Patents

Literature

1797results about "Pressure impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood treatment process

InactiveUS6274199B1High shear stabilityImprove permeabilityWood treatment detailsPretreated surfacesWater basedMolten state

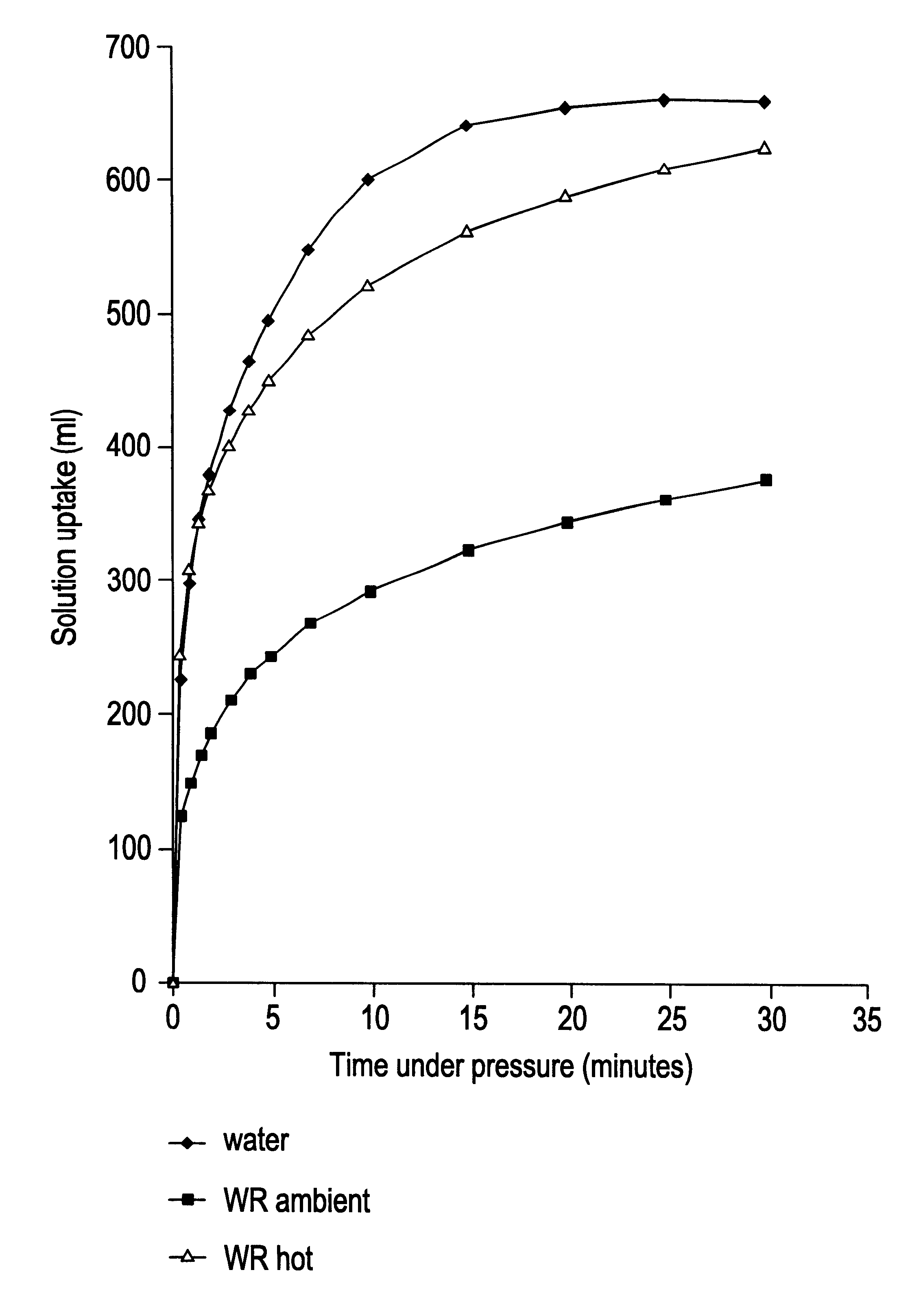

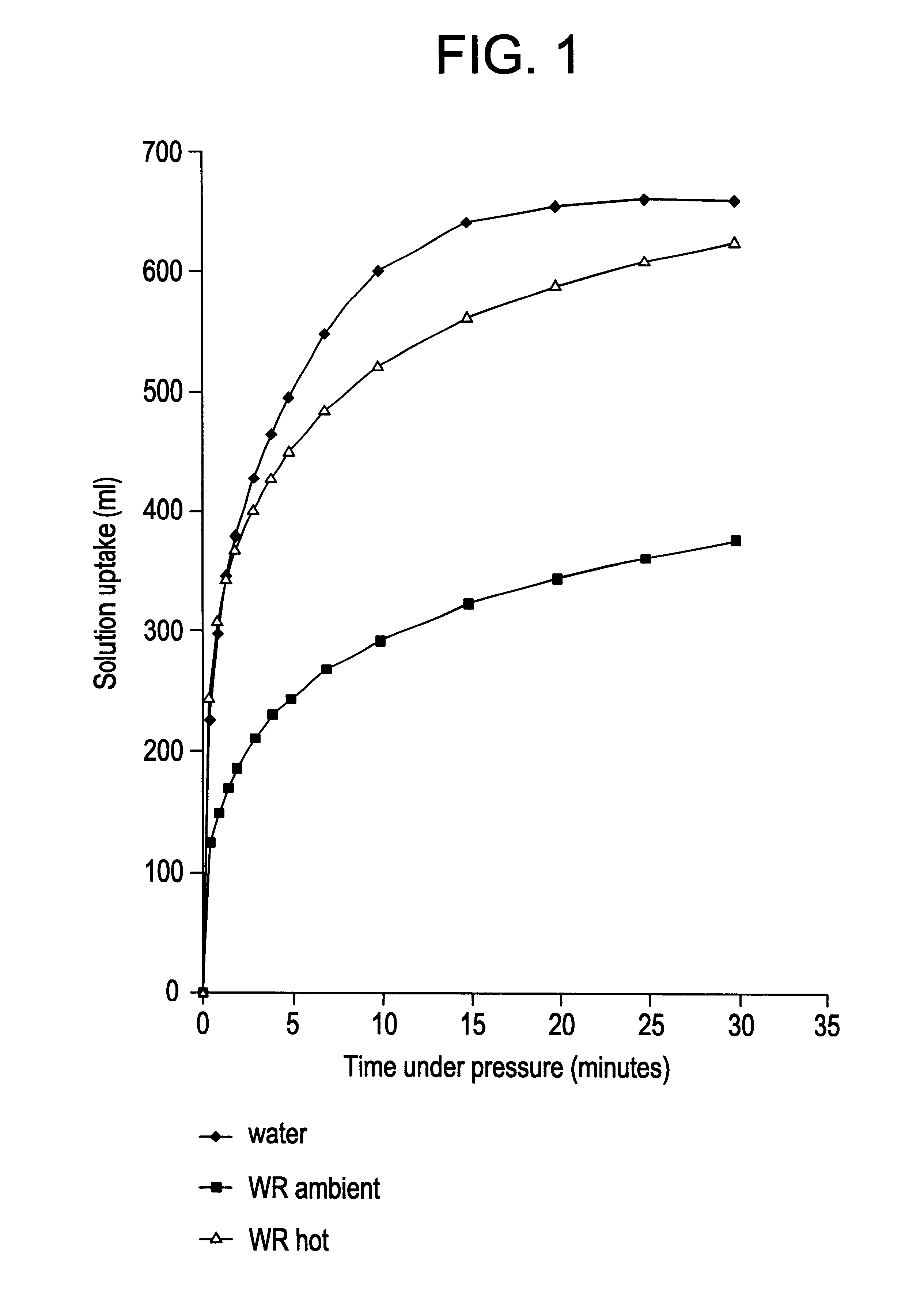

A process for treating a wood substrate with a water-based formulation containing a wax in order to confer water repellency to the substrate comprising the steps of:(a) placing the substrate in a treatment vessel and reducing the pressure in the vessel to remove air in the pores of the substrate;(b) contacting the substrate in the vessel, while reduced pressure is present in the vessel, with the formulation to allow the formulation to flow into said pores, said contacting being carried out at a temperature at or above that required to cause the wax to change into a molten state;(c) applying a positive pressure to the vessel to force the formulation into said pores; and(d) releasing the pressure in the vessel and removing the resultant wood substrate from the vessel.

Owner:VIANCE

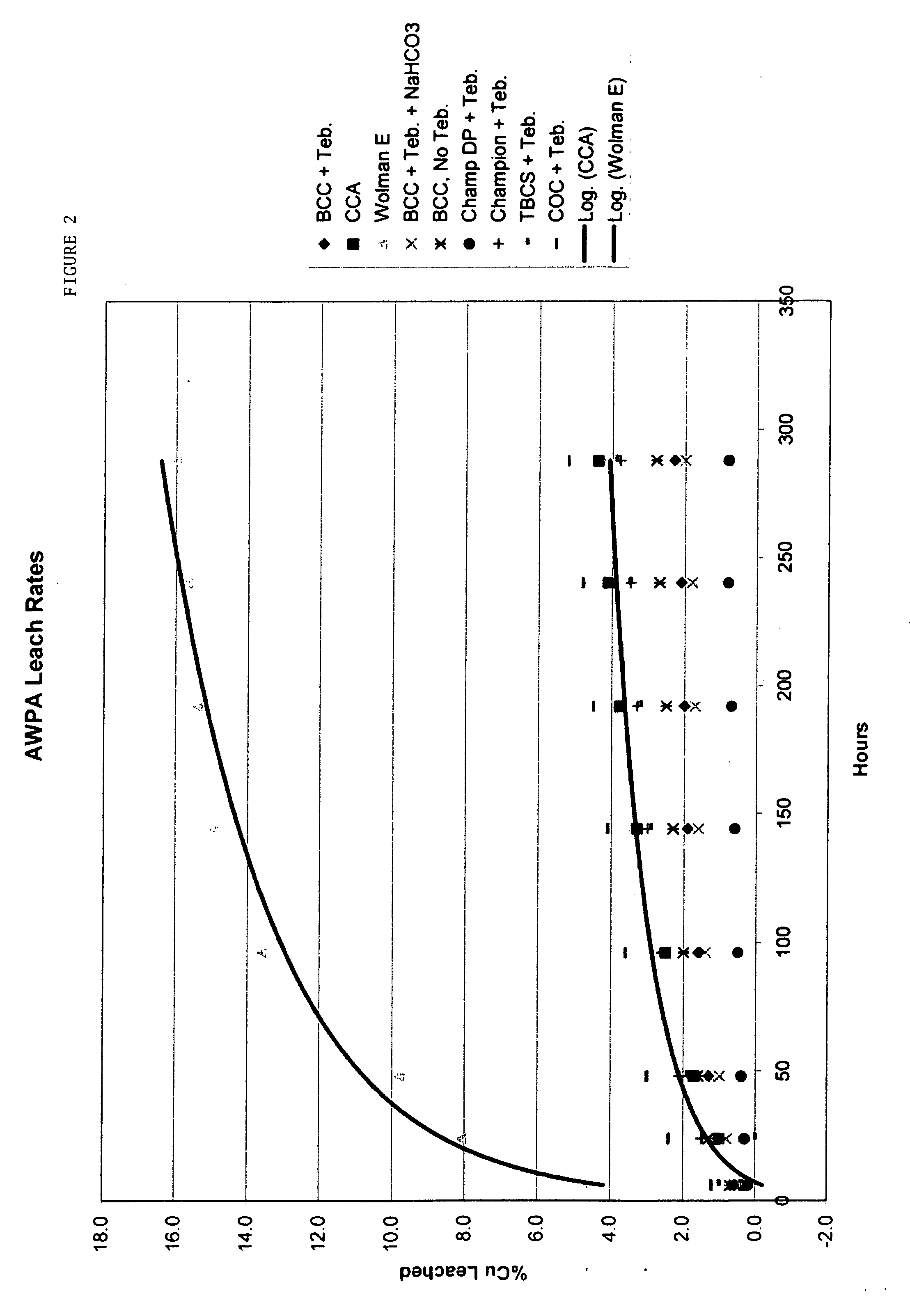

Use of sub-micron copper salt particles in wood preservation

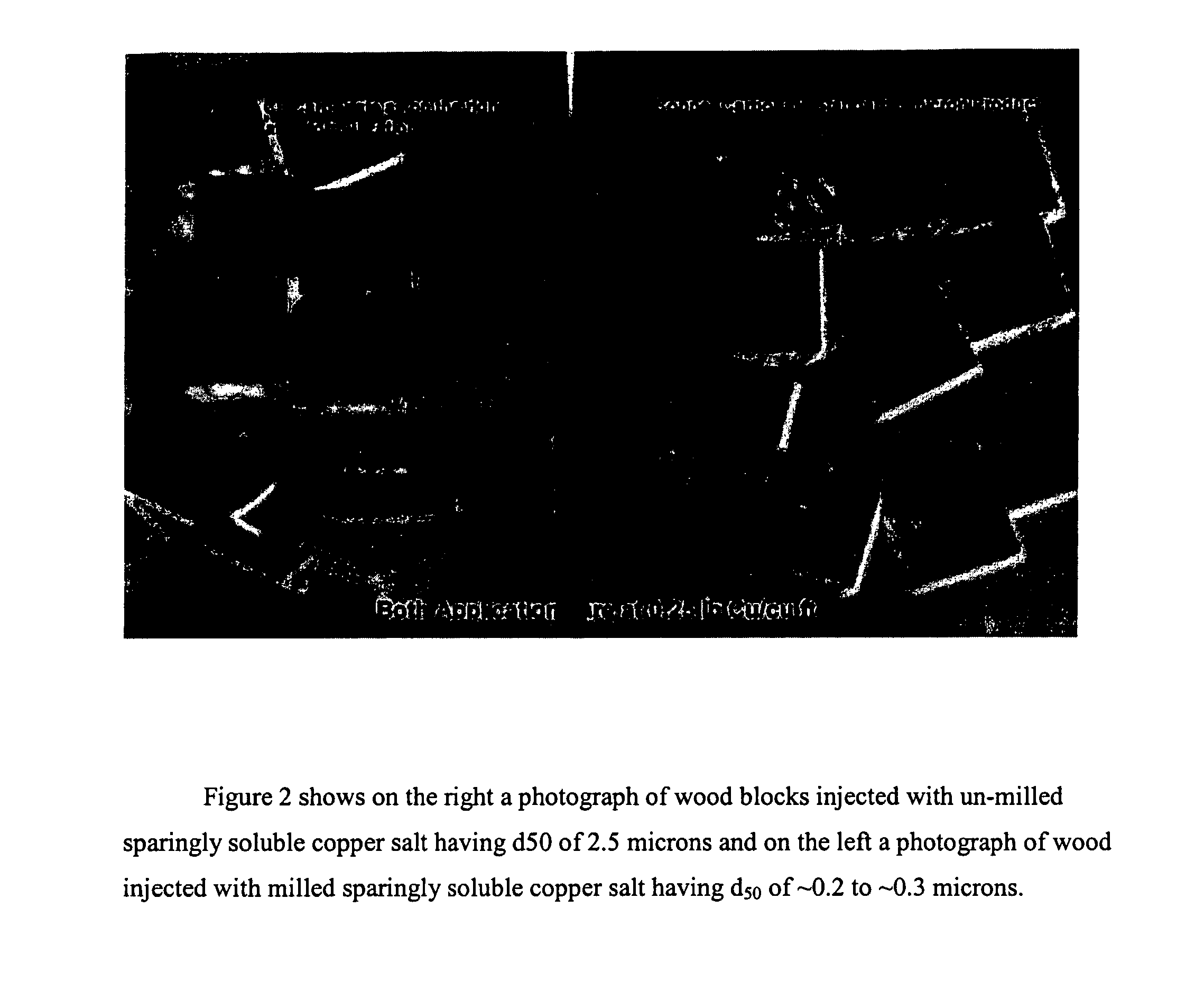

InactiveUS20060062926A1Little dangerSmall particle sizeBiocideLiquid surface applicatorsPhosphateCopper nitrate

