Patents

Literature

35 results about "Hexamethyldisilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

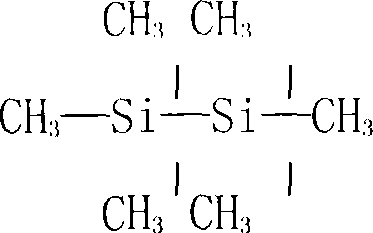

Hexamethyldisilane (TMS₂) is the organosilicon compound with the formula Si₂(CH₃)₆, abbreviated Si₂Me₆. It is a colourless liquid, soluble in organic solvents. The Si-Si bond in hexamethyldisilane is cleaved by strong nucleophiles and electrophiles.

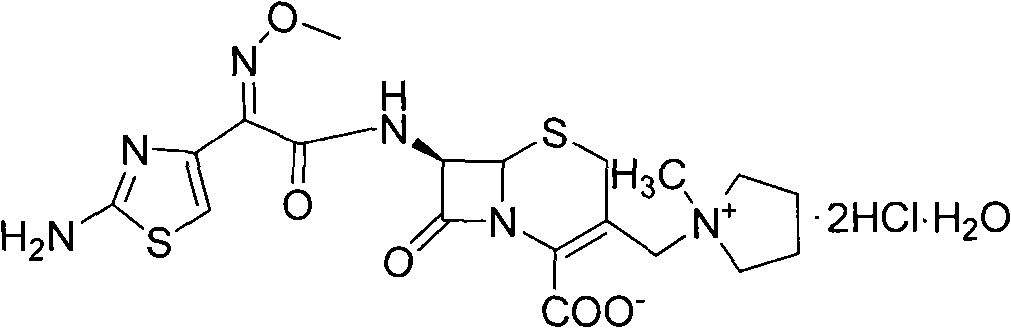

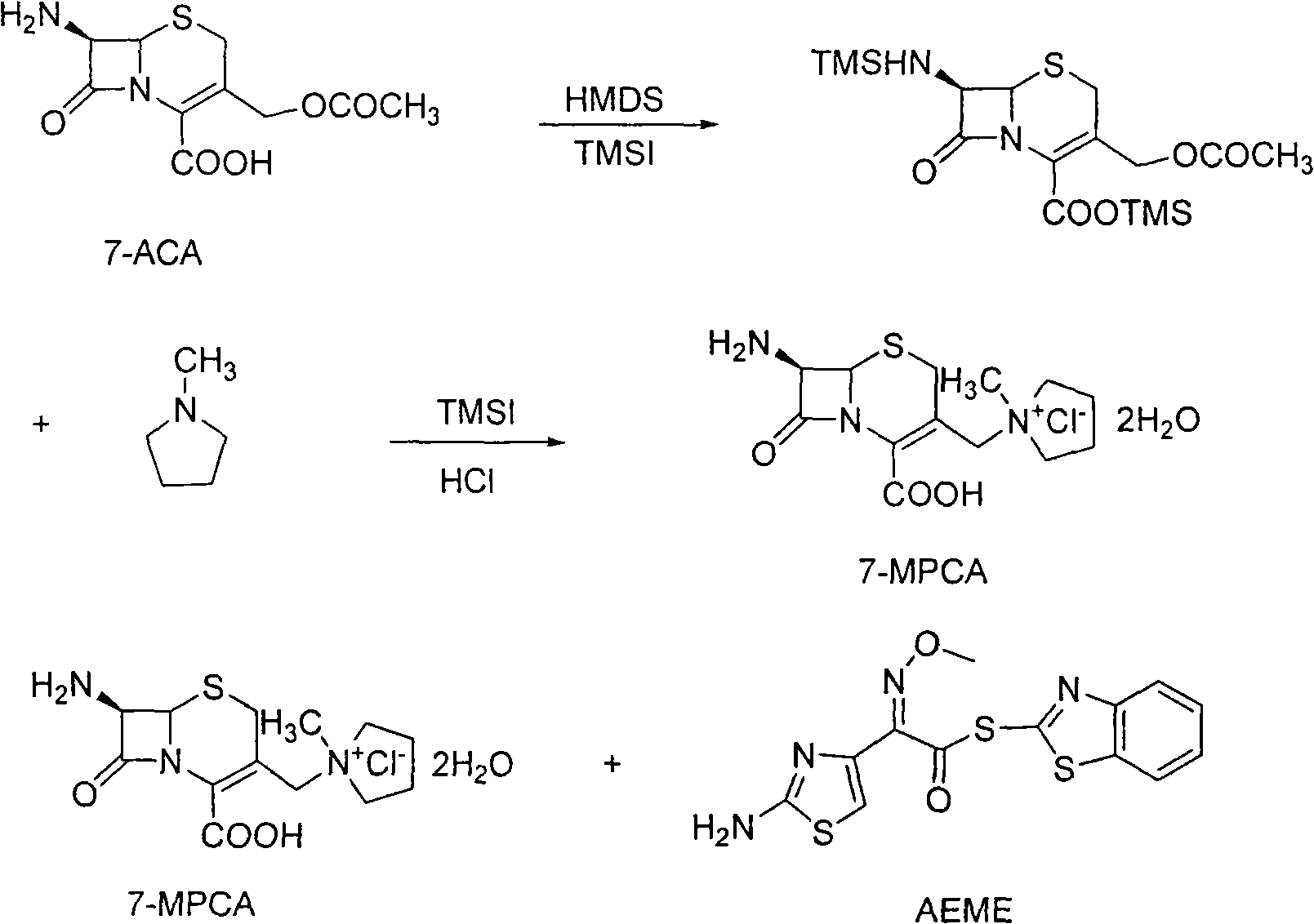

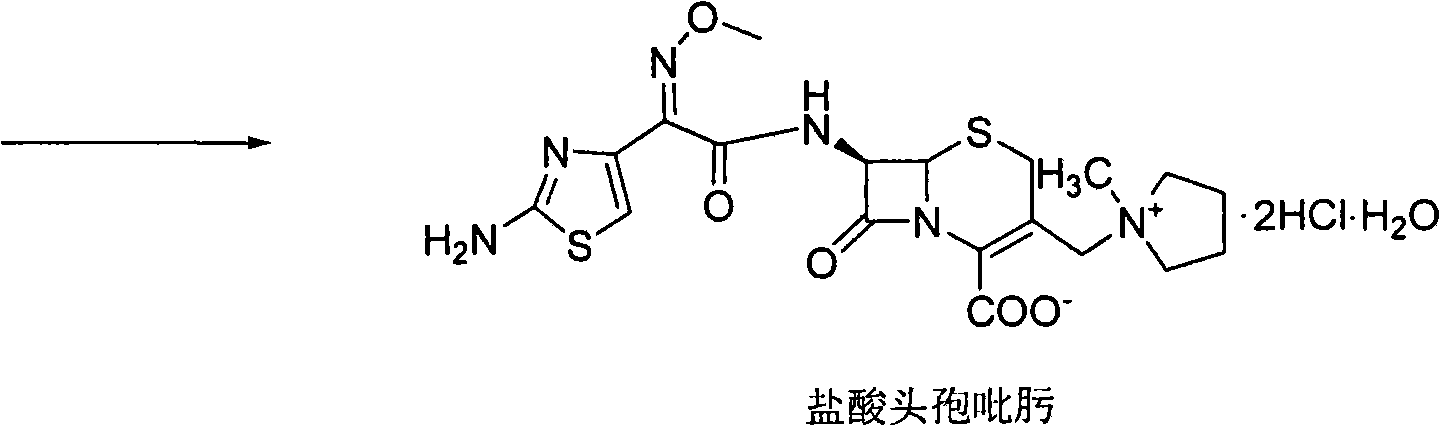

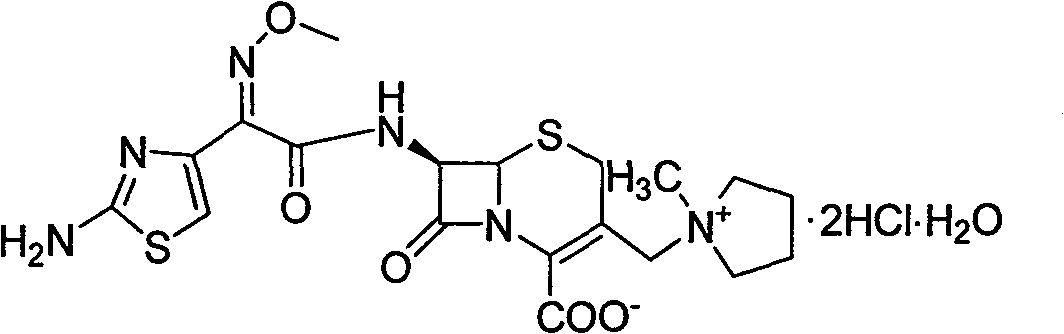

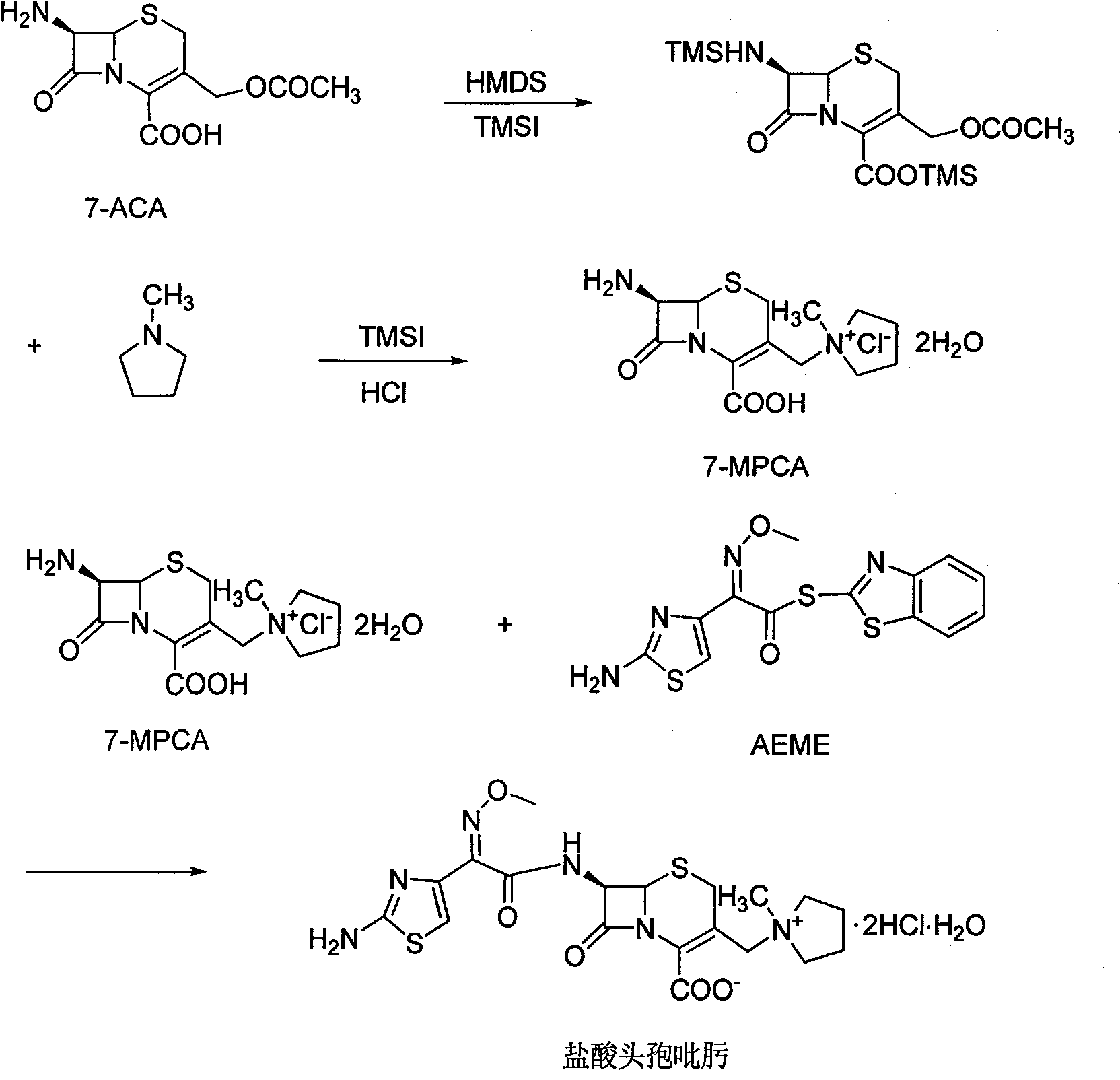

Method for synthesizing antibiotic cefepime hydrochloride

ActiveCN101337971ASimple process conditionsEasy to operateAntibacterial agentsOrganic chemistryCefepime hydrochlorideHexamethyldisilane

The invention relates to a synthesis method of cefepime dihydrochloride that is a bacteriophage. 7-amin cethalosporanic acid (7-ACA) is used as starting material and reacts with hexamethyldisilane amine (HMDS) and iodotrimethylsilane (TMSI) first to obtain 7-ACA for protecting amino and carboxyl; then 7-ACA, amino and carboxyl of which are protected, reacts with iodotrimethylsilane and N-methylpyrrolidine to synthesize (6R, 7R)-7-amino-3-((1-methyl-1-pyrrolidine) methyl) cephalosporin-3-alkene-4-carboxylic acid hydrochloride (7-MPCA) through a one-pot method; 7-MPCA reacts with AE active ester to obtain a product of cefepime dihydrochloride through acidylation reaction and salifying reaction. Compared with the existing technical route, the synthesis method has the advantages that the process conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, the method is suitable for the large-scale industrialized production, etc.

