Patents

Literature

6607results about "Wood veneer joining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material systems and methods of three-dimensional printing

InactiveUS7795349B2Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

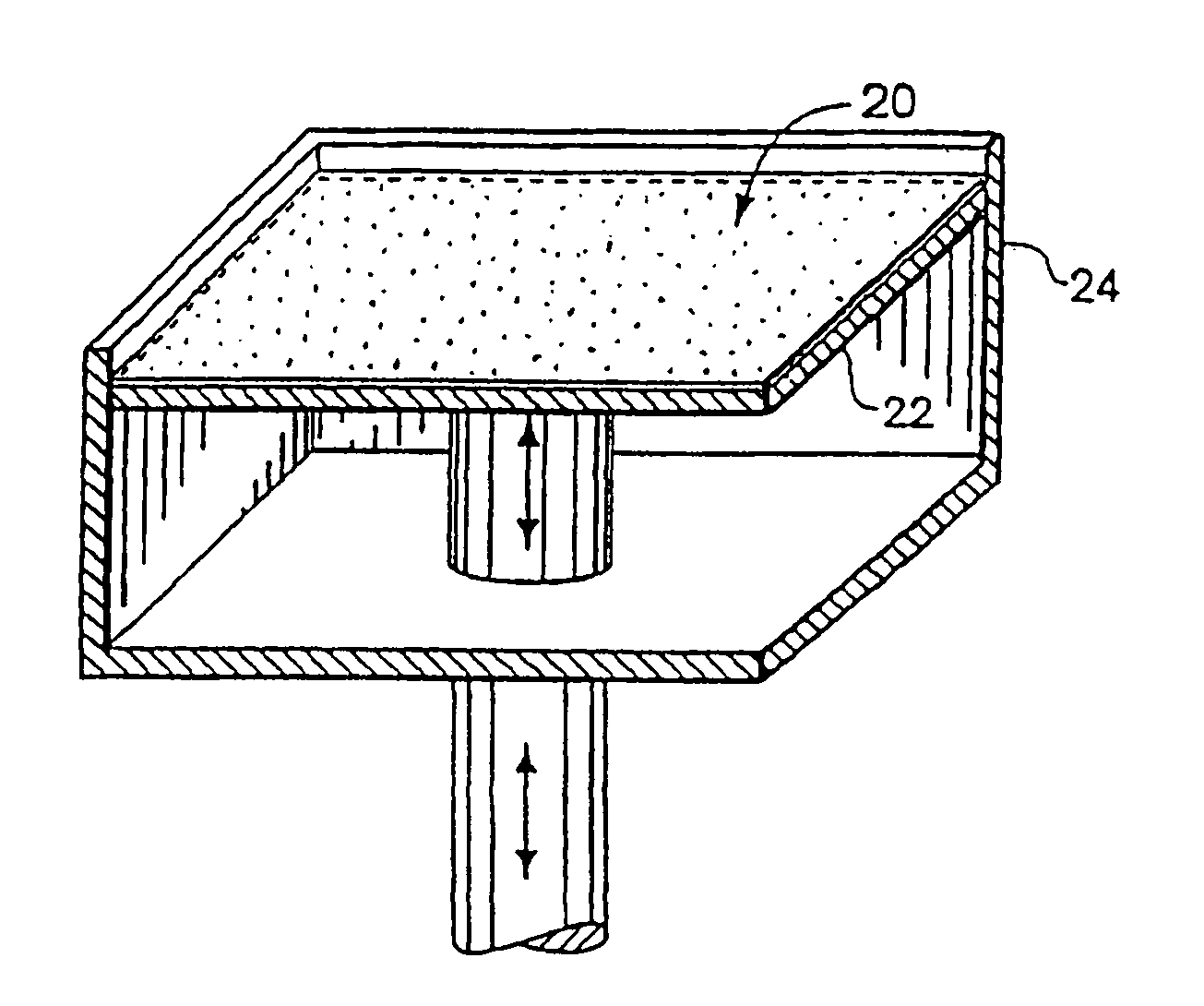

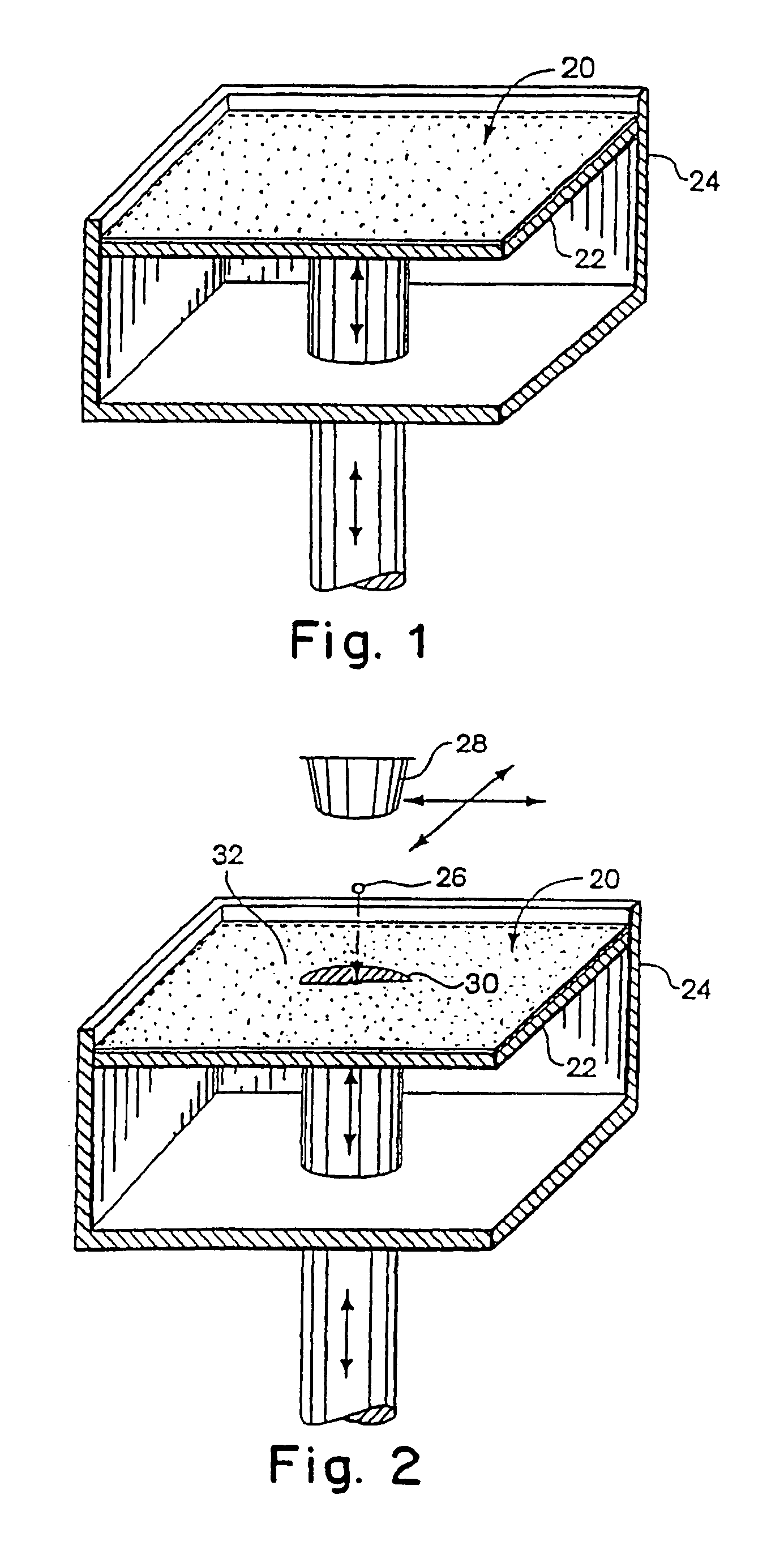

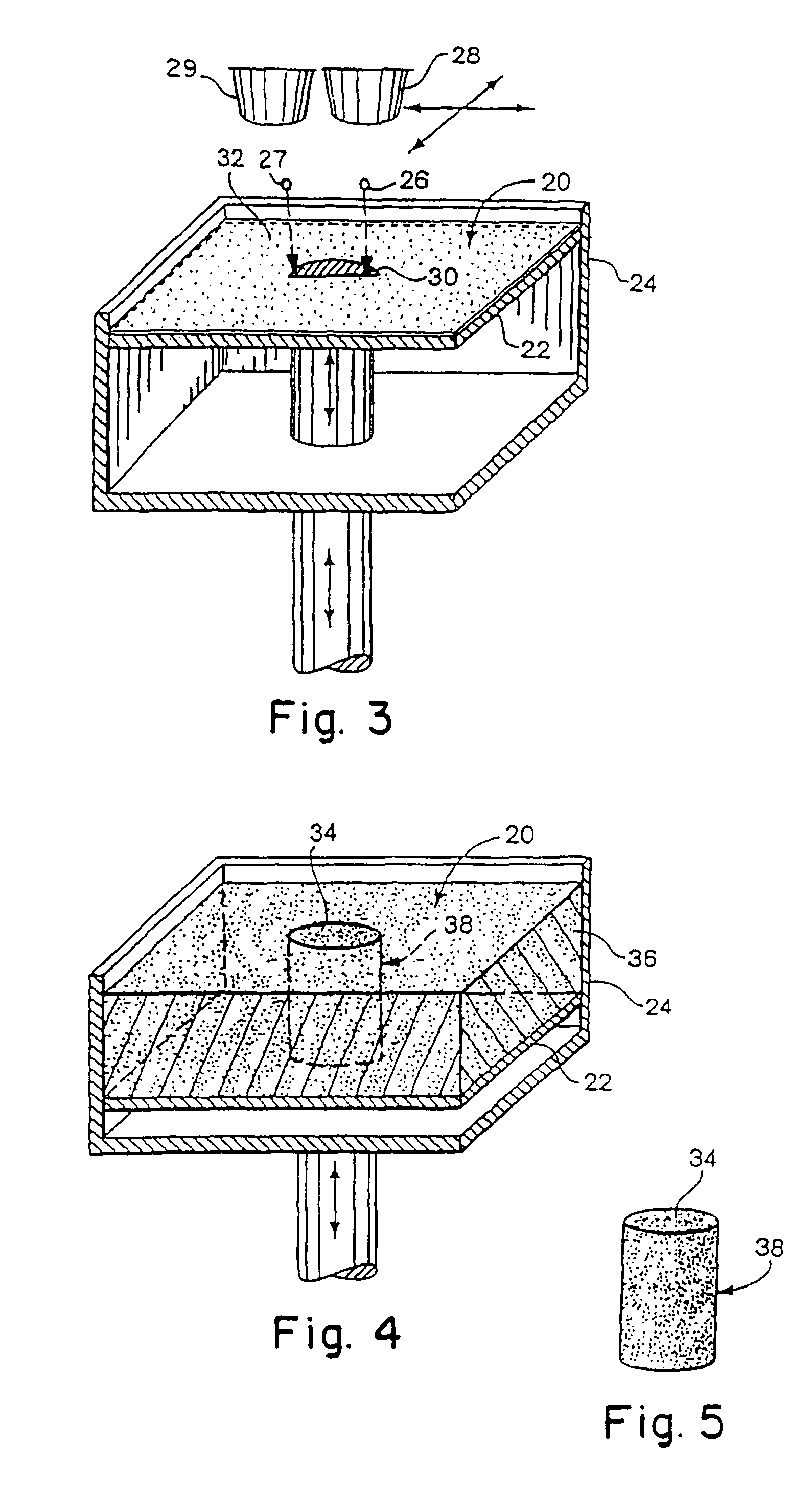

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

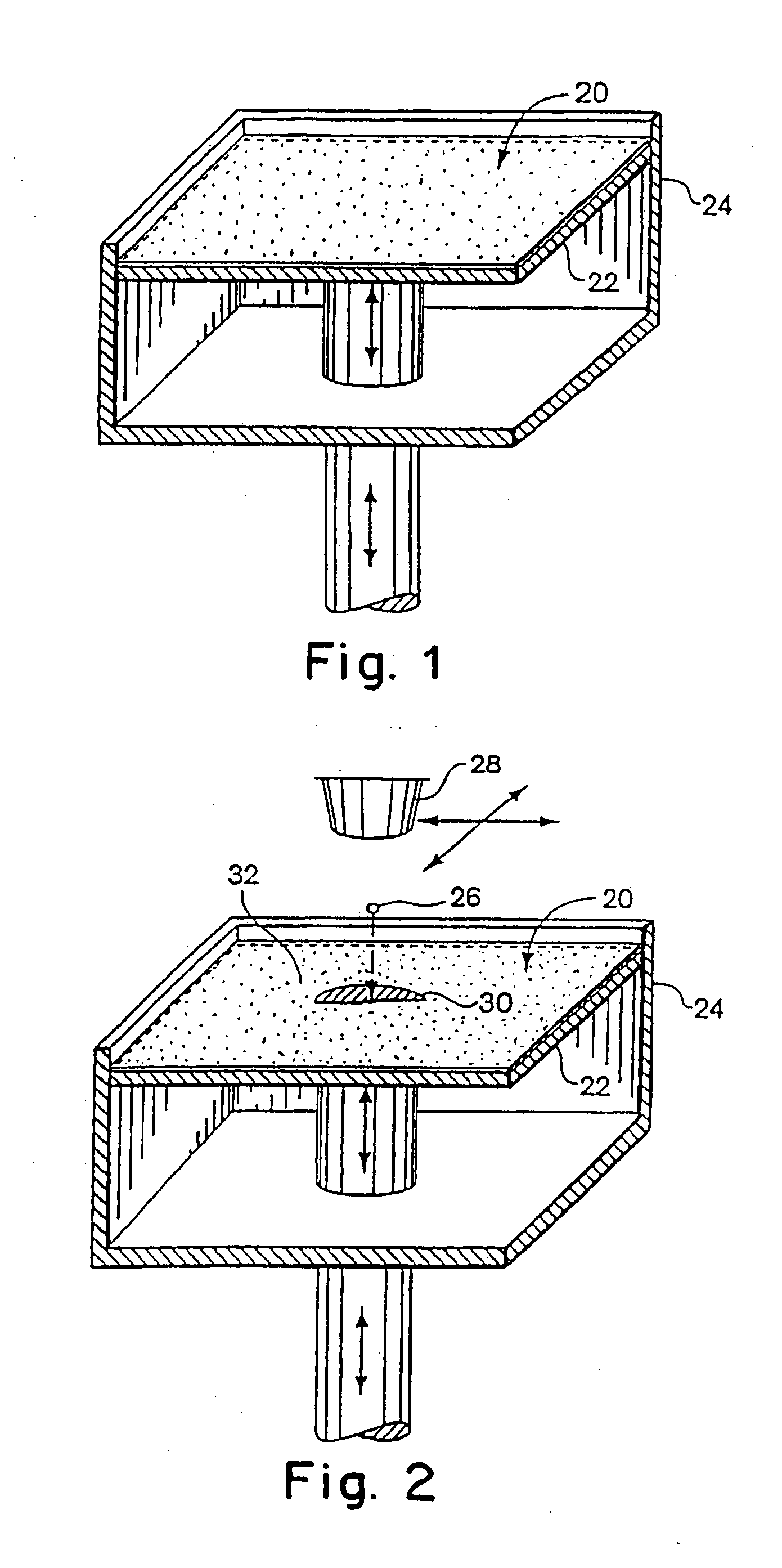

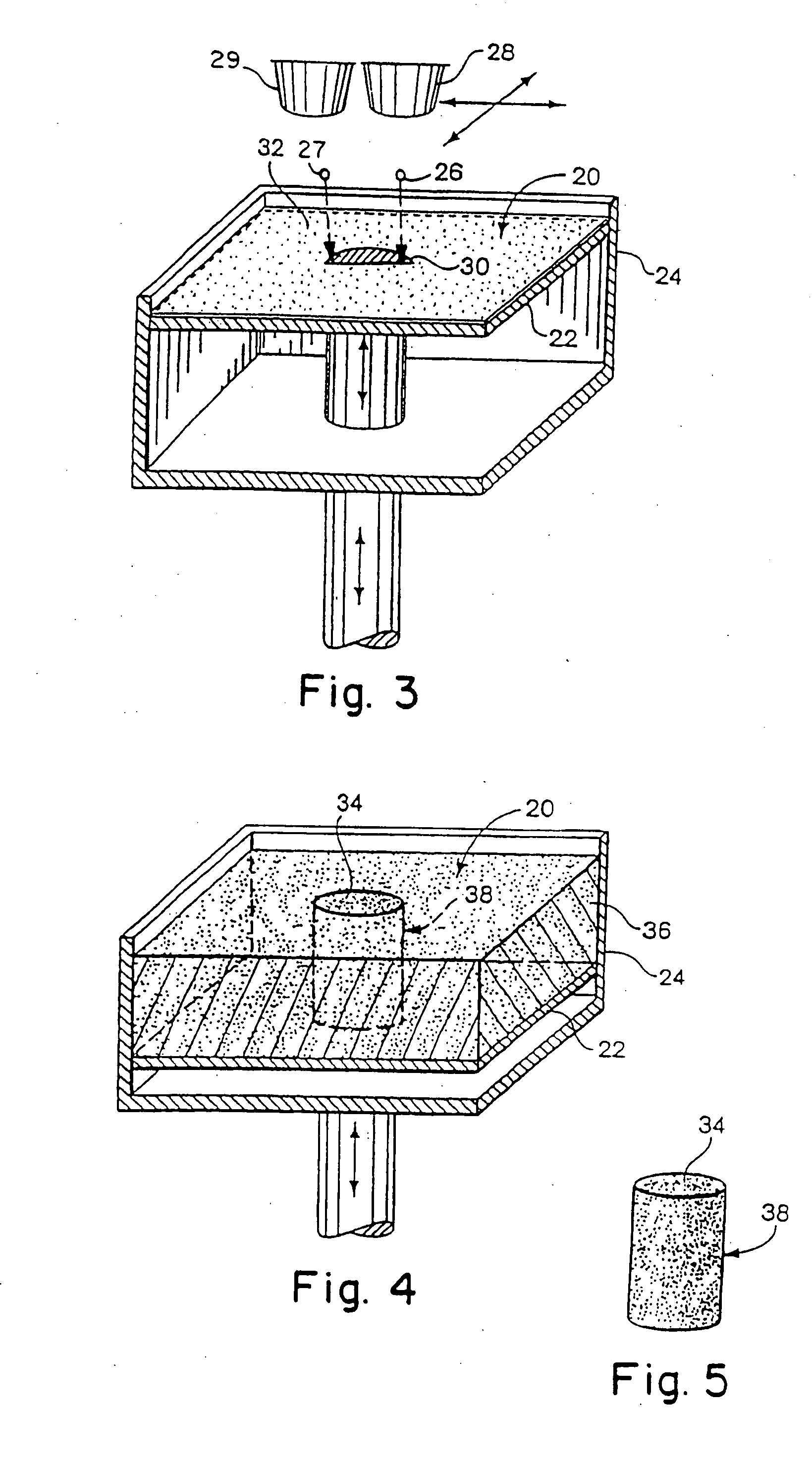

