High-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture

A delayed fracture resistance and atmospheric corrosion resistance technology, applied in the field of alloy steel, can solve the problems of difficulty in meeting the requirements of atmospheric corrosion resistance, deterioration of steel delayed fracture resistance, and no consideration of weather resistance, etc., to achieve excellent atmospheric corrosion resistance and resistance Delayed fracture performance, improvement of toughness and delayed fracture resistance, effect of reducing hydrogen segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0032] Sample Preparation:

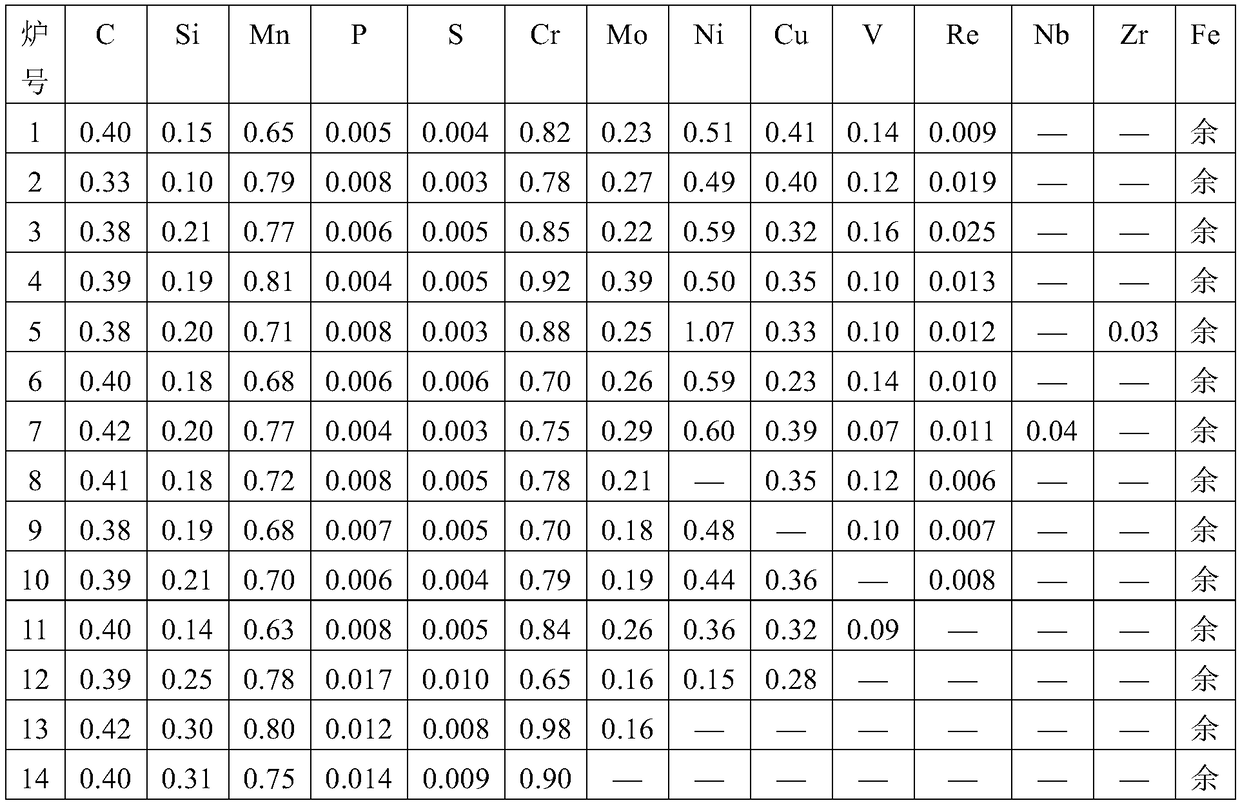

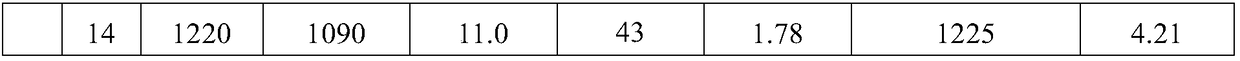

[0033] According to the chemical composition range designed by the present invention, 7 furnaces of the steel of the present invention and 7 furnaces of comparative steel were smelted on a 500kg vacuum induction furnace. Heat numbers 8 to 14 are comparative steels. The specific preparation process of the samples required for the test is as follows: a 500kg steel ingot is smelted in a vacuum induction furnace, and then forged into a bar. The forged test material is heat-treated in an air furnace and then processed into the sample required for the test. In the specific production process, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com