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

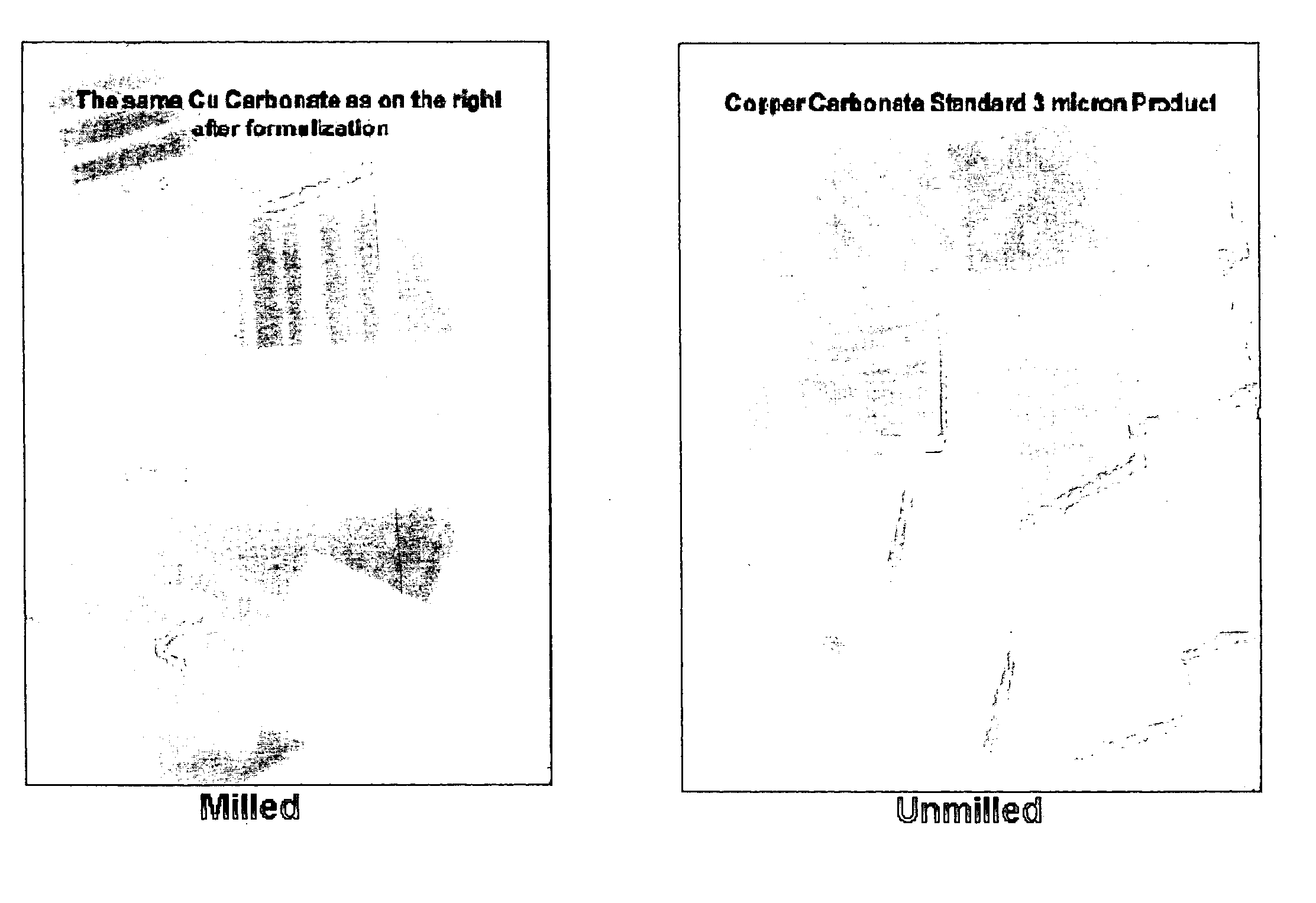

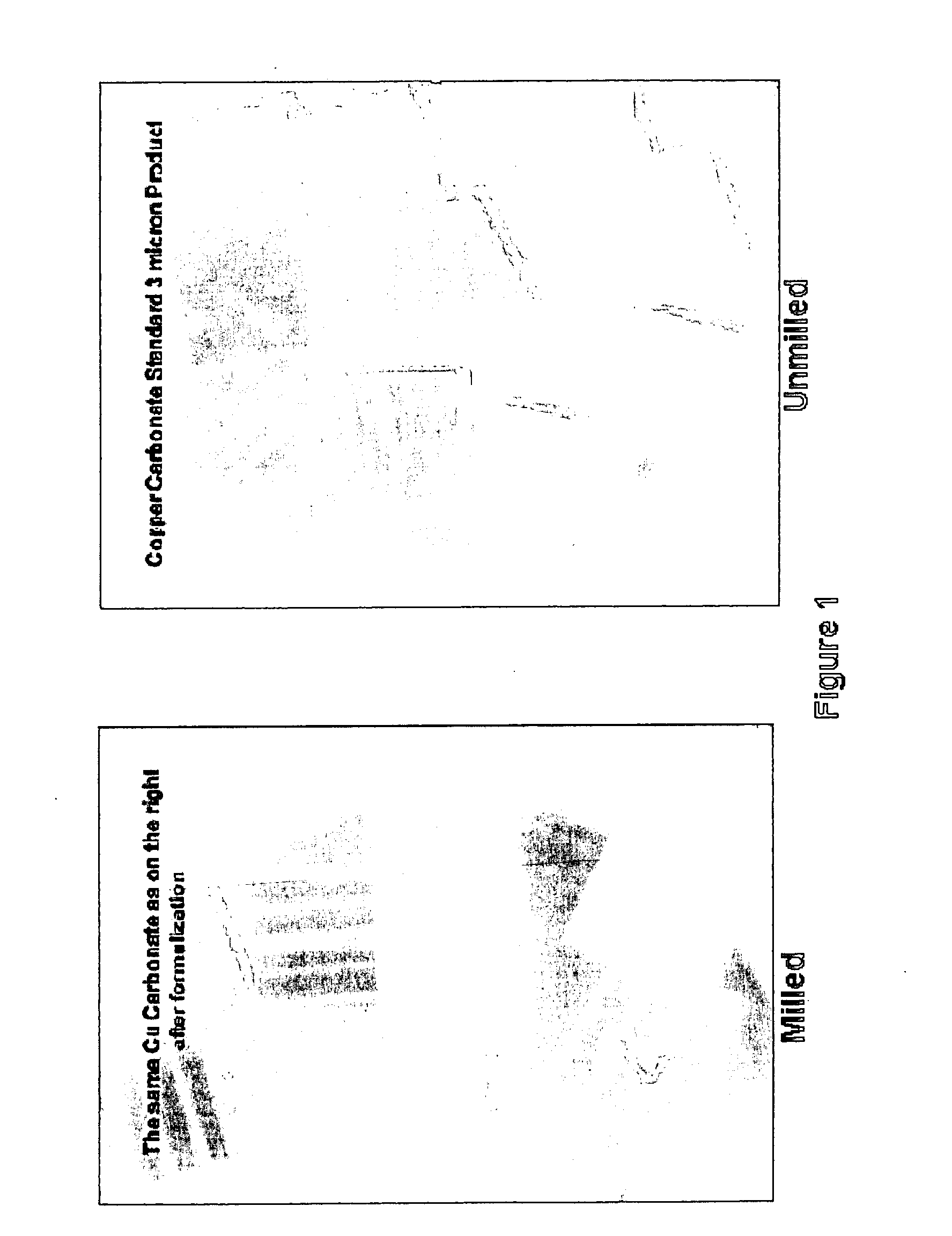

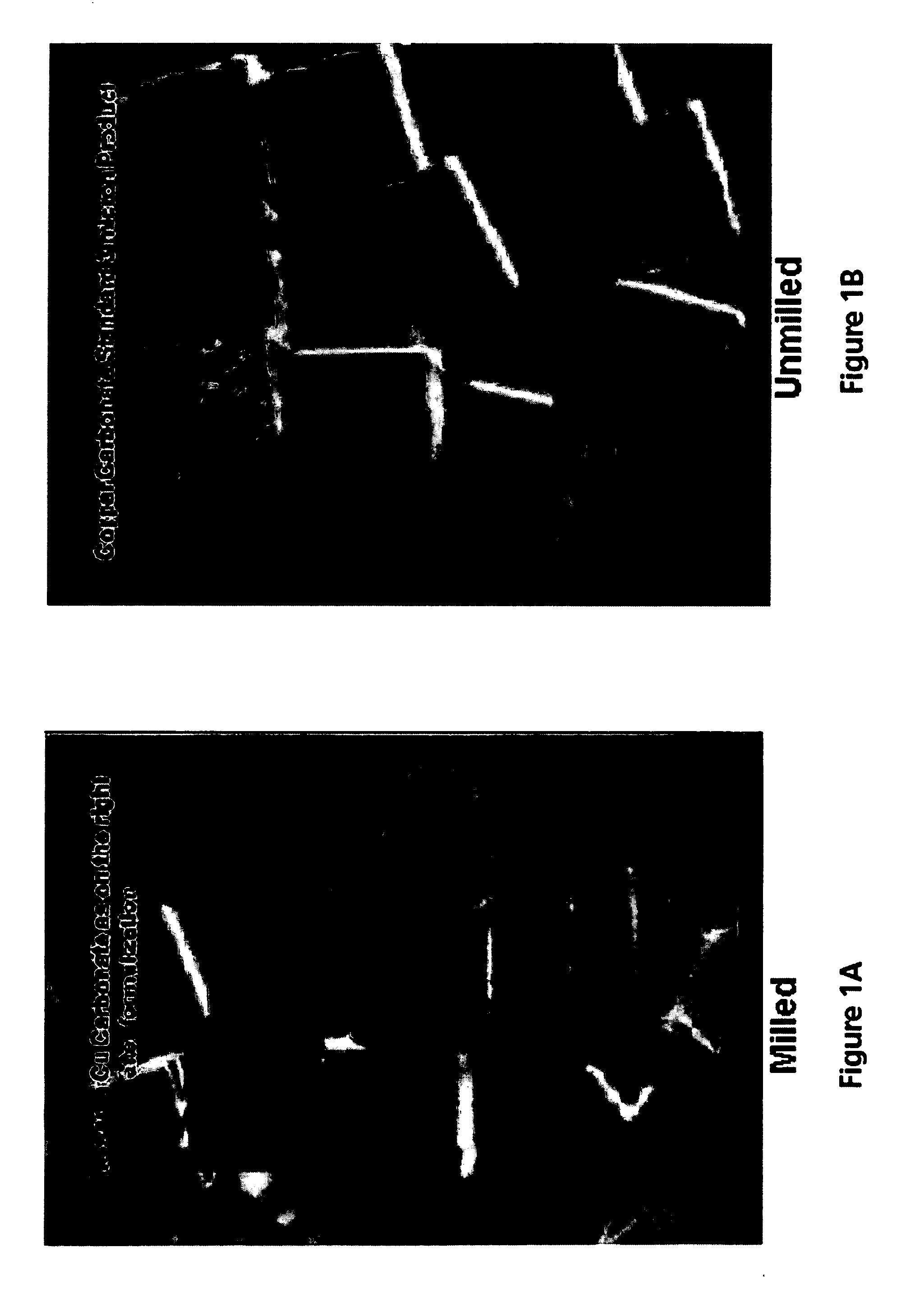

Particulate wood preservative and method for producing same

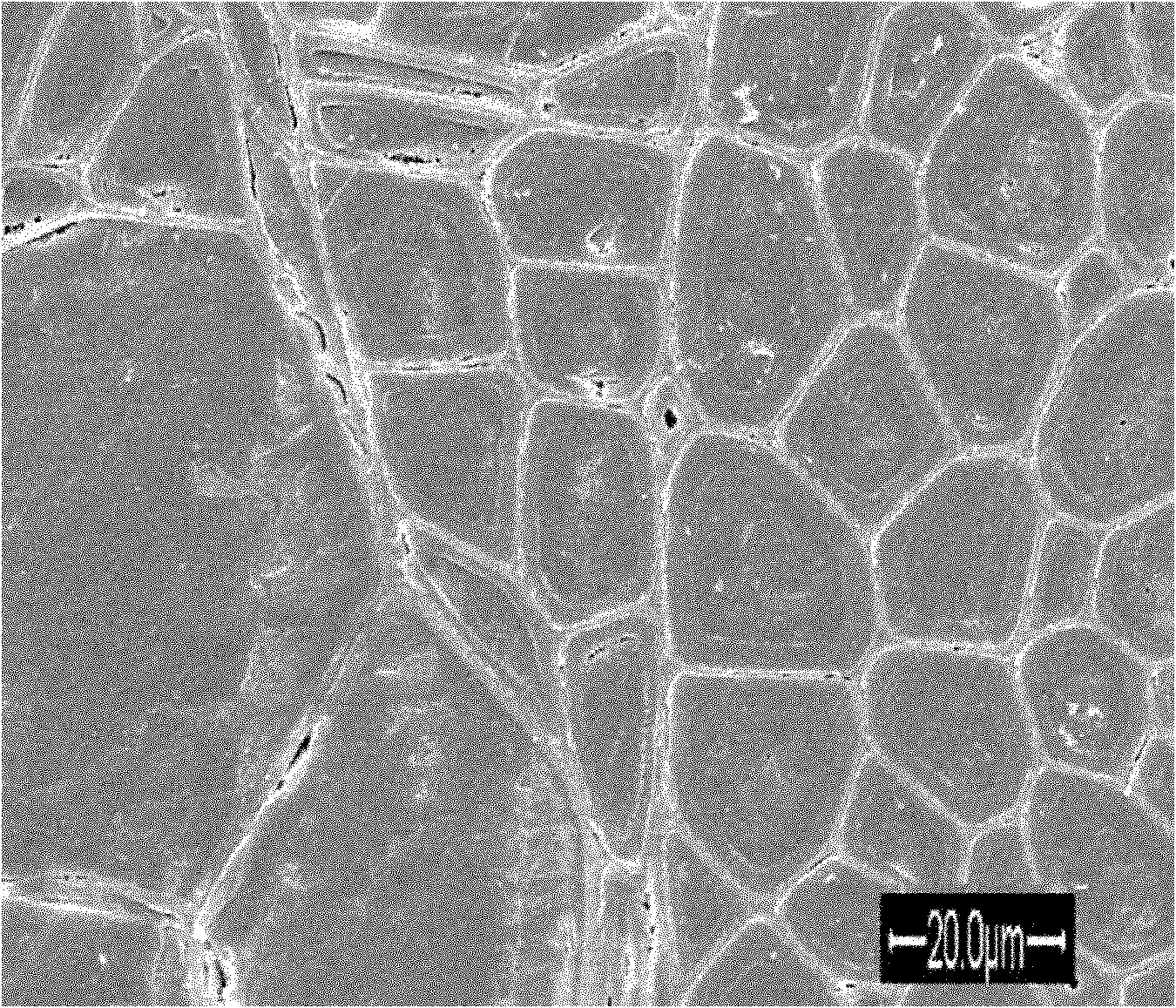

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

Methods for producing and using a Cu(I)-based wood preservative

Soluble copper(I)-amine complexes, particularly copper(I)-ammonia complexes and copper(I)-monoethanmolamine complexes, are useful injectable wood preservatives. Wood treated with the copper(I)-amine complexes contains less amines, and is less corrosive to metals, than woods treated with the prior art copper(II)-amine complexes. A method of preparing an aqueous wood preservative that includes soluble copper(I) complexes comprises reacting a solution comprising a copper(II)-amine complex with metallic copper to form a copper(I)-amine complex. One aspect of the invention comprises injecting a solution comprising a copper(I)-amine complex into wood and allowing the copper(I)-amine complex to precipitate within the wood.

Owner:OSMOSE

Compositions and methods for treating cellulose-based materials with micronized additives

InactiveUS20050265893A1Increase costIncrease residueBiocideDrying using combination processesCelluloseMaterials science

Owner:OSMOSE +1

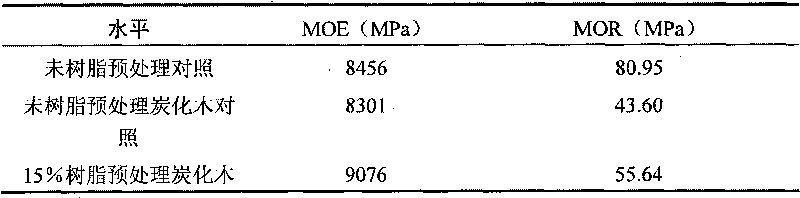

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790AHigh strengthIncrease added valuePressure impregnationWood impregnation detailsPulp and paper industryAdditional values

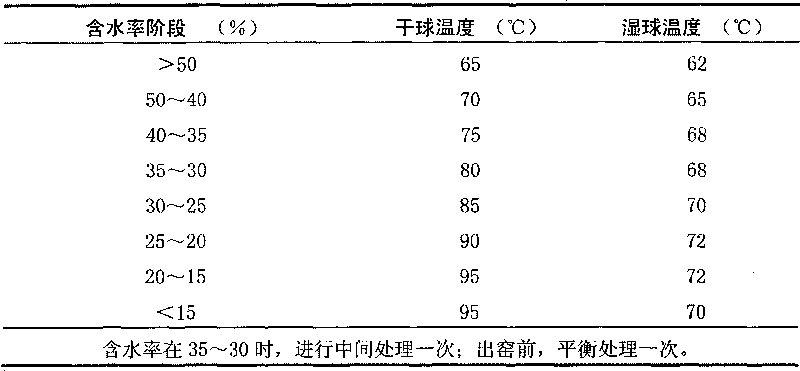

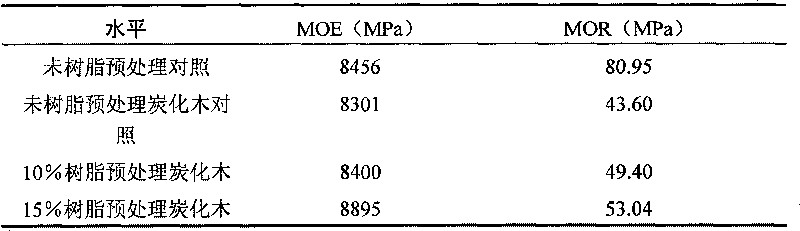

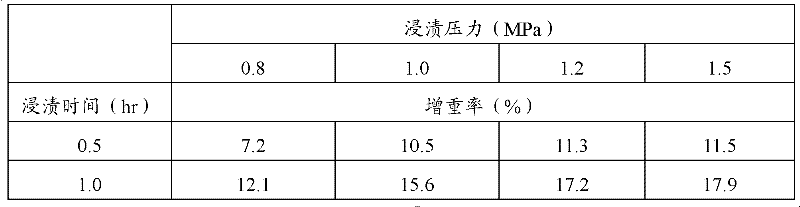

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinely drying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heat treatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the wood from deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

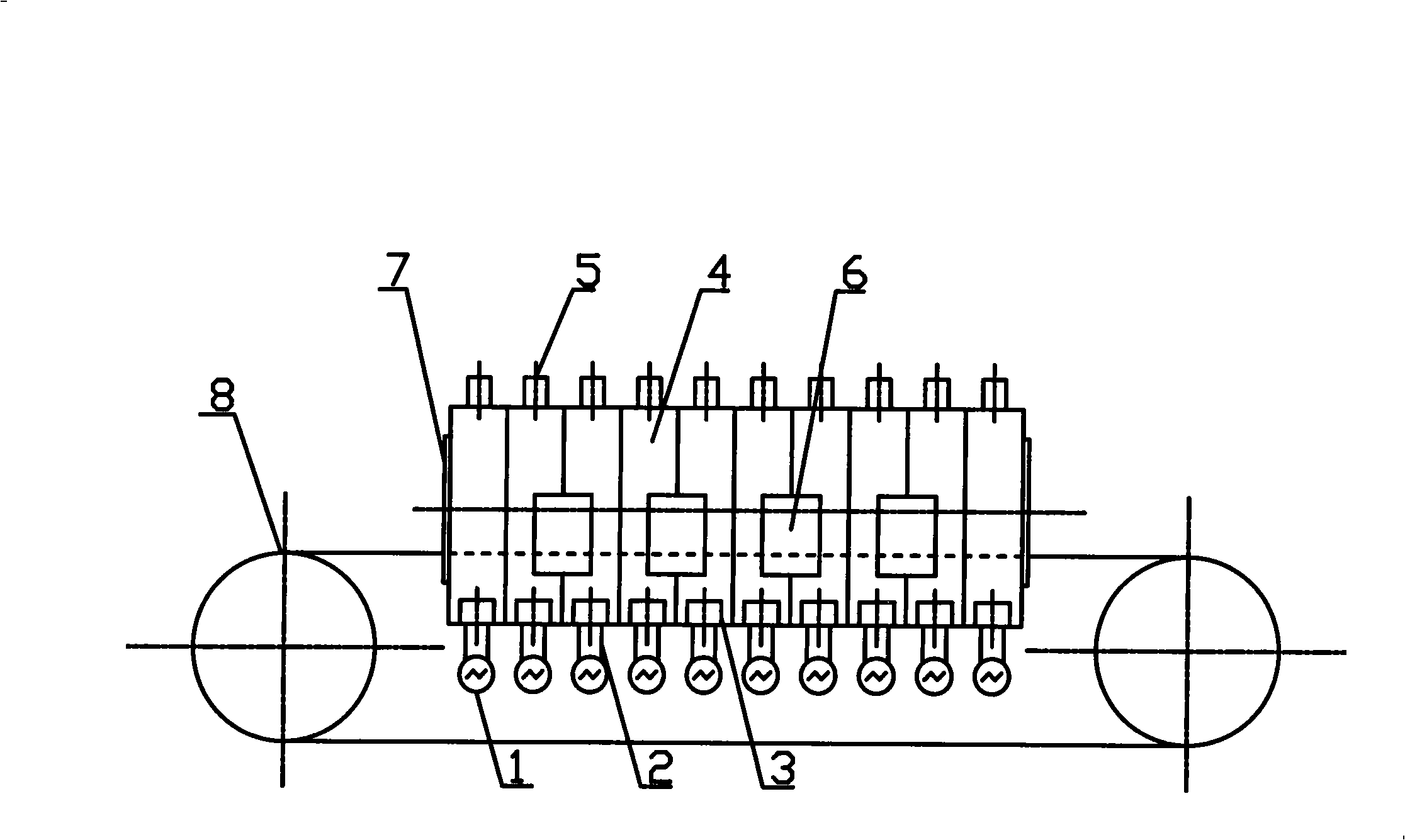

Method of treating fire retardant wood using microwave

InactiveCN101306547ASolve the phenomenon of wet centerNo wet heart phenomenonWood treatment detailsPressure impregnationElectric fieldVacuum pressure

The invention provides a method for processing fire retarding wood with microwave. The method comprises the following steps: heating and processing wood through microwave; subjecting to vacuum pressure treatment; soaking the wood in flame retardant solution with mass ratio being 5-50% and under the atmospheric pressure of 0.1-10MPa for 3-720 minutes; subjecting to vacuum pressure treatment; and heating and treating through microwave to obtain