Patents

Literature

220results about How to "Increase the volume ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

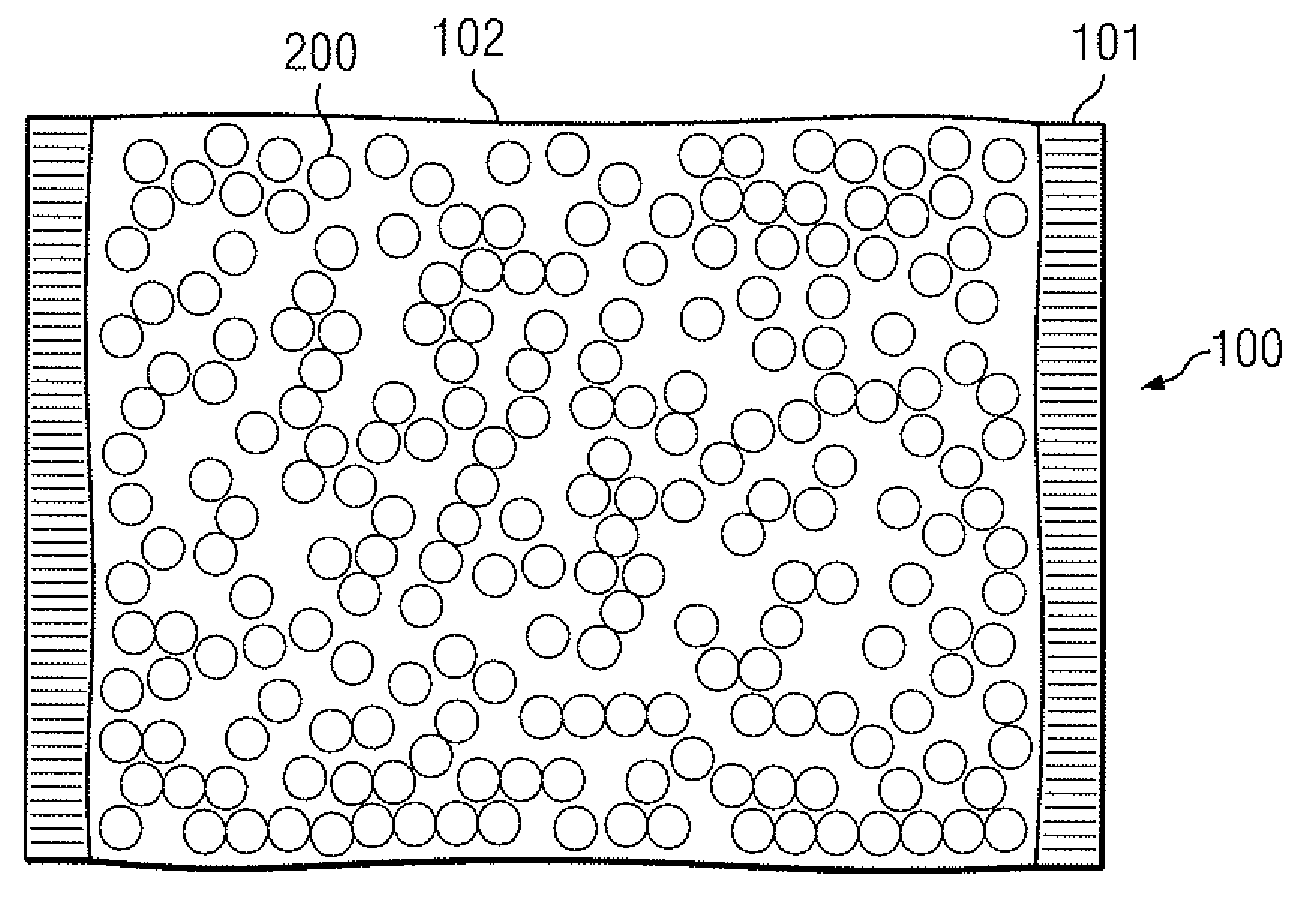

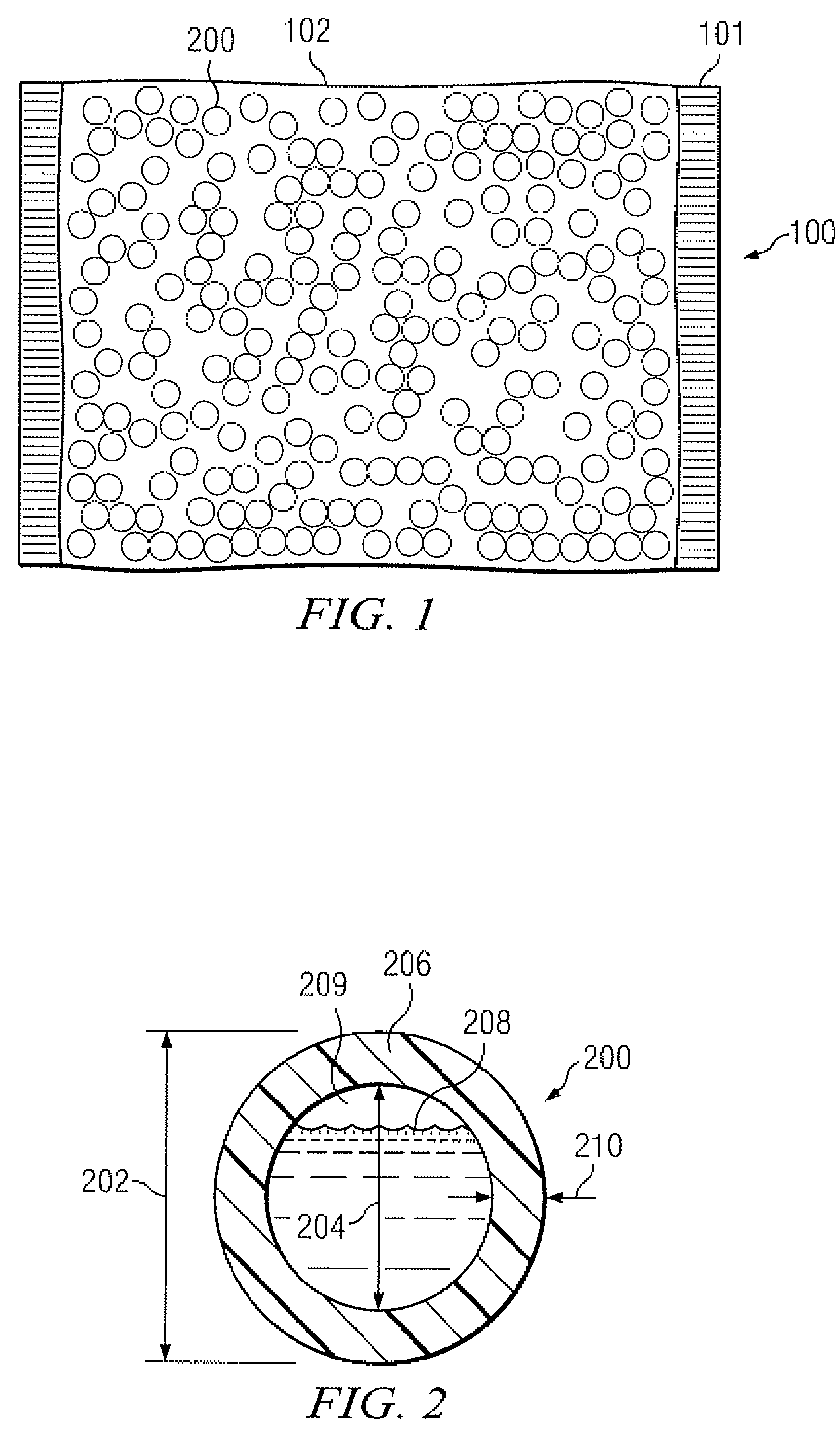

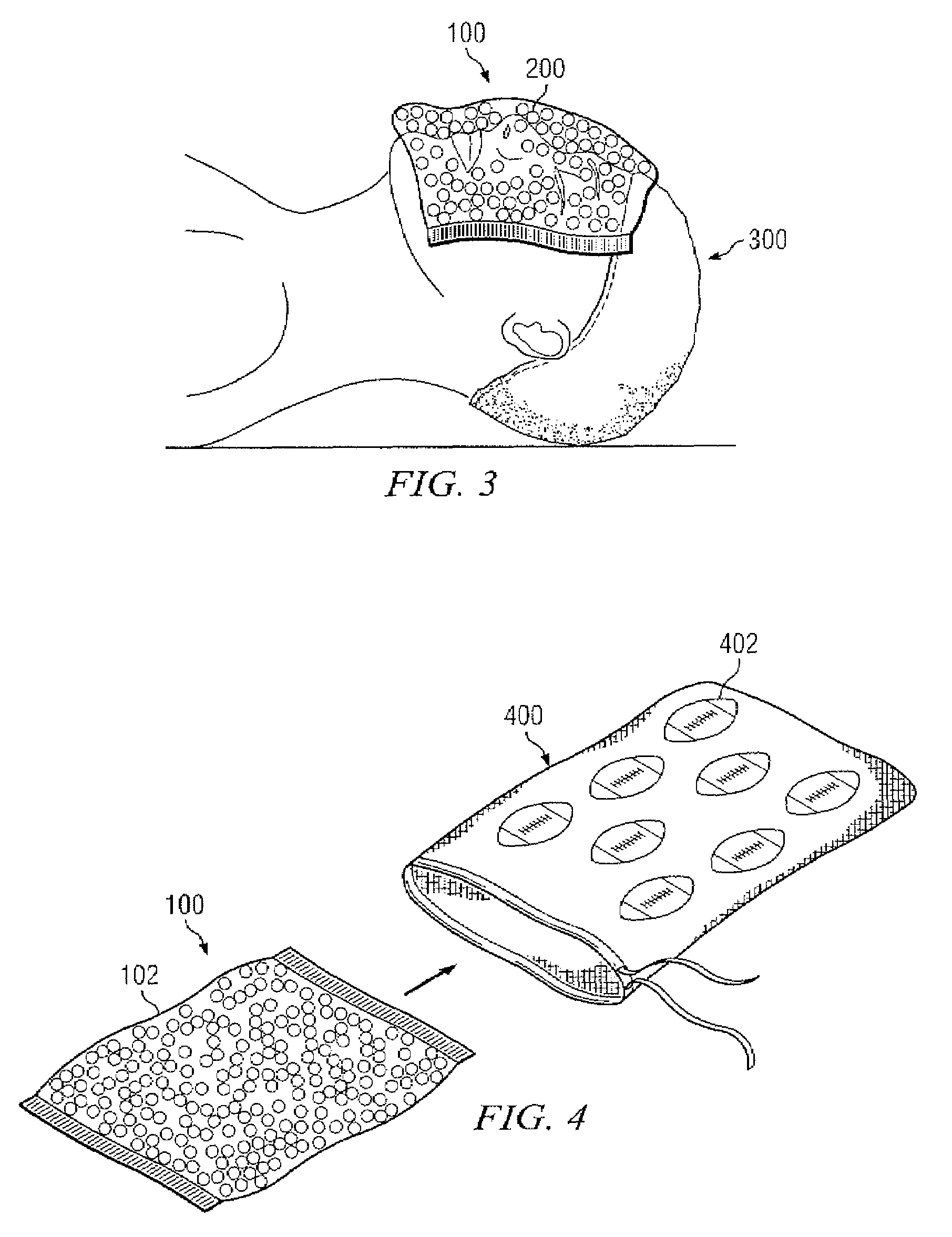

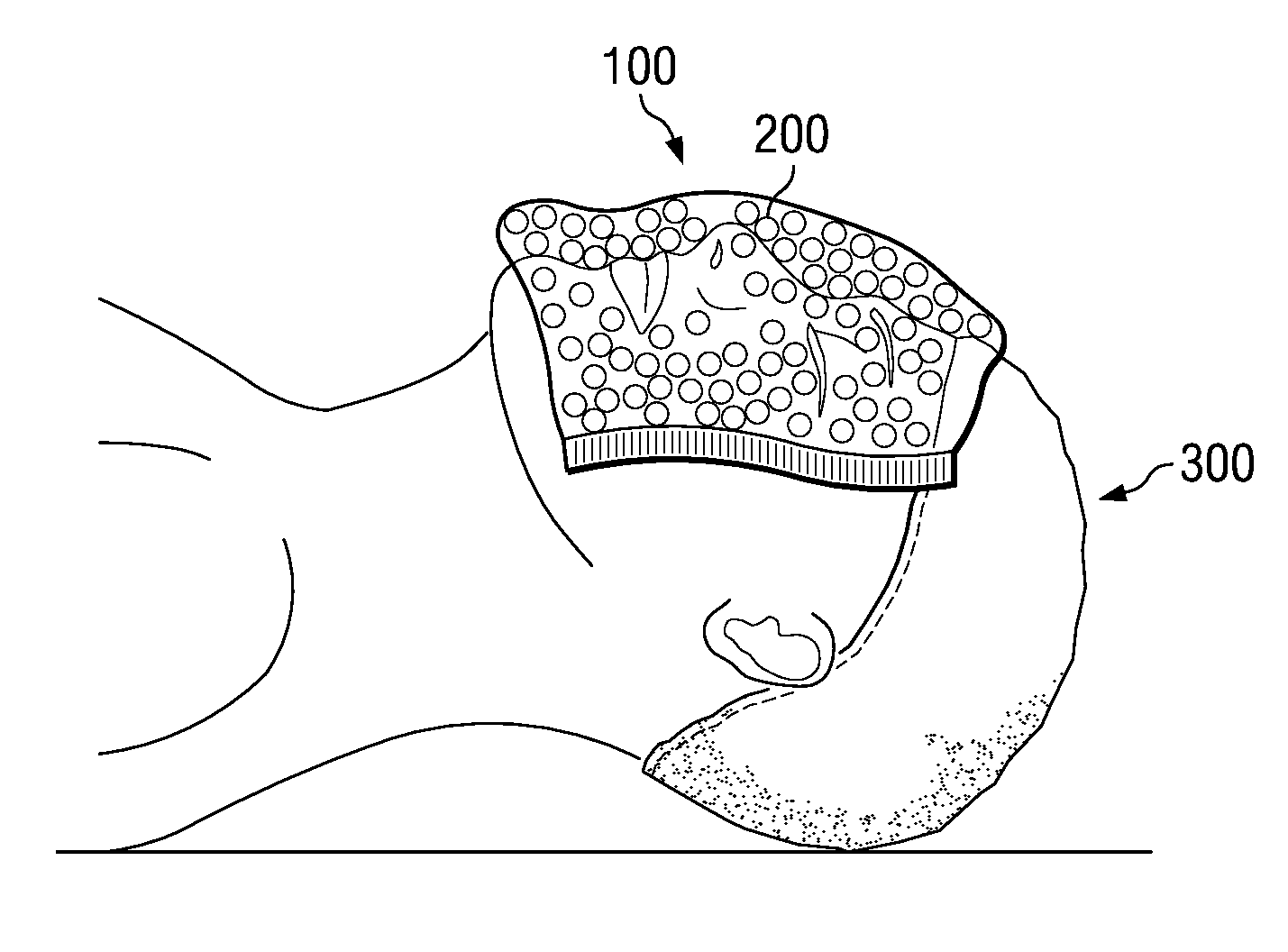

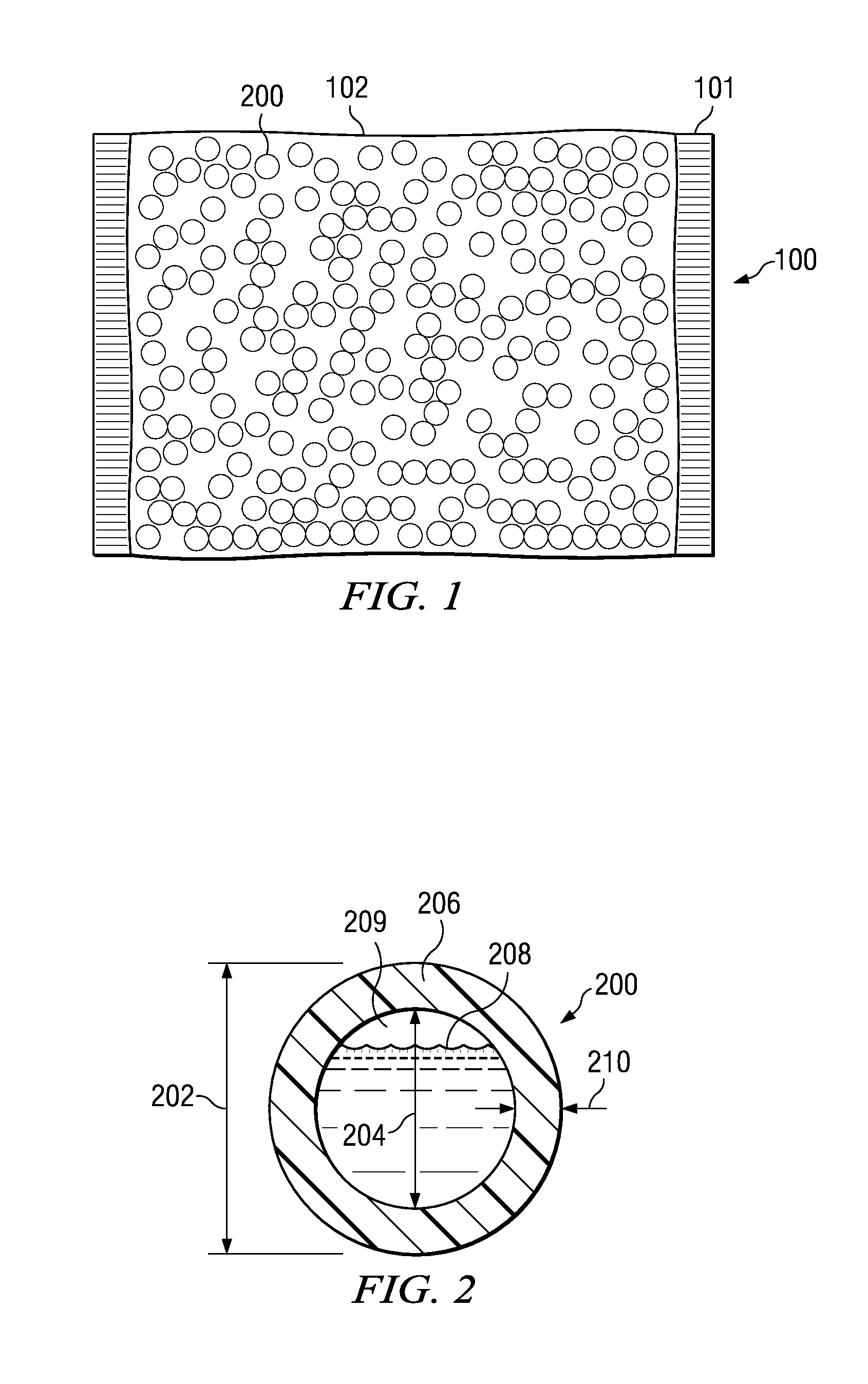

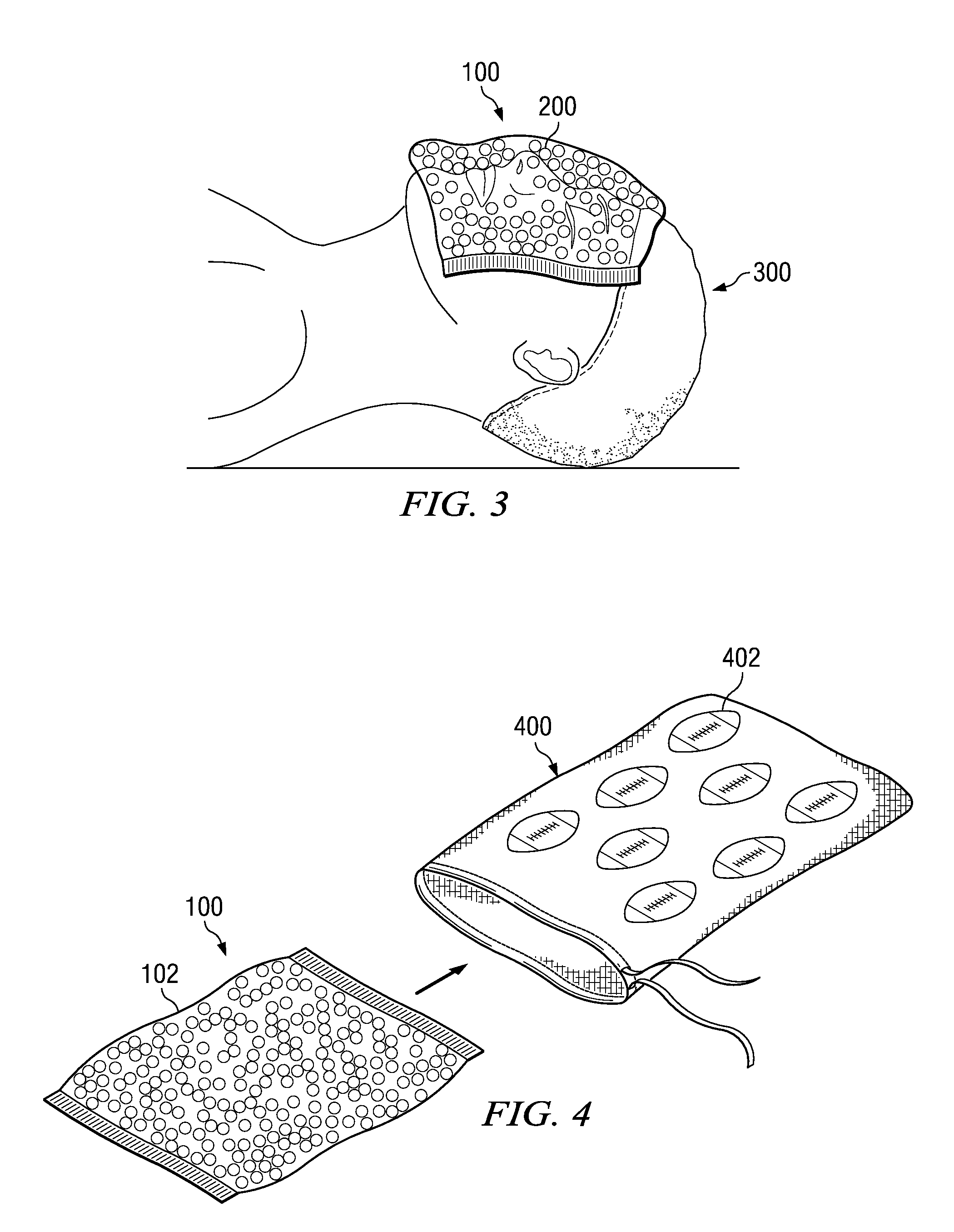

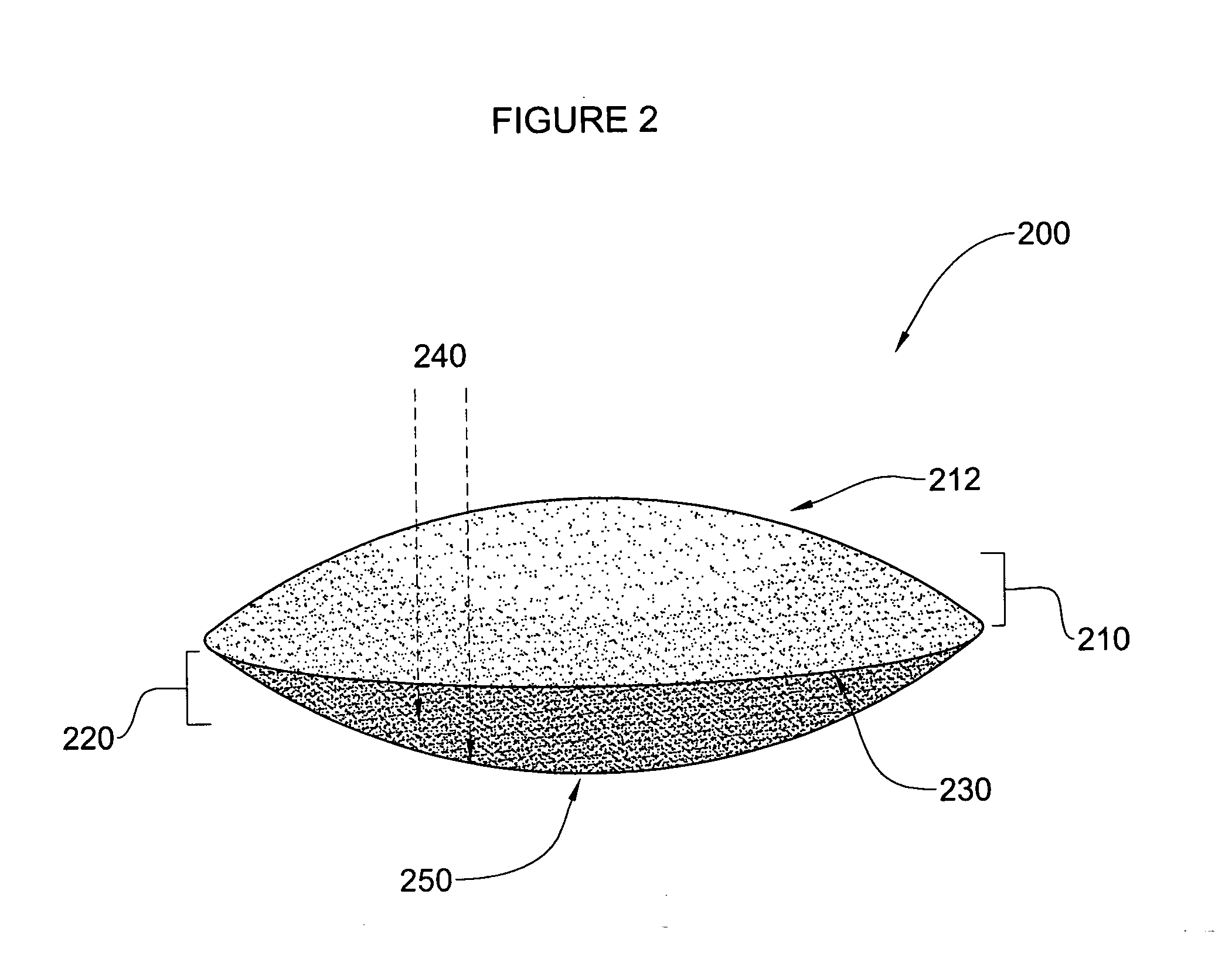

Cold Compress for Therapeutic Cooling

InactiveUS20080119916A1High heat transfer and flexibility and contour abilityIncrease the volume ratioTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