Owner:国药集团致君(苏州)制药有限公司

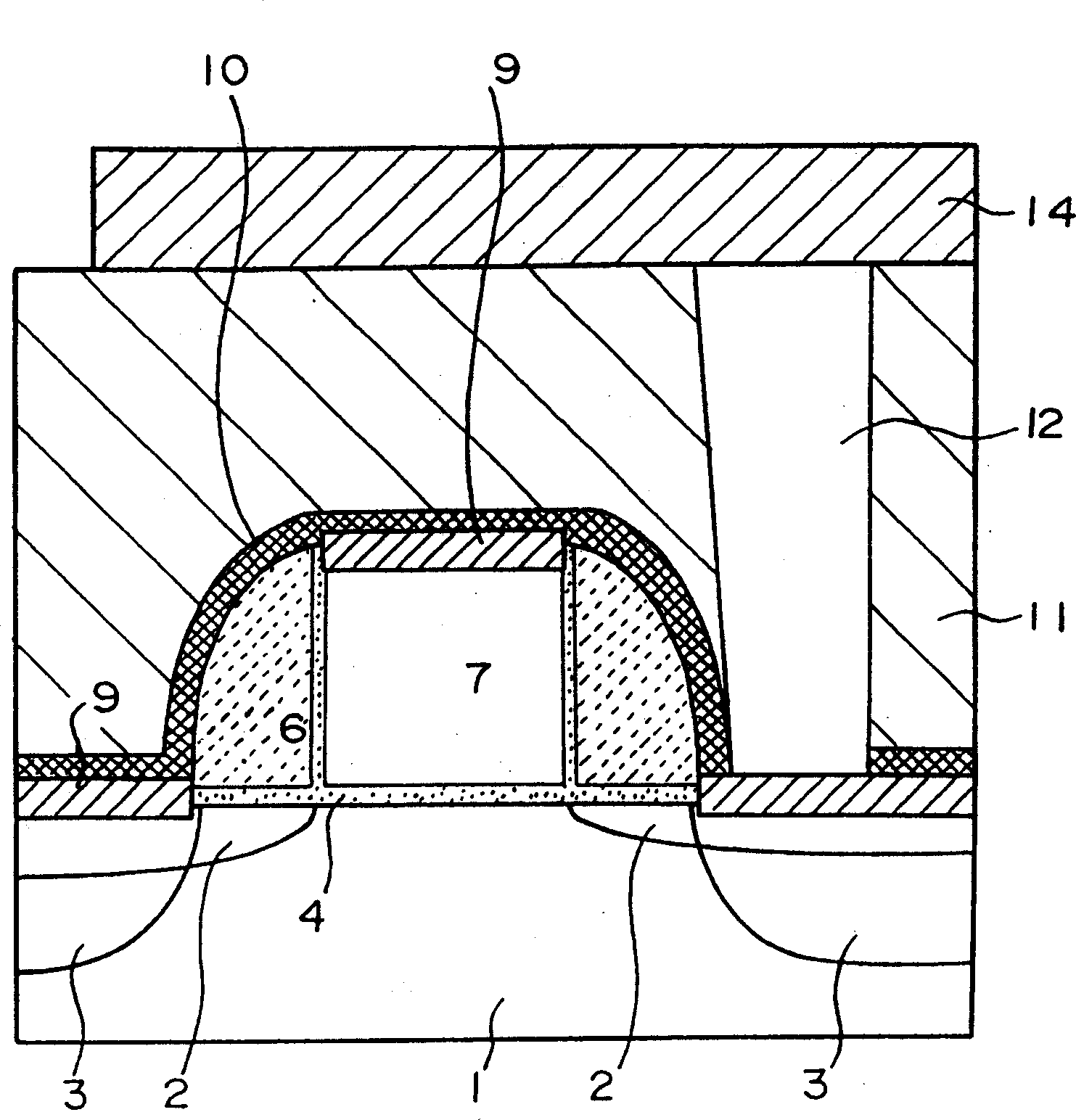

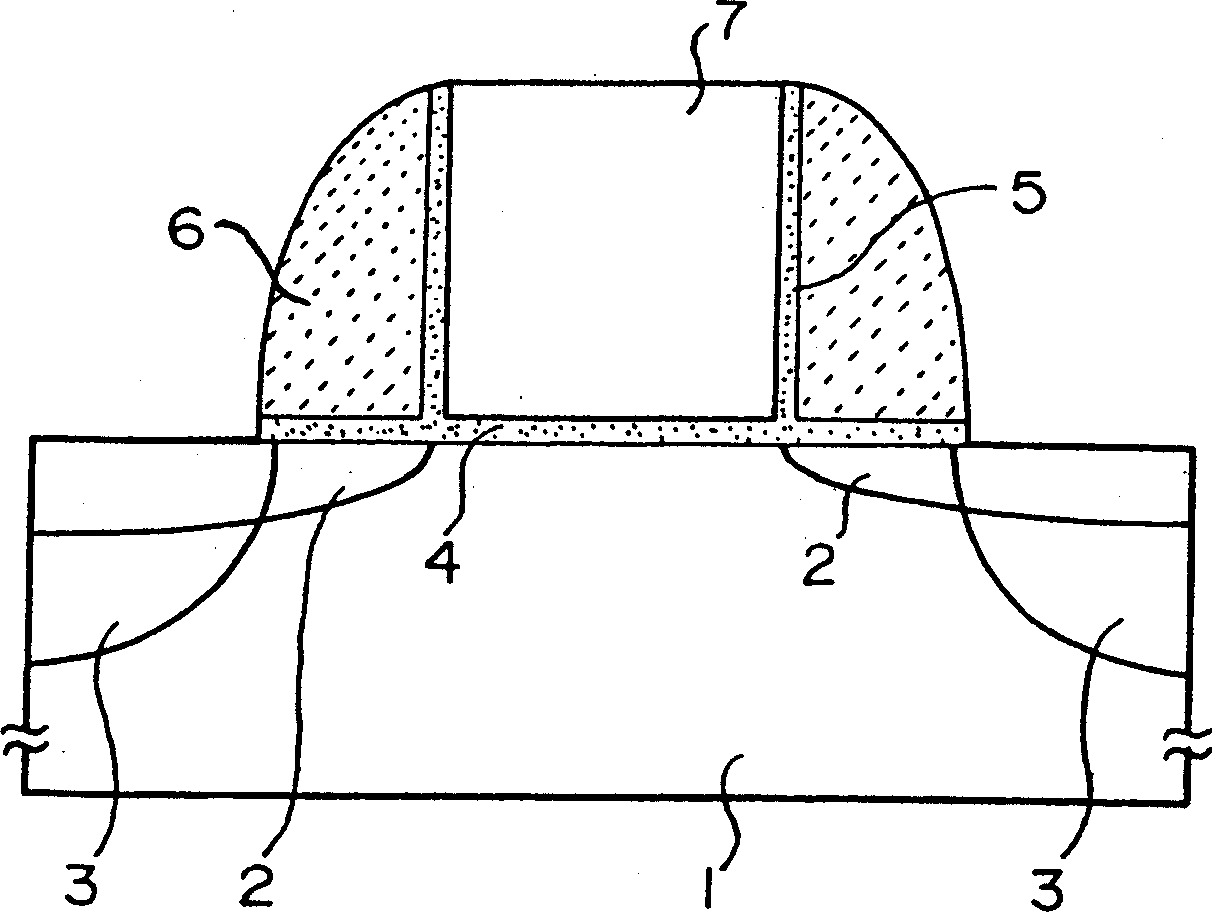

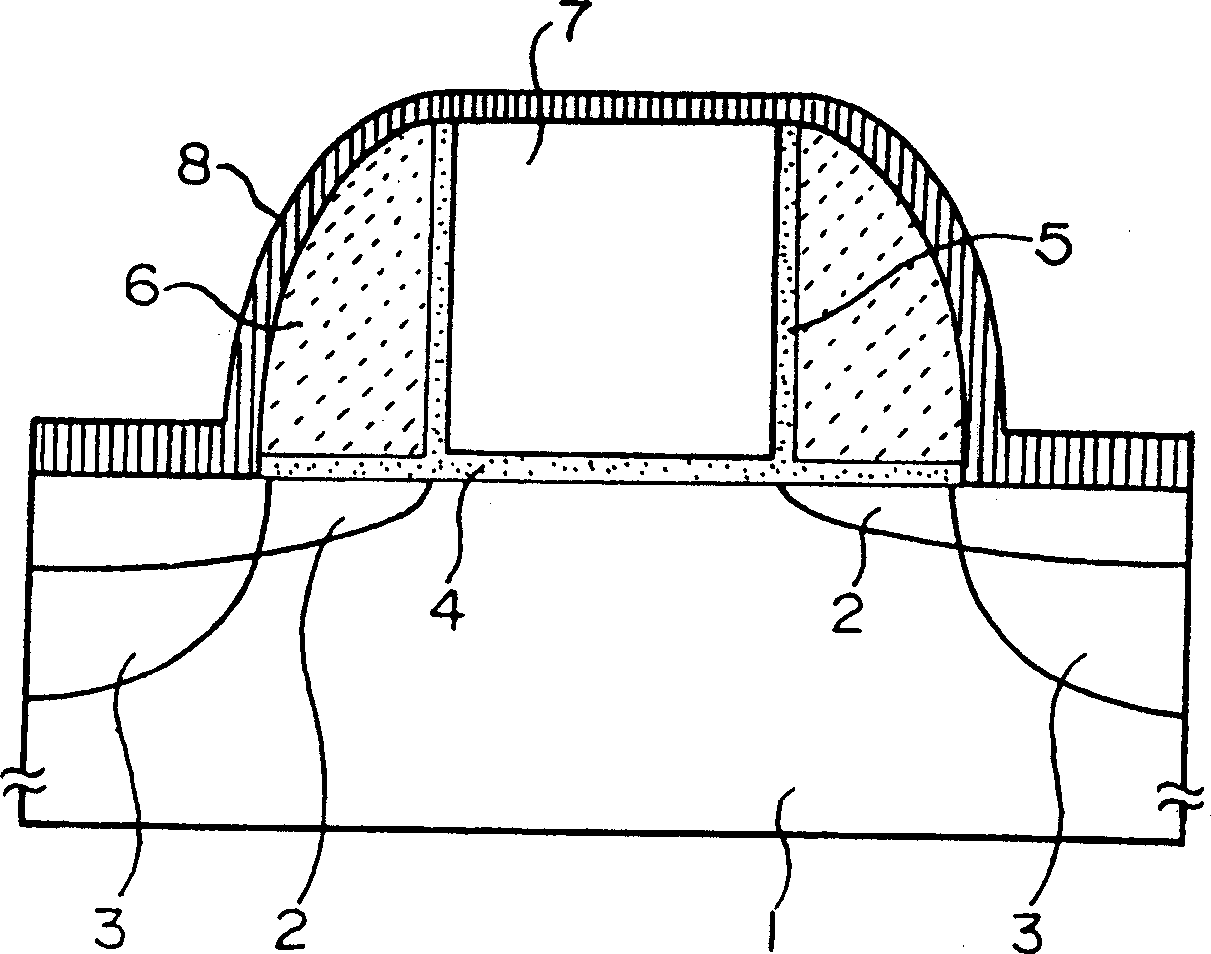

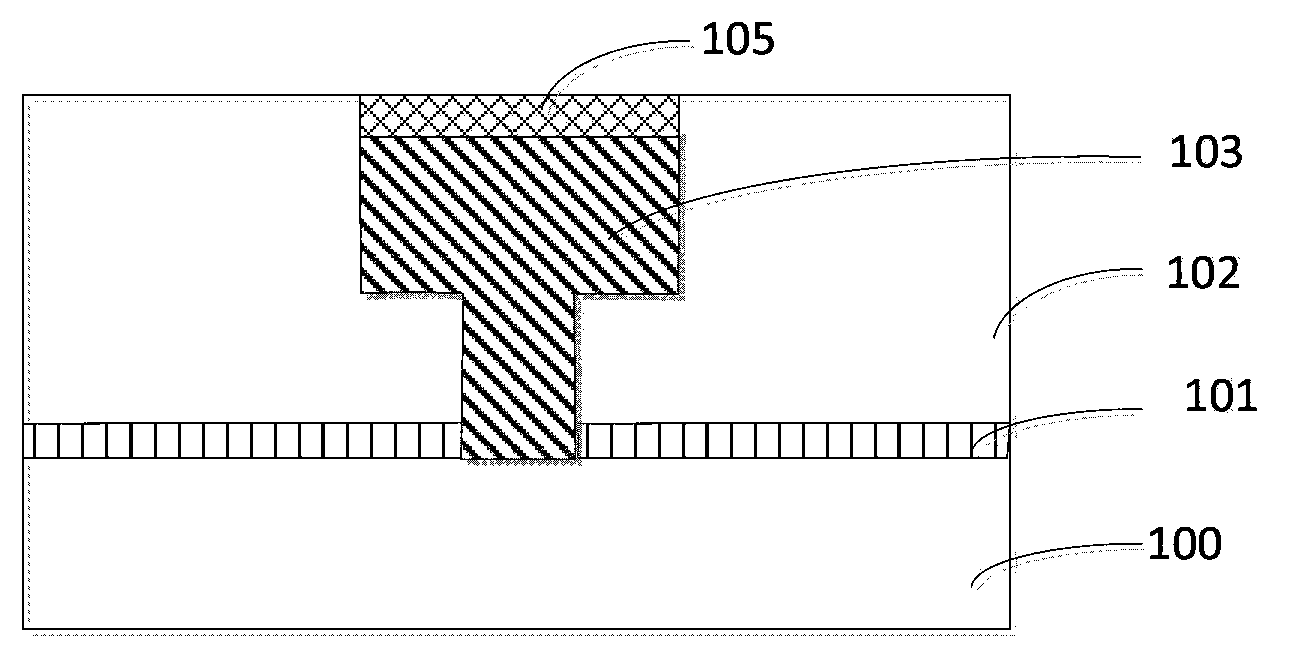

Semiconductor device and its manufacturing method

InactiveCN1497737ANo deteriorationTransistorSemiconductor/solid-state device detailsHexamethyldisilaneSalicide

A semiconductor device having an insulted silicon nitride layer insulated silicon nitride layer without deteriorating the metal silicide composed conduction layer and its manufacturing method are provided. Form an insulated film 10 mainly comprising uniform carbon-contented silicon nitride film on the metal silicide, for example, nickel silicide conduction layer 9. The carbon contented nitride film is made by reacting the nitrified seed and silicon source. Methyl-contented hexamethyldisilane is adopted as the silicon source, so the nitride film formed through the reaction consists of carbon and hydrogen. Furthermore, if it contains methyl, the film becomes porous, so the dielectric constant is reduced. Therefore, the RC delay-induced transistor speed degradation will be suppressed. By means of carbon-contented silicon nitride film, the metal silicide conduction layer is not deteriorated during process. The silicon source could be amino or free radical of amino having carbide.

