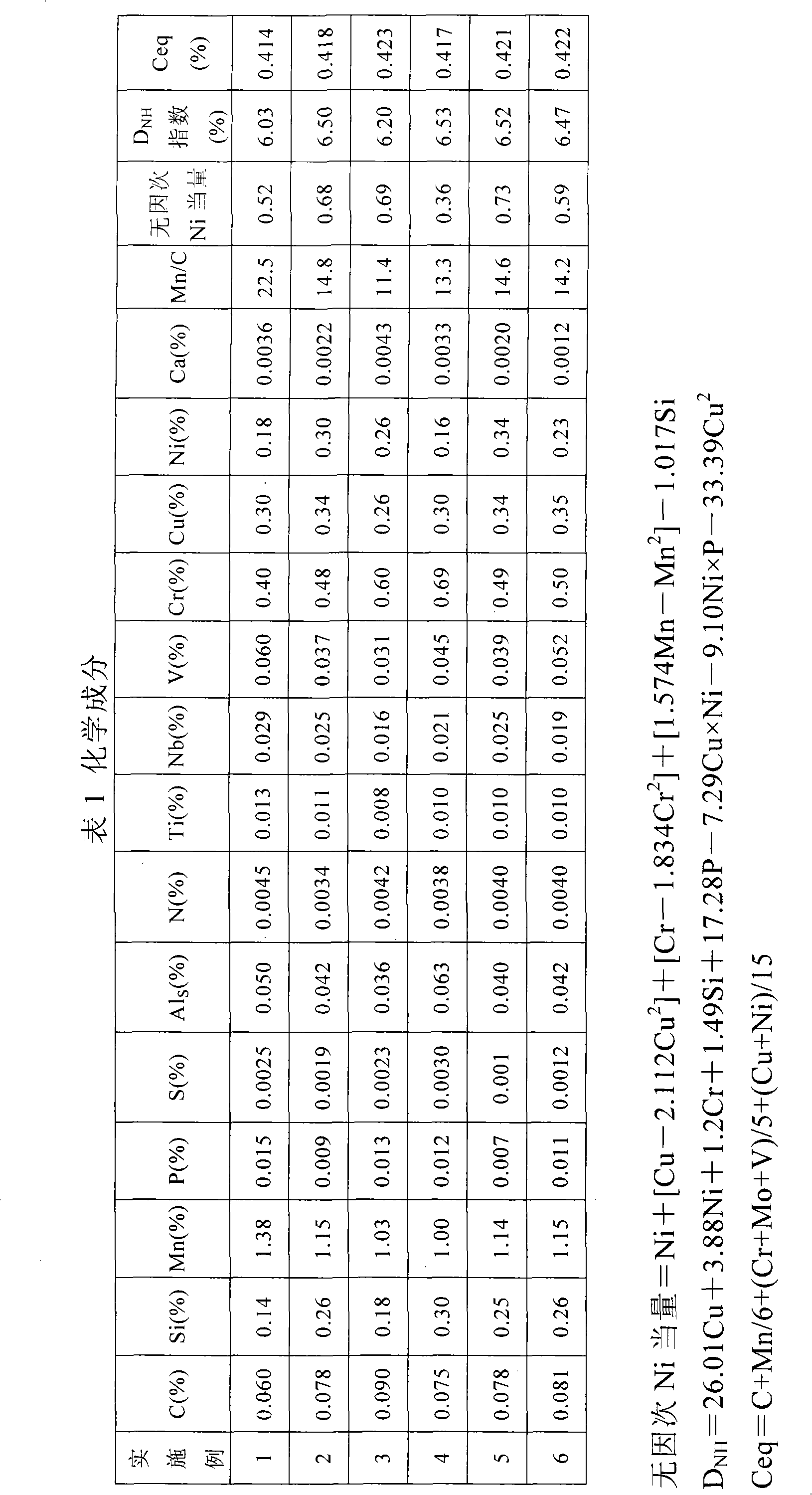

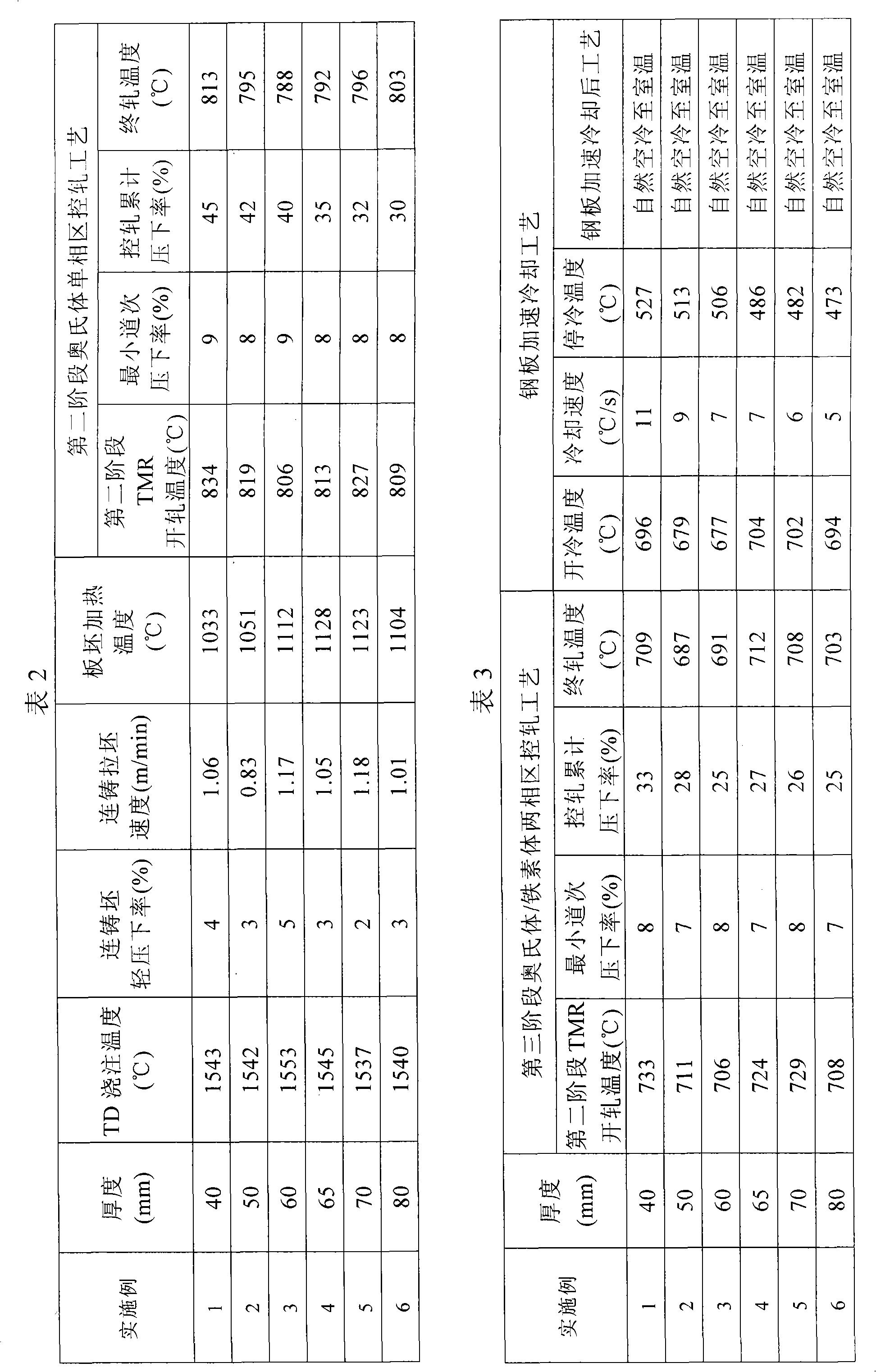

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

High-corrosion resistant high-strength weather resisting steel and manufacturing method thereof

ActiveCN101376953ALight weightReduce manufacturing costTemperature control deviceChemical compositionHigh intensity

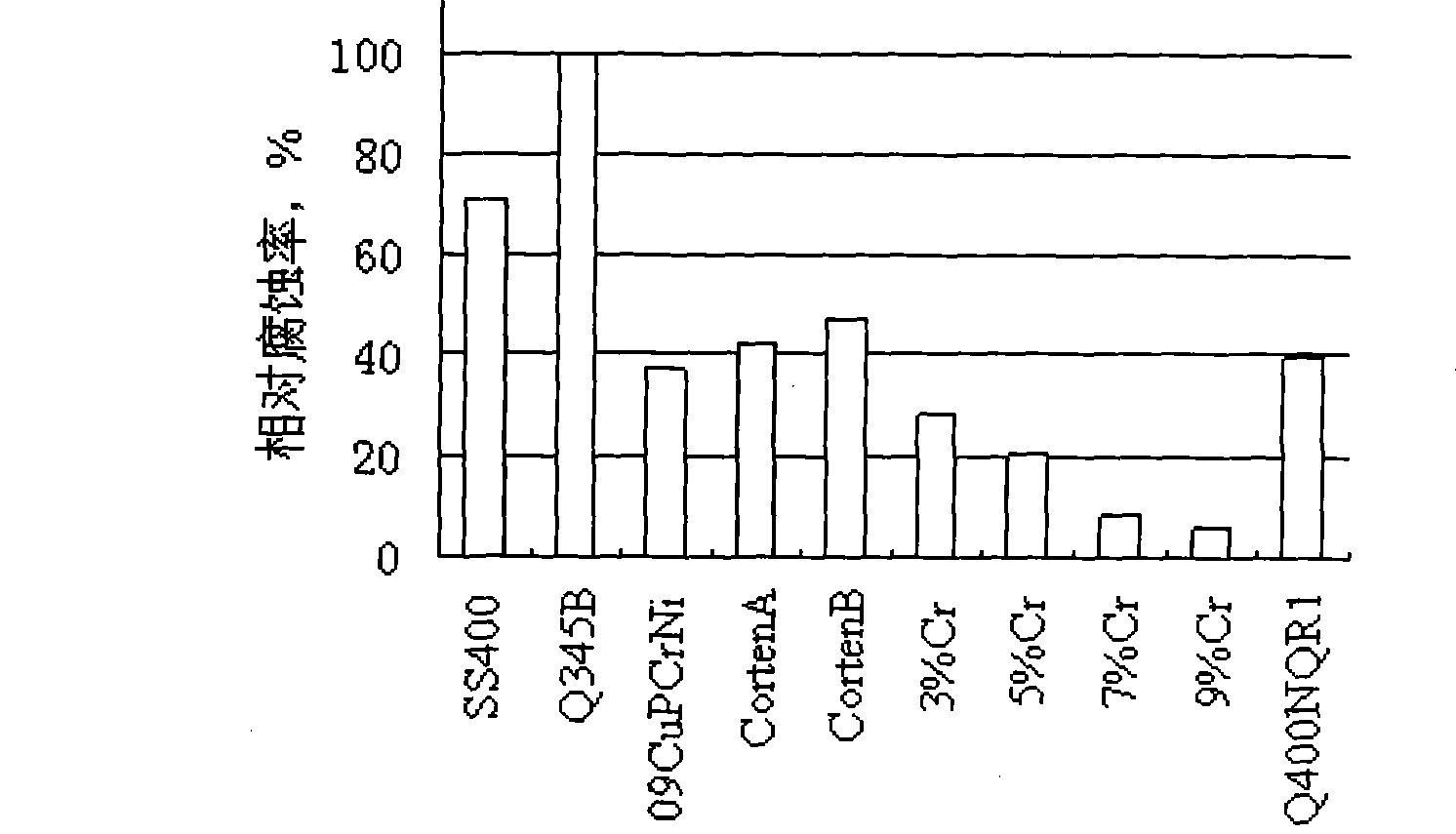

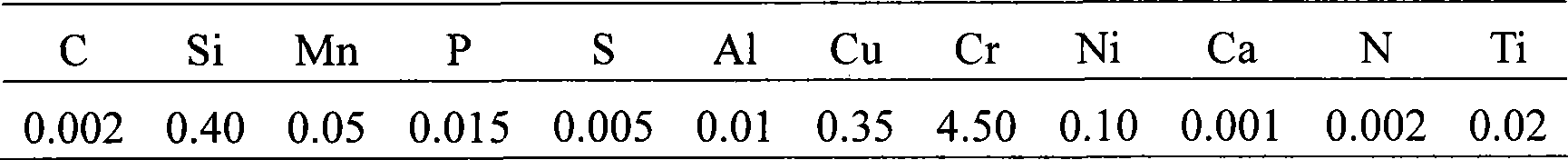

The invention provides high-corrosion resistance and high-strength weather resistant steel which comprises the following chemical components (in weight percentage): 0.002 percent to 0.005 percent of C, 0.20 percent to 0.40 percent of Si, 0.01 percent to 0.05 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.008 percent of S, 0.01 percent to 0.05 percent of Al, 0.20 percent to 0.40 percent of Cu, 4.50 percent to 5.50 percent of Cr, less than or equal to 0.40 percent of Ni, 0.001 percent to 0.006 percent of Ca, 0.001 percent to 0.006 percent of N, less than or equal to 0.03 percent of Ti, and the rest are Fe and other inevitable impurities. The invention also provides a manufacturing method of the weather resistant steel. The yield strength of the weather resistant steel is more than 700MPa, the extensibility is more than 20 percent and the atmospheric corrosion resistance is higher than that of traditional high-strength weather resistant steel; in addition, the steel can be directly used in atmospheric environment without being coated, and meets the requirements of railway freight car, container and bridge building fields.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing high-strength thin strip steel in short process