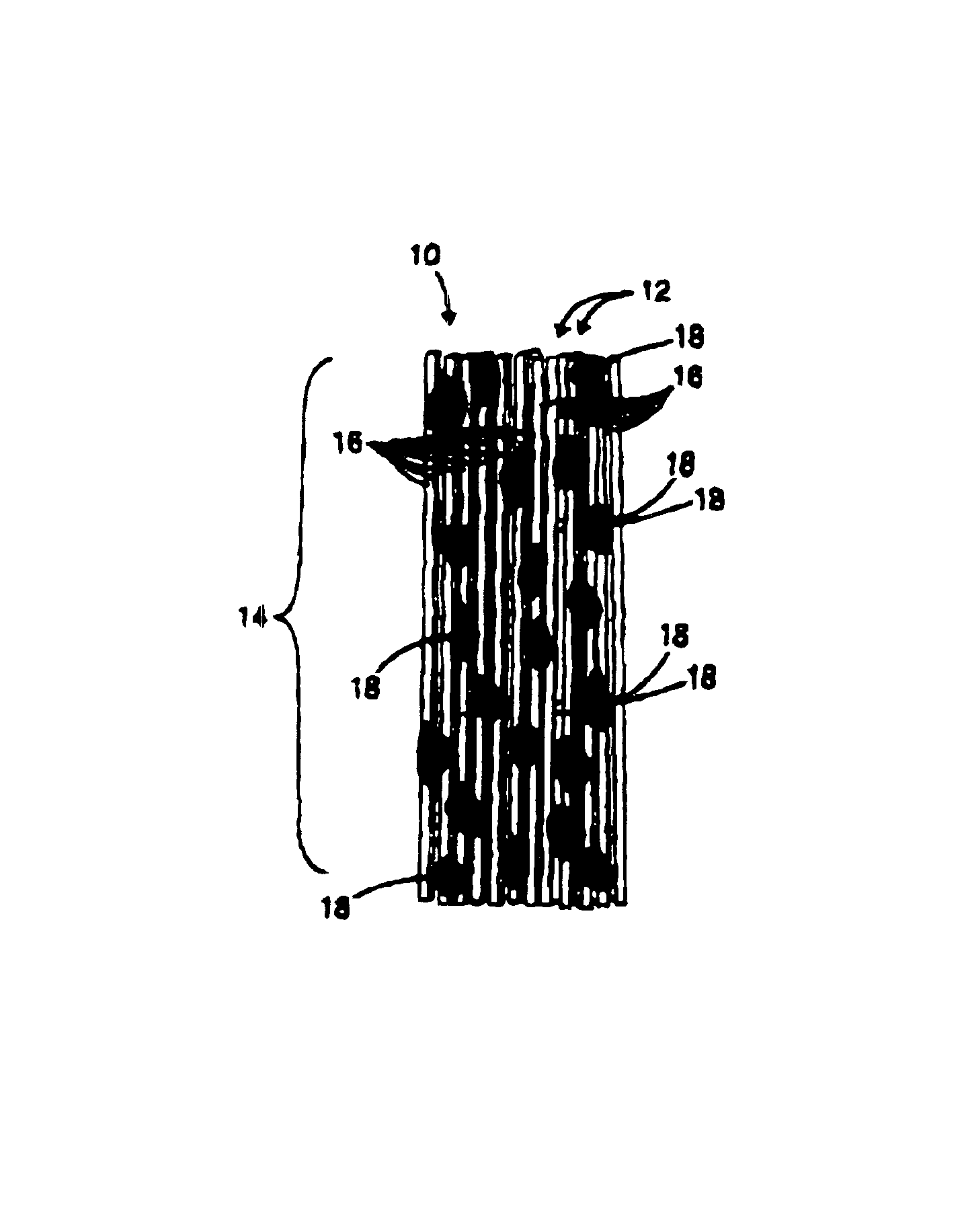

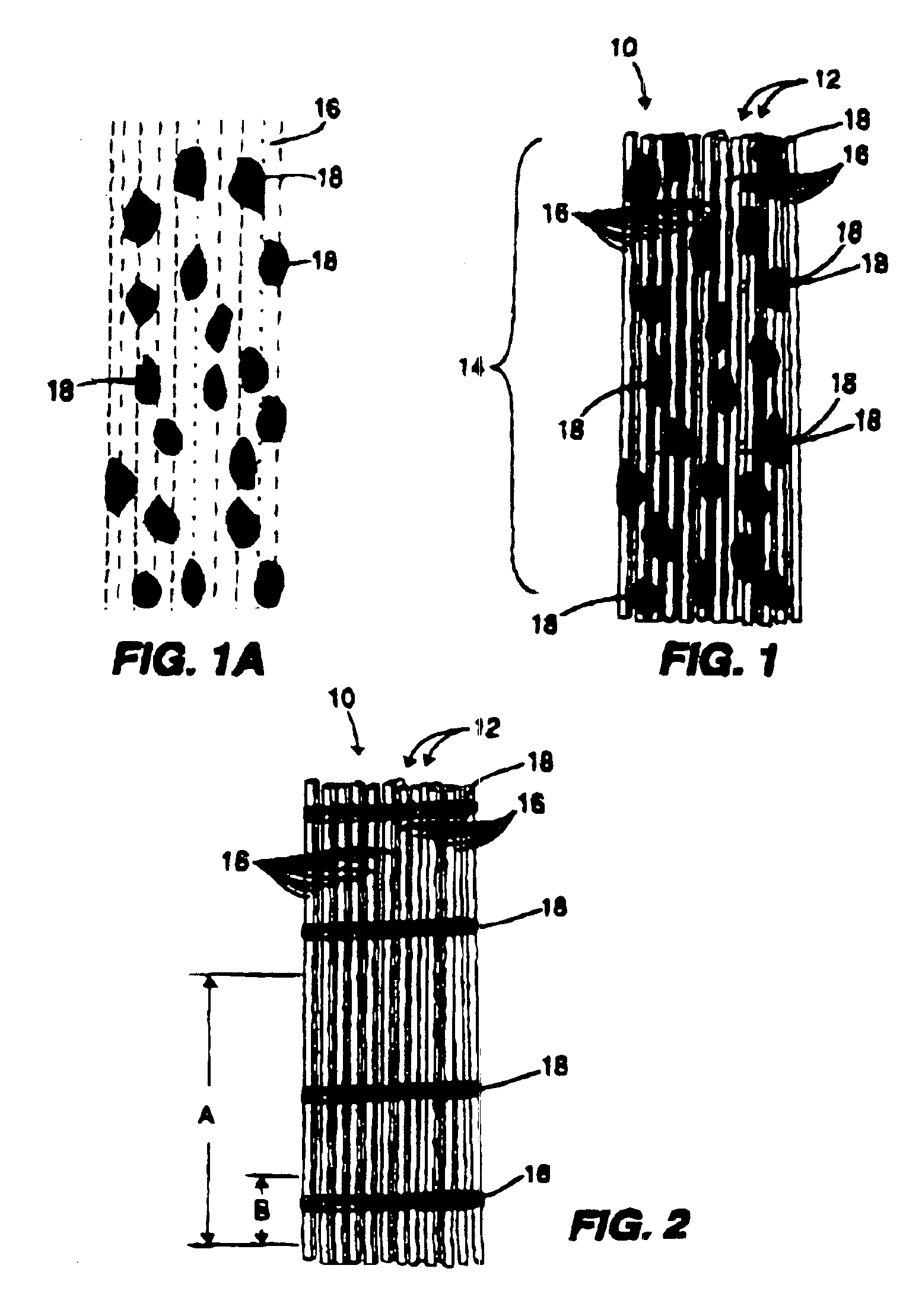

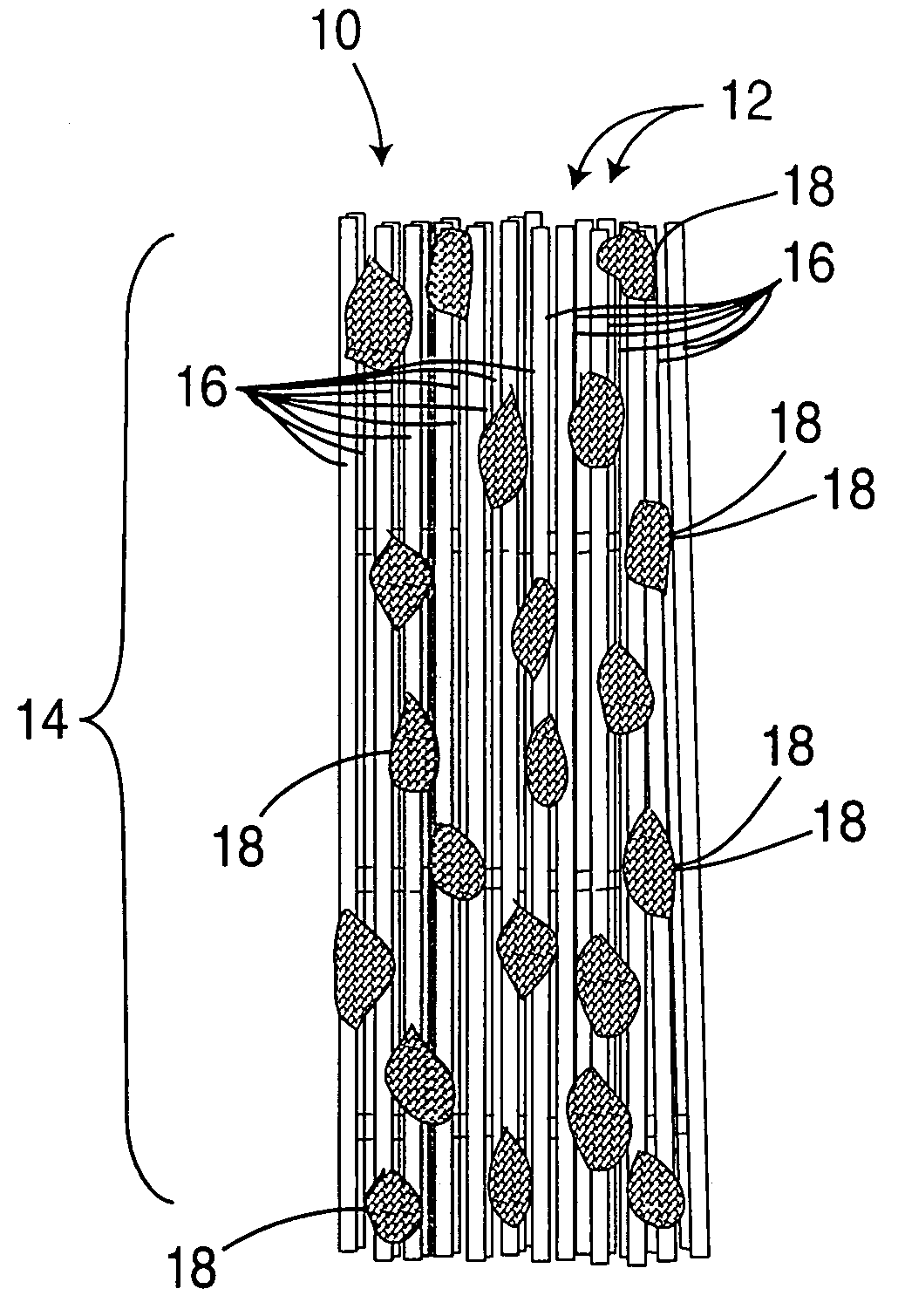

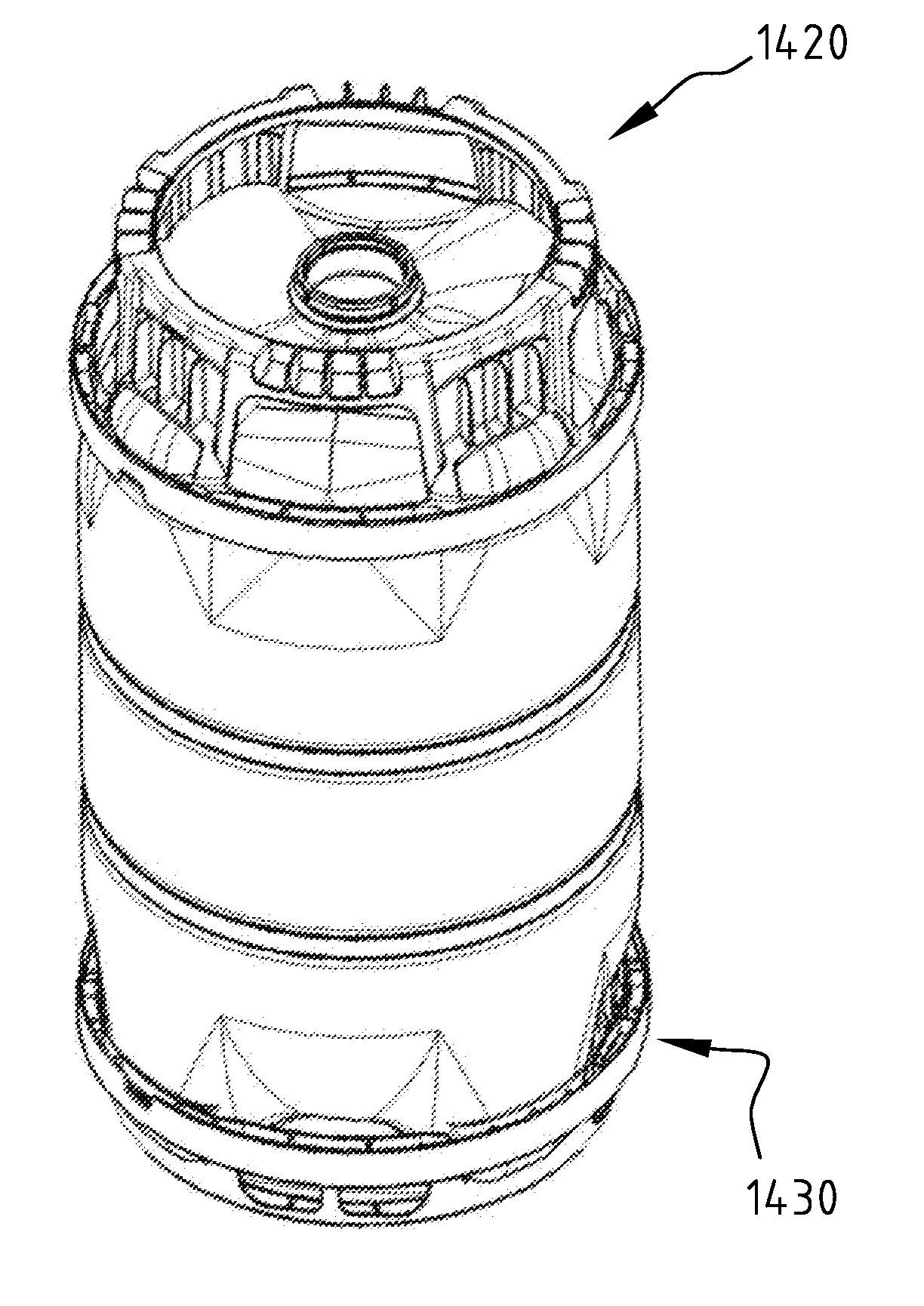

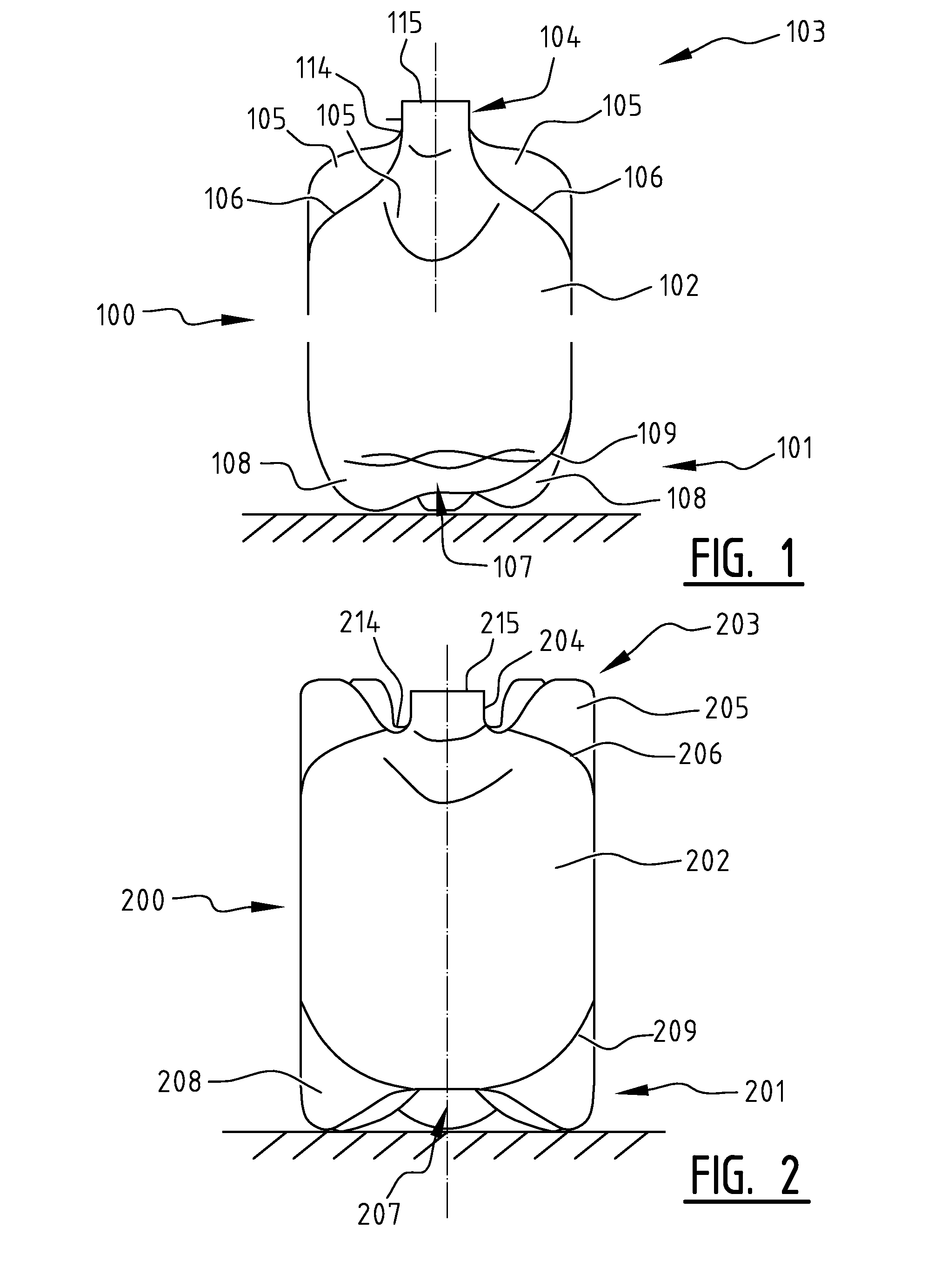

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body pail of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

Cold compress for therapeutic cooling

InactiveUS20120165910A1High heat transferIncrease flexibilityTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body part of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

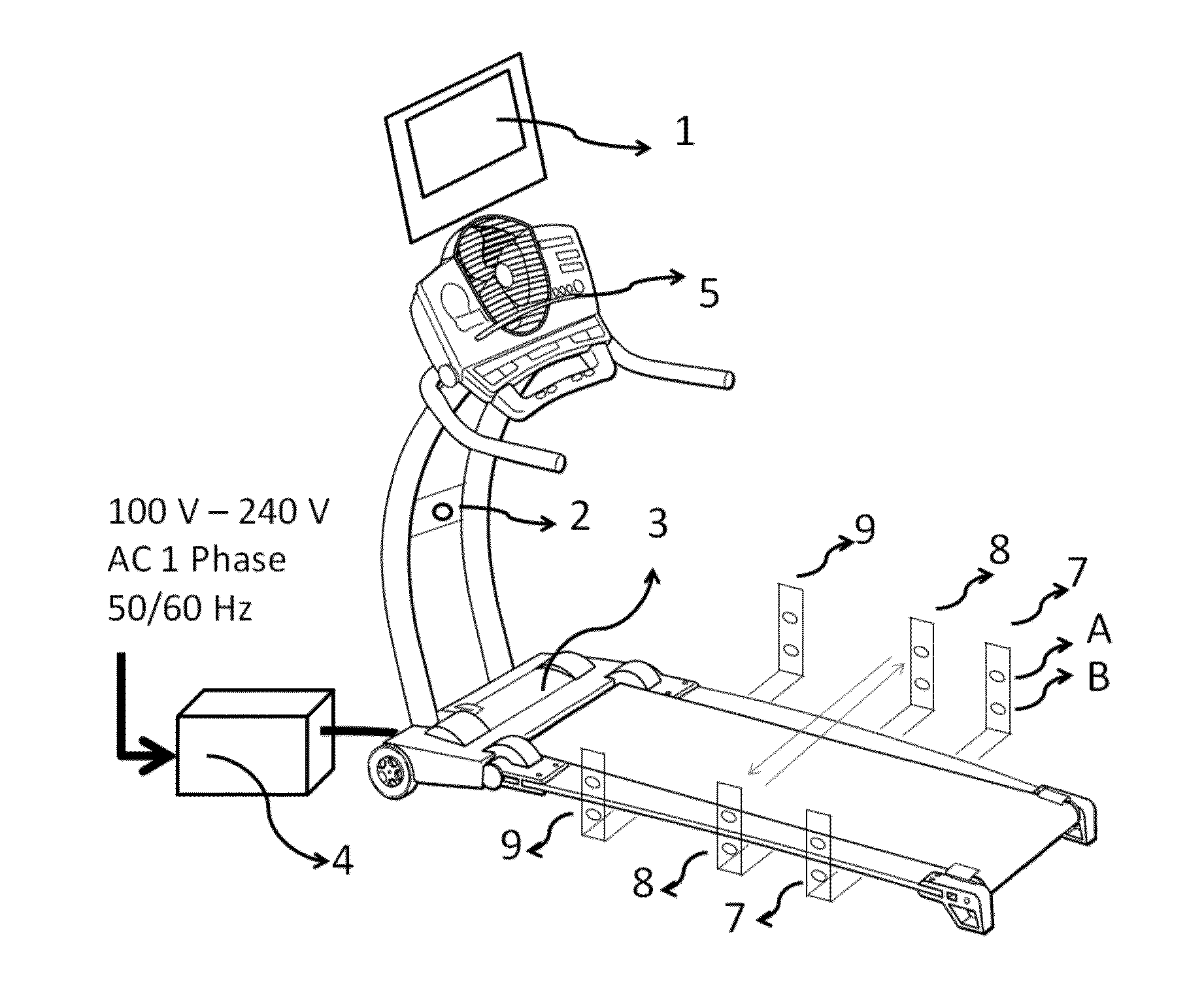

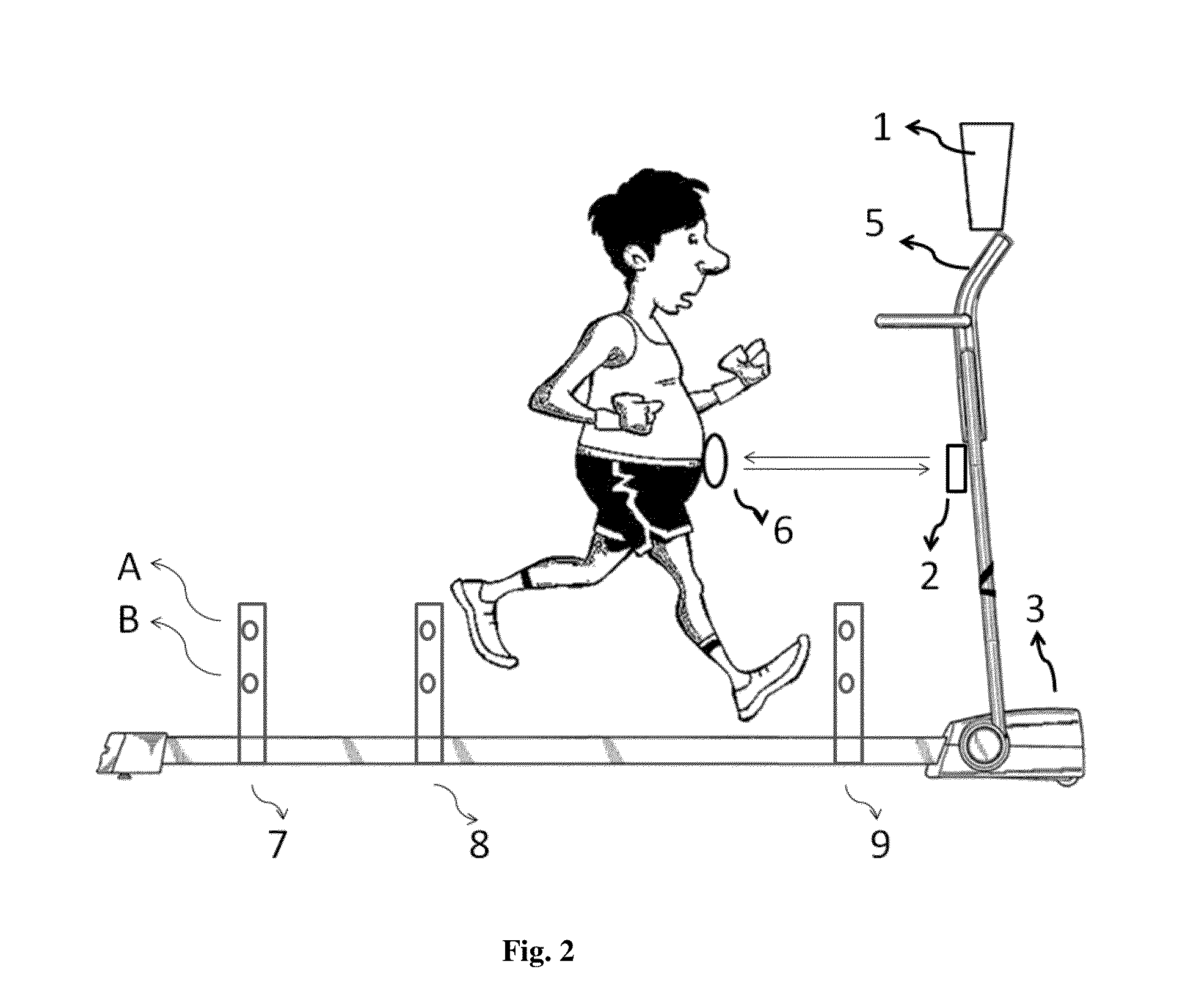

Intelligent Treadmill and Enhancements to Standard Treadmills

InactiveUS20160213976A1Improve transient responseImprove energy efficiencyMovement coordination devicesCardiovascular exercising devicesInduction motorBelt speed

An intelligent treadmill is described with modifications to existing treadmills, and associated methodology. The invention allows the conveyor belt automatically keeps track of and fixes the user's position dynamically with respect to a stationery reference point of the treadmill by adjusting its own speed free hands. Two position measurement techniques and their corresponding belt speed control algorithms are described. Other features of the invention allow users to perceive in real time how their surroundings would be changing by means of video, incline of platform, fan speed, sound and illumination as if they were in fact running in the natural environment. Real time positions of the runner and his partners on other treadmills with respect to a chosen track are displayed. The invention also utilizes a vectored controlled 2 / 3-phase AC induction motor or a BLDC motor to drive the conveyor belt for energy efficiency and fast response.

Owner:SO ALBERT TING PAT +2

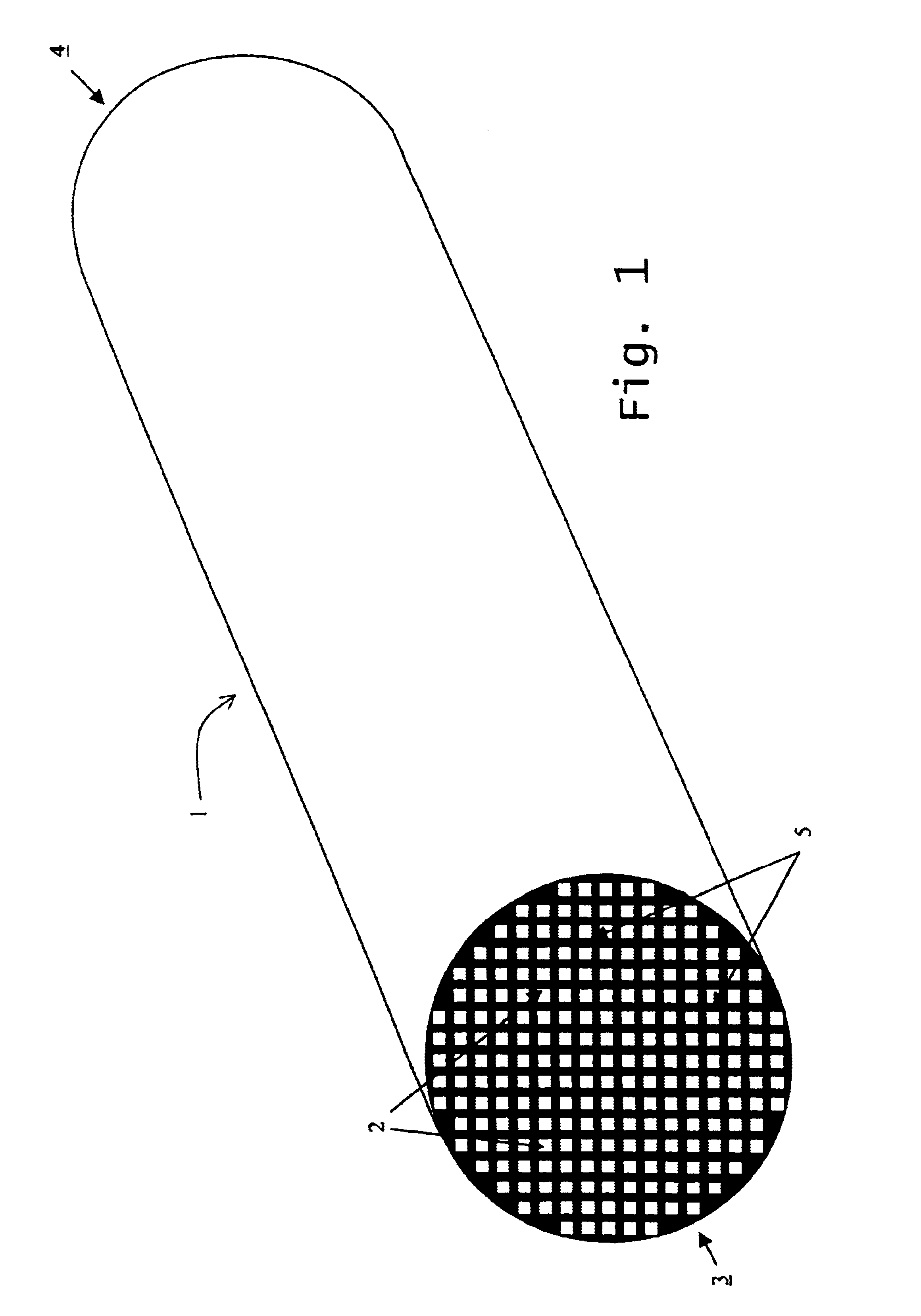

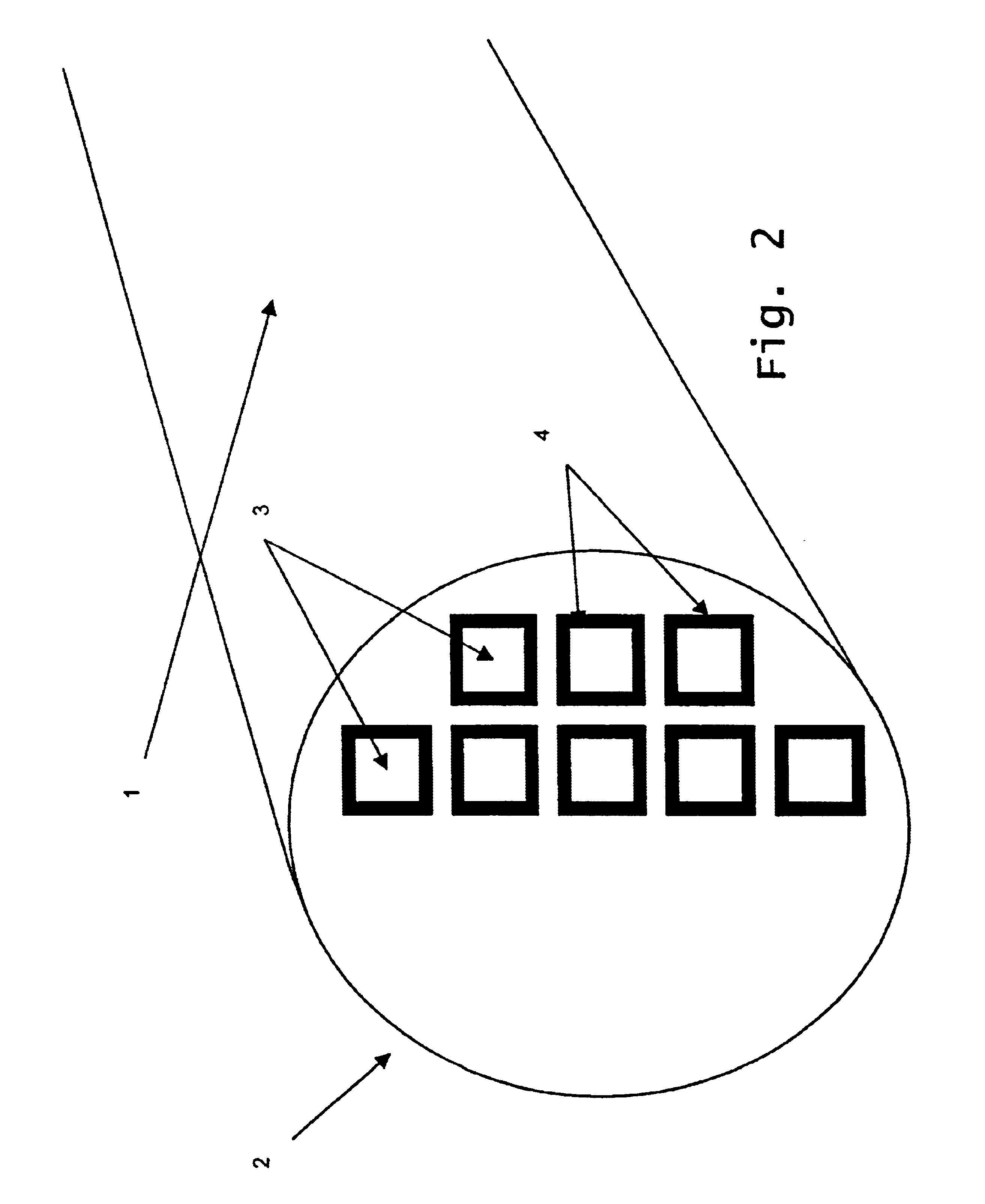

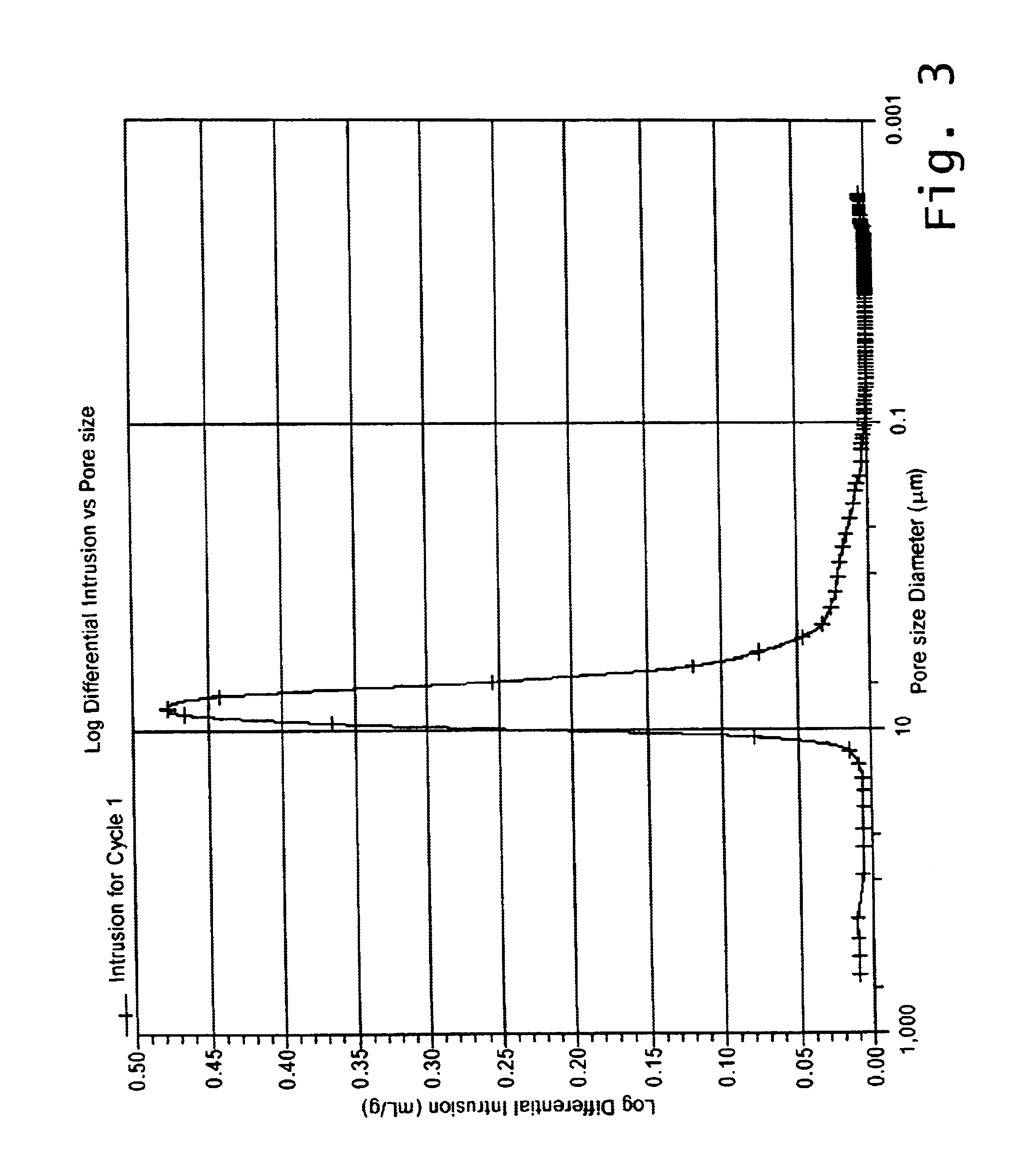

Reaction bonded alumina filter and membrane support

InactiveUS6695967B2Minimize changesIncrease the volume ratioSemi-permeable membranesDispersed particle filtrationAluminum metalMaterials science

A reaction-bonded alpha-alumina filter element is provided. The filter element includes a monolith of porous material having multiple passageways extending from one end face to an opposing end face. The monolith is extruded from a mixture containing at least aluminum metal and alumina powders in a proportion such that on sintering the volume change of the monolith is minimized. The filter body can be used as a filter or as a membrane support for crossflow or dead end flow filter elements. A method for making the filter element is also provided.

