Patents

Literature

56results about How to "Good anti-loss performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

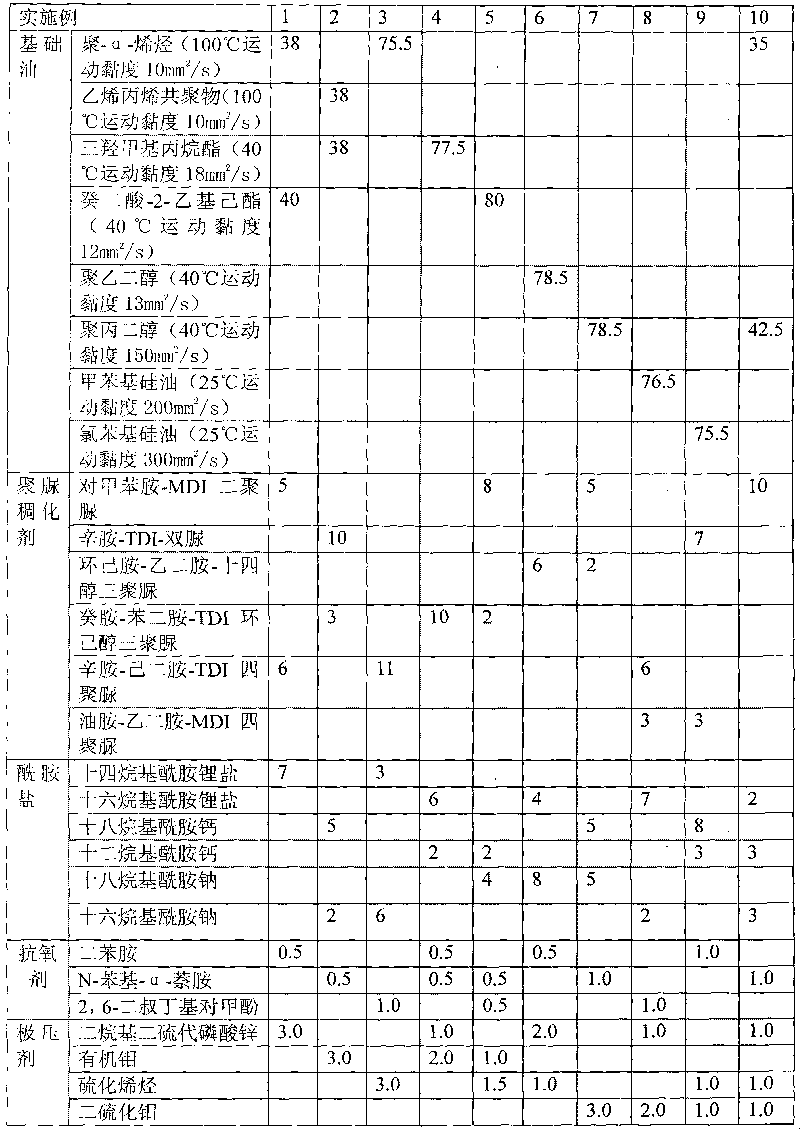

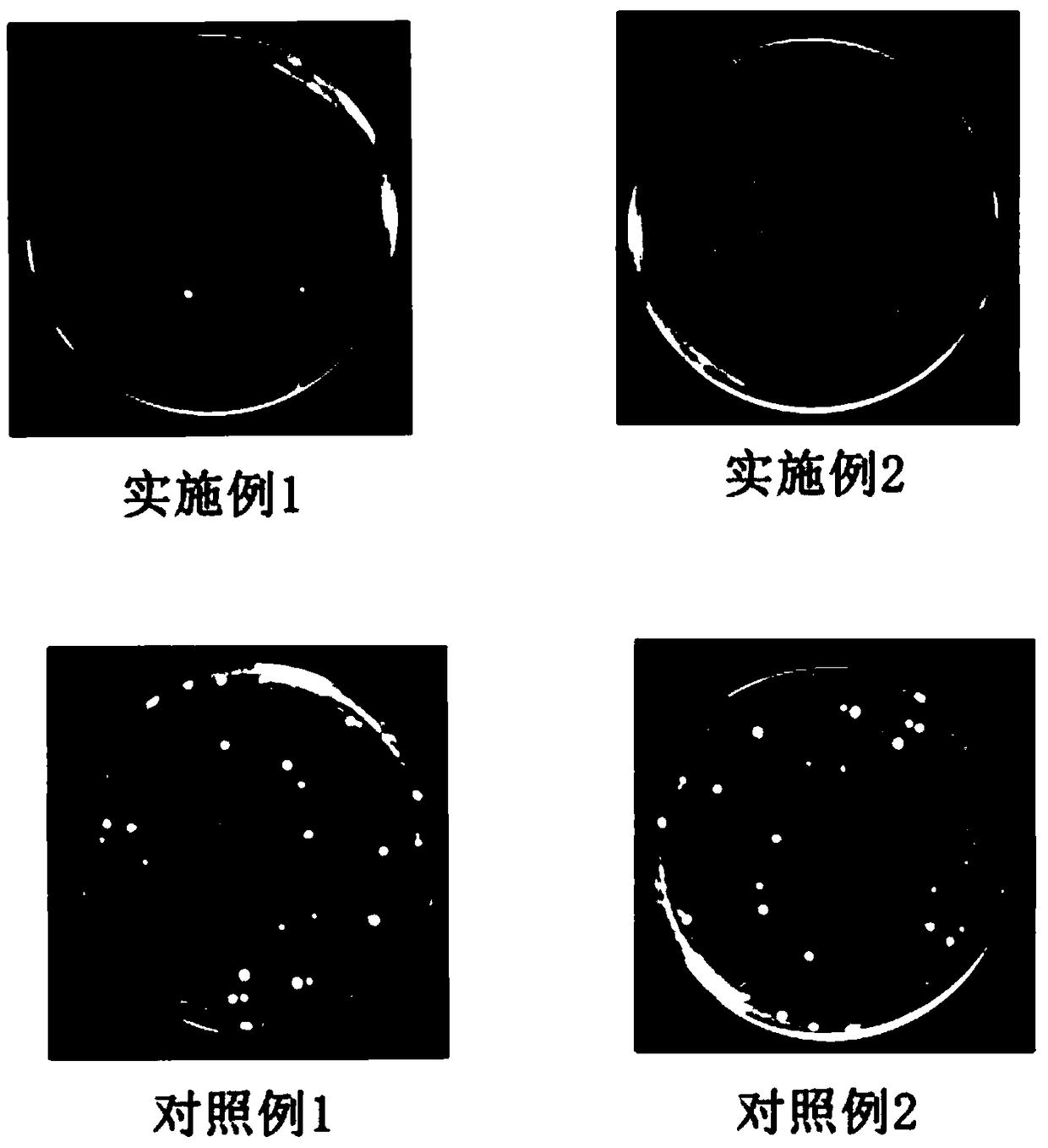

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Multifunctional preservative

InactiveCN105599082AReduce poisonGood loss resistanceWood treatment detailsPressure impregnationCorrosion preventionToxicity

The invention relates to a multifunctional preservative and belongs to the technical field of mold prevention and corrosion prevention. The multifunctional preservative comprises components in parts by weight as follows: 1-6 parts of an antibacterial agent, 3-10 parts of a leaching resistance agent, 0.1-4 parts of a surfactant, 3.5-10 parts of an organic solvent and 2-6 parts of water. The preservative can be used for mold prevention and corrosion prevention of wood, leather, hemp, bamboo, vines and other materials, has little toxicity and is good in leaching resistance.

Owner:安吉汉洲生物科技有限公司

Dyeing method for improving color fastness to light of osier

InactiveCN107486908AImprove color fastness to lightEnhanced photooxidative stabilityRadiation/waves wood treatmentWood treatment detailsVolumetric Mass DensityBinding force

The invention belongs to the technical field of osier dyeing, in particular to a dyeing method for improving color fastness to light of osier. The method specifically comprises the following steps of (1) osier pretreatment and (2) osier dyeing. The permeation of a coloring agent is effectively improved, the degree of aggregation of dye molecules is higher, crosslinking binding between the dye molecules and the ingredients of osier is prompted, the binding force is high, leachability resistance is good, the electronic cloud density of azo group hydrogen atoms is reduced, the shielding effect on azo groups is achieved, the photooxidation resistance stability of the azo groups in the structure of the dye molecules is improved, and finally, the color fastness to light of a dye is improved; and furthermore, osier is evenly dyed and has good color fastness to water, the difference between the color of the interior and the color of the exterior of osier is small, osier is evenly dyed without stains, and is bright and glossy, and the quality of the wickerwork made of osier is effectively improved.

