Method for preparing amorphous SiOC coating by adopting chemical vapor deposition process

A chemical vapor deposition, amorphous technology, applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of easy wear and tear, and achieve the effect of good bonding, compact structure and low vaporization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

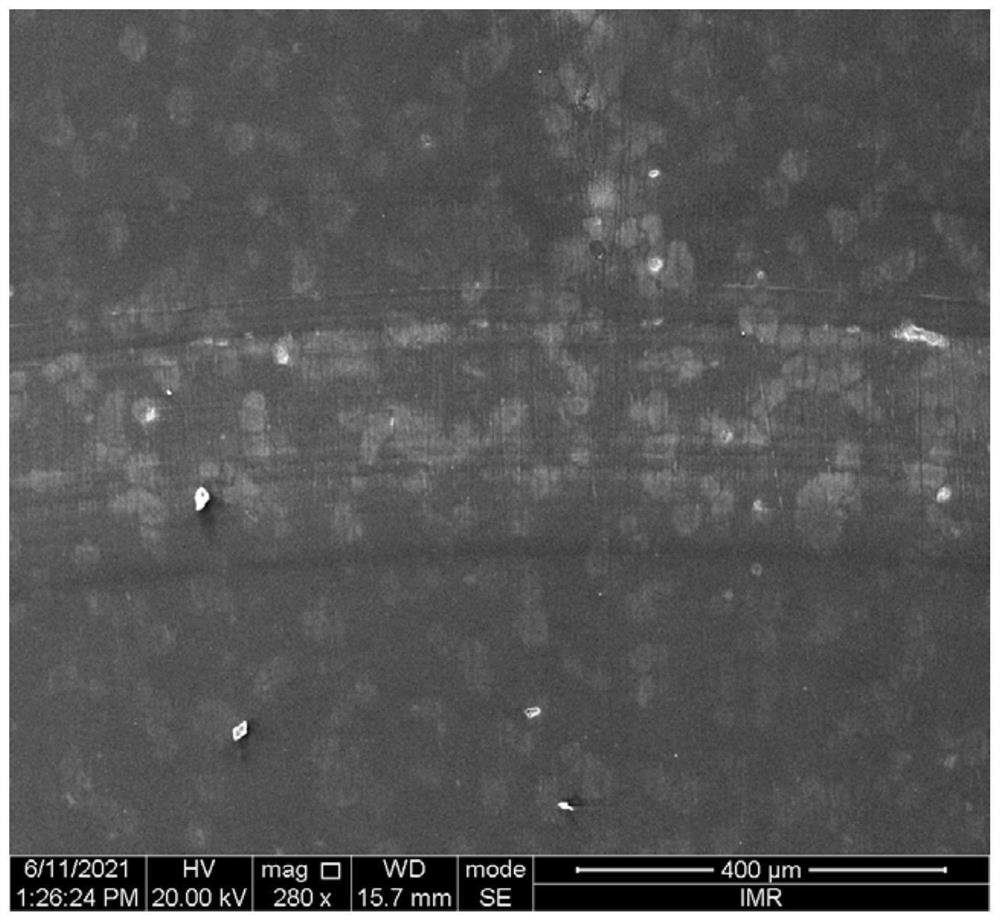

Image

Examples

Embodiment 1

[0033] In this embodiment, the method for preparing an amorphous SiOC coating using a chemical vapor deposition process is as follows:

[0034] (1) Choose 316L stainless steel as the substrate, and use 400#, 800# and 2000# sandpaper to polish off the oxide scale on the surface of 316L stainless steel to make the surface smooth and free of burrs.

[0035] (2) The surface-polished 316L stainless steel was ultrasonically cleaned with isopropanol and ethanol for 15 minutes, and dried with nitrogen gas for later use.

[0036] (3) Mix hexamethyldisiloxane (HMDSO) and absolute ethanol according to a certain volume ratio, the volume ratio is 1, and use it as a precursor raw material after stirring evenly.

[0037] (4) When depositing an amorphous SiOC coating on a 316L stainless steel substrate, the flow rate of the mixed solution of hexamethyldisiloxane and absolute ethanol is 0.5g / min, the flow rate of argon gas is 3000 sccm, and the flow rate of hydrogen gas is 200 sccm. The tempe...

Embodiment 2

[0042] In this embodiment, the method for preparing an amorphous SiOC coating using a chemical vapor deposition process is as follows:

[0043](1) Choose 316 stainless steel as the substrate, and use 400#, 800# and 2000# sandpaper to polish off the scale on the surface of 316 stainless steel to make the surface smooth and free of burrs.

[0044] (2) The polished 316 stainless steel was ultrasonically cleaned with isopropanol and ethanol for 15 minutes respectively, and dried with nitrogen gas for later use.

[0045] (3) Tetraethoxysilane (TEOS) and absolute ethanol are mixed according to a certain volume ratio, the volume ratio is 1, and the mixture is uniformly stirred as a precursor raw material.

[0046] (4) When depositing an amorphous SiOC coating on a 316 stainless steel substrate, the flow rate of the mixed liquid of hexamethyldisilane and absolute ethanol is 0.8g / min, the flow rate of argon gas is 3000 sccm, the flow rate of hydrogen gas is 400 sccm, and the deposition...

Embodiment 3

[0051] In this embodiment, the method for preparing an amorphous SiOC coating using a chemical vapor deposition process is as follows:

[0052] (1) Choose 316L stainless steel as the substrate, and use 400#, 800# and 2000# sandpaper to polish off the oxide scale on the surface of 316L stainless steel to make the surface smooth and free of burrs.

[0053] (2) The surface-polished 316L stainless steel was ultrasonically cleaned with isopropanol and ethanol for 15 minutes, and dried with nitrogen gas for later use.

[0054] (3) Mix hexamethyldisiloxane (HMDSO) and hexamethyldisilane (HMDS) mixture (volume ratio 1:5), absolute ethanol according to a certain volume ratio, the volume ratio is 1, and stir well later as the precursor raw material.

[0055] (4) When depositing an amorphous SiOC coating on a 316L stainless steel substrate, the flow rate of the mixed liquid of organosilane and absolute ethanol is 1 g / min, the flow rate of argon gas is 5000 sccm, the flow rate of hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com