Owner:HPD

Flexible fabric from fibrous web and discontinuous domain matrix

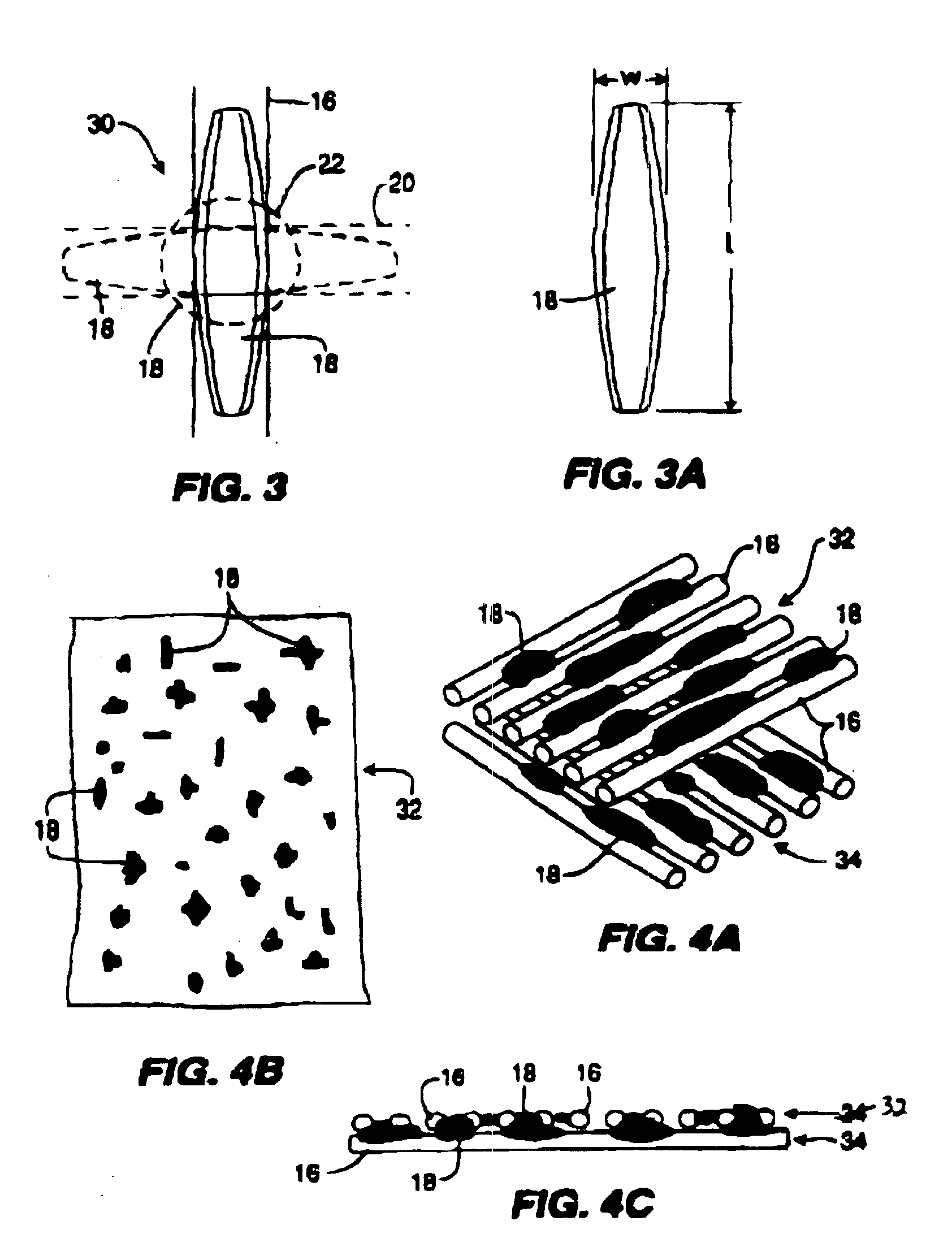

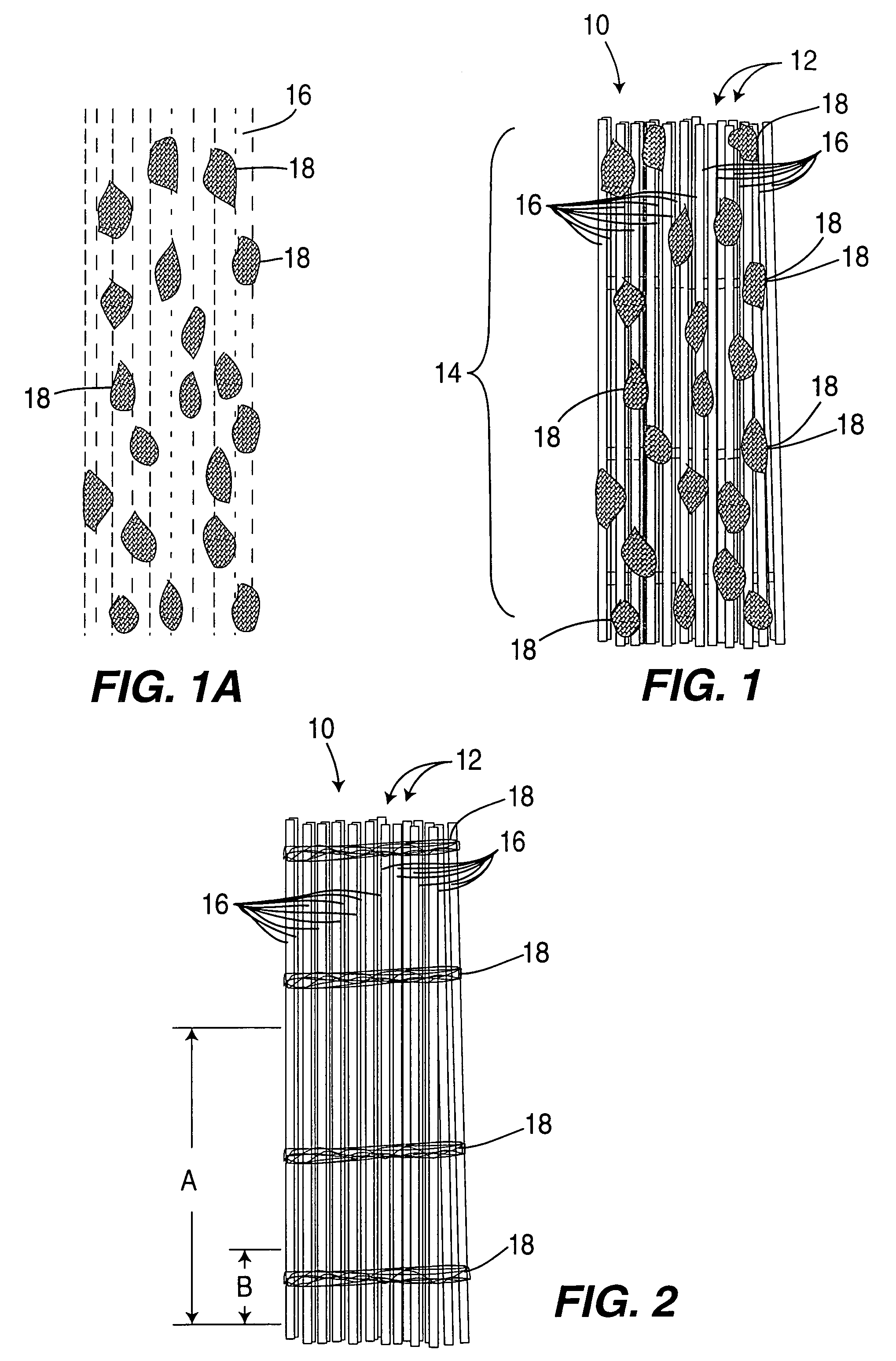

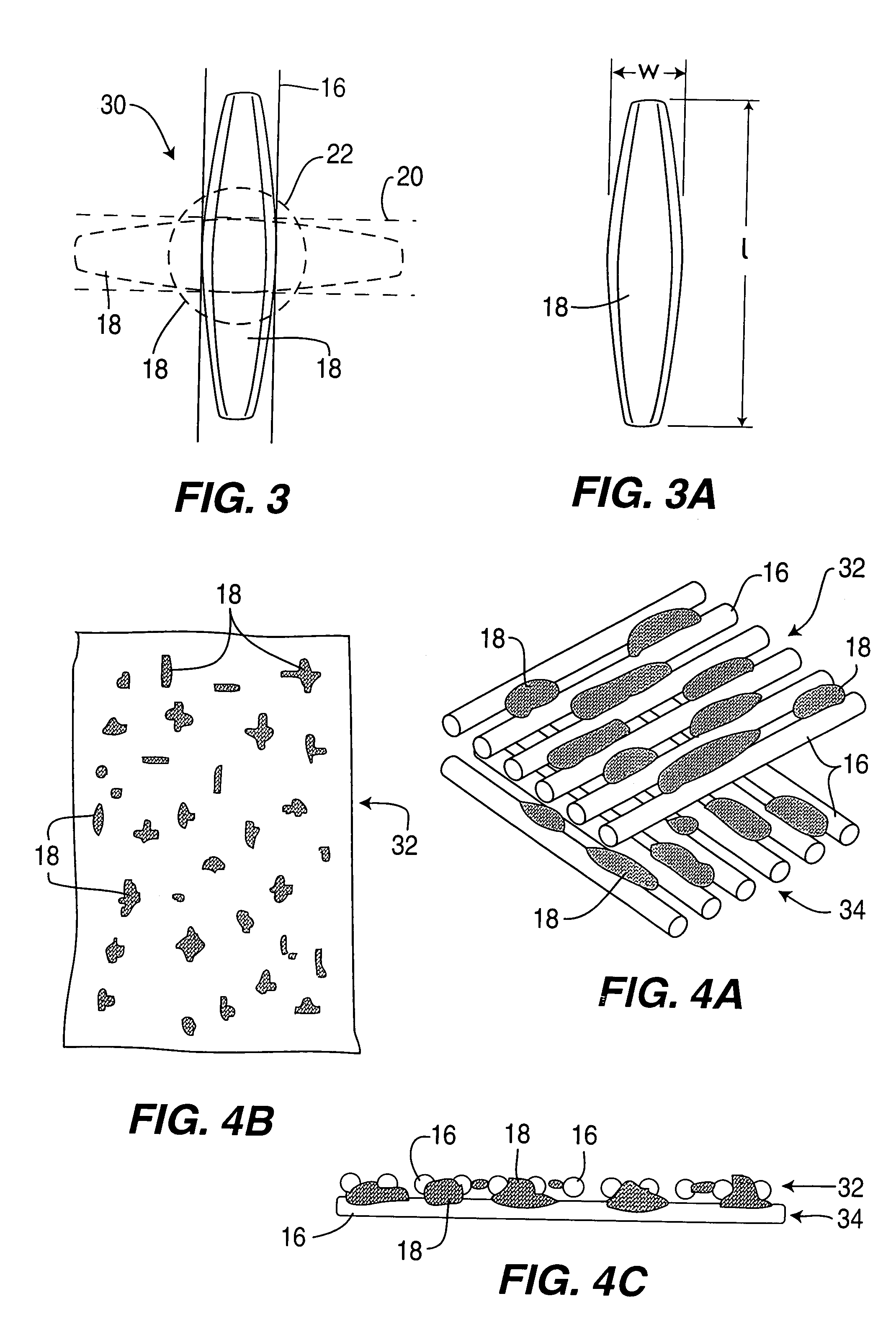

InactiveUS6846548B2Increase the volume ratioBallistically efficientSynthetic resin layered productsAnimal housingPliabilityEngineering

A composite having a plurality of filaments arranged in a fibrous web that is held together in a unitary structure by a domain matrix. The domain matrix comprises a plurality of matrix islands that individually connect, or bond, at least two filaments, to thereby hold the filaments in a unitary structure. Portions of the filament lengths within the unitary structure are free of matrix islands, causing the domain matrix to be discontinuous. The composite possesses a greater flexibility than coated structures. The composite may be formed into cross-plied structures. A method of making the composite also is disclosed.

Owner:HONEYWELL INT INC

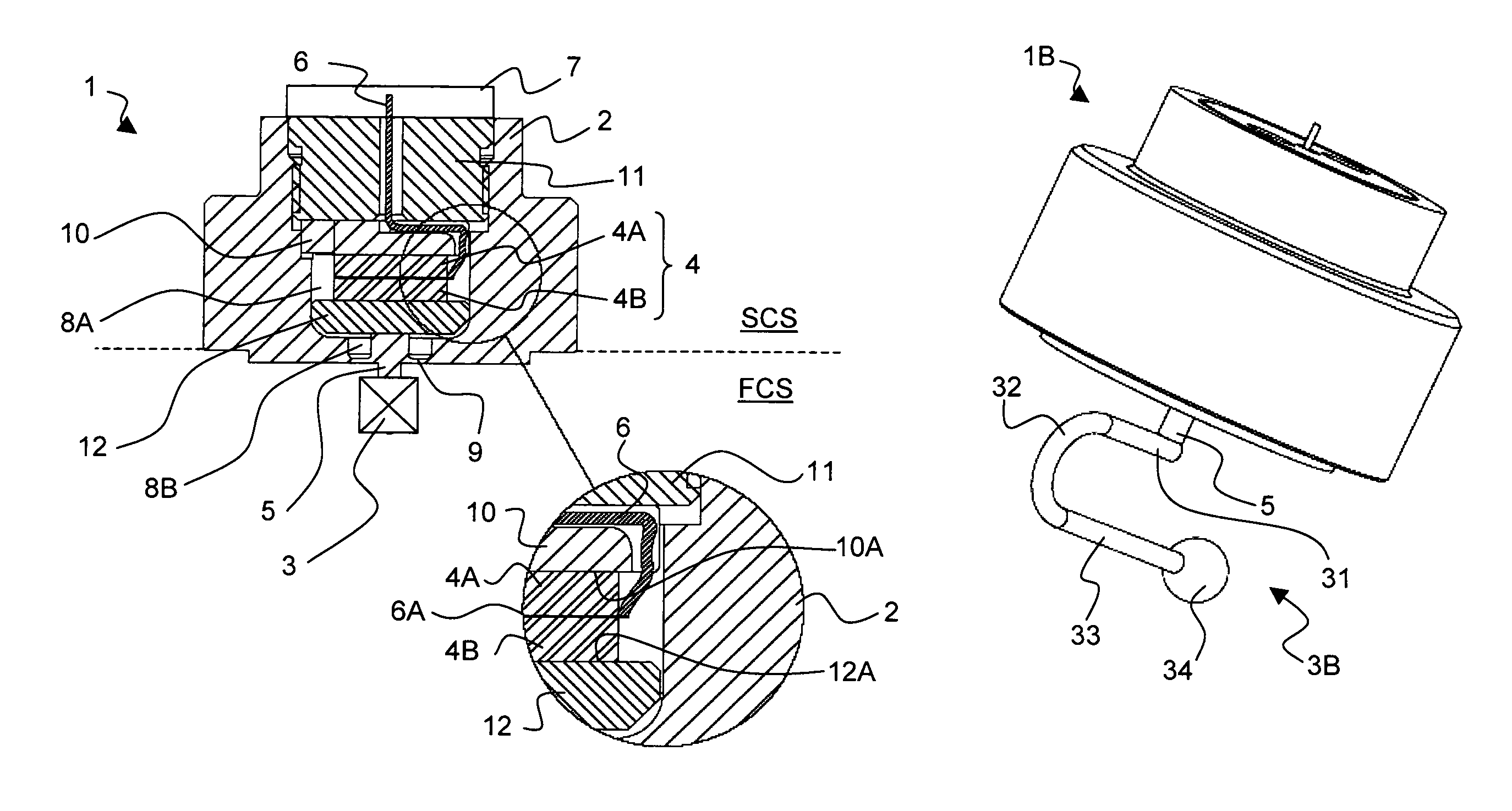

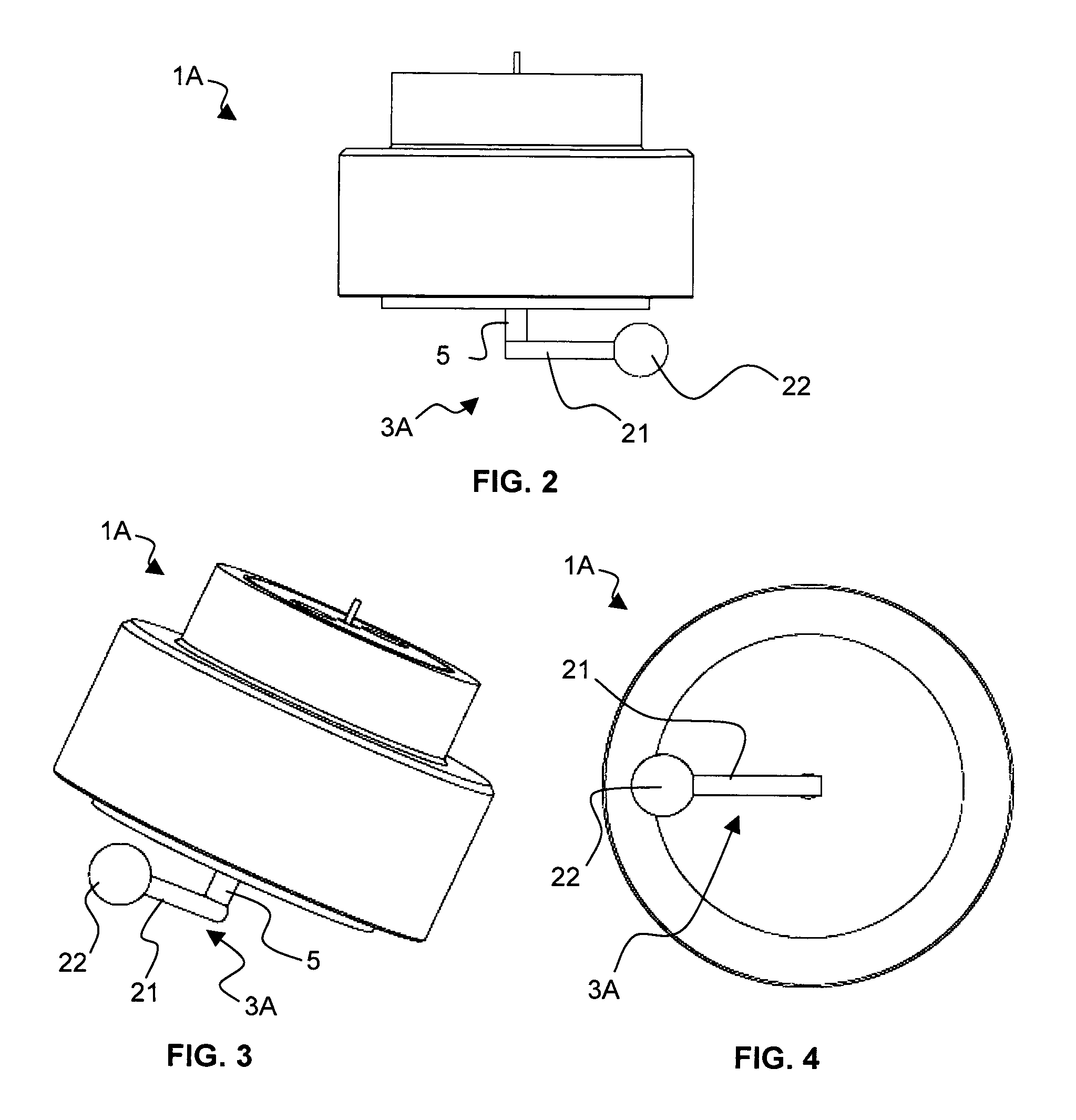

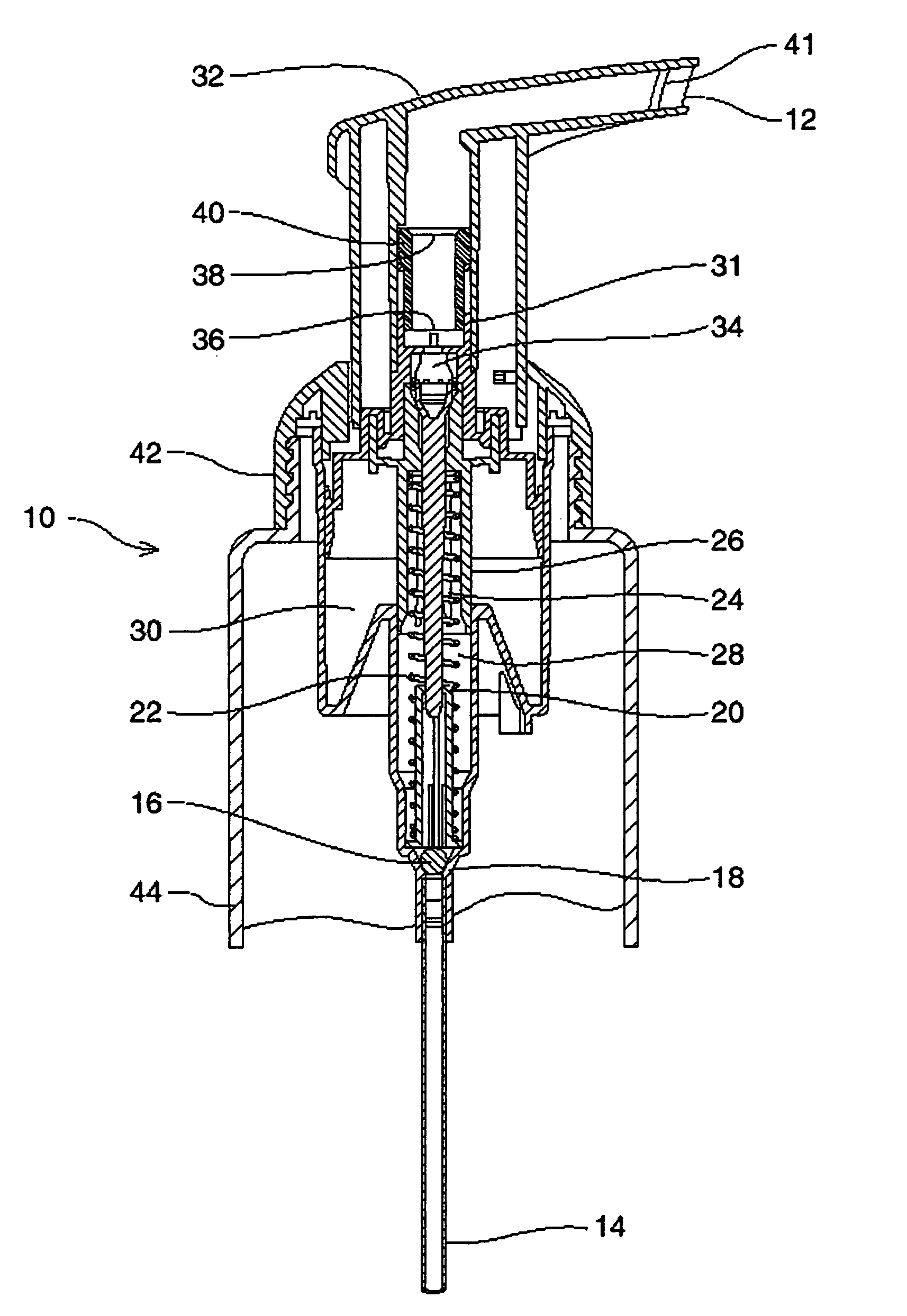

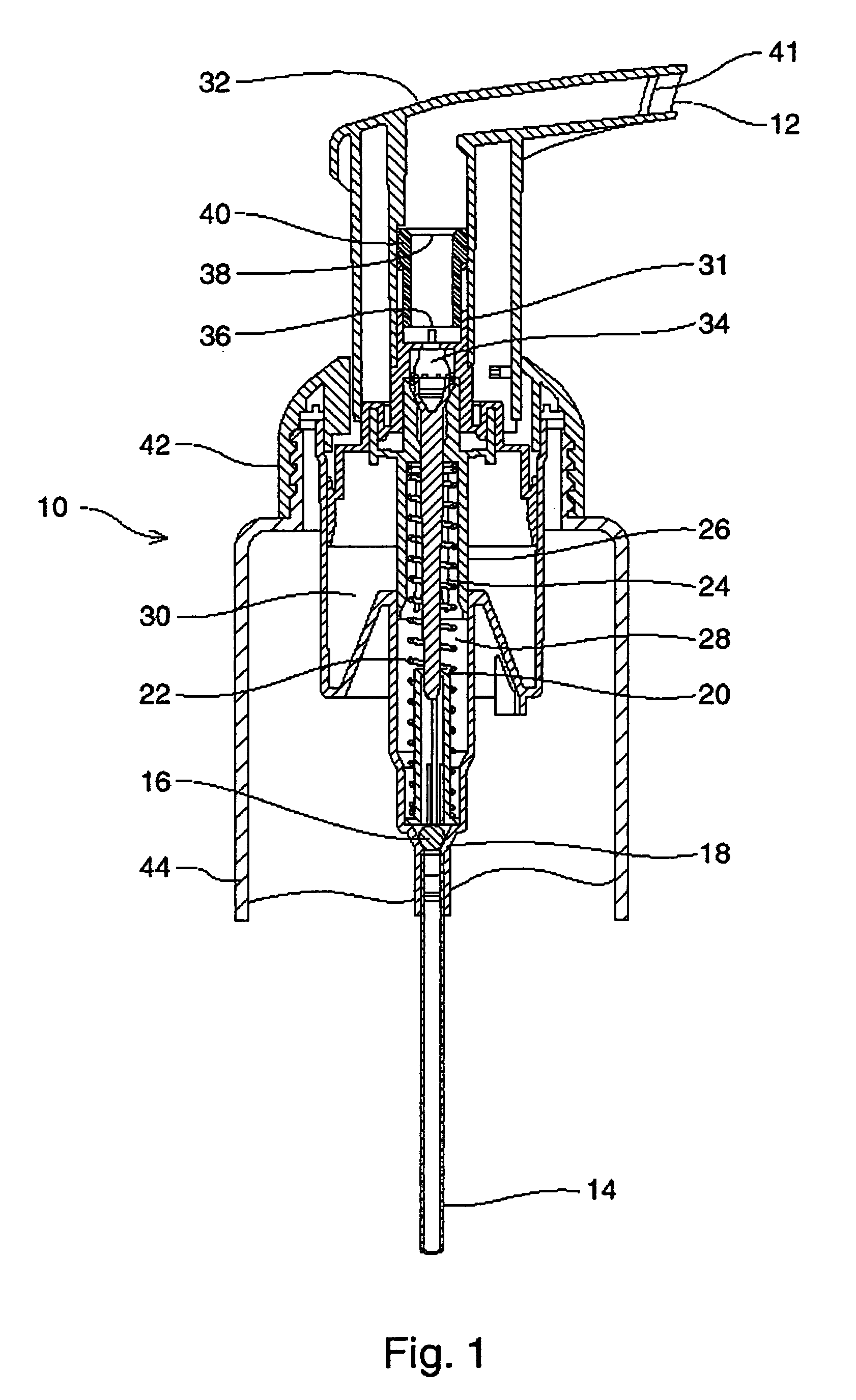

Density and Viscosity Sensor

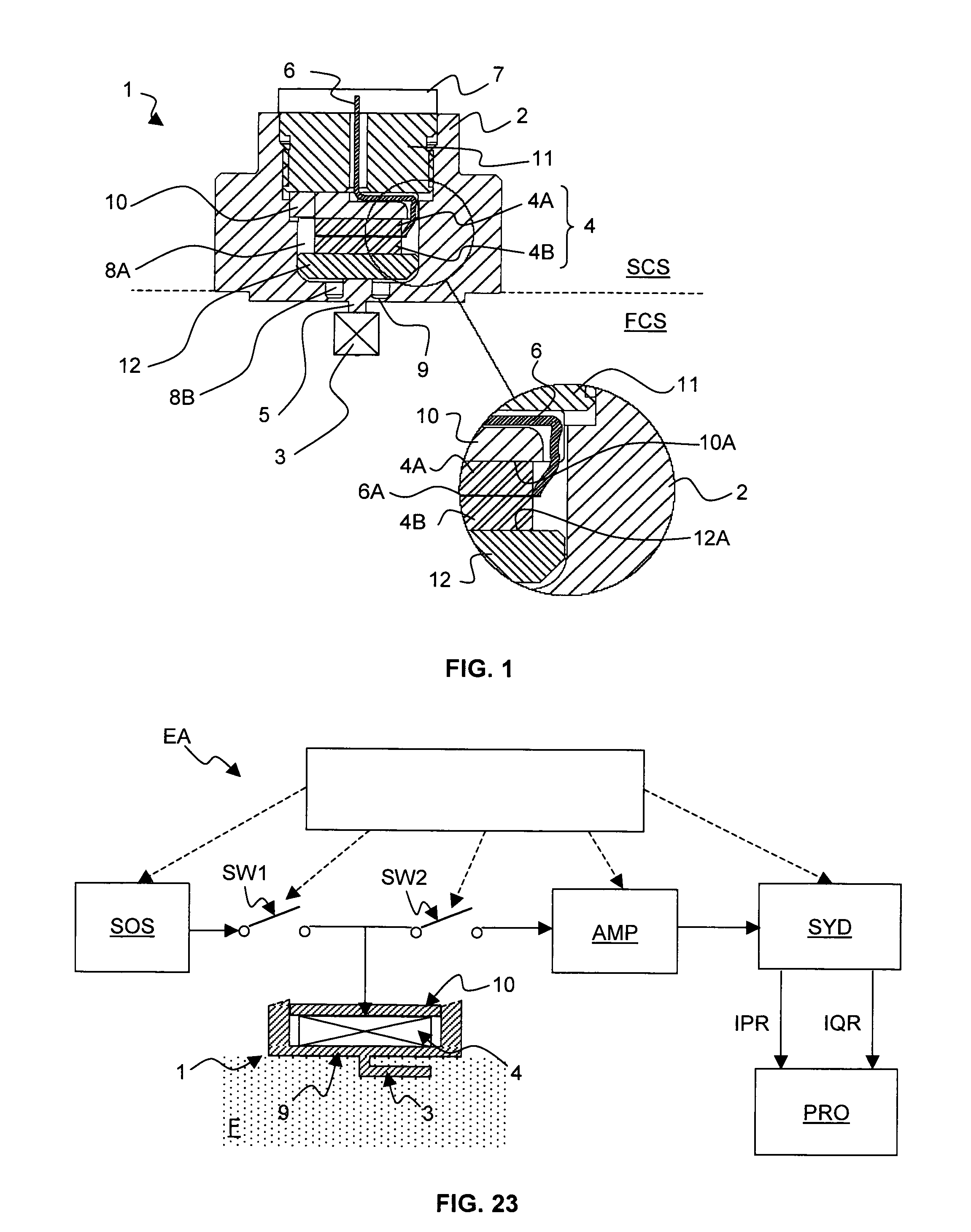

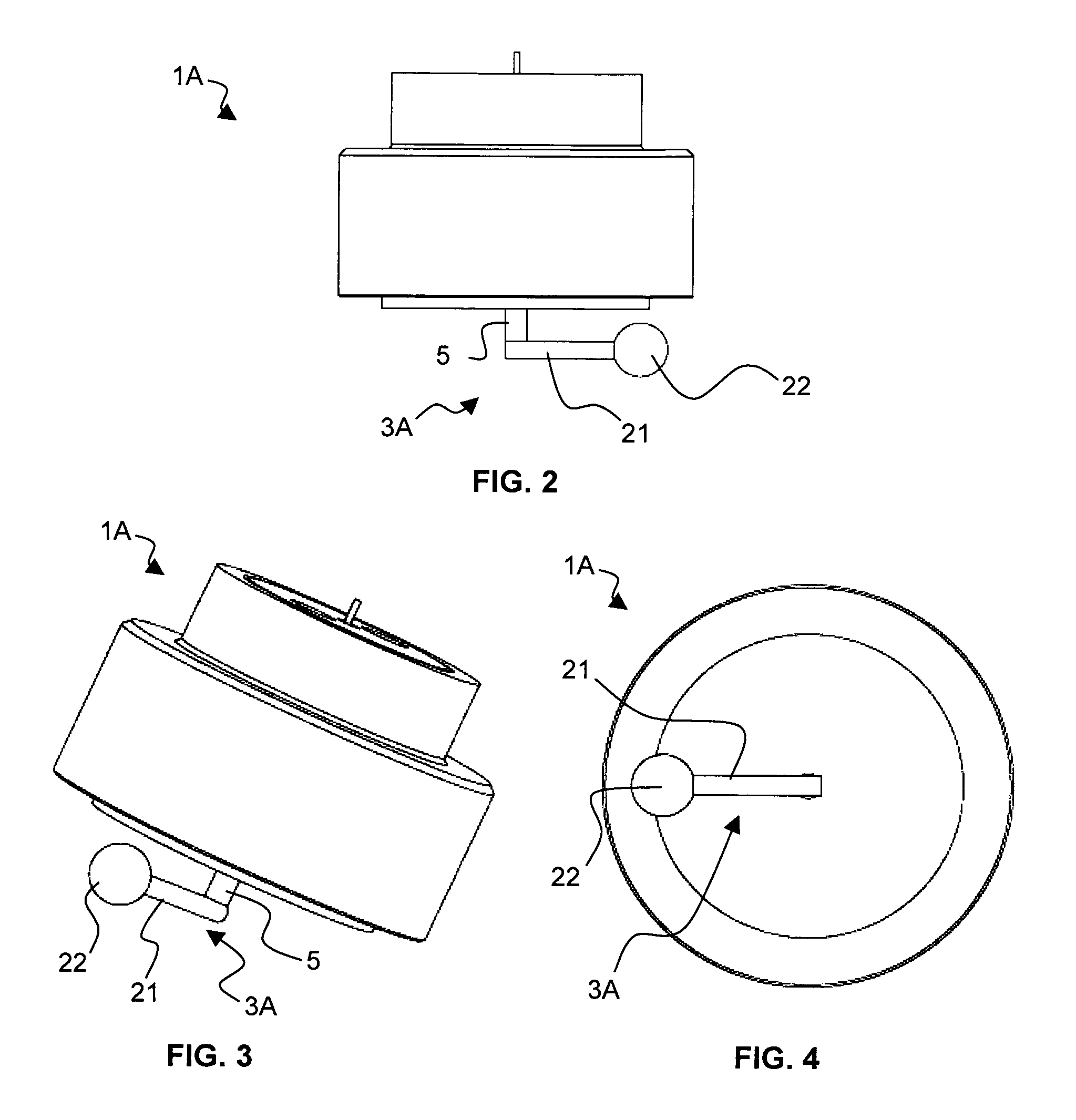

ActiveUS20080257036A1Efficient excitationRegard to overcoming effectsFlow propertiesSpecific gravity using flow propertiesResonanceEngineering