Owner:KK TOSHIBA

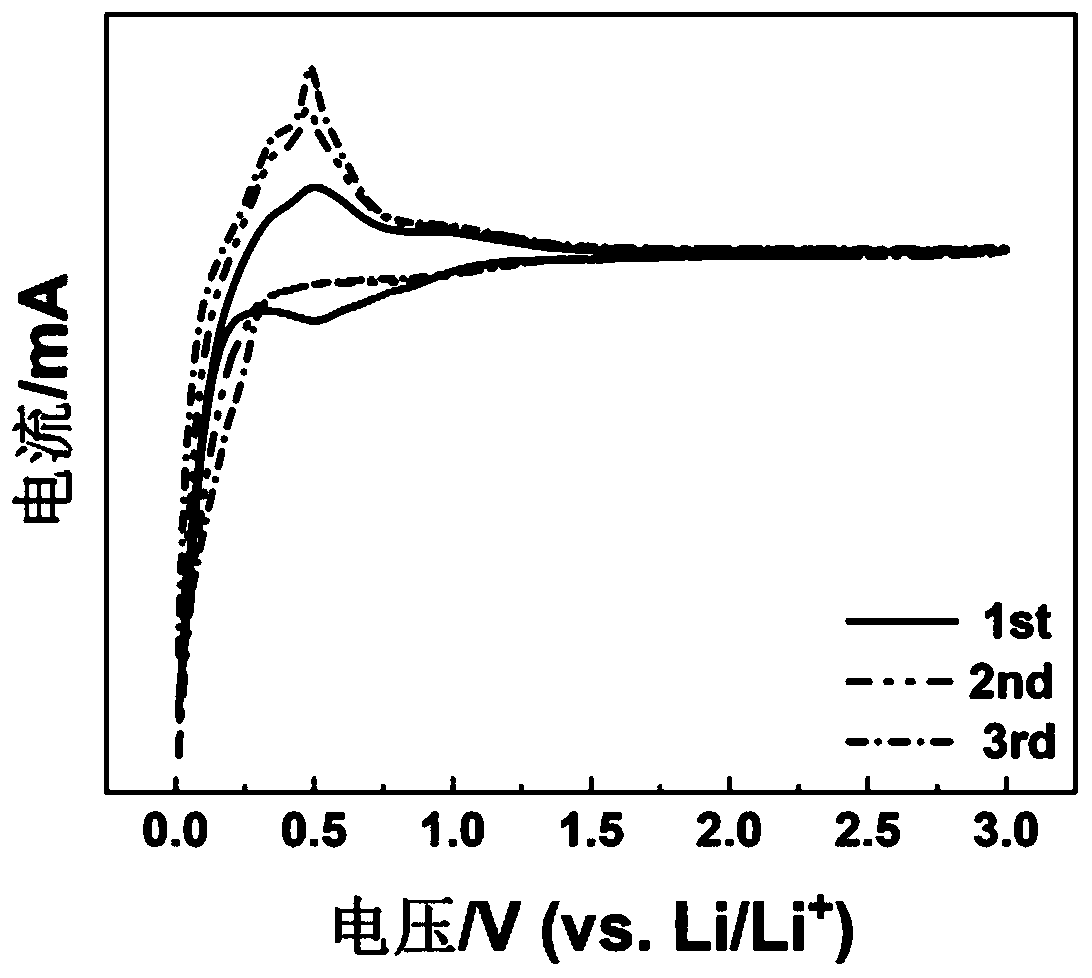

Reference electrolyte capable of improving cycling performance of lithium-sulfur battery and preparation method

InactiveCN107819152ALow priceImprove cycle performanceElectrolytesLi-accumulatorsHexamethyldisilaneLithium–sulfur battery

The invention belongs to reference electrolyte capable of improving the cycling performance of a lithium-sulfur battery and a preparation method. The reference electrolyte is prepared from an ether type solvent, lithium salt, lithium nitrate and an additive for improving the cycling performance, wherein the ether type solvent is a mixture of two solvents; a first solvent is any one of 1,3-dioxolane and 1,4-dioxane; a second solvent is any one of ethylene glycol dimethyl ether, diethylene glycol dimethyl ether and tetraethylene glycol dimethyl ether; the lithium salt is any one of LiPF6, LiBF4,LiTFSi, LiFSi and LiBOB; the additive for improving the cycling performance is any one of 3-aminopropyltriethoxysilane, hexamethyldisilane and tetraethyl silicate. The reference electrolyte has the advantages that a preparation process is simple, the prices of the solvents and the additive are cheap, and materials are saved; the reference electrolyte can have a good negative electrode lithium protection effect; after lithium-sulfur battery electrolyte is used in the lithium-sulfur battery, the cycling performance and the safety of the lithium-sulfur battery can be remarkably improved.

Owner:HUARUI XINXIANG CHEM

Synthesis process of hexamethyldisilane

ActiveCN1974579AHigh purityReduce manufacturing costSilicon organic compoundsHexamethyldisilaneTrimethylsilyl chloride

The synthesis process of hexamethyldisilane is one kind of chemical technological process. The process includes the following steps: throwing xylene, crown ether and metal sodium into reaction kettle in oxygen free condition; heating via stirring and dropping trimethylchlorosilane to react under controlled temperature; maintaining the temperature after reaction for certain time and lower the temperature inside the reaction kettle to 50 deg.c; dropping water into the kettle and settling to delaminate; and distilling in an oil-water separator to obtain crude hexamethyldisilane product. The present invention makes crown ether to participate the reaction of metal sodium and trimethylchlorosilane, and this can alter the potential of metal sodium, raise the activity of metal sodium and raise the crude hexamethyldisilane product yield to 73.17 %.

Owner:扬州三友合成化工有限公司

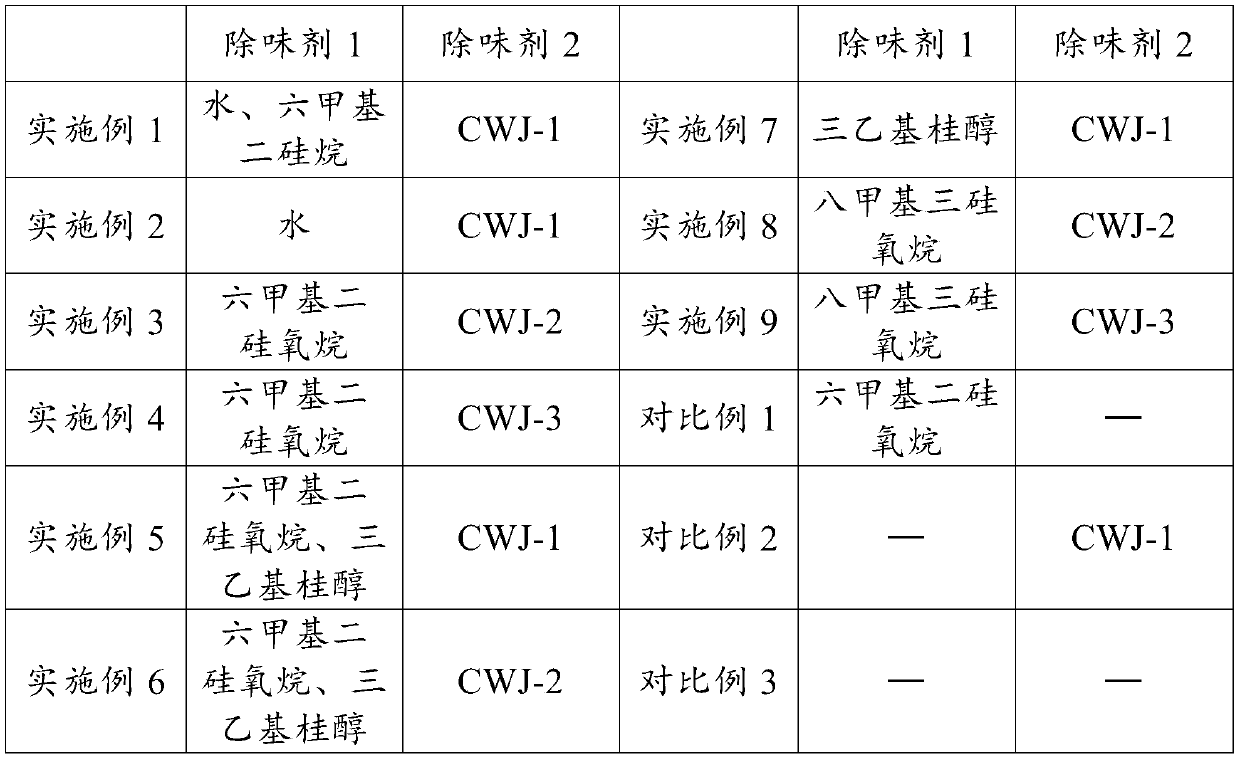

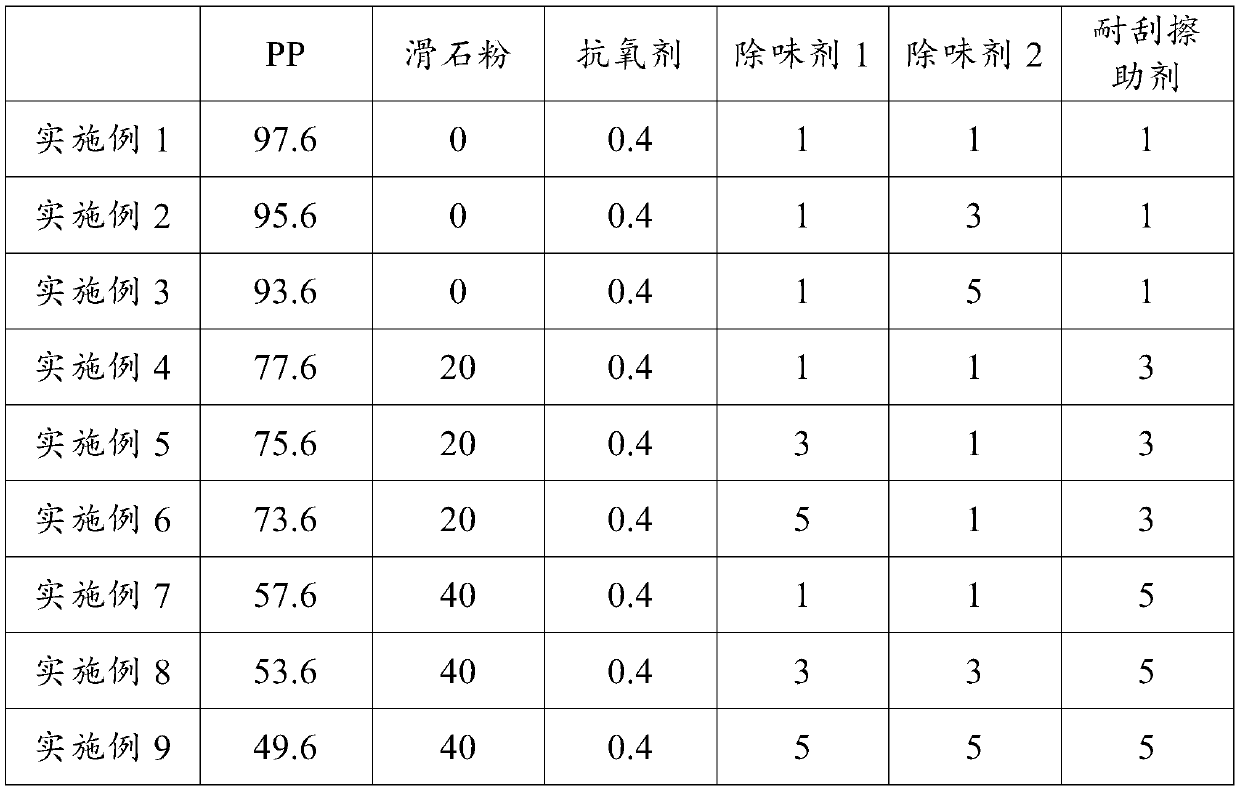

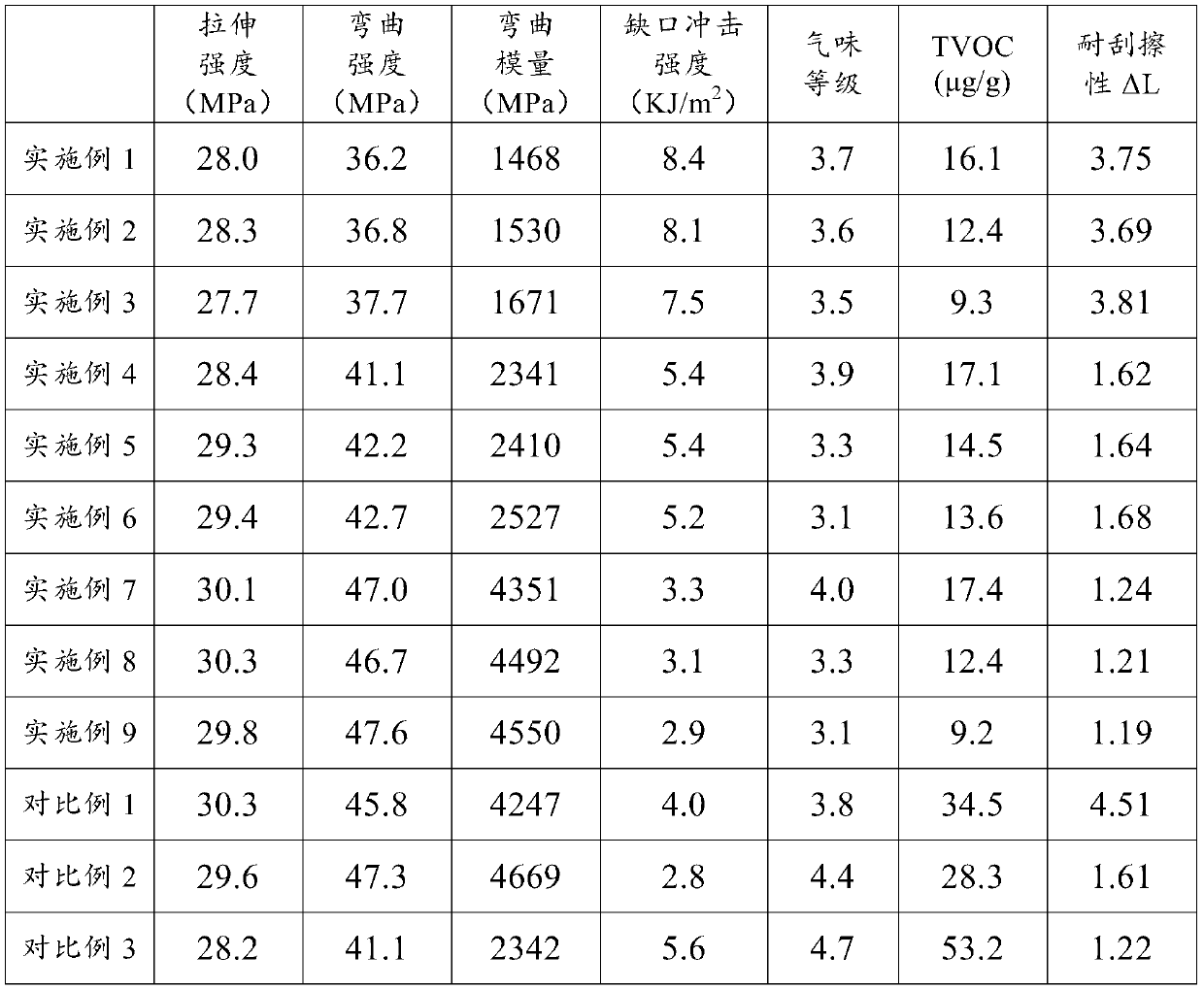

Low-odor scratch-resistant polypropylene composite material and preparation method thereof

The invention relates to a low-odor scratch-resistant polypropylene composite material, which is prepared from the following raw materials by mass: 44.6-96.6% of polypropylene, 0-40% of talcum powder,0.4-4% of an antioxidant, 1-5% of a deodorant 1, 1-5% of a deodorant 2 and 1-5% of a scratch-resistant aid, wherein the deodorant 1 is one or a plurality of materials selected from water, hexamethyldisilane, hexamethyldisiloxane, triethylsilanol and octamethyltrisiloxane, and the deodorant 2 is mesoporous silica or a 13X type zeolite molecular sieve loading at least one selected from ethylenediamine tetraacetic acid salt, methylene triamine pentamethylene phosphoric acid, ethylenediamine tetramethylene phosphoric acid and 2,4-dinitrophenylhydrazine. According to the invention, the product hasexcellent low-odor and excellent scratch resistance, reduces the antagonism among odor, diffusivity and scratch resistance, and finally realizes the balance of odor, diffusivity and scratch resistance of the product.

