Patents

Literature

528results about How to "Overall good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

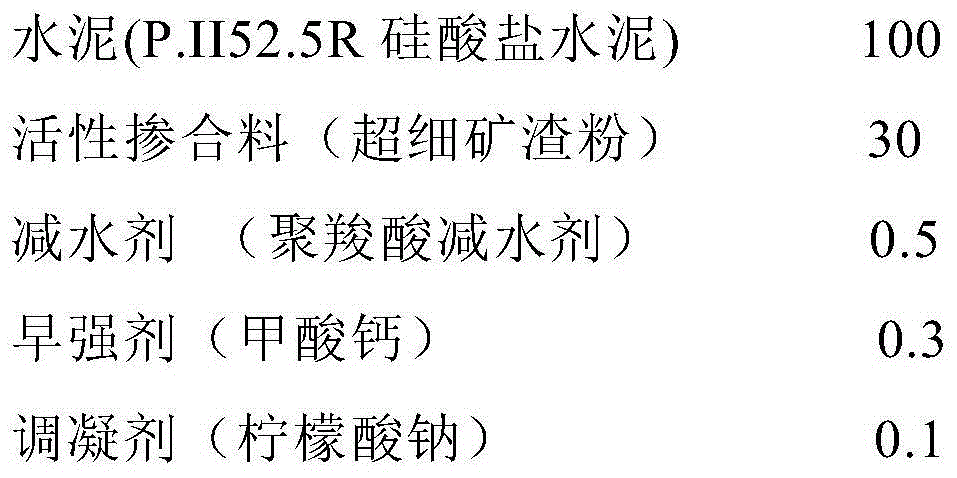

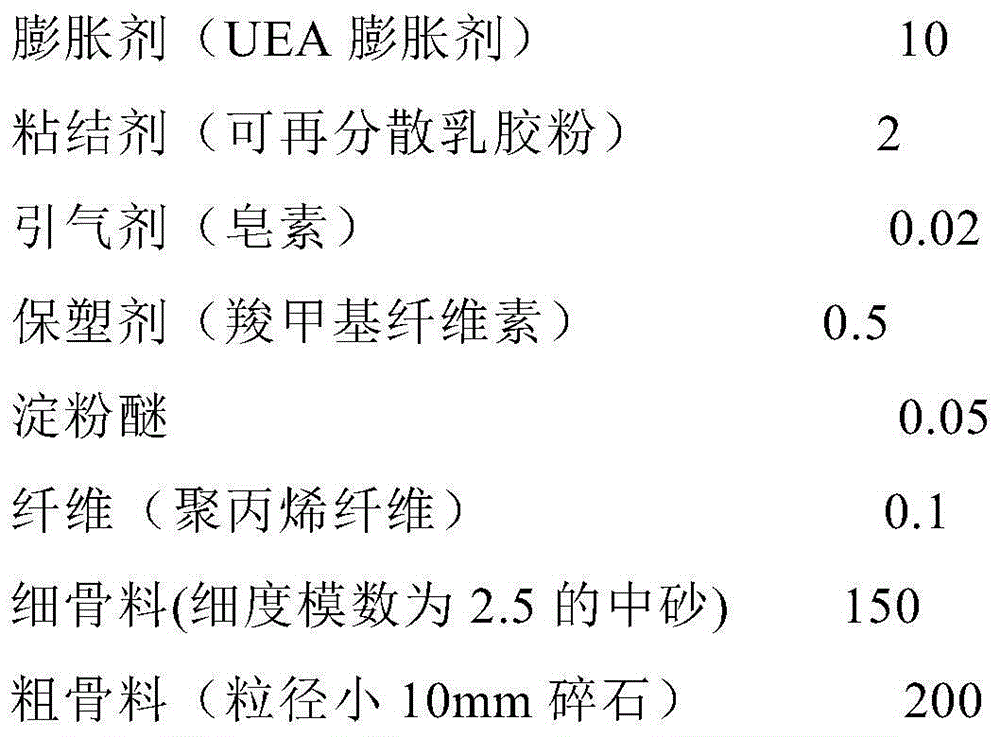

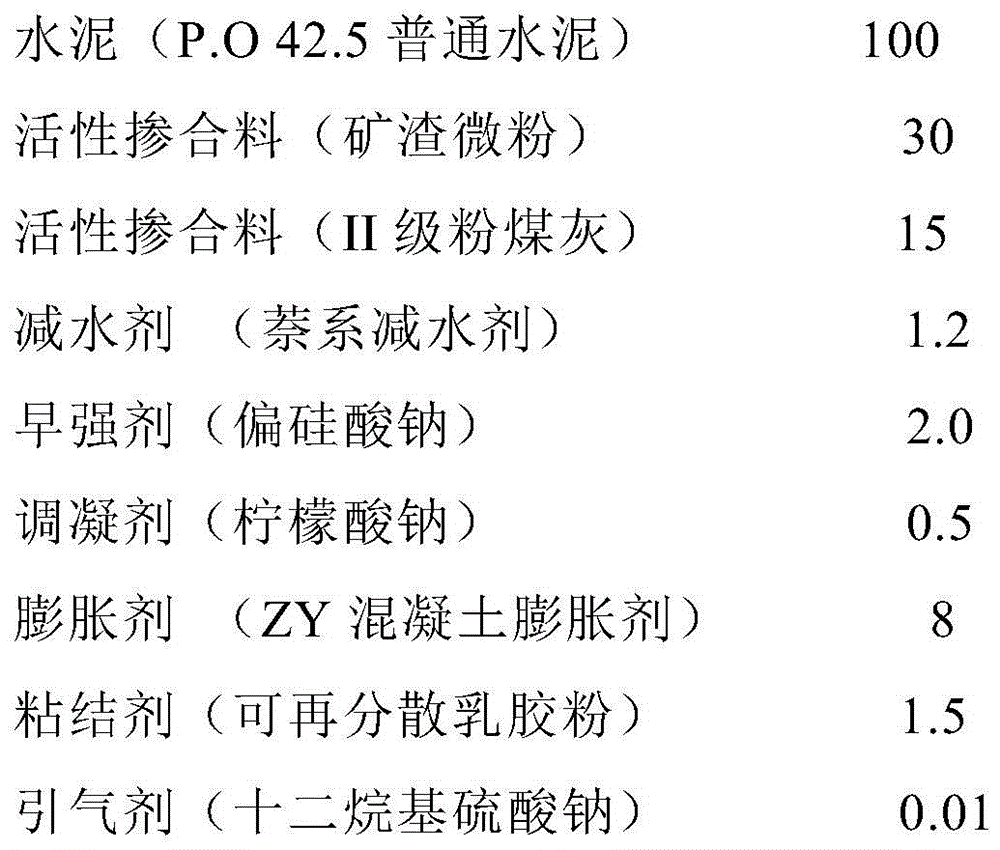

3D printing cement-based material and preparation method thereof

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

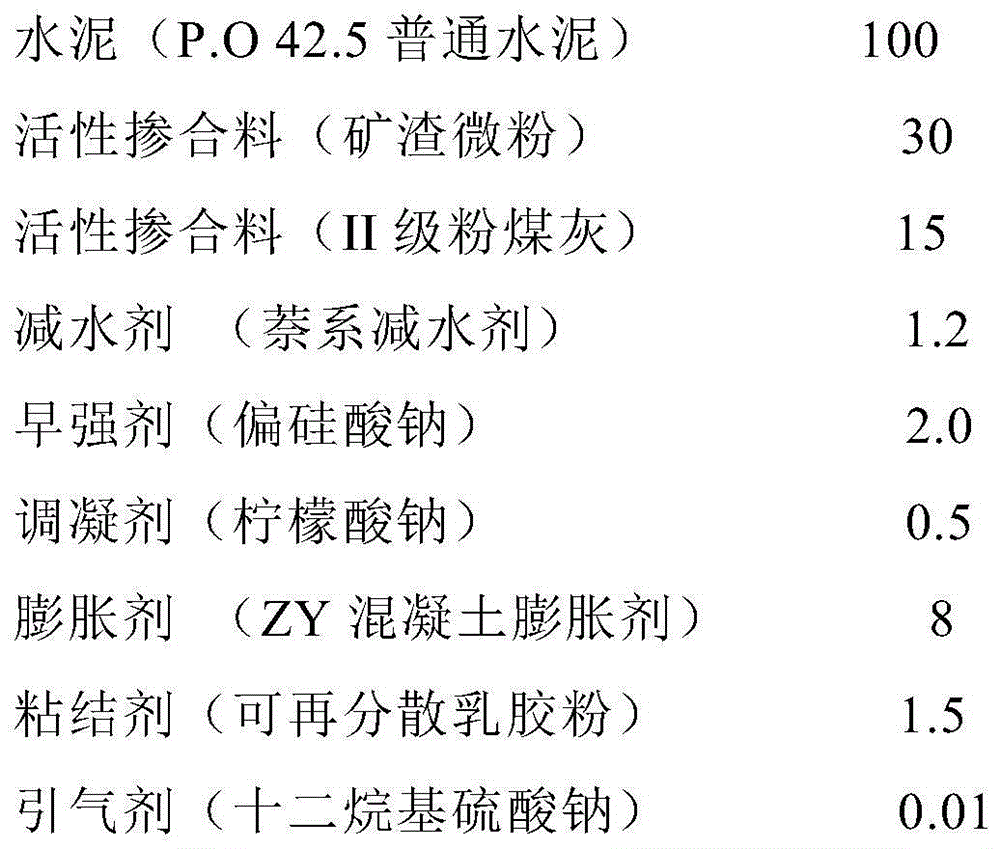

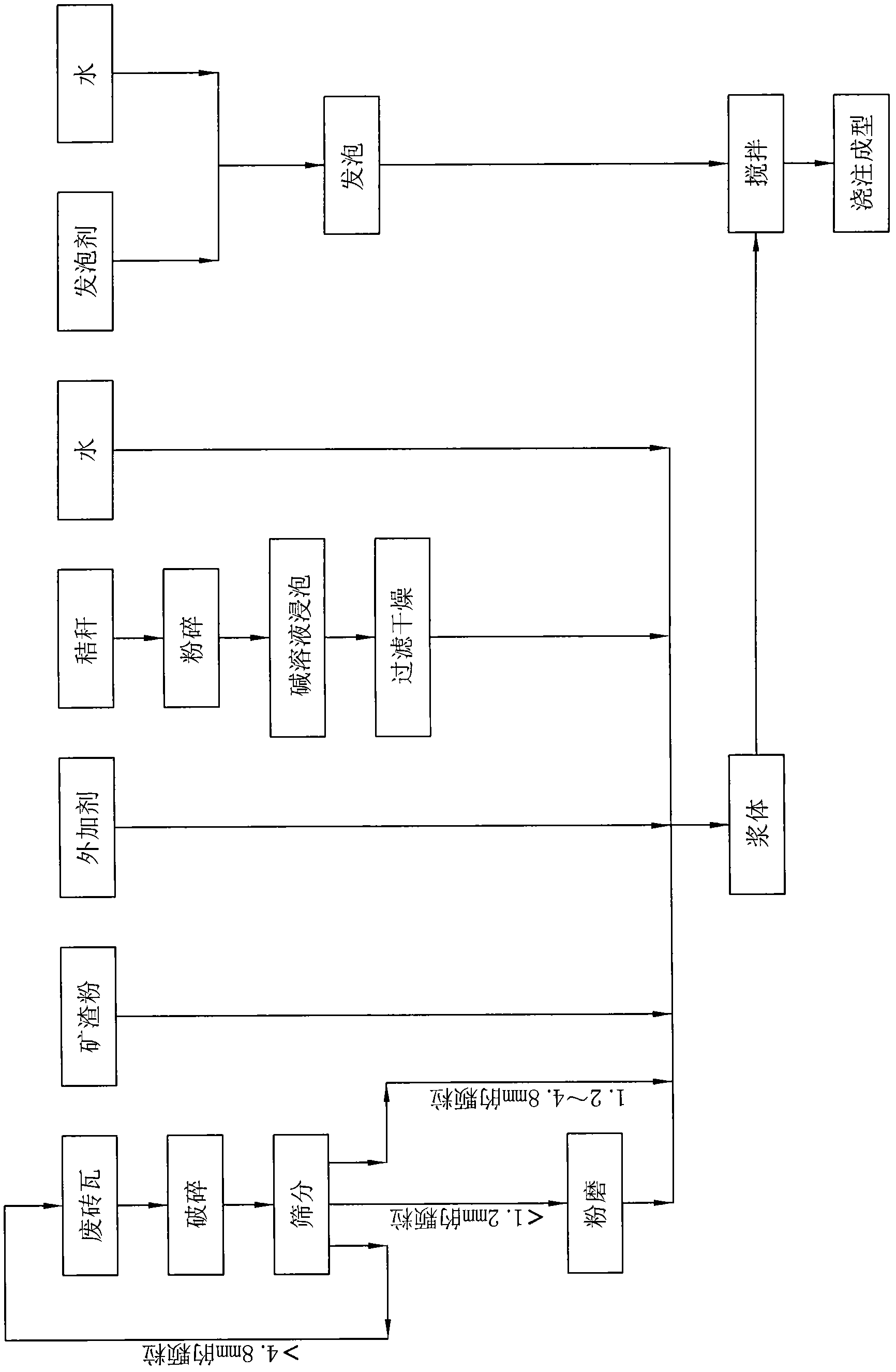

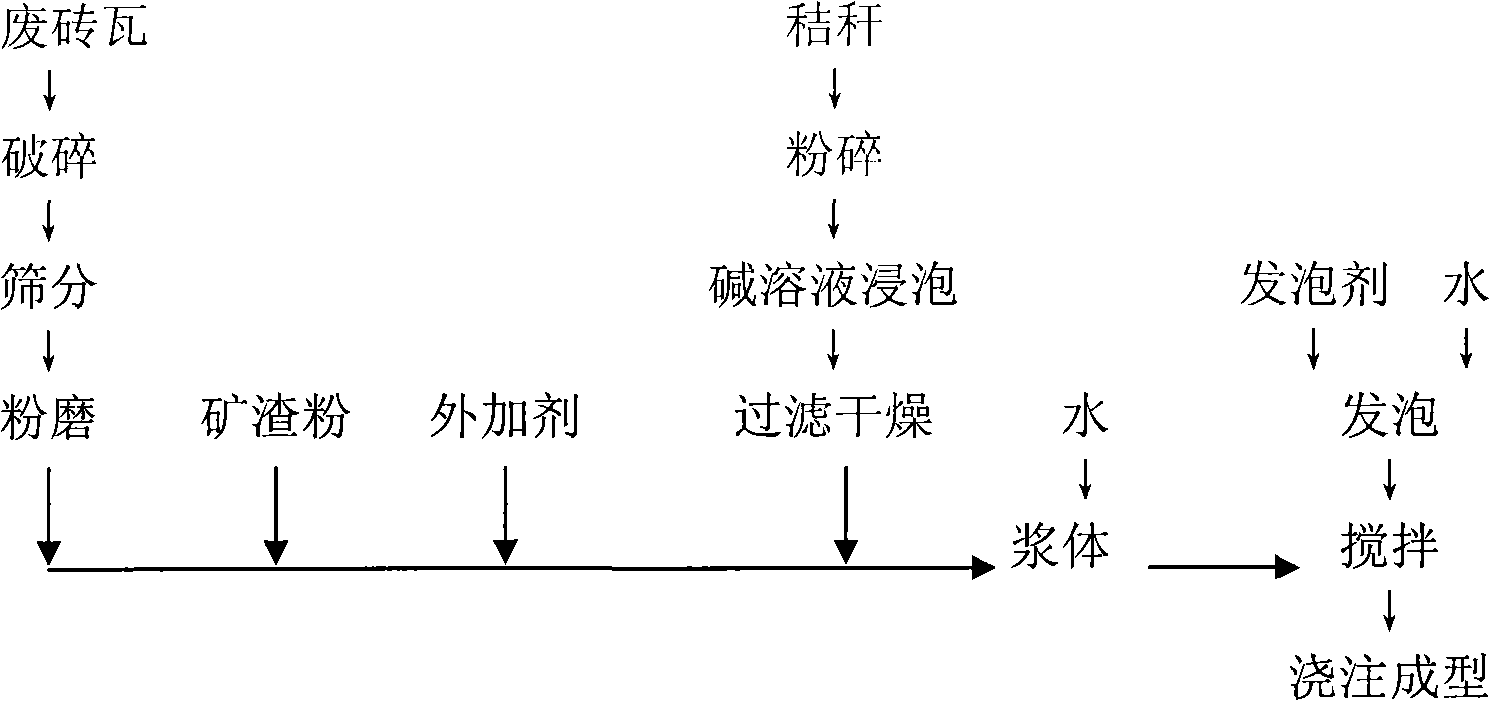

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

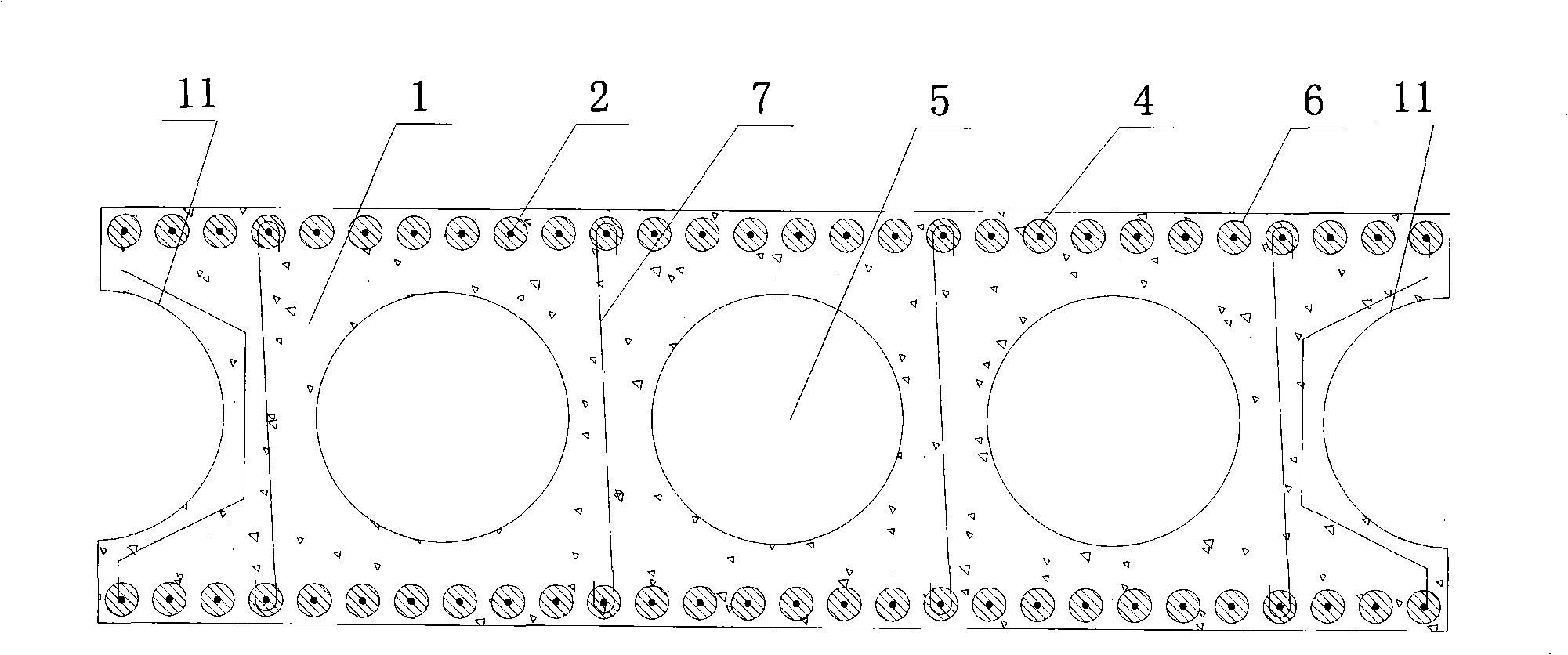

Lattice type prefabricated prestressed underground continuous wall and its construction method

The invention discloses a latticed type precast prestressed underground diaphragm wall, comprising a precast wall body, wherein two rows of prestressing steel strands vertically pass through the inside of the precast wall body; the prestressing steel strands apply prestress after the concrete strength of a concrete wall body reaches over 80 percent, and the upper and lower end faces of the precast wall body are locked by prestressing anchorage device; two rows of the prestressing steel strands are connected at intervals through transverse structure reinforcing steel bars along the height direction; joint parts on two sides of the precast wall body are of a concave semicircular shape; a protective layer is concreted on the periphery of each prestressing steel strand; and a hollow through hole throughout the height direction of the wall body is arranged inside the precast wall body. The diaphragm wall is concreted and precast on the ground, which can well guarantee the shape, size and density of the wall body, ensures that the quality of the wall body cannot be affected by strata or slurry wall, and can thoroughly eradicate joint mud inclusion, wall body sand inclusion, reinforcing steel bar exposure, loosening, wall surface protuberance, water leakage, sand shifting and other quality qualitative common faults.

Owner:万勇 +3

Making method of vapor barrier film for vacuum heat insulating shield

The present invention relates to a making method of a vapor barrier film for a vacuum heat insulating shield, and a choke film of the vacuum heat insulating shield special for construction. The choke film not only satisfies the high choke performance needed by the vacuum heat insulating shield, but also has the advantages of puncture resistance, weather resistance, cracking resistance, easy hot sealing and good protective effect. The making method uses the following technical scheme: upper-layer material is fed to the topside flow way, and middle-layer material, lower-layer material, binder between the middle-layer material and the upper-layer material and binder between the middle-layer material and the lower-layer material are fed to each flow way of a module in turn; the upper-layer material is selected from PDVC, PS or PET, the middle-layer material is selected from PE, PVOH, PA, EVOH, EVA, PET or PP, and the lower-layer material is PE; a film bubble pipe is extruded through the module; the film bubble pipe is cooled; a clamping plate device in a shape of a character of 'ren' is leaded in to planish the film bubble pipe; and a single-layer flat film of 50 t 200 mum is made through a winder.

Owner:ANHUI KERUIKE INSULATION MATERIAL

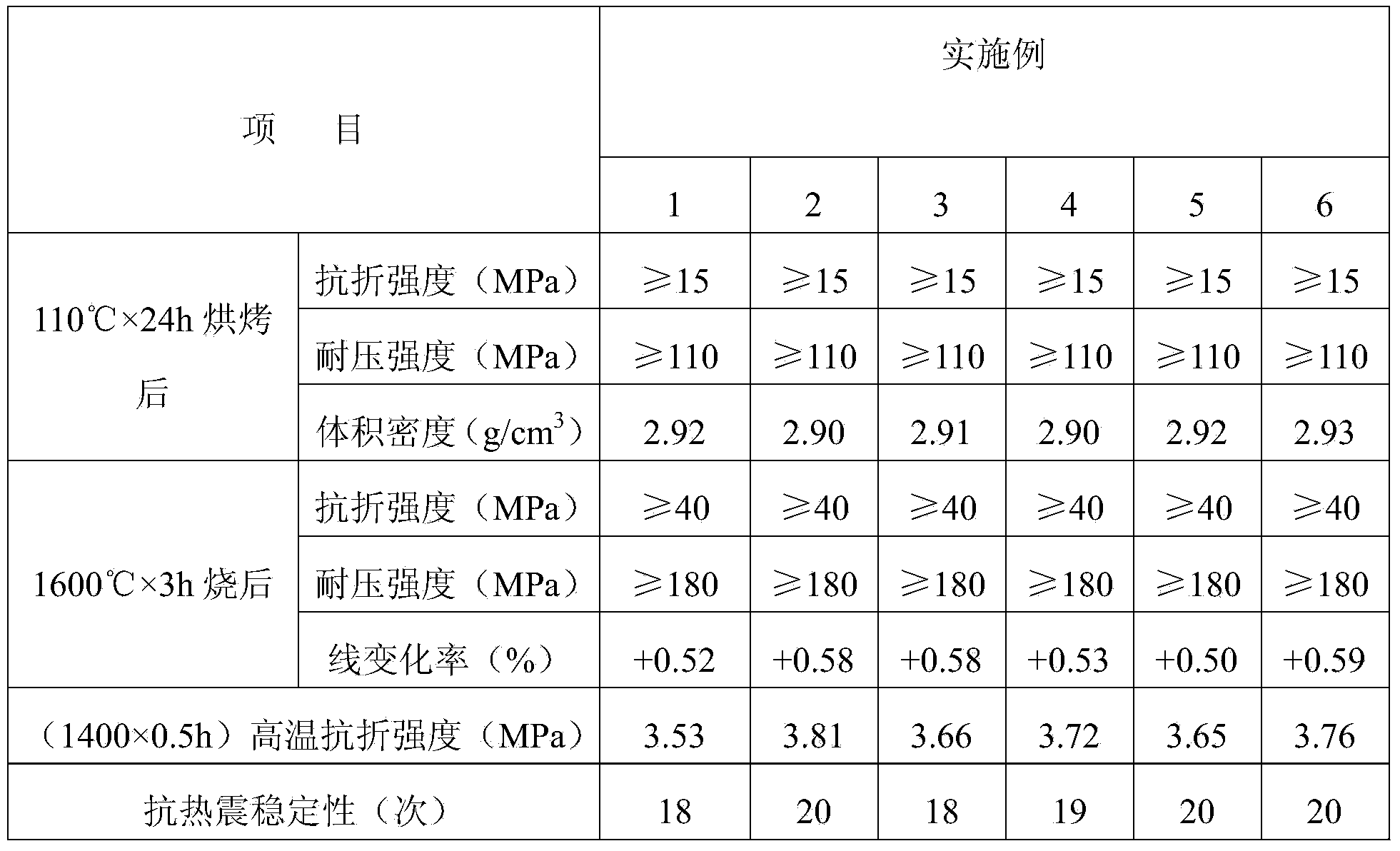

MgO-Cr2O3 ramming material for VOD (Vacuum Oxygen Decarburization) steel ladle safety liner

The invention relates to an MgO-Cr2O3 ramming material for a VOD (Vacuum Oxygen Decarburization) steel ladle safety liner. The MgO-Cr2O3 ramming material is characterized by comprising the following components in parts by weight: 50-100 parts of waste magnesium-chromium bricks, 0-50 parts of magnesite, 3-15 parts of clay or bentonite, and 0.5-10 parts of agglutinant, wherein the waste magnesium-chromium bricks and the magnesite are respectively processed into products with the granularity of 4-1mm and 1-0.74mm and being not more than 0.07mm, and the granularity composition comprises 45-55 parts of processed products of 4-1mm, 25-35 parts of the processed products of 1-0.074mm, and 15-25 parts of the processed products being not more than 0.074mm in parts by weight; and all the materials are mixed uniformly to obtain a finished product which has the chemical components that MgO being not smaller than 60% and CrO3 being not smaller than 4.0%. The ramming material disclosed by the invention has the advantages of lower preparation cost, simplicity for construction, good integrity, favorable performance, stable and reliable quality, no restrains from territorial temperature, territorial humidity and other conditions, and good application effect.