Owner:安徽阜南县万家和工艺品有限公司

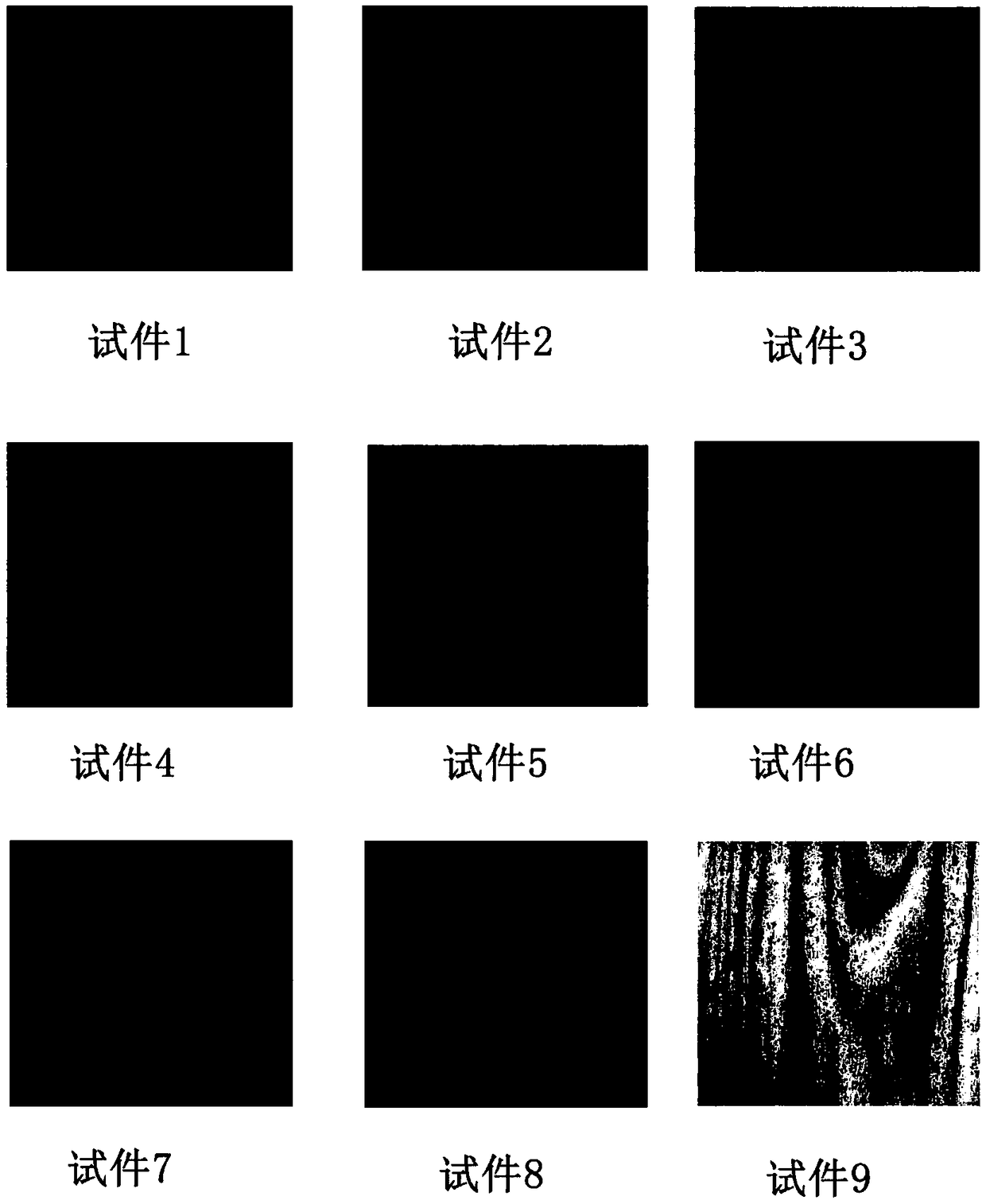

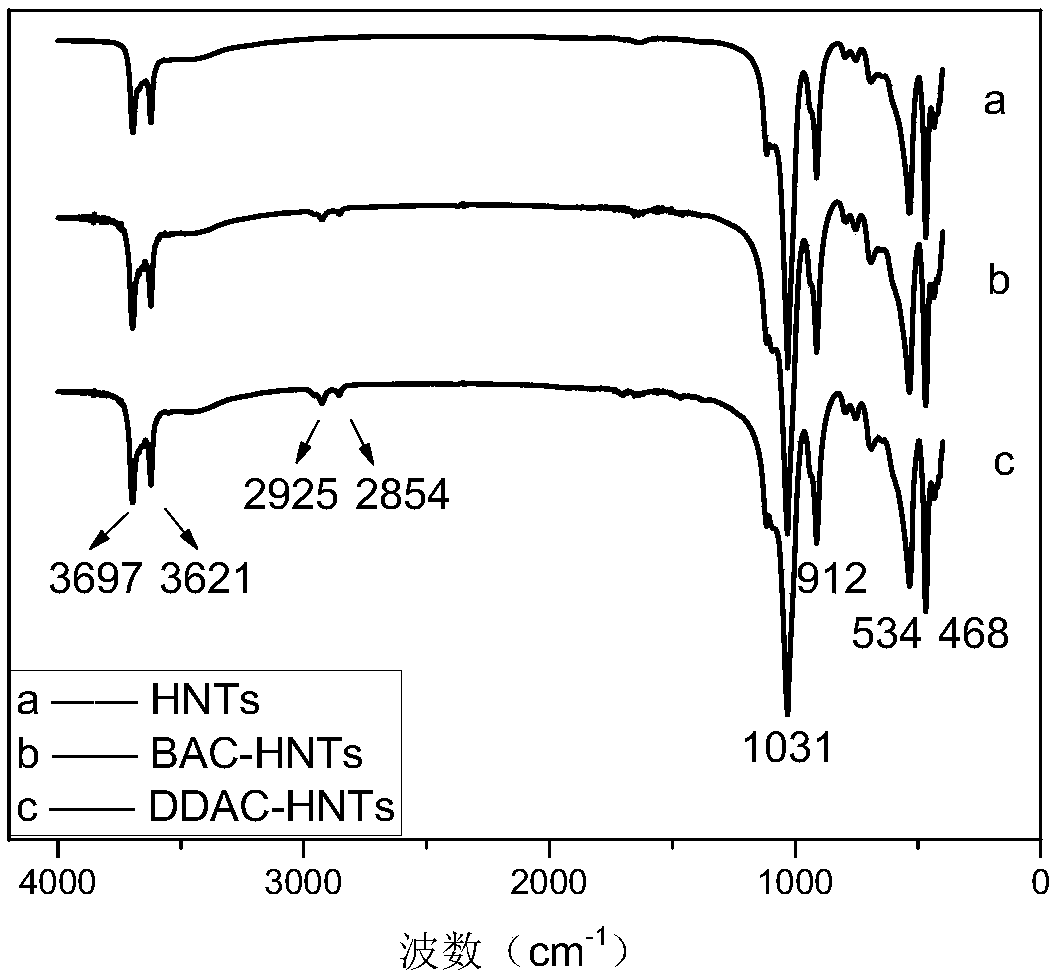

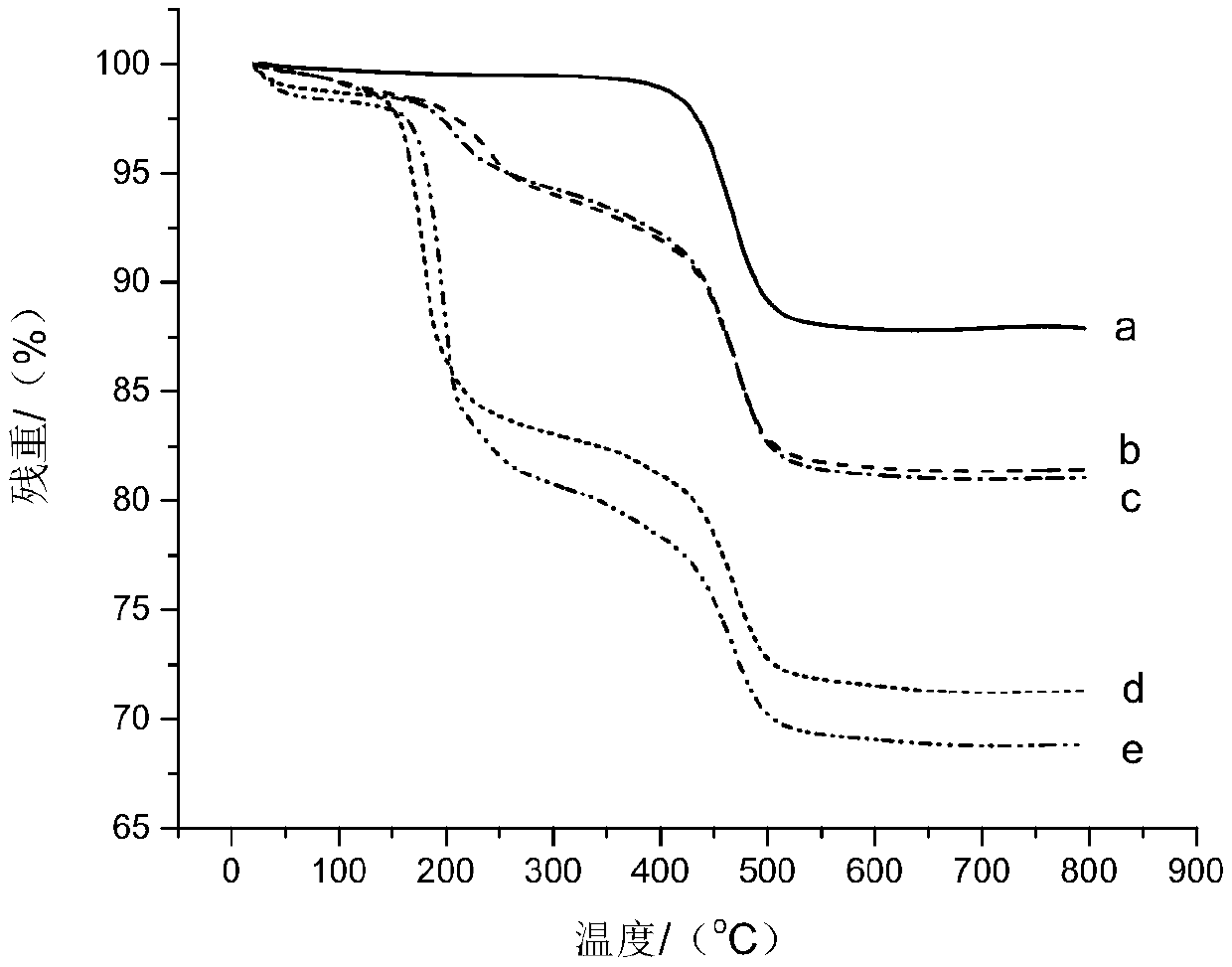

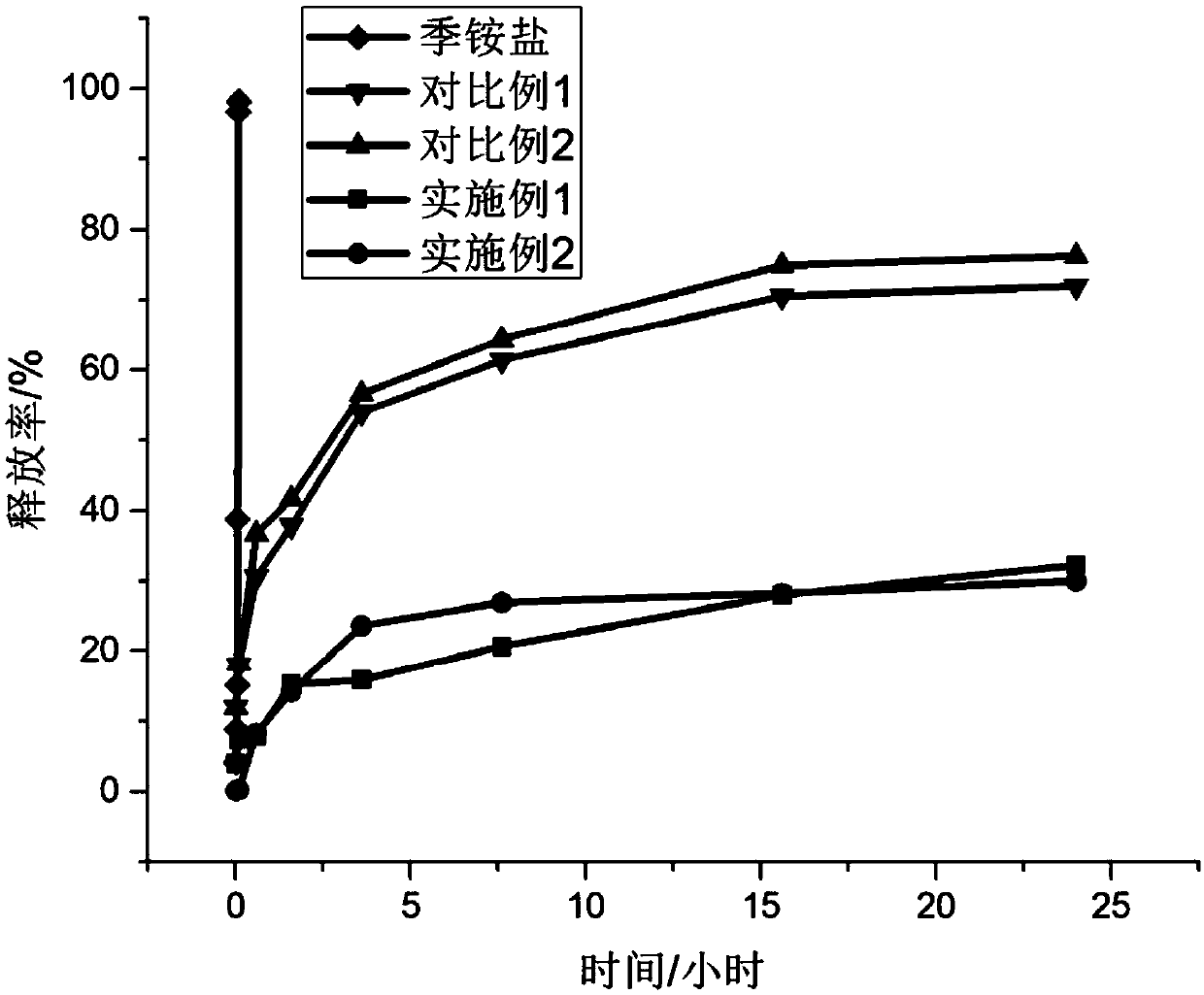

Halloysite nanotube/quaternary ammonium salt composite antibacterial particle and preparation method and application thereof

ActiveCN109619100AExcellent synergistic effectIncreased lumen volumeBiocideFungicidesChemistryWood processing

The invention relates to halloysite nanotube / quaternary ammonium salt composite antibacterial particles and a preparation method and application thereof. According to the composite antibacterial particles, through acidification and capacity expansion of halloysite, intercalation activation treatment, proper selection of quaternary ammonium salt species and improvement of the loading process, the load of the quaternary ammonium salt in halloysite nanotubes is effectively improved, the anti-loss performance of the quaternary ammonium salt is improved, and the composite antibacterial particles have excellent antimicrobial activity against many kinds of fungi, stain fungi, decaying bacteria and bacteria, and have a wide industrial application range in the field of bamboo wood processing.