Owner:中广核俊尔(上海)新材料有限公司

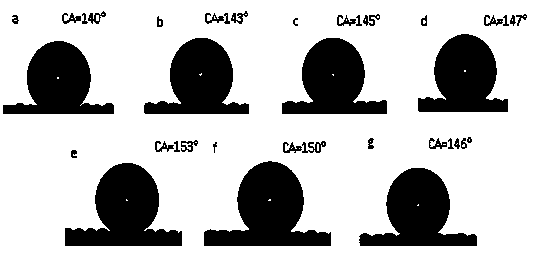

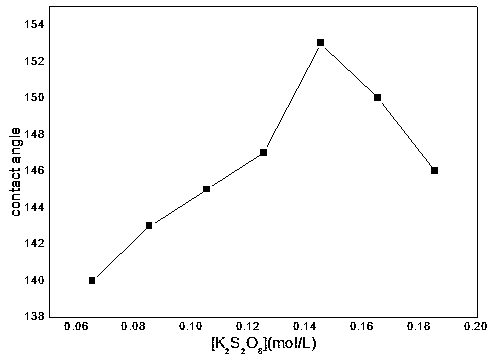

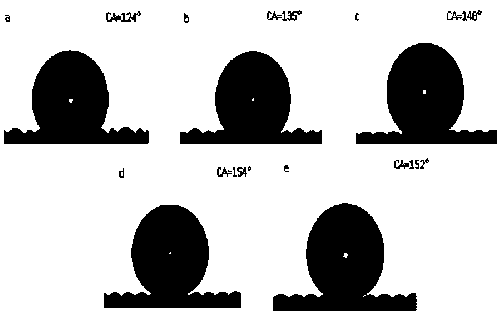

Preparation method for improving metal hydrophobicity based on vapor deposition method

InactiveCN109207979ANo change in appearanceImprove surface hydrophobicityVacuum evaporation coatingSputtering coatingElectricityHexamethyldisilane

The invention discloses a preparation method for improving metal hydrophobicity based on a vapor deposition method. The method comprises the steps that 1, the surface oxidation control method is utilized for generating an oxidation metal film on the metal surface; and 2, hexamethyldisilane modifies oxidation metal through the vapor deposition method. By using the manufacturing method of super-hydrophobic metal, surface hydrophobicity of the metal is improved correspondingly, the hexamethyldisilane is cheap and low in toxicity compared with chlorine and fluorine containing reagent, and is friendly to environment, thus the metal does not corrode easily in the humid environment, or does not frost or freeze easily at the low temperature, thus heat conduction to the metal is avoided, the influence on electricity conducting performance is avoided, the stability of metal products and devices is improved directly and substantially, and the property of people and social safety are guaranteed.

Owner:XUCHANG UNIV

Method for preparing hexamethyldisilane

ActiveCN101182328AHigh yieldPollution-free targetSilicon organic compoundsChemical industryHexamethyldisilane

The present invention discloses a preparation method of an organic silicon material and concretely indicates a preparation method of hexamethyldisilane. The present invention considers one kind of two kinds of dimethylbenzene and trimethylbenzene as solvent, wherein, the dimethylbenzene is preferential; the solvent is put in a reactor under the state without oxygen, metal potassium is put into the solvent, then solution is heated to 60 DEG C to 85 DEG C, furthermore trimethylchlorosilane is added to react for certain time, finally the product can be obtained by normal separation method. The present invention has the advantages of saving energy, short reaction time, high product yield etc. The present invention can be widely applied to almost all national economic fields of the defense and military industry, the aviation and aerospace field, the electronic and electrical field, the building field, the machinery field, the metallurgy, the automobile field, the instrument field, the weaving field, the chemical industry, the light industry, the food field, the medical and health field, the personal health care field etc.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD

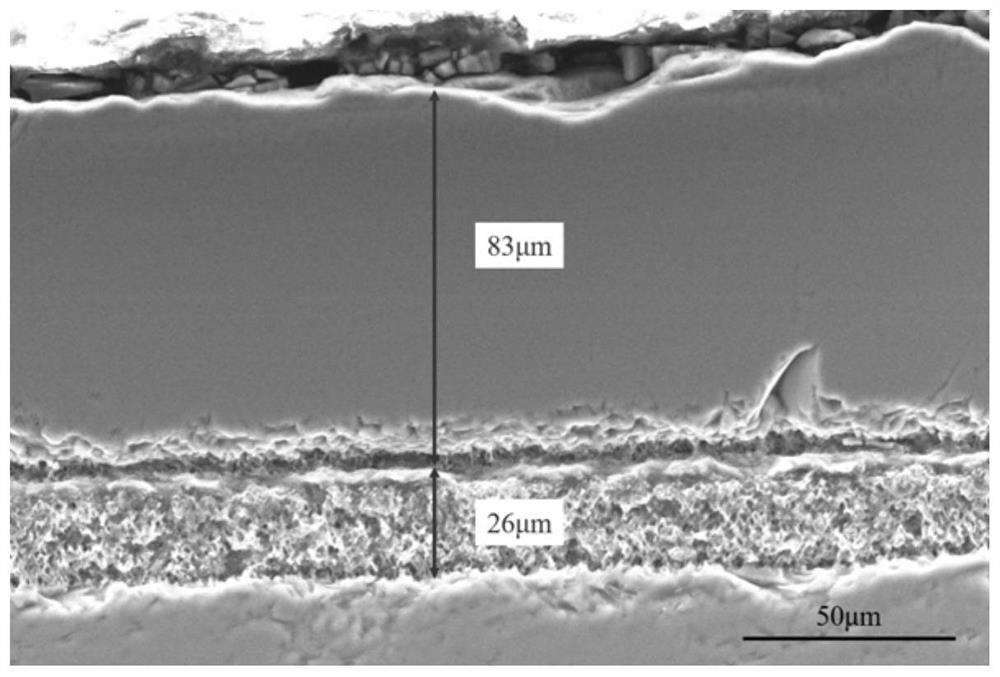

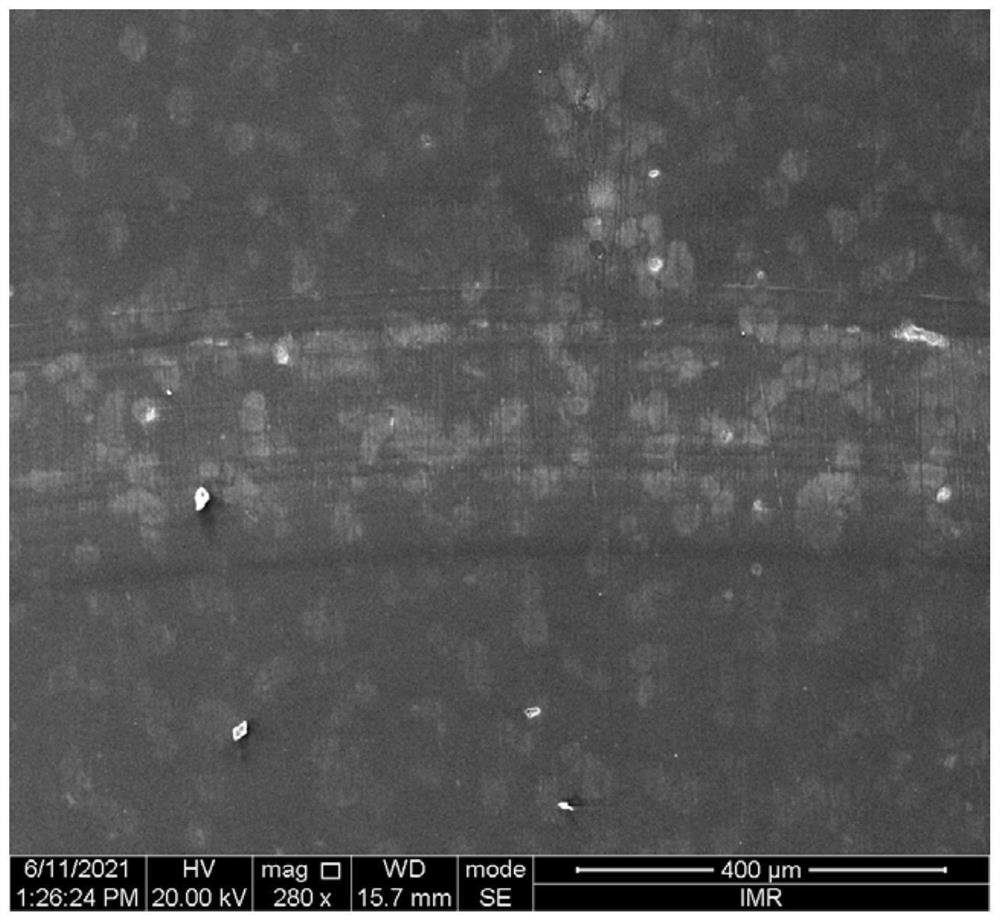

Chemical vapor deposition method for preparing silicon carbide composite coating on monocrystalline silicon or polycrystalline silicon

ActiveCN112647055ASolve the poor interfaceCompact structureChemical vapor deposition coatingHexamethyldisilaneCarbide silicon

The invention belongs to the field of coating preparation, and particularly relates to a chemical vapor deposition method for preparing a silicon carbide composite coating on monocrystalline silicon or polycrystalline silicon. A metal organic compound chemical vapor deposition (MOCVD) system is adopted, a liquid raw material hexamethyldisilane (HMDS) or hexamethyldisiloxane (HMDSO), H<2> and Ar gas system is selected, the working pressure is 10-1000 Pa, and the temperature is 900-1350 DEG C. Before the coating is deposited, pretreatment is carried out on a monocrystalline silicon or polycrystalline silicon substrate to form a porous silicon layer, then the coating is deposited on the porous silicon layer, and the composite coating sequentially comprises a porous silicon layer, a buffer layer, an SiOC layer and a pure SiC layer from a Si matrix. The silicon carbide composite coating deposited by adopting the method has the advantages of being compact in structure, free of obvious cracks, good in combination with the matrix and the like. According to the composite coating designed by the method, the stress matching problem of the SiC coating and the Si matrix is ingeniously coordinated, and the thickness of the composite coating prepared by adopting the method can exceed 1.5 mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Flexible MXene/Si composite material as well as preparation method and application thereof

The invention discloses a flexible MXene / Si composite material as well as a preparation method and application thereof. The preparation method comprises the steps of putting an MXene film into an electroplating solution for electro-deposition, and depositing a layer of silicon film on the surface of the MXene film. The electroplating solution is a mixed solution of a silicon source, a phase transfer catalyst and an organic solvent, wherein the silicon source is one or a mixture of two or more of silicon tetrachloride, hexamethyldisilane, cyclopentyl trichlorosilane, methoxytrimethylsilane, hexaphenyl disiloxane, hexaphenyl cyclotrisiloxane, tetrakis (trimethylsiloxy) silane, ethoxytriphenylsilane, triisopropylsilane, trimethylsilanol potassium, trichlorosilane, tetraethoxysilane and silicon bromide. The preparation method disclosed by the invention is simple and feasible. The production cost can be reduced, and the obtained MXene and silicon have relatively strong acting force.

Owner:SHANDONG UNIV

Iodotrimethylsilane preparing by dissolving and adding iodine

ActiveCN104926851ANo pollutionQuick responseGroup 4/14 element organic compoundsHexamethyldisilaneDistillation

The invention provides an iodotrimethylsilane preparation method. The preparation method comprises the following steps that half hexamethyldisilane is put in a reaction flask, a layer of rectifying column packing glass springs is added in a constant pressure dropping funnel, then elementary substance iodine and half hexamethyldisilane are added in the constant pressure dropping funnel, vacuumizing and nitrogen replacing are performed on a reaction system, and all the steps are repeated for three times; stirring is started, the temperature rises to 65 DEG C, and hexamethyldisilane solutions of the iodine are dropwise added; after dropwise adding is finished, the outer temperature rises to 130 DEG C for backflow, and therefore after being cooled, steam enters the constant pressure dropping funnel to dissolve the undissolved iodine in the constant pressure dropping funnel; after the iodine is dissolved completely and dropwise added in the reaction system, reaction is performed for 2 hours until the reaction is complete; heating is stopped, the temperature is cooled below 30 DEG C, a reaction device is changed into a distillation device to collect main distillate fractions, and then colorless liquid iodotrimethylsilane competitive products are obtained.

Owner:山东博苑医药化学股份有限公司

Method of preparing hexamethyldisilane amine sodium solution

InactiveCN101492466AGroup 4/14 element organic compoundsSodium organic compoundsHexamethyldisilaneBoiling point

The invention provides a preparation method of hexamethyldisilane sodium amine solution which is characterized in that hexamethyldisilazane and sodium hydride react with each other in high boiling point solvent or without solvent. When the reaction is finished completely, tetrahydrofuran is used for the dissolution to obtain hexamethyldisilane sodium amine tetrahydrofuran solution, wherein, the mol ratio of the hexamethyldisilazane to the sodium hydride is 1.0 to 0.8-1.2. The sodium hydride is oil dispersed sodium hydride with the content of 60-70 percent and the reaction temperature of 80-130 DEG C. The reaction temperature in the high boiling point solvent is the reflux temperature, and the reaction time is 3-4 hours of the reflux state. Shown by detection and organic synthesis tests, the preparation method adopted by the invention has the advantages of simplicity, fast reaction speed and completeness of reaction.