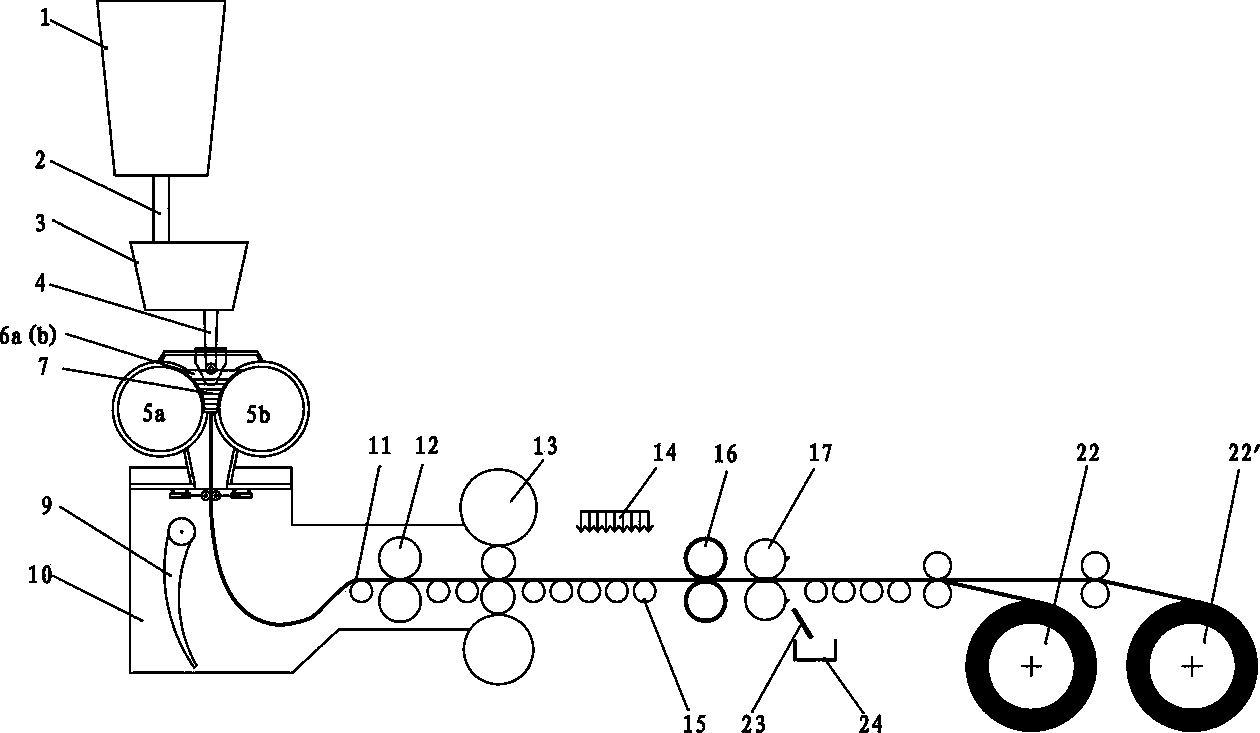

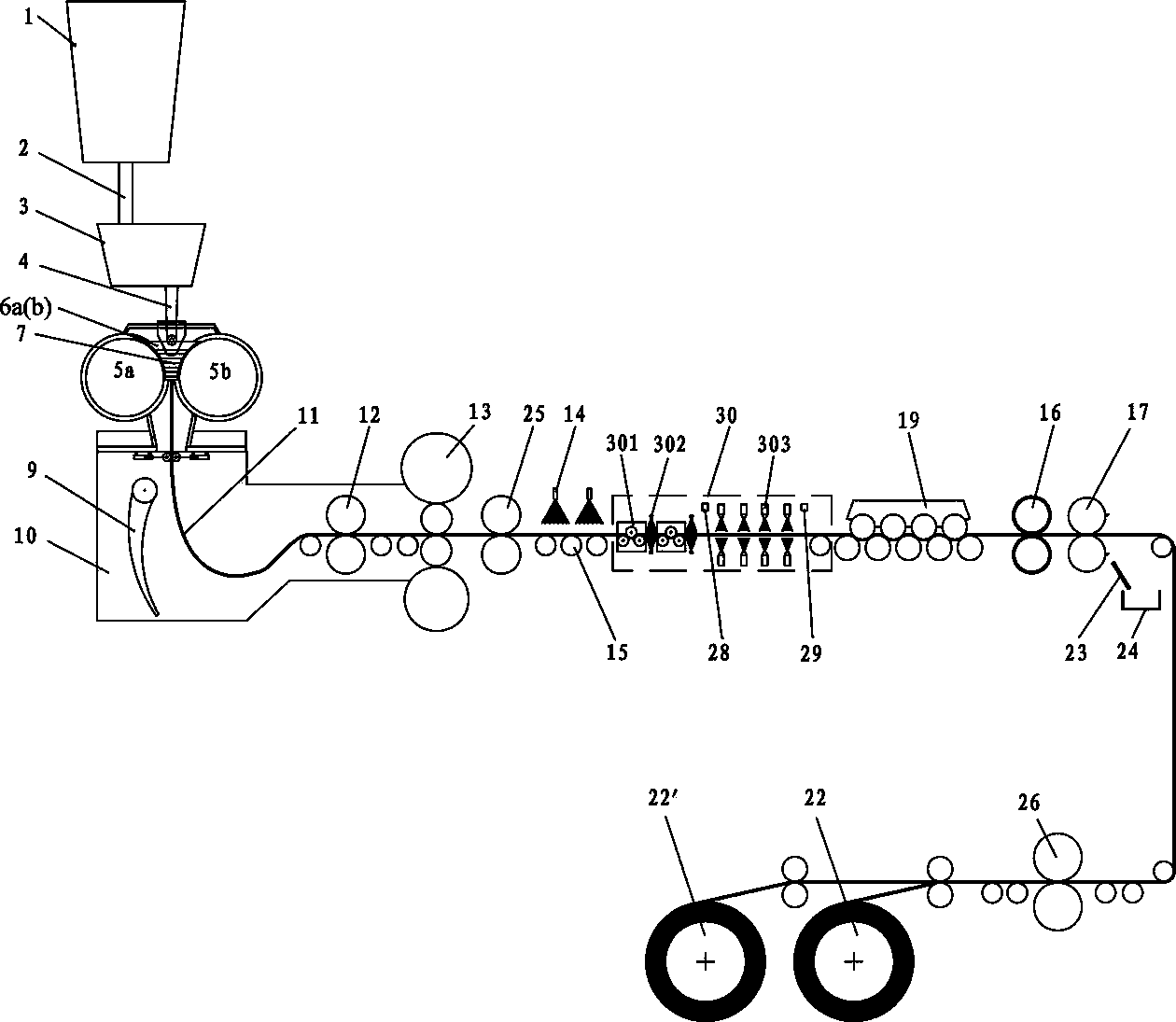

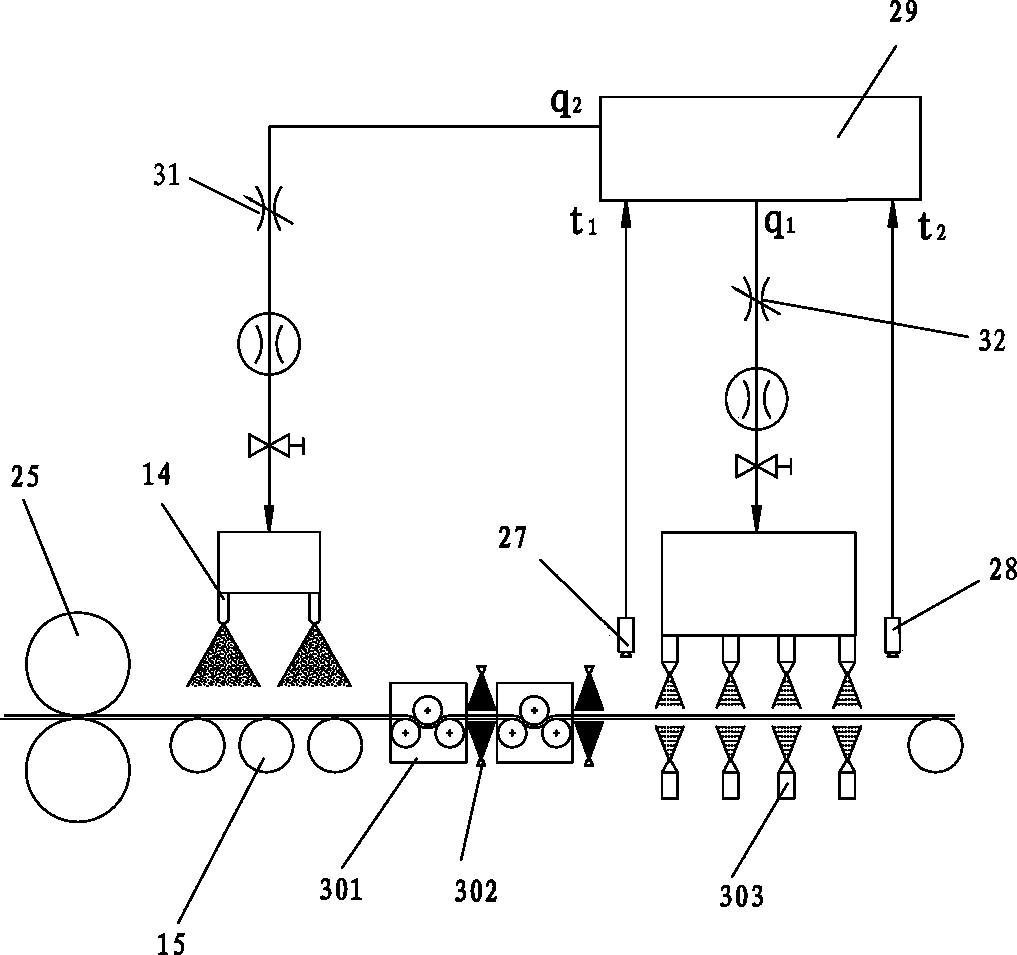

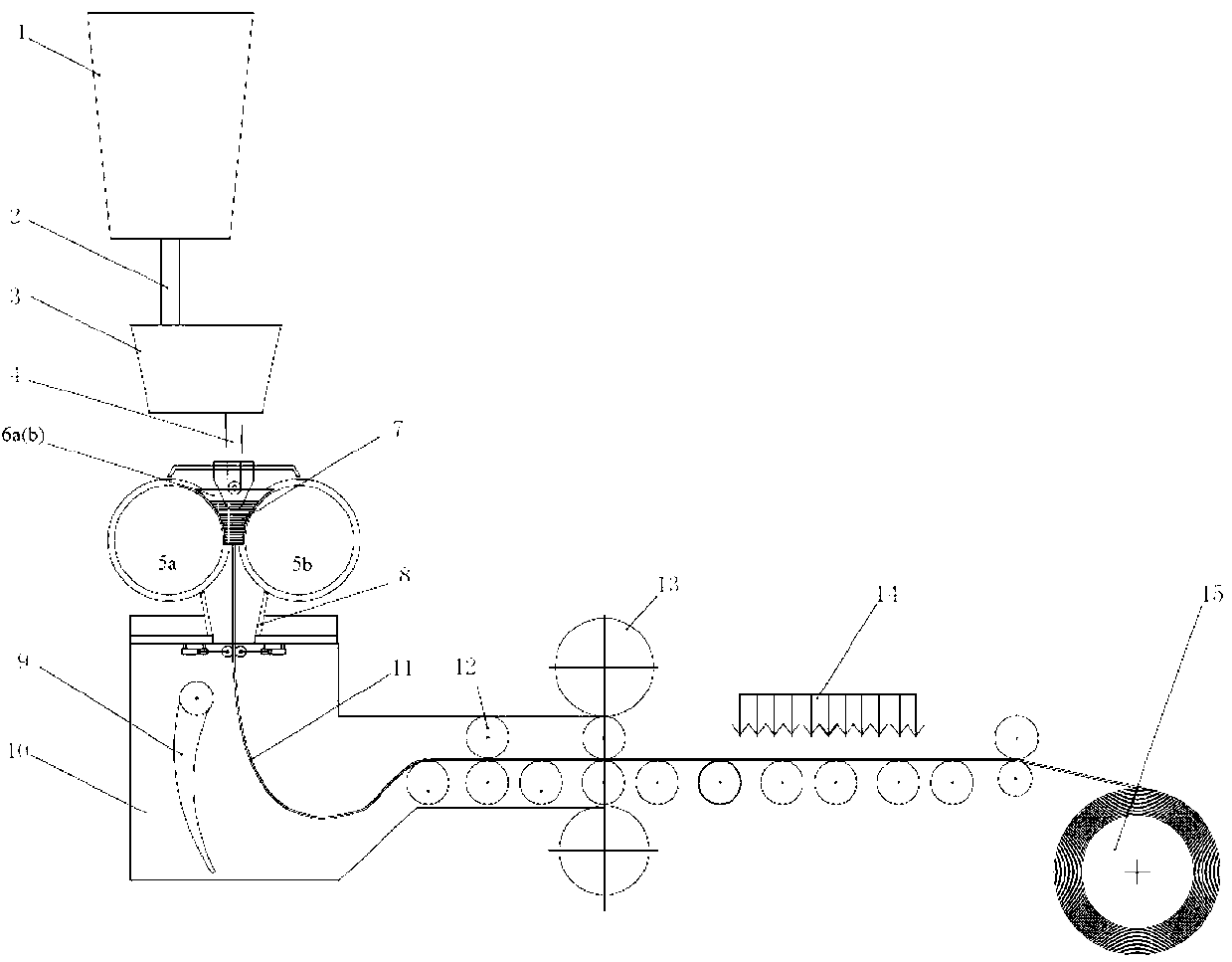

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-strength atmospheric-corrosion resistant steel

The invention discloses a hyperstrength atmospheric corrosion-tolerant steel, which comprises the following parts: 0.01-0.07% C, 0.25-0.50% Si, 1.60-2.00% Mn, not more than 0.018% P, not more than 0.008% S, 0.20-0.50% Cu, 0.40-0.75% Cr, 0.25-0.60% Ni, 0.03-0.08% Nb, 0.10-0.40% Mo, not more than 0.02 Ti, not more than 0.035% Als, not more than 0.003% B and Fe and impurity.

