Patents

Literature

1554results about How to "Improve surface strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

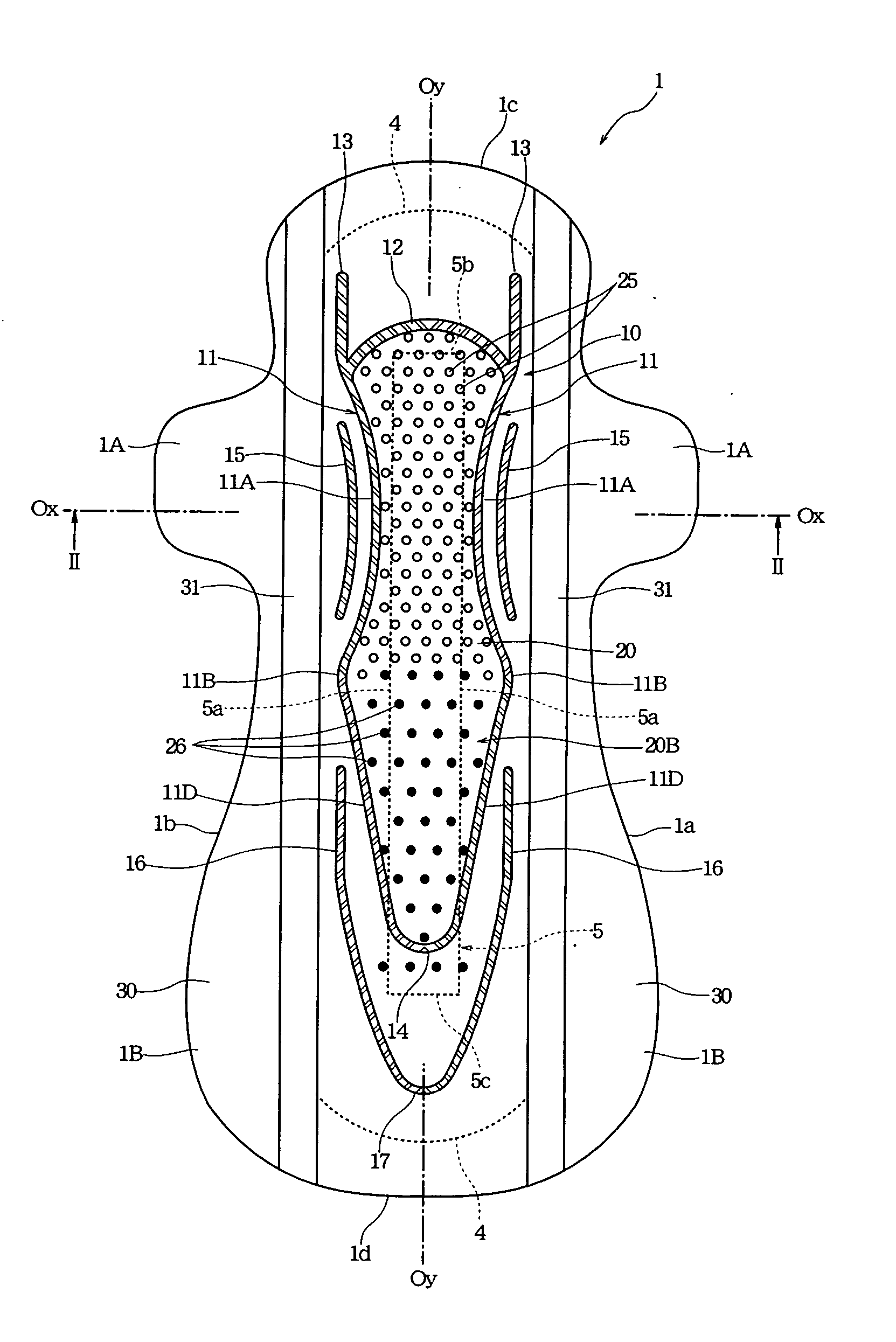

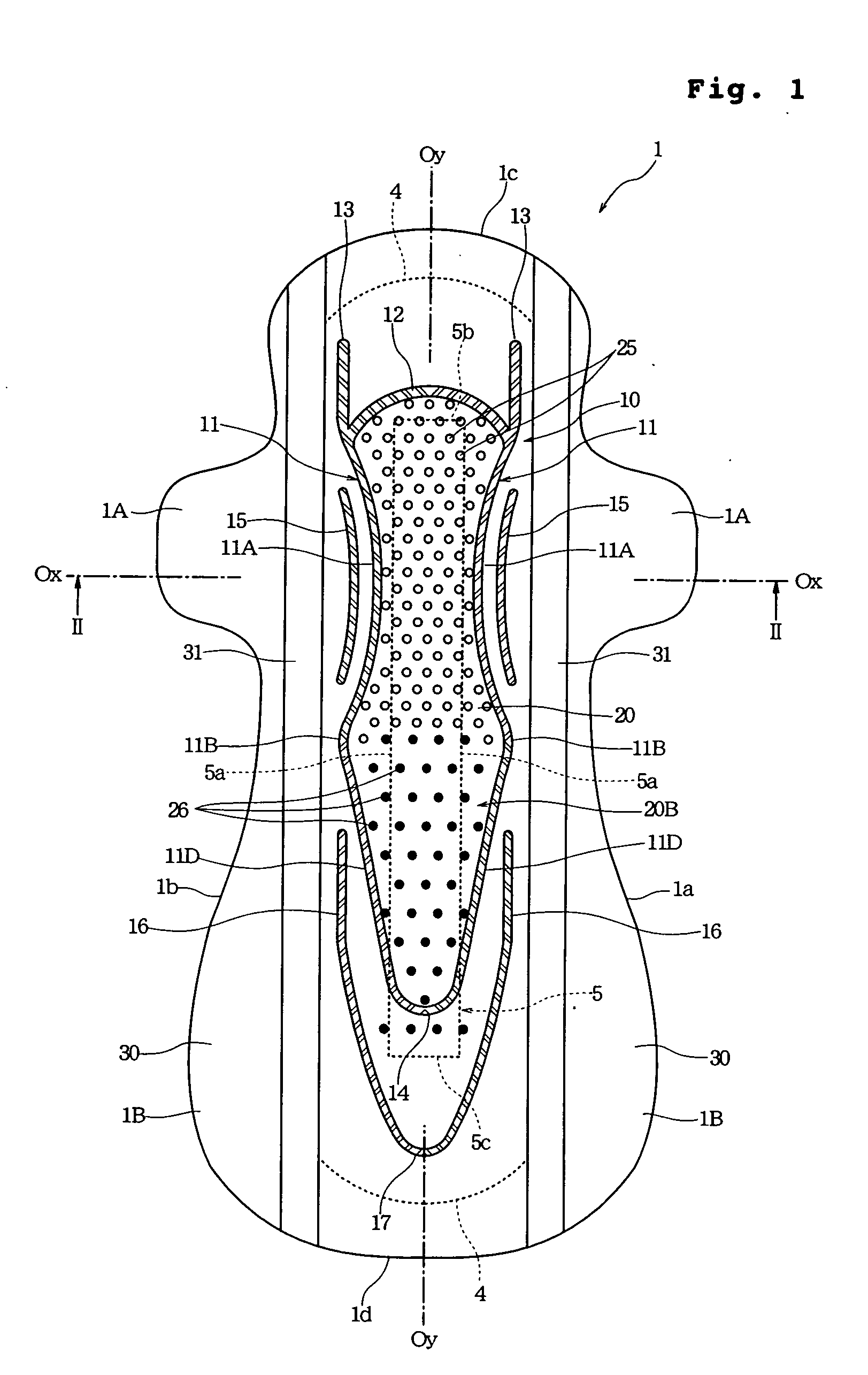

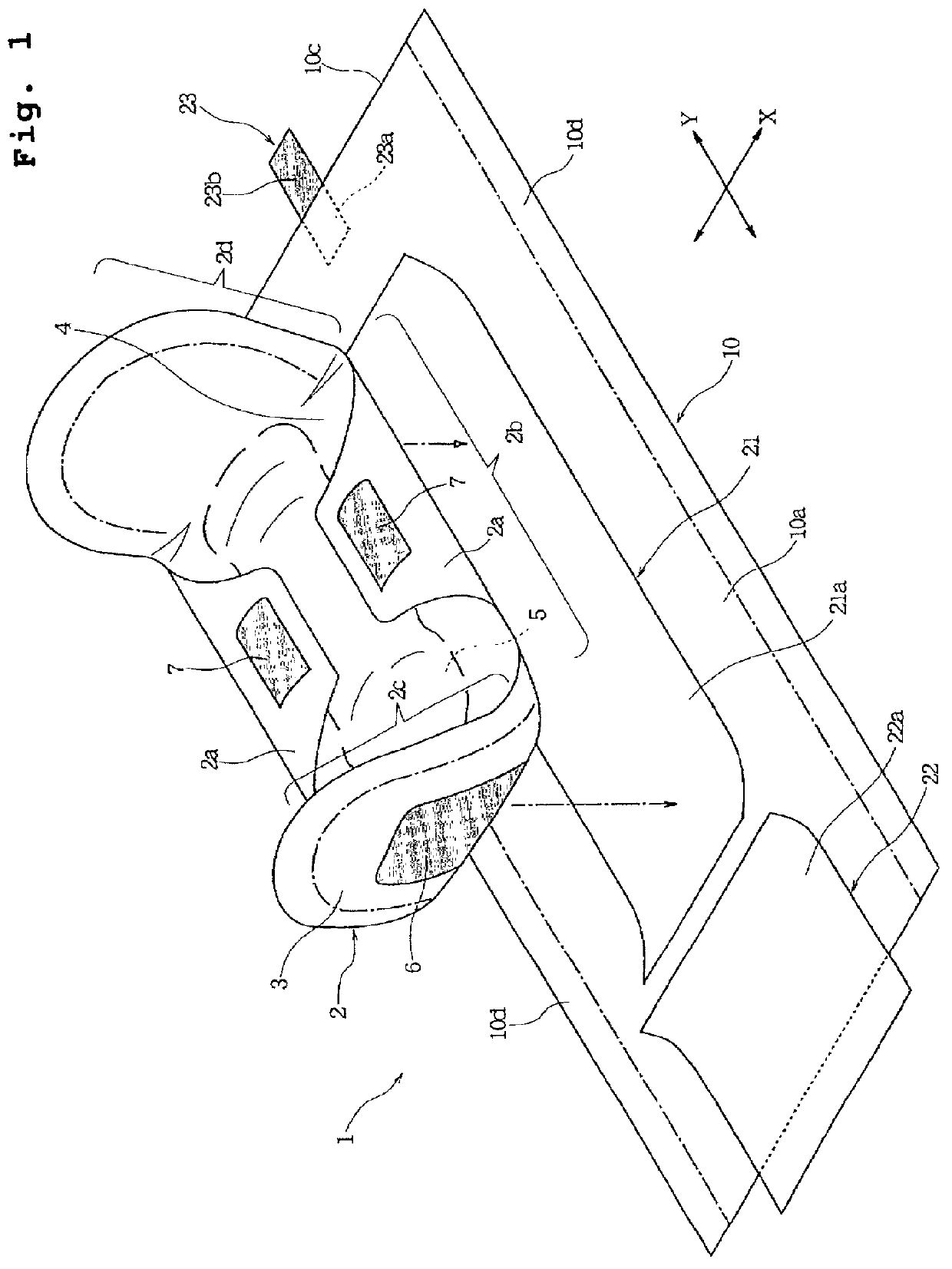

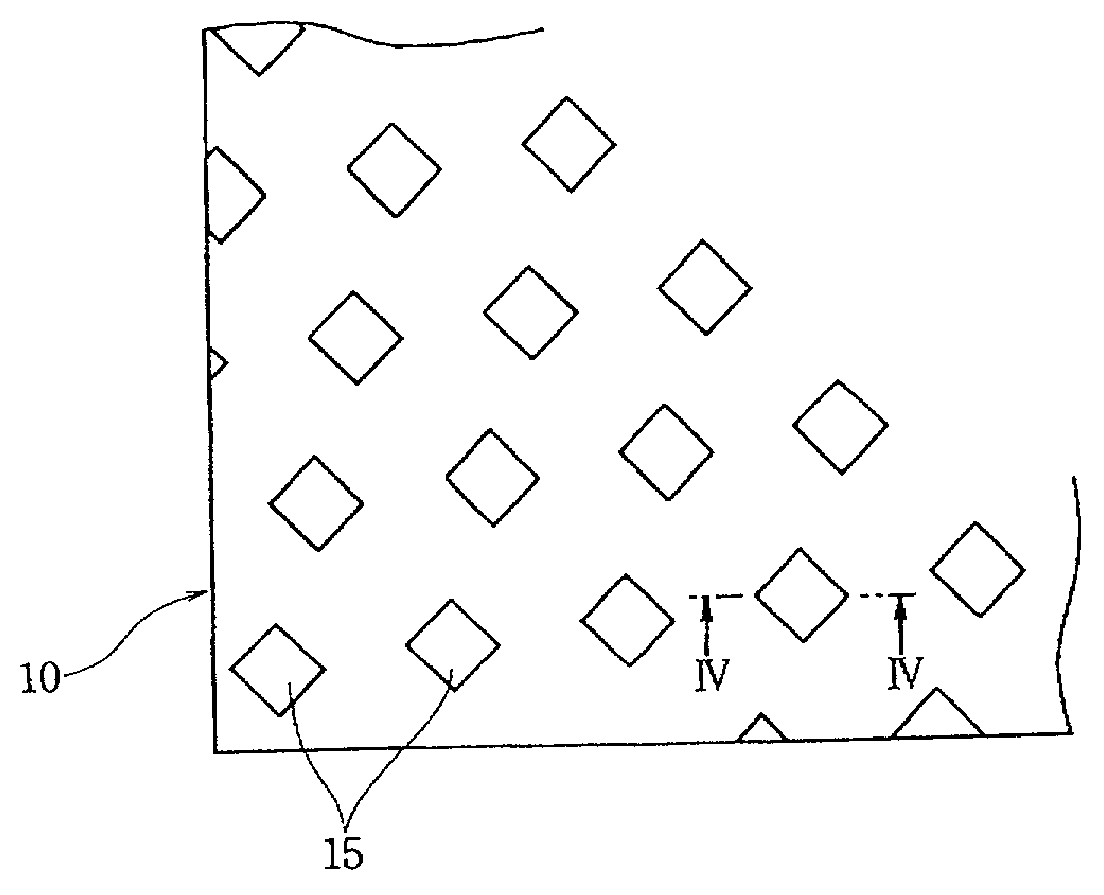

Elongated absorbent article

InactiveUS20050148971A1Penetrate fastSurface strengthBaby linensTamponsVolumetric Mass DensityMechanical engineering

Disclosed is an elongated absorbent article, in which liquid passage holes and embossments are dispersed in a central region including a front portion and a rear portion. Aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the front portion) by (area of the front portion) is higher than aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the rear portion) by (area of the rear portion), while embossment density obtained by dividing (total of areas occupied by the embossments in the rear portion) by (area of the rear portion) is higher than embossment density obtained by dividing (total of areas occupied by the embossments in the front portion) by (area of the front portion).