Owner:SHAANXI DASHENG PHARMA TECH

Super-hydrophobic gel nano-coating for inhibiting bacterial adhesion, and preparation method thereof

ActiveCN111053696AGood biocompatibilityReduce adhesionImpression capsMedical preparationsHexamethyldisilaneBacterial Adhesions

The invention discloses a super-hydrophobic gel nano-coating for inhibiting bacterial adhesion, and a preparation method thereof. The super-hydrophobic gel nano-coating comprises, by weight, 5-10 parts of tetraethoxysilane, 5-10 parts of methanol, 5-20 parts of NH4OH, 5-10 parts of CH3OH, 0.1-0.01 part of dopamine hydrochloride, 50-100 parts of n-hexane and 5-10 parts of hexamethyldisilane. The preparation method comprises the following steps: preparing silica sol from tetraethoxysilane in an alkaline environment, adding dopamine to form a dopamine-silica gel, reacting the dopamine-silica gelwith hexamethyldisilane to form modified gel, drying the modified gel, and dissolving dried modified gel in ethanol to form a super-hydrophobic gel spray. The product has both surface super-hydrophobic property and matrix strong adhesion property, and also has good biocompatibility.

Owner:温州医科大学附属口腔医院

Method of synthesizing 2-deoxy-5-iodo-beta-uridine

InactiveCN101054398AReduce dosageSmall and low dosageSugar derivativesSugar derivatives preparationHexamethyldisilanePresent method

The invention relates to pharmaceutical chemistry technology field. The present invention discloses a synthesis method of 2-deoxy-5-iodo-beta-urdine synthesis method. The method is: heating ura with hexamethyldisilane, reacting with chloro-sugar, removing protecting group in methanol ammonia solution, obtaining 2-deoxy-beta- urdine, reacting with iodine in the presence of silver sulfate to obtain the 2-deoxy-5-iodo-beta-urdine. Compared with the other method, the inventive method has the following character: reaction condition is simple, material is easy to get and toxicity is little, dosage is little. The product yield and purity are high, cost of material reduce 50% more than original method so the present method is suitable for industrial production.

Owner:SHANGHAI DESANO PHARMA INVESTMENT +2

Sound-insulation and anti-fouling wallpaper and preparing method thereof

InactiveCN106592336ASimple preparation processRaw materials are easy to getFibreboardVegetable material additionHexamethyldisilaneOfficinalis

The invention discloses a sound-insulation and anti-fouling wallpaper. The sound-insulation and anti-fouling wallpaper is prepared from, by weight, 20-24 parts of white glues, 23-25 parts of rosin, 120-140 parts of paper pulp, 10-16 parts of a mould-proof agent, 10-14 parts of an anti-fouling agent and 1-3 parts of an interfacial modifier in a mixed mode; a fungus-proof agent is prepared from, by weight, 20-30 parts of pomegranate peels, 11-15 parts of whole herbs of corydalis bungeana and 8-13 parts of asparagus officinalis; the anti-fouling agent is prepared from, by weight, 12-16 parts of hexamethyldisilane, 2-4 parts of polysiloxane and 6-8 parts of sodium borate; the interfacial modifier is prepared from castor oil. The sound-insulation and anti-fouling wallpaper is simple in preparing technology, the raw materials are easy to obtain, the cost is low, the sound-insulation, anti-fouling and anti-mildew properties are good, and the service life of the wallpaper is greatly prolonged.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Organosilicon compound and synthesis method thereof

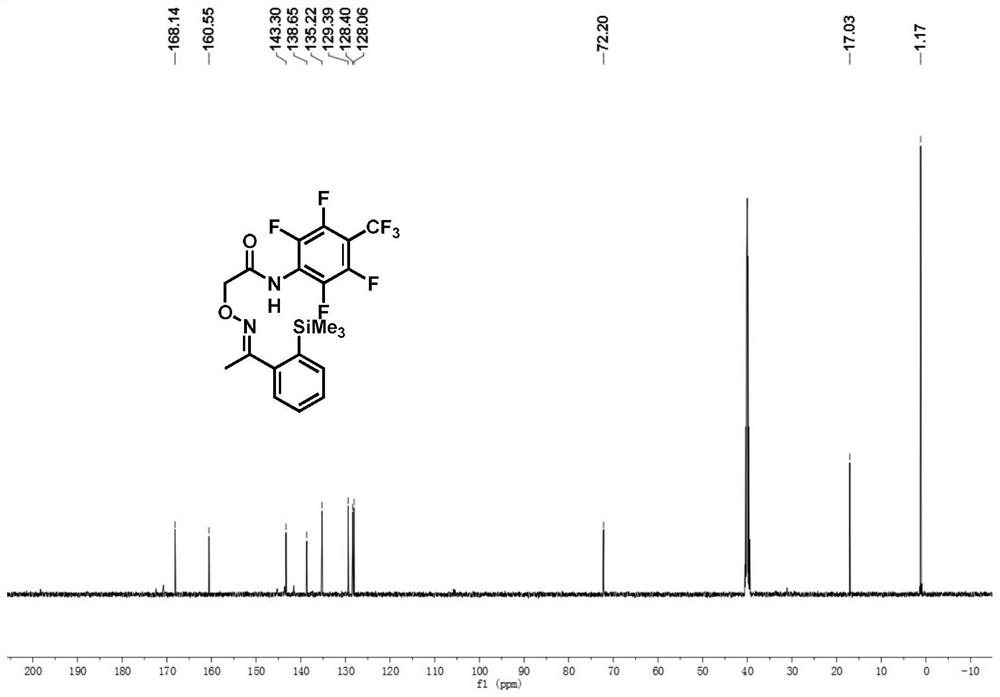

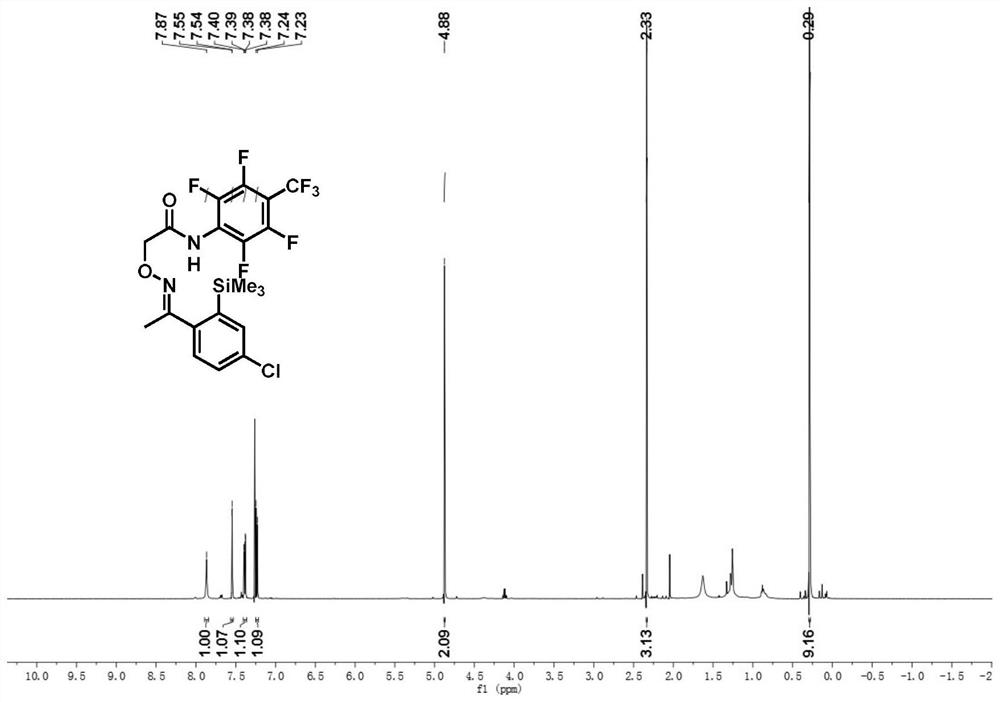

ActiveCN112778352AHigh selectivityEfficient responseSilicon organic compoundsHexamethyldisilaneOrganic synthesis

The invention discloses an organosilicon compound and a synthesis method thereof. The comprises the following steps: under the catalytic action of a palladium catalyst, in the presence of an organic solvent and an oxidizing agent, carrying out a C-H activation reaction on an acetophenone derivative provided with a guiding group and hexamethyldisilane to prepare a target product, namely, the organosilicon compound. The method is higher in reaction efficiency and selectivity, an organosilicon compound with a complex structure is obtained in one step, then commercially available acetophenone micromolecules are directly used as a substrate, ortho-position C-H silicification of acetophenone derivatives can be directionally realized under the auxiliary action of a guiding group by installing the guiding group, and the method has higher selectivity. The compound can be further used in the fields of organic synthesis conversion, materials science, medicinal chemistry and the like, and especially has a relatively high potential value and a wide application prospect in the field of medicinal chemistry.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of PVC special-effect halogen-free flame retardant

PendingCN114196137AComposition Flame RetardancyTransparency has no effectHexamethyldisilaneTetramethylammonium hydroxide

The invention discloses a preparation method of a PVC special-effect halogen-free flame retardant. The preparation method comprises the following steps: adding a magnesium material into a reaction kettle; the preparation method comprises the following steps: adding phosphorus-containing polysiloxane DVP into a reaction kettle, adding a tetramethylammonium hydroxide aqueous solution and hexamethyldisilane, titrating and flocculating to remove unreacted raw materials, water and tetramethylammonium hydroxide, filtering and drying to obtain slightly yellow transparent solid powder; putting the fixed powder into a jet mill experiment machine, and putting the ultrafine crushed raw material into a high-speed surface treatment machine; 3-aminopropyl methyl dimethoxy silane is added, and the mixture enters a stock bin after being qualified; the halogen-free gas barrier powder material and the material in the stock bin are mixed according to the mass ratio of 1: 5 and put into a zero-gravity mixing machine, and finally the mixture is packaged by a packaging machine; the invention has the advantages that: organic silicon molecules accelerate surface carbon formation, improve gas barrier property and effectively improve the flame retardant property of the finished product, the refractive index is close to that of pure PVC resin, the transparency of the finished product is hardly influenced, and the heat resistance is good.

Owner:卢韩

Synthesis process of hexamethyldisilane

ActiveCN100457762CHigh purityReduce manufacturing costSilicon organic compoundsHexamethyldisilaneTrimethylsilyl chloride

The synthesis process of hexamethyldisilane is one kind of chemical technological process. The process includes the following steps: throwing xylene, crown ether and metal sodium into reaction kettle in oxygen free condition; heating via stirring and dropping trimethylchlorosilane to react under controlled temperature; maintaining the temperature after reaction for certain time and lower the temperature inside the reaction kettle to 50 deg.c; dropping water into the kettle and settling to delaminate; and distilling in an oil-water separator to obtain crude hexamethyldisilane product. The present invention makes crown ether to participate the reaction of metal sodium and trimethylchlorosilane, and this can alter the potential of metal sodium, raise the activity of metal sodium and raise the crude hexamethyldisilane product yield to 73.17 %.

Owner:扬州三友合成化工有限公司

Synthesis method of hexamethyl disilane

InactiveCN107652315AHigh activitySimple processSilicon organic compoundsHexamethyldisilaneSynthesis methods

The synthesis method of hexamethyldisilane relates to a chemical process. Under anaerobic conditions, the temperature is raised and stirred in a reaction kettle filled with xylene, crown ether and metal sodium, and trimethylchlorosilane is added dropwise into the reaction kettle , after the end, control the temperature in the reactor, keep warm, and then lower the temperature to 50°C ± 5°C, add water dropwise to the reactor, let it stand for stratification, and distill and dehydrate through an oil-water separator to obtain the crude product Liujia base disilane. The present invention uses metal sodium and trimethylchlorosilane to react with the participation of crown ether, changes the potential of metal sodium, improves the activity of metal sodium, and makes it react with trimethylchlorosilane, and the crude product yield can reach 73.17%; The process of the invention is simple, easy to control and convenient for industrialized production.

Owner:常州润联化工有限公司

Method for preparing triiodomethane silicane

InactiveCN100564384CReduce decompositionReduce manufacturing costGroup 4/14 element organic compoundsHexamethyldisilaneIodide

The invention relates to a preparation method for timethylsilyl iodide. The method comprises the following steps: firstly, hexamethyldisilane is charged into a reaction vessel, and is stirred and heated, after the temperature of the hexamethyldisilane liquid is raised to 65 to 95 DEG C, refined iodine is added in batches, after the refined iodine adding is completed, a reaction system is heated to 100 to 110 DEG C to form a back flow, the back flow and the reaction are performed for 5 to 7 hours at the temperature, so that the raw material reacts to generate the crude product of iodotrimethylsilane, and the mass ratio between hexamethyldisilane and refined iodine is 1: 1.8 to 1: 1.62; secondly, the back flow is continued to the crude product of the iodotrimethylsilane after step (1), then copper powder is added, after the back flow is stopped until no color, a back flow device is changed into a distillation device, and distillation and collection are performed to obtain the timethylsilyl iodide. The mass ratio between the copper powder and the hexamethyldisilane in the raw material is 0.01 to 0.02. Through the preparation method, high-purity timethylsilyl iodide can be obtained, the operation of the method is simple and safe, and the production cost is low.