Owner:武钢集团有限公司

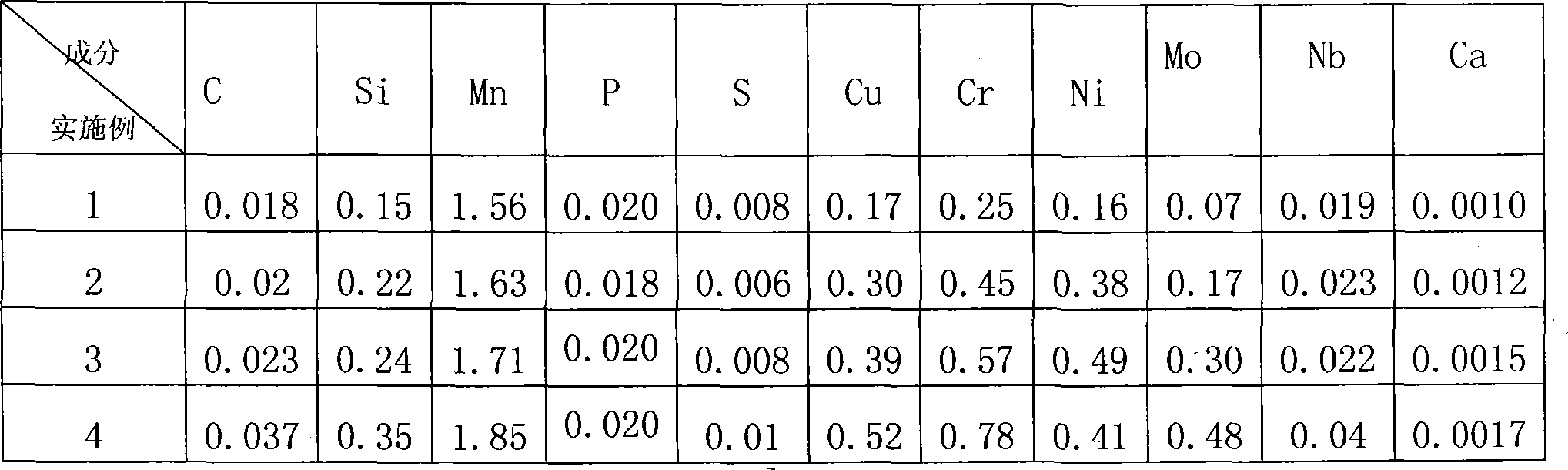

Method for manufacturing 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting

ActiveCN103305770AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsReduction rateChemical composition

The invention provides a method for manufacturing a 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting. The method comprises the following steps of: 1) smelting, wherein molten steel comprises the following chemical components: 0.03-0.08% of C, not more than 0.4% of Si, 0.6-1.5% of Mn, 0.07-0.22% of P, not more than 0.01% of S, not more than 0.012% of N, 0.25-0.8% of Cu, 0.3-0.8% of Cr, 0.12-0.4% of Ni, at least one of microalloy elements including 0.01-0.08% of Nb, 0.01-0.08% of V, 0.01-0.08% of Ti and 0.1-0.4% of Mo, and the balance of Fe and inevitable impurities; 2) strip continuous casting: directly casting a cast strip with thickness of 1-5mm; 3) strip cooling, wherein the cooling rate is more than 20 DEG C / s; 4) online hot rolling of the cast strip, wherein the hot rolling temperature is 1050-1250 DEG C, the reduction rate is 20-50% and the deformation rate is more than 20s<-1>; online austenite recrystallization happens after hot rolling; and the hot-rolled strip is 0.5-3.0mm in thickness; and 5) cooling and coiling, wherein the cooling rate is 10-80 DEG C / s, and the coiling temperature is 570-720 DEG C. The microstructure of the obtained steel strip is mainly formed by fine polygonal ferrite and pearlite.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

High strength anti-atmosphere corrosion steel and production method thereof

The invention relates to high-strength atmospheric corrosion resistant steel and a production method thereof, and belongs to the field of metallurgy. The technical problem to be solved by the invention is to provide the high-strength atmospheric corrosion resistant steel of which the yield strength is more than or equal to 550 MPa. The high-strength atmospheric corrosion resistant steel comprises the following chemical compositions in percentage by weight: less than or equal to 0.12 percent of carbon, less than or equal to 0.75 percent of silicon, less than or equal to 1.50 percent of manganese, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.008 percent of sulfur, 0.30 to 1.25 percent of chromium, 0.12 to 0.65 percent of nickel, 0.20 to 0.55 percent of copper, 0.006 to 0.02 percent of titanium, more than 0.09 percent and less than or equal to 0.15 percent of vanadium, 0.01 to 0.02 percent of nitrogen, 0.015 to 0.03 percent of niobium, and the balance of iron and inevitable impurities. The high-strength atmospheric corrosion resistant steel has superior comprehensive properties of high strength, high toughness, high plasticity, obvious yield point and the like, and has wide application prospect.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

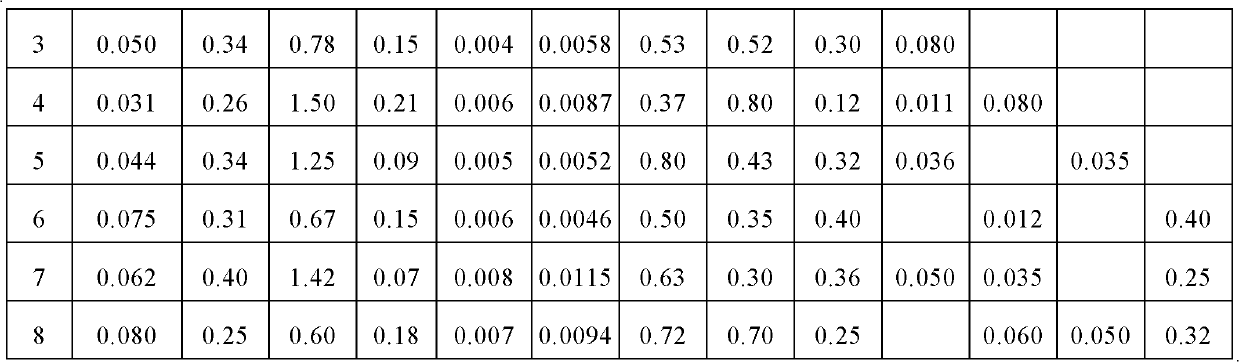

Ultra-low carbon hot rolling weather-resisting steel with yield strength more than 450MPa

InactiveCN101235470AGood mechanical propertiesSimple chemical compositionMechanical propertyAtmospheric corrosion

The invention provides ultra-low carbon hot rolling weathering steel whose yield strength is more than 450MPa aiming at the defects of existing weathering steel that the mechanical property and the atmospheric corrosion resistance are bad and the C content is over high, which is composed of components with following weight percent: C 0.01-0.05%, Si 0.10-0.40%, Mn 1.50-1.90%, P<=0.02%, S<=0.010%, Cu 0.15-0.55%, Cr 0.20-0.80%, Ni 0.10-0.50%, Mo 0.05-0.50, Nb 0.01-0.05% and Ca 0.0010-0.0020, and allowance is Fe and unavoidable impurity. The strength grade of the steel of the invention is higher than that of traditional steel and the steel has excellent low temperature impact toughness, welding performance and atmospheric corrosion resistance, and adopts ultra-low carbon design, which is beneficial for extending and applying.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Control method for coast atmospheric corrosion resistant scale on surface of boat deck

ActiveCN102367546AImprove surface qualityIncrease productivityTemperature control deviceWork treatment devicesHull structureStructural composition

The invention discloses a control method for coast atmospheric corrosion resistant scale on the surface of a boat deck, which belongs to the field of steel for hull structures. According to the invention, the structure and thickness of scale on the surface of a boat deck is controlled by optimizing production processes for boat decks. The method comprises the following key points: controlling parameters of heating temperature, time, residual oxygen and the like for continuous casting billets and reinforcing a de-scaling effect once; controlling the index of chloride ion in water for production, reducing the content of deposited chloride ions in scale and inhibiting corrosive pitting; controlling initial rolling temperature and finishing rolling temperature in the stage of finish rolling, reasonably utilizing a weak water cooling system, increasing the content of Fe3O4 in scale, reducing the content of Fe2O3, retaining a small amount of FeO and enabling the scale to have good plasticity, a bonding force and corrosion resistance. The advantages of the invention are as follows: it does not need to reconstruct existing equipment, and the surface quality and production efficiency of the boat deck can be enhanced through technological optimization; structural composition of the scale is reasonably controlled, which enables the surface of the boat deck to have excellent coast atmospheric corrosion resistance, especially enables corrosive pitting caused by chloride ions to be inhibited, and enables the storage duration of the boat deck in coast environment to be prolonged.

Owner:SHOUGANG CORPORATION

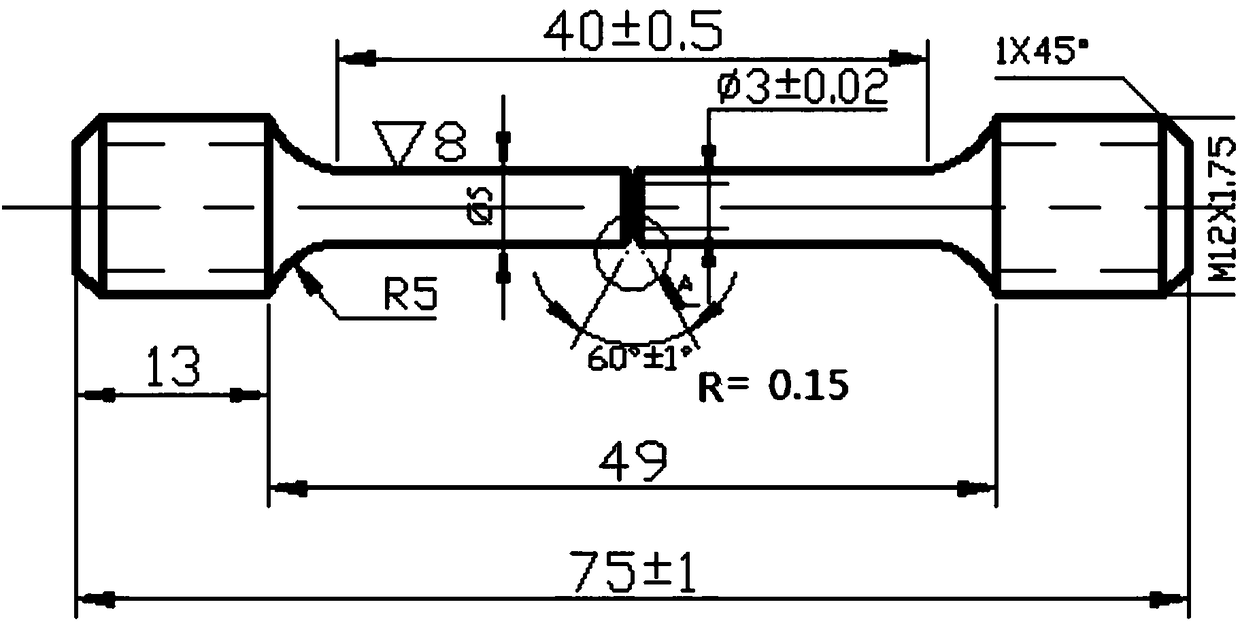

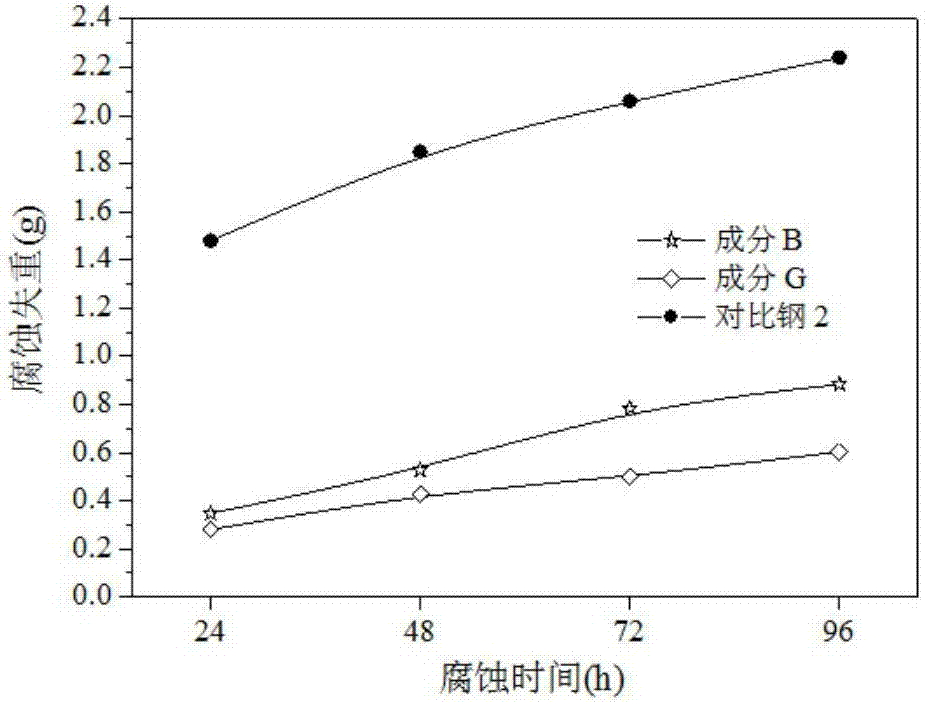

Delay-fracture-resisting 1040 MPa-grade weather-proof bolt

ActiveCN108070796AImproved delayed fracture resistanceReasonable regulationScrewsMetallurgyAtmospheric corrosion

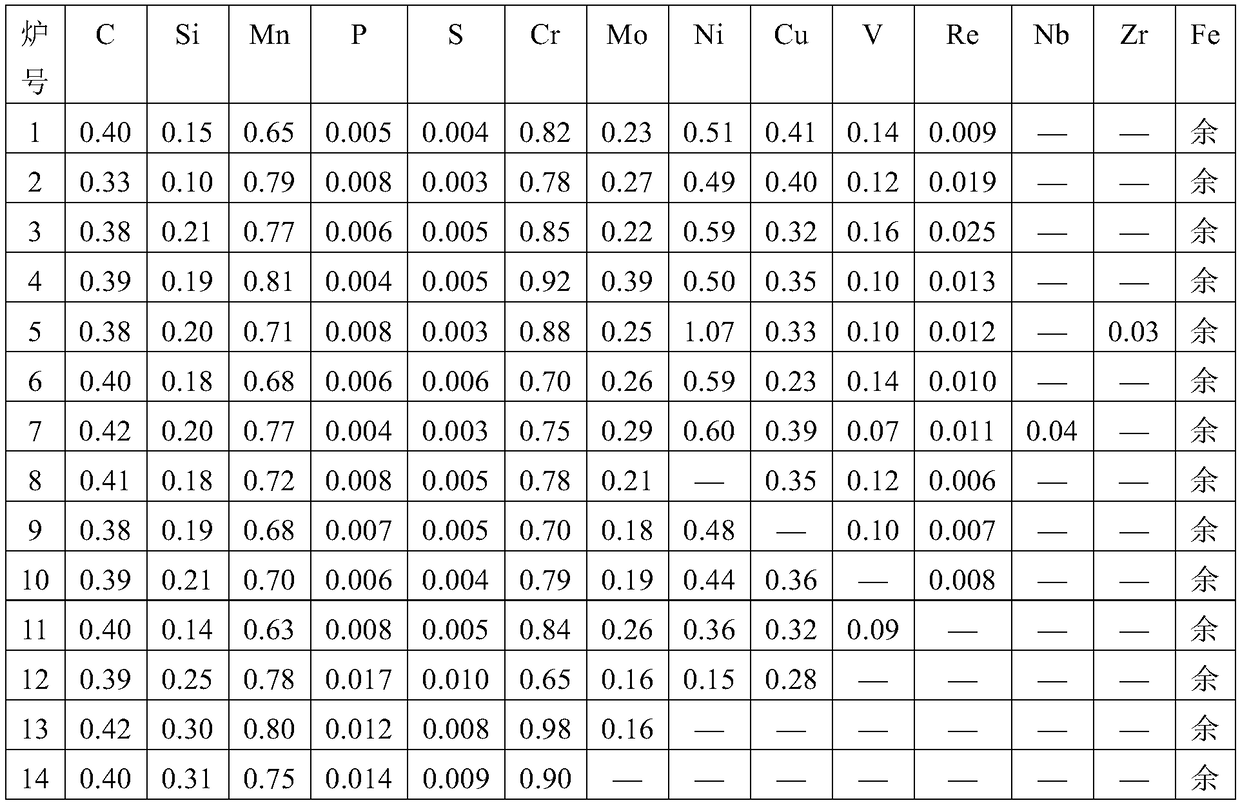

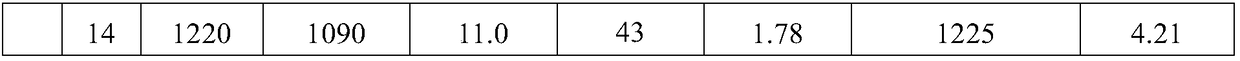

Provided is a delay-fracture-resisting 1040 MPa-grade weather-proof bolt. The Delay-fracture-resisting 1040 MPa-grade weather-proof bolt is prepared from the chemical ingredients including, by mass percent, 0.21% to 0.32% of C, 0.10% to 0.50% of Si, 0.60% to 1.00% of Mn, 0.008% to 0.020% of P, not larger than 0.005% of S, 0.82% to 1.20% of Cr, 0.25% to 0.50% of Ni, 0.25 to 0.50% of Cu, 0.05% to 0.20% of Mo, 0.015% to 0.060% of Nb, 0.015% to 0.090% of V, 0.008% to 0.035% of Ti, 0.0008% to 0.0035% of B, 0.015% to 0.040% of Al, 0.003% to 0.007% of Ca, 0.015% to 0.045% of Zr, 0.010% to 0.045% of Re and the balance Fe and inevitable impurities. According to a method for preparing the bolt, the conventional high-purity smelting-continuous casting-rolling technology is mainly adopted, and metal raw materials are prepared into a steel material for the delay-fracture-resisting weather-proof bolt; and raw material acid pickling, steel pulling, blanking, end face chamfering, head cropping, head forming, head chamfering, shot blasting, semi-finished product surface treatment, hole shrinking, thread rolling, thermal treatment and finished product surface treatment are carried out according to aconventional method. The bolt is resistant to delay fractures and atmospheric corrosion and relatively low in cost.