Owner:INT CENT FOR BAMBOO & RATTAN

Preparation method of bamboo/wood mildew-resistant antiseptic

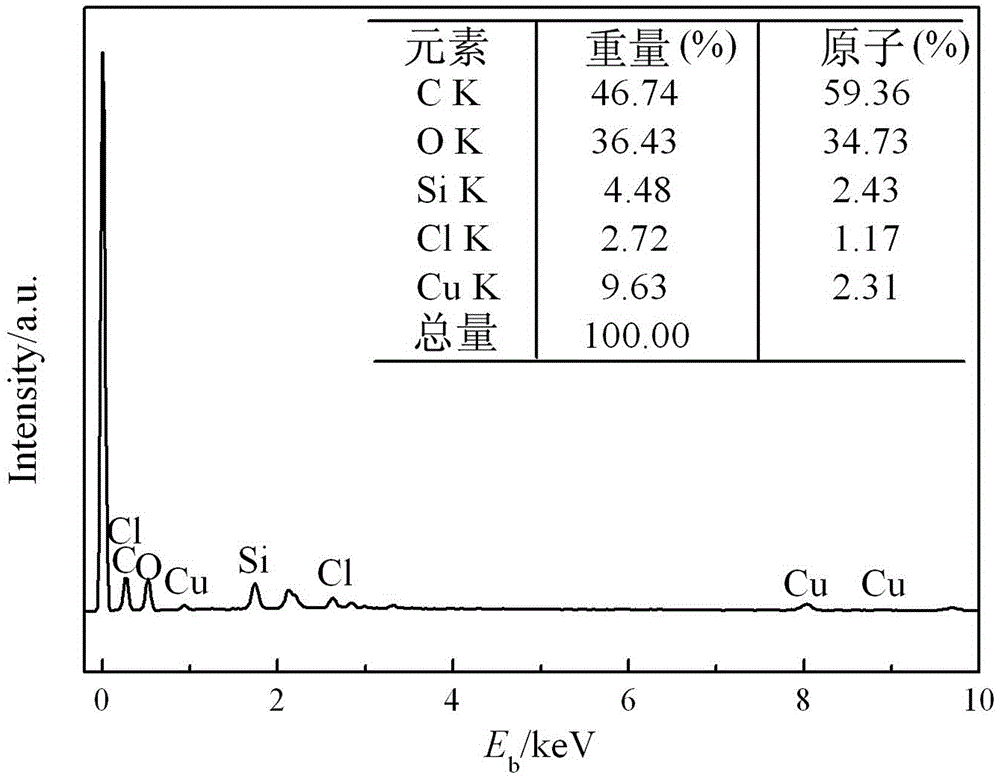

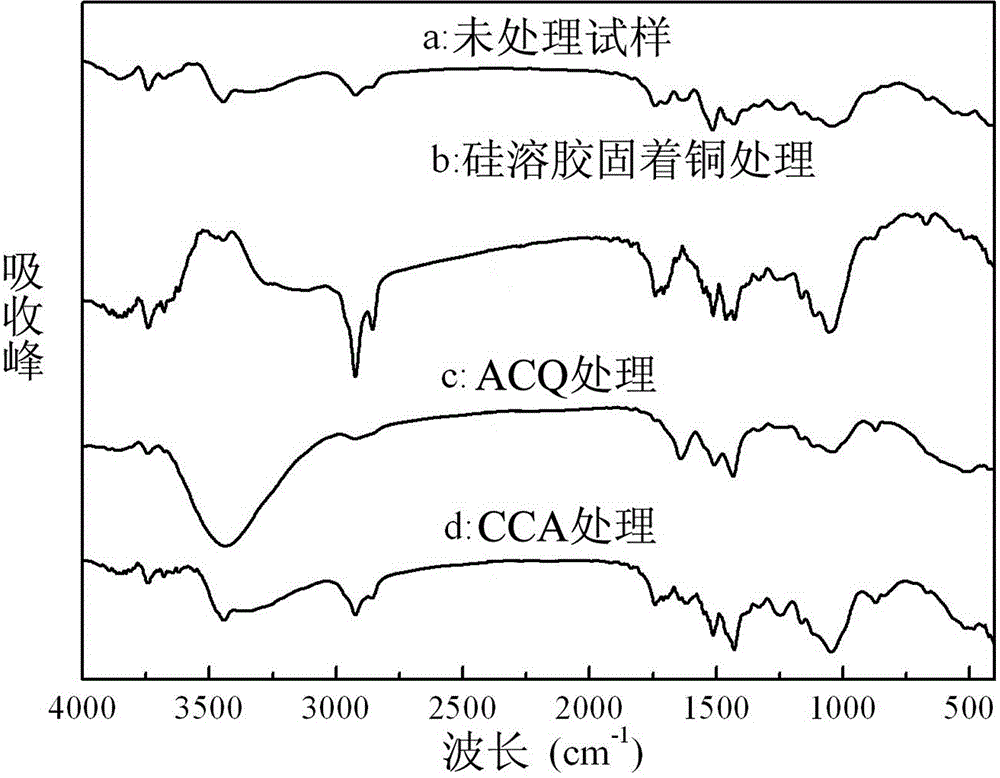

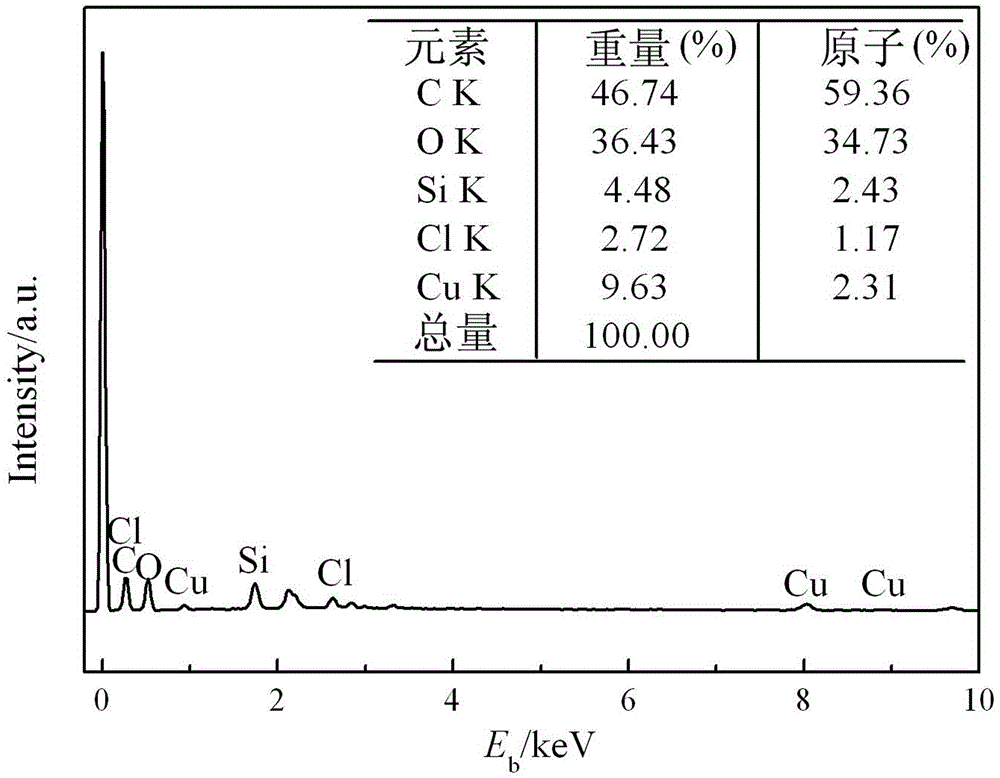

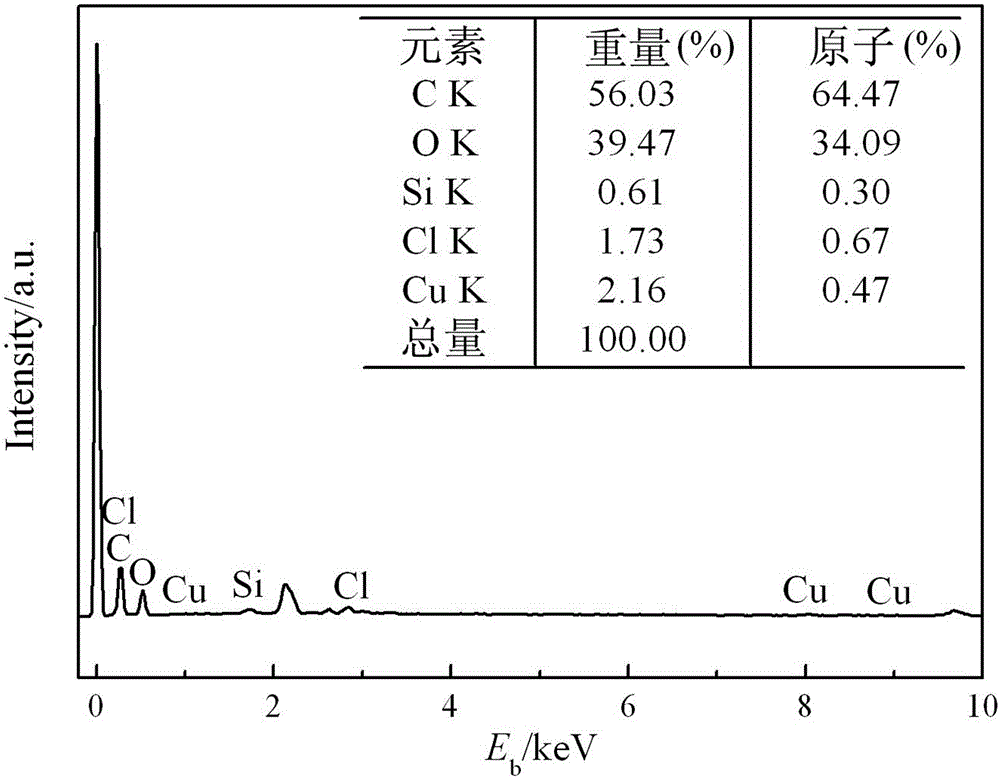

ActiveCN104526806AGood anti-loss performanceImproves loss resistanceWood impregnation detailsSilicic acidEthyl ester

The invention discloses a preparation method of a bamboo / wood mildew-resistant antiseptic. The preparation method comprises the following steps: weighing 60-150 parts by weight of tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide at room temperature, slowly and dropwise adding tetraethoxysilane, sodium silicate solution or titanium tetrabutoxide into a mixed liquor of 40-75 parts by weight of anhydrous ethanol and 30-36 parts by weight of deionized water, and simultaneously treating the mixed liquor by water bath at 40-80 DEG C and stirring; adjusting pH to 3-4 by adding a proper amount of acid, and reacting for 30-45 min to prepare uniform sol; and slowly adding 3-12 parts by weight of an aqueous solution containing a copper compound into the sol under the condition of treating the sol by water bath at 40-80 DEG C and stirring, adding 5-15 parts by weight of an aminosilane coupling agent used as a guiding agent, fully stirring and reacting so as to prepare the bamboo / wood mildew-resistant antiseptic. The prepared bamboo / wood mildew-resistant antiseptic has excellent leach resistance and has simple components. The preparation method is simple, has relatively low production cost, is environmentally friendly and is less harmful to the health of human body.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparing preservative-treated wood by using environmental protection low molecular weight organic pharmaceutical agent

ActiveCN103659968ASolve the synergy problemGood anti-loss performanceWood treatment detailsPressure impregnationLoss ratePreservative

The invention provides a method for preparing a preservative-treated wood by using an environmental protection low molecular weight organic pharmaceutical agent, and relates to a preservative-treated wood preparation method. In the prior art, the existing wood preservative has characteristics of harm on environment and easy loss, the wood treated by separately adopting furfuryl alcohol with a characteristic of no environment pollution or a nitrogen hydroxymethyl resin with a characteristic of no environment pollution as a treatment pharmaceutical liquid can not concurrently have characteristics of excellent loss rate resistance and excellent preservation effect, and the treatment pharmaceutical liquid prepared by simply compounding the furfuryl alcohol and the nitrogen hydroxymethyl resin has problems of poor synergy between the furfuryl alcohol and the nitrogen hydroxymethyl resin, instability and treated wood shrinkage deformation. A purpose of the present invention is to solve the problems in the prior art. The method comprises: 1, carrying out an air dry treatment on wood; 2, preparing a treatment pharmaceutical liquid; 3, carrying out a vacuum pressurization impregnation treatment on the wood; and 4, drying to obtain the high size stability preservative-treated wood prepared by using the environmental protection low molecular weight organic pharmaceutical agent. The present invention relates to the method for preparing the preservative-treated wood by using the environmental protection low molecular weight organic pharmaceutical agent.

Owner:河北优林科技有限公司

Plantation wood modification processing method

InactiveCN104858953AImprove permeabilityGood application effectRadiation/waves wood treatmentWood treatment detailsMicrowaveHardness

The invention discloses a plantation wood modification processing method including steps of preliminary selection, drying and microwave processing; preparation of a modification agent; preparation of a modification solution; vacuum impregnation and post drying. The beneficial effect is that through use of microwave treatment, the permeability of plantation wood is improved, the modification processing effect is improved, the processed wood has flame retardant, smoke suppression, anticorrosive, moth-proofing, color distortion preventing, good erosion resistance and other advantages, and the surface hardness, wear resistance, impact strength, waterproof property and the like are significantly improved, so that the application effect and fields of the plantation wood are well improved, and the plantation wood modification processing method has the very high practical value and promotion prospects.