Owner:海城利尔麦格西塔材料有限公司 +1

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

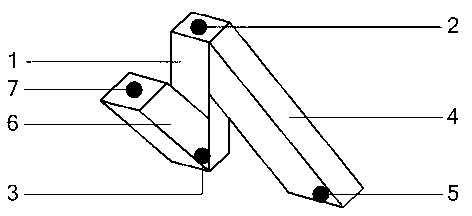

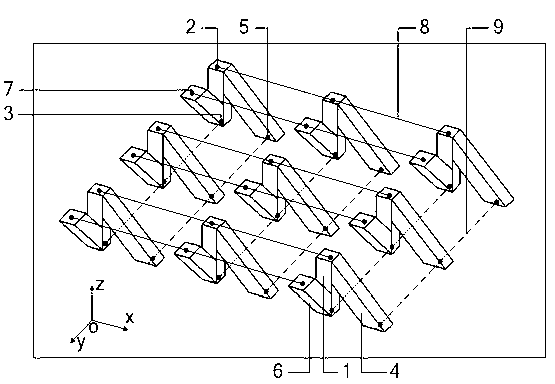

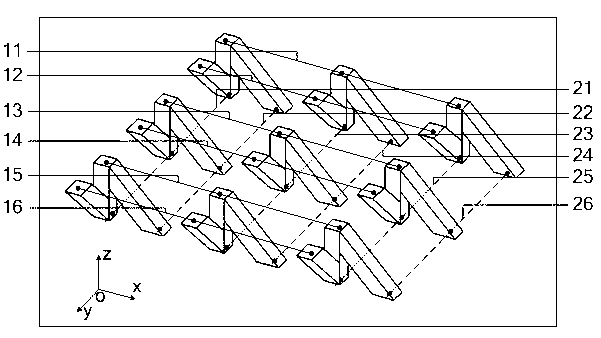

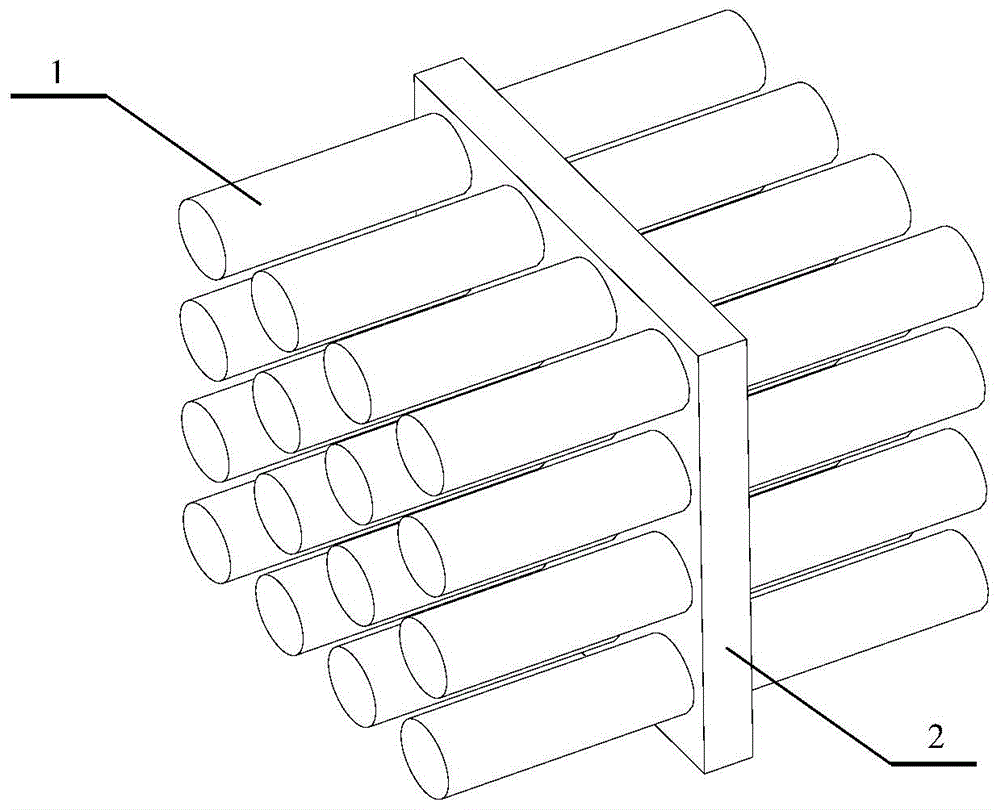

Three-dimensional soft tactile sensor array

InactiveCN103134622AReduce couplingReduce decoupling difficulty and time complexityForce measurement using piezo-resistive materialsManipulatorTactile sensorTactile sense

The invention belongs to the preparation technique of sensors and provides a three-dimensional soft tactile sensor array which comprises a microstructure which is arrayed in an ordered arrangement and a wire which is located between the end points of the microstructures. Non-conducting rubber is put between the microstructures. Each microstructure is composed of three pillar-shaped bodies, wherein the first pillar-shaped body is placed vertically; the upper end face of the second pillar-shaped body is intersected and connected fixedly with the side face of the first pillar-shaped body. The center of the upper end face of each microstructure and the center of the lower end face of each microstructure are respectively provided with an electric contact. A wire is connected between the electric contacts of the upper end face of the first pillar-shaped body of each microstructure, a wire is connected between the electric contacts of the upper end face of the third pillar-shaped body of each microstructure, a wire is connected between the electric contacts of the lower end face of the first pillar-shaped body of each microstructure, and a wire is connected between the electric contacts of the lower end face of the second pillar-shaped body of each microstructure. An upper layer of the wire and a lower layer of the wire are vertical to each. The sensor array has the advantages of lowering dimensionality and difficulty of decoupling, being capable of detecting magnitude of force, being low in response time and tight in structure.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

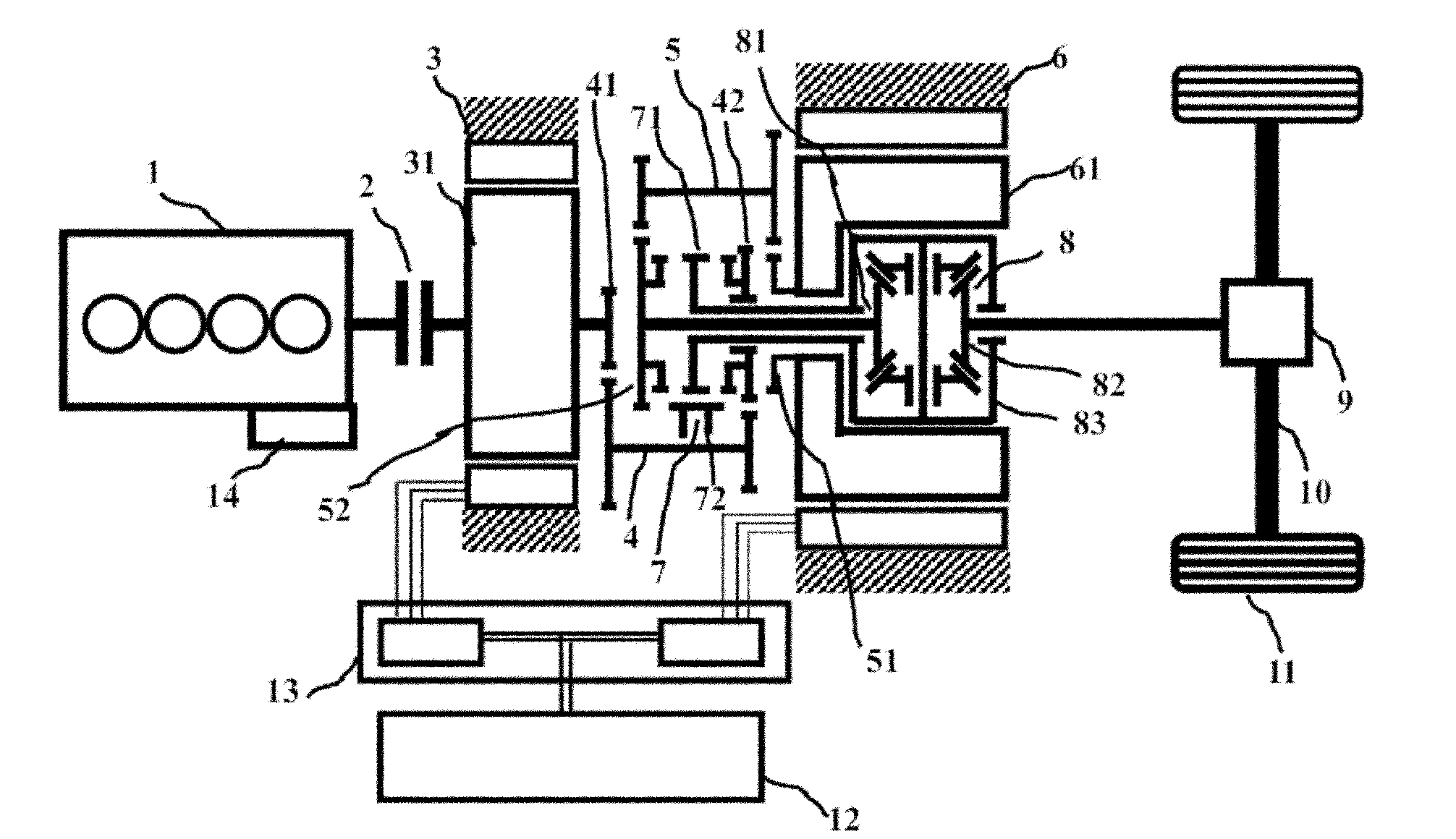

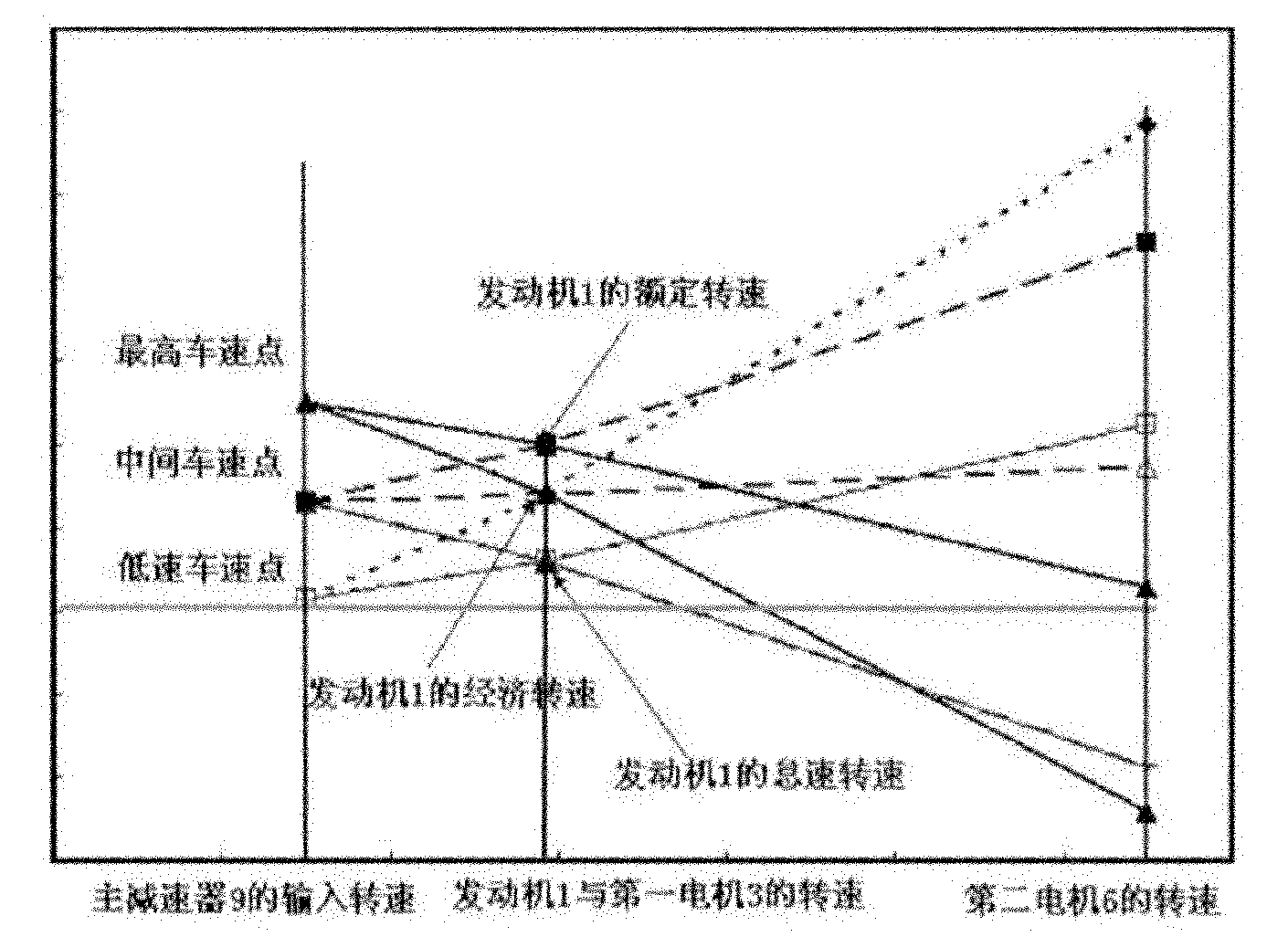

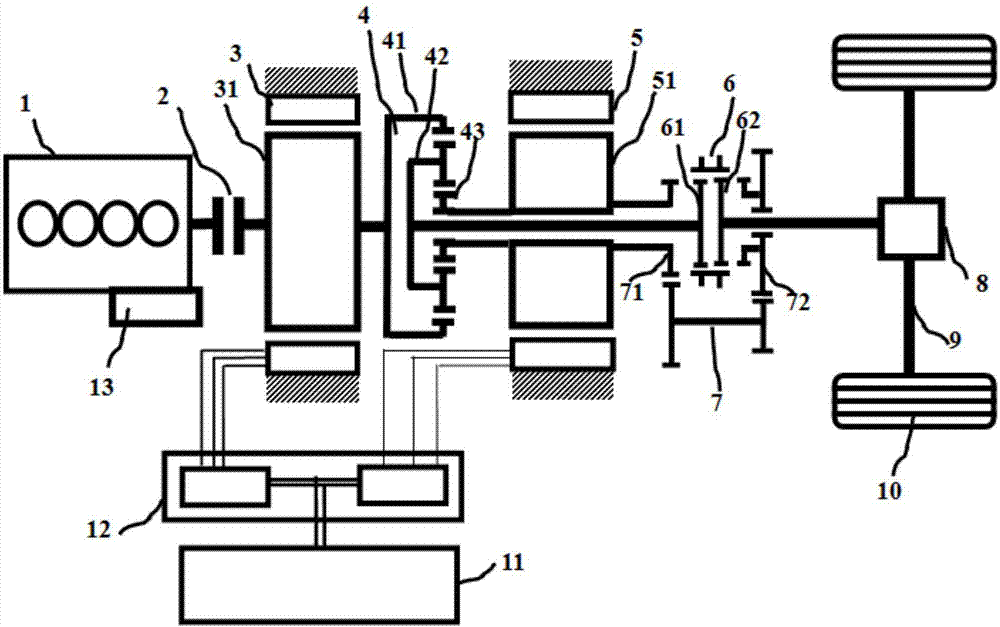

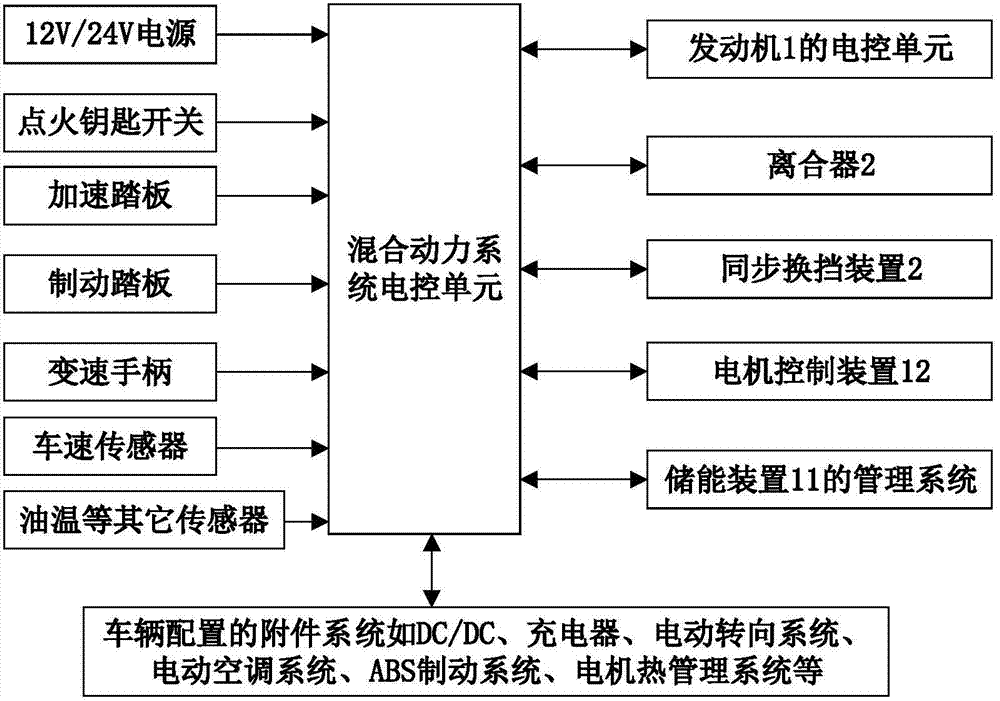

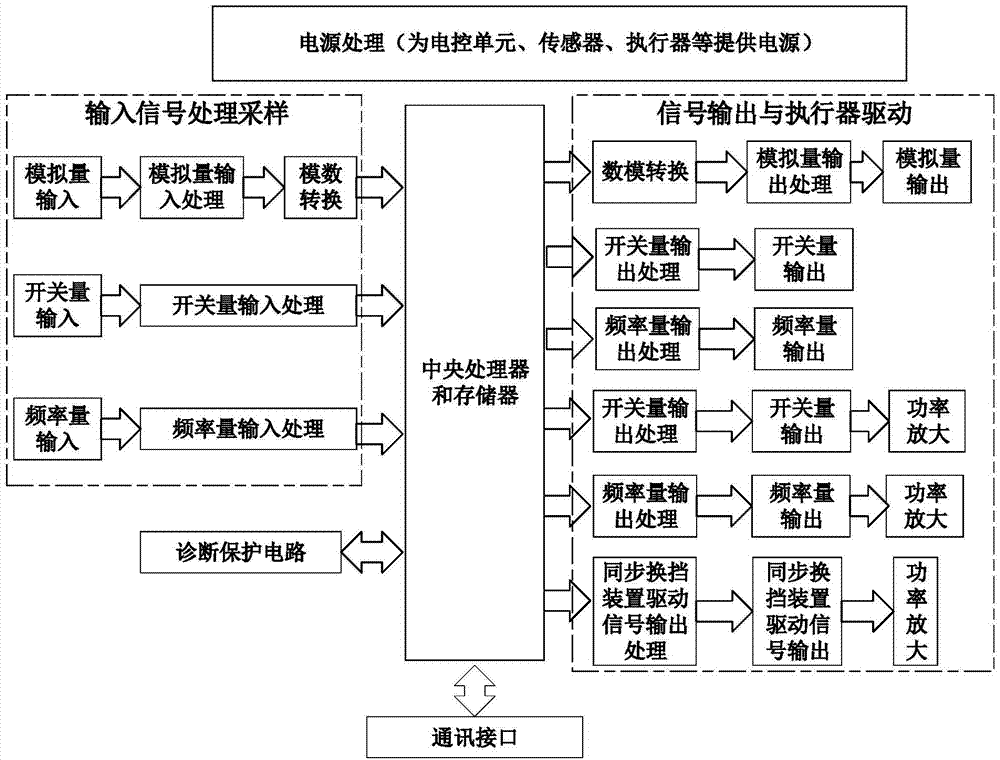

Four-die stepless speed change series-parallel hybrid power driving system

ActiveCN102050001ATight structureEasy to Modular DesignGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchEnergy storage

The invention discloses a four-die stepless speed change series-parallel hybrid power driving system, belonging to the technical field of automobile hybrid driving. The system comprises an engine, a clutch, two motors, corresponding transmission chains of the two motors, a power transfer switching device, a planetary gear differential device, a deceleration differential device, an energy storage device and a motor control device. The system provided by the invention has the characteristics of better technical inheritance with existing vehicles, overall dynamic property, fuel economy and low emission, and has functions of four-die driving, stepless speed change and series-parallel system; the problems of insufficient driving power, lack in ramp starting ability, large system volume and high cost of the existing similar technologies and the problems that the stepless speed regulation of the engine cannot be realized and the batch industrialization is difficult as the electromechanical components are difficult to manufacture are solved, and organic combination of high performance, low development cost, low system cost and easy implementation of scale industrialization is realized.