Owner:YANSHAN UNIV +1

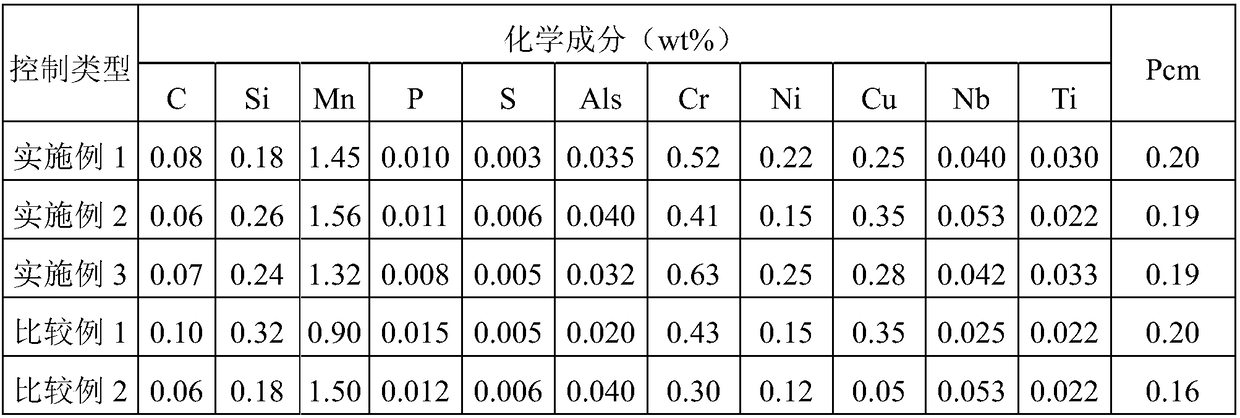

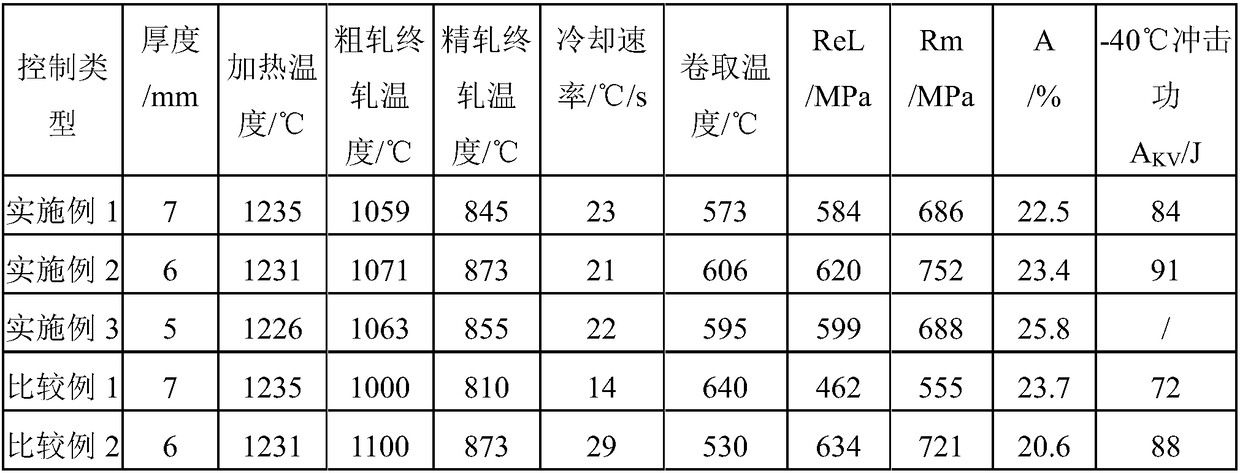

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

600MPa grade low temperature high toughness weather corrosion resistant steel and its production method

InactiveCN1718832ASimple chemical compositionThe process is easy to controlChemical compositionToughness

A steel with high low-temp toughness (600 MPa), weldability and the resistance to atmosphere corrosion contains C (0.05-0.09 wt.%), Si (0.45-0.7), Mn (2.10-3), P (0-0.02), S (0-0.01), Ti (0.005-0.009), Nb (0.095-0.19), Ni (0.1-0.19), Cu (0.45-0.65), Cr (0.75-1.5), Ca (0-0.02) and Fe (rest). It features that Cr+Ni+Cu is 0.70-2.50 and content of Nb is greater than that of 4Ti+3Ca.