Owner:王玉燕

Shield tail sealing grease

The invention provides shield tail sealing grease with high water resistance and high water sealing performance. The shield tail sealing grease has high pump pressure conveyance feasibility, does not corrode spacers among cement annular duct pieces, is easily filled among wire brushes, and has long using cycle and high quality. The shield tail sealing grease comprises the following components: base oil, lubricating oil, chlorinated paraffin, polybutene, fibers and calcium carbonate. When coated on metal plates or concrete surfaces or in the dry and wet state or in water, the shield tail sealing grease has the advantages of high adhesivity, high sealing performance, high abrasion resistance, high leachability resistance, good pumping effect, environmental friendliness, no toxicity, no odor, no corrosion to equipment, reduction in abrasion of shield equipment, stable products, ageing resistance and oxidation resistance.

Owner:东莞市明洁隧道建设材料有限公司

Mildew-proof anticorrosion processing method of bamboo and wood

ActiveCN104476637AIncreased durabilityGood anti-loss performancePressure impregnationWood impregnation detailsComposite materialIndustrial engineering

The invention discloses a mildew-proof anticorrosion processing method of a bamboo and wood. The method comprises the steps: arranging a bamboo and wood sample into a soaking tank, pouring a mildew-proof anticorrosion agent into the soaking tank, vacuumizing the soaking tank, controlling the vacuum pressure to -0.06Mpa to -0.098Mpa, preserving the pressure for 50 to 150 minutes, pressurizing the soaking tank after the pressure is released, controlling the pressurizing pressure at 2MPa to 7MPa, and preserving the pressure for 80 to 240 minutes; or arranging the bamboo and wood sample into the soaking tank, vacuumizing the soaking tank, controlling the vacuum pressure to -0.06Mpa to -0.098Mpa, preserving the pressure for 50 to 150 minutes, pouring the mildew-proof anticorrosion agent after the pressure is released, carrying out the pressurizing treatment, controlling the pressurizing pressure to 2MPa to 7 MPa, and preserving the pressure for 80 to 240 minutes. The mildew-proof anticorrosion processing method is simple, and processed bamboo and wood is high in durability and excellent in loss resistance.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Halogen-free flame retardant for modified wood

InactiveCN104858992AImprove flame retardant performanceImprove anti-corrosion performanceWood treatment detailsWood impregnation detailsPhosphatePyrophosphate

The present invention discloses a halogen-free flame retardant for modified wood, the halogen-free flame retardant comprises the following components by mass: 20%-30% of amidinothiourea phosphate, 15%-20% of water soluble ammonium polyphosphate, 5%-10% of zinc borate, 2%-10% of pentaerythritol-spiro cyclodiphenyl phosphate, 2%-5% of pentaerythritol, 1%-4% of ammonium molybdate, 25%-40% of silica sol, 1%-2% of sodium pyrophosphate and 1%-2% of sodium diethylhexyl sulfosuccinate. The beneficial effect of the halogen-free flame retardant is that the halogen-free flame retardant has excellent flame retardant and anti-corrosion performance, good anti smoking effect, good anti loss performance, is halogen-free, environmentally-friendly, low-cost, stable in performance, and easy to generalize.

Owner:王玉燕

Wood fire retardant

InactiveCN104858975AExcellent flame retardant and smoke suppression performanceGood anti-loss performanceWood treatment detailsWood impregnation detailsAmmonium molybdateDiammonium phosphate

The invention discloses a wood fire retardant which comprises the following components by mass: 20%-30% of amidinourea phosphate, 15%-20% of diammonium phosphate, 8%-15% of boric acid, 2%-5% of ammonium molybdate, 5%-10% of sodium octoborate, and 20%-50% of silica sol, and the silica content in the silicon sol is 20wt%-30wt%. The beneficial effect is that the wood fire retardant has the advantages of flame retardance of the amidinourea phosphate, diammonium phosphate, boric acid and silicon compound, smoke inhibition property of the ammonium molybdate, anti erosion performance of the silica sol, and corrosion resistance of the sodium octoborate,. The flame retardant smoke inhibition performances are excellent, the anti erosion performance is significant, and the anti-corrosion effect is good.