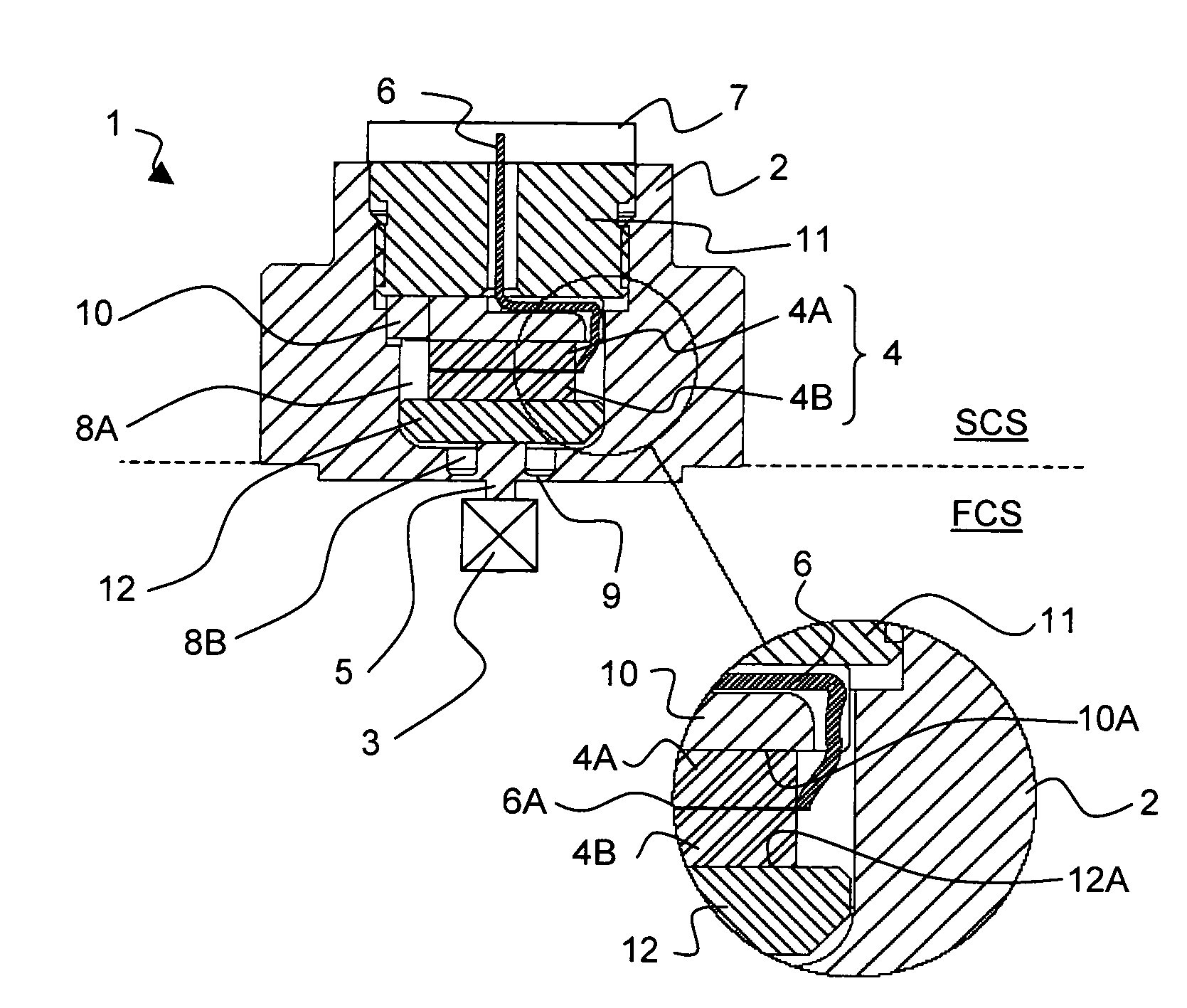

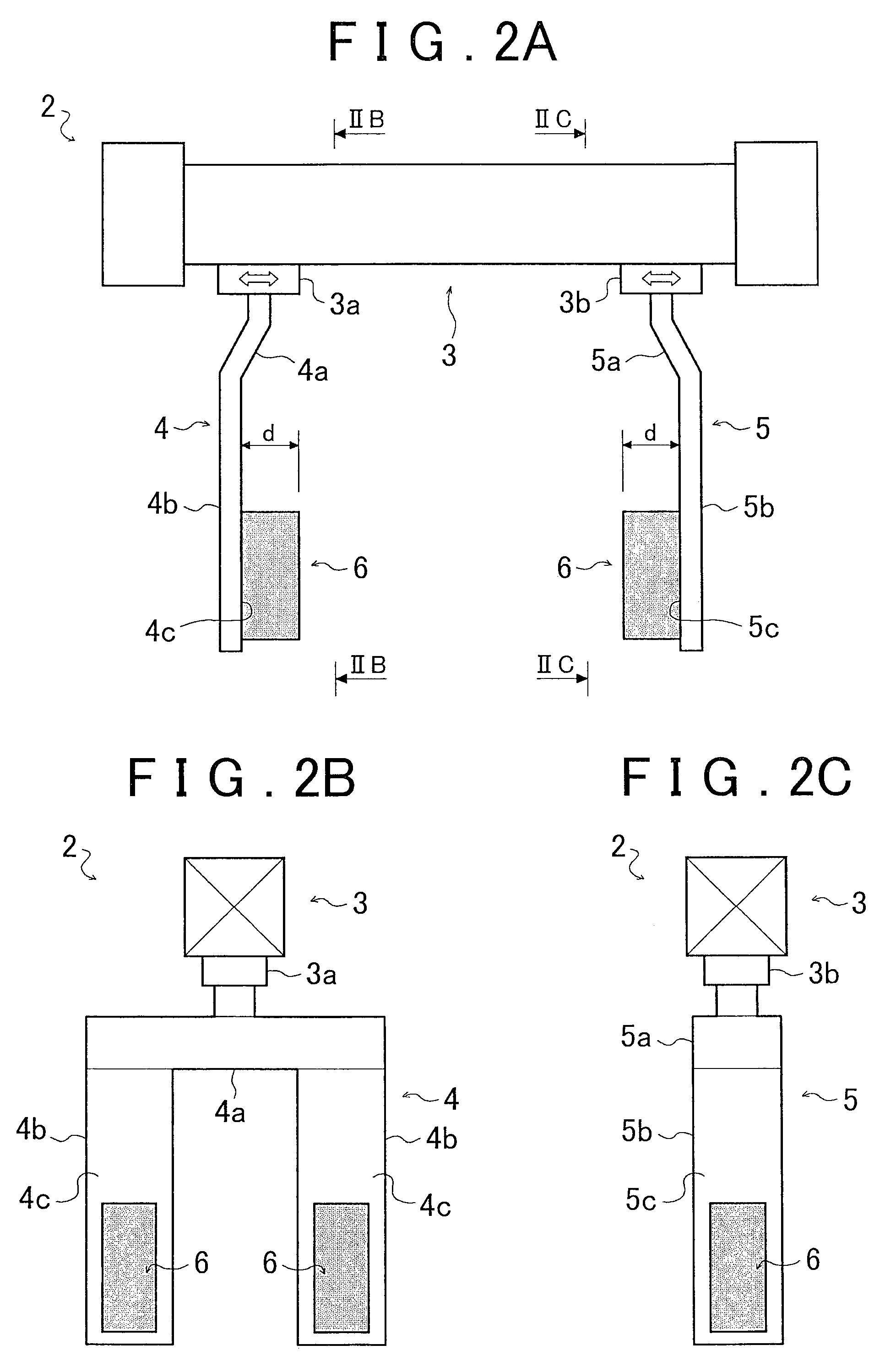

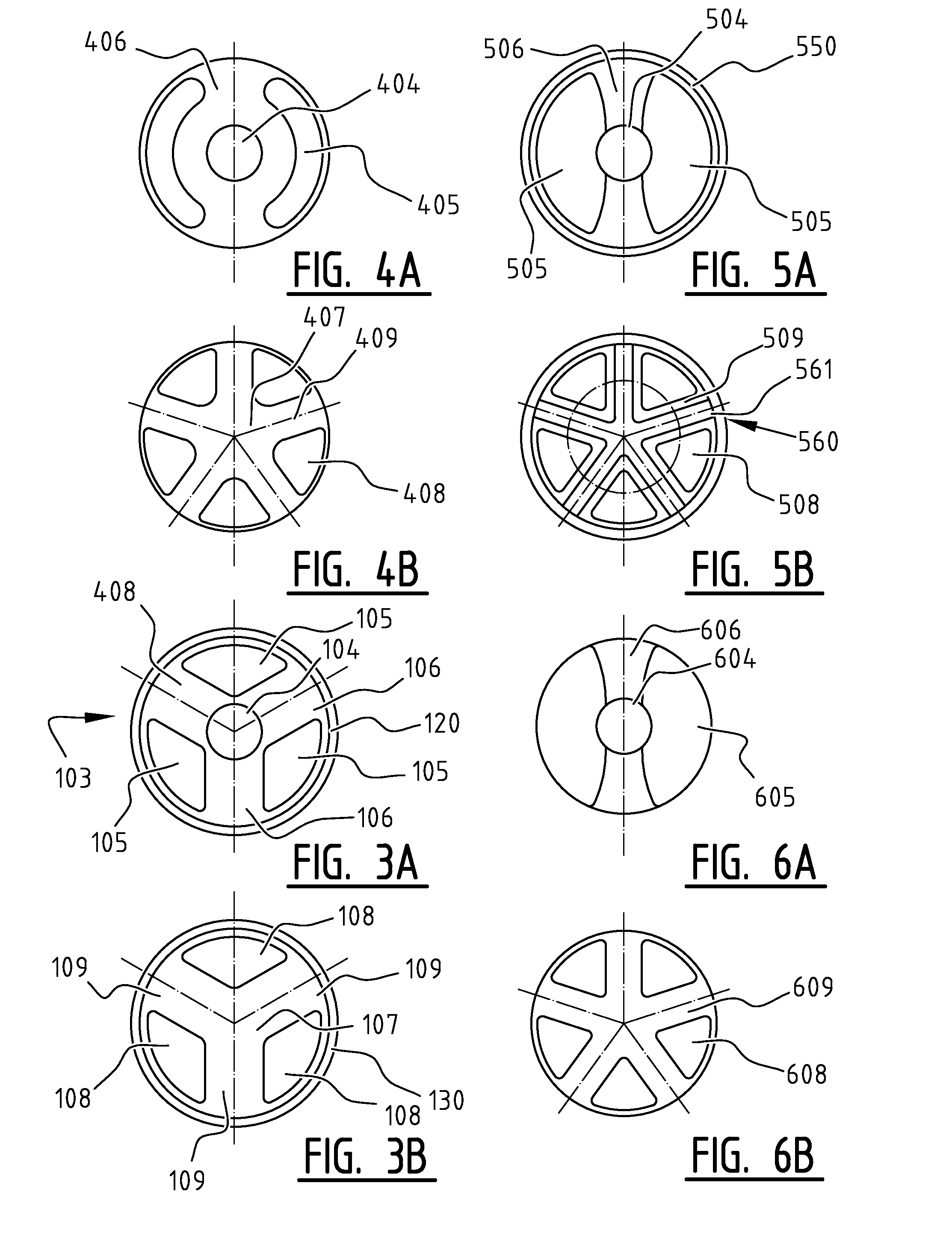

A density and viscosity sensor 1 for measuring density and viscosity of fluid F, the sensor 1 comprising:a resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G arranged to be immersed in the fluid F,an actuating / detecting element 4, 4A, 4B coupled to the resonating element,a connector 7 for coupling to the actuating / detecting element 4, 4A, 4B,a housing 2 defining a chamber 8A isolated from the fluid F, the housing 2 comprising an area of reduced thickness defining a membrane 9 separating the chamber 8A from the fluid F, the membrane 9 having a thickness enabling transfer of mechanical vibration between the actuating / detecting element 4, 4A, 4B and the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G,the actuating / detecting element 4, 4A, 4B is positioned within the chamber so as to be isolated from the fluid F and mechanically coupled to the membrane 9, the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G arranged to be immersed in the fluid F is mechanically coupled to the membrane 9, wherein the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G has a shape defining a first resonance mode and a second resonance mode characterized by different resonant frequencies F1, F2 and different quality factors Q1, Q2, the first resonance mode moving a volume of fluid, the second mode shearing a surrounding fluid.

Owner:SCHLUMBERGER TECH CORP

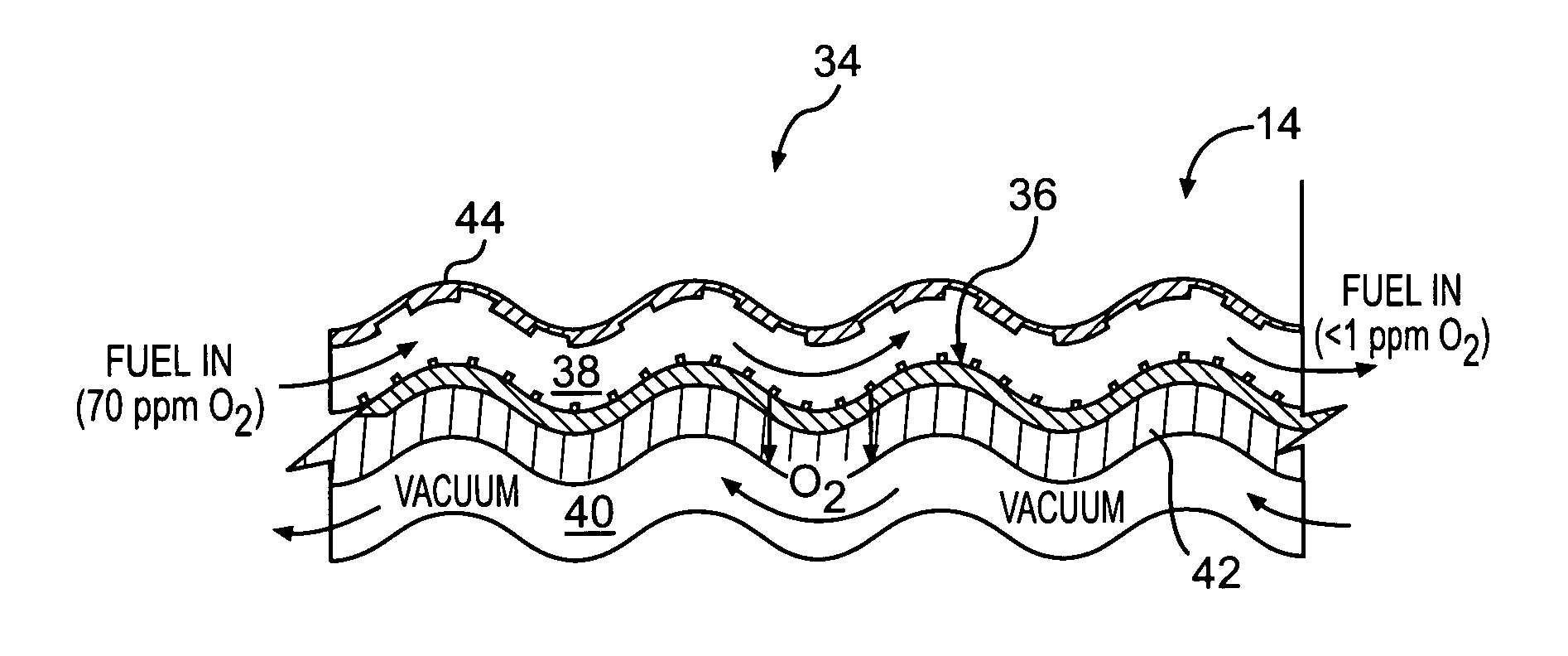

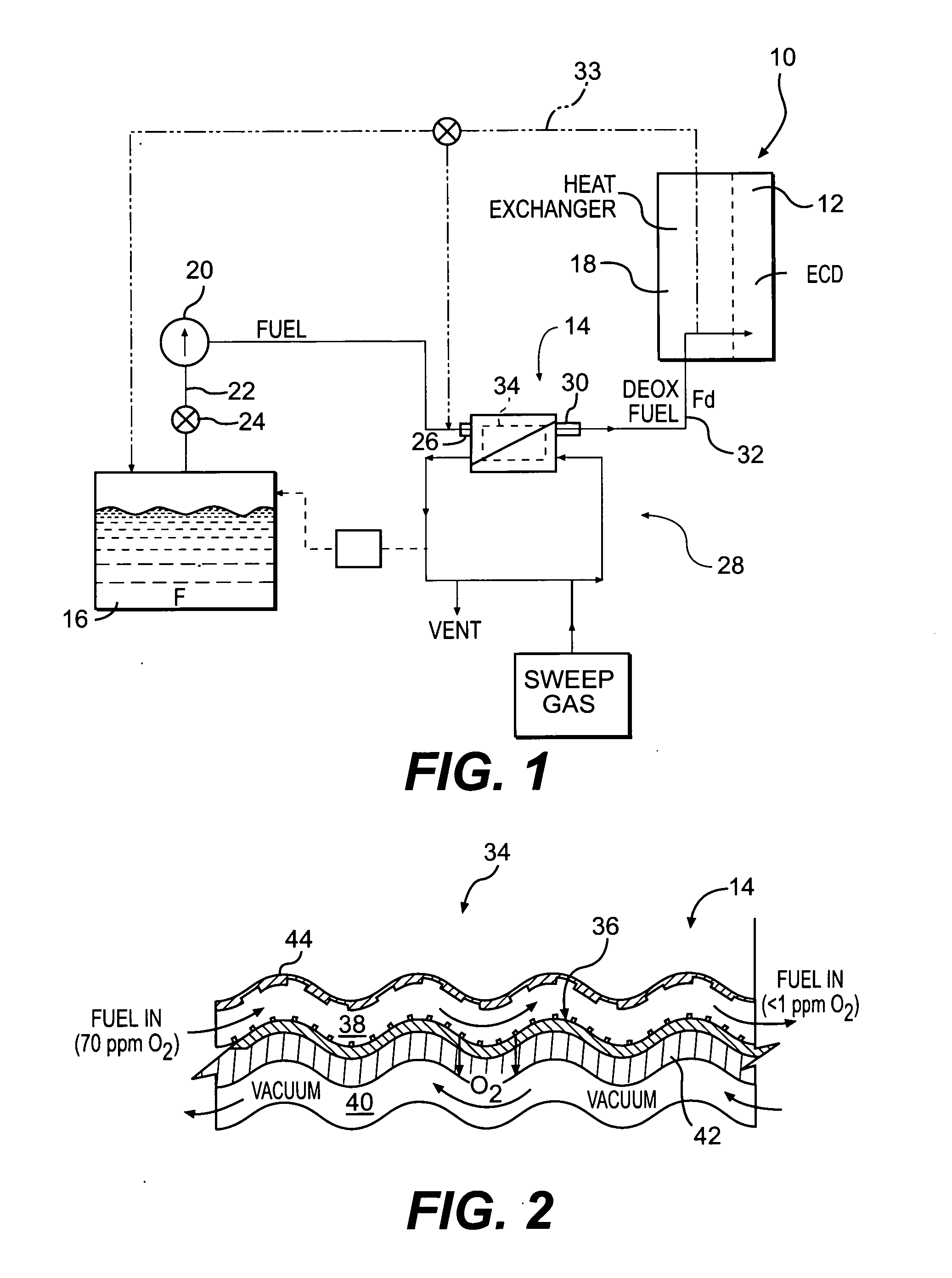

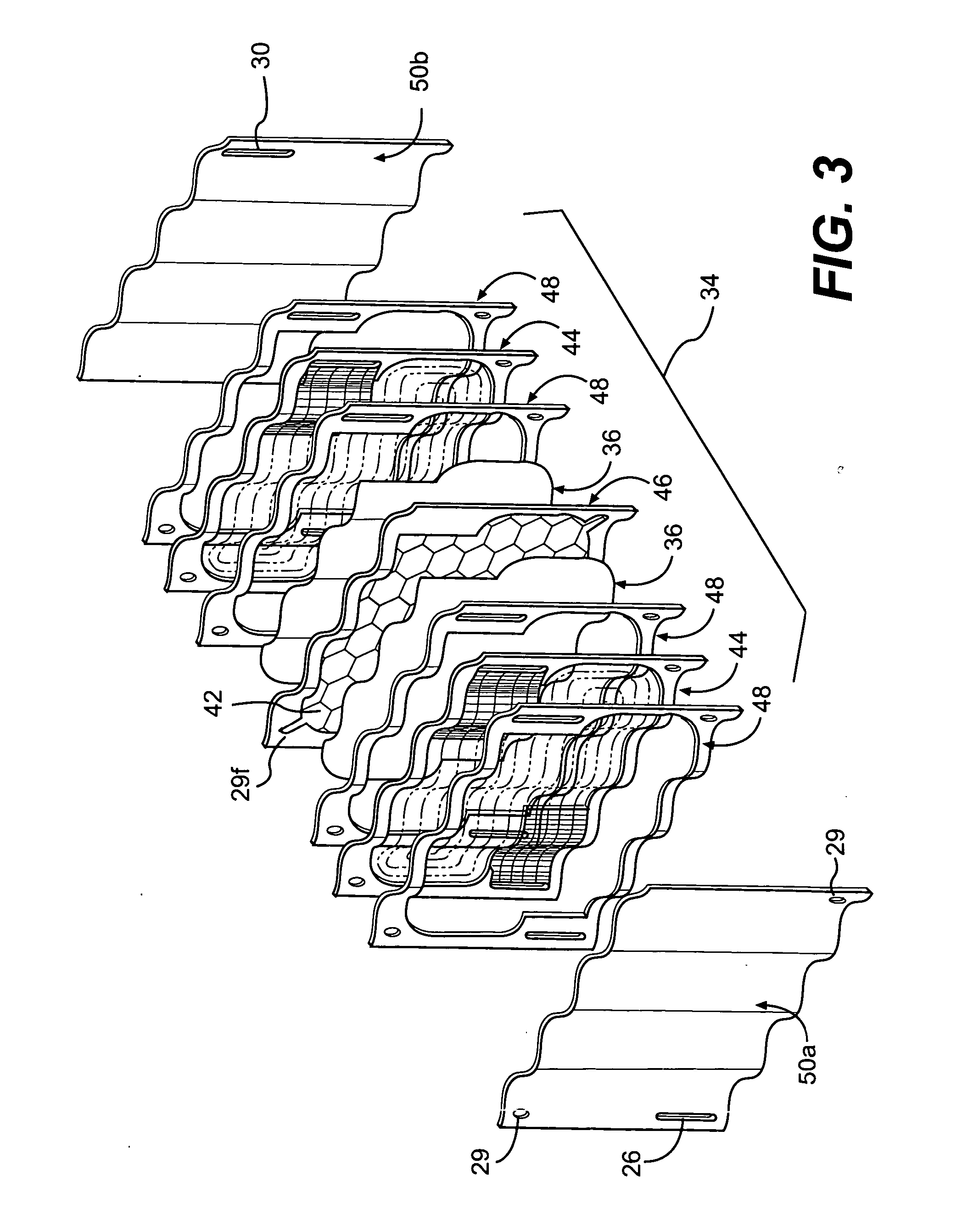

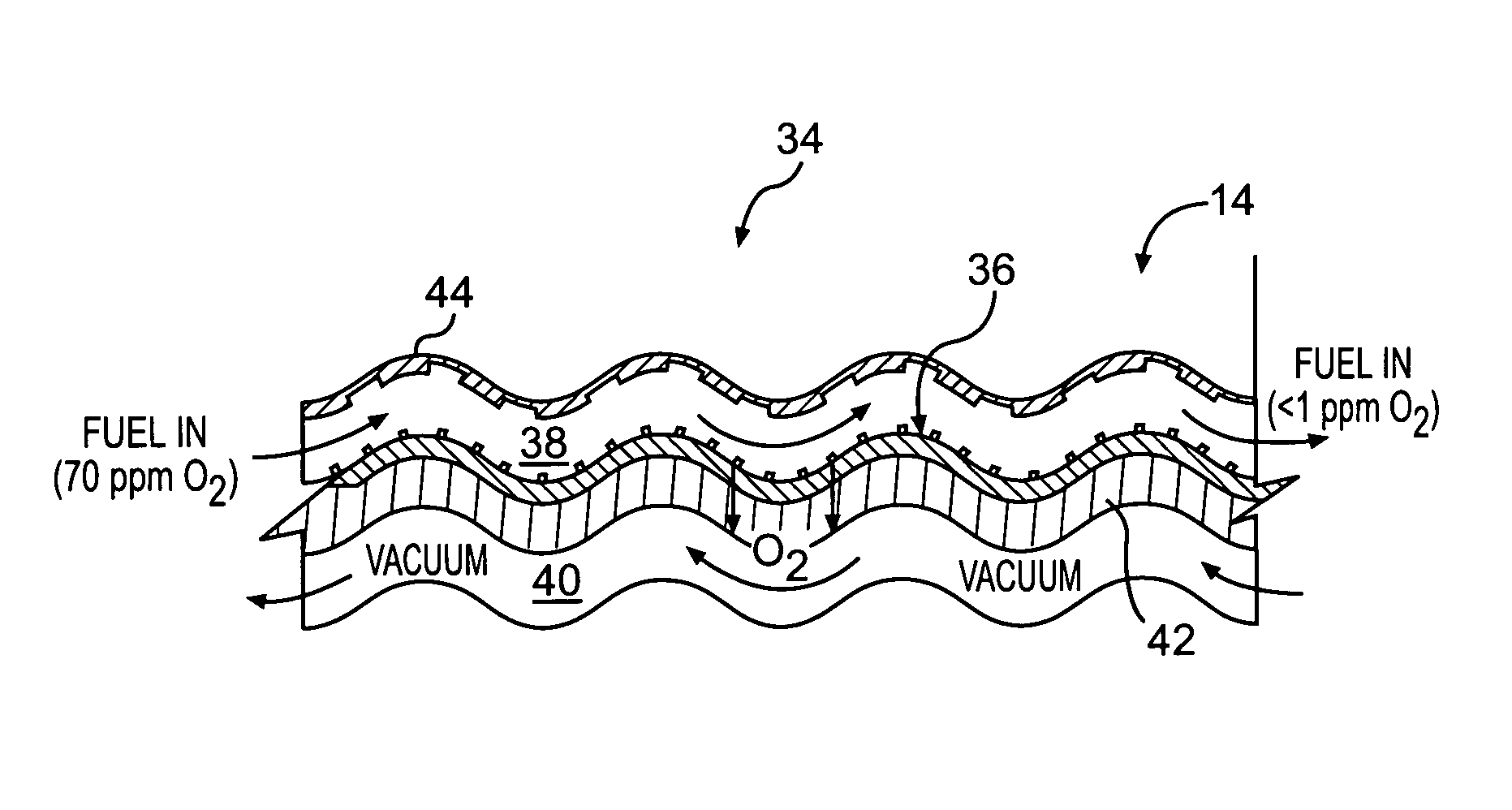

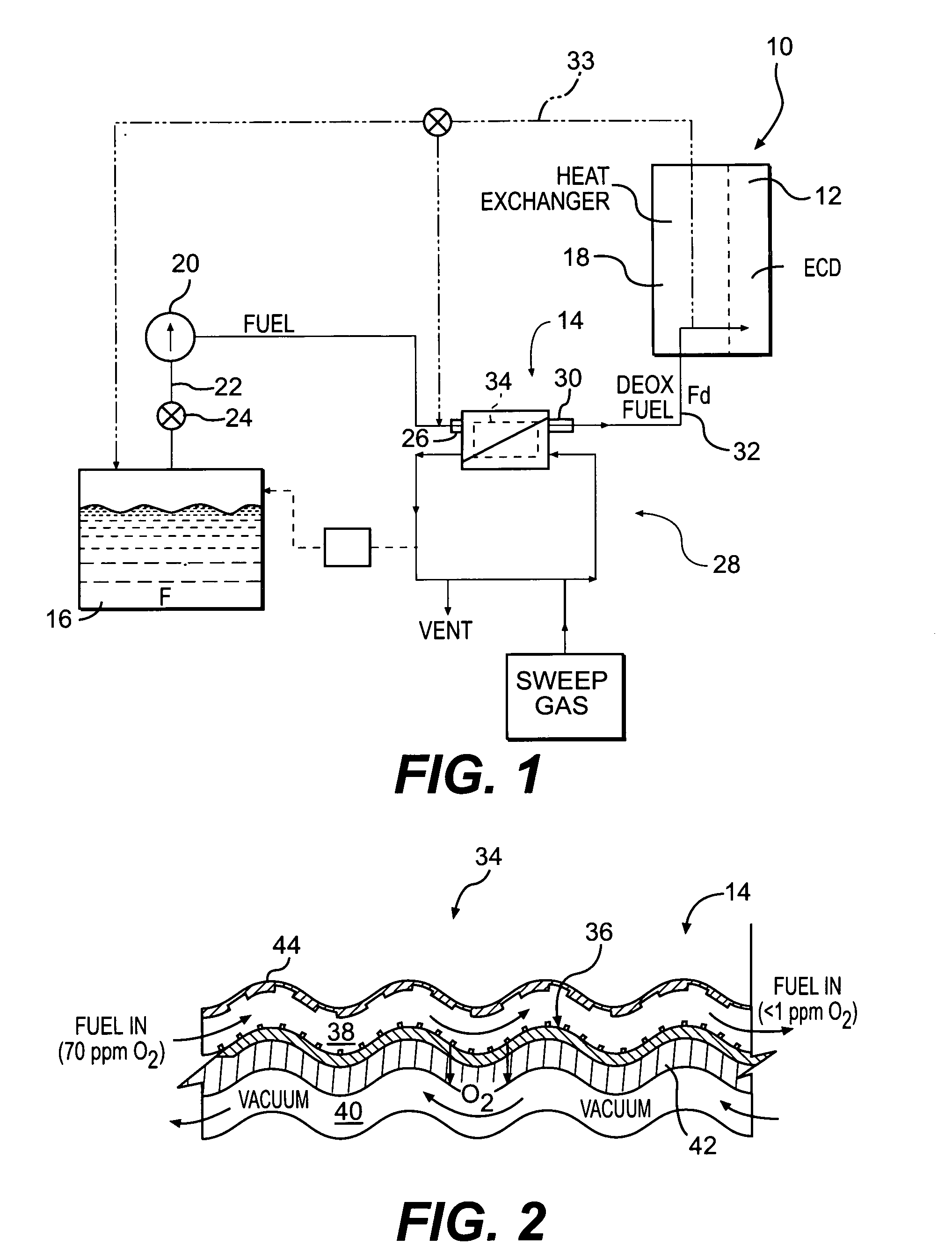

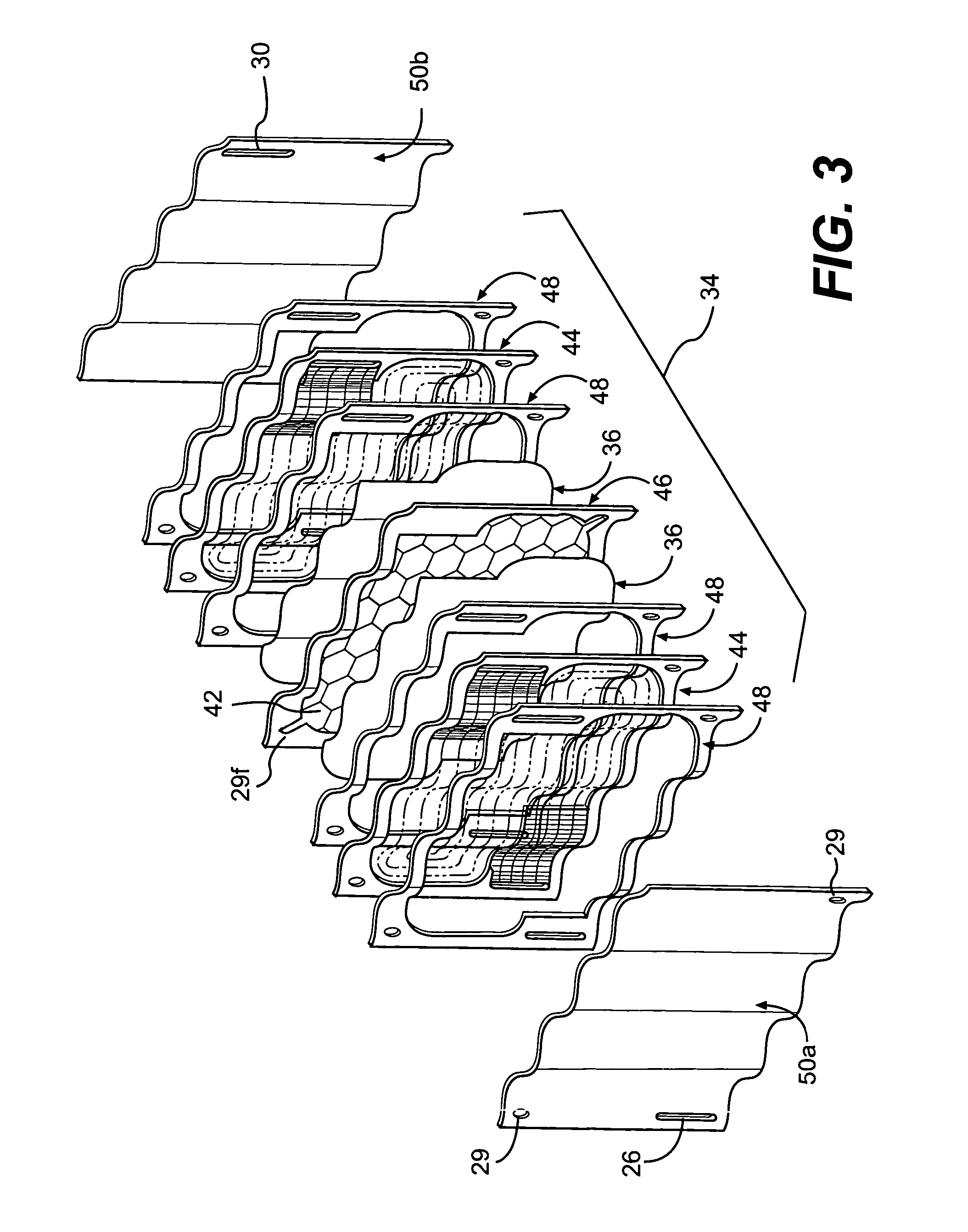

Fuel deoxygenation system with non-planar plate members

ActiveUS20060278073A1Enhances deoxygenationImprove efficiencyPower plant fuel tanksIsotope separationPorous substrateEngineering

A fuel system for an energy conversion device includes a multiple of fuel plates, oxygen permeable membranes, porous substrate plates, and vacuum frame plates which define a wave pattern configuration. The wave configuration enhances deoxygenation by increasing the efficiency and integrality due to higher surface volume ration, increase of flow turbulence, and minimal sharp edges which may otherwise damage the oxygen permeable membranes compared to other configurations.

Owner:RAYTHEON TECH CORP

Density and viscosity sensor

ActiveUS7874199B2High piezoelectric diskIncrease pressureMaterial analysis by observing immersed bodiesFlow propertiesResonanceAcoustics

A density and viscosity sensor for measuring density and viscosity of a fluid, and method for measuring, are presented herein. The sensor comprises a resonating element, and actuating / detecting element, a connector and a housing. The actuating / detecting element is positioned within a chamber defined by the housing so as to be isolated from the fluid. The resonating element is arranged to be immersed in the fluid, and has a shape defining a first resonance mode and a second resonance mode characterized by different resonance frequencies and different quality factors. The first resonance mode is adapted to move a volume of fluid, and the second resonance mode is adapted to shear a surrounding fluid.