Owner:WUHAN IRON & STEEL (GROUP) CORP

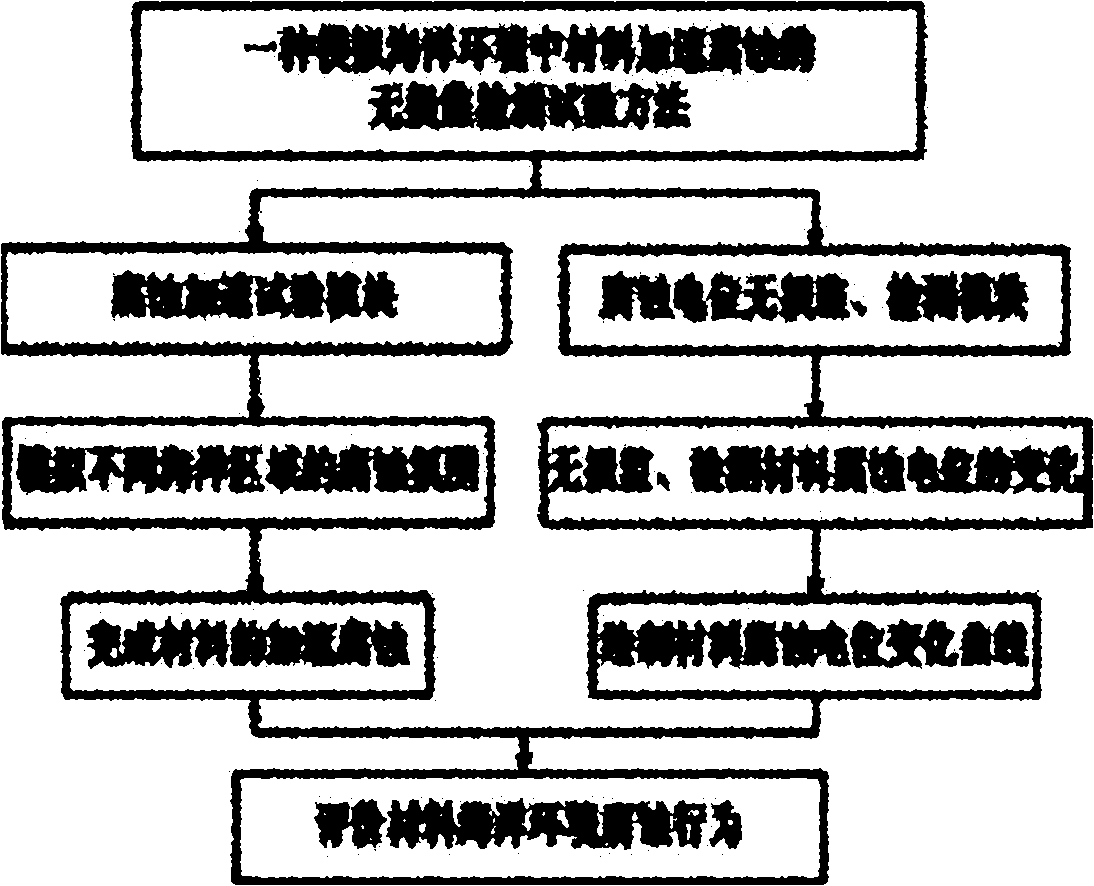

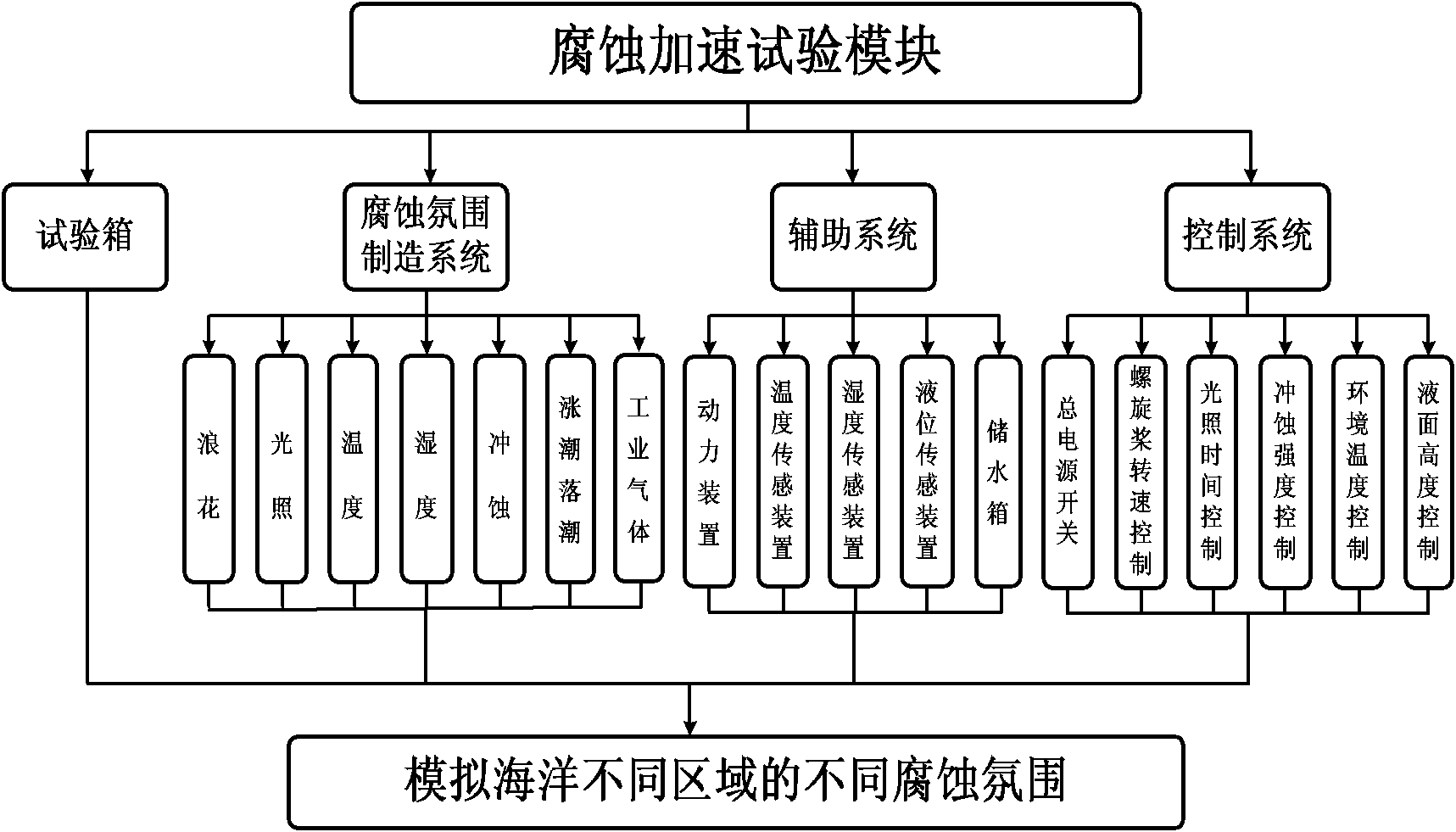

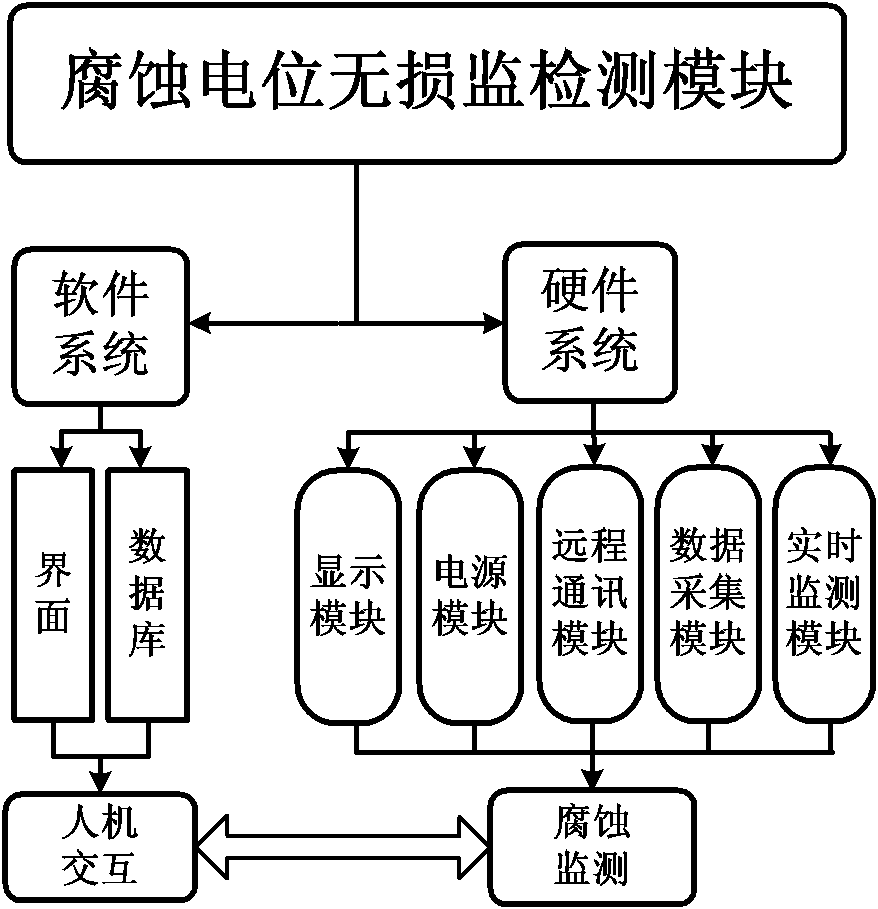

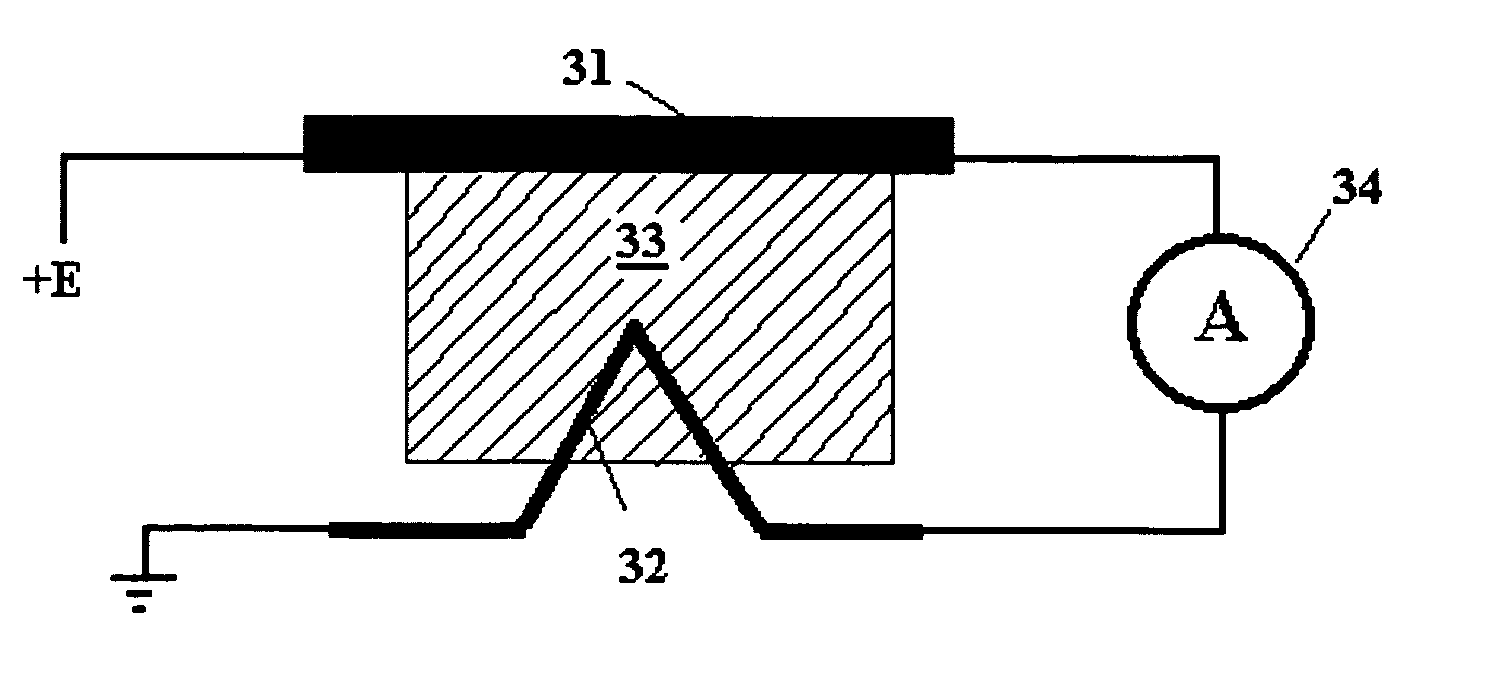

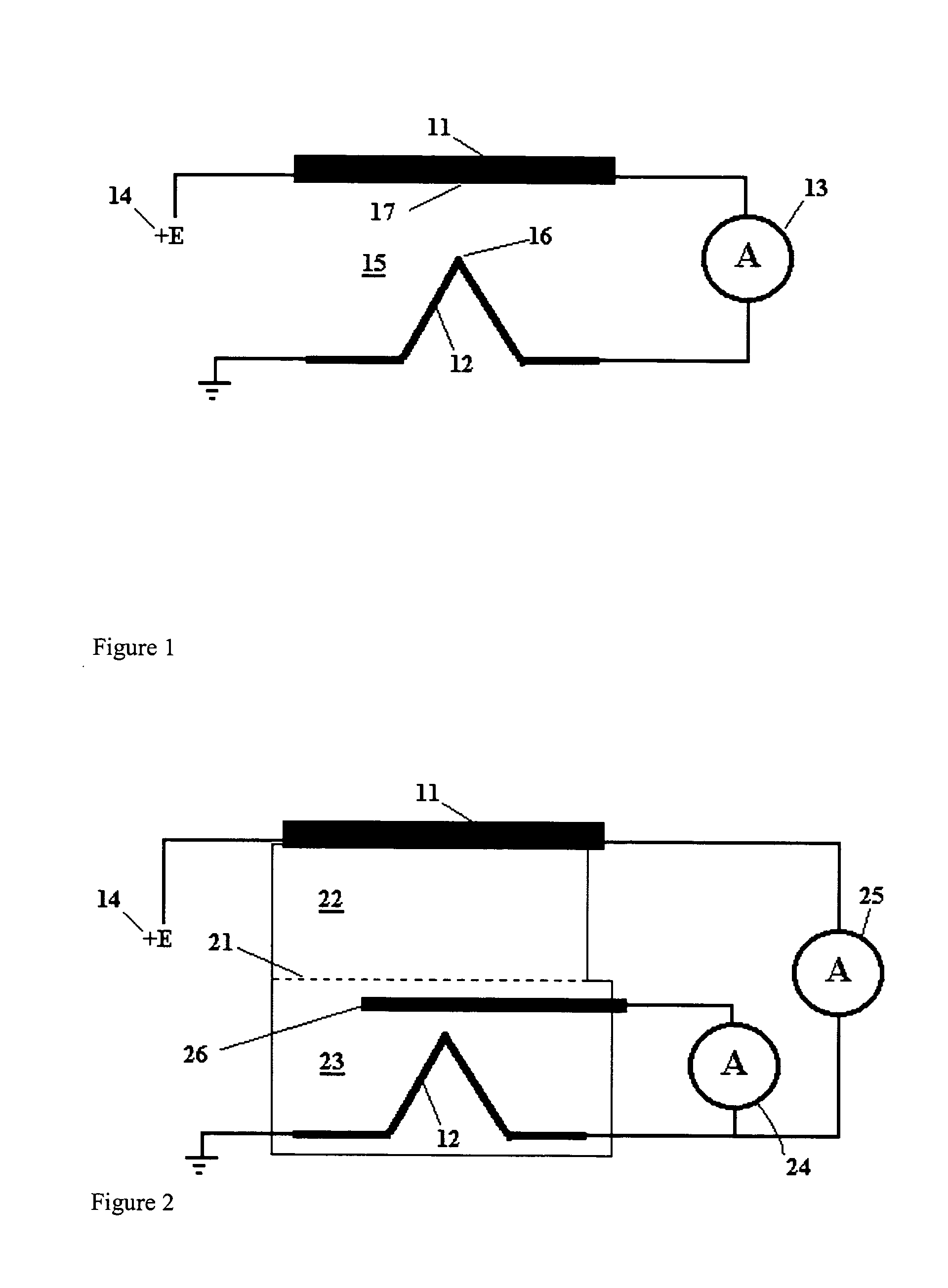

Test method for lossless monitoring and detection for material accelerated corrosion under simulated marine environment

ActiveCN102175595AHigh sensitivityLow costWeather/light/corrosion resistanceMicrobial corrosionAtmospheric corrosion

The invention relates to a test method for lossless monitoring and detection for the material accelerated corrosion under a simulated marine environment, which comprises a corrosion accelerating test under the simulated marine environment and a test for the lossless monitoring and detection for the corrosion potential of material, wherein the corrosion accelerating test under the simulated marine environment is performed on a corrosion accelerating module, which can be used for finishing the tests for the marine or industrial atmospheric corrosion, splashed spoondrift corrosion, tidal range corrosion, full-soaking corrosion and sea mud microbiological corrosion. The test for the lossless monitoring and detection for the corrosion potential of material is finished by using a corrosion potential lossless monitoring and detection module. The method provided by the invention has the advantages that an environment for simulating each corrosion area in the ocean is supplied, the test period is shortened by performing the corrosion accelerating test, and the corrosion degree of the material is monitored and detected in the whole process. The method is used for supplying a technical support for evaluating the corrosion resistance of the material under the marine environment, thereby shortening the period of researching and testing the material.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

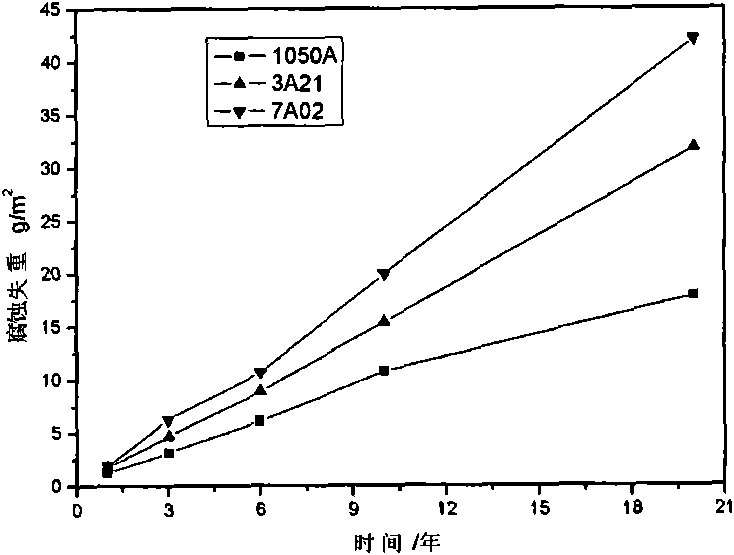

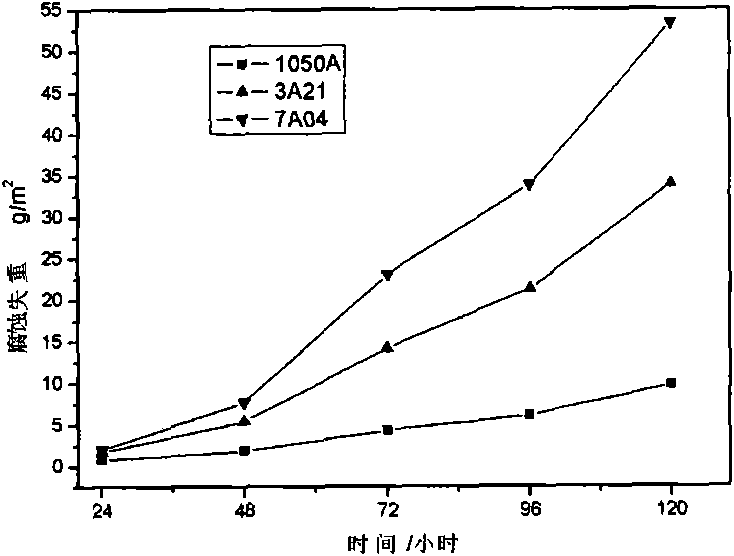

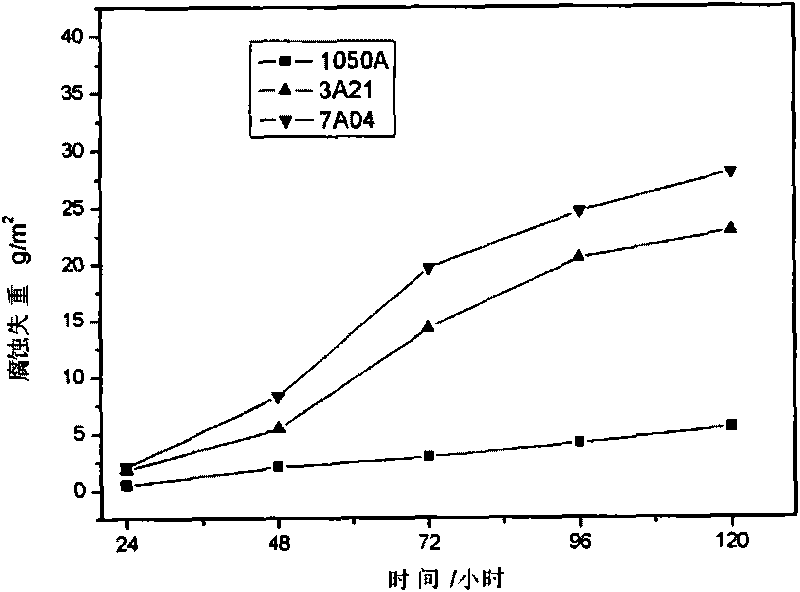

Accelerated test method for simulating atmospheric corrosion of metal materials

InactiveCN101738365AGood atmospheric corrosion resistanceGuaranteed simulation effectWeather/light/corrosion resistanceMetallic materialsAtmospheric corrosion

The invention relates to an accelerated test method for simulating the atmospheric corrosion of metal materials, comprising the following steps: (1) preparing a metal sample; (2) preparing dipping solution from 0.01-1mol / L NaCl, 0.05-0.5mol / L Na2SO4 and 0-0.05mol / L Na2S2O8; (3) dipping the metal sample at 25-50 DEG C, humidifying the metal sample at 25-50 DEG C and drying the metal sample at 40-70 DEG C in a circulating way, and determining the single or total testing time according to the need; and (4) treating the metal sample to analyze the corrosion weight loss, the corrosion products and the morphology. The accelerated test method is used for simulating the behavior and the law on the atmospheric corrosion of the aluminum, the aluminum alloy and other aluminum materials in the humid and hot environment, the marine environment and other different environment and is also used for rapidly evaluating the corrosion resistance of various aluminum materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