Owner:王玉燕

Method for catalyzing and synthesizing biodiesel by virtue of short mesoporous DCNH-Zr-SBA-15 molecular sieve

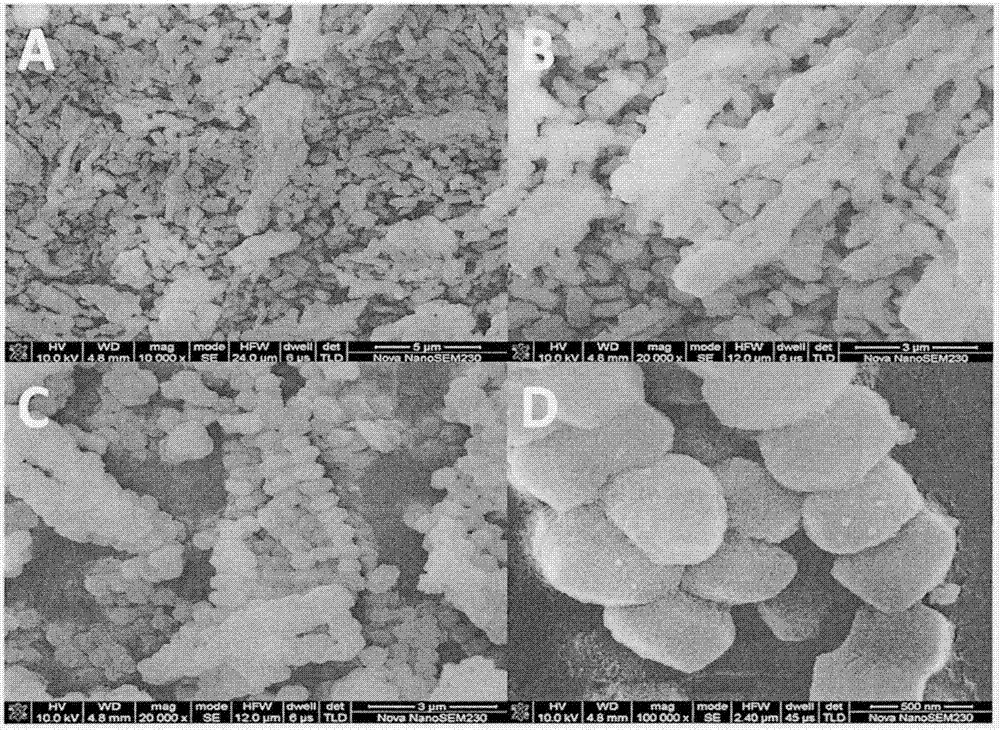

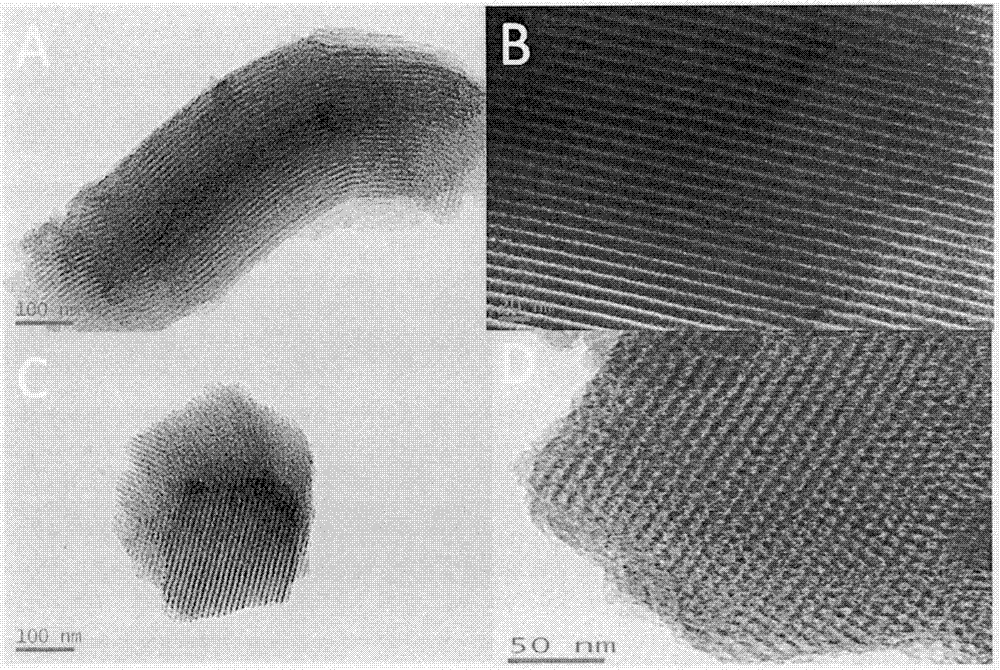

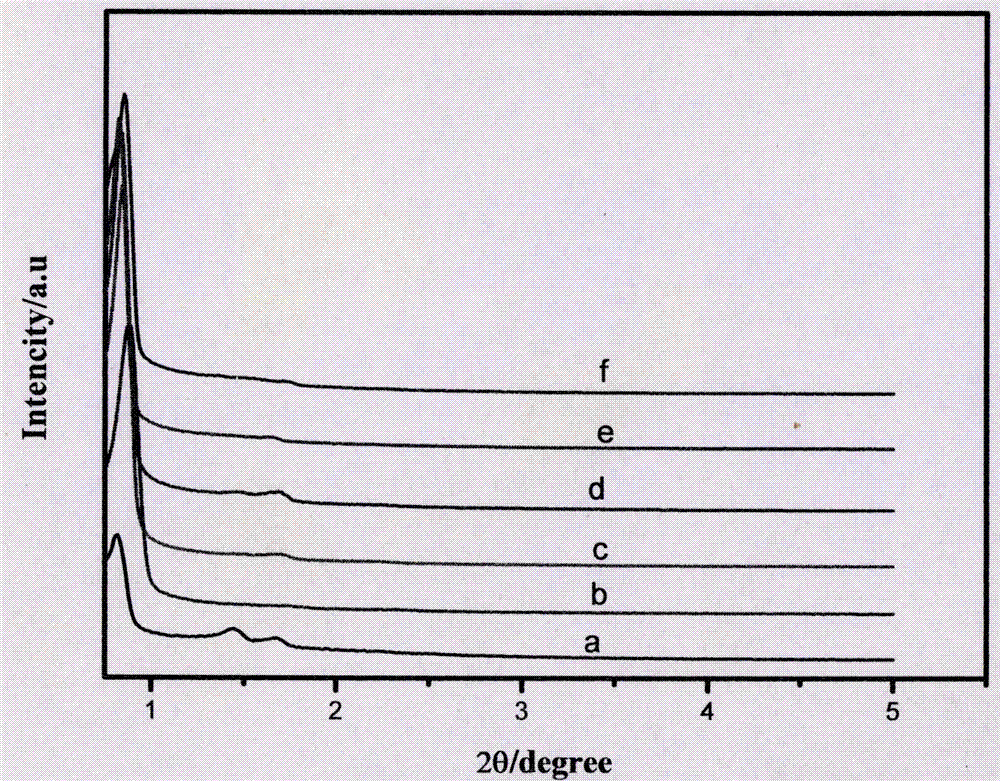

ActiveCN107051589AReduce mass transfer diffusion resistanceHigh yieldFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryMolecular sieve

The invention discloses a method for catalyzing and synthesizing biodiesel by virtue of short mesoporous DCNH-Zr-SBA-15 molecular sieve organic solid alkali. A short mesoporous DCNH-Zr-SBA-15 molecular sieve organic solid alkali catalyst with high activity, large specific surface area and strong alkalinity is prepared by taking a SBA-15 molecular sieve as a carrier, doping Zr and introducing nucleophilic addition and hydroxyl condensation reaction of strong-alkalinity an organic guanidine compound DCNH and is used for catalyzing and synthesizing the biodiesel, so that the mass transfer diffusion resistance of grease molecules in a duct of the molecular sieve is effectively reduced, and the yield of the biodiesel is increased; and reaction conditions are mild, the catalyst can be conveniently separated, recycled and repeated used, and the biodiesel is high in leaching resistance and stability and has industrial application prospects.

Owner:XIANGTAN UNIV

Method for polypeptide biomimetic preparation of platinum catalyst for fuel battery and application of platinum catalyst for fuel battery