Owner:SHANGHAI JIAO TONG UNIV

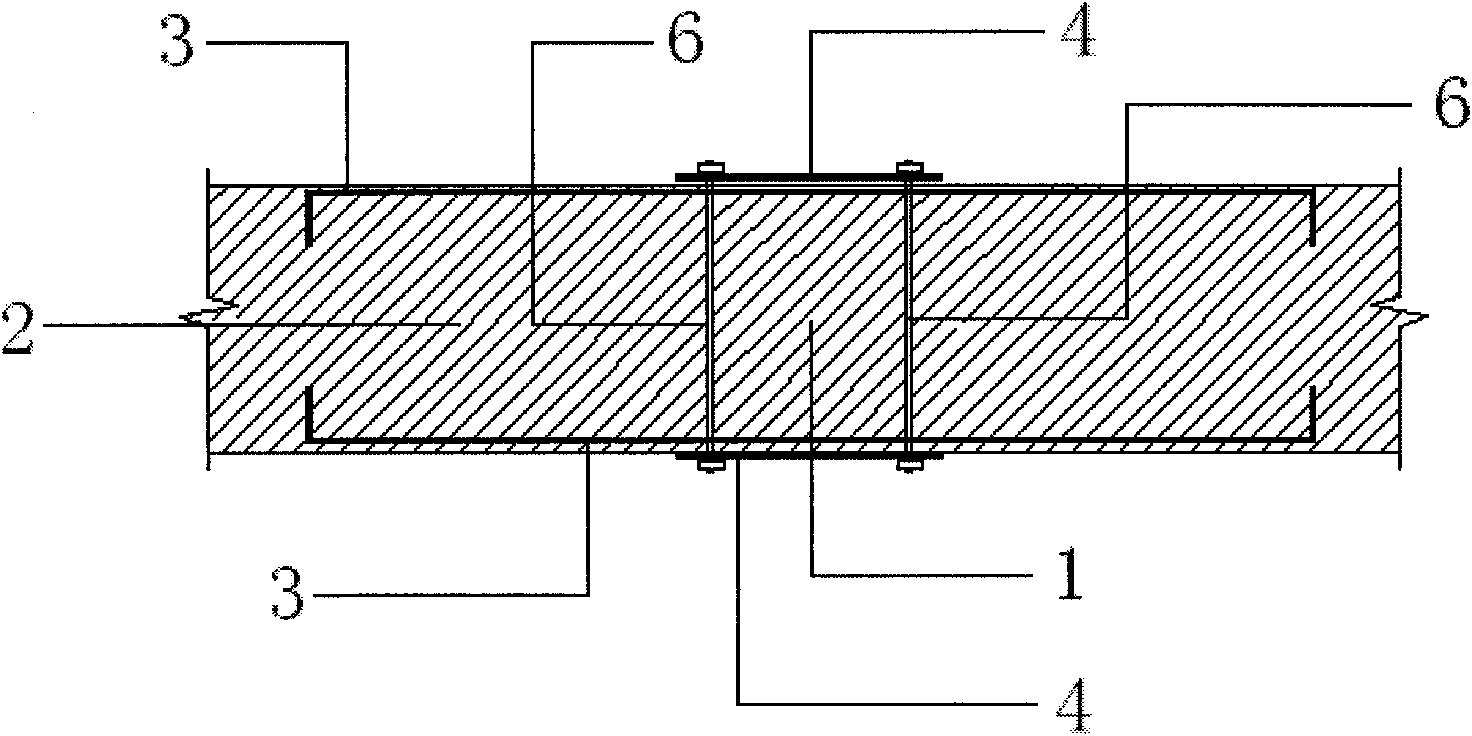

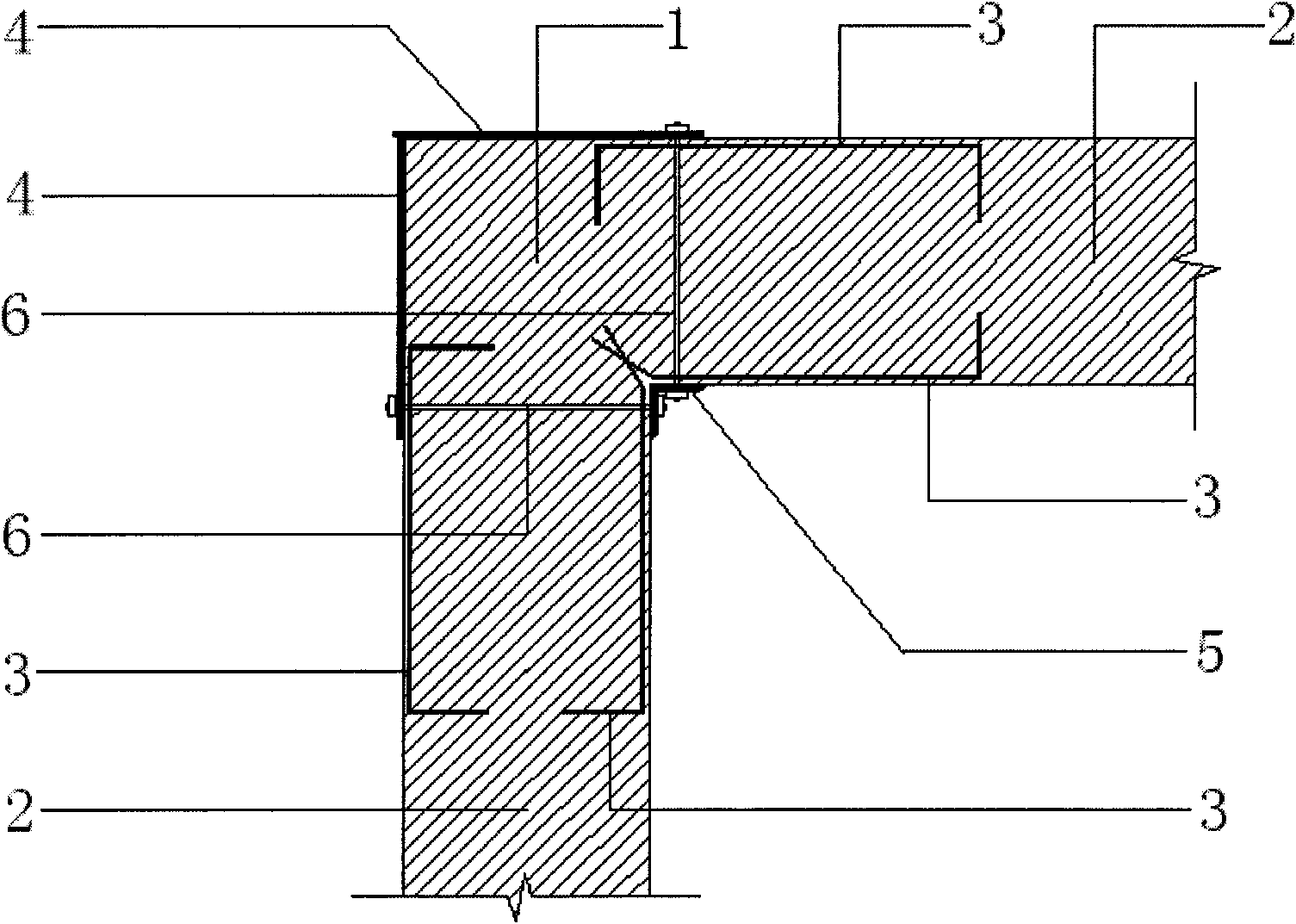

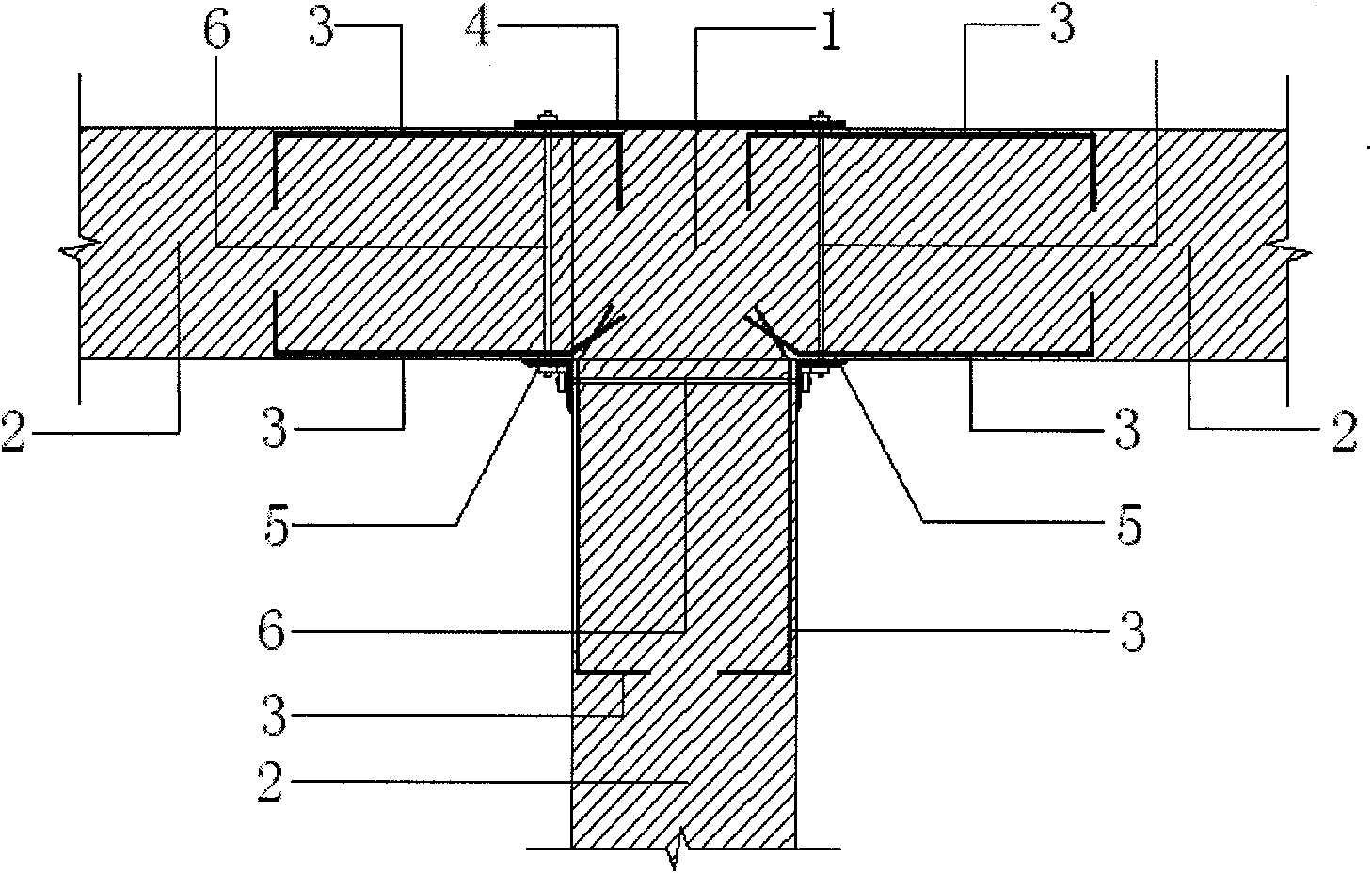

Novel seismic hardening constructional column of masonry structure

The invention discloses a novel seismic hardening constructional column of a masonry structure. The novel seismic hardening construction column comprises a primary-structure wall body, a steel plate, an angle steel, a split bolt and a steel tie, and is designed as follows: the steel plate and the split bolt are hooped with the wall body to form a combination constructional column at the exterior of the primary-structure wall body, and the steel tie is embedded between the combination constructional column and the peripheral wall body. The seismic hardening constructional column is provided with different shapes aiming at different parts, and can be in a linear shape, a L shape, a T shape and a crisscross shape; the steel plate or the angle iron is bonded on the surface of the construction column; and the split bolt pulls and ties the steel plate or the angle steel to form a firm integrated body with the column body. Compared with the traditional seismic hardening constructional column, the novel seismic hardening constructional column has the advantages of safety, practicability, simple structure, convenient construction, good integrity, strong shock resistance, short construction period, no damage on the wall body, no influence on appearance and the like.

Owner:NANCHANG UNIV

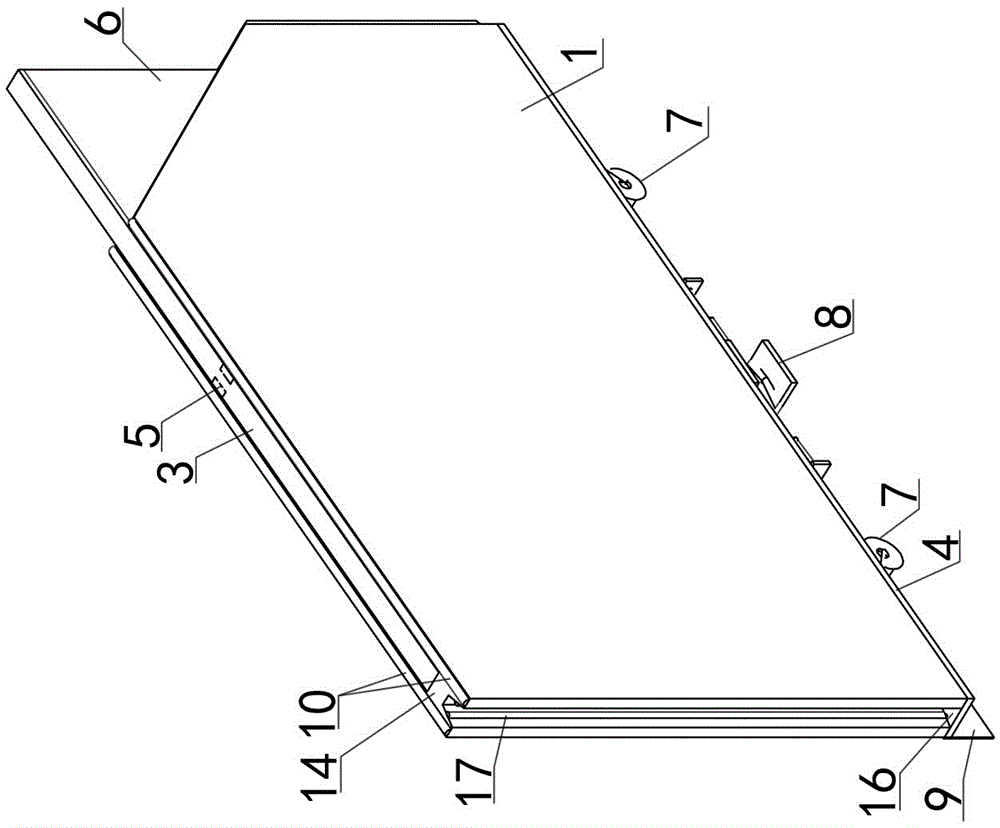

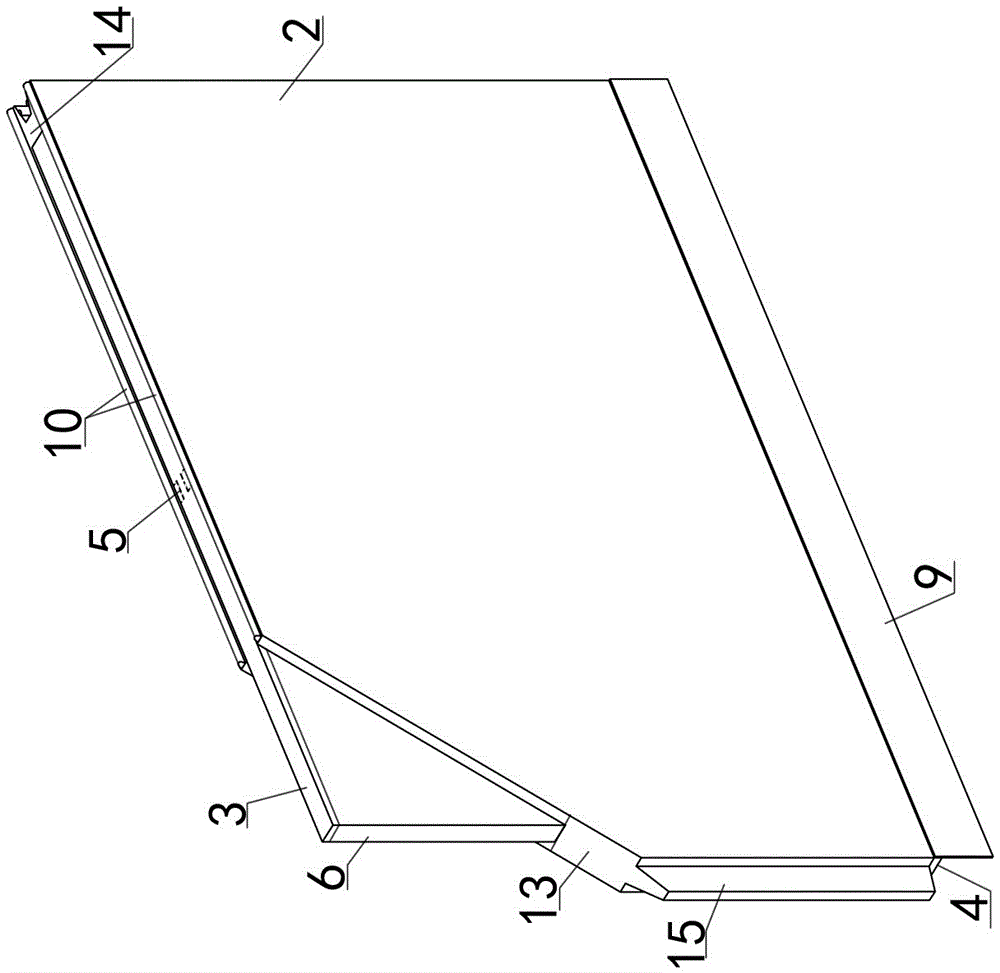

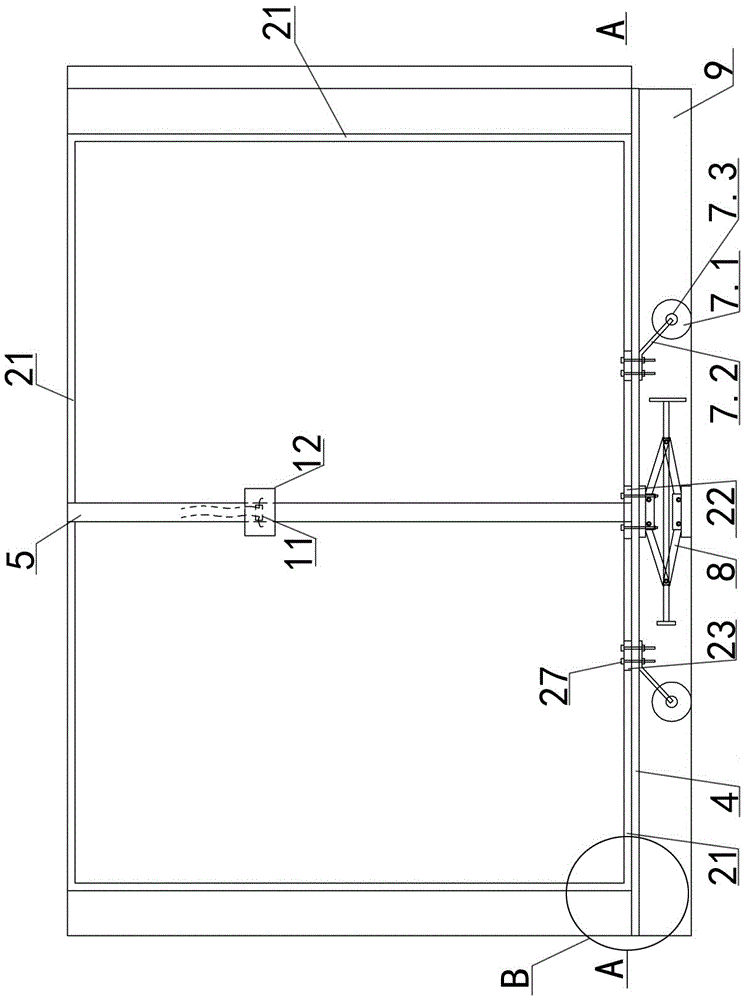

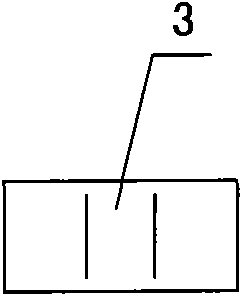

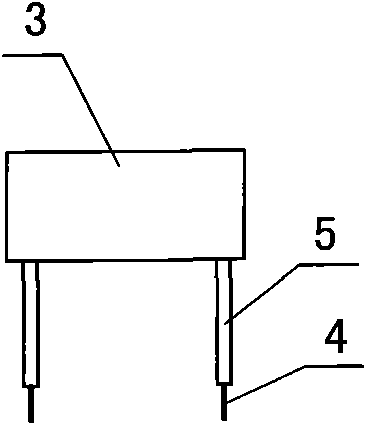

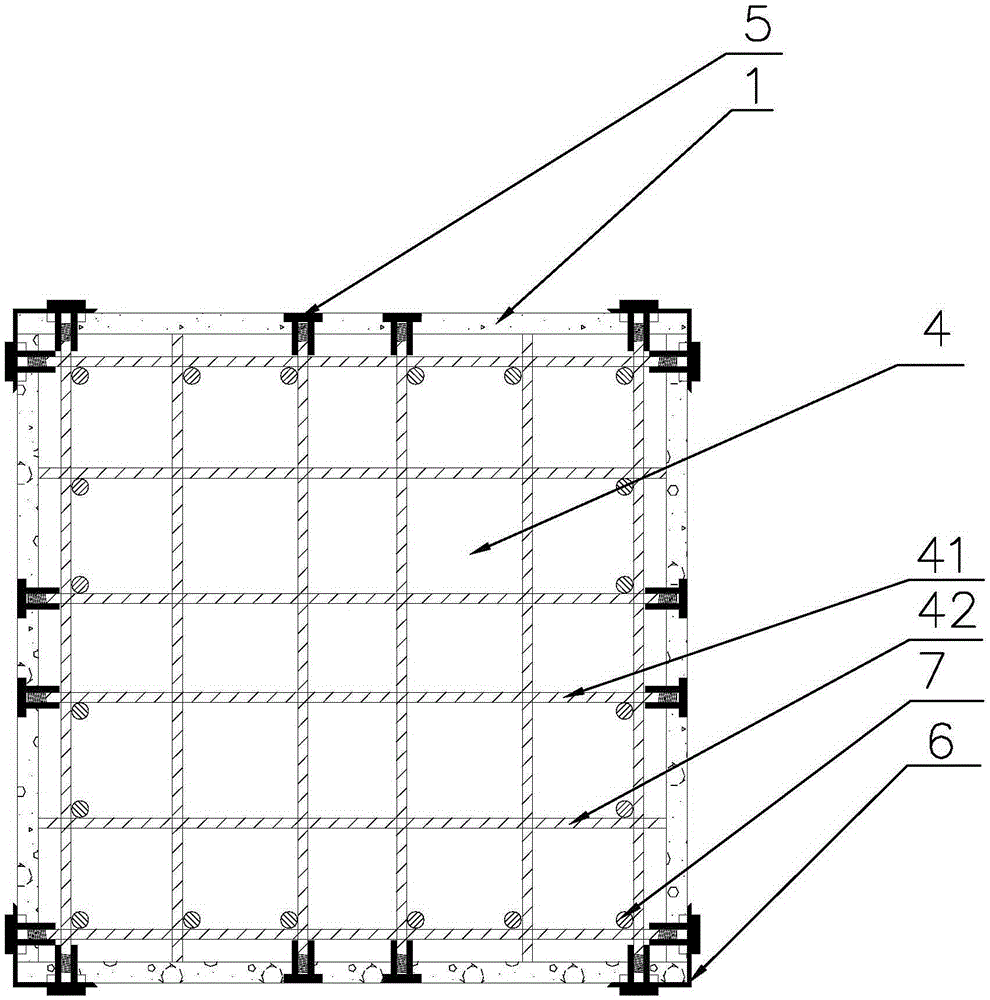

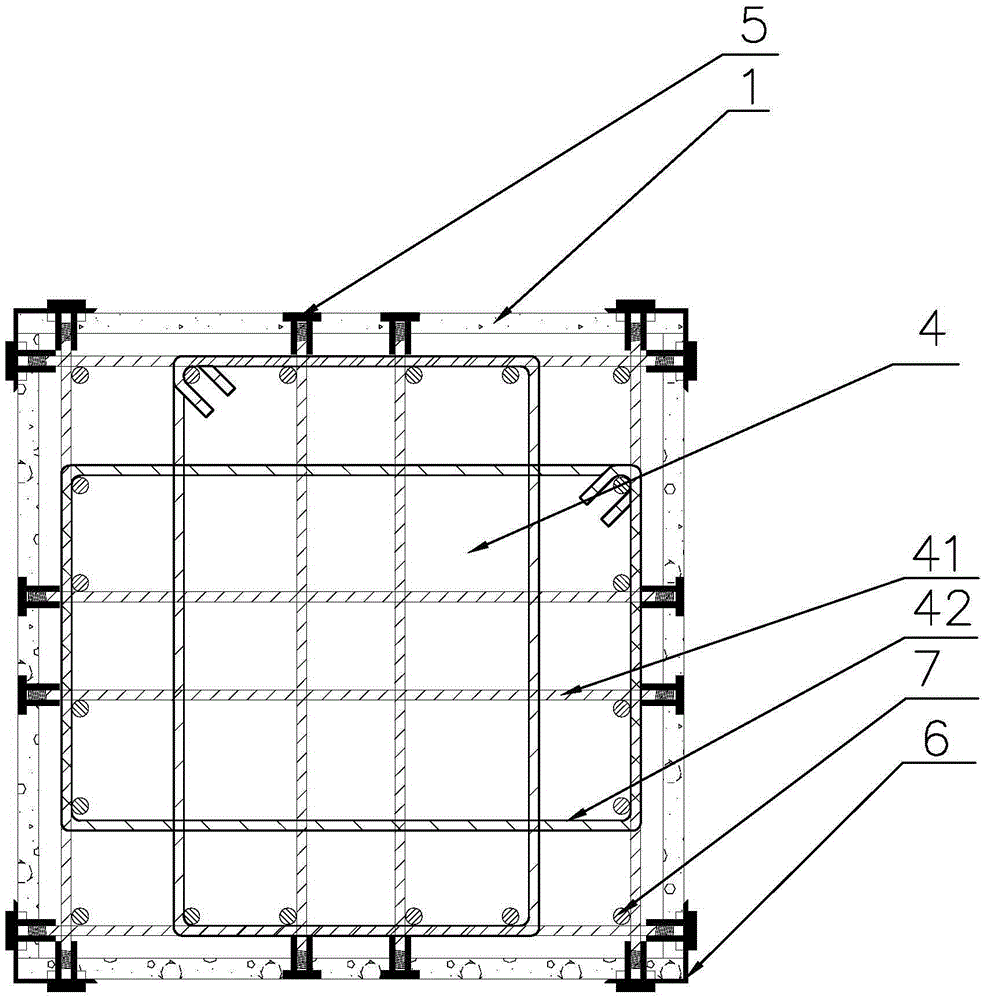

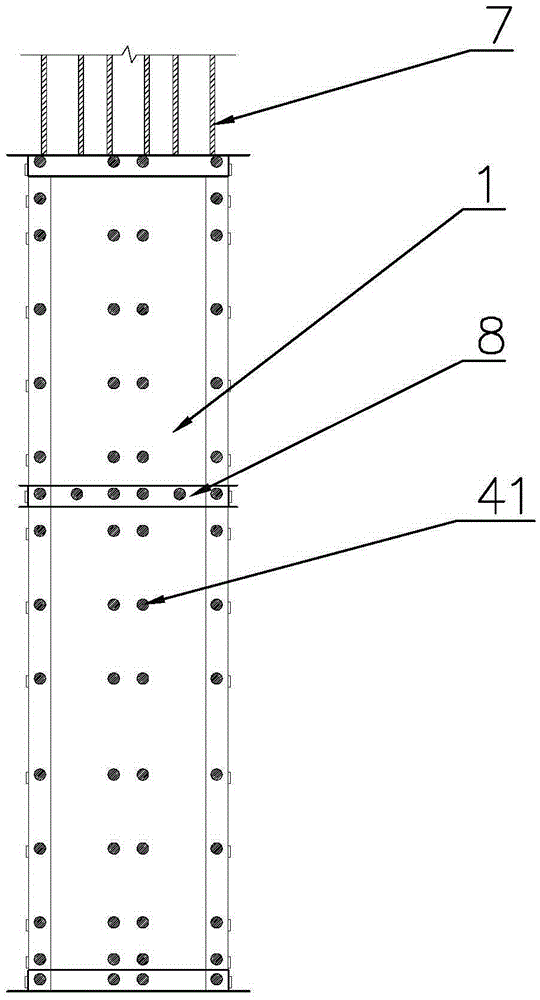

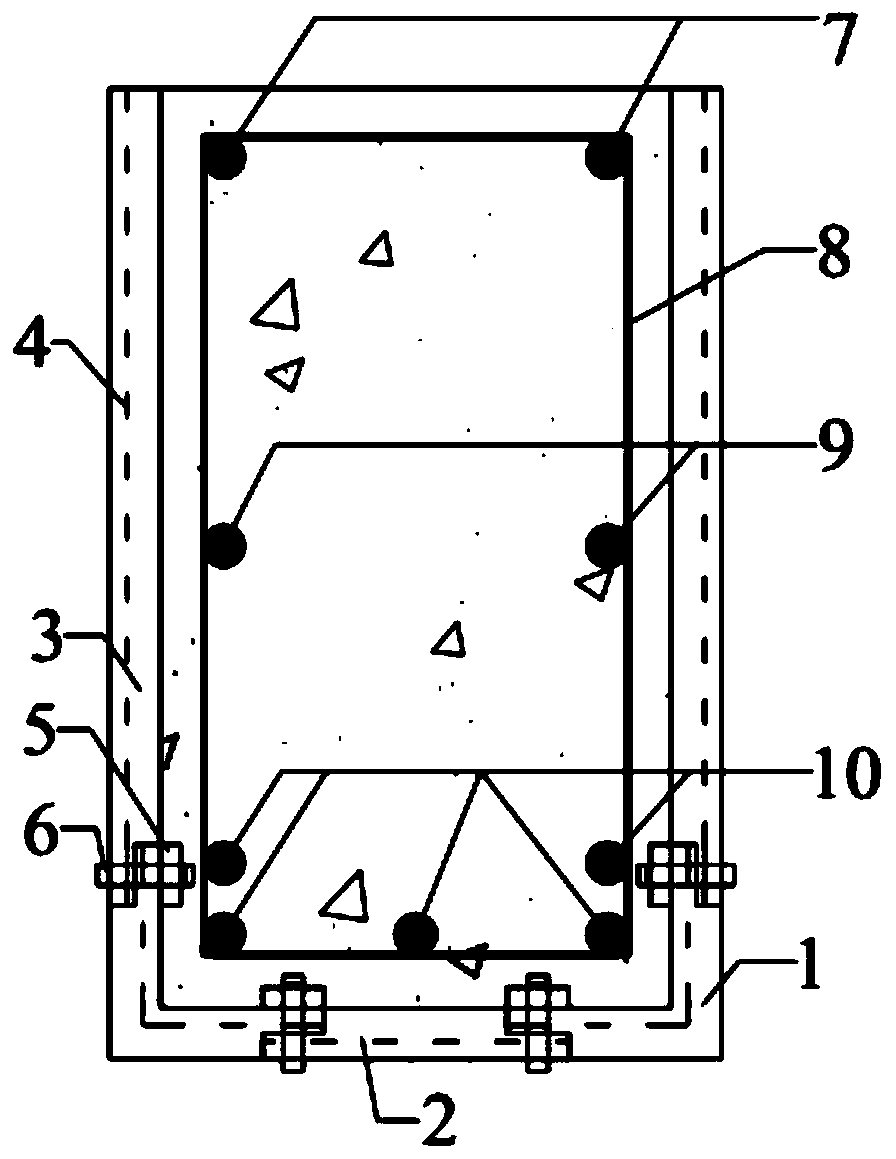

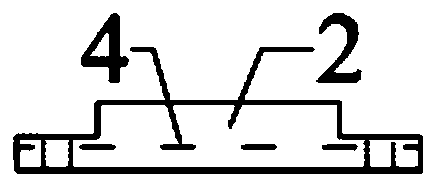

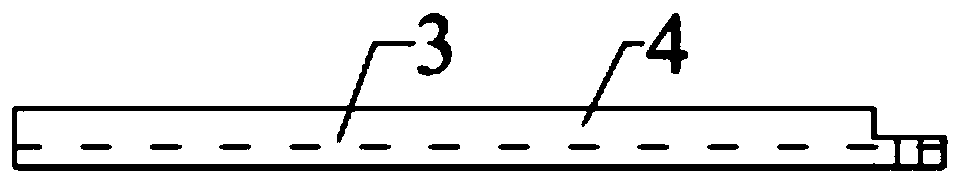

Pre-fabricated building removable partition, wall splicing structure, and construction method

ActiveCN105464251AOverall goodGood sealing performanceWallsBuilding material handlingJoistSurface plate

Provided are a pre-fabricated building removable partition, a wall splicing structure, and a construction method. The pre-fabricated building removable partition comprises a wall main body, and a partition removable mechanism and a partition lifting mechanism added on the lower side of the wall main body. The wall main body comprises a cavity formed by a front panel, a rear panel, an upper blanking plate, a lower supporting plate, a right end plate, and a left end plate. A hollow threading lightgage steel joist and cavity filling foam are arranged in the cavity. The partition removable mechanism and the partition lifting mechanism are fixedly connected with the lower supporting plate. The lower sides of the front panel and the rear panel are respectively connected with a skirting board shielding the removable mechanism and the lifting mechanism. Gaps are filled with the cavity filling foam. The top end face of the wall main body is provided with a sealing band which is abutted against a room roof. The pre-fabricated removable partition can be produced and assembled in a factory, and is lifted and installed on an installation site, and the pre-fabricated removable partition has good dimension stability and good sound insulation, and satisfies variable requirement of people on living space. The pre-fabricated removable partition can greatly improve utilization rate of a building space, and promotes development of buildings.