Owner:UNI CHARM CORP

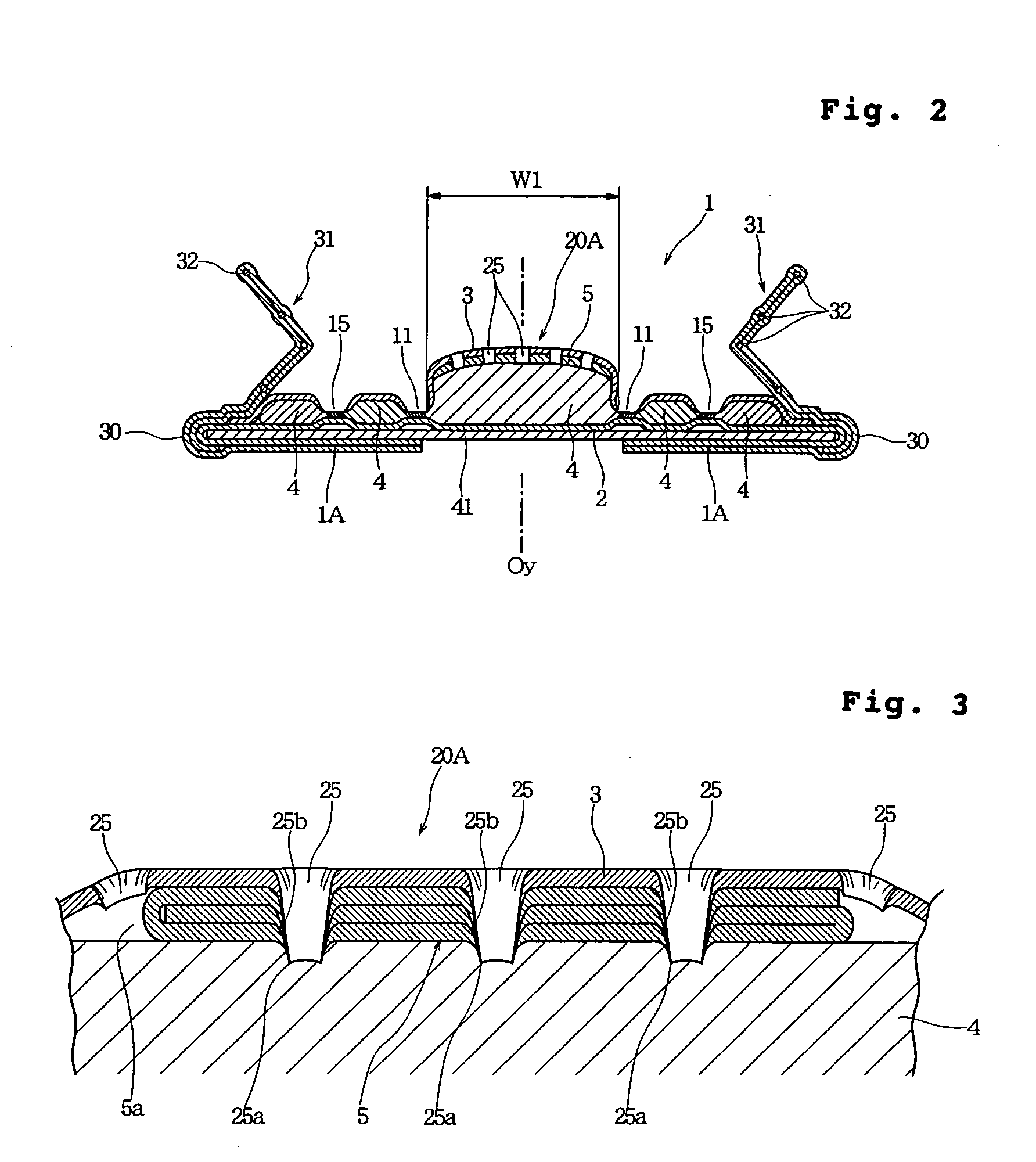

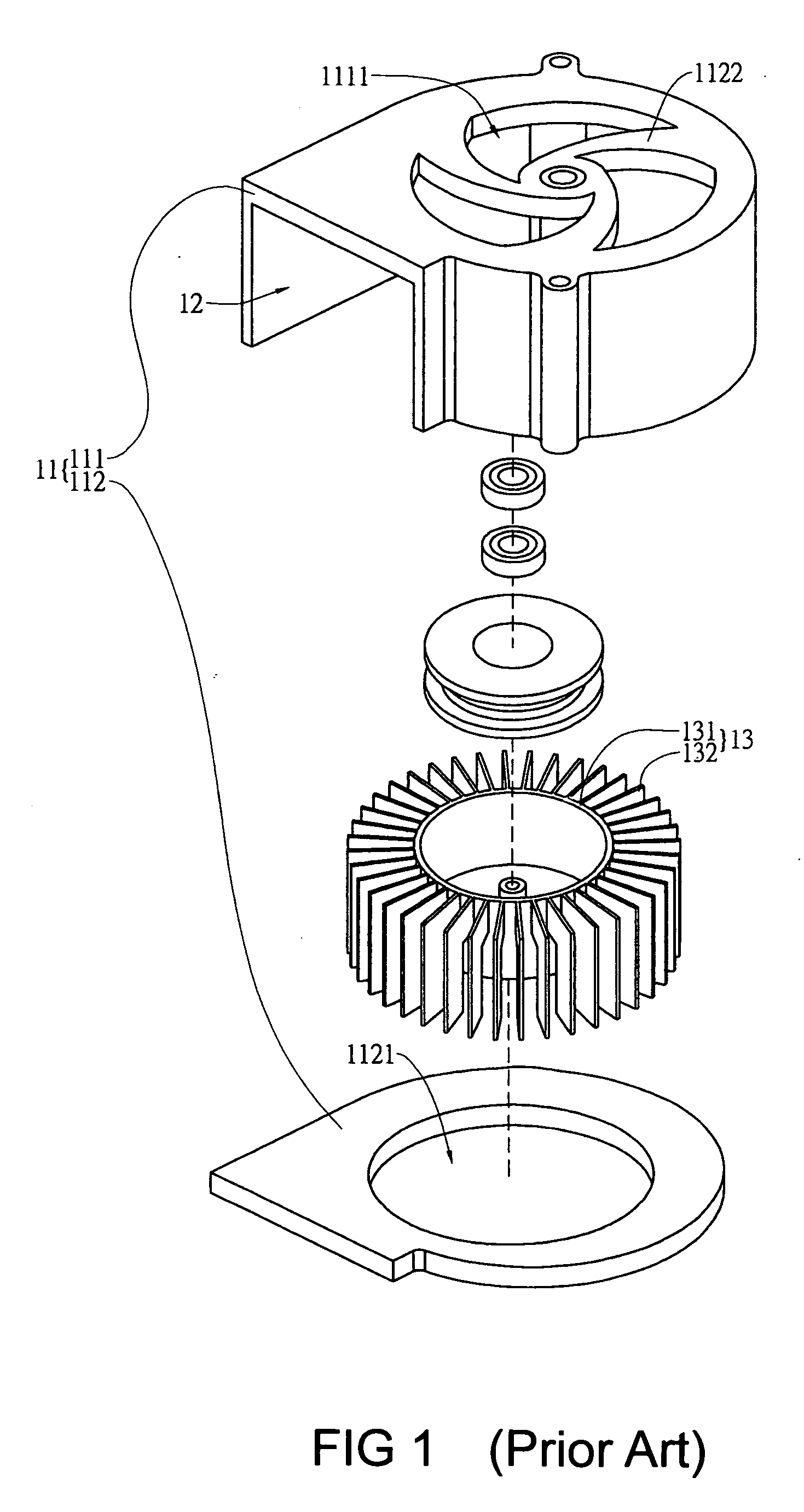

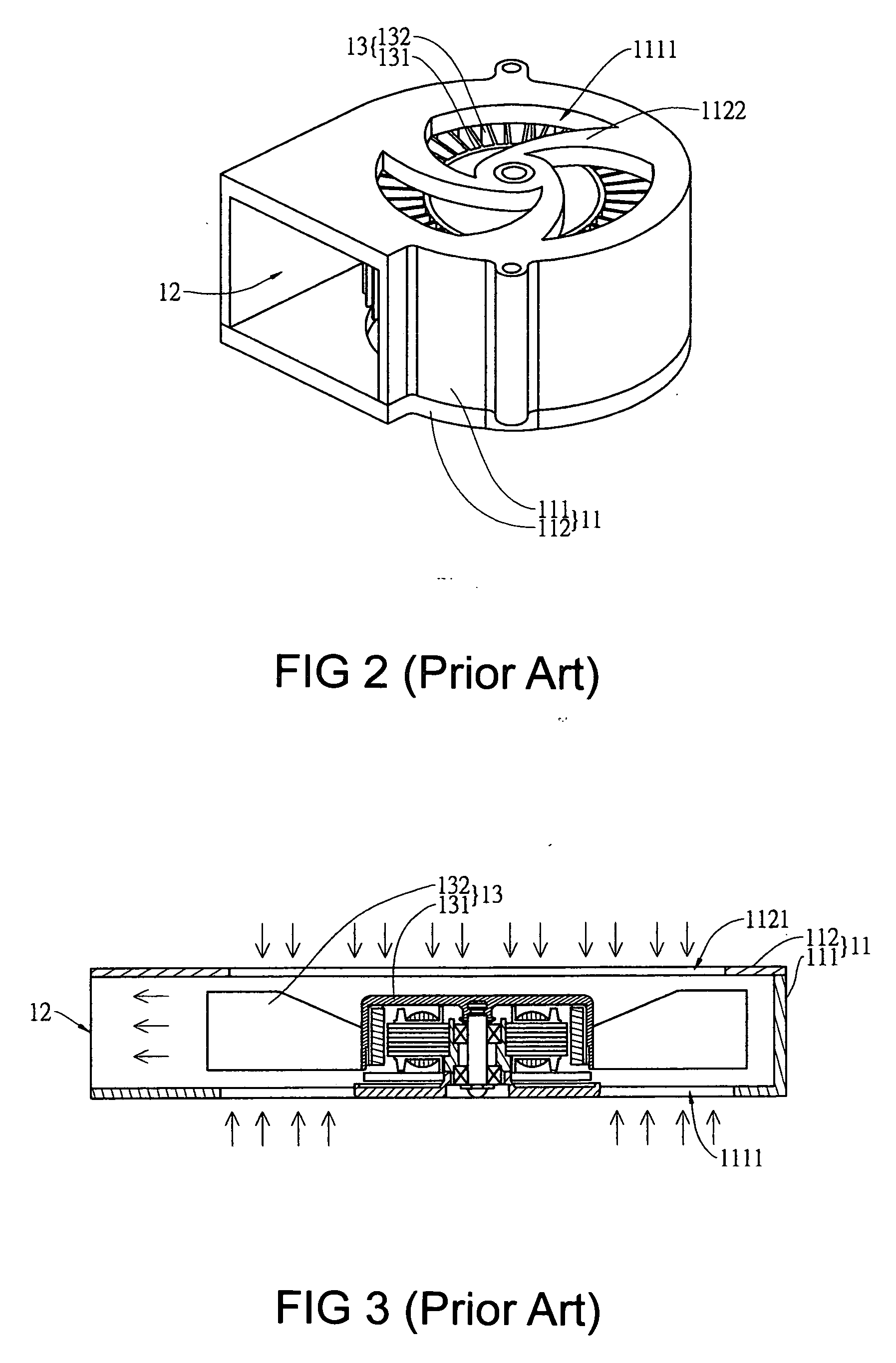

Centrifugal fan with low noise

InactiveUS20070160458A1Reduce noiseReduce transmissionPump componentsBlade accessoriesImpellerLow noise

A centrifugal fan with low noise includes a housing, a fan wheel and a recess unit. The fan wheel has a hub and a plurality of fan blade extending outward from the hub radially. The housing has a chamber therein to receive the fan wheel and has a recess unit at the surface thereof. The recess unit is composed of a projection part and a recess part for reducing noise transmission greatly.

Owner:YEN JUN CHIEN

Concrete superficial hardener and construction method thereof

InactiveCN101407428AHigh mechanical strengthHigh surface hardnessUltimate tensile strengthMaterials science

The invention discloses a concrete surface hardener and a construction method thereof, wherein, the concrete surface hardener comprises the compositions by weight percent of 10-40 percent of inorganic silicate, 1-10 percent of alkali, 0.1-5 percent of catalyst, 0.1-2 percent of wetting dispersant, 1-5 percent of stabilizer and rest of water. The hardener prepared by the invention is characterized by easily-obtained material, simple production and convenient construction, unhealthy and environmentally harmful VOC avoidance, etc. In addition, the hardener can penetrate into the interior of the concrete to seal the capillary of the concrete, thus improving the surface density of the concrete, strengthening the impervious capability and strength of the concrete and prolonging the service life of the concrete. As the hardener does not comprise unhealthy and environmentally harmful substances, the increasingly improved requirements of the present environmental protection can be met, thus having extensive application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