Owner:SCHLUMBERGER TECH CORP

Flexible fabric from fibrous web and discontinuous domain matrix

InactiveUS7211291B2Increase the volume ratioBallistically efficientSynthetic resin layered productsWoven fabricsPliabilityMechanical engineering

Owner:HONEYWELL INT INC

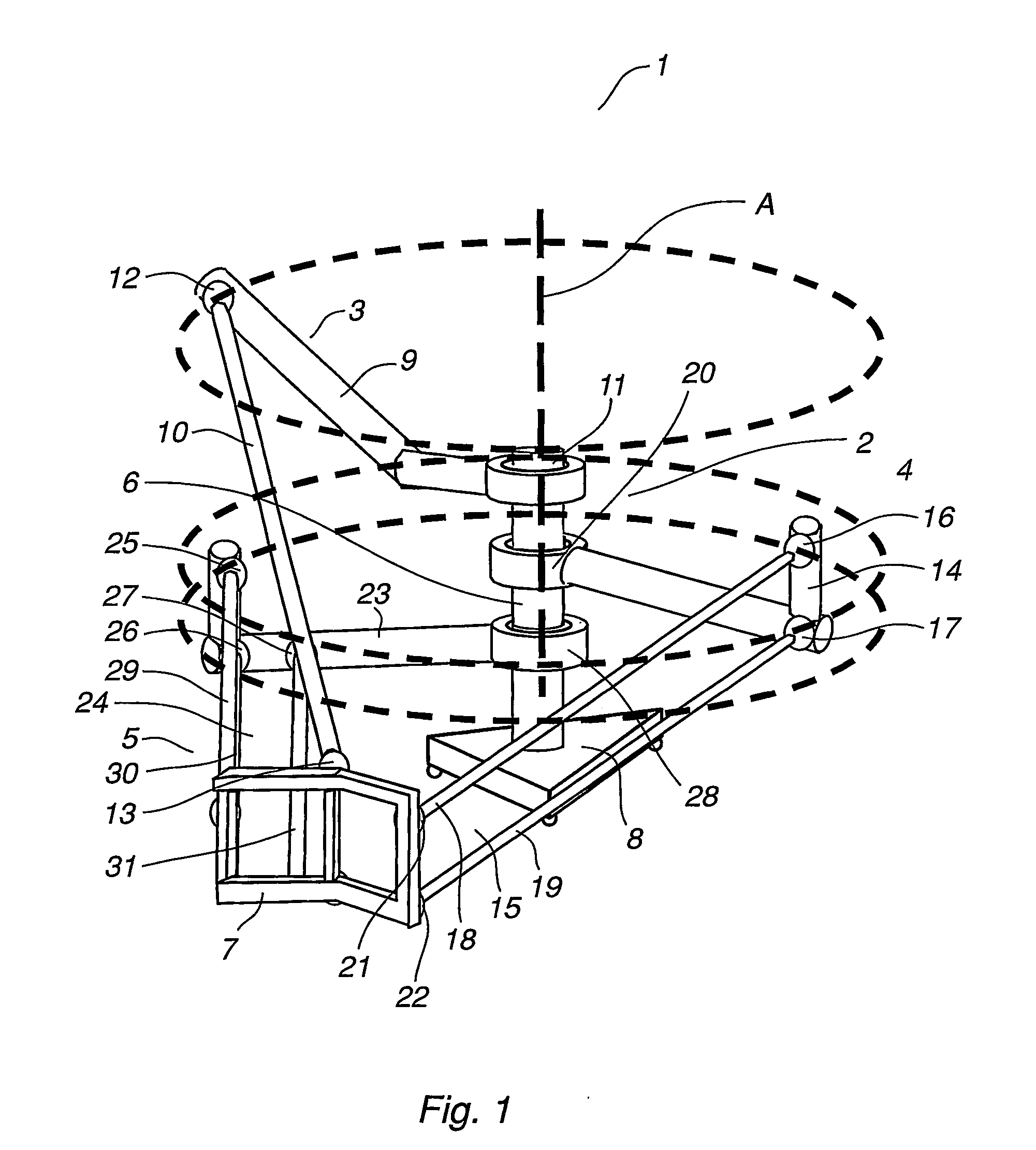

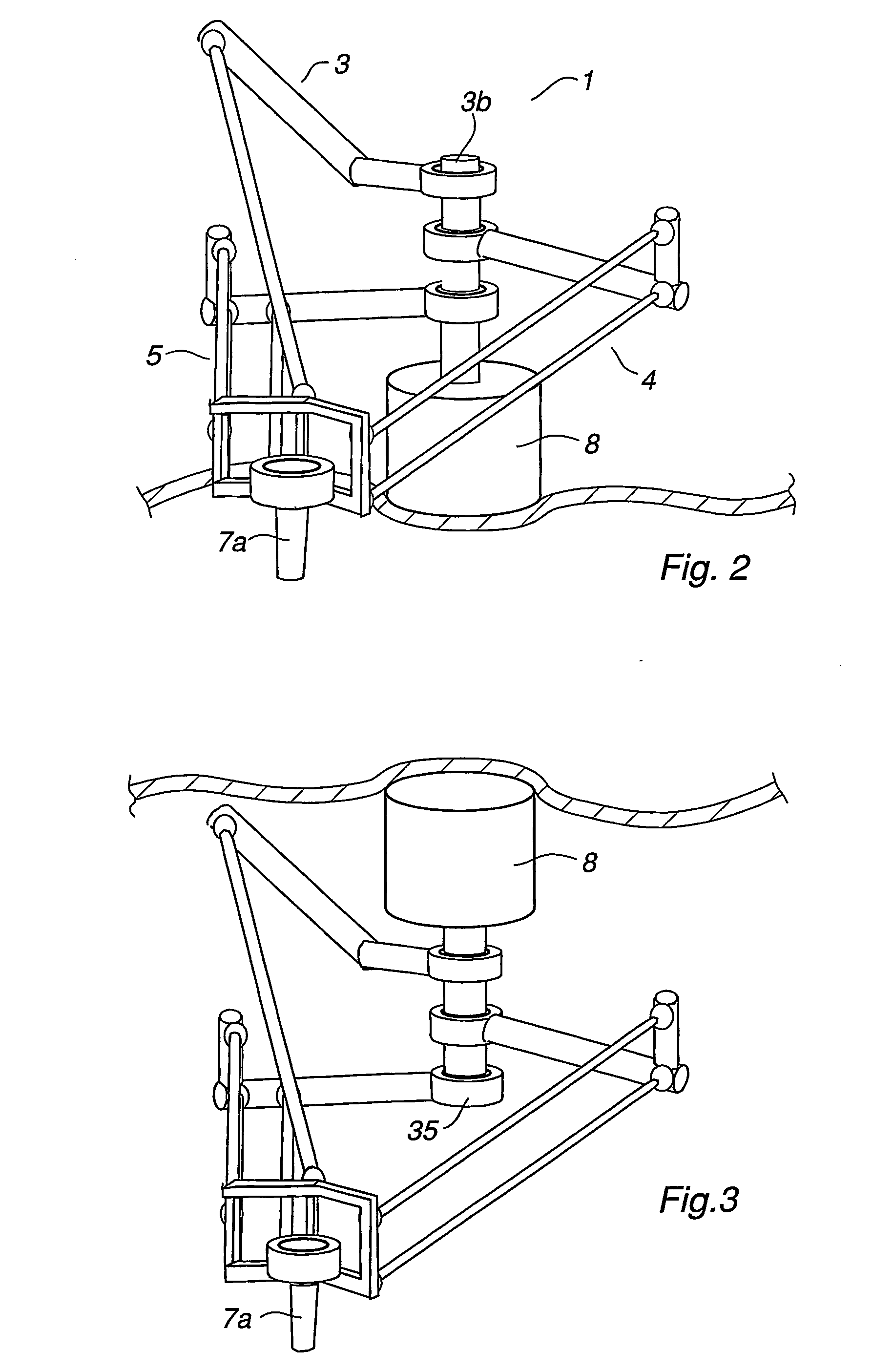

Industrial robot

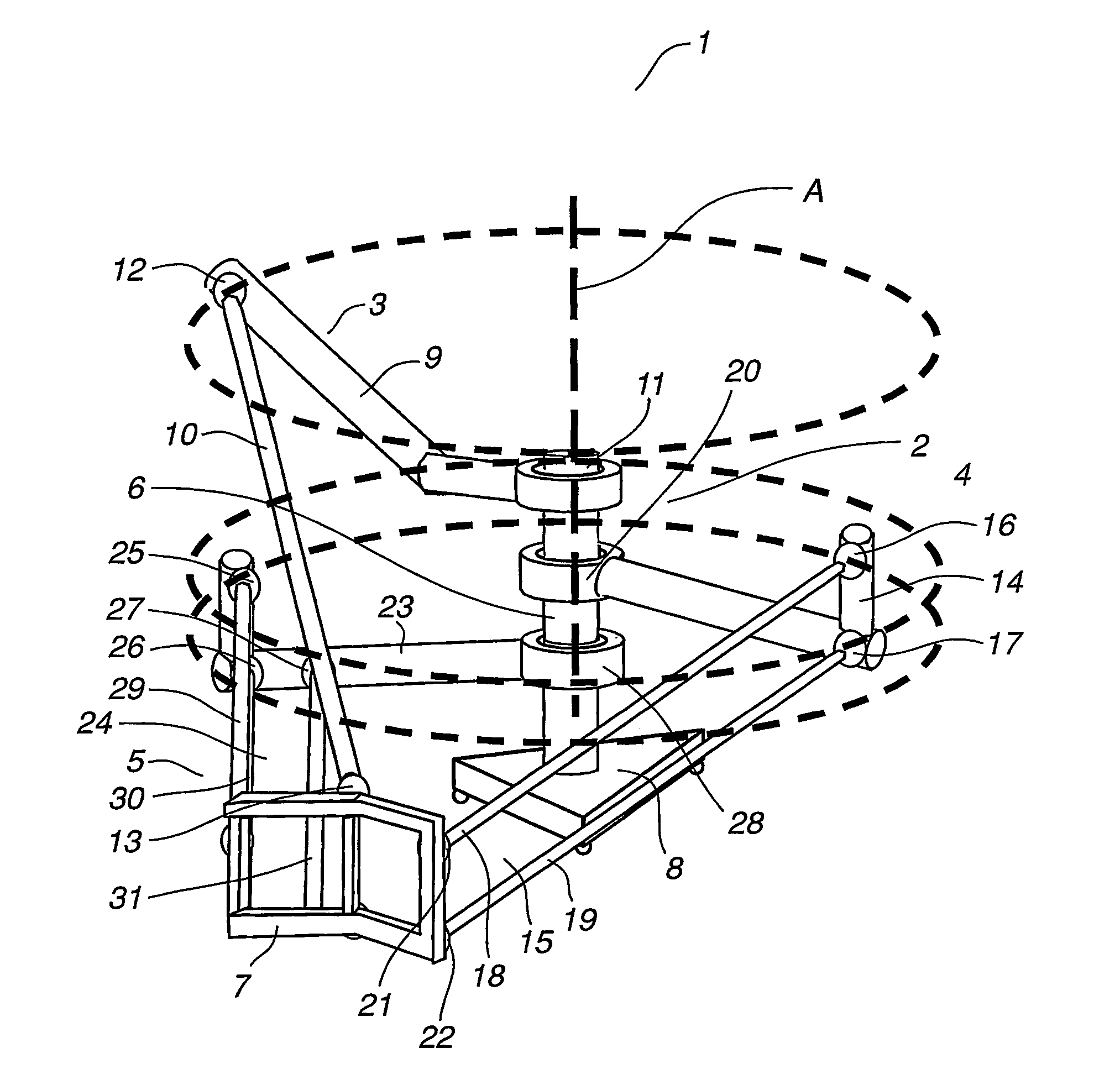

InactiveUS20050172750A1Improve accuracyHigh stiffnessProgramme-controlled manipulatorMechanical apparatusParallel kinematicsManipulator

An industrial robot including a parallel kinematic manipulator (2) of an object (7a) in space, where the manipulator (2) includes a stationary platform (6), a movable platform (7) for carrying the object (7a), at least three arms (3, 4, 5) connecting the platforms (6,7). Each arm comprises a first arm part ( ) connected to the stationary platform for manipulating the movable platform (7).

Owner:ABB (SCHWEIZ) AG

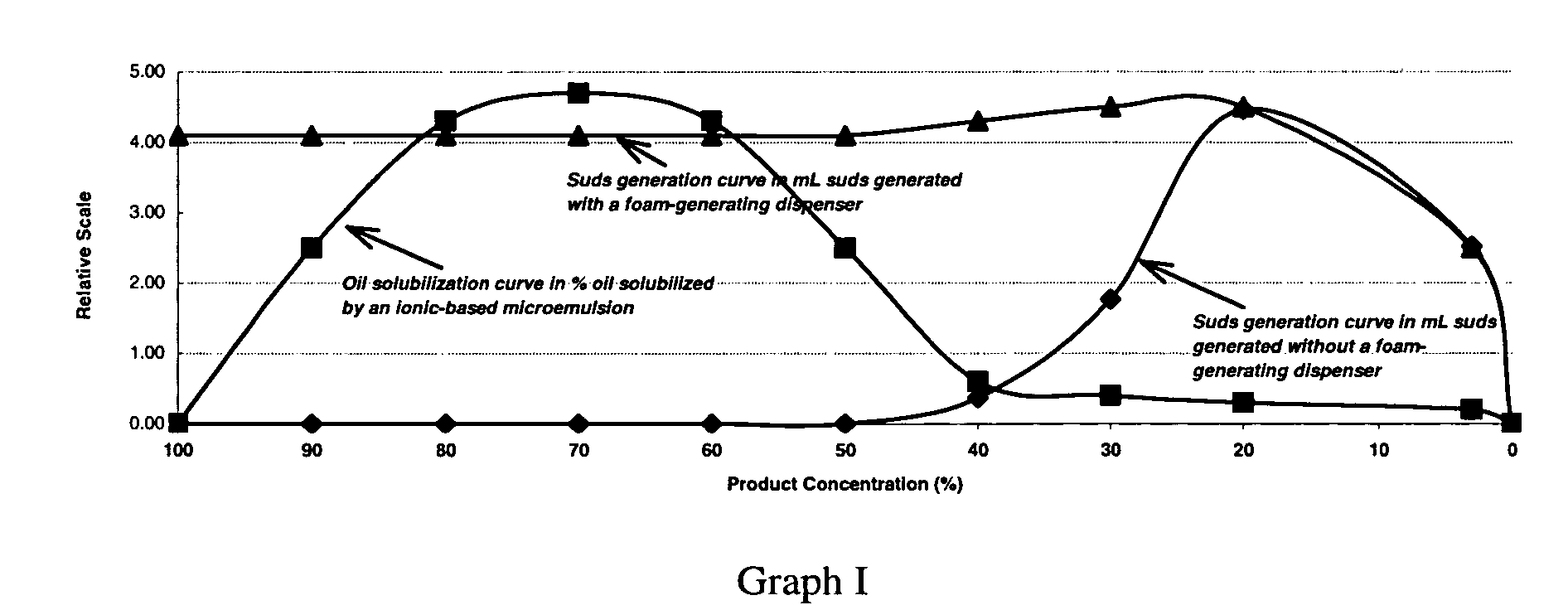

Foam-generating kit containing a foam-generating dispenser and a composition containing a high level of surfactant

ActiveUS20060229227A1Better and faster cleaningIncrease surface areaFlow mixersKitchenware cleanersGlycerolMicroemulsion

A foam-generating kit contains a non-aerosol container with a foam-generating dispenser and a high surfactant microemulsion or protoemulsion composition having at least 20 wt % of a surfactant system and 0.5 wt % glycerol.

Owner:THE PROCTER & GAMBLE COMPANY

Irregularly shaped non-spherical supported catalyst, and a process for hydroconverting heavy oil fractions

InactiveUS20090166260A1High activityIncrease powerOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHalogenFixed bed

The present invention concerns a catalyst for hydrotreating and / or hydroconverting heavy metal-containing hydrocarbon feeds, said catalyst comprising a support in the form of mainly irregular and non-spherical alumina-based agglomerates the specific shape of which results from a crushing step, and containing at least one catalytic metal or a compound of a catalytic metal from group VIB and / or group VIII (groups 8, 9 and 10 of the new periodic table notation), optionally at least one doping element selected from the group constituted by phosphorus, boron and silicon (or silica which does not form part of that which may be contained in the selected support) and halogens, said catalyst essentially being constituted by a plurality of juxtaposed agglomerates each formed by a plurality of acicular platelets, the platelets of each agglomerate generally being oriented radially with respect to each other and with respect to the centre of the agglomerate. The specific shape of the catalyst improves its performance when using it for hydroconverting / hydrotreating heavy metal-containing hydrocarbon feeds.The invention also concerns the use of said catalyst alone or as a mixture in a fixed bed or ebullated bed reactor.

Owner:INST FR DU PETROLE

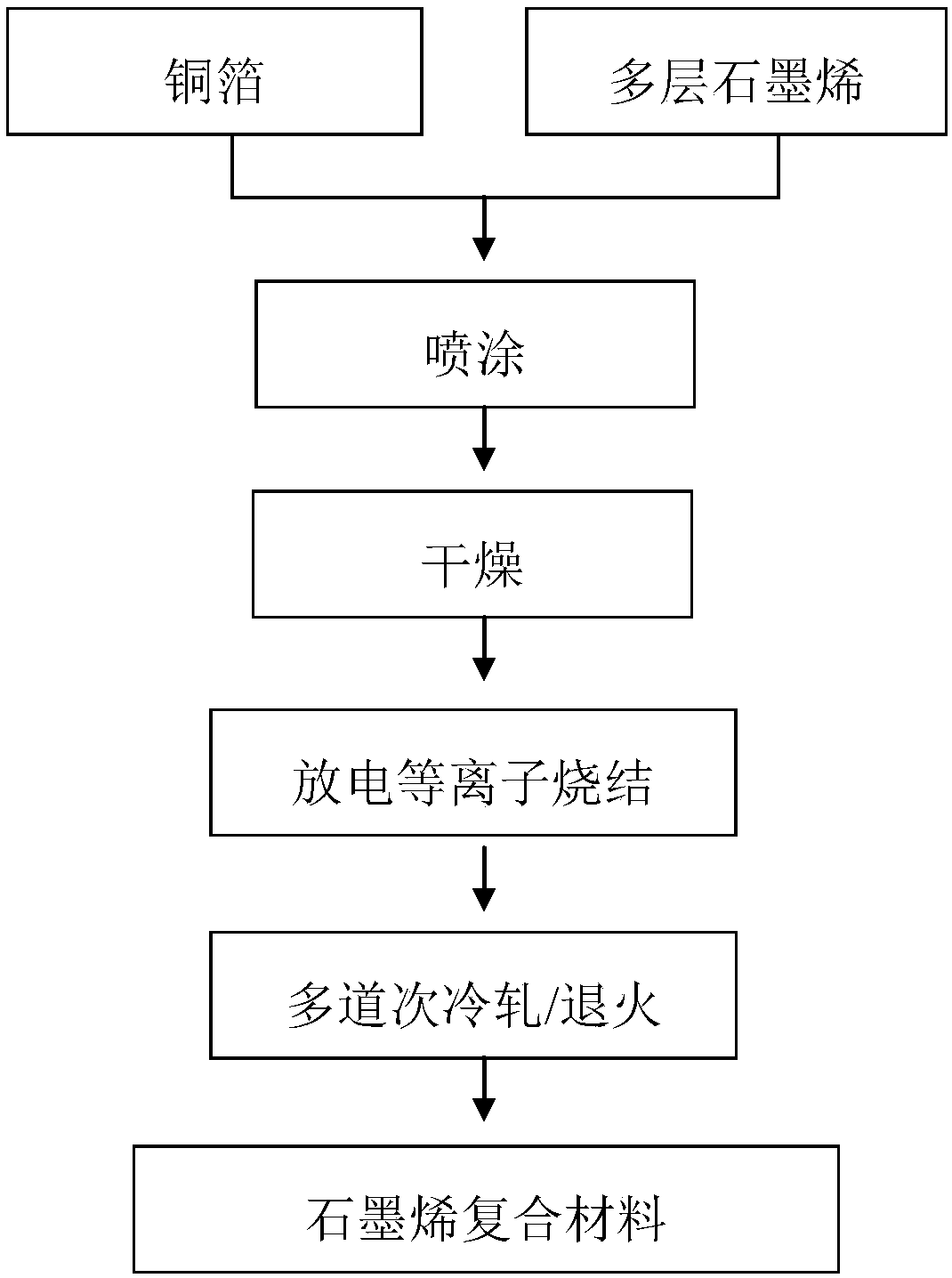

Preparation method for graphene-reinforced copper-based composite material

The invention discloses a preparation method for a graphene-reinforced copper-based composite material. The preparation method comprises the following steps that multilayer graphene is uniformly addedamong the copper foils, the layered multilayer grapheme / Cu composite material is obtained through an SPS sintering and cold rolling process, and the relative density of the obtained composite material is 95.8-99.5 %. According to the preparation method, compared with a traditional powder SPS sintering multilayer grapheme / Cu composite material, the resistivity of the obtained composite material isreduced by 11-18%.