the fire retarding wood. Since heat is not conducted from the outer part of the wood, but in the wood through the interaction between the microwave alternative electric field and water molecules, so as to quickly raise the whole temperature of the wood and improve the permeability of the heat, and meanwhile, kill bristletails and ova in the wood, improve the distribution state of flame retardant in the wood, and enable the flame retardant not to be segregated in-situ along with the migration of the solution, thus basically solving the problems with the traditional method that the flame retardant is present in large amounts on the surface of the wood and serious segregation occurs to the flame retardant when the fire retarding wood is treated. In addition to microwave heating, no additional heat energy is consumed. The fire retarding wood can be directly used as architectural decorative materials.

Owner:KUNMING UNIV OF SCI & TECH

Fire retardant for wood, and preparation method and treatment process thereof

ActiveCN102069519ASimple processRealize industrial productionPressure impregnationWood impregnation detailsEnvironmental resistanceSilicon dioxide

The invention discloses a fire retardant for wood, and a preparation method and a treatment process thereof. The fire retardant for wood is prepared from the following raw materials in percentage by weight: 40 to 60 percent of silica sol, 5 to 20 percent of sodium octaborate tetrahydrate, 1 to 20 percent of ammonium polyphosphate, 1 to 20 percent of carbonate and 0 to 53 percent of water. The preparation method comprises steps of: putting the substances into a stirrer, and uniformly mixing fully to obtain the flame retardant. During use, wood is put into a treatment tank, and is vacuumized, the flame retardant is injected at normal temperature, the treatment tank is vacuumized and the vacuum is eliminated so as to obtain the flame-retardant wood. By utilizing advantages of nontoxicity, environmental friendliness, high flame-retardant efficiency, low price, wide sources and easy preparation of the materials such as the sodium octaborate tetrahydrate and the silica sol, after the materials are compounded, the flame retardant with good anti-loss performance is obtained and can be used for flame-retardant protection of interior and exterior decorative wood and wood structures of buildings.

Owner:ZHEJIANG UNIV

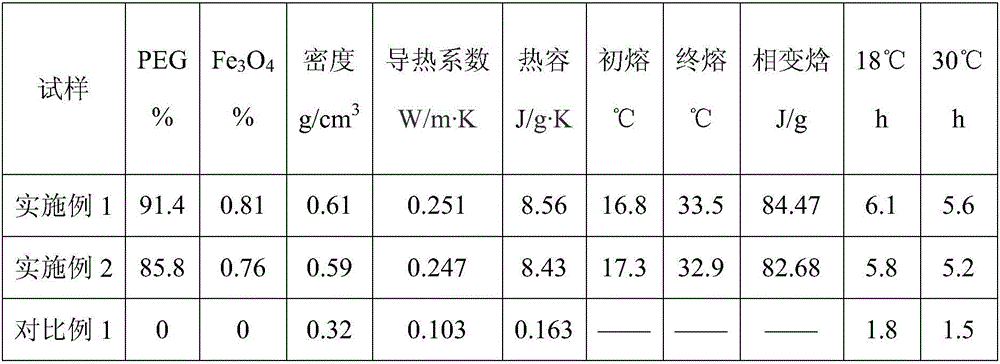

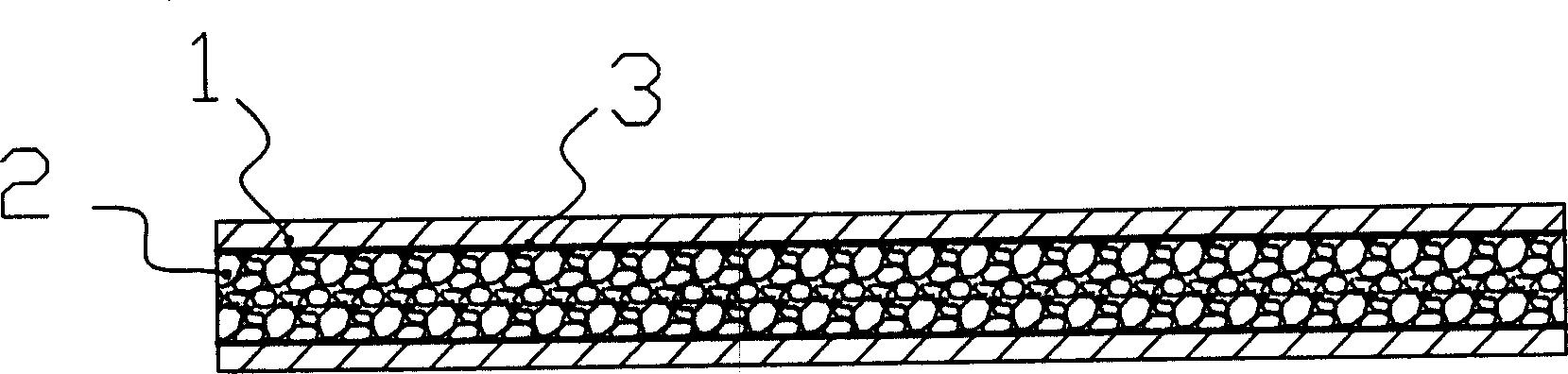

Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

ActiveCN106625930ALow viscosityFacilitated Diffusion MigrationPressure wood treatmentWood treatment detailsSolid woodCell cavity