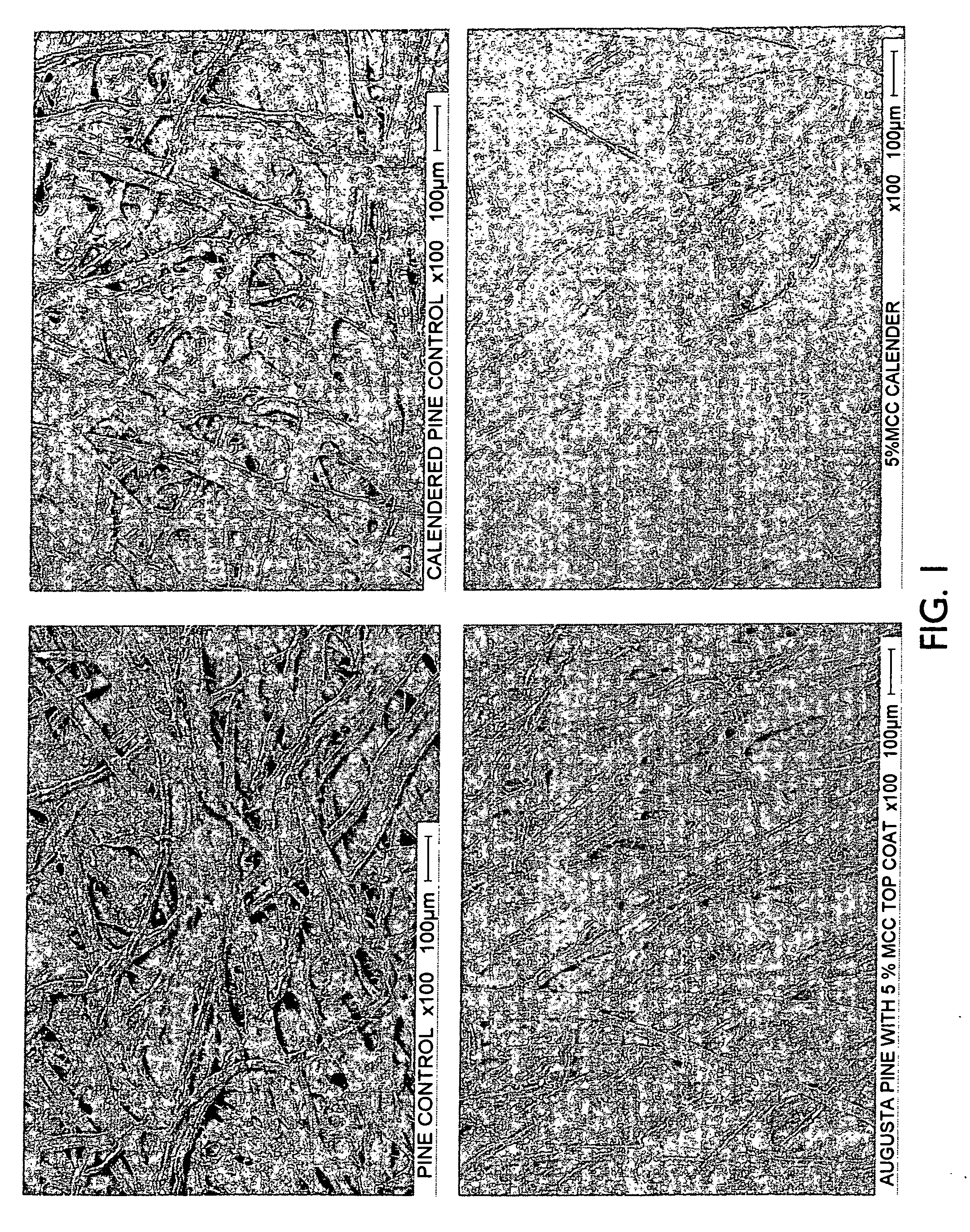

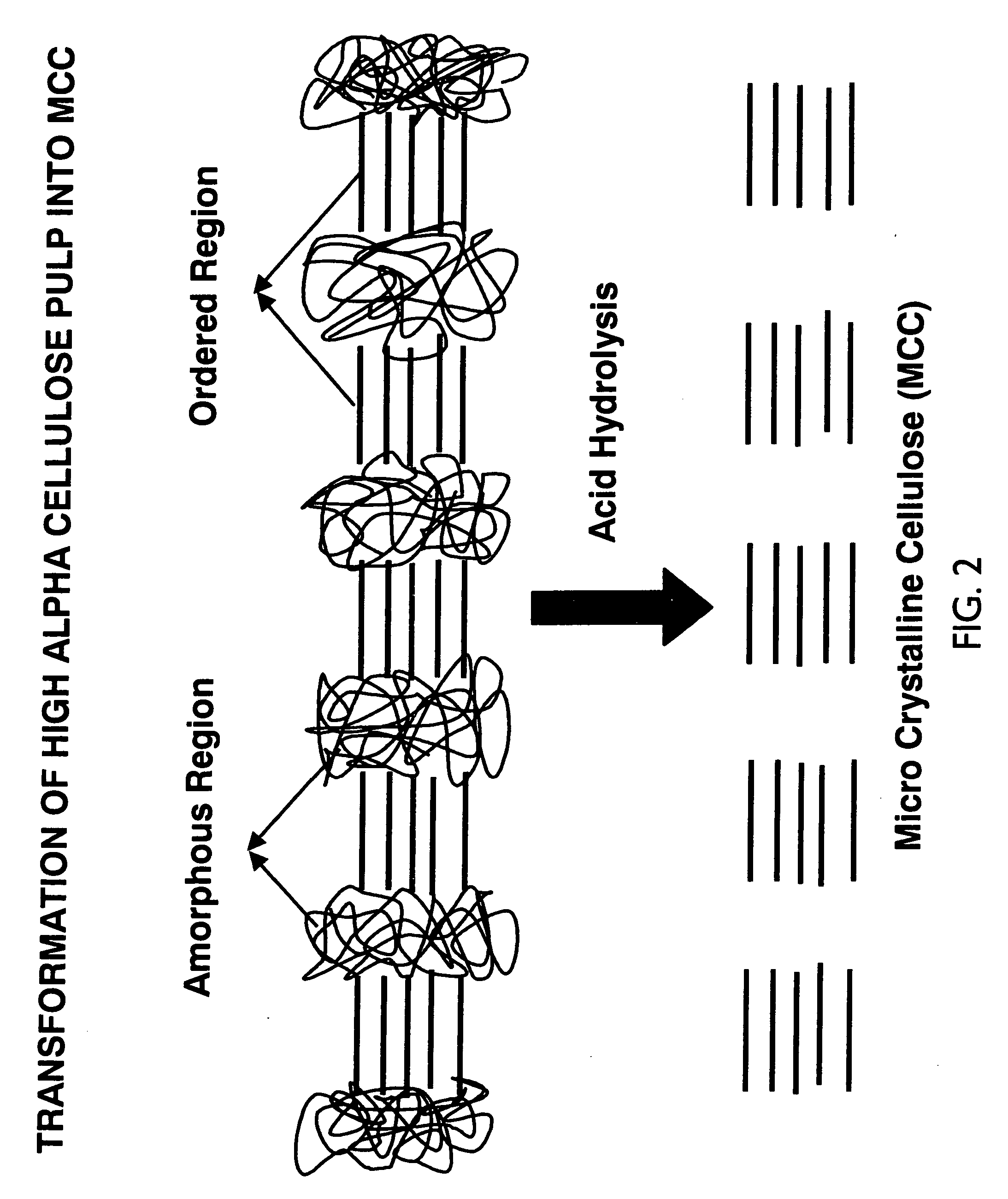

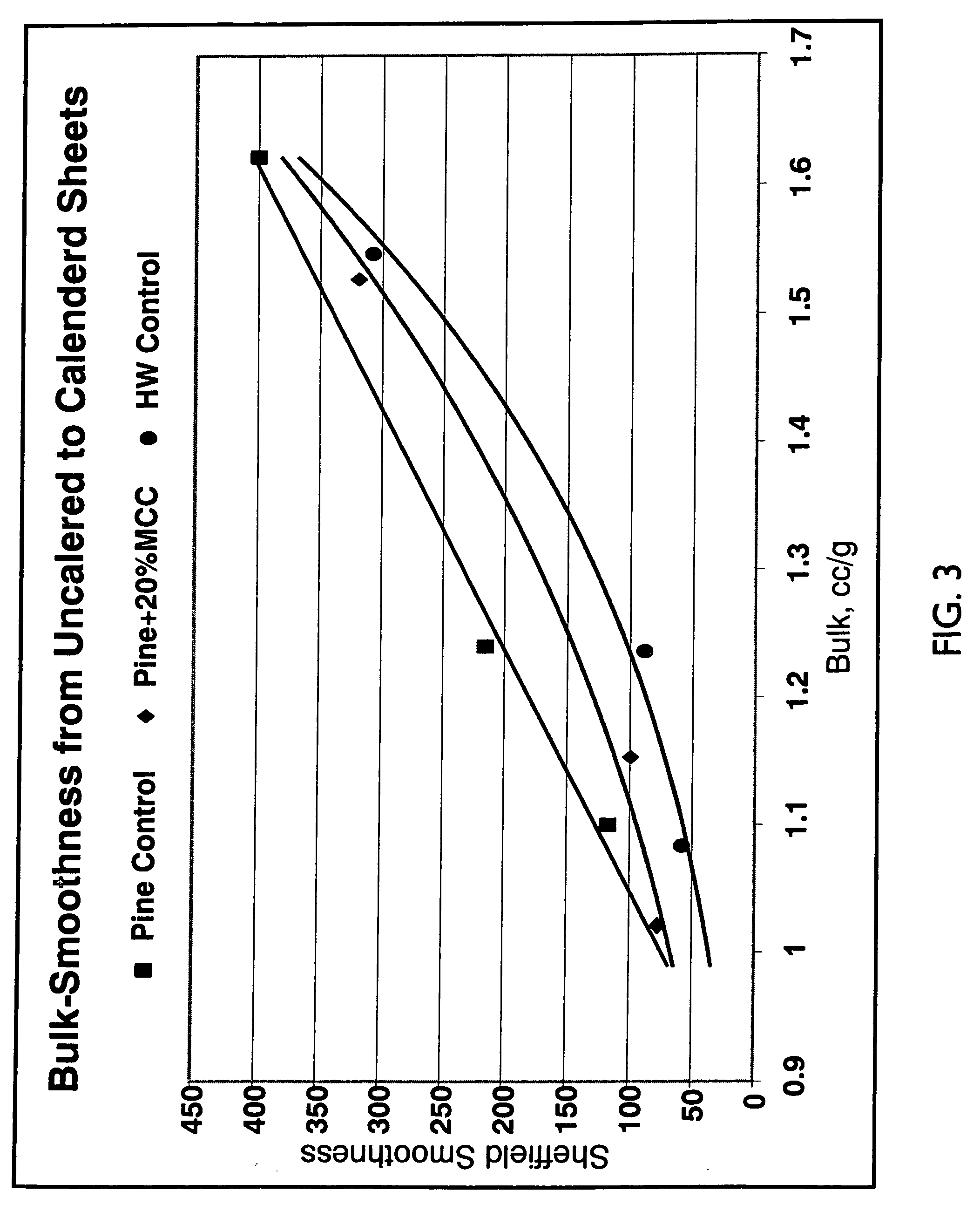

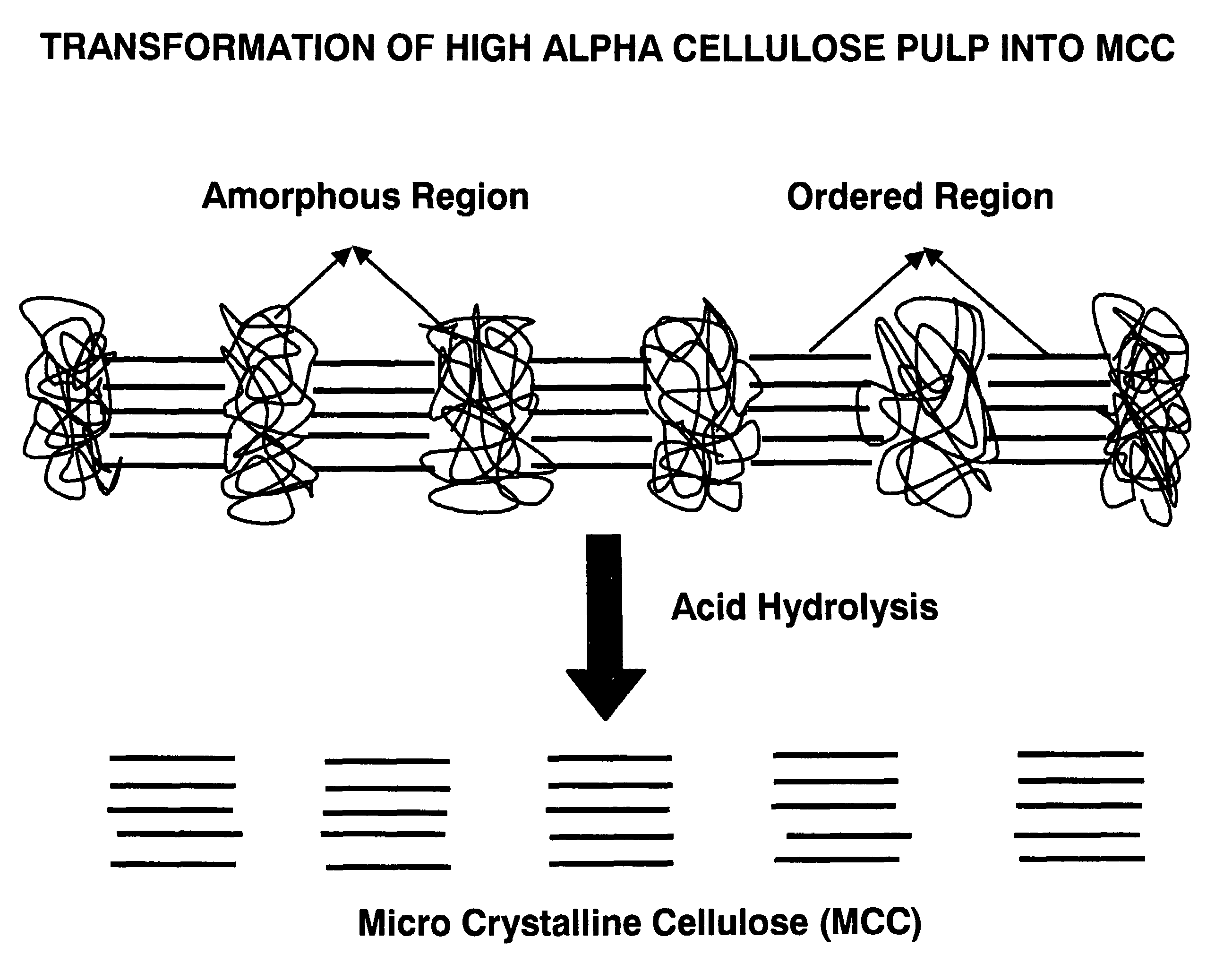

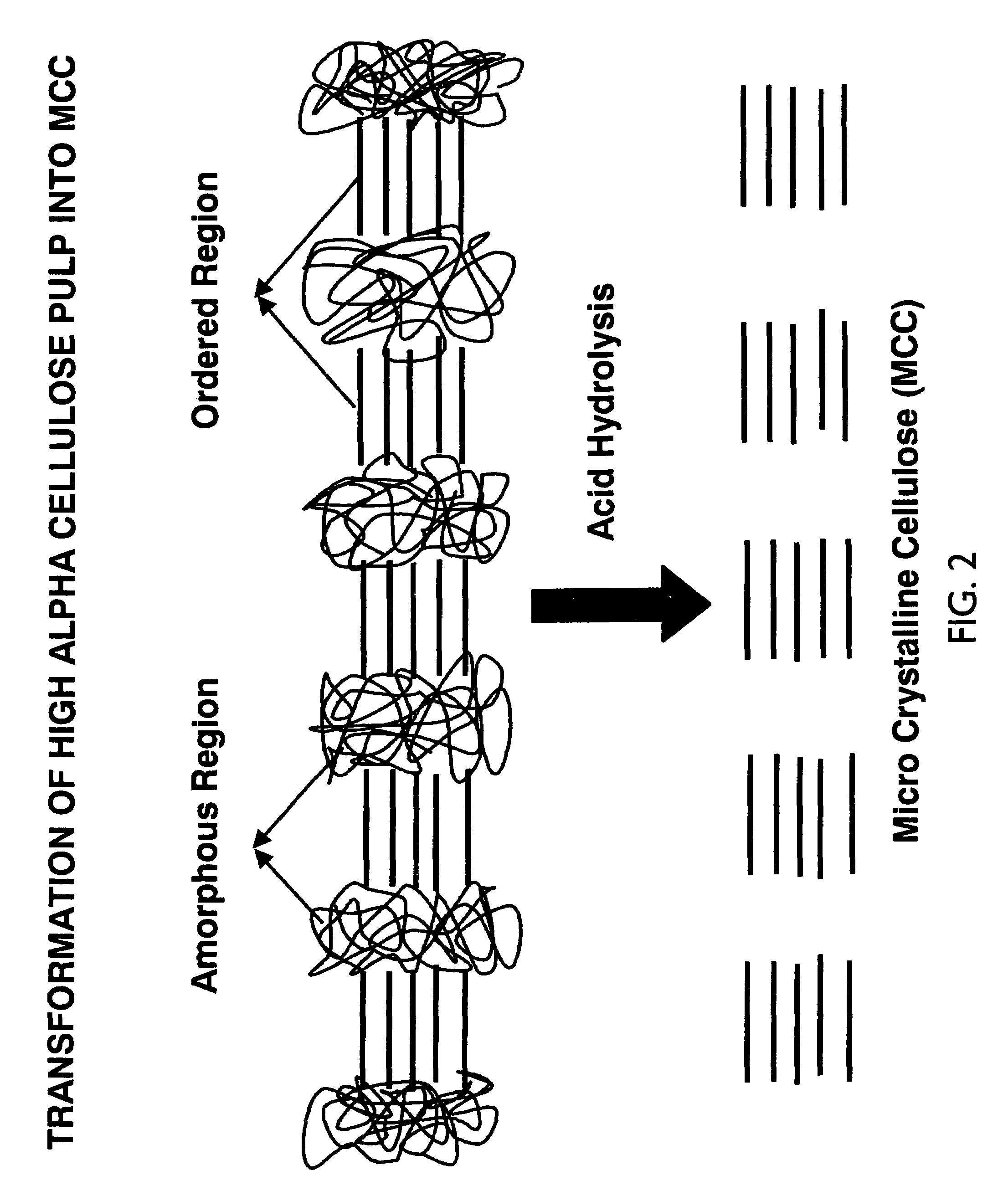

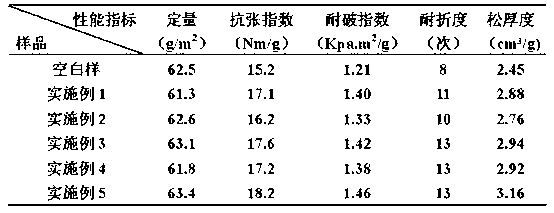

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS20060144535A1High binding capacityImprove abilitiesNon-fibrous pulp additionSpecial paperFiberCardboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