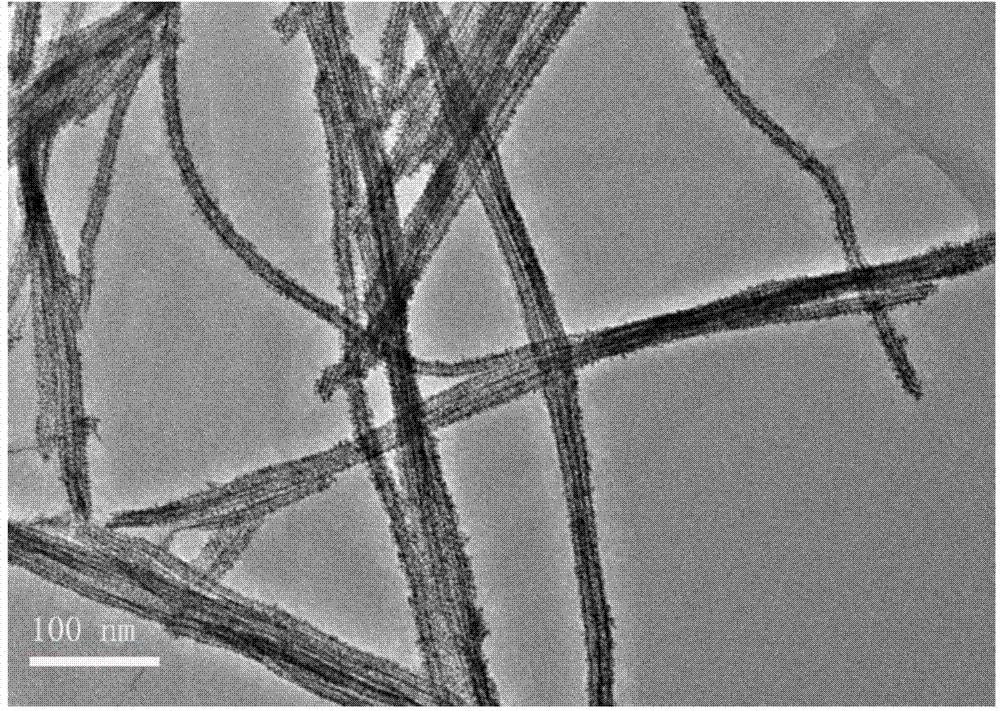

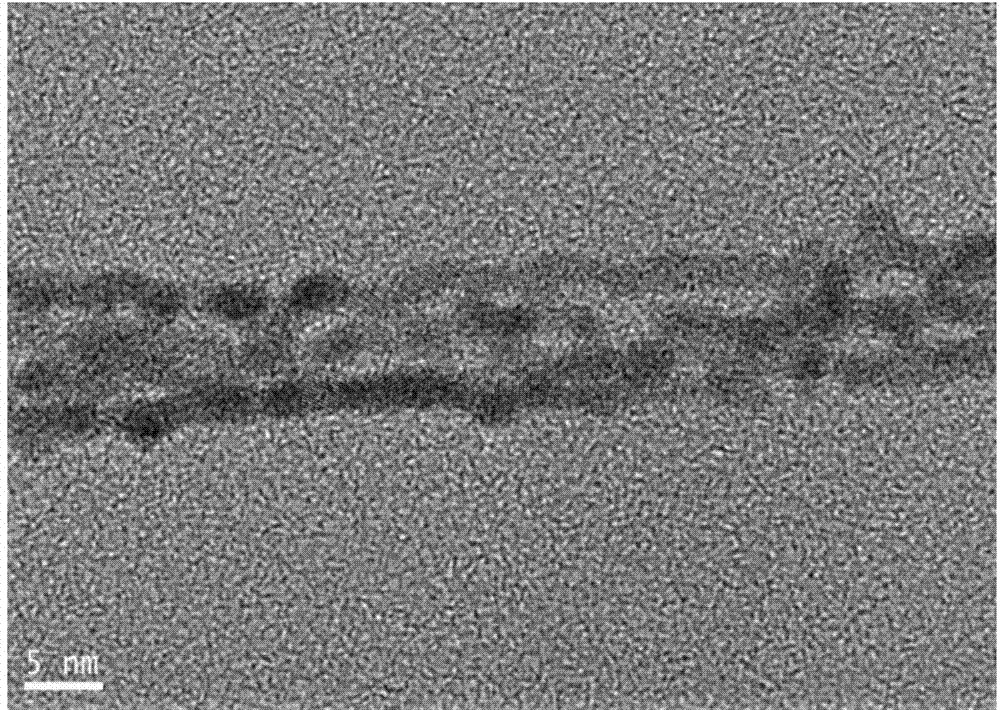

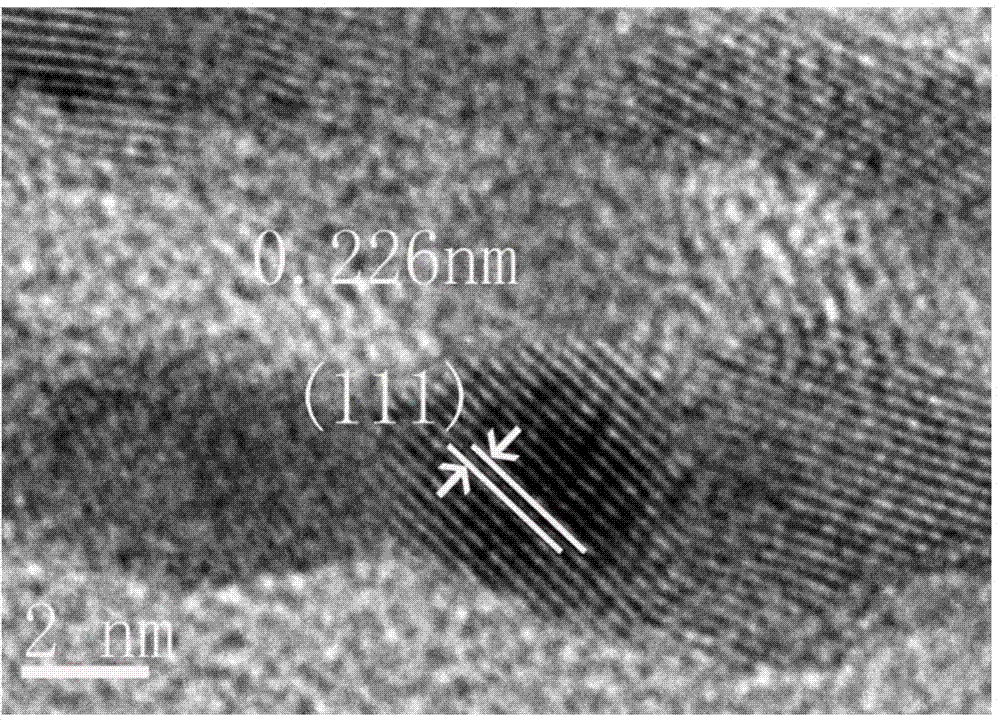

InactiveCN104492427AStrong adjustableMild conditionsCell electrodesNanotechnologySupporting systemFuel cells

The invention relates to a platinum nanometer catalyst. The platinum nanometer catalyst is a one-dimensional continuous platinum nanometer line adsorbed with platinum nanometer particles on the surface by using the self-assembly aggregate of an amphiphilic polypeptide molecule as the template. The platinum catalyst disclosed by the invention has larger length-diameter ratio, less defective sites, less crystal lattice boundaries and good conductivity, and simultaneously has better resistance against aggregation and loss, and the one-dimensional morphology of the platinum nanometer catalyst is beneficial for transferring of reaction materials; the one-dimensional nanometer line of the platinum nanometer catalyst can form a self-supporting system so a carbon carrier is unnecessary, and the reduction of the catalytic activity caused by carrier corrosion effect during use is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Furfuryl alcohol resin optimizing liquid for wood modification based on compound catalyst

InactiveCN106217541AGood anti-loss performanceGood dimensional stabilityWood impregnation detailsEnvironmental resistanceLower grade

The invention relates to furfuryl alcohol resin optimizing liquid for wood modification based on a compound catalyst. The furfuryl alcohol resin optimizing liquid comprises the following components in parts by weight: 50-80% of furfuryl alcohol, 3-8% of maleic anhydride, 1-5% of auxiliary catalyst, 1-10% of stabilizing agent, 1-5% of solvent, and 20-50% of water. The wood optimizing liquid uses maleic anhydride as a main catalyst, uses a citric acid and an oxalic acid compound as the auxiliary catalyst, and is high in efficiency and environment-friendly; a modified wood has such advantages as prominent corrosion resistance, leachability resistance and size stability; the top grade of low-grade wood is realized; and the utilization rate and the service life of the wood are increased and prolonged. The optimizing liquid is free of poison and halogen in formulas, is excellent in environmental protecting performance, belongs to environment-friendly wood modification treatment optimizing liquid, and generates no environmental pollution in the production and use process. The wood modified by the optimizing liquid greatly improves the leachability resitance, the size stability, the corrosion resistance and the mechanical performance.

Owner:NANJING BOJUN NEW MATERIAL CO LTD +1

Eco-friendly anti-loss timber fire retardant and its preparation method and treatment process

InactiveCN104647535AImprove flame retardant performanceGood anti-loss performancePressure impregnationWood impregnation detailsSilicon dioxideFiberboard

The invention discloses an eco-friendly anti-loss timber fire retardant and its preparation method and treatment process. The eco-friendly anti-loss timber fire retardant comprises, by mass, 30-40% of ammonium polyphosphate, 5-15% of zinc borate, 15-30% of silica sol, 5-10% of antimony oxide, 2-6% of sodium molybdate, 0.5-3% of sodium dodecyl benzene sulfonate and 0.1-1% of pentaerythritol. The preparation method utilizes ammonium polyphosphate as a main agent, zinc borate, silica sol and antimony oxide as adjuvants, sodium molybdate as a smoke inhibitor, sodium dodecyl benzene sulfonate as a surfactant and pentaerythritol as a charring agent so that the eco-friendly anti-loss timber fire retardant has excellent flame retardance, smoke inhibition and loss resistance performances, is free of halogen, is environment-friendly, has a low cost, simple preparation processes and industrial production feasibility and is suitable for wood materials such as solid boards, fiberboards, shaving boards and glued boards.

Owner:高天红

Preservative for southern pine outdoor inscribed wooden slip culture walls

ActiveCN109227834AGood light stabilityAntibacterial redivisionWood treatment detailsWood impregnation detailsGlycerolCopper oxide

The invention discloses a preservative for southern pine outdoor inscribed wooden slip culture walls. The preservative comprises the following raw materials in parts by weight: 0.5-0.8 part of cupriccitrate, 0.2-0.6 part of copper ethanolamine, 0.2-1.5 parts of quaternary ammonium salt, 1-3 parts of modified graphene oxide, 0.1-0.8 part of plant extract, 1-1.7 parts of nanometer copper oxide, 0.2-1.5 parts of borax, 2-3.5 parts of imvite, 0.1-0.3 part of lauryl sodium sulfate, 3-5 parts of glycerol, 2-8 parts of water soluble phenol-formaldehyde resin, 2-3.5 parts of chitosan complex and 100-150 parts of water. The preservative for southern pine outdoor inscribed wooden slip culture walls provided by the invention has excellent corrosion resistance, mildew resistance and ageing-resistantperformance.

Owner:广德竹之韵工艺品厂

Wood surface chemical color changing method

ActiveCN109333716ARich in colorRich color varietyWood treatment detailsThermal wood treatmentCopper chlorideColor changes

The invention discloses a wood surface chemical color changing method. According to the wood surface chemical color changing method, the surface of wood is coated with copper chloride solution first,after drying, the surface of the wood is coated with a color changing agent, drying is conducted again, color changing of the wood is completed, and a finished product is obtained. The wood surface chemical color changing method has superior permeability, bonding strength of the color changing solution and the wood is higher, loss resistance is better, thus the color presented by the product madethrough the wood surface chemical color changing method is richer, lines are clearer, the layered feeling is higher, the color changing method is simple to operate, and the processing process is moreenvironmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Multiple-effect timber fire retardant and its preparation method and treatment process

InactiveCN104647537AGood anti-loss performanceGood flame retardant performancePressure impregnationWood impregnation detailsPhosphoric acidAmmonium polyphosphate

The invention discloses a multiple-effect timber fire retardant and its preparation method and treatment process. The multiple-effect timber fire retardant comprises, by mass, 20-40% of phosphoric acid, 10-20% of dicyandiamide, 10-20% of melamine, 5-10% of boric acid, 5-20% of ammonium polyphosphate, 5-20% of silica sol, 3-8% of a smoke inhibitor, 0.5-3% of a surfactant and 0.1-2% of a mildew inhibitor. Compared with the existing timber fire retardant, the multiple-effect timber fire retardant has good fire retardant performances, good smoke inhibition performances, good loss resistance performances, large timber impregnation depth and good corrosion-resistant, mildew-resistant and mothproof effects. The preparation method has simple processes. The multiple-effect timber fire retardant has good timber protection and processing effects and is economical and practical.

Owner:高天红

Wood dipping processing multi-function modifier

InactiveCN104858980AFlame retardantAnti-corrosionWood impregnation detailsWear resistantPhosphoric acid

The invention discloses a wood dipping processing multi-function modifier which comprises the following components by mass: 8%-12% of phenol, 10%-15% of formaldehyde, 6%-9% of phosphoric acid, 3%-8% of melamine, 6%-9% of urea, 3%-6% of zinc borate, 5%-10% of boric acid, 5%-10% of sodium octoborate, 3%-5% of dimethyl dithiocarbamate copper, 15%-50% of silica sol, and 0.5%-1% of fatty alcohol polyoxyethylene ether. The beneficial effect is that the wood dipping processing multi-function modifier has being flame retardant, anticorrosive, moth-proofing, enhancing, wear resistant, well erosion resistant and other advantages of, and can significantly improve the application value of processed wood.