Owner:TIANYUAN CONSTR GROUP

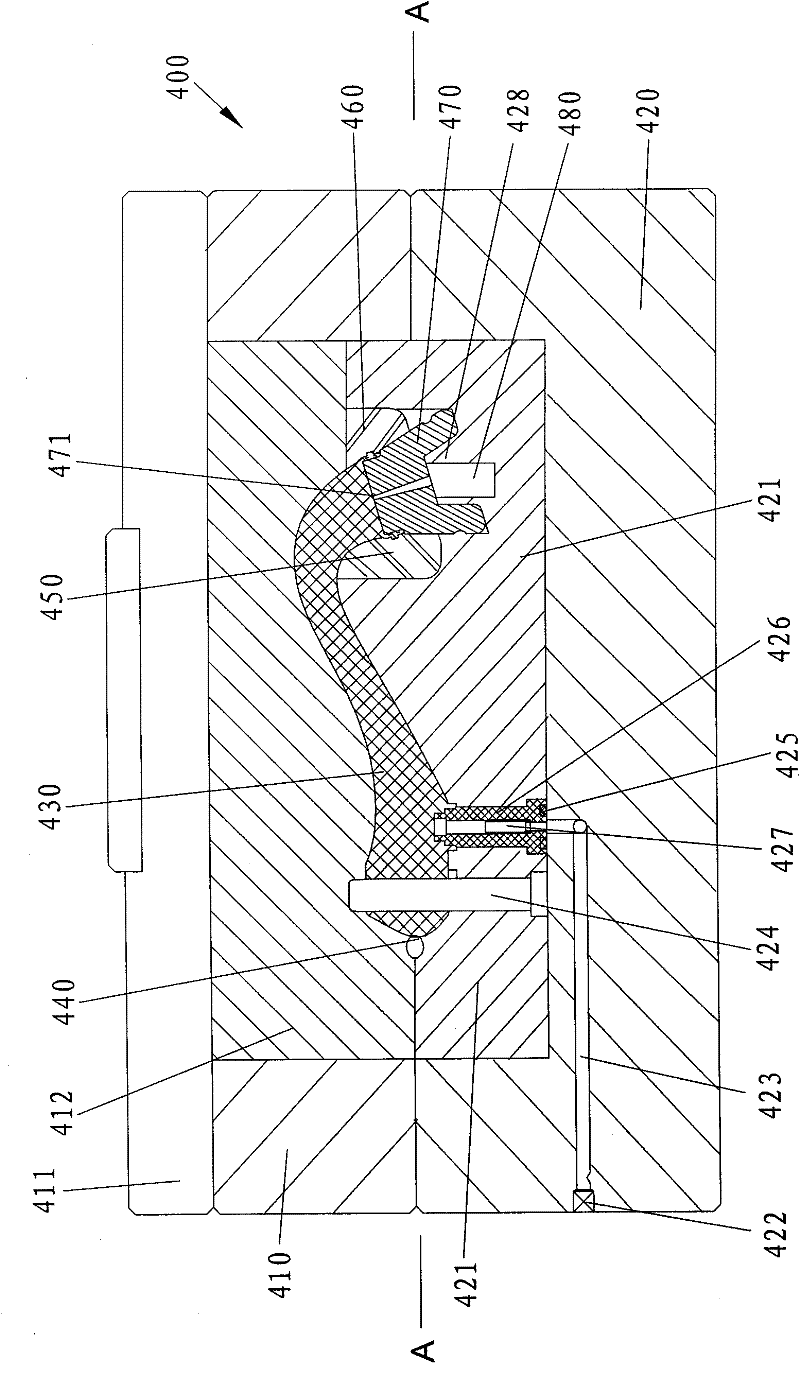

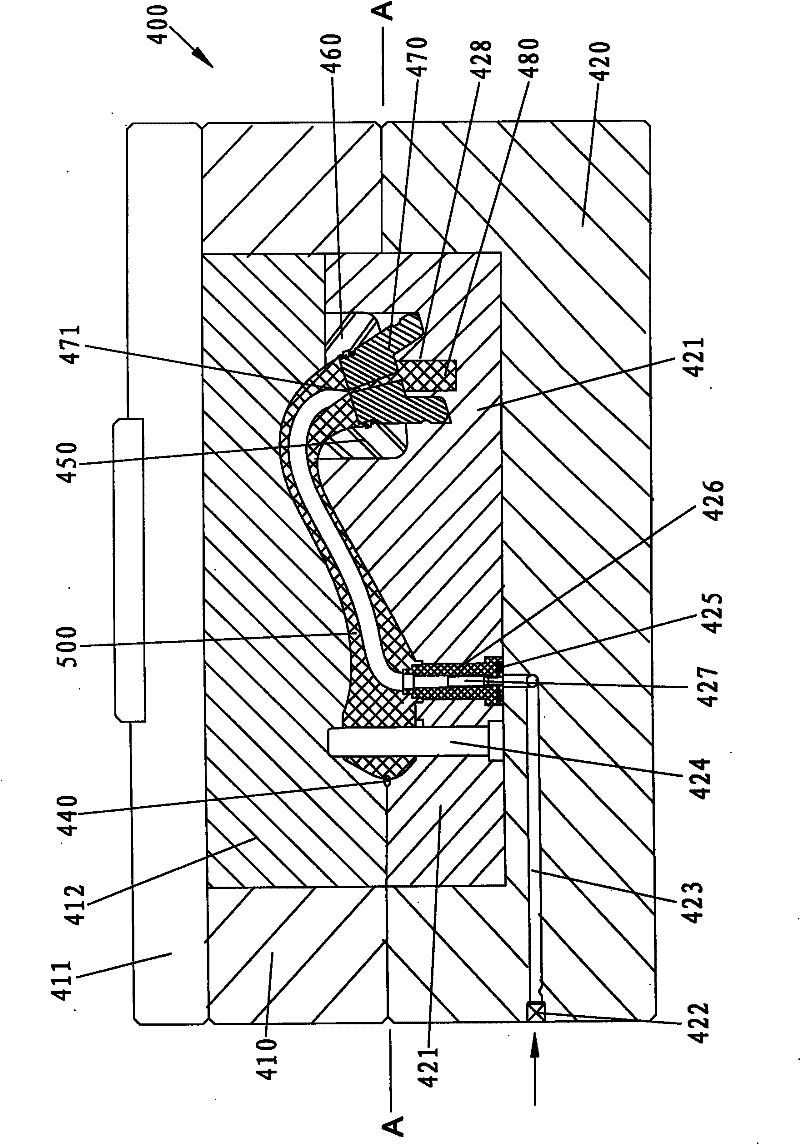

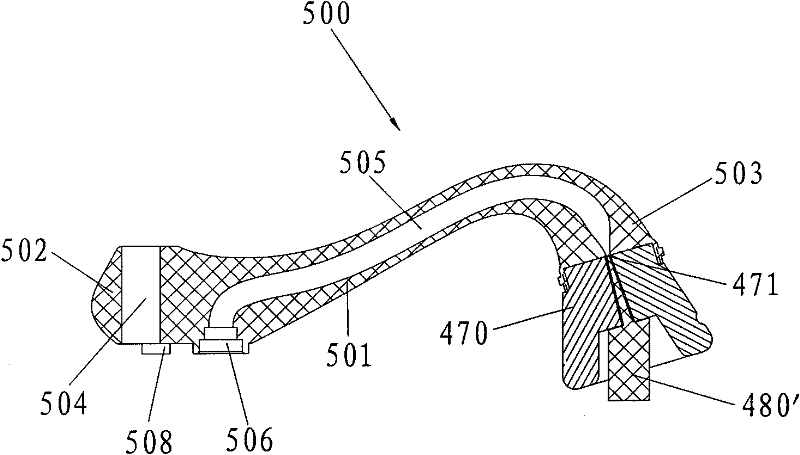

Process for making water channel of outlet water unit

ActiveCN101746012AChange molding methodOverall goodCoatingsTubular articlesWater channelPlastic materials

The invention discloses a process for making a water channel of an outlet water unit. The process is characterized in that an air tap is arranged at a position of an injection mold opposite to a water inlet or a water outlet of a cavity of the outlet water unit; a material-overflowing well is arranged at the water inlet or the water outlet opposite to the outlet water unit; plastic materials are injected to the cavity until the cavity is filled to reach the material-overflowing well; when the part of the plastic materials in the cavity adjacent to the cavity wall is hardened, high pressure nitrogen gas or high pressure fluid is injected from the air tap to extrude an abnormal water channel inside the plastic materials communicated with the water inlet and the water outlet of the outlet water unit body; the part of the plastic material extruded by the high pressure nitrogen gas or the high pressure fluid flows into the material-overflowing well; and the outlet water unit with the abnormal water channel is obtained by cooling. Therefore, the formation of the abnormal water channel inside a plastic product can be realized, the forming method of the water channel inside a conventional plastic product is changed, and the injection-molded product has better integrity, thus the pressure resistance and the service life of the product are ensured.