Owner:CENT SOUTH UNIV

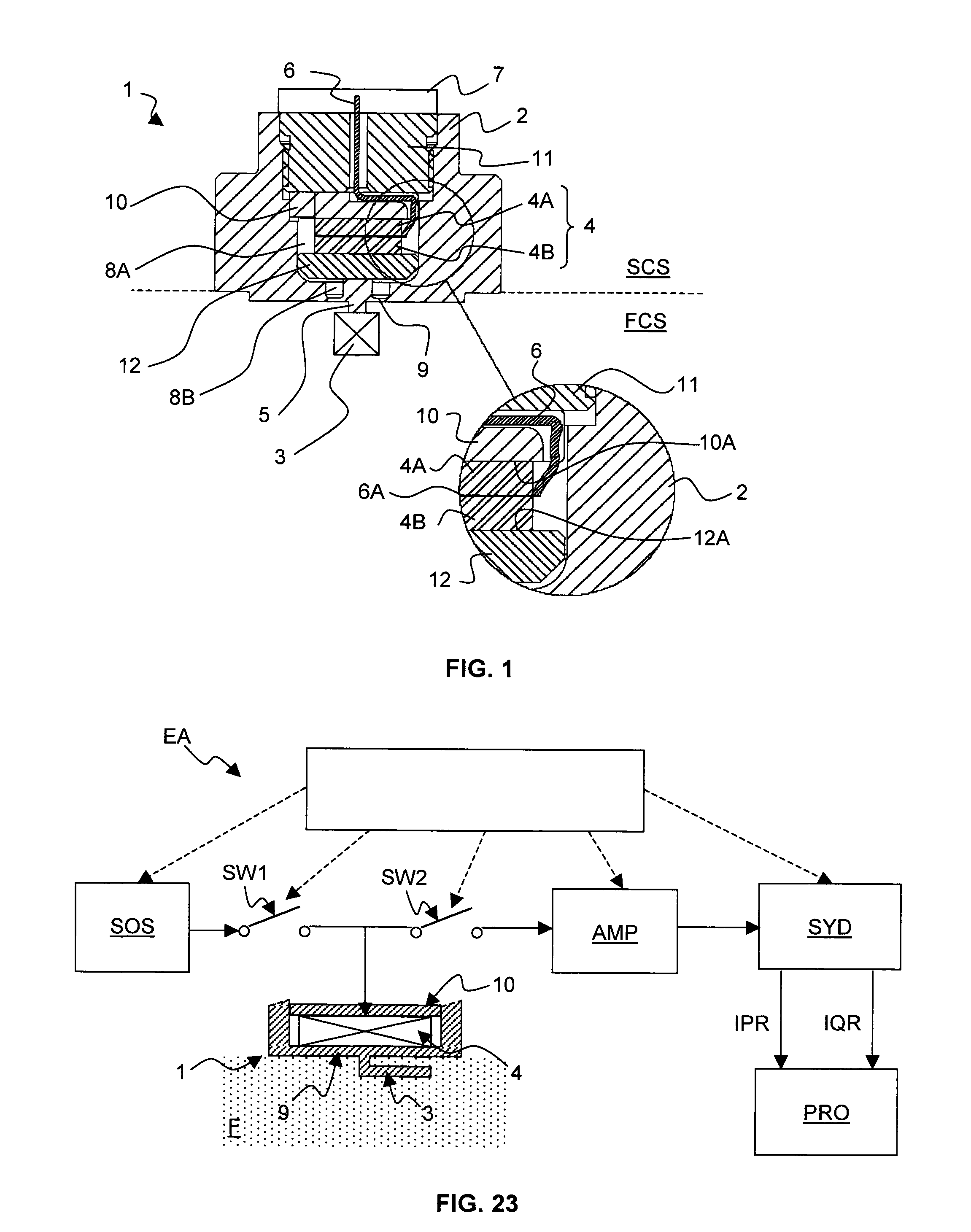

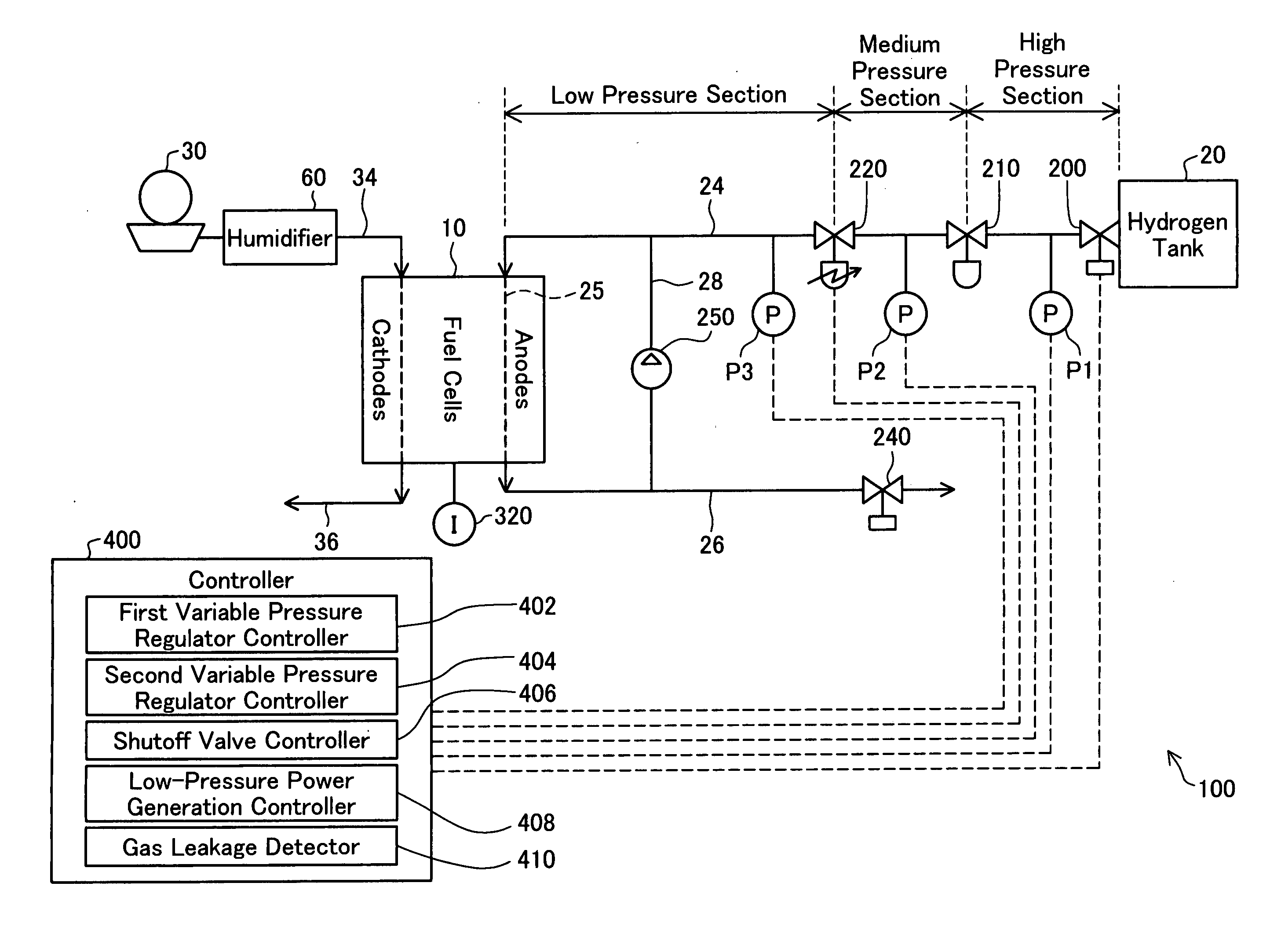

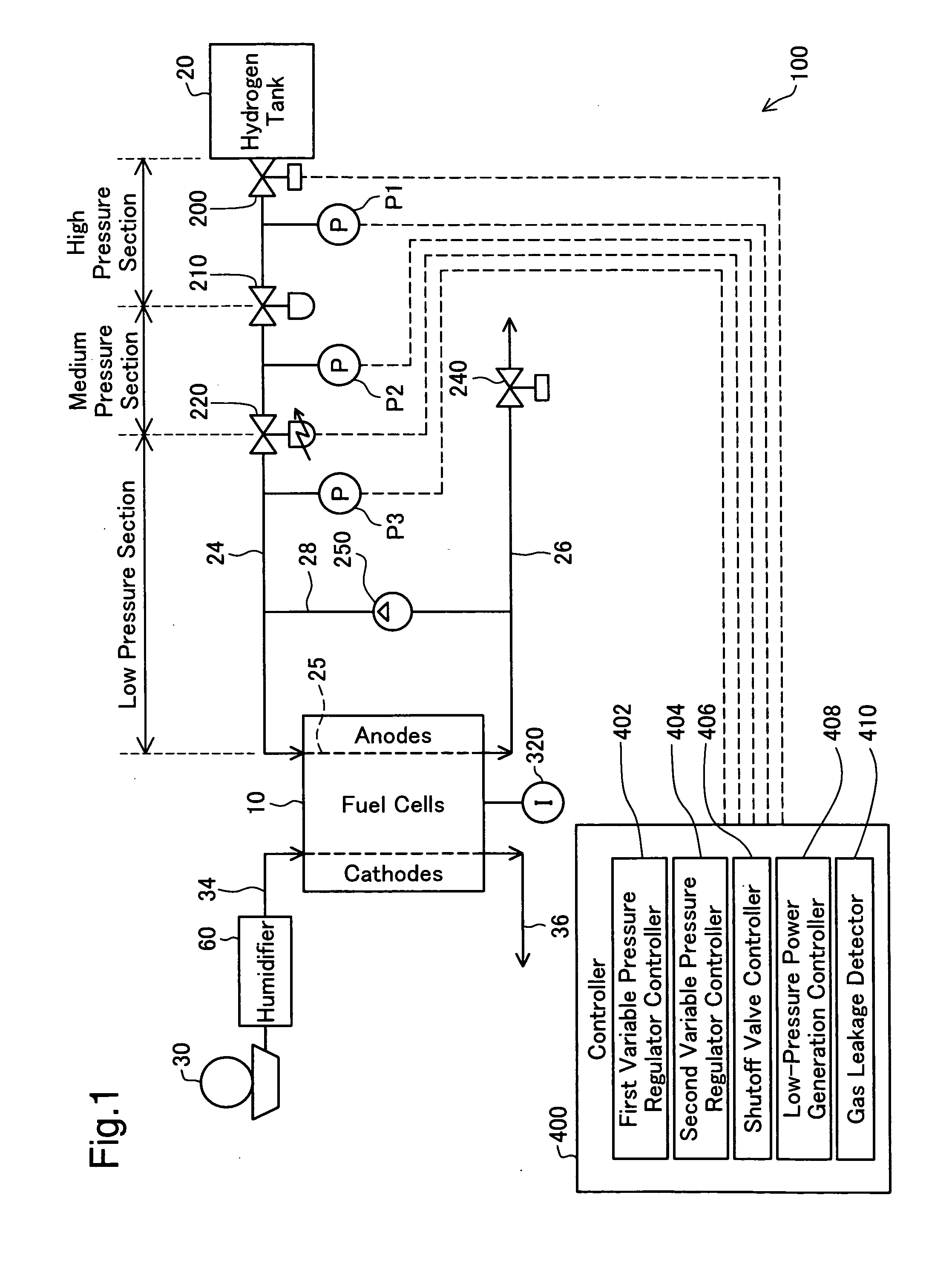

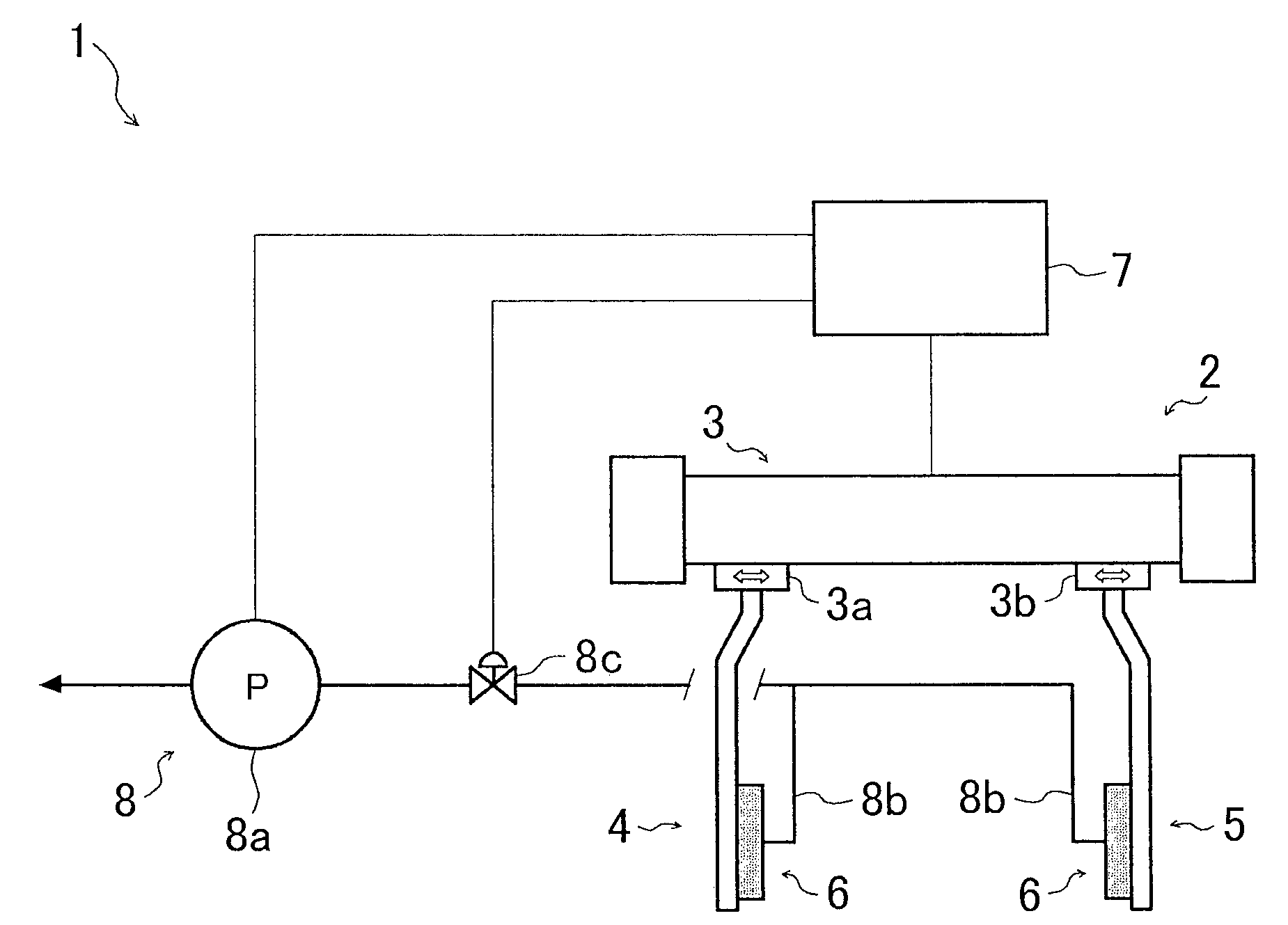

Fuel cell system and gas leakage detection device

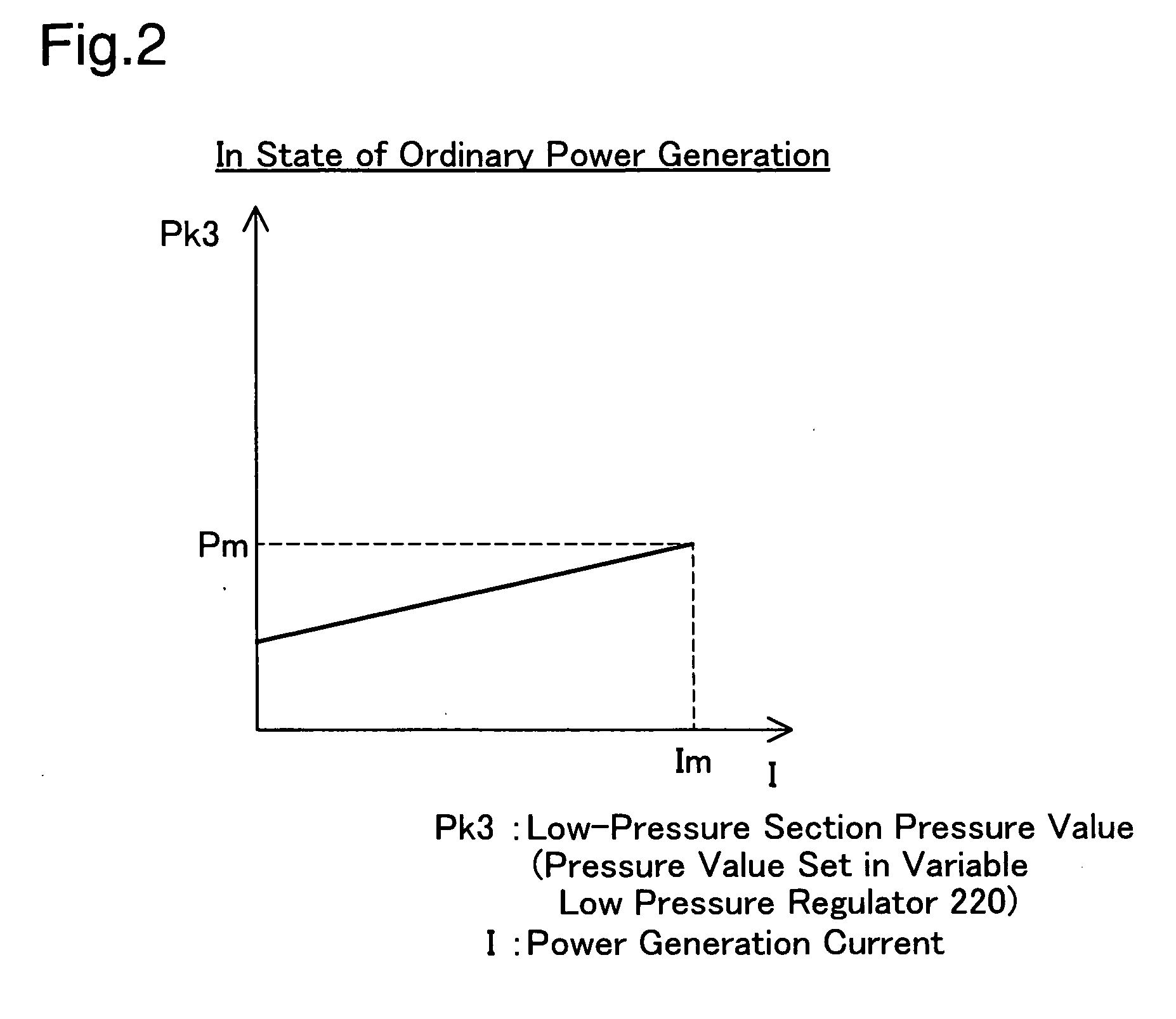

ActiveUS20100151343A1Reduce pressureShorten the timeFuel cells groupingFuel cell auxillariesFuel cellsVariable pressure

A fuel cell system according to one aspect of the invention is operated in an ordinary mode and in a gas leakage detection mode. The fuel cell system includes fuel cells, a fuel gas supplier configured to supply a fuel gas to the fuel cells, a shutoff valve provided in a flow path for leading a flow of the fuel gas supply from the fuel gas supplier to the fuel cells and configured to shut off the fuel gas supply, and a variable pressure regulator provided in the flow path between the shutoff valve and the fuel cells to regulate a pressure of the fuel gas in a downstream in a flow direction of the fuel gas supply to a variable pressure value. In the ordinary mode, the fuel cell system sets the pressure value of the variable pressure regulator to an ordinary power generation pressure value for ordinary power generation. In the gas leakage detection mode, on the other hand, the fuel cell system closes the shutoff valve, sets the pressure value of the variable pressure regulator to a higher value than the ordinary power generation pressure value, and performs leakage detection of the fuel gas from the shutoff valve. Such setting of the pressure value in the variable pressure regulator desirably enables high-speed reduction of the fuel gas pressure in the flow path between the shutoff valve and the variable pressure regulator.

Owner:TOYOTA JIDOSHA KK

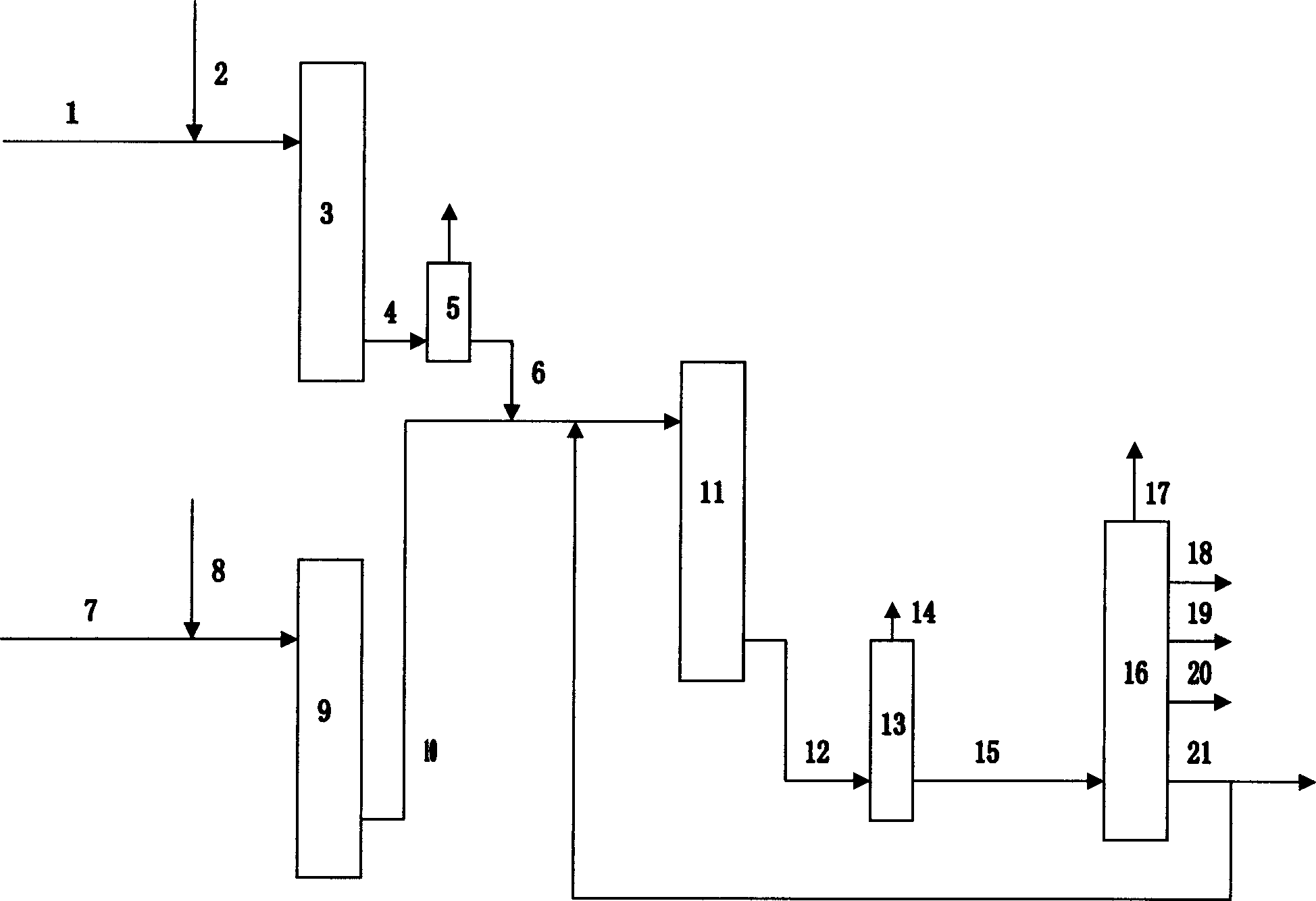

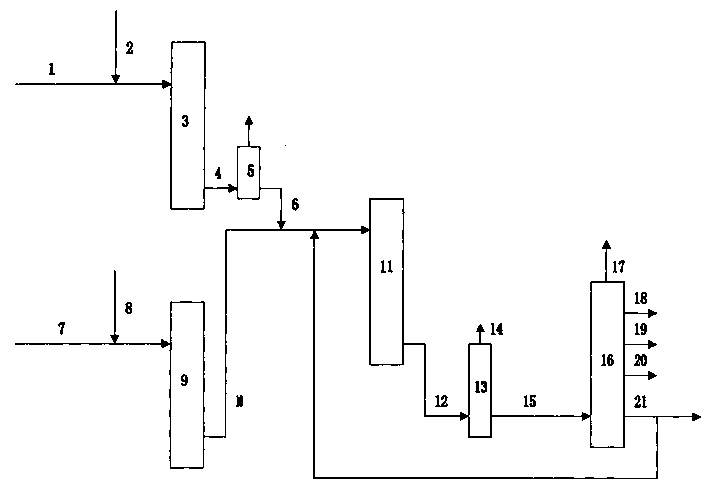

Hydrocracking method for increasing quality of refined diesel oil

InactiveCN1488731AIncrease the volume ratioReduced inlet temperature requirementsTreatment with hydrotreatment processesSulfurHydrodesulfurization

The present invention discloses a hydrocracking process for raising refined diesel oil quality, and is mainly characterized by that the poor diesel oil is undergone the process of hydrodesulfurization treatment, then the desulfurized refined diesel oil is mixed with the refined hydrocracked raw material oil, and fed into the hydrocracking reactor, and the sulfur and nitrogen contents in the mixed oil of the refined diesel oil and refined hydrocracked raw material oil must meet the feeding requirements of hydrocracking reactor. As compared with existent technology said invention can utilize hydrocracking equipment to raise the quality of refined poor diesel oil and can obtain high-quality clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

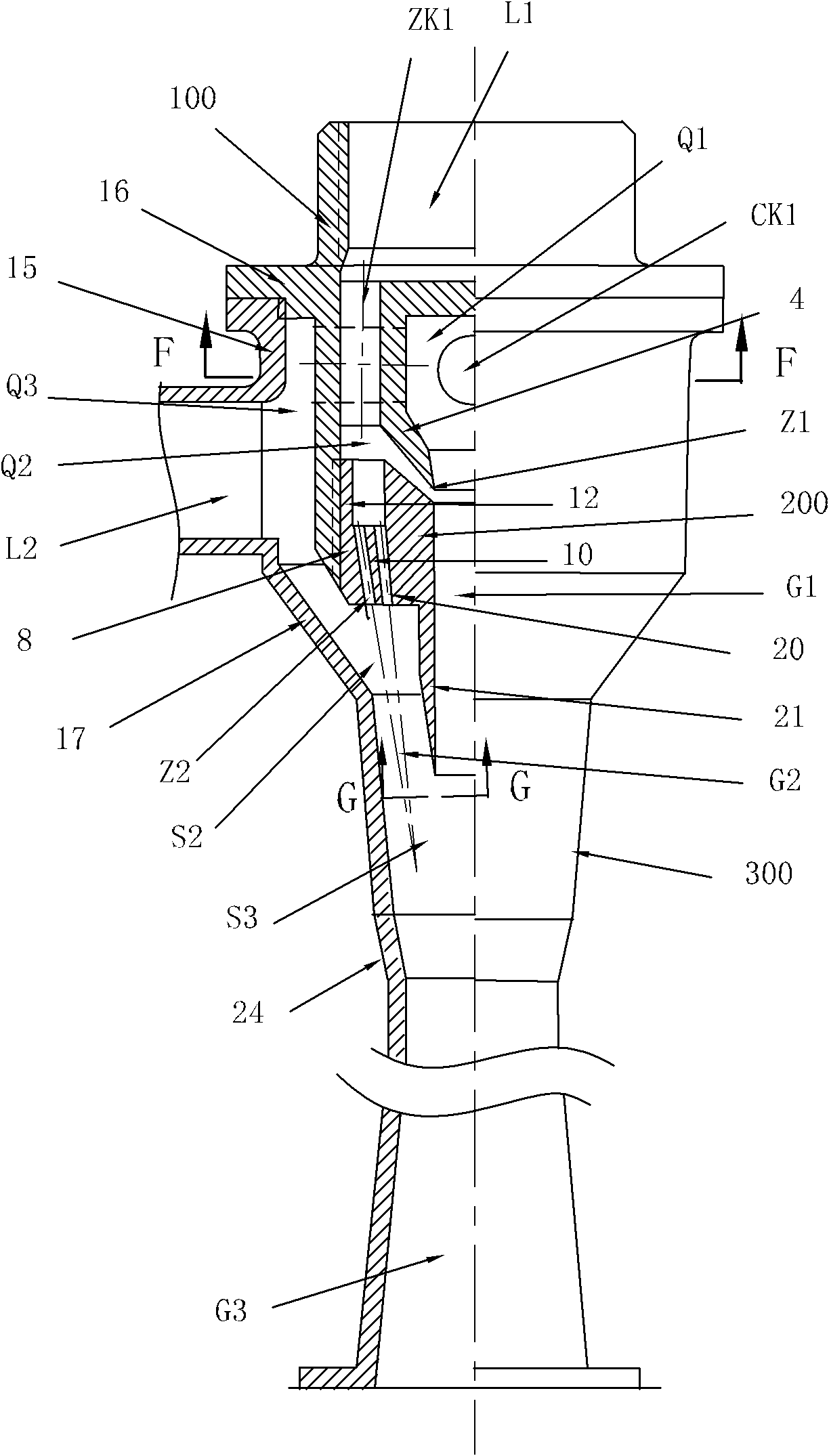

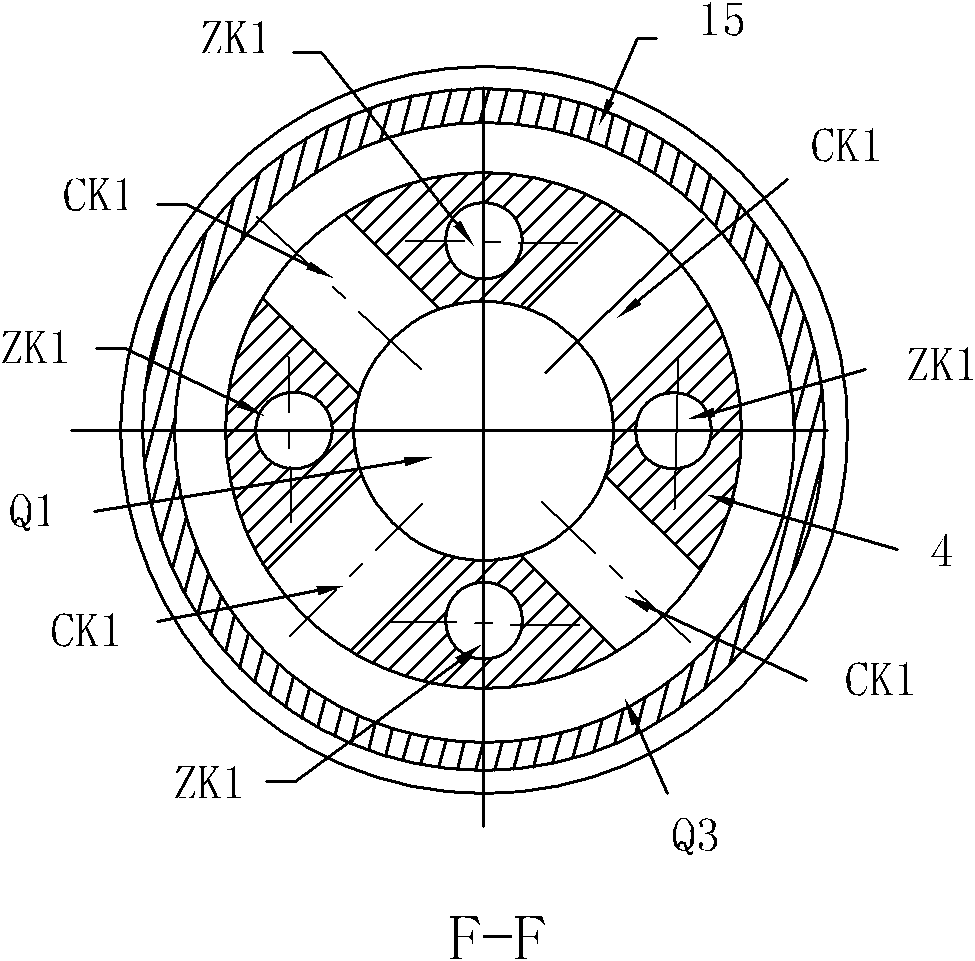

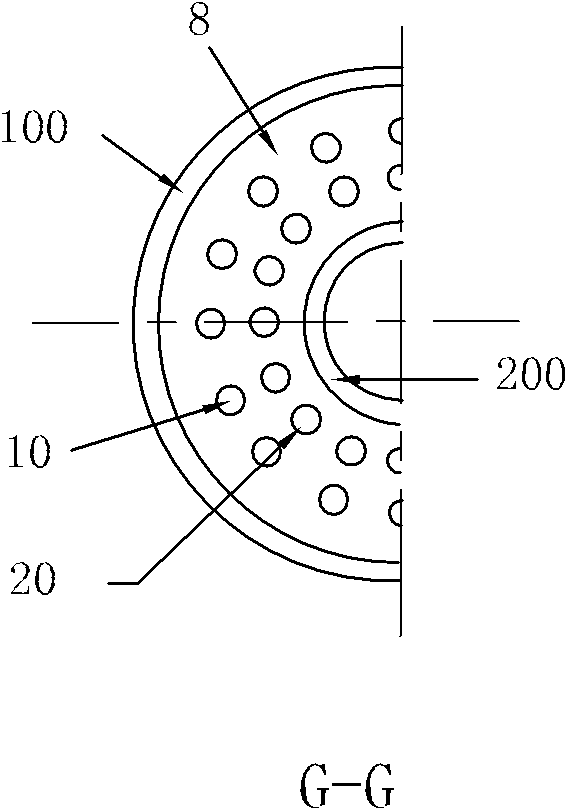

Jet pump

InactiveCN102654145ANovel structureUnique structureJet pumpsMachines/enginesSuction forceEngineering

The invention provides a jet pump, and relates to a mixed flow jet apparatus. The jet pump is composed of a current distributing assembly, an inner pipe assembly and an outer sleeve assembly which have a same shaft core, wherein the current distributing assembly and the inner pipe assembly are fixedly connected in series, thereby forming a blind top centre cavity and a centre mixing tube; the outer sleeve assembly is sleeved outside the current distributing assembly and the inner pipe assembly, thereby forming an annular mixing chamber, an annular mixing pipe, a total mixing chamber and a total mixing output pipe; an internal ring nozzle and an external ring nozzle are arranged between the current distributing assembly and the inner pipe assembly, a mainstream body sprayed by the internal ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the centre mixing tube, and the secondary fluid is mixed in the centre mixing tube so as to output a centre mixed flow; a mainstream body sprayed by the external ring nozzle carries out jet-suction on a secondary fluid of the blind top centre cavity so as to spray to the annular mixing pipe, and the secondary fluid is mixed in the annular mixing pipe so as to output an annular mixed flow; and the two mixed flows are mutually injected to enter the total mixing chamber and the total mixing output pipe so as to further output in an isotrope voltage-sharing manner. The jet pump provided by the invention has the advantages of smaller weight and axial direction size, high injection rate, great suction force and good property in large flow.

Owner:韩铁夫

Fuel deoxygenation system with non-planar plate members

ActiveUS7465336B2Enhances deoxygenationImprove efficiencyPower plant fuel tanksIsotope separationPorous substrateHigh surface

A fuel system for an energy conversion device includes a multiple of fuel plates, oxygen permeable membranes, porous substrate plates, and vacuum frame plates which define a wave pattern configuration. The wave configuration enhances deoxygenation by increasing the efficiency and integrality due to higher surface volume ration, increase of flow turbulence, and minimal sharp edges which may otherwise damage the oxygen permeable membranes compared to other configurations.

Owner:RTX CORP

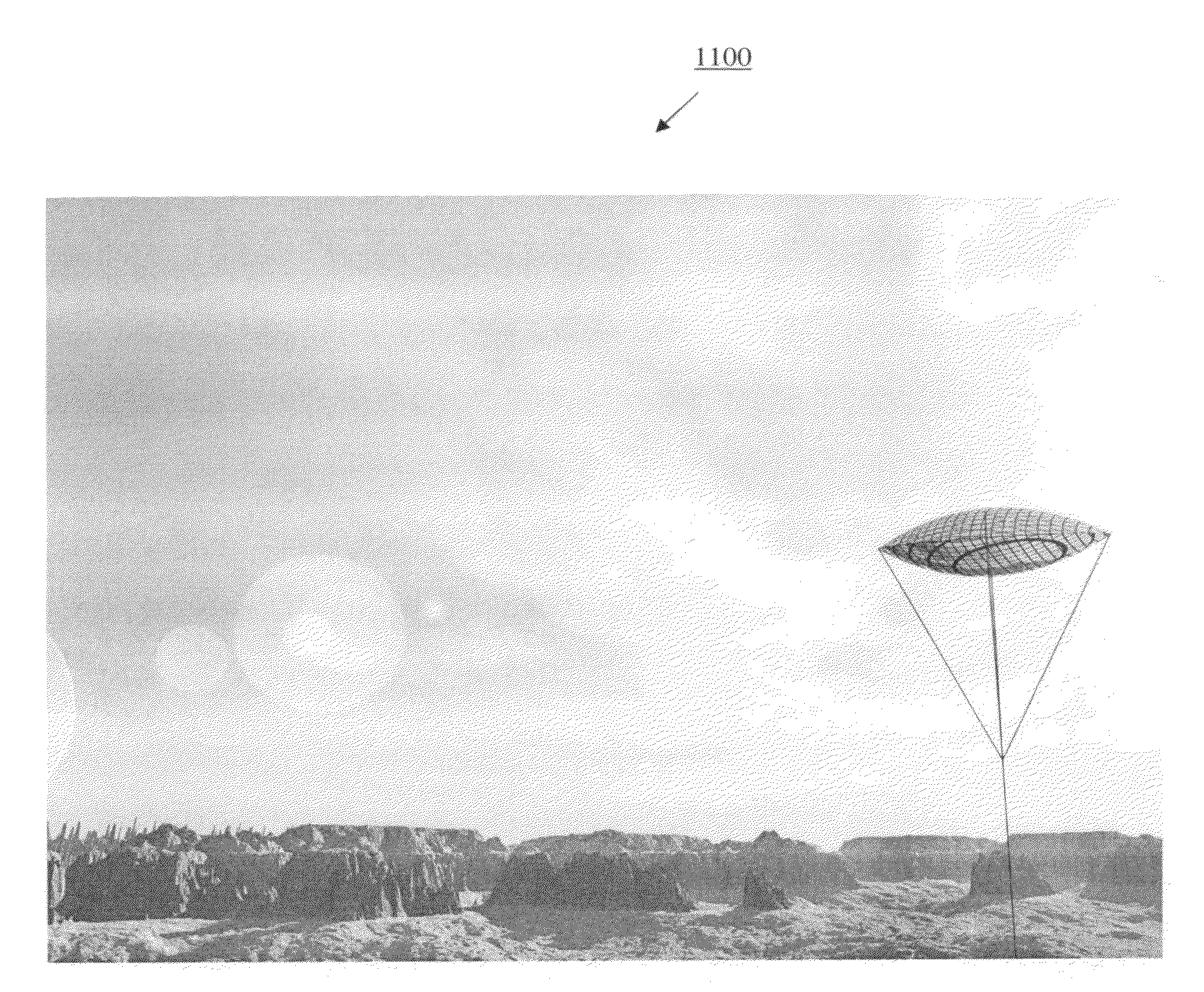

Electric power generators and systems comprising same

InactiveUS20120097211A1Increase the volume ratioIncrease power generationPhotovoltaic supportsPV power plantsLighter than airElectric power

An electric power generator comprising: at least one lighter than air balloon (LAB) with at least one photovoltaic array (PVA) embedded in a surface thereof; and a cable connecting the LAB to the ground and adapted to convey a buoyant gas to an inner volume of the LAB and also to convey an electric current generated by said PVA to a ground installation.

Owner:GURFIL PINCHAS +1

Anticorrosion concrete and construction method

InactiveCN101269941AIncrease the volume ratioImprove compactnessSolid waste managementPortland cementGranularity

The present invention provides anti-corrosion concrete, which is characterized in that the weight of the raw materials that are used for producing the anticorrosion concrete are that: (Portland cement + fly ash): water: water-reducing agent: MS-601 rust-resistant agent: fine aggregate: rough aggregate is 1: 0.52 to 0.72: 0.007 to 0.012: 0.014 to 0.016: 2.1 to 3.6: 2.5 to 4.4; the weight ratio between the Portland cement and the fly ash is 1: 0.25 to 0.43; the fine aggregate is the sand with the granularity of 0.15 to 4.75 mm, and the rough aggregate is the crushed stone with the granularity of 4.75 to 19.00 mm. The anticorrosion concrete provided by the present invention has high compactness and good anticorrosion performance, and the service life of the concrete can reach to 50 years.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