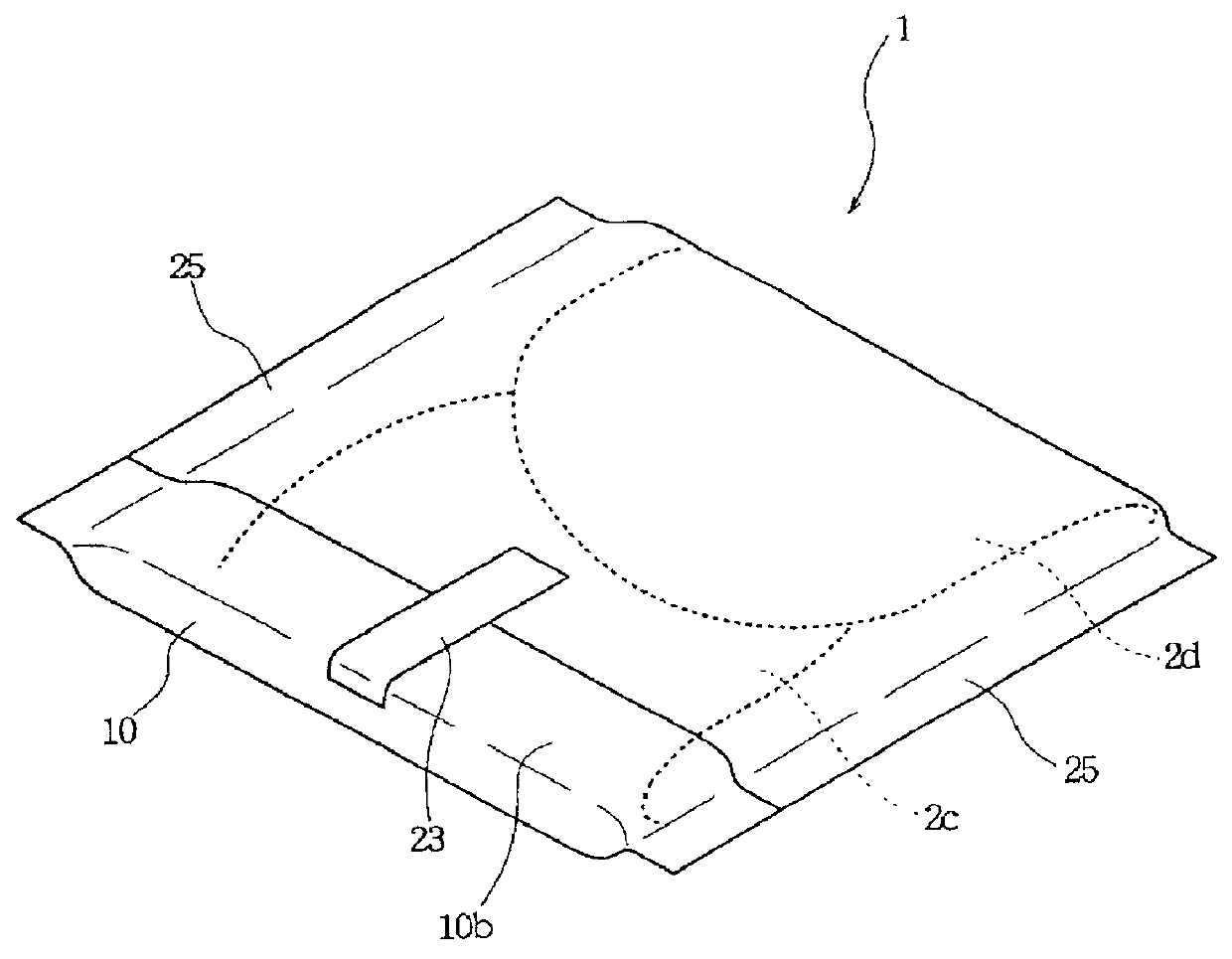

Package for absorbent article

InactiveUS20010056270A1Causes less zipping or rustling soundImprove breathabilityDiagnosticsSurgical needlesEngineeringNonwoven fabric

Owner:UNI CHARM CORP

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Paper substrates containing high surface sizing and low internal sizing and having high dimensional stability

InactiveUS7736466B2Improve surface strengthNatural cellulose pulp/paperSpecial paperEngineeringHigh surface

This invention relates to a paper substrate containing high surface sizing and low internal sizing and having high dimensional stability, as well as methods of making and using the composition.

Owner:GLOBAL HLDG II INC

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Preparation method and application of hydrophobic modified guar gum

InactiveCN102827300ANot easy to degradePreserve macromolecular quality propertiesWater-repelling agents additionCelluloseOrganic acid

The invention discloses a preparation method and an application of hydrophobic modified guar gum. The method comprises the following steps of: suspending guar gum in an ionic liquid, adding a basic catalyst, and alkalifying at the temperature of 10-40 DEG C; gradually heating under the protection of nitrogen, dropwise adding a modifying agent slowly, and heating to 30-80 DEG C for performing a modification reaction; and after the reaction, adding organic acid for adjusting the pH to 5-7, soaking and washing with ethanol, filtering, and drying a filter cake in vacuum to obtain the hydrophobic modified guar gum. A hydrophobic alkyl long chain is introduced into guar gum hydroxyl, and a terminal group is a carboxylic acid group, so that the water dissolving speed of the guar gum is increased, the macromolecular quality characteristic of the guar gum is protected to the maximum extent, and the guar gum is endowed with hydrophobic performance. Compared with other modified guar gum, the hydrophobic guar gum has the advantages of high molecular weight, high compatibility with cellulose, increase in the molecular bonding force of cellulose-guar gum, improvement on the paper strength and applicability to a paper-making wet part chemical process as a reinforcing agent and a surface sizing agent.

Owner:SOUTH CHINA UNIV OF TECH

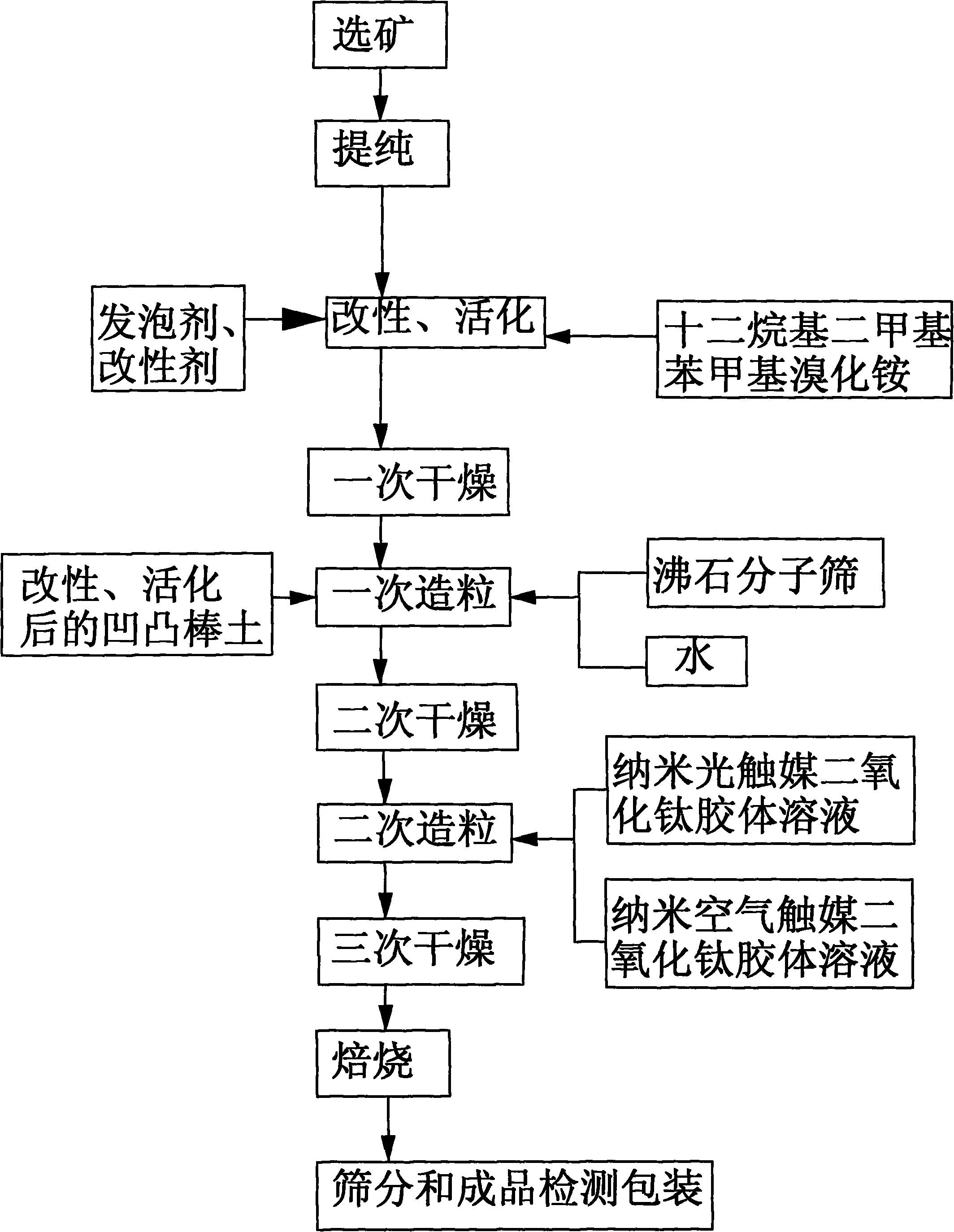

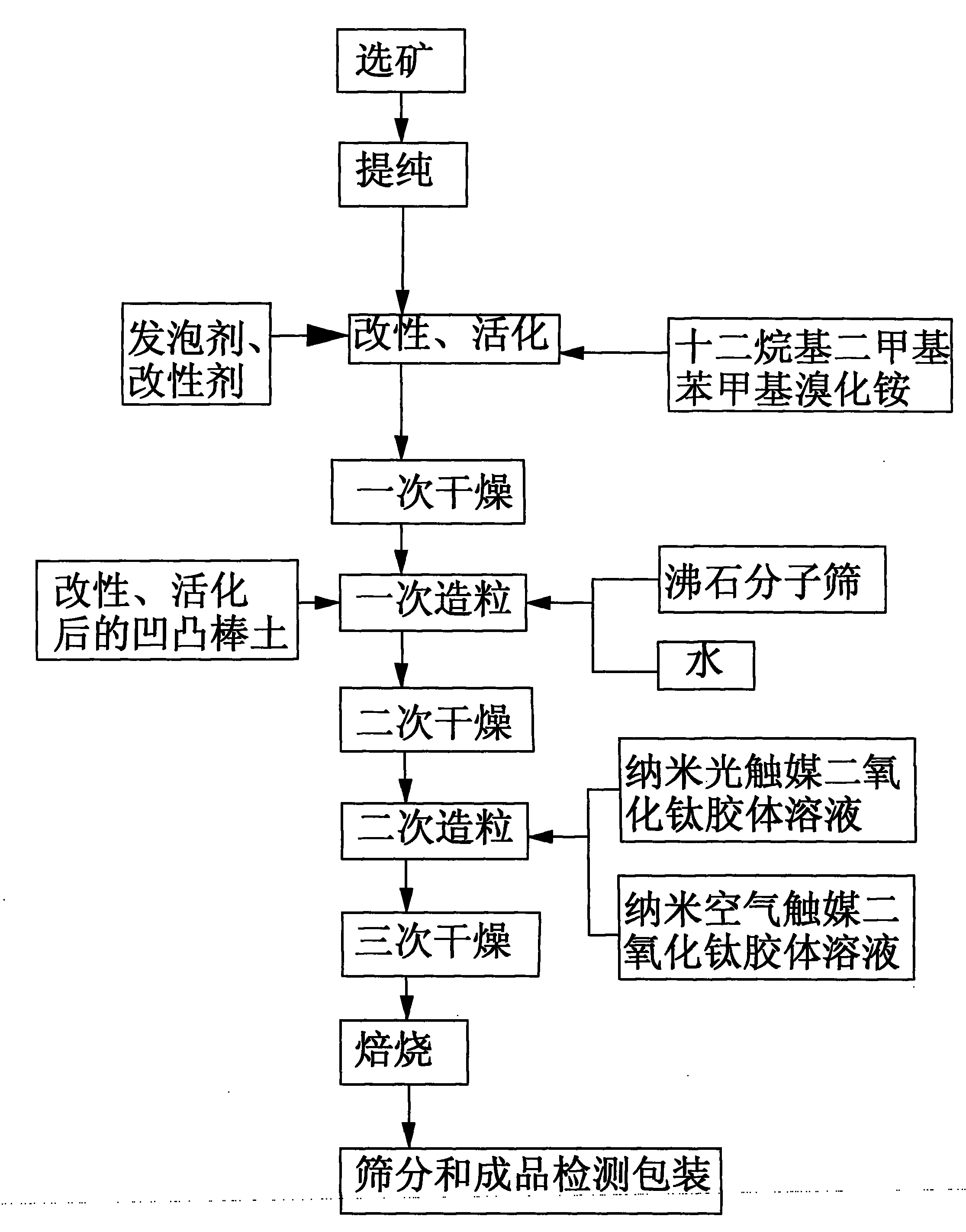

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

Anionic-cationic polymer blend for surface size

InactiveUS20050022956A1Acceptable resistanceSufficient surface smoothnessNatural cellulose pulp/paperSpecial paperCellulosePolymer science