Owner:HARDA INTELLIGENT TECH CO LTD

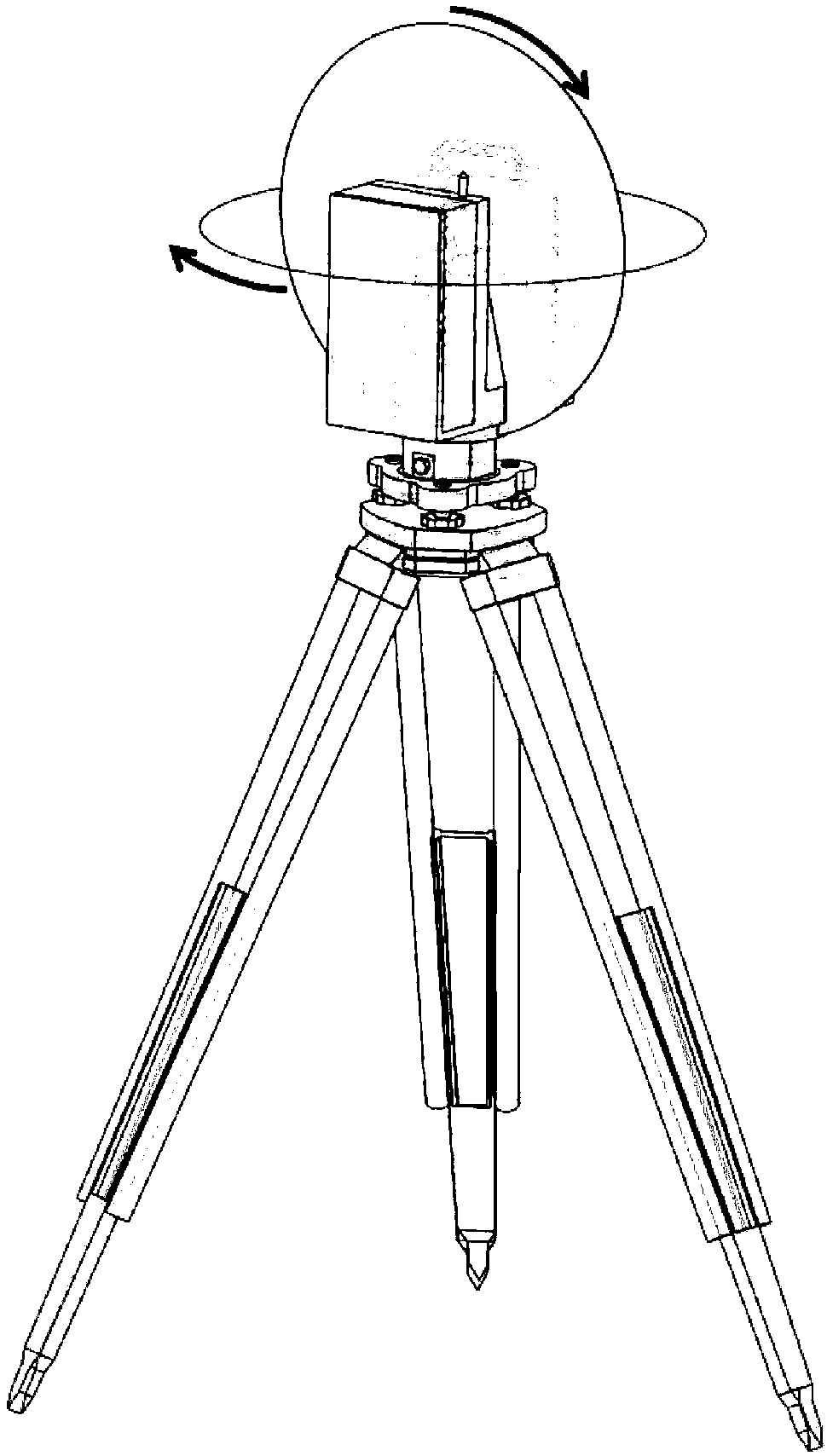

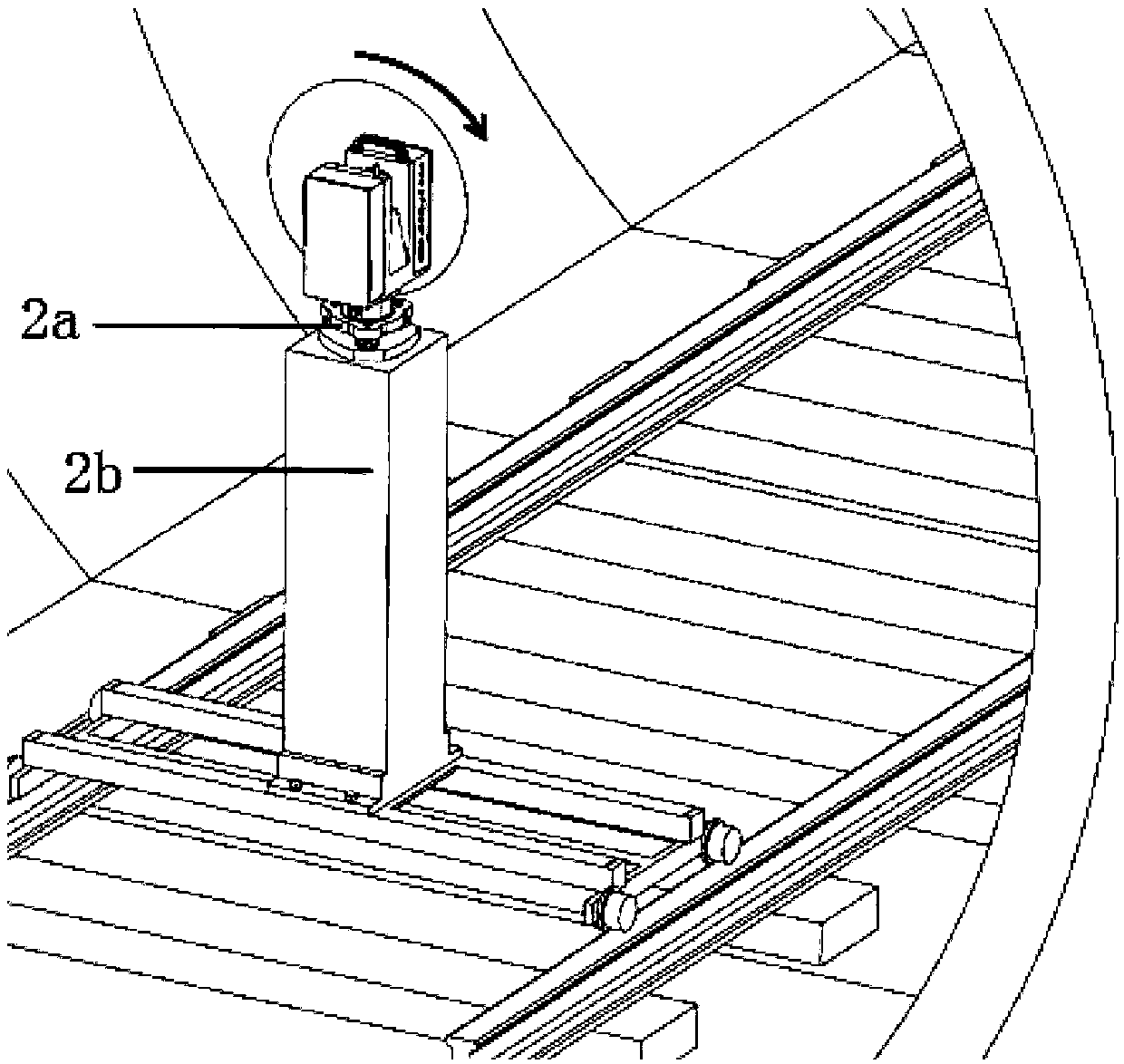

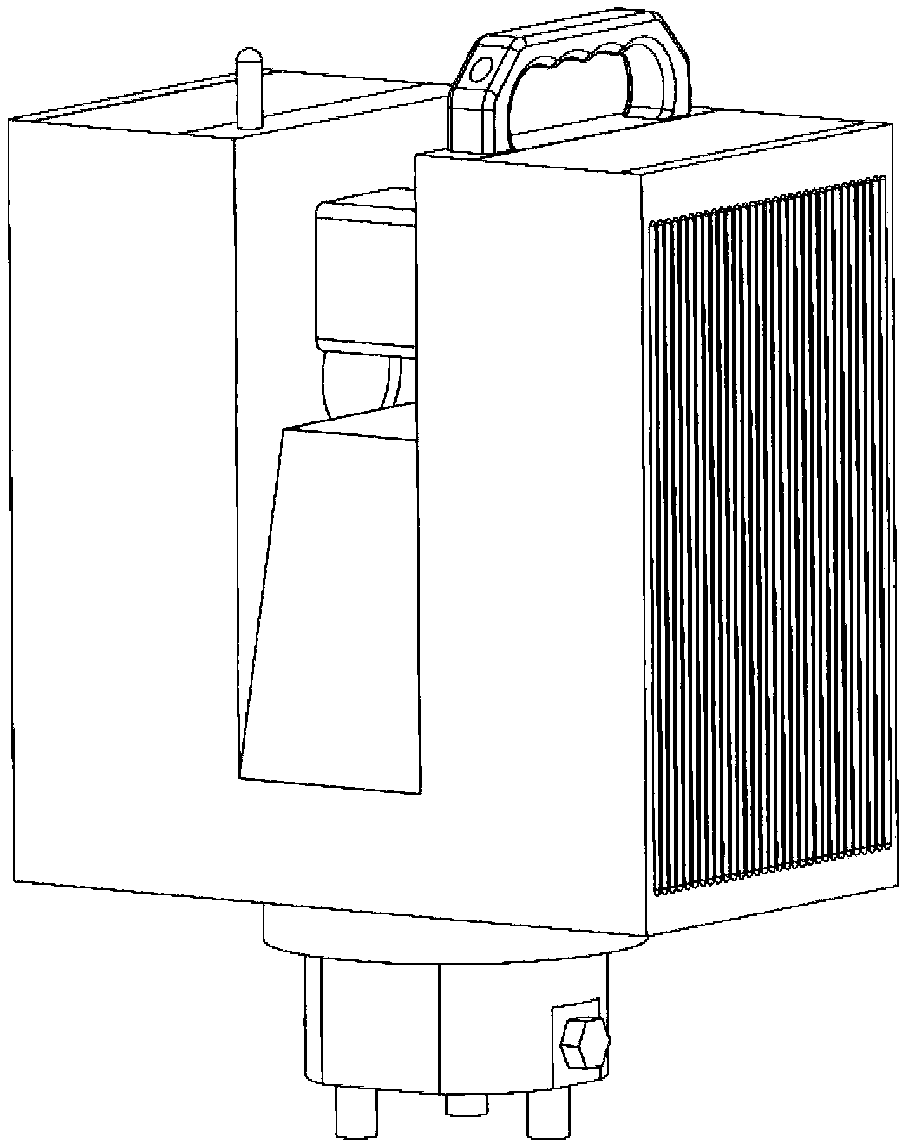

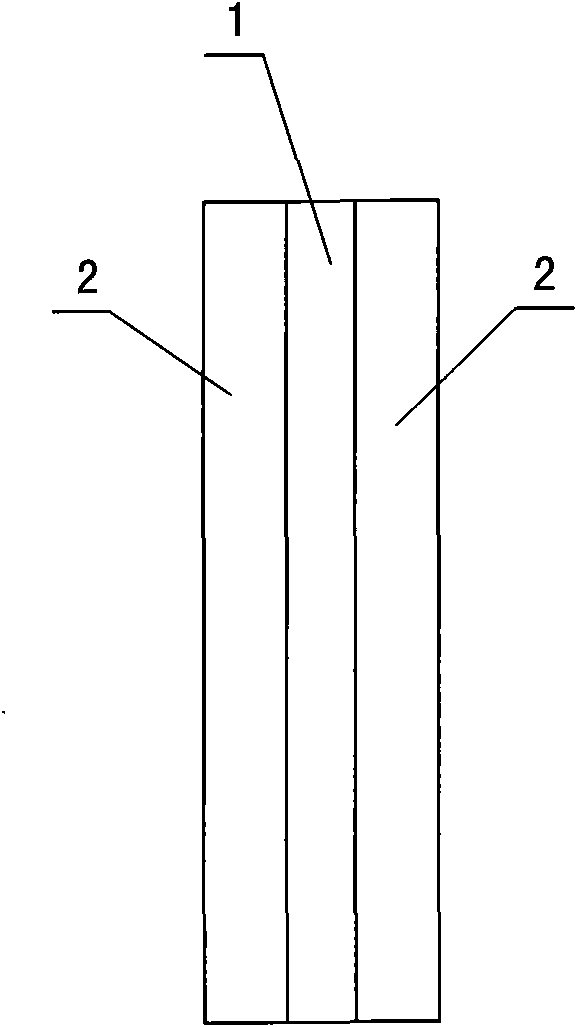

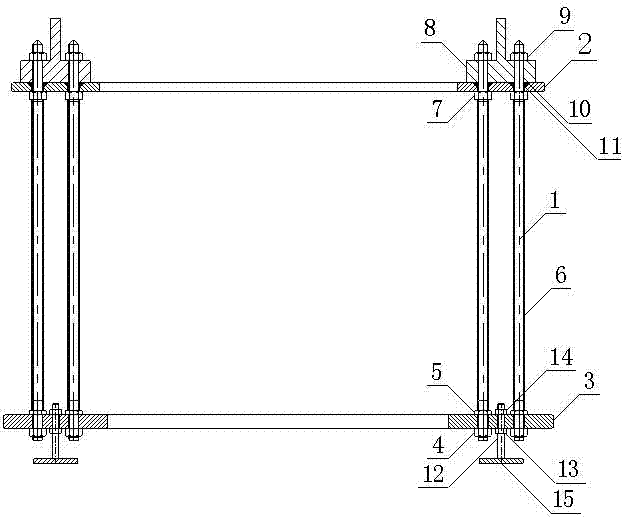

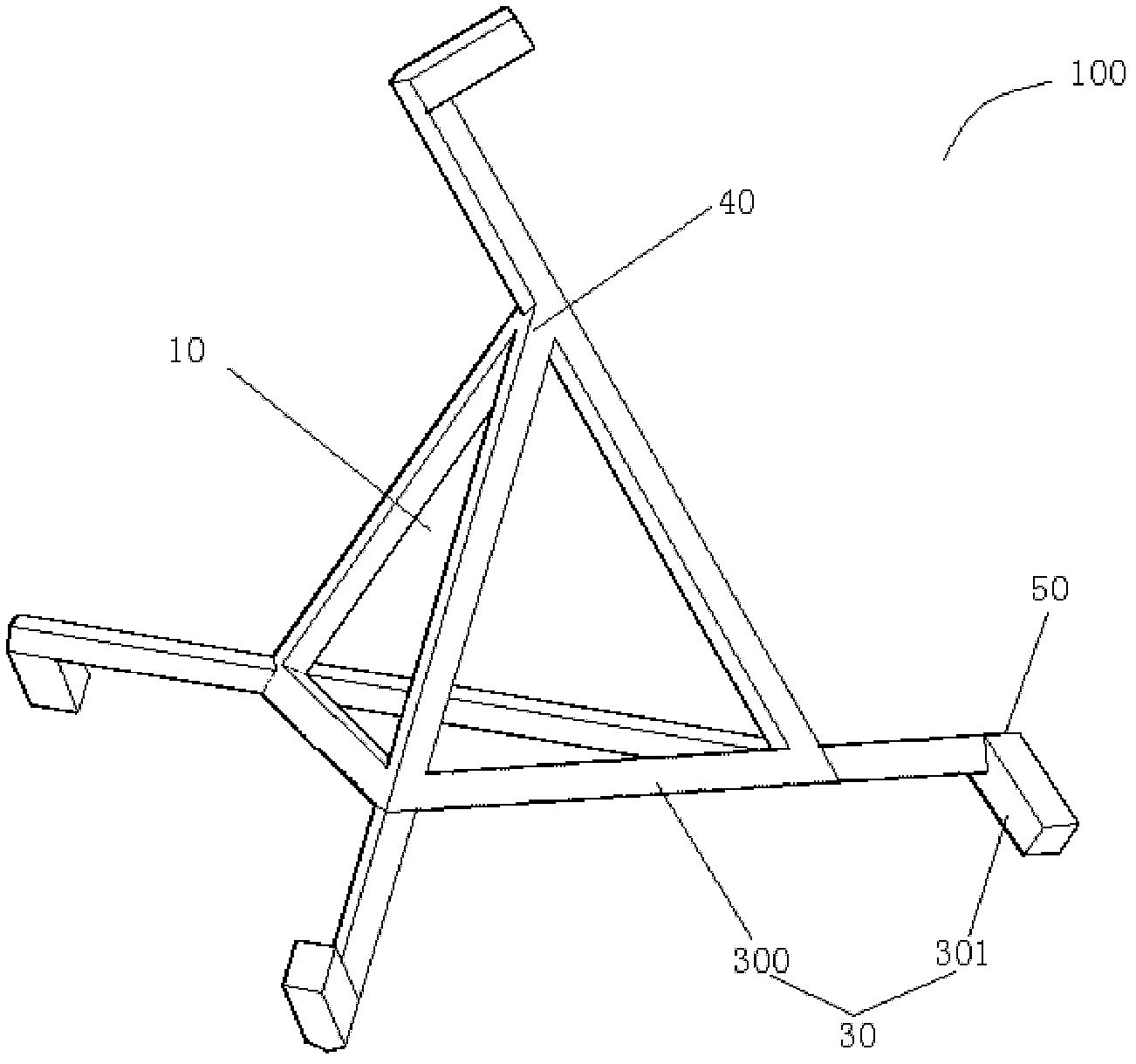

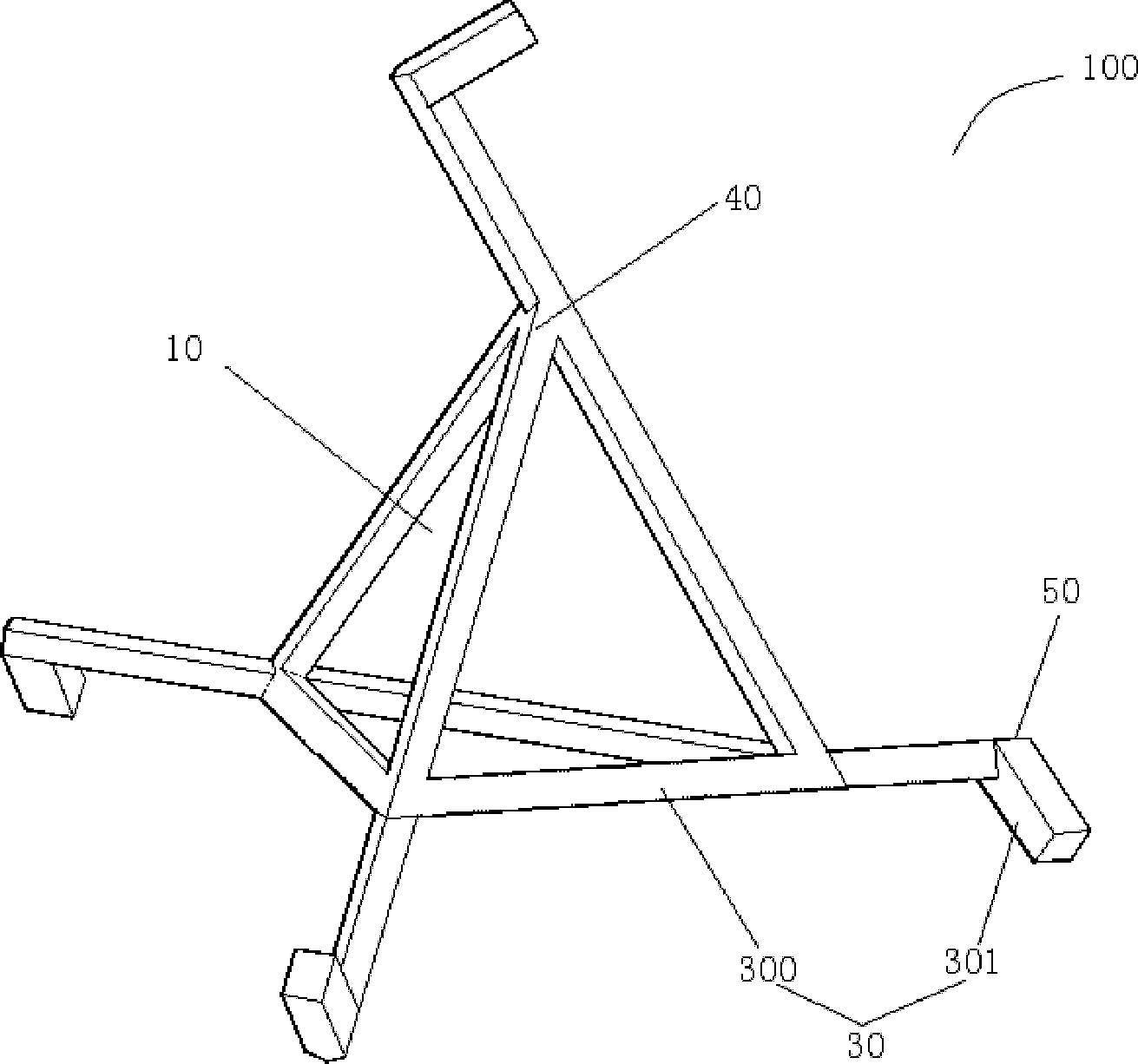

Three-dimensional laser scanner fixing mechanism, and subway tunnel acquisition system and method

PendingCN107941151AReduce installation errorsOverall goodMining devicesUsing optical meansData transmissionDistance sensors

The invention provides a three-dimensional laser scanner fixing mechanism, and a subway tunnel acquisition system and method. The subway tunnel acquisition system comprises a three-dimensional laser scanner fixing mechanism, a railway car module, a range sensor, an RFID reader-writer and a host computer. A three-dimensional laser scanner continuously acquires point cloud data of tunnel segments, the range sensor acquires mileage data in real time and transmits the mileage data to the host computer, the RFID reader-writer returns read and written RFID smart tag signals to the host computer in real time, and the host computer complete multi-source data fusion and storage. According to the invention, the problem that when the three-dimensional laser scanner is in a profile scanning mode, an automatic motor cannot be locked is solved, and damage to the scanner caused by maloperation is avoided. By means of the integrated design of two modules including the constant-speed railway car and the three-dimensional laser scanner, the quality of acquired data is improved, automatic acquisition of tunnel deformation data and disease information is achieved, the labor cost is reduced, and the detection efficiency is improved.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Method for manufacturing precise metal strip resistor

InactiveCN101587766AOverall goodImprove processing efficiencyResistor trimmingResistors adapted for applying terminalsElectrical resistance and conductanceMetal strips

A method for manufacturing precise metal strip resistor comprises: selecting an alloy strip and two metal strips; cleaning them; welding the two metal strips respectively on two sides of the alloy strip by high energy electron beam welding technique to form an integral resistor strip; punching the resistor strip transversely into a plurality of resistor bodies, or punching the alloy thin plate into a plurality of resistor bodies; then adjusting the numerical resistance values of the resistor bodies; and performing subsequent improvement processing to the resistor bodies to form precise metal strip resistor. Compared with the current technologies, The method provided in the invention reduces more than half of the production processes, increases the efficiency by tem times; reduces the product volume greatly, and realizes the production of surface applied precise splitter with low resistance, small volume and heavy bearable current. The resistor manufactured by the method provided in the invention has the characteristics of good performance, small volume and low material consumption.

Owner:BDS ELECTRONICS +1

Treatment method for tunnel local collapse

InactiveCN104389612ASlow downDecrease so as to prevent downward movementUnderground chambersTunnel liningGratingResource consumption

The invention discloses a treatment method for tunnel local collapse. A supporting body with the cross-section shape which is identical to that of a tunnel is produced by a corrugated pipe, the supporting body is pushed into a tunnel collapse affected section and a collapse body, cleaning of the collapse body can be performed, or grouting and solidification are performed on tunnel surrounding rock of the collapse affected section and surrounding rock at the position of the collapse body and then the supporting body is pushed into the collapse body so as to perform cleaning on the collapse body. By means of the treatment method for tunnel local collapse, defects of complicated construction processes, large resource consumption and long construction period in the prior art can be overcome, particularly, defects that totally sealed protection of loose rock and earth mass can not be achieved and personal safety of constructors and device safety are severely threatened in the prior art can be overcome, and construction safety can be effectively improved. According to the treatment method for tunnel local collapse, totally sealed protection is achieved in the tunnel by means of a steel corrugated pipe, the construction period is effectively saved, the tunnel stability and safety can be guaranteed, and processes and steel quantity of I steel supporting, steel grating supporting and the like can be effectively reduced. Besides, the treatment method for tunnel local collapse is suitable for engineering application.

Owner:CENT SOUTH UNIV

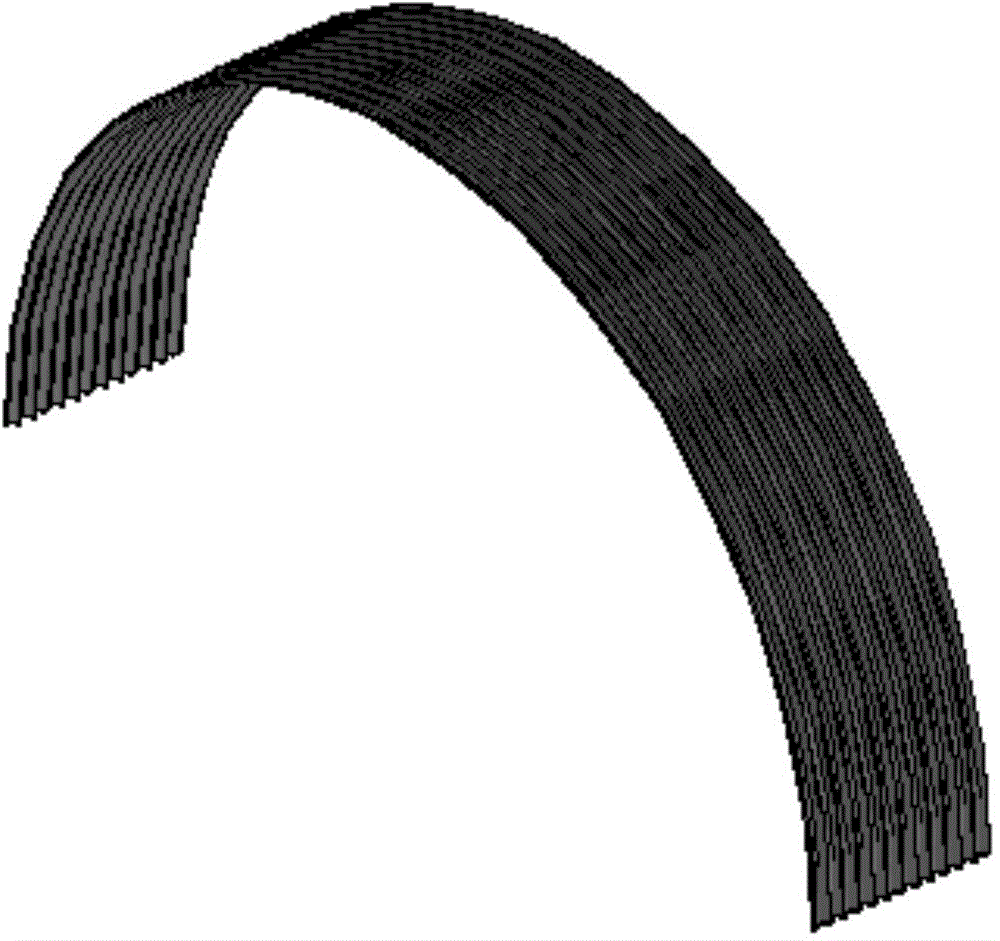

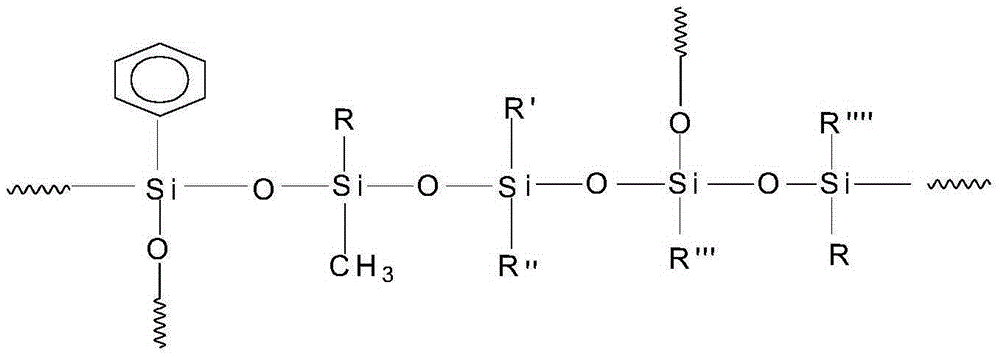

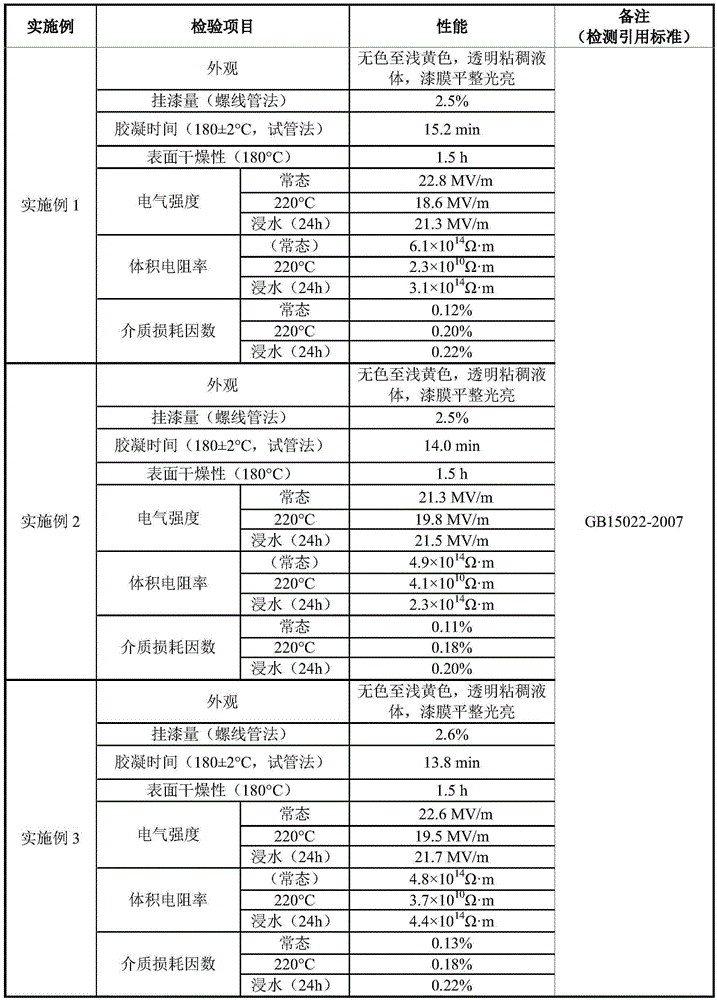

Preparation method for organic silicon impregnating varnish

The invention relates to the field of oil paint chemical engineering and especially relates to organic silicon impregnating varnish, and a preparation method and an application thereof. The organic silicon impregnating varnish is acquired through the hydrolytic condensation of silane monomers and is further acquired through the hydrolytic condensation of the silane monomers containing full alkoxy. The pure resin type organic silicon impregnating varnish not only has the advantages of excellent insulating properties, such as, high heat resistance, hydrophobic property, pressure-withstanding anti-corona property, and the like, and environmental protection, but also has the advantages of excellent adhesive force and bonding strength to the impregnated substrates, so that the phenomena of cracking and insulating painting falling caused by vibration of machinery (such as, high-speed running locomotive, mining machinery, wind power generation equipment, and the like) and heat effect are resisted and avoided.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Wind power generation tower prestress anchor bolt cage

InactiveCN103938647AImprove force transmission performanceOverall goodBulkheads/pilesSteel platesEngineering

The invention relates to a wind power generation tower prestress anchor bolt cage which comprises an anchor bolt, an upper flange and a lower flange. The anchor bolt penetrates through an anchoring nut, the lower flange, a positioning nut, an anchor bolt casing pipe, an adjusting nut, the upper flange, a T-shaped flange at the bottom of a wind power generation tower and a locking nut in sequence. The upper flange is an annular steel plate, an anchor bolt hole is an inverted-cone hole, and the adjusting nut can support the upper flange and adjust the levelness of the upper flange; the lower flange is an annular steel plate, a lower flange support bolt and a support nut bear the weight of the lower flange and can adjust the levelness of the lower flange, the lower flange is fixed through a pressing nut, and the lower flange support bolt is supported on a base plate. According to the wind power generation tower prestress anchor bolt cage, the anchor bolt and foundation concrete are separated through the anchor bolt casting pipe, the anchor bolt applies pretension force, and the concrete is subjected to the stress; the position and levelness of the upper flange are adjusted through the adjusting nut; the inverted-cone hole of the upper flange enables the center area, the inner edge and the outer edge of the T-shaped flange at the bottom to be pressed against the upper flange more tightly, and the inverted-cone hole is filled with sealing materials. The wind power generation tower prestress anchor bolt cage enables the integrality of the connection of a tower frame and the foundation to be good, is even in rigidity, and improves durability and anti-fatigue performance of connection.

Owner:闵怡红

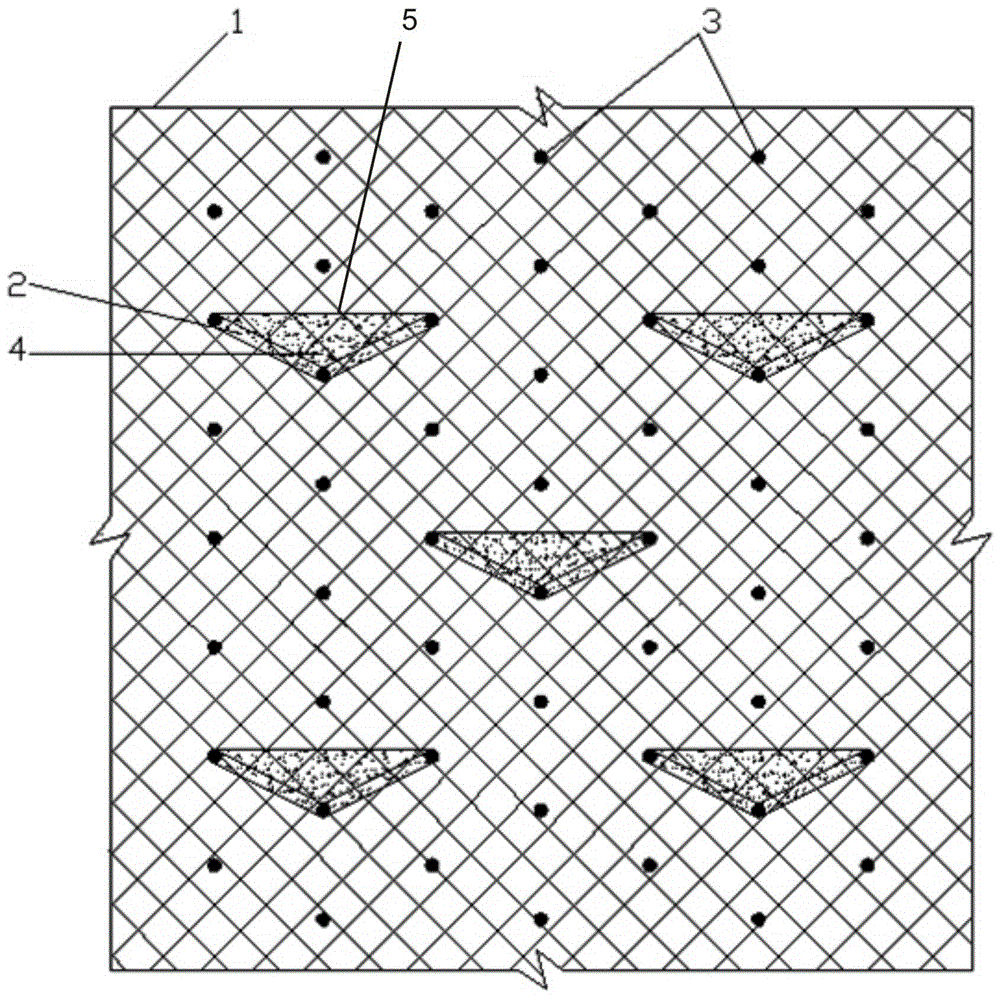

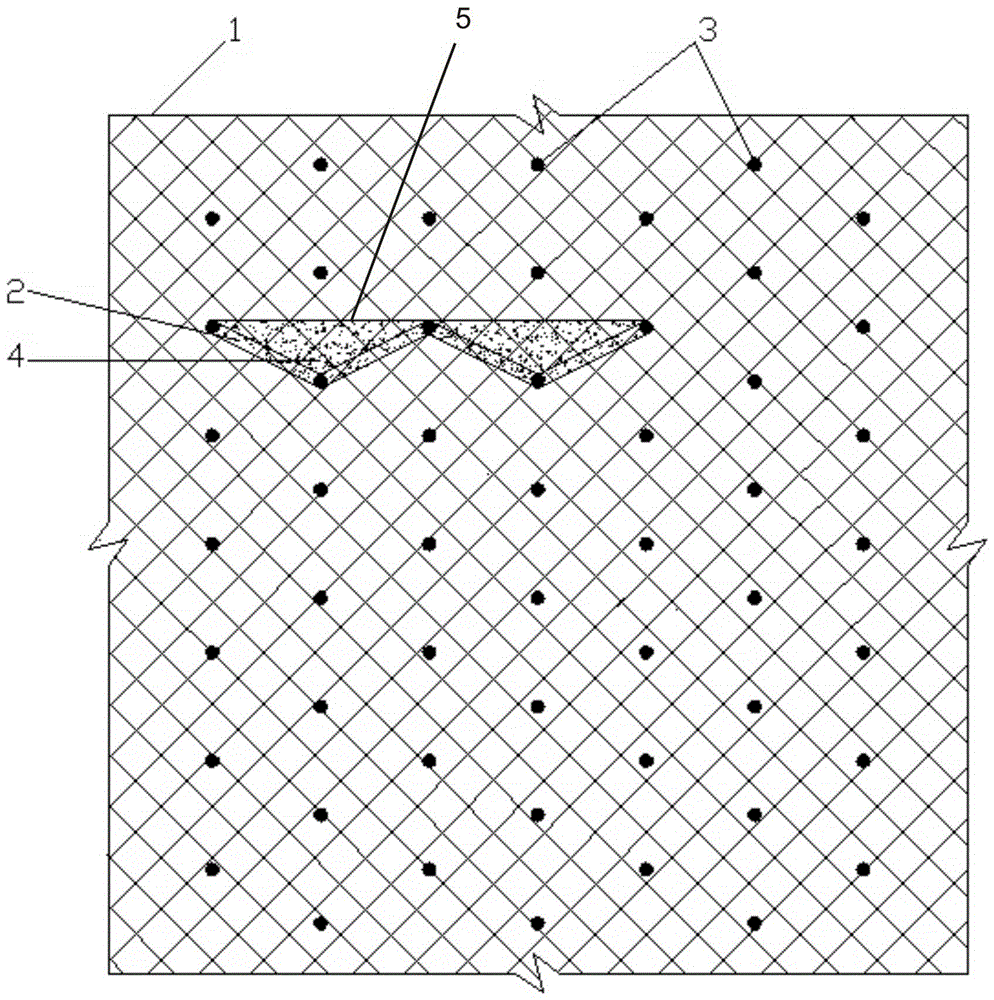

Prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection and construction method of prefabricated steel fiber sludge-made ceramisite concrete wall

A prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection comprises prefabricated wall plates, cast-in-place connection columns and cast-in-place vertical edge components, wherein the two lateral sides of each prefabricated wall plate are each of a T-shaped groove structure, horizontal and vertical reinforcing steel bars are arranged in the prefabricated wall plates, each cast-in-place column is embedded in the T-shaped groove structures of the corresponding adjacent prefabricated wall plates to connect the prefabricated wall plates, each cast-in-place vertical edge component is provided with a longitudinal protrusion structure matched with the corresponding T-shaped groove structure, the longitudinal protrusion structures are embedded in the T-shaped groove structures on the outer sides of the edge prefabricated wall plates, longitudinal ribs are arranged in the cast-in-place vertical edge components, and reliable anchoring is achieved when the longitudinal ribs and the horizontal reinforcing steel bars in the edge prefabricated wall plates are embedded and spot welding is conducted on the joints one by one. The invention further provides a construction method of the prefabricated steel fiber sludge-made ceramisite concrete wall, and by means of the innovation of materials, the connection mode and the rib matching mode, the wall structure can have the advantages of being capable of lowing energy consumption and reducing vibration, ecological, environmentally friendly, capable of being rapidly constructed, economical and practical.