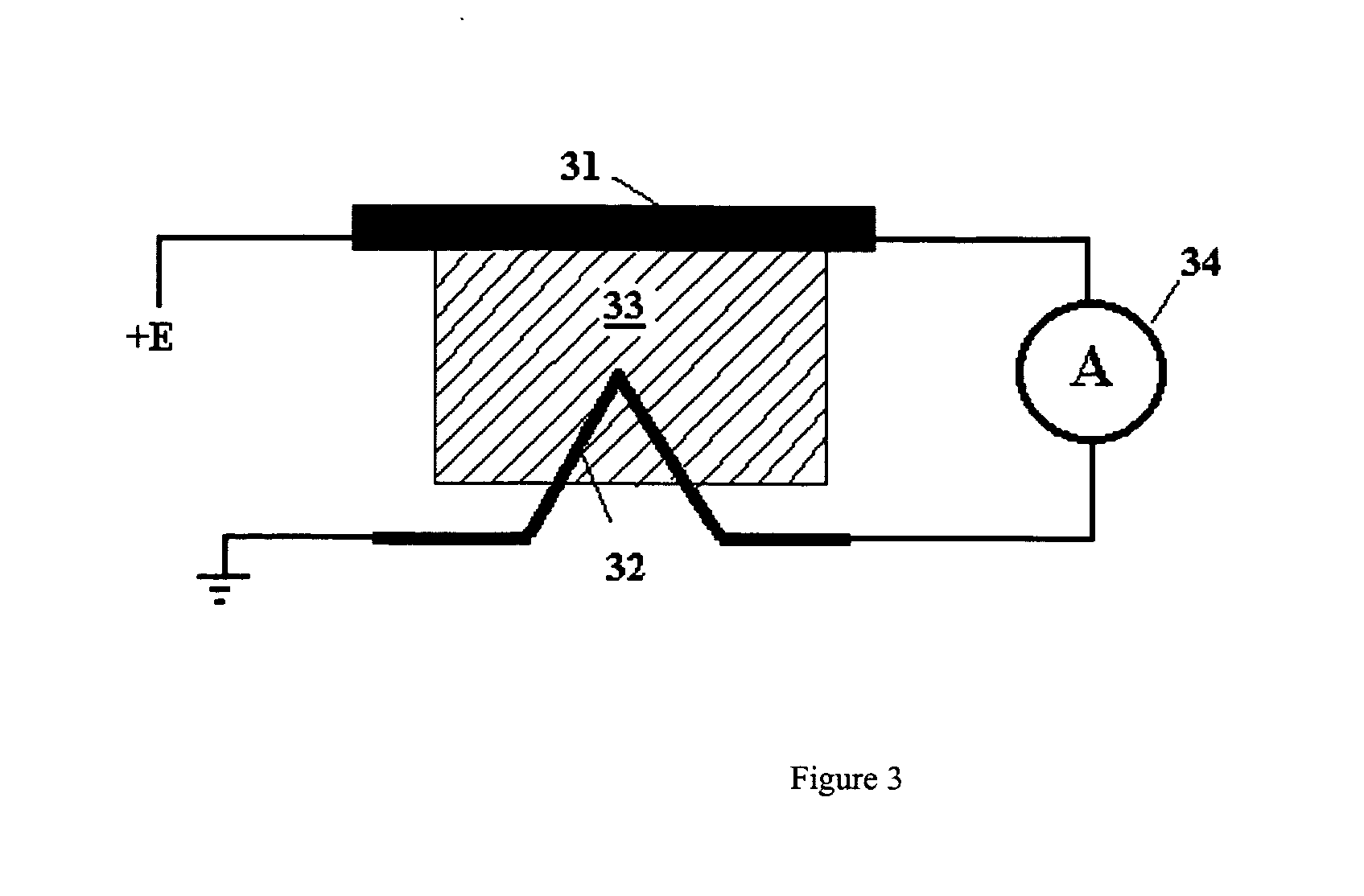

Atmospheric corrosion sensor

ActiveUS20050034985A1Weather/light/corrosion resistanceVolume/mass flow measurementElectrochemistryGas concentration

An electrochemical sensor for corrosive gases that contains at least two electrodes is described. The presence of a target corrosive gas results in the formation of metal ions that can be reduced at an electrode producing an electrical current that depends on the instantaneous corrosive gas concentration and deposition of the metal on the electrode. Extension of this deposit to a second electrode through further deposition will result in a short circuit, the longer the time to the short circuit, the lower the cumulative corrosive gas concentration.

Owner:ZAMANZADEH MEHROOZ +1

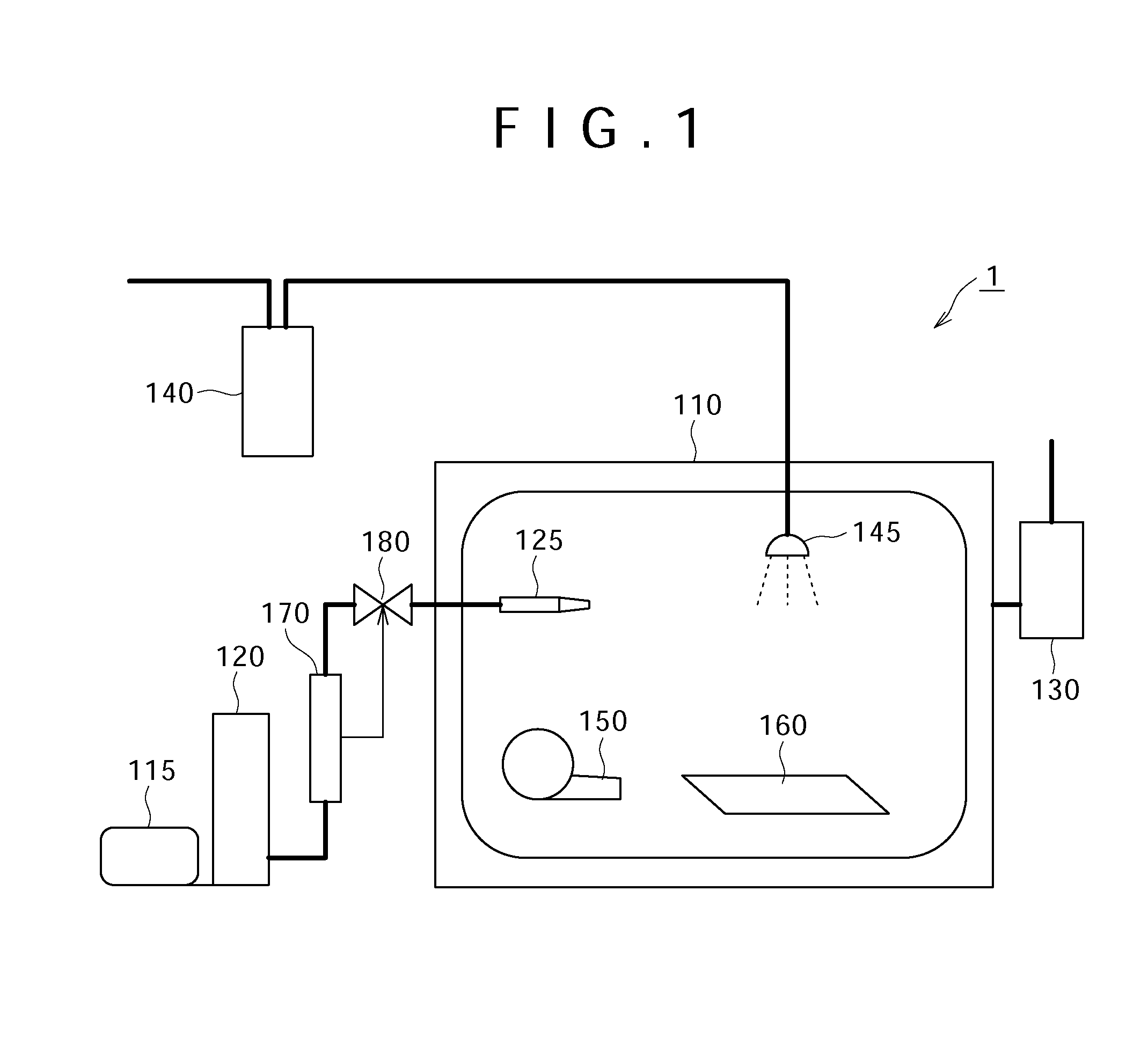

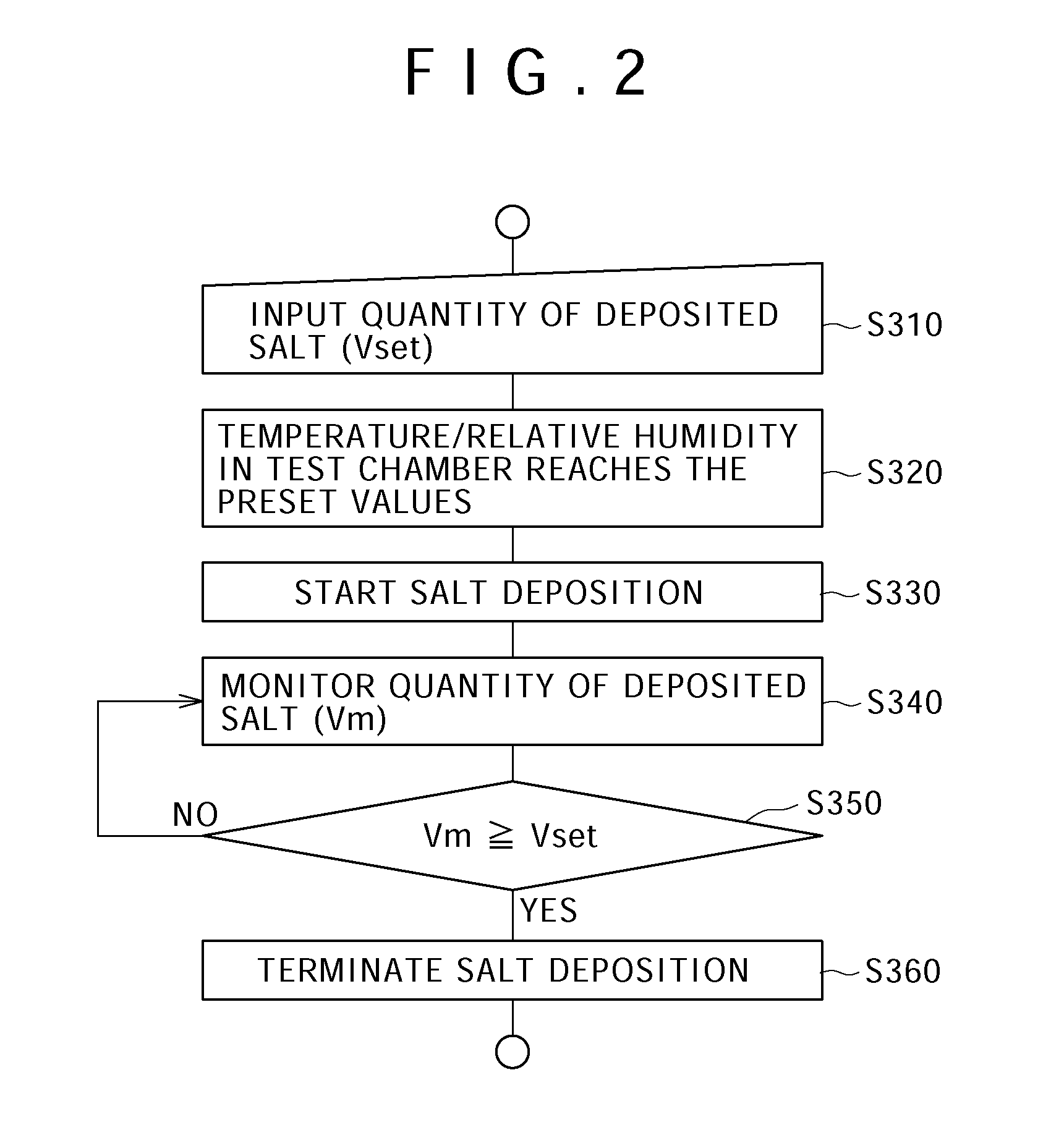

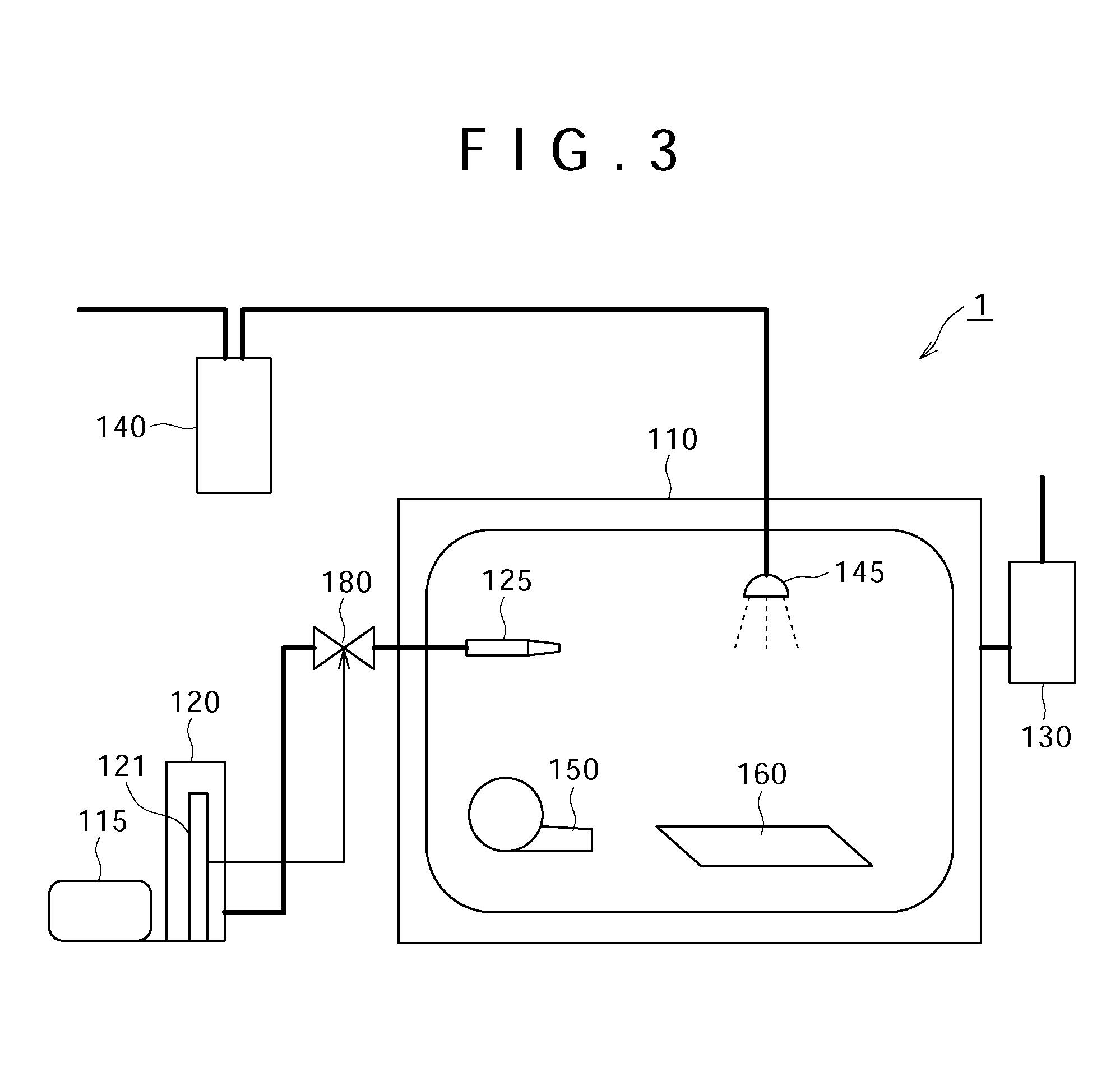

Atmospheric corrosion test procedure and its apparatus

InactiveUS20130164852A1Improve test accuracyReduce varianceWeather/light/corrosion resistanceBiological testingSaline waterSalt content

