Method of treating fire retardant wood using microwave

A microwave treatment and wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve problems such as restricting wood drying speed, carbonization, outer coke and inner drying, etc., to solve a large number of enrichment and serious segregation, and improve distribution conditions. , the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

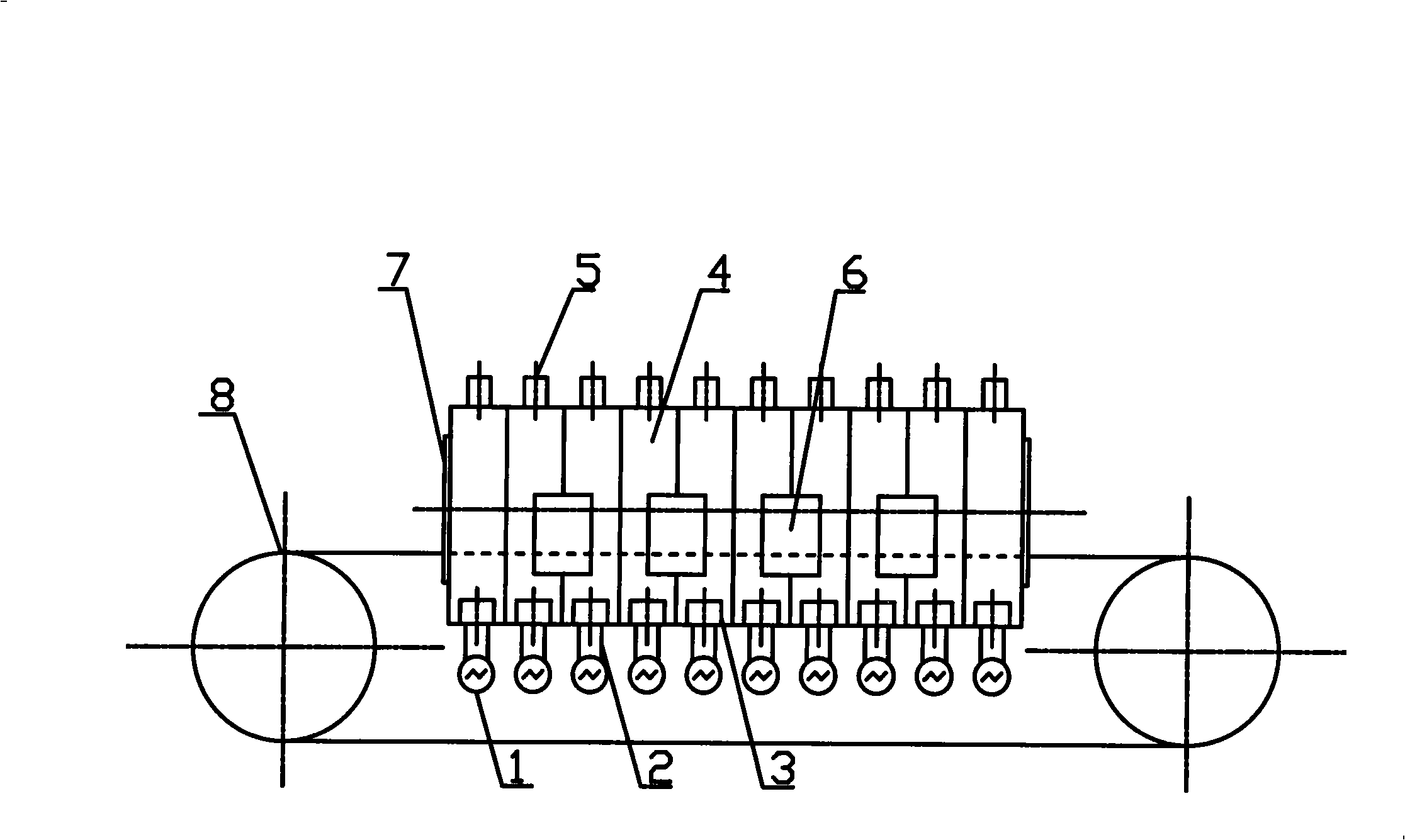

Image

Examples

Embodiment 1

[0021] A. The oak with a size of 1500mm × 200m × 25mm and an initial moisture content of 30% is sent to a microwave processing device with a microwave frequency of 915MHz. Under normal pressure, the drying temperature is controlled at 60°C and dried for 10 minutes. It is dried to a moisture content of 10%; B, the dried wood in step A is sent to a vacuum pressurized tank, vacuumed to a vacuum degree of 77KPa, and the vacuum is released, and a mixed solution is compounded with an inorganic flame retardant in the following mass ratio: 20 % ureidophosphate, 10% boric acid, 70% water, under the gauge pressure of 1.6MPa, soak the wood for 15 minutes, release the pressure, discharge the flame retardant, and then vacuumize to 77KPa vacuum degree, release the vacuum , and then take out the wood; C. Send the wood in step B to a microwave treatment device with a microwave frequency of 915MHz, and under normal pressure, control the drying temperature at 60°C and dry for 3 minutes to obtain...

Embodiment 2

[0023]A, the size is 300mm * 100m * 25mm, the Changbai larch with initial moisture content of 42%, is sent in the microwave treatment device that microwave frequency is 2450MHz, under normal pressure, control drying temperature 80 ℃, dry 10 minutes, namely It can be dried to a moisture content of 8%; B. Send the above-mentioned wood to a vacuum pressurized tank, evacuate to a vacuum of 77KPa, release the vacuum, and compound the mixed solution with the following mass ratio of inorganic flame retardant: 15% Dirukon's FRT in the United States, 12% borax, 73% water, soak the wood for 30 minutes under a gauge pressure of 1.2MPa, release the pressure, discharge the flame retardant, and then vacuumize to 77KPa vacuum degree, release the vacuum , and then take out the wood; C. Send the above wood to a microwave treatment device. Under normal pressure, the drying temperature is controlled at 80°C, and the drying time is 2 minutes to obtain a flame-retardant dry Changbai larch board wit...

Embodiment 3

[0025] A. Put the masson pine with a size of 200mm×100m×60mm and an initial moisture content of 52% into a microwave dryer with a microwave frequency of 2450MHz. Under normal pressure, the drying temperature is controlled at 70°C and dried for 10 minutes. It is dried to a moisture content of 12%; B, the wood is sent to a vacuum pressurized tank, vacuumed to a vacuum degree of 377KPa, and the vacuum is removed, and the mixed solution is compounded with the following mass ratio of inorganic flame retardants: 18% poly Ammonium phosphate APP, 6% ammonium pentaborate, 76% water, under the gauge pressure of 1.4MPa, soak the wood for 25 minutes, release the pressure, discharge the flame retardant, and then vacuumize to 57KPa vacuum degree, release the vacuum, Then take out the wood; C, send the above-mentioned wood to the microwave treatment device, under normal pressure, the drying temperature is controlled at 75°C, and drying for 3 minutes can obtain the flame-retardant dried masson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com