Preparation method for organic silicon impregnating varnish

A technology of organosilicon impregnation and organosilicon, applied in the direction of coating, etc., can solve the problems of poor internal dryness, poor production safety, serious environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

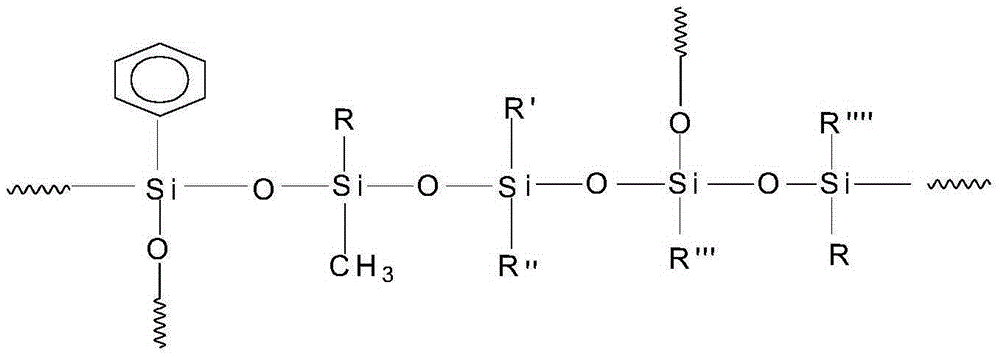

Method used

Image

Examples

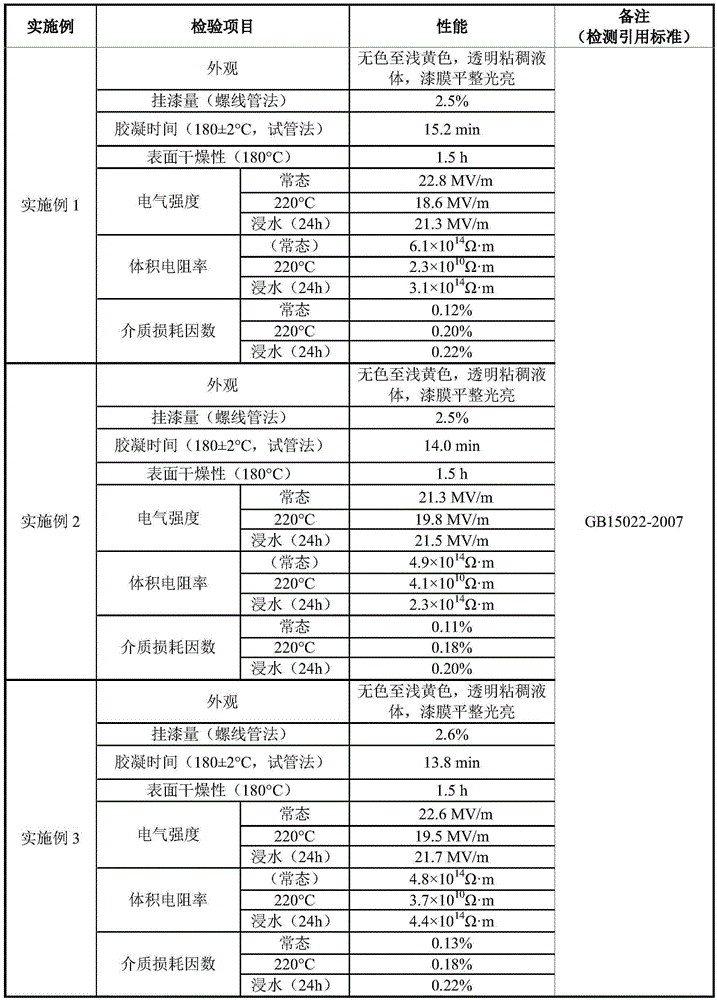

Embodiment 1

[0037] Take 0.6mol of monophenyltrimethoxysilane, 0.1mol of dimethyldiethoxysilane, 0.4mol of methylvinyldimethoxysilane, 0.1mol of diphenyldimethoxysilane, and 0.1mol of hexamethyldisilane Oxane 0.2mol, at a temperature of 50°C, slowly add the organosilicon mixed monomer dropwise at a speed of 5L / min to the mixed solution composed of water and organic solvent with rapid stirring, and the dropwise hydrolysis reaction lasts for 5 hours, during which Keep the hydrolysis reaction temperature not exceeding 60°C, continue stirring for 2 hours after the dropwise addition, remove the acid water layer by layer, separate the organic solvent layer of the resin, then wash with water until neutral, and heat up until the organic solvent layer of the silicone resin boils , concentrated under reflux for 4 hours, and then filtered to obtain a solution of the organosilicon hydrolysis condensation prepolymer; filter the organosilicon solution, and then remove the solvent used for hydrolysis unde...

Embodiment 2

[0041] Take 0.8mol of phenyltrimethoxysilane, 0.1mol of methyltrimethoxysilane, 0.1mol of dimethyldiethoxysilane, 0.4mol of dimethylvinylmethoxysilane, and 0.4mol of methylphenyldimethoxysilane 0.2 mol of base silane and 0.2 mol of hexamethyldisiloxane, at a temperature of 50°C, slowly add the organosilicon mixed monomer dropwise at a rate of 3 L / min into the mixed solution composed of water and organic solvent with rapid stirring , the dropwise hydrolysis reaction continued for 5 hours, during which the hydrolysis reaction temperature was kept not exceeding 60°C, and the stirring was continued for 2 hours after the dropwise addition, and the acid water was removed in layers, and the organic solvent layer of the resin was separated, and then washed with water until neutral. Raise the temperature until the organic solvent layer of the silicone resin boils, concentrate under reflux for 4 hours, and then filter to obtain a solution of the silicone hydrolysis condensation prepolyme...

Embodiment 3

[0045] Take 0.7mol of monophenyltrimethoxysilane, 0.1mol of dimethyldiethoxysilane, 0.45mol of vinyltriethoxysilane, 0.2mol of diphenyldimethoxysilane, and 0.2mol of hexamethyldisiloxane 0.2mol, at a temperature of 50°C, slowly add the organosilicon mixed monomer dropwise at a speed of 8L / min to the mixed solution composed of water and organic solvent with rapid stirring, and the dropwise hydrolysis reaction lasts for 5 hours, during which it keeps The temperature of the hydrolysis reaction does not exceed 60°C. After the dropwise addition, continue to stir for 2 hours, remove the acid water layer by layer, separate the organic solvent layer of the resin, and then wash it with water until it is neutral, and heat up to the organic solvent layer of the silicone resin. Concentrate under reflux for 4 hours, and then filter to obtain a solution of the organosilicon hydrolysis condensation prepolymer; filter the organosilicon solution, and then remove the solvent used for hydrolysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com