Owner:WUJIANG XINYI CHEM

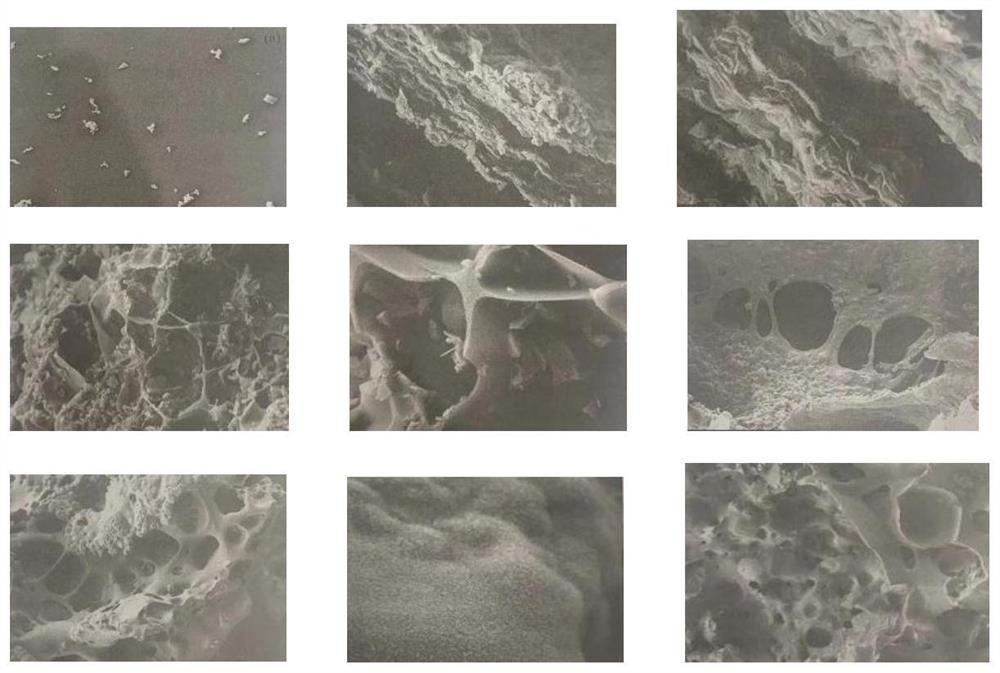

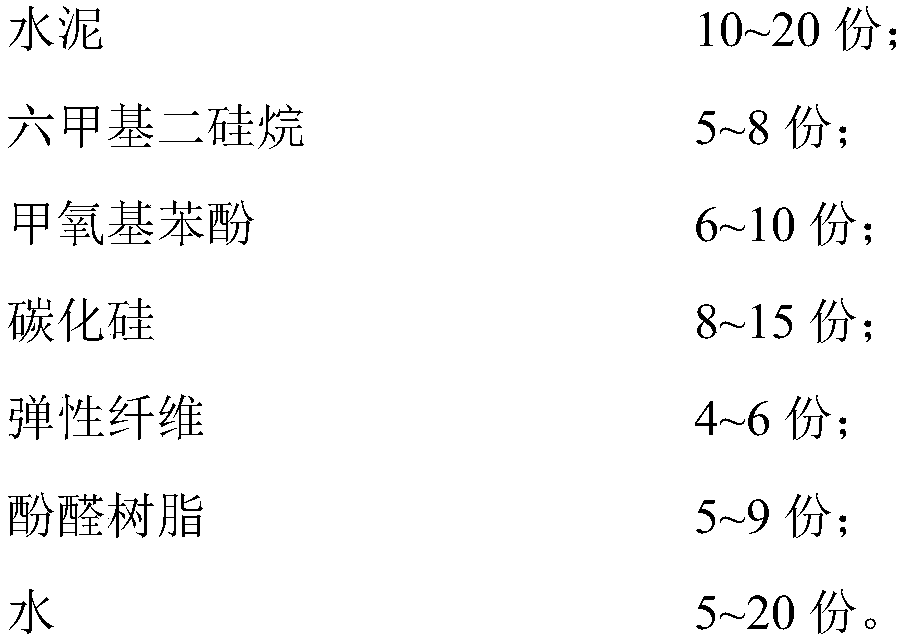

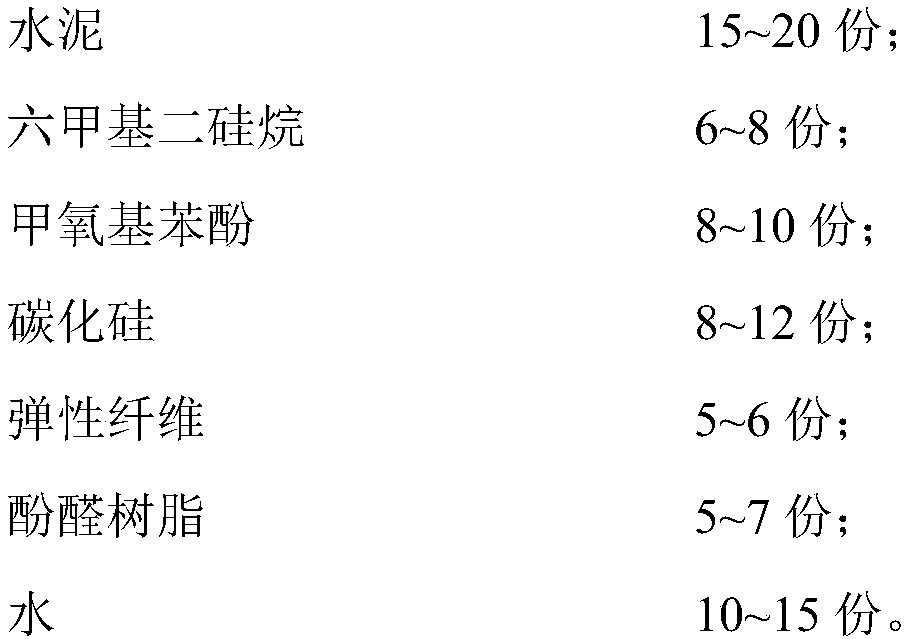

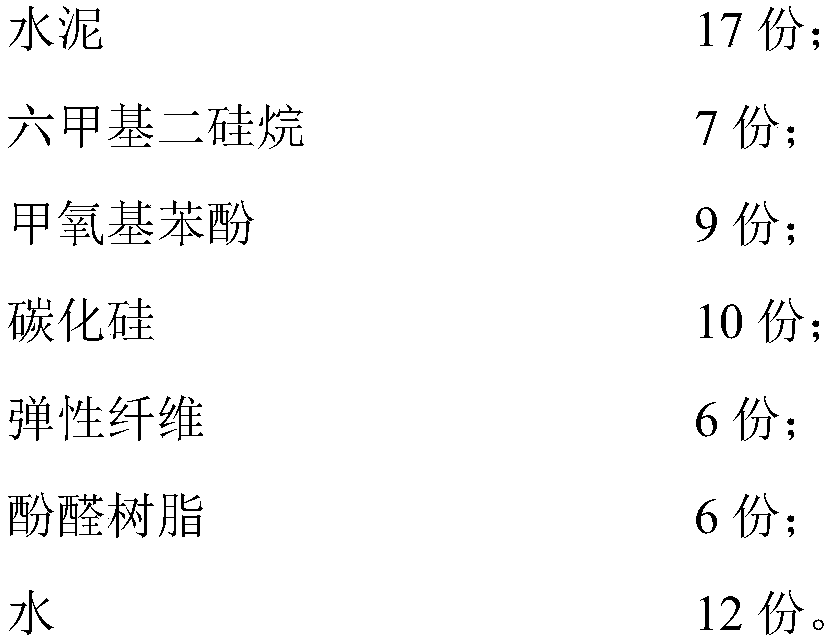

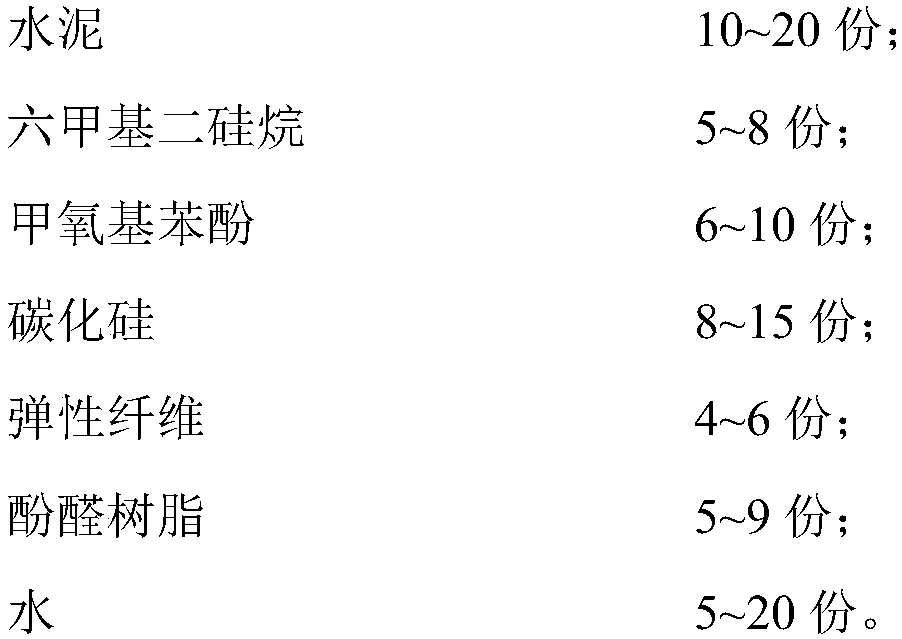

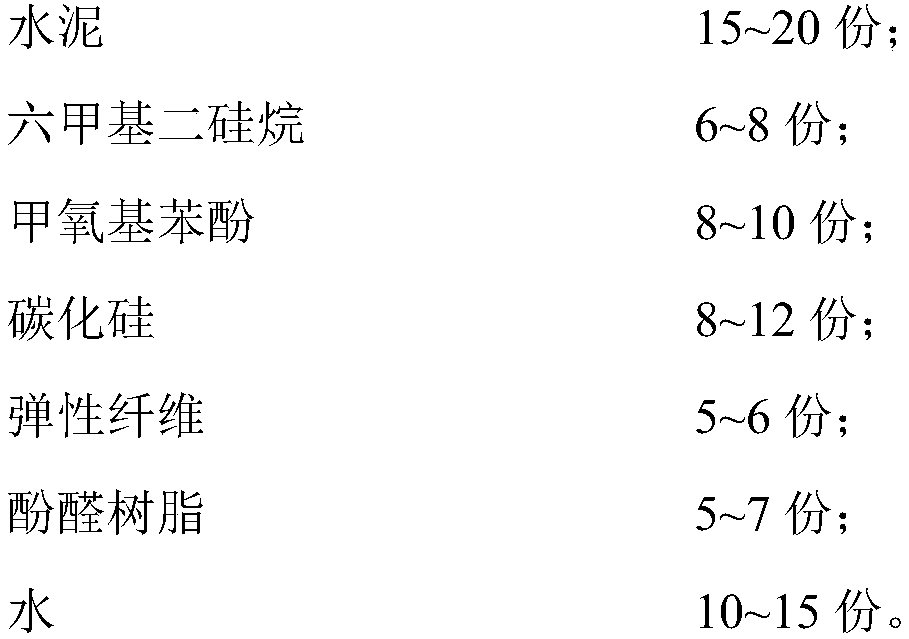

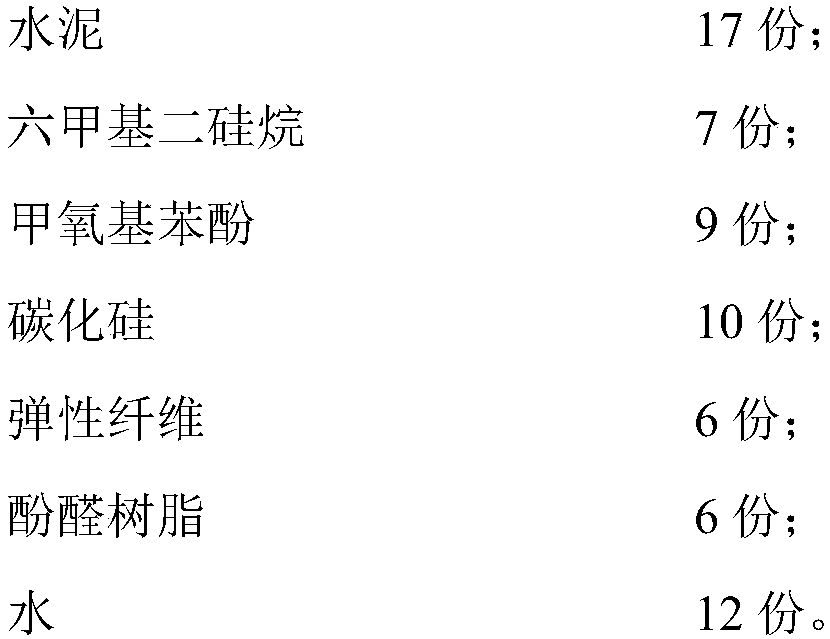

Application of novel material in preparing anti-fogging board

InactiveCN109206057AImprove waterproof performanceGood anti-fog effectHexamethyldisilaneElastic fiber

The invention discloses application of a novel material in preparing an anti-fogging board. The novel material comprises the following components (by weight): 10-20 parts of cement, 5-8 parts of hexamethyldisilane, 6-10 parts of methoxyphenol, 8-15 parts of silicon carbide, 4-6 parts of elastic fiber, 5-9 parts of phenolic resin and 5-20 parts of water. Compared with the prior art, the invention has the advantages as follows: the novel material is low-cost and is simple to operate and easy to promote; and the board prepared from the novel material has better heat-insulation, waterproof and anti-fogging effects.

Owner:南京金邦动力科技有限公司

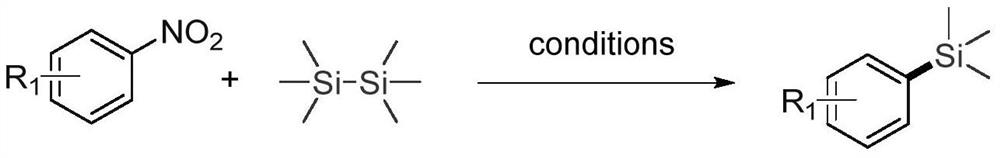

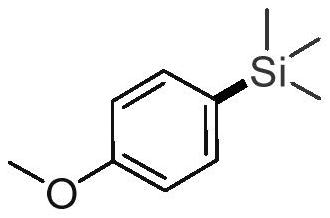

Synthesis method of novel aryl silane compound

PendingCN114507252AStable in natureLow priceSilicon organic compoundsChemical recyclingHexamethyldisilaneSilane compounds

The invention discloses a synthesis method of a novel aryl silane compound, which comprises the following steps: taking hexamethyldisilane and nitro-aromatic hydrocarbon as raw materials, and realizing one-step denitration C-Si coupling of the nitro-aromatic hydrocarbon and the hexamethyldisilane through a palladium catalyst to obtain the aryl silane compound. Wherein the one-step denitration silicon-based reaction is directly utilized, so that the steps and the economic benefits are greatly improved, and the process cost is reduced; compared with silicon-based boric acid ester, hexamethyldisilane has the advantages of stable property, low price, low toxicity and the like. Therefore, compared with the existing method, the method has the advantages of simplicity and convenience in operation, easiness in obtaining raw materials, high efficiency, economy, environment friendliness and the like.

Owner:GUANGXI UNIV

Application of novel material in preparing waterproof board

InactiveCN109206085AImprove waterproof performanceGood anti-fog effectHexamethyldisilaneElastic fiber

The invention discloses application of a novel material in preparing a waterproof board. The novel material comprises the following components (by weight): 10-20 parts of cement, 5-8 parts of hexamethyldisilane, 6-10 parts of methoxyphenol, 8-15 parts of silicon carbide, 4-6 parts of elastic fiber, 5-9 parts of phenolic resin, and 5-20 parts of water. Compared with the prior art, the invention hasthe advantages as follows: the novel material is low-cost and is simple to operate and easy to promote; and the board prepared from the novel material has better heat-insulation, waterproof and anti-fogging effects.

