Container flooring material and method of manufacture

a container flooring and container technology, applied in the field of container flooring materials and methods of manufacture, can solve the problems of increasing demand, long growth cycle, and rapid decline of tropical hardwood forests, and avoiding the tedious, expensive and time-consuming unloading of cargo by ocean shipping methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] When describing the present invention, all terms not defined herein have their common art-recognized meanings. As used herein, the term “about” refers to a margin of plus or minus 10%, or within the tolerance of a suitable measuring device or instrument. As used herein, “specific density” refers to density relative to water. All wood density refers to the density of oven-dried wood.

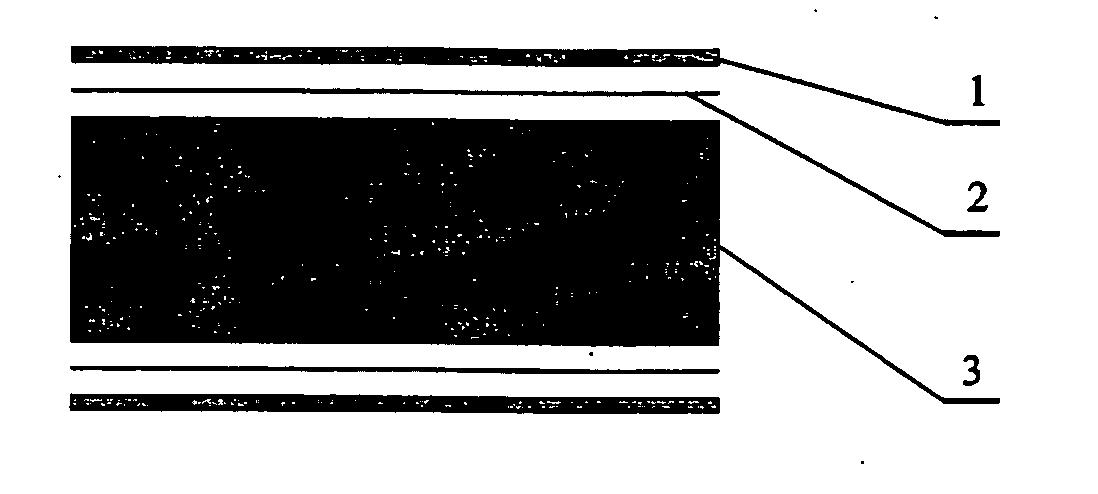

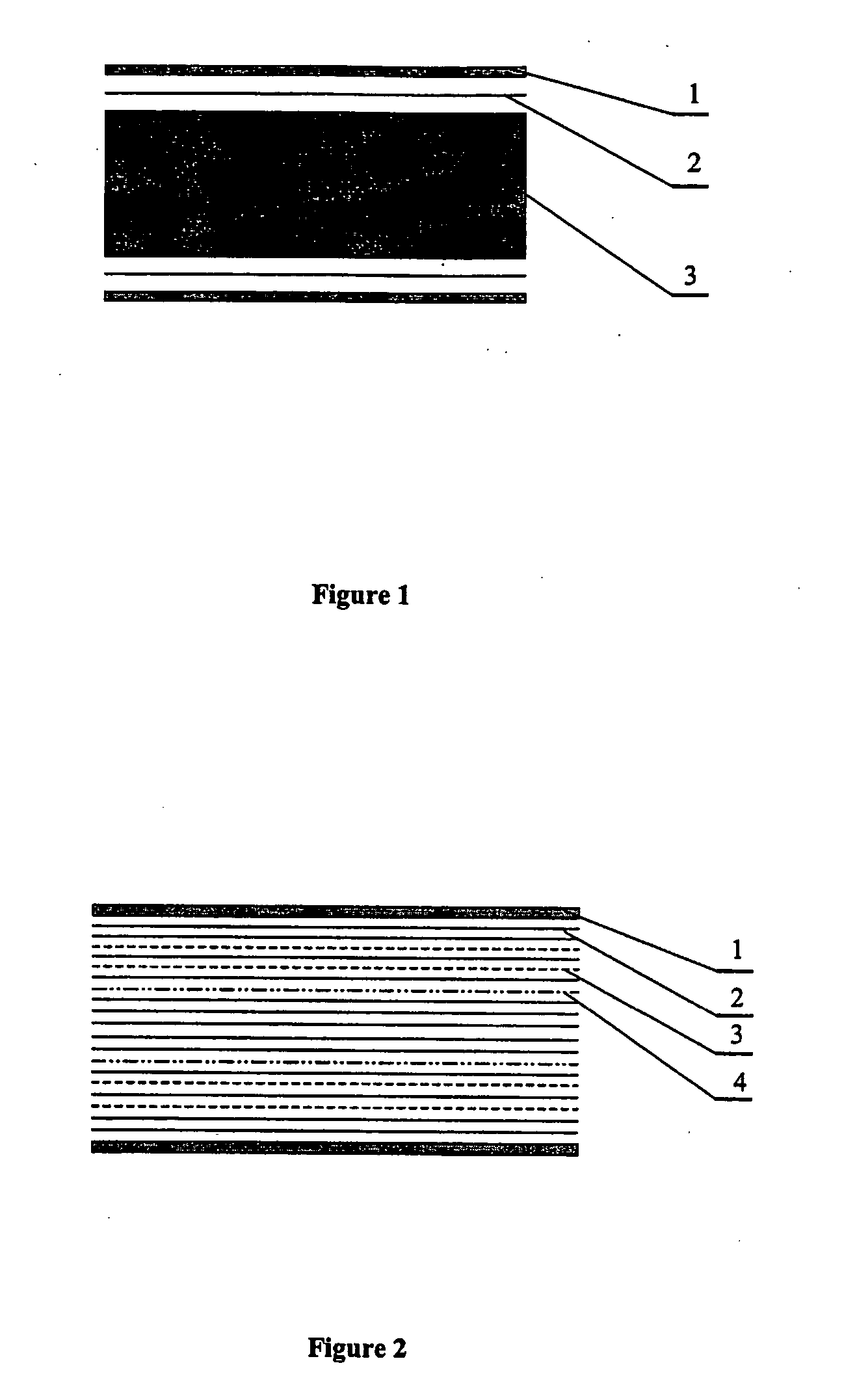

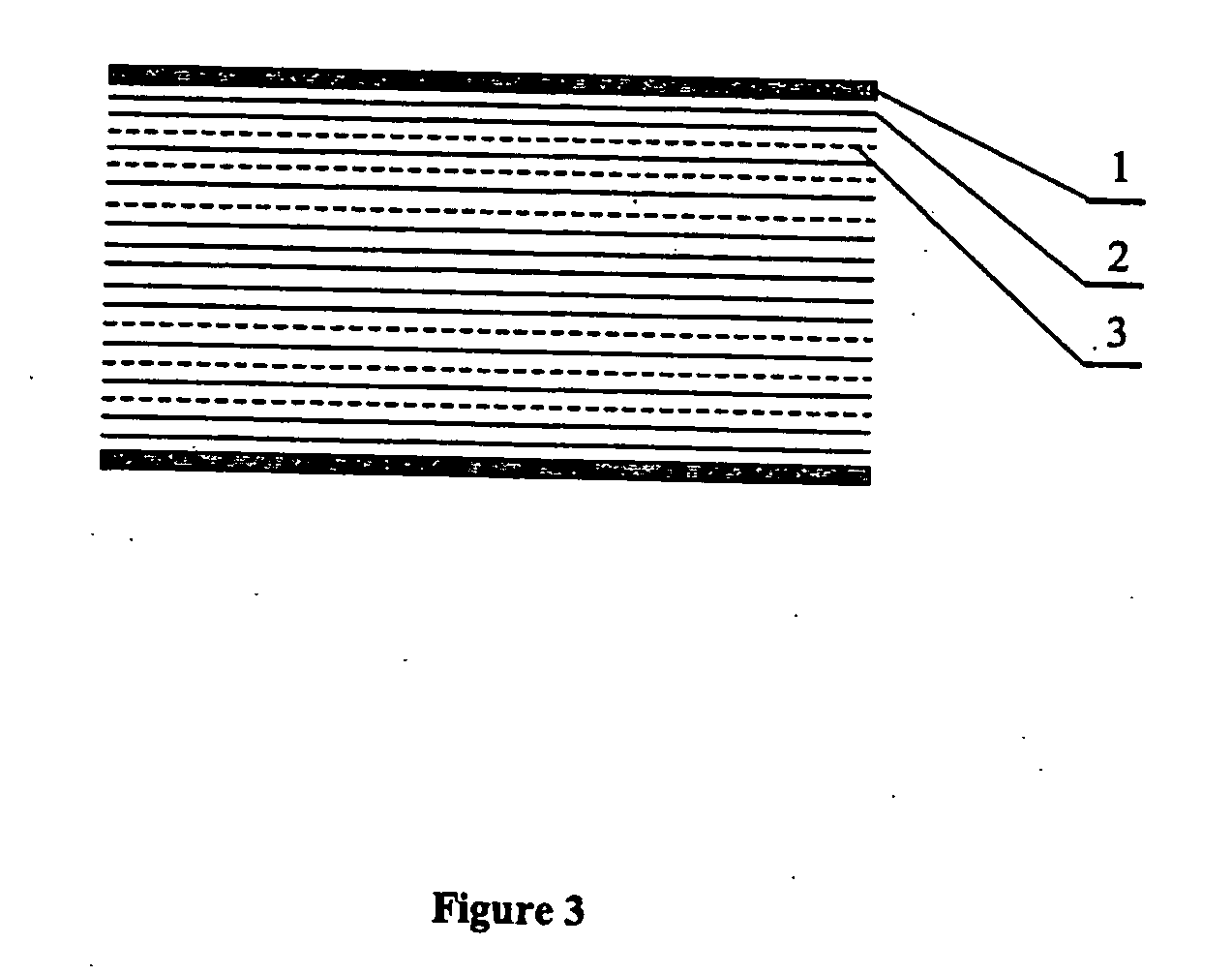

[0014] The present invention relates to a bamboo-wood composite board suitable for use as a container flooring material. In general terms, the invention comprises a multilayer board having a surface composite bamboo layer and a wood core layer. The wood core layer may be comprised of wood veneer layers or a wood strand layer, or both wood veneer and wood strand layers.

[0015] The bamboo layer comprises bamboo stripe sheets made of strips of bamboo and a suitable resin. The bamboo strips may be arranged so that the bamboo strips are all parallel, or parallel and perpendicular combination, or they m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com