Three dimensional printing material system and method

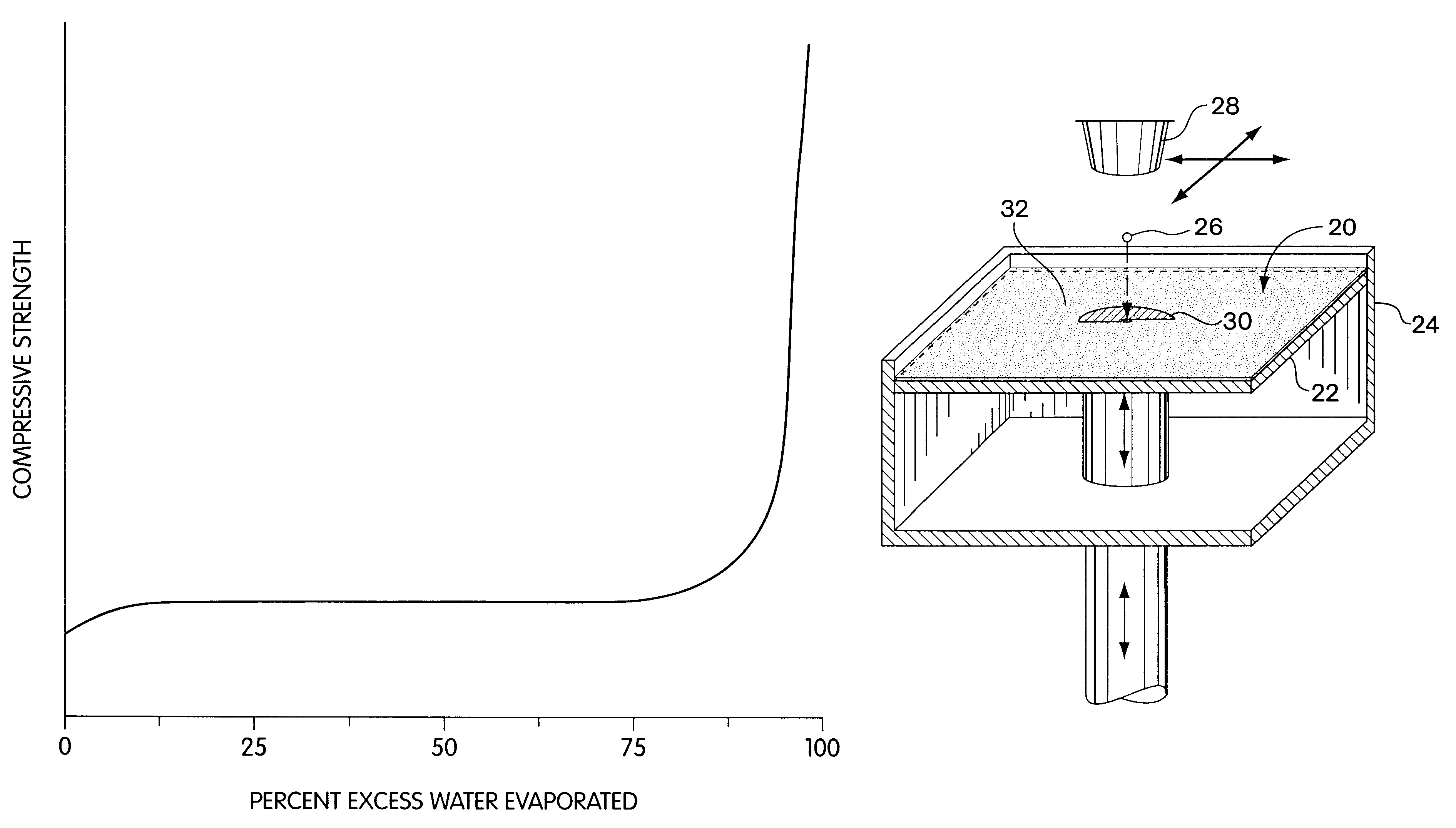

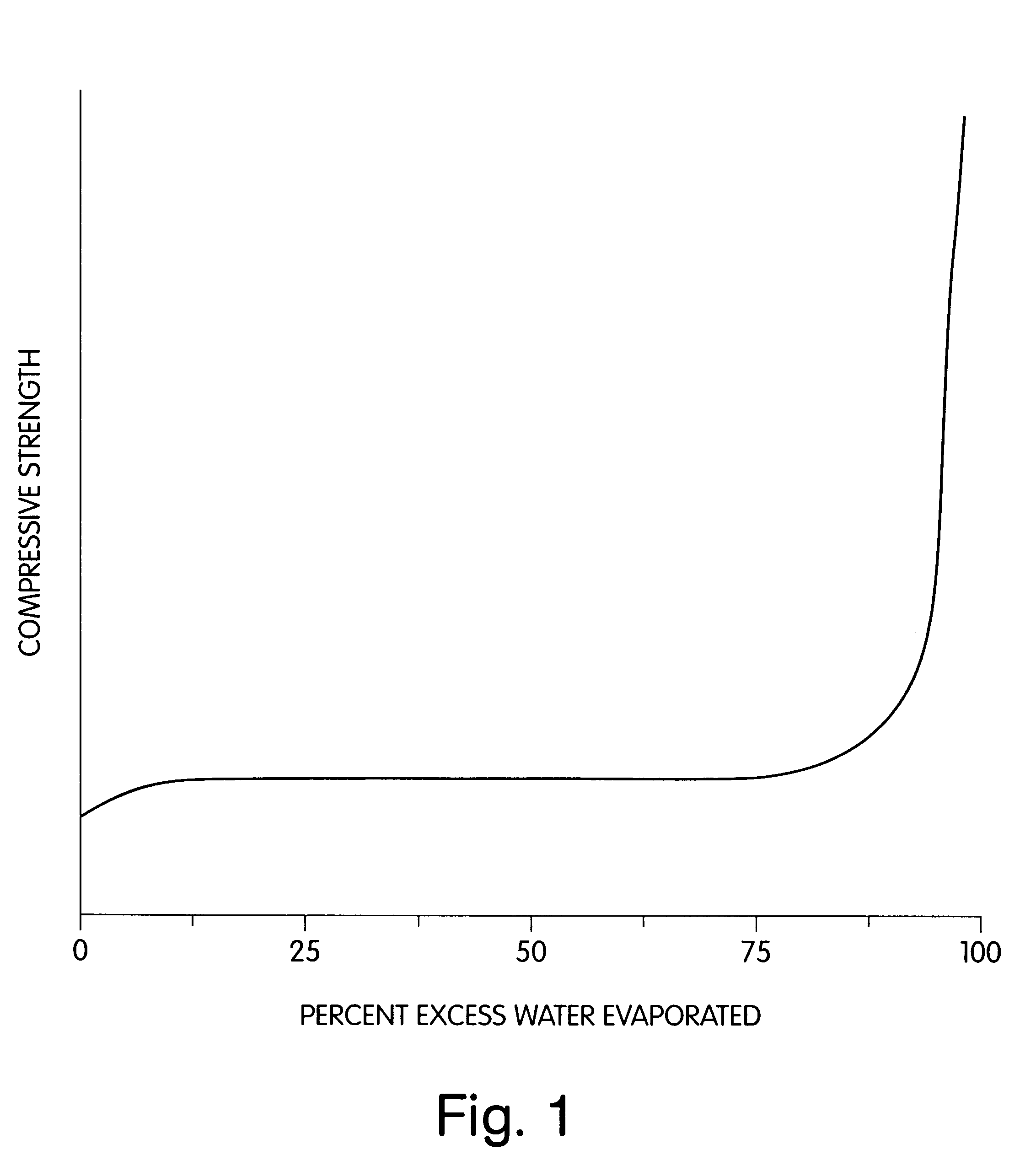

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

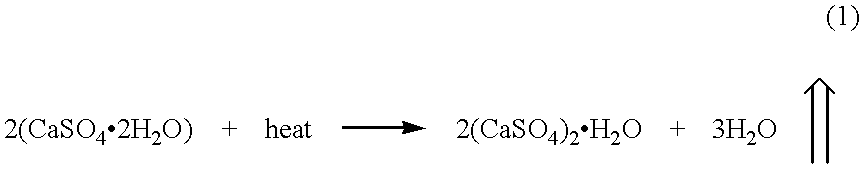

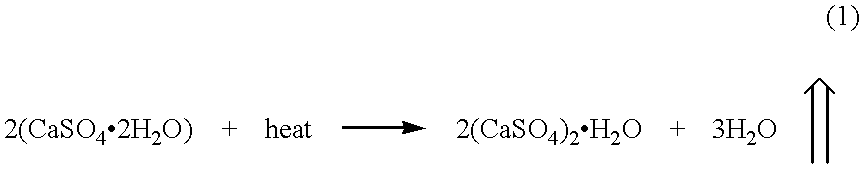

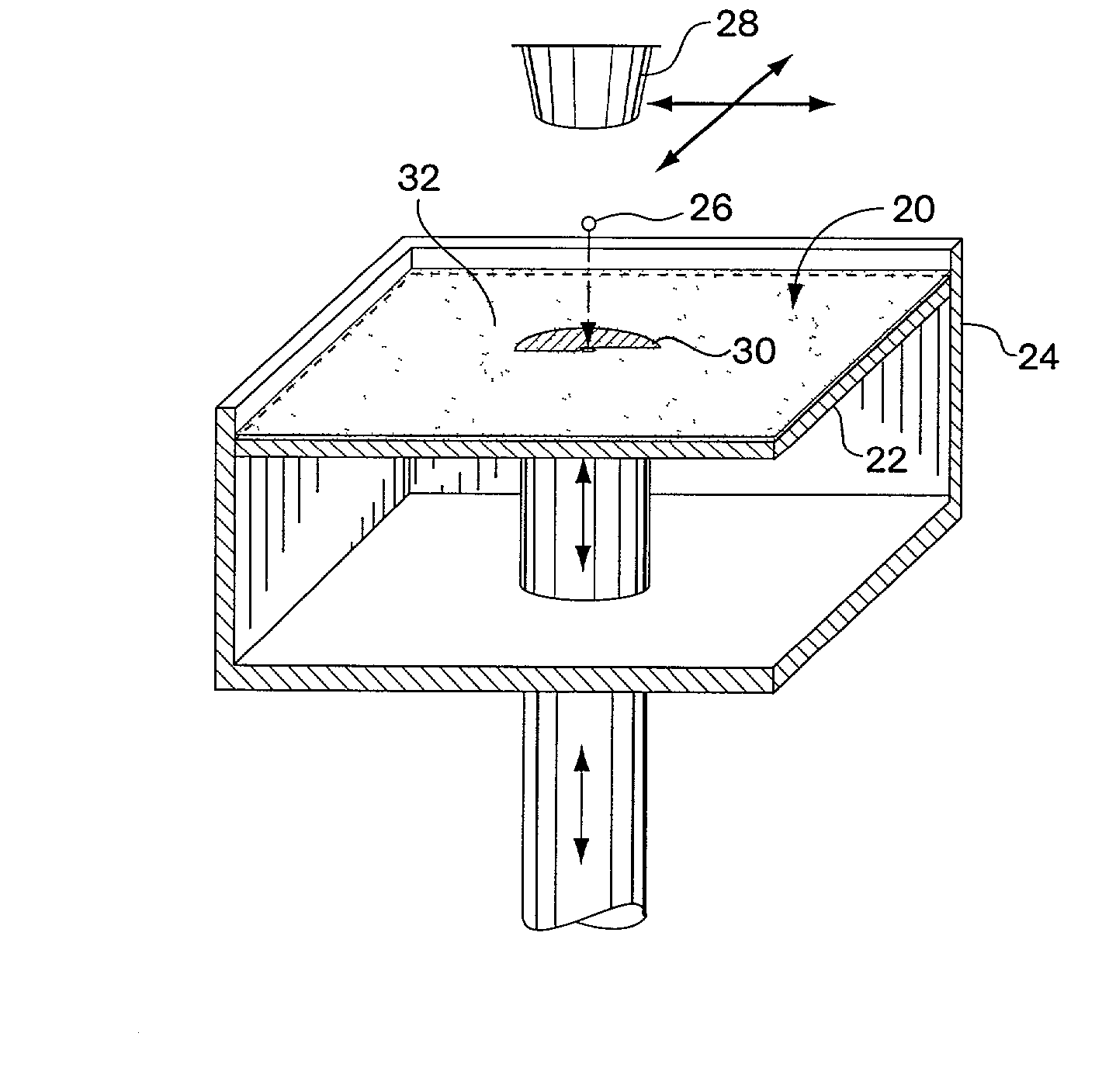

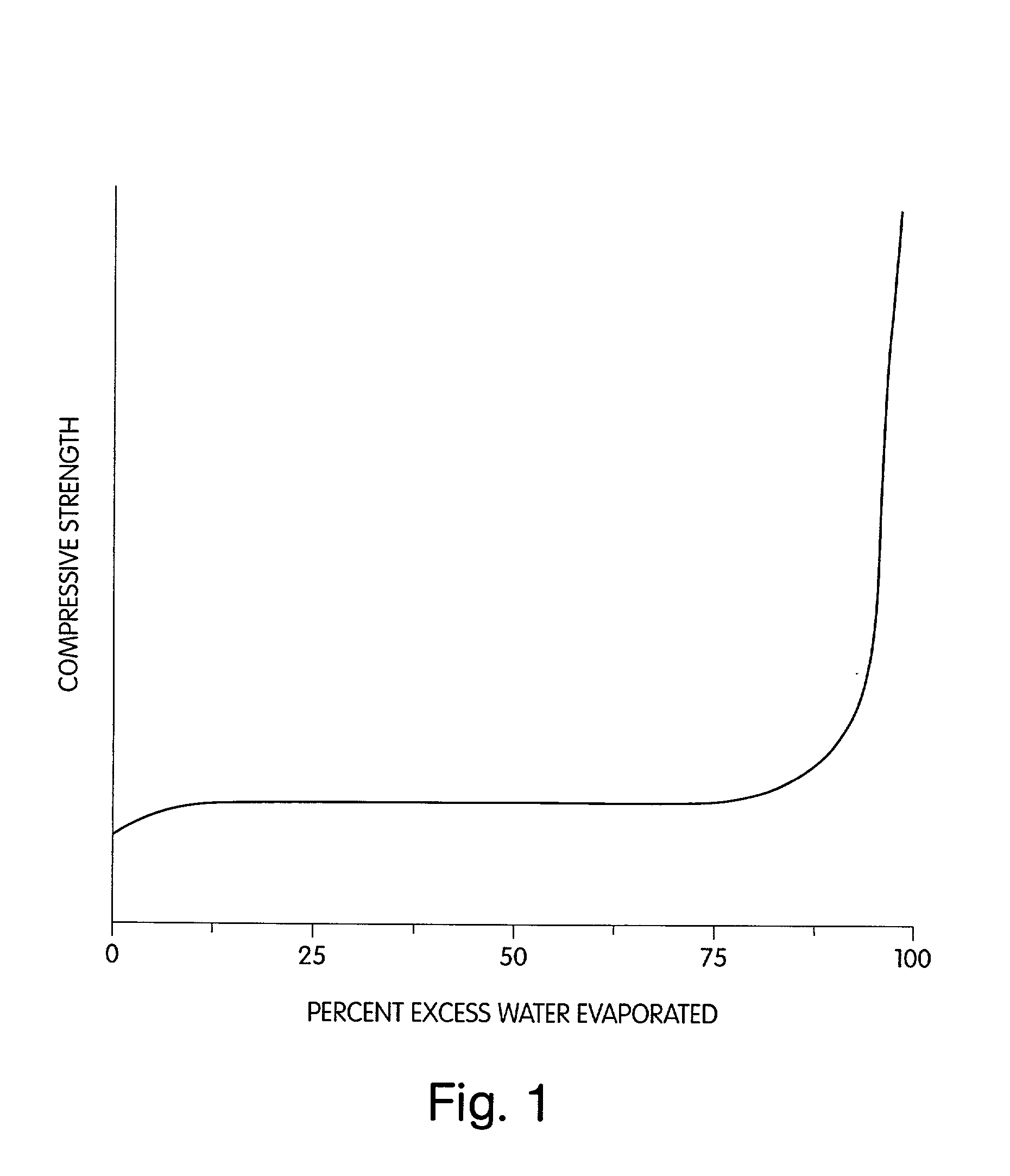

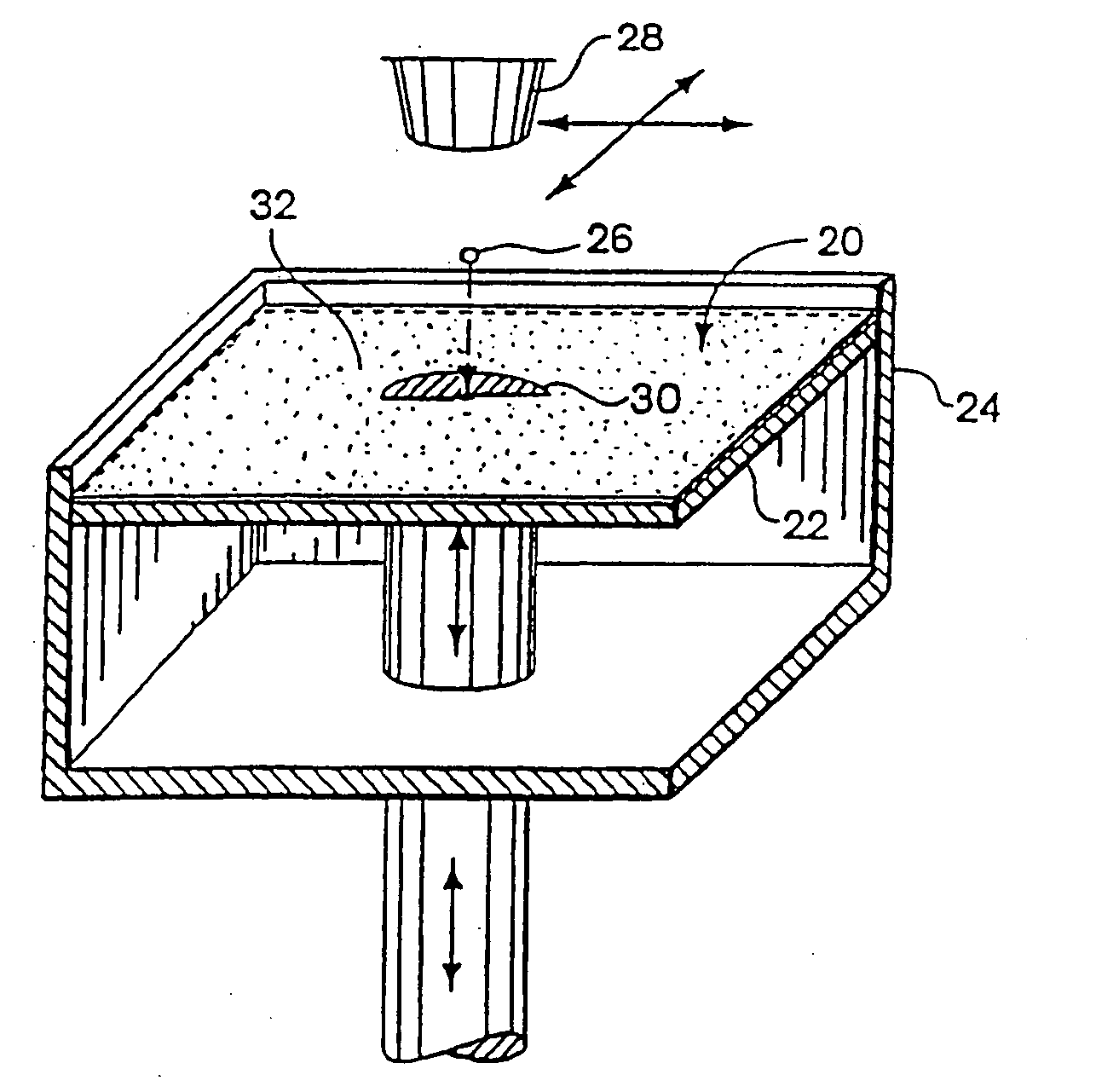

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

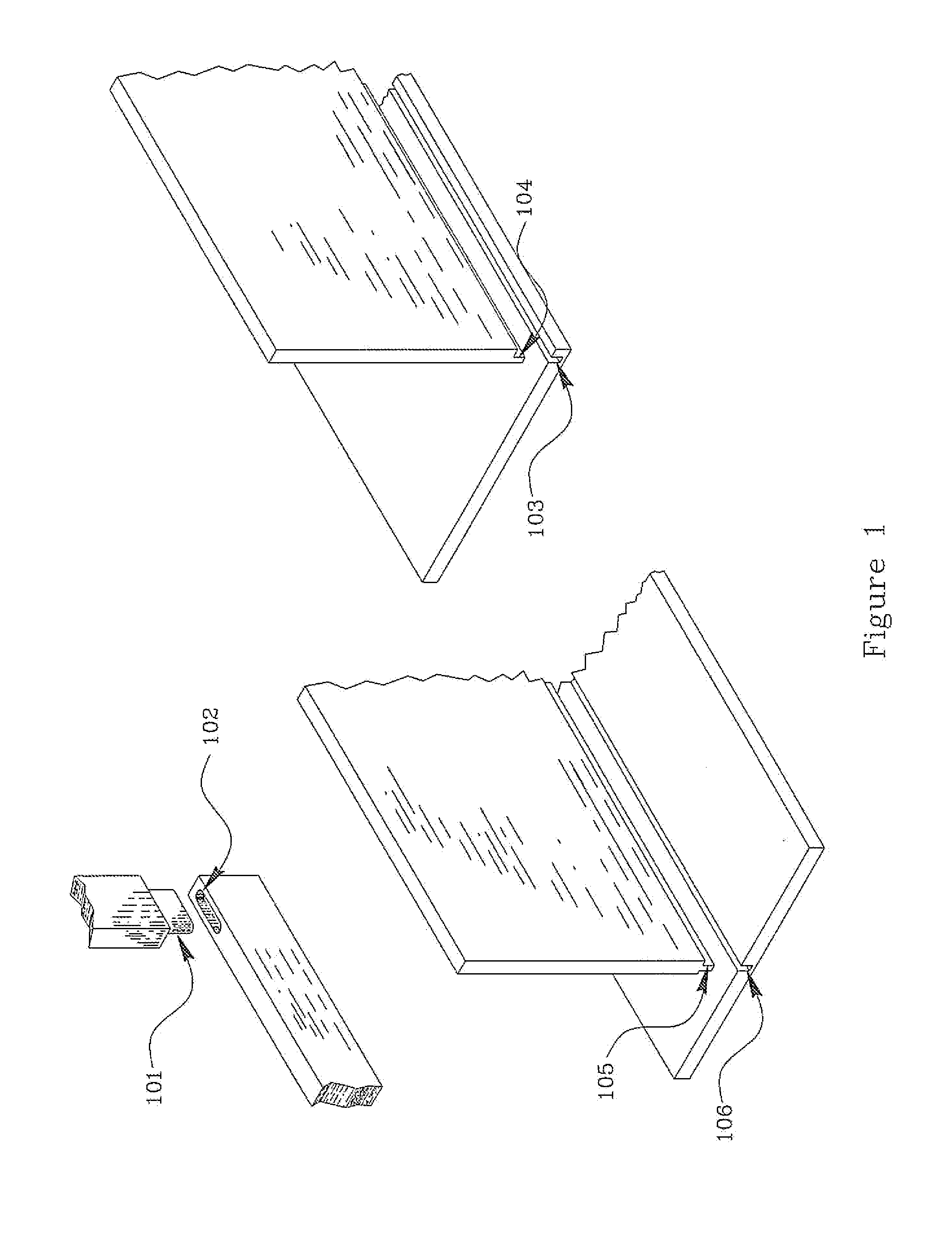