Owner:GEORGIA PACIFIC CHEM LLC

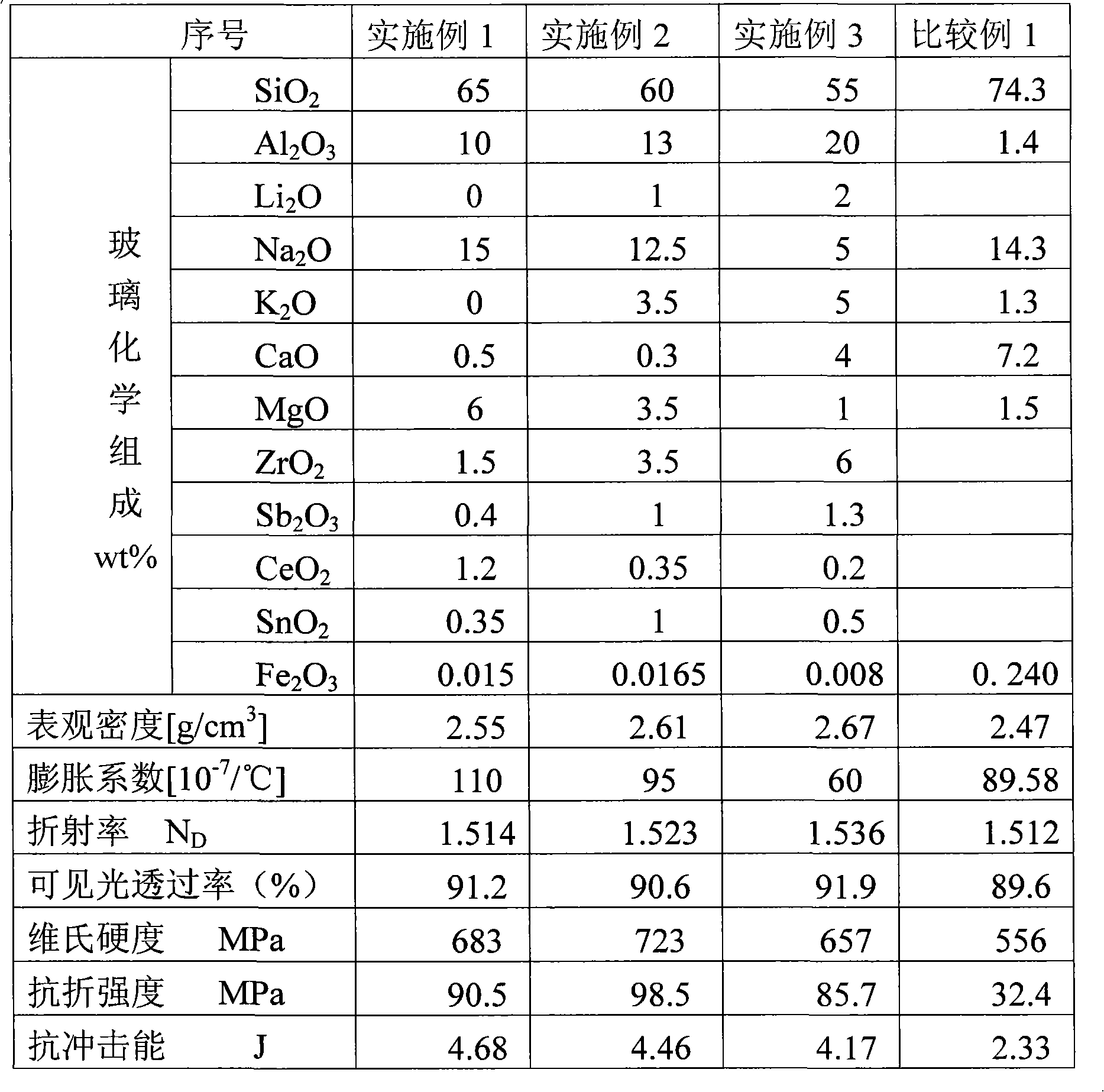

Zirconia aluminosilicate glass

InactiveCN101575167AAvoid damageGood mechanical propertiesChemical compositionLiquid-crystal display

The invention discloses zirconia aluminosilicate glass which is a high-alkali high-alumina glass composition system containing zirconia, is suitable to the manufacture of glass products with high surface hardness and good scratch-resistant property, and has the advantages of being capable of chemical strengthening treatment. The chemical composition (wt percent) of the glass is as follows: 55 to 65 of SiO2, 10 to 20 of Al2O3, 0 to 2 of Li2O, 5 to 15 of Na2O, 0 to 5 of K2O, 1 to 6 of MgO, 0.5 to 4 CaO, 1.5 to 6.0 of ZrO2, 0.35 to 1.0 of SnO2, 0.2 to 1.2 of CeO2 and 0.4 to 1.3 of Sb2O3. The glass material is suitable to screen protecting materials of flat panel display products (such as liquid crystal displays, liquid crystal display-televisions, media machines, touch screens, automated teller machines, cell phones, and personal digital assistants), and can effectively prevent the surface impact and scratch damage of the flat panel display products.

Owner:WUHAN UNIV OF TECH

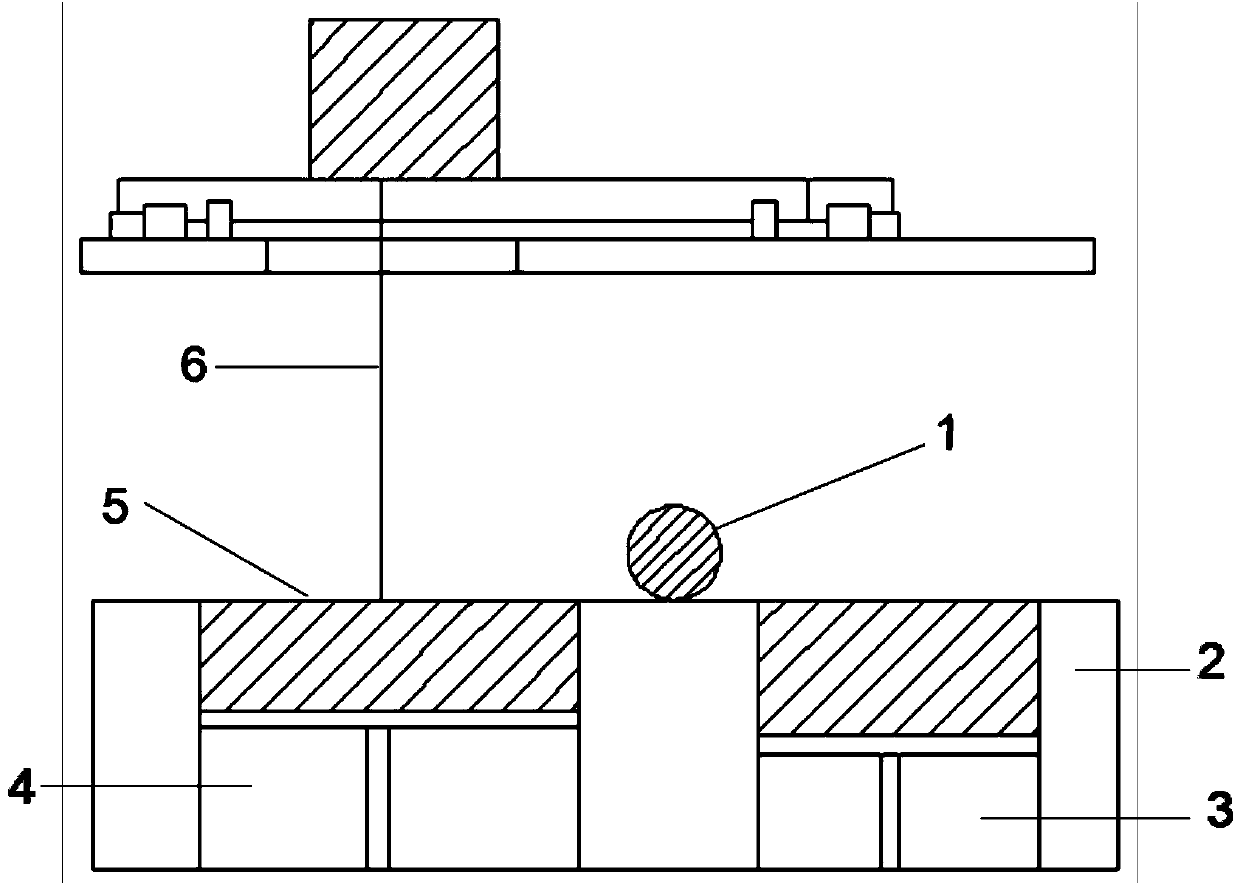

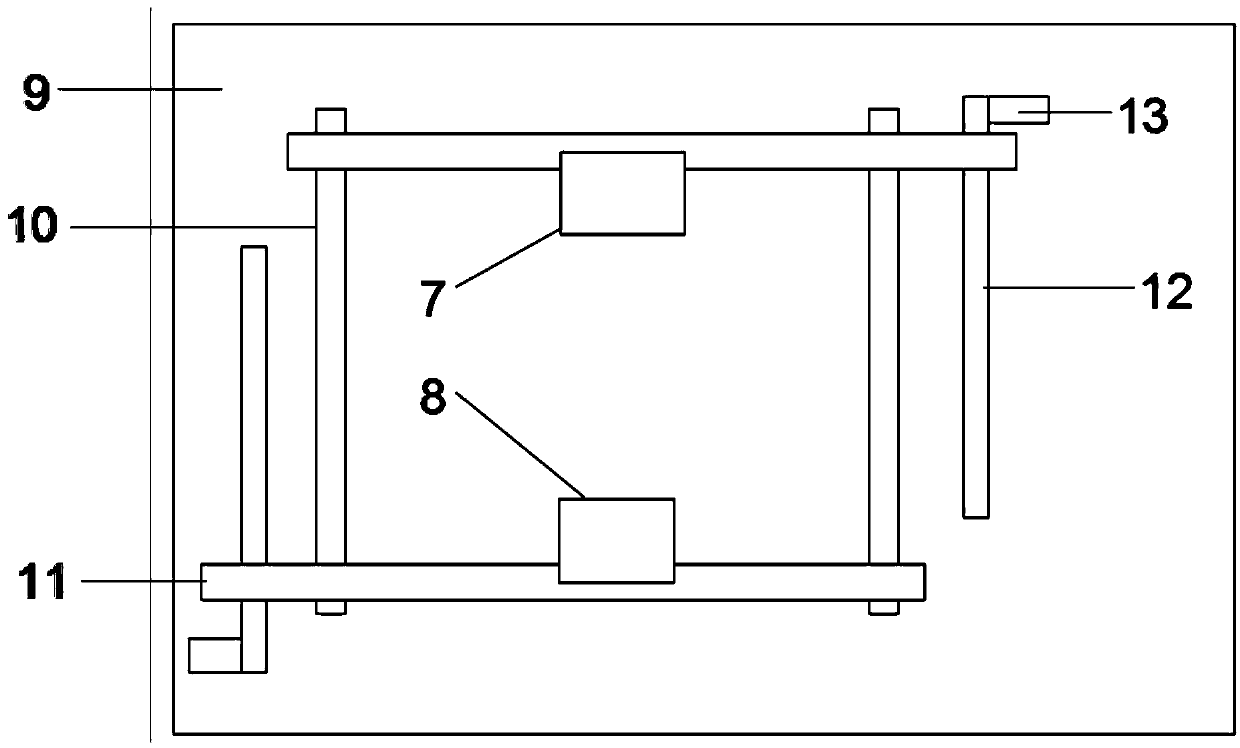

Method and device for manufacturing efficient and high-precision composite additive

ActiveCN104190931AShorten forming timeImprove forming efficiencyIncreasing energy efficiencyLight beamMetal powder

The invention discloses a method and device for manufacturing efficient and high-precision composite additive, and the method and device are achieved through composition of a laser beam and an electron beam. In the process of the action of a high energy beam and metal powder, metal powder of a surface outline is scanned and molten through the laser beam, and the surface of a part has a good surface quality. The electron beam melts the internal powder at a high speed to form a part inner cavity so as to reach the highest forming efficiency. The lower portion of the device comprises a powder laying roller, a workbench, a powder conveying cylinder and a working cylinder. The upper portion of the device comprises an electron beam generating device, a laser beam generating device, a bottom plate, two guide rails, two beams, a synchronous belt wheel and a servo motor. The electron beam generating device and the laser beam generating device are respectively integral and move to the forming area alternately to carry out scanning. By means of the method and device, the defects in the single forming technology can be overcome, and the purposes of reasonably controlling the formed microstructural organization and optimizing the comprehensive performance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Lost foam casting cast iron coating for preventing carbon defects and preparation method thereof

InactiveCN101767184AGood suspensionImprove thixotropyFoundry mouldsFoundry coresPolyvinyl alcoholOctanol

The invention discloses a lost foam casting cast iron coating for preventing carbon defects, which comprises the following components by weight percent: 60.5%-64.5% of bauxite, 13.5-17.5% of kaolin, 3.5%-6.0% of talc powder, 1.7%-3.5% of attapulgite, 0.4%-0.8% of sodium lignosulphonate, 2.5%-6.0% of aluminum sulfate, 1.7%-3.5% of polyvinyl alcohol, 3.5%-5.0% of silica sol, 0.1%-0.2% of iron oxide powder and 0.01%-0.02% of n-octanol, and the sum of the components is 100%. The lost foam casting cast iron coating is prepared by respectively preparing water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, evenly mixing the bauxite, the kaolin, the talc powder and the iron oxide powder for preparing mixed powder material, mixing the water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, the silica sol and the refractory mixed powder material with the n-octanol, stirring and grinding. The coating has the advantages of good thixotropy, good coating property, high coating strength and good gas permeability; and the surface of a cast is smooth and has no wrinkles and other carbon defects.

Owner:NANTONG XINZHENGDA SPECIAL STEEL

Styrene-acrylate emulsion for surface coatings of coated paper

ActiveCN101704930AImprove surface strengthHigh glossPaper coatingCoatingsEmulsionEmulsion polymerization

The invention provides a styrene-acrylate emulsion for surface coatings of coated paper, which is prepared in emulsion polymerization mode by mixing the following raw materials in part by weight: 100 parts of mixed monomers; 0.7 to 4.5 parts of emulsifying agent; 0.4 to 4.5 parts of initiating agent; 2 to 4 parts of accelerating agent; 2 to 8 parts of crosslinking monomers; 4 to 20 parts of aqueous alkali; and 90 to 290 parts of water. The mixed monomers comprise the following monomers in part by weight: 20 to 44 parts of (methyl) acrylic ester; 50 to 74 parts of (methyl) styrene; and 6 to 10 parts of (methyl) acrylic acid. The styrene-acrylate emulsion for the surface coatings of the coated paper of the invention is a high-performance and environmentally-friendly product which can be used for paper coatings. When applied to the surface coatings of the coated paper, the product can obviously increase the surface strength of the coated paper and improve glossiness of paper coatings.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