The invention provides phase-change energy storage heat-insulation solid wood. The wood comprises a solid wood component, wherein magnetic Fe3O4 nanoparticles are formed in a conduit and a cell cavity of the solid wood component through in-situ attached growth, and the conduit and the cell cavity are filled with composite phase-change energy storage materials of polyethylene glycol 600 and polyethylene glycol 800; and a protective coating is painted on the surface of the heat-insulation solid wood. The heat-insulation solid wood is capable of absorbing heat to withstand excessive rise of an indoor temperature during the day, releasing phase-change latent heat for thermal retention and cold dispelling during the night, and maintaining a human body within a comfort temperature range. The invention further provides a manufacturing method of the heat-insulation solid wood. The method comprises the steps of firstly processing the solid wood component according to the required dimension; carrying out degreasing and drying pretreatment on the solid wood component, forming the magnetic Fe3O4 nanoparticles in the solid wood component through in-situ attached growth and then impregnating and filling the composite phase-change energy storage material of the polyethylene glycol 600 and the polyethylene glycol 800; and finally carrying out sanding shaping and painting the protecting coating. According to the manufacturing method, the process is simple and the cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Strengthening and flame-retardant modified artificial forest wood and preparation method thereof

ActiveCN101664945AImprove flame retardant performanceHigh densityWood treatment detailsPressure impregnationCompound aSolubility

The invention discloses a strengthening and flame retardant integrated modified processing method for artificial forest wood and modified artificial forest wood prepared thereby. The method adopts a low molecular weight water-solubility melamine modifying urea-formaldehyde resin solution to compound a flame retardant for dipping the artificial forest wood, comprising the following steps: firstly preparing the melamine modifying urea-formaldehyde resin solution; adding borate to the resin solution for preparing a compound modifier for dipping; then dipping the soft artificial forest wood to ensure that the wood fully absorbs the modifier; and finally drying the dipped wood to obtain the strengthened and flame-retardant processed wood. Because the resin is solidified in the wood, the strengthened and flame-retardant processed wood prepared in the method has the advantages of weight increment and enhanced physical properties including density, size stability, rigidity, strength and the like; meanwhile, because the flame retardant contained in the resin can be uniformly distributed and fixed in the wood, and has strong loss resistance, the processed wood has favorable flame resistance.The processed wood can be extensively applied to the industries of architecture, furniture, interior decoration and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

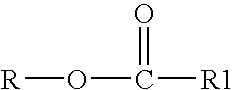

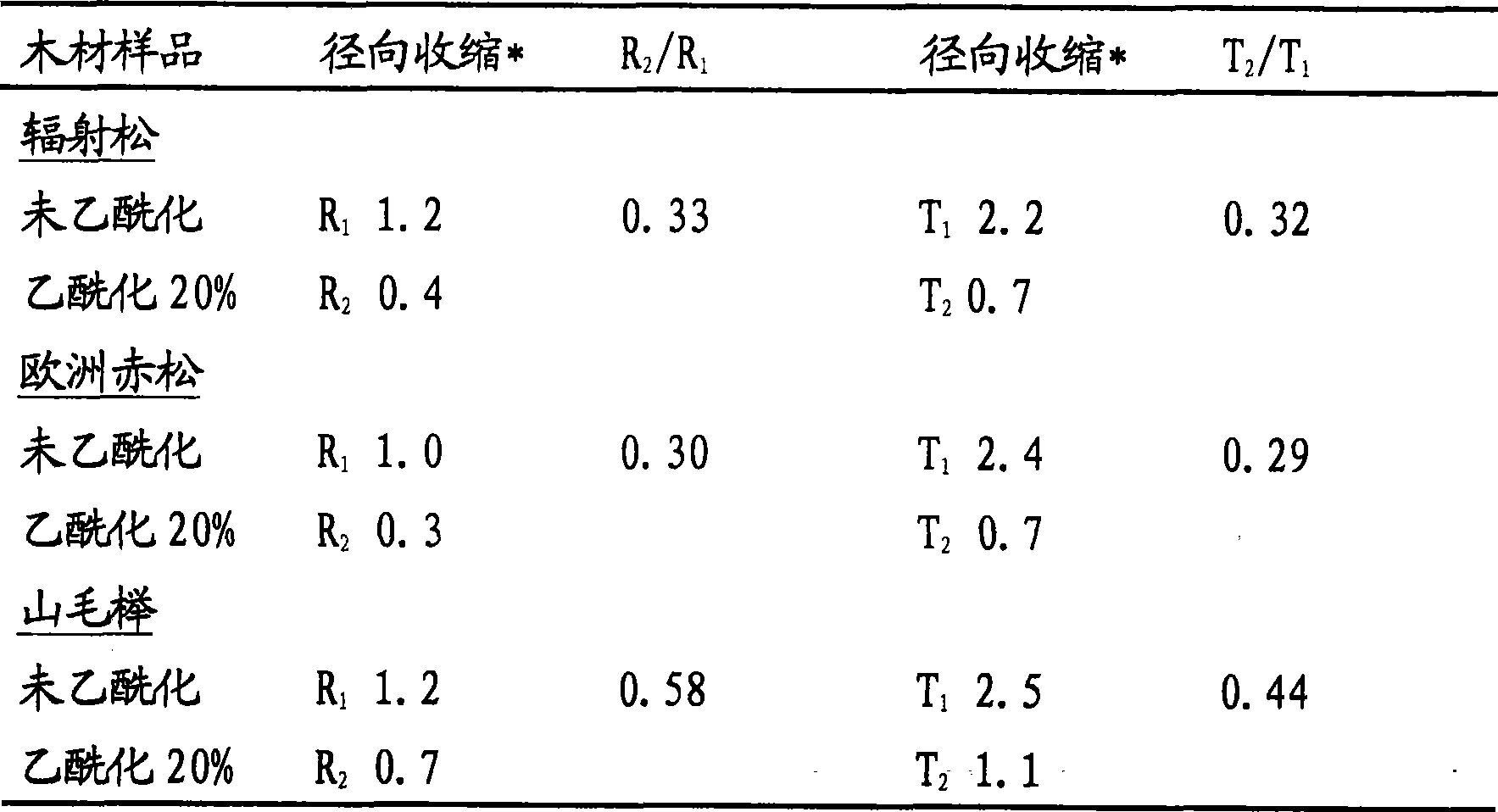

Methods for esterifying hydroxyl groups in wood

ActiveUS7300705B2Cheap methodIncreased durabilityFibre treatmentCellulosic plastic layered productsMicrowaveElectromagnetic radiation

Methods for esterifying hydroxyl groups in cellulose, hemicellulose, and lignin in wood are described, wherein the wood is chosen from loblolly, slash, shortleaf, longleaf or radiata pines. Methods can include solvent drying techniques and heating provided by electromagnetic radiation, such as microwave, and radiofrequency. Products made from the methods are described that have greater decay resistance and dimensional stability as compared with non-esterified wood products.

Owner:TITAN WOOD LTD

Composition and process for coloring and preserving wood

InactiveUS20050152994A1Uniform colorHigh affinityBiocideInorganic boron active ingredientsNuclear chemistryMetal

Owner:OSMOSE +1

Enhanced high-temperature heat treated wood and manufacturing method thereof

InactiveCN104985657AGood dimensional stabilityReduce moisture absorptionWood treatment detailsThermal wood treatmentPulp and paper industryResin adhesive

The invention discloses enhanced high-temperature heat treated wood and a manufacturing method thereof. The manufacturing method comprises the following steps that 1, high-temperature heat treatment is performed, wherein man-made forest wood serves as raw materials, and high-temperature heat treatment is performed on the man-made forest wood to obtain heat treated wood; 2, impregnation enhancing treatment is performed, wherein the heat treated wood obtained by the step 1 is impregnated in resin adhesives to obtain impregnated wood; 3, solidification forming treatment is performed, wherein solidification forming treatment is performed on the impregnated wood obtained by the step 2 to obtain the enhanced high-temperature heat treated wood. According to the manufacturing method, not only can the mechanical properties of the wood be improved, but also the size stability of the wood can be improved, green and environmental protection are achieved, and the prepared enhanced high-temperature heat treated wood takes the man-made forest wood as the raw materials and is high in mechanical strength and good in size stability.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Wood material wood product fire retardant and its treatment method

InactiveCN1651202AEasy to prepareImprove flame retardant performancePressure impregnationWood impregnation detailsChemistryPhosphate

A flame-retarding agent for wood or wooden products is prepared from amino phosphate, boron compound, polyphosphate and phosphate through thermal reaction between amino phosphate and boron compound, thermal reaction between polyphosphate and phosphate, and preparing finished product. It is applied to wood or wooden products through loading wood or wooden products in the treating tank, vacuumizing, filtering said flame-retarding agent, pressurizing, releasing pressure, discharging flame-retarding agent, and repeating above said steps 1-3 times.

Owner:成都铁路防火制品厂

Manufacturing method of flame retardant solid composite floor

InactiveCN102114656AImprove flame retardant performanceSimple production processLiquid surface applicatorsPressure impregnationEnvironmental resistanceSander

The invention discloses a manufacturing method of flame retardant solid composite floors. The method comprises steps of: performing flame retardant treatment on a natural rare tree veneer with the thickness of 0.5mm to 5mm by a vacuum pressure impregnation method, adhering the dried veneer to a glued floor substrate, and performing the processes of assembling, cold pressing, thermal pressing, health preserving, edge cutting, sanding, mortising and the like to obtain the solid composite floor blank; and then performing painting treatment on the surface of the solid composite plate blank, wherein the painting treatment adopts a process of twelve bottoms and two surfaces and the painting is performed according to the order: water primer, putty, elastic primer, wear resistant primer, transparent primer, sander, wear resistant primer, hardening primer, transparent primer, wear resistant primer, hardening primer, transparent primer, sander, finishing paint and finishing paint, and the wear resistant primer, the hardening primer and the sander are added with flame retardant agent. The flame retardant solid composite floor manufactured by the method has excellent flame retardant and fireproof performance and eco-friendly performance, and has excellent physics mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Impregnating method of fast growing wood

ActiveCN102642223ARetain natural propertiesFlame retardantWood treatment detailsPressure impregnationSolid woodHardness

An impregnating method of fast growing wood mainly aims at processing artificial fast growing wood. Processes of two times of drying and matching of vacuuming and high pressure impregnating are utilized, and particularly a vacuuming method is used to accelerate impregnating speed of wood impregnating solution, and the impregnating is uniform and retaining amount of active ingredients is large; not only original natural attributes of wood are retained after the wood is processed through the method matched with the wood impregnating solution, but also the wood has advantages of flame retardance, anticorrosion, termite proofing, deformation resistance, environmental protection, adjustable density and rigidity and the like; the performance of the wood is good, and the wood becomes an ideal substitute for natural precious wood species, usage requirements in fields of furniture, solid wood flooring and the like can be met completely.