Low profile hardwood flooring strip and method of manufacture

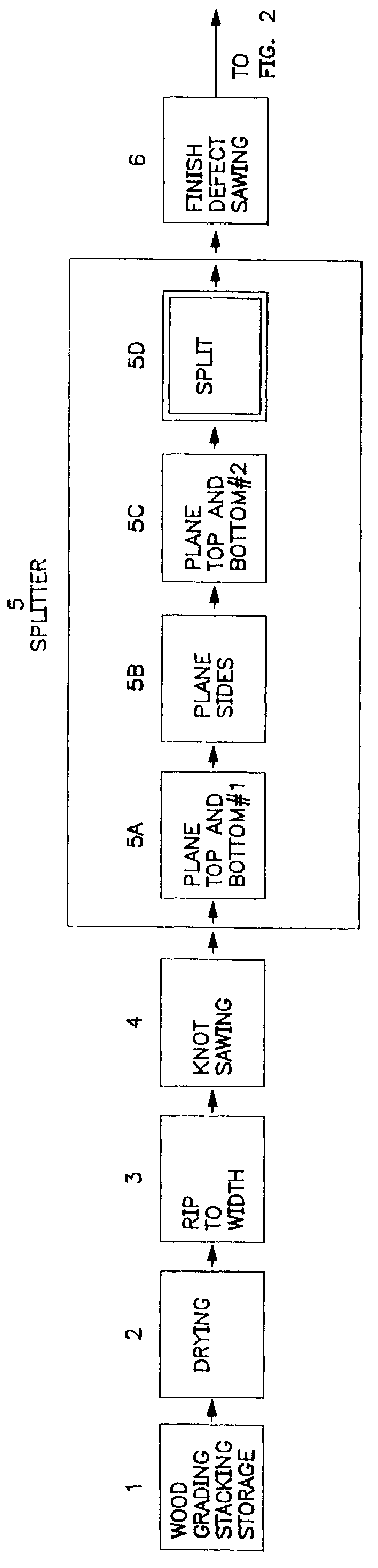

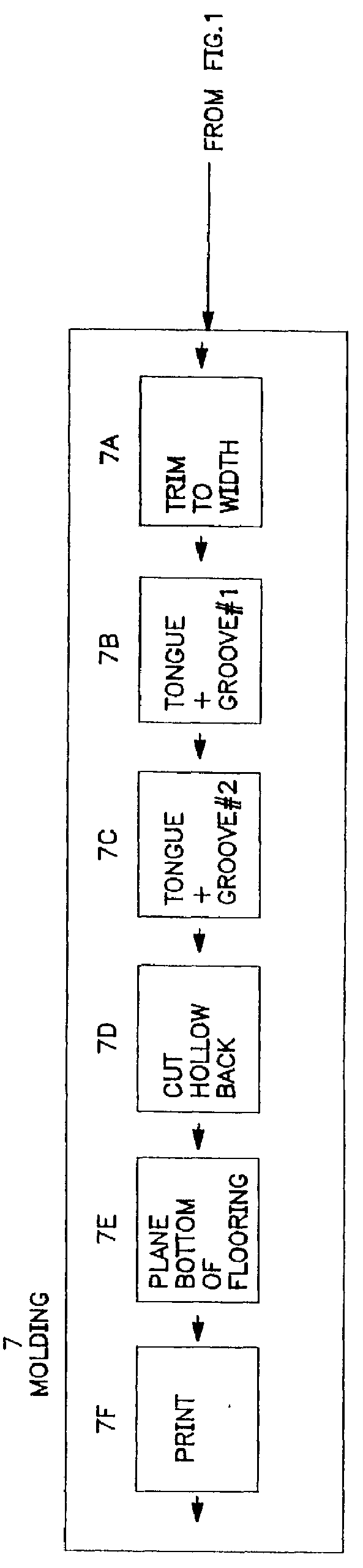

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

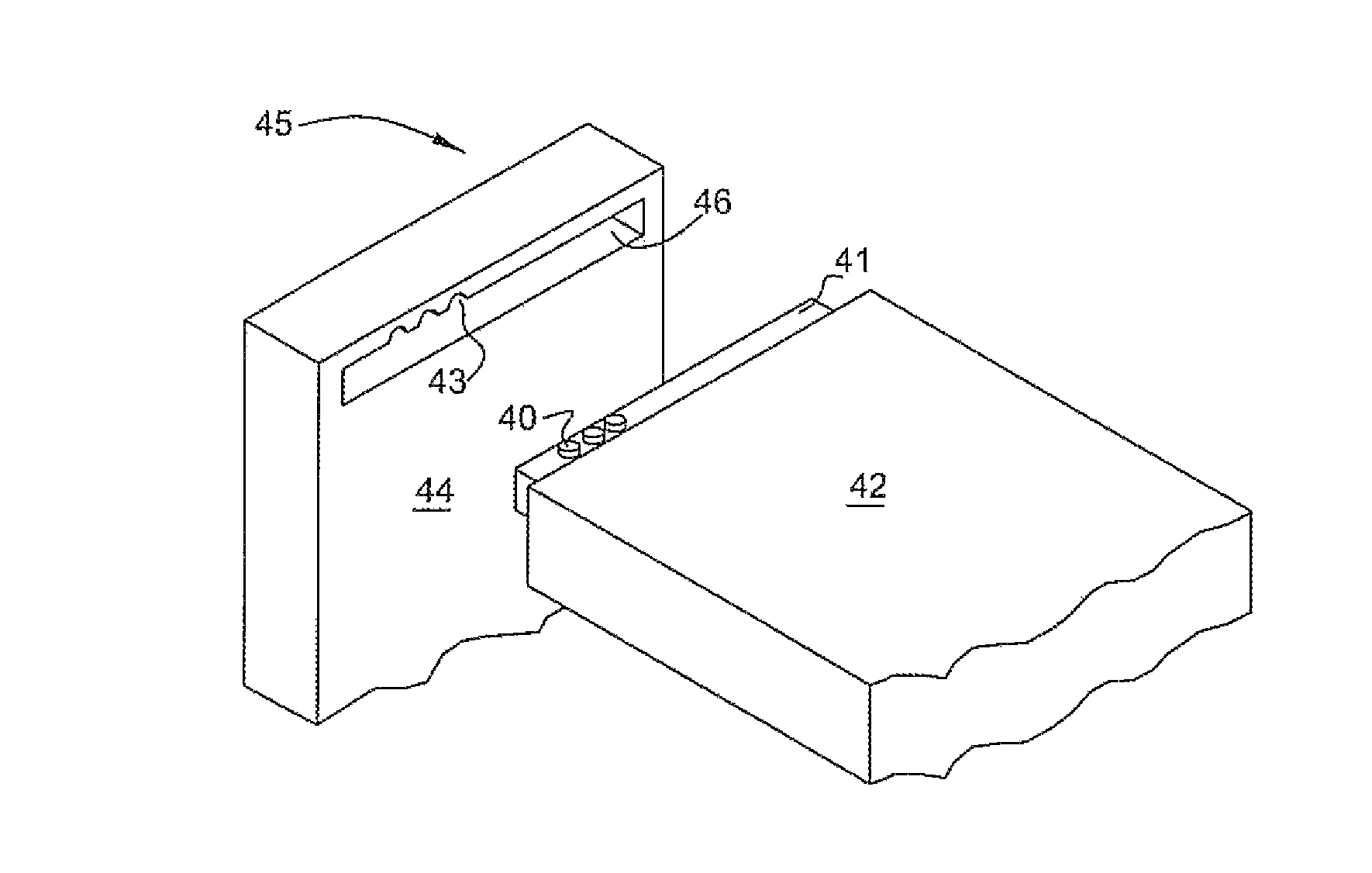

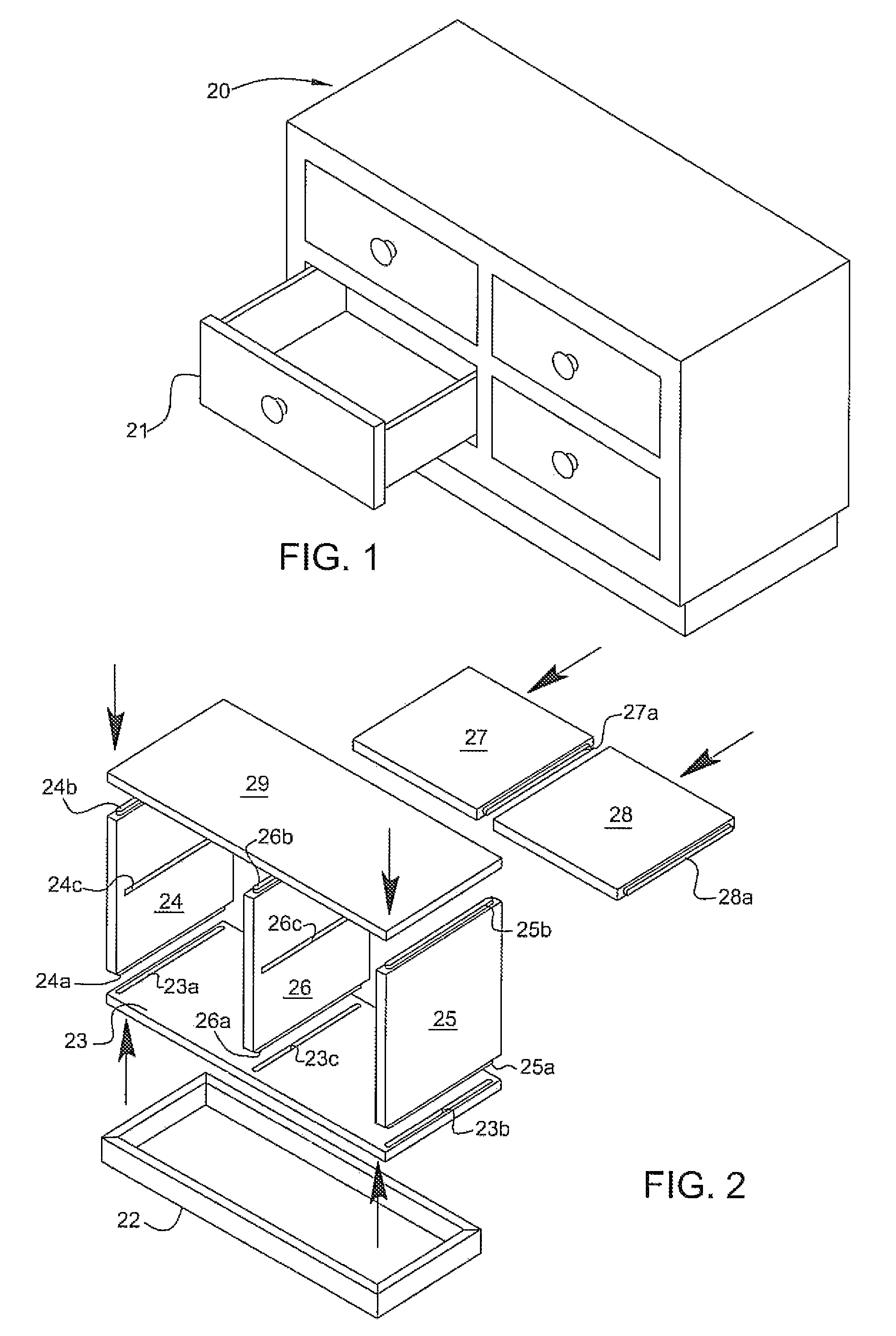

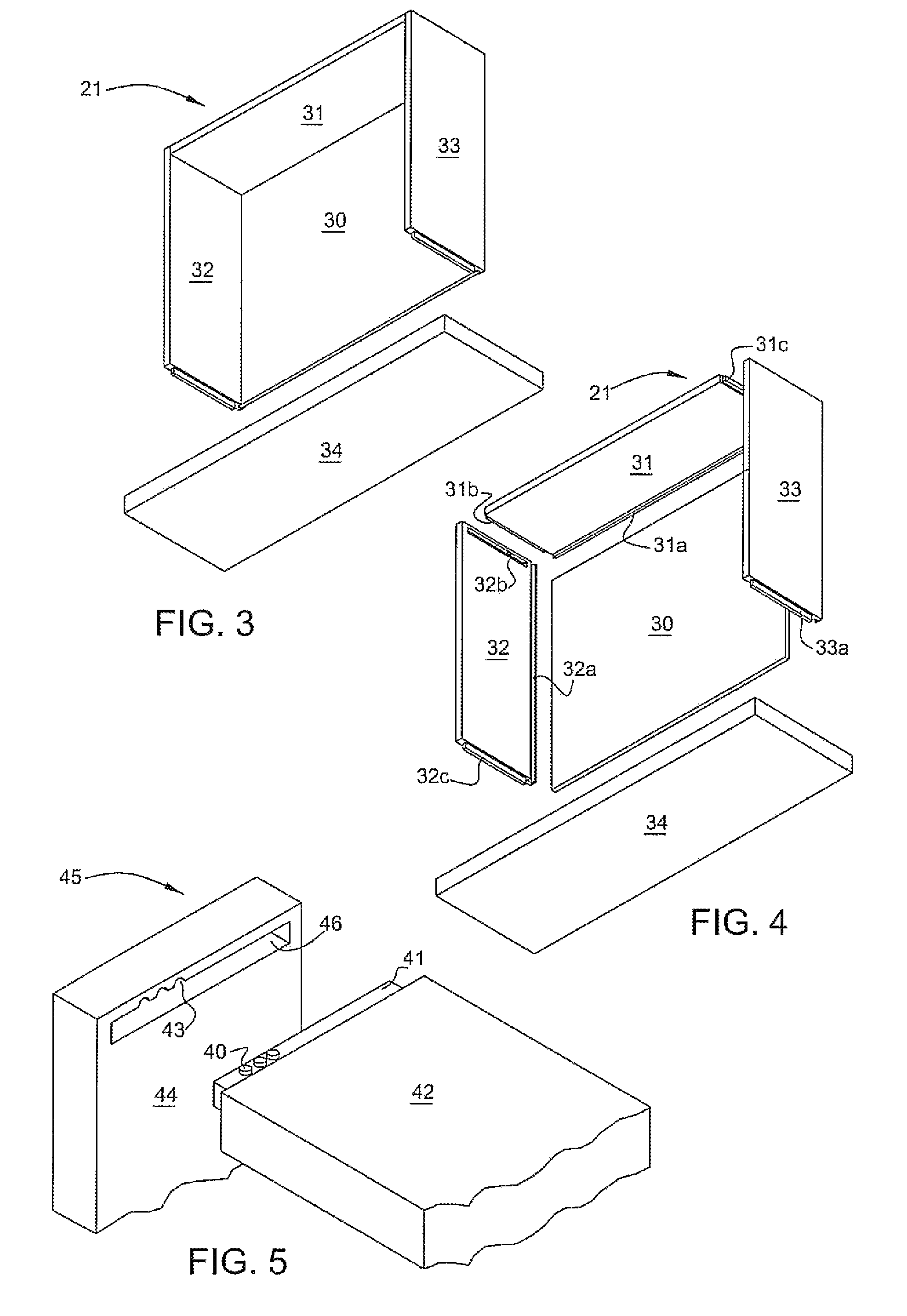

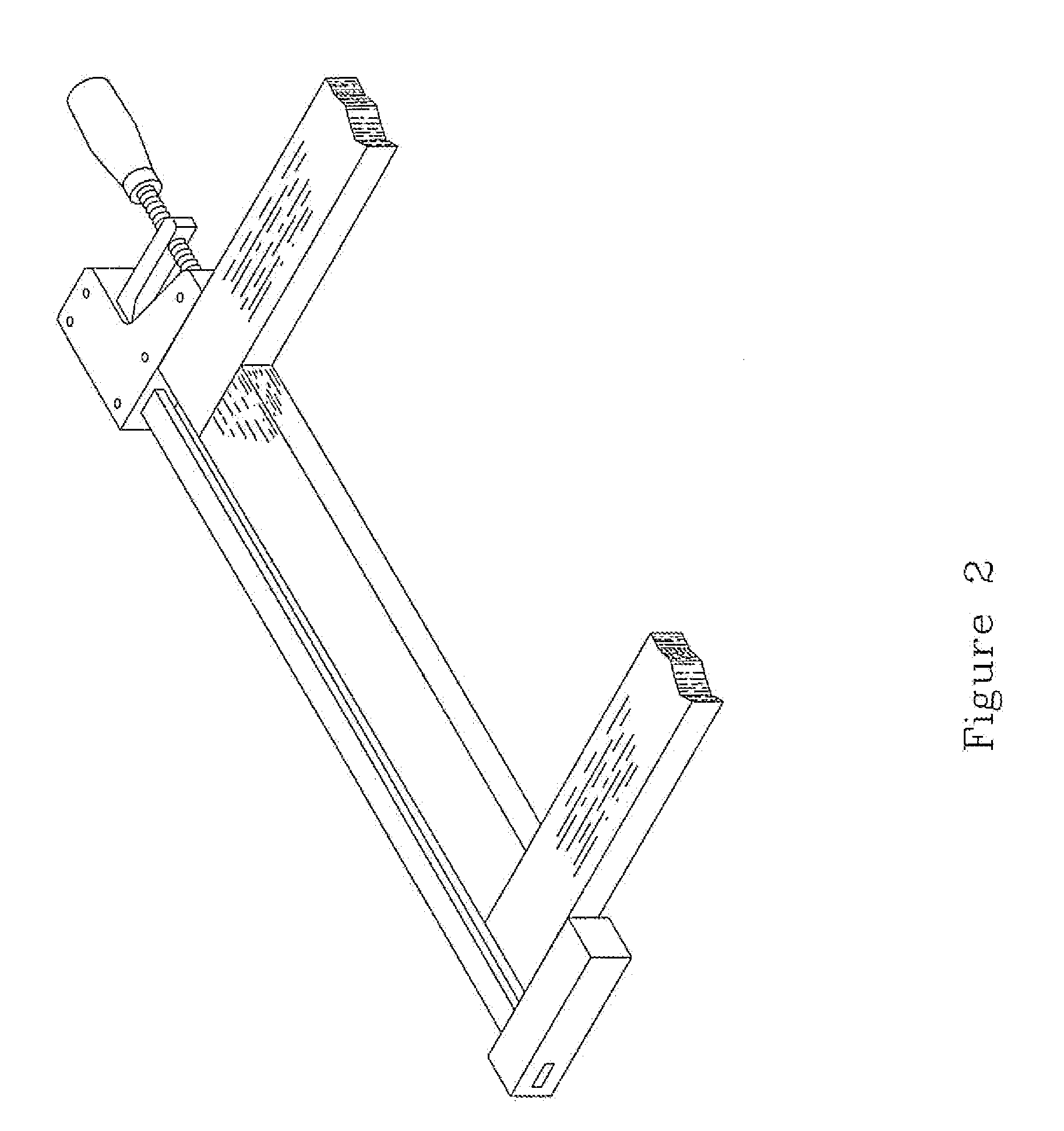

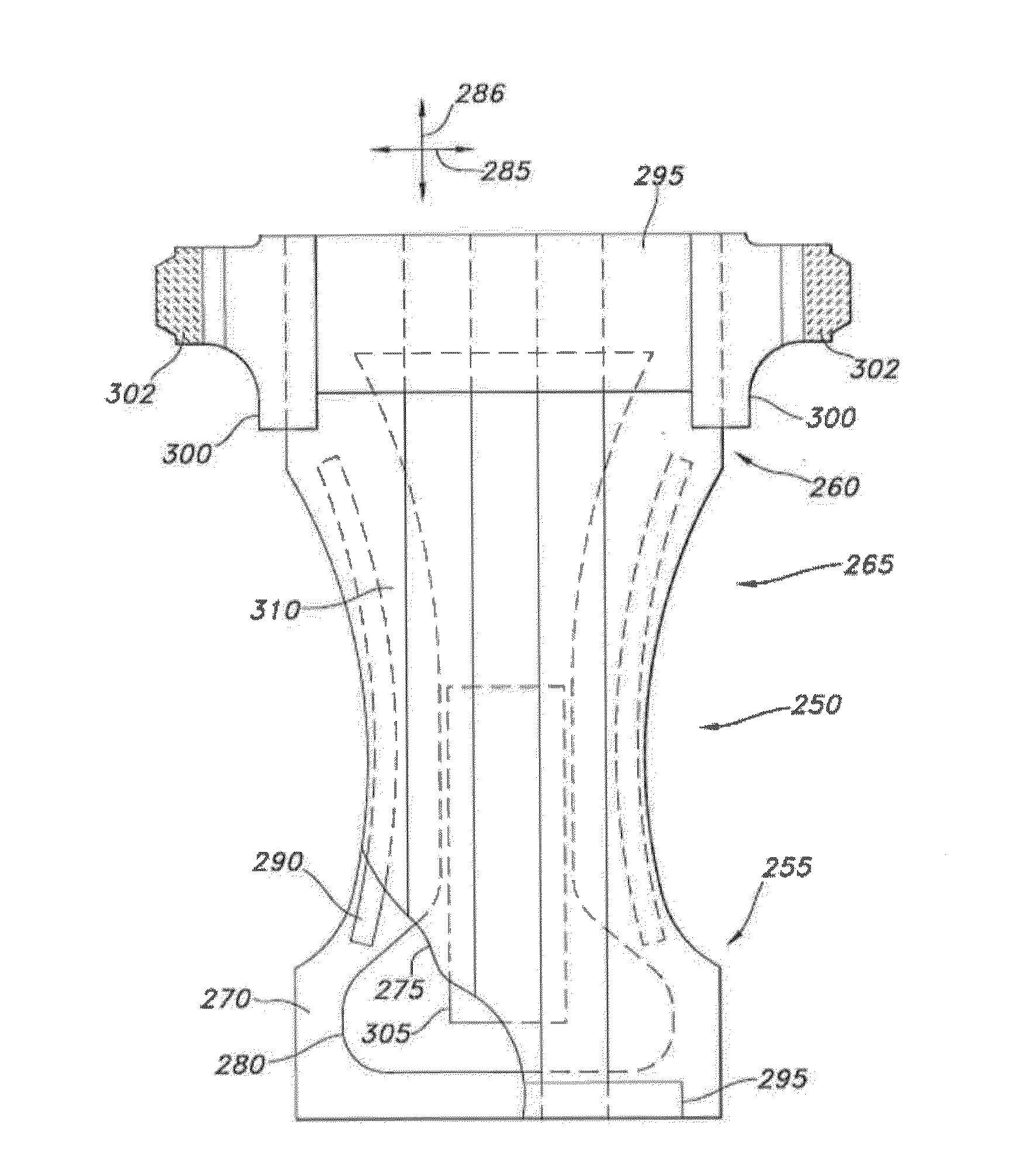

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Material systems and methods of three-dimensional printing