Owner:西咸新区矩阵住宅工业有限公司

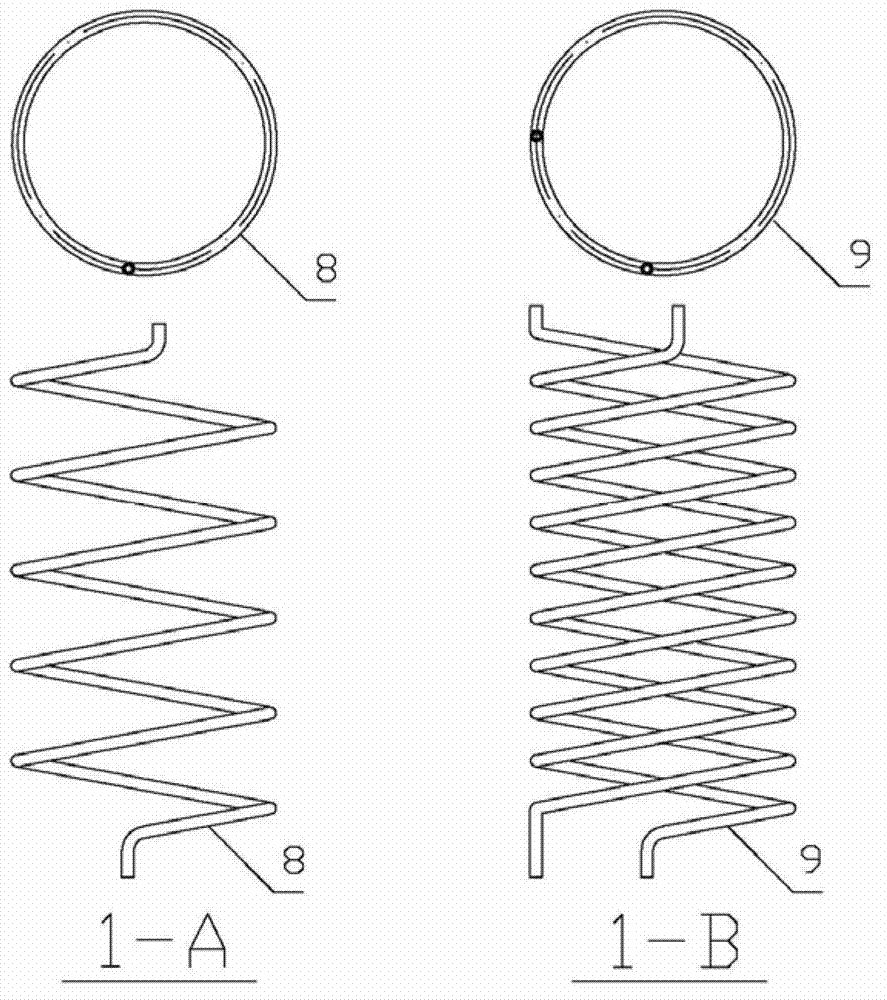

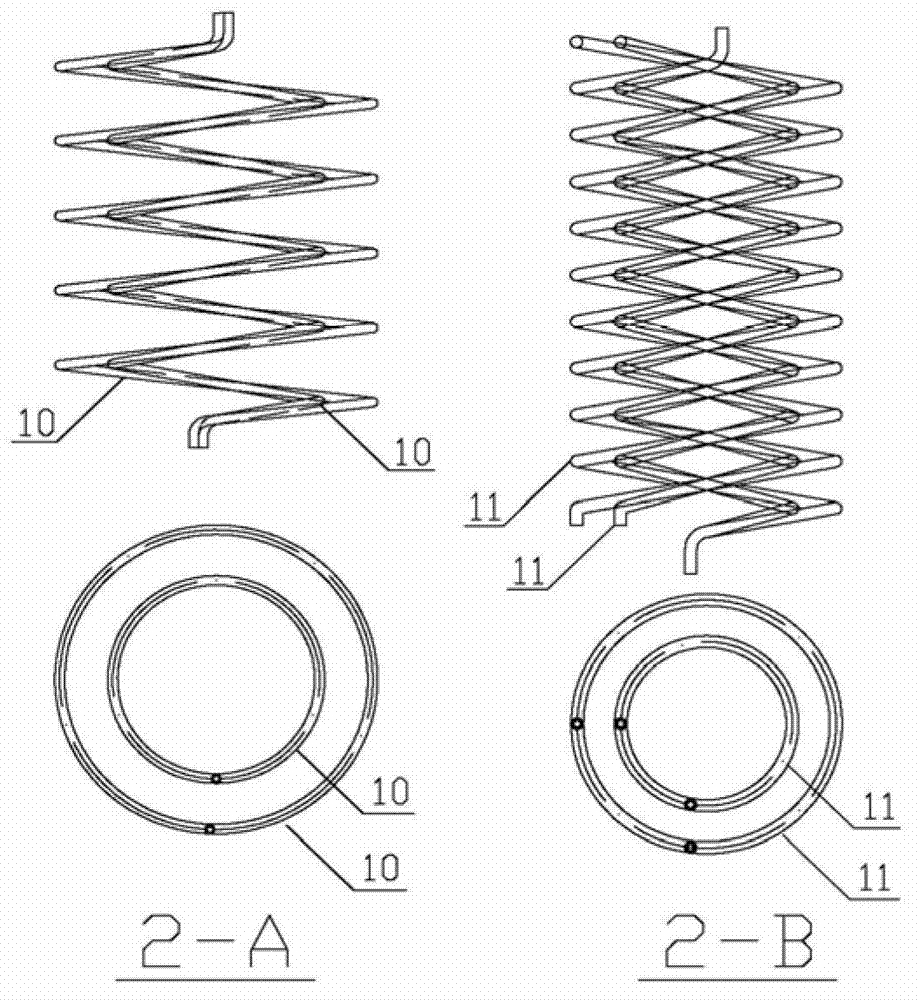

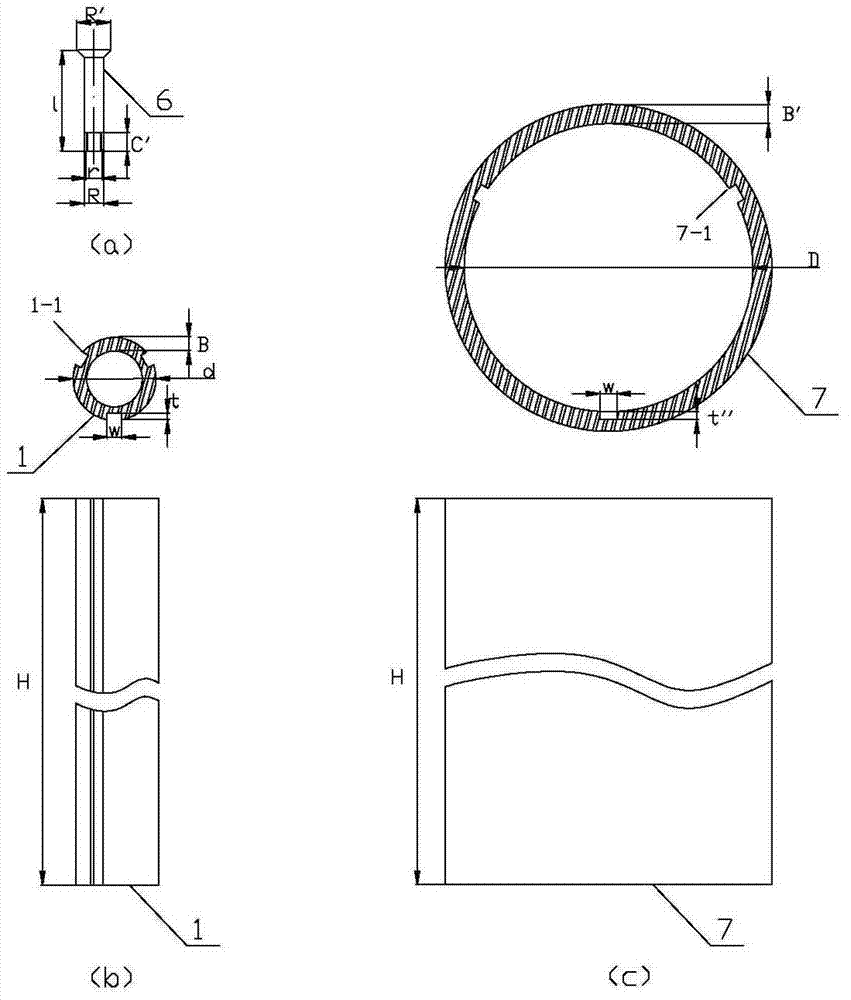

Spiral pipe fixing component and sheathing method

ActiveCN102734557AReduced risk of flow-induced vibrationRelaxation thermal stressPipe supportsMechanical componentsEngineering

The invention relates to a spiral pipe fixing component and a sheathing method, belonging to the technical fields of sheathing and fixation of mechanical components. The fixing component mainly consists of an internal sleeve, an internal barrel bearing strip, a bearing strip, a fixing strip, fixing screws and an external sleeve. The sheathing method comprises following steps: embedding the internal barrel bearing strip into the recess of the internal sleeve; sheathing the first layer of spiral pipe on the outer side of the internal sleeve, placing the fixing strip on the outer side of the spiral pipe, pulling each of the fixing screws through each counter bore in the fixing strip, and screwing the fixing screws into screw holes in the internal sleeve bearing strip; adjusting concentricity; spot-welding the fixing screws and the fixing strip, and flatly polishing; clamping the bearing strip of the next layer of spiral pipe on the fixing strip in order that the fixing strip is embedded into the recess of the bearing strip; and completely sheathing all the layers. A process for manufacturing and assembling the component is simple; additionally, the sheathing method involves low requirement on the manufacturing precision of the component, and results in high stability and high strength to the fixed assembling of the spiral pipes; and therefore, the sheathing method is applicable for large-scale popularization and standardization.

Owner:CHINERGY CO LTD

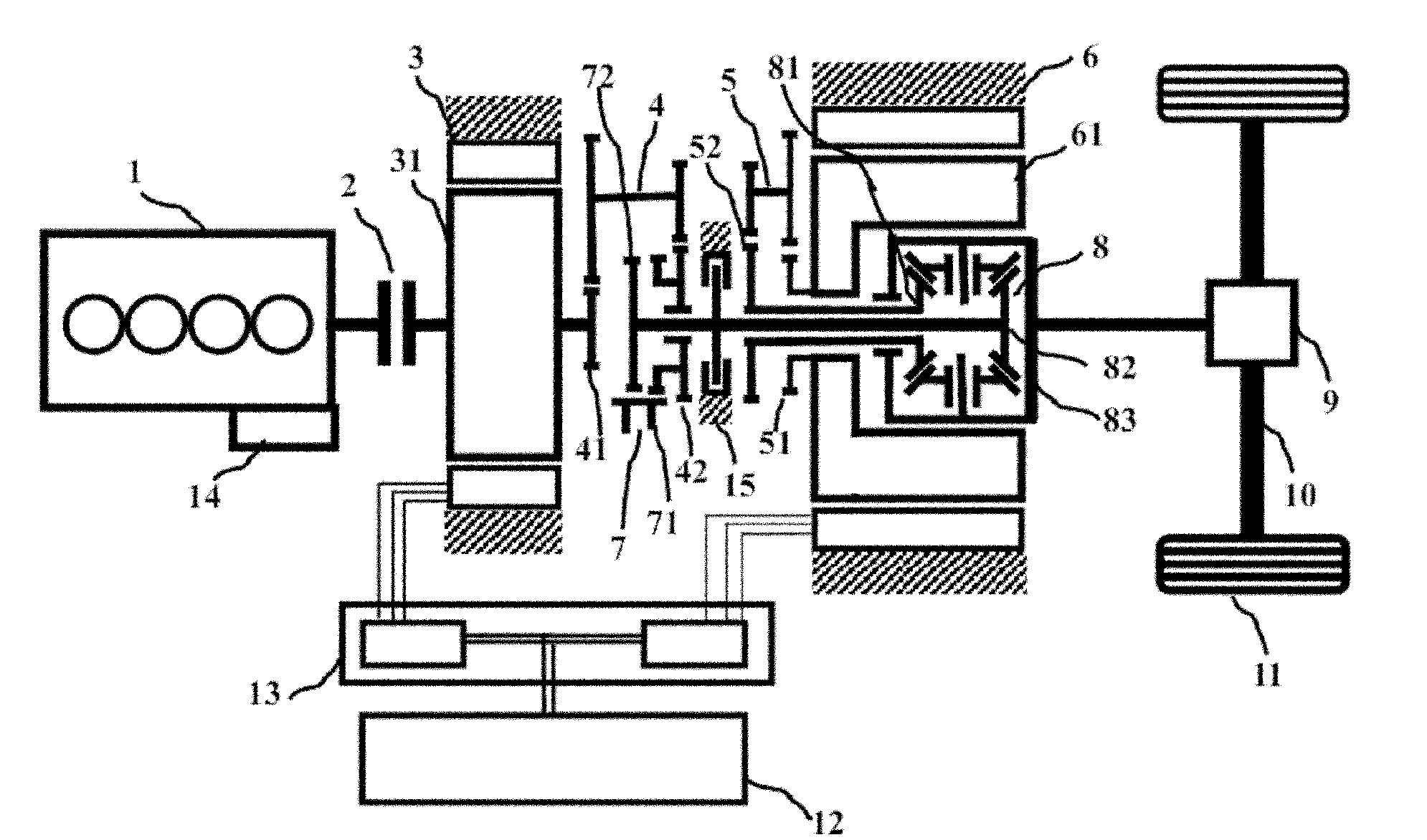

Multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system

ActiveCN104494415AGood loadabilityReduce labor intensityHybrid vehiclesGas pressure propulsion mountingElectric power transmissionVehicle dynamics

The invention provides a multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system. The multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system comprises a first motor and the like; a planetary gear train comprises a gear ring, a planet carrier and a sun gear; the rotor of the first motor is connected with the gear ring of the planetary gear train; the rotor of the second motor is connected with the sun gear of the planetary gear train and the input end of a transmission chain, respectively; a gear shifting device is connected with the input end of a speed reducing differential mechanism and control on power transfer from the planet carrier of the planetary gear train and the output end of the transmission chain to the speed reducing differential mechanism is realized; the output end of the speed reducing differential mechanism is connected with two wheels by use of two half shafts; a motor control device is connected with an energy storage device to transfer electric energy; the motor control device is further connected with the first motor and the second motor, respectively, and outputs control instructions. The multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system has the characteristics of better technical inheritance to the existing vehicles, whole vehicle dynamic property, fuel economy and low emission.

Owner:SHANGHAI JIAO TONG UNIV +1

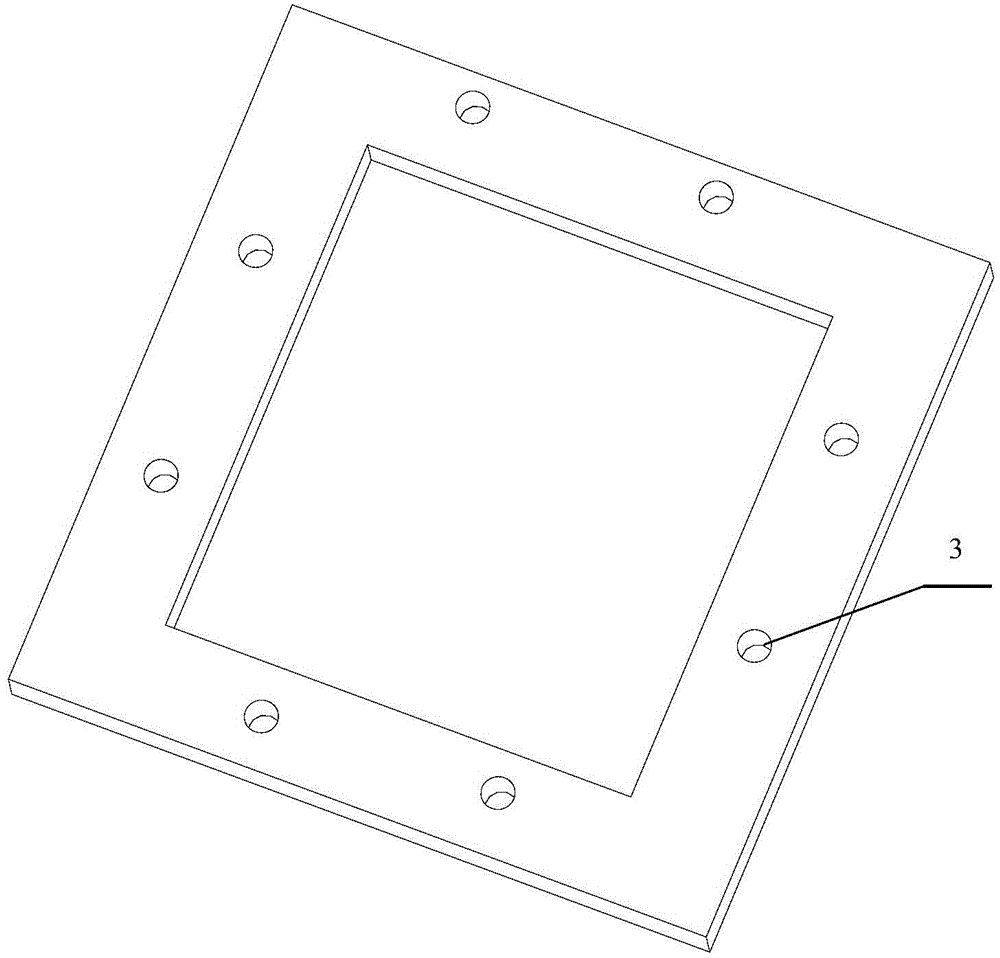

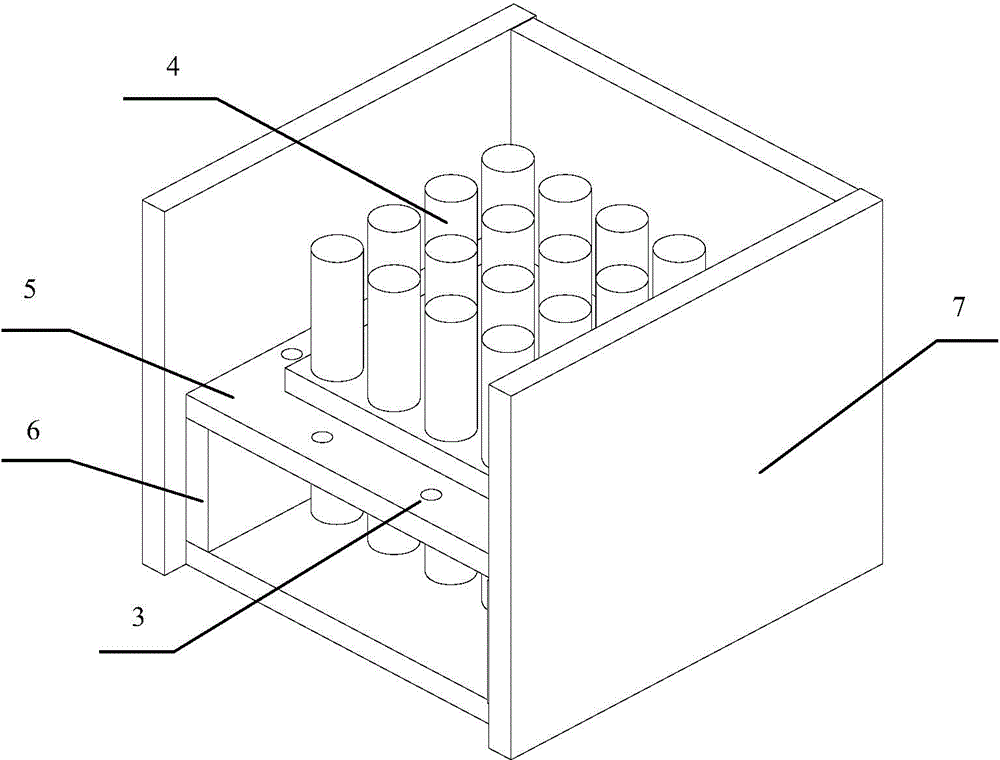

Manufacturing device and method of resin transparent concrete block

The invention discloses a manufacturing device and a method of a resin transparent concrete block, and belongs to the technical field of novel concrete materials. The device used by the method is characterized by comprising a light guide body prototype part, a mold separation piece, cushion plates and a surrounding mold, wherein the light guide body prototype part comprises connecting parts acting a connecting effect, and multiple light guide branches; all the light guide branches can be connected as a whole due to the existence of the connecting parts thereby facilitating demoulding of a silicone mould and facilitating concreting; the mold separation piece is a middle-hollowed rectangular sheet, so that the mold can be naturally divided into two parts of a top mold and a bottom mold, and contact surfaces of the top mold and the bottom mold are smooth and compact in connection; and the cushion plates are two wood plates with the same size to raise the mold separation piece to a needed height. The device can conveniently and quickly apply a mold turning method to manufacture the silicone mold so as to produce resin light guide bodies in batches, so that the production efficiency of resin transparent concrete is improved.

Owner:DALIAN UNIV OF TECH

Plant culture medium for hill afforestating vegetation

InactiveCN1781882AGood adhesionGood air permeabilityHorticulture methodsFertilizer mixturesAdhesiveCulture mediums

The present invention belongs to the field of afforesting technology, and is especially plant culture medium for hill afforesting vegetation. The plant culture medium is prepared with tree bark, stalk, soil, plant ash, carbon powder, paper pulp, organic fertilizer, grass seed, flower seed, tree seed, water retaining agent, curing agent, adhesive, etc. and through mixing. It is sprayed for being adhered to hill rock surface. It is ventilating, integral, and suitable for plant growth, and can form afforesting vegetation well on hill.