Owner:河北爱美森木材加工有限公司

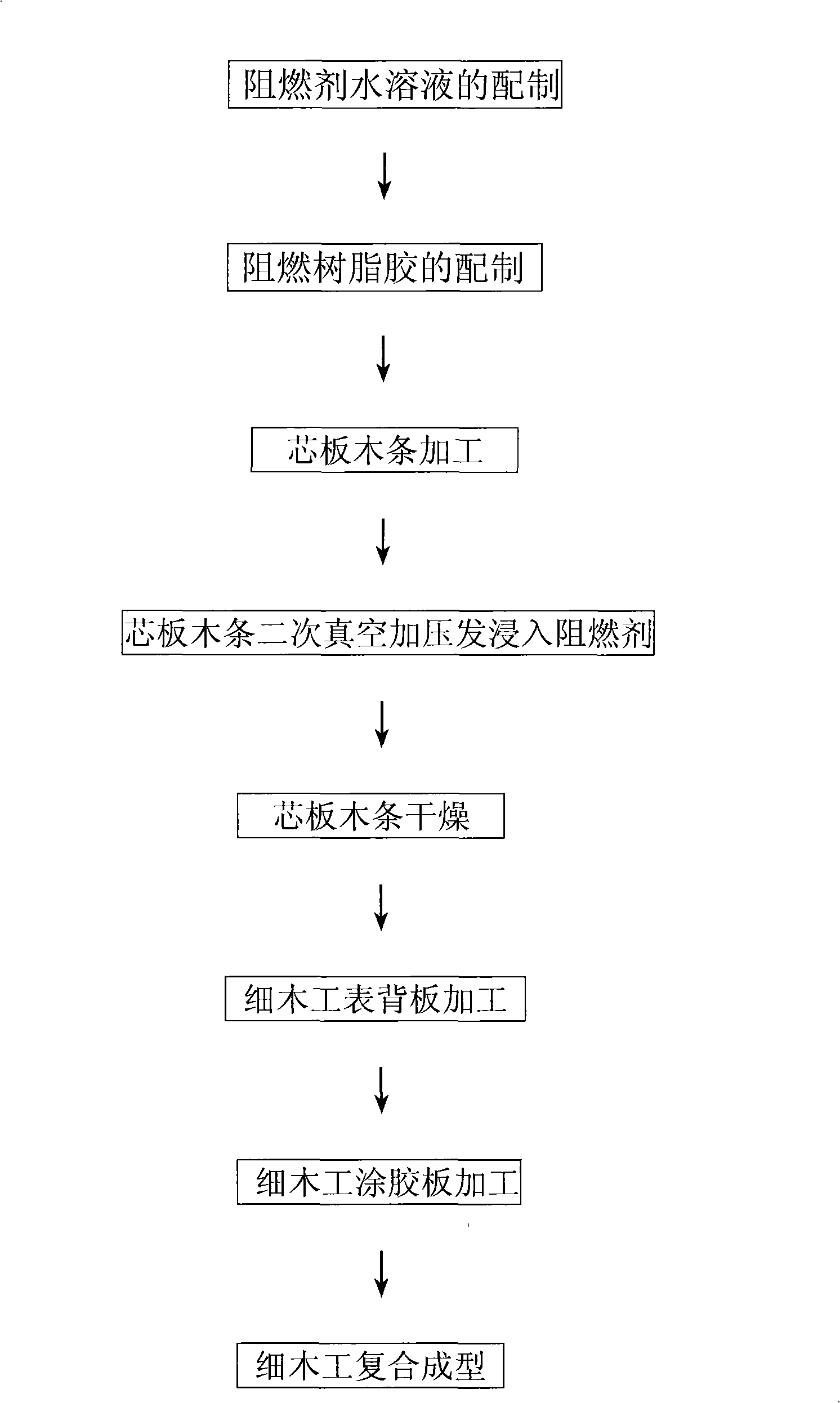

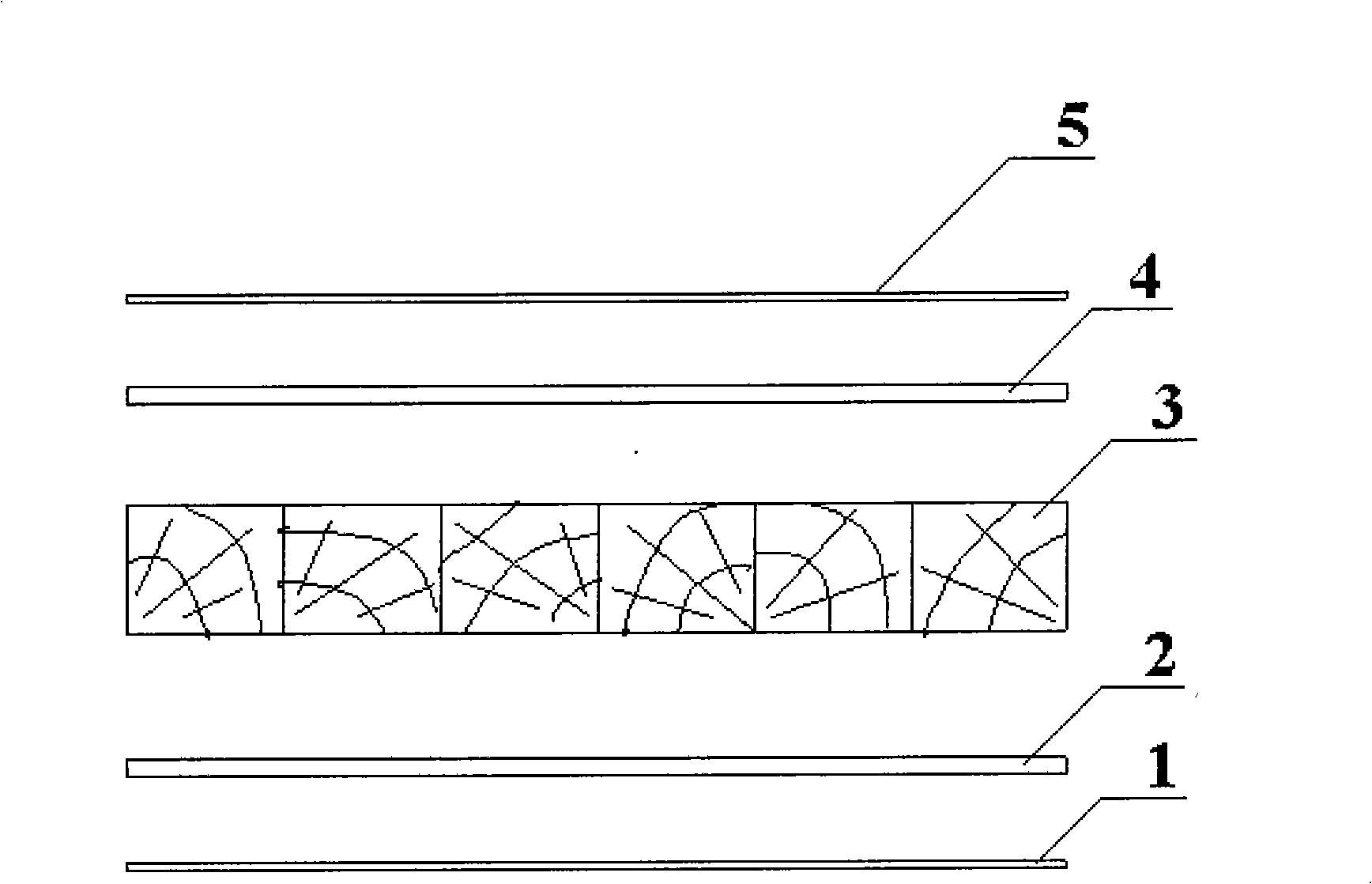

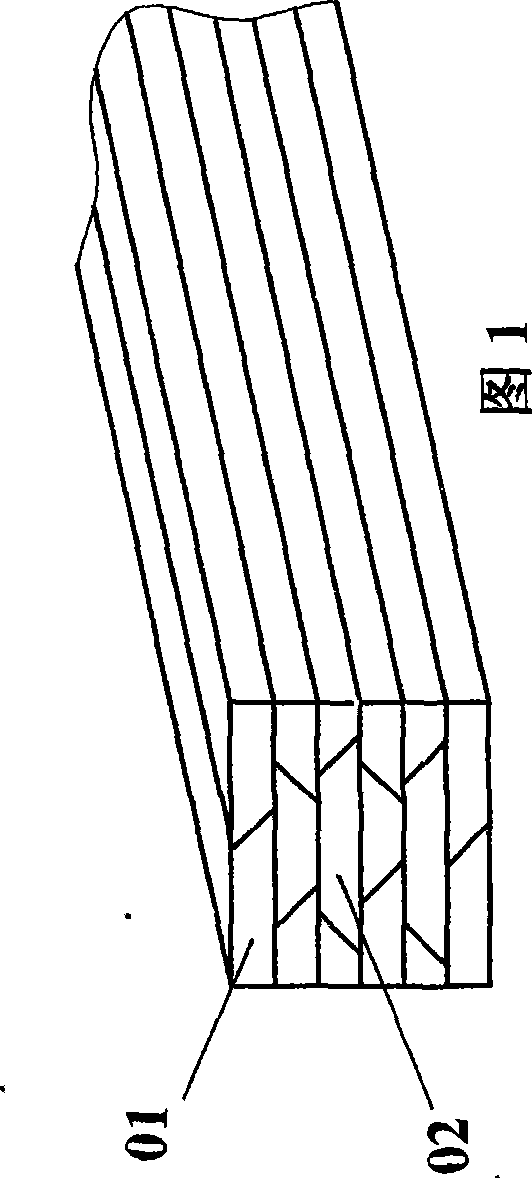

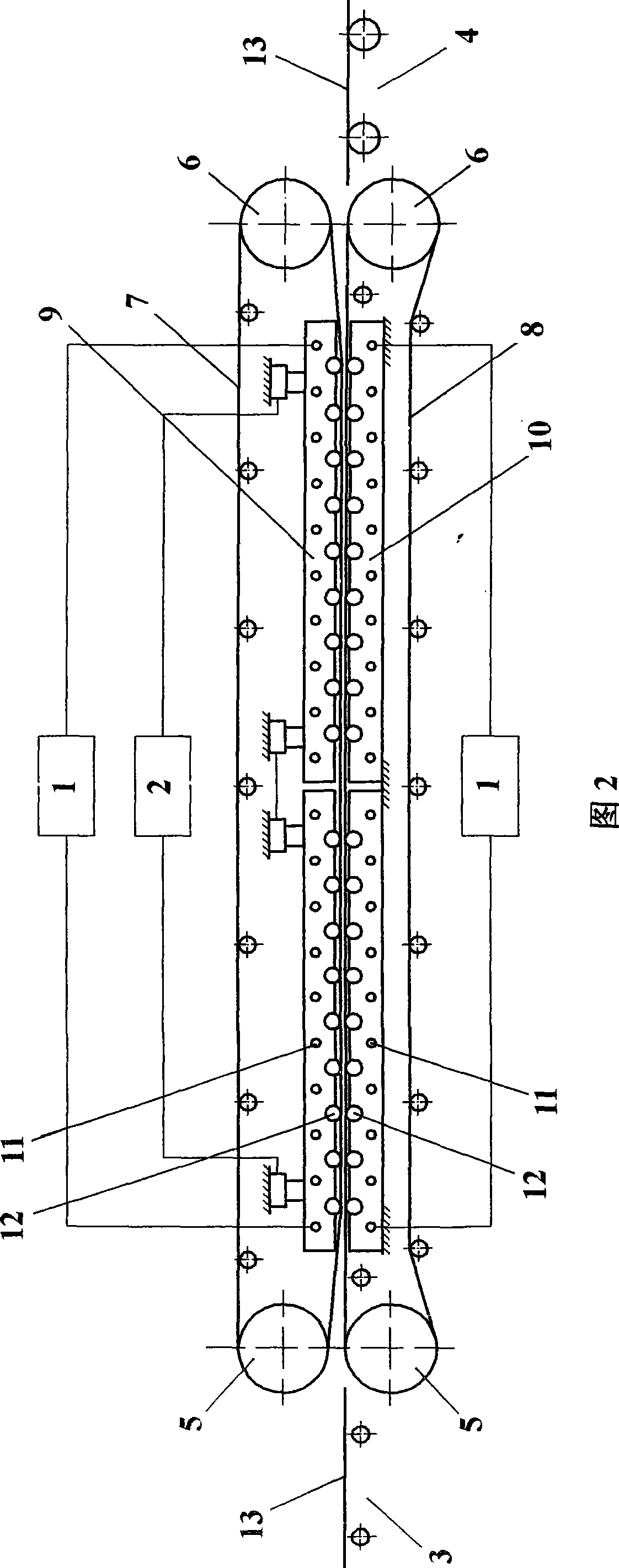

Preparation method for composite inflaming retarding core-board

InactiveCN101513745AFull immersionImprove flame retardant performanceWood treatment detailsWood veneer joiningWater basedLower grade

The invention relates to a preparation method for composite inflaming retarding core-board. The technology of filling a flame retardant by secondary vacuumizing / pressurizing is employed to lead the flame retardant to be more sufficiently dipped into the inside of a core-board strip and improve the inflaming retarding performance of the core-board strip. The flame retardant employs a non-halogen water-base environmental-friendly compound flame retardant which does not contain formaldehyde, has strong inflaming retarding performance, smoke inhibiting and mould-proof effects. The invention is a manufacture method for employing the low-grade wood or leftover materials after processing like undersized logs and removing the quality and processing defects to produce high-grade composite inflaming retarding core-board. The product of the invention has the characteristics of inflaming retarding, corrosion resistance, environment protection, heat preservation, sound isolation, and easy processing, and is an ideal fire-proof inflaming retarding material for the industries like furniture, door manufacture, and building decoration.

Owner:黑龙江省尚志国有林场管理局

Small wood integrated shaving thin-wood manufacture method and leveling drying device thereof

InactiveCN101417451AHighlight substantiveSignificant technological progressVeneer manufacturePressure impregnationAdhesive cementEconomic benefits

The invention relates to a manufacturing method of small-diameter wood glulam slicing veneers and a leveling drying device. Small-diameter wood, tended wood, inferior wood or cordwood produced in the cutting and manufacturing process, and the like which are not easily efficiently used are softened by a composite agent by being infused with pressure, and then after flitches are integrated by finger joining and obliquely slotting the wood with a moisture-curable type adhesive, the flitches are sliced into wet veneers, and the wet veneers are then sent to a special continuous high-temperature ironing leveling dryer to be leveled and dried into sliced veneers in the clamping of upper and lower steel belts. The invention integrates a series of special technologies and transforms small-diameter wood which is not easily used into sliced veneers which meet requirements of various technical specifications with very wide application ranges. Low-grade wood is fully used, which improves the added value of products and comprehensive utilization efficiency of forest resources. The invention has the advantages of simple and reasonable technique method, low equipment cost, good product quality, broad development prospects and the like. Significant social and economic benefits can be produced after the implementation.