ActiveUS20060208388A1Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

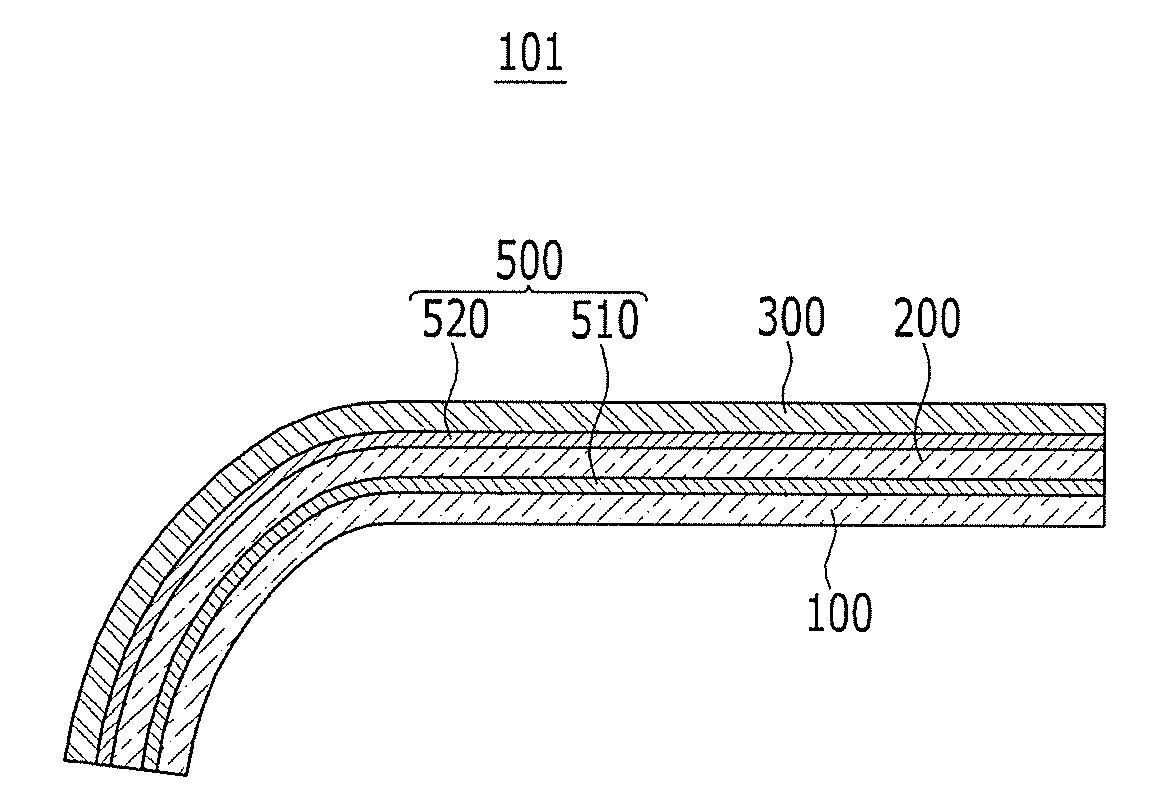

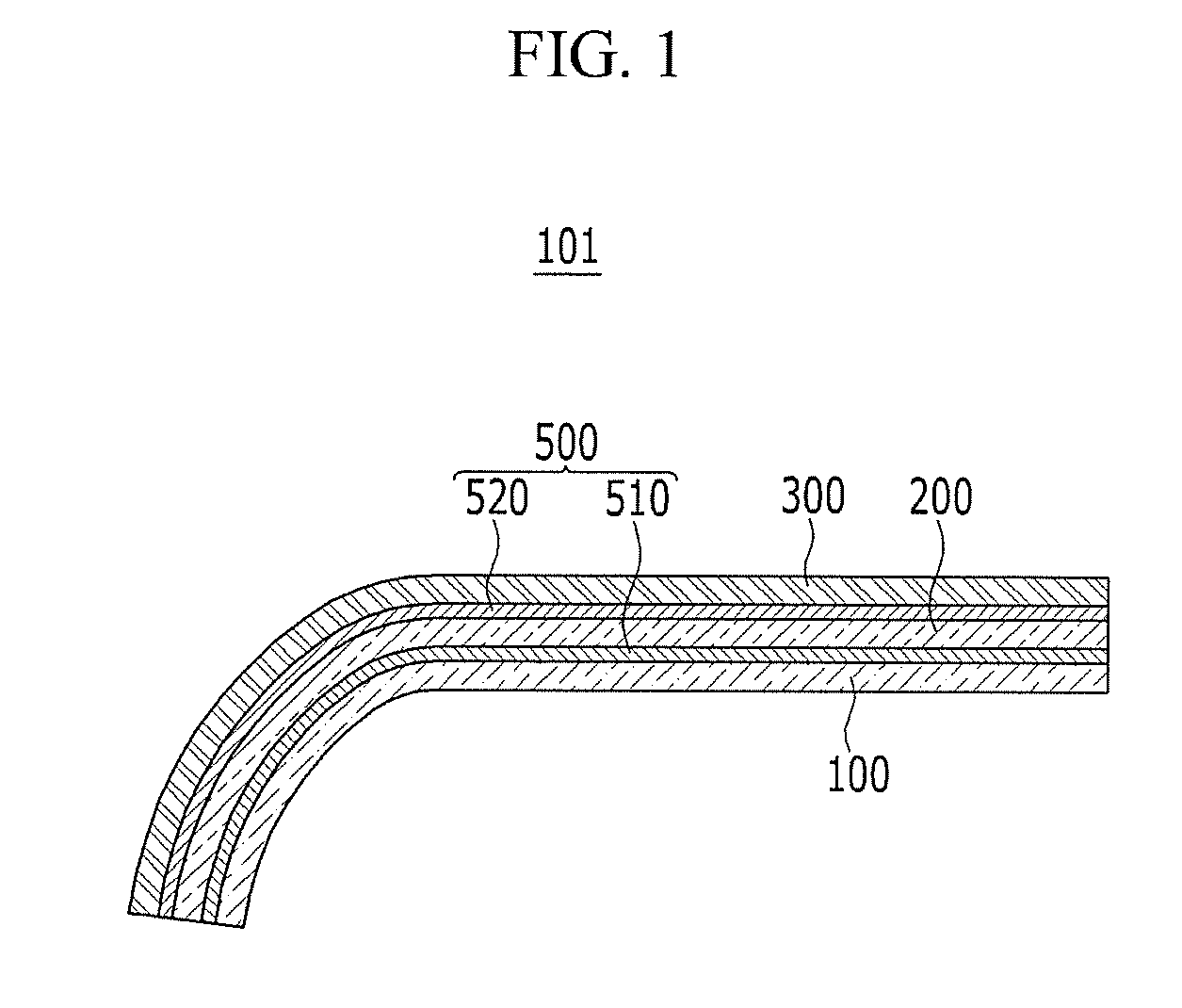

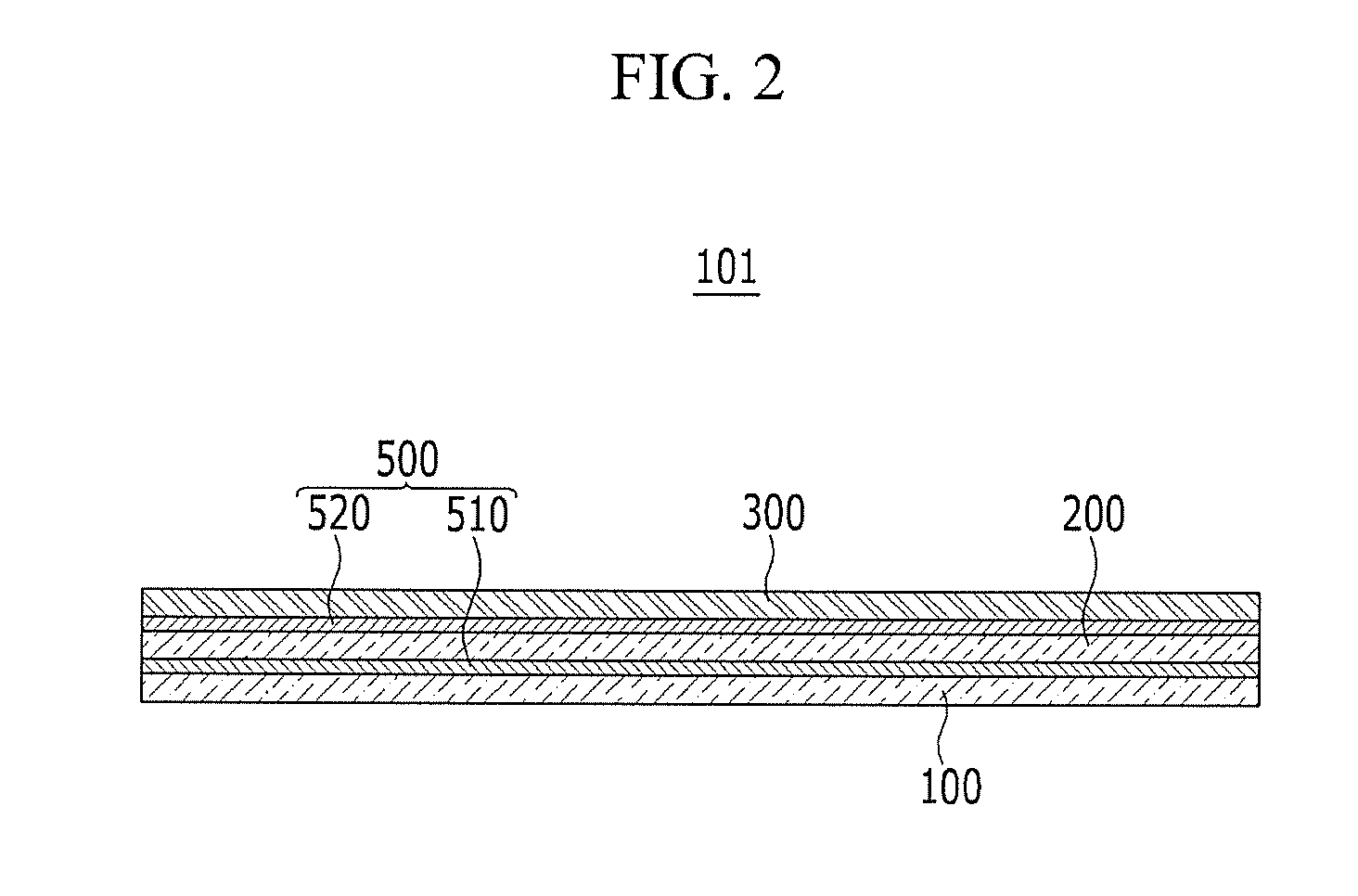

Display device and method for manufacturing the same

InactiveUS20130034685A1Lamination ancillary operationsFinal product manufactureDisplay deviceFlexible display

A display device includes a flexible display panel for displaying an image, a flexible functional plate on the flexible display panel, and a thermosetting resin layer between the flexible display panel and the flexible functional plate, wherein the thermosetting resin layer is cured while the flexible display panel and the flexible functional plate are bent.

Owner:SAMSUNG DISPLAY CO LTD

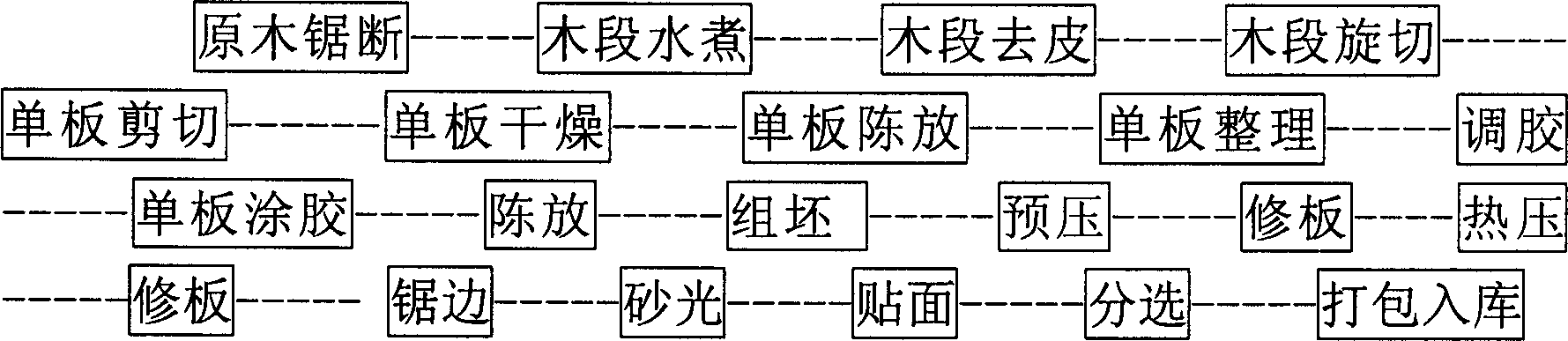

Method for producing plywood with glueing on one side and plywood mould

A method for producing the plywood with the wood plys whose one surface is coated by resin includes such steps as sawing log short, boiling in water, removing bark, spinning cutting, cutting fly, drying, ageing, coating resin on one surface of each ply, ageing, laminating, pre-pressing, trimming, hot pressing, trimming, sawing edge, sticking a paper immersed in resin, and classifying.

Owner:哈尔滨市香坊区人造板胶粘剂研究所 +1

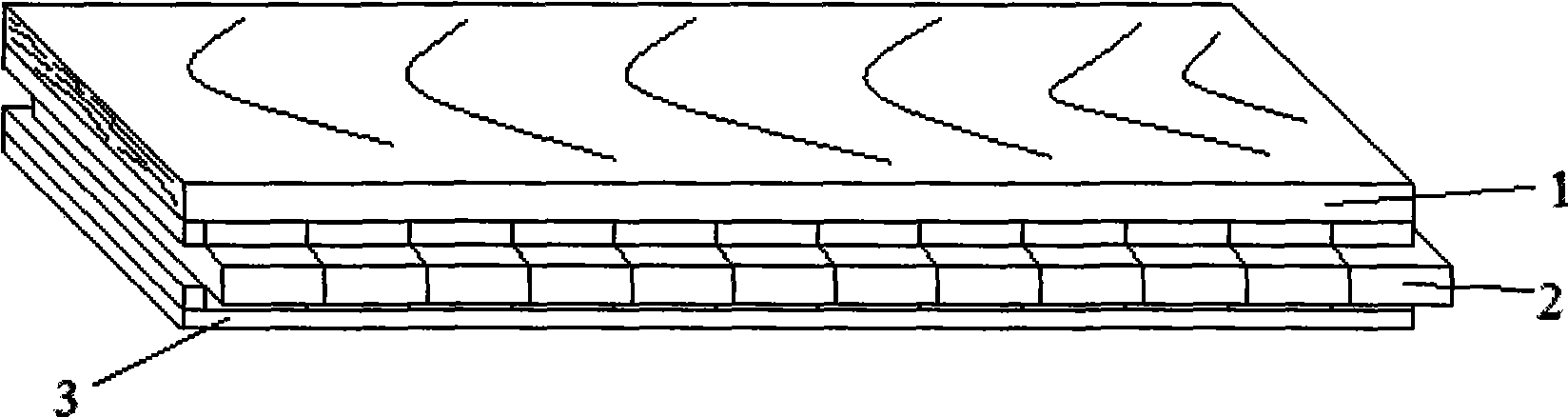

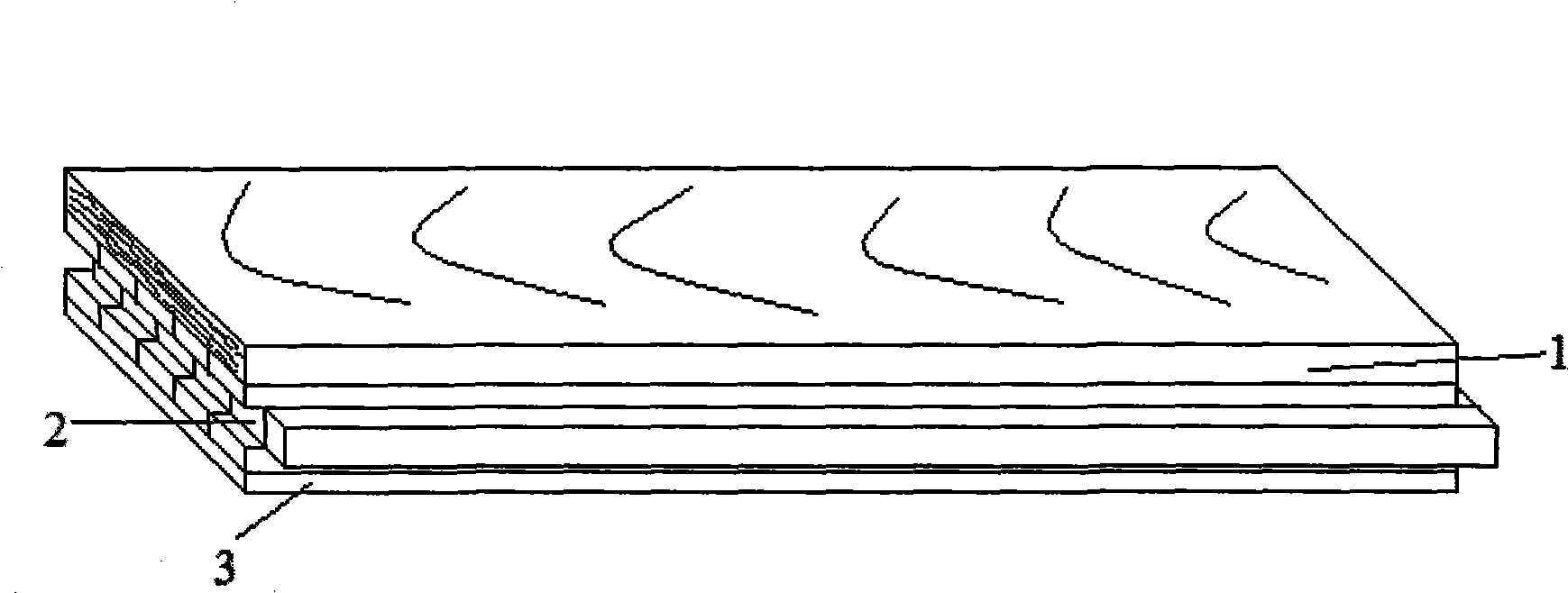

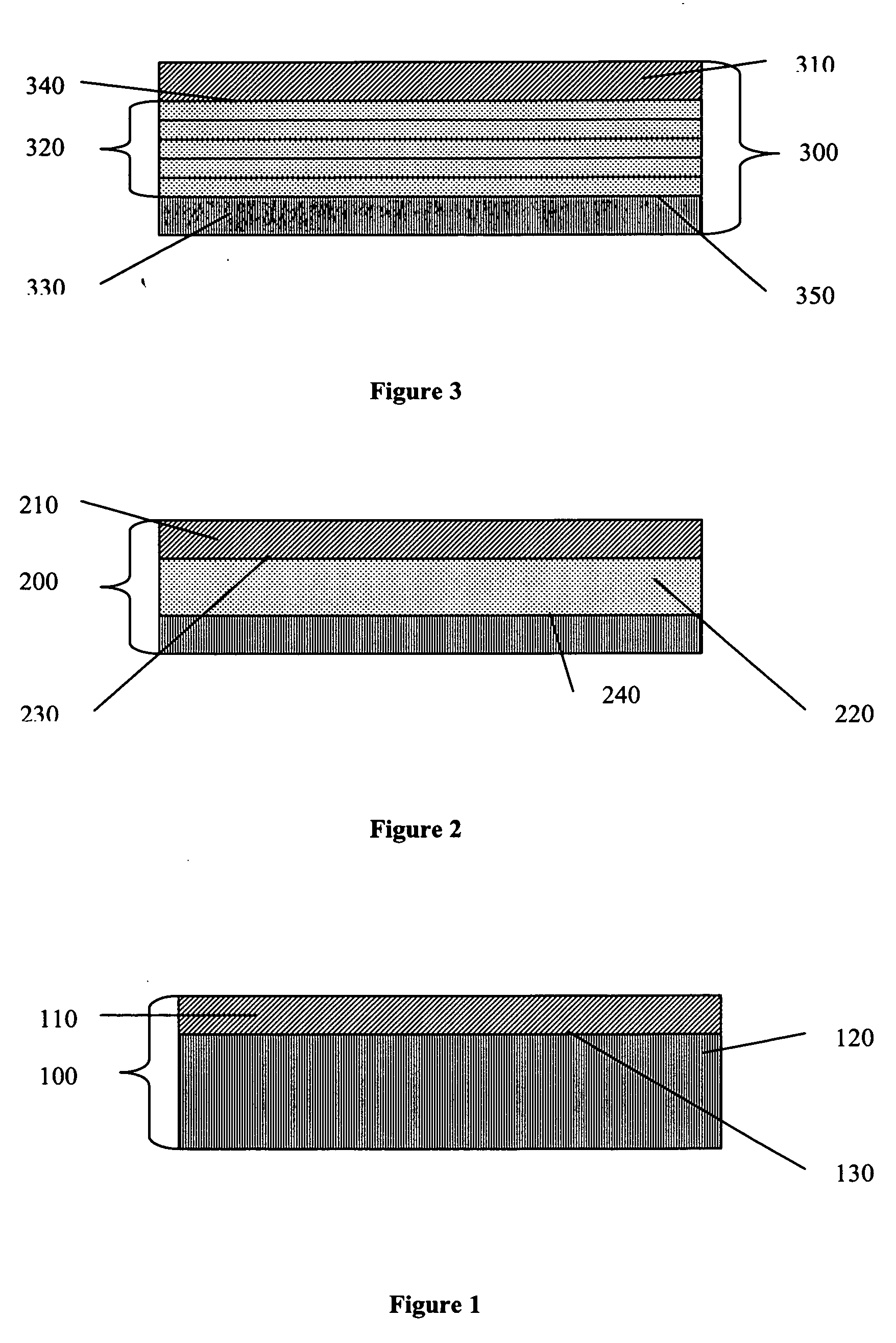

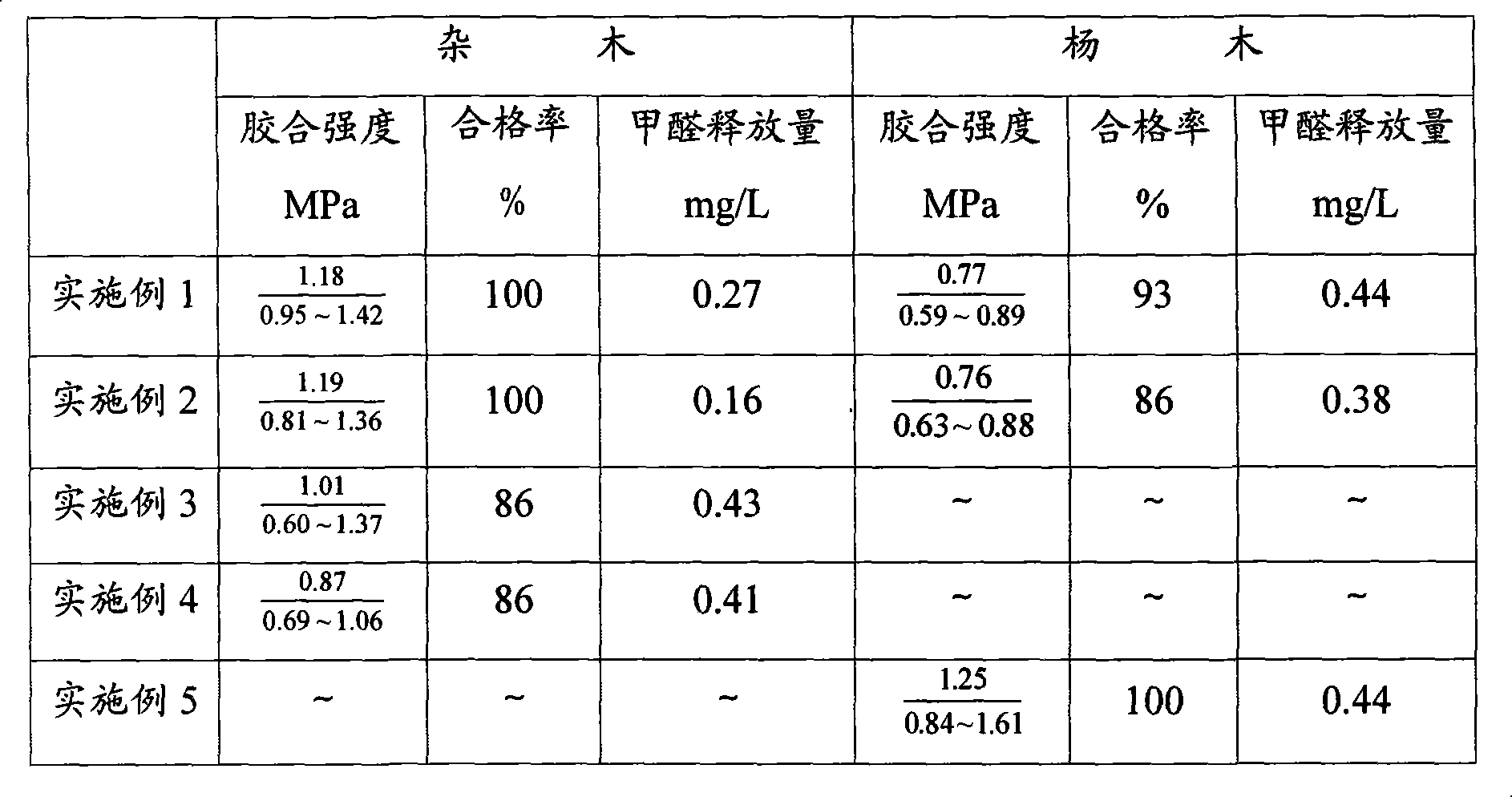

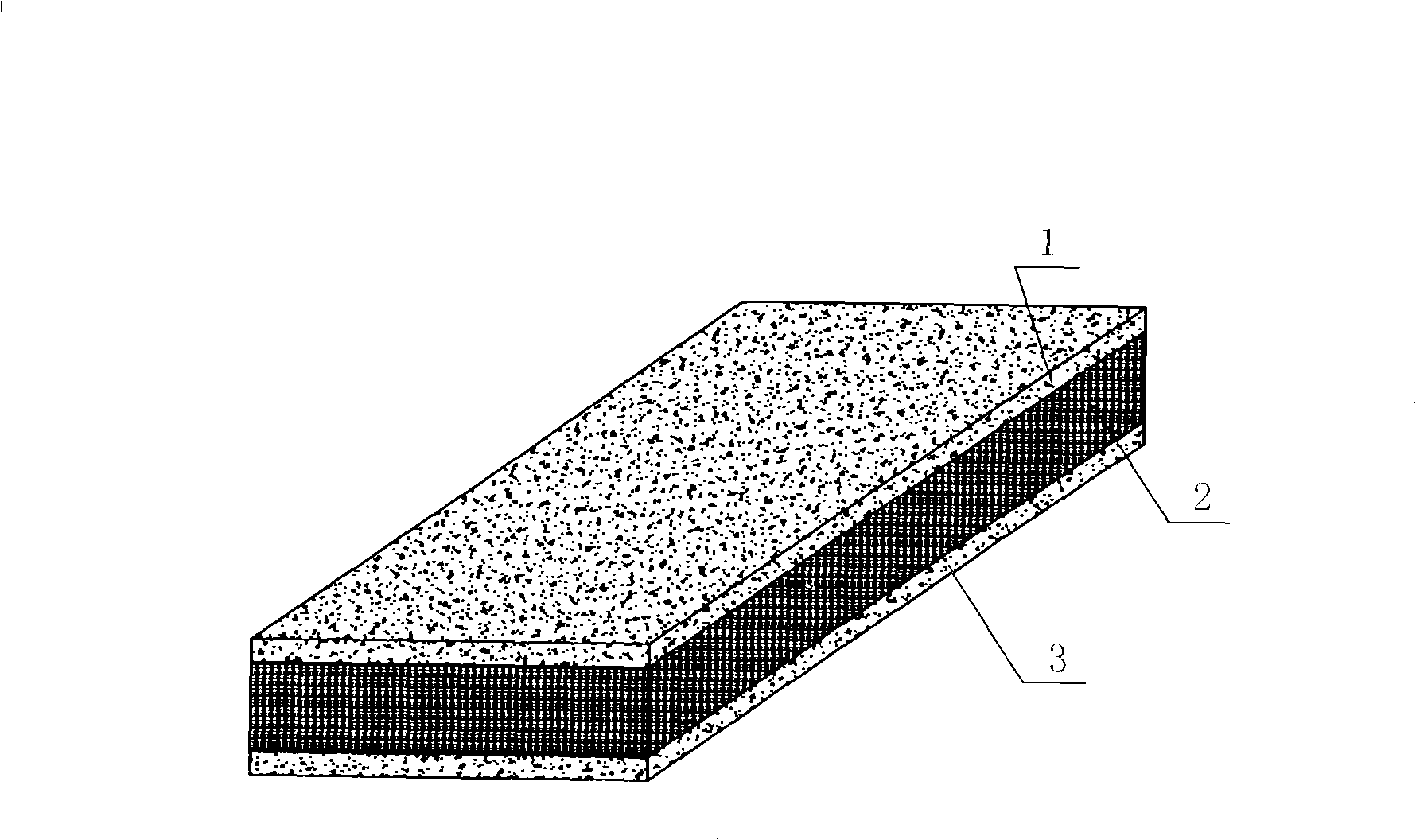

Method for producing compressed charing poplar three-layer wood composite flooring

InactiveCN101486212ALow costHigh densityWood treatment detailsWood veneer joiningSolid woodSurface layer

The invention discloses technology for producing compressed and carbonized poplar three-layer solid wood composite floor fully through utilization of a fast-growing material of poplar. A poplar sheet obtained by a special densification process is used as a surface layer; a common poplar core veneer is used as a core layer; a poplar veneer is used as a bottom layer to manufacture three-layer solid wood composite floor; each performance reaches the requirement of national standard GB / T 18103-2000 on the solid wood composite floor; the technology totally adopts the fast-growing material of the poplar as a raw material, does not add any chemical reagent in the special densification process of the poplar sheet, and does not cause any pollution to environment; after the poplar sheet is subjected to compaction treatment, the density and the hard sense of the wood are strengthened; the late high-temperature carbonization treatment solves the problem of rebounding after the poplar is compressed, changes luster of the wood, and strengthens high grade; and the technology is simple and feasible and has low manufacturing cost.