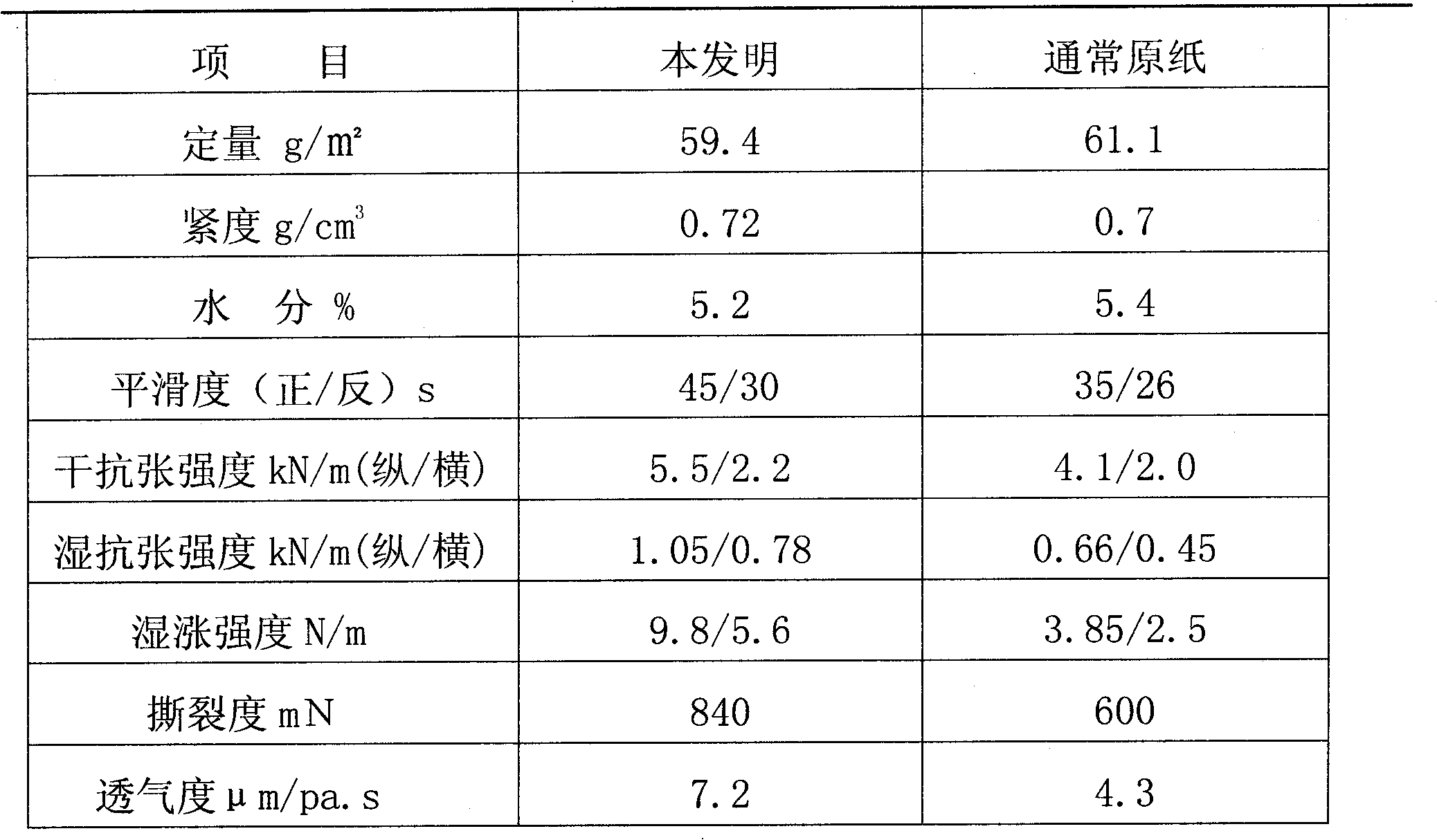

Light coated printing paper and manufacturing method thereof

InactiveCN1455047AEase the strain on resourcesAdjustable structurePaper/cardboardSulfatePulp and paper industry

The present invention discloses a light-weight coated printed paper and its making method. It includes the following steps: using bleached sulfate needle wood (pulp (BKP). Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP), bleached sulfate reed pulp (BKP) or commercial bleached hard wood pulp; respectively beating, proportioning and making them into mixed pulp; adding auxiliary material to obtain material for making paper and making paper. Said invention adopts the advanced making process of AKD neutral sizing, internal coating and calendering by using soft roll, so that said printing paper has good surface strength, bulkness and air permeability, and is suitable for implementing various colour printing.

Owner:YUEYANG FOREST & PAPER CO LTD

Method for producing vehicle-used stabilizer bar with high corrosion resistance

InactiveCN101618508AImprove surface strengthOther manufacturing equipments/toolsSurface plasticQuenching

The invention discloses a method for producing a vehicle-used stabilizer bar with high corrosion resistance, which relates to the processing technology field of metal parts, in particular to a production process of an automotive stabilizer bar. The production process comprises the following steps: blanking, bending, forging, drilling and reaming, boring, quenching and tempering, correcting, rotoblasting, phosphating, surface plastic-spraying and finally pressing into a bushing. Through the process, the corrosion resistance of the surface of the stabilizer bar is effectively improved and the service life is also prolonged. After the corrosion resistance test of 150 hours is carried out according to the method in QC / T484-1999, the spread of unilateral corrosion along the cutting does not exceed 2 mm and the check result shows that the unilateral corrosion is 1.3 mm.

Owner:YANGZHOU DONGSHENG AUTOMOBILE PARTS LTD BY SHARE LTD

Production method for bactericidal packing paper

ActiveCN102154944AImprove breathabilityHigh strengthPaper coatingReinforcing agents additionBursting strengthCarboxymethyl cellulose

The invention discloses a production method for bactericidal packing paper, which comprises the following steps of: (1) preparation working procedure of applying glue solution to pulp; (2) preparation working procedure of applying glue solution to a surface; (3) working procedure of sizing agent repulping, selecting Southern pipes produced in America to make pulp, adding sodium carbonate and carboxymethyl cellulose into a repulping liquid; (4) working procedure of pulp matching, adding a wet strength agent; (5) working procedure of webbing and forming; (6) working procedure of applying glue solution to the surface, using modified tapicoa starch and polyvinyl alcohol for applying the glue solution to the surface; and (7) completion working procedure. The bactericidal packing paper has good air permeability, high surface strength, tearing resistance after disinfection and high bursting strength and can block bacterium invasion.