Owner:BEIHUA UNIV

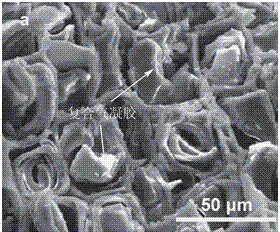

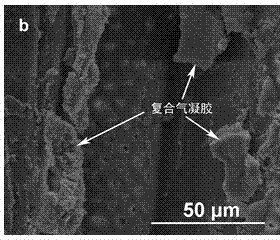

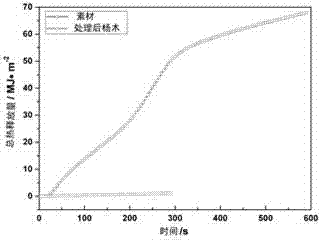

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

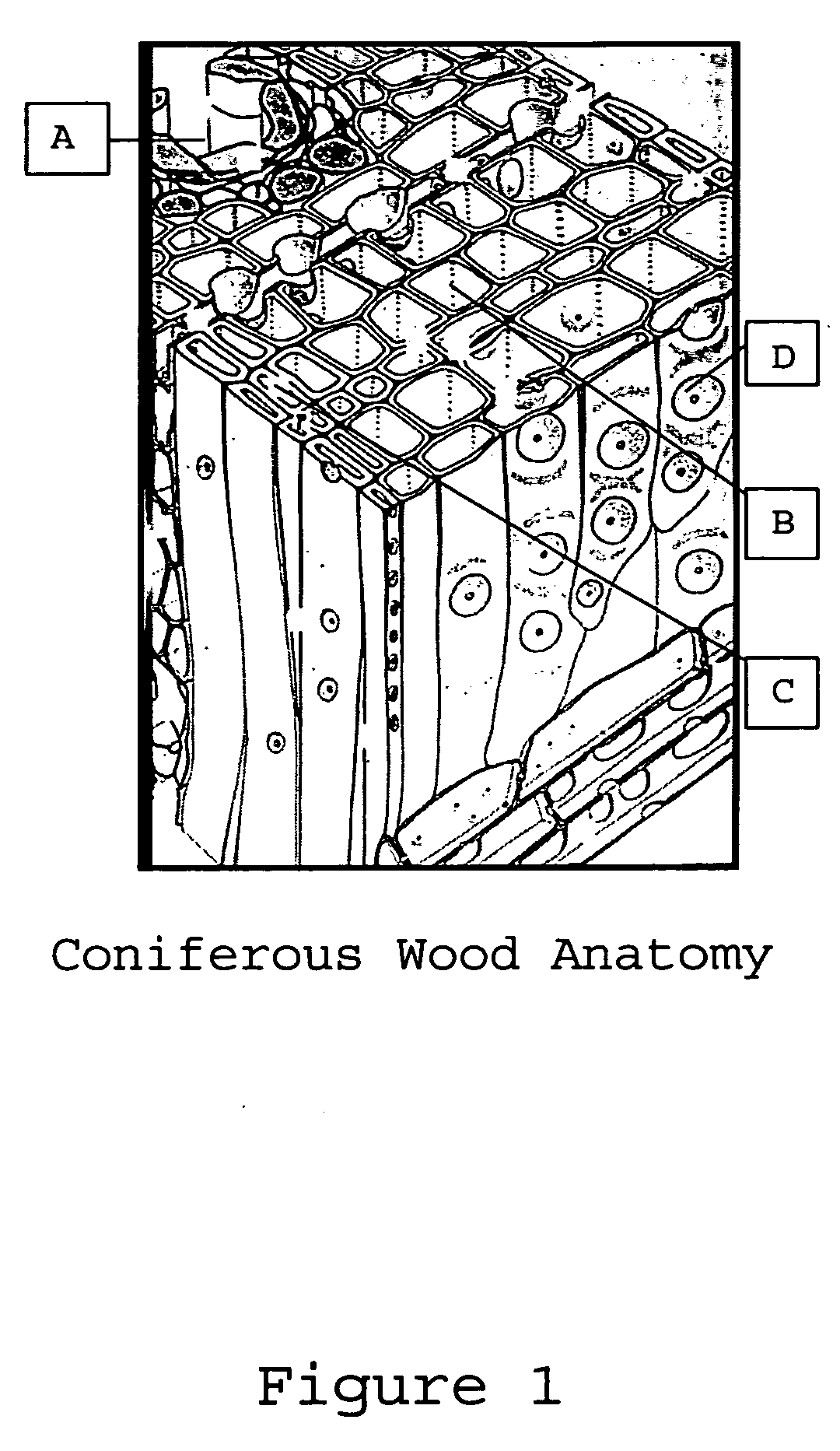

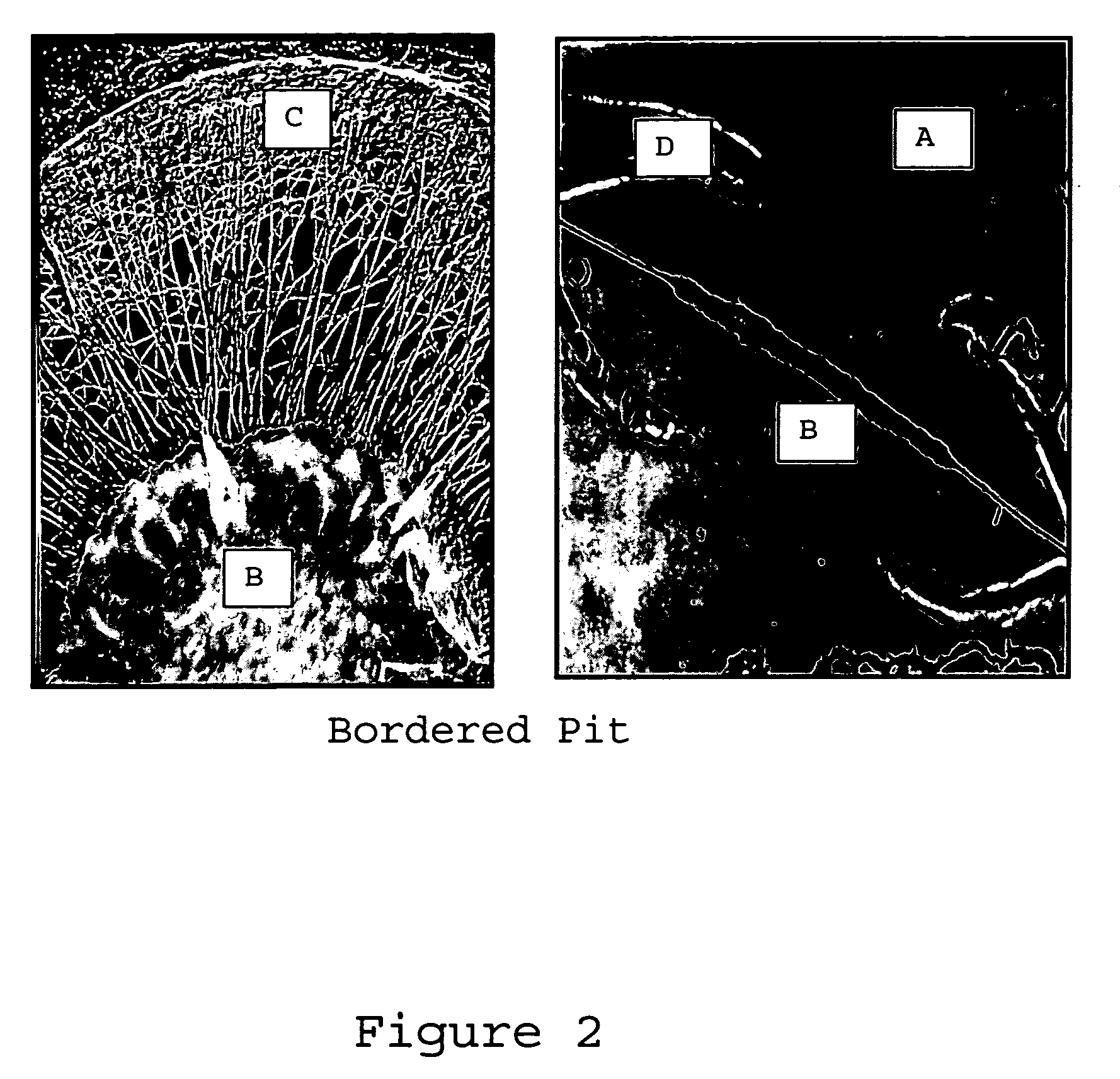

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preservation of wood products

InactiveUS6753016B2Maintain stabilityMaintain surfaceBiocideHeavy metal active ingredientsInorganic saltsIron salts

A method for the protection of wood and other wood materials without affecting dimensional stability or surface integrity of the treated material is described. The method involves treating wood material with an iron salt and selected oxidants where the iron salt is preferably complexed with organic chelating ligands. Preferably, a microbicidal agent is also incorporated into the method to provide treated wood products that demonstrate excellent surface integrity, dimensional stability and retention of the infused microbicidal agents for extended periods of time without incurring the detrimental environmental effects of conventional chromium or copper-based inorganic salt preservation methods.

Owner:ROHM & HAAS CO

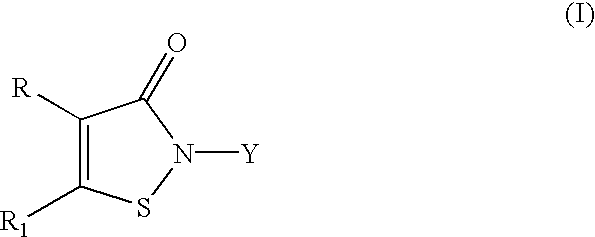

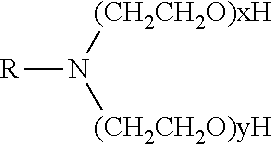

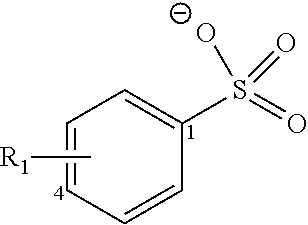

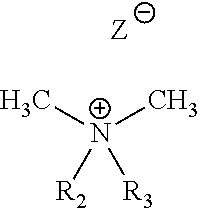

Composition and Method for Treating Wood

The present invention relates to a composition for treating wood comprising a wood preserving compound and a carrier, wherein the carrier is an emulsion comprising a hydrophobic phase, a hydrophilic phase and a surfactant system. In particular, the surfactant system comprises a non-ionic polyethoxylated alkyl amine and an anionic C10-C16 alkylbenzene sulfonate. Methods of using the composition to treat wood, especially timber, are also described.

Owner:HYNE & SON PTY

Composition for wood treatment comprising an injectable aqueous wood preservative slurry having sparingly-soluble biocidal particles and pigments

InactiveUS20090293761A1Inhibition of agglomerationLimited solubilityFireproof paintsBiocideNickel saltHue

Owner:OSMOSE

Method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities

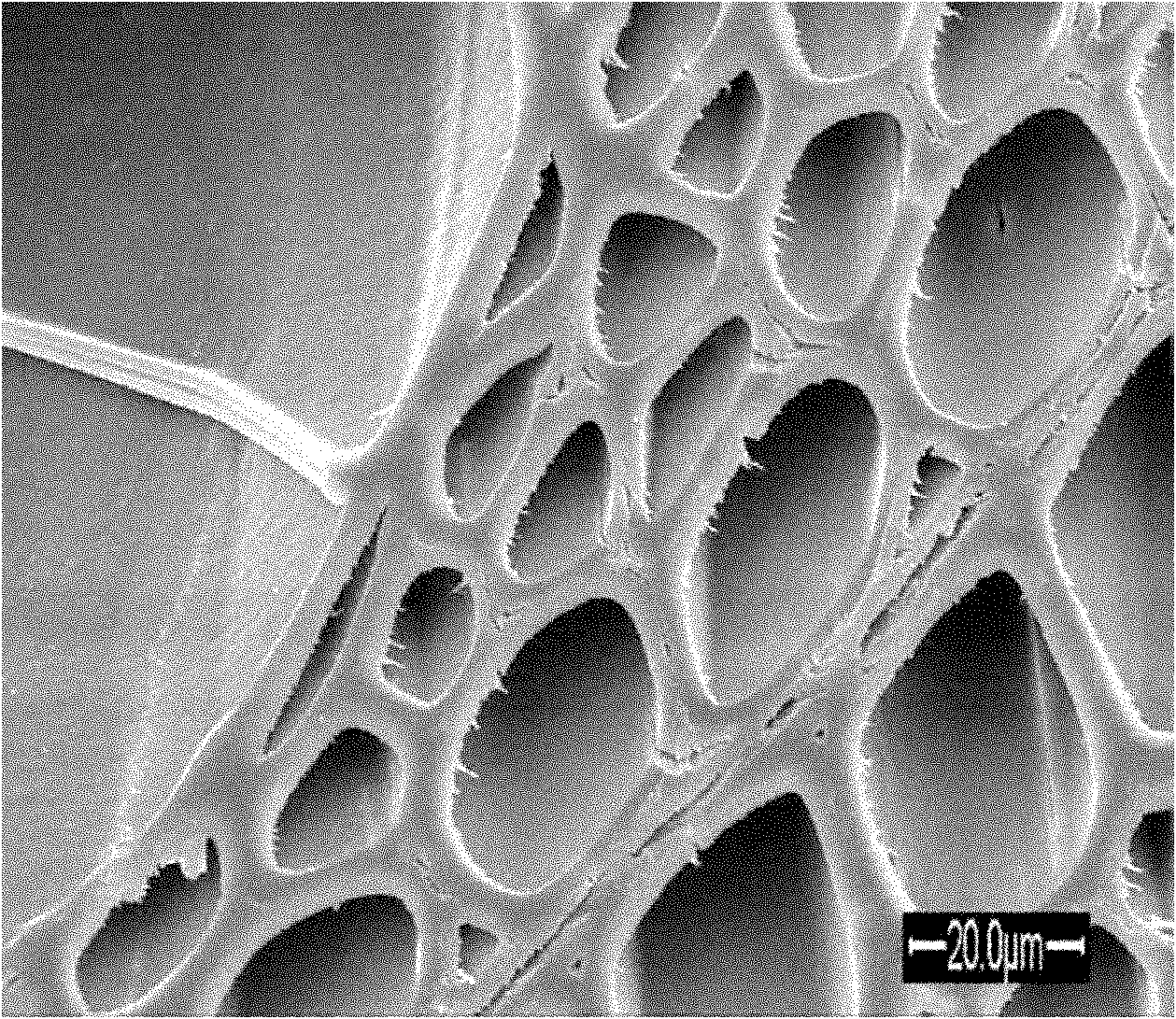

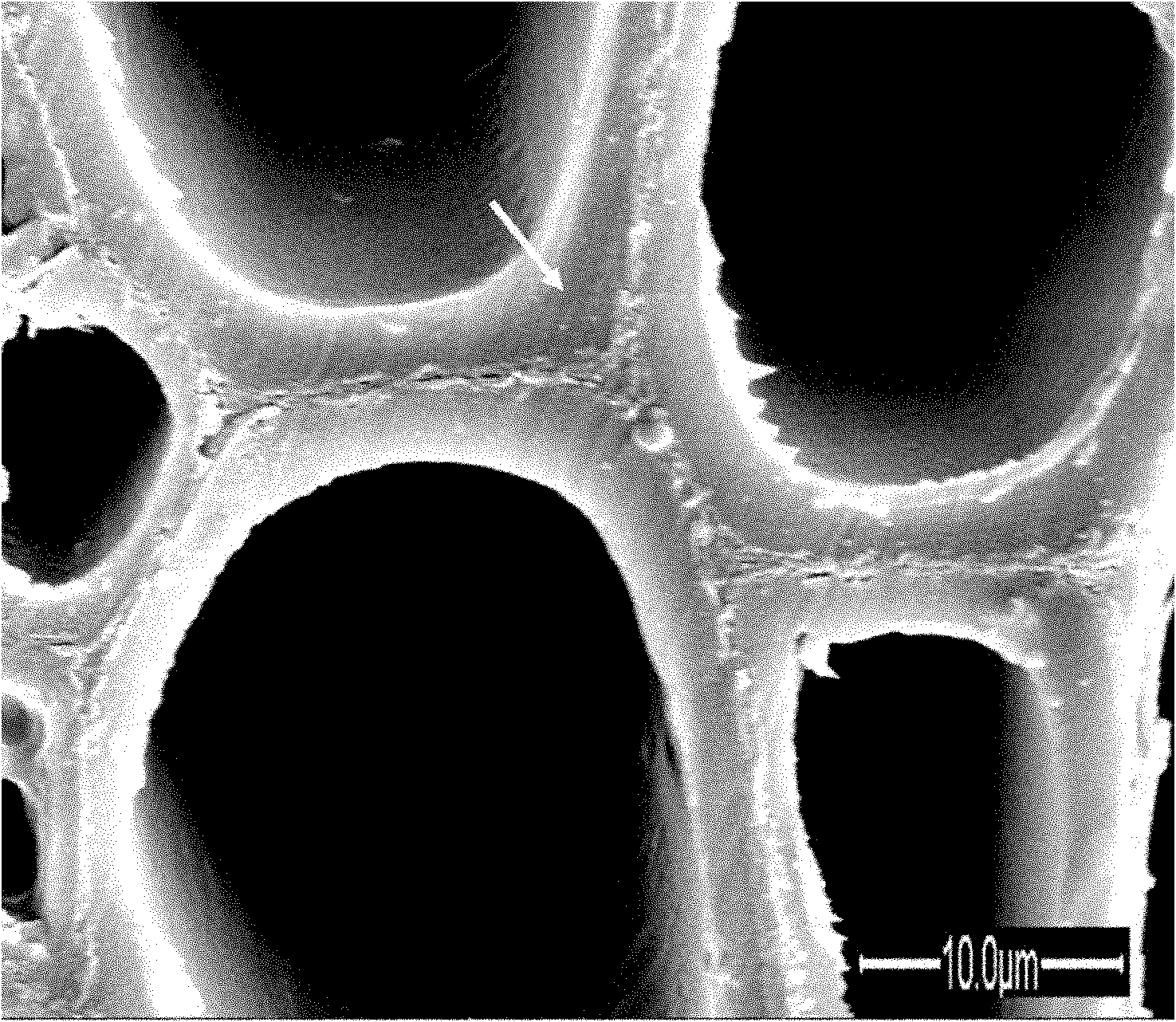

InactiveCN101954662AIncreased durabilityImprove mechanical propertiesPressure impregnationWood impregnation detailsCell cavityCell wall