Provided are an atmospheric corrosion test procedure and an apparatus used for the test. The procedure involves a salt spray step for supplying salt content containing chloride ions on the surfaces of test pieces placed in a thermo-humidistat chamber and a subsequent dry-wet cyclic step including a dry sub-step for drying the surface of the test pieces in the thermo-humidistat chamber at a low relative humidity and a subsequent wet sub-step at a higher relative humidity than that in the dry sub-step, which are cycled. The salt content is supplied by spraying the salt water in the salt spray step. An exhaust step for removing the salt mist sprayed inside thermo-humidistat chamber is further inserted between the salt deposition step and the dry sub-step. The quantity of the salt content deposited on the surfaces of the test pieces is controlled by adjusting the quantity of the sprayed salt water.

Owner:HITACHI LTD

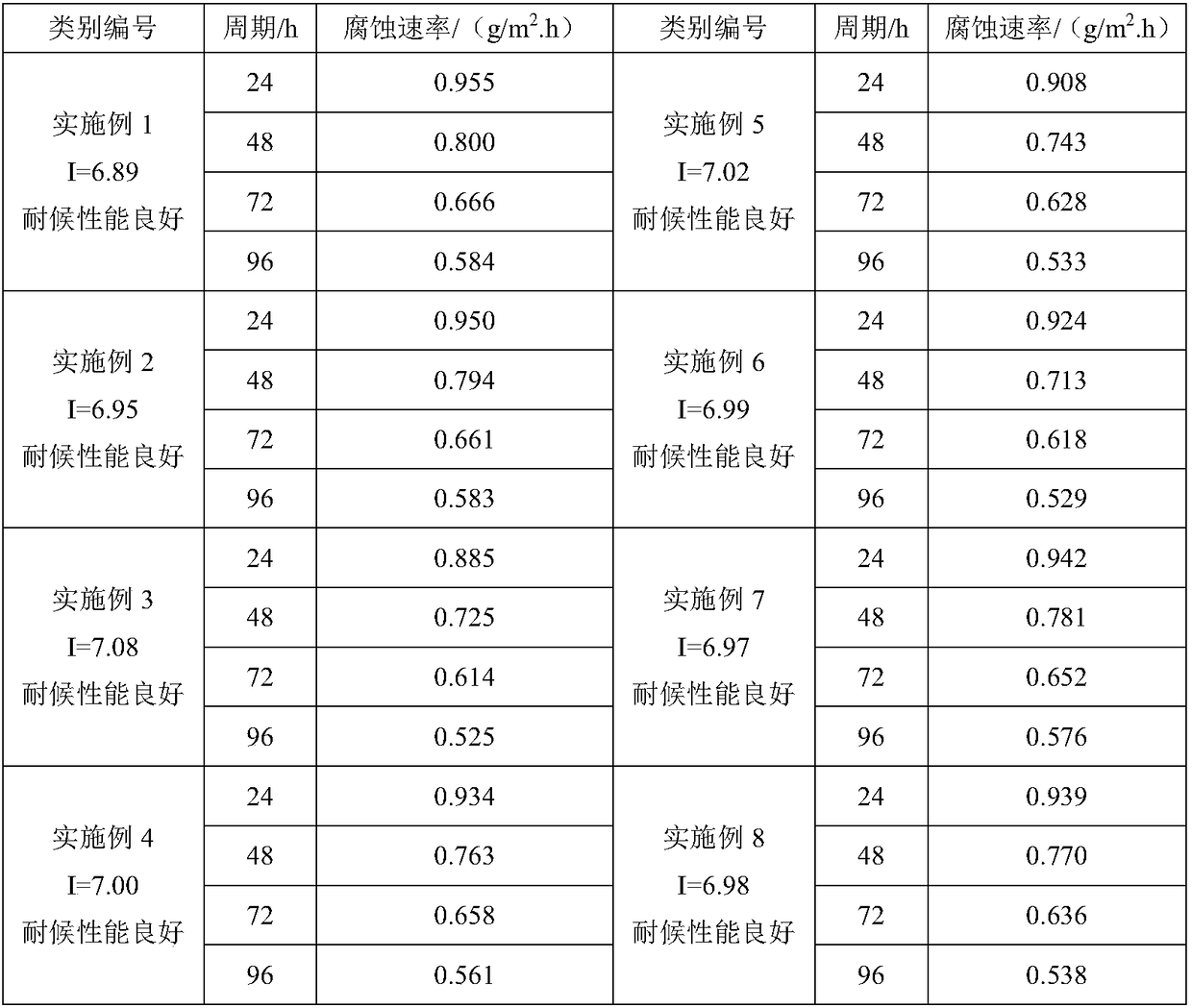

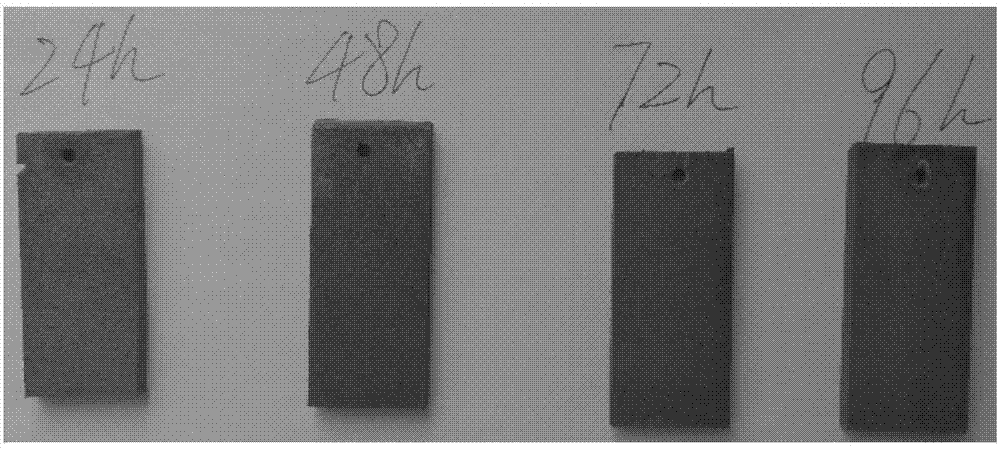

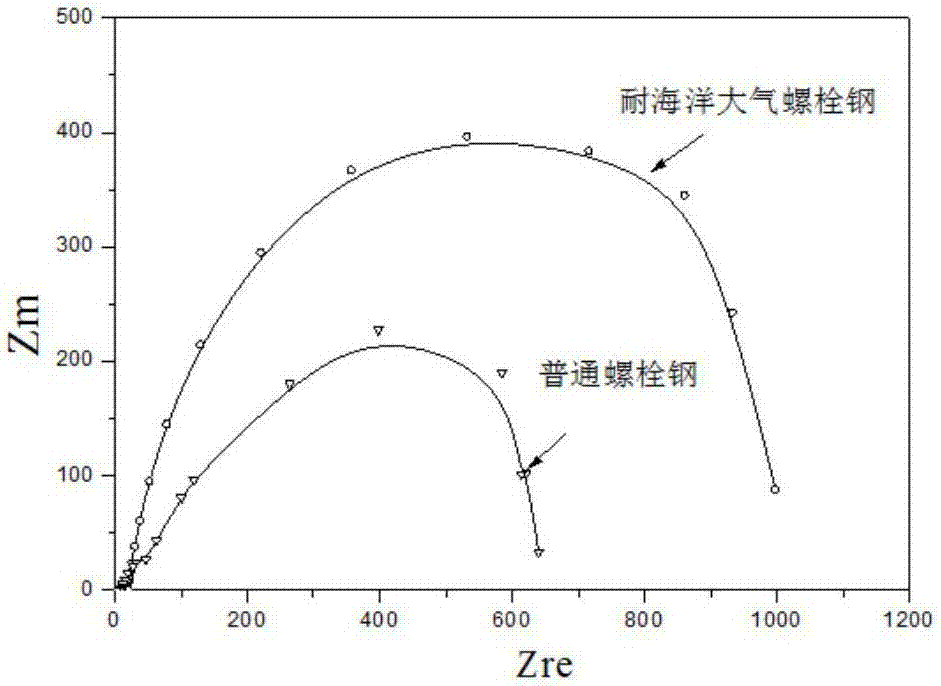

Coating-free ocean atmospheric corrosion resisting high-strength bolt steel for bridge structure and manufacturing method

InactiveCN107022718AAccelerated corrosionImprove low temperature resistanceFurnace typesHeat treatment furnacesToughnessImpurity

The invention discloses ocean atmospheric corrosion resisting high-strength bolt steel for a coating-free bridge structure and a manufacturing method, and belongs to the technical field of steel for bridge structure connection. The steel is prepared from, by weight, 0.16%-0.45% of C, 0.01%-2.2% of Si, 0.3%-2.5% of Mn, 0.001%-0.024% of P, 0.002%-0.025% of S, 0.0005%-0.0100% of B, 0.01%-0.50% of Ti, 0.01%-0.20% of V, 0.001%-0.15% of Al, 0.35%-3.2% of Cr, 0.2%-0.6% of Cu, 0.2%-2.5% of Ni and the balance Fe and trace impurities. The corrosion resisting index I, calculated according to a chemical ingredient prediction formula, of the high-strength weather-proof bolt steel is larger than or equal to 6.3, the properly produced bolt specification range is M16-30 mm, after the bolt steel is beaten into bolts through a bolt machining factory, oil hardening of 840 DEG C to 920 DEG C and tempering of 380 DEG C to 625 DEG C are included in a quenched-tempered heat treatment system, and optimum high toughness matching is obtained. The bolt steel has the beneficial effects that the 10.9-grade high-strength bolts are used for matching connection of coating-free bridge structure plates and profiles, and have excellent ocean atmospheric corrosion and low temperature resisting performance.

Owner:SHOUGANG CORPORATION

Weather-resistant gas-shielded solder wire

ActiveCN1611321AGood atmospheric corrosion resistanceImprove performanceArc welding apparatusWelding/cutting media/materialsExtensibilityIron powder

The present invention relates to a weather-resistant gas shielded welding wire, its chemical components are (by mass percentage):C less than or equal to 0.10, Si less than or equal to 0.6, Mn 1.2-1.6, S less than or equal to 0.030, P less than or equal to 0.030, Cu 0.10-0.60, Gr 0.30-0.90, Ni 0.20-0.60, Ti 0.03-0.12 and the rest is iron powder, in which the optimized range of described Ni is 0.30-0.50. Besides, it contains no elements of B and Re. The deposited metal and welded joint obtained by said invented welding wire have good atmospheric corrosion resistance, at the same time have good comprehensive performance, specially, its low-temp. impact toughness at -40 deg.c is good. The comprehensive performance of deposited metal obtained by said invented welding wire is good, its yield strength is greater than or equal to 450 MPa, tensile strength is greater than or equal to 550 MPa, its extensibility is greater than or equal to 450 MPa, strength is greater than or equal to 550 Mpa, its extensibility is greater than or equal to 220%, and AKv (under the condition of -40 deg.C) is greater than or equal to 100 J.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for manufacturing SPA-H high-strength atmospheric corrosion resistance steel by using continuous annealing machine set

ActiveCN102230138AHigh strengthEasy to reinforceRoll mill control devicesFurnace typesProduction lineMechanical equipment

The invention provides a method for manufacturing SPA-H high-strength atmospheric corrosion resistance steel by using a continuous annealing machine set, belonging to the field of rolling of cold rolled strips. Parameters of a hot rolling process are as follows: the heating temperature is 1180-1260 DEG C, the final rolling temperature is 860+ / -20 DEG C, the rolling temperature is 610+ / -20 DEG C, and the cold rolling screwdown rate is controlled within a range of 35-60% according to different specifications. The temperature of a continuous annealing heating section is 800+ / -20 DEG C, the temperature of a soaking section is 800+ / -20 DEG C, the temperature of a slow cooling section outlet is 680+ / -20 DEG C, the temperature of a quick cooling section outlet is 430+ / -20 DEG C, the temperature of an overageing section is 400+ / -20 DEG C, the process speed is 150-200 mpm, the soaking time is 200-250 s, and the leveling elongation is 1.2+ / -0.3 %. The method provided by the invention has the following advantages that: the SPA-H high-strength atmospheric corrosion resistance steel generally manufactured on a hot rolling production line in the prior art is successfully manufactured on the continuous annealing machine set by using the cold rolling process while the hot rolling production machine set is affected by factors like limit specifications and mechanical equipment capacities and the like; and the cold rolling process, continuous annealing process and other processes are optimized in such a way that the manufactured high-strength atmospheric corrosion resistance steel has high strength and good elongation.

Owner:SHOUGANG CORPORATION

High-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture

PendingCN108754303AAccelerated corrosionImproved delayed fracture resistanceAtmospheric corrosionDelayed fracture

The invention discloses a high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture. The high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture comprises, by mass, 0.30-0.45% of C, below 0.25% of Si, 0.40-1.40% of Mn, below 0.012% of P, below 0.008% of S, 0.40-1.20% of Cr, 0.15-0.50% of Mo, 0.30-1.20% of Ni, 0.20-0.60% of Cu, 0.05-0.20% of V, 0.005-0.030% of Re, and the balance of Fe and inevitable impurity elements. Compared with steels in the prior art, the high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture has the advantages of high strength, excellent resistance to atmospheric corrosion and delayed fracture, and low cost, and can be used to 12.9 level high-strength bolts for bridges and other steel structures.