Owner:王玉燕

Mildew-proof and corrosion-proof treatment process for bamboo materials

ActiveCN110253706ASave time and costSave on shipping costsWood treatment detailsReed/straw treatmentMildewProcessing plants

The invention discloses a mildew-proof and anti-corrosion treatment process for bamboo materials, and belongs to the technical field of mildew-proof and anti-corrosion treatment of bamboo materials. The treatment process comprises the following steps: firstly, soaking bamboo materials, with bamboo joints being broken through, into a mixed enzyme solution, and then soaking the bamboo materials into a modification treatment solution; bundling the bamboo materials, wrapping the bundled bamboo materials with a heat preservation coiled material, connecting the system with a steam generator, and adding an anti-corrosion treatment agent to treat the bamboo materials; and finally drying the bamboo materials. The treatment process employs miniaturized treatment equipment, so that the bamboo materials can be directly sent to a processing site after being treated at the bamboo materials mining position without transport through a processing plant, and the transportation time and the transportation cost are greatly saved.

Owner:北京中竹文化科技有限公司

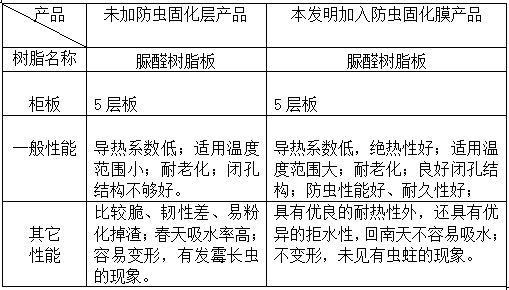

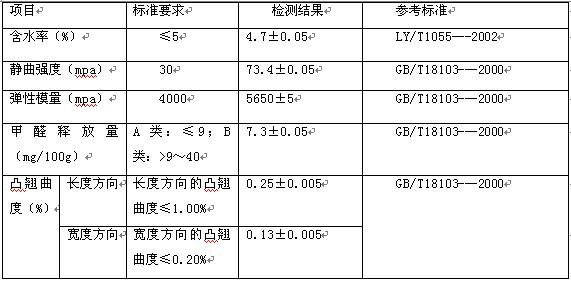

Insect-proof multi-layer eucalyptus wood board and production method thereof

InactiveCN110871477AImprove textureGood dimensional stabilityOther plywood/veneer working apparatusLamination ancillary operationsAdhesive glueSingle plate

The invention provides an insect-proof multi-layer eucalyptus wood board and a production method thereof. The production method of the multi-layer board comprises the steps of single plate thin platesorting, thin plate glue applying, cold pressing, hot pressing, standing curing, dust scraping, sanding, repair, trimming and plate pasting, and is characterized in that a layer of insect-proof curedfilm is sprayed at the peripheral surface, the upper surface and the lower surface of a slab before first hot pressing and final hot pressing to prevents glue from being dried too quickly during the hot pressing process and maintain stress inside the multi-layer board, the urea-formaldehyde glue can be fully reacted completely, the formed multi-layer board is not prone to mildewing, in the use process of a user, volatile formaldehyde is also reduced, and after hot pressing, the board is subjected to standing curing, sanding and plate pasting, so that the insect-proof multi-layer eucalyptus wood board product can be obtained by edge sawing and packaging.

Owner:广西横县正林木业有限公司

Inorganic wood flame retardant with good loss-resistant property

InactiveCN104669380ALow costGood anti-loss performanceWood treatment detailsWood impregnation detailsAmmonium polyphosphateCorrosion prevention

The invention discloses an inorganic wood flame retardant with good loss-resistant property. The inorganic wood flame retardant comprises the following components in percentage by weight: 40%-60% of ammonium polyphosphate, 10%-20% of silicon dioxide solutions, 5%-10% of boric acid, 5%-10% of sodium borate, 2%-10% of basic magnesium carbonate, 0.5%-3% of alkyl sodium sulfonate and 0.1%-1% of pentaerythritol. Compared with the prior art, the inorganic wood flame retardant disclosed by the invention has the beneficial effects of containing no prohibited component, namely halogens, heavy metals and the like, belonging to a green environmental-friendly flame retardant, being low in cost, having the effects of flame retardance, smoke inhibition, corrosion prevention, moth prevention and the like on a wood and being good in loss-resistant property and high in stability.

Owner:QINGDAO JIAYIYANG IND & TRADE

Environment-friendly preservative and preparation method thereof

ActiveCN111391050AThe preparation method is simple and easy to operateImprove preparation efficiencyWood treatment detailsWood impregnation detailsChinese herbsChamaemelum nobile extract

The invention discloses an environment-friendly preservative. The environment-friendly preservative comprises the following components in parts by weight: 35-50 parts of triazole nucleoside carboxylicacid modified hyperbranched polylysine, 2-5 parts of choline borate, 0.5-1.5 parts of lecithin, 4-7 parts of graphene, 0.5-1.5 parts of sodium glycyrrhetate, 6-10 parts of an antiseptic Chinese herbal medicine extract, 1-2 parts of a celery extract, 1-2 parts of a Hamamelis virginiana extract, 10-20 parts of ethanol and 150-200 parts of deionized water. The invention also provides a preparation method of the environment-friendly preservative. The environment-friendly preservative disclosed by the invention has obvious preservative effect, diverse performance, wide range of wood rot bacteria and insects resistance, stable performance in the process of storage and transportation, and safe and environment-friendly use.

Owner:广州海有生物科技有限公司

Processing method for preventing bamboo rotting

InactiveCN108297227AImprove flame retardant performanceGood weather resistanceBiocideWood treatment detailsVacuum pressurePre treatment

The invention discloses a processing method for preventing bamboo rotting. The processing method comprises the following steps that S1, bamboo wood is cut into sections, baked, soaked and washed to obtain pre-treated bamboo wood; S2, the pre-treated bamboo wood is placed into a preservative solution to be subject to vacuum pressure impregnation treatment; and S3, the bamboo wood treated in the step S2 is subject to heat treatment and smudging. By means of the processing method for preventing bamboo rotting, the bamboo rotting resistance and insect resistance are improved, the service life of abamboo product is effectively prolonged, and bamboo wood losses are reduced.

Owner:广德县泉村竹制品有限公司

Preparation method for anti-flaming bamboo floor

InactiveCN102493624AGood physical propertiesPerformance is not affectedFlooringEngineeringHigh pressure

The invention relates to the field of bamboo floor processing, in particular to a preparation method for an anti-flaming bamboo floor. The preparation method for the anti-flaming bamboo floor is realized by the following technical scheme that the preparation method for the anti-flaming bamboo floor comprises the following steps: (1) cutting off and hacking an original bamboo, and sawing to obtain a green blank plate; (2) carrying out carbonized treatment, putting a bamboo chip into a high-pressure processing tank, introducing high-pressure saturated vapor into the tank, improving pressure to 0.2-0.3MPa, keeping warm and pressure for 3-4 hours, finally releasing pressure, and bleaching water to take out after pressure is released; (3) drying to cause the moisture content of the blank plate to be regulated to 5-8%; (4) anti-flaming treatment: adopting a vacuum pressurizing and impregnating method, wherein the vacuum degree is 80-87kPa, the vacuum time is 1.5-2 hours, the impregnating pressure is 0.5-0.6MPa, and the impregnating time is 2-3 hours; and (5) carrying out hot pressure at the hot pressing temperature of 120-150 DEG C and the pressure of 2.5-3MPa for 15-20 minutes. The bamboo floor prepared with the method not only has a good favorable physical performance but also has a good anti-flaming effect.

Owner:朱江福

Well erosion resistant wood treatment agent

InactiveCN104858977AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsWood impregnation detailsCarbamateFatty alcohol

The invention discloses a well erosion resistant wood treatment agent comprising the following components by mass: 15%-20% of glyoxal, 4%-6% of ethylene glycol, 1%-3% of ammonium persulfate, 0.1%-0.5% of sodium hydroxide, 5%-10% of disodium octoborate tetrahydrate, 5%-8% of copper dimethyl dithio carbamate, 2%-5% of dioctyl dimethyl ammonium chloride, 0.5%-2% of fatty alcohol polyoxyethylene ether and 46%-67% of water. The beneficial effect is that the well erosion resistant wood treatment agent gives excellent anti-corrosion, mouldproof, moth-proofing and other functions to treated wood, also has good dimensional stability, good anti erosion effect, low cost and good permeability.

Owner:王玉燕

Chemical agent with adhesiveness and flame resistance, and preparation method thereof

InactiveCN103436207AEasy to useLow costAldehyde/ketone condensation polymer adhesivesWood veneer joiningPhosphoric acidDiammonium phosphate

The invention discloses a chemical agent with adhesiveness and flame resistance, and a preparation method thereof. The chemical agent comprises following raw materials, by weight: 1.0 portion of urea, 0.45 to 4.2 portions of dicyandiamide, 3.6 to 16.3 portions of formaldehyde with a mass concentration of 37%, 0.4 to 2.1 portions of phosphoric acid with a mass concentration of 85%, and 2.75 to 9.0 portions of diammonium hydrogen phosphate. The chemical agent possesses both adhesiveness and flame resistance, and compatibility with urea-formaldehyde resin adhesive which is widely used in production of wood-based plate. Adhesive can be replaced by the chemical agent completely in production of wood-based plate, and be partially replaced by the chemical agent by adding the chemical agent into a prepared glue solution directly, so that it is convenient to use the chemical agent for producing of flame-retardant wood-based plate, and cost is reduced. In addition, the chemical agent possesses adhesiveness, and is excellent in leachibility, so that flame retardant effect lasts long.

Owner:GUANGXI UNIV

Mildew-proof and corrosion-proof treatment technology for wooden furniture materials

InactiveCN106239666AEasy to operateReduce processing costsWood treatment detailsPressure impregnationHydroxyethyl UreaBoric acid

The invention relates to the technical field of wooden furniture, in particular to a mildew-proof and corrosion-proof treatment technology for wooden furniture materials. The mildew-proof and corrosion-proof treatment technology is good in mildew-proof and corrosion-proof effect and harmless to human bodies and environment; and the wood quality is stable and the service life is long. The mildew-proof and corrosion-prevention treatment technology comprises the following steps of vacuum treatment, pressure treatment, secondary pressure treatment, heat treatment and the like; and a used mildew-proof and corrosion-proof solution comprises N-dichloroethenyl salicylamide, 60% of boric acid solution, alkyl polyglucoside, dimethylformamide, furfuralcohol, cashew nut oil, gallic acid, fatty alcohol-polyoxyethylene ether and hydroxyethyl urea. According to the mildew-proof and corrosion-proof treatment technology, wood can be well protected from erosion of microorganisms by using a relative small quantity of the mildew-proof and corrosion-proof solution, so that a good mildew-proof effect is achieved, the whole performance of the wood is improved, and the service life of wooden furniture is prolonged.