The invention discloses a method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities, which relates to a wood modification method. The invention solves the problem of difficulty in simultaneously enhancing mechanical properties and durability of wood in the existing wood modification method. The method comprises the following steps: 1, preparing organic acid anhydride solution; 2, soaking the wood with the organic acid anhydride solution; 3, filling grafted wood cell walls with organic acid anhydride by heating; 4, preparing the organic polymerizable monomer solution; 5, soaking the wood with the organic polymerizable monomer solution; and 6, carrying out polymerization-filling on the wood cell cavities with the monomers by heating. Since organic function micromolecules firstly enter the wood cell walls, the method realizes filling and bonding and eliminates a great deal of hydroxyl groups in the cell walls, thereby enhancing wood durability; and the wood cell cavities are soaked by the organic polymerizable monomers to initiate the polymerization and realize the filling of the cell cavities, so that the wood has higher mechanical properties and durability.

Owner:NORTHEAST FORESTRY UNIVERSITY

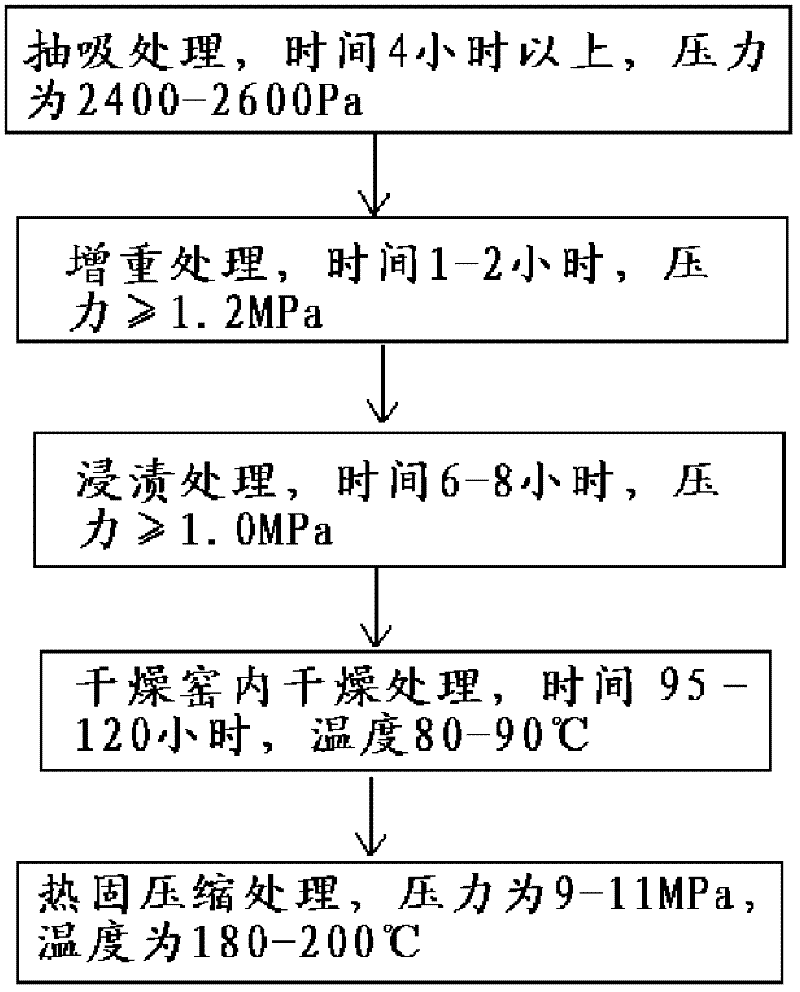

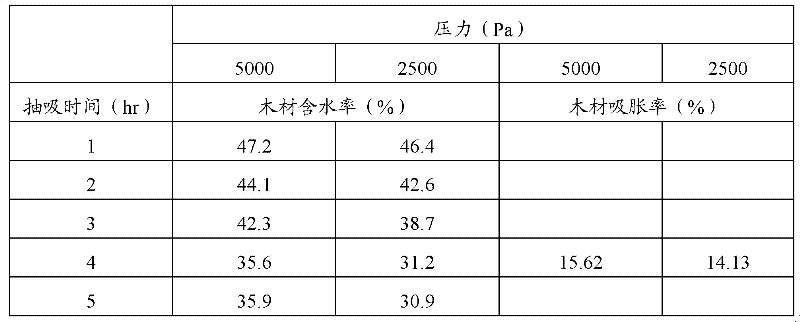

Wood modifying method

ActiveCN102398289AHigh densityHigh strengthPressure impregnationWood impregnation detailsNatural organic matterFire retardant

The invention relates to a method for modifying low-density wood. The method comprises sucking wood, increasing weight, soaking, drying, thermosetting and compressing, wherein the water content of the wood subjected to sucking treatment is 28-32 percent; the gain in weight of wood subjected to weight increasing treatment is 30-35 percent; the gain in weight of the wood subjected to soaking treatment is 15-20 percent; the water content of the wood subjected to drying treatment is 15-18 percent; and a soaking agent comprises the following components in parts by weight: 100 parts of thermosetting resin, 10-20 parts of water-soluble natural organic matter, 3-5 parts of aqueous waterproof agent, 0.5-1 parts of fire retardant and 1-2 parts of surfactant. In the modifying method, a physical modifying technology, a chemical modifying technology and a mechanical modifying technology of hot compression deformation are organically combined, so that modified wood has high density, high intensity and the like of high-level wood, has higher size stability than high-level wood, and has the characteristic of low cost compared with high-level wood.

Owner:夏国华

Production method of high-temperature heating modified rubber wood floor

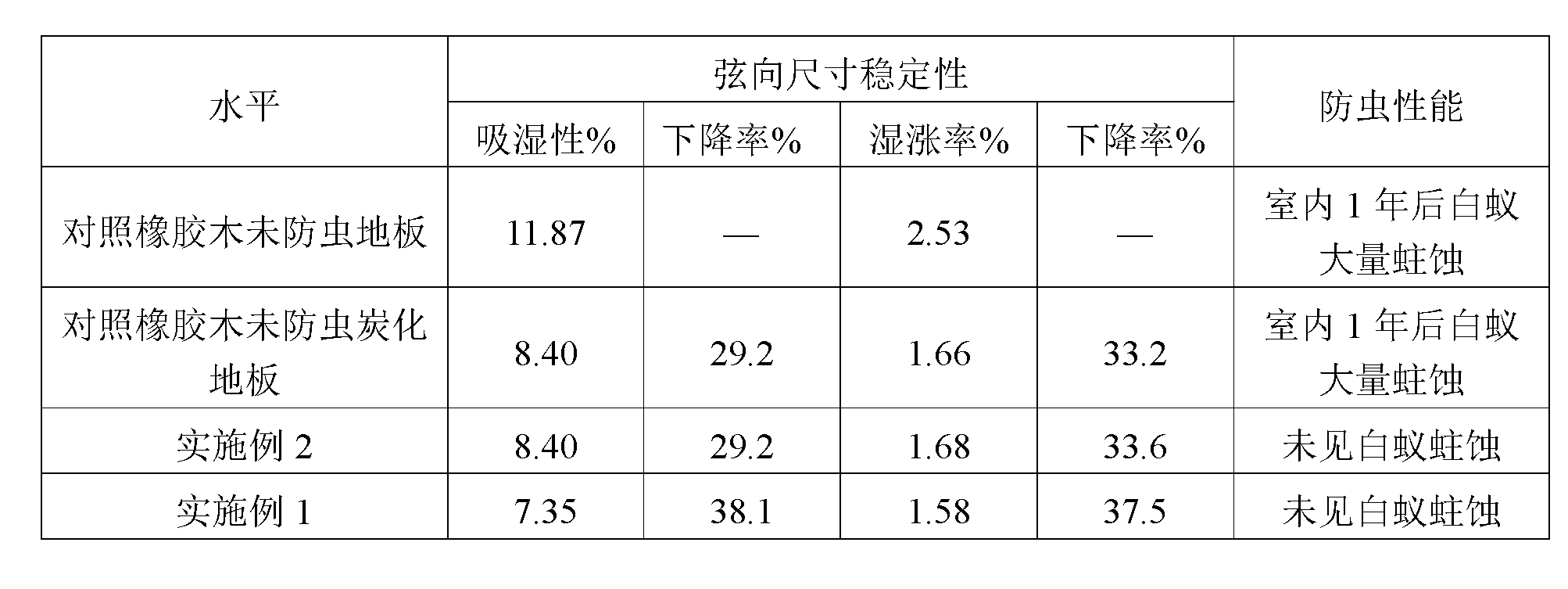

InactiveCN103072165AReduce direct dryingReduce routine drying process timeWood treatment detailsPressure impregnationSolid woodCarbonization

The invention relates to a production method of a high-temperature heating modified rubber wood floor, wherein rubber wood is sawn into wood beams or billets, the wood beams or billets are subjected to insect and termite prevention treatment, drying, carbonization and wood conditioning, the stress and the water content are balanced, and subsequent processing is conducted to obtain the rubber wood floor. The rubber wood is subjected to high temperature heating modified treatment and termite prevention treatment, the manufactured carbonized rubber wood floor is stable in size and excellent in stability and can resist corrosion by moths and termites, the produced carbonized rubber wood solid floor can be used indoors in both the humid south and the dry north, the problem that the solid floor is not easily made in a large width from the rubber wood is solved, and the additional value of the rubber wood is increased. Meanwhile, due to the adoption of the process of subdividing a sheet after carbonizing the wood beams, the problems of large the bending deflection, large reserved allowance in the thickness direction and large loss, resulting from the fact of direct drying and carbonizing of the sheet, can be solved, and the outturn percentage is increased.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Manufacturing method for fluorescent transparent magnetic wood

InactiveCN106313221AWith transparencyAppropriate transparencyPressure wood treatmentWood treatment detailsFluorescenceMagnetite Nanoparticles

The invention relates to a manufacturing method for fluorescent transparent magnetic wood. The manufacturing method for the fluorescent transparent magnetic wood aims to solve the problems that existing wood is not transparent and does not have magnetism or the fluorescence property. The manufacturing method for the fluorescent transparent magnetic wood comprises the steps that firstly, lignin of wood is eliminated; secondly, fluorescent magnetic nanoparticles are prepared; and thirdly, the fluorescent transparent magnetic wood is manufactured and obtained. The method is used for manufacturing the fluorescent transparent magnetic wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

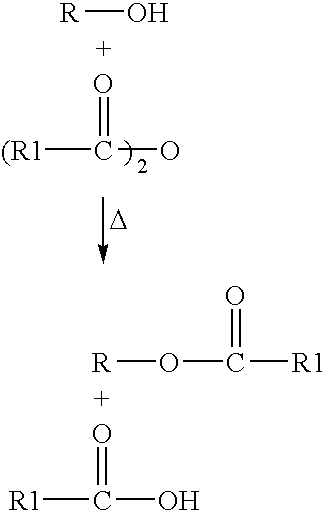

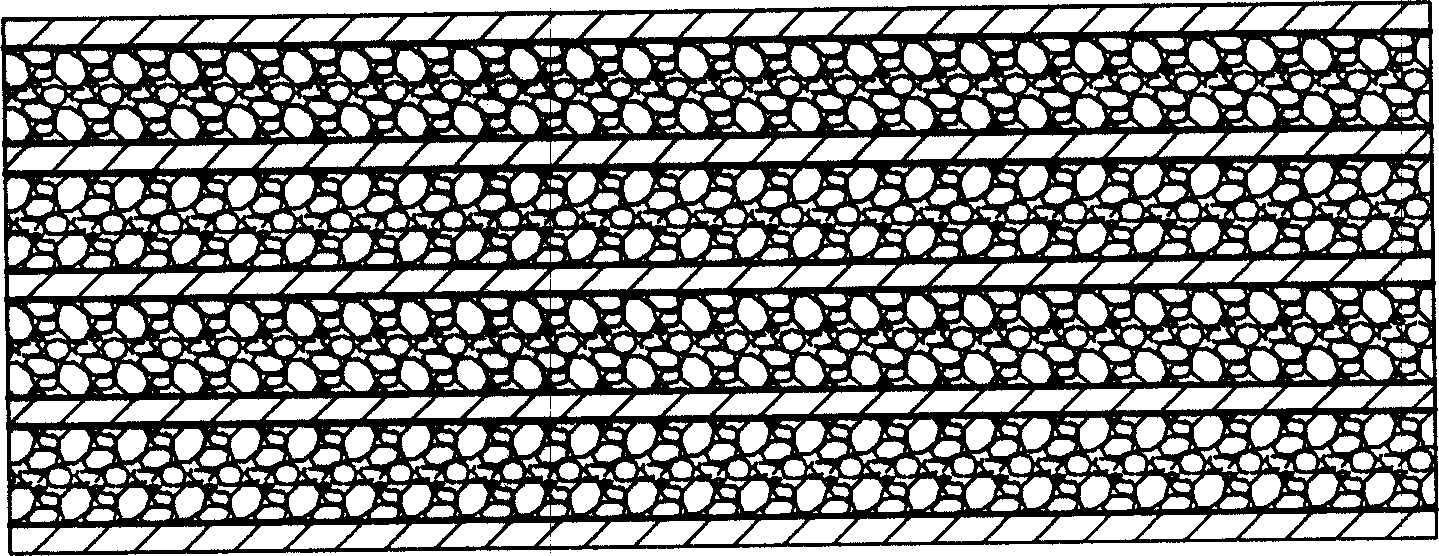

Multilayer flame-retardant composite wood and method for producing same

InactiveCN1883892ANo pestsMaintain propertiesWood treatment detailsWood veneer joiningWood veneerInorganic salts

A multilayer flameproof synthetic wood is at least three-layer laminated structure with 2 to 20 mm wood sheet and 2 to 20mm flameproof sheet, and the surface of the wood is processed by conventional flame retardant treatment, wherein the wood sheet is next to the flameproof sheet, and the wood sheet and the flameproof sheet are bound by adhesive; and the weight ratios of the flameproof sheet components are 100 to 150kg saw dust or crop hull and stalk with the diameter of 1 to 2 mm,65 to 105kg assisted materials, and 780 to 900kg inorganic salts. The production process comprises the steps of flameproof moth-proof and anticorrosion treatment for wood sheet, drying, splicing, and finishing, coating adhesive on the flameproof sheet and extrusion pressing after the wood sheet and the flameproof sheet are bound, and high frequency drying. The multilayer flameproof synthetic wood is provided with the fireproof, dampproof, anticorrosion, soundproof, and thermal-proof performances, high strength, high impact resistance, excellent toughness, and good persistence, and the synthetic wood can be cut, planed, drilled, and nailed.