Owner:南京金邦动力科技有限公司

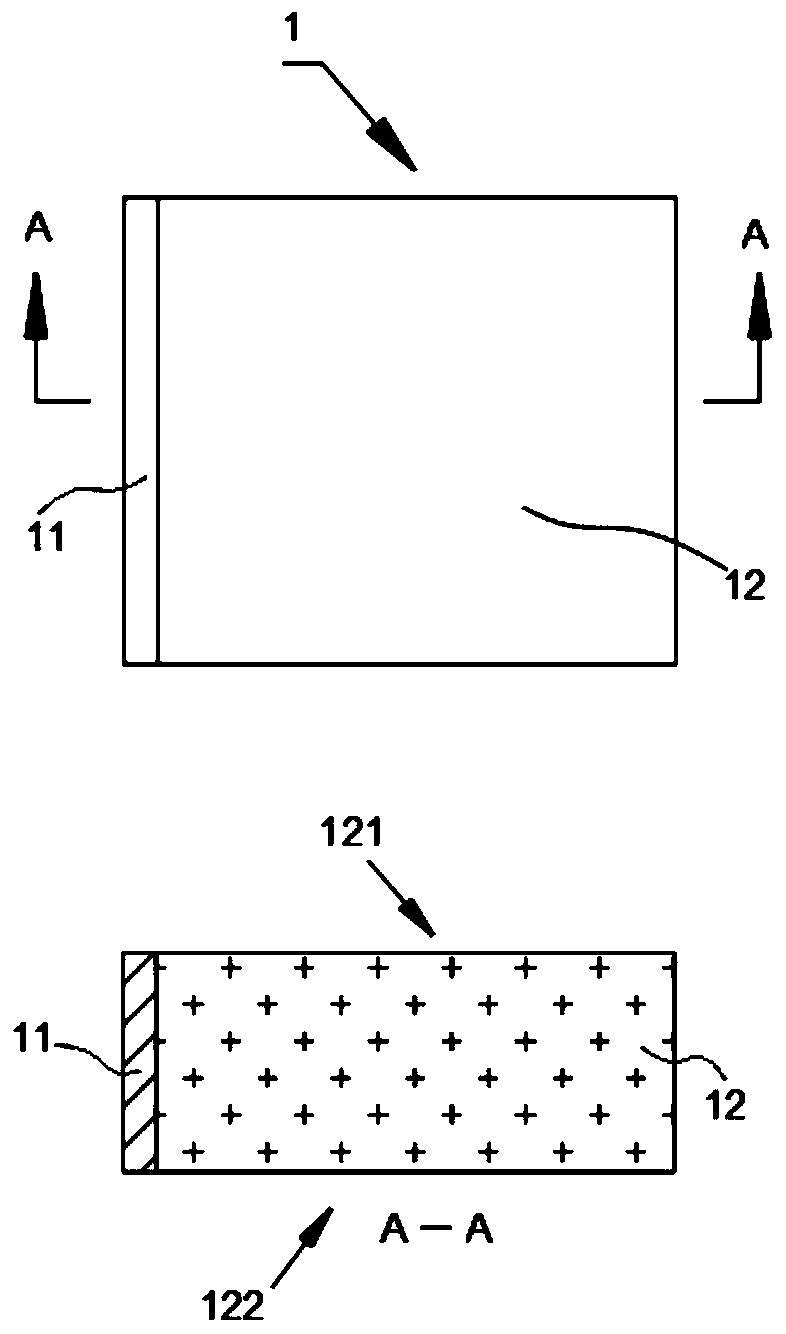

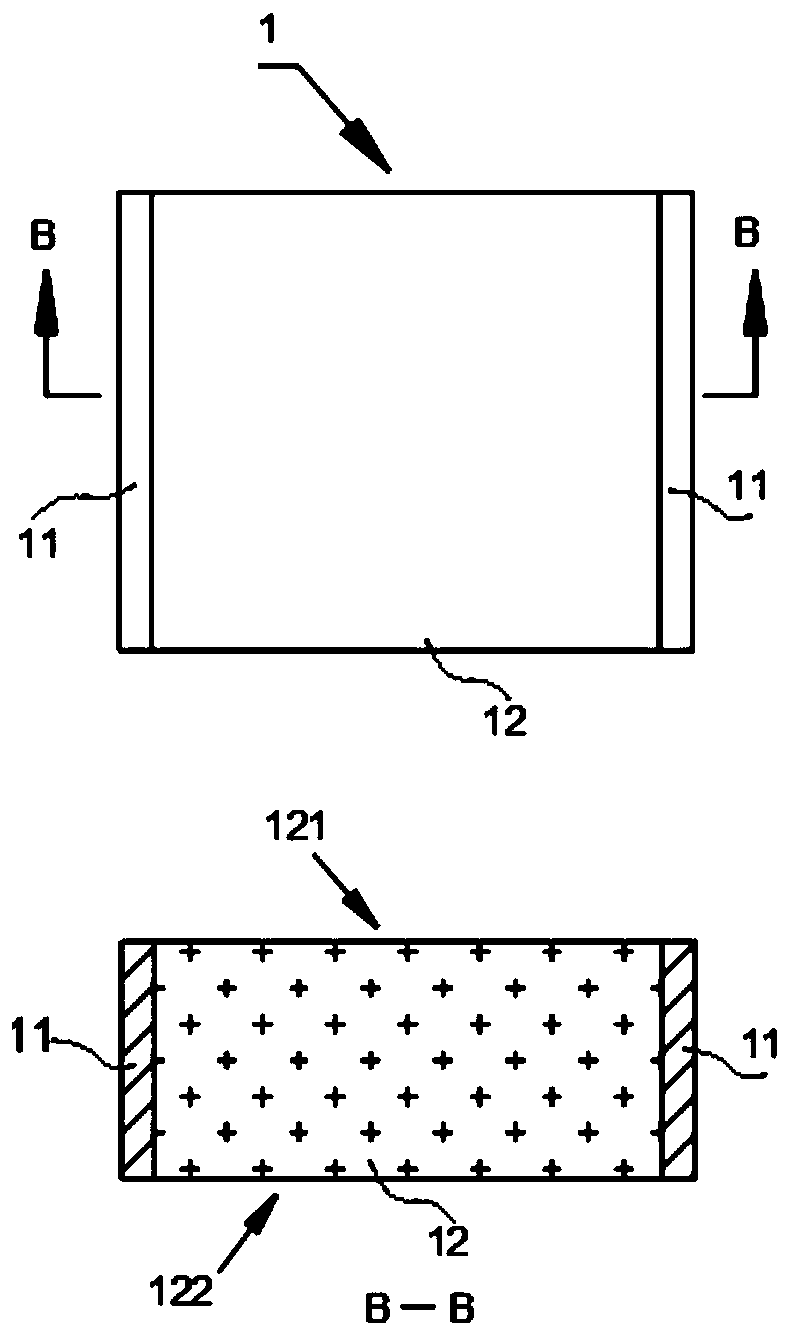

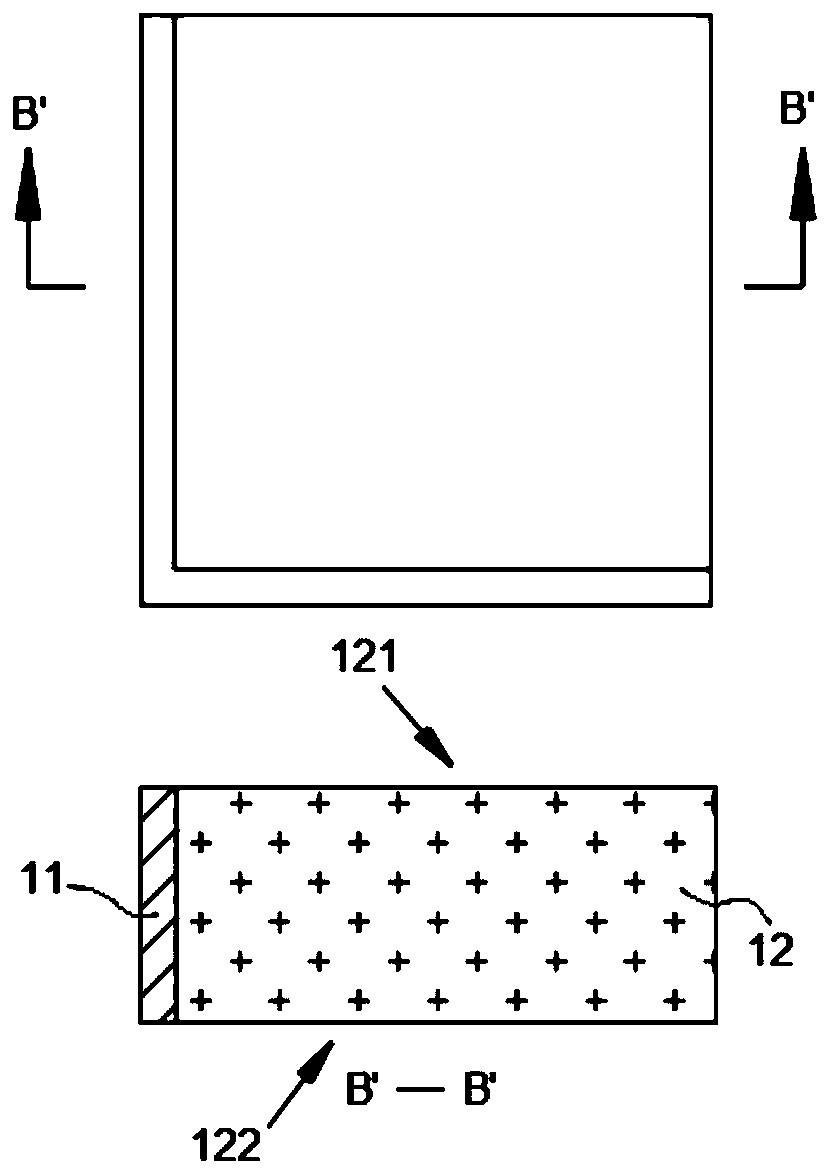

Light guide plate and preparation method thereof

ActiveCN109738982BSimple preparation processImprove mechanical propertiesOptical light guidesPolyethylene terephthalate glycolPolyetherimide

The invention discloses a light guide plate and a preparation method thereof. The light guide plate includes a light emitting surface, a back surface and side surfaces; the light emitting surface is opposite to the back surface; the side surfaces are connected to the light emitting surface and the back surface, wherein at least one side surface is provided with a light incident layer; and a portion other than the light incident layer of the light guide plate is a PS layer. The light incident layer material is composed of the following parts by weight: polyethylene glycol terephthalate, ultrafine modified alumina, n-propyl silicate, hydroxypropyl methylcellulose, ultrafine active silicon micro-powder, dimethyl silicone oil, polyetherimide resin, lauryl sodium sulfate, vinyl methyl ether, ethylene bis stearic acid amide, stearate, dibutyl phthalate, hexamethyldisilane, thermoplastic polyurethane elastomer, calcium hydrogen phosphate, dioctyl ester, stabilizer and composite antioxidant; the light guide plate is prepared by mixing various components; and the light guide plate has strong stability and good light transmittance, and can reduce light loss.

Owner:KUNSHAN CHENGTAI ELECTRIC

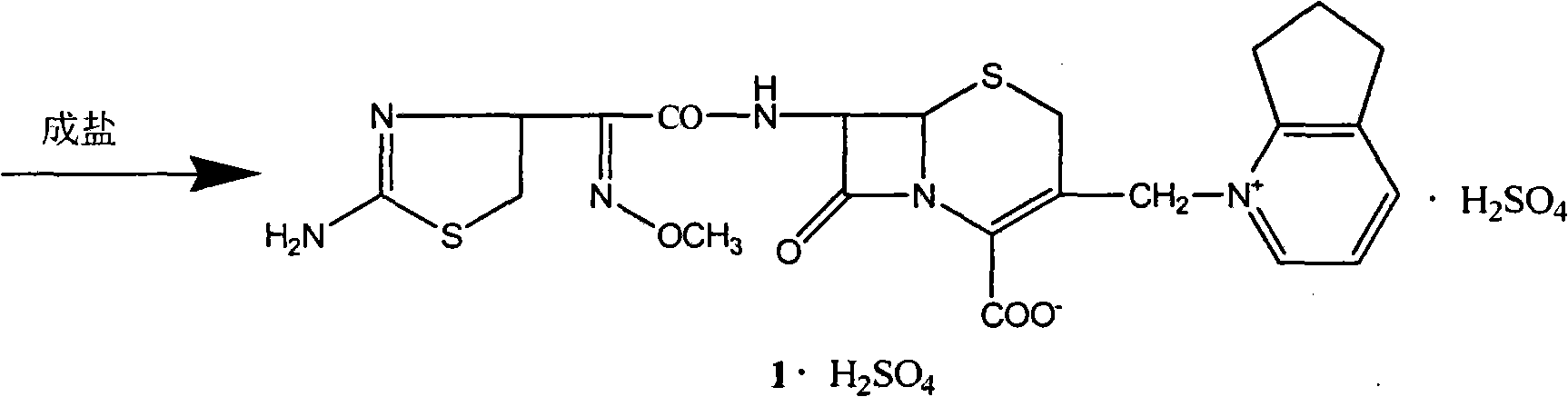

Method for synthesizing antibiotic cefpirome sulfate

InactiveCN101337970BSimple process conditionsEasy to operateAntibacterial agentsOrganic chemistryHexamethyldisilaneSynthesis methods

The invention relates to a synthesis method of cefpirome sulfate that is a bacteriophage. 7-amin cethalosporanic acid (7-ACA) is used as starting material and reacts with hexamethyldisilane amine (HMDS) and iodotrimethylsilane (TMSI) first to obtain 7-ACA for protecting amino and carboxyl; then 7-ACA, amino and carboxyl of which are protected, reacts with iodotrimethylsilane and 2, 3-cyclopenopyridine to synthesize an intermediate 7-ACP through a one-pot method; then 7-ACP reacts with active ester to prepare a product of cefpirome sulfate through acidylation reaction and salifying reaction. Compared with the existing technical route, the synthesis method has the advantages that the process conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, the method is suitable for the large-scale industrialized production, etc.