Owner:安徽华邦古楼新材料有限公司

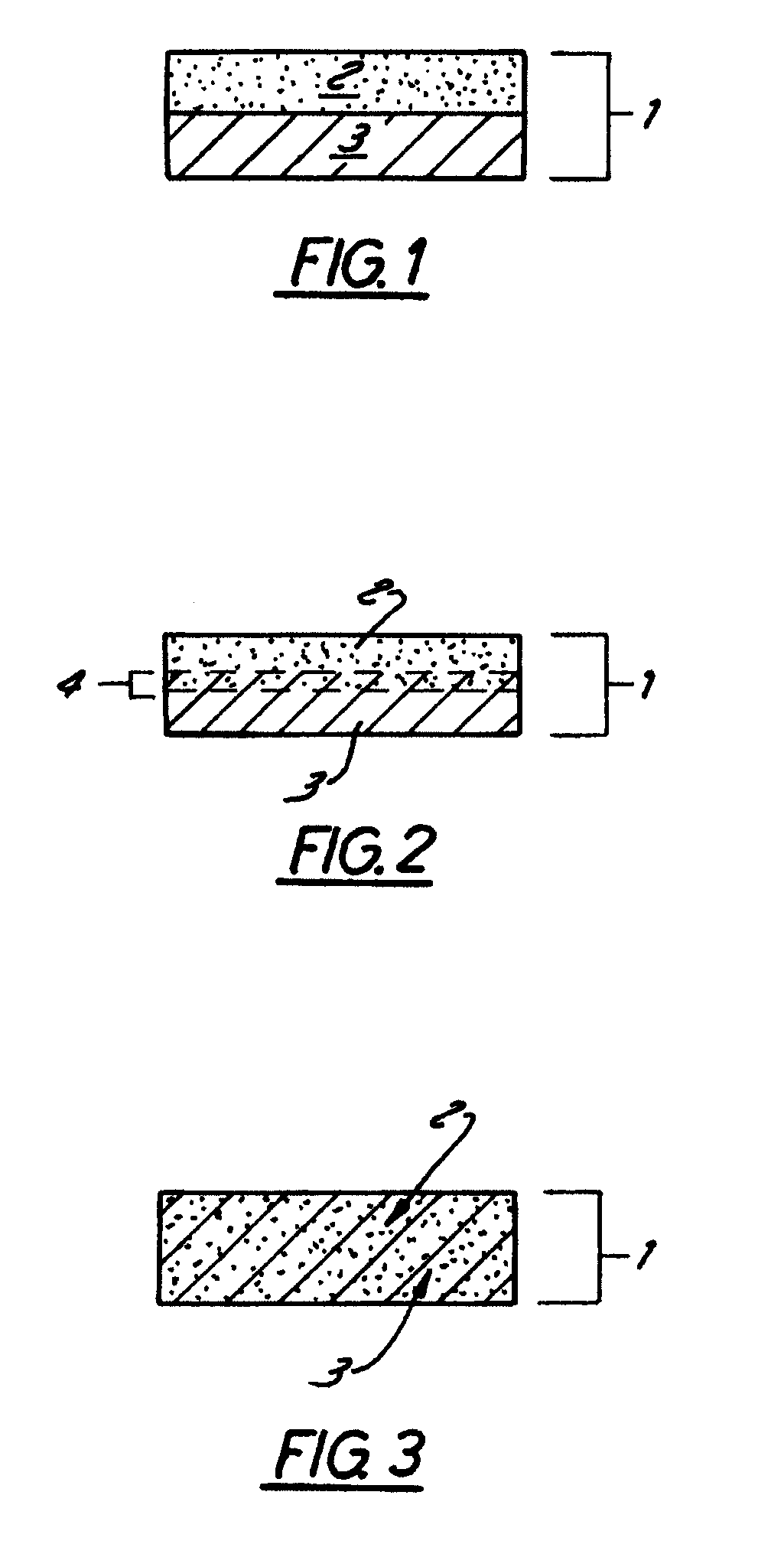

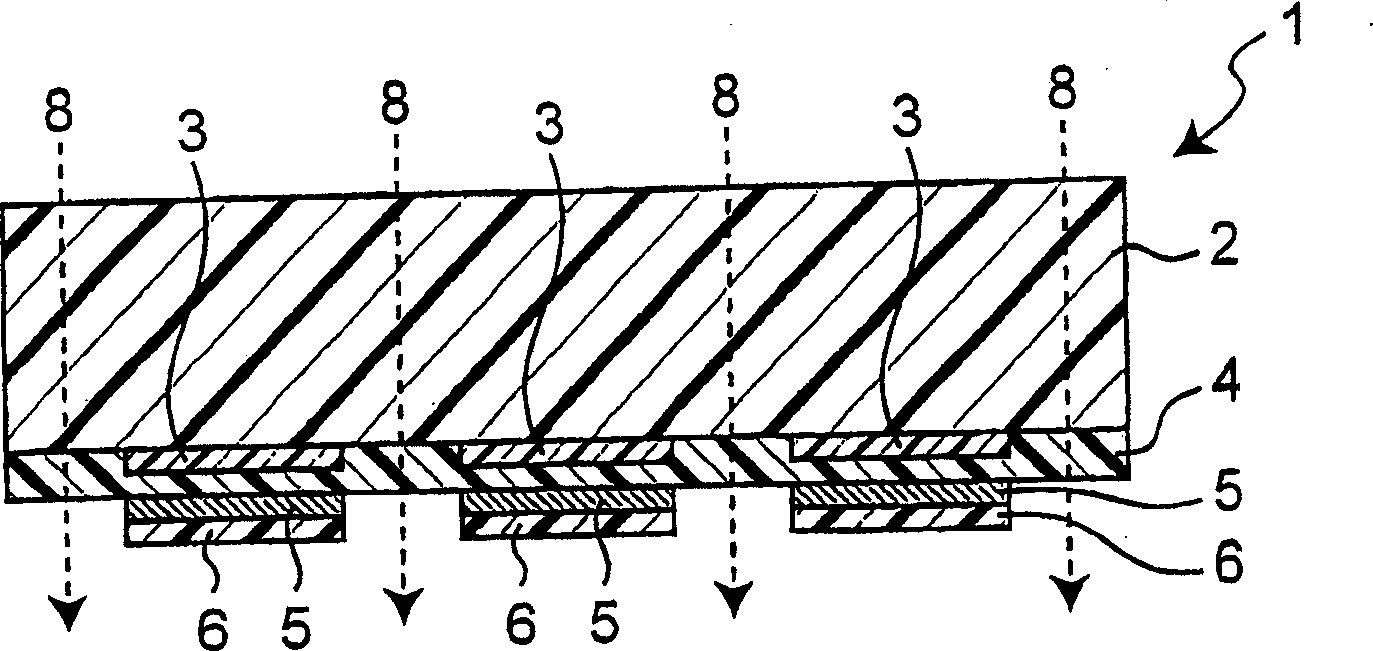

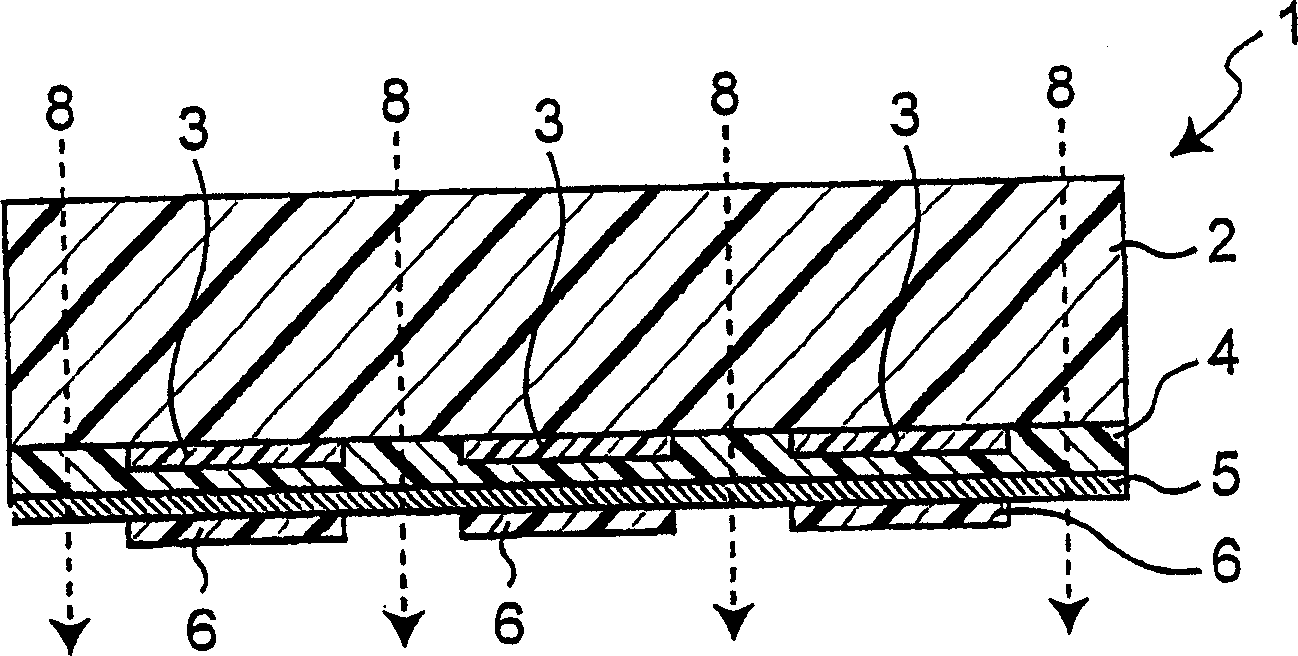

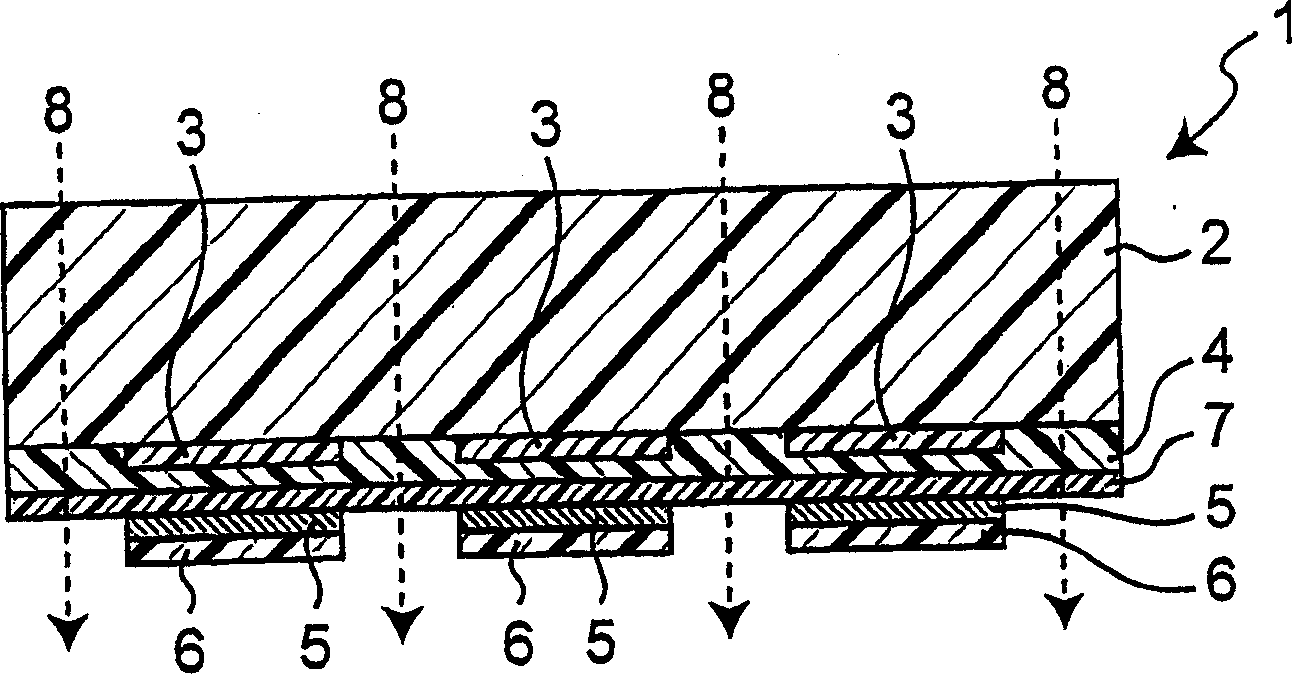

Transfer material

A transfer material comprising a substrate sheet (2, 52), strip-pattern mold release layers (3, 53) laid on the substrate sheet, an ionizing radiation curing layer (4, 54) entirely laid on the mold release layers, pattern layers (5, 55) laid entirely or partially on the ionizing radiation curing layer, and adhesive layers (6, 56) laid partially on the pattern layers at portions only that overlap the mold release layers.

Owner:NISSHA PRINTING COMPANY

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

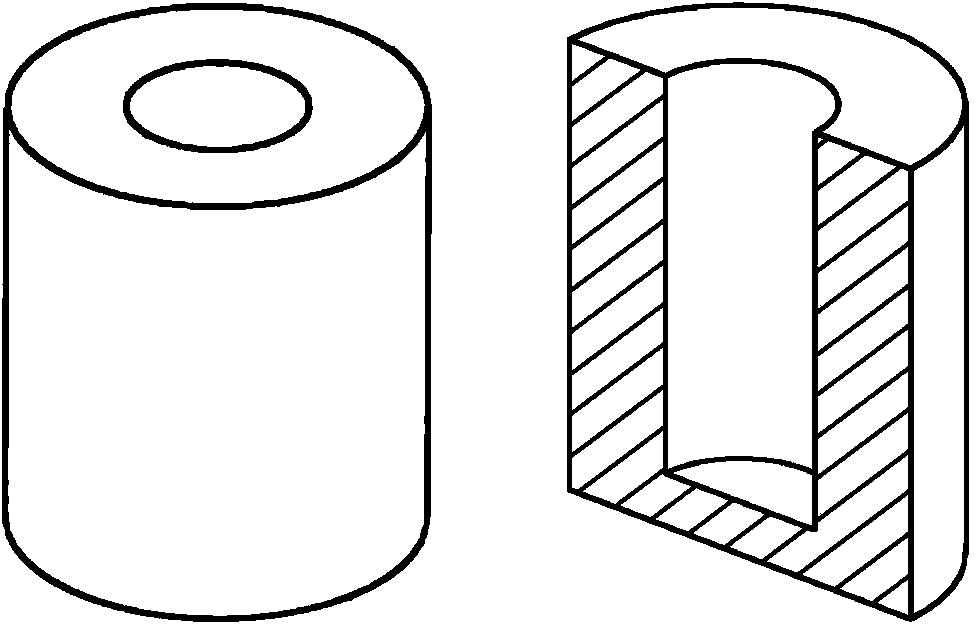

Production method of high-performance latex paper

InactiveCN102191725AImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensile strength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

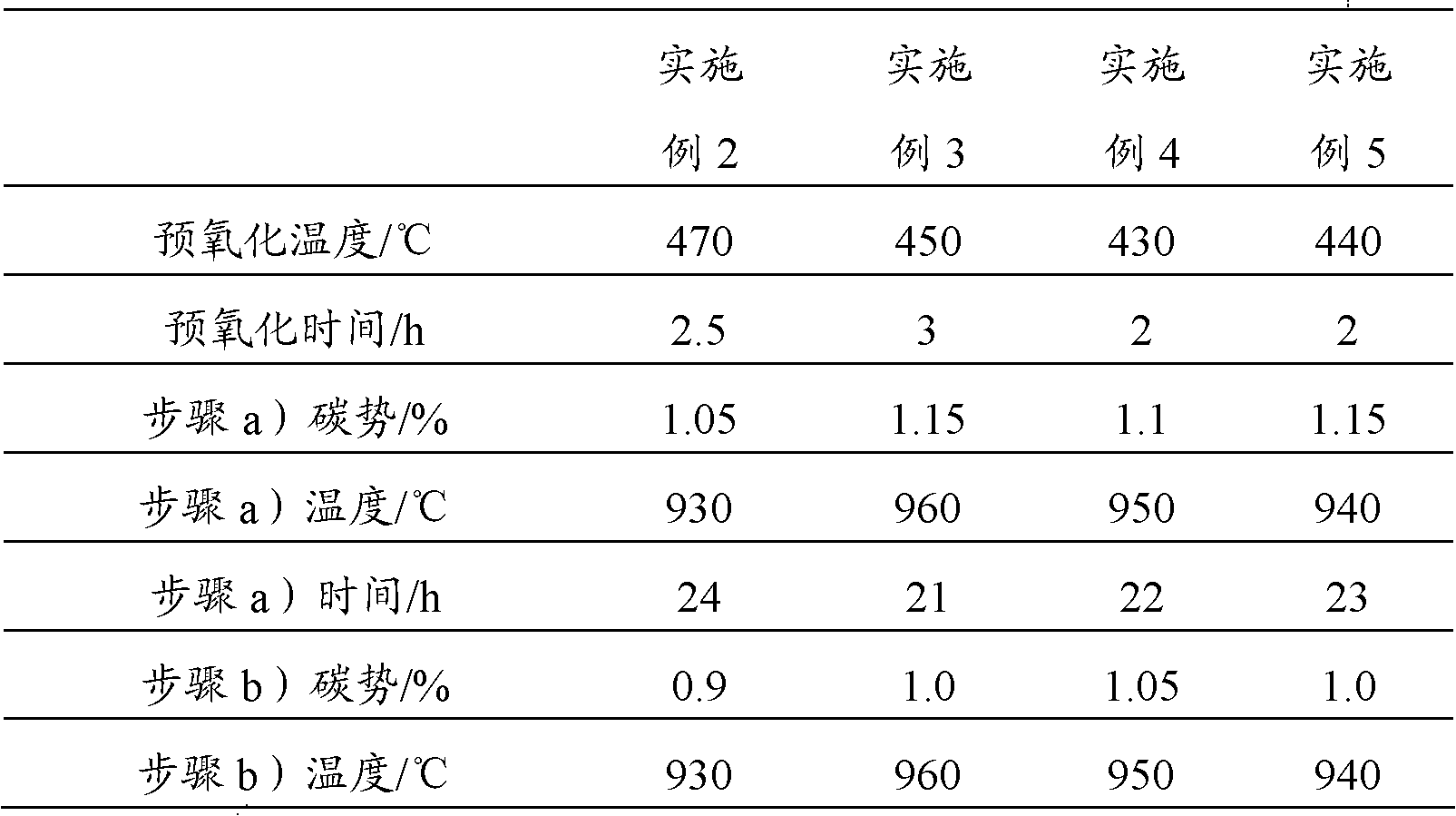

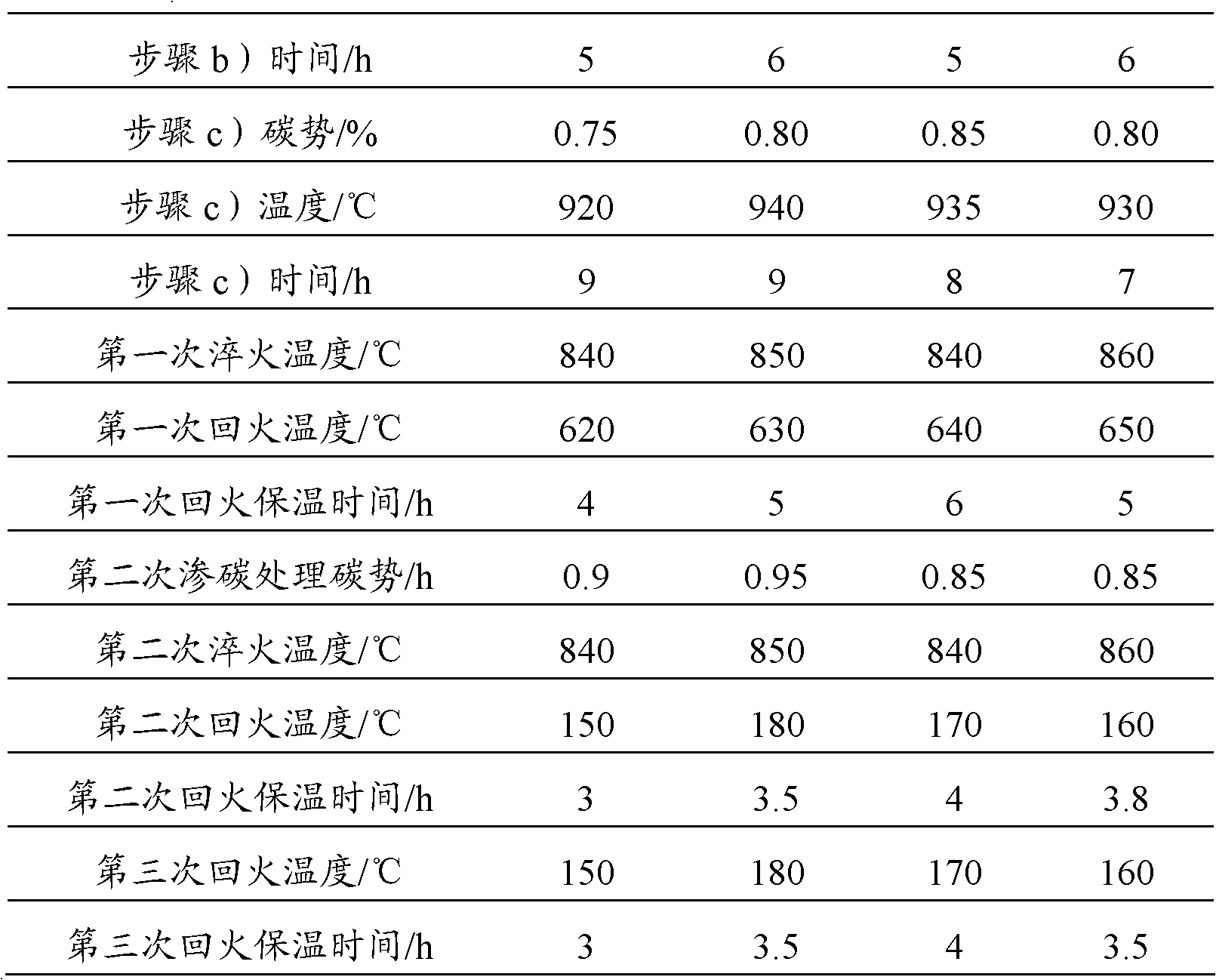

Carburizing method for wind power gear used for wind power generation

ActiveCN101984139AIncrease carbon concentrationImprove surface strengthSolid state diffusion coatingFurnace typesQuenchingSurface strength

The invention provides a carburizing method for a wind power gear used for wind power generation, which comprises the following steps: carrying out first carburizing treatment on the wind power gear to be treated under the atmosphere with carbon potential of 0.8%-1.1%, then carrying out first quenching treatment, further rising the temperature to 600 DEG C-660 DEG C, and carrying out first tempering treatment; then carrying out second carburizing treatment under the atmosphere with the carbon potential of 0.8%-1.0%, and carrying out second quenching treatment after the second carburizing treatment; and further carrying out second tempering treatment on the wind power gear at 150 DEG C-200 DEG C after the second quenching treatment. Compared with the prior art, the carburizing method is characterized by firstly carburizing the wind power gear for 30-40h under the atmosphere with the carbon potential of 0.8%-1.1%, and then uniformly dissolving and dispersing over-saturated carbon in martensite after the first high-temperature tempering so as to be conductive to the next step of the treatment; and further carburizing the wind power gear for 1-4h under the atmosphere with the carbon potential of 0.8%-1.0% after the first high-temperature tempering treatment, thereby further increasing the carbon concentration on the surface of the wind power gear and improving the surface strength during the second carburizing treatment.