Owner:于树林

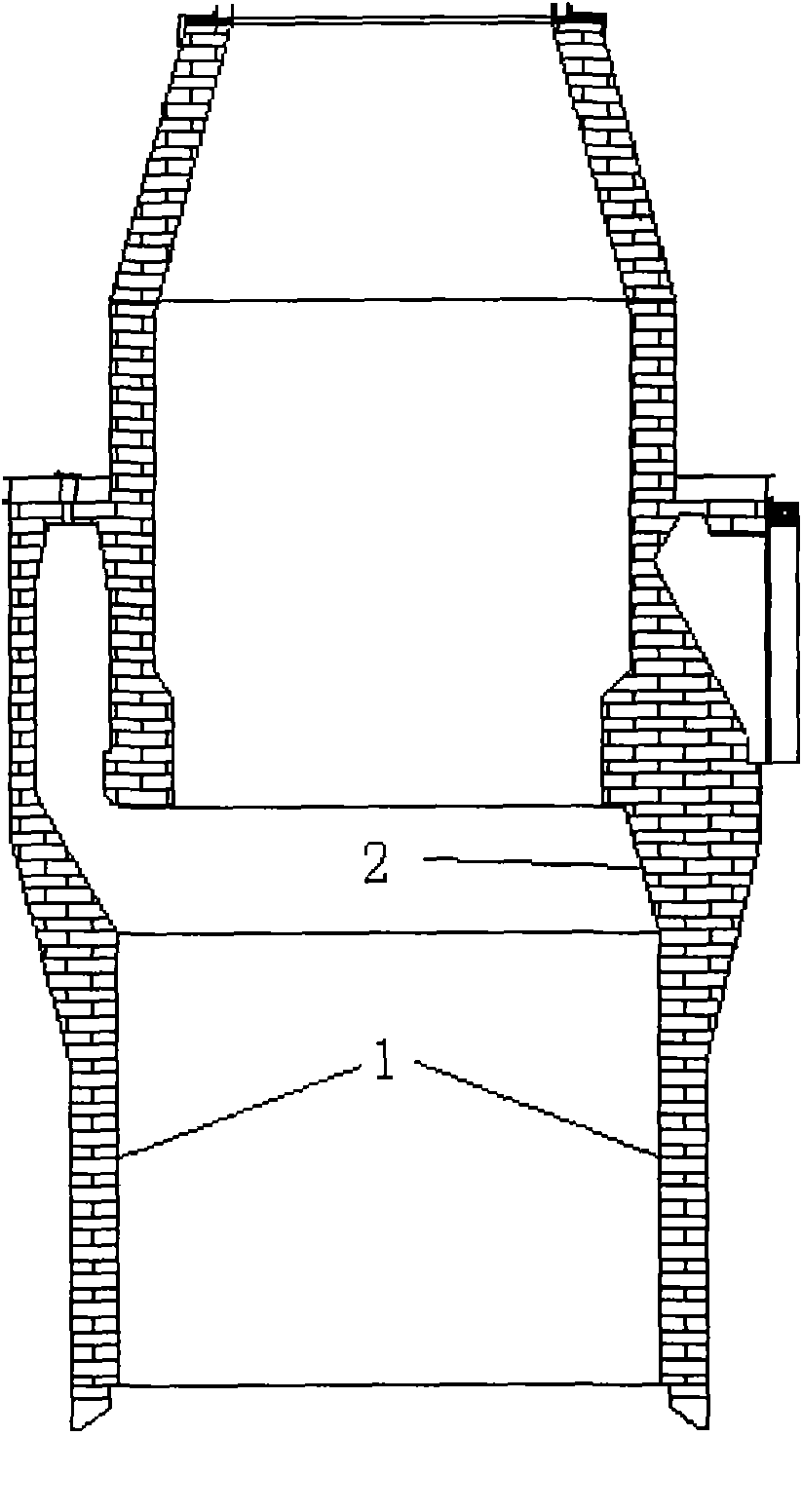

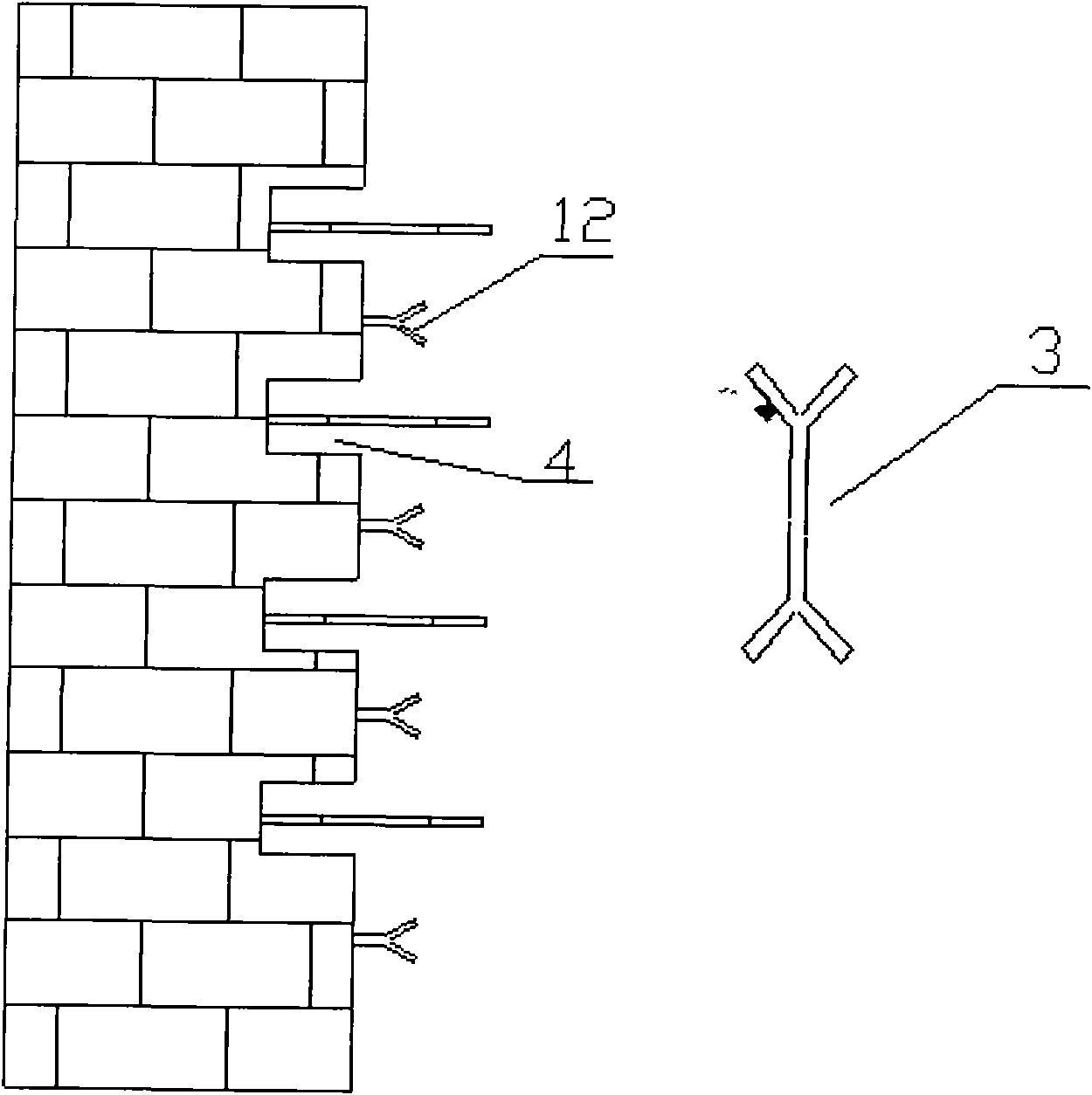

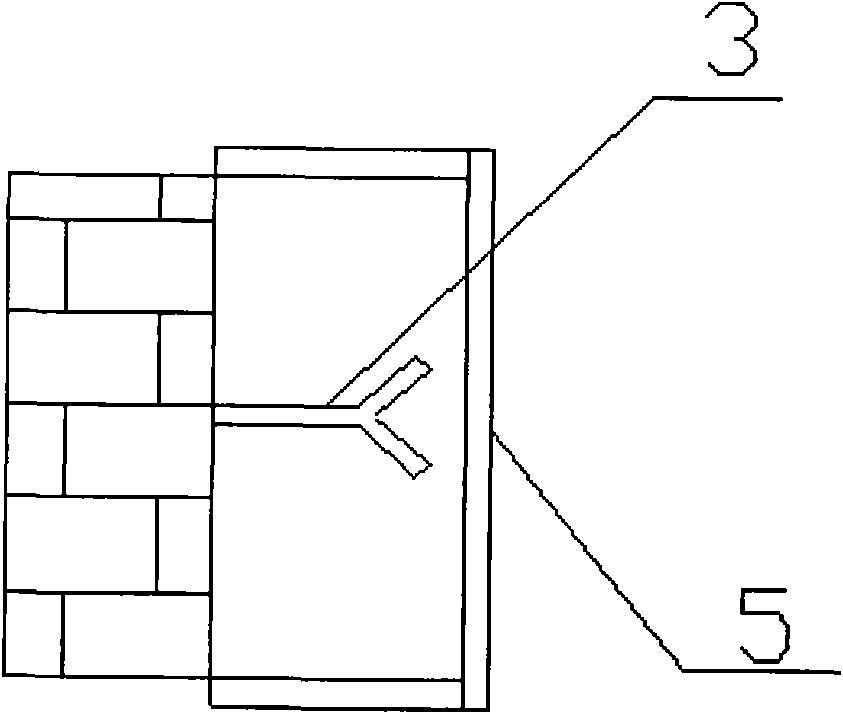

Integral casting construction process of dry quenching furnace

InactiveCN101671569ASolve the large amount of engineeringOverall goodCoke quenchingCoke oven detailsQuenchingMaterials science

The invention relates to an integral casting construction process of a dry quenching furnace, comprising the following steps: casting dry quenching furnace cooling sections, outer part of chute bracket front side, two side walls and the bottom of a boiler inlet and a bifurcation chute of a primary dust remover, integrally casting by adopting automatically-flowing casting materials, baking the dryquenching furnace for 65-84 hours at the temperature of no higher than 600 DEG C after finishing casting. Under the condition of not damaging the prior structural conditions of the dry quenching furnace, the invention thoroughly solves the problem that the work amount is large in the prior bricking inlayed repairing scheme, ensures favorable integrity of laid bricks, saves time and material, and has low cost and long service life.

Owner:SHANDONG IRON & STEEL CO LTD

Rare-earth composite wall heat-insulating layer and heat-insulating layer material preparation method

InactiveCN101215858AHigh strengthImprove insulation effectCovering/liningsClimate change adaptationInfraredRare earth

The invention relates to a heat-insulating layer of a rare earth complex wall body and the manufacturing method of heat-insulating layer material, which belongs to the field of architectural materials. The invention is characterized in that the process for preparation comprises mixing rare earth rubber powder by weight ratio that rubber powder: water = 1:1 to 1.5, adding polyphenyl particles into material which is mixed, the proportion is that rubber powder: EPS particles = 1 kg: 8 L, continuously mixing for 5-10 min to make rare earth rubber powder EPS particle heat-insulating material, mixing rare earth trowel finish sand with water according to the proportion that rare earth trowel finish sand: water = 1: 1 into slurry, making rare earth trowel finish sand slurry, and brushing rare earth rubber powder EPS particle heat-insulating material, trowel finish sand slurry, standard net cloth, rare earth trowel finish sand slurry, flexible putty and face coat on the base layer of the wall body in turn. The invention has good heat-insulating property, strong binding power, high compression strength, good water resistance and flame proof, which is antiseptic, noncorrosive, nontoxic, tasteless and pollution-free, has the function of absorbing ultraviolet ray and infrared ray, and has quick coagulate speed, rapid increase of the strength of materials, and the construction procedure is rapid, timesaving and laborsaving.

Owner:包头市科强新型材料有限公司

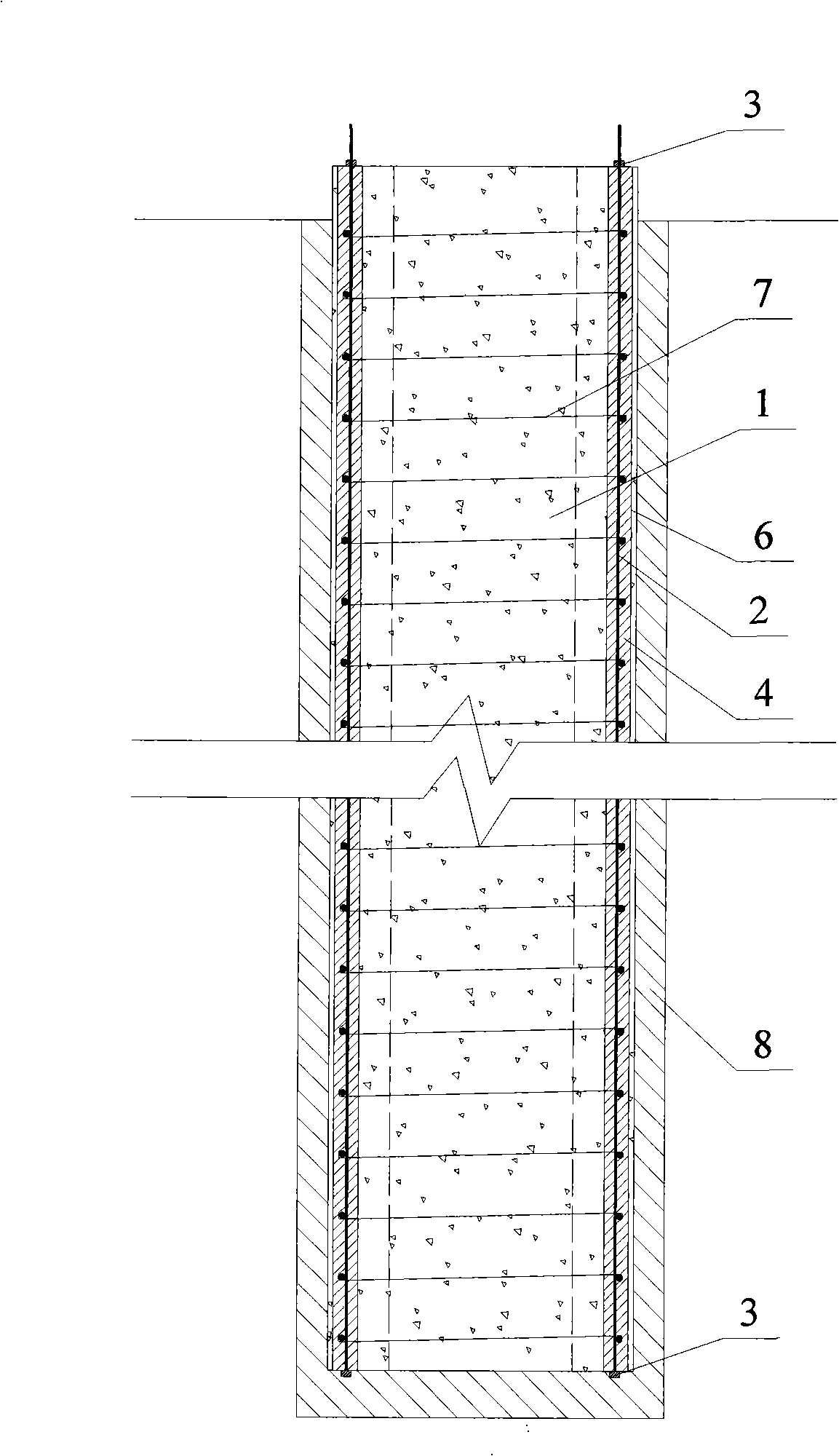

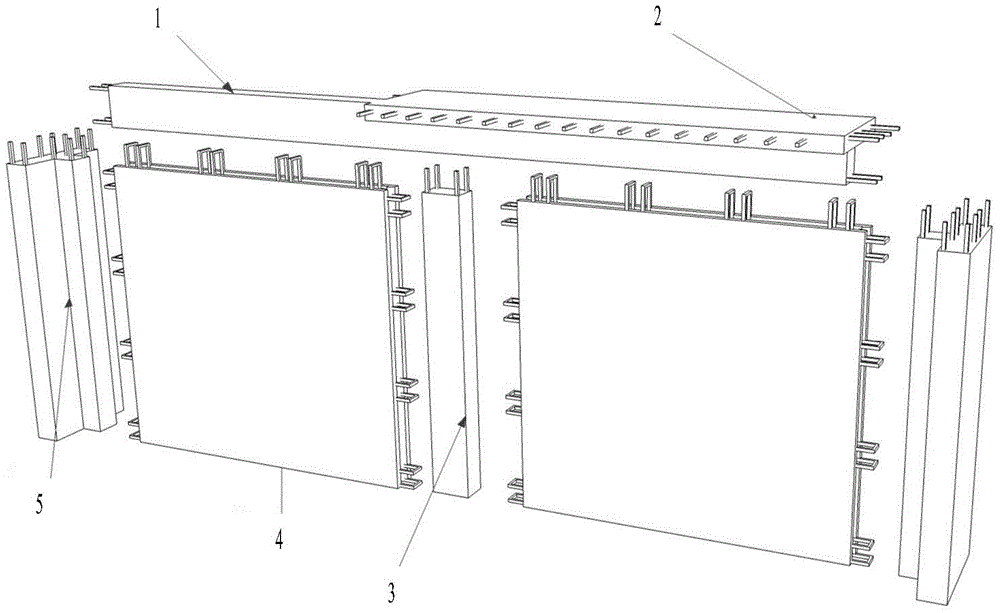

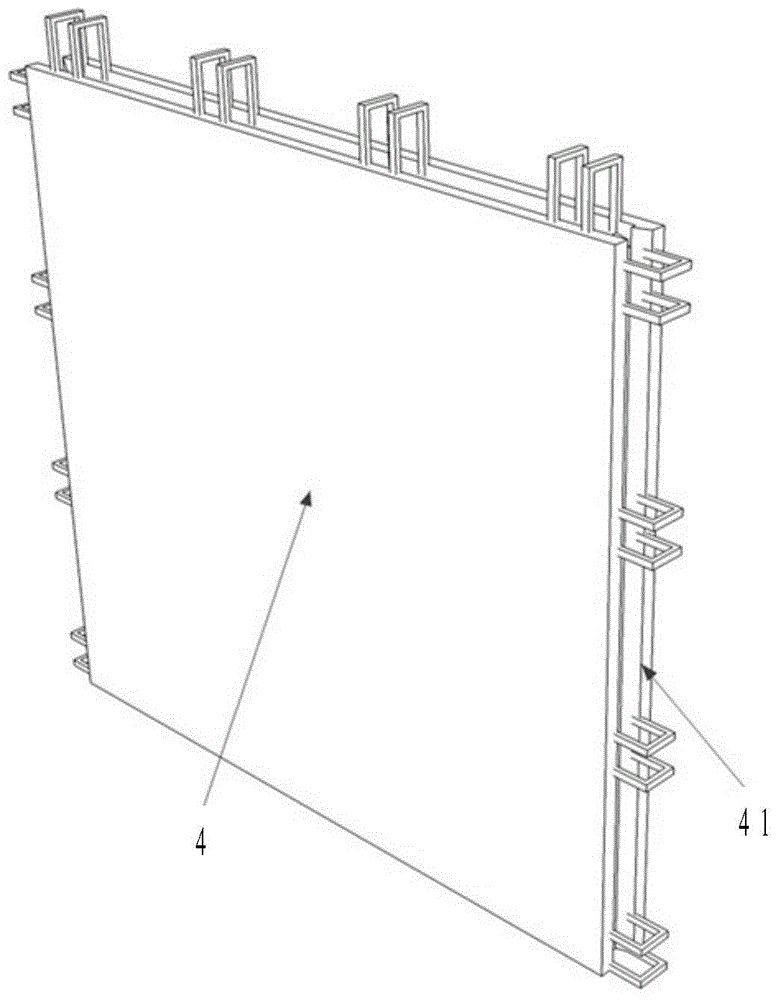

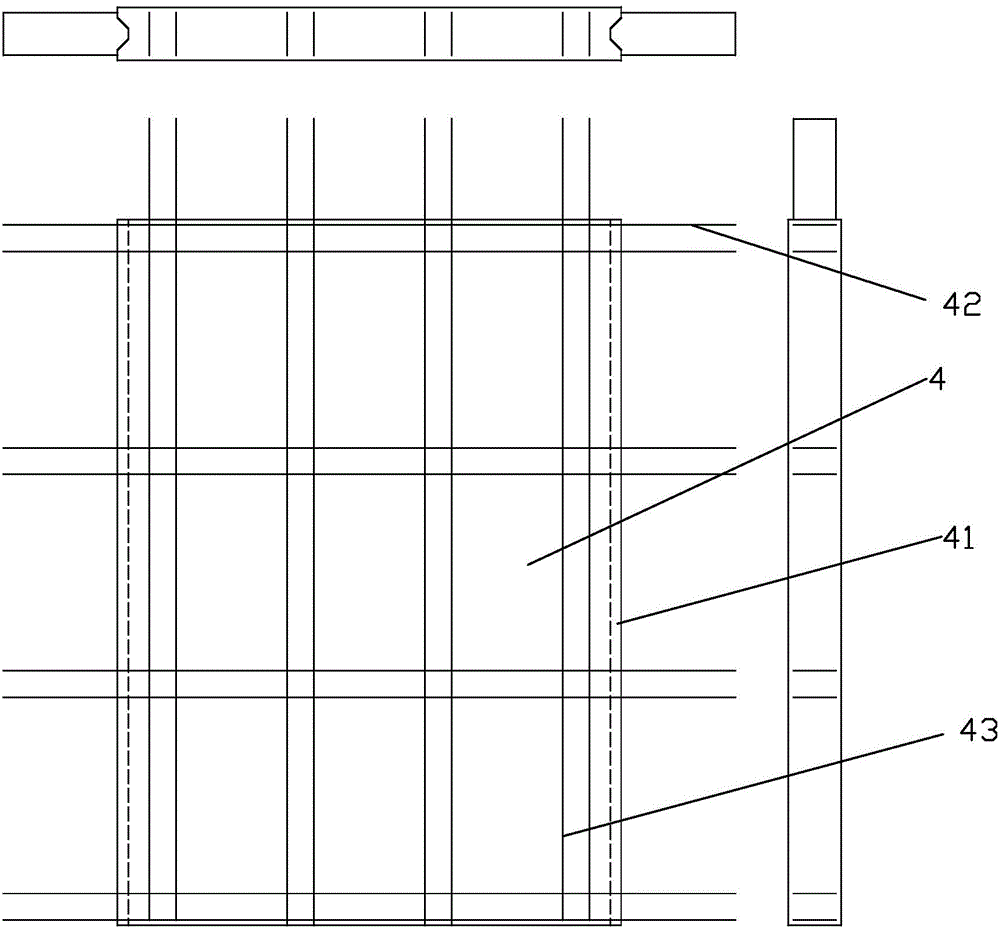

Integral pouring molding construction method for reinforced concrete column

ActiveCN106032692ASimplify on-site construction processesOverall goodStrutsPillarsReinforced concrete columnRebar

The invention discloses an integral pouring molding construction method for reinforced concrete columns. The integral pouring molding construction method for the reinforced concrete column comprises the steps that a column reinforcing cage is composed of a plurality of stirrups and column reinforcing cage vertical reinforced bars, outer-side formworks are fixed by forming outer threads in the ends of framework reinforced bars of the stirrups forming the column reinforcing cage and enabling the outer threads to penetrate through the formworks, all the side face formworks are fixed separately to form an integral formwork splicing structure with the self-balancing performance, and the spliced integral formwork structure is conveniently lifted to a construction site for construction. According to the construction method, the site construction procedures of the concrete columns are simplified, the structural integrality is good, and the construction method is applied to the building construction field.

Owner:RBS PARTNERS S&T CO LTD

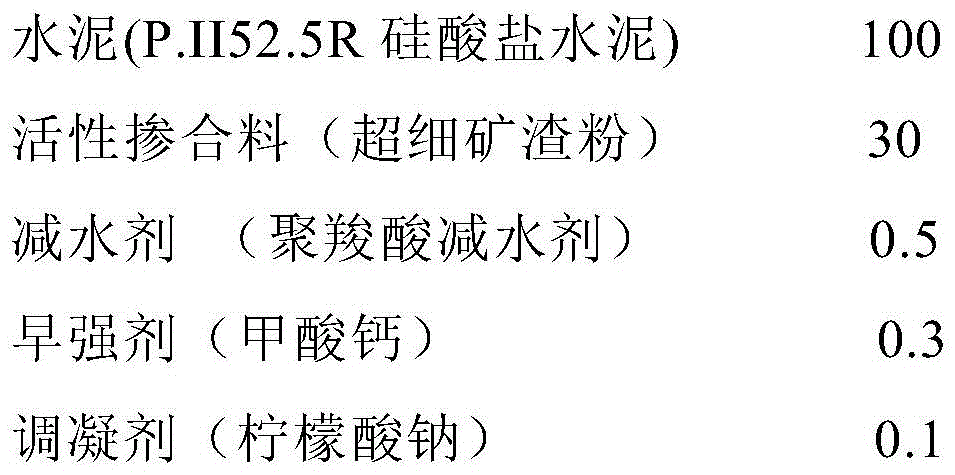

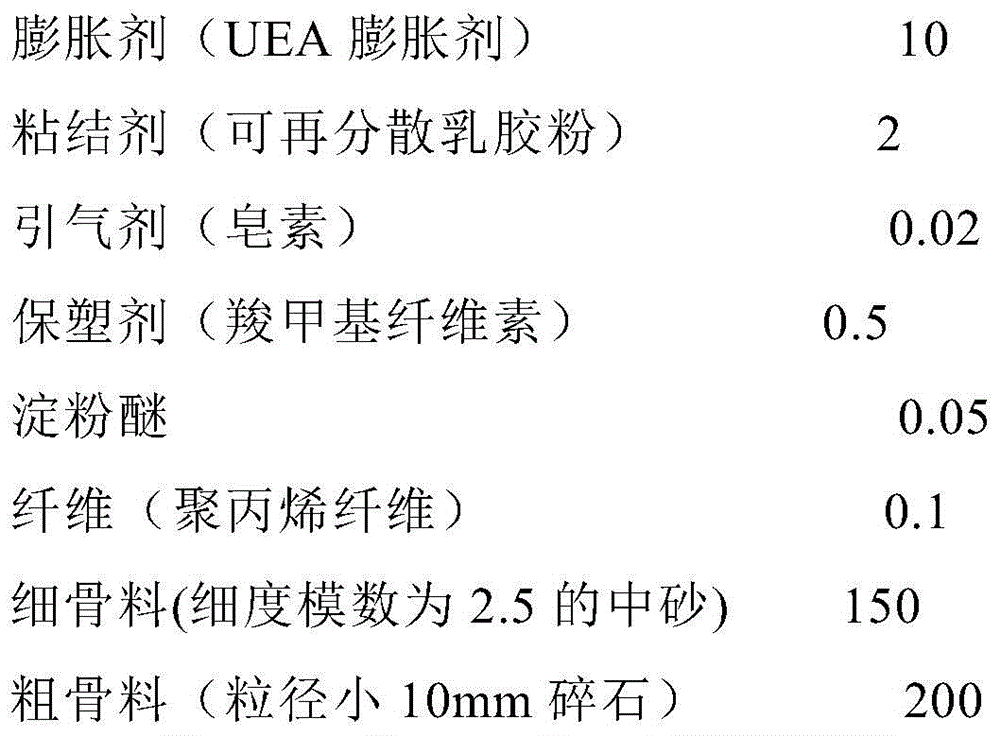

A kind of 3D printing cement-based material and preparation method thereof

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

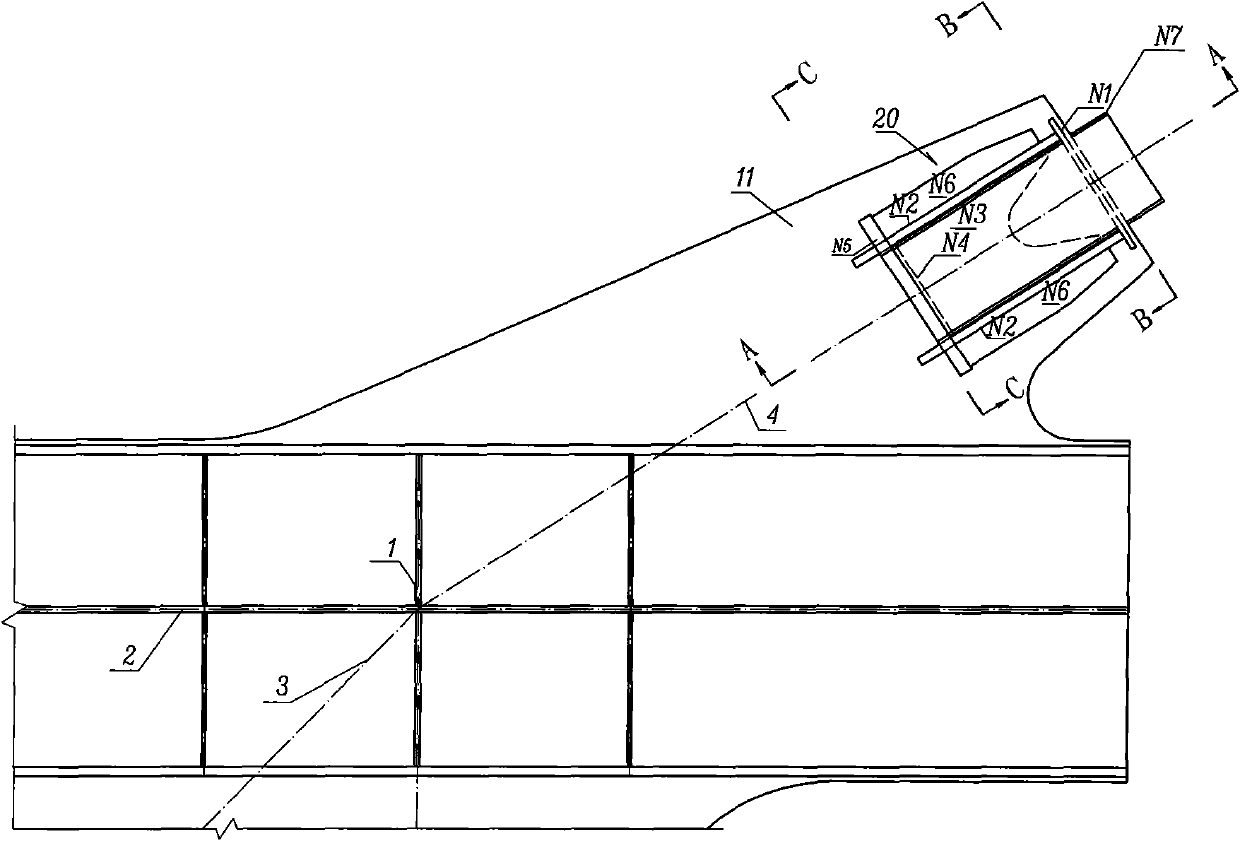

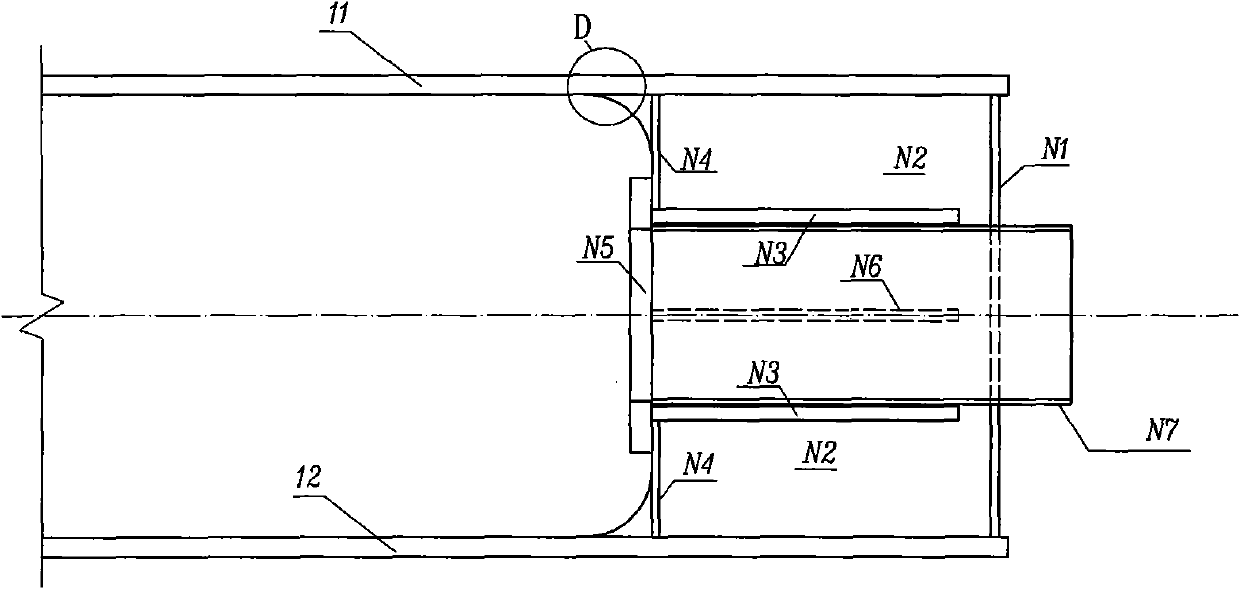

Overall composite towing beam arching structure for railway steel truss girder cable-stayed bridge