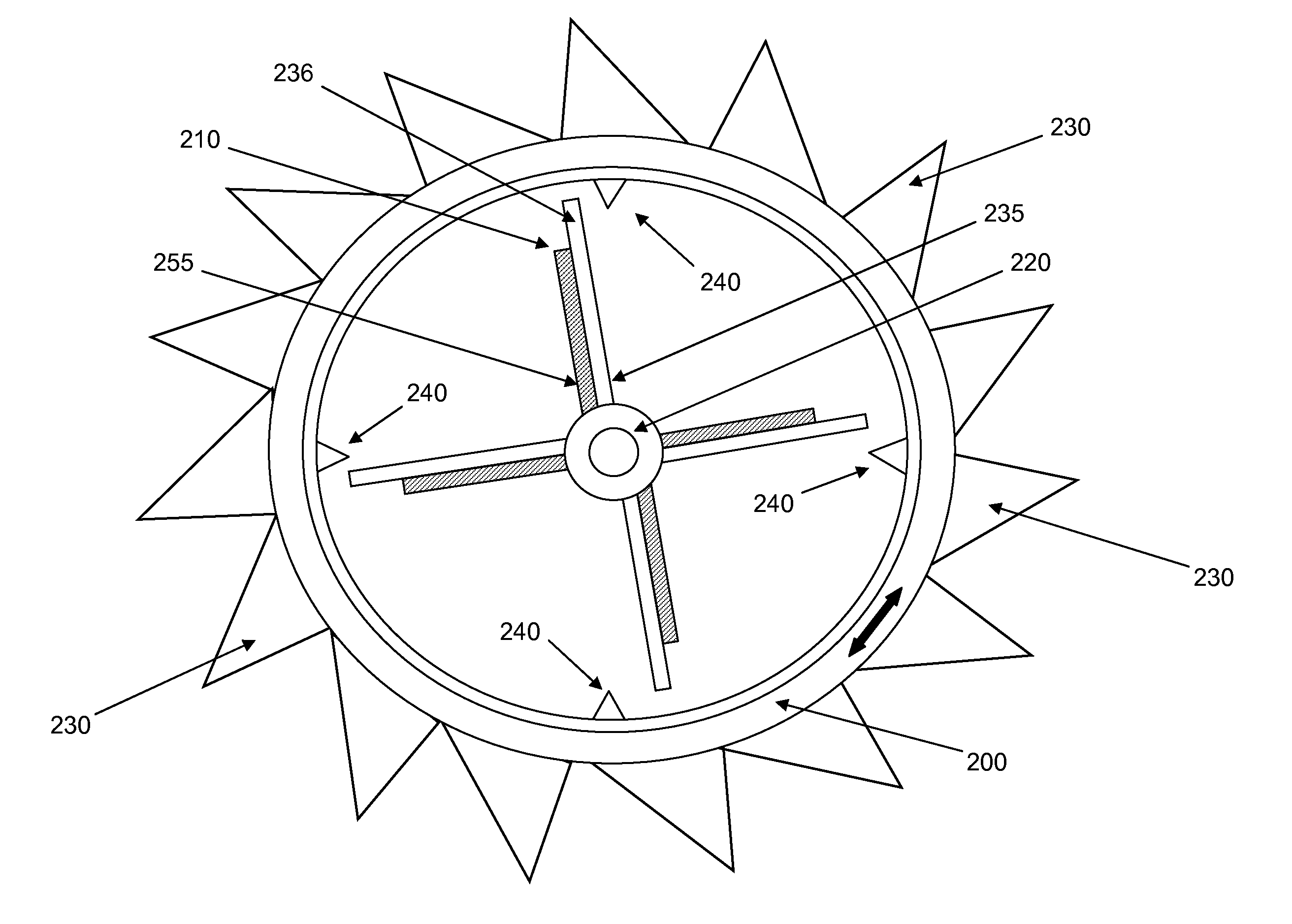

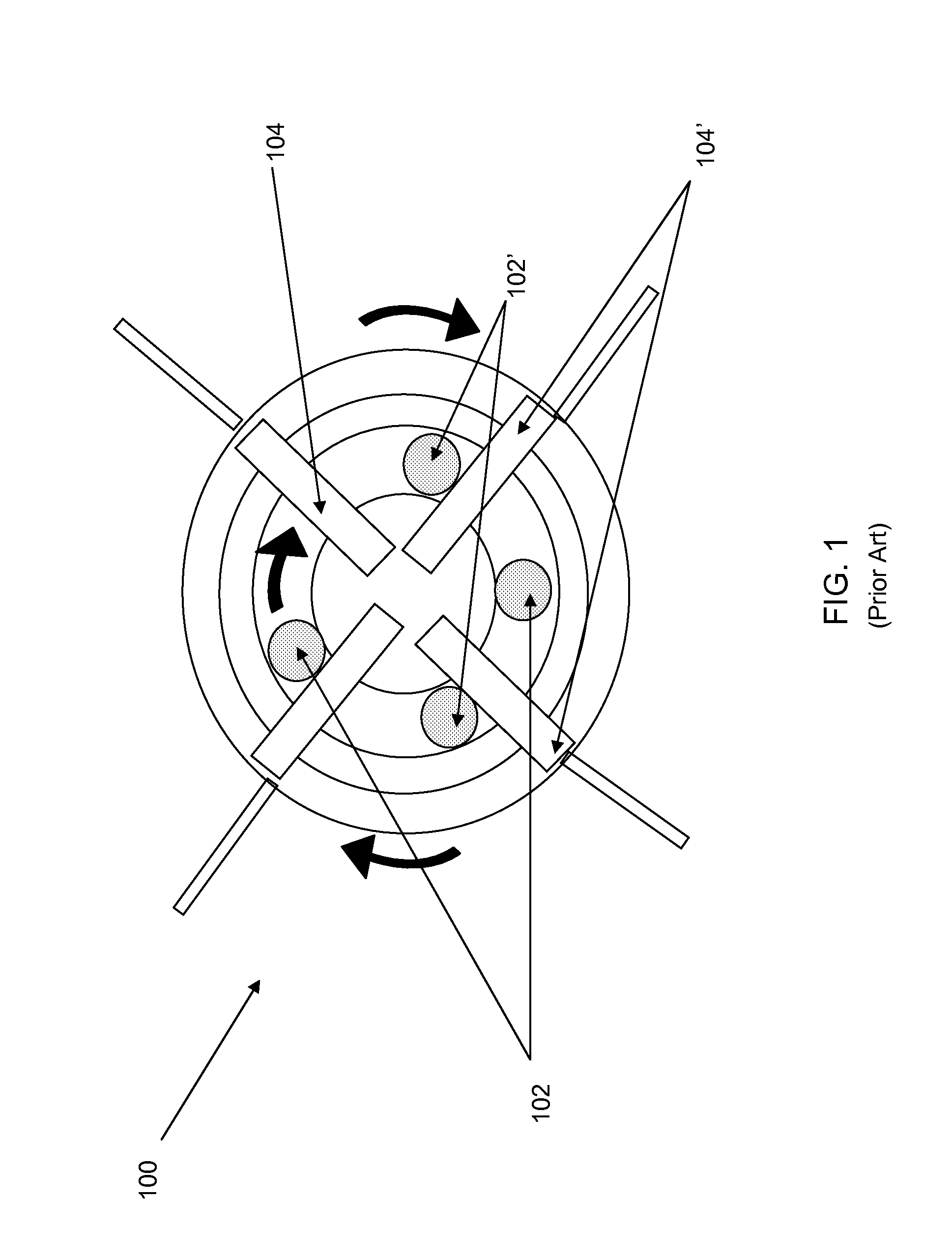

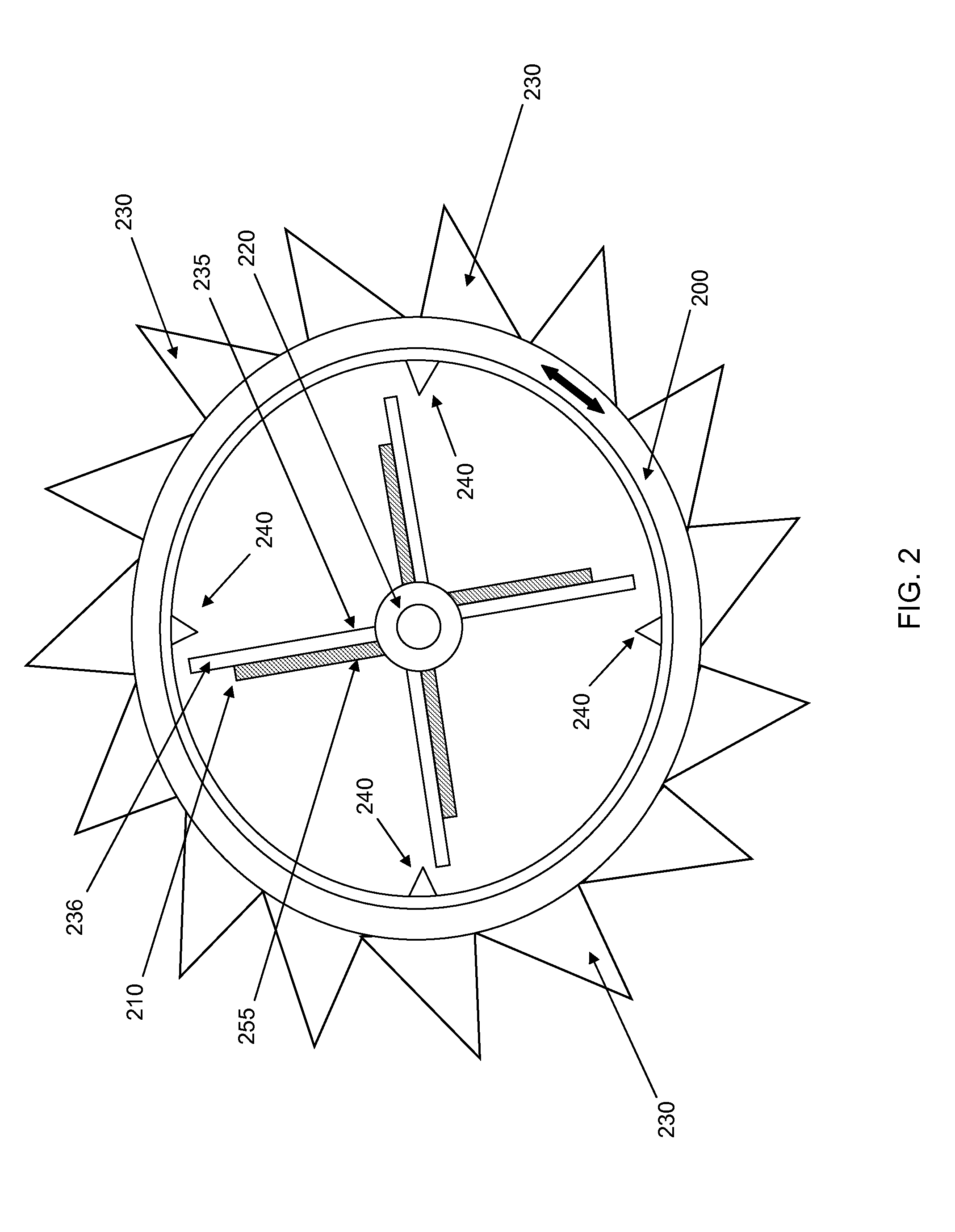

Method and System for Fluid Wave Energy Conversion

InactiveUS20110278990A1Increase the volume ratioPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectric energyElectronics

A system for converting kinetic wave energy from a dynamic fluid into electrical power, the system including a structural housing containing a piezokinetic assembly having a plurality of electromechanical coupled elements, and a dynamic assembly, coupled to the piezokinetic assembly; and charge storage devices or power consumption devices in an electronics module coupled to the piezokinetic assembly. When the exposed to the dynamic fluid medium, the dynamic fluid medium's wave energy couples with the structural housing causing a resulting displacement of the dynamic assembly contained therein. The displacement of the dynamic assembly causes a plurality of the electromechanical coupled elements to simultaneously flex, generating an electrical charge which may be either stored in the charge storage device or which may directly power the power consumption device.

Owner:QORTEK

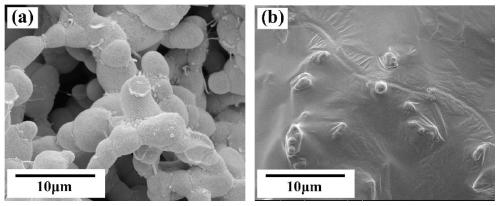

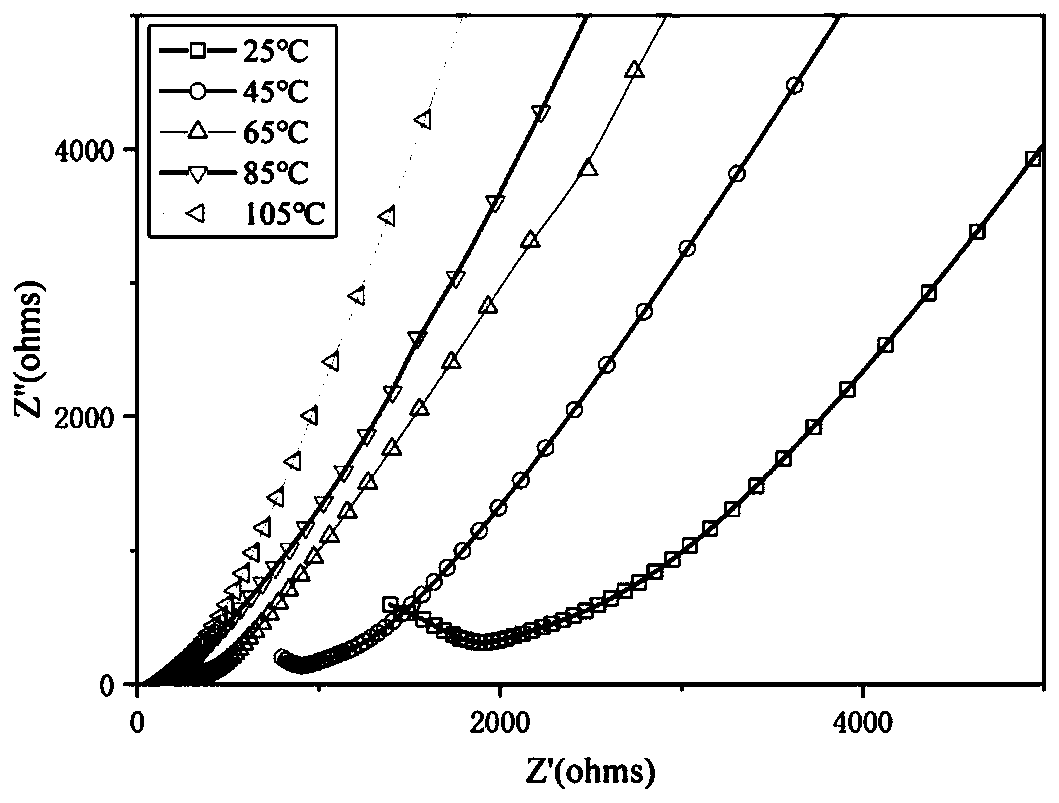

High-ionic-conductivity composite solid electrolyte and preparation method thereof

PendingCN110492170ADense skeletonGood crystallinitySolid electrolytesFinal product manufactureIonCeramic particle

The invention discloses a preparation method of a high-ionic-conductivity composite solid electrolyte, and belongs to the field of ionic conductor electrolytes. The preparation method comprises the following steps: firstly, adding ceramic powder and a dispersing agent into deionized water to obtain slurry through ball-milling and mixing, dispersing the ceramic powder under the steric hindrance action of an organic chain of the dispersing agent adsorbed on the surfaces of ceramic particles, then adding a binder and a cross-linking agent, and continuously ball-milling to prepare water-based ceramic slurry; and before in-situ curing of the slurry, putting the template into the slurry, fully infiltrating, taking out, curing, drying, calcining to remove the template, carrying out high-temperature sintering to obtain a porous ceramic structure, and finally compounding with a polymer to obtain the solid electrolyte. Compared with other technologies, the method has the advantages that the structure of the porous ceramic electrolyte can be flexibly designed according to the selection of the template; meanwhile, the porous ceramic skeleton is compact, the crystallinity is good, the volume ratio is high, and the ionic conductivity of the composite electrolyte is greatly improved; the porous ceramic skeleton is environment-friendly, low in cost and beneficial to large-scale popularizationand application.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

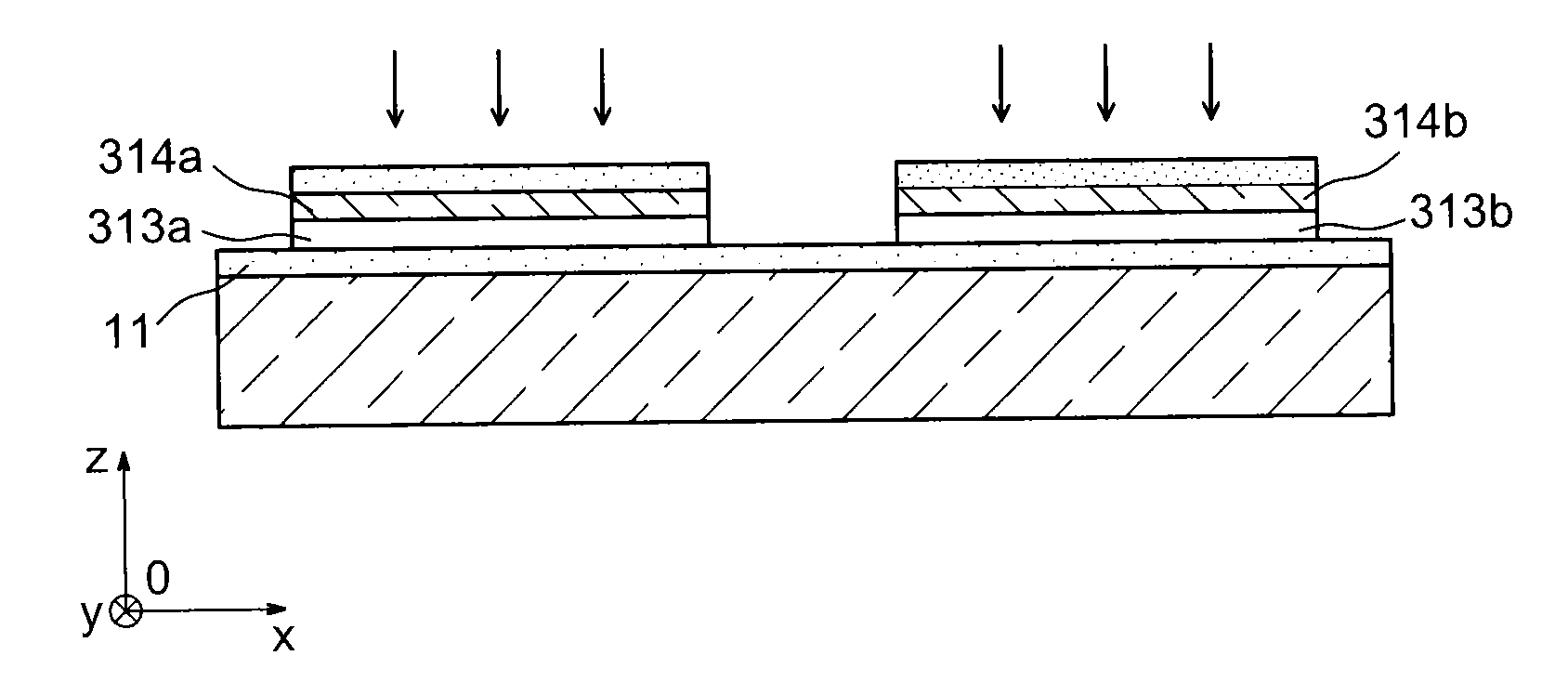

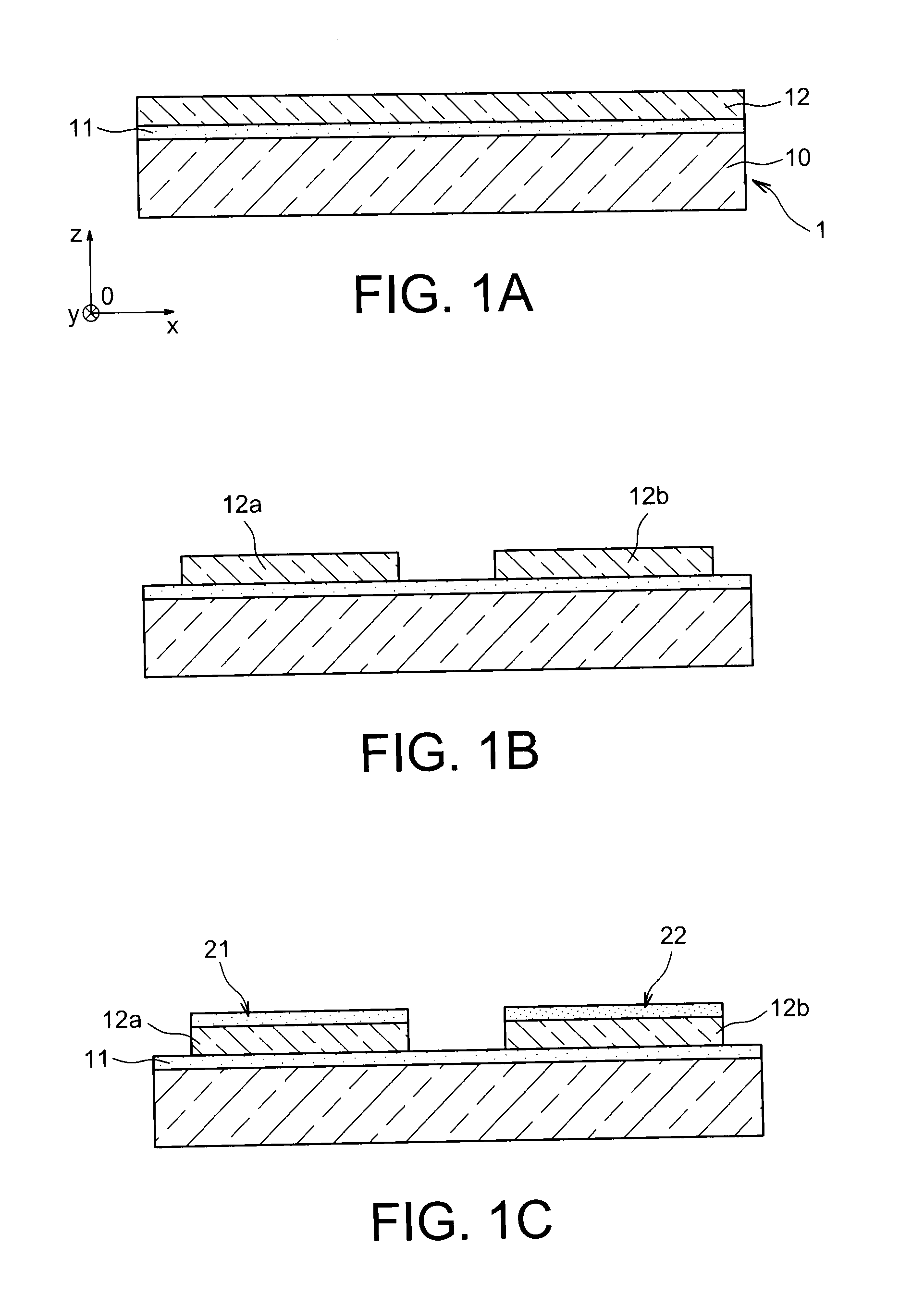

Method for producing strained semi-conductor blocks on the insulating layer of a semi-conductor on insulator substrate

ActiveUS20150179665A1Easy transferIncrease the volume ratioTransistorSolid-state devicesTensile strainCrystalline materials

Method for producing a microelectronic device comprising:a) the formation on an insulating layer of a semi-conductor on insulator type substrate, a first semi-conductor block covered with a first strain zone adapted to induce a compressive strain in said first block and a second semi-conductor block covered with a second strain zone adapted to induce a tensile strain in said second block, the first block and the second block each being formed of a lower region based on amorphous semi-conductor material, covered with an upper region of crystalline semi-conductor material in contact with one of said strain zones,b) the re-crystallization of said lower region of said first block and of said second block while using said upper region of crystalline material as starting zone for a recrystallization front.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

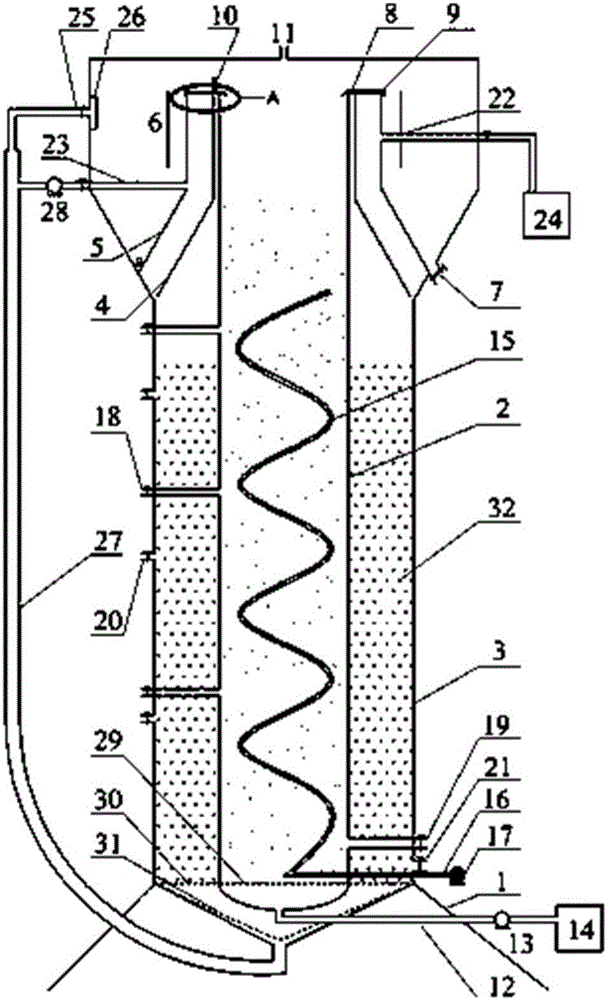

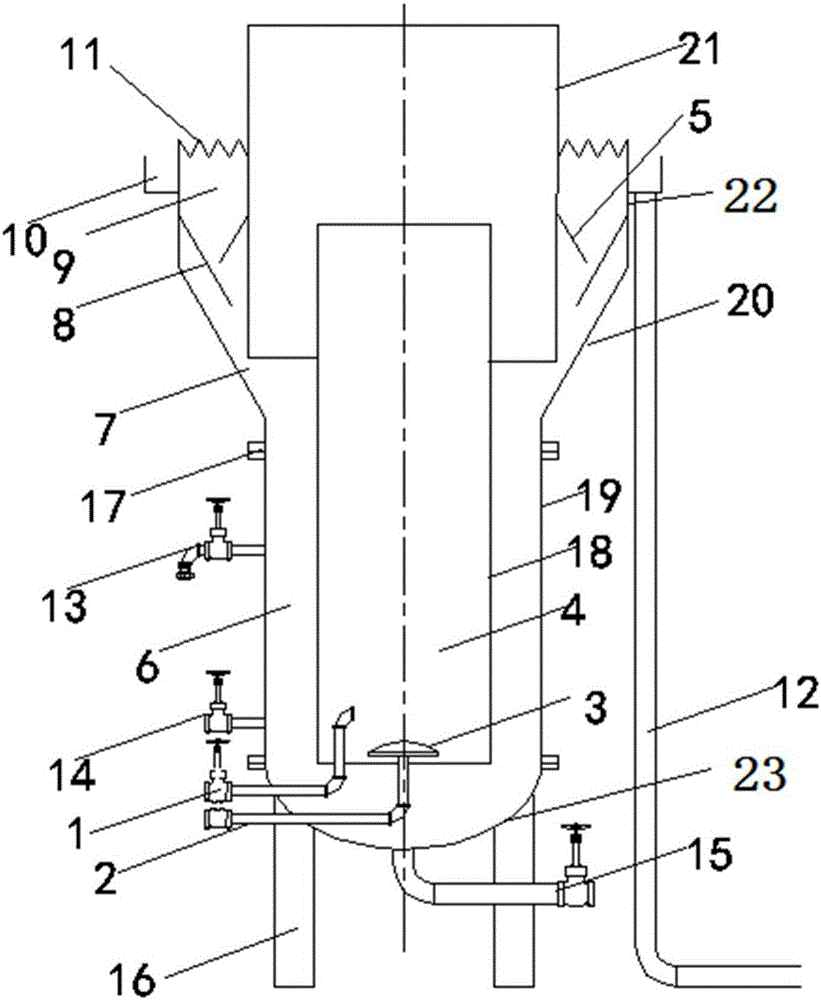

Integrated autotrophic synchronous biological denitrification granulation device

ActiveCN105800787AReduce the difficulty of application promotionPromote growthBiological treatment apparatusTreatment with aerobic and anaerobic processesSludgeEngineering

The invention discloses an integrated autotrophic synchronous biological denitrification granulation device which comprises an outer barrel arranged on a support.An inner barrel is arranged inside the outer barrel, both a water incoming pipe and an air incoming pipe penetrate the undersurface to extend into the inner barrel, the end of the air incoming pipe in the inner barrel is connected with an aeration head, the top of the outer barrel is connected with a sludge backflow slope, a sedimentation barrel is connected above the sludge backflow slope, an overflow weir is arranged at the upper edge of the sedimentation barrel, a water collection tank is arranged outside the sedimentation barrel, an isolation barrel is arranged at the top of the inner barrel in a sleeved manner, a sludge backflow gap is formed between the isolation barrel and the sludge backflow slope, the top of the isolation barrel is higher than the sedimentation barrel, a second gas-water separation annular baffle is connected on the inner wall of the sedimentation barrel, and a first gas-water separation annular baffle is arranged at a position above the second gas-water separation annular baffle and on the outer wall of the isolation barrel.A circulating device does not need to be added externally, so that energy conservation is realized; granular sludge can be cultured under action of self-circulation, and setting performance is good.

Owner:BIOGAS SCI RES INST MIN OF AGRI

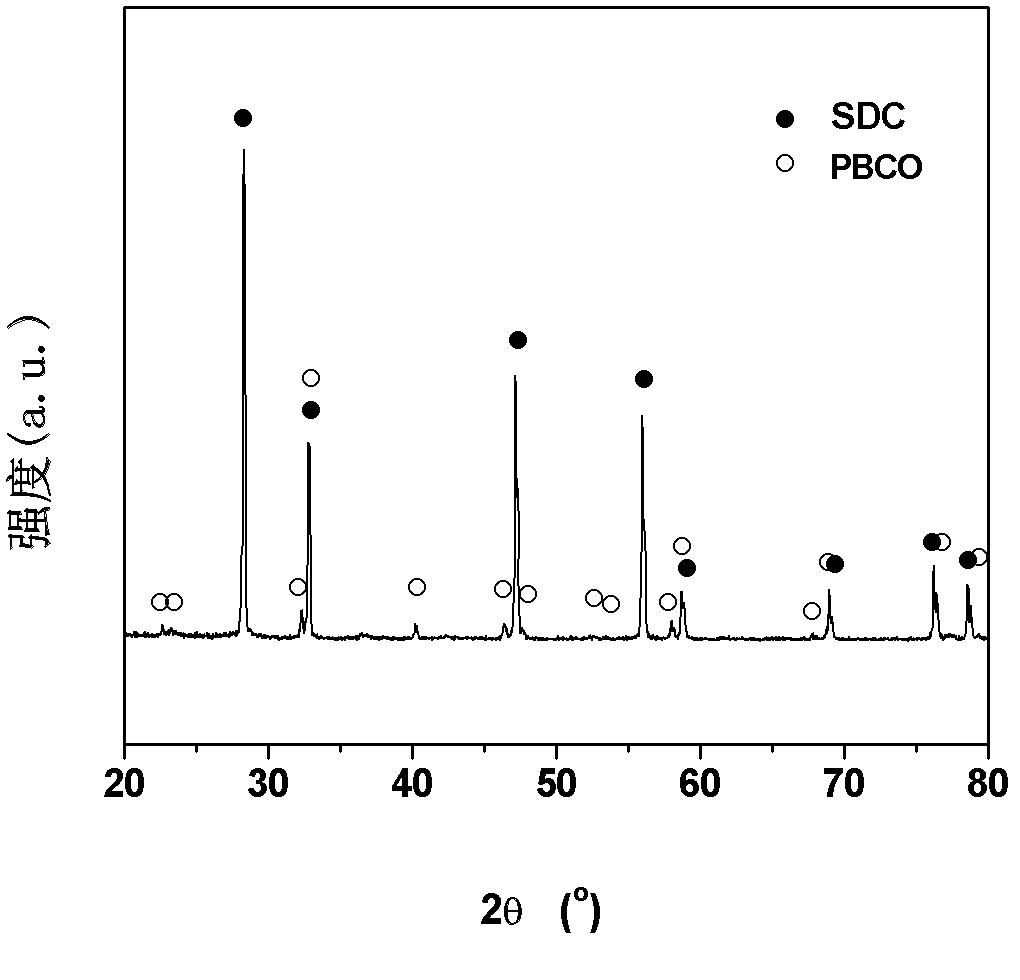

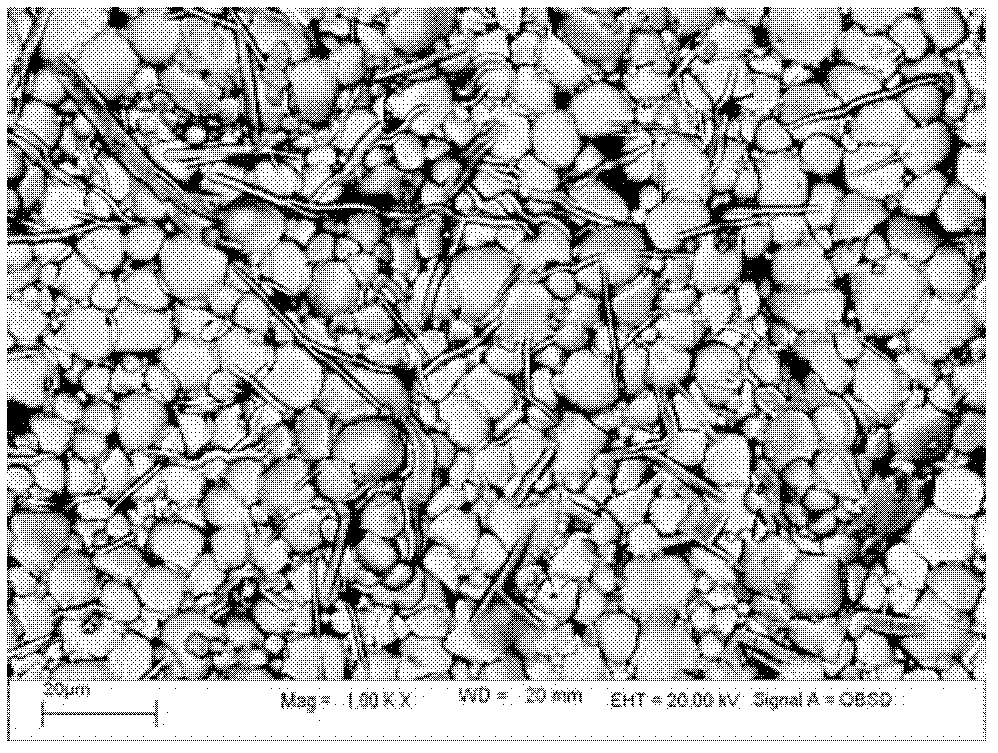

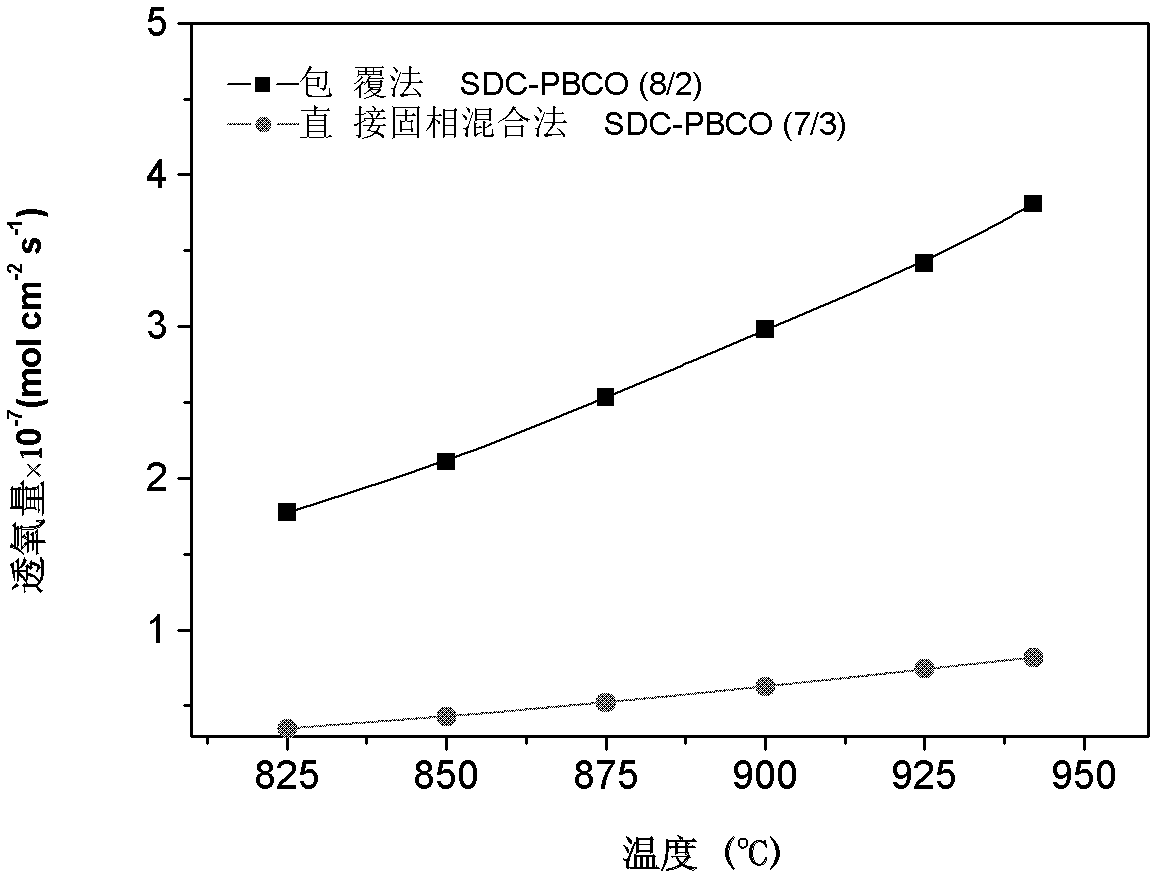

Method for preparing two-phase compact oxygen permeable material with high oxygen permeability

The invention relates to a method for preparing a Ce0.8Sm0.2O2 minus delta and PrBaCo2O5 plus delta two-phase compact oxygen permeable film and belongs to the field of a compact ceramic oxygen permeable film. The method comprises the following steps of: coating an electronic conductive phase PrBaCo2O5 plus delta on the surfaces of an ionic conductive phase, i.e. Ce0.8Sm0.2O2 minus delta particles, by a liquid phase method; and forming a two-phase oxygen permeable material with high ionic conductive phase content by high temperature sintering. Due to the special coating structure, the continuous and through threshold value of a surface to volume ratio of the ionic phase to the electronic phase is improved, which is beneficial for improving the oxygen permeability performance. The material has higher oxygen permeability, chemical stability and mechanical stability and can be used for oxygen separation in the air, a membrane reactor, oxygen enriched combustion and an electrode material of a fuel cell.