Owner:国药集团致君(苏州)制药有限公司

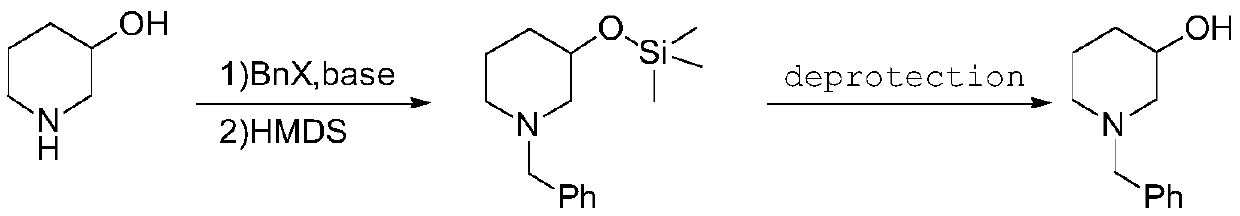

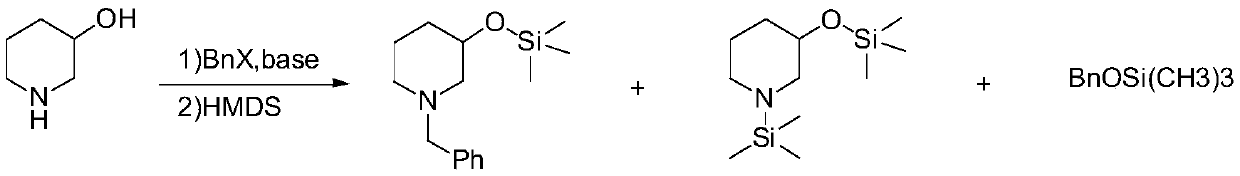

A kind of synthetic method of n-benzyl-3-hydroxypiperidine

ActiveCN107652227BMild reaction conditionsContinuous operationOrganic chemistryHexamethyldisilaneAlcohol

The invention discloses a synthesis method of N-benzyl-3-hydroxypiperidine, and belongs to the technical field of organic synthesis. In the absence of alkaline, and after 3-hydroxypiperidine is protected by halogenated benzyl, hexamethyldisilane is added to continue the reaction to obtain N-benzyl-3-trimethylsiloxidine, and then alcohols solvent or fluorine-containing ionicsalt is added for deprotection to obtain high-purity N-benzyl-3-hydroxypiperidine. According to the synthesis method of N-benzyl-3-hydroxypiperidine, the raw materials and reagents are cheap and easy to obtain, the reactioncondition is mild, continuous operation can be conducted, the product purity reaches up to 99.5% or above, and the method is suitable for enlarged production on a large scale.

Owner:山西库邦生物医药科技有限公司

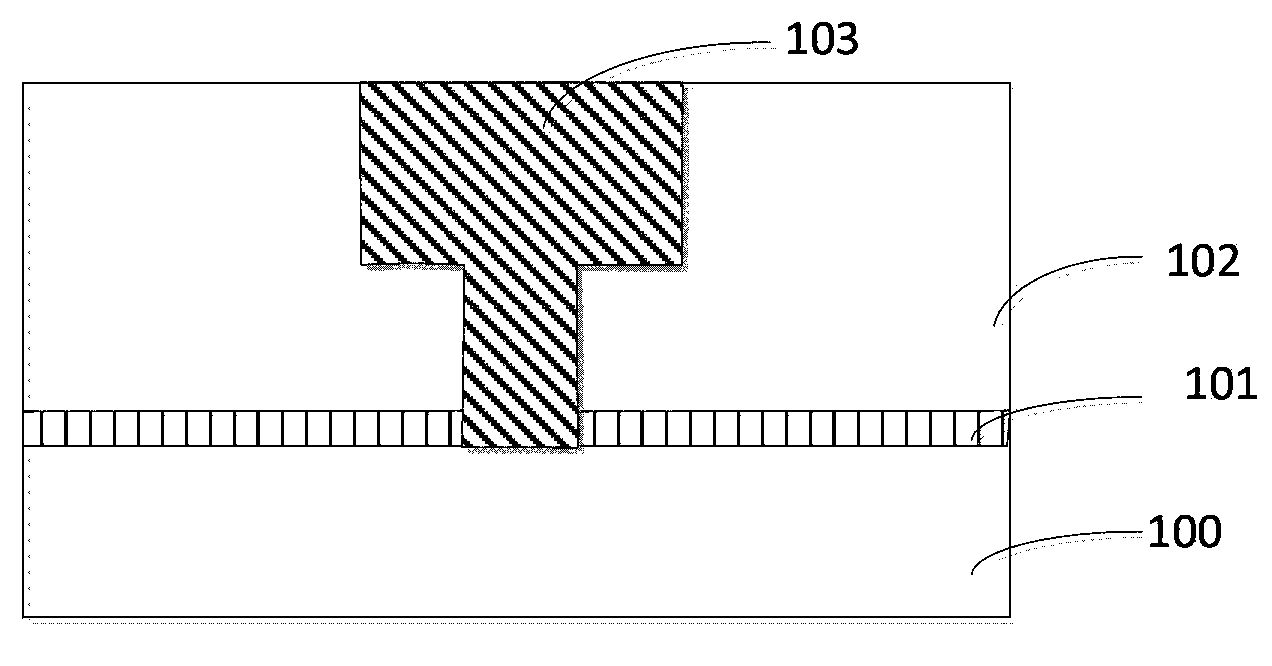

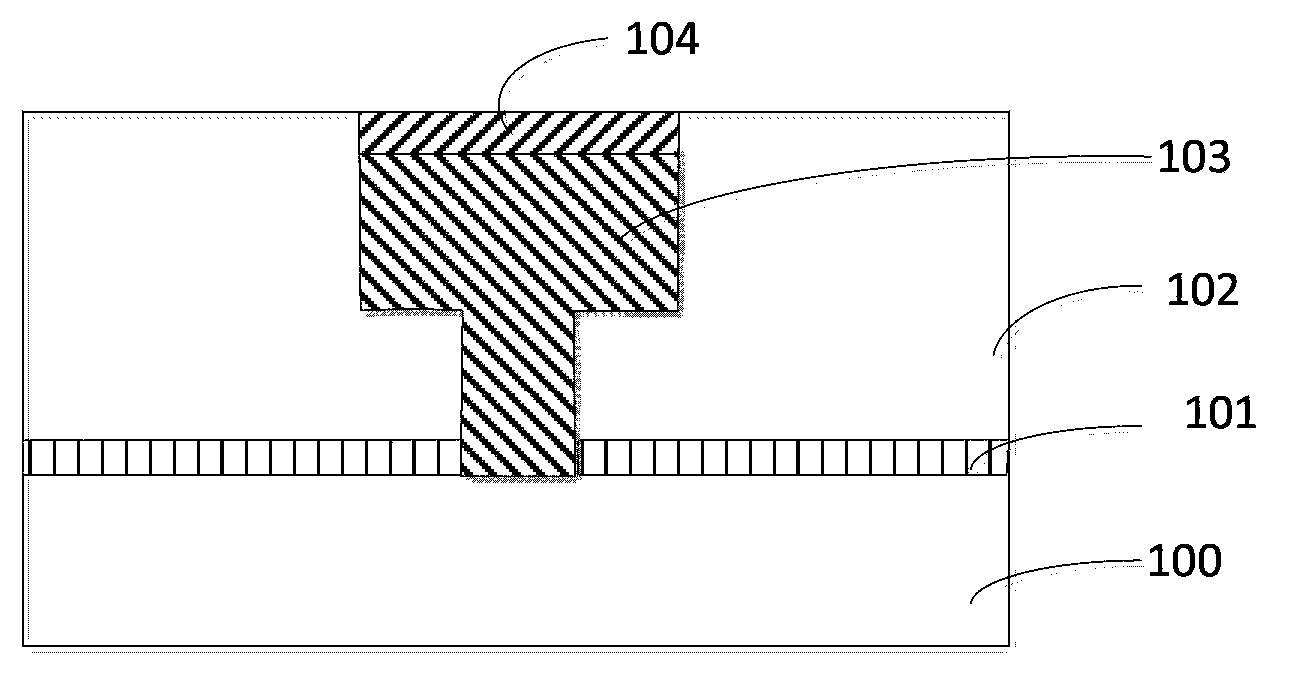

Method for manufacturing semiconductor device

InactiveCN104241192AImprove reliabilityImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingHexamethyldisilaneManufacturing technology

The invention discloses a method for manufacturing a semiconductor device. The method includes the following steps that a semiconductor substrate is provided; a low k interlayer dielectric layer and a metal interconnection structure located in the low k interlayer dielectric layer are formed on the semiconductor substrate; hexamethyldisilane is used for processing the exposed top face of the metal interconnection structure, so that a metal covering layer is formed; an electric dielectric covering layer is formed on the low k interlayer dielectric layer and the metal covering layer. According to the manufacturing technology, the hexamethyldisilane is used for processing a metal copper layer, so that the metal covering layer is formed, better adhesiveness, low wire resistance and the good electromigration performance are provided for the device, and the reliability and the yield of the device are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

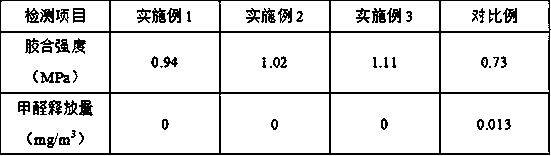

Manufacture method of environment-friendly plywood

InactiveCN107775761AImprove mechanical propertiesIncrease stickinessNon-macromolecular adhesive additivesProtein adhesivesHexamethyldisilaneCellulose

The invention relates to the technical field of plywood, in particular to a manufacture method of environment-friendly plywood. The manufacture method has the advantages that surfaces of veneers are subjected to enzymolysis through soaking liquid, part of organic matters, such as celluloses, of the surfaces of the veneers are degraded, and active groups of the surfaces of the veneers are increased; degreased soybean meal and waterborne polyurethane are subjected to compound modification to improve mechanical property and viscosity of the degreased soybean meal, and mixing and compounding withan organosilicone monomer is then performed; the organosilicone monomer hexamethyldisilane is subjected to pyrolysis under the action of hydroxyacetamide and platinic oxide during hot pressing, is polymerized with methacryloxymethyl tris(trimethylsiloxy)silane and is compounded with the modified degreased soybean meal to improve bonding strength; silicon oxygen bonds are compounded with the activegroups on the veneers to further improve bonding strength; during preparation of the plywood, no formaldehyde is released, and safety and environment protection are achieved.

Owner:吴义峰

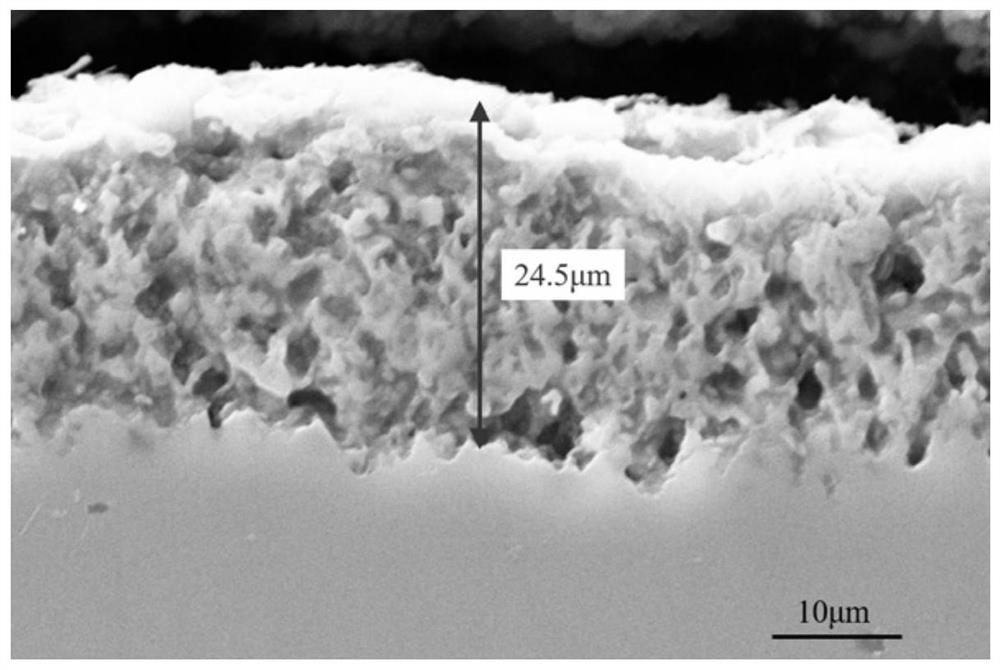

Method for preparing amorphous SiOC coating by adopting chemical vapor deposition process

PendingCN113684467AImprove friction resistance performanceCompact structureChemical vapor deposition coatingHexamethyldisilaneMetallic materials

The invention belongs to the technical field of coating preparation, and particularly relates to a method for preparing an amorphous SiOC coating by adopting a chemical vapor deposition process. A thermal excitation type chemical vapor deposition system is adopted, hexamethyldisiloxane (HMDSO) or hexamethyldisilane or tetraethoxysilane, absolute ethyl alcohol and a hydrogen and argon gas system are selected, the ratio of organosilane to the absolute ethyl alcohol is controlled, under the conditions that the working pressure intensity is 10-1000 Pa and the temperature is 1000-1200 DEG C, the amorphous SiOC coating which is compact in structure and 0.1-50 microns in thickness is deposited on the surface of stainless steel, carbon steel or other alloys, the hardness range of the amorphous SiOC coating is 6-15 GPa, and the friction coefficient range is 0.02-0.2. The amorphous SiOC coating is good in chemical stability, good in wear resistance, high in oxidation resistance, high in creep resistance and good in binding force with stainless steel, carbon steel and other alloy matrixes. The amorphous SiOC coating can remarkably improve the friction and wear performance of the stainless steel and prolong the service life of a metal material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for synthesizing antibiotic cefepime hydrochloride

ActiveCN101337971BSimple process conditionsEasy to operateAntibacterial agentsOrganic chemistryCefepime hydrochlorideHexamethyldisilane

The invention relates to a synthesis method of cefepime dihydrochloride that is a bacteriophage. 7-amin cethalosporanic acid (7-ACA) is used as starting material and reacts with hexamethyldisilane amine (HMDS) and iodotrimethylsilane (TMSI) first to obtain 7-ACA for protecting amino and carboxyl; then 7-ACA, amino and carboxyl of which are protected, reacts with iodotrimethylsilane and N-methylpyrrolidine to synthesize (6R, 7R)-7-amino-3-((1-methyl-1-pyrrolidine) methyl) cephalosporin-3-alkene-4-carboxylic acid hydrochloride (7-MPCA) through a one-pot method; 7-MPCA reacts with AE active ester to obtain a product of cefepime dihydrochloride through acidylation reaction and salifying reaction. Compared with the existing technical route, the synthesis method has the advantages that the process conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, the method is suitable for the large-scale industrialized production, etc.

Owner:国药集团致君(苏州)制药有限公司

Method for preparing silicon carbide tube by adopting chemical vapor deposition process

InactiveCN112647057AQuick take outHigh crystallinityChemical vapor deposition coatingHexamethyldisilaneCarbide silicon

The invention belongs to the technical field of ceramic tube preparation, and particularly relates to a method for preparing a silicon carbide tube by adopting a chemical vapor deposition process. A thermal excitation type chemical vapor deposition (CVD) system is adopted, an aluminum oxide ceramic tube or a graphite tube is selected as a deposition matrix, hexamethyldisilane (HMDS), H<2> and Ar are selected as a gas system, deposition is carried out under the conditions that the working pressure is 10-1000 Pa and the temperature is 650-1350 DEG C, and after the aluminum oxide ceramic tube or the graphite tube is removed, silicon carbide tubes with compact structures and different inner and outer diameters are obtained. The method is used for manufacturing heat exchanger tubes of corrosive media, abrasion-resistant water flow spray tubes, other high-temperature environment devices and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com