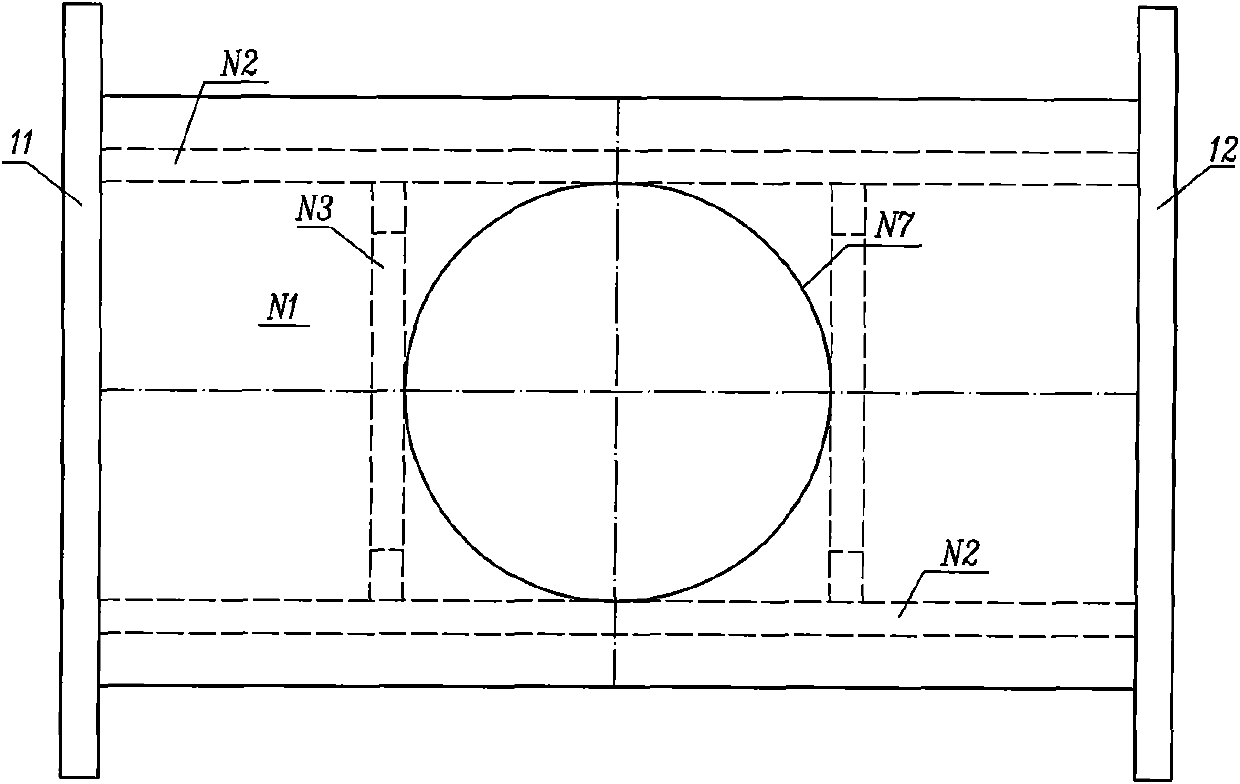

ActiveCN101793002AAvoid defectsTightly boundCable-stayed bridgeBridge structural detailsStress concentrationCable stayed

The invention discloses an overall composite towing beam arching structure for a railway steel truss girder cable-stayed bridge, which aims to uniformly transfer a cable force to a main truss structure, has high integrity without generating greater stress concentration phenomenon at key parts such as a welding seam and the like, and improves the anti-fatigue performance of the structure. The structure comprises a pair of overall arch plates (11 and 12) and a steel anchor box (20), wherein the pair of overall arch plates (11 and 12) are formed by extending upwards directly from node plates on the two sides of the top chord of a main truss; the steel anchor box (20) is arranged between the upper parts of the pair of overall arch plates (11 and 12) and is fixed with the upper parts of the overall arch plates (11 and 12); a steel sleeve tube (N7) through which a stayed-cable can pass is fixedly arranged in the steel anchor (20); and the stayed-cable axis of the steel sleeve tube (N7) is crossed with the central line (1) of a node of the main truss, an upper chord system line (2) and a diagonal web member system line (3).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

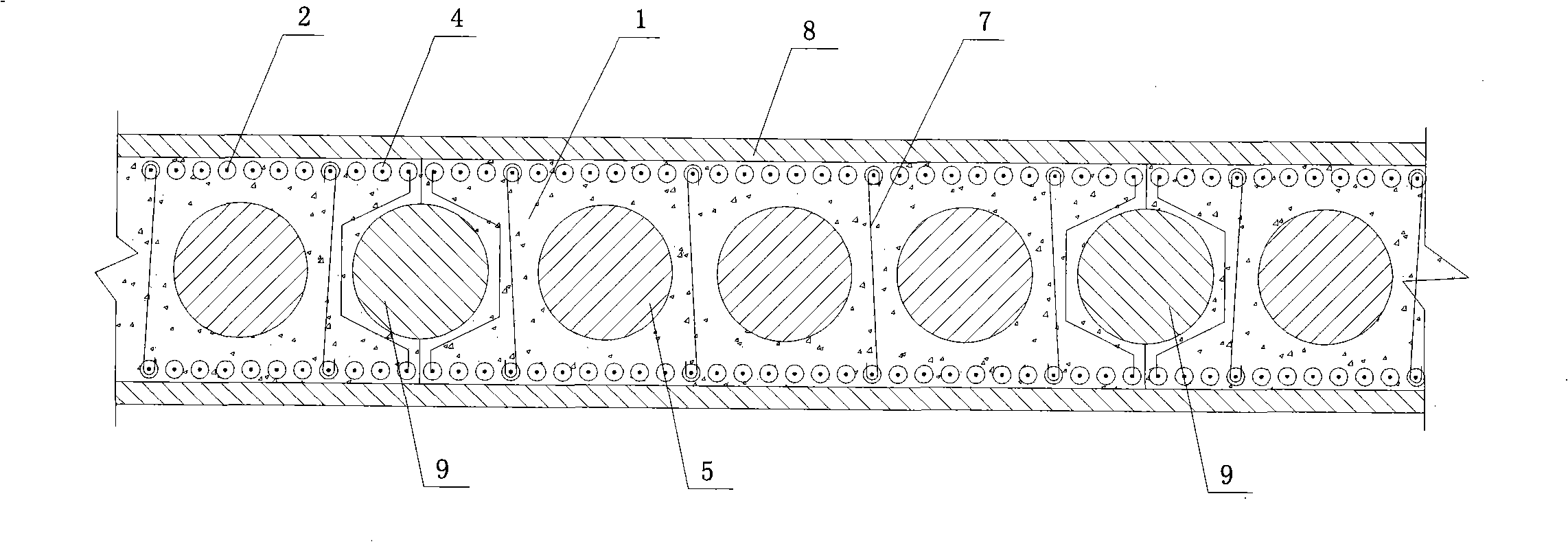

Assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and manufacturing method thereof

ActiveCN110318495AGive Full Play to the "Hoop Effect"Give full play to the "ring effect"MouldsClimate change adaptationConcrete beamsLong term durability

The invention discloses an assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and a manufacturing method thereof. The assembled permanent formwork overlapped FRPrib seawater sea sand recycled concrete beam comprises a prefabricated assembled permanent formwork and an FRP rib seawater sea sand recycled concrete beam. The prefabricated assembled permanent formwork is formed by assembling corer strip assembly blocks, first panels, second panels and positioning connecting parts, and the formwork is manufactured from an engineering cement-based composite (ECC)and a fiber woven mesh. The FRP rib seawater sea sand recycled concrete beam comprises seawater sea sand recycled concrete poured into the prefabricated assembled permanent formwork and an FRP rib framework fixedly arranged in the seawater sea sand recycled concrete. As the TRE formwork and the FRP rib seawater sea sand recycled concrete are compounded, the engineering manufacturing cost of the formwork is effectively reduced, the ductility of the FRP rib seawater sea sand recycled concrete beam is improved, the long-time durability of FRP ribs is guaranteed, and meanwhile the problems that an existing integral formwork is large in occupied space and not easy to transport are solved.

Owner:CHINA UNIV OF MINING & TECH

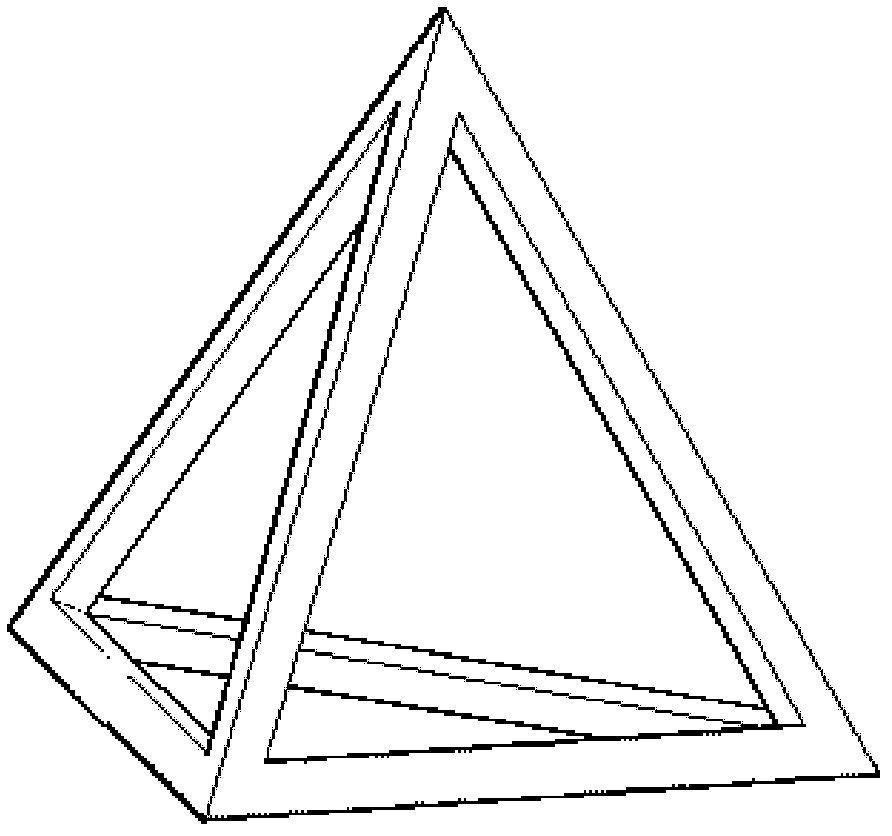

Permeable framework

InactiveCN102619190ANot subject to erosionGood underwater protectionCoastlines protectionWater flowRiver bed

The invention discloses a permeable framework comprising a base frame, and further comprises four hooked connecting components, wherein the base frame is a right pyramid, and comprises 6 frame rods which are the same in length and connected with each other; and the hooked connecting components extend outwards from the four points of the right pyramid along the frame rods respectively, and are L-shaped or C-shaped. The hooked connecting components which are arranged in different directions and can be hooked with each other are additionally arranged on the basis of the right pyramid-shaped permeable framework, so as to be snapped in the right pyramid of an original dispersing body. Therefore, a bottom protection group structure is formed; and even when the speed of part water flow is larger, a single self hooked permeable framework structure can not be scoured away due to the mutual coverture and the protection effect of a periphery structure, so as to perform a favorable underwater bottom protection function and a function of protecting part of a river bed from being scoured.

Owner:SHANGHAI ESTUARINE & COASTAL SCI RES CENT

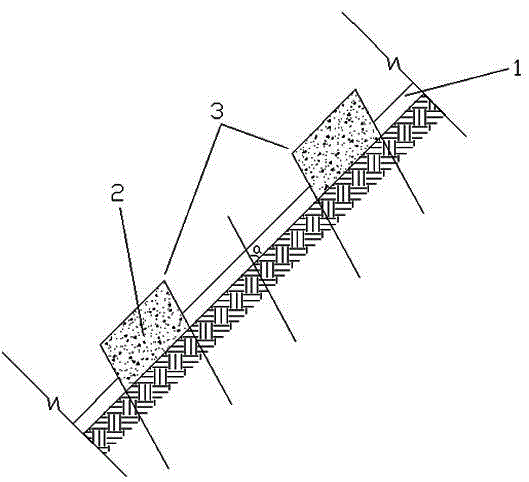

Side slope ecological protection method combining vegetation nursery grooves with hung-net spray-seeding

ActiveCN105178337AOverall goodGood durabilityExcavationsCultivating equipmentsEcologyEnvironmental geology

Disclosed is a side slope ecological protection method combining vegetation nursery grooves with hung-net spray-seeding. The method comprises the following steps that (1) the slope surface of a side slope is cleaned to be smooth; (2) nets are laid; (3) the vegetation nursery grooves are designed; (4) ground anchors are installed; (5) the vegetation nursery grooves are constructed, and the construction of the vegetation nursery grooves is completed according to the vegetation nursery groove design scheme determined in the step (3); (6) the step (5) is repeated to construct the multiple vegetation nursery grooves in the slope surface of the side slope; (7) base material mixtures are sprayed to the whole slope surface; and (8) the vegetation nursery grooves are filled, namely the side slope ecological protection is achieved through the combination of the vegetation nursery grooves and the hung-net spray-seeding. According to the side slope ecological protection method combining the vegetation nursery grooves with the hung-net spray-seeding, the vegetation nursery grooves and the hung-net spray-seeding are combined organically, and the attachment of the nets and the slope surface is improved. In addition, the stability of the side slope is improved, and the project investment is reduced, so that the anticipative ecological protection function on the constructed project can be achieved.

Owner:CHINA THREE GORGES UNIV +2

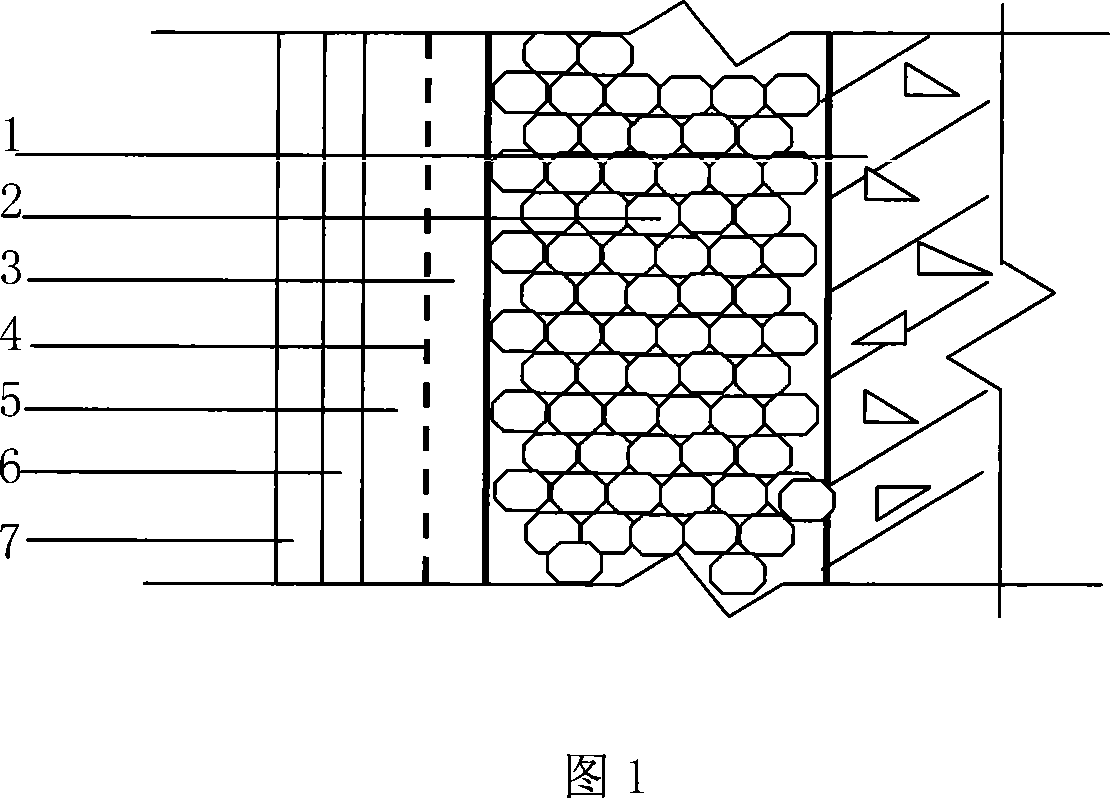

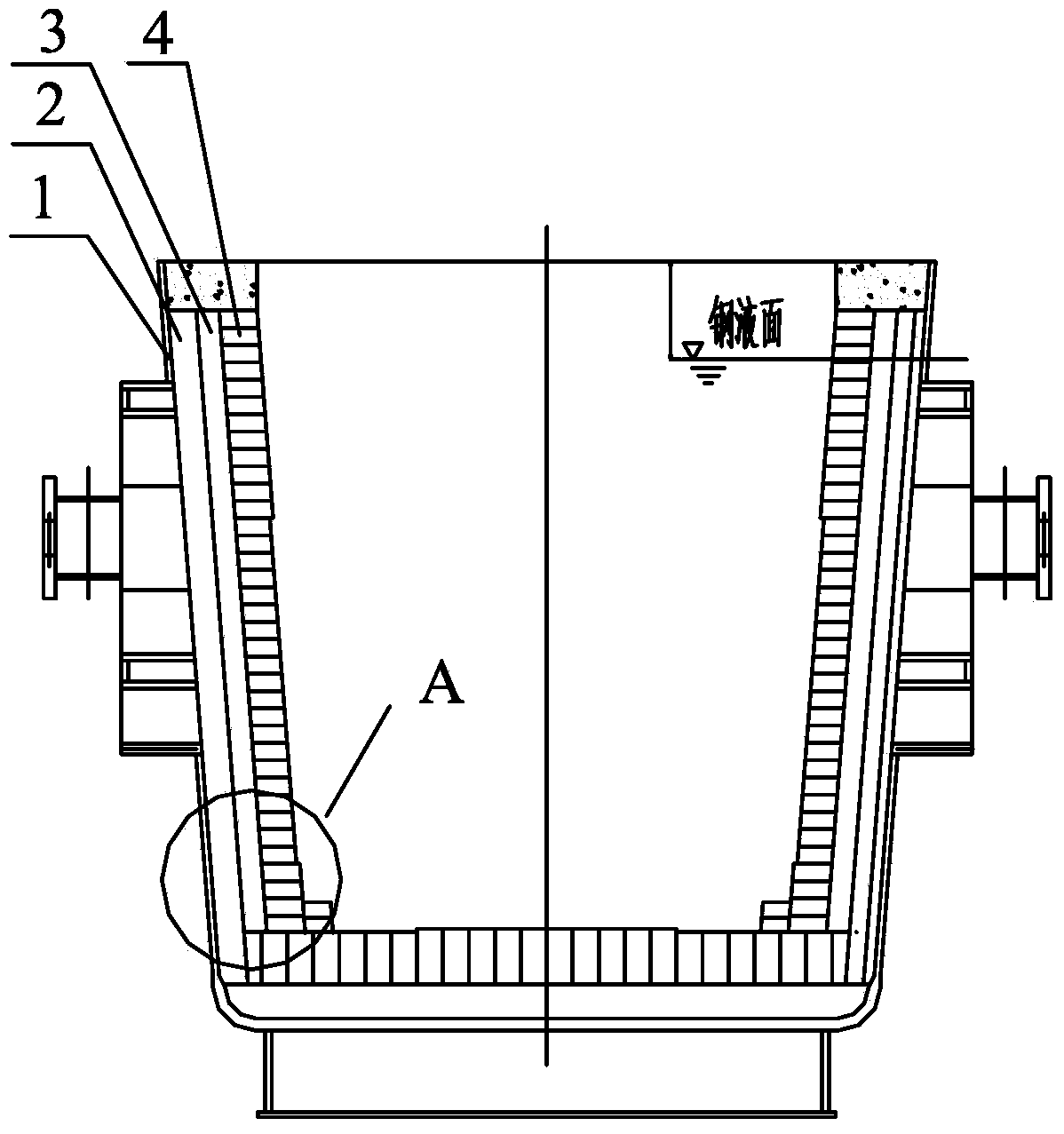

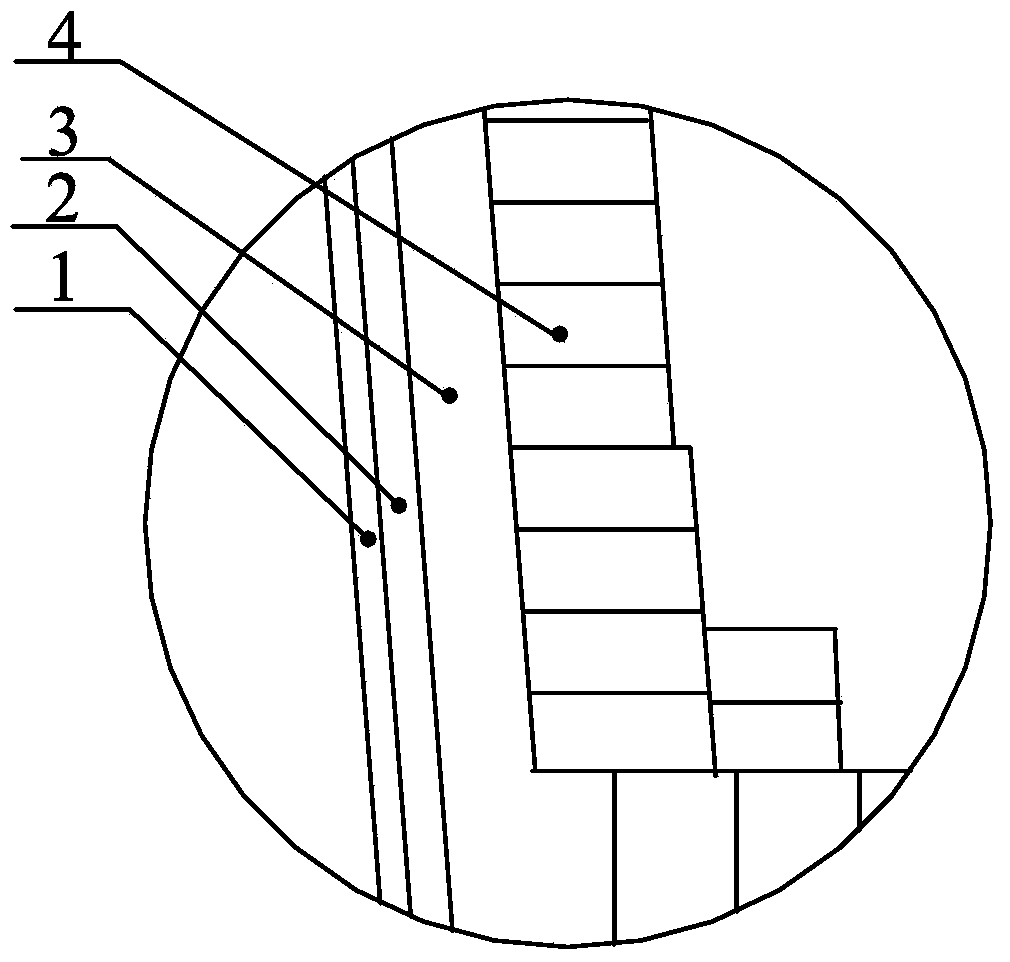

Optimized long-life low-material-consumption refining ladle

ActiveCN104226970AImprove securityHigh temperature working strengthMelt-holding vesselsBrickThermal insulation

The invention discloses an optimized long-life low-material-consumption refining ladle. The ladle comprises a ladle shell, wherein a permanent layer is built on the inner wall of the ladle shell; a cyclic work layer is poured on the inner wall of the permanent layer; a consumptive work layer is built on the inner wall of the cyclic work layer; the castable of the cyclic work layer comprises the following components in parts by weight: 55-70 parts of sintered microporous corundum aggregate, 5-10 parts of magnesium aluminum spinel aggregate, 10-25 parts of fine powder, 2-8 parts of micro powder, 3-8 parts of bonding agent, 0.1-0.5 parts of antidetonant, 0.05-2 parts of water reducing agent and 0.01-0.1 parts of foaming agent. The cast cyclic work layer improves the safety coefficient for use of the refining ladle, has good integrity and effectively blocks the penetration of molten steel from brick joints of the permanent layer, and the cast cyclic work layer has low thermal conductivity and good thermal insulation property and can greatly reduce the consumption of the refractory material per ton of steel.

Owner:WUGANG REFRACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com