Preparation method for graphene-reinforced copper-based composite material

A technology of copper-based composite materials and composite materials, which is applied in the field of preparation of graphene-reinforced copper-based composite materials, can solve the problems of large density difference, large size difference, and non-wetting between graphene and copper powder, and achieve graphene distribution. The effect of uniformity, broadening the application range, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

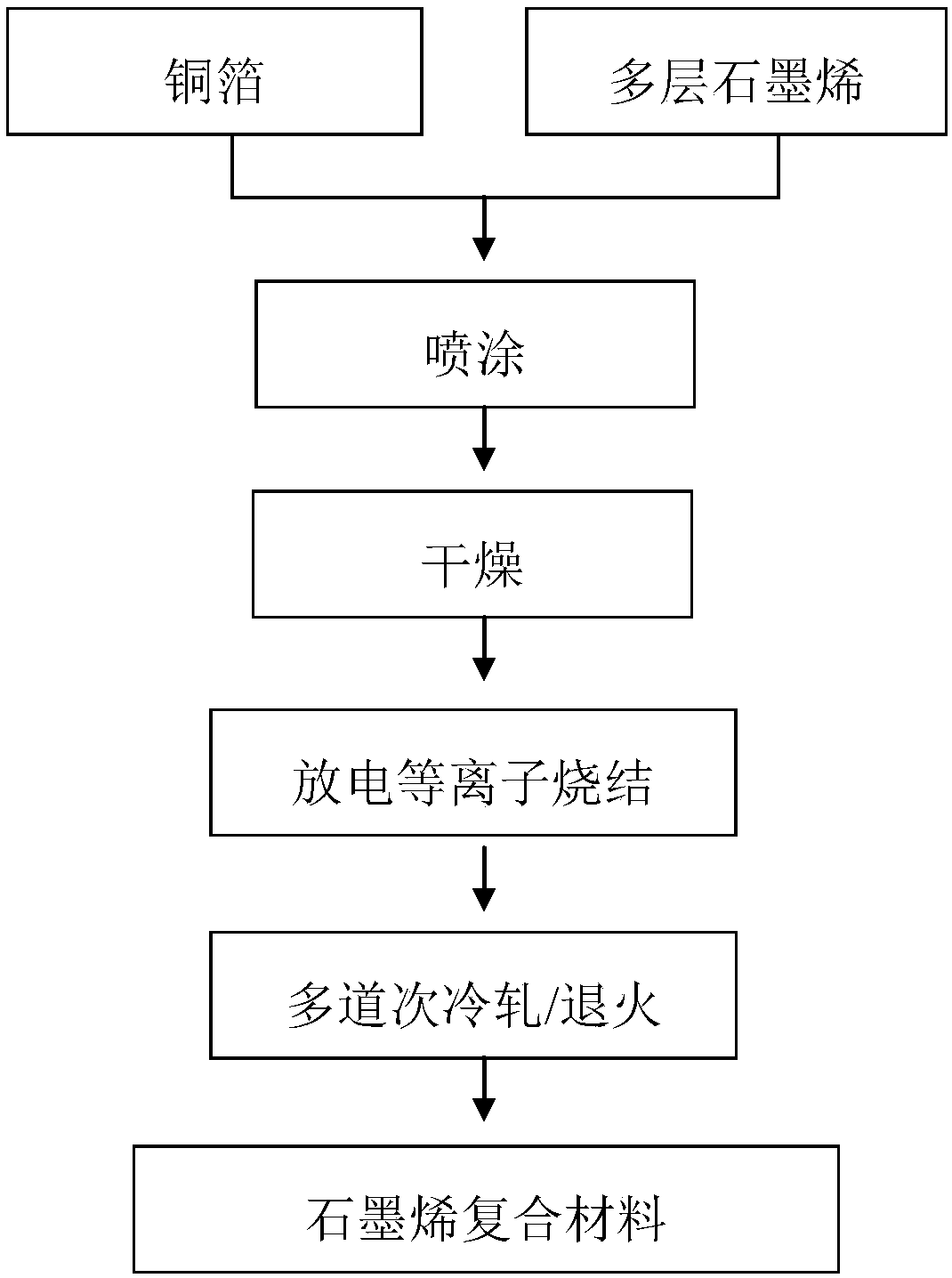

Method used

Image

Examples

Embodiment 1

[0029] (1) Place multilayer graphene with a thickness of 3-8nm and a sheet size of 5-50μm in 7.0M concentrated nitric acid, stir and heat to reflux at 120°C for 4h, dilute, filter, and dry to obtain purified multi-layer graphene; (2) disperse the purified multi-layer graphene in absolute ethanol, and obtain an ink-like suspension after ultrasonic treatment for 2 hours; (3) adopt the method of spraying to suspend the multi-layer graphene The solution is sprayed on a copper foil with a diameter of 40 mm and a thickness of 50 μm, dried, and the mass fraction of multilayer graphene is controlled to be 0.2%; (4) 50 layers of copper foil are stacked and assembled, and placed in a spark plasma sintering (SPS) furnace For sintering, control the sintering temperature to 850°C, the pressure to 20Mpa, and the holding time to 5 minutes; control the heating rate during the sintering process to 40°C / min, and use water cooling to cool the furnace after the heat preservation is completed. (5)...

Embodiment 2

[0031] (1) Place multilayer graphene with a thickness of 3-8nm and a sheet size of 5-50μm in 7.0M concentrated nitric acid, stir and heat at reflux for 4h at 120°C, dilute, filter, and dry to obtain purified multilayer graphene; (2) disperse the purified multilayer graphene in absolute ethanol, and obtain an ink-like suspension after ultrasonic treatment for 2 hours; (3) adopt the method of spraying to suspend the multilayer graphene The solution is sprayed on a copper foil with a diameter of 40 mm and a thickness of 50 μm, dried, and the mass fraction of multilayer graphene is controlled to be 0.4%; (4) 50 layers of copper foil are stacked and assembled, and placed in a spark plasma sintering (SPS) furnace For sintering, control the sintering temperature to 850°C, the pressure to 20Mpa, and the holding time to 5min; control the heating rate during the sintering process to 40°C / min, and use water cooling to cool the furnace after the heat preservation is completed. (5) The lay...

Embodiment 3

[0033](1) Place multilayer graphene with a thickness of 3-8nm and a sheet size of 5-50μm in 7.0M concentrated nitric acid, stir and heat to reflux at 120°C for 4h, dilute, filter, and dry to obtain purified multi-layer graphene; (2) disperse the purified multi-layer graphene in absolute ethanol, and obtain an ink-like suspension after ultrasonic treatment for 2 hours; (3) adopt the method of spraying to suspend the multi-layer graphene The solution is sprayed on a copper foil with a diameter of 40 mm and a thickness of 50 μm, dried, and the mass fraction of multilayer graphene is controlled to be 0.6%; (4) 50 layers of copper foil are stacked and assembled, and placed in a spark plasma sintering (SPS) furnace For sintering, control the sintering temperature to 850°C, the pressure to 20Mpa, and the holding time to 5 minutes; control the heating rate during the sintering process to 40°C / min, and use water cooling to cool the furnace after the heat preservation is completed. (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com