Low-odor scratch-resistant polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of low-odor and scratch-resistant polypropylene composite materials and their preparation, can solve the problems of scratch resistance and strong odor, and achieve the effects of excellent low odor and scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

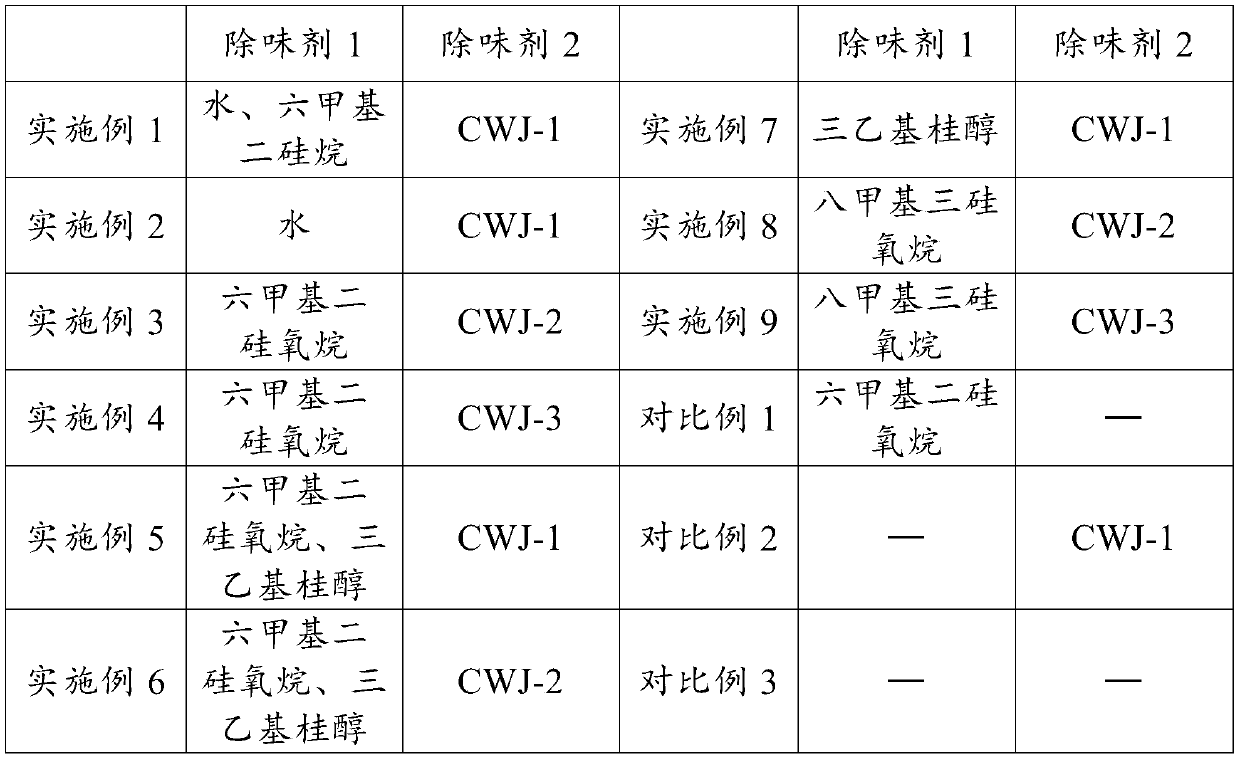

[0032] The preparation method of the deodorant 2: prepare 10% ethanol solution with 2,4-dinitrophenylhydrazine and ethylenediamine tetramethylene phosphoric acid according to the mass ratio of 1:1.5, measure 1L of the solution, Add 450g of 13X-type zeolite molecular sieve, stir for 4 hours and then filter with suction. During the process of suction, rinse with absolute ethanol for 3 times, dry, grind and sieve to obtain the deodorant 2 loaded with reactive porous substances, which is denoted as CWJ-1 .

experiment example 2

[0034] The preparation method of the deodorant 2: make methylenetriamine pentamethylene phosphoric acid into 8% ethanol solution, measure 1L of the solution, add 300g of 13X type zeolite molecular sieve, stir for 5h, then suction filter, During the filtration process, rinse with absolute ethanol for 5 times, dry, grind and sieve to obtain the deodorant 2 loaded with reactive porous substances, which is designated as CWJ-2.

experiment example 3

[0036] The preparation method of the deodorant 2: make ethylenediamine tetraacetate into 3% ethanol solution, measure 1L of the solution, add 300g of 13X zeolite molecular sieve, stir for 3h and then suction filter. Rinse twice with absolute ethanol, dry, grind and sieve to obtain the deodorant 2 loaded with reactive porous substances, which is designated as CWJ-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com