Owner:NANJING FORESTRY UNIV

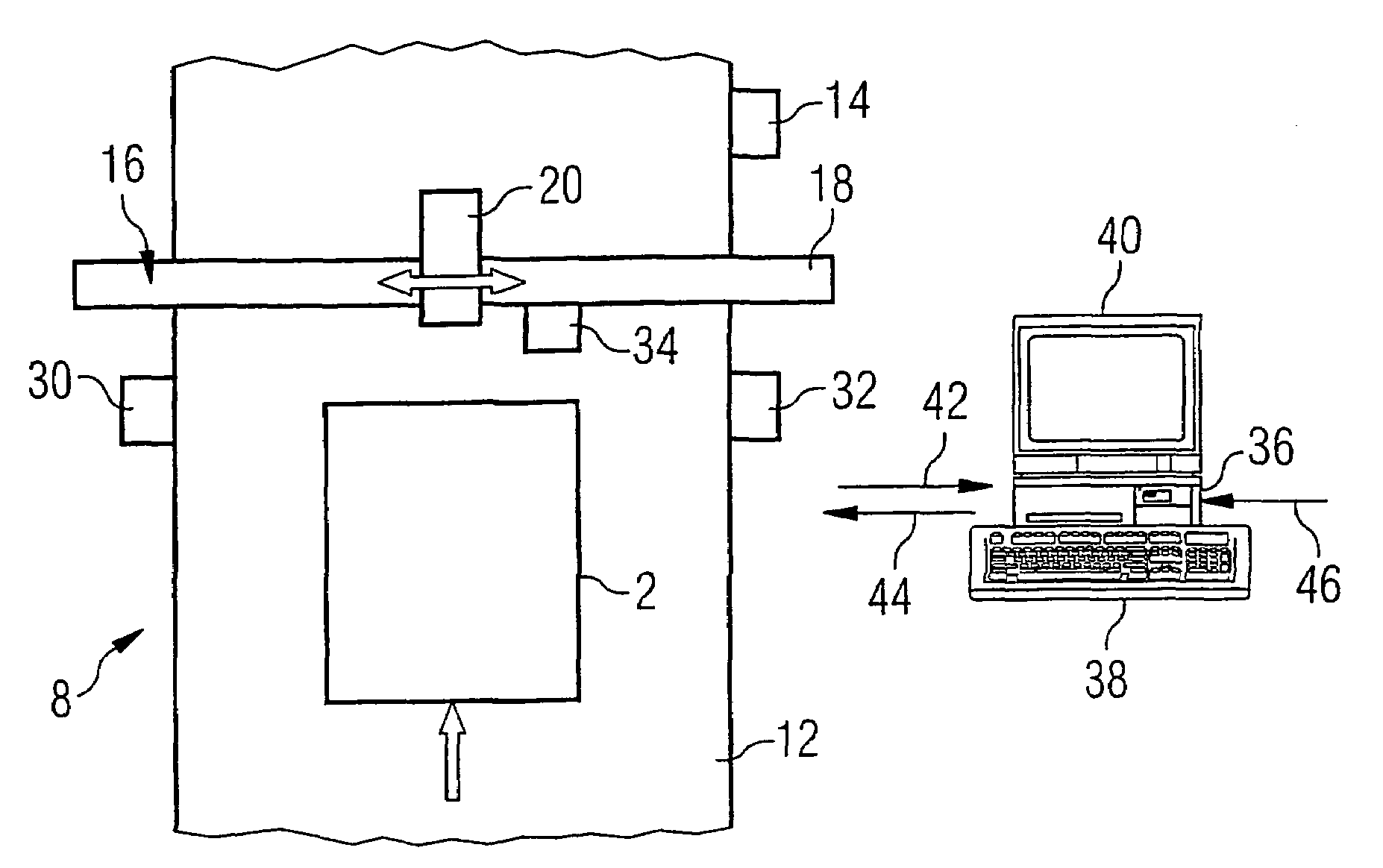

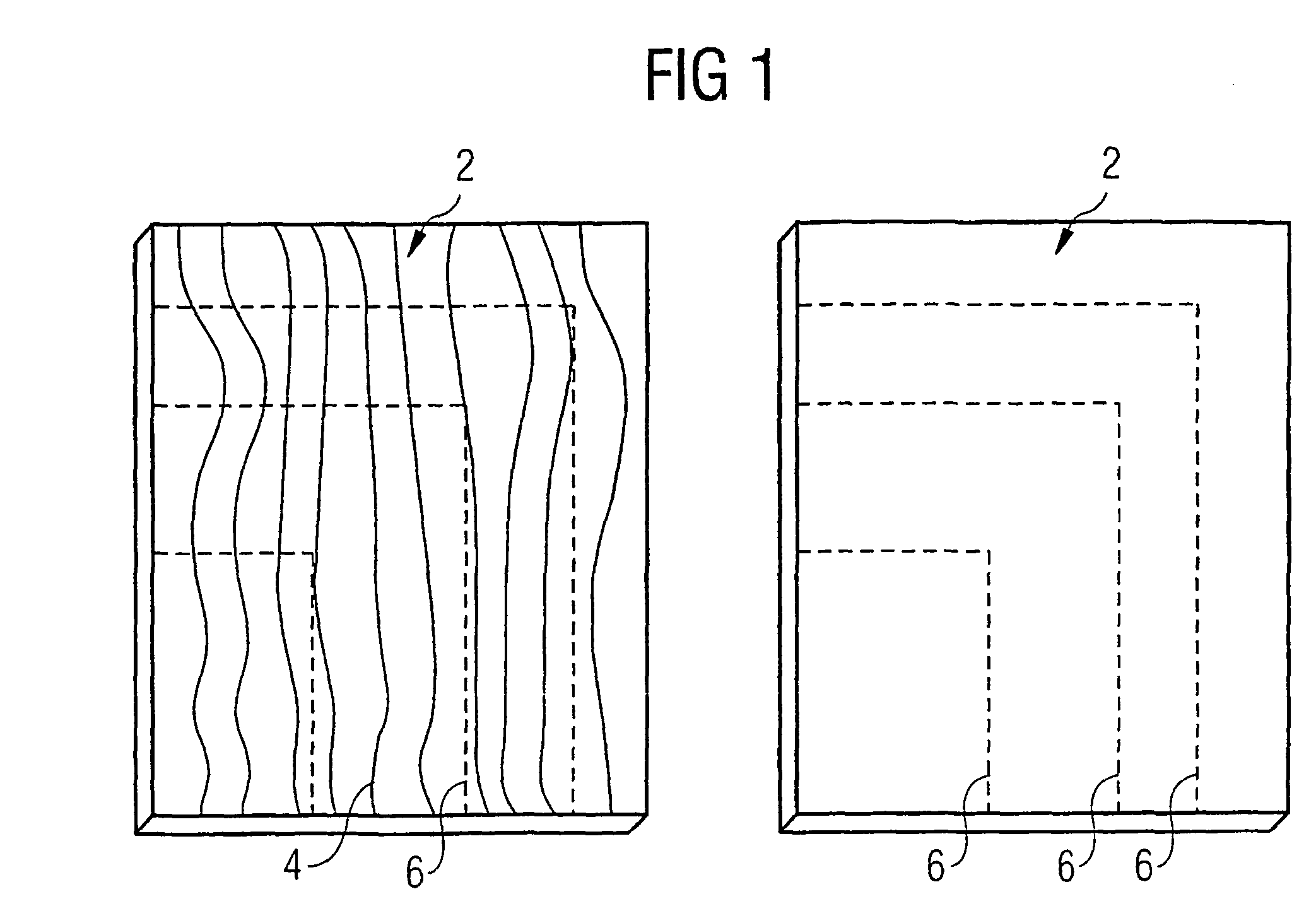

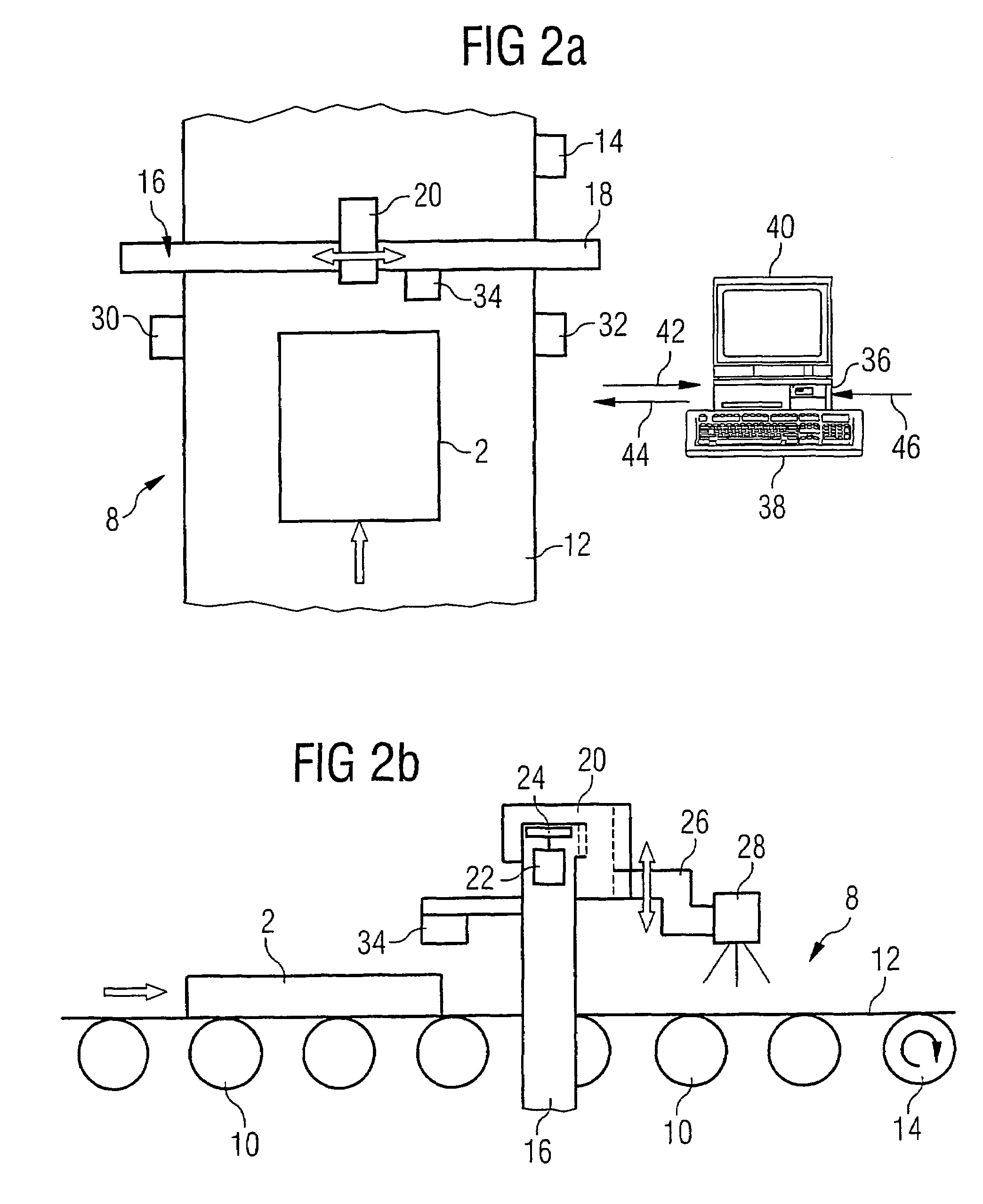

Method, apparatus and system for producing components with a pre-determined outer surface appearance, especially for front panels of kitchen units

InactiveUS7357959B2Low costQuality improvementIrregular area designNatural patternsBiomedical engineeringFront panel

The invention relates to a method for the production of components with a pre-determined surface appearance, in particular for front panels of kitchen units, whereby the components are printed with a pre-determined pattern by means of a printing method which may be programmed corresponding to the appearance achieved. The invention further relates to a device for the production of said components and a system in which groups of said components are produced.

Owner:INTERGLARION LTD (AT)

Making process of E1/E0 level green artificial plate

InactiveCN1526528AThe effect of free formaldehyde content is obviousGuarantee market supplyWood veneer joiningFlat articlesFiberHigh density

The present invention discloses one kind of making process of E1 / E0 level environment protection artificial plate. After plain plate with free formaldehyde releasing amount greater than or equal to E2 level is made with common urea resin adhesive, the plain plate is processed through ammonia vacuum process to lower the free formaldehyde releasing amount to E1 / E0 level. According to the density and initial formaldehyde releasing amount of the plain plate, the ammonia consumption and formaldehyde lowering time are regulated to control the processing effect. The said process has stable product quality and low cost, and is suitable for various artificial plates, including plywood, medium density fiber plate, high density fiber plate and shaving board.

Owner:NANJING FORESTRY UNIV

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

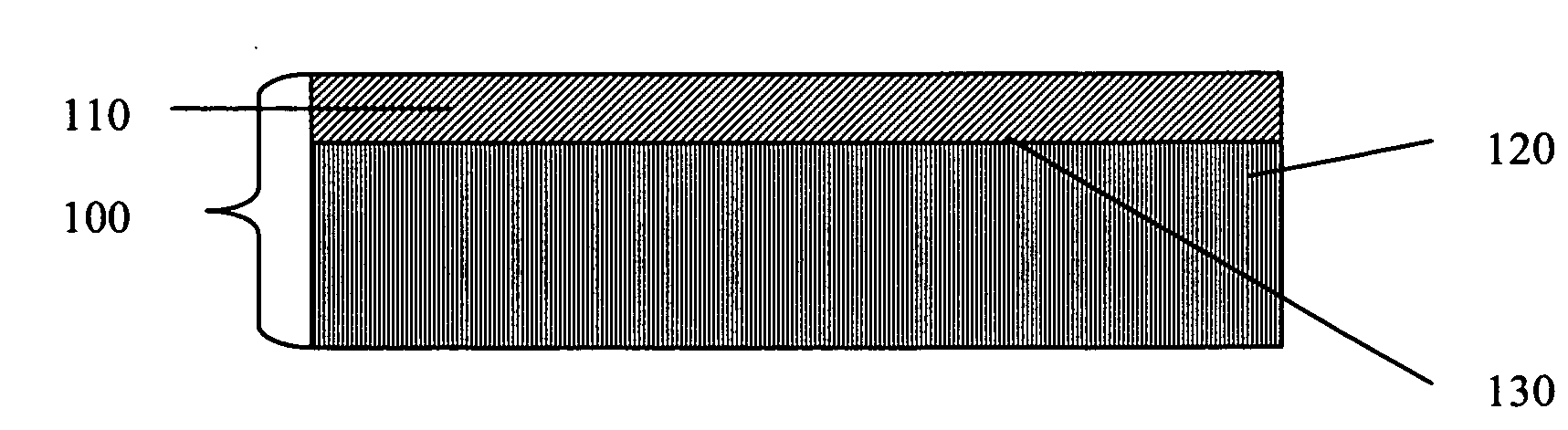

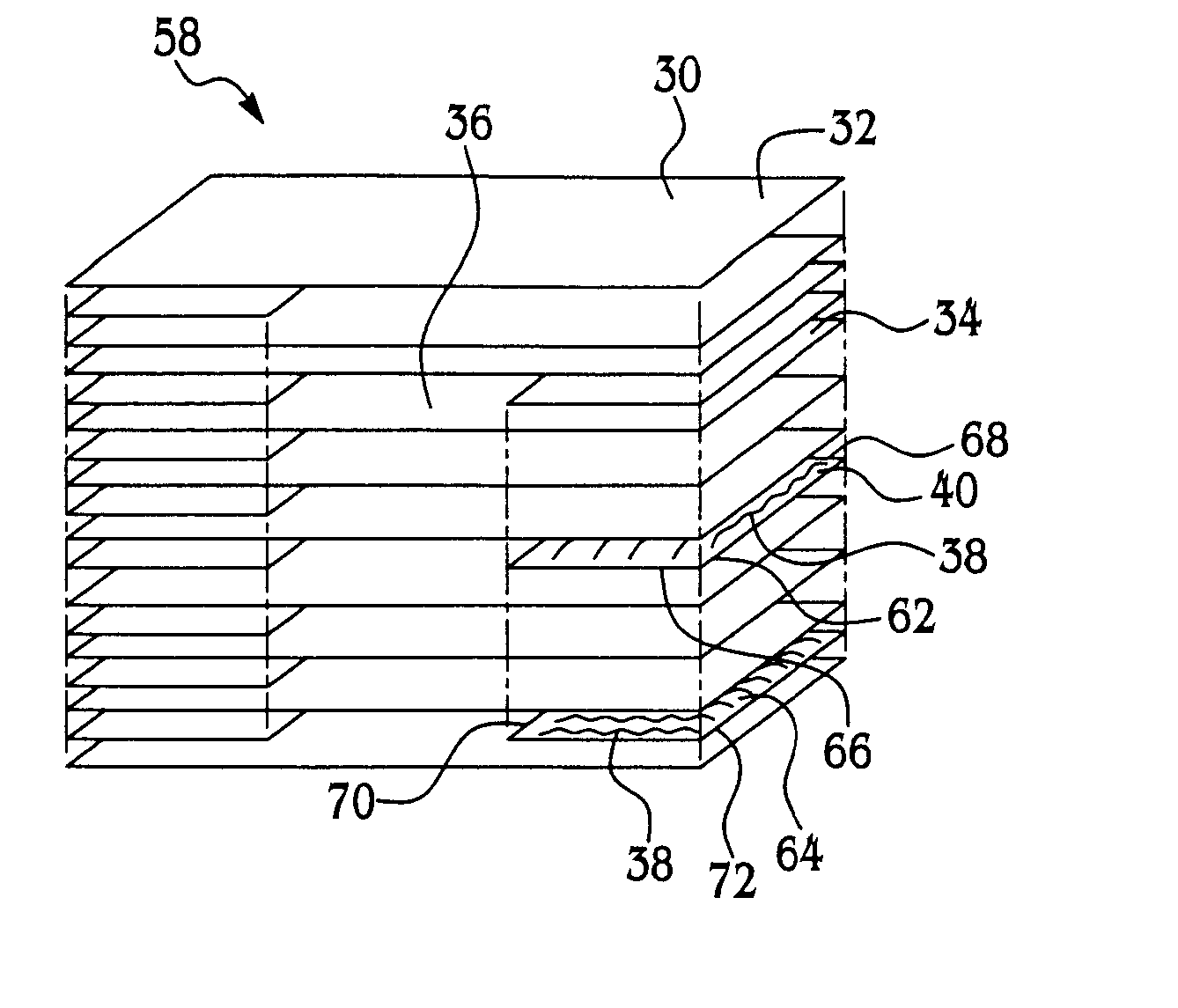

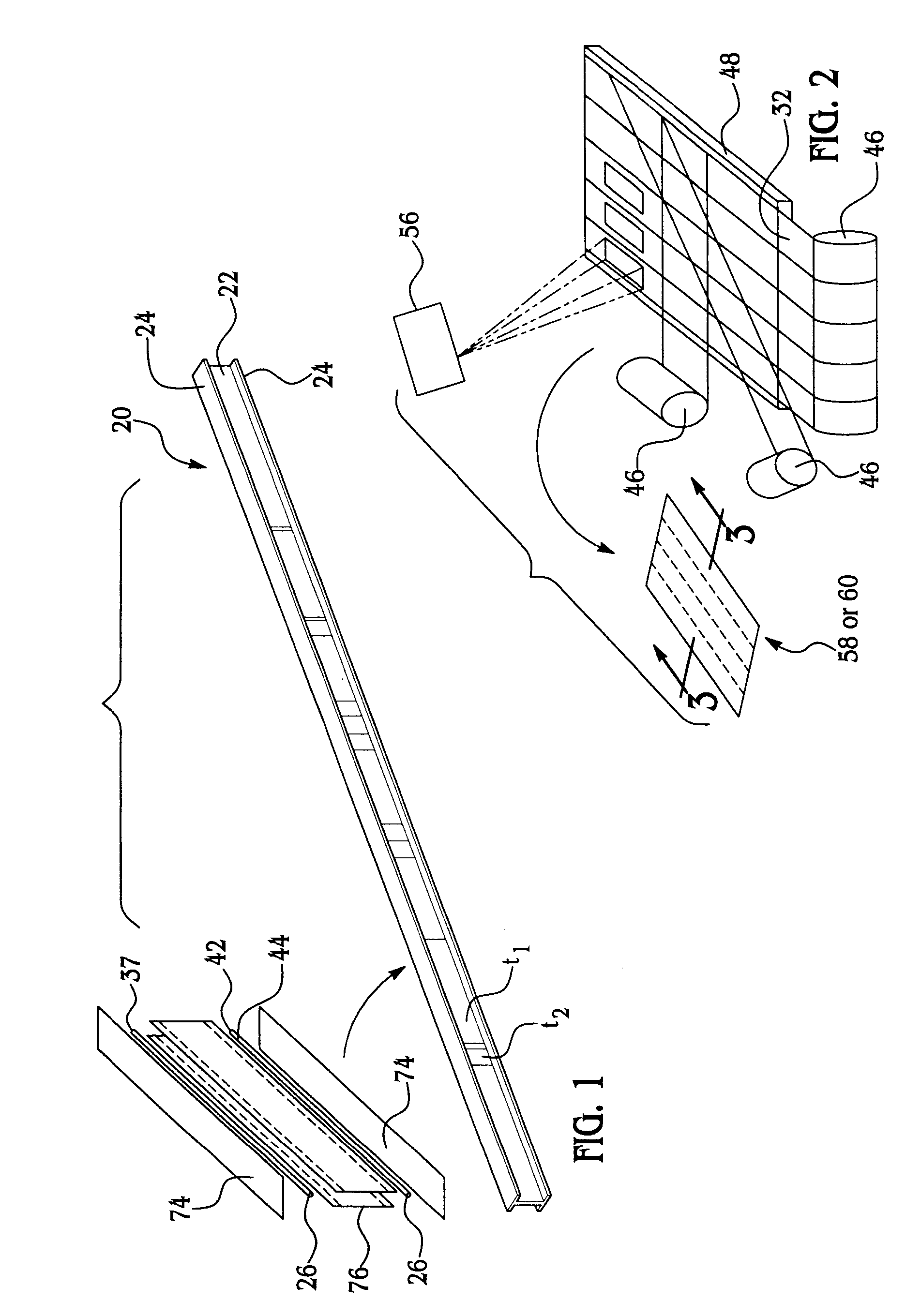

Process for making wood laminates using fast setting adhesives at ambient temperature

InactiveUS20070102108A1Lamination ancillary operationsLayered product treatmentSurface layerAdhesive

A process to form a multilayer article comprising pressing a stack comprising two or more panels, wherein each panel comprises a surface layer and a substrate layer, wherein a side of the surface layer is contacted to a side of the substrate layer, and wherein the contacting sides of the surface layer and substrate layer have a fast-setting adhesive disposed there between; and wherein pressing comprises applying uniform pressure to the stack orthogonal to the plane of the panels, at ambient temperature and for a time of 0.1 to 20 minutes, and with no subsequent hot pressing. Articles prepared using the method are also disclosed.