Owner:BEIJING JIAOTONG UNIV

An industrial atmospheric corrosion resistant rebar and a production method thereof

An industrial atmospheric corrosion resistant rebar and a production method thereof belong to the technical field of steel for corrosion resistant rebars. The rebar comprises the following chemical components, by weight C 0.14-0 .19%, Si 0.4-0 .6%, Mn 0.8-1 .2%, P 0.05-0. 08%, S <0.005%, V 0.03-0 .07%, Cu 0.32-0 .45%, Cr 0.4-0 .6%, and the balance Fe. A process of primary melting in a converter + refining in an LF furnace + continuous casting + high temperature open rolling + medium and low temperature finish rolling + grading cooling is adopted in the production method to obtain high-strength industrial atmospheric corrosion resistant steel. Through a rational component design and establishment of reasonable continuous casting and rolling process parameters to suppress surface enrichment of single-phase Cu, so an economical non-Ni Cu-P series corrosion resistant steel is developed. According to the invention, the advantages are as follows: by employing existing steel production equipment, surface quality problems of ingot blanks and mill bars of non-Ni corrosion resistant steel are solved and ultrafine grain structures are obtained, thus improving corrosion resistance, and meeting performance requirements on industrial atmospheric corrosion resistant rebars at economical costs, having a very broad application space in China.

Owner:SHOUGANG CORPORATION

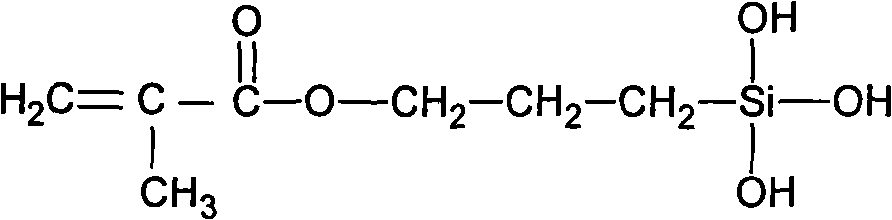

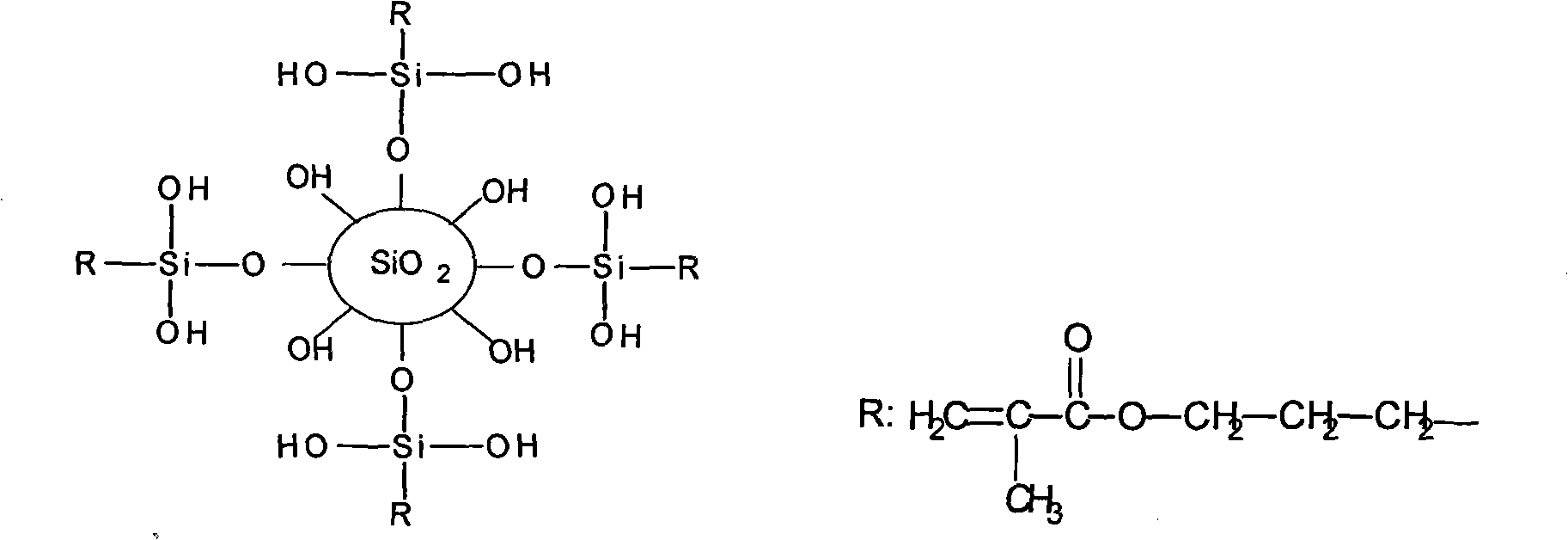

Nano-SiO2 modified aluminium section bar superior atmospheric corrosion resisting polyester powder paint and preparation method thereof

ActiveCN101314696AImprove dispersion stabilityImprove mechanical propertiesPowdery paintsPolyester coatingsWeather resistanceChemistry

The invention discloses nano-SiO2-modified aluminum profile polyester powder coating with high weathering resistance and the preparation method thereof. The nano-SiO2-modified aluminum profile polyester powder coating is characterized in that nano-SiO2 is reacted with hydrolyzed silicane coupling agent; an acrylic acid monomer is subjected to in-situ polymerization with the coupling agent grafted with the nano-SiO2 surface, thus achieving in-situ polymer grafted modification on the nano-SiO2 surface and greatly improving the dispersion stability and the resin compatibility of the nano-SiO2; and the modified nano-SiO2 powder is added into polyester powder coating. The polyester powder coating can be used for electrostatic spraying aluminum profile surface to solve the aging problem of the organic coating of aluminum profile exposed to outdoor UV rays, thus greatly improving the anti-aging performance, tarnish resistance, etc. The weathering resistance of the polyester powder coating is improved by 100 to 250 percent as compared with unmodified polyester powder coating, thus improving the use performance and the use service life of aluminum profile coating.

Owner:GUANGDONG XINGFA ALUMINUM JIANGXI

Steel plate for structure with excellent marine atmospheric corrosion resistance and production method thereof

ActiveCN103194679AImprove corrosion resistanceImprove the immunityChemical compositionLaminar cooling

The invention discloses a steel plate for structure with excellent marine atmospheric corrosion resistance and a production method thereof. The steel plate comprises the chemical ingredients by weight percent: 0.001-0.08% of C, 0.10-0.50% of Si, 0.50-1.60% of Mn, 0.080% or less of P, 0.025% or less of S, 0.01-3.50% of Ni, 0.01-0.50% of Mo, 0.01-1.20% of Cu, 0.001-0.060% of Nb, 0.0005-0.0040% of Ca, 0.010-0.080% of Al, 0.0080% or less of N, the balance of Fe and inevitable impurities. A controlled rolling and cooling process is adopted; the heating temperature of a continuous casting billet before rolling is 1100-1250 DEG C; the roughing end temperature is 990-1080 DEG C; the finishing rolling temperature is 850-970 DEG C; laminar cooling is adopted after rolling; the final rolling temperature is 250-750 DEG C; and the cooling speed is 5-40 DEG C / s. The situation that a steel ball has excellent resistance to the marine-atmosphere environment by low carbon and alloy ingredient is ensured.

Owner:NANJING IRON & STEEL CO LTD

Soft magnetic FeCo based target material

ActiveUS20080112841A1Improve corrosion resistanceImprove magnetic propertiesCellsVacuum evaporation coatingAlloyCobalt

A soft-magnetic FeCo based target material is provided which has a high saturation magnetic flux density and superior atmospheric corrosion resistance. The target material is a soft-magnetic FeCo based target material made of an FeCo based alloy. The FeCo based alloy comprises 0 to 30 at. % of one or more metal elements selected from the group consisting of B, Nb, Zr, Ta, Hf, Ti and V; and the balance being Fe and Co with unavoidable impurities. The Fe:Co atomic ratio ranges from 10:90 to 70:30. The FeCo based alloy may further comprise 0.2 at. % to 5.0 at. % of Al and / or Cr.

Owner:SANYO SPECIAL STEEL COMPANY

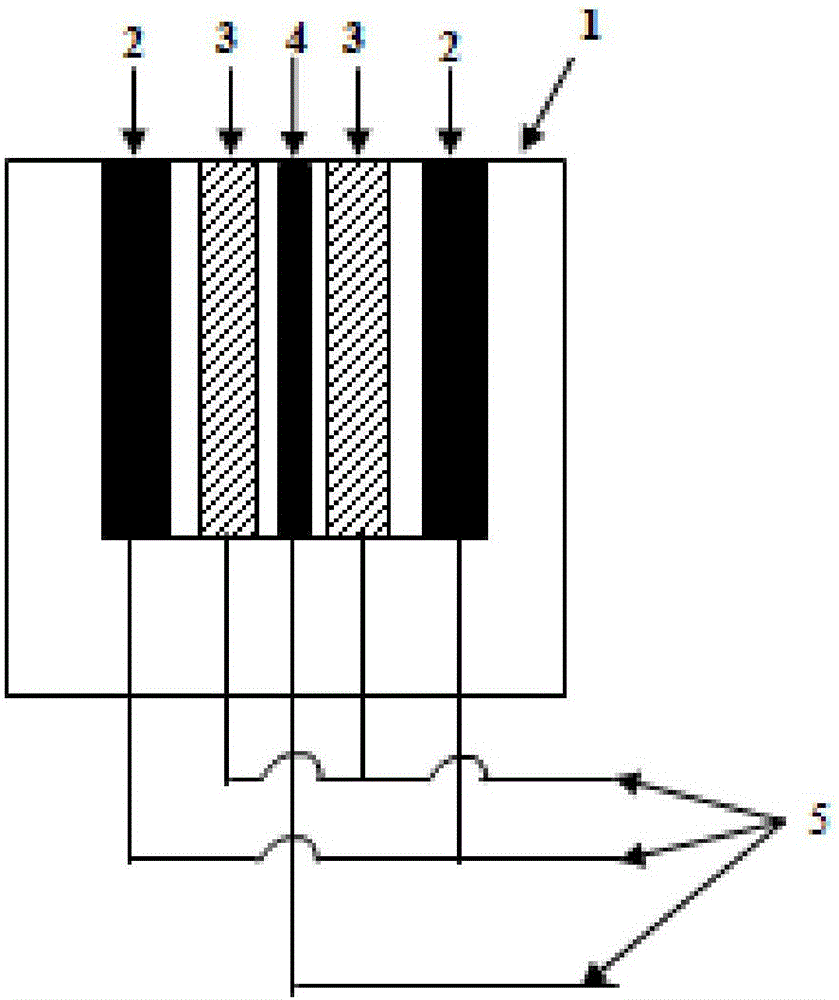

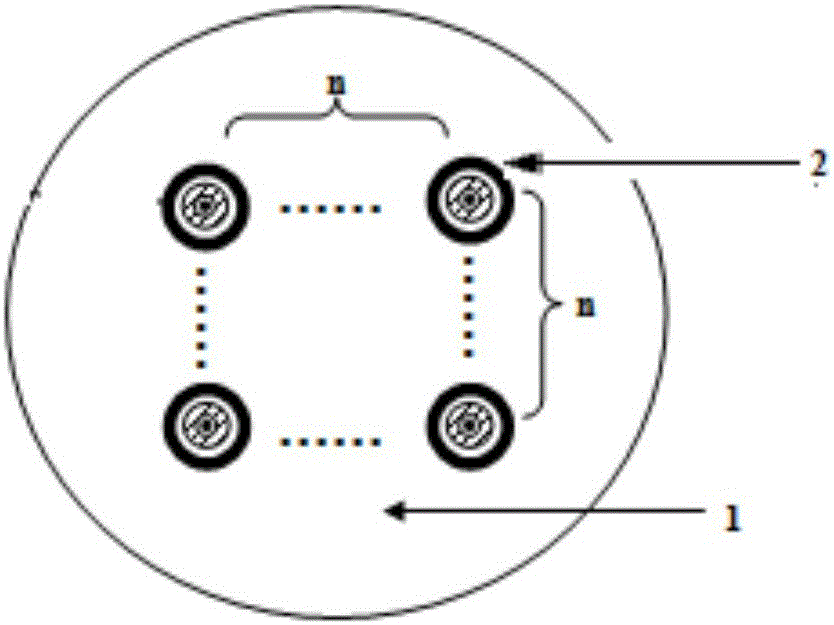

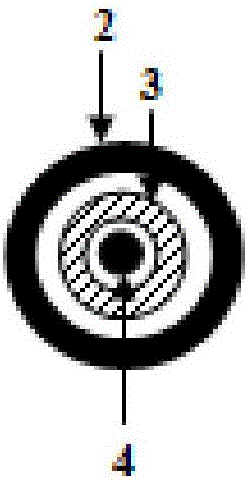

On-line atmospheric corrosion measuring device

ActiveCN105021519AReduce distractionsAccurately monitor the potential change processWeather/light/corrosion resistanceMeasurement deviceOptoelectronics

The invention relates to an on-line atmospheric corrosion measuring device which mainly solves the problems that in the prior art, the measurement accuracy is low and operation is complex. The on-line atmospheric corrosion measuring device comprises epoxy resin daub, at least one electrode set and lead wires; each electrode set is composed of a work electrode with the lead wire, a counter electrode and a reference electrode, and all the electrode sets are entirely packed in the epoxy resin daub; the section of each counter electrode is in the shape of a circular ring, the work electrodes penetrate through the center of the circular rings and are insulated, and the section of each work electrode is in the shape of a circle, wherein a hole is formed in the center of the circle; the reference electrodes penetrate through the holes and are insulated. According to the technical scheme, the problems are well solved, and the device can be applied in on-line atmospheric corrosion measuring.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

High strength anti-weather burial arc welding wire

ActiveCN1714985ASimple designDesign economyArc welding apparatusWelding/cutting media/materialsMetallurgyAtmospheric corrosion

The high strength weather resisting submerged arc welding wire consists of: C 0.04-0.15 wt%, Mn 1.2-2.0 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, Cu 0.10-0.30 wt%, Cr 0.40-1.2 wt%, Ni 0.20-0.80 wt%, and Ti 0.03-0.10 wt%. The welding wire forms fused-on metal and welded joint with excellent atmospheric corrosion resistance and excellent comprehensive performance, including yield strength not lower than 450 MPa, tensile strength not lower than 550 MPa, elongation greater than 22 %, and especially low temperature impact toughness of Akv not lower than 60 J at the temperature of -40 deg c.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com