Owner:UNIV OF SCI & TECH BEIJING

Nanometal bonding agent and polycrystal CBN (cubic boron nitride) composite sheet made by using same

InactiveCN102794448AGood sintering promotion effectIncrease the volume ratioAl powderAlloy substrate

The invention relates to a nanometal bonding agent. The bonding agent consists of the following raw materials in percentage by weight: 35-40% of TiN powder, 20-25% of TiC powder, 15-20% of Si3N4 powder, 15-20% of Co powder and 10-20% of Al powder. The invention also discloses a polycrystal CBN (cubic boron nitride) composite sheet made by using the nanometal bonding agent. The polycrystal CBN composite sheet comprises a CBN polycrystal layer and a hard alloy substrate, wherein the CBN polycrystal layer consists of the following raw materials in percentage by weight: 55-95% of CBN powder and 5-45% of nanometal bonding agent. In the polycrystal CBN composite sheet provided by the invention, by adopting the nanometal bonding agent in the formula of polycrystal layer, the technical bottleneck in high impact toughness and high bending strength of a PCBN composite sheet is broken, the impact resistance of a tool is enhanced, and the service life of the tool is prolonged.

Owner:ZHONGNAN DIAMOND CO LTD

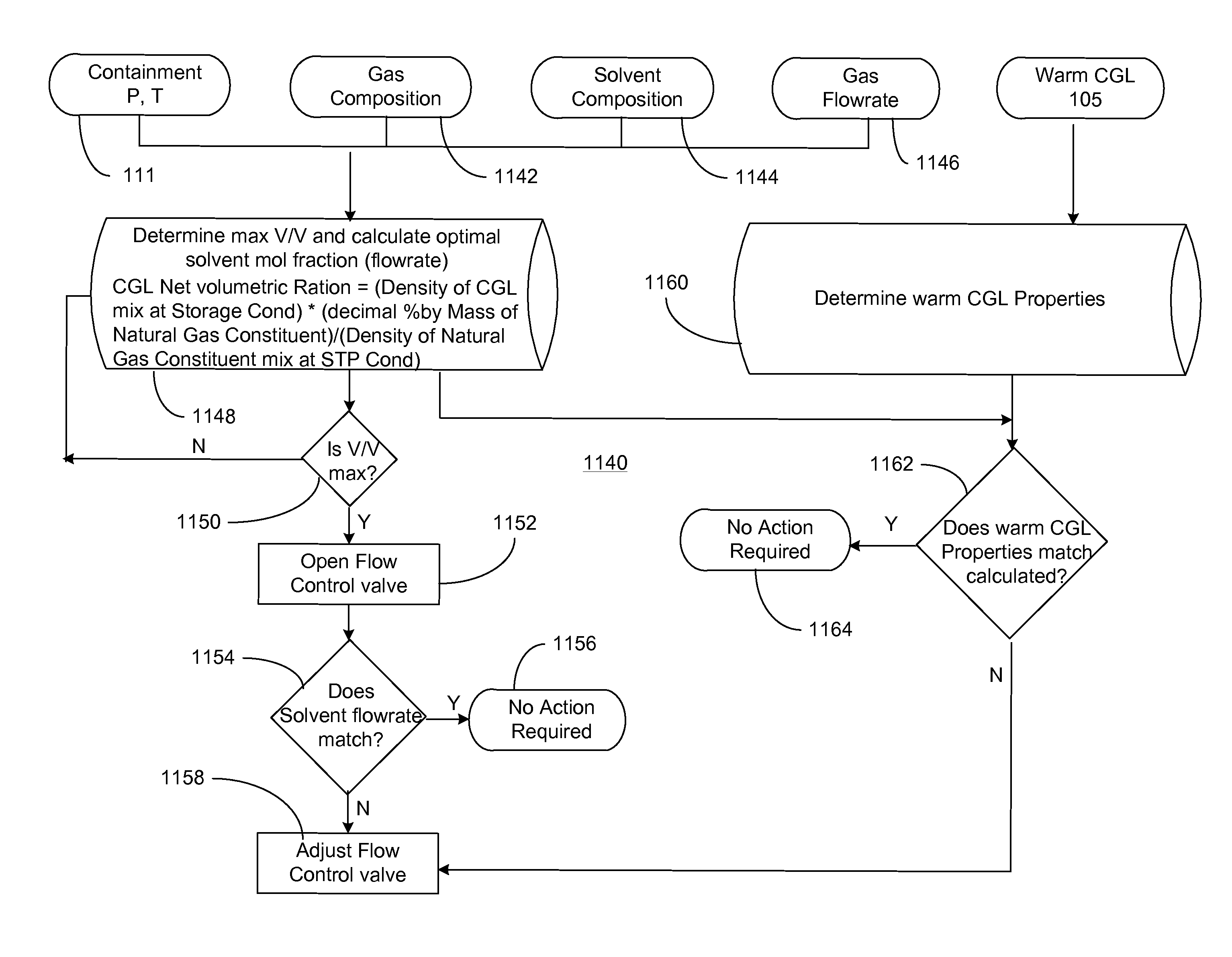

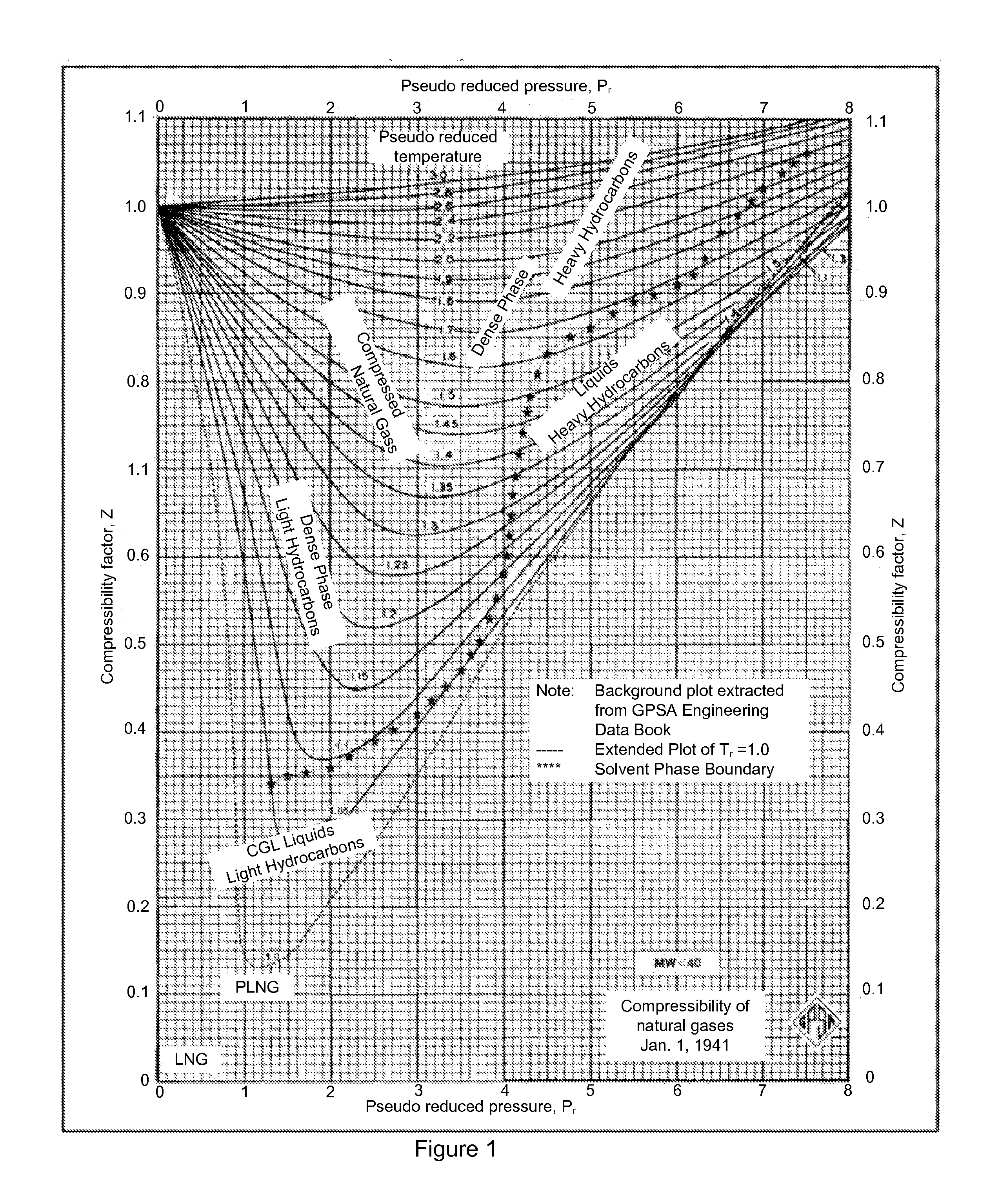

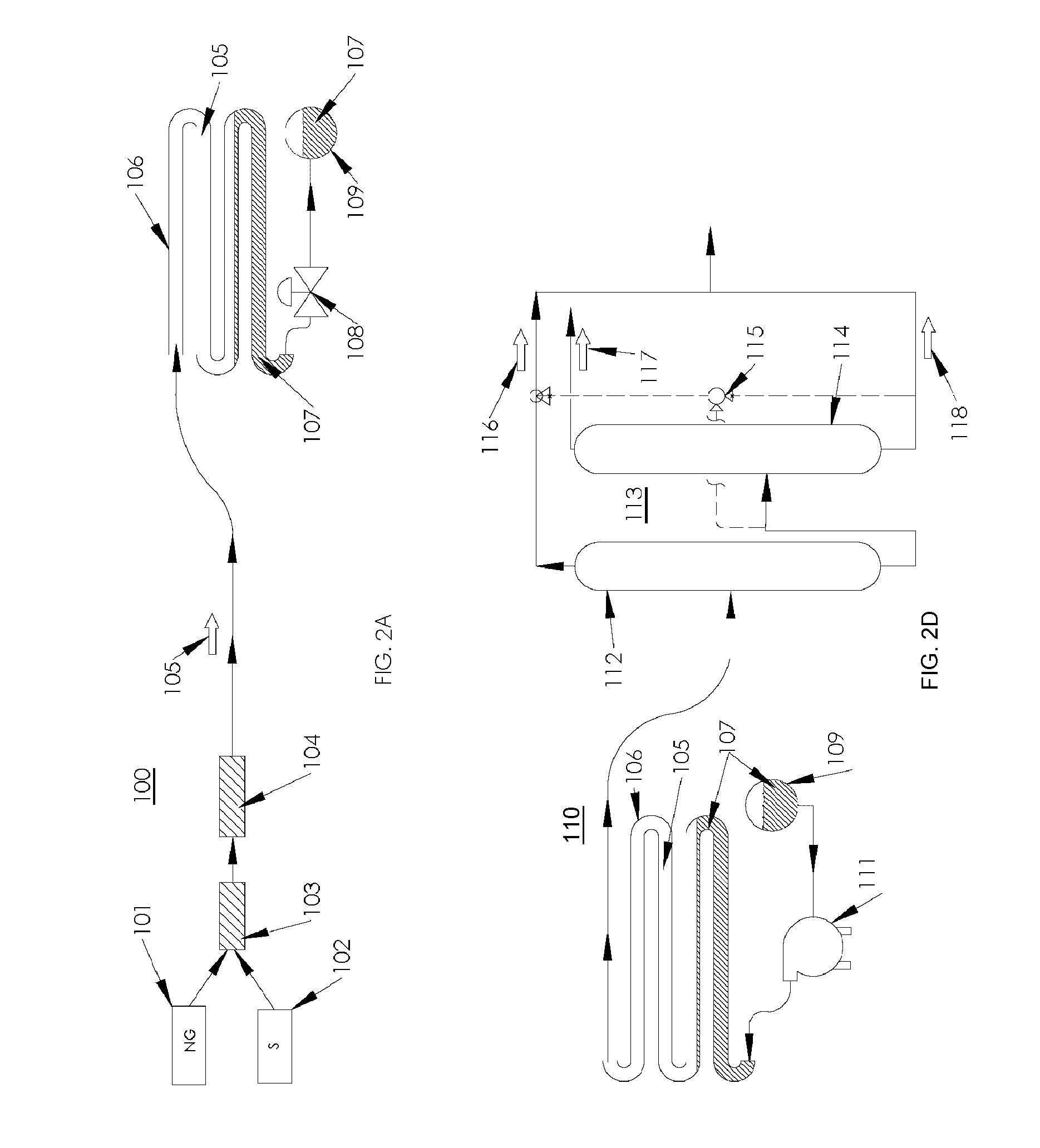

Methods for storage and transportation of natural gas in liquid solvents

ActiveUS20120180502A1Increase the volume ratioImprove storage densityVessel mounting detailsLoad accommodationMass ratioNatural gas fuel

Systems and methods to create and store a liquid phase mix of natural gas absorbed in light-hydrocarbon solvents under temperatures and pressures that facilitate improved volumetric ratios of the stored natural gas as compared to CNG and PLNG at the same temperatures and pressures of less than −80° to about −120° F. and about 300 psig to about 900 psig. Preferred solvents include ethane, propane and butane, and natural gas liquid (NGL) and liquid pressurized gas (LPG) solvents. Systems and methods for receiving raw production or semi-conditioned natural gas, conditioning the gas, producing a liquid phase mix of natural gas absorbed in a light-hydrocarbon solvent, and transporting the mix to a market where pipeline quality gas or fractionated products are delivered in a manner utilizing less energy than CNG, PLNG or LNG systems with better cargo-mass to containment-mass ratio for the natural gas component than CNG systems.

Owner:SEAONE HLDG

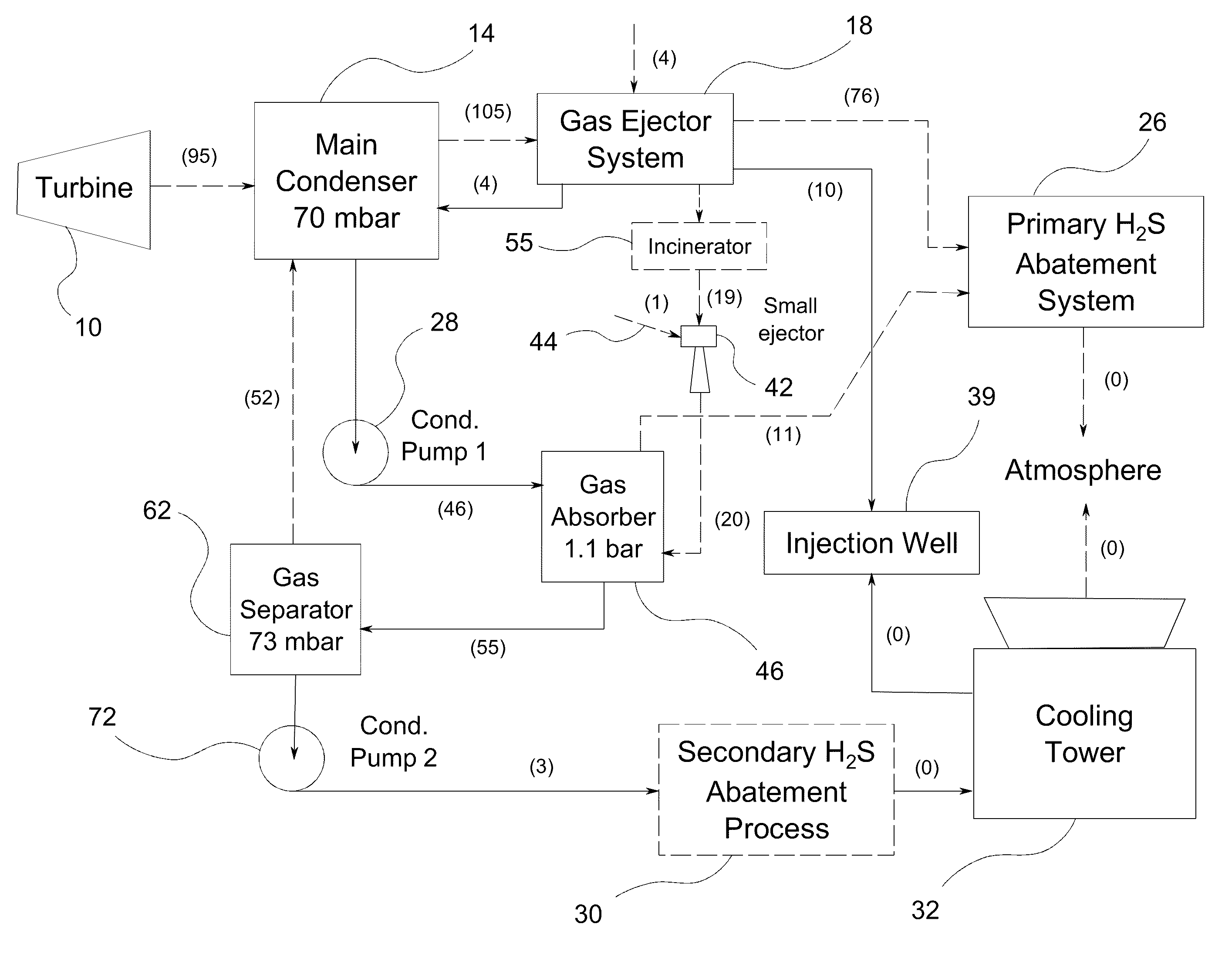

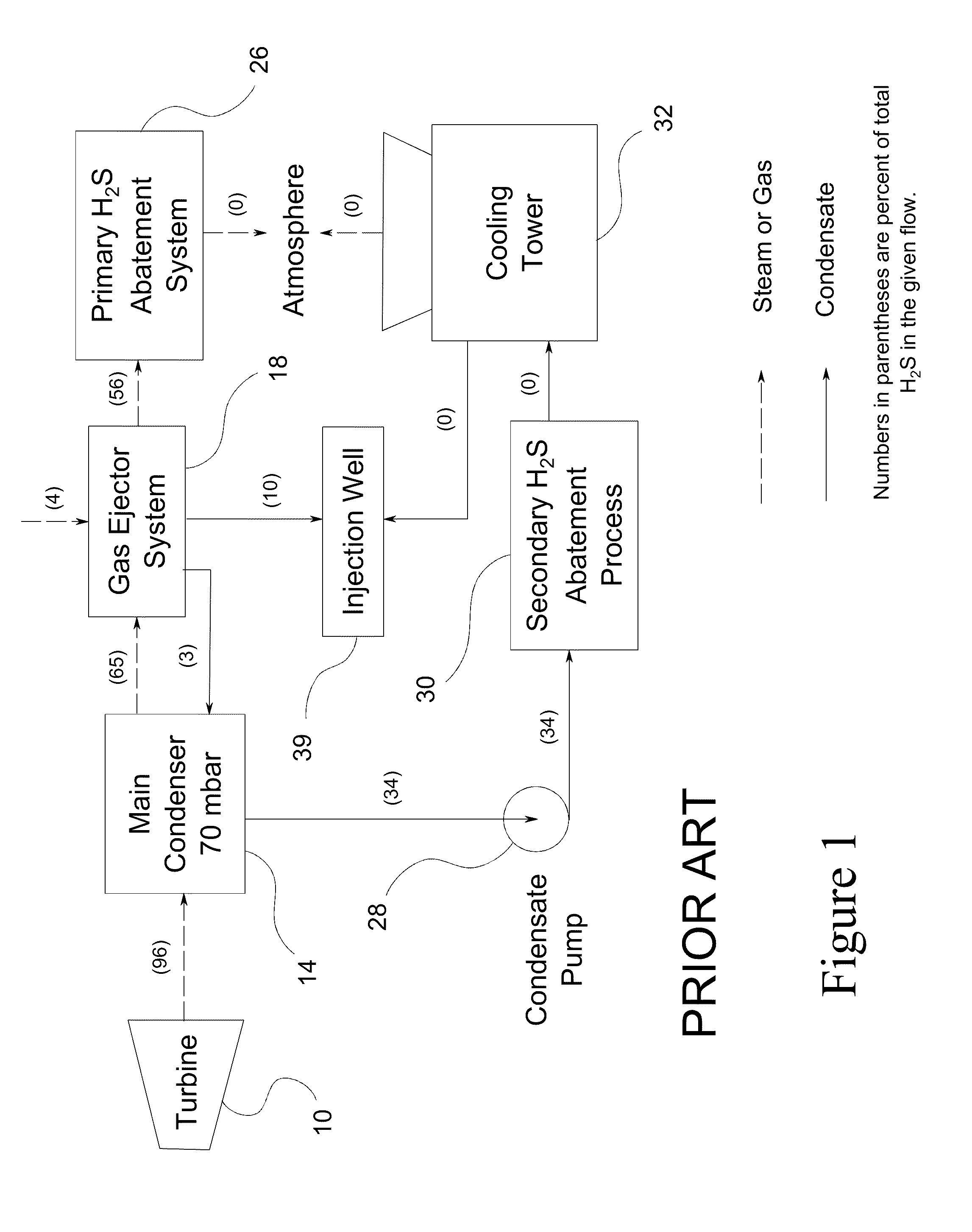

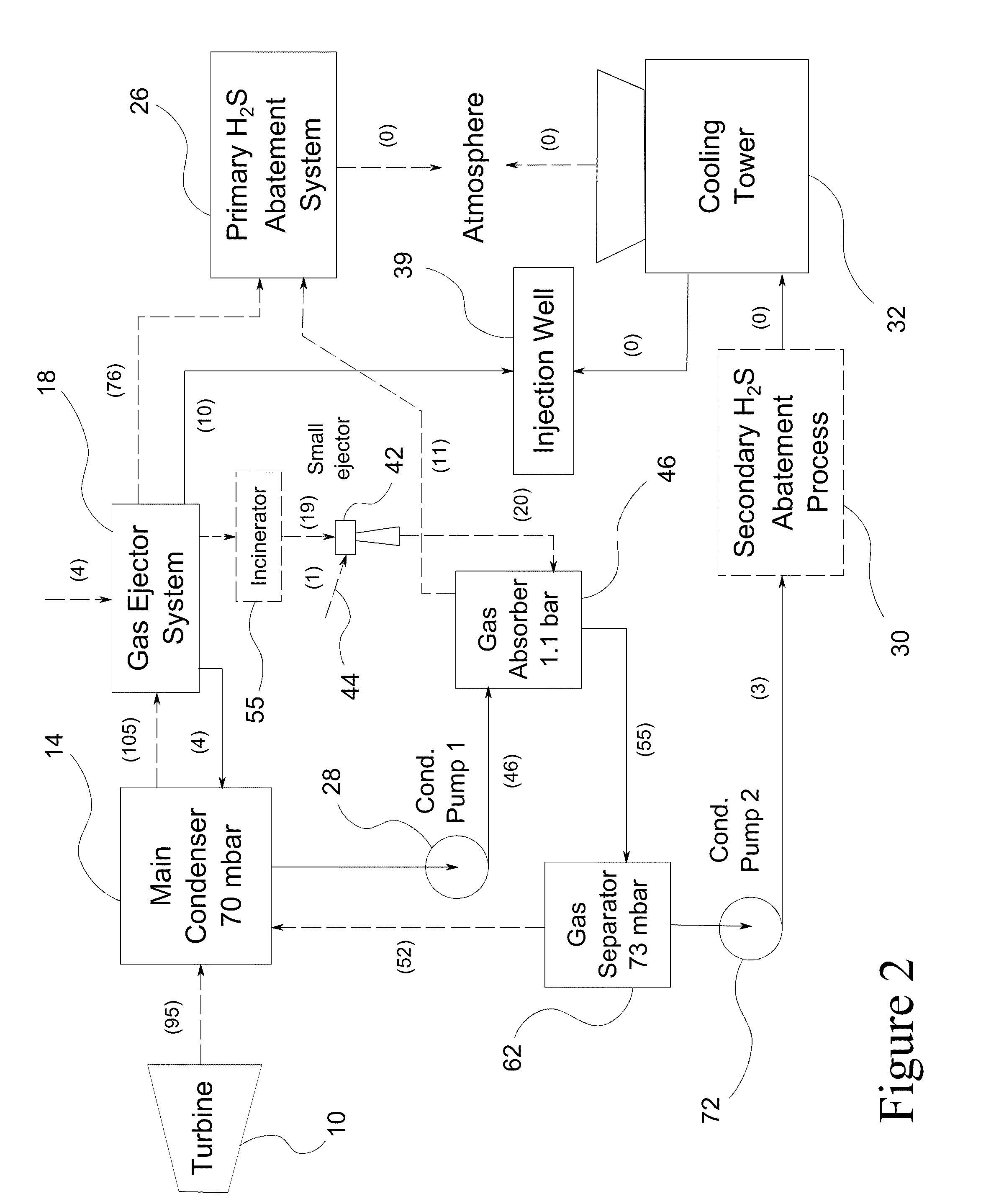

Method and Device to Remove Hydrogen Sulfide from Steam Condensate in a Geothermal Power Generating Unit

InactiveUS20110225971A1Improve condensation effectIncrease the volume ratioUsing liquid separation agentGeothermal energy generationChemical treatmentSolubility

Ammonia sometimes present in geothermal steam increases the solubility of hydrogen sulfide in the steam condensate produced by the surface condenser in a steam cycle geothermal power generating unit by reacting with the hydrogen sulfide to produce nonvolatile ammonium bisulfide. The condenser vent gas also produced contains carbon dioxide. Contacting the steam condensate with the condenser vent gas at a pressure slightly greater than atmospheric causes carbon dioxide to dissolve in the condensate, decreasing pH and converting bisulfide ion back to hydrogen sulfide. Subsequently exposing the acidified condensate to condenser vacuum strips the hydrogen sulfide from the condensate, eliminating the need for further chemical treatment of the condensate to prevent air pollution. Hydrogen sulfide partitioning performance is further improved by converting the hydrogen sulfide in the vent gas to sulfur dioxide before contacting it with the condensate.

Owner:CHEMTREAT

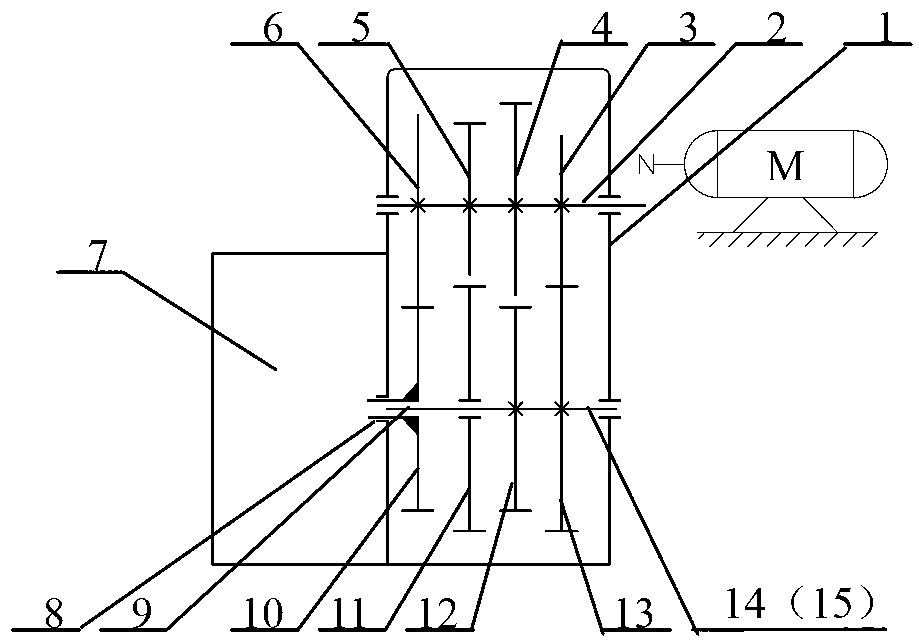

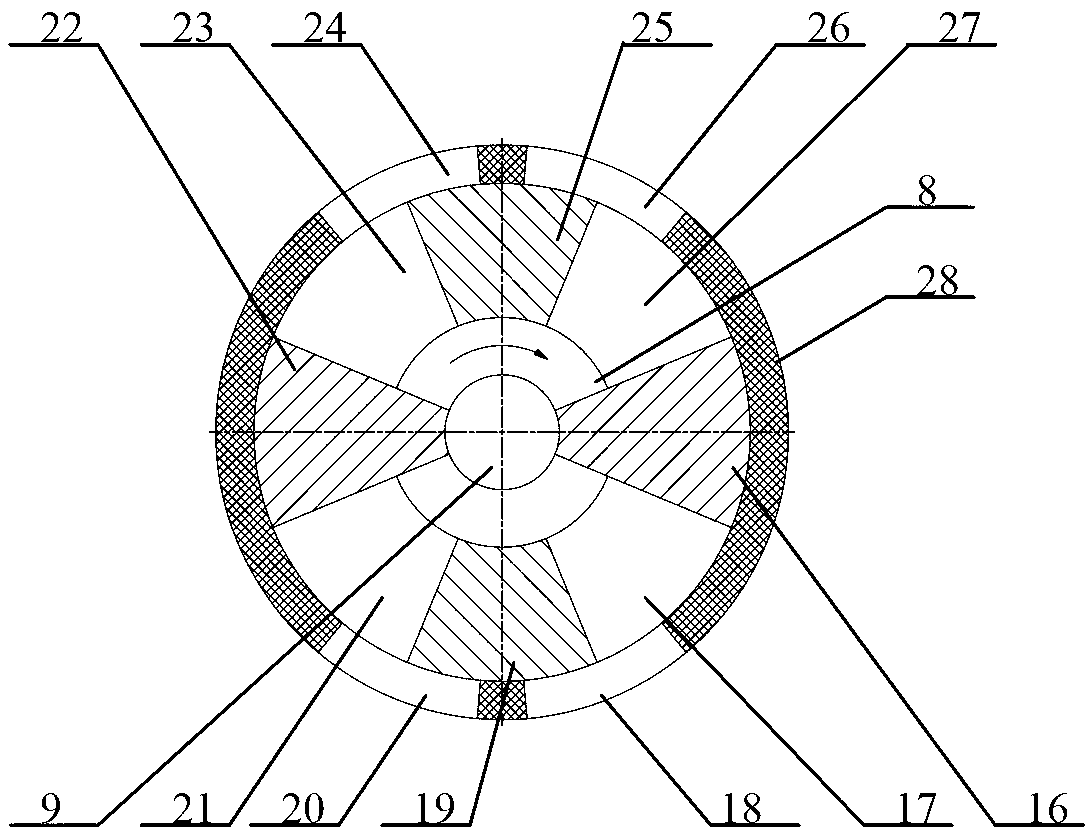

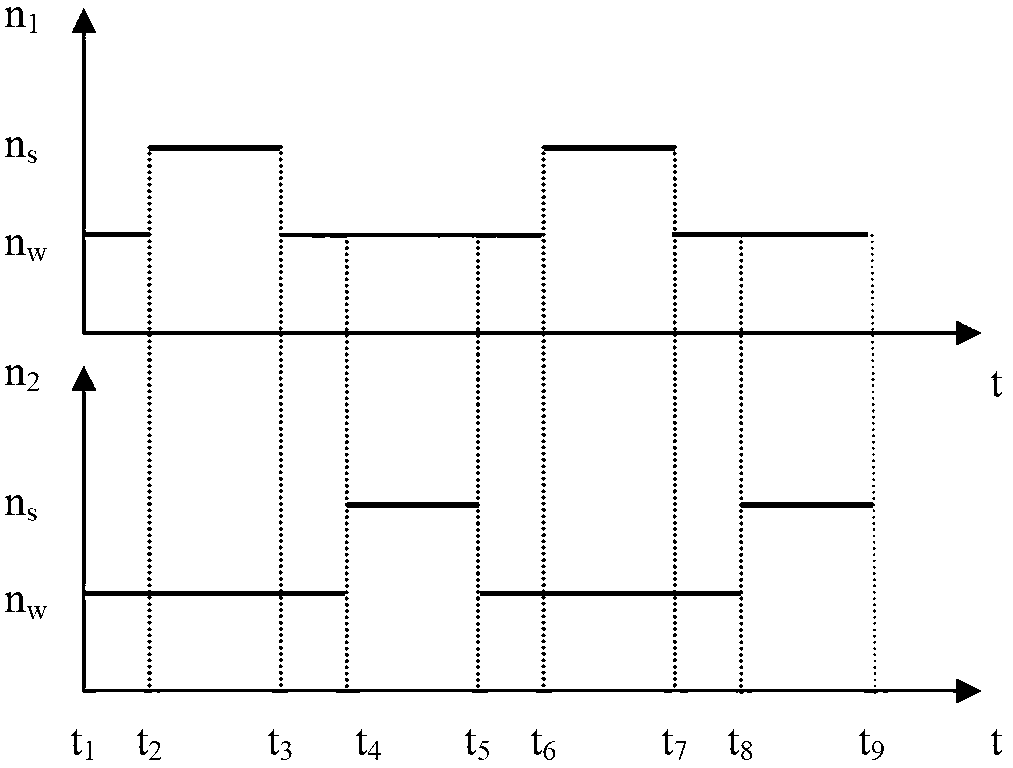

Incomplete gear mechanism-driven blade differential pump

InactiveCN103291607AOvercome the defect of unbalanced radial loadAccurate Periodic Motion LawRotary piston pumpsRotary piston liquid enginesImpellerDrive shaft

The invention discloses an incomplete gear mechanism-driven blade differential pump. The pump comprises an incomplete gear mechanism driving system and a pump body; the incomplete gear mechanism driving system consists of four pairs of incomplete gear mechanisms, a driving shaft and two output shafts, wherein the driving shaft is fixedly connected with a three-phase asynchronous motor, the two output shafts are fixedly connected with two impeller shafts respectively, two blades are arranged on each impeller shaft, and the adjoining blades and a pump housing form a seal cavity. Aiming at the defect that the existing volume pump is small in displacement, unbalanced in radial force and the like, the incomplete gear mechanism driving system and the impellers coaxially installed within the pump housing are combined with one another, and the incomplete gears are periodically meshed with and separated from one another, so that the uniform rotation is converted into the periodic non-uniform velocity rotation, and the blades on the two impellers are periodically opened and closed, therefore, the volume of the seal cavity formed by the adjoining blades and the pump housing is periodically changed, the liquid discharging process and the liquid absorbing process of the pump can be realized, and the applicability of the volume pump in the fields of industrial production and life can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

Grasping method by grasping apparatus

ActiveUS9272422B2Precise positioningIncrease the volume ratioGripping headsLifting devicesEngineering

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com