Owner:HEXION SPECIALTY CHEM INC

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

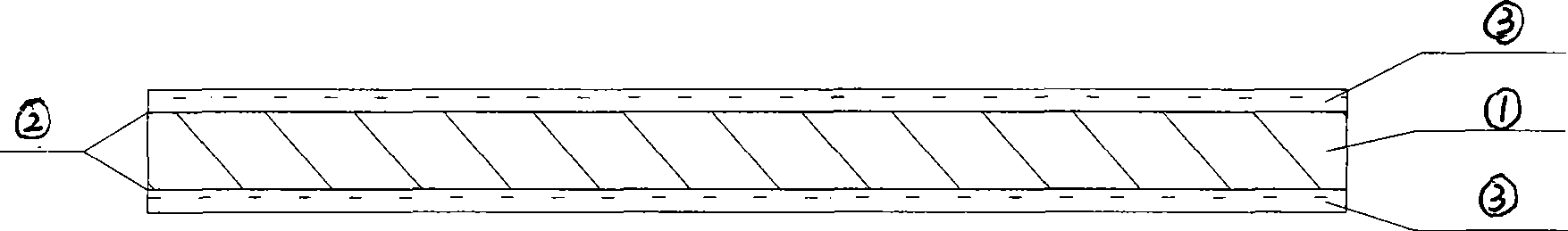

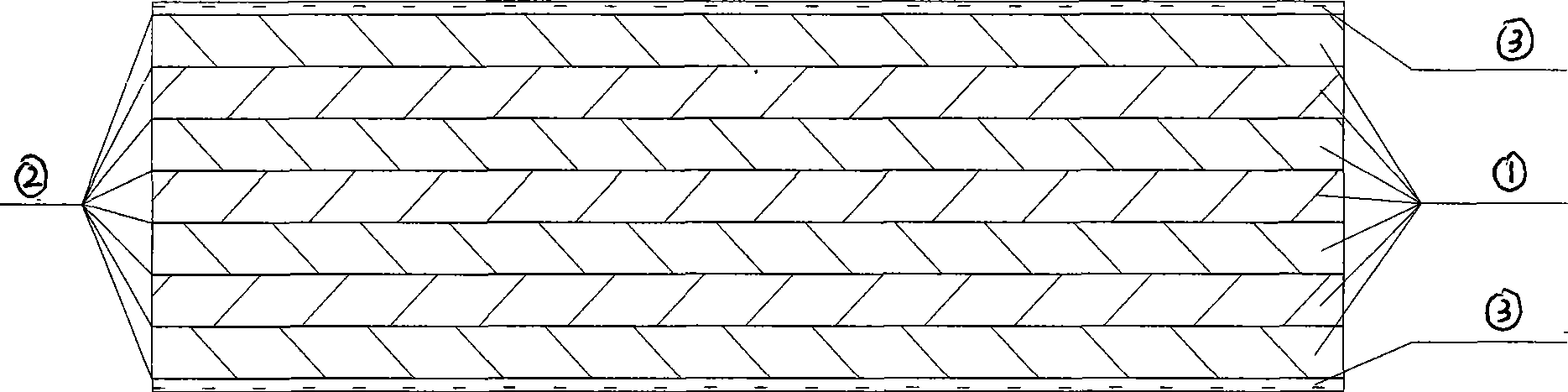

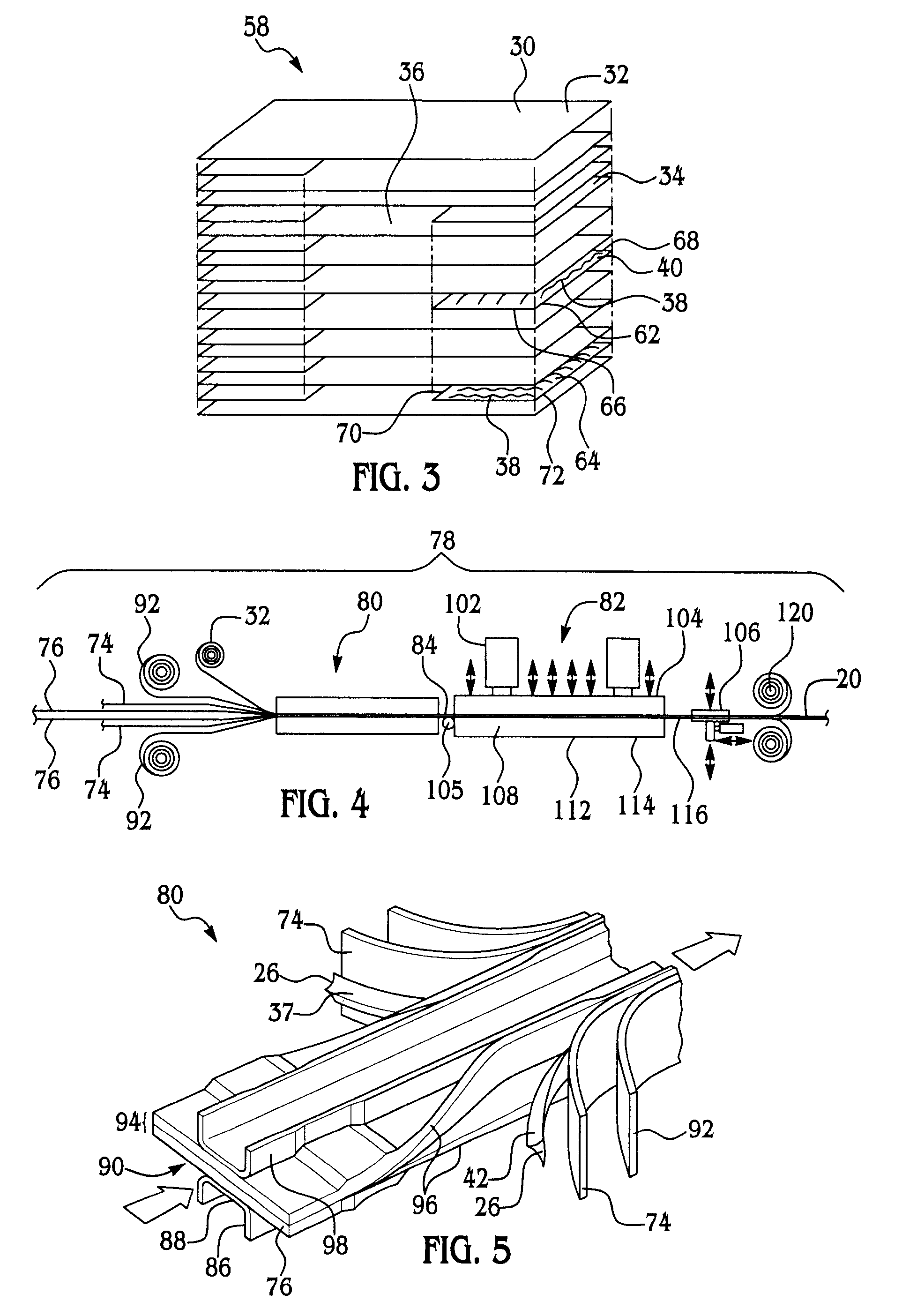

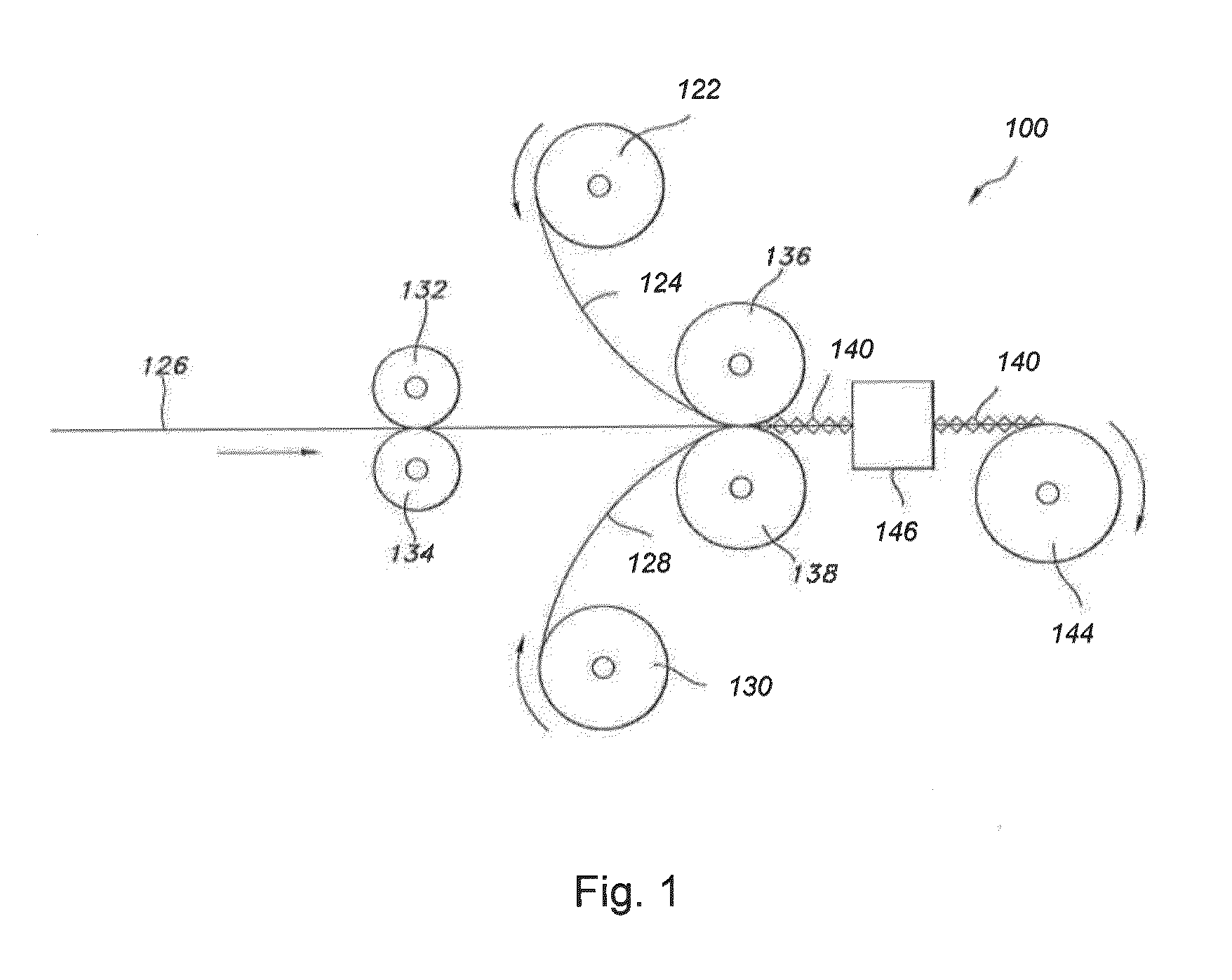

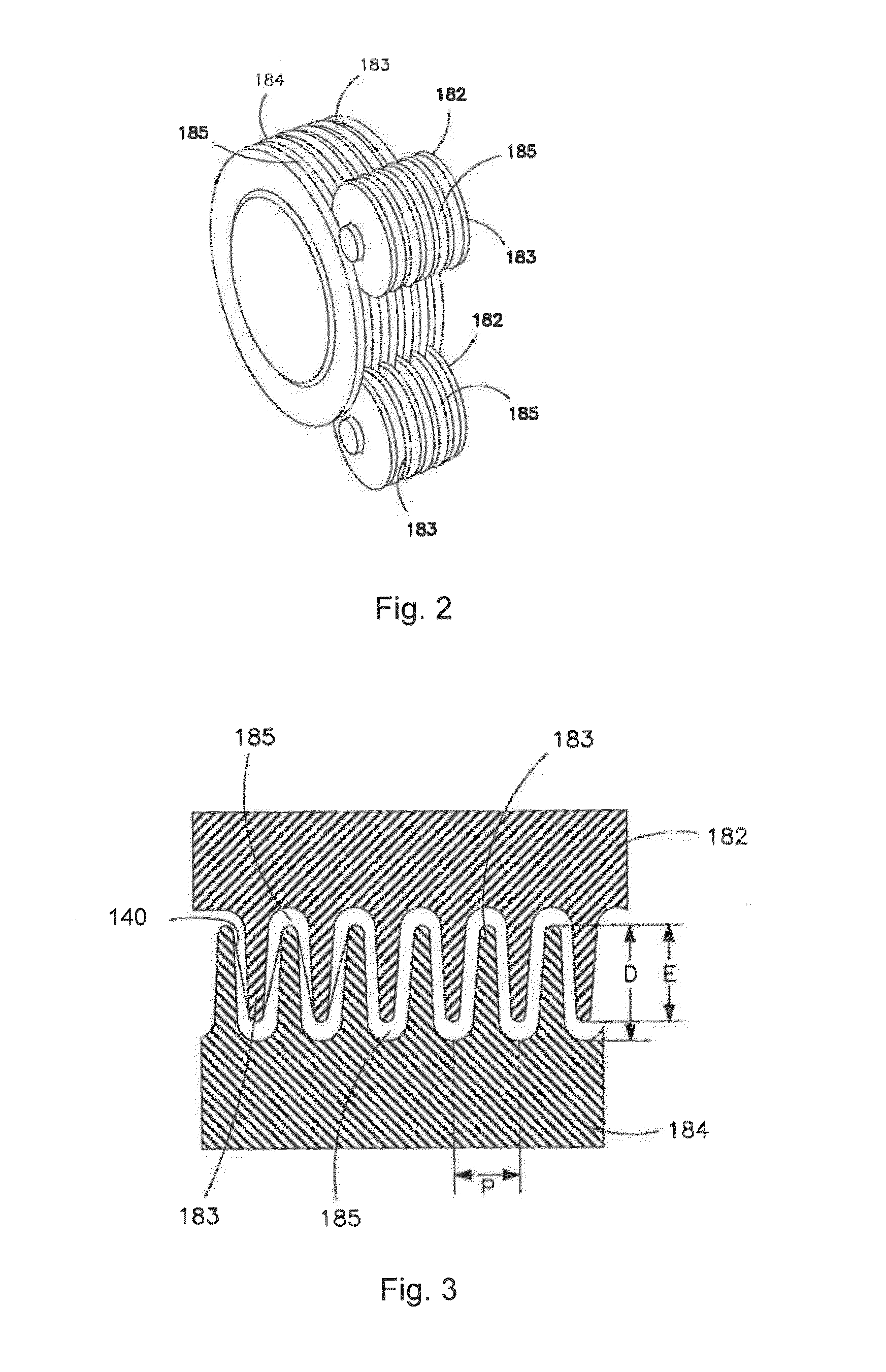

Continuous Fabrication of Parts Using In-Feed Spools of Fiber Reinforced Thermoplastic

ActiveUS20070175572A1Automate processingNeed can be reduced eliminatedWood veneer joiningBaby linensEngineeringVarying thickness

Thermoplastic composite laminate parts with tailored and varying thickness and / or curved sections are manufactured in a continuous process. Automated equipment or hand lay-up is used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Some or all of the plies may be continuously fed from spools of single or multiply ply material. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

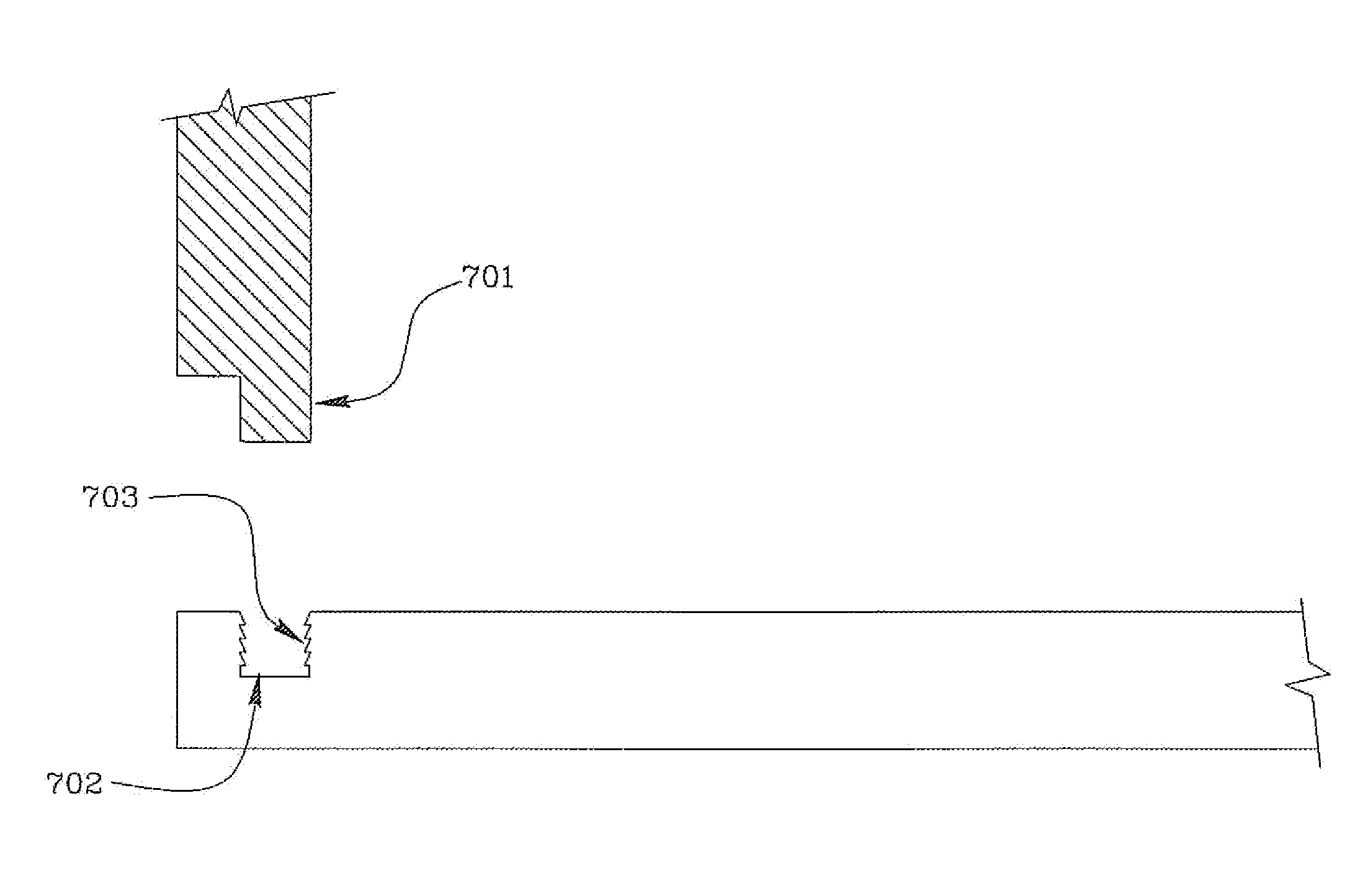

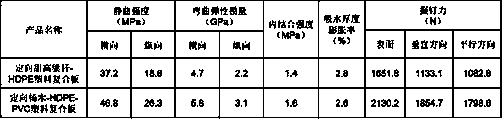

Method for Joining Workpieces Together and Product Made Thereby

A method of forming a joint between first and second workpieces generally consisting of forming a recess in one of such workpieces, provided with at least one side wall having a serrated cross-sectional configuration with inwardly projecting, distortable segments; providing a portion in the other of such workpieces, insertable into such recess, having a cross-sectional configuration sufficient to engage and distort such segments as such portion is inserted into such recess; and inserting such portion of the other workpiece into such recess, causing the segments to distort and thus provide an interference fit between such workpieces.