Owner:江苏丰东热技术有限公司

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

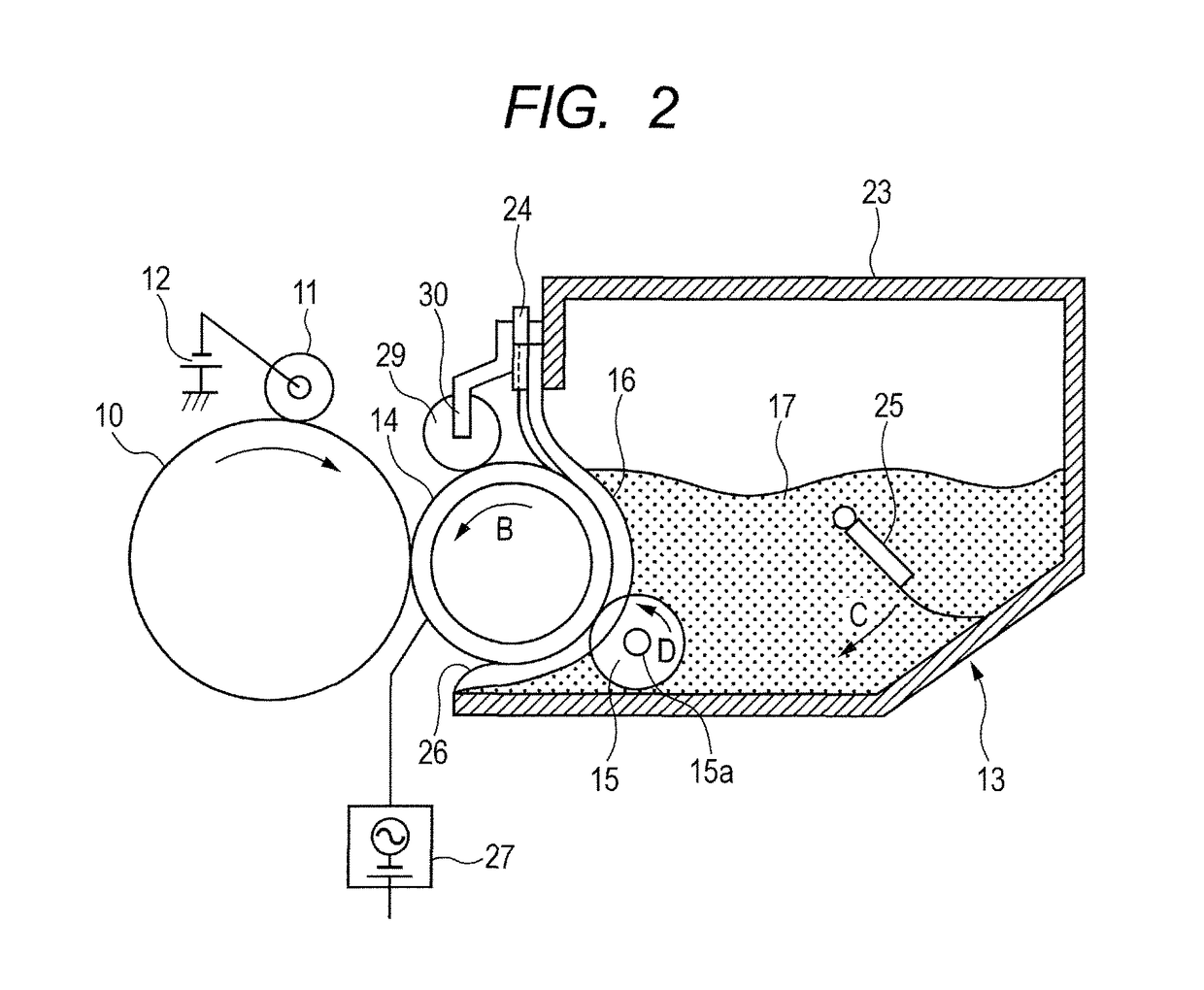

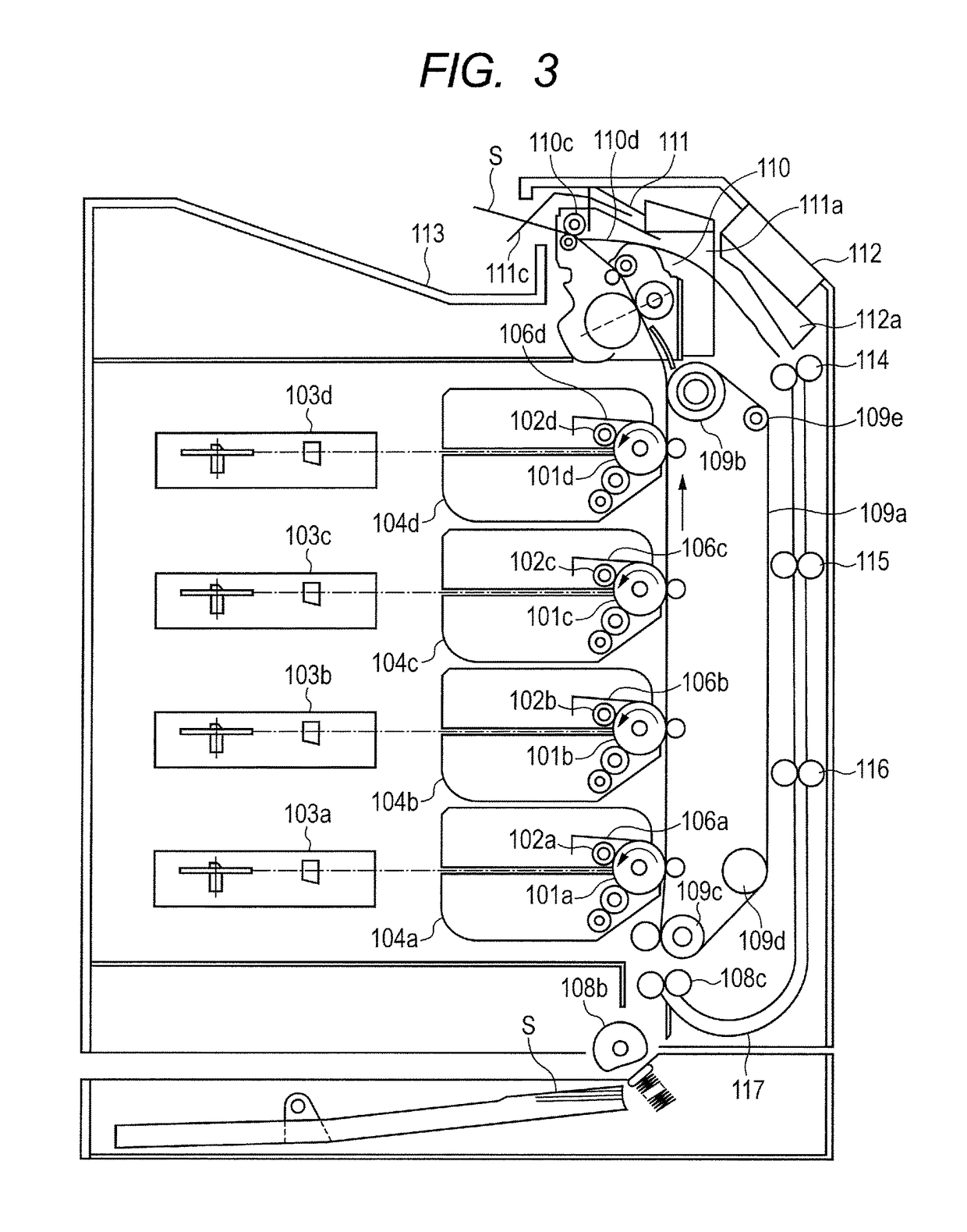

Toner and method for producing toner

The present invention is directed to providing a toner having no environmental difference in charging performance, and having high stability of images after output of a large number of copies under environments at high temperature and high humidity in a higher-speed one-component developing system, and a method for producing the toner, and the toner comprises a toner particle including a toner base particle containing a binder resin, a colorant and a releasing agent; and a resin particle adhering to the surface of the toner base particle, wherein the resin particle contains a resin A, and the resin A has an ionic functional group and an acid dissociation constant pKa of 7.0 or more and 9.0 or less, and the resin A has a monovalent group a represented by Formula (1):

Owner:CANON KK

Styrene-acrylic emulsion for priming paint as well as preparation method and application thereof

ActiveCN101704913AImprove surface strengthImprove the phenomenon of hair loss and powder lossPaper coatingCoatingsCross-linkAccelerant

The invention provides a styrene-acrylic emulsion for priming paint as well as a preparation method and an application thereof. The preparation method comprises the following steps: by using a surfactant compound from an anionic surfactant and a nonionic surfactant as an emulsifier and using peroxide as an initiator, carrying out free-radical emulsion polymerization on (methyl) acrylic monomer, (methyl) acrylate monomer, (methyl) styrene, cross-linking monomer and an accelerant under the conditions of 50-95 DEG C and normal pressure to obtain an emulsion; and then, neutralizing the obtained emulsion with aqueous alkali, and regulating the pH value to be 7-10 to obtain a finished product. The styrene-acrylic emulsion for priming paint is a product which can be used for paper-making paint and has high performance and environmental protection. When the product is applied to the priming paint of coated paper, the surface strength of the coated paper can be obviously increased, and the phenomena of fur falling and powder falling can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Refractory material for steel tapping hole of converter and preparation method for refractory material

The invention relates to a refractory material for a steel tapping hole of a converter and a preparation method for the refractory material. The technical scheme of the invention is as follows: the preparation method comprises the steps of spraying the surface of a magnesia-carbon brick body with a glaze slip coating with the thickness of 1mm to 2mm, carrying out drying, and carrying out heat preservation, thereby preparing the refractory material for the steel tapping hole of the converter. A preparation method for the magnesia-carbon brick body comprises the steps: mulling magnesia fines, flake graphite fines, expandable graphite, aluminum powder and silicon powder in a high-speed mulling machine, so as to prepare mixed fine powder; and then, mulling fused magnesia granules and artificial graphite granules, adding phenol-formaldehyde resin into the mixture, carrying out mulling, then, adding granulated graphite and the mixed fine powder into the mulled mixture, carrying out mulling, carrying out aging, carrying out shaping, and carrying out standing, thereby preparing the magnesia-carbon brick body. A preparation method for glaze slip comprises the steps of adding water into glass powder, spodumene, potassium feldspar, silicon micropowder, potassium carbonate, SiC fines, chrome green and aluminum dihydrogen phosphate, which serve as raw materials of the glaze slip, and carrying out grinding, thereby preparing the glaze slip. The refractory material for the steel tapping hole of the converter, prepared by the preparation method, has the characteristics that the thermal shock stability is good, the integrity is good, the oxidation resistance is good, the erosion resistance is good, and the life is long.

Owner:WUHAN UNIV OF SCI & TECH

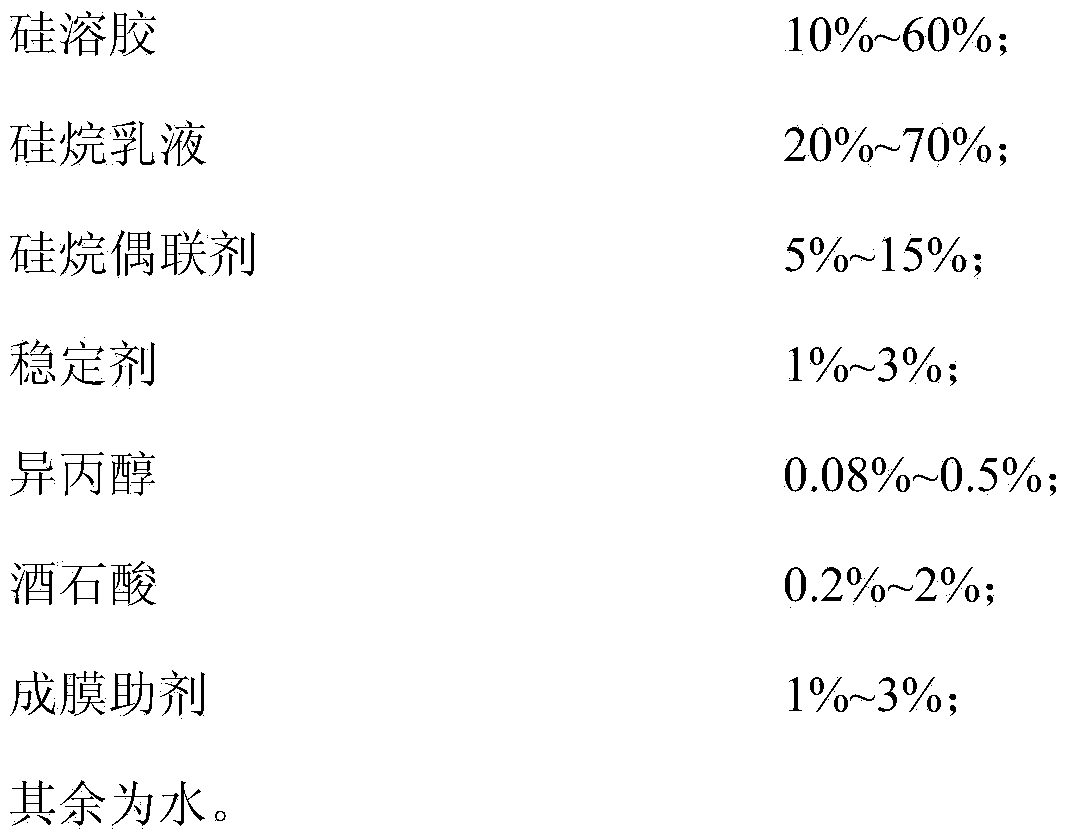

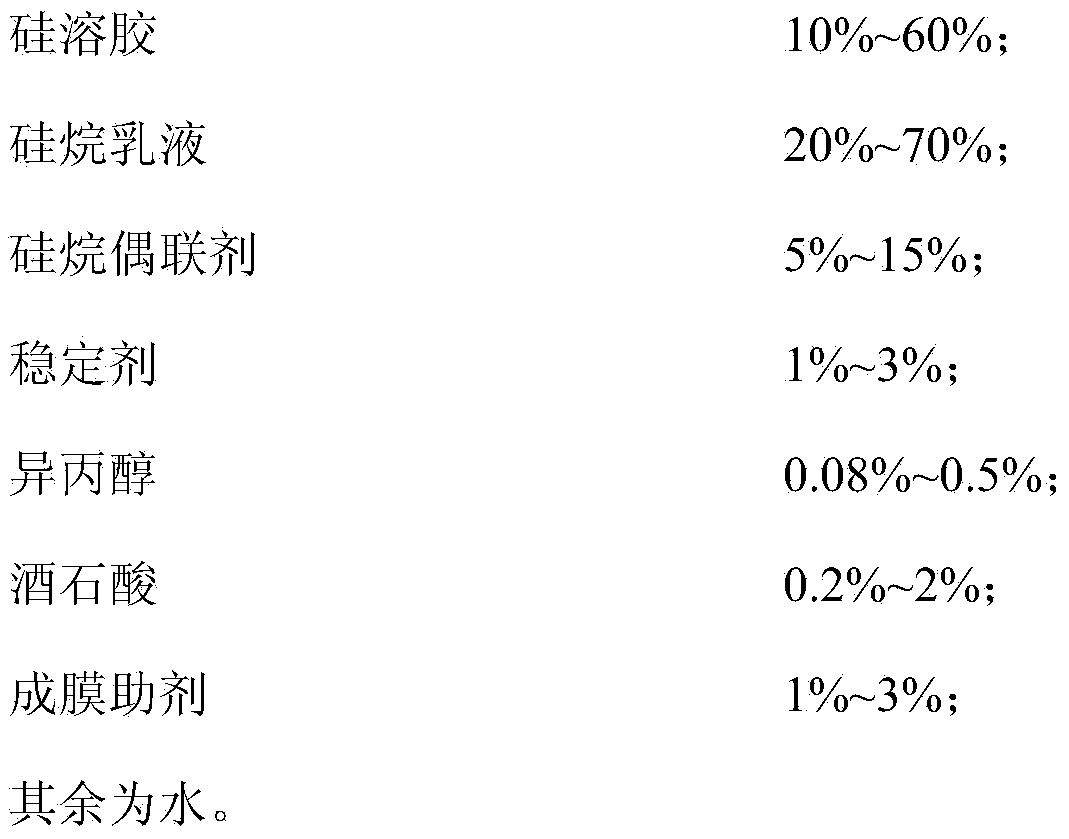

Silica sol-silane emulsion capillary crystalline waterproof material and preparation method thereof

The invention belongs to the technical field of building construction materials and preparation of the building construction materials, and relates to a silica sol-silane emulsion capillary crystalline waterproof material and a preparation method thereof. The preparation method comprises the following steps: at first, mixing silica sol, silane emulsions, silane coupling agents, stabilizers, isopropanol, tartaric acid and coalescing agents, controlling the temperature to 50-70 DEG C, stirring all the time, sufficiently reacting for 4-8 h, cooling, and then regulating the pH value to 3.5-5.5 with phosphoric acid, wherein the weight percentage of the silica sol, the silane emulsions, the silane coupling agents, the stabilizers, the tartaric acid and the coalescing agents are respectively 10%-60%, 20%-70%, 5%-15%, 1%-3%, 0.08%-0.5% and 1%-3%; at last, adding water to enable the weight percentage to 100% to obtain the silica sol-silane emulsion capillary crystalline waterproof material. The preparation process is simple, the cost is low, the water-proof effect is good, and the waterproof material is environment-friendly.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com