Owner:江苏木易阻燃科技股份有限公司

Production method for manufacturing sliced veneer by bamboo split recombined bamboo wood

ActiveCN103878839AIncrease color varietiesIncrease added valueOther plywood/veneer working apparatusWood treatment detailsPulp and paper industryChemistry

The invention relates to a production method for manufacturing sliced veneer by bamboo split recombined bamboo wood and aims to realize that firstly, bamboo splits can be used for manufacturing bamboo veneer decorating materials and bamboo wood utilization rate is increased; secondly, natural-color, carbonized and dyed bamboo splits can be used for manufacturing bamboo veneers and colors of the bamboo veneers are enriched; thirdly, the technical problem of humidifying square timber of the bamboo splits is omitted and procedures are saved. The production method includes steps of 1) manufacturing the bamboo splits; 2) subjecting the bamboo splits to natural-color, carbonized or dyed treatment; 3) drying the bamboo splits; 4) shaping the square timber of the bamboo splits; 5) conditioning the square timber of the bamboo splits; 6) softening the square timber of the bamboo splits; 7) slicing the square timber of the bamboo splits; 8) post processing.

Owner:NANJING FORESTRY UNIV

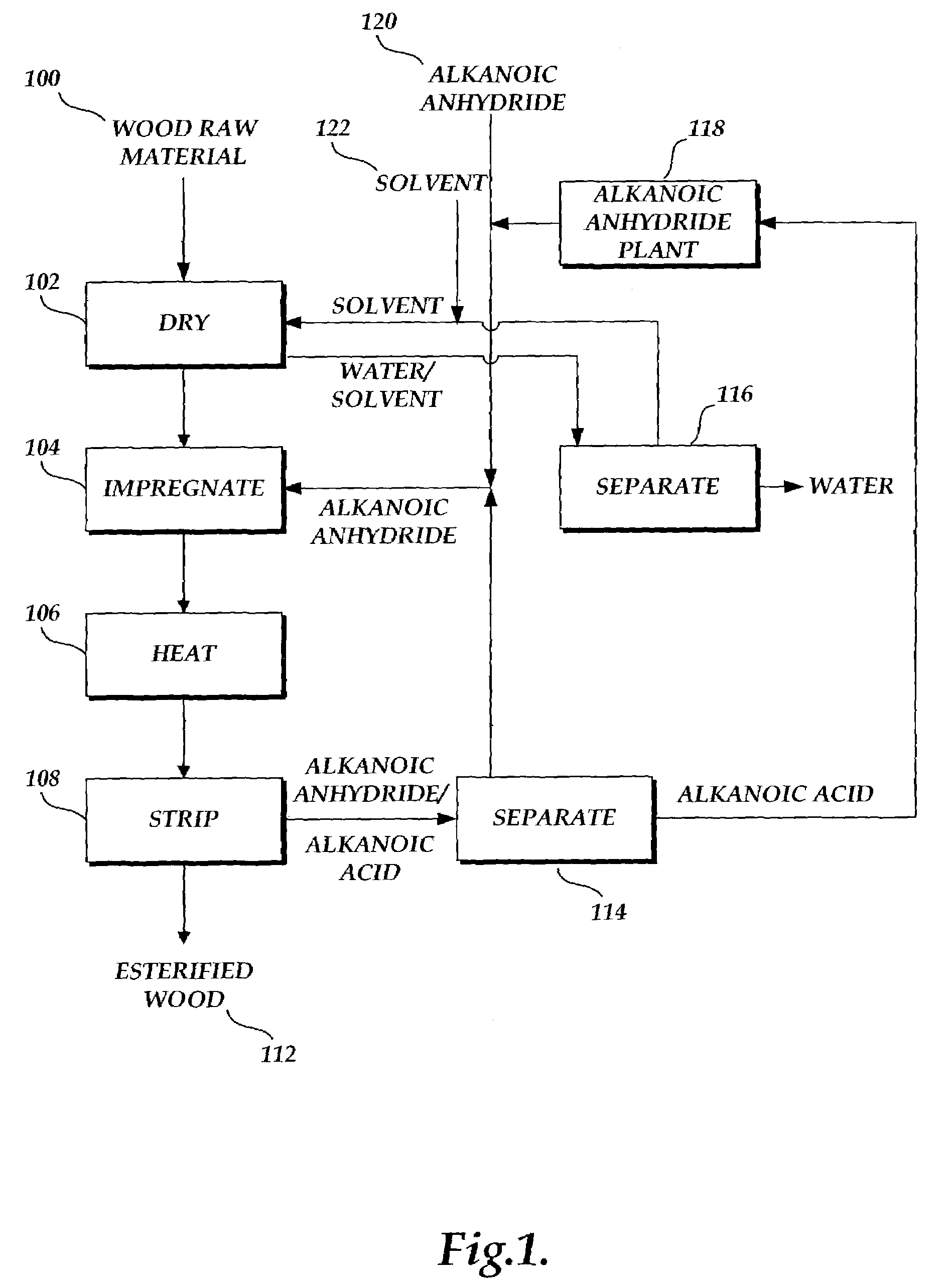

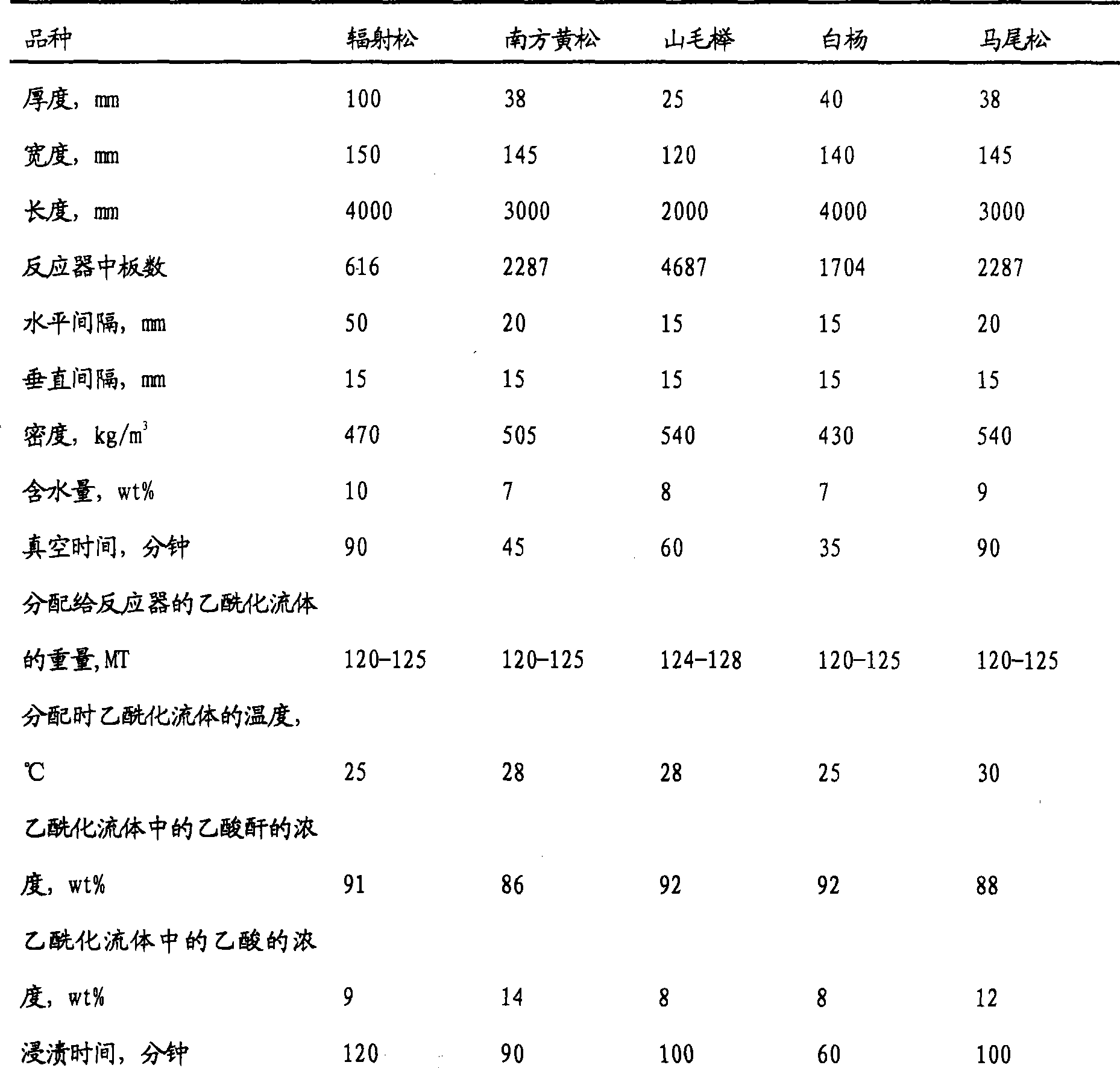

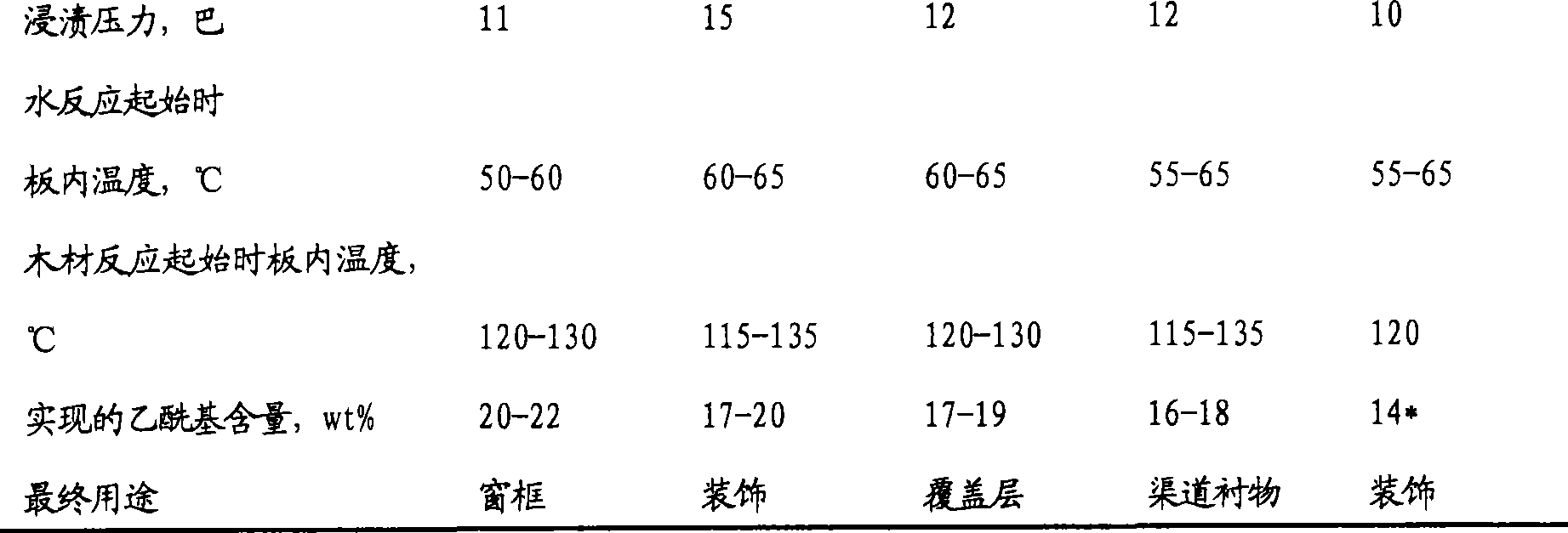

Process for wood acetylation and product thereof

ActiveCN101502975AReduce heat transferPressure impregnationWood impregnation detailsAcetylationChemistry

Owner:TITAN WOOD LTD

Fire retardant treatment process for wood

InactiveCN102615684AAvoid churnCurb churnPressure impregnationWood impregnation detailsFire - disastersEngineering

A fire retardant treatment process for wood comprises the following steps: firstly, preparing a fire retardant solution 1 and a fire retardant solution 2; then putting the wood into an immersion tank; then vacuumizing the immersion tank to form negative pressure in the immersion tank; then using the negative pressure in the immersion tank to pump the fire retardant solution 1 into the immersion tank; then pressurizing the immersion tank to ensure that the fire retardant solution 1 is immersed into the wood as deep as possible; then discharging redundant fire retardant solution 1 into a fire retardant solution 1 storage tank; after that, vacuumizing the immersion tank to form negative pressure; then using the negative pressure in the immersion tank to pump the fire retardant solution 2 into the tank; then pressurizing the immersion tank to ensure that the fire retardant solution 2 is immersed into the wood as deep as possible; then discharging the redundant fire retardant solution 2 into a fire retardant 2 storage tank; then taking out the well immersed wood; and finally, drying the wood to complete the fire retardant treatment for the wood. According to the fire retardant treatment process for wood, the fire retardant efficiency is high, the fire retardant solution in the wood can be effectively prevented from losing, the smoke and poison gas in the wood can be inhibited from releasing in a fire disaster, and the fire retardant treatment cost for the wood is low.

Owner:GUANGDONG YIHUA TIMBER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com