Owner:THERMWOOD CORPORATION

Post-Bonded Grooved Elastic Materials

An elastic nonwoven laminate that contains an elastic film laminated to one or more nonwoven facings is provided. The nonwoven facing contains a conventional polyolefin and can also contain a polyolefin-based plastomer. The laminate is activated by grooving to decouple the nonwoven facing from the elastic film. To reduce fiber-pull out that can result due to activation by grooving, the laminate can be post-bonded at room or elevated temperatures and a specific range of pressures to compact the fibers of the facing and minimize fiber pull-out / fuzziness while not sacrificing the softness, elasticity, and feel of the laminate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for manufacturing E0 level wood veneer

InactiveCN101244571AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesWood veneer joiningWood veneerEther

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

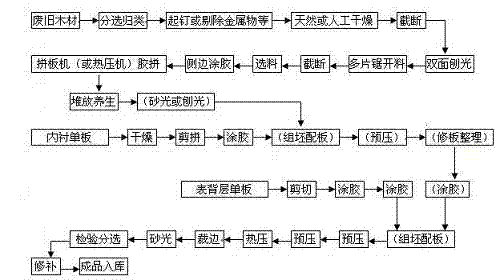

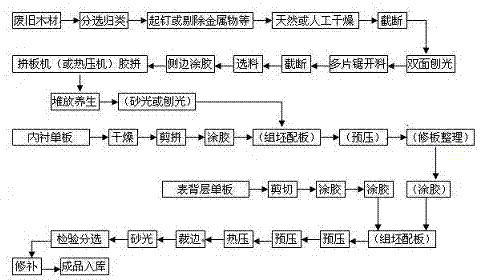

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

Wood decorative material coated with resin composite film and process for producing the same

InactiveUS6352784B1High bonding strengthCrack and breakOther plywood/veneer working apparatusSynthetic resin layered productsSurface layerLacquer

A wood decorative material coated with resin composite film, comprising a laminate of, arranged in the following order, a wood substrate; a heat bonding layer (A) formed from a heat bonding resin composition comprising 100 parts by weight of a thermoplastic resin (a-1) and 0.001 to 80 parts by weight of a tackifier resin (a-2), the above heat bonding resin composition having a melting point or softening temperature of 170° C. or below and exhibiting a melt flow rate (MFR) at 190° C. of 1 to 500 g / 10 min; and a mar-proof surface layer (B). Not only can beautiful appearance be obtained while retaining natural texture without the application of lacquer but also surface protection and bending working properties are improved.

Owner:TOHCELLO CO LTD (JP)

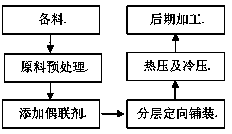

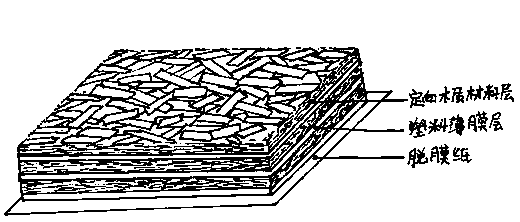

Directional wood-plastic composite plate and manufacturing method thereof

InactiveCN103659946ASmall sizeIncrease contentSynthetic resin layered productsLaminationThermoplasticPulp and paper industry

The invention relates to a directional wood-plastic composite plate and a manufacturing method thereof. The problem that large-slenderness-ratio wood raw materials are used for manufacturing wood-plastic composite materials is solved. The directional wood-plastic composite plate comprises the following ingredients in percent by weight: 70-95% of wood raw materials, 5-30% of thermoplastic plastics and 0.5-4% of coupling agents. The manufacturing method for the directional wood-plastic composite plate comprises the following steps of preparing raw materials; pre-treating the raw materials; adding the coupling agents in the raw materials; directionally laying the wood raw materials and thermoplastic plastic films in a layered manner; and performing hot pressing, cold pressing and later machining procedures on the materials. The directional wood-plastic composite plate has the advantages that the content of the plastics is low, the physical mechanical performance is high, the width of the directional wood-plastic composite plate is large, and release of harmful gas is avoided; and the directional wood-plastic composite plate is applicable to buildings, furniture and packaging materials.

Owner:BEIJING FORESTRY UNIVERSITY

Carbonization wood finger-joint glued-laminated timber and its manufacturing method

InactiveCN101104282AChange part chemistryChange physical propertiesWood veneer joiningWood layered productsCarbonizationFinger joint

The invention relates to a carbonized figure jointed glulam lumber and a manufacturing method. The carbonized figure jointed glulam lumber is a one-layer integrated board, or one or several layers of lateral battens laying in the sandwich layer and the integrated board with more than two layers is glued in parallel in the direction of thickness. Each layer of the integrated board is made of standard battens formed by gluing many short battens through finger-jointing and tenoning, and then the standard width is formed by gelatinizing on the side of the batten and gluing and joining in parallel. The process of the method includes: log truncation, sawing, carbonization, chopping, finger-jointing, repairing, sanding and repairing; second glue jointing: gelatinizing; testing, warehousing. The advantages are that part of the chemical and physical properties of wood are changed permanently; hydrophilic property of the lumber is reduced and the inner stress is eliminated completely; the color of the wood is darkened and the wood texture is clear; the contained resin inside the wood is removed so that the wood can be glued and finished; the drying operation is substituted by the high temperature carbonization technique; the carbonized figure jointed glulam lumber is of stable size and shape, of no craze and resin and of clear texture and good durability.

Owner:NANJING FORESTRY UNIV +1

Container flooring material and method of manufacture

A board suitable for use as container flooring uses bamboo and fast-growth low-density wood. Thin layers of high-density bamboo composites are used to overlay on surfaces of a core layer which can be the composite of wood veneer and wood strand-based composite, or wood veneer and bamboo stripe sheet composite. This invention combines the benefits of bamboo and wood materials to produce a bamboo-wood composite board having sufficient mechanical and physical strength and durability for use as container flooring.

Owner:ALBERTA INNOVATES TECH FUTURES

Method for preparing flame-proof plywood

InactiveCN101121274AImprove flame retardant and smoke suppression performanceAchieve flame retardant and smoke suppressionWood veneer joiningWood impregnation detailsEngineeringFire retardant

A manufacturing method for fire resistant veneer relates to a manufacturing method for veneer. The present invention solves the problem that the present veneers are combustible. The present invention of fire resistant veneer is manufactured by the following steps that a multi-effect wood fire retardant and solution are manufactured; soaking or coating and drying; gelatinization, assembly and hot pressure; in this way, the fire resistant veneer is obtained. The present invention of fire resistant veneer has the effect of fire retardation and smoke restraint and the present invention is antiseptic, mold resistant and mothproof.