Owner:桐乡市美意家具有限公司

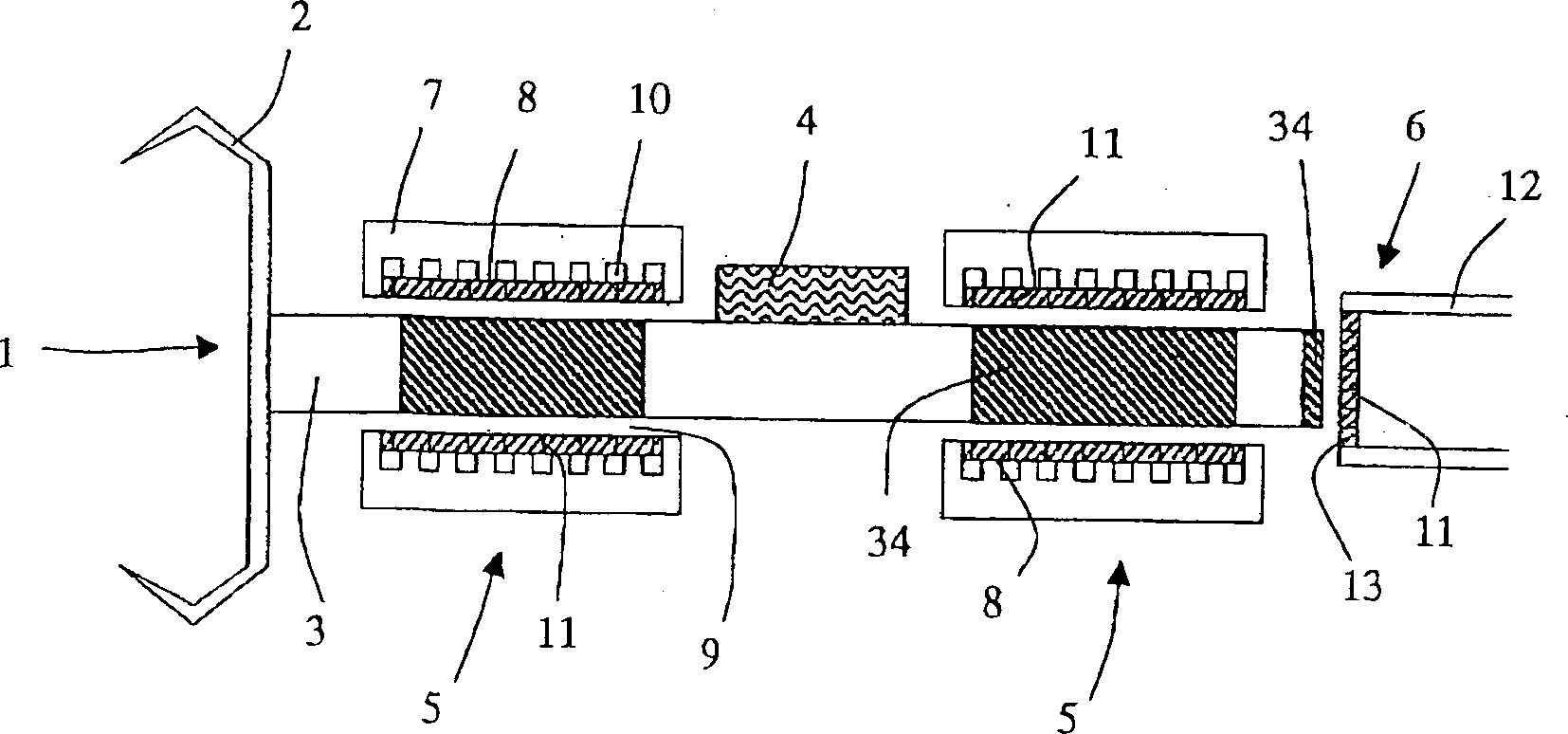

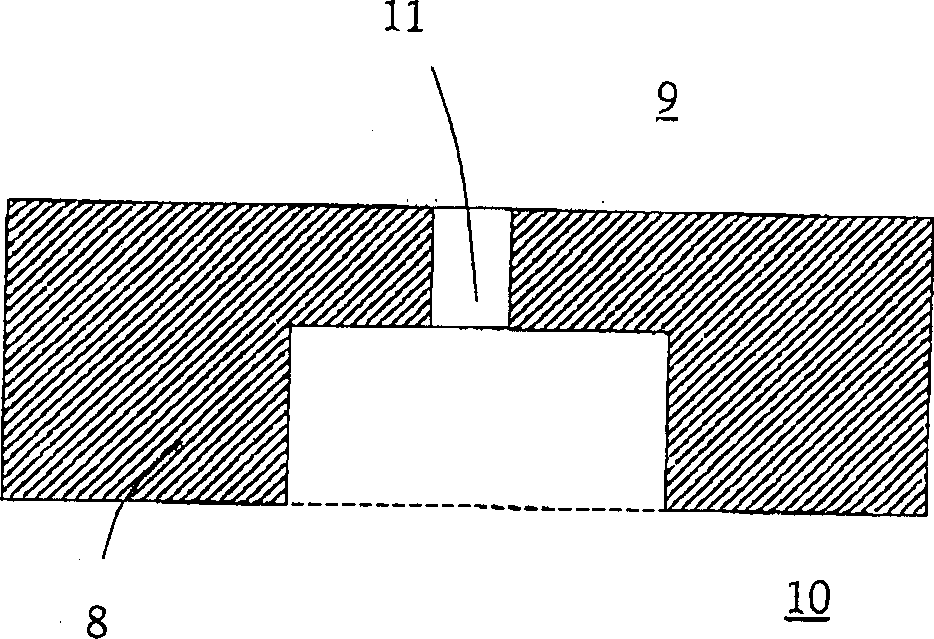

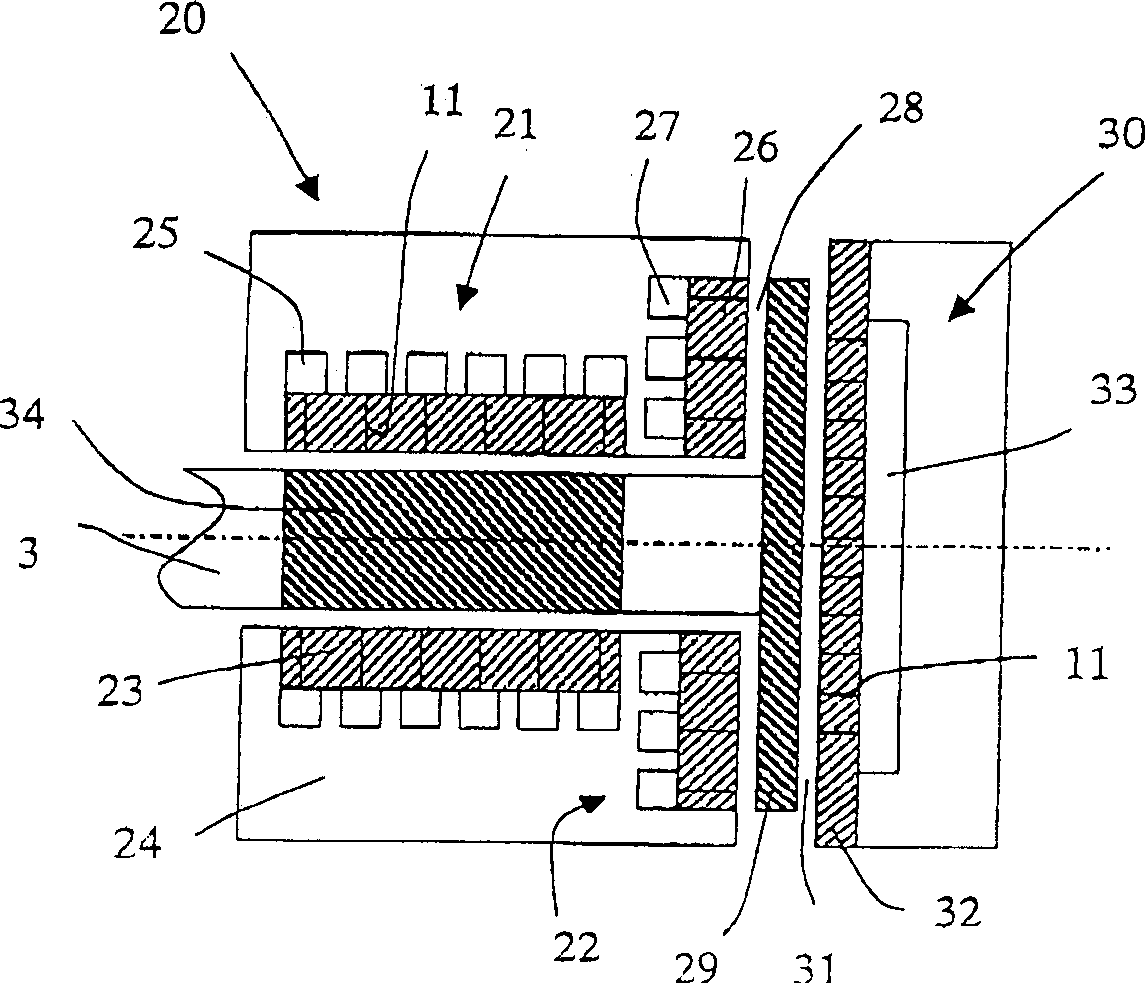

Open spinning appst. having air static force radial bearing for spinning rotor

InactiveCN1369582AWon't hit hardSo as not to damageTextile treatmentGas cushion bearingsWorking lifeEngineering

The invention relates to an open-end spinning device with a spinning rotor (1), the shaft (3) of which passes through an aerostatic radial bearing (9) with a gap (9) between the support device and the shaft (3). 5) are radially supported, and an aerostatic radial bearing for this purpose. According to the present invention, the start-up spinning device also constitutes: the bearing surface of the spinning rotor (1) and / or the bearing surface of the radial bearing (5) is made of a polyimide or Kevlar (keular) of. Even in the unlikely event that contact of the bearing surfaces occurs, the service life of the radial bearing is thereby significantly increased.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com