Owner:NORTHEAST FORESTRY UNIVERSITY

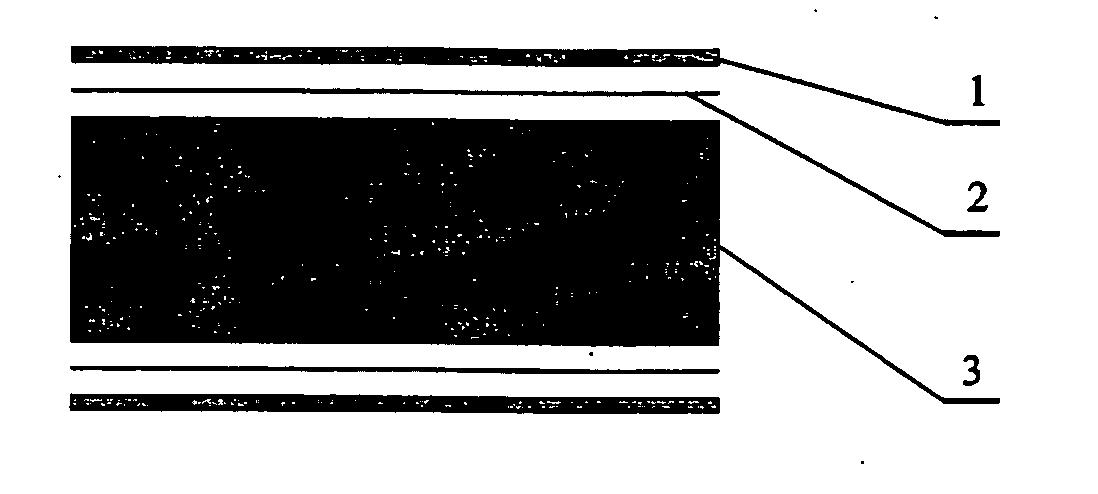

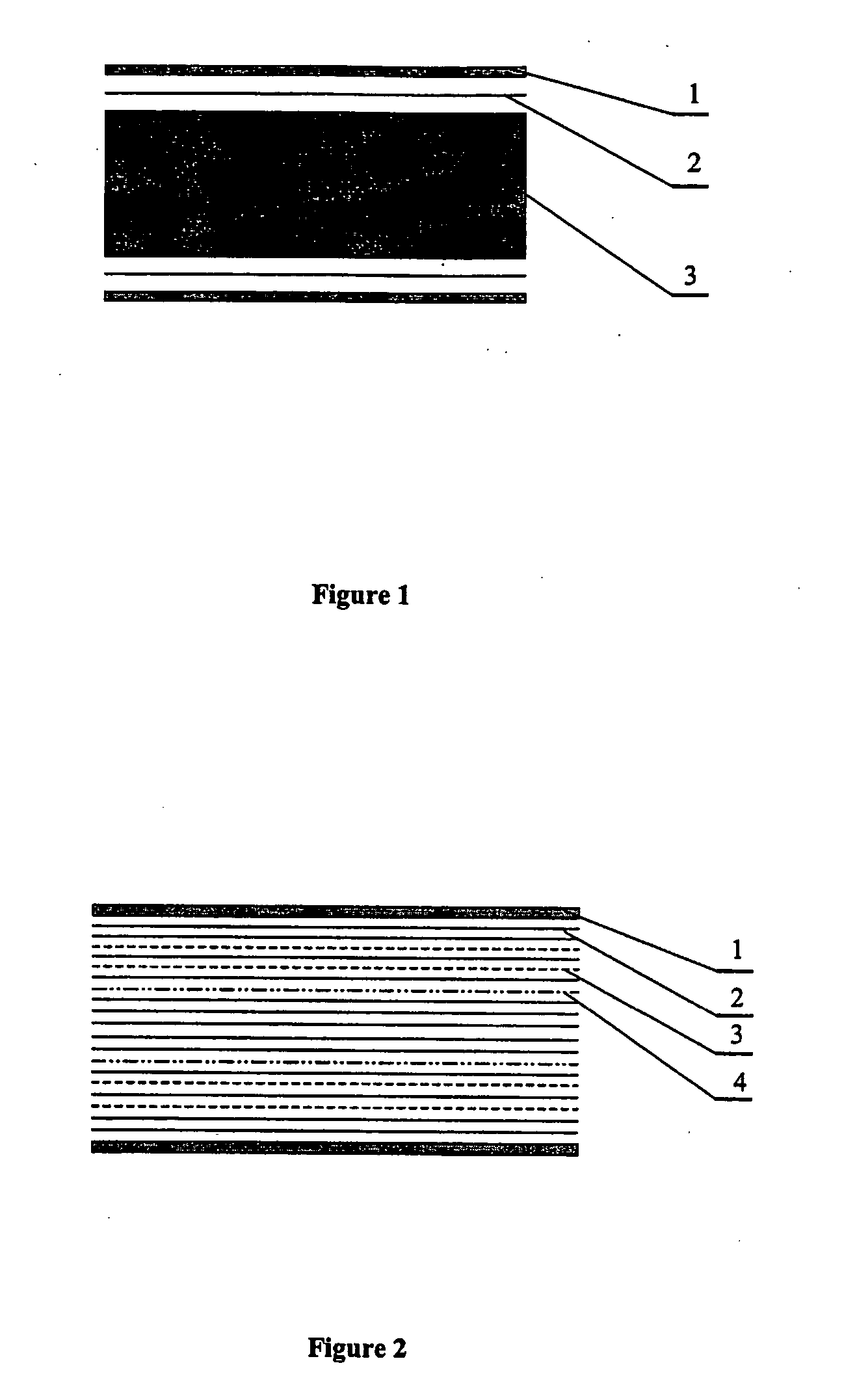

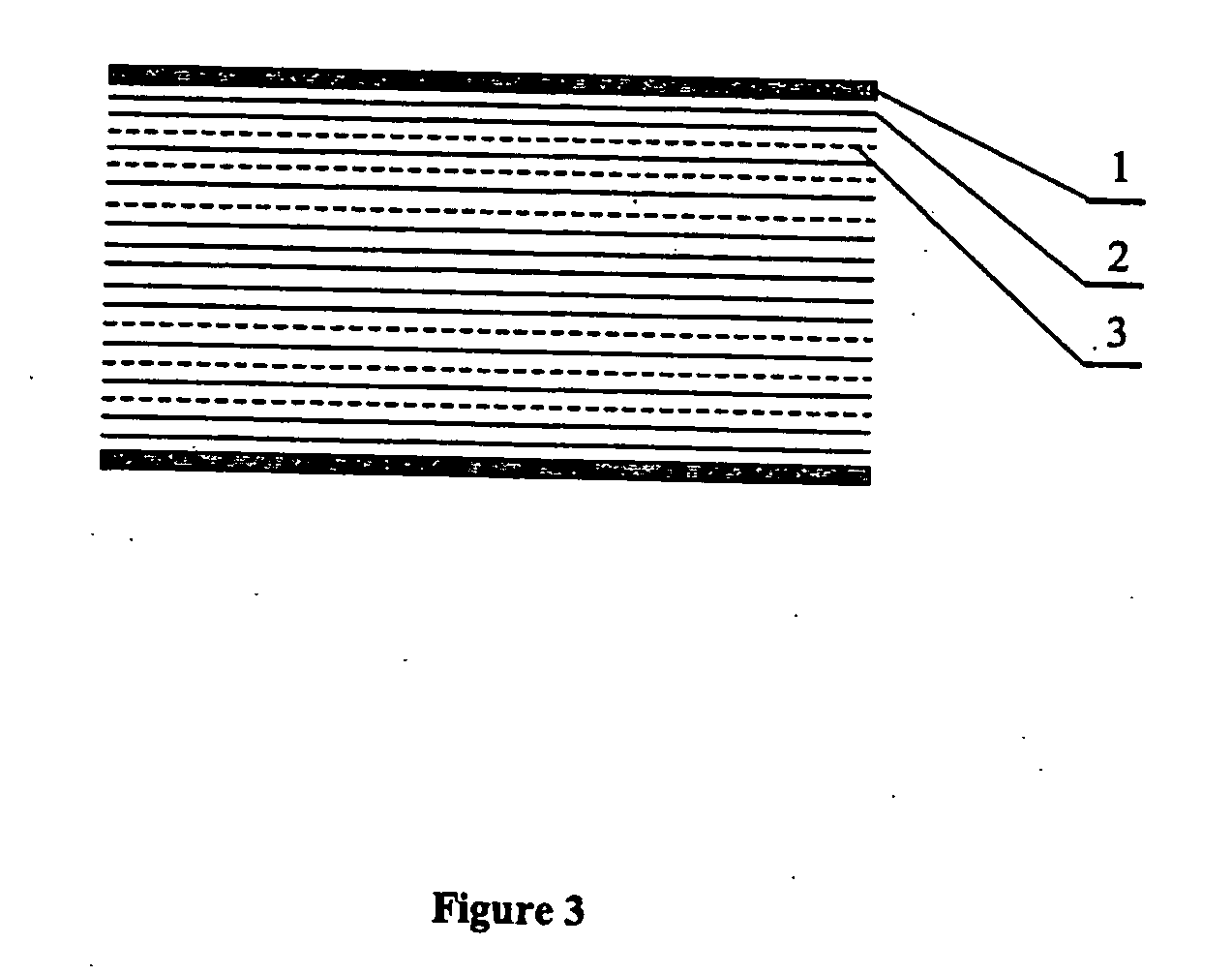

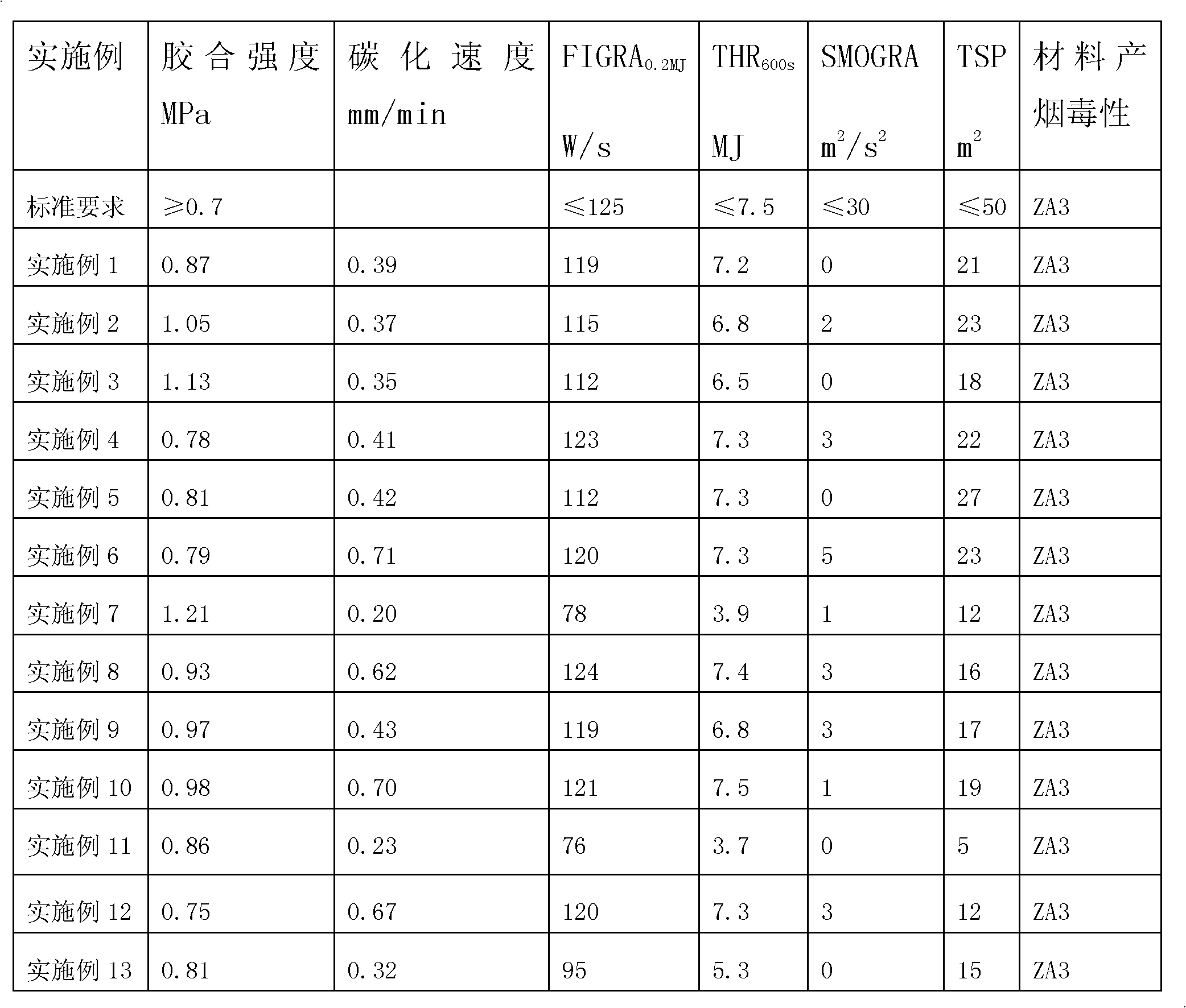

Antiflaming plywood or veneer lamination and manufacturing method thereof

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

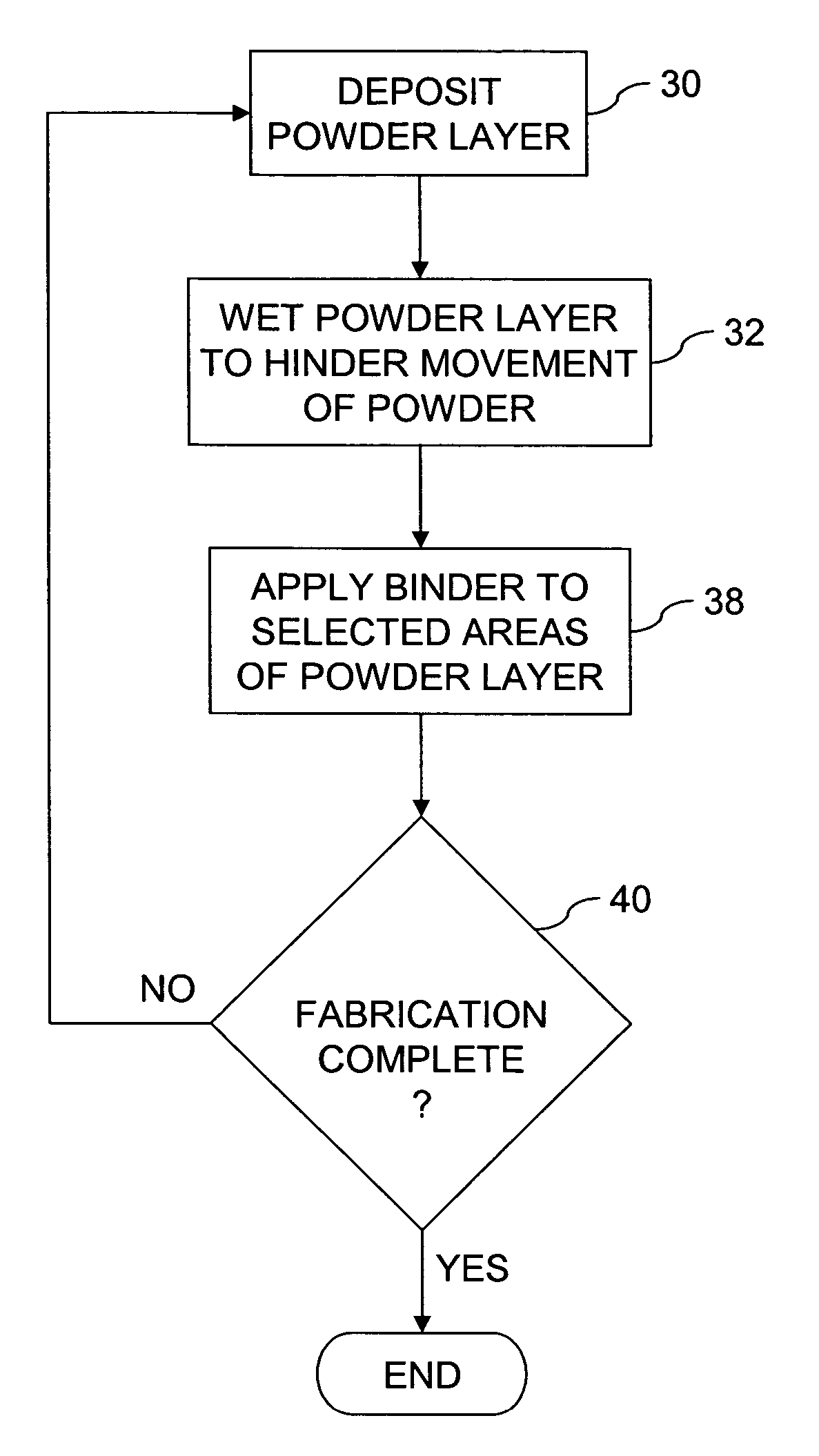

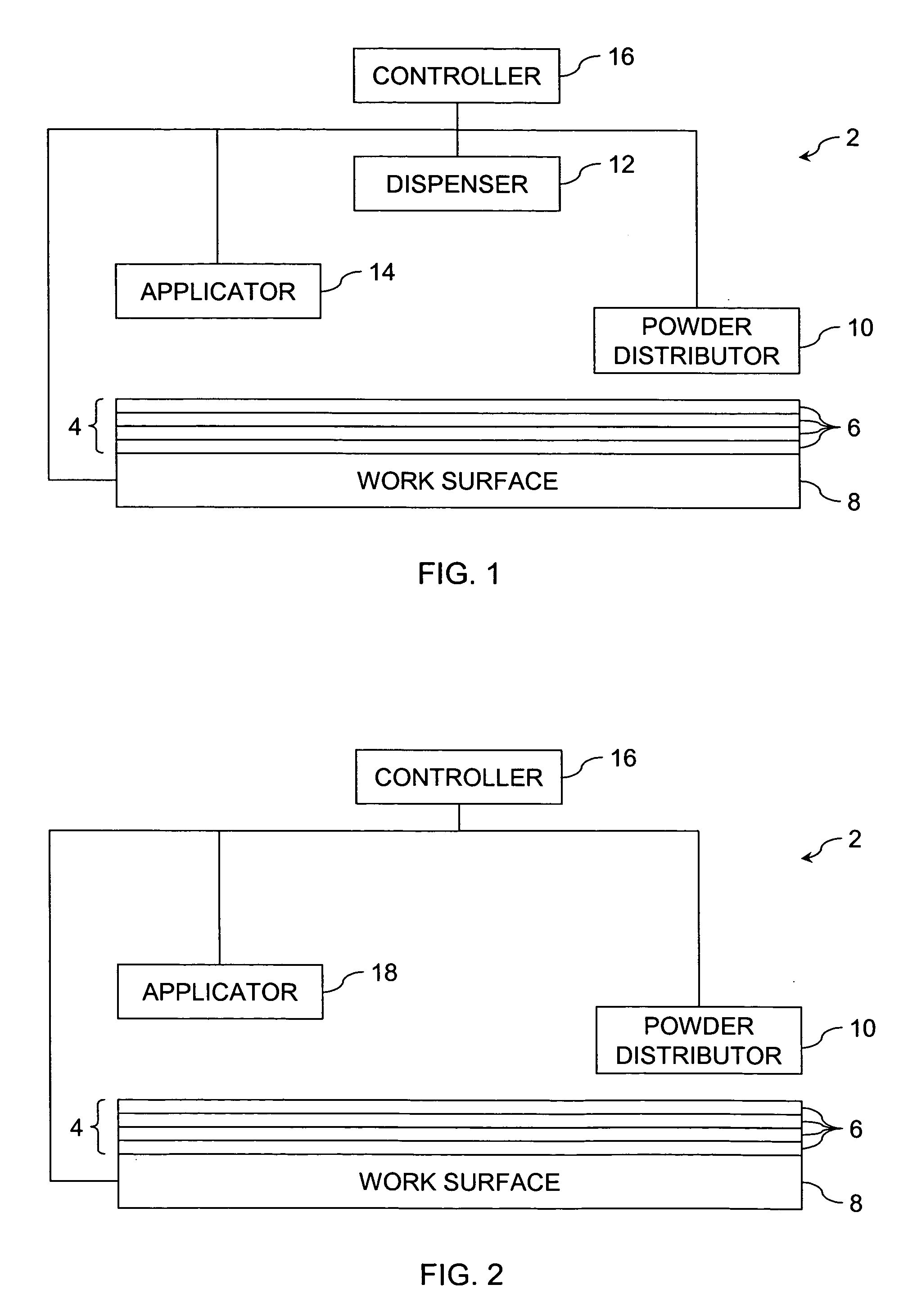

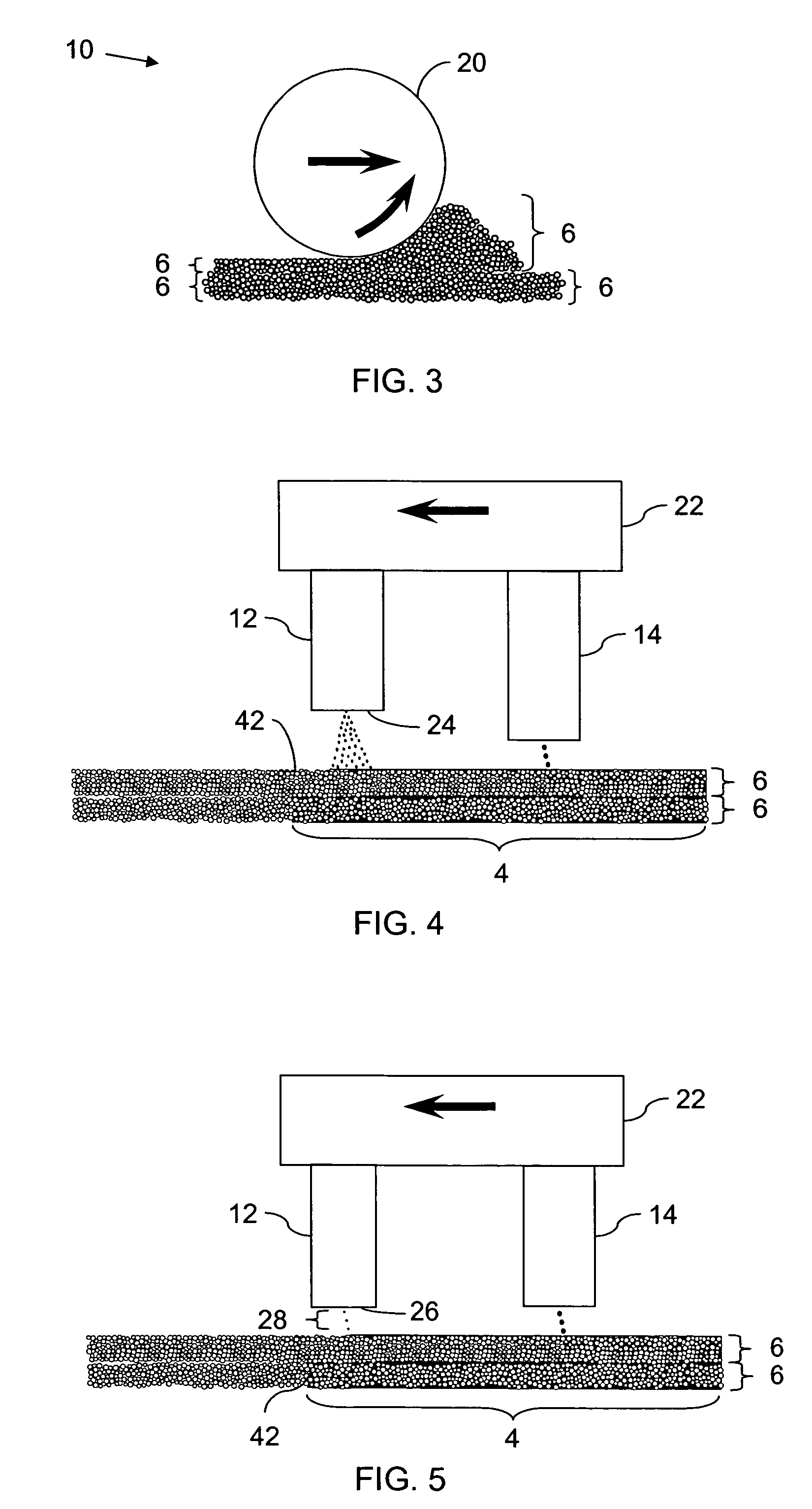

Fabricating a three-dimensional object

ActiveUS20060071367A1Additive manufacturing apparatusLamination ancillary operationsComposite material

A three-dimensional object is fabricated from powder. A powder layer is deposited. The powder layer is selectively wetted to hinder movement of the powder. A binder is applied to selected areas of the powder layer to harden the areas of the powder layer. The steps are repeated until the three-dimensional object is fabricated.

Owner:HEWLETT PACKARD DEV CO LP

Burnishing surface wood oriented structure chipboard and manufacture method and use thereof

The invention provides a smooth surface wood oriented structure flakeboard and a preparation method used for the flakeboard, belonging to the technical field of artificial board, and more particularly relates to a modified wood oriented structure flakeboard and a preparation method of the flakeboard. The smooth surface wood oriented structure flakeboard of the invention is formed by the bonding of a surface layer, a core layer and a bottom layer; the core layer structure is the wood oriented structure flakeboard (OSB); the flakeboard is characterized in that the surface layer and the bottom layer are wood fine layers. The preparation method of the invention comprises the steps as follows: a wood slicing, grinding and fibre separation device is added at the front section of the preparation production line so as to manufacture and produce certain wood fine materials; the fine materials are dried, screened and chosen to carry out the sizing operation; subsequently, a paving machine is respectively arranged at the front section and the final section of the paving production line; a fine material layer is added at the surface layer and the bottom layer before the OSB is formed; subsequently, the hot extruding and plain plate disposals are carried out so as to prepare the flakeboard with smooth and flat surface.

Owner:云南永利发林业有限公司

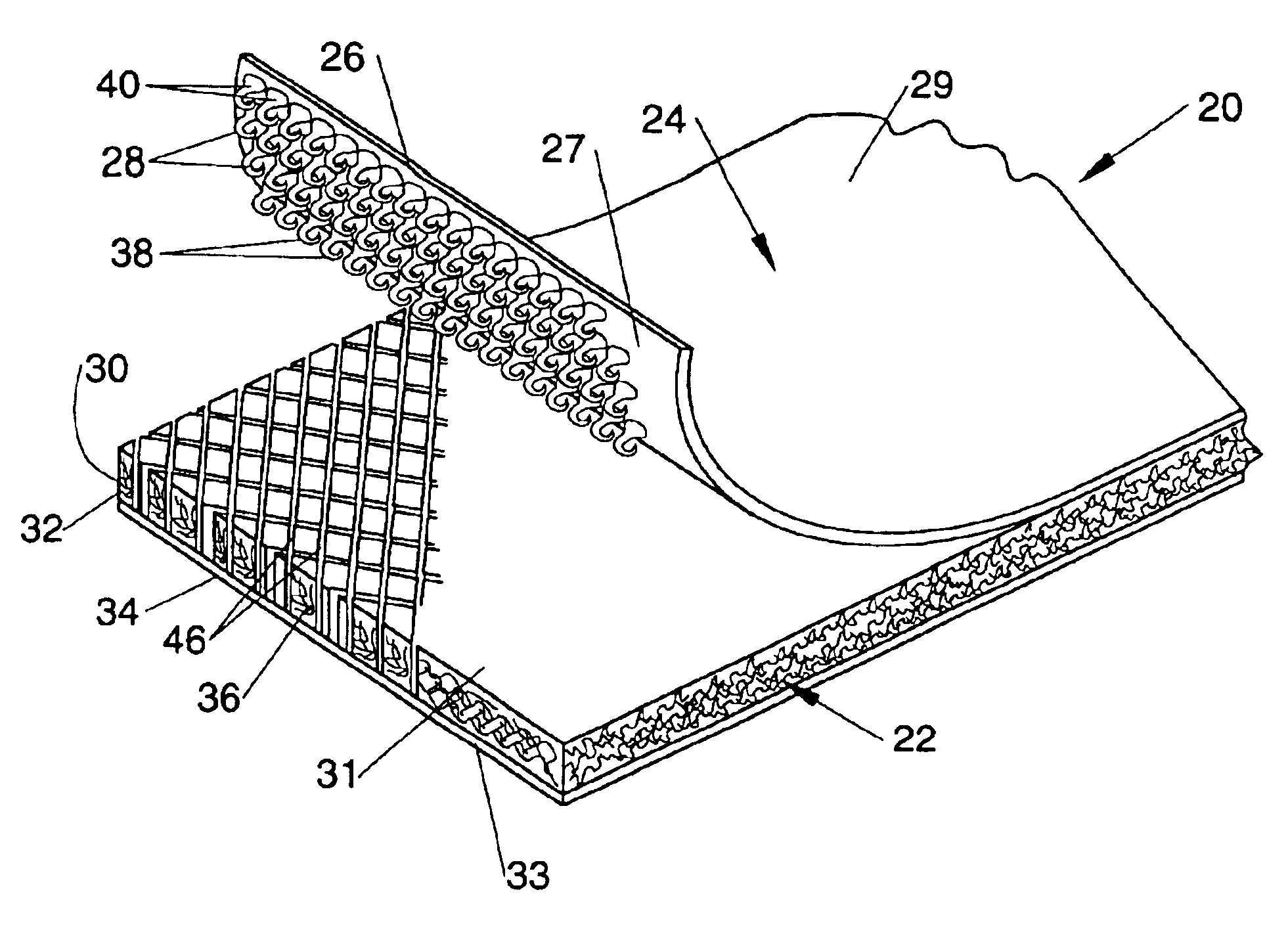

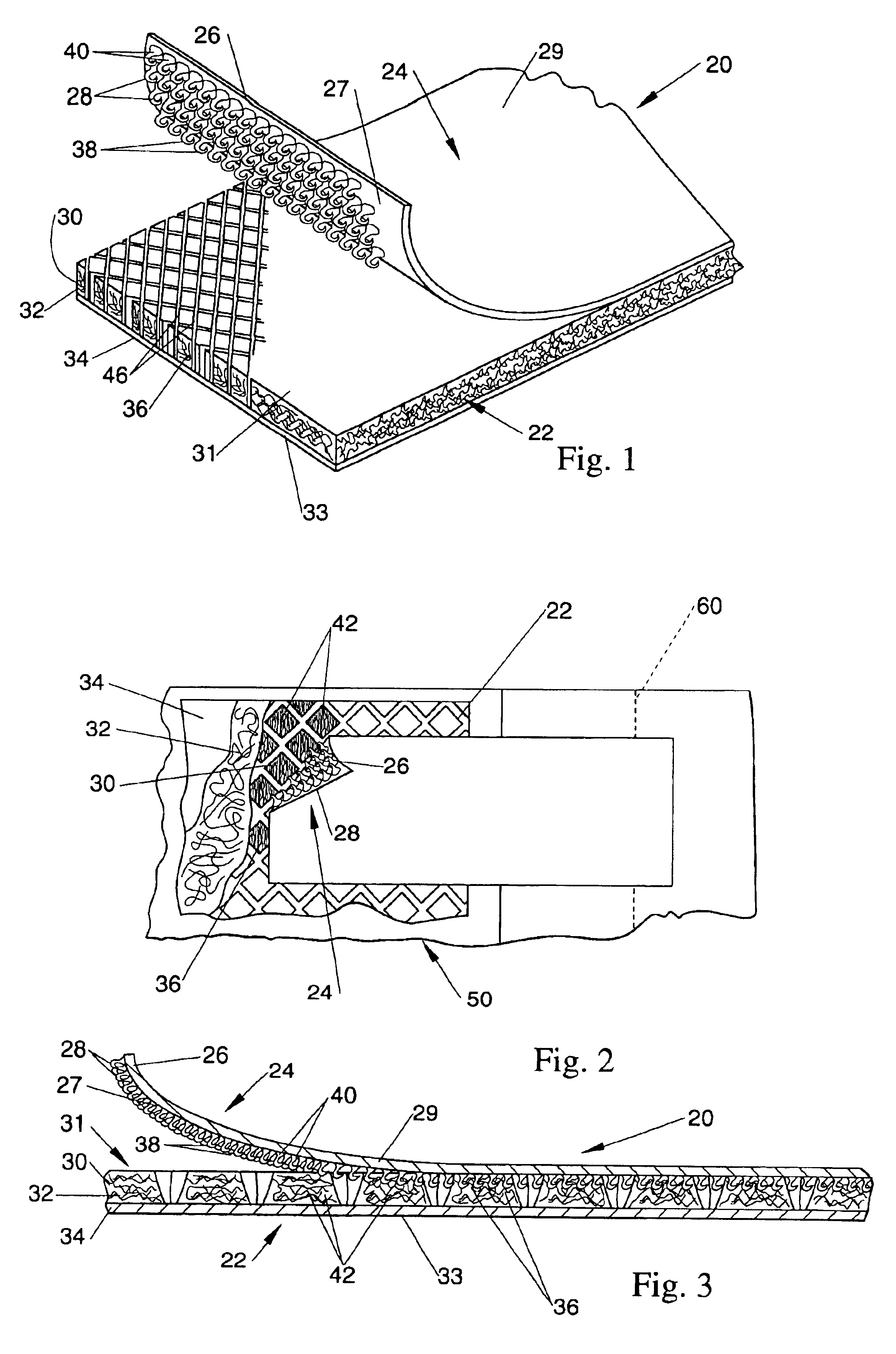

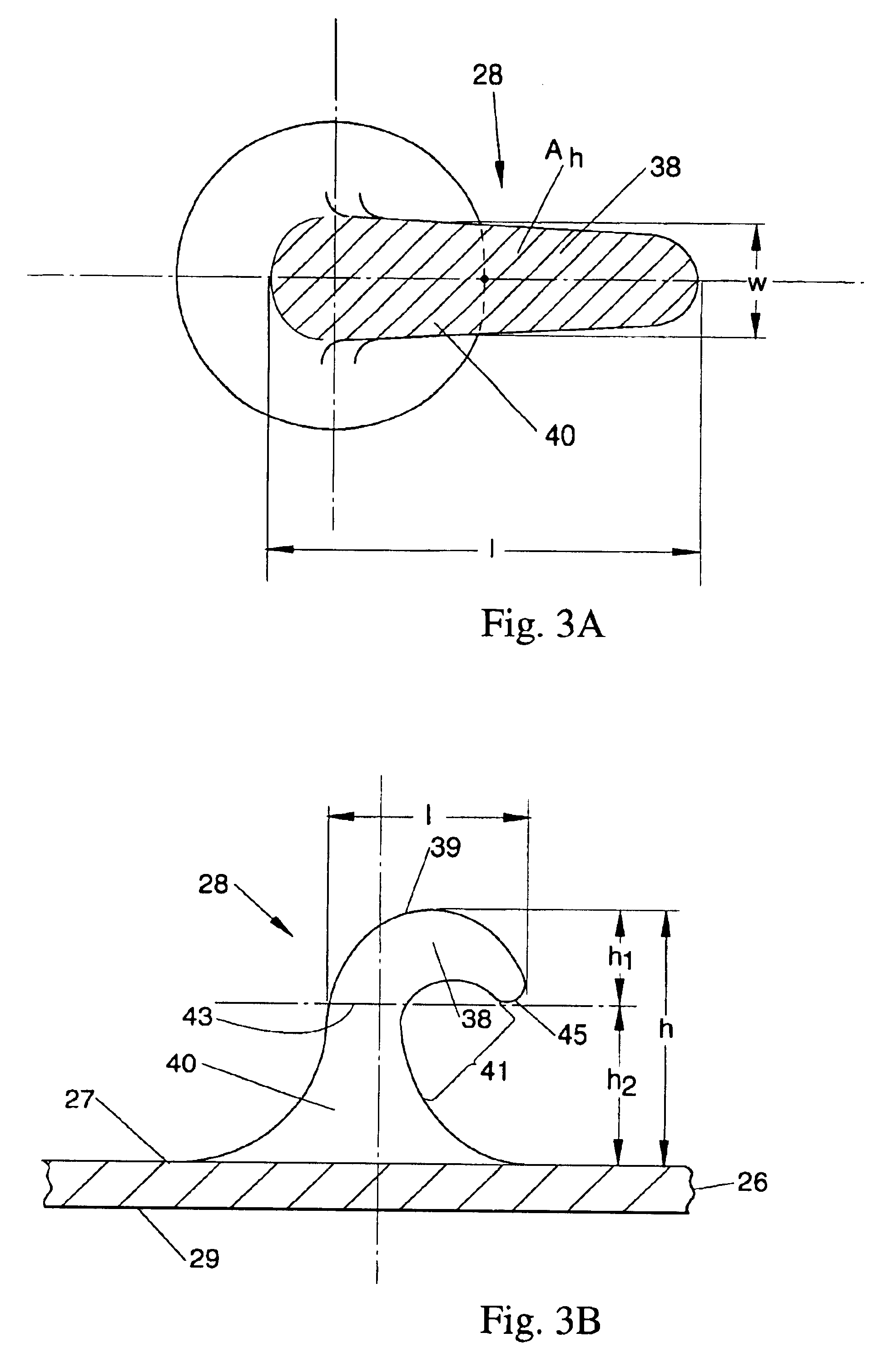

Method of making multi-layer female component for refastenable fastening device

InactiveUS6849142B1Counteracting forceLow costSnap fastenersMechanical working/deformationAnimal scienceMedicine

The female component for engaging a complementary hook component in a refastenable fastening device is capable of engaging a hook component that has flexible, resilient individual hook elements. The female component comprises at least two, and preferably three zones or layers. These include a first zone for admitting and engaging at least some of the hooks of the complementary hook component (the “entanglement” zone), a second zone for providing space for the hooks to occupy after they have been admitted by the entanglement zone (referred to as the spacing zone), and a backing adjacent to the spacing zone. The present invention also provides a fastening device having a hook fastening component and a female component that comprises the multi-layer female component of the present invention. The present invention also relates to disposable articles and more particularly to a disposable diaper having such an improved fastening device.

Owner:THE PROCTER & GAMBLE COMPANY

Healthcare plate material capable of generating anions and far infrared rays and composite healthcare plate

The invention discloses a healthcare plate material capable of generating anions and far infrared rays. The plate material comprises the following raw material components in percentage by weight: 70-80 percent of saw dust, 3-5 percent of eaglewood, 5-9 percent of tourmaline powder, 5-9 percent of anion powder, 1-3 percent of preservative, 2-4 percent of adhesive and 1-3 percent of antibacterial agent. The invention further discloses a composite healthcare plate material with the healthcare plate material capable of generating the anions and the far infrared rays. According to the healthcare plate material, healthcare materials beneficial to a human body such as the eaglewood, the anion powder and the tourmaline are adopted, and healthcare plate materials which are pressed under different pressures according to different using functions and are different in hardness and thickness can have different purposes. The healthcare plate material can release negative oxygen ions, the far infrared rays and a magnetic field, and the fitness and the immunity of a human body are unconsciously improved in the life and work of people by virtue of the fragrance of the eaglewood. Meanwhile, the practicality of the healthcare plate material is improved, so that the using function of the healthcare plate material is diversified, and the healthcare plate material is convenient to commonly use and popularize.

Owner:王文娟

Anti-corrosion recombined composite bamboo material and manufacturing method thereof

ActiveCN103770168AImprove corrosion resistanceGood weather resistanceWood treatment detailsWood veneer joiningNano zinc oxideCorrosion prevention

The invention discloses an anti-corrosion recombined composite bamboo material and a manufacturing method thereof. The anti-corrosion recombined composite bamboo material is manufactured by utilizing bamboo as a main raw material, the density of the anti-corrosion recombined composite bamboo material is 0.9-1.50g / cm<3> and the water-absorbing thickness expansion ratio in the thickness direction and width direction of the anti-corrosion recombined composite bamboo material is respectively less than 1.5%; the anti-corrosion recombined composite bamboo material achieves a strong anti-corrosion level and has a bacterium damaged degree of zero level. The manufacturing method comprises the following steps: processing raw bamboo into bamboo strips, and then rolling the bamboo strips to obtain defibered bamboo bundles; digesting the defibered bamboo bundles by use of a dilute base solution and water sequentially, drying the bamboo bundles, and performing high-pressure transfusing on the bamboo bundles by use of a mixed aqueous solution of nano zinc oxide and bamboo mildew remover; then performing oxygen-exclusion drying treatment, high-temperature treatment and humidifying treatment; performing gumming, drying, curtain weaving, cold pressing and sizing, thermosetting and cooling equalization treatment, so as to obtain the anti-corrosion recombined composite bamboo material. The anti-corrosion recombined composite bamboo material has the advantages of corrosion resistance, weather resistance, insect prevention and good dimensional stability, and can be used for outdoor decoration.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com